Toyota Camry 2007-2009 Service Manual - Steering_Column

STEERING COLUMN – STEERING SYSTEM

STEERING SYSTEM

PRECAUTION

1. HANDLING PRECAUTIONS FOR STEERING SYSTEM

(a) Care must be taken when replacing parts. Incorrect

replacement may affect the performance of the

steering system and result in driving hazards.

2. HANDLING PRECAUTIONS FOR SRS AIRBAG

SYSTEM

(a) The vehicle is equipped with SRS (Supplemental

Restraint System) such as airbags. Failure to carry

out service operations in the correct sequence could

cause the SRS to unexpectedly deploy during

servicing. This may cause a serious accident.

Before servicing (including inspection, replacement,

removal and installation of parts), be sure to read

the precautionary notices for the Supplemental

Restraint System (See page RS-1).

SR–1

SR

SR

SR–2

STEERING SYSTEM

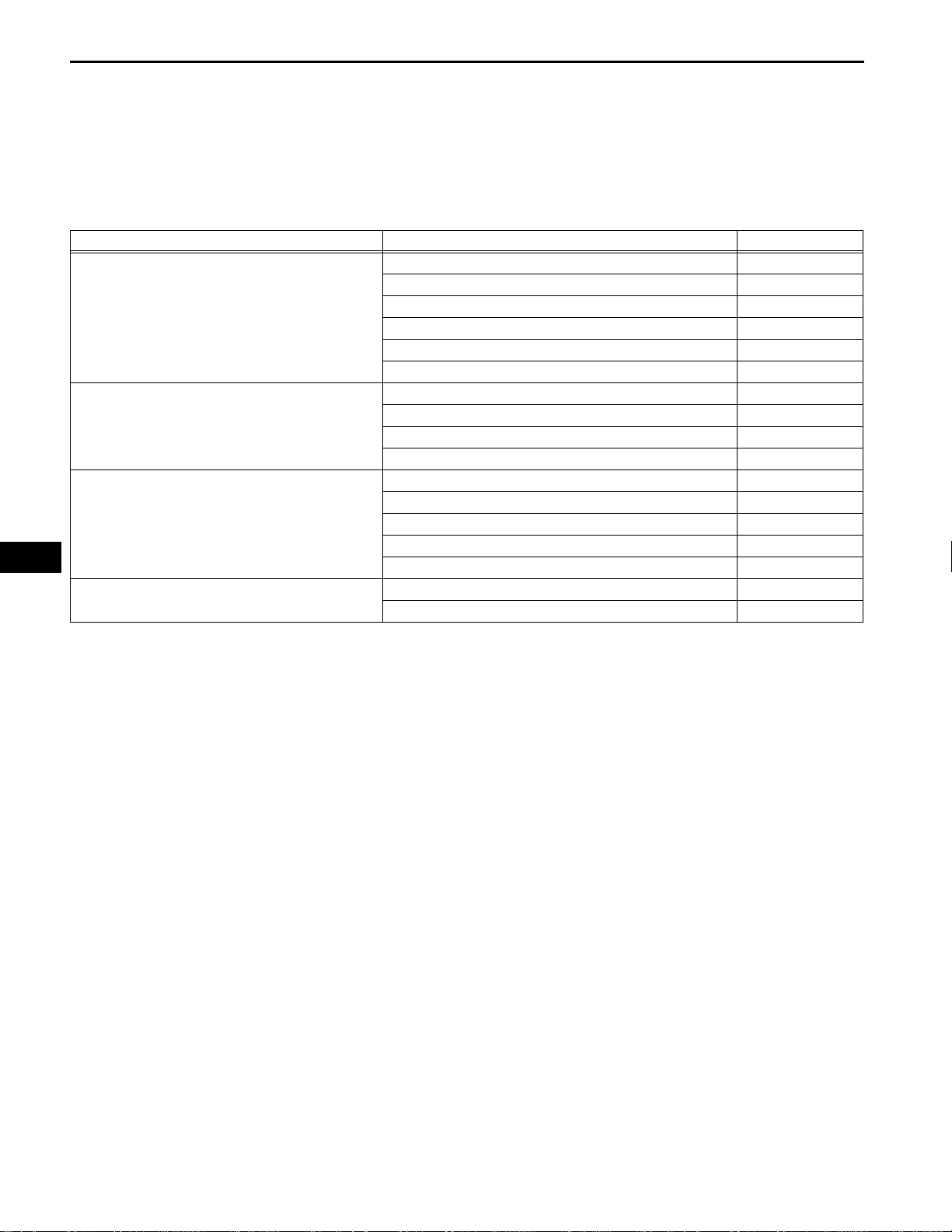

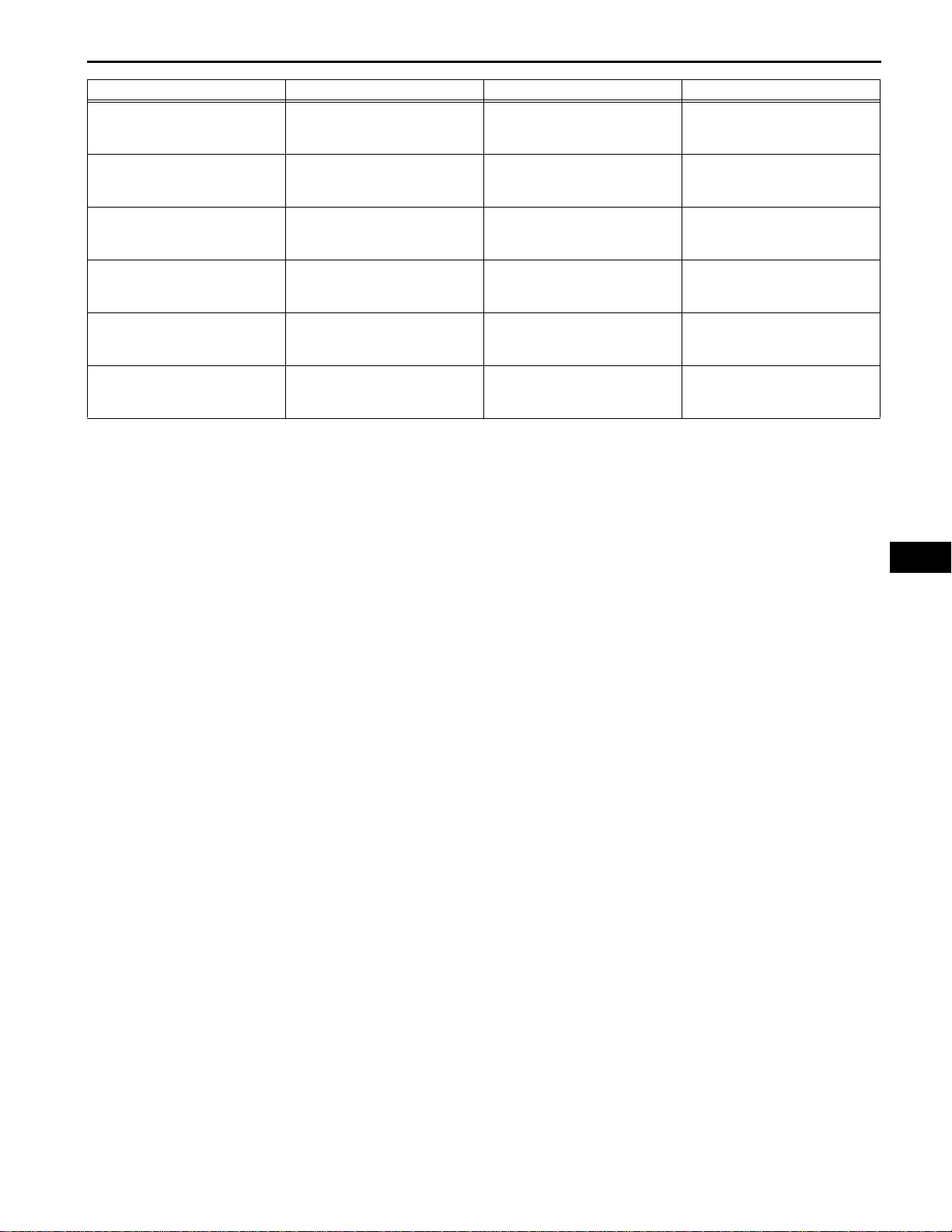

Symptom Suspected area See page

Hard steering

Poor return

Excessive free play

Abnormal noise

STEERING COLUMN – STEERING SYSTEM

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the

problem. The numbers indicate likely causes of the problem

in descending order. Check each part in order. If necessary,

repair or replace the faulty parts.

1. Tires (Improperly inflated) TW-3

2. Front wheel alignment (Incorrect) SP-4

3. Steering system joints (Worn) -

4. Suspension arm ball joints (Worn) SP-28

5. Steering column (Binding) SR-38

6. Power steering gear PS-40

1. Tires (Improperly inflated) TW-3

2. Front wheel alignment (Incorrect) SP-4

3. Steering column (Binding) SR-38

4. Power steering gear PS-40

1. Steering system joints (Worn) -

2. Suspension arm ball joints (Worn) SP-28

3. Intermediate shaft, universal joint, sliding yoke (Worn) -

4. Front wheel bearing (Worn) AH-5

5. Power steering gear PS-40

1. Steering system joints (Worn) -

2. Power steering gear PS-40

STEERING COLUMN – STEERING SYSTEM

ON-VEHICLE INSPECTION

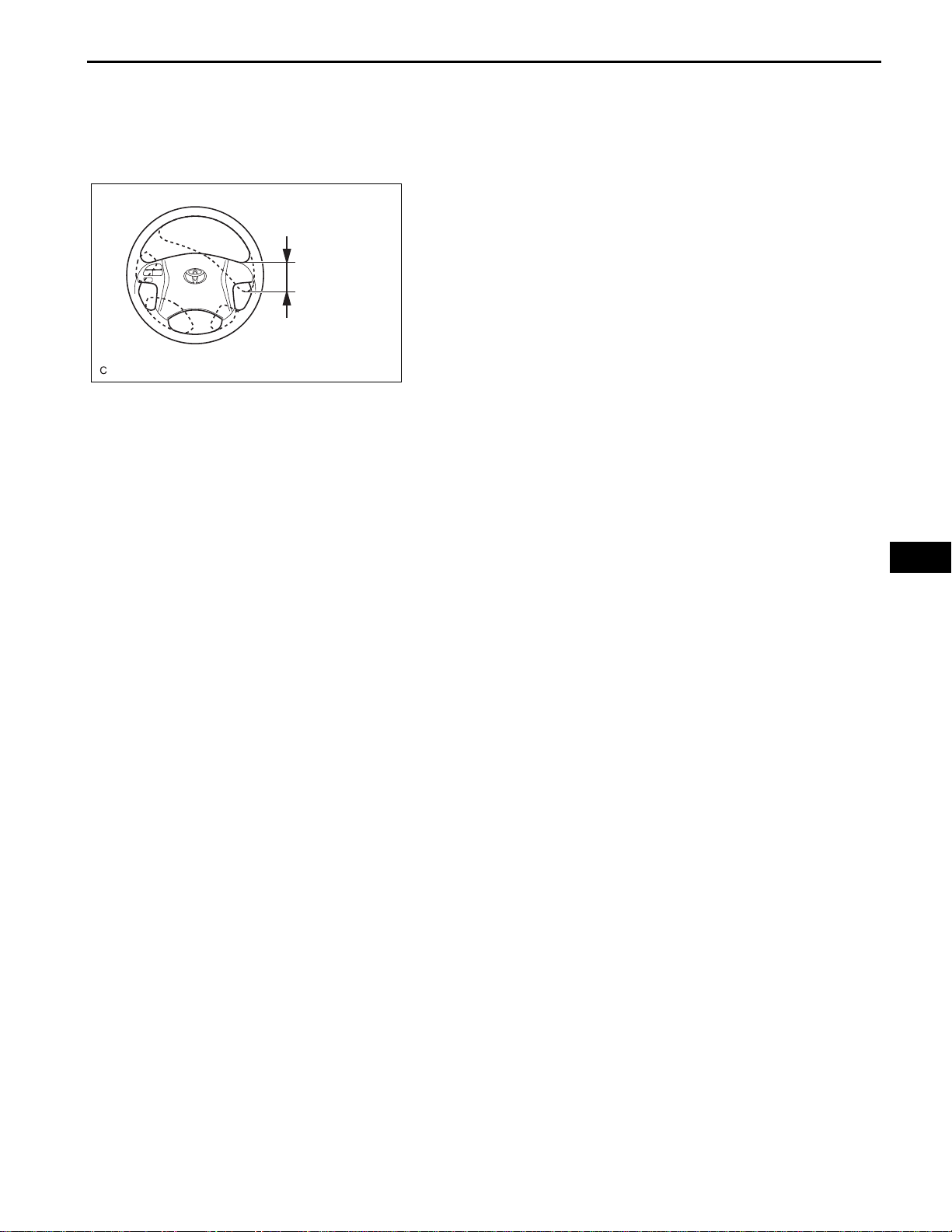

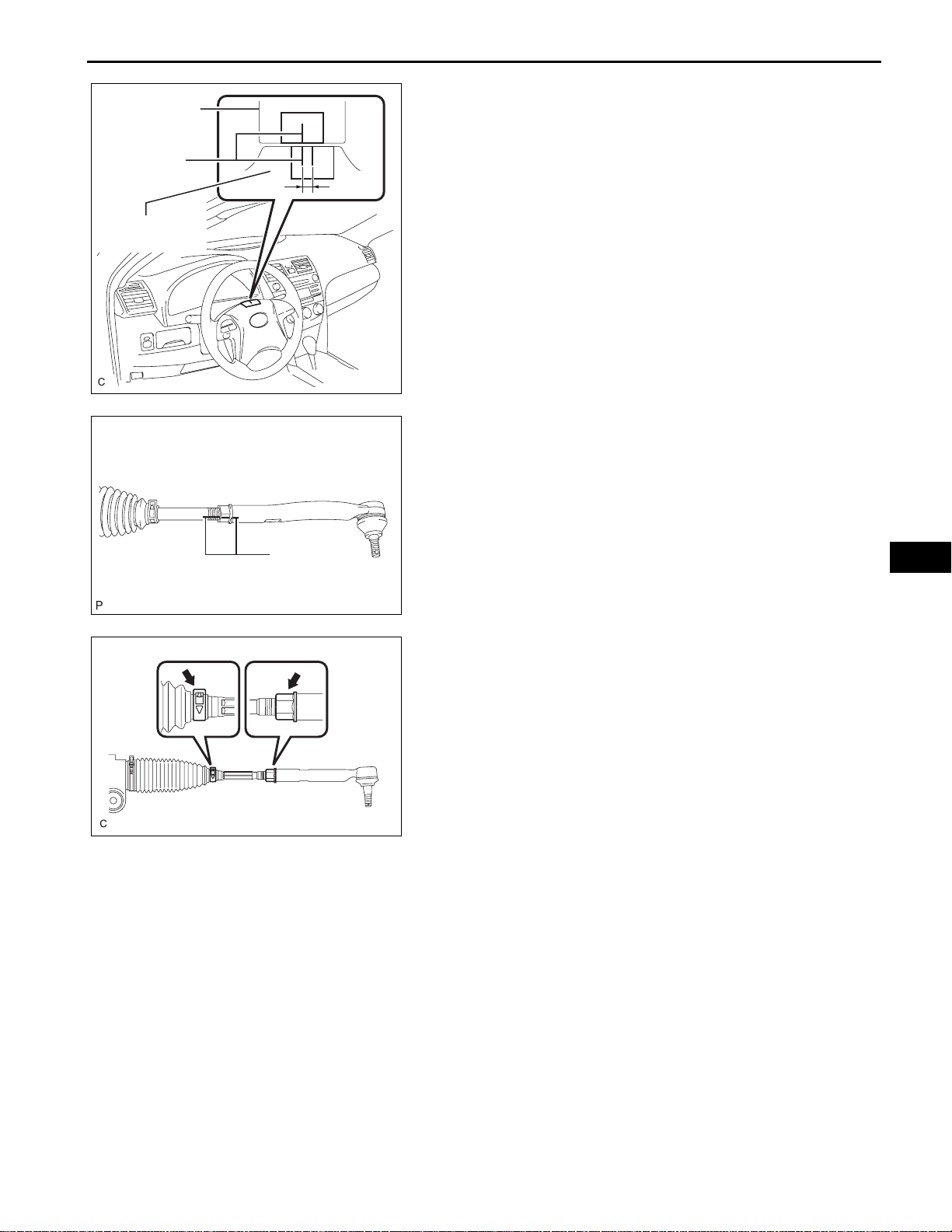

1. INSPECT STEERING WHEEL FREE PLAY

(a) Stop the vehicle and align the tires facing straight

ahead.

SR–3

Maximum Free Play

30 mm (1.18 in.)

C132537E01

(b) Gently turn the steering wheel right and left by hand,

and check the steering wheel free play.

Maximum free play:

30 mm (1.18 in.)

HINT:

If the free play exceeds the maximum, check the

steering column, steering intermediate shaft,

steering sliding yoke, or steering gear.

SR

SR–4

Steering Wheel

Masking Tape

Upper Steering

Column Cover

STEERING COLUMN – STEERING SYSTEM

ADJUSTMENT

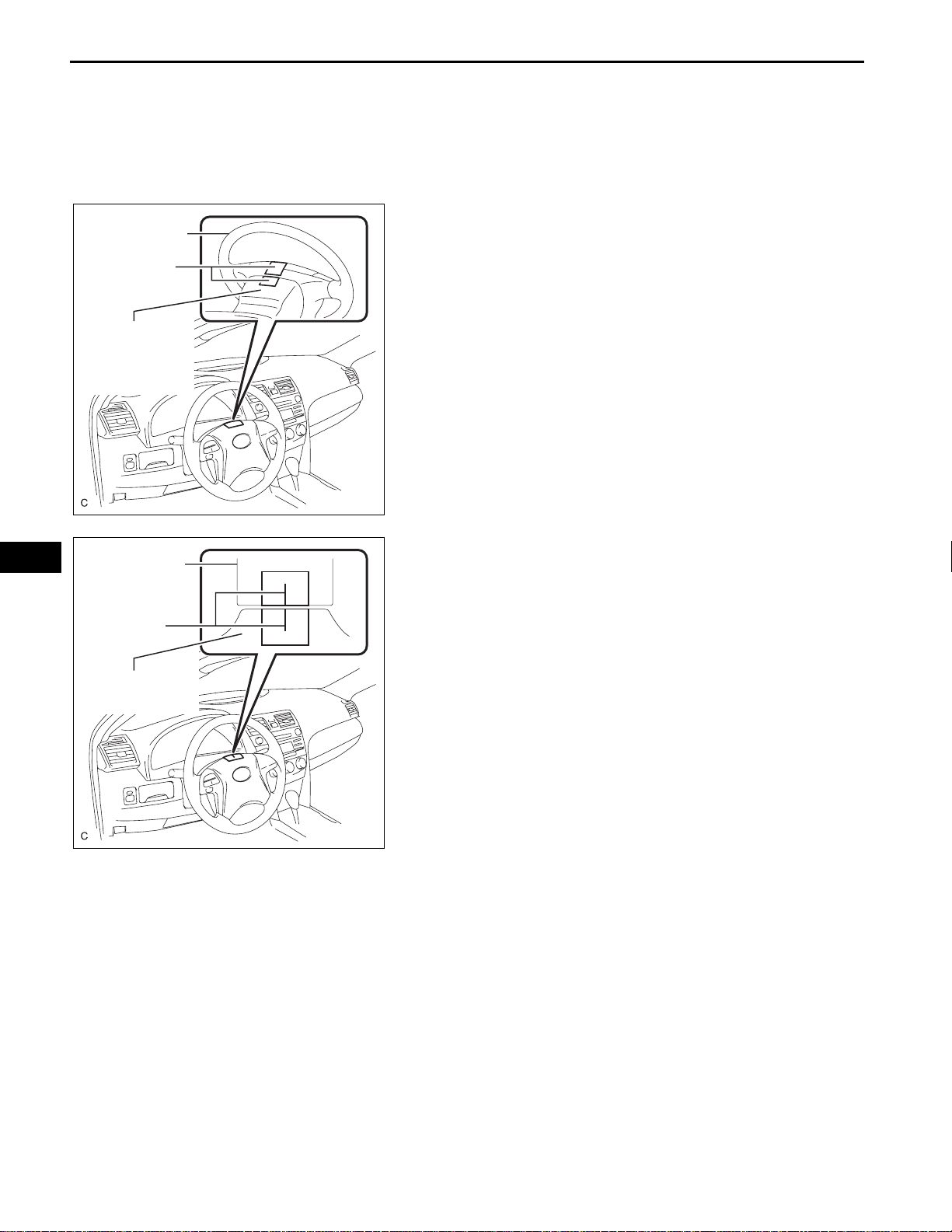

1. STEERING OFF CENTER ADJUSTMENT

PROCEDURE

HINT:

This is the adjustment procedure for steering off center.

(a) Inspect steering wheel off center.

(1) Apply masking tape on the top center of the

steering wheel and steering column upper

cover.

(2) Drive the vehicle in a straight line for 100

meters at a constant speed of 35 mph (56 km/

h), and hold the steering wheel to maintain the

course.

SR

Upper Steering

Column Cover

Marked Line

Steering Wheel

C132538E01

(3) Draw a line on the masking tape as shown in

the illustration.

(4) Turn the steering wheel to the center position.

HINT:

Look at the upper surface of the steering

wheel, steering spoke, and SRS airbag line to

find the center position.

C132539E01

STEERING COLUMN – STEERING SYSTEM

SR–5

Upper Steering

Column Cover

Marked Line

Steering Wheel

Marked Line

C132540E01

C132045E02

(5) Draw a new line on the masking tape on the

steering wheel as shown in the illustration.

(6) Measure the distance between the 2 lines on

the masking tape on the steering wheel.

(7) Convert the measured distance to steering

angle.

HINT:

• Measured distance 1 mm (0.04 in.) =

Steering angle of approximately 1 degree.

• Make a note of the steering angle.

(b) Adjust steering angle.

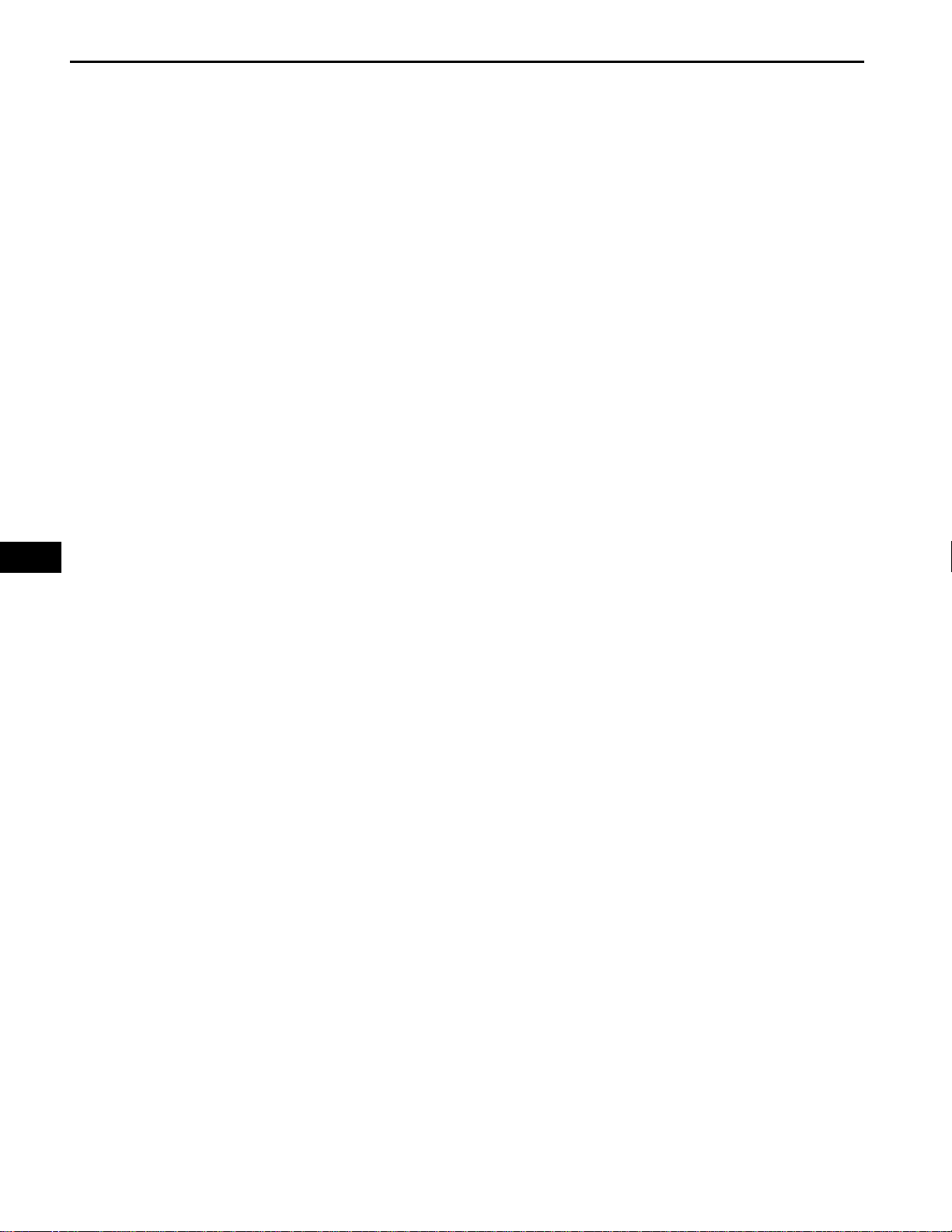

(1) Draw a line on the RH and LH tie rod ends and

rack ends respectively where it can be easily

seen.

(2) Using a paper gauge, measure the distance

from the RH and LH tie rod ends to the rack

end screws.

HINT:

• Measure both the RH and LH sides.

• Make a note of the measured values.

SR

C132541

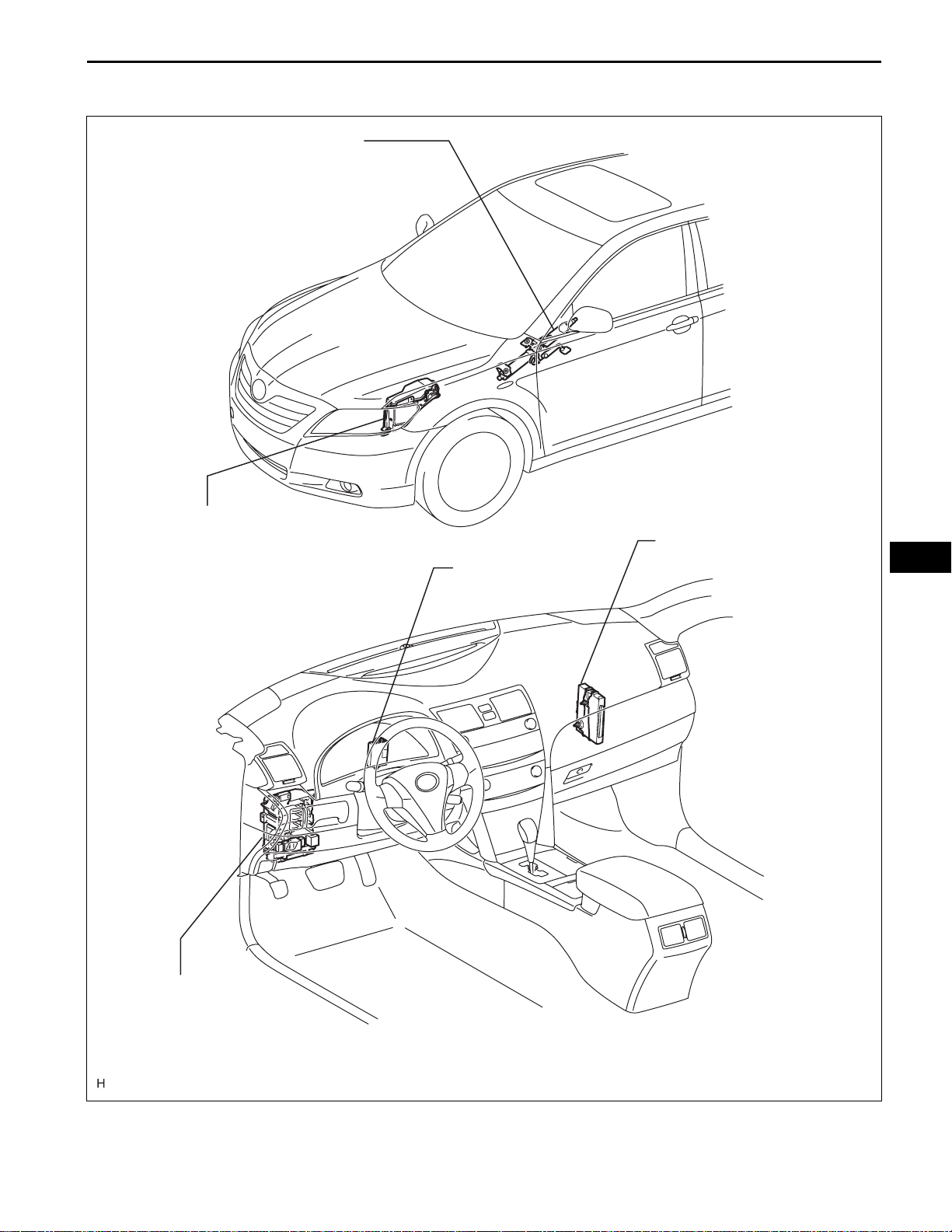

(3) Remove the RH and LH boot clips from the

rack boots.

(4) Loosen the RH and LH lock nuts.

(5) Turn the RH and LH rack ends by the same

amount (but in different directions) according to

the steering angle.

HINT:

One 360 degree turn of the rack end (1.5 mm

(0.059 in.) horizontal movement) equals to 12

degrees of steering angle.

(6) Tighten the RH and LH lock nuts to the

specified torque.

To rque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

NOTICE:

Make sure that the difference in length

between the RH and LH tie rod ends and

rack end screws is within 1.5 mm (0.059 in.).

(7) Install the RH and LH boot clips.

SR

SR–4

STEERING COLUMN – ELECTRIC STEERING LOCK

ELECTRIC STEERING LOCK

PRECAUTION

1. PRECAUTIONS WHEN WORKING ON ELECTRIC

STEERING LOCK

(a) After replacing the steering lock actuator assembly

(steering lock ECU), perform the key ID code

registration.

(b) If the steering lock actuator assembly is replaced,

open and close the driver's door. The engine may

not start until the driver's door is opened or closed.

HINT:

Opening and closing the driver's door causes the

steering lock actuator assembly (steering lock ECU)

to memorize the correct steering lock bar position.

(c) If checking for DTCs of the smart access system

with push-button start function or if checking the

DATA LIST with the engine switch off, make sure

that the driver's door is open.

HINT:

When the engine switch is off, the main body ECU

may be in a sleep mode. If the main body ECU is in

this sleep mode, it will not be possible for the

intelligent tester to communicate with it. Opening

and closing the driver's door will cause the ECU to

exit the sleep mode.

STEERING COLUMN – ELECTRIC STEERING LOCK

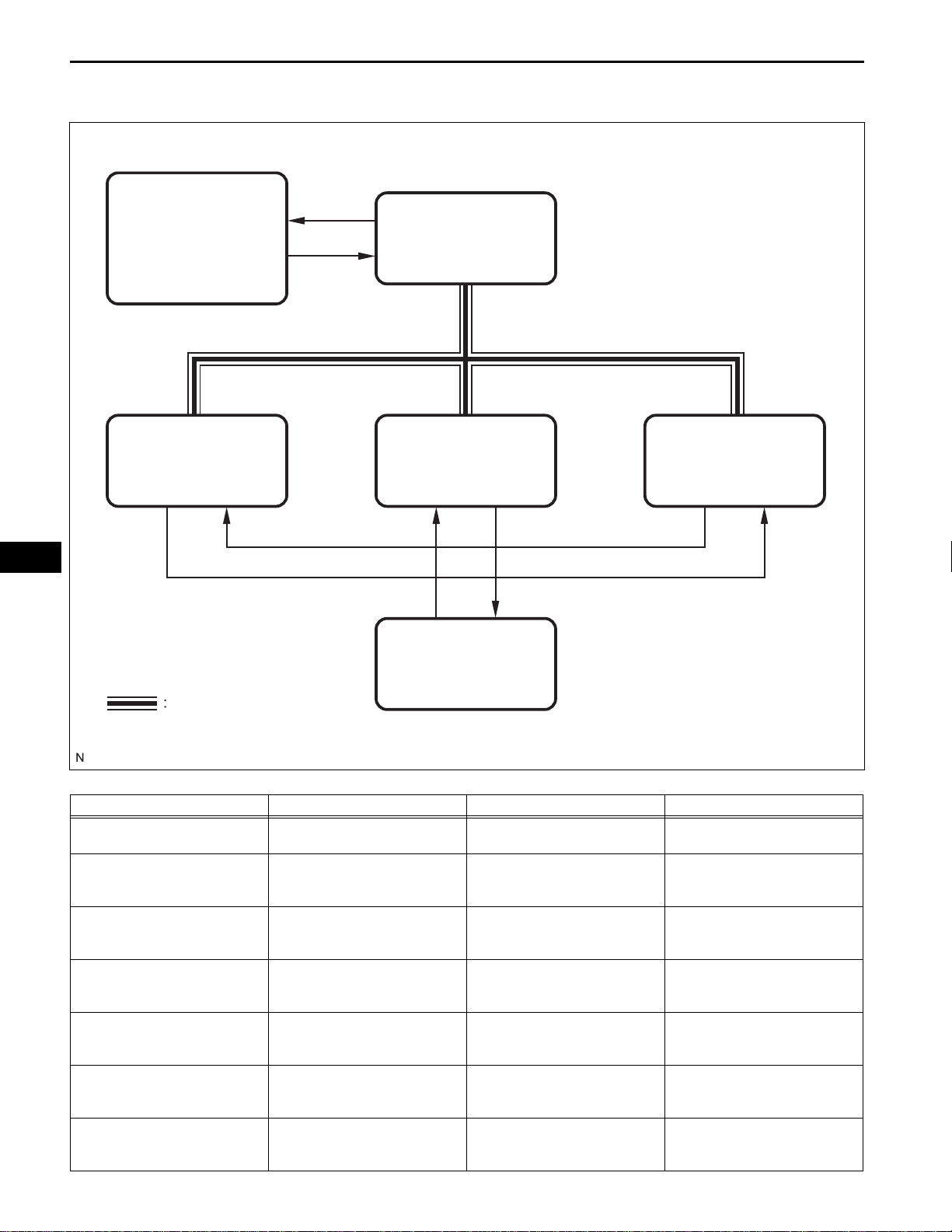

PARTS LOCATION

STEERING COLUMN ASSEMBLY

STEERING LOCK ACTUATOR ASSEMBLY

(STEERING LOCK ECU)

SR–5

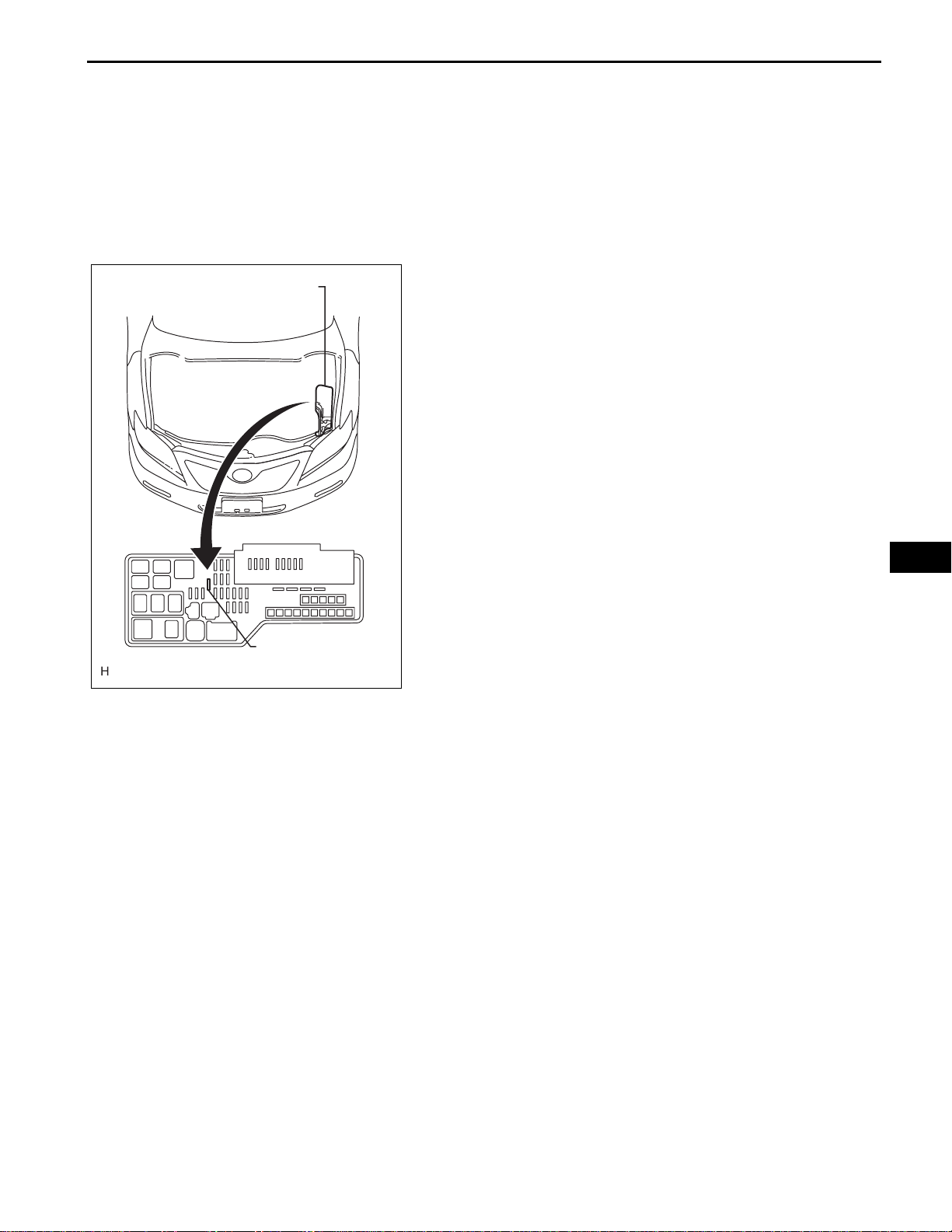

ENGINE ROOM J/B AND R/B

- STR LOCK FUSE

- D.C.C. FUSE

- IG2 FUSE

- AM2 FUSE

- IG2 RELAY

ID CODE BOX

CERTIFICATION ECU

SR

INSTRUMENT PANEL J/B

- MAIN BODY ECU

- IGN FUSE

C113501E01

SR–6

STEERING COLUMN – ELECTRIC STEERING LOCK

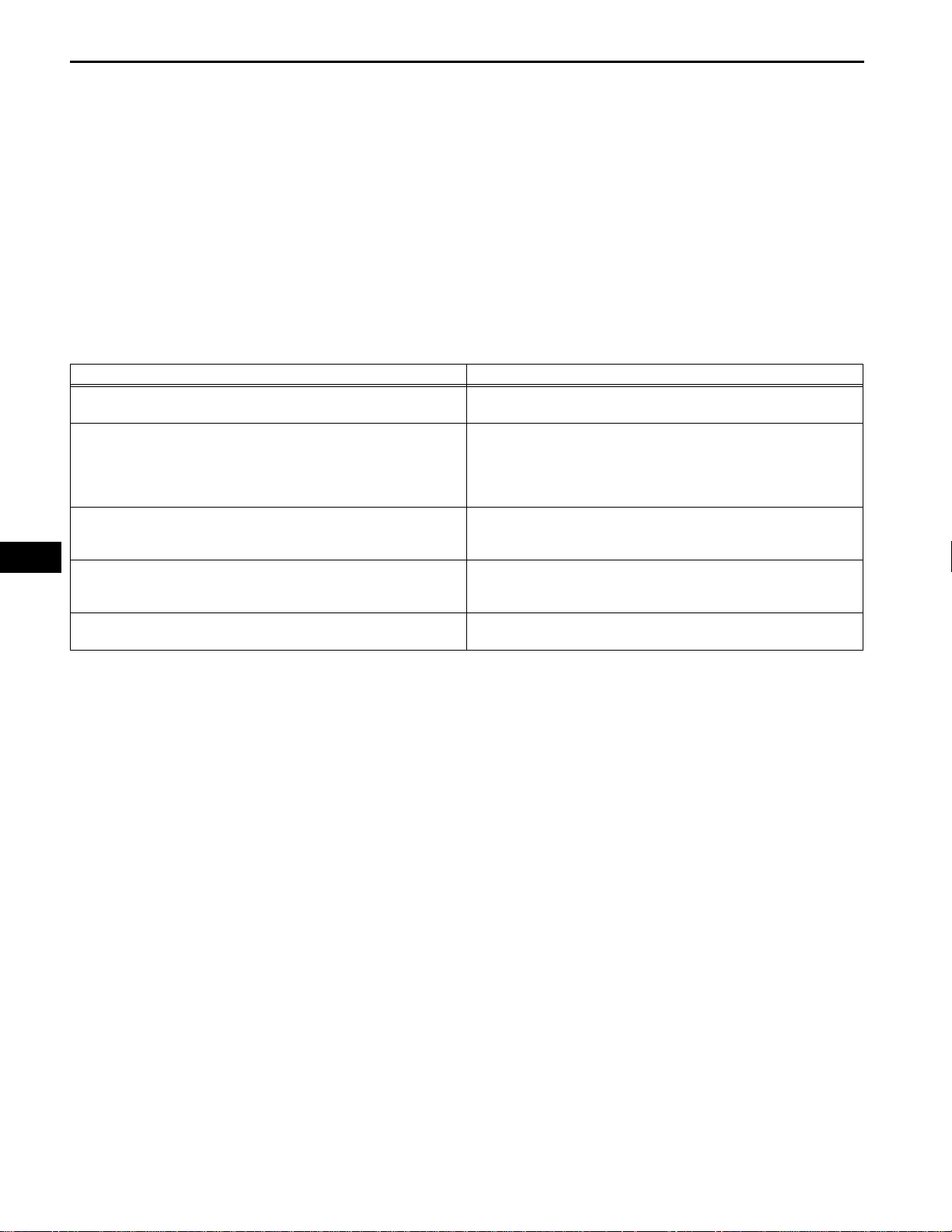

SYSTEM DIAGRAM

Enigine Switch

SR

- Transponder Key

Amplifier (with Key Coil)

Main Body ECU

Certification ECU

ID Code Box

ECM

Steering Lock ECU

LIN Communication Line

Input and output signals of each ECU:

Transmitting ECU (transmitter) Receiving ECU Signals Communication Method

Main Body ECU Steering Lock ECU

• Certification ECU

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

Power supply status (to steering

lock motor)

Sleep available status LIN

Lock / Unlock sensor status LIN

Steering lock status LIN

Motor control status LIN

Diagnostic response status LIN

Lock / Unlock sensor malfunction LIN

LIN

B126245E02

STEERING COLUMN – ELECTRIC STEERING LOCK

Transmitting ECU (transmitter) Receiving ECU Signals Communication Method

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

Steering Lock ECU

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

• Certification ECU

• Main Body ECU

• ID Code Box

Power supply malfunction

(to steering lock motor)

Motor driver malfunction LIN

Lock bar (stuck) status LIN

Push start status LIN

Lock / Unlock relay drive status LIN

Engine start control status LIN

LIN

SR–7

SR

SR

SR–8

STEERING COLUMN – ELECTRIC STEERING LOCK

SYSTEM DESCRIPTION

1. DESCRIPTION

(a) The steering lock system locks or unlocks the

steering lock by activating the steering lock bar with

a motor. The steering lock ECU activates the motor

based on signals from the certification ECU and

main body ECU.

(b) A LIN (Local Interconnect Network) is used for

communication between different ECUs in this

system.

2. FUNCTIONS OF COMPONENTS

(a) The steering lock ECU controls the system based

on information from the following components.

Item Function

Steering lock actuator assembly Consists of a motor, lock bar, lock and unlock position sensors, etc.

Activated by the steering lock ECU.

Steering lock ECU Included in the steering lock actuator assembly. This ECU activates

the steering lock motor based on permission signals from the main

body ECU and certification ECU.

Detects steering lock or unlock state and transmits this status to other

ECUs.

Main body ECU Permits the steering lock ECU to supply power to activate the motor.

The main body ECU and certification ECU permit engine start after

receiving an unlock signal from the steering lock ECU.

Certification ECU Orders the steering lock ECU to lock / unlock the steering. The main

body ECU and certification ECU permit engine start after receiving an

unlock signal from the steering lock ECU.

IG2 relay Controlled by the main body ECU. This ECU sends IG signals to the

steering lock ECU.

1

NEXT

2

NEXT

3

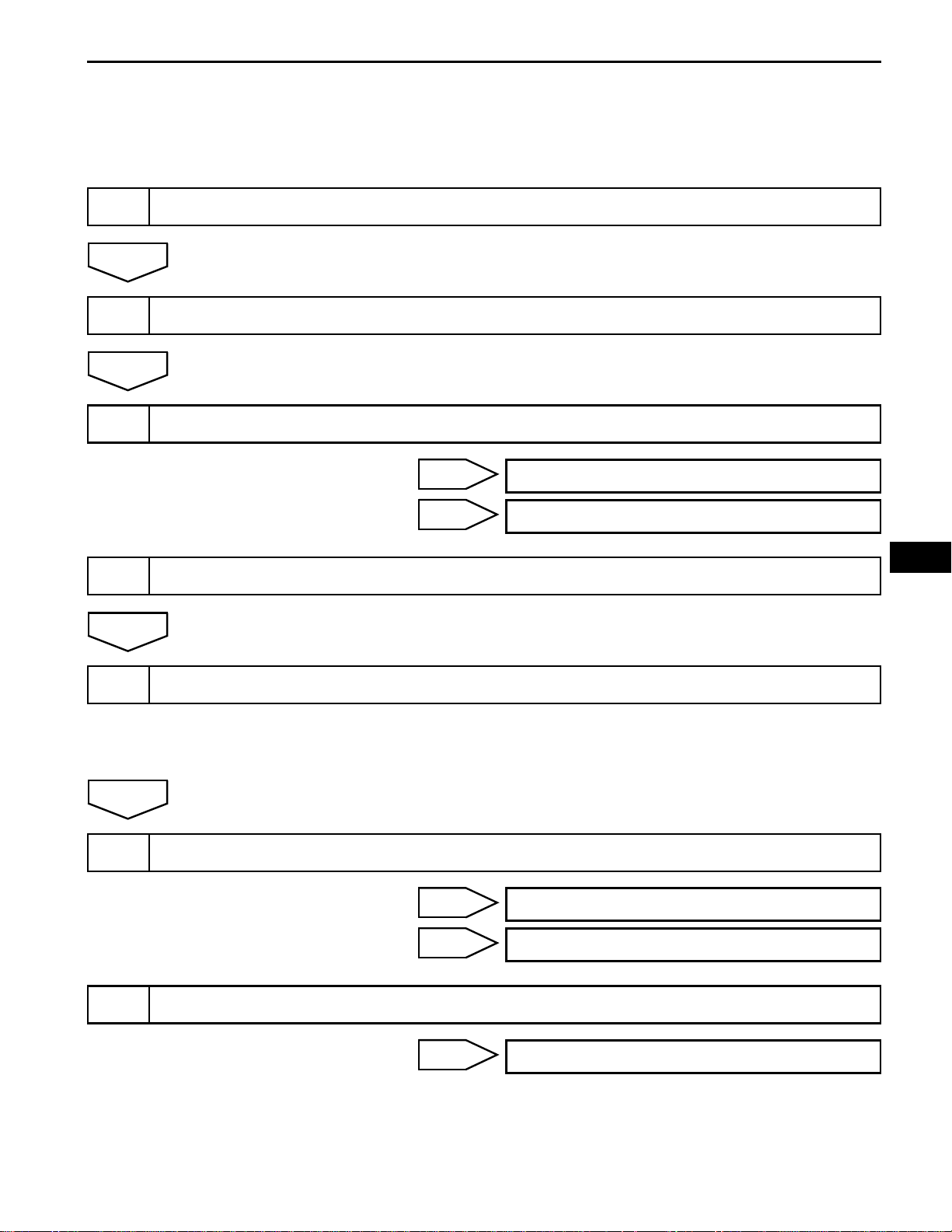

STEERING COLUMN – ELECTRIC STEERING LOCK

HOW TO PROCEED WITH

TROUBLESHOOTING

The intelligent tester can be used at steps 2, 6, 9 and 12.

VEHICLE BROUGHT TO WORKSHOP

CHECK AND CLEAR DTCS

PROBLEM SYMPTOM CONFIRMATION

SR–9

SYMPTOM DOES NOT OCCUR (Go to step 4)

4

NEXT

5

NEXT

6

SYMPTOM SIMULATION

CHECK CAN COMMUNICATION SYSTEM

HINT:

Check that there are no problems in the CAN communication

system before troubleshooting the steering lock system.

DTC CHECK

SYMPTOM OCCURS (Go to step 5)

SR

DTC IS NOT OUTPUT (Go to step 7)

DTC IS OUTPUT (Go to step 8)

PROBLEM SYMPTOMS TABLE

7

Go to step 9

SR–10

8

NEXT

9

NEXT

STEERING COLUMN – ELECTRIC STEERING LOCK

DTC CHART

CIRCUIT INSPECTION

SR

10

NEXT

11

NEXT

12

NEXT

END

PROBLEM IDENTIFICATION

REPAIR OR REPLACEMENT

CONFIRMATION TEST

STEERING COLUMN – ELECTRIC STEERING LOCK

Engine Room J/B

SR–11

INITIALIZATION

HINT:

In vehicles equipped with the smart access system with pushbutton start function, the starting function may not operate

after recharging or while jump-starting a discharged battery.

This condition is most common if the battery voltage drops

below 9 V. The following procedure has been developed to

address this condition.

1. INITIALIZATION PROCEDURE

(a) Confirm that the D.C.C. fuse is installed.

HINT:

If the D.C.C. fuse is not installed, install it at this

time.

(b) Move the shift lever to the P position.

(c) Turn the engine switch off.

(d) Open the driver's door.

HINT:

Opening the driver's door will start an initialization

process between the steering lock ECU and the

engine room J/B.

(e) Depress the brake pedal.

(f) Press the "START STOP" switch.

D.C.C Fuse

SR

C113506E01

SR

SR–12

STEERING COLUMN – ELECTRIC STEERING LOCK

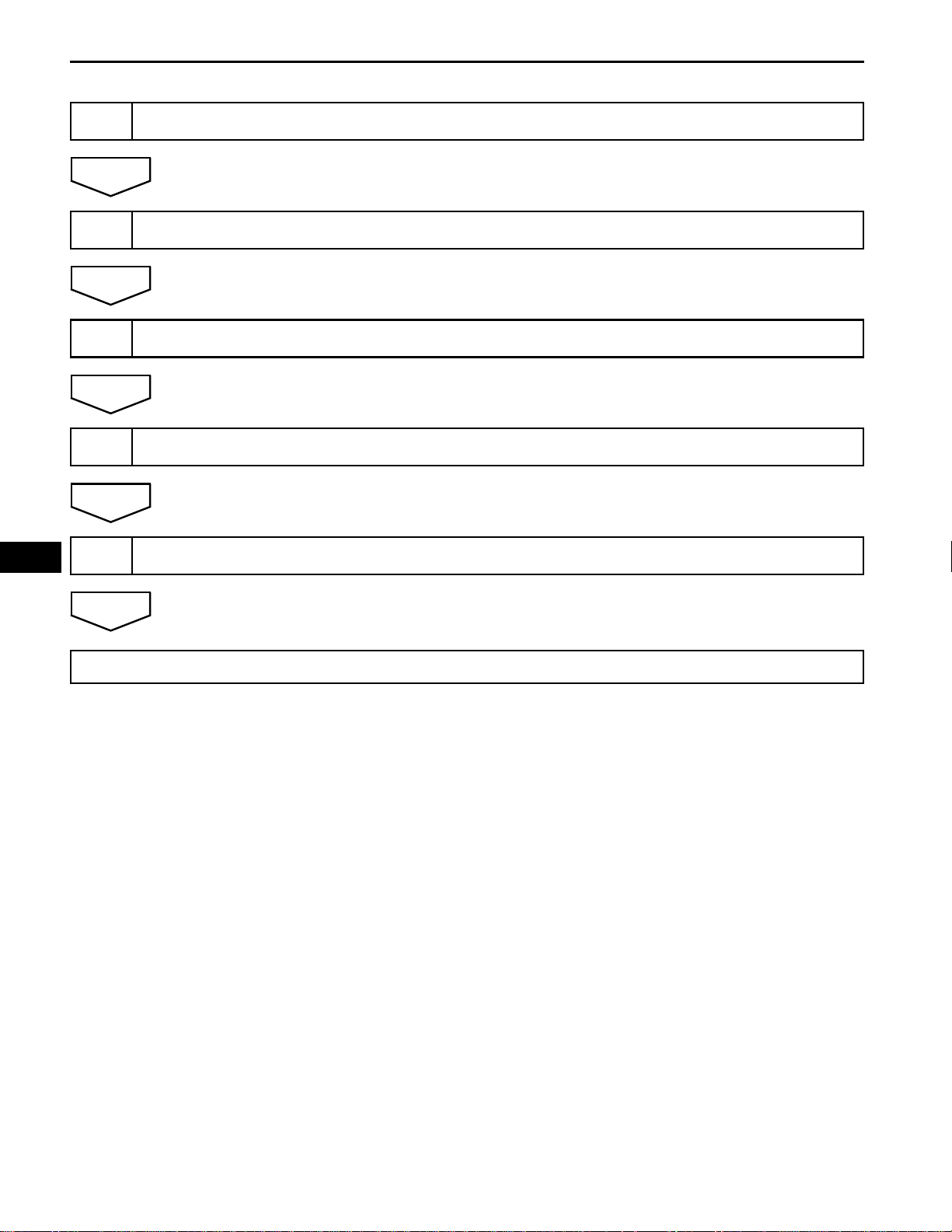

ELECTRIC STEERING LOCK FUNCTION:

Symptom Suspected area See page

Steering wheel cannot be unlocked (the engine cannot

be started).

Steering wheel cannot be unlocked (no steering unlock

command).

Steering wheel cannot be locked.

Steering wheel cannot be locked (no steering lock

command).

PROBLEM SYMPTOMS TABLE

Inspect the suspected areas in numerical order by referring to

the corresponding pages when any of the following

symptoms occurs:

1. Initialization SR-9

2. Check for DTCs in the smart access system with pushbutton start.

3. Check for DTCs in the engine immobiliser system. EI-24

4. Check that the LCK/UNLCK REC item in the DATA LIST of

the certification ECU displays YES within 10 seconds after

starting the engine. (If it displays NO, see "No steering unlock"

command in this table.)

5. Check the input signal from the IGE terminal of the steering

lock ECU.

6. Steering lock ECU power source circuit. SR-30

7. Replace the steering lock ECU. SR-42

1. Check that the S CODE MACH item in the DAT A LIST of the

certification ECU displays OK. (If it displays NG, replace the ID

code box.)

2. Check that the L CODE MACH item in the DATA LIST of the

certification ECU displays OK. (If it displays NG, replace the ID

code box.)

3. Replace the certification ECU. -

1. Check for DTCs in the smart access system with pushbutton start.

2. Check for DTCs in the engine immobiliser system. EI-24

3. With the engine switch off and the shift in the P position,

open and close the driver's door. After that, check that the

LCK/UNLCK REC item in the DATA LIST of the certification

ECU displays YES within 10 seconds. (If it displays NO, see

"No steering lock" command in this table.)

4. Check the input signal from the IGE terminal of the steering

lock ECU.

5. Steering lock ECU power source circuit. SR-30

6. Replace the steering lock ECU. SR-42

1. Courtesy light switch circuit LI-52

2. Check that the S CODE MACH item in the DAT A LIST of the

certification ECU displays OK. (If it displays NG, replace the ID

code box.)

3. Check that the L CODE MACH item in the DATA LIST of the

certification ECU displays OK. (If it displays NG, replace the ID

code box.)

4. Replace the certification ECU. -

ST-26

SR-14

SR-24

-

-

ST-26

SR-14

SR-24

-

-

STEERING COLUMN – ELECTRIC STEERING LOCK

SMART ACCESS SYSTEM WITH PUSH-BUTTON START FUNCTION:

Symptom Suspected area See page

1. Initialization SR-9

2. Check for DTCs in the smart access system with pushbutton start.

3. Check for DTCs in the engine immobiliser system. EI-24

4. Check that the engine switch is turned on (IG). -

5. Check cranking operation. (If cranking operation is possible,

see "Engine does not start due to the engine immobiliser" in

this table.)

Engine does not start.

Engine does not start due to the engine immobiliser.

6. Check SHIFT P SIG in the DATA LIST of the power source

control ECU and confirm that the shift signal is normal.

7. Check whether the steering wheel is locked or unlocked. (If

it is locked, see "Steering wheel cannot be unlocked" in the

steering lock function table.)

8. Check the output from the SLP terminal of the steering lock

ECU.

9. Check the output signal from the ST SW of the certification

ECU (DTC B2275).

10. Replace the main body ECU. -

1. Check that the L CODE MACH item in the DAT A LIST of the

certification ECU displays OK. (If it displays NG, replace the ID

code box.)

2. Check that the ENG START REQ item in the DATA LIST of

the certification ECU displays YES. (If it displays NO, replace

the certification ECU.)

3. Check that the S CODE MACH item in the DAT A LIST of the

certification ECU displays OK. (If it displays NG, replace the ID

code box.)

4. Replace the ID code box. -

ST-26

-

-

-

SR-28

ST-48

-

-

-

SR–13

SR

SR

SR–14

STEERING COLUMN – ELECTRIC STEERING LOCK

TERMINALS OF ECU

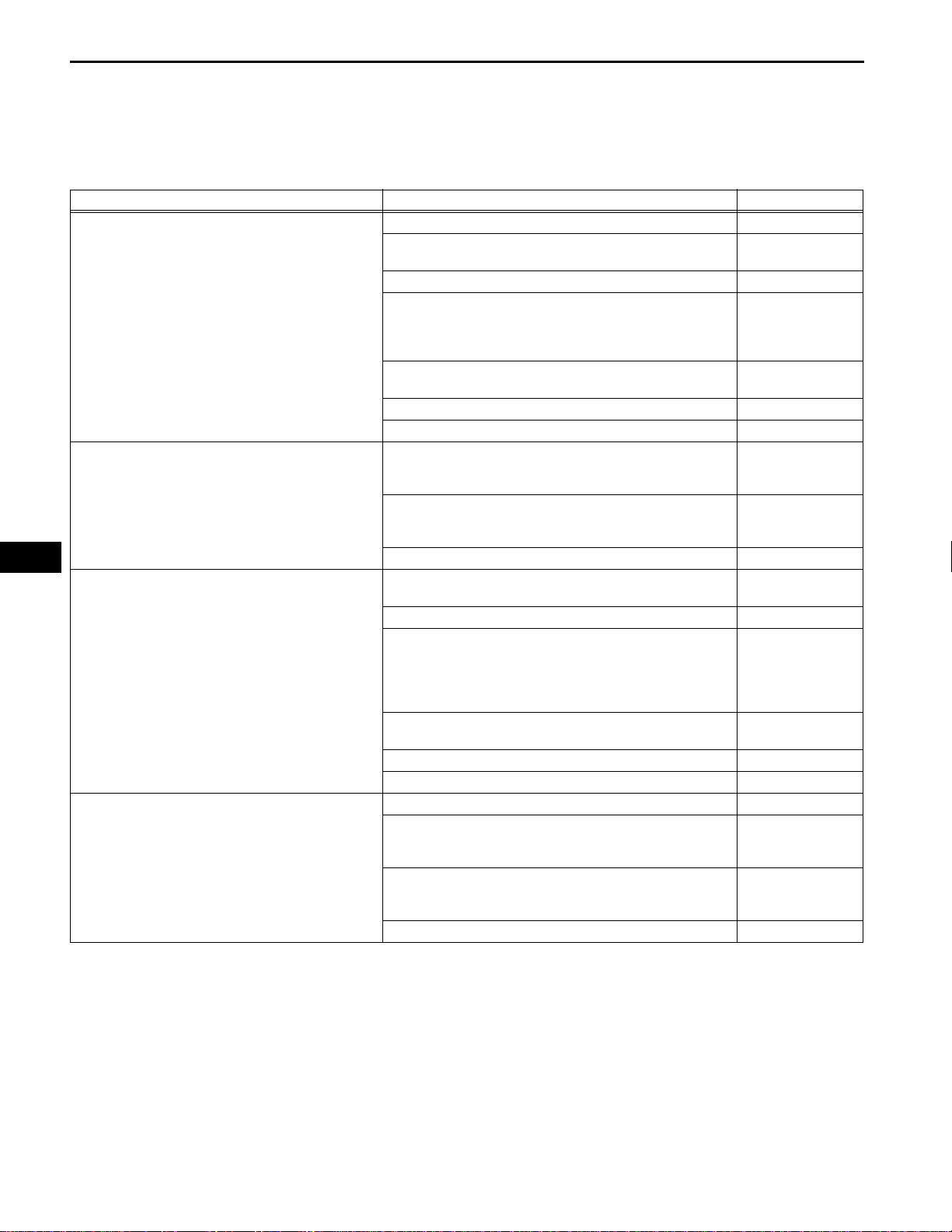

E51

1. STEERING LOCK ACTUATOR ASSEMBLY

(STEERING LOCK ECU)

Terminal No. (Symbols) Wiring Color Terminal Description Condition Specified Condition

E51-1 (GND) - Body

ground

E51-2 (SGND) - Body

ground

E51-3 (IGE) - E51-1

(GND)

E51-4 (SLP1) - E51-2

(SGND)

E51-5 (LIN) - E51-2

(SGND)

E51-6 (IG2) - E51-1

(GND)

E51-7 (B) - E51-1 (GND) P - W-B Power source Always 10 to 14 V

W-B - Body ground Ground Always Below 1 V

W-B - Body ground Signal ground Always Below 1 V

BR - W-B

P - W-B

O - W-B LIN communication bus Engine switch on (IG) Pulse generation

B - W-B IG signal input Engine switch on (IG) 10 to 14 V

Power source for driving

motor

Unlock position sensor

output signal

• Motor is in operation

• Motor is not in

operation

• Steering is locked

• Steering lock is

released

• Below 1 V

• 10 to 12 V

• 10 to 14 V

• Below 1 V

C106482E05

STEERING COLUMN – ELECTRIC STEERING LOCK

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) DIAGNOSTIC SYSTEM

When troubleshooting a vehicle with a diagnostic

system, the only difference from the usual

troubleshooting procedure is connecting the

intelligent tester to the vehicle and reading various

data output from the vehicle's steering lock ECU.

The steering lock ECU records DTCs when the

computer detects a malfunction in the computer

itself or in system circuits.

To check the DTCs, connect the intelligent tester to

the DLC3 on the vehicle. The intelligent tester

enables the DTCs to be cleared, the indicators to be

activated, and the DATA LIST to be checked.

(b) The steering lock ECU diagnosis information cannot

be read directly from the steering lock ECU by the

tester. The diagnosis information from the steering

lock ECU is transmitted to the tester via the

certification ECU to the tester using the controller

area network (CAN).

SR–15

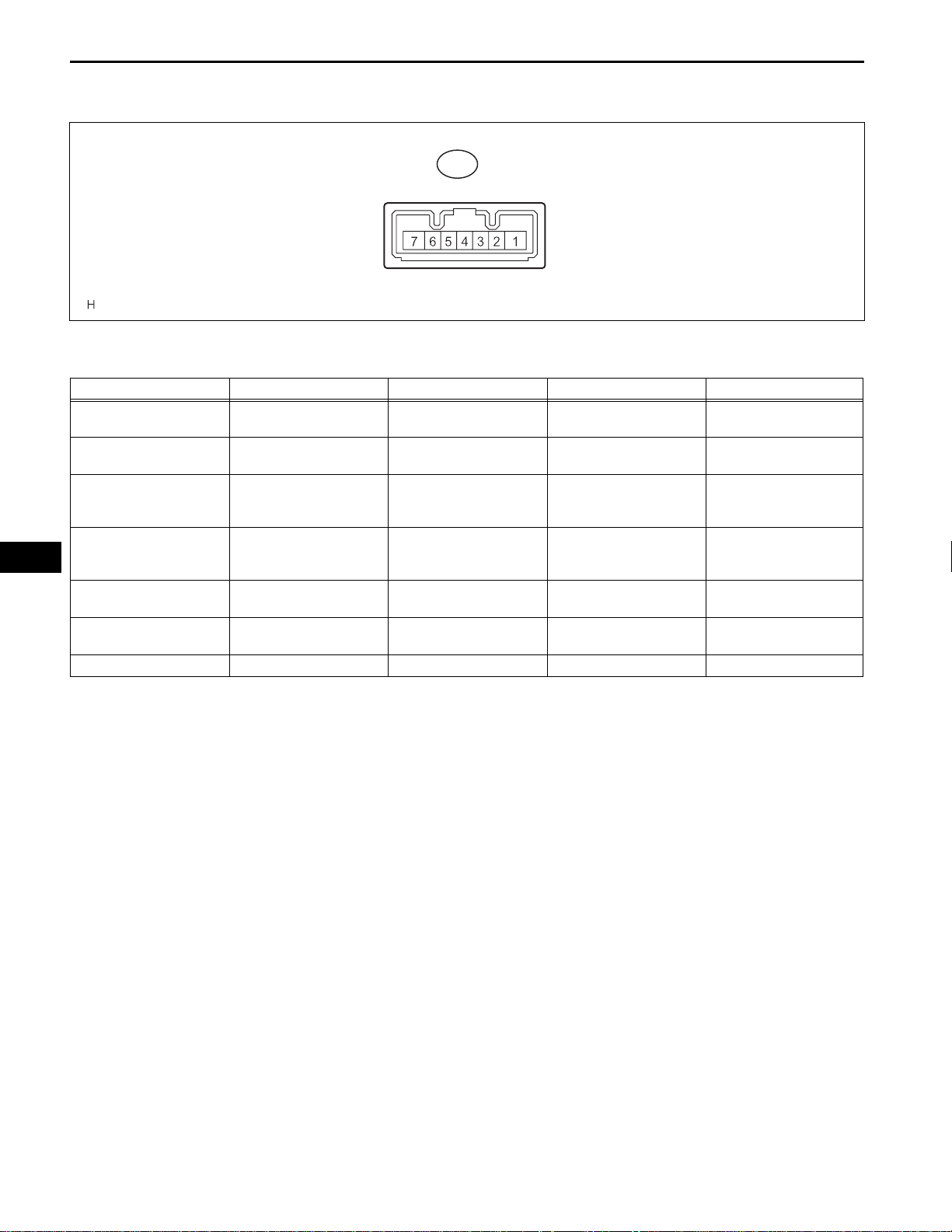

2. CHECK DLC3

(a) The certification ECU uses ISO 15765-4 for

CG

SG

CANH

SIL

communication. The terminal arrangement of the

DLC3 complies with SAE J1962 and matches the

ISO 15765-4 format.

CANL

Symbols (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1 Ω

SG (5) - Body ground Signal ground Always Below 1 Ω

BAT (16) - Body ground Battery positive Always 11 to 14 V

CANH (6) - CANL (14) CAN bus line Engine Switch off* 54 to 69 Ω

CANH (6) - CG (4) HIGH-level CAN bus line Engine Switch off* 200 Ω or higher

CANL (14) - CG (4) LOW-level CAN bus line Engine Switch off* 200 Ω or higher

CANH (6) - BAT (16) HIGH-level CAN bus line Engine Switch off* 6 kΩ or higher

CANL (14) - BAT (16) LOW-level CAN bus line Engine Switch off* 6 kΩ or higher

BAT

H100769E16

SR

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the engine switch, and other switches

or the doors.

If the result is not as specified, the DLC3 may have

a malfunction. Repair or replace the harness and

connector.

SR–16

STEERING COLUMN – ELECTRIC STEERING LOCK

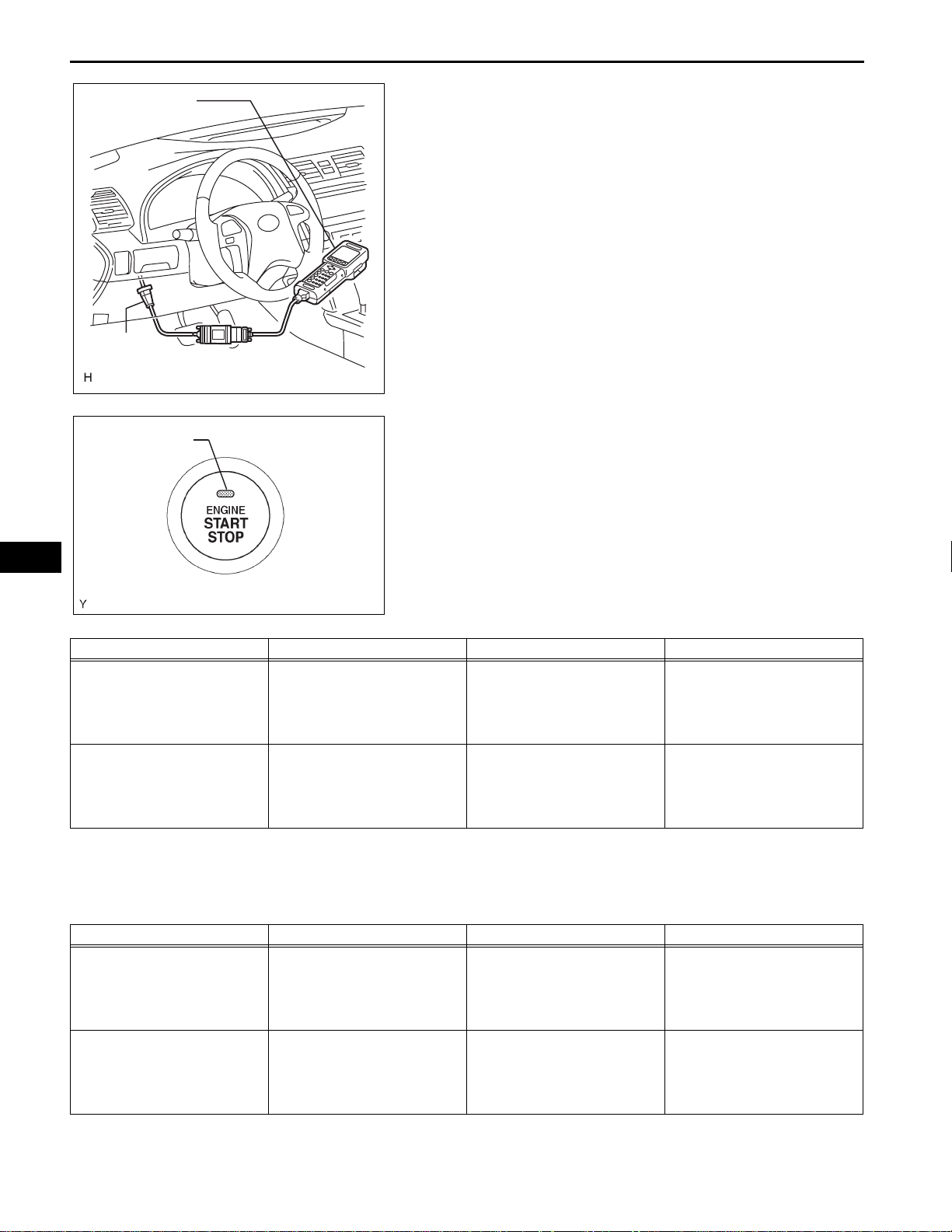

Intelligent Tester

DLC3

Indicator Light

(b) Connect the cable of the intelligent tester to the

DLC3, turn the engine switch on (IG) and attempt to

use the tester. If the display indicates that a

communication error has occurred, there is a

problem either with the vehicle or with the tester.

• If communication is normal when the tester is

connected to another vehicle, inspect the DLC3

of the original vehicle.

• If communication is still not possible when the

tester is connected to another vehicle, the

problem may be in the tester itself. Consult the

Service Department listed in the tester's

instruction manual.

CAN VIM

C131977E05

3. WARNING FUNCTION OF ENGINE SWITCH

INDICATOR

(a) The steering lock ECU blinks the LED indicator of

the engine switch when any of the following

problems occurs in the system:

SR

Detection Item Indicator Light Blink Pattern Indication Status Countermeasure

Steering lock is still not released

Malfunction in smart access

system with push-button start

Detection Item Display Indication Status Countermeasure

Steering lock is still not released

Malfunction in push start system

B083100E01

• Blinks green at 1-second

intervals

• Goes off 15 seconds after

blinking starts

• Blinks amber at 2-second

intervals

• Goes off 15 seconds after the

engine switch is turned off

while blinking

4. WARNING FUNCTION OF COMBINATION METER

(a) The steering lock ECU displays a warning on the

"S/T is not Unlocked"

• Goes off 15 seconds after

blinking starts

"Check S/T Lock"

• Goes off 15 seconds after the

engine switch is turned off

while blinking

The motor operates to release the

steering lock, but the steering

lock cannot be released (e.g. the

lock bar is stuck in the steering

column).

• There is a short in the

devices activating the motor.

• There is a problem in the

steering lock ECU or power

source control ECU.

Push the engine switch while

turning the steering wheel left or

right.

Troubleshoot by following "HOW

TO PROCEED WITH

TROUBLESHOOTING" (See

page SR-7).

combination meter when any of the following

problems occurs in the system.

The motor operates to release the

steering lock, but the steering

lock cannot be released (e.g. the

lock bar is stuck in the steering

column).

• There is a short in the

devices activating the motor.

• There is a problem in the

steering lock ECU or power

source control ECU.

Push the engine switch while

turning the steering wheel left or

right.

Troubleshoot by following "HOW

TO PROCEED WITH

TROUBLESHOOTING" (See

page SR-7).

Loading...

Loading...