Samsung WF393BTPAWR User Manual 2

WASHING MACHINE

Technical Information

•Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or repair of this unit.

•Refer to Service Manual for detailed installation, operating, testing, troubleshooting, and disassembly instructions.

CAUTION

All safety information must be followed as provided in Service Manual.

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

Code No. : DC68-03144B-01_EN

1

WF395BTP-03144B-01_EN.indd 1 |

|

|

2012-10-19 2:05:54 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

GENERAL ERROR FUNCTION

NO |

Error |

Diagnostic Code |

Description |

Corrective Action |

|

Code |

Error Image |

||||

|

|

|

|||

1 |

nd |

nd |

The water level fails to drop below |

Go to “ Will Not Drain” |

|

the Reset Water Level within 15 |

|||||

Troubleshooting Section. |

|||||

|

|

|

minutes. |

||

|

|

|

|

||

|

|

|

|

|

|

2 |

LO |

LO |

Door fails to Unlock After 7 |

Go to “ Will Not Unlock” |

|

attempts. |

Troubleshooting Section. |

||||

|

|

|

|||

|

|

|

|

|

|

3 |

nF |

nF |

When the filling Continues for |

Go to “ No Water Fill” |

|

more than 40 minutes or there is no |

|||||

Troubleshooting Section. |

|||||

|

|

|

change of water level for 6 minutes. |

|

|

|

|

|

|

|

|

4 |

FL |

FL |

Door fails to lock after 7 attempts. |

Go to “ Will Not Lock” |

|

Troubleshooting Section. |

|||||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

A water level lower than the Reset |

|

|

5 |

LE |

LE |

water level (25.6Khz) is detected for |

Go to “No Water Fill” |

|

5 seconds during the Wash/Rinse |

Troubleshooting Section. |

||||

|

|

|

|||

|

|

|

cycle. |

|

|

|

|

|

|

|

|

|

|

|

Water Level Sensor Trouble. (When |

|

|

6 |

LE(1E) |

LE(1E) |

the input signal from the water level |

Go to “No Water Fill” |

|

sensor is out of range, the unit will |

Troubleshooting Section |

||||

|

|

|

send out beeping sounds and halts |

||

|

|

|

the cycle.) |

|

|

|

|

|

A fault is detected in the water level |

|

|

|

|

|

sensor. Data (frequency) shows |

|

|

|

|

|

the water level is at or above the |

First check to see that all of water |

|

7 |

OE |

OE |

overflow water level. (When this |

||

valves are not stuck. If water valves |

|||||

condition is detected, the machine |

|||||

|

|

|

are OK, check water level sensor. |

||

|

|

|

will automatically starts draining |

||

|

|

|

|

||

|

|

|

water until the water level falls |

|

|

|

|

|

below the overflow water level) |

|

|

|

|

|

Unbalance or cabinet bump is |

|

|

8 |

dc |

dc |

detected during final spin, which |

Go to “Wet Clothes” |

|

prevents the drum from spinning |

|||||

Troubleshooting Section. |

|||||

|

|

|

over 140 rpm. (Never exceeds 150 |

||

|

|

|

|

||

|

|

|

RPM due to unbalanced load) |

|

|

|

|

|

Jammed Key.(When key input |

Check all of keys. If A key is sensed |

|

9 |

E2 |

E2 |

signals are coming out for more |

||

to be pressed, all keys will do not |

|||||

than 30 seconds, it is regarded as |

|||||

|

|

|

respond. |

||

|

|

|

a jam.) |

||

|

|

|

|

||

10 |

ds |

ds |

Door is detected as open while it is |

Go to “Quick Test Mode” and then |

|

trying to lock the door. |

do Door Lock/Unlock Test |

||||

|

|

|

|||

|

|

|

|

|

|

|

|

|

2 |

|

WF395BTP-03144B-01_EN.indd 2 |

|

|

2012-10-19 2:05:54 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

NO |

Error |

Diagnostic Code |

Description |

Corrective Action |

|

Code |

Error Image |

||||

|

|

|

|||

|

|

|

Abnormal high/low temperature or |

Go to “ Board Input Test” and check |

|

11 |

tE |

tE |

Water Temperature. Check loose |

||

resistance (Thermal sensor or PBA |

or pinched wires. Replace PCB or |

||||

|

|

|

resistance). |

||

|

|

|

thermistor. |

||

|

|

|

|

||

|

|

|

MICOM is attempting to drive the motor |

|

|

12 |

3E |

3E |

but is not getting any response signals |

Evaluate wire harness for loose or |

|

from the hall sensor. Visual check shows |

unhooked connections. Go to “ |

||||

|

|

|

motor is not running. (Locked, Defective |

Quick Test Mode” and test Motor. |

|

|

|

|

Hall Sensor or Overload) |

|

|

13 |

Hr |

Hr |

This error code appears when the |

Replace PCB |

|

heater is 96°C or above. |

|||||

|

|

|

|

||

|

|

|

This error code appears when the |

|

|

14 |

nF1 |

nF1 |

water temperature is 50°C or above |

Please connect the hot/cold water |

|

for 8 seconds or longer in the Wool |

hose connection correctly. |

||||

|

|

|

|||

|

|

|

and Delicate course. |

|

|

|

|

|

Suds is detected during the washing |

Guide a user to reduce amount of |

|

15 |

suds |

suds |

session. (“SUdS” is not an error. If the |

detergent usage. |

|

|

|

|

washer is in suds period, “SUdS” will |

|

|

|

|

|

light up instead of remaining time.) |

|

|

16 |

AE |

AE |

Communication error between SUB |

Check Main PBA, SUB PBA & Wire- |

|

PBA and MAIN PBA |

harness. Replace PCB |

||||

|

|

|

|||

17 |

SF |

SF |

System Error |

Replace PCB |

|

|

|

|

|

|

|

18 |

2E |

2E |

Voltage for motor control bus is |

Replace PCB |

|

over or under specified limit. |

|||||

|

|

|

|

||

|

|

|

|

|

3

WF395BTP-03144B-01_EN.indd 3 |

|

|

2012-10-19 2:05:54 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

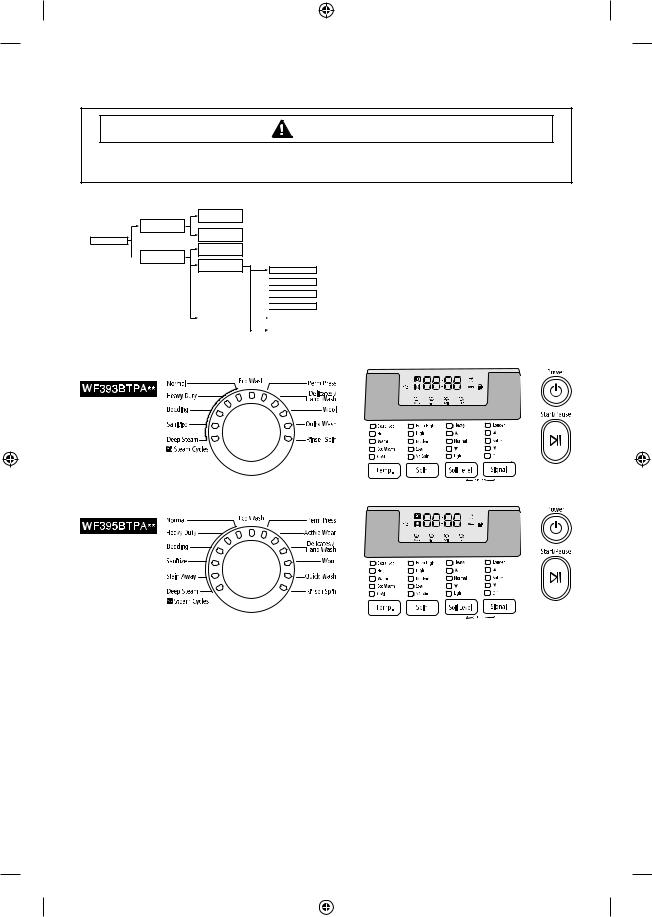

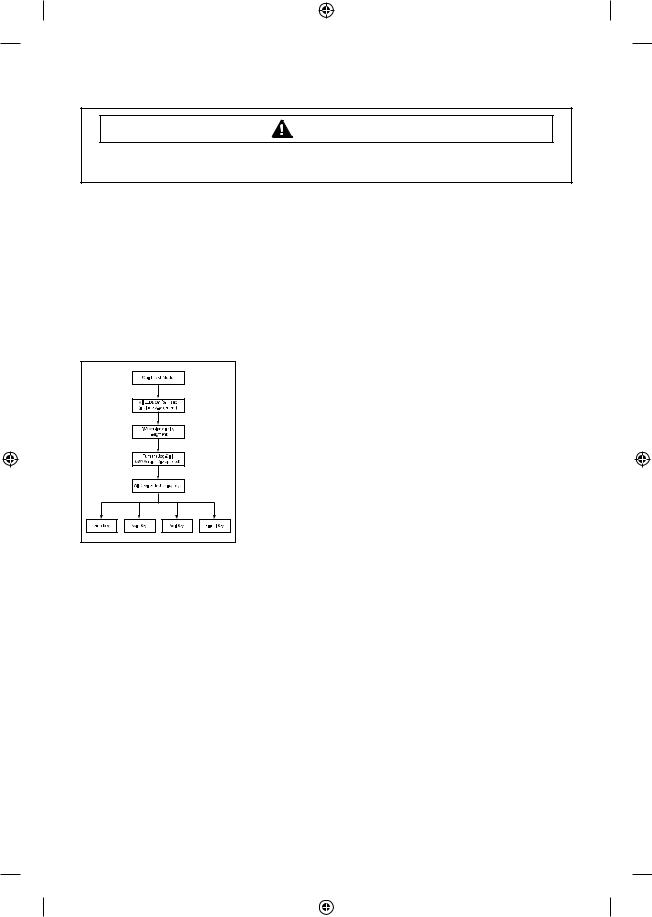

TEST MODE

Quick Test Mode

Power Off State

EEPROM Clear

Mode

Special Test Mode

Continuous Cycle

Power On State Mode

(Normal User Mode)

(Normal User Mode)

Service Mode

Quick Spin Test Mode

Cycle Count Check Mode

Cycle Count Check Mode

S/W Version Check Mode

S/W Version Check Mode

Fast Time Down Test Mode

Fast Time Down Test Mode

Demo Mode |

|

|

|

|

|

|

|

Board Input Test Mode |

|

|

|

|

|

|

|

|

|

|

Diagnostic Code |

|

|

|

|

CheckMode |

Quick Test Mode

Test Mode:

Each Test Mode for the Potomac is as follows in the coming pages. The test modes indicated by the red arrows are modes unable to get an access once the washing cycle has started due to safety reasons.

4

WF395BTP-03144B-01_EN.indd 4 |

|

|

2012-10-19 2:05:55 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

Definition of Quick Test Mode:

-Check operation of all LED’s (Verify faulty LED).

-Check model and software version.

-Check different operating modes (e.g. water valve, motor, door, drain pump, etc.).

How to Enter:

-Plug in the unit.

-Press Soil Level Key + Signal Key and Power Key at the same Time.

Important. Once test mode is performed, all data including the diagnostic code saved in the EEPROM will be erased.

Quick Test Mode:

1. All LED’s light up and it sends out Beep Sound when it enters into the Quick Test Mode. (Including 7-Segment)

2. Displays software version for a sec and Clear EEprom. (Ex. If Machine Version is L9 and S/W Version is 49, 7-Segment will display L949)

3. When the version is displayed, turn the Jog-Dial so that

the version disappears. Press the following keys to test the

various components.

- Temp Key : Water Valve Test

- Spin Key : Door Lock/Unlock Test - Soil Key : Water Heater Test

5

WF395BTP-03144B-01_EN.indd 5 |

|

|

2012-10-19 2:05:55 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

EEPROM Clear Check

Definition of EEPROM Clear Mode:

- EEPROM initialization.

- All course/option settings are to be reset to default values

after EEPROM initialization.

- When Service arises and it needs PCB replacement, EEPROM should be reset.

How to Enter:

- The machine must be turned off.

- Press Delay Start Key, Power Key at the same time.

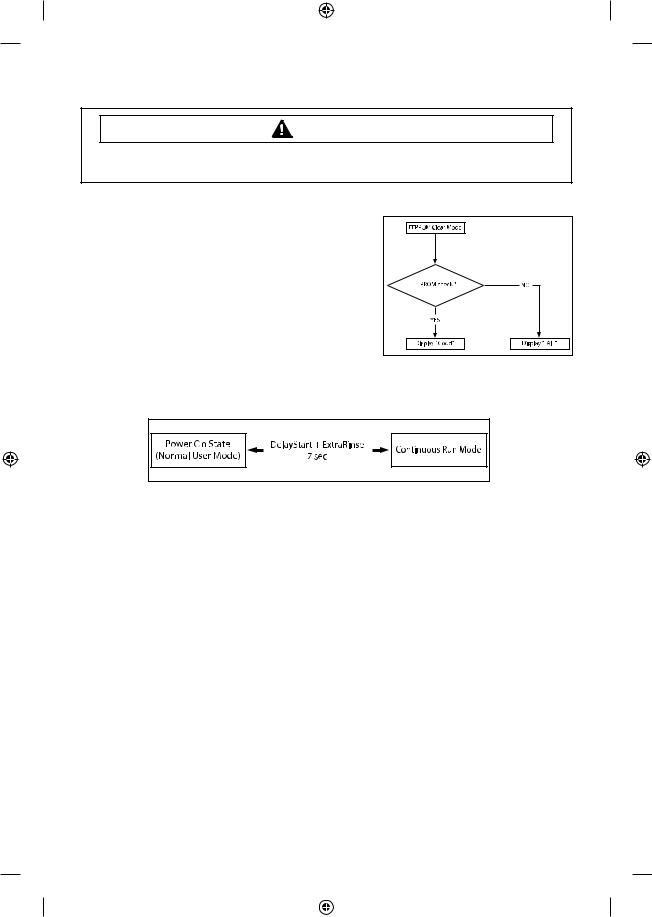

Continuous Run Mode

Definition of Continuous Run Mode:

- Will continuously repeat the current cycle until the Continuous Run Mode is cancelled.

How to Enter:

- Press DelayStart + ExtraRinse together for 7 sec.

Continuous Run Mode:

1.Press DelayStart + ExtraRinse 7 sec during Power On State (Normal User Mode) .

2.Once in Continuous Run Mode, The seven segments will no longer display “0000” and will alternate between displaying the number of cycles of the completed course and the remaining time of the course.

3.The Continuous Run Mode will repeat the previous cycle until continuous run mode is cancelled.

4.During Continuous Run Mode, press DelayStart + ExtraRinse 7 seconds to return to normal user mode. The seven segments will no longer display the number of cycles and will display the maintenance time only.

5.If power is lost in Continuous Run Mode (that is, when the power plug is disconnected or the Power key is pressed turning the washing machine off), the mode is released when the washing machine is turned on again.

6

WF395BTP-03144B-01_EN.indd 6 |

|

|

2012-10-19 2:05:55 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

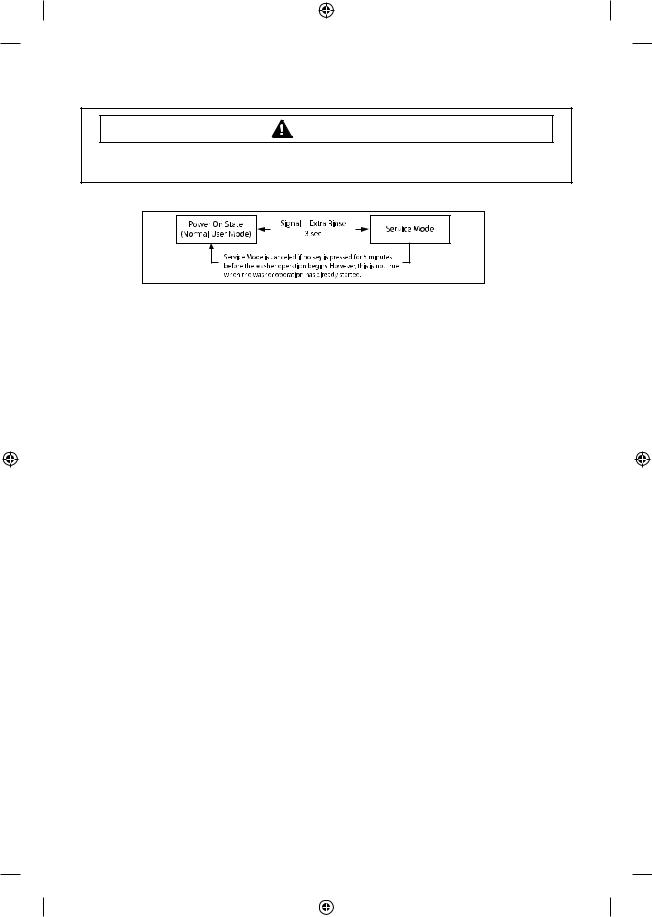

Service Mode

Definition of Service Mode:

-Service Mode enables service technicians to verify the operation of the washing machine and do troubleshooting.

-Service Mode can be entered during all washing cycle without interrupting the cycle except some of test modes.

-Various tests can be done with Service Mode. So, troubleshooting can be done based on the resulting diagnostic codes.

How to Enter:

-To enter the Service Mode, press the Signal + Extra Rinse Keys for 3 seconds or until the unit sends out beeping sounds.

Service Mode:

1.The washer must be on to go into the Service Mode.

2.The motor speed will be displayed when started (It displays 0 when the motor does not spin).

3.The present state of the machine will not be changed.

(i.e., the current cycle in progress will not be interrupted and only the display will change)

4.To exit Service Mode, press Signal + Extra Rinse Keys for 3 second again, or Power Key.If no key is operated during Service Mode for 5 minutes, the machine will return to normal user mode.

7

WF395BTP-03144B-01_EN.indd 7 |

|

|

2012-10-19 2:05:55 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

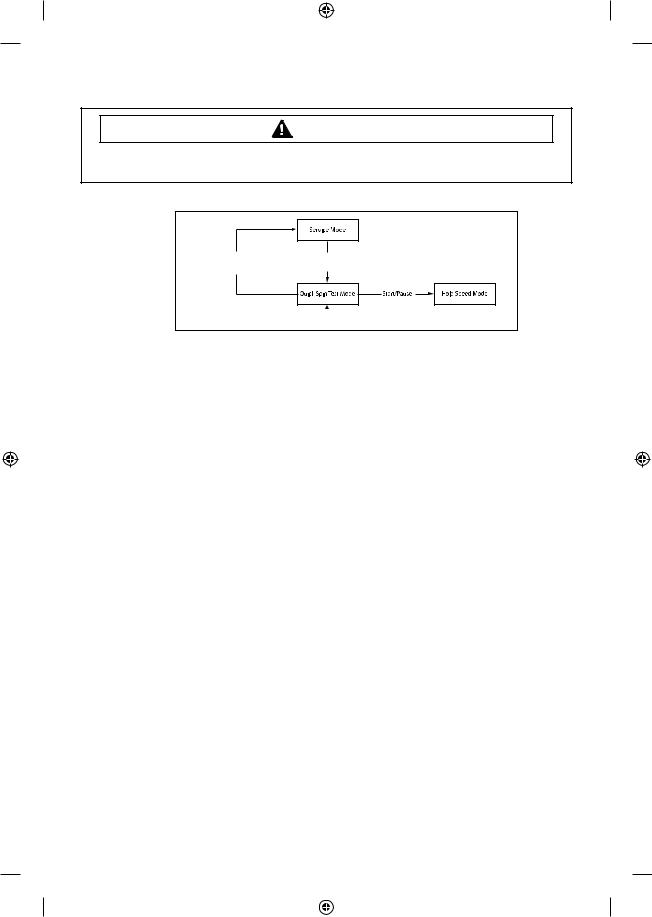

Quick Spin Test Mode

Pre Wash + Soil Level |

Pre Wash + Soil Level |

|

3 sec |

||

While it is not in Hold Speed Mode |

||

While a cycle is not running |

||

|

Pre Wash + Soil Level for 3 sec or after 10 minutes

Pre Wash + Soil Level for 3 sec or after 10 minutes

Definition of Quick Spin Test Mode:

-Quick Spin Test Mode is to do Spin Check. (High RPM)

How to Enter:

-During Service Mode, press the Pre Wash + Soil Level Keys for 3 seconds to enter Quick Spin Test Mode.

-Cannot enter once the washing cycle has started.

Quick Spin Test Mode:

As it enters into the Quick Spin Test Mode, it starts spinning and reaches to its maximum RPM. Once the Spin speed reaches the maximum RPM, the speed drops immediately.

To hold Quick Spin Test Mode (entering Hold Speed Mode), press the Start/Pause button. If the Start/Pause button is pressed during Quick Spin Test Mode, it will stop accelerating and hold its spinning speed for 10 minutes before going back to Quick Spin Test Mode.

Also, to cancel the hold and allow Quick Spin Test Mode to continue, press the Pre Wash + Soil Level Keys together for 3 seconds.

If you hold down the Pre Wash + Soil Level Keys for three (3) seconds when the washing machine is not in Hold Speed Mode, Quick Spin Mode is exited and Service Mode is restored.

8

WF395BTP-03144B-01_EN.indd 8 |

|

|

2012-10-19 2:05:55 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

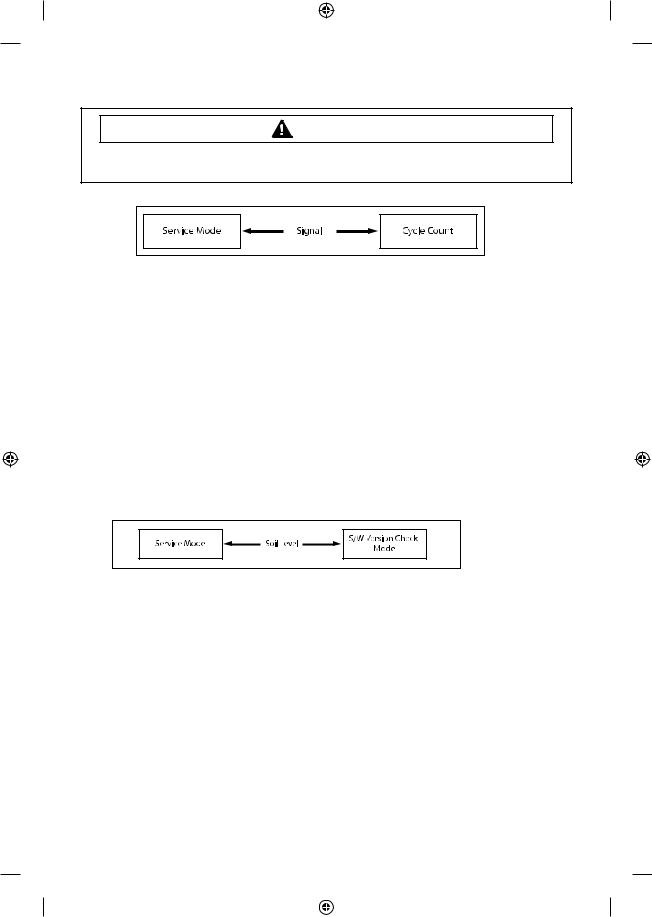

Cycle Count Check Mode

Definition of Cycle Count Check Mode:

-Cycle Count Check Mode is to tally up the number of washings.

How to Enter:

-To enter the Cycle Count Check Mode, press the Signal Key during Service Mode.

Cycle Count Check Mode:

1.Activate the Service Mode in advance.

2.When the Signal key is pressed, the total number of washings will light up and a signal LED will glow.

3.The maximum number of cycles will be 9999.

The counter will roll over to 0 and start counting again after 9999.

4.The counting will be carried out at the end of the normal cycle.

(For normal and Continuous Run cycles, the count is carried out at the end of the cycles.)

5.To exit the Cycle Count Check Mode, press the “Signal” key again.

S/W Version Check Mode

Definition of S/W Version Check Mode:

-S/W Version Check Mode is to bring up S/W Version information.

How to Enter:

-To enter the S/W Version Check Mode, press the Soil Level Key during Service Mode.

S/W Version Check Mode:

1.Activate the Service Mode in advance.

2.Press the Soil Level Key to bring up its software Version

EX) Generate AE49 at Version 49 (AE is Micom code, 49 is it’s software version)

3.To exit the S/W Version Check Mode, press the Soil Level S/W once again. Then, it returns to the Service Mode with motor RPM illuminating.

9

WF395BTP-03144B-01_EN.indd 9 |

|

|

2012-10-19 2:05:55 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

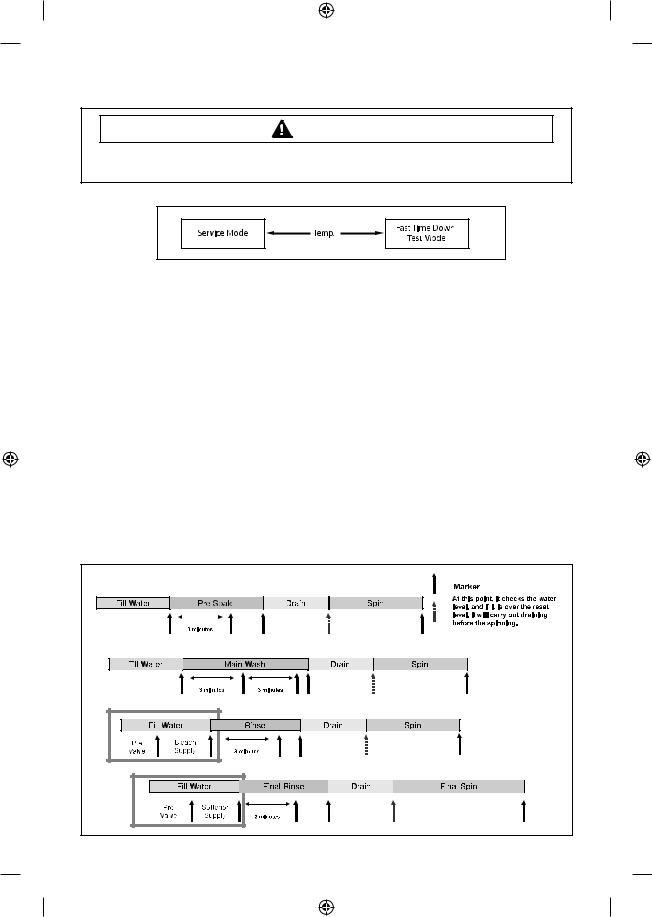

Fast Time Down Test Mode

Definition of Fast Time Down Test Mode:

-Fast Time Down Test Mode is to forward the program to the next cycle stage.

How to Enter:

-To enter the Fast Time Down Test Mode, press the Temp key during Service Mode.

Fast Time Down Test Mode:

1.Activate the Service Mode in advance.

2.To forward the program to the next cycle stage, press the Temp key.

Each stage is located at key points of a complete cycle as follows:

-End of Each Fill (Beginning of Wash or Rinse Tumble Session)

Caution: Check if the current water level is higher than the Reset water level and then perform the Fast time down test.

-Beginning of Drain Session

-Beginning of Spin Session (Here, it checks the water level. So, if it is over the reset level, it carries out draining before the spinning.)

-Beginning of Fill Session

-Beginning of Bleach Fill

-Beginning of Fabric Softener Fill

-Every 3 minutes during Wash and Rinse Tumble Session

|

|

10 |

|

WF395BTP-03144B-01_EN.indd |

10 |

2012-10-19 |

2:05:56 |

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

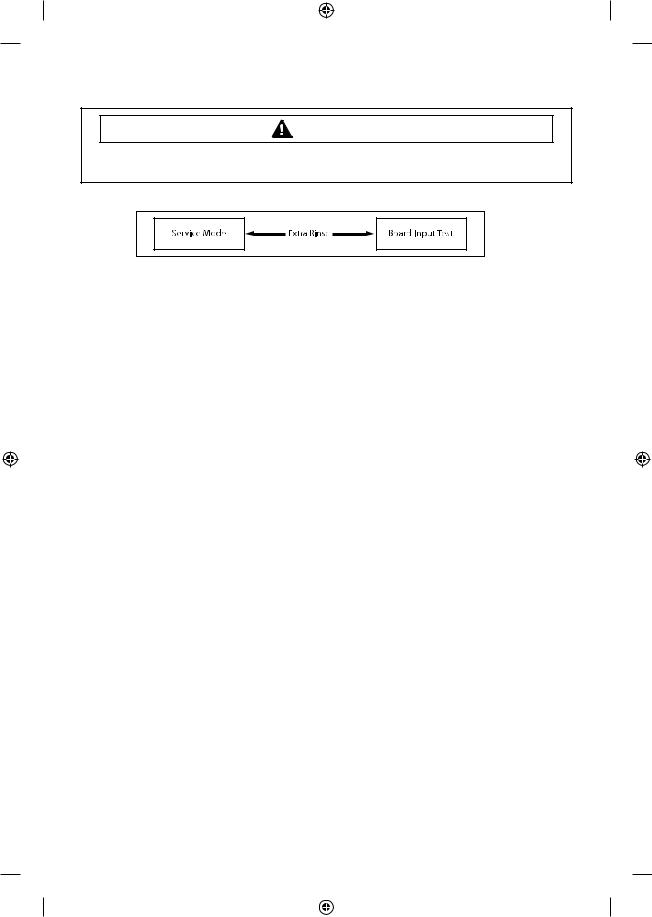

Board Input Test Mode

Definition of Board Input Test Mode:

-Board Input Test Mode is to displays a specified input after a key press.

How to Enter:

-To enter the Board Input Test Mode, press the Extra Rinse Key during Service Mode.

Board Input Test Mode:

1.Activate the Service Mode first.

2.Press the Extra Rinse Key to start Board Input Test.

3.Turn the Jog-Dial so that the Normal Course LED is turned on. The Water Temperature will be displayed in Celsius.

4.Turn the Jog-Dial to counter clockwise direction so that the Next Course LED is turned on. The Water Temperature will be displayed in Fahrenheit.

5.Turn the Jog-Dial to counter clockwise direction so that the Next Course LED is turned on. The door status will be displayed (OP if open, CL if closed).

6.Turn the Jog-Dial to counter clockwise direction so that the Next Course LED is turned on. The Door Lock Switch status will be displayed (UL if unlocked, LO if locked).

7.Turn the Jog-Dial to counter clockwise direction so that the Next Course LED is turned on. The Water Frequency will be displayed.

8.Turn the Jog-Dial to counter clockwise direction so that the Next Course LED is turned on. The SilverCare Status will be displayed. (defualt : “--”)

11

WF395BTP-03144B-01_EN.indd 11 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

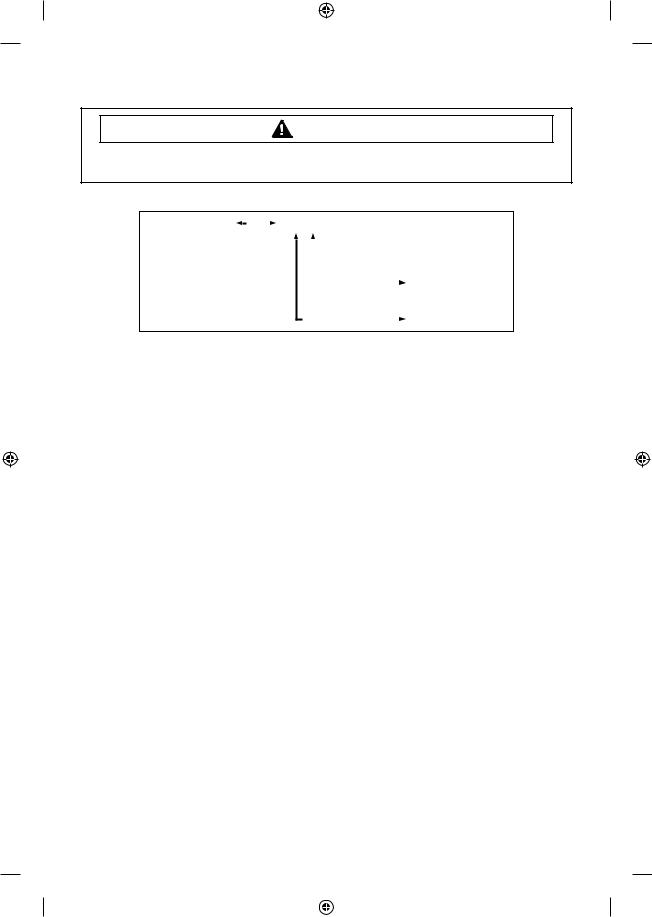

Diagnostic Code Check Mode

Service Mode |

Spin |

|

|

Diagnostic Code |

|

|

|

|

|

|

|

|

|

|

Start/Pause |

|

|

|

Cycle No. |

Signal |

Pressing |

|

|

|

Before making Code |

|

|

|

|

|

|

||

|

|

|

|

Cycle Count |

||

|

|

|

|

|

|

|

Definition of Diagnostic Code Check Mode:

-Diagnostic Code Check Mode is to bring up the stored diagnostic codes (refere nce codes for service technicians).

How to Enter:

-To enter the Diagnostic Code Check Mode with code “d” flashing, press the Spin Key during Service Mode.

Diagnostic Code Check Mode :

1.Activate the Service Mode first.

2.Press the “Spin Key” key to start Diagnostic Code Check Mode with Code “d” flashing.

3.To cycle through the diagnostic codes (d1,d2,d3~d7), turn the Rotary Cycle Selector in one direction (either Clockwise or Counterclockwise).

4.Now, when turning the Rotary Selector Key in the same direction, it shows diagnostic codes from the latest (d1).

5.When turning it in the opposite direction, it shows the diagnostic codes in the reverse order. Ex) When it stops at d5 and turns backward, it shows from d4 down to “d”. Refer to Diagnostic Code.

12

WF395BTP-03144B-01_EN.indd 12 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

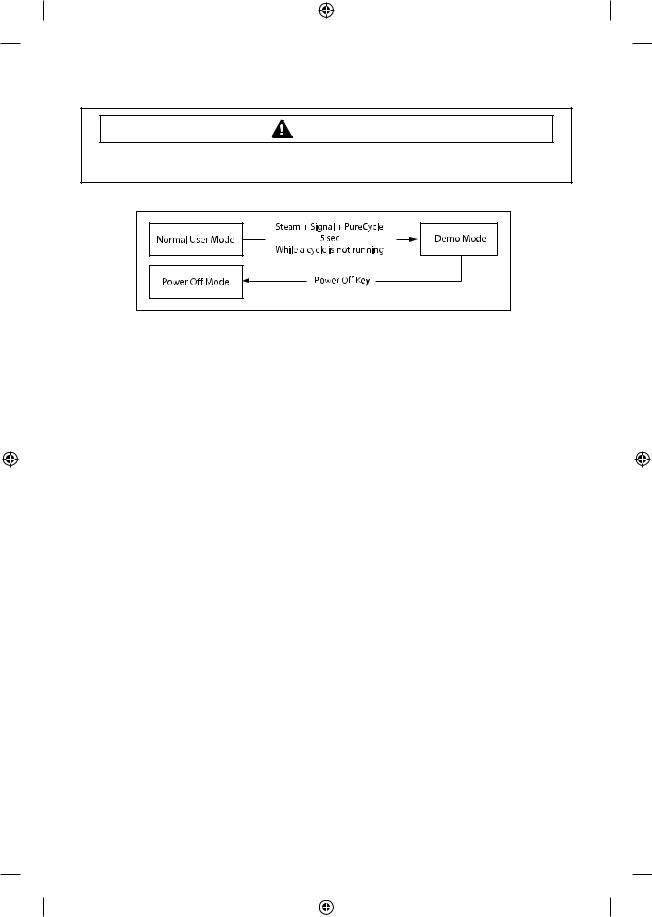

Demo Mode

-Demo mode is entered when the Steam + Signal + PureCycle buttons are held down for five (5) seconds simultaneously in the power on state.

-When entering Demo mode, the buzzer rings three (3) times and “- - - -” is displayed on the 7 segment display and all other LEDs are turned off. (Initial Demo mode)

-Demo mode consists of WASH, SPIN and LED modes.

-If the Temp button is pressed during the initial Demo mode, “WASH” blinks on the 7 segment display and the washing machine enters WASH mode.

-If the Start/Pause button is pressed in WASH mode, the door is locked (Door Lock) and the motor rotates left and right at 45 RPM in a 7 sec on and 3-sec off cycle.

-WASH mode continues up to five (5) minutes once started. After the five (5) minutes have elapsed, “- - - -” is displayed on the 7 segment display and the initial Demo mode is maintained.

-If the Start/Pause button is pressed during a WASH mode operation, “- - - -” is displayed on the 7 segment display and the initial Demo mode is maintained.

-If the Spin button is pressed in the initial Demo mode, “Spin” blinks on the 7 segment display and the washing machine enters SPIN mode.

-If the Start/Pause button is pressed in the SPIN mode, the door is locked (Door Lock) and a spin is operated at 1200 RPM. When the speed reaches 0 RPM, the No Spin, Low, Medium, High, and Extra High LEDs are turned on.

-During a spin operation, the No Spin LED turns on when the speed is lower than 400 RPM. The Low LED turns on between 400 RPM and 700 RPM. The Medium LED turns on between 700 RPM and 900 RPM and The High LED turns on between 900 RPM, and 1100 RPM. The Extra High LED turns on at higher than 1100 RPM.

-SPIN mode continues up to four (4) minutes once started. After the four (4) minutes have elapsed, “- - - -” is displayed on the 7 segment display and the initial Demo mode is maintained.

-If the Start/Pause button is pressed during a SPIN mode operation, “- - - -” is displayed on the 7 segment display and the initial Demo mode is maintained.

-If the Soil Level button is pressed during the initial Demo mode, “LED” is displayed on the 7 segment display and the washing machine enters LED mode.

-If the Start/Pause button is pressed in LED mode, all LEDs are turned on. The LED mode continues up to thirty (30) seconds once started. After the thirty (30) seconds have elapsed, “- - -

-” is displayed on the 7 segment display and the initial Demo mode is entered.

-If the Start/Pause button is pressed during an LED mode operation, “- - - -” is displayed on the 7 segment display and the initial Demo mode is entered.

13

WF395BTP-03144B-01_EN.indd 13 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

-As the micom wash machine is configured of the complicate structure, there might be the service call.

Below information is prepared for exact trouble diagnosis and suitable repair guide.

Caution for the Repair and Replacement

Please follow below instruction for the trouble diagnosis and parts replacement.

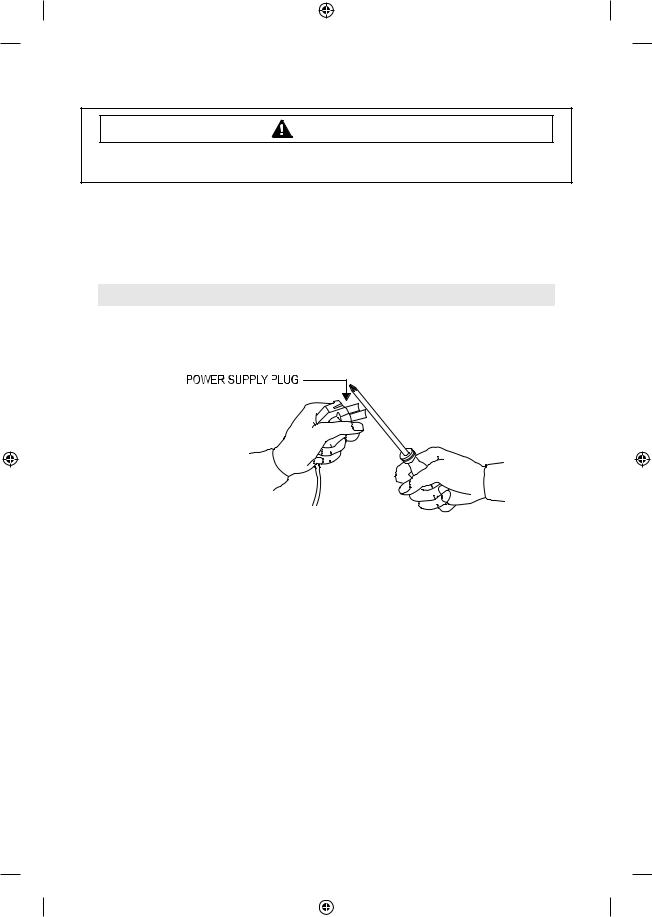

1)As some electronic components are damaged by the charged static electricity from the resin part of machine or the human body, prepare the human body earth or remove the potential difference of the human body and machine by contacting the power supply plug when the work contacting to PCB is executed.

2)Since AC120V is applied to the triac T1 and T2 on P.C.B, the electric shock may occur by touching and be careful that the strong and weak electricity are mixed.

3)As the P.C.B assembly is designed for no trouble, do not replace the P.C.B assembly by the wrong diagnosis and follow the procedure of the trouble diagnosis when the micom is not operated normally.

14

WF395BTP-03144B-01_EN.indd 14 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

Will Not Start

•Plug the unit into the wall outlet. Check for proper voltage.

•Check fuse or reset circuit breaker.

•Push any key to turn on the washer and press the Start/Pause key to run the washer.

•Close door and push the Start/Pause key to run the washer.

•Check if washer is in a pause, soak or suds process. Wait briefly and it may start. (If the washer is in suds period, Suds will light up instead of remaining time.)

•Check for restricted drain system. (If there is electrical problem in drain system, “nd” error will occur after 15 minutes.)

•Check Water Supply.

•Check the line or water valve screen filter.

•Check if PCB connectors are assembled properly.

•Check if CN2 terminals on PCB are in good condition. (Refer to PCB Connector Check.)

•Replace PCB.

Leaking

•Make sure inlet hose connections are not leaking. Check for rubber gasket damage due to over tightening.

•Check standpipe for leak. Wrap a dry rag around the standpipe opening. If rag becomes wet, leak is fault of home plumbing.

Be sure the standpipe is capable of accepting the flow of water from the washer.

•Make sure end of drain hose is correctly inserted and secured to drain standpipe.

•Check internal hose connections (fill, drain systems, dispenser hoses & clamps).

•Check rubber boot. Remove, reposition and reinstall, if necessary.

•Check for possible kinked dispenser to outer tub hose. Hot water pressurization may force door open.

No Tumble

•Start normal cycle with an empty machine and allow a fill to check tumble.

•Perform Quick Spin Test. (Before test, make sure that the tumbler is empty.)

•Check for loose connections at Machine Control Board, Pressure Switch, Motor, Tach Harness and Motor Control. (Refer to the component testing procedure)

•Check motor windings resistance. CN5 pins 1 & 3 = 11.6ohms ±7%, Pins 1 & 2 = 11.6ohms ±7%,

Pins 2 & 3 = 11.6 ohms ±7%

•Faulty Main Control Board.

•Faulty motor.

Will Not Spin

•Make sure to close the door completely.

•Check for water left inside the washer. If so, go to “Will Not Drain”.

•Perform Quick Test Mode or Quick Spin Test. Does the washer spin? (Before the test, empty the unit inside.) If it doesn’t tumble after the above, change PCB. When the problem persists, change the motor.

•Perform Quick Test Mode or Quick Spin Test. Does the washer spin? If it does, Check Possible unbalanced load scenario in normal mode.

•Check for loose connections at PCB, Water Level Sensor, Motor, Hall Sensor Wire Harness. (CN7,CN5,CN6) (Refer to the Component Testing Procedure.)

•Check motor windings resistance. (CN5 Pin1&3 = 11.6 ohms (at ±7% 20°C/68°F), Pin1&2 = 11.6ohms (at ±7% 20°C),

Pin2&3 = 11.6 ohms (at ±7% 20°C))

15

WF395BTP-03144B-01_EN.indd 15 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

No Water Fill

•Perform Quick Test Mode. Check all of Water Valves visually.

(Pre Wash Valve, Cold Water Valve, Bleach Water Valve, Softener dispenses using Cold & Bleach Water Valve, and Hot Water Valve.)

•Check if water taps are turned on fully.

•Check Water Valves and Water Level Sensor (Refer to PCB Connector Check)

•Check if there is any kink in inlet hoses.

•Check if inlet screens are clogged up.

•Check if water has enough pressure. If so, find out its contributors.

•Check if there is any frozen area in the unit (Drain Hose, etc)

•Measure the resistance of Water Valve Coil.

(It should read 1.18K ohms. Check Pin#1 of CN2 and PIN#1,2,7,8,9 of CN3)

•Check Pressure S/W and PCB for loose connections. (Refer to PCB Connector Check.)

Tub Full of Suds

•Go to “Will Not Drain” and “Will Not Spin” and check the draining.

•Check PCB and Drain Pump for any loose wire connection.

•Perform Quick Test Mode or Board Output Test to drain.

•Use HE (High-Efficiency) or low sudsing detergent specially formulated for front load washers.

•Reduce the amount of detergent for that specific load size and soil level. Keep in mind that towel creates more suds generally.

•Reduce the amount of detergent when water is soft, or laundry is small or lightly soiled.

•Do one more washing cycle with cold water and a table spoon of salt without detergent.

16

WF395BTP-03144B-01_EN.indd 16 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

Wet Clothes

•Unbalance due to not enough load. Put additional load.

•Due to excessive suds by using general detergent. Use HE (High-Efficiency) or reduce its quantity.

•Low Spin Speed or Drain Only was selected.

•Go to “ Will Not Spin”.

Will Not Lock

•Door is not aligned or closed properly.

•Perform Quick Test Mode. Check Door Lock. Check the output voltage of Door Lock Coil.

If it reads 120V, change Door Lock Switch, and if not, change PCB. (Refer to PCB Connector Check.)

•Read Lock Switch and PCB (CN3). (Refer to PCB Connector Check.)

•Try Door Lock and check for 120V to Door Lock Connector. If 120V present, change Main Control Board and if not, change Door Lock switch.

Will Not Unlock

•Check if the door is being pushed out, which may keep it from unlocking.

•Door locks itself when the water level is too high. Opening door will result in water draining from door opening.

•Check the following with Board Input Test Mode. Water Level (frequency): Over 23.80 KHz.

If so, refer to “Will Not Drain”.

Temperature (Inside Drum): Higher than 60ºC/140ºF. If so, wait until it drops.

When everything is normal, check PCB connectors and Door Lock Switch.

•Drain manually after removing the plastic drain hose holder.

•Display shows “LO”. Turn off and on the unit. If “LO” keeps illuminating, check PCB and Door Lock Switch.

17

WF395BTP-03144B-01_EN.indd 17 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

•Read Lock Switch and PCB (CN2 & CN3). (Refer to PCB Connector Check.)

•Perform Quick Test Mode. Check Door Lock. Check the output voltage of Door Lock Coil.

If it reads 120V, change Door Lock Switch, and if not, change PCB. (Refer to PCB Connector Check.)

No Key Operation

•Option and Function buttons respond differently according to each cycle.

•Child Lock is being activated. To exit, hold down Soil Level Key and Signal Key simultaneously until it sends out a beeping sound.

•When “End“ illuminates on the display, only Power button works. Press Power button and make new cycle selections.

Will Not Drain

•Check for any kink on the drain hose. If any, straight it out.

•Check for any restriction in the drain hose.

•Close the door and press the Start/Pause Button. For safety reasons, the washer does not tumble or spin with the door open.

•When it is freezing outside, check if it is frozen inside the drain hose.

•Check if the water level signal input is correct. Go to Board Input Test Mode.

•Go to Quick Test Mode and do Drain Pump Test.

•Check if there is any twist in the hose (the one between Tub and Drain Pump).

•Check if it reads AC 120V at the pump when a spin cycle is selected.

•Read the winding resistance of the pump motor. (14.2±7% Ohms)

•Check the pump at CN3(PIN3) on PCB. It should read AC 110~120V. (Refer to PCB Connector Check)

18

WF395BTP-03144B-01_EN.indd 18 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

Wrong Water Temperature

•Check if both of the water taps are fully open.

•Make sure the domestic water heater is set to deliver water lower than 120°F (49°C) hot water at the tap. Also check water heater capacity and recovery rate.

•If the water heater is located far from the washer, screw out the hot water tap and let its water pass until you get hot water.

•Too Hot/Too Cold: Reduced amount of water is supplied while PCB controls the influx to regulate the actual temperature of the water in the tub. This may appear to be significantly hotter/colder than expected.

•Check if the temperature selection is correct.

•Disconnect inlet hoses from the Water Valve and remove any residue in the inlet screens.

Noisy and/or Vibration/Walking

•Check if the washer is leveled and the lock nuts are tightened up on the bottom plate.

•Check if all of the shipping bolts and spacers are removed from the back panel.

•Check if load is big enough and there is no unbalance.If there is not enough load, put in a few towels to balance it.

•Check if the motor is fastened enough.

•Remove various trouble contributors (such as dust coat on the floor).

Rubber Feet Leaving Marks on Floor

•Use a pencil eraser to remove mark.

•Walk washer into location, do not drag.

Additive Cups Full of Water

•Small amount of water in bottom of additive cups is normal.

•Remove and wash Dispenser Tray, removable Cup, and Rinse Cap.

•Level washer.

Buttons do not Respond

•Option and Function buttons respond differently according to each cycle.

•Child Lock feature has been selected. To disable feature press and hold Temp and Spin simultaneously until a beep is heard.

•When display shows “End”, only the Power button will function. Press Power and make new cycle selections.

19

WF395BTP-03144B-01_EN.indd 19 |

|

|

2012-10-19 2:05:56 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

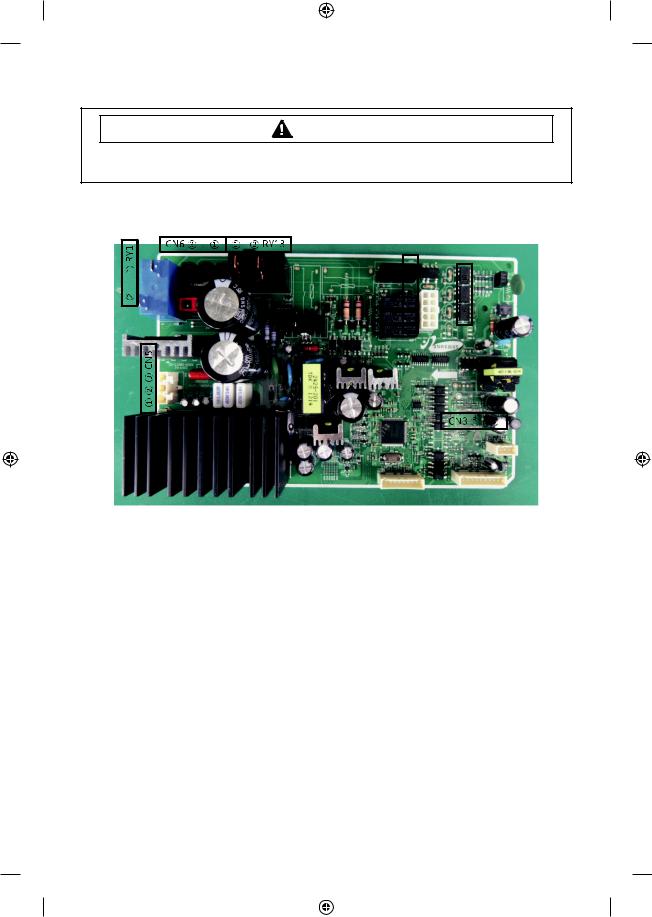

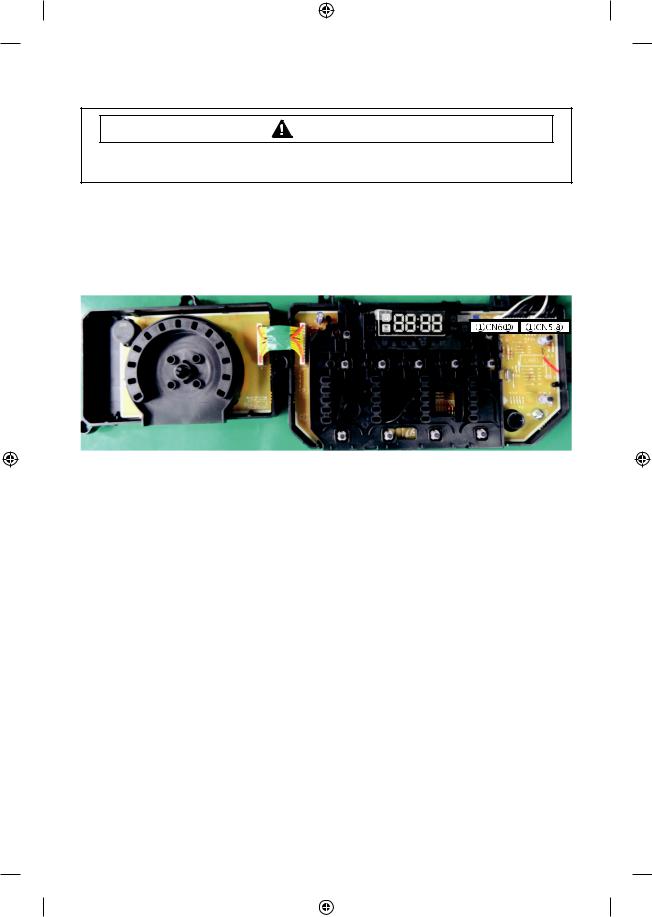

PROBLEM CHECKING AND METHOD OF PCB

-If you plug in the power cord and turn Power S/W on, memorized data is displayed. If any data is not displayed, check the followings.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hall Sensor Check |

Water Valve Check |

||||||||||||

Check Voltage at Pin #4 and #3 of CN3 |

Check Voltage at Pin #1 of RY1 and Pin |

||||||||||||

Tester Check = DC 0V or 1.3V |

#6,7,8,9,10 of CN1 |

||||||||||||

Check Voltage at Pin #4 and #2 of CN3 |

When Each Valve operates = AC 120V |

||||||||||||

Tester Check = DC 0V or 1.3V |

AC Power Check |

||||||||||||

Motor Check |

Check Voltage at Pin #1 of CN6 and #1 of RY1 |

||||||||||||

Resistance at Pin #1 of #2 of CN5 = 12Ω |

When Set Power On = AC 120V |

||||||||||||

Resistance at Pin #2 of #3 of CN5 = 12Ω |

WASH Heater Relay Check |

||||||||||||

Resistance at Pin #3 of #3 of CN5 = 12Ω |

Check Voltage at Pin #1 of RY1 and Pin #2 of RY13 |

||||||||||||

Door Lock Check |

When Wash Heater Relay operates = AC 120V |

||||||||||||

Check AC Voltage at Pin #1 of CN6 and Pin #2 |

|

|

|

|

|

|

|

||||||

of CN6 |

|

|

|

|

|

|

|

||||||

When Door Lock = AC 120V |

|

|

|

|

|

|

|

||||||

Drain Motor Check |

|

|

|

|

|

|

|

||||||

Check Voltage at Pin #1 of RY1 and Pin #3 of CN1 |

|

|

|

|

|

|

|

||||||

When Drain Pump operates = AC 120V |

|

|

|

|

|

|

|

||||||

20

WF395BTP-03144B-01_EN.indd 20 |

|

|

2012-10-19 2:05:57 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

PROBLEM CHECKING AND METHOD OF PCB

-If you plug in the power cord and turn Power S/W on, memorized data is displayed. If any data is not displayed, check the followings.

Thermistor Check

Check Voltage at Pin #4 and #5 of CN5 Tester Check = DC 1.6V

If it ready 5V, check if its connector is engaged properly.

Water Sensor Check

Check Voltage and Frequency at Pin #6 and #5 of CN5 Reset water level = DC1.6V, 26.0KHz

Check Voltage and Frequency at Pin #7 and #5 of CN5 Reset water level = DC1.6V, 26.0KHz

21

WF395BTP-03144B-01_EN.indd 21 |

|

|

2012-10-19 2:05:57 |

|

|

||

|

|

|

|

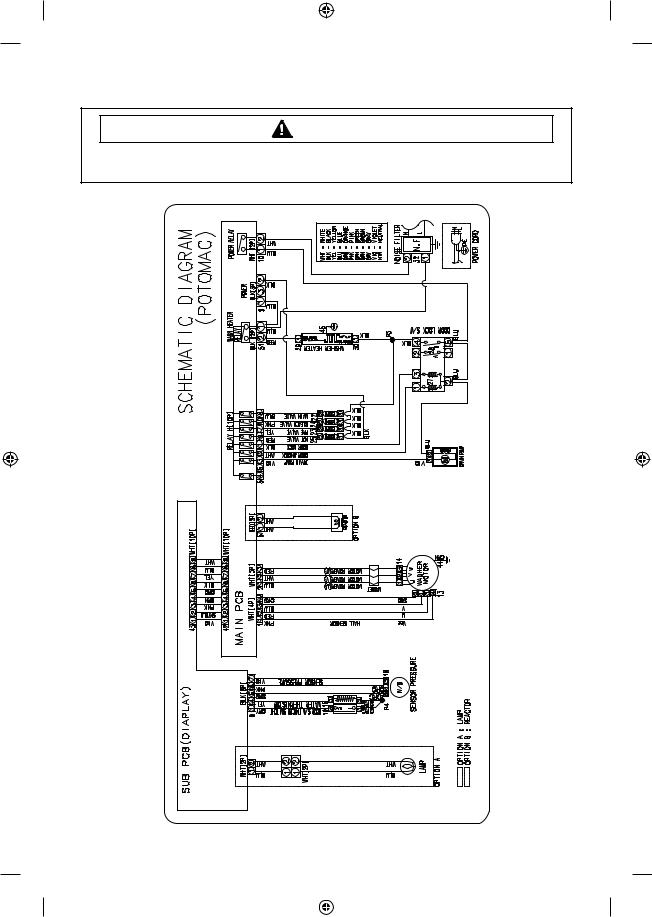

WIRING DIAGRAM

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power.

22 |

WF395BTP-03144B-01_EN.indd 22 |

|

|

2012-10-19 2:05:57 |

|

|

||

|

|

|

|

Loading...

Loading...