Toyota Camry 2007-2009 Service Manual - 2AZ-FE_Cooling

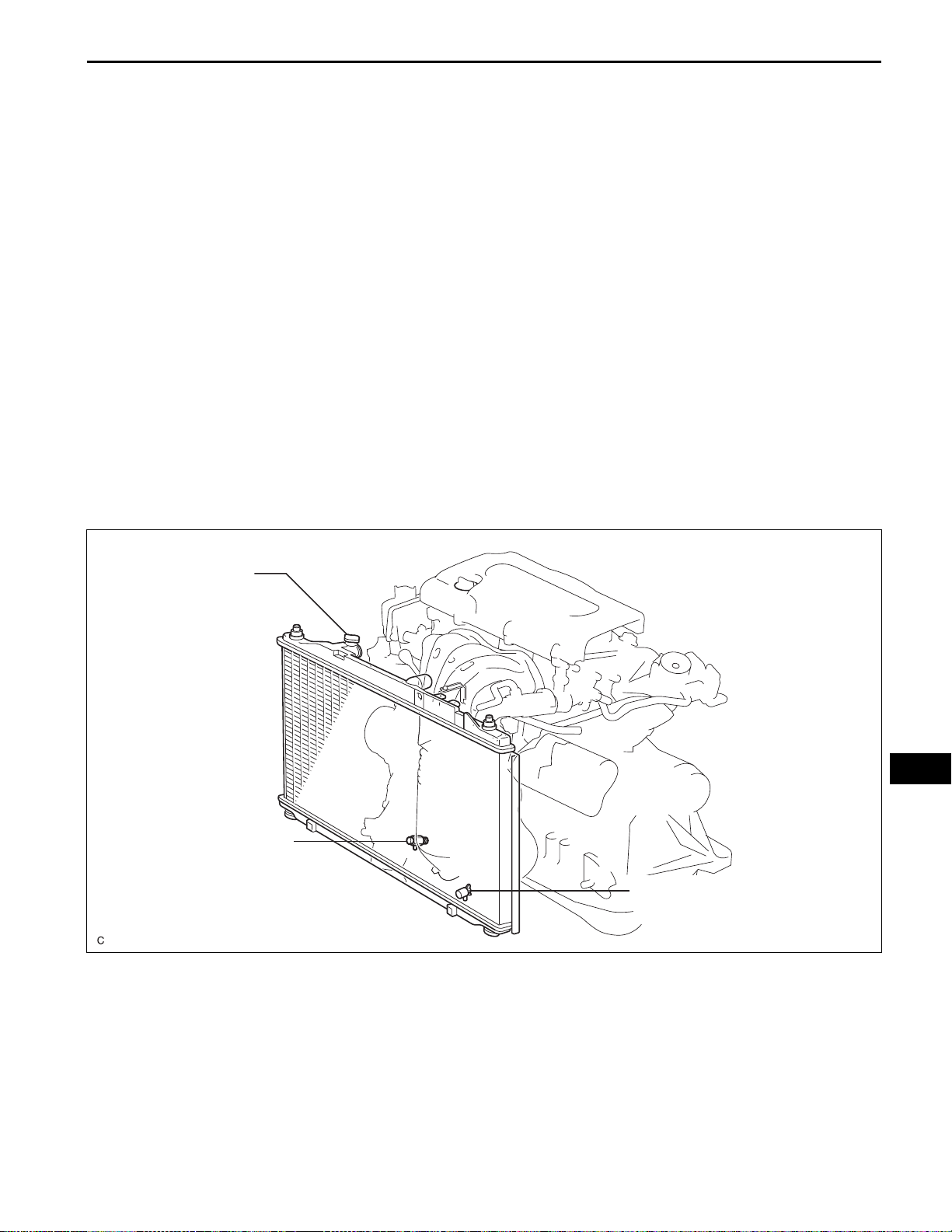

2AZ-FE COOLING – COOLING SYSTEM

COOLING SYSTEM

ON-VEHICLE INSPECTION

1. CHECK FOR ENGINE COOLANT LEAKS

NOTICE:

Before performing each inspection, turn the A/C

switch OFF.

CAUTION:

A135234

Do not remove the radiator cap while the engine and

radiator are still hot. Pressurized, hot engine coolant

and steam may be released and cause serious

burns.

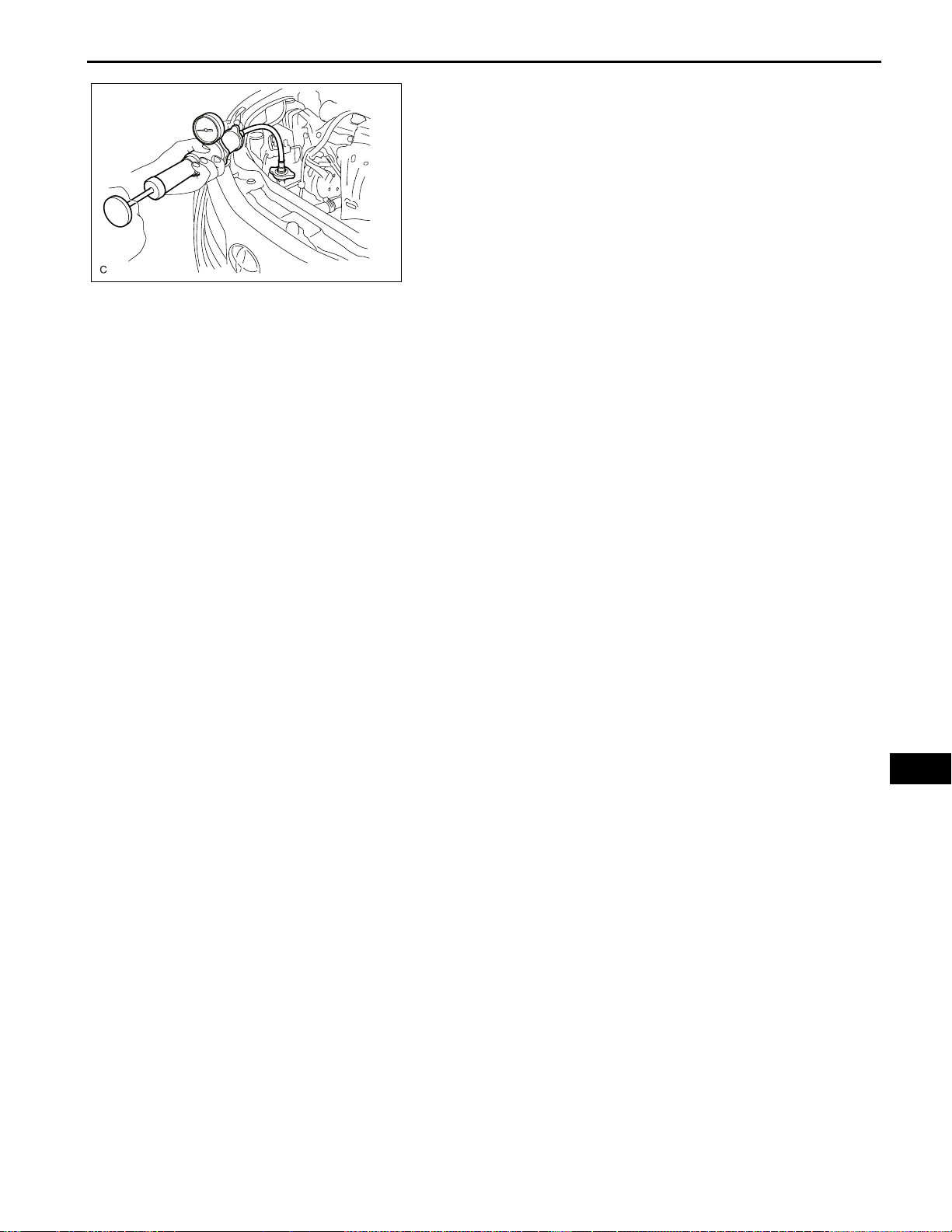

(a) Fill the radiator with coolant and attach a radiator

cap tester .

(b) Warm up the engine.

(c) Using a radiator cap tester, increase the pressure

inside the radiator to 118 kPa (1.2 kgf*cm, 17 psi),

and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and

water pump for leaks. If no external leaks are found,

check the heater core, cylinder block and cylinder

head.

CO–1

2. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR

(a) Check that the engine coolant level is between the

LOW and FULL lines when the engine is cold.

If the engine coolant level is low , check for leaks and

add "TOYOTA Super Long Life Coolant" or similar

high quality ethylene glycol based non-silicate, non-

amine, non-nitrite and non-borate coolant with long-

life hybrid organic acid technology to the FULL line.

NOTICE:

Do not substitute plain water for engine coolant.

3. INSPECT ENGINE COOLANT QUALITY

(a) Remove the radiator cap.

CAUTION:

Do not remove the radiator cap while the engine

and radiator are still hot. Pressurized, hot

engine coolant and steam may be released and

cause serious burns.

(b) Check if there are any excessive deposits of rust or

scales around the radiator cap and radiator filler

hole. Also, the coolant should be free of oil.

If excessively dirty, clean the coolant passage and

replace the coolant.

(c) Install the radiator cap.

CO

CO–2

ENGINE2AZ-FE COOLING

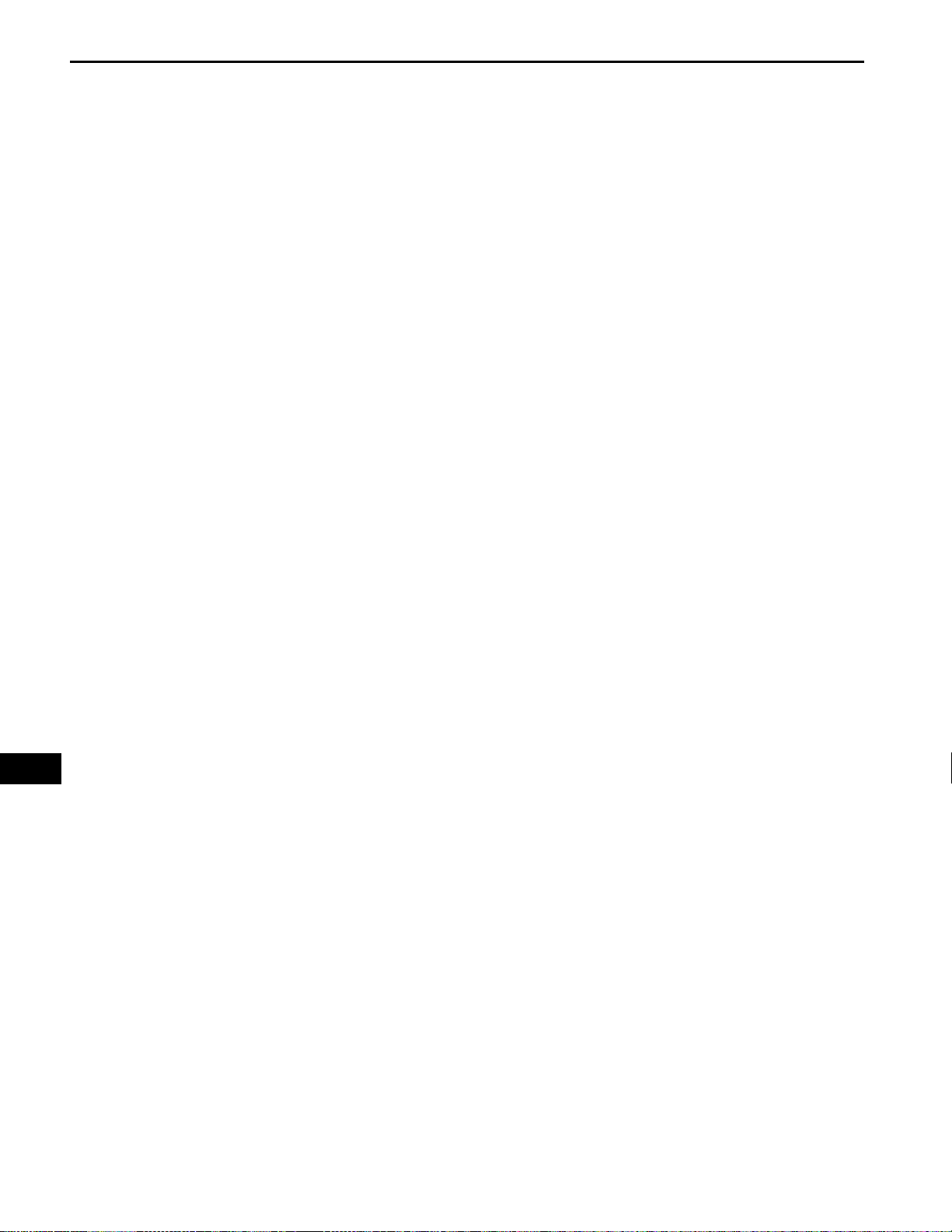

2AZ-FE COOLING – COOLING FAN SYSTEM

COOLING FAN SYSTEM

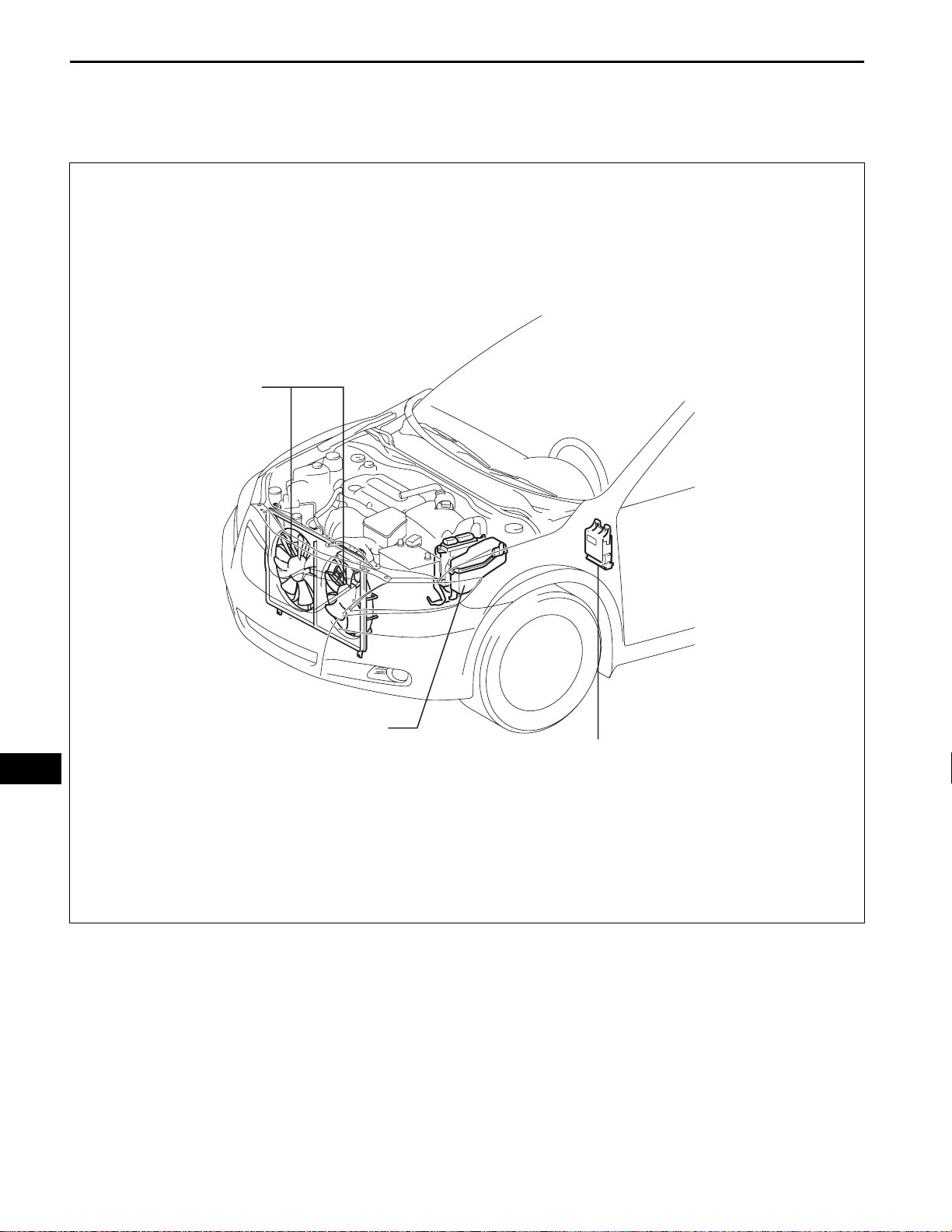

PARTS LOCATION

COOLING FAN MOTOR

CO

ENGINE ROOM RELAY BLOCK

-COOLING FAN RELAY

-CDS FAN FUSE

-RDI FAN FUSE

INSTRUMENT PANEL JUNCTION BLOCK

-ECU IG FUSE NO. 1

A137456E02

2AZ-FE COOLING – COOLING FAN SYSTEM

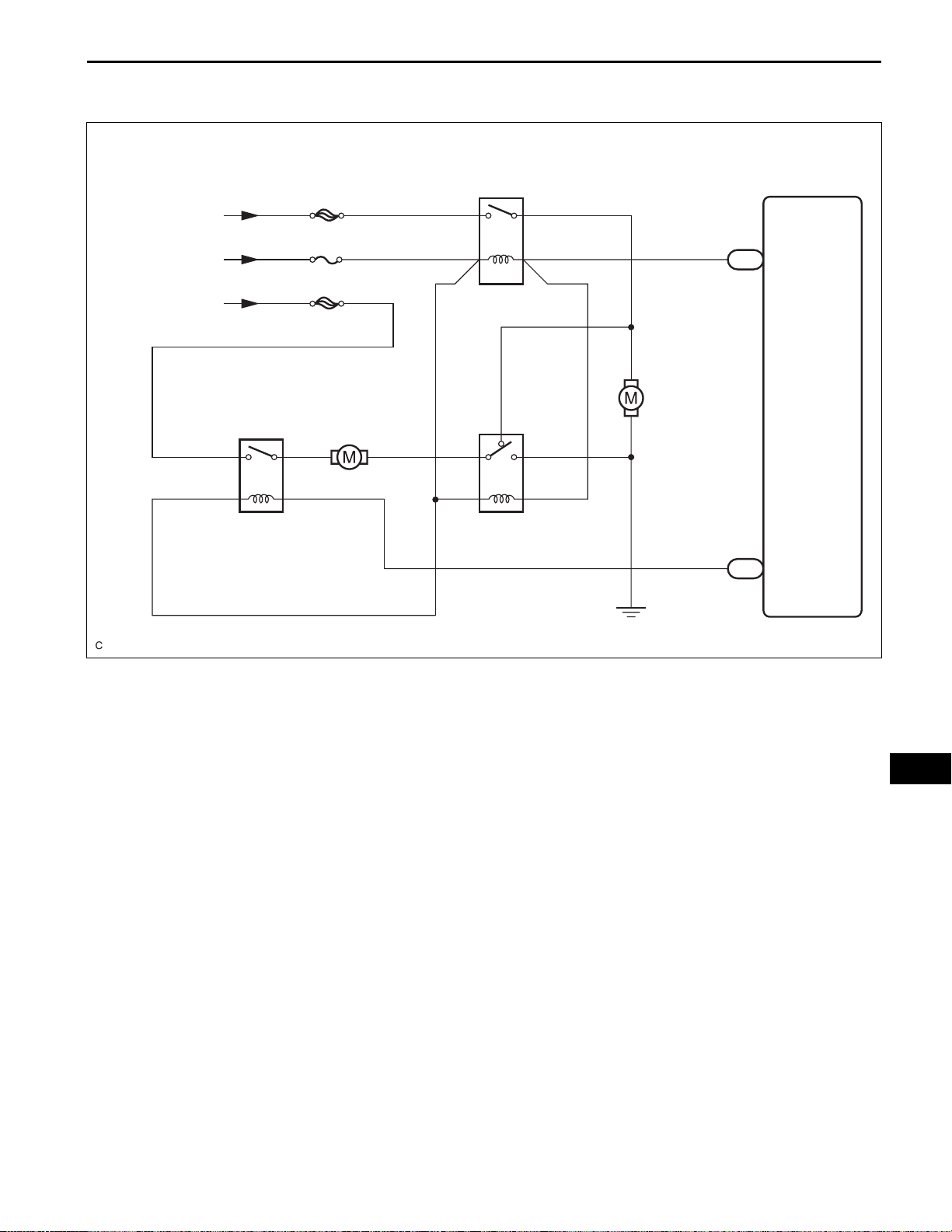

SYSTEM DIAGRAM

CO–3

From Battery

From

Ignition Switch

From Battery

RDI FAN

ECU IG No. 1

CDS FAN

A6

A/C Condenser

Fan Motor

FAN No. 3

5231

1

2

FAN No. 1

35

12

FAN No. 2

4

35

1

2

2

1

ECM

22

FANHA24

A7

Radiator

Fan Motor

21

FANLA24

A137000

CO

CO–4

2AZ-FE COOLING – COOLING FAN SYSTEM

ON-VEHICLE INSPECTION

1. INSPECT COOLING FAN OPERATION AT LOW

TEMPERATURES (Below 83°C (181°F))

(a) Turn the ignition switch to the ON position.

(b) Check that the cooling fan stops.

If not, check the cooling fan relay and engine

coolant temperature sensor, and check whether

there is disconnection or an open circuit between

them.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Check that the cooling fan rotates.

If not, check the fuses, cooling fan relay, ECM and

cooling fan, and check for a short circuit between

the cooing fan relay and engine coolant temperature

sensor.

(e) Reconnect the engine coolant temperature sensor

connector.

2. INSPECT COOLING FAN OPERATION AT HIGH

TEMPERATURES (Above 93°C (199°F))

(a) Start the engine, and raise the engine coolant

temperature to above 93°C (199°F).

HINT:

Engine coolant temperature is detected by the

engine coolant temperature sensor on the water

outlet.

(b) Check that the cooling fan rotates.

If not, replace the engine coolant temperature

sensor.

CO

2AZ-FE COOLING – COOLANT

COOLANT

ON-VEHICLE INSPECTION

1. REMOVE FRONT WHEEL OPENING EXTENSION

PAD RH

2. REMOVE FRONT WHEEL OPENING EXTENSION

PAD LH

3. REMOVE ENGINE UNDER COVER LH

4. REMOVE ENGINE UNDER COVER RH

5. DRAIN ENGINE COOLANT

NOTICE:

Do not remove the radiator cap sub-assembly while

the engine and radiator are still hot. Pressurized, hot

engine coolant and steam may be released and

cause serious burns.

(a) Remove the radiator cap sub-assembly from the

radiator assembly.

(b) Loosen the radiator drain cock plug and cylinder

block drain cock plug, then drain the coolant.

CO–5

Radiator Cap

Cylinder Block Drain

Cock Plug

CO

Radiator Drain Cock Plug

A136224E04

HINT:

Collect the coolant in a container and dispose of it

according to the regulations in your area.

6. ADD ENGINE COOLANT

(a) Close the radiator drain cock plug and 2 cylinder

block drain cock plugs.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf) for

cylinder block drain cock plug

CO–6

2AZ-FE COOLING – COOLANT

(b) Slowly fill the radiator with TOYOT A Super Long Life

Coolant (SLLC).

Specified capacity:

6.2 liters (6.6 US qts, 5.5 lmp. qts)

HINT:

• TOYOTA vehicles are filled with TOYOTA SLLC

at the factory. In order to avoid damage to the

engine cooling system and other technical

problems, only use TOYOTA SLLC or similar

high quality ethylene glycol based non-silicate,

non-amine, non-nitrite, non-borate coolant with

long-life hybrid organic acid technology (coolant

with long-life hybrid organic acid technology

consists of a combination of low phosphates and

organic acids).

• Contact your TOYOTA dealer for further details.

(c) Slowly pour coolant into the radiator reservoir tank

until it reaches the FULL line.

(d) Press the inlet and outlet radiator hoses several

times by hand, and then check the level of the

coolant.

If the coolant level is low, add coolant.

(e) Install the radiator cap sub-assembly and reservoir

tank cap.

(f) Start the engine, and warm it up.

HINT:

Adjust the air conditioner set temperature to MAX

(HOT).

(g) Stop the engine, and wait until the engine coolant

cools down.

(h) Add engine coolant to the FULL line on the radiator

reservoir.

CO

7. CHECK FOR ENGINE COOLANT LEAKS

8. INSTALL ENGINE UNDER COVER RH

9. INSTALL ENGINE UNDER COVER LH

10. INST ALL FRONT WHEEL OPENING EXTENSION P AD

LH

11. INST ALL FRONT WHEEL OPENING EXTENSION P AD

RH

ENGINE2AZ-FE COOLING

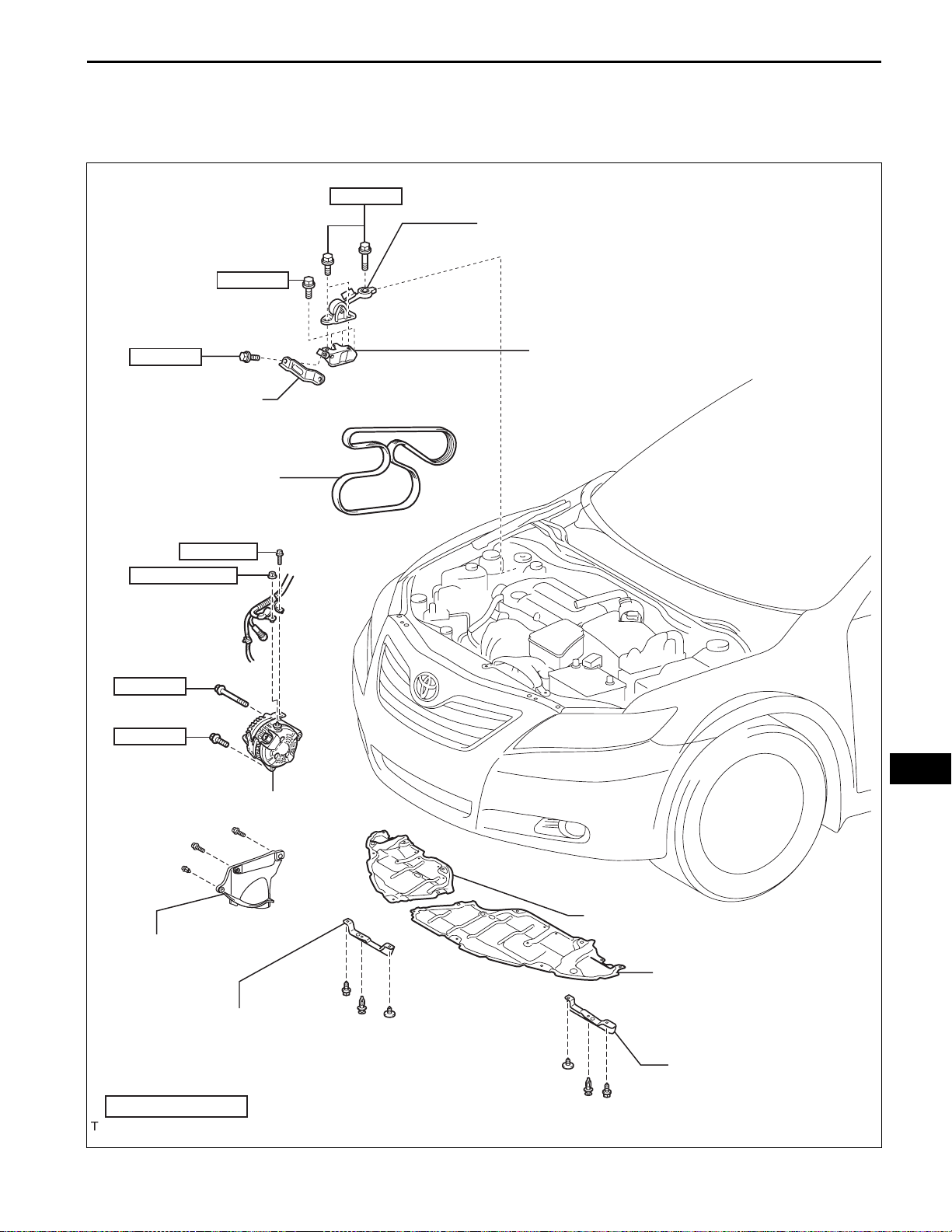

WATER PUMP

COMPONENTS

52 (531, 38)

2AZ-FE COOLING – WATER PUMP

64 (653, 47)

ENGINE MOVING CONTROL ROD SUB-ASSEMBLY

CO–7

64 (653, 47)

NO. 2 ENGINE

MOUNTING STAY RH

V-RIBBED BELT

9.8 (100, 7 )

8.4 (86, 74 in.*lbf)

52 (530, 38)

21 (215, 16)

GENERATOR ASSEMBLY

NO. 2 ENGINE MOUNTING BRACKET RH

CO

FRONT FENDER

APRON SEAL RH

FRONT WHEEL OPENING

EXTENSION PAD LH

N*m (kgf*cm, ft.*lbf)

ENGINE UNDER COVER RH

ENGINE UNDER COVER LH

FRONT WHEEL OPENING

EXTENSION PAD RH

: Specified torque

A136149E02

CO–8

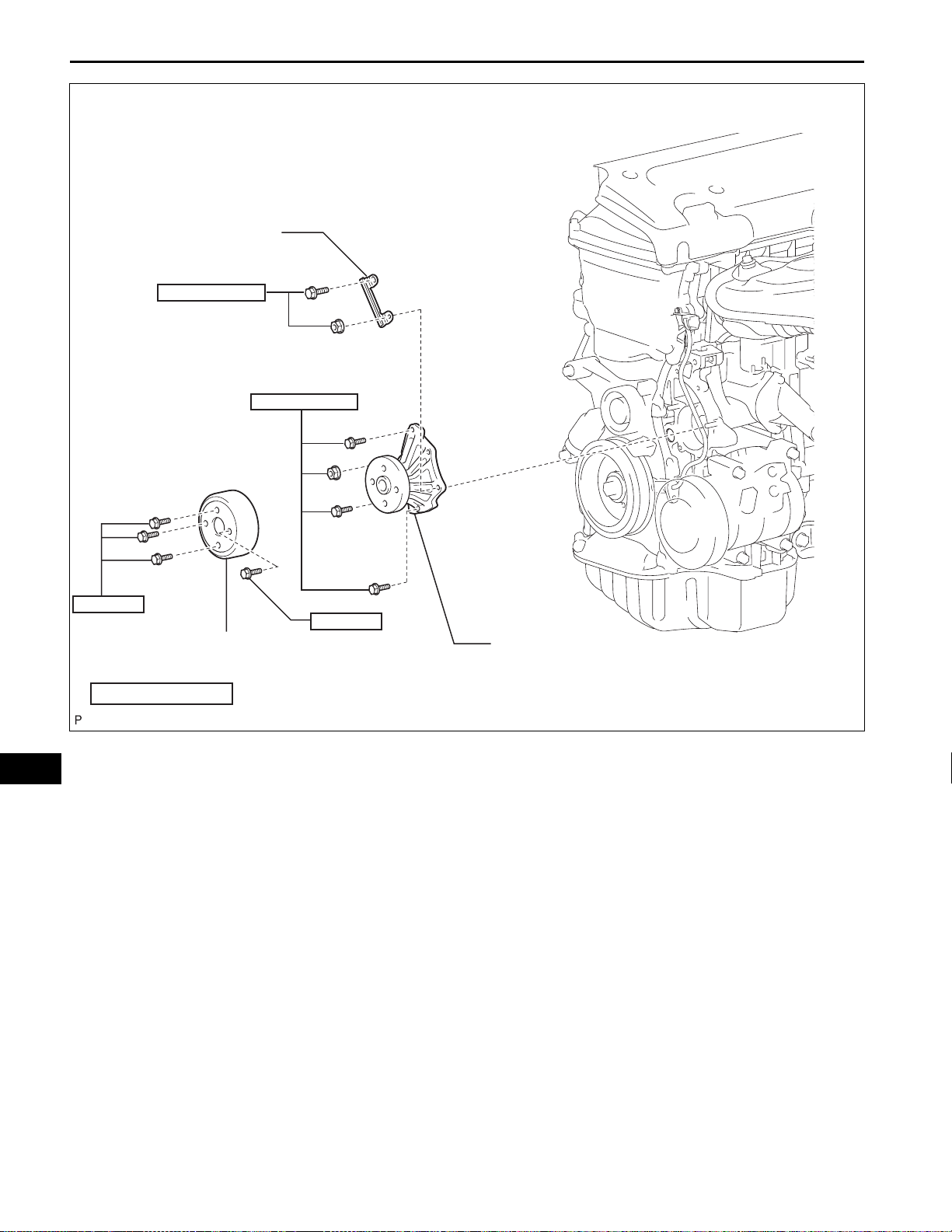

2AZ-FE COOLING – WATER PUMP

CLAMP BRACKET

9.0 (92, 80 in.*lbf)

9.0 (92, 80 in.*lbf)

CO

26 (265, 19)

WATER PUMP PULLEY

N*m (kgf*cm, ft.*lbf)

26 (265, 19)

WATER PUMP ASSEMBLY

: Specified torque

A136759E05

2AZ-FE COOLING – WATER PUMP

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE FRONT WHEEL OPENING EXTENSION

PAD RH

3. REMOVE FRONT WHEEL OPENING EXTENSION

PAD LH

4. REMOVE ENGINE UNDER COVER RH

5. REMOVE ENGINE UNDER COVER LH

6. DRAIN ENGINE COOLANT (See page CO-5)

7. REMOVE FRONT FENDER APRON SEAL RH

8. REMOVE NO. 2 ENGINE MOUNTING STAY RH (See

page EM-95)

9. REMOVE ENGINE MOVING CONTROL ROD SUBASSEMBLY (See page EM-95)

10. REMOVE NO. 2 ENGINE MOUNTING BRACKET RH

(See page EM-96)

CO–9

SST

A098715E03

11. REMOVE V-RIBBED BELT (See page EM-6)

12. REMOVE GENERATOR ASSEMBL Y (See page CH-11)

13. REMOVE WATER PUMP PULLEY

(a) Using SST, remove the 4 bolts and water pump

pulley.

SST 09960-10010 (09962-01000, 09963-00700)

CO

14. REMOVE WATER PUMP ASSEMBLY

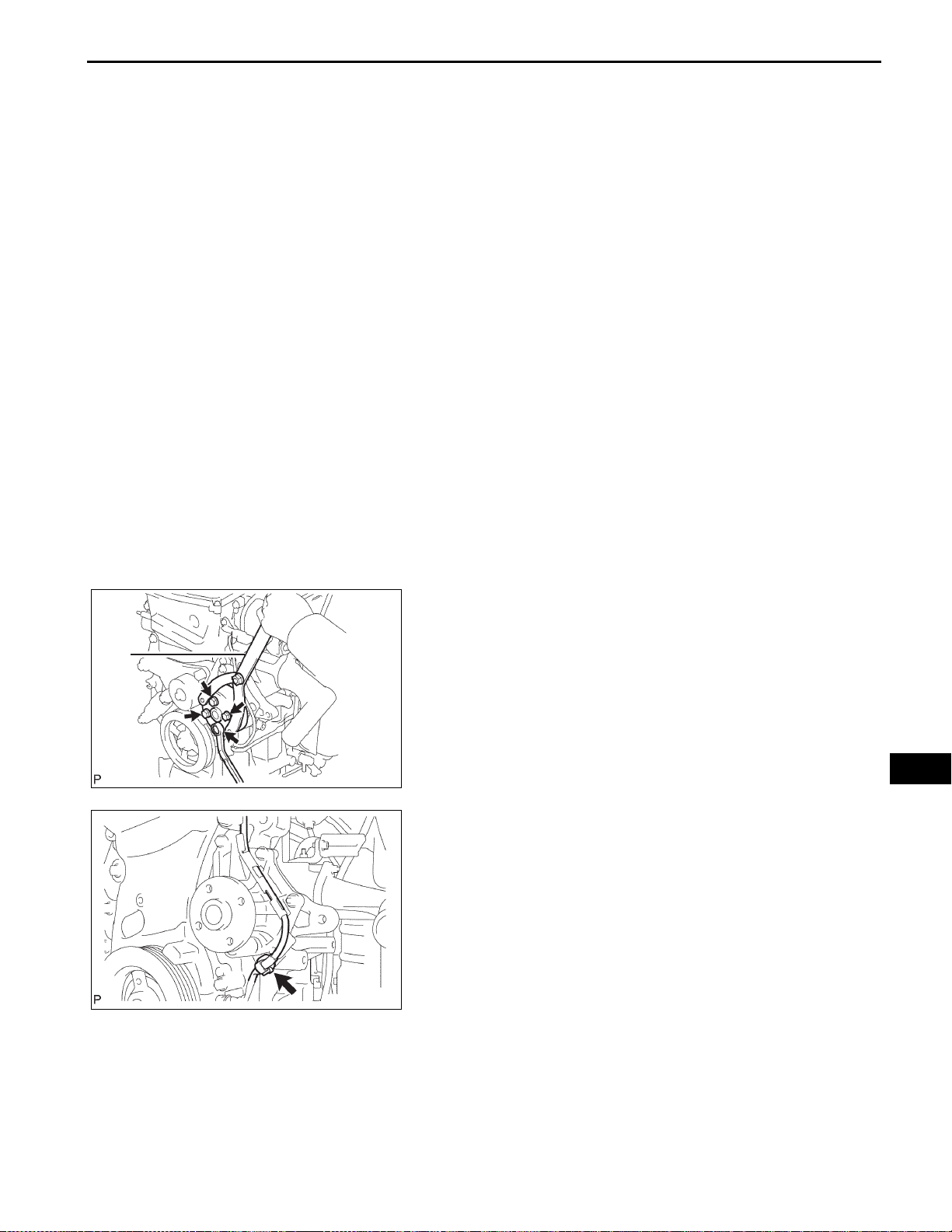

(a) Remove the clamp of the crankshaft position sensor

from the water pump.

(b) Disconnect the wire of the crankshaft position

sensor from the clamp bracket.

A094516E01

CO–10

2AZ-FE COOLING – WATER PUMP

(c) Remove the 4 bolts, 2 nuts and clamp bracket.

Clamp Bracket

B012052E03

(d) Using a screwdriver, pry between the water pump

and cylinder block, and then remove the water

pump.

HINT:

Tape the screwdriver tip before use.

NOTICE:

Be careful not to damage the conta ct surfaces of

the water pump and cylinder block.

A129792

CO

Air Hole

Drain Hole

A128603E01

A112198

INSPECTION

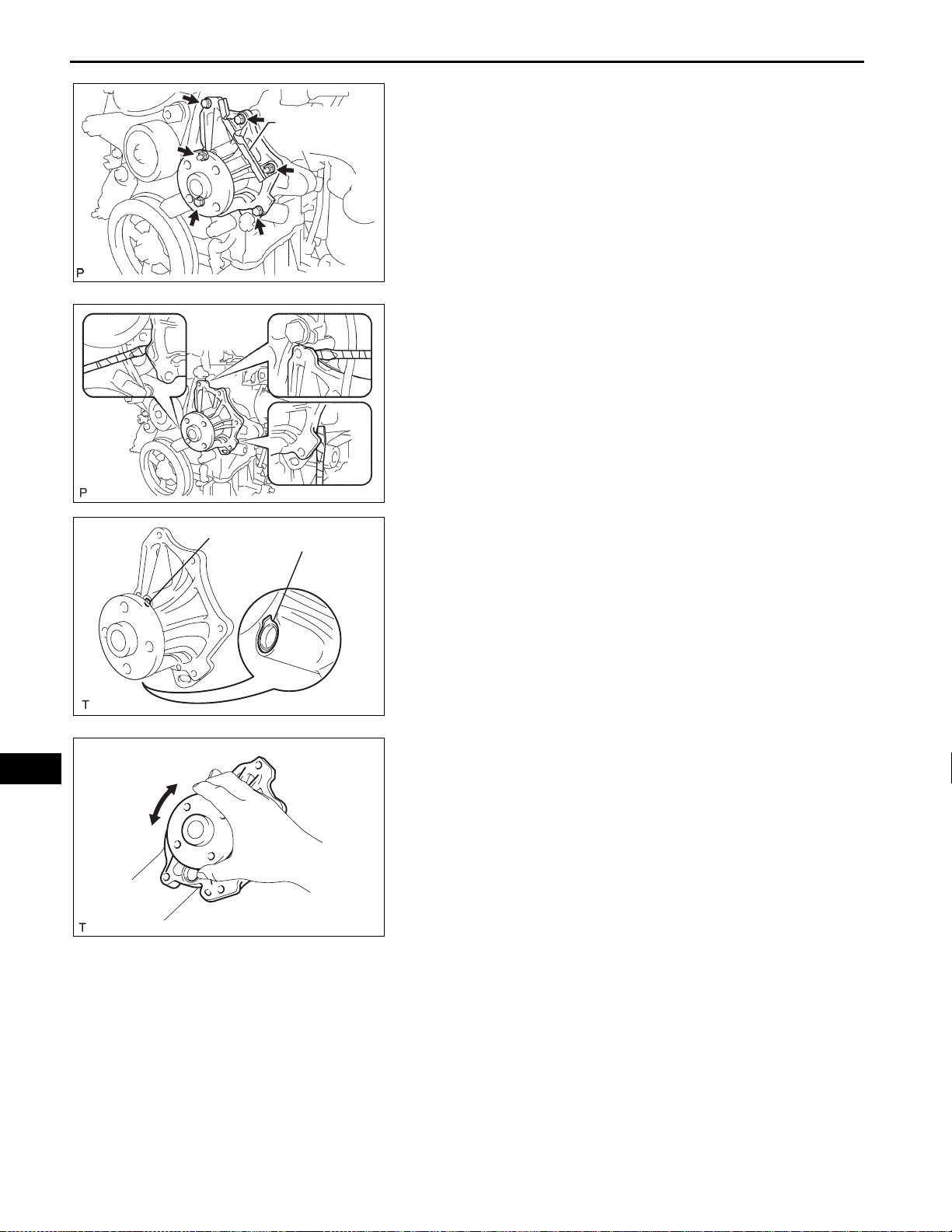

1. INSPECT WATER PUMP ASSEMBLY

(a) Visually check the drain hole and air hole for coolant

leakage.

If leakage is found, replace the water pump

assembly.

(b) Turn the pulley, and then check that the water pump

bearing moves smoothly without making a "click"

sound.

If it does not move smoothly, replace the water

pump assembly.

Seal Diameter

2.2 to 2.5 mm

(0.09 to 0.10 in.)

A-A

AA

0.5 to 1.0 mm

(0.02 to 0.04 in.)

2AZ-FE COOLING – WATER PUMP

INSTALLATION

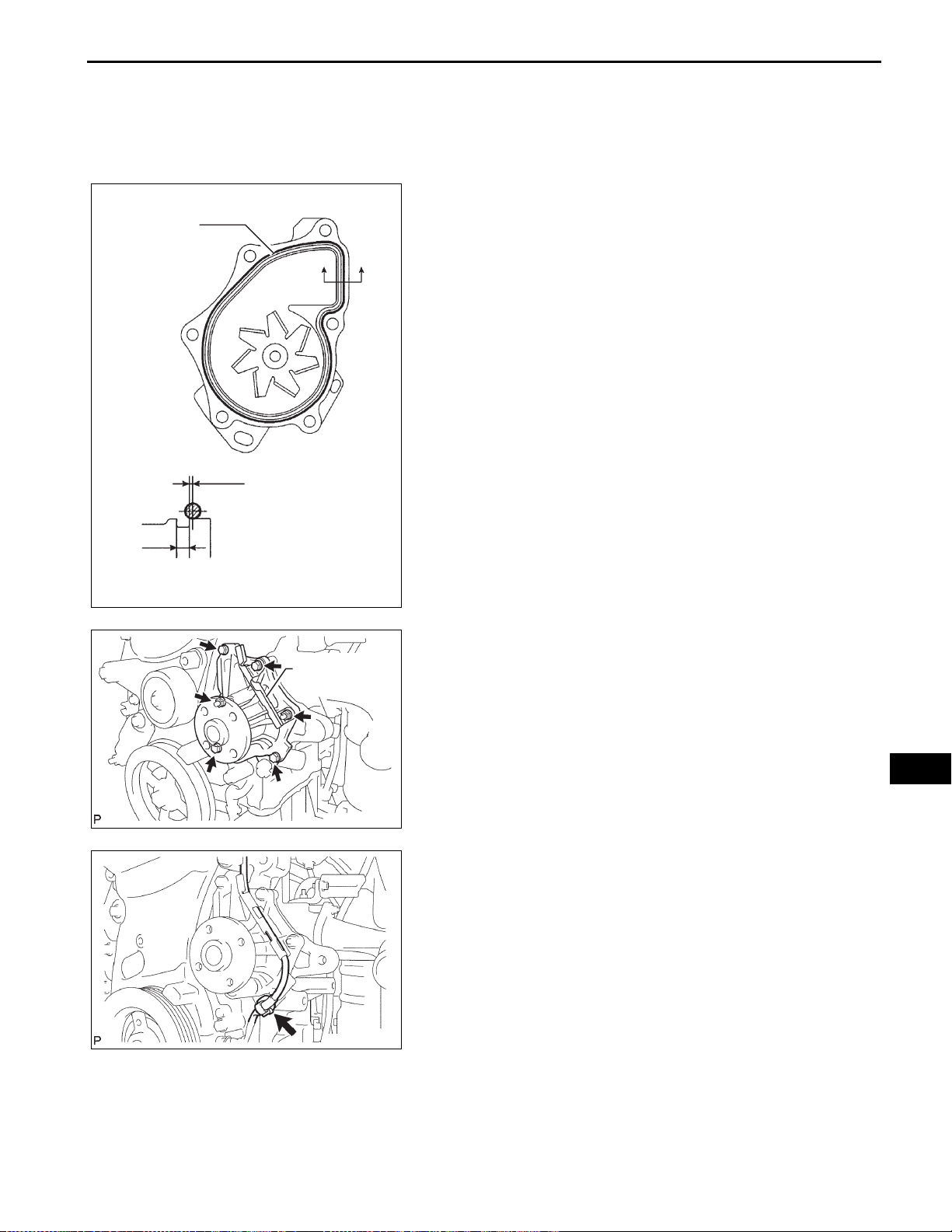

1. INSTALL WATER PUMP ASSEMBLY

(a) Remove any old seal packing material from the

contact surface.

(b) Apply a continuous line of seal packing as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three

Bond 1207B or Equivalent

Standard seal diameter:

2.2 to 2.5 mm (0.09 to 0.10 in.)

NOTICE:

• Remove any oil from the contact surface.

• The parts must be set within 3 minutes after

applying seal packing. Otherwise, the

material must be removed and reapplied.

CO–11

2.5 mm (0.10 in.)

A094495E05

Clamp Bracket

B012052E03

(c) Install the water pump and clamp bracket with the 4

bolts and 2 nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

CO

(d) Install the wire of the crankshaft position sensor

onto the clamp bracket.

(e) Install the clamp of the crankshaft position sensor

onto the water pump.

A094516

Loading...

Loading...