Page 1

Conext™ SW Inverter/Charger

Conext SW 2524 120/240 Split-phase (865-2524)

Conext SW 4024 120/240 Split-phase (865-4024)

Conext SW 4048 120/240 Split-phase (865-4048)

Owner’s Guide

975-0638-01-01 Rev G

9-2018

solar.schneider-electric.com

Page 2

Page 3

Conext SW Inverter/Charger

Conext SW 2524 120/240 Split-phase (865-2524)

Conext SW 4024 120/240 Split-phase (865-4024)

Conext SW 4048 120/240 Split-phase (865-4048)

Owner’s Guide

http://solar.schneider-electric.com

Page 4

Copyright and Contact

Copyright © 2012-2018 Schneider Electric. All Rights Reserved. All trademarks are owned by Schneider Electric

Industries SAS or its affiliated companies.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, SELLER

(A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION

PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION;

(B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION.THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO

MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED.APPROVED CONTENT IS

CONTAINED WITH THE ENGLISH LANGUAGE VERSION WHICH IS POSTED AT SOLAR.SCHNEIDER-ELECTRIC.COM.

Document Number: 975-0638-01-01 Revision: Rev G Date: 9-2018

Product Part Numbers: 865-2524, 865-4024, 865-4048

Contact Information solar.schneider-electric.com

Please contact your local Schneider Electric Sales Representative or visit our website at:

http://solar.schneider-electric.com/tech-support/

Information About Your System

As soon as you open your product, record the following information and be sure to keep your proof of purchase.

Serial Number

Product Number

Purchased From

Purchase Date

_________________________________

_________________________________

_________________________________

_________________________________

Page 5

About This Guide

Purpose

The purpose of this Owner’s Guide is to provide explanations and procedures for

operating, troubleshooting, and maintaining the Conext SW Inverter/Charger.

Scope

The Guide provides safety guidelines, as well as information about operating and

troubleshooting the unit. It does not provide details about particular brands of

batteries. You need to consult individual battery manufacturers for this

information.

Audience

The Guide is intended for users and operators of the Conext SW Inverter/

Charger.

Organization

This Guide is organized into the following chapters.

Chapter 1, “Introduction” covers material list, key features, and basic protection

features.

Chapter 2, “Components and Mechanical Features” provides detailed

information on system components and the product’s main features.

Chapter 3, “Operation” provides operational instructions from the Front Panel

including operation using the System Control Panel (SCP).

Chapter 4, “Configuration via SCP” provides instructions to change inverter and

charger settings using the System Control Panel (SCP).

Chapter 5, “Troubleshooting” covers normal troubleshooting guidelines that also

includes fault detection and warning codes and how to interpret them.

Chapter 6, “Specifications” covers product specifications.

975-0638-01-01 Rev G iii

Page 6

About This Guide

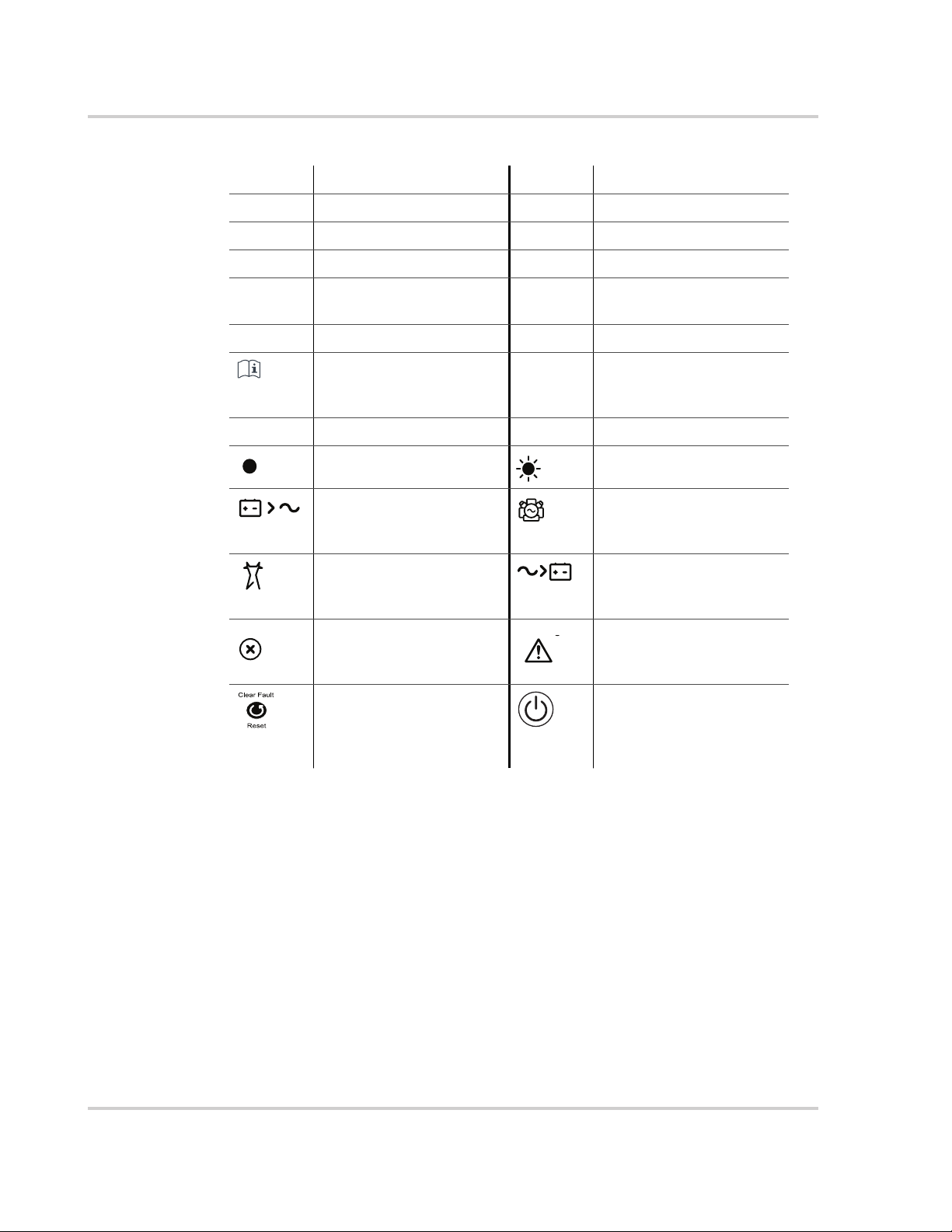

Abbreviations, Acronyms, and Symbols

AC Alternating Current LED Light Emitting Diode

AGS Automatic Generator Start SCP System Control Panel

BOS Balance of System SW Sine Wave

DC Direct Current VAC Volts, Alternating Current

PPE Personal Protective

Equipment

PV Photovoltaic IP20 Ingress protection rating

Reference to see guide

(or manual) for more

information

AC DC

Denotes a steady LED Denotes a flashing LED

Inv Enabled – see “Front

Panel LEDs” on page 3–4

for definition.

AC IN – see “Front Panel

LEDs” on page 3–4 for

definition

Fault – see “Front Panel

LEDs” on page 3–4 for

definition.

Clear Fault | Reset – see

“Conext SW Front and

Side Panels” on page 2–4

for definition.

.

VDC Volts, Direct Current

Ground

Gen Support – see “Front

Panel LEDs” on page 3–4

for definition.

Charging – see “Front

Panel LEDs” on page 3–4

for definition.

Warning – see “Front

Panel LEDs” on page 3–4

for definition.

Inv Enable – see “Conext

SW Front and Side

Panels” on page 2–4 for

definition.

Related Information

You can find more information about Schneider Electric as well as its products

and services at solar.schneider-electric.com.

iv 975-0638-01-01 Rev G

Page 7

Important Safety Instructions

READ AND SAVE THESE INSTRUCTIONS - DO NOT DISCARD

This guide contains important safety instructions for the Conext SW Inverter/

Charger that must be followed during operation and troubleshooting. Read and

keep this Owner’s Guide for future reference.

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service or maintain it. The

following special messages may appear throughout this bulletin or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal

injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided,

can result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided,

can result in moderate or minor injury.

NOTICE

NOTICE indicates a potentially hazardous situation, which, if not avoided, can

result in equipment damage.

975-0638-01-01 Rev G v

Page 8

Safety

Safety Information

ELECTRICAL SHOCK AND FIRE HAZARD

Installation must be done by qualified personnel to ensure compliance with all

applicable installation and electrical codes and regulations. Instructions for

installing the Conext SW are provided in a separate installation guide for use

by qualified installers only.

Failure to follow these instructions will result in death or serious injury.

ELECTRICAL SHOCK AND FIRE HAZARD

• Read all instructions, cautionary markings, and all other appropriate

sections of this guide before operating, troubleshooting, and performing

maintenance on the Conext SW.

• Exercise extreme caution at all times to prevent accidents.

• Do not cover or obstruct ventilation openings.

• Do not mount in a zero-clearance compartment. Overheating may result.

• Do not open nor disassemble the inverter/charger. There are no userserviceable parts inside.

• Do not expose to rain or spray.

• Disconnect and lockout all AC and DC sources before servicing. Servicing

includes maintenance or cleaning or working on any circuits connected to

the inverter/charger. See following note

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

NOTE: Turning off inverter mode using the Inv Enable switch on the front panel,

disabling the inverter and charger functions using the SCP, and putting the unit in

Standby mode will not reduce an electrical shock hazard.

vi 975-0638-01-01 Rev G

Page 9

Safety

DANGER

ELECTRIC SHOCK HAZARD

• For indoor use only. This inverter/charger is designed for off-grid, solar,

backup, and hybrid applications. See the installation guide for information.

• Do not operate the inverter/charger if it has been damaged in any way.

• Do not operate the inverter/charger with damaged or substandard wiring.

Wiring must be done by qualified personnel to ensure compliance with all

applicable installation codes and regulations.

Failure to follow these instructions will result in death or serious injury.

WARNING

EXPLOSION AND FIRE HAZARD

• Charge properly rated lead-acid (GEL, AGM, Flooded, or lead-calcium)

rechargeable batteries because other battery types may explode.

• When using Lithium-Ion batteries, ensure that the battery pack being used

includes a certified Battery Management System (BMS) with safety

controls.

• Do not work in the vicinity of lead-acid batteries. Batteries generate

explosive gases during normal operation. See note #1.

• Do not install and/or operate in compartments containing flammable

materials or in locations that require ignition-protected equipment. See

notes #2 and #3.

Failure to follow these instructions can result in death or serious injury.

NOTES:

1. Follow these instructions and those published by the battery manufacturer

and the manufacturer of any equipment you intend to use in the vicinity of the

battery. Review cautionary markings on these products.

2. This inverter/charger contains components which tend to produce arcs or

sparks.

3. Locations include any space containing gasoline-powered machinery like a

generator, fuel tanks, as well as joints, fittings, or other connections between

components of the fuel system.

CAUTION

FIRE AND BURN HAZARD

Do not cover or obstruct the air intake vent openings and/or install in a zeroclearance compartment.

Failure to follow these instructions can result in moderate or minor injury.

975-0638-01-01 Rev G vii

Page 10

Safety

Precautions When Working With Batteries

IMPORTANT: Battery work and maintenance must be done by qualified

personnel knowledgeable about batteries to ensure compliance with battery

handling and maintenance safety precautions.

WARNING

BURN AND FIRE HAZARD

• Always wear proper, non-absorbent gloves, complete eye protection, and

clothing protection.

• Remove all personal metal items, like rings, bracelets, and watches when

working with batteries.

• Never smoke or allow a spark or flame near batteries.

• Batteries can produce a short circuit current high enough to weld a ring or

metal bracelet or the like to the battery terminal, causing a severe burn.

Failure to follow these instructions can result in death or serious injury.

WARNING

CHEMICAL, BURN, AND EXPLOSION HAZARD

• Never place the Conext SW Inverter/Charger unit in the same compartment

as batteries due to an explosive hazard.

• Make sure the area around the battery is well ventilated.

• Make sure the voltage of the batteries matches the output voltage of the

inverter/charger.

• Never allow battery acid to drip when reading specific gravity or filling

battery.

Failure to follow these instructions can result in death or serious injury.

WARNING

LIMITATIONS ON USE

Do not use in connection with life support systems or other medical

equipment.

Failure to follow these instructions can result in death or serious injury.

LI

viii 975-0638-01-01 Rev G

Page 11

Safety

NOTICE

RISK OF INVERTER/CHARGER DAMAGE

Do not exceed the maximum inverter load limit (power) on either single phase

(L1/N or L2/N). See “Inverter Specifications” on page 6–2.

Failure to follow these instructions can result in damage to equipment.

NOTICE

RISK OF INVERTER/CHARGER DAMAGE

Never place the Conext SW Inverter/Charger unit directly above batteries;

gases from a battery will corrode and damage the inverter/charger.

Failure to follow these instructions can result in damage to equipment.

NOTICE

RISK OF BATTERY DAMAGE

Study and follow all of the battery manufacturer's specific precautions, such

as removing or not removing cell caps while charging, whether equalization is

acceptable for your battery, and recommended rates of charge.

Failure to follow these instructions can result in damage to equipment.

975-0638-01-01 Rev G ix

Page 12

Safety

FCC Information to the User

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

x 975-0638-01-01 Rev G

Page 13

Contents

Important Safety Instructions

Safety Information ----------------------------------------------------------vi

Precautions When Working With Batteries ----------------------------------------viii

FCC Information to the User ---------------------------------------------------x

1 Introduction

Materials List ------------------------------------------------------------1–2

Key Features ------------------------------------------------------------1–3

Key Features Explained --------------------------------------------------1–4

Basic Protection Features ---------------------------------------------------1–5

Grid-interactive and Other Features --------------------------------------------1–6

Load Shaving ---------------------------------------------------------1–6

AC Support ----------------------------------------------------------1–8

AC Support Mode using SOC ------------------------------------------1–9

Enhanced AC Support ------------------------------------------------1–9

Regular AC Support without Xanbus devices ------------------------------1–11

Grid-Interactive Delay Feature --------------------------------------------1–11

AC Coupling ---------------------------------------------------------1–12

AC Couple Smart Charge -----------------------------------------------1–13

Storing the State of the Inverter Mode --------------------------------------- 1–15

NoLoadVD ----------------------------------------------------------1–15

Low Battery Cut Out Hysteresis -------------------------------------------1–15

LBCO Delay --------------------------------------------------------- 1–15

Lithium Ion Battery Type ------------------------------------------------ 1–16

2 Components and Mechanical Features

System Components-------------------------------------------------------2–2

Xanbus System --------------------------------------------------------2–2

Xanbus-enabled Products and Other Accessories -------------------------------2–3

Conext SW Inverter/Charger Mechanical Features----------------------------------2–4

Conext SW Front and Side Panels ------------------------------------------2–4

Front Panel Buttons and Status LEDs -------------------------------------2–5

Conext SW AC/DC/Ports Side Panel --------------------------------------2–6

3 Operation

Start Up Behavior ---------------------------------------------------------3–2

Inverter Operation Using the Front Panel ----------------------------------------3–3

Operating Limits for Inverter Operation ---------------------------------------3–5

Operating Limits for Charger Operation --------------------------------------3–7

975-0638-01-01 Rev G xi

Page 14

Contents

Inverter/Charger Operation using the System Control Panel (SCP) ---------------------- 3–8

SCP Features --------------------------------------------------------- 3–9

Using the Standby Button ----------------------------------------------- 3–10

SCP Navigation ------------------------------------------------------ 3–10

Startup Screen ---------------------------------------------------- 3–10

Viewing the SCP Home Screens --------------------------------------- 3–11

Viewing Other Screens ---------------------------------------------- 3–14

Changing Operational Settings ------------------------------------------- 3–16

4 Configuration via SCP

Viewing the Firmware Revision Number ----------------------------------------- 4–2

Setting the Time and Date--------------------------------------------------- 4–3

Viewing the Basic and Advanced Settings Menus---------------------------------- 4–4

Configuring Basic Settings -------------------------------------------------- 4–7

Configuring Advanced Settings----------------------------------------------- 4–9

Inverter Settings Menu -------------------------------------------------- 4–9

Using the Low Battery Cut Out and LBCO Delay Settings --------------------- 4–11

Low Battery Cut Out Hysteresis ---------------------------------------- 4–11

Using Search Mode ------------------------------------------------ 4–12

Using Inverter Block ------------------------------------------------ 4–13

Charger Settings Menu ------------------------------------------------- 4–13

Battery Charger Functions -------------------------------------------- 4–15

Multi-Stage Charging Process ----------------------------------------- 4–16

Equalize-Charging the Batteries --------------------------------------- 4–18

Using Charger Block ----------------------------------------------- 4–19

Custom Battery Settings Menu ----------------------------------------- 4–20

LithiumIon Battery Settings Menu --------------------------------------- 4–22

AC Settings --------------------------------------------------------- 4–24

AC Support Settings --------------------------------------------------- 4–25

AC Support Mode Setting -------------------------------------------- 4–27

Load Shaving Setting ----------------------------------------------- 4–29

Enhanced AC Support Setting ----------------------------------------- 4–31

Multi Unit Config Menu ------------------------------------------------- 4–32

Setting the Device Name --------------------------------------------- 4–33

Setting the Device Number ------------------------------------------- 4–34

Restoring Factory Default Settings ----------------------------------------- 4–36

Advanced Features Menu ----------------------------------------------- 4–37

EuroFreq Feature -------------------------------------------------- 4–37

xii 975-0638-01-01 Rev G

Page 15

Configuration Sheet ------------------------------------------------------ 4–39

5 Troubleshooting

General Troubleshooting Guidelines -------------------------------------------5–2

Inverter Applications -------------------------------------------------------5–3

View Device Info Logs------------------------------------------------------5–4

Troubleshooting the Conext SW via the SCP --------------------------------------5–5

Fault Detection Types ---------------------------------------------------5–5

Warning Types --------------------------------------------------------5–6

6 Specifications

Inverter Specifications------------------------------------------------------6–2

Charger Specifications -----------------------------------------------------6–3

AC Transfer Specifications --------------------------------------------------6–4

Physical Specifications -----------------------------------------------------6–5

Environmental Specifications -------------------------------------------------6–5

Regulatory --------------------------------------------------------------6–6

Contents

975-0638-01-01 Rev G xiii

Page 16

xiv

Page 17

Figures

Figure 1-1 Materials List------------------------------------------------------1–2

Figure 1-2 Load Shaving in Action ----------------------------------------------1–7

Figure 1-3 AC Support Mode using SOC ------------------------------------------1–9

Figure 1-4 Enhanced AC Support -----------------------------------------------1–9

Figure 1-5 Enhanced AC Support Charge Cycle -----------------------------------1–10

Figure 1-6 Regular AC Support without Xanbus Devices------------------------------ 1–11

Figure 1-7 Load Shaving 2-Hour Delay Example -----------------------------------1–12

Figure 2-1 Xanbus System Components ------------------------------------------2–2

Figure 2-2 Conext SW Front and Side Panels---------------------------------------2–4

Figure 2-3 Front Panel Buttons and Status LEDs ------------------------------------2–5

Figure 2-4 AC and DC Terminals, Network and Communication Ports Panel-----------------2–6

Figure 3-1 Startup Screen --------------------------------------------------- 3–10

Figure 3-2 SCP Top Level Screens --------------------------------------------- 3–11

Figure 3-3 System Status Screen ----------------------------------------------3–12

Figure 3-4 Conext SW Home Screen --------------------------------------------3–12

Figure 3-5 Selecting a Device Setup Menu ---------------------------------------3–14

Figure 3-6 Viewing the Meters Screen -------------------------------------------3–15

Figure 3-7 Navigate To Conext SW Setup Menu------------------------------------ 3–16

Figure 3-8 Conext SW Setup Menu Operational Settings------------------------------ 3–18

Figure 4-1 Selecting Basic Settings---------------------------------------------- 4–4

Figure 4-2 Selecting Advanced Settings ------------------------------------------4–6

Figure 4-3 Menu Map of the Conext SW Basic Settings--------------------------------4–7

Figure 4-4 Inverter Settings Menu Screen -----------------------------------------4–9

Figure 4-5 Charger Settings Menu Screen ----------------------------------------4–13

Figure 4-6 Custom Settings Menu Screen ----------------------------------------4–20

Figure 4-7 LithiumIon Settings Menu Screen -------------------------------------- 4–22

Figure 4-8 AC Settings Menu Screen--------------------------------------------4–24

Figure 4-9 AC Support Menu Screen-------------------------------------------- 4–25

Figure 4-10 Multi Unit Config Menu Screen ----------------------------------------4–32

Figure 4-11 Setting a Device Number -------------------------------------------- 4–35

Figure 4-12 Adv Features Menu Screen ------------------------------------------4–37

Figure 5-1 View Device Info Log ------------------------------------------------5–4

Figure 6-1 Output Power versus Temperature Derating Graph --------------------------6–5

975-0638-01-01 Rev G xv

Page 18

xvi

Page 19

Tables

Table 3-1 Front Panel LEDs---------------------------------------------------3–4

Table 3-2 Conext SW Home Screen States ---------------------------------------3–13

Table 3-3 Meters Screen---------------------------------------------------- 3–15

Table 3-4 Conext SW Setup menu ---------------------------------------------3–17

Table 4-1 Setting Defaults and Ranges ------------------------------------------4–7

Table 4-2 Basic Settings -----------------------------------------------------4–8

Table 4-3 Setting Defaults and Ranges ------------------------------------------4–9

Table 4-4 Inverter Settings Description------------------------------------------ 4–10

Table 4-5 Setting Defaults and Ranges ----------------------------------------- 4–14

Table 4-6 Charger Settings Menu Description------------------------------------- 4–14

Table 4-7 Bulk Voltage Settings for Different Battery Types --------------------------- 4–16

Table 4-8 Preset Absorption Voltage Settings for Different Battery Types -----------------4–16

Table 4-9 Preset Float Voltage Settings for Different Battery Types ----------------------4–17

Table 4-10 Preset Equalization Voltage Settings for Different Battery Types ----------------4–18

Table 4-11 Setting Defaults and Ranges -----------------------------------------4–20

Table 4-12 Custom Battery Settings Menu Description ------------------------------- 4–21

Table 4-13 Setting Defaults and Ranges -----------------------------------------4–22

Table 4-14 LithiumIon Battery Settings Menu Description -----------------------------4–23

Table 4-15 Setting Defaults and Ranges -----------------------------------------4–24

Table 4-16 AC Settings menu ------------------------------------------------- 4–24

Table 4-17 AC Support Menu Description and Values --------------------------------4–25

Table 4-18 Multi Unit Menu Description and Values---------------------------------- 4–32

Table 4-19 Adv Features Description and Values ----------------------------------- 4–37

Table 5-1 Fault Detection Types and Behaviors ------------------------------------5–5

Table 5-2 Warning Types and Behavior ------------------------------------------5–6

Table 5-3 Fault Detection Messages --------------------------------------------5–7

Table 5-4 Warning Messages ------------------------------------------------5–12

975-0638-01-01 Rev G xvii

Page 20

xviii

Page 21

1 Introduction

The following topics will be covered in this

chapter.

• Material List

• Key Features

• Basic Protection Features

• Grid-interactive and Other Features

975-0638-01-01 Rev G 1–1

Page 22

Introduction

Materials List

Congratulations on your purchase of the Conext SW Inverter/Charger (called

Conext SW). The Conext SW has been designed to give you premium true sine

wave power, ease of use, and outstanding reliability for your off-grid and power

backup applications.

The Conext SW ships with the following items:

• One Conext SW unit

• One set of owner’s and installation guides

• One Battery Temperature Sensor (BTS)

• Two Xanbus network terminators

• Two sets of 5/16

• Two DC terminal covers (red and black) with two sets of #6-32 screws

• One Installation bracket with one set of M6 nuts for mounting (not shown)

NOTE: If any of the supplied accessories are missing, contact customer

service for replacement. For code-compliant installations in Canada and USA,

the DC Switch Gear accessory is required. See the Installation Guide for more

information.

"-18

nuts and washers for the DC terminals,

Figure 1-1 Materials List

1–2 975-0638-01-01 Rev G

Page 23

Key Features

Key Features

The Conext SW Inverter/Charger is a true sine wave inverter/charger that can be

used for off-grid, backup, solar, and hybrid applications. The Conext SW Inverter/

Chargers are designed to operate with a wide variety of generators and are

capable of operating in parallel with a generator for short durations to assist with

starting large loads. The Conext SW is a convenient combination of an inverter,

multi-stage battery charger, and transfer switch in one electronic device.

The Conext SW Inverter/Charger’s key features are:

True Sine Wave output

•

power for your microwave, entertainment system, computer, and other loads.

This power is identical to the AC source provided from the utility grid (power

company).

Some of the benefits of high efficiency true sine wave power include consistent

cooking in your microwave, handling of sensitive loads such as your TV set,

dimmer switches, and appliances with speed controls.

•

Multiple unit configuration

versatile platform capable of parallel multiple unit configuration1to increase

power levels.

•

High surge capacity

twice the maximum continuous output power rating to start difficult loads like well

pumps, refrigerators, or A/C compressors. See “Inverter Specifications” on

page 6–2.

•

Power factor correction

input current required for charging, increasing AC pass-through capacity.

•

Multi-stage charging

stage charging capability that minimizes charging time.

•

Adjustable frequency

from a 50Hz and 60Hz power source by extending the AC qualification frequency

range. See “AC Settings” on page 4–24.

•

Temperature-controlled, variable-speed internal cooling fans

on when the internal temperature reaches

speed at

104 °F (

•

Xanbus-enabled

which allows network compatibility and communication with other Xanbusenabled devices. See more information under “Xanbus System” on page 2–2.

158 °F (

40 °C).

70 °C). The fan turns off when the internal temperature falls to

- as an inverter, the Conext SW provides true sine wave

- the Conext SW Inverter/Charger has a highly

- the Conext SW Inverter/Charger has a surge rating that is

- Power factor-corrected (PFC) input minimizes AC

- the Conext SW Inverter/Charger has a high output, multi-

- the Conext SW Inverter/Charger is capable of operating

- the fans turn

113 °F (

- the Conext SW Inverter/Charger is also Xanbus-enabled

45 °C) and reaches maximum

1.In Conext SW Inverter/Chargers, multiple unit configuration (installation) is limited to two

units - one master unit and one slave unit.

975-0638-01-01 Rev G 1–3

Page 24

Introduction

Key Features Explained

Built-in Charge

Formulas

Battery

Temperature

Sensor

Dead Battery

Charging

Manual

Equalization

Load Management The Conext SW has a built-in transfer relay that connects your inverter output or

1

For the unit to perform at the highest level, the batteries must be charged

correctly. The Conext SW has optimized algorithms for flooded, gel, and AGM

batteries.

Since battery temperature is a key factor in correct charging, the charging

formula must be adjusted (automatically and in real time) according to the actual

battery temperature to ensure that batteries are fully charged, but not

overcharged. For this reason, a battery temperature sensor (BTS) is included

with the Conext SW that works with a temperature-compensated charge formula.

Another feature that the Conext SW includes is dead battery charging. The

Conext SW—unlike many chargers—has the ability to recharge batteries even if

the battery voltage is very low, that is, as low as 12 volts.

Over a period of time, the cells in a flooded battery can develop uneven

chemical states. This can result in a weak (undercharged) cell which, in turn, can

reduce the overall capacity of the battery. To improve the life and performance of

a non-sealed, flooded battery, the Conext SW’s multi-stage charging cycle

includes a manual equalize mode that can be used, if recommended by the

battery manufacturer.

AC input from the AC generator to your loads. Because the usual AC power

sources such as small generators often have limited current availability, having

the capability to manage your AC loads is extremely valuable. The Conext SW

provides a number of features to facilitate this.

• The charger is power factor corrected to use AC current as efficiently as

possible. Minimizing the AC current used by the charger means more

current is available for your AC loads.

• The Conext SW has a power share feature which prioritizes your AC

loads by reducing the charge current depending on the load current;

and programmed AC breaker setting.

Occasionally, AC input sources have low voltage. To avoid loading these weak

sources any further, the charger automatically reduces its AC current draw as the

AC voltage approaches the minimum acceptable level.

Multiple Unit

Configuration

1.Requires a 240V AC input. The feature does not work on 120V AC input only.

Conext SW Inverter/Charger supports multiple unit configuration to increase

capacity. Conext SW multiple unit configuration is limited to one master unit and

one slave unit.

Multiple Unit Inverting

Multiple unit configuration allows two inverter/chargers to operate in parallel

thereby doubling the capacity in inverter mode. The multiple inverters

communicate over the Xanbus network and intelligently manage the load

balance between the units.

1–4 975-0638-01-01 Rev G

Page 25

Multiple Unit Charging

Two Conext SW Inverter/Chargers synchronize charging stages to ensure

efficient charging of the battery bank. When a single unit transitions from bulk to

absorption so does the other unit. In absorption, the two units must complete the

absorption stage before transitioning to the next stage. Note that the two units do

not load share when charging except during the bulk stage. The Conext SW units

stop sharing charge current just before completing the bulk stage. The units do

not share charge current during the absorption and float stages.

Each unit charges batteries based on the Max Charge Rate setting and active

internal (temperature-based) deratings.

If equalization is enabled on one or more devices capable of equalization

charging, only those devices perform an equalize cycle after absorption. Other

devices transition to float (if three-stage charging is selected) or transition to AC

pass-through (if two-stage charging is selected).

Basic Protection Features

The Conext SW has the following protection features:

• Over temperature shutdown for critical components such as the transformer

and the power board

• Battery temperature sensor (BTS) failure/battery temperature out-of-range

fault protection

• DC output over voltage protection during charge mode

• AC output overload and short circuit protection during invert mode

Basic Protection Features

• AC backfeed1protection

The Battery Temperature Sensor (BTS) provides these protection features:

• battery over temperature charging protection preventing battery charging at

140 °F (60 °C) or higher, and

• charging voltage compensation based on the temperature of the battery the

BTS is connected to.

1.An AC backfeed error occurs when the AC output of the inverter/charger is connected or

routed back to the inverter/charger’sAC input terminalor ifthe ACinternal transferrelay error is

detected.

975-0638-01-01 Rev G 1–5

Page 26

Introduction

Grid-interactive and Other Features

Load Shaving

Load shaving (Load Shave) allows the Conext SW to support (or assist) the AC

source in powering local loads during a defined window of time (LoadShaveStart

and LoadShaveStop). See “Time-of-Use Metering” on page 1–7. It allows the

inverter to control how much current can be drawn from the AC source.

The Conext SW transitions to load shaving mode only when both the phase

currents exceed Load Shave Amps. It uses battery power to limit the peak load on

the AC input by providing the difference in amps between the actual load current

and the current limit set in Load Shave Amps. Some scenarios are presented

below to reflect this behavior.

Scenario 1

Load Shave Amps = 5A,

L1 = 7A of AC load,

L2 = 3A of AC load

Conext SW will not enter into the AC load shaving mode because one of the

phase currents (L1 or L2) is lower than the value of Load Shave Amps.

(L2 =3A) < (Load Shave Amps = 5A)

Scenario 2

Load Shave Amps = 5A,

L1 = 7A of AC load,

L2 = 9A of AC load

In this scenario, the Conext SW enters into the AC load shaving mode because

both phase currents exceed the value of Load Shave Amps.

(L1 =7A) > (Load Shave Amps = 5A)

The difference between these two values is 2A.

Conext SW will shave off 2A from each phase, meaning, the current draw from L1

will be limited to 5A and L2 limited to 7A.

However, when the battery is in charge mode, the total AC input current is limited

by 80% of Load Shave Amps to avoid the fluctuation between battery charge and

discharge.

This fluctuation is described as follows:

• If the AC input current limit is the same value as Load Shave Amps in battery

charge mode, the charge current can be higher than the limit value due to

the charge dynamics. Under this condition, the battery will enter into

discharge mode because the AC current is higher than Load Shave Amps.

After the battery is in discharge mode, the battery will go back into charge

mode again because the load current is smaller than Load Shave Amps.

1–6 975-0638-01-01 Rev G

Page 27

Grid-interactive and Other Features

• Therefore, the battery will fluctuate between the charge and discharge

modes. In order to avoid this fluctuation, a hysteresis band is set by limiting

the AC input current to 80% of Load Shave Amps when the battery is in the

charge mode.

In a grid-interactive backup system Load shaving combined with time-of-use

metering helps reduce utility peak demand surcharges.

In an off-grid system with generator Load shaving can be used to support the

generator. If the generator is unable to provide enough current to run loads in the

system, load shaving ensures that the system does not exceed the generator’s

current rating. This is done by matching the generator’s manufacturer

recommended current rating with the Load Shave Amps setting.

See “Load Shaving Setting” on page 4–29 for a sample scenario.

NOTE: Current is regulated by placing a limit (Load Shave Amps) on the current

of the AC source.

15 A10 A

5A

Figure 1-2 Load Shaving in Action

Time-of-Use Metering Utilities use time-of-use metering to set utility charges

during peak usage hours and to impose a surcharge. The Conext SW can be

configured (using the LoadShaveStart, LoadShaveStop and charger block [see

the Conext SW Owner’s Guide] settings) to overcome these peak charges by

using utility power to charge the battery bank during the inexpensive energy

hours and consuming the battery energy during expensive energy hours.

For example, if charger block is set between 9:00 AM and 10:00 PM and load

shaving is set between LoadShaveStart=6:00 PM and LoadShaveStop=9:00 PM,

charging on AC Input stops at 9:00 AM and the inverter continues to pass utility

AC through to the loads. If charging is required during the charger block period

then Conext SW can use an alternative external renewable energy source such

as an MPPT solar charge controller to charge the battery bank. The inverter

connects to the utility grid at 6:00 PM and supports running the loads using the

batteries. The inverter continues to run the loads until 9:00 PM.

The Conext SW then stops supporting the utility grid and passes utility AC

through to the loads at 9:01 PM. At the end of charger block at 10:00 PM utility

AC begins maintaining the batteries based on charger settings.

The above example allows an external renewable energy source to be utilized as

a primary charging source during a desired time window. The charger (using

utility power connected to AC Input) can then be used to supplement battery

charging when the utility rates are low.

975-0638-01-01 Rev G 1–7

Page 28

Introduction

AC Support

When using the system for time-of-use metering, the system should be designed

with a battery capacity large enough to support loads during the entire peak rate

period without reaching the low battery cut out (Low Batt Cut Out) setting.

Load shaving can also be used with time-of-use metering and enhanced AC

support feature (see “Enhanced AC Support” on page 1–9 and “Enhanced AC

Support Setting” on page 4–31) to support self-consumption.

AC Support is similar to load shaving because in both cases the Conext SW

inverter supplements AC current. However, unlike load shaving, AC Support

minimizes the AC input current to the Conext SW as long as the battery’s SOC

(state-of-charge) or battery voltage conditions allow it. AC Support allows the

Conext SW to support local loads by converting excess power from external DC

sources connected to its battery bank. Examples of external DC sources are

MPPT solar charge controllers. When local loads demand more energy from the

external DC sources then extra current can be pulled in from the AC source as a

last resort. When operating without a solar charge controller in the system, set

the battery charge cycle to 2StgNoFloat to allow AC Support to function

immediately after the absorption charge stage.

When Conext SW is operating in AC support mode, it only compensates AC

loads which are connected to both phases and having equal power. The

difference in power between the two phases will be drawn from the AC source.

Some scenarios are presented below to reflect this behavior.

Scenario 1

L1 = 3A of AC load,

L2 = 3A of AC load

In this scenario, the Conext SW injects 3A into each phase to offset both loads.

Scenario 2

L1 = 5A of AC load,

L2 = 3A of AC load

In this second scenario where power from the two loads is unequal, the Conext

SW still injects 3A (the lesser of the two AC loads) into each phase. However, the

difference of 2A on L1 shall be drawn from the grid.

AC Support behaves three different ways depending on the type of equipment

that is installed in the Xanbus network with the Conext SW.

• SOC - Xanbus-enabled Conext Battery Monitor is installed

• Enhanced - Xanbus-enabled MPPT solar charge controller is installed

• Regular - neither Xanbus-enabled battery monitor nor MPPT solar charge

controller is installed

1–8 975-0638-01-01 Rev G

Page 29

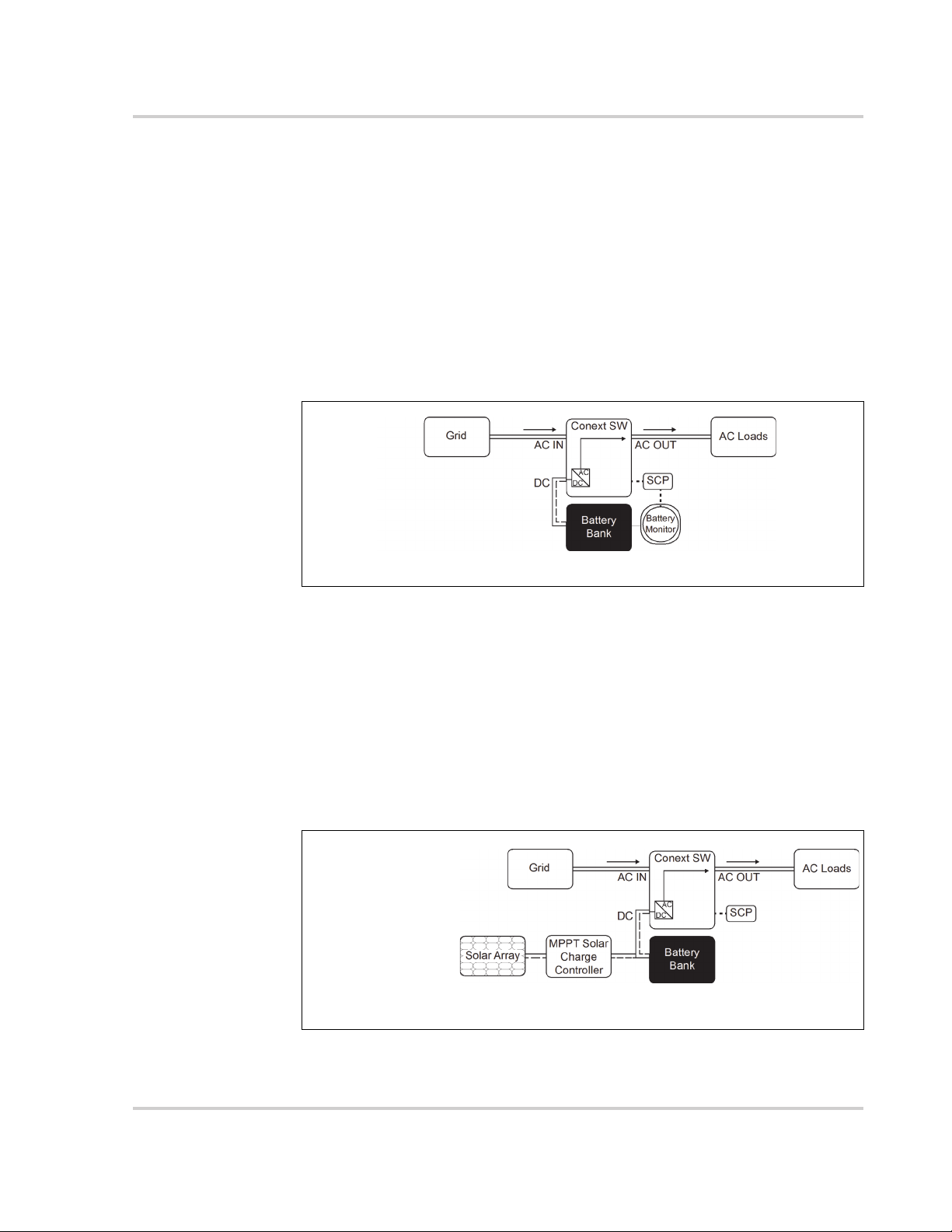

AC Support Mode using SOC

With AC support on SOC (AC Supp on SOC) enabled (default setting), Conext SW

maximizes power utilization using stored energy in a battery bank within a gridinteractive backup power system. AC support mode allows the Conext SW to

accurately determine when grid power can be used to supply energy to the

loads by knowing the state-of-charge (SOC) of the battery bank.

The SOC of a battery bank is monitored by using a Xanbus-enabled battery

monitor. SOC entry and exit points are determined by the user. The SOC entry

point (AC Supp Start Soc) which is a high percentage value determines when

AC support mode is engaged and the SOC exit point (AC Supp Stop Soc) which

is a low percentage value determines when AC support mode is disengaged.

See “AC Support Settings” on page 4–25.

Grid-interactive and Other Features

15 A<2A*

>13A

NOTE: Entry and exit into AC Support

Mode is determined by the SOC. In this

case, AC support mode is engaged.

Figure 1-3 AC Support Mode using SOC

Enhanced AC Support

Enhanced AC Support (EnhancedACSup) works when power systems are DC

coupled with a Xanbus-enabled MPPT Solar Charge Controller. This means that

DC power from a renewable source such as an MPPT Solar Charge Controller is

used to charge the battery bank while simultaneously utilizing its power (by way

of inverting) to power loads. Entry and exit to enhanced AC support are

controlled by the MPPT charger so that they can control the state-of-charge of

the batteries. AC power from the grid is utilized only when load demand exceeds

power available from the MPPT charger for charging and supplying the loads.

NOTE: Entry and exit into

Enhanced AC Support is

determined by the MPPT.

SOC Entry = 80%

actual SOC = 75%

SOC Exit = 50%

* To prevent injecting current into the grid from the inverter, there is less than 2 amps of offset allowed

from the grid to flow into AC IN under all conditions.

15 A<2A*

>13A

* To prevent injecting current into the grid from the inverter, there is less than 2 amps of offset allowed

from the grid to flow into AC IN under all conditions.

Figure 1-4 Enhanced AC Support

975-0638-01-01 Rev G 1–9

Page 30

Introduction

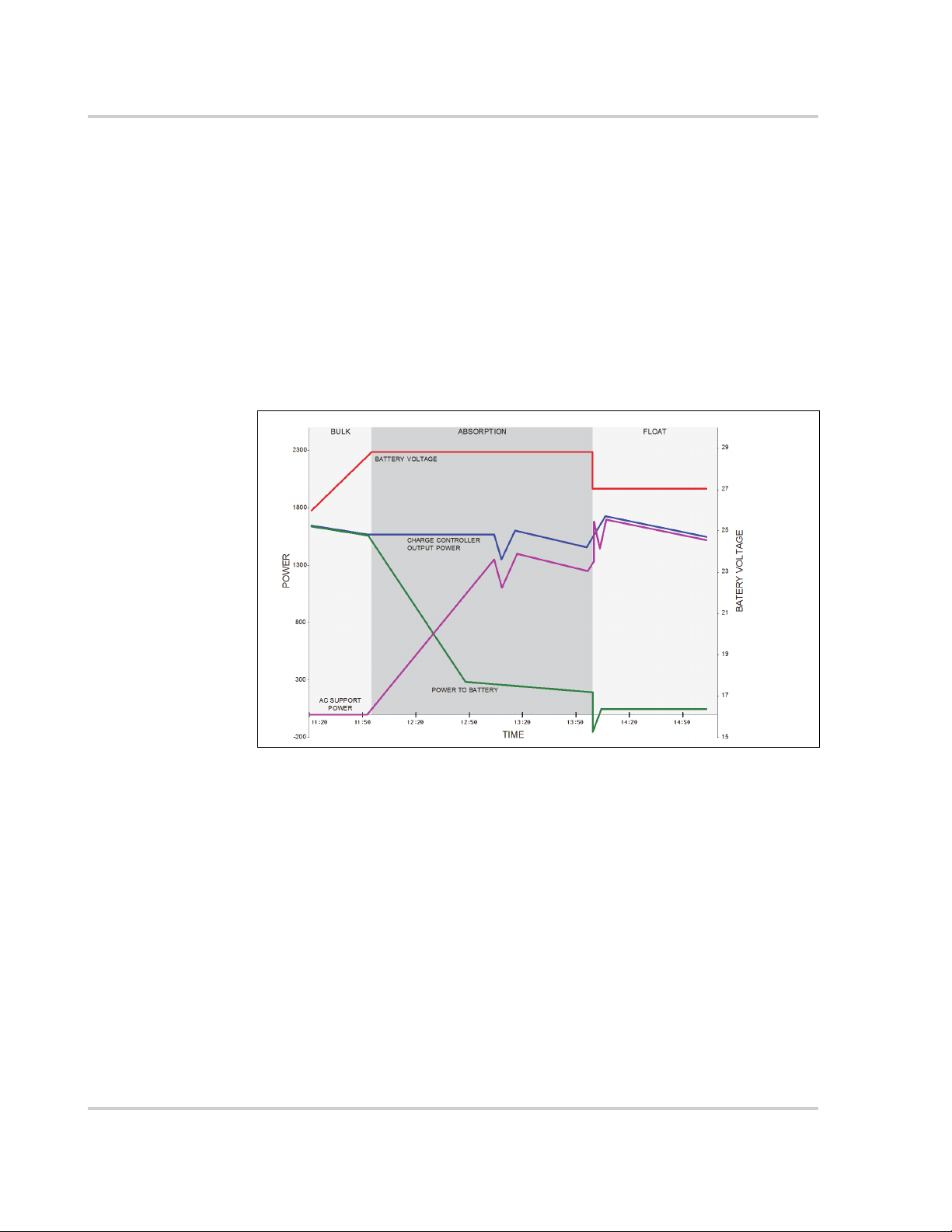

When enhanced AC support mode is enabled, the Conext SW automatically

tracks the MPPT solar charge controller’s charging voltage as it transitions from

bulk to absorption to float. By tracking the voltage, the Conext SW is then able to

execute and finish the charging cycle using DC power from the solar charge

controller while converting its excess DC power to AC power to support the grid

by supplying more current. Conext SW only uses excess DC power not required

by the battery to support the grid thus, it prioritizes charging the battery before

supporting the loads. Battery health is improved because the system always

executes a three stage charging of the battery that ensures battery SOC is as

close as possible to 100% at all times. Systems that use a fixed voltage for AC

support (or similar) start to support loads sooner and may not fully charge the

battery bank, leaving the battery in a partial SOC. Prolonged periods of partial

SOC can degrade battery performance. Enhanced AC support limits this

degrading effect.

Figure 1-5 Enhanced AC Support Charge Cycle

Enhanced AC Support Charging Stages

• BULK Phase - During this phase, all PV energy from the charge controller is

diverted to the battery for maximum charging. During this phase, the Conext

SW does not engage AC support.

• ABSORPTION Phase - Once the charge controller is in absorption phase,

the charge controller output is split between the battery and Conext SW for

supporting AC loads. As the battery approaches full charge, more power

from the charge controller is diverted to Conext SW for AC support.

• FLOAT Phase - Once the battery is full and the charge controller transitions

to float phase, almost all the charge controller output is used by Conext SW

to support AC loads. The battery only receives a trickle charge to maintain a

healthy state of charge.

See “Enhanced AC Support Setting” on page 4–31.

1–10 975-0638-01-01 Rev G

Page 31

Regular AC Support without Xanbus devices

If no Xanbus-enabled devices, such as an MPPT charge controller, are

connected to the power system, then entry and exit into AC support mode is

based solely on battery voltage monitored by Conext SW. If the battery voltage is

above a set limit (AC Supp Volts), then AC support mode is engaged.

Grid-interactive and Other Features

NOTE: Entry and exit into AC Support Mode

is determined by the battery voltage. In this

case, AC support mode is engaged because

actual battery voltage is above the AC

support voltage level.

* To prevent injecting current into the grid from the inverter, there is less than 2 amps of offset allowed

from the grid to flow into AC IN under all conditions.

Figure 1-6 Regular AC Support without Xanbus Devices

With its charger enabled, the Conext SW enters AC support mode only after

completing a charge cycle when it is first powered up or reconnected to the grid.

For regular AC support mode set the Conext SW’s battery charge cycle to

2StgNoFloat to allow AC Support feature to function immediately after the

absorption charge stage.

Grid-Interactive Delay Feature

Conext SW has a delay feature that postpones the engagement of two gridinteractive features, namely load shaving and AC support, until a connected

MPPT solar charge controller has had a chance to charge the battery for two

hours in Float mode. The delay feature is called PLSDelay in SCP. The delay

feature prioritizes the MPPT solar charge controller’s ability to sufficiently charge

the battery bank. The feature works by inhibiting grid-interactive operation for two

hours from the time the charge controller transitions from Absorption to Float

charging. This allows the battery to be fully charged before either load shaving or

AC support mode is engaged. This feature is useful in applications where battery

micro-cycling is to be minimized in order to maximize battery life. See below.

<2A*

15 A

>13A

actual battery voltage = 25V

AC support voltage = 24V

Example: Load Shave = Enabled

LoadShaveStart = 10:00AM

PLSDelay = Enabled

Absorption to float charging starts at 7:00 AM and load shaving is set to start at

10:00 AM. Absorption transitions to float at 9:00 AM but because PLSDelay is

enabled, the 2-hour delay inhibits load shaving to actually start at 10:00 AM.

Because of the 2-hour delay, load shaving does not start until 11:00 AM. See

“Load Shaving 2-Hour Delay Example” on page 1–12.

975-0638-01-01 Rev G 1–11

Page 32

Introduction

Figure 1-7 Load Shaving 2-Hour Delay Example

The feature also ensures that self-consumption of harvested solar energy is

optimized. The 2-hour delay works only under the following conditions:

• Conext SW’s battery charge cycle must be set to 2StgNoFloat

• PLSDelay must be set to Enabled

• an MPPT solar charge controller must be connected and detected in the

Xanbus network

• the feature must not have been activated within that day

AC Coupling

This configuration can be enabled or disabled in “Advanced Features Menu” on

page 4–37. The default setting for PLSDelay is Disabled.

Off-grid AC Coupled system architecture is often used to create a stand-alone

grid. Commonly this means that PV inverters are connected to the output of a

battery-based inverter/charger putting both on the same AC bus along with the

AC loads. In this scenario, the battery powered inverter charger provides the

necessary frequency and voltage to enable the PV inverter to produce power.

This type of system must be able to maintain power generation in balance with

power consumption at all times. If there is more power being generated than can

be consumed by the loads, power will flow to the inverter/charger and be

converted to DC power which flows into the battery. Once the battery reaches

capacity, power generation by the PV inverter must be curtailed to maintain the

balance between generation and consumption. As the battery bank reaches

capacity, Conext SW curtails PV inverter generation by raising the AC line

frequency causing compatible PV inverters to reduce their power output in an

orderly manner. This is called Active Frequency Shift Power Curtailment.

During a grid outage even a home with a grid-tie PV inverter system will be

without power because PV inverters cannot produce power without the presence

of a reference voltage and frequency. To enable the PV inverter to provide power

during a grid outage the Conext SW is retrofitted in front of the PV inverter. The PV

inverter is rewired from the grid connection to a critical load (sub) panel and the

AC Couple is on the Conext SW AC Output port.

1–12 975-0638-01-01 Rev G

Page 33

Grid-interactive and Other Features

Consult the manufacturer's specifications to determine if your PV inverter is

compatible with Active Frequency Shift Power Curtailment. Conext SW’s AC

coupling function is enabled by default (see “Advanced Features Menu” on

page 4–37).

NOTICE

AC COUPLED PV INVERTER COMPATIBILITY

AC power generated by AC coupling PV inverters with Conext SW must be

consumed by AC loads or used to charge batteries. As an alternative, the

excess power produced from a PV inverter can be routed to dump loads. Do

not AC couple PV inverters with the Conext SW that are unable to reduce,

derate or cease the excess PV inverter power in response to the changes in

AC line frequency controlled by the Conext SW. Consult the manufacturer's

specifications of your PV inverter and confirm compatibility.

Failure to follow these instructions can result in equipment damage.

The AC coupling advanced setting should remain enabled except in cases when

the DC voltage level is allowed to have large variations and the line frequency

needs to remain constant.

Further details about AC Coupling can be found in the document “AC Coupling

Solutions Guide (Document Number: 976-0240-01-01)” available at

solar.schneider-electric.com.

AC Couple Smart Charge

AC Couple Smart Charge is a feature of the Conext SW that prioritizes battery

charging over energy export to local AC loads connected upstream of the

Conext CSW battery inverter. AC Coupling must be enabled for this feature to be

functional.

In AC-coupled configuration and with grid present, the Conext SW monitors flow

of power from its load port (AC Output) to the utility grid input (AC Input). When

power flow to the grid is detected and the battery needs charging after a short

delay, the Conext SW initiates a bulk charging cycle by switching to charge

mode and drawing AC power to charge the battery. It only draws enough energy

to keep the flow of power to the grid to zero. As long as the battery is able to

accept the energy, the Conext SW will continue diverting excess PV production

to the battery. Once the battery bank is at a level such that not all excess energy

from the PV Inverter is being absorbed, the balance will then flow out to upstream

loads in the house that are not connected to the Conext SW’s AC output port.

If PV production is lost for a prolonged period of time and the battery bank

discharges below the Recharge Volts setting, the Conext SW will initiate a normal

charge cycle and use power from the grid to charge the battery. For information

on this setting, see “Configuring Basic Settings” on page 4–7. In all of the above

modes of operation, only the PV Inverter exports energy to the grid. The Conext

975-0638-01-01 Rev G 1–13

Page 34

Introduction

SW itself cannot sell to the grid - it simply passes energy from the PV inverter to

the grid. For this reason, the PV Inverter must be fully grid code compliant as it

assumes responsibility for anti-islanding protection.

NOTICE

RISK OF INCOMPATIBLE EQUIPMENT

Check that the PV Inverter warranty covers off-grid applications, specifically

AC coupling with a battery- based inverter.

Check that the PV Inverter is capable of operating when it is AC-Coupled with

the inverter/charger which forms the local grid. PV Inverters with an

impedance sensing anti-islanding scheme are not compatible with the

inverter/charger.

Check that the PV Inverter can be configured to curtail power when the grid

frequency rises above 50.5 Hz and that power ceases to flow when the

frequency reaches 52.0 Hz.

Failure to follow these instructions could result in damage to equipment

not covered by warranty.

NOTICE

RISK OF DAMAGE TO THE GENERATOR

Never connect a generator to the AC Input terminal of a battery inverter

configured for AC coupling. The inverter will not be able to regulate the current

being backfed into the AC input and may backfeed AC current into the

generator.

Failure to follow this instruction can result in equipment damage.

NOTICE

RISK OF BATTERY DAMAGE

• To prevent battery damage in a micro-grid AC system, use only firmware

which has the AC coupling feature implemented. Always be sure to use the

latest firmware available for your inverter. For firmware upgrade

instructions, see the Conext Configuration Tool User’s Guide (document

part number: 975-0365-01-01) available on solar.schneider-electric.com.

• Do not use a Lithium Ion battery pack in AC-Coupled inverters.

Failure to follow this instruction can result in battery damage.

1–14 975-0638-01-01 Rev G

Page 35

Storing the State of the Inverter Mode

You can enable or disable a feature called StoreInvState which, when enabled

remembers the state of the inverter mode prior to a power down (that is, when AC

and DC power sources are disconnected). When the Conext SW is powered up

again, the inverter mode reverts back to its prior state.

See “Advanced Features Menu” on page 4–37.

NoLoadVD

The No Load Voltage Derating (NoLoadVD) feature further reduces tare loss by

adjusting output voltage by +4%/-5% of nominal, over the full load range. That

means at 50% load, the output voltage is at nominal but 5% below nominal at no

load and up to 4% at full load. The feature results in slight increase on overall

operating efficiency but may result in visible flicker of incandescent or similar

lights during large sudden load changes.

See “Advanced Features Menu” on page 4–37.

Low Battery Cut Out Hysteresis

Low battery cut out (Low Batt Cut Out) (LBCO) preserves battery life by

stopping the inverter when battery voltage drops down to the LBCO value for a

few seconds (see LBCO Delay below), then battery charging commences. When

charging starts, the voltage level jumps a little but enough that inverting might

resume abruptly. Then, battery voltage goes down again and charging starts

abruptly. To prevent the inverter from switching abruptly between inverting and

charging, the LBCO Hysteresis value is added to the LBCO value to allow the

battery voltage to reach a sufficient energy capacity level before inverting

resumes. This feature contributes to battery health.

Grid-interactive and Other Features

See “Advanced Features Menu” on page 4–37.

LBCO Delay

LBCO Delay (LBCO Delay) is the amount of time in seconds before inverting is

interrupted due to low battery voltage.

See “Advanced Features Menu” on page 4–37.

975-0638-01-01 Rev G 1–15

Page 36

Introduction

Lithium Ion Battery Type

See “LithiumIon Battery Settings Menu” on page 4–22.

Further details about Lithium Ion support can be found in the document “Lithium

Ion Application Note (Document Number: 976-0319-01-01)” available at

solar.schneider-electric.com.

BATTERY TYPE HAZARD

When using Lithium Ion batteries, ensure that the battery pack being used

includes a certified Battery Management System (BMS) with safety protocols.

Failure to follow these instructions can result in property damage, death

or serious injury.

WARNING

1–16 975-0638-01-01 Rev G

Page 37

2 Components and

Mechanical Features

The following topics will be covered in this

chapter.

• System Components

• Mechanical Features

975-0638-01-01 Rev G 2–1

Page 38

Components and Mechanical Features

System Components

The Conext SW uses Xanbus, a network communications protocol developed to

send Conext SW’s operational settings and status to other Xanbus-enabled

devices. You can configure and monitor the Conext SW and every Xanbusenabled device in the system using an optional System Control Panel (SCP).

Another component is the optional Automatic Generator Start (AGS) which allows

operation with a wide range of generators, supported through a dedicated

generator input. Simply, the AGS automatically starts and stops your generator.

Solar charge controllers allow renewable energy collected from the sun to charge

batteries as might be the case in an off-grid application of Conext SW. The

charge controllers form part of the Xanbus network.

See “Xanbus-enabled Products and Other Accessories” on page 2–3 for part

numbers.

Xanbus System

The Xanbus system includes the Conext SW and other Xanbus-enabled devices.

The Conext SW is the device in a Xanbus system that typically provides network

power—500 mA at 12 VDC. All of the Xanbus-enabled devices, such as the

Conext SW, the SCP, and the AGS are able to communicate their settings and

activity to each other.

Conext SWXanbus Network ________

MPPT 60150

Solar Charge

Controller

network terminator network terminator

SCP

Xanbus System Control Panel

AGS

Xanbus Automatic Generator Start

Conext

ComBox

Figure 2-1 Xanbus System Components

The Xanbus-enabled designation (see left) means that this product works on a

Xanbus network. Xanbus-enabled products are:

• Simple to operate and routine tasks are automated.

• Controlled by software that eliminates analog signalling errors.

• Less susceptible to interference and line loss.

• Upgradable through new software releases.

2–2 975-0638-01-01 Rev G

Page 39

For detailed instructions and a complete list of Xanbus-enabled devices, visit

www.schneider-electric.com.

Xanbus-enabled Products and Other Accessories

1

System Components

5

6

3

2

Product/Accessory (Shown above) Product Number/s

1 Conext SW DC Switch Gear* 865-1016*

2 Conext SW AC Switch Gear 865-1017

3 MPPT 60 150 Solar Charge Controller 865-1030-1

MPPT 80 600 Solar Charge Controller (not shown) 865-1032

4 Conext SW On/Off Remote Switch (not shown) 865-1052

5 System Control Panel (SCP) 865-1050

6 Conext CM (not shown) 865-1058

7 Automatic Generator Start (AGS) 865-1060

8 Conext Battery Monitor 865-1080-01

9 Battery Temperature Sensor (BTS) 808-0232-02

10 3-ft network cable (0.9 m) 809-0935

25-ft network cable (7.6 m) 809-0940

75-ft network cable (22.9 m) 809-0942

* required accessory for code-compliant installation in Canada and USA.

7

8

9

10

7.6 m cable 22.9 m cable0.9 m cable

975-0638-01-01 Rev G 2–3

Page 40

Components and Mechanical Features

Conext SW Inverter/Charger Mechanical Features

1

2

TOP TOP

3

77

4

5

Figure 2-2 Conext SW Front and Side Panels

Conext SW Front and Side Panels

Before you begin to operate the Conext SW, review the front panel features

shown in Figure 2-3 and described in the next table. A detailed view of the lights

and buttons on the front panel is also shown.

Item Description

1 Front Panel contains the Inv Enable and Clear Fault | Reset buttons, as

well as various LEDs (status indicator lights). See “Front Panel Buttons

and Status LEDs” on page 2–5.

2 Network and communications ports. See “AC and DC Terminals,

Network and Communication Ports Panel” on page 2–6.

3 DC battery terminals. See “AC and DC Terminals, Network and

Communication Ports Panel” on page 2–6.

6

2–4 975-0638-01-01 Rev G

Page 41

Item Description

4 AC Ground terminals. See “AC and DC Terminals, Network and

Communication Ports Panel” on page 2–6.

5 AC line terminals. See “AC and DC Terminals, Network and

Communication Ports Panel” on page 2–6.

6 Two variable-speed cooling fans maintain a cool internal temperature

of critical components. The two fans control airflow through the

transformer and power compartments of the unit. Ensure at least

6" (152 mm) of clearance for proper ventilation.

7 Mounting holes for permanent installation.

Front Panel Buttons and Status LEDs

Conext SW Inverter/Charger Mechanical Features

1

Figure 2-3 Front Panel Buttons and Status LEDs

Item Description

1 The Inv Enabled LED illuminates steadily when invert mode is enabled.

If AC is present and invert mode is enabled, this LED remains

illuminated even though AC power is being passed through.

Gen Support LED flashes intermittently when the inverter is in AC

Support mode or Load Shave mode.

2 When AC is present and qualified, the AC IN LED will illuminate steadily

indicating also that AC is passing through.

Charging LED flashes intermittently when the Conext SW is in charge

mode and is producing DC output to charge your batteries.

32

54

3 Fault | Warning LED illuminates steadily if a fault is detected (a fault

detection condition) and flashes intermittently when a warning

condition is active.

4 Clear Fault | Reset button is used to clear any fault detections if

pressed momentarily. If held down for more than three seconds, the

unit will reset (reboot) itself.

5 Inv Enable button is used to enable and disable inverter mode.

“Enabled” is different from the inverter being “on”. When enabled, the

inverter can be on or off. When disabled, the inverter is always off.

975-0638-01-01 Rev G 2–5

Page 42

Components and Mechanical Features

Conext SW AC/DC/Ports Side Panel

ELECTRICAL SHOCK AND FIRE HAZARD

Installation must be done by qualified personnel to ensure compliance with all

applicable installation and electrical codes and regulations. Instructions for

installing the Conext SW are provided in a separate installation guide for use

by qualified installers only.

Failure to follow these instructions will result in death or serious injury.

1

2

DANGER

7

3

4

5

6

8

Figure 2-4 AC and DC Terminals, Network and Communication Ports Panel

Item Description

1 Battery Positive (+)

2 Battery Negative (–)

3 XANBUS interface ports are used to connect Xanbus-enabled devices

including the optional SCP and AGS.

4 STACKING port. Feature not available in these models.

5 Remote (REM) port provides connection for the on/off remote switch.

6 Battery temperature sensor (BTS) port provides connection for the

battery temperature sensor (supplied).

7 AC input/output wiring compartment access panel with the

compartment cover

8 AC knockouts

DC terminal connects to the positive battery cable (red).

DC terminal connects to the negative battery cable (black).

2–6 975-0638-01-01 Rev G

Page 43

3 Operation

The following topics will be covered in this

chapter.

• Start Up Behavior

• Conext SW Front Panel

• Conext SW with the SCP – System Control Panel

• Battery Charging Reference

975-0638-01-01 Rev G 3–1

Page 44

Operation

Start Up Behavior

When the Conext SW is powered up (energized) or has been reset (using the

Reset button on the front panel), all of the front panel LEDs illuminate and remain

on for a minimum of five seconds. During this interval, the fans also turn on as the

unit executes internal diagnostics.

The Conext SW inverter function is initially disabled (meaning the unit will not

invert even if there is sufficient battery voltage) every time the Conext SW is

energized for the first time. After being energized, the Inv Enable button on the

front panel can be used to enable or disable the inverter. A separate control

device called a System Control Panel (or SCP) may also be used to enable or

disable the inverter. However, the unit will remember its inverter function setting in

succeeding operations. This means that if the inverter function is left enabled

before a reset or power down-power up cycle, the inverter function will remain

enabled.

When a function is enabled, it generally means that it is “standing by” and other

conditions may have to be met before the function is utilized. For example, the

charger function on the Conext SW may be enabled, but it will not charge unless

qualified AC power is present. Similarly, even if the inverter function is enabled,

inverting may not occur if the batteries cannot supply the energy required for the

loads.

IMPORTANT: Review the “Important Safety Instructions” on page v before

operating the inverter/charger.

3–2 975-0638-01-01 Rev G

Page 45

Inverter Operation Using the Front Panel

Inverter Operation Using the Front Panel

IMPORTANT: Review the “Important Safety Instructions” on page v before

operating the inverter/charger.

Once the inverter/charger is installed, you can operate it in invert mode. The

steps below will test the unit for normal operation using the front panel.

To test the inverter using the front panel:

1. Press the Inv Enable button on the Conext SW on the front panel. The

Inv Enabled LED illuminates.

2. Turn on the main AC breaker or AC disconnect to supply AC input power to

the inverter.

NOTE: The Inv Enabled LED will remain lit. However, AC will continue to be

passed through (also called AC bypass) to the loads until conditions exist that

cause AC to be disqualified, in which case the unit will start inverting. The AC

IN LED should also illuminate. The Charging LED will start flashing to

indicate that the unit is charging the battery. The charger automatically starts

when qualified AC power is connected and when the battery is not fully

charged.

3. Turn off the main AC breaker or AC disconnect to stop AC input power from

going into the inverter.

4. Place a load on the inverter. This also usually means turning on the inverter’s

AC distribution sub-panel’s breaker switch.

5. Connect a load such as a lamp into an outlet connected to the sub-panel

circuit and turn it on. The lamp lights up.

6. Repeat step #2. The lamp will remain lit up.

7. Repeat step #3. The inverter/charger should invert immediately. The transfer

relay will make a clicking sound and the Inv Enabled LED will illuminate.

The lamp should remain lit up. If any part of this test does not happen

correctly, determine the cause before continuing to use the unit.

8. Monitor the Conext SW front panel.

The indicator LEDs on the front panel show you the operating status of the

Conext SW. A description of the LEDs is provided in Table 3-1.

If none of the front panel LEDs are on, see “General Troubleshooting

Guidelines” on page 5–2.

975-0638-01-01 Rev G 3–3

Page 46

Operation

Table 3-1 Front Panel LEDs

Icon LED Status Action (or Status Item)

Steady

Green

If generator or grid AC is unavailable

and operating conditions are met,

the Conext SW will produce AC

voltage to power loads.

You can run your appliances from

the inverter.

Flashing

Green

Steady

Green

Flashing

Green

Steady

Red

Flashing

Red

The inverter is in AC Support or

Load Shave mode.

When the Conext SW is connected

to a generator or grid and is

producing qualified AC, the AC IN

light illuminates.

Conext SW is connected to a

qualified AC source, is charging and

passing-through power to AC loads.

A fault has been detected on the

network.

A warning is detected. Investigate by examining warning

You can run your appliances from

the inverter.

You can run your appliances using

passed-through AC.

Your battery bank is being

replenished and AC loads are

receiving power from a qualified AC

source.

Investigate and clear the fault

detection condition.

logs on SCP.

Fault Detections and Warnings A fault detection condition affects the

operation of the unit. A fault detection sometimes requires user intervention by

clearing the condition using the Clear Fault button on the inverter/charger’s front

panel. Press the button once to clear the condition. See “Troubleshooting” on

page 5–1 for information on clearing fault detections from the SCP.

A warning alerts you to a condition that could possibly affect operation of the

unit. A warning usually precedes a fault detection condition.

IMPORTANT: If you are having problems with any of your loads, refer to “Inverter

Applications” on page 5–3.

3–4 975-0638-01-01 Rev G

Page 47

Operating Limits for Inverter Operation

Temperature The Conext SW series of inverter/chargers will operate at rated

power continuously at 77 °F (25 °C) with some models capable of continuous

operation at much higher ambient temperature. However, the continuous power

rating at elevated ambient temperature may differ between models. See

“Environmental Specifications” on page 6–5 for full details. In higher ambient

temperatures, if the loads draw full power for an extended period of time, the unit

may shut down to protect itself against overheating.

Surge Power The Conext SW series of inverter chargers feature a surge rating

of 200% of rated power for five seconds at 77 °F (25 °C). See “Inverter

Specifications” on page 6–2 for full details. Operating the inverter/charger in

conditions outside of normal rated power and temperature limits, however, will

result in thermal shutdown and/or significantly decreased performance. See

“Inverter Specifications” on page 6–2 for information on continuous operation at

higher than rated power.

Difficulty on starting loads The inverter/charger should be able to operate all

AC loads rated at or below its power rating. Some high horsepower induction

motors used in pumps and other motor-operated equipment require very high

surge currents to start, and the inverter/charger may have difficulty starting these

loads.

Inverter Operation Using the Front Panel

If you have problems starting certain loads, ensure that:

• The battery connections are tight and clean.

• The DC cabling is no longer than the recommended length. Refer to the

Conext SW Inverter/Charger Installation Guide for this information.

• The AC wiring is of recommended size. Refer to the Conext SW Inverter/

Charger Installation Guide for this information.

• The battery is of sufficient capacity and is fully charged.

Split-phase output during invert mode and AC bypass The Conext SW always

yields a split-phase output when inverting and during AC bypass.

• A split-phase input through L1 and L2 yields a split-phase output of L1

and L2.

• Single-phase input through L1 yields a split-phase output of L1 and L2.

• A single-phase input through L2 does not produce any output. Only the

input in Line 1 is capable of qualifying the AC coming from the power

source.

975-0638-01-01 Rev G 3–5

Page 48

Operation

Battery power during AC bypass When sufficient AC is detected by the

inverter/charger and the battery is sufficiently charged, the AC is automatically

passed through to the loads. However, if the battery is less than 12 V (for 24-volt

models), 24 V (for 48-volt model), or had been disconnected, the inverter/

charger will not pass grid AC through to the loads.

NOTICE

EQUIPMENT DAMAGE

Do not energize and operate the inverter/charger with an AC source before

connecting a battery. Do not rely solely on AC bypass power to provide energy

to connected loads. Always operate with a battery connected to the inverter/

charger.

Failure to follow these instructions can damage the inverter/charger.

NOTICE

EQUIPMENT DAMAGE

Always try to balance load between lines L1 and L2. Damage to the internal

power transformer may occur if one line is overloaded when the other line is

unloaded.

Failure to follow these instructions can damage the inverter/charger.

3–6 975-0638-01-01 Rev G

Page 49

Operating Limits for Charger Operation