Page 1

ALLEN–BRADLEY

Bulletin 2705

RediPANEL Plug & Go Push Button

Modules

(Bulletin 800A 16 and 32 Points)

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

PLC, PLC–2, PLC–3, and PLC–5 are registered trademarks of Allen-Bradley Company, Inc.

SLC, SLC 500, PanelView, RediPANEL, and Dataliner are trademarks of Allen-Bradley Company, Inc.

IBM is a registered trademark of International Business Machines, Incorporated.

Page 3

Page 4

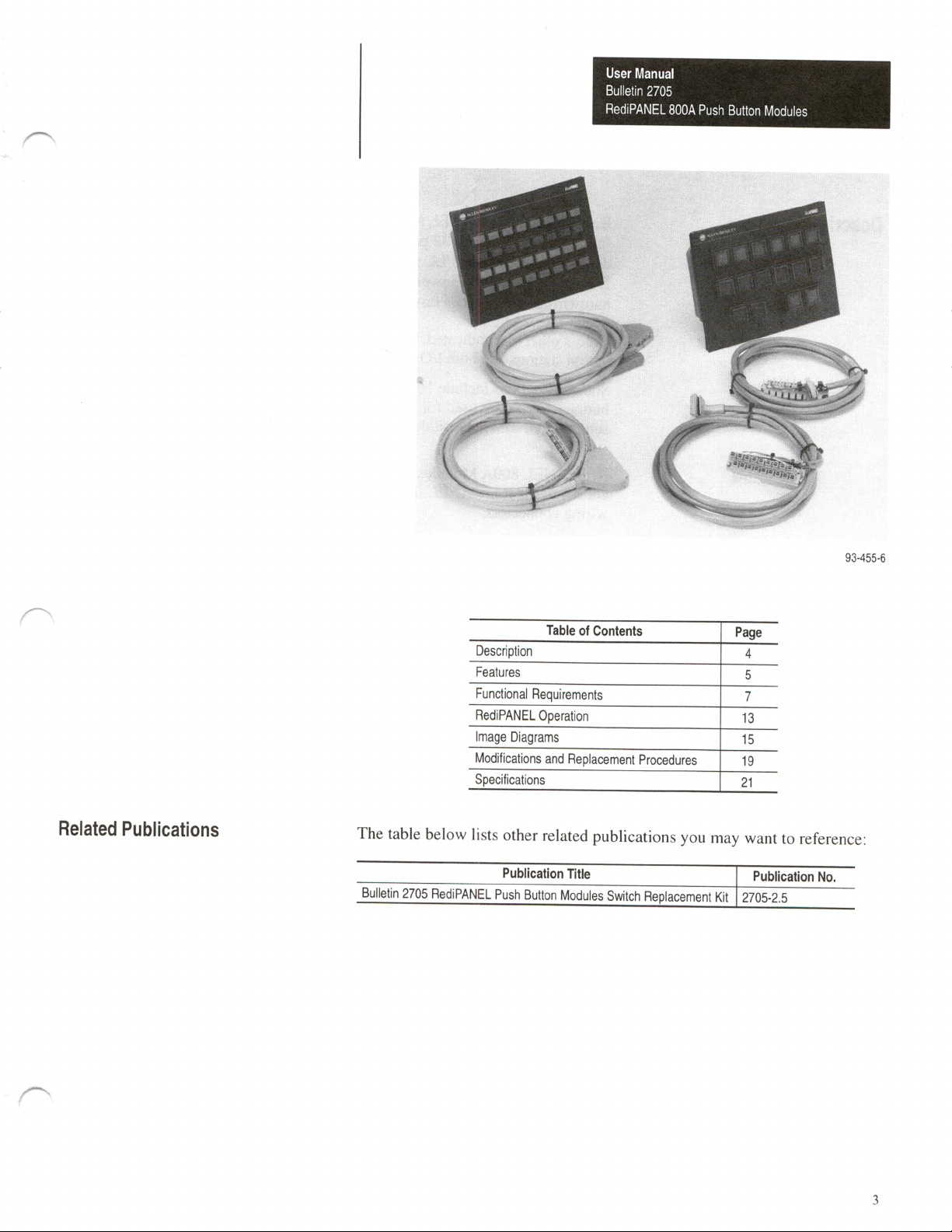

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Description

Bulletin 2705 RediPANEL Modules with Bulletin 800A Push Buttons are

fully assembled 16 and 32 point push button stations that operate with high

density Allen-Bradley PLC and SLC I/O modules. The only wiring required

is a pair of cables and power supply connections, which eliminates costly

hardwiring and provides fast installation and start-up.

Unless otherwise indicated, the descriptions that follow apply to both push

button stations and both I/O modules.

Standard stations include 16 or 32 normally open (N.O.) illuminated push

buttons. LED’s are used for illumination. The industrial 800A version is

suitable for NEMA 13 oil/dust tight industrial enviornments.

RediPANEL 800A Modules can also be ordered as custom models which

consist of the RediPANEL front plate and all the necessary push button

wiring connectors.

These custom Push Button stations can include any of the following

Allen-Bradley Bulletin 800A devices:

D Momentary illuminated or non-illuminated push buttons

D Flush or extended head operators

D Two position non-illuminated selector switches

4

Page 5

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Features

Easy Installation

Each RediPANEL is supplied complete with preassembled push buttons and

front plate. Separately ordered Bulletin 1492 wiring system cables plug

directly between the I/O Modules and the RediPANEL adapter boards,

eliminating hardwiring of individual devices. To install RediPANEL modules

follow these easy steps:

1. Cut an opening in the panel approximately 5.9 in. (149 mm) high x 8.6 in.

(218 mm) wide. See Figure 1.

2. Drill four 0.296” (7.52mm) dia. holes for the top and bottom mounting

brackets. A template is provided with the module to assist in this

operation.

3. Slide the module through the opening.

4. Apply the mounting brackets and tighten all the captive knurled

thumbscrews, being certain gasket is in place. Figure 1 shows screw

locations.

5. Connect the appropriate cables between the RediPANEL modules and the

PLC or SLC I/O modules. See page 10.

6. Connect external 24VDC power supply to pull-apart screw terminals on

the RediPANEL.

7. Connect green ground screw on the RediPANEL to the earth ground.

See pages 9 and 10 for detailed instructions on connecting power and

I/O cables.

Clearance Considerations

RediPANEL 800A Modules mounted inside an enclosure must have adequate

space for wire clearances. See Figure 2 for minimum recommended spacing.

5

Page 6

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

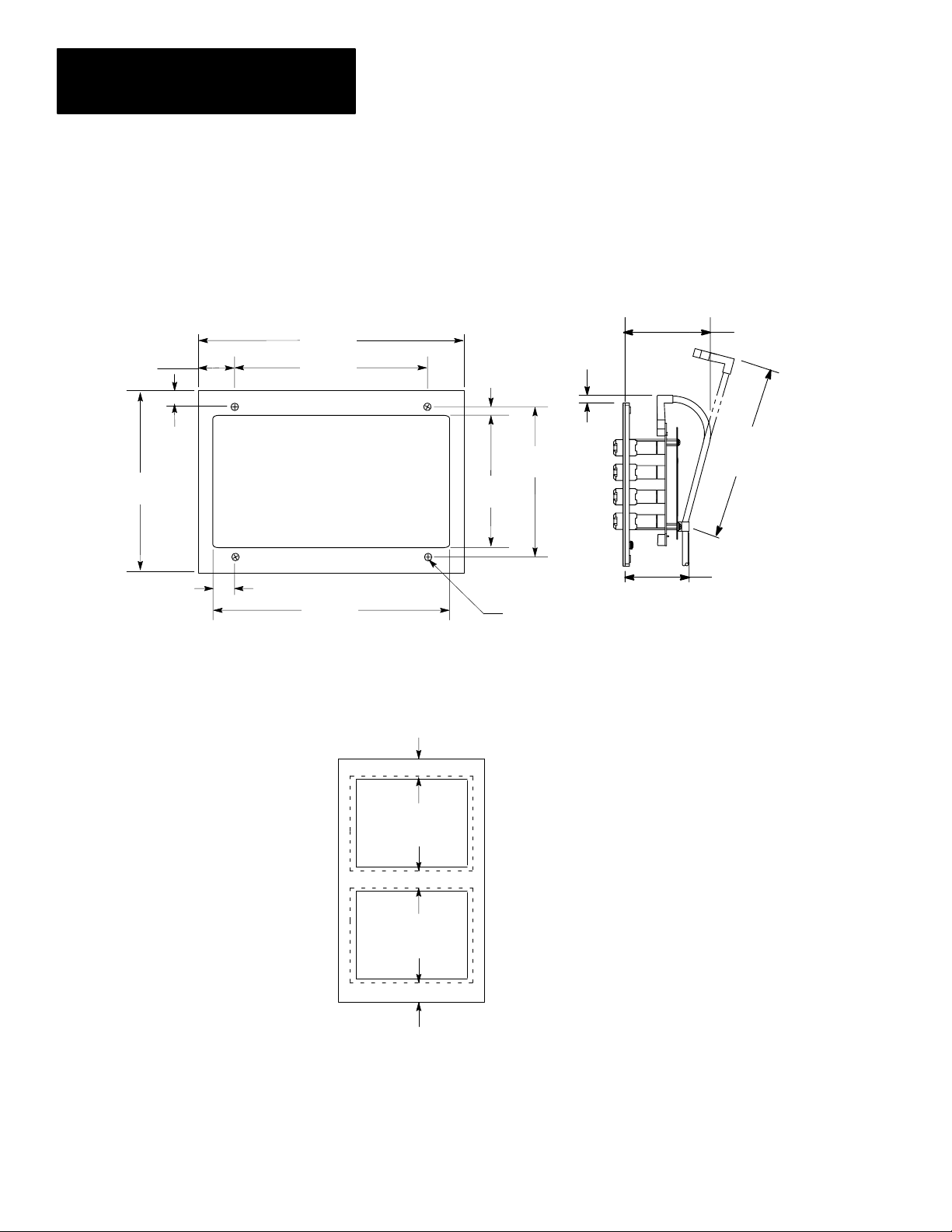

1.06

(26.92)

Figure 1

Mounting Dimensions of the Module in Inches (mm)

FRONT VIEW SIDE VIEW

9.50

(241.30)

7.375

(187.33)

0.26

(6.60)

1.50 (38.1)

Max..

4.0 (101.6) 16 PB

4.5 (114.3) 32 PB

7.25

(184.15)

.44

(11.18)

0.62

(15.75)

Panel Cutout

5.86 x 8.61

(148.84 x 218.69)

8.61

(218.69)

Figure 2

Enclosure spacing in Inches (mm)

2.5 (63.5)

2.5 (63.5)

5.86

(148.84)

6.375

(161.93)

4-.296 (7.52)

Dia. Holes

8.0

(203.2)

2.6 (66.0) 16 PB

2.7 (68.6) 32 PB

Note: T o ensure proper strain relief, be certain that

the distance from the end of the cable to the

tie wrap is 8 inches.

2.5 (63.5)

6

Page 7

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Low System Cost

The RediPANEL reduces overall system cost by reducing wiring,

engineering, installation, and maintenance. Connection to high density

Allen-Bradley I/O modules is simple, easy, and cost effective.

Functional Requirements

Electrical Requirements and Power Supply

An external 24 VDC 10% power supply is used for this module. The

power supply must be able to provide the current requirements for the

Bulletin 800A assembly and the selected PLC or SLC input sinking and

output sourcing modules.

The Bulletin 800A LED’s use the power supply to draw the source current

from the output module and the contacts complete the circuit for the sink

current to the input modules. See Table 1 below for current requirements.

Table 1

RediP ANEL Current Requirements

No. of

Pushbuttons

16

32

32

PC type

SLC

SLC

PLC

PLC

SLC

PLC

PLC

Item

Bulletin 800A LED’s from 1746-OB16 Output module .35 Amps

Bulletin 800A contacts to 1746-IB16 Input module .12 Amps

Total maximum current required .47 Amps

Bulletin 800A LED’s from 1771-OBD Output module .35 Amps

Bulletin 800A contacts to 1771-IBD Input module .20 Amps

Total maximum current required .55 Amps

Bulletin 800A LED’s from 1746-OB32 Output module .71 Amps

Bulletin 800A contacts to 1746-IB32 Input modules

Total maximum current required .95 Amps

Bulletin 800A LED’s from 1771-OBN Output module .71 Amps

Bulletin 800A contacts to 1771-IBN Input module .52 Amps

Total maximum current required 1.23 Amps

Current

Required

.24 Amps

7

Page 8

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Push button Board

The push button assembly used is Bulletin 800A with 24 VDC six chip LED

cluster lamps which have longer life than incandescent lamps. The LED

cluster is polarity sensitive and will be positioned with the plus (+) indicator

facing left when viewing the front of the module. It is NOT acceptable to

interchange LED and incandescent lamps in the Bulletin 800A assembly.

Interchanging lamps could result in intermittent connections, since the lamp

bases have slightly different dimensions and mating contacts will set over

time. The contacts will be operating at 24 VDC.

I/O Modules

A sinking input module is used to interface with the Bulletin 800A contacts.

Each contact will typically draw 8 mA when energized. Connection from the

input module to the pushbutton contacts is through one of the cables

described in Table 2 on the next page.

A sourcing output module is used to interface to the 800A push button

assembly lamps (LED’s). Each LED will typically require 18 mA when

illuminated. Connection from the output module to the LED’s is through one

of the cables described in Table 2 on the next page.

Interconnecting Cables

Two preassembled cables connect the push button assembly and I/O

modules: one cable will connect to the input module and one to the output

module. All connections to Bulletin 800A contacts and LED’s are sent

through these cables. See Table 2 on the next page.

For SLC systems, each end of the cable for the 32 point RediPANEL has a

40 pin connector which mates with a 40 pin receptacle on the RediPANEL.

The other end of the cable has a 40 pin connector which mates with a 40 pin

receptacle on the Bulletin 1746 module. One end of the cable on the 16 point

version has a 20 pin connector which mates with a 20 pin receptacle on the

Bulletin 800A panel assembly and the other end has an 18 position prewired

swing arm which mates with a Bulletin 1746 module.

For PLC systems each end of the cable for the 32 point RediPANEL has a 40

pin connector which mates with a 40 pin receptacle on the RediPANEL. The

other end of the cable has a 40 point prewired swing arm which mates with

the Bulletin 1771 module. One end of the cable on the 16 point version has a

20 pin connector which mates with a 20 pin receptacle on the RediPANEL

and the other end has a 21 point prewired swing arm which mates with a

Bulletin 1771 module.

8

Page 9

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

The input and output cable connectors are identified on the printed circuit

board. It is important that the input and output module connectors are

connected correctly, since the output modules do not have reverse polarity

protection. Connecting the wrong cable and module could result in a short to

the power supply output terminals or a blown module fuse. Some of these

fuses are not field replaceable.

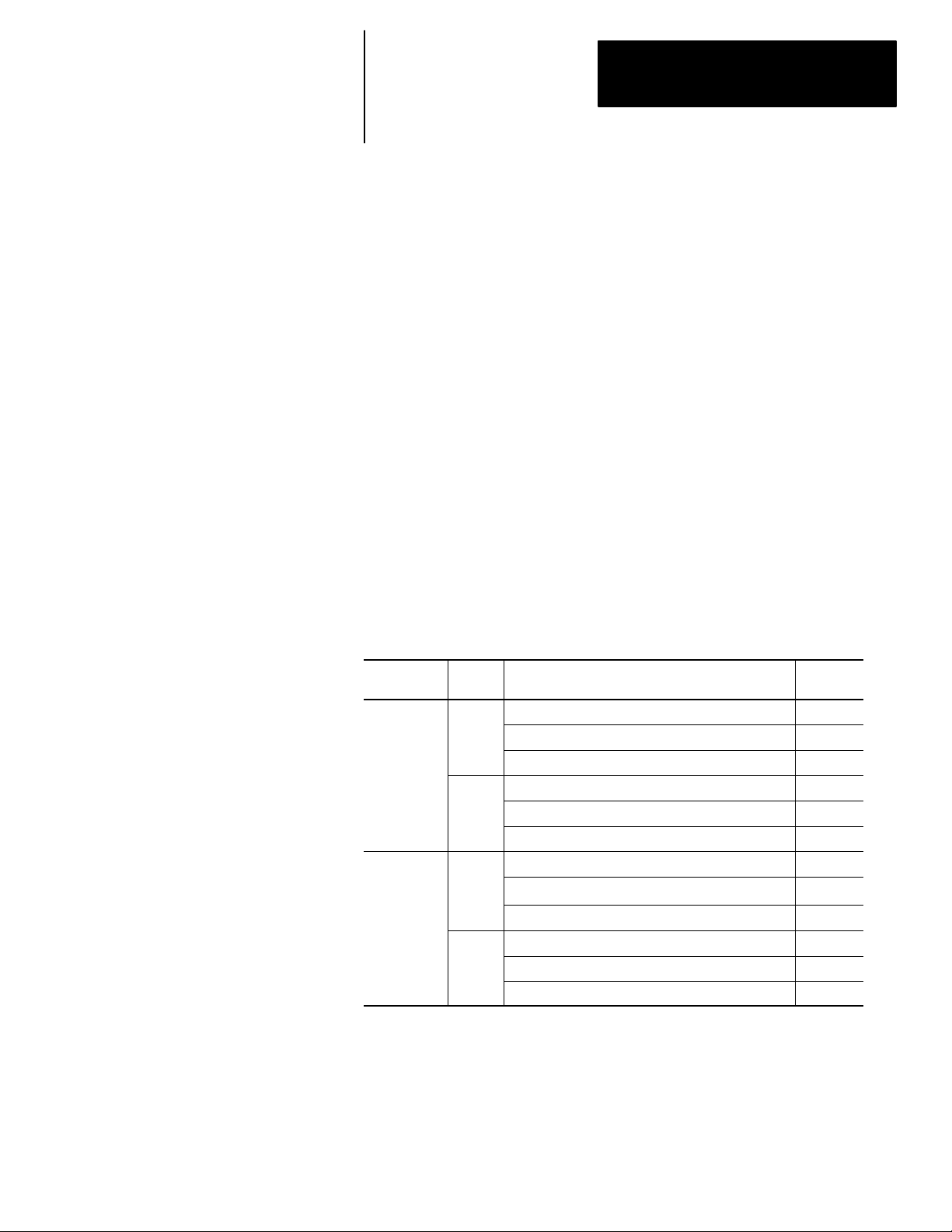

Table 2

Module and Cable Catalog Numbers

No. of PC type Module Type Module Cable Catalog No. based on cable length

Push buttons Catalog No.

Input 1746-IB16 1492-CABLE10B 1492-CABLE25B 1492-CABLE50B

Output 1746-OB16 1492-CABLE10E 1492-CABLE25E 1492-CABLE50E

Input 1771-IBD

Output 1771-OBD

Input 1746-IB32

Output

Input 1771-IBN 1492-CABLE10J 1492-CABLE25J 1492-CABLE50J

Output

1746-OB32

1771-OBN 1492-CABLE10L 1492-CABLE25L 1492-CABLE50L

16

16

32

SLC

PLC

SLC

PLC

1.0 Meter 2.5 Meters 5.0 Meters

1492-CABLE10F 1492-CABLE25F 1492-CABLE50F

1492-CABLE10H 1492-CABLE25H 1492-CABLE50H

9

Page 10

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Faceplate Configurations

Figures 3 and 4 show the push button locations and bit addresses for 16 and

32 point SLC’s and PLC’s.

Figure 3

Faceplate configurations for 16 point SLC’s and PLC’s

PLC Bit Addresses (Octal)

123456

00 01 02 03 04 05

789101112

06 07 10 11 12 13

13 14 15 16

14 15 16 17

Figure 4

Faceplate configurations for 32 point SLC’s and PLC’s

PLC Bit Addresses (Octal)

12345678

00 01 02 03 04 05 06 07

Button #

Address Bit #

Button #

Address Bit #

SLC Bit Addresses (Decimal)

123456

00 01 02 03 04 05

789101112

06 07 08 09 10 11

13 14 15 16

12 13 14 15

SLC Bit Addresses (Decimal)

12345678

00 01 02 03 04 05 06 07

10

9 10111213141516

10 11 12 13 14 15 16 17

17 18 19 20 21 22 23 24

00 01 02 03 04 05 06 07

25 26 27 28 29 30 31 32

10 11 12 13 14 15 16 17

9 10111213141516

08 09 10 11 12 13 14 15

17 18 19 20 21 22 23 24

16 17 18 19 20 21 22 23

25 26 27 28 29 30 31 32

24 25 26 27 28 29 30 31

Page 11

Page 12

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

To connect wires to the power connection from the power source, follow

these easy steps (see Figures 5 and 6):

1. Remove the power connector from the receptacle.

2. Loosen left and right screws on the power connector and insert the wires

into the openings on the bottom of the power connector, being certain that

the correct polarity is observed between the power connection and the

power source.

3. Tighten the screws on the power connector and insert the power connector

into the receptacle.

To connect the preassembled cables between the RediPANEL and I/O

modules, follow these easy steps:

1. Remove the tie wrap from the back of the RediPANEL and place it over

the cable at a distance of 8” from the end.

2. Insert the proper cable (see Table 2 ) into the appropriate connection

terminal (input or output) and secure with locking tabs.

3. Be certain that the distance from the end of the cable to the tie wrap is

8”, then reinstall the tie wrap to the back of the RediPANEL. See Figure 7

below.

Figure 7

Side view of Push button Module

Dimensions in inches (millimeters)

4.0 (101.6) 16 PB

4.5 (114.3) 32 PB

1.50 (38.1)

Max.

8.0

(203.2)

12

2.6 (66.0) 16 PB

2.7 (68.6) 32 PB

Page 13

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

RediPANEL Operation

Connections

RediPANEL modules connect to Allen-Bradley 1746 or 1771 I/O modules

with two preassembled cables. This replaces large wire bundles used in

hardwired implementation. See Figure 8.

Figure 8

Typical RediPANEL I/O Module connection

2705 RediPANEL

I/O Modules

•

•

•

•

•

•

•

•

•

•

•

•

Output Cable

Push Button Panel

Input Cable

Bulletin 800A devices in the RediPANEL module “appear” to the

programmable controller as though they were hardwired to I/O modules in an

I/O rack. No special instructions are required since the push button, lamp,

and switch selection are programmed as discrete I/O devices using the input

and output image tables of the programmable controller.

13

Page 14

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

24 VDC

Power Supply

2705 RediPANEL

Push Button Module

=

Selector Switch

Modules

RediPANEL modules combine the functions of standard push button devices

with the capabilities of a remote I/O rack – all in one package. See Figure 9.

Figure 9

Typical RediPANEL Functionality

+

Push Buttons

Pilot Lights

Key Switch

PC Board

Cables

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

I/O Modules

RediPANEL modules communicate directly with the programmable

controller via cables to I/O modules. Programming the devices in the

modules is identical to programming devices hardwired to I/O racks. This

means that the RediPANEL modules are mapped directly into the I/O image

tables of the programmable controller through the I/O modules.

14

Page 15

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Image Diagrams

Output Image Table

1/4 Rack

Image Table Configurations

Figures 10-13 show a typical I/O image table configuration when using a 16

or 32 button RediPANEL module with a 1746 SLC or a 1771 PLC I/O

module.

Figure 10

Typical Image Table Configuration for 16 Button RediPANEL with 1746 SLC I/O Modules

Lamp Control Bits

SLC Bit Addresses (Decimal)

123456

00 01 02 03 04 05

7 8 9 10 11 12

06 07 08 09 10 11

13 14 15 16

12 13 14 15

Input Image Table

1/4 Rack

0123456789101112131415

WORD 0

WORD 1

Input

Switch Status Bits

Word

Output

I:2

01

Bits

0123456789101112131415

O:3

08

Push Button #2

Push Button #9 Lamp

I:2

01

NOTE: This example has push button #2 (at input module word 2 bit 01) turning on lamp #9 (at output module word 3 bit 08).

O:3

08

15

Page 16

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Figure 11

Typical Image Table Configuration for 16 Button RediPANEL with 1771 PLC I/O Modules

Output Image Table

1/4 Rack

1617 101112131415

Lamp Control Bits

PLC Bit Addresses (Octal)

123456

00 01 02 03 04 05

789101112

06 07 10 11 12 13

13 14 15 16

14 15 16 17

Push Button #2

I:020

Input Image Table

1/4 Rack

01234567 012345671011121314151617

WORD 0

WORD 1

Input

01

Switch Status Bits

Module Group 1

Rack #2

Output

Module Group (Word)

Bits

Push Button #9 Lamp

O:021

(Word)

O:021I:020

10

01

NOTE: This example has push button #2 (at rack 2, word 0, bit 01) turning on lamp #9 (at rack 2, word 1, bit 10).

This example assumes one slot addressing for I/O chassis.

16

10

Page 17

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Figure 12

Typical Image Table Configuration for 32 Button RediPANEL with 1746 SLC I/O Modules

Output Image Table

1/4 Rack

Lamp Control Bits

Lamp Control Bits

SLC Bit Addresses (Decimal)

12345678

00 01 02 03 04 05 06 07

9 10111213141516

08 09 10 11 12 13 14 15

17 18 19 20 21 22 23 24

16 17 18 19 20 21 22 23

25 26 27 28 29 30 31 32

24 25 26 27 28 29 30 31

Input Image Table

1/4 Rack

0123456789101112131415 0123456789101112131415

WORD 0

WORD 1

Input

I:2

16

Switch Status Bits

Switch Status Bits

Word

Bits

Output

O:3

31

Push Button #17

Push Button #32 Lamp

I:2

16

NOTE: This example has push button #17 (at input module word 2, bit 16) turning on lamp #32 (at output module word 3 bit 31).

O:3

31

17

Page 18

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Figure 13

Typical Image Table Configuration for 32 Button RediPANEL with 1771 PLC I/O Modules

Output Image Table

1/4 Rack

Lamp Control Bits

Lamp Control Bits

PLC Bit Addresses (Octal)

12345678

00 01 02 03 04 05 06 07

9 10111213141516

10 11 12 13 14 15 16 17

17 18 19 20 21 22 23 24

00 01 02 03 04 05 06 07

25 26 27 28 29 30 31 32

10 11 12 13 14 15 16 17

Input Image Table

1/4 Rack

012345671011121314151617 012345671011121314151617

WORD 0

WORD 1

Input

00

Switch Status Bits

Switch Status Bits

Module Group 3

Rack #2

Output

Module Group (Word)

Bits

(Word)

O:023I:023

17

Push Button #17

I:023

00

NOTE: This example has push button #17 (at rack 2, word 3, bit 00) turning on lamp #32 (at rack 2, word 3, bit 17).

This example assumes one slot addressing for I/O chassis.

18

Push Button #32 Lamp

O:023

17

Page 19

User Manual

ËËË

Bulletin 2705

RediPANEL 800A Push Button Modules

Modification and Replacement Procedures

Custom 800A RediPANEL Modules

If the standard configuration modules with momentary push buttons do not

meet your requirements, 800A custom modules are available. Custom

modules can contain any combination of the following Bulletin 800A

devices:

Momentary Illuminated Push Buttons

Maintained Illuminated Push Buttons

Two Position Selector Switches

Flush Head or Extended Head Operators

Two Position Key Switches

Installing or Replacing Push Button Legends

ATTENTION: To avoid electrical shock or unintended operation

of the equipment, disconnect power before servicing.

!

1. Remove the lens carrier from the push button on the module by gently

prying it out on either side of the carrier with a screwdriver.

ATTENTION: DO NOT use the slot on either side of the lens

carrier for prying as it may break the assembly.

!

2. Remove the color lens by placing a small screwdriver into the slot on the

back of the lens carrier and gently prying the two pieces apart.

ATTENTION: DO NOT use too much pressure in prying the

assembly apart as it can damage the colored lens.

!

STEP 1 STEP 2

19

Page 20

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Installing or Replacing Push Button Legends (cont’d)

3. Insert the new legend and “snap” the two pieces back together.

4. Replace the keyed lens carrier into the push button.

5. Check for proper operation of the push button.

STEP 3

Lamp Replacement

ATTENTION: To avoid electrical shock or unintended operation

of the equipment, disconnect power before servicing.

STEP 5

!

1. Remove the lens carrier from the push button on the module by gently

prying it out on either side of the carrier with a screwdriver.

ATTENTION: DO NOT use the slot on either side of the lens

carrier for prying as it may break the assembly.

!

2. Remove existing lamp from socket.

20

ATTENTION: DO NOT use the screwdriver or any other metal

object to remove the bulb. Use ONLY the 800M-N5 lamp

!

replacement tool.

Page 21

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Lamp Replacement (cont’d)

800M-N5

STEP 1 STEP 2

3. Carefully insert the new lamp into the socket.

Specifications

ATTENTION: Before replacing the lens carrier into the push

button, be sure the lamp is seated properly or a short may result.

!

The LED must be installed with plus (+) indicator facing to the

left.

4. Replace the keyed lens carrier into the push button.

5. Check for proper operation of the push button.

Electrical

External Power Supply 24 Volts DC "10 %

21.6-26.4 VDC

Input Current and

Power Ratings

(All On)

LEDs

32 Buttons 16 Buttons

SLC .95 Amps .47 Amps

PLC 1.23 Amps .55 Amps

24 VDC six chip cluster lamps

Catalog No. 800T-N62R (red)

-N62G (green)

-N62A (amber)

Power Connector

UL File/Guide Non-Hazardous Locations: E56639/NMTR

CSA Non-Hazardous Locations: LR62923

Two position header (part of printed circuit board

assembly) and two position removable connector

(provided). End user responsible for wiring between

connector and external power supply.

21

Page 22

User Manual

Bulletin 2705

RediPANEL 800A Push Button Modules

Mechanical

Enclosure NEMA Type 13

32 Push Button Module

Configurations

Standard: 8 Red, 16 Green, 8 Amber

16 Push Button Module

Standard: 8 Red, 8 Green

Replacement Illuminated

Push Button

Approximate Dimensions

Approximate Weight of

Module (w/o Cables)

16 PB Units – 800A-C2DG24 (Green)

32 PB Units – 800A-C2CA24 (Amber)

Length: 9.5” (241.3mm)

Height: 7.25

Depth: 4.0

2.9 lbs. (1.3 kg) 16 Button Panel

3.25 lbs. (1.5 kg.) 32 Button Panel

800A-C2DR24 (Red)

800A-C2CG24 (Green)

800A-C2CR24 (Red)

” (184.15mm)

” (101.6 mm - 16 Button Panel)

” (114.3 mm - 32 Button Panel)

4.5

Enviornmental

Temperature

Humidity 5% – 95% non-condensing

Operating: -20_C to +45_C (-4_F to 113_F)

(Operating temperature at 0_C (32_F) is based on the

absence of freezing moisture or liquid.)

Storage: -30_C to +85_C (-22_F to 185_F)

22

Page 23

Allen-Bradley has been helping its customers improve productivity and quality for 90 years.

A-B designs, manufactures and supports a broad range of control and automation products

worldwide. They include logic processors, power and motion control devices, man-machine

interfaces and sensors. Allen-Bradley is a subsidiary of Rockwell International, one of the

world’s leading technology companies.

With major offices worldwide.

Algeria • Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech

Republic • Denmark • Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India •

Indonesia • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • New Zealand • Norway • Oman • Pakistan • Peru • Philippines

• Poland • Portugal • Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain • Switzerland •

Taiwan • Thailand • The Netherlands • Turkey • United Arab Emirates • United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

World Headquarters, Allen-Bradley, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication 2705-803 — March 1994 40061-223-01(A)

Copyright 1994 Allen-Bradley Company, Inc. Printed in USA

Loading...

Loading...