Toyota Camry 2007-2009 Service Manual - Engine_Hood_Door

ENGINE HOOD / DOOR – HOOD

ED–1

HOOD

ON-VEHICLE INSPECTION

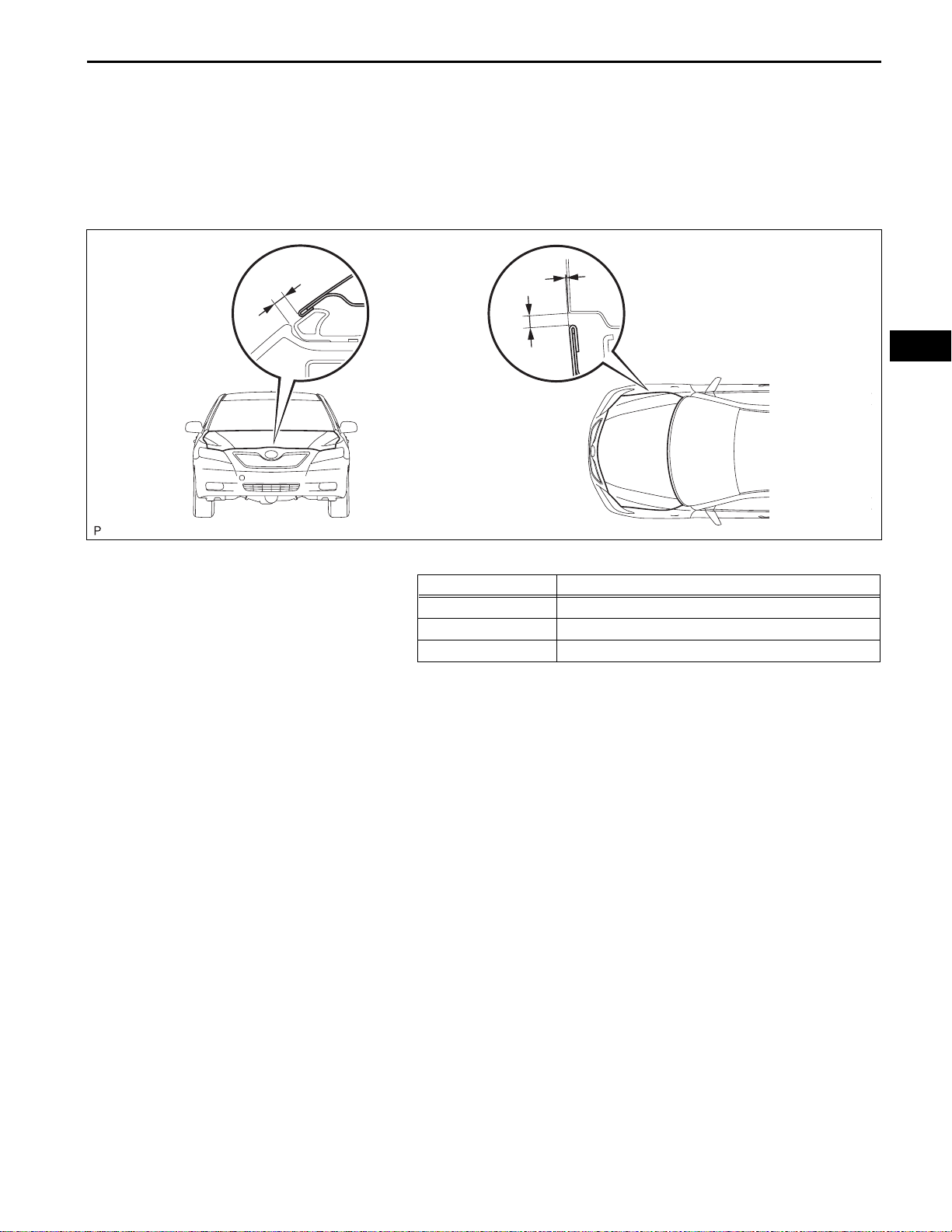

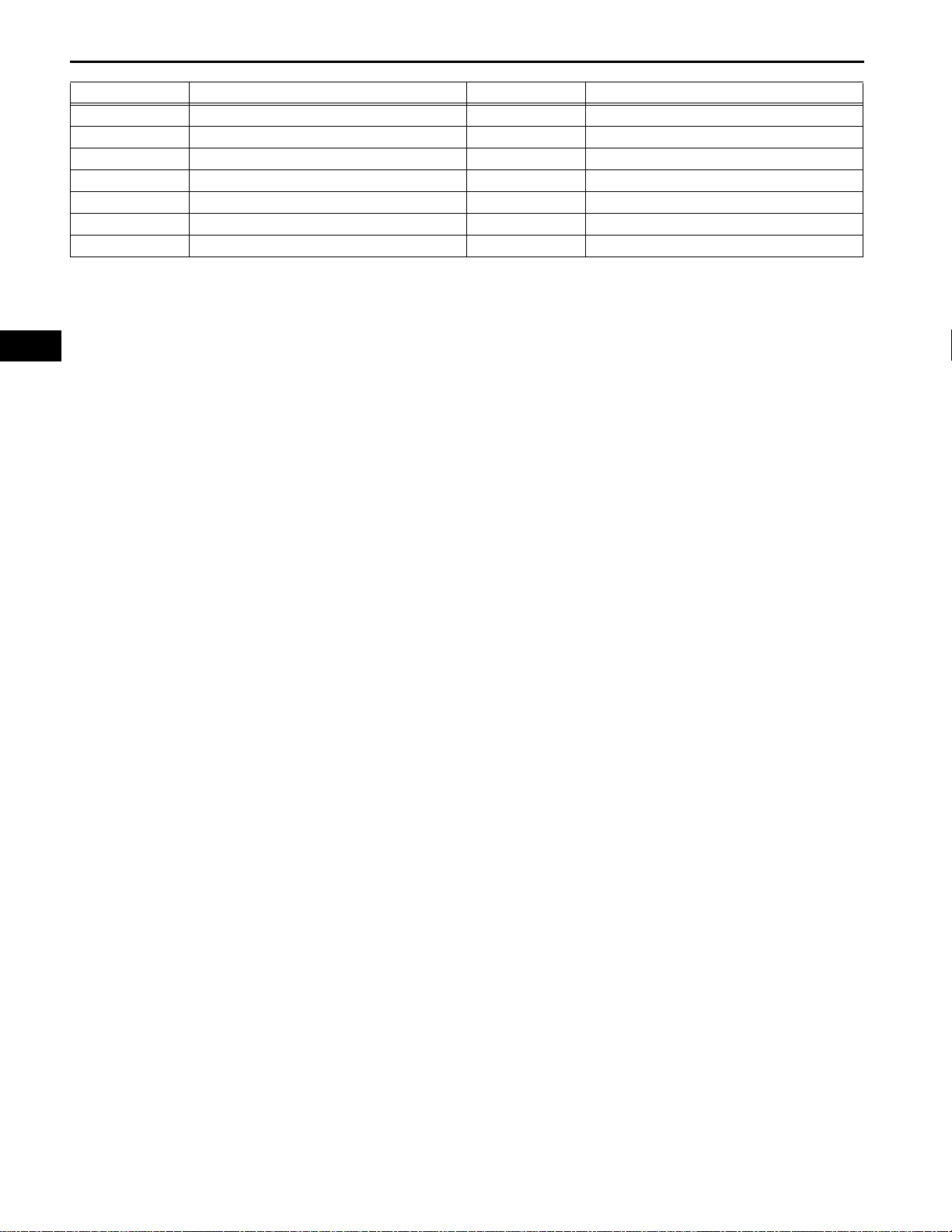

1. INSPECT HOOD SUB-ASSEMBLY

(a) Check that the clearance measurements of areas A

to C are within each standard range.

C

A

B

ED

Standard clearance

Area Measurement

A 2.3 to 5.3 mm (0.091 to 0.209 in.)

B 2.0 to 5.0 mm (0.079 to 0.197 in.)

C -1.4 to 1.6 mm (-0.055 to 0.063 in.)

B132821E01

ED–2

ENGINE HOOD / DOOR – HOOD

ADJUSTMENT

TMMK made:TMC made:

ED

Centering Bolt

Standard Bolt

Centering Bolt

Standard Bolt

B146065E01

HINT:

• Centering bolts are used to mount the hood hinge and

hood lock. The hood and hood lock cannot be adjusted

with the centering bolts on. Substitute the centering bolts

with standard bolts (with washers) when making

adjustments.

• A bolt without a torque specification is shown in the

standard bolt chart (See page SS-2).

1. REMOVE COOL AIR INTAKE DUCT SEAL (for 2GR-

FE) (See page ET-4)

2. REMOVE FRONT BUMPER ASSEMBLY (w/o Fog

Light) (See page ET-5)

3. REMOVE FRONT BUMPER ASSEMBLY (w/ Fog

Light) (See page ET-6)

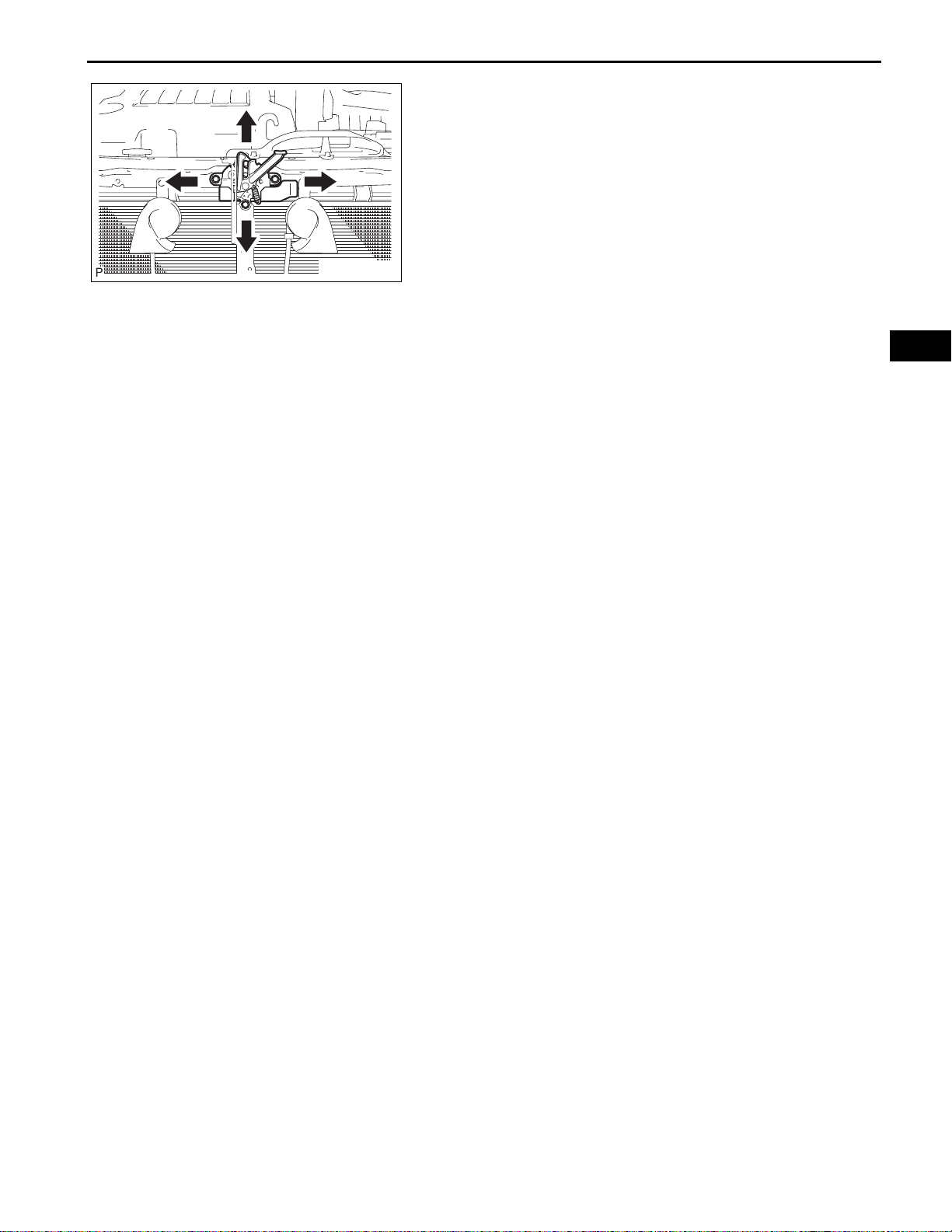

4. ADJUST HOOD SUB-ASSEMBLY

(a) Horizontally and vertically adjust the hood.

(1) Loosen the hood's 4 hinge bolts.

(2) Move the hood and adjust the clearance

between the hood and front fender.

(3) Tighten the hood's 4 hinge bolts after the

adjustment.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

B132829

B132830

(b) Adjust the height of the hood front end using the

cushion rubber.

(1) Adjust the cushion rubber so that the height of

the hood and fender are aligned.

HINT:

Raise or lower the hood's front end by turning

the cushion rubber.

ENGINE HOOD / DOOR – HOOD

(c) Adjust the hood lock.

(1) Loosen the 3 bolts.

(2) Tighten the bolts after the adjustment.

Torque: 7.5 N*m (77 kgf*cm, 66 in.*lbf)

(3) Adjust the hood lock position so that the striker

can enter it smoothly.

5. INSTALL FRONT BUMPER ASSEMBLY (w/o Fog

Light) (See page ET-13)

ED–3

B132832

6. INST ALL FRONT BUMPER ASSEMBLY (w/ Fog Light)

(See page ET-14)

7. INSTALL COOL AIR INTAKE DUCT SEAL (for 2GRFE) (See page ET-14)

ED

8. VEHICLE PREPARATION FOR FOG LIGHT AIM (w/

Fog Light) (See page LI-79)

9. PREPARATION FOR FOG LIGHT AIMING (w/ Fog

Light) (See page LI-80)

10. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-81)

11. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-82)

ENGINE HOOD / DOOR – HOOD SUPPORT ROD

BODYENGINE HOOD / DOOR

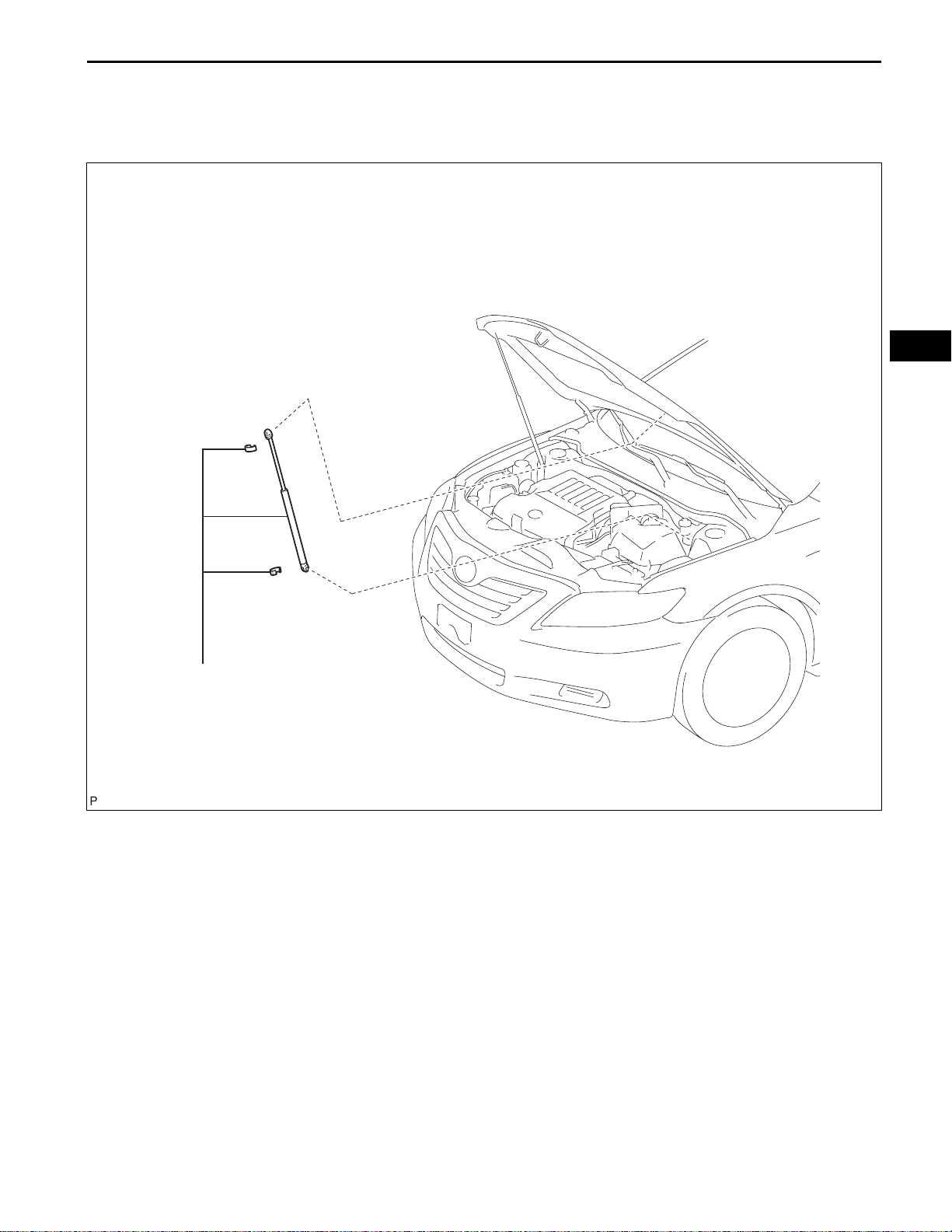

HOOD SUPPORT ROD

COMPONENTS

ED–3

ED

HOOD SUPPORT ASSEMBLY

B136842E01

ED

ED–4

ENGINE HOOD / DOOR – HOOD SUPPORT ROD

REMOVAL

NOTICE:

• Avoid touching the stroke portions of the rod as much

as possible to prevent foreign matter from att aching to

it. Be sure to hold the cylinders while servicing.

• Do not wear cotton gloves or other similar materials

when handling the rod. Fibers may attach to the rod

and result in gas leaks.

• Do not apply any load to the cylinders in the horizont al

direction in order to prevent the rod from being

deformed.

1. REMOVE HOOD SUPPORT ASSEMBLY

(a) Using a screwdriver, remove the hood support

assembly while releasing the 2 clips.

NOTICE:

Remove the hood support assembly while

supporting the hood with hand.

B132831

ENGINE HOOD / DOOR – HOOD SUPPORT ROD

INSTALLATION

NOTICE:

• Avoid touching the stroke portions of the rod as muc h

as possible to prevent foreign matter from attac hing to

it. Be sure to hold the cylinders while servicing.

• Do not wear cotton gloves or other similar materials

when handling the rod. Fibers may attach to the rod

and result in gas leaks.

• Do not apply any load to the cylinders in the horizontal

direction in order to prevent the rod from being

deformed.

1. INSTALL HOOD SUPPORT ASSEMBLY

(a) Install the hood support assembly.

NOTICE:

• Install the hood support assembly while

supporting the hood with hand.

• Check that the hood support assembly is

engaged in the ball joint and it cannot be

pulled out.

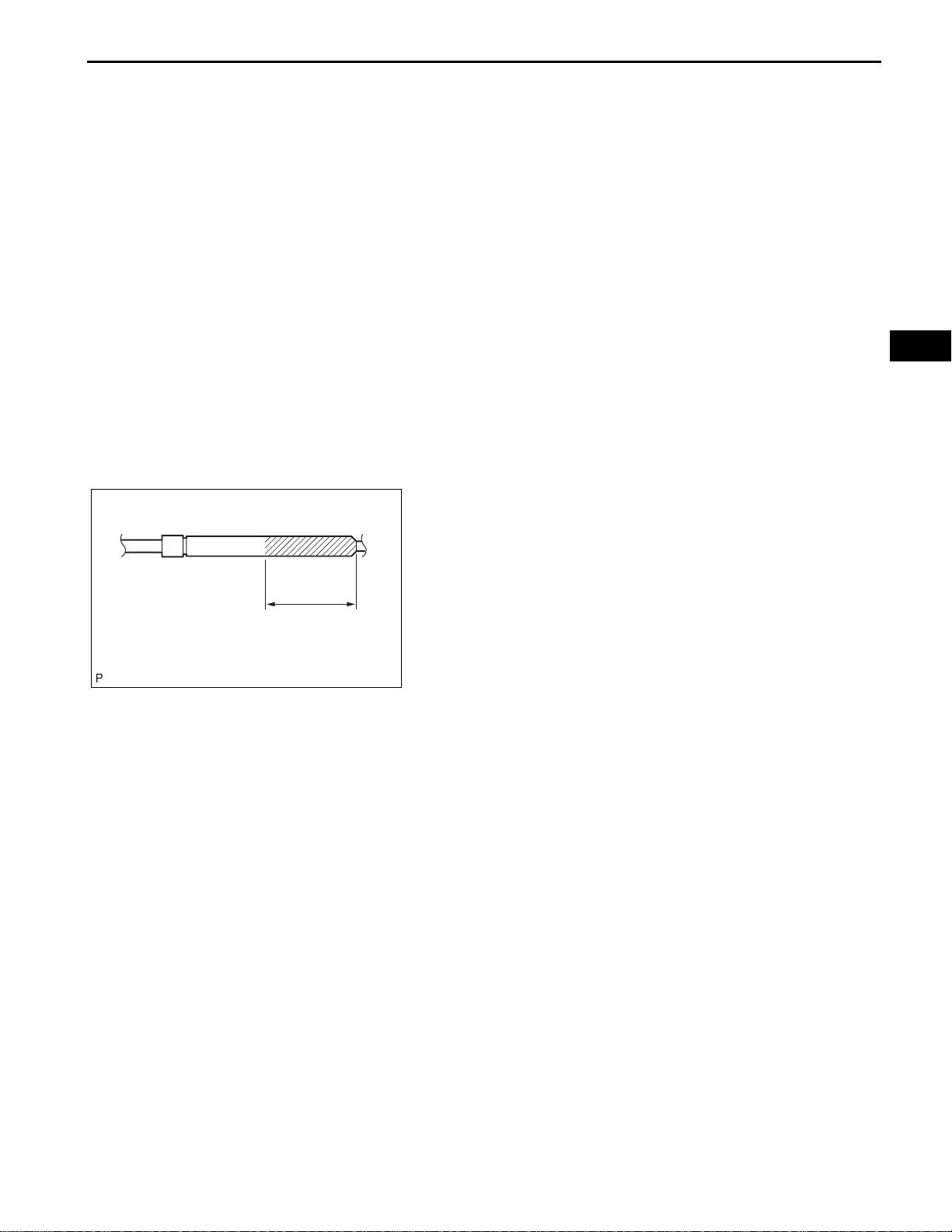

DISPOSAL

ED–5

ED

80 mm

A

(3.150 in.)

B

B127037E01

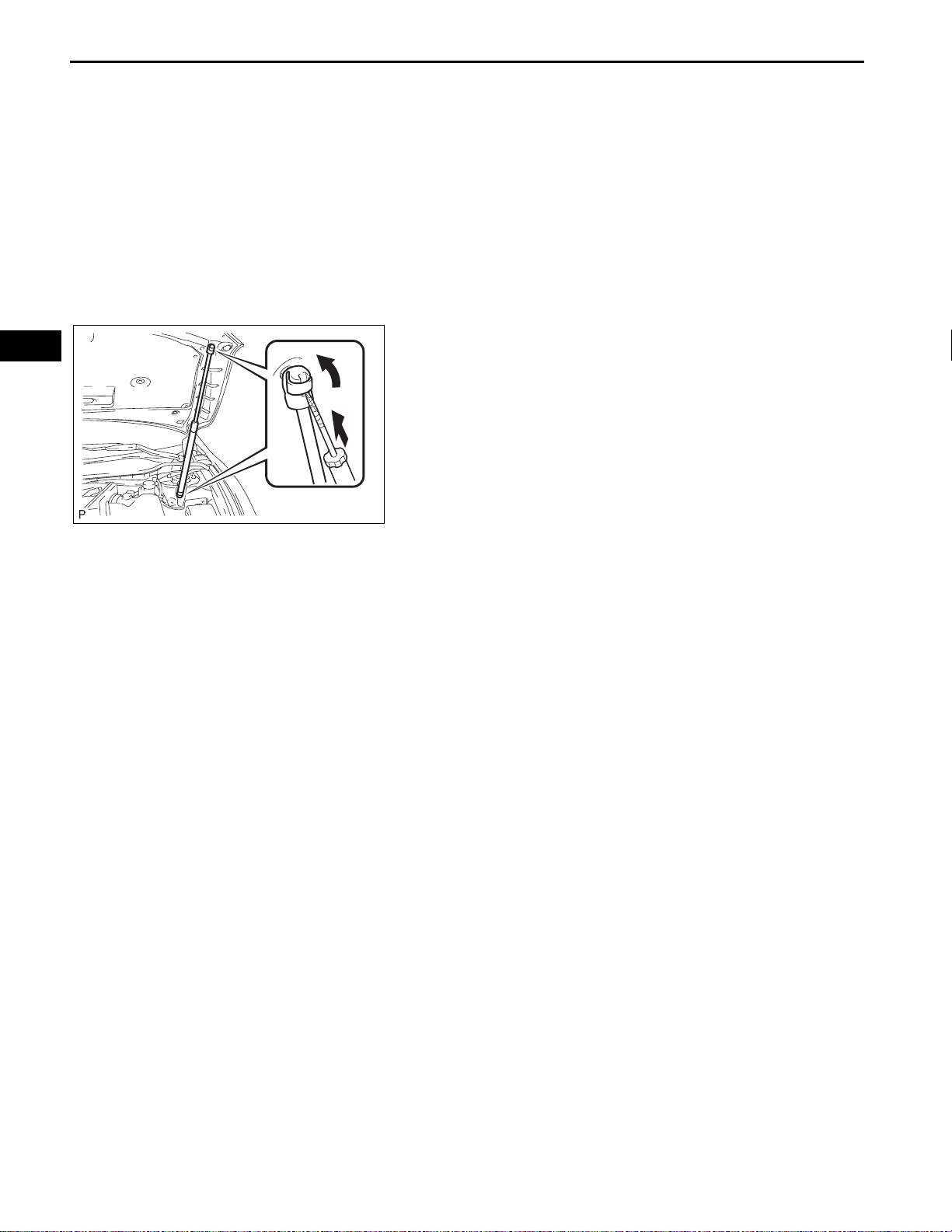

1. DISPOSE OF HOOD SUPPORT ASSEMBLY

(a) Horizontally fix the hood support in a vise with the

piston-rod pulled out.

(b) Wear safety glasses. Gradually cut a part between

A and B shown in the illustration using a metal saw

and gradually release the gas.

NOTICE:

Although the gas inside the hood support is

colorless, odorless and harmless, there is a

possibility that metal debris could scatter.

Therefore, cover it with a piece of cloth or other

material.

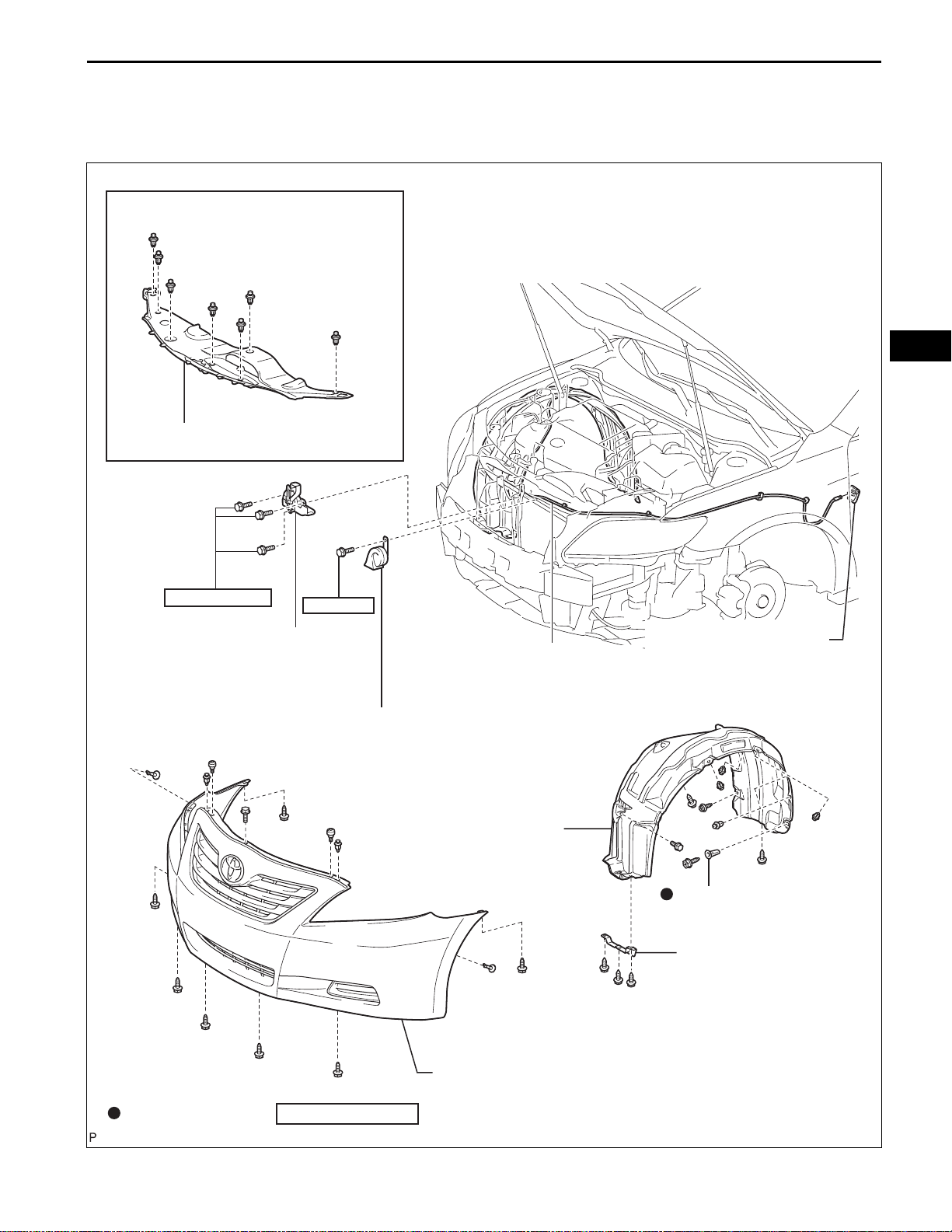

ENGINE HOOD / DOOR – HOOD LOCK CONTROL CABLE ASSEMBLY

BODYENGINE HOOD / DOOR

HOOD LOCK CONTROL CABLE ASSEMBLY

COMPONENTS

for 2GR-FE:

COOL AIR INTAKE DUCT SEAL

ED–5

ED

7.5 (77, 66 in.*lbf)

HOOD LOCK

ASSEMBLY

20 (204, 15)

HIGH PITCHED

HORN ASSEMBLY

FRONT FENDER LINER

HOOD LOCK CONTROL

CABLE ASSEMBLY

HOOD LOCK CONTROL

LEVER SUB-ASSEMBLY

GROMMET

FRONT WHEEL OPENING

EXTENSION PAD

Non-reusable part

N*m (kgf*cm, ft.*lbf)

FRONT BUMPER ASSEMBLY

: Specified torque

B136867E01

ED

ED–6

ENGINE HOOD / DOOR – HOOD LOCK CONTROL CABLE ASSEMBLY

REMOVAL

1. REMOVE FRONT WHEEL

2. REMOVE FRONT WHEEL OPENING EXTENSION

PAD

(a) Remove the 3 screws and the front wheel opening

extension pad.

3. REMOVE COOL AIR INTAKE DUCT SEAL (for 2GRFE) (See page ET-4)

4. REMOVE FRONT BUMPER ASSEMBLY (w/o Fog

Light) (See page ET-5)

B138883

5. REMOVE FRONT BUMPER ASSEMBLY (w/ Fog

Light) (See page ET-6)

6. REMOVE FRONT FENDER LINER

(a) Remove the 5 clips and bolt.

(b) Remove the 4 screws, grommet and the front fender

liner.

7. REMOVE HIGH PITCHED HORN ASSEMBLY (See

page HO-7)

B136871

B136821

B136827

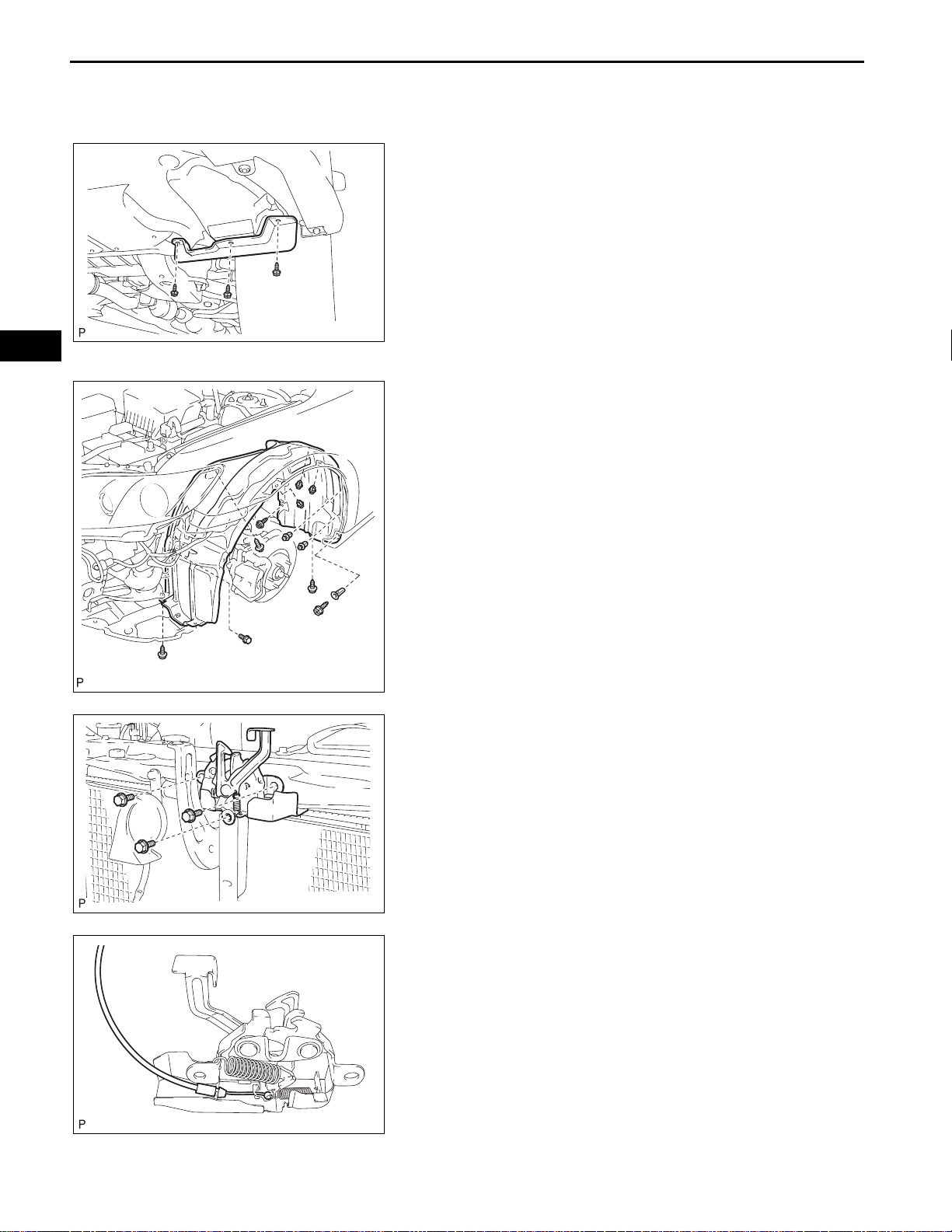

8. REMOVE HOOD LOCK ASSEMBL Y (w/o Engine Hood

Courtesy Switch)

(a) Remove the 3 bolts.

(b) Disconnect the hood lock control cable.

(c) Remove the hood lock assembly.

ENGINE HOOD / DOOR – HOOD LOCK CONTROL CABLE ASSEMBLY

9. REMOVE HOOD LOCK ASSEMBLY (w/ Engine Hood

Courtesy Switch)

(a) Disconnect the connector.

(b) Remove the 3 bolts.

B136822

(c) Disconnect the hood lock control cable.

(d) Remove the hood lock assembly.

B136827

ED–7

ED

10. REMOVE HOOD LOCK CONTROL LEVER SUBASSEMBLY

(a) Disconnect the hood lock control cable and remove

the hood lock control lever.

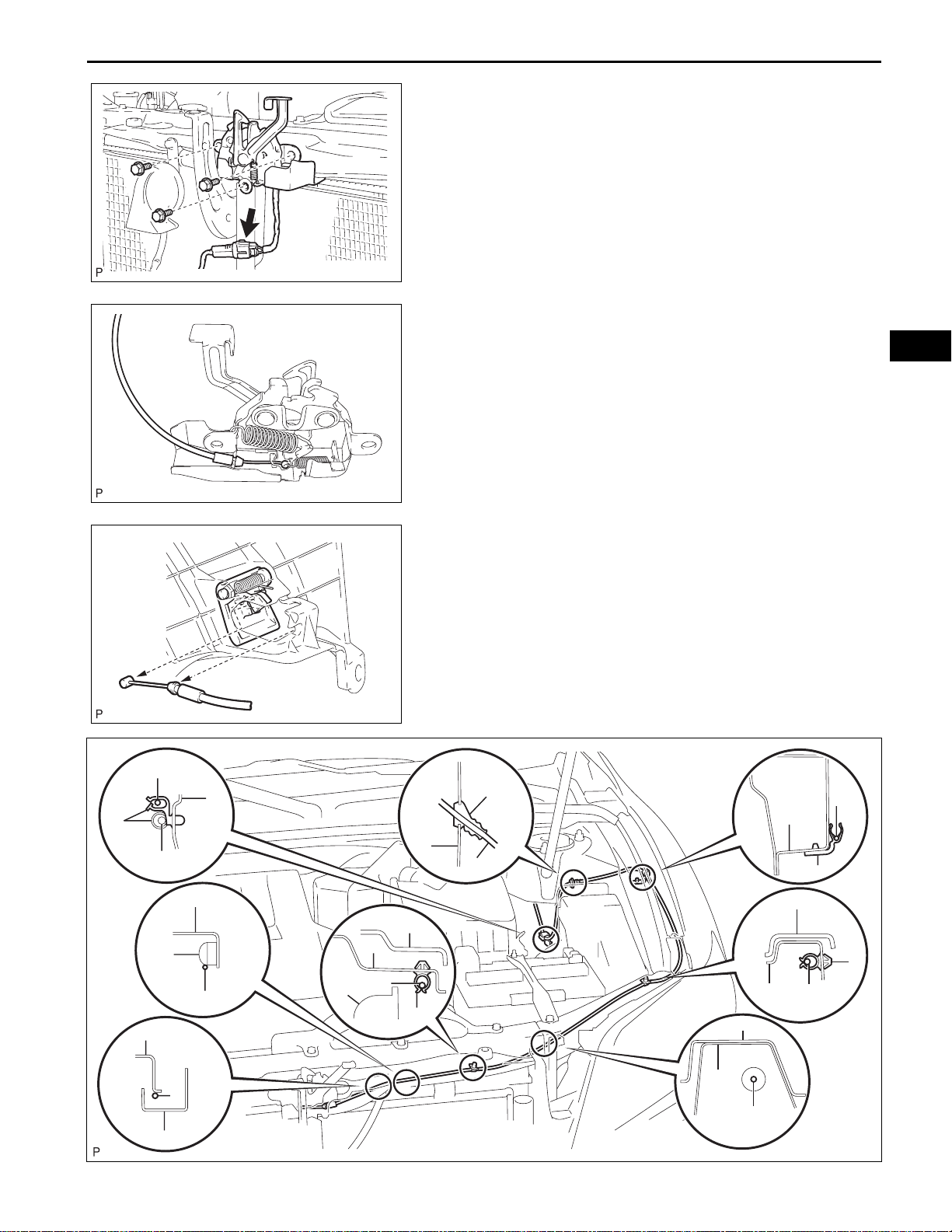

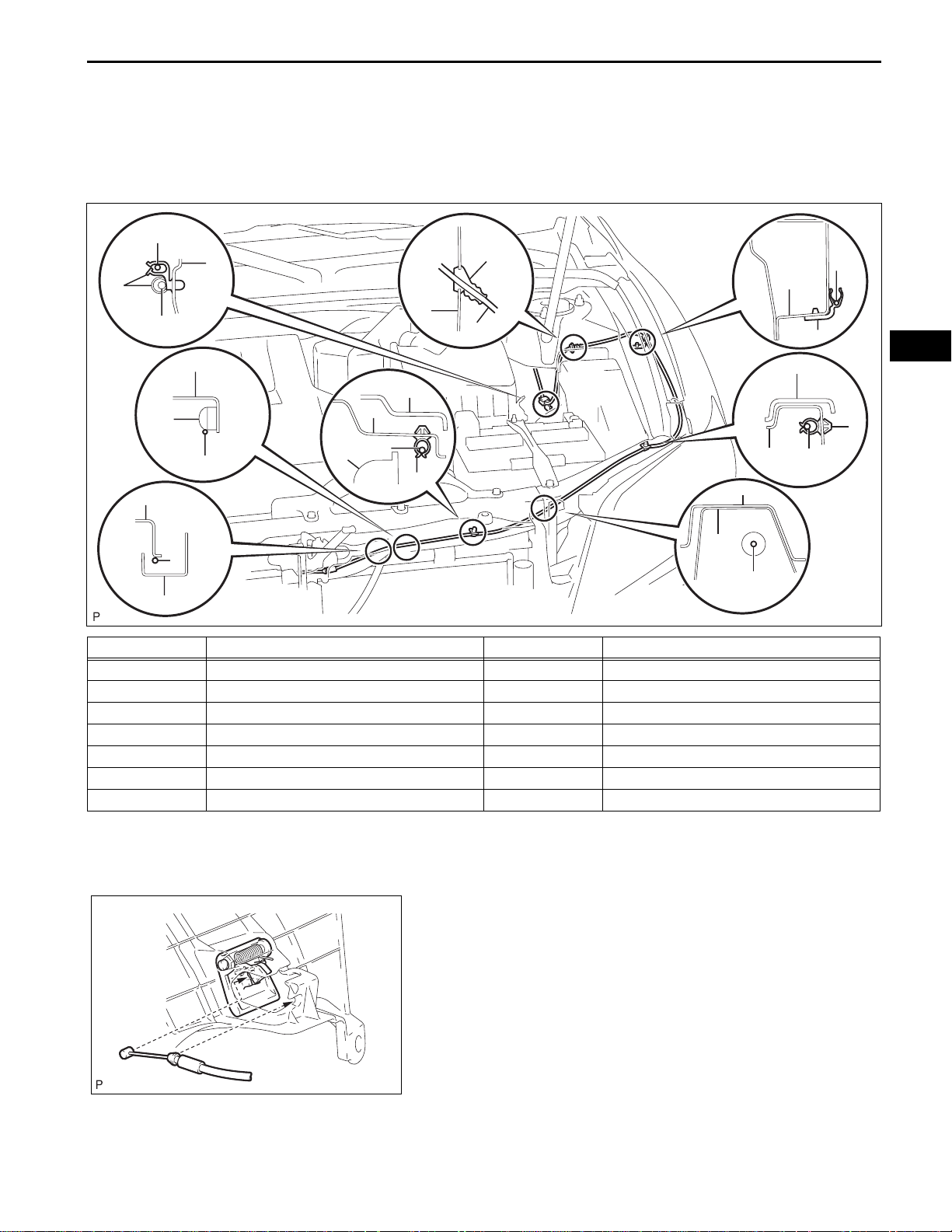

11. REMOVE HOOD LOCK CONTROL CABLE

ASSEMBLY

(a) Using a screwdriver, disconnect the clamps shown

in the illustration.

B136909

A

D

B

C

F

E

A

F

F

J

I

K

A

B

H

L

A

F

F

A

B

K

B

A

M

A

A

G

B136828E01

ED

ED–8

Area Part Name Area Part Name

A Hood lock control cable H Grommet

B Clamp I Side member outer

C Wire harness J Radiator

D Pillar K Radiator support cover

E Nut L Front fender apron

F Radiator support upper M Brace

G Hood lock protector - -

ENGINE HOOD / DOOR – HOOD LOCK CONTROL CABLE ASSEMBLY

HINT:

Tape the screwdriver tip before use.

(b) Pull the cable from the engine compartment and

remove it.

ENGINE HOOD / DOOR – HOOD LOCK CONTROL CABLE ASSEMBLY

ED–9

INSTALLATION

1. INSTALL HOOD LOCK CONTROL CABLE

ASSEMBLY

(a) Pass the hood lock control cable assembly into the

engine compartment.

A

D

B

C

I

H

L

A

A

B

ED

F

K

E

A

F

F

A

J

B

F

K

B

F

A

M

A

A

G

Area Part Name Area Part Name

A Hood lock control cable H Grommet

B Clamp I Side member outer

C Wire harness J Radiator

D Pillar K Radiator support cover

E Nut L Front fender apron

F Radiator support upper M Brace

G Hood lock protector - -

(b) Pass the cable front side through the upper radiator

support.

(c) Connect the clamps as shown in the illustration.

2. INSTALL HOOD LOCK CONTROL LEVER SUBASSEMBLY

(a) Install the hood lock control lever and connect the

hood lock control cable.

B136828E01

B136826

ED

ED–10

ENGINE HOOD / DOOR – HOOD LOCK CONTROL CABLE ASSEMBLY

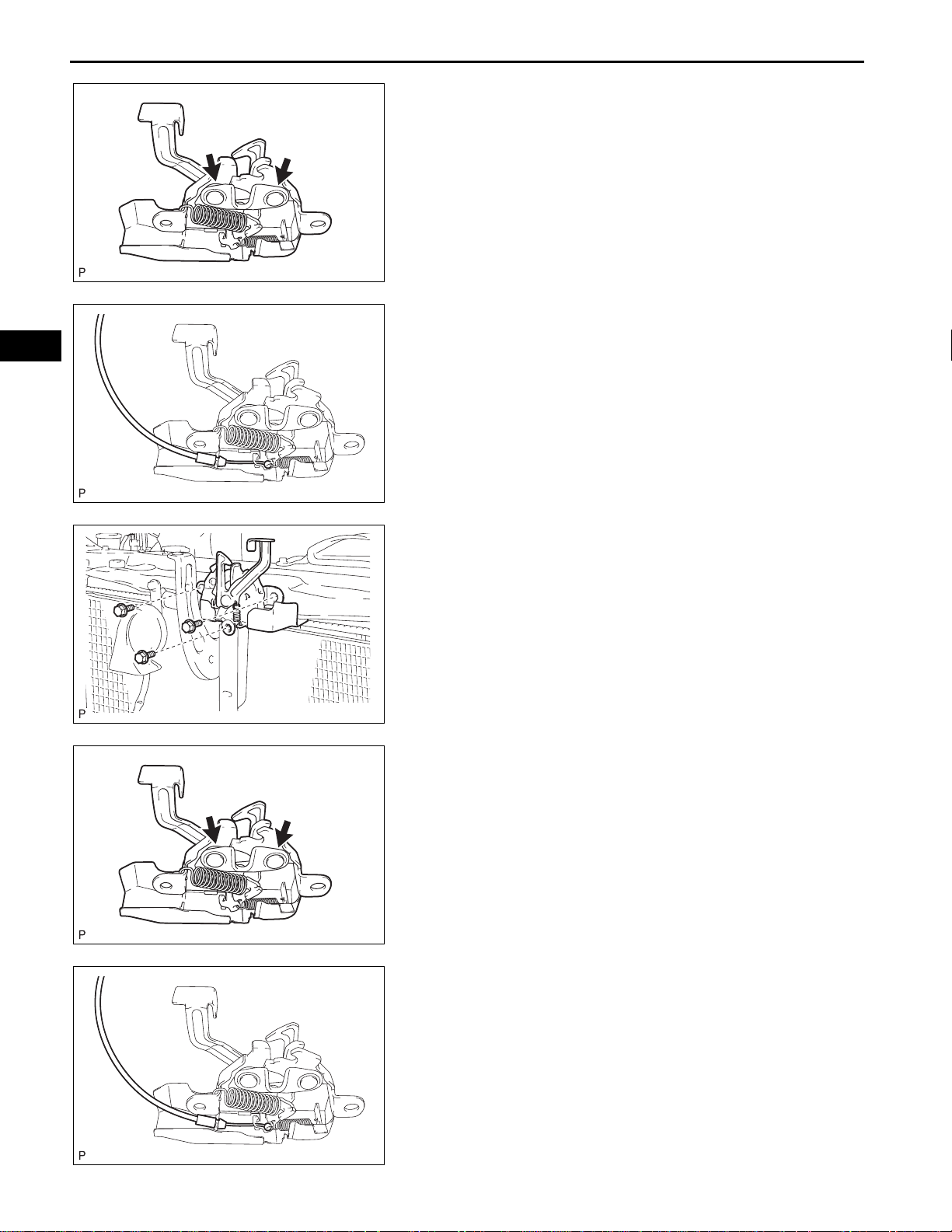

3. INST ALL HOOD LOCK ASSEMBLY (w/o Engine Hood

Courtesy Switch)

(a) Apply MP grease to the sliding areas of the lock.

B136830

(b) Connect the hood lock control cable.

B136827

B136821

B136830

(c) Install the hood lock assembly with the 3 bolts.

Torque: 7.5 N*m (77 kgf*cm, 66 in.*lbf)

4. INSTALL HOOD LOCK ASSEMBLY (w/ Engine Hood

Courtesy Switch)

(a) Apply MP grease to the sliding areas of the lock.

(b) Connect the hood lock control cable.

B136827

ENGINE HOOD / DOOR – HOOD LOCK CONTROL CABLE ASSEMBLY

(c) Install the hood lock assembly with the 3 bolts.

Torque: 7.5 N*m (77 kgf*cm, 66 in.*lbf)

(d) Connect the connector.

5. INSTALL HIGH PITCHED HORN ASSEMBLY (See

page HO-7)

B136822

6. INSTALL FRONT FENDER LINER

(a) Install the front fender liner with the grommet and 4

screws.

(b) Install the bolt and 5 clips.

7. INSPECT HOOD SUB-ASSEMBLY (See page ED-1)

8. ADJUST HOOD SUB-ASSEMBLY (See page ED-2)

9. INSTALL FRONT BUMPER ASSEMBLY (w/o Fog

Light) (See page ET-13)

ED–11

ED

B136871

B138883

10. INST ALL FRONT BUMPER ASSEMBLY (w/ Fog Light)

(See page ET-14)

11. INSTALL COOL AIR INTAKE DUCT SEAL (for 2GRFE) (See page ET-14)

12. INSTALL FRONT WHEEL OPENING EXTENSION PAD

(a) Install the front wheel opening extension pad with

the 3 screws.

13. INSTALL FRONT WHEEL (See page SP-22)

14. VEHICLE PREPARATION FOR FOG LIGHT AIM (w/

Fog Light) (See page LI-79)

15. PREPARATION FOR FOG LIGHT AIMING (w/ Fog

Light) (See page LI-80)

16. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-81)

17. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-82)

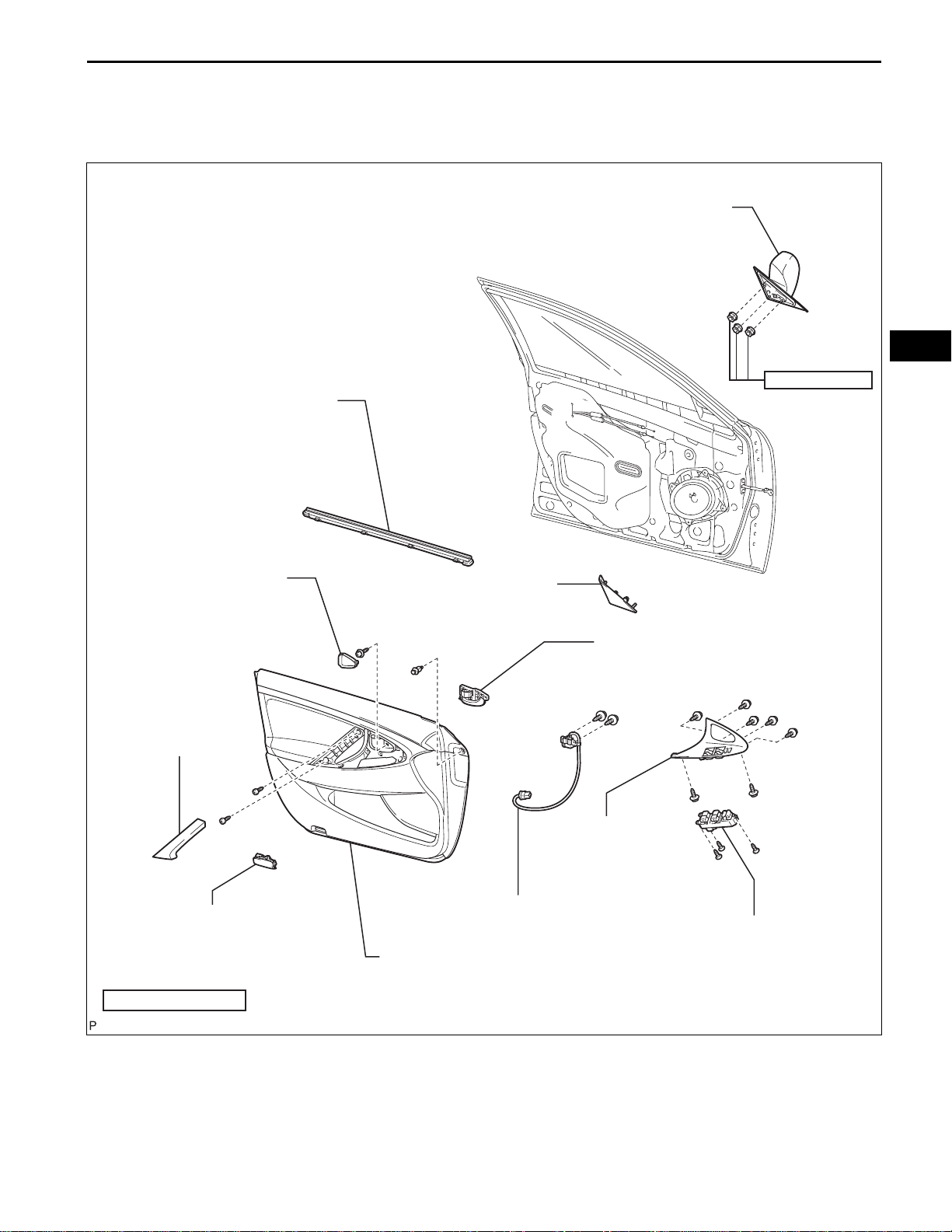

BODYENGINE HOOD / DOOR

FRONT DOOR

COMPONENTS

ENGINE HOOD / DOOR – FRONT DOOR

OUTER REAR VIEW MIRROR ASSEMBLY

ED–11

ED

FRONT DOOR INNER

GLASS WEATHERSTRIP

FRONT DOOR INSIDE

HANDLE BEZEL PLUG

ASSIST GRIP COVER

5.5 (56, 49 in.*lbf)

FRONT DOOR LOWER

FRAME BRACKET GARNISH

FRONT DOOR INSIDE

HANDLE SUB-ASSEMBLY

FRONT ARMREST

BASE PANEL UPPER

COURTESY LIGHT

ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

FRONT DOOR WIRE

FRONT DOOR TRIM

BOARD SUB-ASSEMBLY

POWER WINDOW REGULATOR

MASTER SWITCH ASSEMBLY

B146077E01

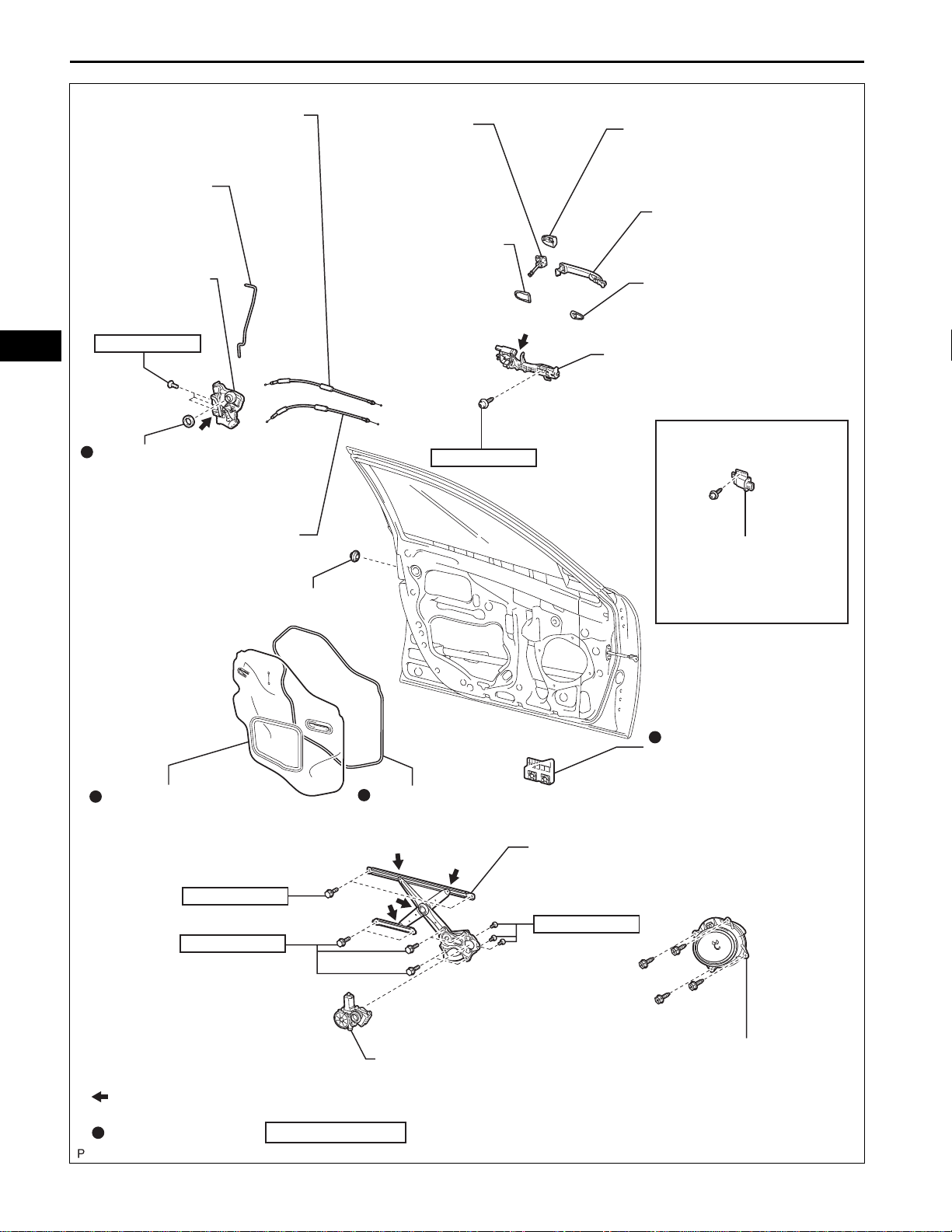

ED–12

ENGINE HOOD / DOOR – FRONT DOOR

ED

FRONT DOOR LOCK REMOTE

CONTROL CABLE ASSEMBLY

FRONT DOOR

LOCK OPEN ROD

FRONT DOOR

LOCK ASSEMBLY

5.0 (51, 44 in.*lbf)

DOOR LOCK WIRING

HARNESS SEAL

FRONT DOOR INSIDE

LOCKING CABLE ASSEMBLY

FRONT DOOR

LOCK CYLINDER

FRONT DOOR REAR

OUTSIDE HANDLE PAD

4.0 (41, 35 in.*lbf)

FRONT DOOR OUTSIDE

HANDLE COVER

FRONT DOOR OUTSIDE

HANDLE ASSEMBLY

FRONT DOOR FRONT

OUTSIDE HANDLE PAD

FRONT DOOR OUTSIDE HANDLE

FRAME SUB-ASSEMBLY

with Smart Key System:

DOOR ELECTRICAL

KEY OSCILLATOR

FRONT DOOR SERVICE

HOLE COVER

5.5 (56, 49 in.*lbf)

8.0 (82, 71 in.*lbf)

HOLE PLUG

FRONT NO. 1 DOOR

STIFFENER CUSHION

BUTYL TAPE

FRONT DOOR WINDOW

REGULATOR SUB-ASSEMBLY

5.4 (55, 48 in.*lbf)

Apply MP grease

Non-reusable part

FRONT POWER WINDOW REGULATOR

MOTOR ASSEMBLY

N*m (kgf*cm, ft.*lbf)

FRONT NO. 1

SPEAKER ASSEMBLY

: Specified torque

B146078E01

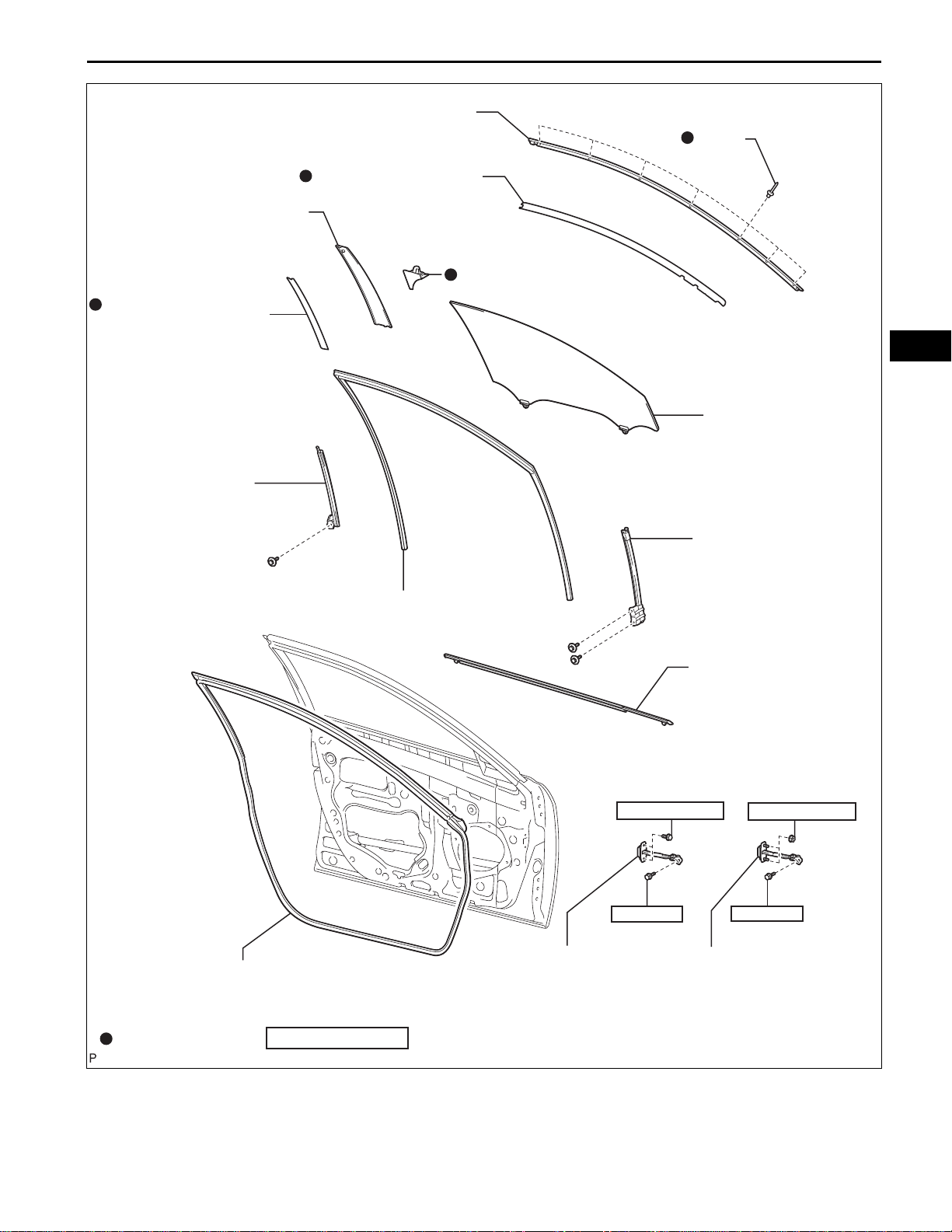

FRONT DOOR UPPER

WINDOW FRAME MOULDING

FRONT DOOR REAR

WINDOW FRAME MOULDING

FRONT DOOR LOWER

OUTSIDE STRIPE

FRONT DOOR REAR

LOWER FRAME

SUB-ASSEMBLY

ENGINE HOOD / DOOR – FRONT DOOR

FRONT DOOR STRIPE

DOOR FRAME GARNISH

ED–13

RIVET

ED

FRONT DOOR GLASS

SUB-ASSEMBLY

FRONT DOOR FRONT

LOWER FRAME

SUB-ASSEMBLY

FRONT DOOR WEATHERSTRIP

Non-reusable part

N*m (kgf*cm, ft.*lbf)

FRONT DOOR GLASS RUN

: Specified torque

TMC made:

8.0 (82, 71 in.*lbf)

26 (265, 19)

FRONT DOOR

CHECK ASSEMBLY

FRONT DOOR BELT

MOULDING ASSEMBLY

TMMK made:

8.0 (82, 71 in.*lbf)

26 (265, 19)

FRONT DOOR

CHECK ASSEMBLY

B146081E01

ED–14

ENGINE HOOD / DOOR – FRONT DOOR

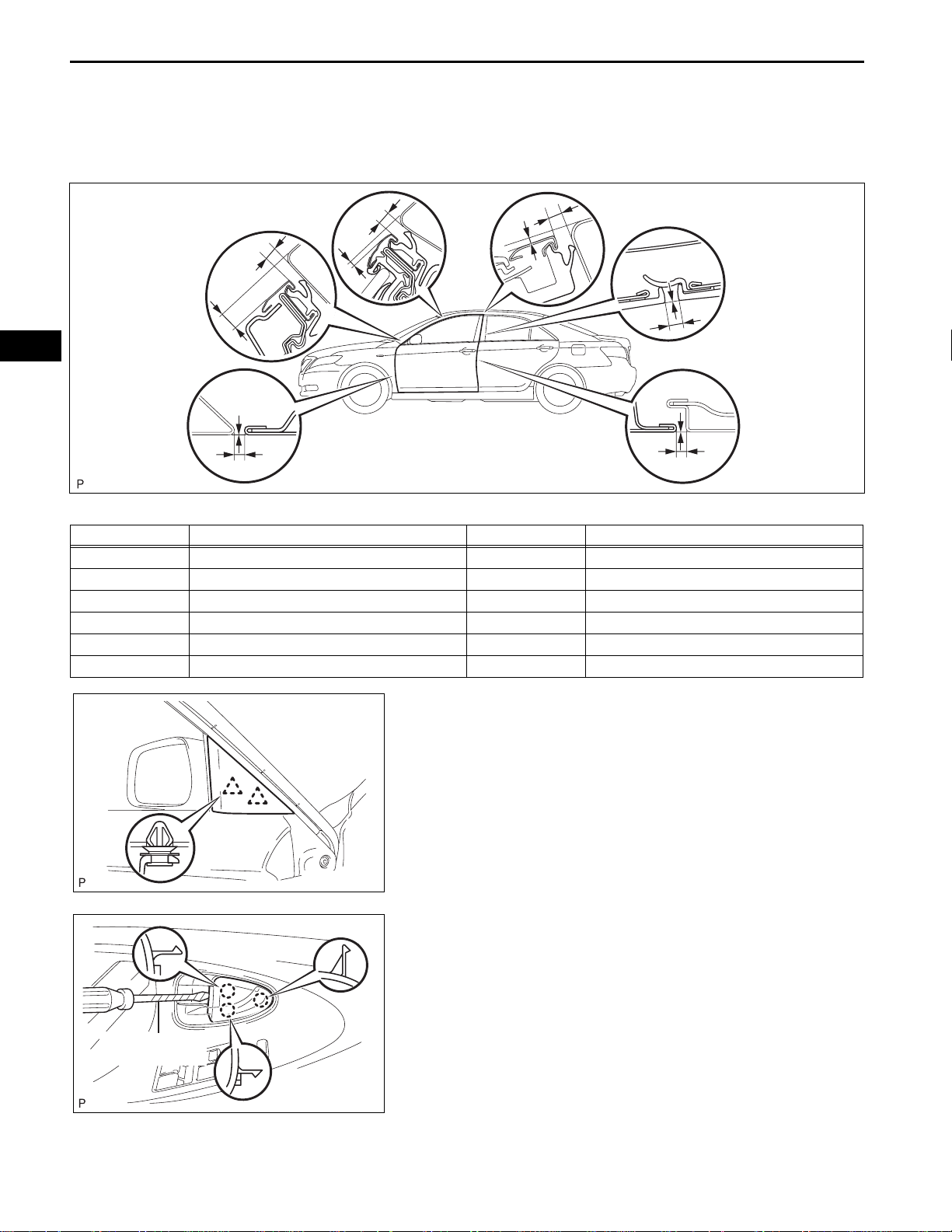

ON-VEHICLE INSPECTION

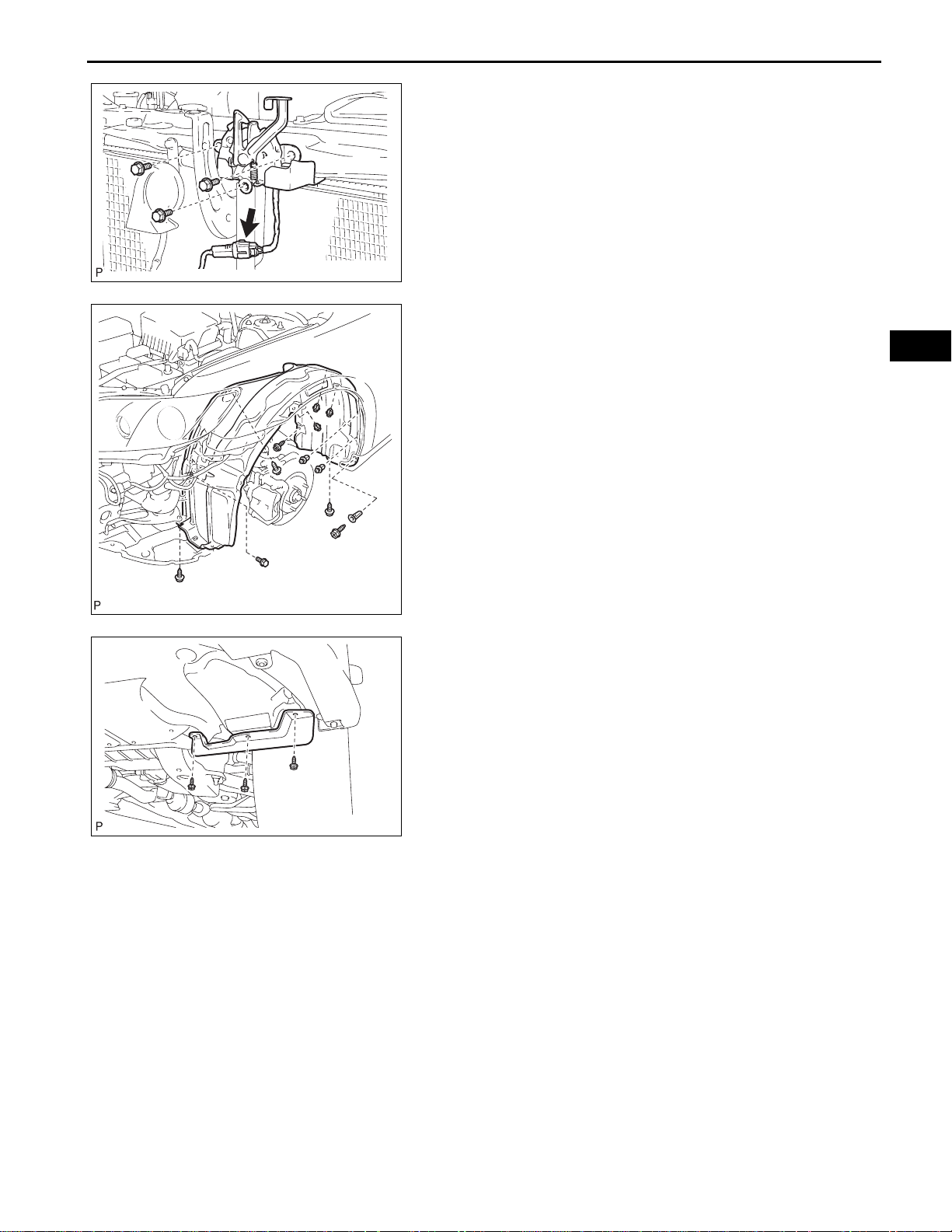

1. INSPECT FRONT DOOR PANEL SUB-ASSEMBLY

(a) Check that the clearance measurements of areas A

to L are within each standard range.

ED

E

C

F

D

B

A

H

G

J

I

L

K

Standard clearance

Area Measurement Area Measurement

A 2.7 to 5.7 mm (0.106 to 0.224 in.) G 3.3 to 6.3 mm (0.130 to 0.248 in.)

B -1.5 to 1.5 mm (-0.059 to 0.059 in.) H -0.3 to 2.7 mm (-0.012 to 0.106 in.)

C 3.3 to 6.3 mm (0.130 to 0.248 in.) I 2.3 to 6.3 mm (0.091 to 0.248 in.)

D 6.4 to 9.4 mm (0.252 to 0.370 in.) J -2.0 to 2.0 mm (-0.079 to 0.079 in.)

E 3.3 to 6.3 mm (0.130 to 0.248 in.) K 2.7 to 5.7 mm (0.106 to 0.224 in.)

F 0.9 to 3.9 mm (0.035 to 0.154 in.) L -1.5 to 1.5 mm (-0.059 to 0.059 in.)

B132823E01

Protective tape

DISASSEMBLY

1. REMOVE FRONT DOOR LOWER FRAME BRACKET

GARNISH

(a) Disengage the 2 clips and remove the front door

lower frame bracket garnish.

B132833

2. REMOVE FRONT DOOR INSIDE HANDLE BEZEL

PLUG

(a) Using a screwdriver wrapped with protective tape,

disengage the 3 claws, and remove the front door

inside handle bezel plug.

B132834E01

Protective

tape

ENGINE HOOD / DOOR – FRONT DOOR

B132836E01

Protective tape

B132838E01

3. REMOVE ASSIST GRIP COVER

(a) Using a screwdriver wrapped with protective tape,

disengage the 6 claws and remove the assist grip

cover.

4. REMOVE COURTESY LIGHT ASSEMBLY

(a) Using a screwdriver wrapped with protective tape,

disengage the claw and remove the courtesy light

assembly.

(b) Disconnect the connector.

ED–15

ED

(A)

B132840E01

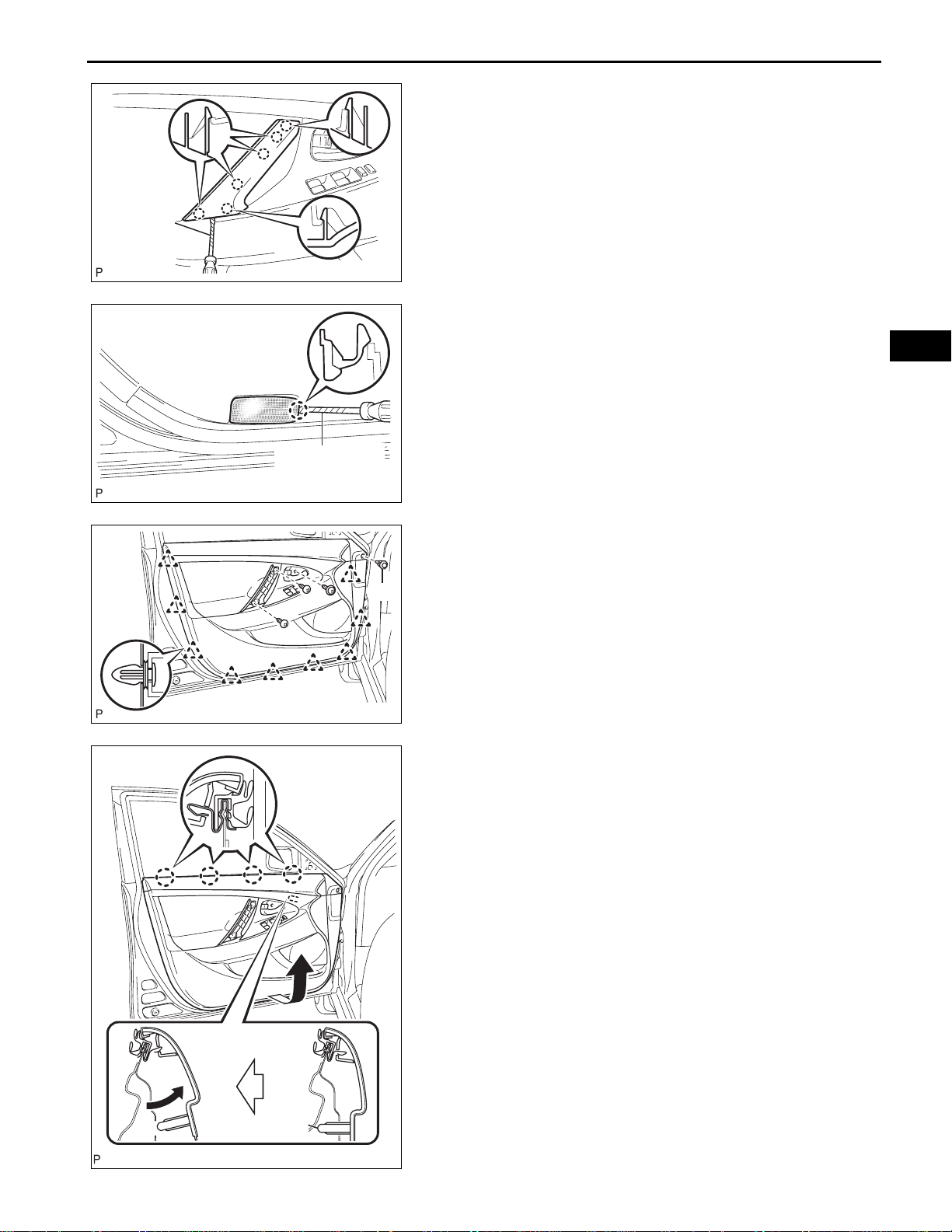

5. REMOVE FRONT DOOR TRIM BOARD SUBASSEMBLY

(a) Remove the 3 screws and clip (A).

(b) Using the clip remover, disengage the 9 clips.

(c) Pull out the front door trim board in the direction

indicated by the arrow.

(d) Remove the reference bosses from the front door

panel.

(e) Raise the front door trim board to disengage the 4

claws and remove the front door trim board together

with the front door inner glass weatherstrip.

Reference Boss

B136401E01

ED

ED–16

ENGINE HOOD / DOOR – FRONT DOOR

(f) Disengage the 2 claws and disconnect the front

door inside handle sub-assembly.

B136403

6. REMOVE POWER WINDOW REGULATOR MASTER

SWITCH ASSEMBLY

(a) Disconnect the connector.

(b) Remove the 3 screws and the power window

regulator master switch assembly.

B136405

Clamp

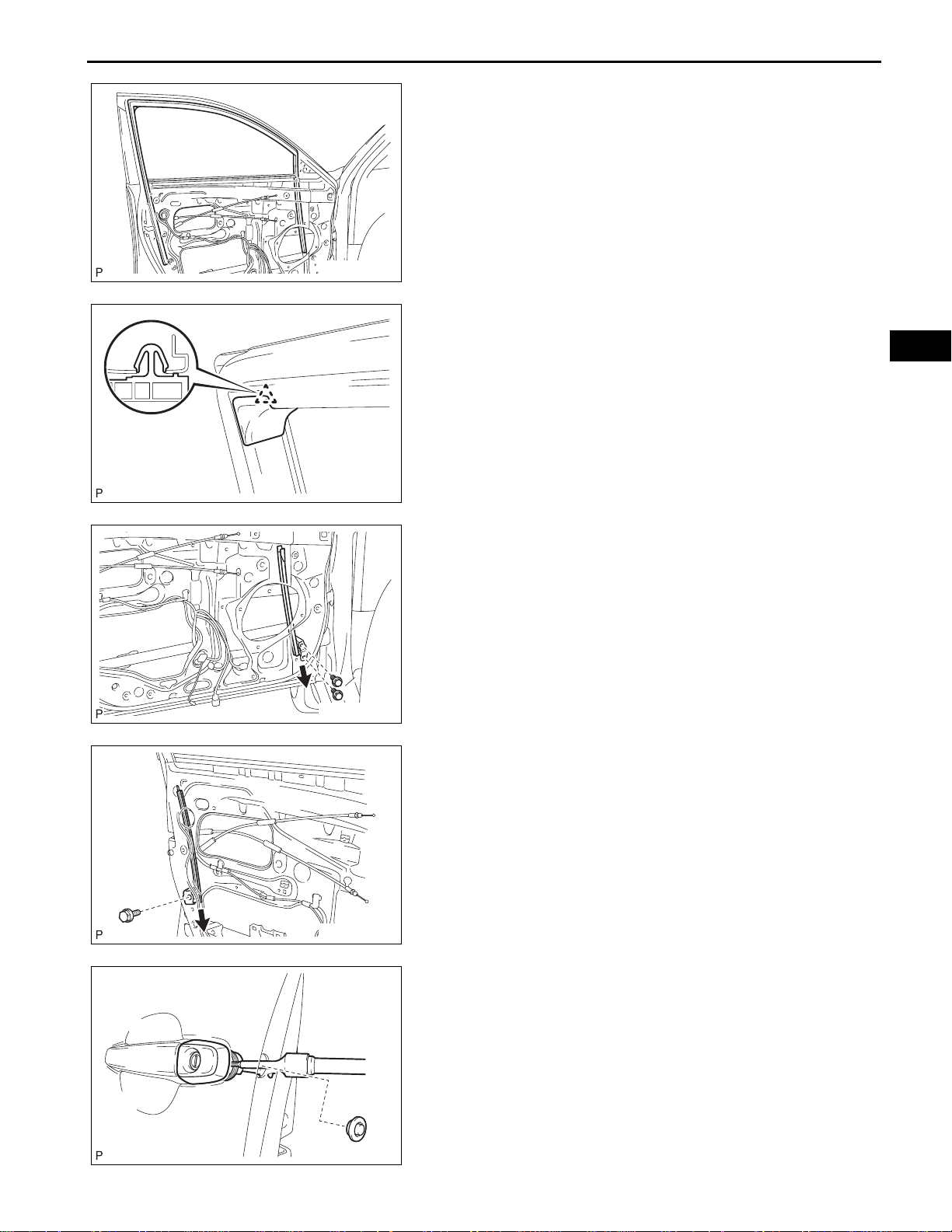

7. REMOVE FRONT DOOR WIRE (for Driver Side)

(a) Disengage the clamp and remove the 2 screws and

front door wire.

B136406E01

8. REMOVE FRONT DOOR INNER GLASS

WEATHERSTRIP

(a) Using a screwdriver, disengage the 4 clip s as shown

in the illustration and remove the front door inner

glass weatherstrip from the front door trim board.

B136404

ENGINE HOOD / DOOR – FRONT DOOR

9. REMOVE FRONT ARMREST BASE PANEL UPPER

(a) Remove the 7 screws.

(b) Disengage the 4 claws and remove the front

armrest base panel upper.

B136407

10. REMOVE FRONT DOOR INSIDE HANDLE SUBASSEMBLY

(a) Disconnect the front door lock remote control cable

and front door inside locking cable and remove the

front door inside handle sub-assembly.

11. REMOVE FRONT NO. 1 SPEAKER ASSEMBLY (See

page AV-155)

12. REMOVE OUTER REAR VIEW MIRROR ASSEMBLY

B136408

(See page MI-15)

ED–17

ED

Clamp

B146069E01

B136412

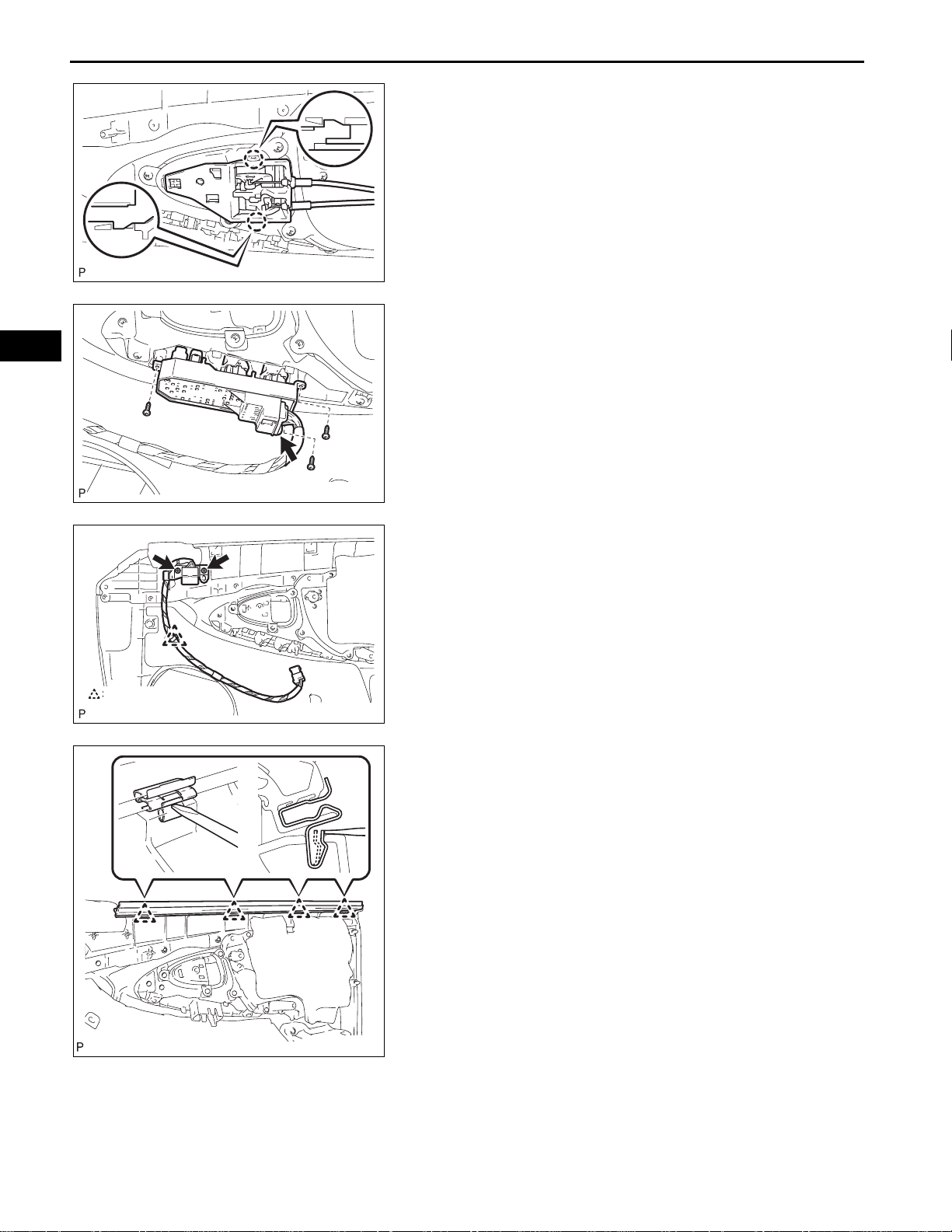

13. REMOVE FRONT DOOR SERVICE HOLE COVER

(a) Disconnect the connector and each clamp, and

remove the front door service hole cover.

HINT:

Remove the remaining butyl tape on the door side.

14. REMOVE FRONT DOOR GLASS SUB-ASSEMBLY

(a) Connect the front power window regulator motor

assembly connector.

(b) Connect the power window regulator master switch

assembly and move the front door glass subassembly so that the door glass bolts can be seen.

(c) Remove the 2 bolts.

NOTICE:

After the bolts are removed, the door glass may

fall and become deformed.

ED

ED–18

(1)

Temporary Bolt

(2)

ENGINE HOOD / DOOR – FRONT DOOR

(d) Remove the front door glass sub-assembly as

shown in the illustration.

NOTICE:

Do not damage the door glass.

(e) Disconnect the power window regulator master

switch assembly and front power window regulator

motor assembly connector.

B136413E01

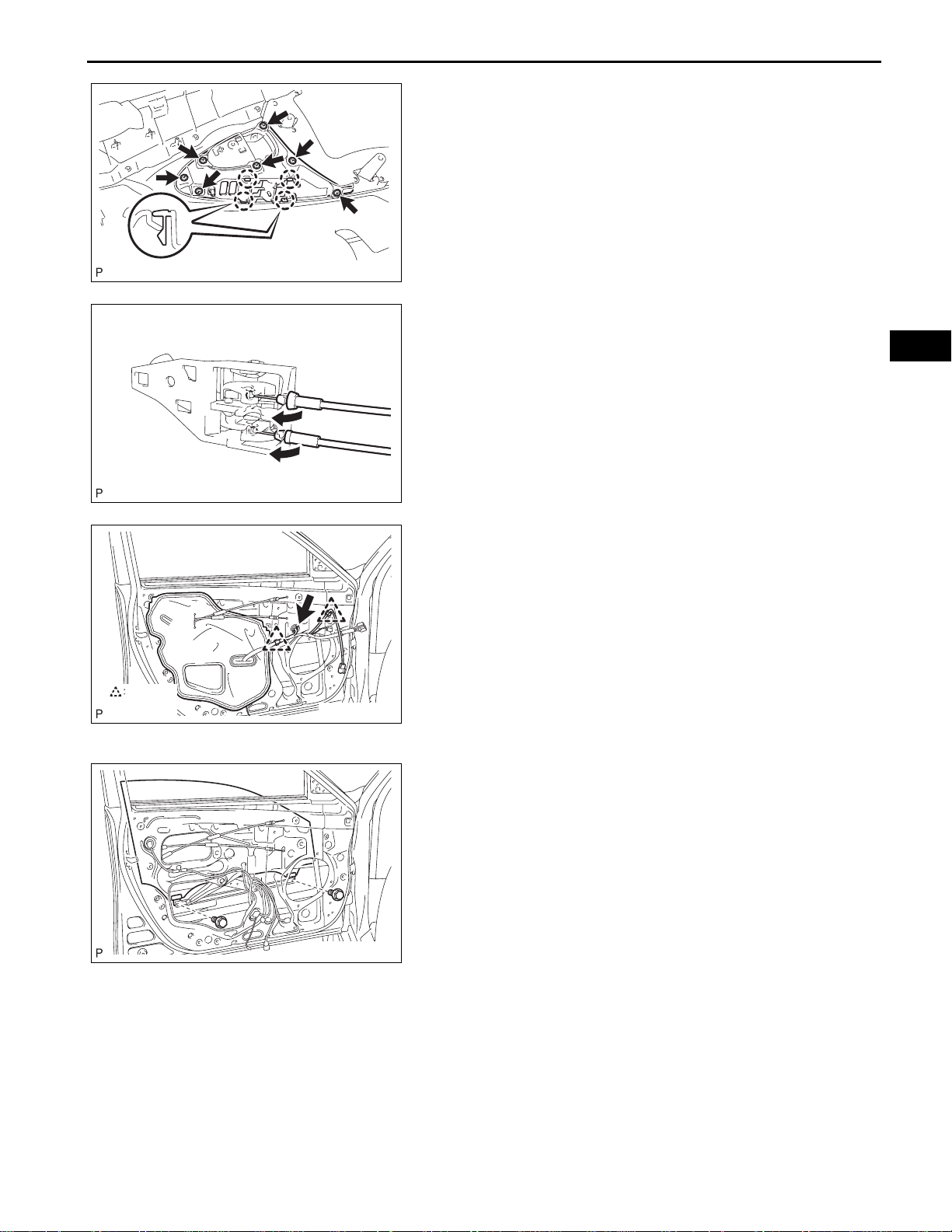

15. REMOVE FRONT DOOR WINDOW REGULATOR

SUB-ASSEMBLY

(a) Loosen the temporary bolt.

NOTICE:

If the temporary bolt is removed, the front door

window regulator may fall and become

deformed.

(b) Remove the 5 bolts.

(c) Remove the front door window regulator sub-

B136415E01

assembly and the power window regulator motor

assembly front as a unit.

(d) Remove the temporary bolt from the front door

window regulator sub-assembly.

Double-sided

Ta pe

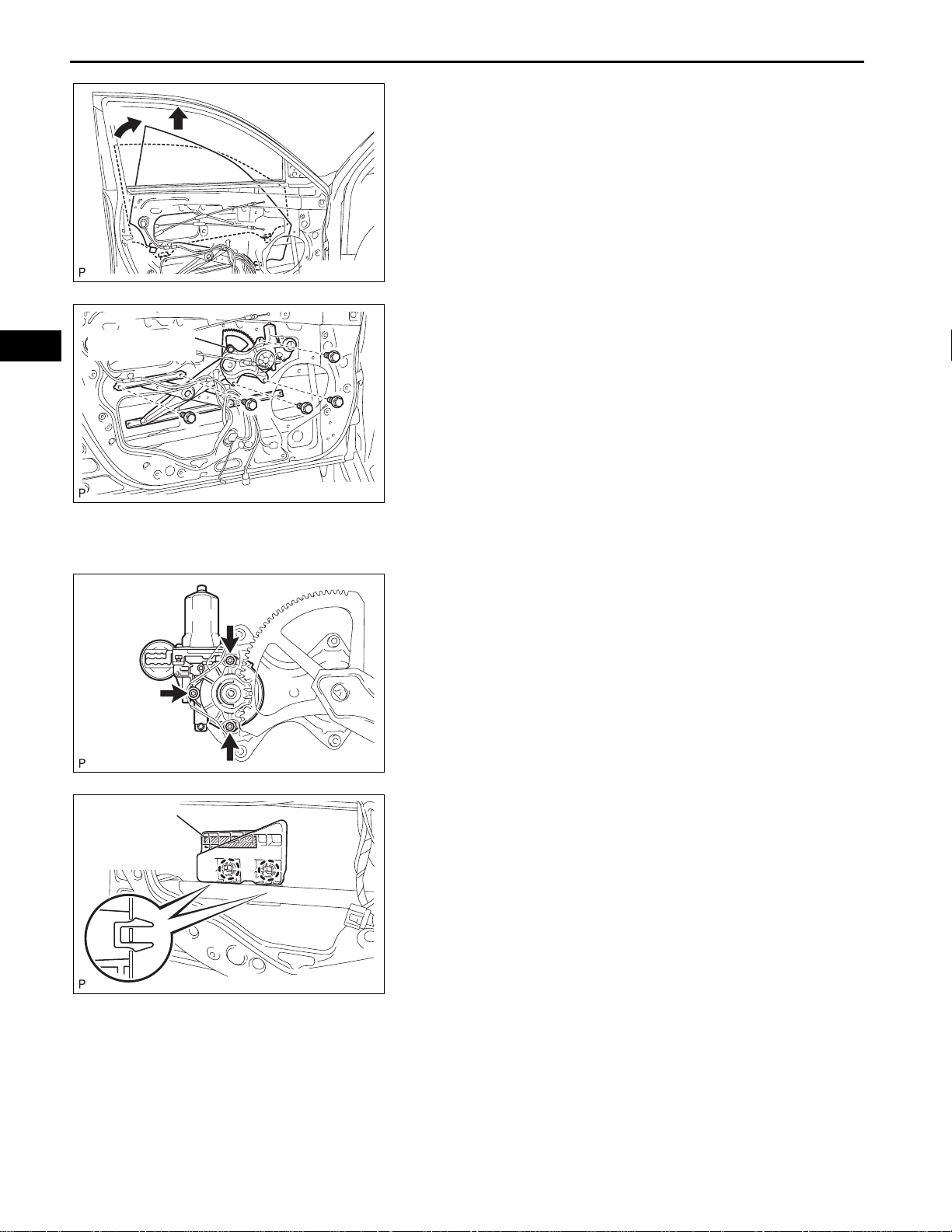

16. REMOVE FRONT POWER WINDOW REGULATOR

MOTOR ASSEMBLY

(a) Using a "torx" driver (T25), remove the 3 screws

and the front power window regulator motor

assembly.

B136416

17. REMOVE FRONT NO. 1 DOOR STIFFENER CUSHION

(a) Disengage the 2 claws.

(b) Remove the double-sided tape and the front No. 1

door stiffener cushion.

B136417E01

ENGINE HOOD / DOOR – FRONT DOOR

18. REMOVE FRONT DOOR GLASS RUN

(a) Remove the front door glass run.

B136418

19. REMOVE DOOR FRAME GARNISH

(a) Disengage the clip and remove the door frame

garnish.

B136435

ED–19

ED

B136419E01

B136420E01

B136421

20. REMOVE FRONT DOOR FRONT LOWER FRAME

SUB-ASSEMBLY

(a) Remove the 2 bolts and the front door front lower

frame sub-assembly as shown in the illustration.

21. REMOVE FRONT DOOR REAR LOWER FRAME SUBASSEMBLY

(a) Remove the bolt and the front door rear lower frame

sub-assembly as shown in the illustration.

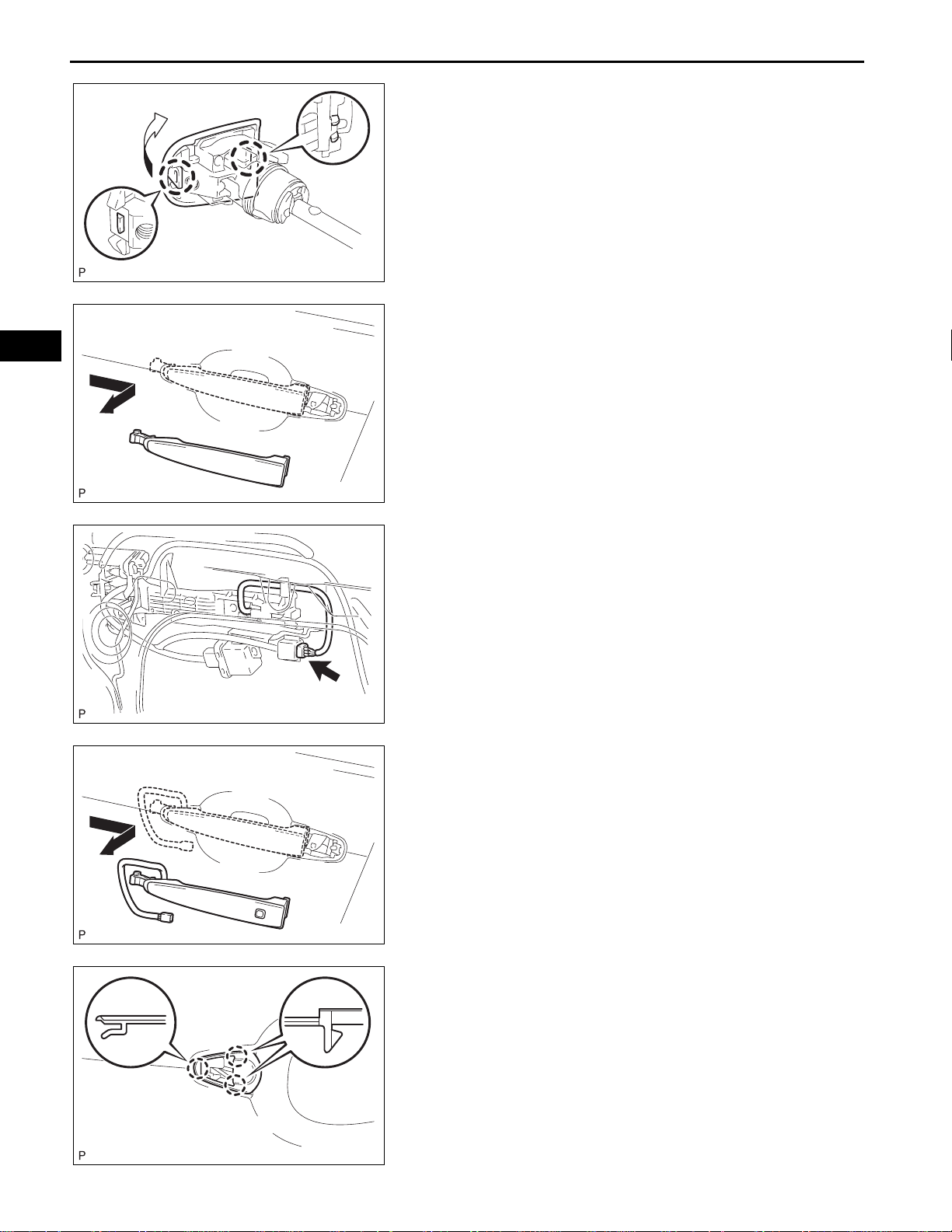

22. REMOVE FRONT DOOR OUTSIDE HANDLE COVER

(a) Remove the hole plug.

(b) Using a "torx" socket wrench (T30), loosen the

screw and remove the front door outside handle

cover and the door lock key cylinder as a unit.

HINT:

The screw cannot be removed because it is

integrated into the front door outside handle frame

sub-assembly.

ED

ED–20

ENGINE HOOD / DOOR – FRONT DOOR

(c) Using a screwdriver, disengage the 2 claws and

remove the front door outside handle cover.

B136424

23. REMOVE FRONT DOOR OUTSIDE HANDLE

ASSEMBLY (w/o Smart Key System)

(a) Remove the front door outside handle assembly as

shown in the illustration.

B136858

B136857

B136422

24. REMOVE FRONT DOOR OUTSIDE HANDLE

ASSEMBLY (w/ Smart Key System)

(a) Disconnect the connector.

(b) Remove the front door outside handle assembly as

shown in the illustration.

25. REMOVE FRONT DOOR FRONT OUTSIDE HANDLE

PAD

(a) Disengage the 3 claws and remove the front door

front outside handle pad.

B136426

Loading...

Loading...