Toyota Camry 2007-2009 Service Manual - Suspension

A-PDF Merger DEMO : Purchase from www.A-PDF.com to remove the watermark

SUSPENSION & AXLESUSPENSION

SUSPENSION – SUSPENSION SYSTEM

SUSPENSION SYSTEM

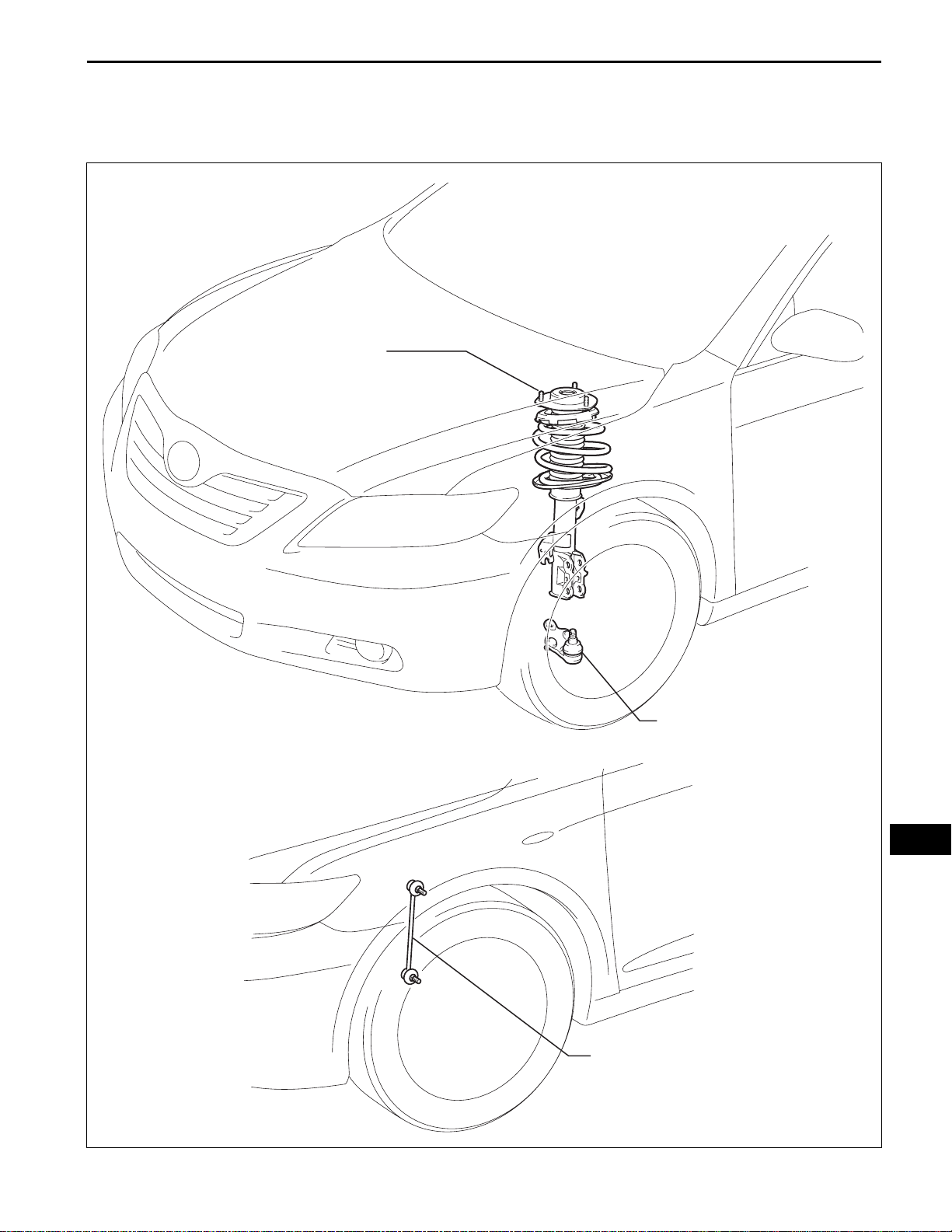

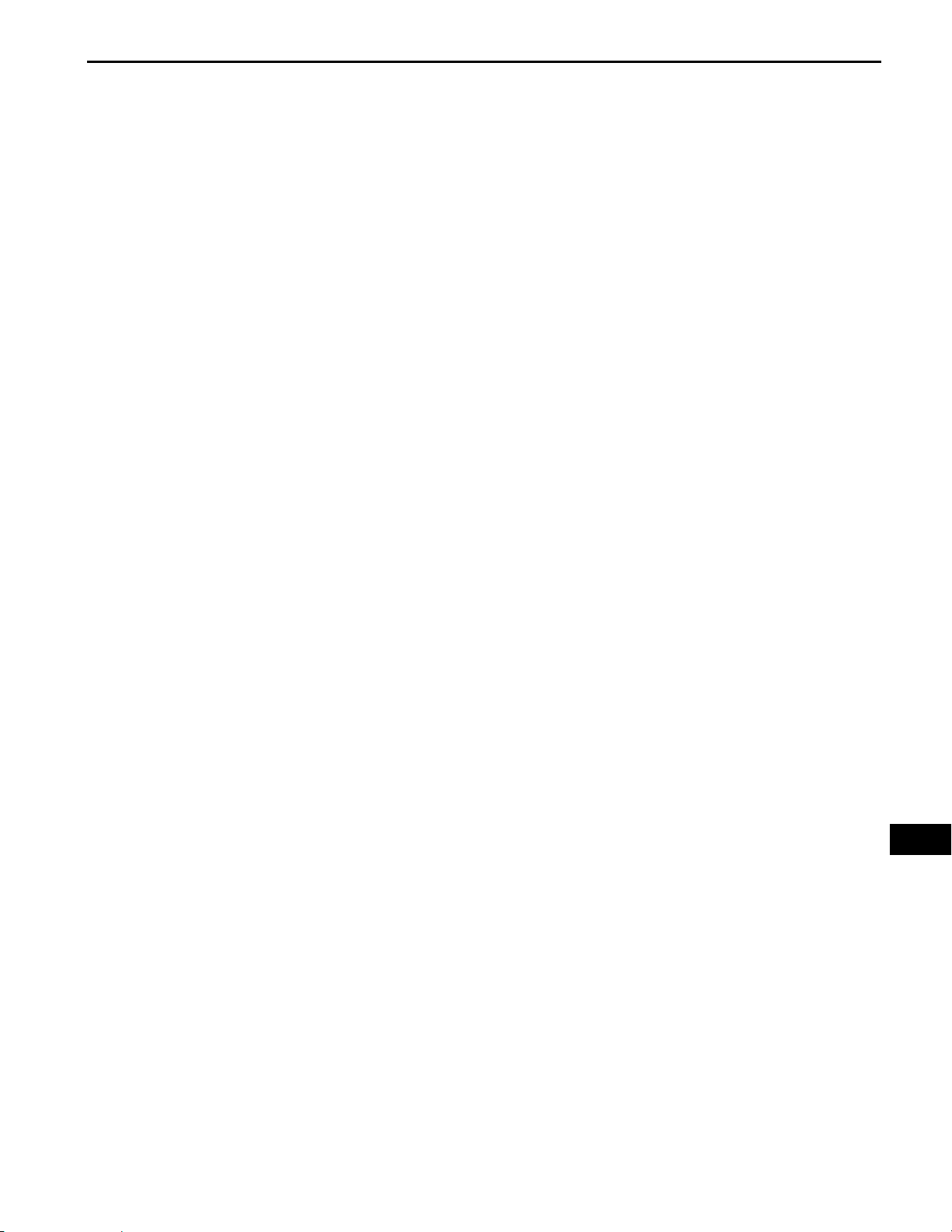

PARTS LOCATION

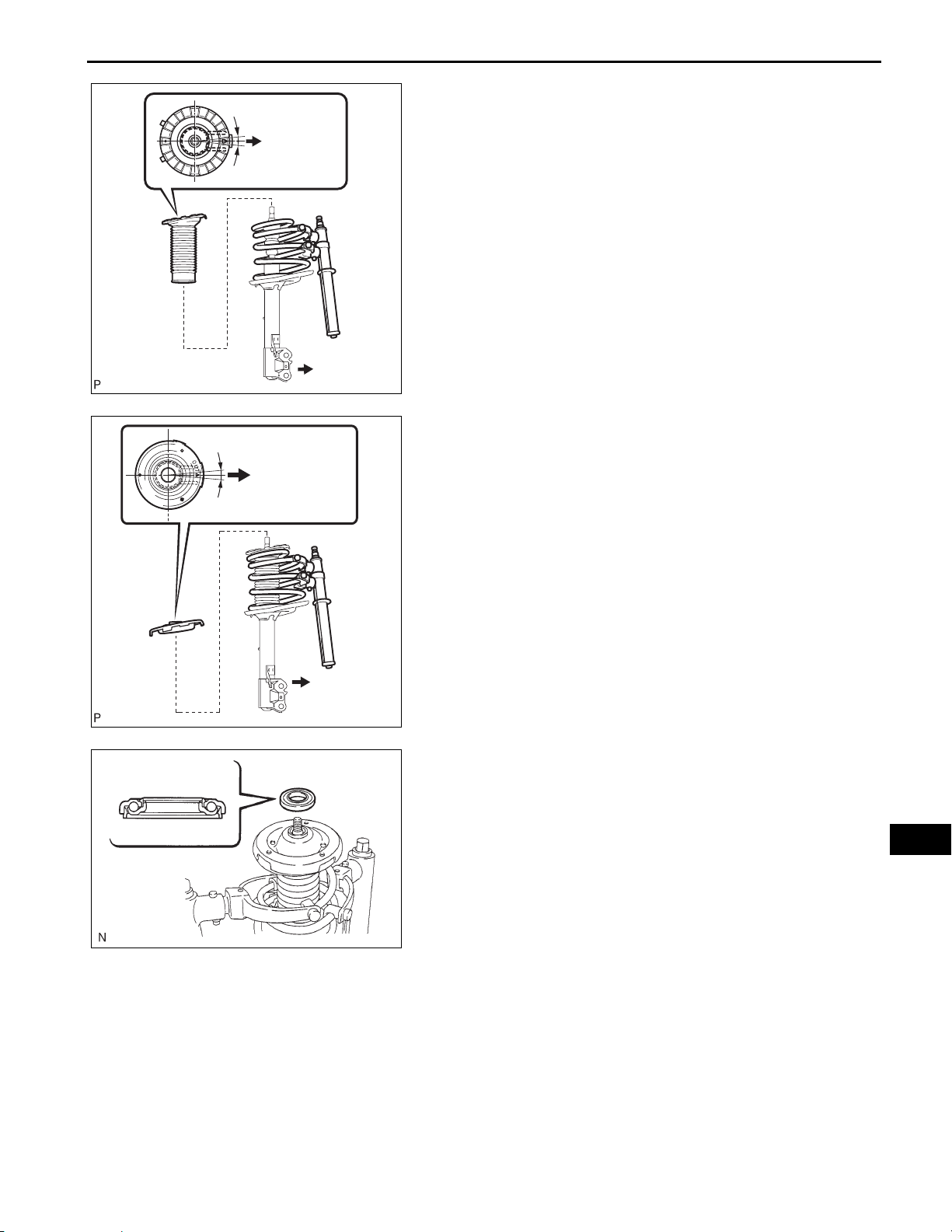

FRONT SHOCK ABSORBER

SP–1

FRONT LOWER BALL JOINT

FRONT STABILIZER LINK ASSEMBLY

C143401E01

SP

SP–2

SUSPENSION – SUSPENSION SYSTEM

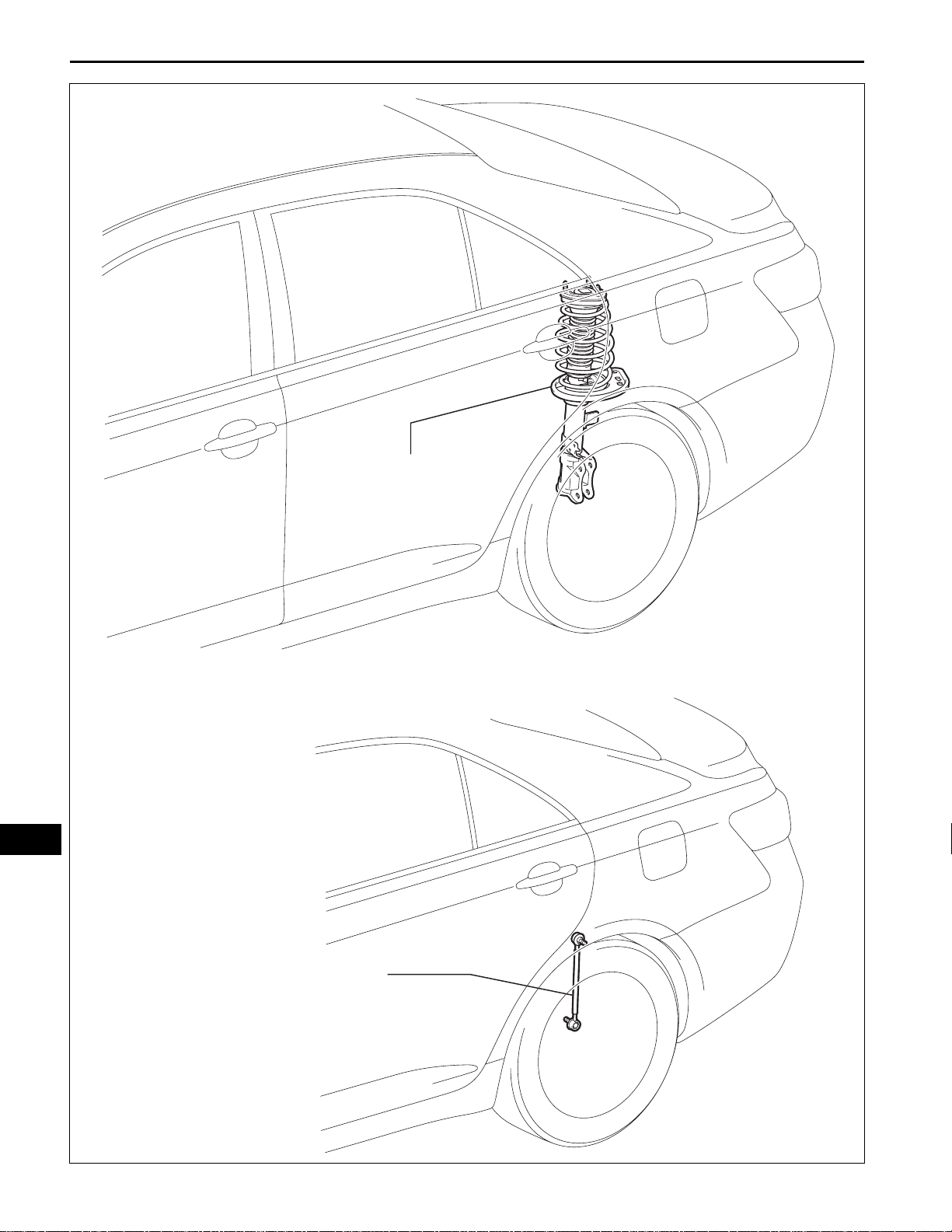

REAR SHOCK ABSORBER

SP

REAR STABILIZER LINK ASSEMBLY

C143402E01

SUSPENSION SYSTEM

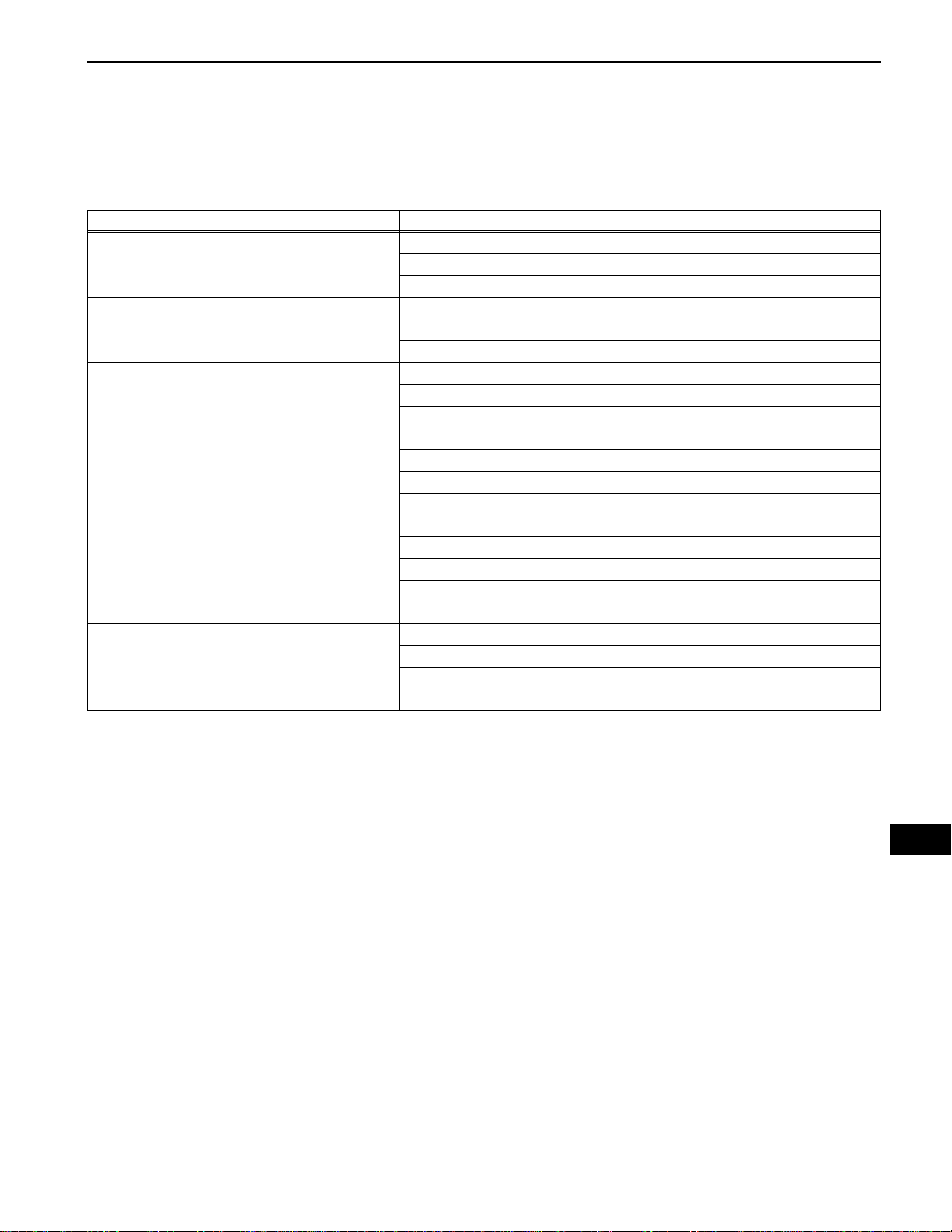

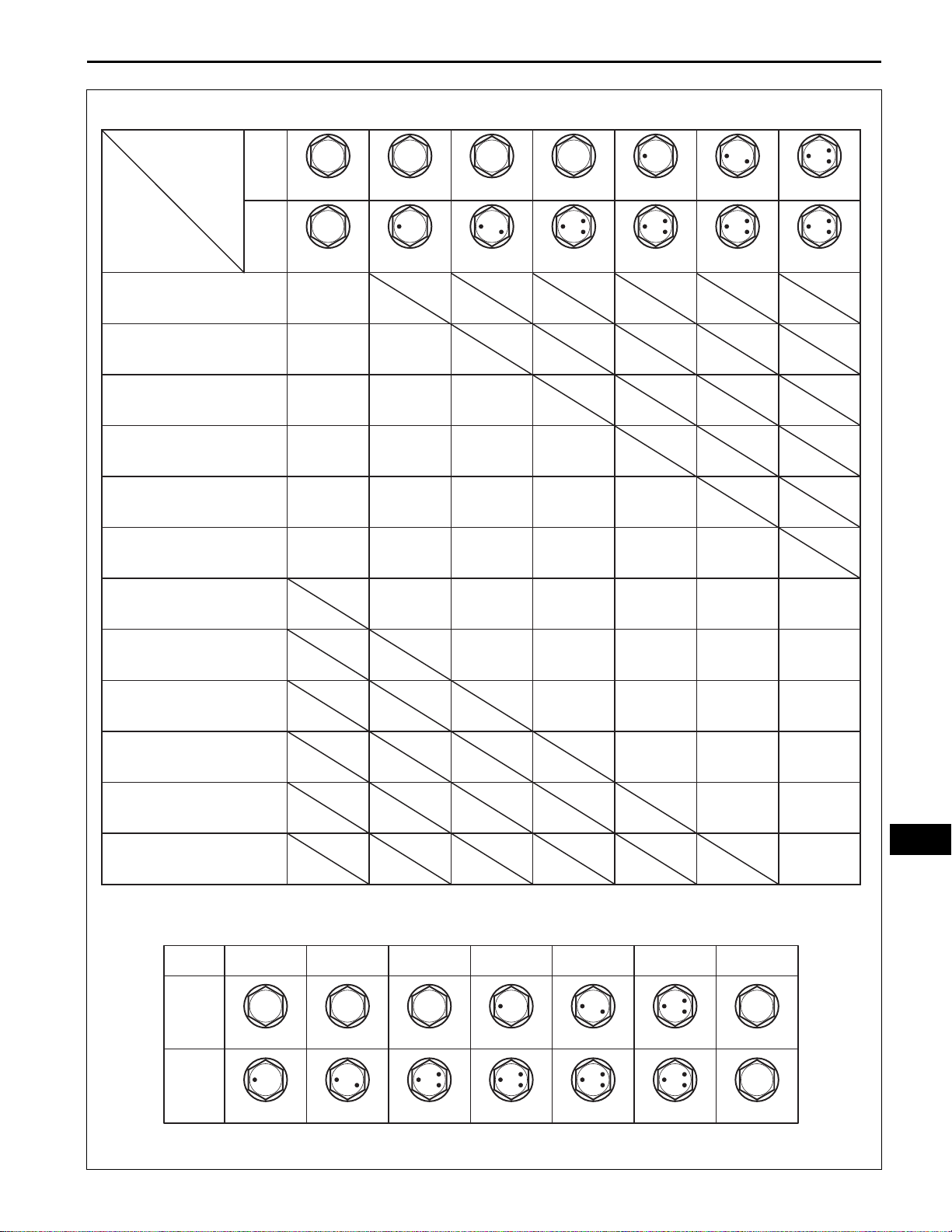

Symptom Suspected Area See page

Bottoming

Sways/pitches

Front wheel shimmy

Rear wheel shimmy

Abnormal tire wear

SUSPENSION – SUSPENSION SYSTEM

PROBLEM SYMPTOMS TABLE

Use the table below to help find the cause of the problem.

The numbers indicate the priority of the likely cause of the

problem. Check each part in order. If necessary, replace

these parts

1. Vehicle (Overloaded) -

2. Spring (Weak) SP-15

3. Shock absorber (Worn) SP-15

1. Tire (Worn or improperly inflated) TW-3

2. Stabilizer bar (Bent or broken) SP-28

3. Shock absorber (Worn) SP-15

1. Tire (Worn or improperly inflated) TW-3

2. Wheel (Out of balance) TW-3

3. Shock absorber (Worn) SP-15

4. Wheel alignment (Incorrect) SP-4

5. Lower ball joint (Worn) SP-23

6. Hub bearing (Worn) AH-5

7. Steering gear (Out of adjustment or broken) PS-61

1. Tire (Worn or improperly inflated) TW-3

2. Wheel (Out of balance) TW-3

3. Shock absorber (Worn) SP-35

4. Wheel alignment (Incorrect) SP-11

5. Hub bearing (Worn) AH-5

1. Tire (Worn or improperly inflated) TW-3

2. Wheel alignment (Incorrect) TW-3

3. Shock absorber (Worn) SP-15

4. Suspension parts (Worn) -

SP–3

SP

SP–4

SUSPENSION – FRONT WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT

ADJUSTMENT

1. INSPECT TIRES

(See page TW-3)

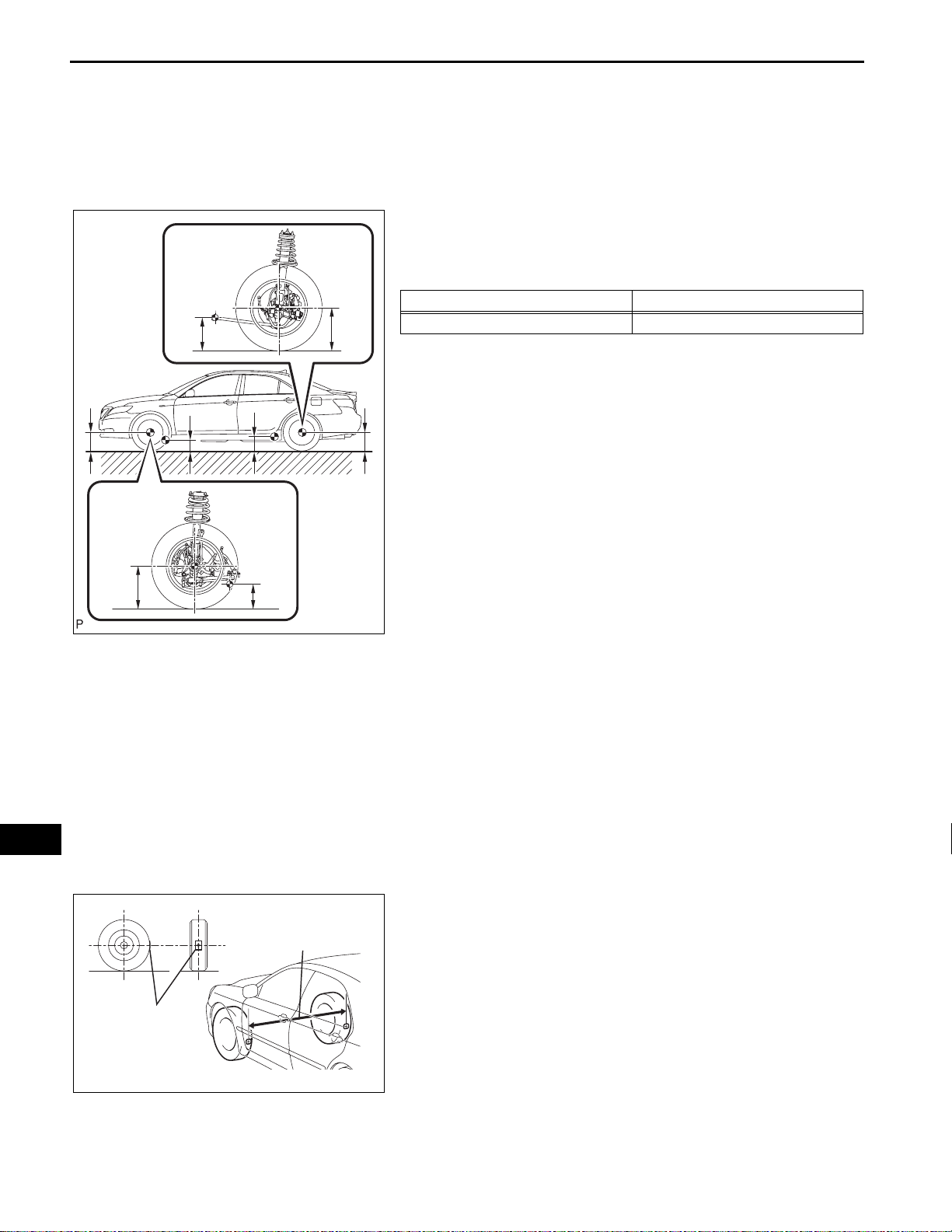

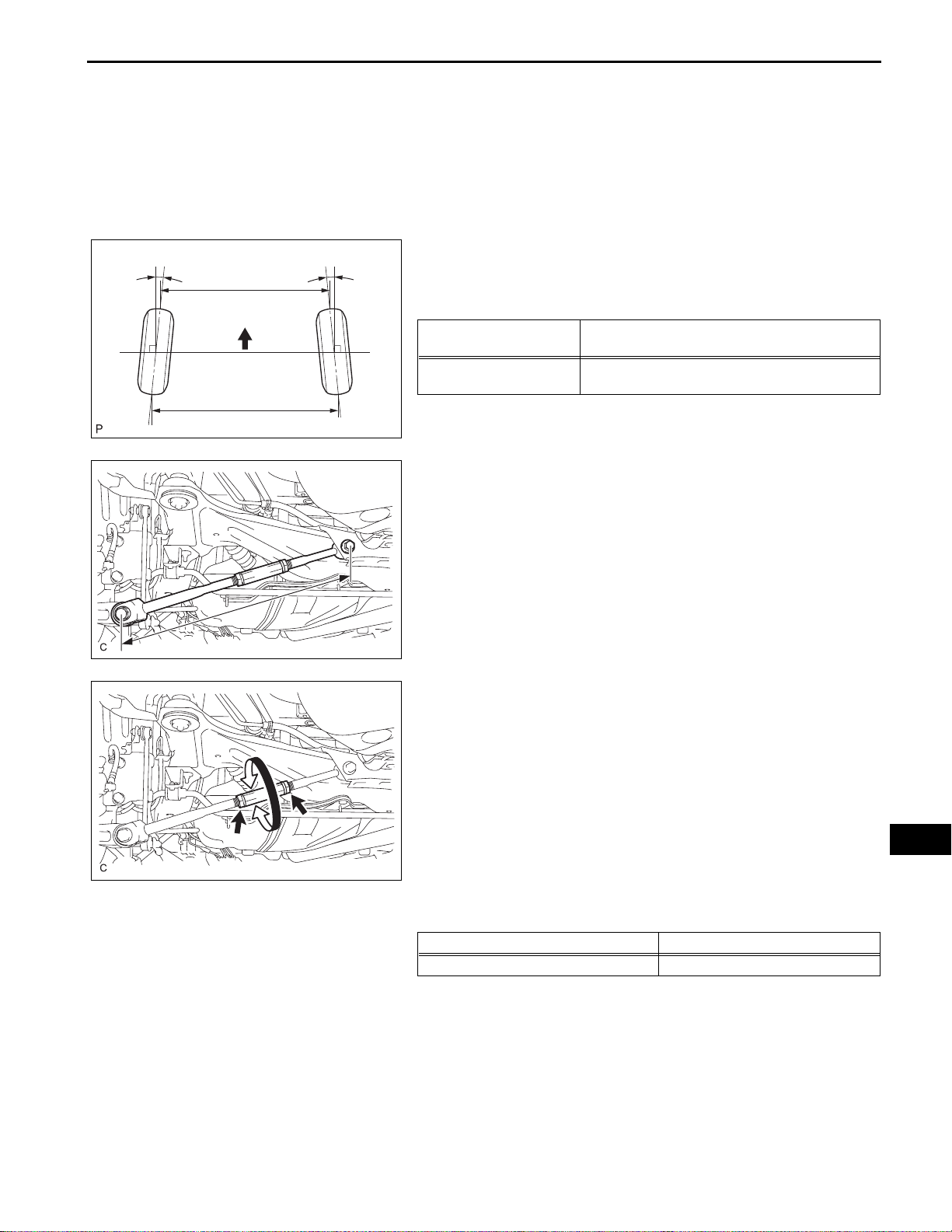

2. MEASURE VEHICLE HEIGHT

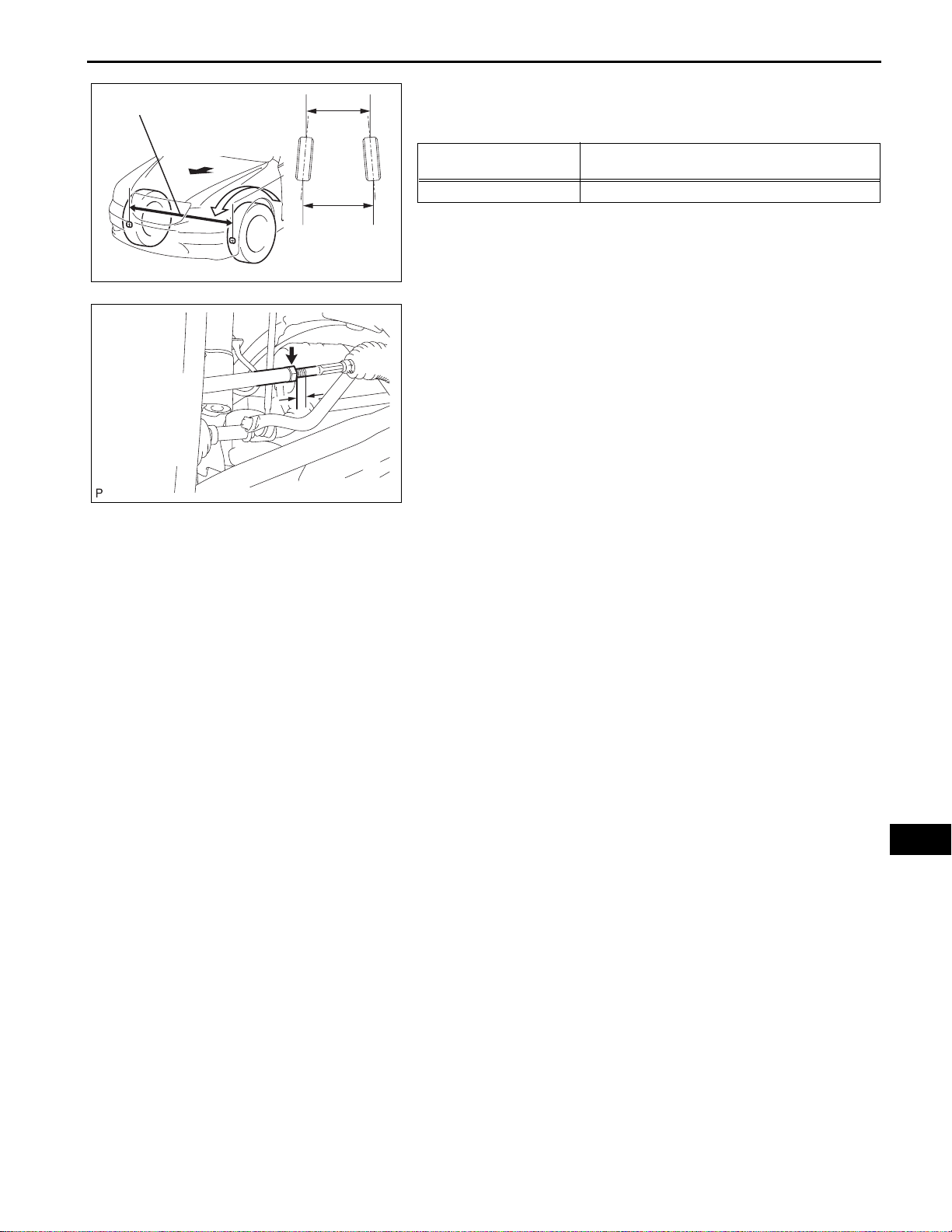

(a) Bounce the vehicle up and down at the corners to

stabilize the suspension. Inspect the vehicle height.

Vehicle height

Front A - B Rear C - D

D

A

B

C

C132408E01

129 mm (5.08 in.) 56 mm (2.20 in.)

Measuring points:

A:

Ground clearance of front wheel center

B:

Ground clearance of lower suspension arm

No. 2 bushing set bolt center

C:

Ground clearance of rear wheel center

D:

Ground clearance of strut rod set bolt center

NOTICE:

• Before inspecting the wheel alignment, adjust

the vehicle height to the specified value.

• Be sure to perform measurement on a level

surface.

• If it is necessary to go under the vehicle for

measurement, confirm that the parking brake

is applied and the vehicle is secured with

chocks.

SP

Tread Center

Marks

Dimension B

C125225E02

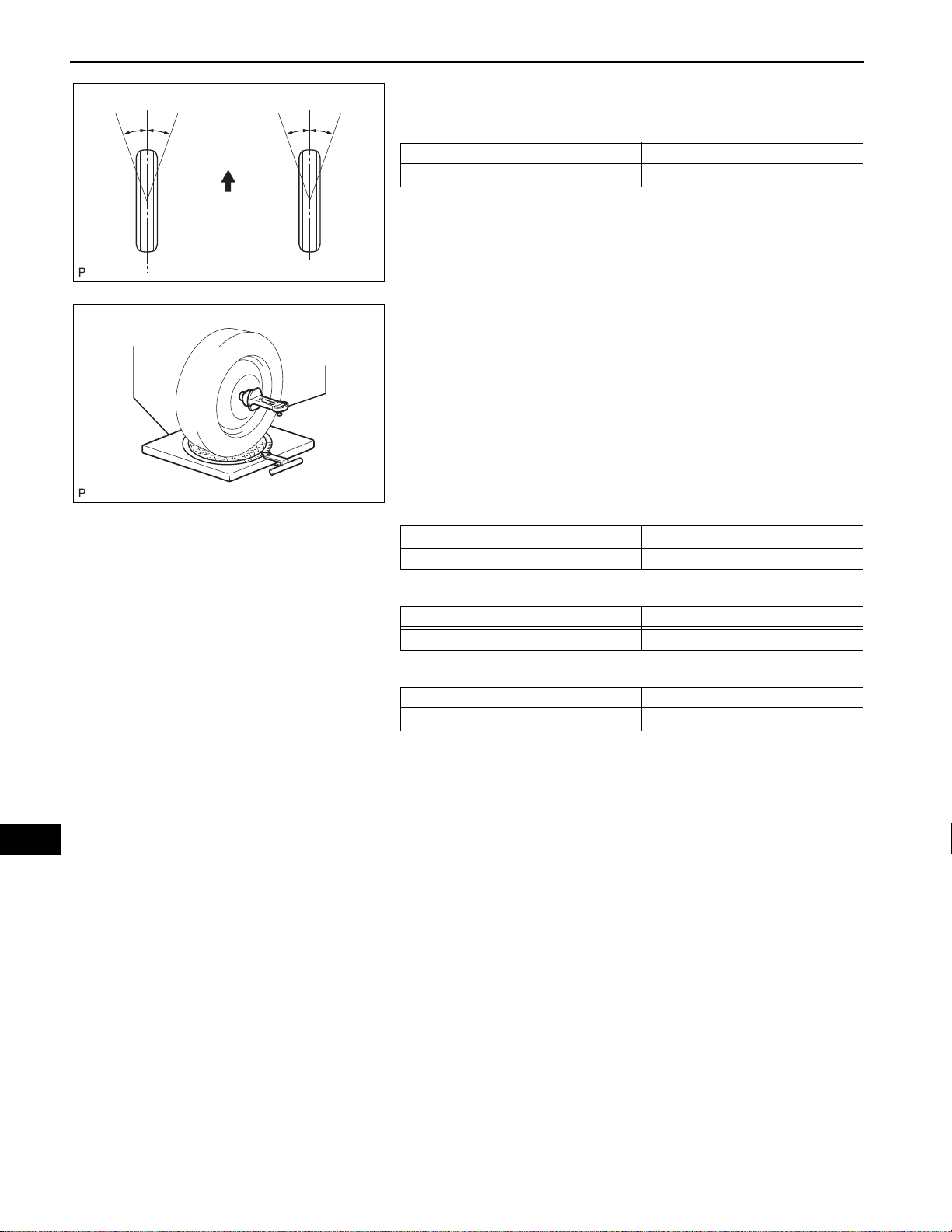

3. INSPECT TOE-IN

(a) Bounce the vehicle up and down at the corners to

stabilize the suspension.

(b) Release the parking brake and move the shift lever

to the neutral position.

(c) Push the vehicle straight ahead approximately 5 m

(16.4 ft). (*1)

(d) Put tread center marks on the rearmost points of the

front wheels and measure the distance between the

marks (dimension B).

(e) Slowly push the vehicle straight ahead to cause the

front wheels to rotate 180° using the front tire valve

as a reference point.

HINT:

Do not allow the wheels to rotate more than 180°. If

the wheels rotate more than 180°, perform the

procedure from *1 again.

SUSPENSION – FRONT WHEEL ALIGNMENT

SP–5

Dimension A

Front

A

B

C125226E03

C140712

(f) Measure the distance between the tread center

marks on the front side of the wheels.

Toe-in

Toe-in

(total)

A - B: 0 +- 2 mm (0 +- 0.08 in.)

-

HINT:

If toe-in is not within the specified range, adjust it at

the rack ends.

4. ADJUST TOE-IN

(a) Measure the thread lengths of the right and left rack

ends.

Standard:

Difference in thread length between the right

and left rack ends is 1.5 mm (0.06 in.) or less.

(b) Remove the rack boot set clips.

(c) Loosen the tie rod end lock nuts.

(d) Adjust the rack ends if the difference in thread

length between the right and left rack ends is not

within the specified range.

(1) Extend the shorter rack end if the measured

toe-in deviates toward the outside.

(2) Shorten the longer rack end if the measured

toe-in deviates toward the inside.

(e) Turn the right and left rack ends by equal amounts

to adjust the toe-in.

HINT:

Try to adjust the toe-in to the center of the specified

range.

(f) Make sure that the lengths of the right and left rack

ends are the same.

(g) Tighten the tie rod end lock nuts.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

NOTICE:

Temporarily tighten the lock nut while holding

the hexagonal part of the steering rack end so

that the lock nut and the steering rack end do

not turn together. Hold the flats on the tie rod

end and tighten the lock nut.

(h) Place the boots on the seats and install the clips.

HINT:

Make sure that the boots are not twisted.

SP

5. INSPECT WHEEL ANGLE

(a) Put tread center marks on the rearmost points of the

turning radius gauge.

SP–6

SUSPENSION – FRONT WHEEL ALIGNMENT

(b) Turn the steering wheel fully to the left and right and

B

A

AB

measure the turning angle.

Wheel turning angle

Front

Inside wheel Outside wheel reference

38°22' +- 2° (38.37° +- 2°)33°33' (33.55°)

Alignment Tester

A: Inside

B: Outside

Gauge

C132439E01

C132440E01

If the right and left inside wheel angles differ from

the specified value, check the right and left rack end

lengths.

6. INSPECT CAMBER, CASTER AND STEERING AXIS

INCLINATION

(a) Put the front wheel on the center of the alignment

tester.

(b) Remove the center ornament.

(c) Set the camber-caster-king pin gauge and

attachment at the center of the axle hub or drive

shaft.

(d) Inspect the camber, caster, and steering axis

inclination.

Camber

Camber Right-left difference

-0°40' +- 45' (-0.67° +- 0.75°) 45' (0.75°) or less

Caster

Caster Right-left difference

2°55' +- 45' (2.92° +- 0.75°) 45' (0.75°) or less

SP

Steering axis inclination

Steering axis inclination Right-left difference

12°15' +- 45' (12.25° +- 0.75°) 45' (0.75°) or less

NOTICE:

• Perform the inspection while the vehicle is

unloaded.

• The maximum tolerance of the right and left

difference for the camber and caster is 45'

(0.75°) or less.

(e) Remove the camber-caster-king pin gauge and

attachment.

(f) Install the center ornament.

(g) If the caster and steering axis inclination are not

within the specified range after the camber has

been correctly adjusted, recheck the suspension

parts for damage and/or wear.

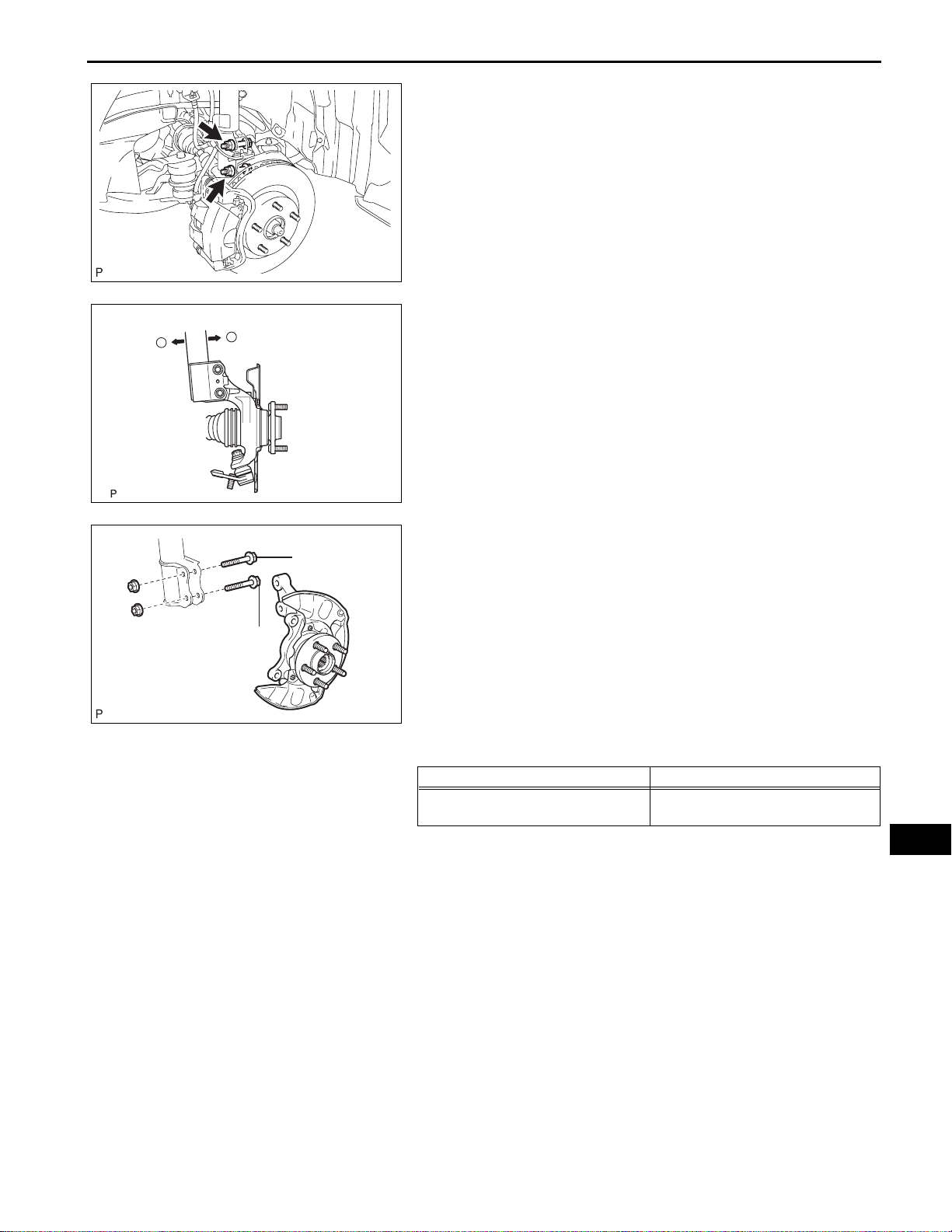

7. ADJUST CAMBER

NOTICE:

Inspect toe-in after the camber has been adjusted.

(a) Remove the front wheel.

SUSPENSION – FRONT WHEEL ALIGNMENT

SP–7

(b) Remove the 2 nuts on the lower side of the front

shock absorber.

NOTICE:

Keep the bolts inserted.

(c) Clean the installation surfaces of the front shock

absorber and the steering knuckle.

(d) Temporarily install the 2 nuts (Step A).

C132409

(e) Fully push or pull the front axle hub in the direction

-

+

of the required adjustment (Step B).

(f) Tighten the nuts.

Torque: 210 N*m (2,141 kgf*cm, 155 ft.*lbf)

NOTICE:

Keep the bolts from rot ating when tightening the

nuts.

(g) Install the front wheel.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

C111319E01

(h) Check the camber.

1

If the measured value is not within the specification,

calculate the required adjustment amount using the

formula below.

Camber adjustment amount = center of the

2

specified range center - measured value

Check the combination of installed bolts. Select

appropriate bolts from the table below to adjust the

camber to the specified values.

C140710E01

HINT:

Try to adjust the camber to the center of the

specified values.

Move the axle toward (+) in step (B) Move the axle toward (-) in step (B)

Refer to table (1) (Move the axle toward

the positive side)

Refer to table (2) (Move the axle toward

the negative side)

SP

SP–8

SUSPENSION – FRONT WHEEL ALIGNMENT

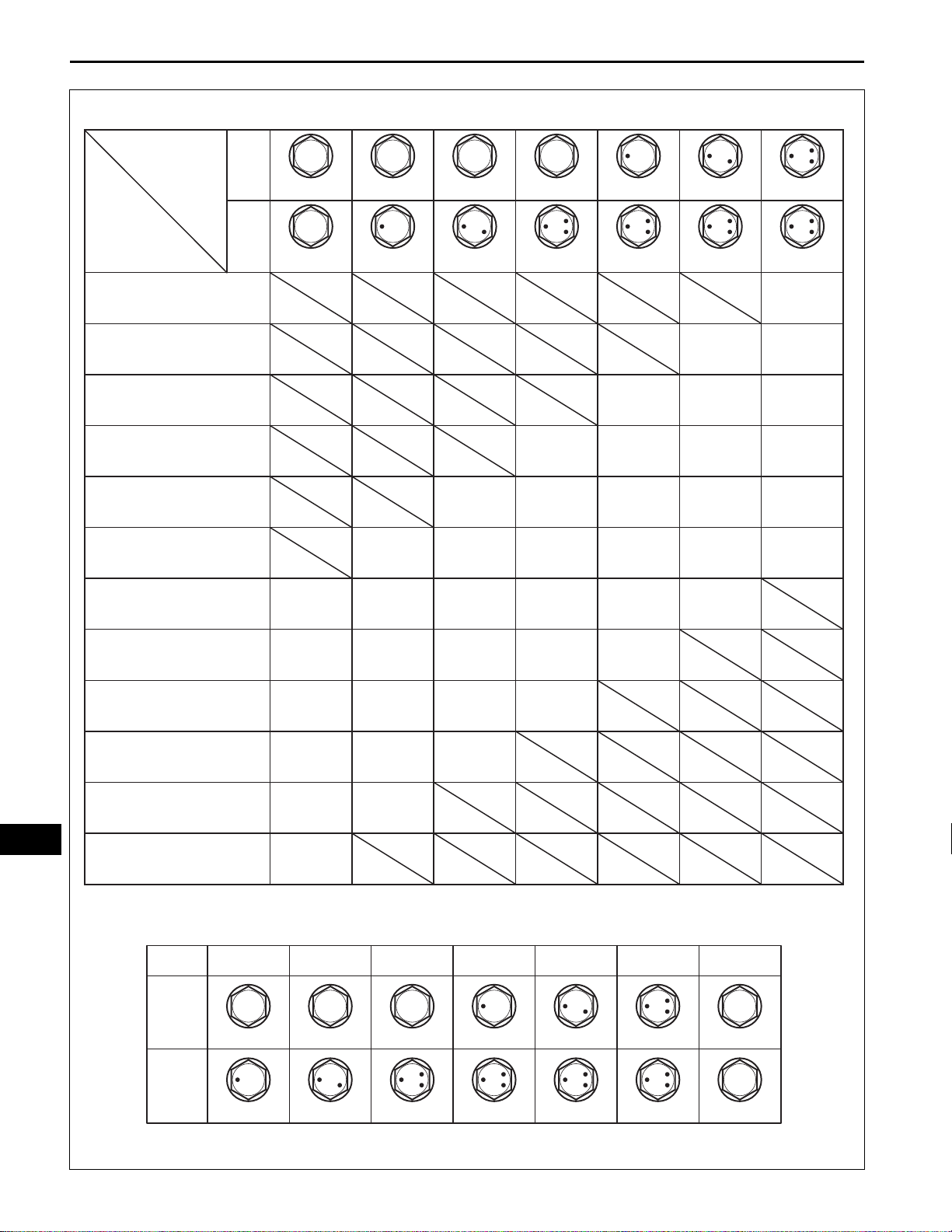

Table (1) (Move the axle toward the positive side)

Installed Bolt

1

90105-17012

90105-1701290105-1701290105-17012

90105-1701490105-17013

90105-17015

Adjusting Value

-1°30' to -1°15'

(-1.50° to -1.25°)

-1°15' to -1°00'

(-1.25° to -1°)

-1°00' to -0°45'

(-1° to -0.75°)

-0°45' to -0°30'

(-0.75° to -0.5°)

-0°30' to -0°15'

(-0.5° to -0.25°)

-0°15' to 0°

(-0.25° to 0°)

0° to 0°15'

(0° to 0.25°)

0°15' to 0°30'

(0.25° to 0.5°)

2

90105-17012 90105-17013

A

B

90105-1701590105-17014

90105-1701590105-17015 90105-17015

G

G

G

G

G

G

C

A

D

B

E

A

BA

C

F

A

B

C

D

FCEBD

F

A

B

C

D

E

SP

0°30' to 0°45'

(0.50° to 0.75°)

0°45' to 1°00'

(0.75° to 1°)

1°00' to 1°15'

(1° to 1.25°)

1°15' to 1°30'

(1.25° to 1.5°)

Selected Bolt Combination

1

2

C

D

E

D

E

E

F

F

F

F

AFCEBD G

90105-1701390105-1701290105-17012 90105-17012

90105-1701490105-17013

90105-17015 90105-17015 90105-17015

90105-17015

90105-1701590105-17014

90105-17012

90105-17012

C138332E01

SUSPENSION – FRONT WHEEL ALIGNMENT

Table (2) (Move the axle toward the negative side)

Installed Bolt

1

90105-17012

SP–9

90105-1701290105-1701290105-17012

90105-1701490105-17013

90105-17015

Adjusting Value

-1°30' to -1°15'

(-1.50° to -1.25°)

-1°15' to -1°00'

(-1.25° to -1°)

-1°00' to -0°45'

(-1° to -0.75°)

-0°45' to -0°30'

(-0.75° to -0.5°)

-0°30' to -0°15'

(-0.5° to -0.25°)

-0°15' to 0°

(-0.25° to 0°)

0° to 0°15'

(0° to 0.25°)

0°15' to 0°30'

(0.25° to 0.5°)

2

90105-17012 90105-17013

F

E

D

C

B

A

90105-1701590105-17014

90105-1701590105-17015 90105-17015

F

E

D

C

G

F

E

D

F

E

F

CEBD

A

B

G

C

BA

F

D

C

E

D

0°30' to 0°45'

(0.50° to 0.75°)

0°45' to 1°00'

(0.75° to 1°)

1°00' to 1°15'

(1° to 1.25°)

1°15' to 1°30'

(1.25° to 1.5°)

Selected Bolt Combination

1

2

G

A

G

B

A

G

C

B

A

SP

G

AFCEBD G

90105-1701390105-1701290105-17012 90105-17012

90105-1701490105-17013

90105-17015 90105-17015 90105-17015

90105-17015

90105-1701590105-17014

90105-17012

90105-17012

C138332E02

SP–10

SUSPENSION – FRONT WHEEL ALIGNMENT

The body and suspension may be damaged if the

camber is not correctly adjusted according to the

above table.

NOTICE:

Replace the nut with a new one when replacing

the bolt.

(i) Repeat the steps mentioned above. In step (A),

replace 1 or 2 selected bolts.

HINT:

Replace one bolt at a time when replacing 2 bolts.

SP

SUSPENSION – REAR WHEEL ALIGNMENT

REAR WHEEL ALIGNMENT

ADJUSTMENT

1. INSPECT TIRES

(See page TW-3)

2. MEASURE VEHICLE HEIGHT (See page SP-4)

SP–11

A

D

Front

C

B

C132438E01

(a) Bounce the vehicle up and down at the corners to

stabilize the suspension. Inspect the toe-in.

Toe-in

Toe-in

(total)

A + B:

C - D:

0° +- 24' (0° +- 0.4°)

4 +- 2 mm (0.16 +- 0.08 in.)

-

If the toe-in is not within the specified range, inspect

the suspension parts and replace them if necessary.

4. ADJUST TOE-IN

(a) Measure the lengths of the right and left rear No. 2

suspension arms.

Difference in the length between the right and

left rear No. 2 suspension arms:

1.5 mm (0.06 in.) or less

If the left-right difference is larg er than 1.5 mm (0.06

in.), adjust it by following the procedures below.

3. INSPECT TOE-IN

C141329

(b) Loosen the lock nuts.

(c) Turn the right and left adjusting tubes by an equal

amount to adjust toe-in.

HINT:

• Try to adjust toe-in to the center of the specified

range.

• One turn of each adjusting tube will adjust toe-in

by approximately 10.8 mm (0.425 in.).

SP

C141330

(d) Tighten the lock nuts.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

5. INSPECT CAMBER

Camber

Camber Right-left difference

-1°20' +- 45' (-1.33° +- 0.75°) 45' (0.75°) or less

HINT:

Camber is not adjustable. If the measurement is not

within the specification range, inspect the suspension

parts for damage and/or wear, and replace them if

necessary.

SP–12

SUSPENSION & AXLESUSPENSION

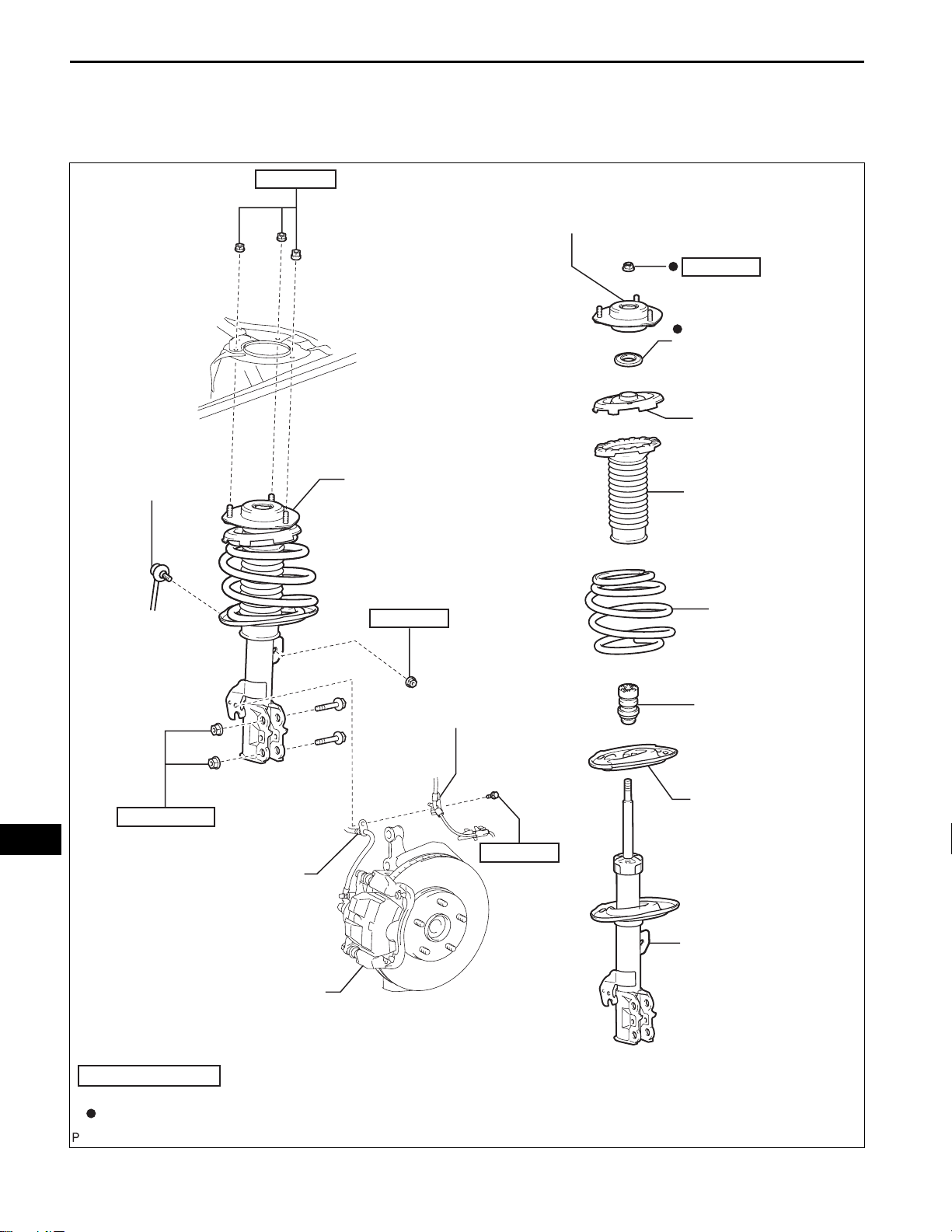

SUSPENSION – FRONT SHOCK ABSORBER

FRONT SHOCK ABSORBER

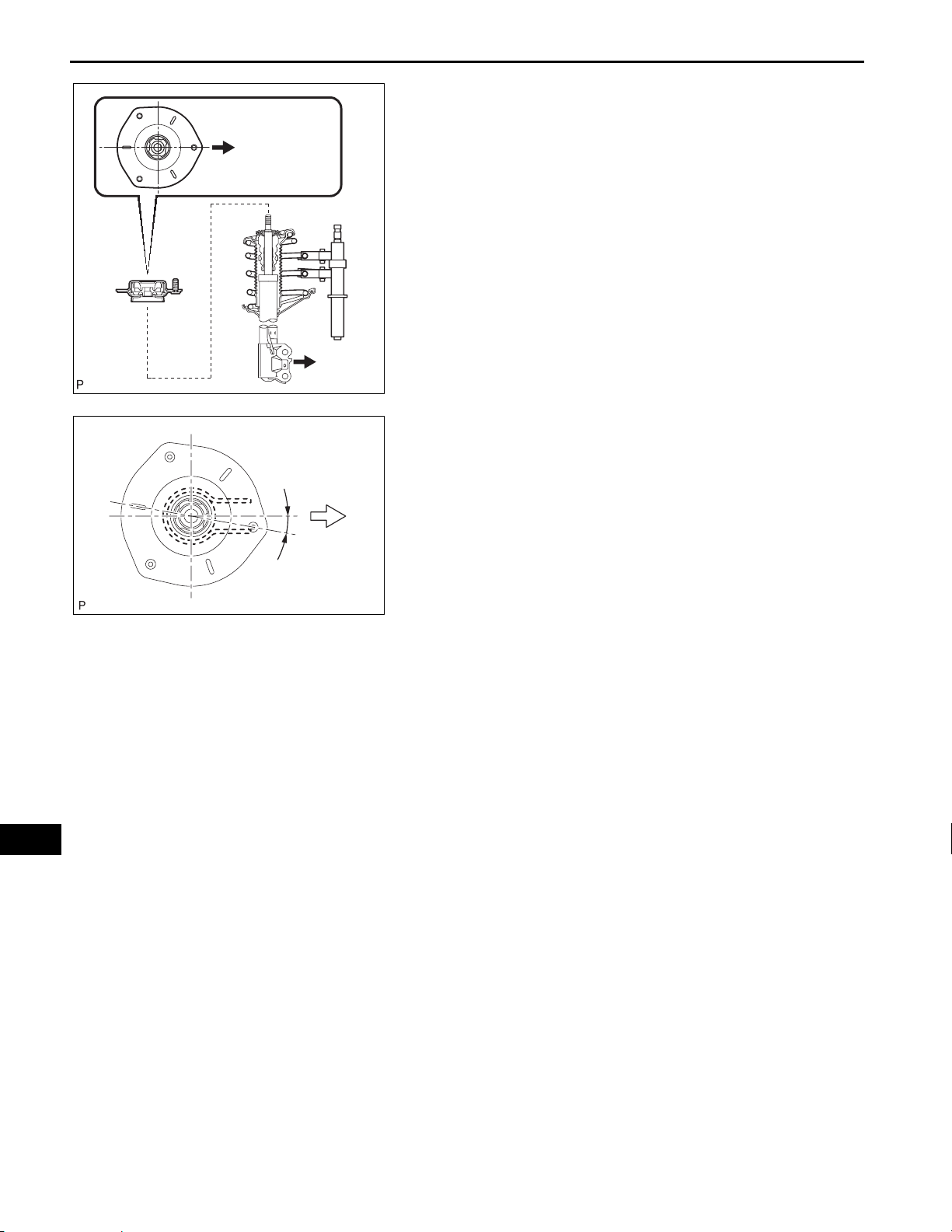

COMPONENTS

FRONT STABILIZER

LINK ASSEMBLY

85 (867, 63)

FRONT SUSPENSION SUPPORT

SUB-ASSEMBLY

FRONT SHOCK ABSORBER

WITH COIL SPRING

74 (755, 55)

70 (714, 52)

FRONT SUSPENSION

SUPPORT BEARING

FRONT COIL SPRING

UPPER SEAT

FRONT COIL SPRING

UPPER INSULATOR

FRONT COIL

SPRING

SP

210 (2,141, 155)

FRONT FLEXIBLE HOSE

FRONT AXLE ASSEMBLY

N*m (kgf*cm, ft.*lbf)

Non-reusable part

: Specified torque

FRONT SPEED SENSOR

19 (194, 14)

FRONT SPRING

BUMPER

FRONT COIL SPRING

LOWER INSULATOR

FRONT SHOCK

ABSORBER

C132427E01

SUSPENSION – FRONT SHOCK ABSORBER

REMOVAL

HINT:

• Use the same procedures for the RH side and the LH side.

• The procedures listed below are for the LH side.

1. REMOVE FRONT WHEEL

2. SEPARATE FRONT STABILIZER LINK ASSEMBLY

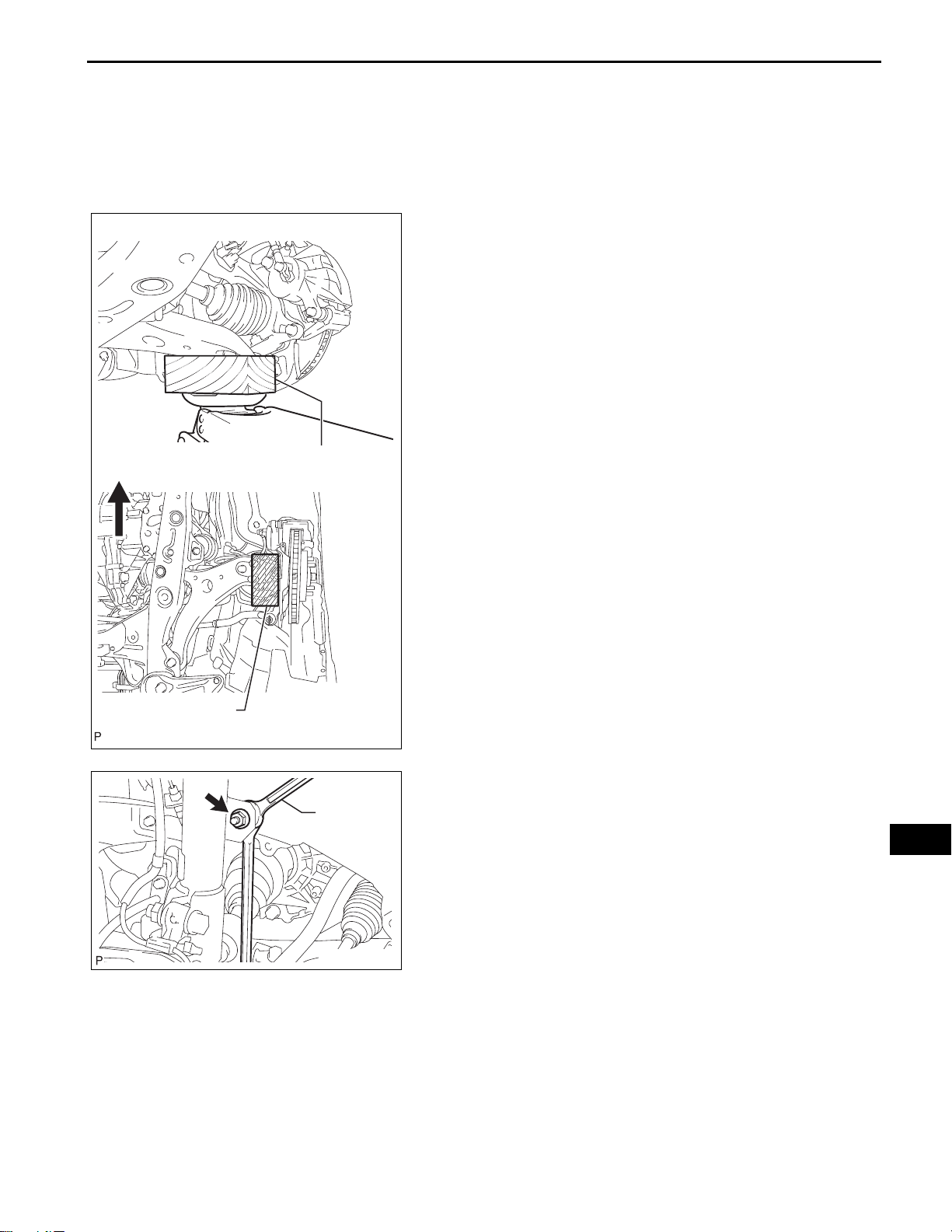

(a) Support the front No. 1 suspension lower arm with a

jack using a wooden block to avoid damage.

SP–13

Front

Wooden Block

Wooden Block

C132410E01

Wrench

(b) Remove the nut and separate the front stabilizer link

assembly from the front shock absorber.

HINT:

If the ball joint turns together with the nut, use a

wrench (19 mm) to hold the stud.

SP

C147096E01

SP–14

SUSPENSION – FRONT SHOCK ABSORBER

3. REMOVE FRONT SHOCK ABSORBER WITH COIL

SPRING

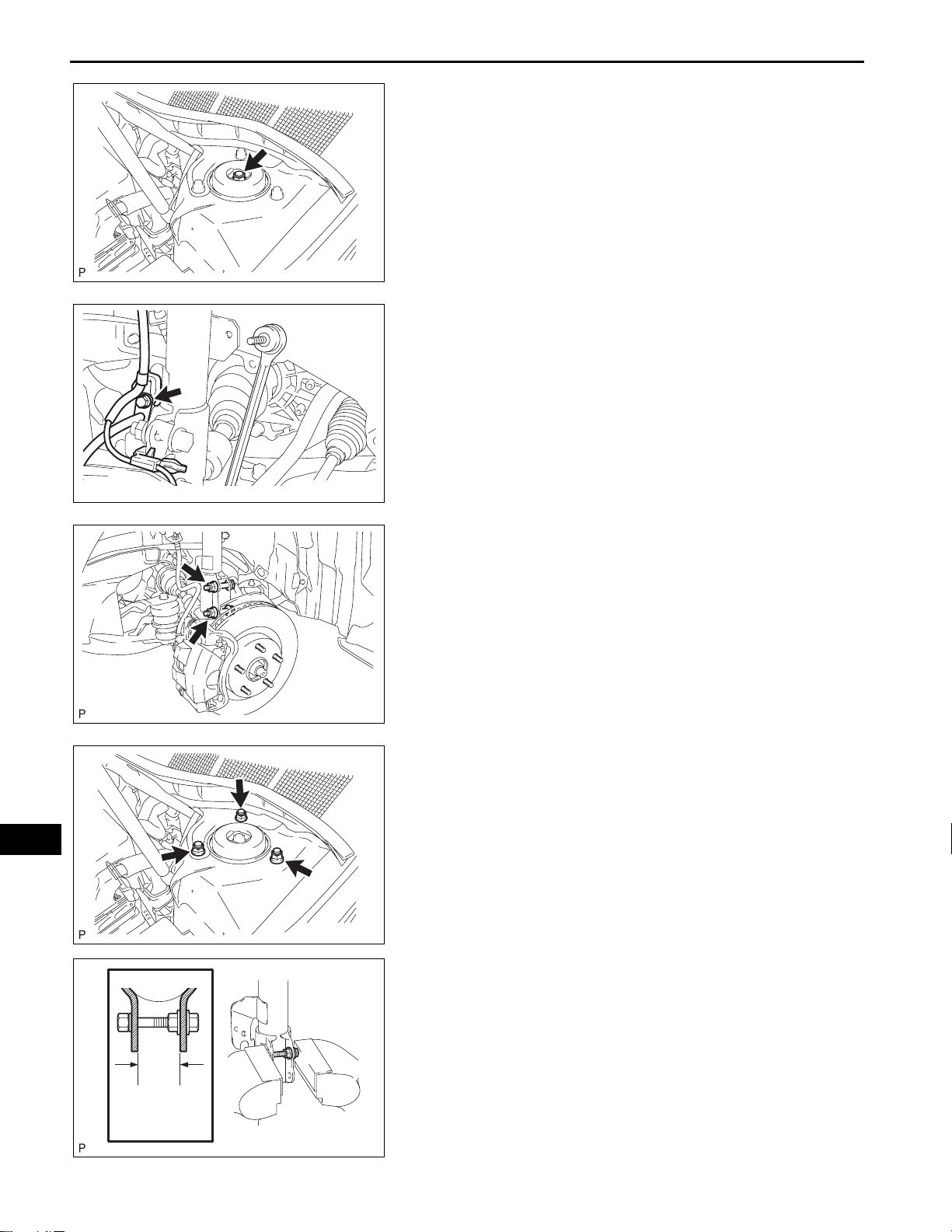

(a) Loosen the lock nut of the front shock absorber with

coil spring.

NOTICE:

• Do not remove the lock nut.

• Only loosen the nut when disassembling the

front shock absorber with coil spring.

C132412

(b) Remove the bolt and disconnect the front flexible

hose and front speed sensor wire harness from the

front shock absorber with coil spring.

NOTICE:

Be sure to remove the front speed sensor from

the front shock absorber with coil spring.

C132413

SP

(c) Remove the 2 nuts on the lower side of the front

shock absorber with coil spring.

NOTICE:

• When removing the nuts, keep the bolts from

rotating.

• Keep the bolts inserted to secure the front

axle assembly.

C132414

(d) Remove the 3 nuts on the upper side of the front

shock absorber with coil spring.

(e) Lower the front axle assembly, and remove the 2

bolts on the lower side of the front shock absorber.

(f) Remove the front shock absorber with coil spring.

NOTICE:

Make sure that the front speed sensor is

disconnected from the front shock absorber

with coil spring.

C132415

DISASSEMBLY

28 mm

(1.1 in.)

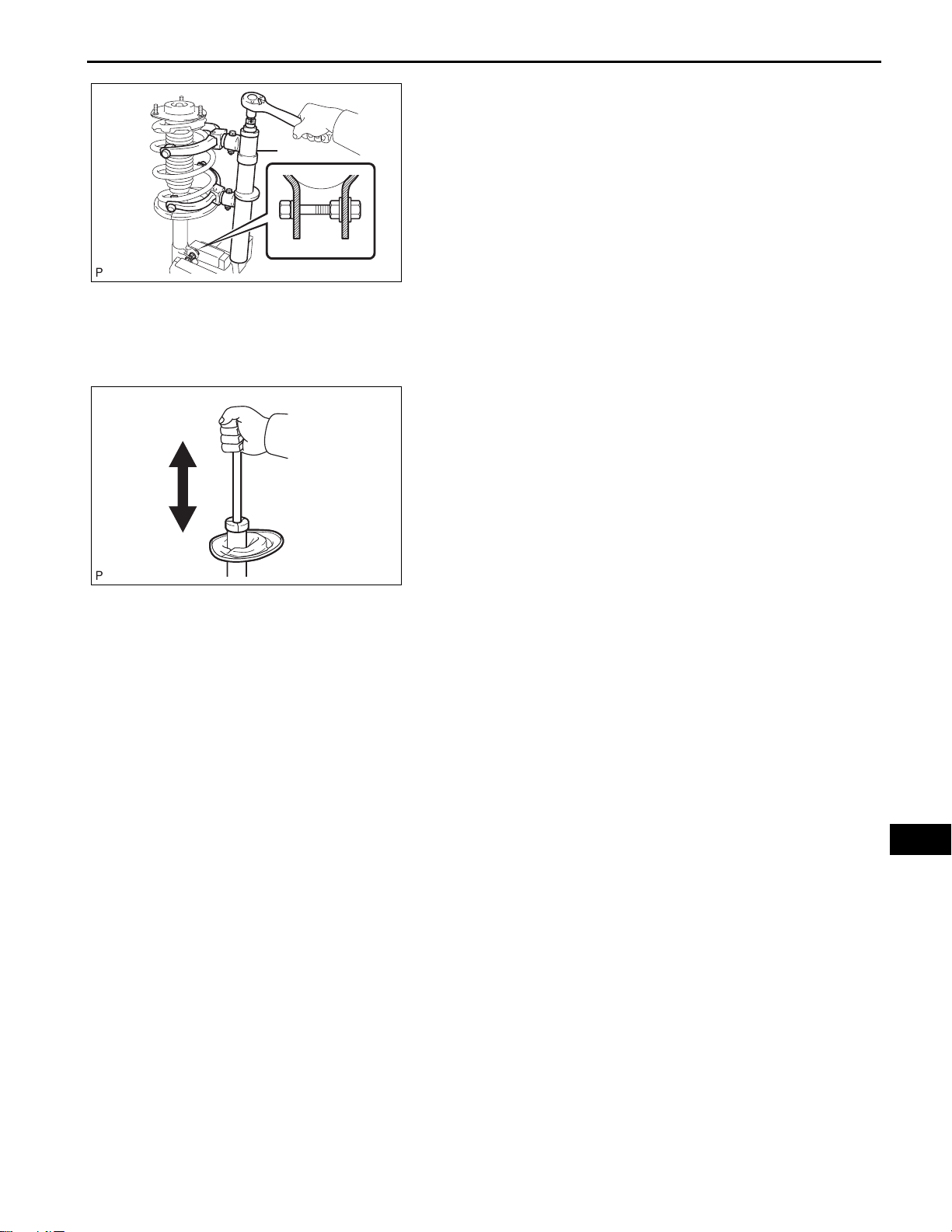

1. FIX FRONT SHOCK ABSORBER WITH COIL SPRING

(a) As shown in the illustration, secure the front shock

absorber with coil spring in a vise using aluminum

plates by clamping onto a double nutted bolt affixed

to the bracket at the bottom of the absorber.

C140711E01

SUSPENSION – FRONT SHOCK ABSORBER

2. REMOVE FRONT SHOCK ABSORBER

(a) Using SST, compress the front coil spring.

SST 09727-30021 (09727-00010, 09727-00021,

SST

09727-00031)

NOTICE:

Do not use an impact wrench.

HINT:

If the front coil spring is compressed at an angle,

using 2 SST will make the work easier.

C132416E01

(b) Remove the front suspension support sub-

assembly, front suspension support bearing, front

coil spring upper seat, front coil spring upper

insulator, front coil spring, front spring bumper, and

front coil spring lower insulator from the front shock

absorber.

INSPECTION

1. INSPECT FRONT SHOCK ABSORBER

(a) Compress and extend the shock absorber rod 4 or

more times.

Standard:

There is no abnormal resistance or sound and

operation resistance is normal.

HINT:

C132417

If there is any abnormality, replace the front shock

absorber with a new one.

SP–15

SP

SP–16

SUSPENSION – FRONT SHOCK ABSORBER

REASSEMBLY

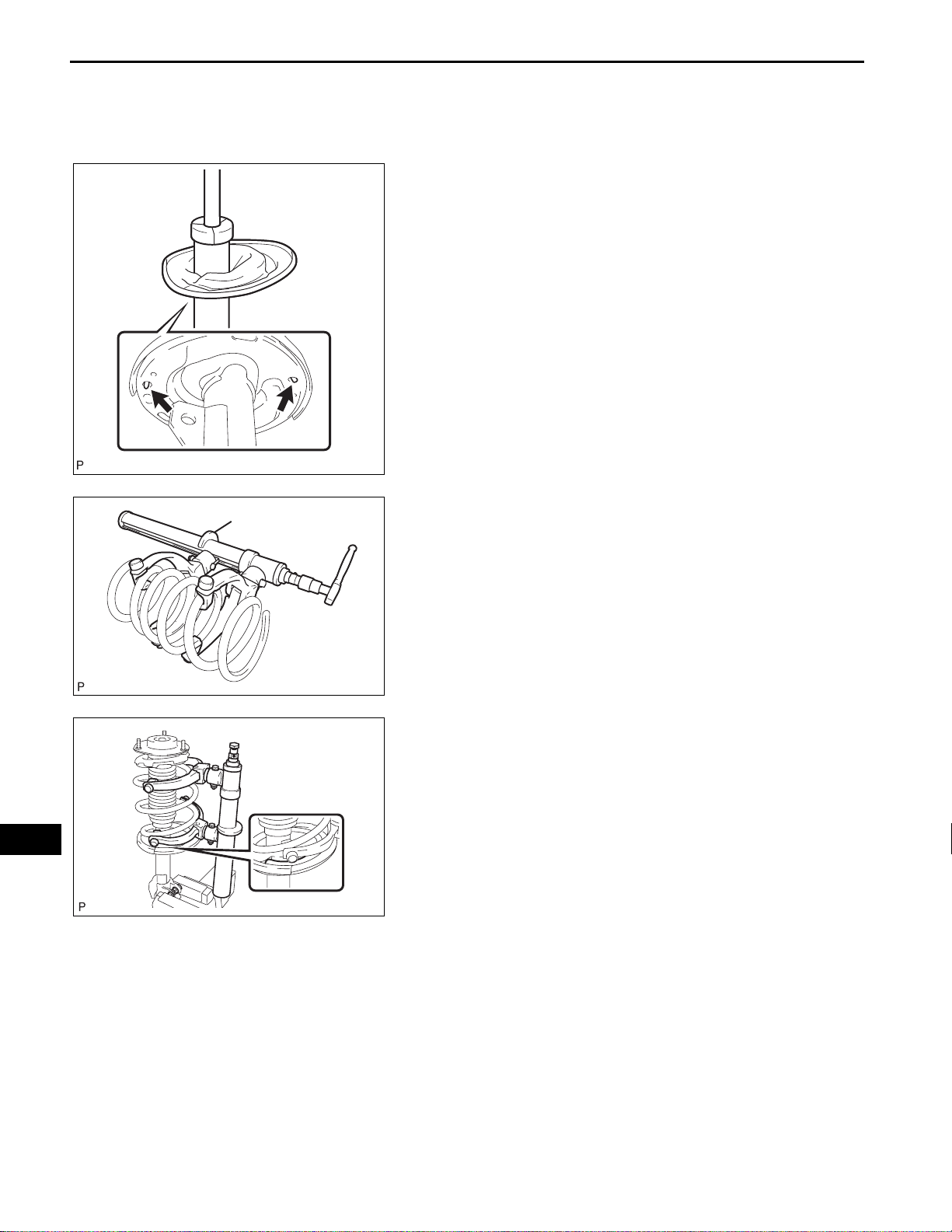

1. INSTALL FRONT SHOCK ABSORBER

(a) Install the front spring bumper to the piston rod.

(b) Install the front coil spring lower insulator onto the

front shock absorber.

NOTICE:

Align the 2 protrusions of the front coil spring

lower insulator and the 2 holes in the front

shock absorber.

C132418

SP

SST

(c) Using SST, compress the front coil spring.

SST 09727-30021 (09727-00010, 09727-00021,

09727-00031)

NOTICE:

Do not use an impact wrench.

HINT:

If the front coil spring is compressed at an angle,

using 2 SST will make the work easier.

C104393E01

(d) Install the front coil spring to the front shock

absorber.

NOTICE:

The smaller diameter end of the front coil spring

must face upward.

HINT:

Fit the lower end of the front coil spring into the gap

of the insulator.

C132419

5°

5°

5°

Outside

5°

Outside

SUSPENSION – FRONT SHOCK ABSORBER

(e) Install the front coil spring upper insulator as shown

in the illustration.

HINT:

Any misalignment between the front shock absorber

lower bracket and the matchmark must be +-5°.

C132420E01

(f) Install the front coil spring upper seat with the mark

facing to the outside of the vehicle.

HINT:

Any misalignment between the front shock

absorber lower bracket and the matchmark must be

+-5°.

SP–17

C132421E01

F040162

(g) Install a new front suspension support bearing as

shown in the illustration.

HINT:

If there is foreign matter inside the front suspension

support bearing, replace it with a new one.

SP

SP–18

Outside

SUSPENSION – FRONT SHOCK ABSORBER

(h) Install the front suspension support sub-assembly.

Temporarily tighten a new lock nut.

NOTICE:

Check that the flats on the piston rod and the

flats on the front suspension support subassembly are aligned.

C132422E01

(i) Remove the SST slowly in order to release the coil

spring.

NOTICE:

Outside

Do not use an impact wrench.

HINT:

Any misalignment between the front shock absorber

lower bracket and the arrows must be +-5°.

SP

10° +- 5°

C132423E01

SUSPENSION – FRONT SHOCK ABSORBER

INSTALLATION

1. INSTALL FRONT SHOCK ABSORBER WITH COIL

SPRING

(a) Install the front shock absorber with coil spring to

the front axle assembly and insert the 2 bolts from

the front side of the vehicle.

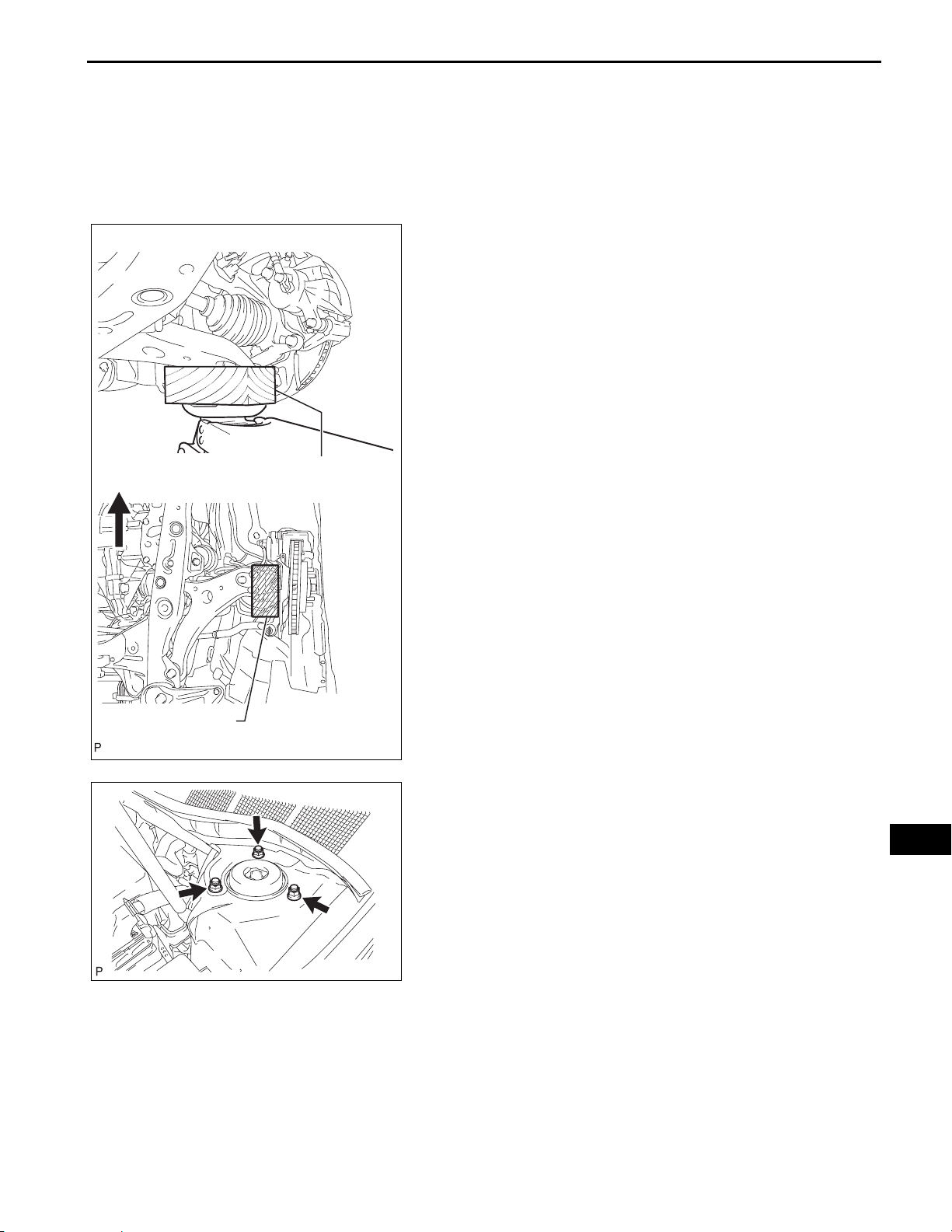

(b) Slowly jack up the vehicle using a wooden block

and install the front shock absorber with coil spring

(upper side) to the vehicle.

SP–19

Front

Wooden Block

Wooden Block

C132410E01

(c) Install the 3 nuts to the upper side of the front shock

absorber with coil spring.

Torque: 85 N*m (867 kgf*cm, 63 ft.*lbf)

SP

C132415

SP–20

SUSPENSION – FRONT SHOCK ABSORBER

(d) Install the 2 nuts to the lower side of t he fro nt shock

absorber with coil spring.

Torque: 210 N*m (2,140 kgf*cm, 155 ft.*lbf)

NOTICE:

When installing the nuts, keep the bolts from

rotating.

C132414

(e) Install the front flexible hose and front speed sensor

wire harness with the bolt.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

HINT:

If the ball joint turns together with the nut, use a

wrench (19 mm) to hold the stud.

NOTICE:

Do not twist the front speed sensor wire harness

when installing it.

C132413

SP

(f) Fully tighten the lock nut.

Torque: 70 N*m (714 kgf*cm, 52 ft.*lbf)

C132412

2. INSTALL FRONT STABILIZER LINK ASSEMBLY

(a) Install the front stabilizer link assembly with the nut.

Wrench

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

HINT:

If the ball joint turns together with the nut, use a

wrench (19 mm) to hold the stud.

3. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

C147096E01

4. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

(See page SP-4)

A

25 mm (0.98 in.)

B

DISPOSAL

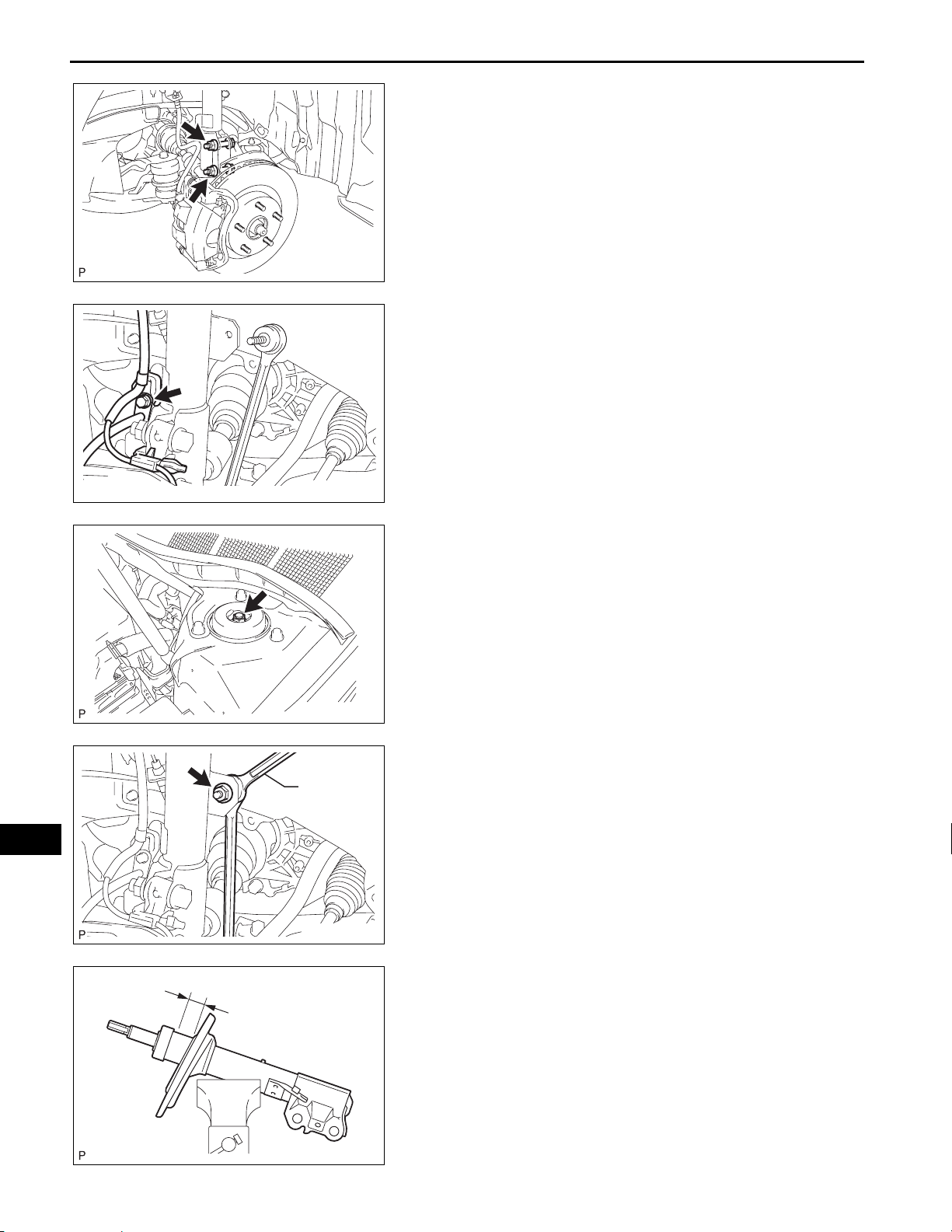

1. DISPOSE OF FRONT SHOCK ABSORBER

(a) Fully extend the shock absorber rod.

(b) Using a drill, make a hole in the cylinder between A

and B as shown in the illustration to discharge the

gas inside.

CAUTION:

• Be careful when drilling because shards of

C137486E01

metal may fly about. Always use the proper

safety equipment.

SUSPENSION – FRONT SHOCK ABSORBER

• The gas is colorless, odorless and nonpoisonous.

SP–21

SP

SP–20

SUSPENSION & AXLESUSPENSION

SUSPENSION – FRONT SUSPENSION LOWER NO. 1 ARM

FRONT SUSPENSION LOWER NO. 1 ARM

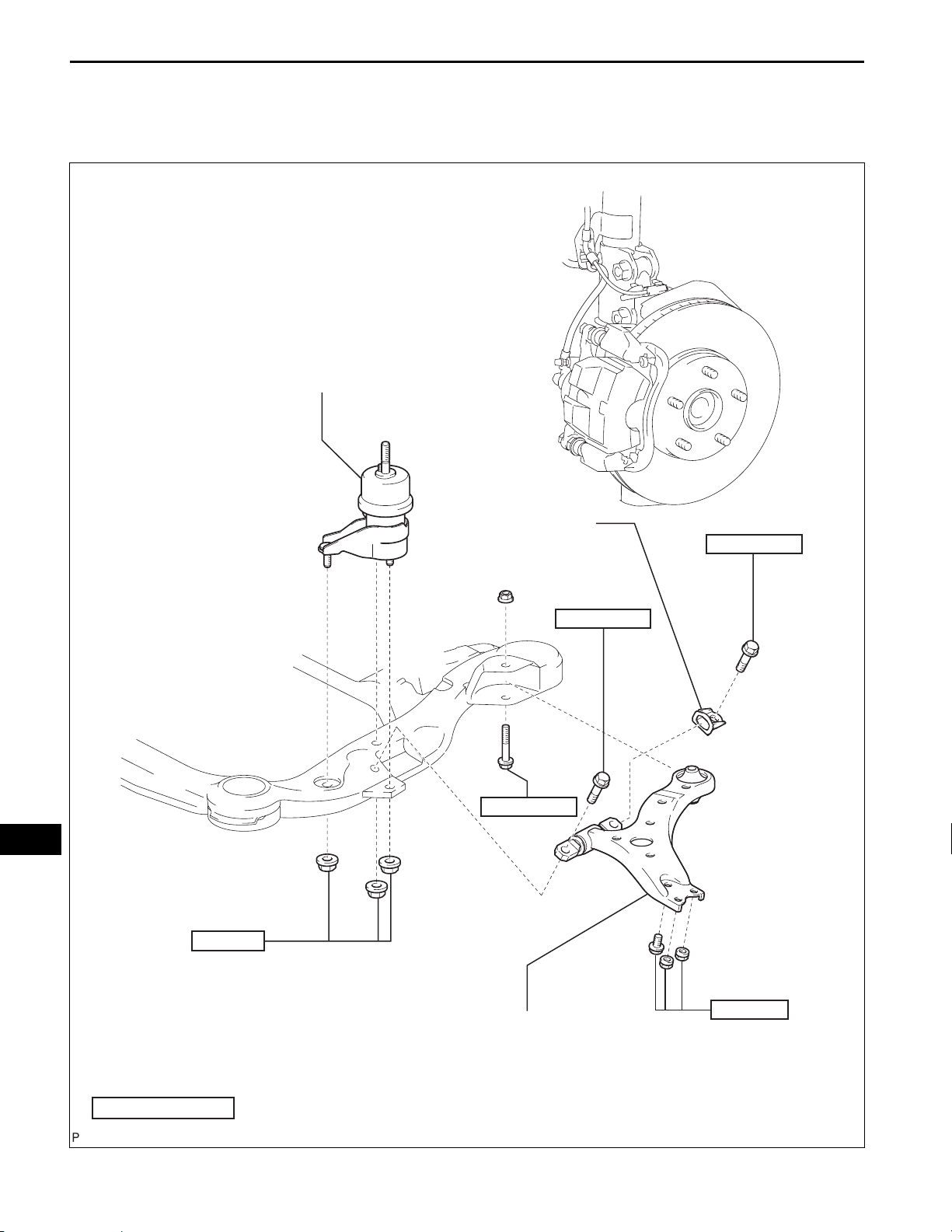

COMPONENTS

ENGINE MOUNTING INSULATOR

SP

87 (887, 64)

FRONT LOWER ARM

BUSHING STOPPER

200 (2,040, 148)

206 (2,100, 152)

200 (2,040, 148)

N*m (kgf*cm, ft.*lbf)

75 (765, 55)

FRONT SUSPENSION

LOWER NO. 1 ARM

: Specified torque

C141678E01

SUSPENSION – FRONT SUSPENSION LOWER NO. 1 ARM

REMOVAL

HINT:

• Use the same procedures for the RH side and the LH side.

• The procedures listed below are for the LH side.

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

Refer to the instructions for removal of the engine

assembly (See page EM-96).

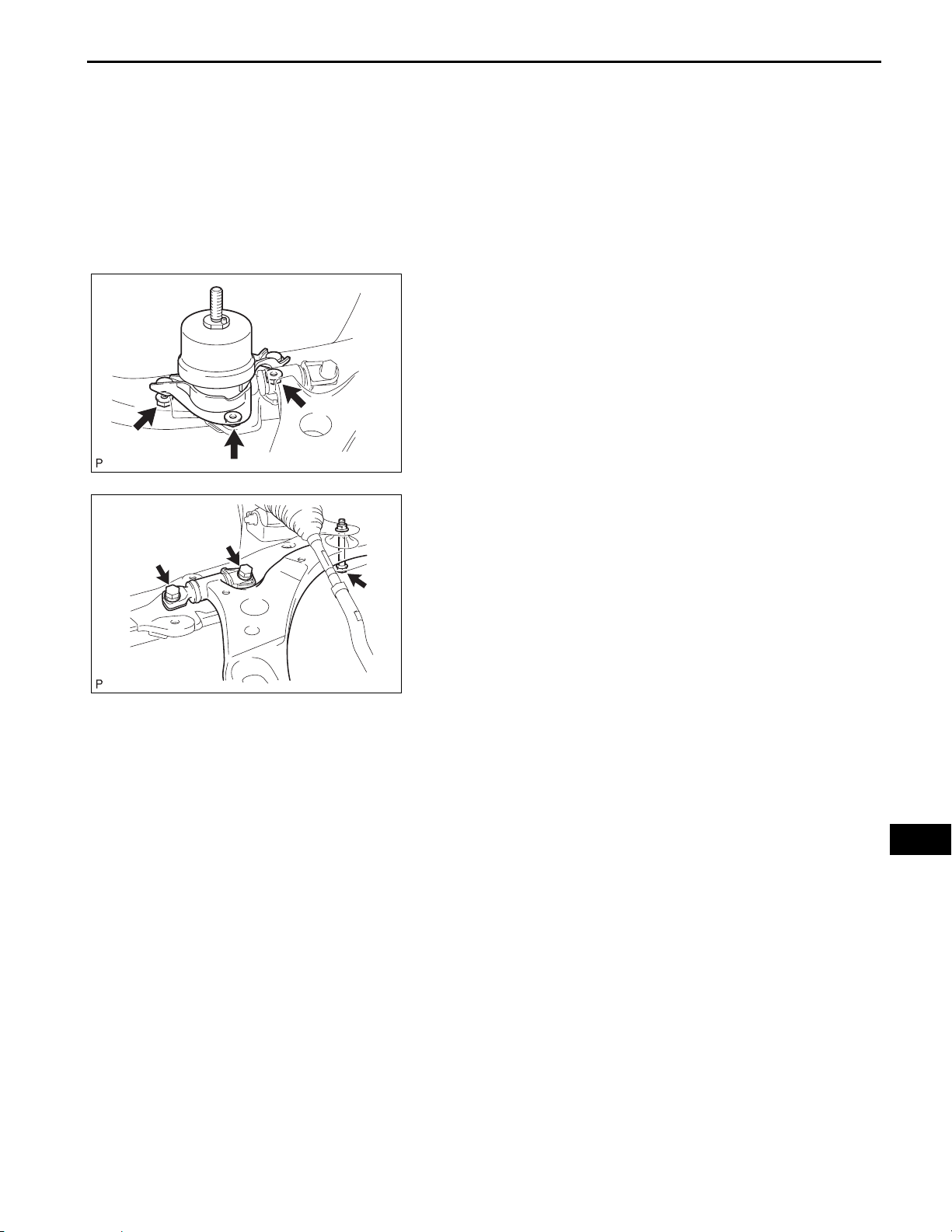

2. REMOVE ENGINE MOUNTING INSULATOR

(a) Remove the 3 nuts and the engine mounting

insulator.

C141491

SP–21

C145854

3. REMOVE FRONT SUSPENSION LOWER NO. 1 ARM

(a) Remove the 3 bolts and the nut on the front

suspension lower No. 1 arm and remove it from the

front frame assembly.

(b) Remove the front lower arm bushing stopper.

SP

Loading...

Loading...