Page 1

TAC Vista

TAC Pangaea

WorkStation

TAC Xenta 500/700/911/913

Product Manual

Page 2

Page 3

TAC Vista

TAC Xenta 500/700/911/913

Product Manual

Page 4

Copyright © 2011 Schneider Electric Buildings AB. All rights reserved.

This document, as well as the product it refers to, is only intended for licensed users. Schneider Electric Buildings AB owns the copyright of

this document and reserves the right to make changes, additions or deletions. Schneider Electric Buildings AB assumes no responsibility for

possible mistakes or errors that might appear in this document.

Do not use the product for other purposes than those indicated in this document.

Only licensed users of the product and the document are permitted to use the document or any information therein. Distribution, disclosure,

copying, storing or use of the product, the information or the illustrations in the document on the part of non-licensed users, in electronic or

mechanical form, as a recording or by other means, including photo copying or information storage and retrieval systems, without the express

written permission of Schneider Electric Buildings AB, will be regarded as a violation of copyright laws and is strictly prohibited.

Trademarks and registered trademarks are the property of their respective owners.

Page 5

TAC Xenta 500/700/911/913, Product Manual Contents

Contents

INTRODUCTION

1 About this Manual 11

1.1 Structure..................................................................................................................... 12

1.2 Typographic Conventions.......................................................................................... 12

1.3 Terminology............................................................................................................... 13

1.4 Related Documents .................................................................................................... 14

REFERENCE

2 TAC Xenta 500/700/911/913 17

2.1 Hardware.................................................................................................................... 17

2.1.1 Communication Interface........................................................................................... 18

2.1.2 Port Pins ..................................................................................................................... 21

2.1.3 Fail-Safe State............................................................................................................23

2.1.4 LEDs .......................................................................................................................... 23

2.2 Configuring the TAC Xenta 500/700/911/913 .......................................................... 25

2.2.1 Configuration Data..................................................................................................... 25

2.2.2 Configuring Windows HyperTerminal ...................................................................... 26

2.2.3 Configuring the TAC Xenta....................................................................................... 28

2.3 Verifying the TAC Xenta Communication................................................................ 31

2.3.1 Accessing the TAC Xenta.......................................................................................... 32

2.3.2 Changing the Root Password ..................................................................................... 34

2.4 Temporary Login ID.................................................................................................. 35

2.5 Upgrading the System Program................................................................................. 36

3 Connecting the TAC Xenta to Your Network 41

3.1 Alternative Port Settings............................................................................................ 42

3.1.1 HTTP and HTTPS...................................................................................................... 42

4 TAC Xenta 511 43

4.1 Configuration Phase................................................................................................... 43

4.1.1 Connections, configuration........................................................................................ 44

4.2 Engineering Phase...................................................................................................... 45

4.2.1 Connections, engineering........................................................................................... 46

4.3 Operating Phase ......................................................................................................... 47

4.3.1 Directly Connected..................................................................................................... 47

4.3.2 Connections, operation directly ................................................................................. 48

4.3.3 Dialed-Up, operation.................................................................................................. 49

4.3.4 Connections................................................................................................................, op-

eration dial-up ............................................................................................................ 50

Schneider Electric Buildings AB, Feb 2011 5 (134)

04-00071-04-en

Page 6

Contents TAC Xenta 500/700/911/913, Product Manual

4.4 Port Usage ..................................................................................................... .... ..... .... 51

5 TAC Xenta 527 53

5.1 Configuration Phase ................................................................................................... 53

5.1.1 Connections................................................................................................................54

5.2 Engineering Phase ...................................................................................................... 55

5.2.1 Connections................................................................................................................56

5.3 Operating Phase.................................................................. ........................................ 58

5.3.1 Directly Connected..................................................................................................... 58

5.3.2 Connections................................................................................................................58

5.3.3 Dialed-Up................................................................................................................... 60

5.3.4 Connections................................................................................................................60

5.4 Port Usage ........................................................ .......................................................... 63

5.5 Connecting the TAC Xenta 527 to an I/NET Controller LAN .................................. 64

5.6 Using a Direct Connection to I/NET.......................................................................... 65

6 TAC Xenta 555 67

6.1 Configuration Phase ................................................................................................... 67

6.1.1 Connections................................................................................................................68

6.2 Engineering Phase ...................................................................................................... 69

6.2.1 Connections................................................................................................................70

6.2.2 RS485 LAN Wiring.................................................................................................... 72

6.3 Operating Phase.................................................................. ........................................ 73

6.3.1 Connections................................................................................................................73

6.4 Port Usage ..................................................................................................... .... ..... .... 75

6.5 Connecting the TAC Xenta 555 to a MicroNet Controller LAN............................... 76

6.5.1 Connecting to a MicroNet NCP network (MN MI not used)..................................... 77

6.5.2 Connecting to a MicroNet ARCNET network (MN MI used)................................... 78

6.5.3 Connecting to a Satchnet network (MIU not used).................................................... 78

7 TAC Xenta 701/711/721 79

7.1 Configuration Phase ................................................................................................... 79

7.1.1 Connections................................................................................................................80

7.2 Engineering Phase ...................................................................................................... 81

7.2.1 Connections................................................................................................................82

7.3 Operating Phase.................................................................. ........................................ 83

7.3.1 Directly Connected..................................................................................................... 83

7.3.2 Connections................................................................................................................84

7.3.3 Dialed-Up................................................................................................................... 85

7.3.4 Connections................................................................................................................86

7.4 Port Usage ..................................................................................................... .... ..... .... 87

8 TAC Xenta 731 89

8.1 Configuration Phase ................................................................................................... 89

8.1.1 Connections................................................................................................................90

8.2 Engineering Phase ...................................................................................................... 91

8.2.1 Connections................................................................................................................92

8.3 Operating Phase.................................................................. ........................................ 94

8.3.1 Directly Connected..................................................................................................... 94

8.3.2 Connections................................................................................................................95

8.3.3 Dialed-Up................................................................................................................... 97

8.3.4 Connections................................................................................................................98

6 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 7

TAC Xenta 500/700/911/913, Product Manual Contents

8.4 Port Usage.................................................................................................................. 100

9 Connecting the OP7 to Xenta 700 103

9.1 Connecting the OP7 ................................................................................................... 103

9.2 Remote (cabinet door) mounting ............................................................................... 103

9.3 Wall mounting............................................................................................................ 104

9.4 Handheld terminal...................................................................................................... 104

10 TAC Xenta 911 105

10.1 Configuration Phase................................................................................................... 105

10.1.1 Connections................................................................................................................ 105

10.2 Engineering Phase...................................................................................................... 106

10.2.1 Connections................................................................................................................ 106

10.3 Operating Phase ......................................................................................................... 107

10.3.1 LonTalk Adapter........................................................................................................ 107

10.3.2 Connections................................................................................................................ 107

10.3.3 IP Modem........................................................ .... ..... .................................................. 108

10.3.4 Connections................................................................................................................ 108

10.3.5 Serial Gateway ........................................................................................................... 110

10.4 Port Usage..................................................................................................................111

11 TAC Xenta 913 113

11.1 Configuration Phase................................................................................................... 113

11.1.1 Connections................................................................................................................ 114

11.2 Programming and Operating Phase............................................................................ 115

11.2.1 Connections................................................................................................................ 115

11.3 Port Usage..................................................................................................................117

12 Engineering TAC Xenta 911 119

12.1 Programming the TAC Xenta 911 ............................................................................. 119

APPENDIX

A Hardware 125

A.1 Adapters .....................................................................................................................125

A.1.1 DB9/Female-to-RJ45/Female Adapter....................................................................... 125

A.1.2 DB25/Female-RJ45/Female Adapter......................................................................... 126

A.1.3 RJ45/Female-to-DB25/Male Adapter........................................................................ 127

A.1.4 DB9/Female-to-DB25/Male Adapter......................................................................... 128

A.2 Cables......................................................................................................................... 129

A.2.1 RJ45-to-RJ45 Rollover Cable.................................................................................... 129

A.2.2 RJ45-to-RJ10 Cable ................................................................................................... 129

A.2.3 RJ-45-to-RJ-45 TAC Xenta-to-Xenta Cable.............................................................. 130

Schneider Electric Buildings AB, Feb 2011 7 (134)

04-00071-04-en

Page 8

Contents TAC Xenta 500/700/911/913, Product Manual

8 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 9

INTRODUCTION

1 About this Manual

Page 10

Page 11

TAC Xenta 500/700/911/913, Product Manual 1 About this Manual

1 About this Manual

This handbook describes

• The hardware interface of the Xenta 500/700/911/913 devices

• Cables required for various communication configurations for the

Xenta 500/700/911/913 devices

• The upgrading of the system program for the

Xenta 500/700/911/913 devices

• The engineering procedure of the Xenta 911

For more information on engineering Xenta 500/700/913, see

• TAC Xenta Server – TA C Networks, Technical Manual

• TAC Xenta Server – Web Server, Technical Manual

• TAC Xenta Server – Controller, Technical Manual

• TAC Xenta Server – Gateway, Technical Manual

For more information on the use of the OP7 operator panel, together

with the TAC Xenta 700 series, see

• TAC OP7 Operator Panel, Mini Manual

Notes

• We are continuously improving and correcting our documentation. This manual may have been updated.

• Please check ExchangeOnline at http://extranet.tac.com for the

latest version.

The Xenta devices as well as other products mentioned in this manual,

must not be used for any other purposes than those for which they were

designed.

Installation, connection and repair should only be carried out by authorized personnel.

Schneider Electric Buildings AB, Feb 2011 11 (134)

04-00071-04-en

Page 12

1 About this Manual TAC Xenta 500/700/911/913, Product Manual

!

1.1 Structure

The manual is divided into the following parts:

• Introduction

The Introduction section contains information on how this manual

is structured and where to find additional information.

• Reference

The Reference section contains comprehensive information about

the products. It also provides you with information on mounting

and electrical installation.

1.2 Typographic Conventions

Throughout the manual the following specially marked texts may occur.

Warning

• Alerts you that failure to take, or avoid, a specific action might

result in physical harm to you or to the hardware.

Caution

• Alerts you to possible data loss, breaches of security, or other

more serious problems.

Important

• Alerts you to supplementary information that is essential to the

completion of a task.

Note

• Alerts you to supplementary information.

Tip

• Alerts you to supplementary information that is not essential to

the completion of the task at hand.

12 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 13

TAC Xenta 500/700/911/913, Product Manual 1 About this Manual

1.3 Terminology

• DHCP – Dynamic Host Configuration Protocol. A protocol for

assigning dynamic IP addresses to devices on a network. With

dynamic addressing, a device can have a different IP address every

time it connects to the network. In some systems, the device's IP

address can even change while it is connected. DHCP also supports a mix of static and dynamic IP addresses.

• DNS – Domain Name System (or Service), an Internet service that

translates domain names into IP addresses. Because domain names

are alphabetic, they are easier to remember. The Internet however,

is based on IP addresses. Consequently, every time you use a

domain name a DNS service must translate the name into the corresponding IP address.

• FTP – File Transfer Protocol. An application used to transfer files

from one host to another and to store the files on the requesting

host.

• IP Network – A network (for example Internet or Intranet) using

the Internet Protocol (IP) and IP addressing.

• LTA – LonTalk Adaptor . A computer interface with the LonWorks

network.

• NTP – Network Time Protocol. An Internet standard protocol

(used on top of TCP/IP) that assures accurate synchronization to

the millisecond of computer clock times in a network of computers.

• SNMP – Simple Network Management Protocol. A set of proto-

cols for managing complex networks. SNMP works by sending

messages, called protocol data units (PDUs), to different parts of a

network.

• SNTP – Simple Network Time Protocol. A simplified version of

NTP.

• SSL – Secure Sockets Layer. A protocol developed by Netscape

for transmitting private documents via the Internet. By convention,

URLs that require an SSL connection start with https: instead of

http:.

• TCP/IP – Transmission Control Protocol/Internet Protocol. The

suite of protocols that when combined create the “language of the

Internet”.

Schneider Electric Buildings AB, Feb 2011 13 (134)

04-00071-04-en

Page 14

1 About this Manual TAC Xenta 500/700/911/913, Product Manual

1.4 Related Documents

• TAC Xenta Server – TAC Networks, Technical Manual

Part No.: 04-00121

• TAC Xenta Server – Web Server, Technical Manual

Part No.: 04-00122

• TAC Xenta Server – Controller, Technical Manual

Part No.: 04-00123

• TAC Xenta Server – Gateway, Technical Manual

Part No.: 04-00124

• TAC OP7 Operator Panel, Mini Manual

Part No.: 04-00072

14 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 15

REFERENCE

2 TAC Xenta 500/700/911/913

3 Connecting the TAC Xenta to Your

Network

4 TAC Xenta 511

5 TAC Xenta 527

6 TAC Xenta 555

7 TAC Xenta 701/711/721

8 TAC Xenta 731

10 TAC Xenta 911

11 TAC Xenta 913

12 Engineering TAC Xenta 911

Page 16

Page 17

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

2 TAC Xenta 500/700/911/913

The Xenta 500/700/911/913 all share the same hardware design and

hardware layout. For a more detailed description on each Xenta device,

see the Docnet site at

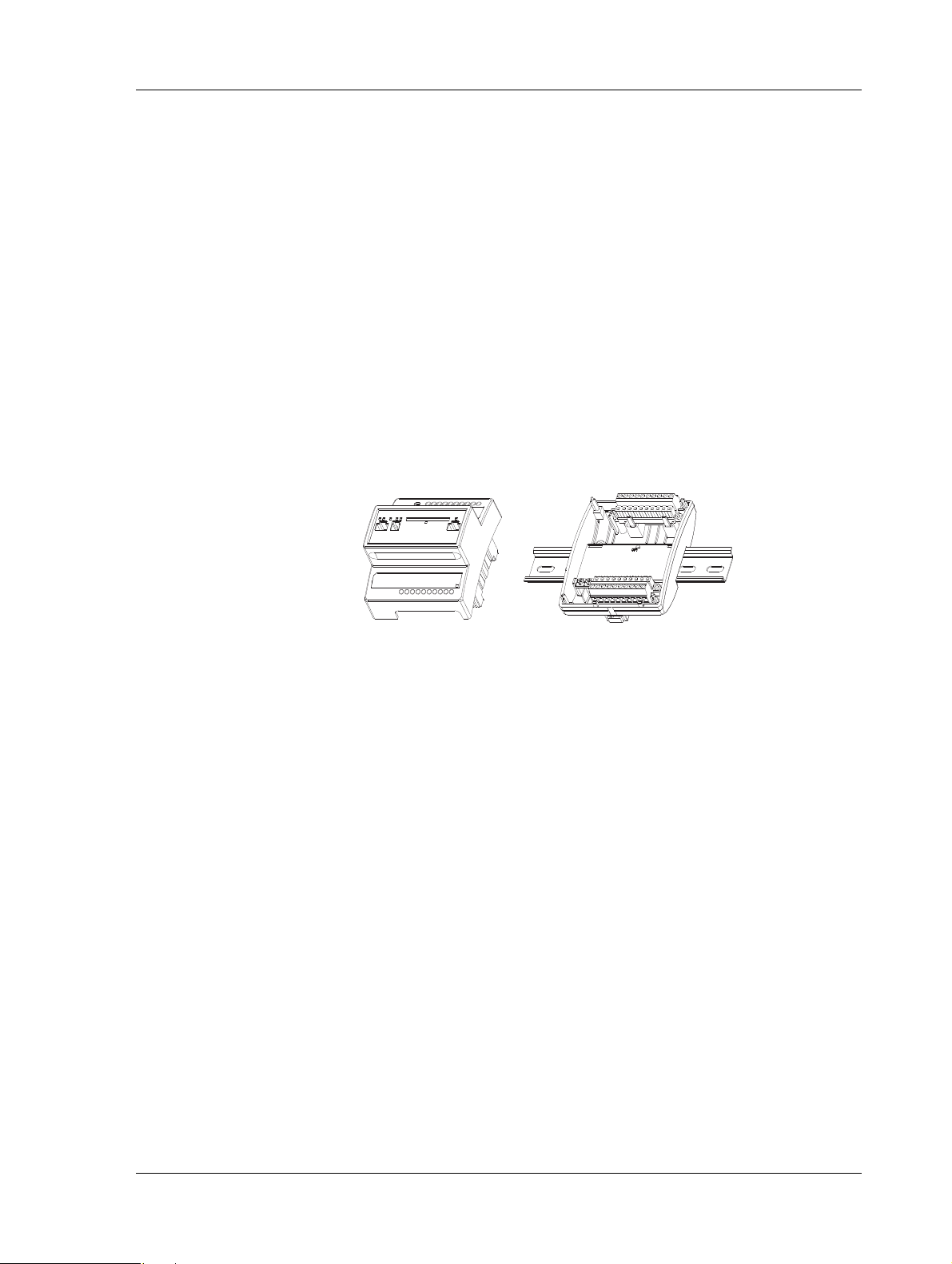

2.1 Hardware

The Xenta device is designed around a microprocessor. The module

consists of two parts, an electronics unit containing the circuit boards

and contacts, and a terminal part including the terminal blocks.

Fig. 2.1: The Xenta device – Electronics and terminal.

• Power Outage Protection – Settings like configurations and web

pages are stored in the non-volatile (flash) memory and will not be

lost in the event of a power outage. A built-in capacitor maintains

operation of the RAM memory for at least 72 hours in the event of

a power outage.

• Real Time Clock – The real time clock provides the internal event

log with a time stamp. The capacitor maintains operation of the

clock for at least 72 hours in the event of a power outage.

• Mounting – The Xenta device is cabinet mounted on a TS 35 mm

norm rail EN 50022.

To simplify commissioning, the terminal part can be pre-mounted

in the cabinet.

If the Xenta device is to be wall-mounted, a wide range of standardized boxes are available.

Schneider Electric Buildings AB, Feb 2011 17 (134)

04-00071-04-en

Page 18

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

1 2345678910

11

12 13 14 15 16 17 18 19 20

21

22

23

24

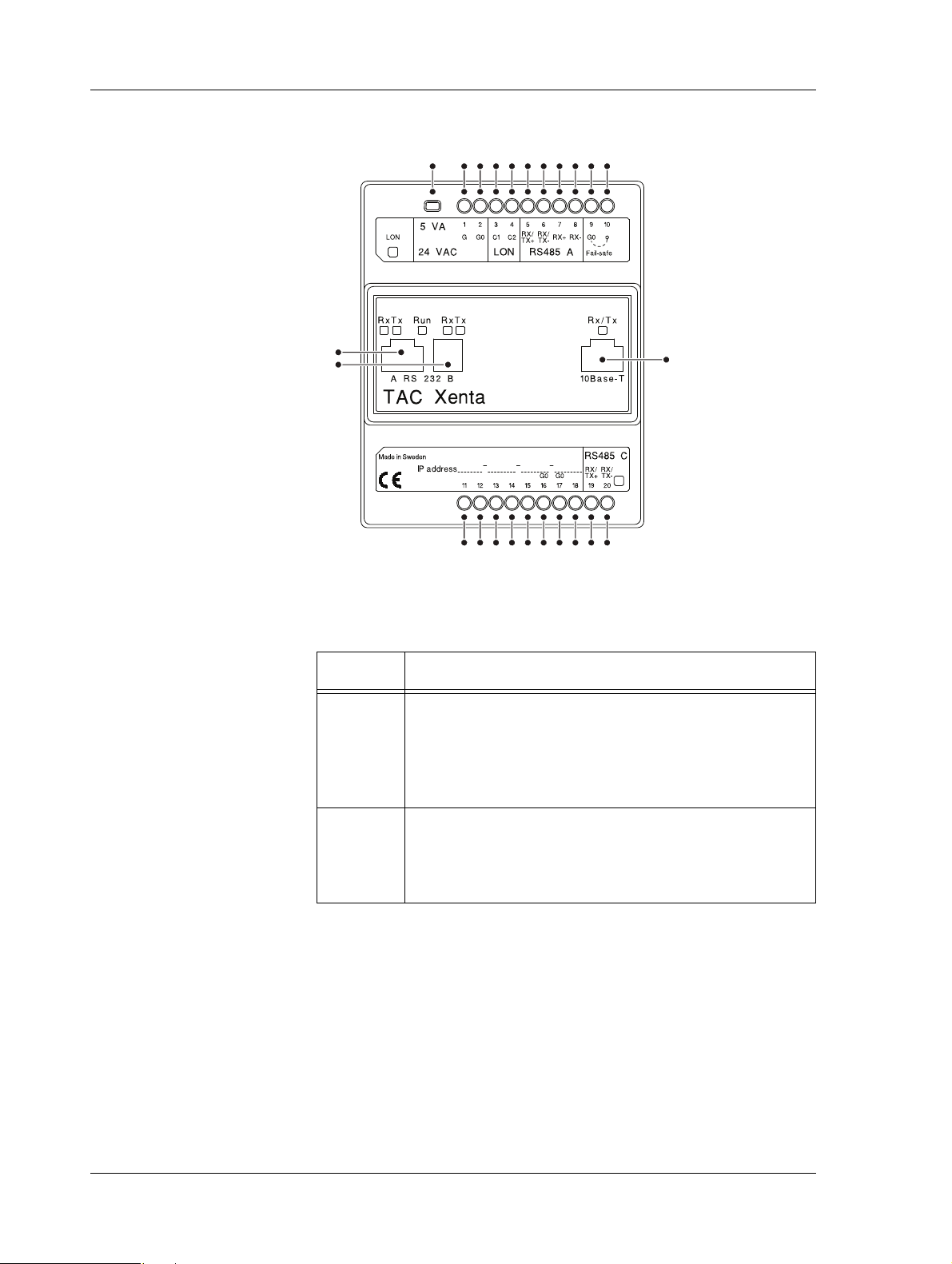

2.1.1 Communication Interface

Fig. 2.2: Connections on the Xenta device.

Table 2.1: Connections on the Xenta device.

Position Description

1–2 Power supply. Minimum cross-sectional area 0.75 mm2

(AWG-19).

• 1 (G) – 24 V AC (or DC+)

• 2 (G0) – Ground

3–4 LonWorks TP/FT-10 connection.

•3 (C1)

•4 (C2)

18 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 19

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

Table 2.1: Connections on the Xenta device. (Contd.)

Position Description

5–8

Internal

port A

RS-485 A connection.

•5 (RX/TX+)

• 6 (RX/TX-)

•7 (RX+)

•8 (RX-)

Note that the interface RS-232 A (position 21) and

interface RS-485 A (position 5–8) are internally connected to port A on the processor. Only one should be

connected.

9 Ground.

•9 (G0)

10 Fail-safe.

11–15 Unused.

16–17 Ground.

•16 (G0)

•17 (G0)

18 Unused.

19–20

Internal

port C

RS-485 C (SDLC) connection.

• 19 (RX/TX+)

• 20 (RX/TX-)

21

Internal

port A

RS-232 A connection.

Note that the interface RS-232 A (position 21) and

interface RS-485 A (position 5–8) are internally connected to port A on the processor. Only one should be

connected.

22

RS-232 B console connection.

Internal

port B

23 Ethernet 10Base-T connection.

24 Service pin.

Schneider Electric Buildings AB, Feb 2011 19 (134)

04-00071-04-en

Page 20

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

Caution

• G0 equals GROUND.

• Only G0 may be connected to protective ground.

20 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 21

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

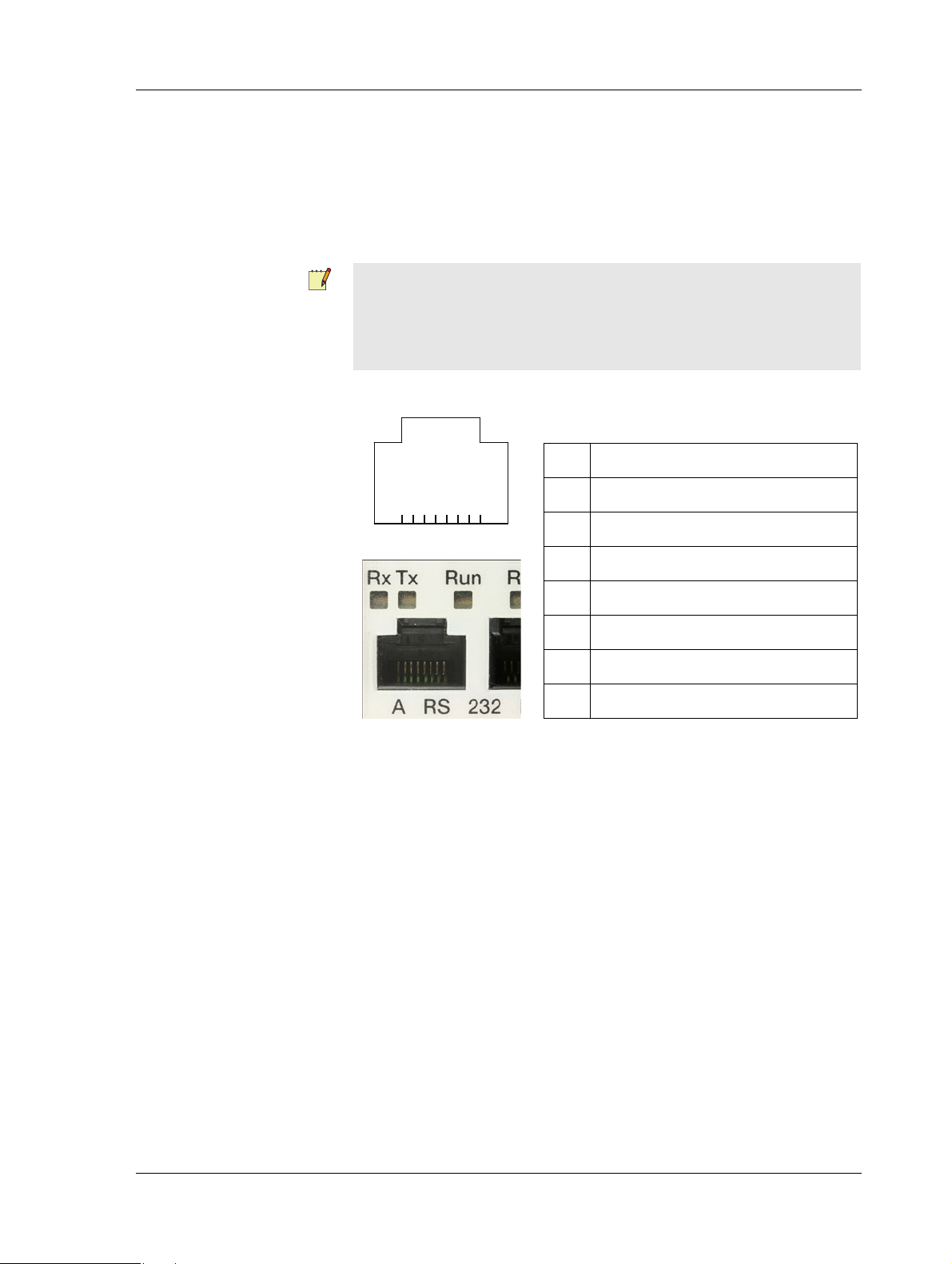

Table 2.2: Port pins – RS-232 A.

1 CTS/RI (input)

2 RTS (output)

3 TxD (output)

4 RxD (input)

5Ground

6 DSR (input)

7 DCD (input)

8DTR (output)

2.1.2 Port Pins

Serial Port – RS-232 A

The RS-232 A port (position 21) is used for serial communication

between the Xenta device and the connected unit. The connector is an

8-pin modular jack (RJ-45).

Note

• The interface RS-232 A (position 21) and interface RS-485 A

(position 5–8) are internally connected to port A on the processor. Only one should be connected.

The port uses the following signals:

87654321

Fig. 2.3: Connection using hardware signals for modem communication.

Schneider Electric Buildings AB, Feb 2011 21 (134)

04-00071-04-en

Page 22

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

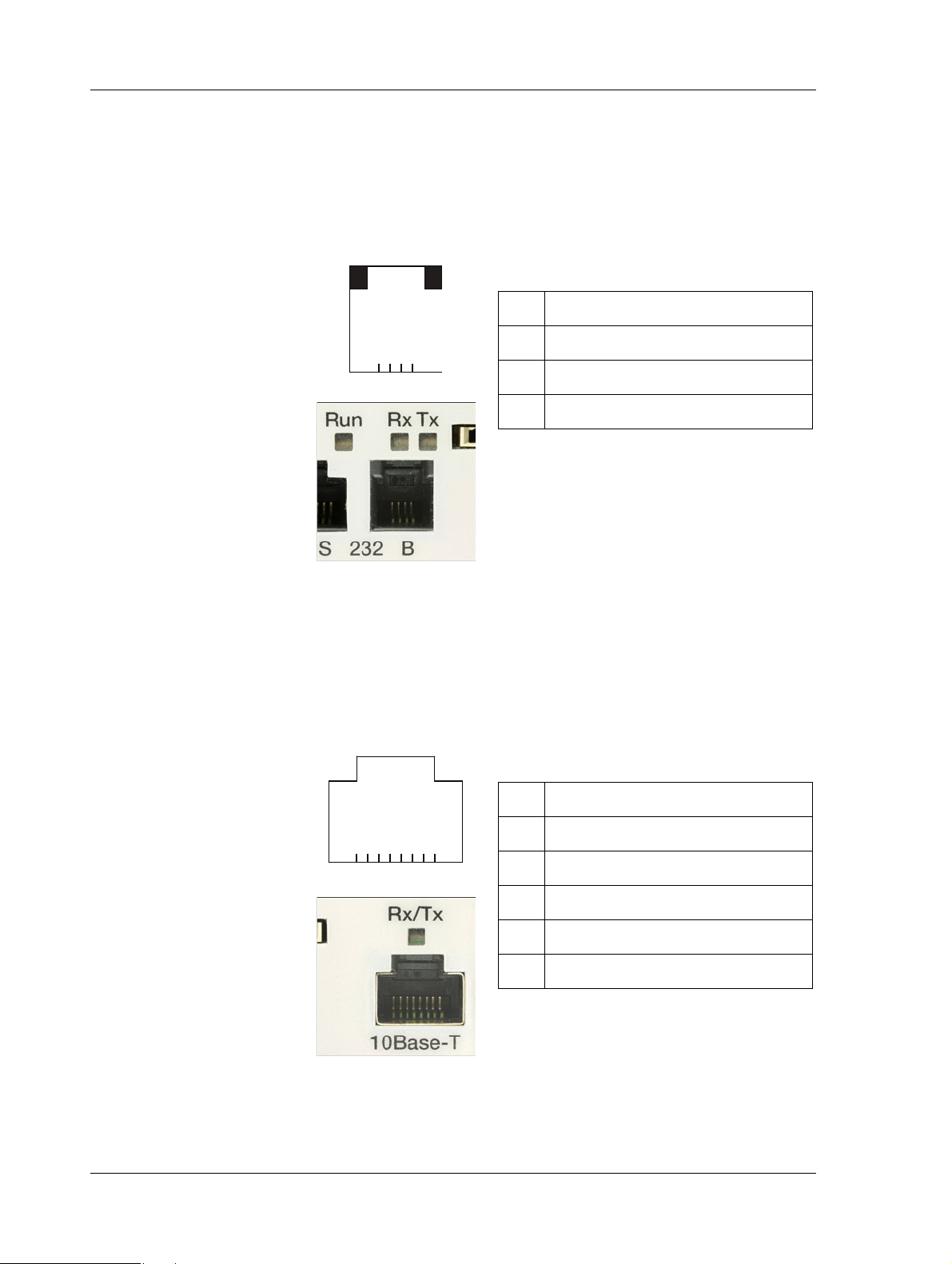

Table 2.3: Port pins – RS-232 B

1 TxD (output)

2 RxD (input)

3 Not used

4Ground

Table 2.4: Port pins – 10Base-T

1TX+

2TX3RX+

4–5 Connected to ground via 75 ohms

6RX7–8 Connected to ground via 75 ohms

Serial Port – RS-232 B

The RS-232 B port is used for communication between the Xenta

device and a computer. It is used for configuration of the Xenta device

using Windows HyperTerminal. The connector is a 4-pin modular jack

(RJ-10).

The port uses the following signals:

4321

Fig. 2.4: Connection using basic RS-232 signals, primarily intended for a

computer running, for example Windows HyperTerminal during the

configuration phase.

Ethernet Port – 10Base-T

The Ethernet 10Base-T port is used for communication between the

Xenta device and the TCP/IP network.

The port uses the following signals:

87654321

Fig. 2.5: Connection for a LAN (Ethernet) cable.

22 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 23

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

1

4

3

2

6

5

2.1.3 Fail-Safe State

The Xenta can enter a fail-safe state if a severe problem arises in the system program.

The unit can be forced into fail-safe mode by shorting terminals 9 and

10 in Fig. 2.2 during power-up. This can be useful if the system program

experiences problems.

The overall Run indicator (position 3 in Fig. 2.6) will show a steady red

light in the fail-safe state.

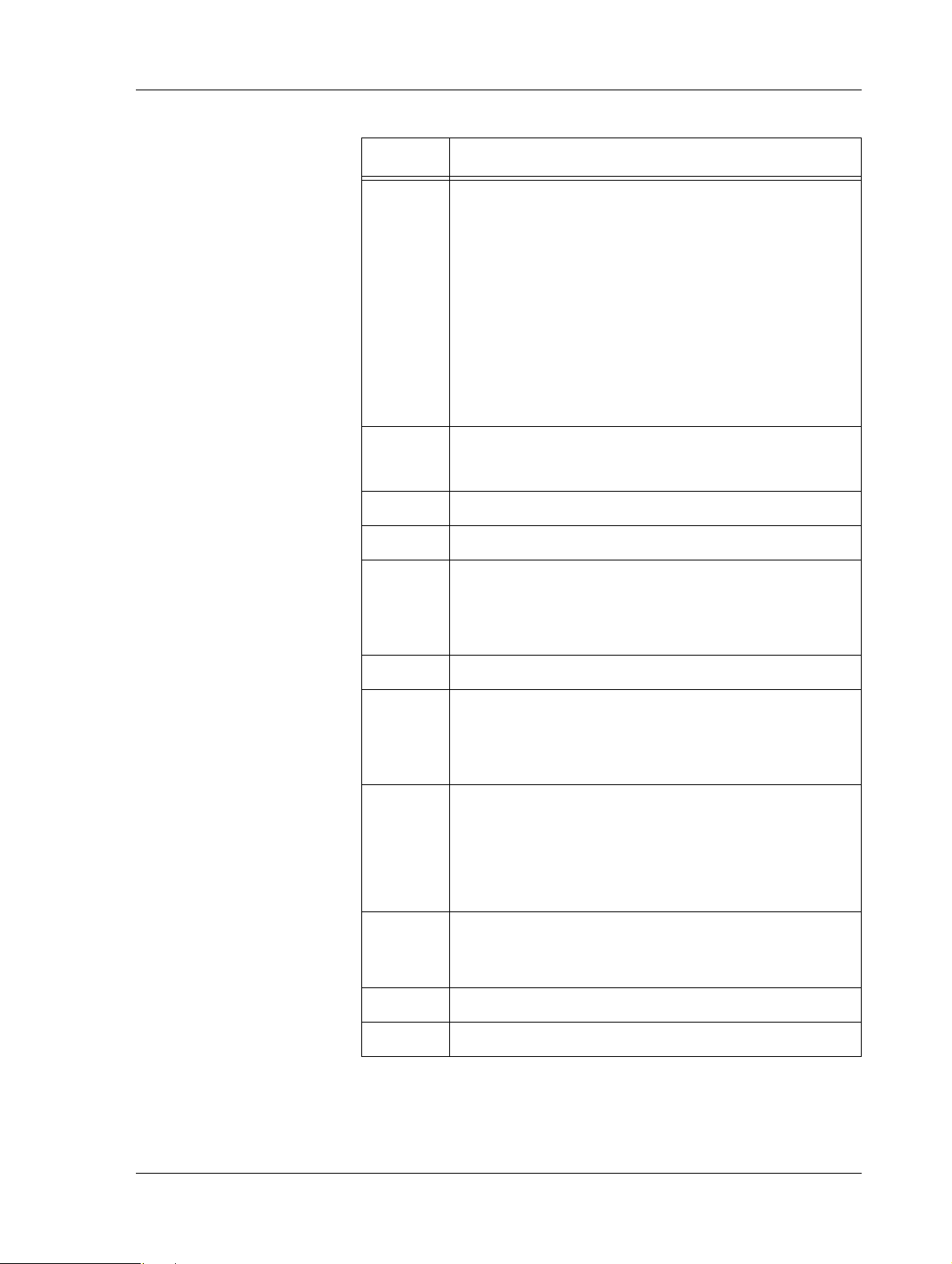

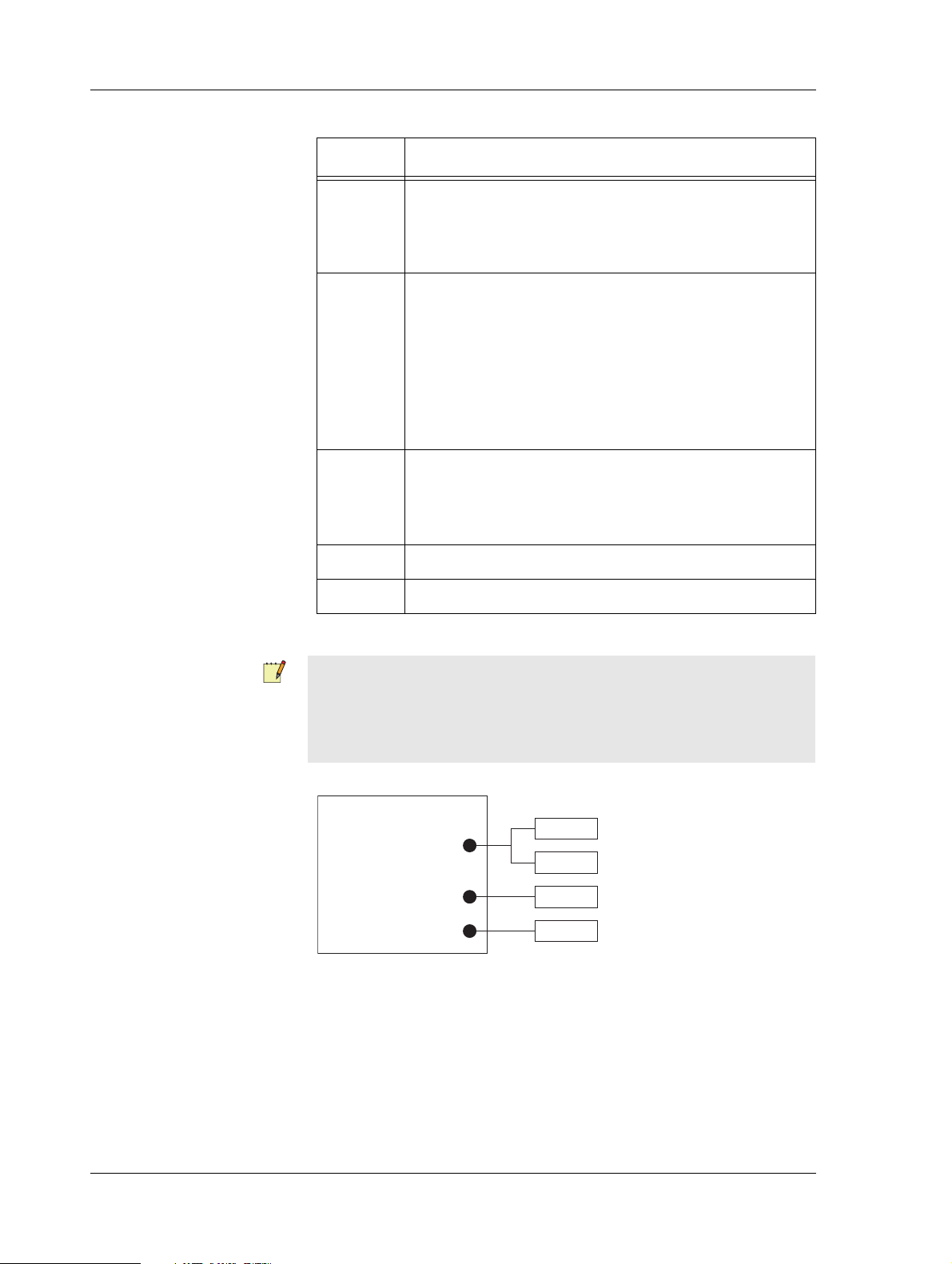

2.1.4 LEDs

A number of light-emitting diodes (LEDs) on the Xenta device indicate

that the application program is running and when communication is in

progress.

Fig. 2.6: LEDs on the Xenta device.

Table 2.5: LEDs on the Xenta device.

Position Description

1 Neuron status indicator

Schneider Electric Buildings AB, Feb 2011 23 (134)

04-00071-04-en

•Off – Normal mode

• Red, blinking – Unconfigured mode

• Red, steady – Hardware fault

Page 24

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

Serial Ports

A

C

B

Processor

RS-232

RS-485

RS-232

RS-485

Por t 21

Port pins 5, 6 (7, 8)

Por t 22

Port pins 19, 20

Table 2.5: LEDs on the Xenta device. (Contd.)

Position Description

2 Serial RS-232 B port activity indicators:

• RX – Indicates that data is received

• TX – Indicates that data is transmitted

3 Overall Run indicator

• Green, steady – Normal mode

• Green, blinking – Start mode

• Red, steady – Fail-safe mode

(see description below)

• Red, blinking – Unit fault

4 Serial RS-232 A port activity indicators:

• RX – Indicates that data is received

• TX – Indicates that data is transmitted

5 Serial RS-485 C port activity indicator.

6 Ethernet 10Base-T activity indicator

Note

• The LEDs for the RS-232 A interface (position 4) do not indicate

communication when using the RS-485 A interface although

internal port A is used for both.

Fig. 2.7: Internal serial ports and RS-232/485 interfaces.

24 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 25

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

2.2 Configuring the TAC Xenta 500/700/911/913

The technician uses Microsoft Windows and HyperTerminal to initialize and configure the Xenta.

• For more information on how to connect the Xenta 511, see

Section 4.1, “Configuration Phase”, on page 43.

• For more information on how to connect the Xenta 527, see

Section 5.1, “Configuration Phase”, on page 53.

• For more information on how to connect the Xenta 555, see

Section 6.1, “Configuration Phase”, on page 67.

• For more information on how to connect the Xenta 701/711/721,

see Section 7.1, “Configuration Phase”, on page 79.

• For more information on how to connect the Xenta 731, see

Section 8.1, “Configuration Phase”, on page 89.

• For more information on how to connect the Xenta 911, see

Section 10.1, “Configuration Phase”, on page 105.

• For more information on how to connect the Xenta 913, see

Section 11.1, “Configuration Phase”, on page 113.

2.2.1 Configuration Data

To configure the Xenta, the following information should be obtained

from the network administrator:

• DHCP is used or not used

• IP address (only if DHCP is not used)

• Subnet mask (only if DHCP is not used)

• Default gateway

•DNS server

• Web site name (can be set later, using XBuilder)

• Domain name (only used as information)

• Host name (only used as information)

This information is used once you have connected to the Xenta using

HyperTerminal and a serial cable (null modem cable).

Schneider Electric Buildings AB, Feb 2011 25 (134)

04-00071-04-en

Page 26

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

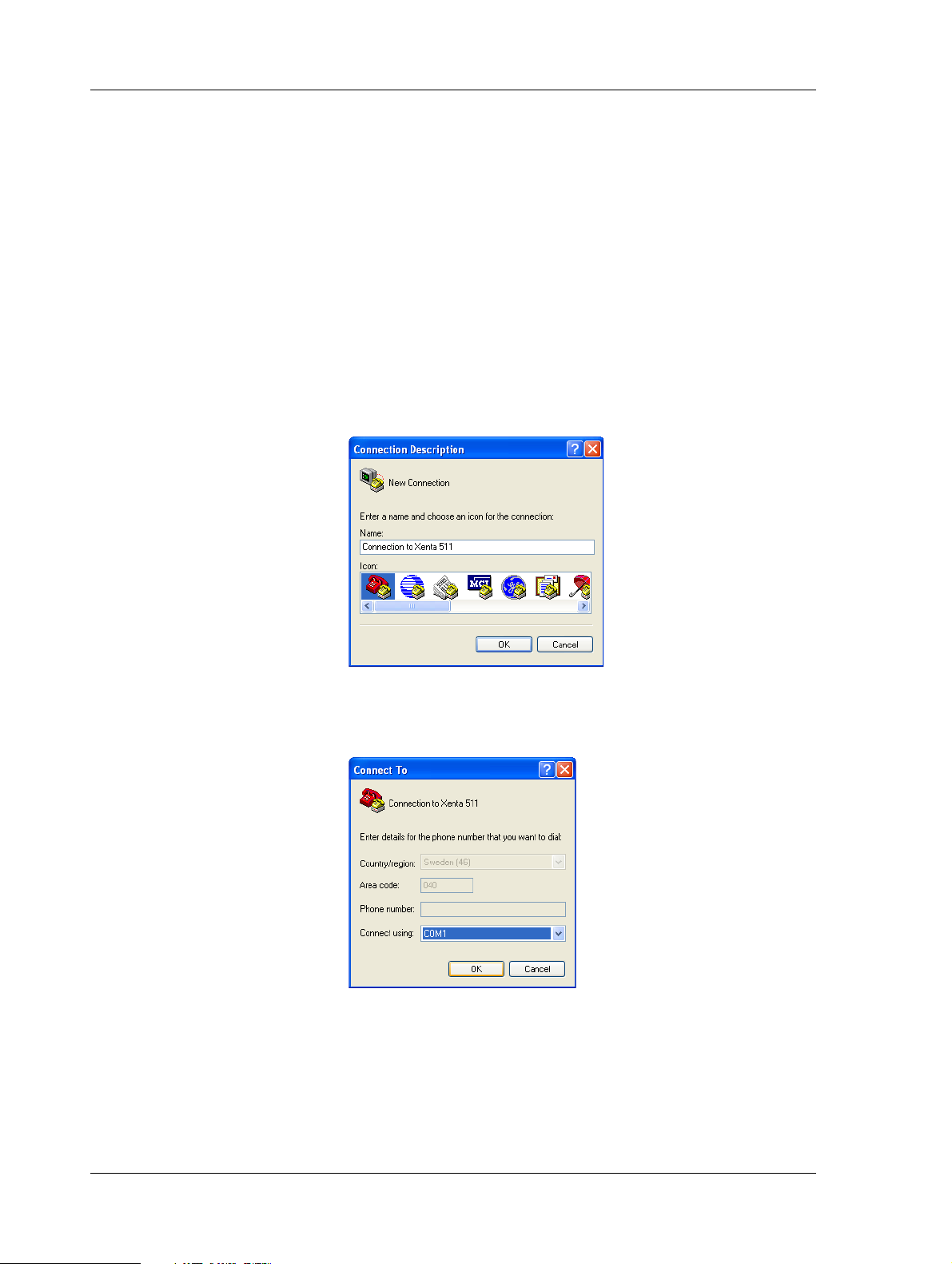

2.2.2 Configuring Windows HyperTerminal

When you use Windows HyperTerminal you need to set up a connection. Once created it can be used when required. In the example below

a Xenta 511 is configured.

To configure Windows HyperTerminal

1 Connect the Xenta to the engineering PC.

2 On the Start menu, point to All Programs, point to Accessories,

point to Communications, and then click HyperTerminal.

3 In the Connection Description dialog box, in the Name box, type

a name that describes the connection. In the example “Connection

to Xenta 511”.

4 In the Icon box, click the required icon.

5 Click OK.

6 In Connect To dialog box, in the Connect using list, click the

COM port used in step 1 above.

7 Click OK.

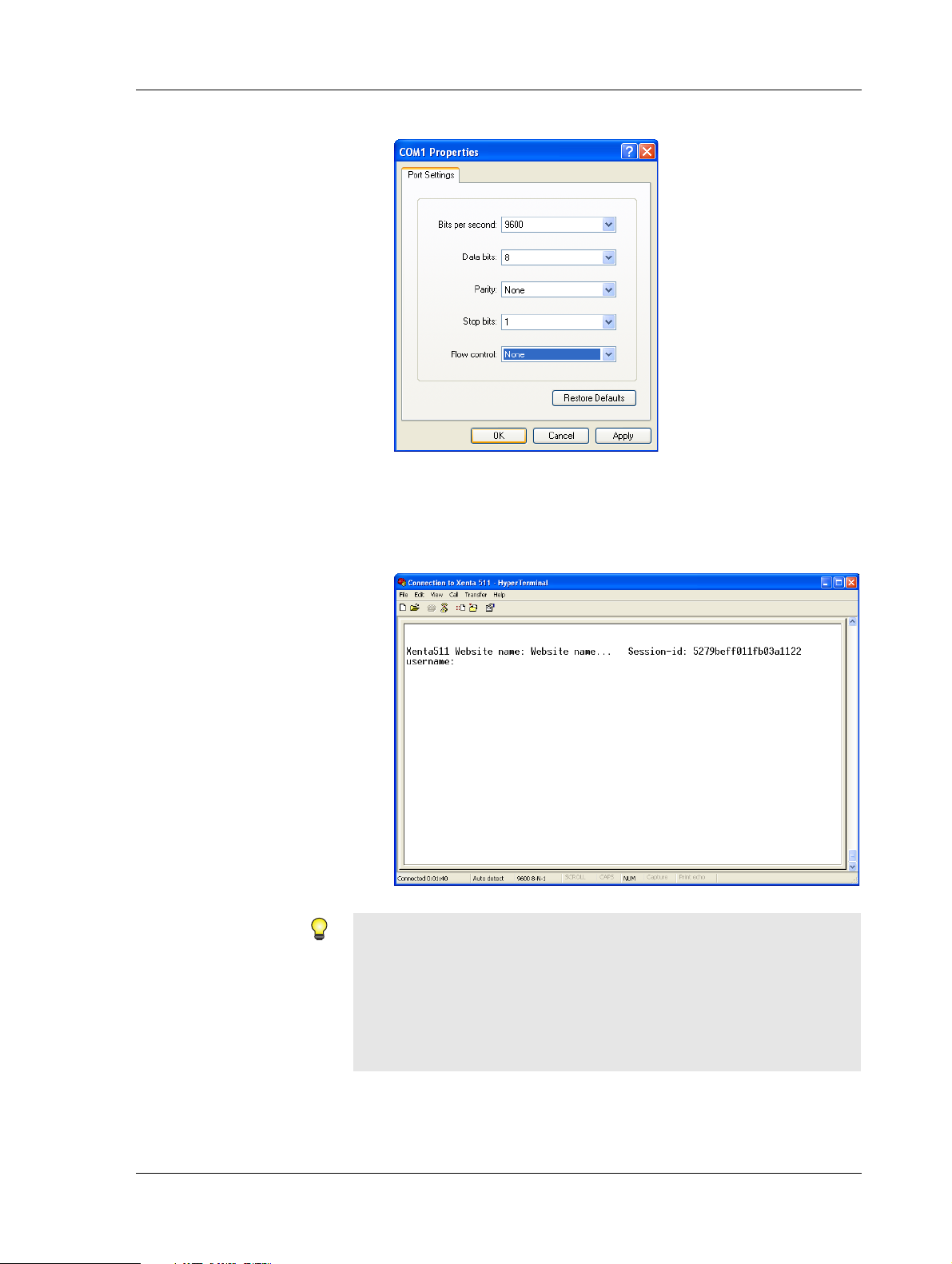

8 In the COM1 Properties dialog box, in the Bits per second list,

click 9600.

26 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 27

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

9 In the Flow control list, click None.

10 Click OK.

11 On the File menu, click Save to save the HyperTerminal connec-

tion. The HyperTerminal for the Xenta is now ready to use.

12 Press ENTER to activate the command prompt.

Tips

• To reopen the HyperTerminal connection to the Xenta, click

Start, point to All Programs, point to Accessories, point to

Communications, point to HyperTerminal and then click Connection to Xenta 511. ht .

• You can also click Open on the File menu in HyperTerminal.

Schneider Electric Buildings AB, Feb 2011 27 (134)

04-00071-04-en

Page 28

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

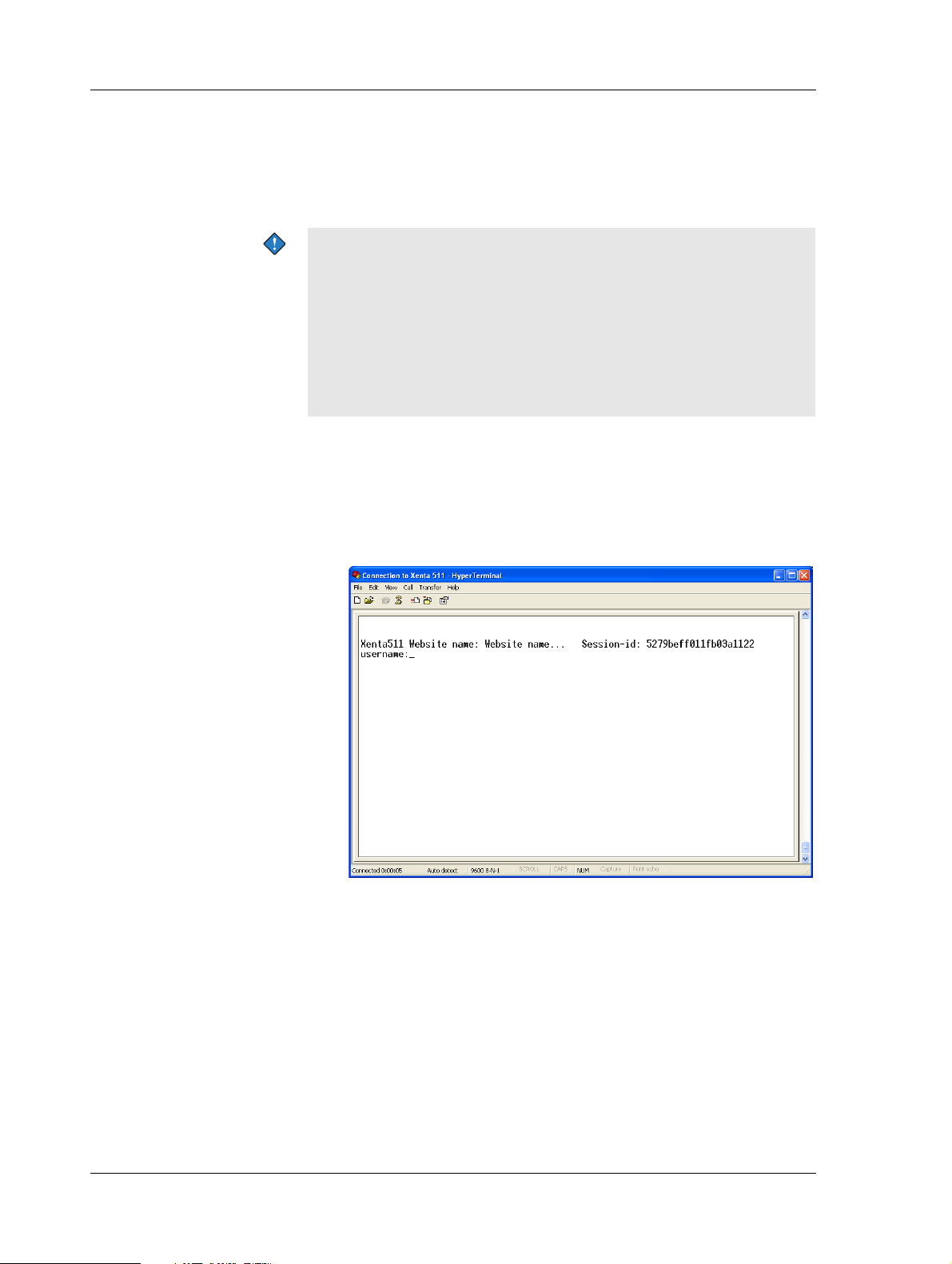

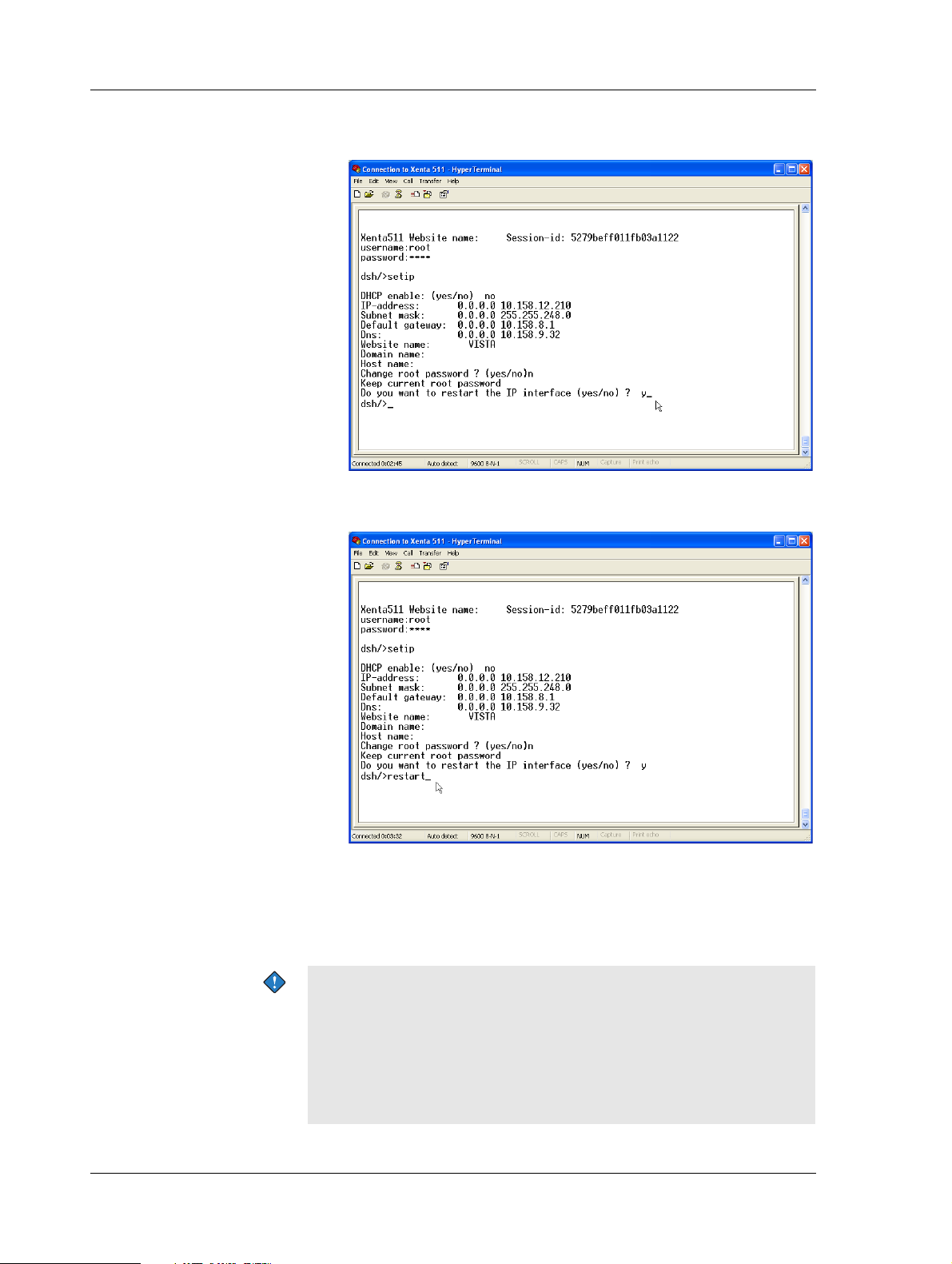

2.2.3 Configuring the TAC Xenta

The configuration parameters for the Xenta are entered using HyperTerminal. The parameters enable the Xenta to communicate using its

TCP/IP port.

Important

• Because the Xenta’s TCP/IP default parameters are set at the factory, you can immediately access it using a web browser and

change the parameters without having to use HyperTerminal.

The default parameters are:

• IP address: 192.168.255.2

• Subnet mask: 255.255.255.0

To configure the TAC Xenta

1 Start Windows HyperTerminal using the connection created in

Section 2.2.2, “Configuring Windows HyperTerminal”, on

page 26.

2 Press ENTER to activate the command prompt.

3 Type the user name “root” and press ENTER.

28 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 29

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

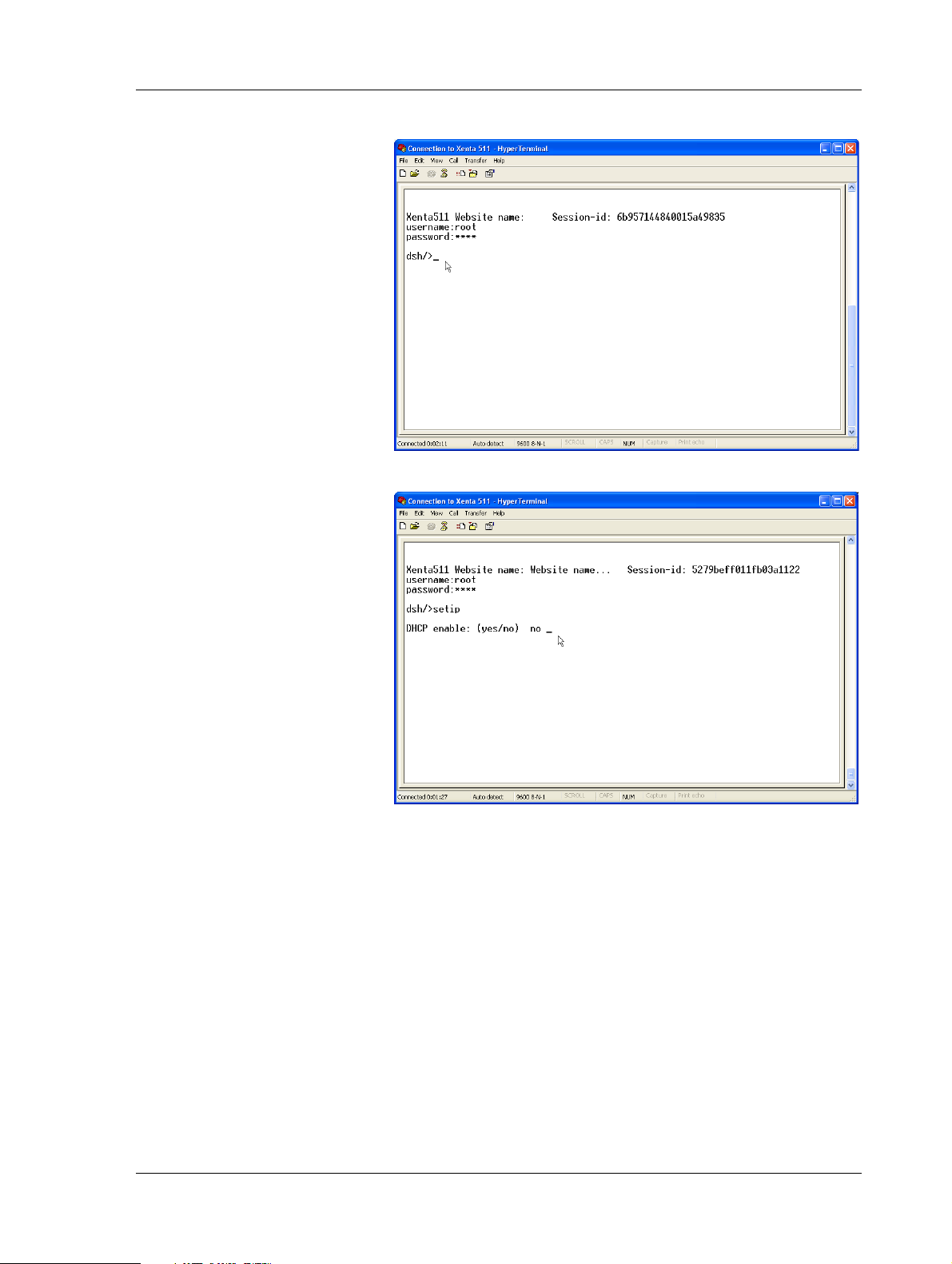

4 Type the password “root” and press ENTER.

5 Type the command “setip” and press ENTER.

6 Type the configuration parameters, collected in Section 2.2.1,

“Configuration Data”, on page 25. Press ENTER after each entry.

Schneider Electric Buildings AB, Feb 2011 29 (134)

04-00071-04-en

Page 30

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

In the example, the configuration parameters appear as follows.

The root password is not changed.

7 T ype the command “restart” and press ENTER, to activate the new

configuration parameters.

8 Quit HyperTerminal.

The Xenta is now configured to communicate over TCP/IP, this means

that you can access the Xenta through a web browser and that you can

send web pages to the Xenta using XBuilder.

Important

• The password can be changed from a configuration page on the

web site in the Xenta.

• The user name and the password are used by the operator when

logging on to the web site and by XBuilder when sending the

project to the Xenta.

30 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 31

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

2.3 Verifying the TAC Xenta Communication

Once the Xenta has been configured with respect to its address on the

TCP/IP network, it can be accessed through a web browser.

• For more information on how to connect the Xenta 511, see

Section 4.2, “Engineering Phase”, on page 45.

• For more information on how to connect the Xenta 527, see

Section 5.2, “Engineering Phase”, on page 55.

• For more information on how to connect the Xenta 555, see

Section 6.2, “Engineering Phase”, on page 69.

• For more information on how to connect the Xenta 701/711/721,

see Section 7.2, “Engineering Phase”, on page 81.

• For more information on how to connect the Xenta 731, see

Section 8.2, “Engineering Phase”, on page 91.

• For more information on how to connect the Xenta 911, see

Section 10.2, “Engineering Phase”, on page 106.

• For more information on how to connect the Xenta 913, see

Section 11.2, “Programming and Operating Phase”, on page 115.

Schneider Electric Buildings AB, Feb 2011 31 (134)

04-00071-04-en

Page 32

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

2.3.1 Accessing the TAC Xenta

The Xenta is accessed using an standard web browser.

To access the TAC Xenta

1 Start Internet Explorer.

2 In the Address box, type the IP address of the Xenta. In the ex am-

ple “10.158.12.210”.

3 Press ENTER.

A security alert appears, similar to the following figure, with information about the site’s security certificate.

4 Click Yes.

5 In the Username box, type “root”.

32 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 33

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

6 In the Password box, type the password. In the example, “root”.

7 Click Login.

The default web page in the Xenta appears.

Note

• A java applet security dialog warning may be displayed. Click

Yes in the dialog.

Schneider Electric Buildings AB, Feb 2011 33 (134)

04-00071-04-en

Page 34

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

2.3.2 Changing the Root Password

The default password for the system administrator is widely known. To

avoid unauthorized access to the system the password has to be

changed. You can change the password using the Change Password

page on the Xenta web site.

To change the password

1 In the navigator, expand Configuration-User Administrator, and

click Change Password.

2 In the Old password box, type the old password. In the example,

“root”.

3 In the New password box, type the new password. In the example,

“seagull3”.

4 In the Confirm new password box, confirm the new password.

5 Click Save.

Use the new password the next time you log on as system administrator.

34 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 35

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

2.4 Temporary Login ID

If you do not have access to the root password when you try to connect

to a Xenta 500/700/913, a temporary user name and password can be

used. The temporary password is generated by based on the Session ID

displayed on the Login page.

Send the Session ID to helpdesk@tac.com, which generates and returns

a temporary password. Then type the Session ID in the Username box

and the temporary password in the Password box.

Tip

• You can select the text on the login page, copy it and then paste it

into the e-mail message and the Username box.

The Session ID changes each day, so the temporary password is only

valid on the day it is generated.

Schneider Electric Buildings AB, Feb 2011 35 (134)

04-00071-04-en

Page 36

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

2.5 Upgrading the System Program

The Xenta system program can be upgraded via the IP network from a

computer running the installation program. The installation program is

distributed by Schneider Electric. In the example the Xenta 511 will be

upgraded.

Note

• To upgrade the system program of the Xenta device you must

first configure the Xenta using Windows HyperTerminal. For

more information on how to configure the Xenta, see

Section 2.2, “Configuring the TAC Xenta 500/700/911/913”, on

page 25.

To upgrade the system program

1 Connect the Xenta and a computer to a TCP/IP network according

to the figure.

TCP/IP TCP/IP

2 Obtain the installation program from Schneider Electric’ s web site

or from the TAC Software CD-ROM.

3 Double-click the installation program to start the installation.

The following screen shots show the installation procedure for a

Xenta 511 but they are similar for other Xenta devices.

4 Read the instructions.

5 If the requirements are met, click Next.

36 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 37

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

6 Select temporary folder for the installation program.

7 Click Next.

8 Select skin.

9 Click Next.

10 Select which kind of installation you want to carry out. In our

example, select Install full system.

Schneider Electric Buildings AB, Feb 2011 37 (134)

04-00071-04-en

Page 38

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

11 Click Next.

12 In the TAC Xenta 511 target unit parameters dialog box, in the

Username box, type root.

13 In the Password box, type the password for root.

14 In the IP address box, type the IP address (or the URL address) of

the Xenta device.

15 Click Next.

16 Read the list of actions that will be carried out during the installa-

tion.

38 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 39

TAC Xenta 500/700/911/913, Product Manual 2 TAC Xenta 500/700/911/913

17 Click Yes.

18 Click Finish to complete the installation.

Schneider Electric Buildings AB, Feb 2011 39 (134)

04-00071-04-en

Page 40

2 TAC Xenta 500/700/911/913 TAC Xenta 500/700/911/913, Product Manual

40 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 41

TAC Xenta 500/700/911/913, Product Manual 3 Connecting the TAC Xenta to Your Network

3 Connecting the TAC Xenta to Your

Network

The Xenta integrates with your building control system by communicating across the Ethernet using TCP/IP transport protocols.

In order for the Xenta to successfully establish communications with

your building control system, certain network criteria must be met.

More specifically, the ports required for proper communication with

these systems must be open and available to the Xenta . The Xenta uses

the following communication ports:

• Port 80 (HTTP access, configurable)

• Port 443 (HTTPS access, configurable)

• Port 20/21 (FTP access)

• Port 25 (SMTP access)

• Port 80 (Status Viewer, Alarm Viewer and Graphics Viewer)

• Port 1068 (LTA for Vista)

• Port 161 (SNMP access)

Schneider Electric Buildings AB, Feb 2011 41 (134)

04-00071-04-en

Page 42

3 Connecting the TAC Xenta to Your Network TAC Xenta 500/700/911/913, Product Manual

3.1 Alternative Port Settings

3.1.1 HTTP and HTTPS

Perhaps you are unable to make the necessary configuration changes to

your proxies/firewalls because of restrictions imposed by your company’s network security policies. In this case, you have the option of

choosing different numbers for the HTTP and HTTPS communication

ports shown above.

The following steps describe how to select other communication ports:

1 From the web browser, expand the navigation tree as shown in the

following figure and select

HTTP Server.

2 Set the HTTP and HTTPS communication port assignments to the

appropriate values.

3 Accept your settings by selecting

4 Configure your network to allow communication on the ports you

assigned to the Xenta.

5 Verify that the Xenta can now successfully communicate across

the Internet and with your building control systems.

Save & Restart.

42 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 43

TAC Xenta 500/700/911/913, Product Manual 4 TAC Xenta 511

RS-232

Windows HyperTerminal

4 TAC Xenta 511

A Xenta 511 can be configured as a web-based presentation system for

LonWorks networks. Using a standard web browser, the operator can

easily view and control the devices in the LonWorks network.

4.1 Configuration Phase

The technician uses Microsoft Windows and HyperTerminal via an

RS-232 connection to initialize and configure the Xenta 511. For more

information on how to initialize and configure the Xenta 511,

see Section 2.2, “Configuring the TAC Xenta 500/700/911/913”, on

page 25.

Fig. 4.1: Windows HyperTerminal communicating with a TAC Xenta 511

using RS-232 during the configuration phase.

Schneider Electric Buildings AB, Feb 2011 43 (134)

04-00071-04-en

Page 44

4 TAC Xenta 511 TAC Xenta 500/700/911/913, Product Manual

12

4.1.1 Connections, configuration

Cables that can be ordered from Schneider Electric are ordered as cable

kits. Below you find information on which kit to order and how to connect the cables.

Required Cable Kit

Part. No. 007309200.

Fig. 4.2: Connections during the configuration phase.

Pos. Description Qty Part No.

1 DB9/Female-to-RJ45/Female adapter connecting the computer

serial port to the cable directly below.

2 Serial cable (null modem cable) connecting adapter directly above

to the Xenta serial port RS-232 B.

1. Part of cable kit no. 007309200. The cable kit also contains a RJ-45-to-RJ-45 rollover cable

(3-781-0118-0). This cable is not needed during the configuration phase.

1 3-621-3056-0

1 3-781-0128-0

1

1

44 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 45

TAC Xenta 500/700/911/913, Product Manual 4 TAC Xenta 511

ial

l

4.2 Engineering Phase

The technician uses XBuilder to program the Xenta 511 via the TCP/IP

network. To access the Xenta 511 web site a standard web browser is

used.

LonTalk

TCP/IP

TAC XBuilder

Web browser

Fig. 4.3: TAC XBuilder or a web browser communicating with a TAC

Xenta 511 using IP during the engineering phase.

Modbus Master, ser

Modbus Slave, seria

Modbus TCP Client

Schneider Electric Buildings AB, Feb 2011 45 (134)

04-00071-04-en

Page 46

4 TAC Xenta 511 TAC Xenta 500/700/911/913, Product Manual

4.2.1 Connections, engineering

Below you find information on which cables to use and how to connect

the cables.

3

4

12

TCP/IP

TxD 3

RxD 4

Cr 5

5

Fig. 4.4: Connections during the engineering phase.

Pos. Description Qty Part No.

11TP UTP/STP CAT.6 RJ-45 cable connecting the computer network

port to the TCP/IP network.

1

TP UTP/STP CAT.6 RJ-45 cable connecting the TCP/IP network to

2

the Xenta 10Base-T port.

3 Cable connecting the Xenta port pins 3–4 to the LonWorks device.

For more information on cables approved by Echelon,

see www.echelon.com.

2

Cable connecting the Xenta RS485Aport pins 5–6 (5–8) to the

4

Modbus device.

For more information on cable requirements, see the Modbus equipment documentation.

1N/A

1N/A

1N/A

1N/A

2

Cable connecting the Xenta port RS-232 A to the Modbus device.

5

1N/A

For more information on cable requirements, see the Modbus equipment documentation.

1. TAC Xenta 511does not support Ethernet MDI, a crossover cable may be required.

2. Only one may be connected.

46 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 47

TAC Xenta 500/700/911/913, Product Manual 4 TAC Xenta 511

Web browser

TCP/IP

LonTalk

Modbus Master, serial

Modbus Slave, serial

Modbus TCP Client

4.3 Operating Phase

The operator uses a standard web browser to view and control the

devices in the LonWorks network, either via a directly connected or

using a dialed-up connection.

4.3.1 Directly Connected

The operator uses a standard web browser to view and control the

devices in the LonWorks network.

Fig. 4.5: A web browser communicating with a TAC Xenta 511 using

TCP/IP during the operating phase.

Schneider Electric Buildings AB, Feb 2011 47 (134)

04-00071-04-en

Page 48

4 TAC Xenta 511 TAC Xenta 500/700/911/913, Product Manual

TxD 3

RxD 4

Cr 5

TCP/IP

12

5

3

4

4.3.2 Connections, operation directly

Below you find information on which cables to use and how to connect

the cables.

Fig. 4.6: Connections during the operating phase.

Pos. Description Qty Part No.

11TP UTP/STP CAT.6 RJ-45 cable connecting the computer network

port to the TCP/IP network.

1

TP UTP/STP CAT.6 RJ-45 cable connecting the TCP/IP network to

2

the Xenta 10Base-T port.

3 Cable connecting the Xenta port pins 3–4 to the LonWorks device.

For more information on cables approved by Echelon,

see www.echelon.com.

2

Cable connecting the Xenta RS485Aport pins 5–6 (5–8) to the

4

Modbus device.

For more information on cable requirements, see the Modbus equipment documentation.

2

Cable connecting the Xenta port RS-232 A to the Modbus device.

5

For more information on cable requirements, see the Modbus equipment documentation.

1. TAC Xenta 511does not support Ethernet MDI, a crossover cable may be required.

2. Only one may be connected.

1N/A

1N/A

1N/A

1N/A

1N/A

48 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 49

TAC Xenta 500/700/911/913, Product Manual 4 TAC Xenta 511

RS232

ISP Modem

Web browser

TCP/IP

4.3.3 Dialed-Up, operation

The operator uses a standard web browser to view and control the

devices in the LonWorks network, using a dialed-up connection via

RS-232 with the possibility to use a TCP/IP network.

RS232

Web browser

RS232

Fig. 4.7: Dialed-up connection.

Fig. 4.8: Dialed-up connection via TCP/IP.

Schneider Electric Buildings AB, Feb 2011 49 (134)

04-00071-04-en

Page 50

4 TAC Xenta 511 TAC Xenta 500/700/911/913, Product Manual

Modem

3

4

21

5

4.3.4 Connections, operation dial-up

Cables that can be ordered from Schneider Electric are ordered as cable

kits. Below you find information on which kit to order and how to connect the cables.

Required Cable Kit

Part. No. 007309160.

Fig. 4.9: Connections during the engineering phase.

Pos. Description Qty Part No.

1 DB25/Male-to-RJ45/Female adapter connecting the modem serial

port to the cable directly below.

22RJ-45-to-RJ-45 rollover cable connecting the adapter to the Xenta

serial port RS-232 A.

3 Cable connecting the Xenta port pins 3–4 to the LonWorks device.

For more information on cables approved by Echelon,

see www.echelon.com

2

4

Cable connecting the Xenta port pins 5–6 (5–8) to the Modbus

device.

For more information on cable requirements, see the Modbus equipment documentation.

5 TP UTP/STP CAT.6 RJ-45 cable connecting the TCP/IP to the

Xenta 10Base-T port.

1. Part of cable kit no. 007309160.

2. Only one should be connected.

1 3-621-3052-0

1 3-781-0118-0

1N/A

1N/A

1N/A

1

1

50 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 51

TAC Xenta 500/700/911/913, Product Manual 4 TAC Xenta 511

4.4 Port Usage

If a Xenta 511 and the IP network are located on opposite sides of one

or several firewalls, these firewalls must be configured to allow traffic

through.

The Xenta 511 uses the following ports:

Table 4.1: Port Usage

Local/

Protocol IP Ports

FTP 20, 21 Local No File transfer protocol.

HTTP 80 Local Yes HTTP traffic.

HTTPS 443 Local Yes HTTP traffic over SSL, secure socket

Remote

Xenta

Port

Configurable Comments

layer.

DHCP Server 67 Remote No

DHCP Client 68 Local No

DNS 53 Remote No

VarTransfer-http 80 Local/

Remote

VarTransfer-TCP

VarTransfer-UDP

SNMP 161 Local No Network management protocol

SNMP Trap 162 Remote No Network management protocol

SMTP 25 Remote No Mail protocol.

LTA IP 1068 Local/

1233

9088/9089

Local/

Remote

Remote

Yes Dynamic data protocol, used by

applets to communicate on-line data.

The port number is the same as the

http port.

Dynamic data protocol, used between

No

Yes Protocol used between Vista Server

Xenta 500/700/913s that exchange

variable data.

(UDP).

(UDP).

and Xenta 511 operating as an LTA

port.

NTP, SNTP 123 Local/

Remote

Modbus TCP

Client

Schneider Electric Buildings AB, Feb 2011 51 (134)

04-00071-04-en

502 Remote Yes Modbus TCP client to a server or

No Time synchronization (UDP).

router on a network.

Page 52

4 TAC Xenta 511 TAC Xenta 500/700/911/913, Product Manual

52 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 53

TAC Xenta 500/700/911/913, Product Manual 5 TAC Xenta 527

RS-232

Windows HyperTerminal

5 TAC Xenta 527

A Xenta 527 can be configured as a web-based presentation system for

I/NET networks. Using a standard web browser, the operator can easily

view and control the devices in the LonW o rks network via the Internet

or a local intranet.

5.1 Configuration Phase

The technician uses Microsoft Windows and HyperTerminal via a

RS-232 connection to initialize and configure the Xenta 527. For more

information, see Section 2.2, “Configuring the

TAC Xenta 500/700/911/913”, on page 25.

Fig. 5.1: Windows HyperTerminal communicating with a TAC Xenta 527

using RS-232 during the configuration phase.

Schneider Electric Buildings AB, Feb 2011 53 (134)

04-00071-04-en

Page 54

5 TAC Xenta 527 TAC Xenta 500/700/911/913, Product Manual

12

5.1.1 Connections

Cables that can be ordered from Schneider Electric are ordered as cable

kits. Below you find information on which kit to order and how to connect the cables.

Required Cable Kit

Part. No. 007309200.

Fig. 5.2: Connections during the configuration phase.

Pos. Description Qty Part No.

1 DB9/Female-to-RJ45/Female adapter connecting the computer

serial port to the cable directly below.

2 Serial cable (null modem cable) connecting adapter directly above

to the Xenta serial port RS-232 B.

1. Part of cable kit no. 007309200. The cable kit also contains a RJ-45-to-RJ-45 rollover cable

(3-781-0118-0). This cable is not needed during the configuration phase.

1 3-621-3056-0

1 3-781-0128-0

1

1

54 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 55

TAC Xenta 500/700/911/913, Product Manual 5 TAC Xenta 527

TAC XBuilder

Web browser

TCP/IP

I/NET

LonTalk

Modbus Master, serial

Modbus Slave, serial

Modbus TCP Client

5.2 Engineering Phase

The technician uses XBuilder to program the Xenta 527 via the TCP/IP

network. To access the Xenta 527 web site a standard web browser is

used.

Fig. 5.3: TAC XBuilder or a web browser communicating with a TAC

Xenta 527 using IP during the engineering phase.

Schneider Electric Buildings AB, Feb 2011 55 (134)

04-00071-04-en

Page 56

5 TAC Xenta 527 TAC Xenta 500/700/911/913, Product Manual

LAN

WAN

TCP/IP

12

3

4

TxD 3

RxD 4

Cr 5

6

5

5.2.1 Connections

Below you find information on which cables to use and how to connect

the cables.

Fig. 5.4: Connections during the engineering phase.

56 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 57

TAC Xenta 500/700/911/913, Product Manual 5 TAC Xenta 527

Pos. Description Qty Part No.

11TP UTP/STP CAT.6 RJ-45 cable connecting the computer network

port to the TCP/IP network.

1

TP UTP/STP CAT.6 RJ-45 cable connecting the TCP/IP network to

2

the Xenta 10Base-T port.

3 Cable connecting the Xenta port pins 3–4 to the LonWorks device.

For more information on cables approved by Echelon,

see www.echelon.com.

2

I/NET Controller LAN cable connected to serial port RS-485 C.

4

Use either of the following wire types:

2

• 22 AWG (0.324 mm

) shielded, twisted pair, 5000' (1500 m)

maximum per segment, 150 Ω impedance, 9 pF/ft. conductor-to-conductor, 14 pF/ft. conductor-to-shield.

or

• 24 AWG (0.206 mm

2

) shielded, twisted pair, 4000' (1200 m)

maximum per segment, 120 Ω impedance, 13 pF/ft. conduc-

tor-to-conductor, 23 pF/ft. conductor-to-shield.

3

5

Cable connecting the Xenta port pins 5–6 (5–8) to the Modbus

device.

For more information on cable requirements, see the Modbus equipment documentation.

1N/A

1N/A

1N/A

1

Belden 9184

Belden 9841

1N/A

3

Cable connecting the Xenta port RS-232 A to the Modbus device.

6

1N/A

For more information on cable requirements, see the Modbus equipment documentation.

1. TAC Xenta 527 does not support Ethernet MDI, a crossover cable may be required.

2. Maintain proper polarity when connecting this cable to each device on the controller LAN.

3. Only one may be connected.

Schneider Electric Buildings AB, Feb 2011 57 (134)

04-00071-04-en

Page 58

5 TAC Xenta 527 TAC Xenta 500/700/911/913, Product Manual

ial

l

TCP/IP

12

3

4

TxD 3

RxD 4

Cr 5

6

5

5.3 Operating Phase

The operator uses a standard web browser to view and control the

devices in the LonWorks network, either via a directly connected or

using a dialed-up connection.

5.3.1 Directly Connected

The operator uses a standard web browser to view and control the LonWorks devices directly connected via TCP/IP.

I/NET

LonTalk

TCP/IP

Web browser

Fig. 5.5: A web browser communicating with a TAC Xenta 527 using

TCP/IP during the operating phase.

5.3.2 Connections

Modbus Master, ser

Modbus Slave, seria

Modbus TCP Client

Below you find information on which cables to use and how to connect

the cables.

Fig. 5.6: Connections during the operating phase.

58 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 59

TAC Xenta 500/700/911/913, Product Manual 5 TAC Xenta 527

Pos. Description Qty Part No.

11TP UTP/STP CAT.6 RJ-45 cable connecting the computer network

port to the TCP/IP network.

1

TP UTP/STP CAT.6 RJ-45 cable connecting the TCP/IP network to

2

the Xenta 10Base-T port.

3 Cable connecting the Xenta port pins 3–4 to the LonWorks device.

For more information on cables approved by Echelon,

see www.echelon.com.

2

I/NET Controller LAN cable connected to serial port RS-485 C.

4

Use either of the following wire types:

2

• 22 AWG (0.324 mm

) shielded, twisted pair, 5000' (1500 m)

maximum per segment, 150 Ω impedance, 9 pF/ft. conductor-to-conductor, 14 pF/ft. conductor-to-shield.

or

• 24 AWG (0.206 mm

2

) shielded, twisted pair, 4000' (1200 m)

maximum per segment, 120 Ω impedance, 13 pF/ft. conduc-

tor-to-conductor, 23 pF/ft. conductor-to-shield.

3

5

Cable connecting the Xenta port pins 5–6 (5–8) to the Modbus

device.

For more information on cable requirements, see the Modbus equipment documentation.

1N/A

1N/A

1N/A

1

Belden 9184

Belden 9841

1N/A

3

Cable connecting the Xenta port RS-232 A to the Modbus device.

6

1N/A

For more information on cable requirements, see the Modbus equipment documentation.

1. TAC Xenta 527 does not support Ethernet MDI, a crossover cable may be required.

2. Maintain proper polarity when connecting this cable to each device on the controller LAN.

3. Only one may be connected.

Schneider Electric Buildings AB, Feb 2011 59 (134)

04-00071-04-en

Page 60

5 TAC Xenta 527 TAC Xenta 500/700/911/913, Product Manual

RS232

RS232

Web browser

RS232

ISP Modem

Web browser

TCP/IP

5.3.3 Dialed-Up

The operator uses a standard web browser to view and control the LonWorks devices using a dialed-up connection via RS-232 with the possibility to use a TCP/IP network.

Fig. 5.7: Dialed-up connection.

5.3.4 Connections

Fig. 5.8: Dialed-up connection via TCP/IP.

Cables that can be ordered from Schneider Electric are ordered as cable

kits. Below you find information on which kit to order and how to connect the cables.

60 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 61

TAC Xenta 500/700/911/913, Product Manual 5 TAC Xenta 527

Required Cable Kit

Part. No. 007309160.

3

12

Fig. 5.9: Connections during the operating phase.

4

Schneider Electric Buildings AB, Feb 2011 61 (134)

04-00071-04-en

Page 62

5 TAC Xenta 527 TAC Xenta 500/700/911/913, Product Manual

Pos. Description Qty Part No.

1 DB25/Male-to-RJ45/Female adapter connecting the modem serial

1 3-621-3052-0

port to the cable directly below.

22RJ-45-to-RJ-45 rollover cable connecting the adapter directly above

1 3-781-0118-0

to the Xenta serial port RS-232 A.

3 Cable connecting the Xenta port pins 3–4 to the LonWorks device.

1N/A

For more information on cables approved by Echelon,

see www.echelon.com

3

4

I/NET Controller LAN cable connected to serial port RS-485 C.

1

Use either of the following wire types:

2

• 22 AWG (0.324 mm

) shielded, twisted pair, 5000' (1500 m)

maximum per segment, 150 Ω impedance, 9 pF/ft. conductor-to-conductor, 14 pF/ft. conductor-to-shield.

or

• 24 AWG (0.206 mm

2

) shielded, twisted pair, 4000' (1200 m)

maximum per segment, 120 Ω impedance, 13 pF/ft. conductor-to-conductor, 23 pF/ft. conductor-to-shield.

1. Part of Modem Connect Cable Kit no. 007309160.

2. Only one should be connected.

3. Maintain proper polarity when connecting this cable to each device on the controller LAN.

1

1

Belden 9184

Belden 9841

62 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 63

TAC Xenta 500/700/911/913, Product Manual 5 TAC Xenta 527

5.4 Port Usage

If a Xenta 527 and the IP network are located on opposite sides of one

or several firewalls, these firewalls must be configured to allow traffic

through. The Xenta 527 uses the following ports:

Table 5.1: Port Usage

Local/

Protocol IP Ports

FTP 20, 21 Local No File transfer protocol.

HTTP 80 Local Yes HTTP traffic.

HTTPS 443 Local Yes HTTP traffic over SSL, secure socket

DHCP Server 67 Remote No

Remote

Xenta

Port

Configurable Comments

layer.

DHCP Client 68 Local No

DNS 53 Remote No

VarTransfer-http 80 Local/

Remote

VarTransfer-TCP

VarTransfer-UDP

SNMP 161 Local No Network management protocol

SNMP Trap 162 Remote No Network management protocol

SMTP 25 Remote No Mail protocol.

LTA IP 1068 Local/

NTP, SNTP 123 Local/

1233

9088/9089

Local/

Remote

Remote

Remote

Yes Dynamic data protocol, used by

applets to communicate on-line data.

The port number is the same as the

http port.

Dynamic data protocol, used between

No

Yes Protocol used between Vista Server

No Time synchronization (UDP).

Xenta 500/700/913s that exchange

variable data.

(UDP).

(UDP).

and Xenta 527 operating as an LTA

port.

I/NET 50069 Local No I/NET UDP/IP.

Modbus TCP

Client

Schneider Electric Buildings AB, Feb 2011 63 (134)

04-00071-04-en

502 Remote Yes Modbus TCP client to a server or

router on a network.

Page 64

5 TAC Xenta 527 TAC Xenta 500/700/911/913, Product Manual

A RS 232 B

TAC X e nt a

RS485 C

RX/

TX+

RX/

TX–

10Base-T

11 12 13 14 15 16 17 18 19 20

IP address..........

.......-..

..

............-...............-................

Controller LAN

Connections

5.5 Connecting the TAC Xenta 527 to an I/NET Controller LAN

The Xenta 527 connects to the I/NET controller LAN through terminal

19 and 20 of its lower terminal block connector.

Fig. 5.10: Controller LAN Connections

To connect the Xenta 527 to an I/NET controller LAN

1 Connect the positive (+) line to position 19.

2 Connect the negative (–) line to position 20.

3 Splice shield wires together at each device on the controller LAN,

and connect to a good earth ground at one location only. Ensure

that shield wire continuity is maintained across the controller

LAN.

Note

• The polarity of the RS485 connection is important. It is recommended that you observe the network’s polarity convention (the

positive line connected to position 1, and the negative line to

position 2, on all devices). This convention will help ensure consistent voltage measurements should diagnostic troubleshooting

become necessary.

04-00071-04-en

64 (134) Schneider Electric Buildings AB, Feb 2011

Page 65

TAC Xenta 500/700/911/913, Product Manual 5 TAC Xenta 527

5.6 Using a Direct Connection to I/NET

The Xenta 527 is intended for use on an Ethernet LAN. However, you

can also directly connect an I/NET host workstation to the RS-232 A

port on the front of the Xenta 527. This allows the directly connected

I/NET host to communicate with devices on the Xenta 527’s controller

LAN. This type of connection can also be used when you are configuring the Xenta 527’s communication parameters.

In order to directly connect an I/NET host workstation to the Xenta 527,

you must connect a cable from the workstation’s serial COM port to the

Xenta 527’s RS-232 B port. TAC Xenta Programming Serial Kit

007309200 provides that adapters and cables required for this type of

connection, as well as for a console connection. to the Xenta 527’s

RS-232 B port.

Once you have connected an I/NET host workstation to Xenta 527, set

I/NET’s link type to “NetPlus Router” in the I/NET Configuration editor. Refer to TCON298, I/NET Seven Getting Started, for complete

instructions.

Schneider Electric Buildings AB, Feb 2011 65 (134)

04-00071-04-en

Page 66

5 TAC Xenta 527 TAC Xenta 500/700/911/913, Product Manual

66 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 67

TAC Xenta 500/700/911/913, Product Manual 6 TAC Xenta 555

55

6 TAC Xenta 555

A Xenta 555 can be configured as a web-based presentation system for

MicroNet networks. Using a standard web browser, the operator can

easily view and control the devices in the MicroNet network via the

Internet or a local intranet.

6.1 Configuration Phase

The technician uses Microsoft Windows and HyperTerminal via an

RS-232 connection to initialize and configure the Xenta 555. For more

information, see Section 2.2, “Configuring the

TAC Xenta 500/700/911/913”, on page 25 of this handbook.

RS-232

Xenta 5

Windows HyperTerminal

Fig. 6.1: Windows HyperTerminal communicating with a Xenta 555

using RS-232 during the configuration phase.

Schneider Electric Buildings AB, Feb 2011 67 (134)

04-00071-04-en

Page 68

6 TAC Xenta 555 TAC Xenta 500/700/911/913, Product Manual

6.1.1 Connections

Cables that can be ordered from Schneider Electric are ordered as cable

kits. Below you find information on which kit to order and how to connect the cables.

Required Cable Kit

Part. No. 007309200.

Fig. 6.2: Connections during the configuration phase.

Table 6.1: Connector descriptions (configuration phase)

Pos. Description Qty Part No.

1 DB9/Female-to-RJ45/Female adapter connecting the computer

serial port to the cable directly below.

2 RJ-45-to-RJ-10 Serial cable (null modem cable) connecting adapter

directly above to the Xenta serial port RS-232 B.

1. Part of cable kit no. 007309200. The cable kit also contains a RJ-45-to-RJ-45 rollover cable

(3-781-0118-0). This cable is not needed during the configuration phase.

1 3-621-3056-0

1 3-781-0128-0

1

1

68 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 69

TAC Xenta 500/700/911/913, Product Manual 6 TAC Xenta 555

TCP/IP

MicroNet or Satchnet

LonTalk

Modbus TCP Client

TAC XBuilder

Web browser

6.2 Engineering Phase

The technician uses XBuilder to program the Xenta 555 via the TCP/IP

network. To access the Xenta 555 web site a standard web browser is

used.

Fig. 6.3: TAC XBuilder or a web browser communicating with a

Xenta 555 using IP during the engineering phase.

Schneider Electric Buildings AB, Feb 2011 69 (134)

04-00071-04-en

Page 70

6 TAC Xenta 555 TAC Xenta 500/700/911/913, Product Manual

6.2.1 Connections

Cables that can be ordered from Schneider Electric are ordered as cable

kits. Below you will find information on which cables to use and how

to connect the cables.

Required Cable Kit

Part. No. 007309200.

TCP/IP

MNMI

PL4

Fig. 6.4: Connections during the engineering phase.

70 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 71

TAC Xenta 500/700/911/913, Product Manual 6 TAC Xenta 555

Table 6.2: Connector descriptions (engineering phase)

Pos. Description Qty Part No.

11TP UTP/STP CAT.6 RJ-45 cable connecting the computer network

1N/A

port to the TCP/IP network.

1

TP UTP/STP CAT.6 RJ-45 cable connecting the TCP /IP network to

2

1N/A

the Xenta 10Base-T port.

2

MicroNet or Satchnet Controller LAN cable connecting the Xenta

3

serial port RS-485 A pins 5-6 to a MicroNet device

Use one of the following cable types (as appropriate)

2

• 24 AWG (0.206 mm

), 7 x 32 stranded, shielded5, twisted pair,

3

.

4

:

1

Belden 9502

3281' (1000 m) maximum per segment, 75 Ω impedance,

30 pF/ft. conductor-to-conductor, 50 pF/ft. conductor-to-shield.

or

2

• 20 AWG (0.519 mm

), 7 x 28 stranded, shielded5, twisted pair,

Belden 8762

3281' (1000 m) maximum per segment, 56 Ω impedance,

27 pF/ft. conductor-to-conductor, 49 pF/ft. conductor-to-shield.

4 DB9/Female-to-RJ45/Female adapter connecting the MicroNet

1 3-621-3056-0

Manager Interface PL4 to the cable directly below.

5 RJ-45-to-RJ-45 rollover cable connecting the cable directly above

1 3-781-0118-0

to the Xenta RS 232 Port A.

1. TAC Xenta 555 does not support Ethernet MDI, a crossover cable may be required.

2. Maintain proper polarity when connecting this cable to a device on the MicroNet controller LAN.

3. Alternative communication is also possible by connecting the MicroNet Manager Interface directly to the

MicroNet network, using the same cable.

4. For MN50 Series networks, use Belden 9502. For older MicroNet or Satchnet networks, use Belden 8762.

5. Connect the shield at one end of the network only, either at the MicroNet end (see MicroNet data sheets)

or to a verified good earth at the Xenta end.

6. Connect the second twisted pair (i.e the LAN REF) to Pin 2 (G0) at the Xenta 555. Maintain the LAN REF

at all devices.

7. Part of cable kit no. 007309200. The cable kit also contains a serial cable no. 3-781-0128-0 (null modem

cable) which is not needed during the engineering phase.

6

7

7

Schneider Electric Buildings AB, Feb 2011 71 (134)

04-00071-04-en

Page 72

6 TAC Xenta 555 TAC Xenta 500/700/911/913, Product Manual

Xenta 555 MN500 MN440

5 6 6 5 13 12

1

GND

+– +– +–

65

+–

MN620

6.2.2 RS485 LAN Wiring

The following illustrations show example RS485 LAN connections

from the Xenta 555 to MicroNet networks. For full MicroNet network

wiring details refer to the MicroNet System Engineering Guide and to

the relevant MicroNet controller data sheets.

1st twisted pair (signal)

Xenta 555 MN550 MN450

5 6 21 20 14 13

+– +– +–

243151

G0 LAN

REF

2nd twisted pair (LAN REF)

LAN

REF

GND

Fig. 6.5: RS485 LAN from Xenta 555 to a MicroNet MN50 Series

network (Belden 9502 dual twisted pair used).

Fig. 6.6: RS485 LAN from Xenta 555 to an older MicroNet network

(Belden 8762 single twisted pair used).

Note

• NCP networks are shown.

72 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 73

TAC Xenta 500/700/911/913, Product Manual 6 TAC Xenta 555

TCP/IP

MicroNet

or Satchnet

Web browser

TCP/IP

MNMI

PL4

6.3 Operating Phase

The operator uses a standard web browser to view and control the

devices in the MicroNet network via TCP/IP.

Fig. 6.7: A web browser communicating with a Xenta 555 using TCP/IP

during the operating phase

6.3.1 Connections

Cables that can be ordered from Schneider Electric are ordered as cable

kits. Below you find information on which cables to use and how to connect the cables.

Required Cable Kit

Part. No. 007309200.

Fig. 6.8: Connections during the operating phase.

Note

• Items 4 and 5 are required whenever an ARCNET network is

used.

Schneider Electric Buildings AB, Feb 2011 73 (134)

04-00071-04-en

Page 74

6 TAC Xenta 555 TAC Xenta 500/700/911/913, Product Manual

Table 6.3: Connector descriptions (operating phase)

Pos. Description Qty Part No.

11TP UTP/STP CAT.6 RJ-45 cable connecting the computer network

1N/A

port to the TCP/IP network.

1

TP UTP/STP CAT.6 RJ-45 cable connecting the TCP/IP network to

2

1N/A

the Xenta 10Base-T port.

2

MicroNet or Satchnet Controller LAN cable connecting the Xenta

3

serial port RS-485 A pins 5-6 to a MicroNet device

Use one of the following cable types (as appropriate)

• 24 AWG (0.206 mm2), 7 x 32 stranded, shielded

3

.

4

:

5

, twisted pair,

1

Belden 9502

5000' (1500 m) maximum per segment, 75 W impedance,

30 pF/ft. conductor-to-conductor, 50 pF/ft. conductor-to-shield.

or

5

• 22 AWG (0.324 mm2), 7 x 28 stranded, shielded

, twisted pair,

Belden 8762

4000' (1200 m) maximum per segment, 120 W impedance,

17 pF/ft. conductor-to-conductor, 24.3 pF/ft. conductor-to-shield.

4 DB9/Female-to-RJ45/Female adapter connecting the MicroNet

1 3-621-3056-0

Manager Interface PL4 to the cable directly below.

5 RJ-45-to-RJ-45 rollover cable connecting the cable directly above

1 3-781-0118-0

to the Xenta RS 232 Port A.

1. TAC Xenta 555 does not support Ethernet MDI, a crossover cable may be required.

2. Maintain proper polarity when connecting this cable to a device on the MicroNet controller LAN.

3. Alternative communication is also possible by connecting the MicroNet Manager Interface directly to the

MicroNet network, using the same cable.

4. For MN 50 Series networks, use Belden 9502. For older MicroNet or Satchnet networks, use Belden 8762.

5. Connect the shield at one end of the network only, either at the MicroNet end (see MicroNet data sheets)

or to a verified good earth at the Xenta end.

6. Connect the second twisted pair (i.e the LAN REF) to Pin 2 (G0) at the Xenta 555. Maintain the LAN REF

at all devices.

7. Part of cable kit no. 007309200. The cable kit also contains a serial cable no. 3-781-0128-0 (null modem

cable) which is not needed during the operating phase.

6

7

7

74 (134) Schneider Electric Buildings AB, Feb 2011

04-00071-04-en

Page 75

TAC Xenta 500/700/911/913, Product Manual 6 TAC Xenta 555

6.4 Port Usage

If a Xenta 555 and the IP network are located on opposite sides of one