Toyota Camry 2007-2009 Service Manual - 2GR-FE_Lubrication

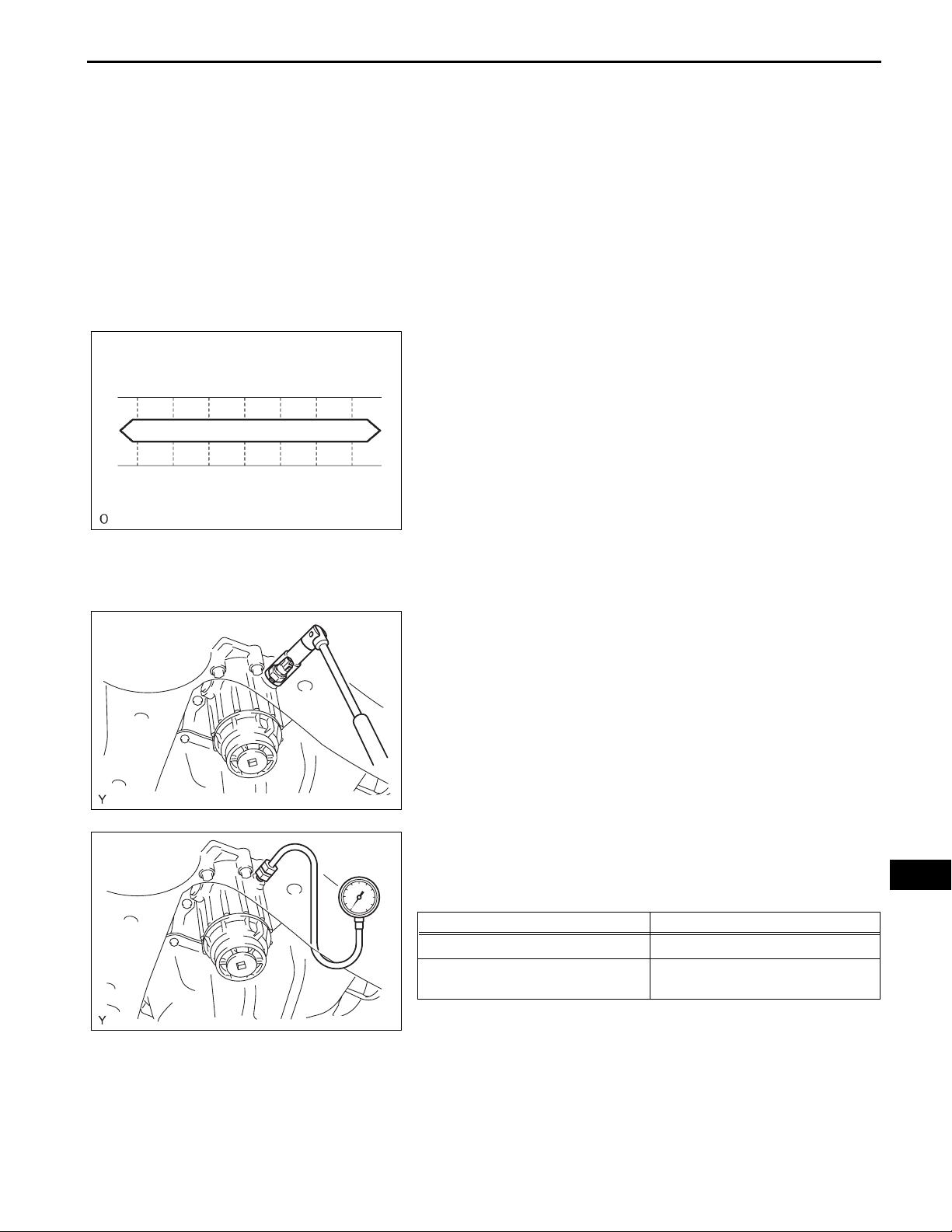

Recommended Viscosity (SAE)

5W-30

-29

°C

°F

-18 -7 4 16 27 38

-20

0 20 40 60 80 100

2GR-FE LUBRICATION – LUBRICATION SYSTEM

LUBRICATION SYSTEM

ON-VEHICLE INSPECTION

1. CHECK ENGINE OIL LEVEL

(a) Warm up the engine, stop it and wait 5 minutes. The

oil level should be between the dipstick's low level

mark and full level mark.

If low, check for leakage and add oil up to the full

level mark.

NOTICE:

Do not fill above the full level mark.

2. CHECK ENGINE OIL QUALITY

(a) Check the oil for deterioration, water contamination,

discoloring or thinning.

If the quality is visibly poor, replace the oil.

Oil grade:

Use ILSAC multigrade engine oil. SAE 5W-30

engine oil may be used. However, SAE 5W-30

is the best choice for good fuel economy and

good starting in cold weather.

A066623E21

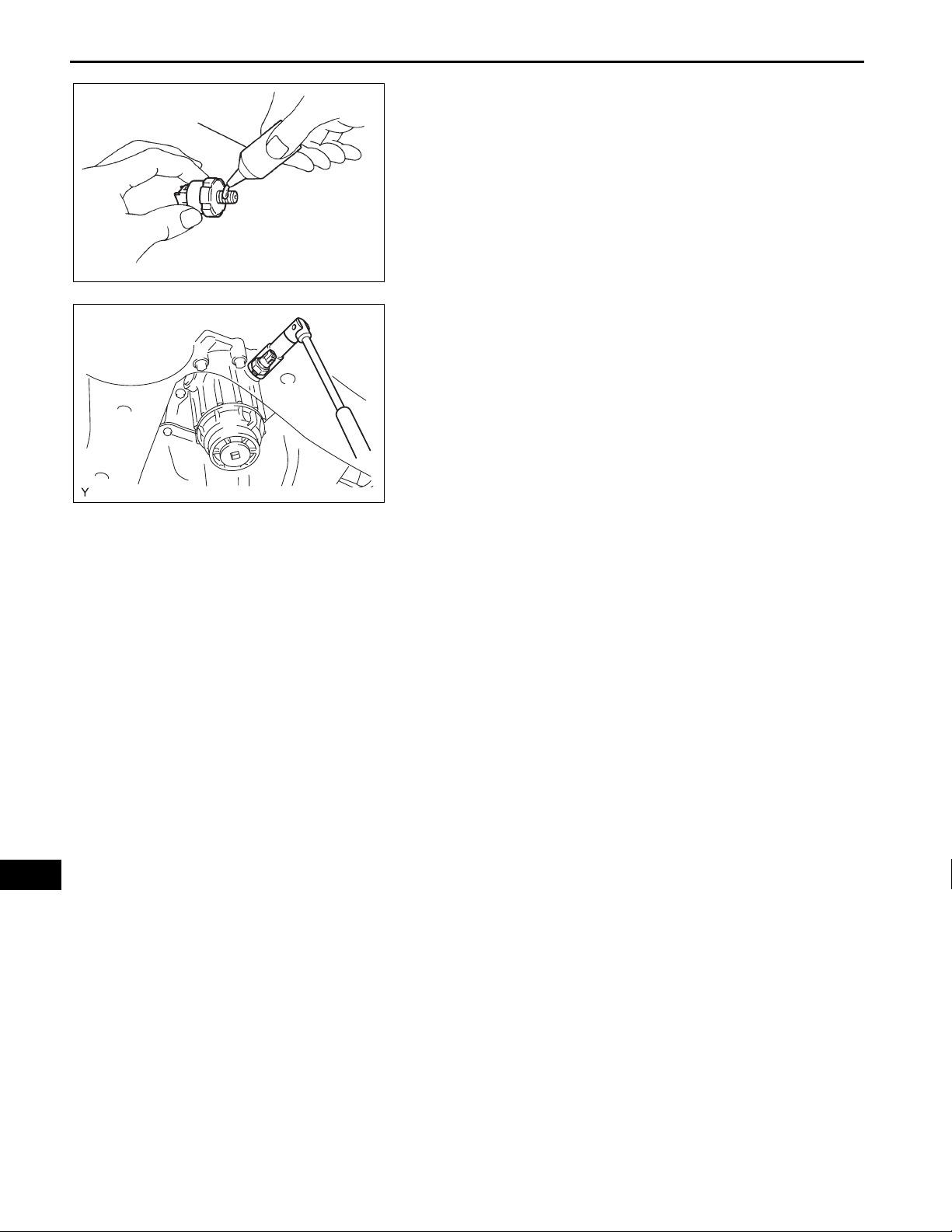

3. CHECK OIL PRESSURE

(a) Remove the engine under cover LH.

(b) Remove the engine under cover RH.

(c) Disconnect the oil pressure switch connector.

LU–1

A127994

A127995

(d) Using a 24 mm deep socket wrench, remove the oil

pressure switch.

(e) Install the oil pressure gauge with adapter.

(f) Warm up the engine.

(g) Measure the oil pressure.

Standard oil pressure

Engine Condition Oil Pressure

Idle

6,000 rpm

80 kPa (0.8 kgf* cm

380 kPa (3.9 kgf*cm

2

, 11.6 psi) or more

2

, 55.5 psi) or

more

If the oil pressure is not as specified, check the oil

pump (See page LU-13).

LU

LU–2

Adhesive

2GR-FE LUBRICATION – LUBRICATION SYSTEM

(h) Remove the oil pressure gauge.

(i) Apply adhesive to 2 or 3 threads of the oil pressure

switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or equivalent

A050082E14

(j) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 15 N*m (153 kgf*cm, 11 ft.*lbf)

NOTICE:

Do not start the engine within 1 hour after

installation.

(k) Connect the oil pressure switch connector.

(l) Check for engine oil leaks.

(m) Remove the engine under cover RH.

A127994

(n) Remove the engine under cover LH.

LU

ENGINE2GR-FE LUBRICATION

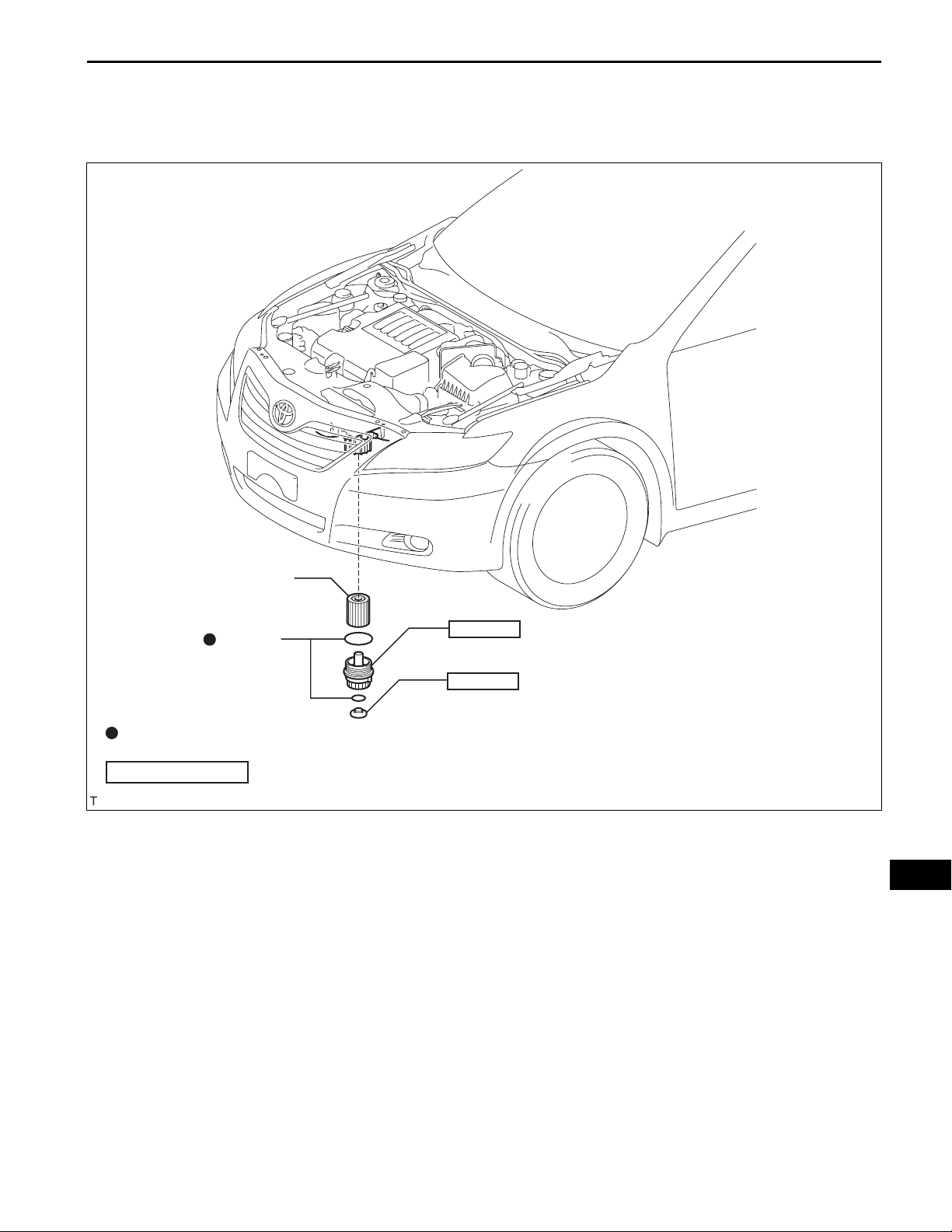

OIL FILTER

COMPONENTS

2GR-FE LUBRICATION – OIL FILTER

LU–3

OIL FILTER ELEMENT

O-RING

Non-reusable part

N*m (kgf*cm, ft.*lbf)

25 (255, 18)

OIL FILTER CAP ASSEMBLY

13 (127, 10)

OIL FILTER DRAIN PLUG

: Specified torque

A133361E01

LU

LU–4

2GR-FE LUBRICATION – OIL FILTER

REPLACEMENT

CAUTION:

• Prolonged and repeated contact with engine oil will

result in the removal of natural oils from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

• Precautions should be taken when replacing engine

oil to minimize the risk of your skin making contact

with used engine oil. Protective clothing and gloves

that cannot be penetrated by oil should be worn. The

skin should be washed with soap and water, or use

water-less hand cleaner, to remove any used engine

oil thoroughly. Do not use gasoline, thinners, or

solvents.

• In order to preserve the environment, used oil and

used oil filters must be disposed of at designated

disposal sites.

1. DRAIN ENGINE OIL

(a) Remove the oil filler cap.

(b) Remove the oil drain plug and drain the oil into a

container.

LU

Pipe

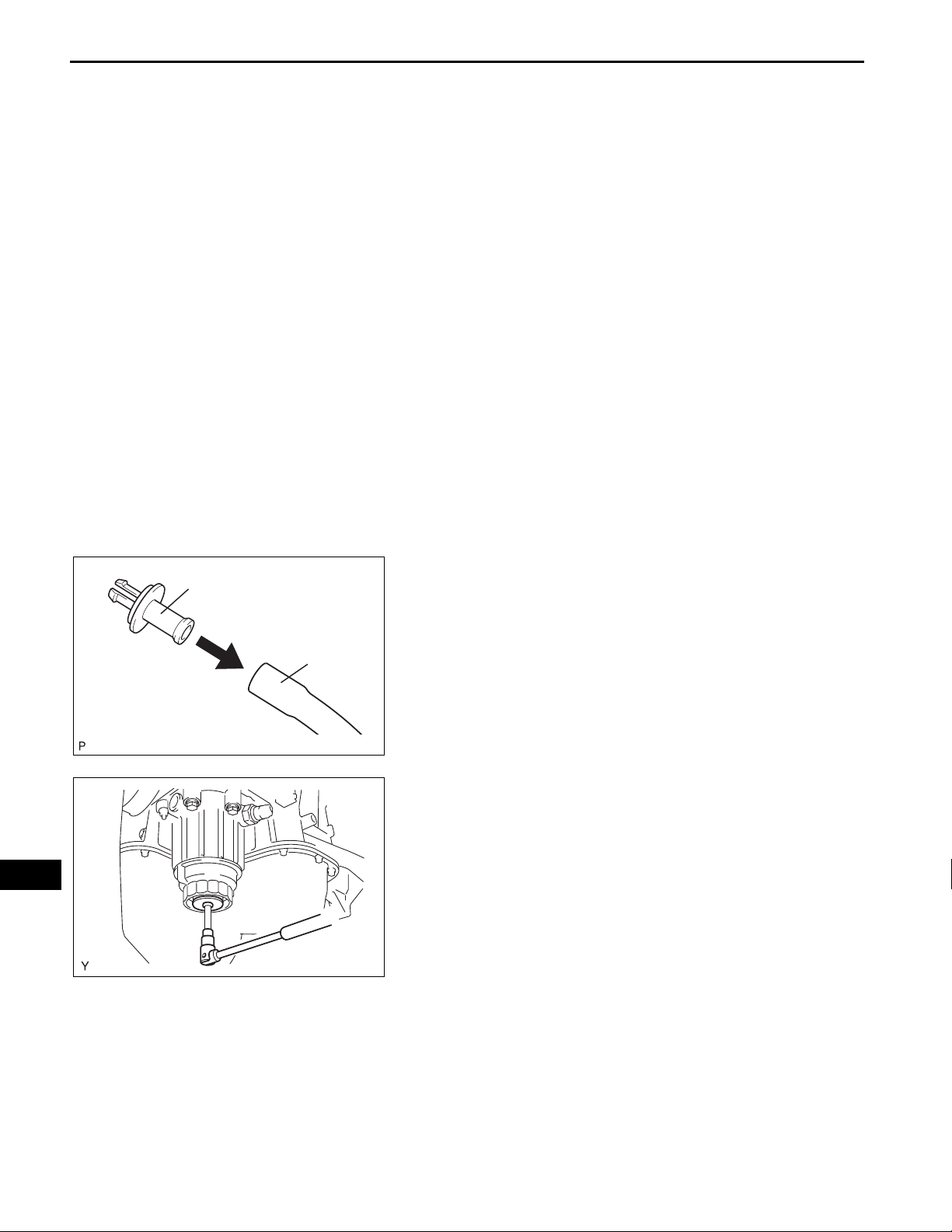

2. REMOVE OIL FILTER ELEMENT

(a) Connect the hose with an inside diameter of 15 mm

(0.59 in.) to the pipe.

Hose

A127996E01

(b) Remove the oil filter drain plug from the oil filter cap.

A127997

Cap

O-Ring

Pipe

2GR-FE LUBRICATION – OIL FILTER

(c) Insert the pipe with the hose into the oil filter cap.

NOTICE:

Be sure to insert the pipe with the O-ring

installed on the oil filter cap side.

HINT:

Place the hose end into a container before draining

the oil from the hose.

A127998E02

(d) Make sure that oil is completely drained, and

remove the pipe and O-ring.

HINT:

Be sure to turn the pipe in the direction of the arrow

to remove it.

A127999

LU–5

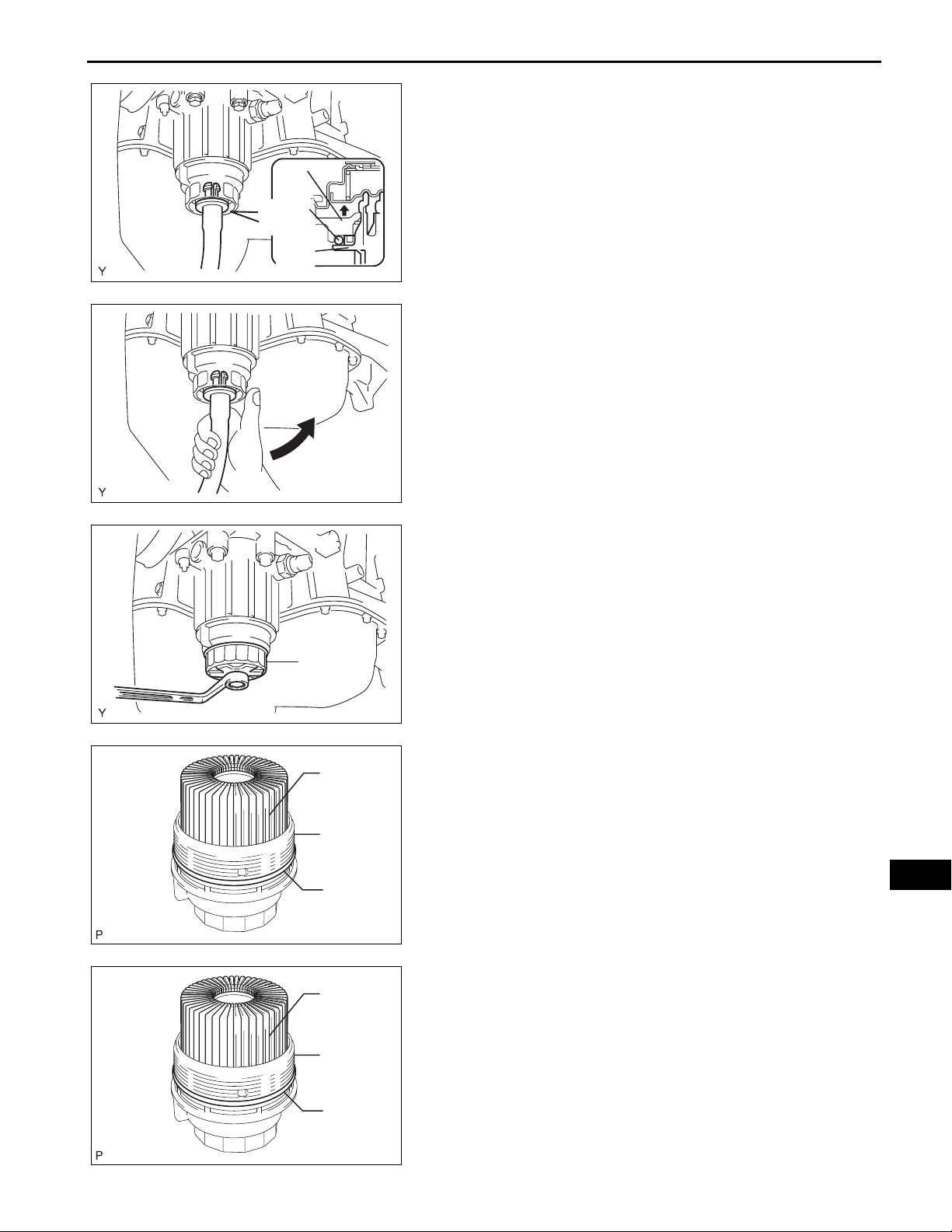

SST

Oil Filter

Element

Oil Filter

Cap

O-Ring

Oil Filter

Element

Oil Filter

Cap

O-Ring

(e) Using SST, remove the oil filter cap.

SST 09228-06501

A128000E01

(f) Remove the oil filter element and O-ring from the oil

filter cap.

NOTICE:

Do not use any tools to remove the O-ring in

order to prevent the cap from being damaged.

Be sure to remove it by hand.

LU

A128001E01

3. INSTALL OIL FILTER ELEMENT

(a) Clean the inside of the oil filter cap, threads, and O-

ring groove.

(b) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap.

NOTICE:

Make sure that the O-ring does not get twisted

on the groove.

(c) Install a new oil filter element to the oil filter cap.

A128001E02

LU–6

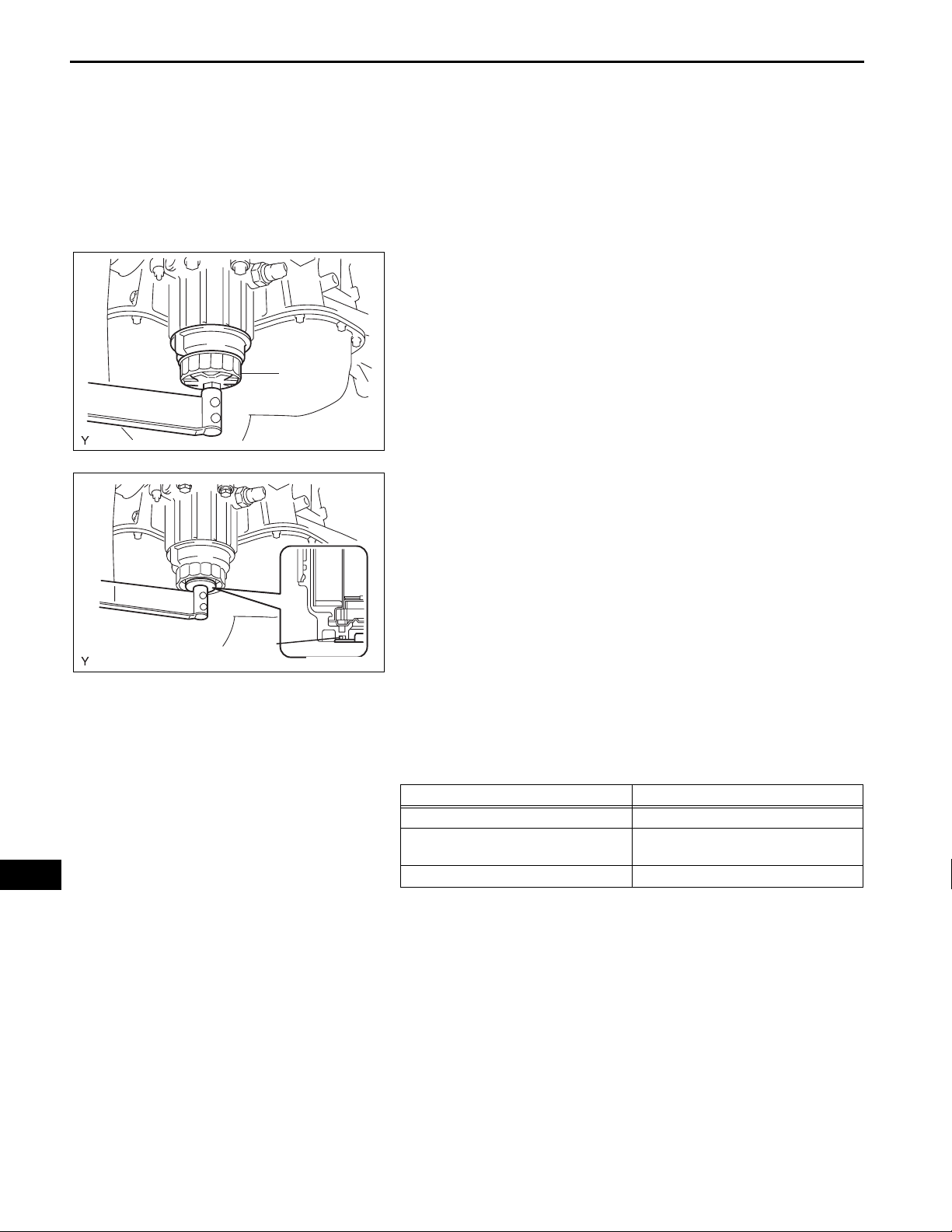

O-Ring

SST

2GR-FE LUBRICATION – OIL FILTER

(d) Remove all dirt and foreign matter from the

installation surface and the inside of the cap on the

engine side.

(e) Apply a light coat of engine oil to the O-ring again

and install the oil filter cap.

NOTICE:

Make sure that the O-ring does not get caught

between the parts.

(f) Using SST, install the oil filter cap.

SST 09228-06501

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

NOTICE:

Make sure that there is no clearance between

the parts after tightening the oil filter cap.

A128002E01

(g) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap.

NOTICE:

Remove all dirt and foreign matter from the

installation surface.

(h) Install the oil filter drain plug to the oil filter cap.

Torque: 13 N*m (127 kgf*cm, 10 ft.*lbf)

NOTICE:

Make sure that the O-ring does not get caught

A128003E01

between the parts.

LU

4. ADD ENGINE OIL

(a) Clean and install the oil drain plug with a new gasket

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf)

(b) Add new oil.

Standard capacity

Item Standard Condition

Drain and refill with oil filter change 6.1 liters (6.4 US qts, 5.4 lmp. qts)

Drain and refill without oil filter

change

Dry fill 6.5 liters (6.9 US qts, 5.7 lmp. qts)

5.7 liters (6.0 US qts, 5.0 lmp. qts)

(c) Install the oil filler cap.

5. CHECK FOR ENGINE OIL LEAKS

(a) Start the engine. Check for engine oil leaks from the

connected parts of the oil filter cap and oil filter drain

plug.

Loading...

Loading...