Toyota Camry 2007-2009 Service Manual - Tire_and_Wheel

TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

TIRE AND WHEEL SYSTEM

PRECAUTION

1. REMOVAL AND INSTALLATION OF THE TIRE

PRESSURE WARNING VALVE SUB-ASSEMBLY

(a) When installing a tire, make sure that the tire

pressure warning valve sub-assembly does not

interfere with the tire bead in order to prevent

damage to the tire pressure warning valve subassembly.

(b) After completing the operation, remove the valve

core to rapidly release the air in the tire and check

that the warning light comes on. If the warning light

does not come on, the system may be defective.

(c) If there is air leakage, tighten the nut to a torque of

4.0 N*m (41 kgf*cm, 35 in.*lbf) and push the valve

core 2 or 3 times to remove any dirt attached to the

valve core. If air continues to leak, replace the

grommet, washer, and nut.

(d) When installing the tire pressure warning valve sub-

assembly , check whether the rim, grommet, washer,

and nut are clean. Use a manufacturer-specified

cap.

(e) When putting air into the tire, first install the tire

pressure valve straight onto the stem of the tire

pressure warning valve sub-assembly.

2. TIRE AND WHEEL REPLACEMENT

(a) If replacing a tire, be sure to check the grommet of

the tire valve for damage. If the grommet is

damaged, replace the grommet, washer, and the

nut.

(b) If tires and wheels are replaced, register the

transmitter ID (see page TW-15).

TW–1

TW

TW–2

TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

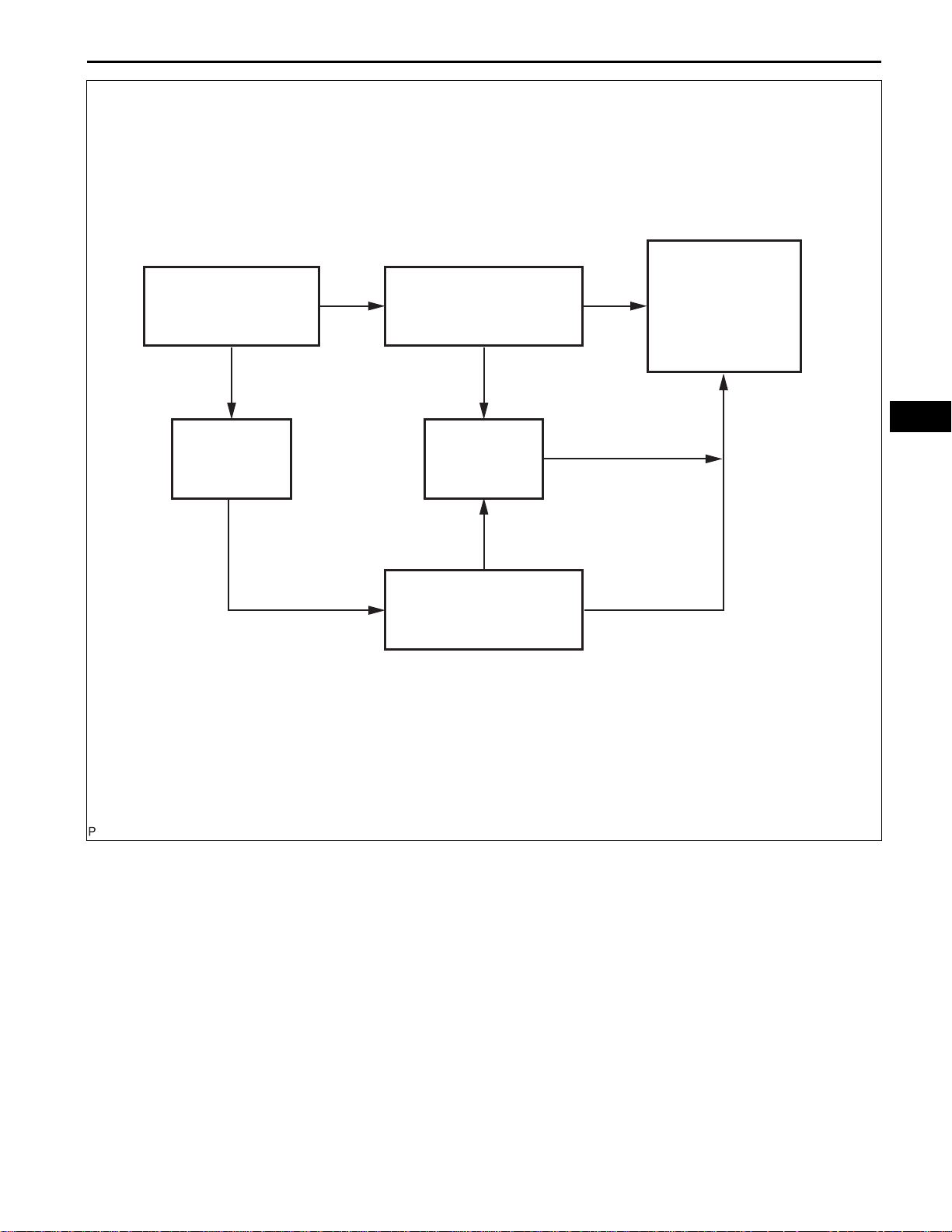

HOW TO PROCEED WITH

TROUBLESHOOTING

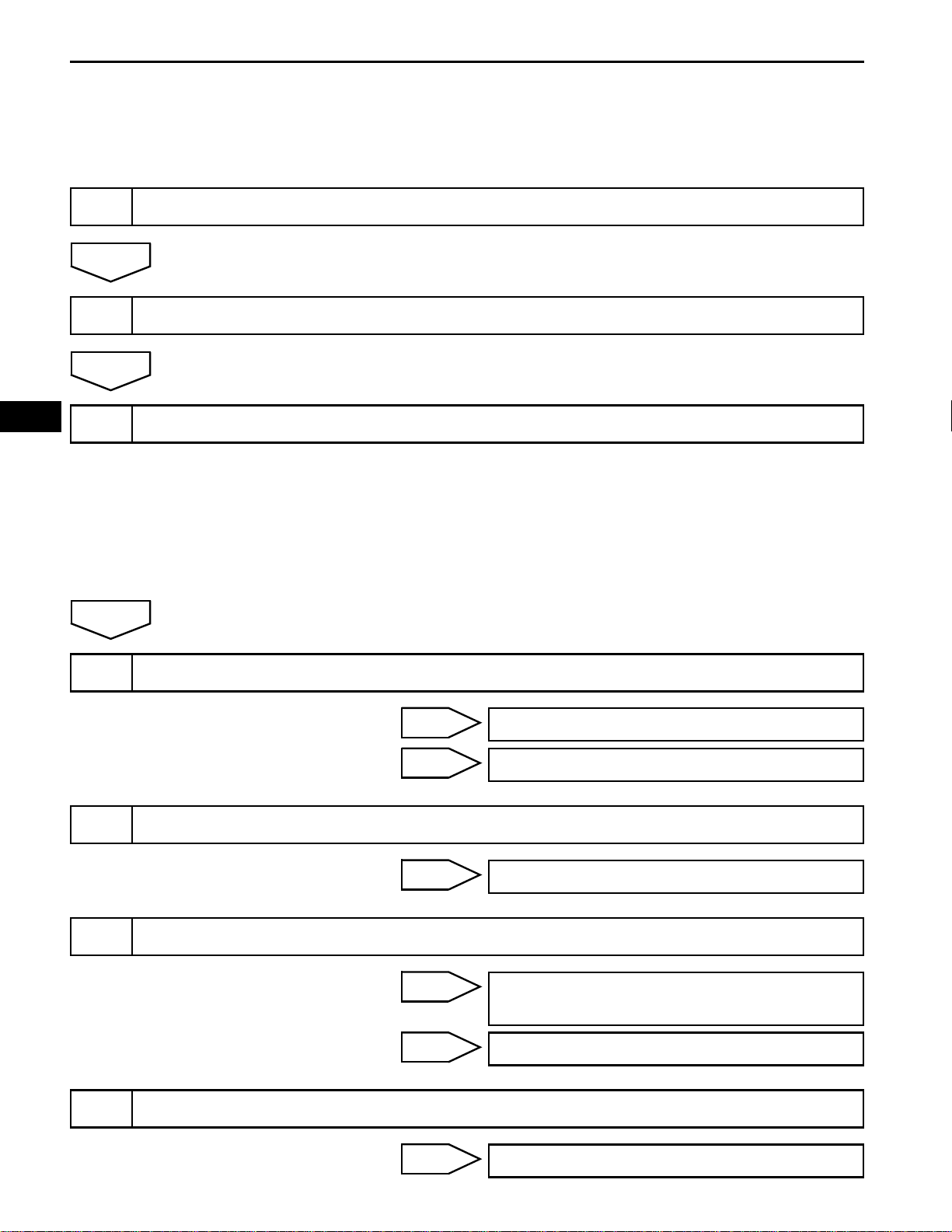

1. DIAGNOSIS OF TIRE VIBRATION

(a) Inspection procedure

TW

Check that the wheel

nuts are fully tightened.

OK

Check tire pressure.

NG

NG

OK

Repair

Check wheel balance.

NG

NG

Inspect bearing looseness.

Inspect axle hub runout.

OK

Repair tire(s).

OK

Return the vehicle

to the customer.

OK

Adjustment

Adjustment

NG

Check wheel balance.

2. DIAGNOSIS OF IRREGULAR TIRE WEAR

(a) Inspection procedure

Inspect bearing looseness.

Inspect axle hub runout.

OK

NG

Repair

C107882E08

TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

TW–3

Check tire pressure.

NG

Adjustment Adjustment

OK

Check wheel alignment.

Check wheel alignment.

NG

NG

OK

Rotate or replace

the tire(s).

TW

OK

C107883E01

TW

TW–4

TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

INSPECTION

1. INSPECT TIRE

(a) Check the tires for wear and proper inflation

pressure.

Cold tire inflation pressure

Tire size

P215/60R16 94V 210 (2.1, 31) 210 (2.1, 31)

P215/55R17 93V 220 (2.2, 32) 220 (2.2, 32)

Front kPa (kgf*cm

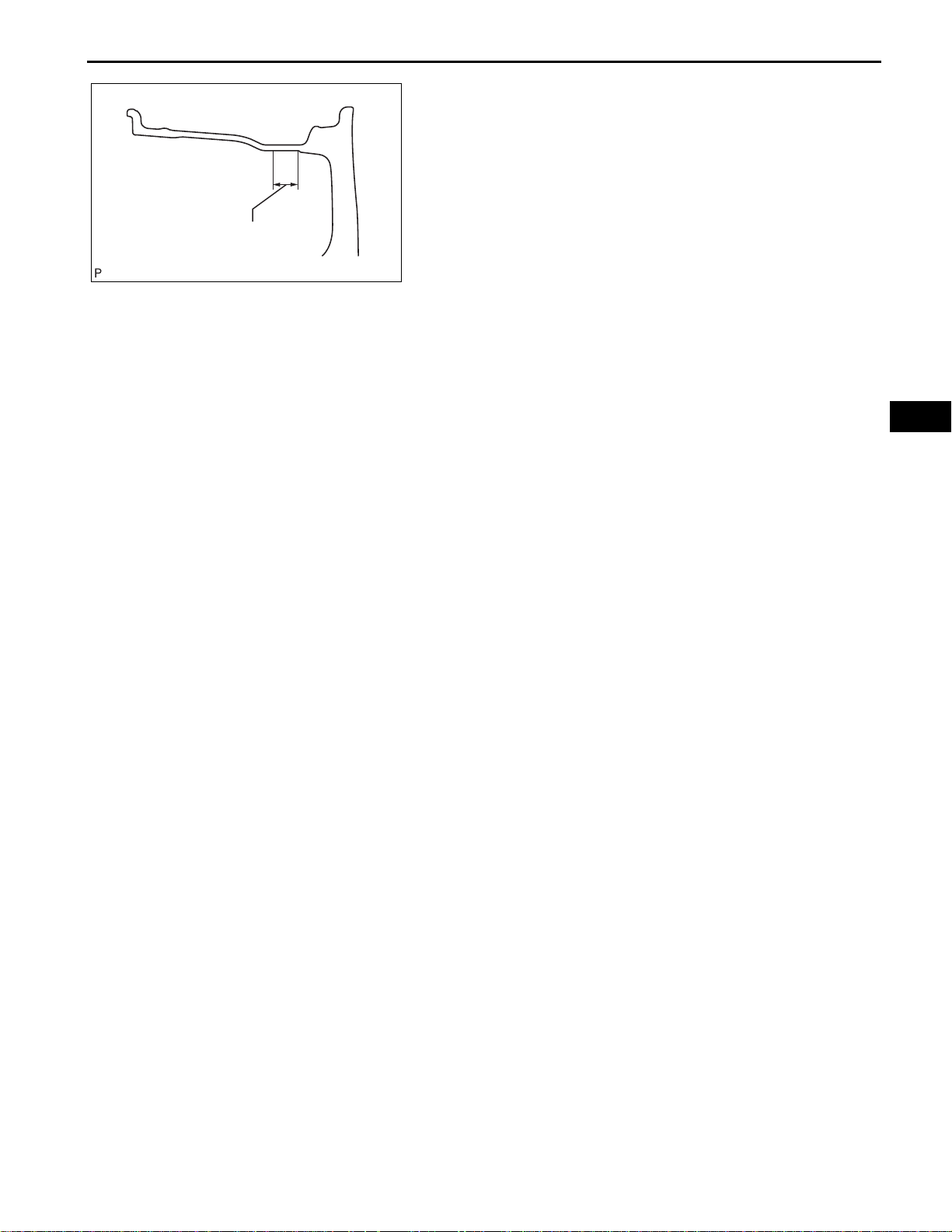

(b) Using a dial indicator, check the runout of the tires.

2

, psi) Rear kPa (kgf*cm2, psi)

When driving under the above vehicle conditions at

sustained high speeds above 160 km/h (100 mph),

in countries where such speeds are permitted bylaw, inflate the front and rear tires to 240 kPa (2.4

2

kgf*cm

, 35 psi) provided that it does not exceed the

maximum cold tire inflation pressure molded on the

tire sidewall.

Tire runout:

1.4 mm (0.055 in.) or less

Front

(A)

(B)

C137874

2. ROTATE TIRE

(a) Rotate the tires as shown in illustration (A). If the

vehicle is equipped with a grand spare tire, rotate

the tires as shown in illustration (B).

C135236E01

3. INSPECT WHEEL BALANCE

(a) Check and adjust the off-the-car balance.

(b) Steel wheel

(1) If necessary, check and adjust the on-the-car

balance.

Imbalance after adjustment:

8.0 g (0.018 lb.) or less.

C080976

TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

Approximately 25 mm (0.984 in.)

C110354E03

(c) Except for steel wheel

(1) If necessary, check and adjust the on-the-car

balance.

Imbalance after adjustment:

8.0 g (0.018 lb.) or less.

NOTICE:

• Remove dirt, oil and water from the

surface where the balance weight is to be

adhered with a cleaning detergent.

• Do not touch the sticking surface of the

tape.

• Adhere the sticking type balance weight

to the flat position shown in the

illustration.

• Push the balance weight securely with a

finger to adhere it to the position.

• Do not reuse the balance weight.

HINT:

The inner side balance weight should be

installed by clipping it to the rim.

TW–5

TW

4. INSPECT BEARING LOOSENESS

(See page AH-5 for FRONT AXLE, AH-15 for REAR

AXLE)

5. INSPECT AXLE HUB RUNOUT

(See page AH-6 for FRONT AXLE, AH-15 for REAR

AXLE)

TW

TW–6

Expression

Cold tire inflation pressure

P215/60R16 94W

P215/55R17 93V

Switch Type Ignition Switch (position) Engine Switch (condition)

Tire Pressure

Warning Light

Tire size

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TIRE PRESSURE WARNING

SYSTEM

PRECAUTION

1. EXPRESSIONS OF IGNITION SWITCH

(a) The type of ignition switch used on this model differs

according to the specification of the valves

Ignition switch off LOCK Off

Ignition switch on (IG) ON On (IG)

Ignition switch on (ACC) ACC On (ACC)

Engine start START Start

2. TIRE PRESSURE WARNING SYSTEM PRECAUTION

(a) When the tire pressure warning light comes on,

immediately check the tire pressure of the tire and

adjust it to the specified value. (The tire pressure

warning light will blink (come on after blinking for 1

minute) if there is an open in the tire pressure

warning light circuit.)

NOTICE:

Check the ground spare tire as well since this

E129450E01

210 (2.1, 31)

220 (2.2, 32)

Front kPa (kgf/cm

*1

240 (2.4, 35)

*1

240 (2.4, 35)

system monitors pressure of all tires including

the ground spare tire.

2

, psi) Rear kPa (kgf/cm2, psi)

*2

*2

210 (2.1, 31) *1 240 (2.4, 35)

220 (2.2, 32) *1 240 (2.4, 35)

*2

*2

*1: For driving under 100 mph (160 km/h)

*2: For driving at 100 mph (160 km/h) or over

(b) When the tire pressure warning light blinks (comes

on after blinking for 1 minute), there is a malfunction

in the system. Check for DTCs.

(c) It is necessary to register the transmitter ID in the

tire pressure warning ECU after replacing the tire

pressure warning valve and transmitter and/or tire

pressure warning ECU (See page TW-15).

(d) When replacing the tire pressure warning ECU;

(1) Using the DATA LIST, read the transmitter IDs

registered in the ECU and make a note of them

before removing the tire pressure warning ECU.

(2) Register the transmitter IDs after installing a new

tire pressure warning ECU.

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

Tire pressure warning valve and transmitter:

TW–7

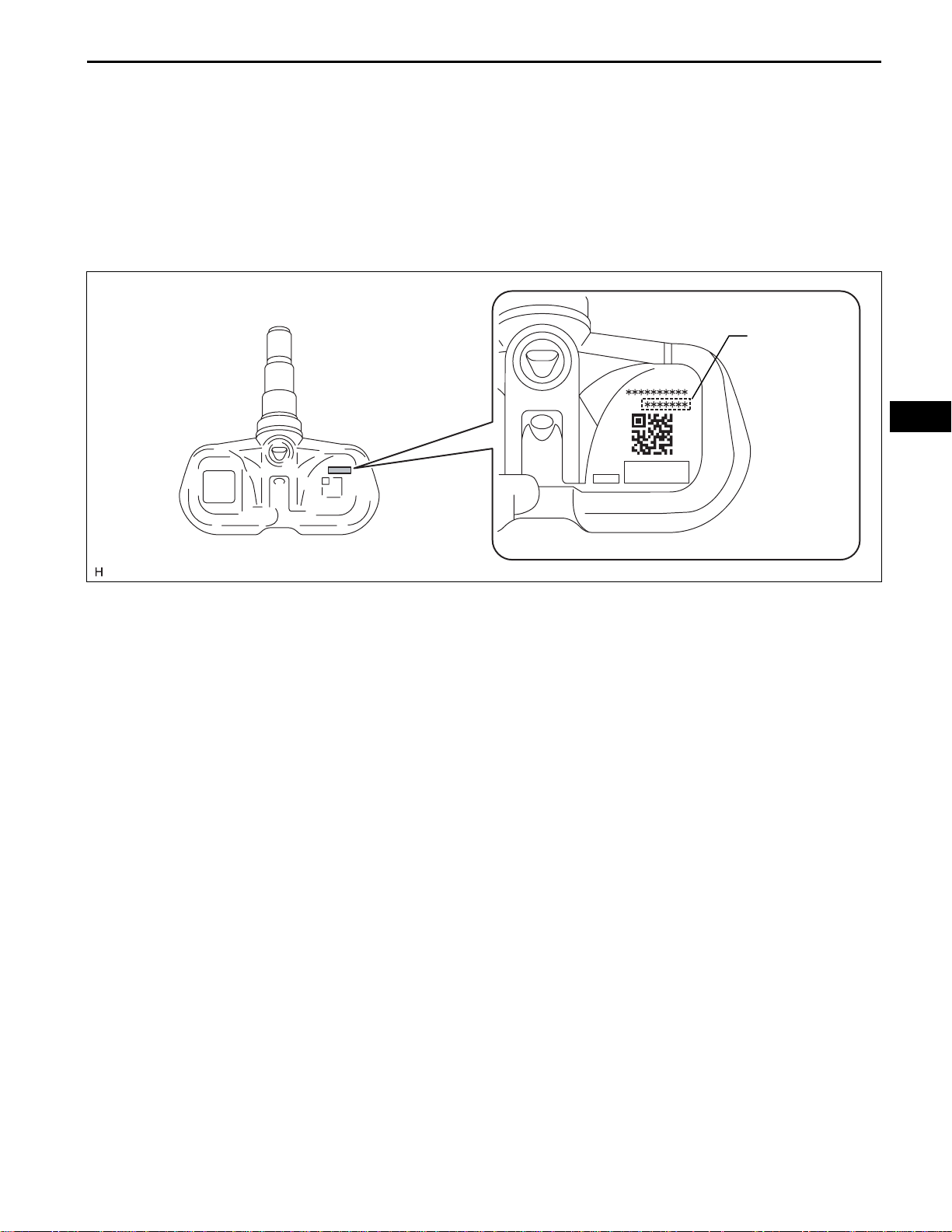

(e) When replacing the tire pressure warning valve and

transmitter;

(1) Take a note of the 7 digit number (transmitter ID)

written on the tire pressure warning valve and

transmitter when replacing it. Register the

transmitter IDs in the tire pressure warning ECU

after replacing the tire pressure warning valve

and transmitter and installing the tires and

wheels on the vehicle.

Transmitter ID

(7 digit number)

TW

NOTICE:

The transmitter ID is written on the tire

pressure warning valve and transmitter. It

will be unable to be read after installing the

tire pressure warning valve and transmitter

on the tire and wheel. Therefore, take a note

of the transmitter ID before installing the tire

pressure warning valve and transmitter.

(f) When replacing the tire pressure warning ECU and

the tire pressure warning valves and transmitters; It

is necessary to perform the initialization (See page

TW-18) after the registration (See page TW-15).

(g) Precautions about the tire pressure;

• The tire pressures decrease naturally.

• In winter, tire pressure may decrease due to low

ambient temperatures (tire pressure decreases

by approximately 10 kPa (0.2 kgf/cm

2

, 1.45 psi)

for every 10°C (50°F) drop in the ambient

temperature). Therefore, the tire pressure

warning is more likely to operate if the tire

pressures are not adjusted appropriately. If the

daily temperature variation is large, pressurize

the tires high so that the tire pressures are

suitable under cold conditions. Incorrect tire

pressure warning operation becomes less likely.

3. IN CASE OF TIRE AND WHEEL REPLACEMENT

(a) When tires and wheels are replaced, always ensure

that each transmitter ID is correctly registered.

E128762E02

TW

TW–8

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

4. IN CASE OF REPLACEMENT OF TIRE PRESSURE

WARNING ECU, TIRE PRESSURE WARNING VALVE

AND TRANSMITTER, OR TIRE(S) WITH DIFFERENT

TIRE PRESSURE

(a) Initialize the tire pressure warning system after any

of the following is performed:

• Replacing the tire pressure warning ECU or the

tire pressure warning valve and transmitter

• Installing tire(s) which require different tire

pressure

HINT:

The tire pressure warning system will not operate

properly if it is not initialized (See page TW-18).

5. FAIL-SAFE FUNCTION

(a) When a system malfunction occurs in the tire

pressure warning system, the tire pressure warning

light blinks (comes on after blinking for 1 minute)

and informs the driver of the system failure.

(b) The result of this diagnosis is stored in the tire

pressure warning ECU.

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

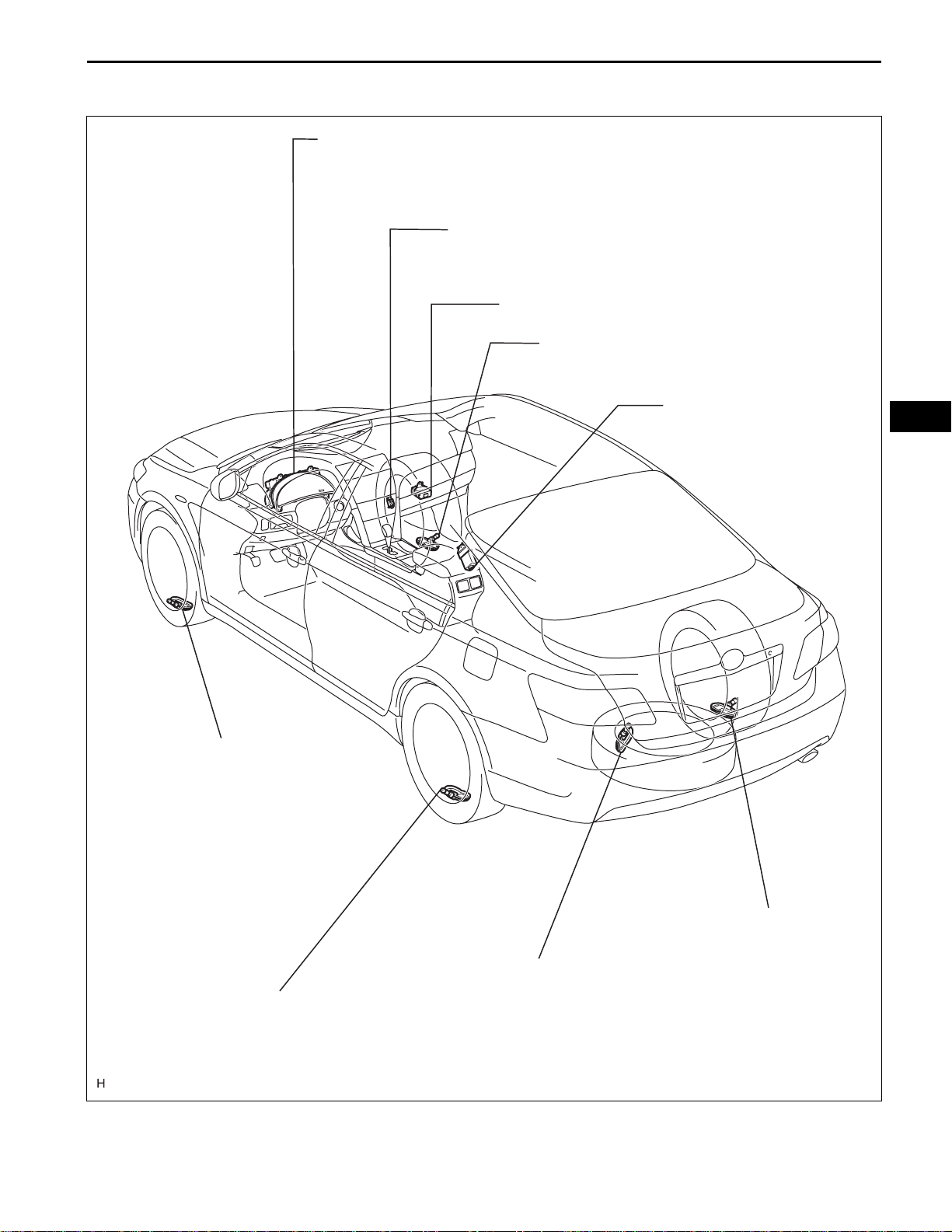

PARTS LOCATION

COMBINATION METER ASSEMBLY

- TIRE PRESSURE WARNING LIGHT

TIRE PRESSURE WARNING

RESET SWITCH

TIRE PRESSURE WARNING ECU

TIRE PRESSURE WARNING

VALVE AND TRANSMITTER

TW–9

TIRE PRESSURE WARNING

ANTENNA AND RECEIVER

TW

TIRE PRESSURE WARNING

VALVE AND TRANSMITTER

TIRE PRESSURE WARNING

VALVE AND TRANSMITTER

TIRE PRESSURE WARNING

VALVE AND TRANSMITTER

TIRE PRESSURE WARNING

VALVE AND TRANSMITTER (*)

*1: GROUND SPARE TIRE

E129453E01

TW–10

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

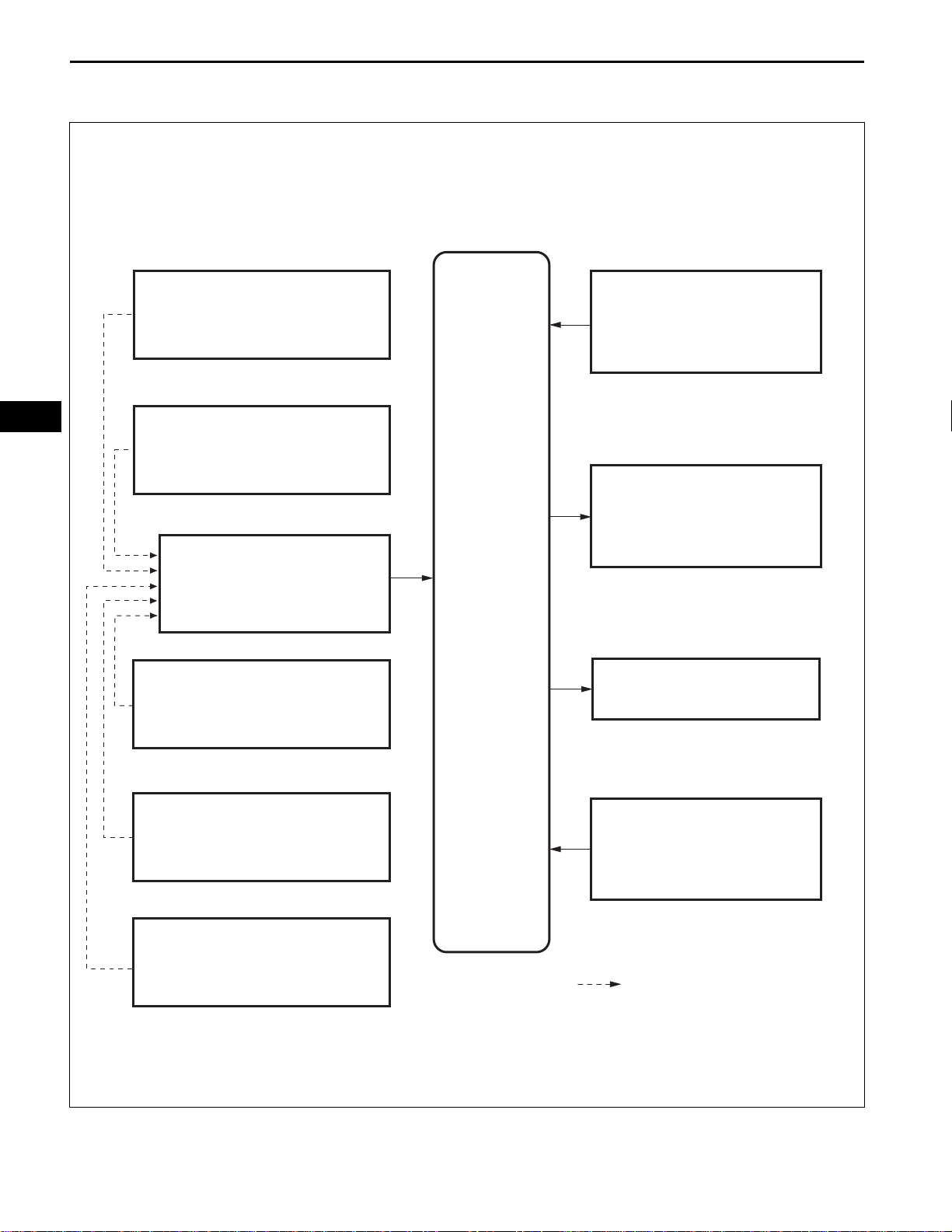

SYSTEM DIAGRAM

TW

Front Tire Pressure Warning Valve

and Transmitter LH

Front Tire Pressure Warning Valve

and Transmitter RH

Tire Pressure Warning Antenna

and Receiver

Rear Tire Pressure Warning Valve

and Transmitter LH

Combination Meter

(Vehicle Speed Signal)

Combination Meter (Tire

Pressure Warning Light)

Tire Pressure

Warning ECU

DLC3

Rear Tire Pressure Warning Valve

and Transmitter RH

Tire Pressure Warning Valve and

Transmitter (Spare Tire) (*)

Tire Pressure Warning

Reset Switch

:

Radio Signal

*: Ground Spare Tire

C138248E01

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

SYSTEM DESCRIPTION

1. DESCRIPTION OF SYSTEM

(a) A tire pressure warning valve and transmitter is

equipped with a tire pressure sensor and a

transmitter and is installed in a tire wheel assembly.

The sensor measures the tire pressure. The

measured value and transmitter ID are transmitted

to the tire pressure warning antenna and receiver on

the body as radio waves and then sent to the tire

pressure warning ECU from the tire pressure

warning antenna and receiver. If the transmitter ID

has already been registered, the ECU compares the

measured air pressure value with the standard

value. When the value is less than the standard

value registered in the tire pressure monitor ECU,

the warning light on the combination meter comes

on.

• For the differences in the air pressure settings by

the type of tires, a tire pressure warning reset

switch has been adopted.

TW–11

TW

Combination Meter Assembly

- Tire Pressure Warning Light

Tire Pressure

Warning Reset

Switch

Front

Tire Pressure Warning ECU

Tire Pressure Warning Valve and Transmitter

Tire Pressure Warning Valve and Transmitter

2. WHEN TIRE PRESSURE WARNING LIGHT IS LIT

(a) When the tire pressure warning light does not go off,

or when it comes on during driving, check tire

pressure. If the tire pressure warning light comes on

within several hours after adjusting the tire

pressure, the tire may have a slow air leak.

(b) Under the following conditions, the system may not

function properly.

• Facilities or devices that use similar radio

frequencies are located in the vicinity of the

vehicle.

Tire Pressure Warning

Antenna and Receiver

Tire Pressure

Warning Valve and

Transmitter (*)

*: Ground Spare Tire

E129451E02

TW

TW–12

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

• A radio device of similar frequency is used in the

vehicle.

• A large amount of snow or ice is stuck to the

vehicle, especially onto the wheels and around

the wheel houses.

• The battery of the sensor has been depleted.

• The tires without tire pressure warning valve and

transmitter are used.

• Tire chains are used.

• When the ground spare tire is not within the

receivable range of the electric wave, a signal

may not be received because the ground spare

tire is fixed. Accordingly, the system may not

function properly. If there is a possibility that the

tire pressure warning system does not receive a

signal from the grounde spare tire, rotate the tire

90°.

• If any wheels other than the specified ones are

used, the system may not function properly

because interference may prevent the radio

waves from being correctly transmitted from the

tire pressure sensor.

• Depending on the tire type, the system may not

function properly even though the specified

wheels are used.

(c) The average usage life of the grommet of the tire

pressure warning valve and transmitter is

approximately 5 years, at which time it must be

replaced.

Re-tighten the valve nut if the valve is leaking air,

although it is less than 5 years old and there is no

problem with grommets.

(d) After removing and installing the ECU or a sensor,

check for a diagnostic code and verify that it is a

normal code.

3. FUNCTION OF COMPONENTS

Components Function

Combined as a single unit with a disc wheel air valve, it measures tire pressure and

Tire pressure warning valve and transmitter

Tire pressure warning antenna and receiver

Tire pressure warning ECU

Tire pressure warning light

Tire pressure warning reset switch Enters the initialization mode for tire or wheel replacement.

temperature and transmits an ID number for measurement value and identification.

Built-in the battery.

Receives and transmits a necessary signal from the transmitter to the tire pressure

warning ECU.

Receives the signal from the receiver and identifies it as vehicle's own signal. If the

measured value is equal to or lower than the specified value, it transmits a signal so

that the air pressure warning light on the combination meter comes on.

Located in the combination meter, it informs the driver of lowered tire air pressure

and system failure.

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

4. TIRE PRESSURE WARNING RESET SWITCH

• By operating the tire pressure warning reset switch,

the tire pressure warning ECU can be set to issue a

warning at an inflation pressure that corresponds to

the type of tires.

Therefore, the dealer must set the warning threshold

to the proper value in order to comply with the local

regulations.

• Operate the tire pressure warning reset switch only

after the inflation pressures of all tires (including the

full-size spare tire) have been adjusted on the vehicle.

• To initialize the system, press and hold the tire

pressure warning reset switch for 3 seconds or longer

with the ignition switch on (IG). After the initialization

process has started, the warning light blinks 3 times

(1 second on, 1 second off).

• During initialization, the tire pressure warning valve

and transmitter measures the inflation pressure of the

tires, and registers the signals that are transmitted

into the tire pressure warning ECU at a frequency of

once per minute. The initialization process is

completed when signals from the all tires (including

the ground spare tire) have been received.

TW–13

TW

TW–14

1

NEXT

2

NEXT

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

HOW TO PROCEED WITH

TROUBLESHOOTING

The intelligent tester can be used at steps 3, 7 and 9.

Vehicle Brought to Workshop

Customer Problem Analysis

TW

3

NEXT

4

5

Check Tire Pressure Warning Light and Indicator Condition

(a) Turn the ignition switch on (IG).

(b) Record the condition of the tire pressure warning light on

the combination meter assembly.

(c) Refer to the "TIRE PRESSURE WARNING LIGHT AND

INDICATOR CHART" section of the DIAGNOSIS

SYSTEM for checking the condition of the tire pressure

warning light (See page TW-24).

DTC Check and Clear

DTC is output: Go to step 5

DTC is not output: Go to step 6

DTC Chart

Problem Symptom Confirmation

6

Problem Symptoms Table

7

Go to step 8

Symptom does not occur: Symptom

simulation

Symptom occurs: Go to step 7

Go to step 9

8

NEXT

9

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

Circuit Inspection

Repair

TW–15

(a) Refer to PRECAUTION (See page TW-6).

(b) Refer to SYSTEM DESCRIPTION (See page TW-11).

(c) Set the tire pressures to the appropriate specified

values.

(d) Perform initialization (See page TW-18).

(e) Perform test mode procedure (See page TW-20).

(1) Check for a DTC (See page TW-28).

(2) Clear the DTC.

(3) Identify the transmitter corresponding to a DTC.

(f) Perform registration of the transmitter ID (See page TW-

15).

(g) Check the terminals of ECU (See page TW-23).

(h) Refer to DATA LIST / ACTIVE TEST (See page TW-29).

TW

NEXT

10

NEXT

End

Confirmation Test

(a) Check for a DTC (See page TW-28).

(b) Perform initialization (See page TW-18).

(c) Confirm that the initialization has been completed.

TW

TW–16

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

REGISTRATION

1. READ TRANSMITTER ID

Prepare the all transmitter ID data before starting

registration.

HINT:

• Read the registered transmitter IDs that are stored in

the ECU using the intelligent tester and note them

down.

• If reading stored transmitter IDs is impossible due to

malfunctions of components such as the tire pressure

warning antenna and receiver, remove the tires from

the wheels and check the IDs located on the tire

pressure warning valves and transmitters (See page

TW-6).

• When replacing the tire pressure warning ECU, read

the IDs stored in the old ECU using the intelligent

tester.

• When replacing the tire pressure warning valves and

transmitters, note down the IDs written on the tire

pressure warning valves and transmitters.

DLC3

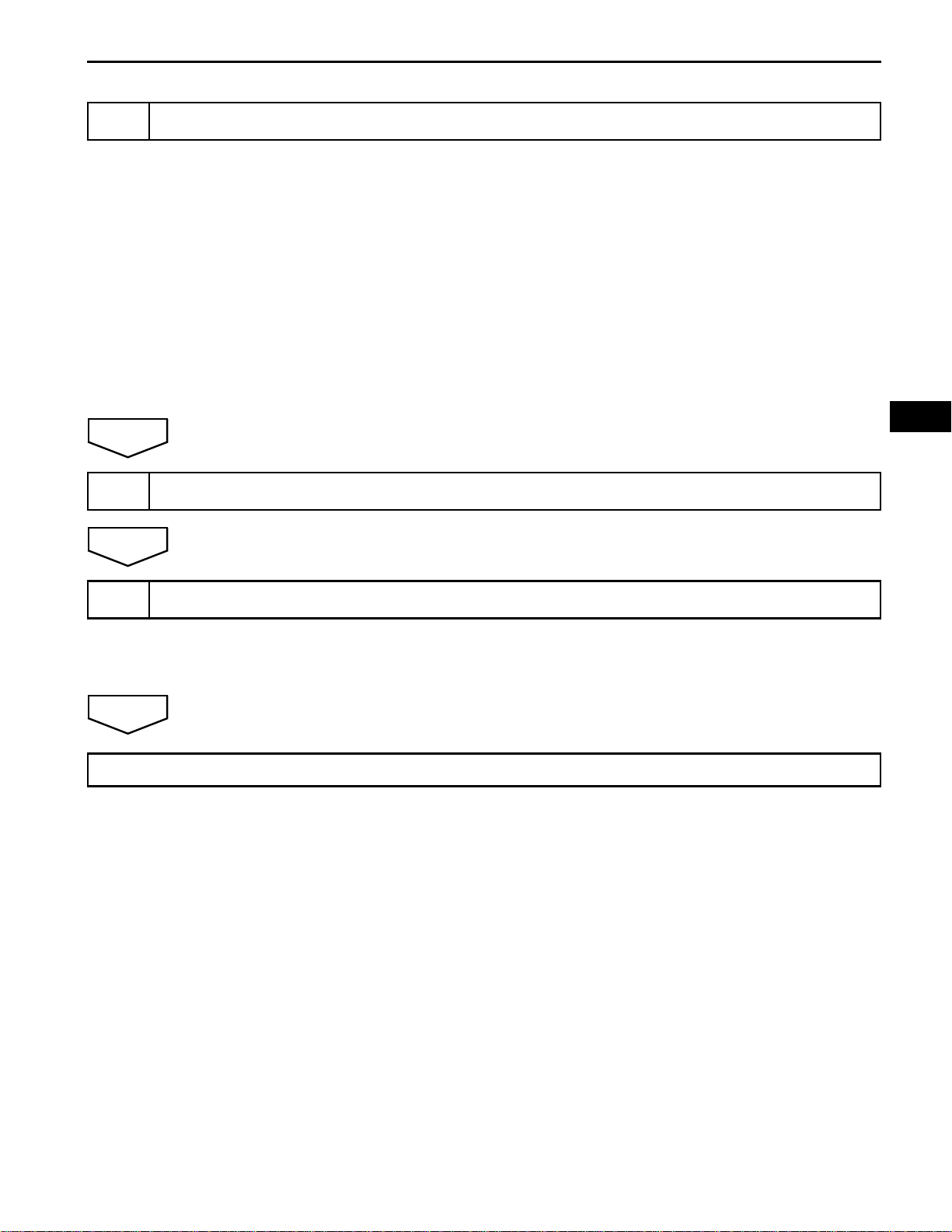

2. REGISTER TRANSMITTER ID

NOTICE:

It is necessary to register the transmitter ID in the

tire pressure warning ECU when replacing the tire

pressure warning valve and transmitter and/or tire

pressure warning ECU.

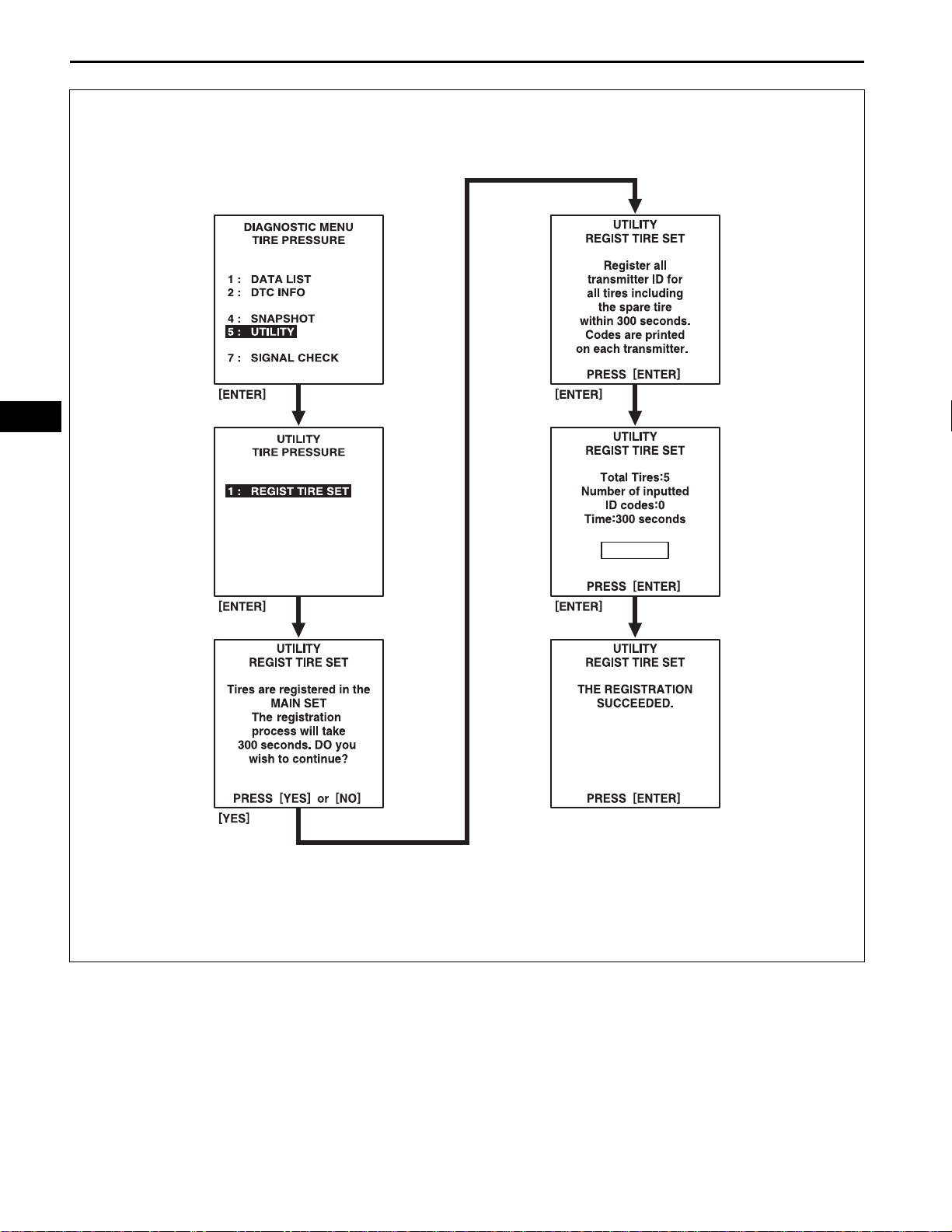

(a) Connect the intelligent tester to DLC3 (Procedure

"A").

(b) Turn the ignition switch on (IG) (Procedure "B").

(c) Select the REGIST TIRE following the intelligent

tester screen (UTILITY - REGIST TIRE) (Procedure

"C").

Intelligent Tester

C131977E09

F100622

(d) Input the IDs (ID1 to ID4 or ID5) using the intelligent

tester and transmit them to the tire pressure warning

ECU (Procedure "D").

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

(e) Set the ID transmission condition to "ID Registration

is complete" (Procedure "E").

HINT:

• The previously registered IDs will be deleted

from the memory when the registration is

completed.

• If the procedures "C" to "D" are not completed

within 5 min. , the mode will return to the normal

operation mode.

C107265

• When the system is in initialization mode after

the tire pressure warning reset switch has been

operated, the registration is disabled until the

initialization process is canceled or completed.

TW–17

TW

TW

TW–18

Registration Procedure

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

3. CONFIRMATION OF TRANSMITTER ID

REGISTRATION

(a) Connect the intelligent tester to DLC3 (ignition

switch is off).

(b) Turn the ignition switch on (IG).

(c) Select "TIREPRESS" by following the prompts

displayed on the intelligent tester.

F101083E01

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

(d) Confirm that the data of tire pressure of all tires

(including the ground spare tire) are displayed on

the intelligent tester screen.

NOTICE:

• It may take up to 1 minute or more to update

the tire pressure data.

• If the IDs have not been registered, some of

DTC C2171/71 is set in the tire pressure

warning ECU after 51 minutes or more.

TW–19

TW

TW

TW–20

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

Cold tire inflation pressure

Tire size

P215/60R16 94W

P215/55R17 93V

INITIALIZATION

1. INITIALIZATION

Front kPa (kgf/cm

210 (2.1, 31)

220 (2.2, 32)

NOTICE:

• Perform initialization after the transmitter ID

registration is completed.

• Initialization is necessary after replacing any of

the ECU, tires with different tire pressure, or tire

pressure warning valve and transmitter, or when a

new vehicle is delivered.

• Perform the tire pressure adjustment after the

vehicle has sufficiently cooled down. If the

vehicle is not sufficiently cooled down, increase

the air pressure by 20 to 30 kPa (0.2 to 0.3 kgf/

2

cm

, 2.9 to 4.3 psi) above the specified value.

(a) Set the air pressure of all wheels, including the

ground spare tire, to the specified value.

2

, psi) Rear kPa (kgf/cm2, psi)

*1

240 (2.4, 35)

*1

240 (2.4, 35)

*2

*2

210 (2.1, 31) *1 240 (2.4, 35)

220 (2.2, 32) *1 240 (2.4, 35)

*2

*2

Tire Pressure

Warning Reset

Switch

Tire Pressure Warning Light Output Pattern:

1 sec.

*1: For driving under 100 mph (160 km/h)

*2: For driving at 100 mph (160 km/h) or over

(b) Keep the tire pressure warning reset switch pressed

for 3 seconds or more with the ignition switch on

(IG).

(c) Check that the tire pressure warning light blinks 3

times (1 second ON, 1 second OFF).

HINT:

• Initialization will be completed if signals are

received from all the wheels. Initialization will be

canceled if the ignition switch is turned off during

initialization.

ON

OFF

1 sec.

E129454E01

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW–21

DLC3:

CG

TC

(d) Wait for 2 or 3 minutes with the ignition switch on

(IG).

NOTICE:

• The initialization is normally completed

87654321

within 2 to 3 minutes.

• If the initialization has not been completed

161514131211109

successfully, DTC C2177/77 is set

approximately 20 minutes.

• The initialization can be terminated by

F100115E55

making a short circuit between terminals TC

and CG of the DLC3 connector.

(e) Confirm that the initialization has been completed

using the intelligent tester.

(1) Change the mode to test mode using intelligent

tester and check that test DTCs have been

stored.

• The test DTCs will not be indicated until the

system initialization is complete.

TW

• After the initialization has been completed

successfully, the test DTCs (C2181/81 to

C2191/91) are indicated.

NOTICE:

The following operations can be used

instead of above procedure

1. T urn the ig nition switch from off to on (IG).

2. Monitor the tire pressure values of all the

wheels using intelligent tester.

3. If the tire pressure values cannot be

displayed on the intelligent tester screen,

the initialization has failed.

4. It takes 2 to 3 minutes to display the tire

pressure data.

HINT:

• In winter, as the tire pressure may decrease

depending on the ambient temperature,

increase the tire pressure by 20 to 30 kPa

(0.2 to 0.3 kgf/cm

2

, 2.9 to 4.3 psi) above the

specified value after confirmation that the

initialization has been completed.

TW

TW–22

DLC3

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

Intelligent Tester

C131977E01

TEST MODE PROCEDURE

1. ENTER TEST MODE

HINT:

• Operation of the tire pressure warning reset switch

can be checked in TEST MODE.

• During TEST MODE, the system is not initialized by

pushing the tire pressure warning reset switch. The

circuit of the tire pressure warning reset switch can be

inspected during this mode.

(a) Make sure that the ignition switch is off.

(b) Connect the intelligent tester to DLC3.

(c) Turn the ignition switch on (IG).

(d) Select the TEST MODE on intelligent tester.

(e) Confirm that the tire pressure warning light in the

combination meter blinks at 0.125 second intervals.

2. PERFORM SIGNAL CHECK

HINT:

• When entering signal check mode, the tire pressure

warning ECU sets all the signal check DTCs first.

After completing signal check for each inspection

item, the DTCs for systems that are determined to be

normal by the tire pressure warning ECU will be

erased.

The DTCs for other inspection items may not be

erased when only a certain signal is inspected.

• When signal check returns to normal mode, all the

signal check DTCs will be erased.

DLC3

(a) Make sure that the ignition switch is off.

(b) Connect the intelligent tester to DLC3.

(c) Turn the ignition switch on (IG).

Intelligent Tester

C131977E01

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

(d) Select the SIGNAL CHECK on intelligent tester.

TW–23

TW

(e) Drive the vehicle at 12 mph (20 km/h) or more for 10

seconds or more. For checking the vehicle speed

signal (C2191/91).

(f) Loosen the valve core and rapidly reduce the

pressure (at least 40 kPa (0.41 kg/cm

within 30 seconds or more). For checking the

transmitter data (C2181/81 to C2185/85).

HINT:

The transmitter ID can be transmitted by rapidly

reducing the tire pressure.

(g) Check that the tire pressure warning system test

mode DTCs are erased.

SIGNAL CHECK DTC Test Signal Signal Check DTC Clear Condition

C2181/81 to C2185/85 Transmitter Data

C2191/91 Vehicle Speed Signal

Receive data from the transmitter which has a registered ID in

the tire pressure warning ECU

Vehicle speed of 12 mph (20 km/h) or more is detected for 3

seconds or more

(h) Check the tire pressure warning reset switch.

(1) Press the tire pressure warning reset switch.

(2) Check the tire pressure warning indicator light.

Test Signal Normal Condition

Tire Pressure Warning Reset Switch

• Switch ON: TPWS indicator comes on

• Switch OFF: TPWS indicator blinks

2

, 5.8 psi)

C110644

TW

TW–24

SIGNAL CHECK DTC is output Repair the faulty part and enter SIGNAL CHECK again

SIGNAL CHECK DTCs are cleared No problem

DTC No. Detection Item Trouble Area

C2181/81

(TW-38)

C2182/82

(TW-38)

C2183/83

(TW-38)

C2184/84

(TW-38)

C2185/85 (TW-38) Transmitter ID5 not received

C2191/91

(TW-61)

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

Condition Procedure

Transmitter ID1 not received

Transmitter ID2 not received

Transmitter ID3 not received

Transmitter ID4 not received

Vehicle speed signal error

(i) Result

HINT:

After the signal check is completed, check for a

DTC and signal check DTC to confirm the system

status.

(j) End of SIGNAL CHECK

After completing the test mode (SIGNAL CHECK), turn the

ignition switch off and disconnect the tester.

DTC of SIGNAL CHECK (TEST DIAGNOSIS) function:

If a trouble code is displayed during the test mode DTC

check, check the circuit listed for that code. For details

of each code, refer to the relevant page listed under

respective "DTC No." in the chart.

• Tire pressure warning valve and transmitter

• Tire pressure warning antenna and receiver

• Wire harness or connector

• Tire pressure warning ECU

• Tire pressure warning valve and transmitter

• Tire pressure warning antenna and receiver

• Wire harness or connector

• Tire pressure warning ECU

• Tire pressure warning valve and transmitter

• Tire pressure warning antenna and receiver

• Wire harness or connector

• Tire pressure warning ECU

• Tire pressure warning valve and transmitter

• Tire pressure warning antenna and receiver

• Wire harness or connector

• Tire pressure warning ECU

• Tire pressure warning valve and transmitter

• Tire pressure warning antenna and receiver

• Wire harness or connector

• Tire pressure warning ECU

• Vehicle speed sensor

• Combination meter assembly

• Wire harness or connector

• Tire pressure warning ECU

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TIRE PRESSURE WARNING SYSTEM:

Symptom Suspected area See page

Tire pressure warning system does not operate.

DTC check cannot be done.

Tire pressure warning light malfunctions (Remains on).

Tire pressure warning light malfunctions (Blinking).

Initialization cannot be done.

TW–25

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected Area"

column of table. Check each symptom by checking the

suspected areas in the order they are listed. Replace p arts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

1. Tire pressure warning valve and transmitter TW-77

2. Tire pressure warning antenna and receiver TW-73

3. Power source circuit TW-67

4. TC and CG terminal circuit TW-69

5. Combination meter assembly ME-15

6. Tire pressure warning ECU TW-82

1. Power source circuit TW-82

2. TC and CG terminal circuit TW-69

3. Tire pressure warning ECU TW-82

1. Tire pressure check TW-3

2. Initialization TW-18

3. Tire pressure warning ECU connector poorly connected TW-24

4. Tire pressure warning light circuit TW-65

5. Tire pressure warning ECU TW-82

1. Check DTC TW-28

2. Tc and CG terminal circuit TW-69

3. Test mode (SIGNAL CHECK) TW-20

4. Tire pressure warning ECU TW-82

1. Test mode (SIGNAL CHECK) TW-20

2. Tire pressure reset switch TW-85

3. Tire pressure warning ECU TW-82

TW

TW

TW–26

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

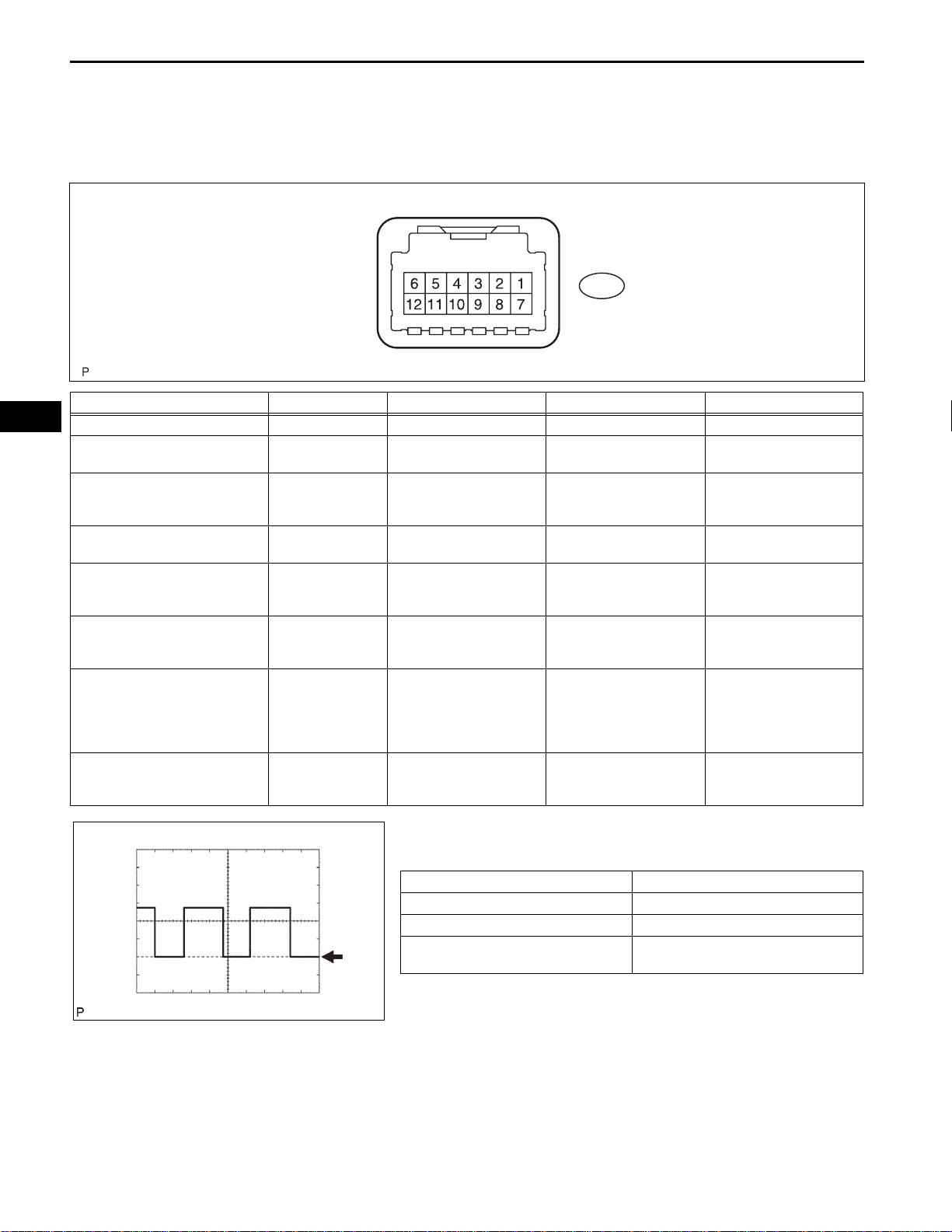

TERMINALS OF ECU

HINT:

Inspect the connectors from the back side while the

connectors are connected.

E60

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

IG (E60-7) - GND (E60-9) B - W-B IG power source Ignition switch on (IG) 10 to 16 V

SPD (E60-2) - GND (E60-9) V - W-B Vehicle speed signal Ignition switch on (IG)

• Ignition switch on (IG)

• Intelligent tester is

connected to DLC3

Ignition switch on (IG) 10 to 16 V

Ignition switch on (IG) 4.5 to 5.5 V

• Ignition switch on (IG)

• Tire pressure warning

reset switch on

• Ignition switch on (IG)

• The Tire pressure

warning antenna and

receiver is not

connected

Always Below 1 Ω

SIL (E60-10) - GND (E60-9) GR - W-B

IND (E60-5) - GND (E60-9) L - W-B

RF5V (E60-6) - GND (E60-9) LC - W-B

CLSW (E60-1) - GND (E60-9) O - W-B

RDA (E60-12) - GND (E60-9) G - W-B

GND2 (E60-11) - GND (E60-9) BR - W-B

Diagnostic communication

terminal

Tire pressure warning light

signal

Tire pressure warning

antenna and receiver

power source

Tire pressure warning

reset switch

Tire pressure warning

antenna and receiver

signal

Tire pressure warning

antenna and receiver

ground

Pulse generation (See

waveform 1)

Pulse generation (See

waveform 2)

8 to 15V

9 to 16 V

E129452E01

GND

F047507E05

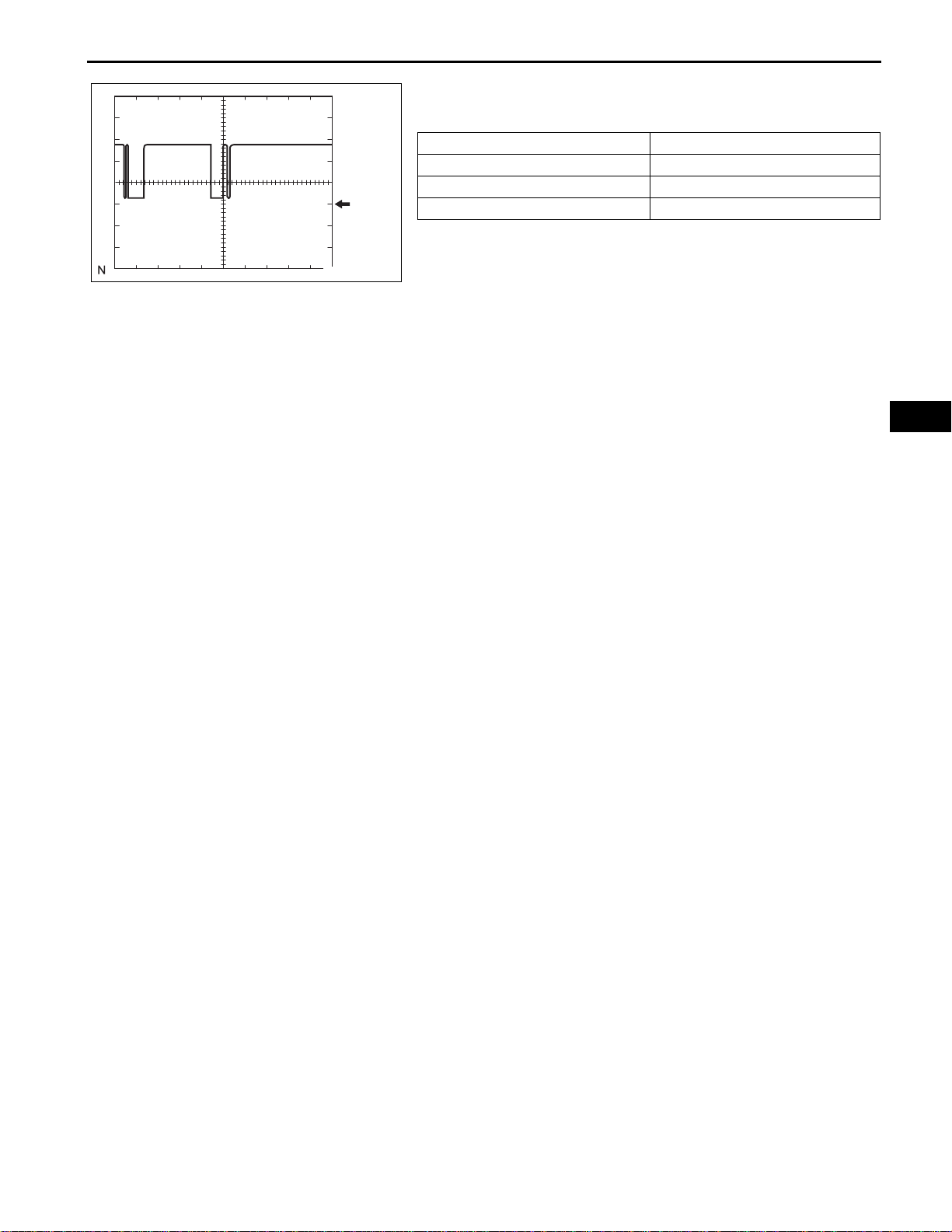

1. Waveform 1 (Reference)

(a) Waveform

Item Contents

Terminal SPD - GND

Tool setting 5V/DIV, 200ms/DIV.

Vehicle condition

While driving at approximately 12 mph

(20 km/h).

5 V

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

2. Waveform 2 (Reference)

1 ms

GND

C107353E03

(a) Waveform

Item Contents

Terminal SIL - Body ground

Tool setting 5 V/DIV., 1 ms/DIV.

Vehicle condition Communicating using intelligent tester

TW–27

TW

TW–28

CG

SG

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

DIAGNOSIS SYSTEM

1. CHECK BATTERY VOLTAGE

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge the battery before

proceeding.

2. CHECK DLC3

(a) The ECU uses the ISO 15765-4 for communication

CANH

SIL

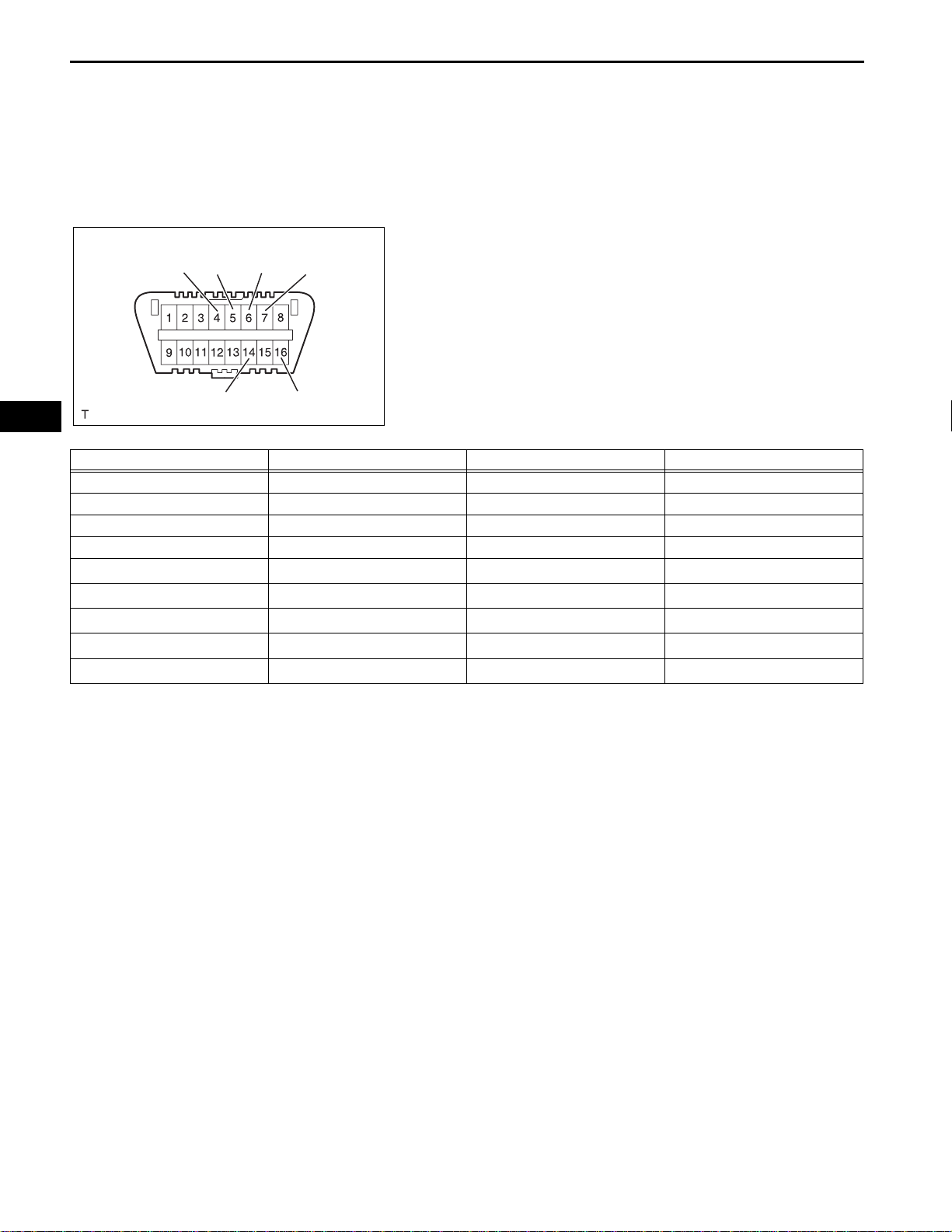

protocol. The terminal arrangement of the DLC3

complies with SAE J1962 and matches the ISO

15765-4 format.

TW

CANL

Symbols (Terminal NO. ) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1 Ω

SG (5) - Body ground Signal ground Always Below 1 Ω

BAT (16) - Body ground Battery positive Always 11 to 14 V

CANH (6) - CANL (14) CAN bus line

CANH (6) - CG (4) HIGH-level CAN bus line

CANL (14) - CG (4) LOW-level CAN bus line

CANH (6) - BAT (16) HIGH-level CAN bus line

CANL (14) - BAT (16) LOW-level CAN bus line

BAT

H100769E16

Ignition switch off

Ignition switch off

Ignition switch off

Ignition switch off

Ignition switch off

*

*

*

*

*

54 to 69 Ω

200 Ω or higher

200 Ω or higher

6 kΩ or higher

6 kΩ or higher

NOTICE:

*

Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the power switch, or any other switches

or the doors.

(b) If the result is not as specified, DLC3 may have a

malfunction. Repair or replace the harness and

connector.

HINT:

Connect the cable of the intelligent tester to DLC3,

turn the ignition switch on (IG) and attempt to use

the tester. If the display indicates that a

communication error has occurred, there is a

problem either with the vehicle or with the tester.

• If communication is normal when the tester is

connected to another vehicle, inspect DLC3 of

the original vehicle.

• If communication is still not possible when the

tester is connected to another vehicle, the

problem may be in the tester itself. Consult the

Service Department listed in the tester's

instruction manual.

Loading...

Loading...