Toyota Camry 2007-2009 Service Manual - 2AZ-FE_Lubrication

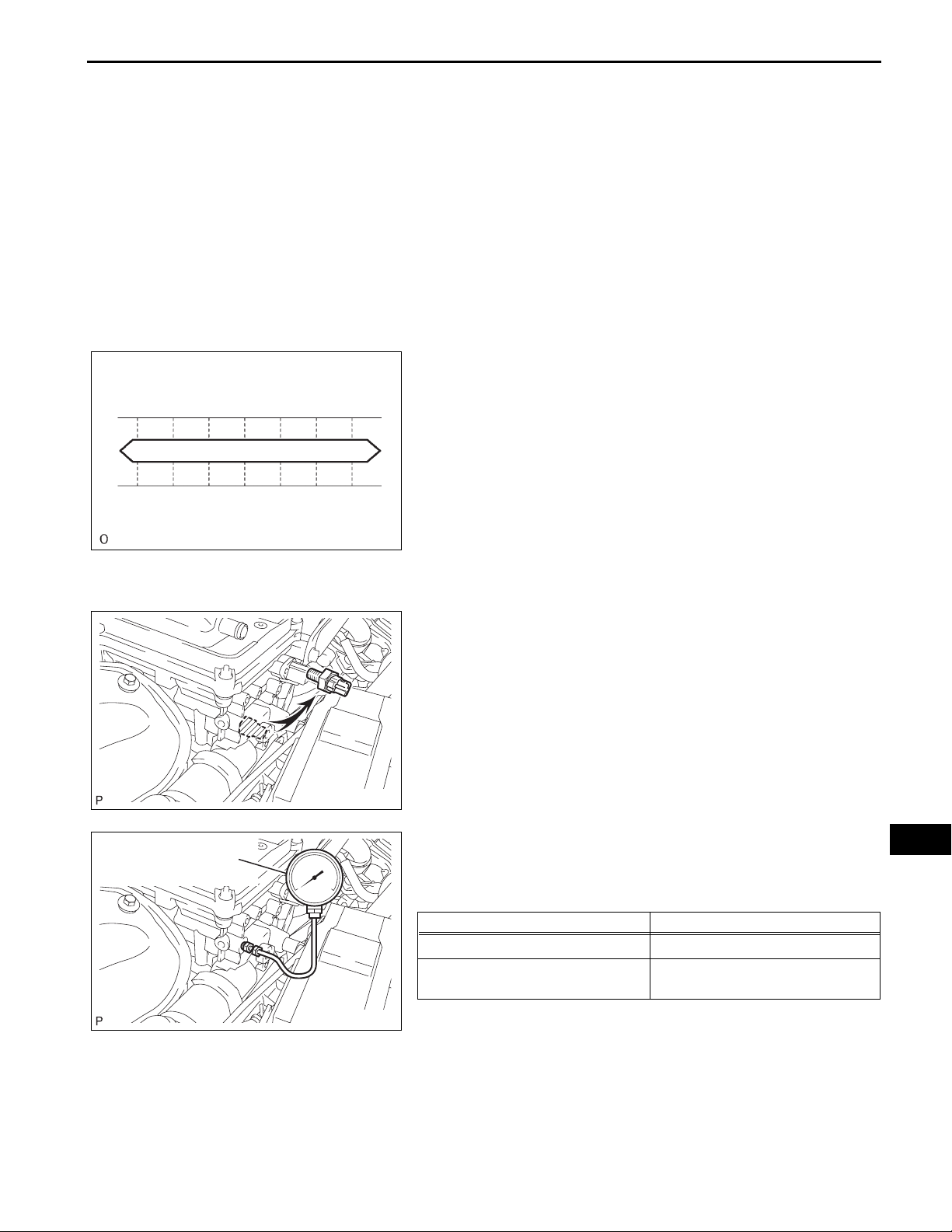

Recommended Viscosity (SAE)

5W-20, 0W-20

-29

°C

°F

-18 -7 4 16 27 38

-20

0 20 40 60 80 100

2AZ-FE LUBRICA TION – LUBRICATION SYSTEM

LUBRICATION SYSTEM

ON-VEHICLE INSPECTION

1. CHECK ENGINE OIL LEVEL

(a) Warm up the engine, stop the engine and wait for 5

minutes.

(b) Check that the engine oil level is between the L and

F marks of the oil dipstick.

If low, check for leakage and add oil up to the F

mark.

NOTICE:

Do not add engine oil above the F mark.

2. CHECK ENGINE OIL QUALITY

(a) Check the oil for deterioration, water intrusion,

discoloration or thinning.

If the quality is visibly poor, replace the oil.

Oil grade:

Use ILSAC multigrade engine oil. SAE 5W-20

and SAE 0W-20 engine oil may be used.

However, SAE 0W-20 is the best choice for

good fuel economy and good starting in cold

A066623E18

weather.

LU–1

Oil Pressure Gauge

A112272

A112273E01

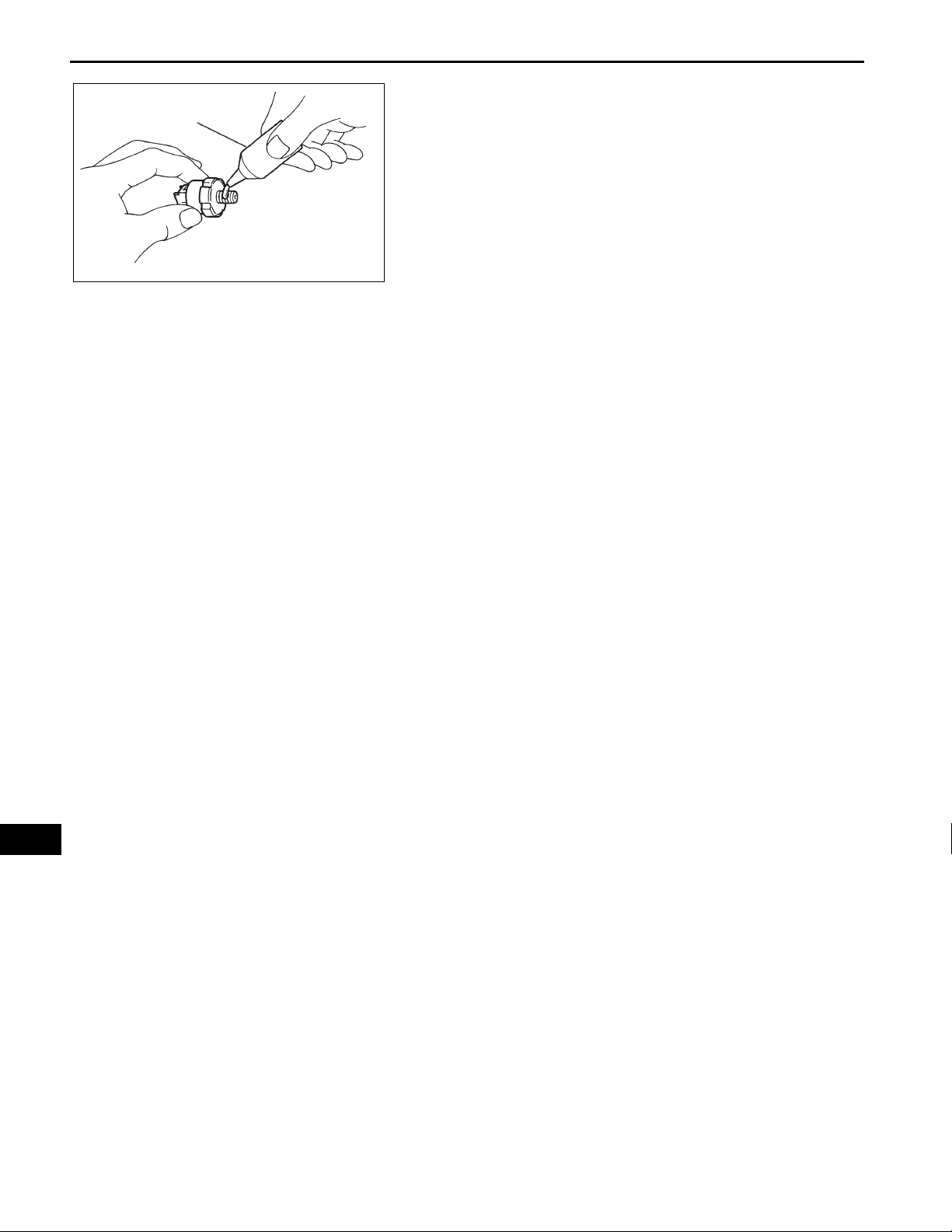

3. CHECK OIL PRESSURE

(a) Disconnect the oil pressure switch connector.

(b) Using a 24 mm deep socket wrench, remove the oil

pressure switch.

(c) Install the oil pressure gauge.

(d) Warm up the engine.

(e) Measure the oil pressure.

Standard oil pressure

Condition Specified Condition

Idle

3,000 rpm

29 kPa (0.3 kgf/cm

170 to 300 kPa (1.7 to 3.1 kgf/cm

2

, 4.3 psi) or more

to 44 psi)

2

LU

, 24

LU–2

Adhesive

2AZ-FE LUBRICATION – LUBRICATION SYSTEM

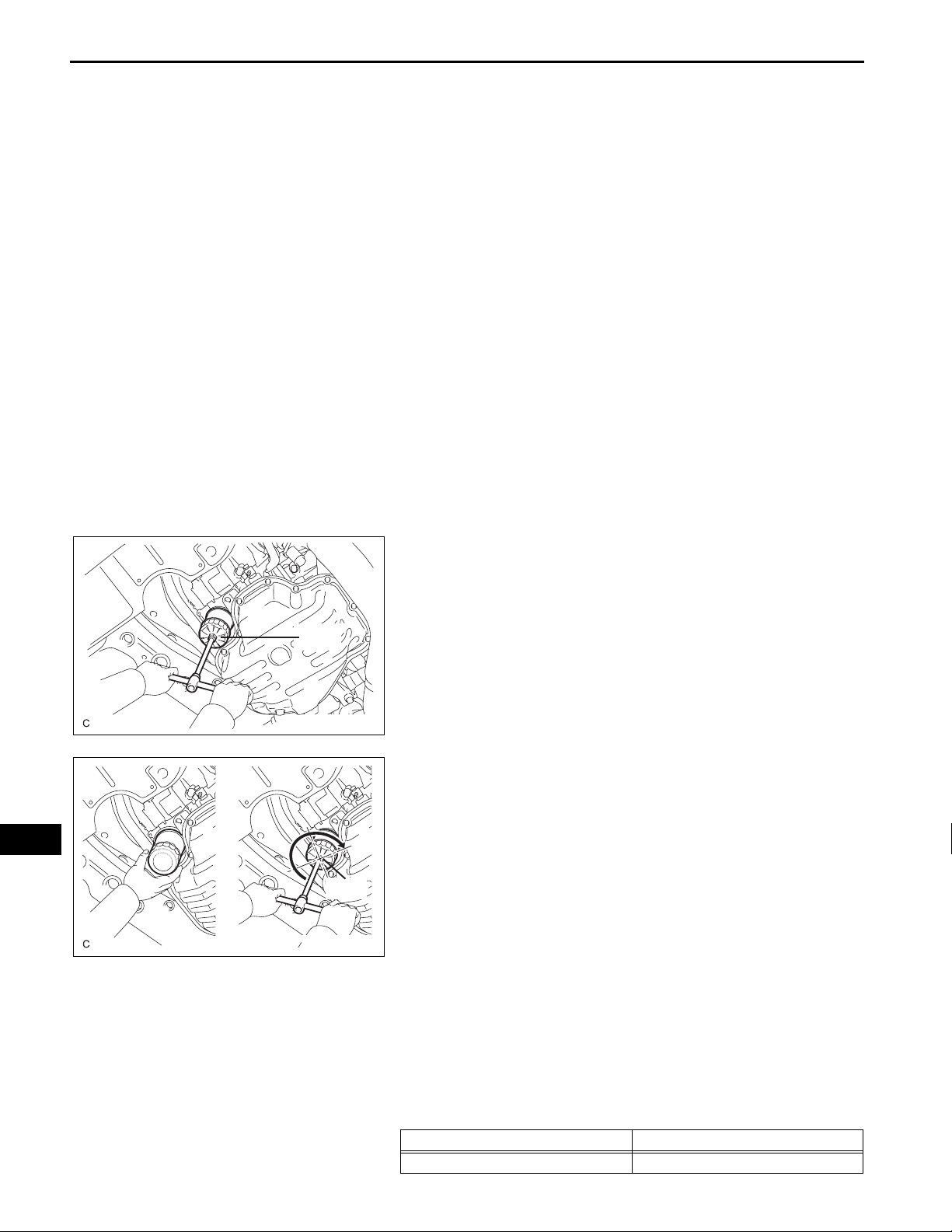

(f) Apply adhesive to 2 or 3 threads of the oil pressure

switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or Equivalent

(g) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 15 N*m (153 kgf*cm, 11 ft.*lbf)

NOTICE:

A085603E02

Do not start the engine within 1 hour of

installation.

(h) Connect the oil pressure switch connector.

(i) Check for engine oil leaks.

LU

ENGINE2AZ-FE LUBRICATION

OIL FILTER

COMPONENTS

2AZ-FE LUBRICATION – OIL FILTER

LU–3

N*m (kgf*cm, ft.*lbf)

: Specified torque

13 (133, 10)

OIL FILTER SUB-ASSEMBLY

Non-reusable part

A134971E01

LU

LU–4

2AZ-FE LUBRICA TION – OIL FILT ER

REPLACEMENT

CAUTION:

• Prolonged and repeated contact with engine oil will

cause the loss of natural oils from the skin, leading to

dryness, irritation and dermatitis. In addition, used

engine oil contains potentially harmful contaminants

which may cause skin cancer.

• Precautions should be taken when replacing engine

oil to minimize the risk of your skin making contact

with used engine oil. Wear protective clothing and

gloves. Wash your skin thoroughly with soap and

water, or use a waterless hand cleaner to remove any

used engine oil. Do not use gasoline, thinners or

solvents.

• For environmental protection, used oil and used oil

filters must be disposed of at designated disposal

sites.

1. DRAIN ENGINE OIL

(a) Remove the oil filler cap.

(b) Remove the oil drain plug and drain the oil into a

container.

LU

SST

A136225E01

SST

A136227E01

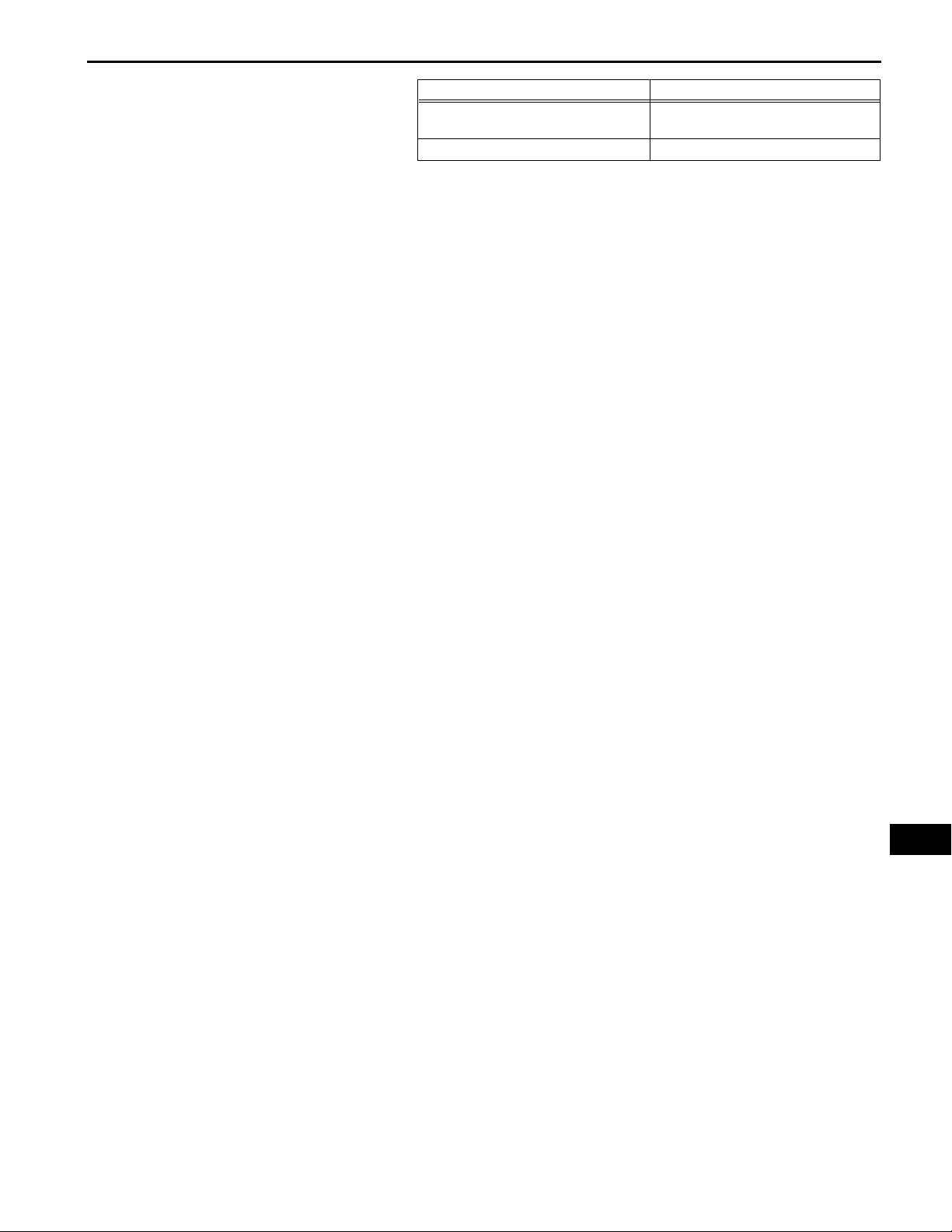

2. REMOVE OIL FILTER SUB-ASSEMBLY

(a) Using SST, remove the oil filter.

SST 09228-06501

3. INSTALL OIL FILTER SUB-ASSEMBLY

(a) Check and clean the oil filter installation surface.

(b) Apply clean engine oil to the gasket of a new oil

filter.

(c) Lightly screw the oil filter into place by hand. Tighten

it until the gasket contacts the seat.

(d) Using SST, tighten the oil filter.

SST 09228-06501

(1) Depending on the work space available,

choose from the following.

1. If enough space is available, use a torque

wrench to tighten the oil filter.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

2. If enough space is not available to use a

torque wrench, tighten the oil filter a 3/4 turn by

hand or use a common wrench.

4. ADD ENGINE OIL

(a) Clean and install the oil drain plug with a new

gasket.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

(b) Add new oil.

Standard capacity

Item Standard Condition

Drain and refill with oil filter change 4.3 liters (4.5 US qts, 3.8 Imp. qts)

2AZ-FE LUBRICATION – OIL FILTER

Item Standard Condition

Drain and refill without oil filter

change

Dry fill 5.0 liters (5.3 US qts, 4.4 Imp. qts)

(c) Install the oil filler cap.

5. CHECK FOR ENGINE OIL LEAKS

LU–5

4.1 liters (4.3 US qts, 3.6 Imp. qts)

LU

ENGINE2AZ-FE LUBRICATION

OIL PUMP

COMPONENTS

2AZ-FE LUBRICATION – OIL PUMP

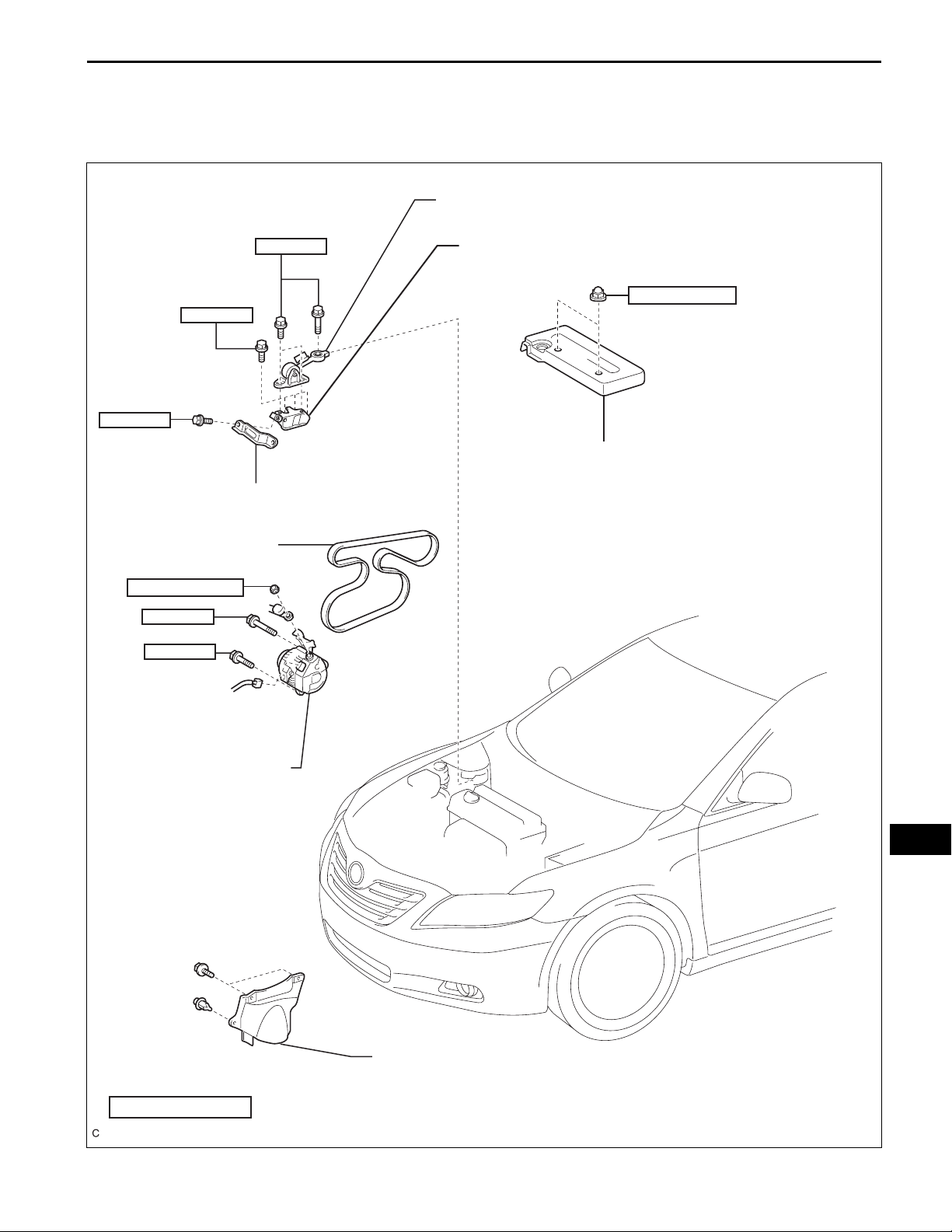

ENGINE MOVING CONTROL ROD SUB-ASSEMBLY

LU–5

64 (653, 47)

52 (531, 38)

64 (653, 47)

NO. 2 ENGINE MOUNTING STAY RH

V-RIBBED BELT

9.8 (100, 87 in.*lbf)

52 (531, 38)

21 (214, 15)

NO. 2 ENGINE MOUNTING BRACKET RH

9.0 (92, 80 in.*lbf)

NO. 1 ENGINE COVER SUB-ASSEMBLY

GENERATOR ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

LU

FRONT FENDER APRON SEAL RH

A134948E01

LU–6

43 (439, 32)

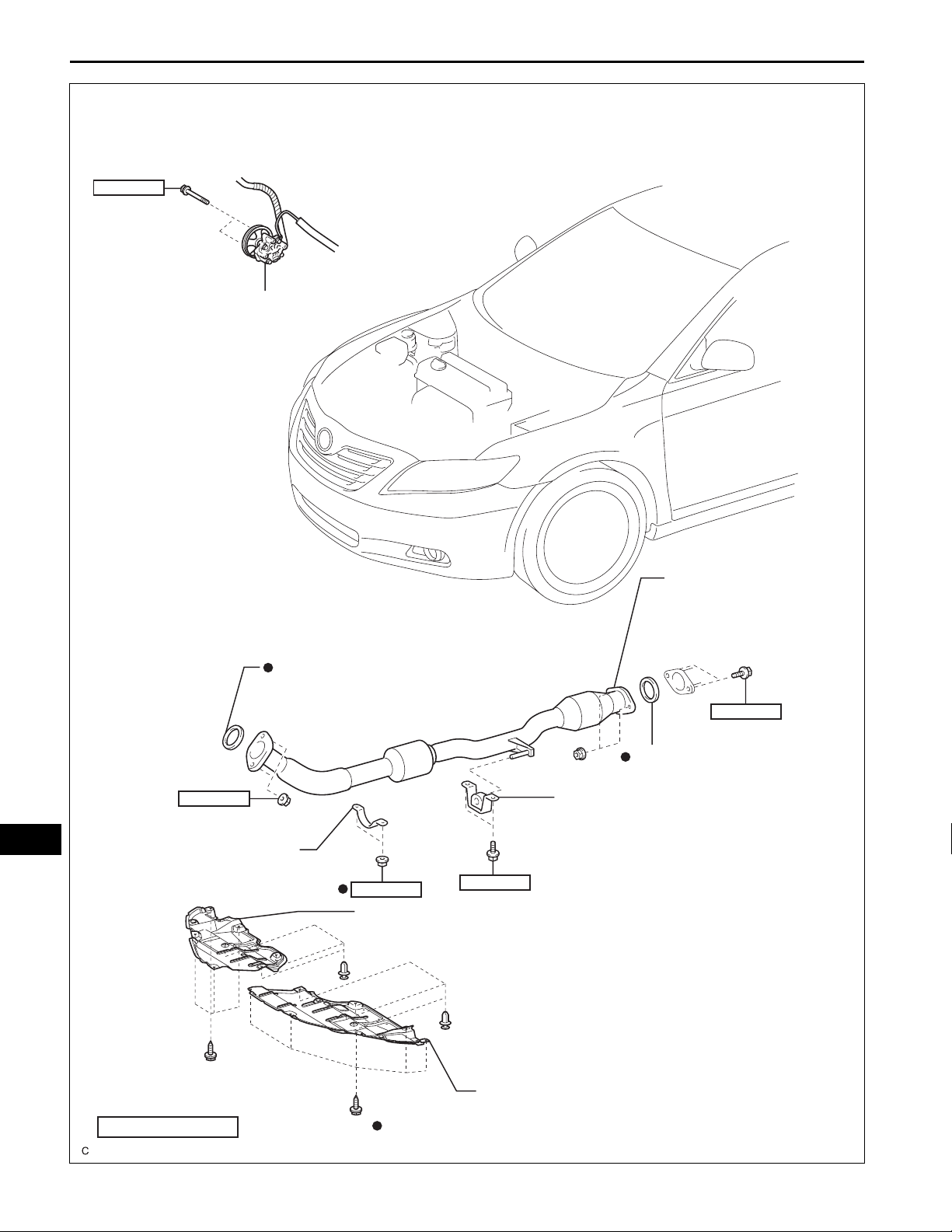

2AZ-FE LUBRICATION – OIL PUMP

VANE PUMP ASSEMBLY

LU

EXHAUST PIPE GASKET

62 (633, 46)

FRONT EXHAUST PIPE NO. 1

SUPPORT BRACKET

33 (337, 24)

33 (337, 24)

ENGINE UNDER COVER RH

FRONT EXHAUST

PIPE ASSEMBLY

56 (571, 41)

EXHAUST PIPE GASKET

REAR EXHAUST PIPE NO. 1

SUPPORT BRACKET

N*m (kgf*cm, ft.*lbf)

: Specified torque

ENGINE UNDER COVER LH

Non-reusable part

A134947E01

Loading...

Loading...