Toyota Camry 2007-2009 Service Manual - 2GR-FE_Ignition

ENGINE2GR-FE IGNITION

IGNITION SYSTEM

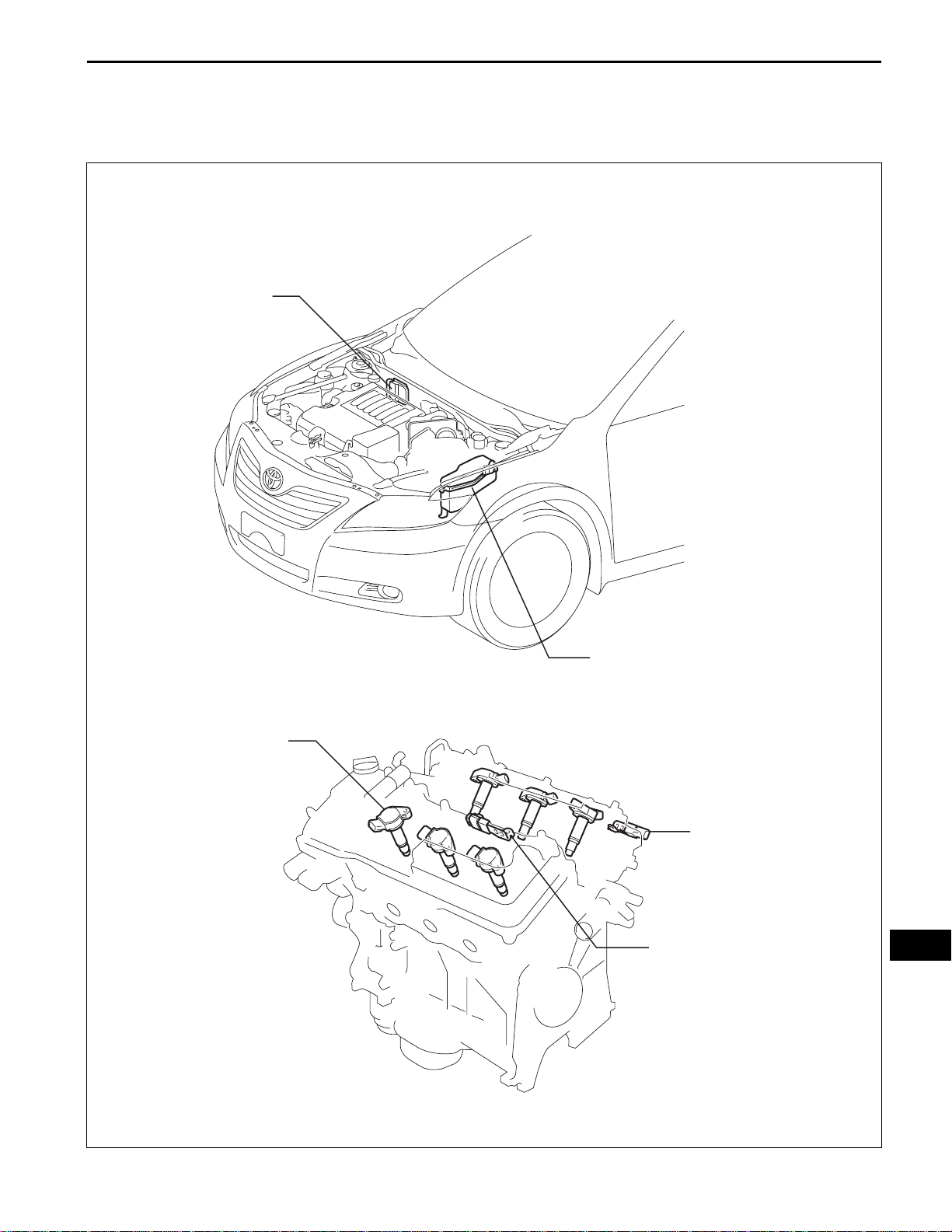

PARTS LOCATION

ECM

2GR-FE IGNITION – IGNITION SYSTEM

IG–1

IGNITION COIL

ENGINE ROOM R/B

- IG2 FUSE

- ST/AM FUSE

NOISE FILTER

NOISE FILTER

IG

A137458E01

IG–2

2GR-FE IGNITION – IGNITION SYSTEM

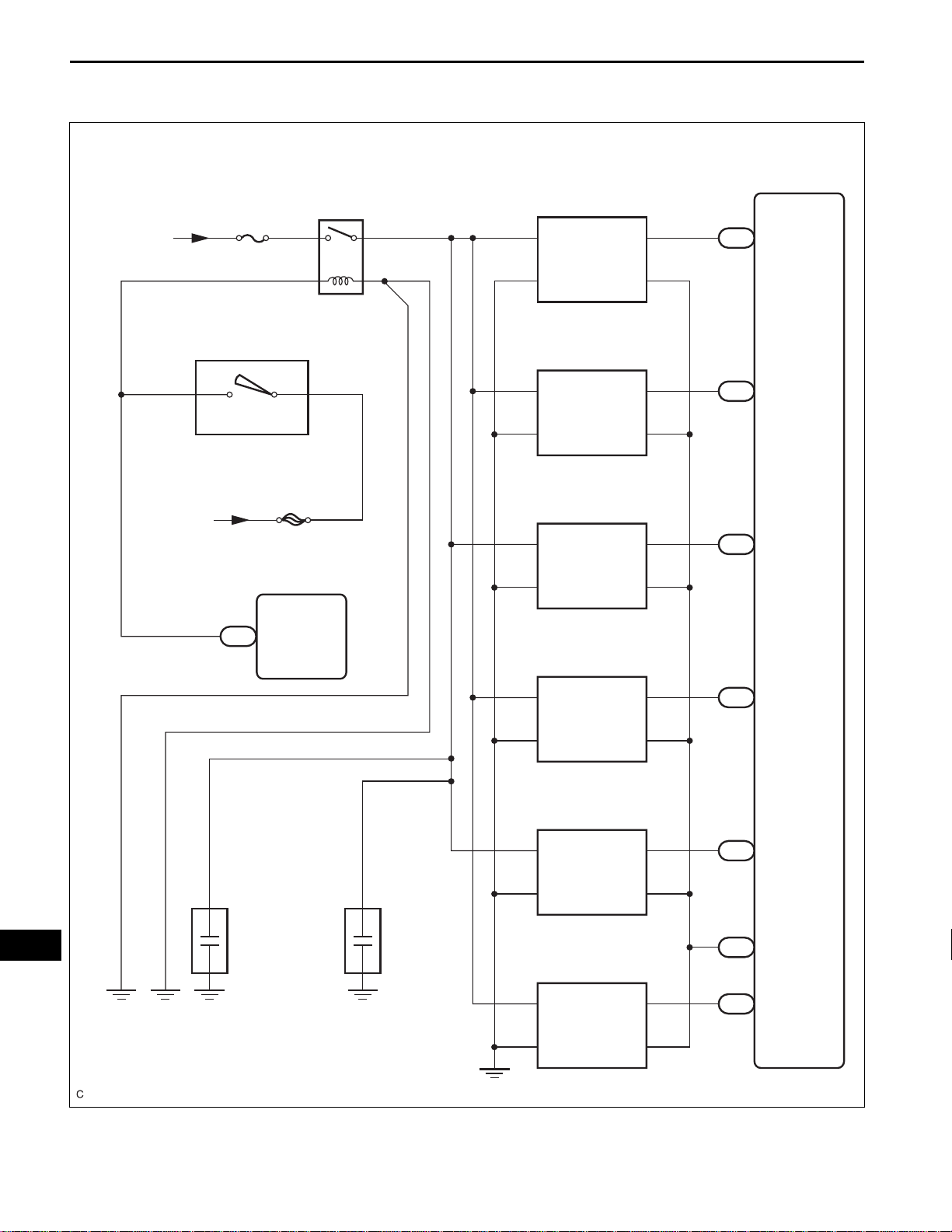

SYSTEM DIAGRAM

From

Battery

*2

IG2

IG2

53

12

E23 Ignition Switch

65

IG2

From

Battery

*1

AM2

ST/AM2

E6 Main Body ECU

11

IG2D

E6

*2

C11

Ignition Coil (No. 1)

40

13

42

C13

Ignition Coil (No. 2)

13

42

C12

Ignition Coil (No. 3)

13

42

C14

Ignition Coil (No. 4)

IGT1+B

IGFGND

IGT2+B

IGFGND

IGT3+B

IGFGND

C55 IGT1

39

C55 IGT2

38

C55 IGT3

ECM

IG

C16

Noise Filter

(Ignition RH)

*1: with Smart Key System

*2: without Smart Key System

C49

Noise Filter

(Ignition LH)

11

37

13

42

C38

Ignition Coil (No. 5)

1

42

C39

Ignition Coil (No. 6)

13

42

IGT4+B

IGFGND

IGT5+B

IGT6+B

3

IGFGND

IGFGND

C55 IGT4

36

C55 IGT5

35

C55 IGT6

106

C55 IGF1

A136999E01

2GR-FE IGNITION – IGNITION SYSTEM

ON-VEHICLE INSPECTION

NOTICE:

In this section, the terms "cold" and "hot" refer to the

temperature of the coils. "Cold" means approximately 10°C (14°F) to 50°C (122°F). "HOT" means approximately

50°C (122°F) to 100°C (212°F).

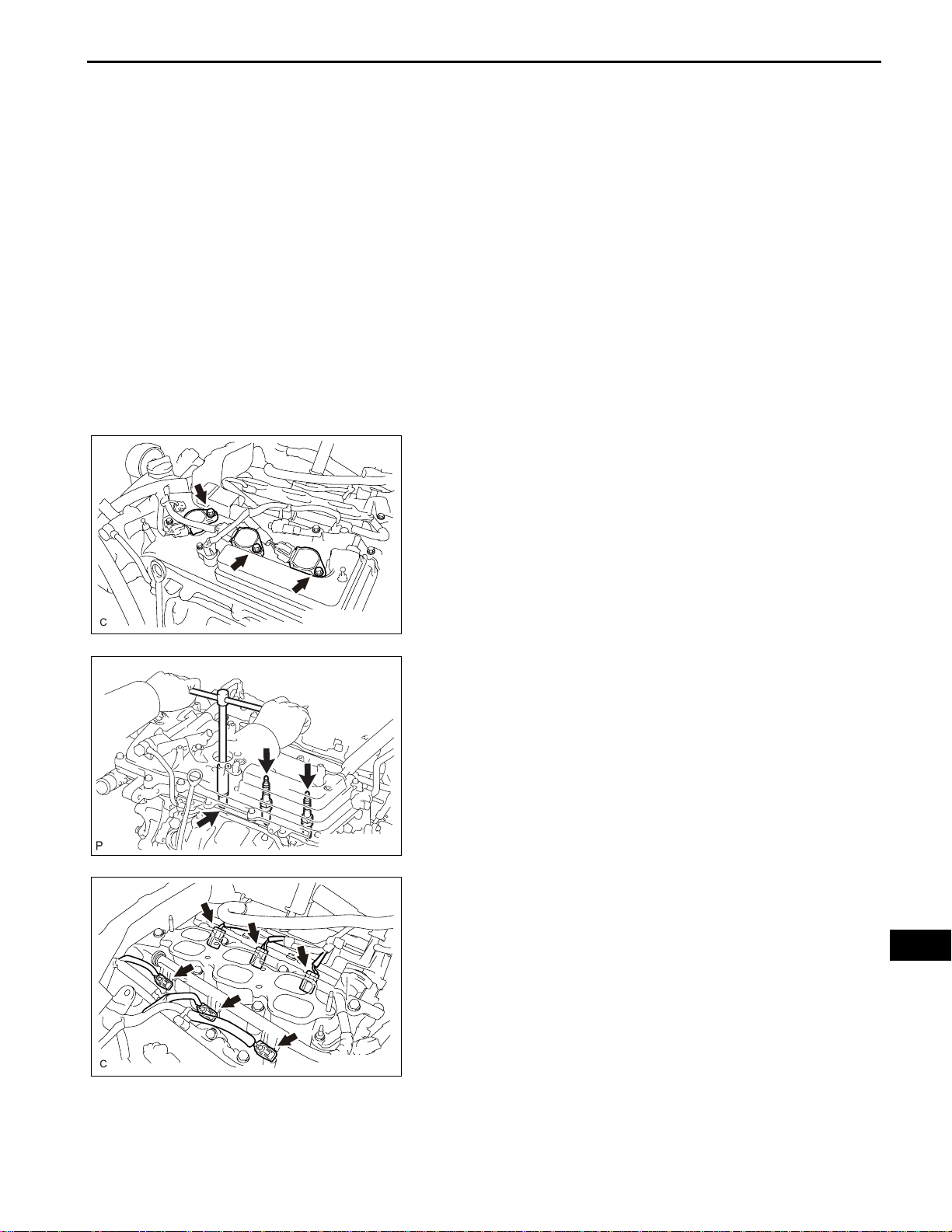

1. INSPECT IGNITION COIL ASSEMBLY

(a) Check for DTCs.

NOTICE:

If any DTC is present, perform troubleshooting

in accordance with the procedures for that DTC.

(b) Check that sparks occur.

(1) Remove the intake air surge tank (See page

FU-13).

(2) Remove the No. 1 surge tank stay (see page

IG-10).

(3) Disconnect the 6 ignition coil connectors and

remove the 6 bolts and 6 ignition coils.

IG–3

A133896

A137604

A133895

(4) Using a 16 mm (0.63 in.) plug wrench, remove

the 6 spark plugs.

(5) Disconnect the 6 fuel injector connectors.

(6) Install the spark plugs to each ignition coil, and

connect the ignition coil connectors.

IG

IG–4

2GR-FE IGNITION – IGNITION SYSTEM

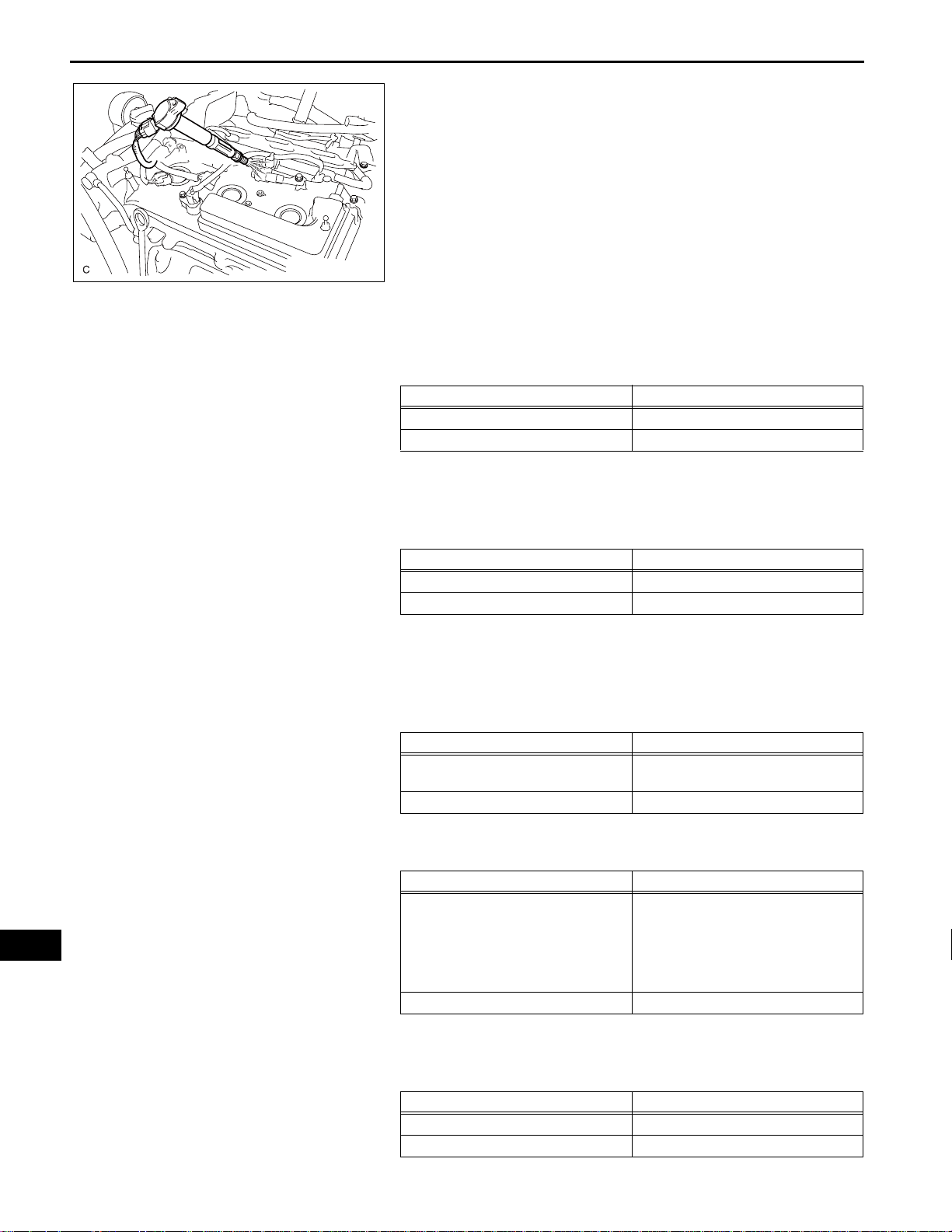

(7) Ground the spark plugs.

(8) Check if a spark occurs at each spark plug

while the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking.

• Replace the ignition coil if it receives an

impact.

• Do not crank the engine for more than 2

A133897

seconds.

(c) Perform the spark test according to the flowchart

below.

(1) Check that the ignition coil connector is

securely connected.

Result

Result Proceed to

NG Connect securely

OK Go to next step

(2) Perform a speak test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

Result Proceed to

OK Replace ignition coil

NG Go to next step

IG

(3) Check the power supply to the ignition coil.

1. Turn the ignition switch on (IG).

2. Check that there is battery voltage at the

ignition coil positive (+) terminal.

Result

Result Proceed to

NG Check wiring between ignition

switch and ignition coil

OK Go to next step

(4) Check the VVT sensor output voltage.

Result

Result Proceed to

NG Check that there is resistance

between ECM and VVT sensor. If

there is no resistance, replace VVT

sensor. If there is resistance, repair

wiring between VVT sensor and

ECM.

OK Go to next step

(5) Measure the resistance of the crankshaft

position sensor.

Standard resistance

Temperature Specified Condition

Cold 1,630 to 2,740 Ω

Hot 2,065 to 3,225 Ω

Loading...

Loading...