Toyota Camry 2007-2009 Service Manual - 2GR-FE_Fuel

Expression

2GR-FE FUEL – FUEL SYSTEM

FU–1

FUEL SYSTEM

PRECAUTION

1. EXPRESSIONS OF IGNITION SWITCH

(a) The type of the ignition switch used on this model

differs according to the specifications of the vehicle.

The expressions listed in the table below are used

in this section.

Switch Type Ignition Switch (position) Engine Switch (condition)

Ignition Switch off LOCK Off

Ignition Switch on (IG) ON On (IG)

Ignition Switch on (ACC) ACC On (ACC)

Engine Start START Start

2. PRECAUTION

(a) Before inspecting and repairing the fuel system,

disconnect the negative (-) battery terminal.

(b) Do not smoke or work near fire when handling the

fuel system.

(c) Keep gasoline away from rubber or leather parts.

3. DISCHARGE FUEL SYSTEM PRESSURE

CAUTION:

• Perform the following procedures to prevent fuel

from spilling out before removing any fuel system

parts.

• Pressure will still remain in the fuel line even after

performing the following procedures. When

disconnecting the fuel line, cover it with a shop

rag or a piece of cloth to prevent fuel from

spraying or coming out.

FU

A129607

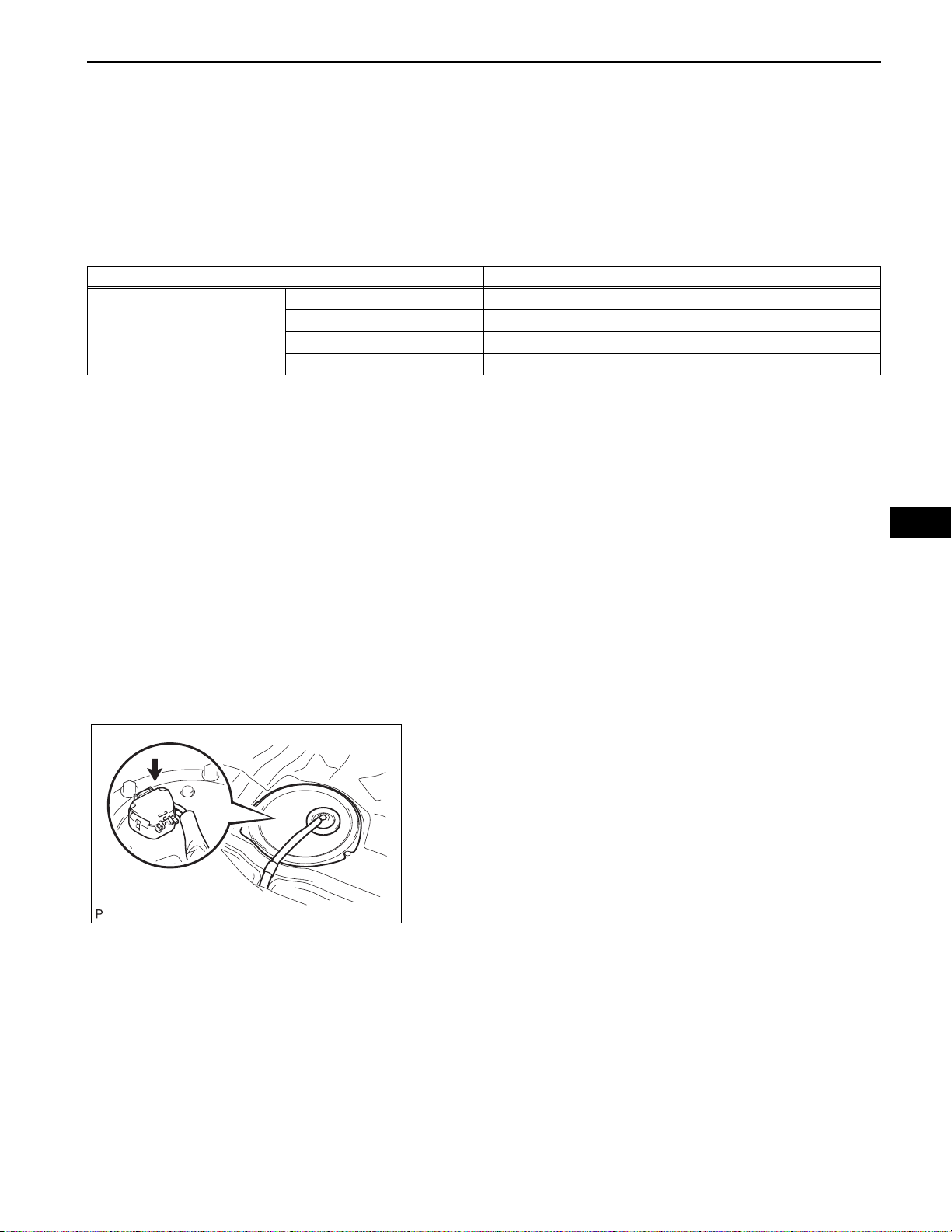

(a) Disconnect the fuel pump connector.

(1) Remove the rear seat cushion assembly.

(2) Remove the rear floor service hole cover.

(3) Disconnect the fuel pump connector.

(4) Start the engine.

(5) After the engine stops, turn the ignition switch

off.

HINT:

DTC P0171/25 (fuel problem) and/or P0191/49

(fuel pressure sensor signal error) may be

detected.

(6) Crank the engine again. Check that the engine

does not start.

(7) Remove the fuel tank cap to discharge pressure

from the fuel tank.

(8) Disconnect the negative (-) battery terminal

cable.

(9) Reconnect the fuel pump connector.

(10)Install the rear floor service hole cover.

(11)Install the rear seat.

FU–2

Plastic Bag

2GR-FE FUEL – FUEL SYSTEM

4. FUEL SYSTEM

(a) When disconnecting the high fuel pressure line, a

large amount of gasoline will spill out, so observe

the following procedures:

(1) Discharge the fuel system pressure. (step 3)

(2) Disconnect the fuel pump tube (See page FU-

27).

(3) Drain the fuel that remains inside the fuel pump

tube.

(4) To protect the disconnected fuel pump tu be from

damage and contamination, cover it with a

plastic bag.

(5) Put a container under the connection part.

B000679E07

FU

O-Ring

O-ring

Injector

Insulator

CORRECT

INCORRECT

Delivery Pipe

Delivery Pipe

Intake

Manifold

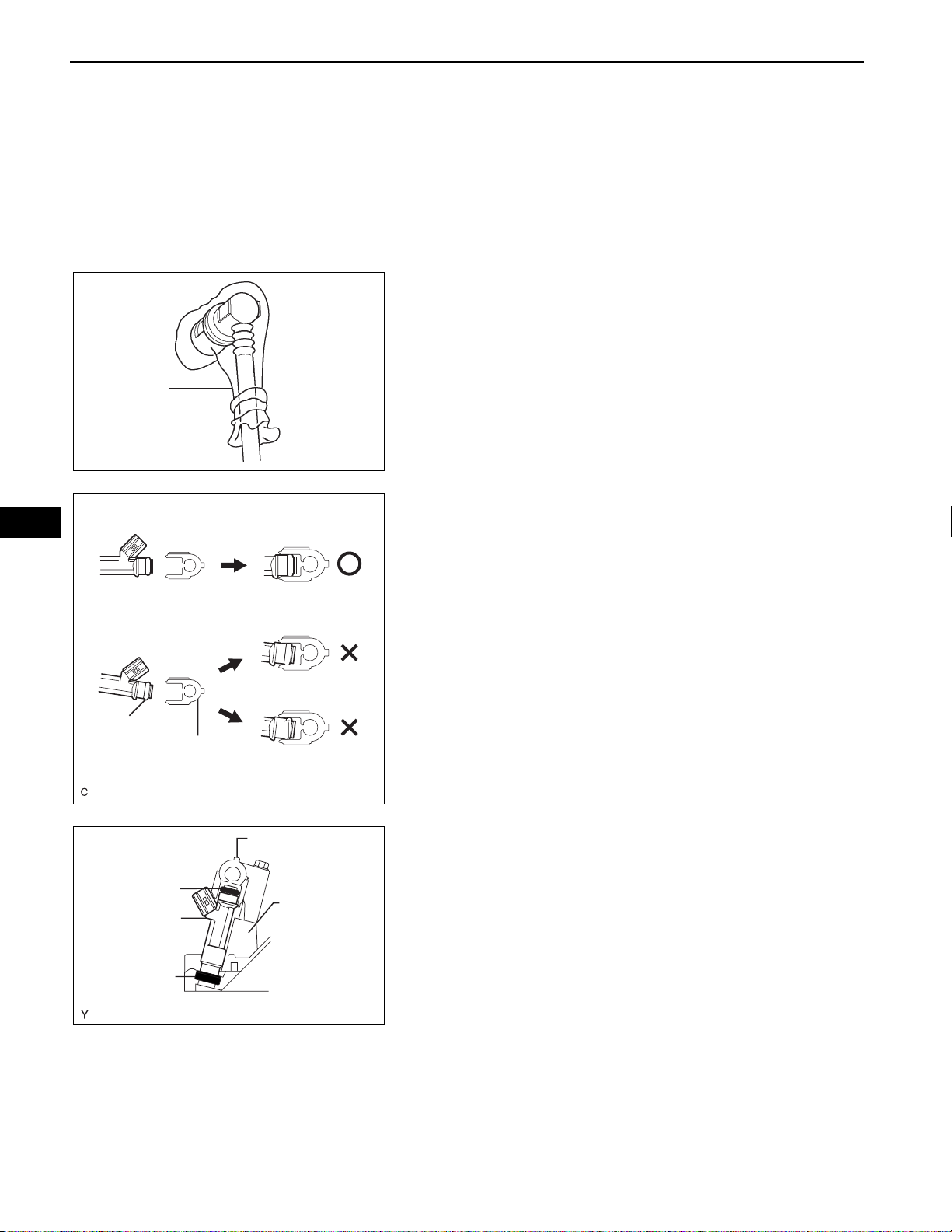

(b) Observe the following precautions when removing

and installing the fuel injectors:

(1) Never reuse an O-ring.

(2) When placing a new O-ring on the injector, do

not damage the O-ring.

(3) Coat a new O-ring with spindle oil or gasoline

before installing it.

NOTICE:

Do not use engine oil, gear oil or brake fluid.

A140742E01

(c) Install the injector to the delivery pipe and lower

intake manifold as shown in the illustration.

NOTICE:

Before installing the injector, be sure to apply

grease or gasoline to the place where the

delivery pipe or cylinder head contacts the Oring of the injector.

A129458E01

No. 1 Fuel

Pipe Clamp

2GR-FE FUEL – FUEL SYSTEM

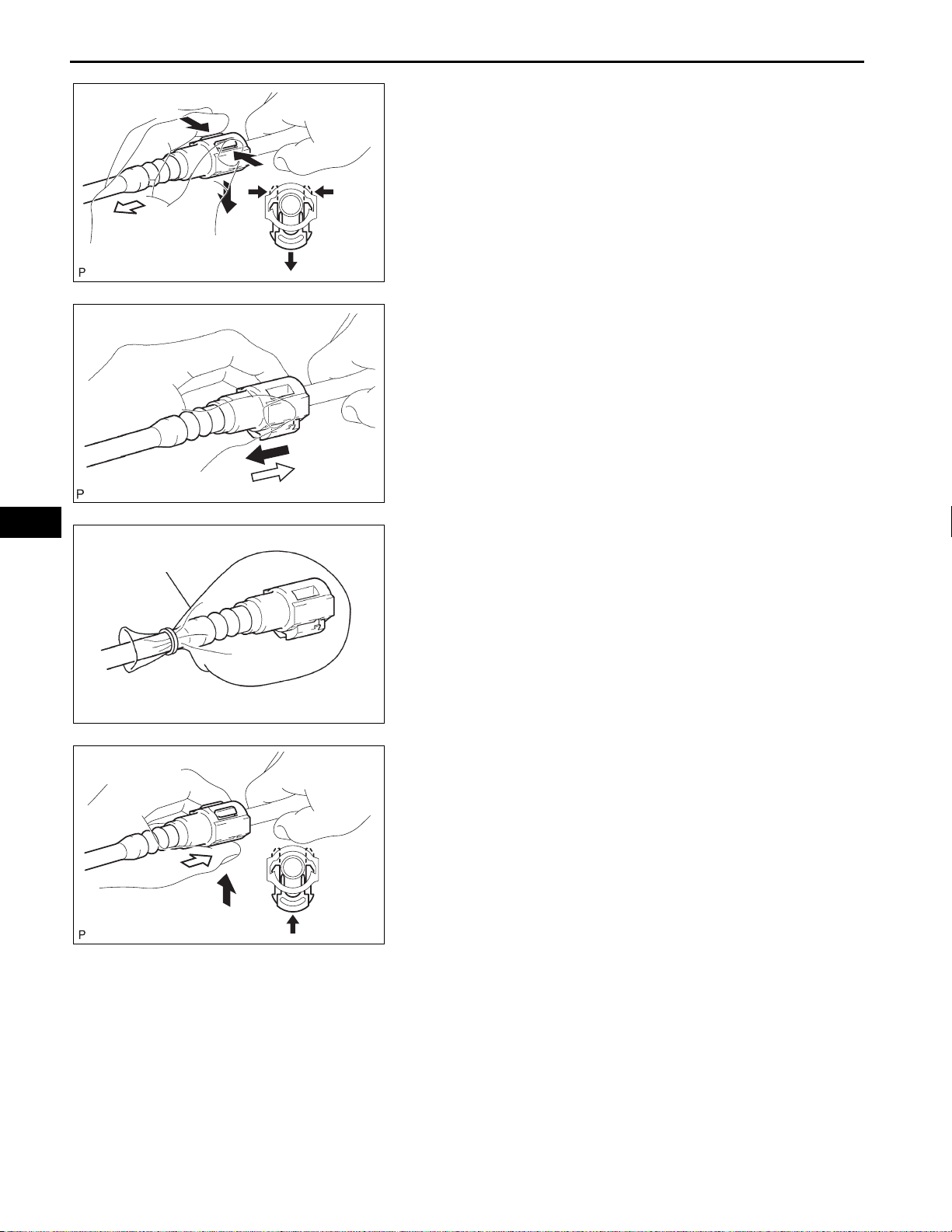

(d) Observe the following precautions when

disconnecting the fuel tube connectors (Quick type

A):

(1) Remove the No. 1 fuel pipe clamp.

(2) Check that there is no dirt or other foreign

objects on the pipe and around the connector

before disconnecting them. Clean them if

necessary.

A060083E16

FU–3

Quick Type A

Quick Type A

Quick Type A

Push

Plastic Bag

A088336E10

B009222E04

(3) Disconnect the connector from the pipe by hand.

(4) When the connector and the pipe are stuck,

push in and pull on the connector to release it.

Pull the connector out of the pipe carefully.

(5) Check that there is no dirt or other foreign

objects on the sealing surface of the

disconnected pipe. Clean it away if necessary.

(6) Do not damage the disconnected pipe and

connector, and prevent entry of foreign objects

by covering them with a plastic bag.

(e) Observe the following precautions when connecting

the fuel tube connectors (Quick Type A):

(1) Check if there is any damage or foreign objects

on the connecting parts of the pipes.

(2) Line up the two parts of the pipes to be

connected, and push them together until the

connector makes a "click" sound. If the pipe is

difficult to push into the connector, apply a small

amount of clean engine oil to the tip of the pipe

and reinsert it.

(3) After connecting the pipes, check that the pipe

and connector are securely connected by pulling

on them.

(4) Check for fuel leaks.

FU

Pull

A121423E01

FU–4

2GR-FE FUEL – FUEL SYSTEM

FU

Quick Type B

Quick Type B

Quick Type B

Plastic Bag

A129459E01

A091246E06

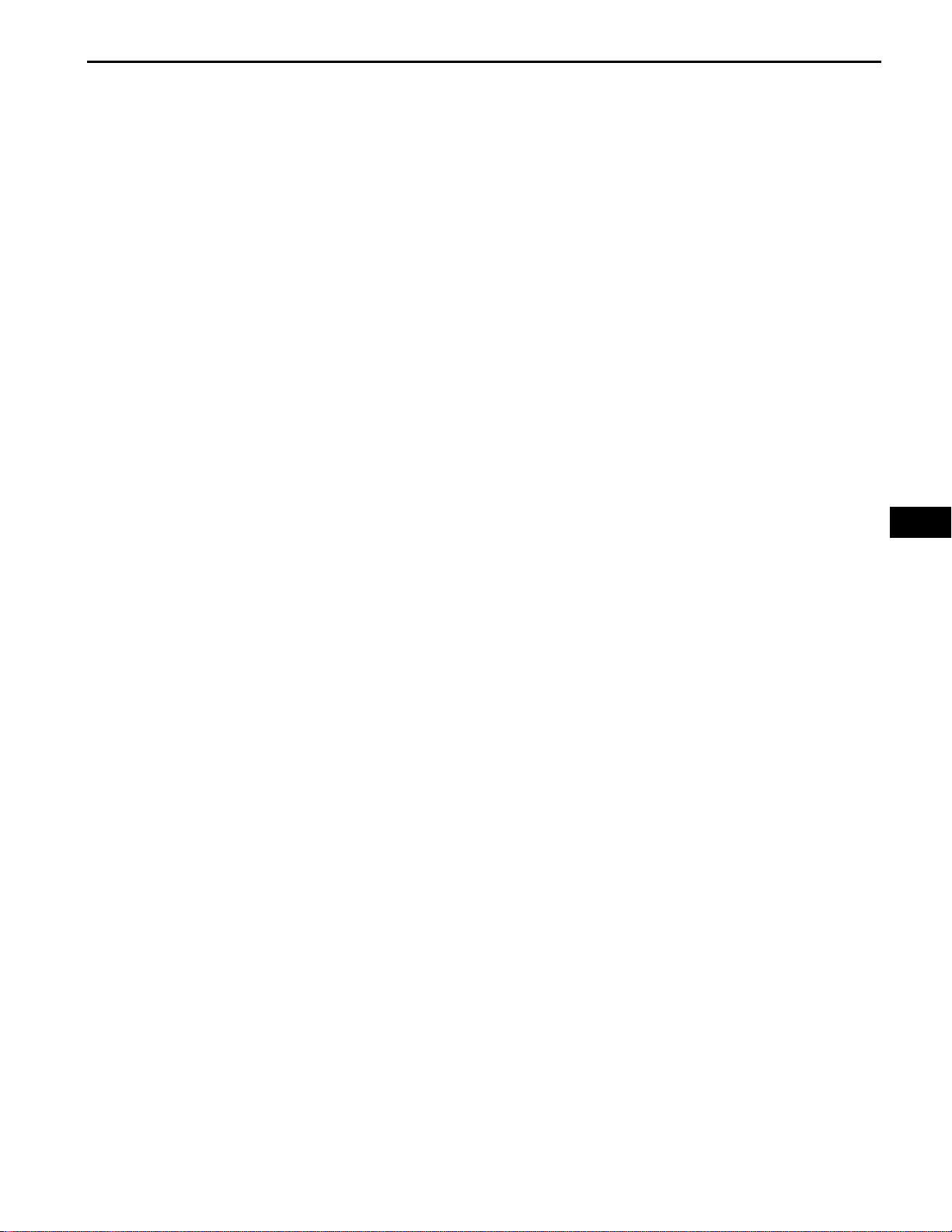

(f) Observe the following precautions when

disconnecting the fuel tube connector (Quick type

B):

(1) Before disconnecting the connector, clean off

any dirt that may be present.

(2) Pinch the tabs of the fuel tube retainer to

disengage the 2 claws. Push the retainer down

as shown in the illustration.

HINT:

Be sure to disconnect the connector by hand.

(3) If the connector and pipe are stuck, hold the fuel

pipe by hand, and push and pull on the

connector. Pull the two pipes apart to separate

the connector.

(4) If there is any dirt or any other foreign objects on

the sealing surfaces of the disconnected pipes,

clean them if necessary.

(5) Do not damage the disconnected pipe and

connector, and prevent entry of foreign objects

by covering them with a plastic bag.

Quick Type B

A093309E03

A132390E01

(g) Observe the following precautions when connecting

the fuel tube connector (Quick Type B):

(1) Line up the two parts of the pipes to be

connected, and fully push the fuel tube

connector and pipe together until they are fully

seated. Next, push the retainer into the

connector until its claws lock. If the pipe is

difficult to push in to the connector , apply a small

amount of clean engine oil to the tip of the pipe

and reinsert it.

(2) After connecting the pipes, check that the pipe

and connector are securely connected by pulling

on them.

(3) Check for fuel leaks.

(h) Observe the following precautions when handling a

nylon tube:

CAUTION:

• Do not twist the connection part of the nylon

tube and the quick connector when

connecting them.

• Do not bend or twist the nylon tube.

2GR-FE FUEL – FUEL SYSTEM

• Do not remove the EPDM protector on the

outside of the nylon tube.

• Do not close the piping by bending the nylon

tube.

5. CHECK FOR FUEL LEAKS

(a) Check that there are no fuel leaks from the fuel

system after doing any maintenance or repairs (See

page FU-8).

FU–5

FU

FU–6

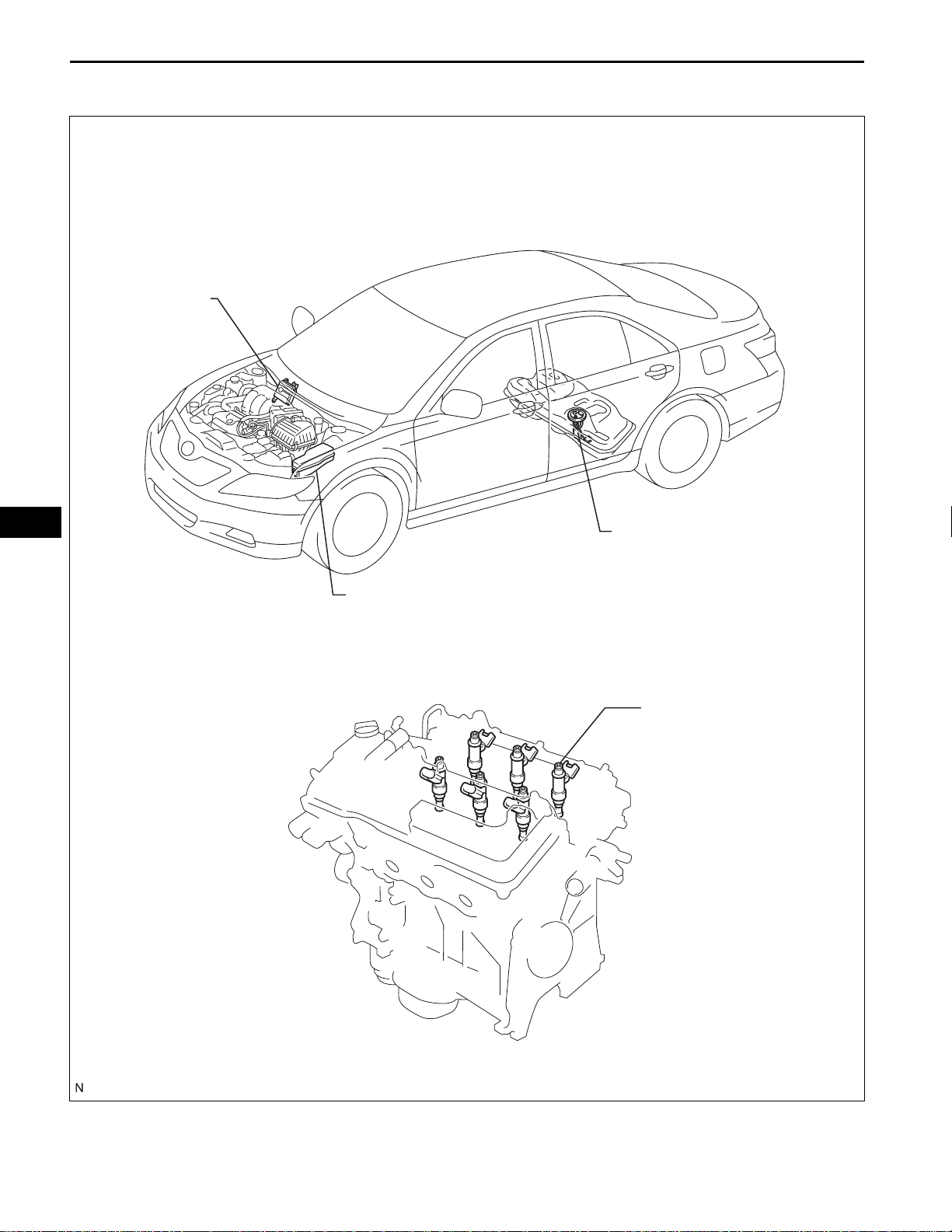

PARTS LOCATION

ECM

2GR-FE FUEL – FUEL SYSTEM

FU

FUEL PUMP

ENGINE ROOM RELAY BLOCK

FUEL INJECTOR

A136014E01

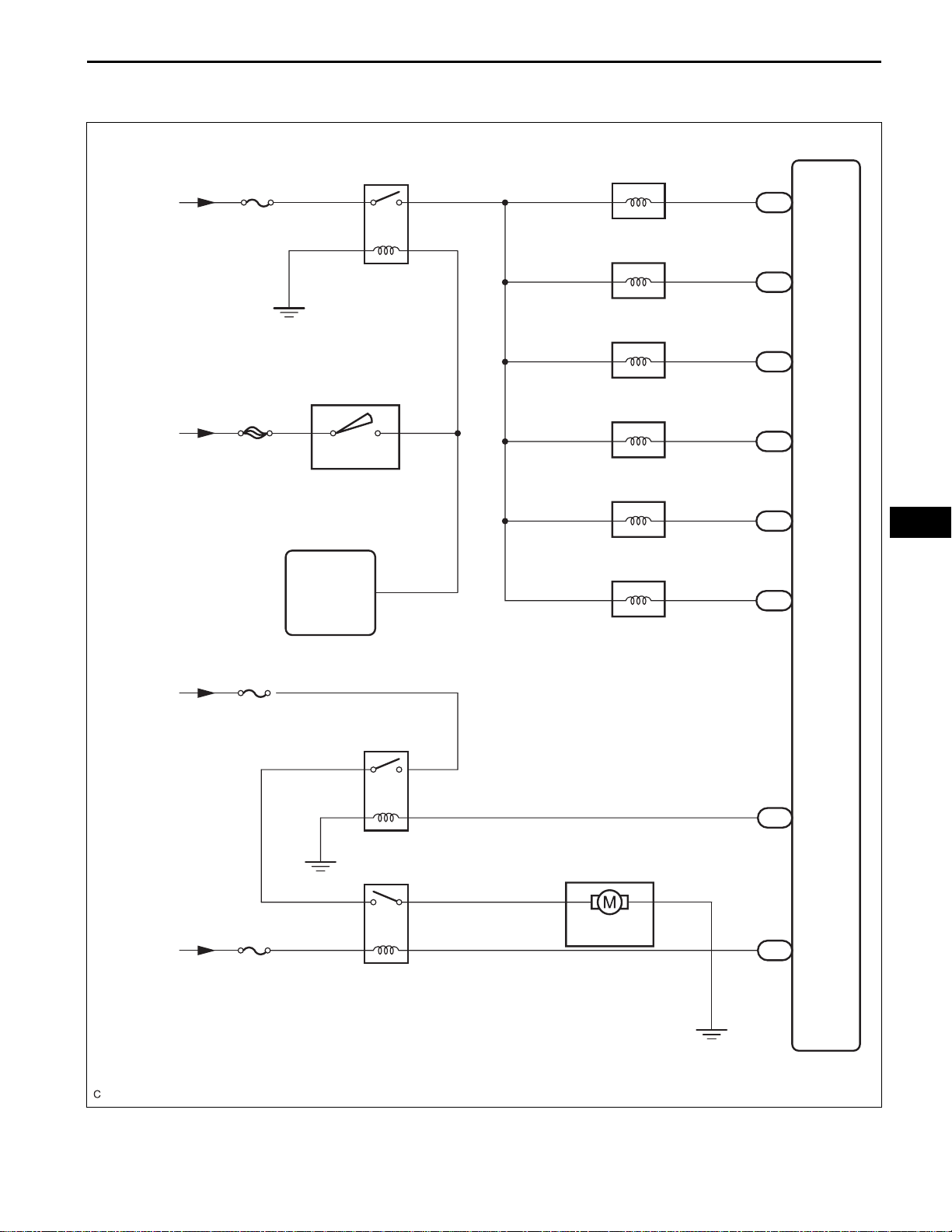

From

Battery

From

Battery

IG2

ST/AM2

E6 Main Body ECU

2GR-FE FUEL – FUEL SYSTEM

SYSTEM DIAGRAM

IG2

53

21

E23 Ignition Switch

*2

56

AM2

IG2

C7 Fuel Injector (No. 1)

21

C9 Fuel Injector (No. 2)

21

C8 Fuel Injector (No. 3)

21

C10 Fuel Injector (No. 4)

21

C36 Fuel Injector (No. 5)

21

45

C55

85

C55

44

C55

84

C55

43

C55

#10

#20

#30

#40

#50

FU–7

ECM

FU

From

Battery

From

Ignition

Switch

EFI MAIN

IGN

IG2D

11

EFI

C/OPN

C37 Fuel Injector (No. 6)

*1

21

N10 Fuel Suction Pump and Gauge Assembly

45

Pump

83

C55

44

A55

7

A55

#60

MREL

FC

*1: with Smart Key System

*2: without Smart Key System

A140778E01

FU

FU–8

2GR-FE FUEL – FUEL SYSTEM

ON-VEHICLE INSPECTION

1. CHECK FOR FUEL PUMP OPERATION AND FUEL

LEAKS

(a) Check fuel pump operation.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch on (IG) and push the

intelligent tester main switch on.

NOTICE:

Do not start the engine.

(3) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / FUEL

PUMP / SPD.

(4) Check for pressure in the fuel inlet tube from

the fuel line. Check that sound of fuel flowing in

the fuel tank can be heard. If no sound can be

heard, check the integration relay, fuel pump,

ECM and wiring connector.

(b) Check for fuel leaks.

(1) Check that there are no fuel leaks anywhere on

the system after performing maintenance. If

there is a fuel leak, repair or replace parts as

necessary.

(c) Turn the ignition switch off.

(d) Disconnect the intelligent tester from the DLC3.

2. CHECK FUEL PRESSURE

(a) Discharge the fuel system pressure (See page FU-

1).

(b) Using a voltmeter, measure the battery voltage.

Standard voltage:

11 to 14 V

(c) Disconnect the negative (-) battery terminal.

(d) Disconnect the fuel hose from the fuel main tube

(See page FU-1).

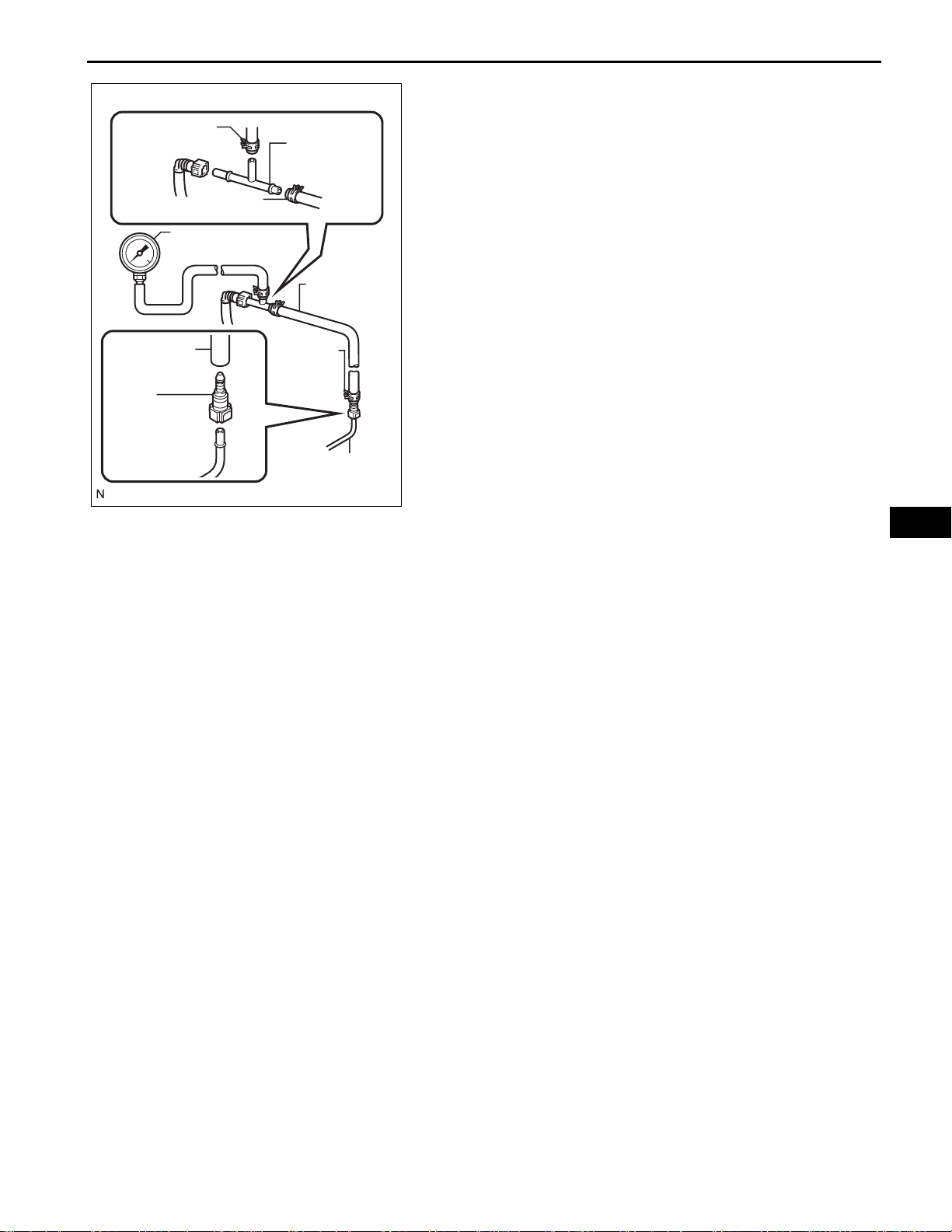

SST (Clip)

SST (Gauge)

SST (Hose)

SST

(Tube

Connector)

SST (Clip)

SST (T-joint)

SST (Hose)

SST (Clip)

Fuel Tube

2GR-FE FUEL – FUEL SYSTEM

(e) Install SST (pressure gauge) using SST and a fuel

tube connector as shown in the illustration.

SST 09268-31011 (09268-41500, 90467-13001,

95336-08070), 09268-45014 (09268-41200,

09268-41220, 09268-41250)

(f) Wipe up any gasoline.

(g) Connect the negative (-) battery terminal.

(h) Connect the intelligent tester to the DLC3.

(i) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / FUEL PUMP

/ SPD.

(j) Measure the fuel pressure.

Fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf*cm

psi)

• If the fuel pressure is greater than the standard

value, replace the fuel pressure regulator.

• If the fuel pressure is less than the standard

value, check the fuel hoses and connections, fuel

pump, fuel filter and fuel pressure regulator.

A129461E01

(k) Disconnect the intelligent tester from the DLC3.

(l) Start the engine.

(m) Measure the fuel pressure at idle.

Fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf*cm

psi)

(n) Stop the engine.

(o) Check that the fuel pressure remains as specified

for 5 minutes after the engine stops.

Fuel pressure:

147 kPa (1.5 kgf*cm

If the fuel pressure is not as specified, check the fuel

pump, pressure regulator and/or fuel injectors.

(p) After checking the fuel pressure, carefully

disconnect the negative (-) battery cable, and

remove the SST and fuel tube connector to prevent

gasoline from splashing.

(q) Reconnect the fuel tube to the main fuel tube (fuel

tube connector).

(r) Install the No. 1 fuel pipe clamp to the fuel tube

connector.

(s) Check for fuel leaks (step 1).

2

, 44.1 to 49.7

2

, 44.1 to 49.7

2

, 21 psi) or more

FU–9

FU

FU–10

ENGINE2GR-FE FUEL

FUEL INJECTOR

COMPONENTS

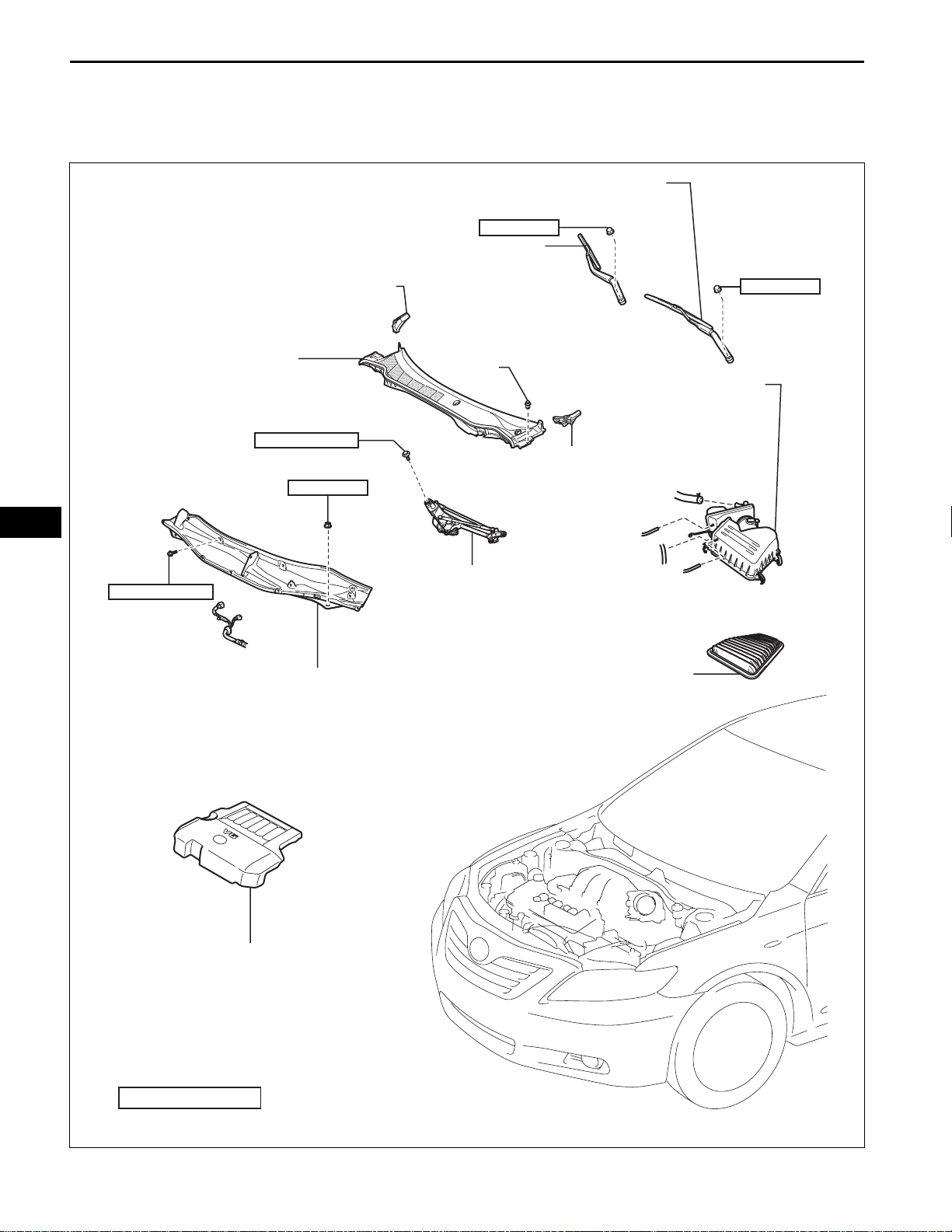

FRONT WIPER ARM AND BLADE ASSEMBLY RH

2GR-FE FUEL – FUEL INJECTOR

FRONT WIPER ARM AND BLADE ASSEMBLY LH

20 (204, 15)

FU

FRONT FENDER TO COWL SIDE SEAL RH

COWL TOP VENTILATOR

LOUVER SUB-ASSEMBLY

7.0 (71, 62 in.*lbf)

80 (816, 59)

5.0 (51, 44 in.*lbf)

COWL TOP PANEL

OUTER SUB-ASSEMBLY

CLIP

x2

x4

WINDSHIELD WIPER MOTOR

AND LINK ASSEMBLY

AIR CLEANER FILTER ELEMENT

FRONT FENDER TO

COWL SIDE SEAL LH

20 (204, 15)

AIR CLEANER CAP

SUB-ASSEMBLY

V-BANK COVER SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

A137328E01

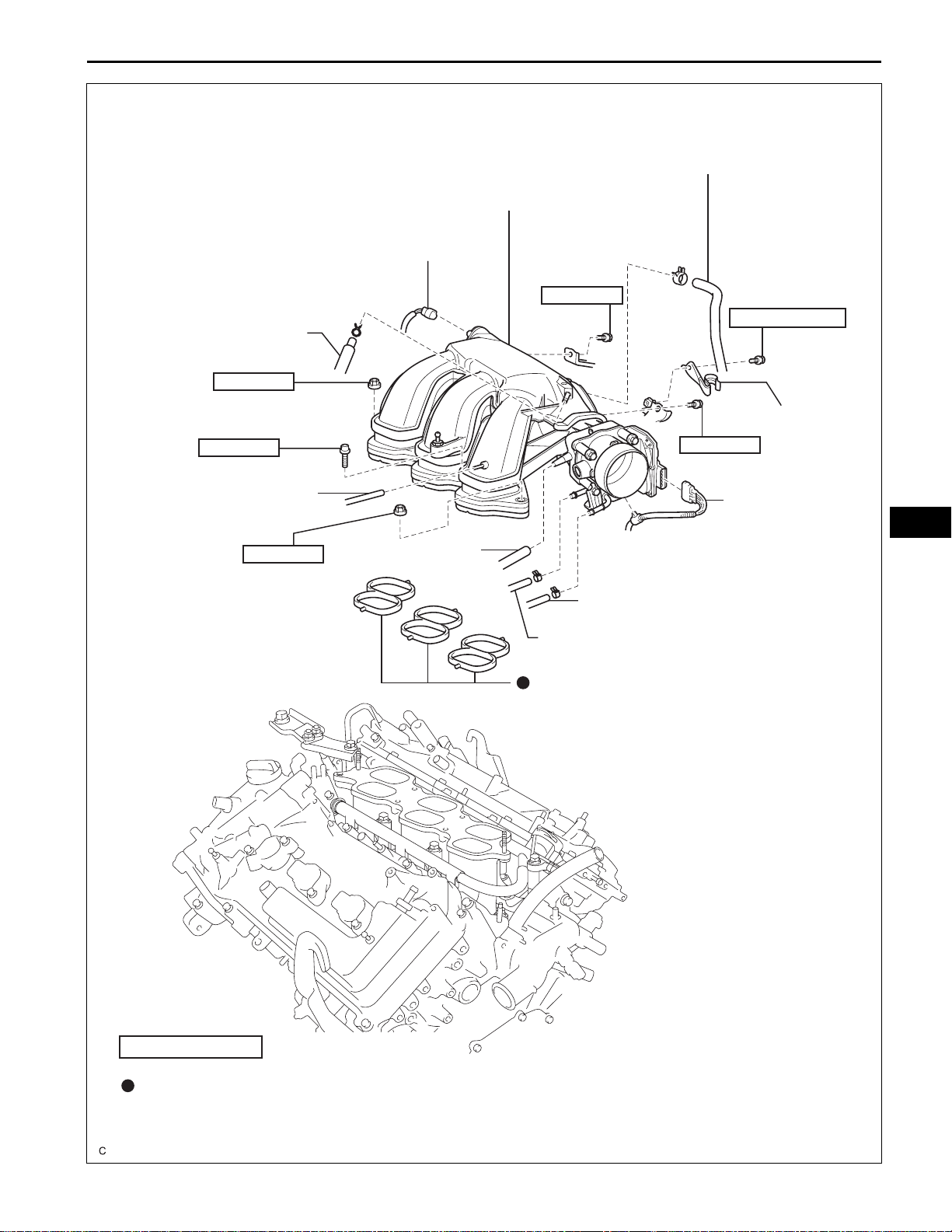

NO. 1 VENTILATION HOSE

16 (163, 12)

2GR-FE FUEL – FUEL INJECTOR

UNION TO CHECK VALVE HOSE

INTAKE AIR SURGE TANK ASSEMBLY

CONNECTOR

21 (214, 15)

*

FU–11

5.4 (55, 48 in.*lbf)

18 (184, 13)

*

VACUUM HOSE

16 (163, 12)

x4

VAPOR FEED HOSE

21 (214, 15)

*

AIR FLOW METER

CONNECTOR

NO. 2 WATER BY-PASS HOSE

NO. 3 WATER BY-PASS HOSE

AIR SURGE TANK TO INTAKE

MANIFOLD GASKET

HOSE CLAMP

FU

N*m (kgf*cm, ft.*lbf) : Specified torque

Non-reusable part

* DO NOT apply oil

A114551E03

FU–12

2GR-FE FUEL – FUEL INJECTOR

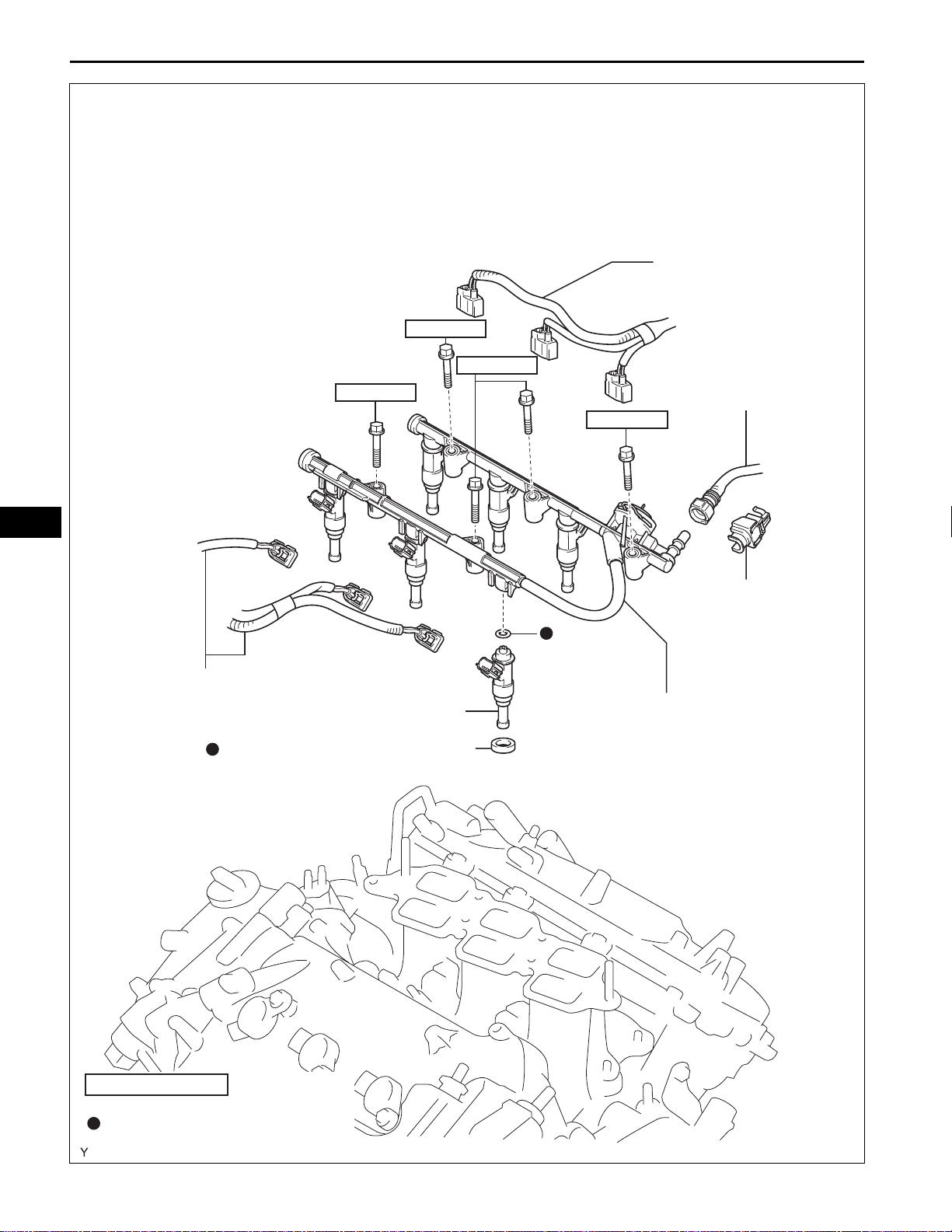

21 (214, 15)

21 (214, 15)

21 (214, 15)

WIRE HARNESS

FUEL TUBE SUB-ASSEMBLY

21 (214, 15)

FU

WIRE HARNESS

INJECTOR VIBRATION INSULATOR

FUEL INJECTOR ASSEMBLY

NO. 2 FUEL PIPE CLAMP

O-RING

FUEL DELIVERY PIPE

SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf) : Specified torque

Non-reusable part

A114552E03

2GR-FE FUEL – FUEL INJECTOR

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. DRAIN ENGINE COOLANT (See page CO-5)

4. REMOVE FRONT WIPER ARM AND BLADE

ASSEMBLY LH (See page WW-9)

5. REMOVE FRONT WIPER ARM AND BLADE

ASSEMBLY RH (See page WW-9)

6. REMOVE FRONT FENDER TO COWL SIDE SEAL LH

(See page WW-9)

7. REMOVE FRONT FENDER TO COWL SIDE SEAL RH

(See page WW-9)

8. REMOVE COWL TOP VENTILATOR LOUVER SUBASSEMBLY (See page WW-10)

FU–13

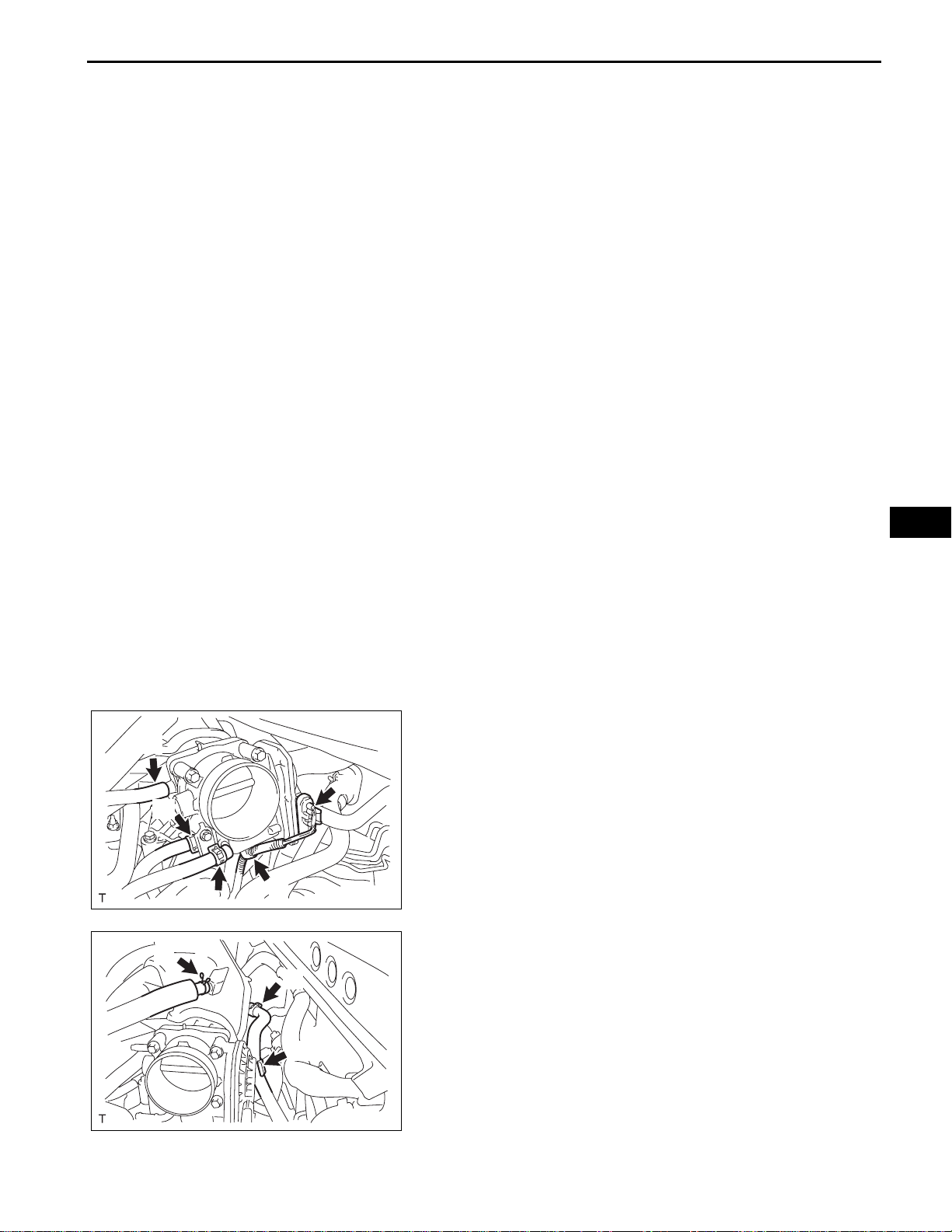

(b)

(a)

(d)

(a)

(c)

(e)

(c)

A129464E01

9. REMOVE WINDSHIELD WIPER MOTOR AND LINK

ASSEMBLY (See page WW-10)

10. REMOVE COWL TOP PANEL OUTER SUBASSEMBLY (See page ES-481)

11. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-23)

12. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-503)

13. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

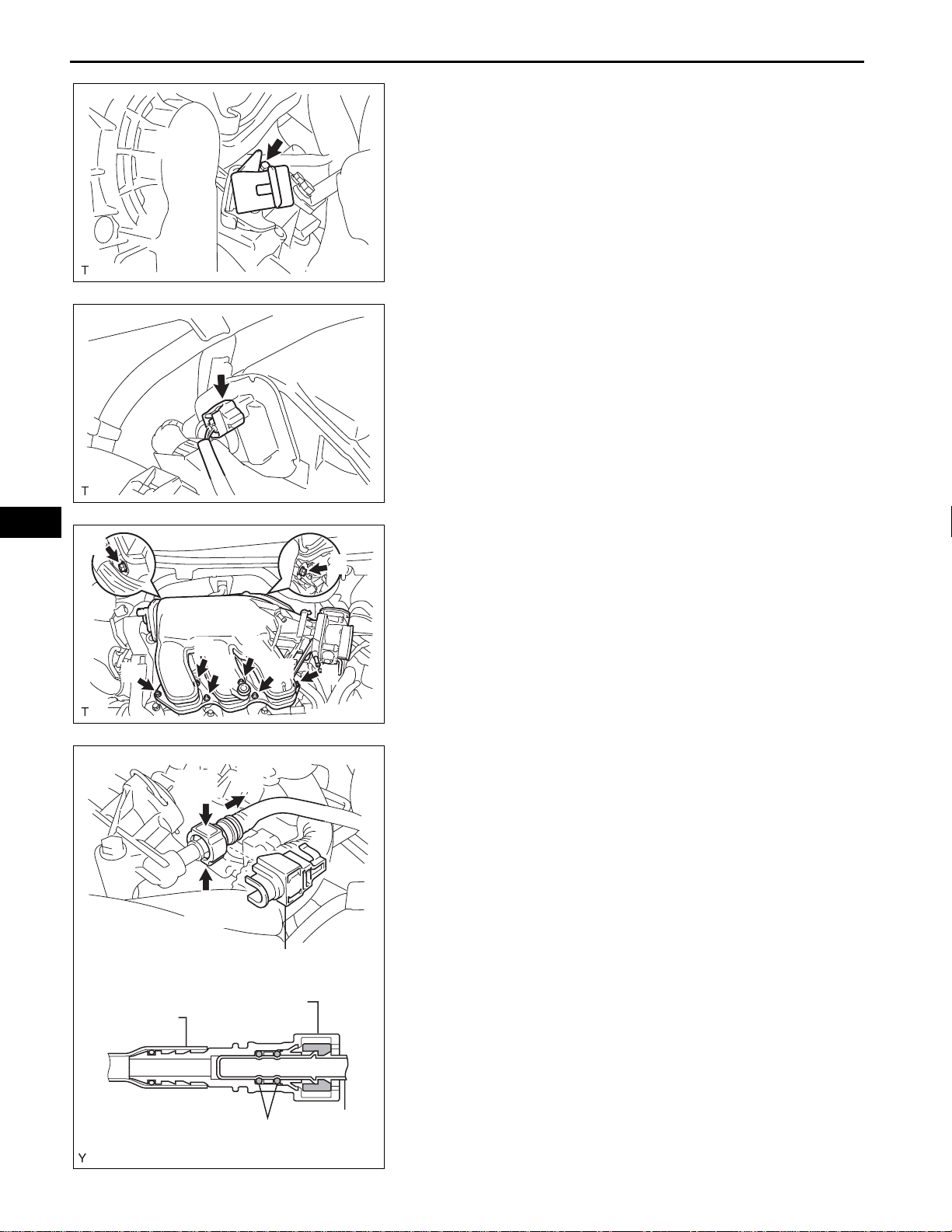

(a) Disconnect the 2 water by-pass hoses from the

throttle with motor body assembly.

(b) Disconnect the vapor feed hose.

(c) Disconnect the throttle with motor body assembly

connector and clamp.

(d) Disconnect the No. 1 ventilation hose.

(e) Disconnect the union to check valve hose.

FU

(e)

A129465E05

FU–14

2GR-FE FUEL – FUEL INJECTOR

(f) Remove the bolt and vacuum hose clamp.

A129466

(g) Disconnect the connector.

A129467

FU

(i)

(i)

Nylon Tube

(h)

Pinch

Pinch

Tube Connector

(h)

(h)

Pull

Fuel Pipe Clamp

O-Ring

(h)

(i)

(i)

A129468E01

Pipe

A129469E02

(h) Using a 5 mm socket hexagon wrench, remove the

4 bolts.

(i) Remove the 2 nuts, 2 bolts and intake air surge

tank.

(j) Remove the gasket from the intake air surge tank.

14. DISCONNECT FUEL TUBE SUB-ASSEMBLY

(a) Remove the No. 2 fuel pipe clamp.

(b) Pinch the tube connector and then pull out the fuel

pipe.

NOTICE:

• Check that there is no dirt or other foreign

objects around the connector before this

operation and clean the connector as

necessary.

• It is necessary to prevent mud or dirt from

entering the quick connector. If mud enters

the connector, the O-rings may not seal

properly.

• Remove the quick connector by hand.

• Do not bend or twist the nylon tube. Protect

the connector by covering it with a plastic

bag.

• If the pipe and the connector are stuck, try

wiggling or pushing and pulling the

connector to release it and pull the connector

off of the pipe carefully.

Loading...

Loading...