Toyota Camry 2007-2009 Service Manual - Harness_Repair

FOREWORD

This manual has been prepared for use when

performing terminal repairs, wire repairs, or connector

repairs on vehicles.

A step–by–step section on connector repair and

terminal repair is included.

There is a section of charts with terminal and connector

illustrations, part numbers, and notes on terminal

removal.

By using this guide, a satisfactory repair of the wiring

harness and connectors in Toyota vehicles will be easy

to achieve.

All information in this manual is based on the latest

product information at the time of publication. However,

specifications and procedures are subject to change

without notice.

2002

All rights reserved. This book may not be

reproduced or copied, in whole or in part, without t he

written permission of Toyota Motor Corporation.

A

A–1

INTRODUCTION–GENERAL INFORMATION

GENERAL INFORMATION

This manual provides instruction in the following repairs:

How to Inspect for System Inspection

Circuit Protection

Terminal and Connector Repair Procedure

NOTICE:

When inspecting or repairing the SRS AIRBAG, be sure to carefully read the precautionary

instructions and procedure in the Repair Manual for the applicable model.

After any electrical repair is made, always test the circuit by operating the devices in the circuit. This

confirms not only that the repair is correct, but also that the cause of the complaint was correctly

identified.

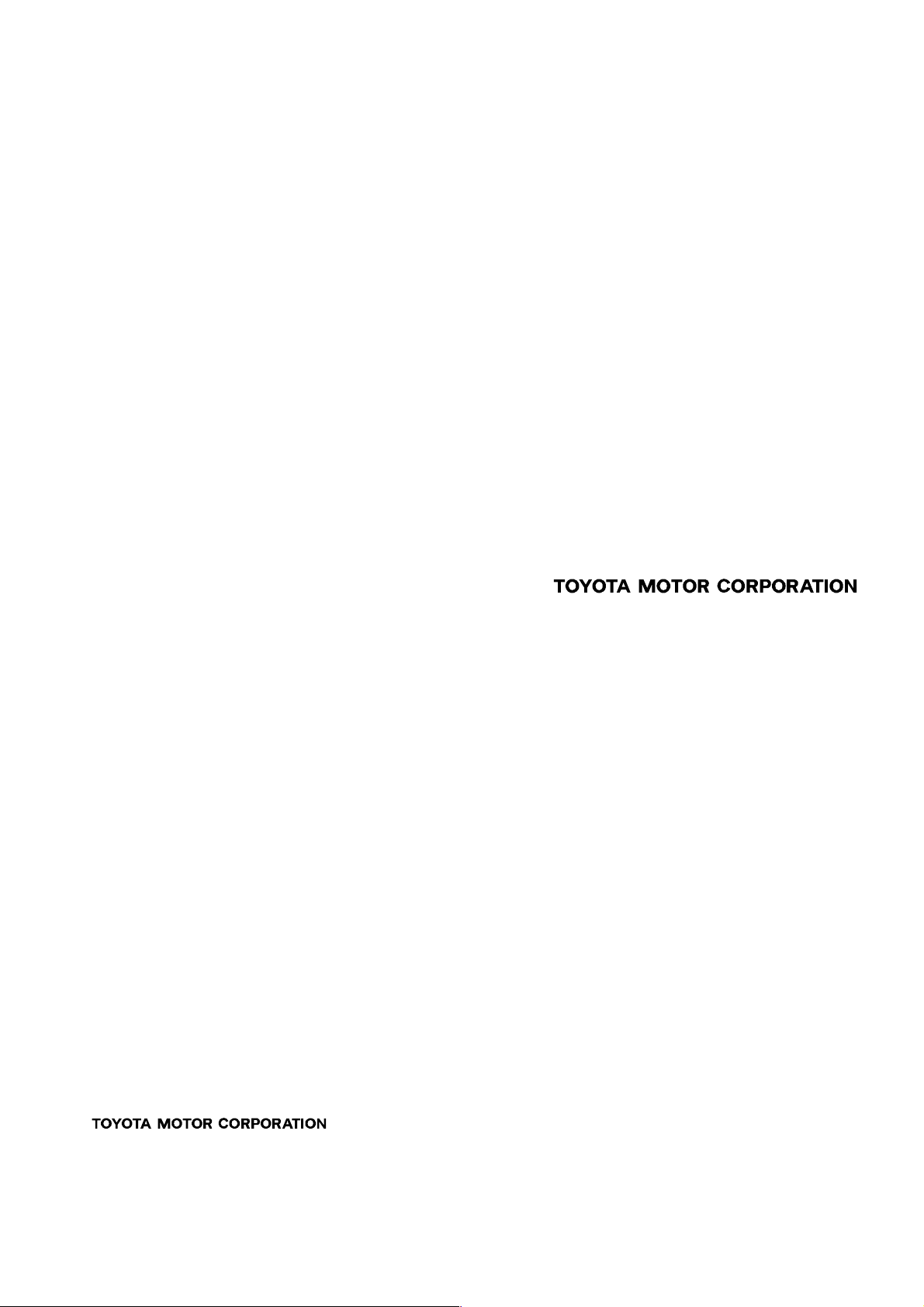

Tab width

0.64 mm

Terminal type number name

The terminal type number naming system has changed:

the metric system will be used in place of the inch system.

To be more specific, male tab width ”in millimeters” will be

used as terminal type number from now on –– in place of

male tab width in inches which has been in use so far.

Below is a table of comparison:

Old terminal type No.

(inch)

025 → 0.64

040 (II, III, IV) → 1.0 (II, III, IV)

050 → 1.3

070 (II) → 1.8 (II)

090 (II) → 2.3 (II)

187 → 4.8

250 (II) → 6.3 (II)

305 → 7.7

New terminal type No.

(mm)

2

312 → 8.0

375 → 9.5

For those connectors which are not shown above, the

terminal type numbers remain unchanged.

Wire Harness Repair Manual (RM1022E)

INTRODUCTION–GENERAL INFORMATION

A–2

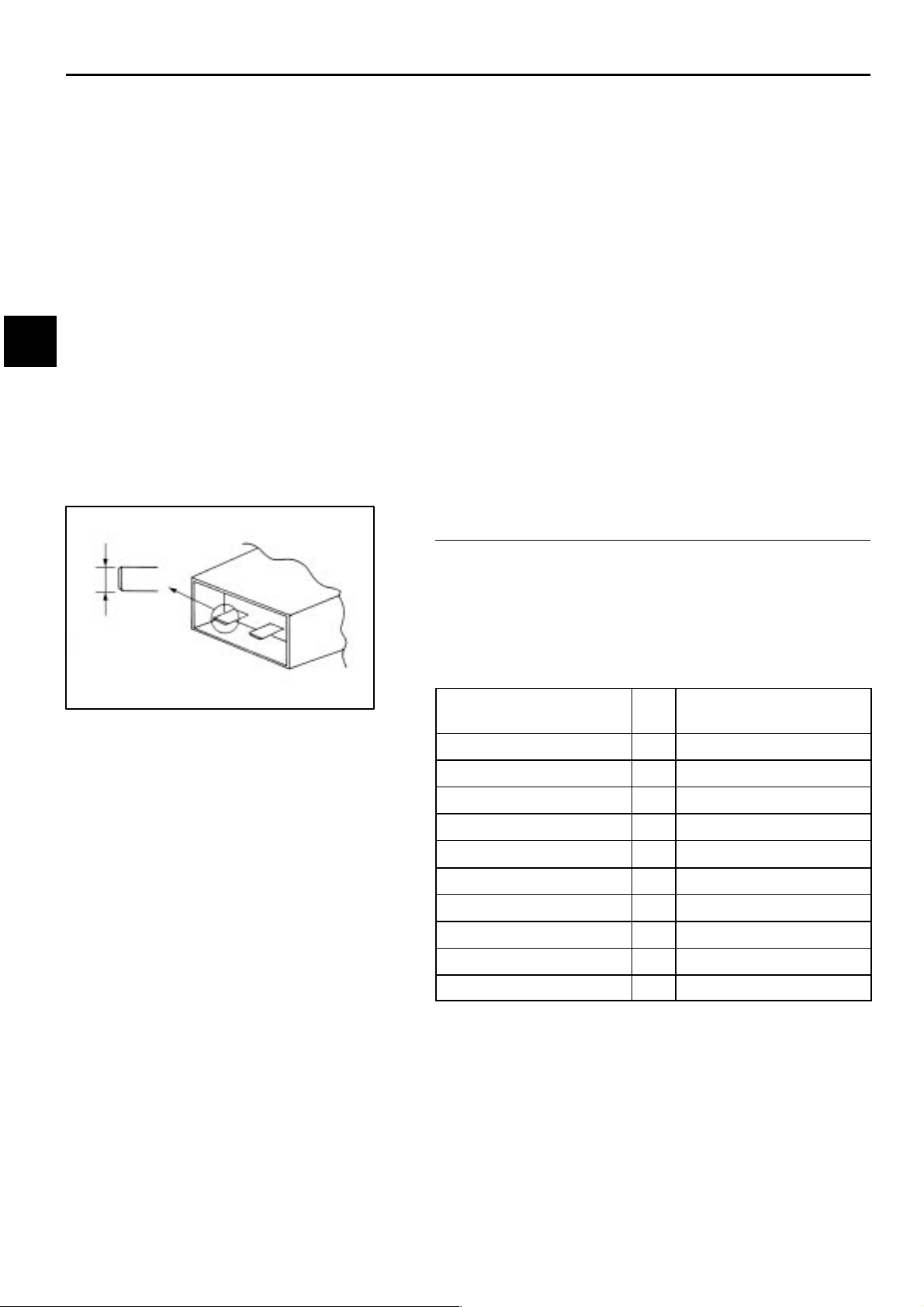

Terminal (Female)

Housing (Female)

Wire

Harness

(W/H)

Housing (Male)

Terminal (Male)

Electric Wire

Terminal

Housing

Fuse

J/B

(Junction Block)

R/B

(Relay Block)

Other

What is Wire Harness?

The wire harness (W/H) is systems of electric wires for

automobiles to connect all the electronics parts in

automobile electrically and work them. As more electronics

parts are introduced in automobiles recently, the electric

wires used for the wire harness are increasing in number

and the structure is becoming more complicated. As a

result of that, there are hundreds of connectors, which is

the parts which connects wires mechanically and

electrically, in one vehicle. Therefore, numbers of the

connector terminal (Terminal) or the connector housing

(Housing) are designed to meet many kinds of uses of

circuits. Various components have been improved to

ensure the product reliability or realize a wider space in the

vehicles.

Wire Harness Components

Wire harness mainly consists of wires, terminals, or

housings.

There are various components are designed for many

parts of vehicles, such as one with high heat–resistance,

water–resistance, or bending ability, ones have different

current capacities, or ones are hardly influenced by

electromagnetic noise.

A

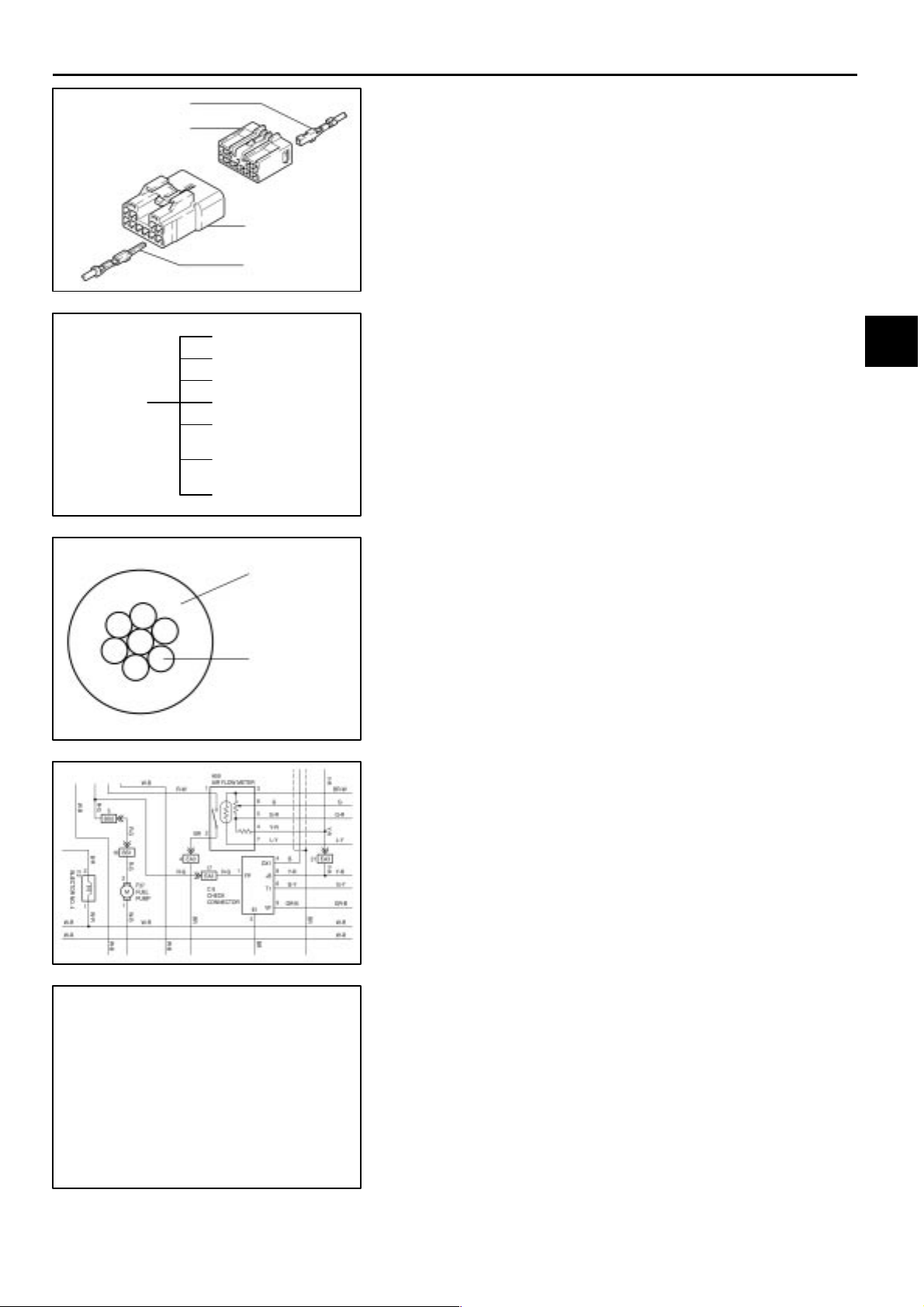

Insulator

Copper Wires

(Conductor)

Electric Wire

The electric wires used for the wire harness consists of the

conductor made from numbers of twisted mild copper wire

with a diameter of less than 0.5 mm and the insulator

surrounding the conductor.

The insulator is generally made from vinyl chloride and

covers the conductor with even thickness. The insulators

are color–coded in order to distinguish each wire. The base

colors or the stripe patterns is used to make difference

between insulators. Each color of wires is indicated by the

abbreviation in the repair manual and the electrical wiring

diagram.

B = Black W = White

L = Blue BR = Brown

V = Violet SB = Sky Blue

R = Red G = Green

P = Pink LG = Light Green

Y = Yellow GR = Gray

O = Orange

Wire Harness Repair Manual (RM1022E)

3

A

A–3

Example: L–Y

Tab width

1.3 mm

Rubber

Plug

Housing Lance

Type

LY–

(Blue) (Yellow)

Rubber Ring

INTRODUCTION–GENERAL INFORMATION

The first letter indicates the basic wire color and the second

letter indicates the color of the stripe.

Terminal and housing

Terminal connects wires and housing insulates connecting

parts.

There are the male terminal and the female terminal. The

types of terminals are decided by tab width of male

terminal. And the terminal with the rubber plug or the

rubber ring is used in the part, such as the engine

compartment, which become wet. For the circuit with slight

current at EFI system or ABS system, the gold–plated

terminal is introduced for ensuring reliabilities.

As the number of the circuit is increasing recently, there are

new types of parts introduced. For example, there is the

hybrid type housing, which is a combination of terminals

with different tab width, such as the power source terminal

or the signal terminal. Also, new type of connector such as

the double lock housing, which is designed with the

retainer in addition to the lance to prevent terminal from

slipping off, is available. The new type of connectors are

produced to realize higher product reliabilities and utilized

widely recently. The major characteristics of these new

connectors are shown in the table 1.

There are two types of lances: housing lance, which is

inside the housing and terminal lance, which is inside the

terminal.

Terminal Lance

Type

4

Wire Harness Repair Manual (RM1022E)

INTRODUCTION–GENERAL INFORMATION

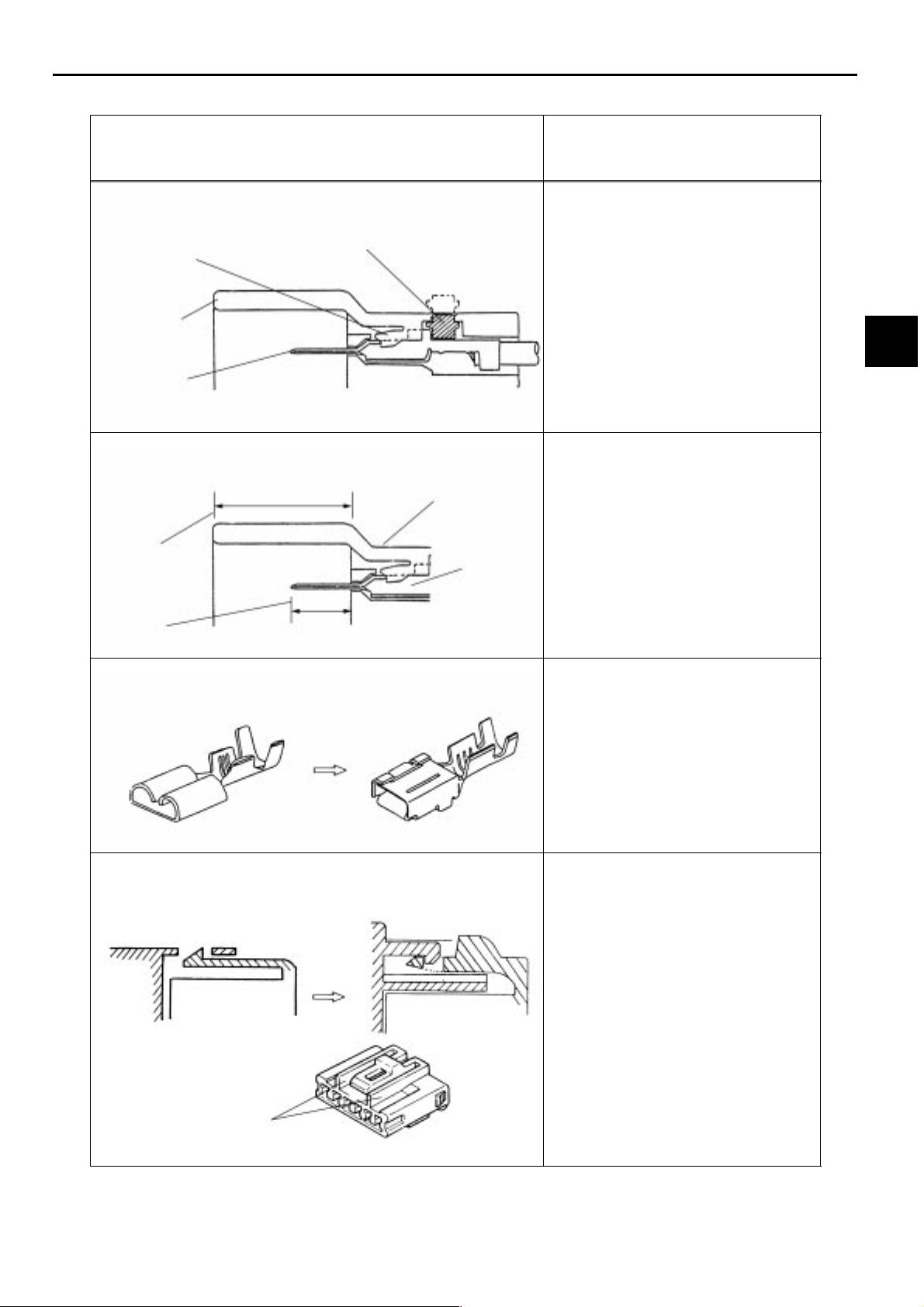

Table 1 : Characteristics of the new types of connector (Improvement)

Characteristics (Improvement) Note

A–4

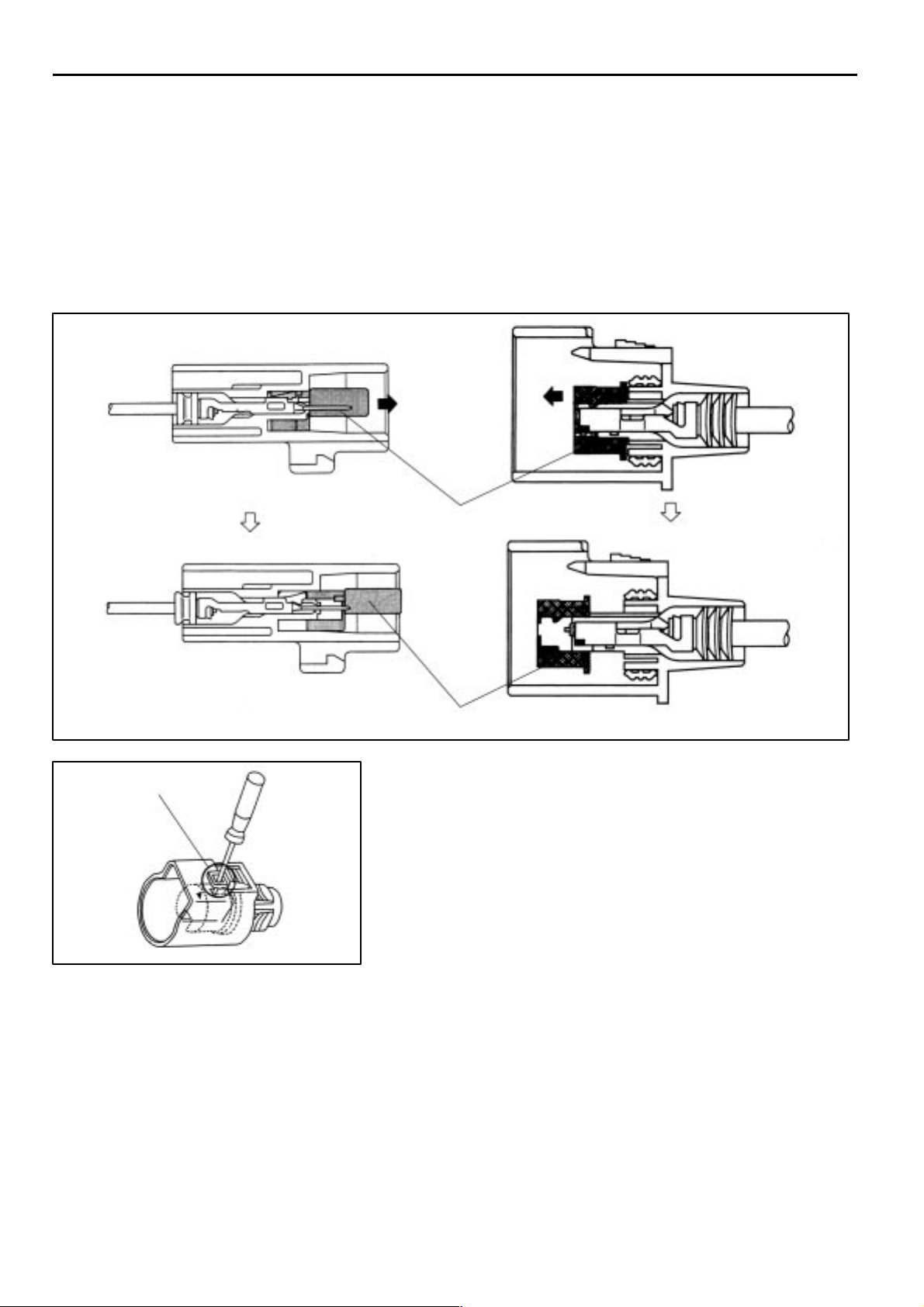

1. Double Lock

Lance (Primary Lock)

Housing

Terminal

2. Extension of Housing

Extension

Shortening

Retainer (Double Lock)

Housing

Terminal

If terminal is not inserted to

housing correctly, the retailer

does not fit.

A

This is to prevent deformation of

the terminal when it is inserted

diagonally.

3. Change of Contact Structure and

Introduction of Box–Shaped Structure

4. Change of Locking Shape

Ribs are added

Expansion of contact section

Stabilization of contact pressure

This improves the close fit of

locking and you can hear the

click sound and feel that the

connector is completely

installed.

Wire Harness Repair Manual (RM1022E)

5

A

A–5

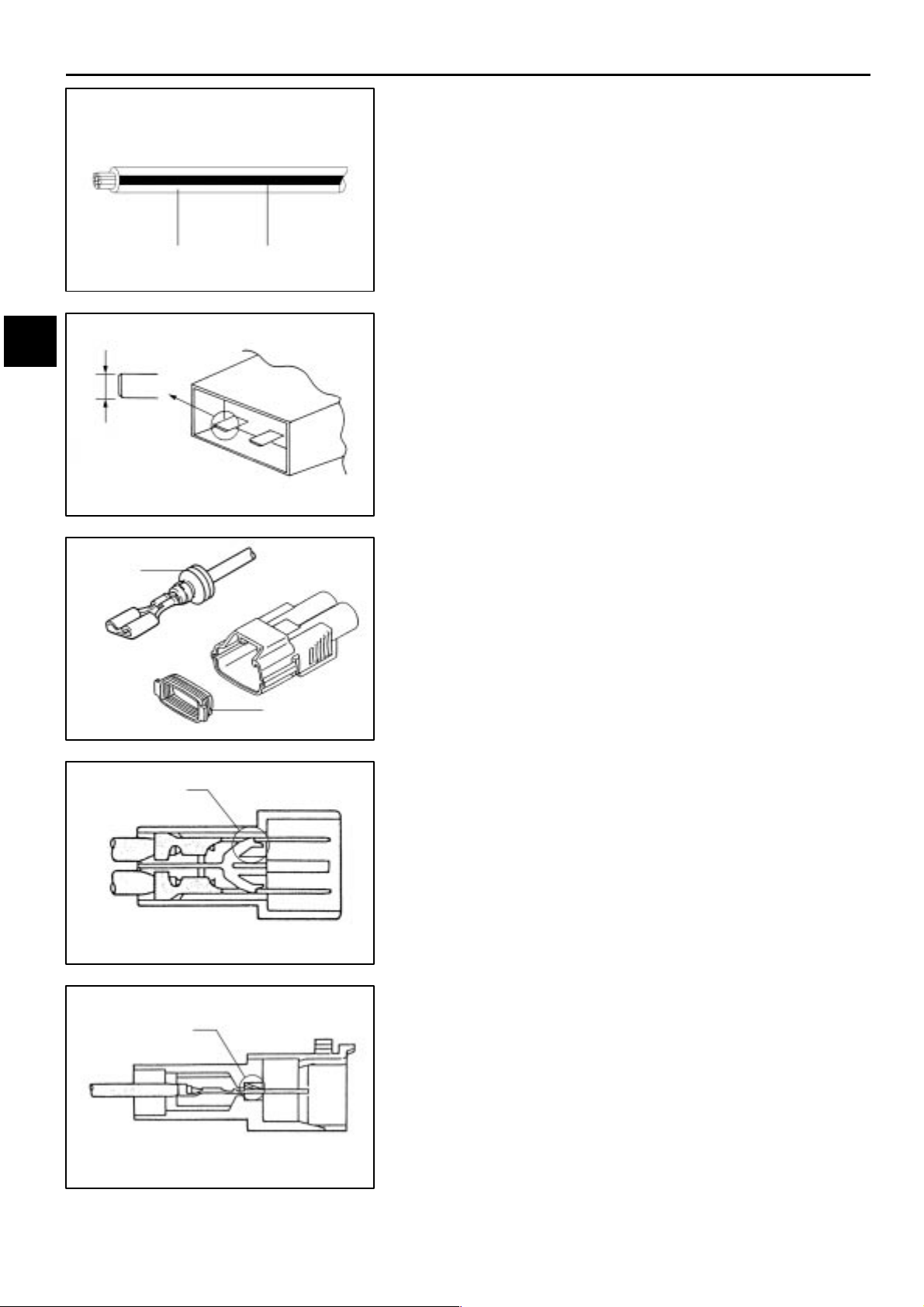

INTRODUCTION–HOW TO PERFORM FOR SYSTEM INSPECTION

HOW TO PERFORM FOR SYSTEM INSPECTION

This inspection procedure is a simple troubleshooting which should be carried out on the vehicle during

system operation and is based on the assumption of system component trouble

Always inspect the trouble taking the following items into consideration:

Ground point fault

Open or short circuit of the wire harness

Connector or terminal connection fault

Fuse or fusible link fault

NOTICE:

This is an on–vehicle inspection during system operation.

Therefore, inspect the trouble with due regard for safety.

If connecting the battery directly, be careful not to cause a short circuit, and select the applicable

voltage.

To Ignition SW

IG Terminal

Fuse

[A]

SW1

[B]

Relay

[C]

SW2 Solenoid

Voltmeter

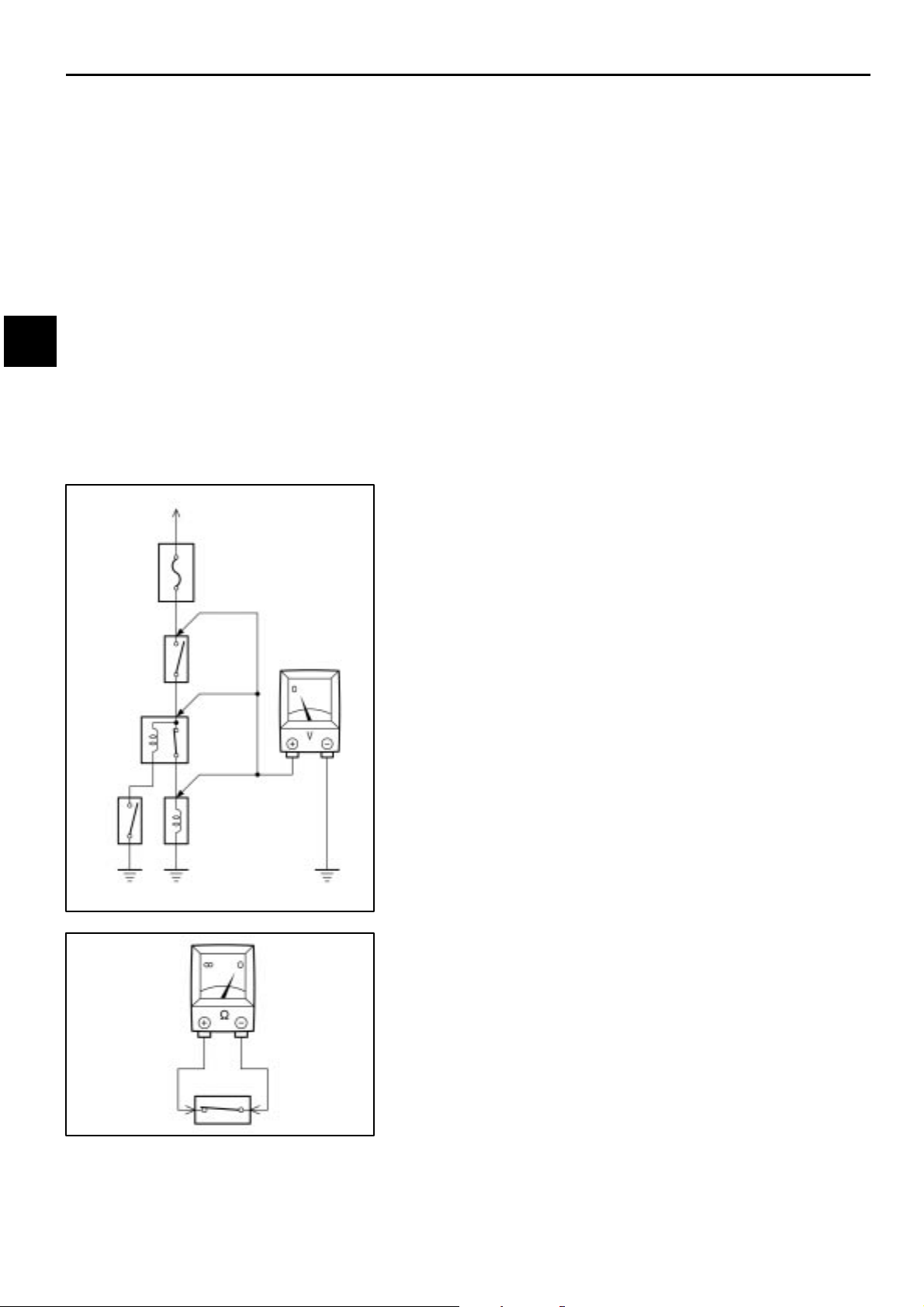

1. Voltage Check

(a) Establish conditions in which voltage is present at the

check point.

Example:

[A] – Ignition SW on

[B] – Ignition SW and SW 1 on

[C] – Ignition SW, SW 1 and Relay on (SW 2 off)

(b) Using a voltmeter, connect the negative (–) lead to a

good ground point or negative (–) battery terminal

and the positive (+) lead to the connector or

component terminal. This check can be done with a

test bulb instead of a voltmeter.

2. Continuity and Resistance Check

6

Ohmmeter

SW

(a) Disconnect the battery terminal or wire so there is no

voltage between the check points.

(b) Contact the two leads of an ohmmeter to each of the

check points.

Wire Harness Repair Manual (RM1022E)

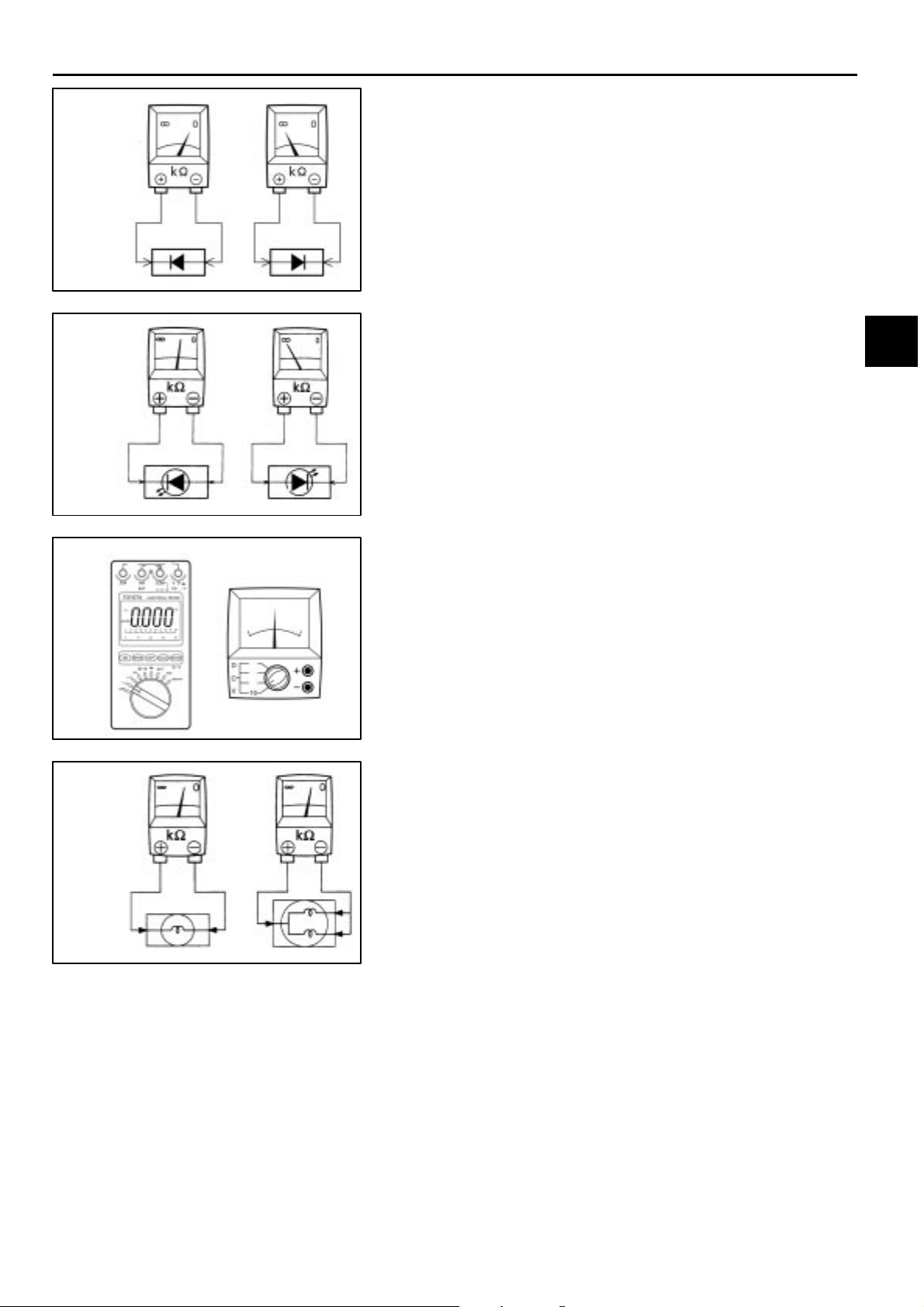

Ohmmeter

Diode

Ohmmeter

Diode

INTRODUCTION–HOW TO PERFORM FOR SYSTEM INSPECTION

If the circuit has diodes, reverse the two leads and check

again.

When touching the negative (–) lead to the diode positive

(+) side and the positive (+) lead to the negative (–) side,

there should be continuity. When touching the two leads in

reverse, there should be no continuity.

HINT: Specifications may vary depending on the type of

tester, so refer to the tester’s instruction manual before

performing the inspection.

Check LED (Light Emitting Diode) in the same manner as

that for diodes.

HINT:

Use a tester with a power source of 3V or greater to

overcome the circuit resistance.

If a suitable tester is not available, apply battery

voltage and check that the LED lights up.

A–6

A

Digital Type Analog Type

Ohmmeter

Bulb

(c) Use a volt/ohmmeter with high impedance (10kΩ/V

minimum) for troubleshooting of the electrical circuit.

3. Bulb Check

(a) Remove the bulb.

(b) There should be continuity between the respective

terminals of the bulb together with a certain amount

of resistance.

(c) Apply the two leads of the ohmmeter to each of the

terminals.

(d) Apply battery voltage and check that the bulb light up.

Wire Harness Repair Manual (RM1022E)

7

A–7

INTRODUCTION–HOW TO PERFORM FOR SYSTEM INSPECTION

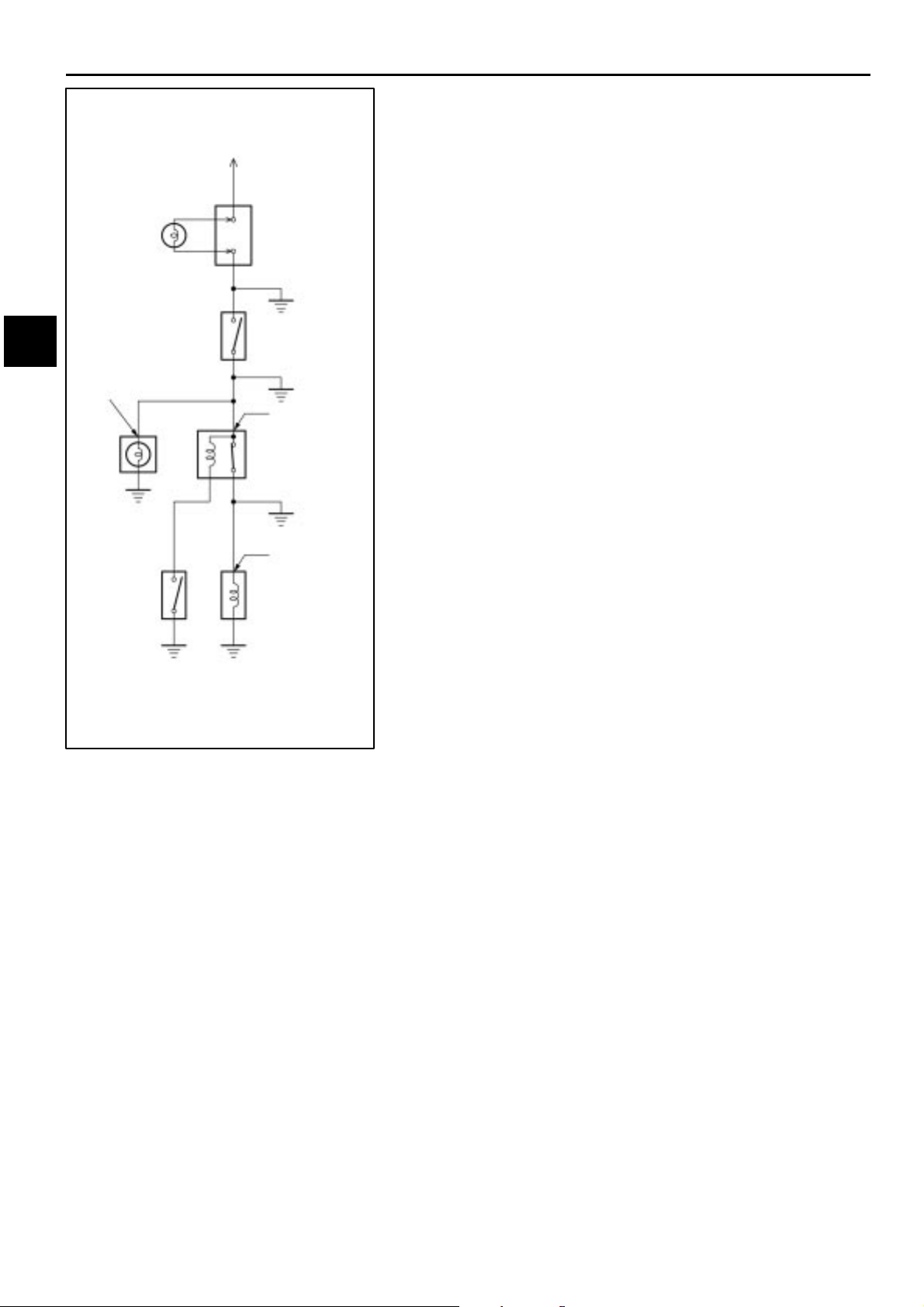

4. Finding a Short Circuit

(a) Remove the blown fuse and eliminate all loads from

the fuse.

To Ignition SW

IG Terminal

Fuse CaseTest Bulb

Short [A]

(b) Connect a test bulb in place of the fuse.

(c) Establish conditions in which the test bulb comes on.

Example:

[A] – Ignition SW on

[B] – Ignition SW and SW 1 on

[C] – Ignition SW, SW 1 and Relay on (Connect the Relay)

and SW 2 off (or disconnect SW 2)

A

Disconnect

Light

SW2 Solenoid

SW1

Short [B]

Disconnect

Relay

Short [C]

Disconnect

(d) Disconnect and reconnect the connectors while

watching the test bulb. The short lies between the

connector where the test bulb stays lit and the

connector where the bulb goes out.

(e) Find the exact location of the short by lightly shaking

the problem wire along the body.

CAUTION:

(a) Do not open the cover or the case of the ECU

unless absolutely necessary. (If the IC terminals

are touched, the IC may be destroyed by static

electricity.)

(b) When replacing the internal mechanism (ECU

part) of the digital meter, be careful that no part of

your body or clothing comes in contact with the

terminals of leads from the IC, etc. of the

replacement part (spare part).

8

Wire Harness Repair Manual (RM1022E)

INTRODUCTION–CIRCUIT PROTECTION

CIRCUIT PROTECTION

All electrical circuits are protected against excessive loads which might occur because of shorts or

overloads in the wiring system. Such protection is provided by a fuse, circuit breaker, or fusible link, A

short circuit may cause a fuse to blow or a circuit breaker to open.

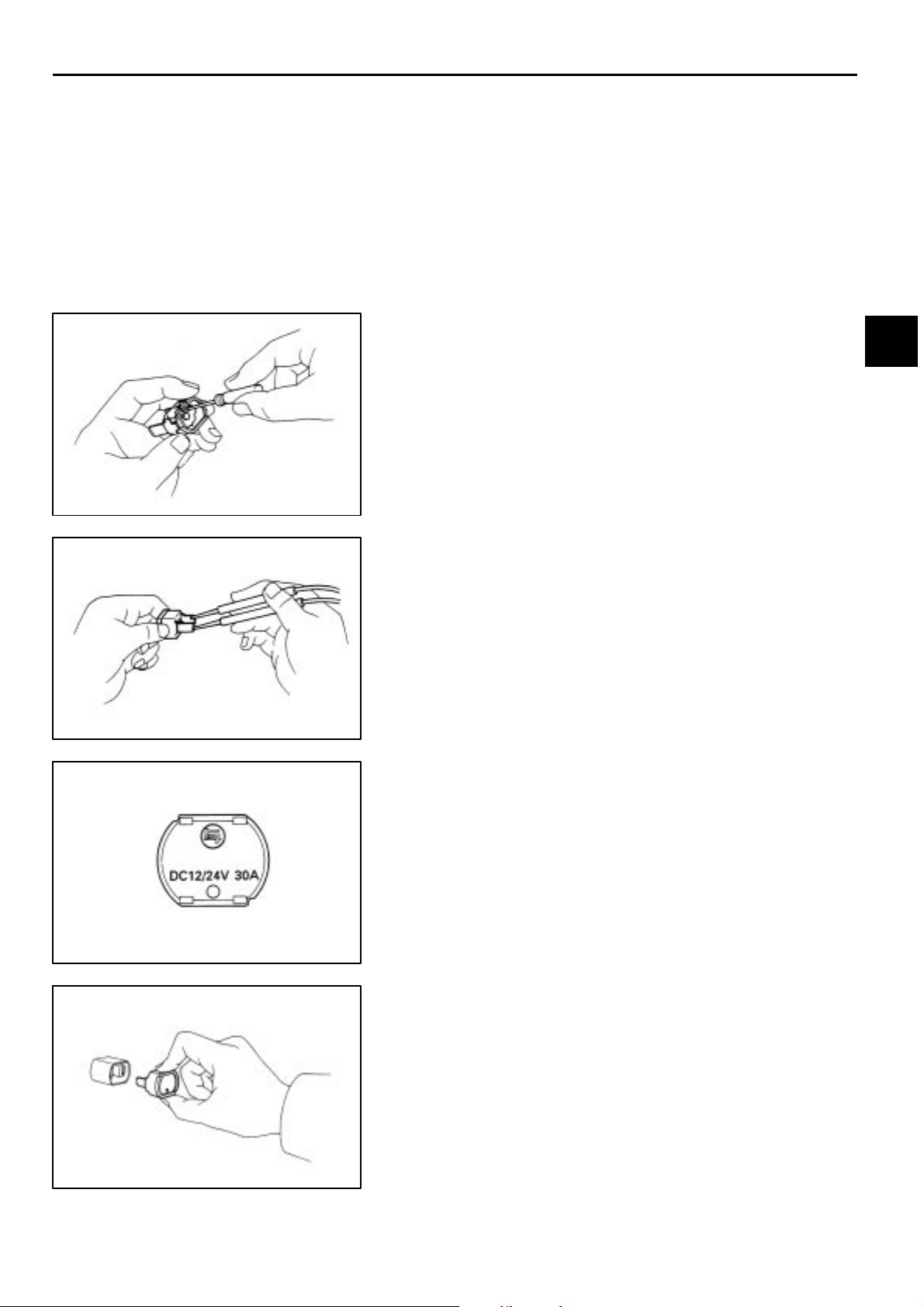

RESET CIRCUIT BREAKER

1. Remove Circuit Breaker

Push

(a) Disconnect the negative (–) cable from the battery.

(b) Remove the circuit breaker.

2. Reset Circuit Breaker

(a) Insert the needle into the reset hole and push it.

A–8

A

Equal Amperage Rating

(b) Using an ohmmeter, check that there is continuity

between both terminals of the circuit breaker.

If continuity is not as specified, replace the circuit breaker.

HINT: If replacing the circuit breaker, be sure to replace

it with a breaker with an equal amperage rating.

3. Install Circuit Breaker

(a) Install the circuit breaker.

(b) Connect the negative (–) cable to the battery.

HINT: If a circuit breaker continues to cut out, a short

circuit is indicated. Have the system checked by a qualified

technician.

Wire Harness Repair Manual (RM1022E)

9

A–9

Equal Amperage Rating

INTRODUCTION–CIRCUIT PROTECTION

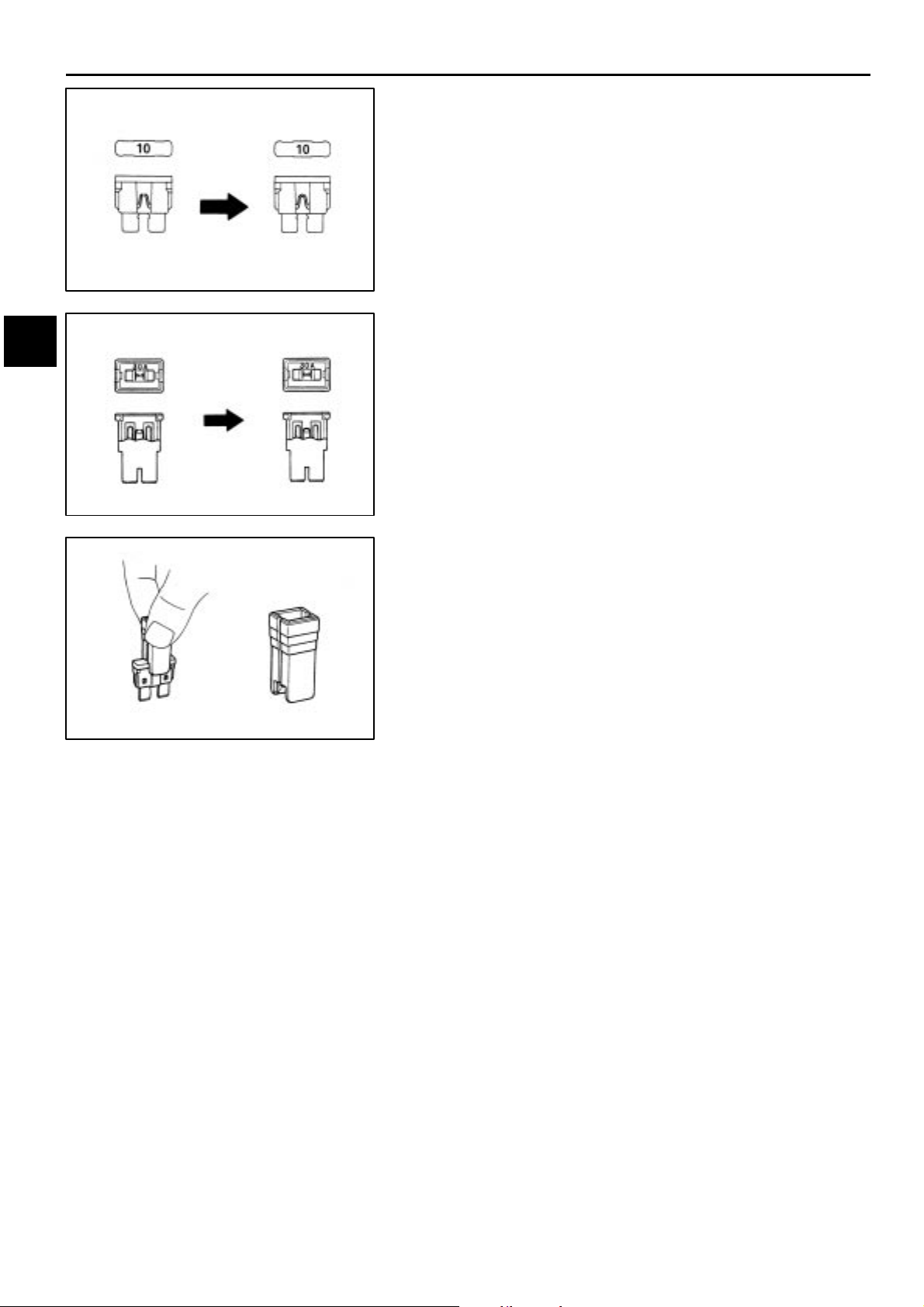

REPLACEMENT OF FUSE AND FUSIBLE LINK

HINT: If replacing the fuse or fusible link, be sure to

replace it with a fuse or fusible link with an equal amperage

rating.

A

Equal Amperage Rating

Puller

NOTICE:

1. Turn off all electrical components and the ignition

switch before replacing a fuse or fusible link. Do

not exceed the fuse or fusible link amperage rating.

2. Always use a fuse puller for removing and

inserting a fuse. Remove and insert straight in and

out without twisting. T wisting could force open the

terminals too much, resulting in a bad connection.

If a fuse or fusible link continues to blow, a short circuit is

indicated. The system must be checked by a qualified

technician.

HINT: The puller is located at Junction Block No.2.

10

Wire Harness Repair Manual (RM1022E)

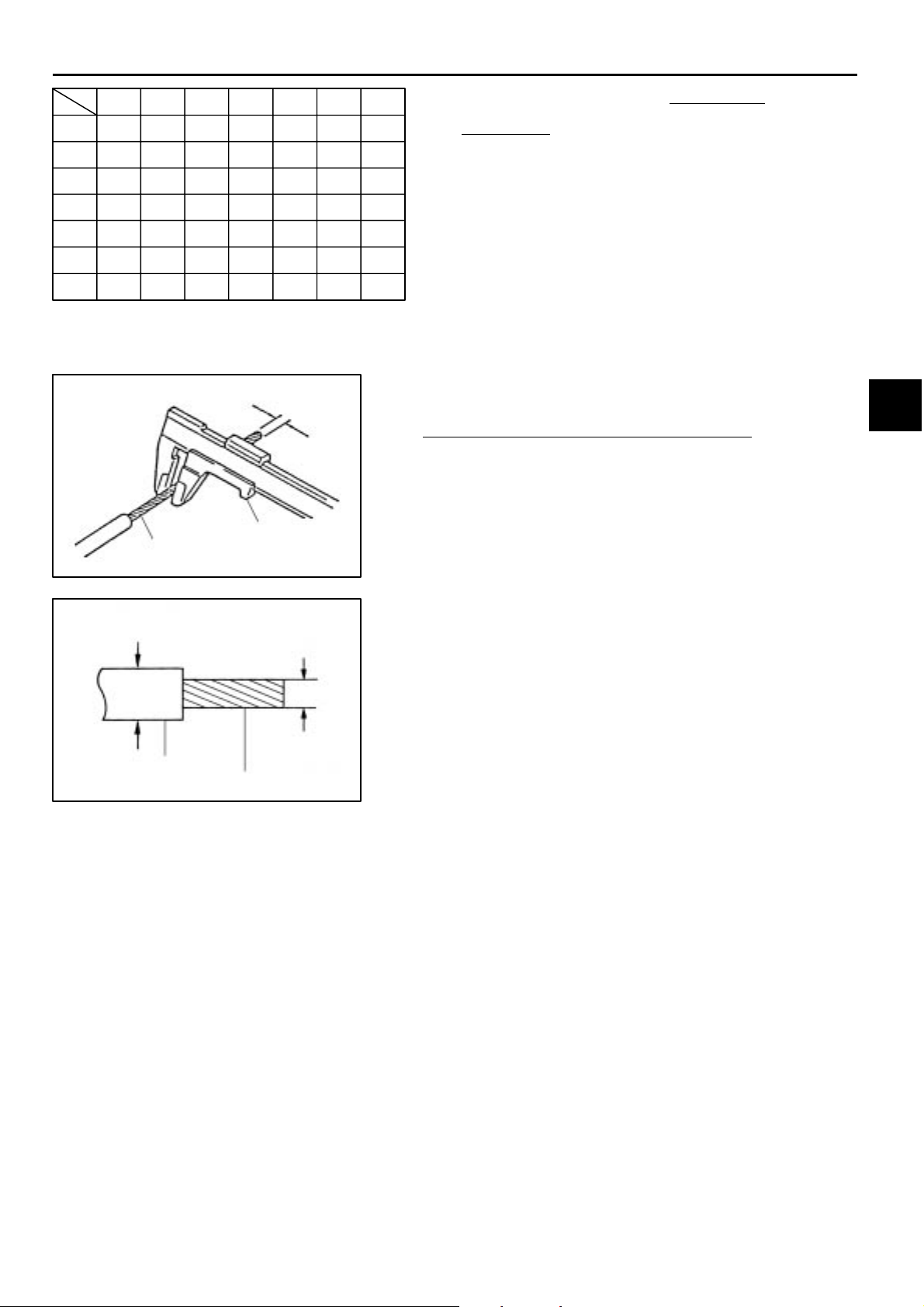

TERMINAL AND CONNECTOR REPAIR–PREPARATORY ITEMS

Oth

PREPARATORY ITEMS

B–1

Tool

Gauge

ers

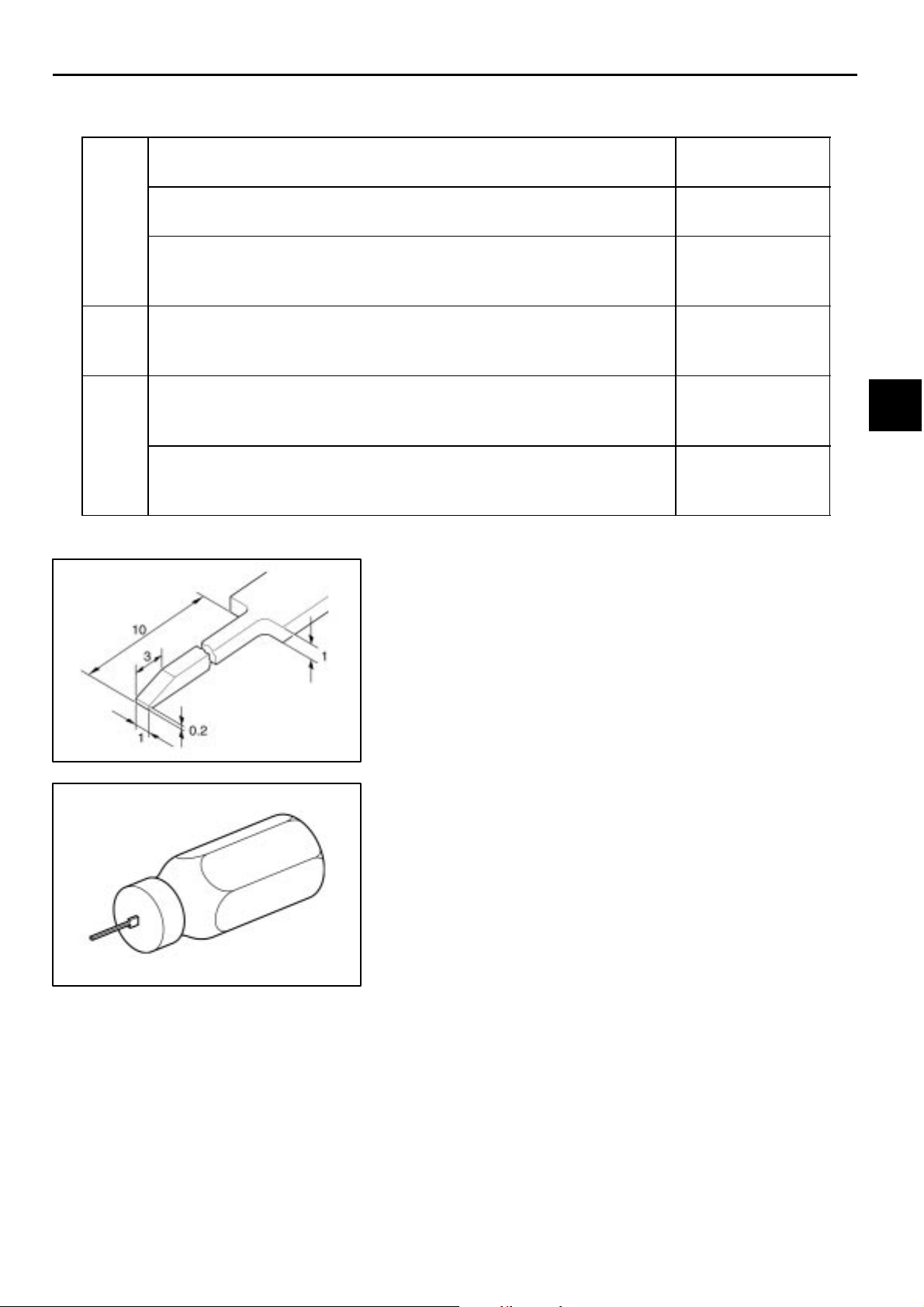

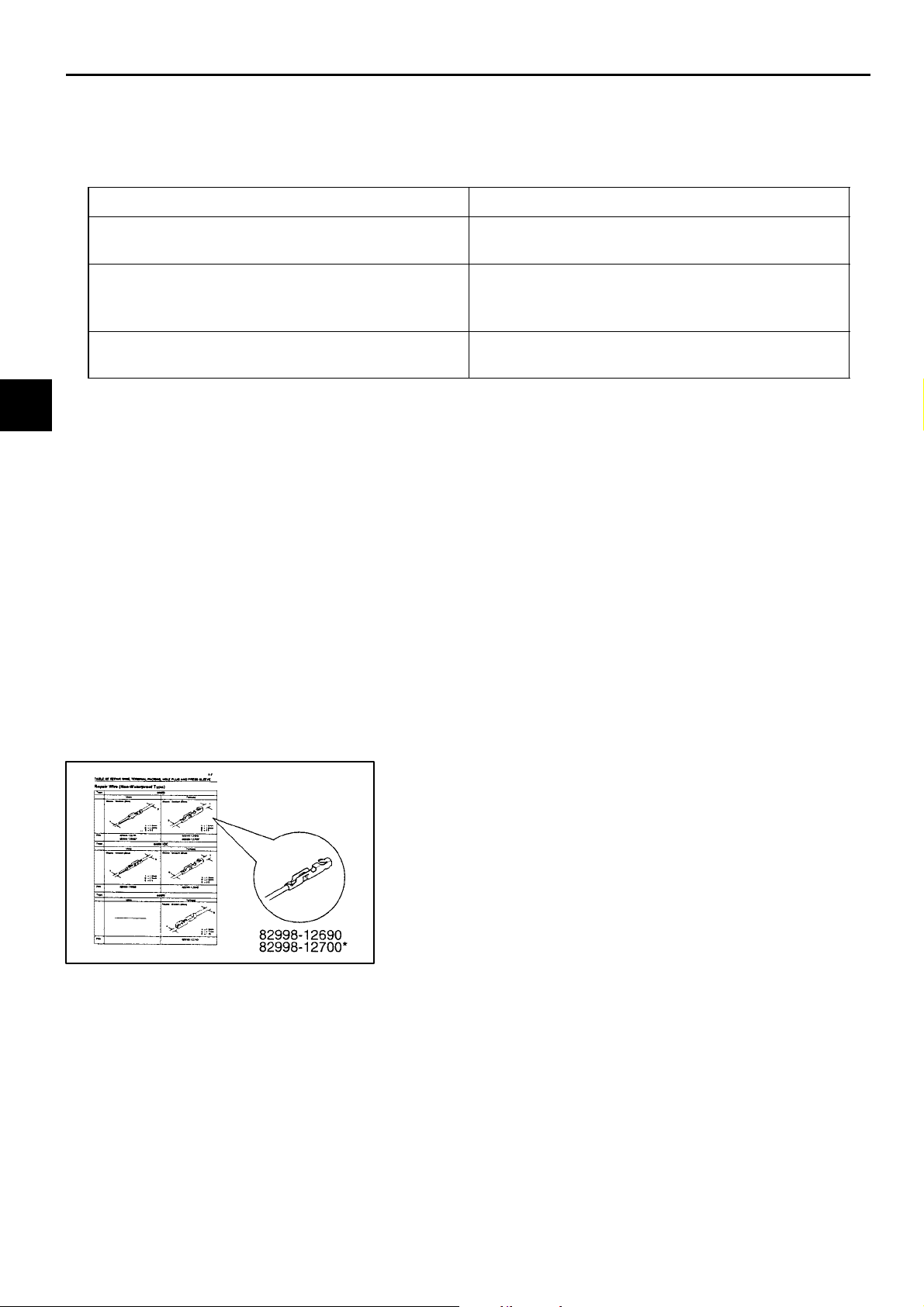

Reference:

Crimping tool AMP Part No. 169060

Special tool Refer to the following illustration

SST 09991–00500

Caliper 0–150 mm

82999–12010 (Red)

Press sleeve 82999–12020 (Blue)

82999–12030 (Yellow)

Silicon tape 08231–00045

Special Tool

HINT: To remove the terminal from the connector, please

construct and use the special tool or like object shown on

the left.

For caulking

press sleeves

To remove the

terminal

To remove the

0.64 connector

terminal

To measure the

diameter of the

core

To connect wires

To waterproof

the connected

section

B

(mm)

Preparation of the SST to release the 0.64 connector terminal.

SST 09991–00500

HINT:

This is a SST for releasing terminals from 0.64 connectors.

Wire Harness Repair Manual (RM1022E)

11

B–2

TERMINAL AND CONNECTOR REPAIR–CONNECTOR REPAIR

CONNECTOR REPAIR

The repair parts now in supply are limited to those connectors having common shapes and terminal

cavity numbers. Therefore, when there is no available replacement connector of the same shape or

terminal cavity number, please use one of the alternative methods described below. Make sure that the

terminals are placed in the original order in the connector cavities, if possible, to aid in future diagnosis.

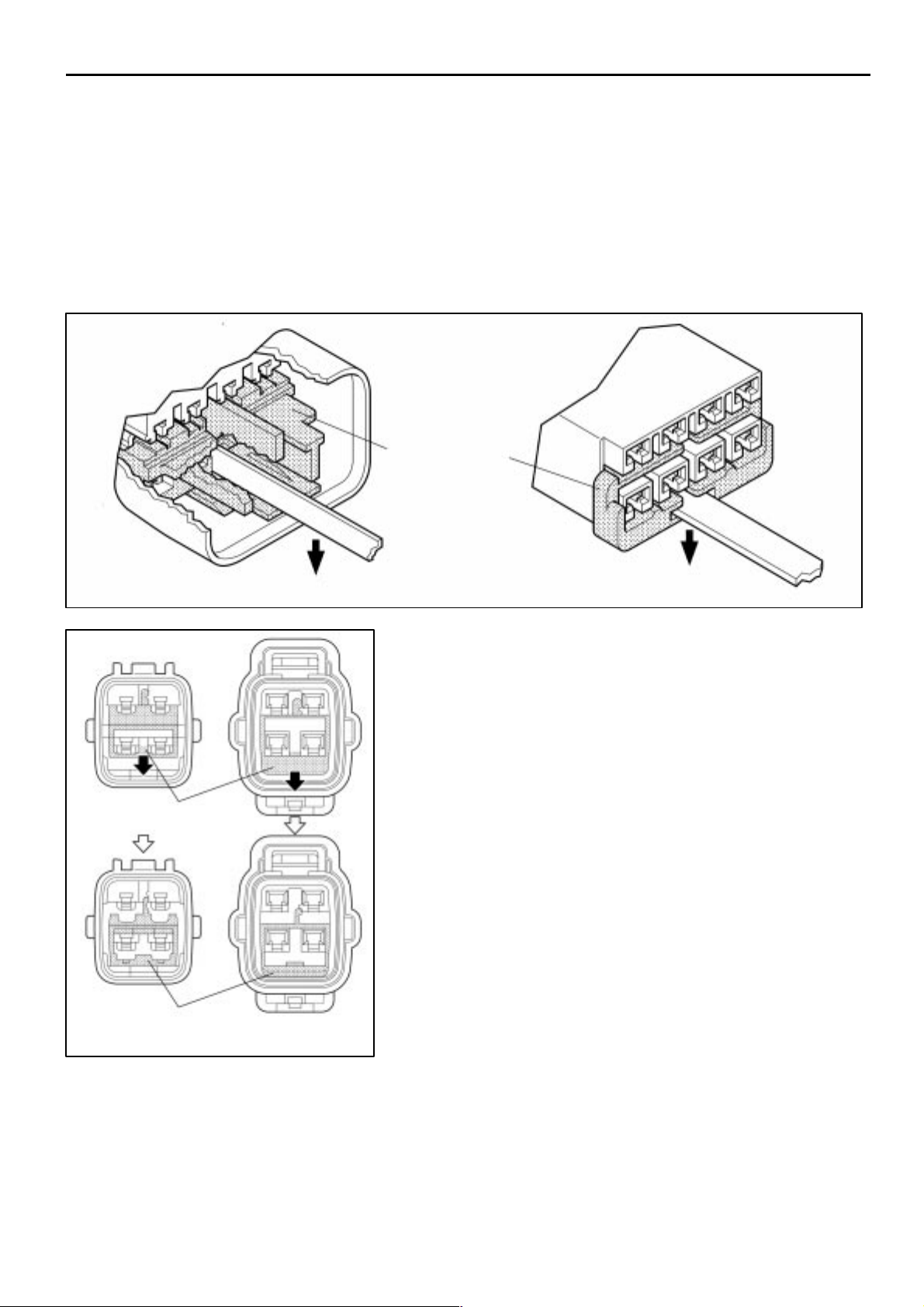

1. When a connector with a different number of terminals

having more terminal cavities than required, and replace both the male and female connector parts.

EXAMPLE: You need a connector with six terminals, but the only replacement available is a connector

with eight terminal cavities. Replace both the male and female connector parts with the eight terminal part,

transferring the terminals from the old connectors to the new connectors.

2. When several different type terminals

connector part for each terminal type used, and replace both male and female connector parts.

B

EXAMPLE: You need to replace a connector that has two different types of terminals in one connector.

Replace the original connector with two new connectors, one connector for one type of terminal, another

connector for the other type of terminal.

3. When a different shape of connector

appropriate number of terminal cavities, and one that uses terminals of the same size as, or larger than,

the terminal size in the vehicle. The wire lead on the replacement terminal must also

or larger than, the nominal size of the wire in the vehicle. (”Nominal” size may be found by looking at the

illustrations in the section F or by direct measurement across the diameter of the insulation). Replace all

existing terminals with the new terminals, then insert the terminals into the new connector.

EXAMPLE: You need to replace a connector that is round and has six terminal cavities. The only round

replacement connector has three terminal cavities. You would select a replacement connector that has

six or more terminal cavities and is not round, then select terminals that will fit the new connector. Replace

the existing terminals, then insert them into the new connector and join the connector together.

are used in one connector, select an appropriate male and female

is used, first select from available parts a connector with the

than the original part is used, select a connector

be the same size as,

12

Wire Harness Repair Manual (RM1022E)

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

TERMINAL REPLACEMENT

These steps must be followed when replacing a terminal.

Step 1. Identify the connector and the terminal type.

Step 2. Disconnect the terminal from the connector.

B–3

B

Step 3. Replace the terminal.

Step 4. Install the terminal into the connector.

Wire Harness Repair Manual (RM1022E)

13

B–4

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

Step 1. Identify the connector and the terminal type.

Confirm whether the connector you require is the non–waterproof, waterproof or combined terminal type

connector from the pictures provided in the following charts.

Connector Description

Non–Waterproof Type Those connectors which are not of the

waterproof or combined terminal type.

Waterproof Type Waterproof material (hole plug or terminal

packing) is provided on the terminal/connector

body.

Combined Terminal Type Terminals of different shape/size are located in

one connector.

B

1. Terminal with Wire

Identify the part number of the terminal with wire by picking

out the corresponding illustration from the pictures

provided on the following charts.

HINT: In some of the illustrations, there are two part

numbers for the same illustration of terminal with wire,

because although the shapes of the terminals are

completely the same, there is a difference in with /without

gold–plating (gilded).

Remark: The l ength of the wire connected to the

terminal is approximately 150 mm.

14

Wire Harness Repair Manual (RM1022E)

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

NOTICE:

When the terminal used is gold plated, be sure to

replace it with a gold plated terminal when marking

repairs.

Do not use male and female terminals which are

made of different materials from each other.

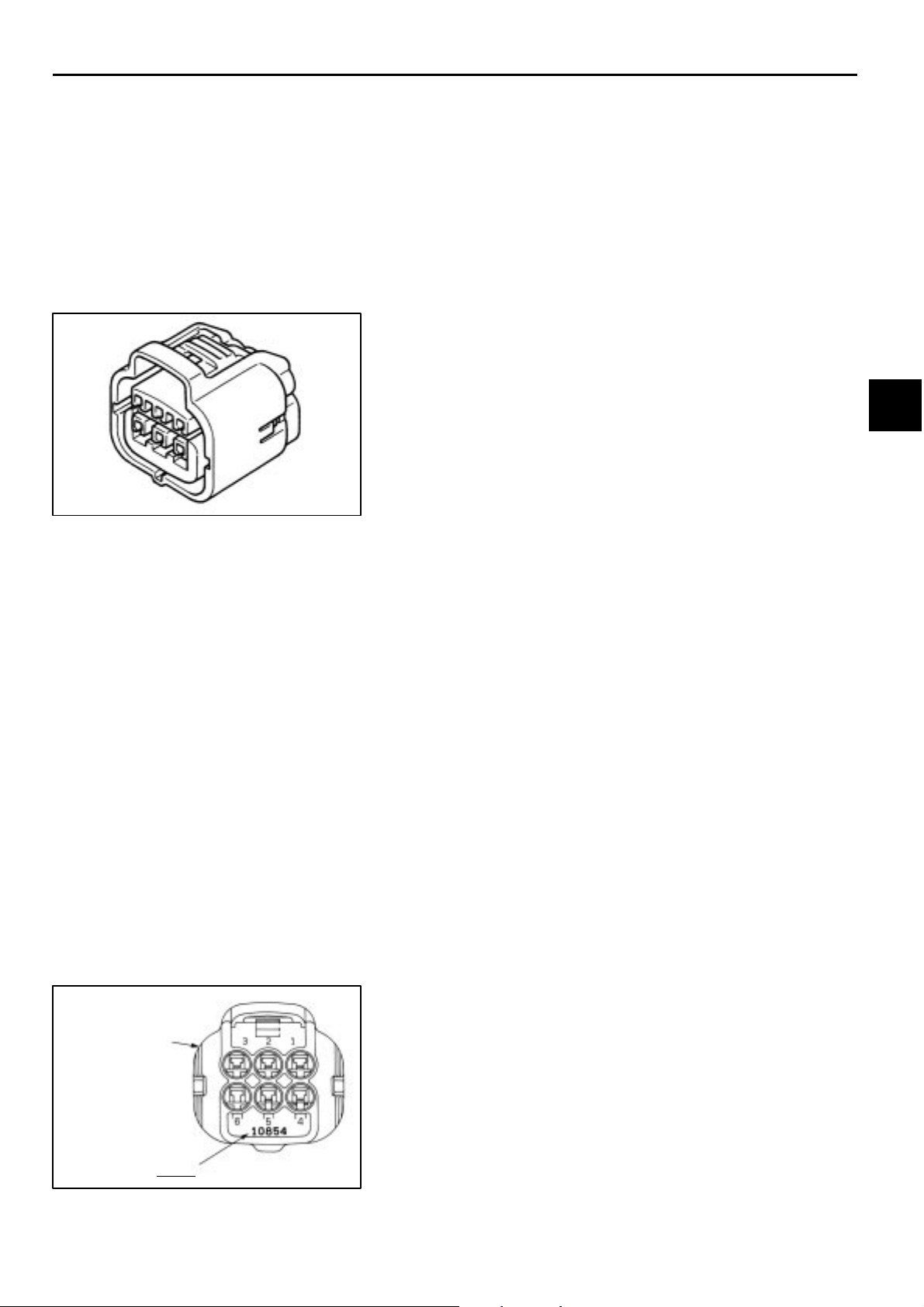

2. Connector Body

(a) Identify the part number of the corresponding

terminal with wire according to the above–mentioned

1.

(b) Identify the part number of the connector body by

picking out the correct one from the illustrations

according to the number of terminals and the shape.

B–5

B

Example:

Back of the

Connector Body

HINT:

(a) If you can find no connector which matches the type

you require, pick out male and female connector

bodies as a set which have more terminals than you

require.

For the combined terminal type connector body, pick

out and appropriate connector body for each terminal

being used.

Example:

When two types of terminal are used in one connector

body, pick out a male and female for two different

connector bodies.

(b) The part number has been stamped on the back of

the connector body. (This will continue to be done to

new types of connector.)

P/N 90980–10854

Wire Harness Repair Manual (RM1022E)

15

B

B–6

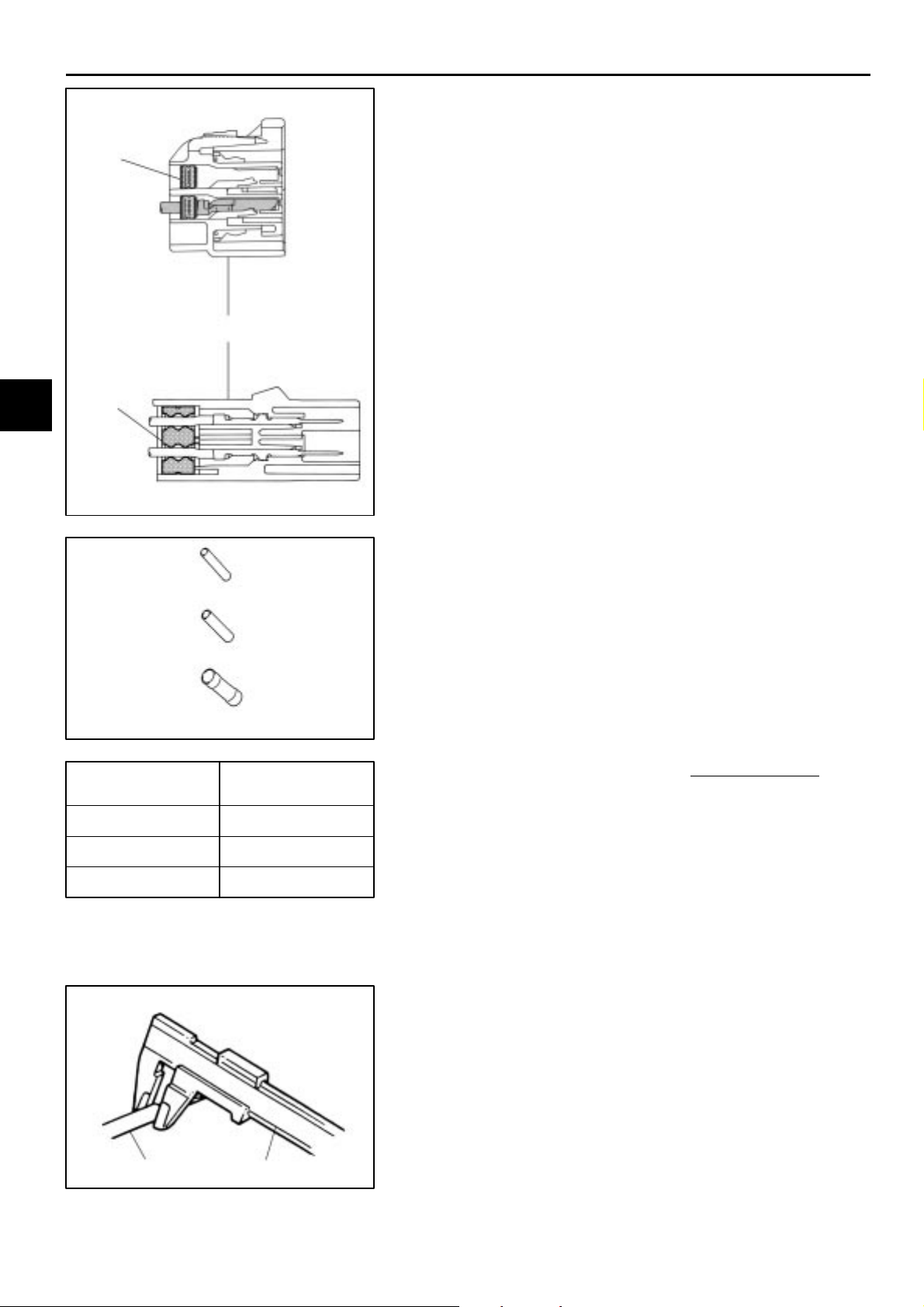

Hole Plug

Terminal

Packing

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

3. Hole Plug/Terminal Packing

(a) Identify the part number of the appropriate terminal

with wire/connector body from the illustrations of

waterproof type connector according to the

above–mentioned 1 and 2.

(b) Identify the part number of the hole plug/terminal

packing from the corresponding illustration.

Connector Body

Medium (Blue)

Wire Outside

Diameter

Small (Red)

Large (Yellow)

Sleeve Size

Small (Red)0.2–1.0 mm

Medium (Blue)1.0–2.0 mm

Large (Yellow)3.0–5.0 mm

(Color)

4. Sleeve

When connecting two wires using a sleeve, select the

sleeve according to the following table.

(a) When size is based on the outside diameter of the

wire.

Wire Outside Diameter

Insulation Calipers

16

Wire Harness Repair Manual (RM1022E)

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

B–7

∗

0.3

0.5

0.85

∗

0.3

0.5

0.85

1.25

2

3

5

M

M

M

M

S

M

M

M

M

M

L

L

L

L

1.25

M

M

M

M

L

L

L

∗ Nominal size of the wire

Nominal Size of Wire

Twist Evenly

M

M

M

M

L

L

L

Wire Lead

Diameter

Calipers

M

M

––

2

3

L

L

L

L

(b) When size is based on the nominal size of the wire.

5

L

L

L

Sleeve size

S : Small (Red)

M : Medium (Blue)

L : Large (Yellow)

L

L

L

L

L

––

L

L

––

––

––

HINT: To calculate the ”Nominal Size” of the wire.

Nominal size =

3.14 x (Diameter of stripped wire harness)

2

B

4

Wire Outside Diameter

Insulation

Stripped Wire Harness Section

HINT: Outside Diameter and Nominal Size

Nominal Size

Wire Harness Repair Manual (RM1022E)

17

B–8

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

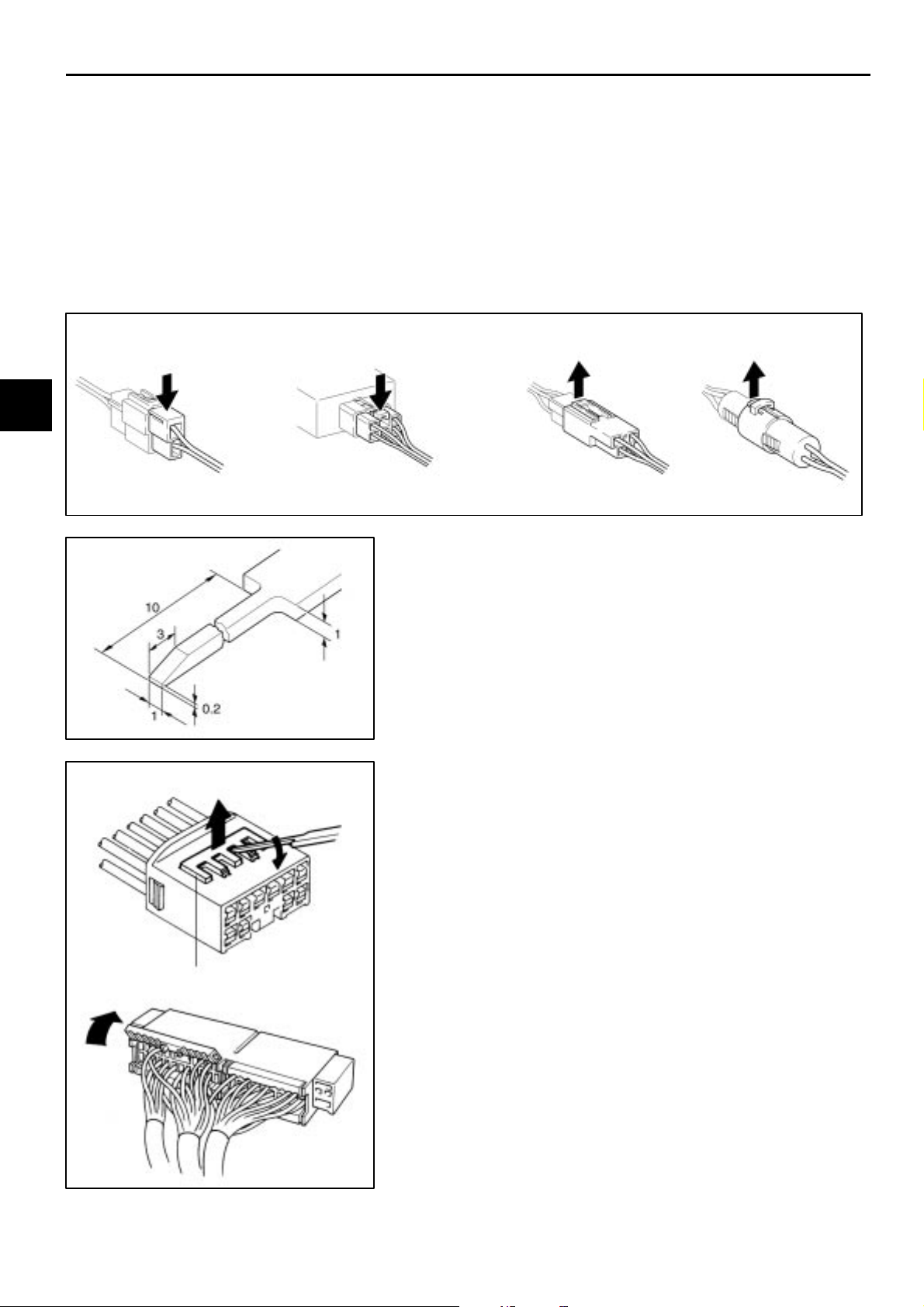

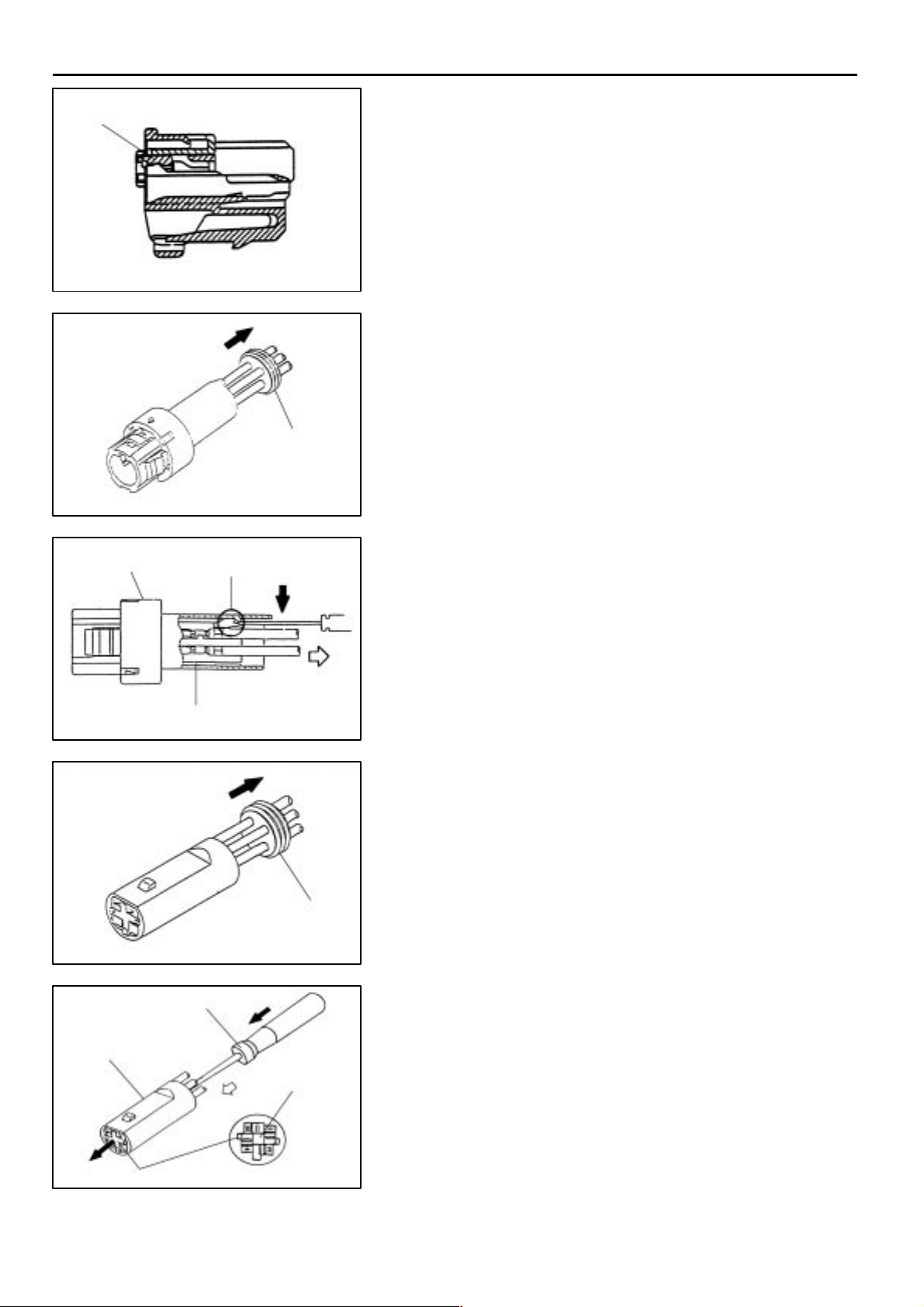

Step 2. Disconnect the Terminal from the Connector.

1. Disconnect Connector

To pull apart the connectors, pull on the connector itself,

not the wire harness.

HINT: Check to see what kind of connector you are

disconnecting before pulling apart.

Press down type is mainly used.

Example:

Press Down

Press Down

B

Pull Up Pull Up

Refereance:

Example:

Up

Terminal Retainer

Tool

2. Prepare the Special Tool

HINT: To remove the terminal from the connector, please

construct and use the special tool or like object shown on

the left.

(mm)

3. Disengage the double locking device or terminal

retainer.

(a) Locking device must be disengaged before the

terminal locking clip can be released and the terminal

removed from the connector.

(b) Use a special tool or the terminal pick to unlock the

double locking device.

NOTICE:

Do not remove the terminal retainer from connector

body.

18

Wire Harness Repair Manual (RM1022E)

Terminal Retainer

Terminal Retainer

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

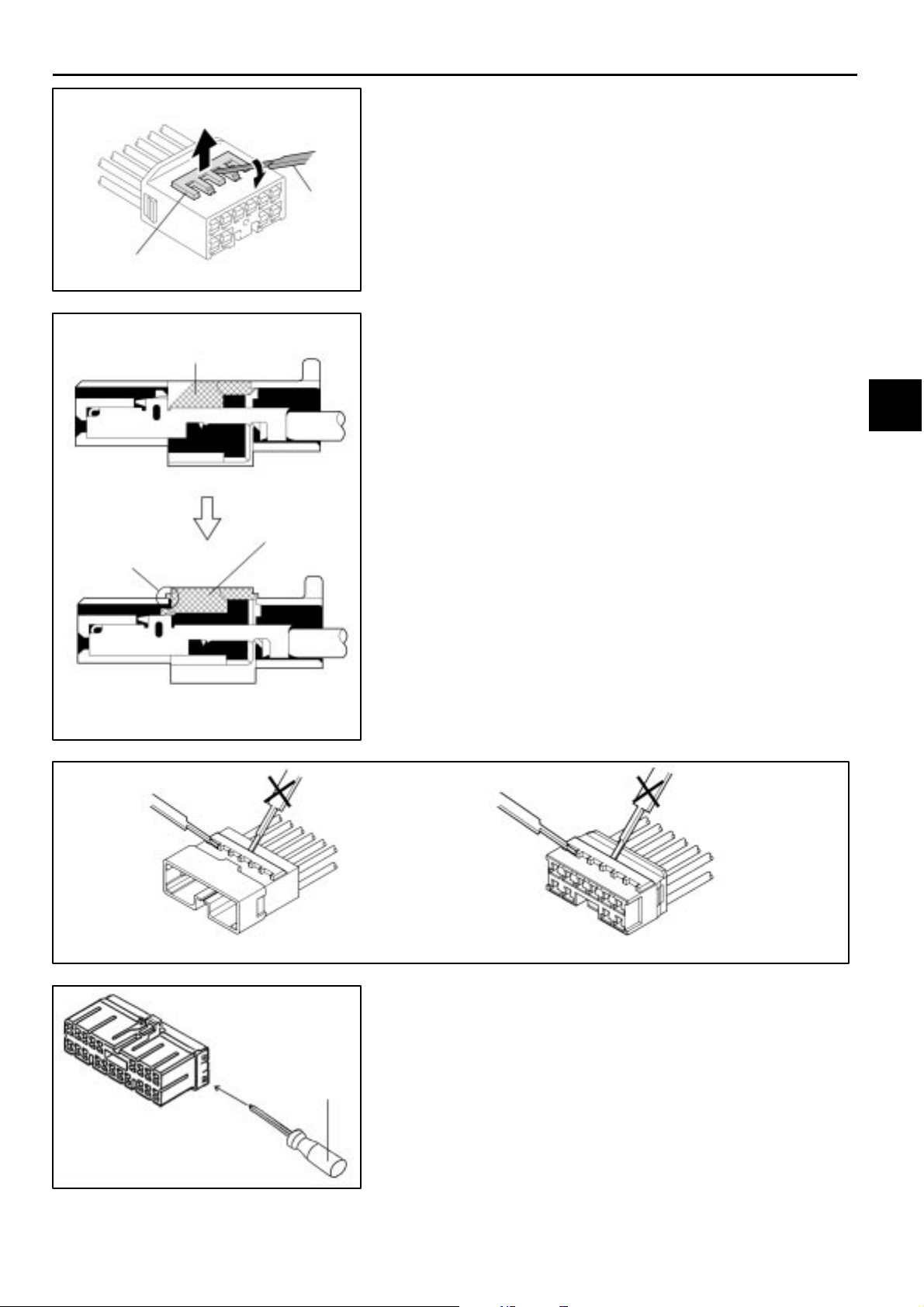

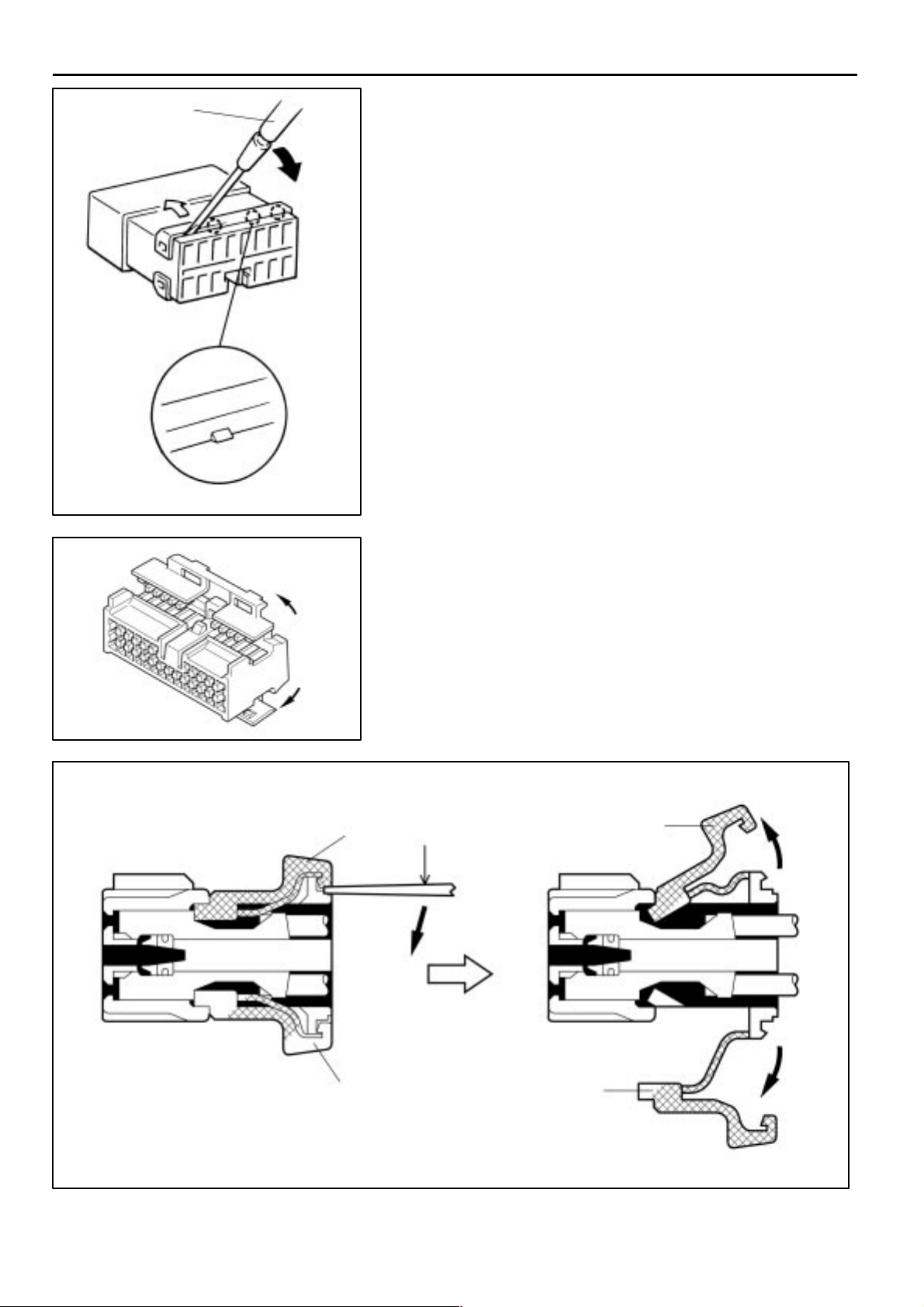

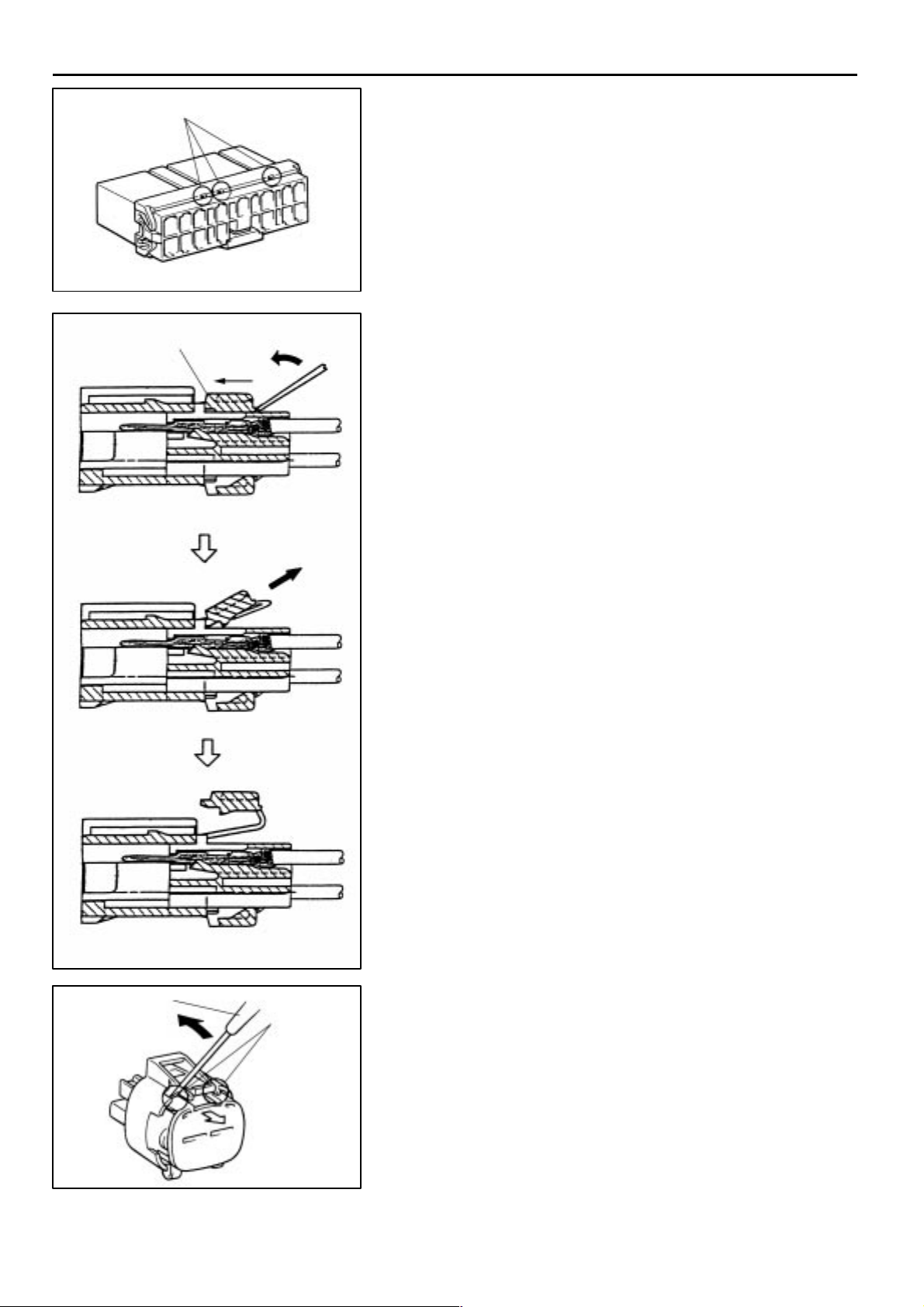

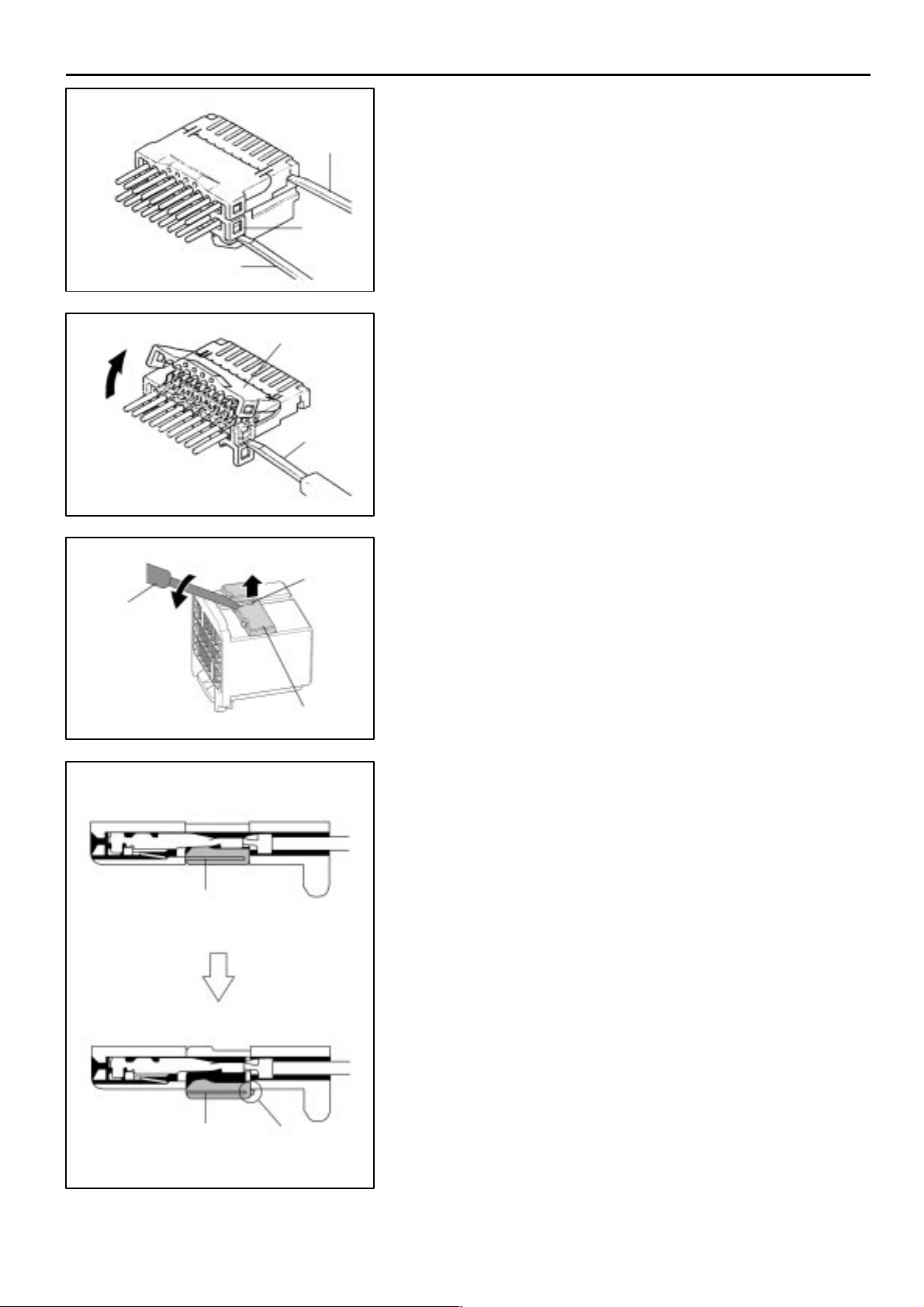

Type A (For 1.0II, 1.8, 2.3II, 4.8 and 8.0 of Non–Waterproof

Raise Up

Type Connector)

(1) Using the special tool, raise the retainer up to the

temporary lock position.

Special

Tool

HINT: The needle insertion position varies according to

the connector’s shape (number of terminals, etc.), so

check the position before inserting it.

B–9

B

[Retainer at Full Lock Position]

Terminal

Stopper

[Retainer at Temporary Lock Position]

Retainer

Good BadGood Bad

[Male] [Female]

Type B (For 1.8, 1.0 and TLC of Non–Waterproof Type

Connector)

Special Tool

Wire Harness Repair Manual (RM1022E)

19

B

B–10

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

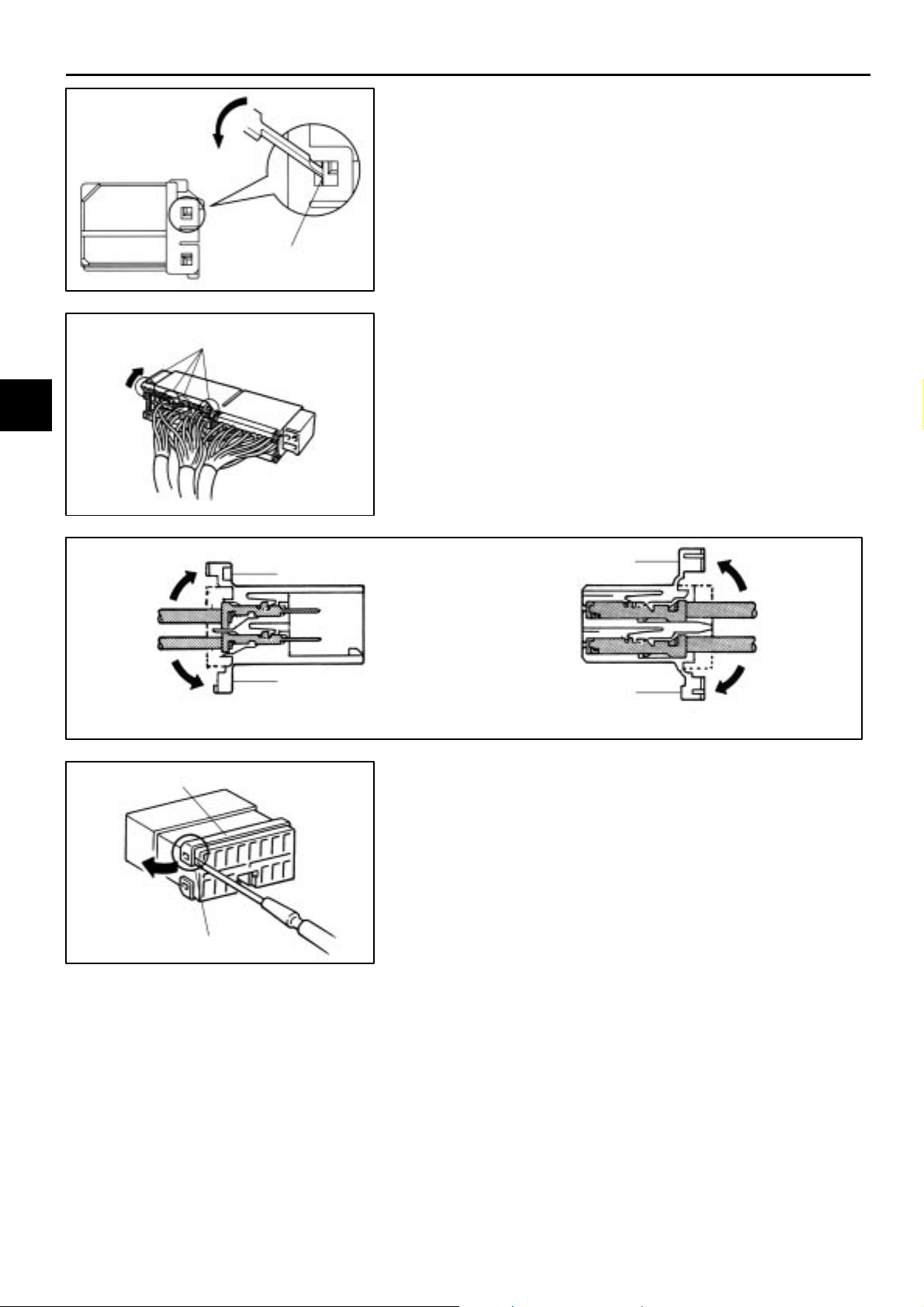

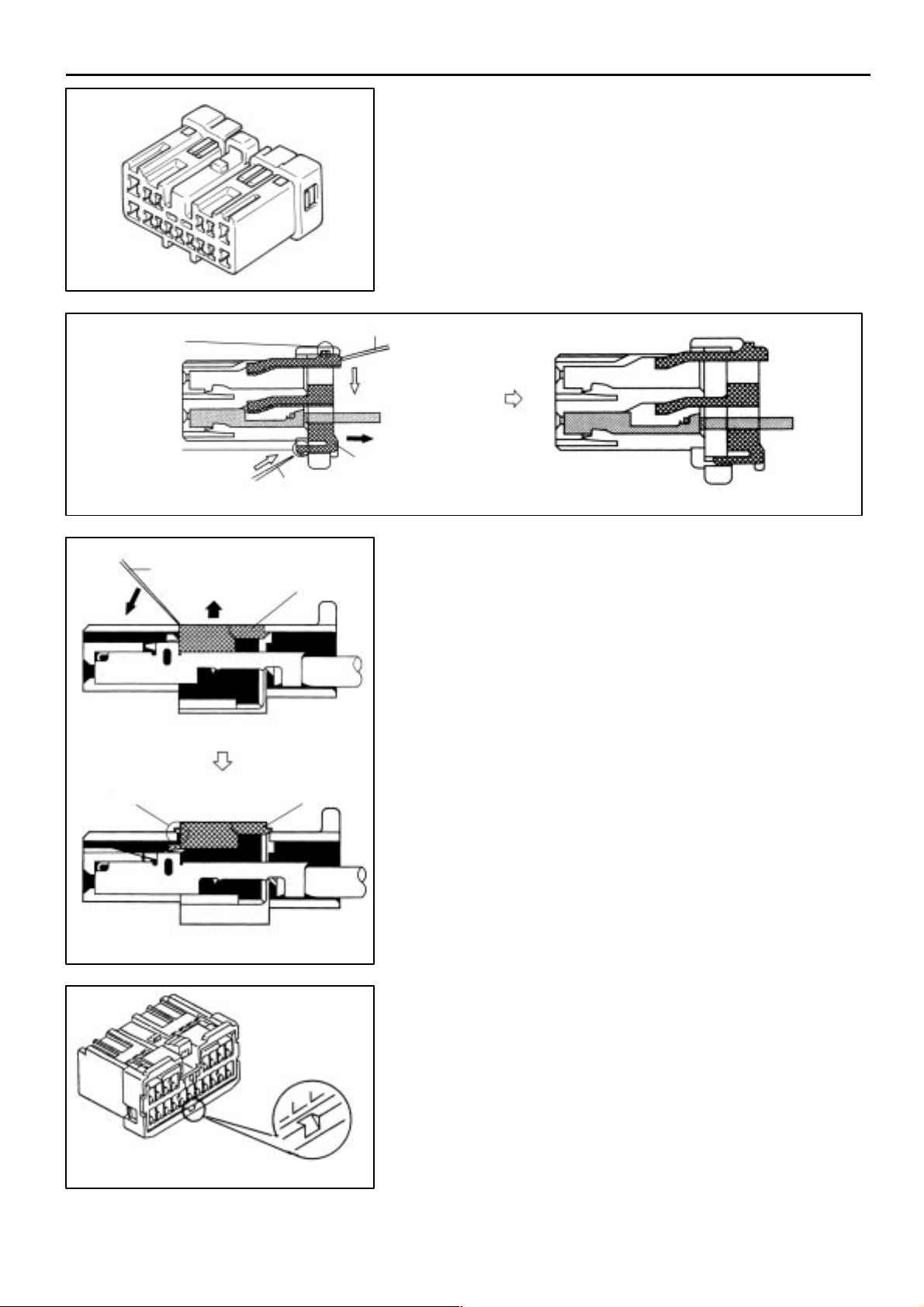

(1) Press the special tool at a 45° angle into the locking

lug access hole as shown.

Raise the double locking device up as far as possible.

Access Hole

(2) Remove the special tool and open the double locking

Tab

device

NOTICE:

TLC housing is not be reusable. Please replace it with

the new one after replacement of the terminal.

Open

Retainer

Side Lock

[Male]

∗

∗

∗

∗

[Female]∗ Double Locking Device.

Open

Type C (For TNS, FTC Type Connector)

(1) Widen the side lock part of the retainer from side to

side using the special tool.

20

Wire Harness Repair Manual (RM1022E)

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

B–11

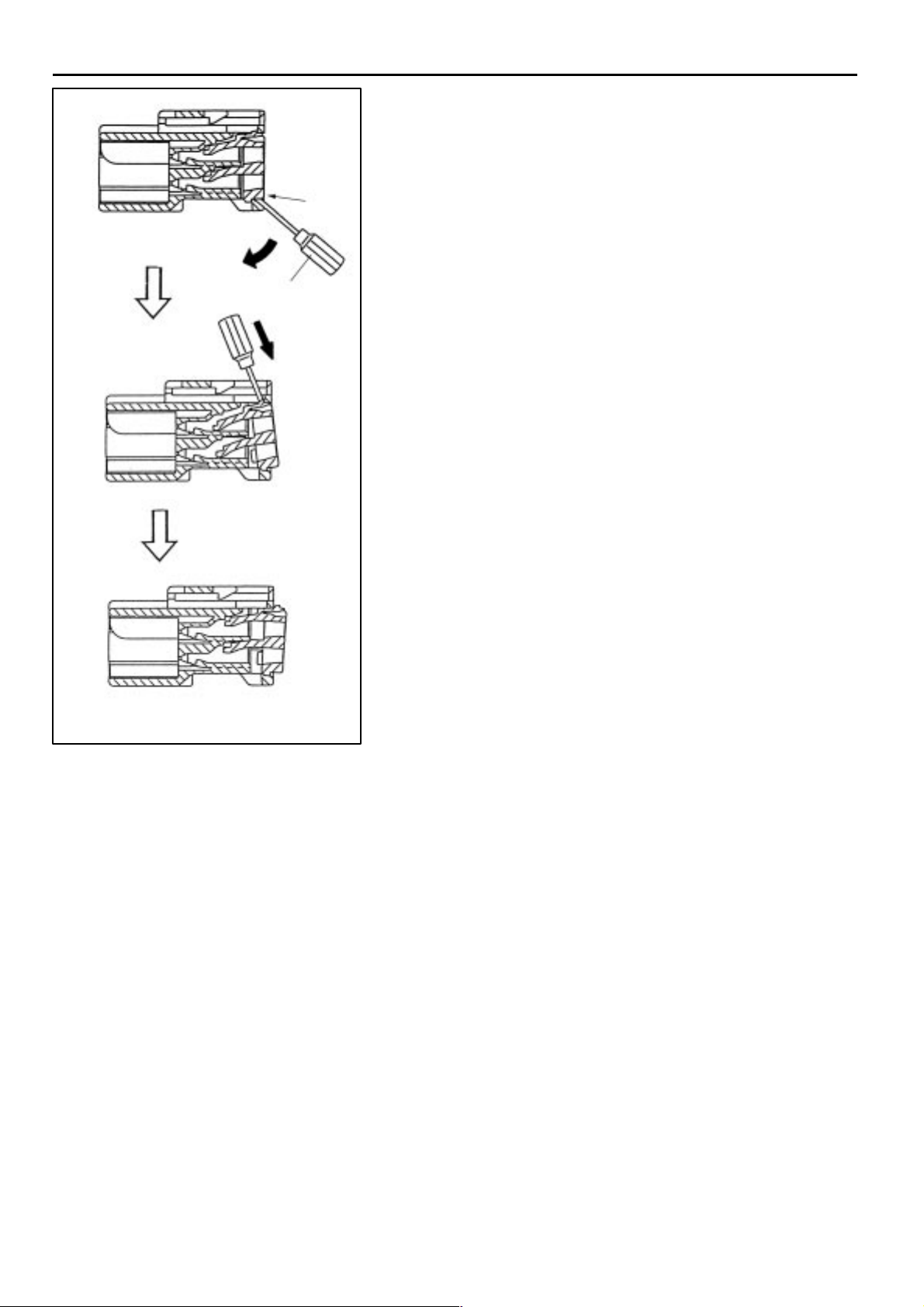

Special tool

(2) Inset the special tool into the chink between the

retainer and the terminal itself. Then pry it to the

direction of the arrow shown in the illustration and

push the retainer up to release the lock.

NOTICE:

Do not insert the special tool too much. It may cause

damage on the fit section of the terminal and the

wire harness.

TNS housing is not reusable. Please replace it with

the new one after replacement of the terminal.

Lock

∗

Type D (For 1.3 of Non–Waterproof Type Connector)

[Case 1]

(1) Use the special tool to unlock the double locking

device.

Special Tool

∗

∗ Double Locking Device.

∗

Wire Harness Repair Manual (RM1022E)

∗

21

B–12

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

[Case 2]

(1) Using the special tool, push the terminal retainer

locking lug (clip) and pull the terminal retainer up to

the temporary lock position.

Locking

Lug

Locking

Lug

Special Tool

[Retainer at Full Lock Position] [Retainer at Temporary Lock Position]

Special

Tool

[Retainer at Full Lock Position]

Stopper

Terminal Retainer

Special Tool

Terminal

Retainer

[Case 3]

(1) Using the special tool, raise the retainer up to the

temporary lock position.

Terminal

Retainer

[Retainer at Temporary Lock Position]

22

[Case 4]

Service hole

Wire Harness Repair Manual (RM1022E)

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

(1) Insert the special tool into the service hole and move

it to the direction of the arrow to release the lock on

the side A.

A

Special tool

(2) Push the lock on the side B up by the special tool and

B

release the lock. Then pull the retainer forward.

B–13

Appearance when the double

locking is released

Wire Harness Repair Manual (RM1022E)

23

B–14

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

Type E (For 1.8, 2.3, 2.3II, 4.8, 6.3 and 8.0 of Waterproof

Type Connector)

HINT: Terminal retainer color is different according to

connector body.

Example:

Terminal Retainer : Connector body

Black or White : Gray

Black or White : Dark Gray

Gray or White : Black

[Case 1]

Type where terminal retainer is pulled up to the

temporary lock position (Pull Type).

Special Tool

Terminal

Retainer

Special

Tool

Special Tool

Access Hole

( Mark)

Terminal

Retainer

24

[Female]

Special Tool

[Male]

Wire Harness Repair Manual (RM1022E)

Example:

B–15

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

(1) Insert the special tool into the terminal retainer

access hole ( Mark) and pull the terminal retainer

up to the temporary lock position.

HINT: The needle insertion position varies according to

the connector’s shape (Number of terminals etc.), so check

the position before inserting it.

Access hole

Terminal Retainer at

Full Lock Position

[Male] [Female]

Temporary Lock Position

HINT: In some cases insert the special tool from the

access hole on the flank of the housing.

Wire Harness Repair Manual (RM1022E)

25

B–16

Example:

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

[Case 2]

Type which cannot be pulled as far as Power Lock

HINT: There are few cases of this type of connector

Terminal Retainer

Example:

Retainer at

Full Lock Position

Retainer at

Temporary Lock Position

[Male]

[Male] [Female]

Press Down

(1) Insert the tool straight into the access hole of terminal

retainer as shown.

Push the terminal retainer down to the temporary lock

position.

[Female]

Press Down

26

Wire Harness Repair Manual (RM1022E)

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

B–17

Service hole

Retainer

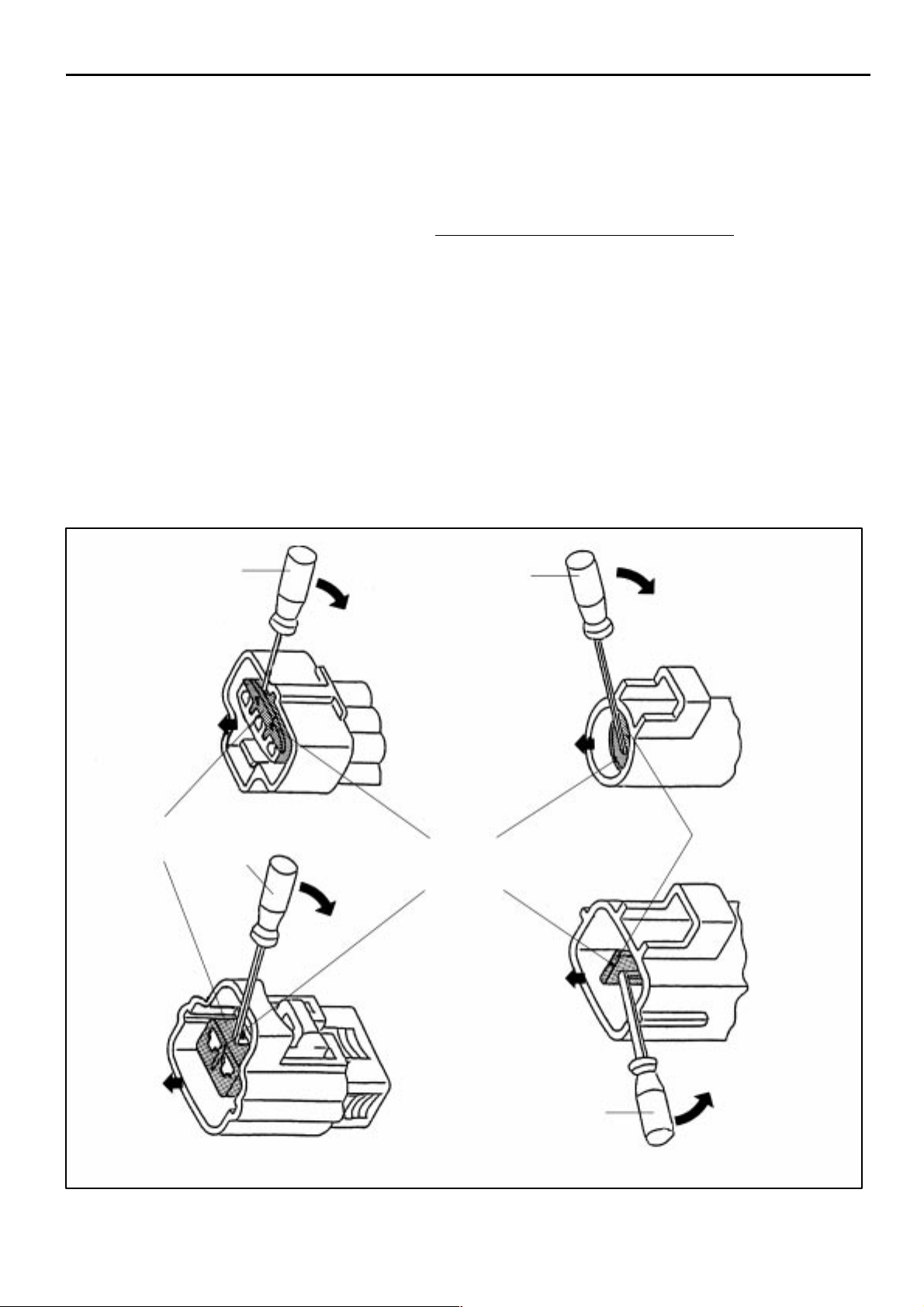

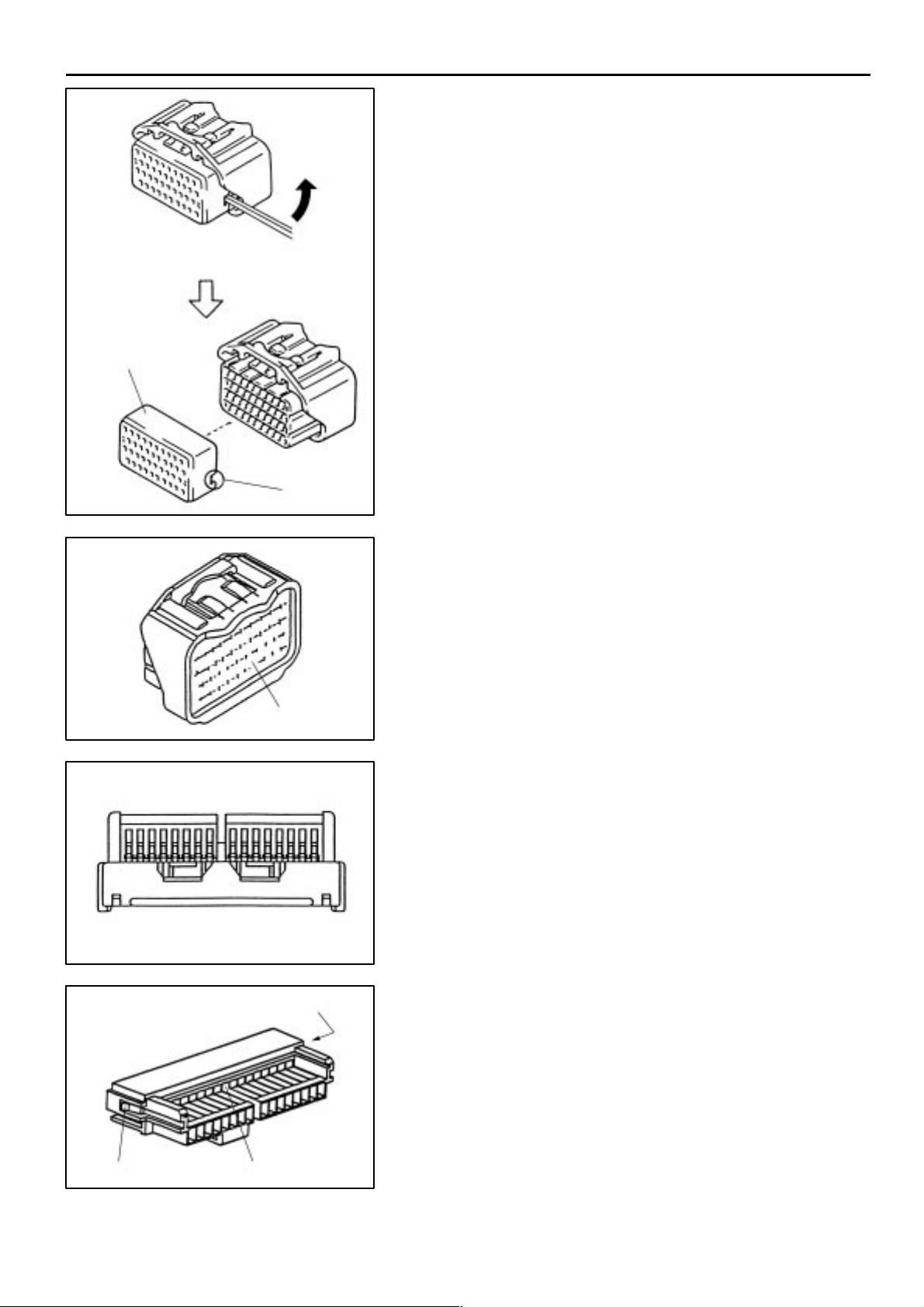

Type F (For C–Type Connector)

(1) Insert the special tool into the service hole.

(2) Move the special tool to the direction of the arrow and

release the lock.

HINT: Lift the retainer up after moving it to the direction

of the thin arrow shown in the illustration.

Special tool

Lock

(3) Pull the retainer forward by hand and remove the

retainer from the housing.

Type G

Insert the special tool into the position shown in the

illustration. Pry it to the direction of the arrow and

push the lock up to release it.

Wire Harness Repair Manual (RM1022E)

27

B–18

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

Type H (For 1.0II Type Connector)

(1) Move the special tool into the notch of the retainer to

the direction of the arrow with the edge of the housing

as the fulcrum. Then the pull the retainer out.

NOTICE:

Do not insert the special tool into areas except

notches. (This may damage the seal ring that is

attached behind the retainer.)

(2) As same as the procedure (1), pull the retainer

straight out using hand after releasing the lock on the

other side.

Retainer

(Yellow)

Notch

Seal rubber

Condition of cover opening

NOTICE:

Do not remove the seal rubber when pulling the

terminal out.

If the seal rubber is peeled off when puling the

terminal out, press it down to stick it to the original

condition.

Be sure and not fit the connector when the retainer

is not installed.

Type I (For SFPC Type Connector)

(1) Open the cover (white)

28

Side Lock

Center Lock

Side Lock

(2) Remove the side lock of the retainer. (One side)

(3) Remove the center lock of the housing.

(4) Remove the side lock of the retainer. (The other side)

NOTICE:

Following the above order is not required.

No center lock on the housing with ten poles.

Wire Harness Repair Manual (RM1022E)

Retainer

B–19

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

(5) Move the retainer until it becomes the initial condition.

Initial condition

Type J

[Male]

(1) Remove the rubber plug.

Rubber Plug

Outer

Outer

Lock

Inner

Special tool

(2) Push the lock of the inner using the special tool.

(3) Pull the wire to the direction of the arrow pushing the

lock up and remove the inner from the outer.

[Female]

(1) Remove the rubber plug.

Rubber Plug

(2) Insert the special tool into the outer shown in the

illustration. Then push the area A of the inner and

remove the inner from the outer.

Inner

B

Illustration from side B

A

Wire Harness Repair Manual (RM1022E)

29

B–20

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

Type J (For Insulation Displacement Connector)

(1) Separate Connector

Special Tool

Using a special tool, release the lock and separate the

connector into 2.

NOTICE:

Do not apply too muck force to the lock arm.

Lock

Special Tool

Special Tool

Raise Up

Cover

Special Tool

Special Tool

Insert Mark

Terminal

Retainer

(2) w/ Cover : Open Connector Cover

Using a special tool, release the lock and open the cover.

NOTICE:

Do not apply too much force to the lock arm.

Type K (0.64 Type Connector)

(1) Using the special tool, raise the retainer up to the

temporary lock position.

HINT: The needle insertion position varies according to

the connector’s shape (number of terminals, etc.), so

check the position before inserting it.

Terminal Retainer

[Retainer at Full Lock Position]

Terminal

Retainer

[Retainer at Temporary Lock Position]

30

Stopper

Wire Harness Repair Manual (RM1022E)

Loading...

Loading...