Toyota Camry 2007-2009 Service Manual - Air_Conditioning

Charging

Cylinder

AIR CONDITIONING – AIR CONDITIONING SYSTEM

AIR CONDITIONING SYSTEM

PRECAUTION

1. DO NOT HANDLE REFRIGERANT IN AN ENCLOSED

AREA OR NEAR AN OPEN FLAME

2. ALWAYS WEAR EYE PROTECTION

AC02810E02

3. BE CAREFUL NOT TO GET LIQUID REFRIGERANT

IN YOUR EYES OR ON YOUR SKIN

If liquid refrigerant gets in your eyes or on your skin:

(a) Wash the area with lots of cold water.

CAUTION:

Do not rub your eyes or skin.

(b) Apply clean petroleum jelly to the skin.

(c) Go immediately to a hospital or see a physician for

professional treatment.

AC02811

4. NEVER HEAT CONTAINER OR EXPOSE THE

CONTAINER TO OPEN FLAME

5. BE CAREFUL NOT TO DROP CONT AINER OR APPLY

PHYSICAL SHOCKS TO IT

AC–1

LO

OkayWrong

HI

HILO

ENOUGH REFRIGERANT IN REFRIGERANT SYSTEM

If there is not enough refrigerant in the A/C system, oil

lubrication will be insufficient and the compressor may

be damaged.

AC

Necessary care should be taken to avoid this.

7. DO NOT OPEN HIGH PRESSURE MANIFOLD VALVE

WHILE COMPRESSOR IS OPERATING

(a) Open and close only the low pressure valve.

6. DO NOT OPERATE COMPRESSOR WITHOUT

N011084E03

If the high pressure valve is opened, refrigerant

flows in the reverse direction causing the charging

cylinder to rupture.

8. BE CAREFUL NOT TO OVERCHARGE SYSTEM WITH

REFRIGERANT

If refrigerant is overcharged, it causes problems such as

insufficient cooling, poor fuel economy, engine

overheating, etc.

9. DO NOT OPERATE ENGINE AND COMPRESSOR

WITH NO REFRIGERANT

CAUTION:

Doing so may damage the inside of the compressor

because the compressor parts always move

regardless of whether the A/C system is turned on or

off.

AC–2

Expression

AIR CONDITIONING – AIR CONDITIONING SYSTEM

10. SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(a) This vehicle is equipped with an SRS

(Supplemental Restraint System) such as the driver ,

front passenger, side, and curtain shield air bags.

Failure to carry out service operation in the correct

sequence could cause the SRS to unexpectedly

deploy during servicing, possibly leading to a

serious accident. Before servicing (including

removal or installation of parts, inspection or

replacement), be sure to read the precautionary

notices (See page RS-1).

11. GENERAL PRECAUTION

(a) While using the battery during inspection, do not

bring the positive and negative tester probes too

close to each other as a short circuit may occur.

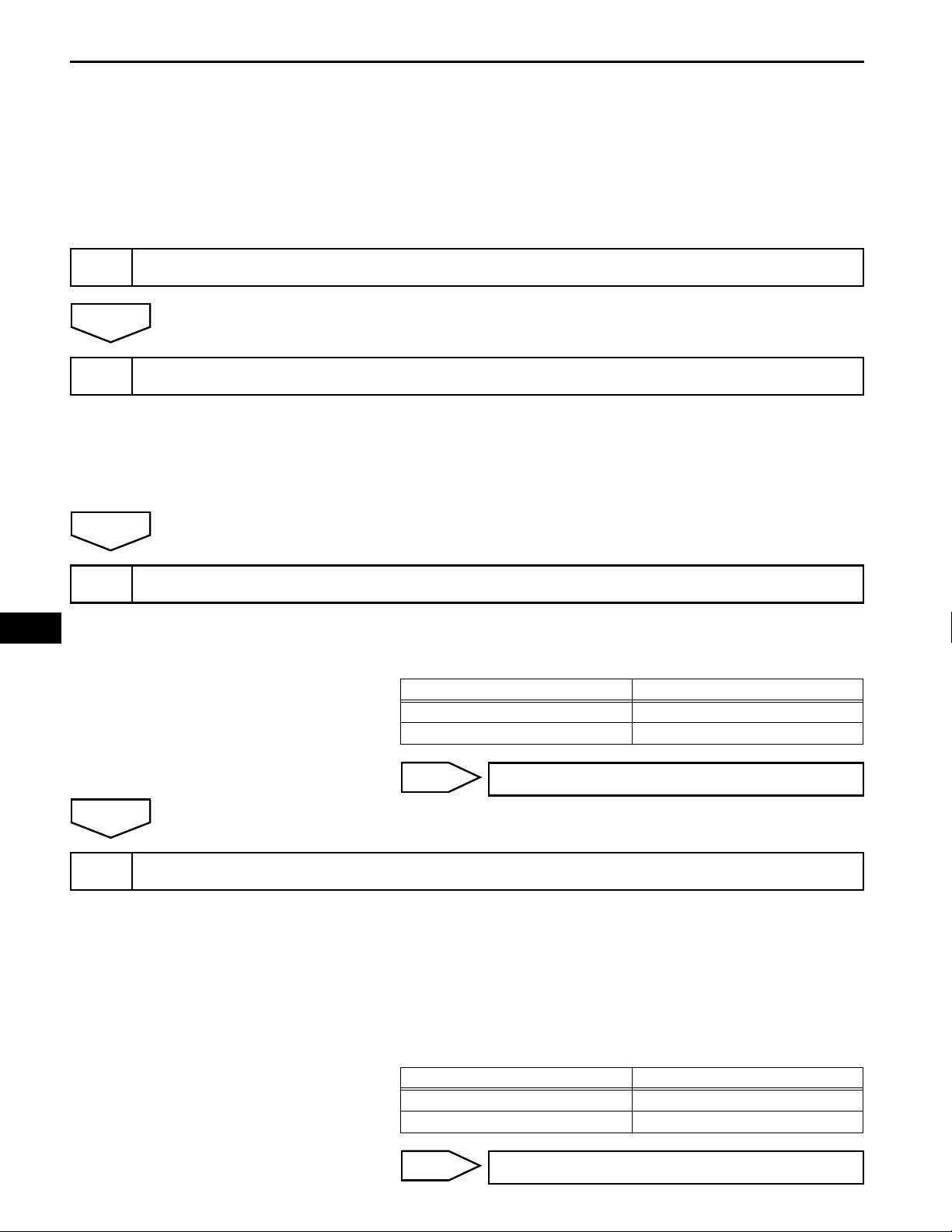

12. EXPRESSIONS OF IGNITION SWITCH

(a) The type of ignition switch used on this model differs

according to the specifications of the vehicle.

The expressions listed in the table below are used

in this section.

Switch Type

Ignition switch off LOCK Off

Ignition switch on (IG) ON On (IG)

Ignition switch on (ACC) ACC On (ACC)

Engine start START Start

Ignition Switch

(Position)

Engine Switch

(Condition)

AC

AIR CONDITIONING – AIR CONDITIONING SYSTEM

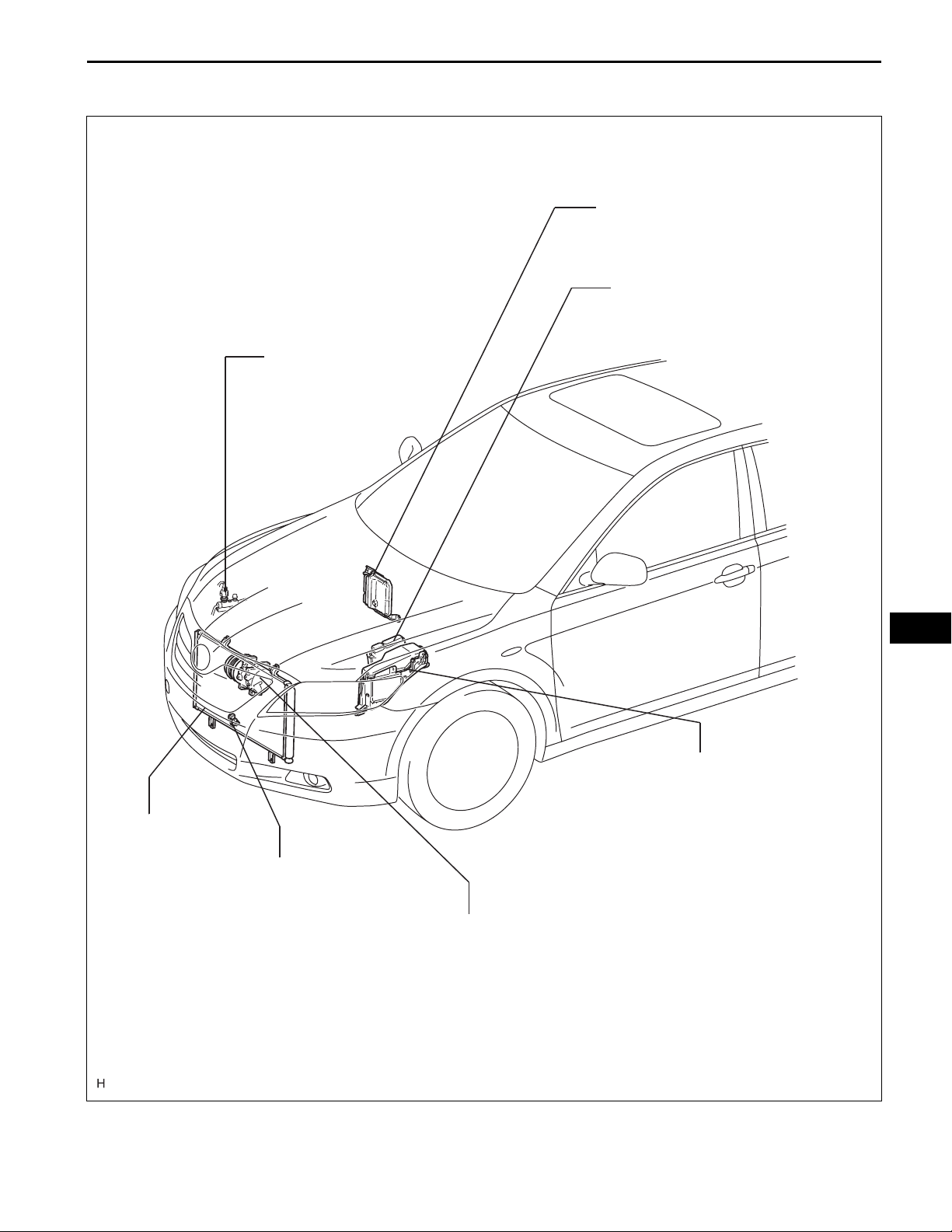

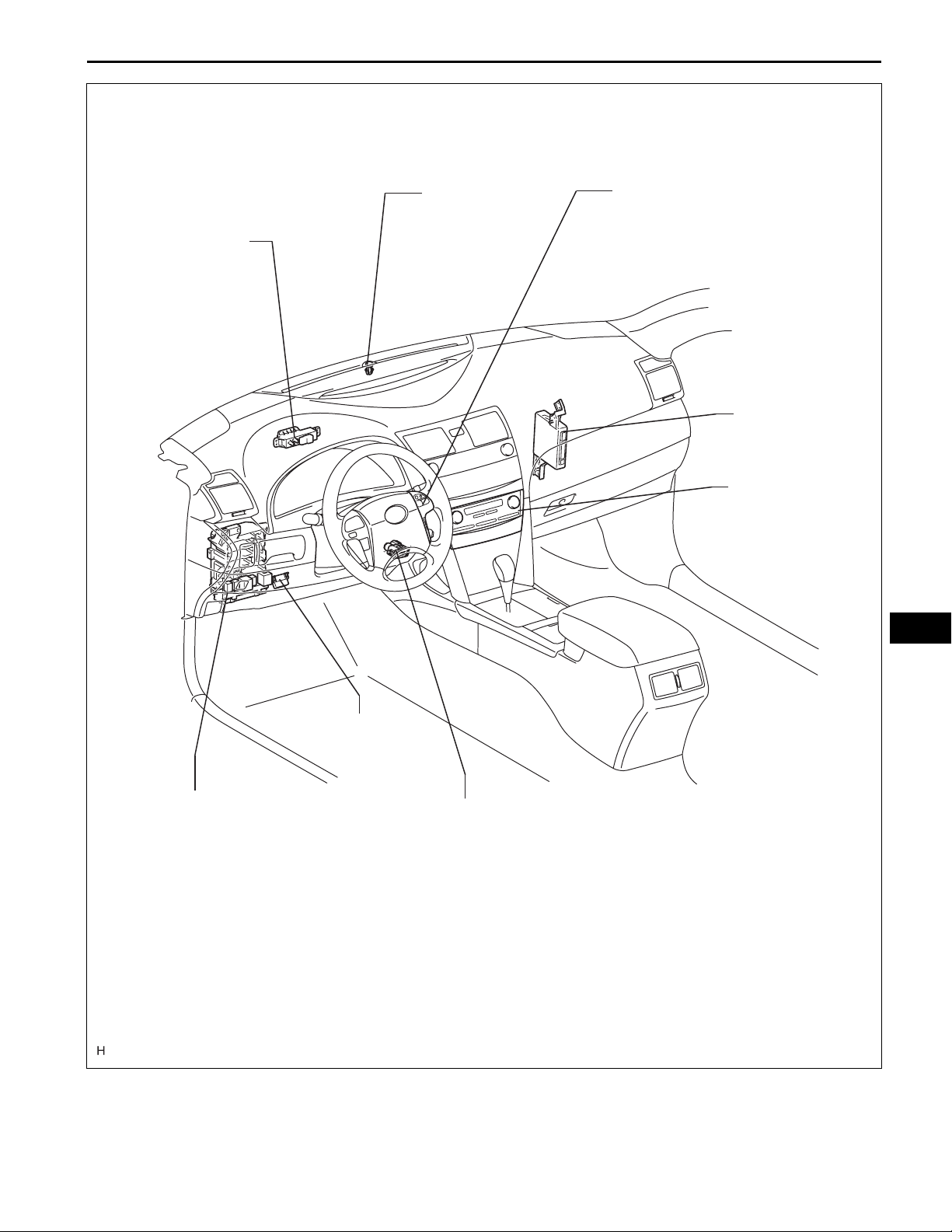

PARTS LOCATION

AIR CONDITIONING

PRESSURE SENSOR

AC–3

ECM (for 2GR-FSE)

ECM (for 2AZ-FE)

CONDENSER

AMBIENT

TEMPERATURE

SENSOR

ENGINE ROOM RELAY BLOCK

AND JUNCTION BLOCK

-

HTR FUSE

-

MG CLT RELAY

COMPRESSOR AND MAGNETIC CLUTCH

COMPRESSOR AND PULLEY

(for 2AZ-FE)

AC

(for 2GR-FSE)

E124494E01

AC–4

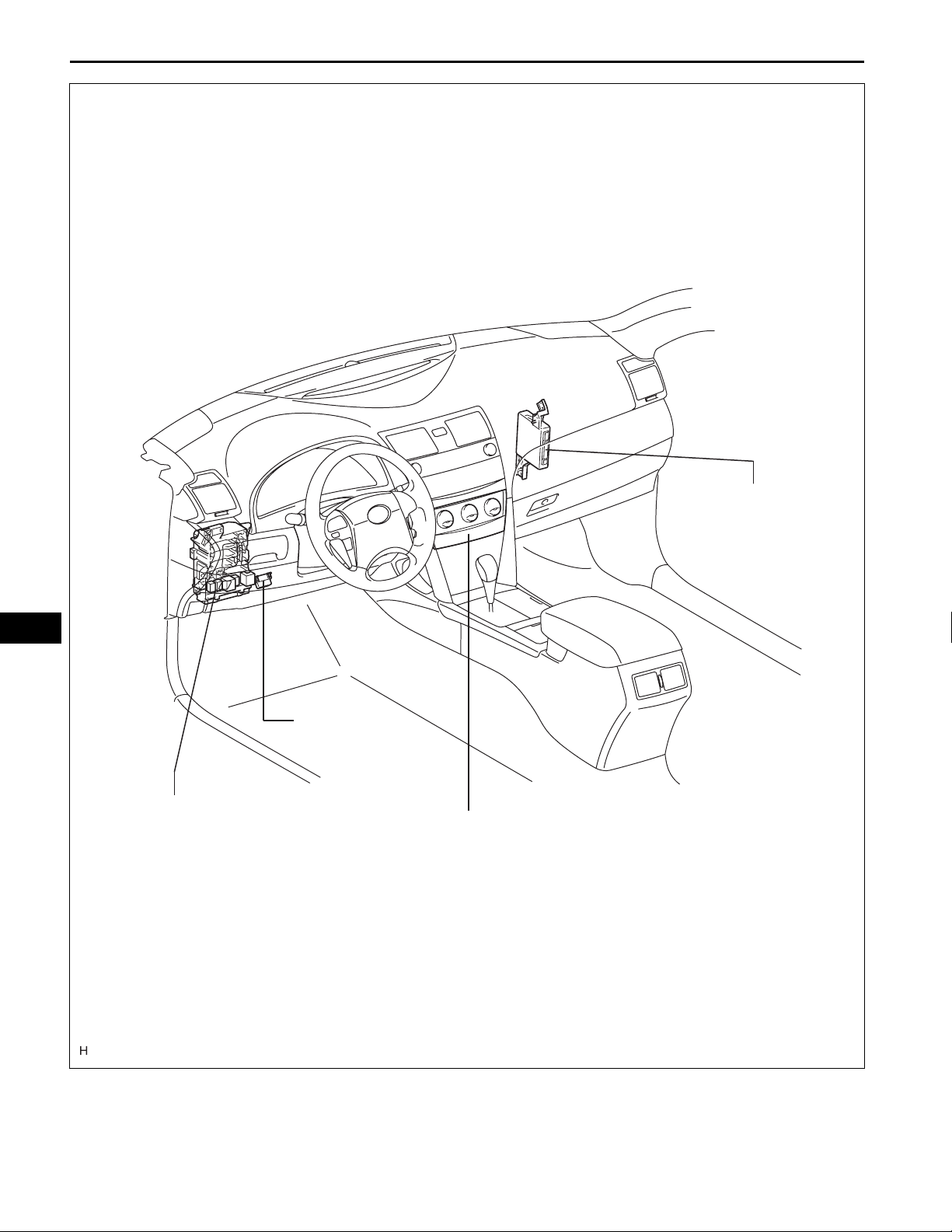

MANUAL A/C:

AIR CONDITIONING – AIR CONDITIONING SYSTEM

AC

INSTRUMENT PANEL

JUNCTION BLOCK

-

A/C NO. 2 FUSE

-

A/C FUSE

A/C AMPLIFIER

DLC3

A/C CONTROL ASSEMBLY

E124498E01

AUTO A/C:

AIR CONDITIONING – AIR CONDITIONING SYSTEM

AC–5

ION GENERATOR

(PLASMACLUSTER )

TM

SOLAR

SENSOR

STEERING PAD SWITCH

A/C AMPLIFIER

A/C CONTROL

ASSEMBLY

AC

INSTRUMENT PANEL

JUNCTION BLOCK

-

MAIN BODY ECU

-

A/C NO. 2 FUSE

-

A/C FUSE

DLC3

ROOM TEMPERATURE

SENSOR

E124496E01

AC–6

EVAPORATOR

AIR CONDITIONING – AIR CONDITIONING SYSTEM

AIR INLET CONTROL

SERVO MOTOR

AIR OUTLET CONTROL

SERVO MOTOR

EXPANSION VALVE

AC

AIR MIX CONTROL

SERVO MOTOR

(for DRIVER SIDE)

EVAPORATOR

TEMPERATURE

SENSOR

HEATER RADIATOR UNIT

SUB-ASSEMBLY

AIR CONDITIONING

HARNESS

BLOWER MOTOR

AIR MIX CONTROL

SERVO MOTOR

(for FRONT

PASSENGER

SIDE)

E124499E01

Auto A/C, Manual A/C:

AIR CONDITIONING – AIR CONDITIONING SYSTEM

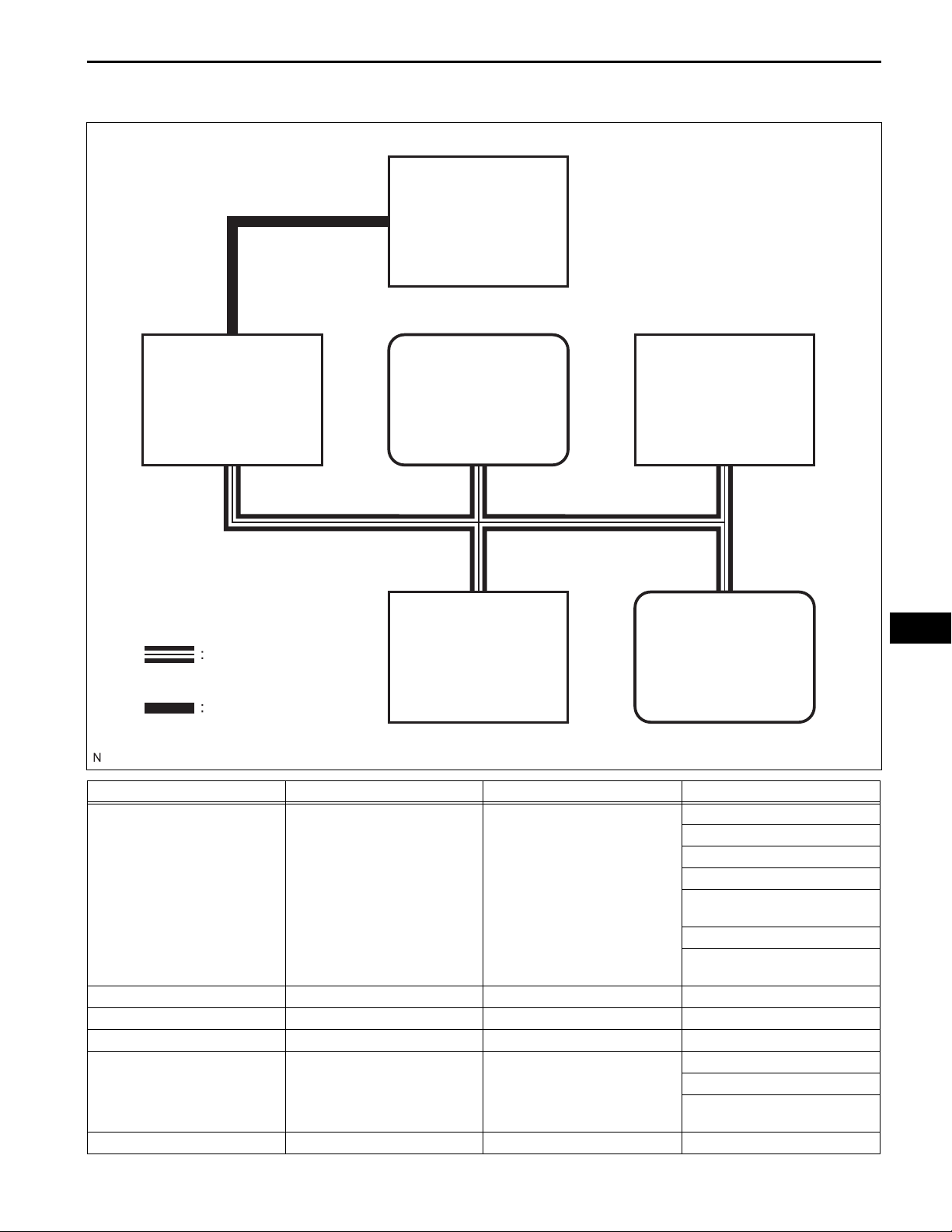

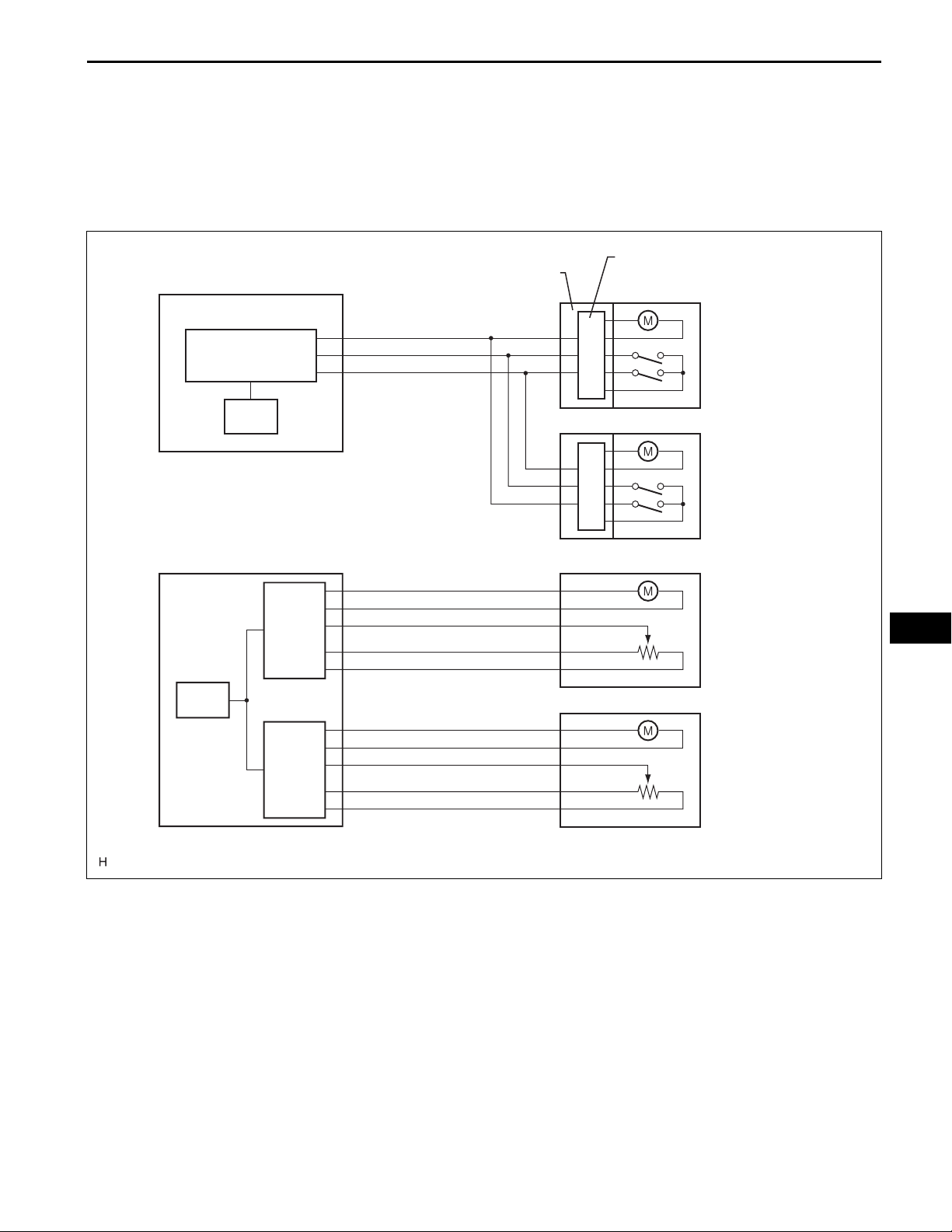

SYSTEM DIAGRAM

A/C Control Assembly

AC–7

A/C Amplifier

CAN (V-BUS)

Main Body ECU

Combination Meter

DLC3

ECM

LIN

Transmitter Receiver Line Signal

Magnetic Clutch Request Signal

Heater Idle Up Request Signal

A/C Idle Up Request Signal

Outside Temperature Data

A/C Amplifier ECM CAN

A/C Amplifier Combination Meter CAN Outside Temperature Data

A/C Amplifier DLC3 CAN Diagnostic Tool Response

A/C Amplifier A/C Control Assembly LIN A/C Operating State Signal

Main Body ECU A/C Amplifier CAN

Combination Meter A/C Amplifier CAN Vehicle Speed Signal

External Variable Control

Solenoid Current Signal

Prior A/C Control Request Signal

Refrigerant Gas Pressure Sensor

Signal

Auto Dimmer Signal

Destination Package

Destination Symbol Steering

Wheel

AC

E124510E01

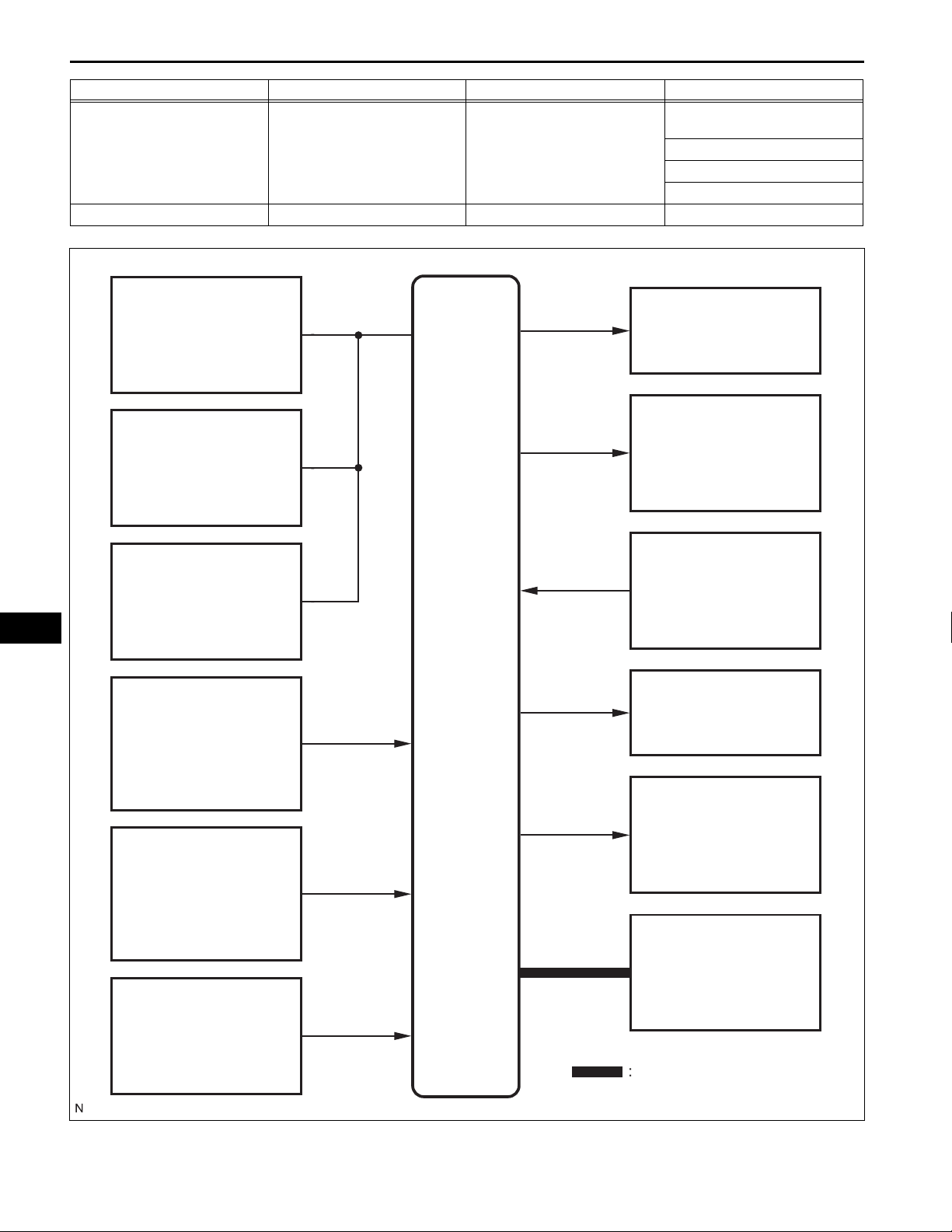

AC–8

Transmitter Receiver Line Signal

ECM A/C Amplifier CAN

A/C Control Assembly A/C Amplifier LIN A/C Operation Signal

AIR CONDITIONING – AIR CONDITIONING SYSTEM

Engine Coolant Temperature

Signal

Engine rpm Data

A/C Control Cut-off Signal

A/C-E/G Cooperation Control

Manual A/C:

AC

Air Mix Control

Servo Motor

Air Inlet Control

Servo Motor

Air Outlet Control

Servo Motor

A/C Ambient Temperature

Sensor

A/C Solenoid

A/C Magnetic Clutch

(for 2GR-FSE)

A/C Pressure Sensor

A/C Amplifier

Blower Motor

A/C Evaporator

Temperature Sensor

A/C Lock Sensor

(for 2GR-FSE)

Rear Defogger Relay

A/C Control Assembly

LIN

E124512E01

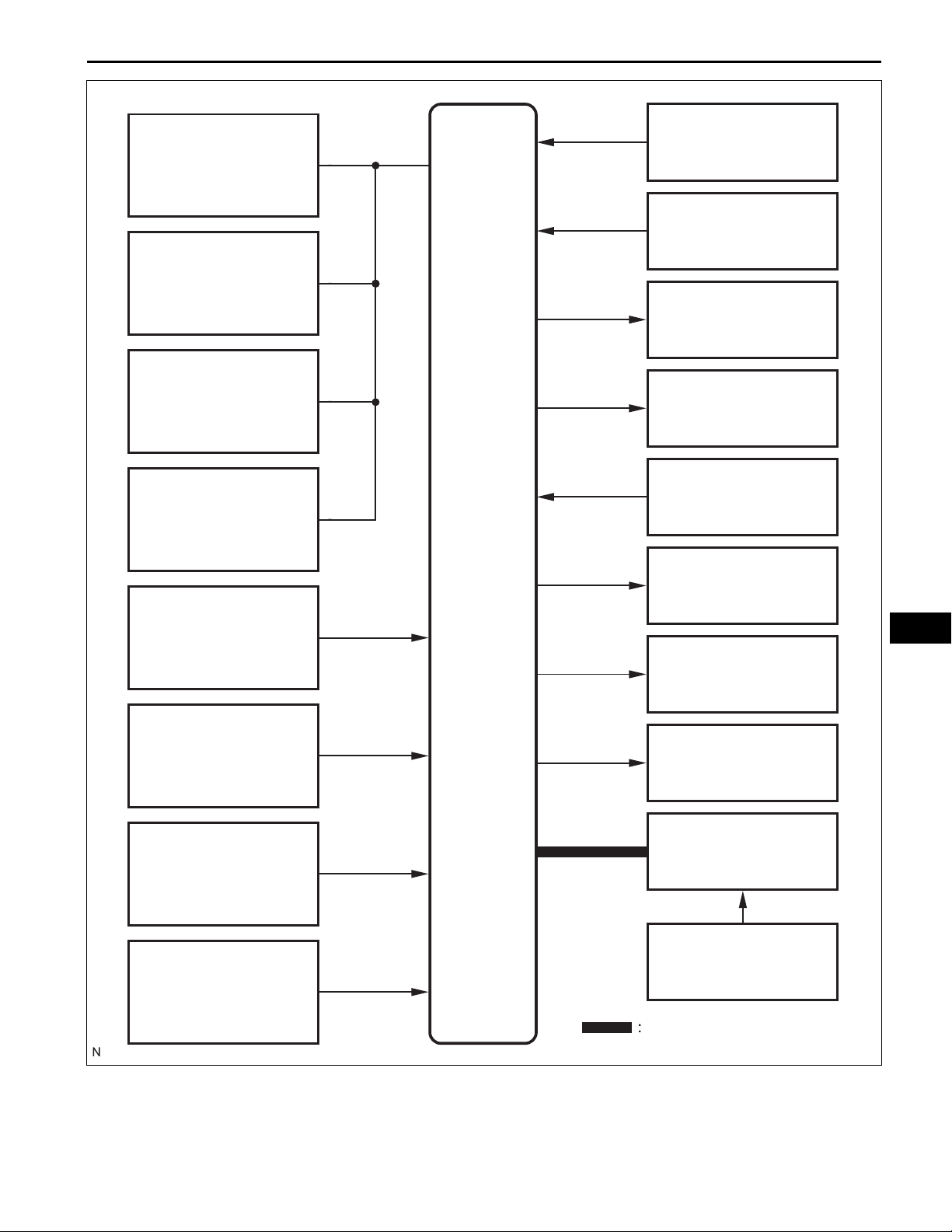

Auto A/C:

Air Mix Control Servo

Motor (for Driver Side)

Air Mix Control Servo

Motor (for Front Passenger

Side)

AIR CONDITIONING – AIR CONDITIONING SYSTEM

A/C Solar Sensor (for

Front Passenger Side)

AC–9

A/C Solar Sensor

(for Driver Side)

A/C Solenoid

Air Inlet Control

Servo Motor

Air Outlet Control

Servo Motor

A/C Room Temperature

Sensor

A/C Ambient Temperature

Sensor

A/C

Amplifier

A/C Magnetic Clutch

(for 2GR-FSE)

A/C Lock Sensor

(for 2GR-FSE)

Plasmacluster

(Ion Generator)

Blower Motor

Rear Defogger Relay

TM

AC

A/C Evaporator

Temperature Sensor

A/C Pressure Sensor

A/C Control Assembly

Steering Pad Switch

Assembly

LIN

E124511E01

AC

AC–10

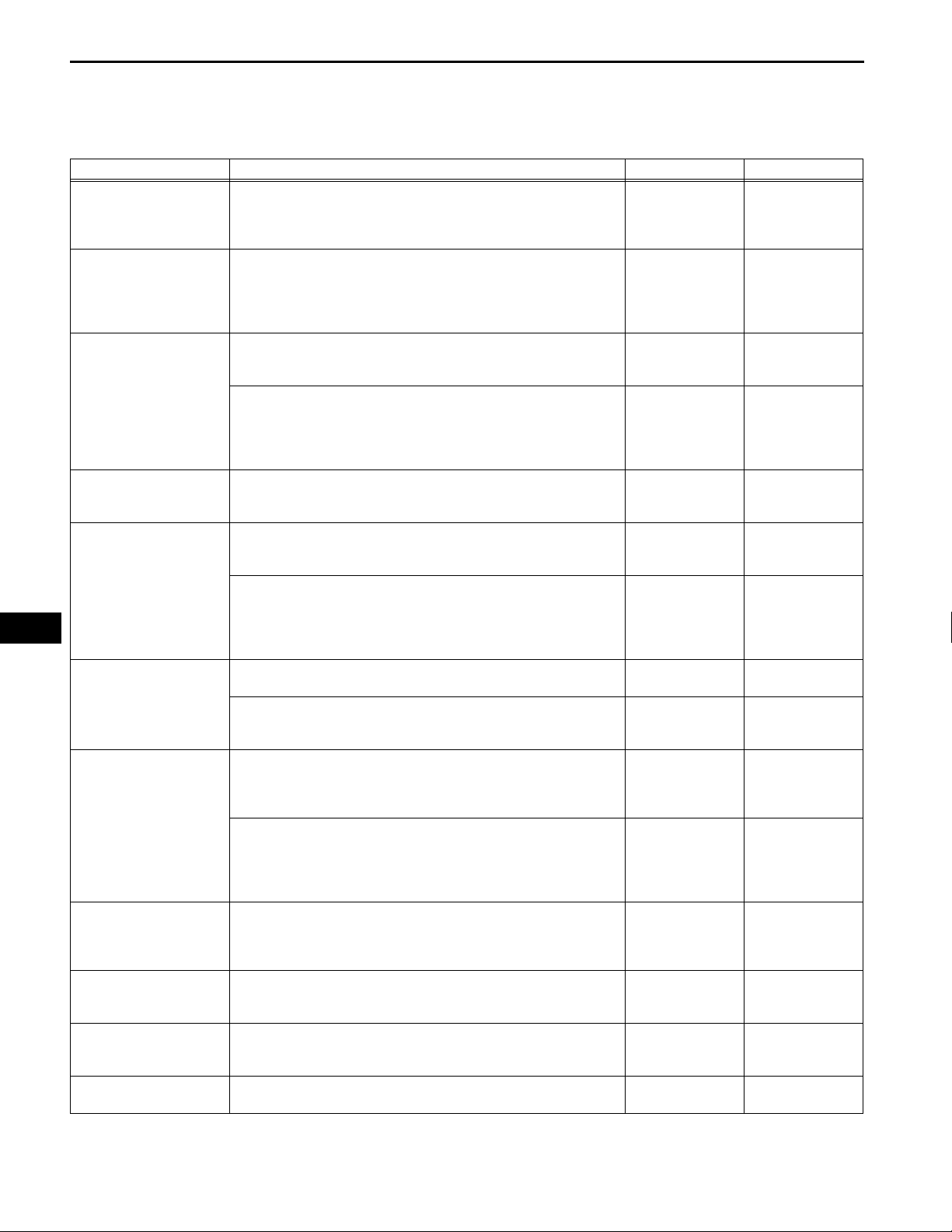

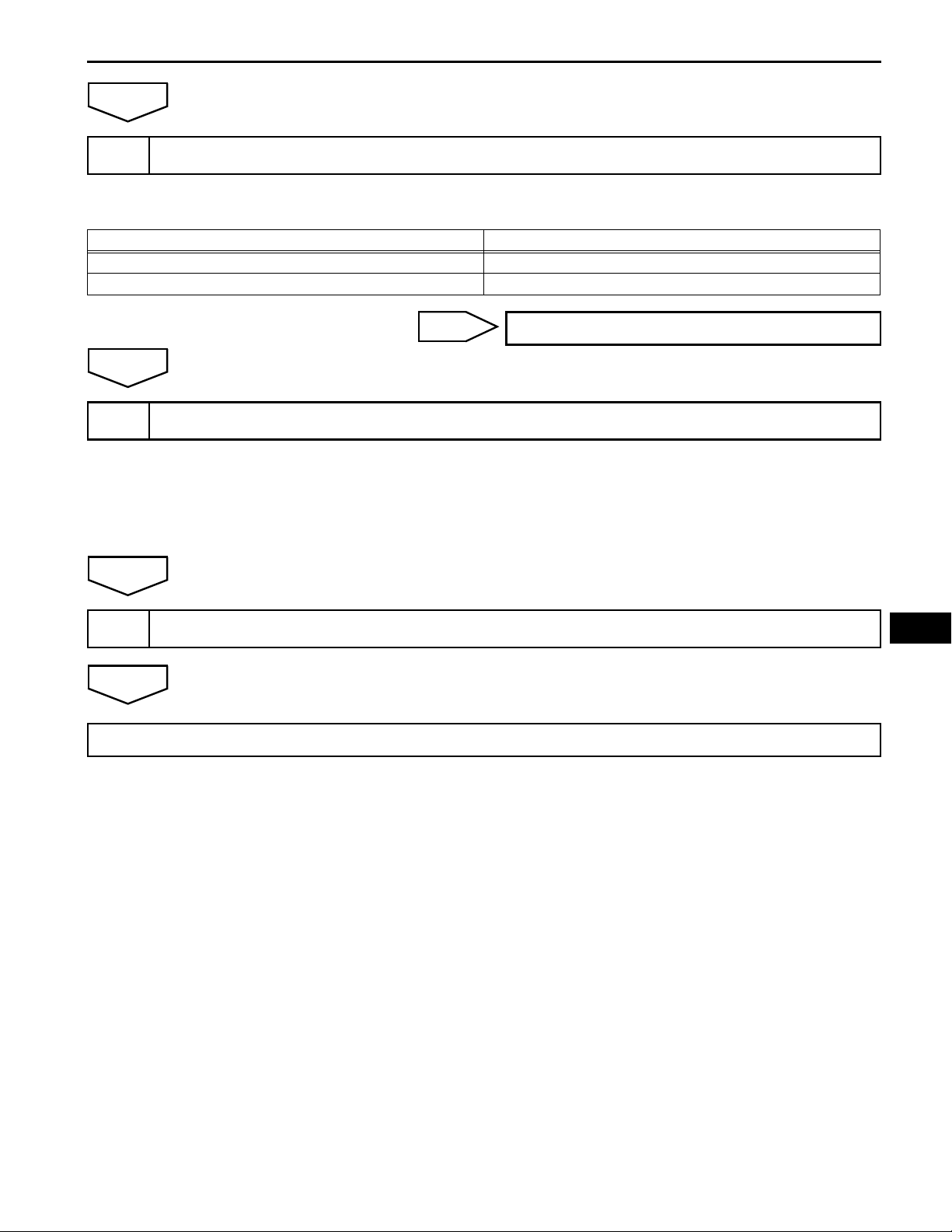

Control Outline Manual A/C Automatic A/C

Neural Network Control

Manual Control

Outlet Air Temp. Control

Blower Control

Air Outlet Control

Air Inlet Control

Compressor Control

MAX A/C Control

Rear Window Defogger

Control

Outside Temperature

Indication Control

Self-Diagnosis

AIR CONDITIONING – AIR CONDITIONING SYSTEM

SYSTEM DESCRIPTION

1. GENERAL

The air conditioning system has the following controls:

This control is capable of effecting complex control by artificially

simulating the information processing method of the nervous system

of living organisms in order to establish a complex input / output

relationship that is similar to a human brain.

The A/C amplifier controls the damper positions (air inlet control

damper, air mix control damper and mode control damper) and blower

speed in accordance with the positions of the switches (temperature

control switch, blower switch, mode select switch and air inlet control

switch).

Based on the temperature set at the temperature control switch, the

neural network control calculates the outlet air temperature based on

the input signals from various sensors.

The temperature setting for the driver and front passenger are

controlled independently in order to provide a separate vehicle interior

temperatures for the right and left side of the cabin. Thus, air

conditioning that accommodates the occupants' preferences has been

realized.

Controls the blower motor in accordance with the airflow volume that

has been calculated by the neural network control based on the input

signals from various sensors.

Automatically switches the air outlets in accordance with the outlet

mode that has been calculated by the neural network control based on

the input signals from various sensors.

In accordance with the engine coolant temperature, outside air

temperature, amount of sunlight, required blower, outlet temperature,

and vehicle speed conditions, this control automatically switches the

blower outlet to the FOOT / DEF mode to prevent the windows from

becoming fogged when the outside air temperature is low.

Automatically controls the air inlet control damper to achieve the

calculated required outlet air temperature.

Drives the servo motor (for air inlet) according to the operation of the

air inlet control switch and moves the dampers to the FRESH or

RECIRC position.

Through the calculation of the target evaporator temperature based on

various sensor signals, the A/C amplifier optimally controls the

discharge capacity by regulating the opening extent of the A/C

compressor solenoid valve.

The A/C amplifier compares the A/C pulley speed signals, which are

transmitted by the lock sensor located on the A/C compressor, with

the engine speed signals, which are transmitted by the ECM

(crankshaft position sensor). When the A/C amplifier determines that

the A/C pulley is locked, it turns off the magnetic clutch. (for 2GR-FE)

When the temperature control switch is in the MAX A/C position, the

A/C amplifier turns the compressor on and activates the servomotor

(air inlet) to set the air inlet control damper to the RECIRC position,

improving the cooling efficiency.

Switches the rear defogger and outside rear view mirror heaters on for

15 minutes when the rear defogger button is pressed. Switches them

off if the button is pressed while they are operating.

Calculates the outside temperature using signals transmitted by the

outside temperature sensor. Calculated values are corrected by the A/

C amplifier and then indicated on the multi-information display.

A DTC (Diagnostic Trouble Code) is stored in the memory when the A/

C amplifier detects a problem with the air conditioning system.

- {

{ -

- {

- {

- {

- {

- {

- {

- {

{{

{{

{ -

{{

{{

{{

AIR CONDITIONING – AIR CONDITIONING SYSTEM

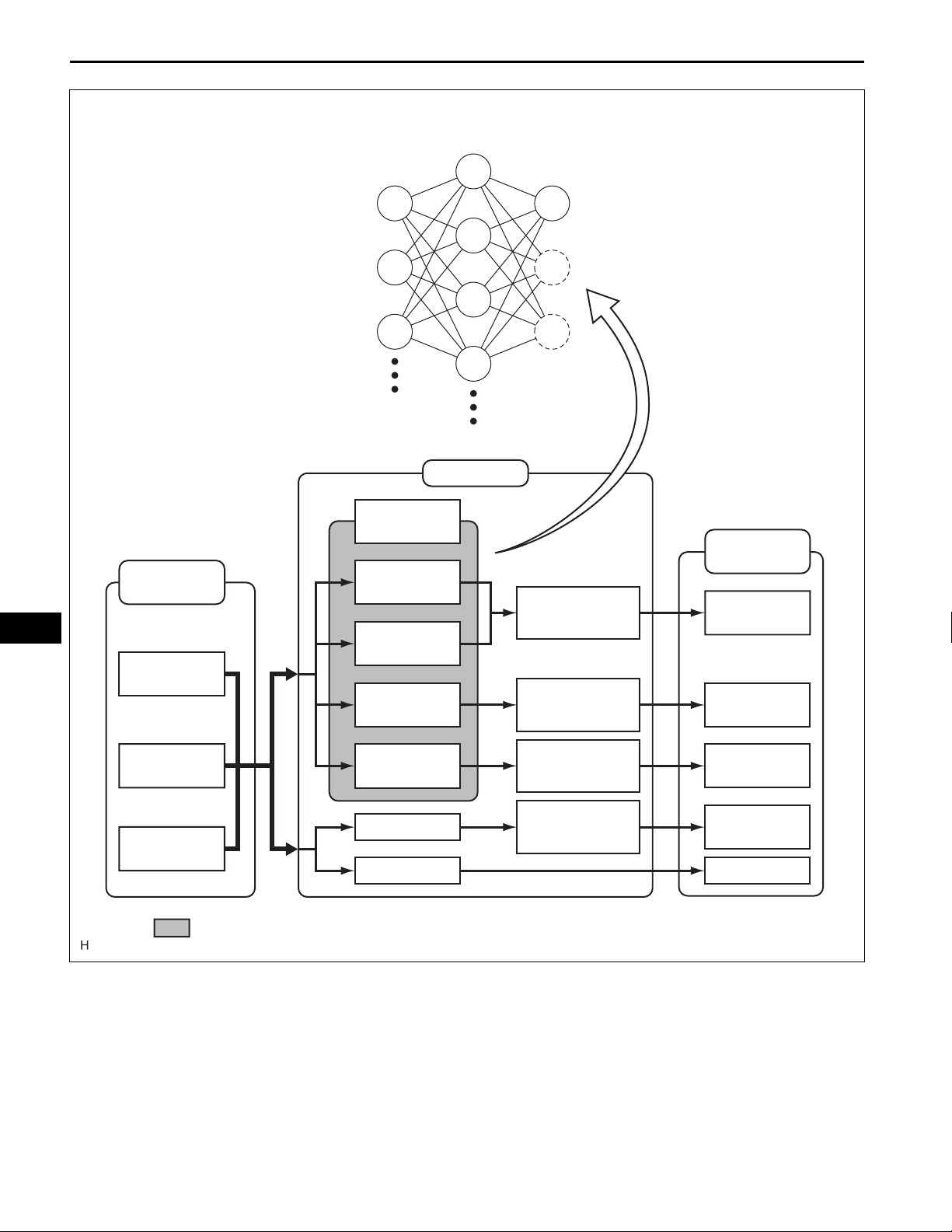

2. NEURAL NETWORK CONTROL

• In previous automatic air conditioning systems, the A/

C amplifier determined the required outlet air

temperature and blower air volume in accordance

with the calculation formula that has been obtained

based on information received from the sensors.

However, because the senses of a person are rather

complex, a given temperature is sensed differently,

depending on the environment in which the person is

situated. For example, a given amount of solar

radiation can feel comfortably warm in a cold climate,

or extremely uncomfortable in a hot climate.

Therefore, as a technique for effecting a higher level

of control, a neural network has been adopted in the

automatic air conditioning system. With this

technique, the data that has been collected under

varying environmental conditions is stored in the A/C

amplifier. The A/C amplifier can then effect control to

provide enhanced air conditioning comfort.

• The neural network control consists of neurons in the

input layer, intermediate layer, and output layer. The

input layer neurons process the input data of the

outside temperature, the amount of sunlight, and the

room temperature based on the outputs of the

switches and sensors, and output them to the

intermediate layer neurons. Based on this data, the

intermediate layer neurons adjust the strength of the

links among the neurons. The sum of these is then

calculated by the output layer neurons in the form of

the required outlet temperature, solar correction,

target airflow volume, and outlet mode control

volume. Accordingly, the A/C amplifier controls the

servo motors and blower motor in accordance with

the control volumes that have been calculated by the

neural network control.

AC–11

AC

AC–12

AIR CONDITIONING – AIR CONDITIONING SYSTEM

Intermediate Layer

Outer LayerInput Layer

AC

Input Processing

Temp. Setting

Ambient Temp.

Amount of Sunlight

Room Temp.

Neural Network

Terget Outlet Temp.

Amount of Sunlight

Correction

Target Airflow

Volume

Control

Target Output Temp.

Temp. Control

Correction

Various Types of Airflow

Volume Correction

Outlet Processing

Air Mix Control

Damper

Blower Motor

Sensor Input

Switch Input

Outlet Mode

Inlet Mode

Compressor

: Neural Network Operation Range

Various Types of

Mode Correction

Various Types of

Correction

Mode Control

Damper

Air Inlet Control

Damper

Compressor

E116942E01

AIR CONDITIONING – AIR CONDITIONING SYSTEM

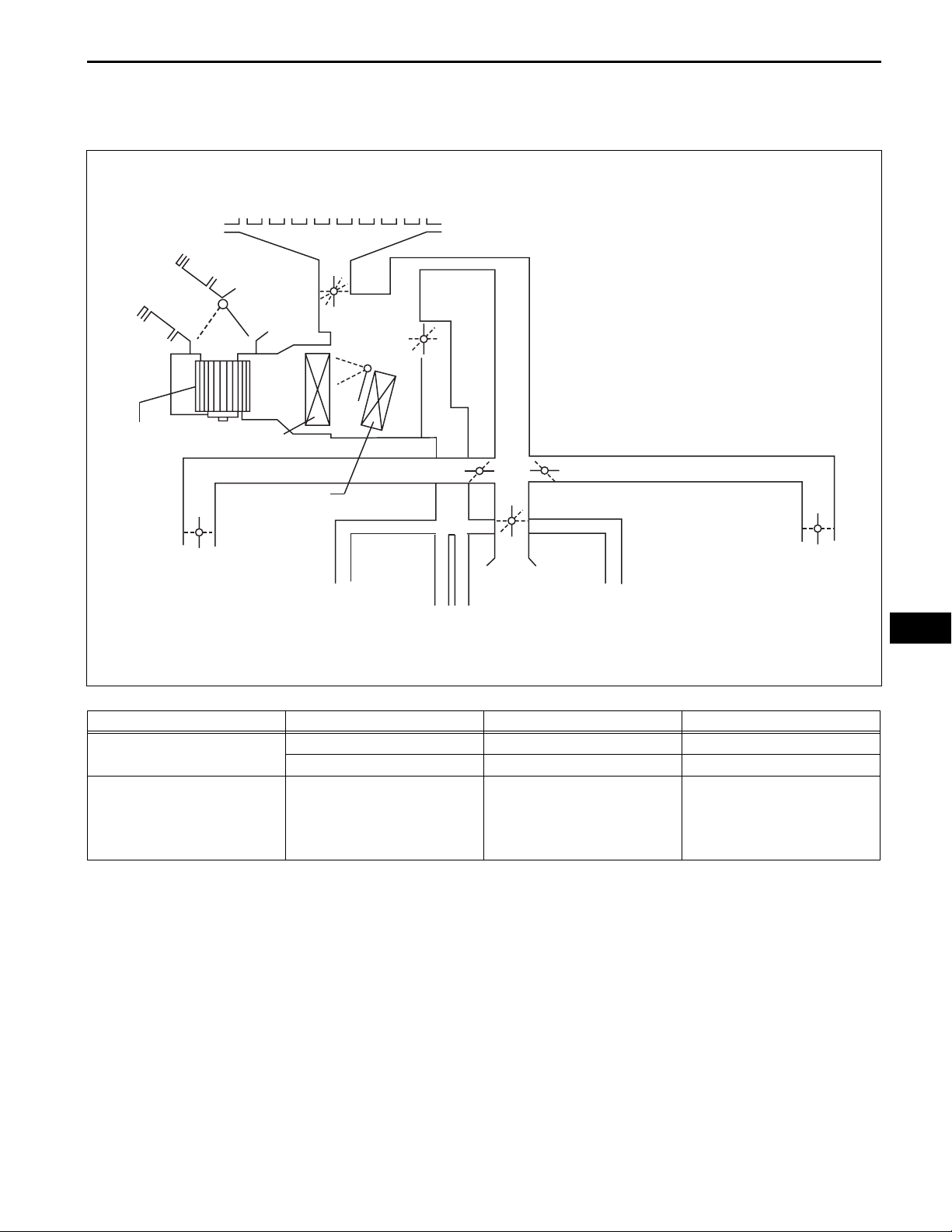

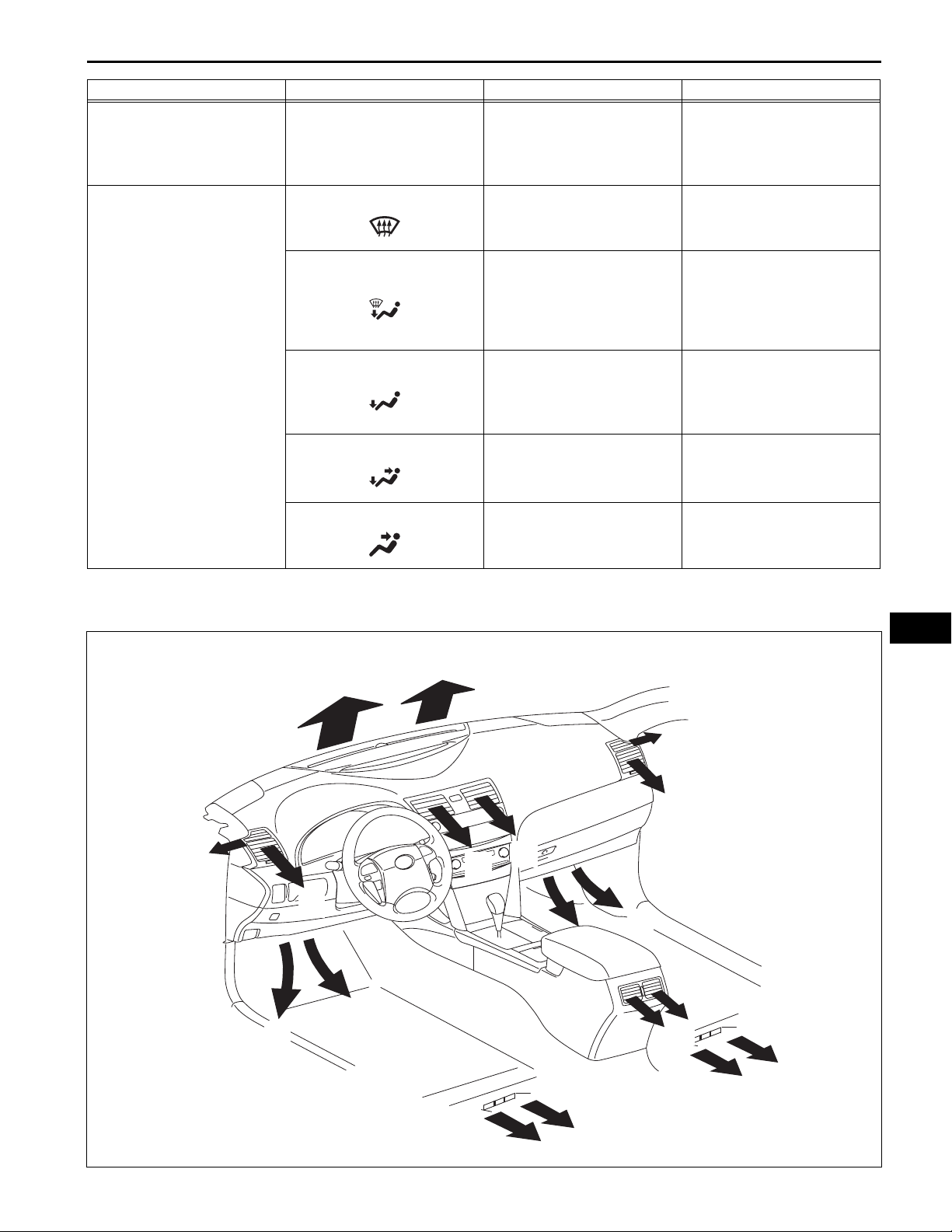

3. MODE POSITION AND DAMPER OPERATION

(a) Mode Position and Damper Operation (for Manual

A/C)

Center Defroster

AC–13

Side Defroster

Fresh Air

Recirc. Air

A

B

Blower Motor

Evaporator

Heater Core

Side Register

Front Foot Well

Register Duct

Y

Functions of Main Dampers:

Control Damper Operation Position Damper Position Operation

Air Inlet Control Damper

Air Mix Control Damper

Side Defroster

F

G

H

I

E

S

Q

R

D

C

J

K

M

O

P

L

N

Front Center

Register

Rear Foot Well

Front Foot Well

Register Duct

Register Duct

FRESH A Brings in fresh air.

RECIRC B Recirculates internal air.

Varies the mixture ratio of the

MAX COLD to MAX HOT

Temperature Setting

C - D - E

fresh air and the recirculation air

in order to regulate the

temperature continuously from

HOT to COLD.

Side Register

AC

E133954E01

AC–14

Control Damper Operation Position Damper Position Operation

Air Outlet Control Damper

AIR CONDITIONING – AIR CONDITIONING SYSTEM

DEF

F, J, L, P, S

FOOT / DEF

G, J, L, P, Q

FOOT

H, J, L, P, Q

BI-LEVEL

I, K, N, O, R

Defrosts the windshield through

the center defroster, side

defroster, side register, and rear

register.

Defrosts the windshield through

the center defroster, side

defroster, side register, and rear

register, while air is also blown

out from the front and rear foot

well register ducts.

Air blows out of the foot well

register duct and side register. In

addition, air blows out slightly

from the center defroster and side

defroster.

Air blows out of the front center

register, side register and front

and rear foot well register ducts.

AC

Side Defroster

Fresh Air

Blower Motor

Recric. Air

AB

Evaporator

Heater Core

FACE

Center Defroster

F

G

H

I

E

D

C

V

I, K, M, O, S

Air blows out of the front center

register and side register.

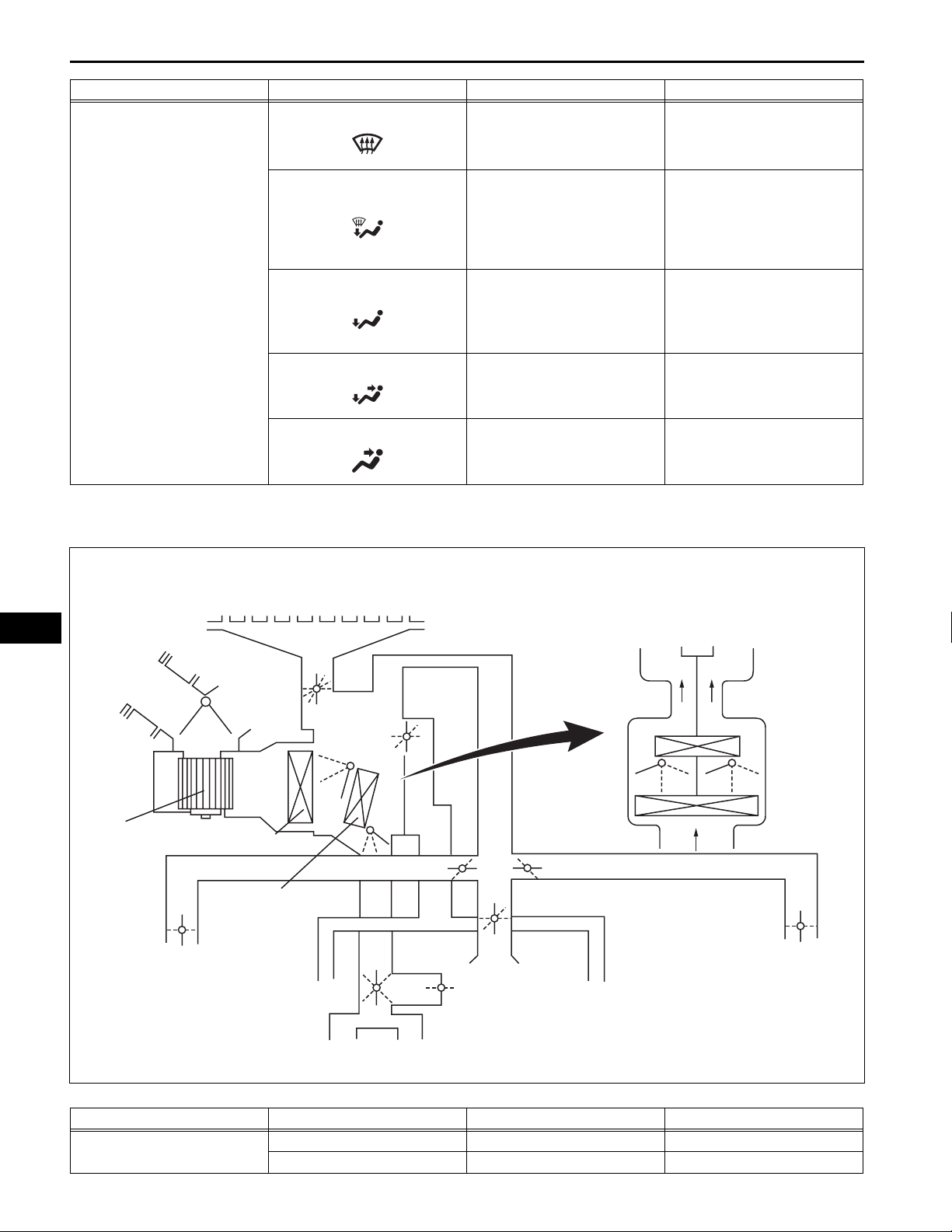

(b) Mode Position and Damper Operation (for

Automatic A/C)

Side Defroster

S

Q

R

T

U

K

J

L

M

P

N

O

To Driver Side

E

C

D

To Passenger Side

E‘

C‘

D‘

Side Register

Front Foot Well Register Dust

Rear Foot Well Register Dust

Y

Functions of Main Dampers:

Control Damper Operation Position Damper Position Operation

Air Inlet Control Damper

X

W

FRESH A Brings in fresh air.

RECIRC B Recirculates internal air.

Y

Front Center Register

Raer Center Register

Front Foot Well Register Dust

Side Register

C118756E03

AIR CONDITIONING – AIR CONDITIONING SYSTEM

Control Damper Operation Position Damper Position Operation

Varies the mixture ratio of the

Air Mix Control Damper

Air Outlet Control Damper

MAX COLD to MAX HOT

Temperature Setting

DEF

FOOT / DEF

FOOT

BI-LEVEL

FACE

C - D - E

(C' - D' - E')

T - U - V

F, J, L, P, S, Y

G, J, L, P, Q, X

H, J, L, P, Q, X

I, K, N, O, R, X

I, K, M, O, S, W

fresh air and the recirculation air

in order to regulate the

temperature continuously from

HOT to COLD.

Defrosts the windshield through

the center defroster, side

defroster, and side register.

Defrosts the windshield through

the center defroster, side

defroster, side register, and rear

center register, while air is also

blown out from the front and rear

foot well register ducts.

Air blows out of the foot well

register dust, and side register. In

addition, air blows out slightly

from the center defroster and side

defroster.

Air blows out of the front and rear

center registers, side register and

front and rear foot well register

ducts.

Air blows out of the front and rear

center registers, and side

register.

AC–15

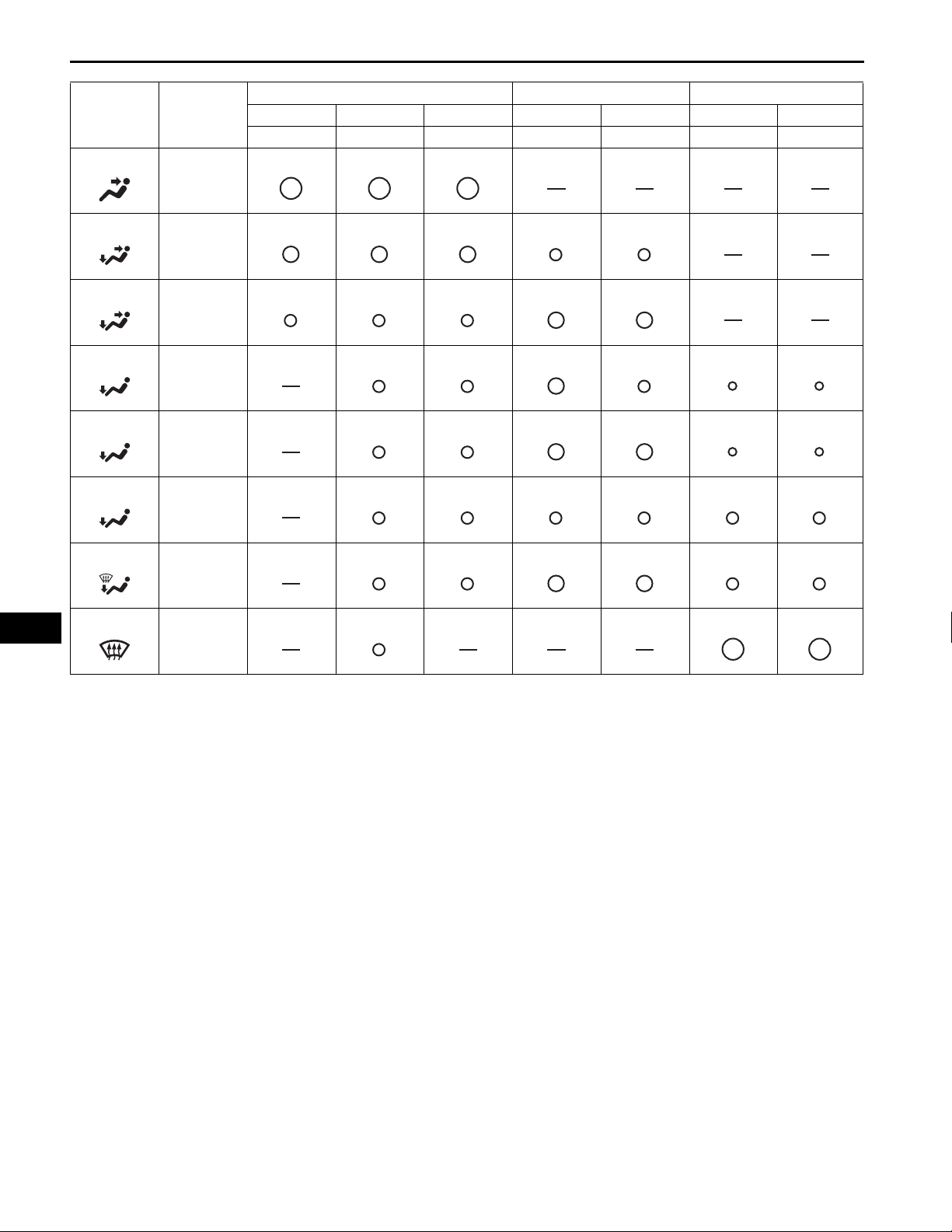

4. AIR OUTLETS AND AIRFLOW VOLUME

(a) Air Outlets and Airflow Volume

AC

F

G

B

D

D

F

G

B

A

A

D

D

C

E

Y

E

E133944E02

AC–16

AIR CONDITIONING – AIR CONDITIONING SYSTEM

INDICATION

(MODE)

FACE

B/L-U*1

B/L-L*2

FOOT-F*3

FOOT-R*4

FOOT-D*5

SELECTION

(Auto /

Manual)

{ / {

{ / {

{ / -

{ / {

{ / -

{ / -

FACE FOOT DEF

CTR SIDE RR FR RR CTR SIDE

ABC*6DEFG

AC

F/D

{ / {

DEF

{ / {

The size of the circle { indicates the proportion of

airflow volume.

*1: Greater airflow volume at the upper area

*2: Greater airflow volume at the lower area

*3: Greater airflow volume at the front

*4: Greater airflow volume at the rear

*5: Greater airflow volume at the defroster

*6: Only for models with automatic air conditioning.

5. PLASMACLUSTER ION GENERATOR CONTROL

(a) General:

(1) A Plasmacluster ion generator is provided inside

the air duct of the side register on the driver seat

side to improve the air quality and comfort in the

cabin.

(2) This generator is controlled by the A/C amplifier

and operates in conjunction with the blower

motor.

NOTICE:

• The Plasmacluster ion generator uses a

high voltage, which is hazardous.

Therefore, if the Plasmacluster ion

generator requires repairs, be sure to

have them done at a TOYOTA dealer.

AIR CONDITIONING – AIR CONDITIONING SYSTEM

• Do not apply any type of spray (such as a

cleaning solvent or hair spray) or stick

any foreign matter into the Plasmacluster

ion outlet, as this could cause improper

operation or a malfunction.

• After use, dust may accumulate around

the side register on the driver seat side. If

this occurs, press the OFF switch on the

heater control panel to stop the blower

motor before cleaning the area.

• It is normal for the Plasmacluster ion

generator to emit a slight sound during

operation. This sound is created when

electrons collide with the electrode while

Plasmacluster ions are being generated.

HINT:

Plasmacluster

plasmacluster ions are a trademark of the

SHARP Corporation.

(b) Operation:

(1) The Plasmacluster ion generator produces

positive and negative ions from the water

molecules (H2O) and oxygen molecules (O2) in

the air, and emits them into the air. These ions

reduce airborne germs.

6. BLOWER MOTOR

The blower motor has a built-in blower controller, and is

controlled with duty control from the A/C amplifier.

TM

, plasmacluster, and

AC–17

AC

AC–18

AIR CONDITIONING – AIR CONDITIONING SYSTEM

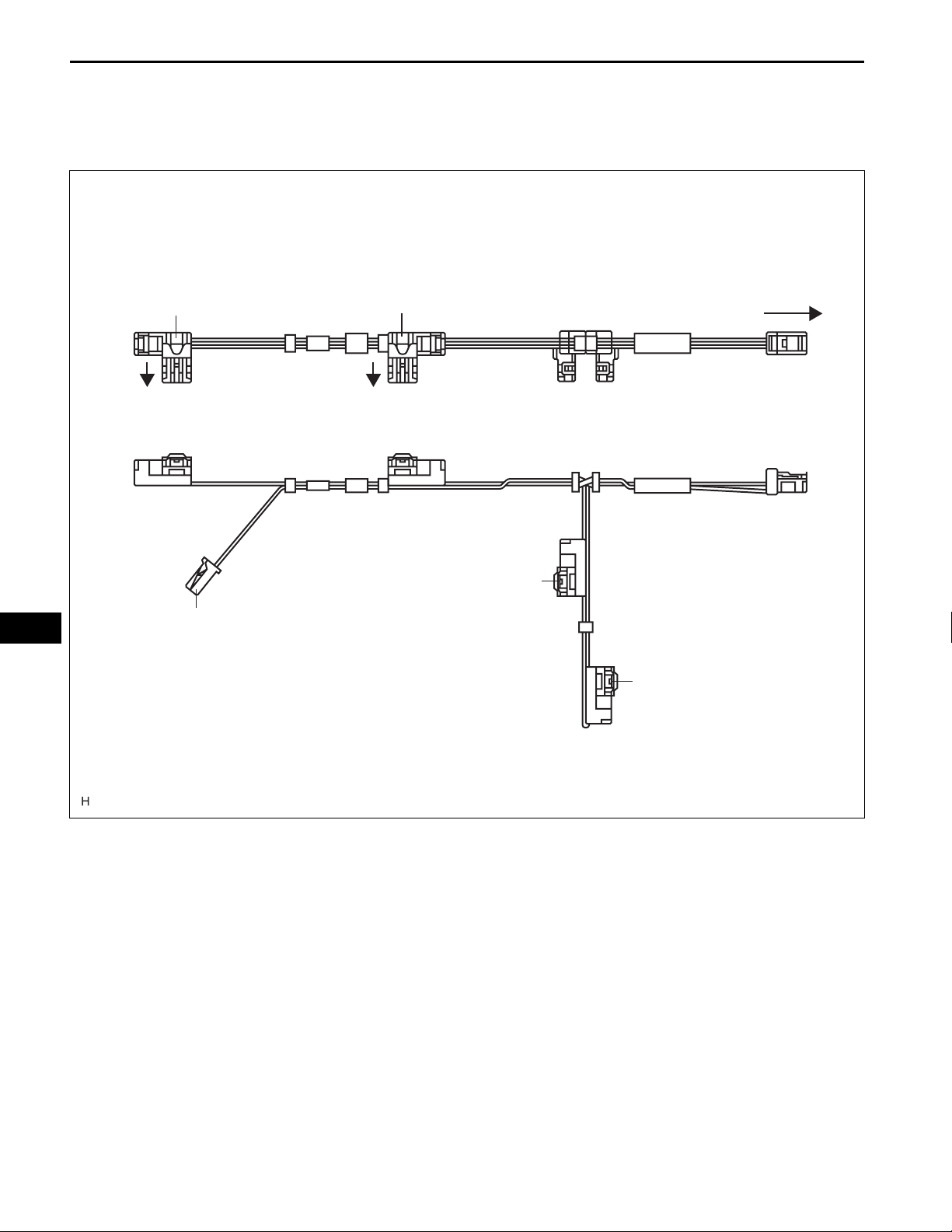

7. BUS CONNECTOR

(a) A BUS connector is used in the wire harness

connection that connects the servo motor from the

A/C amplifier.

Top View:

AC

Bus Connector

To Air Mix Servo Motor

(For Driver)

Evaporator

Temp. Sensor

Bus Connector

To Air Inlet Servo Motor

Bus Connector

To Air Outlet

Servo Motor

To A/C Amplifier

Side View:

Bus Connector

To Air Mix Servo Motor

(For Front Passenger)

E116948E01

AIR CONDITIONING – AIR CONDITIONING SYSTEM

(b) The BUS connector has a built-in communication/

driver IC which communicates with each servo

motor connector, actu ates the se rvo mot or, and has

a position detection function. This enables bus

communication for the servo motor wire harness, for

a more lightweight construction and a reduced

number of wires.

AC–19

with BUS Connector:

A/C Amplifier

Communication IC

CPU

without BUS Connector:

A/C Amplifier

CPU

BUS Connector

Communication/Driver IC

Servo Motor

Drive IC

AC

Servo Motor

Drive IC

E116949E01

AC–20

AIR CONDITIONING – AIR CONDITIONING SYSTEM

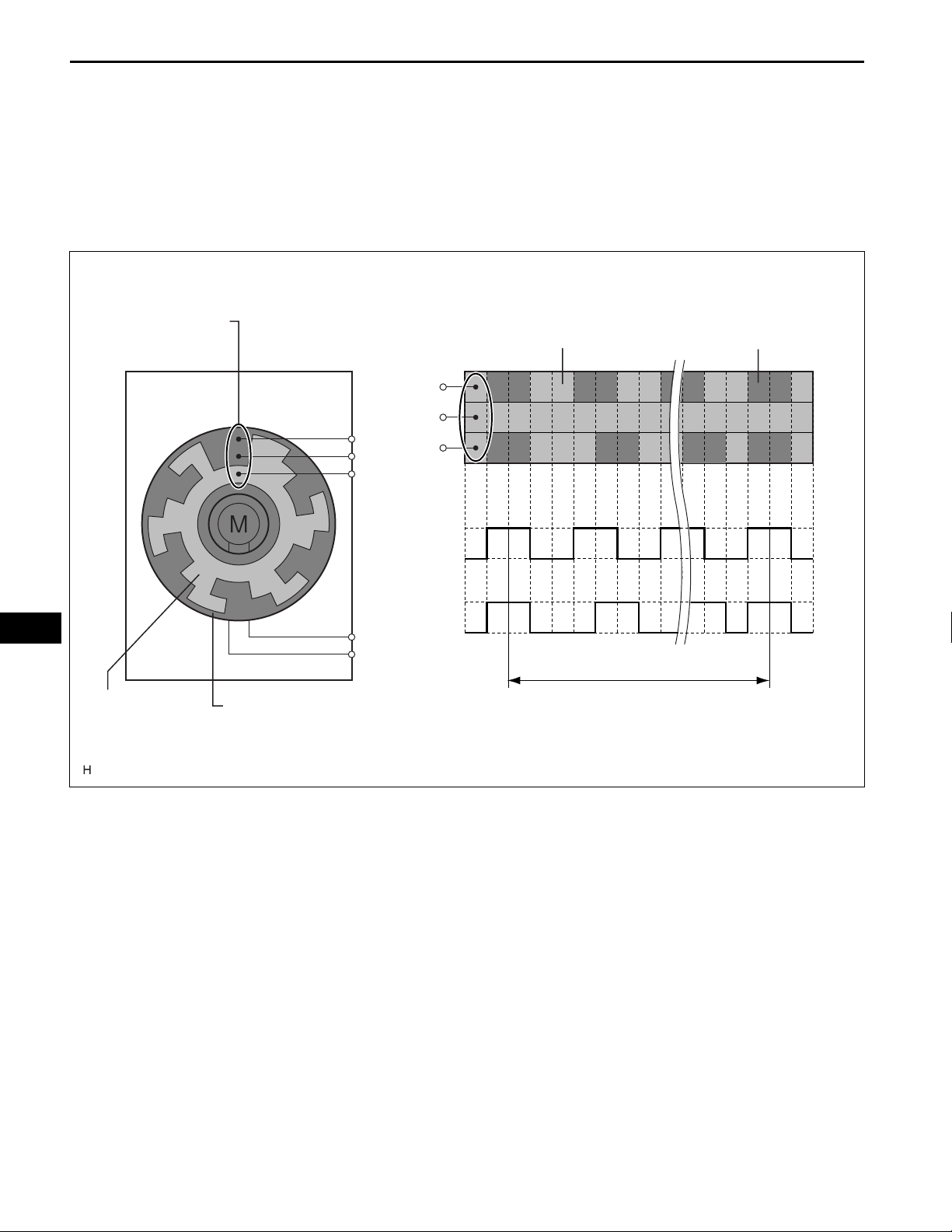

8. SERVO MOTOR

(a) The pulse pattern type servo motor consists of a

printed circuit board and servo motor. The printed

circuit board has three contact points, and transmit s

to the A/C amplifier two ON-OFF signals for the

difference of the pulse phase. The BUS connector

detects the damper position and movement

direction with this signal.

AC

Contact Points

Portion

Conductive Portion

Contact Points

A

GND

A

B

GND

Printed-circuit BoardConductive

B

Hi

A

Lo

Hi

B

Lo

1 Rotation

Printed-circuit Board

E116950E01

9. A/C COMPRESSOR

(a) General

(1) The A/C compressor is a continuously variable

capacity type in which its capacity ca n be varied

in accordance with the cooling load of the air

conditioning.

(2) This compressor consists of the A/C pulley,

shaft, lug plate, swash plate, piston, shoe, crank

chamber, cylinder, and solenoid valve.

(3) The A/C pulley with built-in magnetic clutch and

the lock sensor that detects whether the

magnetic clutch is locked are installed on

models with the 2GR-FE.

(4) The DL (Damper Limiter) type A/C pulley is

installed on models with the 2AZ-FE.

(5) A solenoid valve that adjusts the suction

pressure so that the compressor capacity can be

controlled as desired is provided.

AIR CONDITIONING – AIR CONDITIONING SYSTEM

(6) The internal valve is provided on models with

2AZ-FE to improve the A/C compressor

durability under the high speed and large

thermal load conditions. The internal valve is

integrated into the solenoid valve.

(b) Solenoid Valve Operation

(1) The crank chamber is connected to the

discharge passage. A solenoid valve is provided

between the discharge passage (LO pressure)

and the discharge passage (HI pressure).

(2) The solenoid valve operates under duty cycle

control in accordance with the signals from A/C

amplifier.

(3) When the solenoid valve closes (solenoid coil is

energized), a difference in pressure is created

and the pressure in the crank chamber

decreases. Then, the pressure that is applied to

the right side of the piston becomes greater than

the pressure that is applied to the left side of the

piston. This compresses the spring and tilts the

swash plate. As a result, the piston stroke

increases and the discharge capacity increases.

(4) When the solenoid valve opens (solenoid coil is

not energized), the difference in pressure

disappears. Then, the pressure that is applied to

the left side of the piston becomes the same as

the pressure that is applied to the right side of

the piston. Thus, the spring elongates and

eliminates the tilt of the swash plate. As a result,

there is no piston stroke and the discharge

capacity is reduced.

(c) Internal Valve Operation (for 2AZ-FE)

(1) The internal valve operates when the A/C

compressor speed has increased rapidly, the A/

C compressor speed is high, or when thermal

load has suddenly changed. As a result, the A/C

compressor capacity is reduced, increasing the

durability of the A/C compressor.

(d) DL type A/C Pulley (for 2AZ-FE)

(1) This pulley contains a damper to absorb the

torque fluctuations of the engine and a limiter

mechanism to protect the drive belt in case the

compressor locks. In the event that the

compressor locks, the limiter mechanism causes

the spoke portion of the pulley to break, thus

separating the pulley from the compressor.

10. LOCK SENSOR (for 2GR-FE)

The lock sensor sends A/C pulley speed signals to the A/

C amplifier. The A/C amplifier determines whether the

magnetic clutch is locked or not by using those signals

and engine speed signals.

AC–21

AC

AC–22

AIR CONDITIONING – AIR CONDITIONING SYSTEM

11. ROOM TEMPERATURE SENSOR (for AUTO A/C)

The room temperature sensor detects the cabin

temperature based on changes in the resistance of its

built-in thermistor and sends a signal to the A/C

amplifier.

12. AMBIENT TEMPERATURE SENSOR

The ambient temperature sensor detects the outside

temperature based on changes in the resistance of its

built-in thermistor and sends a signal to the A/C

amplifier.

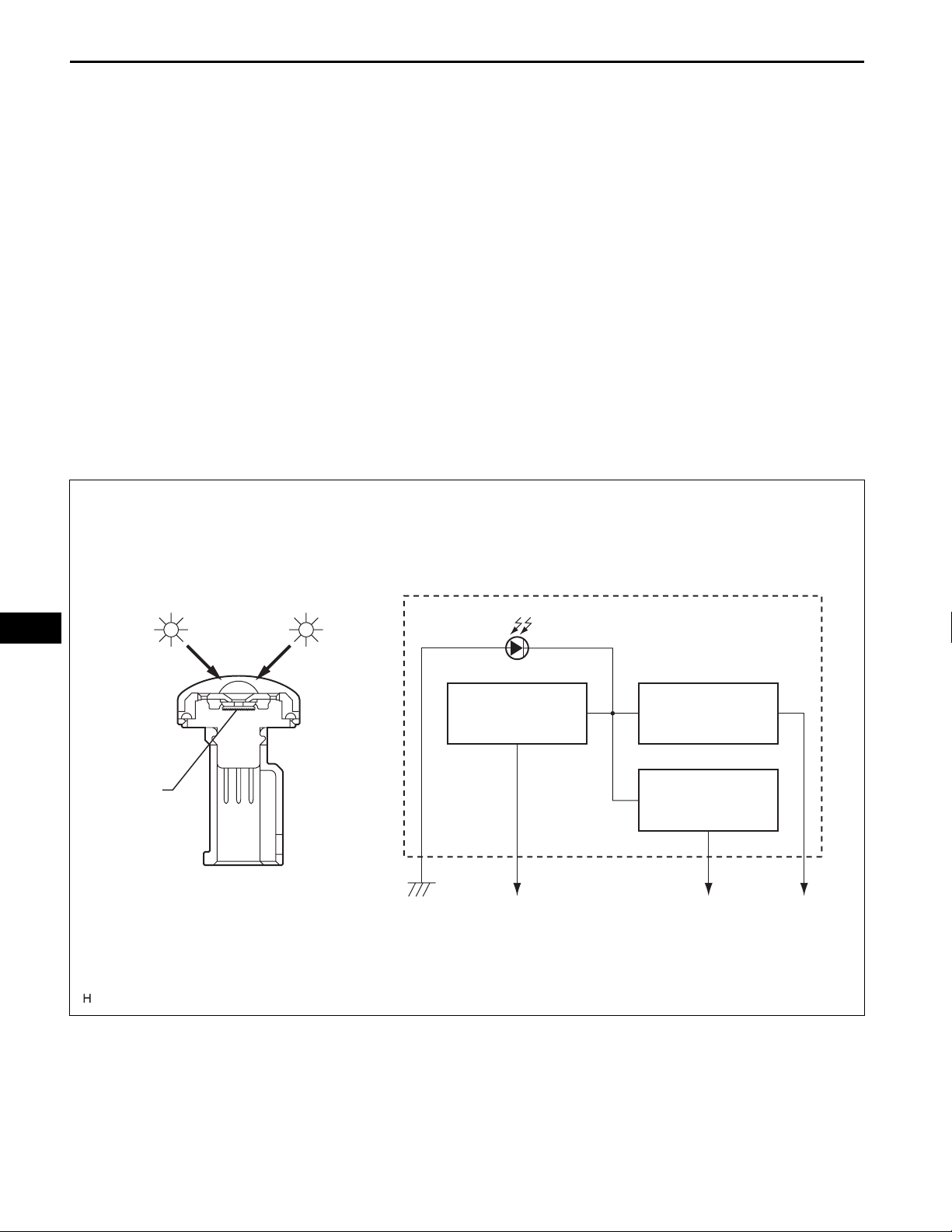

13. SOLAR SENSOR (for AUTO A/C)

(a) The solar sensor consists of a photo diode, two

amplifier circuits for the solar sensor , and frequency

converter circuit for the light control sensor.

(b) A solar sensor detects (in the form of changes in the

current that flows through the built-in photo diode)

the changes in the amount of sunlight from the LH

and RH sides (2 directions) and outputs these

sunlight strength signals to the A/C amplifier.

AC

LH Side RH Side

Sensor

Portion

Internal circuit of the solar sensor

Photo Diode

Frequency

Convert Circuit

To Main Body ECU

Amplifier Circuit

(LH)

Amplifier Circuit

(RH)

To A/C Amplifier

E116951E01

14. EVAPORATOR TEMPERATURE SENSOR

The evaporator temperature sensor detects the

temperature of the cool air immediately past the

evaporator in the form of resistance changes, and

outputs it to the A/C amplifier.

AIR CONDITIONING – AIR CONDITIONING SYSTEM

15. A/C PRESSURE SENSOR

The A/C pressure sensor detects the refrigerant

pressure and outputs it to the A/C amplifier in the form of

voltage changes.

AC–23

AC

AC–24

1

NEXT

2

AIR CONDITIONING – AIR CONDITIONING SYSTEM

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use the following procedures to troubleshoot the air

conditioning system.

• *: Use the intelligent tester.

VEHICLE BROUGHT TO WORKSHOP

INSPECT BATTERY VOLTAGE

(a) Inspect the battery voltage.

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the

battery before proceeding.

AC

NEXT

3

A

4

CHECK COMMUNICATION FUNCTION OF CAN COMMUNICATION SYSTEM*

(a) Use the intelligent tester to check if the CAN

Communication System is functioning normally.

Result

Result Proceed to

CAN DTC is not output A

CAN DTC is output B

B

CHECK FOR DTC*

(a) Check for DTCs and note any codes that are output.

HINT:

Refer to the DTC CHECK / CLEAR (See page AC-32).

(b) Delete the DTCs.

(c) Recheck for DTCs. Based on the DTCs output above, try

to force output of the A/C system DTC by simulating the

operation indicated by the DTC.

Result

Go to CAN COMMUNICATION SYSTEM

Result Proceed to

DTC is not output A

DTC is output B

B

Go to step 7

AIR CONDITIONING – AIR CONDITIONING SYSTEM

A

PROBLEM SYMPTOMS TABLE

5

(a) Refer to the problem symptoms table (See page AC-25).

Result

Result Proceed to

Fault is not listed in problem symptoms table A

Fault is listed in problem symptoms table B

AC–25

6

NEXT

7

NEXT

END

B

A

OVERALL ANALYSIS AND TROUBLESHOOTING*

(a) Actuator Check (See page AC-43 for AUTO A/C)

(b) DATA LIST / ACTIVE TEST (See page AC-38)

(c) Terminals of ECU (See page AC-29)

(d) On-vehicle Inspection

(e) Inspection

ADJUST, REPAIR OR REPLACE

Go to step 8

AC

AC

AC–26

AIR CONDITIONING – AIR CONDITIONING SYSTEM

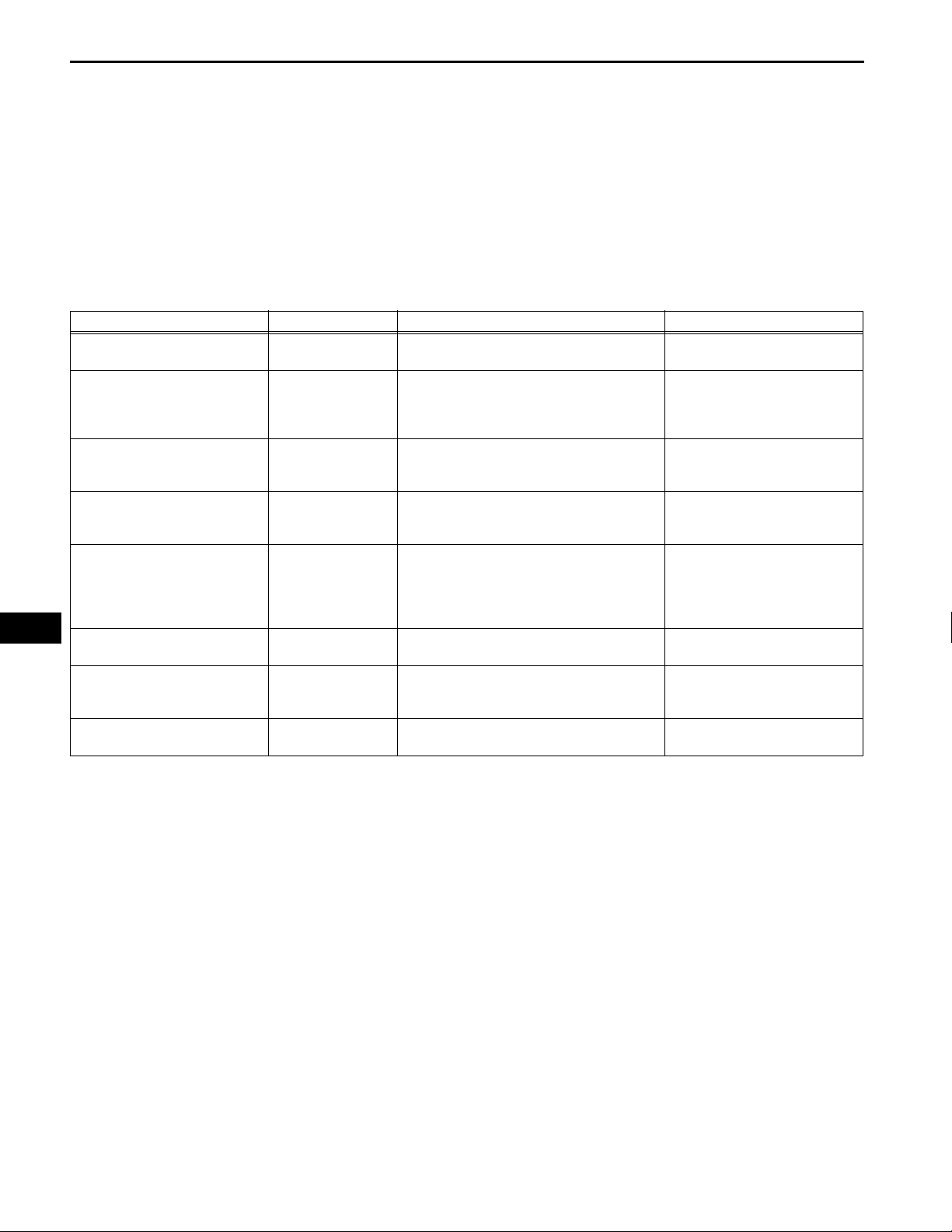

AIR CONDITIONER (AUTO A/C)

DISPLAY (ITEM) DEFAULT CONTENTS SETTING

SET TEMP SHIFT

(Set Temperature Shift)

AIR INLET MODE

(Air Inlet Mode)

COMPRESSOR MODE

(Compressor Mode)

COMPRS / DEF OPER

(Compressor / Air Inlet DEF

Operation)

EVAP CTRL

(Evaporator Control)

FOOT / DEF MODE

(Foot / DEF auto mode)

AUTO BLOW UP

(Foot / DEF automatic blower up

function)

AMBIENT TMP SFT

(Ambient Temperature Shift)

NORMAL

NORMAL

AUTO

AUTO

LINK

AUTO

ON

ON

CUSTOMIZE PARAMETERS

HINT:

The following items can be customized.

NOTICE:

• When the customer requests a change in a function,

first make sure that the function can be customized.

• Be sure to make a note of the current settings before

customizing.

• When troubleshooting a function, first make sure that

the function is set to the default setting.

To shift the temperature against the displayed

temperature

In case of turning the A/C ON when you desire

to make the compartment cool down quickly,

this is the function to change the mode

automatically to RECIRCULATION mode

Function to turn the A/C ON automatically by

pressing the AUTO button when the blower is

ON and the A/C is OFF

Function to turn the A/C ON automatically

linked with the FRONT DEF button when the

A/C is OFF

Function to set the evaporator control to the

AUTOMATIC position (AUTO) to save power,

or to the coldest position (MANUAL) to

dehumidify the air and to prevent the windows

from fogging up

Function to turn the airflow from FOOT / DEF

ON automatically when AUTO MODE is ON

Function to change the blower level

automatically when the defroster is ON

Function to shift the ambient temperature

against the displayed ambient temperature

+2 C / +1 C / NORMAL / -1 C / -2

C

MANUAL / AUTO

MANUAL / AUTO

NORMAL / LINK

MANUAL / AUTO

OFF / ON

OFF / ON

+3 C / +2 C / +1 C / NORMAL / -1

C / -2 C / -3 C

AIR CONDITIONING – AIR CONDITIONING SYSTEM

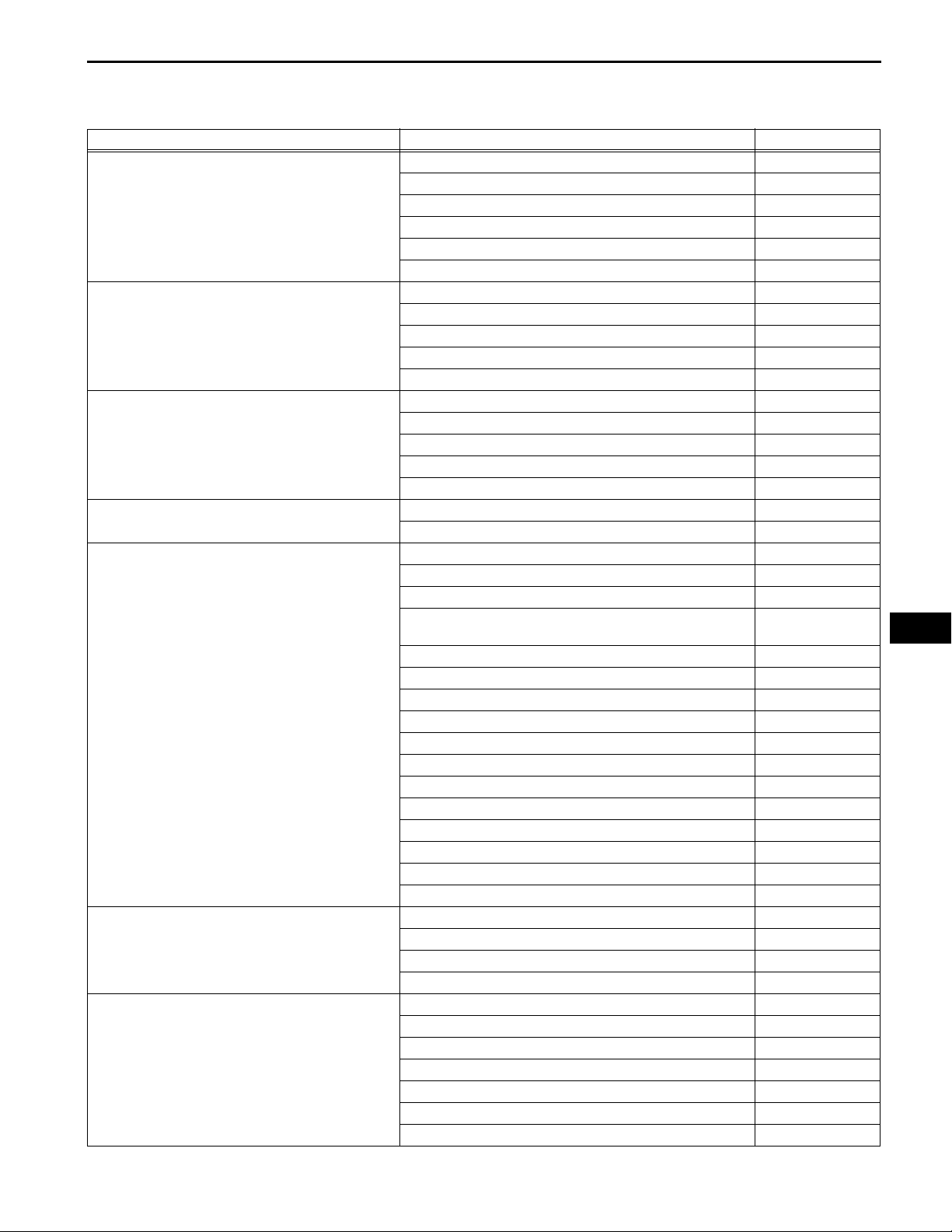

MANUAL A/C:

Symptom Suspected area See page

All functions of the A/C system do not operate

Air Flow Control: No blower operation

Air Flow Control: No blower control

Air Flow Control: Insufficient air flow

Temperature Control: No cool air comes out

Temperature Control: No warm air comes out

Temperature Control: Output air is warmer or cooler

than the set temperature or response is slow.

PROBLEM SYMPTOMS TABLE

1. IG power source circuit AC-113

2. Back-up power source circuit AC-116

3. Heater control panel power source circuit AC-98

4. LIN communication circuit AC-118

5. A/C control assembly AC-255

6. A/C amplifier AC-258

1. Blower motor circuit AC-91

2. Heater control panel power source circuit AC-98

3. LIN communication circuit AC-118

4. A/C control assembly AC-255

5. A/C amplifier AC-258

1. Blower motor circuit AC-91

2. Heater control panel power source circuit AC-98

3. LIN communication circuit AC-118

4. A/C control assembly AC-255

5. A/C amplifier AC-258

1. Blower motor circuit AC-91

2. A/C amplifier AC-258

1. Refrigerant volume AC-120

2. Refrigerant pressure AC-120

3. Pressure switch circuit AC-65

4. Air conditioning compressor magnetic clutch circuit (for

2GR-FSE)

5. Compressor lock sensor circuit (for 2GR-FSE) AC-61

6. Compressor solenoid circuit AC-84

7. Air mix control servo motor circuit AC-74

8. Evaporator temperature sensor circuit AC-53

9. Ambient temperature sensor circuit AC-49

10. Heater control panel power source circuit AC-98

11. LIN communication circuit AC-118

12. Expansion valve AC-159

13. A/C control assembly AC-255

14. A/C amplifier AC-258

15. ECM (for 2AZ-FE) ES-432

16. ECM (for 2GR-FSE) ES-518

1. Air mix control servo motor circuit AC-74

2. Evaporator temperature sensor circuit AC-53

3. Ambient temperature sensor circuit AC-49

4. A/C amplifier AC-258

1. Refrigerant volume AC-120

2. Refrigerant pressure AC-120

3. Ambient temperature sensor circuit AC-49

4. Air mix control servo motor circuit AC-74

5. Radiator unit sub-assembly AC-159

6. Expansion valve AC-159

7. A/C amplifier AC-258

AC-100

AC–27

AC

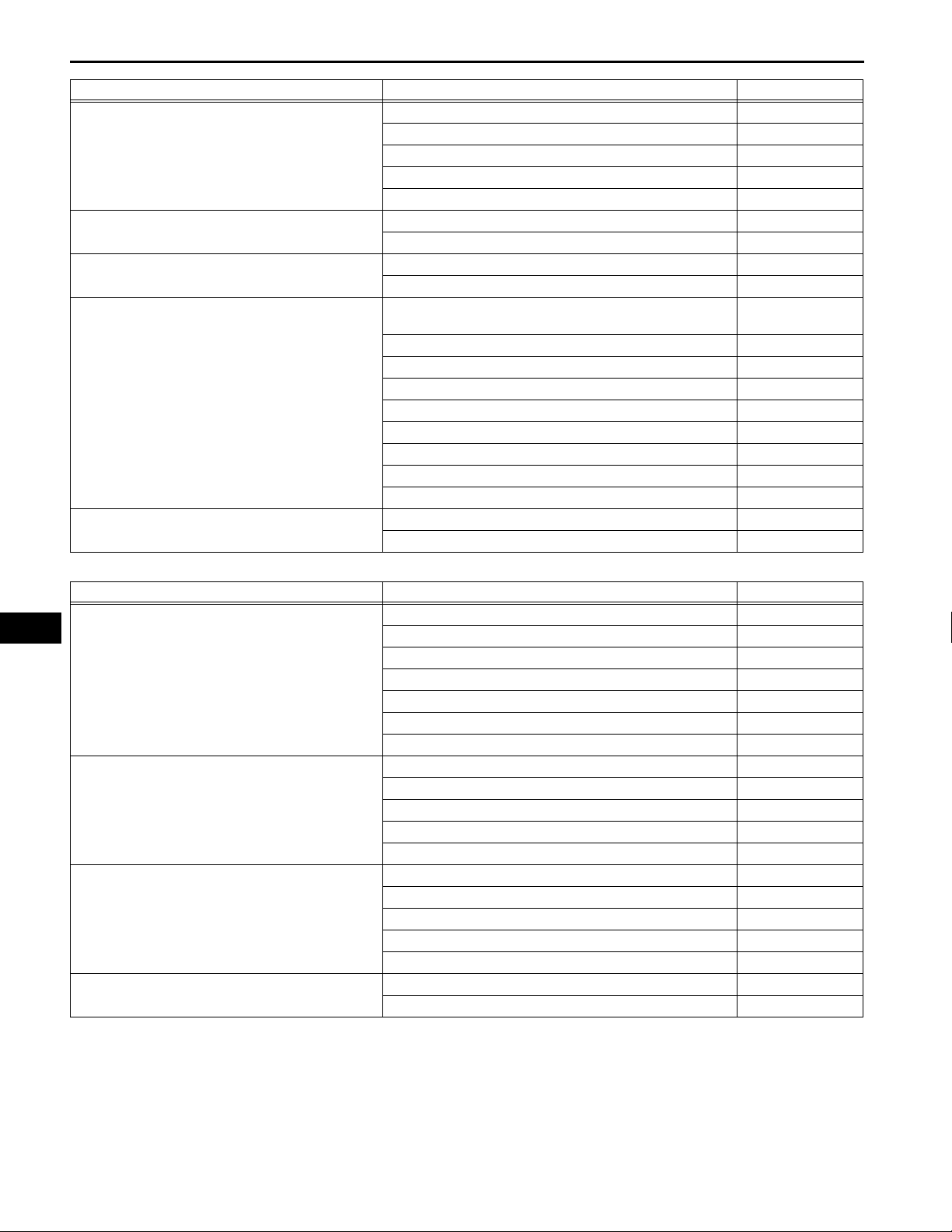

AC–28

Symptom Suspected area See page

Temperature control: No temperature control ( only

Max. cool or Max. warm)

No air inlet control

No air flow mode control

Engine idle up does not occur, or is continuous

Diagnostic trouble codes are not recorded. Set mode

is cleared when ignition switch is turned OFF.

AIR CONDITIONING – AIR CONDITIONING SYSTEM

1. Air mix control servo motor circuit AC-74

2. Ambient temperature sensor circuit AC-49

3. Evaporator temperature sensor circuit AC-53

4. A/C control assembly AC-255

5. A/C amplifier AC-258

1. Air inlet control servo motor circuit AC-77

2. A/C amplifier AC-258

1. Air outlet control servo motor circuit AC-79

2. A/C amplifier AC-258

1. Air conditioning compressor magnetic clutch circuit (for

2GR-FSE)

2. Compressor lock sensor circuit (for 2GR-FSE) AC-61

3. Compressor solenoid circuit AC-84

4. Heater control panel power source circuit AC-98

5. LIN communication circuit AC-118

6. A/C control assembly AC-255

7. A/C amplifier AC-258

8. ECM (for 2AZ-FE) ES-432

9. ECM (for 2GR-FSE) ES-518

1. Back-up power source circuit AC-116

2. A/C amplifier AC-258

AC-100

AC

AUTO A/C:

Symptom Suspected area See page

All functions of the A/C system do not operate

Air Flow Control: No blower operation

Air Flow Control: No blower control

Air Flow Control: Insufficient air flow

1. IG power source circuit AC-113

2. Back-up power source circuit AC-116

3. Heater control panel power source circuit AC-98

4. LIN communication circuit AC-118

5. Steering pad switch circuit AC-108

6. A/C control assembly AC-255

7. A/C amplifier AC-258

1. Blower motor circuit AC-91

2. Heater control panel power source circuit AC-98

3. LIN communication circuit AC-118

4. A/C control assembly AC-255

5. A/C amplifier AC-258

1. Blower motor circuit AC-91

2. Heater control panel power source circuit AC-98

3. LIN communication circuit AC-118

4. A/C control assembly AC-255

5. A/C amplifier AC-258

1. Blower motor circuit AC-91

2. A/C amplifier AC-258

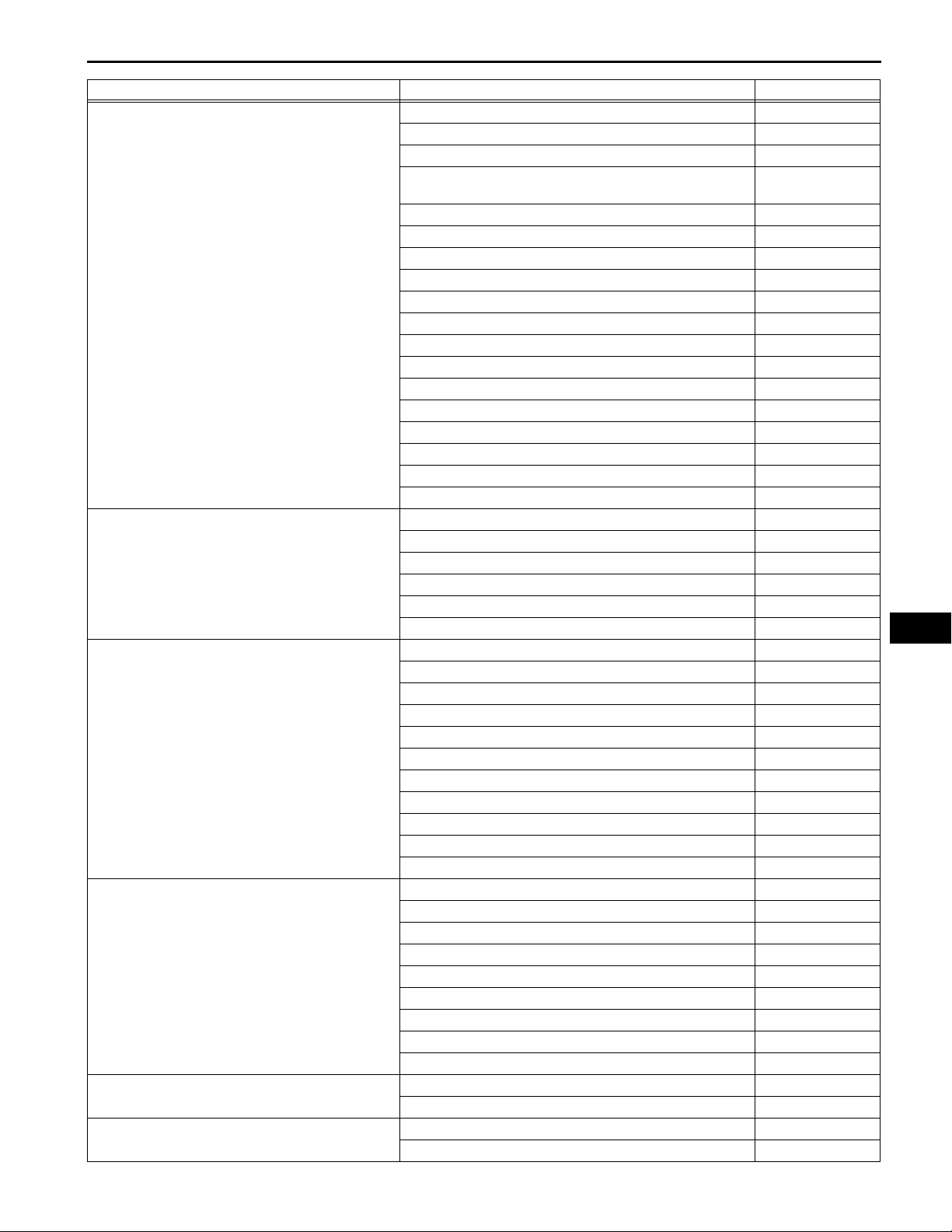

AIR CONDITIONING – AIR CONDITIONING SYSTEM

Symptom Suspected area See page

Temperature Control: No cool air comes out

Temperature Control: No warm air comes out

Temperature Control: Output air is warmer or cooler

than the set temperature or response is slow.

Temperature control: No temperature contr o l (only

Max. cool or Max. warm)

No air inlet control

No air flow mode control

1. Refrigerant volume AC-120

2. Refrigerant pressure AC-120

3. Pressure switch circuit AC-65

4. Air conditioning compressor magnetic clutch circuit (for

2GR-FSE)

5. Compressor lock sensor circuit (for 2GR-FSE) AC-61

6. Compressor solenoid circuit AC-84

7. Air mix control servo motor circuit (Driver side) AC-82

8. Air mix control servo motor circuit (Passenger side) AC-74

9. Evaporator temperature sensor circuit AC-53

10. Room temperature sensor circuit AC-45

11. Ambient temperature sensor circuit AC-49

12. Heater control panel power source circuit AC-98

13. LIN communication circuit AC-118

14. Expansion valve AC-159

15. A/C control assembly AC-255

16. A/C amplifier AC-258

17. ECM (for 2AZ-FE) ES-432

18. ECM (for 2GR-FSE) ES-518

1. Air mix control servo motor circuit (Driver side) AC-82

2. Air mix control servo motor circuit (Passenger side) AC-74

3. Evaporator temperature sensor circuit AC-53

4. Room temperature sensor circuit AC-45

5. Ambient temperature sensor circuit AC-49

6. A/C amplifier AC-258

1. Refrigerant volume AC-120

2. Refrigerant pressure AC-120

3. Solar sensor circuit (Driver side) AC-69

4. Solar sensor circuit (Passenger side) AC-56

5. Room temperature sensor circuit AC-45

6. Ambient temperature sensor circuit AC-49

7. Air mix control servo motor circuit (Driver side) AC-82

8. Air mix control servo motor circuit (Passenger side) AC-74

9. Radiator unit sub-assembly AC-159

10. Expansion valve AC-159

11. A/C amplifier AC-258

1. Air mix control servo motor circuit (Driver side) AC-82

2. Air mix control servo motor circuit (Passenger side) AC-74

3. Room temperature sensor circuit AC-45

4. Ambient temperature sensor circuit AC-49

5. Evaporator temperature sensor circuit AC-53

6. Solar sensor circuit (Driver side) AC-69

7. Solar sensor circuit (Passenger side) AC-56

8. A/C control assembly AC-255

9. A/C amplifier AC-258

1. Air inlet control servo motor circuit

2. A/C amplifier AC-258

1. Air outlet control servo motor circuit AC-79

2. A/C amplifier AC-258

AC-100

AC-77

AC–29

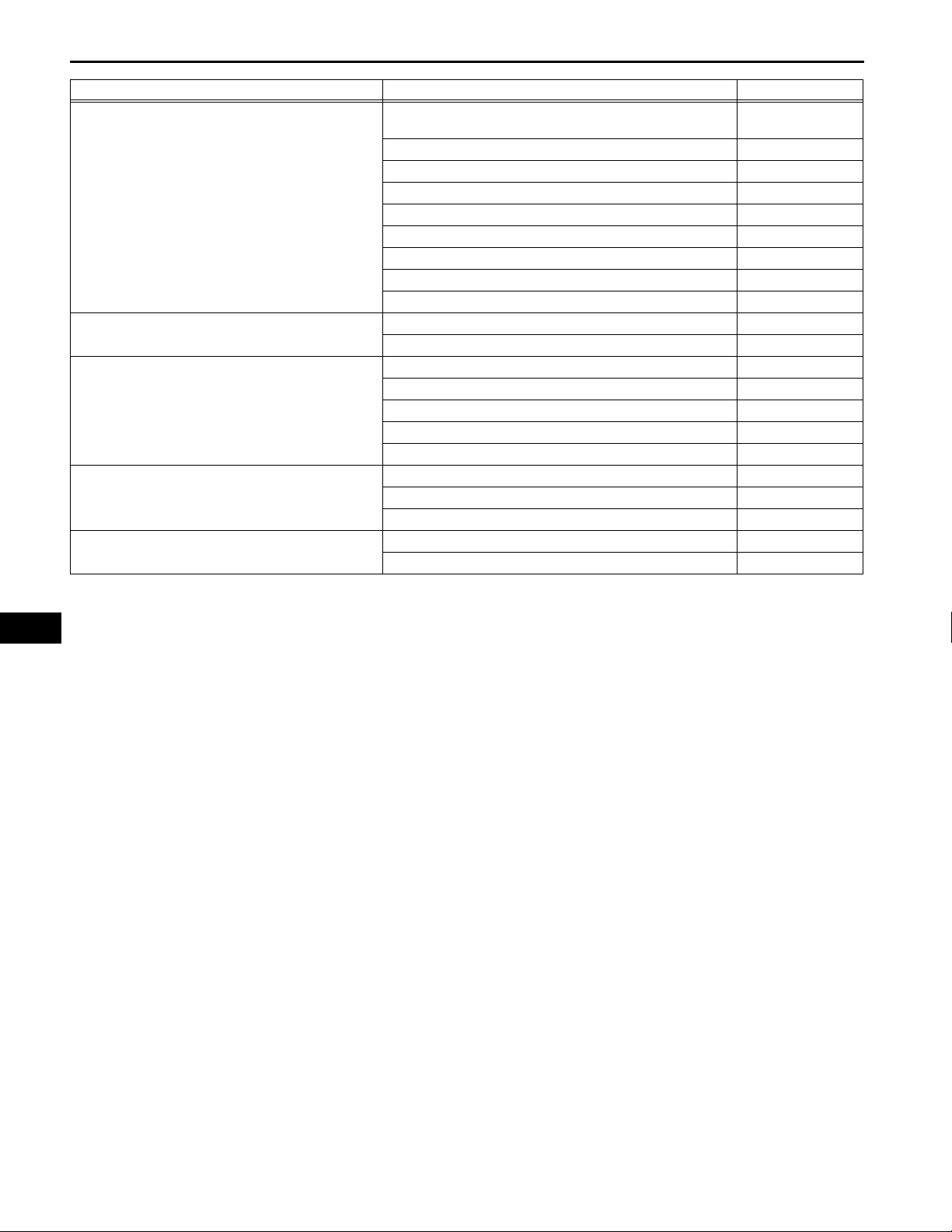

AC

AC–30

Symptom Suspected area See page

Engine idle up does not occur, or is continuous

Blinking of A/C indicator

Unable to control A/C with the steering pad switch

Plasmacluster indicator does not come on

(Plasmacluster does not operate)

Diagnostic trouble codes are not recorded. Set mode

is cleared when ignition switch is turned OFF.

AIR CONDITIONING – AIR CONDITIONING SYSTEM

1. Air conditioning compressor magnetic clutch circuit (for

2GR-FSE)

2. Compressor lock sensor circuit (for 2GR-FSE) AC-61

3. Compressor solenoid circuit AC-84

4. Heater control panel power source circuit AC-98

5. LIN communication circuit AC-118

6. A/C control assembly AC-255

7. A/C amplifier AC-258

8. ECM (for 2AZ-FE) ES-432

9. ECM (for 2GR-FSE) ES-518

1. Compressor solenoid circuit AC-84

2. A/C amplifier AC-258

1. Steering pad switch circuit AC-108

2. Heater control panel power source circuit AC-98

3. LIN communication circuit AC-118

4. A/C control assembly AC-255

5. A/C amplifier AC-258

1. Blower motor circuit AC-91

2. Plasmacluster circuit AC-105

3. A/C amplifier AC-258

1. Back-up power source circuit AC-116

2. A/C amplifier AC-258

AC-100

AC

Loading...

Loading...