2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

SFI SYSTEM

PRECAUTION

NOTICE:

• Perform RESET MEMORY (AT initialization) when

replacing the automatic transmission assembly,

engine assembly or ECM (See page AX-16).

• Perform REGISTRATION (VIN registration) when

replacing the ECM (See page ES-16).

HINT:

Initialization cannot be completed by removing the battery.

ES–1

ES

ES

ES–2

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

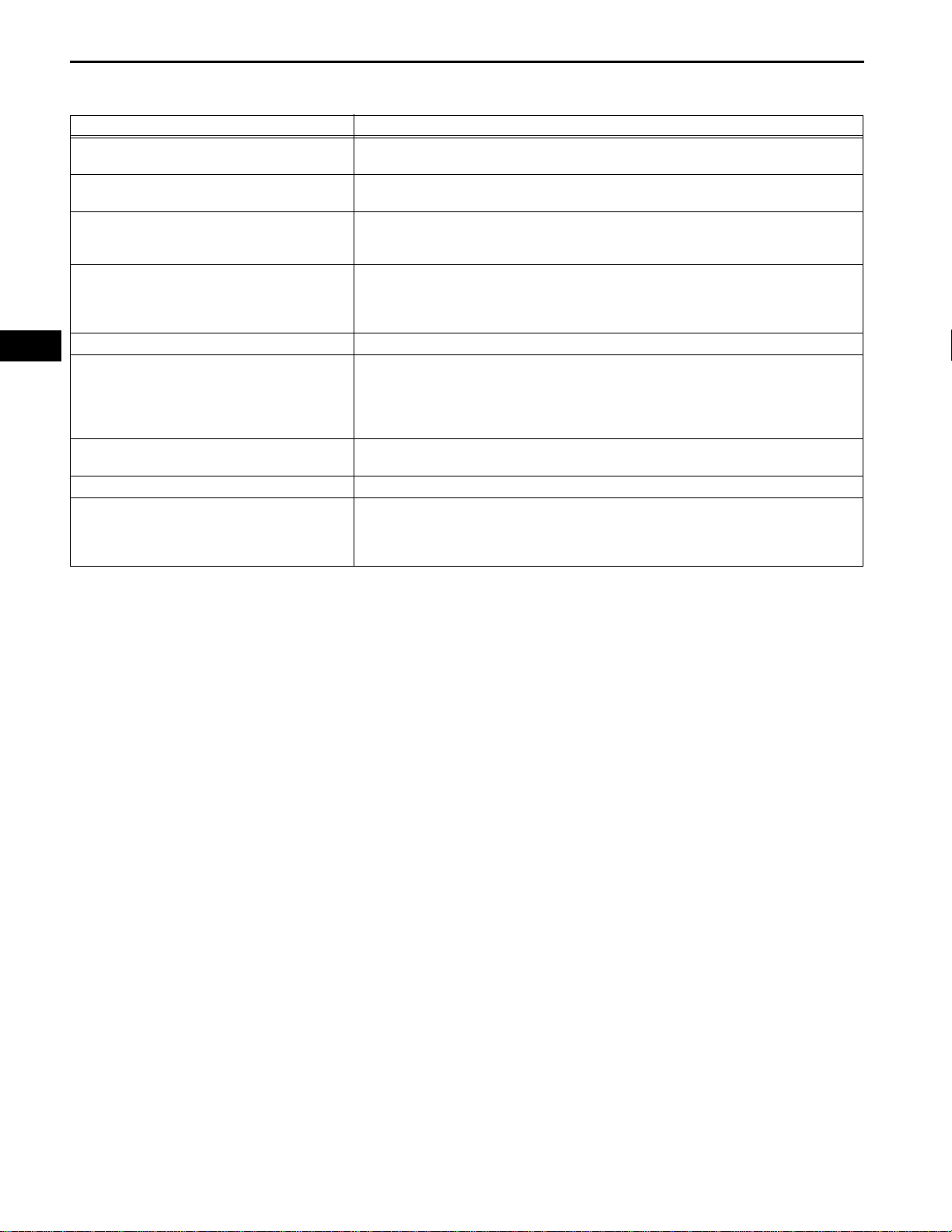

DEFINITION OF TERMS

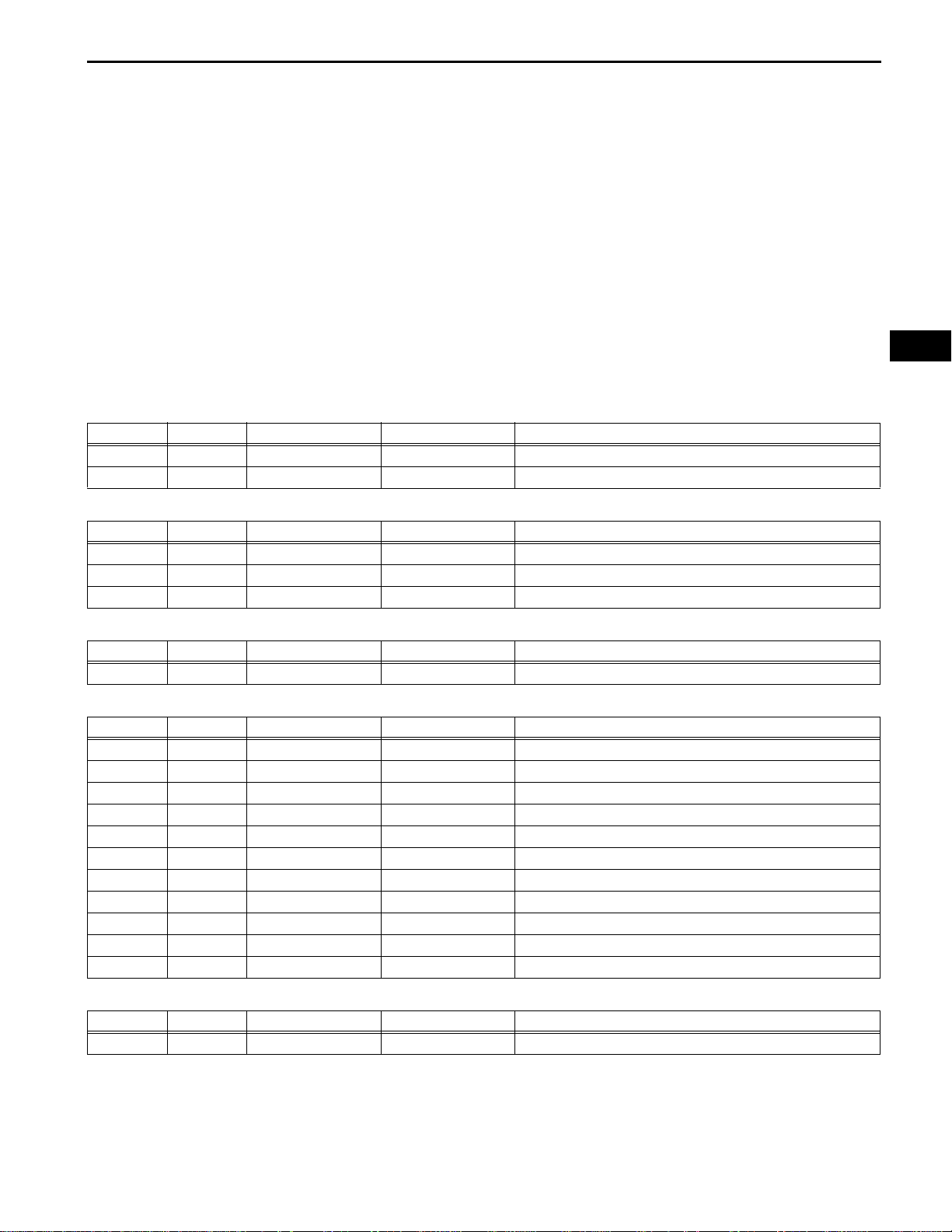

Terms Definition

Monitor Description

Related DTCs

Typical Enabling Condition

Sequence of Operation

Required Sensor/Components Sensors and components used by ECM to detect each malfunction.

Frequency of Operation

Duration

Malfunction Thresholds Value, beyond which, ECM determines malfunctions exist and sets DTCs.

MIL Operation

Description of what ECM monitors and how detects malfunctions (monitoring purpose and

details).

Group of diagnostic trouble codes that are output by ECM based on the same malfunction

detection logic.

Preconditions that allow ECM to detect malfunctions.

With all preconditions satisfied, ECM sets DTC when monitored value(s) exceeds

malfunction threshold(s).

Order of monitor priority, applied if multiple sensors and components involved in single

malfunction detection process.

Each sensor and component monitored in turn, when previous detection operation is

completed.

Number of times ECM checks for each malfunction during each driving cycle.

"Once per driving cycle" means ECM only performs checks for that malfunction once in

single driving cycle.

"Continuous" means ECM performs checks for that malfunction whenever enabling

conditions are met.

Minimum time for which ECM must detect continuous deviation in monitored value(s) in

order to set DTC. Timing begins when Typical Enabling Conditions are met.

Timing of MIL illumination after malfunction is detected.

"Immediate" means ECM illuminates MIL as soon as malfunction is detected.

"2 driving cycle" means ECM illuminates MIL if the same malfunction is detected second

time in the next sequential driving cycle.

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

PARTS LOCATION

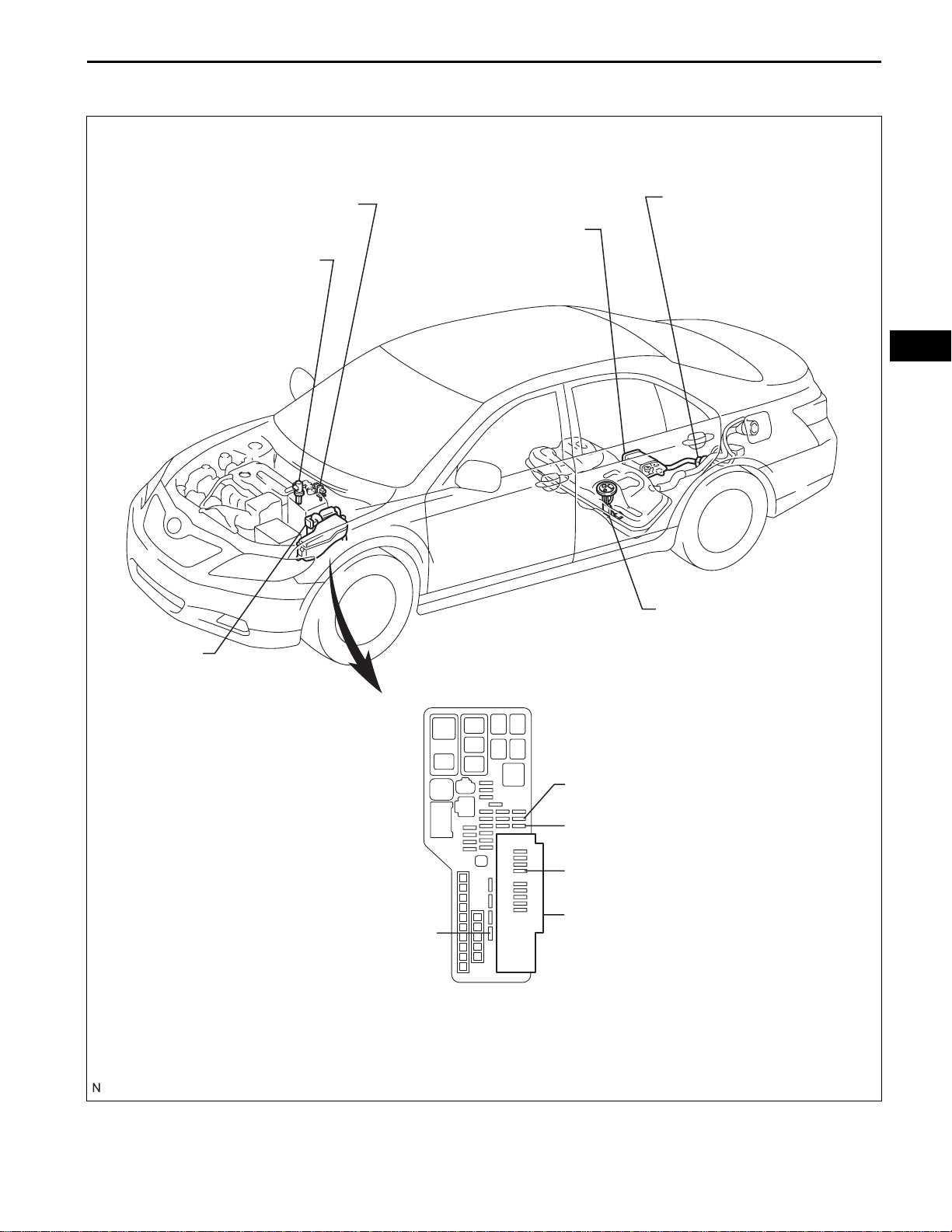

PZEV:

ES–3

PURGE VSV

MASS AIR FLOW METER

CANISTER PUMP MODULE

CANISTER

ES

FUEL PUMP

ECM

ENGINE ROOM R/B AND

ENGINE ROOM J/B

EFI MAIN FUSE

EFI NO. 3 FUSE

EFI NO. 2 FUSE

EFI NO. 1 FUSE

INTEGRATION RELAY

(ENGINE ROOM J/B)

-

EFI RELAY

CIRCUIT OPENING RELAY

-

A137360E01

ES

ES–4

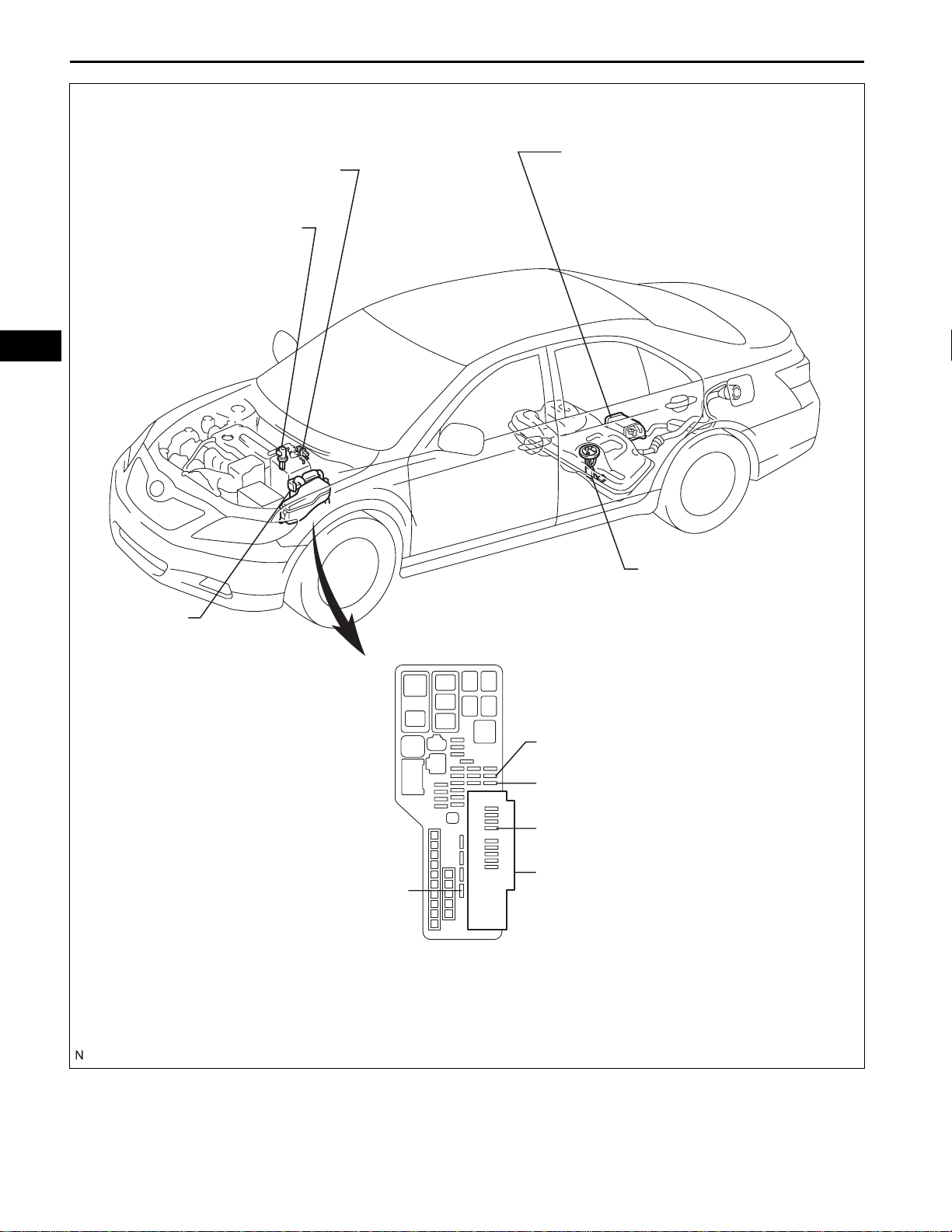

EXCEPT PZEV:

MASS AIR FLOW METER

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CANISTER

PURGE VSV

CANISTER PUMP MODULE

ECM

ENGINE ROOM R/B AND

ENGINE ROOM J/B

EFI MAIN FUSE

FUEL PUMP

EFI NO. 3 FUSE

EFI NO. 2 FUSE

EFI NO. 1 FUSE

INTEGRATION RELAY

(ENGINE ROOM J/B)

-

EFI RELAY

-

CIRCUIT OPENING RELAY

A137361E01

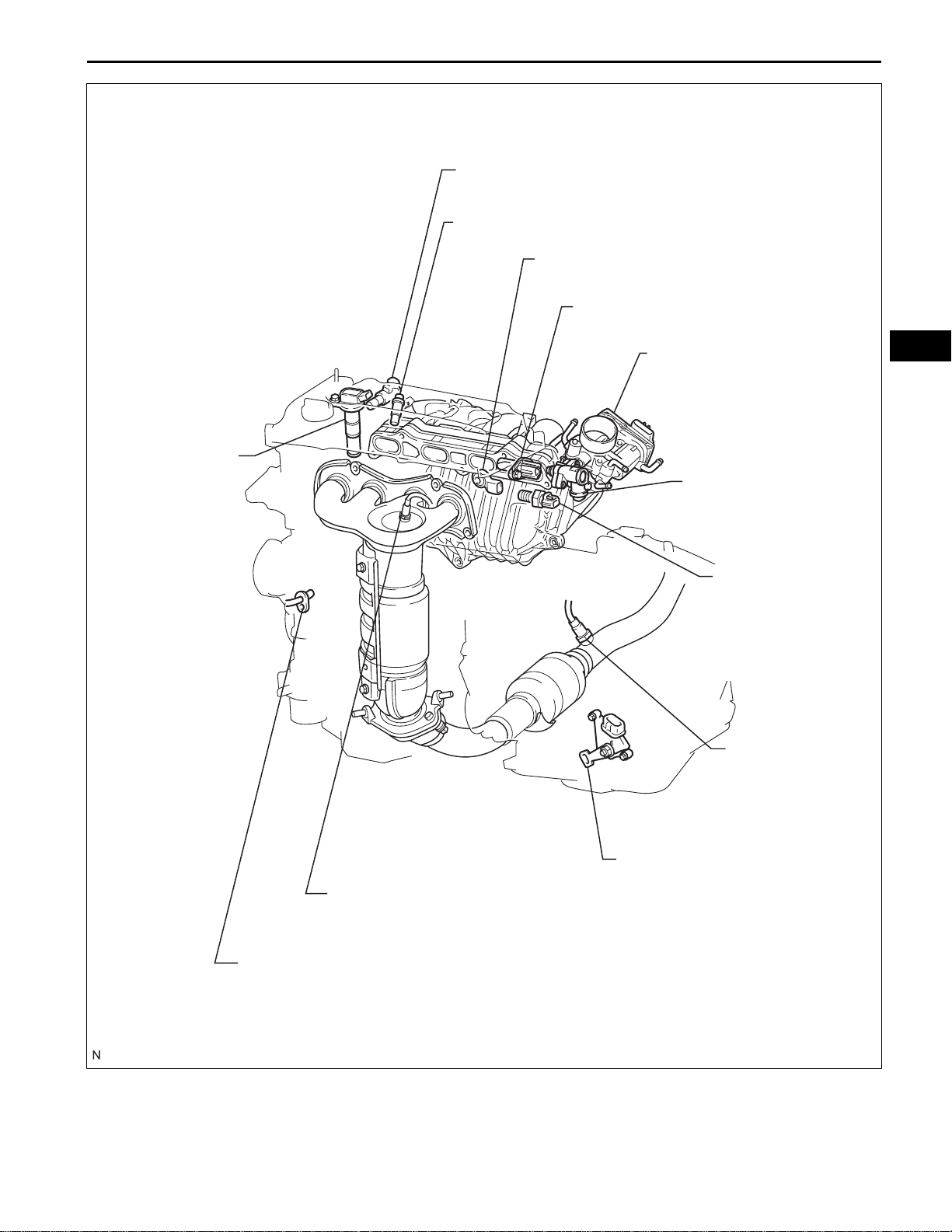

PZEV:

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

FUEL INJECTOR

KNOCK SENSOR

CAMSHAFT POSITION SENSOR

ES–5

IGNITION COIL

THROTTLE BODY

INTAKE MANIFOLD

RUNNER VALVE (IMRV)

ENGINE COOLANT

TEMPERATURE

SENSOR

HEATED OXYGEN

SENSOR

ES

AIR-FUEL RATIO SENSOR

CRANKSHAFT POSITION SENSOR

PARK/NEUTRAL POSITION SW

A135059E01

ES–6

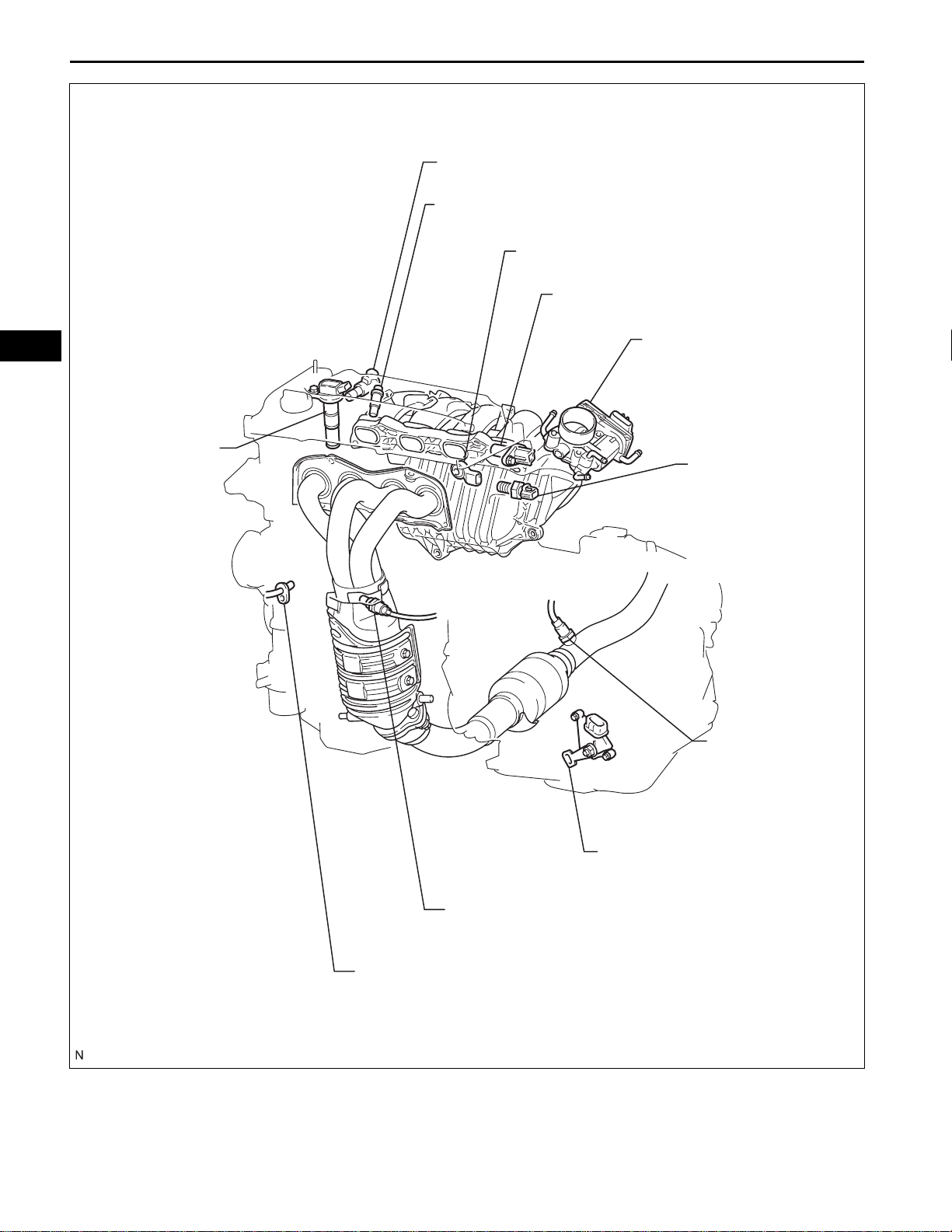

EXCEPT PZEV:

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

FUEL INJECTOR

KNOCK SENSOR

CAMSHAFT POSITION SENSOR

ES

THROTTLE BODY

IGNITION COIL

ENGINE COOLANT

TEMPERATURE

SENSOR

HEATED OXYGEN

SENSOR

AIR-FUEL RATIO SENSOR

CRANKSHAFT POSITION SENSOR

PARK/NEUTRAL POSITION SW

A132270E01

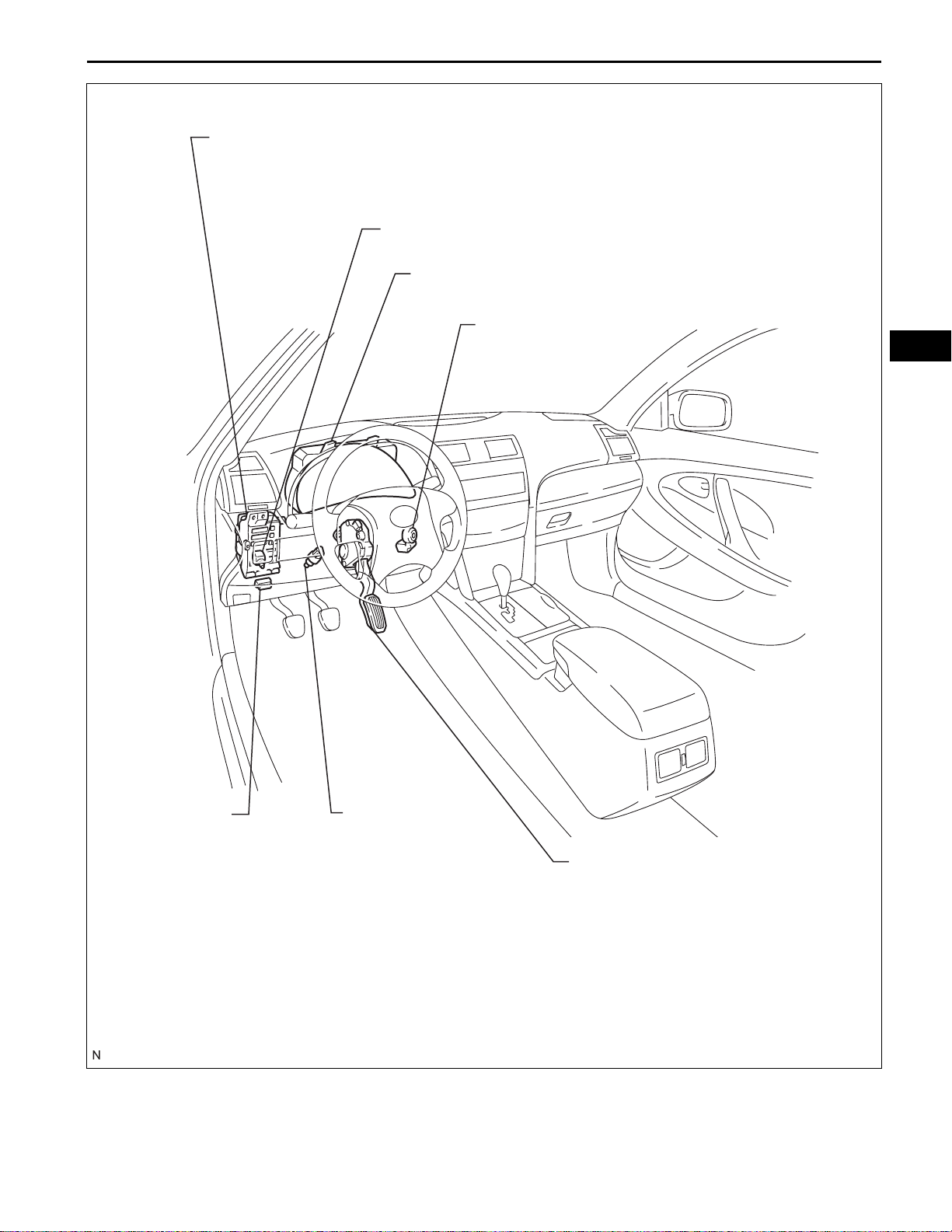

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

INSTRUMENT PANEL J/B

- IGN FUSE

- STOP FUSE

ES–7

CLUTCH START SWITCH

COMBINATION METER

IGNITION SWITCH

ES

DLC3

STOP LIGHT SW

ACCELERATOR PEDAL ROD

A132271E01

ES–8

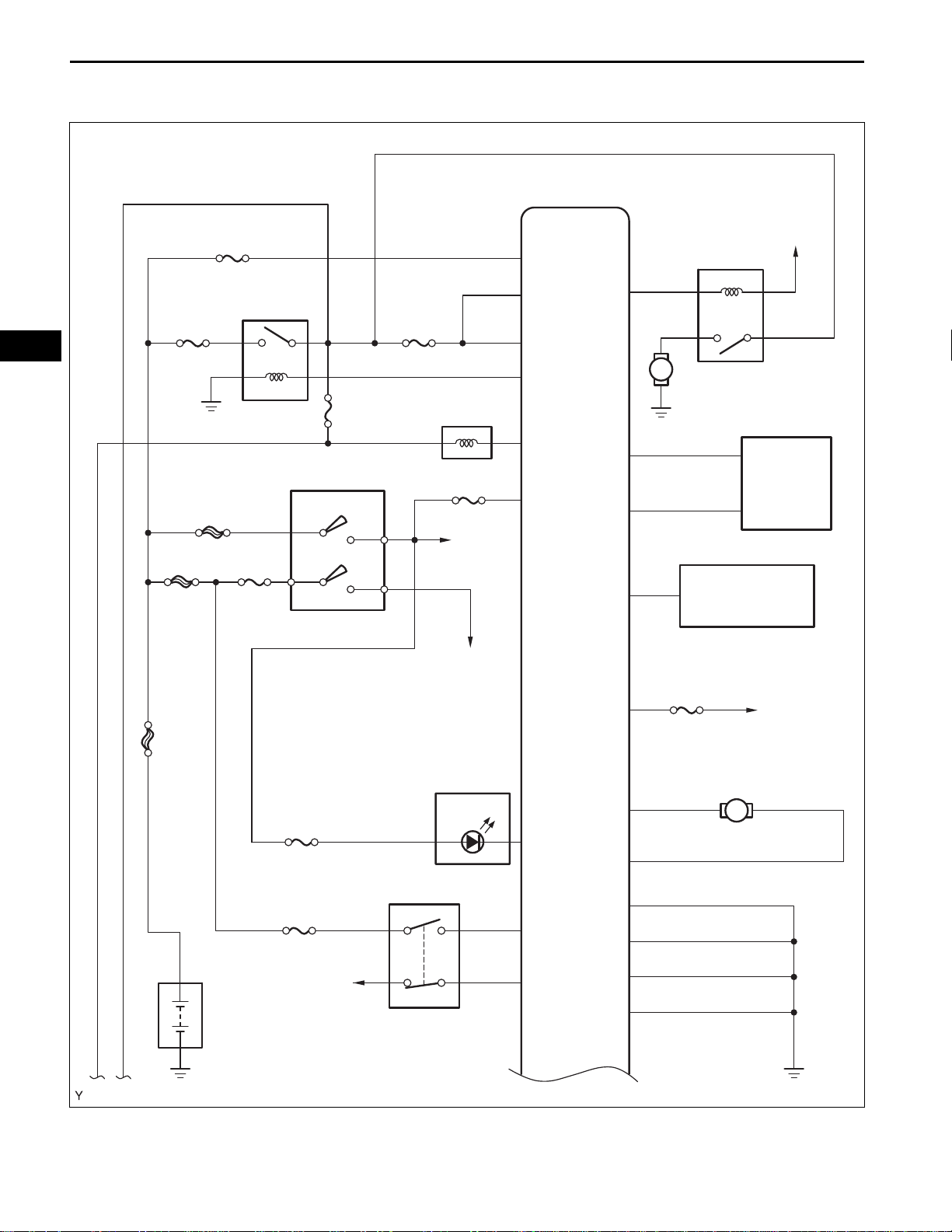

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

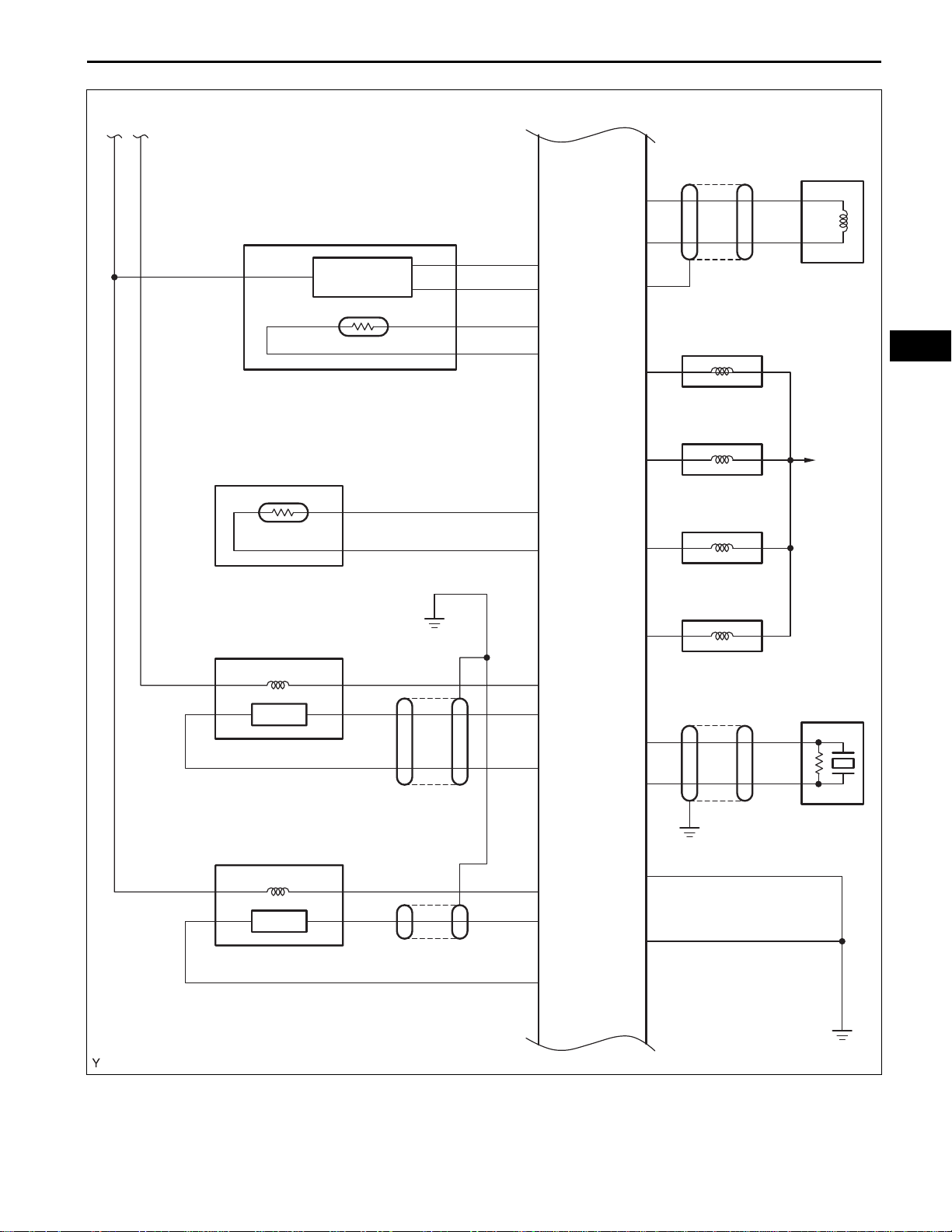

SYSTEM DIAGRAM

ECM

ES

EFI No. 1

EFI MAIN

ST/AM2

ALT

FL

MAIN

AM1

EFI

EFI No. 2

Purge VSV

EFI No. 3

IG SW

AM2

AM1

IG2

IG1

To Park/Neutral Position SW

Combination

Meter

IGN

To

C/OPN

BATT

+B

+B2

MREL

PRG

IGSW

FC

TC

TACH

ALT

+BM

To IGN

C/OPN

M

Fuel Pump

DLC3

Generator

ETCS

To Battery

IMRV (Intake Manifold

Runner Valve) Motor

Battery

GAUGE No. 2

STOP

To IGN

Stop Light SW

*1: PZEV Only

MIL

W

STP

ST1-

IAC+*1

IAC-*1

E1

E01

E03

E04

M

A132314E01

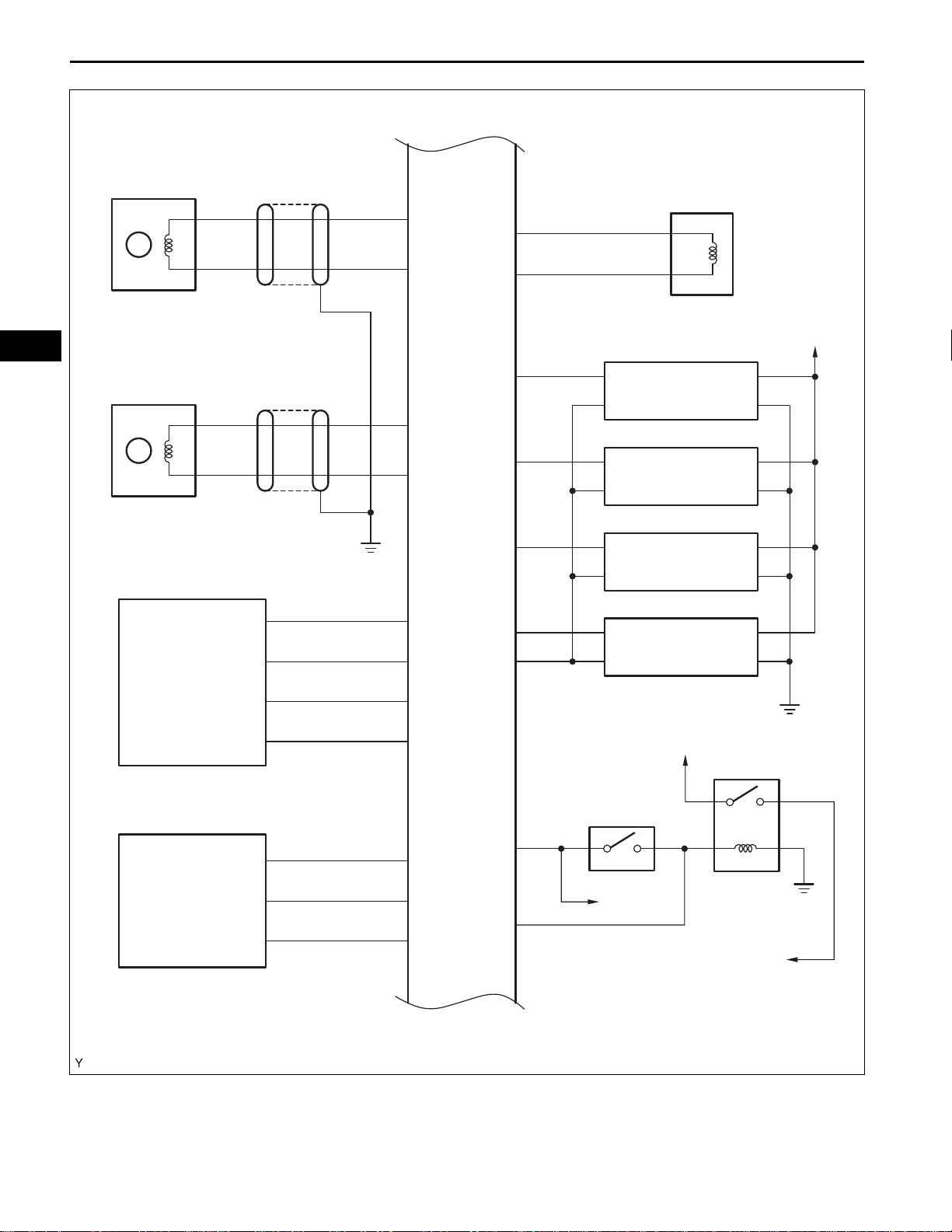

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ECM

ES–9

Throttle Actuator

Mass Air Flow Meter

Engine Coolant Temperature Sensor

Air-fuel Ratio Sensor

E2G

VG

THA

ETHA

THW

ETHW

M+

M-

GE01

#40

#30

#20

#10

No. 4 Fuel Injector

ES

No. 3 Fuel Injector

To

INJ

No. 2 Fuel Injector

No. 1 Fuel Injector

Heated Oxygen Sensor

HA1A

A1A+

A1A-

HT1B

OX1B

EX1B

Knock Sensor

KNK1

EKNK

E02

ME01

A132315E01

ES–10

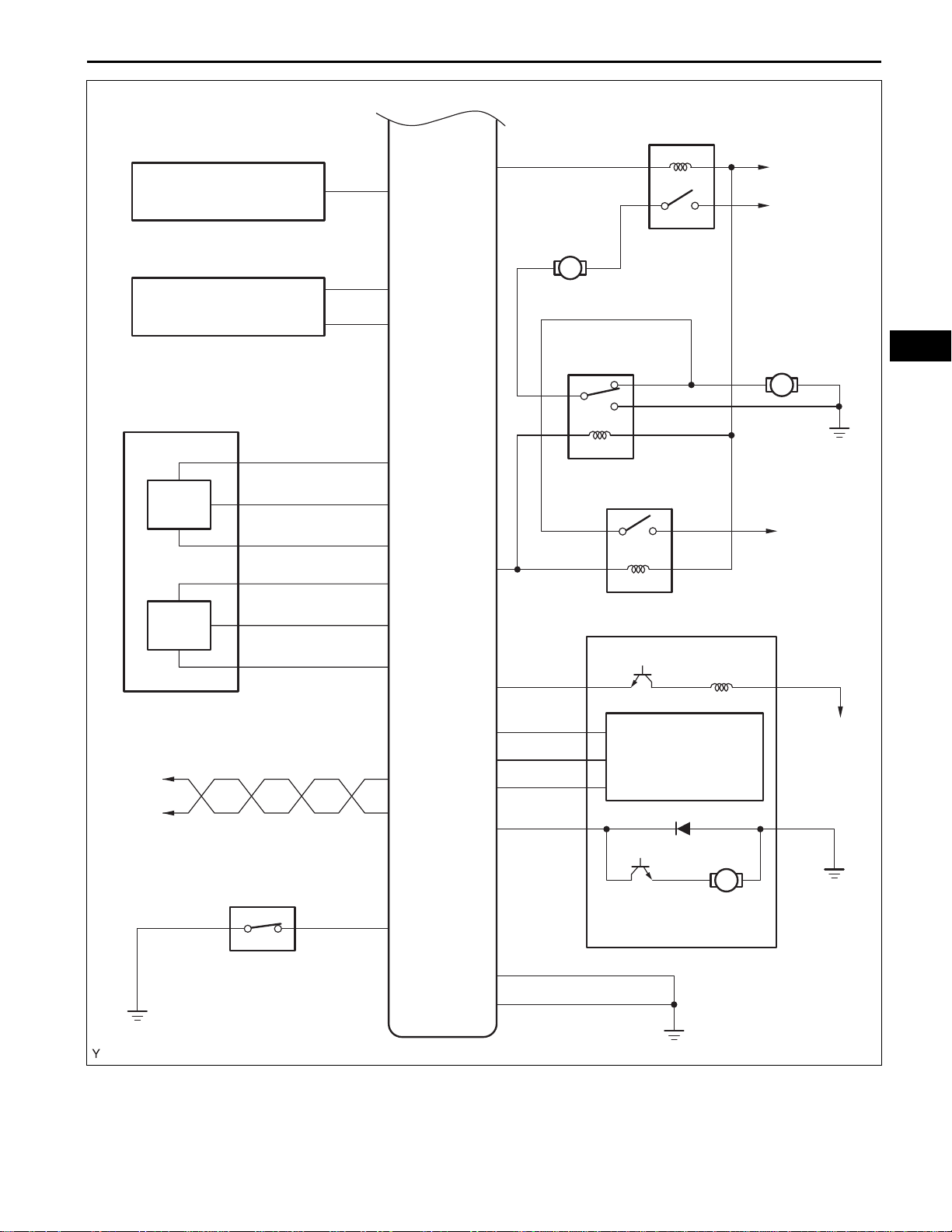

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ECM

ES

Crankshaft Position Sensor

Camshaft Position Sensor

NE+

NE-

G2-

G2+

OC1+

OC1-

IGT1

IGT2

IGT3

Camshaft Timing Oil Control Valve

To INJ

No. 1 Ignition Coil

No. 2 Ignition Coil

No. 3 Ignition Coil

Throttle Position

Sensor

IMRV Position

Sensor

*1: PZEV Only

*2: Automatic Transaxle Only

VCTA

VTA1

VTA2

ETA

VCIA*1

IACA*1

EIA*1

IGT4

IGF1

NSW*2

STA

No. 4 Ignition Coil

Park/Neutral

Position SW or

Clutch Start SW

To IG SW

To IG SW

ST

To Starter

A132316E01

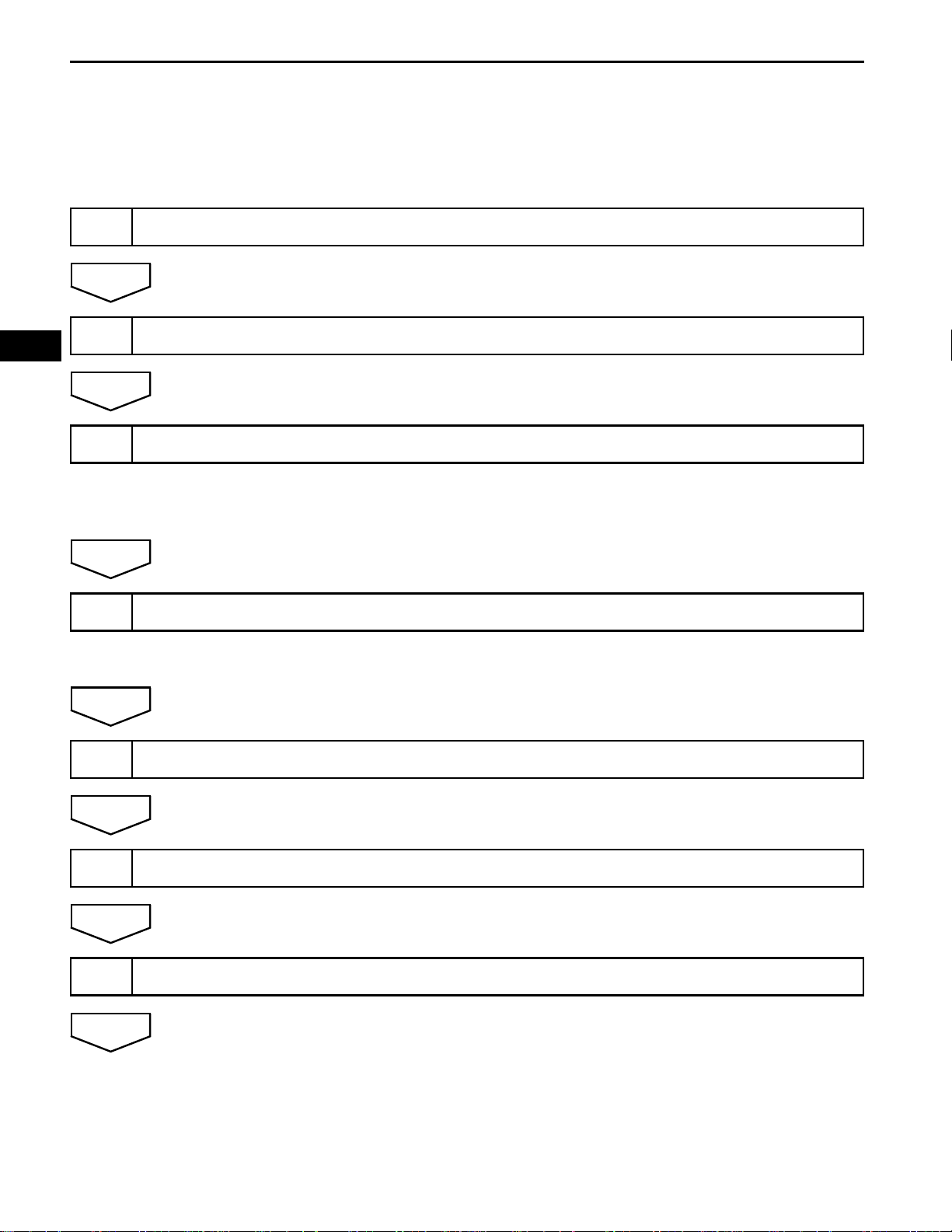

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ECM

FAN No. 3

ES–11

Combination Meter

Transponder Key ECU

Accelerator Pedal Position Sensor

IC

IC

SPD

IMO

IMI

VCP2

VPA2

EPA2

VCPA

VPA

FANL

FANH

A/C Condenser

Fan Motor

M

FAN No. 2

FAN No. 1

Canister Pump Module

To IG1

To Battery

Radiator Fan Motor

M

To Battery

ES

CANH

CANL

PS Oil Pressure SW

EPA

CANH

CANL

PSW

VPMP

VCPP

PPMP

EPPM

MPMP

EC

EOM

Vent Valve

Canister Pressure

Sensor

M

Leak Detection Pump

To EFI No. 3

A132317E01

ES

ES–12

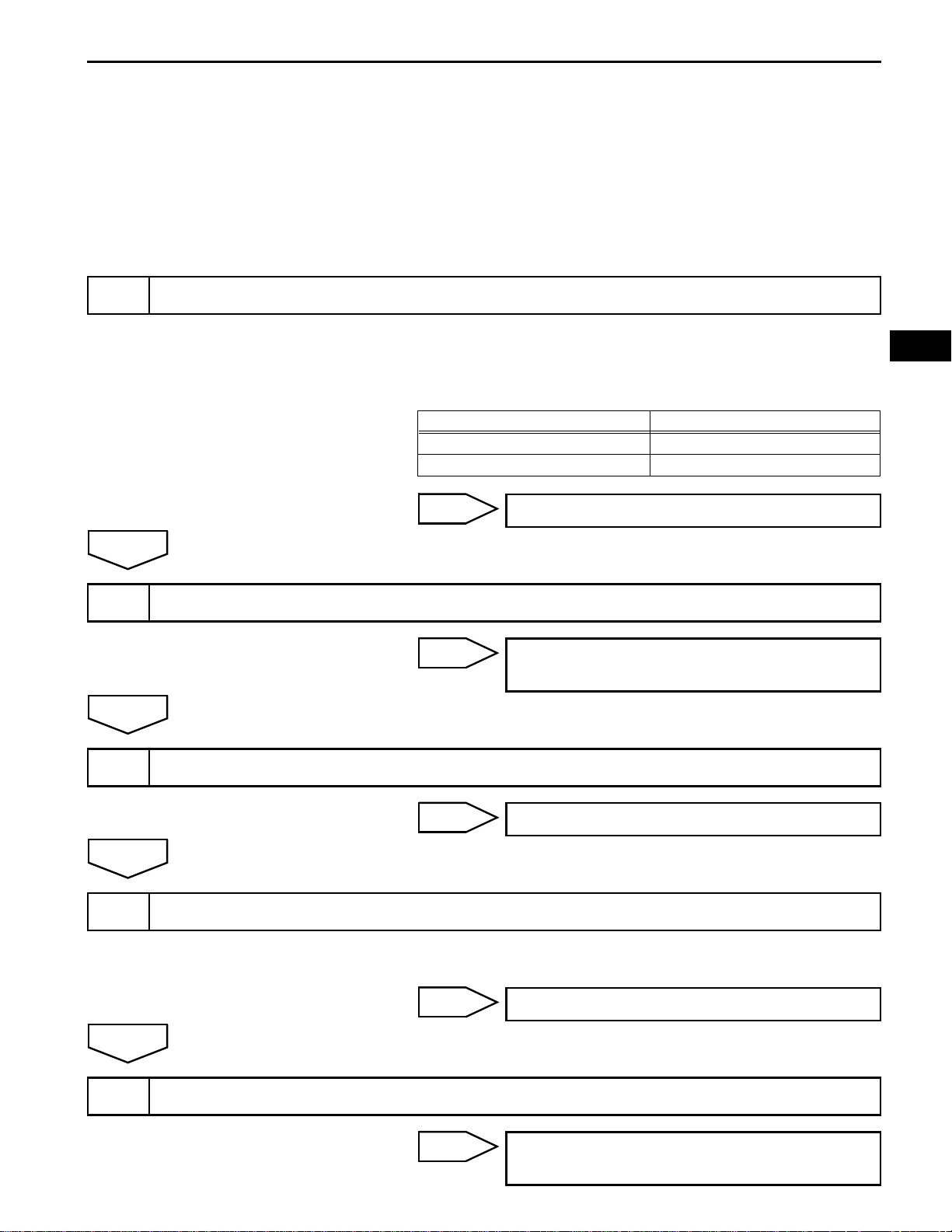

1

NEXT

2

NEXT

3

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

*: Use the intelligent tester.

VEHICLE BROUGHT TO WORKSHOP

CUSTOMER PROBLEM ANALYSIS

CONNECT INTELLIGENT TESTER TO DLC3*

HINT:

If the display indicates a communication fault in the tester,

inspect the DLC3.

NEXT

4

NEXT

5

NEXT

6

NEXT

7

CHECK FOR DTC AND FREEZE FRAME DATA*

HINT:

Record or print DTCs and freeze frame data, if necessary.

CLEAR DTC AND FREEZE FRAME DATA*

CONDUCT VISUAL INSPECTION

SET CHECK MODE DIAGNOSIS*

NEXT

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CONFIRM PROBLEM SYMPTOMS

8

ES–13

HINT:

If the engine does not start, first perform the "CHECK DTC"

procedures and "CONDUCT BASIC INSPECTION"

procedures below.

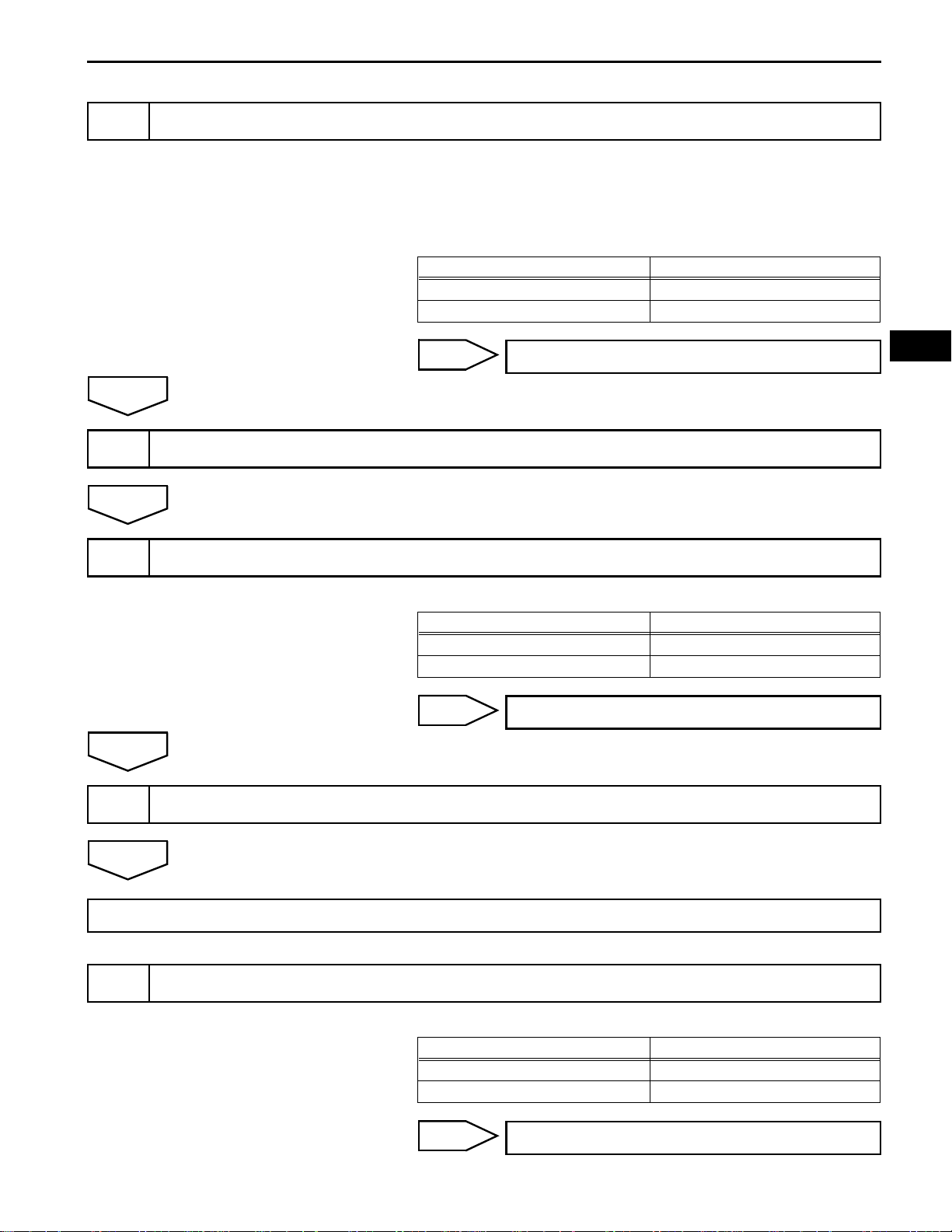

Result

Result Proceed to

Malfunction does not occur A

Malfunction occurs B

A

9

NEXT

10

A

SIMULATE SYMPTOMS

CHECK FOR DTC*

B

Result

B

GO TO STEP 10

Result Proceed to

Trouble code A

No code B

GO TO STEP 12

ES

11

REFER TO DTC CHART

NEXT

GO TO STEP 14

12

CONDUCT BASIC INSPECTION

Result

Result Proceed to

Malfunctioning parts not confirmed A

Malfunctioning parts confirmed B

B

GO TO STEP 17

ES–14

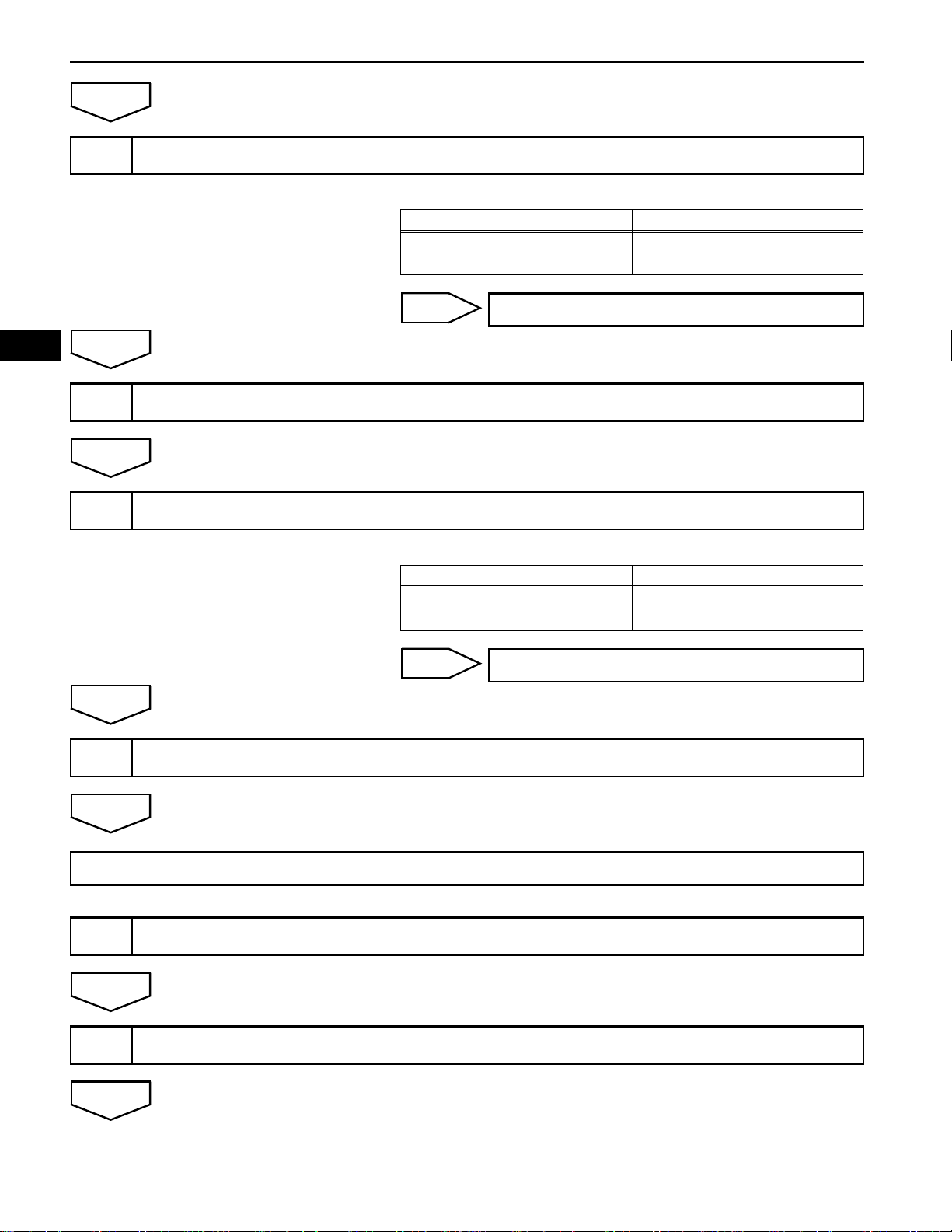

A

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

13

A

14

NEXT

15

REFER TO PROBLEM SYMPTOMS TABLE

Result

Malfunctioning circuit confirmed A

Malfunctioning parts confirmed B

B

CHECK ECM POWER SOURCE CIRCUIT

CONDUCT CIRCUIT INSPECTION

Result

Malfunction not confirmed A

Malfunction confirmed B

Result Proceed to

GO TO STEP 17

Result Proceed to

A

16

NEXT

GO TO STEP 18

17

NEXT

18

NEXT

CHECK FOR INTERMITTENT PROBLEMS

CONDUCT PARTS INSPECTION

IDENTIFY PROBLEM

B

GO TO STEP 18

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–15

19

NEXT

20

NEXT

END

ADJUST AND/OR REPAIR

CONDUCT CONFIRMATION TEST

ES

ES

ES–16

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CHECK FOR INTERMITTENT

PROBLEMS

HINT:

Inspect the vehicle's ECM using check mode. Intermittent

problems are easier to detect with the intelligent tester when

the ECM is in check mode. In check mode, the ECM uses 1

trip detection logic, which is more sensitive to malfunctions

than normal mode (default), which uses 2 trip detection logic.

1. Clear the DTCs (See page ES-38).

2. Switch the ECM from normal mode to check mode using

the intelligent tester (See page ES-41).

3. Perform a simulation test.

4. Check and wiggle the harness(es), connector(s) and

terminal(s).

CHECK BATTERY VOLTAGE

1

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

BASIC INSPECTION

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently . Therefo re, using this check is essential

when engine troubleshooting.

NOTICE:

Conduct this check with the engine stopped and ignition

switch off.

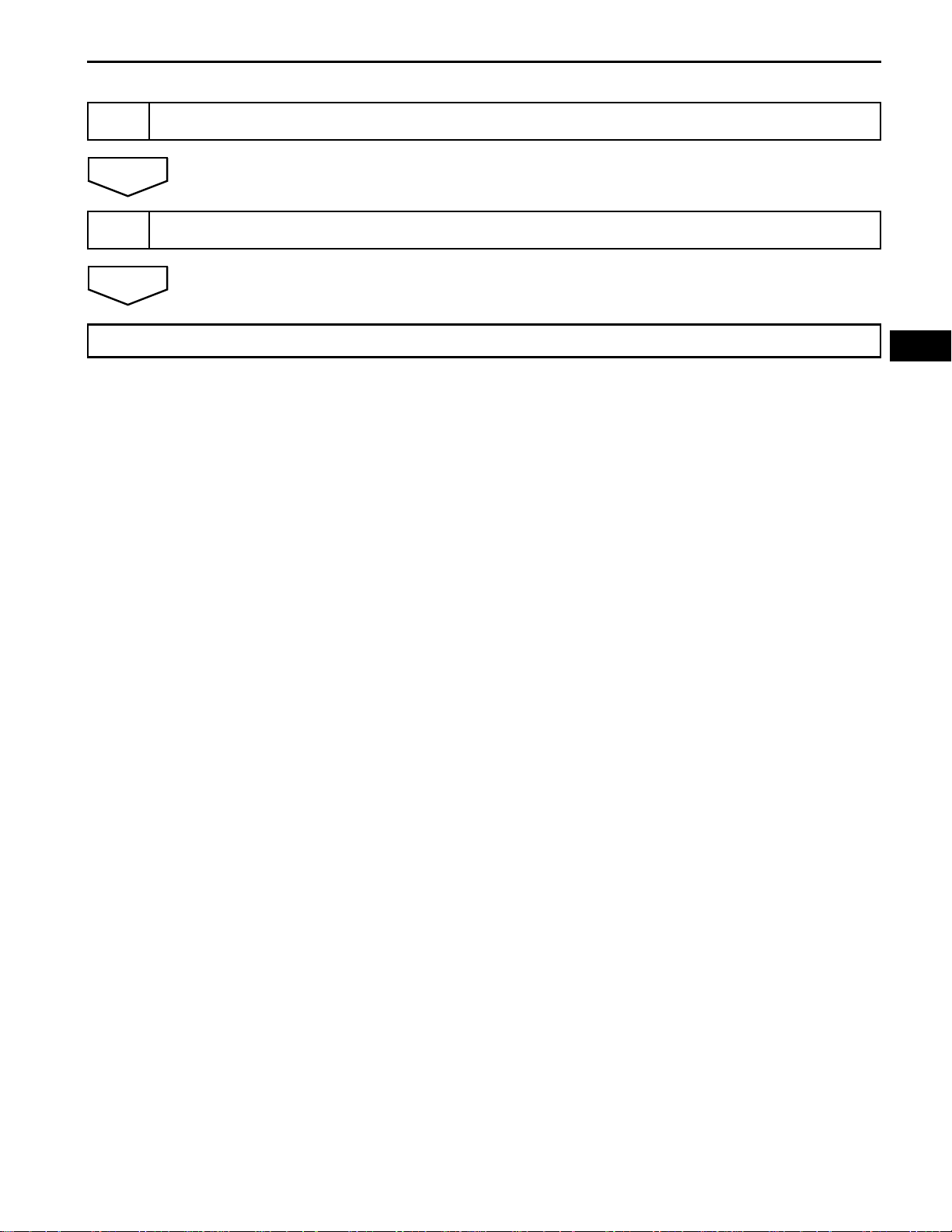

Result

Result Proceed to

11 V or more OK

Below 11 V NG

ES–17

ES

OK

CHECK WHETHER ENGINE WILL CRANK

2

OK

CHECK WHETHER ENGINE STARTS

3

OK

CHECK AIR FILTER

4

NG

NG

NG

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

CHARGE OR REPLACE BATTERY

PROCEED TO PROBLEM SYMPTOMS

TABLE

GO TO STEP 6

OK

CHECK IDLING SPEED

5

NG

NG

REPLACE AIR FILTER

TROUBLESHOOT IDLING SPEED AND

PROCEED TO NEXT STEP

ES–18

OK

6

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CHECK FUEL PRESSURE

ES

NG

OK

CHECK FOR SPARKS

7

NG

OK

PROCEED TO PROBLEM SYMPTOMS TABLE

TROUBLESHOOT FUEL PRESSURE AND

PROCEED TO NEXT STEP

TROUBLESHOOT SPARK AND PROCEED

TO NEXT STEP

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

REGISTRATION

NOTICE:

The Vehicle Identification Number (VIN) must be input

into the replacement ECM.

HINT:

The VIN is a 17-digit alphanumeric number. The intelligent

tester is required to register the VIN.

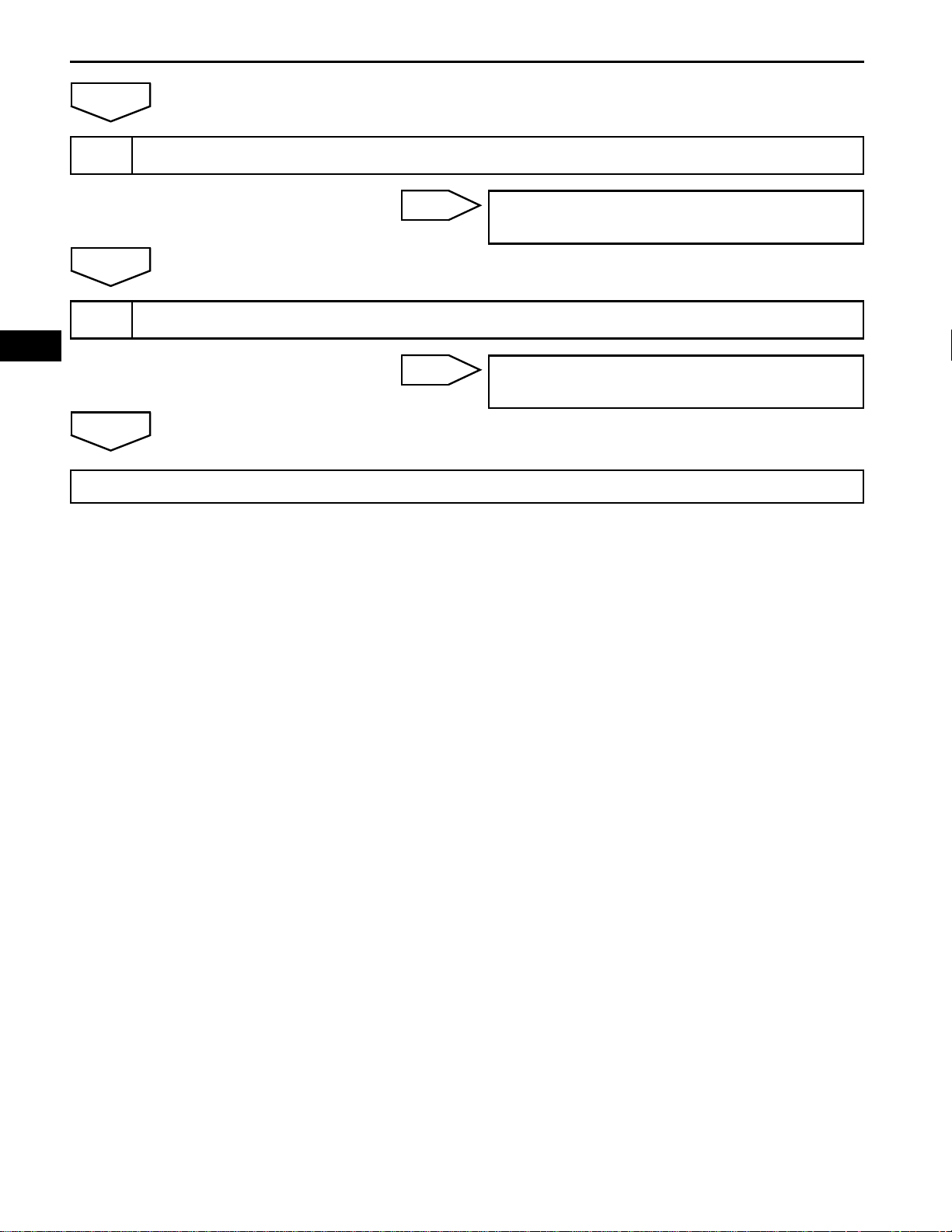

1. DESCRIPTION

This registration section consists of 3 parts: Input

Instructions, Read VIN and Write VIN.

(a) Input Instructions: Explains the general VIN input

instructions when using the intelligent tester.

(b) Read VIN: Explains the VIN reading process in a

flowchart. This process allows the VIN stored in the

ECM to be read in order to confirm that the two

VINs, provided with the vehicle and stored in the

vehicle's ECM, are the same.

(c) Write VIN: Explains the VIN writing process in a

flowchart. This process allows the VIN to be input

into the ECM. If the ECM is changed, or the vehicle

VIN and ECM VIN do not match, the VIN can be

registered or overwritten in the ECM by following

this procedure.

ES–19

ES

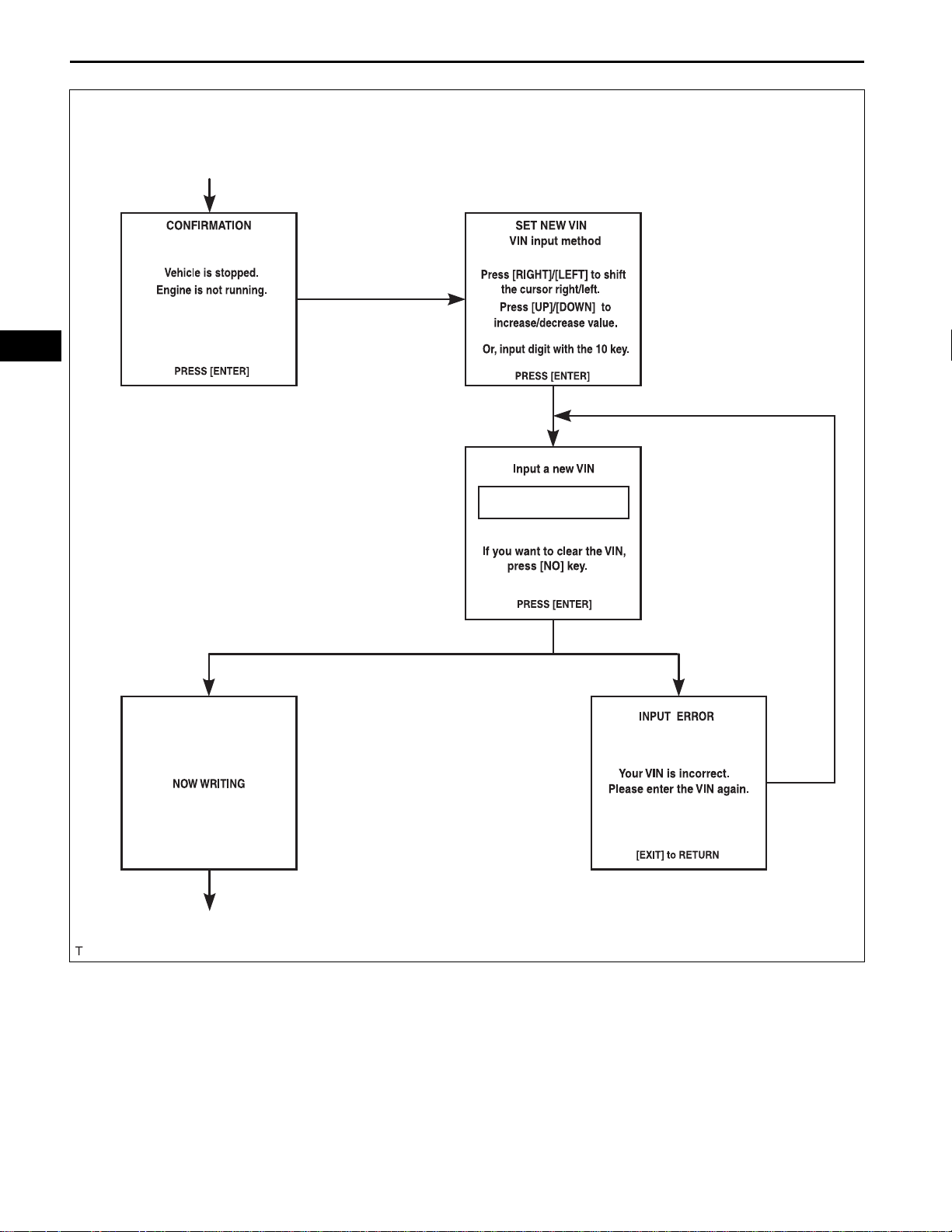

2. INPUT INSTRUCTIONS

(a) Intelligent tester

The arrow buttons (UP, DOWN, RIGHT and LEFT)

and numerical buttons (0 to 9) are used to input the

VIN.

(b) Cursor Operation

To move the cursor around the tester screen, press

the RIGHT and LEFT buttons.

(c) Alphabetical Character Input

(1) Press the UP and DOWN buttons to select the

desired alphabetical character.

(2) After selection, the cursor should move.

(d) Numeric Character Input

(1) Press the numerical button corresponding to

the number that you want to input.

(2) After input, the cursor should move.

HINT:

Numerical characters can also be selected by

using the UP and DOWN buttons.

(e) Correction

(1) When correcting the input character(s), put the

cursor onto the character using the RIGHT and

LEFT buttons.

(2) Select or input the correct character using the

UP/DOWN buttons, or the numerical buttons.

(f) Finishing Input Operation

(1) Make sure that the input VIN matches the

vehicle VIN after input.

(2) Press the ENTER button on the tester.

ES

ES–20

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

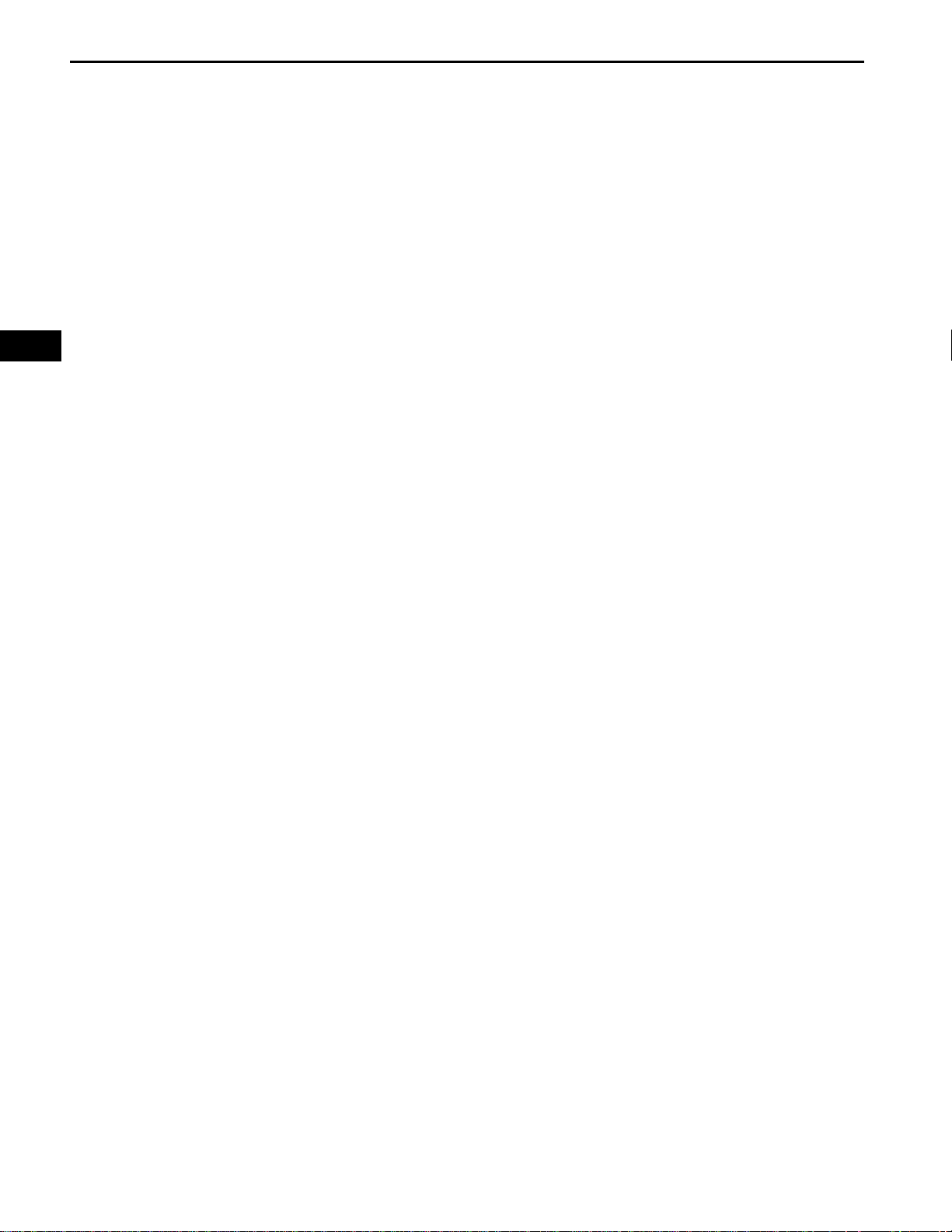

3. READ VIN

(a) Confirm the vehicle VIN.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position.

(d) Turn the tester on.

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II/ VIN.

Menu Screen:

Select VIN READ

DTC P0630 Set

[EXIT]

VIN Previously Stored

[EXIT]

To Menu Screen

VIN Not Stored

17-digit VIN

displayed

[EXIT]

A103812E03

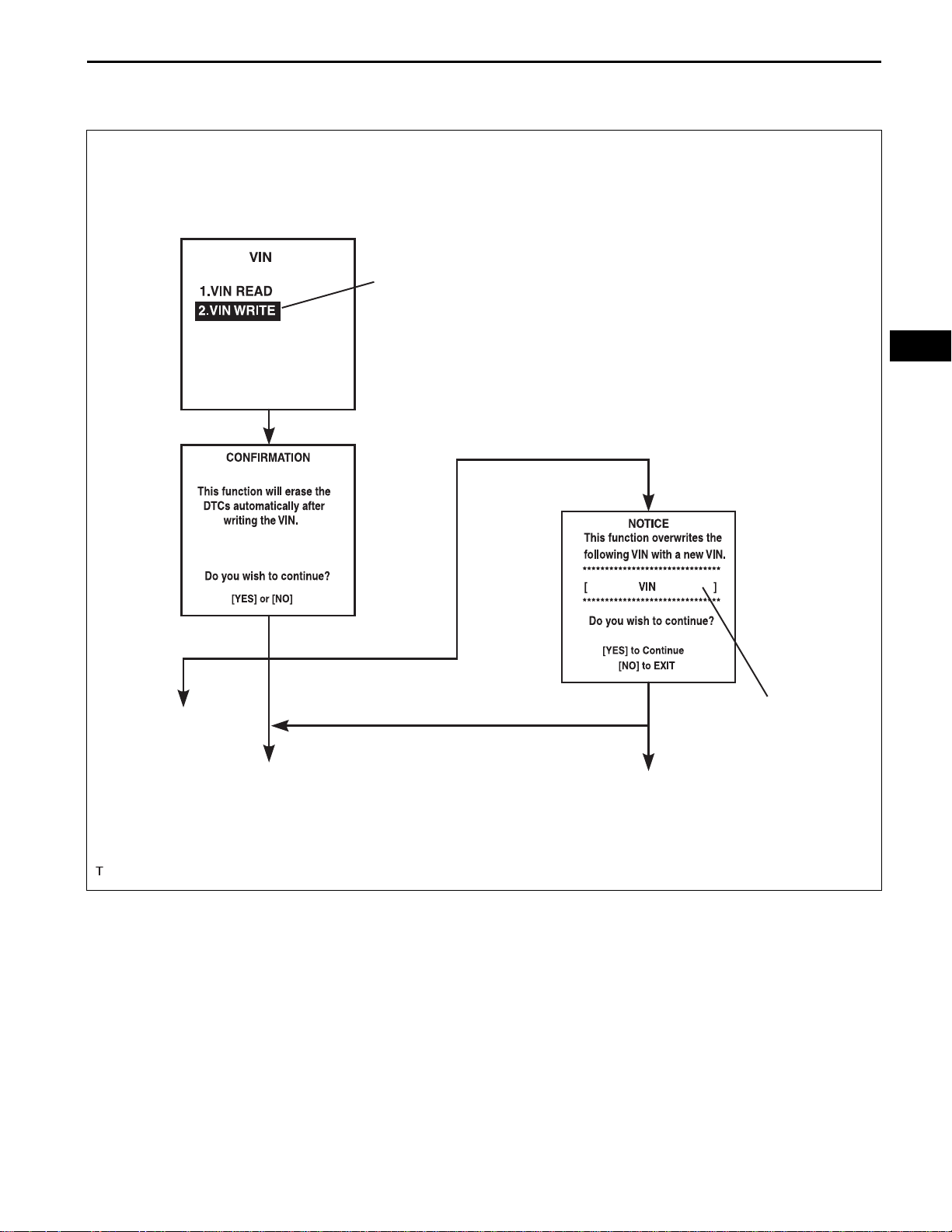

4. WRITE VIN

(a) Confirm the vehicle VIN.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position.

(d) Turn the tester on.

Menu Screen:

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II/ VIN.

Select VIN WRITE

ES–21

ES

VIN Previously Stored

To Menu

Screen

[YES][NO]

[YES]

Continue to next illustration

[YES]

17-digit VIN displayed

[NO]

To Menu Screen

A103813E01

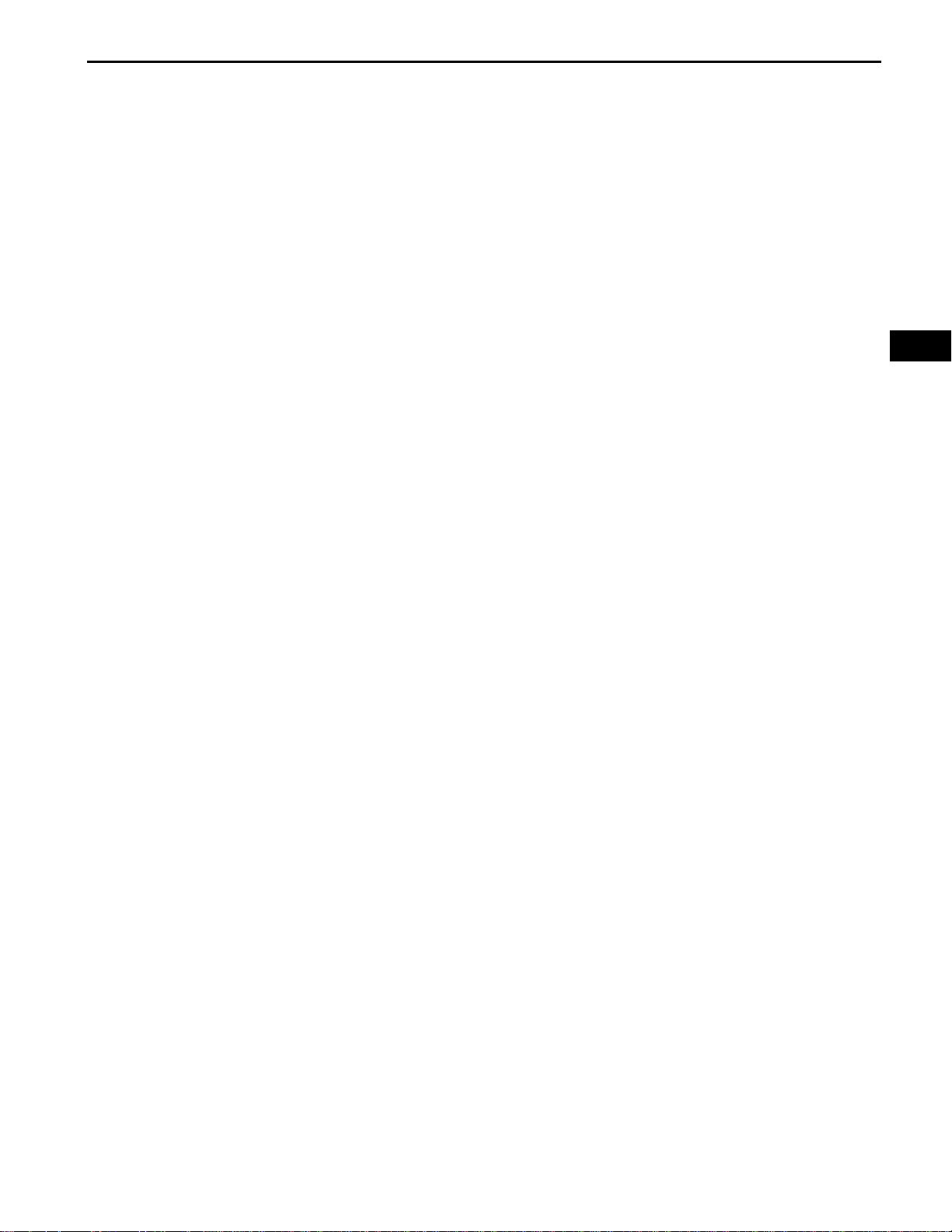

ES–22

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

New Registration

[ENTER]

Input Instructions

[ENTER]

[ENTER]

[ENTER]

Continue to next illustration

Input Error

[Exit]

A136113E01

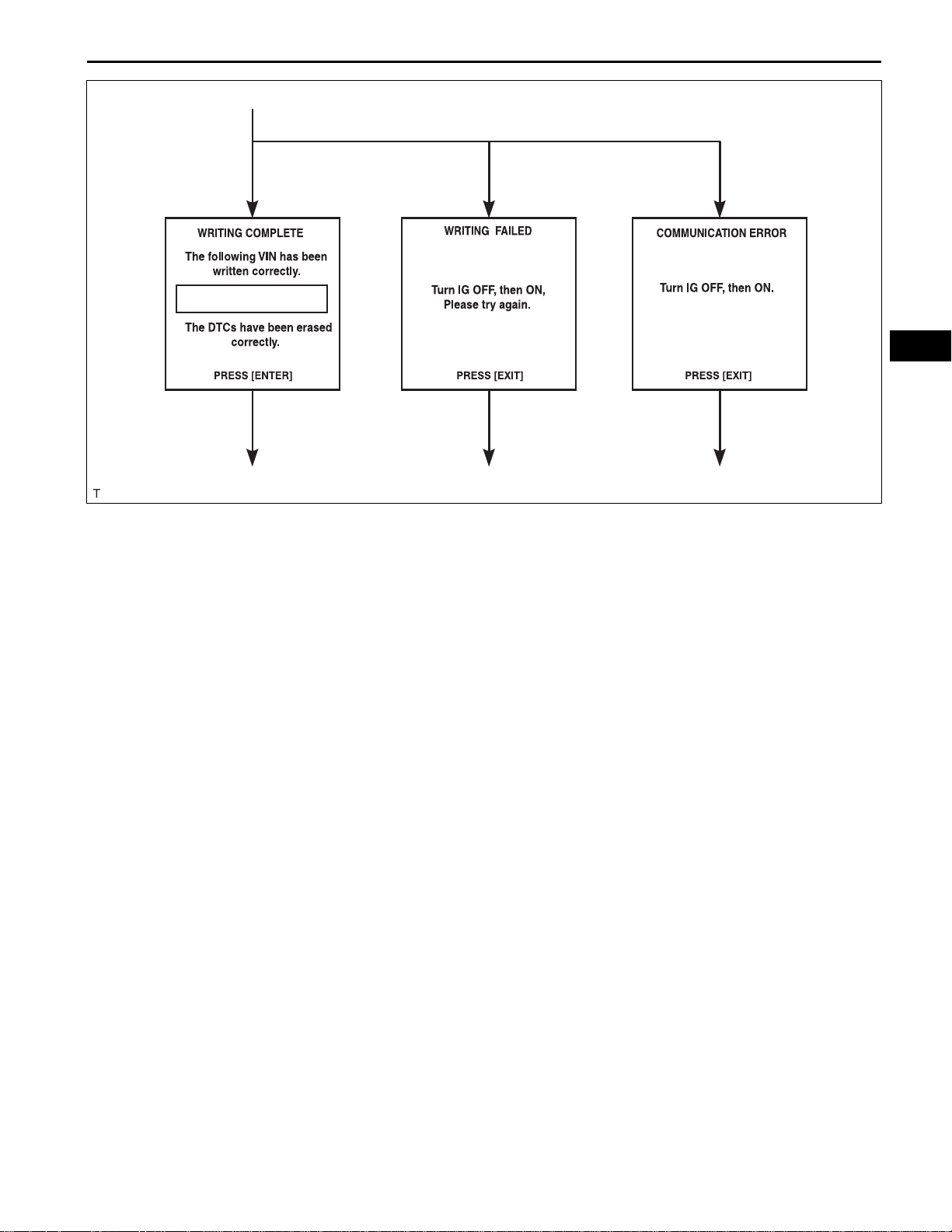

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Writing Successful Writing Error Communication Error

[ENTER] [EXIT] [EXIT]

ES–23

ES

To Menu Screen To Menu Screen To Menu Screen

A103815E03

ES

ES–24

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow

access to the results of on-board diagnostic monitoring tests

of specific components/systems that are not continuously

monitored. Examples are catalysts and evaporative

emissions (EVAP).

The monitor result allows the OBD II scan tool to display the

monitor status, test value, minimum test limit and maximum

test limit. These data are displayed after the vehicle has been

driven to run the monitor.

When the test value is not between the minimum test limit

and maximum test limit, the ECM (PCM) interprets this as a

malfunction. If the test value is on the borderline of the test

limits, the component is likely to malfunction in the near

future.

Perform the following instructions to view the monitor status.

Although this instruction refers to the Lexus/Toyota diagnostic

tester, it can be checked using a generic OBD II scan tool.

Refer to your scan tool operator's manual for specific

procedural information.

1. PERFORM MONITOR DRIVE PATTERN

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn

the tester on.

(c) Clear the DTCs (See page ES-38).

(d) Run the vehicle in accordance with the applicable

drive pattern described in READINESS MONITOR

DRIVE PATTERN (See page ES-23). Do not turn

the ignition switch off.

NOTE:

The test results will be lost if the ignition

switch is turned off.

2. ACCESS MONITOR RESULT

(a) Select the following items from the intelligent tester

menus: DIAGNOSIS / ENHANCED OBD II /

MONITOR INFO and MONITOR RESULT. The

monitor status appears after the component name.

• INCMP: The component has not been monitored

yet.

• PASS: The component is functioning normally.

• FAIL: The component is malfunctioning.

(b) Confirm that the component is either PASS or FAIL.

(c) Select the component and press ENTER. The

accuracy test value appears if the monitor status is

either PASS or FAIL.

3. CHECK COMPONENT STATUS

(a) Compare the test value with the minimum test limit

(MIN LIMIT) and maximum test limit (MAX LIMIT).

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(b) If the test value is between the minimum test limits

and maximum test limits, the component is

functioning normally. If not, the component is

malfunctioning. The test value is usually not near

the test limit. If the test value is on the borderline of

the test limits, the component is likely to malfunction

in the near future.

HINT:

The monitor result might be PASS on rare

occasions even if the malfunction indicator lamp

(MIL) is illuminated. This indicates the system

malfunctioned on a previous driving cycle. This

might be caused by an intermittent problem.

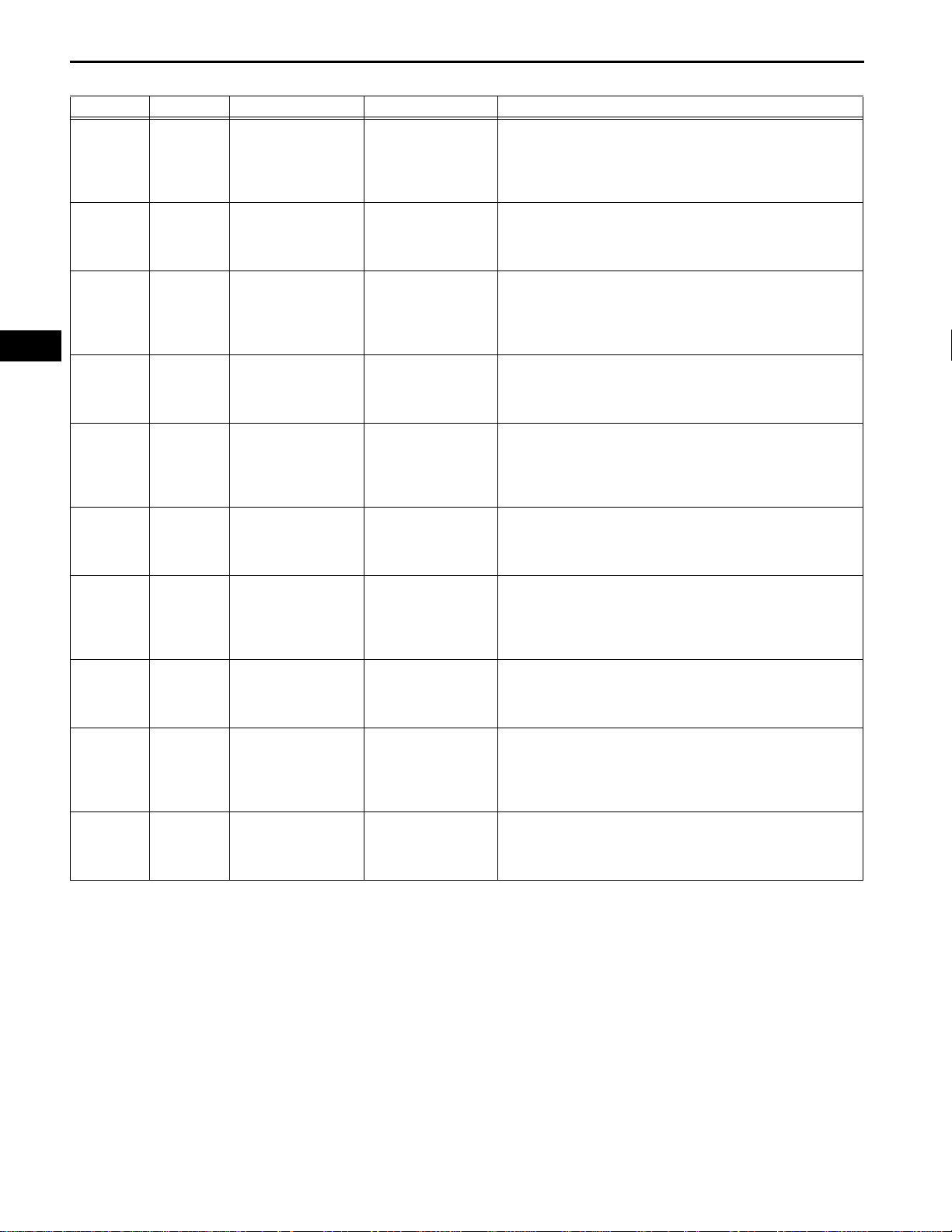

4. MONITOR RESULT INFORMATION

If you use a generic scan tool, multiply the test value by

the scaling value listed below.

A/F Sensor (Sensor 1):

Monitor ID Test ID Scaling Unit Description

$01 $8E Multiply by 0.001 V A/F sensor deterioration level

$01 $91 Multiply by 0.004 mA A/F sensor current

ES–25

ES

HO2 Sensor (Sensor 2):

Monitor ID Test ID Scaling Unit Description

$02 $07 Multiply by 0.001 V Minimum sensor voltage

$02 $08 Multiply by 0.001 V Maximum sensor voltage

$02 $8F Multiply by 0.0003 g Maximum oxygen storage capacity

Catalyst:

Monitor ID Test ID Scaling Unit Description

$21 $A9 Multiply by 0.0003 No dimension Oxygen storage capacity of catalyst

EVAP:

Monitor ID Test ID Scaling Unit Description

$3D $C9 Multiply by 0.001 kPa Test value for small leak (P0456)

$3D $CA Multiply by 0.001 kPa Test value for gross leak (P0455)

$3D $CB Multiply by 0.001 kPa Test value for leak detection pump stuck OFF (P2401)

$3D $CD Multiply by 0.001 kPa Test value for leak detection pump stuck ON (P2402)

$3D $CE Multiply by 0.001 kPa Test value for vent valve stuck OFF (P2420)

$3D $CF Multiply by 0.001 kPa Test value for vent valve stuck ON (P2419)

$3D $D0 Multiply by 0.001 kPa Test value for re ference orifice low flow (P043E)

$3D $D1 Multiply by 0.001 kPa Test value for re ference orifice high flow (P043F)

$3D $D4 Multiply by 0.001 kPa Test value for purge VSV stuck closed (P0441)

$3D $D5 Multiply by 0.001 kPa Test value for purge VSV stuck open (P0441)

$3D $D7 Multiply by 0.001 kPa Test value for purge flow insufficient (P0441)

Rear Oxygen Sensor Heater:

Monitor ID Test ID Scaling Unit Description

$42 $91 Multiply by 0.001 Ohm Oxygen sensor resistance bank 1 sensor 2

ES

ES–26

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Misfire:

Monitor ID Test ID Scaling Unit Description

Exponential Weighted Moving Average (EWMA) misfire for all

cylinders:

$A1 $0B Multiply by 1 Time

$A1 $0C Multiply by 1 Time

$A2 $0B Multiply by 1 Time

$A2 $0C Multiply by 1 Time

$A3 $0B Multiply by 1 Time

$A3 $0C Multiply by 1 Time

$A4 $0B Multiply by 1 Time

$A4 $0C Multiply by 1 Time

$A5 $0B Multiply by 1 Time

$A5 $0C Multiply by 1 Time

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

Ignition switch to the ON position: Total misfire counts for last

driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - all cylinders

Exponential Weighted Moving Average (EWMA) misfire for

cylinder 1:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

Ignition switch to the ON position: Total misfire counts for last

driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 1

Exponential Weighted Moving Average (EWMA) misfire for

cylinder 2:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

Ignition switch to the ON position: Total misfire counts for last

driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 2

Exponential Weighted Moving Average (EWMA) misfire for

cylinder 3:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

Ignition switch to the ON position: Total misfire counts for last

driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 3

Exponential Weighted Moving Average (EWMA) misfire for

cylinder 4:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

Ignition switch to the ON position: Total misfire counts for last

driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 4

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

READINESS MONITOR DRIVE

PATTERN

1. PURPOSE OF READINESS TESTS

• The On-Board Diagnostic (OBD II) system is designed to

monitor the performance of emission related components,

and indicate any detected abnormalities with DTCs

(Diagnostic Trouble Codes). Since various components

need to be monitored during different driving conditions,

the OBD II system is designed to run separate monitoring

programs called Readiness Monitors.

• The intelligent tester's software must be version 9.0 or

newer to view the Readiness Monitor Status. To view the

status, select the following menu items: DIAGNOSIS /

ENHANCED OBD II / MONITOR INFO / MONITOR

STATUS.

• When the Readiness Monitor status reads COMPL

(complete), the necessary conditions have been met for

running the performance tests for that Readiness Monitor.

• A generic OBD II scan tool can also be used to view the

Readiness Monitor status.

HINT:

Many state Inspection and Maintenance (I/M) programs

require a vehicle's Readiness Monitor status to show COMPL

before beginning emission tests.

The Readiness Monitor will be reset to INCMPL (incomplete)

if:

• The ECM has lost battery power or blown a fuse.

• DTCs have been cleared.

• The conditions for running the Readiness Monitor have not

been met.

If the Readiness Monitor status shows INCMPL, follow the

appropriate Readiness Monitor Drive Pattern to change the

status to COMPL.

CAUTION:

Strictly observe posted speed limits, traffic laws, and

road conditions when performing these drive patterns.

NOTICE:

These drive patterns represent the fastest method of

satisfying all conditions necessary to achieve complete

status for each specific Readiness Monitor.

In the event of a drive pattern being interrupted (possibly

due to factors such as traffic conditions), the drive

pattern can be resumed. In most cases, the Readiness

Monitor will still achieve complete status upon

completion of the drive pattern.

To ensure completion of the Readiness Monitors, avoid

sudden changes in vehicle load and speed (driving up

and down hills and/or sudden acceleration).

ES–27

ES

ES

ES–28

Vehicle Speed

Between

40 mph and 70 mph

(64 km/h and 113 km/h)

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

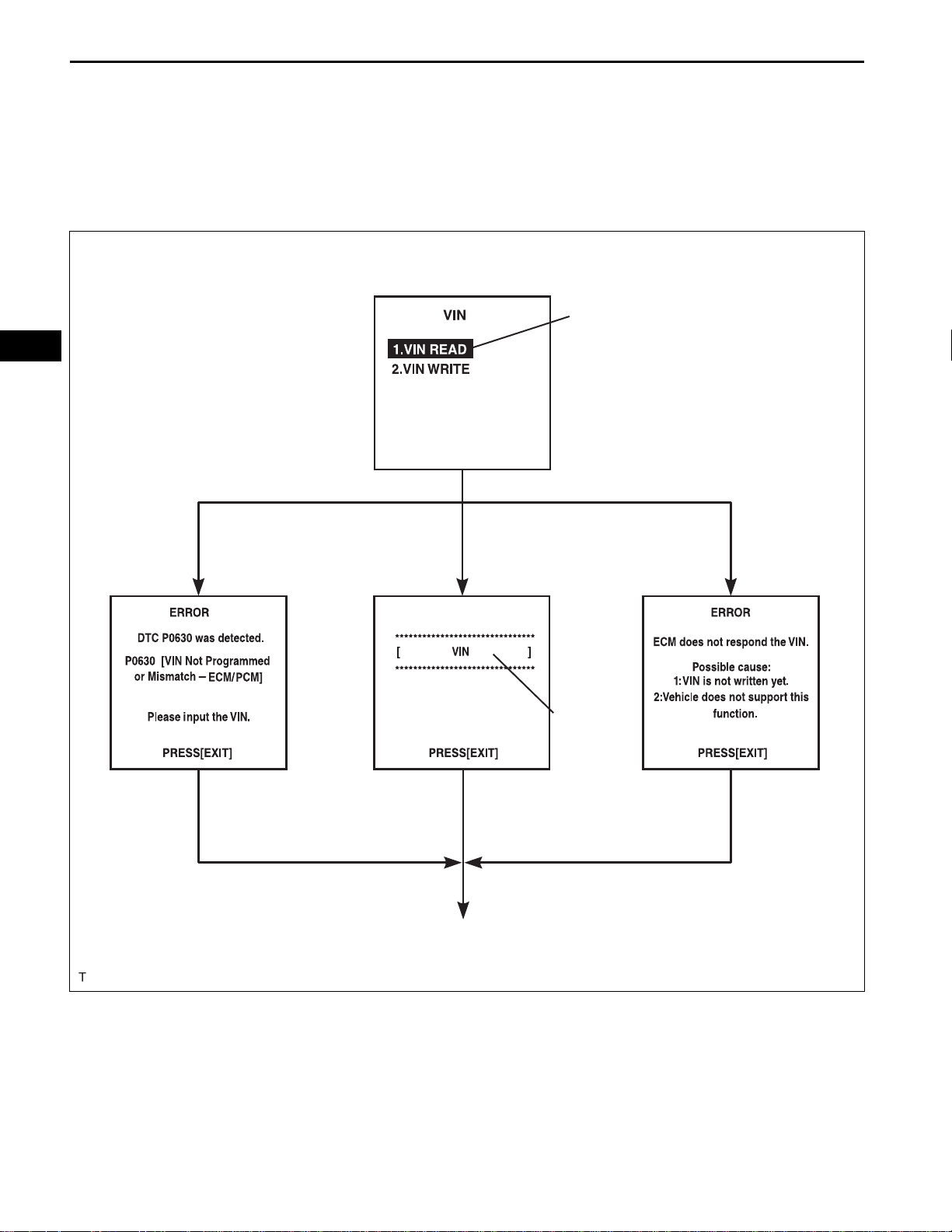

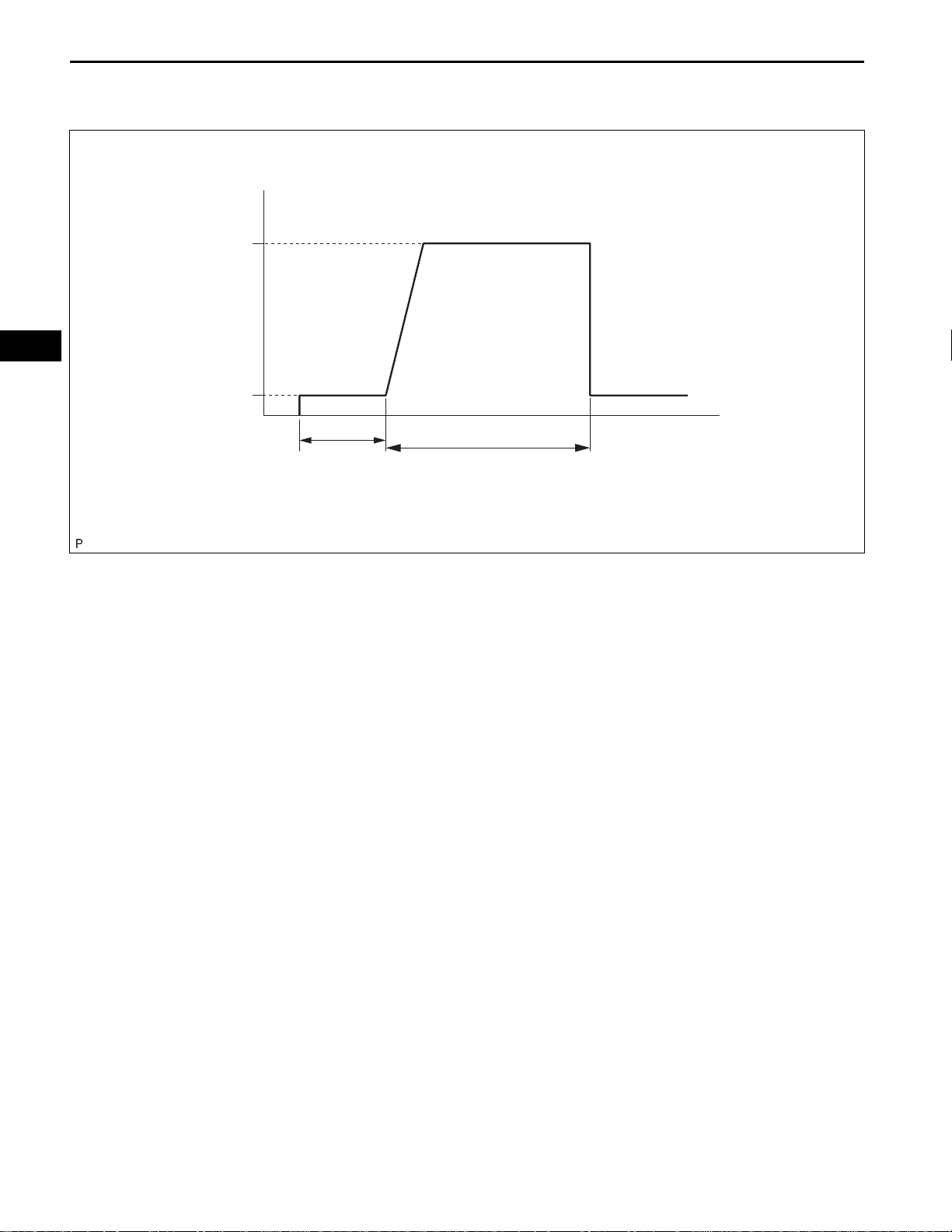

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

NOTICE:

This test will not be completed

if the vehicle is driven at

absolutely constant speed

(6)

such as with cruise control

activated.

Idling

Ignition Switch OFF

(Note: Even when vehicle stops during driving pattern, test can be resumed)

(5)

Time

Warm up 10 minutes

A115372E50

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester on.

(4) Clear the DTCs (if set) (See page ES-38).

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

Check the Readiness Monitor status displayed on

the tester .

If the status does not switch to COMPL (complete),

extend the driving time.

3. EVAP SYSTEM MONITOR (KEY OFF TYPE)

(a) Preconditions

The monitor will not run unless:

– The fuel tank is less than 90% full.

– The altitude is less than 8,000 ft. (2,450 m).

– The vehicle is stationary.

– The engine coolant temperature is between

4.4°C and 35°C (40°F and 95°F).

– The intake air temperature is between 4.4°C and

35°C (40°F and 95°F).

– Vehicle was driven in a city area (or o n free-way)

for 10 minutes or more.

Monitor Drive Pattern

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester on.

(4) Check the Readiness Monitor status displayed

on the tester.

If the status does not switch to COMPL (complete), rest art the

engine, make sure that the preconditions have been met, and

then perform the Monitor Conditions again.

4. AIR-FUEL RA TIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR MONITORS (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

ES–29

ES

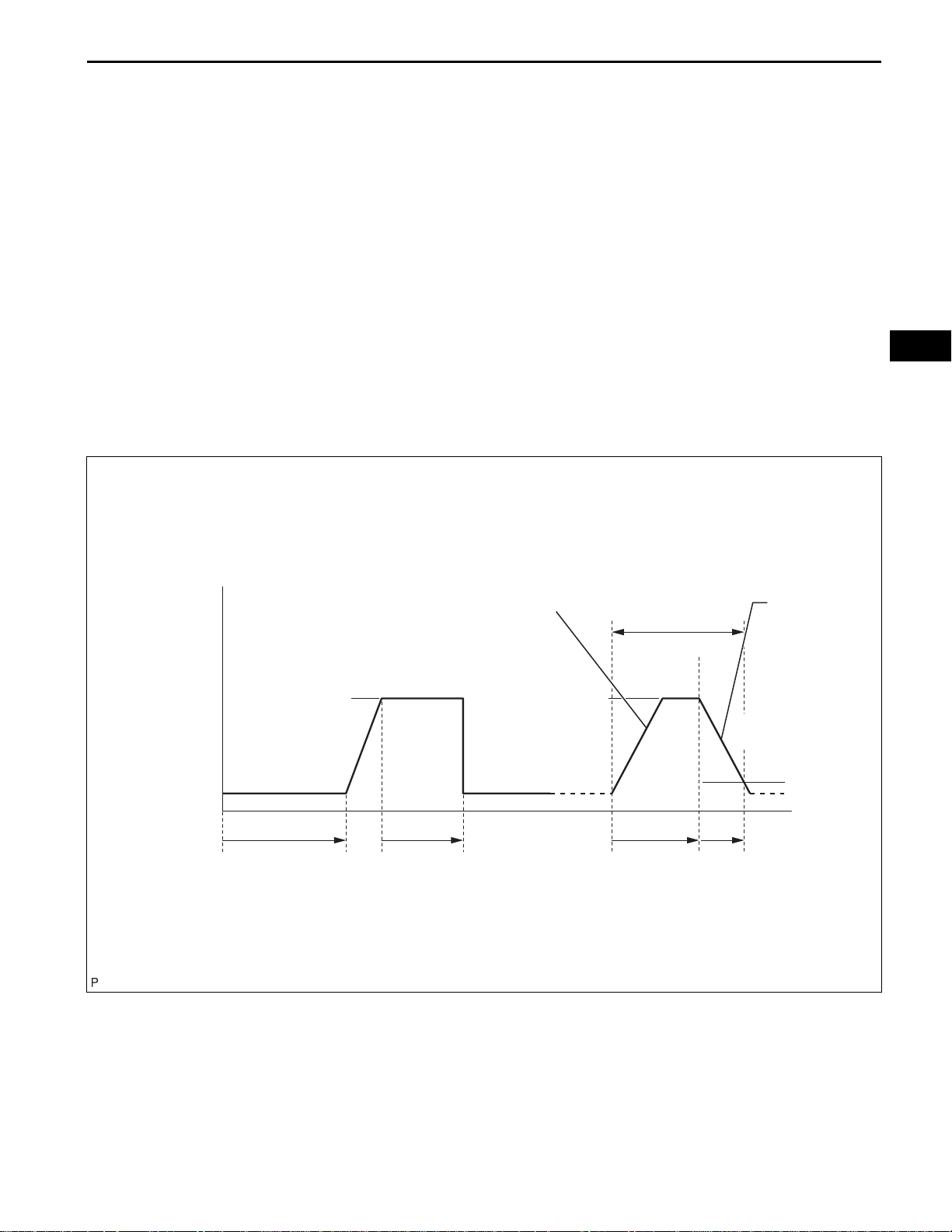

ECT: 75°C (167°F) or more

Vehicle Speed

Between 38 and 75 mph

(60 and 120 km/h)

(5)

Idling

Warming up

Accelerator Pedal

Depressed

(6)

10 minutes

or more

40 mph (64 km/h)

or more

(7)

At least 3 times

(8)

10 seconds

or more

Accelerator

Pedal

Released

(Fuel-cut)

(9)

(10)

6 mph

(10 km/h)

Time

4 seconds

or more

(a) Preconditions

The monitor will not run unless:

– 2 minutes or more have elapsed since the engine

was started.

– The Engine Coolant Temperature (ECT) is 75°C

(167°F) or more.

– Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

– Air-fuel ratio feedback control is performed.

A115374E09

ES

ES–30

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(b) Drive Pattern for front A/F sensor and HO2 sensor

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester on.

(4) Clear the DTCs (See page ES-38).

(5) Start the engine, and warm it up until the ECT

reaches 75°C (167°F) or higher

(6) Drive the vehicle at between 38 mph (60 km/h)

and 75 mph (120 km/h) for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds.

(9) Soon after performing step (8) above, release

the accelerator pedal for at least 4 seconds

without depressing the brake pedal, in order to

execute fuel-cut control.

(10)Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h).

(11)Repeat steps from (8) through (10) above at

least 3 times in one driving cycle.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met, and then perform steps from (5)

through (11) in the Drive Pattern above.

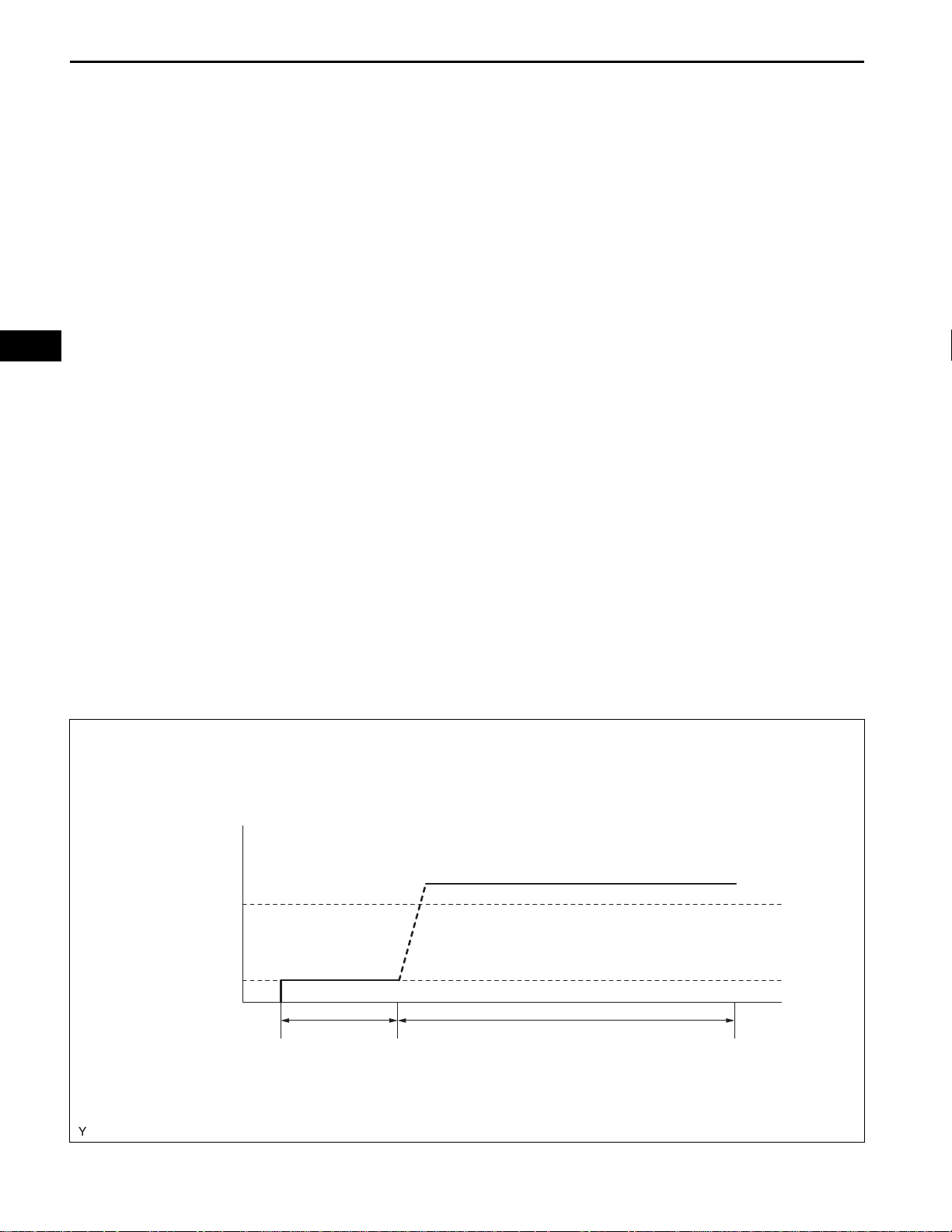

5. AIR-FUEL RA TIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONITORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

Vehicle Speed

25 mph (40 km/h)

Idling

Ignition Switch OFF

(6)

10 minutes or more

(7)

2 minutes or more

A121604E07

Loading...

Loading...