Samsung WF-S1062, WF-S862 Service manual

WASHING MACHINE

WF-S1062/YLR

S862/YLR

BASIC MODEL

WF-F1061

SERVICE Manual

WF-S1062 |

|

THE FEATURE OF PRODUCT |

1. Delay start

2. Coloureds

3. Hand wash

4. Prewash

5. Quick wash

Refer to the service manual in the itself (http://itself.sec.samsung.co.kr/) for the more information.

CONTENTS |

|

1. PRECAUTIONS |

|

1-1. SAFE PRECAUTIONS .......................................................................................................................................... |

1 |

1-2. PRECAUTIONS UPON INSTALLATION ................................................................................................................ |

2 |

2. THE FEATURE OF PRODUCT |

|

2-1. SPECIFICATIONS.................................................................................................................................................. |

5 |

2-2. OVERVIEW OF THE WASHING MACHINE .......................................................................................................... |

6 |

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT ...................................................................................... |

7 |

3. PRODUCT SPECIFICATIONS |

|

3-1. OVERVIEW OF THE CONTROL PANEL ............................................................................................................... |

8 |

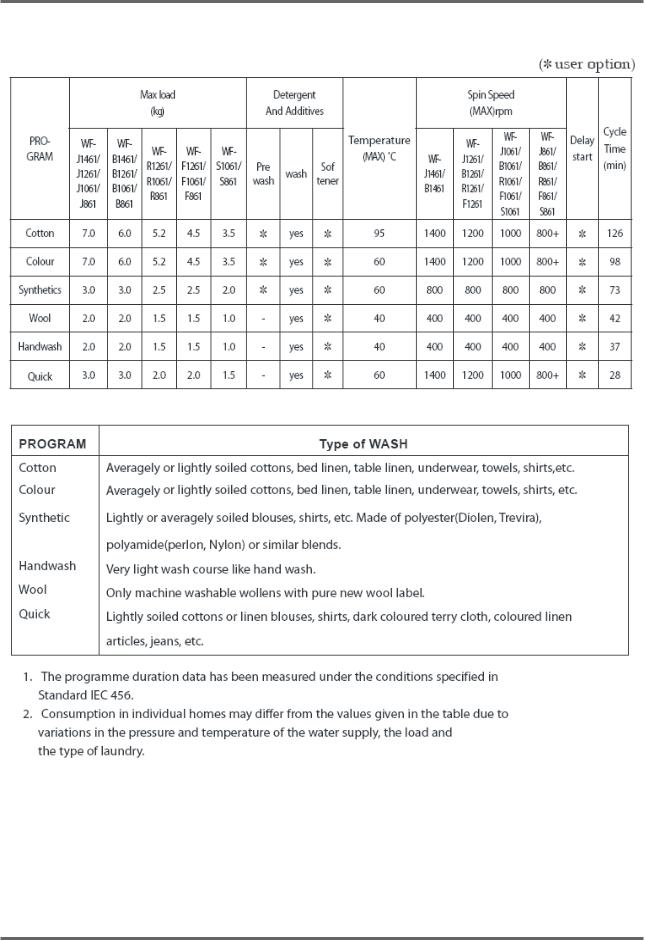

3-2. PROGRAMME CHART .......................................................................................................................................... |

9 |

3-3. MAIN FUNCTION................................................................................................................................................. |

11 |

3-4. TECHNICAL POINT ............................................................................................................................................. |

13 |

3-5. DESIGNATION OF MAIN COMPONENTS .......................................................................................................... |

16 |

4. ALIGNMENT AND ADJUSTMENTS |

|

4-1. GENERAL ERROR FUNCTION........................................................................................................................... |

19 |

4-2. TEST MODE......................................................................................................................................................... |

21 |

5. ASSEMBLY AND DISASSEMBLY |

|

5-1. TOOLS FOR DISASSEMBLY AND ASSEMBLY .................................................................................................. |

22 |

5-2. ASSEMBLY AND DISASSEMBLY ........................................................................................................................ |

23 |

6. TROUBLE DIAGNOSIS5 |

|

6-1. TROUBLE DIAGNOSIS........................................................................................................................................ |

32 |

6-2. PROBLEM CHECKING AND METHOD OF PCB................................................................................................. |

34 |

6-3. DETAILED DIAGNOSIS ....................................................................................................................................... |

40 |

7. EXPLODED VIEWS AND PARTS LIST |

|

7-1. EXPLODED VIEWS OF TOP(FRONT) ................................................................................................................ |

41 |

7-2. EXPLODED VIEWS OF TUB ............................................................................................................................... |

42 |

7-3. EXPLODED VIEWS OF CASE ............................................................................................................................ |

43 |

7-4. PARTS LIST ......................................................................................................................................................... |

44 |

CONTENTS

8. BLOCK DIAGRAM ................................................................................................................................... |

47 |

9. WIRING DIAGRAM |

|

9-1. PCB ASSY’ LAYOUT............................................................................................................................................ |

48 |

9-2.CONNECTOR & RELAY TERMINALS DESCRIPTION (MAIN PCB).................................................................... |

49 |

10. SCHEMATIC-DIAGRAM |

|

10-1. EMZ (WF-S1062) ............................................................................................................................................... |

50 |

11. PCB CIRCUIT DIAGRAM

11-1. PCB CIRCUIT DIAGRAM ................................................................................................................................... |

51 |

12. CIRCUIT DESCRIPTION |

|

12-1. OVERALL SYSTEM ........................................................................................................................................... |

52 |

12-2. AC INPUT & POWER CIRCUIT ......................................................................................................................... |

53 |

12-3. DRIVING SYSTEM CIRCUIT ............................................................................................................................ |

54 |

12-4. MOTOR CIRCUIT .............................................................................................................................................. |

55 |

12-5. SENSOR DETECTION CIRCUIT ...................................................................................................................... |

56 |

12-6. MOTOR TACHO INPUT SYSTEM .................................................................................................................... |

57 |

13. REFERENCE INFORMATION |

|

13-1. MODEL NAME ................................................................................................................................................... |

58 |

13-2. TERMINOLOGY................................................................................................................................................. |

59 |

13-3. FABRIC CARE CHART ...................................................................................................................................... |

60 |

13-4. ELECTRICAL WARNINGS................................................................................................................................. |

60 |

13-5. Q & A .................................................................................................................................................................. |

61 |

1. Precautions

1-1. Safe Precautions

1. Do not allow the customer to repair the product.

It may cause personal injury or product damage when the unit is serviced by unqualifi ed personnel.

It may cause personal injury or product damage when the unit is serviced by unqualifi ed personnel.

2. Disconnect power to the appliance before servicing.  Be aware of the possibilities of an electric shock.

Be aware of the possibilities of an electric shock.

3. Do not use multi-plug.

Power outlet may be overloaded causing the socket to overheat.

Power outlet may be overloaded causing the socket to overheat.

4. Check for any damage on power plug or power outlet.

Replace it immediately if it has problem. (It may cause an electric shock or fi re)

Replace it immediately if it has problem. (It may cause an electric shock or fi re)

5. Make sure to earth the product.  May cause electric shock.

May cause electric shock.

6. Do not clean the product with water.

May cause electric shock / fi re or shorten product life.

May cause electric shock / fi re or shorten product life.

7. The wiring harness should be free from moisture and connected properly during serving.  It should be proof against any external force.

It should be proof against any external force.

8. Remove any dust or dirt in the product, wiring section and connections during servicing.  Protect against possibilities of fi re due to tracking etc.

Protect against possibilities of fi re due to tracking etc.

9. Check for any water trace on electrical parts, harness, etc.  Replace the parts or wipe dry the water.

Replace the parts or wipe dry the water.

10.Check the assembled status of the parts after servicing.

Check if the product is assembled in the same status as before servicing.

Check if the product is assembled in the same status as before servicing.

11.Be sure not to pull on the power cord but to unplug it by holding the plug.  Beware of possibility of electric shock or fi re when the power cord is damaged.

Beware of possibility of electric shock or fi re when the power cord is damaged.

12.Unplug the power plug from the outlet when the washing machine is not used.  Beware of possibility of electric shock or fi re while lightening.

Beware of possibility of electric shock or fi re while lightening.

13.Do not use or put fl ammable materials (including gasoline, alcohol, thinner etc) around the washing machine.

Flammable materials may spark an explosion or fi re.

Flammable materials may spark an explosion or fi re.

14.Do not put a water containing bowl or wet laundry on the washing machine.

It may cause an electric shock or fi re, or shorten the product life when its water penetrates into the washing machine.

It may cause an electric shock or fi re, or shorten the product life when its water penetrates into the washing machine.

15.Do not install the washing machine in a place where it is exposed to snow or rain etc.  It may cause an electric shock or fi re and shorten the product life.

It may cause an electric shock or fi re and shorten the product life.

16.Do not press control buttons with pointed objects such as pins, needles, etc.  It may cause an electric shock or other problems.

It may cause an electric shock or other problems.

17.Check the washing machine is leveled horizontally on the fl oor and is installed properly.  Vibration may shorten the product life.

Vibration may shorten the product life.

18.Make sure to use connectors when connecting wires.

If wires are connected without connectors, it may cause a tracking fi re.

If wires are connected without connectors, it may cause a tracking fi re.

19.When the washing machine is to be laid down for servicing, put a pad on the fl oor and lay the product on its side slowly.

If the wash machine is laid on its front, internal components may be damaged by the tub.

If the wash machine is laid on its front, internal components may be damaged by the tub.

1

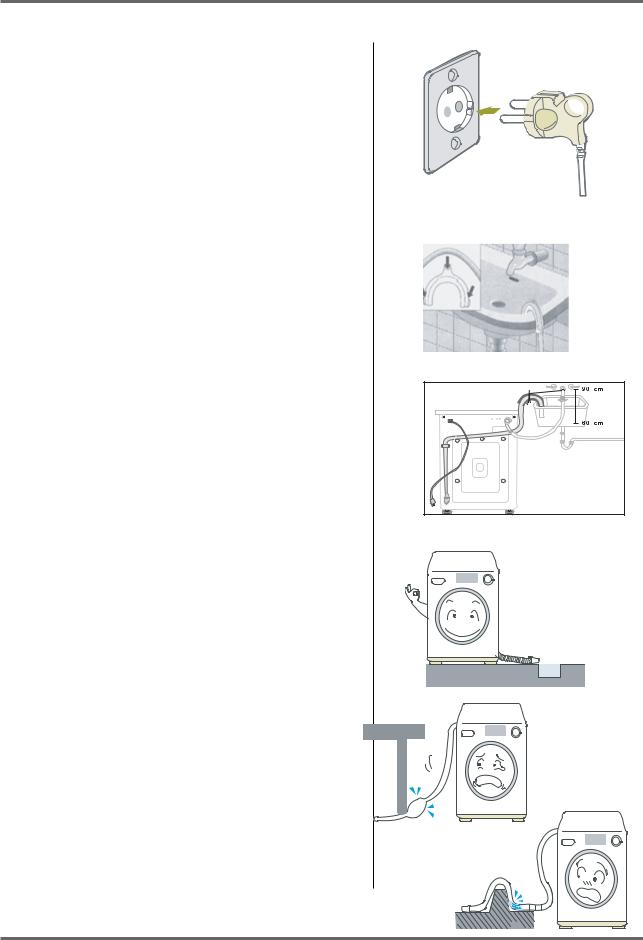

1-2. Precautions upon Installation

■ How to Remove Shipping Bolts

1. Remove the screws by using the supplied spanner.

3. Fill the holes with the supplied plastic caps.

2. Remove the shipping bolts from the back of the unit.

4. Keep the shipping bolts and screws for future use.

■ Precautions before Installation

The unit is quite heavy. So, make sure to have 2 or more personnel move it.

Install the unit at a place with a wall outlet easily accessible.

Make sure that the unit stands on a fi rm and leveled fl oor.

Keep the unit away from places in which it is freezing, especially in winter.

keep it away from direct sunlight or high humidity, and install it in a place with good ventilation.

Keep the unit away from heat appliances such as a heater.

2

■ Grounding

Make sure to ground the unit to prevent electric leak age or shock.

With a grounded receptacle

It does not need an additional grounding.

■ Water Drainage

Hook the drain hose over the Wash Basin or Laundry Tub or plug the end of the drai hose into the Standpipe.

-Hook the drain hose over the Wash Basin or Laundry Tub or plug the end of the drain hose into the Standpipe.

-The outlet end of the drain hose must be at least 60-90 cm above the base of the machine.

Seal the drain pipe connections.

-If not, it may cause water leakage.

Prevent water from siphoning away.

-If the end of the drain hose is put in water, it could siphon away water during washing. So, make sure that the end of the drain hose is not put in water.

Note: Caution must always be exercised to avoid collapsing or damaging the drain hose. For best performance the drain hose should not be restricted in any way, through elbows, couplings or excessive lengths.

3

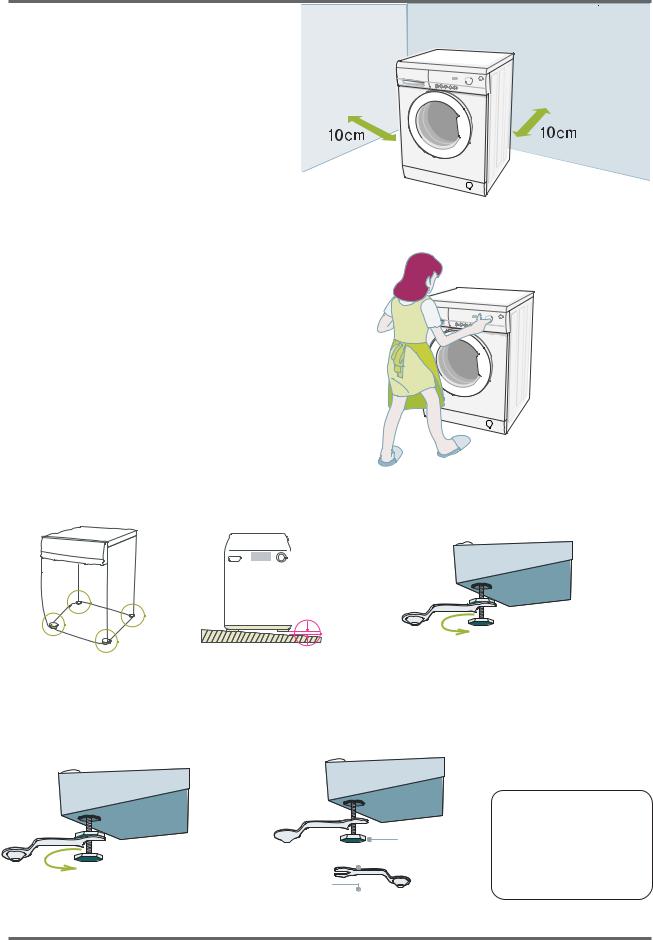

■ How to Level the Unit

1.Select an installation place. Install the unit with 10cm or more

clearance from its surrounding walls.

2.Check if the unit is leveled.

If the unit wabbles, adjust the leveling legs.

3.Adjust the leveling legs.

The 4 leveling legs should touch the fl oor all together.

When the unit is not leveled

Lift up the unit a little bit and adjust the shortest.

Turn the leveling bolt counter clockwise as shown in the picture above (The leveling leg gets longer.)

After adjusting the leveling bolt, tighten the lock nut by turning it clockwise.

Lock Nut

Leveling Bolt

Spanner

Flat Head

Screwdriver

Caution

Caution

Tighten the lock nut after the leveling. If not, it could generate vibrations & noises.

4

2. THE FEATURE OF PRODUCT

2-1. SPECIFICATIONS

WASH TYPE |

|

|

FRONT LOADING TYPE |

|

||

|

|

|

|

|

||

DIMENSION |

|

NET |

W 598mm X D 340mm X H 844mm |

|||

GROSS |

W 668mm X D 456mm X H 890mm |

|||||

|

||||||

WATER PRESSURE |

|

|

50 kPa ~ 800 kPa |

|

||

|

|

|

|

|

|

|

WEIGHT |

|

NET |

55 kg |

|

||

GROSS |

58 kg |

|

||||

|

|

|||||

WASH and SPIN CAPACITY |

|

|

3.5 kg (DRY LAUNDRY) |

|

||

|

|

|

|

|

|

|

|

WASHING |

220V |

|

180W |

||

|

240V |

|

180W |

|||

|

|

|

|

|||

|

WASHING |

220V |

|

1800W |

||

POWER CONSUMPTION |

AND HEATING |

240V |

|

2100W |

||

|

|

|

|

|

|

|

|

SPIN |

MODEL |

WF-S1062 |

|

WF-S862 |

|

|

220~240V |

250W |

|

200W |

||

|

|

|

||||

|

PUMPING |

34 w |

|

|||

WATER CONSUMPTION |

|

|

43ℓ(STANDARD COURSE) |

|

||

|

|

|

|

|||

SPIN REVOLUTION |

MODEL |

WF-S1062 |

|

WF-S862 |

||

rpm |

1000 |

|

800 |

|||

|

|

|||||

PACKAGE Wt |

PAPER |

1.8kg |

|

|||

PLASTIC |

0.8kg |

|

||||

|

|

|||||

Drain Hose

Plug

5

2-2. OVERVIEW OF THE WASHING MACHINE

OPTION

6

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

THE COMPARATIVE SPECIFICATIONS OF PRODUCT

THE COMPARATIVE SPECIFICATIONS OF PRODUCT

Item |

3.5kg |

Old (4.5kg) |

|

|

|

Model Name |

WF-S1062 |

WF-F1061 |

|

|

|

Capacity (Washing) |

3.5kg |

4.5kg |

|

|

|

Drum Capacity |

43ℓ |

48ℓ |

|

|

|

Washing Motor |

HXGP2I |

HXGN2I |

|

|

|

Supply/Drain |

All temperatures /Drain pump |

All temperatures /Drain pump |

|

|

|

Balancer |

Weight |

Weight |

|

|

|

SIZE(W*D*H) |

598*340*890 |

598*404*890 |

|

|

|

THE COMPARATIVE SPECIFICATIONS OF PRODUCT

THE COMPARATIVE SPECIFICATIONS OF PRODUCT

3.5kg

|

Model Name |

WF-S1062 |

|

WF-S862 |

|

|

|

|

|

|

|

|

Function |

|

|

|

|

|

|

|

Water-level Control |

O |

|

O |

|

|

|

|

|

|

Add Laundry |

X |

|

X |

|

|

|

|

|

Exterior Replacement |

|

Specifi cations |

||

|

Part Name |

|

||

|

|

|

|

|

|

|

|

|

|

|

Cover Door |

Neat-white |

|

Neat-white |

Design |

|

|

|

|

Handle Door |

Neat-white |

|

Neat-white |

|

|

|

|||

|

|

|

|

|

7

3. PRODUCT SPECIFICATIONS

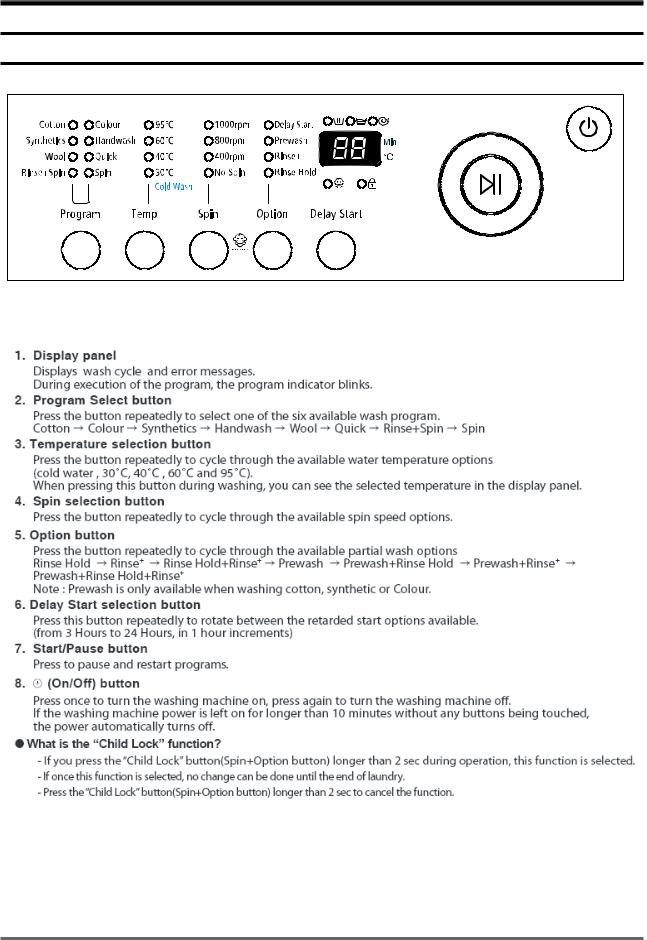

3-1. OVERVIEW OF THE CONTROL PANEL

8

3-2. PROGRAMME CHART

WF- |

|

WF- |

|

WF- |

|

WF- |

|

WF- |

J1462/ |

|

B1462/ |

|

R1262/ |

|

F1262/ |

|

S1062/ |

J1262/ |

|

B1262/ |

|

R1062/ |

|

F1062/ |

|

S862 |

J1062/ |

|

B1062/ |

|

R862 |

|

F862 |

|

|

J862 |

|

B862 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WF- |

|

WF- |

|

WF- |

|

WF- |

J1462/ |

|

J1262/ |

|

J1062/ |

|

J862/ |

B1462/ |

|

B1262/ |

|

B1062/ |

|

B862/ |

|

|

R1262/ |

|

R1062/ |

|

R862/ |

|

|

F1262 |

|

F1062/ |

|

F862/ |

|

|

|

|

S1062 |

|

S862 |

|

|

|

|

|

|

|

9

3-3. MAIN FUNCTION

1)Auto power S/W off function

●After power on, the auto power S/W off function automatically switches power off for you if you do not press selection button for 10 minutes

●After selecting the function, the auto power S/W off function automatically switches power off for you if you do not press start/pause button for 10 minutes

●until 5 minutes past, After fi nishing the last function, the auto power S/W off function automatically switches power off for you if you do not re-select the course button or manual button

2)Door open function

● Door just can be opened at water level 24.80 KHz over, water temperature 55 below, motor off, if power is off door is not opened (only auto-door model)

●If door is open during the operating, all operating is halted, and door error message will be displayed (2-digit panel displays “dE” 4-digit panel displays “door”) and error melody will coming out

●Door open error can be cleared by closing the door. the operating keeps going on

3)Rinse hold function

●If rinse hold function selected, the operating is fi nished , the machine do not drain the water after last rinse

4)No spin function

●If no spin function selected, the operating is fi nished after last rinse

5)Drain function

●Drain function is over, after pumping out the water for 2 minutes , without motor rotating

6)Pre-washing function

●Pre-washing function can be selected ,when you choice the following mode; cotton, coloreds, syn thetics, delicates, baby cotton, baby coloreds, baby delicates, baby stains

●Water level/reverse time is the same with the selected course

●Pre-washing takes about 16 minutes

7)Power-out compensation function

●If power is out on selected process, the process before power out is stored to EEPROM, once power is

back the process before power out continues.

● When power is back, washing process starts from the process at the point of the power out, rinse/drain process starts from the initial process.

POWER-OUT COMPENSATION FUNCTION PROCESS

START |

WASHING |

RINSE/DRAIN |

RINSE/DRAIN |

FINISH |

|

|

START |

PROCESS |

|

|

|

|

||

|

POWER OUT |

|

POWER OUT |

|

|

|

SAVE DATA |

|

|

|

|

|

|

|

SAVE DATA |

|

to EEPROM |

|

|

|

|

|

|

|

to EEPROM |

POWER BACK |

|

POWER BACK |

|

|

MICOM RESTORE |

|

MICOM RESTORE |

|

10

8)Fuzzy washing function (weight-sensing)

●After fi nishing initial water supply, when the fall of the water level needs supplementary water supply, Sensing function perceives the weight with the supplementary water supply numbers and starts to work. Under the course of Cotton, or Coloureds, if the supplementary water supply numbers become over 2 times the function is going at default condition ( high water level ), if 1 time that is going at middle level, if 0 below low water level, heating hours and rinse hours depend on the above data.

ECO PRE mode is selected, the process going on at default condition.

|

|

Washing hours |

Rinse water level |

|

|

Cotton |

|

Coloureds |

|

|

|

|

||

|

|

|

|

|

High |

Default |

|

Default |

Default |

Middle |

Default-20 min |

|

Default-10min |

23.80KHZ |

Low |

Default-30 min |

|

Default-15min |

24.10KHZ |

After sensing weight, above hours is decreased from above default hours

9) Bubble - detecting function

At the each condition of washing&dehydrating , rinse&dehydrating , hydrating, bubble -detecting function

works, this function works 5times normally, if the function detects bubbles at 6 times , the bubble-detecting function stops and go on to the next process.

●The bubble-detecting function during washing & dehydrating to rinse & dehydrating

after 2 times instant dehydrating and before main dehydrating, if the water level is under 24.50KHZ, Bubble

→Detecting function thinks there are bubbles and add the bubbles-removing rinse, needing hours are above hours and 8 Min 40 sec.

→The bubble-detecting function during single hydrating process

after 2 times instant dehydrating and before main dehydrating , if the water level is 24.50KHZ below or during main dehydrating, water level data is 24.50KHZ below Bubble-detecting function thinks there are bubbles and add the bubbles-removing rinse 1 times, needing hours are above hours and 5 min 50 sec.

Bubble-detecting function operating process |

||

|

500rpm |

|

|

220rpm |

|

|

18 sec |

|

|

laundry scattering |

|

draining &reverse |

unbalance |

|

detecting range |

||

50 sec |

||

|

||

|

bubble detection |

|

|

(default water level 24.50KHZ below) |

|

11

10)Unbalance detecting & laundry balance positioning system

Just before the hydrating process and just after reversal rotation for balancing laundry position, this function is carried out

The initial 6 sec is the period of reversal rotation for balancing laundry position , Drum rotates 50rpm for initial 6 sec

Next 12 sec, the rotation increases the speed from 50 rpm to 95 rpm slowly

During the next 8 sec, drum rotates at the speed of 95 rpm, the sensor decides the degree of laundry unbalance with TACHO data which is attached to motor

If the degree of unbalanced laundry is over 6 times to default value, laundry balancing system carryies out feed back process 3 times.

Unbalance detecting & laundry balance positioning system |

490rpm |

500rpm |

210rpm |

220rpm |

20 sec |

laundry scattering |

unbalance |

detecting range |

95rpm |

11) R.P.M control

The rotating motor enables the magnetics( i.e generator) to generate magnetic fl ux in proportion to r.p.m, magnetic fl ux induced by coil sensor in the opposite side produces the wave like the fi gure below to dΦ/dt and via rectangular wave generating circuit, the waves reaches MICOM and micom controls r.p.m with the pulse, count and cycle inputted by program.

<COIL electrical wave at both ends> |

V (VOLT) |

|

Vp

T (HOUR)

12

3-4. TECHNICAL POINT

1) Motor on/off time at each course

|

|

|

|

|

unit:sec |

|

Model |

|

|

Washing |

|

Motor r.p.m |

|

Course |

Cw |

Off |

Ccw |

Off |

||

|

||||||

Cotton |

13 |

4 |

13 |

4 |

50 |

|

Coloureds |

12 |

8 |

12 |

8 |

50 |

|

Synthetics |

7 |

8 |

7 |

8 |

40 |

|

Wool |

2 |

48 |

2 |

48 |

50 |

|

Handwash |

2 |

58 |

2 |

58 |

50 |

|

Quick |

12 |

8 |

12 |

8 |

50 |

|

Pre |

10 |

10 |

10 |

10 |

50 |

2) Final dehydrating r.p.m at each course

unit:rpm

Course |

Model |

WF-S1062 |

WF-S862 |

|

|||

|

|

|

|

Cotton |

|

1000 |

800 |

|

|

|

|

Coloureds |

|

1000 |

800 |

|

|

|

|

Synthetics |

|

800 |

800 |

|

|

|

|

Wool |

|

400 |

400 |

|

|

|

|

Quick |

|

1000 |

800 |

|

|

|

|

Handwash |

|

400 |

400 |

|

|

|

|

You can change the r.p.m to the above a table by use spin button under no spin situation.

13

3) The water supply control at each process cycle

Model

WF-S1062,WF-S862

Process cycle

Pre Washing |

Cold water 5L/min |

Washing |

Cold water 10L/min + (Hot water 10L/min) |

Rinse |

Cold water 10L/min |

Final rinse |

Cold water 10L/min + Cold water 5L/min |

4) The water level data at each course

|

|

|

|

unit:Khz |

|

|

Model |

Default water level |

Supplementary water |

Supplementary water |

|

Course |

|

(kHz) |

START (kHz) |

End (kHz) |

|

Normal |

Washing |

24.60 |

25.00 |

24.80 |

|

Rinse |

23.60 |

24.50 |

24.20 |

||

|

|||||

Colours |

Washing |

24.60 |

25.00 |

24.80 |

|

Rinse |

23.60 |

24.50 |

24.20 |

||

|

|||||

Synthetics |

Washing |

23.80 |

25.00 |

24.30 |

|

Rinse |

23.65 |

24.55 |

24.30 |

||

|

|||||

Wools /Hand- |

Washing |

23.45 |

24.35 |

24.00 |

|

wash |

Rinse |

23.15 |

24.35 |

24.00 |

|

Quick |

Washing |

24.40 |

25.00 |

24.70 |

|

Rinse |

23.80 |

25.00 |

24.70 |

||

|

14

5) The other water level data

unit:Khz

The water data unter each conditon |

|

WF-S1062,WF-S862 |

|

1st water supply (only preparation) |

|

25.50 |

1st water supply level to washing tub |

Overfl ow error |

|

21.50 |

The water supplied reach 2/3 of door |

Bubble |

|

24.50 |

Bubble -detecting water level |

detectingatwashing/rinse/dehydrating |

|

|

|

Bubble detecting rinse water level |

|

23.00 |

The water level which can detect bubbles |

Water level which can open door |

|

24.80 over |

It is possible to open the door |

Water level which can drive heater |

|

25.50 |

Safety water level of wash heater |

Water level which can reset the drain |

|

25.50 |

The water level can be detected after 1st drain- |

|

|

|

ing |

If water level is 15KHZ below or 30 KHZ above , Sensor-pressure is out of order so needs changing.

15

3-5. DESIGNATION OF MAIN COMPONENTS

3-5-1. Normal / Reverse Revolution of Motor and R. P. M. Control

8 |

Rotor |

9 |

+ |

|

|

|

|

|

|

|

CW |

5 |

Stator coil |

1 |

0 |

|

|

|

- |

8 |

Rotor |

9 |

+ |

|

|

|

|

|

|

|

CCW |

|

|

|

5 |

|

|

|

- |

|

Stator coil |

|

10 |

5 |

|

|

|

|

<Figure1> |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

DEE PS-H GIH |

|

OHC AT |

|

DEE PS-E LDD IM |

|

ROT ) CET C05 OR 1( P |

ROT OR |

|

|

|

|

|

|

ROT ATS |

|

|

|

|

|

|

|

|

|

|

|

STATOR |

|

||

|

|

WASHING MOTOR |

|

H |

|||||

<Figure2>

(± 7%) |

STATOR(5.1) |

STA |

ROTOR(8.9) |

TACHO(3.4) |

PROTEC |

“H”(mm) |

Code-No. |

Remark |

|

TOR(5.10) |

TOR(6.7) |

||||||||

|

|

|

|

|

|

|

|||

Resist |

2.07Ω |

0.90Ω |

1.99Ω |

38.8Ω |

0 |

39 |

DC31- |

WF-S1062 |

|

ancevalue |

00002K |

WF-S862 |

|||||||

|

|

|

|

|

|

||||

Rated |

|

|

|

220~240V/50Hz |

|

|

|

||

value |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||

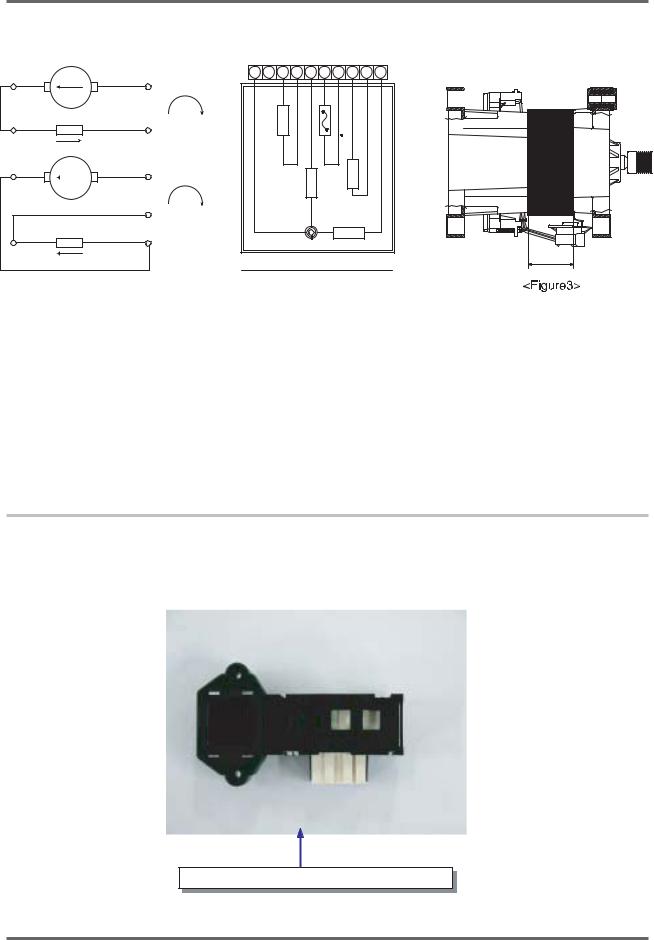

3-5-2. Door safety Device

When Door is closed, door stay closed. if “set” is operated, power supplied to ,wires have solenoid or bimetal keep the door closed, and electronical power fl ows between and make it operate.

DC64-00653A ( EMZ )

16

3-5-3. Detergent tub and water supply value

A Detergent tub is composed of housing and 3 drawers . supplied water fl ows into the 3 drawer-detergent tub by way of classifi er at each washing process.

three open drainage way with detergent and supplied water by way of connector located under the housing fl ows into washing tub.

the water supply valve is composed of a cold water valve(2way) and water fl ow per Min in the valve is below.

|

Hot water |

|

Cold water valve (2 way) |

||

|

valve (1 way) |

|

|

|

|

|

(Option) |

|

V1 |

|

V2 |

water fl ow(L/min) |

10ℓ |

|

12 ℓ |

|

5 ℓ |

resistance value |

4.4 kΩ |

|

4.2 kΩ |

|

4.2 kΩ |

power consumption |

|

AC 220~240V |

50HZ |

||

usable water pressure |

|

|

0.5 ~ 8Kg /cm3 |

||

3-5-4. Shock absorber and buffer spring

This wash machine is equipped with 2 Shock absorbers with same capacity and with 2 buffer springs. 2 Shock absorber are placed under the tub and outside case , 2 buffer springs are placed on the right and left of the upper side of outside case.

Shock absorber function: during wash, dehydration absorb the shock. buffer spring: buffering the vibration

device |

capacity of Shock absorber |

Shock absorber |

8±2 kg |

17

4. ALIGNMENT AND ADJUSTMENTS

4-1. GENERAL ERROR FUNCTION

1.An occurrence of an Error will make a sound of error melody for 5sec and continuously show one of the Error Displays from the following errors. (But, Fault Check Led will fl ash for 0.5sec.)

2.All of the steering parts will be off at that time until that error was released.

3.Water Supply Error

-If there is no higher change in water frequency than 100Hz for 2 minutes during the initial time of water supply and if water level doesn’t reach the preset level in 10 minutes, this error will occur.

This error will be released using Start/Pause button, which performs the initial condition of operation.

-Display : “4E”

4.Water Drain Error

-If water level frequency is still lower than the reset level frequency (25.20kHz) in 10 minutes after starting of water drain, this error will occur.

This error will be released using Start/Pause button, which performs the initial condition of operation.

-Display : “5E”

5.Over Flow Error

-If an abnormal water level frequency is sensed (for occurrence of Over Flow :21.00kHz), Auto Power Off may release this error and continuously progress water drain until the frequency reached 25.00kHz.

-If Over Flow is also sensed even after the following check of water level frequency indicating that error, it functions to progress water drain.

-Display : “OE”

6.Door Open Error

-This error will be released by closing Door.

-Display : “dE”

7.Unbalance Error

-This error will be released by pressing start/pause S/W.

-DISPLAY : “ UE”

8.Water Heater Error

-This error will be released by turning off Power S/W.

-Display : “HE1”(Over Heat),

-Display : “HE2”, indicating no operation of HE.

9.Pressure S/W (Single Part Trouble) Error

Frequency signals(kHz) generated by water level S/W

Water Level |

Low |

High |

Abnormal Frequency |

30.00 KHz |

15.00 KHz |

-If the above frequency signals are displayed longer than 5sec, it indicates Pressure S/W Error.

-Drain water for 3 minutes for that Error, and turn OFF water drain pump. Pressure S/W Error display “ IE” will be shown. .

10.Abnormal Water Temperature ERROR

-Water drain begins if abnormal water temperature is sensed at the initial time of water supply. If the frequency higher than 25.20KHz is sensed, water will be drained by force.

-Display : “CE”

-This error will be released by turning off Power S/W.

18

Loading...

Loading...