Page 1

TAC Vista

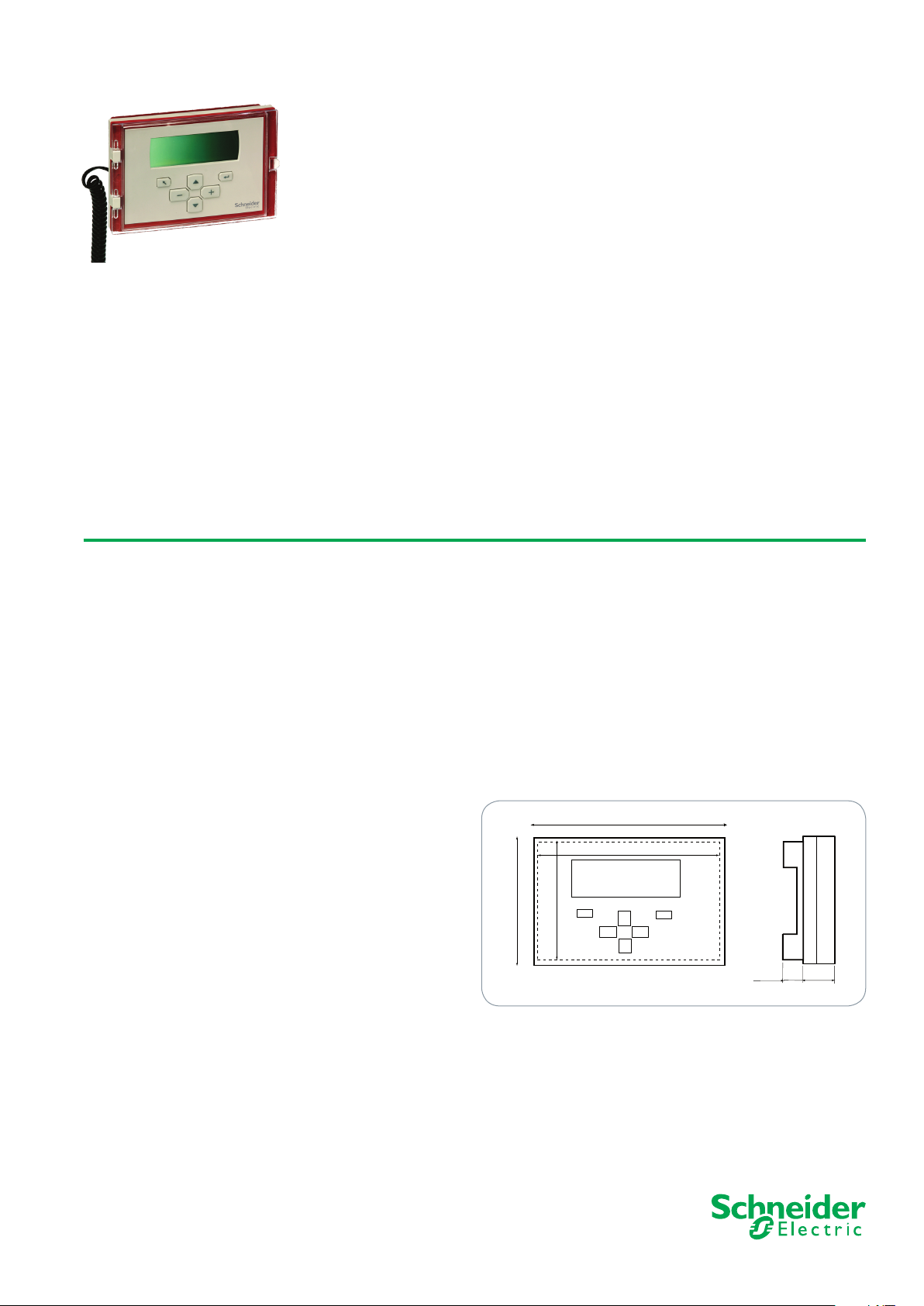

144 (5.7)

96 (3.8)

20

(0.8)

135.5 (5.3)

91 (3.6)

14

(0.6)

TAC Xenta OP

Operator Panel

TAC Xenta OP is a small operator panel designed to be used with the TAC Xenta 100, 300 or 400 units. It has an LCD display with

4x20 characters and six push buttons.

TAC Xenta OP/RU can also display Cyrillic characters. TAC Xenta OP is connected via a modular jack situated on the rear of the unit.

Both communication and power supply are handled by this cable. TAC Xenta OP may also be connected directly to the network,

using the screw terminals.

The LCD display may be backlit.

The operator panel allows access to the parameters and makes it possible to list alarms without communicating with a central system.

Additionally, it is used to monitor status, adjust setpoints and time channels. All values are displayed with an explanatory text in the

alphanumeric display.

The operator panel can be placed on the TAC Xenta units, mounted on a cabinet front or used as a hand-held terminal.

TECHNICAL DATA

Supply voltage (from TAC Xenta or external source)

...........................24 V AC ±20%, 50/60 Hz

................................... or 20–40 V DC

Power consumption.........................max. 0.5 W

With the display backlight on, in total ......... max 1.2 W

Transformer sizing ............................... 3 VA

Ambient Temperature

Storage ...............–20 °C to +50 °C (–4 °F to +122 °F)

Operation .............±0 °C to +50 °C (+32 °F to +122 °F)

Humidity ..................max. 90% RH non-condensing

Mechanical

Enclosure....................................ABS/PC

Dimensions ...............................see diagram

Weight (including package)................0.4 kg (0.88 lb)

Panel cutout .................136 x 91.5 mm (5.4 x 3.6 in)

Enclosure rating:

Hand-held panel ..............................IP 20

Cabinet mounted ..............................IP 43

Network communication ................TP/FT-10, 78 kbps

Communication protocol ........................LonTalk

Flammability class, materials ...................UL 94 5VB

Unit Connection

TAC Xenta 100 ............via modular jack on Wall Module

TAC Xenta 300 ............. modular jack or screw terminal

TAC Xenta 400 ............. modular jack or screw terminal

Agency Compliances

Emission:

CE ..................EN 61000-6-3, C-Tick, FCC Part 15

Immunity:

CE ..................................EN 61000-6-1

Safety:

CE ....................................EN 61010-1

UL 916, C-UL US ..Enclosed Energy Management Equipment

RoHS directive............................ 2002/95/EG

Part Numbers

Operator terminal TAC Xenta OP ..............007309072

Operator terminal TAC Xenta OP/RU ...........007309231

Mounting kit panel TAC Xenta OP .............007309040

03-00058-02-en

Page 2

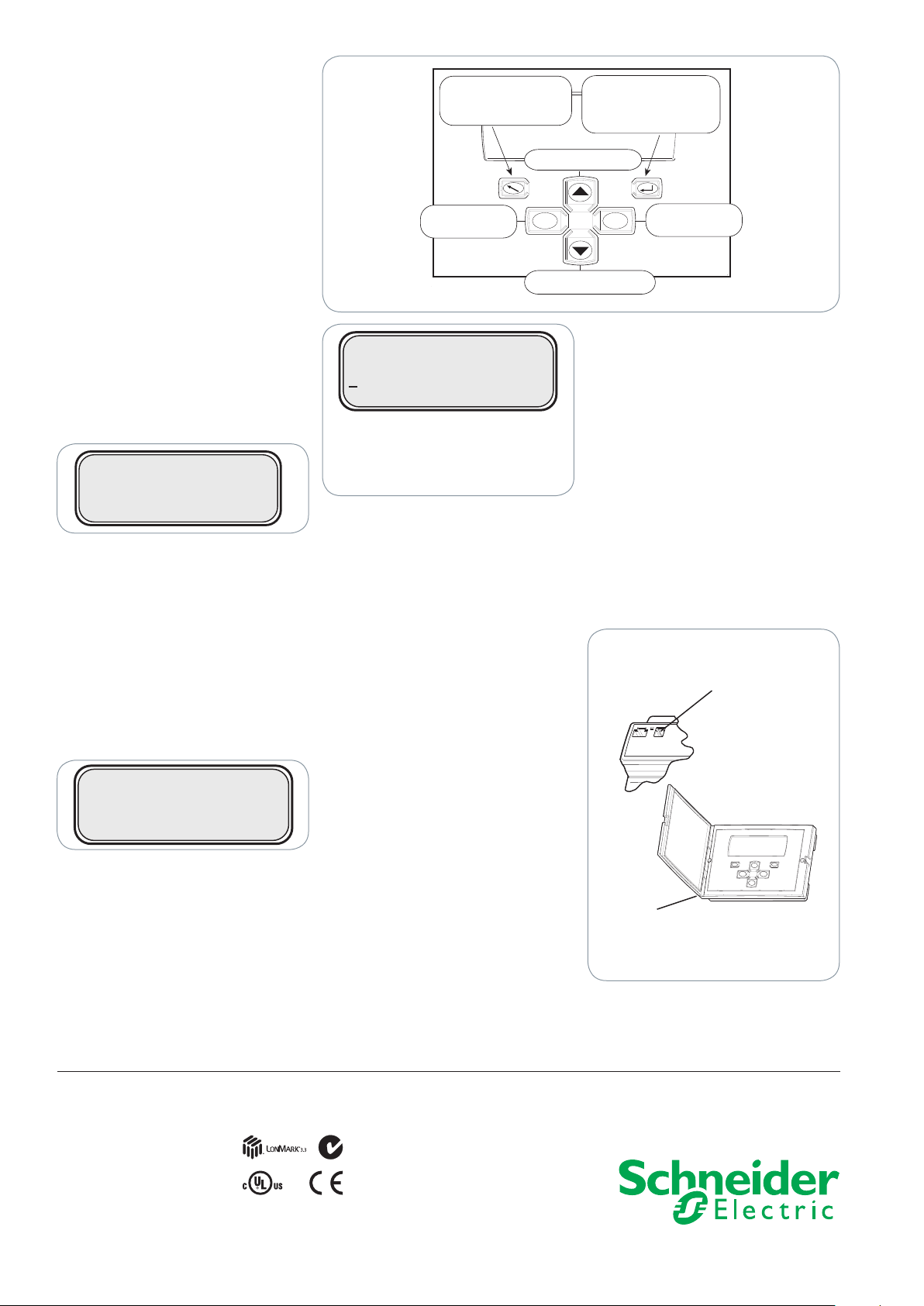

OPERATOR PANEL

AHU2 Air_Handler_2

Temperatures

Time program

Alarm

AHU2 Temperatures

Room temp AHU2-T1

Measured temp 19,7°C

Setpoint 20,0°C

AHU2 Week Schedule

1234567

08:00-12:00 MTWTF

13:00–17:00 MTWTF

"HOME"

- Step up one level

in the menu hierarchy

"ENTER"

- Select the marked line

- Move between values

and conrm alteration

- Move up in the list

- Increase value

- Toggle

- Move down in the list

- Decrease value

- Toggle

+

–

Values can be read and/or altered from

the operator panel (see fig. 1). The operator panel can be mounted on the front

of the controller, on a cabinet front or

used as a hand held panel.

All values are displayed with explanatory

texts. Finding and altering a setting requires a minimum of key operations since

all values are arranged in logical order.

Authorization check

The system manager may choose to

use an access code to limit access to the

program.

List of contents

The TAC Xenta controller’s program functions are presented as a list of contents,

with the most common daily functions at

the top (see figure below).

The operator steps up and down in the

list by means of the arrow buttons.

IDs

(The top line of the list of contents

displays the current unit’s full ID together

with a short four letter ID which is shown

in all displays. To change object (AHU,

boiler etc.), press “Home” and select a

new object in the presented list.

To select and show a function

The function of the upper line in the list

of contents is shown when pressing the

“Enter” button. The displayed data are

dynamically updated.

To show the next/previous function, press

the arrow buttons. To return to the list of

contents just press the “Home” button.

To alter a value

The operator can move the cursor

between the alterable values with the

“Enter” button. The value can then be

increased, decreased or toggled by means

of the “+” or “–” buttons. The arrow

buttons are used to present the next/previous function.

Figure 1

Example:

When adjusting the week schedule, the

cursor can be moved between On time

(08:00), Off time (12:00), and Day IDs

(Monday, Tuesday etc.).

FUNCTIONS

Some examples of functions that are

available on the TAC Xenta OP:

- Select and display Groups and individual

Xenta controllers

- Display values and status indicators

INSTALLATION

The operator panel is either mounted

onto the TAC Xenta unit by means of the

snap-in connector, or flush-mounted in

the cabinet front or used as a hand-held

terminal.

When connecting the operator panel

there are two alternatives:

Use the modular jack on the front of

1.

the TAC Xenta and on the back of the

OP. This requires a special cable, for

both power supply and communication. Such a cable (about 1.5 m or

4.9 ft.) is included. If another cable

is used, its length should not exceed

10 m (33 ft.).

If the connection is done to the comms2.

line, use the screw terminals on the

back of the OP, labelled 1-4.

Terminals 1 and 2 are used for communication and terminals 3 and 4 for

24 V AC or DC.

The polarity is important only for the

DC connection.

– List and acknowledge alarms

– Set week charts and holidays

– Set date and time

If the correct access code has been

entered more functions are accessible, for

example:

– Modify control parameters

– Change access code

– Manual control

– Set daylight saving time

– Initiate supervisory system test dial-up

If no changes have been made within

5 minutes, the operator will be logged

off and the access level returned to the

default access level low.

TAC Xenta

300/400

controller

Socket for the TAC Xenta controller

and screw terminals 1-4

Figure 2

Socket for

TAC Xenta OP

Recommended cable type and length for

the communication: please refer to the

TAC Xenta Network guide.

Copyright © 2008-2010, Schneider Electric

All brand names, trademarks and registered trademarks are

the property of their respective owners. Information contained

within this document is subject to change

without notice. All rights reserved.

03-00058-02-en Mar 2010

Loading...

Loading...