Samsung WF326LAS, WF326LAW, WF316LAS, WF316CAW, WF316BAC User Manual

...

WASHING MACHINE

Model code : WF306LAW/XAA

WF316LAW/XAA

WF316LAS/XAA

WF326LAS/XAA

WF306BHW/XAA

WF316BAW/XAA

WF316BAC/XAA

WF306BAW/XAA

WF306C1W/XAA

WF316CAW/XAA

SERVICE WF326LAW/XAA

MANUAL

WASHING MACHINE |

|

THE FEATURE OF PRODUCT |

1. SilverCare

2. SuperSize Capacity

3. Direct Drive Motor

4. Child Lock

5. My Cycle

CONTENTS

1. Precautions |

|

1-1. Safety Precautions............................................................................................................................. |

1-1 |

1-2. Precautions upon Installation............................................................................................................. |

1-2 |

2. PRODUCT SPECIFICATIONS |

|

2-1. THE FEATURE OF PRODUCT......................................................................................................... |

2-1 |

2-2. SPECIFICATIONS OF PRODUCT.................................................................................................... |

2-2 |

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT.................................................................. |

2-3 |

2-4. OPTION SPECIFICATIONS.............................................................................................................. |

2-4 |

3. OPERATING INSTRUCTIONS AND INTALLATION |

|

3-1. Each Key and Display........................................................................................................................ |

3-1 |

3-2. FUNCTION OF CONTROL KEYS..................................................................................................... |

3-2 |

3-3. MAIN FUNCTIONS............................................................................................................................ |

3-6 |

3-4 SPECIAL FUNCTIONS....................................................................................................................... |

3-8 |

4. ALIGNMENT AND ADJUSTMENTS |

|

4-1. GENERAL ERROR FUNCTION........................................................................................................ |

4-1 |

4-2. TEST MODE...................................................................................................................................... |

4-2 |

5. ASSEMBLY AND DISASSEMBLY |

|

5-1. TOOLS FOR DISASSEMBLY AND ASSEMBLY................................................................................ |

5-1 |

5-2. DISASSEMBLY.................................................................................................................................. |

5-2 |

5-3. ASSEMBLY........................................................................................................................................ |

5-5 |

6. TROUBLE SHOOTING |

|

6-1. TROUBLE DIAGNOSIS..................................................................................................................... |

6-1 |

6-2. PROBLEM CHECKING AND METHOD OF PCB.............................................................................. |

6-3 |

6-3 Control Panel...................................................................................................................................... |

6-4 |

6-4 Driving Unit......................................................................................................................................... |

6-5 |

7. EXPLODED VIEWS AND PARTS LIST |

|

7-1. ASSY-COVER TOP............................................................................................................................ |

7-1 |

7-2. ASSY-TUB OUTER(SPIN BASKET).................................................................................................. |

7-2 |

7-3. ASSY-CASE OUTER......................................................................................................................... |

7-3 |

7-4. BOLT/SCREW PARTS LIST.............................................................................................................. |

7-4 |

CONTENTS

8. ELECTRICAL PARTS LIST...................................................................................................................... |

8-1 |

9. BLOCK DIAGRAM................................................................................................................................... |

9-1 |

10. WIRING DIAGRAM.............................................................................................................................. |

10-1 |

11. PCB DIAGRAM.................................................................................................................................... |

11-1 |

12. SCHEMATIC-DIAGRAMS .................................................................................................................. |

12-1 |

13. CIRCUIT DESCRIPTIONS................................................................................................................... |

13-1 |

14. REFERENCE INFORMATION |

|

14-1. MODEL NAME............................................................................................................................... |

14-1 |

14-2. TERMINOLOGY............................................................................................................................ |

14-2 |

14-3. FABRIC CARE CHART.................................................................................................................. |

14-3 |

14-4. ELECTRICAL WARNINGS............................................................................................................ |

14-4 |

14-5. Q & A.............................................................................................................................................. |

14-5 |

1. |

P r e c a uti o n s |

|

|

|

|

1 - 1. |

S af et y P r e c a uti o n s |

|

|

|

|

1. |

D o |

n ot all o w t h e c u st o m e r t o r e p ai r t h e p r o d u ct. |

It may cause personal injury or product damage when the unit is serviced by unqualified personnel.

2. |

Di s c o n n e ct |

p o w e r t o t h e a p pli a n c e b ef o r e s e r vi ci n g. |

|

|

|

|

|||||||

Be aware of the possibilities of an electric shock. |

|

|

|

|

|

||||||||

3. |

D o |

n ot u s e |

m ulti - pl u g. |

|

|

|

|

|

|

|

|

|

|

Power outlet may be overloaded causing the socket to overheat. |

|

|

|||||||||||

4. |

C h e c k f o r a n y d a m a g e o n p o w e r pl u g o r p o w e r o utl et. |

|

|

|

|

||||||||

Replace it immediately if it has problem. (It may cause an electric shock or fire) |

|

||||||||||||

5. |

M a k e s u r e t o e a rt h t h e p r o d u ct. |

|

|

|

|

|

|

|

|||||

May cause electric shock. |

|

|

|

|

|

|

|

|

|

||||

6. |

D o |

n ot cl e a n t h e p r o d u ct |

wit h |

w at e r. |

|

|

|

|

|

|

|

||

May cause electric shock / fire or shorten product life. |

|

|

|

|

|||||||||

7. |

T h e |

wi ri n g |

h a r n e s s s h o ul d |

b e f r e e f r o m |

m oi st u r e a n d c o n n e ct e d p r o p e rl y d u ri n g s e r vi n g. |

||||||||

It should be proof against any external force. |

|

|

|

|

|

|

|||||||

8. |

R e m o v e a n y d u st o r di rt i n t h e p r o d u ct, |

wi ri n g s e cti o n |

a n d |

c o n n e cti o n s |

d u ri n g |

s e r vi ci n g. |

|||||||

Protect against possibilities of fire due to tracking etc. |

|

|

|

|

|||||||||

9. |

C h e c k f o r |

a n y |

w at e r t r a c e |

o n |

el e ct ri c al |

p a rt s, |

h a r n e s s, |

et c. |

|

|

|

||

Replace the parts and /or wipe dry the water. |

|

|

|

|

|

|

|||||||

1 0. C h e c k t h e |

a s s e m bl e d st at u s of t h e p a rt s aft e r |

s e r vi ci n g. |

|

|

|

||||||||

Check if the product is assembled in the same status as before servicing. |

|

|

|||||||||||

1 1. B e |

s u r e n ot t o |

p ull o n t h e |

p o w e r c o r d |

b ut t o |

u n pl u g it |

b y |

h ol di n g t h e |

pl u g. |

|

||||

Beware of possibility of electric shock or fire when the power cord is damaged. |

|

||||||||||||

1 2. U n pl u g t h e p o w e r pl u g f r o m t h e o utl et |

w h e n t h e |

w a s hi n g m a c hi n e i s n ot u s e d. |

|

||||||||||

Beware of possibility of electric shock or fire while lightening. |

|

|

|

||||||||||

1 3. D o |

n ot u s e |

o r |

p ut fl a m m a bl e |

m at e ri al s (i n cl u di n g |

g a s oli n e, |

al c o h ol, t hi n n e r et c ) |

a r o u n d t h e |

||||||

|

w a s hi n g |

m a c hi n e. |

|

|

|

|

|

|

|

|

|

||

Flammable materials may spark an explosion or fire. |

|

|

|

|

|

||||||||

1 4. D o |

n ot p ut a |

w at e r c o nt ai ni n g |

b o wl o r |

w et l a u n d r y o n t h e |

w a s hi n g m a c hi n e. |

|

|||||||

It may cause an electric shock or fire, or shorten the product life when its water penetrates into the washing machine.

1 5. D o n ot i n st all t h e |

w a s hi n g m a c hi n e i n a pl a c e |

w h e r e it i s e x p o s e d t o s n o w o r r ai n et c. |

||||

It may cause an electric shock or fire and shorten the product life. |

|

|||||

1 6. D o n ot p r e s s c o nt r ol b utt o n s |

wit h p oi nt e d o bj e ct s |

s u c h a s pi n s, |

n e e dl e s, et c. |

|||

It may cause an electric shock or other problems. |

|

|

|

|||

1 7. C h e c k t h e |

w a s hi n g |

m a c hi n e i s l e v el e d h o ri z o nt all y |

o n t h e fl o o r |

a n d i s i n st all e d p r o p e rl y. |

||

Vibration may shorten the product life. |

|

|

|

|||

1 8. M a k e s u r e t o u s e c o n n e ct o r s |

w h e n c o n n e cti n g |

wi r e s. |

|

|||

If wires are connected without connectors, it may cause a tracking fire. |

||||||

1 9. W h e n t h e |

w a s hi n g |

m a c hi n e i s t o b e l ai d d o w n f o r s e r vi ci n g, p ut a p a d o n t h e fl o o r a n d l a y t h e |

||||

p r o d u ct o n it s si d e sl o wl y. |

|

|

|

|

||

If the wash machine is laid on its front, internal components may be damaged by the tub.

1-1

1-2. Precautions upon Installation

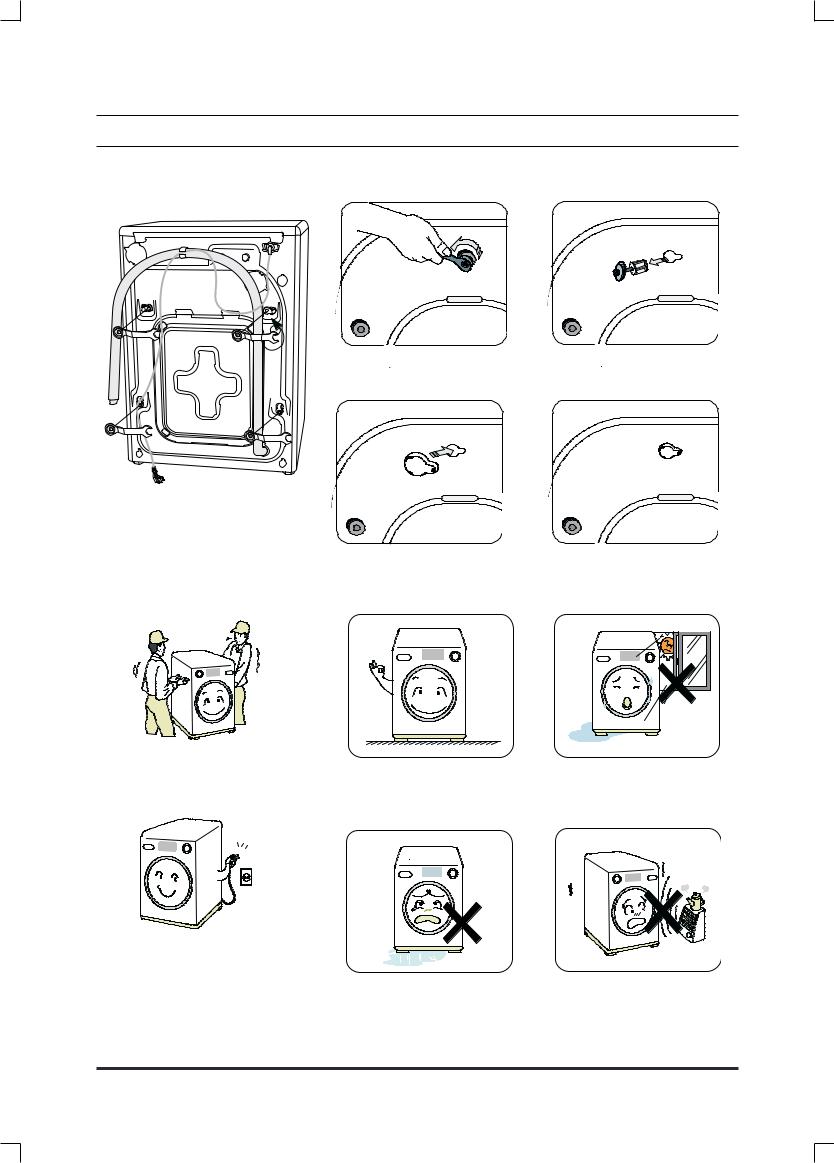

■ How to Remove Shipping Bolts

1.Remove the screws by using the supplied spanner.

2.Remove the shipping bolts from the back of the unit.

3. Fill the holes with the supplied |

4. Keep the shipping bolts and |

plastic caps. |

screws for future use. |

■ Precautions before Installation |

|

The unit is quite heavy. So, make sure to have 2 or more personnel move it.

Install the unit at a place with a wall outlet easily accessible.

Make sure that the unit stands on a firm and leveled floor.

Keep the unit away from places in which it is freezing, especially in winter.

eep it away from direct sunlight or high humidity, and install it in a place with good ventilation.

Keep the unit away from heat appliances such as a heater.

1-2

1-2. Precautions upon Installation

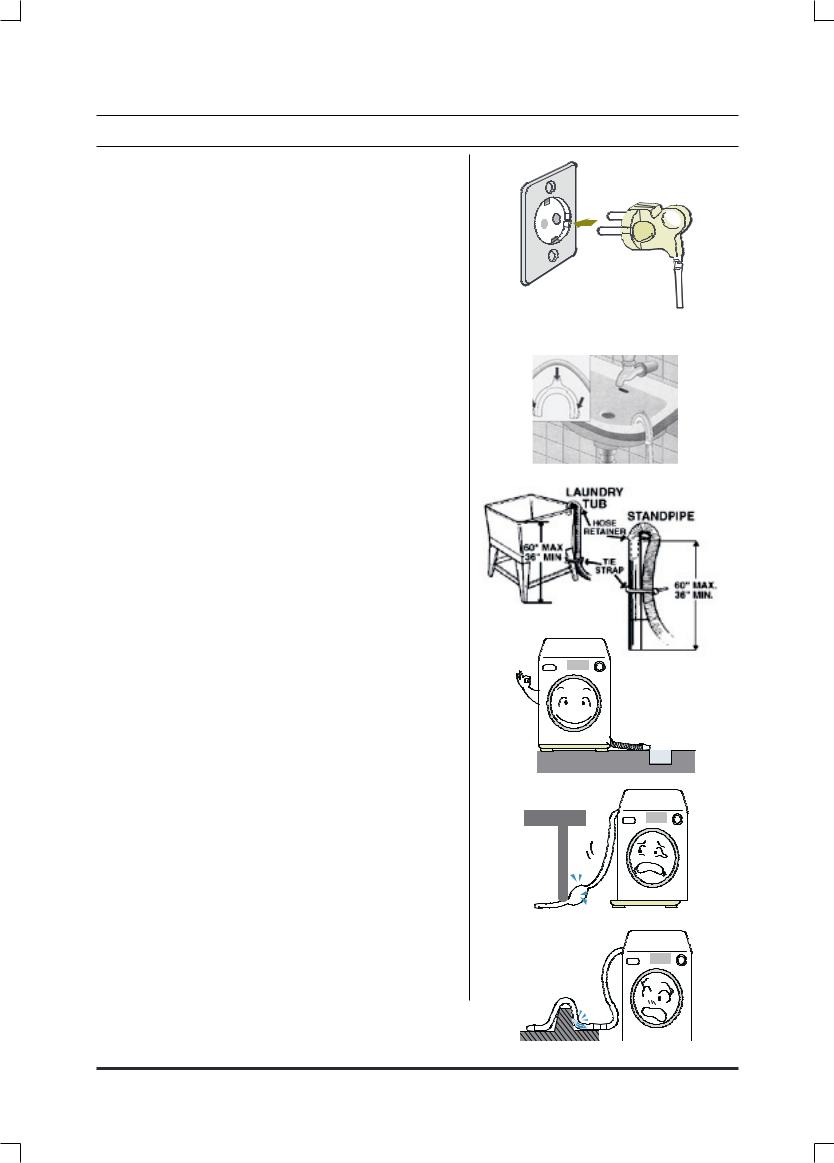

■ Grounding

►Make sure to ground the unit to prevent electric leakage or shock.

With a grounded receptacle

►It does not need an additional grounding.

■Water Drainage

►Hook the drain hose over the Wash Basin or Laundry Tub or plug the end of the drai hose into the Standpipe

-Hook the drain hose over the Wash Basin or Laundry Tub or plug the end of the drain hose into the Standpipe

-The outlet end of the drain hose must be at least 60-90 cm above the base of the machine.

►Seal the drain pipe connections - If not, it may cause water leakage.

►Prevent water from siphoning away

-If the end of the drain hose is put in water, it could siphon away water during washing.

So, make sure that the end of the drain hose is not put in water.

Note: Caution must always be exercised to avoid collapsing or damaging the drain hose.

For best performance the drain hose should not be restricted in any way, through elbows, couplings or excessive lengths.

1-3

1-2. Precautions upon Installation

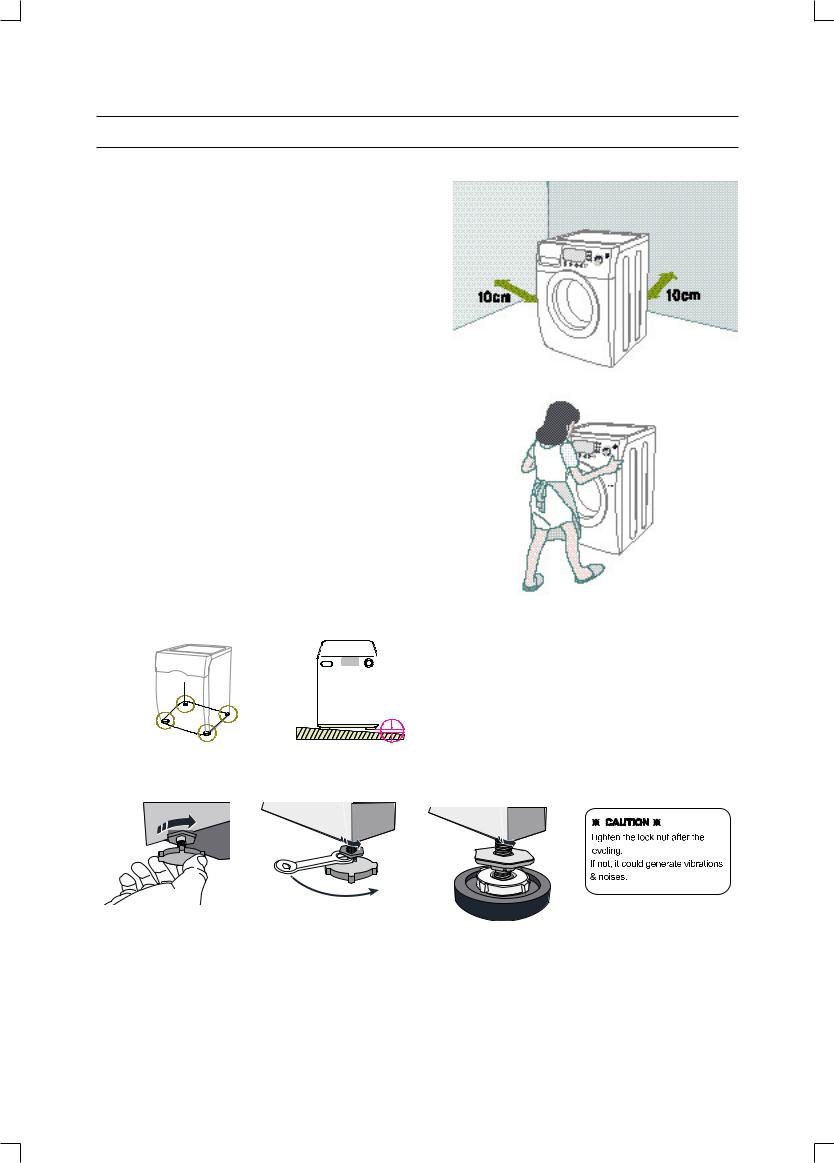

■ How to Level the Unit

1.Select an installation place.

►Install the unit with 10cm or more clearance from its surrounding walls.

2.Check if the unit is leveled.

►If the unit wabbles, adjust the leveling legs.

3.Adjust the leveling legs.

When the unit is not leveled

►Lift up the unit a little bit and adjust the shortest.

►Turn the leveling bolt counter clockwise as shown in the picture above (The leveling leg gets longer.)

►The 4 leveling legs should touch the floor all together.

► Slide your Washer into |

► Level your Washer by |

► If you install your washer on |

position. |

turning the leveling legs |

softfloor, you should place the |

|

in or out as necessary |

rubber cup under adjustable |

|

by hand. When your |

eg. Before put rubber cup, please |

|

Washer is level, tighten |

remove film for double-side tape |

|

the nuts using |

attached on rubber cup. |

|

the wrench included |

|

|

with your Washer. |

|

|

|

|

1-4 |

|

|

2. PRODUCT SPECIFICATIONS

2-1. SPECIFICATIONS OF PRODUCT

TYPE |

|

FRONT LOADINGWASHER |

|

|

|

|

|

|

|

|

Div |

Inches (cm) |

Div |

Inches (cm) |

|

|

|

|

|

DIMENSION |

A. Height-Overall |

38 (96.5) |

C. Depth With Door Open 90° |

49 (124.5) |

|

|

|

|

|

|

B. Width |

27 (68.6) |

D. Depth |

30.25 (77.0) |

|

|

|

|

|

WATER PRESSURE |

|

|

50 kPa ~ 800 kPa |

|

|

|

|

|

|

WEIGHT |

|

|

89.9 kg |

|

|

|

|

|

|

CAPACITY |

|

|

3.29 Cu.ft |

|

|

|

|

|

|

|

WASHING |

|

120V |

226W |

|

|

|

|

|

|

WASHINGAND HEATING |

120V |

997W |

|

POWER CONSUMPTION |

|

|

|

|

SPIN |

|

120V |

379W |

|

|

|

|||

|

|

|

|

|

|

DRAIN |

|

120V |

41W |

|

|

|

|

|

|

WF326 * |

|

1200rpm |

|

SPIN REVOLUTION |

WF316* |

|

1100rpm |

|

|

WF306 * |

|

1000rpm |

|

2-1

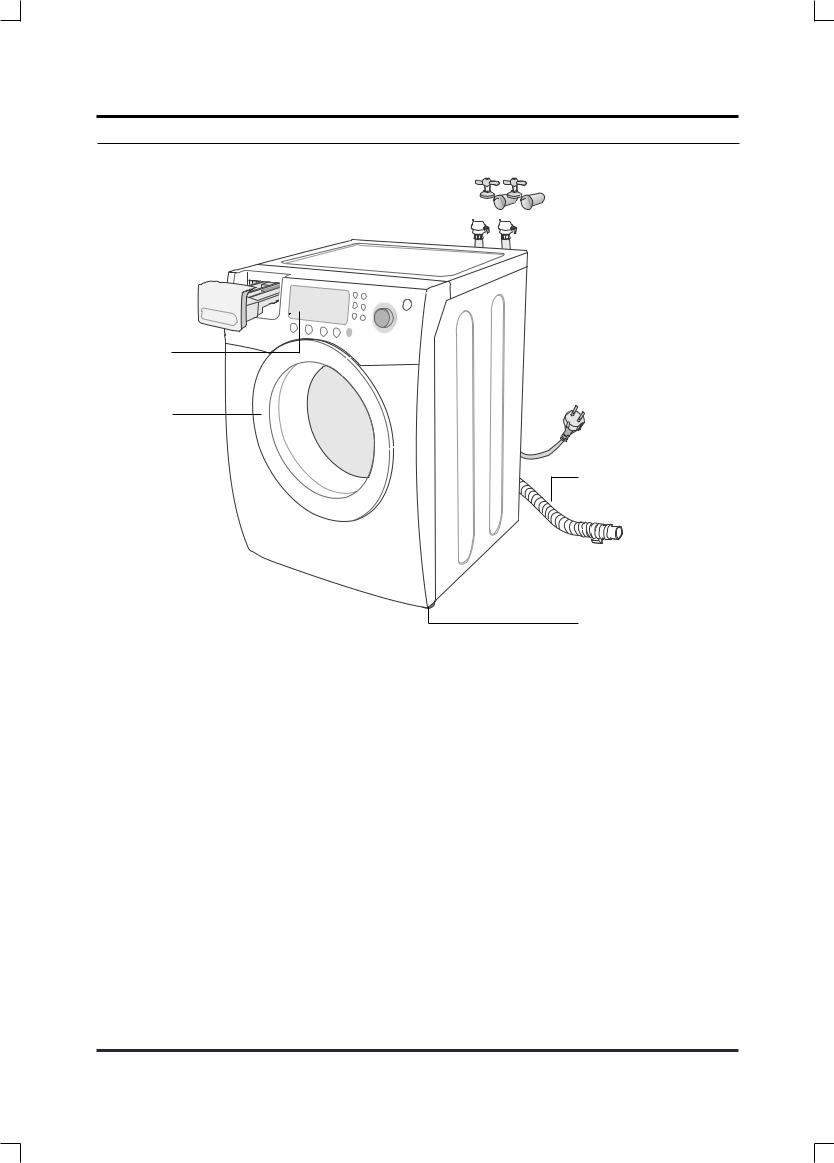

2-2. OVERVIEW OF THE WASHING MACHINE

Hot water supply hose

Cold water supply hose

Cold water supply hose

Detergent

drawer

Control

panel

Door

Drain Hose

Adjustable leg

2-2

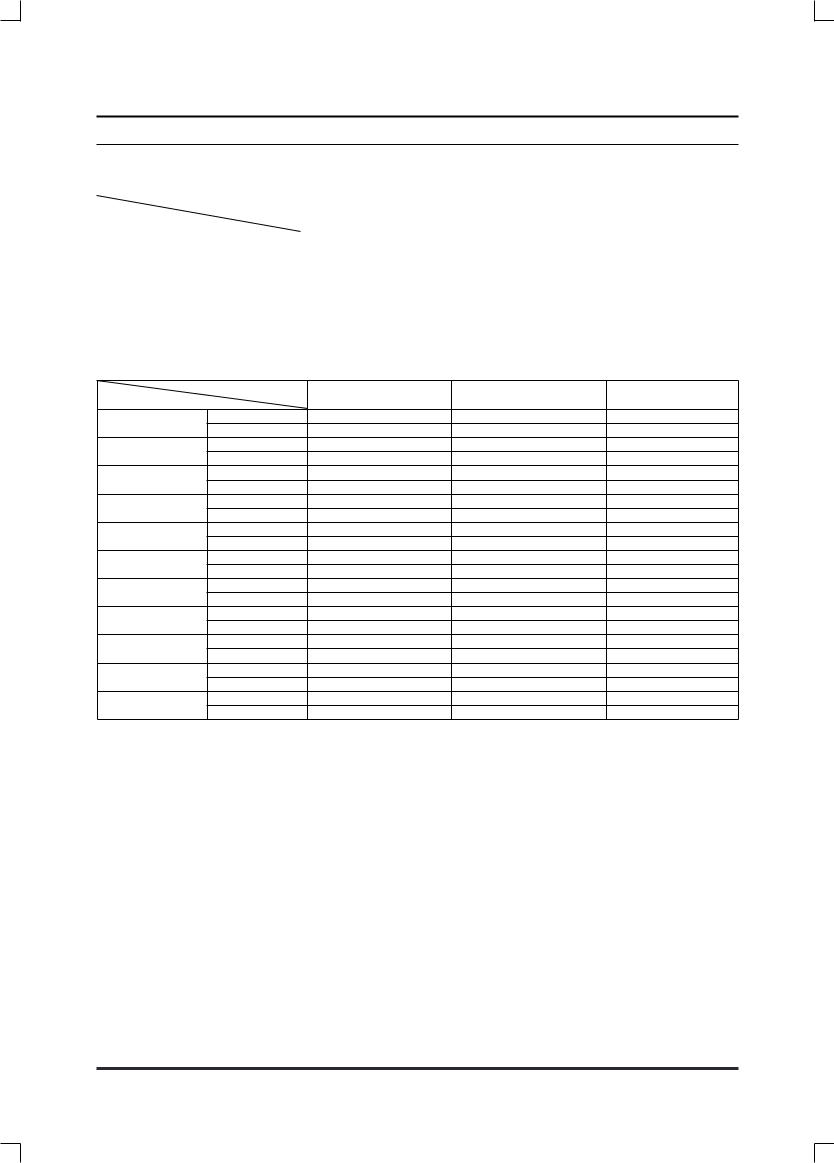

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

Item |

Samsung |

Whirlpool |

LG |

Bosch |

|

(WF316LAW) |

(GHW9250M) |

(WM2432HW) |

(WFMC6400) |

||

|

|||||

|

|

|

|

|

|

Capacity (Cu.ft) |

3.29 (DOE) |

3.21 (DOE) |

3.22 (3.72) |

2.93 (DOE) |

|

|

|

|

|

|

|

Volume of Spinner (ℓ) |

93.4 |

90 |

91 |

83 |

|

|

|

|

|

|

|

Motor |

Direct Drive |

3-Phase |

Direct Drive |

3-Phase |

|

|

|

|

|

|

|

User Interface |

LED |

LED |

LED |

LCD (red) |

|

|

|

|

|

|

|

Cycle Time |

57 |

52 |

59 |

66 |

|

|

|

|

|

|

|

Wash Performance |

1.01 |

1.00 |

0.99 |

1.02 |

|

|

|

|

|

|

|

Water Consumption/Cycle |

48 Liter |

56 Liter |

49 Liter |

61 Liter |

|

|

|

|

|

|

|

Energy Consumption |

128 |

105 |

114 |

189 |

|

(W/O Heater Wh/Cycle) |

|||||

|

|

|

|

||

|

|

|

|

|

|

RPM |

1,100 |

1,100 |

1,200 |

1,200 |

|

|

|

|

|

|

|

Noise |

57 dB |

59 dB |

66 dB |

62 dB |

|

|

|

|

|

|

2-3

2-4. OPTION SPECIFICATIONS |

|

|

|

Item |

Item Name |

CODE.NO |

Remark |

|

|

DC60-4014 6A |

|

|

|

DC61-10688A |

|

|

HOSE DRAIN |

DC97-07126Afor HOT |

|

|

DC97-07127Afor COLD |

|

|

|

|

|

|

|

MANUAL-BOOK |

DC68-02291A |

|

2-4

Memo

2-5

3. O P E R R A TI N G I N S T |

A L L A TI O N A N D I N S T A L L A TI O N |

|

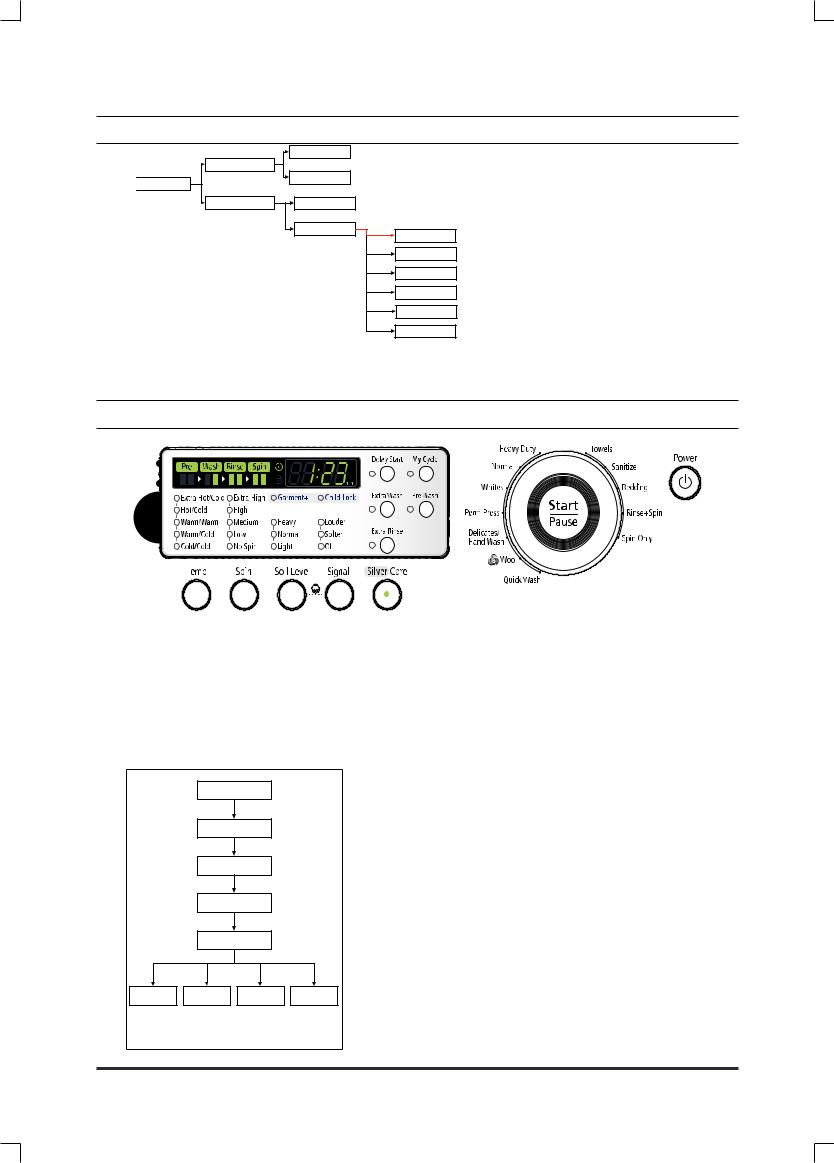

|

3 - 1. O V E R VI E W O F T H E C |

O N T R O L P A N E L |

|

|

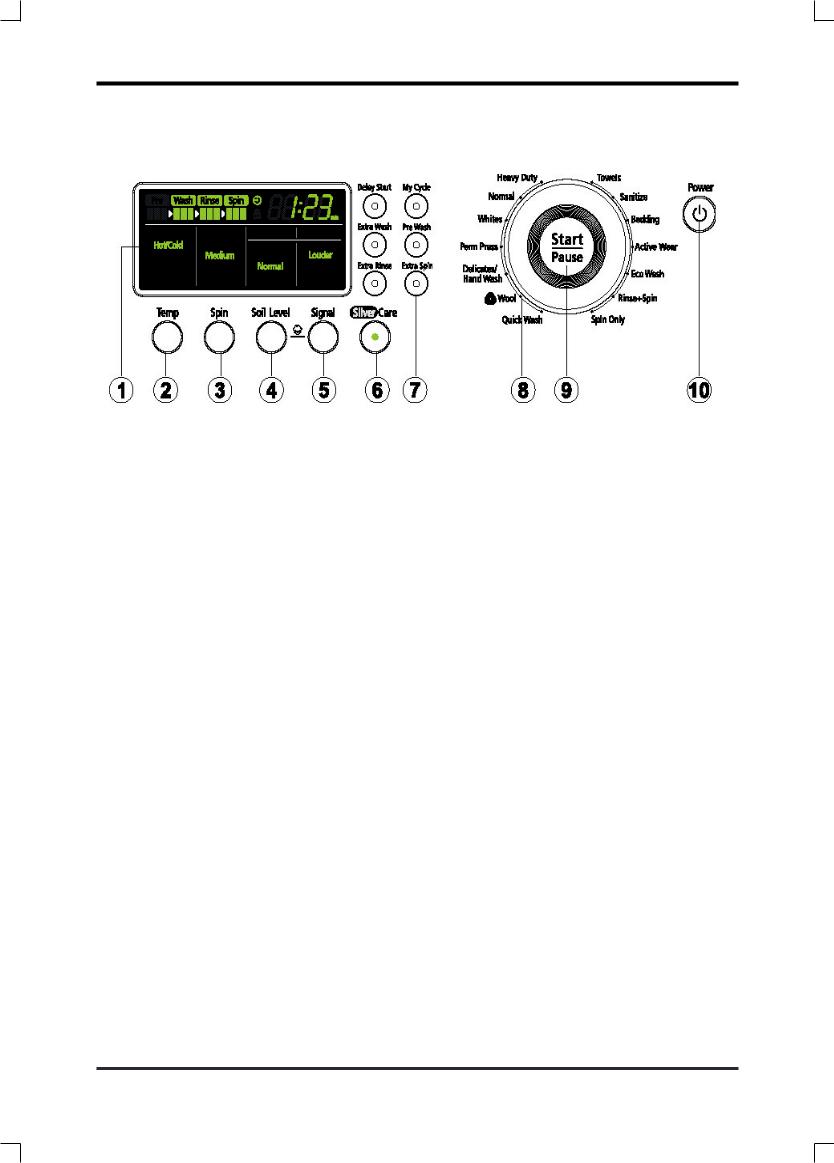

1.Digital graphic display

Displays the remaining wash time, all wash information, and error messages.

2.Temperature selection button

Pressthebuttonrepeatedlytocyclethroughthedifferentwatertemperatureoptions. Extra Hot/Cold -Heavilysoiled,colorfastitems.OnlyavailablewiththeSanitizecycle. Hot/Cold -Whitesandheavilysoiled,colorfastitems.

Warm/Warm -Colorfastitems.Whenwarmrinseisselected,onlythefinalrinsewillbewarm.Theotherrinseswillbecoldto conserveenergy.

Warm/Cold -Moderatelysoiled,colorfastitems;mostwrinkle-freeitems. Cold/Cold -Brightlycolored,verylightlysoileditems;washablewoolens.

3.Spin selection button

Pressthebuttonrepeatedlytocyclethroughthedifferentspinspeedoptions. Extra High -Removesmorewaterfromloadsduringspin.

NOTE:Tominimizewrinklingofwrinkle-freeandno-ironfabrics,DONOTusetheExtraHighspinoptionfortheseloads,noroverload yourWasher.

High -Useforunderwear,t-shirts,jeansandsturdycottons.

Medium -Useforjeans,wrinkle-freeorwash-and-wearitemsandsynthetics.

Low - Use for delicate items needing a slow spin speed because of fabric and construction.

No Spin -DrainsyourWasherwithoutspinning.Useforextremelydelicateitemsthatcannottolerateanyspin.

4.Soil Level selection button

PressthebuttontoselecttheSoilLevel/washingtime. Heavy -Forheavilysoiledloads.

Normal -Formoderatelysoiledloads.Thissettingwillbeappropriateformostloads. Light -Forlightlysoiledloads.

5.Signal selection button

Pressthebuttontoincreaseordecreasetheendofcyclesignalvolumeorturnoffthesignal.

6.SilverCare button

Silverionsareaddedduringthewashandrinsecyclestomaximizethesanitizingandantibioticeffects.

3-1

3 - 1. O V E R VI E W O F T H E C O N T R O L P A N E L

7.Select Cycle Option

Delay Start -Anycyclecanbedelayedforupto12,19or24hours(selectmodels)inone-hourincrements.Displayedhourindicates thetimeatwhichthewashwillbefinished.

ExtraWash -Add additional time to the wash for better stain removal.

Extra Rinse -Add an additional rinse at the end of the cycle to more thoroughly remove laundry additives and perfumes. Extra Spin -Add additional time to remove more water from loads

My Cycle - Choose your favorite cycle including temperature, spin, soil level, option, etc.

PreWash -Add detergent to the Pre Wash selection of the detergent compartment. Washer fills with cold water and detergent, tumbles, then drains and advances to the selected wash cycle. Some cycles cannot be selected with this option.*

* You can`t select PreWash option in Delicate/Hand Wash, Wool, Quick Wash andActive Wear cycles.

8.Cycle Selector

Selecttheappropriatecycleforthetypeofload.

Thiswilldeterminethetumblepatternandspinspeedforthecycle.

NOTE: To minimize wrinkling of loads, select the Perm Press cycle.

Heavy Duty -Forsturdy,colorfastfabricsandheavilysoiledgarments.

Normal -Formostfabricsincludingcottons,linens,andnormallysoiledgarments.

Whites - For white fabrics with or without bleach.

Perm Press - For wash-and-wear, synthetic fabrics, and lightly to normally soiled garments.

Delicates/HandWash - For sheer fabrics, bras, lingerie silk, and other handwash-only fabrics. For best results, use liquid detergent.

Wool - For machine-washable wool. Loads should be under 8 pounds.

The wool wash cycle of this machine has been approved by Woolmark for the washing of machine washable Woolmark products provided that the products are washed according to the instructions on the garment label and those issued by the manufacturer of this washing machine, M0509.

QuickWash - For lightly soiled or wrinkled garments needed quickly.

Towels - For bath towels and washcloths. Do not load too many towels because they absorb lots of water.

Sanitize -Forheavilysoiled,colorfastgarments.Thiscycleheatsthewaterto150°Ftoeliminatebacteria.

NOTE: If Pause is selected during the heating portion of the Sanitize Cycle, your Washer door will remain locked for your safety.

Bedding -Forbulkyitemssuchasblanketsandsheets. ActiveWear -Forwashablesportswear.

EcoWash -Forgeographicareaswhereenergyandwaterconservationisneeded.

Rinse + Spin -Useforloadsthatneedrinsingonlyortoaddrinse-addedfabricsoftenertoaload. Spin Only -Providesaspintoremovemorewaterfromtheload.

9.Start/Pause selection button

Presstopauseandrestartprograms.

10.Power button

Press once to turn your Washer on, press again to turn your Washer off. If your Washer is left on for more than 10 minutes without any buttons being touched, the power automatically turns off.

NOTE : Cycles and options vary by model. Refer to cycle chart inAppendix.

3-2

3 - 2. P R O G R A M M E C H A R T

326LAW, 326LAS

|

Functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Options |

|

|

|

|

|

|

|

|

|

|

Time |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temp |

|

|

|

|

|

|

|

Spin |

|

|

|

|

|

|

|

Soil Level |

|

|

Delay |

Extra |

|

Extra |

My |

Pre |

|

Extra |

Silver |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start |

Wash |

|

Rinse |

Cycle |

Wash |

|

Spin |

Care |

|

|||||

|

EH/ |

|

H/C |

W/ |

W/ |

C/C |

|

EH |

H |

M |

|

|

L |

|

NS |

H |

N |

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

C |

|

|

|

W |

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heavy |

|

|

|

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

90 |

|||||||||

Duty |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Normal |

|

|

|

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

53 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Whites |

|

|

|

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

60 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Perm Press |

|

|

|

|

√ |

√ |

√ |

|

|

|

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

45 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Delicates/ |

|

|

|

|

√ |

√ |

√ |

|

|

|

|

|

|

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

|

|

√ |

√ |

|

|

|

|

√ |

39 |

||||||

HandWash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wool |

|

|

|

|

|

|

|

√ |

|

|

|

|

|

|

|

|

√ |

|

√ |

|

|

√ |

|

|

√ |

|

|

|

|

|

√ |

|

|

|

|

|

|

57 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quick |

|

|

|

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

|

|

√ |

√ |

|

|

|

|

√ |

33 |

||||||||

Wash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Towels |

|

|

|

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

64 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sanitize |

√ |

|

|

|

|

|

|

|

|

√ |

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

110 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bedding |

|

|

|

|

√ |

√ |

√ |

|

|

|

|

|

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

69 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Active |

|

|

|

|

√ |

√ |

√ |

|

|

|

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

|

|

√ |

√ |

|

|

|

|

√ |

49 |

|||||||

Wear |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EcoWash |

|

|

|

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

√ |

√ |

45 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rinse + |

|

|

|

|

|

|

|

√ |

|

√ |

√ |

√ |

|

|

√ |

|

√ |

|

|

|

|

|

√ |

|

|

|

√ |

√ |

|

|

|

√ |

√ |

18 |

||||||

Spin |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spin Only |

|

|

|

|

|

|

|

|

|

√ |

√ |

√ |

|

|

√ |

|

√ |

|

|

|

|

|

√ |

|

|

|

|

|

√ |

|

|

|

√ |

|

|

9 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

306LAW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Options |

|

|

|

|

Time |

|||||||

|

|

|

|

|

Temp |

|

|

|

|

|

|

|

Spin |

|

|

|

|

|

|

Soil Level |

|

Delay |

|

Extra |

Extra |

|

Silver |

|

|

|||||||||||

|

H/C |

|

W/W |

|

W/C |

C/C |

|

|

H |

|

M |

|

L |

|

NS |

|

H |

|

|

N |

|

L |

|

Start |

|

Wash |

Rinse |

|

Care |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Heavy |

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

√ |

|

√ |

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

65 |

||||

Duty |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Normal |

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

√ |

|

√ |

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

53 |

||||

Whites |

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

√ |

|

√ |

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

60 |

||||

Perm Press |

|

|

|

|

√ |

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

√ |

|

√ |

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

45 |

|||

Delicates/ |

|

|

|

|

√ |

|

√ |

√ |

|

|

|

|

|

|

|

|

√ |

|

√ |

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

|

√ |

|

|

√ |

|

39 |

|||

HandWash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wool |

|

|

|

|

|

|

|

√ |

|

|

|

|

|

|

|

|

√ |

|

√ |

|

|

|

|

√ |

|

|

|

|

√ |

|

|

|

|

|

|

|

|

57 |

||

Quick |

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

√ |

|

√ |

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

|

√ |

|

|

√ |

|

33 |

||||

Wash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Towels |

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

√ |

|

√ |

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

|

√ |

|

64 |

||||

Rinse + |

|

|

|

|

|

|

|

√ |

|

|

√ |

|

√ |

|

|

|

√ |

|

√ |

|

|

|

|

|

|

|

|

|

√ |

|

|

√ |

|

|

√ |

|

18 |

|||

Spin |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-3

3 - 2. P R O G R A M M E C H A R T

316LAW, 316BAW, 316BAC

|

|

|

|

|

|

|

|

|

|

|

Functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

Options |

|

|

|

|

|

Time |

||||||||||

|

|

|

|

|

|

|

|

Temp |

|

|

|

|

|

|

Spin |

|

|

|

|

SoilLevel |

|

Delay |

Extra |

Extra |

My |

Pre |

|

Silver |

|

|

|||||||||||

|

|

|

EH/ |

|

H/ |

W/ |

|

W/C |

C/ |

|

EH |

H |

M |

|

L |

NS |

H |

|

N |

L |

|

Start |

Wash |

Rinse |

Cycle |

Wash |

|

Care |

|

|

|||||||||||

|

|

|

|

C |

|

C |

W |

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heavy Duty |

|

|

|

|

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

√ |

√ |

|

√ |

90 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Normal |

|

|

|

|

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

√ |

√ |

|

√ |

53 |

|

||||||||||

|

Whites |

|

|

|

|

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

√ |

√ |

|

√ |

60 |

|

||||||||||

|

Perm Press |

|

|

|

|

|

|

√ |

|

√ |

√ |

|

|

|

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

√ |

√ |

|

√ |

45 |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Delica-tes/ |

|

|

|

|

|

|

√ |

|

√ |

√ |

|

|

|

|

|

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

|

|

√ |

√ |

|

|

|

√ |

39 |

|

||||||

|

HandWash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wool |

|

|

|

|

|

|

|

|

|

√ |

|

|

|

|

|

|

√ |

√ |

|

|

√ |

|

|

√ |

|

|

|

|

√ |

|

|

|

|

|

57 |

|

||||

|

QuickWash |

|

|

|

|

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

|

|

√ |

√ |

|

|

|

√ |

33 |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Towels |

|

|

|

|

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

√ |

√ |

|

√ |

64 |

|

||||||||||

|

Sani-tize |

|

√ |

|

|

|

|

|

|

|

|

√ |

√ |

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

√ |

√ |

|

√ |

110 |

|

||||||||||

|

Bed-ding |

|

|

|

|

|

|

√ |

|

√ |

√ |

|

|

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

√ |

√ |

√ |

√ |

√ |

|

√ |

69 |

|

||||||||

|

Rinse + Spin |

|

|

|

|

|

|

|

|

|

√ |

|

√ |

√ |

√ |

|

√ |

√ |

|

|

|

|

|

|

√ |

|

|

√ |

√ |

|

|

|

√ |

18 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spin Only |

|

|

|

|

|

|

|

|

|

|

|

√ |

√ |

√ |

|

√ |

√ |

|

|

|

|

|

|

√ |

|

|

|

|

√ |

|

|

|

|

|

9 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

306BHW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

Options |

|

|

|

Time |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

Temp |

|

|

|

|

|

|

|

Spin |

|

|

|

|

Soil Level |

|

Delay |

|

Extra |

|

Extra |

|

Silver |

|

|

|

||||||||||

|

|

EH/ |

H/C |

|

W/ |

|

W/ |

C/C |

|

|

H |

M |

|

|

L |

|

NS |

|

|

H |

|

N |

L |

|

Start |

|

Wash |

|

Rinse |

|

Care |

|

|

|

|||||||

|

|

C |

|

|

|

|

W |

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heavy Duty |

|

|

|

√ |

|

√ |

|

√ |

√ |

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

√ |

|

√ |

|

|

√ |

|

65 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Normal |

|

|

|

√ |

|

√ |

|

√ |

√ |

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

√ |

|

√ |

|

|

√ |

|

53 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Whites |

|

|

|

√ |

|

√ |

|

√ |

√ |

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

√ |

|

√ |

|

|

√ |

|

60 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Perm Press |

|

|

|

|

|

|

√ |

|

√ |

√ |

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

√ |

|

√ |

|

|

√ |

|

45 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Delicates/ |

|

|

|

|

|

|

√ |

|

√ |

√ |

|

|

|

|

|

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

|

|

√ |

|

|

√ |

|

39 |

|

||

|

HandWash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Wool |

|

|

|

|

|

|

|

|

|

√ |

|

|

|

|

|

|

|

√ |

|

√ |

|

|

|

|

√ |

|

|

√ |

|

|

|

|

|

|

|

|

57 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

QuickWash |

|

|

|

√ |

|

√ |

|

√ |

√ |

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

|

|

√ |

|

|

√ |

|

33 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Towels |

|

|

|

√ |

|

√ |

|

√ |

√ |

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

√ |

|

√ |

|

|

√ |

|

64 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Sanitize |

√ |

|

|

|

|

|

|

|

|

|

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

√ |

|

√ |

|

|

√ |

|

110 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Bedding |

|

|

|

|

|

|

√ |

|

√ |

√ |

|

|

|

√ |

|

|

√ |

|

√ |

|

|

√ |

|

√ |

√ |

|

√ |

|

√ |

|

√ |

|

|

√ |

|

69 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Rinse + Spin |

|

|

|

|

|

|

|

|

|

√ |

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

|

|

|

|

√ |

|

|

|

√ |

|

|

√ |

|

18 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Spin Only |

|

|

|

|

|

|

|

|

|

|

|

|

|

√ |

√ |

|

|

√ |

|

√ |

|

|

|

|

|

|

|

√ |

|

|

|

|

|

|

|

|

9 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-4

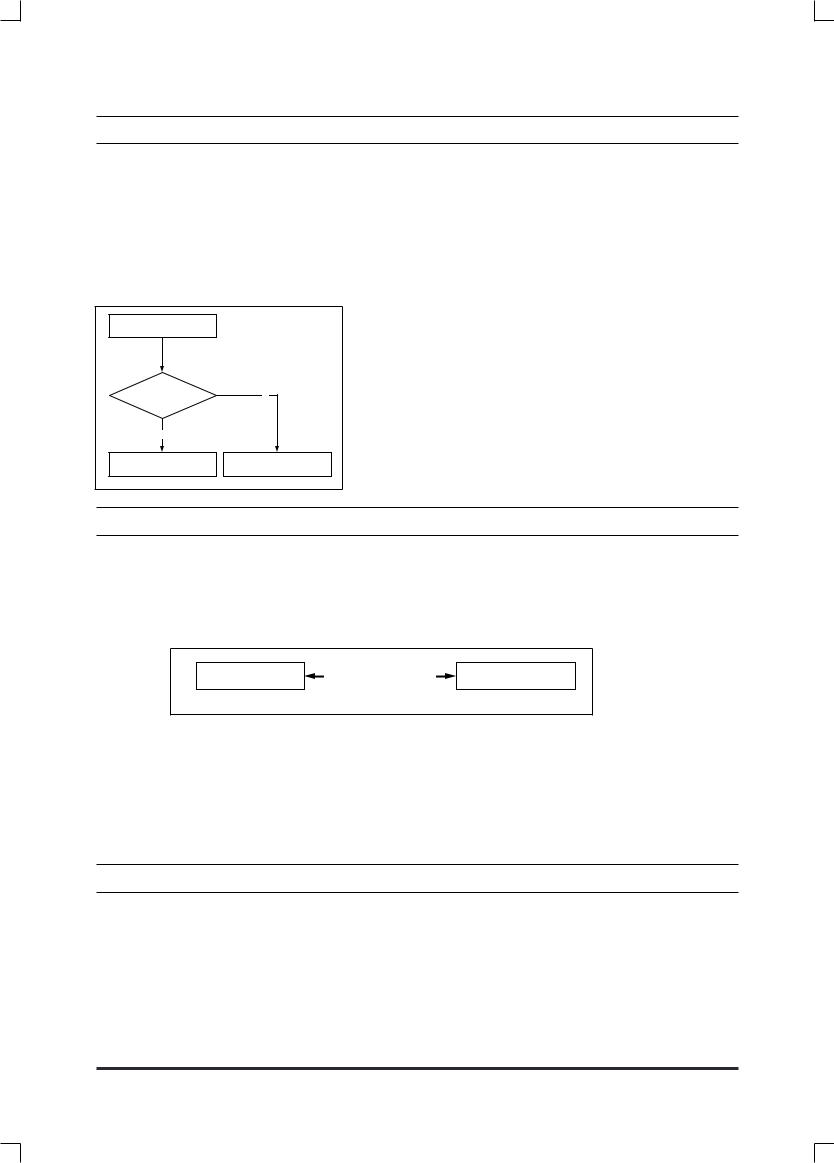

3 - 3. M AI N F U N C TI O N

CHILD LOCK

Afunction that prevents children from playing with your Washer.

ACTIVATING/DEACTIVATING

If you want to activate/deactivate the Child Lock function, press the Soil Level and Signal buttons at the same time for 3 seconds.

How It Works:

1.Child Lock can be activated while your Washer is running.

2.Once you activate Child Lock, all controls (except for the Power button) will be locked until you deactivate Child Lock.

3.The Child Lock button will be lit while it is in effect.

Note: When buttons, other than the Power button, do not respond, please check if the Child Lock button is on.

GARMENT +

You can add or take laundry items even after the wash has started, as long as the Garment+ light is on. Pushing the Start/ Pause button unlocks the door, unless the water is too hot or if there is too much water in your Washer. If you are able to unlock the door and wish to continue the wash cycle, close the door and press the Start/Pause button.

MY CYCLE

Allows you to activate your custom wash (temperature, spin, soil level, etc.) with one–button convenience.

By pushing the My Cycle button, you activate the settings used during the last My Cycle mode. The My Cycle light will indicate activation.

You can select all options as follows in My Cycle mode.

1.SelectcycleusingCycleSelectordial.

2.Aftercycleselection,seteachoption.

Note: At this time, the option will follow as per each cycle’s default option selection.

Then you can start My Cycle by pushing the Start/Pause button in My Cycle mode.

The cycle and options you select will be displayed next time you choose My Cycle.

3-5

3 - 3. M AI N F U N C TI O N

FOR SILVERCARE WASHING

Silver ions are added during the wash and rinse cycles to maximize the sanitizing and antibiotic effects, treating fabrics with a microscopic coating protection that kills more than 650 kinds of bacteria.

1.Open the door, put in the clothes and close the door again.

2.Press the Power button.

3.Select a Cycle by turning the Cycle Selection dial.

4.Press SilverCare button.

5.Add detergent in the dispenser tray for main washing, and add fabric softener up to the marked line.

: For Pre Wash, put a supplementary detergent in the dispenser.

SilverCare: If it is used together with fabric softener, its effect may be decreased.

6.Press Start/Pause button.

: Automatically selects optimal washing conditions by sensing the laundry’s weight.

Note :

FOR HOME USE ONLY– COMMERCIALUSERS SHOULD NOTIFYTHEIR LOCALWASTE TREATMENT AUTHORITIES BEFORE USE

You can find # of times you used SilverCare option by pushing signal and SilverCare button.

LU3:lessthan1000times

LU2:between1000to2000times

LU1:between2000to2999times

LU0:over2999times

You should replace the silver kit when it display “LU0”. Contact 1-800-SAMSUNG.

Note :

For some model which has no heater if you choose SilverCare, Temp will be fixed to Cold/Cold. If you change Temp selection, SilverCare will be canceled.

3-6

3 - 4. T E C H NI C A L P OI N T

1) Motor on/off time at each course

unit:sec

Course |

|

|

W a s hi n g |

|

M ot o r r. p. m |

|

|

C w |

Off |

|

C c w |

Off |

|

|

|

|

||||

Heavy Duty |

13 |

4 |

|

13 |

4 |

52 |

Normal |

12 |

8 |

|

12 |

8 |

50 |

Whites |

7 |

8 |

|

7 |

8 |

40 |

Perm Press |

5 |

10 |

|

5 |

10 |

40 |

Delicate/Hand wash |

2 |

48 |

|

2 |

48 |

50 |

Wool |

2 |

58 |

|

2 |

58 |

50 |

QuickWash |

12 |

8 |

|

12 |

8 |

50 |

Towels |

10 |

10 |

|

10 |

10 |

50 |

Sanitize |

8 |

12 |

|

8 |

12 |

45 |

Bedding |

10 |

10 |

|

10 |

10 |

45 |

Rinse + Spin |

5 |

10 |

|

5 |

10 |

40 |

2) Final dehydrating r.p.m at each course

unit:rpm

|

Model |

W F 3 1 6 L |

Course |

|

|

|

|

|

Heavy Duty |

|

1200 |

|

|

|

Normal |

|

1200 |

|

|

|

Whites |

|

1200 |

|

|

|

Perm Press |

|

800 |

|

|

|

Delicate/Hand wash |

|

800 |

Wool |

|

400 |

|

|

|

QuickWash |

|

1200 |

|

|

|

Towels |

|

400 |

|

|

|

Sanitize |

|

1200 |

|

|

|

Bedding |

|

1200 |

|

|

|

Rinse + Spin |

|

800 |

|

|

|

Spin Only |

|

1200 |

|

|

|

3-7

3 - 4. T E C H NI C A L P OI N T

3) The water supply control at each process cycle

|

Model |

WF316,WF306 |

Process cycle |

|

|

|

|

|

|

|

|

PreWashing |

|

Cold water 5L/min |

Washing |

|

Cold water 10L/min + (Hot water 10L/min) |

Rinse |

|

Cold water 10L/min |

Final rinse |

|

Cold water 10L/min + Cold water 5L/min |

4) The water level data at each course

|

|

|

|

unit:Khz |

|

|

Model |

Default water level |

Supplementary water START |

Supplementary water |

|

Course |

|

(kHz) |

(kHz) |

End (kHz) |

|

Heavy Duty |

Washing |

24.25 |

24.90 |

23.60 |

|

Rinse |

23.60 |

25.00 |

24.60 |

||

|

|||||

Normal |

Washing |

24.25 |

24.90 |

23.60 |

|

Rinse |

23.60 |

25.00 |

24.60 |

||

|

|||||

Whites |

Washing |

24.40 |

25.00 |

24.75 |

|

Rinse |

23.60 |

25.00 |

24.60 |

||

|

|||||

Perm Press |

Washing |

23.80 |

24.55 |

24.30 |

|

Rinse |

23.65 |

24.55 |

24.30 |

||

|

|||||

Delicate/Hand wash |

Washing |

23.45 |

24.35 |

24.00 |

|

Rinse |

23.15 |

24.35 |

24.00 |

||

Wool |

Washing |

24.40 |

25.00 |

24.70 |

|

Rinse |

23.80 |

25.00 |

24.70 |

||

|

|||||

QuickWash |

Washing |

24.25 |

24.90 |

23.60 |

|

Rinse |

23.50 |

25.00 |

24.60 |

||

|

|||||

Towels |

Washing |

24.25 |

24.90 |

24.60 |

|

Rinse |

23.50 |

25.00 |

24.60 |

||

|

|||||

Sanitize |

Washing |

24.25 |

24.90 |

24.60 |

|

Rinse |

23.50 |

25.00 |

24.60 |

||

|

|||||

Bedding |

Washing |

24.25 |

24.90 |

24.60 |

|

Rinse |

23.50 |

25.00 |

24.60 |

||

|

|||||

Rinse + Spin |

Washing |

24.25 |

24.90 |

24.60 |

|

Rinse |

23.50 |

25.00 |

24.60 |

||

|

3-8

Memo

3-9

4. ALIGNMENT AND ADJUSTMENTS

4-1. GENERAL ERROR FUNCTION

NO |

LED |

Diagnostic |

Description |

Corrective Action |

|

Display |

Code |

||||

1 |

nd |

1 |

The water level fails to drop below the Reset Water Level |

Go to “ Will Not Drain” Troubleshooting |

|

within 15 minutes. |

|||||

Section. |

|||||

|

|

|

|

||

|

|

|

|

|

|

2 |

LO |

2 |

Door fails to unlock after 3 attempts. |

Go to “ Will Not Unlock” Troubleshooting |

|

Section. |

|||||

|

|

|

|

||

3 |

nF |

3 |

When the filling continues for more than 16 minutes or there |

Go to “ No Water Fill” Troubleshooting |

|

is no change of water level for 3 minutes |

Section. |

||||

|

|

|

|||

4 |

FL |

4 |

|

Go to “ Will Not Lock” Troubleshooting |

|

Door fails to lock after 3 attempts. |

Section. |

||||

|

|

|

|

|

|

|

|

|

Water Level Sensor Trouble. |

|

|

5 |

LE |

8 |

(When the input signal from the water level sensor is out of |

Go to “No Water Fill” Troubleshooting Section. |

|

range, the unit will send out beeping sounds and halts the |

|||||

|

|

|

|

||

|

|

|

cycle.) |

|

|

|

|

|

Afault is detected in the water level sensor. |

|

|

6 |

OE |

E |

Data (frequency) shows the water level is at or above the |

First check to see that all of water valves are |

|

overflow water level. (When this condition is detected, the |

not stuck. If water valves are OK, check water |

||||

|

|

|

machine will automatically starts draining water until the water |

level sensor. |

|

|

|

|

level falls below the overflow water level) |

|

|

7 |

dc |

10 |

Unbalance or cabinet bump is detected during final spin, |

|

|

which prevents the drum from spinning over 400 rpm. (Never |

Go to “Wet Clothes” Troubleshooting Section. |

||||

|

|

|

exceeds 400 RPM due to unbalanced load) |

|

|

8 |

- |

11 |

|

Go to “EEPROM Clear Mode” If display |

|

EEPROM Fault. (Program settings are being reset.) |

shows “FAiL”,Replace Machine Control |

||||

|

|

|

|

Board. |

|

9 |

E2 |

15 |

Jammed Key.(When key input signals are coming out for |

Check all of keys. IfAkey is sensed to be |

|

more than 30 seconds, it is regarded as a jam.) |

pressed, all keys will do not respond. |

||||

|

|

|

|||

10 |

dL |

18 |

|

Check for loose wire connections. |

|

Door is detected as open when the motor is operating. |

Go to “Quick Test Mode” and then do Door |

||||

|

|

|

|

lock/Unlock Test and Motor Test. |

|

11 |

dS |

22 |

Door is detected as open while it is trying to lock the door. |

Go to “Quick Test Mode” and then do Door |

|

Lock/Unlock Test |

|||||

|

|

|

|

||

12 |

bE |

25 |

Motor hall sensor signals come out without motor operation. |

Replace Machine Control Board. |

|

|

|

|

|

|

|

13 |

tE |

29 |

Abnormal high/low temperature or resistance (Thermal |

Go to “ Board Input Test” and check Water |

|

Temperature. Check loose or pinched wires. |

|||||

sensor or PBA) resistance. |

|||||

|

|

|

Replace PCB or thermistor. |

||

|

|

|

|

||

|

|

|

MICOM is attempting to drive the motor but is not getting any |

Evaluate wire harness for loose or unhooked |

|

14 |

E3 |

2E |

response signals from the hall sensor. Visual check shows |

connections. Go to “ Quick Test Mode” and |

|

motor is not running. (Locked, Defective Hall Sensor or |

|||||

|

|

|

test Motor. |

||

|

|

|

Overload) |

||

|

|

|

|

||

15 |

Sr |

34 |

System Relay (Main Relay) Failure. (PCB does not notice the |

Replace PCB. |

|

|

|

|

relay operation when there should be.) |

|

|

16 |

Hr |

36 |

Heater Relay Failure (No Heater Relay Check Signal) |

Replace PCB |

|

|

|

|

|

|

|

17 |

3E |

3E |

Over-current is detected. Motor won’t turn. |

Evaluate wire harness for loose or unhooked |

|

connections. |

|||||

(IPM detects over-current.) |

|||||

|

|

|

Go to “ Quick Test Mode” to test Motor. |

||

|

|

|

|

||

18 |

2E |

91 |

Voltage for motor control bus is over specified limit. |

Replace PCB |

|

|

|

|

|

|

|

19 |

2E |

92 |

Voltage for motor control bus is under specified limit. |

Replace PCB |

|

|

|

|

|

|

|

20 |

8E |

8E |

MEMS Sensor Failure. (No MEMS Sensor Check Signal) |

Check MEMS PCB ,Main PCB & Wire- |

|

harness |

|||||

|

|

|

|

||

21 |

7E |

7E |

Silver Care Kit (Silver Care PCB) Failure. |

Check Silver Care PCB ,Main PCB & Wire- |

|

harness |

|||||

|

|

|

|

||

22 |

PF |

- |

It occurs when there is power failure during the washing.(“PF” |

- |

|

|

|

|

is not an error. It is to inform the user of power failure.) |

|

|

23 |

SUdS |

- |

Suds is detected during the washing session. (“SUdS” is not |

Guide a user to reduce amount of detergent |

|

an error. If the washer is in suds period, “SUdS” will light up |

usage. |

||||

|

|

|

instead of remaining time.) |

|

4-1

4-2. TEST MODE

Test Mode: