SEW-Eurodrive MOVITRAC MC07B, MC07B0055-5A3-4-00, MC07B0030-5A3-4-S0, MC07B0040-5A3-4-S0, MC07B0015-5A3-4-S0 User Manual

...Page 1

Drive Technology \ Drive Automation \ System Integration \ Services

Manual

MOVITRAC

®

MC07B

Functional Safety

Edition 12/2011 19396414 / EN

Page 2

SEW-EURODRIVE—Driving the world

Page 3

Manual – Functional Safety MOVITRAC® MC07B

3

Contents

Contents

1 General Information............................................................................................ 4

1.1 How to use this documentation................................................................... 4

1.2 Underlying standards.................................................................................. 4

1.3 Structure of the safety notes......................................... ... .... ... ... ... ... .... ....... 5

1.4 Rights to claim under warranty ................................................................... 6

1.5 Exclusion of liability..................................................................................... 6

1.6 Copyright notice.......................................................................................... 6

1.7 Document content....................................................................................... 6

1.8 Other applicable publications...................................................................... 6

2 Integrated Safety Technology............................................................................ 7

2.1 Safe condition ............... ... ... ... .......................................... .... ... ... ... .............. 7

2.2 Safety concept ............................................................................................ 7

2.3 Schematic representation – "safety concept for MOVITRAC

®

B"............... 8

2.4 Safety functions .......................................................................................... 9

2.5 Restrictions ............................................................................................... 11

3 Safety Conditions.............................................................................................. 12

3.1 Approved devices ..................................................................................... 13

3.2 Installation requirements........................................................................... 14

3.3 Requirements on the external safety controller ........................................ 16

3.4 Requirements on startup........................................................................... 17

3.5 Requirements on operation....................................................................... 17

4 Connection Variants ............. ... ... ... .... .......................................... ... ... ... ... .... ..... 18

4.1 General information ................................................................................ .. 18

4.2 Requirements............................................................................................ 19

4.3 Disconnection of a single drive ................................................................. 20

4.4 Disconnection of group drives................................................................... 26

5 Technical Data .................................................................................................. 30

5.1 Safety characteristics................................................................................ 30

5.2 Electronics data X17: Signal terminal block for STO safety contact......... 30

Index................................................................................................................... 31

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 4

4

Manual – Functional Safety MOVITRAC® MC07B

1

How to use this documentation

General Information

Functional Safety MOVITRAC® MC07B

1 General Information

1.1 How to use this documentation

The documentation is an integral part of the product and contains impo rtant information

on operation and service. The documentation is written for all employees wh o assemble,

install, start up, and service this product.

The documentation must be accessible and legib le. Make sure that persons responsible

for the system and its operation, as well as persons who wor k independently on the unit,

have read through the documentation carefully and understood it. If you are unclear

about any of the information in this documentation, or if you require further information,

contact SEW-EURODRIVE.

Make sure you always use the latest documentation and software version.

Our documentation is available in various languages for download from the SEW

homepage

. Consult SEW-EURODRIVE if you are unclear

about any of the info

rmation in this docu

mentation, or if you require further information.

You can also order the printed documentatio n from SEW-EURODRIVE.

1.2 Underlying standards

The safety assessment of the unit is based on the following standards and safety

classes:

Underlying standards

Safety class/underlying standard

• Performance level (PL) according to EN ISO 138491:2008

• Category 3 according to EN 954-1:1996

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 5

Manual – Functional Safety MOVITRAC® MC07B

5

1

Structure of the safety notes

General Information

1.3 Structure of the safety notes

1.3.1 Meaning of signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to property, an d ot he r no te s.

1.3.2 Structure of the section safety notes

Section safety notes do not apply to a specific action but to several actions pertaining to

one subject. The symbols used either indicate a general hazard or a specific hazard.

This is the formal structure of a section safety note:

1.3.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD Type and source of danger.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situ ation M inor injuries

NOTICE Possible damage to property Damage to the drive system or its

environment

INFORMATION Useful information or tip:

implifies the handling of the

drive system.

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 6

6

Manual – Functional Safety MOVITRAC® MC07B

1

Rights to claim under warranty

General Information

1.4 Rights to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the MOVITRAC

®

documentation.

Therefore, read the operating instructions before you start working with the unit.

Make sure that the documentation is available to persons responsible for the system and

its operation as well as to persons who work independently on the unit. You must also

ensure that the documentation is legible.

1.5 Exclusion of liability

Adherence to the operating instructions is essential to ensure safe operation of

MOVITRAC

®

MC07B units and to achieve the specified product characteristics and

performance features. SEW-EURODRIVE assumes no liability for injury to persons or

damage to equipment or property resulting from non-adherence to these operating

instructions. In such cases, any liability for defects is excluded.

1.6 Copyright notice

© 2010 – SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized duplication, modification, distribution, and use

of this document, in whole or in part.

1.7 Document content

This publication contains conditions and amendments related to MOVITRAC® MC07B

units in safety-related applications.

The system comprises a drive inverter with AC motor and safety-tested external

disconnecting device.

1.8 Other applicable publications

This document supplements the MOVITRAC® MC07B operating instructions and limits

the application notes according to the following information. It may only be used together

with the MOVITRAC

®

MC07B operating instructions.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 7

Manual – Functional Safety MOVITRAC® MC07B

7

2

Safe condition

Integrated Safety Technology

2 Integrated Safety Technology

The safety technology of MOVITR AC®MC07B units described below has been developed and tested in accordance with the following safety requirements:

• Category 3 according to EN 954-1: 1996

• PL d according to EN ISO 13849-1: 2008

This was certified by TÜV Nord. Copies of the TÜV certificate can be obtained from

SEW-EURODRIVE.

2.1 Safe condition

For safety-related operation of MOVITRAC®MC07B, safe torque off is defined as safe

condition (see STO safety function). The safety concept is based on this definition.

2.2 Safety concept

• In the event of danger, any potential risk related to a machine must be eliminated as

quickly as possible. Standstill with restart prevention is generally the safe condition

for preventing dangerous movements.

• The MOVITRAC

®

MC07B inverter is characterized by the option to connect an

external safety relay. This safety re lay disconnects all active elem ents (disconnection of the safety-related 24 V power supply of the output stag e control) that generate

the pulse trains to the power output stage (IGBT) when a connected control device

(E-STOP button with latching function) is activated.

• Disconnecting the safety-related 24 V supply voltage ensures that the supply

voltages required for operating the inverter and consequently for generating a rotating field of pulse patterns (whic h allow the generation of a rotating field) are saf ely

interrupted, preventing automatic restart.

• Instead of galvanic separation of the drive from the power supply by means of relays

or switches, the disconnection of the 24 V supply described here safely prevents the

control of the power semiconductors in the drive inverter. This process disconnects

the rotating field generation for the respective motor. The individual motor cannot

develop any torque in this state even though the line voltage is still present.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 8

8

Manual – Functional Safety MOVITRAC® MC07B

2

Schematic representation – "safety concept for MOVITRAC® B"

Integrated Safety Technology

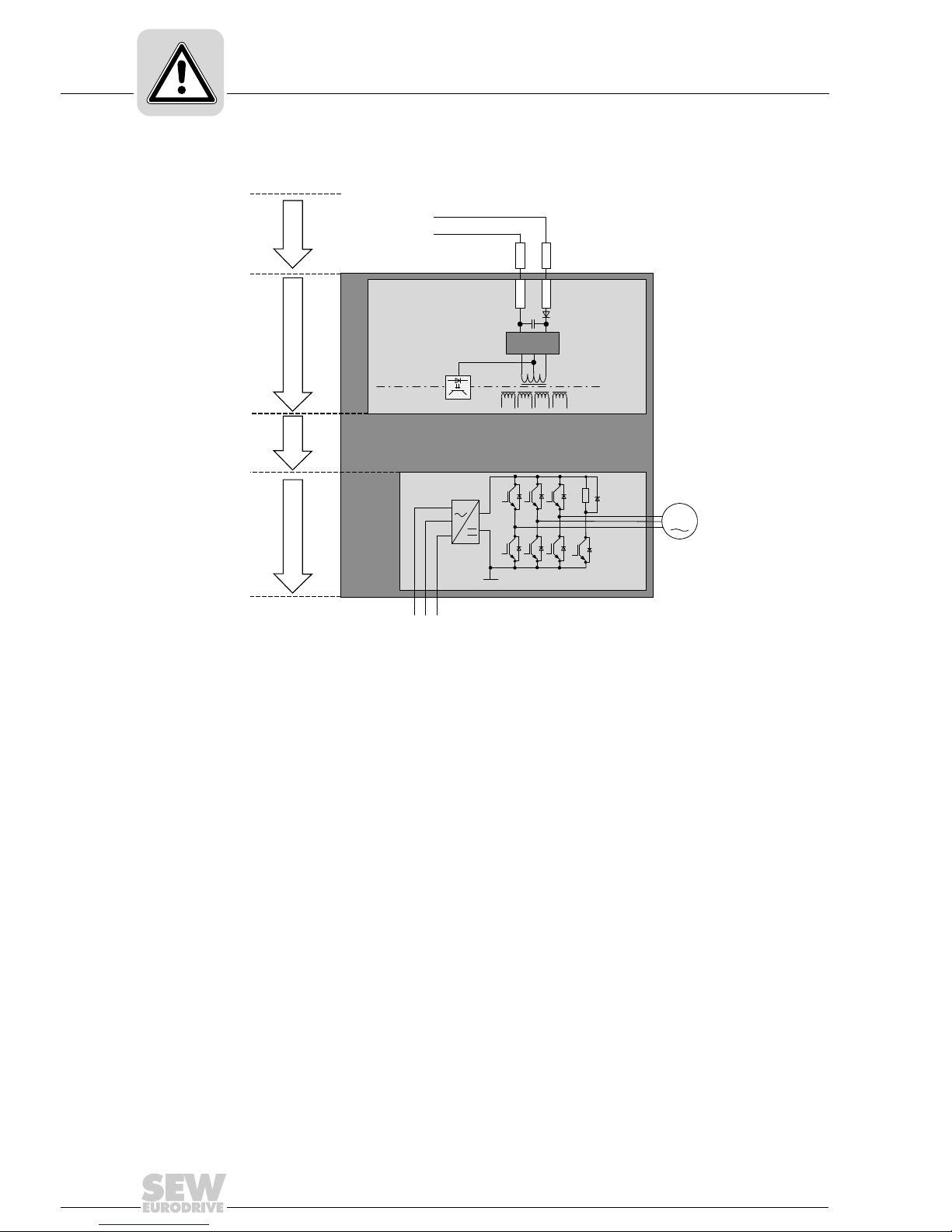

2.3 Schematic representation – "safety concept for MOVITRAC® B"

1797262603

[1] Safety-related DC 24 V voltage supply

[2] Electrical isolation

[3] Voltage supply for control of power transistors

[4] Pulse width modulated signals for the output stage

S24V

S0V24

M

Uz-

Uz+

24V

SNT

S0V24

SVI24

L1 L2 L3

GND

[1]

[2]

[3]

[4]

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 9

Manual – Functional Safety MOVITRAC® MC07B

9

2

Safety functions

Integrated Safety Technology

2.4 Safety functions

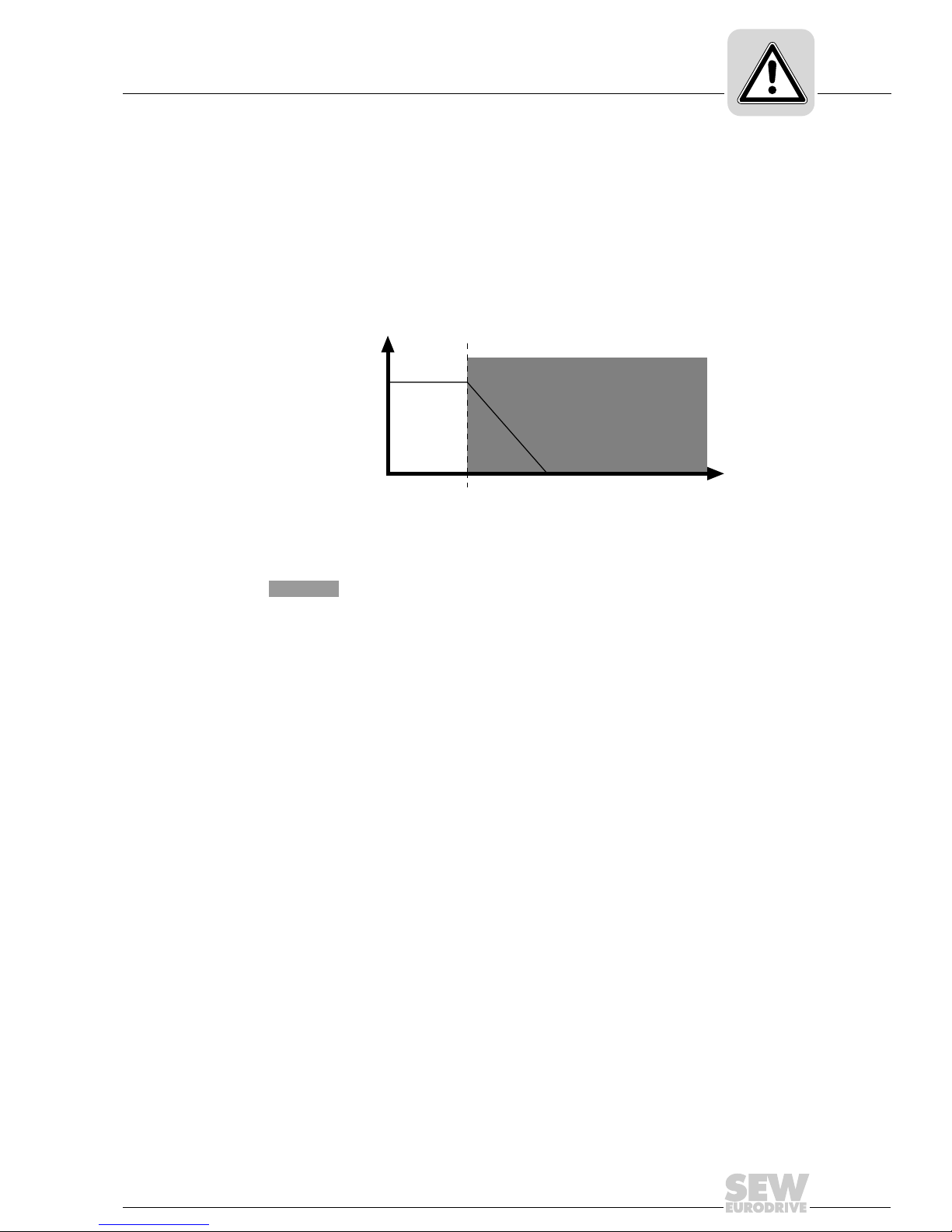

The following drive-related safety functions can be used:

• STO (safe torque off according to EN 61800-5-2) by disconnecting the STO input.

If the STO function is activated, the frequency inverter no longer supplies power to

the motor for generating torque. This safety function corresponds to a non-co ntrolled

stop according to EN 60204-1, stop category 0.

The STO input must be disabled by a suitable external safety controller/safety relay.

The following figure shows the STO function:

2463228171

v Velocity

tTime

t

1

Time at which STO is triggered

Disconnection range

v

t

t

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 10

10

Manual – Functional Safety MOVITRAC® MC07B

2

Safety functions

Integrated Safety Technology

• SS1(c) (safe stop 1, function variant c according to EN 61800-5-2) by means of

suitable external control (e.g. safety relay with delayed disconnection)

The following sequence is mandatory:

– Decelerate the drive using an appropriate brake ramp specified via setpoints.

– Disconnect the STO input (= triggering the STO function) after a specified safety-

related time delay.

This safety function corresponds to a controlled stop according to EN 602041, stop

category 1.

The following figure illustrates the SS1(c) function:

2463226251

v Velocity

tTime

t

1

Point of time when the brake ramp is initiated

t

2

Point of time when STO is triggered

∆t Time between initiating the brake ramp and STO

Safe time delay range

Disconnection range

v

t

t

1

tt

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 11

Manual – Functional Safety MOVITRAC® MC07B

11

2

Restrictions

Integrated Safety Technology

2.5 Restrictions

• Note that if the drive does not have a mechanical brake, or if the brake is defective,

the drive may coast to a halt (depending on the friction and mass moment of inertia

of the system). In case of regenerative loads, the drive can even accelerate. This

must be taken into account in a risk assessment of the system/machine. Additional

safety measures might have to be implemented (e.g. safety brake system).

MOVITRAC

®

MC07B cannot be used without an additional brake system for appli-

cation-specific safety functions that require active deceleration (braking).

• When using the SS1(c) function as described in chapter "Safety functions", the brake

ramp of the drive is not monitored with respect to safety. In case of a fault, the drive

might not be decelerated after the delay time, or it might be accelerated in the worst

case. In this case, th e STO function (see chapter "Safety functions") is only activated

after the set time delay has elapsed. The re sulting danger must be taken into account

in the risk assessment of the system/machine. Additional safety measures might

have to be implemented.

WARNING

The safety concept is only suitable for performing mechanical work on the system/

machine components.

When the STO signal is disconnected, the line voltage is still present at the DC link of

MOVITRAC

®

MC07B.

Severe or fatal injuries from electric shock.

• Before working on the electric part of the drive system, disconnect it from the

supply system using an appropriate external disconnecting device and secure it

against unintentional reconnection to the power supply.

INFORMATION

In case of safety-related disconnection of the DC 24 V supply at X17 (STO activated),

the brake is always applied. The brake control in MOVITR AC

®

MC07B is not safety-

related.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 12

12

Manual – Functional Safety MOVITRAC® MC07B

3

Safety Conditions

3 Safety Conditions

The requirement for safe operation is that the safety functions of MOVITRAC® MC07B

are properly integrated into an application-specific higher-level safety function. A

system/machine-specific risk assessment must be carried out by the system/machine

manufacturer and taken into account for operating the drive system with MOVITRAC

®

MC07B.

The system/machine manufacturer and the operator are responsible for compliance of

the system/machine with applicable safety regulations.

The following requirements are mandatory when installing and operating MOVITRAC

®

MC07B units in safety-related applications.

The requirements are divided into:

• Approved devices

• Requirements on the installation

• Requirements on external safety controllers and safety relays

• Requirements on startup

• Requirements on operation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 13

Manual – Functional Safety MOVITRAC® MC07B

13

3

Approved devices

Safety Conditions

3.1 Approved devices

The following unit variants of MOVITRAC® MC07B are permitted for safety-related

applications:

3.1.1 MOVITRAC

®

MC07B for a supply voltage of 3 × AC 380 – 500 V

3.1.2 MOVITRAC

®

MC07B for a supply voltage of AC 200 – 240 V

Power

kW

Size Type

0.55 0S MC07B0005-5A3-4-S0

0.75 0S MC07B0008-5A3-4-S0

1.1 0S MC07B0011-5A3-4-S0

1.5 0S MC07B0015-5A3-4-S0

2.2 0L MC07B0022-5A3-4-S0

3.0 0L MC07B0030-5A3-4-S0

4.0 0L MC07B0040-5A3-4-S0

5.5 2S MC07B0055-5A3-4-00

7.5 2S MC07B0075-5A3-4-00

11 2 MC07B0110-5A3-4-00

15 3 MC07B0150-503-4-00

22 3 MC07B0220-503-4-00

30 3 MC07B0300-503-4-00

37 4 MC07B0370-503-4-00

45 4 MC07B0450-503-4-00

55 5 MC07B0550-503-4-00

75 5 MC07B0750-503-4-00

Power

kW

Size Type

0.55 0S MC07B0005-2A3-4-S0

0.75 0S MC07B0008-2A3-4-S0

1.1 0L MC07B0011-2A3-4-S0

1.5 0L MC07B0015-2A3-4-S0

2.2 0L MC07B0022-2A3-4-S0

3.7 1 MC07B0037-2A3-4-00

5.5 2 MC07B0055-2A3-4-00

7.5 2 MC07B0075-2A3-4-00

11 3 MC07B0110-203-4-00

15 3 MC07B0150-203-4-00

22 4 MC07B0220-203-4-00

30 4 MC07B0300-203-4-00

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 14

14

Manual – Functional Safety MOVITRAC® MC07B

3

Installation requirements

Safety Conditions

3.2 Installation requirements

• For size 0 units of the type MC07B...-S0, an external 24V supply must always be

connected because the control electronics can only be powered in this way.

• The safety-related DC 24 V supply voltage must be routed according to EMC guidelines as follows:

– Outside an electrical installation space, shielded cables must be routed perma-

nently (fixed) and protected against external damage, or other equivalent mea-

sures have to be taken.

– Individual conductors can be routed inside an electrical installation space.

– Adhere to the regulations in force for the application.

• Power lines and safety-related control lines have to be installed in separate cables.

• Make sure that no parasitic voltages can be generated in the safety-related control

lines.

• Wiring technology must comply with EN 60204-1.

• Use only grounded voltage sources with safe isolation (PELV) according to VDE0100

and EN 60204-1. In case of a single fault, the voltage between the outputs or

between any output and grounded parts must not exceed DC 60 V.

• Observe the notes in the "MOVITRAC

®

MC07B" operating instructions for information on EMC-compliant cabling. It is essential that you connect the shield of the

safety-related DC 24 V supply cable to the housing at both ends.

• The lines of the safety-related 24 V voltage supply (terminal X17) must be clamped

under the signaling electronics shield clamp.

• When planning the installation, observe the technical data of MOVITRAC

®

MC07B.

• Observe the values specified for safety components when designing the safety circuits.

• The cable length of the safety-related DC 24 V supply may not exceed 100 m.

• The safety-related DC 24 V supply may not be used for feedback.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 15

Manual – Functional Safety MOVITRAC® MC07B

15

3

Installation requirements

Safety Conditions

• All connections (such as lines or data communication using bus systems) must

already have been taken into account in the performance level of one of the subsystems involved, or it must be possible that faults in the connections can be

excluded or neglected.

The fault assumption "short circuit between any two conductors" can be excluded

according to EN ISO 13849-2: 2008 under the following conditions:

The conductors are

– permanently (fixed) installed and protected against external dam age (for example

using a cable duct or armored conduit)

– installed in different light plastic-sheathed cables in an electrical installation space

provided that both the lines and the installation space meet the relevant require-

ments, see EN 60204-1

– protected individually by a ground connection

The fault assumption "short circuit between any conductor and an exposed conduc-

tive part or earth or a protective conductor" can be excluded under the following

conditions:

– Short circuit between conductor and any exposed conductive part in an installa-

tion space.

• For applications with safety-related disconnection of the drive, remove the jumpers

on X17:1 to X17:4 (→ following figure).

1797603595

Removing jumpers

SVI

SOV

24V

GND

X17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 16

16

Manual – Functional Safety MOVITRAC® MC07B

3

Requirements on the external safety controller

Safety Conditions

3.3 Requirements on the external safety controller

A safety relay can be used as an alternative to a safety controller. The following requirements apply analogously.

• The safety controller and all other safety-related subsystems must be approved for

at least that safety class which is required in the overall system for the respective,

application-related safety function.

The following table shows an example of the required safety class of the safety

controller:

1593958923

[1] Safety relay with approval

[2] DC 24 V voltage supply

[3] Fuses in accordance with the manufacturer's specifications of the safety relay

[4] Safety-related DC 24 V voltage supply

[5] Reset button for manual reset

[6] Approved EMERGENCY STOP actuating device

Application Safety controller requirements

Performance level d according to EN ISO

13849-1

Performance level d according to EN ISO

13849-1

SIL 2 according to EN 61508

[4]

[3]

[1]

[5]

[6]

[2] U

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 17

Manual – Functional Safety MOVITRAC® MC07B

17

3

Requirements on startup

Safety Conditions

• The wiring of the safety controller must be suitable for the required safety class, (see

manufacturer documentation).

– If the DC 24 V supply is safely disconnected at the positive pole only, no test

pulses must be applied to this pole in disconnected condition.

If the DC 24 V supply is disconnected at both poles, the test pulses must not be

applied at the same time at the plus and minus outputs. In this case , the test pulse

must be applied with a time delay.

– SEW-EURODRIVE recommends to switch off the 24 V supply at two poles.

• The values specified for the safety controller must be strictly adhered to wh en designing the circuit.

• The switching capacity of the safety relays or the relay outputs of the safety controller

must correspond at least to t he maximally permitted, limited output current of the

24 V voltage supply.

Observe the manufacturer's instructions concerning the permitted contact loads and

fusing that may be required for the safety contacts. If the manufacturer provides no

specific information, the contacts must be protected with 0.6 times the nominal value

of the maximum contact rating specified by the manuf ac tu re r.

• To ensure protection against unintended restart in accordance with EN 1037, the

safe control system must be designed and connecte d in such a way that resetting the

control device alone does not lead to a restart. A restart may only b e carried out after

a manual reset of the safety circuit.

3.4 Requirements on startup

• To validate the implemented safety functions, they must be documented and

checked after successful startup (validation).

Observe the limitations for safety functions in chapter "Limitations" for the validation

of the safety functions. Non-safety-related parts and components that affect the

result of the validation test (e.g. motor brake) must be deactivated, if necessary.

• For using MOVITRAC

®

MC07B in safety-relevant applications, it is essential that you

perform and record startup checks for the disconnectin g device and for proper wiring.

3.5 Requirements on operation

• Operation is only allowed within the limits specified in the data sheets. This pr inciple

applies to the external safety control as well as toMOVITRAC

®

MC07B and approved

options.

• You must check the safety functions on a regular basis to ensure proper functioning.

The test intervals should be specified in accordance with the risk assessment.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 18

18

Manual – Functional Safety MOVITRAC® MC07B

4

General information

Connection Variants

4 Connection Variants

4.1 General information

Generally, all the connection variants listed in this documentation are permitted for

safety-relevant applications as long as the basic safety concept is met. This means you

have to make sure that the DC 24 V safety inputs are operated by an external safety

relay or a safety controller, thus preventing an automatic restart.

All safety conditions mentioned in chapter 2, 3 and 4 of this docu mentation must be met

for the basic selection, installation, and application of the safety components, such as

safety relay, EMERGENCY STOP switch, etc., and the approved connection variants.

The wiring diagrams are block diagrams whose only purpose is to show the safety

function(s) with the relevant components. Circuit-related measures, which usually

always have to be implemented additionally, are not shown in the diagrams to enh ance

clarity. Such measures are t aken , fo r exam ple, to ensure protection against contact, to

handle overvoltage and undervoltage, to detect insulation faults, line-to-ground faults

and short circuits, which can occur on externally installed lines, or to ensure the necessary immunity against electromagnetic interference.

4.1.1 X17 terminal on MOVITRAC

®

MC07B

The following figure shows the X17 terminal at the bottom of the control unit.

3210370059

* View of the underside of the unit

[1] X17: Signal terminal block for STO safety contacts

[1]

[1]

X17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 19

Manual – Functional Safety MOVITRAC® MC07B

19

4

Requirements

Connection Variants

4.2 Requirements

4.2.1 Use of safety relays

The requirements of the manufacturers of safety relays (such as protecting the output

contacts against welding) or other safety components must be strictly observed. For

cable routing, the basic requirements apply as described in this publication.

For connecting MOVITRAC

®

with the safety relays, observe the installation require-

ments in chapter "Installation requirements" (page 14).

Other instructions by the manufacturer on the use of safety relays for specific applica-

tions must also be observed.

4.2.2 Use of safety relays

Observe the ZVEI specifications for safety sensors if you use a safety PLC.

The starting and stopping pulses of the safe digital outputs (F-DO) used must be ≤ 1ms.

The ratio must not fall below 1:1000.

3211043979

<1ms >1000ms

High

Low

t

INFORMATION

If the DC 24 V supply at X17 is switched off safely (STO activated), you must observe

chapter "Requirements on the exter nal safety co ntroller (pa ge 16)" with regard to the

test pulses.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 20

20

Manual – Functional Safety MOVITRAC® MC07B

4

Disconnection of a single drive

Connection Variants

4.3 Disconnection of a single drive

4.3.1 STO according to PL d (EN ISO 13849-1)

The procedure is as follows:

• Recommendation: X12:1 and X12:4 are disconne cted at the same time, e.g. in case

of an emergency stop.

• The 24 V safety input X17 is disabled.

• The motor coasts to a halt, if no brake is installed.

STO – Safe Torque Off (EN 6180 0-5-2)

4949829771

t

n

X17

X12:4

X12:1

INFORMATION

• The illustrated STO disconnections can be used up to PL d according to

EN ISO 13849 -1 taking account of chapter "Requirements" (page 19).

•MOVITRAC

®

MC07B size 0 requires an external DC 24 V voltage supply.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 21

Manual – Functional Safety MOVITRAC® MC07B

21

4

Disconnection of a single drive

Connection Variants

Binary control with safety relay (dual-channel)

Binary control with safety relay (single-channel)

4891650443

+24 V

Feedback

emergency stop

Reset

Higher-level

controller

PLC

IN

OUT

Safety

relay

Emerg. stop

Start

Stop

GND

Mains

MC07B

2

X12

1

4

X17

456

1

2

3

4

'0'=Controller inhibit

'1'=Controller enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

24VIO

9

GND

DGND

VO24

SVI24

SOV24

X2

M

UVW

4891648523

+24 V

Feedback

emergency stop

Reset

Higher-level

controller

PLC

IN

OUT

Safety

relay

Emerg. stop

Start

Stop

Mains

MC07B

2

X12

1

4

X17

456

1

2

3

4

'0'=Controller inhibit

'1'=Controller enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

24VIO

9

GND

DGND

VO24

SVI24

SOV24

X2

M

UVW

INFORMATION

With single-channel disconnection, certain fault assumptions have to be made and

handled through fault exclusion. Observe the "Requirements" (page 19) chapter.

SEW-EURODRIVE recommends to switch off the 24 V supply of the STO input X17

at two poles.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 22

22

Manual – Functional Safety MOVITRAC® MC07B

4

Disconnection of a single drive

Connection Variants

Binary control with safety PLC

Fieldbus control with safety PLC

4891654283

+24 V

Higher-level

controller

Standard Safe

IN

OUT

Emerg. stop

Start

Stop

GND

Mains

IN

OUT

MC07B

2

X12

1

4

X17

456

1

2

3

4

'0'=Ctrl. inhibit

'1'=Ctrl. enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

9

24VIO

GND

DGND

VO24

SVI24

SOV24

X2

M

UVW

4891656203

+24 V

Higher-level

controller

Standard

Safe

IN

Emerg. stop

Start

Stop

GND

GND

Mains

IN

MC07B

X12

X30

DFS 21B

X17

456

1

2

3

4

DGND

VO24

SVI24

SOV24

(GND)

(24 V_LS)

GND

(F_DO_M)

(F_DO_P)

24VIO

X2

M

UVW

1

2

3

4

8

9

PROFINET

PROFIsafe

INFORMATION

• Controller inhibit/enable and rapid stop/enable are set via fieldbus.

• Note the respective fieldbus manuals, e.g.

– "DFS11B PROFIBUS DP-V1 Fieldbus Interface with PROFIsafe" manual

– "DFS21B PROFINET IO Fieldbus Interface with PROFIsafe" manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 23

Manual – Functional Safety MOVITRAC® MC07B

23

4

Disconnection of a single drive

Connection Variants

4.3.2 SS1(c) according to PL d (EN ISO 13849-1)

The procedure is as follows:

• X12:1 must not be disconnected.

• X12:4 is disconnected, e.g. in case of an emergency stop.

• During the safety time interval t

1

, the motor decelerates to a complete stop along the

ramp.

• After t

1

has elapsed, the safety input X17 is disconnected. The safety time interval t

1

must be sufficient for the motor to reach a complete stop.

SS1(c) – Safe Stop 1 (EN 61800-5-2)

4949929739

t

n

X17

X12:4

t

1

X12:1

INFORMATION

• The illustrated SS1(c) disconnections can be used up to PL d according to

EN ISO 13849 -1 taking account of chapter "Requirements" (page 19).

•MOVITRAC

®

MC07B size 0 requires an external DC 24 V voltage supply.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 24

24

Manual – Functional Safety MOVITRAC® MC07B

4

Disconnection of a single drive

Connection Variants

Binary control with safety relay (dual-channel)

Binary control with safety relay (single-channel)

4891646603

+24 V

Feedback

emergency stop

Reset

Higher-level

controller

PLC

IN

OUT

Safety

relay

Emerg. stop

Start

Stop

GND

Mains

MC07B

2

X12

1

4

X17

456

1

2

3

4

'0'=Controller inhibit

'1'=Controller enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8 24VIO

9 GND

DGND

VO24

SVI24

SOV24

X2

M

UVW

t

1

4891658123

+24 V

Feedback

emergency stop

Reset

Higher-level

controller

PLC

IN

OUT

Safety

relay

Emerg. stop

Start

Stop

Mains

MC07B

2

X12

1

4

X17

456

1

2

3

4

'0'=Controller inhibit

'1'=Controller enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

24VIO

9

GND

DGND

VO24

SVI24

SOV24

X2

M

UVW

t

1

INFORMATION

With single-channel disconnection, certain fault assumptions have to be made and

handled by fault exclusion. Observe the "Requirements" (page 19) chapter.

SEW-EURODRIVE recommends to switch off the 24 V supply of the STO input X17

at two poles.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 25

Manual – Functional Safety MOVITRAC® MC07B

25

4

Disconnection of a single drive

Connection Variants

Binary control with safety PLC

Fieldbus control with safety PLC

4891654283

+24 V

Higher-level

controller

Standard Safe

IN

OUT

Emerg. stop

Start

Stop

GND

Mains

IN

OUT

MC07B

2

X12

1

4

X17

456

1

2

3

4

'0'=Ctrl. inhibit

'1'=Ctrl. enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

9

24VIO

GND

DGND

VO24

SVI24

SOV24

X2

M

UVW

4891656203

+24 V

Higher-level

controller

Standard

Safe

IN

Emerg. stop

Start

Stop

GND

GND

Mains

IN

MC07B

X12

X30

DFS 21B

X17

456

1

2

3

4

DGND

VO24

SVI24

SOV24

(GND)

(24 V_LS)

GND

(F_DO_M)

(F_DO_P)

24VIO

X2

M

UVW

1

2

3

4

8

9

PROFINET

PROFIsafe

INFORMATION

• Controller inhibit/enable and rapid stop/enable are set via fieldbus.

• Note the respective fieldbus manuals, e.g.

– "DFS11B PROFIBUS DP-V1 Fieldbus Interface with PROFIsafe" manual

– "DFS21B PROFINET IO Fieldbus Interface with PROFIsafe" manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 26

26

Manual – Functional Safety MOVITRAC® MC07B

4

Disconnection of group drives

Connection Variants

4.4 Disconnection of group drives

This chapter describes how several MOVITRAC® MC07B units are controlled safely.

4.4.1 Requirements

For group drives, the 24 V safety inputs of several MOVITRAC

®

MC07B inverters can

be made available by a single safety relay. The maximum number of axis modules

results from the maximum permitted contact load of the sa fety relay or safety controller .

Other requirements of the manufacturers of safety relays (such as protecting the output

contacts against welding) or other safety components must be strictly observed. For

cable routing, observe the basic requirements in chapter "Installation requirements"

(page 14).

For connecting MOVITRAC

®

inverters with safety relays, observe the installation

requirements in chapter "Installation requirements" (page 14).

Other instructions by the manufacturer on the use of safety relays for specific applica-

tions must also be observed.

Determining the maximum number of MOVITRAC

®

units for group disconnection

The number (n units) of MOVITRAC

®

MC07B units that can be controlled with group

disconnection is limited by the following points:

1. Switching capacity of the safety relay.

A fuse must be connected in front of the safety contacts according to the specifications of the emergency stop relay manufacturer to prevent contact welding.

The project planner is responsible for ensuring that the specifications for the switching capacity to EN 60947-4-1, 02/1 and EN 60947-5-1, 11/97 as well as on contact

fuse protection given in the operating instructions of the safety relay manufacturer

are strictly observed.

2. Maximum permitted voltage drop in the 24 V power supply cable.

Values concerning cable lengths and permitted voltage drops must be observed

during project planning for axis systems.

3. Maximum cable cross section of 1 × 1.5 mm

2

or 2 × 0.75 mm2.

4. Power consumption of STO input X17: Input voltage, see chapter "Technical Data"

(page 30).

5. When using self-testing semiconductor outputs, the increased capacitances of STO

input X17 caused by group disconnection (parallel connection) might result in

diagnostics errors.

INFORMATION

SEW-EURODRIVE does not recommend group disconnection via safety PLC.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 27

Manual – Functional Safety MOVITRAC® MC07B

27

4

Disconnection of group drives

Connection Variants

4.4.2 Implementing group disconnection with a safety relay

Group disconnection with one safety relay

The safety inputs of all MOVITRAC

®

MC07B can be controlled with one safety relay.

Group disconnection with two safety relays

The safety inputs of the assigned MOVITRAC

®

MC07B inverters can be controlled with

several safety relays. In the following example, MOVITRAC

®

MC07B size 3 inverters

and MOVITRAC

®

MC07B size 0 inverters each form one group, and each group is

controlled by a safety relay.

4892037259

MC07B

Safety

relay (SG)

®

Control cabinet

X17

X17

X17

BG0BG0

BG3 BG3

X17 X17

BG3

SG1

MOVITRAC

MC07B

MC07B

MC07B

MC07B

4891918091

MC07

Safety

relay (SG)

®

Control cabinet

X17

X17

X17

BG0BG0

BG3

MC07

BG3

X17 X17

BG3

MOVITRAC

SG1 SG1

MC07 MC07

MC07

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 28

28

Manual – Functional Safety MOVITRAC® MC07B

4

Disconnection of group drives

Connection Variants

4.4.3 STO according to PL d (EN ISO 13849-1)

The procedure is as follows:

• Recommendation: X12:1 and X12:4 are disconne cted at the same time, e.g. in case

of an emergency stop.

• The 24 V safety input X17 is disconnected.

• The motor coasts to a halt, if no brake is installed.

STO – Safe Torque Off (EN 6180 0-5-2)

4949829771

t

n

X17

X12:4

X12:1

INFORMATION

The displayed STO disconnections can be used up to PL d according to EN ISO

13849-1.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 29

Manual – Functional Safety MOVITRAC® MC07B

29

4

Disconnection of group drives

Connection Variants

Example: Group disconnection with three MOVITRAC® MC07B

+24 V

Feedback

emergency stop

Reset

Higher-level

controller

PLC

IN

OUT

Safety

relay

Emergency stop

Start

Stop

GND

Mains

MC07B

2

X12

1

4

X17

4 56

1

2

3

4

'0'=Controller inhibit

'1'=Controller enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

24VIO

9

GND

DGND

VO24

SVI24

SOV24

X2

X1

M

UVW

MC07B

2

X12

1

4

X17

4 56

1

2

3

4

'0'=Controller inhibit

'1'=Controller enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

24VIO

9

GND

DGND

VO24

SVI24

SOV24

X2

Power supply connection

L3L2L1

1

2

3

X1

M

UVW

Power supply connection

L3L2L1

1

2

3

MC07B

2

X12

1

4

X17

4 56

1

2

3

4

'0'=Controller inhibit

'1'=Controller enable

'0'=Stop

'1'=START CW

'0'=Rapid stop

'1'=Enable

8

24VIO

9

GND

DGND

VO24

SVI24

SOV24

X2

Power supply connection

L3L2L1

1

2

3

X1

M

UVW

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 30

30

Manual – Functional Safety MOVITRAC® MC07B

5

Safety characteristics

Technical Data

5 Technical Data

The table below shows the technical data of MOVITRAC® MC07B related to integrated

safety technology. The technical data and approvals in the respective MOVITRAC

®

MC07B operating instructions must also be observed.

5.1 Safety characteristics

5.2 Electronics data X17: Signal terminal block for STO safety contact

Safety characteristics

Tested safety class / underlying standards • Category 3 according to EN 954-1

• Performance Level d according to EN ISO 13849-1

Probability of dangerous failure per hour (PFH

value)

0 (fault exclusion)

Service life 20 years, after which the component must be replaced with a new one.

Safe condition Safe torque off (STO)

Safety function STO, SS1

1)

according to EN 61800-5-2

1) With suitable external control

MOVITRAC® MC07B General electronics data

Safety contact X17:1

X17:2

X17:3

X17:4

Permitted cable cross section

Power consumption X17:4

Input capacitance X17:4

DGND: Reference potential for X17:2

VO24: : V

OUT

= DC 24 V, only to supply X17:4 of the same unit; cannot be used to

supply other units.

SOV24: Reference potential for DC +24 V "STO" input (safety contact)

SVI24: DC+24 V "STO" input (safety contact)

One core per terminal: 0.08...1.5 mm

2

(AWG28...16)

Two cores per terminal: 0.25 ... 1.0 mm

2

(AWG23...17)

Size 0: 3 W

Size 1: 5 W

Size 2: 6 W

Size 3: 7.5 W

Size 4: 8 W

Size 5: 10 W

Size 0: 27 µF

Sizes 1 to 5: 270 µF

Technical data of the STO input Min. Typical Max.

Input voltage range DC 19.2 V DC 24 V DC 30 V

Time to inhibit the output stage BG0 = 20 ms

BG1 – 5 = 100 ms

Time for restart 200 ms

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 31

Manual – Functional Safety MOVITRAC® MC07B

31

Index

Index

A

Approved devices ..................................................13

C

Checking the disconnection device.... .... ... ... ... .... ...17

Connection variants ...............................................18

Copyright notice.......................................................6

D

Disconnection of a single drive ....... ... .... ... ... ... .... ...20

STO according to PL d (EN 13849-1)...... ....... ...20

Disconnection of group drives................................26

Requirements.....................................................26

Disconnection of single drive

Requirements.....................................................19

Document content........................ ... ... .... ... ...... .... ... ..6

E

Embedded safety notes ...........................................5

Exclusion of liability..................................................6

External safety controller........................................16

G

Group disconnection

STO according to PL d (EN 13849-1)...... ....... ...28

With safety relay ................................................27

H

How to use this documentation.......... .... ... ... ... .... ... ..4

I

Information, general.................................................4

Installation

Notes on routing the control leads.....................14

Requirements.....................................................14

O

Operation, requirements ........................................17

P

Publications, applicable ...........................................6

R

Requirements

External safety controller...................................16

Installation..........................................................14

Operation...........................................................17

Startup...............................................................17

Right to claim under warranty..................................6

S

Safe condition..........................................................7

Safe stop 1, function variant c (SS1(c)).................10

Safe torque off (STO) ..............................................9

Safety concept.........................................................7

Restrictions........................................................11

Schematic representation....................................8

Safety conditions ...................................................12

Safety controllers, requirements............................19

Safety controller, external......................................16

Requirements ....................................................16

Safety control, requirements................................ ..19

Safety notes

Designation in the documentation .......................5

Structure of the embedded safety notes..............5

Structure of the section safety notes ...................5

Safety notes, structure.............................................5

Safety technology

Safe condition......................................................7

Scope.......................................................................4

Section safety notes ................................................5

Signal words in safety notes...... ... .... ... ... ...... .... ... ... .5

Single disconnection

SS1 according to PL d (EN 13849-1) ................23

SS1 according to PL d (EN 13849-1) ....................23

SS1(c) (safe stop 1, function variant c)..................10

Standards ................................................................4

Startup, requirements ....................... ... ... ... ... .... ... ..17

STO according to PL d (EN 13849-1)..............20, 28

STO input................... ... ... .... ... ... ... .........................30

STO (safe torque off)...............................................9

Structure of the safety notes....................................5

Switching capacity of the safety relay....................17

V

Validation...............................................................17

Verification of safety functions...............................17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...