Page 1

MODEL 5496

Intelligent Power Module

Installation and

Operations Manual

Document 151276

08/12/10 Rev:

P/N 151276:E1 ECN: 10-484

E1

Page 2

Page 3

Contents

Section 1

Overview ......................................................................................................................................................1-1

1.1 5496 Description ......................................................................................................................................1-1

1.2 Agency Requirements ..............................................................................................................................1-1

1.3 About This Manual ..................................................................................................................................1-1

1.4 How to Contact Silent Knight ...................................... .................................... ........................................ 1-1

Section 2

Before You Begin Installing ............................................................................................... 2-1

2.1 What’s in the Box? ...................................................................................................................................2-1

2.2 Environmental Specifications ..................................................................................................................2-1

2.3 Preventing Water Damage .......................................................................................................................2-1

2.4 5496 Board and Terminal Strip Description ............................................................................................2-2

2.5 Earth Fault Resistance ..............................................................................................................................2-3

2.6 Calculating Current Draw and Standby Battery ......................................................................................2-4

2.6.1 Worksheet Requirements ..................................................................................................................2-4

Filling in the Current Draw Worksheet .........................................................................................2-4

2.6.1.1 Maximum Battery Standby Load ...........................................................................................2-4

2.6.2 Current Draw Worksheet ..................... ..................................... .................................... ....................2-5

2.6.3 Wire Routing ............................................. ........................................................................................2-6

Section 3

Hardware Installation ..................................................................................................................3-1

3.1 AC Power ................................................................................................................................................. 3-1

3.2 Battery Connection ..................................................................................................................................3-2

3.3 Connecting the 5496 to the FACP ...........................................................................................................3-3

3.3.1 Setting the Device ID ........................................................................................................................3-4

3.4 Notification Appliance Wiring ................................................................................................................. 3-5

3.4.1 Class A Supervised Wiring .................................................................. .............................................3-5

Class A Output Notification Circuits ............................................................................................3-5

3.4.2 Class B Supervised Wiring ...............................................................................................................3-6

Class B Output Notification Circuits ............................................................................................ 3-6

3.4.3 Releasing Operations .................................................................................................... ....................3-6

3.4.4 Auxiliary Power Configuration ........................................................................................................ 3-7

3.4.4.1 Door Holder Power ................................................................................................................3-8

3.4.4.2 Constant Power ......................................................................................................................3-8

3.4.4.3 Resettable Power ............................... ..................................... ................................................3-8

151276 i

Page 4

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Appendix A

Compatible Devices

..................................................................................................................... A-1

Silent Knight Fire Product Warranty and Return Policy

Manufacturer Warranties and Limitation of Liability

ii 151276

Page 5

Section 1 Overview

1.1 5496 Description

The Model 5496 Intelligent Power Module provides additional power and notification circuits

to a Silent Knight addressable FACP. The 5496 can power all IntelliKnight compatible

notification appliances and auxiliary power modules.

The 5496 is capable of performing single or dual interlocking operations for pre-action and

deluge releasing systems. See Section 8.6 of FACP installation manual.

The 5496 has four output circuits that can be configured as notification or auxiliary power

circuits. Outputs are rated 3.0 A (6.0 A total for each 5496).

The 5496 is optically isolated, providing ground loop isolation and transient protection.

The 5496 provides configuration options that eliminate the need for sychronization modules

when using AMSECO, Faraday, Gentex, System Sensor, or Wheelock synchronization

appliances.

1.2 Agency Requirements

The 5496 has the same requirements as the main control panel. These requirements are listed

in Silent Knight addressable FACP Installation Manuals. Silent Knight Addressable FACP

Installation Manuals can be found on Silent Knight’s web site at www.silentknight.com.

1.3 About This Manual

This manual covers installation of 5496 hardware. Software configuration information is

contained in a Silent Knight addressable FACP Installation Manuals. Silent Knight

Addressable FACP Installation Manuals can be found on Silent Knight’s web site at

www.silentknight.com.

1.4 How to Contact Silent Knight

If you have a question or encounter a problem not covered in this manual, contact Silent

Knight Technical Support at 800-446-6444.

To order parts, contact Silent Knight Sales at 800-328-0103 or (203) 484-7161.

151276 1-1

Page 6

Model 5496 Intelligent Power Module Installation and Oper ation Manual

1-2 151276

Page 7

Section 2 Before You Begin Installing

2.1 What’s in the Box?

The Model 5496 ships with the following hardware:

• A cabinet with all hardware assembled

• Two keys for the 5496 front door

• Ten 4.7K ohm end-of-line resistors

Note: For UL installations Model 7628 4.7k end-of-line resistor (ordered separately) must be used.

• A battery wiring harness and jumper to wire batteries in series

2.2 Environmental Specifications

It is important to protect the 5496 control panel from water. To prevent water damage, the

following conditions should be AVOIDED when installing the units:

• Do not mount directly on exterior walls, especially masonry walls (condensation)

• Do not mount directly on exterior walls below grade (condensation)

• Protect from plumbing leaks

• Protect from splash caused by sprinkler system inspection ports

• Do not mount in areas with humidity-generating equipment (such as dryers, production

machinery)

When selecting a location to mount the 5496, the unit should be mounted where it will NOT

be exposed to temperatures outside the range of 0°C-49°C (32°F-120°F) or humidity outside

the range of 10%-93% at 30°C (86°F) noncondensing.

2.3 Preventing Water Damage

Water damage to the fire system can be caused by moisture entering the cabinet through the

conduits. Conduits that are installed to enter the top of the cabinet are most likely to cause

water problems. Installers should take reasonable precautions to prevent water from entering

the cabinet. Water damage is not covered under warranty.

151276 2-1

Page 8

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Dipswitches for

Setting ID

To AC

Regulated

SBUS Module

Connections

Battery

Connections

Output Circuits

All Circuits

Supervised Power

limited, except

Battery and AC

which are

supervised

non-power limited.

2.4 5496 Board and Terminal Strip Description

Figure 2-1 shows the 5496 circuit board including location of terminals and the dipswitch for

setting the module ID.

Figure 2-1 The 5496 Board Layout

2-2 151276

Page 9

Before You Begin Installing

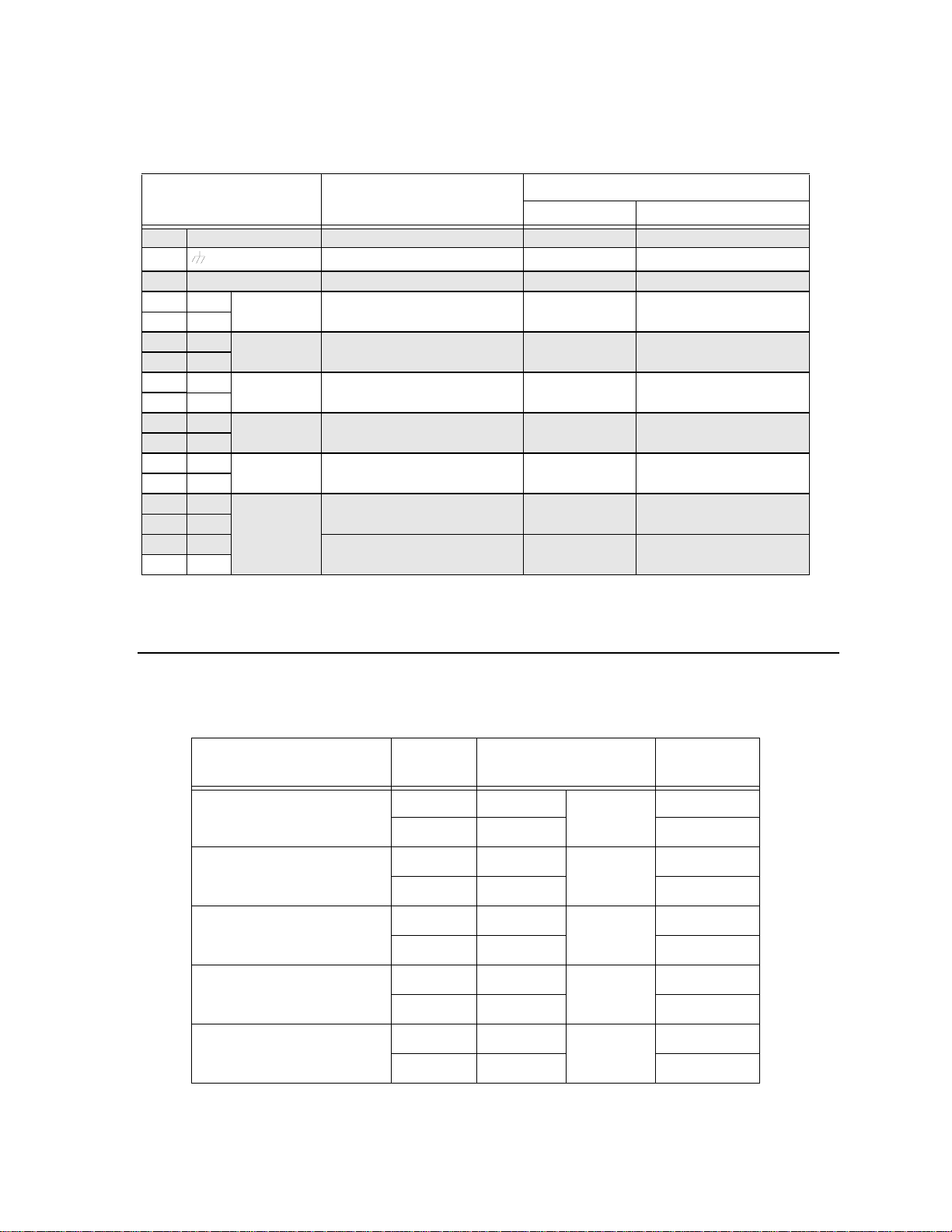

Table 2-1 describes the 5496 connections and provides electrical ratings where appropriate.

Table 2-1: Terminal Strip Description and Electrical Ratings

Terminal # and Label

B AC input (hot) 120 VAC, 60 Hz 2.7 A

Earth ground N/A N/A

W AC input (neutral) 120 VAC, 60 Hz 2.7 A

12+

3 4 +

56+

7 8 +

910 +

11 12 +

13 A

14 B

* Regulated/special application when used for releasing.

Battery Battery 24 VDC 0.75 A

I/O 4* Output circuit 24 VDC

I/O 3* Output circuit 24 VDC

I/O 2* Output circuit 24 VDC

I/O 1* Output circuit 24 VDC

SBUS power 24 VDC 1.0 A

SBUS

SBUS communication 5 VDC 100 mA

Description

2.5 Earth Fault Resistance

Rating

Voltage Current

3.0 A

Notification Circuits

3.0 A

Notification Circuits

3.0 A

Notification Circuits

3.0 A

Notification Circuits

Table 2-2 lists the earth fault resistance detection for each applicable terminal on the FACP.

Table 2-2: Earth Fault Resistance Values by Terminal

Function

Battery

Notification Appliance Circuit 4

Notification Appliance Circuit 3

Notification Appliance Circuit 2

Notification Appliance Circuit 1

Terminal

Number

12+ 0

3H44 H4+ 0

5H36 H3+ 0

7H28 H2+ 0

9H110 H1+ 0

Terminal Label

BATTERY

OUT4

OUT3

OUT2

OUT1

Value

(in ohms)

0

0

0

0

0

151276 2-3

Page 10

Model 5496 Intelligent Power Module Installation and Oper ation Manual

2.6 Calculating Current Draw and Standby Battery

This section is for helping you determine the current draw and standby battery needs for your

installation.

2.6.1 Worksheet Requirements

Follow the steps below to determine 5496 current draw and standby battery requirements.

Filling in the Current Draw Worksheet

Refer Table 2-4 in Section 2.6.2 to complete the following steps.

1. Add up the current draw for all auxiliary devices and record in the table at Line B.

2. Add up all notification appliance loads and record in the table at Line C.

3. For notification appliances and auxiliary devices not mentioned in the manual, refer to the

device manual for the current ratings.

4. Make sure that the total alarm current you calculated, including current for the panel itself,

does not exceed 6.0 A. This is the maximum alarm current allowable.

5. Complete the remaining instructions in Table 2-4 to determine battery size requirements.

2.6.1.1 Maximum Battery Standby Load

Table 2-3 shows the maximum battery standby load for the 5496 based on 24 and 60 hours of

standby. The standby load calculations of line J in the Current Draw Calculation Worksheet

(Table 2-4) must be less than the number shown in Table 2-3 for the battery size used and

standby hours required.

Table 2-3: Maximum Battery Standby Load

Rechargeable

Battery Size

7 AH 270 mA 105 mA

12 AH 475 mA 190 mA

18 AH 685 mA 270 mA

35 AH 1370 mA 540 mA

* Required for NFPA 72 Auxiliary Protected Fire Alarm systems for Fire Alarm Service (City Box) and

Remote Station Protected Fire Alarm systems (Polarity Reversal) and Digital Alarm Communicator/

Transmitter (DACT).

Note: 33 max battery size for FM (Factory Mutual) installations

Max. Load for 24 hrs. Standby ,

5 mins. Alarm

*Max. Load for 60 hrs. Standby , 5

mins. Alarm

2-4 151276

Page 11

Before You Begin Installing

2.6.2 Current Draw Worksheet

For each 5496 in the installation, use this worksheet to determine current requirements during

alarm/battery standby operation. (Copy this page if additional space is required.)

Table 2-4: Current Draw Calculation Worksheet

Device

For each device use this formula: This column X This column = Current per number of devices.

5496 Intelligent Power Module

(Current draw from battery)

A

Auxiliary Devices Refer to device manual for current ratings.

B

Notification appliances Refer to device manual for current ratings.

C

Total current ratings of all devices in system (line A + line B + line C)

D

Total current ratings converted to amperes (line D x .001):

E

Number of standby hours (24 or 60 for NFPA 72, Chapter 1, 1-5.2.5).

F

Multiply lines E and F. Total standby AH

G

Alarm sounding period in hours.

H

(For example, 5 minutes = .0833 hours.)

Multiply lines E and H. Total alarm AH

I

Add lines G and I. Total standby and alarm AH

J

Number of

Devices

1

Current per Device

Standby: 40 mA 40 mA

Alarm: 160 mA 160 mA

5496 Current 40 mA 160 mA

Alarm/Standby mA mA mA

Alarm/Standby mA mA mA

Alarm/Standby mA mA mA

Alarm/Standby mA mA mA

Auxiliary Devices Current mA mA

Alarm: mA 0 mA mA

Alarm: mA 0 mA mA

Alarm: mA 0 mA mA

Alarm: mA 0 mA mA

Notification Appliances Current

Standby

Current

0 mA mA

mA mA

AA

H

AH

AH

Alarm

Current

H

AH

151276 2-5

Page 12

Model 5496 Intelligent Power Module Installation and Oper ation Manual

5496 Board

To AC

Power

To Battery

To SBUS

Terminals

To NACs

2.6.3 Wire Routing

You must follow power-limited wiring techniques, which include maintaining one-quarter

inch spacing between power-limited and non-power limited circuits and separating high and

low voltage circuits.

Figure 2-2 Wire Routing Example

2-6 151276

Page 13

Section 3

To AC

To 120 VAC

Power Source

Supervised

Non-power limited

Hardware Installation

5496 installation involves the following steps:

• Connect AC power (Section 3.1) and backup battery (Section 3.2).

• Make physical connection to a Silent Knight addressable FACP (see Section 3.3).

• Set an ID for the 5496 (Section 3.3.1).

• Make physical connection to any outputs that will be powered by this 5496. See Section

3.4 for notification appliance wiring information. Refer to Silent Knight addressable

FACP Installation Manuals for software configuration information and other information

about installing outputs. Silent Knight Addressable FACP Installation Manuals can be

found on Silent Knight’s web site at www.silentknight.com.

3.1 AC Power

At installation, connect the AC terminals to 120 VAC source as shown in Figure 3-1. It may

be necessary for a professional electrician to make this connection.

The AC terminals are rated as 120 VAC, 50 or 60 Hz, 2.5 A.

Figure 3-1 AC Power Connection

151276 3-1

Page 14

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Red

To Panel

Black

UL Listed 12V BatteryUL Listed 12V Battery

Battery Jumper

(P/N 140694)

Shipped With 5496

Supervised

Non-Power Limited

Replace batteries every 5 years.

Gell Cell Gell Cell

3.2 Battery Connection

The 5496 battery charge capacity is 7.0 AH not to exceed 35.0 AH. Use 12V batteries of the

same AH rating. It is recommended that you replace batteries every five years. Determine the

correct AH rating per your current load calculation (see Table 2-4).

Note: If you require the power of back up batteries that are too large for the 5496, you can use the RBB cabinet.

The RBB Remote Battery Box, holds batteries up to the 35 AH size. (Refer to P/N 151306 for RBB installation instructions.

Wire batteries in series to produce a 24-volt equivalent. Do not parallel batteries to increase

the AH rating.

3-2 151276

Figure 3-2 Battery Connection

Page 15

Hardware Installation

5820XL

(Main SBUS)

5496 Board

Supervised

Power Limited

3.3 Connecting the 5496 to the FACP

1. Connect the 5496 to the appropriate SBUS. The 5496 is connected directly to a Silent

Knight addressable FACP.

2. Use the on-board dipswitch to assign an ID number to the 5496. (See Section 3.3.1) Figure

2-1 shows the location of the dipswitches on the 5496 board.

3. Configure the 5496 module by adding it to the system (through JumpStart or manually).

You can also assign a name to the module. These procedures are described in Silent

Knight addressable FACP Installation Manuals. Silent Knight Addressable FACP

Installation Manuals can be found on Silent Knight’s web site at www.silentknight.com.

Figure 3-3 Class B 5496 Connection to FACP

151276 3-3

Page 16

Model 5496 Intelligent Power Module Installation and Oper ation Manual

3.3.1 Setting the Device ID

All SBUS modules in the system must have a unique number (1-31) to identify them to the

FACP. Use the DIP switch on the 5496 board to set the module ID number. Figure 2-1 shows

the location of the dipswitch on the board. Figure 3-4 shows dipswitch setting and the

corresponding module ID numbers.

Figure 3-4 Possible Module Addresses

3-4 151276

Page 17

Hardware Installation

Power Limited

1.5max

3.4 Notification Appliance Wiring

Note: Not all devices can use the Sync feature. Be sure to check Table A-1 in Appendix A to ensure the device

you have chosen will work with this feature.

3.4.1 Class A Supervised Wiring

Figure 3-5 shows how to wire for Class A output supervision. Use in/out wiring methods for

proper supervision. Refer to Section 4 for notification appliances compatible with the 5496.

Class A Output Notification Circuits

The configuration shown in Figure 3-5 shows two, 3-amp devices wired as Class A circuits.

When you are using the outputs as Class A circuits, loop the wiring back to the corresponding

circuit pair. For Class A wiring, no external EOL is necessary since it is built into the 5496

board.

Figure 3-5 Class A Supervised Input/Output Connections

151276 3-5

Page 18

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Power Limited

1.5max

3.4.2 Class B Supervised Wiring

Figure 3-6 shows how to wire for Class B output supervision. Use in/out wiring methods for

proper supervision. Refer to Section 4 for notification appliances that must be used with the

5496.

Class B Output Notification Circuits

Figure 3-6 shows four, 1.5 amp devices wired as Class B circuits.

Place a 4.7k ohm EOL resistor (provided) at the end of each circuit to enable supervision

when using all outputs as Class B notification appliance circuits. The 4.7k EOLs must be

wired to the terminals whether or not you are using all output terminals.

Figure 3-6 Regulated Class B Supervised Input/Output Connections

3.4.3 Releasing Operations

Approved releasing solenoids are list in Table 3-1. Do not mix cross alarming zones with

smoke verification zones. There must be at least two automatic detection devices in each

protected space. Spacing must be reduced to 0.7 times the linear spacing in accordance with

NFPA 72.

Table 3-1: Approved Releasing Solenoids

Manufacturer Part Number Rating Current Freq

Asco T8210A107 24 VDC 3A max 0 Hz

8210G207 24 VDC 3A max 0 Hz

3-6 151276

Page 19

Hardware Installation

Power Limited

Supervised when used with the

Power Supervision Relay (PN160150)

3.4.4 Auxiliary Power Configuration

Output circuits 1-4 on the control panel can be used as auxiliary power circuits. The three

types of auxiliary power available are:

• Door Holder (see Section 3.4.4.1 for description)

• Constant (see Section 3.4.4.2 for description)

• Resettable (see Section 3.4.4.3 for description)

Auxiliary power circuits are power limited. Each circuit can source up to 3A (total current for

all output circuits must not exceed 6 A).

To configure an output circuit as auxiliary power:

1. Wire the output circuit(s) that will be used for auxiliary power . See Figure 3-7 for location

of the output circuits.

2. Configure the auxiliary power output through programming for Door Holder, Constant or

Resettable power.

Figure 3-7 Output Circuits Used as Auxiliary Power

151276 3-7

Page 20

Model 5496 Intelligent Power Module Installation and Oper ation Manual

3.4.4.1 Door Holder Power

Door holder is intended for fire door applications. When there are no alarms in the system and

the panel has AC power, door holder circuits have 24-volt power present at their terminals.

Any alarm will cause power to discontinue. Power will be re-applied when the system is reset.

If AC power is off for more than 15 seconds the auxiliary door holder power will be

discontinued to conserve the battery backup power. When AC power is restored, power is

immediately restored to the door holder circuits.

3.4.4.2 Constant Power

Use constant power for applications that require a constant auxiliary power source. Power is

always present at Constant circuits.

3.4.4.3 Resettable Power

Resettable power is typically used to power beam detectors, flame detectors, and conventional

4-wire smoke detectors. For circuits selected as Resettable, 24-volt power is always present at

the terminals unless a system reset occurs. If a system reset occurs, power is removed from the

terminals for 30 seconds, then re-applied.

3-8 151276

Page 21

Appendix A Compatible Devices

For proper operation, you must use polarized devices with a Model 7628 4.7k ohm EOL

resistor on each circuit. All supervised notification appliances used with the IFP-FFT must be

polarized.

A.1 Notification Appliances

Note: Not all devices can use the Sync feature, be sure to check A.1 to ensure the device you have chosen will

work with this feature. This control is UL listed for single circuit synchronization.

Table A-1 below lists notification appliances compatible with the fire alarm control panel.

Appliances which can be synchronized indicate the type of sync available in the columns

marked Audio and/or Visual

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

SH24W-153075 Horn/Strobe

SAD24-153075 Strobe

SAD24-75110 Strobe

SL24W-75110 Strobe

SL24C-3075110 Strobe

SLB24-75 Strobe

RSD24-153075 Strobe

RSD24-75110 Strobe

AMSECO

SH24W-75110 Horn/Strobe

SH24W-3075110 Horn/Strobe

SHB24-75 Horn/Strobe

SCM24W-153075 Chimes/Strobe

SCM24W-75110 Chimes/Strobe

SCM24C-3075110 Chimes/Strobe

SCM24C-177 Chimes/Strobe

H24W Horn

H24R Horn

151276 A-1

Page 22

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

446 Vibrating Bell

476 Vibrating Bell

477 Single Stroke Bell

2700 -M. -R, -T, -Y, -Z Strobe

2701 Series Strobe

2705 Series Strobe

2820 Snyc Temporal Horn/Strobe

2821 Snyc Temporal Horn/Strobe

2824 Horn Strobe

5333 Multi-Tone Horn)

5336 Multi-Tone Horn/Strobe

5337 Multi-Tone Horn/Strobe

5338 Multi-Tone Horn/Strobe

5343 Single Tone Horn/Strobe

Faraday

5346 Electronic Horn with Strobe

5347 Electronic Horn with Strobe

5348 Single Tone Horn/Strobe

5373 8-Tone Horn/Strobe

6321 Sync Mini Horn/Strobe

6322 Mini Horn/Sync Strobe

6380 8-Tone Electronic Signal/Strobe

5376 8-Tone Horn/Strobe

5377 8-Tone Horn/Strobe

5378 8-Tone Horn/Strobe

5383 8-Tone Horn/Strobe with Sync Strobe

5386 8-Tone Horn/Strobe with Sync Strobe

5387 8-Tone Horn/Strobe with Sync Strobe

5388 8-Tone Horn/Strobe with Sync Strobe

5508 Single Gang Sync Strobe

5509 Strobe

A-2 151276

Page 23

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

5510 Strobe

5511 Strobe

5512 Strobe

5516 Strobe

5517 Strobe

5518 Strobe

5519 Strobe

5521 4” Square Sync Strobe

5522 4” Square Sync Strobe

6120 Horn

6140 Horn

6223 Horn

6226 Horn/Strobe

6227 Horn/Strobe

Faraday

con’t

6228 Horn/Strobe

6243 Electron-Mechanical Horn

6244 Electron-Mechanical Horn

6245 Electron-Mechanical Horn

6246 Electron-Mechanical Horn/Strobe

6247 Electron-Mechanical Horn/Strobe

6248 Electron-Mechanical Horn/Strobe

6300 Mini-Horn

6301 Mini-Horn

6302 Mini-Horn

6310 Mini-Horn/Strobe

6311 Mini-Horn/Strobe

6312 Mini-Horn/Strobe

6314 Series -M, -R, -T, -Y, -Z Strobe

6320 Sync Mini Horn/Strobe

Compatible Devices

151276 A-3

Page 24

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

S2415-FC Strobe

S241575-FC Strobe

S2430-FC Strobe

130-3117C Mini Horn

130-3147C Mini Horn

BLV-6 Vibrating Bell

BLV-10 Vibrating Bell

BLVCH Vibrating Chime

H12/24-FC Horn

H12/24W-FC Horn

FCI

FCI

Federal Signal

H12/24K-FC Horn

HC12/24-FC Horn

HC12/24W-FC Horn

HC12/24K-FC Horn

P2415-FC Horn/Strobe

P2415W-FC Horn/Strobe

P2415K-FC Horn/Strobe

P241575-FC Horn/Strobe

P241575W-FC Horn/Strobe

P241575F-FC Horn/Strobe

P241575K-FC Horn/Strobe

P2430-FC Horn/Strobe

P2430W-FC Horn/Strobe

P2430K-FC Horn/Strobe

P2475-FC Horn/Strobe

P2475W-FC Horn/Strobe

P2475K-FC Horn/Strobe

P24110-FC Horn/Strobe

P24110W-FC Horn/Strobe

P24110K-FC Horn/Strobe

S2430W-FC Strobe

S2430K-FC Strobe

S2475-FC Strobe

S2475W-FC Strobe

S2475K-FC Strobe

S24110-FC Strobe

S24110W-FC Strobe

S24110K-FC Strobe

450 Horn

VALS Horn/Strobe

A-4 151276

Page 25

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

GEC-24-15 Horn/Strobes

GEC-24-30 Horn/Strobes

GEC-24-60 Horn/Strobes

GEC-24-75 Horn/Strobes

GEC-24-177 Horn/Strobes

GEC-24-110 Horn/Strobe

GEC-24-15/75 Horn/Strobe

GX91 MiniHorn Steady Tone

GX93 MiniHorn Temporal Tone

HG124 Horn

HS24-15 Horn/Strobe

HS24-30 Horn/Strobe

HS24-60 Horn/Strobe

Gentex

Gentex

con’t

HS24-75 Horn/Strobe

HS24-110 Horn/Strobe

HS24-1575 Horn/Strobe

GCC24 Multi Candella Horn/Strobe Ceiling Mount

GCCR24 Multi Candella Horn/Strobe Ceiling Mount

GCS24 Multi Candella Strobe Ceiling Mount

GCSR24 Multi Candella Strobe Ceiling Mount

GECR-24 Multi Candella Horn/Strobe

GES24-15 Strobes

GES24-30 Strobes

GES24-60 Strobes

GES24-75 Strobes

GES24-110 Strobes

GES24-15/75 Strobes

GES24-177 Strobes

GES3-24 Multi Candella Strobe

GESR-24 Multi Candella Strobe

GEH-24 Horn

ST24-30 Strobe

ST24-60 Strobe

ST24-75 Strobe

ST24-110 Strobe

ST24-1575 Strobe

WGEC24-75W Weatherproof Horn/Strobe

WGES24-75W Weatherproof Strobe

WGMS-24-X Horn/Strobe

Compatible Devices

151276 A-5

Page 26

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

CHR Chime

CHW Chime

CHSR 2-Wire Chime/Strobe

CHSW 2-Wire Chime/Strobe

HR Horn

HW Horn

HRK Horn

P2R 2-Wire Horn/Strobe

P2R-P 2-Wire Horn/Strobe

PC2R 2-Wire Horn/Strobe

PC2R-P 2-Wire Horn/Strobe

P2RH 2-Wire Horn/Strobe High Candela

P2RH-P 2-Wire Horn/Strobe High Candela

PC2RH 2-Wire Horn/Strobe High Candela

PC2RH-P 2-Wire Horn/Strobe High Candela

System Sensor

P2W 2-Wire Horn/Strobe

P2W-P 2-Wire Horn/Strobe

PC2W 2-Wire Horn/Strobe

PC2W-P 2-Wire Horn/Strobe

P2WH 2-Wire Horn/Strobe High Candela

P2WH-P 2-Wire Horn/Strobe High Candela

PC2WH 2-Wire Horn/Strobe High Candela

PC2WH-P 2-Wire Horn/Strobe High Candela

P2RK 2-Wire Horn/Strobe

PC2RK 2-Wire Horn/Strobe

P2RHK 2-Wire Horn/Strobe High Candela

PC2RHK 2-Wire Horn/Strobe High Candela

P4R 4-Wire Horn/Strobe

PC4R 4-Wire Horn/Strobe

P4RH 4-Wire Horn/Strobe High Candela

P4W 4-Wire Horn/Strobe

A-6 151276

Page 27

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

PC4W 4-Wire Horn/Strobe

P4WH 4-Wire Horn/Strobe High Candela

PC4WH 4-Wire Horn/Strobe High Candela

P4RK 4-Wire Horn/Strobe

PC4RK 4-Wire Horn/Strobe

P4RHK 4-Wire Horn/Strobe High Candela

PC4RHK 4-Wire Horn/Strobe High Candela

PC4RH 4-Wire Horn/Strobe High Candela

SR Strobe

SR-P Strobe

SCR Strobe

SCR-P Strobe

SRH Strobe High Candela

System Sensor

con’t

SRH-P Strobe High Candela

SCRH Strobe High Candela

SCRH-P Strobe High Candela

SW Strobe

SW-P Strobe

SCW Strobe

SCW-P Strobe

SWH Strobe High Candela

SWH-P Strobe High Candela

SCWH Strobe High Candela

SCWH-P Strobe High Candela

SRK Strobe

SCRK Strobe

SRHK Strobe High Candela

SCRHK Strobe High Candela

Compatible Devices

151276 A-7

Page 28

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

AH-12 Horn

AH-24 Horn

AH-12WP Horn Weatherproof

AH-24WP Horn Weatherproof

AMT-241575W Multi-Tone Horn Strobe

AMT-24MCW Mutli-Tone Horn St robe

AMT-241575W-NYC Multi-Tone Horn Strobe

AMT-12/24 Multi-tone Horn

AMT-12/24 NYC Multi-tone Horn

AS-121575W Horn/Strobe

NH-12/24 Horn

AS-241575W Horn/Strobe

Wheelock

AS-24MCC Horn/Strobe

AS-24MCCH Horn/Strobe

AS-24MCW Horn/Strobe

AS-24MCWH Horn/Strobe

ASWP-2475W Horn/Strobe Weatherproof

ASWP-2475C Horn/Strobe Weatherproof

ASWP-24MCWH Horn/Strobe

ASWP-24MCCH Horn/Strobe

CH-70 Chime

CH-90 Chime

CH70-241575W Chime/Strobe

CH70-24MCW Chime/Strobe

CH70-24MCWH Chime/Strobe

CH90-24MCC Chime/Strobe

A-8 151276

Page 29

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

CH90-24MCCH Chime/Strobe

HS-24 Horn

HS4-241575W Horn/Strobe

HS4-24MCW Horn/Strobe

HS4-24MCWH Horn/Strobe

HS4-24MCC Horn/Strobe

MIZ-24S Mini Horn Strobe

MT-121575W MultitoneHorn Strobe

MT-241575W Multitone Horn Strobe

MT-24MCW Multitone Horn Strobe

MTWP-2475W Multitone Horn Strobe

MTWP-2475C Multitone Horn Strobe

MTG-121575W Multitone Horn Strobe

MTR-121575W Multitone Horn Strobe

Wheelock

con’t

MTWPA-2475W Multitone Horn Strobe

MTWPB-2475W Multitone Horn Strobe

MTWPG-2475W Multitone Horn Strobe

MTWPR-2475W Multitone Horn Strobe

MTWPA-24MCCH Multitone Horn Strobe

ZNH Horn

NS-121575W Horn/Strobe

NS-241575W Horn/Strobe

NS-24MCW Horn/Strobe

NS-24MCC Horn/Strobe

NS-24MCCH Horn/Strobe

ZNS-MCW Horn/Strobe

ZNS-MCWH Horn/Strobe

ZNS-24MCC Horn/Strobe

ZNS-24MCCH Horn/Strobe

Compatible Devices

151276 A-9

Page 30

Model 5496 Intelligent Power Module Installation and Oper ation Manual

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

RSS-121575W Strobe

RSS-241575W Strobe

RSS-24MCC Strobe

RSS-24MCCR Strobe

RSS-24MCCH Strobe

RSS-24MCCHR Strobe

RSS-24MCW Strobe

RSS-24MCWH Strobe

RSSP-121575W Strobe

RSSP-241575W Strobe

RSSR-2415W Strobe

RSSR-2415C Strobe

RSSR-2475W Strobe

RSSR-2475C Strobe

Wheelock

con’t

RSSR-24110C Strobe

RSSA-24110W Strobe

RSSB-24110W Strobe

RSSG-24110W Strobe

RSSR-24110W Strobe

RSSA-24MCC Multi-Cd Strobe

RSSB-24MCC Multi-Cd Strobe

RSSG-24MCC Multi-Cd Strobe

RSSR-24MCC Multi-Cd Strobe

RSSWPA-2475W Strobe Weatherproof

RSSWPA-24MCCH Strobe Weatherproof

RSSWPG-24MCCH Strobe Weatherproof

RSSWPR-24MCCH Strobe Weatherproof

RSSWP-2475W Strobe Weatherproof

RSSWP-2475C Strobe We atherproof

A-10 151276

Page 31

Table A-1: Compatible Notification Appliances

Manufacturer Model Audio Visual Type

RSSWP-24MCWH Strobe Weatherproof

ZRS-MCWH Strobe

ZRS-24MCC Strobe

ZRS-24MCCH Strobe

MB-G6-24 Motor Bell

MB-G10-24 Motor Bell

MB-G6-12 Motor Bell

MB-G10-12 Motor Bell

MIZ-24-R Mini-Horn

Wheelock

con’t

MT-12/24-R Multitone Horn

MT4-12/24 Multitone Horn

ZRS-MCW Strobe

MTWPR-24MCCH Multitone Horn Strobe

NH-12/24R Horn

HSR Horn/Strobe

HSW Horn/Strobe

STR Strobe

STW Strobe

HNR Horn

HNW Horn

Compatible Devices

Door Holder Device

The following UL listed door holder can be used with the IFP-FFT: ESL DHS-1224

151276 A-11

Page 32

Model 5496 Intelligent Power Module Installation and Oper ation Manual

A-12 151276

Page 33

Silent Knight Fire Product Warranty and Return Policy

General Terms and Conditions

• All new fire products manufactured by Silent Knight have a limited warranty period of

36 months from the date of manufacture against defects in materials and workmanship.

See limited warranty statement for details.

• This limited warranty does not apply to those products that are damaged due to misuse,

abuse, negligence, exposer to adverse environmental conditions, or have been modified in

any manner whatsoever.

Repair and RA Procedure

• All products that are returned to Silent Knight for credit or repair require a RMA (Return

Authorization) number. Call Silent Knight Customer Service at 800-328-0103 or

203-484-7161 between 8:00 A.M. and 5:00 P.M. EST , Monday through Friday to obtain a

return authorization number.

• Silent Knight Technical Support is available at 800-446-6444 between 8:00 A.M. and

5:00 P.M. CST, Monday through Friday.

• All returns for credit are subject to inspection and testing at the factory before actual

determination is made to allow credit.

• RMA number must be prominently displayed on the outside of the shipping box. See

return address example under Advanced Replacement Policy.

• Include a packing slip that has the RMA number, a content list, and a detailed description

of the problem should be included with each return.

• All products returned to Silent Knight must be sent freight pre-paid. After product is

processed, Silent Knight will pay for shipping product back to customer via UPS ground.

• Return the Silent Knight product circuit board only. Products that are returned in cabinets

will be charged an additional $50 to cover the extra shipping and handling costs over

board only returns. Do not return batteries. Silent Knight has the authority to determine

if a product is repairable. Products that are deemed un-repairable will be returned to the

customer.

• Product that is returned that has a board date code more than 36 months from date of

manufacture will be repaired and the customer will be assessed the standard Silent Knight

repair charge for that model.

Advanced Replacement Policy

• Silent Knight offers an option of advance replacement for fire product printed circuit

boards that fail during the first 6 months of the warranty period. These items must be

returned with transportation charges prepaid and must be accompanied by a return

authorization.

• For advance replacement of a defective board contact your local Silent Knight Distributor

Page 34

or call Silent Knight at 203-484-7161 to obtain a RMA (Return Authorization) number

and request advanced replacement,

• A new or refurbished board will be shipped to the customer . The customer will initially be

billed for the replacement board but a credit will be issued after the repairable board is

received at Silent Knight. All returned products must comply with the guidelines

described under “General Terms and Conditions”.

• The defective board must be returned within 30 days of shipment of replacement board for

customer to receive credit. No credit will be issued if the returned board was damaged due

to misuse or abuse.

• Repairs and returns should be sent to:

Silent Knight / Honeywell

Attn: Repair Department

12 Clintonville Road

Northford, CT 06472

USA

RMA Number:___________________

Page 35

Manufacturer Warranties and Limitation of Liability

Manufacturer Warranties. Subject to the limitations set forth herein, Manufacturer

warrants that the Products manufactured by it in its Northford, Connecticut facility and

sold by it to its authorized Distributors shall be free, under normal use and service,

from defects in material and workmanship for a period of thirty six months (36)

months from the date of manufacture (effective Jan. 1, 2009). The Products

manufactured and sold by Manufacturer are date stamped at the time of production.

Manufacturer does not warrant Products that are not manufactured by it in its

Northford, Connecticut facility but assigns to its Distributor, to extent possible, any

warranty offered by the manufacturer of such product. This warranty shall be void if a

Product is altered, serviced repaired by anyone other than Manufacturer or its

authorized Distributors.This warranty shall also be void if there is a failure to maintain

the Products and the systems in which they operate in proper working conditions.

MANUFACTURER MAKES NO FURTHER WARRANTIES, AND DISCLAIMS ANY

AND ALL OTHER WARRANTIES, EITHER EXPRESSED OR IMPLIED, WITH

RESPECT TO THE PRODUCTS,TRADEMARKS, PROGRAMS AND SERVICES

RENDERED By MANUFACTURER INCLUDING WITHOUT LIMITATION,

INFRINGEMENT, TITLE, MERCHANTABILITY, OR FITNESS FOR ANY

PARTICULAR PURPOSE. MANUFACTURER SHALL NOT BE LIABLE FOR ANY

PERSONAL INJURY OR DEATH WHICH MAY ARISE IN THE COURSE OF, OR AS

A RESULT OF, PERSONAL, COMMERCIAL OR INDUSTRIAL USES OF ITS

PRODUCTS.

This document constitutes the only warranty made by Manufacturer with respect to its

products and replaces all previous warranties and is the only warranty made by

Manufacturer. No increase or alteration, written or verbal, of the obligation of this

warranty is authorized. Manufacturer does not represent that its products will prevent

any loss by fire or otherwise.

Warranty Claims. Manufacturer shall replace or repair, at Manufacturer's discretion,

each part returned by its authorized Distributor and acknowledged by Manufacturer to

be defective, provided that such part shall have been returned to Manufacturer with

all charges prepaid and the authorized Distributor has completed Manufacturer's

Return Material Authorization form. The replacement part shall come from

Manufacturer's stock and may be new or refurbished. THE FOREGOING IS

DISTRIBUTOR'S SOLE AND EXCLUSIVE REMEDY IN THE EVENT OF A

WARRANTY CLAIM

Warn-HL-08-2009.fm

Page 36

Page 37

Page 38

Silent Knight

12 Clintonville Road

Northford, CT 06472-1610

203-484-7161

Fax: 203-484-7118

www.silentknight.com

Loading...

Loading...