Toyota Camry 2007-2009 Service Manual - E351_Manual_Transaxle

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE SYSTEM

Manual transaxle system (MTM)

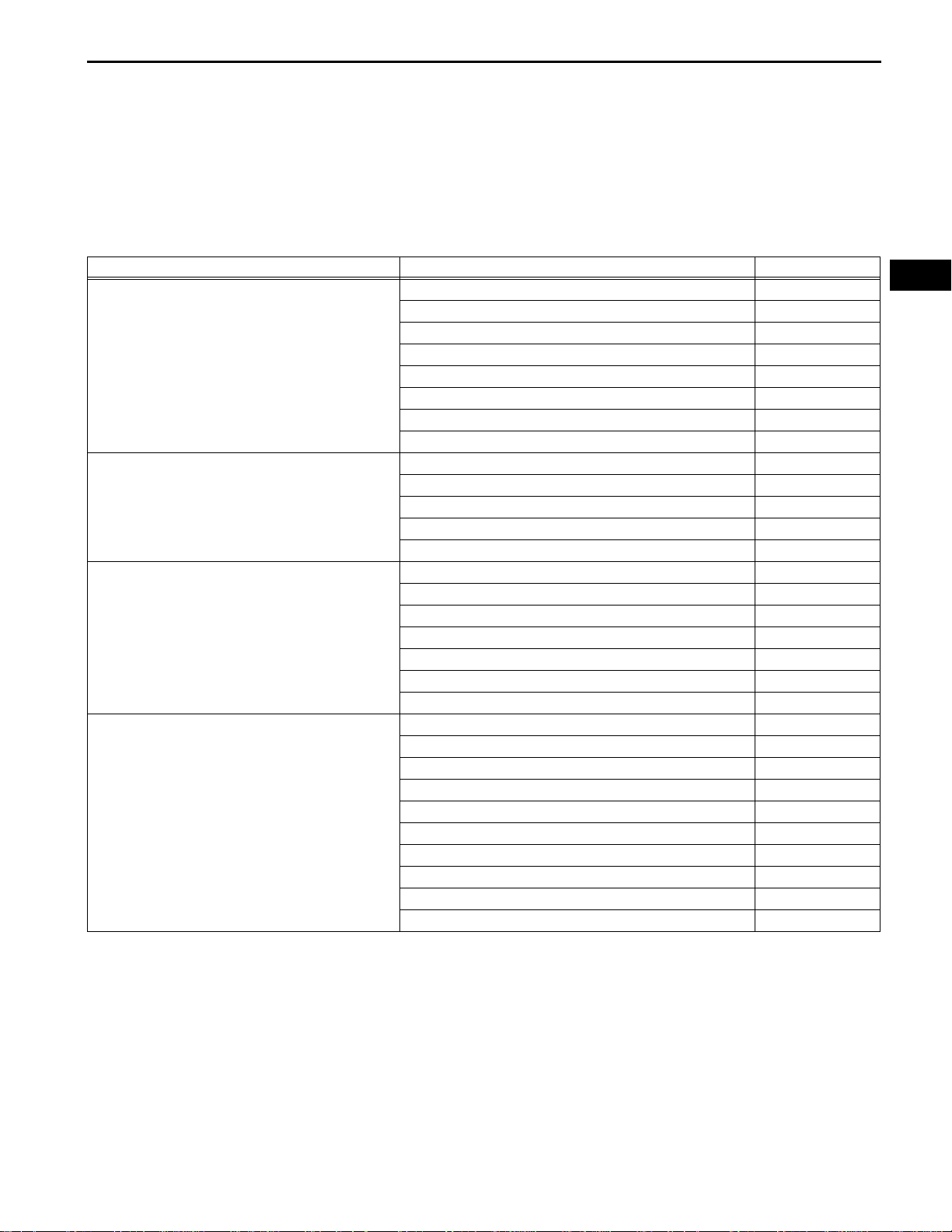

Symptom Suspected area See page

Noise

Oil leakage

Hard to shift or will not shift

Jumps out of gear

MX–1

MANUAL TRANSAXLE SYSTEM

PROBLEM SYMPTOMS TABLE

Use the table below to help you find the cause of the problem.

The numbers indicate the ranked order of probability of each

of the possible causes. Check each part in order. Replace

parts as necessary.

1. Oil (Level low) MX-2

2. Oil (Wrong) MX-2

3. Gear (Worn or damaged) MX-54

- MX-79

- MX-89

4. Bearing (Worn or damaged) MX-40

- MX-79

- MX-89

1. Oil (Level too high) MX-2

2. Gasket (Damaged) MX-40

3. Oil seal (Worn or damaged) MX-5

- MX-99

4. O-Ring (Worn or damaged) MX-40

1. Control cable assembly MX-13

2. Synchronizer ring (Worn or damaged) MX-54

- MX-79

- MX-89

3. Shift key spring (Damaged) MX-40

- MX-77

- MX-87

1. Locking ball spring (Damaged) MX-40

2. Shift fork (Worn) MX-54

- MX-79

- MX-89

3. Gear (Worn or damaged) MX-54

- MX-79

- MX-89

4. Bearing (Worn or damaged) MX-40

- MX-79

- MX-89

MX

MX

MX–2

0 to 5 mm

(0 to 0.20 in.)

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE OIL

MANUAL TRANSAXLE OIL

ON-VEHICLE INSPECTION

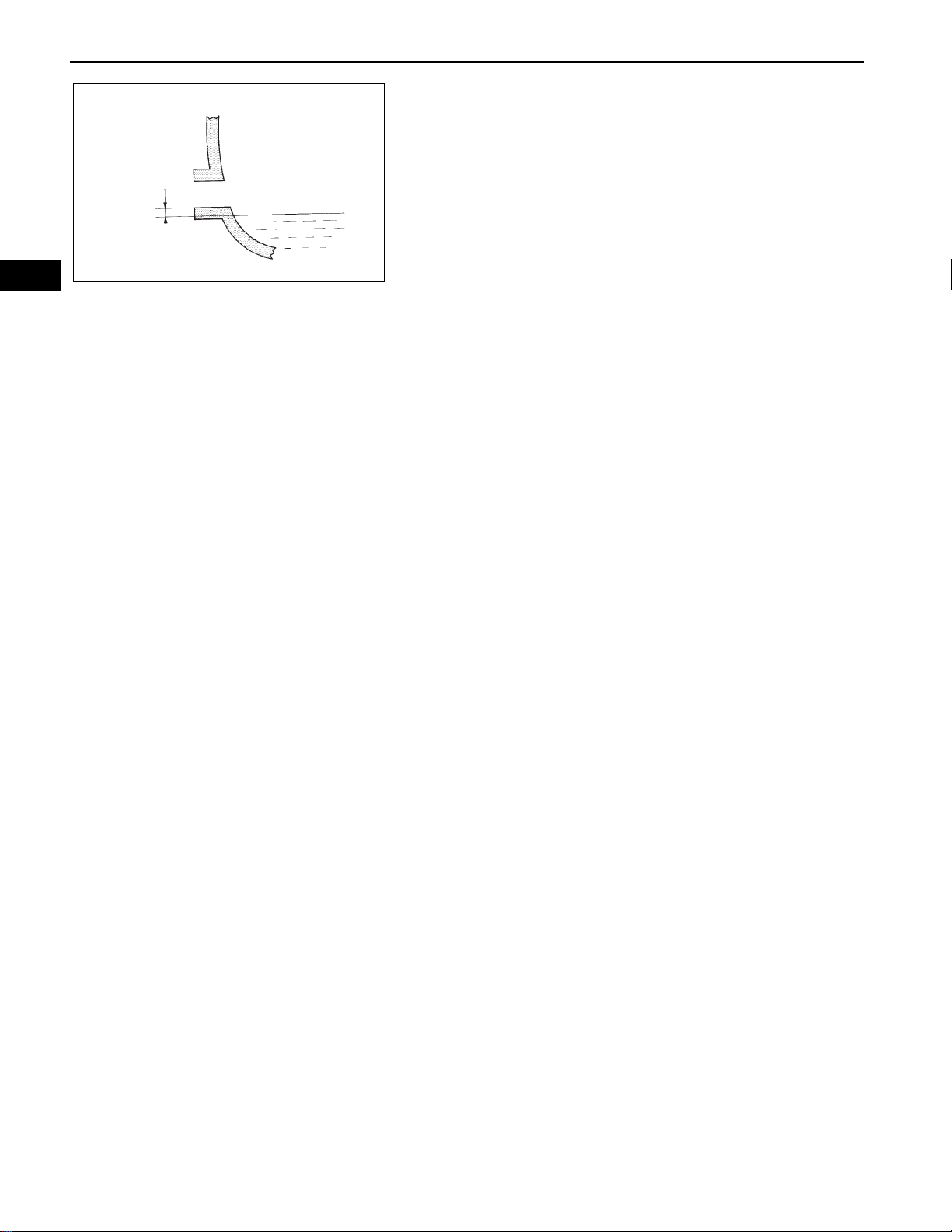

1. INSPECT MANUAL TRANSAXLE OIL

(a) Stop the vehicle on a level surface.

(b) Remove the transmission filler plug and gasket.

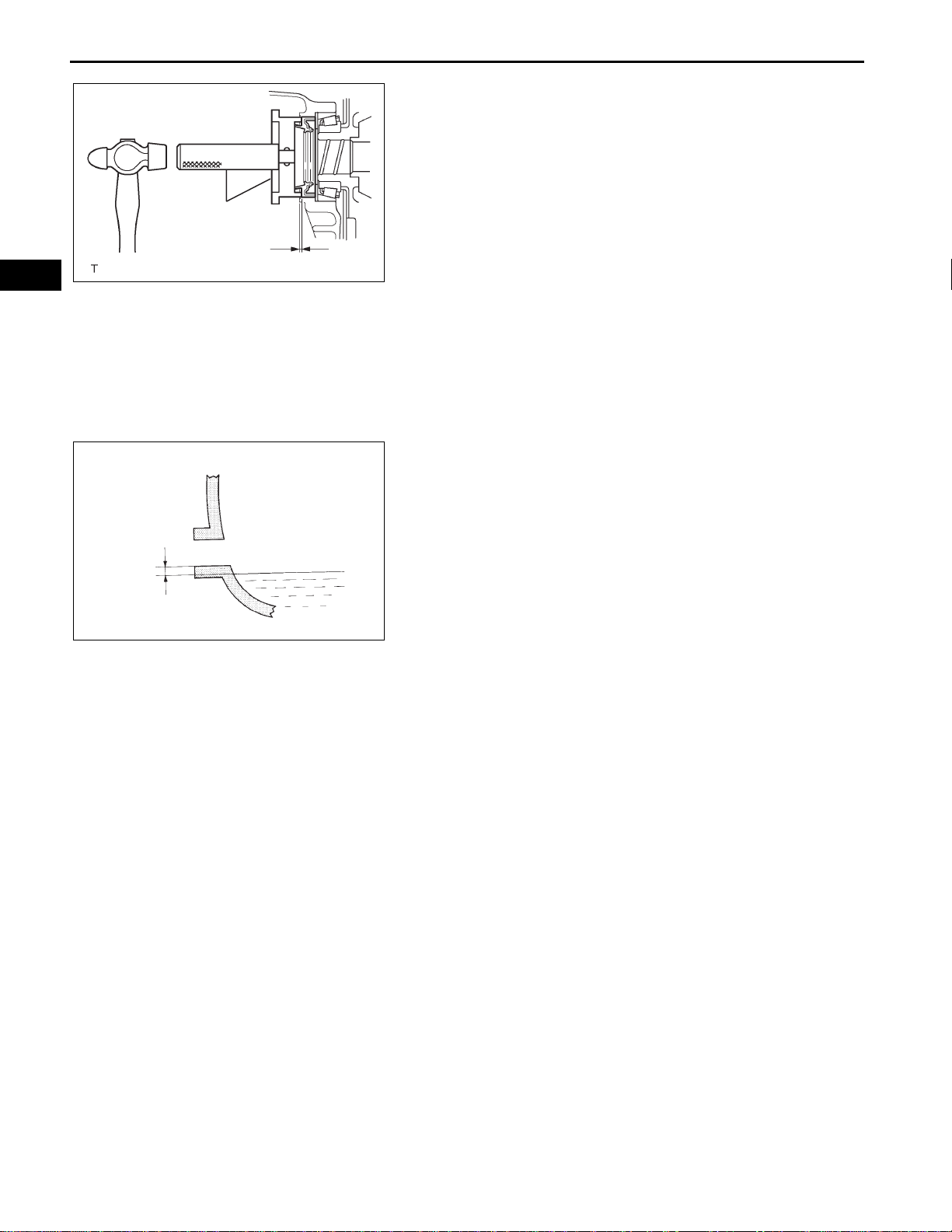

(c) Check that the oil surface is within 5 mm (0.20 in.) of

the bottom of the transmission filler plug opening.

D025304E01

NOTICE:

• Excessively large or small amounts of oil may

cause trouble.

• After replacing the oil, drive the vehicle and

check the oil level again.

HINT:

Insert your finger into the filler plug hole. You should

be able to just touch the surface of the oil if the oil is

at the correct level.

(d) Check for oil leakage if the oil level is low.

(e) Install the transmission filler plug and a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

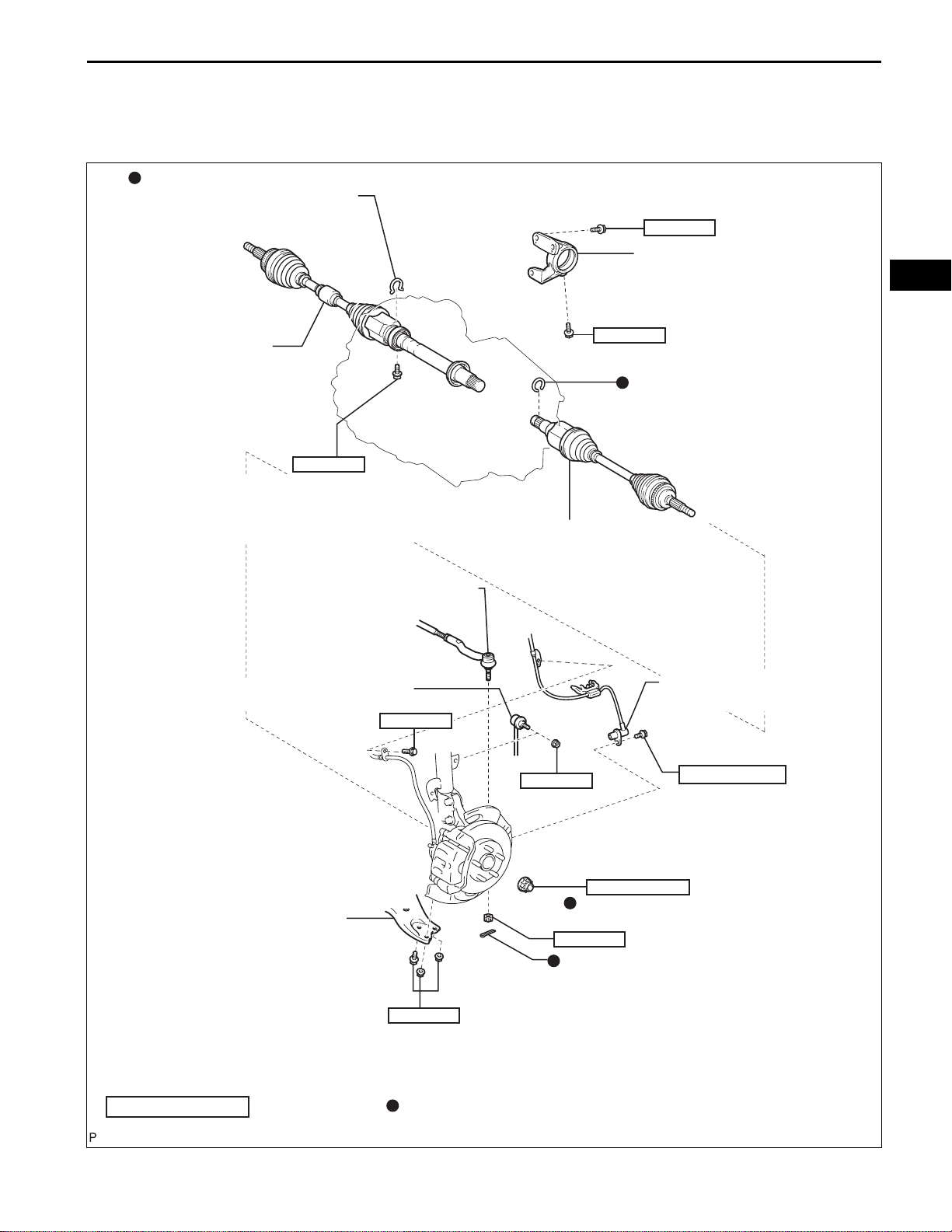

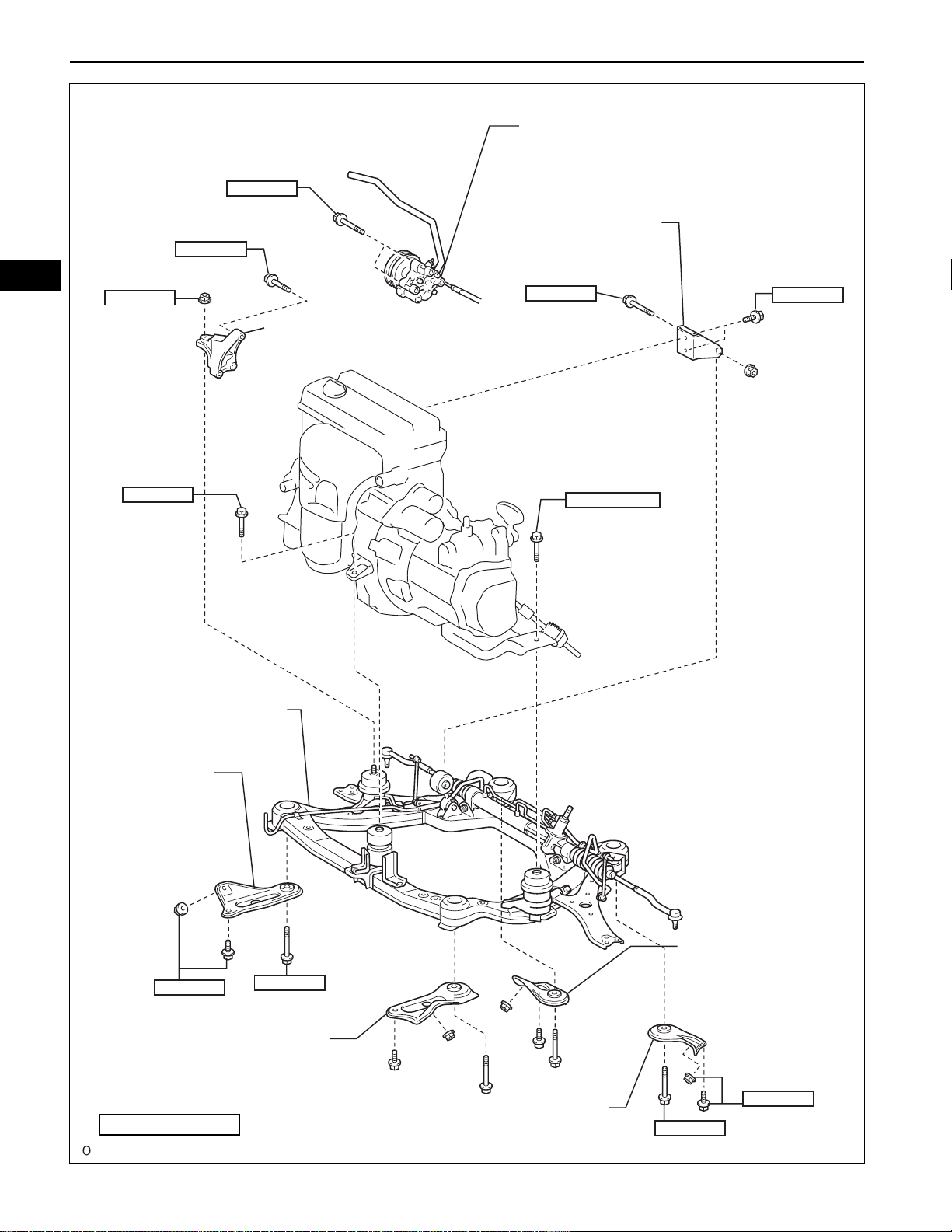

E351 MANUAL TRANSAXLE – DIFFERENTIAL OIL SEAL

TRANSMISSIONE351 MANUAL TRANSAXLE

DIFFERENTIAL OIL SEAL

COMPONENTS

DRIVE SHAFT BEARING

BRACKET HOLE SNAP RING

MX–3

FRONT DRIVE SHAFT

ASSEMBLY RH

DRIVE SHAFT BEARING

BRACKET SETTING NO. 1 BOLT

TIE ROD END SUB-ASSEMBLY

32 (330, 24)

x3

64 (653, 47)

FRONT DRIVE SHAFT

ASSEMBLY LH

64 (653, 47)

DRIVE SHAFT BEARING

BRACKET

FRONT DRIVE INNER SHAFT

OUTER LH SHAFT SNAP RING

MX

FRONT STABILIZER LINK ASSEMBLY

FRONT SUSPENSION

LOWER NO. 1 ARM

N*m (kgf*cm, ft.*lbf)

: Specified torque

19 (192, 14)

75 (765, 55)

Non-reusable part

74 (755, 55)

49 (500, 36)

COTTER PIN

FRONT SPEED SENSOR

8.0 (82, 71 in.*lbf)

294 (3,000, 217)

FRONT AXLE HUB NUT

C135412E01

MX

MX–4

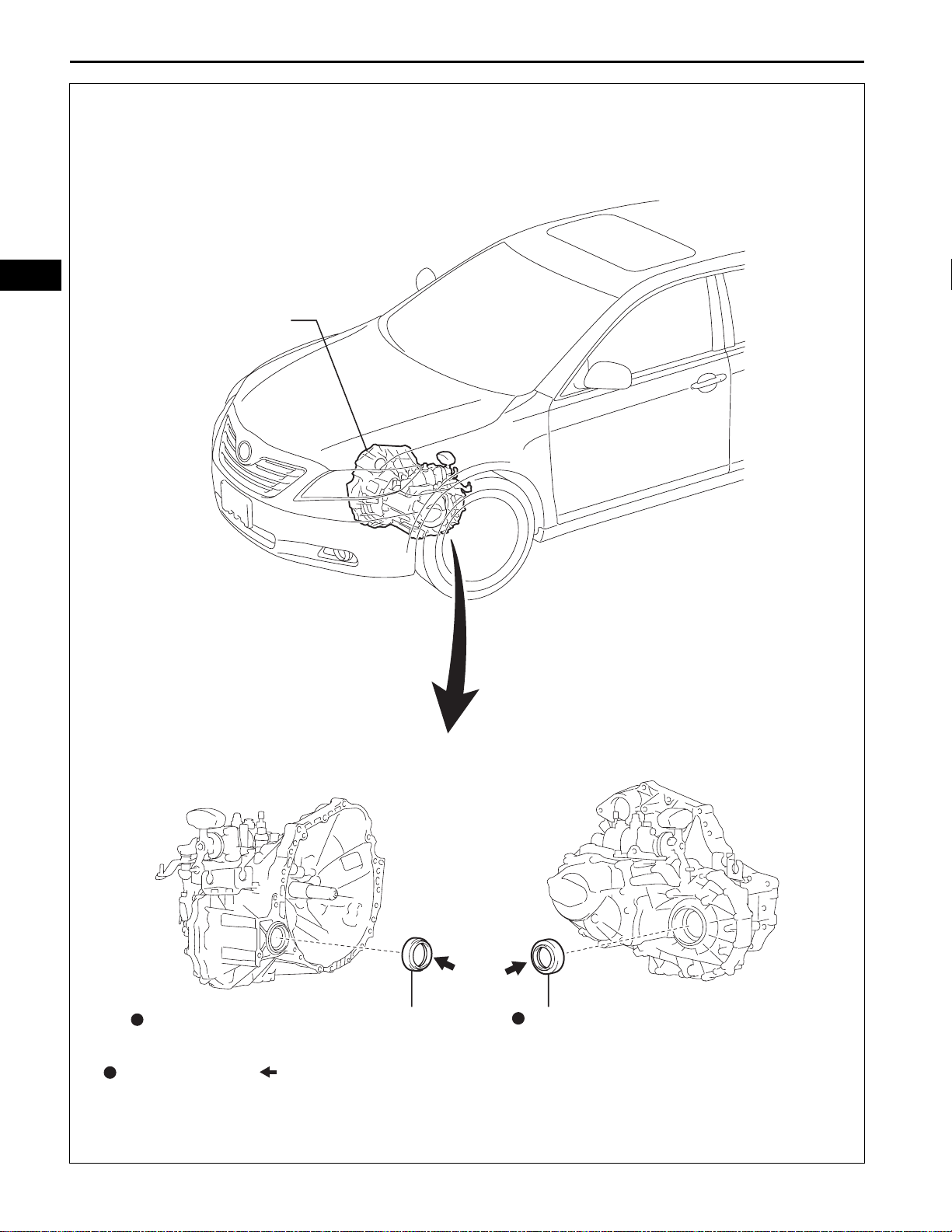

E351 MANUAL TRANSAXLE – DIFFERENTIAL OIL SEAL

MANUAL TRANSAXLE

FRONT TRANSAXLE CASE COVER OIL SEAL

Non-reusable part

Apply MP grease

TRANSAXLE CASE OIL SEAL

C135407E01

E351 MANUAL TRANSAXLE – DIFFERENTIAL OIL SEAL

REMOVAL

HINT:

• Use the same procedures for the RH side (transaxle case

oil seal) and LH side (transaxle case cover oil seal).

• The procedures listed below are for the LH side (transaxle

case cover oil seal).

1. DRAIN MANUAL TRANSAXLE OIL

(a) Remove the filler plug and the gasket.

(b) Remove the drain plug and gasket, and drain the

manual transaxle oil.

(c) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

2. REMOVE FRONT WHEELS

3. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

TMC made: (See page DS-7).

TMMK made: (See page DS-25).

4. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

MX–5

MX

SST

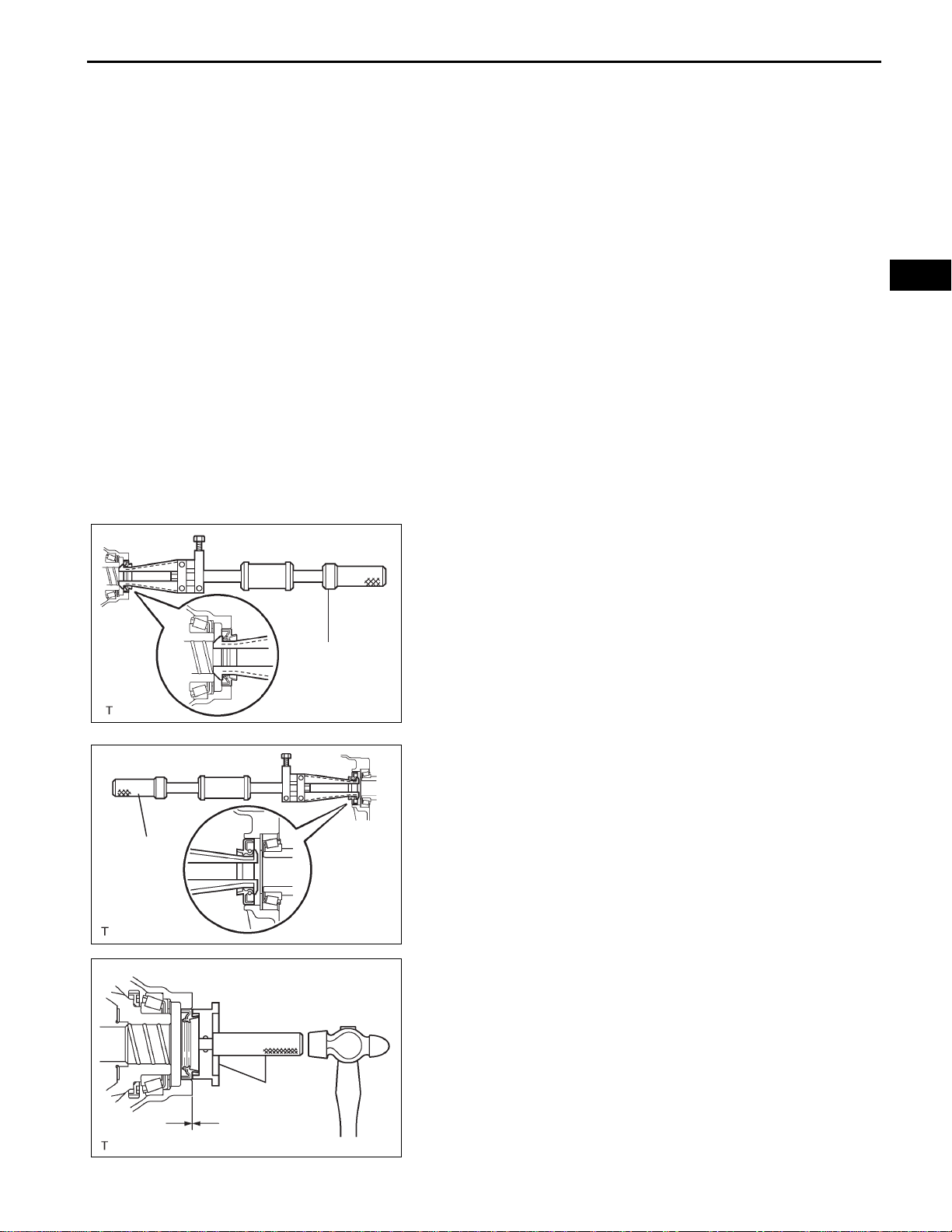

5. REMOVE FRONT TRANSAXLE CASE COVER OIL

SEAL

(a) Using SST, remove the oil seal.

SST 09308-00010

SST

D026285E01

6. REMOVE TRANSAXLE CASE OIL SEAL

(a) Using SST, remove the oil seal.

SST 09308-00010

D025305E01

INSTALLATION

SST

D025722E02

1. INSTALL FRONT TRANSAXLE CASE COVER OIL

SEAL

(a) Coat a new oil seal lip with MP grease.

(b) Using SST and a hammer, install the oil seal.

SST 09608-10010, 09950-70010 (09951-07200)

Installation depth:

-0.5 to 0.5 mm (-0.020 to 0.020 in.)

NOTICE:

Be careful not to damage the oil seal lip.

MX–6

SST

E351 MANUAL TRANSAXLE – DIFFERENTIAL OIL SEAL

2. INSTALL TRANSAXLE CASE OIL SEAL

(a) Coat a new oil seal lip with MP grease.

(b) Using SST and a hammer, install the oil seal.

SST 09608-32010, 09950-70010 (09951-07200)

Installation depth:

3.0 to 4.0 mm (0.1181 to 0.1575 in.)

NOTICE:

Be careful not to damage the oil seal lip.

MX

0 to 5 mm

(0 to 0.20 in.)

D026133E04

D025304E01

3. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

TMC made: (See page DS-20).

TMMK made: (See page DS-34).

4. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

5. INSTALL FRONT WHEELS

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

6. ADD MANUAL TRANSAXLE OIL

(a) Park the vehicle on a level place.

(b) Remove the filler plug and gasket.

(c) Check that the oil surface is within 5 mm (0.20 in.)

below the lowest point of the filler plug opening.

Oil grade:

API GL-4 or GL-5

Viscosity:

SAE 75W-90

NOTICE:

• Problems may occur if the oil level is too high

or too low.

• After replacing the oil, drive the vehicle and

check the oil level again.

(d) Check for oil leakage if the oil level is low.

(e) Install the filler plug and a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

7. INSPECT MANUAL TRANSAXLE OIL

8. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

See page SP-4.

9. CHECK ABS SPEED SENSOR SIGNAL

See page BC-11.

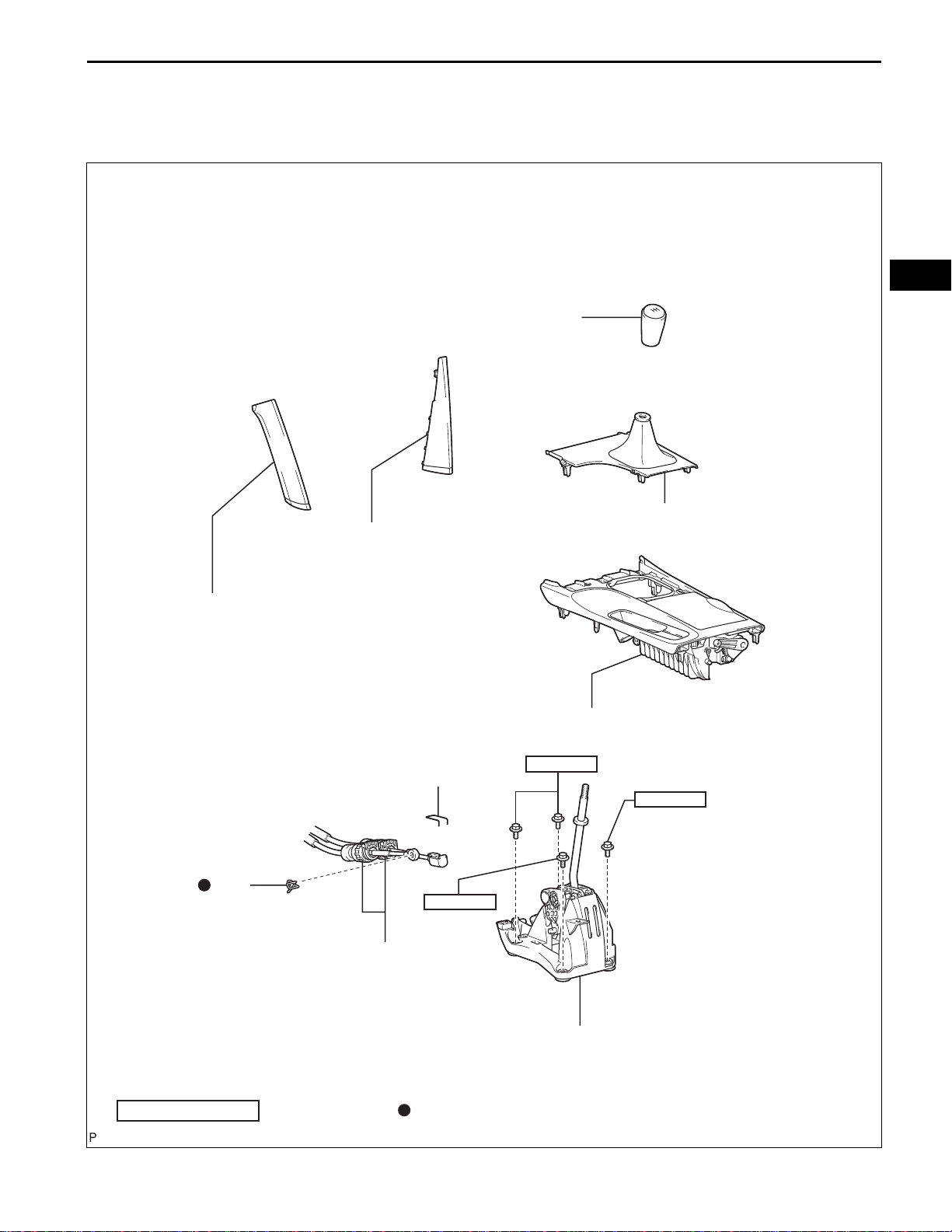

E351 MANUAL TRANSAXLE – FLOOR SHIFT LEVER ASSEMBLY

TRANSMISSIONE351 MANUAL TRANSAXLE

FLOOR SHIFT LEVER ASSEMBLY

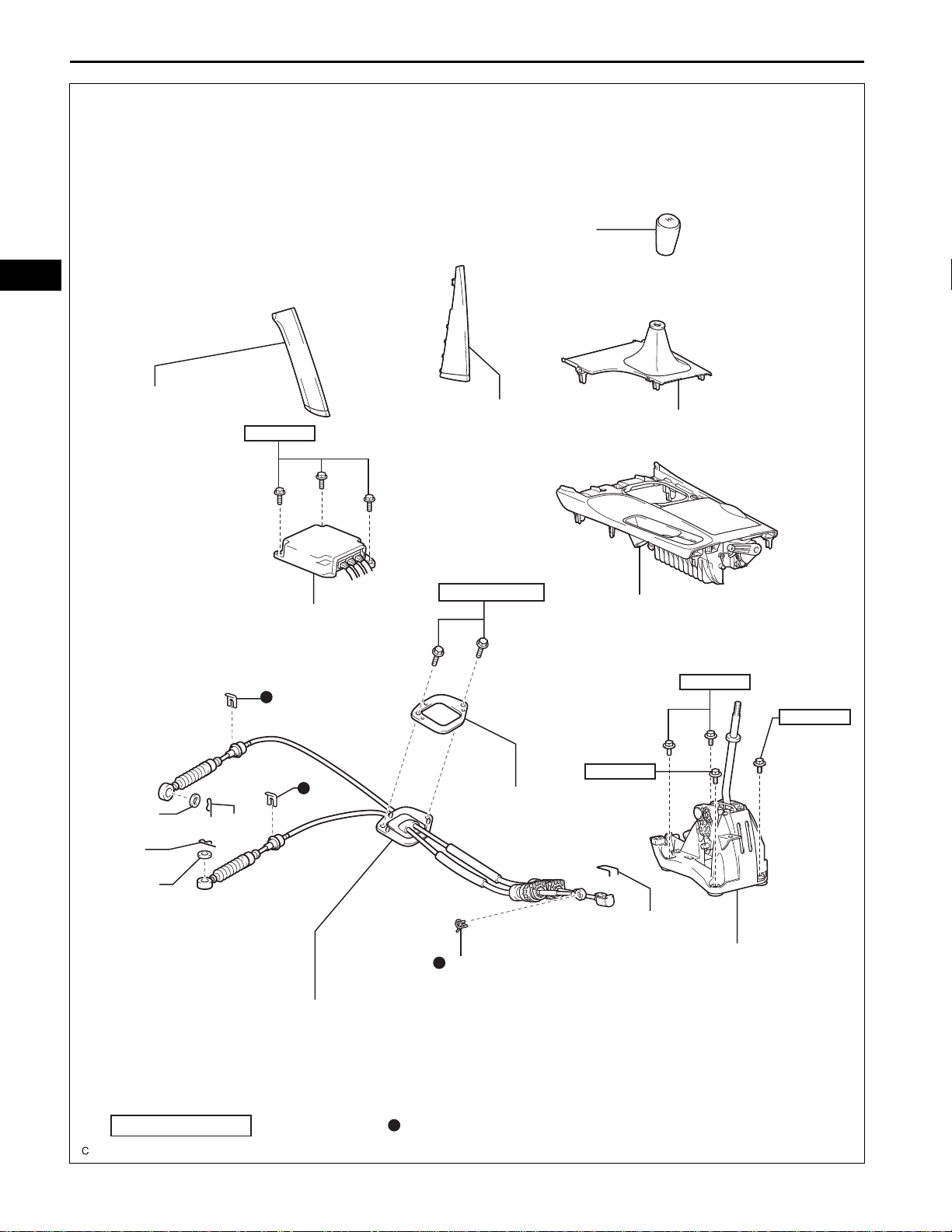

COMPONENTS

SHIFT LEVER KNOB SUB-ASSEMBLY

MX–7

MX

NO. 2 INSTRUMENT CLUSTER

FINISH PANEL GARNISH

NO. 1 INSTRUMENT CLUSTER

FINISH PANEL GARNISH

CLIP

TRANSMISSION CONTROL CABLE ASSEMBLY

UPPER CONSOLE PANEL

UPPER CONSOLE REAR PANEL SUB-ASSEMBLY

12 (122, 9)

CLIP

12 (122, 9)

12 (122, 9)

N*m (kgf*cm, ft.*lbf)

: Specified torque

FLOOR SHIFT LEVER ASSEMBLY

Non-reusable part

C130477E01

MX–8

E351 MANUAL TRANSAXLE – FLOOR SHIFT LEVER ASSEMBLY

REMOVAL

1. REMOVE NO. 1 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-24)

2. REMOVE NO. 2 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-25)

3. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY (See

page IP-24)

MX

4. REMOVE UPPER CONSOLE PANEL (See page IP-25)

5. REMOVE UPPER CONSOLE REAR PANEL SUBASSEMBLY (See page IP-26)

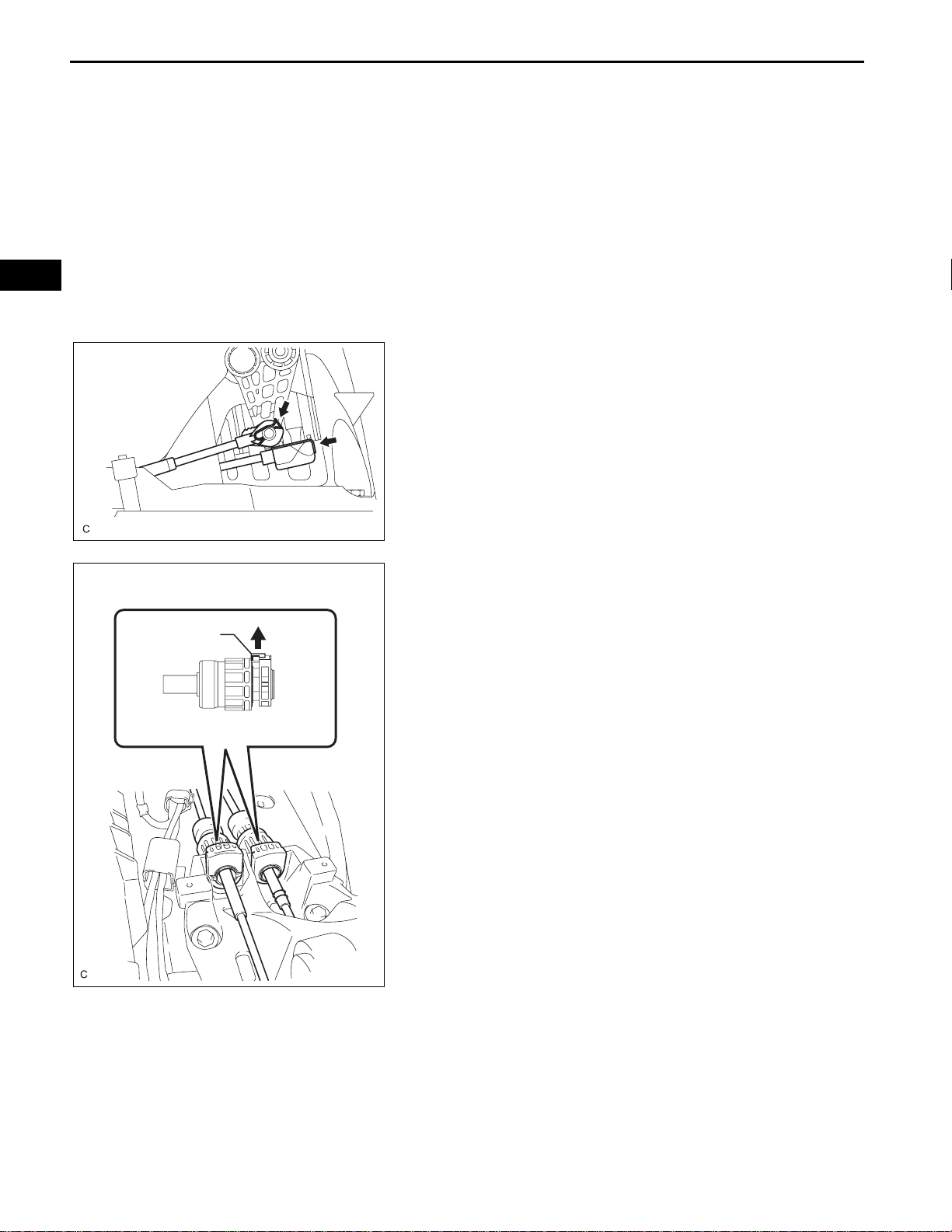

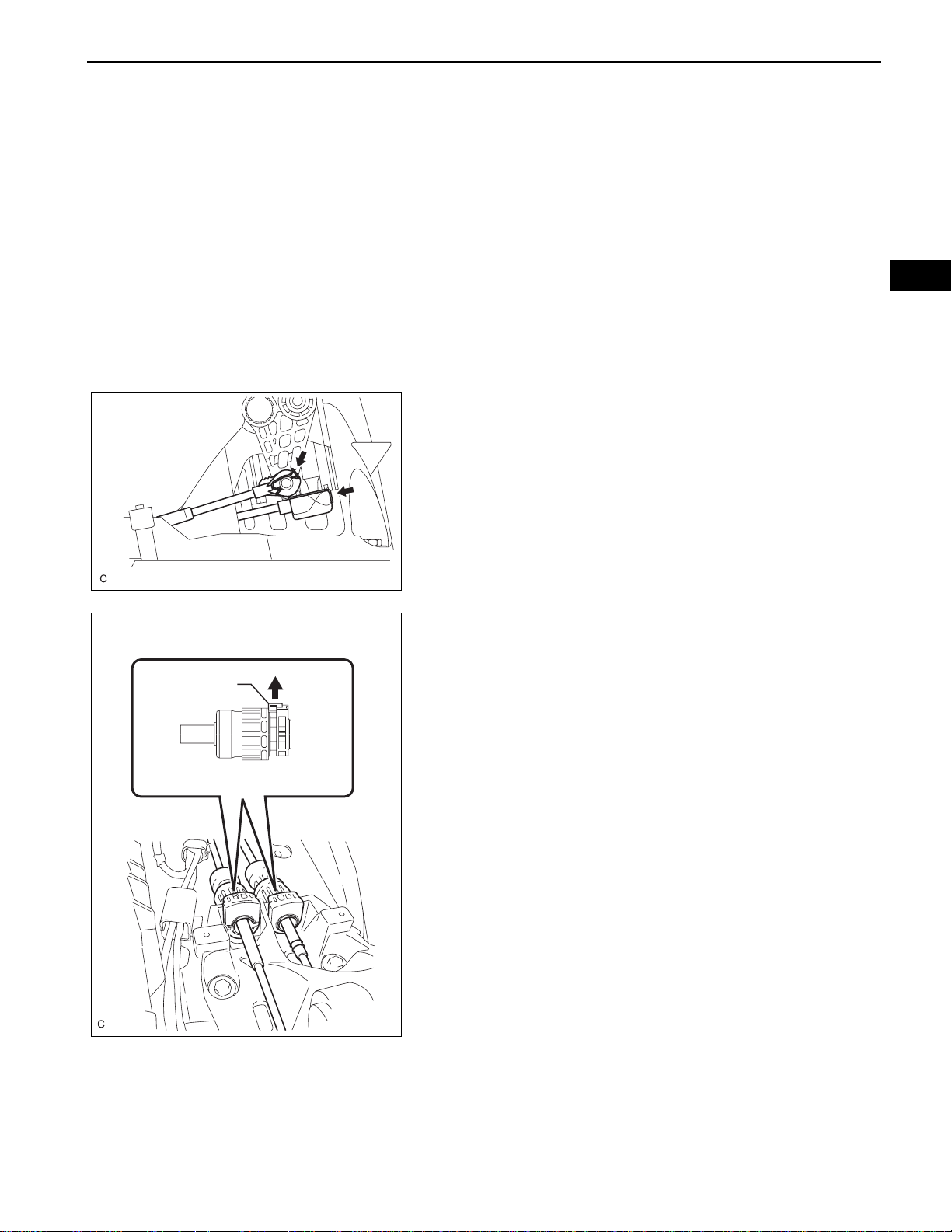

6. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Remove the 2 clips and disconnect the end of the

transmission control cable.

C132951

(b) Pull out the control cable assembly locks.

Lock

C135402E01

E351 MANUAL TRANSAXLE – FLOOR SHIFT LEVER ASSEMBLY

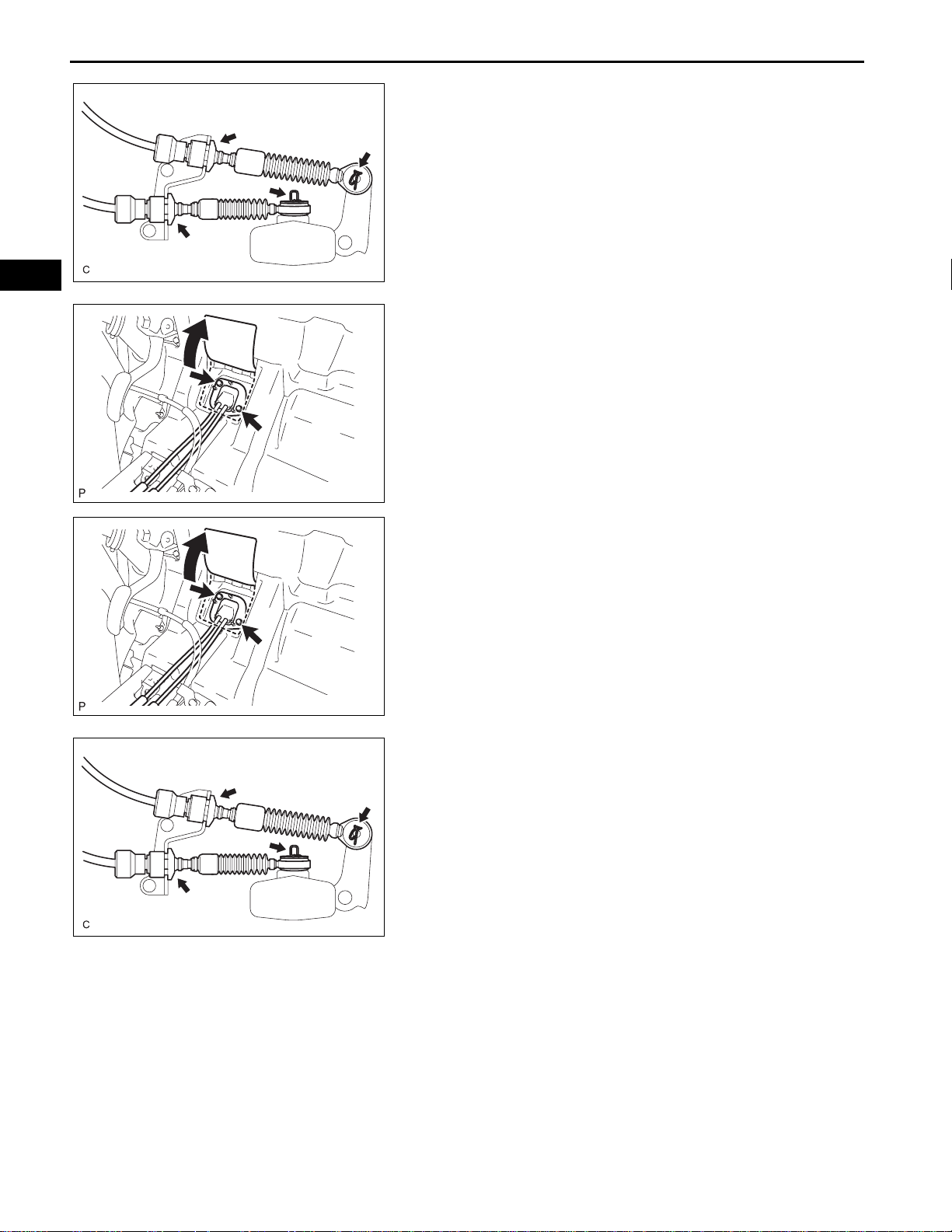

(c) Turn the adjust nut 180° clockwise. While holding

the adjust nut, separate the control cable assembly.

MX–9

C132953

C132955

C132955

MX

7. REMOVE FLOOR SHIFT LEVER ASSEMBLY

(a) Remove the 4 bolts and shift lever assembly.

INSTALLATION

1. INSTALL FLOOR SHIFT LEVER ASSEMBLY

(a) Install the shift lever assembly with the 4 bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

Projecting Part

Lock

A

C132954E01

2. INSTALL TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Connect the control cable to the shift lever retainer.

NOTICE:

• The projecting part of the cable outer should

face upward when the shift cable is

connected.

• After installation, make sure that the cable

outer lock is projecting from A as shown in

the illustration.

MX

MX–10

Serrated Part

E351 MANUAL TRANSAXLE – FLOOR SHIFT LEVER ASSEMBLY

Select Cable

Shift Cable

C132951E01

(b) Connect the end of the shift cable to the shift lever

assembly with the clip.

(c) Connect the end of the select cable to the shift lever

assembly with a new clip.

NOTICE:

• The serrated part of the select cable point

should face upward when the select cable

point is connected.

• The clip should be installed in the direction

as shown in the illustration.

3. INSTALL UPPER CONSOLE REAR PANEL SUBASSEMBLY (See page IP-53)

4. INSTALL UPPER CONSOLE PANEL (See page IP-53)

5. INSTALL NO. 2 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-54)

6. INSTALL NO. 1 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-55)

7. INSTALL SHIFT LEVER KNOB SUB-ASSEMBLY (See

page IP-55)

E351 MANUAL TRANSAXLE – TRANSMISSION CONTROL CABLE

TRANSMISSIONE351 MANUAL TRANSAXLE

TRANSMISSION CONTROL CABLE

COMPONENTS

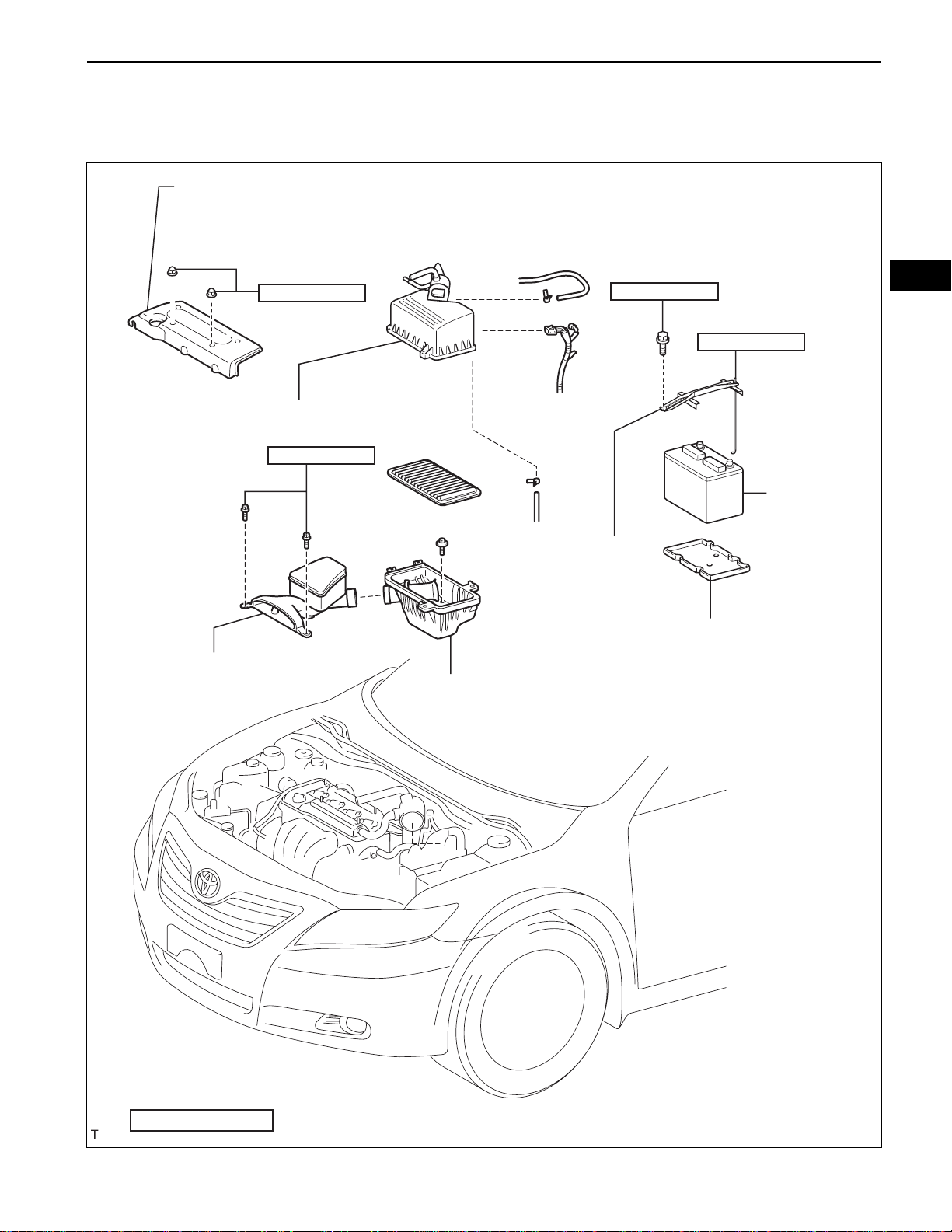

NO. 1 ENGINE COVER

SUB-ASSEMBLY

MX–11

7.0 (71, 62 in.*lbf)

AIR CLEANER CAP SUB-ASSEMBLY

5.0 (51, 44 in.*lbf)

AIR CLEANER INLET ASSEMBLY

9.0 (92, 80 in.*lbf)

BATTERY CLAMP

SUB-ASSEMBLY

BATTERY TRAY

AIR CLEANER CASE SUB-ASSEMBLY

MX

3.5 (36, 31 in.*lbf)

BATTERY

N*m (kgf*cm, ft.*lbf)

: Specified torque

C138374E01

MX

MX–12

E351 MANUAL TRANSAXLE – TRANSMISSION CONTROL CABLE

SHIFT LEVER KNOB SUB-ASSEMBLY

NO. 1 INSTRUMENT

CLUSTER FINISH

PANEL GARNISH

CENTER AIRBAG SENSOR ASSEMBLY

WASHER

CLIP

18 (180, 13)

CLIP

CLIP

NO. 2 INSTRUMENT

CLUSTER FINISH

PANEL GARNISH

5.0 (51, 44 in.*lbf)

NO. 2 SHIFT CABLE

GROMMET RETAINER

UPPER CONSOLE PANEL

UPPER CONSOLE REAR

PANEL SUB-ASSEMBLY

12 (122, 9)

12 (122, 9)

12 (122, 9)

CLIP

WASHER

TRANSMISSION CONTROL CABLE ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

CLIP

Non-reusable part

CLIP

FLOOR SHIFT LEVER ASSEMBLY

C135395E01

E351 MANUAL TRANSAXLE – TRANSMISSION CONTROL CABLE

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE NO. 1 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-24)

3. REMOVE NO. 2 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-25)

MX–13

Lock

C132951

4. REMOVE SHIFT LEVER KNOB SUB-ASSEMBL Y (See

page IP-24)

5. REMOVE UPPER CONSOLE PANEL (See page IP-25)

6. REMOVE UPPER CONSOLE REAR PANEL SUBASSEMBLY (See page IP-53)

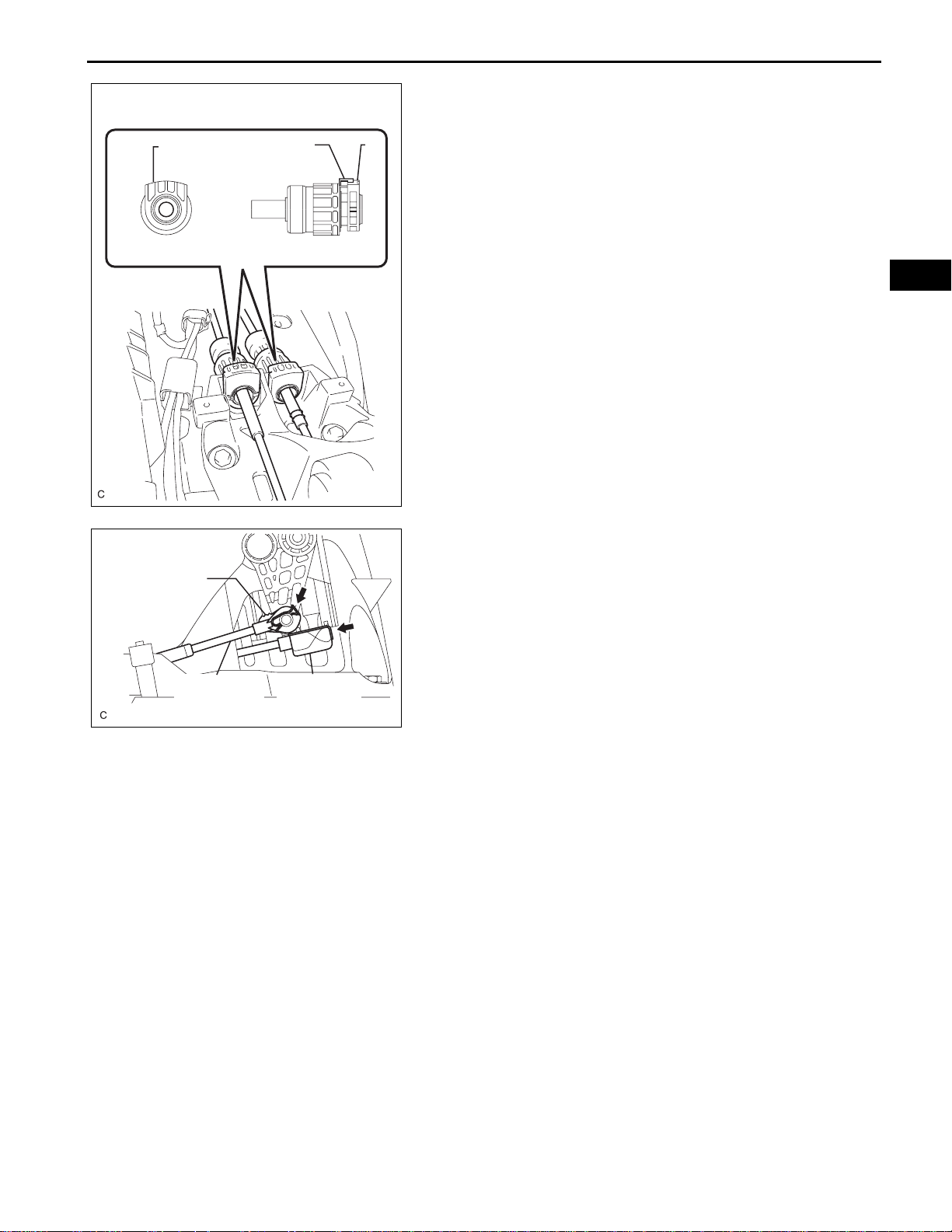

7. SEPARATE TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Remove the 2 clips and disconnect the end of the

transmission control cable.

(b) Pull out the control cable assembly locks.

(c) Turn the adjust nut 180° clockwise. While holding

the adjust nut, separate the control cable assembly.

8. REMOVE INSTRUMENT PANEL SAFETY PAD SUBASSEMBLY

See page IP-20.

MX

C135402E01

9. REMOVE AIR CONDITIONER UNIT ASSEMBLY

See page AC-151.

10. REMOVE CENTER AIRBAG SENSOR ASSEMBLY

(See page RS-442)

11. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

(See page EM-94)

12. REMOVE AIR CLEANER INLET ASSEMBLY (See

page EM-94)

13. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-416)

14. REMOVE AIR CLEANER CASE SUB-ASSEMBL Y (See

page EM-95)

15. REMOVE BATTERY (See page EM-95)

MX–14

E351 MANUAL TRANSAXLE – TRANSMISSION CONTROL CABLE

16. REMOVE TRANSMISSION CONTROL CABLE

ASSEMBLY

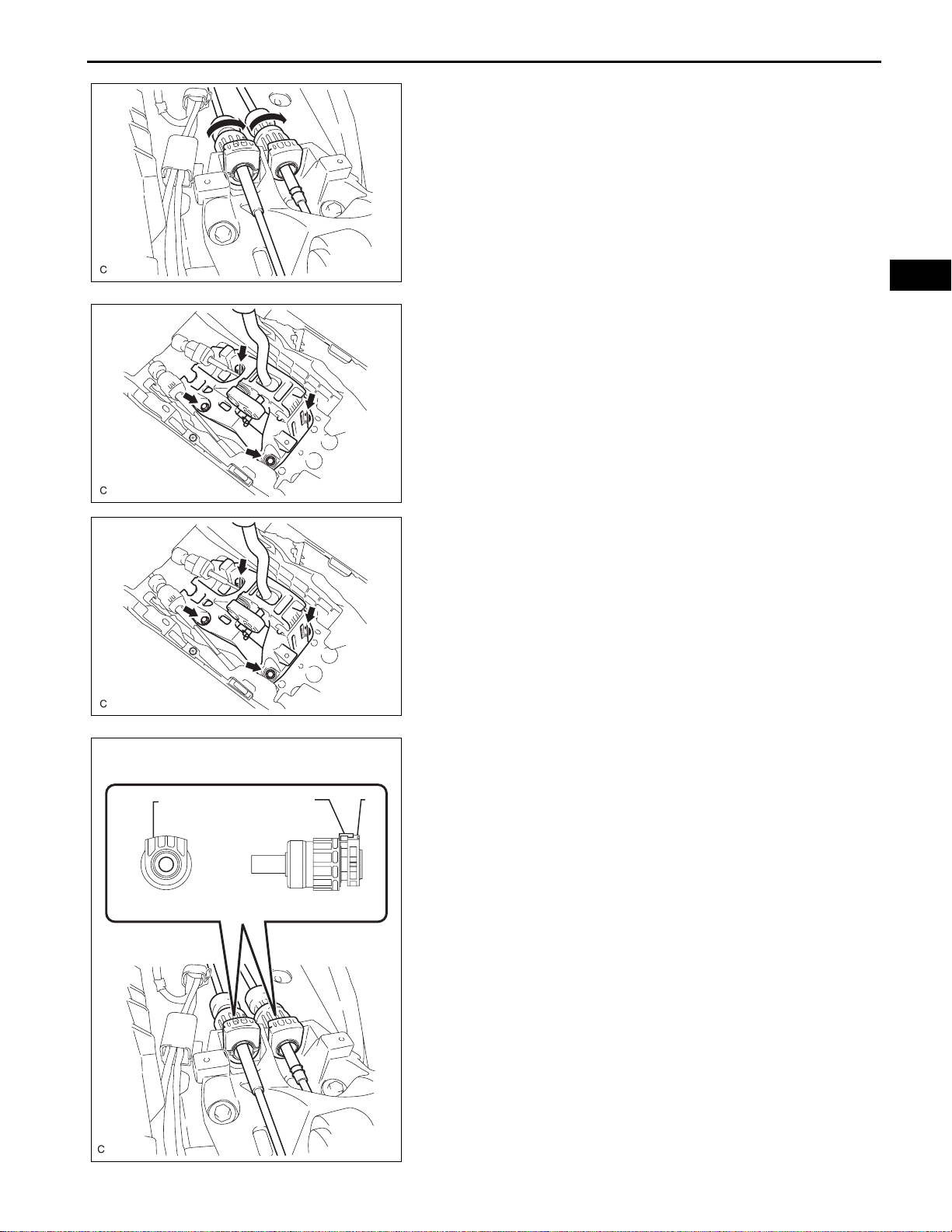

(a) Remove the 2 clips and 2 washers and disconnect

the 2 cables from the transaxle.

(b) Remove the 2 clips and disconnect the 2 cables

from the control cable bracket.

MX

C132952

C135401

C135401

(c) Remove the 2 bolts and control cable assembly.

(d) Remove the No. 2 shift cable grommet retainer from

the control cable assembly.

INSTALLATION

1. INSTALL TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Install the No. 2 shift cable grommet retainer to the

transmission control cable assembly.

(b) Install the control cable assembly through the floor

hole.

(c) Install the control cable assembly with the 2 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

C132952

(d) Connect the ends of the 2 cables and install the 2

washers and 2 clips.

(e) Install 2 new clips to the control cable bracket.

E351 MANUAL TRANSAXLE – TRANSMISSION CONTROL CABLE

Projecting Part

Lock

A

C132954E01

MX–15

2. INSTALL TRANSMISSION CONTROL CABLE

ASSEMBLY

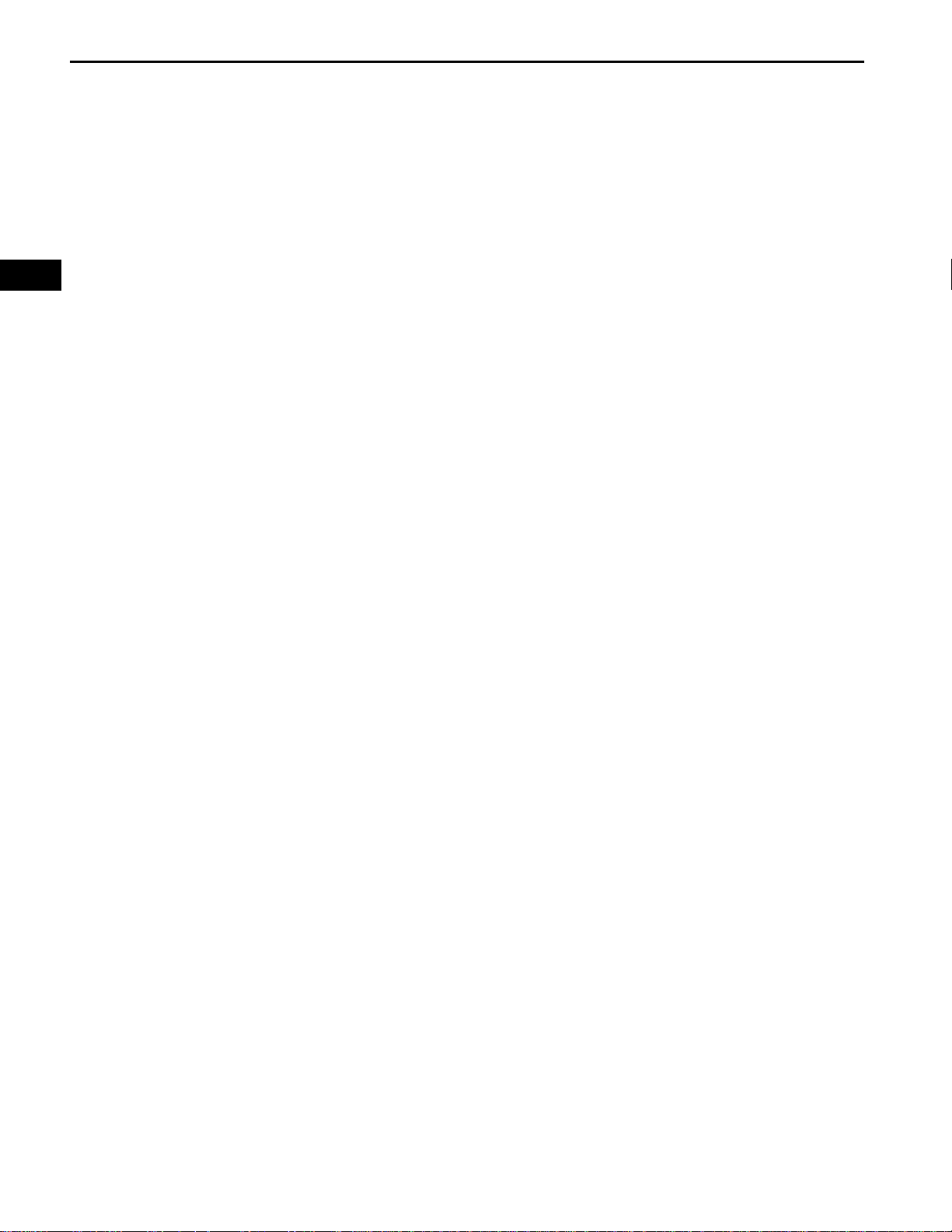

(a) Connect the control cable to the shift lever retainer.

NOTICE:

• The projecting part of the cable outer should

face upward when the shift cable is

connected.

• After installation, make sure that the cable

outer lock is projecting from A as shown in

the illustration.

MX

Serrated Part

Select Cable

Shift Cable

C132951E01

(b) Connect the end of the shift cable to the shift lever

assembly with the clip.

(c) Connect the end of the select cable to the shift lever

assembly with a new clip.

NOTICE:

• The serrated part of the select cable point

should face upward when the select cable

point is connected.

• The clip should be installed in the direction

as shown in the illustration.

3. INSTALL CENTER AIRBAG SENSOR ASSEMBLY

(See page RS-442)

4. INSTALL AIR CONDITIONER UNIT ASSEMBLY

See page AC-173.

5. INSTALL INSTRUMENT PANEL SAFETY PAD SUBASSEMBLY

See page IP-43.

6. INSTALL UPPER CONSOLE REAR PANEL SUBASSEMBLY (See page IP-53)

7. INSTALL UPPER CONSOLE PANEL (See page IP-54)

8. INSTALL NO. 2 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-54)

9. INSTALL NO. 1 INSTRUMENT CLUSTER FINISH

PANEL GARNISH (See page IP-55)

10. INSTALL SHIFT LEVER KNOB SUB-ASSEMBLY (See

page IP-55)

11. INSTALL BATTERY (See page EM-119)

MX

MX–16

E351 MANUAL TRANSAXLE – TRANSMISSION CONTROL CABLE

12. INST ALL AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-120)

13. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-419)

14. INST ALL AIR CLEANER INLET ASSEMBLY (See page

EM-120)

15. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

(See page EM-121)

16. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL (See page EM-120)

MX–24

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

4. REMOVE FRONT WHEELS

MX

5. REMOVE ENGINE UNDER COVER LH

6. REMOVE ENGINE UNDER COVER RH

7. REMOVE FRONT FENDER APRON SEAL RH

8. DRAIN ENGINE OIL (See page LU-4)

9. DRAIN ENGINE COOLANT (See page CO-5)

10. DRAIN MANUAL TRANSAXLE OIL (See page MX-5)

11. DRAIN BRAKE FLUID (See page BR-28)

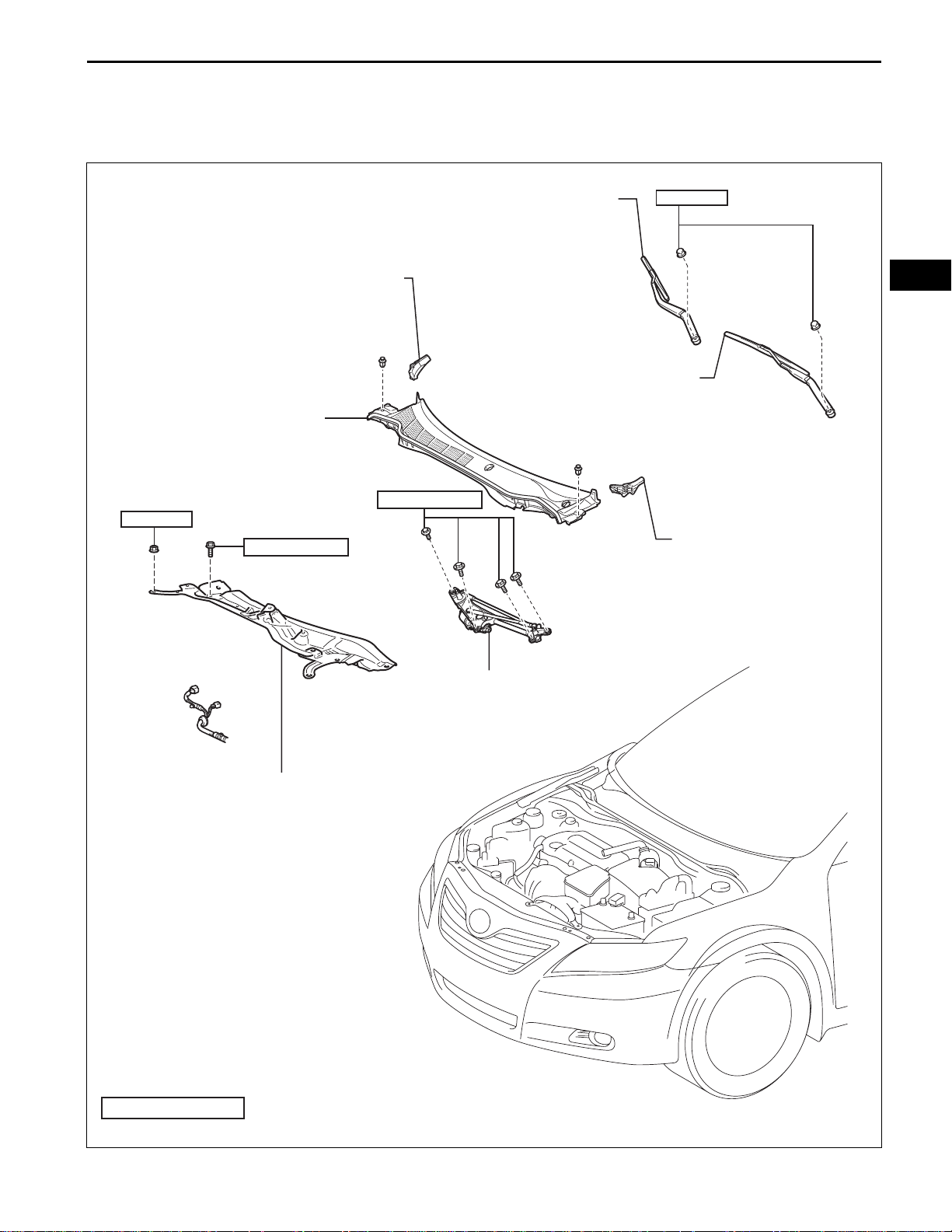

12. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

See page WW-9.

13. REMOVE COWL TOP PANEL OUTER SUBASSEMBLY (See page ES-424)

14. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

(See page EM-94)

15. REMOVE V-RIBBED BELT (See page EM-6)

16. REMOVE AIR CLEANER INLET ASSEMBLY (See

page EM-94)

17. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-416)

18. REMOVE AIR CLEANER CASE SUB-ASSEMBL Y (See

page EM-95)

19. REMOVE BATTERY (See page EM-95)

20. REMOVE NO. 2 ENGINE MOUNTING STAY RH (See

page EM-95)

21. REMOVE ENGINE MOVING CONTROL ROD SUBASSEMBLY (See page EM-95)

22. REMOVE NO. 2 ENGINE MOUNTING BRACKET RH

(See page EM-96)

23. DISCONNECT NO. 1 VACUUM HOSE CONNECTOR

(See page EM-96)

24. DISCONNECT RADIATOR HOSE INLET (See page

EM-96)

25. DISCONNECT RADIATOR HOSE OUTLET (See page

EM-96)

26. DISCONNECT HEATER INLET WATER HOSE (See

page EM-97)

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

27. DISCONNECT HEATER OUTLET WATER HOSE (See

page EM-97)

28. REMOVE ECM

See page ES-432.

29. DISCONNECT ENGINE WIRE (See page EM-97)

30. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY (See page EM-98)

31. DISCONNECT NO. 1 OIL RESERVOIR TO PUMP

HOSE (See page EM-98)

32. DISCONNECT RETURN TUBE SUB-ASSEMBLY (See

page EM-99)

33. REMOVE CLUTCH ACCUMULATOR ASSEMBLY

See page CL-15.

34. REMOVE CLUTCH RELEASE CYLINDER ASSEMBLY

See page CL-23.

35. DISCONNECT FUEL TUBE SUB-ASSEMBLY (See

page EM-99)

MX–25

MX

36. REMOVE GENERATOR ASSEMBLY (See page CH-11)

37. SEPARATE COMPRESSOR AND MAGNETIC

CLUTCH (See page EM-99)

38. REMOVE FRONT EXHAUST PIPE ASSEMBLY

See page EX-2.

39. REMOVE FRONT AXLE HUB NUT LH (See page DS-

7)

40. REMOVE FRONT AXLE HUB NUT RH

HINT:

Use the same procedures described for the LH side.

41. REMOVE FRONT STABILIZER LINK ASSEMBLY LH

(See page DS-7)

42. REMOVE FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

43. REMOVE FRONT SPEED SENSOR LH (See page DS-

7)

44. REMOVE FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

45. DISCONNECT TIE ROD ASSEMBLY LH (See page

DS-8)

46. DISCONNECT TIE ROD ASSEMBLY RH

47. DISCONNECT FRONT SUSPENSION LOWER NO. 1

ARM LH (See page DS-8)

MX

MX–26

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

48. DISCONNECT FRONT SUSPENSION LOWER NO. 1

ARM RH

HINT:

Use the same procedures described for the LH side.

49. SEPARATE FRONT AXLE ASSEMBLY LH (See page

DS-8)

50. SEPARATE FRONT AXLE ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

51. SEPARATE STEERING SLIDING YOKE (See page PS-

40)

52. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(See page EM-100)

53. REMOVE VANE PUMP ASSEMBLY (See page EM-

101)

54. REMOVE FRONT FRAME ASSEMBLY (See page EM-

101)

D025747

55. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH (See

page DS-9)

56. REMOVE FRONT DRIVE SHAFT ASSEMBL Y RH (See

page DS-9)

57. REMOVE STARTER ASSEMBLY (See page ST-5)

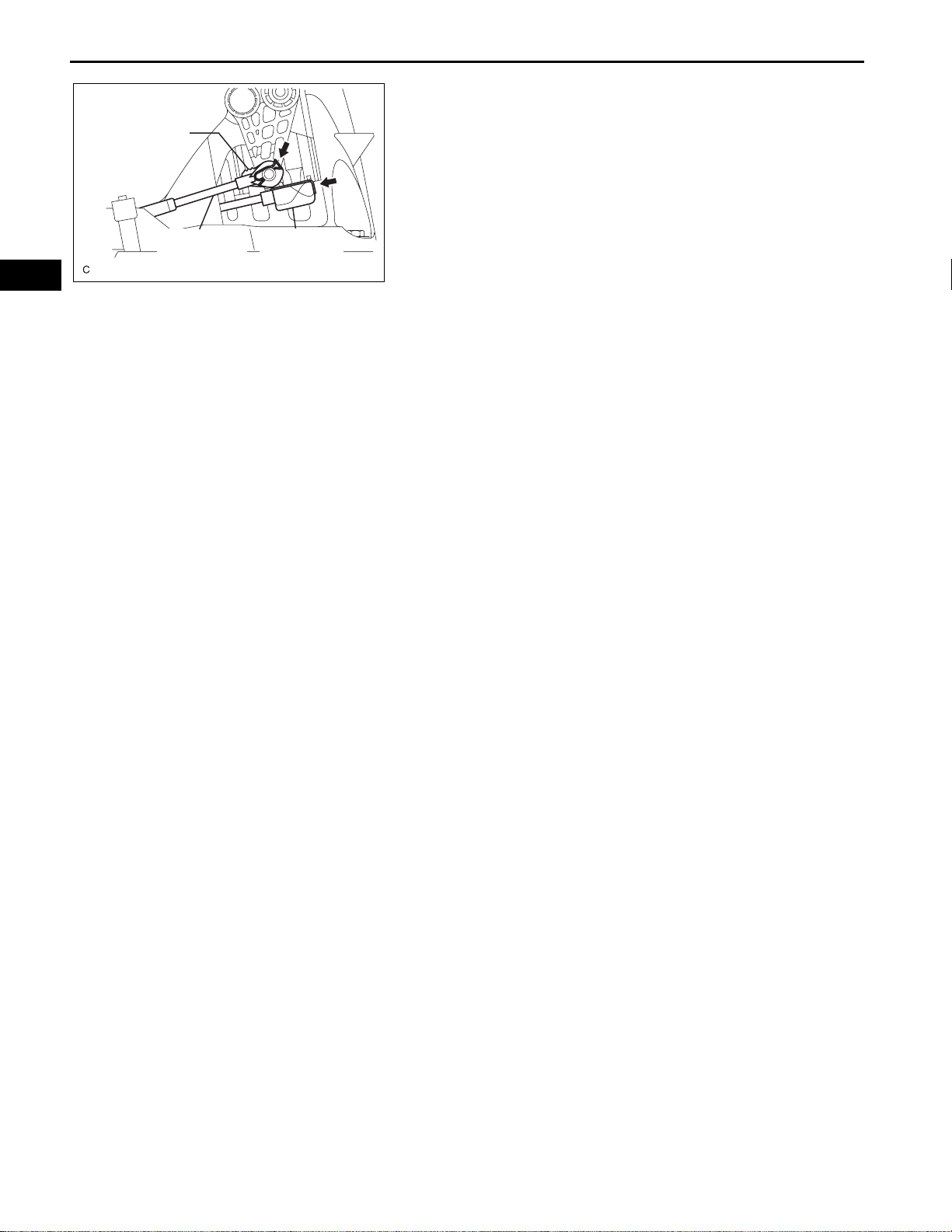

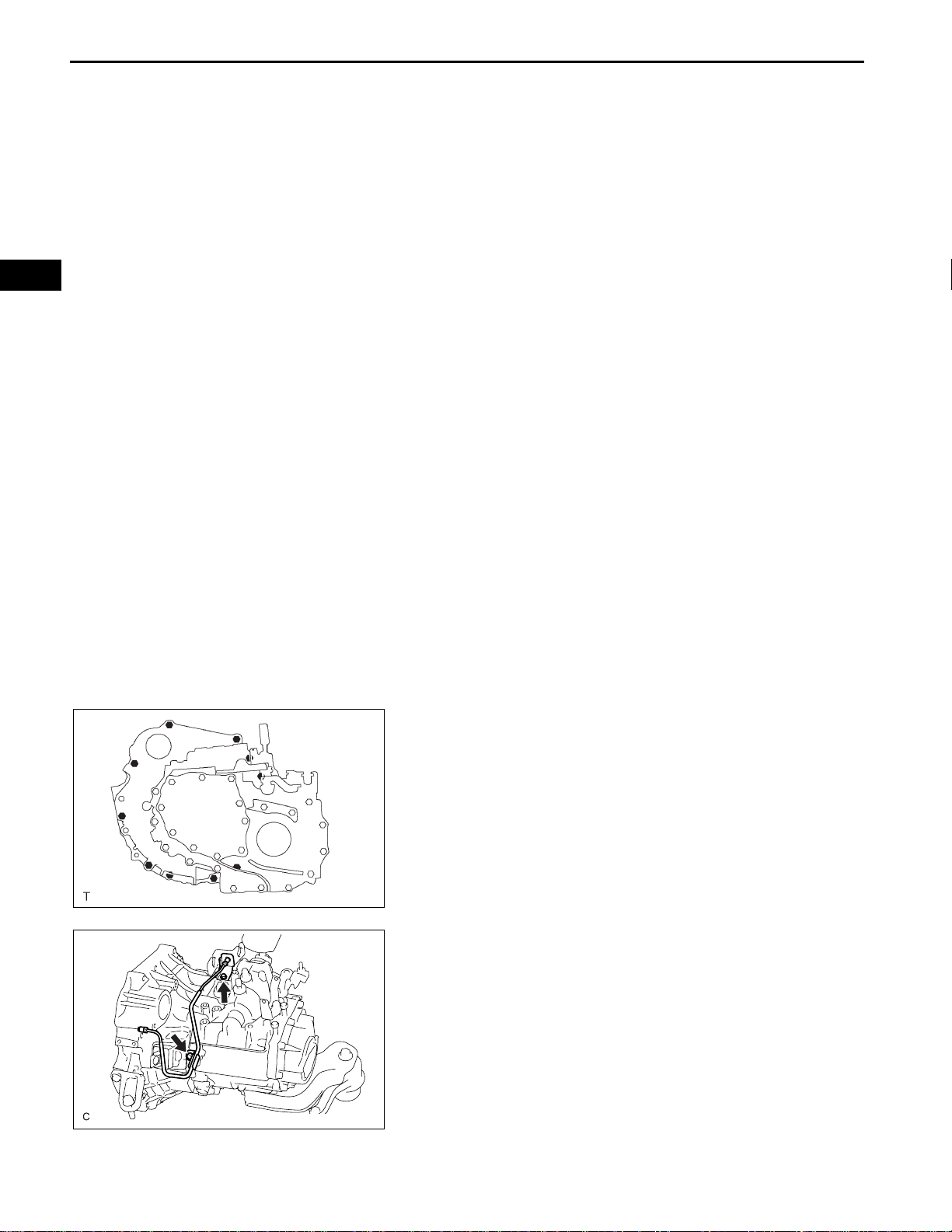

58. DISCONNECT WIRE HARNESS

(a) Remove the bolt and separate the ground cable.

(b) Disconnect the back-up light switch connector.

(c) Disconnect the wire harness.

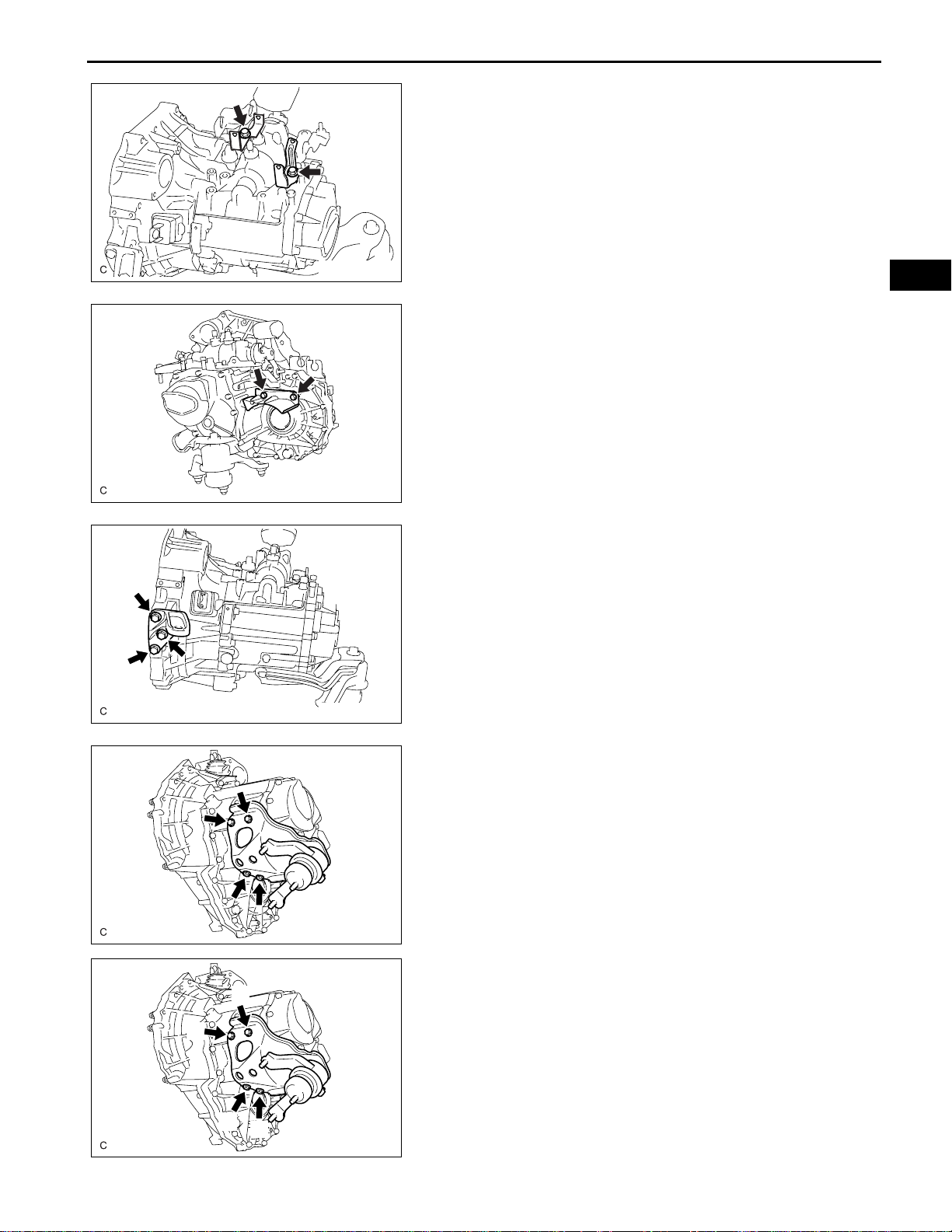

59. REMOVE MANUAL TRANSAXLE ASSEMBLY

(a) Remove the 10 bolts.

(b) Separate and remove the transaxle from the engine.

60. REMOVE CLUTCH LINE

(a) Remove the 2 bolts, clutch line and bracket.

C132979

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

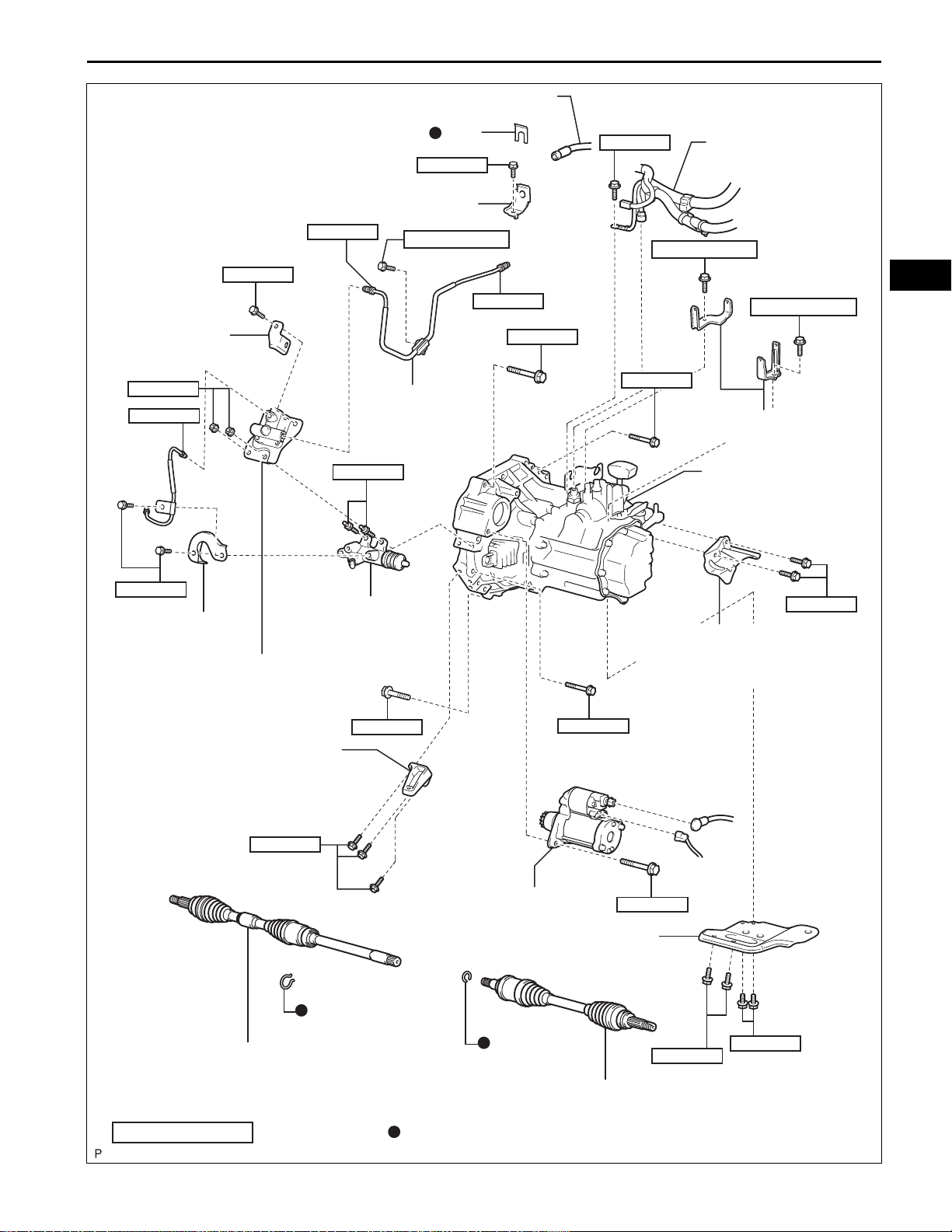

TRANSMISSIONE351 MANUAL TRANSAXLE

MANUAL TRANSAXLE ASSEMBLY

COMPONENTS

MX–17

FRONT FENDER TO

COWL SIDE SEAL RH

COWL TOP VENTILATOR

LOUVER SUB-ASSEMBLY

85 (867, 63)

5.0 (51, 44 in.*lbf)

FRONT WIPER ARM AND

BLADE ASSEMBLY RH

7.5 (77, 66 in.*lbf)

20 (204, 15)

MX

FRONT WIPER ARM AND

BLADE ASSEMBLY LH

FRONT FENDER TO

COWL SIDE SEAL LH

COWL TOP PANEL OUTER SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

WINDSHIELD WIPER

LINK ASSEMBLY

A136912E01

MX–18

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

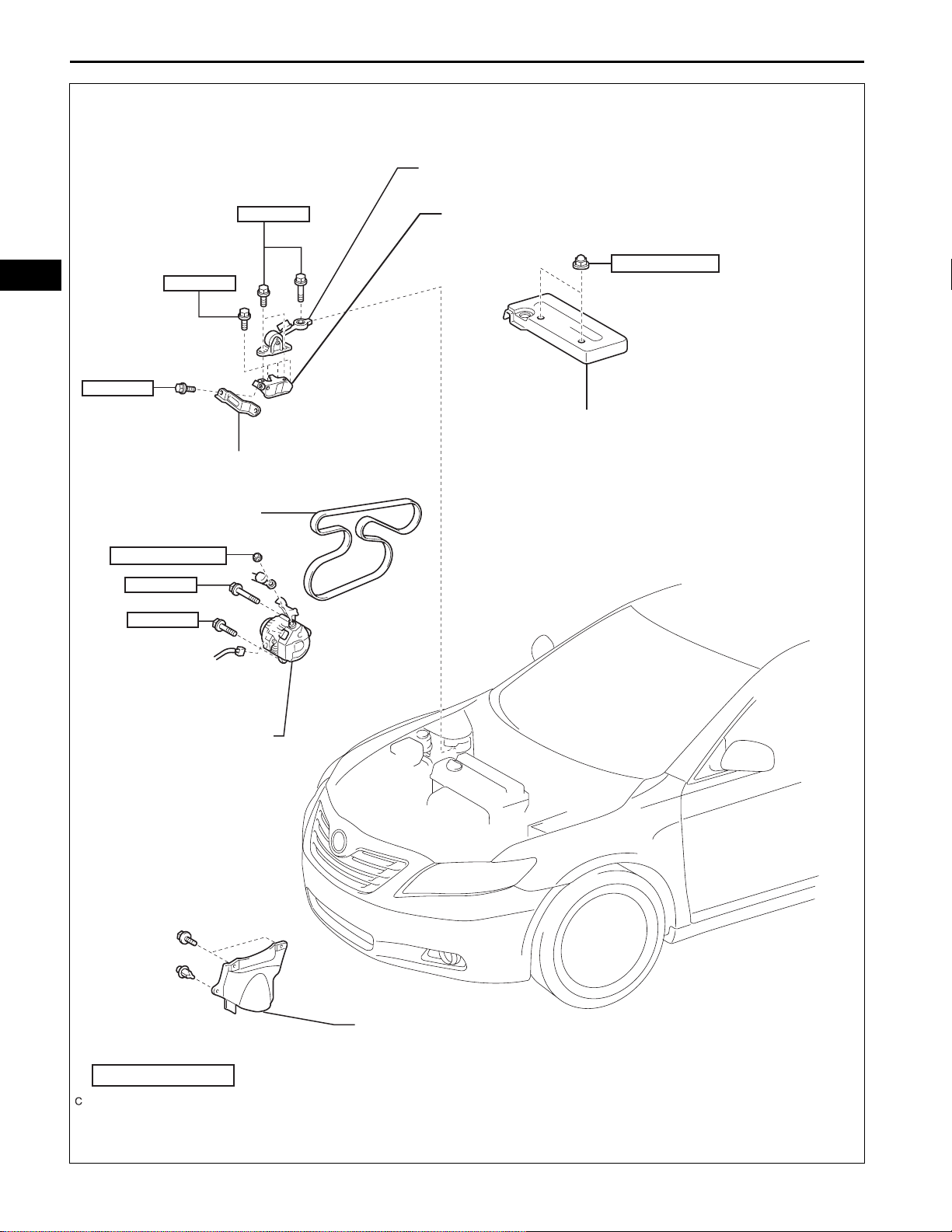

ENGINE MOVING CONTROL ROD SUB-ASSEMBLY

MX

64 (653, 47)

52 (531, 38)

64 (653, 47)

NO. 2 ENGINE MOUNTING STAY RH

V-RIBBED BELT

9.8 (100, 87 in.*lbf)

52 (531, 38)

21 (214, 15)

NO. 2 ENGINE MOUNTING BRACKET RH

9.0 (92, 80 in.*lbf)

NO. 1 ENGINE COVER SUB-ASSEMBLY

GENERATOR ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

FRONT FENDER APRON SEAL RH

A134948E01

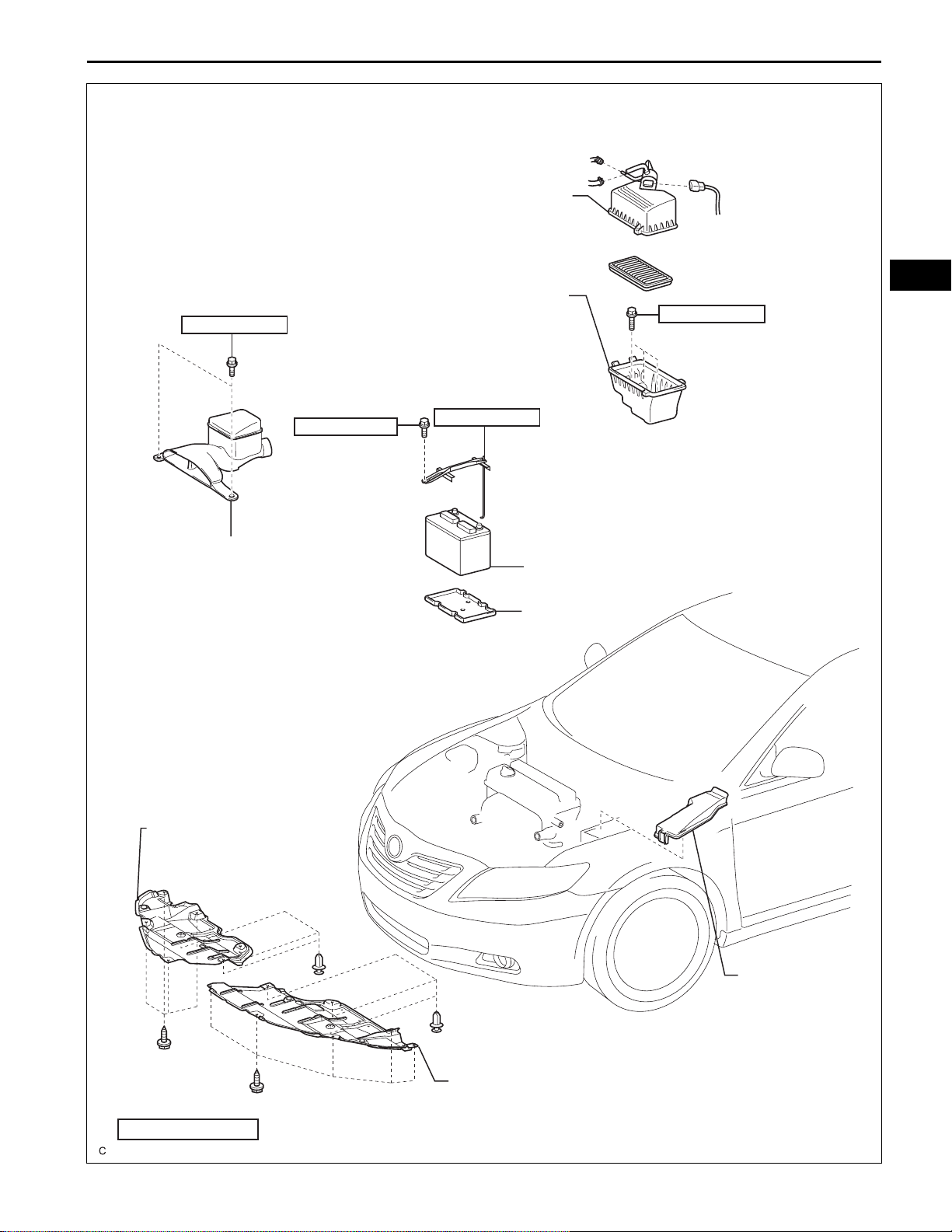

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

AIR CLEANER CAP SUB-ASSEMBLY

MX–19

AIR CLEANER CASE SUB-ASSEMBLY

5.0 (51, 44 in.*lbf)

9.0 (92, 80 in.*lbf)

AIR CLEANER INLET ASSEMBLY

MX

5.0 (51, 44 in.*lbf)

3.5 (36, 31 in.*lbf)

BATTERY

BATTERY TRAY

ENGINE UNDER COVER RH

N*m (kgf*cm, ft.*lbf)

: Specified torque

R/B COVER

ENGINE UNDER COVER LH

A134915E01

MX

MX–20

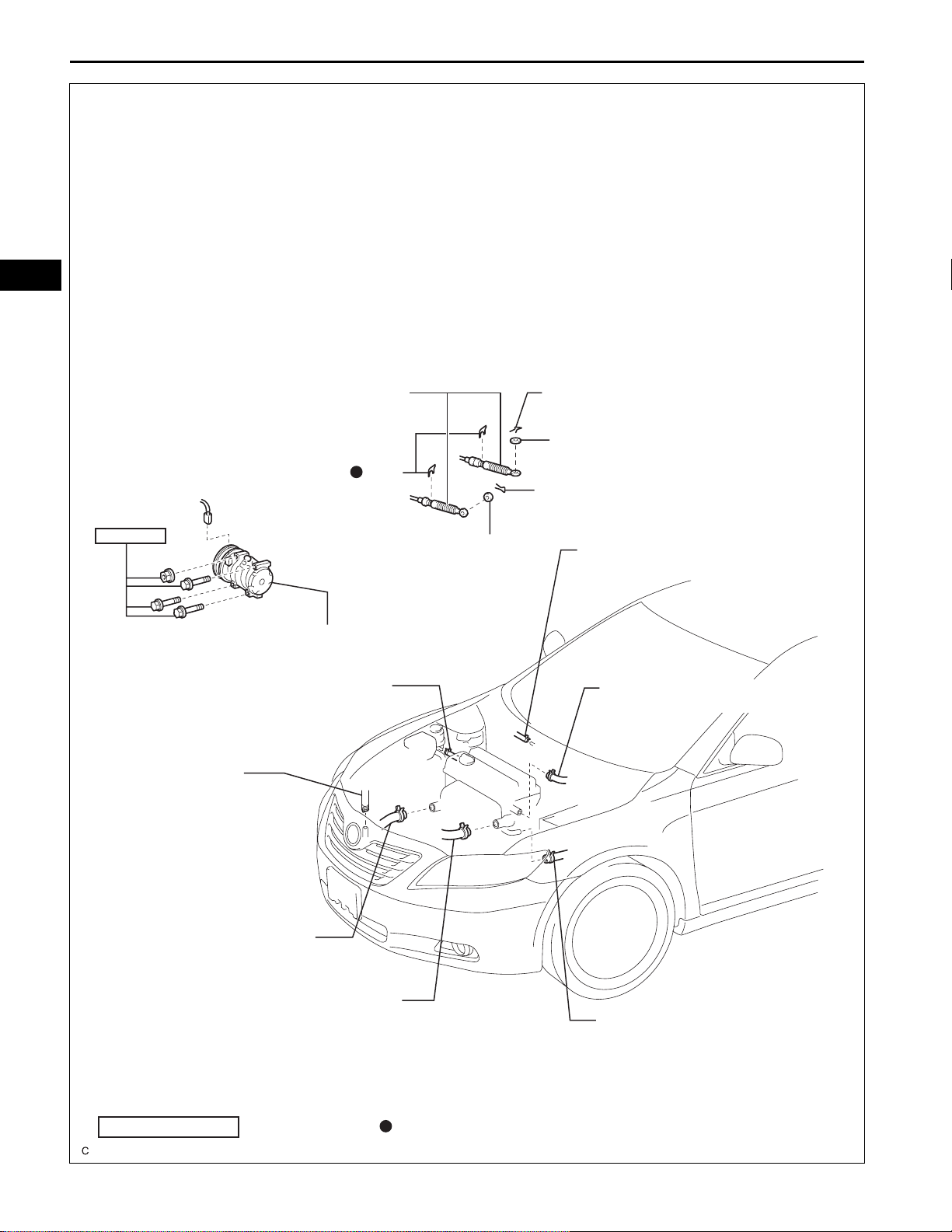

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

TRANSMISSION CONTROL

CABLE ASSEMBLY

25 (250, 18)

COMPRESSOR AND MAGNETIC CLUTCH

NO. 1 OIL RESERVOIR TO PUMP HOSE

RETURN TUBE

SUB-ASSEMBLY

CLIP

WASHER

CLIP

WASHER

CLIP

NO. 1 VACUUM HOSE CONNECTOR

HEATER INLET WATER HOSE

RADIATOR HOSE OUTLET

RADIATOR HOSE INLET

N*m (kgf*cm, ft.*lbf)

: Specified torque

HEATER OUTLET WATER HOSE

Non-reusable part

C138377E01

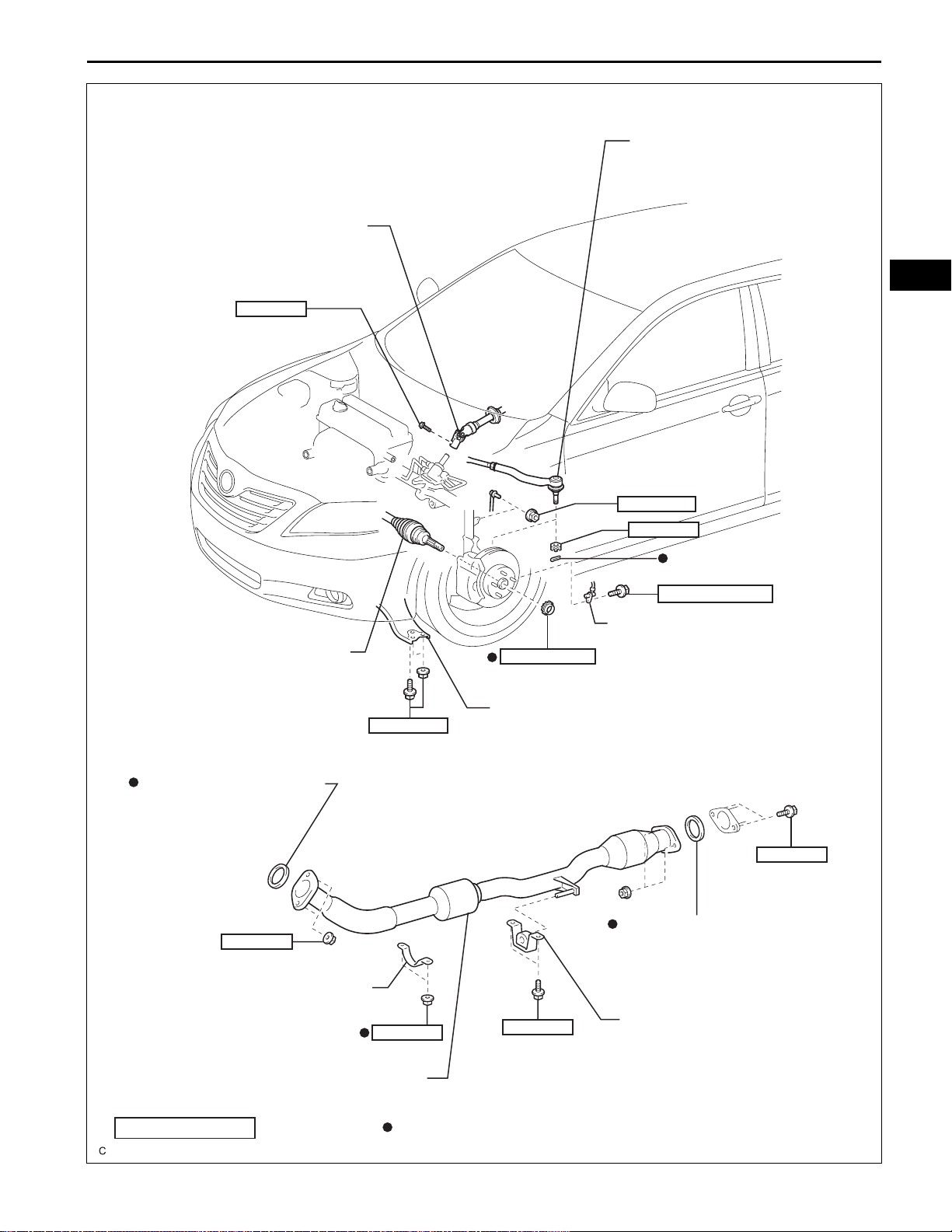

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

STEERING SLIDING YOKE

35 (357, 26)

MX–21

TIE ROD ASSEMBLY LH

MX

DRIVE SHAFT ASSEMBLY LH

EXHAUST PIPE GASKET

62 (633, 46)

75 (755, 55)

74 (755, 55)

49 (500, 36)

COTTER PIN

8.0 (82, 71 in.*lbf)

FRONT SPEED SENSOR LH

294 (3,000, 217)

FRONT AXLE HUB NUT LH

FRONT SUSPENSION

LOWER NO. 1 ARM LH

56 (571, 41)

EXHAUST PIPE GASKET

FRONT EXHAUST PIPE NO. 1

SUPPORT BRACKET

FRONT EXHAUST PIPE ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

33 (337, 24)

Non-reusable part

33 (337, 24)

REAR EXHAUST PIPE NO. 1

SUPPORT BRACKET

C143322E01

MX–22

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

VANE PUMP ASSEMBLY

43 (439, 32)

NO. 2 ENGINE MOUNTING

BRACKET REAR

54 (551, 40)

MX

95 (969, 70)

ENGINE MOUNTING BRACKET RH

87 (888, 64)

FRONT FRAME ASSEMBLY

89 (910, 66)

143 (1,459, 105)

64 (653, 47)

FRAME SIDE RAIL

PLATE SUBASSEMBLY RH

32 (326, 24)

FRAME SIDE RAIL PLATE

SUB-ASSEMBLY LH

N*m (kgf*cm, ft.*lbf)

85 (867, 63)

: Specified torque

FRAME SUSPENSION

MEMBER BRACE REAR LH

FRAME SUSPENSION

MEMBER BRACE

REAR RH

32 (326, 24)

85 (867, 63)

A109017E03

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

CLUTCH TUBE

MX–23

BRACKET

12 (120, 9)

15 (155, 11)

12 (120, 9)

15 (155, 11)

12 (120, 9)

CLIP

12 (122, 9)

BRACKET

7.0 (71, 62 in.*lbf)

CLUTCH LINE

15 (155, 11)

64 (653, 47)

x3

12 (122, 9)

46 (470, 34)

WIRE HARNESS

8.4 (86, 74 in.*lbf)

MX

8.4 (86, 74 in.*lbf)

WIRE HARNESS CLAMP

x2

MANUAL TRANSAXLE

ASSEMBLY

12 (120, 9)

HEAT INSULATOR

CLUTCH ACCUMULATOR

ASSEMBLY

ENGINE MOUNTING

FRONT BRACKET

CLUTCH RELEASE

CYLINDER ASSEMBLY

44 (449, 32)

64 (653, 47)

HOLE SNAP RING

x4

46 (470, 34)

STARTER ASSEMBLY

39 (398, 29)

ENGINE MOUNTING INSULATOR LH

18 (184, 13)

MANUAL TRANSMISSION

CASE PROTECTOR

x2

FRONT DRIVE SHAFT ASSEMBLY RH

N*m (kgf*cm, ft.*lbf)

: Specified torque

SNAP RING

FRONT DRIVE SHAFT ASSEMBLY LH

Non-reusable part

64 (653, 47)

64 (653, 47)

C132978E01

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

61. REMOVE WIRE HARNESS CLAMP

(a) Remove the 2 bolts and wire harness clamps.

MX–27

C132983

C132980

C132981

MX

62. REMOVE MANUAL TRANSMISSION CASE

PROTECTOR

(a) Remove the 2 bolts and manual transmission case

protector.

63. REMOVE ENGINE MOUNTING FRONT BRACKET

(a) Remove the 3 bolts and engine mounting front

bracket.

64. REMOVE ENGINE MOUNTING INSULATOR LH

(a) Remove the 4 bolts and engine mounting insulator

LH.

C132982

INSTALLATION

B

A

C

D

C132982E01

1. INSTALL ENGINE MOUNTING INSULATOR LH

(a) Install the engine mounting insulator LH with the 4

bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

HINT:

Tighten the bolts in order: A, B, C and D.

MX–28

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

2. INSTALL ENGINE MOUNTING FRONT BRACKET

(a) Install the engine mounting front bracket with the 3

bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

MX

C132981

3. INSTALL MANUAL TRANSMISSION CASE

PROTECTOR

(a) Install the manual transmission case protector with

the 2 bolts.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

C132980

4. INSTALL WIRE HARNESS CLAMP

(a) Install the 2 wire harness clamps with the 2 bolts.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

C132983

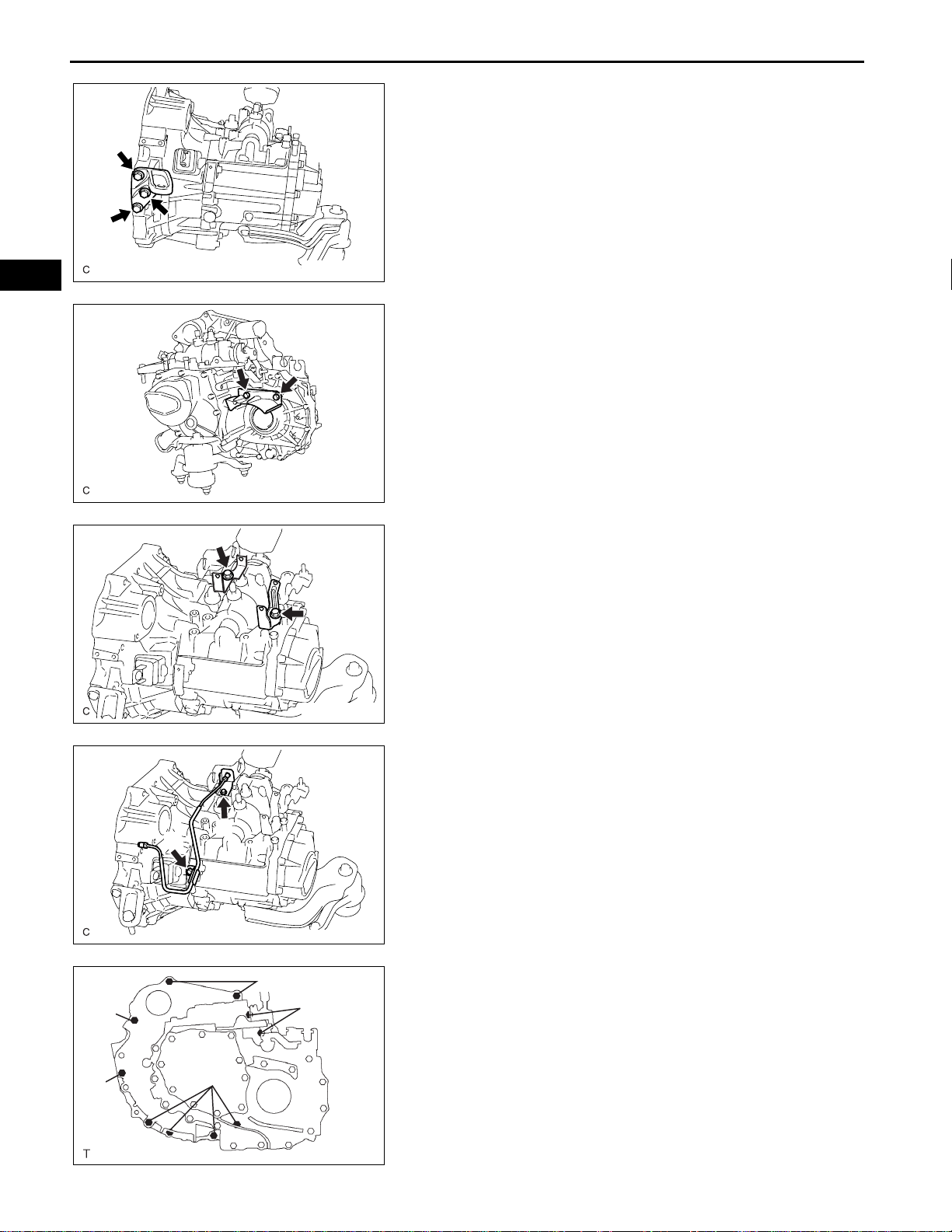

5. INSTALL CLUTCH LINE

(a) Install the clutch line and bracket with the 2 bolts.

Torque: Bolt A

12 N*m (122 kgf*cm, 9 ft.*lbf)

B

A

Bolt B

7.0 N*m (71 kgf*cm, 62 in.*lbf)

6. INSTALL MANUAL TRANSAXLE ASSEMBLY

(a) Align the input shaft with the clutch disc and install

C132979E01

A

E

B

the transaxle to the engine.

(b) Install the 10 bolts.

Torque: Bolt A

64 N*m (653 kgf*cm, 47 ft.*lbf)

Bolt B

46 N*m (470 kgf*cm, 34 ft.*lbf)

D

C

Bolt C

44 N*m (449 kgf*cm, 32 ft.*lbf)

Bolt D

46 N*m (470 kgf*cm, 34 ft.*lbf)

D025747E04

Bolt E

64 N*m (653 kgf*cm, 47 ft.*lbf)

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

Bolt length:

Bolt A:

60 mm (2.3622 in.)

Bolt B:

60 mm (2.3622 in.)

Bolt C:

32 mm (1.2598 in.)

Bolt D:

65 mm (2.5591 in.)

Bolt E:

74.5 mm (2.9331 in.)

7. CONNECT WIRE HARNESS

(a) Install the wire harness.

(b) Connect the back-up light switch connector.

(c) Install the ground cable with the bolt.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

8. INSTALL STARTER ASSEMBLY (See page ST-13)

9. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH (See

page DS-20)

MX–29

MX

10. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (See

page DS-21)

11. INSTALL FRONT FRAME ASSEMBLY (See page EM-

112)

12. INSTALL VANE PUMP ASSEMBLY (See page EM-113)

13. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(See page EM-114)

14. INSTALL STEERING SLIDING YOKE (See page PS-

65)

15. INSTALL FRONT AXLE ASSEMBLY LH (See p age DS-

21)

16. INSTALL FRONT AXLE ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

17. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM

LH (See page DS-21)

18. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM

RH

HINT:

Use the same procedures described for the LH side.

19. INSTALL TIE ROD ASSEMBLY LH (See page DS-21)

20. INSTALL TIE ROD ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

21. INSTALL FRONT SPEED SENSOR LH (See page DS-

21)

MX–30

E351 MANUAL TRANSAXLE – MANUAL TRANSAXLE ASSEMBLY

22. INSTALL FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

23. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(See page DS-22)

24. INSTALL FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

MX

25. INSTALL FRONT AXLE HUB NUT LH (See page DS-7)

26. INSTALL FRONT AXLE HUB NUT RH

HINT:

Use the same procedures described for the LH side.

27. INSTALL FRONT EXHAUST PIPE ASSEMBLY

See page EX-3.

28. INSTALL COMPRESSOR AND MAGNETIC CLUTCH

(See page EM-115)

29. INSTALL GENERATOR ASSEMBLY (See page CH-19)

30. CONNECT FUEL TUBE SUB-ASSEMBLY (See page

EM-115)

31. INSTALL CLUTCH RELEASE CYLINDER ASSEMBLY

See page CL-25.

32. INSTALL CLUTCH ACCUMULATOR ASSEMBLY

See page CL-29.

33. CONNECT RETURN TUBE SUB-ASSEMBLY (See

page EM-116)

34. CONNECT NO. 1 OIL RESERVOIR TO PUMP HOSE

(See page EM-116)

35. INSTALL TRANSMISSION CONTROL CABLE

ASSEMBLY (See page EM-116)

36. CONNECT ENGINE WIRE (See page EM-117)

37. INSTALL ECM

See page ES-433.

38. CONNECT HEATER INLET WATER HOSE (See page

EM-117)

39. CONNECT HEATER OUTLET WATER HOSE (See

page EM-118)

40. CONNECT OIL COOLER INLET HOSE (See page CO-

30)

41. CONNECT OIL COOLER OUTLET HOSE (See page

CO-30)

42. CONNECT RADIATOR HOSE INLET (See page EM-

118)

43. CONNECT RADIATOR HOSE OUTLET (See page EM-

118)

Loading...

Loading...