Page 1

SD505-ADHR Duct Detector Housing

With Relay Module & SD505-DTS

Installation Instructions

The following are instructions on how to install

the SD505-ADHR & SD505-DTS to a Silent

Knight Addressable control panel.

SD505-ADHR Installation

The SD505-ADHR is a duct detector housing

with a built-in relay module that is used to

control a fan motor to stop air flow in a fire

alarm situation.

Specifications

Specification Parameter Rating

Alarm Relay Contact Rating: 10 A @ 120/240 VAC

Trouble Relay Contact Rat-

ing:

Operating Volt-

age:

Aux. Input Power

Current:

SLC Current for

Battery Calculations

Max. SLC Loop Resistance: 50Ω

Operating Temperature: 32° to 120° F (0° to 49° C)

Humidity: 10-85% RH

Air Velocity: 500-4000 fpm 300-4000

Sensitivity: 0.85 to 1.15%

SLC

Loop:

Aux. Pwr.

Input:

24 VDC Standby: 35 mA

24 VAC Standby: 50 mA

120 VAC Standby: 10 mA

240 VAC Standby: 5 mA

Alarm: .018 mA

Standby: .018 mA

2.5 A @ 30VDC

32 VDC

120/240 VAC, 24 VDC/VAC

Alarm: 75 mA

Alarm: 90 mA

Alarm: 20 mA

Alarm: 10 mA

SD505-APS SD505-AIS

fpm

0.5 to 0.81%

per foot

per foot

Mounting Instructions

Follow these steps to mount the SD505-ADHR:

1. Remove paper backing from mounting

template (packaged in installation kit) and

affix to duct at installation location.

2. Using the template as a guide, drill the four

mounting holes (3/32” diameter) for duct

detector mounting screws provided (4 # 12 x

1/2” sheet metal screws).

3. Use template as guide to drill or punch holes

for the sampling tubes in the air ducts (13/8” diameter).

4. Clean all holes.

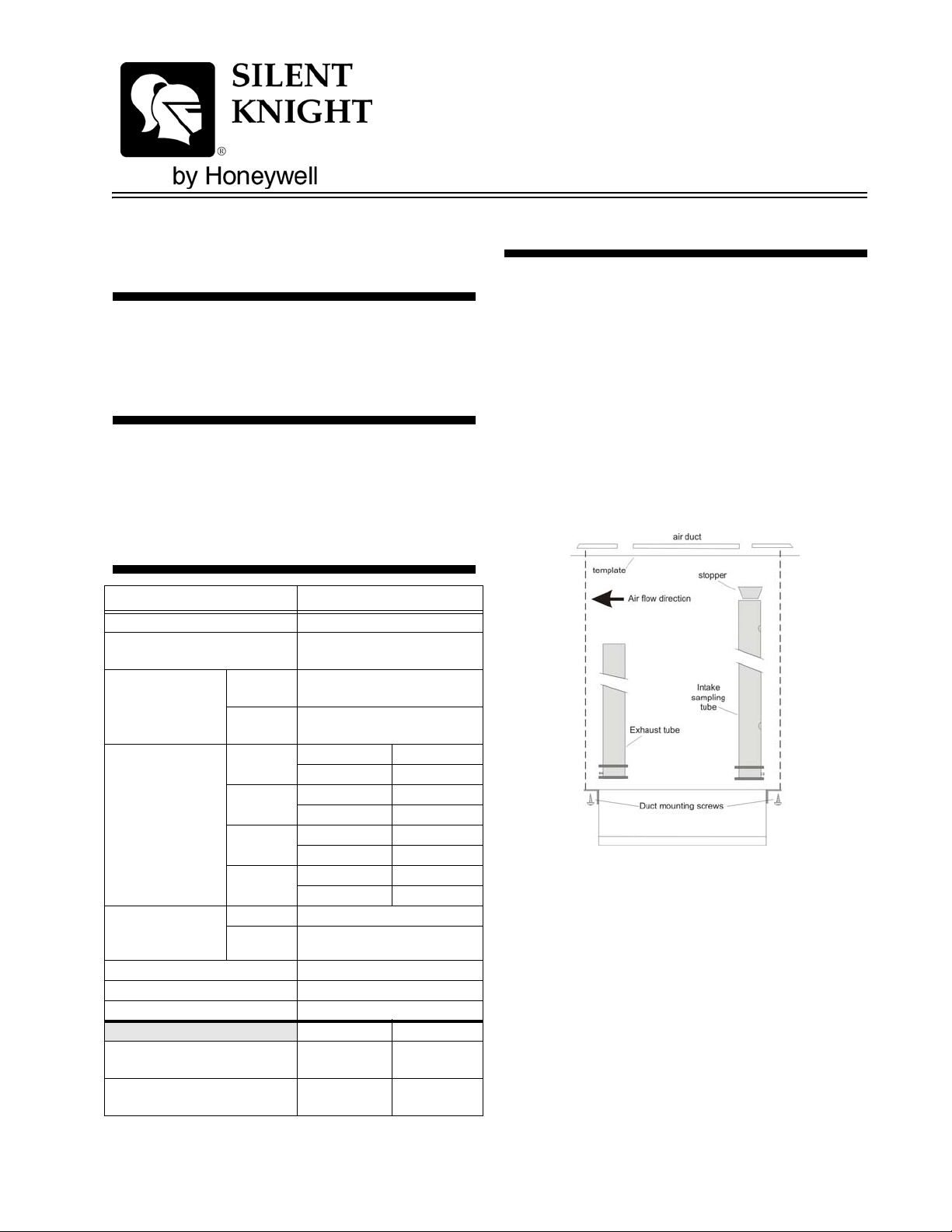

Sampling Tube Assembly

The sampling tubes can be ordered in standard

lengths and cut per requirements. See chart

below for available standard sizes. The intake

sampling tube is a piece of steel piping with a

series of holes drilled the entire length of the

tube. The tube should be cut to a size that allows

it to extend the entire width of the duct.

The holes must be facing into the air flow (see

Figure 1). The exhaust tube is a piece of steel

piping measuring 7 inches.

P/N 151126

Page 2

SD505-ADHR Duct Detector Housing With Relay Module & SD505-DTS Installation Instructions

The pressure differential between the input

sampling tube and exhaust tube should be

greater than 0.01” and less than 1.2” of water.

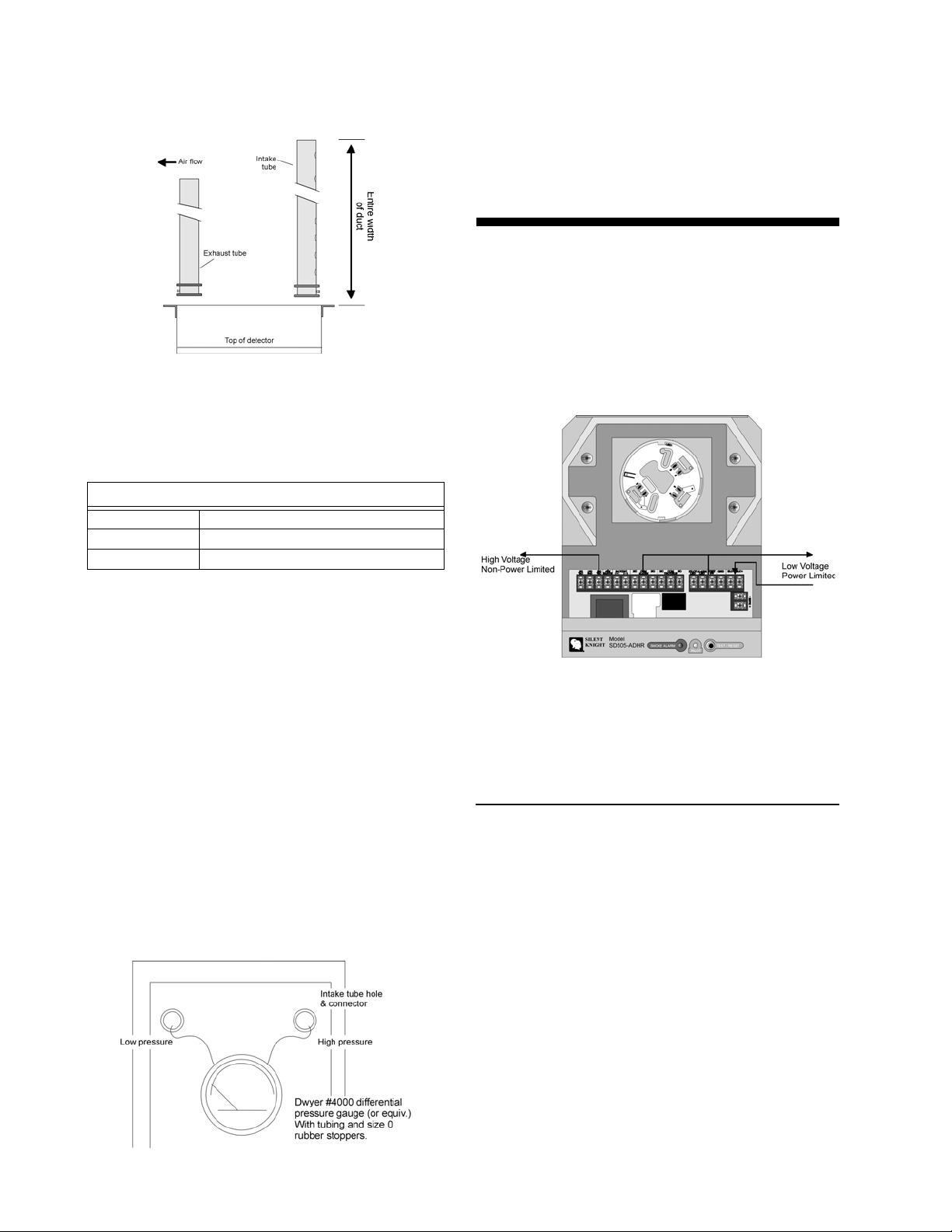

Wiring Instructions

This section contains information on how to

connect the SD505-ADHR to a power source, to

a fan motor, and to a SD505-DTS remote test

station. Wiring must conform to applicable local

codes, ordinances, and regulations covering this

Figure 1: Sampling Tube Orientation

5. Cut intake sampling tube to the desired

length.

6. Firmly insert the provided stopper into the

end of the intake sampling tube.

Standard Lengths for Intake Sampling Tubes

STS-2.5 For duct widths of 1.0’ to 2.5’

STS-5.0 For duct widths of 2.5’ to 5.0’

STS-10.0 For duct widths of 5.0’ to 10.0’

type of device. Refer to NFPA 90A and NFPA

72E for additional information on duct smoke

detector operation and installation.

7. Mount the detector by placing the

detector/sampling tube assembly into

position and secure to duct housing using

mounting screws.

Verify Air Flow and Direction

8. Verify that air velocity is appropriate for the

type of smoke detector you are using by

checking specifications of installation and, if

necessary, by using air velocity meter (Alnor

Model 6,000P or equivalent). See Figure 1.

Air Sampling Verification

9. Verify proper air sampling by using a

differential pressure gauge (Dwyer Model

4000 or equivalent). See Figure 2 for

connections.

Figure 3: Wire Routing Example

Important! 1/4" spacing must be maintained between

High and Low voltage circuits; as well as

between power limited and non-power

limited circuits.

Power Connections

The SD505-ADHR can be powered from a 120

VAC, 240 VAC, or 24 VDC/VAC power source.

Note: Only one power source can be used to power the SD505-

ADHR.

Figure 4 illustrates how to connect the various

types of power sources to the SD505-ADHR.

2 P/N 151126

Figure 2: Air Sampling Verification

Page 3

SD505-ADHR Duct Detector Housing With Relay Module & SD505-DTS Installation Instructions

FACP

Supervised

Power Limited

SD505-ADHR

Figure 4: Power Source Connections

FACP Connections

Follow these steps to properly connect the

SD505-ADHR to the FACP:

1. Turn power off and leave the detector head

off.

2. Wire the SD505-ADHR as show in Figure 5

or Figure 6.

FACP

Supervised

Power Limited

Figure 6: Class A (Style 6)

Alarm Relay

The Alarm relay can be used to shut off a fan

motor of a HVAC system to prevent the transfer

of smoke. See Figure 7.

Figure 7: Fan Motor Shut-off Block Diagram

Trouble Relay

SD505-ADHR

Figure 5: Class B (Style 4)

P/N 151126 3

The trouble relay is a form C relay that activates

if the input power is lost.

Page 4

SD505-ADHR Duct Detector Housing With Relay Module & SD505-DTS Installation Instructions

SD505-DTS Installation

The SD505-DTS is an optional remote test

switch station that connects to the SD505ADHR. The SD505-DTS also provides visual

access to the SD505-ADHR in installations

where the SD505-ADHR cannot physically be

seen.

SD505-DTS Wiring

Wire the SD505-DTS to the SD505-ADHR as

shown in Figure 8.

Figure 9: SD505-DTS Mounting and Assembly

Supervised

Power Limited

Figure 8: SD505-DTS Wiring Connections

Mounting The SD505-DTS

SD505-DTS Specifications

Parameter Rating

Current Draw Standby: 6 mA

Alarm: 6 mA

Dimensions (including red

trim plate):

Operating Temperature: 32° F to 120° F (0° C to 49° C)

Operating Voltage: 10 VDC

4-3/4” H x 3” W x 1-3/4” D

12.07 cm x 7.62 cm x 4.45 cm

The SD505-DTS mounts into a single gang

electrical switch box. See Figure 9.

4

Maple Grove, MN 55369-4927

763-493-6455 or 800-328-0103

© 2006 Silent Knight PN 151126 Rev C

7550 Meridian Circle

Fax: 763-493-6475

www.silentknight.com

Loading...

Loading...