Toyota Camry 2007-2009 Service Manual - 2GR-FE_Starting

2GR-FE STARTING – STARTING SYSTEM

ENGINE2GR-FE STARTING

STARTING SYSTEM

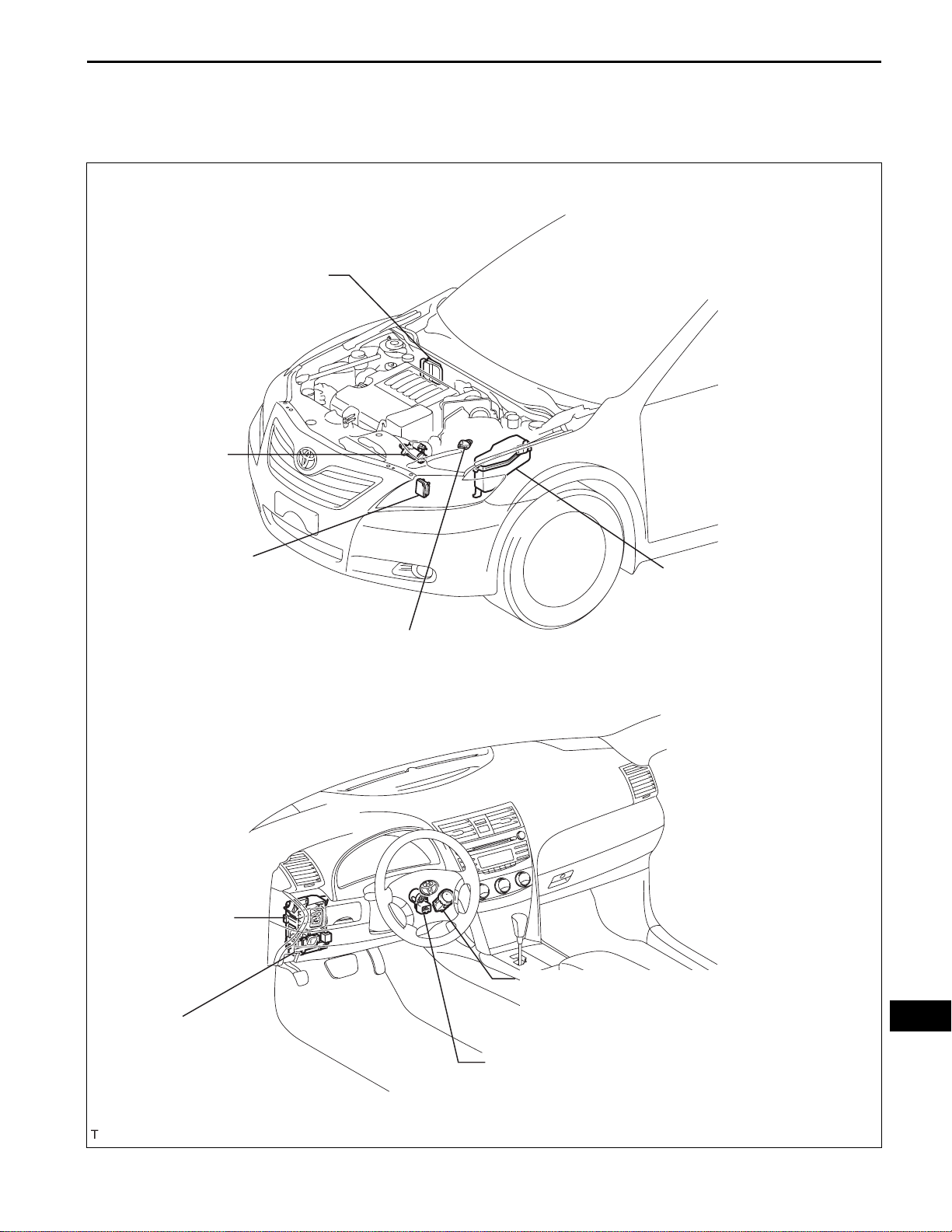

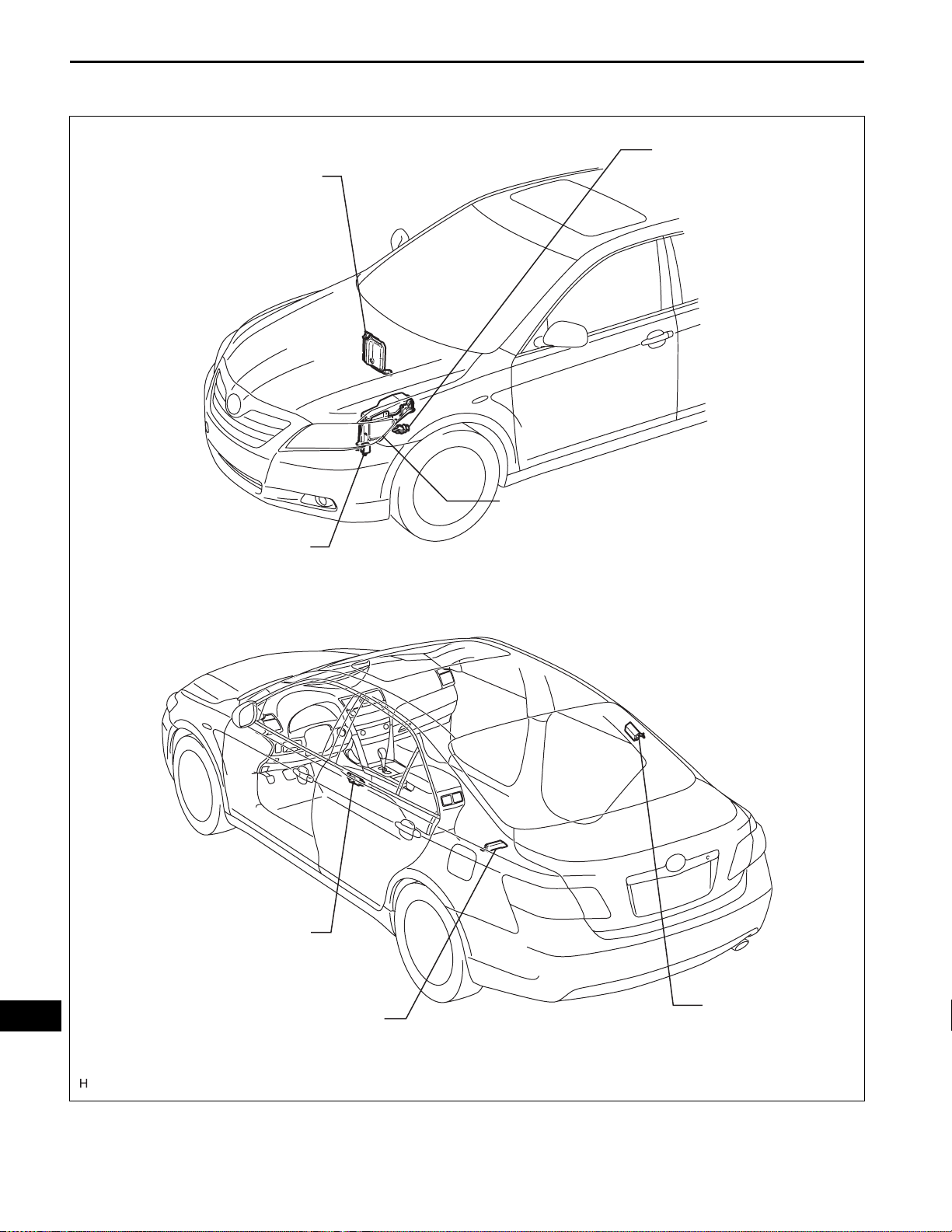

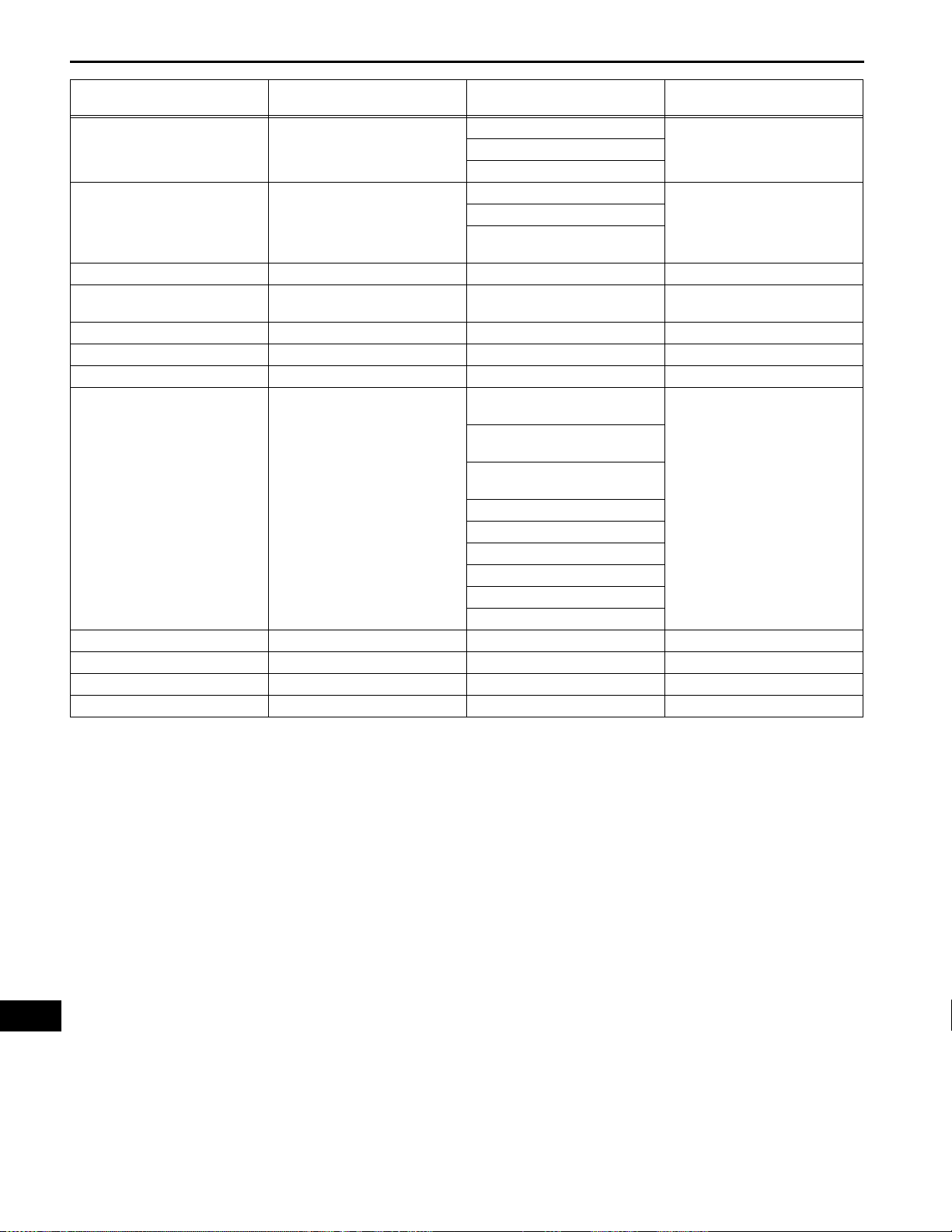

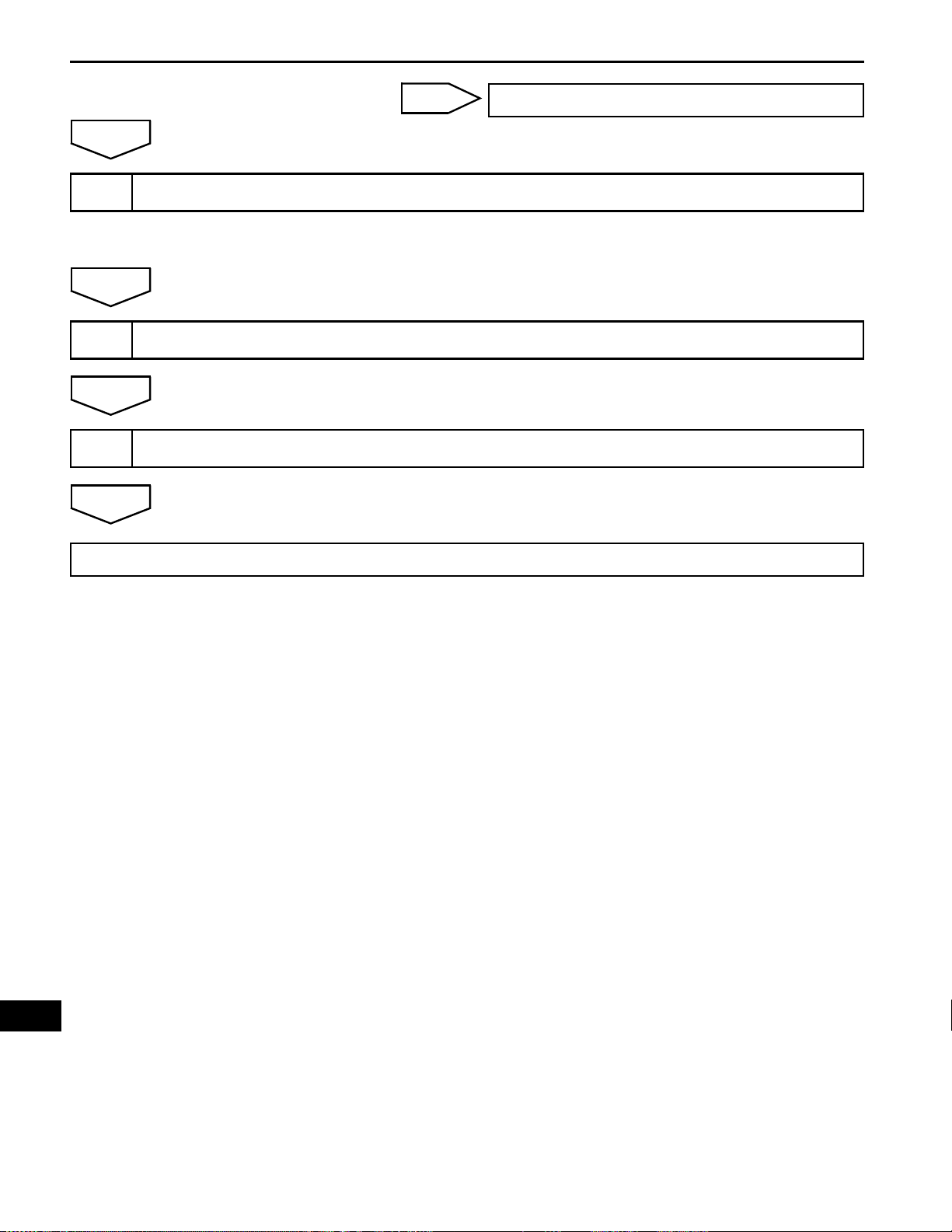

PARTS LOCATION

ECM

STARTER

ST–1

TRANSMISSION

CONTROL ECU

MAIN BODY ECU

PARK/NEUTRAL

POSITION SWITCH

ENGINE ROOM R/B

-STARTER RELAY

-IGNITION RELAY

-STARTER CUT RELAY

-IG2 FUSE

-AM2 FUSE

-ST/AM2 FUSE

-ALT FUSE

with SMART KEY SYSTEM:

INSTRUMENT PANEL J/B

-IGN FUSE

-AM1 FUSE

-ENGINE SWITCH

without SMART KEY SYSTEM:

-IGNITION SWITCH

ST

A135519E01

ST–2

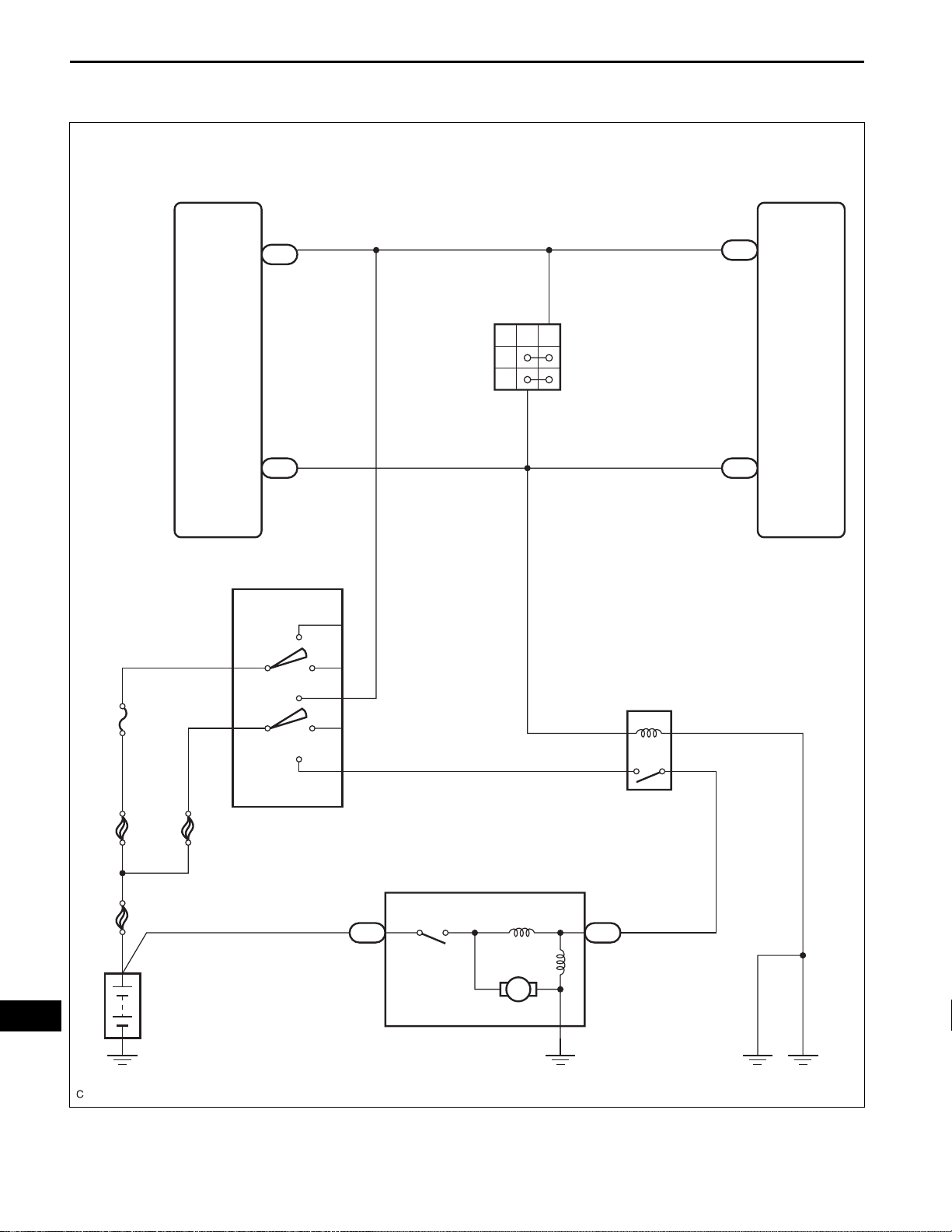

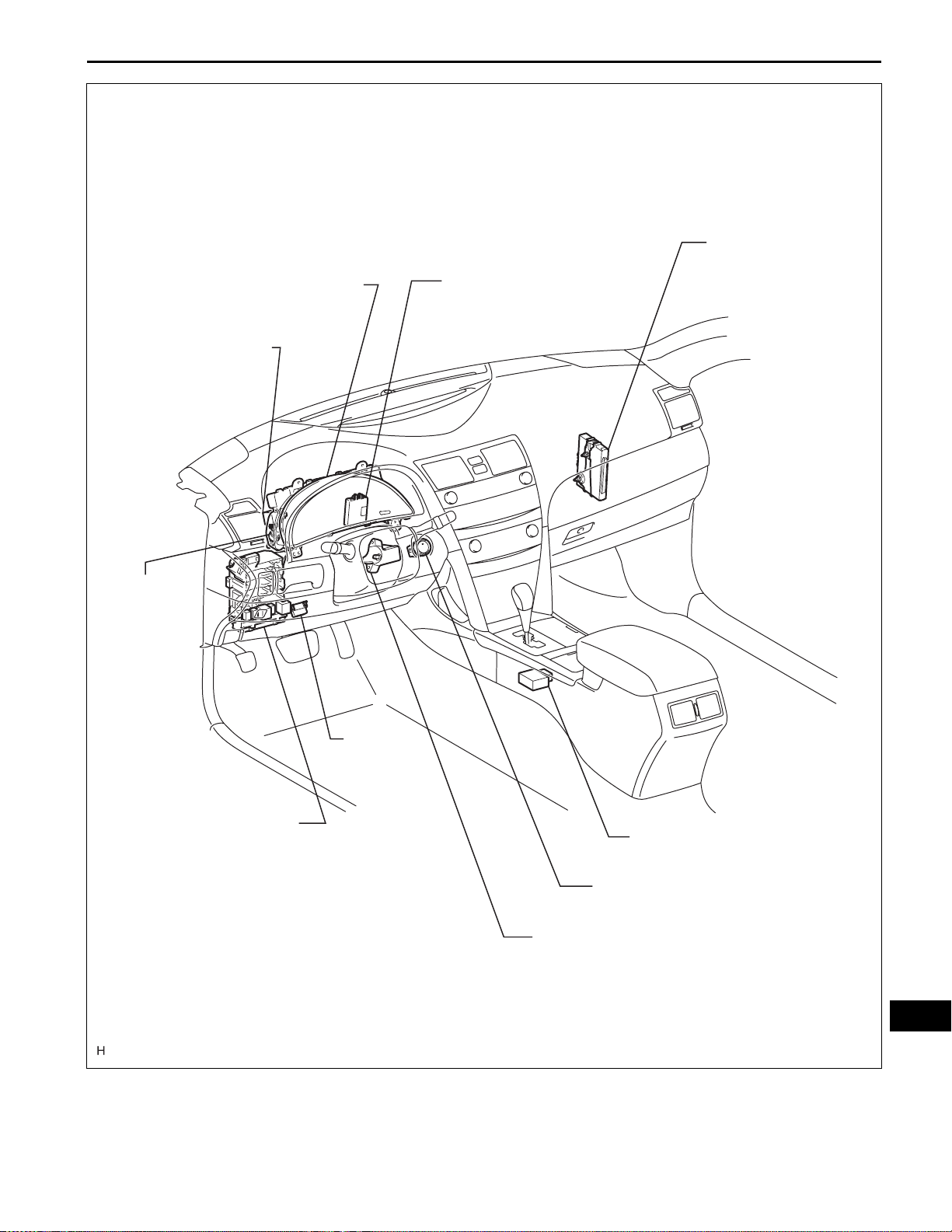

without Smart Key System:

2GR-FE STARTING – STARTING SYSTEM

SYSTEM DIAGRAM

Transmission Control ECU

11

NSW C56

10

STA C56

E23 Ignition Switch

ACC

C1

Park/Neutral

Position Switch

ECM

62

C55

NSW

4

BL

P

N

9

48

A55

STA

ST

AM1

FL MAIN

Battery

AM1

4

AM2

5

ST/AM2ALT

IG1

ST1

IG2

ST2

1

C3

ST

1

5

2

3

A135061E01

3

7

Starter

1

D1

M

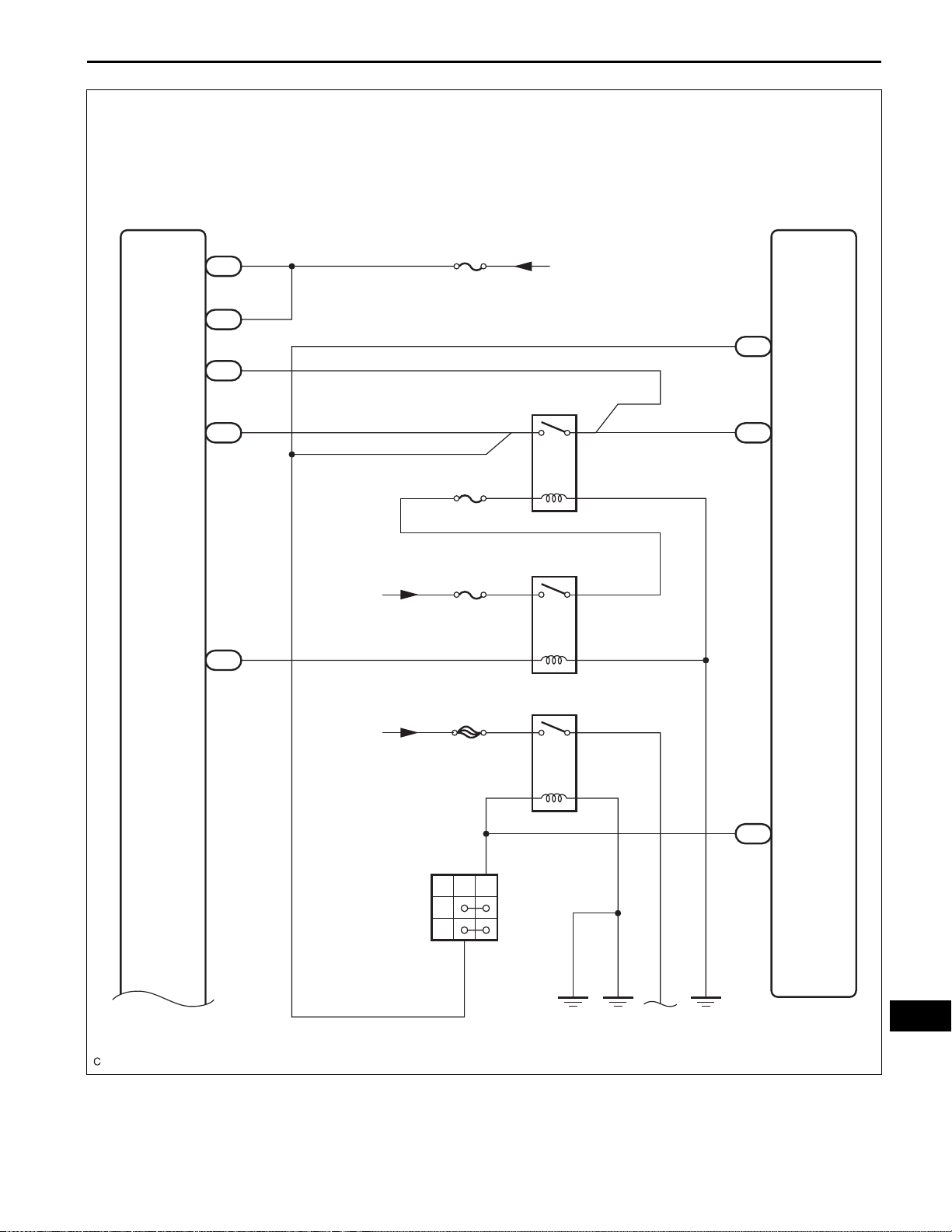

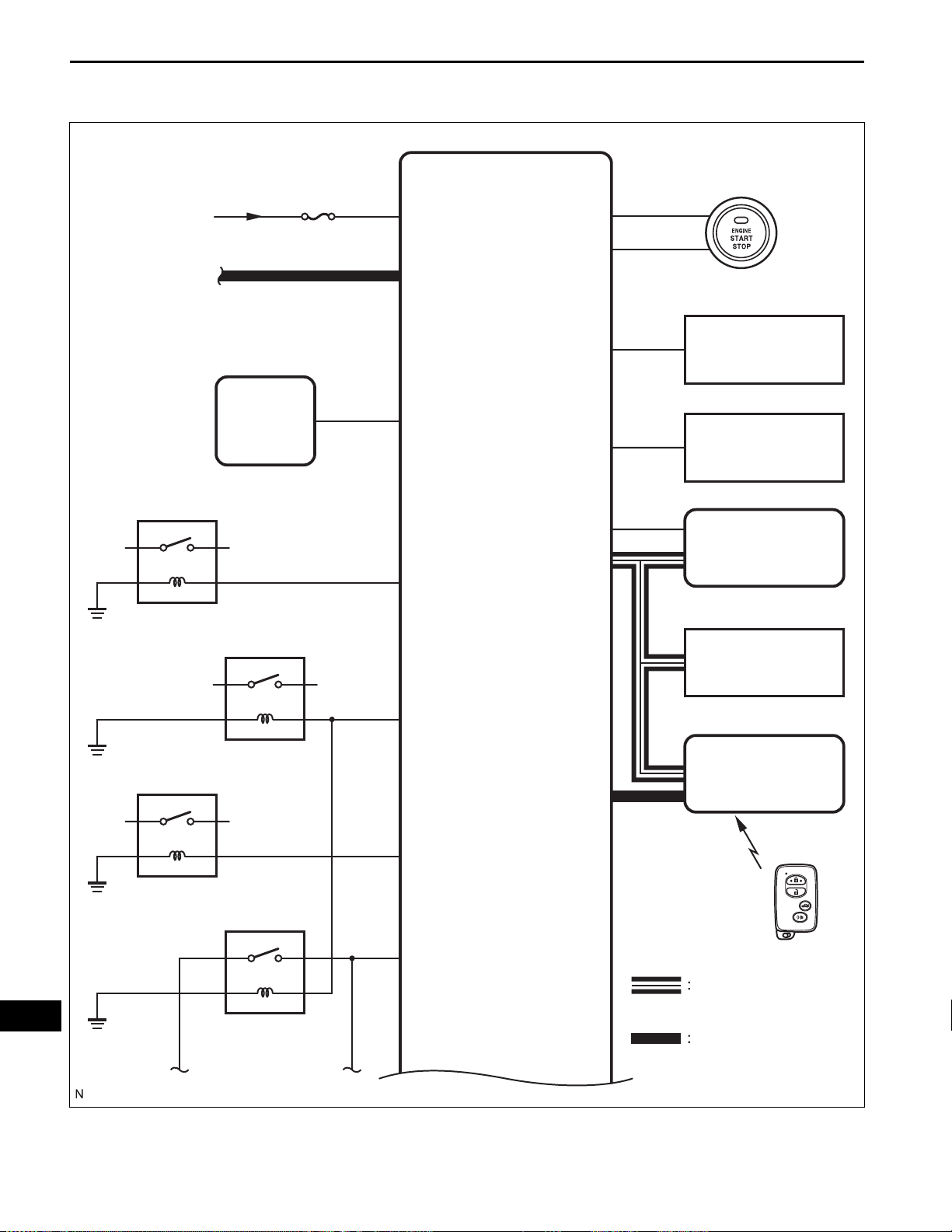

with Smart Key System:

2GR-FE STARTING – STARTING SYSTEM

ST–3

Main Body ECU

AM1

AM2

STR2

STR

IG2D

6

E7

1

E6

6

E9

8

E7

11

E6

From

Battery

AM2

IGN

IG2

From Battery

ST CUT

5

2

IG2

5

1

ECM

62

NSW

C55

63

C55

3

1

3

2

STAR

From

Battery

C1

Park/Neutral

Position Switch

ST/AM2

9

BL

P

N

4

ST

5

1

3

2

48

A55

STA

ST

A135062E01

ST–4

SSW1

SSW2

17

E7

16

E7

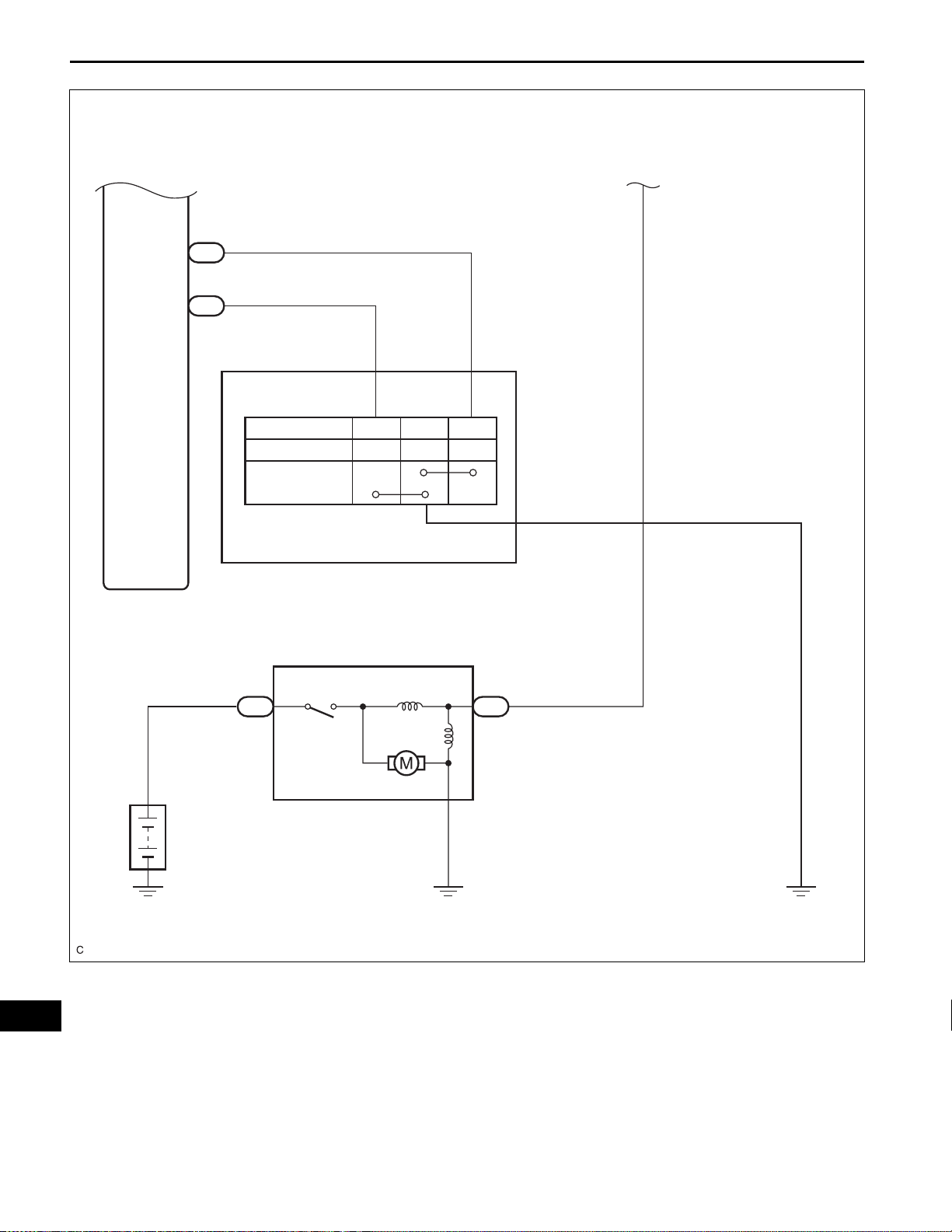

2GR-FE STARTING – STARTING SYSTEM

27

SS2 SS1

SS2 SS1GND

Free

Full

Traveling

E52

Engine Switch

Battery

1

D1

Starter

GND

1

C3

5

A135063E01

ST

2GR-FE STARTING – SMART KEY SYSTEM

SMART KEY SYSTEM

PRECAUTION

1. EMERGENCY ENGINE START CONTROL

(a) If there is a malfunction in the stop light switch or

STOP fuse, their signals may not be correctly

transmitted to the main body ECU. This may result

in the engine not starting even if the engine switch is

pressed while the brake pedal is depressed and the

shift lever is in the P position.

To activate the starter:

(1) Turn the engine switch from off to on (ACC).

(2) Press and hold the engine switch for 15

seconds.

2. PRECAUTIONS FOR PUSH-BUTTON START

FUNCTION:

(a) Before starting the engine, firmly depress the brake

pedal until the indicator in the engine switch turns

green.

(b) The power source mode (off, on (ACC), on (IG)) is

always retained in memory by the vehicle. If the

battery is disconnected, the power source mode

that was present before disconnection will be

restored after the battery is reconnected. Be sure to

turn the engine switch off before disconnecting the

cable from the negative battery terminal. Be careful

if the power source mode of a vehicle with a

discharged battery is not known.

(c) After the battery is reconnected, be sure to wait 10

seconds or more before attempting to start the

engine. The engine may not start immediately after

the battery is reconnected.

(d) If the electrical key is held near the engine switch to

start the engine when the electrical key battery is

depleted, the following warnings will sound:

(1) Driver's door open → closed

• An exit warning will sound if the shift lever is

in a position other than P and the power

source is in a mode other than off.

• An exit warning will sound if the shift lever is

in the P position and the power source is in a

mode other than off.

(2) Doors other than the driver door open → closed

• A warning will sound to indicate that the

electrical key has been taken out of the

vehicle.

These warnings will sound because it is not possible for the

vehicle to determine if the key is present in the vehicle (due to

the depleted key battery). These warnings do not indicate

system malfunctions.

ST–5

ST

ST–6

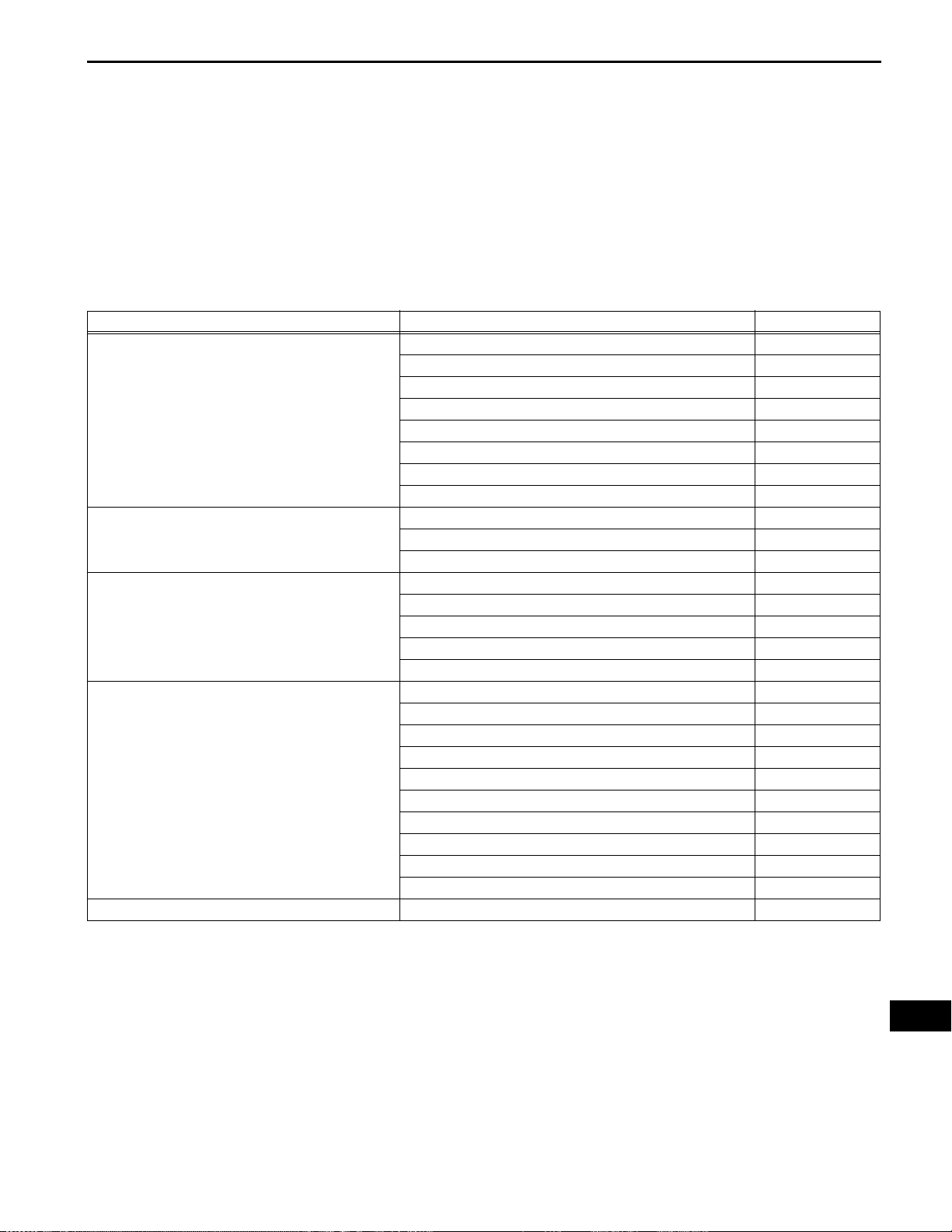

PARTS LOCATION

ECM (2GR-FE)

2GR-FE STARTING – SMART KEY SYSTEM

PARK / NEUTRAL

POSITION SWITCH

WIRELESS BUZZER

ELECTRICAL KEY OSCILLATOR

(CONSOLE)

ENGINE ROOM J/B AND R/B

- AM2 FUSE

- IG2 FUSE

- IG2 RELAY

- ST RELAY

- ST / AM2 FUSE

- ECU-B NO. 1 FUSE

- ST CUT RELAY

ST

ELECTRICAL KEY OSCILLATOR

(REAR SEAT)

DOOR CONTROL

RECEIVER

B137944E01

COMBINATION METER

TURN SIGNAL

FLASHER ASSEMBLY

2GR-FE STARTING – SMART KEY SYSTEM

ID CODE BOX

ST–7

CERTIFICATION

ECU

STOP LIGHT

SWITCH

MAIN BODY ECU

(INSTRUMENT PANEL J/B)

- IG1 RELAY

- ACC RELAY

- ECU-ACC FUSE

- ECU IG NO. 1 FUSE

- DOOR NO. 2 FUSE

DLC3

SHIFT LOCK CONTROL ECU

ENGINE SWITCH

STEERING LOCK ECU

ST

B137945E01

ST–8

2GR-FE STARTING – SMART KEY SYSTEM

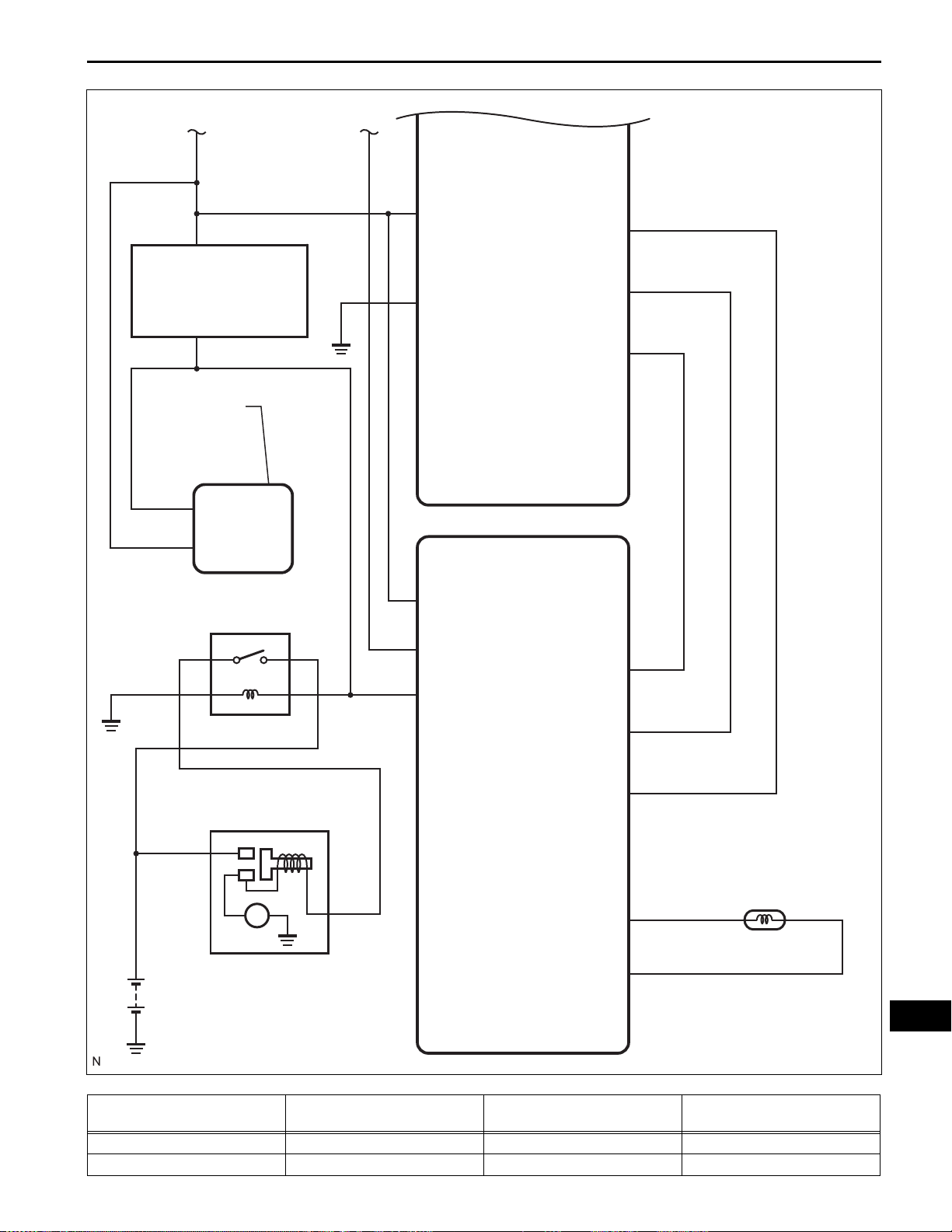

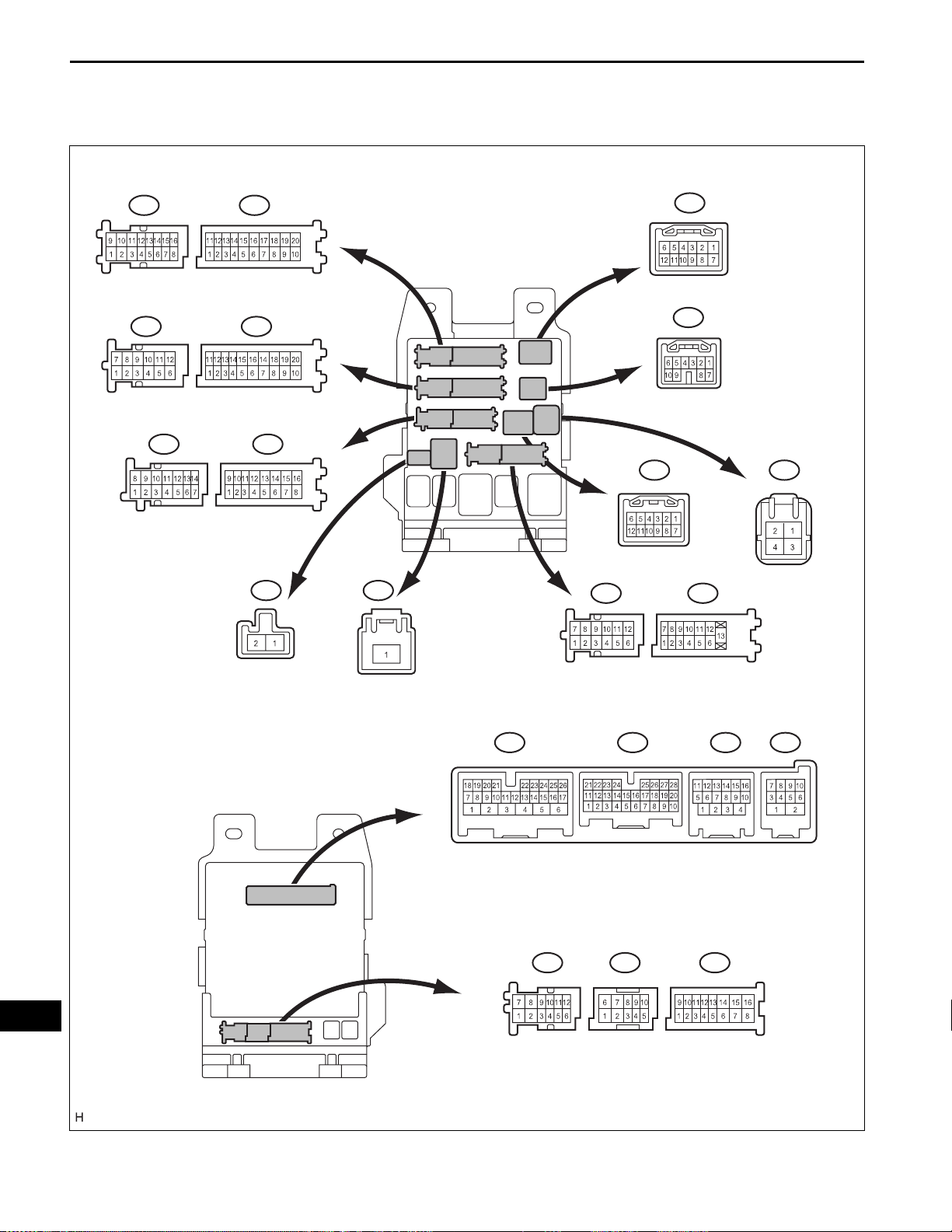

SYSTEM DIAGRAM

AM2

From Battery

CAN Line CAN

Shift Lock

Control ECU

IG1

MAIN BODY ECU

AM1

AM2

P

IG1D

SSW1

SSW2

STP

SPD

SLP

LIN1

Engine Switch

Stop Light Switch

Combination Meter

Steering Lock ECU

ST

IG2

IG2D

ACC

ACCD

ST CUT

STR2

AB

ID Code Box

Certification ECU

Key

LIN

CAN

B137946E01

2GR-FE STARTING – SMART KEY SYSTEM

AB

STR

Park / Neutral

Position Switch

GND1

GND2

Transmission

Control ECU

ST–9

STSW

TACH

ACCR

MAIN BODY ECU

STA

NSW

ECM

NSW

ST

STAR

ACCR

STA

TACH

STSW

Starter

Crankshaft Position Sensor

NE+

NE-

Battery

Communication table:

Transmitting ECU

(Transmitter)

Combination meter Main body ECU Vehicle speed signal CAN/Local communication

Steering lock ECU Main body ECU Steering lock/unlock signal LIN/Local communication

Receiving ECU

(Receiver)

Signal Communication method

ST

B137970E01

ST–10

2GR-FE STARTING – SMART KEY SYSTEM

Transmitting ECU

(Transmitter)

ECM Main body ECU

Main body ECU Certification ECU

Main body ECU Combination meter Entry start key signal CAN

Main body ECU Combination meter

Certification ECU Main body ECU Illumination light request signal CAN

Certification ECU Driver seat ECU Memory call replay request signal CAN

Certification ECU Main body ECU Light answer back signal CAN

Certification ECU Combination meter

Combination meter Certification ECU/Main body ECU Vehicle speed signal CAN

Shift lock control ECU Main body ECU Shift position signal CAN/Local communication

Certification ECU Main body ECU Key ID matching request signal LIN

Main body ECU Certification ECU ID required signal LIN

Receiving ECU

(Receiver)

Signal Communication method

Starter signal

Engine revolution speed signal

Engine switch position signal

Courtesy light switch signal

Wireless door lock buzzer

request signal

Wireless door lock buzzer

request signal

Meter buzzer single-shot request

signal

Meter buzzer intermittence

request signal

Meter buzzer continuation

request signal

Door open display signal

Key loss warning signal

Low key battery warning signal

Shift position warning signal

Steering lock abnormal warning

Steering lock unlock warning

CANShift position signal

CAN

CAN

CAN

ST

2GR-FE STARTING – SMART KEY SYSTEM

SYSTEM DESCRIPTION

1. PUSH-BUTTON START FUNCTION DESCRIPTION

(a) The push-button start function uses a push-type

engine switch, which the driver can operate by

merely carrying the electrical key. This system

consists primarily of the main body ECU, engine

switch, ID code box, steering lock ECU, electrical

key , ACC relay, IG1 relay, IG2 relay and certification

ECU. The main body ECU controls the function.

This function operates in cooperation with the smart

key system.

2. FUNCTION OF COMPONENT

Component Function

• Transmits engine switch signal to main body ECU.

Engine Switch

• Transponder Key Amplifier

Electrical Key

Electrical Key Oscillator

• Console and Rear Seat

Steering Lock ECU

Entry Door Control Receiver

Main body ECU

Certification ECU

Stop Light Switch Outputs state of brake pedal to main body ECU.

ID Code Box

ECM

• Informs driver of power source mode or system abnormality with

illumination of indicator light.

• Receives ID code and transmits it to certification ECU when key

battery is low.

Receives signals from oscillators and returns ID code to entry door

control receiver.

Receives request signals from certification ECU and forms detection

area in vehicle interior.

Receives lock/unlock request signals from certification ECU and main

body ECU.

Receives ID code from electrical key and transmits it to certification

ECU.

• Changes power source mode in 4 stages (off, on (ACC), on (IG),

start) in accordance with shift position and state of stop light

switch.

• Controls push-button start function in accordance with signals

received from switches and each ECU.

Certifies ID code received from entry door control receiver and

transmits certification results to ID code ECU and steering lock ECU.

Receives steering unlock or engine immobiliser unset signals from

certification ECU, certifies them, and transmits each unset signal to

steering lock ECU or ECM.

• Receives engine start request signal from main body ECU, turns

ON ST relay, and starts engine.

• Receives signal from ID code ECU and performs engine ignition

and injection.

ST–11

Engine switch control

Diagnosis

3. SYSTEM FUNCTION

The electric controls of the push-button start fu nction are

described below:

Control Outline

• When driver operates engine switch with electrical key in driver's

possession, certification ECU starts indoor electrical key oscillator,

which transmits request signal to electrical key. Upon receiving

this signal, the electrical key transmits ID code signal to main body

ECU.

• ID code box verifies check results received from certification ECU

via LIN and sends them to main body ECU. Based on these

results, main body ECU authorizes operation of engine switch.

When main body ECU detects malfunction, main body ECU

diagnoses and memorizes failed section.

ST

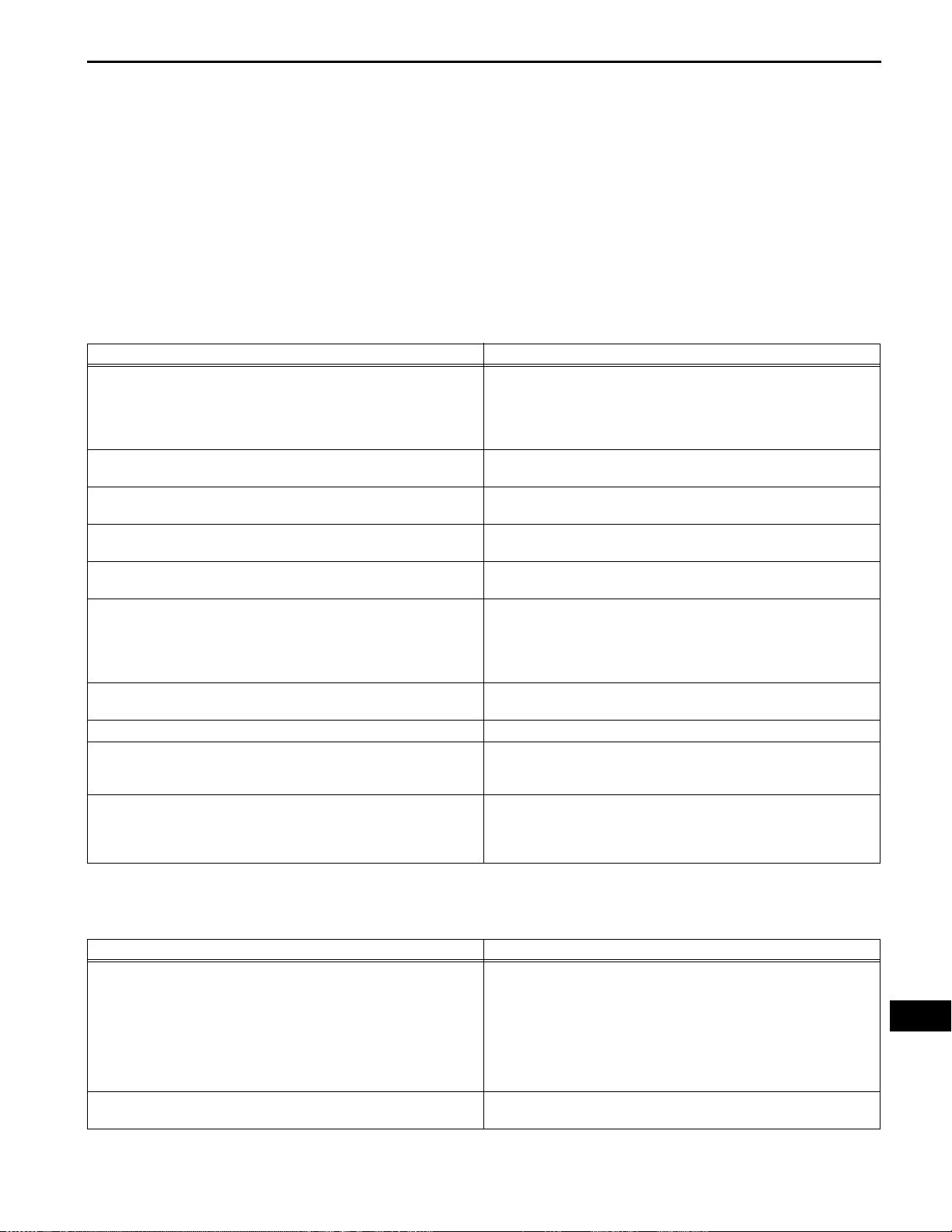

ST–12

Indicator Light

START

STOP

2GR-FE STARTING – SMART KEY SYSTEM

A109251E01

Engine switch indicator light condition:

Power Source Mode/Condition

off OFF ON (Green) (When key and vehicle IDs match)

on (ACC, IG) ON (Amber) ON (Green)

Engine running OFF OFF

Steering lock not unlocked Flashes (Green) for 15 sec. Flashes (Green) for 15 sec.

System malfunction Flashes (Amber) for 15 sec. Flashes (Amber) for 15 sec.

Brake pedal released Brake pedal depressed, shift lever in P or N

4. CONSTRUCTION AND OPERATION

(a) Engine Switch

The engine switch consists of a momentary type

switch, 3 color (amber, green, greenish white)

LEDs, and a transponder key amplifier.

• The greenish white LED is for illumination.

• The amber and green LEDs are for the indicator

lights. The driver can check the present power

source mode and whether the engine can start in

accordance with the illumination state of the

indicator light.

• When the main body ECU detects an

abnormality in the push-button start function, it

makes the amber indicator light flash. If the

engine stopped in this state, it may not be

possible to restart it.

(b) Indicator Light Condition

Indicator Light Condition

ST

(c) Main body ECU

The main body ECU consists of the IG1 and IG2

relay actuation circuits and CPU.

HINT:

Before removing the battery, make sure to turn the

engine switch off. The main body ECU constantly

stores the present power source mode in its

memory. Therefore, if the main body ECU is

interrupted by disconnecting the battery, the main

body ECU restores the power source mode after the

battery is reconnected. For this reason, if the battery

is disconnected when the engine switch is not off,

the power will be restored to the vehicle at the same

time the power is restored to the main body ECU (by

reconnecting the battery).

5. PUSH-BUTTON START FUNCTION OPERATION

(a) This system has different power source mode

patterns depending on the brake pedal condition

and shift lever position.

Brake Pedal Shift Lever Power Source Mode Pattern

When the engine switch is pushed once.

Depressed P or N position

P position

Not depressed

Except P position

•off → engine start

• on (ACC) → engine start

• on (IG) → engine start

Each time the engine switch is pushed.

•off → on (ACC) → on (IG) → off

Each time the engine switch is pushed.

•off → on (ACC) → on (IG) → on (ACC)

2GR-FE STARTING – SMART KEY SYSTEM

Brake Pedal Shift Lever Power Source Mode Pattern

When the engine switch is pushed with power

- P position

- Except P position

source mode on (IG) (engine running).

• on (IG) → off

When the engine switch is pushed with power

source mode on (IG) (engine running).

• on (IG) → on (ACC)

When the battery of the key is low, the push-button

start function can be operated by holding the key

against the engine switch.

• After approximately 1 hour has passed with the

engine switch on (ACC) and the shift position in

P, the main body ECU will automatically cut the

power supply (the power source mode changes

to off).

ST–13

ST

ST–14

2GR-FE STARTING – SMART KEY SYSTEM

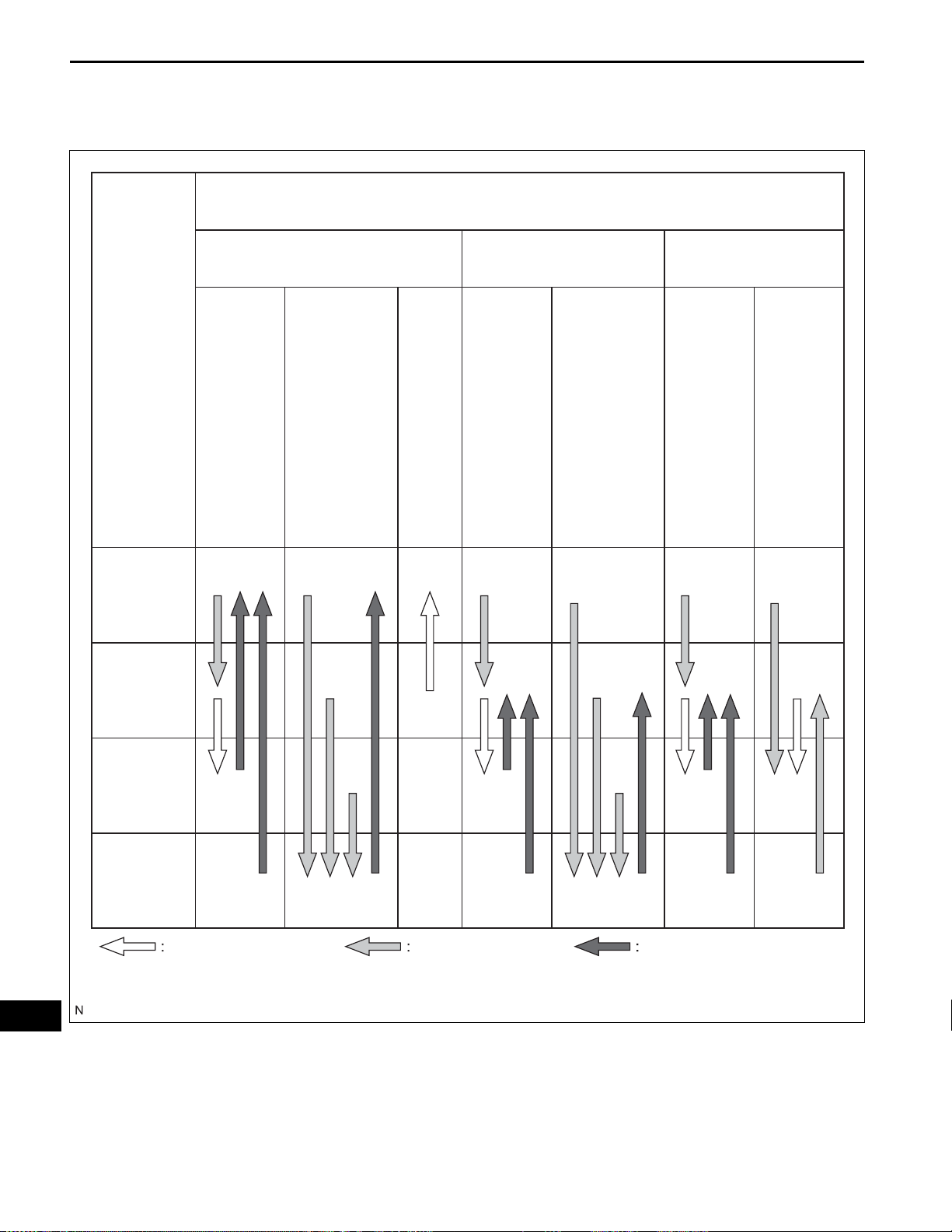

• The illustration below shows the transition of

power source modes.

Transition of power source mode:

Shift Position

Engine Switch

Position

off

on (ACC)

Engine

switch

pushed

P

Engine

switch

pushed

Brake

pedal

depressed

Not

operated

for 1

hour

Engine

switch

pushed

N Except P and N

Engine

switch

pushed

Brake pedal

depressed

Engine

switch

pushed

Engine

switch

pushed

Brake pedal

depressed

ST

on (IG)

Engine

start

Transition of power source

mode (Always)

Transition of power source

mode (only when key

code is certified)

Transition of power source mode

(only with vehicle stopped)

B138065E01

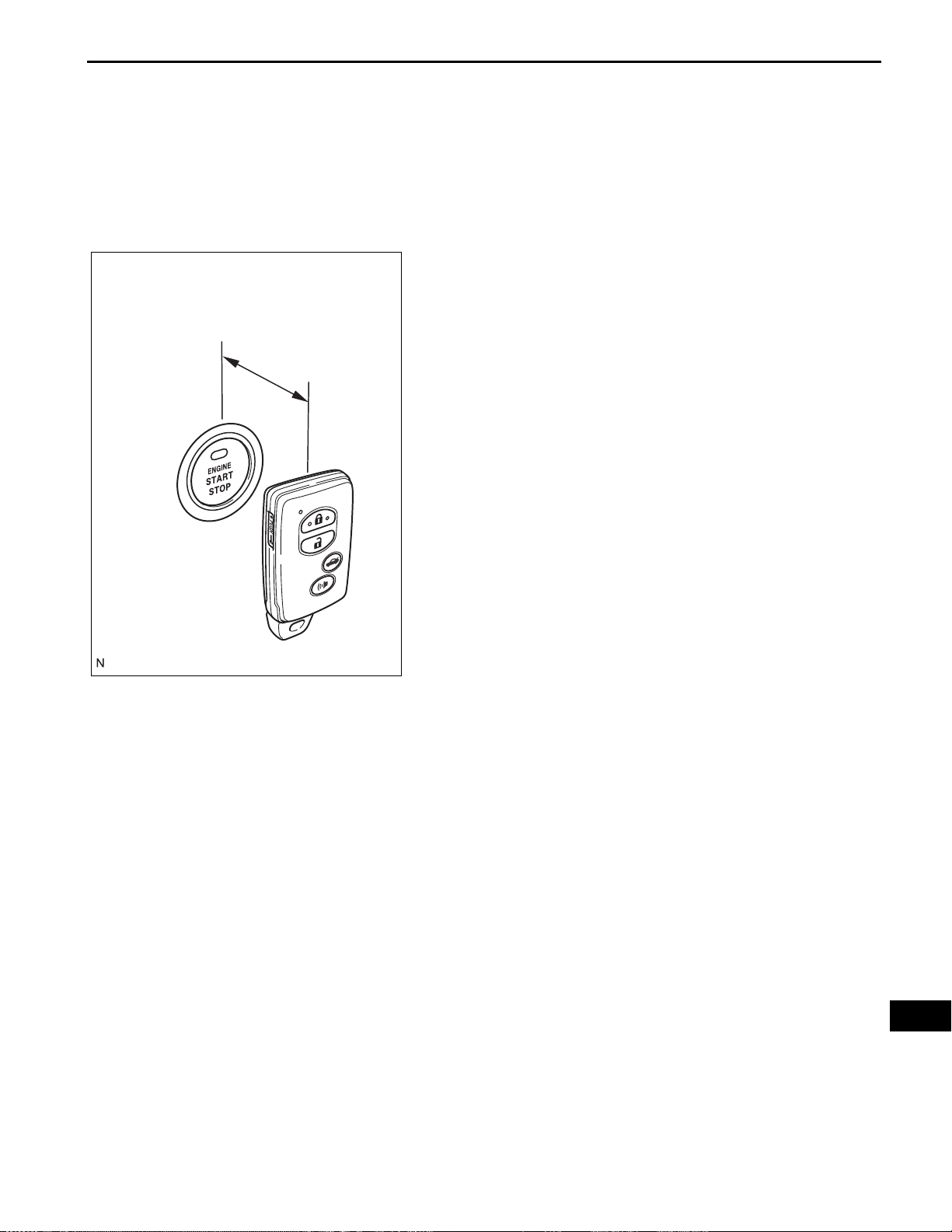

Engine Switch

2GR-FE STARTING – SMART KEY SYSTEM

Required Distance:

10 mm (0.39 in.)

Key

B137947E01

ST–15

HINT:

While the vehicle is being driven normally,

operation of the engine switch is disabled.

However, if the engine must be stopped in an

emergency while the vehicle is being driven,

pressing the engine switch for 3 seconds or more

stops the engine. Power source mode changes

from start to on (ACC).

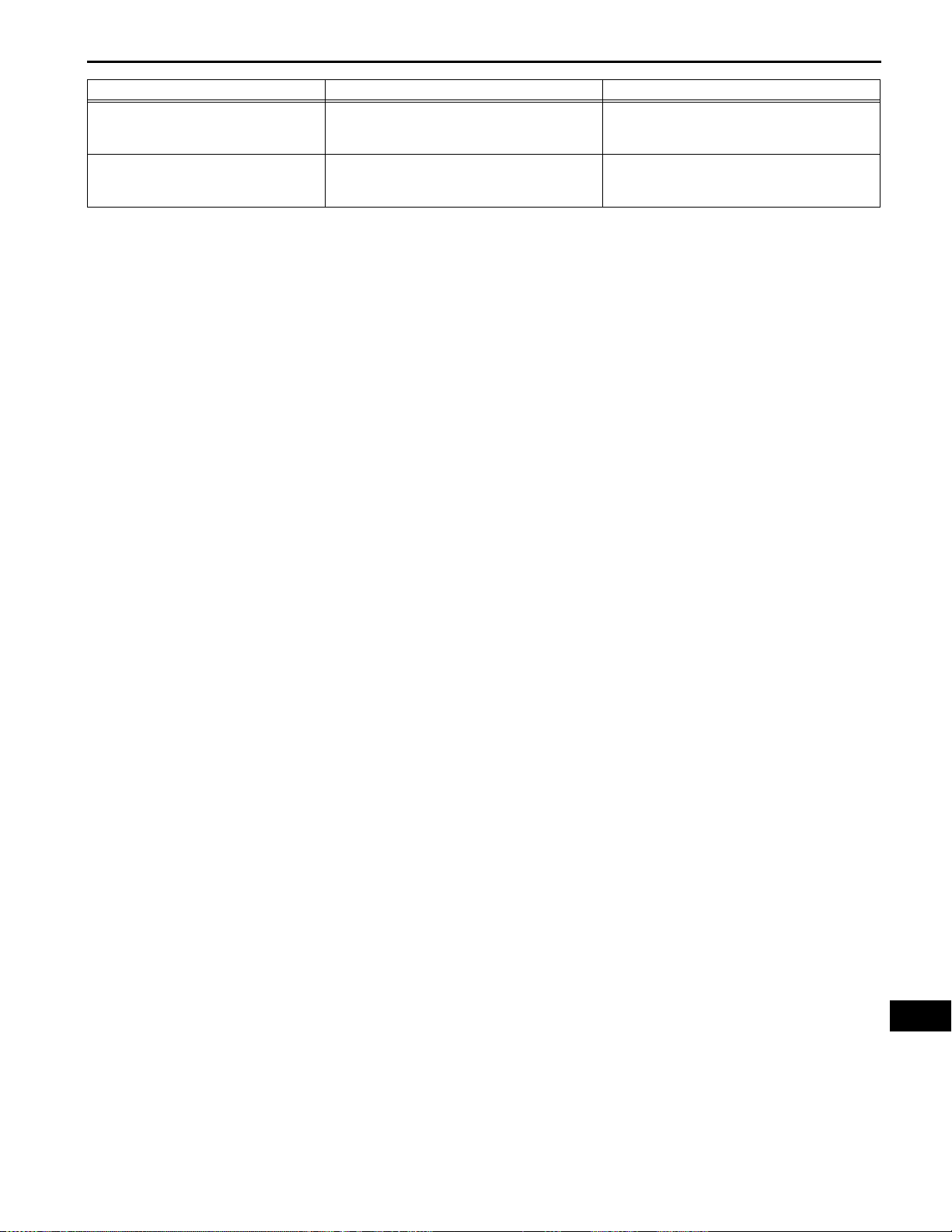

6. WHEN KEY BATTERY IS LOW

(a) To operate the push-button start function when the

key battery is low, hold the key close to the engine

switch with the brake pedal depressed.

(b) The main body ECU transmits a key verification

request signal from the stop light switch to the

certification ECU.

(c) The certification ECU does not receive an ID code

response from the entry door control receiver, so it

actuates the transponder key amplifier built into the

engine switch.

(d) The transponder key amplifier outputs an engine

immobiliser radio wave to the key.

(e) The key receives the radio wave, and returns a

radio wave response to the transponder key

amplifier.

(f) The transponder key amplifier combines the key ID

codes with the radio wave response, and transmits

it to the certification ECU.

(g) The certification ECU judges and verifies the ID

code, and transmits a key verification OK signal to

the main body ECU. The buzzer in the combination

meter sounds at the same time.

(h) After the buzzer sounds, if the engine switch is

pressed within 5 seconds with the brake pedal not

depressed, the power source mode changes to on

(ACC) or on (IG), the same as in the normal

condition.

7. DIAGNOSIS

The main body ECU can detect malfunctions in the pushbutton start function when the power source mode is on (IG).

When the ECU detects a malfunction, the amber indicator

light of the engine switch flashes to warn the driver. At the

same time, the ECU stores a 5-digit DTC (Diagnostic Trouble

Code) in the memory.

• The indicator light warning continues for 15 seconds even

after the power source mode is changed to off.

• The DTC can be read by connecting the intelligent tester

to the DLC3.

• The push-button start function cannot be operated if a

malfunction occurs.

ST

ST–16

1

NEXT

2

2GR-FE STARTING – SMART KEY SYSTEM

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use the following procedures to troubleshoot the pushbutton start function.

• The intelligent tester should be used in steps 4, 5 and 8.

VEHICLE BROUGHT TO WORKSHOP

CUSTOMER PROBLEM ANALYSIS CHECK

HINT:

• In troubleshooting, confirm that the problem symptoms

have been accurately identified. Preconceptions should be

discarded in order to make an accurate judgment. To

clearly understand what the problem symptoms are, it is

extremely important to ask the customer about the

problem and the conditions at the time the malfunction

occurred.

• Gather as much information as possible for reference.

Past problems that seem unrelated may also help in some

cases.

• The following 5 items are important points in the problem

analysis:

ST

What Vehicle model, system name

When Date, time, occurrence frequency

Where Road conditions

Under what conditions? Running conditions, driving conditions, weather conditions

How did it happen? Problem symptoms

NEXT

INSPECT BATTERY VOLTAGE

3

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

INSPECT COMMUNICATION FUNCTION OF CAN COMMUNICATION SYSTEM

4

(a) Use the intelligent tester to check if the CAN

Communication System is functioning normally (See

page CA-8).

2GR-FE STARTING – SMART KEY SYSTEM

Result

Result Proceed to

CAN DTC is not output A

CAN DTC is output B

ST–17

A

CHECK FOR DTC

5

A

INSPECT BASIC OPERATION

6

B

GO TO CAN COMMUNICATION SYSTEM

(a) Check for DTCs and note any codes that are output (See

page ST-26).

(b) Delete DTCs.

(c) Recheck for DTCs.

Result

Result Proceed to

DTC does not reoccur A

DTC reoccurs B

B

GO TO DIAGNOSTIC TROUBLE CODE

CHART

(a) Turn the engine switch on (START) and check that the

engine starts normally. Make sure the brake pedal is

depressed and the shift position is P at this time.

(b) Check that the engine switch mode can be changed by

pushing the engine switch.

HINT:

Without depressing the brake pedal, push the engine

switch repeatedly. Engine switch mode should turn from

off to on (ACC) to on (IG) and back to off.

With the brake pedal depressed, push the engine switch

repeatedly. Engine switch mode should turn to ENGINE

START from any status.

OK:

Engine can start normally.

NEXT

PROBLEM SYMPTOMS TABLE

7

Result

Result Proceed to

Fault is not listed in the problem symptoms table A

Fault is listed in the problem symptoms table B

ST

ST–18

2GR-FE STARTING – SMART KEY SYSTEM

A

8

NEXT

9

NEXT

10

NEXT

B

OVERALL ANALYSIS AND TROUBLESHOOTING

(a) Terminals of ECU (See page ST-19)

(b) DATA LIST/ACTIVE TEST (See page ST-26)

REPAIR OR REPLACE

CONFIRMATION TEST

Go to step 9

END

ST

2GR-FE STARTING – SMART KEY SYSTEM

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace p arts

as necessary.

• Inspect the fuses and relays related to the system before

inspecting the suspected areas below.

PUSH-BUTTON START FUNCTION:

Symptom Suspected area See page

1. AM2 Fuse ST-114

2. Engine Switch -

3. Wire Harness or Connector -

Power does not turn on (neither ACC nor IG is

possible).

Power is not turned on (only ACC is not turned on).

Power is not turned on (only IG is not turned on).

Engine does not start.

Engine switch indicator light does not come on. Engine Switch Indicator Light Circuit ST-110

4. Main Body ECU (Instrument Panel J/B) -

5. Certification ECU -

6. ID Code Box -

7. Steering Lock ECU -

8. Smart Key System (Entry Function) -

1. AM2 Fuse ST-131

2. Wire Harness or Connector -

3. Main Body ECU (Instrument Panel J/B) -

1. AM2 Fuse ST-122

2. IG1 Relay -

3. IG2 Relay -

4. Wire Harness or Connector -

5. Main Body ECU (Instrument Panel J/B) -

1. Main Body ECU (Instrument Panel J/B) ST-95

2. Certification ECU -

3. Shift Lock Control ECU -

4. ID Code Box -

5. Stop SW Fuse -

6. Stop Light Switch -

7. Electrical Steering Lock Function -

8. Engine Control System -

9. Engine Immobiliser System -

10. Wire Harness or Connector -

ST–19

ST

ST–20

Front Side:

2GR-FE STARTING – SMART KEY SYSTEM

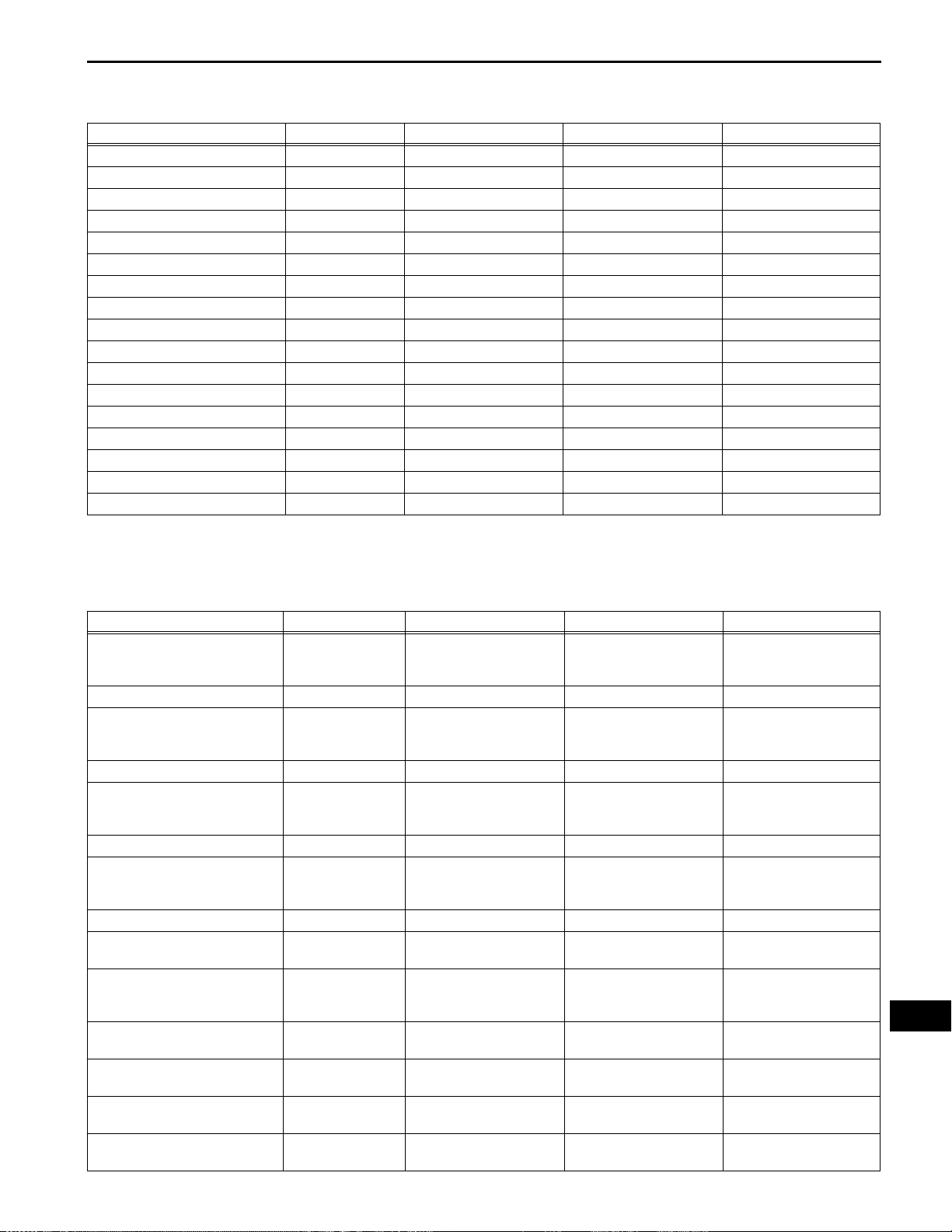

TERMINALS OF ECU

1. CHECK MAIN BODY ECU (INSTRUMENT PANEL J/B)

IK

IL

IC

IM

IF

ID

IB

IA

IP

IR

IJ

IE

IN

IO

ST

Back Side:

E7 E6

IG

II IH

E8

E9

B112605E03

(a) Disconnect the IR, IA, IK, ID, IF, IM E6, E7 and E8

ECU connectors.

2GR-FE STARTING – SMART KEY SYSTEM

(b) Measure the voltage and resistance of the wire

harness side connector.

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

AM1 (E7-6) - Body ground L - Body ground +B power supply Always 10 to 14 V

AM2 (E6-1) - Body ground L - Body ground +B power supply Always 10 to 14 V

SSW1 (E7-17) - Body ground L - Body ground Engine switch signal Engine switch pushed Below 1 Ω

SSW1 (E7-17) - Body ground L - Body ground Engine switch signal Engine switch not pushed 10 kΩ or higher

SSW2 (E7-16) - Body ground V - Body ground Engine switch signal Engine switch pushed Below 1 Ω

SSW2 (E7-16) - Body ground V - Body ground Engine switch signal Engine switch not pushed 10 kΩ or higher

GND3 (E8-1) - Body ground W-B - Body ground Ground Always Below 1 Ω

LIN1 (IR-9) - Body ground O - Body ground LIN line Always 10 kΩ or higher

BATB (IA-1) - Body ground B - Body ground +B Power supply Always 10 to 14 V

GND1 (IF-10) - Body ground W-B - Body ground Ground Always Below 1 Ω

GND2 (IM-9) - Body ground W-B - Body ground Ground Always Below 1 Ω

CANN (E8-15) - Body ground W - Body ground CAN Line Always 10 kΩ or higher

CANP (E8-16) - Body ground L - Body ground CAN Line Always 10 kΩ or higher

CANH (E8-5) - Body ground R - Body ground CAN Line Always 10 kΩ or higher

CANL (E8-6) - Body ground W - Body ground CAN Line Always 10 kΩ or higher

ACC (IA-1) - Body ground B - Body ground ACC power supply Always 10 to 14 V

IG (IA-1) - Body ground B - Body ground IG power supply Always 10 to 14 V

ST–21

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Reconnect the ECU connectors.

(d) Measure the voltage of the connector.

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

Output voltage at terminal

ACCD (E7-22) - GND3 (E8-1) W - W-B ACC signal Engine switch on (ACC)

ACCD (E7-22) - GND3 (E8-1) W - W-B ACC signal Engine switch off Below 1 V

IG1D (E7-3) - GND3 (E8-1) P - W-B IG1 signal Engine switch on (IG)

IG1D (E7-3) - GND3 (E8-1) P - W-B IG1 signal Engine switch on (ACC) Below 1 V

IG2D (E6-11) - GND3 (E8-1) LG - W-B IG2 signal Engine switch on (IG)

IG2D (E6-11) - GND3 (E8-1) LG - W-B IG2 signal Engine switch on (ACC) Below 1 V

STP (IL-7) - GND3 (E8-1) L - W-B Stop light signal Brake pedal depressed

STP (IL-7) - GND3 (E8-1) L - W-B Stop light signal Brake pedal released Below 1 V

SLR+ (E7-19) - GND3 (E8-1) BR - W-B Steering lock motor signal

SLR+ (E7-19) - GND3 (E8-1) BR - W-B Steering lock motor signal

SLP (E7-18) - GND3 (E8-1) P - W-B

SLP (E7-18) - GND3 (E8-1) P - W-B

SPD (E8-9) - GND3 (E8-1) V - W-B Vehicle speed signal

TACH (E8-8) - GND3 (E8-1) B - W-B Tachometer signal Engine running

Steering lock actuator

position signal

Steering lock actuator

position signal

Steering lock motor

operating

Steering lock motor does

not operate

Steering lock is locked

Steering lock is released

Engine switch on (IG),

rotate rear wheel slowly

AM1 or AM2 is -2 V or

more.

Output voltage at terminal

AM1 or AM2 is -2 V or

more.

Output voltage at terminal

AM1 or AM2 is -2 V or

more.

Output voltage at terminal

AM1 or AM2 is -2 V or

more.

Below 1 V

Output voltage at terminal

AM1 or AM2 is -2 V or

more.

Pulse generation

(See waveform 3)

Pulse generation

(See waveform 3)

Pulse generation

(See waveform 1)

Pulse generation

(See waveform 2)

ST

ST–22

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

P (E9-2) - GND3 (E8-1) G - W-B Shift lock signal Shift lever P position

P (E9-2) - GND3 (E8-1) G - W-B Shift lock signal Shift lever not P position Below 1 V

ACCR (E6-3) - GND3 (E8-1) P - W-B Starter assist signal

STSW (E9-4) - GND3 (E8-1) GR - W-B

STR (E7-8) - GND3 (E8-1) G - W-B

STR2 (E9-6) - GND3 (E8-1) V - W-B Starter signal

INDS (E7-15) - GND3 (E8-1) LG - W-B Vehicle condition signal

INDW (E7-14) - GND3 (E8-1) P - W-B Warning signal

SWIL (E7-25) - GND3 (E8-1) O - W-B Illumination signal

2GR-FE STARTING – SMART KEY SYSTEM

Brake pedal depressed,

shift lever P position,

engine switch is pushed

once → on (IG)

Starter activation request

signal

Park/neutral position

switch

Brake pedal depressed,

engine switch held on (ST)

Shift lever P or N position Below 1 V

Brake pedal depressed,

shift lever P or N position,

engine switch on (ST)

Brake pedal depressed,

shift lever P position.

Brake pedal depressed,

shift lever P position,

engine switch on (ACC,

Light control switch TAIL

or HEAD

IG)

Output voltage at terminal

AM1 or AM2 is -2 V or

more.

0.1 to 0.8 V *

→ Output voltage at

terminal AM1 or AM2 is -2

V or more.

Output voltage at terminal

AM1 or AM2 is -2 V or

more.

Output voltage at terminal

AM1 or AM2 is -3.5 V or

more. *

Output voltage at terminal

AM1 or AM2 is -3 V or

more.

Output voltage at terminal

AM1 or AM2 is -3 V or

more.

Output voltage at terminal

AM1 or AM2 is -2 V or

more.

1

2

ST

GND

I042329E01

HINT:

1

: Voltage is output only when the engine is

*

cranking.

2

: Voltage is output for 0.3 seconds when the

*

engine is cranking to start. Disconnect the C55

connector from the ECM before measuring the

voltage.

If the result is not as specified, the ECU may have a

malfunction.

(e) Using an oscilloscope, check the signal waveform of

the ECU.

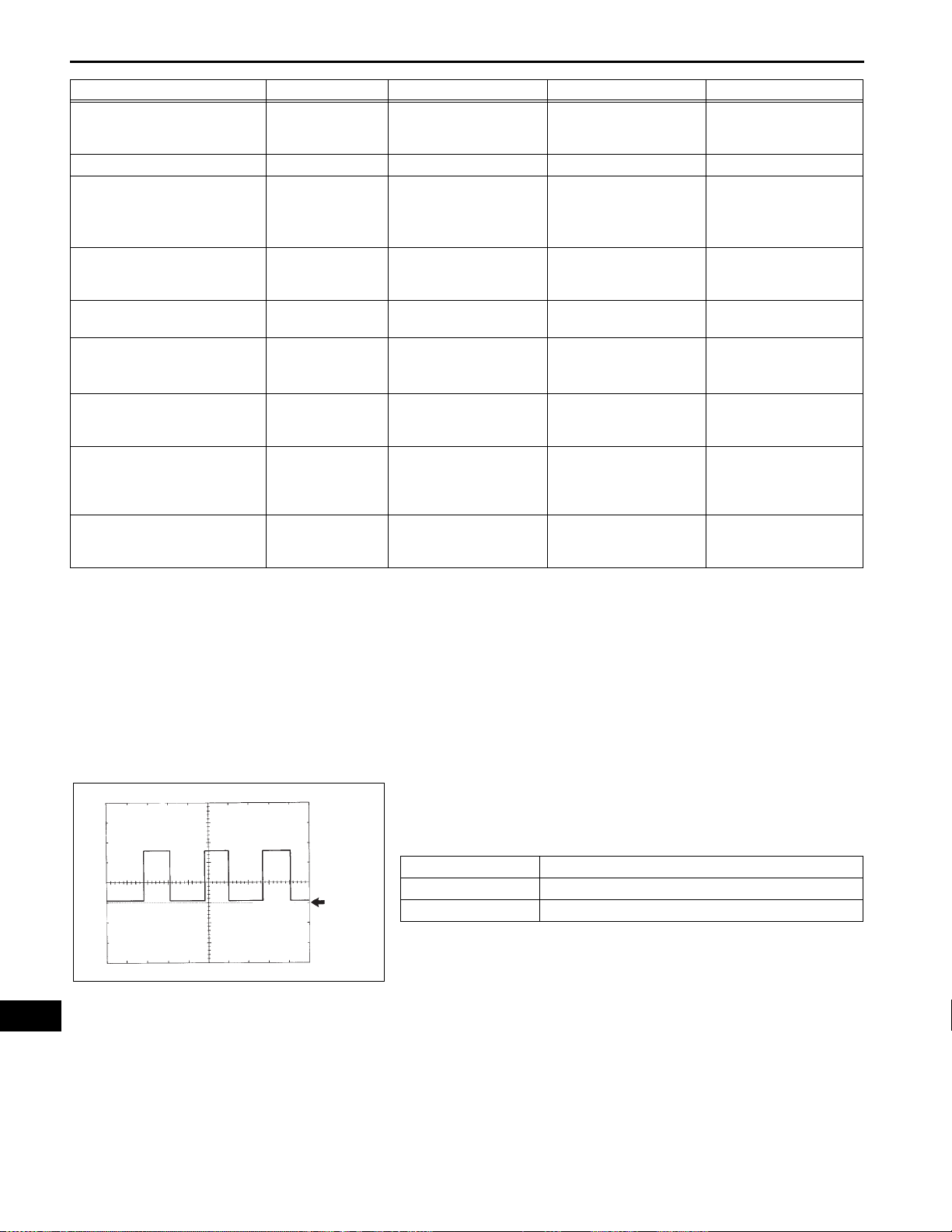

(1) Waveform 1

Waveform 1 (Reference):

Terminal No. E8-9 (SPD) - Body ground

Tool Setting 5 V/DIV., 10 ms./DIV.

Vehicle Condition Driving at approx. 20 km/h (12 mph)

HINT:

As the vehicle speed increases, the wavelength

shortens.

2GR-FE STARTING – SMART KEY SYSTEM

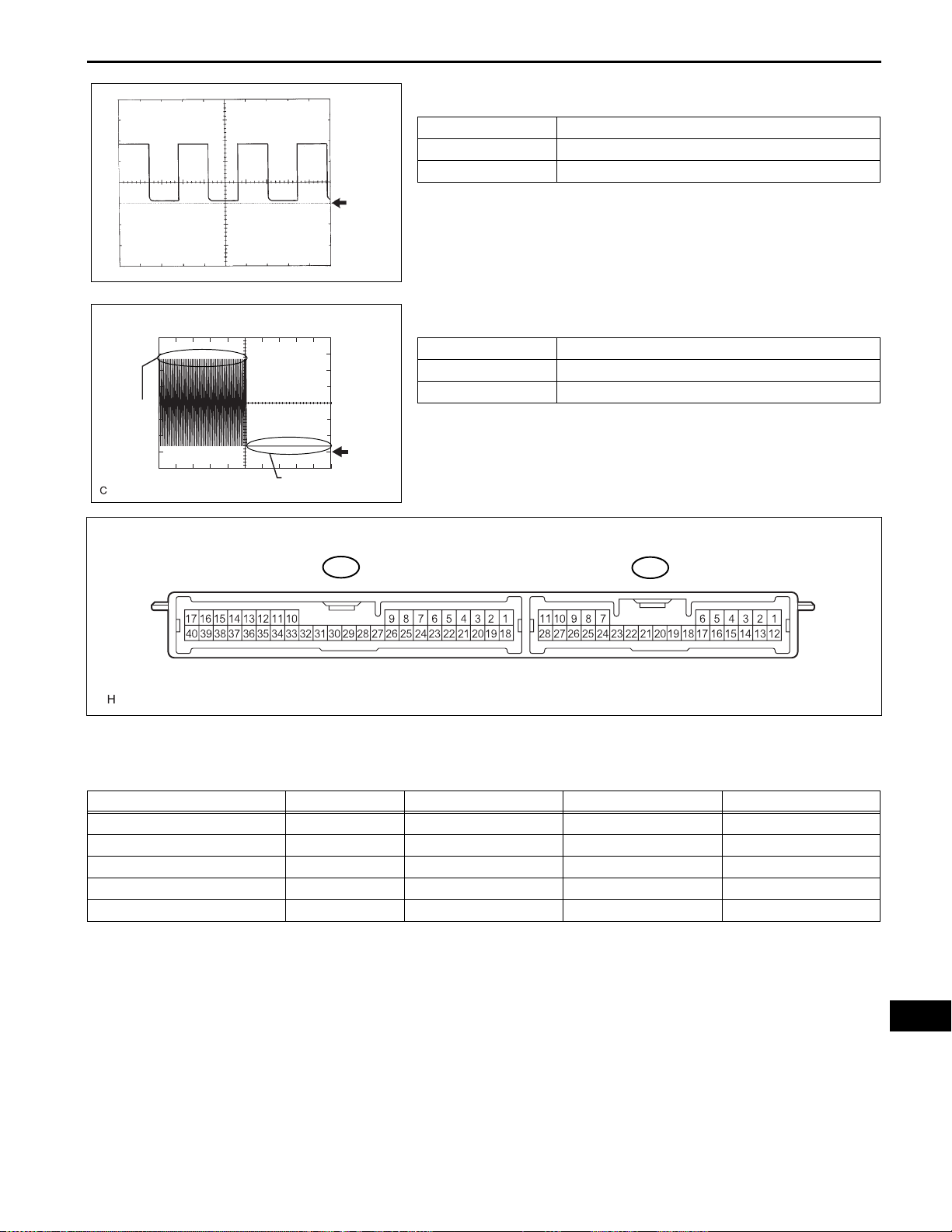

(2) Waveform 2

Waveform 2 (Reference):

Terminal No. E8-8 (TACH) - Body ground

Tool Setting 5 V/DIV., 10 ms./DIV.

Vehicle Condition Engine idling

ST–23

Lock

Unlock

E58

GND

I042330E01

GND

A130277E01

HINT:

As the engine revolution speed increases, the

wavelength shortens.

(3) Waveform 3

Waveform 3 (Reference):

Terminal No. E7-18 (SLP) - Body ground

Tool Setting 2 V/DIV., 100 ms./DIV.

Vehicle Condition Steering lock/unlock

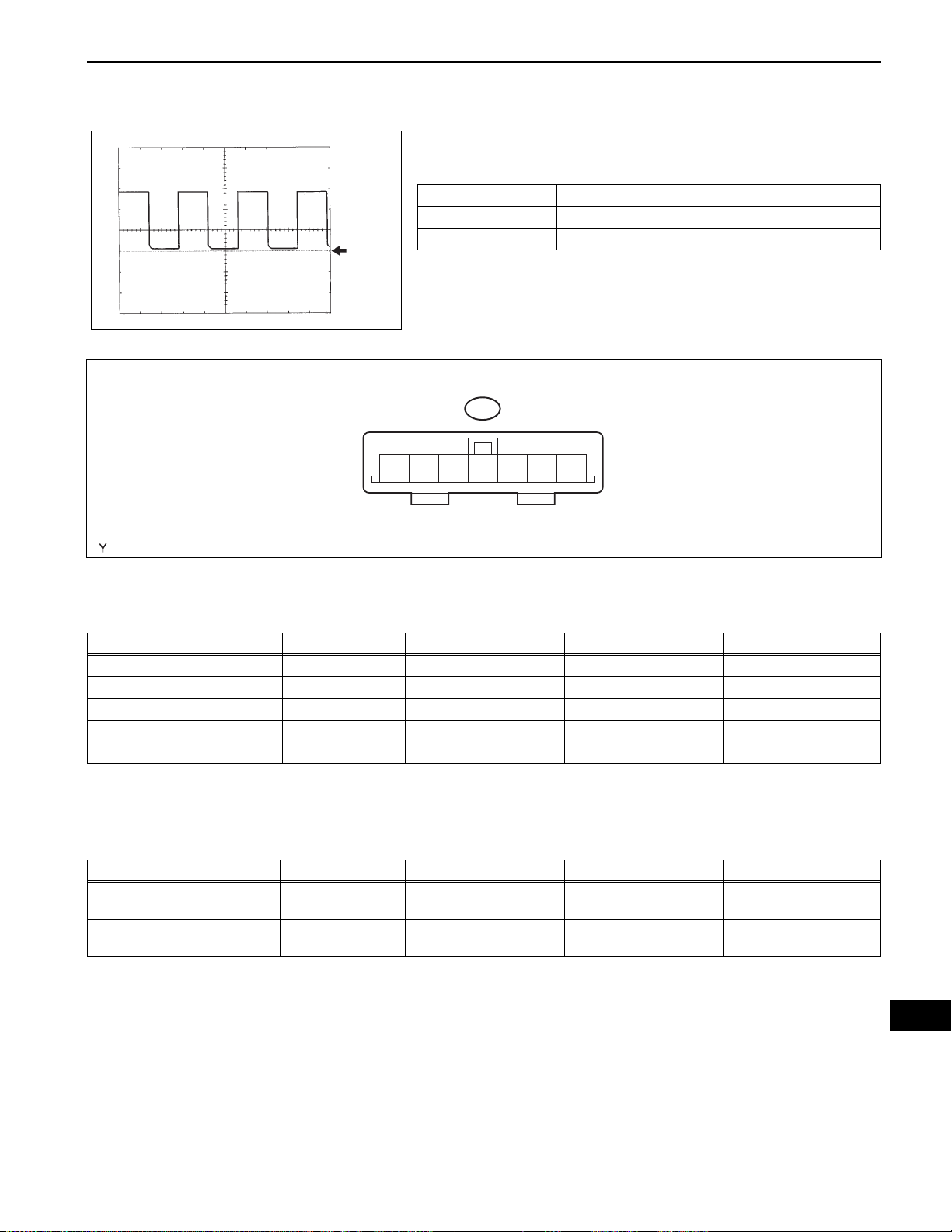

2. CHECK CERTIFICATION ECU

E59

(a) Disconnect the E58 ECU connector.

(b) Measure the voltage and resistance of the wire

harness side connector.

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

+B (E58-1) - Body ground W - Body ground +B power supply Always 10 to 14 V

IG (E58-18) - Body ground LG - Body ground Ignition power supply Engine switch on (IG) 10 to 14 V

IG (E58-18) - Body ground LG - Body ground Ignition power supply Engine switch off Below 1 V

LIN (E58-10) - Body ground O - Body ground LIN line Always 10 kΩ or higher

E (E58-17) - Body ground W-B - Body ground Ground Always Below 1 Ω

If the result is not as specified, there may be a

malfunction on the wire harness side.

E125964E05

ST

ST–24

2GR-FE STARTING – SMART KEY SYSTEM

3. CHECK ECM

C55

A55

(a) Disconnect the C55 and A55 ECM connectors.

(b) Measure the voltage and resistance of the wire

harness side connectors.

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

+B (A55-2) - Body ground R - Body ground Power source of ECM Engine switch on (IG) 10 to 14 V

+B2 (A55-1) - Body ground R - Body ground Power source of ECM Engine switch on (IG) 10 to 14 V

IGSW (A55-28) - Body ground Y - Body ground Ignition switch signal Engine switch on (IG) 10 to 14 V

E01 (C55-22) - Body ground W-B - Body ground Ground Always Below 1 Ω

E02 (C55-21) - Body ground W-B - Body ground Ground Always Below 1 Ω

E03 (C55-104) - Body ground B - Body ground Ground Always Below 1 Ω

E04 (C55-23) - Body ground W - Body ground Ground Always Below 1 Ω

E05 (C55-46) - Body ground W - Body ground Ground Always Below 1 Ω

E1 (C55-81) - Body ground W-B - Body ground Ground Always Below 1 Ω

ME01 (C55-20) - Body ground B - Body ground Ground Always Below 1 Ω

A107881E32

ST

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Reconnect the ECM connectors.

(d) Measure the voltage of the connectors.

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

STA (A55-48) - E1 (C55-81) V - W-B

ACCR (A55-13) - E1 (C55-81) B - W-B

TACH (A55-15) - E1 (C55-81) B - W-B

STP (A55-36) - E1 (C55-81) W - W-B

STP (A55-36) - E1 (C55-81) W - W-B

STAR (C55-63) - E1 (C55-81) R - W-B PNP switch signal (input)

Starter relay operation

signal

ACC relay cut signal

(output)

Engine revolution signal

(output)

Stop light switch signal

(input)

Stop light switch signal

(input)

Cranking 10 to 14 V

Brake pedal depressed,

shift lever P position,

engine switch is pushed

once → on (IG)

Idling

Brake pedal depressed 7.5 to 14 V

Brake pedal released Below 1.5 V

Engine switch on (IG),

shift position P or N

0.1 to 0.8 V *

voltage at terminal AM1 or

AM2 is -2 V or more.

Pulse generation (see

1

→ Output

waveform 1)

10 to 14 V

HINT:

1

: Voltage is output only when the engine is

*

cranking.

2GR-FE STARTING – SMART KEY SYSTEM

If the result is not as specified, the ECM may have a

malfunction.

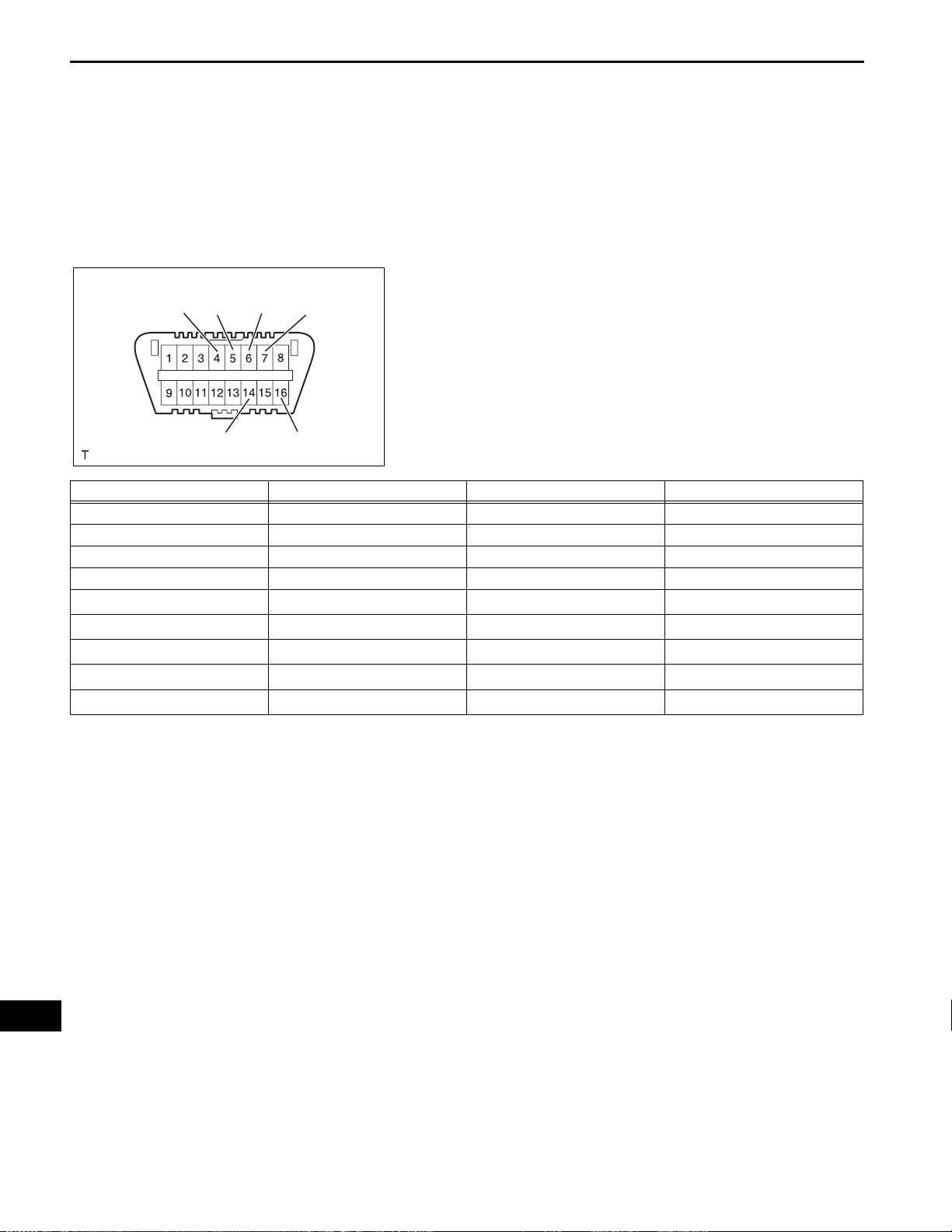

(e) Using an oscilloscope, check the signal waveform of

the ECM.

Waveform 1 (Reference):

Terminal No. A55-15 (TACH) - C55-81 (E1)

Tool Setting 5 V/DIV., 10 ms./DIV.

Vehicle Condition Engine idling

GND

HINT:

As the vehicle speed increases, the wavelength

I042330E01

shortens.

4. CHECK STEERING LOCK ECU

E51

1234567

ST–25

(a) Disconnect the E51 ECU connector.

(b) Measure the voltage and resistance of the wire

harness side connector.

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

B (E51-7) - Body ground P - Body ground +B power supply Always 10 to 14 V

IG2 (E51-6) - Body ground B - Body ground Ignition power supply Engine switch on (IG) 10 to 14 V

IG2 (E51-6) - Body ground B - Body ground Ignition power supply Engine switch off Below 1 V

GND (E51-1) - Body ground W-B - Body ground Ground Always Below 1 Ω

SGND (E51-2) - Body ground W-B - Body ground Ground Always Below 1 Ω

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Reconnect the E51 ECU connector.

(d) Measure the voltage of the connector.

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

SLP1 (E51-4) - GND (E51-1) P - W-B

SLP1 (E51-4) - GND (E51-1) P - W-B

Steering lock actuator

position signal

Steering lock actuator

position signal

Steering is locked 10 to 14 V

Steering is released Below 1 V

If the result is not as specified, the ECU may have a

malfunction.

B106649E13

ST

ST–26

CG

SG

CANH

2GR-FE STARTING – SMART KEY SYSTEM

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Push-button start function data and the Diagnostic

Trouble Codes (DTCs) can be read through the

Data Link Connector 3 (DLC3) of the vehicle. When

the function seems to be malfunctioning, use the

intelligent tester to check for malfunctions and

perform repairs.

2. CHECK DLC3

HINT:

SIL

The ECU uses ISO 15765-4 communication protocol.

The terminal arrangement of the DLC3 complies with

SAE J1962 and matches the ISO 15765-4 format.

CANL

Symbols (Terminal No.) Terminal Description Condition Specified Condition

CG (4) - Body ground Chassis ground Always Below 1 Ω

SG (5) - Body ground Signal ground Always Below 1 Ω

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

BAT (16) - Body ground Battery positive Always 10 to 14 V

CANH (6) - CANL (14) CAN bus line

CANH (6) - CG (4) HIGH-level CAN bus line

CANL (14) - CG (4) LOW-level CAN bus line

CANH (6) - BAT (16) HIGH-level CAN bus line

CANL (14) - BAT (16) LOW-level CAN bus line

BAT

H100769E16

Engine Switch OFF

Engine Switch OFF

Engine Switch OFF

Engine Switch OFF

Engine Switch OFF

*

*

*

*

*

56 to 69 Ω

200 Ω or more

200 Ω or more

6 kΩ or more

6 kΩ or more

NOTICE:

*: Before measuring the resistance, leave the vehicle

as is for at least 1 minute and do not operate the

engine switch, any other switches or the doors.

If the result is not as specified, the DLC3 may have a

malfunction. Repair or replace the harness and

connector.

ST

DLC3

DLC3

CAN VIM

Intelligent Tester

CAN VIM

Intelligent Tester

2GR-FE STARTING – SMART KEY SYSTEM

HINT:

Connect the cable of the intelligent tester to the DLC3,

turn the engine switch on (IG) and attempt to use the

tester. If the display indicates that a communica tion error

has occurred, there is a problem either with the vehicle

or with the tester.

• If communication is normal when the tester is

connected to another vehicle, inspect the DLC3 of the

original vehicle.

• If communication is still not possible when the tester

is connected to another vehicle, the problem may be

in the tester itself. Consult the Service Department

listed in the tester's instruction manual.

3. INSPECT BATTERY VOLTAGE

C131977E12

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the

battery before proceeding.

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the intelligent tester to the DLC3.

(b) Turn the engine switch on (IG).

(c) Enter the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES.

(d) Read the DTC by following the prompts on the

tester screen.

HINT:

Refer to the intelligent tester operator's manual for

further details.

2. CLEAR DTC

C131977E12

(a) Connect the intelligent tester to the DLC3.

(b) Turn the engine switch on (IG).

(c) Enter the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR CODES.

(d) Erase the DTC by following the directions on the

tester screen.

HINT:

Refer to the intelligent tester operator's manual for further

details.

ST–27

ST

ST

ST–28

MAIN BODY:

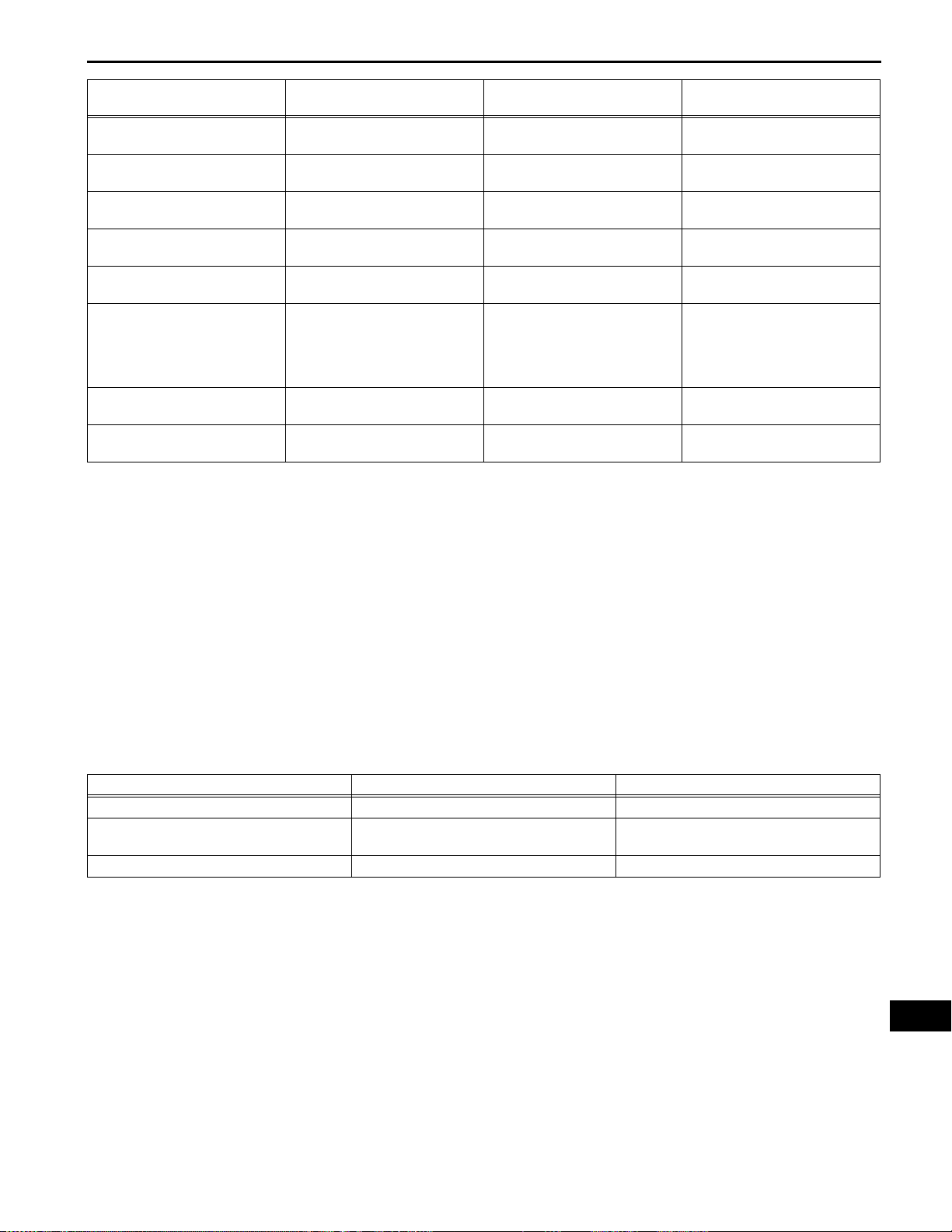

Item

ACC SW

IG SW

SHIFT P SIG

STR UNLOCK SW

STOP LAMP SW Stop light switch / ON or OFF

STSW1 Start switch 1 / ON or OFF

START SW2 Start switch 2 / ON or OFF

N SW / C SW Neutral start switch / ON or OFF

RATCH CIRCUIT Ratch circuit / ON or OFF

IG1 RELAY MON1

IG1 RELAY MON2

IG2 RELAY MON1

IG2 RELAY MON2

ST RELAY MON

2GR-FE STARTING – SMART KEY SYSTEM

DATA LIST / ACTIVE TEST

1. READ DATA LIST

HINT:

Using the intelligent tester to read the Data List allows

the values or states of switches, sensors, actuators and

other items to be read without removing any parts. This

non-intrusive inspection can be very useful as

intermittent conditions or signals may be discovered

before parts or wiring is disturbed. Reading the DATA

LIST information early in troubleshooting is one way to

save diagnostic time.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

When using the intelligent tester with the engine

switch off, turn on and off any of the door courtesy

light switches repeatedly at 1.5 or less second

intervals until communication between the tester

and vehicle starts.

(b) Turn the engine switch on (IG).

(c) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / DATA LIST.

(d) Read the DATA LIST.

Measurement Item / Display

(Range)

Engine switch on (ACC) / ON or

OFF

Engine switch on (IG) / ON or

OFF

Shift P position signal / ON or

OFF

Steering lock condition / ON or

OFF

IG1 outer relay monitor / ON or

OFF

IG1 inner relay monitor / ON or

OFF

IG2 outer relay monitor / ON or

OFF

IG2 inner relay monitor / ON or

OFF

STARTER relay monitor / ON or

OFF

Normal Condition Diagnostic Note

ON: Engine switch on (ACC)

OFF: Engine switch off

ON: Engine switch on (IG)

OFF: Engine switch off

ON: Shift position is P

OFF: Shift position is not P

ON: Steering is unlocked

OFF: Steering is locked

ON: Brake pedal depressed

OFF: Brake pedal released

ON: Engine switch is pushed

OFF: Engine switch is not pushed

ON: Engine switch is pushed

OFF: Engine switch is not pushed

ON: Shift position is P or N

OFF: Shift position is neither P

nor N

ON: Engine switch on (IG) or

engine running

OFF: Engine switch off or on

(ACC)

ON: Engine switch on (IG)

OFF: Engine switch off

ON: Engine switch on (IG)

OFF: Engine switch off

ON: Engine switch on (IG)

OFF: Engine switch off

ON: Engine switch on (IG)

OFF: Engine switch off

ON: Engine is cranking

OFF: Engine is not cranking

-

-

-

-

-

-

-

-

-

-

-

-

-

Engine is cranking with engine

switch on (IG) and shift lever in P

or N

2GR-FE STARTING – SMART KEY SYSTEM

ST–29

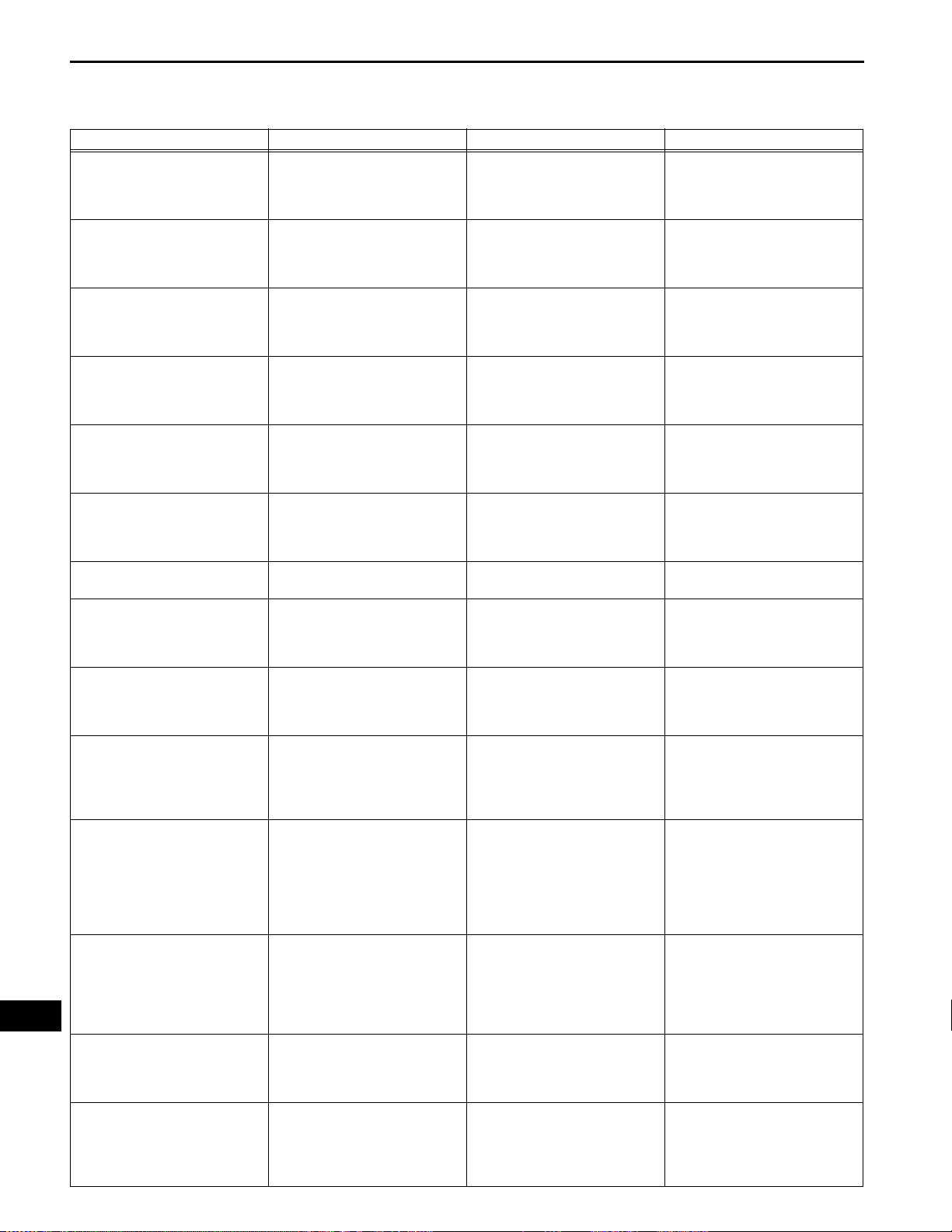

Item

ST REQUEST SIG

ACC RELAY MON ACC relay monitor / ON or OFF

ACC CUT SIG ACC relay cut signal / ON or OFF

E/G COND Engine condition / STOP or RUN

VEHICLE SPD SIG

PWR COND

READY SIG

COM ENTRY&STRT

Measurement Item / Display

(Range)

Starter request signal monitor /

ON or OFF

Vehicle speed signal / STOP or

RUN

Power supply condition / ALL,

ACC ON, IG1 IG2, ST ON

Ready Signal / ON or OFF or

Unknown

Communication for certification

ECU / OK or STOP

Normal Condition Diagnostic Note

ON: ST relay is ON

OFF: ST relay is OFF

ON: Engine switch on (ACC)

OFF: Engine switch off

ON: Engine is cranking

OFF: Engine is not cranking

STOP: Engine is stopped

RUN: Engine is running

STOP: Vehicle is stopped

RUN: Vehicle is running

ALL: All relays are OFF

ACC ON: ACC relay is ON

IG1: IG1 relay is ON

IG2: IG2 relay is ON

ST ON: ST request signal is ON

OK: Communication

STOP: No communication

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester's ACTIVE TEST allows

the relay, VSV, actuator and other items to be operated

without removing any parts. Performing the ACTIVE

TEST early in troubleshooting is one way to save time.

The DATA LIST can be displayed during the ACTIVE

TEST.

(a) Connect the intelligent tester to the DLC3

(b) Turn the engine switch on (IG).

(c) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST.

(d) Perform the ACTIVE TEST according to the display

on the tester.

MAIN BODY:

Item Test Details Diagnostic Note

LIGHTING IND Indicator for lighting ON / OFF IND CONDITION Engine switch indicator Green / Amber / No

STR LOCK PWR Power supply for steering lock ECU ON / OFF -

Sig

Engine switch pressed and held

with shift lever in P or N

-

-

-

-

-

-

-

-

ST

ST

ST–30

2GR-FE STARTING – SMART KEY SYSTEM

PUSH-BUTTON START FUNCTION:

DTC No. Detection Item Trouble Area See page

B2271 Ignition Hold Monitor Malfunction 1. AM2 fuse

B2272 Ignition 1 Monitor Malfunction 1. IG1 relay

B2273 Ignition 2 Monitor Malfunction 1. IG2 relay

B2274 ACC Monitor Malfunction 1. ACC relay

B2275 STSW Monitor Malfunction 1. ECM

B2276 ACCR Signal Circuit Malfunction 1. Main body ECU (Instrument

B2277 Detecting Vehicle Submersion Main body ECU (Instrument panel

B2278 Engine Switch Circuit Malfunction 1. Engine switch

B2281 "P" Signal Malfunction 1. Main body ECU (Instrument

B2282 Vehicle Speed Signal Malfunction 1. CAN communication system

B2283 Vehicle Speed Sensor

Malfunction

B2284 Brake Signal Malfunction 1. Stop light switch

B2285 Steering Lock Position Signal

Circuit Malfunction

B2286 Runnable Signal Malfunction 1. CAN communication system

DIAGNOSTIC TROUBLE CODE CHART

ST-31

2. Main body ECU (Instrument

panel J/B)

3. Wire harness or connector

2. Main body ECU (Instrument

panel J/B)

3. Wire harness or connector

2. Main body ECU (Instrument

panel J/B)

3. Wire harness or connector

2. Main body ECU (Instrument

panel J/B)

3. Wire harness or connector

2. Main body ECU (Instrument

panel J/B)

3. Wire harness or connector

panel J/B)

2. ECM

3. Wire harness or connector

J/B)

2. Main body ECU (Instrument

panel J/B)

3. Wire harness or connector

panel J/B)

2. Shift lock control ECU

3. Wire harness or connector

2. Combination meter system

3. Main body ECU (Instrument

panel J/B)

4. Wire harness or connector

1. B2282 detection area

2. Combination meter

3. Speed sensor

4. Skid control ECU

5. Main body ECU (Instrument

panel J/B)

6. Wire harness or connector

2. CAN communication system

3. ECM

4. Main body ECU (Instrument

panel J/B)

5 Wire harness or connector

1. Main body ECU (Instrument

panel J/B)

2. Steering lock ECU

3. Wire harness or connector

2. ECM

3. Main body ECU (Instrument

panel J/B)

4. Wire harness or connector

ST-34

ST-39

ST-43

ST-48

ST-51

ST-54

ST-55

ST-60

ST-63

ST-69

ST-72

ST-77

ST-81

Loading...

Loading...