2GR-FE ENGINE MECHANICAL – ENGINE

ENGINE

ON-VEHICLE INSPECTION

1. INSPECT ENGINE COOLANT

(a) Inspect the engine coolant (See page CO-1).

2. INSPECT ENGINE OIL

(a) Inspect the engine oil (See page LU-1).

3. INSPECT BATTERY

(a) Inspect the battery (See page CH-4).

4. INSPECT SPARK PLUGS

(a) Inspect the spark plugs (See page IG-5).

5. INSPECT AIR CLEANER FILTER ELEMENT SUBASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

(b) Visually check that there is no dirt, blockage, and/or

damage to the air cleaner filter element.

HINT:

• If there is any dirt or a blockage in the air cleaner

filter element, clean it with compressed air.

• If any dirt or a blockage remains even after

cleaning the air cleaner filter element with

compressed air, replace it.

EM–1

EM

DLC3

Intelligent Tester

CAN VIM

C110200E02

6. INSPECT VALVE LASH ADJUSTER NOISE

(a) Rev up the engine several times. Check that the

engine does not emit unusual noises.

If unusual noises occur, warm up the engine and

idle it for over 30 minutes. Then repeat this

procedure.

HINT:

If any defects or problems are found during the

inspection above, perform lash adjuster inspection

(See page EM-87).

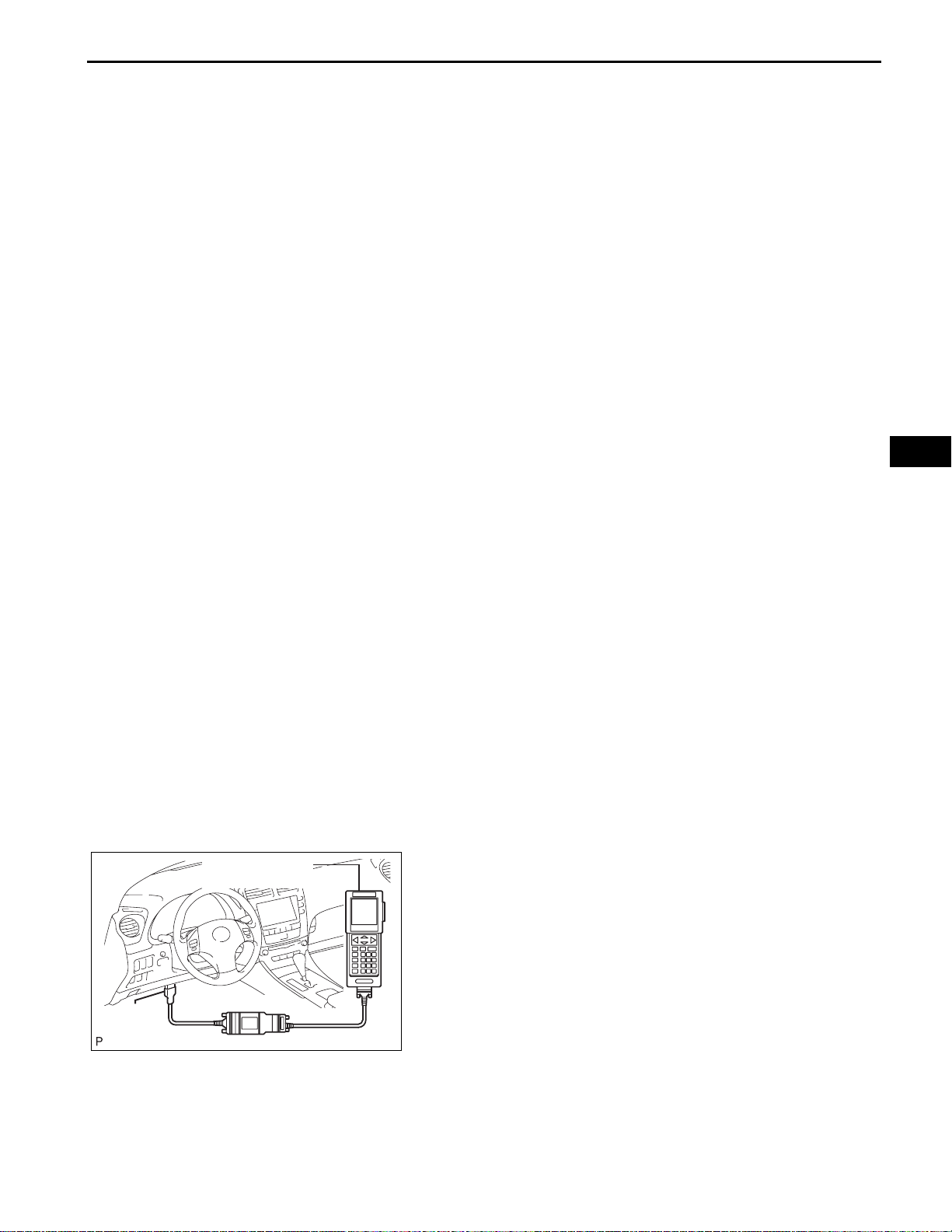

7. INSPECT IGNITION TIMING

(a) Warm up the engine.

(b) When using the intelligent tester:

Check the ignition timing.

(1) Connect the intelligent tester to the DLC3.

(2) Enter DATA LIST mode with the intelligent

tester.

Ignition timing:

8 to 12° BTDC at idle

HINT:

Refer to the intelligent tester operator's manual

for help when selecting the DATA LIST.

EM–2

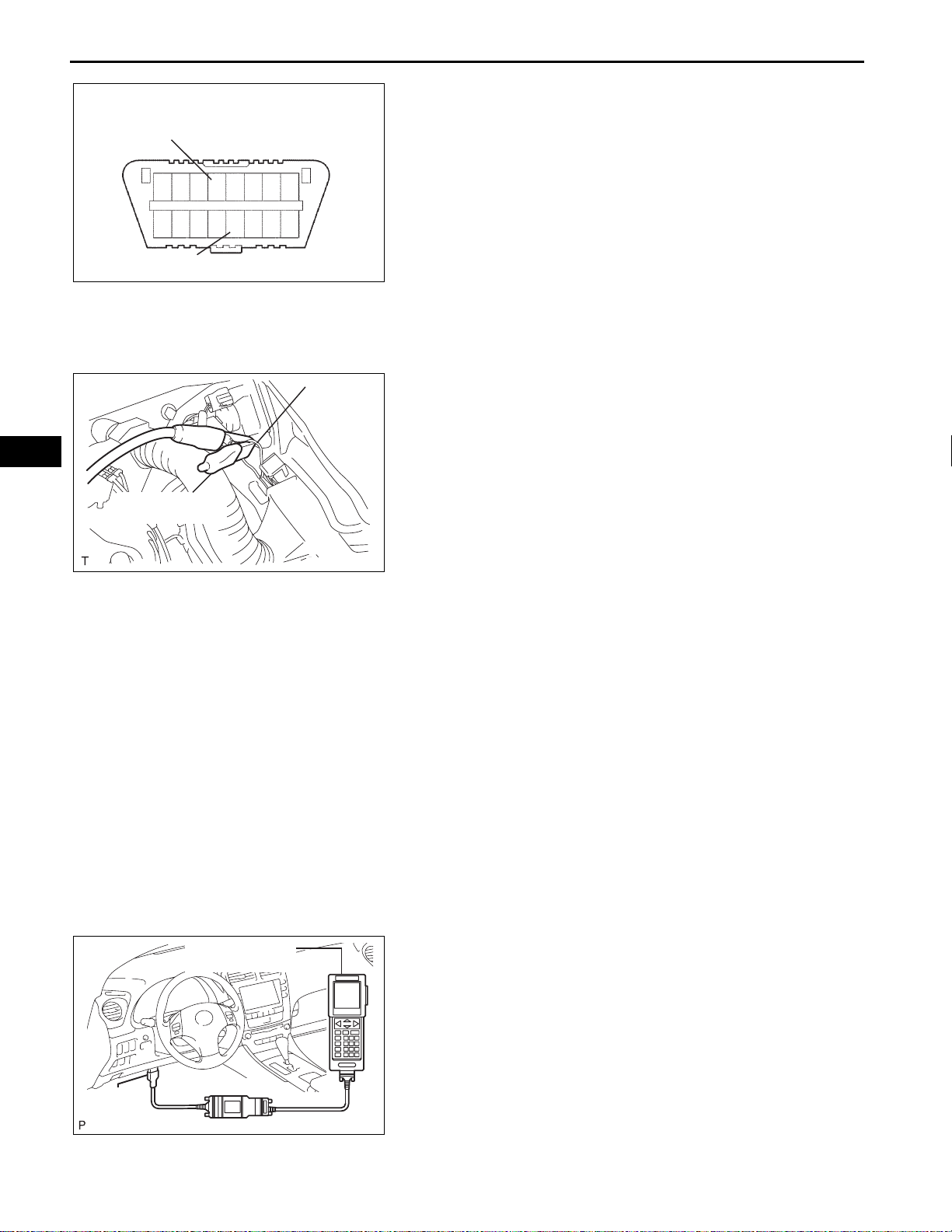

DLC3

CG

1

2345678

910111213141516

TC

2GR-FE ENGINE MECHANICAL – ENGINE

(c) When not using the intelligent tester:

Check the ignition timing.

(1) Using SST, connect terminals 13 (TC) and 4

(CG) of the DLC3.

SST 09843-18040

NOTICE:

• Confirm the terminal numbers before

connecting them. Connection with a

wrong terminal can damage the engine.

A122830E14

• Turn off all electrical systems before

connecting the terminals.

• Perform this inspection after the cooling

fan motor is turned off.

(2) Remove the V-bank cover.

EM

Tester Terminal

Red Lead

Wire

A129620E01

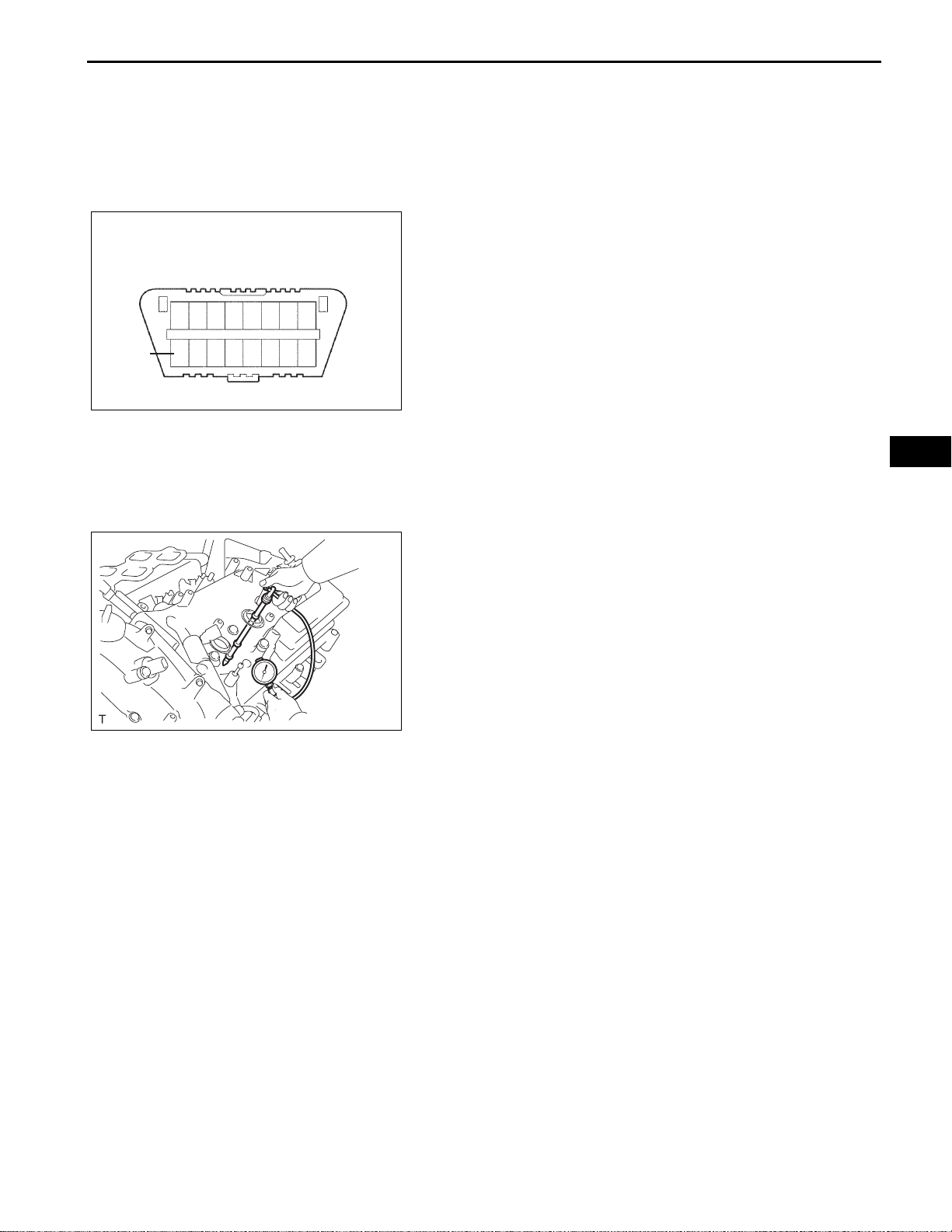

(3) Pull out the red lead wire harness.

(4) Connect the tester terminal of the timing light to

the red lead wire as shown in the illustration.

NOTICE:

Use a timing light which can detect the first

signal.

(5) Check the ignition timing at idle.

Ignition timing:

8 to 12° BTDC at idle

NOTICE:

When checking the ignition timing, the

transmission should be in neutral.

HINT:

Run the engine at 1,000 to 1,300 rpm for 5

seconds, and then check that the engine rpm

returns to idle speed.

(6) Disconnect terminals 13 (TC) and 4 (CG) of the

DLC3.

(7) Check the ignition timing at idle.

Ignition timing:

12 to 22° BTDC at idle

(8) Confirm that the ignition timing moves to the

advanced angle side when the engine rpm is

increased.

(9) Remove the timing light.

DLC3

Intelligent Tester

CAN VIM

C110200E02

8. INSPECT ENGINE IDLE SPEED

(a) Warm up the engine.

(b) When using the intelligent tester:

Check the idle speed.

(1) Connect the intelligent tester to the DLC3.

(2) Enter DATA LIST mode with the intelligent

tester.

Idle speed:

600 to 700 rpm

NOTICE:

• When checking the idle speed, the

transmission should be in neutral.

• Check the idle speed with the cooling fan

off.

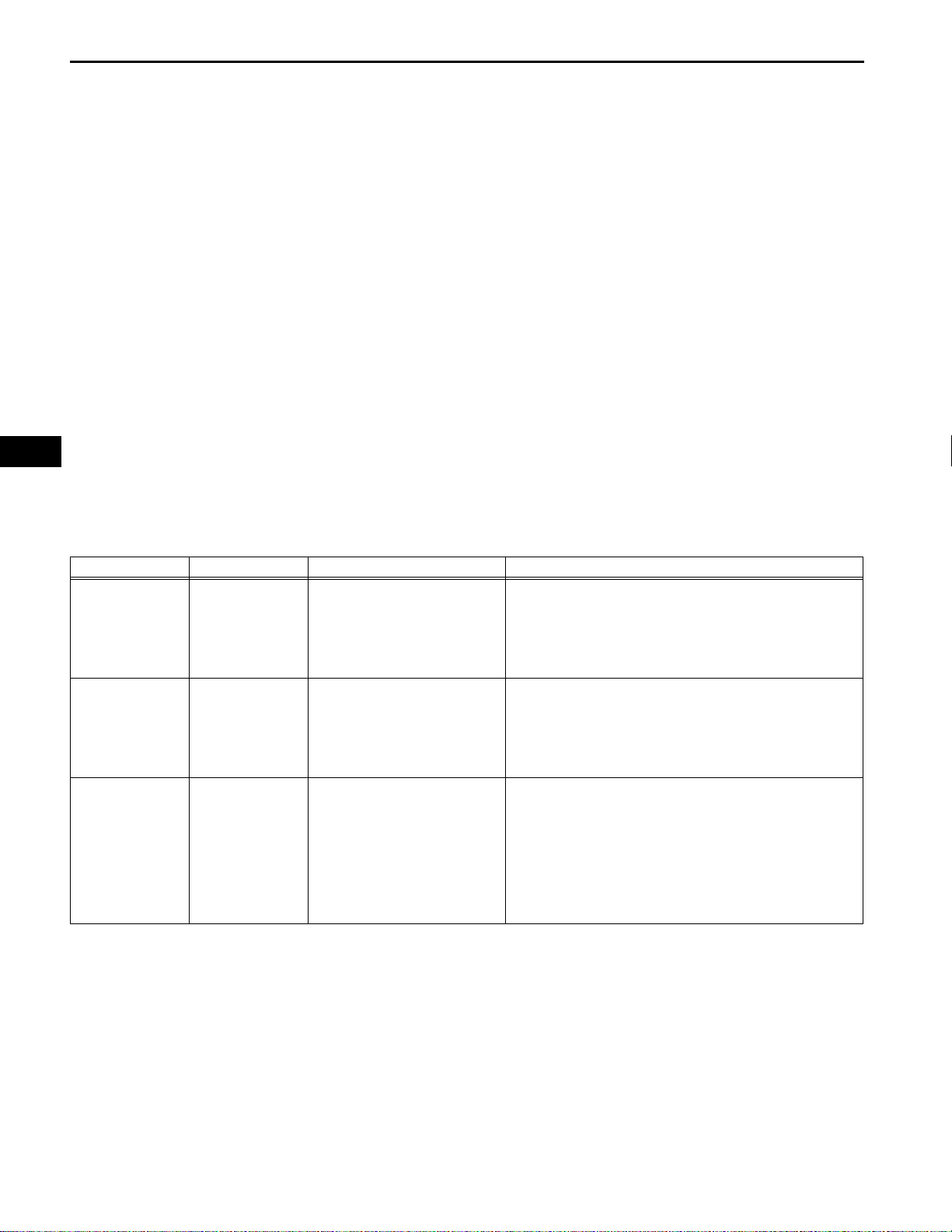

TAC

DLC3

1

2345678

910111213141516

2GR-FE ENGINE MECHANICAL – ENGINE

• Switch off all accessories and air

conditioning before connecting the

intelligent tester.

HINT:

Refer to the intelligent tester operator's manual

for further details.

(c) When not using the intelligent tester:

Check the idle speed.

(1) Using SST, connect the tachometer test probe

to terminal 9 (TAC) of the DLC3.

SST 09843-18030

(2) Check the idle speed.

Idle speed:

600 to 700 rpm

EM–3

A122830E15

A129621

9. INSPECT COMPRESSION

(a) Warm up and stop the engine.

(b) Disconnect the injector connectors.

(c) Remove the intake air surge tank (See page FU-

13).

(d) Remove the 6 ignition coils.

(e) Remove the 6 spark plugs.

(f) Check the cylinder compression pressure.

(1) Insert a compression gauge into the spark plug

hole.

(2) While cranking the engine, measure the

compression pressure.

Compression pressure:

1.4 MPa (14 kgf/cm

2

, 199 psi)

Minimum pressure:

2

0.98 MPa (10 kgf/cm

, 142 psi)

Difference between each cylinder:

2

0.1 MPa (1.0 kgf/cm

, 15 psi)

NOTICE:

• Always use a fully charged battery to

obtain an engine speed of 250 rpm or

more.

• Check the other cylinders' compression

pressure in the same way.

• This measurement must be done as

quickly as possible.

(3) If the cylinder compression is low, pour a small

amount of engine oil into the cylinder through

the spark plug hole and inspect again.

HINT:

• If adding oil increases the compression, the

piston rings and/or cylinder bore may be

worn or damaged.

• If pressure stays low, a valve may be stuck

or seated improperly, or there may be

leakage in the gasket.

(g) Install the 6 spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

EM

EM

EM–4

2GR-FE ENGINE MECHANICAL – ENGINE

(h) Install the 6 ignition coils.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(i) Install the intake air surge tank. (See page FU-17).

10. INSPECT CO/HC

(a) Start the engine.

(b) Run the engine at 2,500 rpm for approximately 180

seconds.

(c) Insert the CO/HC meter testing probe at least 40 cm

(1.3 ft) into the tailpipe during idling.

(d) Check CO/HC concentration at idle and/or 2,500

rpm.

HINT:

Check regulations and restrictions in your area

when performing 2 mode CO/HC concentration

testing (engine check at both idle speed and at

2,500 rpm).

If the CO/HC concentration does not comply with

regulations, perform troubleshooting in the order

given below.

(1) Check A/F sensor and heated oxygen sensor

operation.

(2) See the table below for possible causes, and

then inspect and repair.

CO HC Problems Causes

1. Faulty ignitions:

– Incorrect timing

Normal High Rough idle

Low High

High High

Rough idle

(fluctuating HC reading)

Rough idle

(black smoke from exhaust)

– Fouled, shorted or improperly g apped plugs

2. Incorrect valve clearance

3. Leaks in intake and exhaust valves

4. Leaks in cylinders

1. Vacuum leaks:

– PCV hoses

– Intake manifold

– Throttle body

– Brake booster line

2. Lean mixture causing misfire

1. Restricted air filter

2. Plugged PCV valve

3. Faulty SFI system:

– Faulty fuel pressure regulator

– Defective ECT sensor

– Defective MAF meter

–Faulty ECM

– Faulty injectors

– Faulty throttle position sensor

ENGINE2GR-FE ENGINE MECHANICAL

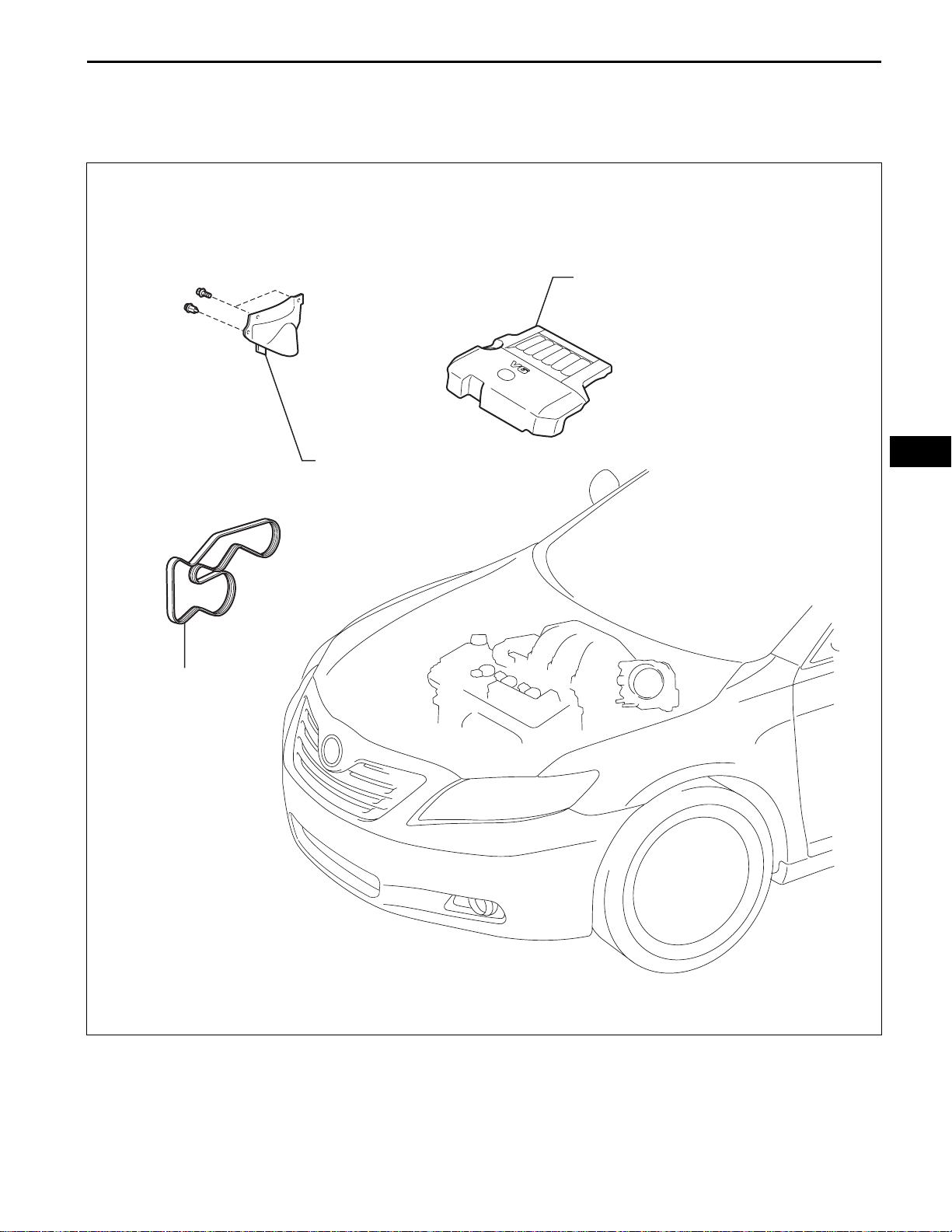

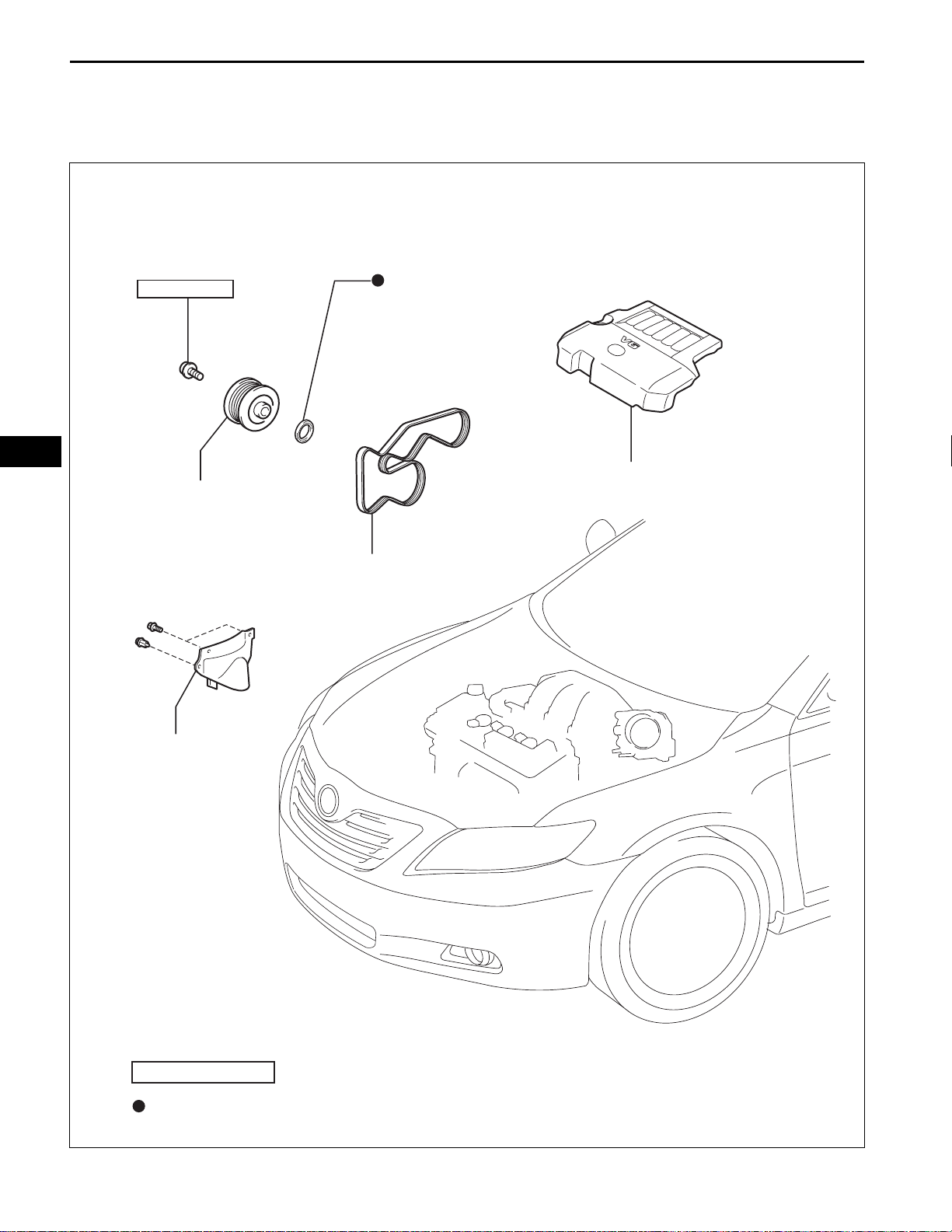

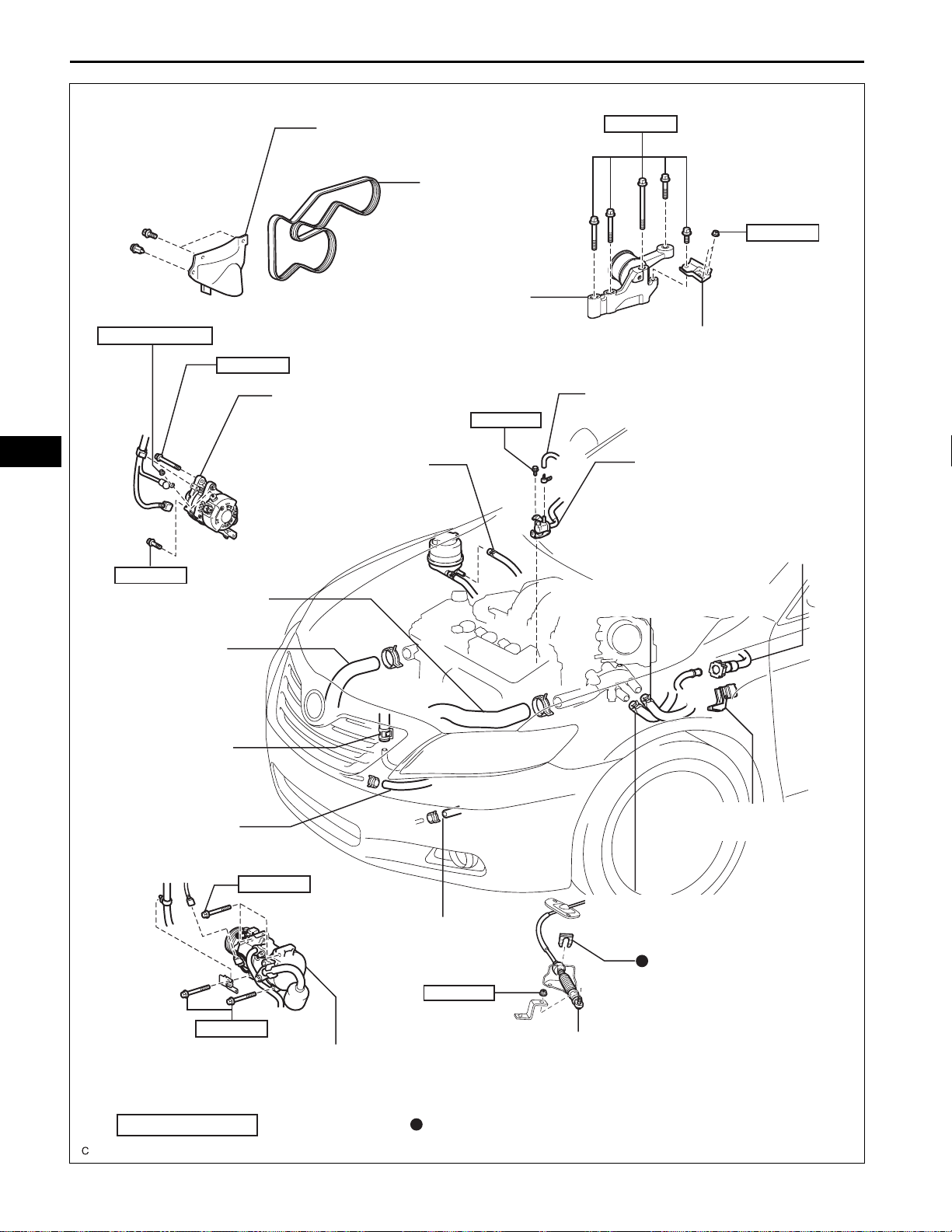

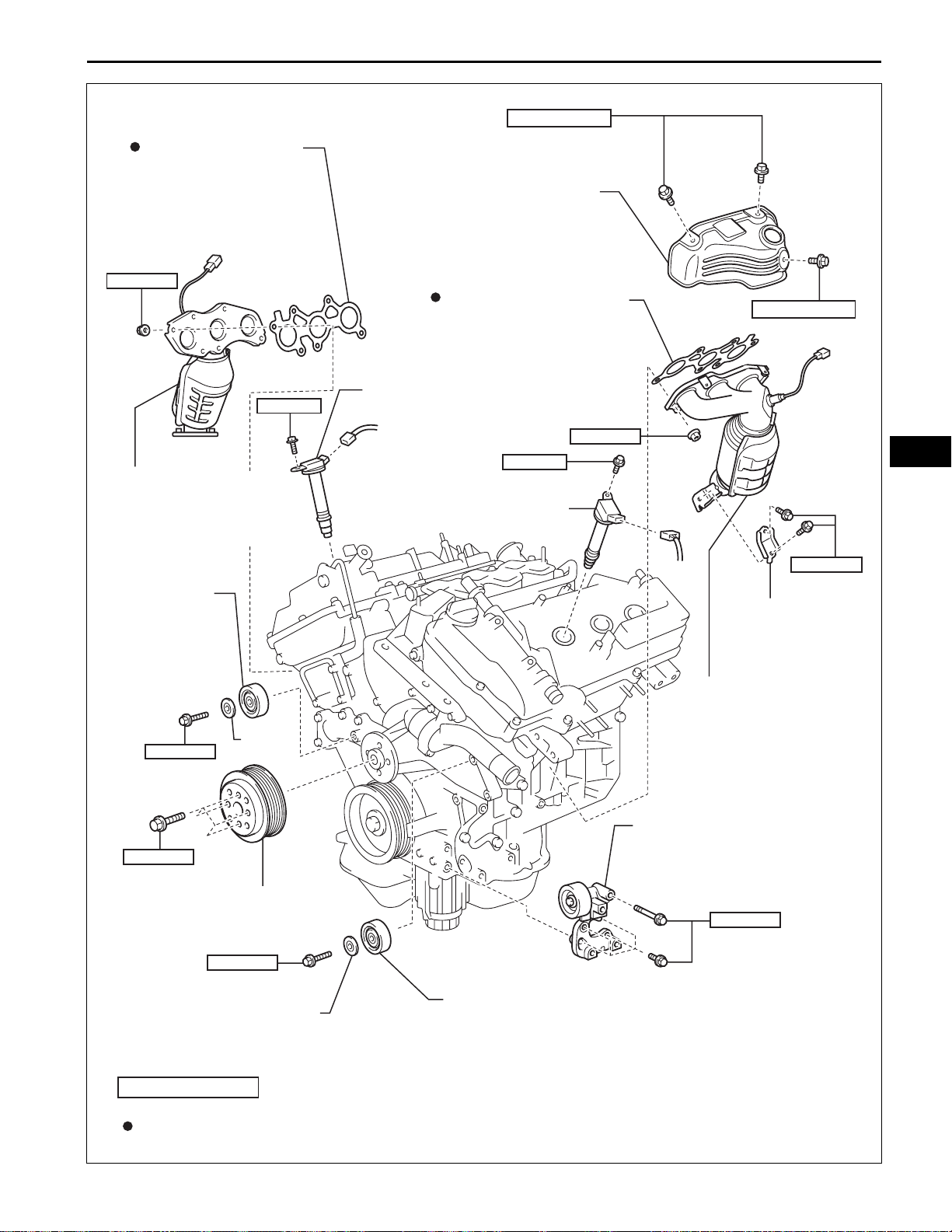

DRIVE BELT

COMPONENTS

2GR-FE ENGINE MECHANICAL – DRIVE BELT

V-BANK COVER SUB-ASSEMBLY

EM–5

V-RIBBED BELT

FRONT FENDER APRON SEAL RH

EM

A134931E01

EM

EM–6

2GR-FE ENGINE MECHANICAL – DRIVE BELT

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH

3. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-23)

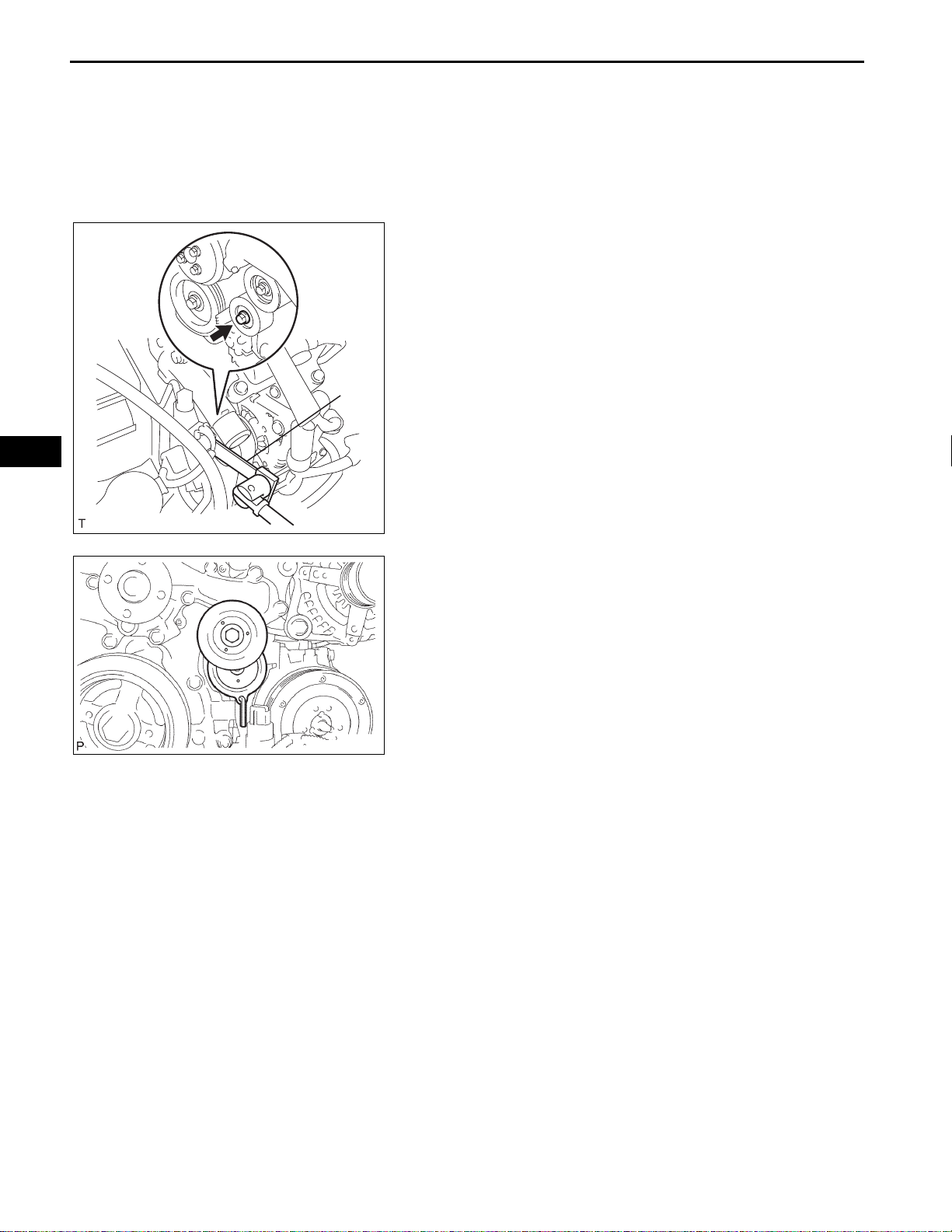

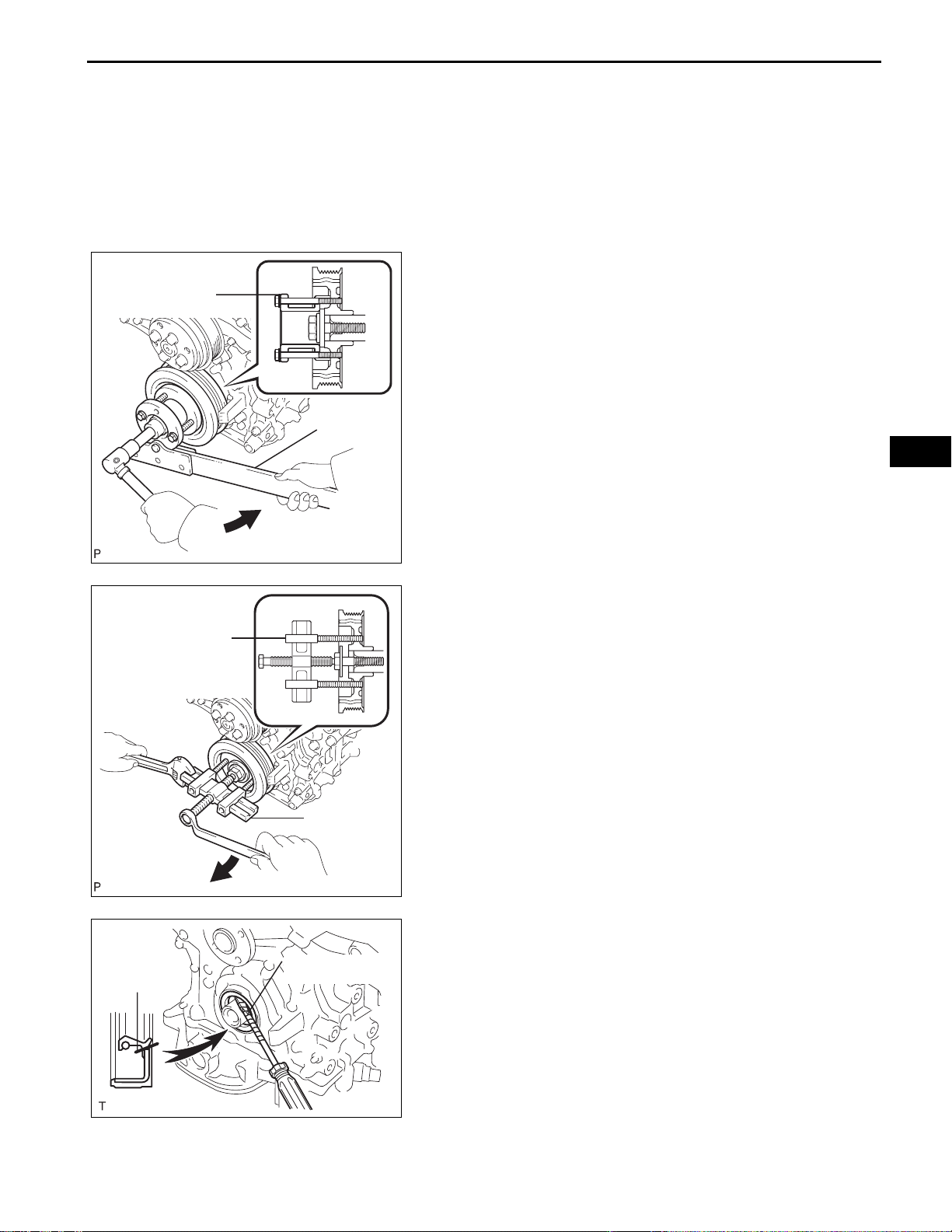

4. REMOVE V-RIBBED BELT

(a) Using SST, release the belt tension by turning the

belt tensioner counterclockwise, and remove the Vribbed belt from the belt tensioner.

SST 09249-63010

SST

A129622E01

A095070

(b) While turning the belt tensioner counterclockwise,

align with its holes, and then insert the 5 mm bihexagon wrench into the holes to fix the V-ribbed

belt tensioner.

2GR-FE ENGINE MECHANICAL – DRIVE BELT

EM–7

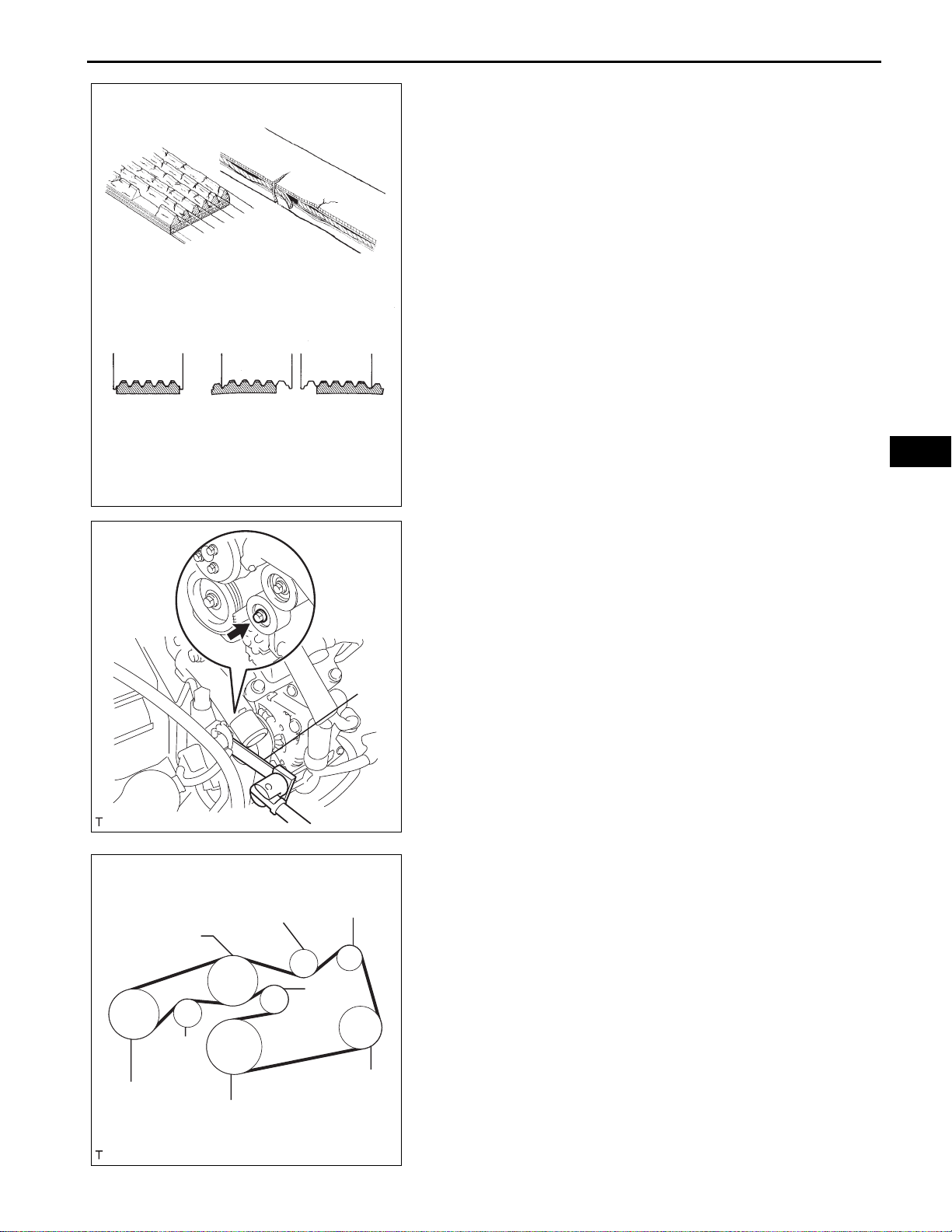

REPLACE

CORRECT INCORRECT

A131418E01

INSPECTION

1. INSPECT V-RIBBED BELT

(a) Visually check the V-ribbed belt for excessive wear,

frayed cords, etc.

If any defect has been found, replace the V-ribbed

belt.

HINT:

Cracks on the rib side of a V-ribbed belt are

considered acceptable.

If the drive belt has chunks missing from its ribs, it

should be replaced.

HINT:

• A "new belt" is a belt which has been used for

less than 5 minutes with the engine running.

• A "used belt" is a belt which has been used for 5

minutes or more with the engine running.

2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Check that nothing gets caught in the tensioner by

turning it clockwise and counterclockwise.

If a malfunction exitsts, replace the tensioner.

INSTALLATION

EM

Water Pump

Vane Pump

Idler

Crankshaft

Generator

Idler

Tensioner

A/C Compressor

SST

A129622E01

A129623E01

1. INSTALL V-RIBBED BELT

(a) Install the V-ribbed belt.

(b) Using SST, turn the belt tensioner counterclockwise

and remove the bar.

SST 09249-63010

(c) If it is difficult to install the V-ribbed belt, perform the

following procedure:

(1) Put the V-rib bed belt on every pulley except the

tensioner pulley as shown in the illustration.

(2) While releasing the belt tension by turning the

belt tensioner counterclockwise, put the Vribbed belt on the tensioner pulley.

NOTICE:

• Put the backside of the V-ribbed belt on

the tensioner pulley and idler pulley.

• Check that the V-ribbed belt is properly

set to each pulley.

(3) After installing the V-ribbed belt, check that it

fits properly in the ribbed grooves. Confirm that

the belt has not slipped out of the grooves on

the bottom of the crank pulley by hand.

EM

EM–8

2GR-FE ENGINE MECHANICAL – DRIVE BELT

2. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-52)

3. INSTALL FRONT FENDER APRON SEAL RH

4. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

EM–8

ENGINE2GR-FE ENGINE MECHANICAL

2GR-FE ENGINE MECHANICAL – ENGINE FRONT OIL SEAL

ENGINE FRONT OIL SEAL

COMPONENTS

EM

250 (2,550, 184)

CRANKSHAFT PULLEY

TIMING CHAIN CASE OIL SEAL

V-BANK COVER SUB-ASSEMBLY

V-RIBBED BELT

FRONT FENDER APRON

SEAL RH

N*m (kgf*cm, ft.*lbf)

Non-reusable part

: Specified torque

A134932E01

SST

2GR-FE ENGINE MECHANICAL – ENGINE FRONT OIL SEAL

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH

3. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-23)

4. REMOVE V-RIBBED BELT (See page EM-6)

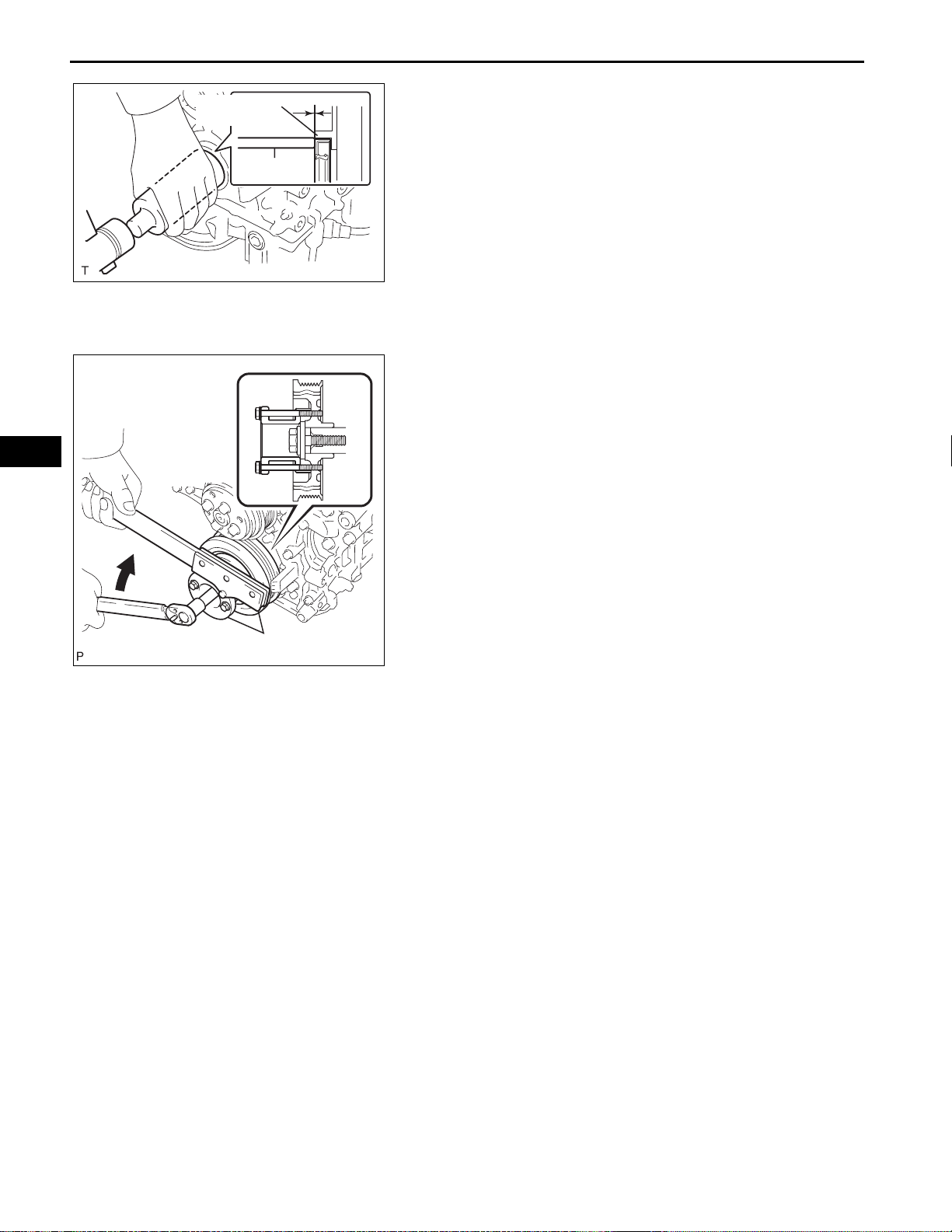

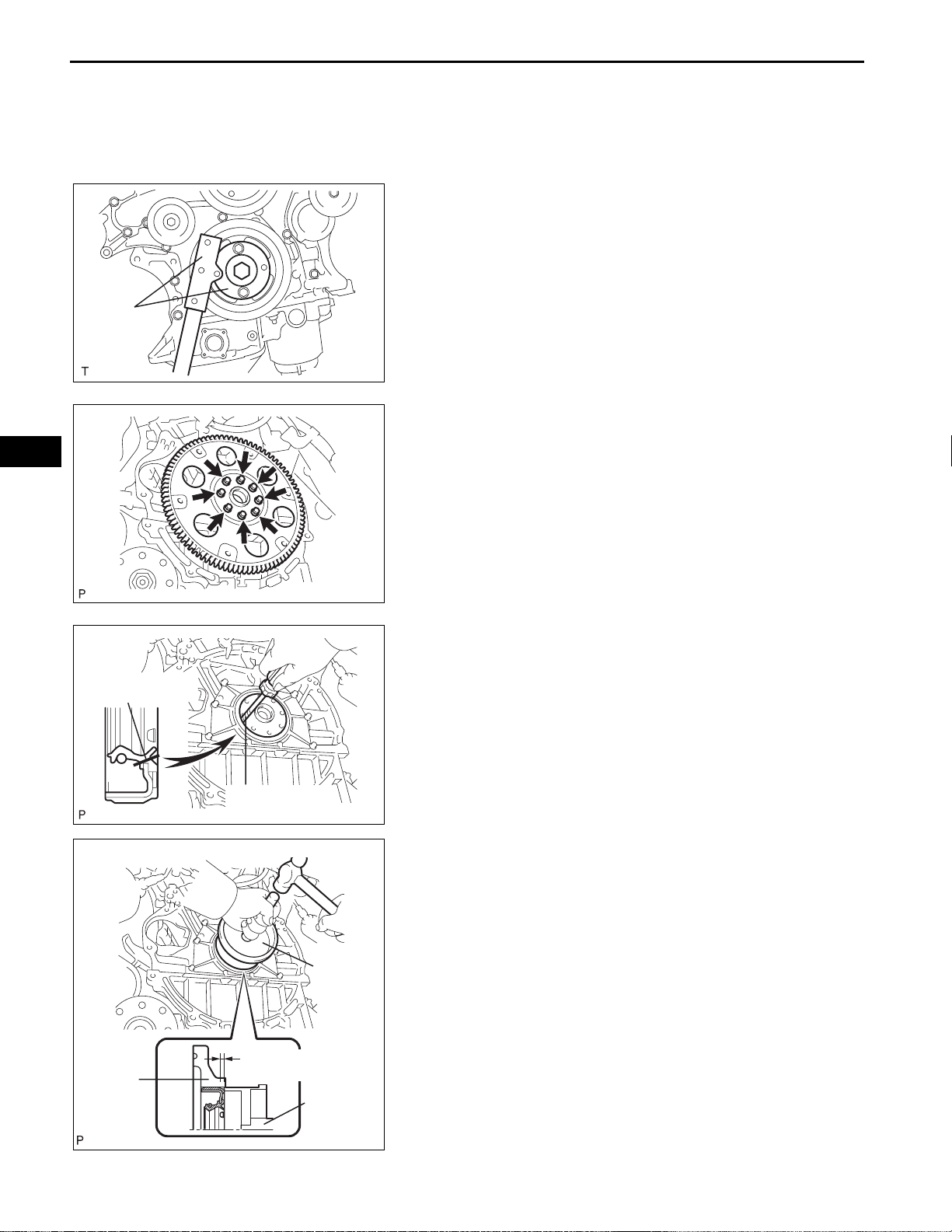

5. REMOVE CRANKSHAFT PULLEY

(a) Using SST, loosen the crankshaft pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

SST

EM–9

EM

Cut Position

SST

A119083E01

SST

A119085E01

Protective Tape

(b) Using SST, remove the crankshaft pulley bolt and

crankshaft pulley.

SST 09950-50013 (09951-05010, 09952-05010,

09953-05020, 09954-05021)

6. REMOVE TIMING CHAIN CASE OIL SEAL

(a) Using a screwdriver, pry out the oil seal.

HINT:

Tape the screwdriver tip before use.

NOTICE:

After the removal, check the crankshaft for

damage. If it is damaged, smooth the surface

with 400-grit sandpaper.

A132241E01

EM–10

2GR-FE ENGINE MECHANICAL – ENGINE FRONT OIL SEAL

EM

Chain Cover

SST

A132242E01

INSTALLATION

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Apply MP grease to a new oil seal lip.

(b) Using SST and a hammer , ta p in the oil seal until it s

surface is flush with the timing chain cover edge.

SST 09316-60011 (09316-00011)

NOTICE:

• Keep the lip free of foreign matter.

• Do not tap the oil seal at an angle.

2. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the

pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

Torque: 250 N*m (2,550 kgf*cm, 184 ft.*lbf)

3. INSTALL V-RIBBED BELT (See page EM-7)

4. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-52)

5. INSTALL FRONT FENDER APRON SEAL RH

6. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

SST

A119084E01

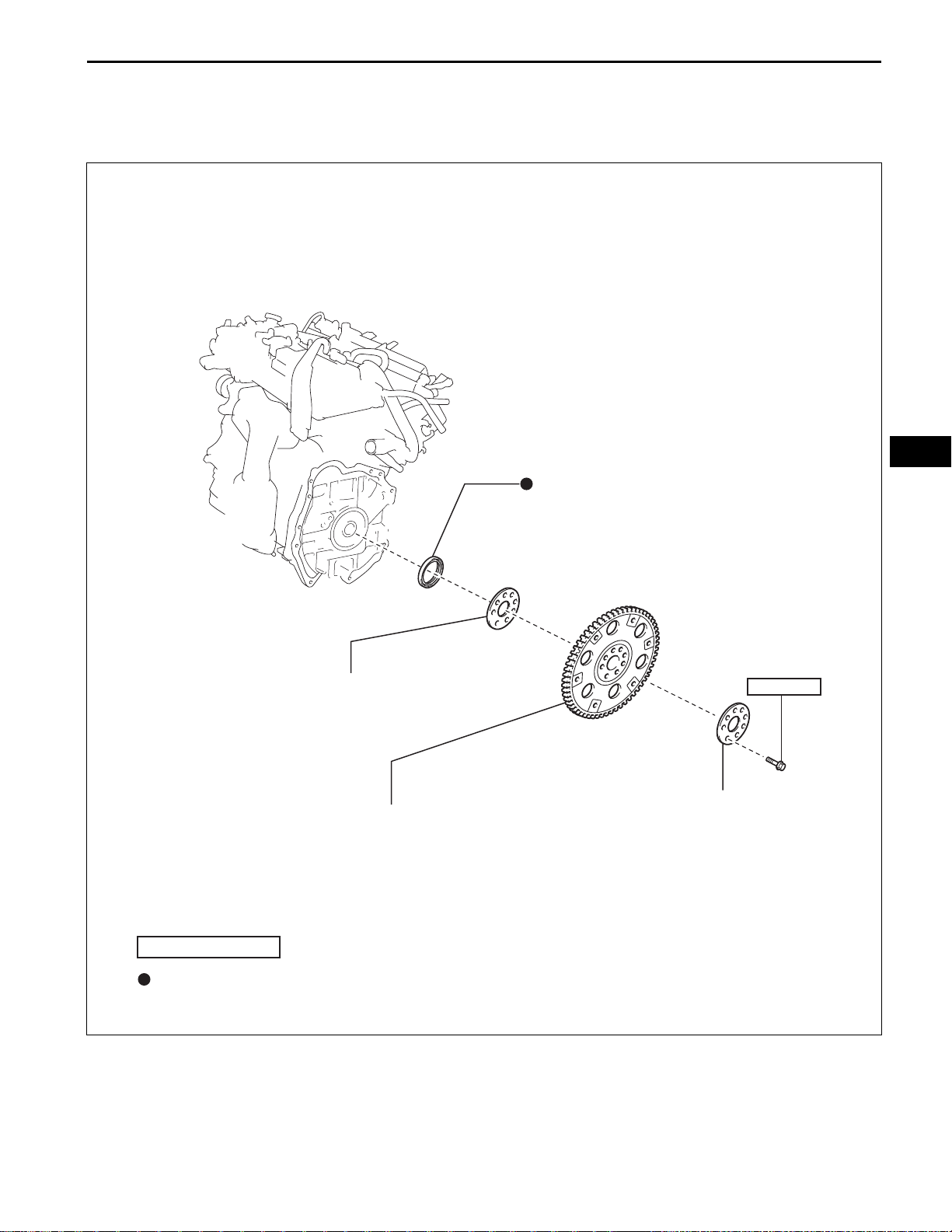

2GR-FE ENGINE MECHANICAL – ENGINE REAR OIL SEAL

ENGINE2GR-FE ENGINE MECHANICAL

ENGINE REAR OIL SEAL

COMPONENTS

EM–11

EM

ENGINE REAR OIL SEAL

DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf)

Non-reusable part

FRONT SPACER

: Specified torque

83 (850, 61)

x8

REAR SPACER

A134930E01

EM

EM–12

SST

2GR-FE ENGINE MECHANICAL – ENGINE REAR OIL SEAL

REMOVAL

1. REMOVE AUTOMATIC TRAN SAXLE ASSEMBLY

HINT:

See page AX-207.

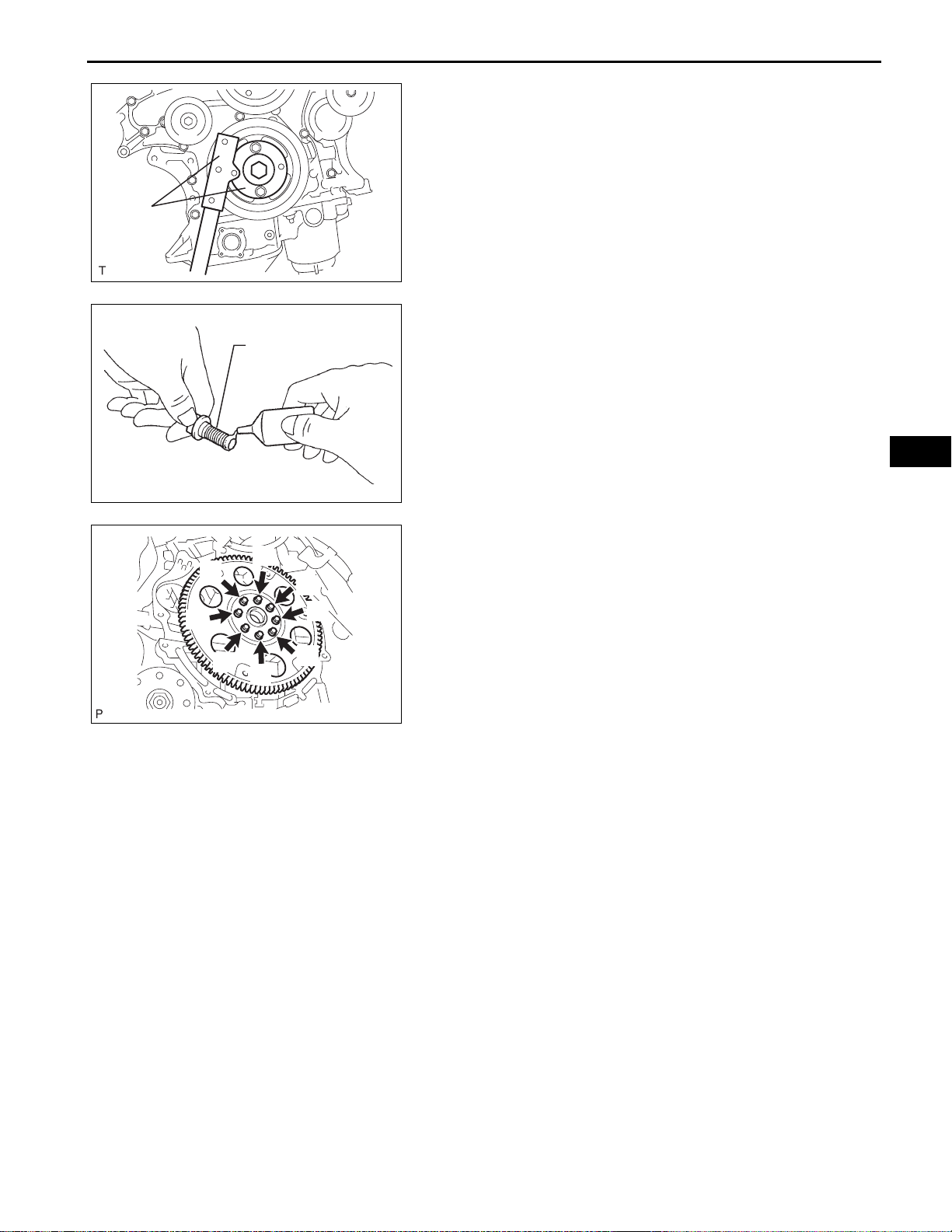

2. REMOVE DRIVE PLATE AND RING GEAR SUBASSEMBLY

(a) Using SST, hold the crankshaft.

SST 09213-70011 (09213-70020), 09330-00021

A129631E01

(b) Remove the 8 bolts, front spacer, drive plate and

rear spacer.

Cut Position

Protective Tape

SST

A132243

3. REMOVE ENGINE REAR OIL SEAL

(a) Using a knife, cut off the oil seal lip.

(b) Using a screwdriver, pry out the oil seal.

NOTICE:

Be careful not to damage the crankshaft. Tape

the screwdriver tip before use.

A132244E01

INSTALLATION

1. INSTALL ENGINE REAR OIL SEAL

(a) Apply MP grease to a new oil seal lip.

(b) Using SST and a hammer, tap in the oil seal.

SST 09223-15030, 09950-70010 (09951-07150)

Oil seal tap in depth:

-0.5 to 0.5 mm (-0.020 to 0.020 in.)

Retainer

-0.5 to 0.5 mm

SST

A132245E01

SST

2GR-FE ENGINE MECHANICAL – ENGINE REAR OIL SEAL

2. INSTALL DRIVE PLATE AND RING GEAR SUBASSEMBLY

(a) Using SST, hold the crankshaft.

SST 09213-70011 (09213-70020), 09330-00021

A129631E01

(b) Apply adhesive to 2 or 3 threads of the mounting

bolt end.

Adhesive

Adhesive:

Part No. 08833-00070, THREE BOND 1324 or

equivalent

P000601E04

EM–13

EM

(1) Install the front spacer, drive plate and rear

5

3

1

7

4

spacer on the crankshaft.

(2) Install and tighten the 8 mounting bolts

uniformly in several steps.

Torque: 83 N*m (850 kgf*cm, 61 ft.*lbf)

3. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

8

6

2

A132243E01

HINT:

See page AX-214.

EM–14

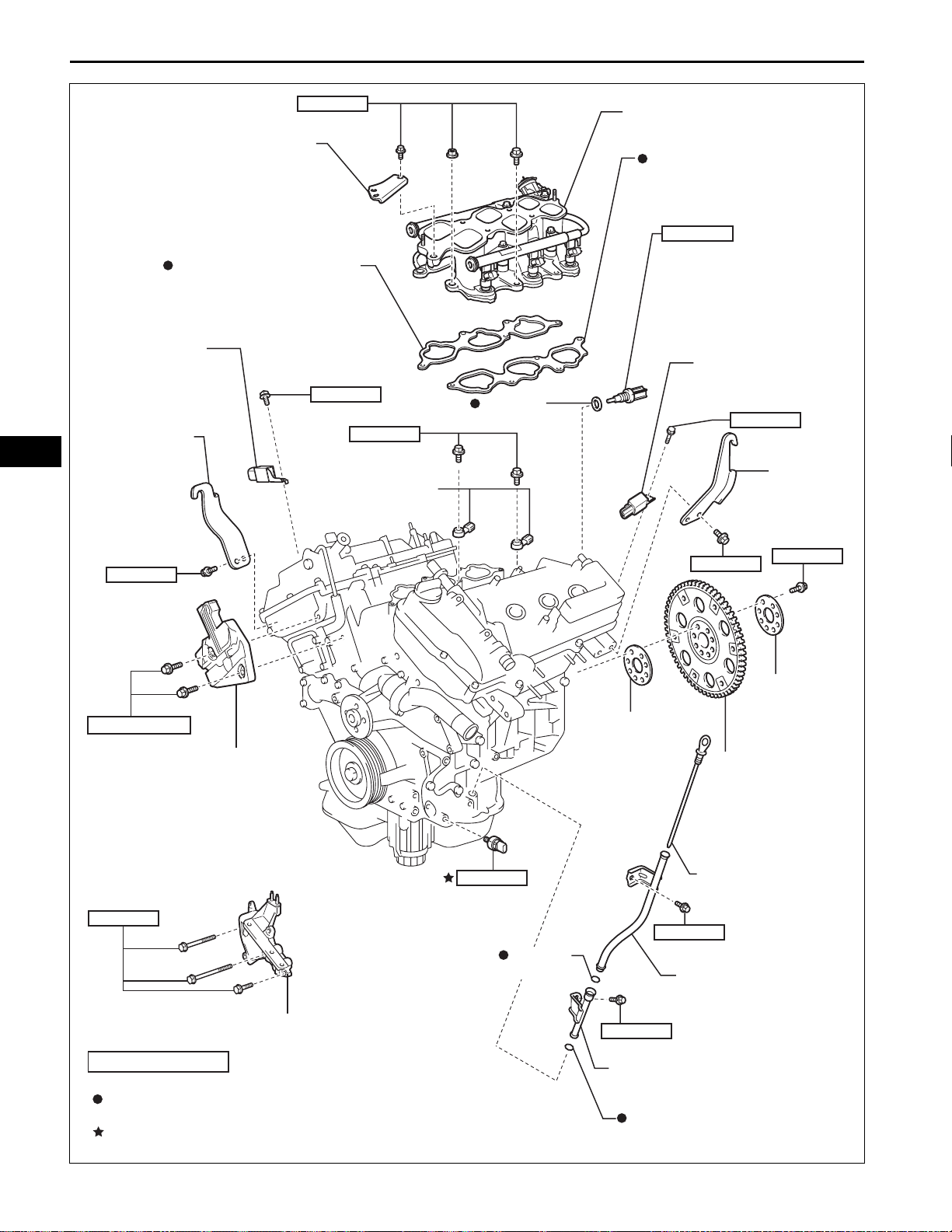

ENGINE2GR-FE ENGINE MECHANICAL

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

ENGINE ASSEMBLY

COMPONENTS

EM

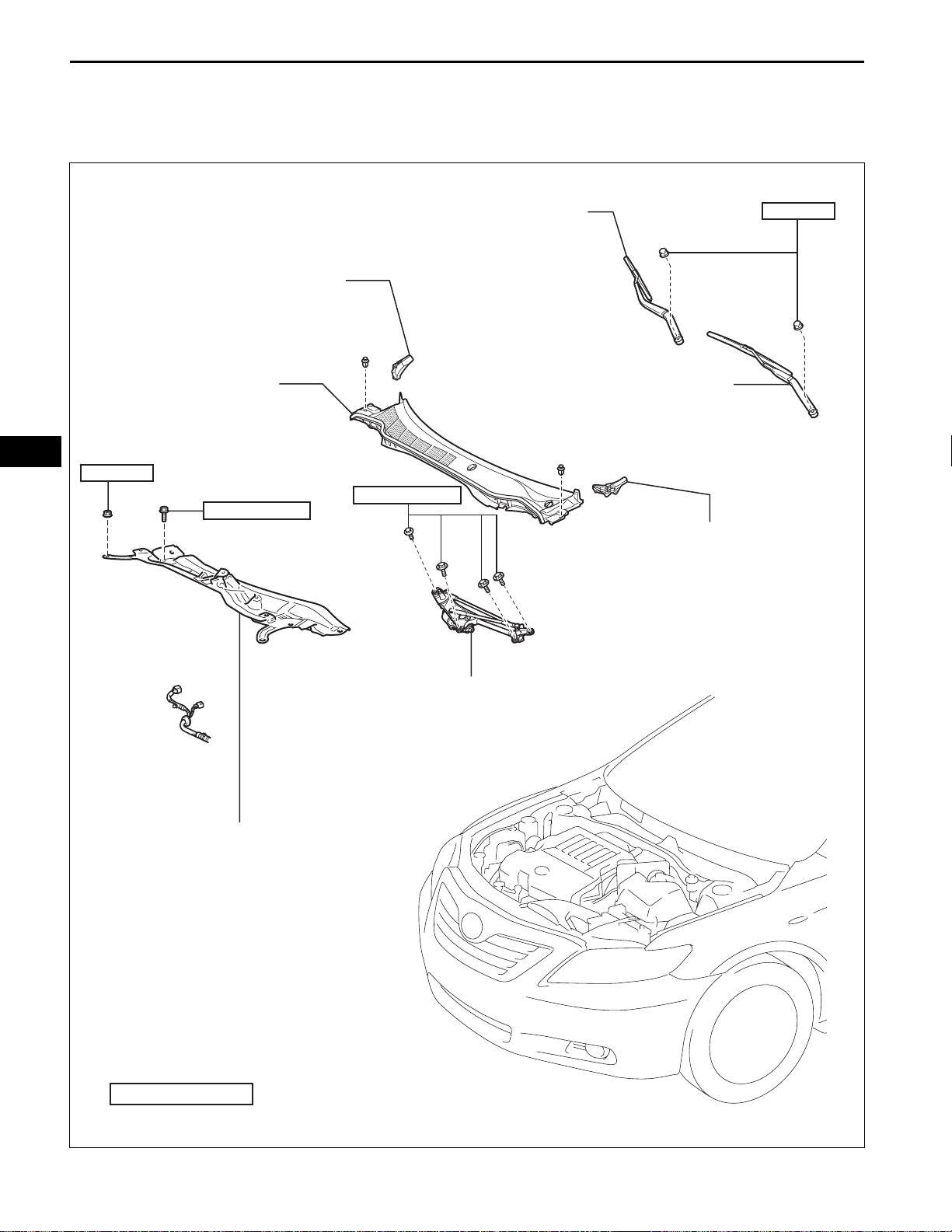

FRONT FENDER TO COWL

SIDE SEAL RH

COWL TOP VENTILATOR

LOUVER SUB-ASSEMBLY

85 (867, 63)

5.0 (51, 44 in.*lbf)

FRONT WIPER ARM AND

BLADE ASSEMBLY RH

7.5 (77, 66 in.*lbf)

20 (204, 15)

FRONT WIPER ARM AND

BLADE ASSEMBLY LH

FRONT FENDER TO COWL

SIDE SEAL LH

COWL TOP PANEL OUTER SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

WINDSHIELD WIPER

LINK ASSEMBLY

A134938E01

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

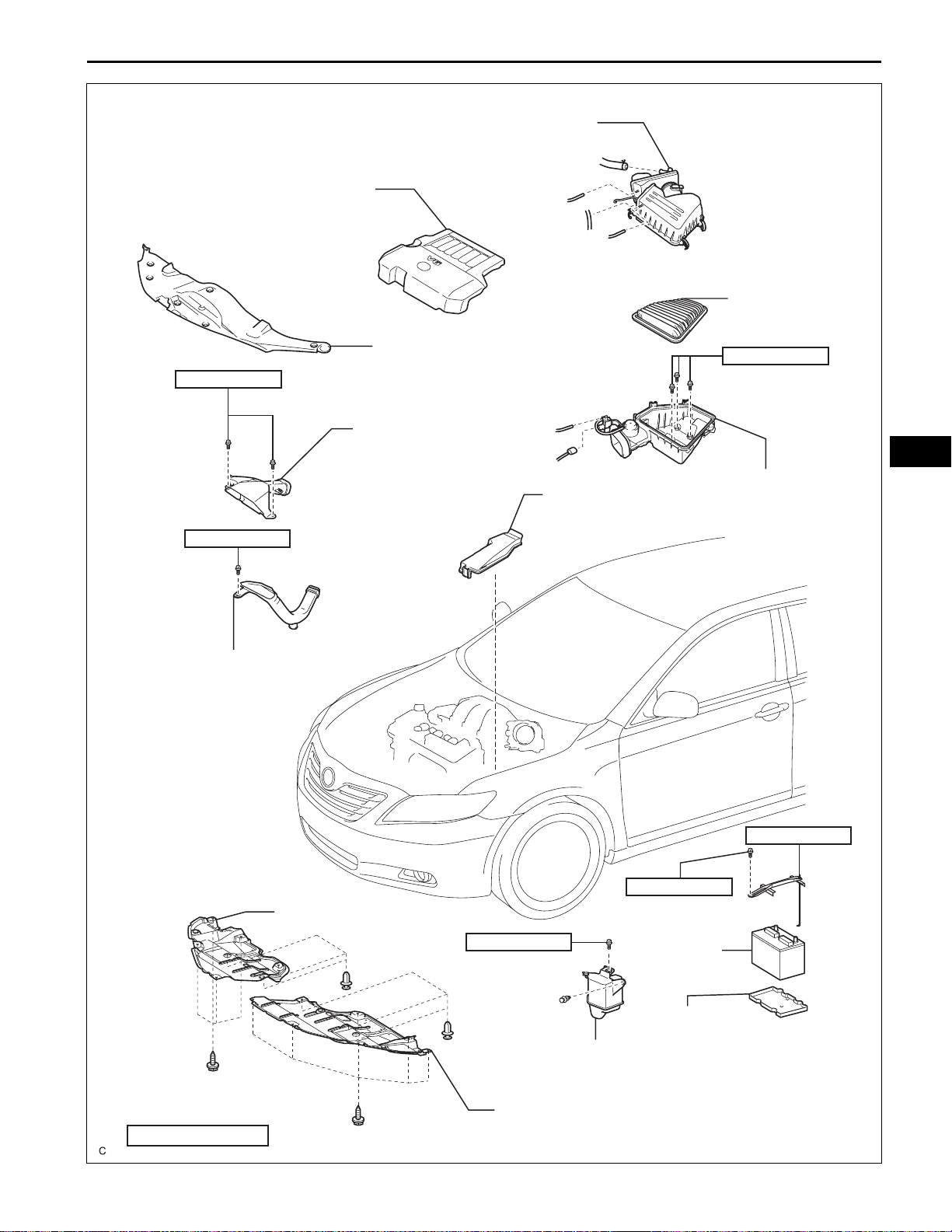

AIR CLEANER CAP SUB-ASSEMBLY

V-BANK COVER SUB-ASSEMBLY

EM–15

AIR CLEANER

FILTER ELEMENT

5.0 (51, 44 in.*lbf)

5.0 (51, 44 in.*lbf)

NO. 1 AIR CLEANER INLET

COOL AIR INTAKE DUCT SEAL

AIR CLEANER INLET

ASSEMBLY

RELAY BLOCK

COVER UPPER

5.0 (51, 44 in.*lbf)

EM

AIR CLEANER CASE

SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf)

ENGINE UNDER COVER RH

: Specified torque

5.0 (51, 44 in.*lbf)

INTAKE AIR RESONATOR

SUB-ASSEMBLY

ENGINE UNDER COVER LH

3.5 (36, 31 in.*lbf)

9.0 (92, 80 in.*lbf)

BATTERY

BATTERY TRAY

A132994E01

EM–16

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

9.8 (100, 87 in.*lbf)

FRONT FENDER APRON SEAL RH

ENGINE MOVING CONTROL

ROD SUB-ASSEMBLY

43 (438, 32)

GENERATOR ASSEMBLY

NO. 1 OIL RESERVOIR

TO PUMP HOSE

38 (388, 28)

V-RIBBED BELT

23 (235, 17)

NO. 2 ENGINE MOUNTING STAY RH

NO. 1 FUEL VAPOR FEED HOSE

10 (102, 7)

NO. 1 VACUUM SWITCHING

VALVE ASSEMBLY

FUEL TUBE SUB-ASSEMBLY

43 (438, 32)

RADIATOR HOSE INLET

RADIATOR HOSE

OUTLET

RETURN TUBE

SUB-ASSEMBLY

NO. 1 OIL COOLER

INLET HOSE

25 (250, 18)

HEATER INLET WATER HOSE

NO. 1 FUEL PIPE CLAMP

HEATER OUTLET WATER HOSE

NO. 1 OIL COOLER

OUTLET HOSE

CLIP

13 (130, 9)

25 (250, 18)

COOLER COMPRESSOR ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

TRANSMISSION CONTROL

CABLE ASSEMBLY

Non-reusable part

A132995E01

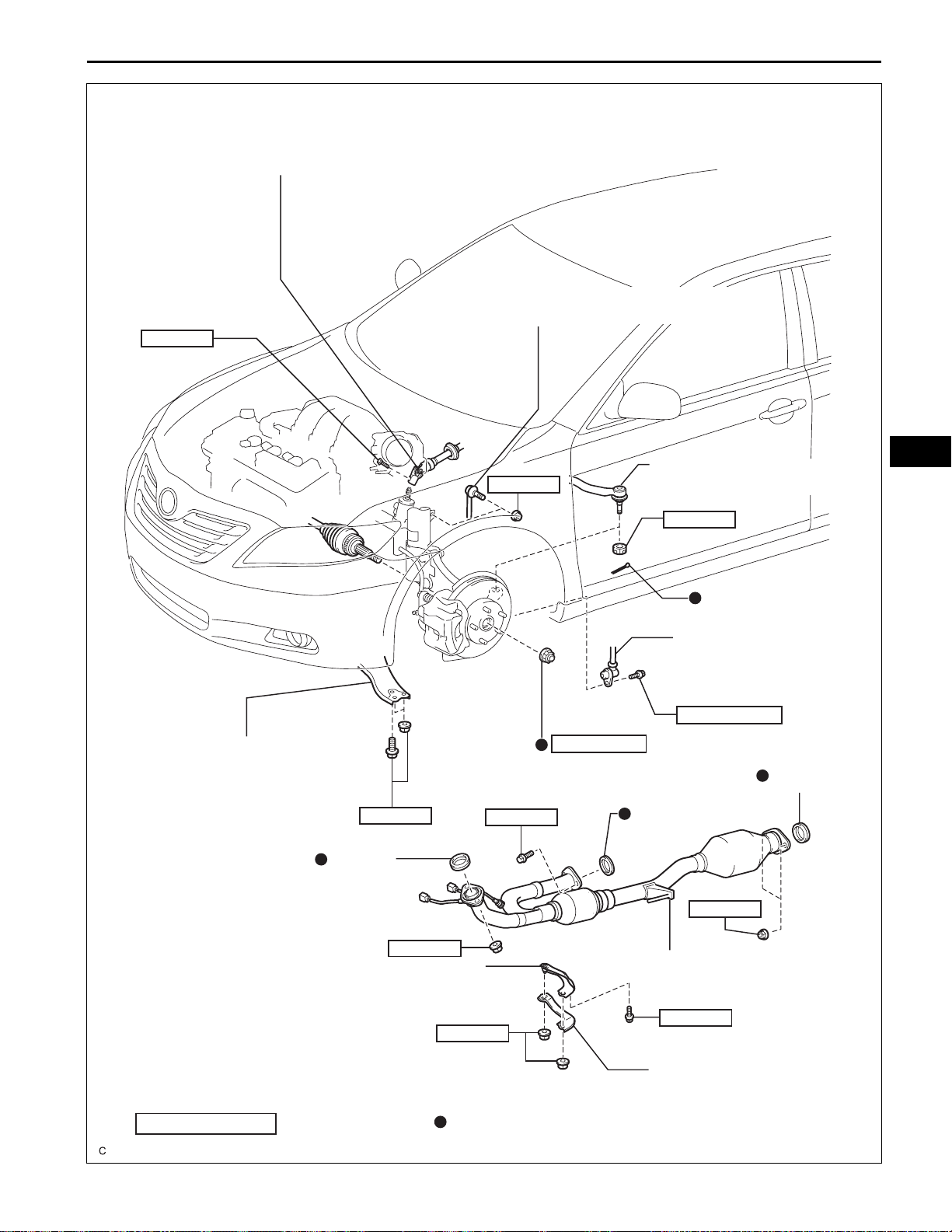

STEERING SLIDING YOKE

35 (360, 26)

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

FRONT STABILIZER LINK ASSEMBLY LH

EM–17

FRONT SUSPENSION

LOWER NO. 1 ARM LH

75 (765, 55)

GASKET

74 (755, 55)

62 (632, 46)

TIE ROD ASSEMBLY LH

49 (500, 36)

COTTER PIN

FRONT SPEED

SENSOR LH

8.0 (85, 71 in.*lbf)

294 (3,000, 217)

FRONT AXLE HUB NUT LH

GASKET

56 (571, 41)

EM

GASKET

62 (632, 46)

NO. 1 EXHAUST PIPE SUPPORT BRACKET

N*m (kgf*cm, ft.*lbf)

: Specified torque

EXHAUST PIPE ASSEMBLY FRONT

21 (214, 15)

33 (337, 24)

EXHAUST PIPE NO. 1

SUPPORT BRACKET

Non-reusable part

A132996E01

EM–18

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

95 (969, 70)

87 (887, 64)

ENGINE ASSEMBLY

WITH TRANSAXLE

95 (969, 70)

43 (439, 32)

ENGINE WIRE

VANE PUMP ASSEMBLY

NO. 2 FUEL PIPE CLAMP

FUEL TUBE SUB-ASSEMBLY

STARTER ASSEMBLY

37 (380, 26)

FRONT FRAME

ASSEMBLY

FRAME SIDE RAIL

32 (329, 24)

85 (867, 63)

32 (329, 24)

PLATE RH

FRAME SIDE RAIL PLATE LH

N*m (kgf*cm, ft.*lbf)

: Specified torque

32 (329, 24)

85 (867, 63)

37 (380, 26)

7.8 (80, 69 in.*lbf)

85 (867, 63)

32 (329, 24)

85 (867, 63)

32 (329, 24)

FRONT SUSPENSION

MEMBER BRACE REAR LH

9.8 (100, 87 in.*lbf)

FRONT SUSPENSION

MEMBER BRACE

REAR RH

32 (329, 24)

A134929E01

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

54 (551, 40)

ENGINE MOUNTING BRACKET RH

DRIVE SHAFT BEARING BRACKET HOLE SNAP RING

EM–19

FRONT DRIVE SHAFT

ASSEMBLY RH

NO. 1 DRIVE SHAFT BEARING

BRACKET SETTING BOLT

32 (334, 30)

DRIVE SHAFT BEARING BRACKET

64 (650, 47)

EM

FRONT DRIVE SHAFT INNER

LH SHAFT SNAP RING

46 (469, 34)

FRONT DRIVE SHAFT ASSEMBLY LH

7.8 (80, 69 in.*lbf)

FLYWHEEL HOUSING

UNDER COVER

64 (653, 47)

43 (438, 32)

64 (653, 47)

41 (413, 30)

DRIVE PLATE AND TORQUE

CONVERTER CLUTCH

SETTING BOLT

N*m (kgf*cm, ft.*lbf)

: Specified torque

EXHAUST PIPE

SUPPORT BRACKET

AUTOMATIC TRANSAXLE

ASSEMBLY

ENGINE MOUNTING BRACKET FR

Non-reusable part

A134940E01

EM–20

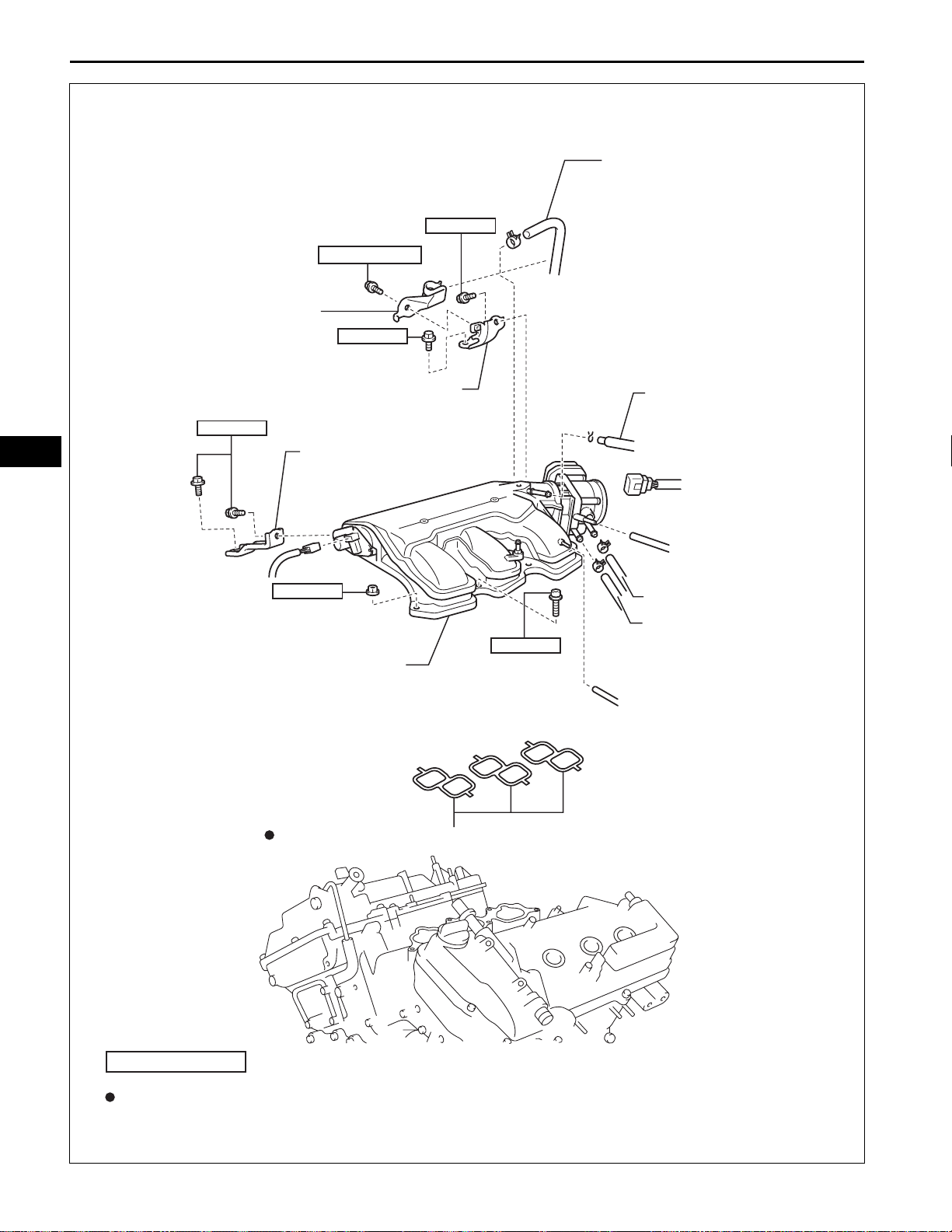

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

VACUUM HOSE CLAMP

5.4 (55, 48 in.*lbf)

21 (214, 15)

*

21 (214, 15)

*

UNION TO CHECK VALVE HOSE

EM

THROTTLE BODY BRACKET

21 (214, 15)

*

NO. 1 SURGE TANK STAY

16 (163, 12)

INTAKE AIR SURGE TANK

AIR SURGE TANK TO INTAKE MANIFOLD GASKET

18 (184, 13)

*

x4

VENTILATION HOSE

NO. 3 WATER BY-PASS HOSE

NO. 2 WATER BY-PASS HOSE

N*m (kgf*cm, ft.*lbf)

Non-reusable part

* DO NOT apply oil

: Specified torque

A134939E01

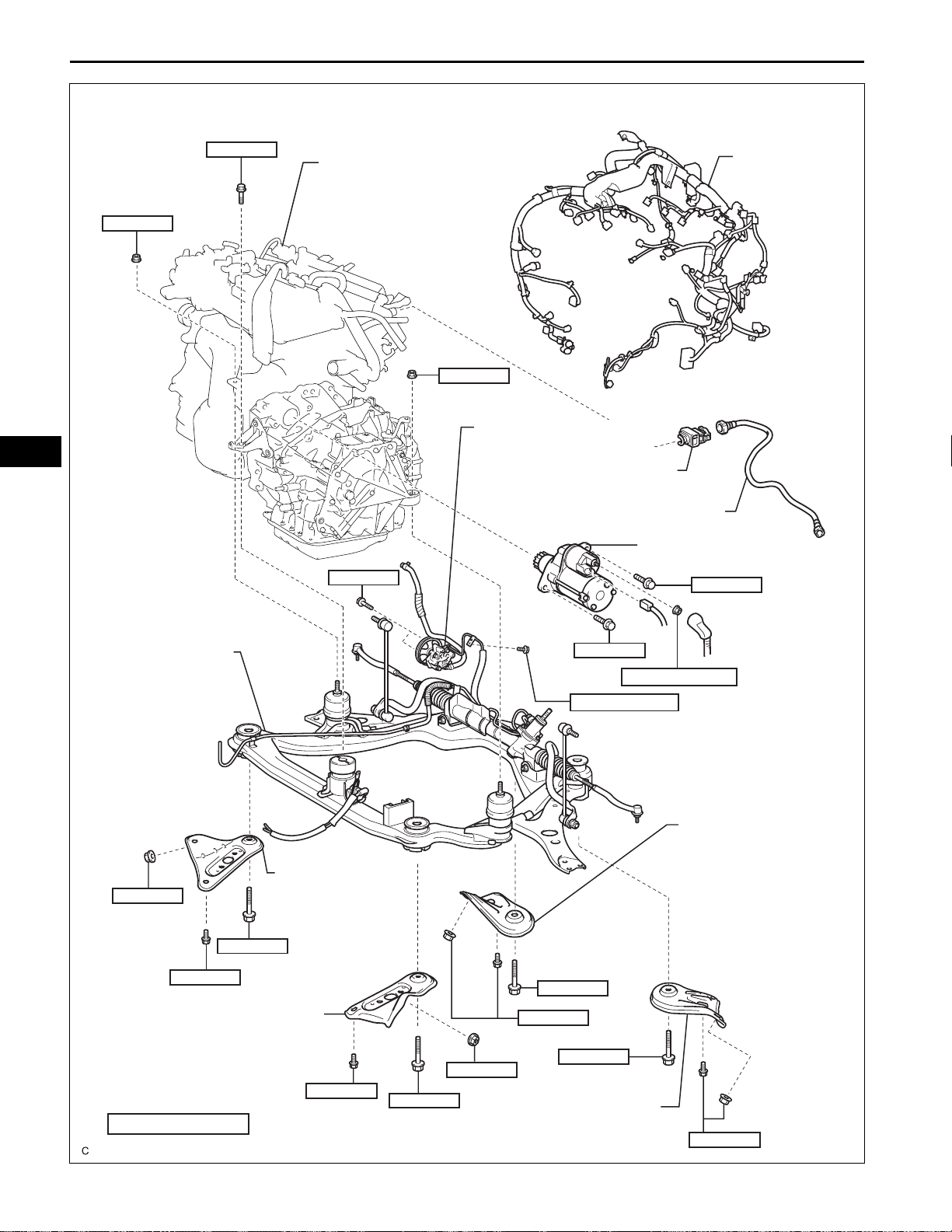

EXHAUST MANIFOLD

TO HEAD GASKET

21 (214, 15)

x6

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

8.5 (87, 75 in.*lbf)

NO. 2 EXHAUST MANIFOLD

HEAT INSULATOR

EXHAUST MANIFOLD TO

HEAD LH GASKET

EM–21

8.5 (87, 75 in.*lbf)

EXHAUST MANIFOLD

SUB-ASSEMBLY RH

NO. 2 IDLER

PULLEY SUBASSEMBLY (RR

SIDE)

43 (438, 32)

21 (214, 15)

PLATE

10 (102, 7)

IGNITION COIL ASSEMBLY

10 (102, 7)

IGNITION COIL ASSEMBLY

21 (214, 15)

x6

EM

34 (347, 25)

NO. 2 MANIFOLD

STAY

EXHAUST MANIFOLD

SUB-ASSEMBLY LH

V-RIBBED BELT TENSIONER

ASSEMBLY

WATER PUMP PULLEY

43 (438, 32)

N*m (kgf*cm, ft.*lbf)

Non-reusable part

PLATE

: Specified torque

43 (438, 32)

NO. 2 IDLER PULLEY

SUB-ASSEMBLY (FR SIDE)

A134941E01

EM–22

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

NO. 2 ENGINE MOUNTING

STAY RH

NO. 1 INTAKE MANIFOLD

TO HEAD GASKET

RADIO SETTING

CONDENSER

NO. 1 ENGINE

HANGER

21 (214, 15)

10 (102, 7)

20 (204, 15)

KNOCK CONTROL

SENSOR

x4

GASKET

x6

INTAKE MANIFOLD

NO. 2 INTAKE MANIFOLD

TO HEAD GASKET

20 (200, 14)

ENGINE COOLANT

TEMPERATURE

SENSOR

RADIO SETTING

CONDENSER

10 (102, 7)

NO. 2

ENGINE

HANGER

33 (337, 24)

6.0 (61, 53 in.*lbf)

NO. 2 TIMING GEAR COVER

ENGINE OIL PRESSURE

54 (551, 40)

SWITCH ASSEMBLY

x3

x2

NO. 1 ENGINE MOUNTING BRACKET FRONT LH

21 (214, 15)

O-RING

DRIVE PLATE

SPACER FRONT

21 (214, 15)

NO. 2 OIL LEVEL

GAUGE GUIDE

21 (214, 15)

33 (337, 24)

83 (846, 61)

x8

DRIVE PLATE

SPACER REAR

DRIVE PLATE

AND RING GEAR

SUB-ASSEMBLY

OIL LEVEL GAUGE

N*m (kgf*cm, ft.*lbf)

Non-reusable part

Precoated Part

: Specified torque

NO. 1 OIL LEVEL GAUGE GUIDE

O-RING

A134942E01

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

4. REMOVE FRONT WHEELS

5. REMOVE ENGINE UNDER COVER LH

6. REMOVE ENGINE UNDER COVER RH

7. REMOVE FRONT FENDER APRON SEAL RH

8. DRAIN ENGINE OIL (See page LU-4)

9. DRAIN ENGINE COOLANT (See page CO-5)

EM–23

A132967

A132968

10. DRAIN AUTOMATIC TRANSAXLE FLUID (See page

AX-207)

11. REMOVE WINDSHIELD WIPER LINK ASSEMBLY

See page WW-9.

12. REMOVE COWL TOP PANEL OUTER SUBASSEMBLY (See page ES-481)

13. REMOVE COOL AIR INTAKE DUCT SEAL

(a) Remove the 7 clips and intake duct seal.

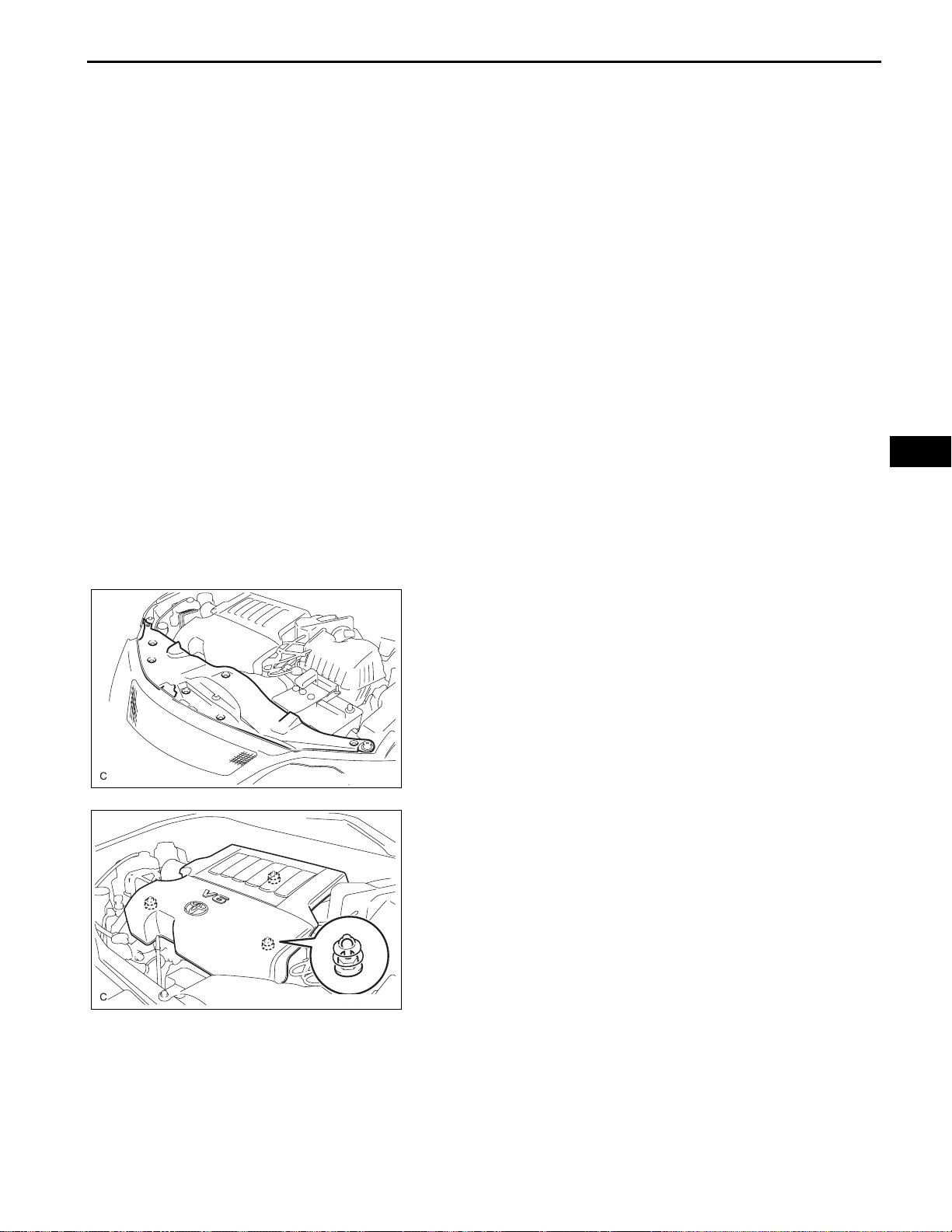

14. REMOVE V-BANK COVER SUB-ASSEMBLY

(a) Hold the front of the V-bank cover and raise it to

disengage the 2 clips on the front of the cover.

Continue to raise the cover to disengage the clip on

the rear of the cover and remove the cover.

NOTICE:

Attempting to disengage both front and rear

clips at the same time may cause the cover to

break.

15. REMOVE V-RIBBED BELT (See page EM-6)

EM

EM

EM–24

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

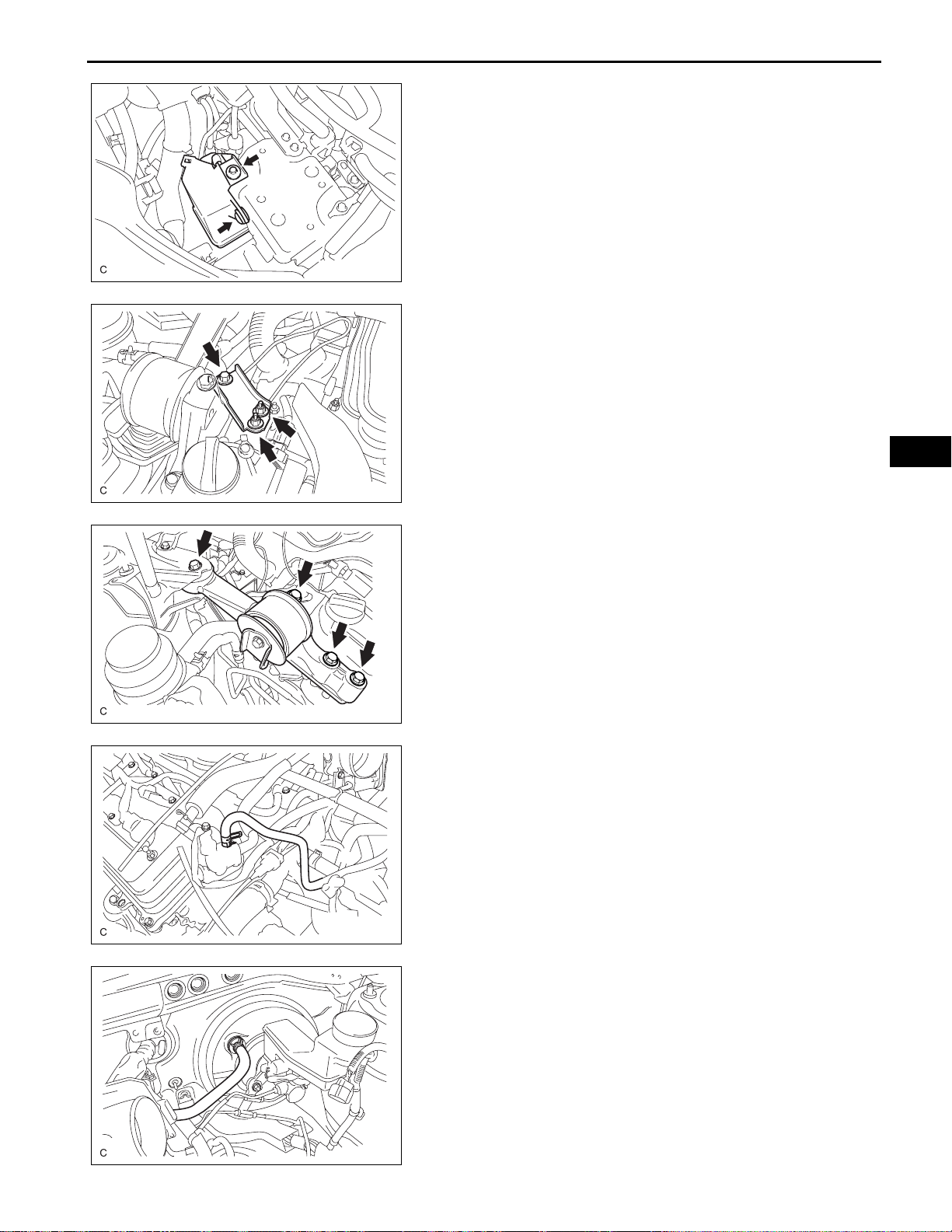

16. REMOVE AIR CLEANER INLET ASSEMBLY

(a) Remove the 2 bolts, clamp and air cleaner inlet.

17. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-503)

A132969

18. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

(a) Disconnect the vacuum hose and hose clamp.

(b) Remove the 3 bolts and air cleaner case.

A132971

A132970

A132972

19. REMOVE NO. 1 AIR CLEANER INLET

(a) Remove the bolt and No. 1 air cleaner inlet.

20. REMOVE BATTERY

(a) Loosen the bolt and nut, and remove the battery

clamp.

(b) Remove the battery and battery tray.

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

21. REMOVE INTAKE AIR RESONATOR SUB-ASSEMBLY

(a) Remove the clip, bolt and intake air resonator.

A133928

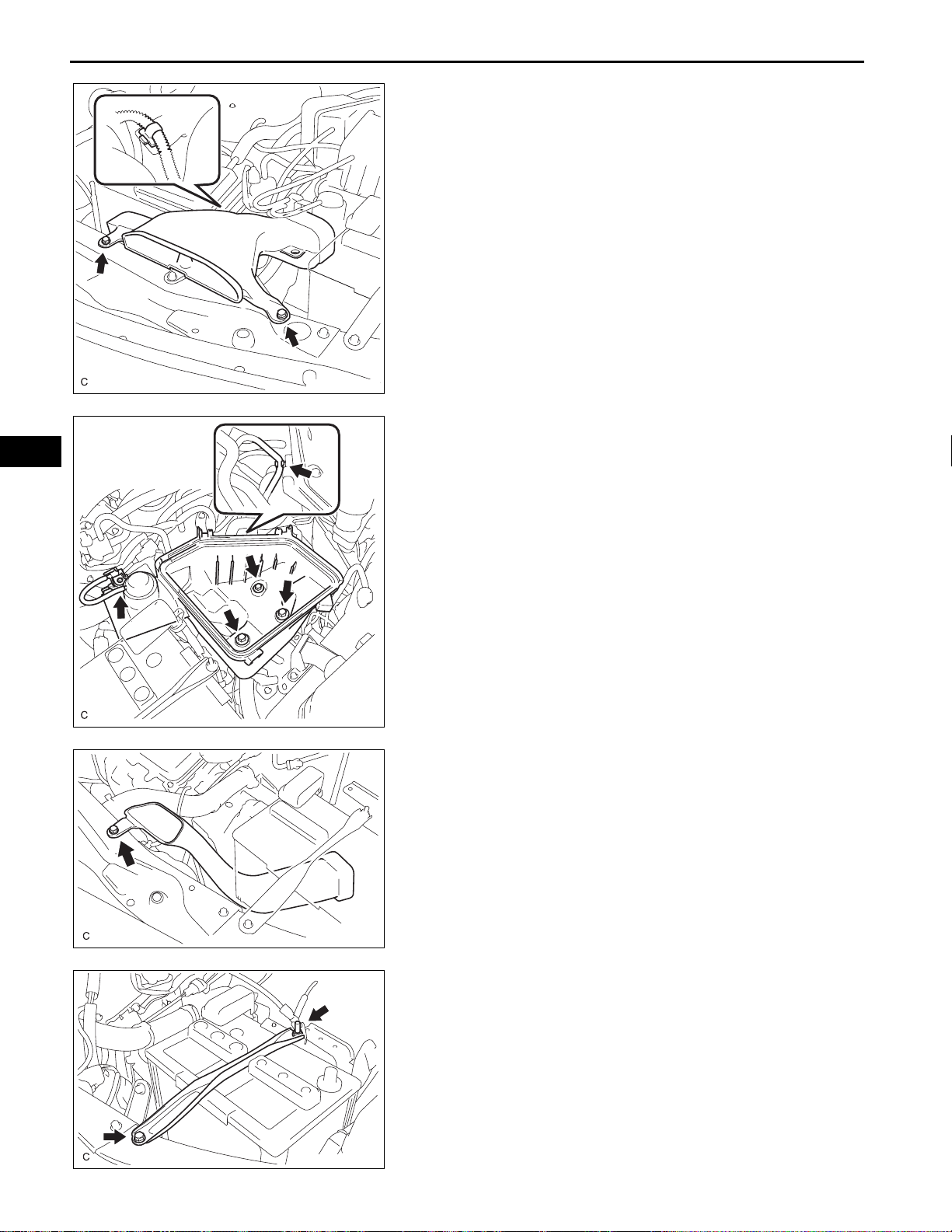

22. REMOVE NO. 2 ENGINE MOUNTING STAY RH

(a) Remove the bolt, 2 nuts, and No. 2 mounting stay

RH.

A132985

EM–25

EM

A132986

A132983

23. REMOVE ENGINE MOVING CONTROL ROD SUBASSEMBLY

(a) Remove the 4 bolts and engine moving control rod.

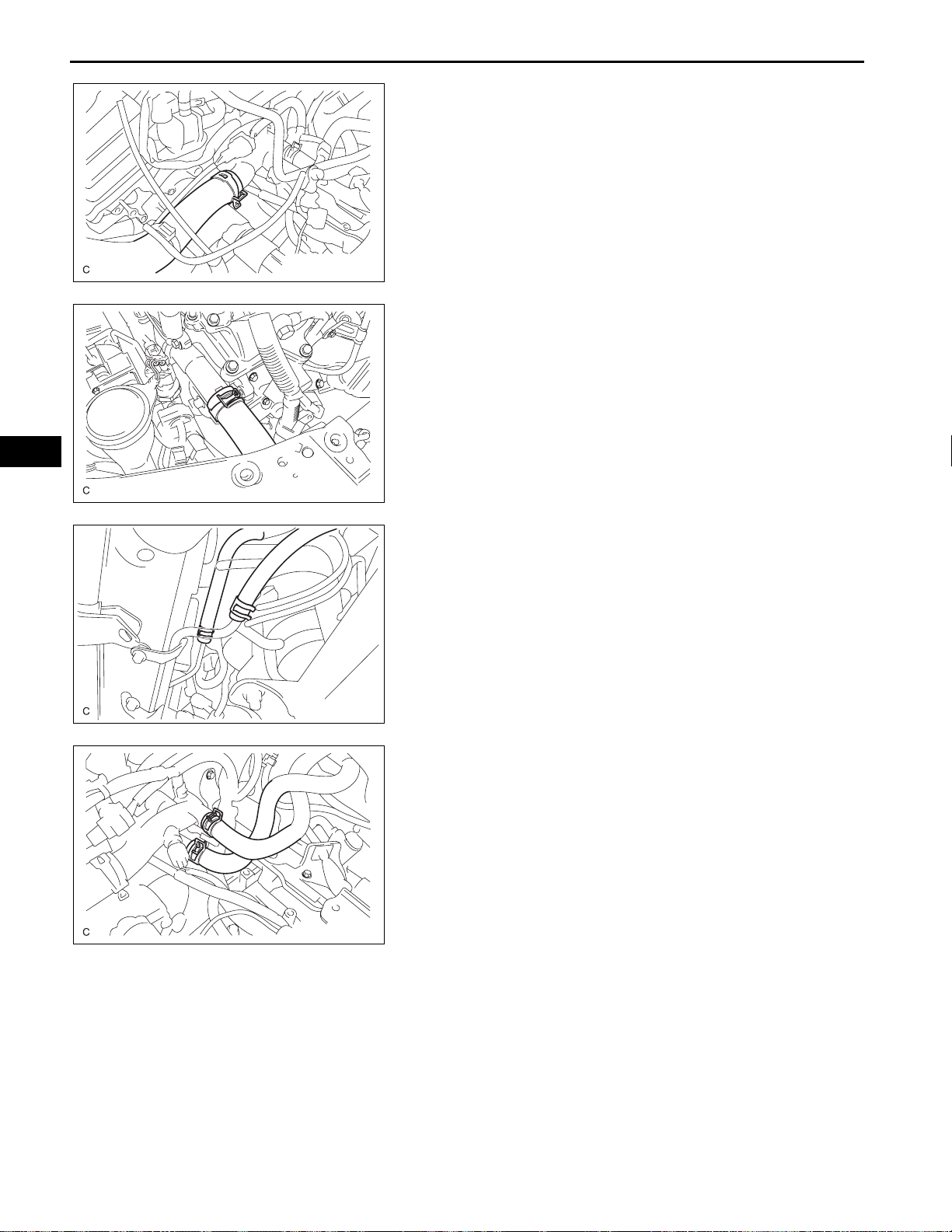

24. DISCONNECT NO. 1 FUEL VAPOR FEED HOSE

(a) Remove the clamp and disconnect the No. 1 fuel

vapor feed hose.

25. DISCONNECT CHECK VALVE TO BRAKE BOOSTER

HOSE

(a) Remove the clamp and disconnect the check valve

to brake booster hose.

A132982

EM

EM–26

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

26. REMOVE RADIATOR HOSE INLET

(a) Remove the clamp and disconnect the radiator hose

inlet.

A132979

27. REMOVE RADIATOR HOSE OUTLET

(a) Remove the clamp and disconnect the radiator hose

outlet.

A132980

A133003

A132978

28. DISCONNECT NO. 1 OIL COOLER INLET HOSE

(a) Remove the clamp and disconnect the oil cooler

inlet hose.

29. DISCONNECT NO. 1 OIL COOLER OUTLET HOSE

(a) Remove the clamp and disconnect the oil cooler

outlet hose.

30. DISCONNECT HEATER INLET WATER HOSE

(a) Disconnect the heater inlet water hose.

31. DISCONNECT HEATER OUTLET WATER HOSE

(a) Disconnect the heater outlet water hose.

32. REMOVE ECM

HINT:

See page ES-518.

33. REMOVE RELAY BLOCK COVER UPPER

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

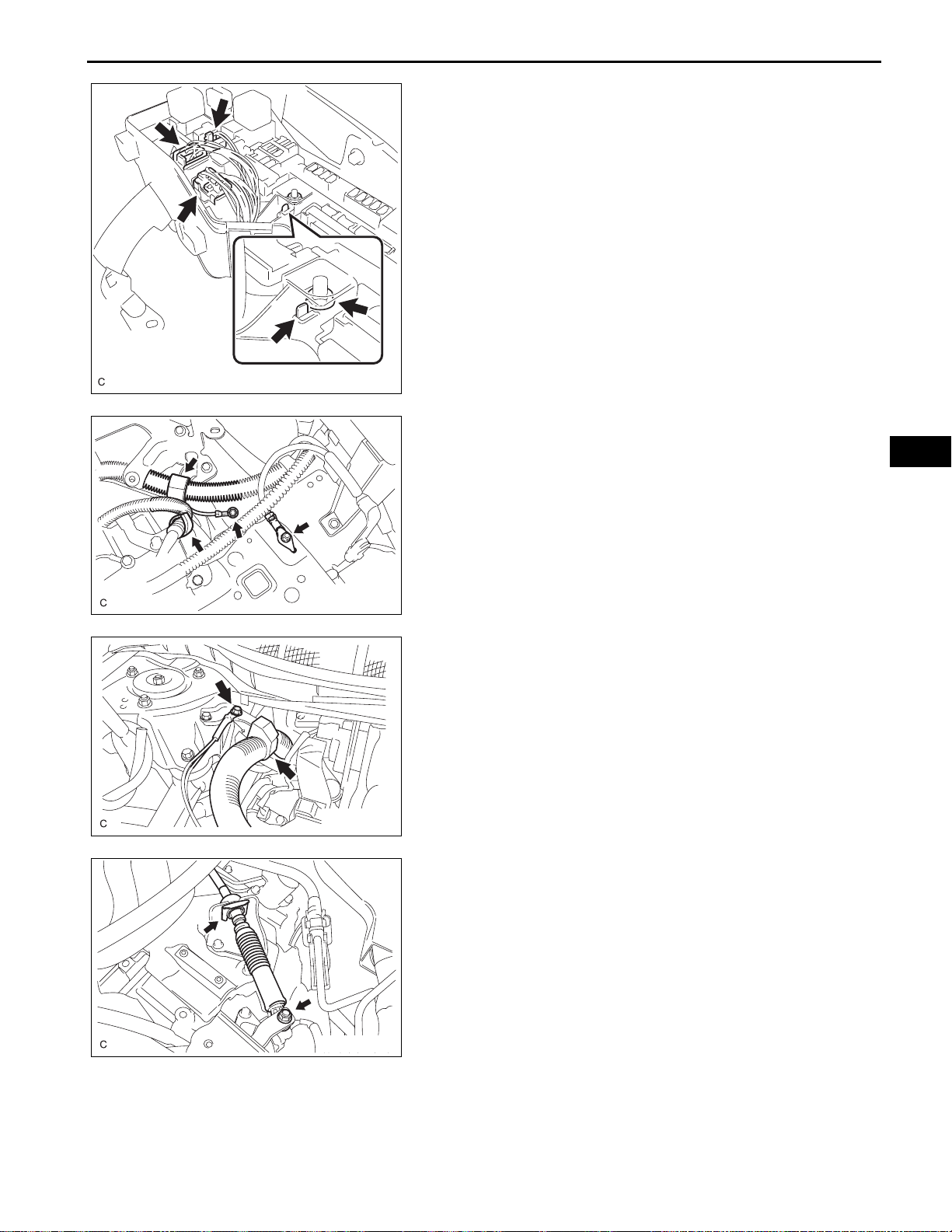

34. DISCONNECT ENGINE WIRE

(a) Disconnect the engine wire from the engine room

junction block.

(1) Remove the nut and separate the wire harness.

(2) Using a screwdriver, unlock the engine room J/

B. Pull the engine room J/B upward.

(3) Disconnect the engine wire connectors.

A132975

(b) Remove the 2 bolts and 2 clamps from the body.

EM–27

EM

A132976

A132981

A132973

(c) Remove the bolt and clamp from the bracket.

35. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Remove the clip and nut, and separate the cable

from the transaxle.

EM

EM–28

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

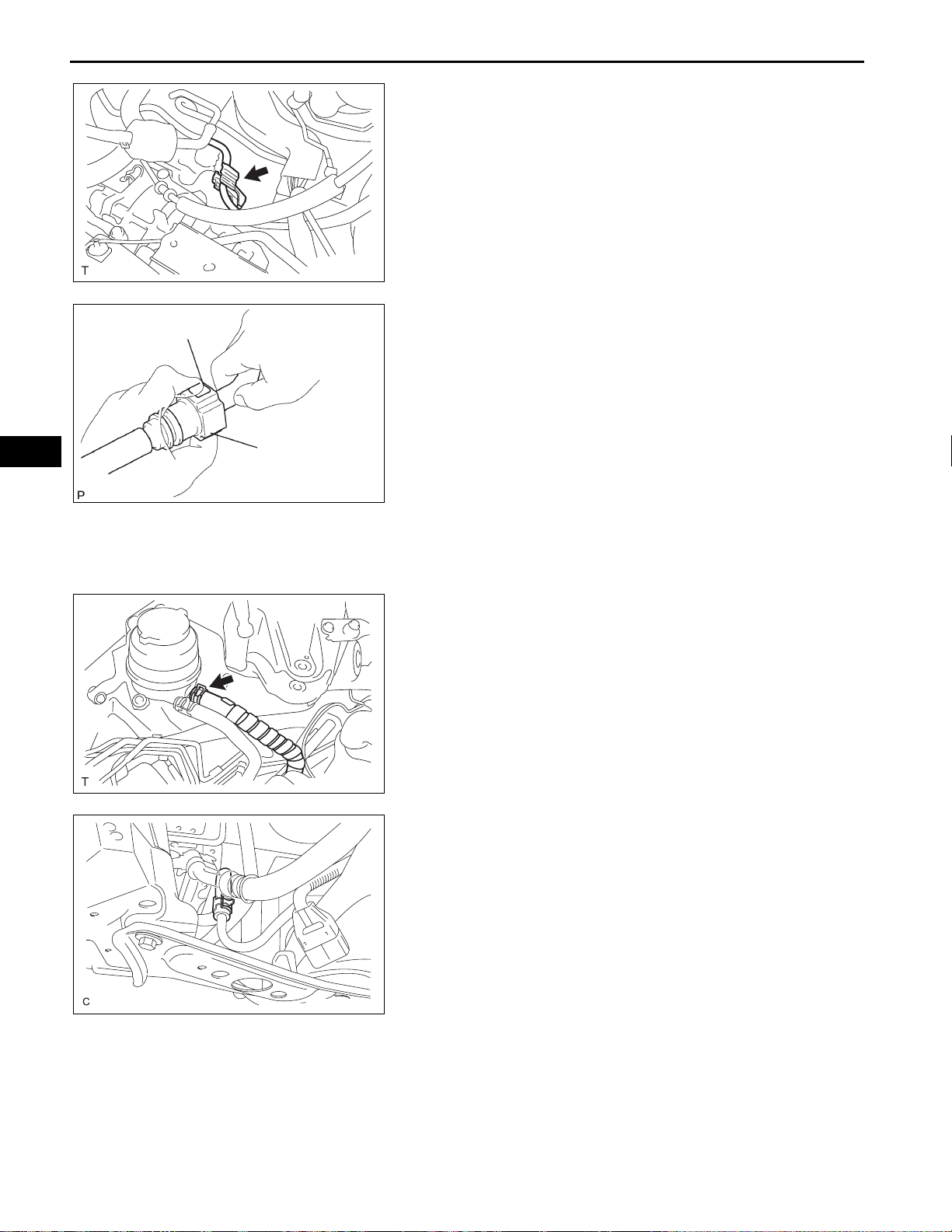

36. SEPARATE FUEL TUBE SUB-ASSEMBLY

(a) Remove the No. 1 fuel pipe clamp.

A129626

(b) Disconnect the connector from the tube while

A

pinching part A with your fingers as shown in the

illustration.

NOTICE:

• Check for contamination in the pipe and

around the connector . Clean if necessary and

then disconnect the connector.

A

• Disconnect the connector by hand.

• Do not bend, fold or rotate the nylon tube.

B012941E15

• If the pipe and connector are stuck together,

push and pull the connector until it becomes

free.

• Put the pipe and connector ends in vinyl bags

to prevent damage and contamination.

A129629

A132984

37. DISCONNECT NO. 1 OIL RESERVOIR TO PUMP

HOSE

(a) Disconnect the No. 1 oil reservoir to pump hose.

38. DISCONNECT RETURN TUBE SUB-ASSEMBLY

(a) Disconnect the return tube sub-assembly.

39. REMOVE EXHAUST PIPE NO. 1 SUPPORT BRACKET

(See page EX-3)

40. REMOVE EXHAUST PIPE ASSEMBLY FRONT (See

page EX-2)

41. REMOVE FRONT AXLE HUB NUT LH (See page DS-

7)

42. REMOVE FRONT AXLE HUB NUT RH

HINT:

Use the same procedures described for the LH side.

43. DISCONNECT FRONT STABILIZER LINK ASSEMBLY

LH (See page DS-7)

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

44. DISCONNECT FRONT ST ABILIZER LINK ASSEMBLY

RH

HINT:

Use the same procedures described for the LH side.

45. DISCONNECT FRONT SPEED SENSOR LH (See page

DS-7)

46. DISCONNECT FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

47. DISCONNECT TIE ROD ASSEMBLY LH (See page

DS-8)

48. DISCONNECT TIE ROD ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

49. DISCONNECT FRONT SUSPENSION LOWER NO. 1

ARM LH (See page DS-8)

50. DISCONNECT FRONT SUSPENSION LOWER NO. 1

ARM RH

HINT:

Use the same procedures described for the LH side.

EM–29

EM

51. SEPARATE FRONT AXLE ASSEMBLY LH (See page

DS-8)

52. SEPARATE FRONT AXLE ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

53. REMOVE NO. 1 EXHAUST PIPE SUPPORT BRACKET

(a) Remove the No. 1 exhaust pipe support bracket

with the 2 bolts.

54. REMOVE DRIVE PLATE AND TORQUE CONVERTER

CLUTCH SETTING BOLT (See page AX-211)

55. DISCONNECT STEERING SLIDING YOKE (See page

PS-40)

56. REMOVE GENERATOR ASSEMBLY (See page CH-14)

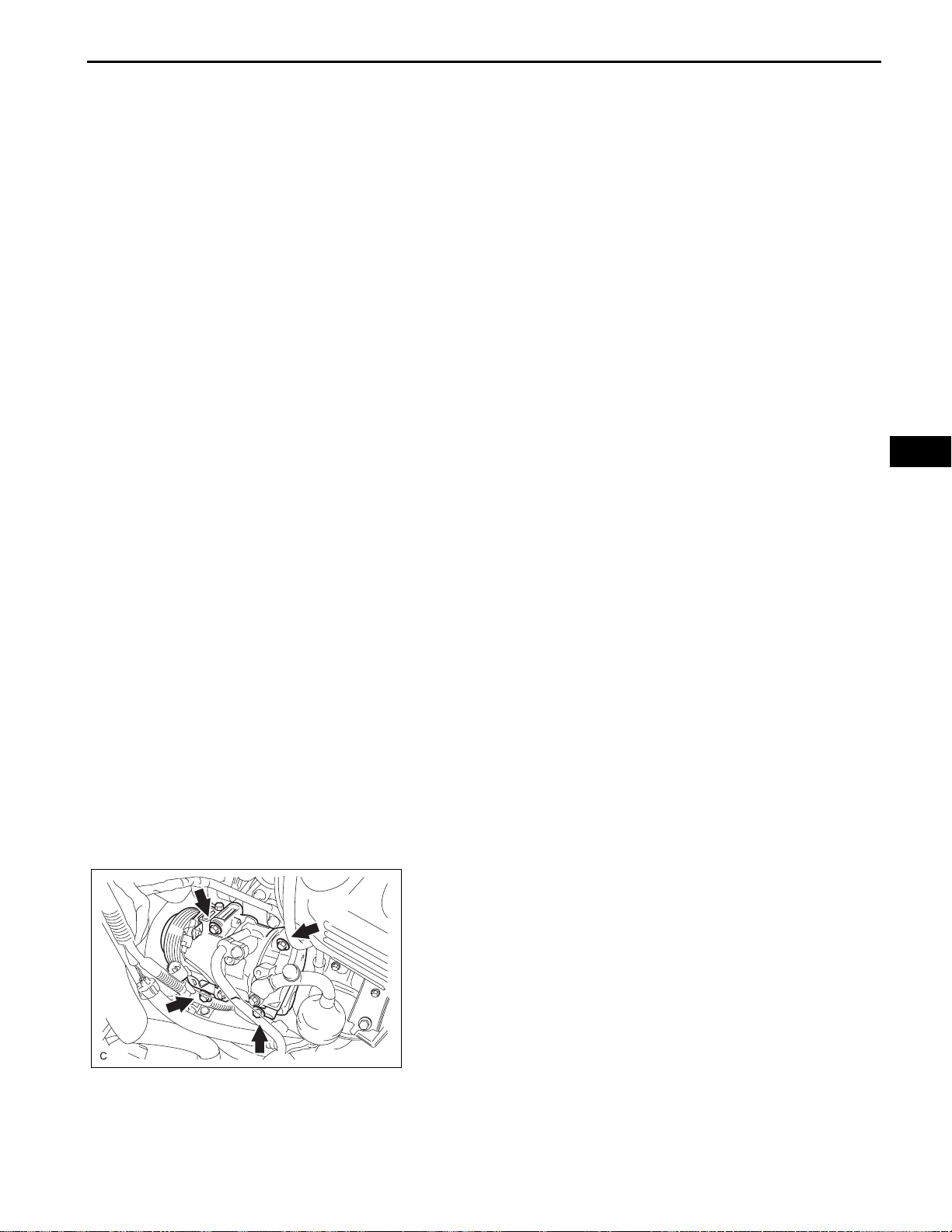

57. SEPARATE COOLER COMPRESSOR ASSEMBLY

(a) Remove the 2 connector clamps.

(b) Remove the 4 bolts and separate the compressor.

HINT:

Hang up the hoses instead of detaching them.

58. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set the engine lifter.

A132977

Loading...

Loading...