Toyota Camry 2007-2009 Service Manual - 2AZ-FE_Engine_Mechanical

2AZ-FE ENGINE MECHANICAL – ENGINE

ENGINE

INSPECTION

1. INSPECT ENGINE COOLANT

(a) Inspect the engine coolant (See page CO-1).

2. INSPECT ENGINE OIL

(a) Inspect the engine oil (See page LU-1).

3. INSPECT BATTERY

(a) Inspect the battery (See page CH-4).

4. INSPECT SPARK PLUGS

(a) Inspect the spark plugs (See page IG-5).

5. INSPECT AIR CLEANER FILTER ELEMENT SUBASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

(b) Visually check that there is no dirt, blockage, and/or

damage to the air cleaner filter element.

HINT:

• If there is any dirt or a blockage in the air cleaner

filter element, clean it with compressed air.

• If any dirt or a blockage remains even after

cleaning the air cleaner filter element with

compressed air, replace it.

EM–1

EM

DLC3

Intelligent Tester

CAN VIM

DLC3

12345678

91011

12

CG

14 16

13

15

TC

C110200E02

A082779E69

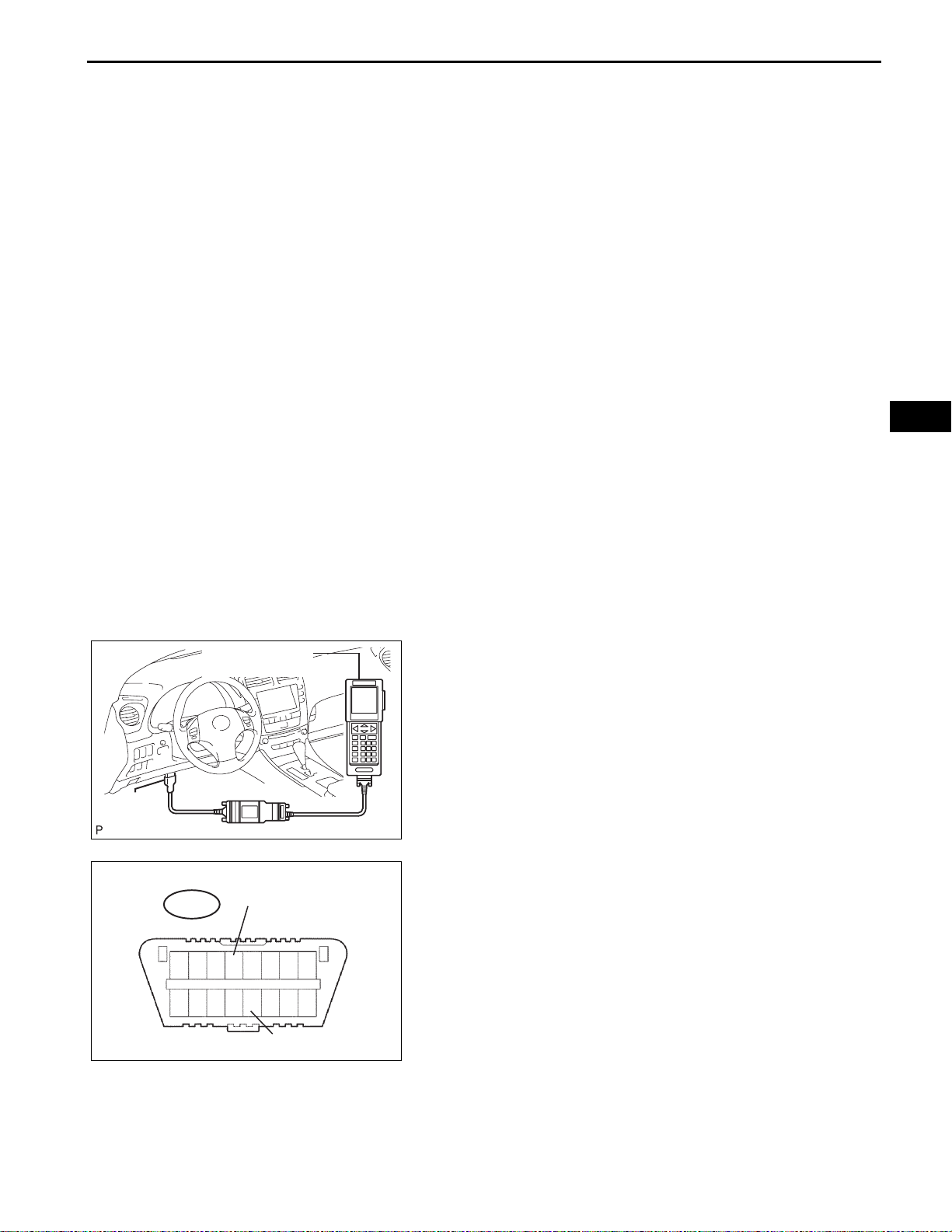

6. INSPECT IGNITION TIMING

(a) Warm up the engine.

(b) When using the intelligent tester:

Check the ignition timing.

(1) Connect the intelligent tester to the DLC3.

(2) Enter DATA LIST MODE on the intelligent

tester.

Ignition timing:

8 to 12° BTDC at idle

HINT:

Refer to the intelligent tester operator's manual

for help when selecting the DATA LIST.

(c) When not using the intelligent tester:

Check the ignition timing.

(1) Using SST, connect terminals 13 (TC) and 4

(CG) of the DLC3.

SST 09843-18040

NOTICE:

• Confirm the terminal numbers before

connecting them. Connection with a

wrong terminal can damage the engine.

• Turn off all electrical systems before

connecting the terminals.

• Perform this inspection after the cooling

fan motor is turned off.

EM

EM–2

2AZ-FE ENGINE MECHANICAL – ENGINE

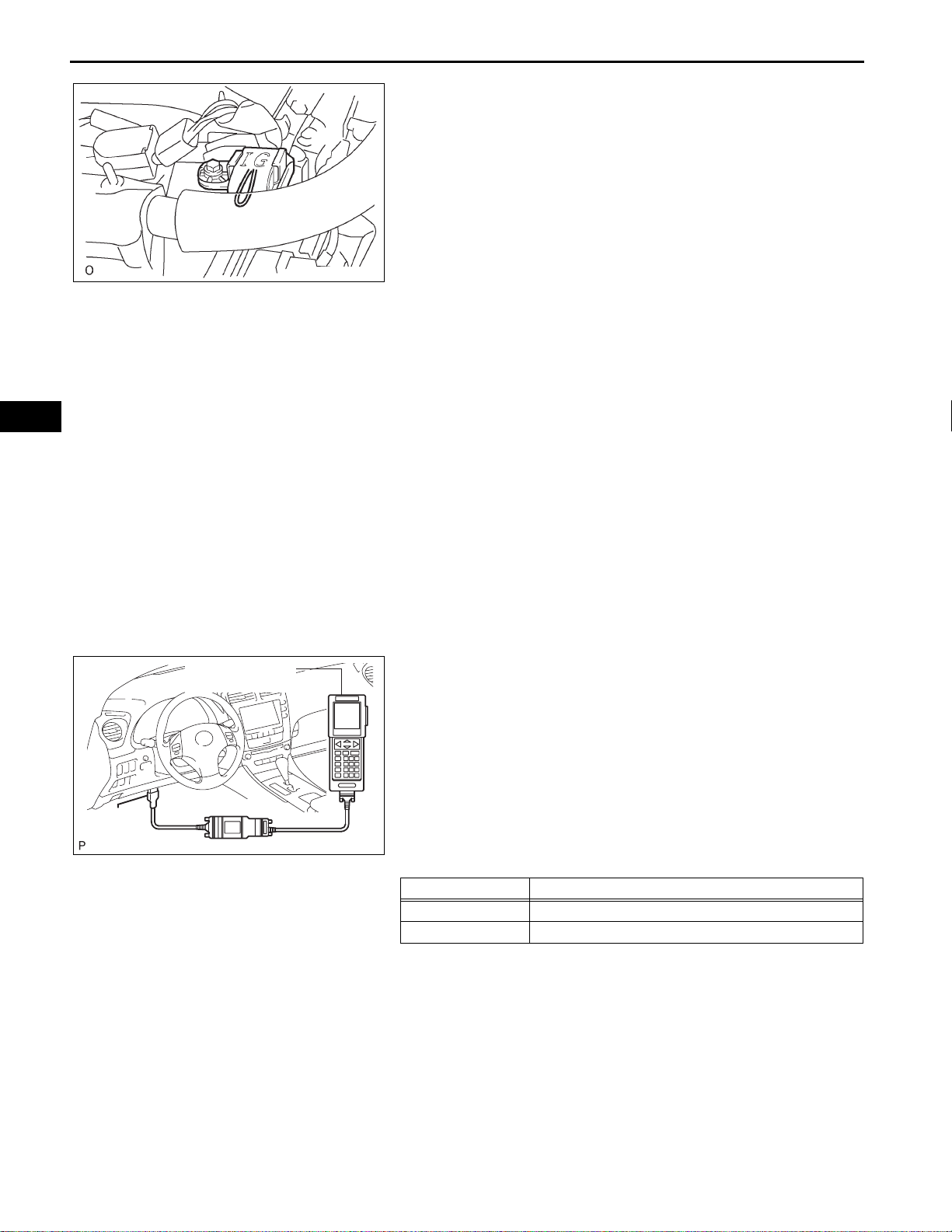

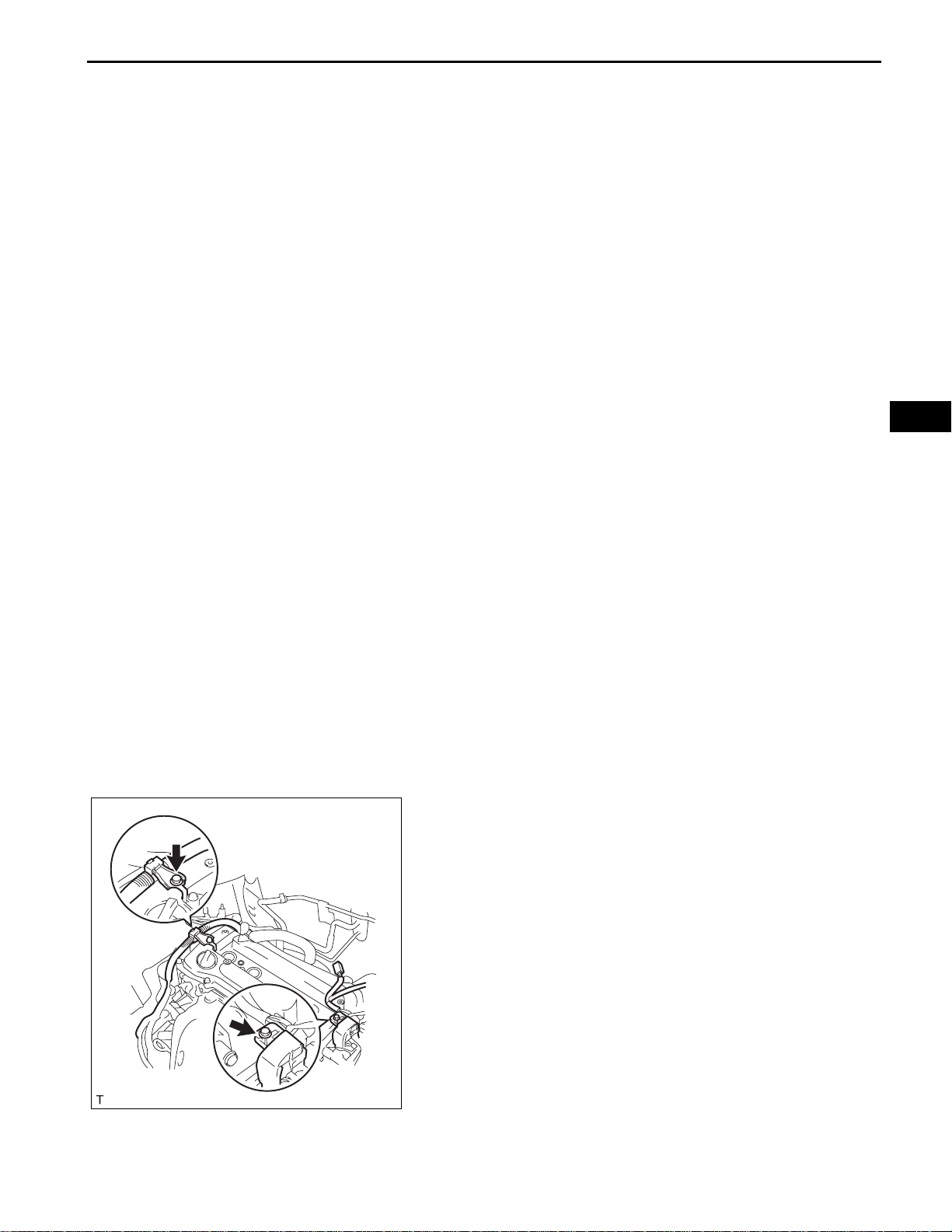

(2) Remove the No. 1 engine cover.

(3) Pull out the wire harness as shown in the

illustration. Connect the clip of the timing light

to the wire harness.

NOTICE:

• Use a timing light which can detect the

first signal.

• After checking, be sure to tape the wire

harness.

A052004

(4) Check the ignition timing at idle.

Ignition timing:

8 to 12° BTDC at idle

NOTICE:

When checking the ignition timing, the

transmission should be in neutral.

HINT:

After engine rpm is kept at 1,000 to 1,300 rpm

for 5 seconds, check that it returns to idle

speed.

(5) Disconnect terminals 13 (TC) and 4 (CG) of the

DLC3.

(6) Check the ignition timing at idle.

Ignition timing:

5 to 15° BTDC at idle

(7) Confirm that the ignition timing moves to the

advanced angle side when the engine rpm is

increased.

(8) Remove the timing light.

DLC3

Intelligent Tester

CAN VIM

C110200E02

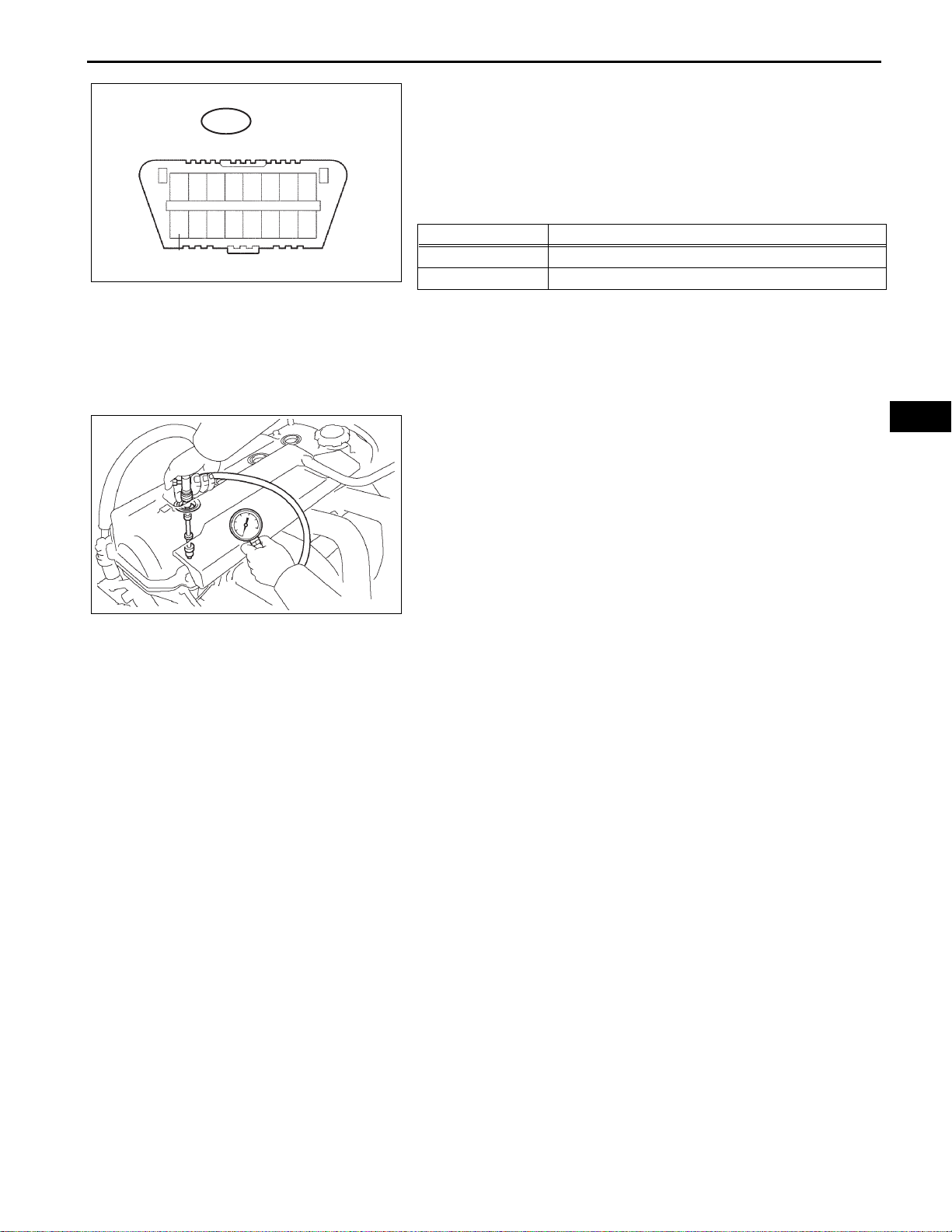

7. INSPECT ENGINE IDLE SPEED

(a) Warm up the engine.

(b) When using the intelligent tester:

Check the idle speed.

(1) Connect the intelligent tester to the DLC3.

HINT:

Refer to the intelligent tester operator's manual

for further details.

(2) Enter DATA LIST MODE on the intelligent

tester.

Idle speed

Item Specified Condition

M/T 650 to 750 rpm

A/T 610 to 710 rpm

NOTICE:

• When checking the idle speed, the

transmission should be in neutral.

• Check the idle speed with the cooling fan

off.

• Switch off all accessories and air

conditioning before connecting the

intelligent tester.

DLC3

345678

2

1

9101112

TAC

1314

15

2AZ-FE ENGINE MECHANICAL – ENGINE

(c) When not using the intelligent tester:

Check the idle speed.

(1) Using SST, connect the tachometer tester

probe to terminal 9 (TAC) of the DLC3.

SST 09843-18030

(2) Check the idle speed.

Idle speed

16

A082779E70

Item Specified Condition

M/T 650 to 750 rpm

A/T 610 to 710 rpm

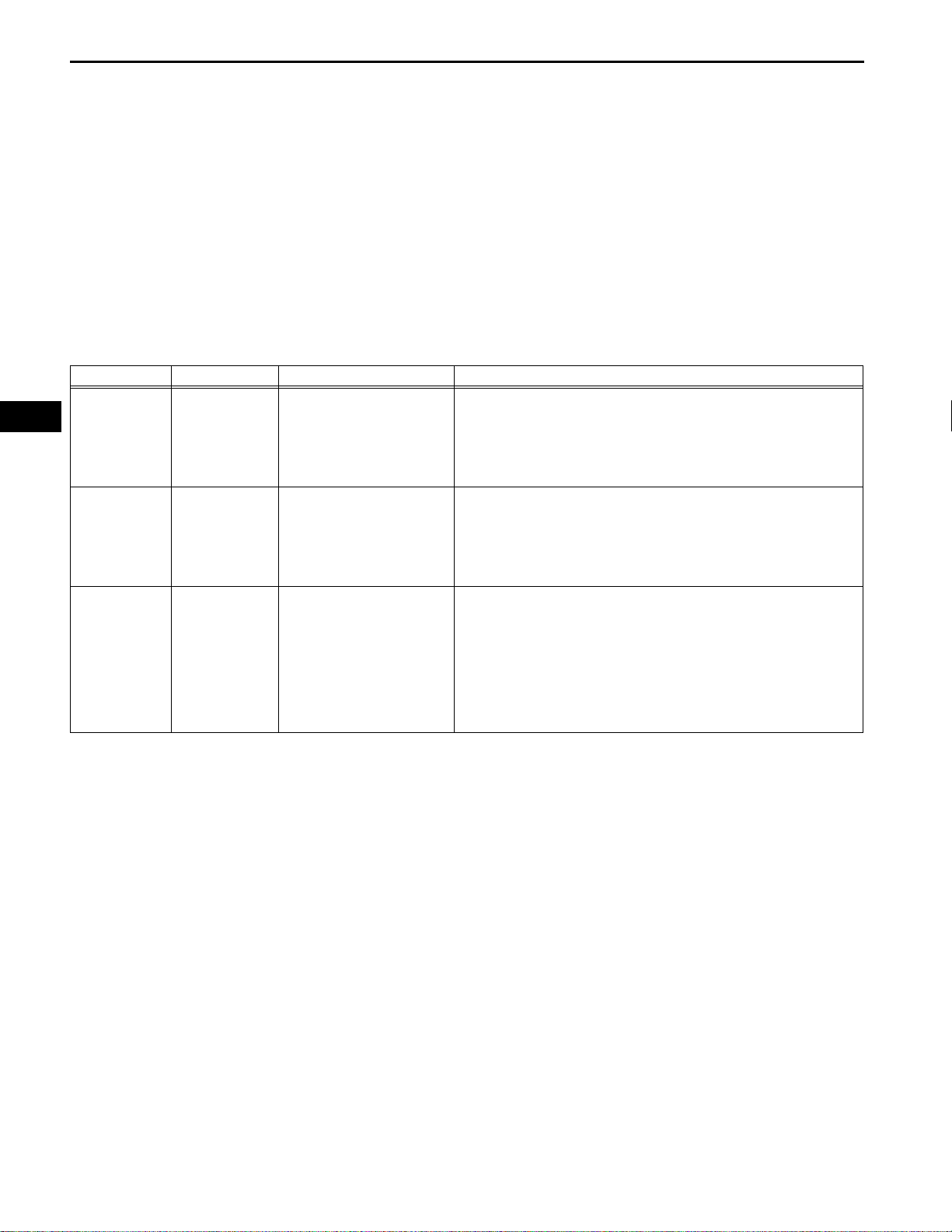

8. INSPECT COMPRESSION

(a) Warm up and stop the engine.

(b) Disconnect the injector connectors.

(c) Remove the ignition coils.

(d) Remove the spark plugs.

EM–3

A001037

(e) Check the cylinder compression pressure.

(1) Insert a compression gauge into the spark plug

hole.

(2) Fully open the throttle.

(3) While cranking the engine, measure the

compression pressure.

Compression pressure:

1.360 MPa (13.9 kgf/ cm

2

, 198 psi)

Minimum pressure:

2

0.98 MPa (10 kgf/ cm

, 142 psi)

Difference between each cylinder:

100 kPa (1.0 kgf/ cm

2

, 14 psi)

NOTICE:

• Always use a fully charged battery to

obtain an engine speed of 250 rpm or

more.

• Check the other cylinders' compression

pressure in the same way.

• This measurement must be done as

quickly as possible.

(4) If the cylinder compression is low, pour a small

amount of engine oil into the cylinder through

the spark plug hole and inspect again.

HINT:

• If adding oil increases the compression, the

piston rings and/or cylinder bore may be

worn or damaged.

• If pressure stays low, a valve may be stuck

or seated improperly, or there may be

leakage in the gasket.

EM

9. INSPECT CO/HC

(a) Start the engine.

(b) Run the engine at 2,500 rpm for approximately 180

seconds.

(c) Insert the CO/HC meter testing probe at least 40 cm

(1.3 ft) into the tailpipe during idling.

EM

EM–4

2AZ-FE ENGINE MECHANICAL – ENGINE

(d) Immediately check CO/HC concentration at idle

and/or 2,500 rpm.

HINT:

• Complete the measuring within 3 minutes.

• Check regulations and restrictions in your area

when performing 2 mode CO/HC concentration

testing (engine check at both idle speed and at

2,500 rpm).

(e) If the CO/HC concentration does not comply with

regulations, troubleshoot in the order given below.

(1) Check A/F sensor and heated oxygen sensor

operation (See page EC-21).

(2) See the table below for possible causes, and

then inspect and repair.

CO HC Problems Causes

1. Faulty ignitions:

– Incorrect timing

Normal High Rough idle

Low High

High High

Rough idle

(fluctuating HC reading)

Rough idle

(black smoke from exhaust)

– Fouled, shorted or improperly g apped plugs

2. Incorrect valve clearance

3. Leaky intake and exhaust valves

4. Leaky cylinders

1. Vacuum leaks:

– PCV hoses

– Intake manifold

– Throttle body

– Brake booster line

2. Lean mixture causing misfire

1. Restricted air filter

2. Plugged PCV valve

3. Faulty SFI system:

– Faulty pressure regulator

– Defective ECT

– Defective MAF meter

–Faulty ECM

– Faulty injectors

– Faulty throttle po sition sensor

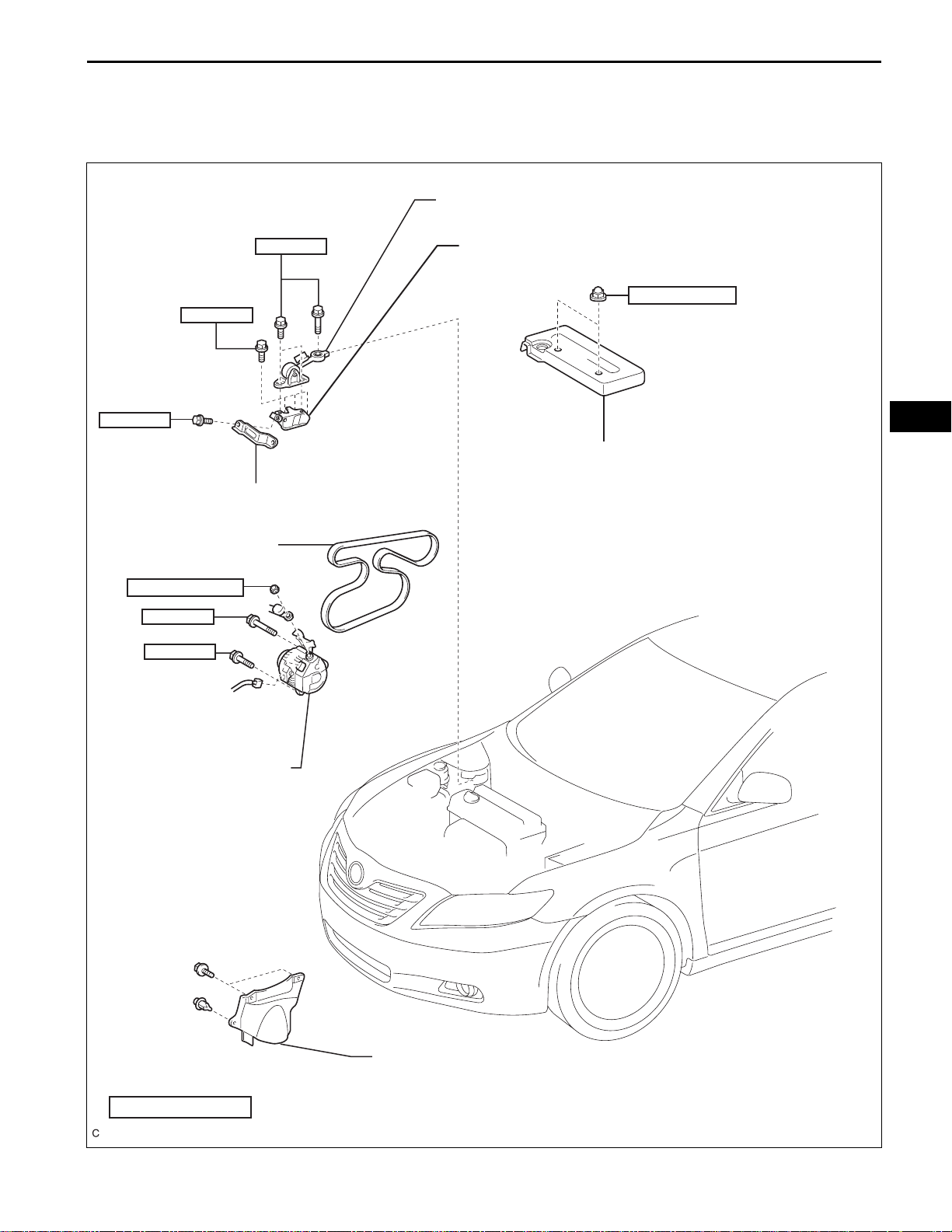

ENGINE2AZ-FE ENGINE MECHANICAL

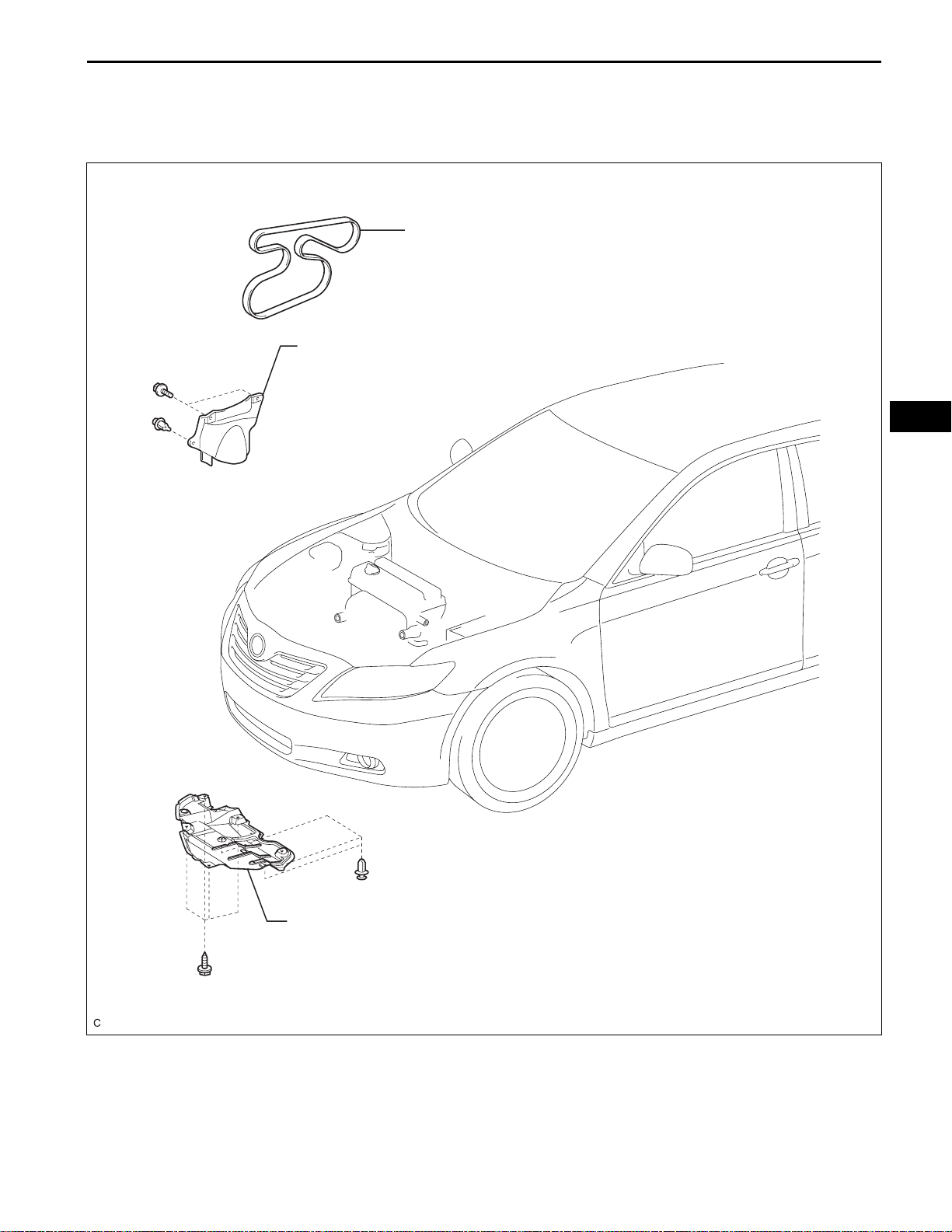

DRIVE BELT

COMPONENTS

2AZ-FE ENGINE MECHANICAL – DRIVE BELT

V-RIBBED BELT

FRONT FENDER APRON SEAL RH

EM–5

EM

ENGINE UNDER COVER RH

A134946E01

EM

EM–6

SST

REPLACE

2AZ-FE ENGINE MECHANICAL – DRIVE BELT

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE ENGINE UNDER COVER RH

3. REMOVE FRONT FENDER APRON SEAL RH

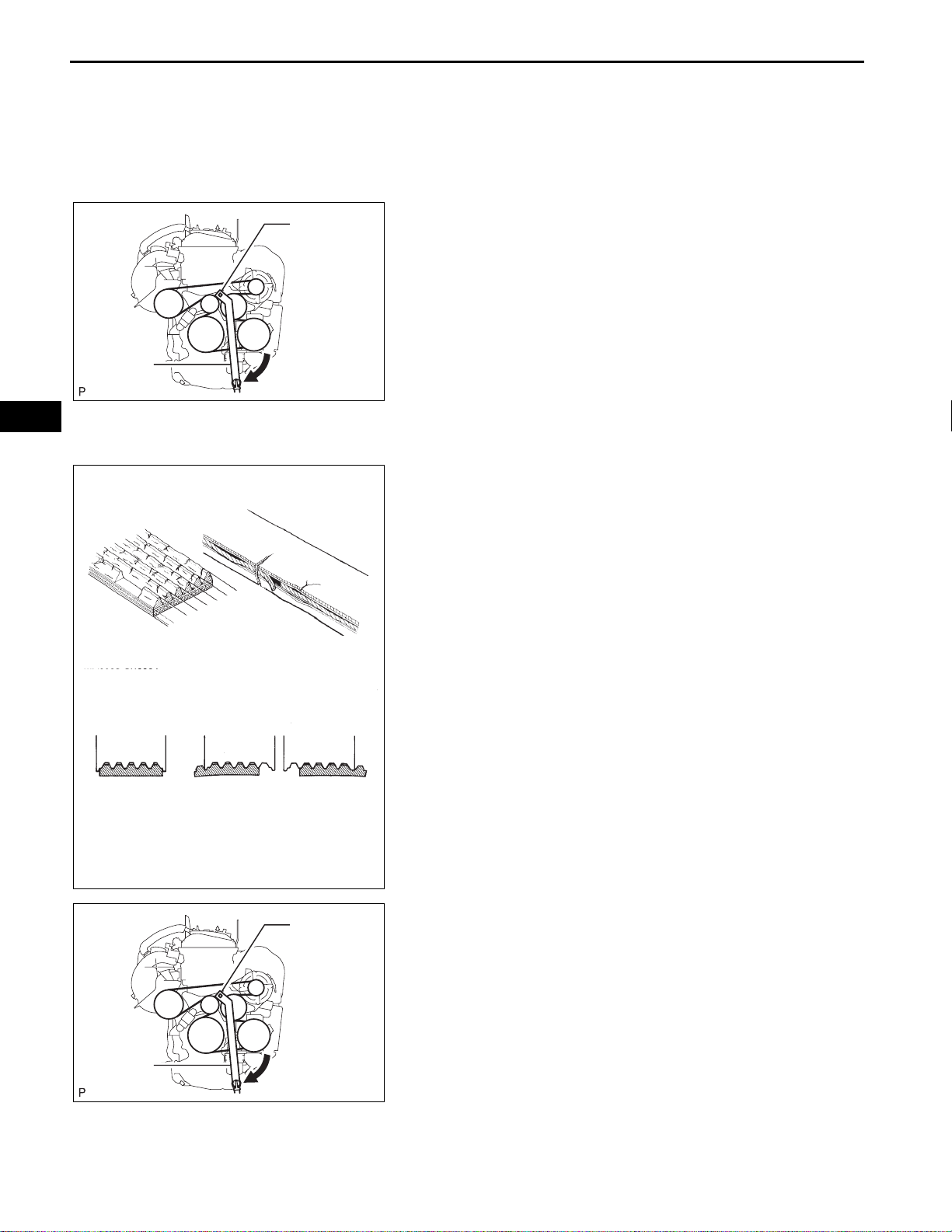

4. REMOVE V-RIBBED BELT

19 mm

Socket

Wrench

(a) Using SST and 19 mm socket wrench, loosen the V -

ribbed belt tensioner arm clockwise, then remove

the V-ribbed belt.

SST 09216-42010

NOTICE:

• Be sure to connect SST and the tools so that

they are in line during use.

• When retracting the tensioner, turn it

A114351E03

clockwise slowly for 3 seconds or more. Do

not apply force rapidly.

• After the tensioner is fully retracted, do not

apply force any more than necessary.

INSPECTION

1. INSPECT V-RIBBED BELT

(a) Visually check the V-ribbed belt for excessive wear,

frayed cords, etc. If any defect has been found,

replace the V-ribbed belt.

HINT:

• Cracks on the rib side of a belt are considered

acceptable. If the belt has chunks missing from

the ribs, it should be replaced.

• A "new belt" is a belt which has been used for

less than 5 minutes with the engine running.

• A "used belt" is a belt which has been used for 5

minutes or more with the engine running.

CORRECT INCORRECT

19 mm

Socket

Wrench

SST

A131418E01

A114351E03

INSTALLATION

1. INSTALL V-RIBBED BELT

(a) Using SST and 19 mm socket wrench, loosen the V -

ribbed belt tensioner arm clockwise, then install the

V-ribbed belt.

SST 09216-42010

NOTICE:

• Be sure to connect SST and the tools so that

they are in line during use.

• When retracting the tensioner, turn it

clockwise slowly for 3 seconds or more. Do

not apply force rapidly.

2AZ-FE ENGINE MECHANICAL – DRIVE BELT

• After the tensioner is fully retracted, do not

apply force any more than necessary.

(b) After installing the V-ribbed belt, check that it fits

properly in the ribbed grooves. Check to confirm

that the belt has not slipped out of the grooves on

the bottom of the crank pulley by hand.

2. INSTALL FRONT FENDER APRON SEAL RH

3. INSTALL ENGINE UNDER COVER RH

4. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

EM–7

EM

EM

EM–8

Timing Mark

Timing Mark

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

VALVE CLEARANCE

ADJUSTMENT

1. REMOVE FRONT WHEEL RH

2. REMOVE ENGINE UNDER COVER LH

3. REMOVE ENGINE UNDER COVER RH

4. REMOVE FRONT FENDER APRON SUB-ASSEMBLY

RH

5. REMOVE NO. 1 ENGINE COVER (See page EM-94)

6. REMOVE IGNITION COIL ASSEMBLY (See page EM-

106)

7. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-21)

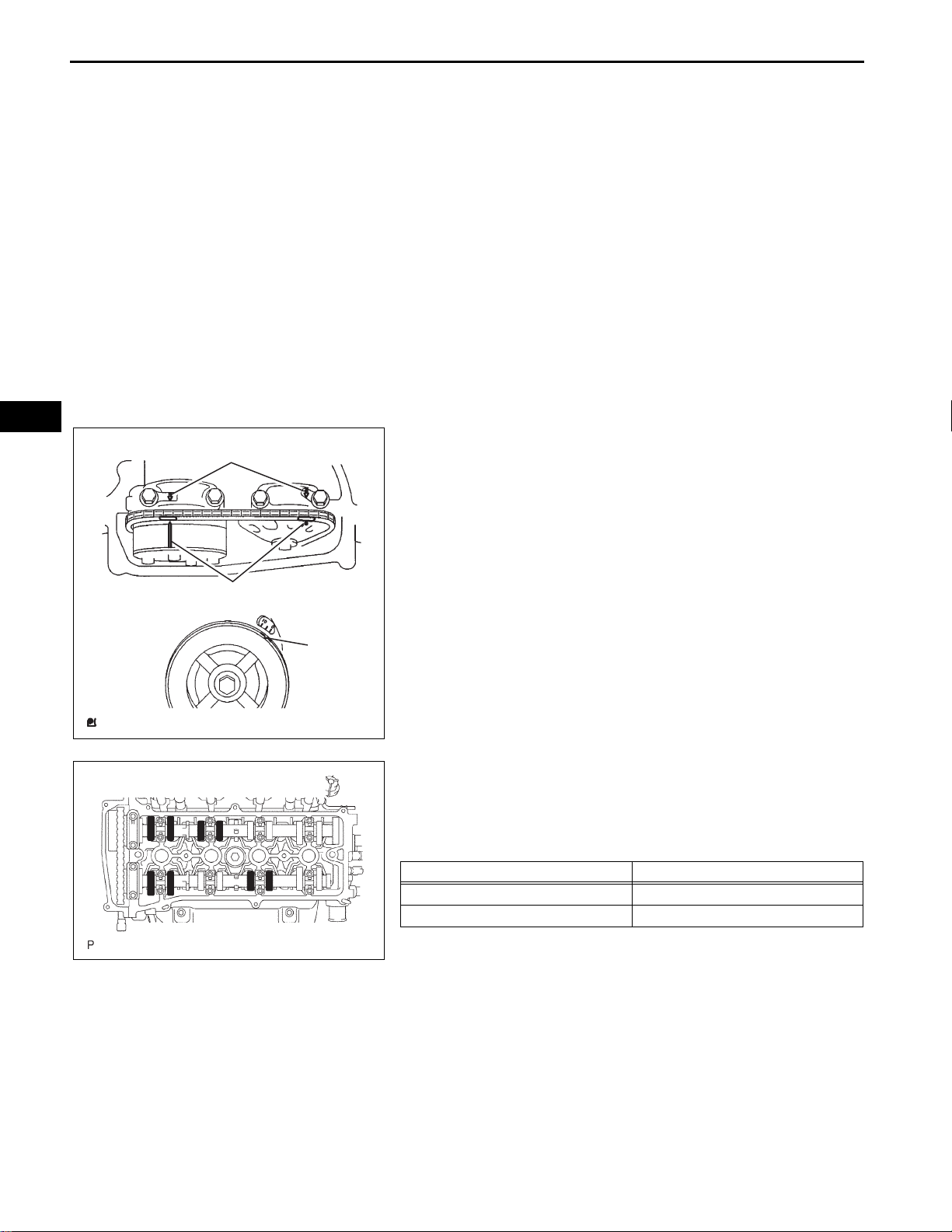

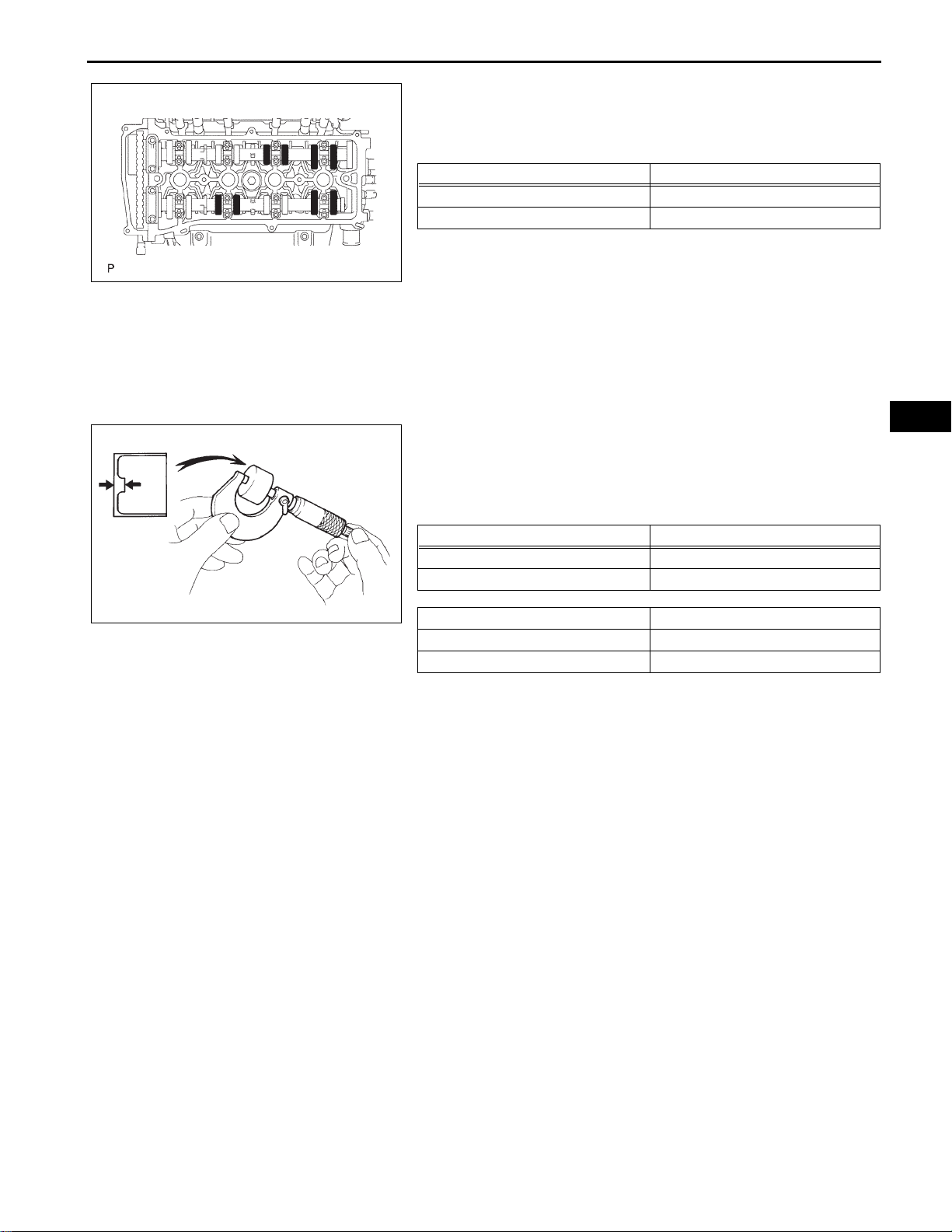

8. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration. If not, turn the crankshaft

by 1 revolution (360°) to align the timing marks as

above.

No. 1 Cylinder TDC/Compression

IN

EX

Groove

A098345E09

A098170E04

9. CHECK VALVE CLEARANCE

(a) Check only the valves indicated.

(1) Using a feeler gauge, measure the clearance

between the valve lifter and camshaft.

Standard valve clearance (cold)

Item Standard Condition

Intake 0.19 to 0.29 mm (0.0075 to 0.0114 in.)

Exhaust 0.38 to 0.48 mm (0.0150 to 0.0189 in.)

(2) Record any out-of-specification valve clearance

measurements. They will be used later to

determine the required replacement valve

clearance lifters.

(b) Turn the crankshaft 1 revolution (360°) and set the

No. 4 cylinder to the TDC/compression.

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

EM–9

No. 4 Cylinder TDC/Compression

IN

EX

A098171E04

(c) Check only the valves indicated.

(1) Using a feeler gauge, measure the clearance

between the valve lifter and camshaft.

Standard valve clearance (cold)

Item Standard Condition

Intake 0.19 to 0.29 mm (0.0075 to 0.0114 in.)

Exhaust 0.38 to 0.48 mm (0.0150 to 0.0189 in.)

(2) Record any out-of-specification valve clearance

measurements. They will be used later to

determine the required replacement valve

lifters.

10. ADJUST VALVE CLEARANCE

(a) Remove the No. 2 camshaft (see page EM-38).

(b) Remove the camshaft (see page EM-38).

(c) Remove the valve lifters.

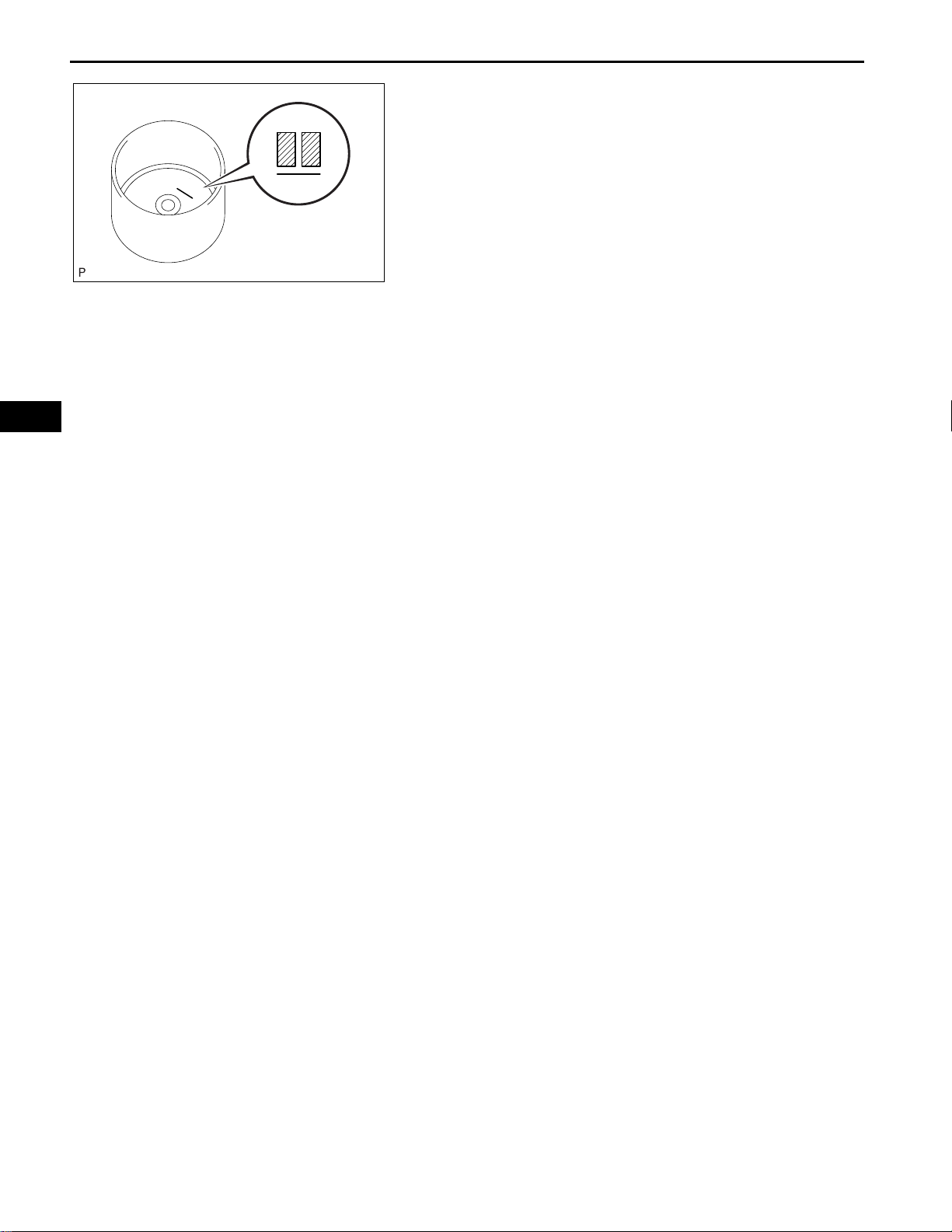

(d) Using a micrometer, measure the thickness of the

removed valve lifters.

(e) Calculate the thickness of a new lifter so that the

valve clearance comes within the specified values.

New lifter thickness

Item Specification

Intake A = B + (C - 0.24 mm (0.0095 in.))

Exhaust A = B + (C - 0.43 mm (0.0169 in.))

EM

A001082E01

A New lifter thickness

B Used lifter thickness

C Measured valve clearance

CALCULATION EXAMPLE (Intake):

1. Measured intake valve clearance = 0.40 mm

(0.0158 in.)

(Measured - Specification = Excess clearance)

(a)0.40 mm (0.0158 in.) - 0.24 mm (0.0095 in.) =

0.16 mm (0.0063 in.)

2. Measured used lifter measurement = 5.250 mm

(0.2067 in.)

3. New lifter thickness = 5.410 mm (0.2130 in.)

(Excess clearance + Used lifter thickness = Ideal

new lifter)

(a)0.16 mm (0.0063 in.) + 5.250 mm (0.2067 in.)

= 5.410 mm (0.2130 in.)

4. Closest new lifter = 5.420 mm (0.2134 in.)

– Select No. 42 lifter

EM

EM–10

42

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

(f) Select a new lifter with a thickness as close as

possible to the calculated values.

HINT:

• Lifters are available in 35 sizes in increments of

0.020 mm (0.0008 in.), from 5.060 to 5.740 mm

(0.1992 to 0.2260 in.).

• The identification number inside the valve lifters

shows the value to 2 decimal places. (The

illustration shows 5.420 mm (0.2134 in.)

A126901E01

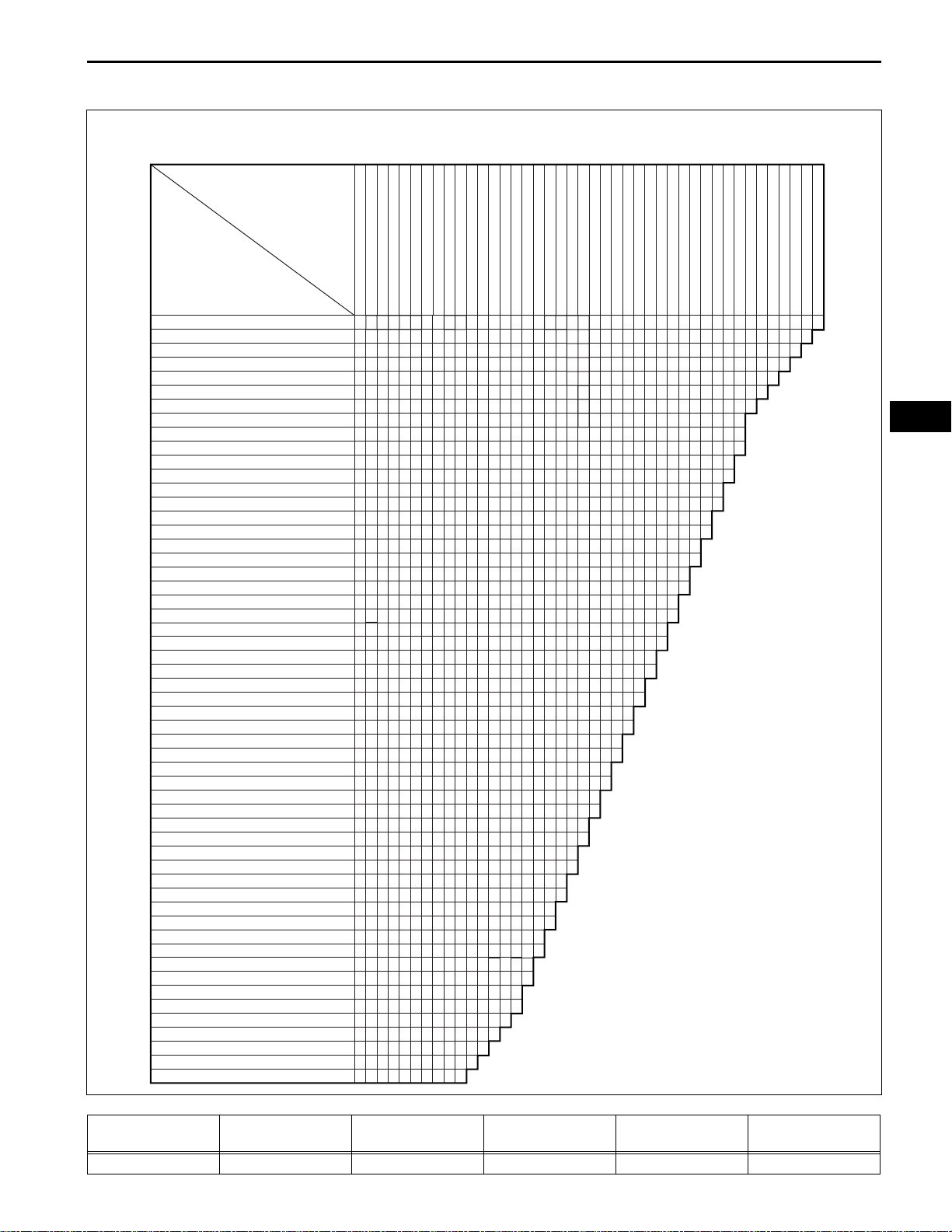

Measured clearance

Installed lifter

thickness

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

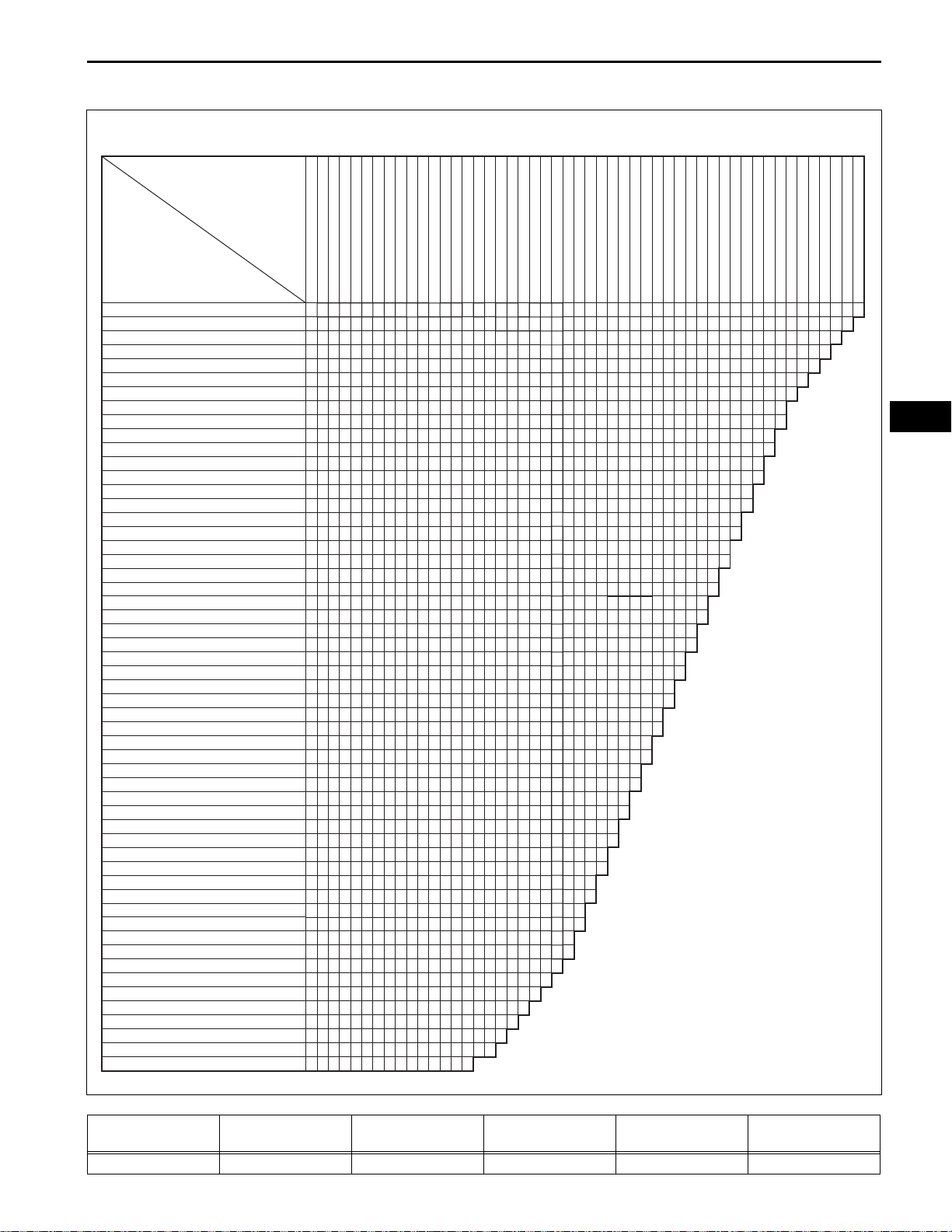

(g) Valve lifter selection chart (intake).

mm (in.)

EM–11

mm (in.)

5.060 (0.1992)

5.080 (0.2000)

5.100 (0.2008)

5.120 (0.2016)

5.140 (0.2024)

5.160 (0.2031)

5.180 (0.2039)

5.200 (0.2047)

5.210 (0.2051)

5.220 (0.2055)

5.230 (0.2059)

5.240 (0.2063)

5.250 (0.2067)

5.260 (0.2071)

5.270 (0.2075)

5.280 (0.2079)

5.290 (0.2083)

5.300 (0.2087)

5.310 (0.2091)

5.320 (0.2094)

5.330 (0.2098)

5.340 (0.2102)

5.350 (0.2106)

5.360 (0.2110)

5.370 (0.2114)

5.380 (0.2118)

5.390 (0.2122)

5.400 (0.2126)

5.410 (0.2130)

5.420 (0.2134)

5.430 (0.2138)

5.440 (0.2142)

5.450 (0.2146)

5.460 (0.2150)

5.470 (0.2154)

5.480 (0.2157)

5.490 (0.2161)

5.500 (0.2165)

5.510 (0.2169)

5.520 (0.2173)

5.530 (0.2177)

5.540 (0.2181)

5.550 (0.2185)

5.560 (0.2189)

5.570 (0.2193)

5.580 (0.2197)

5.590 (0.2201)

5.600 (0.2205)

5.620 (0.2213)

5.640 (0.2220)

5.660 (0.2228)

5.680 (0.2236)

5.700 (0.2244)

5.720 (0.2252)

)

5.740 (0.2260)

0.000 - 0.030 (0.0000 - 0.0012)

0.031 - 0.050 (0.0012 - 0.0020)

18 20 22 24 26 28 3016

12

18 20 22 24 26 28 30

1614

20

1814

16

182022 24 26 28 30 32

2016

22 24 26 28 30 32 34

2018

22 24 26 28 30 32 34

2218 24 26 28 30 32 34 36

2220 24 26 28 30 32 34 36

2420 26 28 30 32 34 36 38

2422 26 28 30 32 34 36 38

2622 28 30 32 34 36 38 40

2624 28 30 32 34 36 38 40

2824 30 32 34 36 38 40 42

2826 30 32 34 36 38 40 42

3026 32 34 36 38 40 42 44

3028 32 34 36 38 40 42 44

3228 34 36 38 40 42 44 46

3230 34 36 38 40 42 44 46

3430 36 38 40 42 44 46 48

3432 36 38 40 42 44 46 48

3632 38 40 42 44 46 48 50

3634 38 40 42 44 46 48 50

3834 40 42 44 46 48 50 52

3836 40 42 44 46 48 50 52

4036 42 44 46 48 50 52 54

40

38 42 44 46 48 50 52 54

4238 44 46 48 50 52 54 56

4240 44 46 48 50 52 54 56

4440 46 48 50 52 54 56 58

4642 48 50 52 54 56 58 60

4844 50 52 54 56 58 60 62

5046 52 54 56 58 60 62 64

5248 54 56 58 60 62 64 66

5450 56 58 60 62 64 66 68

5652 58 60 62 64 66 68 70

5854 60 62 64 66 68 70 72

0.131 - 0.150 (0.0052 - 0.0059)

0.190 - 0.290 (0.0075 - 0.0114)

0.291 - 0.310 (0.0115 - 0.0122)

0.151 - 0.170 (0.0059 - 0.0067)

0.171 - 0.189 (0.0067 - 0.0074)

0.111 - 0.130 (0.0044 - 0.0051)

0.051 - 0.070 (0.0020 - 0.0028)

0.071 - 0.090 (0.0028 - 0.0035)

0.091 - 0.110 (0.0036 - 0.0043)

0806 10

0806 10 12

0806 10 12 14

0806 10 12 14 16

18 200806 10 12 14 16

18 200806 10 12 14 16

18 200806 10 12 14 16

18 20 2208 10 12 14 16

18 20 2208060610 12 14 16

18 20 22 2410 12 14 16

18 20 22 2408 10 12 14 16

18 20 22 241208 2614 16

18 20 22 24 26101012 14 16

18 20 22 24 26 2814 16

18 20 22 24 26 281412 16

22 24 26 28 30 32

0.311 - 0.330 (0.0122 - 0.0130)

0.331 - 0.350 (0.0130 - 0.0138)

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

12

1406 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

160806

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

180806 10 12 14 16

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

42 44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

44 46 48 50 52 54 56 58 60 62 64 66 68 707274 74

46 48 50 52 54 56 58 60 62 64 66 68 70

46 48 50 52 54 56 58 60 62 64 66 68 707274 74

48 50 52 54 56 58 60 62 64 66 68 707274 74

48 50 52 54 56 58 60 62 64 66 68 707274 74

50 52 54 56 58 60 62 64 66 68 707274 74

50 52 54 56 58 60 62 64 66 68 707274 74

52 54 56 58 60 62 64 66 68 707274 74

52 54 56 58 60 62 64 66 68 707274 74

54 56 58 60 62 64 66 68 707274 74

54 56 58 60 62 64 66 68 707274 74

56 58 60 62 64 66 68 707274 74

56 58 60 62 64 66 68 707274 74

58 60 62 64 66 68 707274 74

58 60 62 64 66 68 707274 74

60 62 64 66 68 707274 74

60 62 64 66 68 707274 74

62 64 66 68 707274 74

62 64 66 68 707274 74

64 66 68 707274 74

64 66 68 707274 74

66 68 707274 74

66 68 707274 74

68 707274 74

707274 74 74

72

74 74 74

74 74 74

747474

0.431 - 0.450 (0.0170 - 0.0177)

0.351 - 0.370 (0.0138 - 0.0146)

0.391 - 0.410 (0.0154 - 0.0161)

0.451 - 0.470 (0.0178 - 0.0185)

0.471 - 0.490 (0.0185 - 0.0193)

0.411 - 0.430 (0.0162 - 0.0169)

0.371 - 0.390 (0.0146 - 0.0154)

0.571 - 0.590 (0.0225 - 0.0232)

0.531 - 0.550 (0.0209 - 0.0217)

0.551 - 0.570 (0.0217 - 0.0224)

0.511 - 0.530 (0.0201 - 0.0209)

0.491 - 0.510 (0.0193 - 0.0201)

72

74 74

0.691 - 0.710 (0.0272 - 0.0280)

0.611 - 0.630 (0.0241 - 0.0248)

0.651 - 0.670 (0.0256 - 0.0264)

0.591 - 0.610 (0.0233 - 0.0240)

0.631 - 0.650 (0.0248 - 0.0256)

0.751 - 0.770 (0.0296 - 0.0303)

0.671 - 0.690 (0.0264 - 0.0272)

0.711 - 0.730 (0.0280 - 0.0287)

0.731 - 0.750 (0.0288 - 0.0295)

0.771 - 0.790 (0.0304 - 0.0311)

0.831 - 0.850 (0.0327 - 0.0335)

0.811 - 0.830 (0.0319 - 0.0327)

0.791 - 0.810 (0.0311 - 0.0319)

0.851 - 0.870 (0.0335 - 0.0343)

0.871 - 0.890 (0.0343 - 0.0350)

New lifter thickness

Lifter No. Thickness

mm (in.)

06 5.060 (0.1992) 30 5.300 (0.2087) 54 5.540 (0.2181)

Lifter No. Thickness

mm (in.)

Lifter No. Thickness

mm (in.)

0.891 - 0.910 (0.0351 - 0.0358)

0.911 - 0.930 (0.0359 - 0.0366)

EM

A126931E02

EM–12

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

EM

Lifter No. Thickness

mm (in.)

08 5.080 (0.2000) 32 5.320 (0.2094) 56 5.560 (0.2189)

10 5.100 (0.2008) 34 5.340 (0.2102) 58 5.580 (0.2197)

12 5.120 (0.2016) 36 5.360 (0.2110) 60 5.600 (0.2205)

14 5.140 (0.2024) 38 5.380 (0.2118) 62 5.620 (0.2213)

16 5.160 (0.2031) 40 5.400 (0.2126) 64 5.640 (0.2220)

18 5.180 (0.2039) 42 5.420 (0.2134) 66 5.660 (0.2228)

20 5.200 (0.2047) 44 5.440 (0.2142) 68 5.680 (0.2236)

22 5.220 (0.2055) 46 5.460 (0.2150) 70 5.700 (0.2244)

24 5.240 (0.2063) 48 5.480 (0.2157) 72 5.720 (0.2252)

26 5.260 (0.2071) 50 5.500 (0.2165) 74 5.740 (0.2260)

28 5.280 (0.2079) 52 5.520 (0.2173) - -

Lifter No. Thickness

mm (in.)

Lifter No. Thickness

mm (in.)

Standard intake valve clearance (cold):

0.19 to 0.29 mm (0.0075 to 0.0114 in.)

EXAMPLE:

The 5.250 mm (0.2067 in.) lifter is installed , and the

measured clearance is 0.400 mm (0.0157 in.).

Replace the 5.250 mm (0.2067 in.) lifter with a new

No. 42 lifter.

Measured clearance

Measured clearance

Installed lifter

thickness

mm (in.)

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

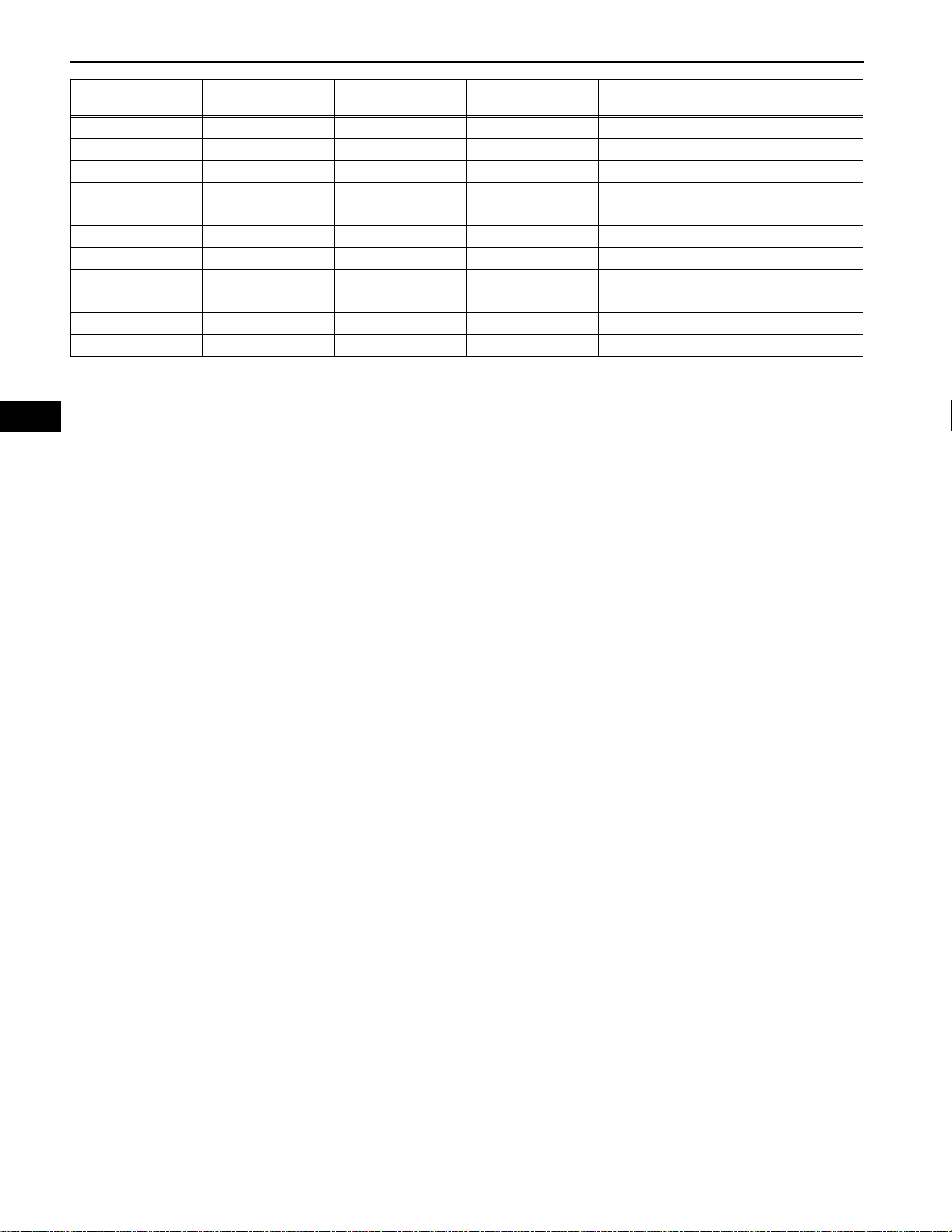

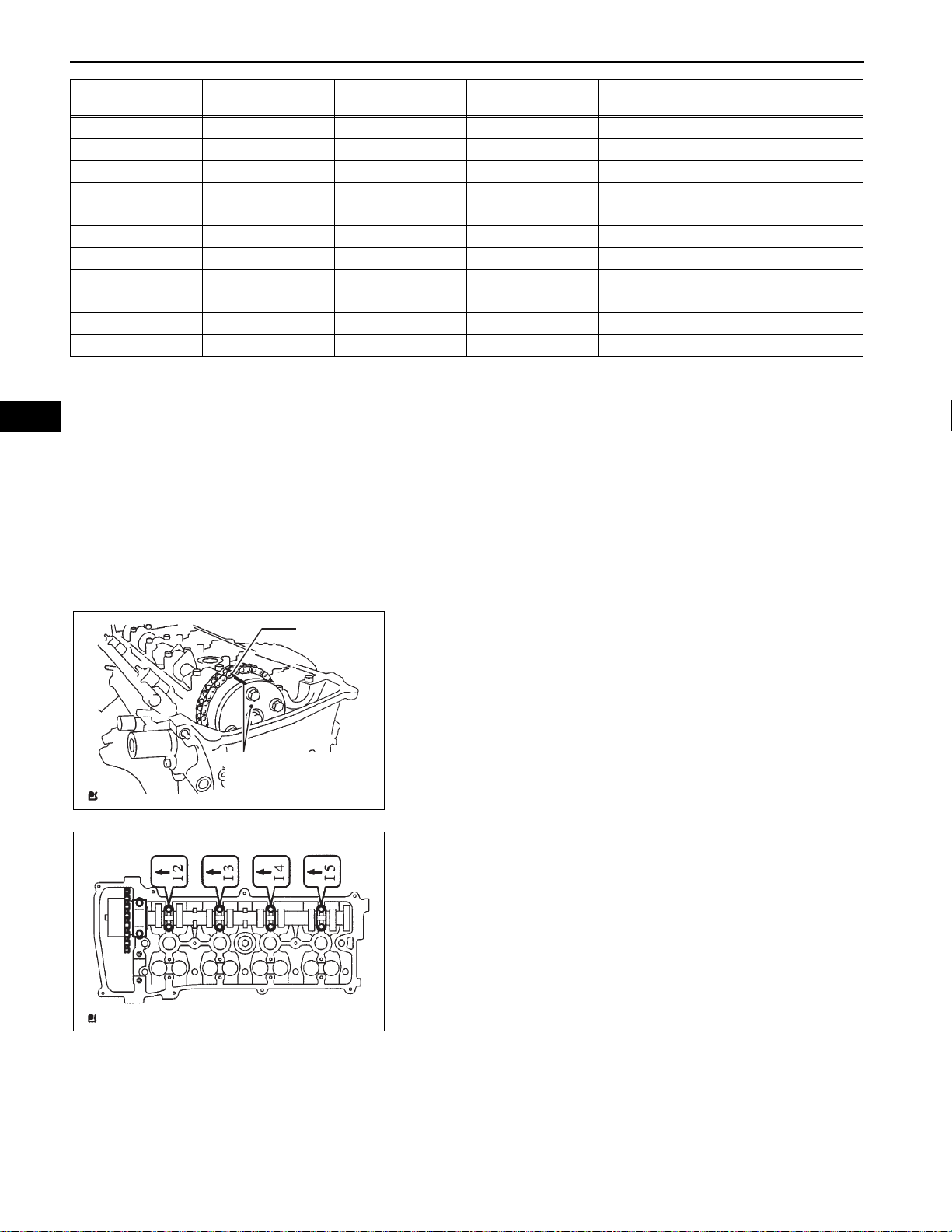

(h) Valve lifter selection chart (exhaust).

mm (in.)

EM–13

Installed lifter thickness

mm (in.)

mm (in.)

5.060 (0.1992)

5.080 (0.2000)

5.100 (0.2008)

5.120 (0.2016)

5.140 (0.2024)

5.160 (0.2031)

5.180 (0.2039)

5.200 (0.2047)

5.210 (0.2051)

5.220 (0.2055)

5.230 (0.2059)

5.240 (0.2063)

5.250 (0.2067)

5.260 (0.2071)

5.270 (0.2075)

5.280 (0.2079)

5.290 (0.2083)

5.300 (0.2087)

5.310 (0.2091)

5.320 (0.2094)

5.330 (0.2098)

5.340 (0.2102)

5.350 (0.2106)

5.360 (0.2110)

5.370 (0.2114)

5.380 (0.2118)

5.390 (0.2122)

5.400 (0.2126)

5.410 (0.2130)

5.420 (0.2134)

5.430 (0.2138)

5.440 (0.2142)

5.450 (0.2146)

5.460 (0.2150)

5.470 (0.2154)

5.480 (0.2157)

5.490 (0.2161)

5.500 (0.2165)

5.510 (0.2169)

5.520 (0.2173)

5.530 (0.2177)

5.540 (0.2181)

5.550 (0.2185)

5.560 (0.2189)

5.570 (0.2193)

5.580 (0.2197)

5.590 (0.2201)

5.600 (0.2205)

5.620 (0.2213)

5.640 (0.2220)

5.660 (0.2228)

5.680 (0.2236)

5.700 (0.2244)

5.720 (0.2252)

5.740 (0.2260)

0.000 - 0.030 (0.0000 - 0.0012)

0.031 - 0.050 (0.0012 - 0.0020)

12 14 16 18 20 22 24 26 28 30 32 34 361008

12 14 16 18 20 22 24 26 28 30 32 34 361008

12 14 16 18 20 22 24 26 28 30 32 34 36 3810

10

12 14 16 18 20 22 24 26 28 30 32 34 36 38

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

16 18 20 22 24 26 28 30 32 34 36 38 40 42 44

16 18 20 22 24 26 28 30 32 34 36 38 40 42 44

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48

22 24 26 28 30 32 34 36 38 40 42 44 46 48 50

22 24 26 28 30 32 34 36 38 40 42 44 46 48 50

24 26 28 30 32 34 36 38 40 42 44 46 48 50 52

24 26 28 30 32 34 36 38 40 42 44 46 48 50 52

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68

42 44 46 48 50 52 54 56 58 60 62 64 66 68 70

44 46 48 50 52 54 56 58 60 62 64 66 68 7270

0.131 - 0.150 (0.0052 - 0.0059)

0.111 - 0.130 (0.0044 - 0.0051)

0.071 - 0.090 (0.0028 - 0.0035)

0.091 - 0.110 (0.0036 - 0.0043)

0.051 - 0.070 (0.0020 - 0.0028)

12 14 16 18 20 22 24 26100806

12 14 16 18 20 22 24 26100806

12 14 16 18 20 22 24 26 28100806

12 14 16 18 20 22 24 26 28100806

12 14 16 18 20 22 24 26 28100806

12 14 16 18 20 22 24 26 283030100806

12 14 16 18 20 22 24 26 28 30 32100806

12 14 16 18 20 22 24 26 28 30 32100806

12 14 16 18 20 22 24 26 28 30 32 34100806

12 14 16 18 20 22 24 26 28 30 32 34100806

0.231 - 0.250 (0.0091 - 0.0098)

0.151 - 0.170 (0.0059 - 0.0067)

0.211 - 0.230 (0.0083 - 0.0091)

0.251 - 0.270 (0.0099 - 0.0106)

0.191 - 0.210 (0.0075 - 0.0083)

0.171 - 0.190 (0.0067 - 0.0075)

12 14 16 18 20 22

100806

12 14 16 18 20 22100806

12 14 16 18 20 22 24100806

12 14 16 18 20 22 24100806

0.271 - 0.290 (0.0107 - 0.0114)

06 08 10

12 14100806

12 14 16100806

12 14 16 18100806

12 14 16 18 20100806

12 14 16 18 20100806

0.481 - 0.500 (0.0189 - 0.0197)

0.291 - 0.299 (0.0115 - 0.0118)

06 14 16 18

12100806

0.461 - 0.480 (0.0181 - 0.0189)

0.300 - 0.400 (0.0118 - 0.0157)

0.441 - 0.460 (0.0174 - 0.0181)

0.401 - 0.420 (0.0158 - 0.0165)

160806

18

20

22

24

26

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

70

72

74

7474

74

0.501 - 0.520 (0.0197 - 0.0205)

0.421 - 0.440 (0.0166 - 0.0173)

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74

70686664

747474727068

7474747270

74747472

747474

7474

0.561 - 0.580 (0.0221 - 0.0228)

0.641 - 0.660 (0.0252 - 0.0260)

0.681 - 0.700 (0.0268 - 0.0276)

0.621 - 0.640 (0.0244 - 0.0252)

0.601 - 0.620 (0.0237 - 0.0244)

0.541 - 0.560 (0.0213 - 0.0220)

0.521 - 0.540 (0.0205 - 0.0213)

0.581 - 0.600 (0.0229 - 0.0236)

32 34 36 38 40

28 30

54525048464442403836

60585654525048464442

74747472706866646260585654

747474727068666462605856

747474727068666462605856

7474747270686664626058

7474747270686664626058

74747472706866646260

74747472706866646260

747474727068666462

747474727068666462

74747472

7474747270686664

74747472706866

0.721 - 0.740 (0.0284 - 0.0291)

0.741 - 0.760 (0.0292 - 0.0299)

0.661 - 0.680 (0.0260 - 0.0268)

0.701 - 0.720 (0.0276 - 0.0283)

42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 7474

747474727068666462605856545250484644

7474747270686664626058565452504846

7474747270686664626058565452504846

7474

7472706866646260585654525048

74747472706866646260585654525048

747474727068666462605856545250

747474727068666462605856545250

7474747270686664626058565452

7474747270686664626058565452

74747472706866646260585654

0.881 - 0.900 (0.0347 - 0.0354)

0.861 - 0.880 (0.0339 - 0.0346)

0.821 - 0.840 (0.0323 - 0.0331)

0.801 - 0.820 (0.0315 - 0.0323)

0.761 - 0.780 (0.0300 - 0.0307)

0.781 - 0.800 (0.0307 - 0.0315)

6260585654525048464442403836343230282624

727068666462605856545250484644424038363432

7474747270686664626058565452504846444240383634

74747472706866646260585654525048464442403836

747474727068666462605856

747474727068666462605856545250484644424038

747474727068666462605856545250484644424038

7474747270686664626058565452504846444240

7474747270686664626058565452504846444240

747474727068666462

74747472706866646260585654525048464442

747474727068666462605856545250484644

0.921 - 0.940 (0.0363 - 0.0370)

0.841 - 0.860 (0.0331 - 0.0339)

0.901 - 0.920 (0.0355 - 0.0362)

0.941 - 0.960 (0.0370 - 0.0378)

7474747270686664

747474727068666462605856545250484644424038363432302826

7474747270686664626058565452504846444240383634323028

7474747270686664626058565452504846444240383634323028

7474

747270686664626058565452504846444240383634323028

74747472706866646260585654525048464442403836343230

74747472706866646260585654525048464442403836343230

747474727068666462605856545250484644424038363432

747474

7474747270686664626058565452504846444240383634

0.961 - 0.980 (0.0378 - 0.0386)

)

New lifter thickness

Lifter No. Thickness

mm (in.)

06 5.060 (0.1992) 30 5.300 (0.2087) 54 5.540 (0.2181)

Lifter No. Thickness

mm (in.)

Lifter No. Thickness

mm (in.)

0.981 - 1.000 (0.0386 - 0.0394)

1.061 - 1.080 (0.0418 - 0.0425)

1.001 - 1.020 (0.0394 - 0.0402)

1.021 - 1.040 (0.0402 - 0.0409)

1.041 - 1.060 (0.0410 - 0.0417)

74

74747472706866646260585654525048464442403836343230282624222018

747474727068666462605856545250484644424038363432302826242220

7474747270686664626058565452504846444240383634323028262422

A114356E01

EM

EM–14

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

EM

Lifter No. Thickness

mm (in.)

08 5.080 (0.2000) 32 5.320 (0.2094) 56 5.560 (0.2189)

10 5.100 (0.2008) 34 5.340 (0.2102) 58 5.580 (0.2197)

12 5.120 (0.2016) 36 5.360 (0.2110) 60 5.600 (0.2205)

14 5.140 (0.2024) 38 5.380 (0.2118) 62 5.620 (0.2213)

16 5.160 (0.2031) 40 5.400 (0.2126) 64 5.640 (0.2220)

18 5.180 (0.2039) 42 5.420 (0.2134) 66 5.660 (0.2228)

20 5.200 (0.2047) 44 5.440 (0.2142) 68 5.680 (0.2236)

22 5.220 (0.2055) 46 5.460 (0.2150) 70 5.700 (0.2244)

24 5.240 (0.2063) 48 5.480 (0.2157) 72 5.720 (0.2252)

26 5.260 (0.2071) 50 5.500 (0.2165) 74 5.740 (0.2260)

28 5.280 (0.2079) 52 5.520 (0.2173) - -

Lifter No. Thickness

mm (in.)

Lifter No. Thickness

mm (in.)

Standard exhaust valve clearance (cold):

0.38 to 0.48 mm (0.0150 to 0.0189 in.)

EXAMPLE:

The 5.340 mm (0.2102 in.) lifter is installed , and the

measured clearance is 0.430 mm (0.0169 in.).

Replace the 5.340 mm (0.2102 in.) lifter with a new

No. 42 lifter.

(i) Install the selected valve lifter.

Paint Mark

Timing Mark

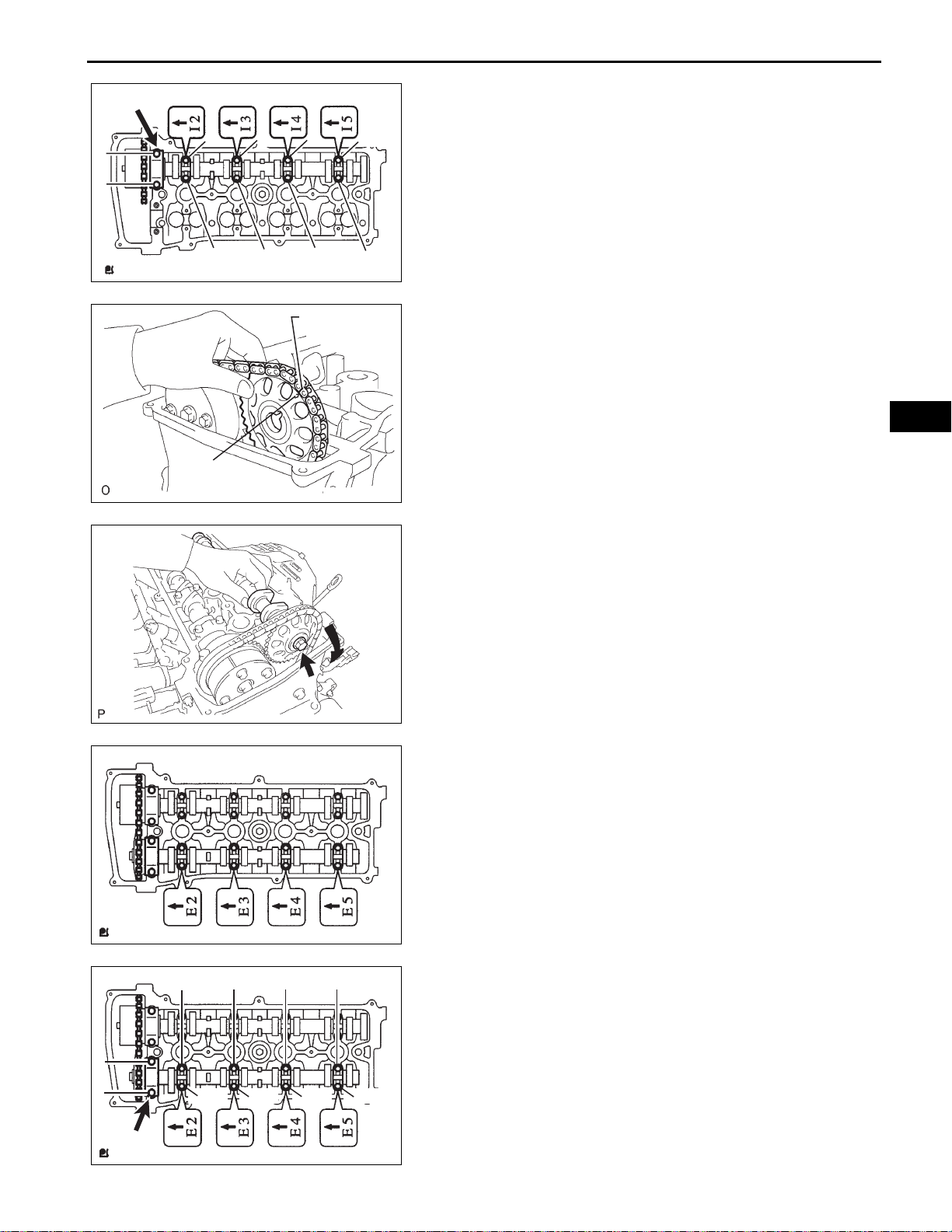

11. INSTALL CAMSHAFT

(a) Apply a light coat of engine oil to the journal portion

of the camshaft.

(b) Install the timing chain onto the camshaft timing

gear with the paint mark aligned with the timing

mark on the camshaft timing gear as shown in the

illustration.

A098176E04

(c) Examine the front marks and numbers, and check

that the order is as shown in the illustration. Then

install the bearing caps into the cylinder head.

(d) Apply a light coat of engine oil to the threads and

under the heads of the bearing cap bolts.

A098177E03

No. 1

7

8

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

315 9

426

10

A098177E06

EM–15

(e) Using several steps, uniformly tighten the 10

bearing cap bolts in the sequence shown in the

illustration.

Torque: No. 1 bearing cap

30 N*m (301 kgf*cm, 22 ft.*lbf)

No. 3 bearing cap

9.0 N*m (92 kgf*cm, 80 in.*lbf)

12. INSTALL NO. 2 CAMSHAFT

(a) Apply a light coat of engine oil to the journal portion

of the No. 2 camshaft.

Timing Mark

Paint Mark

(b) Put the No. 2 camshaft on the cylinder head with the

paint mark of the chain aligned with the timing mark

on the camshaft timing sprocket.

EM

A098178E03

(c) While holding the No. 2 camshaft by hand,

temporarily tighten the camshaft timing sprocket set

bolt.

A086659

(d) Examine the front marks and numbers, and check

that the order is as shown in the illustration. Then

install the bearing caps onto the cylinder head.

(e) Apply a light coat of engine oil to the threads and

under the heads of the bearing cap bolts.

7

8

No. 2

A098174E05

3

159

(f) Using several steps, uniformly tighten the 10

bearing cap bolts in the sequence shown in the

illustration.

Torque: No. 2 bearing cap

30 N*m (301 kgf*cm, 22 ft.*lbf)

No. 3 bearing cap

4

26

10

A098174E07

9.0 N*m (92 kgf*cm, 80 in.*lbf)

EM–16

Paint Mark

Tighten

7 Links

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE

(g) While holding the camshaft with a wrench, tighten

the camshaft timing sprocket set bolt.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

NOTICE:

Be careful not to damage the valve lifter.

Hold

A098173E04

(h) Check that the paint marks on the chain are aligned

with the timing marks on the camshaft timing gear

and camshaft timing sprocket. Also, check that the

Paint Mark

crankshaft pulley groove is aligned with the timing

mark "0" of the timing chain cover.

EM

Timing Mark Timing Mark

Groove

A098180E04

13. INSTALL NO. 1 CHAIN TENSIONER (See page EM-32)

14. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-33)

15. INSTALL IGNITION COIL ASSEMBLY (See page EM-

33)

16. CHECK FOR ENGINE OIL LEAKS

17. INSTALL NO. 1 ENGINE COVER (See page EM-121)

18. INSTALL FRONT FENDER APRON RH

19. INSTALL ENGINE UNDER COVER LH

20. INSTALL ENGINE UNDER COVER RH

21. INSTALL FRONT WHEEL RH

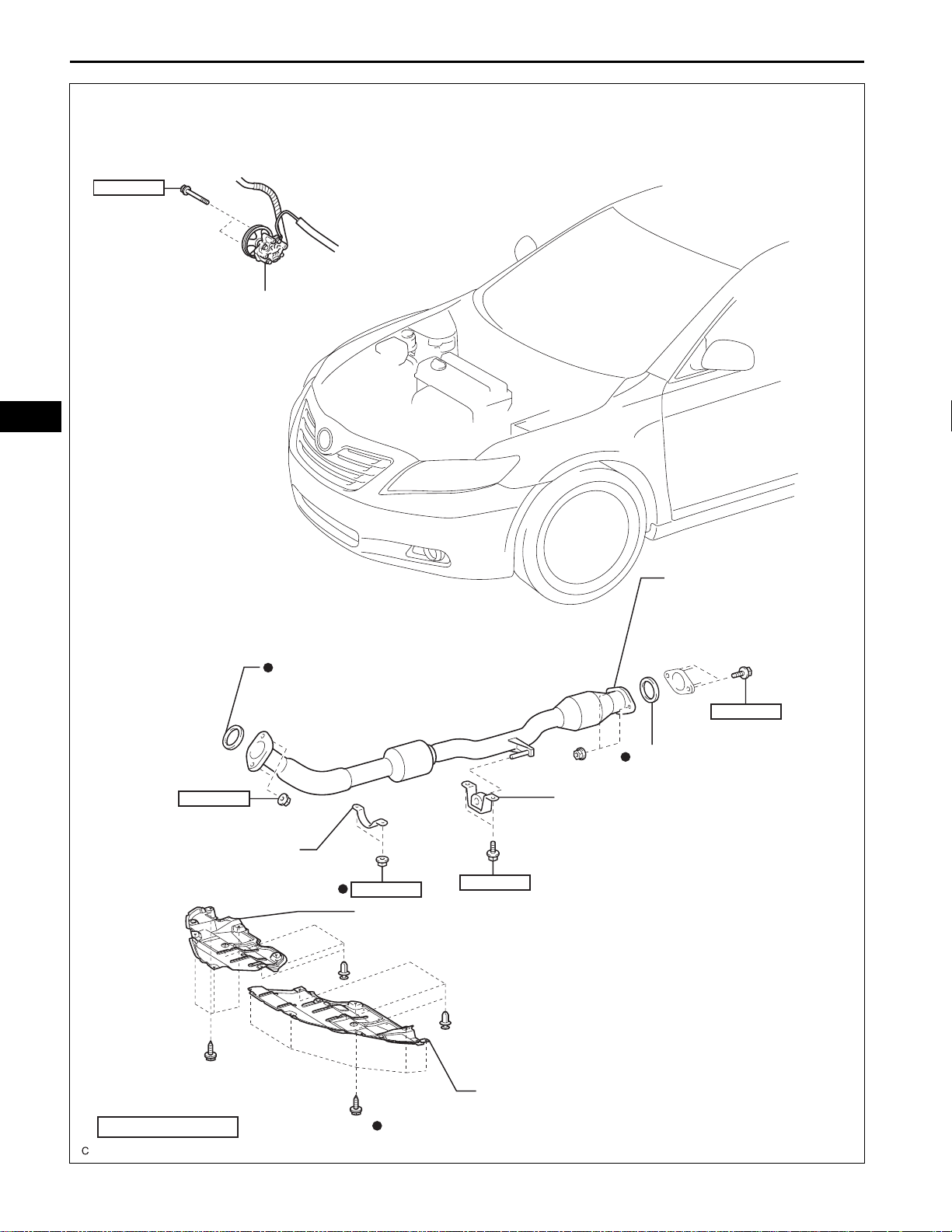

ENGINE2AZ-FE ENGINE MECHANICAL

TIMING CHAIN

COMPONENTS

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

ENGINE MOVING CONTROL ROD SUB-ASSEMBLY

EM–17

64 (653, 47)

52 (531, 38)

64 (653, 47)

NO. 2 ENGINE MOUNTING STAY RH

V-RIBBED BELT

9.8 (100, 87 in.*lbf)

52 (531, 38)

21 (214, 15)

NO. 2 ENGINE MOUNTING BRACKET RH

9.0 (92, 80 in.*lbf)

EM

NO. 1 ENGINE COVER SUB-ASSEMBLY

GENERATOR ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

FRONT FENDER APRON SEAL RH

A134948E01

EM

EM–18

43 (439, 32)

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

VANE PUMP ASSEMBLY

EXHAUST PIPE GASKET

62 (633, 46)

FRONT EXHAUST PIPE NO. 1

SUPPORT BRACKET

33 (337, 24)

33 (337, 24)

ENGINE UNDER COVER RH

FRONT EXHAUST

PIPE ASSEMBLY

56 (571, 41)

EXHAUST PIPE GASKET

REAR EXHAUST PIPE NO. 1

SUPPORT BRACKET

N*m (kgf*cm, ft.*lbf)

: Specified torque

ENGINE UNDER COVER LH

Non-reusable part

A134947E01

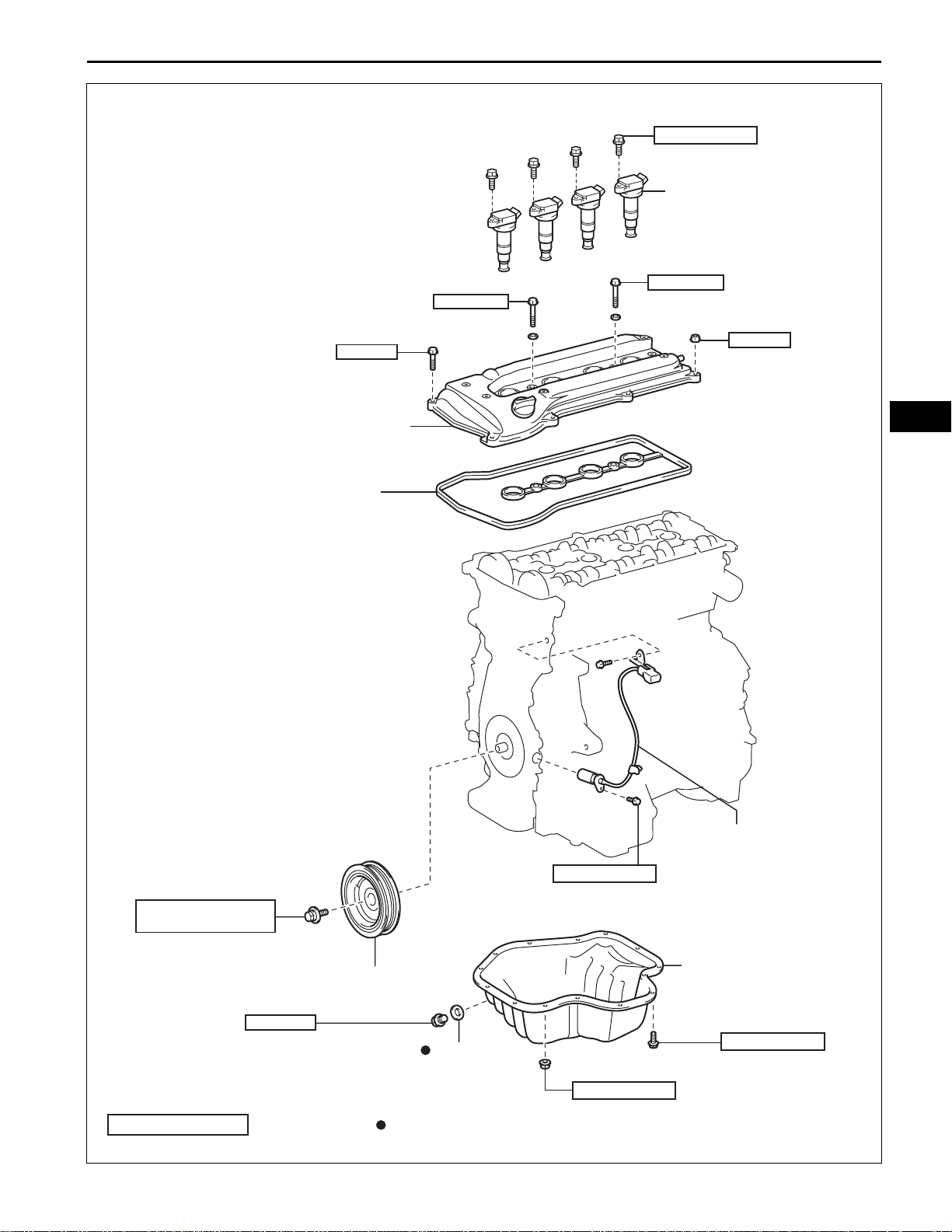

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

14 (143, 10)

EM–19

9.0 (92, 80 in.*lbf)

IGNITION COIL ASSEMBLY

14 (143, 10)

11 (110, 8)

CYLINDER HEAD COVER SUB-ASSEMBLY

CYLINDER HEAD COVER GASKET

x6

11 (110, 8)

x2

EM

TMMK: 170 (1,733, 125)

TMC: 180 (1,835, 133)

N*m (kgf*cm, ft.*lbf)

CRANKSHAFT PULLEY

25 (255, 18)

OIL PAN DRAIN PLUG

: Specified torque

GASKET

Non-reusable part

9.0 (92, 80 in.*lbf)

x2

9.0 (92, 80 in.*lbf)

CRANK POSITION

SENSOR

OIL PAN SUB-ASSEMBLY

9.0 (92, 80 in.*lbf)

x12

A134922E01

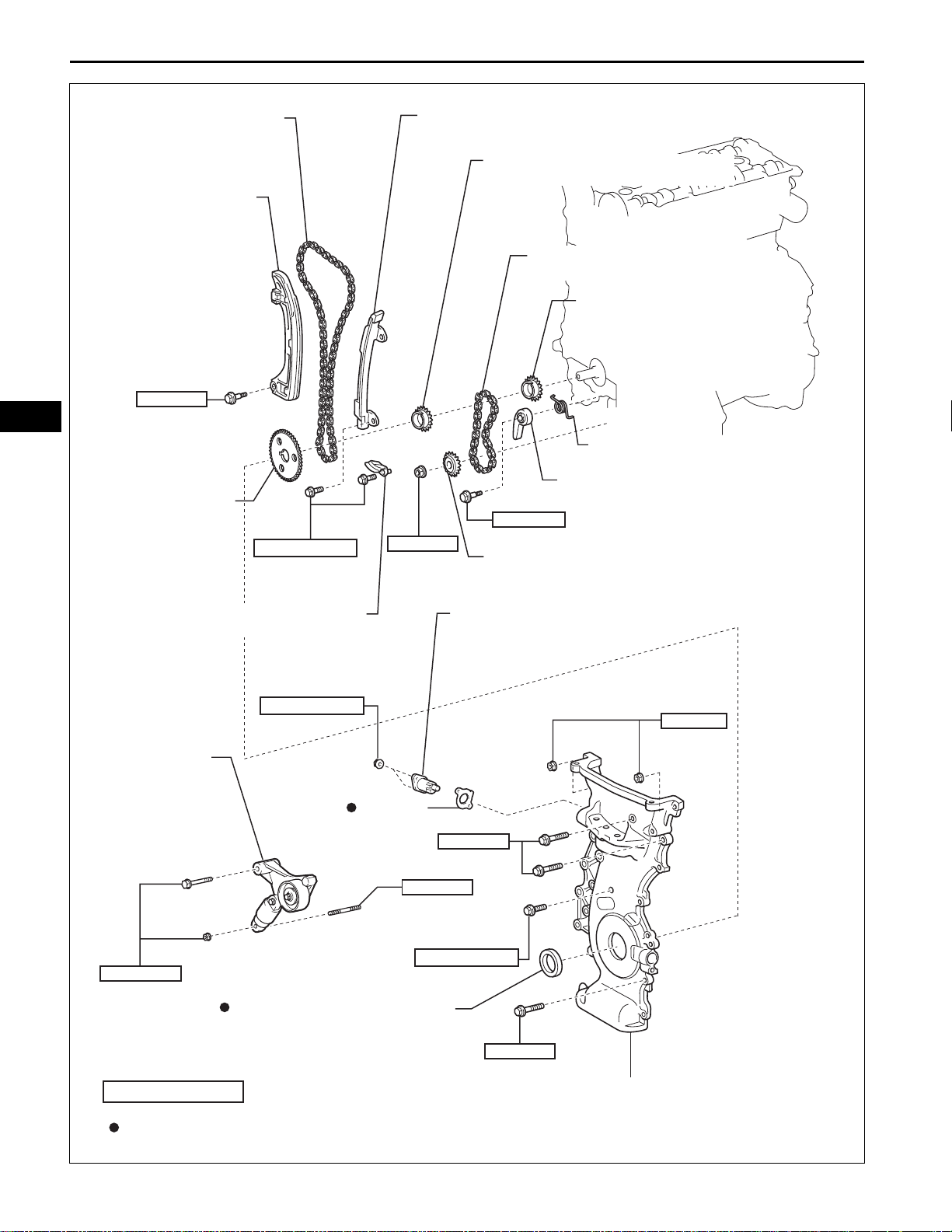

EM–20

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

CHAIN SUB-ASSEMBLY

CHAIN TENSIONER

SLIPPER

19 (194, 14)

NO. 1 CRANKSHAFT

POSITION SENSOR

PLATE

9.0 (92, 80 in.*lbf)

NO. 1 CHAIN VIBRATION DAMPER

CRANKSHAFT TIMING SPROCKET

NO. 2 CHAIN SUB-ASSEMBLY

OIL PUMP DRIVE SPROCKET

SPRING

CHAIN TENSIONER

12 (122, 9.0)

30 (301, 22)

OIL PUMP DRIVEN SPROCKET

V-RIBBED BELT

TENSIONER

ASSEMBLY

60 (607, 44)

TIMING CHAIN GUIDE

9.0 (92, 80 in.*lbf)

GASKET

TIMING CHAIN CASE OIL SEAL

NO. 1 CHAIN TENSIONER

ASSEMBLY

55 (561, 41)

22 (220, 16)

STUD BOLT

9.0 (92, 80 in.*lbf)

11 (112, 8)

x4

x8

25 (255, 18)

N*m (kgf*cm, ft.*lbf)

Non-reusable part

: Specified torque

TIMING CHAIN COVER SUB-ASSEMBLY

A134923E01

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

(See page EM-94)

3. REMOVE FRONT WHEEL RH

4. REMOVE ENGINE UNDER COVER LH

5. REMOVE ENGINE UNDER COVER RH

6. REMOVE FRONT FENDER APRON SEAL RH

7. DRAIN ENGINE OIL (See page LU-4)

8. REMOVE FRONT EXHAUST PIPE ASSEMBLY

HINT:

See page EX-2.

9. REMOVE NO. 2 ENGINE MOUNTING STAY RH (See

page EM-95)

10. REMOVE ENGINE MOVING CONTROL ROD SUBASSEMBLY (See page EM-95)

EM–21

EM

11. REMOVE NO. 2 ENGINE MOUNTING BRACKET RH

(See page EM-96)

12. REMOVE V-RIBBED BELT (See page EM-6)

13. REMOVE GENERATOR ASSEMBLY (See page CH-11)

14. REMOVE VANE PUMP ASSEMBLY (See page EM-

101)

15. REMOVE IGNITION COIL ASSEMBLY (See page EM-

106)

16. DISCONNECT VENTILATION HOSE

17. DISCONNECT NO. 2 VENTILATION HOSE

18. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

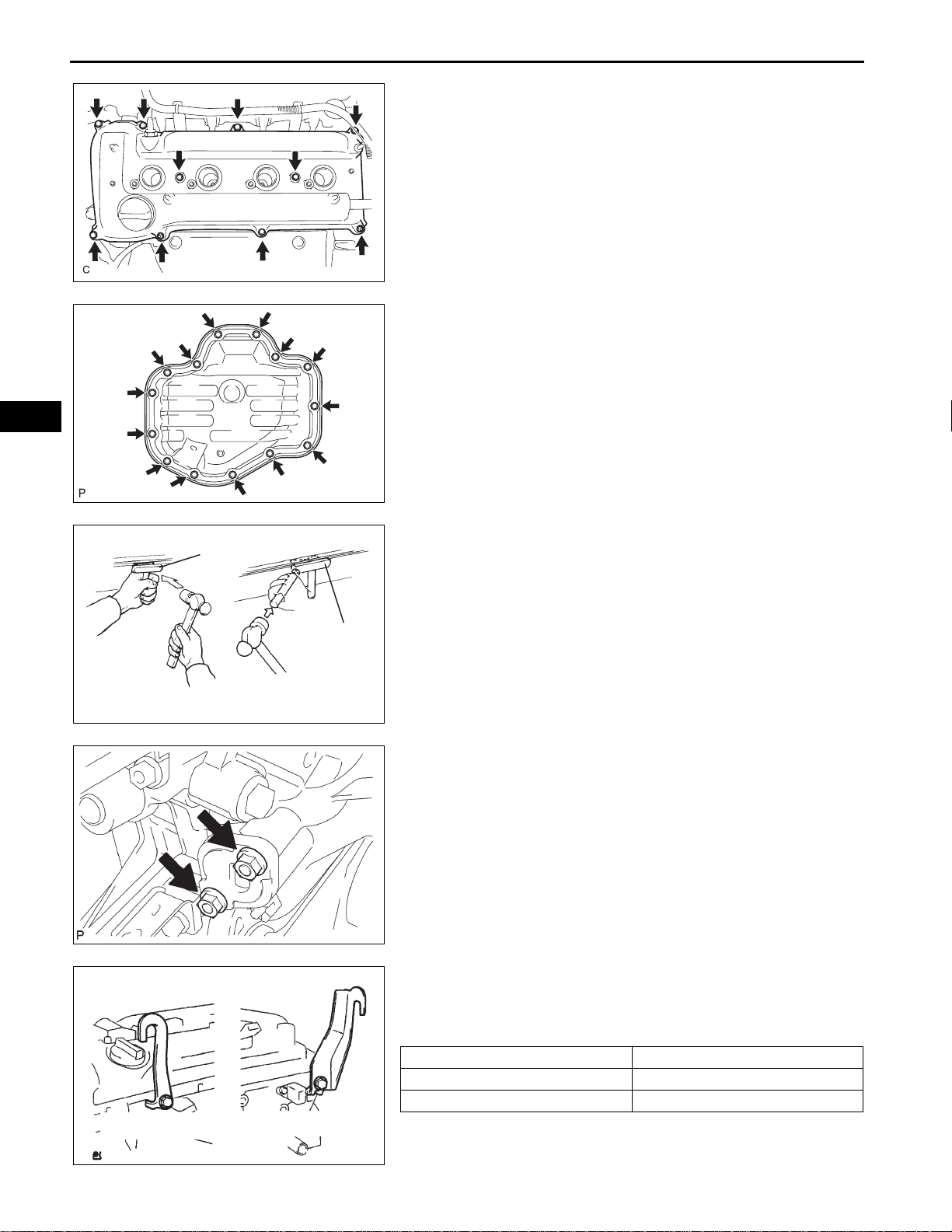

(a) Remove the 2 bolts and disconnect the 2 engine

wires.

A112210E01

EM

EM–22

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

(b) Remove the 8 bolts, 2 nuts, and the cylinder head

cover.

19. SET NO. 1 CYLINDER TO TDC/COMPRESSION (See

page EM-8)

20. REMOVE CRANKSHAFT PULLEY (See page EM-75)

21. REMOVE CRANK POSITION SENSOR (See page ES-

411)

A127550E02

22. REMOVE OIL PAN SUB-ASSEMBLY

(a) Remove the 12 bolts and 2 nuts.

A114333

SST

No. 1 Engine Hanger

SST

A000019E05

A098348E01

No. 2 Engine Hanger

A052507E05

(b) Insert the blade of SST between the crankcase and

oil pan. Cut through the sealer and remove the oil

pan.

SST 09032-00100

NOTICE:

Be careful not to damage the conta ct surfaces of

the crankcase, chain cover and oil pan.

23. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Remove the 2 nuts, tensioner and gasket.

NOTICE:

Do not turn the crankshaft without the chain

tensioner.

24. INSTALL ENGINE HANGERS

(a) Install the No. 1 engine hanger and No. 2 engine

hanger with the bolts as shown in the illustration.

Parts No.:

No. 1 Engine hanger 12281-28010

No. 2 Engine hanger 12282-28010

Bolt 91512-61020

Torque: 38 N*m (387 kgf*cm, 28 ft.*lbf)

(b) Attach the sling device to the engine hangers and

chain block.

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

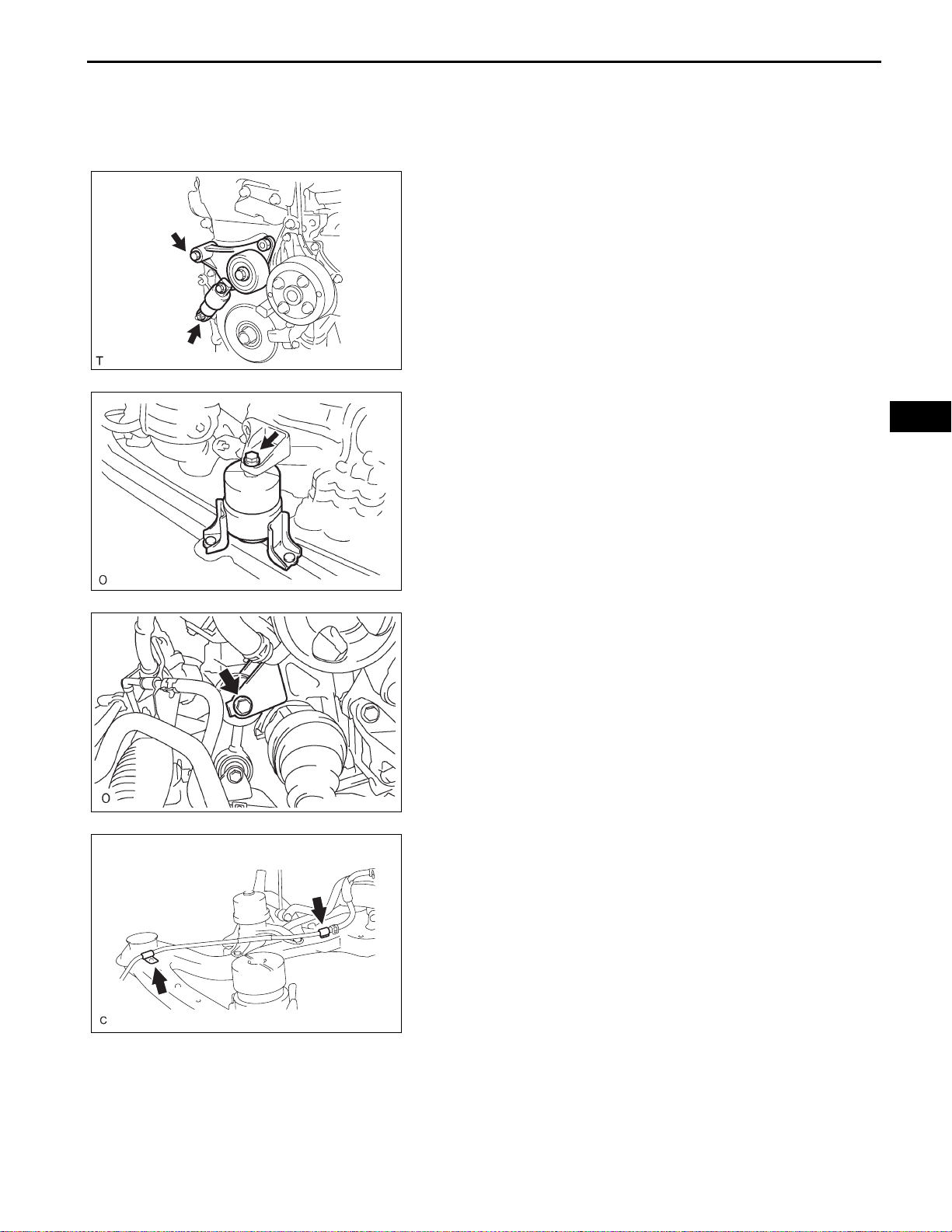

25. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a) Lift the engine upward using the chain block.

NOTICE:

Do not lift the engine more than necessary.

(b) Remove the bolt, nut and V-ribbed belt tensioner.

A112212

26. REMOVE ENGINE MOUNTING INSULATOR

(a) Attach the engine chain hoist to the engine hangers.

CAUTION:

Do not attempt to hang the engine by hooking

the chain to any other part.

(b) Remove the bolt and disconnect the engine

mounting insulator FR.

EM–23

EM

M/T

A059880

(c) M/T:

Remove the bolt and disconnect the engine lateral

control rod.

A060825E02

(d) Remove the 2 bolts and disconnect the steering

gear return tube clamps from the frame.

A138332

EM

EM–24

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

(e) Remove the 4 nuts from the engine mounting

insulator RH.

(f) Raise the engine and remove the engine mounting

insulator RH.

A059900

27. REMOVE ENGINE MOUNTING BRACKET RH

(a) Remove the 3 bolts and engine mounting bracket.

28. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(See page LU-11)

29. REMOVE TIMING CHAIN CASE OIL SEAL (See page

LU-12)

A052481

A132571

A125372

30. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR

PLATE

(a) Remove the crankshaft position sensor plate.

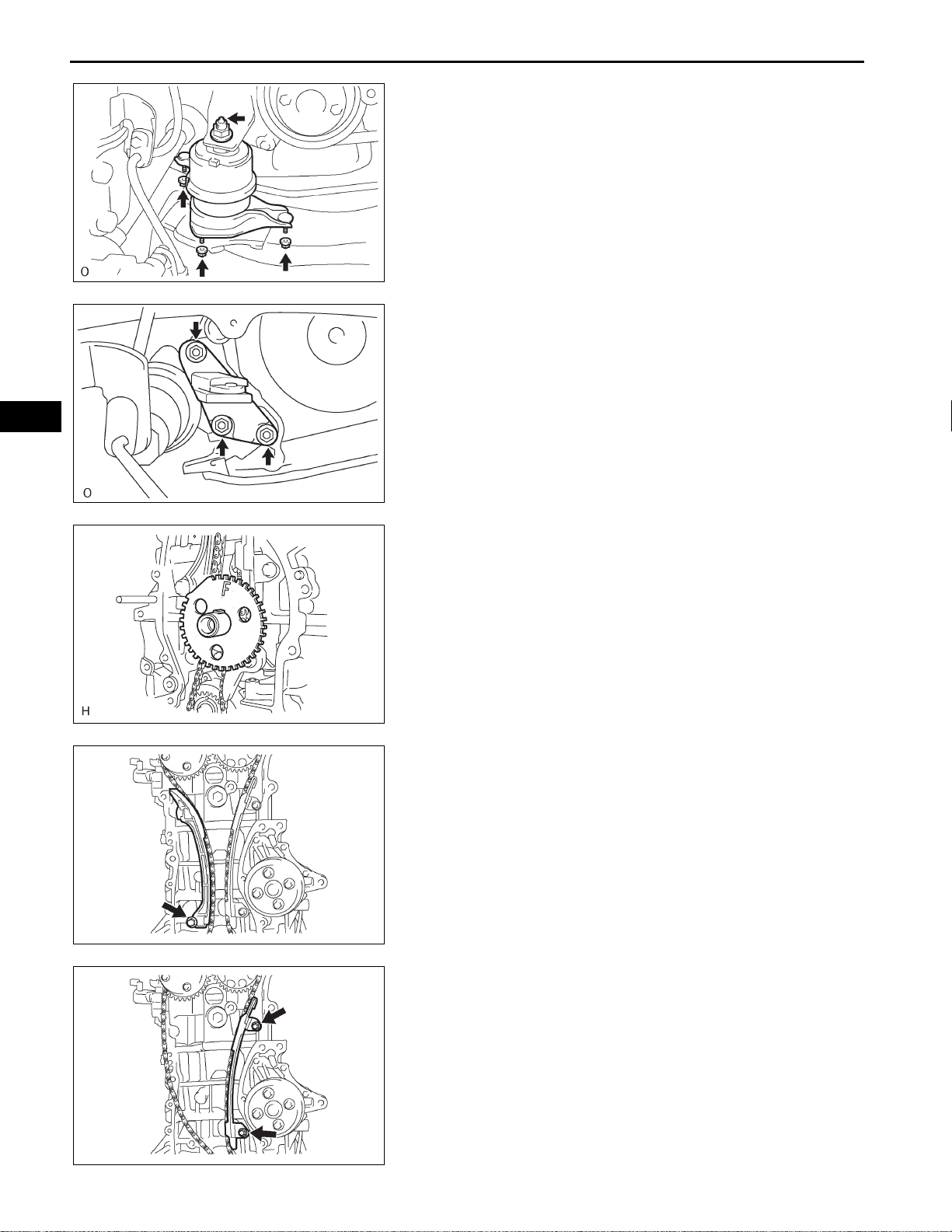

31. REMOVE CHAIN TENSIONER SLIPPER

(a) Remove the bolt and chain tensioner slipper.

32. REMOVE NO. 1 CHAIN VIBRATION DAMPER

(a) Remove the 2 bolts and chain vibration damper.

A125371

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

33. REMOVE TIMING CHAIN GUIDE

(a) Remove the bolt and timing chain guide.

A125373

34. REMOVE CHAIN SUB-ASSEMBLY

(a) Remove the chain sub-assembly.

A128185

EM–25

EM

90°

35. REMOVE CRANKSHAFT TIMING SPROCKET

(a) Remove the crankshaft timing sprocket.

A125374

36. REMOVE NO. 2 CHAIN SUB-ASSEMBLY

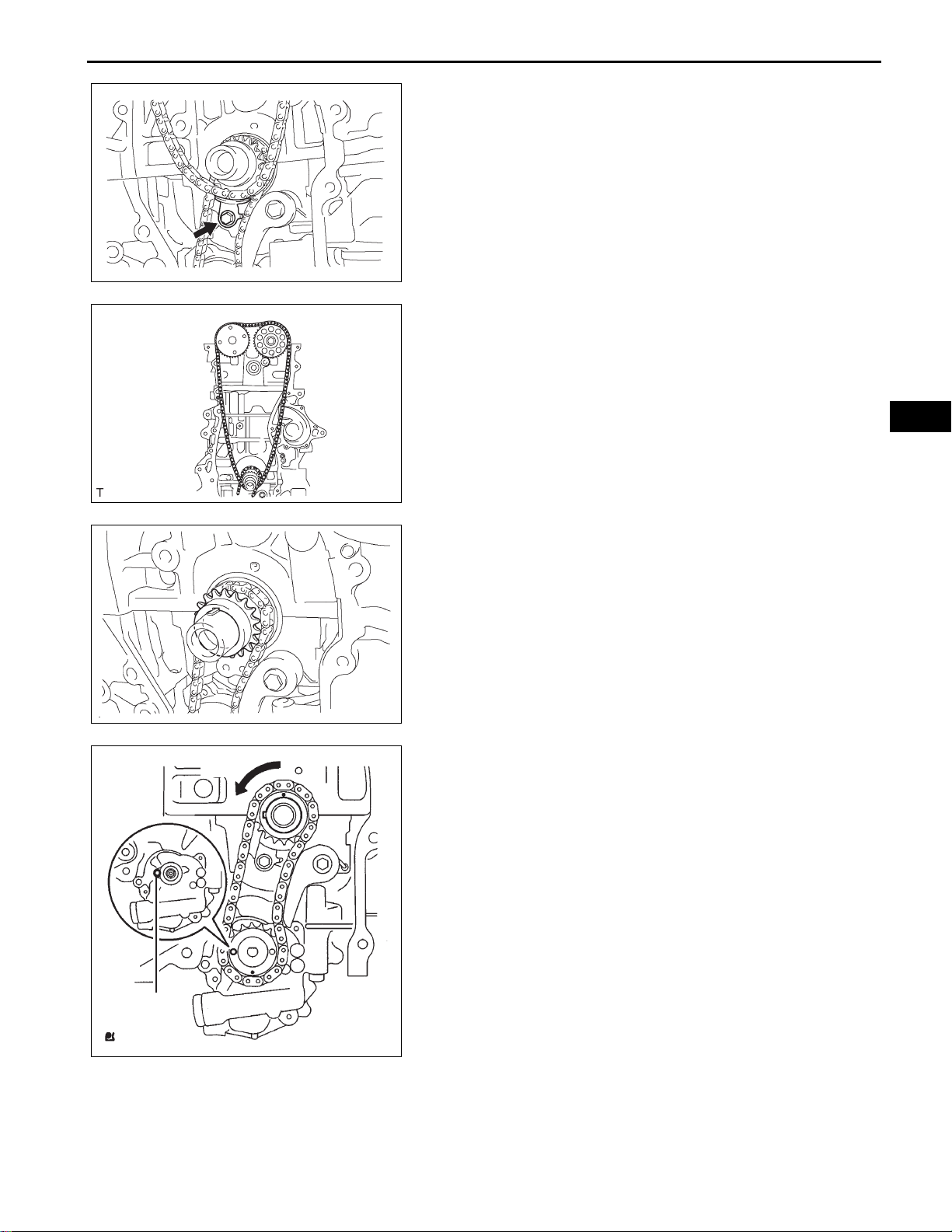

(a) Turn the crankshaf t by 90° counterclockwise to align

the adjusting hole of the oil pump drive shaft

sprocket with the groove of the oil pump.

Groove

A098351E01

EM

EM–26

Groove

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

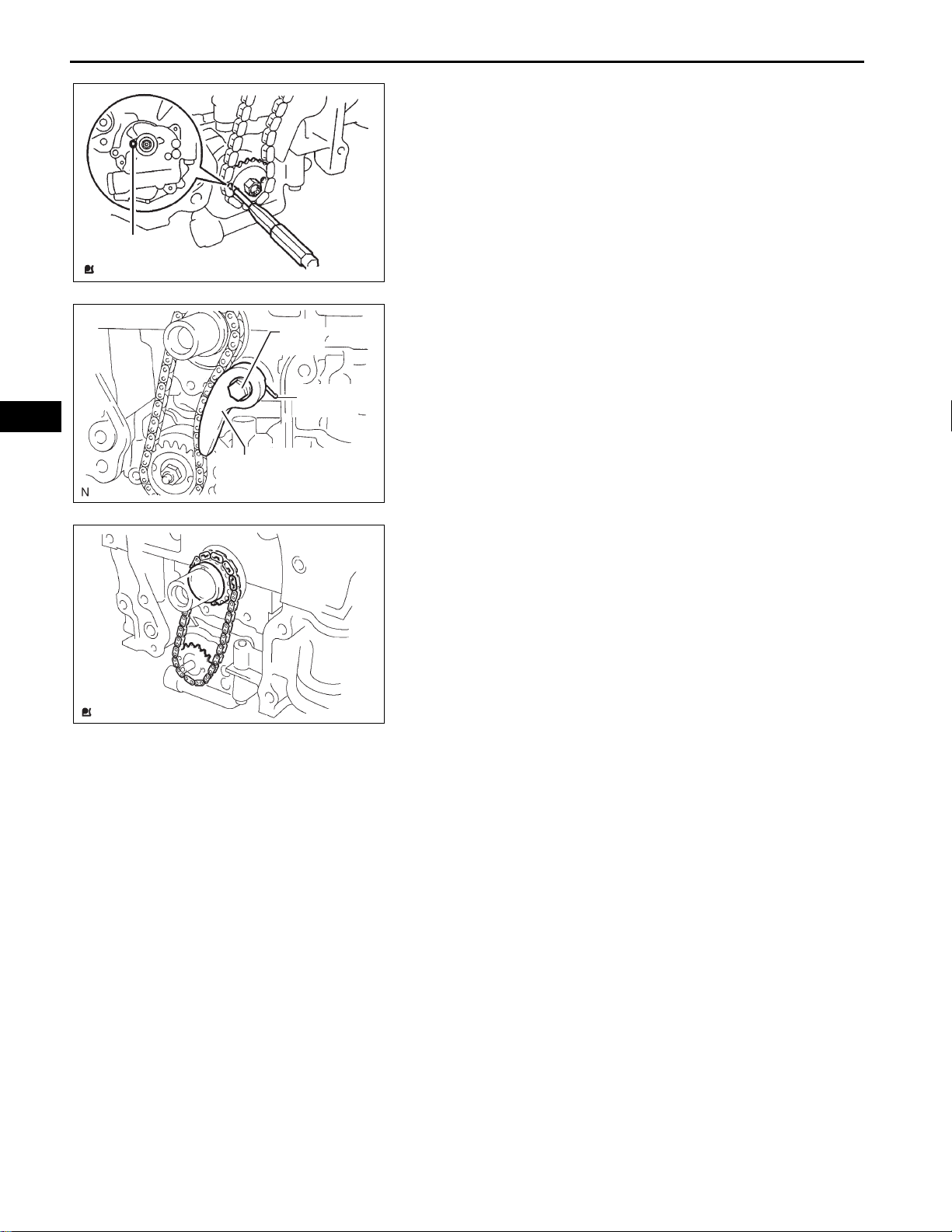

(b) Insert a 4 mm diameter bar into the adjusting hole of

the oil pump drive shaft sprocket to lock the gear in

position, and then remove the nut.

A098352E01

(c) Remove the bolt, chain tensioner plate and spring.

Bolt

Spring

Chain Tensioner Plate

B011415E03

A063847

(d) Remove the chain tensioner, oil pump driven

sprocket and chain.

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

INSPECTION

1. INSPECT CHAIN SUB-ASSEMBLY (See page EM-138)

2. INSPECT NO. 2 CHAIN SUB-ASSEMBLY (See page

EM-138)

3. INSPECT OIL PUMP DRIVE SPROCKET (See page

EM-138)

4. INSPECT OIL PUMP DRIVE SHAFT SPROCKET (See

page EM-139)

5. INSPECT CHAIN TENSIONER SLIPPER (See page

EM-140)

6. INSPECT NO. 1 CHAIN VIBRATION DAMPER (See

page EM-140)

7. INSPECT CHAIN TENSIONER PLATE (See page EM-

140)

8. INSPECT NO. 1 CHAIN TENSIONER (See page EM-

140)

INSTALLATION

EM–27

EM

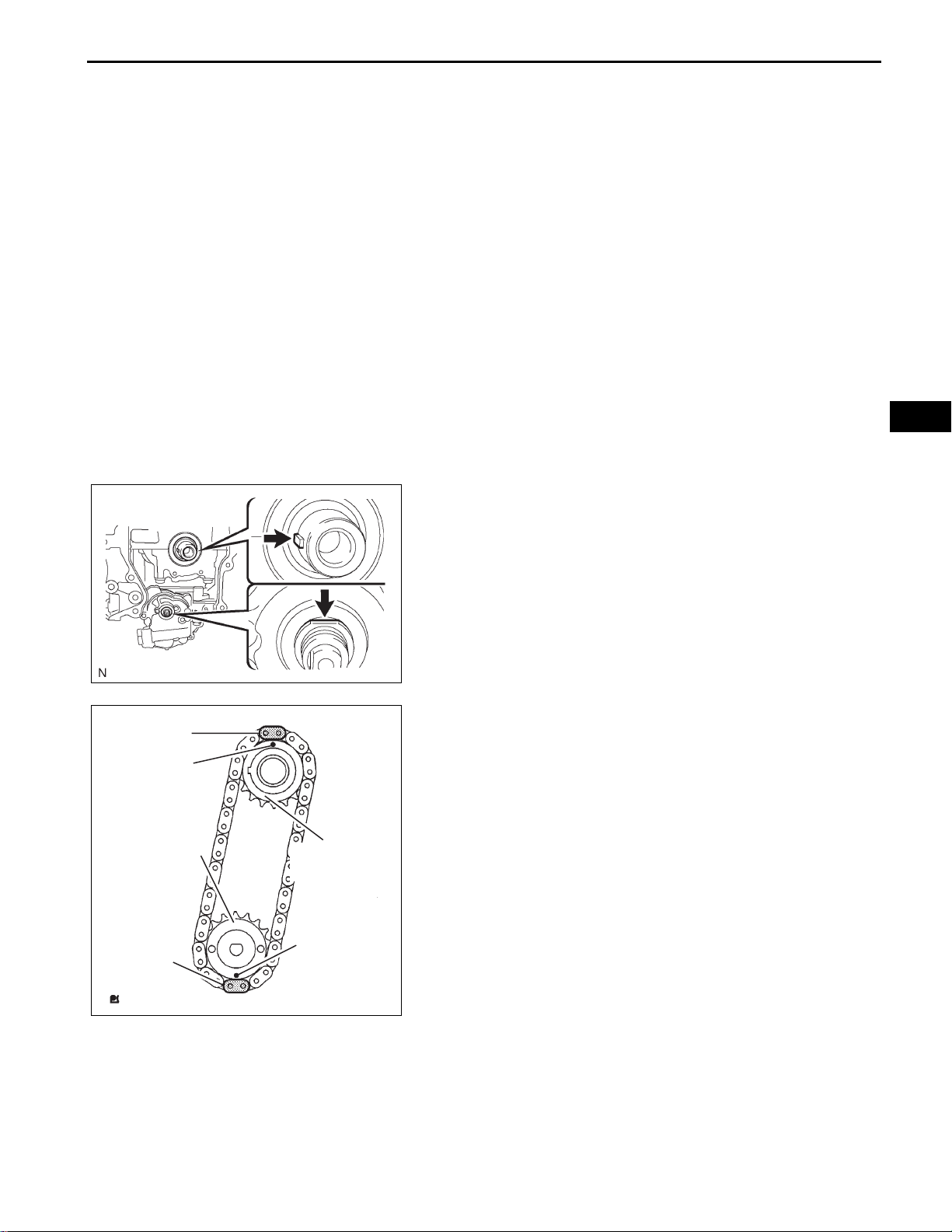

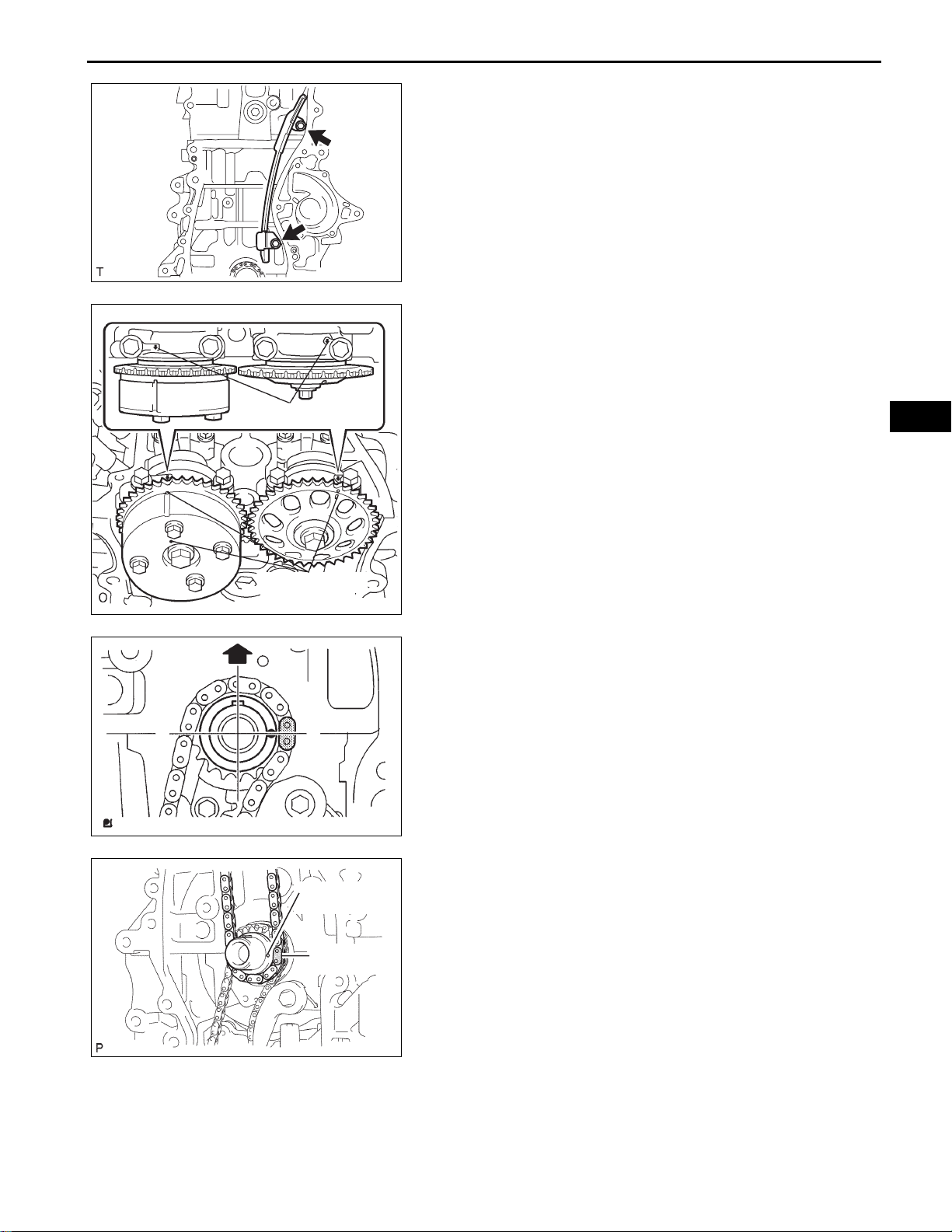

Mark Link

Timing Mark

Oil Pump Drive

Shaft Sprocket

Mark Link

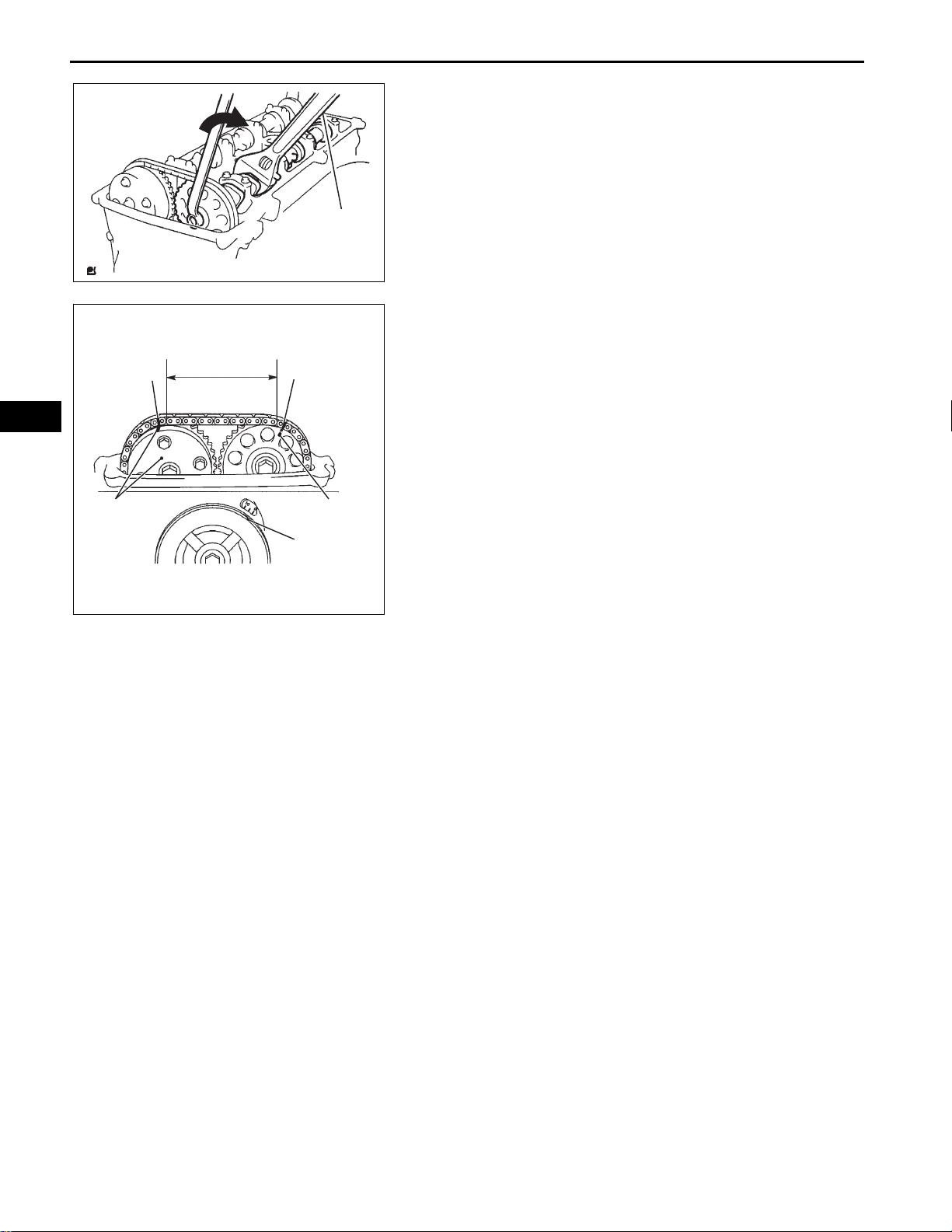

1. INSTALL NO. 2 CHAIN SUB-ASSEMBLY

(a) Set the crankshaft key into the left horizontal

position.

(b) Turn the drive shaft so that the cutout faces upward.

B011424

(c) Align the yellow mark links with the timing marks of

each gear as shown in the illustration.

(d) Install the sprockets onto the crankshaft and oil

pump shaft with the chain wrapped on the gears.

(e) T emporarily tighten the oil pump drive shaf t sprocket

with the nut.

Oil Pump

Drive Sprocket

Timing Mark

A094198E06

EM–28

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

(f) Insert the damper spring into the adjusting hole, and

then install the chain tensioner plate with the bolt.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

Bolt

Spring

Chain Tensioner Plate

A090851E03

EM

(g) Align the adjusting hole of the oil pump drive shaft

sprocket with the groove of the oil pump.

(h) Insert a 4 mm diameter bar into the adjusting hole of

the oil pump drive shaft gear to lock the gear in

position, and then tighten the nut.

Torque: 30 N*m (301 kgf*cm, 22 ft.*lbf)

Groove

A052512E02

(i) Rotate the crankshaft clockwise by 90°, and align

the crankshaft key to the top.

A036525

2. INSTALL CRANKSHAFT TIMING SPROCKET

(a) Install the crankshaft timing sprocket.

A125374

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

Timing Marks

A132570

3. INSTALL NO. 1 CHAIN VIBRATION DAMPER

(a) Install the chain vibration damper with the 2 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

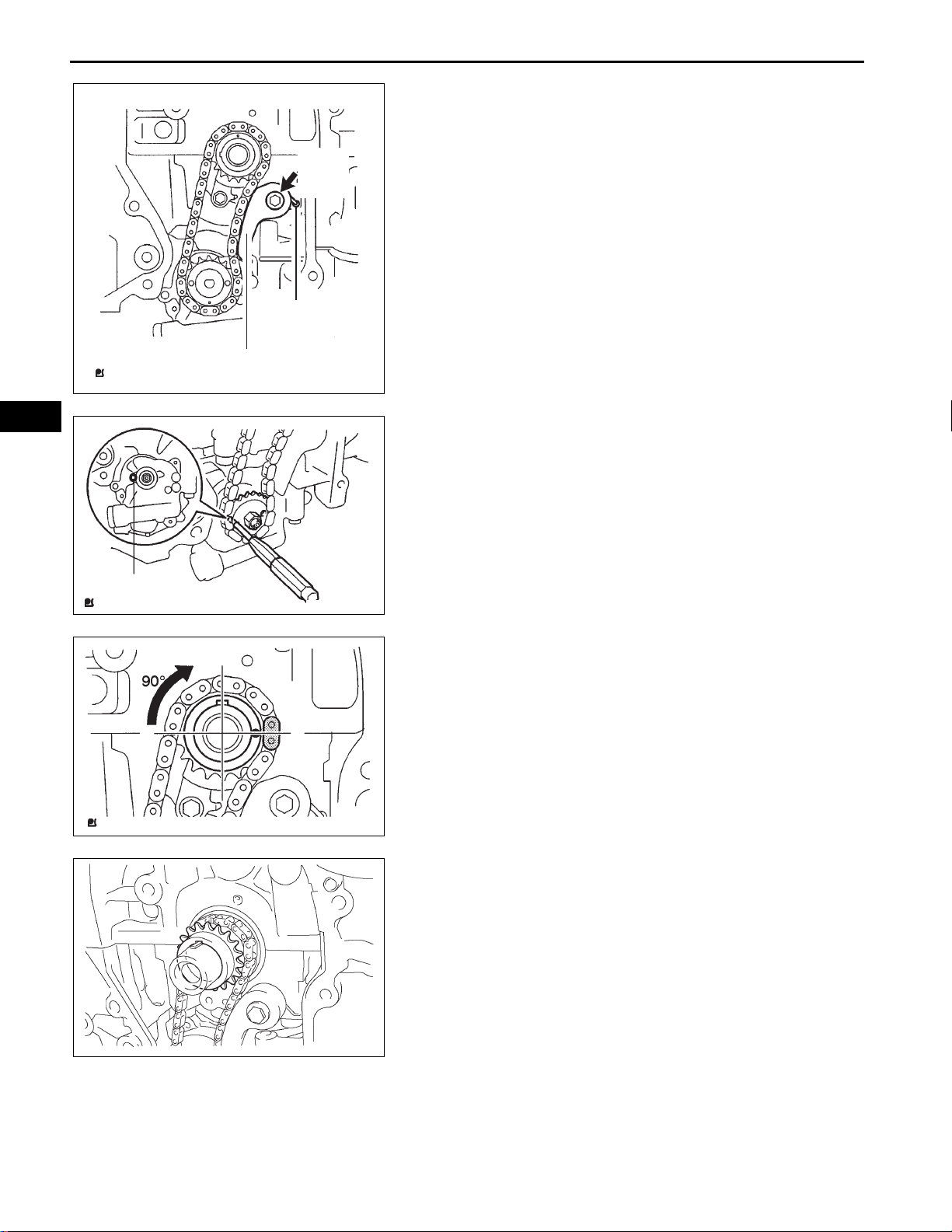

4. INSTALL CHAIN SUB-ASSEMBLY

(a) Set the No. 1 cylinder to TDC/compression.

(1) Turn the camshafts with a wrench (using the

hexagonal lobe) to align the timing marks of the

camshaft timing gear with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

EM–29

EM

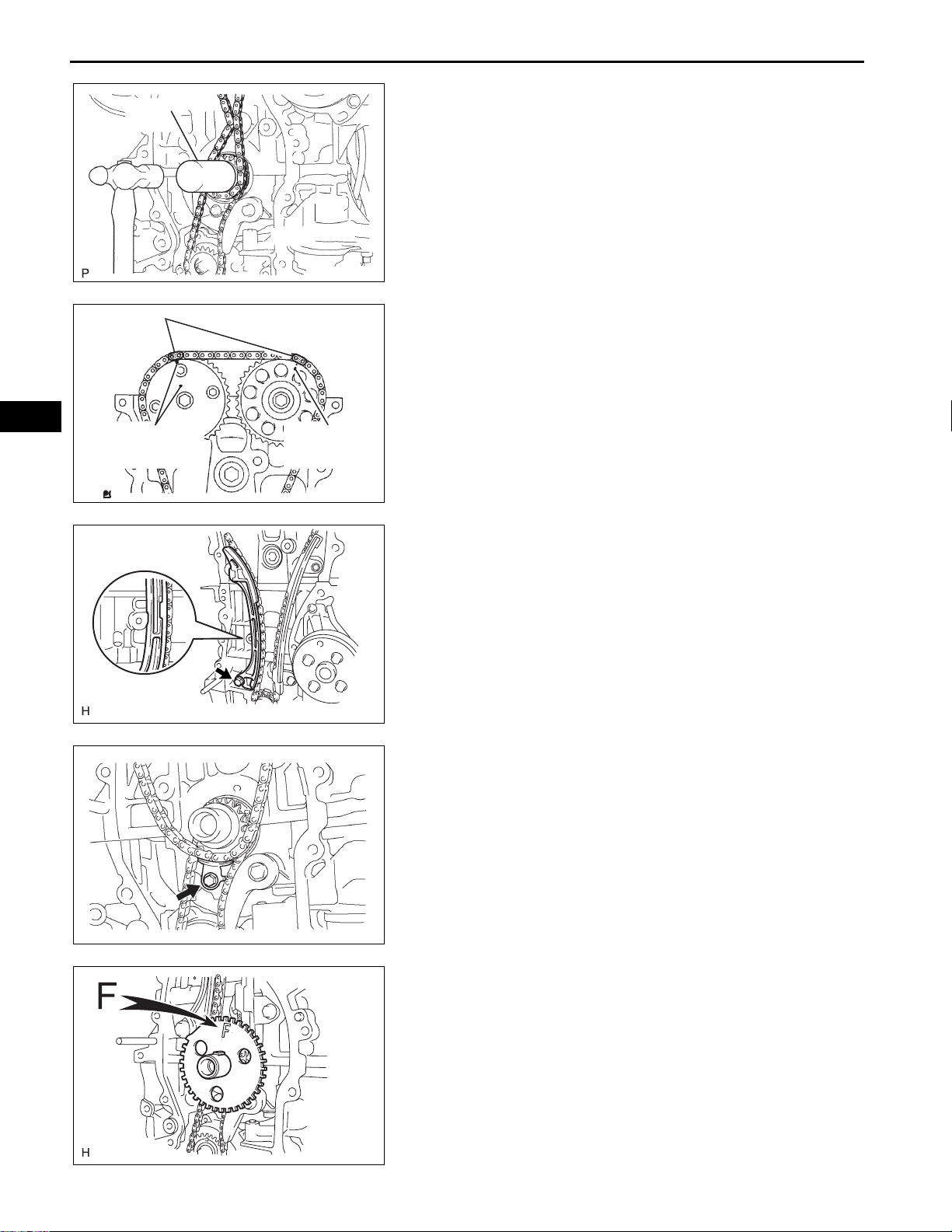

Timing Marks

Timing Mark

Mark Link

A053018E05

(2) Using the crankshaft pulley bolt, turn the

crankshaft to position with the key on the

crankshaft upward.

A052505

(b) Install the chain onto the crankshaft timing sprocket

with the gold or pink mark link aligned with the

timing mark on the crankshaft.

A094576E01

EM–30

SST

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN

(c) Using SST and a hammer, tap in the crankshaft

timing sprocket.

SST 09309-37010

A098369E01

EM

Mark Link

Timing Mark

Hold

(d) Align the gold or yellow link with each timing mark

located on the camshaft timing gear and sprocket,

then install the chain.

Timing Mark

A098370E01

5. INSTALL CHAIN TENSIONER SLIPPER

(a) Install the chain tensioner slipper with the bolt.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

A124787E01

6. INSTALL TIMING CHAIN GUIDE

(a) Install the timing chain guide with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

A125373

A124770

7. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR

PLATE

(a) Install the sensor plate with the "F" mark facing

forward.

8. INSTALL TIMING CHAIN CASE OIL SEAL (See page

LU-15)

9. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

(See page LU-15)

Loading...

Loading...