Page 1

Conext™ SW Inverter/Charger

Conext SW 2524 120/240 (865-2524)

Conext SW 4024 120/240 (865-4024)

Conext SW 4048 120/240 (865-4048)

Installation Guide

975-0639-01-01 Rev F

9-2018

solar.schneider-electric.com

This guide for use by qualified personnel only

Page 2

Page 3

Conext SW Inverter/Charger

Conext SW 2524 120/240 (865-2524)

Conext SW 4024 120/240 (865-4024)

Conext SW 4048 120/240 (865-4048)

Installation Guide

solar.schneider-electric.com

Page 4

Copyright and Contact

Copyright © 2013-2018 Schneider Electric. All Rights Reserved. All trademarks are owned by Schneider Electric

Industries SAS or its affiliated companies.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, SELLER

(A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION

PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION;

(B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION.THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO

MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED.APPROVED CONTENT IS

CONTAINED WITH THE ENGLISH LANGUAGE VERSION WHICH IS POSTED AT SOLAR.SCHNEIDER-ELECTRIC.COM.

Document Number: 975-0639-01-01 Revision: Rev F Date: 9-2018

Product Part Numbers: 865-2524, 865-4024, 865-4048

Contact Information solar.schneider-electric.com

Please contact your local Schneider Electric Sales Representative or visit our website at:

http://solar.schneider-electric.com/tech-support/

Information About Your System

As soon as you open your product, record the following information and be sure to keep your proof of purchase.

Serial Number

Product Number

Purchased From

Purchase Date

_________________________________

_________________________________

_________________________________

_________________________________

Page 5

About This Guide

Purpose

The purpose of this Installation Guide is to provide explanations and procedures

for installing the Conext SW Inverter/Charger to a main AC power source such as

an AC generator for off-grid application or AC mains (main power grid) for power

backup application.

Scope

The Guide provides safety and installation guidelines as well as information on

tools and wiring. Complete balance of system installation is not covered. For a

complete balance of system installation using the Conext SW AC Switchgear, DC

Switchgear, and solar charge controllers, consult the Conext SW System Guide.

It does not provide details about particular brands of batteries. You need to

consult individual battery manufacturers for this information.

Audience

Organization

The Guide is intended for use by anyone who plans to install an off-grid/backup

system involving the Conext SW Inverter/Charger. The information in this manual

is intended for qualified personnel. Qualified personnel have training,

knowledge, and experience in:

• Installing electrical equipment and PV power systems (up to 1000 volts).

• Applying all applicable installation codes.

• Analyzing and reducing the hazards involved in performing electrical work.

• Selecting and using Personal Protective Equipment (PPE).

This Guide is organized into:

Chapter 1, “Installation” covers installation instructions.

Chapter 2, “Specifications” covers product specifications.

Chapter 3, “Wiring Diagrams” covers overviews of Conext SW BOS installations

and wiring diagrams.

975-0639-01-01 Rev F iii

This guide for use by qualified personnel only

Page 6

About This Guide

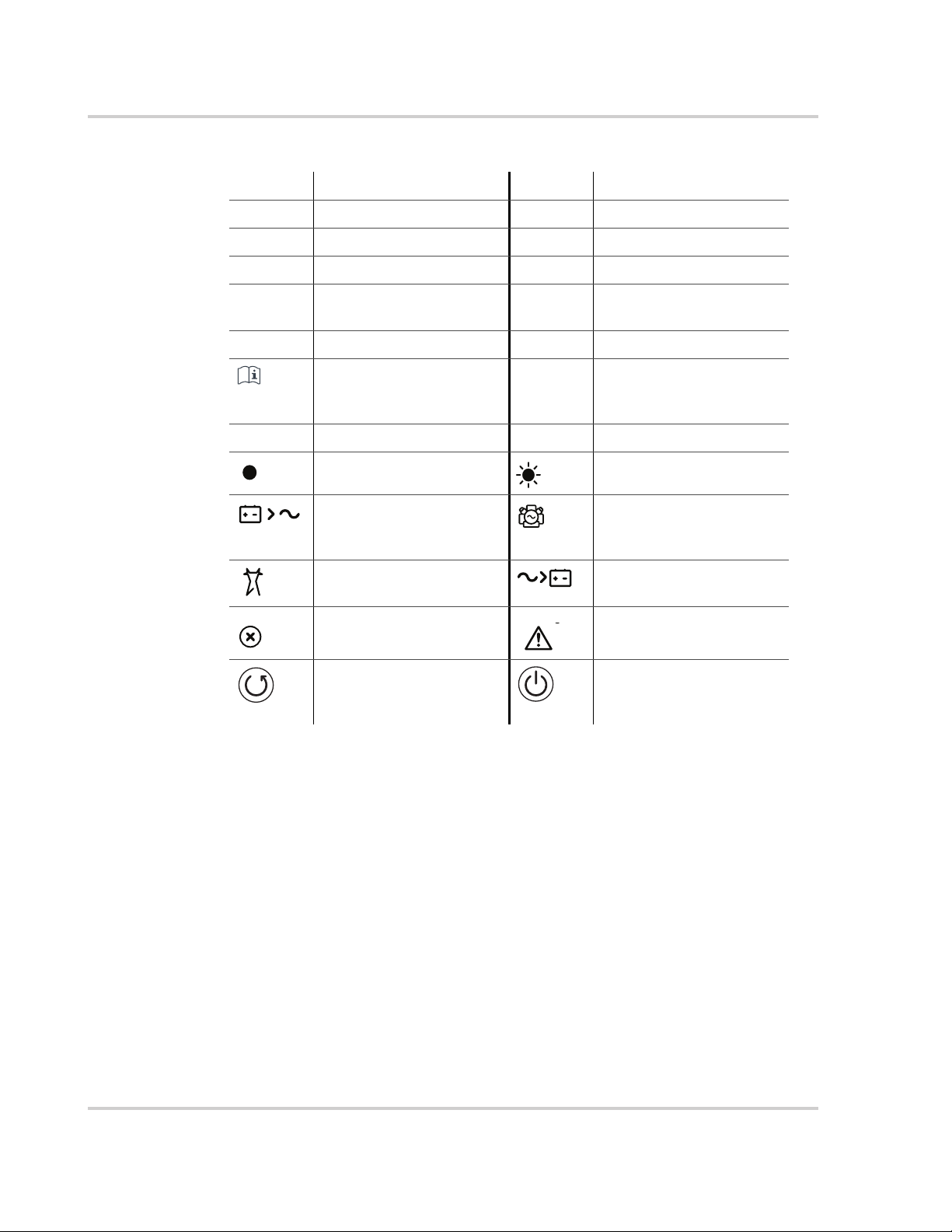

Abbreviations, Acronyms, and Symbols

AC Alternating Current LED Light Emitting Diode

AGS Automatic Generator Start SCP System Control Panel

BOS Balance of System SW Sine Wave

DC Direct Current VAC Volts, Alternating Current

PPE Personal Protective

Equipment

PV Photovoltaic IP20 Ingress protection rating

Reference to see guide

(or manual) for more

information

AC DC

Denotes a steady LED Denotes a flashing LED

Inv Enabled – see

Owner’s Guide for

definition.

AC IN – see Owner’s

Guide for definition.

Fault – see Owner’s Guide

for definition.

Clear Fault | Reset – see

Owner’s Guide for

definition.

VDC Volts, Direct Current

Ground

Gen Support – see

Owner’s Guide for

definition.

Charging – see Owner’s

Guide for definition.

Warning – see Owner’s

Guide for definition.

Inv Enable – see Owner’s

Guide for definition.

Related Information

You can find more information about Schneider Electric as well as its products

and services at solar.schneider-electric.com.

iv 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 7

Important Safety Instructions

READ AND SAVE THESE INSTRUCTIONS - DO NOT DISCARD

This guide contains important safety instructions for the Conext SW Inverter/

Charger that must be followed during operation and troubleshooting. Read and

keep this Installation Guide for future reference.

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service or maintain it. The

following special messages may appear throughout this bulletin or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal

injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided,

can result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided,

can result in moderate or minor injury.

NOTICE

NOTICE indicates a potentially hazardous situation, which, if not avoided, can

result in equipment damage.

975-0639-01-01 Rev F v

This guide for use by qualified personnel only

Page 8

Safety

Safety Information

ELECTRICAL SHOCK AND FIRE HAZARD

Installation must be done by qualified personnel to ensure compliance with all

applicable installation and electrical codes and regulations. Instructions for

installing the Conext SW are provided here for use by qualified installers only.

Failure to follow these instructions will result in death or serious injury.

ELECTRICAL SHOCK AND FIRE HAZARD

• Read all instructions, cautionary markings, and all other appropriate

sections of this guide before installing the Conext SW.

• Exercise extreme caution at all times to prevent accidents.

• Do not cover or obstruct ventilation openings.

• Do not mount in a zero-clearance compartment. Overheating may result.

• Do not open nor disassemble the inverter/charger. There are no userserviceable parts inside.

• Do not expose to rain or spray.

• Disconnect and lockout all AC and DC sources before servicing. Servicing

includes maintenance or cleaning or working on any circuits connected to

the inverter/charger. See following note.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

NOTE: Turning off inverter mode using the Inv Enable switch on the front panel,

disabling the inverter and charger functions using the SCP, and putting the unit in

Standby mode will not reduce an electrical shock hazard.

vi 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 9

Safety

DANGER

ELECTRIC SHOCK HAZARD

• For indoor use only. This inverter/charger is designed for off-grid, solar,

backup, and hybrid applications.

• Do not operate the inverter/charger if it has been damaged in any way.

• Do not operate the inverter/charger with damaged or substandard wiring.

Wiring must be done by qualified personnel to ensure compliance with all

applicable installation codes and regulations.

Failure to follow these instructions will result in death or serious injury.

WARNING

EXPLOSION AND FIRE HAZARD

• Charge properly rated lead-acid (GEL, AGM, Flooded, or lead-calcium)

rechargeable batteries because other battery types may explode.

• When using Lithium-Ion batteries, ensure that the battery pack being used

includes a certified Battery Management System (BMS) with safety

controls.

• Do not work in the vicinity of lead-acid batteries. Batteries generate

explosive gases during normal operation. See note #1.

• Do not install and/or operate in compartments containing flammable

materials or in locations that require ignition-protected equipment. See

notes #2 and #3.

Failure to follow these instructions can result in death or serious injury.

NOTES:

1. Follow these instructions and those published by the battery manufacturer

and the manufacturer of any equipment you intend to use in the vicinity of the

battery. Review cautionary markings on these products.

2. This inverter/charger contains components which tend to produce arcs or

sparks.

3. Locations include any space containing gasoline-powered machinery like a

generator, fuel tanks, as well as joints, fittings, or other connections between

components of the fuel system.

CAUTION

FIRE AND BURN HAZARD

Do not cover or obstruct the air intake vent openings and/or install in a zeroclearance compartment.

Failure to follow these instructions can result in moderate or minor injury.

975-0639-01-01 Rev F vii

This guide for use by qualified personnel only

Page 10

Safety

Precautions When Working With Batteries

IMPORTANT: Battery work and maintenance must be done by qualified

personnel knowledgeable about batteries to ensure compliance with battery

handling and maintenance safety precautions.

DANGER

ELECTRIC SHOCK HAZARD

• Determine if the battery is inadvertently earthed (grounded). If inadvertently

grounded, remove the source from ground.

• Avoid contact with any part of a grounded battery.

• Remove ground during installation and maintenance.

Failure to follow these instructions can result in moderate or minor injury.

WARNING

BURN AND FIRE HAZARD

• Always wear proper, non-absorbent gloves, complete eye protection, and

clothing protection.

• Remove all personal metal items, like rings, bracelets, and watches when

working with batteries. See CAUTION below.

• Never smoke or allow a spark or flame near batteries.

• Batteries can produce a short circuit current high enough to weld a ring or

metal bracelet or the like to the battery terminal, causing a severe burn.

Failure to follow these instructions can result in death or serious injury.

CAUTION

CHEMICAL, BURN, AND EXPLOSION HAZARD

• Never allow battery acid to drip when reading specific gravity or filling

battery.

• Make sure the area around the battery is well ventilated.

• Make sure the voltage of the batteries matches the output voltage of the

inverter/charger.

Failure to follow these instructions can result in moderate or minor injury.

viii 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 11

Safety

WARNING

LI

LIMITATIONS ON USE

Do not use in connection with life support systems or other medical

equipment.

Failure to follow these instructions can result in death or serious injury.

NOTICE

RISK OF INVERTER/CHARGER DAMAGE

• Never place the Conext SW Inverter/Charger unit directly above batteries;

gases from a battery will corrode and damage the inverter/charger.

• Never place the Conext SW Inverter/Charger unit in the same compartment

as batteries due to an explosive hazard.

Failure to follow these instructions can result in damage to equipment.

NOTICE

RISK OF BATTERY DAMAGE

Study and follow all of the battery manufacturer's specific precautions, such

as removing or not removing cell caps while charging, whether equalization is

acceptable for your battery, and recommended rates of charge.

Failure to follow these instructions can result in damage to equipment.

975-0639-01-01 Rev F ix

This guide for use by qualified personnel only

Page 12

Safety

FCC Information to the User

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

x 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 13

Contents

Important Safety Instructions

Safety Information ----------------------------------------------------------vi

Precautions When Working With Batteries ----------------------------------------viii

FCC Information to the User ---------------------------------------------------x

1 Installation

Materials List ------------------------------------------------------------1–2

Conext SW Front and Side Panels ------------------------------------------1–3

Front Panel Buttons and Status LEDs -------------------------------------1–4

Conext SW AC/DC/Ports Side Panel --------------------------------------1–5

Conext SW Supplied Accessories ------------------------------------------1–6

Conext SW Required Accessory --------------------------------------------1–7

Installation Information -----------------------------------------------------1–8

Before You Begin the Installation -------------------------------------------1–8

Installation Codes ------------------------------------------------------1–8

Xanbus Network System ----------------------------------------------------1–9

Xanbus System --------------------------------------------------------1–9

Xanbus-enabled Products and Other Accessories ------------------------------1–10

Installation Planning ------------------------------------------------------ 1–11

Planning Preparations -------------------------------------------------- 1–11

Components of the Inverter Power System ----------------------------------- 1–11

AC, DC, and Network Components -------------------------------------1–12

Unpacking and Inspecting the Conext SW Inverter/Charger -----------------------1–16

Installation Tools and Materials ------------------------------------------- 1–17

Tools ----------------------------------------------------------- 1–17

Materials -------------------------------------------------------- 1–17

Inverter/Charger Installation------------------------------------------------- 1–18

Overview -----------------------------------------------------------1–18

Step 1: Choosing a Location for the Inverter/Charger ---------------------------- 1–19

Step 2: Mounting the Inverter/Charger --------------------------------------1–20

Step 3: Connecting the AC Input and AC Output Wires -------------------------- 1–22

General AC Wiring Considerations -------------------------------------- 1–22

AC System Bonding --------------------------------------------------- 1–23

Step 4: Installing the DC Switchgear and Connecting the DC Cables ---------------- 1–25

DC Connection Precautions ------------------------------------------- 1–25

Installing the DC Switchgear next to Conext SW Inverter/Charger ---------------- 1–26

Connecting the DC Cables to the DC Switchgear --------------------------- 1–27

Step 5: Connecting the BTS and Xanbus-enabled Components -------------------- 1–29

Step 6: Performing Checks Prior to Initial Start-Up ------------------------------ 1–31

Step 7: Testing Your Installation ------------------------------------------- 1–31

Testing in Invert Mode ----------------------------------------------- 1–32

975-0639-01-01 Rev F xi

This guide for use by qualified personnel only

Page 14

Contents

Testing in Charge Mode and AC Bypass Mode ----------------------------- 1–32

Installation Complete ----------------------------------------------- 1–33

Multiple Unit Configuration ------------------------------------------------- 1–34

DC Connections for Multiple Unit Configuration -------------------------------- 1–36

Configuring the System for Multiple Unit Operation ----------------------------- 1–37

Search Mode Operation in Multiple Unit Configuration --------------------------- 1–38

Wiring Schematic ----------------------------------------------------- 1–38

Battery Information ------------------------------------------------------- 1–39

Battery Bank Sizing --------------------------------------------------- 1–39

Estimating Battery Requirements ------------------------------------------ 1–40

Calculating Battery Size --------------------------------------------- 1–40

Battery Banks ----------------------------------------------------- 1–41

Battery Bank Sizing Worksheet ---------------------------------------- 1–41

Restrictions on Motor Size ----------------------------------------------- 1–42

Battery Cabling and Hook-up Configurations --------------------------------- 1–43

Battery Parallel Connection ------------------------------------------- 1–43

Battery Series Connection -------------------------------------------- 1–44

Battery Series-Parallel Connections ------------------------------------- 1–44

2 Specifications

Inverter Specifications ----------------------------------------------------- 2–2

Charger Specifications ----------------------------------------------------- 2–3

AC Transfer Specifications -------------------------------------------------- 2–4

Physical Specifications ----------------------------------------------------- 2–5

Environmental Specifications ------------------------------------------------ 2–5

Regulatory-------------------------------------------------------------- 2–6

3 Wiring Diagrams

Single-Inverter System (Off-Grid/Power Backup)----------------------------------- 3–3

Single-Inverter System Renewable Energy (Solar)---------------------------------- 3–5

xii 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 15

Figures

Figure 1-1 Materials List------------------------------------------------------1–2

Figure 1-2 Conext SW Front and Side Panels---------------------------------------1–3

Figure 1-3 Front Panel Buttons and Status LEDs ------------------------------------1–4

Figure 1-4 AC and DC Terminals, Network and Communication Ports Panel-----------------1–5

Figure 1-5 Supplied Accessories -----------------------------------------------1–6

Figure 1-6 DC Switchgear ----------------------------------------------------1–7

Figure 1-7 Xanbus System Diagram Example -------------------------------------- 1–9

Figure 1-8 AC, DC, and Network Components ------------------------------------- 1–12

Figure 1-9 AC, DC, and Network Components ------------------------------------- 1–13

Figure 1-10 Conext SW Mounting Instructions --------------------------------------1–21

Figure 1-11 Conext SW AC INPUT and OUTPUT Connections--------------------------- 1–24

Figure 1-12 Installing the DC Switchgear------------------------------------------1–26

Figure 1-13 Conext SW DC Connections ------------------------------------------1–28

Figure 1-14 Conext SW BTS and Xanbus Connections -------------------------------- 1–30

Figure 1-15 Conext SW Front Panel---------------------------------------------- 1–32

Figure 1-16 Multiple (Dual) Unit Configuration Using Two Conext SW Units ----------------- 1–35

Figure 1-17 Connecting Battery Cables-------------------------------------------1–36

Figure 1-18 Multi Menu Screen ------------------------------------------------- 1–37

Figure 1-19 Batteries Connected in Parallel ----------------------------------------1–43

Figure 1-20 Batteries Connected in Series-----------------------------------------1–44

Figure 1-21 Batteries in Series-Parallel Connections----------------------------------1–44

Figure 2-1 Output Power versus Temperature Derating Graph --------------------------2–5

Figure 3-1 Single-Inverter System (Off-Grid/Backup) Overview --------------------------3–3

Figure 3-2 Single-Inverter System (Off-Grid/Backup) Wiring ----------------------------3–4

Figure 3-3 Single-Inverter System Renewable Energy (Solar) Overview --------------------3–5

Figure 3-4 Single-Inverter System Renewable Energy (Solar) Wiring ----------------------3–6

975-0639-01-01 Rev F xiii

This guide for use by qualified personnel only

Page 16

xiv

Page 17

Tables

Table 1-1 AC Wire Size In and Out of the Inverter/Charger---------------------------- 1–14

Table 1-2 Recommended Battery Cable Sizes ------------------------------------ 1–15

Table 1-3 Recommended Fuse and Breaker Sizes --------------------------------- 1–15

Table 1-4 Battery Sizing Example --------------------------------------------- 1–41

Table 1-5 Battery Sizing Worksheet -------------------------------------------- 1–42

975-0639-01-01 Rev F xv

This guide for use by qualified personnel only

Page 18

xvi

Page 19

1 Installation

The following topics will be covered in this

chapter.

• Materials List

• Installation Information

• Xanbus Network System

• Installation Planning

• Inverter/Charger Installation

• Multiple Unit Configuration

• Battery Information

• Wiring Diagrams

975-0639-01-01 Rev F 1–1

This guide for use by qualified personnel only

Page 20

Installation

Materials List

The Conext SW ships with the following items:

• One Conext SW unit

• One set of owner’s and installation guides

• One Battery Temperature Sensor (BTS)

• Two Xanbus network terminators

• Two sets of 5/16

• Two DC terminal covers (red and black) with two sets of #6-32 screws

• One Installation bracket with one set of M6 nuts for mounting (not shown)

NOTE: If any of the items are missing, contact your dealer and/or sales

representative. For code-compliant installations in Canada and USA, the DC

Switchgear accessory is required. See “Conext SW DC Switchgear*” on

page 1–10.

"-8

nuts and washers for the DC terminals,

Figure 1-1 Materials List

1–2 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 21

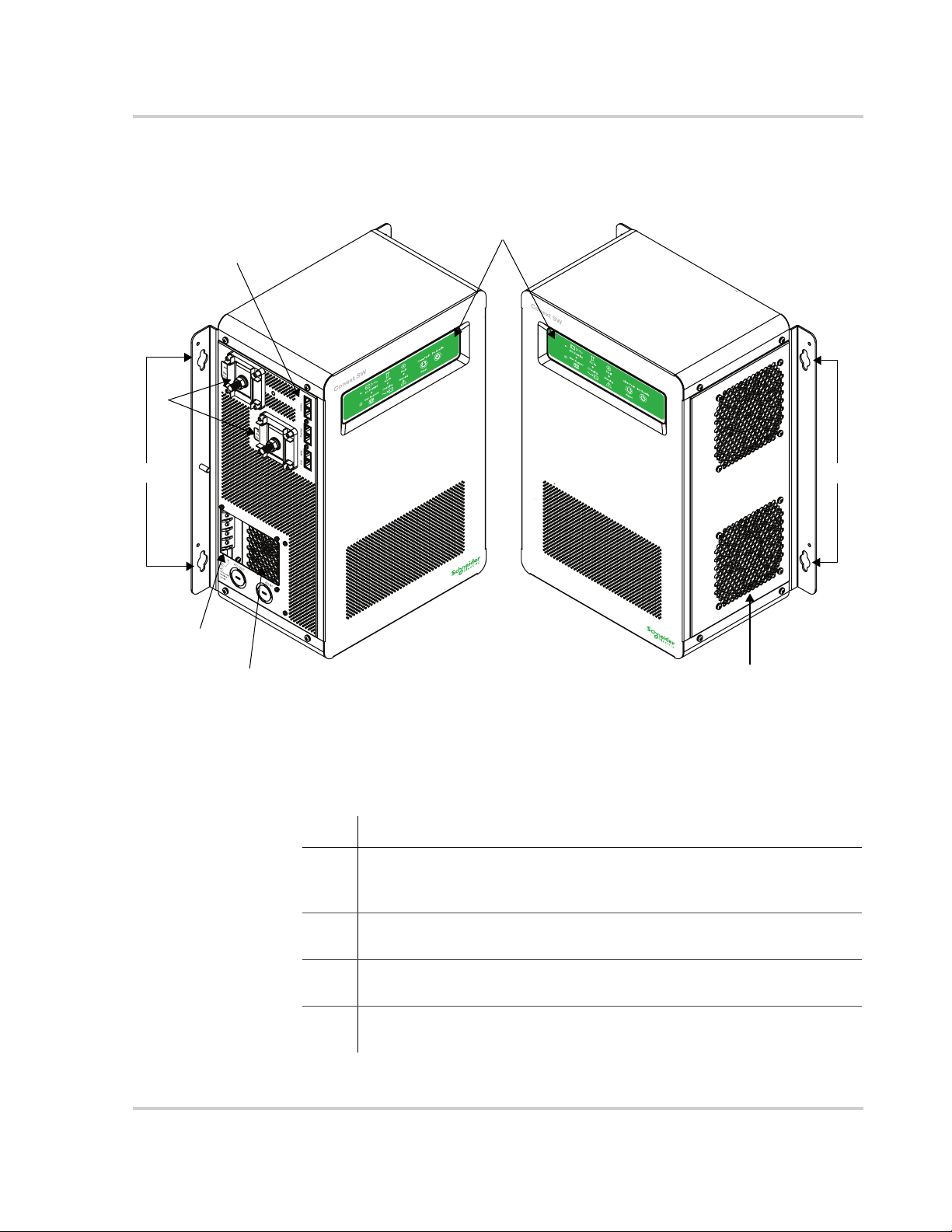

Conext SW Front and Side Panels

2

TOP TOP

3

Materials List

1

77

4

5

Figure 1-2 Conext SW Front and Side Panels

Before you begin to operate the Conext SW after installation, review the front

panel features shown in Figure 1-3 and described in the next table. A detailed

view of the lights and buttons on the front panel is also shown.

Item Description

1 Front Panel contains the Inv Enable and Clear Fault | Reset buttons, as

well as various LEDs (status indicator lights). See “Front Panel Buttons

and Status LEDs” on page 1–4.

2 Network and communications ports. See “AC and DC Terminals,

Network and Communication Ports Panel” on page 1–5.

3 DC battery terminals. See “AC and DC Terminals, Network and

Communication Ports Panel” on page 1–5.

4 AC Ground terminals. See “AC and DC Terminals, Network and

Communication Ports Panel” on page 1–5.

6

975-0639-01-01 Rev F 1–3

This guide for use by qualified personnel only

Page 22

Installation

Item Description

5 AC line terminals. See “AC and DC Terminals, Network and

Communication Ports Panel” on page 1–5.

6 Two variable-speed cooling fans maintain a cool internal temperature

of critical components. The two fans control airflow through the

transformer and power compartments of the unit. Ensure at least

10" (254 mm) of clearance for proper ventilation.

7 Mounting holes for permanent installation. See “Step 2: Mounting the

Inverter/Charger” on page 1–20.

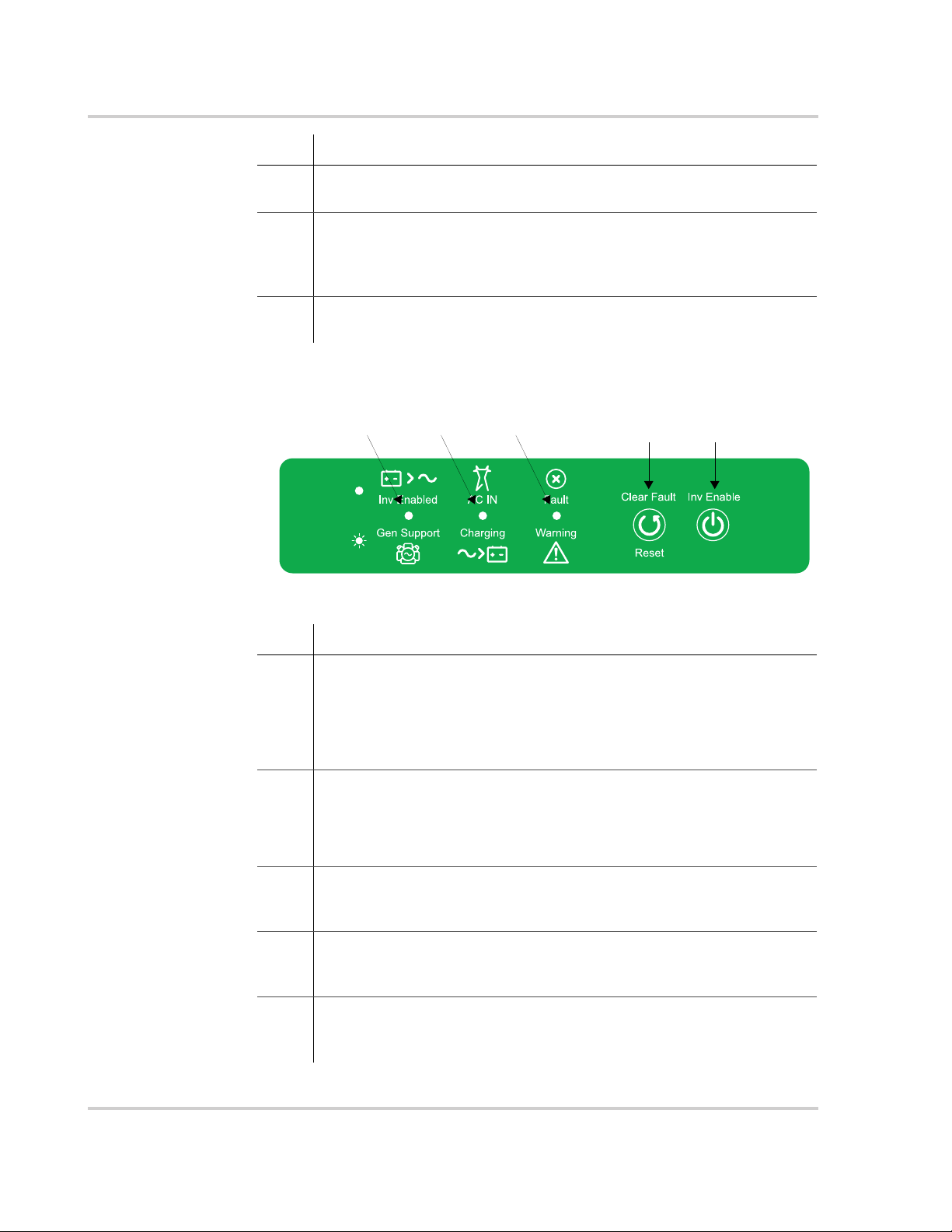

Front Panel Buttons and Status LEDs

54321

Figure 1-3 Front Panel Buttons and Status LEDs

Item Description

1 The Inv Enabled LED illuminates steadily when invert mode is enabled.

If AC is present and invert mode is enabled, this LED remains

illuminated even though AC power is being passed through.

Gen Support LED flashes intermittently when the inverter is in AC

support mode and load shaving mode.

2 When AC is present and qualified, the AC IN LED will illuminate steadily

indicating also that AC is passing through.

Charging LED flashes intermittently when the Conext SW is in charge

mode and is producing DC output to charge your batteries.

3 Fault | Warning LED illuminates steadily if a fault is detected (a fault

detection condition) and flashes intermittently when a warning

condition is active.

4 Clear Fault | Reset button is used to clear any detected faults if

pressed momentarily. If held down for more than three seconds, the

unit will reset (reboot) itself.

5 Inv Enable button is used to enable and disable inverter mode.

“Enabled” is different from the inverter being “on”. When enabled, the

inverter can be on or off. When disabled, the inverter is always off.

1–4 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 23

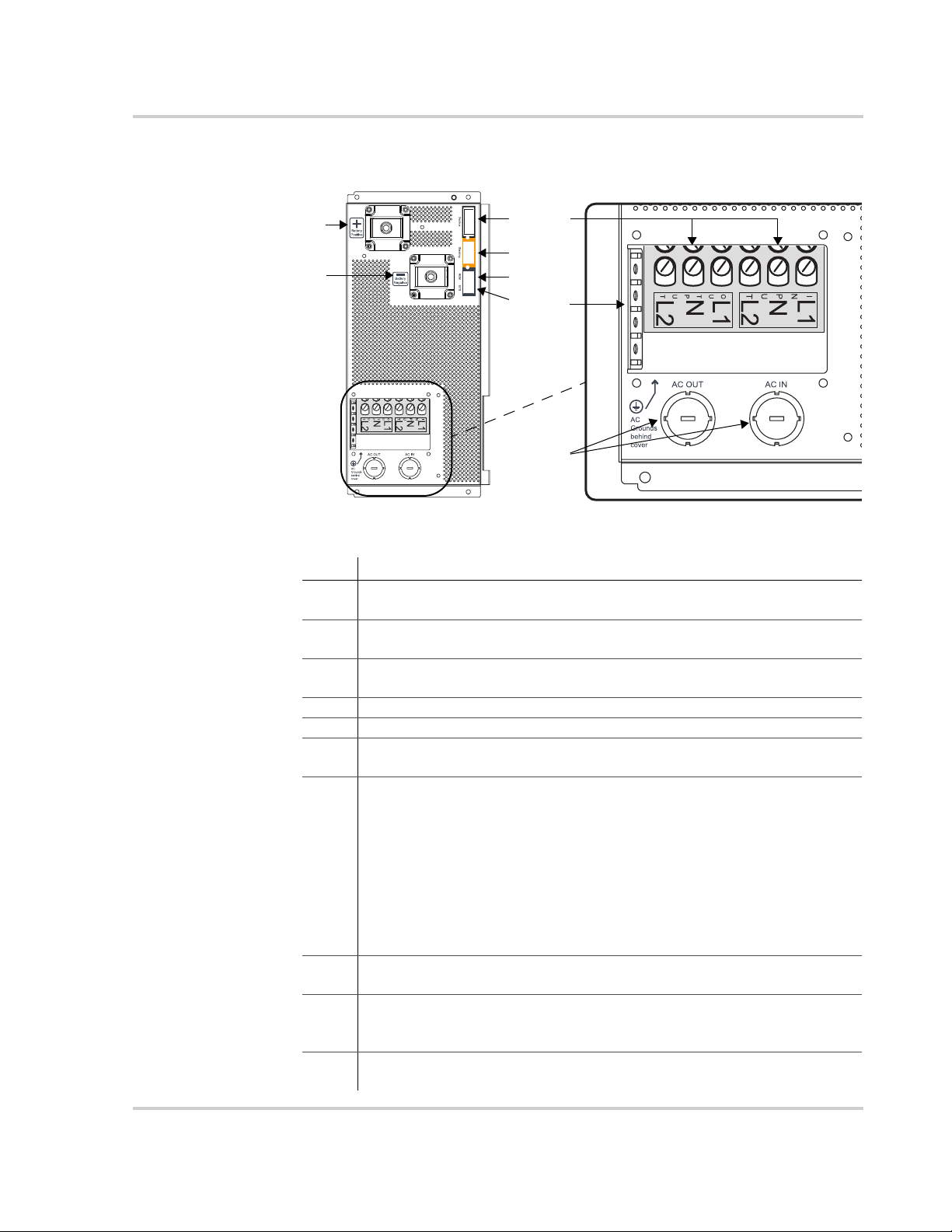

Conext SW AC/DC/Ports Side Panel

1

2

Figure 1-4 AC and DC Terminals, Network and Communication Ports Panel

Materials List

7

3

4

5

6

8

9

ab

Item Description

1 Battery Positive (+) (red) DC terminal connects to the positive bus bar

of the DC Switchgear.

2 Battery Negative (–) (black) DC terminal connects to the negative bus

bar of the DC Switchgear.

3 XANBUS interface ports are used to connect Xanbus-enabled devices

including the optional SCP and AGS.

4 STACKING port. Feature not available in this model.

5 Remote (REM) port provides connection for the on/off remote switch.

6 Battery temperature sensor (BTS) port provides connection for the

battery temperature sensor (supplied).

7 AC input/output lines wiring compartment access panel without the

compartment cover.

(a) AC Input terminal block is a screw-type terminal block for attaching

AC input wires. The terminals are labeled INPUT N for Neutral and

INPUT L1 and L2 for split-phase lines 1 and 2 respectively.

(b) AC Output terminal block is a screw-type terminal block for

attaching AC output wires. The terminals are labeled OUTPUT N for

Neutral and OUTPUT L1 and L2 for split-phase lines 1 and 2

respectively.

8 All Ground terminals are along the tab (as shown) of the AC wiring

compartment access panel opening.

9 AC knockouts (3/4" and 1") provide access for AC cables (both input

and output wiring). Detach the knockout covers and install strain-relief

clamps available in hardware and electrical stores.

Not

shown

AC wiring compartment cover that is taken out during wiring and put

back in when wiring has been completed.

975-0639-01-01 Rev F 1–5

This guide for use by qualified personnel only

Page 24

Installation

Conext SW Supplied Accessories

Figure 1-5 Supplied Accessories

NOTE: If any of the supplied accessories are missing, contact customer service

for replacement. See “Contact Information solar.schneider-electric.com” on

page ii.

1

2

3

Item Description

1 BTS, the Battery Temperature Sensor consists of:

• Connector that plugs into the BTS port on the Conext SW.

• Sensor cable is 25 feet (7.6 meters).

• Sensor can be mounted on the side of the battery case or on

the negative battery terminal.

NOTE: The BTS continuously measures the temperature of the battery

and adjusts the charger output for a more accurate, temperaturecompensated charge.

2 Two sets of M6 nuts and washers are used to secure the DC

Switchgear’s bus bars to the DC battery terminals.

3 Two Xanbus network terminators are used to properly terminate each of

the two ends of the daisy-chained Xanbus network. For example, if the

SCP is connected to the inverter/charger, one terminator will be

plugged to the SCP, one network cable will connect both devices, and

one terminator will be plugged to the inverter/charger.

IMPORTANT: The SCP may perform erratically if the Xanbus network is

not properly terminated.

4 Two DC terminal covers (not shown) - not needed for installation with

the DC Switchgear which is required in Canada and the USA.

5 Installation bracket (not shown)

1–6 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 25

Conext SW Required Accessory

Figure 1-6 DC Switchgear

NOTE: The DC Switchgear is required by electrical code to be installed with the

Conext SW inverter/charger in installations within Canada and the USA.

Materials List

975-0639-01-01 Rev F 1–7

This guide for use by qualified personnel only

Page 26

Installation

Installation Information

Before You Begin the Installation

Before beginning your installation:

• Read the entire Installation Guide so you can plan the installation from

beginning to end.

• Assemble all the tools and materials you require for the installation.

• Review the Important Safety Instructions on page v.

• Be aware of all safety and electrical codes which must be met.

ELECTRICAL SHOCK AND FIRE HAZARD

• All wiring must be done by qualified personnel to ensure compliance with

all applicable installation codes and regulations.

• Disconnect and lockout all AC and DC power sources.

• Disable and secure all AC and DC disconnect devices and automatic

generator starting devices.

Failure to follow these instructions will result in death or serious injury.

DANGER

Installation Codes

Applicable installation codes vary depending on the specific location and

application of the installation. Some examples are:

Applicable installation codes vary depending on the specific location and

application of the installation. Some examples are:

• National Electrical Code (NFPA 70)

• Canadian Electrical Code (CSA C22.1)

1–8 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 27

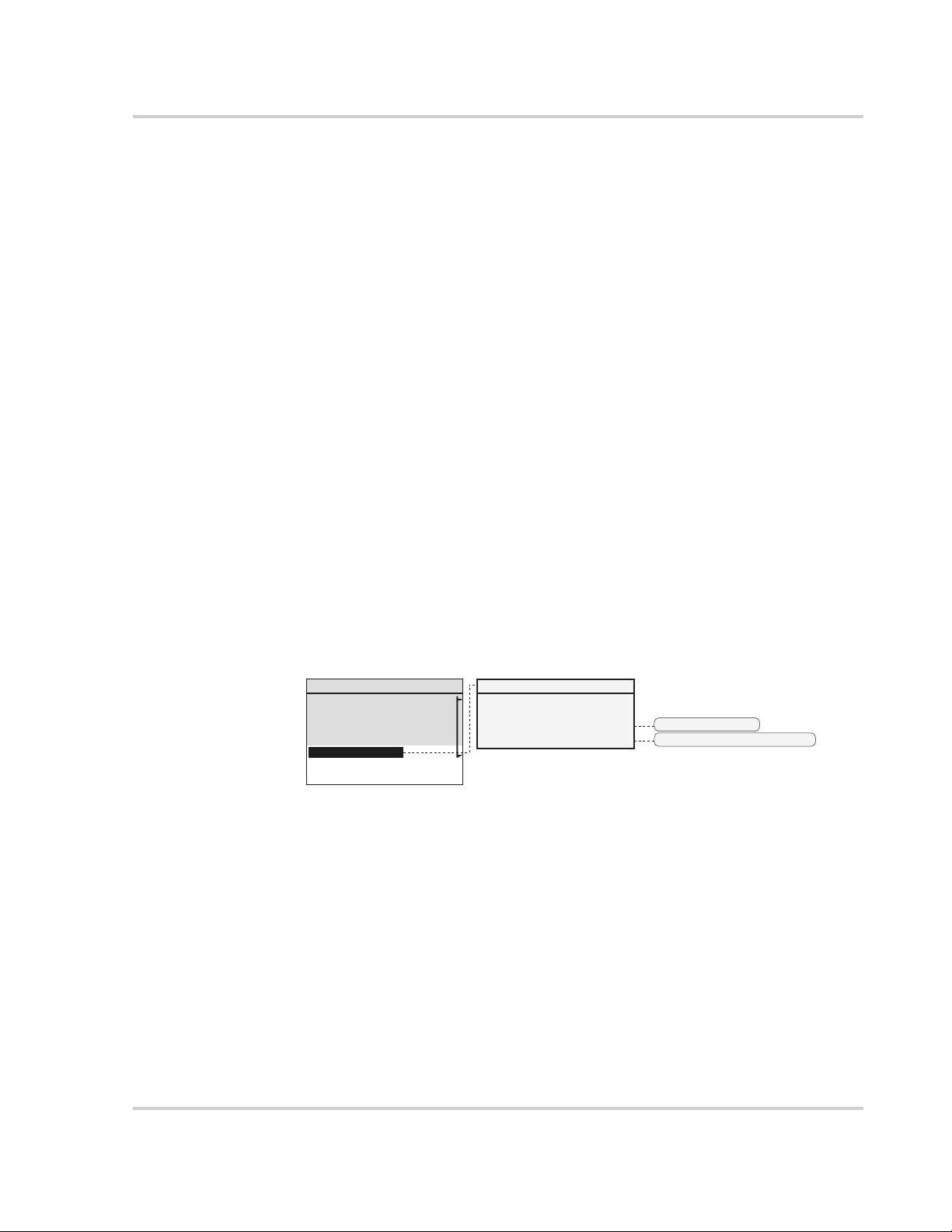

Xanbus Network System

Xanbus System

The Xanbus system includes the Conext SW and other Xanbus-enabled devices.

The Conext SW is the device in a Xanbus system that typically provides network

power—500 mA at 12 VDC. All of the Xanbus-enabled devices, such as the

Conext SW, the SCP, and the AGS are able to communicate their settings and

activity to each other.

Xanbus Network System

Xanbus Network ________

Solar

Charge

Controller

SCP

Xanbus System Control Panel

network terminator

Xanbus Automatic Generator Start

AGS

Conext

ComBox

Conext SW

network terminator

Figure 1-7 Xanbus System Diagram Example

The Xanbus-enabled designation (see below) means that this product works on a

Xanbus network. Xanbus-enabled products are:

• Simple to operate and routine tasks are automated.

• Controlled by software that eliminates analog signalling errors.

• Less susceptible to interference and line loss.

• Upgradable through new software releases.

NOTICE

EQUIPMENT DAMAGE

Do not remove Xanbus cables during system operation.

Failure to follow these instructions can damage connected equipment.

975-0639-01-01 Rev F 1–9

This guide for use by qualified personnel only

Page 28

Installation

Xanbus-enabled Products and Other Accessories

5

6

3

Product/Accessory (Shown above) Product Number/s

1 Conext SW DC Switchgear* 865-1016*

2 Conext SW AC Switchgear 865-1017

3 MPPT 60 150 Solar Charge Controller 865-1030-1

MPPT 80 600 Solar Charge Controller (not shown) 865-1032

4 Conext SW On/Off Remote Switch (not shown) 865-1052

5 System Control Panel (SCP) 865-1050

6 Conext ComBox 865-1058

7 Automatic Generator Start (AGS) 865-1060

8 Conext Battery Monitor 865-1080-01

9 Battery Temperature Sensor (BTS) 808-0232-02

10 3-ft network cable (0.9 m) 809-0935

25-ft network cable (7.6 m) 809-0940

75-ft network cable (22.9 m) 809-0942

* required accessory for code-compliant installation in Canada and USA.

1

2

7

8

9

10

25-ft cable 75-ft cable3-ft cable

1–10 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 29

Installation Planning

Planning Preparations

This section provides information to help plan for a basic installation of the

Conext SW. There are two key factors that will have a major impact on system

performance.

1. Size and Length of DC Cables

To select the appropriate size and length of DC cables, see “DC Cabling” on

page 1–14.

The DC cables should be as short as possible and large enough to handle the

required current, in accordance with the electrical codes or regulations

applicable to your installation. If there are long battery cables which are in

excess of 3 meters each and not of sufficient size, the voltage drop across the

cables will have a negative impact on overall system performance.

2. Mounting Location of the Conext SW

See “Step 1: Choosing a Location for the Inverter/Charger” on page 1–19.

Installation Planning

Components of the Inverter Power System

Inverter power systems vary depending on the power requirements of the user

and where the user is located. Inverter power systems typically involve one AC

source, one DC source, one inverter/charger, and a control and monitoring

device.

One example is an off the grid house with an AC generator, a battery, and a

Conext SW inverter/charger with a System Control Panel (SCP). Another example

is a house in the city, that is connected to the power grid but needs a power

backup solution to cope with rolling blackouts during summer. Some power

systems involve harvesting renewable energy such as solar energy in

conjunction with off-grid or power backup solutions.

Before installing a Conext SW inverter/charger, know your power requirements

then divide the components of the power system into AC, DC, and Xanbus

network devices. Xanbus network devices control and monitor the Conext SW

inverter/charger as well as AC generators and solar panels.

975-0639-01-01 Rev F 1–11

This guide for use by qualified personnel only

Page 30

Installation

AC, DC, and Network Components

The illustration below shows the different components that can go into a Conext

SW inverter/charger installation.

/

DC Sources

AC Loads

Inverter panel

Figure 1-8 AC, DC, and Network Components

AC Generator for

off-grid applications

Xanbus Network

Devices

AC Sources

Grid for power backup

applications

1–12 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 31

The illustration below shows which components you may need before you begin

your installation.

DC Components Xanbus Network Components

•

24- or 48-volt battery

Component -Batteries” on page 1–14.

• DC-rated fuse and/or circuit breaker,

see “DC Disconnects and Overcurrent

Devices” on page 1–15.

• Conext SW DC Switchgear (required

component in Canada and USA)

• Battery Temperature Sensor

(BTS, supplied)

• DC cables, see “DC

Cabling” on page 1–14.

• solar panel for renewable

energy application

or batteries, see “DC

• System Control Panel (SCP)

• Automatic Generator Start (AGS)

• Battery Monitor

• Solar charge controller

• Conext ComBox

• CAT-5 network cables

• Xanbus network terminators

(supplied)

Installation Planning

120/240-volt split-phase, 60 Hz

AC Loads (AC OUTPUT)

• Inverter electrical

distribution panel

• AC-rated 30-amp circuit

breakers to provide overcurrent

protection and means of disconnect

• Conext SW AC Switchgear

(recommended)

• AC cable (4-wire) and connectors, see

“AC Wiring” on page 1–13.

Figure 1-9 AC, DC, and Network Components

AC Wiring Definition AC wiring includes input wiring (all the wires and connectors

between the main AC source panel and the inverter/charger AC INPUT) and

output wiring (all the wires between the inverter/charger AC OUTPUT and the AC

load panels, circuit breakers, and loads).

protection and means of disconnect

• Transfer switch (between two AC

sources, if applicable)

• Conext SW AC Switchgear

(recommended)

• AC cable (4-wire) and connectors, see

“AC Wiring” on page 1–13.

120/240-volt split-phase, 60 Hz

AC Source (AC INPUT)

• Main electrical distribution

panel (grid and/or generator)

• AC-rated 30-amp circuit

breakers to provide overcurrent

Type The type of wiring required varies according to the electrical codes or

regulations applicable to your installation. Wiring may be solid in multi-conductor

cables, but stranded wire is required if single conductors are used. All wiring

must be rated 90 °C or higher.

975-0639-01-01 Rev F 1–13

This guide for use by qualified personnel only

Page 32

Installation

Size of AC Input Wiring Wire size must be coordinated with the overcurrent

protection provided ahead of the wire involved, in accordance with the electrical

codes or regulations applicable to your installation.

Therefore, the wiring used between the main AC source panel’s circuit breaker

and the inverter/charger AC INPUT must be sized to match the input breaker

rating.

Table 1-1 AC Wire Size In and Out of the Inverter/Charger

Conext SW

Breaker Size Used 30 amps per line

Wire Size No. 8 AWG

Color Coding L1/L2: red or black

N: white or gray

: green or bare

Size of AC Output Wiring Wire size must be coordinated with the current the

wiring will carry. For example, this current may be determined by the 15-amp

maximum inverter current, or by the bypass current, which is determined by the

overcurrent protection provided ahead of the Conext SW 4024 120/240.

Size of Wiring Downstream of the AC Output Breaker The wiring used

between the AC output breaker and your loads must be sized to match the

output breaker.

DC Component Batteries

DC Cabling Definition DC cabling and connectors between the batteries, the DC

The Conext SW system requires a 24-volt or 48-volt, lead-acid deep-cycle

battery or group of batteries to provide the DC current that the inverter/charger

converts to AC power. The battery may be a flooded, gel, or AGM type.

See “Battery Information” on page 1–39 for information on:

• Estimating the battery size that will meet your requirements.

• Designing battery banks.

• Restrictions on the size of appliances.

For information on cabling and hooking up batteries, see “Battery Cabling and

Hook-up Configurations” on page 1–43.

For detailed information about specific brands of batteries, consult individual

battery manufacturers or a local battery distributor.

disconnect and overcurrent protection device, and the inverter/charger.

Type All installations require multi-strand insulated cables. The DC cables must

be copper and must be sized based on 75 °C ampacity and must have an

insulation rating of at least 75 °C.

Size and Length See Table 1-2 for required DC cable length, cable size and

required fuse size for the Conext SW. Wire size is usually marked on the cables.

1–14 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 33

Installation Planning

Table 1-2 Recommended Battery Cable Sizes

Model Maximum

Current (A)

a

Conduit

b

Cable Length

<5ft

Cable Length

5to10ft

SW 2524 120/240 120 1 AWG

SW 4024 120/240 200 3/0 AWG

SW 4048 120/240 120 1 AWG

a.From National Electrical Code (NEC) requirements.

b.Per NEC Table 310.16 for 177 °F (75 °C) rated copper conductor.

IMPORTANT: Using a smaller gauge cable or a longer cable may cause the

inverter to shut down under heavy load.

WARNING

FIRE AND BURN HAZARD

Do not use battery cables that are insufficiently sized for expected current.

Check local electrical codes carefully.

Failure to follow this instruction can result in death or serious injury.

DC Disconnects

and Overcurrent

Devices

Conext SW DC

Switchgear

The DC circuit from the battery to the inverter/charger must be equipped with a

disconnect and overcurrent protection device. Refer to your applicable

installation code.

TypeThis device usually consists of a circuit breaker, a “fused-disconnect,” or a

separate fuse (installed at each positive cable near the battery terminal) and DC

disconnect. Do not confuse AC circuit breakers with DC circuit breakers. They

are not interchangeable.

RatingThe rating of the fuse or breaker must be matched to the size of cables

used in accordance with the applicable installation codes.

LocationThe breaker or fuse and disconnect should be located as close as

possible to the battery in the positive cable. Applicable codes may limit how far

the protection can be from the battery.

Table 1-3 Recommended Fuse and Breaker Sizes

Model Fuse Size (A) Minimum Breaker Size (A)

SW 2524 120/240 250 250

SW 4024 120/240 250 250

SW 4048 120/240 250 250

The DC Switchgear (part number: 865-1016) provides complete DC disconnect

and overcurrent protection for the Conext SW Inverter/Charger. The Conext DC

Switchgear contains a master DC breaker that stops DC power from the main DC

source. The DC Switchgear must be installed with the Conext SW Inverter/

Charger in Canada and USA.

975-0639-01-01 Rev F 1–15

This guide for use by qualified personnel only

Page 34

Installation

Unpacking and Inspecting the Conext SW Inverter/Charger

CAUTION

HEAVY LOAD HAZARD

Do not lift the unit by yourself. Use two people to lift and mount the unit. Always

use proper lifting techniques during installation to prevent injury.

Failure the follow these instructions can result in injury.

To unpack and inspect:

IMPORTANT: Keep the carton and packing material in case you need to return

the Conext SW for servicing.

1. Unpack the unit and check the materials list. If anything is missing from the

shipping box, contact your local Schneider Electric customer service

representative. See page ii for information.

2. Record the serial number of the Conext SW and other purchase information

in the beginning section under Information About Your System of the Conext

SW Inverter/Charger Owner’s Guide.

3. Save your purchase receipt to use as proof of purchase. This receipt is

required if the inverter/charger requires warranty service.

4. Save the original shipping carton and packing materials. If the inverter/

charger needs to be returned for service, it should be shipped in the original

carton. Packing the Conext SW in the original shipping carton is also a good

way to protect the inverter/charger if it ever needs to be moved.

1–16 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 35

Installation Tools and Materials

Tools

You will need the following tools to install the Conext SW and the battery

temperature sensor.

❐ Wire stripper

❐ Crimping tools for fastening lugs and terminals on DC cables

❐ Phillips screwdriver: #2

❐ Slot screwdriver (1/4" [6mm] wide blade max.)

❐ Needle-nose pliers

❐ Wrench for DC terminals and Installation bracket: 5/16" and M6

❐ Power drill/driver

Materials

You will need the following materials to complete your installation:

❐ DC Switchgear

❐ Strain-relief clamp(s) for AC cables (not provided): 3/4" and/or 1"

❐ DC battery cables sized according to Table 1-2 on page 1–15

❐ Terminals and/or crimp connectors for DC cables (3/8" [9.5mm] stud size)

❐ AC and DC disconnect switches and overcurrent protective devices and

connectors as required. See page 1–14

❐ AC output and input wire. See “AC Wiring” on page 1–13

❐ If the AC ground wire is stranded, each ground wire requires a ring terminal

❐ Four M6 nuts to secure the unit to the installation bracket (supplied)

❐ Four #12 (or equivalent) screws or bolts to mount the installation bracket to a

non-flammable wall (see page 1–19 for definition)

❐ Four #10 (or equivalent) screws for securing the DC Switchgear to the

installation bracket

Installation Planning

975-0639-01-01 Rev F 1–17

This guide for use by qualified personnel only

Page 36

Installation

Inverter/Charger Installation

Overview

This section provides detailed information on installing the Conext SW. The

overall procedure is divided into seven steps:

Step 1: Choosing a Location for the Inverter/Charger on page 1–19

Step 2: Mounting the Inverter/Charger on page 1–20

Step 3: Connecting the AC Input and AC Output Wires on page 1–22

Step 4: Installing the DC Switchgear and Connecting the DC Cables on page 1–25

Step 5: Connecting the BTS and Xanbus-enabled Components on page 1–29

Step 6: Performing Checks Prior to Initial Start-Up on page 1–31

Step 7: Testing Your Installation on page 1–31

1–18 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 37

Step 1: Choosing a Location for the Inverter/Charger

WARNING

FIRE HAZARD

For indoor use only.

• Do not install and/or operate in compartments containing flammable

materials or in locations that require ignition-protected equipment.

• Do not cover or obstruct the ventilation openings.

• Do not install this unit in a compartment with limited airflow.

• Do not install where access to disconnecting means is obstructed.

Failure to follow these instructions can result in death or serious injury.

\

Flammable or combustible materials are defined as “any material containing

wood, compressed paper, cellulose, plant fibers, plastics, liquids, or other

material that will ignite and burn, whether flame-proofed or not” according to the

NFPA. Flammable liquids are defined as “any liquid whose flash point does not

exceed 100 °F (38 °C).” Examples of flammable liquids are gasoline, methanol,

and ether.

Inverter/Charger Installation

When choosing a wall to install the Conext SW, choose a wall that is not

considered a flammable material such as concrete, brick, or metal.

The inverter should only be installed in a location that meets the following

requirements:

Dry Do not allow water or other fluids to drip or splash on the

inverter/charger. Do not expose to rain, snow or water.

Cool Normal ambient air temperature should be between

32 °F and 77 °F (0 °C and 25 °C).

Close to battery

but not in the

same

compartment

Clearance Allow as much space around the inverter/charger as

The length and size of your DC cables will affect

performance. Use the DC cables recommended in

Table 1-2 on page 1–15. The unit should not be installed

in the battery compartment due to the possible presence

of explosive hydrogen gas from the batteries.

possible. It is recommended that other objects and

surfaces be at least 10" (254 mm) away from the

ventilation openings for best performance.

975-0639-01-01 Rev F 1–19

This guide for use by qualified personnel only

Page 38

Installation

Step 2: Mounting the Inverter/Charger

HEAVY LOAD HAZARD

• Do not lift the unit by yourself. Use two people to lift and mount the unit.

Always use proper lifting techniques during installation to prevent injury.

• Do not install in drywall using drywall anchors.

Failure the follow these instructions can result in injury.

IMPORTANT: Mount the inverter/charger before connecting any wires or cables.

CAUTION

1–20 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 39

Inverter/Charger Installation

NOTE: These mounting instructions are general guidelines and are provided here for information purposes only.

You must install with care and heed precautions and warnings as stated beginning in “Step 1: Choosing a

Location for the Inverter/Charger” on page 1–19 and all subsequent steps.

(1) Place the

installation bracket flat

on non-flammable wall

(see page 1–19 for

definition) and mark

the positions of the

5 7/8 in.

mounting holes on the

wall.

(2)

149.0 mm

(2) Pilot drill the four

mounting holes on the

wall. Install the

appropriate anchors.

(3) Fasten the

installation bracket to

the mounting surface

with four #12 (or

equivalent) screws (or

bolts).

(4) With two people,

hang the Conext SW to

the installation bracket

carefully aligning the

Conext SW’s mounting

holes to the threaded

bolts on the installation

bracket.

(5) Secure the Conext

SW to the installation

bracket using the

supplied M6 nuts.

Figure 1-10 Conext SW Mounting Instructions

TIP: Use these

mounting holes.

975-0639-01-01 Rev F 1–21

This guide for use by qualified personnel only

Page 40

Installation

Step 3: Connecting the AC Input and AC Output Wires

DANGER

ELECTRICAL SHOCK AND FIRE HAZARD

Make sure wiring being connected to the inverter/charger is disconnected

(physically or by opening and locking out the breaker) from all electrical

sources before handling. All wiring must be done in accordance with local and

national electrical wiring codes.

Failure to follow these instructions will result in death or serious injury.

General AC Wiring Considerations

AC and DC Wiring Separation Do not mix AC and DC wiring in the same

conduit or panel. Consult the applicable installation code for details.

AC Knockouts There are two dual 3/4" /1" trade-size knockouts on the side

panel and another two on the bottom panel for AC wiring. Use the same trade

size of strain relief as the trade size of the knockout(s) you are using.

AC Wiring Terminals The AC wiring terminals accept cables of a specific size.

See “AC Wiring” on page 1–13 for required sizes.

NOTICE

EQUIPMENT DAMAGE

Do not mix input and output wires. The terminal block is split into INPUT and

OUTPUT sections. Damage may occur if the unit is wired incorrectly.

Failure to follow these instructions can damage the inverter/charger.

WARNING

ELECTRICAL SHOCK AND FIRE HAZARD

Turn off all electrical sources (by opening and locking out main and inverter

panel breakers) before connecting wires to and from the inverter/charger. All

wiring must be done in accordance with local and national electrical wiring

codes.

Failure to follow these instructions can result in death or serious injury.

1–22 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 41

AC System Bonding

MULTIPLE AC NEUTRAL-TO-GROUND BONDS

Verify that only one neutral-to-ground bond exists in the system. Having more

than one neutral-to-ground bond in a system violates local electrical codes,

may create a shock or fire hazard, and may cause some sensitive equipment

to malfunction.

Failure to follow these instructions can result in death or serious injury.

System bonding refers to connection (bonding) of one of the current-carrying

conductors of an electrical system to ground. This creates a "grounded

conductor" or "neutral" that is at ground potential, but is separate from the

equipment ground conductor. System bonding must be done at only one

location. Procedures for system bonding vary between on-grid and off-grid

systems.

Inverter/Charger Installation

WARNING

System bonding for

on-grid systems

System bonding for

off-grid systems

The Conext SW does not connect the neutral to ground. The AC input neutral is

already bonded to ground by the incoming utility grid system. Do not connect the

neutral to ground in any additional location.

The Conext SW does not switch or disconnect the AC neutral in any mode of

operation, so even in invert (back-up) mode, the inverter load sub-panel neutral

is bonded to ground by the utility grid system. It must not be grounded again in

the inverter load sub-panel.

In a system without a generator, or with a generator that does not provide a

grounded neutral, you must make the connection from neutral to ground in the

inverter load sub-panel or main distribution panel, as applicable.

In a system with a generator that provides a grounded neutral, no additional

connection from neutral to ground is needed. Do not connect neutral to ground in

the inverter load sub-panel or main distribution panel, as applicable.

975-0639-01-01 Rev F 1–23

This guide for use by qualified personnel only

Page 42

Installation

(1) Make the wiring connections to the AC

source main panel.

(2) Route the AC cable to the inverter/

charger.

(3) Remove the wiring compartment cover

panel on the inverter/charger.

(4) Remove the AC knockouts from the side

or bottom (or both). Do not leave the

knockout inside the wiring compartment.

(5) Install strain-relief clamps in the AC

knockouts.

(6) Route the AC input cable through the AC

input knockouts and inside the wiring

compartment.

(7) Connect Lines1&2toL1 & L2, Neutral

to N, ground to on the AC input terminals.

If solid ground wire is being used, the wire

can be connected directly under the screw

heads. If stranded ground wire is being

used, ring terminals must be used.

(8) Tighten the terminal screws. Leave a

service loop in the wires inside the wiring

box.

(9) Route the AC output cable through the

AC output knockouts and inside the wiring

compartment.

(10) Connect Lines 1 & 2 to

L1 & L2, Neutral to N,

ground to on the AC

output terminals. If solid

ground wire is being used,

the wire can be connected

directly under the screw

heads. If stranded ground

wire is being used, ring

terminals must be used.

(3)

strip at least

1/2” (13mm)

side AC

knockouts

(4)

bottom AC

knockouts

strip at least

2” (50mm)

L1

N

L2

AC Cable

to Inverter

AC INPUT

(2)

(11) Tighten the terminal

(9)

screws. Leave a service

loop in the wires inside the

wiring box.

(12) Make the wiring

connections to the inverter

load panel.

(1)

AC Source

Main Panel

(13) Replace the wiring

Inverter Load Panel

compartment cover panel

on the inverter/charger.

Transfer switch

Figure 1-11 Conext SW AC INPUT and OUTPUT Connections

1–24 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 43

Inverter/Charger Installation

Step 4: Installing the DC Switchgear and Connecting the DC Cables

DC Connection Precautions

WARNING

BURN AND FIRE HAZARD

Connect and disconnect DC wiring only after opening and locking out the

disconnect switches or breakers at all AC and DC sources.

Failure to follow these instructions can result in death or serious injury.

Recommended

Cable Sizes and

Lengths and Fuse

Size

Preparing the

Cables

Guidelines for

Routing the DC

Cables

For recommended DC cables and fuse sizes, see Table 1-2 and Table 1-3 on

page 1–15.

Cut the negative and positive cables to the required length. Strip off enough

insulation so you can install the terminals you will be using.

Use of crimp connectors – The connector should have a 3/8" stud size to

connect to the Conext SW. If a crimp connector is used, it should be crimped

using the tool indicated by the connector manufacturer.

Attach the connectors to the ends of both cables. Make sure no stray wire

strands protrude from the connectors.

Follow these guidelines to ensure maximum performance.

WARNING

FIRE HAZARD

Route the cables away from sharp edges that can cut into or scrape the

insulation. Wires can become exposed. Avoid sharp bends in the cable.

Failure to follow these instructions can result in death or serious injury.

To reduce the chance of radio frequency interference, keep the positive and

negative cables close together—ideally, held together by straps, loom, or

insulated clamps at regular intervals.

975-0639-01-01 Rev F 1–25

This guide for use by qualified personnel only

Page 44

Installation

Installing the DC Switchgear next to Conext SW Inverter/Charger

T

WARNING

FIRE HAZARD

• Make sure the supplied nuts on the inverter/charger are tightened to a

torque of 10–11 ft-lbs (13.5–14.9 Nm). Torque all other connections to the

manufacturer’s specifications.

• Make sure the bus bar, washer, and nut are assembled in the order shown

in Figure 1-12 on page 1–26.

Failure to follow these instructions can result in death or serious injury.

(1) Unpack the DC Switchgear

from its box, if not already.

(2) Prepare four #10 (M5)

machine screws. Use two

screws to secure the DC

Switchgear to the installation

brackets of the Conext SW

and two screws to secure the

connecting bracket. The

connecting bracket attaches

to the Conext SW and DC

Switchgear.

(3) Remove the nuts and

washers from the inverter/

charger’s DC terminals, if

present.

(4) Position the DC Switchgear

next to the inverter/charger

carefully aligning the

mounting holes with the precut mounting holes on the

installation bracket and the

copper bus bar connectors

with the inverter/charger’s DC

terminals.

(5) Fasten the screws to the

mounting holes on the DC

Switchgear with the pre-cut

mounting holes on the

installation bracket of the

inverter/charger.

(6) Fasten the screws to the

connecting bracket to join the

DC Switchgear and the

Conext SW together.

(7) Fasten the nuts and

washers of the inverter/

charger’s DC terminal bolts to

secure the copper bus bars.

connecting

bracket

mounting hole

copper bus bar

connector

copper bus bar

connector (+)

copper bus bar

connector (–)

flat washer

nut

(5)

(5)

(6)

pre-cut

mounting hole

(7)

pre-cut

mounting hole

positive (+) DC

terminal (red)

negative (–) DC

terminal (black)

DC terminal

Figure 1-12 Installing the DC Switchgear

1–26 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 45

Connecting the DC Cables to the DC Switchgear

WARNING

FIRE HAZARD

• Use only appropriately sized copper cable. Loose connections, improper

connections, and under-rated cables will overheat.

• Make sure the supplied nuts on the inverter/charger are tightened to a

torque of 10–11 ft-lbs (13.5–14.9 Nm). Torque all other connections to the

manufacturer’s specifications.

• Make sure the DC cables, washers, and nuts are assembled in the order

shown in Terminal Connection in Figure 1-13 on page 1–28.

Failure to follow these instructions can result in death or serious injury.

REVERSE POLARITY DAMAGE

Check cable polarity at both the battery and the inverter/charger before

making the final DC connection or closing the DC breaker or disconnect.

Positive (+) must be connected to positive (+). Negative (–) must be

connected to negative (–).

Failure to follow these instructions can damage the inverter/charger.

Inverter/Charger Installation

NOTICE

975-0639-01-01 Rev F 1–27

This guide for use by qualified personnel only

Page 46

Installation

(1) Route the DC cables from the battery bank to the DC Switchgear.

(2) Install a DC fuse (a) on the positive cable near the battery terminal.

(3) Open the DC circuit breaker on the DC Switchgear.

(4) Connect one connector on the POSITIVE (+) cable to the POSITIVE terminal on the DC

Switchgear. The connector goes on first, then the flat washer (steel), then the 3/8”

(9.5mm) bolt (brass).

(5) Connect the other connector to the POSITIVE (+) terminal on the battery.

(6) Connect one connector on the NEGATIVE (–) cable to the BATTERY NEGATIVE

terminal on the DC Switchgear.

(7) Connect the other end of the cable to the NEGATIVE (–) terminal on the battery.

(6)

(4)

(2)(a)

Terminal Connection

(7)

(5)

Battery or Battery

Enclosure

Figure 1-13 Conext SW DC Connections

1–28 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 47

Inverter/Charger Installation

Step 5: Connecting the BTS and Xanbus-enabled Components

WARNING

ELECTRICAL SHOCK HAZARD

Connect and disconnect DC wiring only after opening and locking out the

disconnect switches or breakers at all AC and DC sources.

Failure to follow these instructions can result in death or serious injury.

Battery

Temperature

Sensor (BTS)

Xanbus-enabled

Components

Installing a BTS extends the life of a battery by preventing overcharging in warm

temperatures and undercharging in cold temperatures. With a BTS monitoring

the battery temperature, the voltage delivered to the battery is adjusted

according to the battery’s actual temperature.

The BTS has a self-adhesive backing and attaches to the side of the battery. The

BTS also comes with a metal tab. A 25-ft (7.6-m) cable is supplied with the BTS.

These include the SCP, the AGS, Conext ComBox, and a solar charge controller.

The order in which the components are connected to the inverter/charger does

not matter. The most important aspect of the installation of these components is

the attachment of network terminators at each end of the network.

NOTICE

EQUIPMENT DAMAGE

Do not remove Xanbus cables during system operation.

Failure to follow these instructions can damage connected equipment.

975-0639-01-01 Rev F 1–29

This guide for use by qualified personnel only

Page 48

Installation

WARNING

FIRE HAZARD

Follow the stacking of wires as shown in 1(a) of the illustration below.

Failure to follow these instructions can result in death or serious injury.

(1) Install the BTS sensor on the

battery.

Method

sensor to the negative battery post

which allows the internal battery

temperature to be sensed providing

the most accurate results.

Method

side of the battery using the selfadhesive backing which also

provides good results in most

situations.

(2) Plug the BTS connector to the BTS

port of the inverter/charger.

(a) involves mounting the

(b) attaches the sensor to the

(3) Connect the Xanbus-enabled devices

using the provided network cable. Terminate

each end of the network with a network

terminator

(c) and (d).

/

Battery

Positive

Battery

Negative

Xanbus Stacking REM BTS

(c)

(3)

(2)

(1)(a)

BTS

battery cable

battery terminal

Figure 1-14 Conext SW BTS and Xanbus Connections

(d)

(1)(b)

1–30 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 49

Step 6: Performing Checks Prior to Initial Start-Up

WARNING

ELECTRICAL SHOCK HAZARD

The Inv Enable button on the Conext SW front panel and the SCP do not

disconnect DC or AC input power to the Conext SW. Open and lockout the

disconnect switches or breakers at all AC and DC sources. Test with a

multimeter before tightening electrical connections.

Failure to follow these instructions can result in death or serious injury.

Before testing your installation, ensure these conditions are met.

❐ AC ground are properly installed.

❐ AC input connections and AC output connections are wired correctly on the

terminal block and not reversed.

❐ Positive (+) battery cable from the DC Switchgear is connected to the

positive (+) battery terminal through the DC fuse.

❐ Negative (–) battery cable from the DC Switchgear is connected to the

negative (–) battery terminal.

❐ Battery voltage is within the proper range for this unit: 20–34 volts DC for 24-

volt models and 42–66 VDC for the 48-volt model.

❐ DC disconnect switch or breaker is turned off.

❐ AC input and output breakers are turned off.

❐ All connections are tight.

Inverter/Charger Installation

Step 7: Testing Your Installation

WARNING

ELECTRICAL SHOCK HAZARD

The Inv Enable button on the Conext SW front panel and the SCP do not

disconnect DC or AC input power to the Conext SW. Isolate energy by turning

off and locking out all AC and DC circuit breakers and test with a multimeter

before checking or tightening electrical connections.

Failure to follow these instructions can result in death or serious injury.

There are several tests to be performed for testing your installation. These tests

will verify that:

• The Conext SW works in invert mode.

• The Conext SW works in charge mode.

• The Conext SW works in AC bypass mode.

975-0639-01-01 Rev F 1–31

This guide for use by qualified personnel only

Page 50

Installation

If the test fails at any point, go to “Step 6: Performing Checks Prior to Initial StartUp” on page 1–31 and go through the checklist again to check the installation.

Then perform the test again. If the test fails again, see the troubleshooting

section in the Conext SW Inverter/Charger Owner’s Guide.

Figure 1-15 Conext SW Front Panel

Testing in Invert Mode

To test the Conext SW in invert mode, using a 100 watt light bulb as the test

load:

1. Close the DC disconnect switch or the DC circuit breaker to supply DC

2. After initialization, observe that none of the lights on the front panel should

3. Press the Inv Enable button. Verify that the green Inv Enabled LED

4. Connect the Conext SW to the test load by closing the AC breaker that

5. Press the Inv Enable button to disable inverter mode. The Inv Enabled LED

power to the Conext SW.

Wait for the LEDs on the front panel to flash on and off, indicating that the unit

is successfully initializing (10 to 30 seconds). The LEDs will turn off after

initialization.

If none of the LEDs come on or flash intermittently, make sure the voltage at

the DC terminals on the Conext SW is correct, as described in “Step 6:

Performing Checks Prior to Initial Start-Up” on page 1–31.

remain illuminated.

illuminates.

controls the circuit that the test load is connected to.

If the light bulb illuminates, the Invert mode is working.

goes off.

Testing in Charge Mode and AC Bypass Mode

1. Start the AC generator, if off-grid. If grid-connected proceed to step #2.

2. Close the main breaker in the AC input panel (the AC input panel feeds

power from either the generator or grid) in order to supply AC power to the

unit.

Verifying charging: 3. After a few seconds, verify that the AC IN / Charging LED on the front panel is

turned on and that it starts flashing indicating that the batteries are being

charged.

Verifying AC

bypass:

1–32 975-0639-01-01 Rev F

4. Disable the AC source by opening the main breaker in the AC input panel

and turn off inverter mode by pressing the Inv Enable button.

5. Connect the test load to the AC output connection of the unit.

6. Enable the AC source by closing main breaker in the AC input panel and the

test load should turn on after ten seconds.

This guide for use by qualified personnel only

Page 51

Installation Complete

Your installation is now complete. The inverter/charger is ready for use.

The preceding tests use a light test load (a light bulb) as a test case. If you

encounter problems when using a load over 1000 watts (for example, a hair dryer

or microwave), see the troubleshooting information in the Conext SW Inverter/

Charger Owner’s Guide.

Inverter/Charger Installation

975-0639-01-01 Rev F 1–33

This guide for use by qualified personnel only

Page 52

Installation

Multiple Unit Configuration

The Conext SW inverter/chargers support multiple unit configuration to increase

power output. This gives the system engineer and/or installer more options to

work with when tailoring a system to meet load demands.

In a multiple unit configuration, only two Conext SW inverter/chargers of the same

model can be used. For example, two Conext SW 4024 120/240 units can be

configured because both units each have a 24-volt rating and a continuous

power rating of up to 3500 watts.

In this configuration, the inverter and charger capacity of a system is doubled. In

the case of two Conext SW 4024 120/240 units, the inverter power rating doubles

to 7000 watts and the charging output current doubles to 180 amps. However,

the AC transfer relay rating of 30-amps remains the same. Inverter/chargers can

operate from different battery banks, meaning each unit is connected to its own

battery bank. However, it is highly recommended to use only a single battery

bank. See “DC Connections for Multiple Unit Configuration” on page 1–36.

IMPORTANT: In a multiple unit configuration where two Conext SW units are set

up together, the AC transfer relay rating remains the same at 30 amps. This AC

transfer relay rating does not double to become 60 amps.

WARNING

FIRE HAZARD

Do not power multiple loads in excess of 30 amps even in a multiple unit

configuration.

Failure to follow this instruction can result in death or serious injury.

1–34 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 53

Multiple Unit Configuration

The Input and Output Neutrals are electrically tied at the inverter terminals. Only a

Neutral wire (from the AC Out cable) is necessary from each inverter.

AC Out

Cable

AC Out

Cable

AC In

Cable

AC In

Cable

AC Output Breakers AC Input Breakers

AC Bypass breakers are not shown. For detailed wiring illustration, see “DualInverter System Renewable Energy (Solar) Wiring” on page 3–8.

Figure 1-16 Multiple (Dual) Unit Configuration Using Two Conext SW Units

975-0639-01-01 Rev F 1–35

This guide for use by qualified personnel only

Page 54

Installation

DC Connections for Multiple Unit Configuration

Individual overcurrent devices are to be used between the battery positive and each

positive cable leading to the DC Switchgear. Keep cable lengths to the two DC

switchgears the same in order to balance cable losses.

Connect the units as follows:

1. Connect the positive cables.

Follow the steps in “Connecting the DC Cables to the DC Switchgear” on page 1–

27.

Also, do not tie the positives in series together between inverters.

2. Connect the negative cables.

Follow the steps in “Connecting the DC Cables to the DC Switchgear” on page 1–

27.

3. Connect the battery temperature sensors (BTS), if needed.

Follow the steps in “Step 5: Connecting the BTS and Xanbus-enabled Components”

on page 1–29.

Xanbus Stacking REM BTS Xanbus Stacking REM BTS

A DC fuse for

each (+) cable

1

24 V

2

3

Figure 1-17 Connecting Battery Cables

1–36 975-0639-01-01 Rev F

This guide for use by qualified personnel only

Page 55

Configuring the System for Multiple Unit Operation

Verify all DC and AC connections. Check Xanbus network connections and ensure that

terminators are installed at devices at each end of the network. The simplest system

includes a Xanbus SCP, the two multi-unit-configured Conext SW inverter/chargers, and

two Xanbus terminators.

For both units to operate in multiple unit configuration, a Master and Slave have to be

assigned. The default out-of-box configuration for all Conext SW inverter/chargers is

Master which causes a conflict the first time the system is powered up. The installer will

need to change configuration on one of the inverter/chargers to Slave mode.

To configure the system for multiple unit configuration:

1. Apply DC power to both inverter/chargers.

Power up order has no impact. Because there are now two Master units in the

system, the SCP will detect an F71 fault, a “system configuration fault”.

2. From the SCP System Status screen, press Enter. The Select Device screen

appears.

3. Select the inverter to configure as a Slave unit from the list, then press Enter.

4. Bring up the Advanced Settings screen by pressing Enter, Up, and Down arrow

buttons all together.

5. Select Advanced Settings and press Enter. The Advanced Settings screen

appears.

6. Scroll down to select Multi Unit Config.

At this point all devices in the system will be automatically placed in standby mode.