Page 1

PowerLogic® ION8800

Energy & Power Quality Meter

Installation Guide

05/2007

Page 2

Page 3

Danger

This symbol indicates the presence of dangerous voltage within and outside the product enclosure

that may constitute a risk of electric shock, serious injury or death to persons if proper precautions

are not followed.

Caution

This symbol alerts the user to the presence of hazards that may cause minor or moderate injury to

persons, damage to property or damage to the device itself, if proper precautions are not followed.

Consult this document whenever this symbol is used on the meter, to determine the nature of the

potential hazard and any actions which need to be taken.

Note

This symbol directs the user’s attention to important installation, operating and maintenance

instructions.

Installation Considerations

Installation and maintenance of the ION 8800 meter should only be performed by qualified, competent personnel

that have appropriate training and experience with high voltage and current devices. The meter must be installed in

accordance with all local and national electrical codes.

If this equipment is used in a manner not specified by the manufacturer, the protection from electric shock, fire, etc.

provided by this equipment may be impaired.

DANGER

Failure to observe the following instructions may result in severe injury or death.

During normal operation of the ION 8800 meter, hazardous voltages are present on its connector pins,

and throughout the connected potential transformer (PT), current transformer (CT), direct connect without

PTs, digital (status) input, control power and external I/O circuits. PT and CT secondary circuits are capable

of generating lethal voltages and currents with their primary circuit energized. Follow standard safety precautions while performing any installation or service work (i.e. removing PT fuses, shorting CT

secondaries, etc).

Do not use digital output devices for primary protection functions. These include applications where the

devices perform energy limiting functions or provide protection of people from injury. Do not use the ION

8800

in situations where failure of the devices can cause injury or death, or cause sufficient energy to be

released that can start a fire. The meter can be used for secondary protection functions.

The ION 8800 meter’s chassis ground must be properly connected to a good earth ground for safety, and

for the noise and surge protection circuitry to function correctly. Failure to do so will void the warranty, and

create a risk of electric shock, injury or death.

When installing the meter, all voltage paths (measurement voltage and all auxiliary circuits such as the

power supply and the tariff control voltage) must be fused according to applicable local safety standards.

CAUTION

Observe the following instructions, or permanent damage to the meter may occur.

The ION 8800 meter offers a range of hardware options that affect input ratings. The ION 8800 meter’s

serial number label lists all equipped options. Applying current levels incompatible with the current inputs

will permanently damage the meter. This document provides installation instructions applicable to each

hardware option.

Do not HIPOT/Dielectric test the digital (status) inputs, digital outputs, power supply terminals or commu-

nications terminals. Refer to the label on the ION 8800 meter for the maximum voltage level the device

can withstand.

Replacing the meter battery with the wrong type or voltage rating could result in damage to the meter. Use

only a lithium LiSOCl2 battery with a rated voltage of 3.6 V, and the same construction as the original

battery, as a replacement.

3

Page 4

Network Compatibility Notice for the Internal Modem

The internal modem in meters equipped with this option is compatible with the telephone systems of most countries

in the world. Use in some countries may require modification of the internal modem’s initialization strings. If problems

using the modem on your phone system occur, please contact Schneider Electric Technical Support.

Standards Compliance

Made by Power Measurement Ltd.

PowerLogic, ION, ION Enterprise, MeterM@il and Modbus are either trademarks or registered trademarks of

Schneider Electric.

Covered by one or more of the following patents:

U.S. Patent No's 7010438, 7006934, 6990395, 6988182, 6988025, 6983211, 6961641, 6957158,

6944555, 6871150, 6853978, 6825776, 6813571, 6798191, 6798190, 6792364, 6792337, 6751562,

6745138, 6737855, 6694270, 6687627, 6671654, 6671635, 6615147, 6611922, 6611773, 6563697,

6493644, 6397155, 6236949, 6186842, 6185508, 6000034, 5995911, 5828576, 5736847, 5650936,

D505087, D459259, D458863, D443541, D439535, D435471, D432934, D429655, D427533.

4

Page 5

ION8800 Models

Feature Set Description

C

B

A

Available Options

Basic Tariff/Energy revenue meter

Feature Set C + EN50160 and IEC 61000-4-30 Class A compliant power

quality monitoring

Feature Set B + power quality analysis (waveforms and transient capture

with 1024 samples/cycle resolution)

Logging and

Recording

5 MB memory

10 MB memory

I/O Options

Ordering

Code

A

B

C

D

E

Before You Begin

Before installing the meter, familiarize yourself with the steps in this guide and

read the safety precautions presented on the “Installation Considerations”

page.

Current

Inputs

Low Current

(In=1A, 2A)

High Current

(In=5A)

8 digital Form A solid-state outputs

1 Form C mechanical relay

4 Form C solid-state outputs

8 digital Form A solid-state outputs

1 Form C mechanical relay

4 Form C solid-state outputs

8 digital Form A solid-state outputs

1 Form C mechanical relay

4 Form C solid-state outputs

1 Form C mechanical relay

4 Form C solid-state outputs

IRIG-B

1 Form C mechanical relay

4 Form C solid-state outputs

IRIG-B

Optical IEC 1107

RS-485 and optical IEC 1107

Communications Module (RS-485,

RS-232, modem, 10-Base-T Ethernet,

10-Base-FL Fiber Ethernet)

Outputs Digital Inputs Com

Communications Security

Standard

Hardware

locked

None

3 Low voltage None

3 High voltage None

3 Low voltage

3 High voltage

One RS-485 port on

Essailec connector

One RS-485 port on

Essailec connector

One RS-485 port on

Essailec connector

© 2007 Schneider Electric. All rights reserved. 5

Page 6

Meter Overview

Meter Front (Cover Closed)

Operational

LEDs

Display

Optical

Communications

Port

Operational

LEDs

Display

Optical

Communications

Port

Slot-head

Screw

varh

Pulsing

Port

Cover

Seal

Meter Front (Cover Open)

Wh

Pulsing

Port

Navigation

Buttons

Slot-head

Screw

Sealed

Buttons

Navigation

Buttons

Battery

Cover

Slot-head

Screw

varh

Pulsing

Port

Cover

Seal

Wh

Pulsing

Port

Slot-head

Screw

Meter Back

Communications

Module Cover

Plate

Essailec

Connector

6 © 2007 Schneider Electric. All rights reserved.

Ground

Te rm i n al

Page 7

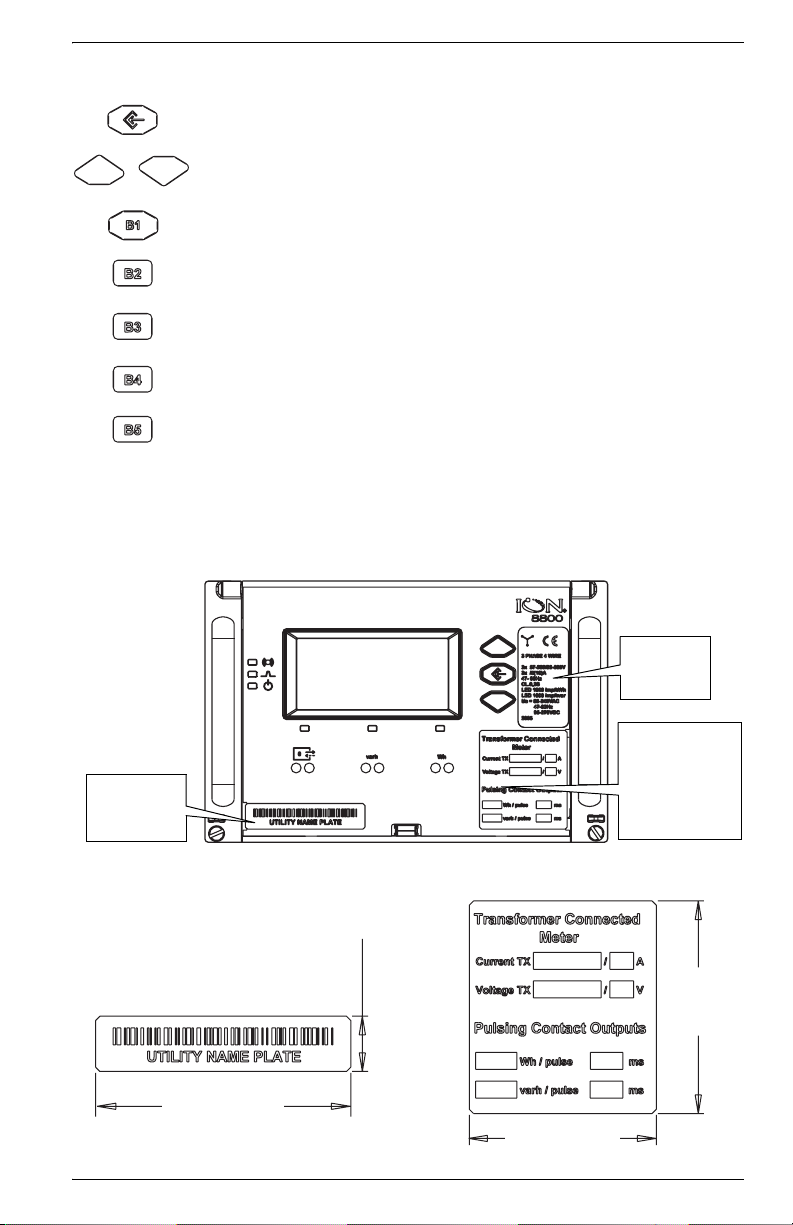

Front Panel Button Functions

ALT/ENTER: Press this button once to enter ALT mode. Press and hold to enter

Setup mode. In Setup mode, press this button to accept changes.

NAVIGATION: Press the UP / DOWN arrow buttons to highlight menu items, or

increment / decrement numbers. Press and hold to shift cursor left and right.

DEMAND RESET: Press this button to reset all maximum demand registers. Not

accessible when cover is sealed.

TEST MODE: Press this button to enter Test Mode. Billable quantities do not

accumulate when meter is in Test Mode. Not accessible when cover is sealed.

ALT CONFIG: Press this button to enter the Alternate Configuration menu. Not

accessible when cover is sealed.

MASTER RESET: Press this button to reset meter quantities. Not accessible when

cover is sealed.

SPARE: This button is not currently implemented. Not accessible when cover is

sealed.

Meter Labels

Front of Meter (Cover Closed)

Voltage and

Current

Ratings

Transformer

Factors and

Energy Pulse

Nameplate

Removable

User Label

Weigh t Factor s

Removable

User Label

Removable User Labels

Insert user labels between bezel label and

plastic lid while cover is open.

50.0 mm

(1.97“)

13.0 mm

(0.51“)

60.0 mm

(2.36“)

44.0 mm

(1.73“)

© 2007 Schneider Electric. All rights reserved. 7

Page 8

Unit Dimensions

Meter dimensions conform to DIN standard 43862.

132.2 mm

(5.21“)

Front View of Meter

190.5 mm

(7.50“)

202.1 mm

(7.96“)

4.6 mm

(0.18“)

M3 Thread

Screw

57.2 mm

(2.25“)

38.4 mm

(1.51“)

Side View of Meter

Front of Rack View

482.0 mm

(18.98“)

to fit 19 inch rack

461.0 - 469.0 mm

(18.15 - 18.46“)

260.0 mm

(10.24“)

111.8 mm

(4.40“)

132.5 mm

(5.22“)

3U high

8 © 2007 Schneider Electric. All rights reserved.

Page 9

Essailec Connections

Voltage, current, power supply, I/O and communication connections are

made via the Essailec connector on the rear of the meter. Meters can be

ordered with multiple connector configurations.

Order Options B/C Circuit & Pinout Diagrams

This pinout drawing details the various pins

on the meter side of the connector. The

table below maps the pins to their

corresponding inputs and outputs in the

meter.

Code 07 Code 05 Code 03 Code 01

Code 13 Code 17 Code 15 Code 13

Rack

Meter

ABCDE

© 2007 Schneider Electric. All rights reserved. 9

Page 10

Order Option A Circuit & Pinout Diagrams

This pinout drawing details the various pins

on the meter side of the connector. The

table below maps the pins to their

corresponding inputs and outputs in the

meter.

Code 07 Code 05 Code 03 Code 01

Rack

Code 15 Code 17 Code 15 Code 13

Meter

ABCDE

10 © 2007 Schneider Electric. All rights reserved.

Page 11

Current

Measurement Inputs

Voltage

Measurement Inputs

Form A Outputs

Form C Solid-state

Relays

Unused

Form A Outputs

Form C Mechanical

Relay

Digital Inputs or

RS-485 Com

Power Supply Inputs

(AC/DC)

Order Options A/B/C Essailec Connector Arrangement

Meter Port Essailec Connector Pin Description

I11 A01 standard

I12 A1 standard

I21 A02 standard

I22 A2 standard

I31 A03 standard

I32 A3 standard

I41 A04 optional

I42 A4 optional

Uref B0 standard

U1 B1 standard

U2 B2 standard

U3 B3 standard

DO7 & DO8 K B4 standard; Common

DO5 & DO6 K B5 standard; Common

DO5 B6 standard; NO

DO6 B7 standard; NO

DO7 B8 standard; NO

DO8 B9 standard; NO

DO1 & DO2 K C0 standard; Common

DO1 C1 standard; NO

DO1 C2 standard; NC

DO2 C3 standard; NO

DO2 C4 standard; NC

DO3 & DO4 K C5 standard; Common

DO3 C6 standard; NO

DO3 C7 standard; NC

DO4 C8 standard; NO

DO4 C9 standard; NC

-D0 Unused

-D1 Unused

-D2 Unused

-D3 Unused

DO11 & DO12 K D4 standard; Common

DO9 & DO10 K D5 standard; Common

DO9 D6 standard; NO

DO10 D7 standard; NO

DO11 D8 standard; NO

DO12 D9 standard; NO

Alarm K E0 standard; Common

Alarm E1 standard; NO

Alarm E2 standard; NC

DI-SCOM (or RS-485

Shield)

DI1 (or RS-485 +) E6 RS-485 +

DI2 (or RS-485 -) E7 RS-485 DI3 (or unused) E8 standard

-E3 Unused

Power Supply N/- E4 Power Supply neutral (-)

Power Supply L/+ E9 Power Supply line (+)

E5 standard; Common

© 2007 Schneider Electric. All rights reserved. 11

Page 12

Order Options D/E Circuit & Pinout Diagrams

This pinout drawing details the various pins

on the meter side of the connector. The

table below maps the pins to their

corresponding inputs and outputs in the

meter.

Code 07 Code 03 Code 05

Code 15 Code 15 Code 15

Rack

Meter

ABCD

12 © 2007 Schneider Electric. All rights reserved.

Page 13

Current

Measurement Inputs

Voltage

Measurement Inputs

Digital Inputs

Power Supply Inputs

(AC/DC)

Form C Solid-state

Relays

Form C Mechanical

Relay

RS-485 Com

IRIG-B Clock

Synchronization

Input

Order Options D/E Essailec Connector Arrangement

Meter Port Essailec Connector Pin Description

I11 A01 standard

I12 A1 standard

I21 A02 standard

I22 A2 standard

I31 A03 standard

I32 A3 standard

I41 A04 optional

I42 A4 optional

Uref B0 standard

U1 B1 standard

U2 B2 standard

U3 B3 standard

DI-SCOM B5 standard; Common

DI1 B6 standard

DI2 B7 standard

DI3 B8 standard

Power Supply N/- B4 Power Supply neutral (-)

Power Supply L/+ B9 Power Supply line (+)

DO1 & DO2 K C0 standard; Common

DO1 C1 standard; NO

DO1 C2 standard; NC

DO2 C3 standard; NO

DO2 C4 standard; NC

DO3 & DO4 K C5 standard; Common

DO3 C6 standard; NO

DO3 C7 standard; NC

DO4 C8 standard; NO

DO4 C9 standard; NC

Alarm K D0 standard; Common

Alarm D1 standard; NO

Alarm D2 standard; NC

-D3 Unused

RS-485 Shield D5 RS-485 Shield

RS-485 + D6 RS-485 +

RS-485 - D7 RS-485 -

-D8 Unused

IRIG-B input common D4

IRIG-B input D9 optional; clock synch input

optional; clock synch input

Common

Step 1: Mount the Meter

Meter Battery Considerations

The meter’s battery life expectancy depends on both temperature and the

amount of time the meter is without power. For typical installations, the

battery should last 10 years minimum at 25ºC meter ambient operating

temperature. The battery is field replaceable (see “Replacing the Battery” on

page 31).

© 2007 Schneider Electric. All rights reserved. 13

Page 14

Environmental Specifications (IEC62052-11)

Mounting Location Indoor use

Metrological -10 to +45ºC (14 to +113ºF)

Operating Range

-25 to +55ºC (-13 to +131ºF)

No formation of ice

Max. Altitude 2000 metres (6562 feet) above sea level

Display Operating Range -10 to +60ºC (14 to +140ºF)

Storage Range -25 to +70ºC (-13 to +158ºF)

Relative Humidity Range 5 to 95% non-condensing

Enclosure Rating IP51 (IEC60529)

Installation

DANGER

Do not power up the meter until the ground terminal is connected -- risk of

electric shock.

Meter Ground

Te rm i na l

1. Connect the ground terminal on the rear of the meter to a good earth

ground on the rack, using a 3.3 mm

2

(12 AWG) wire. Ensure that the

terminal nut is tightened down securely onto the ground wire. The wire

must be a minimum of 30 cm long (11.8”) to allow racking and

unracking.

2. Slide the meter into the DIN standard 43862 rack (half-width 19 inch/

482.6 mm rack with plug-in Essailec connector).

465 mm (18.31”)

37.9 mm

(1.49”)

451 mm (17.76”)

7 mm

(0.28”)

Cut-out for 482.6 mm (19”)

133 mm

(5.24”)

57.1 mm

(2.25”)

Chassis

M6

3. Ensure the rear connector fits tightly.

4. Tighten the 2 slot-head screws (M3 thread) into the front of the meter rack,

to hold the meter firmly in place.

Meter Essailec

Connector

Rack Essailec

Connector

ION8800

Meter

482.6 mm (19”)

Rack

Slot-head

Screws

14 © 2007 Schneider Electric. All rights reserved.

Page 15

Step 2: Wire the Digital I/O

Form C Digital Output: Mechanical Alarm Relay

Contacts common, NO, NC

Max. Switching Voltage 250 VAC/125 VDC (internally limited to 300 V peak)

Max. Switching Current 1 A AC/0.1 A DC

Operate Time (max.) 8 ms

Release Time (max.) 4 ms

Isolation to Ground 2,000 VAC for 60 s (50 Hz)

Rating Installation category II (local), Pollution degree 2

Minimum Operations 5,000,000

Form C Digital Output: Solid State Relay Outputs DO1 - DO4

Excitation External only

Contacts common, NO, NC

Max. Switching Voltage 250 VDC/ 210 VAC (internally limited to 350 V peak)

Max. Switching Current 100 mA AC/DC

Isolation to Ground 2,000 VAC for 60 s (50 Hz)

Rating Installation category II (local), Pollution degree 2

Form A Digital Outputs: Solid State Relay Outputs DO5 - DO12

Excitation External only

Max. Switching Voltage 250 VDC/ 210 VAC (internally limited to 350 V peak)

Max. Switching Current 100 mA AC/DC

Isolation to Ground 2,000 VAC for 60 sec. (50 Hz)

Rating Installation category II (local), Pollution degree 2

Digital Inputs: Solid State DI1 - DI3

Excitation External only

Minimum Pulse Width 1 ms

Maximum Pulse Rate 20 Hz

Timing Resolution 1 ms

Updated ½ cycle (does not affect timing resolution)

Isolation to Ground and to

Contacts

Rating Installation category II (local), Pollution degree 2

Hi-Voltage Range 75 - 280 VDC or VAC (RMS)

Lo-Voltage Range 15 - 75 VDC or VAC (RMS)

Hi-Voltage Input Impedance 100 kΩ

Lo-Voltage Input Impedance 20 kΩ

CAUTION

Field Hi-Pot testing to the above isolation levels is not recommended -- risk

of meter damage.

© 2007 Schneider Electric. All rights reserved. 15

2,000 VAC for 60 sec. (50 Hz)

Page 16

Step 3: Wire the Voltage and Current Inputs

Voltage Inputs

Inputs U1, U2, U3, Uref

Accuracy and Rating

Range

Fault Capture 1200 V peak (L-N)

Overload 1500 VAC RMS continuous

Dielectric Withstand 3320 VAC RMS at 50 Hz for 60 s

Input Impedance 5 MΩ/phase (phase - Vref)

Rating Measurement category IV

Current Inputs: High Current Option

Accuracy Range 0.05 - 10 A autoranging

Rated Nominal 5 A

Starting Current 0.001 A RMS

Max. Current 10 A

Fault Capture 14 A peak

Max. Voltage 288 V RMS (Cat IV IEC 61010-1)

Overload 200 A RMS for 0.5 s, non-recurring

Dielectric Withstand 3320 VAC RMS at 50 Hz for 60 s

Burden 0.25 VA per phase (at 5 A)

Impedance 10 mΩ per phase

Rating Measurement category IV

Current Inputs: Low Current Option

Accuracy Range 0.01 - 6 A autoranging

Rated Nominal 1 A and 2 A

Starting Current 0.001 A RMS

Max Current 10 A

Fault Capture 14 A peak

Max. Voltage 288 V RMS (Cat IV IEC 61010-1)

Overload 200 A RMS for 0.5 s, non-recurring

Dielectric Withstand 3320 VAC RMS at 50 Hz for 60 s

Burden 0.01 VA per phase (at 1 A)

Impedance 10 mΩ per phase

Rating Measurement category IV

57 - 288 L-N VAC RMS

99 - 500 L-L VAC RMS

NOTE

The appropriate Volts Mode setting is included with each wiring diagram.

Refer to Step 7 to learn how to configure Volts Mode on the meter.

CT & PT Selection

Consult your local instrument transformer expert, either at the local utility or

through a vendor or supplier, to obtain CT and PT selection standards for

high accuracy revenue metering applications in your regions.

16 © 2007 Schneider Electric. All rights reserved.

Page 17

4-Wire Wye, 3-Element, Direct Connection Diagram

LINE

288 V L-N / 500 V L-L max.

VOLTS MODE = 4W-Wye

LOAD

4-Wire Wye, 3-Element, 3 PTs Connection Diagram

LINE

Use PTs for voltages over 288 V L-N / 500 V L-L.

Wye (Star) wiring for PT primaries and secondaries.

VOLTS MODE = 4W-Wye

4-Wire Wye, 2½-Element, 2 PTs Connection

LINE

LOAD

LOAD

Phase 2 voltage (U2) displayed by meter is derived from phase 1 and

phase 3, not measured. U2 will display a value even if no voltage is

present on Phase 2. U2 values are only accurate for balanced loads.

VOLTS MODE = 3W-Wye

© 2007 Schneider Electric. All rights reserved. 17

Page 18

3-Wire Solid-Grounded Wye, 3-Element, Direct Connection

LINE

When the common or star point of a 3-wire Wye system is grounded,

the meter may be connected directly without using PTs, provided that the

phase voltages are within the meter’s range.

VOLTS MODE = 4W-Wye

LOAD

3-Wire Delta, 2½-Element, Direct Connection

LINE

LOAD

500 V L-L max.

VOLTS MODE = Delta

3-Wire Delta, 2-Element 2 PTs & 2 CTs

LINE

Use PTs for voltages over 500 V L-L.

VOLTS MODE = Delta

18 © 2007 Schneider Electric. All rights reserved.

LOAD

Page 19

3-Wire Delta, 2½-Element, 2 PTs & 3 CTs

LINE

Use PTs for voltages over 500 V L-L

VOLTS MODE = Delta

Single Phase Connection Diagram

LINE

PF = 0.9 (25°) Lag

LOAD

LOAD

288 V L-N / 500 V L-L max. Use PTs for higher voltages.

VOLTS MODE = Single

Using Potential Transformers

System Mode Voltage Range Requires PTs

Wye/

Single Phase

Delta

© 2007 Schneider Electric. All rights reserved. 19

up to 288 V L-N or 500 V L-L no

over 288 V L-N or 500 V L-L yes

up to 500 V L-L no

over 500 V L-L yes

Page 20

Step 4: Wire the Communications

ION8800 meters are equipped with one standard optical port. Other

communications ports are available as options.

The Communications module cover plate (found on the back of the meter)

should never be removed unless a communications module is installed in its

place.

Infrared Connections (COM1)

Connect an optical probe cable (not included) to communicate between the

meter optical port and a PC serial port.

Interface IEC 1107 optical port

Location Front of meter

Data Rate 1,200 – 19,200 bps

Isolation Optical

Duplex Half

RS-485 Connections (COM2 and COM3)

Ports Av ai lable

Connectors Captured-wire (+, –, Common*, Shield)

Wire Shielded 2 or 3-conductor RS-485 cable

Maximum Cable Length 1219 m (4,000 ft) total for entire bus

Data Rate 300 – 57,600 bps

Maximum Devices (per bus) 32

Isolation Optical

Duplex Half

* Use optional Common wire for improved communications performance.

COM2: optional module or Essailec

COM3: optional module only

RS-232 Connections (COM3 optional module)

DB9 Null Modem

DTE

Wiring Diagram

(meter)

51

96

(computer)

Specification Meter Connected to Computer

Connector Type DB9 female end for mating with male connector on the meter

Wire Null modem RS-232 cable Straight-through RS-232 cable

Maximum Cable Length 15.2 m (50 ft)

Data Rate 300 – 115,200 bps

Isolation Optical

Duplex Full

20 © 2007 Schneider Electric. All rights reserved.

Null modem cable pinout

Pin 3 - Transmit Data - Pin 2

Pin 2 - Receive Data - Pin 3

Pin 7 - Request to Send- Pin 8

Pin 8 - Clear to Send- Pin 7

DTE

Pin 5 - Signal Ground- Pin 5

Pin 6 - Data Set Ready- Pin 4

Pin 4 - Data Terminal ReadyPin 6

Meter Connected to External

Modem

Page 21

Ethernet Connections (optional module)

10Base-T

Pin 1: Transmit Data +

Pin 2: Transmit Data Pin 3: Receive Data Pin 6: Receive Data +

Wire Type High quality Category 3 or 5 unshielded twisted pair cable

Connector Type RJ45 modular

Maximum Length 100 m (328 ft)

Type IEEE 802.3 10Base-T for 10 Mbps base band CSMA/CD LANs

Data Rate 10 Mbps

Isolation Transformer isolated to 1500 VAC/2250 VDC RMS

Max. Connections Allowed 4 simultaneous

10Base-FL (Fiber)

Wire Type 62.5/125 micrometer multimode fiber optic cable

Connector Type ST

Maximum Length 2000 m (6562 ft)

Data Rate 10 Mbps

Isolation Optical

NOTE

ST type fiber cables

Ethernet connection should be made to either the Fiber p ort or RJ45 port, not

both, or communications conflicts may result.

Ethernet TCP/IP Service Ports

Only one EtherGate

connection per port

is allowed at a time

ION 7700

Modbus RTU 7701

Modbus TCP 502

EtherGate (COM2) 7802

EtherGate (COM3) 7803

DNP TCP 20,000

Protocol Port

Internal Modem Connection (COM4 optional module)

Pin 3: Ring

Pin 4: Tip

Connector Type RJ11

Wire Type Part 68 compliant telephone cord

Data Rate 300 bps – 56 kbps

Error Correction V.42 LAPM, MNP 2-4, V.44

Data Compression V.42 bis/MNP 5

© 2007 Schneider Electric. All rights reserved. 21

Page 22

Step 5: Wire the Power Supply

ION8800 meter power supply connections are found on the Essailec

connector.

Single Phase Power Supply

Fuse for N/terminal required if

neutral is

ungrounded.

Rated Inputs

Rating Installation category II (local), Pollution degree 2

Dielectric Withstand 2,000 VAC RMS for 60s (50Hz)

Max. Burden 9 W (20 VA) for base unit without comm module

Ride-through

85 - 240 VAC ±10%

110 - 270 VDC ±10%

Min: 120 ms (6 cycles @ 50 Hz)

Typical: 0.5 - 5 s (depending on input voltage and

configuration)

(47 - 63 Hz)

Step 6: Power Up the Meter

DANGER

Before you apply power to the meter, ensure that ground is securely

connected and that the supply voltage is within the allowed range of the

meter’s power supply.

Step 7: Set Up the Meter Using the Front Panel

The following Setup screens are available for meter configuration via the

front panel:

BASIC SETUP

DEMAND SETUP

COM1 SETUP

COM2 SETUP

COM3 SETUP

COM4 SETUP

NETWORK SETUP

FORMAT SETUP

DISPLAY SETUP

SECURITY SETUP

The following example shows Volts Mode setup using the meter front panel.

Press and hold

Press

Press

Press

Press ALT/ENTER and

hold for 3 seconds

enter Setup Mode

from Display Mode.

22 © 2007 Schneider Electric. All rights reserved.

Use arrow buttons to

move up and down in

to

list. Press ALT/ENTER to

select Basic Setup.

Use arrow buttons to

move up and down in

list. Press ALT/ENTER to

select Volts Mode.

Press

Use arrow buttons to

move up and down in

list. Press ALT/ENTER to

select 4W-WYE.

Page 23

The following table lists all settings that can be configured via the front panel,

with the meter cover seal in place.

Menu Setting Description Range (Values) Default

4W-WYE

Volts Mod e

PT Primary

PT Secondary

CT Primary

CT Secondary

I4 Primary

I4 Secondary

U1 Polarity

Basic Setup

U2 Polarity

U3 Polarity

I1 Polarity

I2 Polarity

I3 Polarity

I4 Polarity

Phase Rotation Power system’s phase rotation 123, 132 123

SWD Subinterval

SWD #

Subintervals

Demand

SWD Pred Resp 0,00 to 99,00 70

Protocol Specifies which protocol is active

Baud Rate

Transmit Delay

COM1

Unit ID

Serial Port Parity and stop bits for the port 8N1,8N2,8E1,8E2,8O1,8O2 8N1

The power system’s configuration –

WYE, DELTA, etc.

The Potential Transformer’s primary

winding voltage rating

The Potential Transformer’s

secondary winding voltage rating

The Current Transformer’s primary

winding current rating

The Current Transformer’s

secondary winding current rating

Primary rating for the I4 current

transformer

Secondary rating for the I4 current

transformer

The polarity of the Potential

Transformer on U1

The polarity of the Potential

Transformer on U2

The polarity of the Potential

Transformer on U3

The polarity of the Current

Transformer on I1

The polarity of the Current

Transformer on I2

The polarity of the Current

Transformer on I3

The polarity of the Current

Transformer on I4

Intervals used to compute your

Sliding Window Demand values

The number of SWD periods in use 1 to 15 3

Specifies COM port baud rate

during serial communications

Specifies the meter’s transmit delay

setting (in seconds)

Identifies the meter during serial

communications

DELTA

3W-WYE

SINGLE

DEMO

1 to 999 999 999 120,00

1 to 999 999 999 120,00

1 to 999 999 999 5

1 to 999 999 999 5

1,0 - 999 999,00 5

1,0 - 999 999,00 5

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

1 to 5 940 600

ION, Modbus RTU, DNP,

DLMS, Factory

1 200 to 19 200 9 600

0 to 1,0 0,010

1 to 9 999

4W-WYE

ION

From serial

number

2

© 2007 Schneider Electric. All rights reserved. 23

Page 24

Menu Setting Description Range (Values) Default

ION, Modbus RTU, Modbus

3

, DNP, DLMS,

Protocol Specifies which protocol is active

Specifies COM port baud rate

during serial communications

Specifies the meter’s transmit delay

setting (in seconds)

Identifies the meter during serial

communications

COM2

1

Baud Rate

Transmit Delay

Unit ID

Serial Port Pari ty an d s to p b it s f or the port 8N1,8N2,8E1,8E2,8O1,8O2 8N1

Port Lo ca ti on

Specifies physical connection point

for COM2

Protocol Specifies which protocol is active Same as COM2 ION

Specifies COM port baud rate

during serial communications

Specifies the meter’s transmit delay

setting (in seconds)

Identifies the meter during serial

communications

COM3

1

Baud Rate

Transmit Delay

Unit ID

Serial Port Pari ty an d s to p b it s f or the port 8N1,8N2,8E1,8E2,8O1,8O2 8N1

RS-232 or RS-485 Specifies RS-232 or RS-485 RS-232, RS-485 RS-232

RTS/CTS

Handshake

Specifies if hardware flow control is

used during RS-232 communication

Protocol Specifies which protocol is active

Baud Rate

COM4

Transmit Delay

Unit ID

1

Specifies COM port baud rate

during serial communications

Specifies the meter’s transmit delay

setting (in seconds)

Identifies the meter during serial

communications

IP Address Specifies TCP/IP Ethernet address

Mask Specifies Subnet Mask 0.0.0.0 to 255.255.255.0 None

Gateway Specifies Ethernet gateway (if used)

Network Setup

SMTP Address Specifies location of SMTP Server

Master

EtherGate, ModemGate,

GPS: Truetime/Datum

GPS: Arbiter, Factory

ION

300 to 57 600 9 600

0 to 1,0 0,010

1 to 9 999

From serial

number

Essailec or Comm Module Essailec

300 to 115 200 9 600

0 to 1,0 0,010

1 to 9999

RTS with delay

RTS/CTS

ION, Modbus RTU, DNP,

DLMS, GPS: Truetime/Datum

GPS: Arbiter, Factory

From serial

number

RTS + delay

ION

300 to 115 200 9 600

0 to 1,0 0,010

1 to 9 999

000.000.000.000 to

255.255.255.255

000.000.000.000 to

255.255.255.255

000.000.000.000 to

255.255.255.255

From serial

number

None

None

None

2

2

2

24 © 2007 Schneider Electric. All rights reserved.

Page 25

Menu Setting Description Range (Values) Default

Phase Labels Specifies how phases are labelled ABC, RST, XYZ, RYB, 123 123

PF Symbol LD (leading)/LG (lagging) LD/LG, +/-, CAP/IND LD/LG

Digit Group

Date Format Specifies how dates are displayed

Show DST Determines if DST is shown or not Yes or No Yes

Format

Volts Dec im al

Current Decimal

Power Decimal

Update Rate

Contrast Higher numbers are sharper 0 to 9 7

Backlight Timeout

DMD Lock

TEST Mode TO

Display

Display Scale

Scaling Mode

Delta Vectors

Modify Passwd Modifies standard password 0 to 999 999 999 0

Disable Security Disables meter security Disabled or Enabled Enabled

Web Config Allow configuration via web server Disabled or Enabled Enabled

Security

Ack Alarms

Specifies symbols used to delimit

thousands and decimal place holder

Number of decimal places

displayed for voltages

Number of decimal places

displayed for currents

Number of decimal places

displayed for power measurements

Sets when the display updates (in

seconds)

Specifies the time it takes (in

seconds) for the backlight to turn off

(0 = the display stays lit indefinitely)

Controls the minimum allowable

time between consecutive demand

resets (in seconds)

Defines how long the meter remains

in TEST mode before switching back

to NORM mode

Determines the scale applied to

displayed parameters

Specifies whether parameters are

divided or multiplied by the scale

before being displayed

Specifies how vector diagrams are

displayed when in Delta mode

Sends a pulse to acknowledge

alarms when selected

1

A baud rate of 300 bps is only intended for paging applications.

2

Serial number = PA-0302B222-01, Unit ID = 2222

3

Available on ION8800A and B meters only.

1000.0 or 1,000.0 or 1000,0 1000,0

MM/DD/YYYY, DD/MM/YYYY,

YYYY/MM/DD

1. to 123 456 789,XXX 1,XX

1. to 123 456 789,XXX 1,XXX

1. to 123 456 789,XXX 1,XXX

1 to 6 1

0 to 7 200 (two hours)

0 (disabled) to 5 184 000

(60 days)

1 to 999 999 1000

Multiply or Divide Divide

System or Instrument System

--

MM/DD/

YYYY

300 (five

minutes)

216 000

(25 days)

30 minutes

© 2007 Schneider Electric. All rights reserved. 25

Page 26

The following table lists all settings that can be configured using the ALT

CONFIG menu (not available when meter cover is sealed).

Setting Description Range (Values) Default

IR Config Allows meter configuration via the front optical port Disabled or Enabled Enabled

When meter is locked, most meter configuration is

Meter Lock

Clear Alarms Sends a pulse to clear alarms when pushed - -

1

prevented, as are meter resets

1

After a meter is unlocked, it automatically relocks if you do not perform any

Locked or Unlocked

Locked

configuration for 30 minutes. This function is not available on nonhardware lockable meters.

2

Default = ‘Locked’ on meters ordered with Hardware Lock option.

Default = ‘Unlocked’ on all other meters (setting is non-functioning).

Step 8: Verify Meter Operation

Three LEDs on the left-hand side of the Front Panel indicate the following:

Alarm (red) Top LED is user programmable; by default, it flashes to indicate

serious meter faults. Contact Technical Support if this occurs.

Indicator (green) Middle LED is user programmable.

Power (green) Bottom LED indicates the meter is powered. The light should

always remain on when the meter is in service.

Phasor Diagrams

You can also view the meter’s phasor diagram in real time. Use the Phasor

Viewer available in ION Setup v2.1 and later (free to download from the

website) to verify your meter’s wiring. See the ION Setup online help for

details.

2

NOTE

The following DELTA phasor diagrams are represented in system mode.

DELTA phasors for UNITY Power Factor (resistive load)

Applicable Volts Mode = DELTA

U31

Rotation 123

26 © 2007 Schneider Electric. All rights reserved.

I3

U12

I2

U23

I1

Rotation 132

U23

I2

I1

U12

I3

U31

Page 27

WYE - 123 Rotation

Applicable Volts Mode = 4W-WYE and 3W-WYE

Rotation

Active Power

-kW

U3

I2

I1

U2

I3

+kvar

U1

Reactive Power

Q1: Lagging PF (-) Q2: Leading PF (+)

U3

I3

Rotation

U1

I2

U2

I1

Active Power

+kW

Q4: Leading PF (+) Q3: Lagging PF (-)

U3

Rotation

I1

U2

I2

I3

-kvar

U1

WYE - 132 Rotation

Applicable Volts Mode = 4W-WYE and 3W-WYE

Rotation

Active Power

-kW

U2

I3

I1

U3

U2

I2

+kvar

U1

U3

Reactive Power

Rotation

I3

U2

Reactive Power

Q1: Lagging PF (-) Q2: Leading PF (+)

U2

Rotation

I3

U3

I1

U1

I2

I2

U1

I1

Active Power

+kW

Q4: Leading PF (+) Q3: Lagging PF (-)

U2

Rotation

Rotation

I1

U3

I3

I2

Reactive Power

-kvar

U1

I2

U3

I1

U1

I3

© 2007 Schneider Electric. All rights reserved. 27

Page 28

2 Element (3Wire) DELTA - 123 Rotation

Applicable Volts Mode = DELTA

Q2: Leading PF (+)

U31

I2

Rotation

I1

I3

U31

U23

I1

I3

U23

I2

Active Power

-kW

Rotation

2 Element (3Wire) DELTA - 132 Rotation

Applicable Volts Mode = DELTA

Q2: Leading PF (+) Q1: Lagging PF (-)

U23

I3

Rotation Rotation

I1

U31

Active Power

-kW

I2

U12

U12

U12

Reactive Power

+kvar

Q1: Lagging PF (-)

U31

Rotation Rotation

I2

U23

I3

U12

I1

Active Power

+kW

Q4: Leading PF (+) Q3: Lagging PF (-)

U31

Reactive Power

-kvar

Reactive Power

+kvar

I3

U23

U23

Rotation Rotation

I2

I3

U31

I1

U12

I2

U12

I1

Active Power

+kW

Q4: Leading PF (+) Q3: Lagging PF (-)

U23

I3

I1

I2

28 © 2007 Schneider Electric. All rights reserved.

U12

Reactive Power

-kvar

U23

I1

I2

I3

U12

Page 29

Step 9: View Meter Data

NORM mode

Use the Up and Down buttons to scroll through NORM mode display screens.

NORM Screen Contents

kWh kWh delivered/received

kvarh kvarh delivered/received

kVAh kVAh delivered/received

Peak Demand Delivered Maximum delivered kW value (timestamped)

Peak Demand Received Maximum received kW value (timestamped)

Peak Demand Reset Number of Demand Resets (timestamped)

Q Metering Approximated varh measurements

Disk Simulator Simulates mechanical watt-hour meter disk

All Segments Black screen to indicate functioning display

ALT mode

Press the Alt/Enter button once for ALT display modes. Press the Up or Down

buttons to scroll through displays.

ALT Screen Contents

Name Plate 1

Name Plate 2 Sliding window settings

Event Log Most recent high priority (255) events

Vector Diagram

Instantaneous Voltage Average voltage, L-N or L-L

Instantaneous Current Phase current, average current

Instantaneous Power

Instantaneous Demand kW delivered/received

Voltage Harmonics (3 screens) Per-phase voltage harmonic histograms

Current Harmonics (3 screens) Per-phase current harmonic histograms

Availability Number of nines measurement

Instantaneous Demand kW delivered/received

Owner, firmware version, TAG 1 & 2,

meter serial number

Phasors and values for phase current/

voltage

kW total, kvar total, kVA total, power

factor

© 2007 Schneider Electric. All rights reserved. 29

Page 30

TOU Display Screen Contents

TOU Energy by Rate kWh delivered values for each TOU rate

kW Peak Demand Maximum kW delivered for each TOU rate

Previous Billing Energy kWh delivered in PB

Prev Billing Peak Demand Maximum kW delivered in PB

Previous Season Energy kWh delivered for each TOU rate in PB

Prev Season Peak Demand Max kW delivered for each TOU rate in PB

Prev Billing/Season Energy

Prev Bill/Season Pk Dem

kWh delivered/received in PB & billing

season

Max kW sd received from PB & billing

season

Prev Billing/Season Energy kvarh del/rec in PB & billing season

Prev Bill/Season Pk Demand kvar del/rec in PB & billing season

Prev Billing/Season Energy kVAh del/rec from PB & billing season

Pre Bill/Season Pk Demand kVA del/rec in PB & billing season

Active TOU Rate Active TOU billing rate

Active TOU Season Active TOU billing season

Flicker Flicker measurements from U1, U2 & U3

Frequency Frequency information

NOTE

PB = Previous Billing period.

TEST Mode

TEST Screen Contents

kWh Test TEST mode kWh delivered/received

kvarh/KVAh Test

Instantaneous Demand Test TEST mode kW delivered/received

TEST mode kvarh/KVAh delivered/

received

To Enter TEST Mode

Meter Type Method

Standard Meter

(no hardware lock)

Hardware Locked Meter

Use ION software

Open cover and press TEST mode button (see

“Front Panel Button Functions” on page 7)

Open cover and press TEST mode button (see

“Front Panel Button Functions” on page 7)

NOTE

The meter always returns to NORM mode after exiting TEST mode.

30 © 2007 Schneider Electric. All rights reserved.

Page 31

Replacing the Battery

The battery in the ION8800 meter keeps the real time clock running when

supply power is lost. Replace the battery if the meter has been stored for an

extended period of time without power (longer than two years). If the meter

will be without power for an extended length of time, disconnect the battery

cable so that the battery maintains its 10-year shelf life.

Battery Specifications

Ty pe

Nominal Capacity 1.0 Ah

Rated Voltage 3.6 V

Connector Gold-plated

The battery can be changed when the meter is either powered or

unpowered.

Lithium LiSOCl

NOTE

Replacing the battery on an unpowered meter resets the internal clock and

may affect revenue parameters.

To replace the battery

1. To prevent electrostatic damage to the unit, make sure you are

grounded or wear an anti-static wrist strap during this procedure.

2. Open the front cover of the meter.

3. Remove the Phillips screw that holds the battery cover in place and

remove the battery cover.

4. Remove the battery from the housing and disconnect the battery

connector from the meter.

Battery Dimensions

2

Gold-plated

Connector

Battery

Connector

Battery Cover

Battery

5. Connect the new battery’s wire to the meter. and place the battery in the

housing.

6. Replace the battery cover and the Phillips screw.

7. Close the cover of the meter.

© 2007 Schneider Electric. All rights reserved. 31

Page 32

Meter Security

Security features depend on the meter ordering options. See below.

All ION8800 meters

Standard security includes traditional anti-tamper mechanical sealing points

on the meter case and cover.

ION8800 meters with Hardware Locked Security Option

Standard security plus a hardware-locked security system that prevents

modification of revenue quantities after the meter is sealed.

Hardware Locked Security Option

To make configuration changes to billing parameters on a hardware-locked

meter, you must first unlock the meter. The Meter Lock setting is located in the

ALT Config menu, which is reached by pressing the ALT Config button under

the anti-tamper sealed cover (see “ALT Config Button” on page 7). This

button cannot be activated remotely with a Hardware Lock meter.

Typical values that are protected include:

kWh, kvarh, kVAh delivered, received, del-rec, del+rec.

kW, kvar, kVA and Sliding Window demand min and max values.

Digital Outputs controlling the energy pulsing applications.

All Power system settings, including PT and CT ratios.

For a complete list of locked values specific to your meter and its firmware,

contact Technical Support.

Anti-Tamper Sealing Methods

The ION8800 meter uses the following anti-tamper sealing methods.

Meter Seals

Rear of Meter

Meter Case

Sealing Bars

32 © 2007 Schneider Electric. All rights reserved.

Page 33

Front of Meter

Front Panel

Sealing Point

Cover

Sealing Point

Front Panel

Sealing Point

The meter incorporates sealing bars and chassis screws with through-holes,

through which traditional lead/wire seals can be inserted. When utilized,

these lead/wire seals effectively prevent unauthorized personnel from

gaining access to meter internals or to buttons under the cover.

These seals are installed as follows:

1. Insert the sealing wire through both the screw hole and sealing bar.

Sealing Bar

Screw with

Through-hole

Sealing Wire

Lead Sealing Tab

2. Twist the wire and crimp the lead-sealing tab on to the wire.

© 2007 Schneider Electric. All rights reserved. 33

Page 34

34 © 2007 Schneider Electric. All rights reserved.

Page 35

Page 36

ION8800

Installation Guide

Schneider Electric

2195 Keating Cross Road

Saanichton, BC Canada V8M 2A5

www.powerlogic.com

Electrical equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

70000-0280-01

© 2007 Schneider Electric. All rights reserved.

05/2007

Loading...

Loading...