Sta-Rite DSS3HG3T Installation Manual

OWNER’S MANUAL

Self-Priming Horizontal

Three and Four Stage Pumps

293 Wright Street, Delavan, WI 53115

Phone: 888-782-7483 Fax: 800-426-9446 Web Site: sta-rite.com

DSS3HG, DSS3HG3T, |

DSS4HG, DSS4HG3T |

Installation/Operation/Parts

For further operating, installation, or maintenance assistance:

Call 1-888-782-7483

© 2012 |

S682 (02/27/12) |

Safety |

2 |

|

|

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains important instructions that should be followed during installation, operation, and maintenance of the product. Save this manual for future reference.

This is the safety alert symbol. When you see this symbol on your pump or in this manual, look for one of the following signal words and be alert to the potential for personal injury!

This is the safety alert symbol. When you see this symbol on your pump or in this manual, look for one of the following signal words and be alert to the potential for personal injury!

indicates a hazard which, if not avoided, will result in death or serious injury.

indicates a hazard which, if not avoided, will result in death or serious injury.

indicates a hazard which, if not avoided, could result in death or serious injury.

indicates a hazard which, if not avoided, could result in death or serious injury.

indicates a hazard which, if not avoided, could result in minor or moderate injury.

indicates a hazard which, if not avoided, could result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

Carefully read and follow all safety instructions in this manual and on pump.

Keep safety labels in good condition. Replace missing or damaged safety labels.

Electrical Safety

Hazardous voltage. Follow these rules to avoid potential harm:

Hazardous voltage. Follow these rules to avoid potential harm:

•Wire motor for correct voltage. See “Electrical” section of this manual and motor nameplate.

•Ground motor before connecting to power supply.

•Meet National Electrical Code, Canadian Electrical

Code, and local codes for all wiring.

•Follow wiring instructions in this manual when connecting motor to power lines.

•Make workshops childproof; use padlocks and master switches; remove starter keys.

Risk of burns. Do not touch an operating motor. Motors can operate at high temperatures. To avoid burns when servicing pump, allow it to cool for 20 minutes after shut-down before handling.

Risk of burns. Do not touch an operating motor. Motors can operate at high temperatures. To avoid burns when servicing pump, allow it to cool for 20 minutes after shut-down before handling.

WARNING

WARNING

Hazardous voltage.

Can shock, burn, or cause death.

Ground pump before connecting to power supply.

WARNING

WARNING

Hazardous pressure!

Do not run pump against closed discharge.

Release all pressure on system before working on any component.

General Safety

To avoid heat built-up in pump, over pressure hazard and possible injury, do not use in a pressure tank

(domestic water) system. Do not use as a booster pump; pressurized suction may cause pump body to explode.

Do not allow pump or piping system to freeze. Freezing can damage pump and pipe, may lead to injury from equipment failure and will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components. Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted; store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Maximum inlet pressure . . . . . . . . . . . . . 30 psi Maximum operating pressure . . . . . . . . . . . 130 psi Maximum liquid temperature . . . . . . . . . . . 120° F Maximum motor starts per hour . . . . . . . . . . . . 15

Warranty |

3 |

|

|

Limited Warranty

STA-RITE warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from defects in material and workmanship for the Warranty Period shown below.

Product |

Warranty Period |

|

|

|

|

Water Systems Products — jet pumps, small centrifugal pumps, |

whichever occurs first: |

|

12 months from date of original installation, |

||

submersible pumps and related accessories |

||

or 18 months from date of manufacture |

||

|

||

|

|

|

Pro-Source™ Composite Tanks |

5 years from date of original installation |

|

|

|

|

Pro-Source™ Steel Pressure Tanks |

5 years from date of original installation |

|

|

|

|

Pro-Source™ Epoxy-Lined Tanks |

3 years from date of original installation |

|

|

|

|

Sump/Sewage/Effluent Products |

12 months from date of original installation, or |

|

18 months from date of manufacture |

||

|

||

|

|

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication, improper installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and STA-RITE’s only duty, is that STA-RITE repair or replace defective products (at STA-RITE’s choice). You must pay all labor and shipping charges associated with this warranty and must request warranty service through the installing dealer as soon as a problem is discovered. No request for service will be accepted if received after the Warranty Period has expired. This warranty is not transferable.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION EXPRESSLY PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

STA-RITE INDUSTRIES

293 Wright Street • Delavan, WI U.S.A. 53115 Phone: 1-888-782-7483 • Fax: 1-800-426-9446 • Web Site: sta-rite.com

Installation |

4 |

|

|

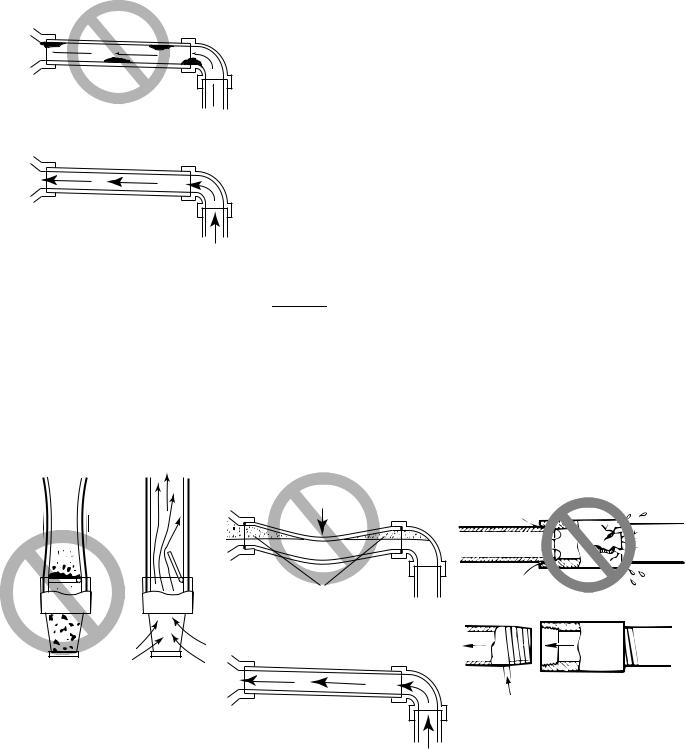

Dirt and Scale Plug Pump and Pipes!

Use New Pipe for Best Results.

Pump

Body

Clean Flow!

From

Well

Figure 1 – No Dirt or Scale in Suction Pipe

Before you install your pump

NOTICE: Well must not be more than 20’ depth to water.

1.Long runs and many fittings increase friction and reduce flow. Locate pump as close to well as possible: use as few elbows and fittings

as possible.

2.Be sure well is clear of sand. Sand will plug the pump and void the warranty.

3.Protect pump and all piping from freezing. Freezing will split pipe, damage pump and void the warranty. Check locally for frost protection requirements (usually pipe must be 12” below frost line and pump must be insulated).

4.Be sure all pipes and foot valve are clean and in good shape.

5.No air pockets in suction pipe.

6.No leaks in suction pipe. Use PTFE pipe thread sealant tape to seal pipe joints.

7.Unions installed near pump and well will aid in servicing. Leave room to use wrenches.

8.

Risk of explosion. Pump body may explode if used as a booster pump. DO NOT use in a booster application.

Risk of explosion. Pump body may explode if used as a booster pump. DO NOT use in a booster application.

NOTICE: Use the installation method which matches your well type.

9.Install a check valve in the pump suction port. Be sure that the flow arrow points toward the pump. Failure to install a check valve on the inlet side of the pump may allow the pump body to drain between pump cycles, causing dry running, seal or internal failure, and voiding the warranty.

Figure 2 – Foot Valve Must

Work Freely

No Sags

Sags Allow Air Pockets

If Air Pockets Form, Water Won’t Flow.

Keep Pipe Straight and Angled up to Pump.

Use PTFE pipe thread sealant tape or pipe joint compound approved for use on PVC.

No air leaks In

Suction pipe.

If air flows water won’t

Use PTFE tape.

Figure 4 – Suction Pipe Must Not Leak

Figure 3 – No Air Pockets in

Suction Pipe

Loading...

Loading...