Samsung PS42P2SBXXEC Schematic

PLASMA DISPLAY TV

Chassis : D53A(P)_42”_SetTop

Model: PS42P2SBX/XEC

PS42P2SBX/XEH

PS42P2SBX/XEU

PS42PNSBX/XEC

PLASMA DIAPLAY TV CONTENTS

Precautions

Reference Information

Specifications

Alignment and Adjustments

Circuit Operation Description

Troubleshooting

Exploded View and Parts List

Electric Parts List

Handling Description

Glossary

Wiring Diagram

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

ELECTRONICS

© Samsung Electronics Co., Ltd. Nov. 2002

Printed in Korea

AA82-00157A

Alignment and Adjustments

Samsung Electronics 4-1

4. Alignment and Adjustments

4-1 Service Mode

4-1-1 SERVICE MODE ENTRY METHOD

1. Turn off the power to make the SET STAND-BY mode.

2. In order to enter the Service Mode, press the “Display→Menu→Mute→Power” key of remote Control.

✳ In case entry into SERVICE MODE is unsuccessful, repeat the procedures above.

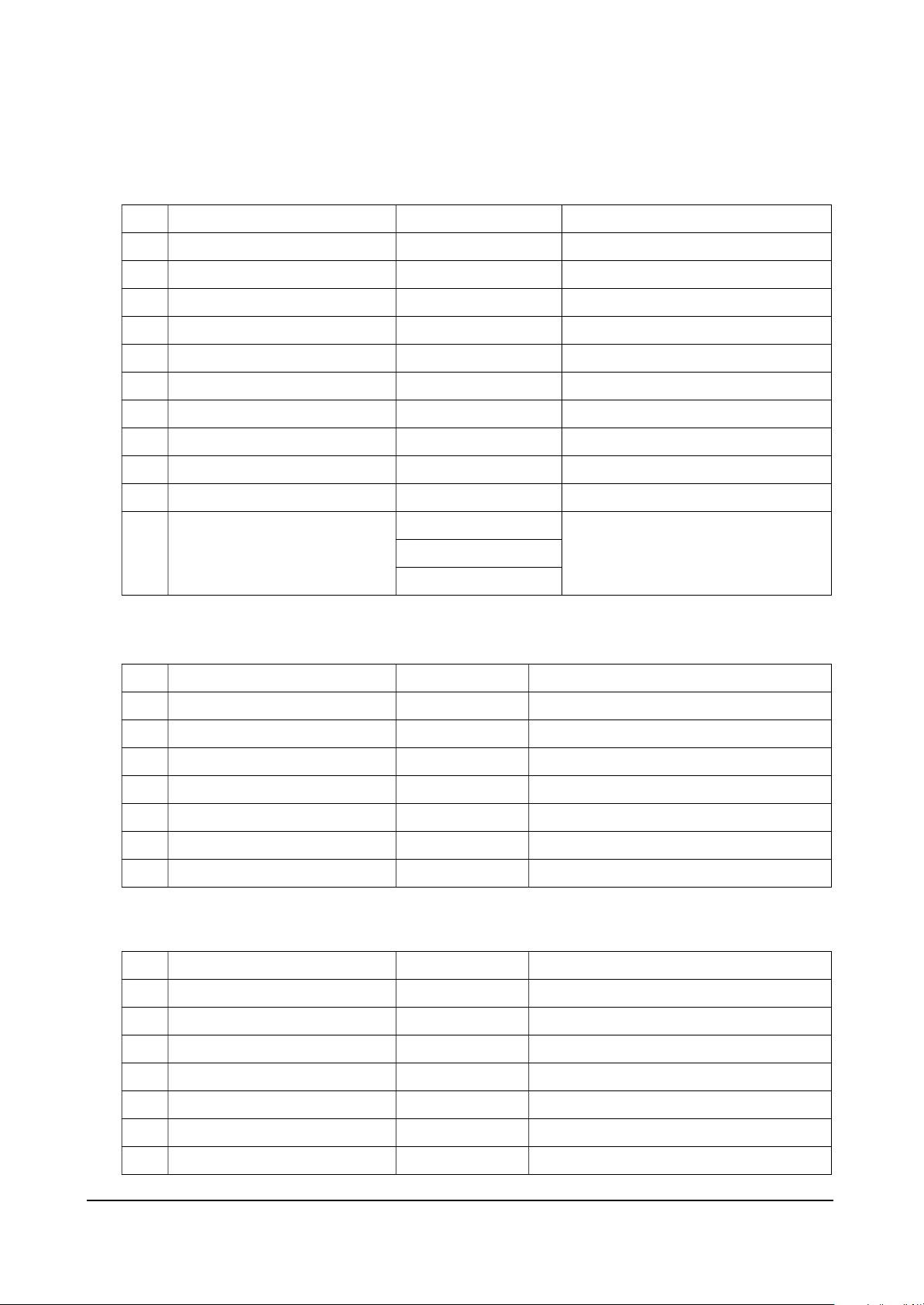

4-1-2 Initial DISPLAY State in times of SERVICE MODE Switch overs

4-1-2(A) OSD DISPLAY

4-1-2(B) BUTTONS OPERATIONS WITHIN SERVICE MODE

1. PW166B 8. SDA6001

2. VPC3230-Main 9. OSD Position

3. VPC3230-Sub 10. Test Position

4. FLI2200 11. Option Table

5. AD9888 12. Color Control

6. CXA2151Q-1 13. Reset

7. MN82860

Release Time :

Menu

Joystick UP/DOWN

Joystick Left/Right

Entire menu display

Cursor move to select items

Enable to increase and decrease the data of the selected items

Alignment and Adjustments

4-2 Samsung Electronics

4-1-3 Details of Control

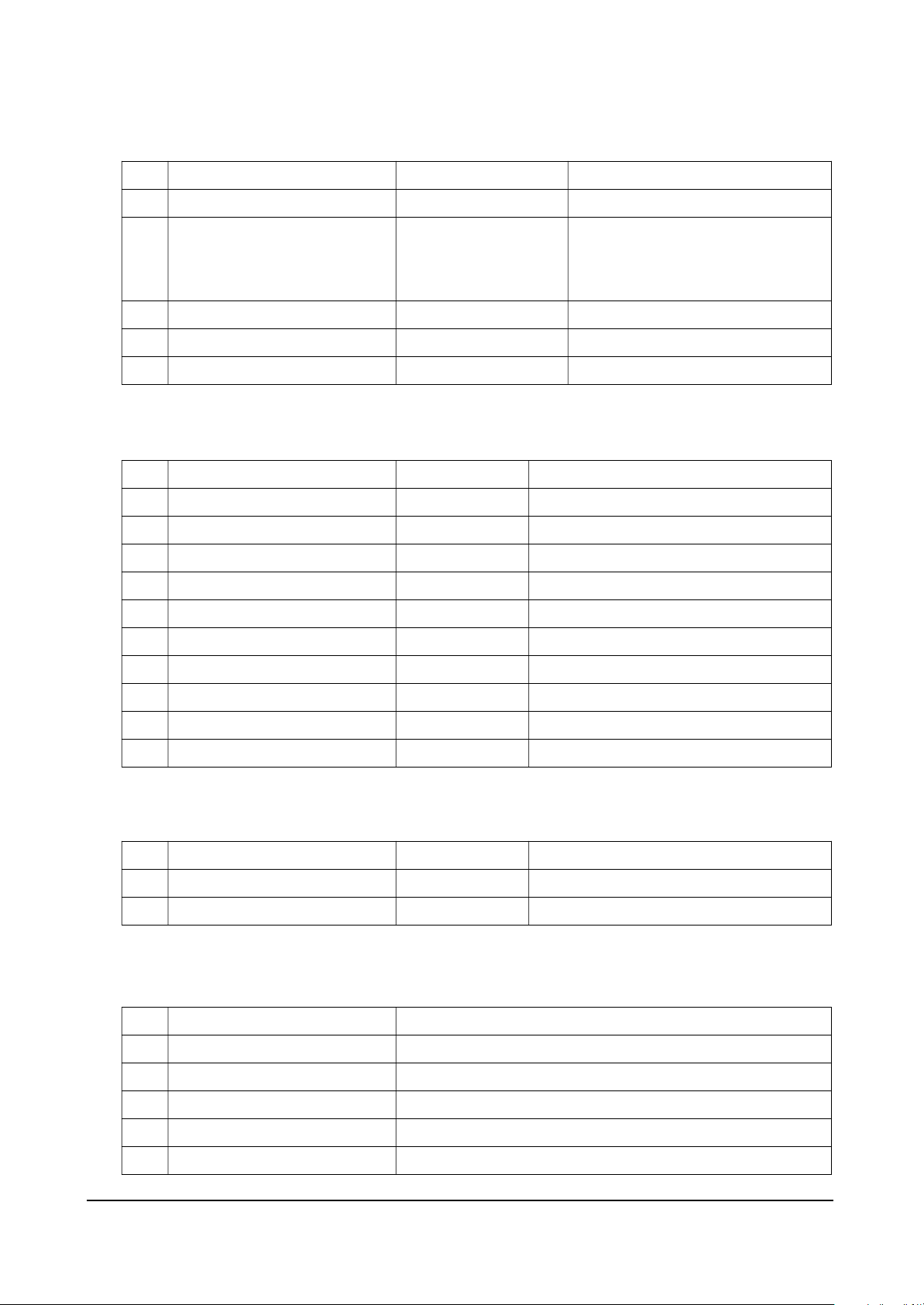

4-1-3(A) PW166B

NO

1

2

3

4

5

6

7

8

9

10

11

Sub Item

Red Gain

Green Gain

Blue Gain

Red offset

Green offset

Blue offset

APL

Pixel Shift

Pixel Number

Time

Virtual Framelock

Range

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

On/Off

Video Port/V&G Port/Off

1 ~ 7

0 ~ 60

V&G Port

Video Port

OFF

Default Value

128

128

128

128

128

128

OFF

Video Port

4

4

V&G Port

NO

1

2

3

4

5

6

7

Sub Item

Bright YUV

Cont YUV

HPLL Speed

Luma Delay

Bright

Contrast

H Peaking

Range

0 ~ 127

0 ~ 63

0 ~ 3

0 ~ 8

0 ~ 127

0 ~ 63

0 ~ 7

Default Value

64

41

1

5

50

36

2

4-1-3(B) VPC3230-MAIN

NO

1

2

3

4

5

6

7

Sub Item

PIP H-Position

PIP V-Position

Bright YUV

Cont YUV

Luma Delay

Brightness

Contrast

Range

0 ~ 63

0 ~ 63

0 ~ 127

0 ~ 63

0 ~ 9

0 ~ 127

0 ~ 63

Default Value

0

0

64

41

5

50

36

4-1-3(C) VPC3230-SUB

Alignment and Adjustments

Samsung Electronics 4-3

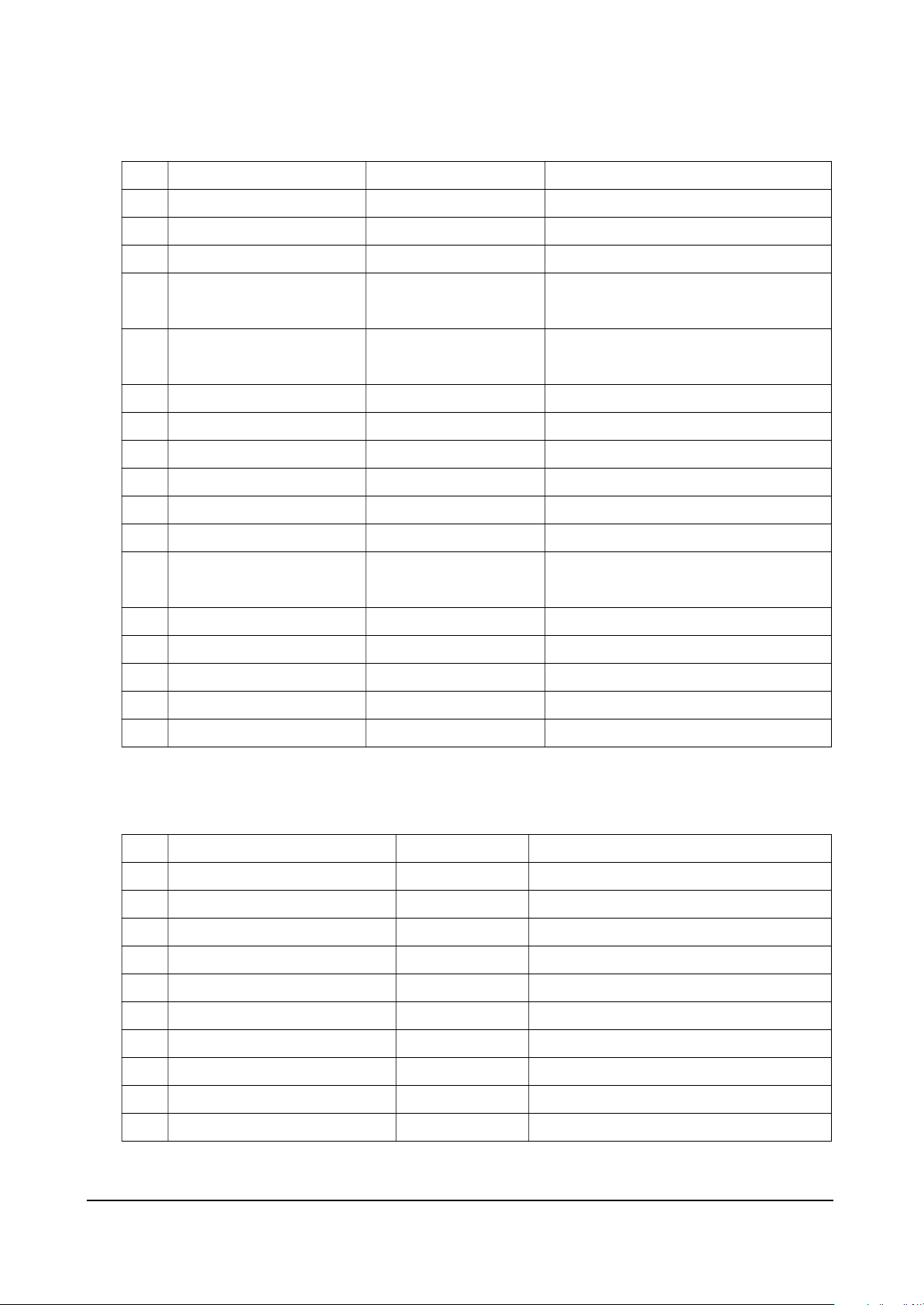

NO

1

2

3

4

5

6

7

Sub Item

C Delay

Y Delyay

DCDI

Adaptive Motion

Film Mode(3D)

Film Mode(3E)

Film Mode(3F)

Range

0 ~ 5

0 ~ 8

0, 1

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

Default Value

11

4

1

60

32

8

128

4-1-3(D) FLI2200

NO

1

2

3

4

Sub Item

G Gain Sel

Cb Gain

Cr Gain

Y Gain

Range

0 ~ 3

0 ~15

0 ~15

0 ~15

Default Value

1

7

7

7

4-1-3(F) CXA2151Q-1

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Sub Item

Red Gain

Green Gain

Blue Gain

Red Offset

Green Offset

Blue Offset

Current

VCO

Pr Gain

Y Gain

Pb Gain

Pr Offset

Y Offset

Pb Offset

TTX Phase

ADC calibration

Range

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 127

0 ~ 127

0 ~ 127

0 ~ 7

0 ~ 3

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 127

0 ~ 127

0 ~ 127

0 ~ 248

Default Value

140

140

140

70

70

70

0

0

145

128

145

49

64

49

96

4-1-3(E) AD9888

Only for white balance adjustment

Alignment and Adjustments

4-4 Samsung Electronics

NO

1

2

3

4

5

Sub Item

TTX Contrast

TTX Group

TTX H-Position

ATM Read

WSS Read

Range

1 ~ 4

Turkish/Greek, Cyrillic,

Arabic/Hebrew, Farsi,

West Europe, East Europe

0 ~ 255

Only Read Value

Only Read Value

Default Value

4

West Group

95

0000

0000

4-1-3(G) SDA6001

NO

1

2

3

4

5

Sub Item

Luma Ramp(16 Step)

Luma Ramp(256 Step)

White 16

White 240

Color Bar

Sub_Item Description

Internal Test Pattern

Internal Test Pattern

Internal Test Pattern

Internal Test Pattern

Internal Test Pattern

4-1-3(J) TEST PATTERN

NO

1

2

Sub Item

OSD H-Position

OSD V-Position

Range

0 ~ 100

0 ~100

Default Value

50

50

4-1-3(I) OSD POSITION

NO

1

2

3

4

5

6

7

8

9

10

Sub Item

H Peak

CTI

R Drive

G Drive

B Drive

R Cutoff

G Cutoff

B Cutoff

RYITH

HLIM

Range

0 ~ 3

0 ~ 3

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 128

0 ~ 128

0 ~ 128

0, 1

0, 4

Default Value

0

2

255

255

255

128

128

128

0

2

4-1-3(H) MN82860

Alignment and Adjustments

Samsung Electronics 4-5

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Sub Item

Language

Jack Type

PAL/NTSC

ATM/Area

CS/CW

LNA

Mega TTX

High Deviation

Carrier Mute

Frame Lock

Picture Aspect

SCART WSS

Clock Display

Blue Screen

OSD Width

Melody Volume

Panel Life Time

Range

English/Chinese/Japanese

SCART/RCA

PAL/NTAC

ATM/AREA

CS/CW

On/Off/Force On

On/Off

On/Off

On/Off

On/Off

Last Memory/Wide

Normal/Wide/Panorama

24 Hour/12 Hour

0 ~ 30

*1, *2

0 ~ 19

( )Hour

Default Value

Selection of the destination country

Selection of the AV1, 2, 3 Jack Type

Selection of te Broadcasting system

- Europe Model : ATM function

- Asia Model : Area function

- Europe Model : CW

- Asia Model : CS

Control LNA function

Control TTX function

Control High Deviation function

Control Carrier Mute function

Control Frame Lock function

Selection of Picture Aspect Default mode

Selection of SCART WSS Signal Option

function

Selection of Clock Display Format

Control Blue Density of the Blue Screen

Selection of OSD Font Option

Control Melody Volume level

Total Displayed time

4-1-3(K) OPTION TABLE

NO

1

2

3

4

5

6

7

8

9

10

Sub Item

Sub Brightness

Red Offset

Green Offset

Blue Offset

Brightness

Sub Contrast

Red Gain

Green Gain

Blue Gain

Contrast

Range

0 ~ 100

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 100

0 ~ 100

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 100

Default Value

Low Light Luminance Adjustment

Low Light X-Coordinate Adjustment

No Adjustment

Low Light Y-Coordinate Adjustment

No Adjustment

High Light Luminance Adjustment

Hight Light X-Coordinate Adjustment

No Adjustment

High Light Y-Coordinate Adjustment

No Adjustment

4-1-3(L) COLOR CONTROL

Alignment and Adjustments

4-6 Samsung Electronics

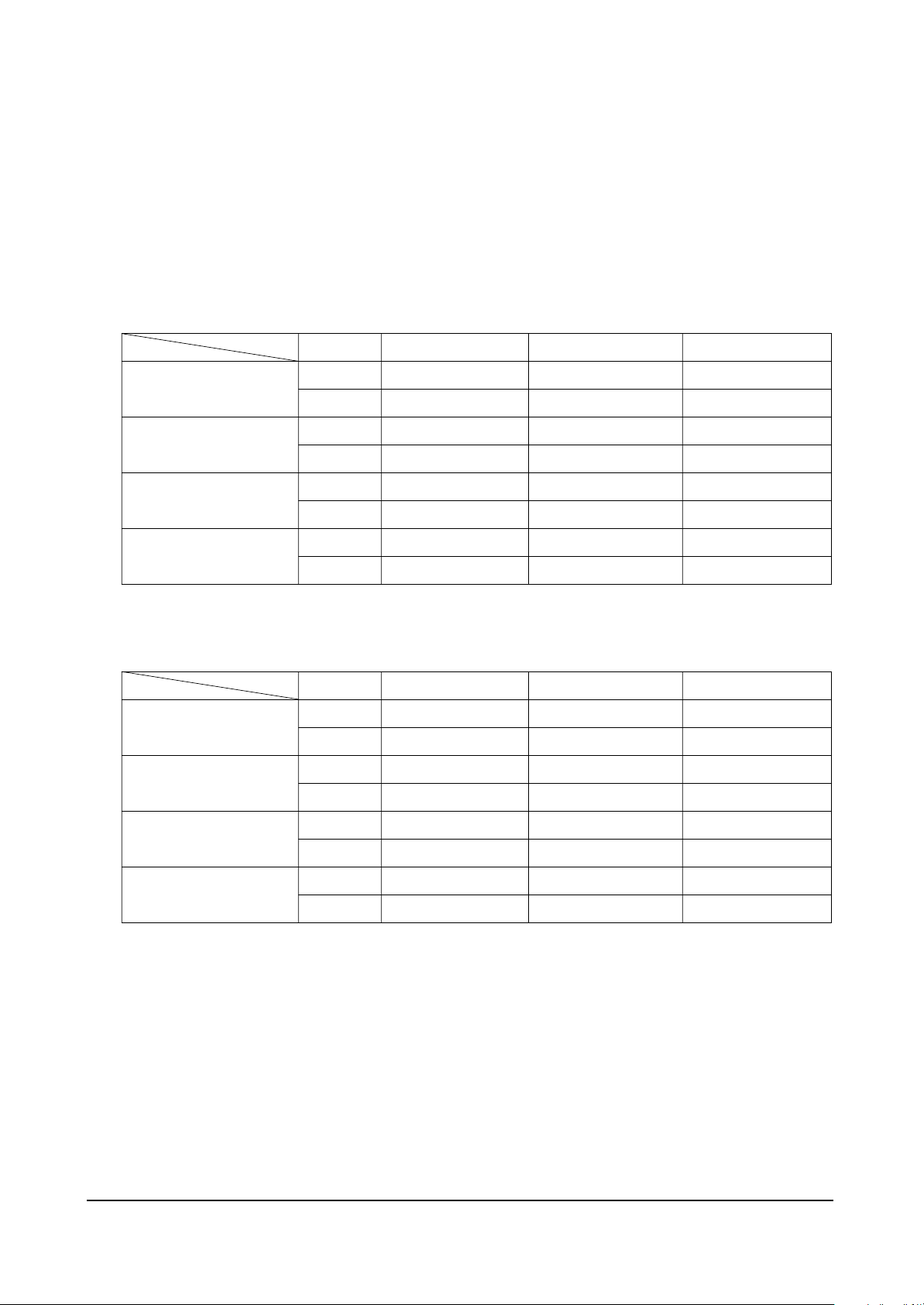

4-1-4 White Balance Adjust Method

4-1-4(A) W/B ADJUSTMENT SPECIFICATION

➣ Measurement equipment : Pattern Generator Master[MSPG-925LTH]

➣. Measured Pattern : ABL Pattern

➣ W/B Coordinate(Varied By the Input Source)

❈ Europe Model(Scart Jack Type)

❈ Asia Model(RCA Jack Type)

VIDEO

DTV Source

(480P, 720P, 1080i)

PC Source

1024 x 768(60Hz)

DVI Source

720P

x

285

285

285

280

285

285

282

280

Field

High

Low

Highe

Low

High

Low

High

Low

y

300

300

300

295

295

295

297

294

Y(fL)

30.0

0.75

25.0

0.40

28.5

0.55

21.0

0.80

VIDEO

DTV Source

(480P, 720P, 1080i)

PC Source

1024 x 768(60Hz)

DVI Source

720P

x

275

275

280

280

282

280

280

280

Field

High

Low

Highe

Low

High

Low

High

Low

y

280

280

285

285

297

294

285

285

Y(fL)

30.0

0.75

28.0

0.60

21.0

0.80

28.5

0.75

❈ Europe Model(Scart Jack Type)

❈ Asia Model(RCA Jack Type)

Alignment and Adjustments

Samsung Electronics 4-7

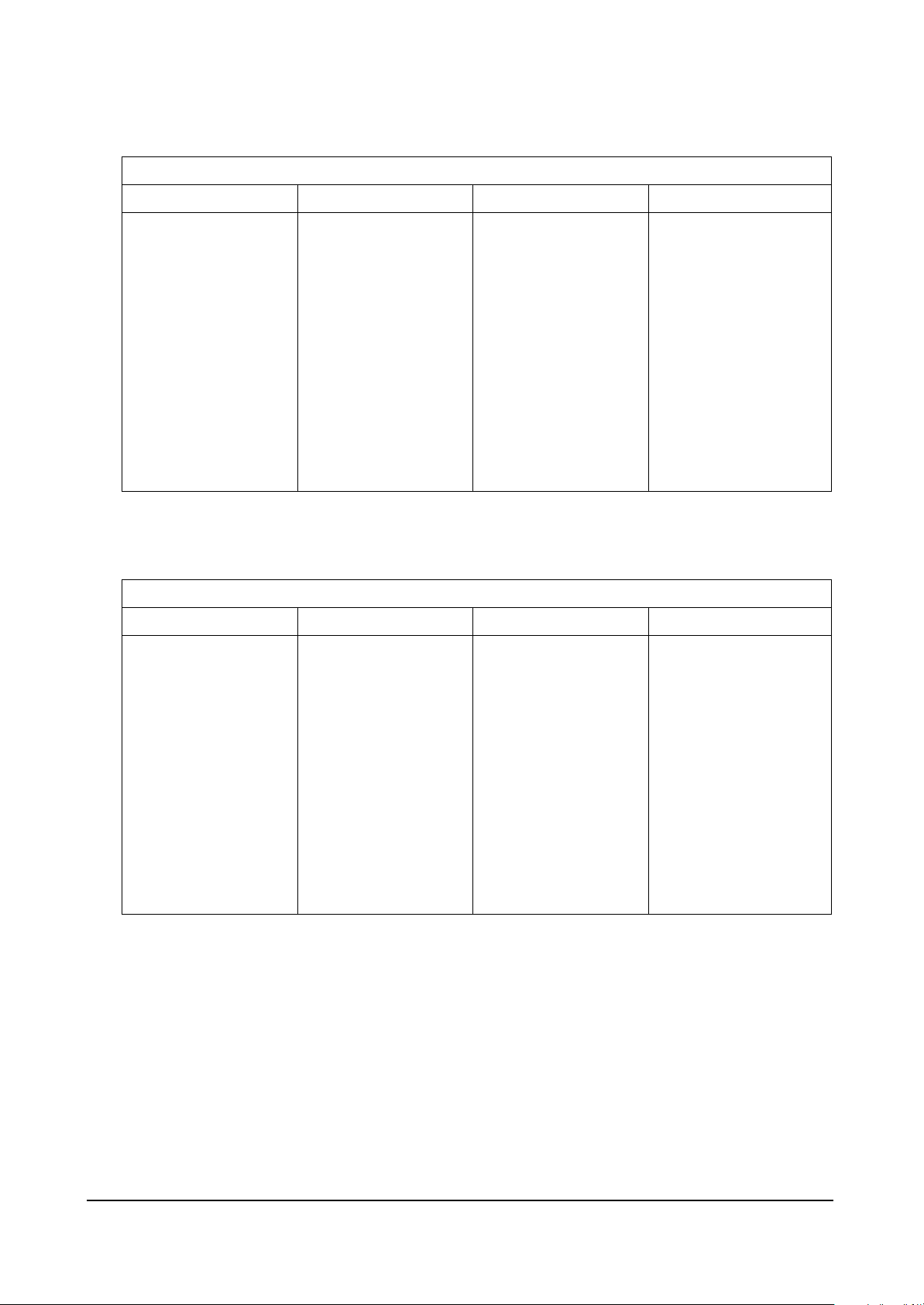

Video

Sub-Brightness 55

Red Offset 99

Green Offset 100

Blue Offset 100

Birghtness 45

Sub-Contrast 56

Red Gain 133

Green Gain 128

Blue Gain 128

Contrast 100

Component

Sub-Brightness 24

Red Offset 130

Green Offset 128

Blue Offset 130

Brightness 45

Sub-Contrast 37

Red Gain 127

Green Gain 128

Blue Gain 126

Contrast 100

DVI

Sub-Brightness 43

Red Offset 129

Green Offset 128

Blue Offset 130

Brightness 60

Sub-Contrast 39

Red Gain 125

Green Gain 128

Blue Gain 126

Contrast 75

PC

Sub-Brightness 31

Red Offset 130

Green Offset 128

Blue Offset 121

Birghtness 60

Sub-Contrast 18

Red Gain 124

Green Gain 128

Blue Gain 130

Contrast 75

Color Control Item Data

Video

Sub-Brightness 60

Red Offset 101

Green Offset 100

Blue Offset 103

Birghtness 45

Sub-Contrast 51

Red Gain 128

Green Gain 128

Blue Gain 138

Contrast 100

Component

Sub-Brightness 28

Red Offset 137

Green Offset 128

Blue Offset 133

Brightness 45

Sub-Contrast 41

Red Gain 122

Green Gain 128

Blue Gain 133

Contrast 100

DVI

Sub-Brightness 58

Red Offset 130

Green Offset 128

Blue Offset 126

Brightness 60

Sub-Contrast 29

Red Gain 126

Green Gain 128

Blue Gain 133

Contrast 75

PC

Sub-Brightness 48

Red Offset 132

Green Offset 128

Blue Offset 126

Birghtness 60

Sub-Contrast 19

Red Gain 124

Green Gain 128

Blue Gain 129

Contrast 75

Color Control Item Data

Alignment and Adjustments

4-8 Samsung Electronics

✳ White Balance Coordinate in Internal Test Pattern. After Adjustment in the each Mode

→ Enter the factory mode

→ Select the “10. Test Pattern” Item.

→ And select the “1. Luma Ramp” Sub-Item.

➣ White Balance Coordinate Table in above Position

1. PW166B 8. SDA6001

2. VPC3230-MAIN 9. OSD Position

3. VPC3230-SUB 10. Test Position

4. FLI2200 11. Option Table

5. AD9888 12. Color Control

6. CXA2151Q-1 13. Reset

7. MN82860

Release Time

:

10. Test Pattern

1. Luma Ramp(16 Step)

2. Luma Ramp(256 Step)

3. White 16

4. White 240

5. Color Bar

VIDEO

Component

(480P)

PC

(1024 x 768,60Hz)

DVI

(720P)

x

284

284

287

286

289

311

291

277

Field

High

Low

Highe

Low

High

Low

High

Low

y

296

302

305

301

308

307

304

293

Y(fL)

30.0

0.58

28.9

0.31

29.4

0.54

28.0

0.76

L

L

H

Alignment and Adjustments

Samsung Electronics 4-9

4-1-4(B) ADJUSTMENT METHOD

1. Press the “Display → Factory” Factory Remote Control button, or

Press the “ Display → Menu → Mute → Power” Normal Remote Control button.

Scr

een Result :

2. Choose the “No. 12 Color Control Item.

Result

:

➣ Using the above Sub-Items, We recommend the order of Luminance → Y Coordinate → X Coordinate so

as to adjust the White Balance

➣ In Adjusting the X, Y Coordinates. To get the decreased Coordinates Value, must increase the Sub-Item

value.

1. PW166B 8. SDA6001

2. VPC3230-Main 9. OSD Position

3. VPC3230-Sub 10. Test Position

4. FLI2200 11. Option Table

5. AD9888 12. Color Control

6. CXA2151Q-1 13. Reset

7. MN82860

Release Time :

12. Color Control

Sub-Brightness 51 Sub-Contrast 50

Red Offset 94 Red Gain 130

Green Offset 100 Green Gain 128

Blue Offset 94 Blue Gain 135

Brightness 45 Contrast 100

Sub Items

Sub-Brightness

Red Offset

Blue Offset

Description

Adjust the Low-Light

Luminance

Adjust the Low-LIight

X-Coordinate

Adjust the Low-Light

Y-Coordinate

Sub Items

Sub-Contrast

Red Gain

Blue Gain

Description

Adjust the High-Light

Luminance

Adjust the High-LIight

X-Coordinate

Adjust the High-Light

Y-Coordinate

Alignment and Adjustments

4-10 Samsung Electronics

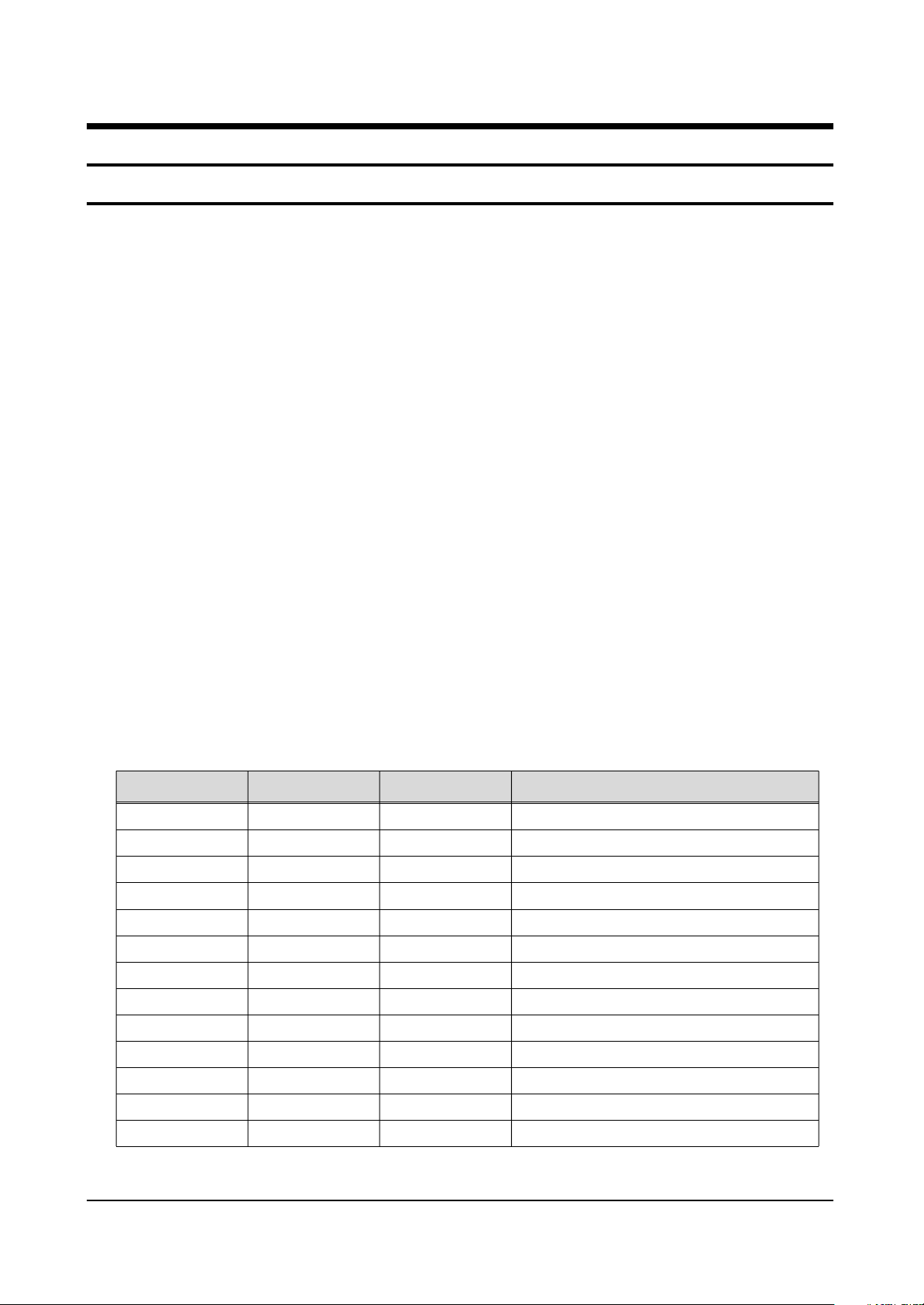

4-2 PC Input Table

Vertical

ferquency(Hz)

85.0

75.0

72.8

59.9

70.1

85.1

75.

72.2

60.3

56.3

85.0

75.0

70.1

60.0

85

75

72

70

60

Dot x Line

640 x 480

720 x 400

800 x 600

1024 x 768

848 x 480

Standrd

VGA

SVGA

XGA

WXGA

Horizontal

ferquency(Hz)

43.3

37.5

37.9

31.5

31.5

53.7

46.9

48.1

37.9

35.2

68.7

60.0

56.5

48.3

42.9

37.5

36.1

35.0

29.8

Vertical

polarity

N

N

N

N

P

P

P

P

P

P

P

P

N

N

P

P

P

P

P

Horizontal

polarity

N

N

N

N

N

P

P

P

P

P

P

P

N

N

N

N

N

N

N

(N : Negative / P : Positive)

Alignment and Adjustments

Samsung Electronics 4-11

4-3 Discharge Voltage Adjustment Method (Monitor) in Times of ASS’Y Repair

and Replacement

-All VR (Variable Resistor), except for VR for Vs, voltage goes down when turned counterclockwise.

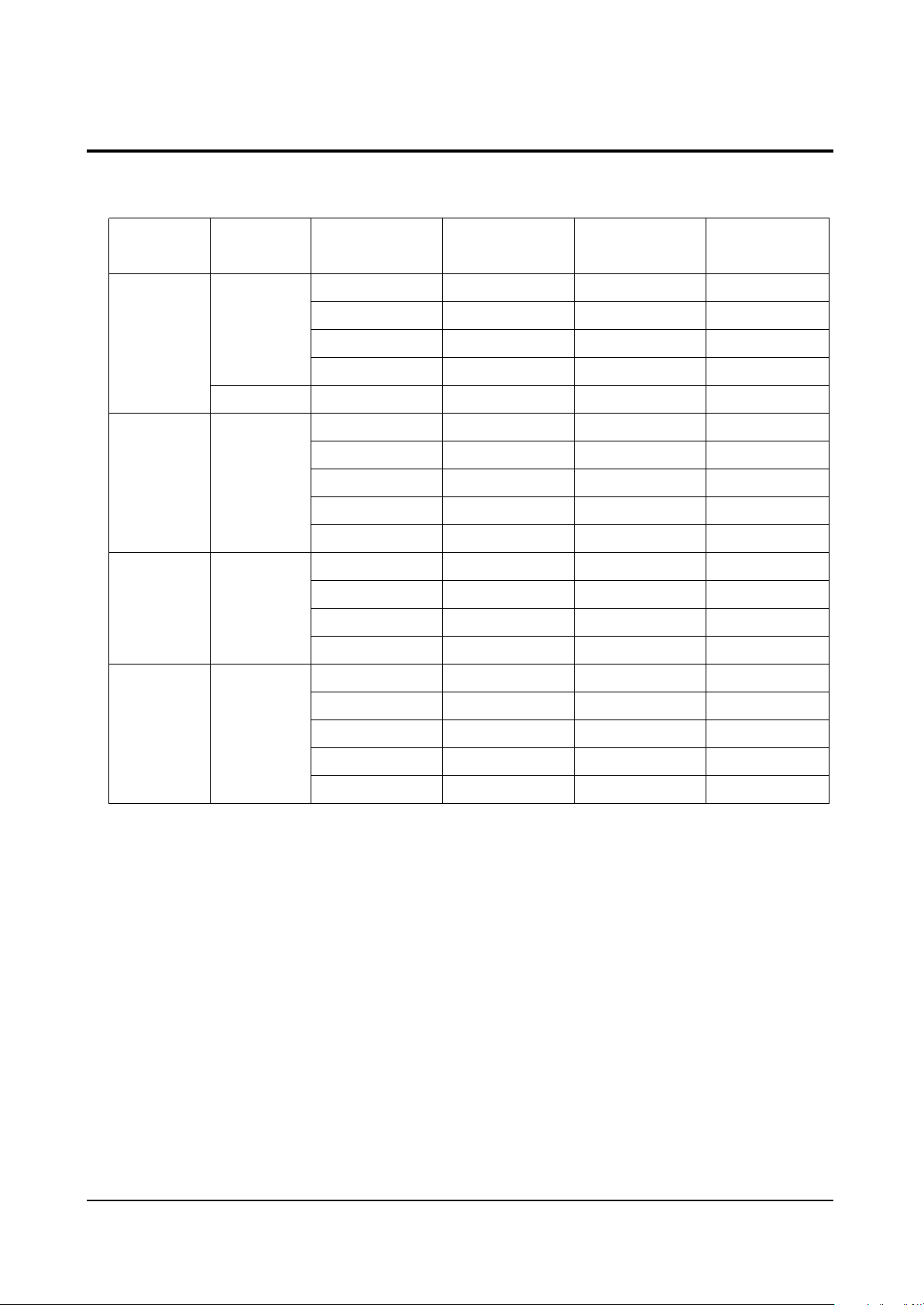

● Vsc and Vy Adjustment Method

● Vs and Va Adjustment Method

■ Vsc is the voltage of the left terminal

for D5207

■ Voltage adjustment is made for Vsc by

using VR5201

■ Standard voltage for Vsc is –55V±10V

■ Vy is the voltage of the right terminal

for D5207

■ Voltage adjustment is made for Vy by

using VR5200

■ Standard voltage for Vy is 132V±10V

■ Vs is the voltage of the no.11 PIN of

SX Connector.

■ Voltage adjustment is made for Vs by

using VR in 7

■ Vs is 175±5V

■ Va is the voltage of the no.7 PIN of SX

Connector.

■ Voltage adjustment is made for Va by

using right VR in 6

■ Va is 75±5V

Y-Main

Alignment and Adjustments

4-12 Samsung Electronics

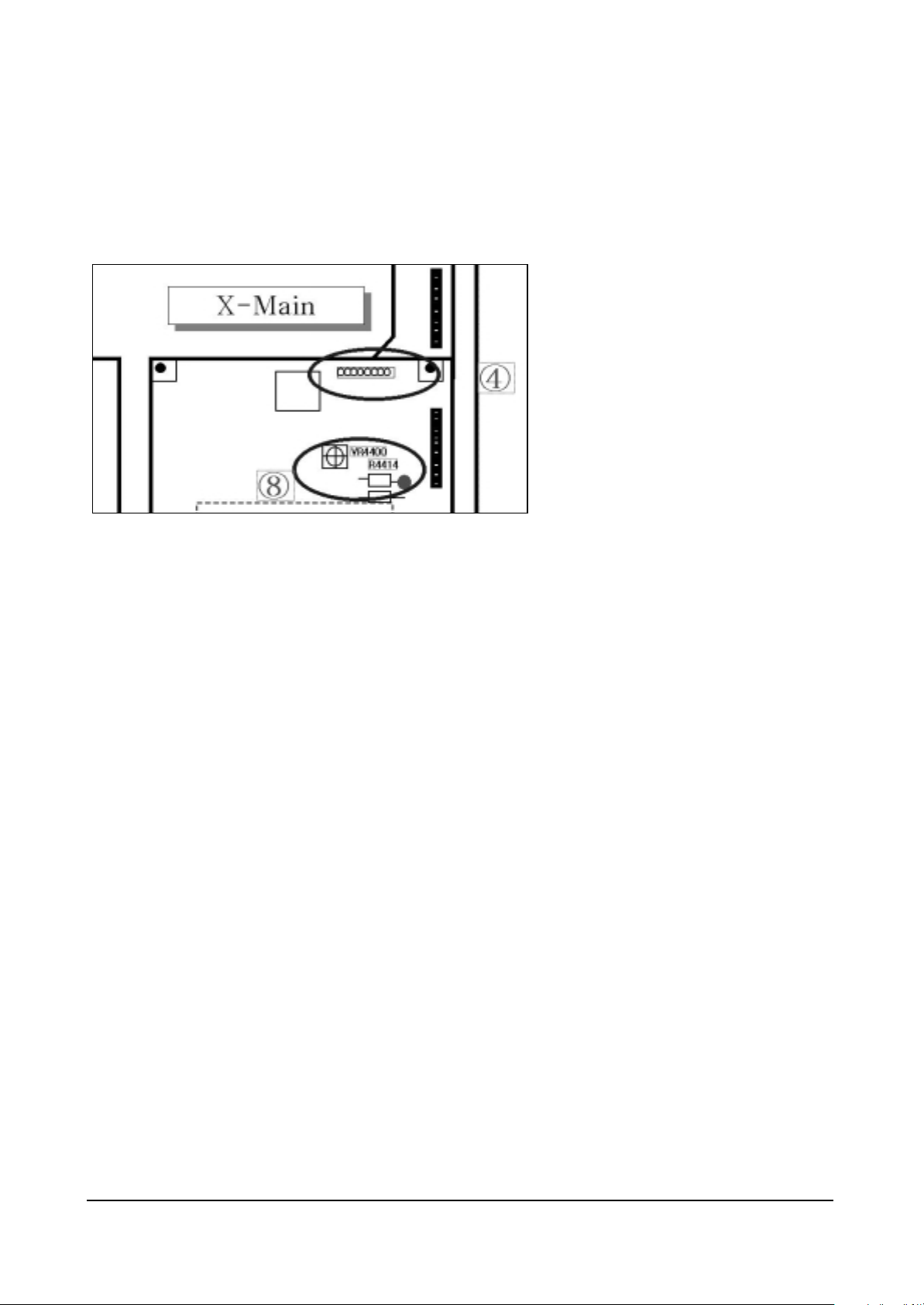

■ Vw is the voltage of the right terminal

for R4414

■ Voltage adjustment is made for Vw by

using VR4400

■ Standard voltage for Vw is 175V±5V

Alignment and Adjustments

Samsung Electronics 4-13

4-4 Fault Finding Using MULTI METER

Parts defects can be found for DIODE TRANSISTOR IC, using MULTI TEST including

Forward/Reverse direction Multi Test. Of course, in case resistance of several ohms and COIL are connected in parallel circuit, the lock out circuit parallel connected to part must be severed.

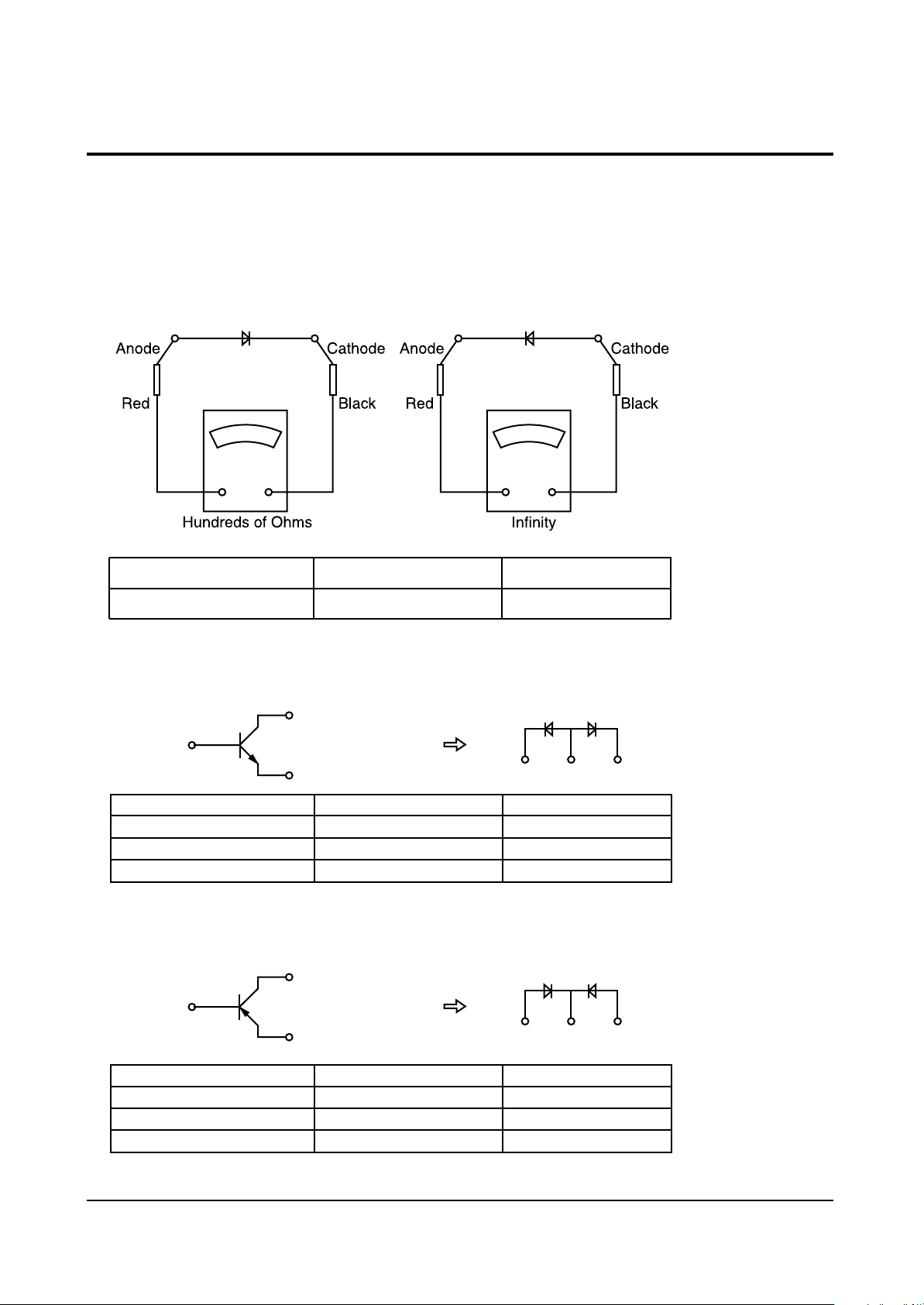

1.DIODE

2. TRANSISTOR

● For NPN(KSC815-Y, 2SC2068, 2SC2331-Y)

● For PNP(KSA539-Y)

Forward Direction

Hundreds of ohms

Reverse Direction

Infinity

Between Anode and Cathode

C (COLLECTOR)

E

B(BASE)

BC

C (COLLECTOR)

E

B(BASE)

BC

E (EMITTER)

E (EMITTER)

Forward Direction

Hundreds of ohms

Hundreds of ohms

Infinity

Reverse Direction

Infinity

Infinity

Infinity

Between B and E

Between B and C

Between E and C

Forward Direction

Hundreds of ohms

Hundreds of ohms

Infinity

Reverse Direction

Infinity

Infinity

Infinity

Between B and E

Between B and C

Between E and C

+- +-

Alignment and Adjustments

4-14 Samsung Electronics

3. IC (INTEGRATED CIRCUIT)

IC has built in DIODE against overvoltage in PIN. Generally, except for internal circuit defects, IC defects

can be found, by measuring the DIODE.

✴ Defects have SHORT(0 ohm) for both forward and reverse direction.

Hundreds of ohms

Forward Direction

Reverse Direction

Varying depending on IC but generally normal

Infinity in DIODE TEST MODE

Circuit Operation Description

Samsung Electronics 5-1

5. Circuit Description

5-1 Power supply

5-1-1 Outline(PDP SMPS)

Considering various related conditions, the switching regulator with good efficiency and allowing for its

small size and lightweight was used as the power supply for PDP. Most of the power supply components

used forward converter, and Vsamp and Vsb used simple flyback converter.

To comply with the international harmonics standards and improve the power factor, active PFC (Power

Factor Correction) was used to rectify AC input into +400V DC output, which in turns used as input to the

switching regulator.

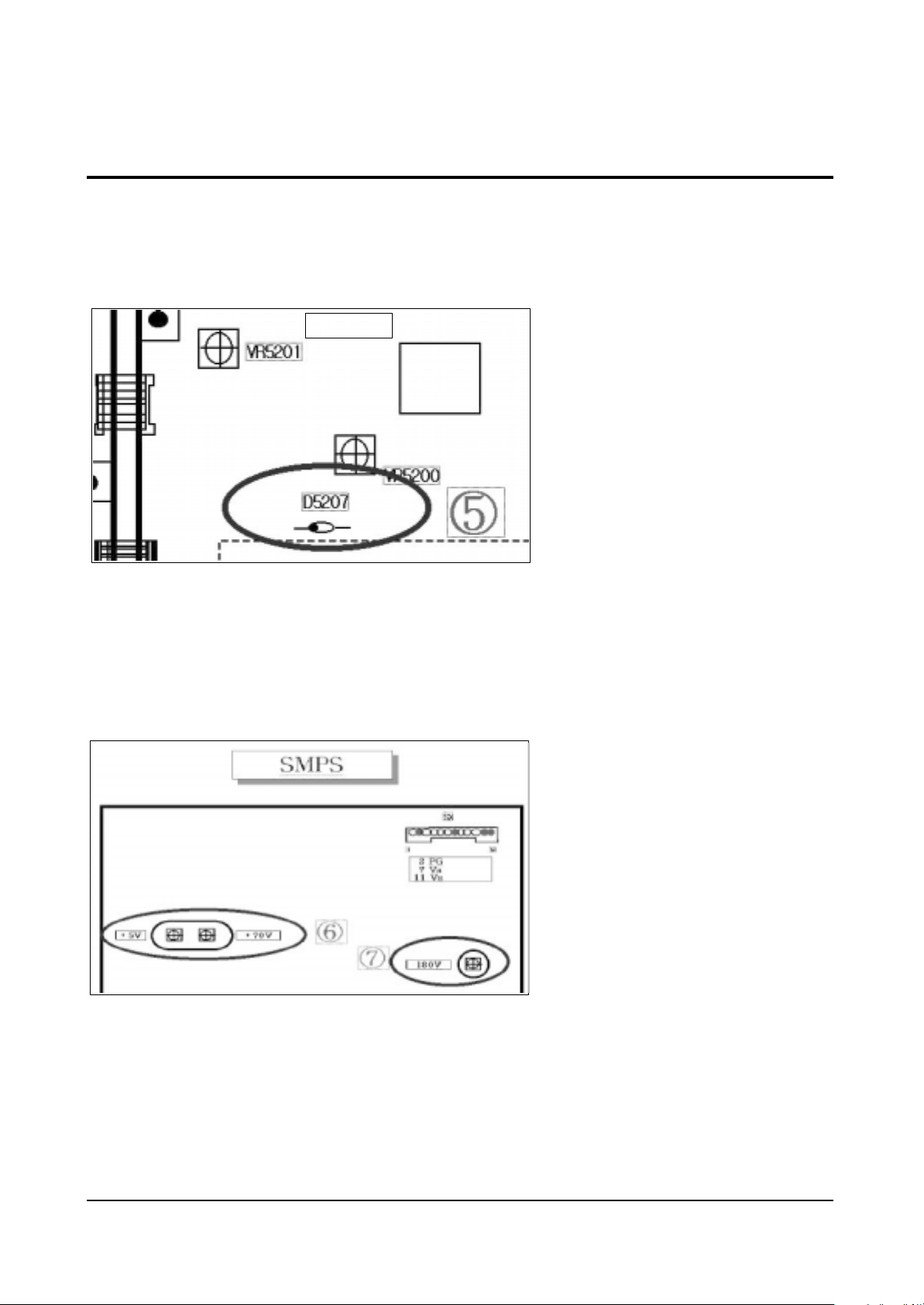

5-1-2 42"SD SMPS SPECIFICATION

5-1-2(A) INPUT

PDP-42PS board is designed so that input power can be used within AC 90 VAC to 264 VAC with

50/60Hz ± 3Hz.

5-1-2(B) OUTPUT

PDP-42PS board provides 13 output switching power supplies for PDP 50inch (+165Vs, +220Set, +185Ve,

+75Va, +80Scan, +18Vg, +5Vsb, +5V(D), +5V(A), +12V. +9V, +12Vfan, and +12Vsamp). The output voltage, and current requirements for continuous operation are stated below (Table 3).

Table1. Specifications of Output Power Supplies for PDP SMPS

Output Name

Vs

Va

Vscan

Vset

Ve

Vg

Vfan

V9

V5(A)

V5(D)

Vsb

V12

Vsamp

Output Voltage

+165V

+75V

+80V

+220V

+185V

+18.3V

+12V

+9V

+5V

+5.3V

+5V

+12V

+12V

Output Current

1.4A

0.5A

0.05A

0.05A

0.05A

0.3A

0.8A

0.3A

1.0A

3.5A

0.4

1.2A

1.5A

Using in PDP driving

Sustain Voltage of Drive Board

Address Voltage of Drive Board

Analog IC Drive Voltage of Video Board

IC Drive Voltage of Logic Board

Stand-by for Remote Control

Circuit Operation Description

5-2 Samsung Electronics

Table 2. Specifications to Protect PDP SMPS

Division

Vs

Va

+5V

OCP Current

5A

2A

10A

OVP Voltage

195V

90V

6.2V

Short Circuit

O.K

O.K

O.K

5-1-2(C) FUNCTION OF BOARD

(1) Remote control

Using 250V/ 10A relay, the board makes remote control available.

(2) Free voltage

The board designed so that input voltage can be used within 90 VAC to 264VAC.

(3) Embedded thermal sensor

The board is equipped with thermal sensor to detect the internal temperature of the unit, and to short

relay when the internal temperature is higher than specified temperature so as to shutdown the unit.

(4) Improvement of power factor

The board is designed using PFC circuit so that PF (Power Factor) can be over 0.95, because low PF

can be a problem in high voltage power.

(5) Protection

The OCP (Over Current Protection), the OVP (Over voltage Protection), and the Short Circuit

Protection functions are added against system malfunction.

Circuit Operation Description

Samsung Electronics 5-3

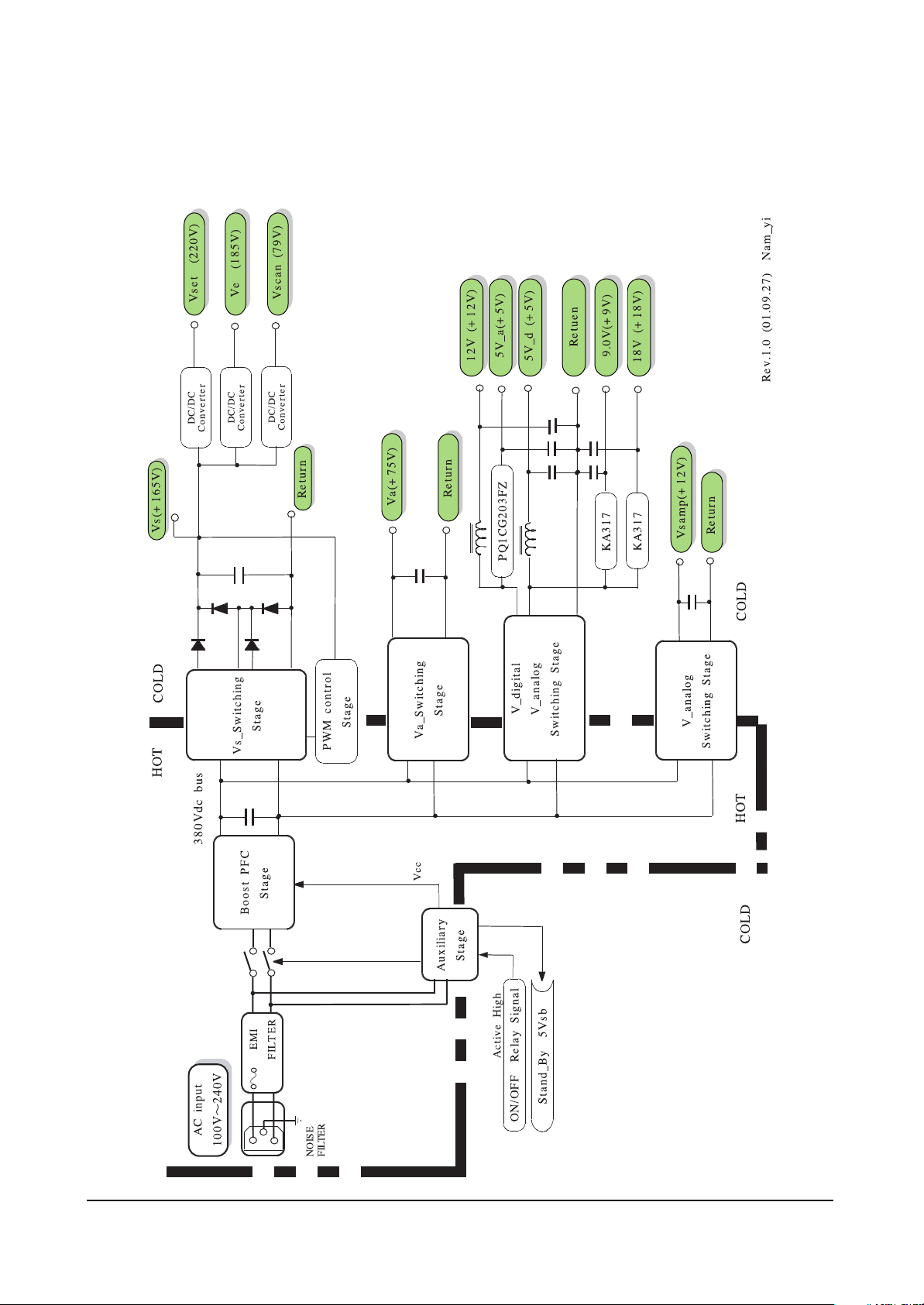

5-1-2(D) PDP-PS-42 BLOCK DIAGRAM

Circuit Operation Description

5-4 Samsung Electronics

(1) AC-DC Converter

PDP-42PS outputs +400V DC from the common AC power supply using the active PFC booster converter. This converter is designed for improving the power factor and preventing the noise with high

frequency and finally becomes the input power system for the switching regulator on the output side.

(2) Auxiliary Power Supply

The auxiliary power supply is a block generating power of •Ï-com for remote controlling. Once the

power plug is inserted, this block always comes into operation, causing •Ï-com to get into the standby state for the output. Thus, this output is called the stand-by voltage. And with the relay ON signal

inputted through the remote controller, this block turns the mechanical switch of relay to ON for driving the main power supply.

(3) Implementation of Sustain Voltage

As the main part of a SMPS for PDP, sustain voltage must supply a high power, +165V/ 1.4A. It is

designed using forward converter basically. At the output stage two 90V converters are connected

serially for high efficiency and reduction of system size against a single 180V converter.

(4) Implementation of Small Power Output (Va, V(D), V(A), Vfan, V9, Vsamp, Ve, Vset, Vscan, V12, and

Vg)Vset, Ve, and Vscan used DC-DC module. V(D), Va, V12, and Vfan used forward converter, and

Vsamp used flyback converter. V(A), V9, and Vg are simply implemented using switching regulator.

5-1-3 Requirements of PDP SMPS

Since SMPS does not operate alone, but it operates with the load of the whole system, it should be designed

carefully considering the load of the system. In addition, it should be designed considering emerging issues

such as EMC, and protection against heat as well as system stability especially.

5-1-3(A) SAFETY AND REMOTE CONTROL CAPABILITY

Stability is one of the most important requirements for SMPS. SMPS should be designed to prevent

abnormal status due to abnormal load variation so as to keep the system stable, and guarantee customer

safety.

The protection circuits of SMPS include over-current protection (OCP), over voltage protection (OVP),

and under voltage lock-out (UVLO), and short circuit protection circuit. Although each circuit can be

implemented by various procedures, the most popular is implementing with comparator that compares

current value with that of standard and determine abnormality of the circuit.

In addition, surge current protection, insulation management, and static electricity protection circuit

should be added, because it uses commercial power source as an input.

PDP SMPS should be designed using auxiliary power and relay to provide remote control capability.

Circuit Operation Description

Samsung Electronics 5-5

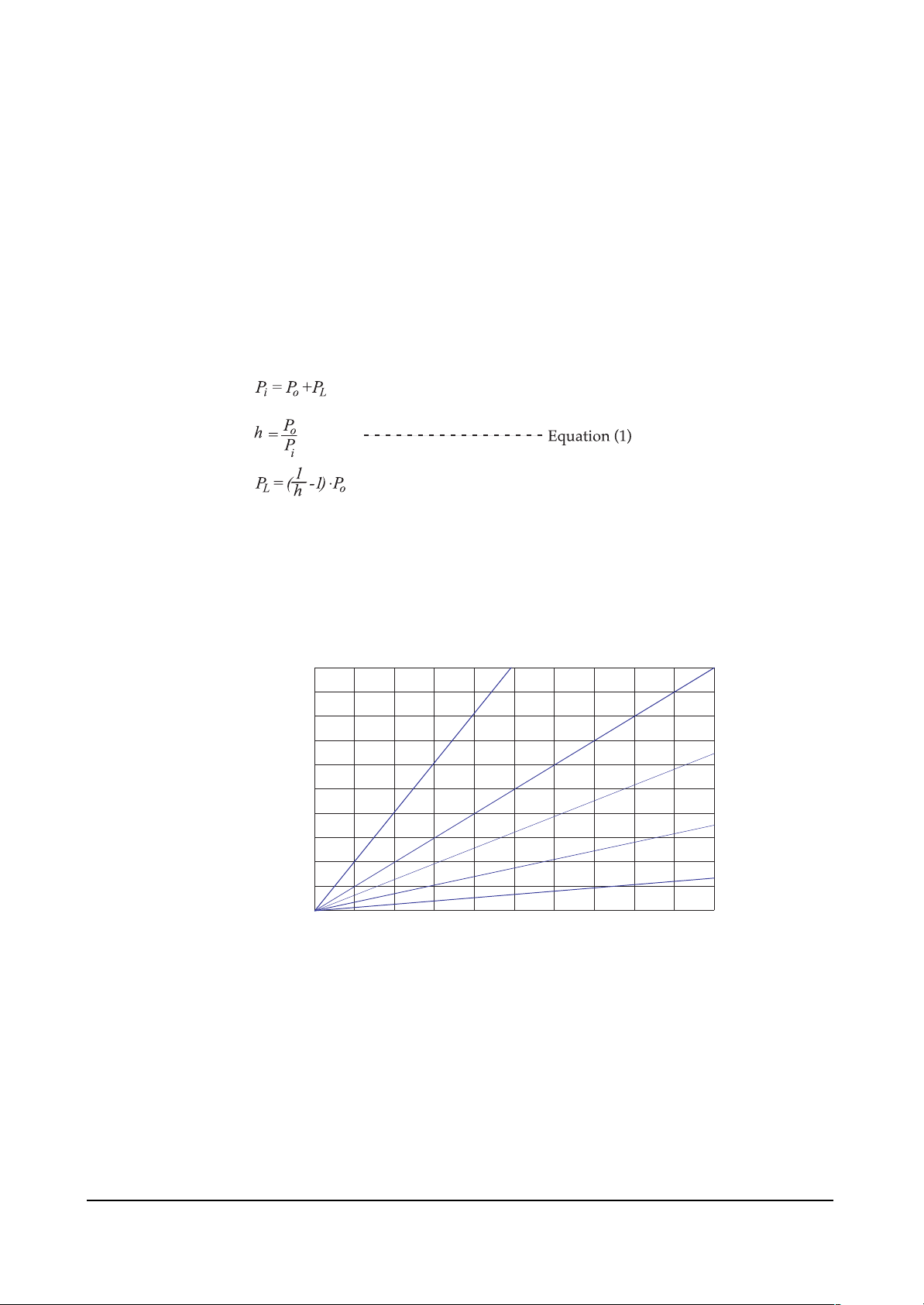

5-1-3(B) THE RELATION BETWEEN POWER CONSUMPTION AND POWER CONVERSION Efficiency

The power consumption and the power conversion efficiency of SMPS affect protection against heat and

system operation much.

[ If the power conversion efficiency of 100W SMPS is 70%, is the power loss of internal circuit 30W? ]

Output power consumption Po is determined by the multiplication of DC output voltage Vo and output

current Io. Input power consumption Pi is determined by the addition of output power consumption

Po and internal power loss of SMPS Pl.

Provided that the power conversion efficiency is _,

If the power conversion efficiency of 100W SMPS is 70%, the internal power loss is about 42.8W by

Equation (1). If the power conversion efficiency of 400W SMPS for 42"SD is 82%, the internal power loss

is 87.8W by Equation (1). Table 4 shows internal power loss as a function of output power for various

power conversion efficiencies.

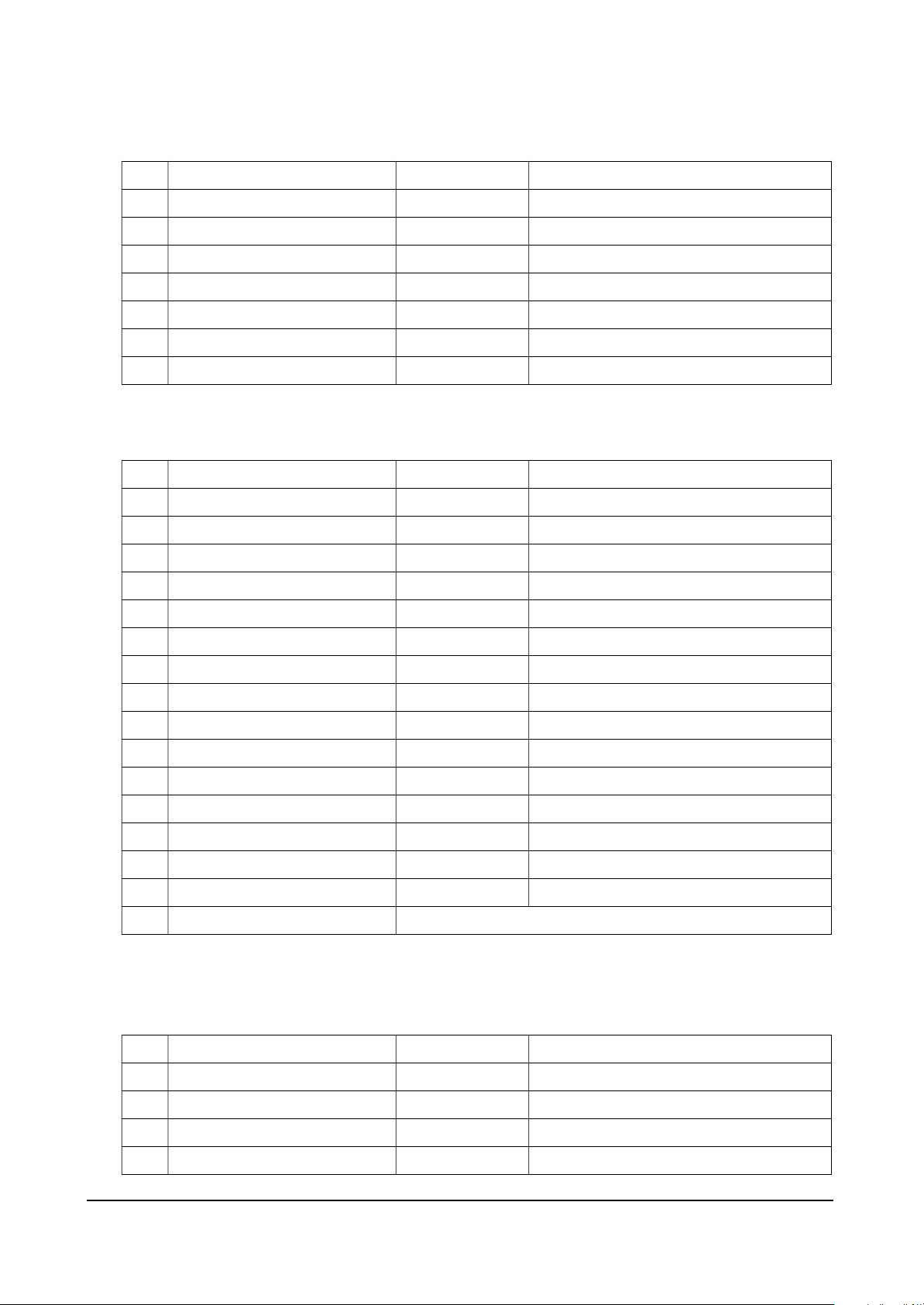

Table 4. Power Conversion Efficiency vs. Internal Power Loss

0

20

40

60

80

100

120

140

160

180

200

120 140 160 180 200 240220 260 280 300

50%

60%

90%

70%

80%

η

=

η

=

η

=

η

=

η

=

Internal

Power

Loss ( W)

Direct Current Output Power (W)

Circuit Operation Description

5-6 Samsung Electronics

5-1-3(C) PFC (Power Factor Correction) Circuit Descriptions

The current electric devices use DC power supply and require a rectifier circuit converting AC into DC.

As most rectifier circuits apply a capacitor input type, the rectifier circuit becomes the core of the occurrence of harmonics with lower reverse rate.If various electronic and electric devices are connected to a

power system, high-frequency current will occur due to a power rectifier circuit, a phase control circuit

with power input current of non-sine wave, or components with non-linear load characteristics, such as

capacitor, inductor, etc. As the result, the disturbance of voltage occurs, and finally a power capacitor or

a transformer generates heat, fire or noise occurs, controls malfunction, or the accessed devices abnormally operate or their lives are shortened.To prevent those symptoms, IEC (International

Electrotechnical Commission) regulated standards for Power Supply Harmonics.

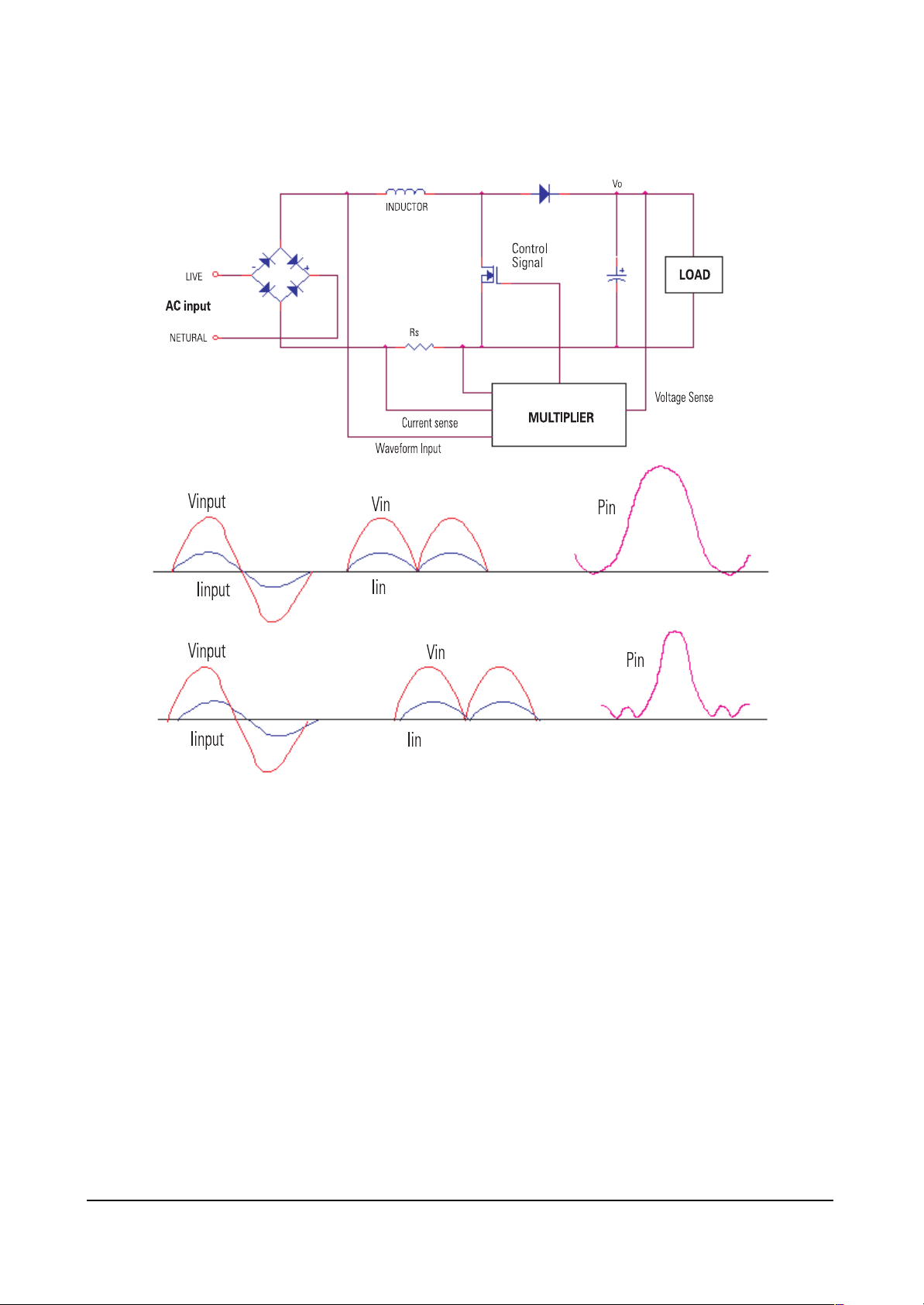

(Refer to IEC 1000-3-2.)Figure 8 shows the basic structure of Active Boost PFC and waveforms.

Standards for Power Supply Harmonics

Scale: Devices accessed to 220V/380V, 230V/400V, 240V/425V and lower than 16A (IEC 100-3-2)

Devices with AC 230V and lower than 16A (IEC 555-2)

Applied Classes :

♣ Class A: Devices not included in another class

♣ Class B : Portable tools

♣ Class C : Lighting devices

♣ Class D : Devices with special current waveforms

Application Schedule : Except the devices less than rating input of 75W (1996~1999)

Except the devices less than rating input of 50W (2000 and after)

Circuit Operation Description

Samsung Electronics 5-7

5-1-3(D) CONCLUSION

Although SMPS (Switching Mode Power Supply) enables small lightweight high-power consumption

power design, it is hard to be used when stability and precise control are required. Power stage for PDP

can be designed using the lightweight SMPS feature. It is important to design SMPS considering

system load, stability, and related international standards.

The architecture and the pulse of active boost PFC

Circuit Operation Description

5-8 Samsung Electronics

5-2 Driver Circuit

5-2-1 Driver Circuit Overview

5-2-1(A) WHAT IS THE DEFINITION OF DRIVE CIRCUIT?

It is a circuit generating an appropriate pulse (High voltage pulse) and then driving the panel to implement

images in the external terminals (X electrode group, Y electrode group and address electrode), and this high

voltage switching pulse is generated by a combination of MOSFET’s.

5-2-1(B) PANEL DRIVING PRINCIPLES

In PDP, images are implemented by impressing voltage on the X electrode, Y electrode and address electrode, components of each pixel on the panel, under appropriate conditions. Currently, ADS (Address &

Display Separate: Driving is made by separating address and sustaining sections) is most widely used to

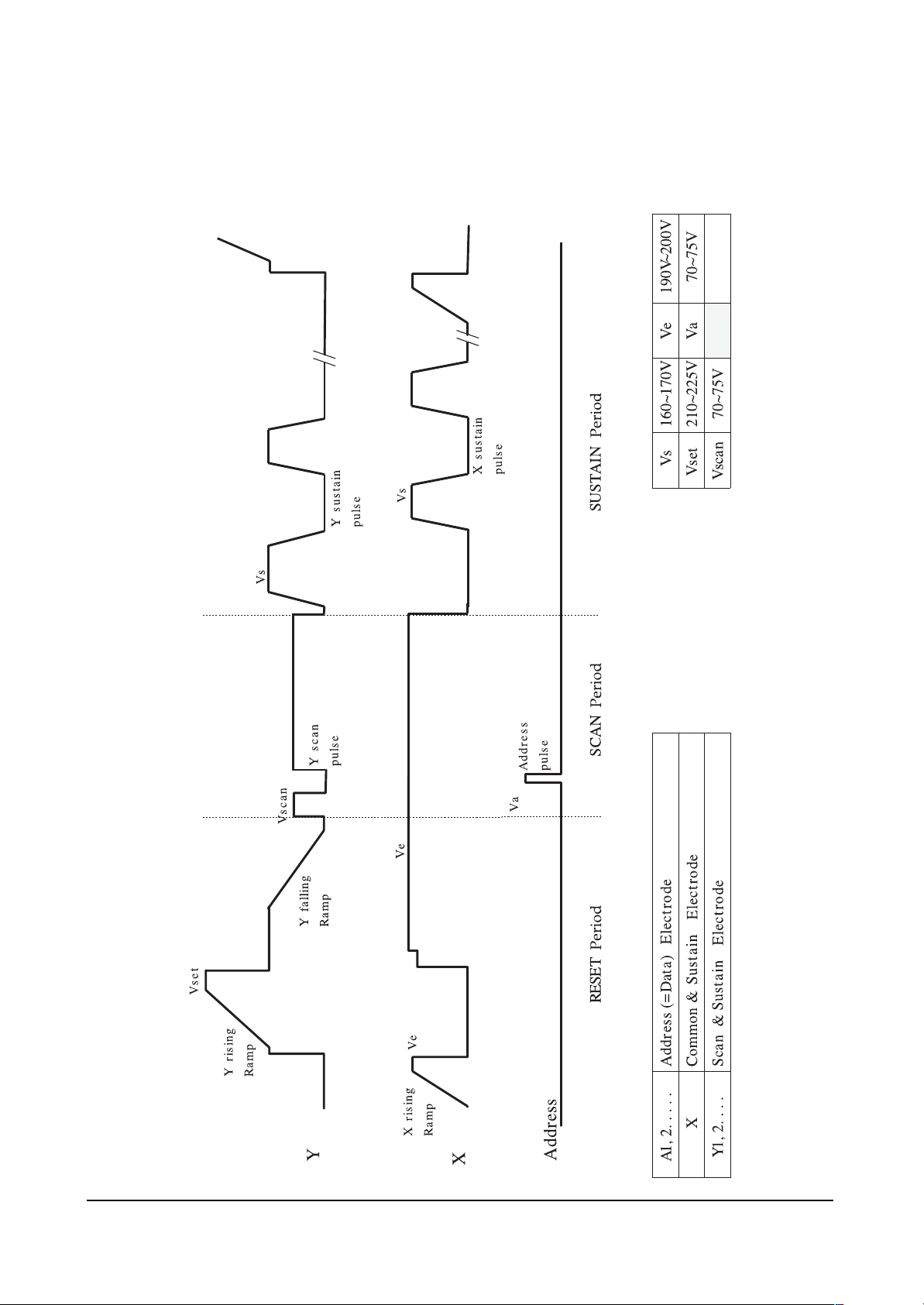

generate the drive pulse. Discharges conducted within PDP pixels using this method can largely be classified into 3 types, as follows:

(1) Address discharge : This functions to generate wall voltage within pixels to be lighted by addressing

information to them (i.e., impressing data voltage)

(2) Sustain discharge : This means a display section where only pixels with wall voltage by the address

discharge display self-sustaining discharge by the support of such wall voltage. (Optic outputs realizing images are generated.)

(3) Erase discharge : To have address discharge occur selectively in pixels, all pixels in the panel must

have the same conditions (i.e., the same state of wall and space electric discharges). The ramp reset

discharge section, therefore, is important to secure the drive margin, and methods most widely used

to date include wall voltage controlling by ramp pulse.

Circuit Operation Description

Samsung Electronics 5-9

5-2-1(C) TYPES AND DETAILED EXPLANATION OF DRIVE DISCHARGES

(1 ) Sustaining discharge

Sustaining discharge means a self-sustaining discharge generated by the total of the sustaining pulse

voltage (usually, 160~170V) alternately given to X and Y electrodes during the sustaining period and

the wall voltage that varies depending upon pixels' previous discharge status. It is operated by the

memory function (through this, the current status is defined by previous operation conditions) AC

PDP basically possesses. That is, when there is existing wall voltage in pixels (in other words, when

pixels remain ON), the total of wall voltage and a sustaining voltage to be impressed subsequently

impresses a voltage equal to or above the discharge start voltage, thereby generating discharge again,

but when there is no existing wall voltage in pixels (in other words, when pixels remain OFF), the sustaining voltage only does not reach the discharge start voltage, thus causing no discharge. The sustaining discharge is a section generating actual optic outputs used in displaying images.

(2) Address discharge

This means a discharge type generated by the difference between positive voltage of the address electrode (normally 70~75V determined by supplied Va voltage + positive wall charge) and the negative

potential of Y electrode (supplied GND level voltage + negative wall charge). The address discharge

serves to generate wall voltage in pixels where images are to be displayed (that is, discharge is to be

generated) prior to the sustaining discharge section. Namely, pixels with wall voltage by the address

discharge will generate sustaining discharge by the following sustaining pulses.

(3) Erase discharge

The purpose of resetting or erase discharge is to make even wall voltage in all pixels on the panel.

Wall voltage, which may vary depending upon the previous sustaining discharge status, must be

made even. That is, wall voltage generated by the sustaining discharge must surely be removed, by

making discharges and then supplying ions or electrons. Wall voltage can be removed by making discharges and then setting a limitation on time for opposite polarity charging of the wall voltage or generating weak discharge (Low voltage erasing) to supply an appropriate quantity of ions or electrons

and keep polarities from being charged oppositely. The weak discharge (Low voltage erasing) methods, which have been known to date, can largely be into two types: 1) the log pulse adopted by most

companies including F Company, and 2) the ramp pulse adopted by Matsushita. In both two methods,

impression is made with a slow rising slope of the erasing pulse. Because the total of the existing wall

voltage and a voltage on the rising pulse must be at least the drive start voltage to generate discharges, external impressed voltage is adjusted based on the difference in wall voltage between pixels.

And, weak discharge is generated because of a small impressed voltage.

Circuit Operation Description

5-10 Samsung Electronics

5-2-2 SPECIFICATION OF DRIVE PULSES

5-2-2(A) DRIVE PULSES

Circuit Operation Description

Samsung Electronics 5-11

5-2-2(B) FUNCTIONS OF PULSES

(1) X rising ramp pulse

Just before X rising ramp pulse is impressed, the last Y electrode sustain pulse of previous sub field is

impressed. The pulse causes sustain discharge. Consequently, positive wall charge is accumulated in X

electrode, and negative wall charge is accumulated in Y electrode. X rising ramp erases wall charge

produced by the last sustain discharge pulse using weak-discharge.

(2) Y rising ramp pulse

During Y rising ramp period, weak-discharge begins when external voltage of about 390V~400V is

impressed to Y electrode, and each gap voltage is equal to discharge start voltage. Sustaining the

weak-discharge, positive wall charge is accumulated in X electrode and address electrode, and negative wall charge is accumulated in Y electrode of the entire panel.

(3) Y falling ramp pulse

During Y falling ramp period, the negative wall charge in Y electrode accumulated by 200V of X bias

is used to erase positive wall charge in X electrode. Address electrode (0V) sustains most of the positive electric charge accumulated during rising ramp period so that it can maintain wall charge distribution beneficial to the upcoming address discharge.

(4) Y scan pulse

This is called the scan pulse, selecting each of Y electrodes on a one-line-at-a-time basis. In this case,

Vscan means the scan bias voltage. About 70 V (Vscan) voltage is impressed on the selected electrode

lines, while 0 V (GND) voltage is impressed on the other lines.

In the cells the address pulse (70V~75V) is impressed on, address discharge is occurred because negative wall charge is accumulated in Y electrode, positive wall charge is accumulated in address electrode by the applied ramp pulse, and the sum of impressed voltage is greater than discharge start

voltage. Thus, because scan pulse and data pulse are impressed line by line, very long time is taken

for PDP addressing.

(5) 1st sustain pulse

The sustaining pulse always begins with the Y electrode. This is because when address discharge is

generated, positive wall voltage is generated on the Y electrodes. Because wall electric charge generated by address discharge is generally smaller than wall voltage generated by sustaining discharge, initial discharges have small discharge strength, and stabilization is usually obtained after 5~6 times discharges, subject to variations depending on the structure and environment of electrodes. The purpose

of impressing the initial sustaining pulses long is to obtain stable initial discharges and generate wall

electric charges as much as possible.

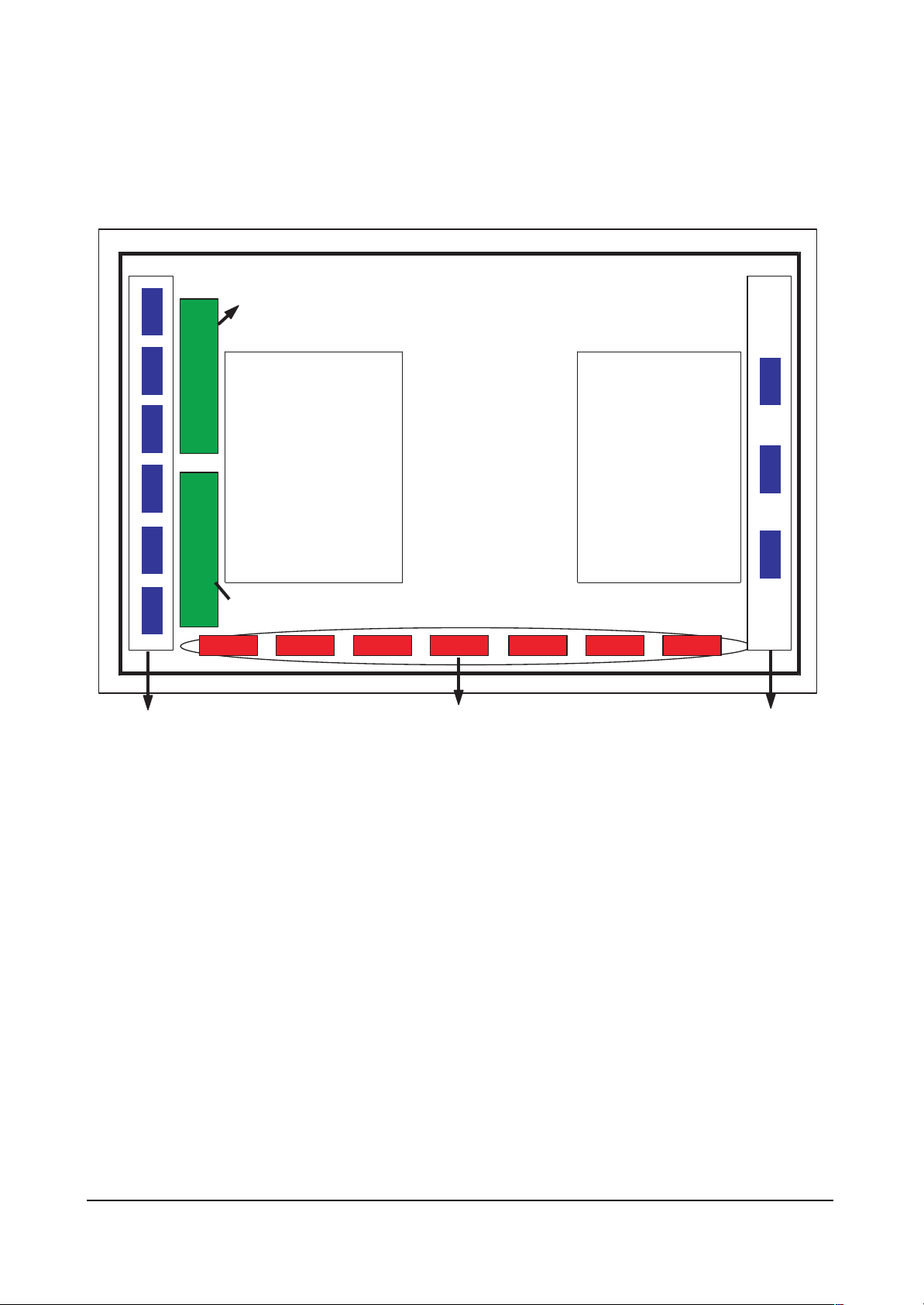

5-2-3(A) FUNCTIONS OF EACH BOARD

(1) X board

X board is connected to the panel’s X-electrode blocks, 1) generates sustain voltage pulse (including

ERC), 2) generates X rising ramp pulse, and 3) sustains Ve bias during scan period.

(2) Y board

Y board is connected to the Y-electrode blocks of panel, 1) generates sustain voltage pulse (including

ERC), 2) generates Y rising and falling ramp pulse, and 3) sustains Vscan bias.

(3) Y buffer board (upper and lower)

Y buffer board impresses scan pulse to Y electrodes, and consists of upper and lower sub-boards. In

case of SD class, one board is equipped with 4 scan driver IC’s (STMicroelectronics STV7617 with 64

or 65 outputs).

(4) COF

Impresses Va pulse on address electrodes in the address section and generates address discharge

based on a difference between such Va pulse and scan pulse impressed on Y electrodes. It is in the

form of COF, and a COF is equipped with 4 data drive IC’s (STMicroelectronics STV7610A with 96

outputs). For a single scan, 7 COF’s are required.

Circuit Operation Description

5-12 Samsung Electronics

5-2-3 Configuration and Operation Principles of Driver Circuit

Y-Buffer (Upper)

Y Drive board

- Sustain pulse

(Energy recovery)

- Rising ramp pulse

- Falling ramp pulse

X Drive board

- Sustain pulse

(Energy recovery)

- Rising ramp pulse

- Ve bias

- Vscan pulse

Y-Buffer (Lower)

Y-electrode blocks

COF X-electrode blocks

(6 blocks)

(3 blocks)

Circuit Operation Description

Samsung Electronics 5-13

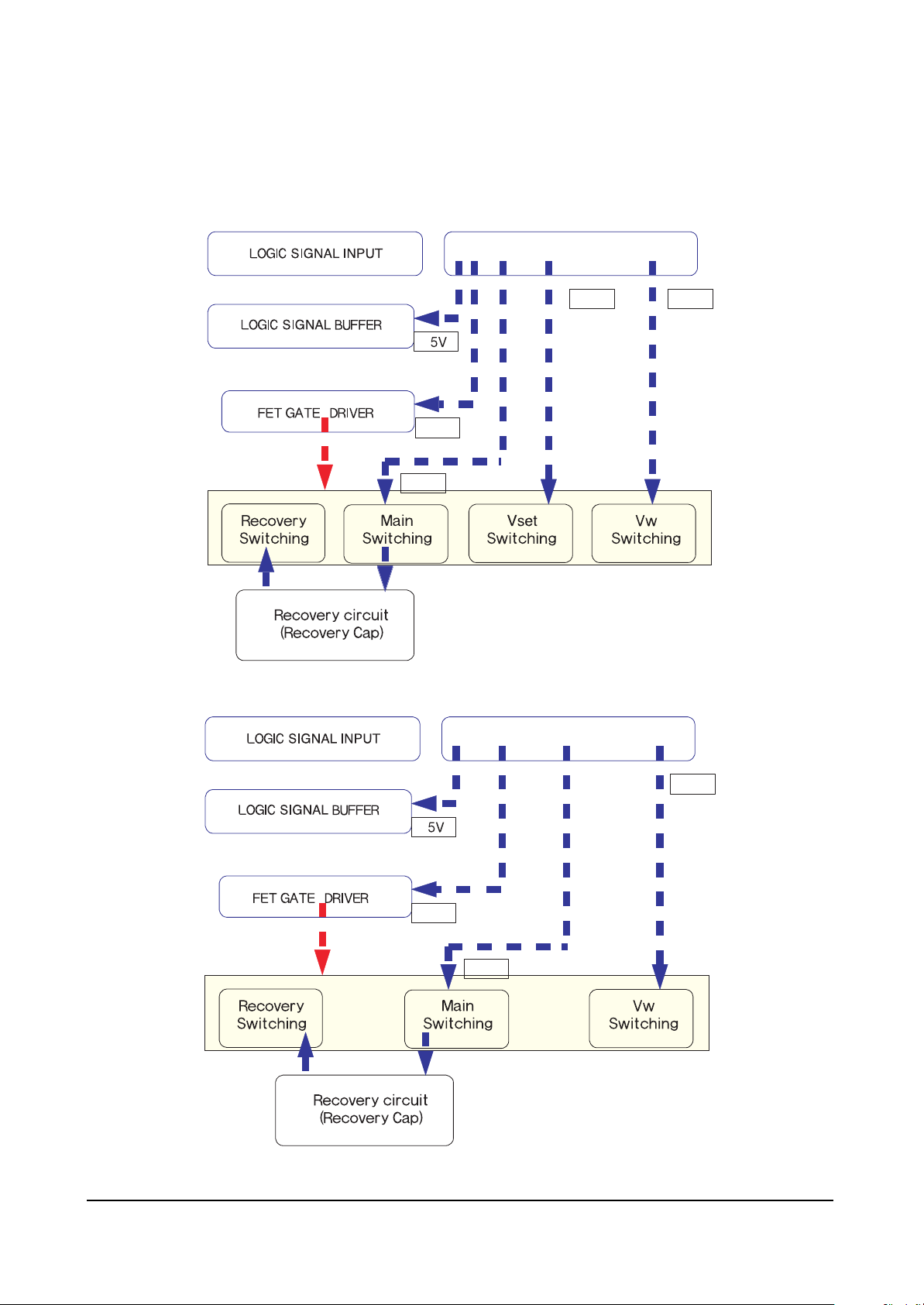

5-2-3(B) DRIVING BOARD'S BLOCK DIAGRAM

(1) Y

(2) X

17V

170V

POWER

220V

75V

POWER

220V

17V

170V

Circuit Operation Description

5-14 Samsung Electronics

➣ Components of driving board's operations

1. Power supply

1) Supplied from the power supply board

- For sustaining discharge: 180V;

- For logic signaling buffer: 5V; and

- For gate driver IC: 15V.

2) Generated by the internal DC/DC part

- For generating Vw pulse: 180V.

2. Logic signal

1) Supplied from the logic board

- Gate signals for FETs.

Loading...

Loading...