Page 1

Allen-Bradley

Bulletin 2705

RediPANEL

ALLEN–BRADLEY

User

Push Button

Modules

Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC, PLC–2, PLC–3, and PLC–5 are registered trademarks of Allen-Bradley Company, Inc.

SLC, SLC 500, PanelView, RediPANEL, and Dataliner are trademarks of Allen-Bradley Company, Inc.

IBM is a registered trademark of International Business Machines, Incorporated.

Page 3

Table of Contents

Bulletin 2705 RediPANEL Modules

User Manual

Preface

Contents of Manual P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview

Configuring the RediPANEL Module

Wiring and Installation

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

800A (16mm) Push Button Modules 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

800EP/EM (22.5mm) Push Button Modules 1–2. . . . . . . . . . . . . . . . . . . . .

800T/H (30mm) Push Button Modules 1–4. . . . . . . . . . . . . . . . . . . . . . . . .

NEMA Type 4X Membrane Push Button Modules 1–5. . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculating Rack Size 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switches 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Switch Bank 1 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Switch Bank 2 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input and Output Image Tables 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Precautions 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Power 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosures 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Space and Clearance Requirements 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spacing of 800A Modules 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spacing of 800EM/EP Modules 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spacing of 800T/H Modules 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the 800A and Sealed Membrane Modules 3–8. . . . . . . . . . . . . . .

Installing the 800EM/EP Push Button Modules 3–10. . . . . . . . . . . . . . . . . .

800EM/EP Panel Mounting 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

800EM/EP Fiberglass Enclosure Mounting 3–12. . . . . . . . . . . . . . . . . . .

800EM/EP Steel Enclosure Mounting 3–13. . . . . . . . . . . . . . . . . . . . . . .

Installing the 800T/H Push Button Modules 3–14. . . . . . . . . . . . . . . . . . . . .

Connecting to a Remote I/O Link 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to a Scanner Module 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

Bulletin 2705 RediPANEL Modules

User Manual

Programming the RediPANEL Module

Maintenance and Troubleshooting

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Bit Addresses 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Addresses for 8 Button Modules 4–1. . . . . . . . . . . . . . . . . . . . . . . .

Bit Addresses for 16 Button Modules 4–2. . . . . . . . . . . . . . . . . . . . . . .

Bit Addresses for 32 Button Modules 4–5. . . . . . . . . . . . . . . . . . . . . . .

Addressing Examples for 32 Button Modules 4–8. . . . . . . . . . . . . . . . .

Using a PLC-2 with a 1772-SD Scanner 4–9. . . . . . . . . . . . . . . . . . . . . . . .

Using a PLC-2 with a Sub I/O Scanner 4–11. . . . . . . . . . . . . . . . . . . . . . . . .

Using a PLC-5 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using a PLC-5 with a Sub I/O Scanner 4–15. . . . . . . . . . . . . . . . . . . . . . . . .

Operating Cycles 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Response Time 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handshake Mode 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5 – Flashing Lamp Example 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC 5/02 Programming Example 4–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the FAULT Indicator 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the COMM Indicator 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Push-to-Test Button 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Back Panel of RediPANEL 800T/H Modules 5–5. . . . . . . .

Basic Troubleshooting Questions 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Appendix B

Appendix C

Appendix D

Appendix E

Appendix F

Appendix G

Appendix H

ii

Specifications

Custom RediPANEL Modules

800A Switch Replacement Kit and LED Upgrade Kit

Adding/Replacing Push Button Legends

Replacing Lamps

Converting from Incandescent to LED Lamps

Installing/Replacing Push Buttons

Installing Color Inserts in Membrane Modules

Page 5

List of Figures

.

.

.

.

.

.

.

.

.6

.7

.9

.

.

.

.

.64.7

.94.

.

.A

.A2.B5.A

.B

Table of Contents

Bulletin 2705 RediPANEL Modules

User Manual

Figure

2

1

2

2

3

2

3

1

2

3

3

3

4

3

5

3

3

3

3.8

3

4.1

4

2

3

4

4

4

5

4

4

4.8

4

10

1

G

Title

!7,5&+ $0- !#9

$&- ''3(44 !(55,0*4 )13 9 7,5+ 9! !6% !&$00(3

DIP Switch Bank 1 (SW-1)

$&- ''3(44 !(55,0*4 )13 9 9 $0' ! 31&(44134

DIP Switch Bank 2 (SW-2) Settings

$0(. 65165 ,/(04,104 1) $0' !($.(' 1'6.(4

(25+ ,/(04,104 1) $0' !($.(' 1'6.(4

1605,0* 3$&-(5 "+6/%4&3(74

$0(. 65165 ,/(04,104 1) 64+ 65510 1'6.(4

(25+ ,/(04,104 1) 64+ 65510 1'6.(4

,%(3*.$44 0&.1463( 1605,0* ,/(04,104 1)

64+ 65510 1'6.(4

!5((. 0&.1463( 1605,0* ,/(04,104 1)

64+ 65510 1'6.(4

1605,0* ,/(04,104 1) 65510 " 1'6.(4

1605,0* ,/(04,104 1) 65510 " 1'6.(4

9 13 9 31*3$//,0* 8$/2.(

.1&- "3$04)(3 %(57((0 !6% !&$00(3 $0' 9

(/15( ''3(44,0* 7,5+ $ !6% !&$00(3

9 13 9 31*3$//,0* 8$/2.(

9 .1&- "3$04)(3

9 $0' !6% !&$00(3 31*3$//,0* 8$/2.(

9 $0' !6% !&$00(3 $''(3 1*,& 8$/2.(

$''(3 1*,& $0'4+$-( 60*

$0'4+$-( ",/,0* ,$*3$/4

.$4+,0* $ 65510 $/2

(2.$&,0* " 64+ 655104

Page

Table

1

2

5

List of Tables

Title

NEMA Ratings for 800EP/EM Devices 1–2. . . . . . . . . . . . . . . . . . . . . .

Rack Size Requirements for 8, 16 or 32 Button Modules 2–2. . . . . . . . .

DIP Switch Bank 2 (SW-2) Functions 2–7. . . . . . . . . . . . . . . . . . . . . . . .

Testing the Contacts of Illuminated Push Buttons 5–4. . . . . . . . . . . . . . .

Testing the Contacts of Illuminated Selector Switches 5–4. . . . . . . . . . .

Page

iii

Page 6

Preface

A–B

Preface

This manual gives an overview of the Bulletin 2705 RediPANEL Push

Button Modules and describes how to configure, install, program and

troubleshoot the device on the Allen-Bradley Remote I/O network.

Contents of Manual

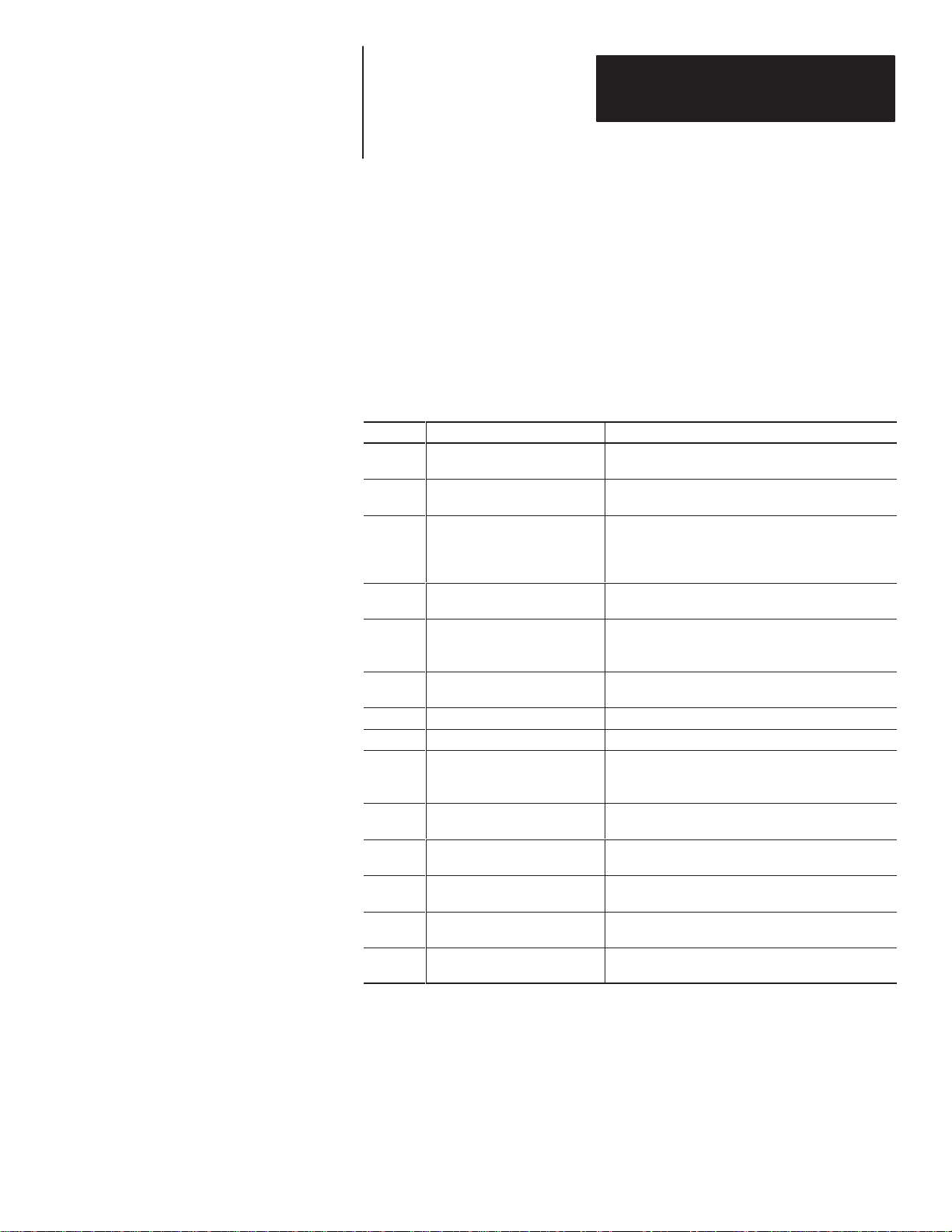

This manual is organized as follows:

Chapter Title Description

Preface

1 Overview

2

3 Wiring and Installation

4

5

A Specifications Provides specifications for the RediPANEL modules.

B Custom RediPANEL Modules Describes how to create a custom unit.

C

D

E Replacing Lamps

F

G

H

Configuring the

RediPANEL Module

Programming the

RediPANEL Module

Troubleshooting

and Maintenance

800A Switch Replacement Kit

and LED Upgrade Kit

Adding/Replacing Push Button

Legends

Converting form Incandescent

Lamps to LED Lamps

Installing/Replacing

Push Buttons

Installing Color Inserts

in Membrane Modules

Describes the purpose and contents of the manual,

and the intended audience.

Provides an overview of the Bulletin 2705 RediPANEL

modules and the configurations available.

Describes how to configure RediPANEL functions

using the module’s DIP Switches. Configuration

includes the rack address, baud rate, handshaking,

flashing lamps, last state and fault mode behavior.

Describes how to install the RediPANEL module and

connect the module to a remote I/O link.

Describes how to program the RediPANEL module

from a PLC or SLC controller. Also covers handshake

mode and response times.

Describes how to troubleshoot and maintain the RediPANEL module.

Describes how to replace push buttons in the appropriate module. Also provides information for upgrading

from incandescent to LED lamps

Describes how to replace push button legends in Bulletin 800A Push Button Modules.

Describes how to replace lamps in Bulletin 800A Push

Button Modules.

Describes how to upgrade a Bulletin 800A Push Button Module from incandescent to LED lamps.

Describes how to replace push buttons in a RediPANEL module.

Describes how to install color legend inserts in Membrane type Modules.

P–1

Page 7

Preface

Intended Audience

Related Publications

This manual is for the individuals responsible for installing, mounting and

operating a RediPANEL Push Button Module in an industrial environment.

You must know how to program a PLC or SLC controller to operate the

RediPANEL module on a Remote I/O network. You must be able to:

• create a ladder logic program in your PLC or SLC controller

• understand basic PLC or SLC ladder logic addressing

• program block transfer instructions (when using Sub I/O Scanners)

Related publications you may want to refer to include:

• User manual and other support documentation for your processor and

scanner.

• Allen-Bradley Publication 1770-4.1 for grounding and wiring guidelines.

• National Electrical Code published by the National Fire Protection

Association of Boston, Massachusetts (refer to sections on wire sizes and

types for grounding electrical equipment).

P–2

Page 8

Chapter

Chapter Objectives

Description

A–B

1

Overview

This chapter describes the features, functions and operation of the Bulletin

2705 RediPANEL Push Button Modules.

Section Page

Description 1–1

800A (16mm) Push Button Modules 1–2

800EM/EP (22.5mm) Push Button Modules 1–2

800T/H (30mm) Push Button Modules 1–4

NEMA Type 4X Membrane Push Button Modules 1–5

The Bulletin 2705 RediPANEL Push Button Modules are prepackaged push

button stations that connect to Allen-Bradley programmable controllers over

a Remote I/O link.

RediPANEL Push Button Modules are available with:

• Bulletin 800A (16mm) devices

• Bulletin 800EP or 800EM (22.5mm) devices

• Bulletin 800T or 800H (30mm) devices

• Sealed membrane buttons for NEMA 4X (indoor) applications

Features of the RediPANEL Push Button Modules include:

• standard and custom configurations with 8, 16, or 32 push buttons

• remote I/O operations

• built-in diagnostics

• simultaneous push button applications

• handshake mode for data input integrity

• Diagnostic Indicators

1–1

Page 9

Chapter 1

Overview

800A (16mm) Push Button Modules

RediPANEL 800A Modules support Bulletin 800A push buttons in 2

configurations:

• standard

• custom

The 800A modules can operate in Class 1, Division 2, Groups A, B, C, and D

hazardous locations.

Standard Configuration

Standard configurations support 8, 16 or 32 momentary illuminated 800A

push buttons.

Custom Configuration

Custom configurations support any 8, 16 or 32 of the following 800A

devices:

• Momentary push buttons, illuminated

• Maintained push buttons, illuminated

• Flush head or extended head operators

• 2 position selector switches

• 2 position key switches

800EP/EM (22.5mm) Push Button Modules

1–2

RediPANEL 800EP/EM Modules support Bulletin 800EP and 800EM

22.5mm devices. Table 1.A lists NEMA ratings for 800EP/EM devices.

Table 1.A

NEMA IEC Ratings for 800EP/EM Devices

Type of Enclosure

Device

800EP 4/12/13, IP66 4/4X/12/13, IP66 12/13, IP65 4/4X/12/13, IP66

800EM 4/12/13, IP66 4/12/13, IP66 12/13, IP65 4/12/13, IP66

Cold Rolled Steel

Faceplate

Stainless Steel

Faceplate

Metal Enclosure

Fiberglass

Enclosure

RediPANEL 800EP/EM modules are available in 3 configurations:

• standard

• custom

• unpopulated

Standard Configuration

Standard configurations support 16 or 32 illuminated 800EP/EM push

buttons.

Page 10

Chapter 1

Overview

Custom Configuration

Custom configurations support any 16 or 32 of the following 800EP or

800EM devices:

• Momentary push buttons, illuminated/non-illuminated

• Maintained push buttons, illuminated/non-illuminated

• Flush head, extended head, or 40mm mushroom head operators

• Pilot lights

• 2 position selector switches, illuminated/non-illuminated

• 3 position selector switches, illuminated/non-illuminated

• Hole closing plugs

3 position devices use two RediPANEL inputs leaving an unused hole on the

front panel (hole plug 800E-N2).

Unpopulated Configuration

You can order an unpopulated 800EM/EP RediPANEL Module. The

unpopulated configuration consists of the enclosure and electronics without

the 800EM or 800EP devices. Each 800EM/EP device is ordered separately.

ATTENTION: Only install Allen-Bradley 800EM or 800EP

devices in the RediPANEL module. Using operators from other

!

manufacturers voids the warranty.

1–3

Page 11

Chapter 1

Overview

800T/H (30mm) Push Button Modules

RediPANEL 800T/800H Modules support Bulletin 800T and 800H 30mm

120 VAC, Class 1, Div. 2 Groups A, B, C, and D devices only. The 800T

devices have a NEMA Type 12/13 rating for applications requiring

protection from oil and dust. The stainless steel faceplate of 800H devices is

designed for NEMA Type 4, 4X applications (hosedown or corrosive

environments).

RediPANEL 800T/H modules are available in 3 configurations:

• standard

• custom

• unpopulated

Standard Configuration

Standard configurations support 16 or 32 illuminated 800T/H push buttons.

Custom Configuration

Custom configurations support any 16 or 32 of the following 800T or 800H

devices:

1–4

• Momentary push buttons, illuminated/non-illuminated

• Push/Pull push buttons, illuminated/non-illuminated

• Flush head, extended head or mushroom head operators

• Pilot lights

• 2 position selector switches, illuminated/non-illuminated

• 3 position selector switches, illuminated/non-illuminated

• 4 position selector switches

• Hole closing plugs

3 or 4 position devices use 2 RediPANEL inputs (and 2 connector cables),

leaving a physical location with an output bit only. You can either:

1. Reduce the total number of push button devices by one for each 3 or 4

position device. Use a hole plug (Catalog No. 800T-N1B) to cover the

unused hole.

For example, a 16 button module that includes a 3 or 4 position device

can have a maximum of 14 additional push buttons.

2. Use a pilot light adapter cable (Catalog 800T-N309) to install a 3 or 4

position pilot light instead of the hole plug.

The above example would then support an additional pilot light for a total

of 16 devices.

Page 12

Chapter 1

Overview

Unpopulated Configuration

You can order an unpopulated 800T/800H RediPANEL module. The

unpopulated configuration consists of the enclosure and electronics without

the 800T or 800H devices. Each 800H/T device is ordered separately.

ATTENTION: Only install Allen-Bradley 800T or 800H

devices in the RediPANEL. Using operators from other

!

manufacturers voids the warranty.

NEMA Type 4X Membrane Push Button Modules

The NEMA Type 4X Membrane Push Button Module has a standard

configuration of 4 rows of 4 buttons. Each button has an LED in the upper

right corner. These LEDs perform the same function as the lamp on the

standard push button modules.

The module comes with five different color inserts to legend each button

location. The inserts are coated mylar stock for writing (ink, pencil, or

marker), typing, or printing a legend.

1–5

Page 13

Chapter

Chapter Objectives

Calculating Rack Size

A–B

2

Configuring the RediPANEL Module

This shows how to configure the RediPANEL Module using DIP Switches.

Section Page

Calculating Rack Size 2–1

DIP Switches 2–3

Setting Switch Bank 1 2–4

Setting Switch Bank 2 2–6

Input and Output Image Tables 2–8

DIP Switches on the RediPANEL are used to set Input/Output (I/O)

requirements. On a Remote I/O network, I/O is measured in terms of racks.

The smallest unit is a 1/4 rack.

Rack size determines the amount of space the module uses in the Input and

Output Image tables. When you select a rack size (using DIP switches),

space is reserved in the Input and Output Image Tables of your processor.

Three factors determine rack size:

• Input/Output size

• Flashing functions

• Handshaking functions

Input/Output Size

Input/Output Size directly relates to the number of push buttons on the

RediPANEL module. A 16 push button module has 16 inputs and 16

outputs. A 32 push button module has 32 inputs and 32 outputs.

Flashing Function

The flashing function causes the RediPANEL outputs to flash without

additional PLC programming. If flashing is enabled, the processor allocates

additional memory in the I/O Image Table. By branching the RediPANEL

output bits with the corresponding flashing bits, the RediPANEL outputs

blink at a 0.5 second rate.

A 16 push button module requires 16 additional outputs. A 32 push button

module requires 32 additional outputs to enable the flashing function.

Handshake

The handshake function latches an input bit until it is acknowledged by the

processor. Handshaking requires an additional output bit in the Output

Image Table.

2–1

Page 14

Chapter 2

Lighted

Num er

Lighted

Lighted

1/4

1

1

3

Configuring the RediPANEL Module

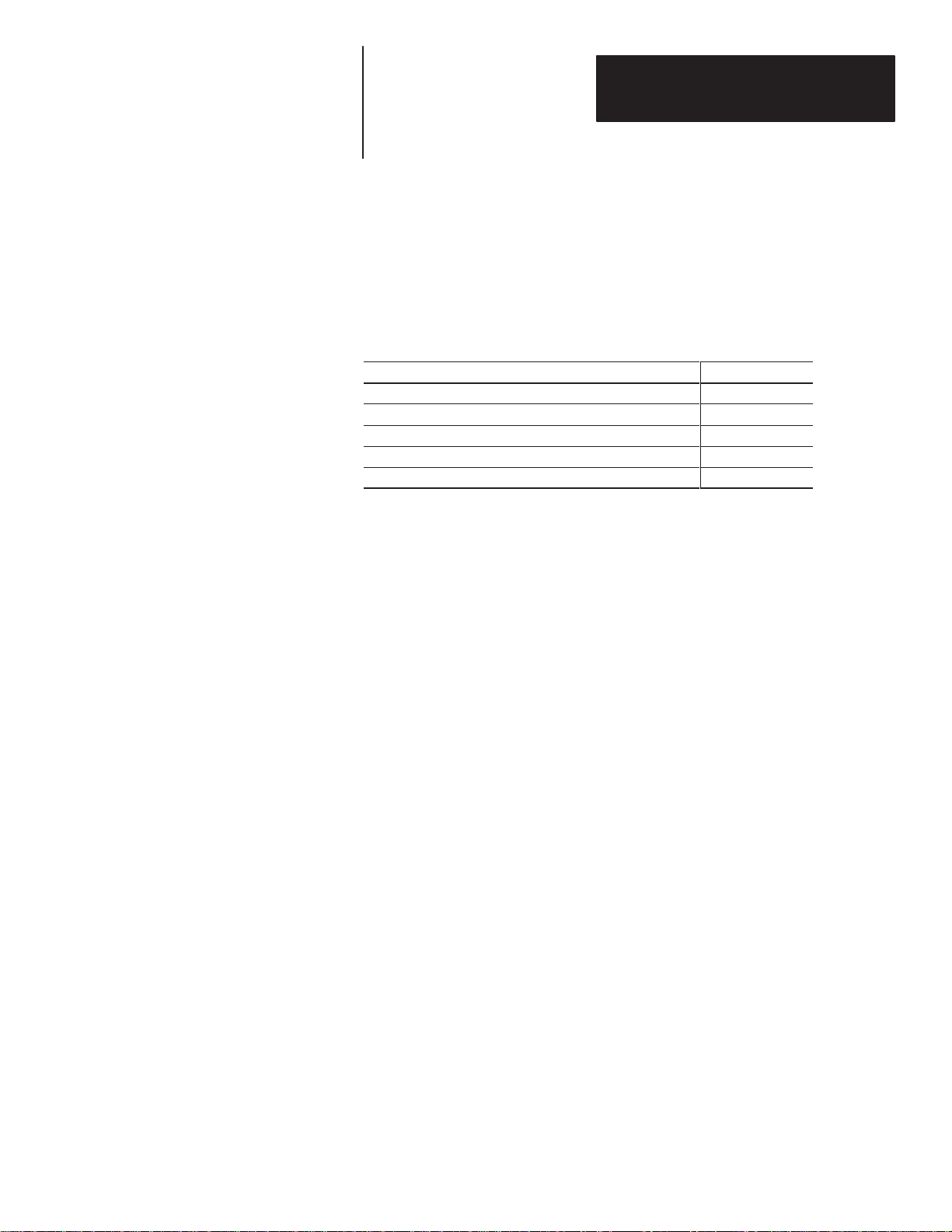

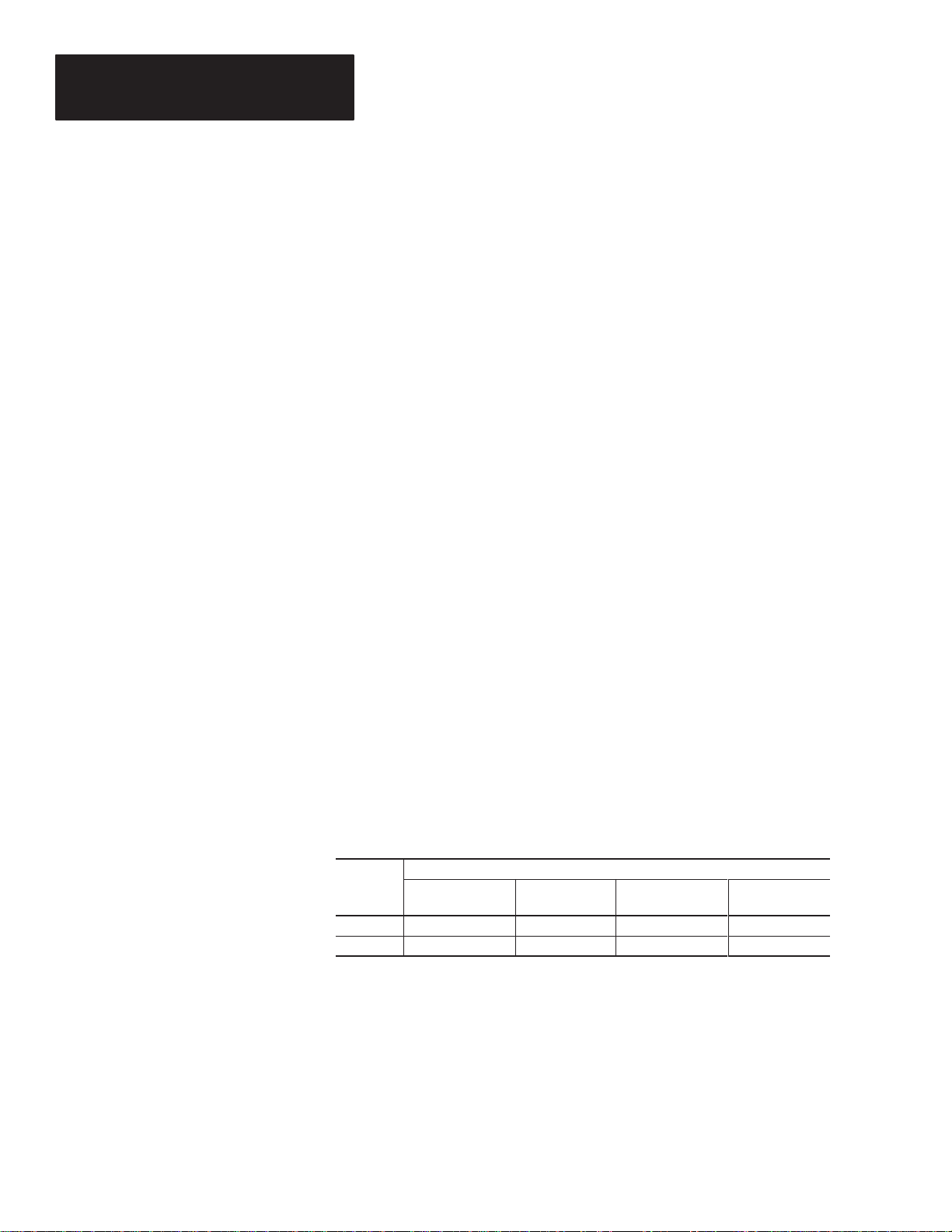

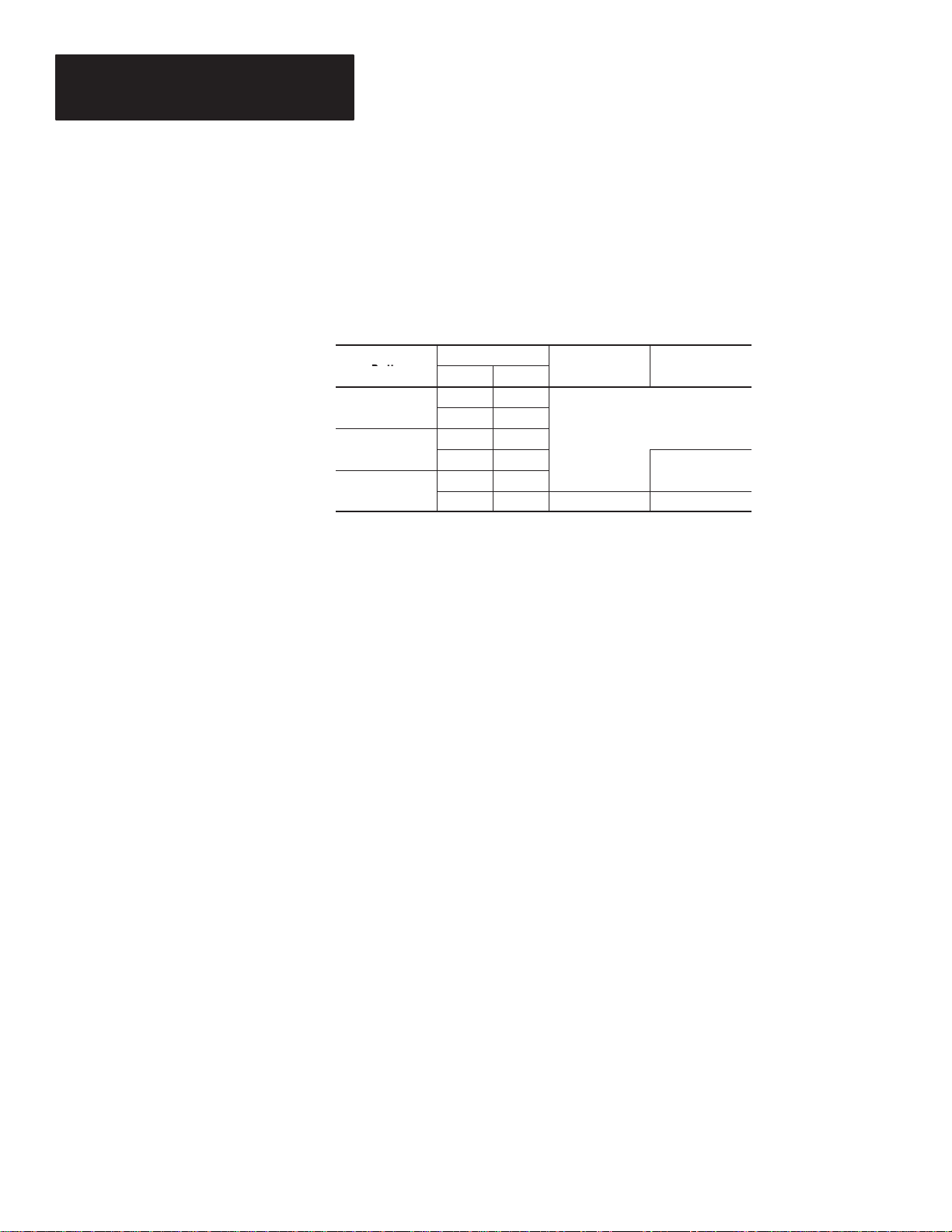

Table 2.A lists the rack size requirements for an 8, 16 or 32 button

RediPANEL module. The rack size varies depending on the number of push

buttons and the functions used.

Table 2.A

Rack Size Requirements for 8, 16, and 32 Button RediPANEL Modules

Number

of Buttons

8

16

32

Handshake

No Yes

and Flashing

1/2 3/4

/2

You can ignore the I/O requirements in the table and specify a full rack by

setting switch 6 in DIP Switch Bank 2 on the RediPANEL. A full rack is

automatically reserved in the Input/Output Image Tables of the processor.

2–2

Page 15

Chapter 2

Configuring the RediPANEL Module

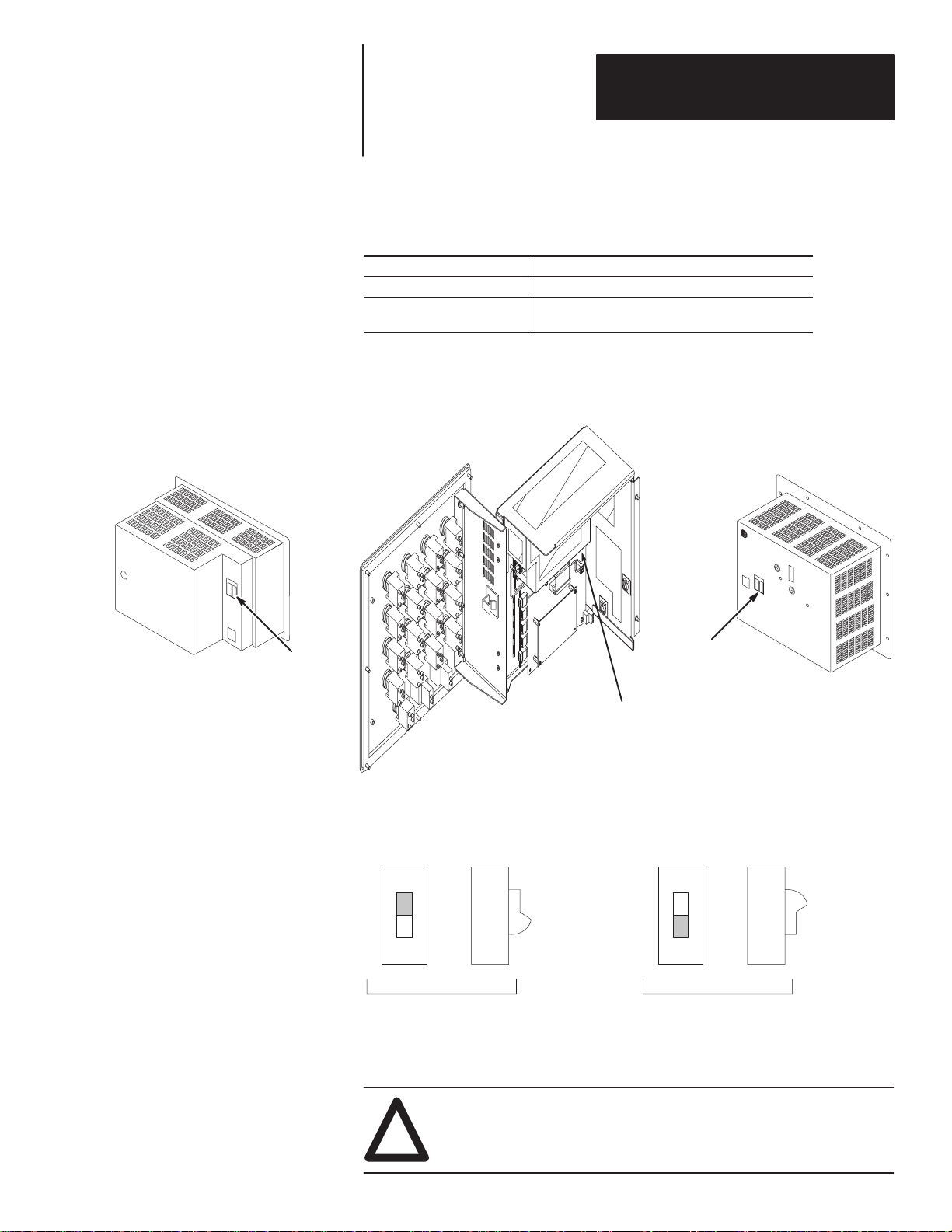

DIP Switches

DIP Switches

The RediPANEL module has two DIP Switch banks.

Switch Bank Function

Switch Bank 1 (SW-1) Sets rack address.

Switch Bank 2 (SW-2) Controls baud rate, flashing lamps, fault mode

behavior, handshaking and last states.

The DIP Switch banks are located on the back of the RediPANEL module.

You can access the DIP switches by opening the back panel, as shown below.

DIP Switches

800A Push Button Module

800T/H Module

DIP Switches

800EM/EP Module

(Steel enclosure mounting shown.

Other styles similar)

The following figure shows ON/OFF positions of the rocker style switches.

ON

OFF

FRONT SIDE

ON

ON and OFF switch settings are indicated by shading.

ON

OFF

FRONT SIDE

OFF

ATTENTION: Remove power from the module before setting

switches. Switch settings are scanned only on power-up.

!

The new settings take effect when you power-up the module.

2–3

Page 16

Chapter 2

Configuring the RediPANEL Module

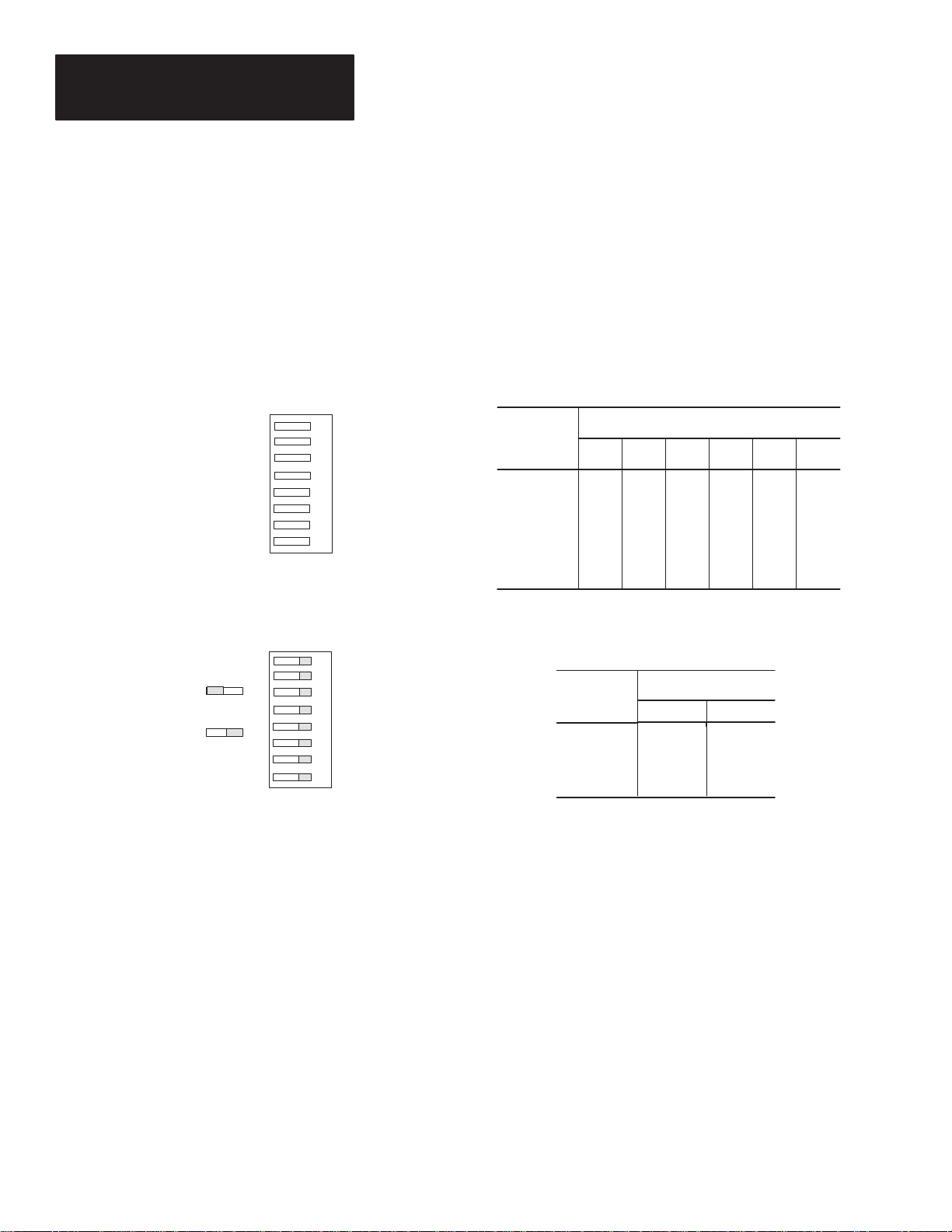

Setting Switch Bank 1

OFF

ON

SW-1

Example

SW-1

Switch Bank 1 (SW-1) sets the rack address.

Figure 2.1 shows rack address settings for the PLC-2 or any PLC using a

1771-SN Sub Scanner.

Figure 2.1

DIP Switch Bank 1

Rack Address Settings for PLC-2 or PLC with 1771-SN Sub Scanner

ONOFF

Rack address, MSB

1

Rack address

2

Rack address

3

Rack address

4

Rack address

5

Rack address, LSB

6

First I/O group, MSB

7

First I/O group, LSB

8

ONOFF

1

PLC-2

2

I/O rack

3

number 1

4

5

6

7

First I/0

8

group 0

Rack Address Settings for PLC-2 and 1771-SN Scanner

I/O Rack

Address

1

2

3

4

5

6

7

First I/O

Group

Switch Settings – Series B

on

on

on

on

on

on

on

on

on

Specifying First I/O Group

on

on

on

on

on

on

on

on

on

on

on

on

Switch Settings

78

0

2

4

6

on

on

off

off

on

on

on

on

off

off

off

on

on

off

off

on

on

off

on

off

on

off

653421

on

off

on

off

on

off

on

2–4

Figure 2.2 lists rack address settings for the PLC-3 and PLC-5 family.

Page 17

Chapter 2

I/O Rack

I/O Rack

I/O Rack

I/O Rack

rst I/O

rst I/O

Configuring the RediPANEL Module

Figure 2.2

DIP Switch Bank 1

Rack Address Settings for PLC-3, PLC-5 and SLC Processors

Address

00 ➀

01 on on on on on off 41 off on on on on off

02 on on on on off on 42 off on on on off on

03 on on on on off off 43 off on on on off off

04 on on on off on on 44 off on on off on on

05 on on on off on off 45 off on on off on off

06 on on on off off on 46 off on on off off on

07 on on on off off off 47 off on on off off off

10 on on off on on on 50 off on off on on on

11 on on off on on off 51 off on off on on off

12 on on off on off on 52 off on off on off on

13 on on off on off off 53 off on off on off off

14 on on off off on on 54 off on off off on on

15 on on off off on off 55 off on off off on off

16 on on off off off on 56 off on off off off on

17 on on off off off off 57 off on off off off off

20 on off on on on on 60 off off on on on on

21 on off on on on off 61 off off on on on off

22 on off on on off on 62 off off on on off on

23 on off on on off off 63 off off on on off off

24 on off on off on on 64 off off on off on on

25 on off on off on off 65 off off on off on off

26 on off on off off on 66 off off on off off on

27 on off on off off off 67 off off on off off off

1

on on on on on on 40 off on on on on on

Switch Settings

2 3 4 5 6

Address

1

Switch Settings

2 3 4 5 6

30 on off off on on on 70 off off off on on on

31 on off off on on off 71 off off off on on off

32 on off off on off on 72 off off off on off on

33 on off off on off off 73 off off off on off off

34 on off off off on on 74 off off off off on on

35 on off off off on off 75 off off off off on off

36 on off off off off on 76 off off off off off on

37 on off off off off off

➀ Rack 00 not valid with PLC-5s.

Specifying First I/O Group

Fi

Fi

Group

0 on on

2 on off

4 off on

6 off off

Switch Settings

7

8

2–5

Page 18

Chapter 2

Configuring the RediPANEL Module

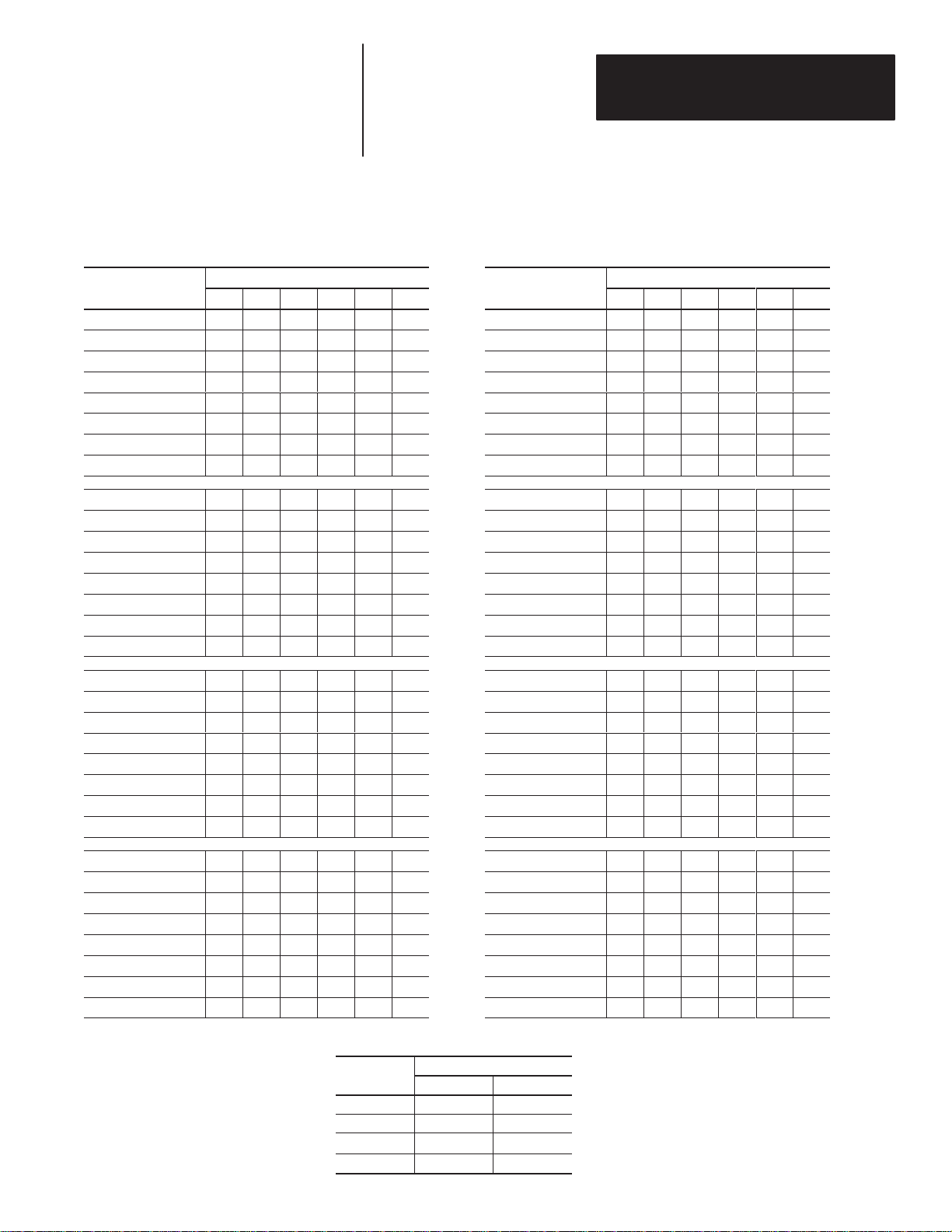

Setting Switch Bank 2

ONOFF

Baud Rate

1

2

Baud Rate

3

Flashing Lamps ENABLED

4

Switch Fault Mode

Last Rack

5

Rack Size

6

7

Handshake ENABLED

8

Last State ENABLED

SW-2

ONOFF

1

OFF

ON

SW-2

Baud Rate

2

Baud Rate

3

Flashing Lamps (DISABLED)

4

Switch Fault (HALT)

5

Last Chassis (NOT LAST)

6

Rack Size (TABLE)

7

Handshake (DISABLED)

8

Last State (DISABLED)

Example

Figure 2.3 shows the functions and settings for Switch Bank 2 (SW-2).

Table 2.B defines the DIP Switch functions.

Figure 2.3

DIP Switch Bank 2 (SW-2) Settings

RediPANEL 800A and 800EP/EM Membrane Modules

Switch Description Switch Setting

(57.6K)

1 & 2 Baud Rate 57.K 1=ON 2=ON

3 Flashing Lamps OFF=Disabled ON=Enabled

4 Switch Fault OFF=Continue ON=Halt

5 Last Chassis OFF=Last ON=Not Last

6 Rack Size OFF=Full ON=Table

7 Handshake OFF=Disabled ON=Enabled

8 Last State OFF=Disabled ON=Enabled

115.2K 1=OFF 2=ON

230.4K 1=ON 2=OFF

N/A 1=OFF 2=OFF

OFF

ON

SW-2

SW–2

ONOFF

Baud Rate

1

2

Steady Lamps ENABLED

3

Flashing Lamps ENABLED

Switch Fault

4

Last Chassis

5

Rack Size

6

7

Handshake ENABLED

8

Last State ENABLED

ONOFF

Example

1

Baud Rate (57.6K)

2

Steady Lamps (ENABLED)

3

Flashing Lamps (DISABLED)

4

Switch Fault (HALT)

5

Last Chassis (NOT LAST)

6

Rack Size (TABLE)

7

Handshake (DISABLED)

8

Last State (DISABLED)

RediPANEL 800T/H Modules

Switch Description Switch Setting

OFF ON

1 Baud Rate 115.2K 57.6K

2 Steady Lamps Disabled Enabled

3 Flashing Lamps Disabled Enabled

4 Switch Fault Continue Halt

5 Last Chassis Last Not Last

6 Rack Size Full Table

7 Handshake Disabled Enabled

8 Last State Disabled Enabled

2–6

Page 19

Chapter 2

Options

Description

Configuring the RediPANEL Module

Table 2.B

DIP Switch Bank 2 (SW-2) Functions

DIP Switch SW2

Number Function

1, 2 ➀➁

3 Flashing Lamps

4 Switch Fault Mode

5 Last Rack

6 Rack Size

7 Handshake

8 Last State

➀ Switches 1 and 2 set the baud rate on RediPANEL 800A, 800EM/EP, and Membrane modules. Switch 1 only sets the baud rate on RediPANEL 800T/H

modules.

➁ Switch 2 sets steady lamps for the 800T/H RediPANEL.

Baud Rate

• 57.6K

• 115.2K

• 230.4K

• Enabled

• Disabled

• Halt

• Continue

• Last

• Not Last

• Full

• Table

• Enabled

• Disabled

• Enabled

• Disabled

• 57.6K for links up to 10,000 feet (3,000 meters)

• 115.2K for links up to 5,000 feet (1,500 meters)

• 230.4K for links up to 2,500 feet (750 meters)

When enabled, the Module uses the built-in flash feature to flash the lamps inside the

push button at a 0.5 sec. rate. Programming ON/OFF Timers is not necessary,

• Halt stops all push button operations when a fault is detected using the Push-to-Test

button. Communications with the PLC is disabled, the COMM LED turns off, and the

FAULT LED illuminates.

• Continue forces all associated input image table bits to the released state. The rest of

the push buttons continue to operate while the faulted button remains inoperable.

• Last tells the controller that the RediPANEL module is the last device in that logical rack,

not necessarily the last remote rack on the I/O link.

The Last setting is not a terminator resistor for the remote I/O link.

• Not Last specifies that the RediPANEL module is not the last device in the logical rack.

• Full configures the module as a full rack (regardless of the I/O requirements in Table

2.A).

The Full setting is required when connecting RediPANEL modules directly to

PLC-5/15 (Series B Revision G or earlier) or PLC-5/25 (Series A Revision C

or earlier) controllers.

• Table configures the rack size of the module using Table 2.A.

• When enabled, handshaking allows the use of the handshake bit. Any push button

depression is held ON until the controller verifies that it has received the signal.

The controller’s ladder logic must contain a handshake rung or the

RediPANEL module will not function properly.

See page 4–21 for details on using the Handshake Mode.

• When disabled, handshaking holds any push button depression ON for 100

milliseconds.

• If Last State is enabled, when communications is lost, the module stops sending signals

and the COMM LED turns off. Any output signals that were on when communication

was lost return to that state when communications is regained. The module locks up

and ignores any push button depressions. Lamps remain in their last state.

• If Last State is disabled, the module turns off any lamps that were on when

communications is lost. When communications is regained, the module updates itself

and resumes operations.

2–7

Page 20

Chapter 2

Configuring the RediPANEL Module

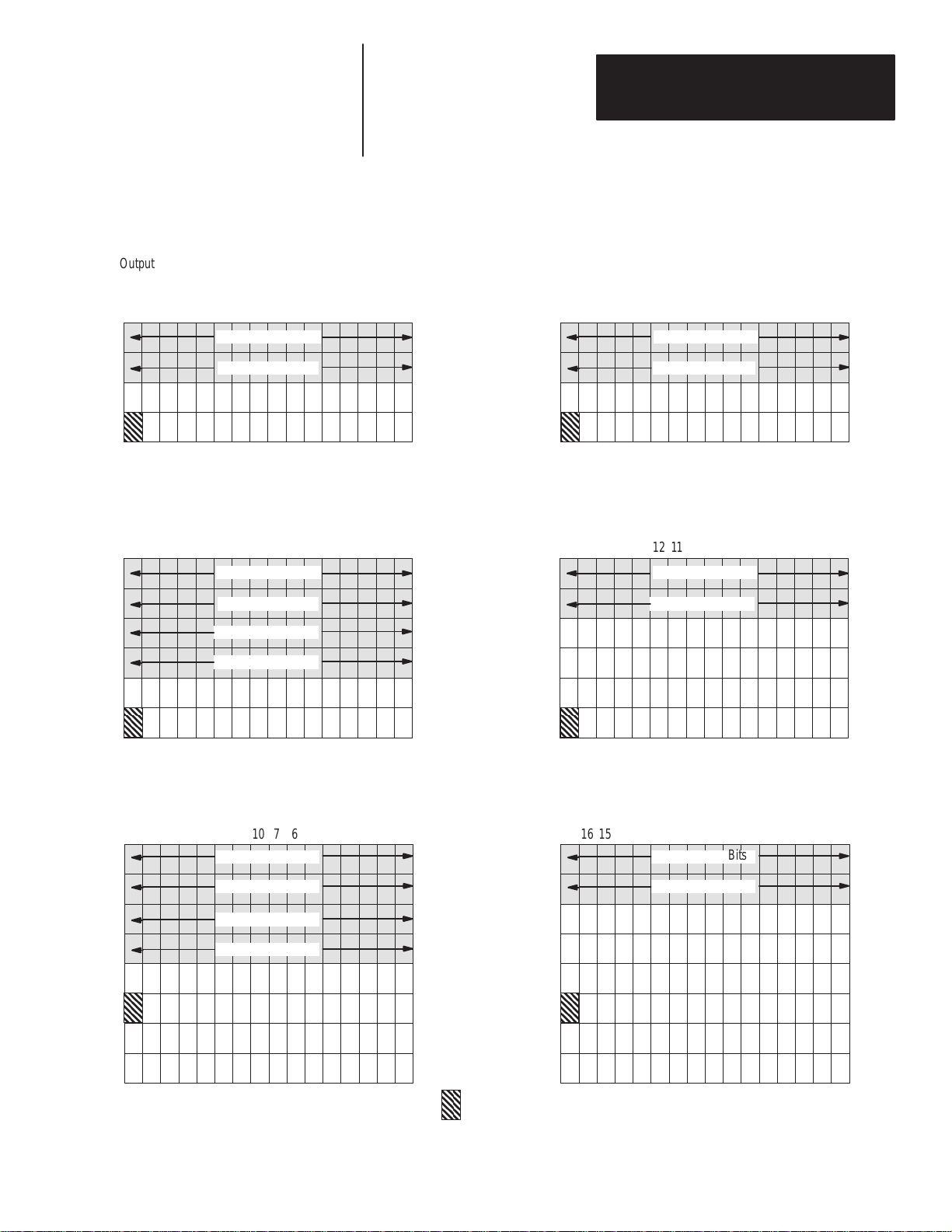

Input and Output Image Tables

Output Image Table - 1/4 Rack

(Handshaking , Lamps and Flash Enabled)

Output Image Table

This section shows the Input and Output Image Tables for 8, 16 and 32

button RediPANEL modules.

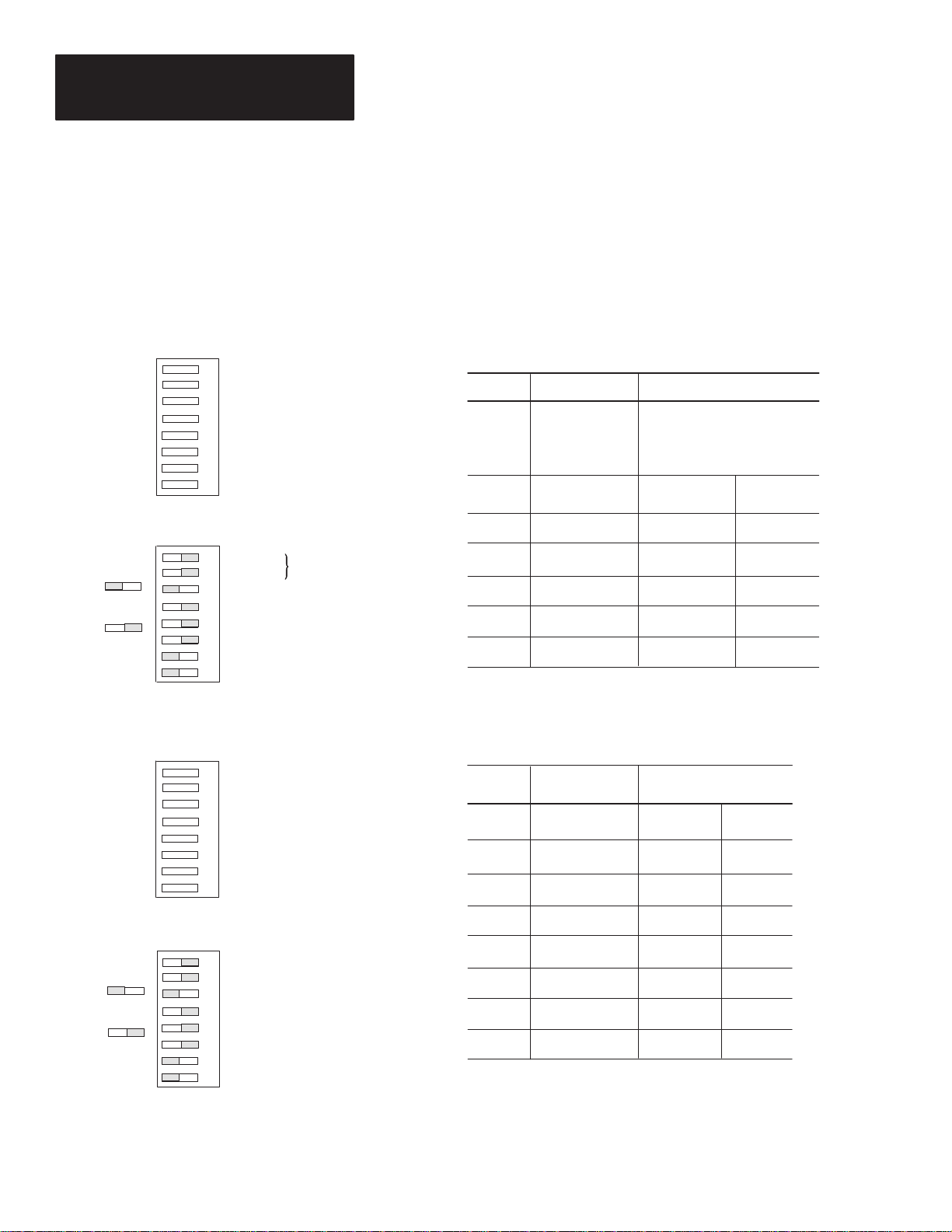

I/O Image Tables for 8 Push Button Modules

8 Push Button Module 1/4 Rack

Flash Control Bits

8 Push Button Module Set to Full Rack

012345671011121314151617 012345671011121314151617

WORD 0

WORD 1

Handshake Bit

Input Image Table - 1/4 Rack

(Handshaking Enabled)

Switch Status BitsLamp Control Bits

Input Image Table

Lamp Control Bits

Flash Control Bits

WORD 0

WORD 1

WORD 2

WORD 3

WORD 4

WORD 5

WORD 6

WORD 7

Handshake Bit

012345671011121314151617012345671011121314151617

Switch Status Bits

2–8

Page 21

Output Image Table

Î

Î

1

Rack (Lamps Enabled)

/4

Chapter 2

Configuring the RediPANEL Module

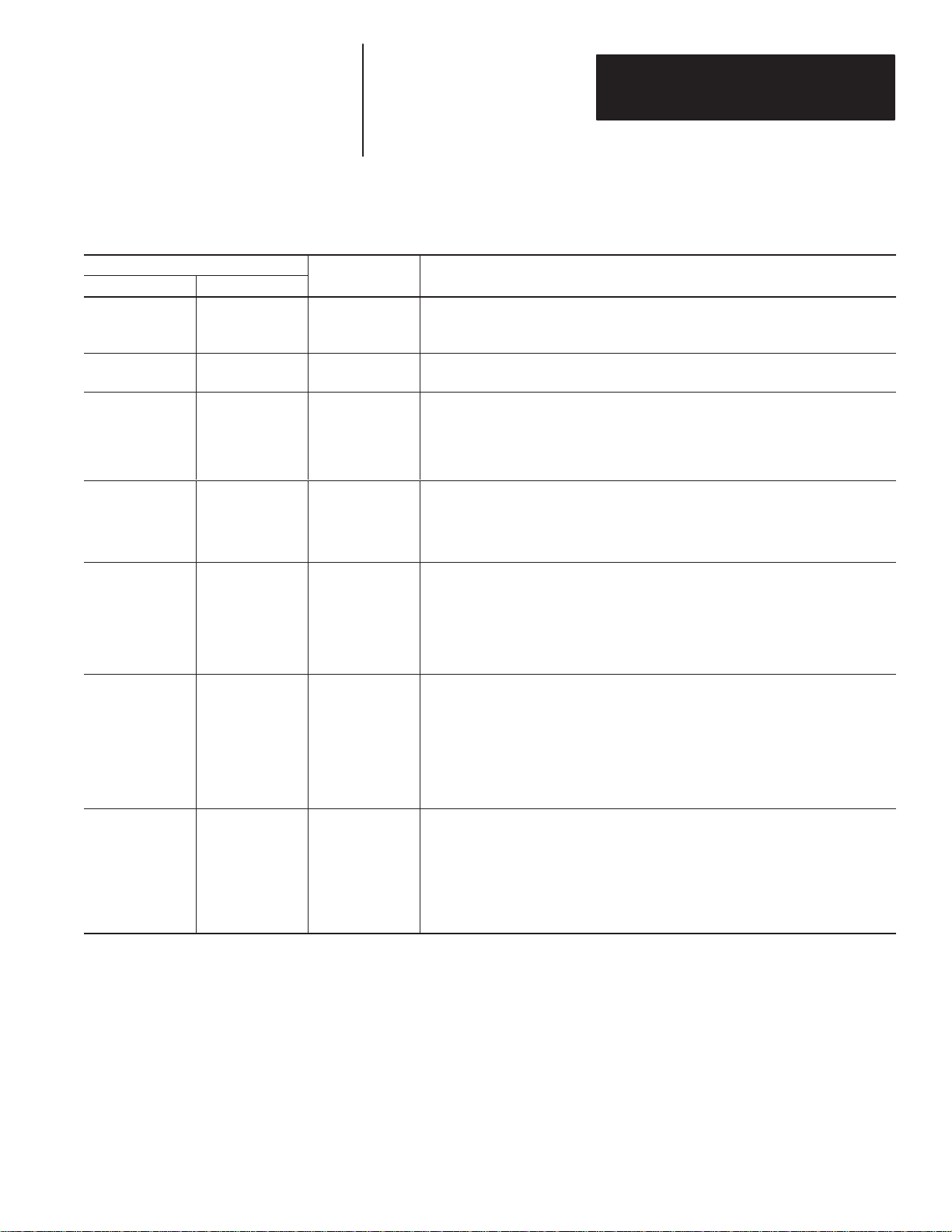

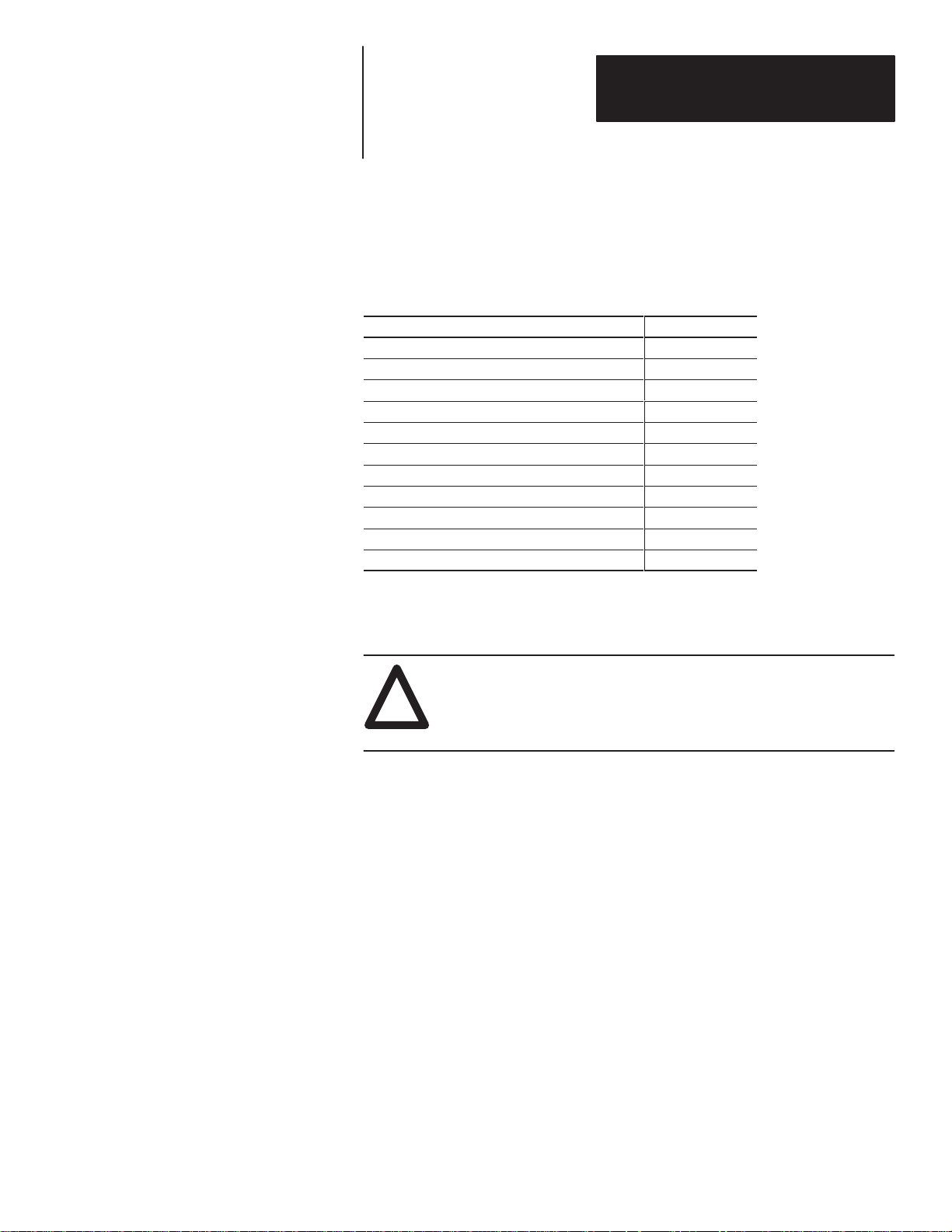

I/O Image Tables for 16 Push Button Modules

16 Push Button Module, 1/4 and 1/2 Rack

Input Image Table

1

/4 Rack

Lamp Control Bits

Output Image Table

1

/

Rack (Lamps & Flash Enabled)

4

Lamp Control Bits

Flash Control Bits

Output Image Table

1

/4 Rack (Handshaking & Lamps Enabled)

Lamp Control Bits

012345671011121314151617

WORD 0

Switch Status Bits

012345671011121314151617

WORD 1

Input Image Table

1

/4 Rack

012345671011121314151617

WORD 0

Switch Status Bits

012345671011121314151617

WORD 1

Input Image Table

1

/

Rack

4

012345671011121314151617

WORD 0

Switch Status Bits

012345671011121314151617

Output Image Table

1

/2 Rack (Handshaking, Lamps & Flash Enabled)

Lamp Control Bits

Flash Control Bits

WORD 1

Input Image Table

1

/

Rack (Handshaking Enabled)

4

012345671011121314151617

WORD 0

Switch Status Bits

012345671011121314151617

WORD 1

WORD 2

WORD 3

Handshake Bit

2–9

Page 22

Chapter 2

Configuring the RediPANEL Module

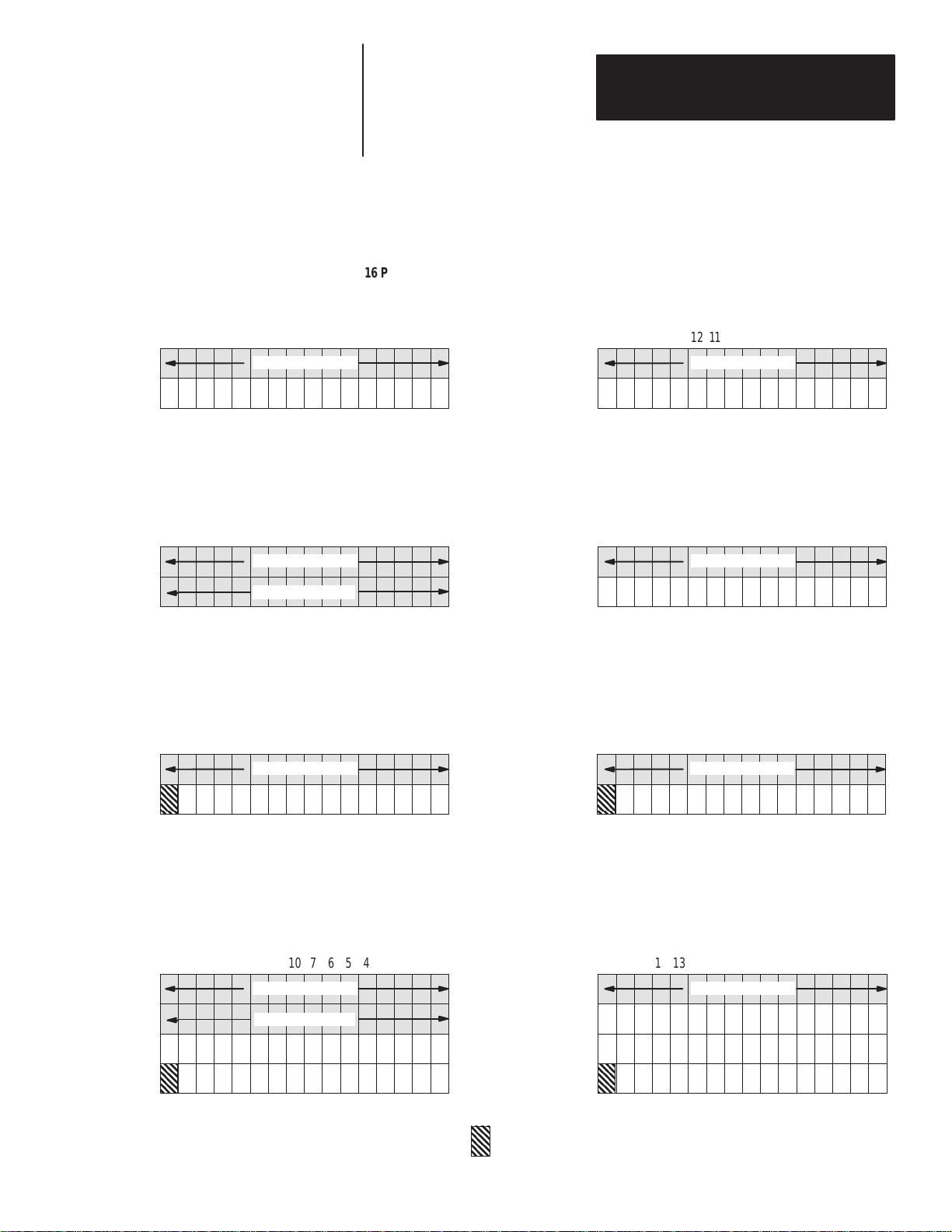

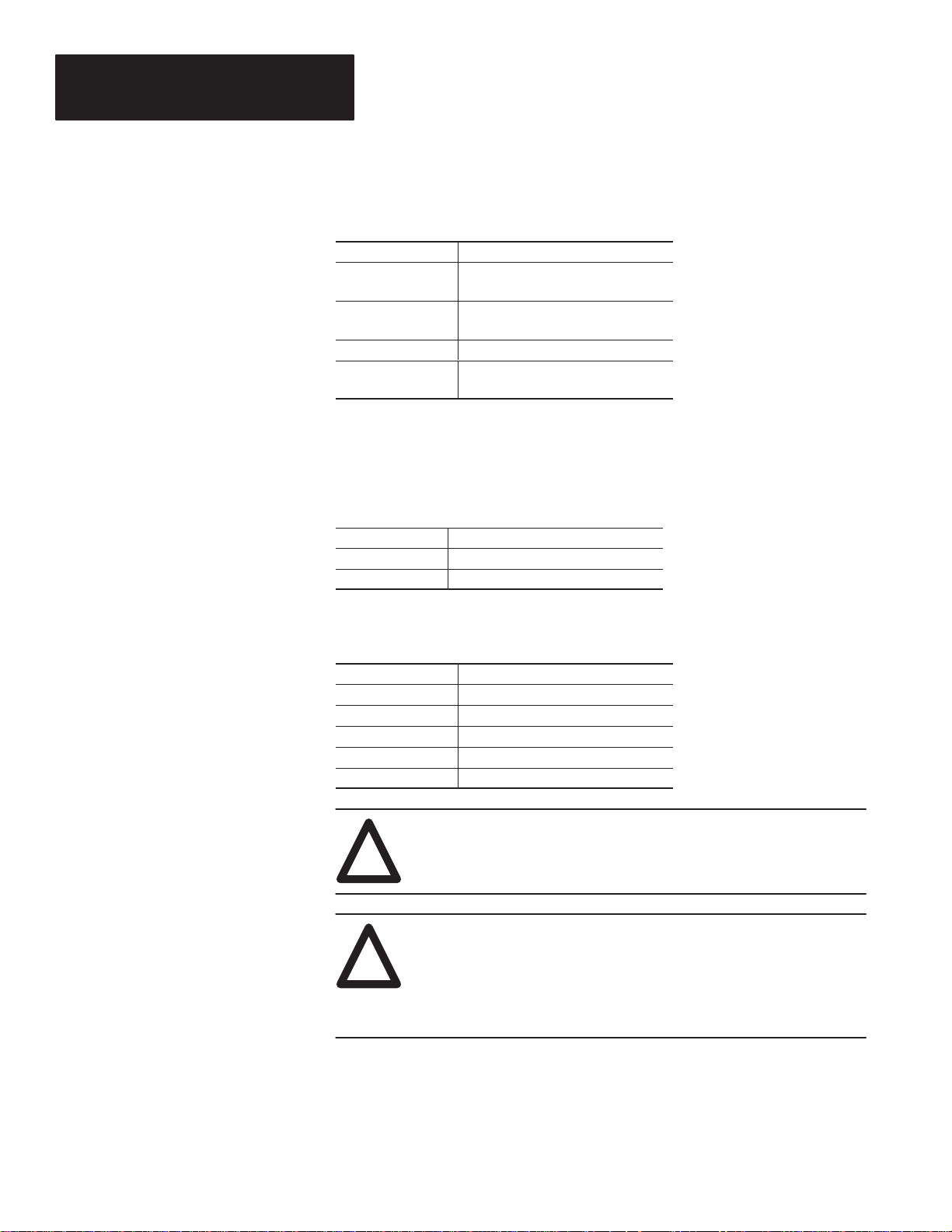

16 Push Button Module, Full Rack

Output Image Table

Full Rack (Lamps, Flash and Handshaking Enabled)

Lamp Control Bits

Flash Control Bits

Output Image Table

Full Rack (Lamps Enabled)

Lamp Control Bits

Input Image Table

Full Rack (Handshaking Enabled)

012345671011121314151617

WORD 0

WORD 1

WORD 2

WORD 3

WORD 4

WORD 5

WORD 6

WORD 7

Input Image Table

Full Rack

012345671011121314151617

WORD 0

Switch Status Bits

Switch Status Bits

012345671011121314151617

012345671011121314151617

WORD 1

WORD 2

WORD 3

WORD 4

WORD 5

WORD 6

WORD 7

Handshake Bit

Note: In 800T/H Push Button Modules, the cables that connect to the push buttons are marked A00- A17.

This corresponds to input and output bit locations 00-17.

2–10

Page 23

Chapter 2

Configuring the RediPANEL Module

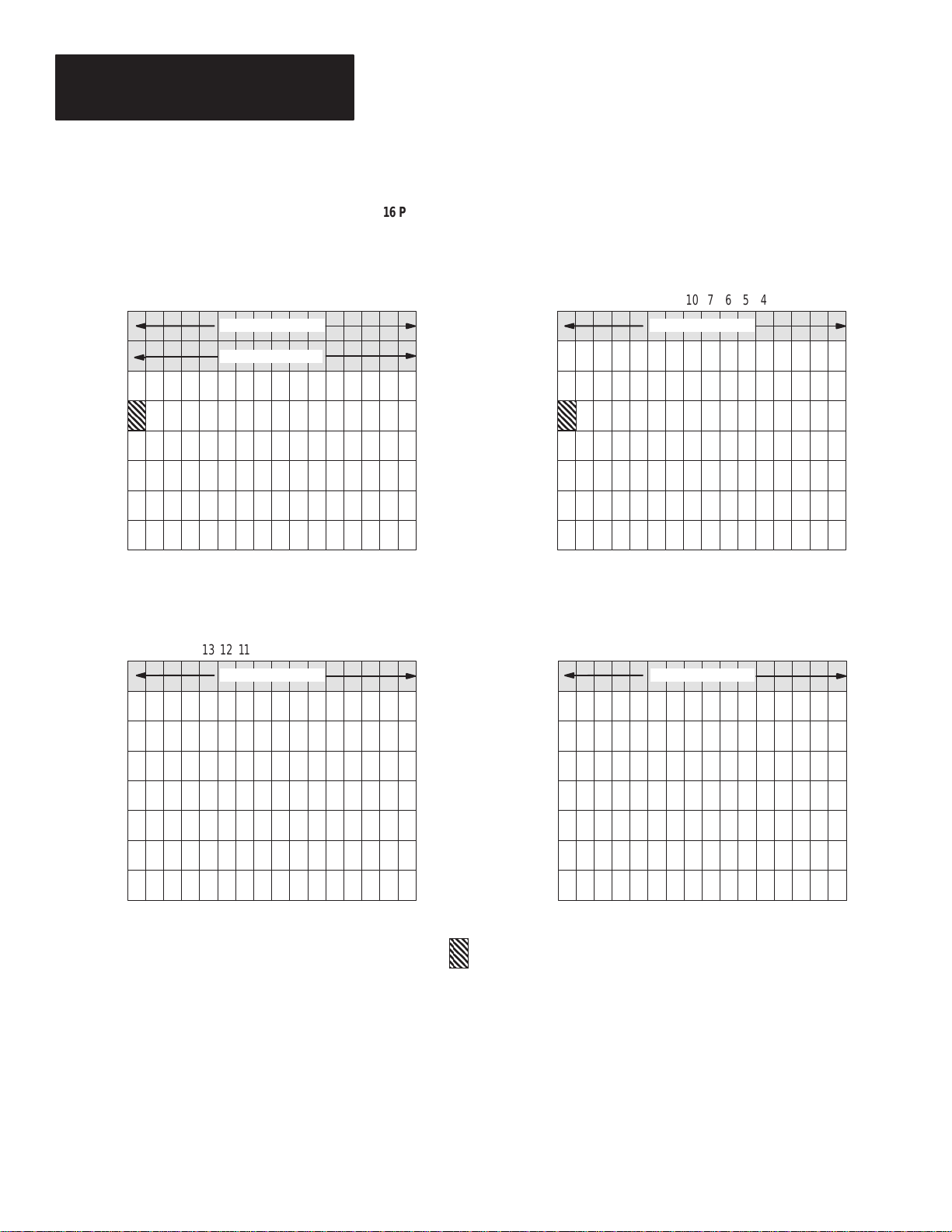

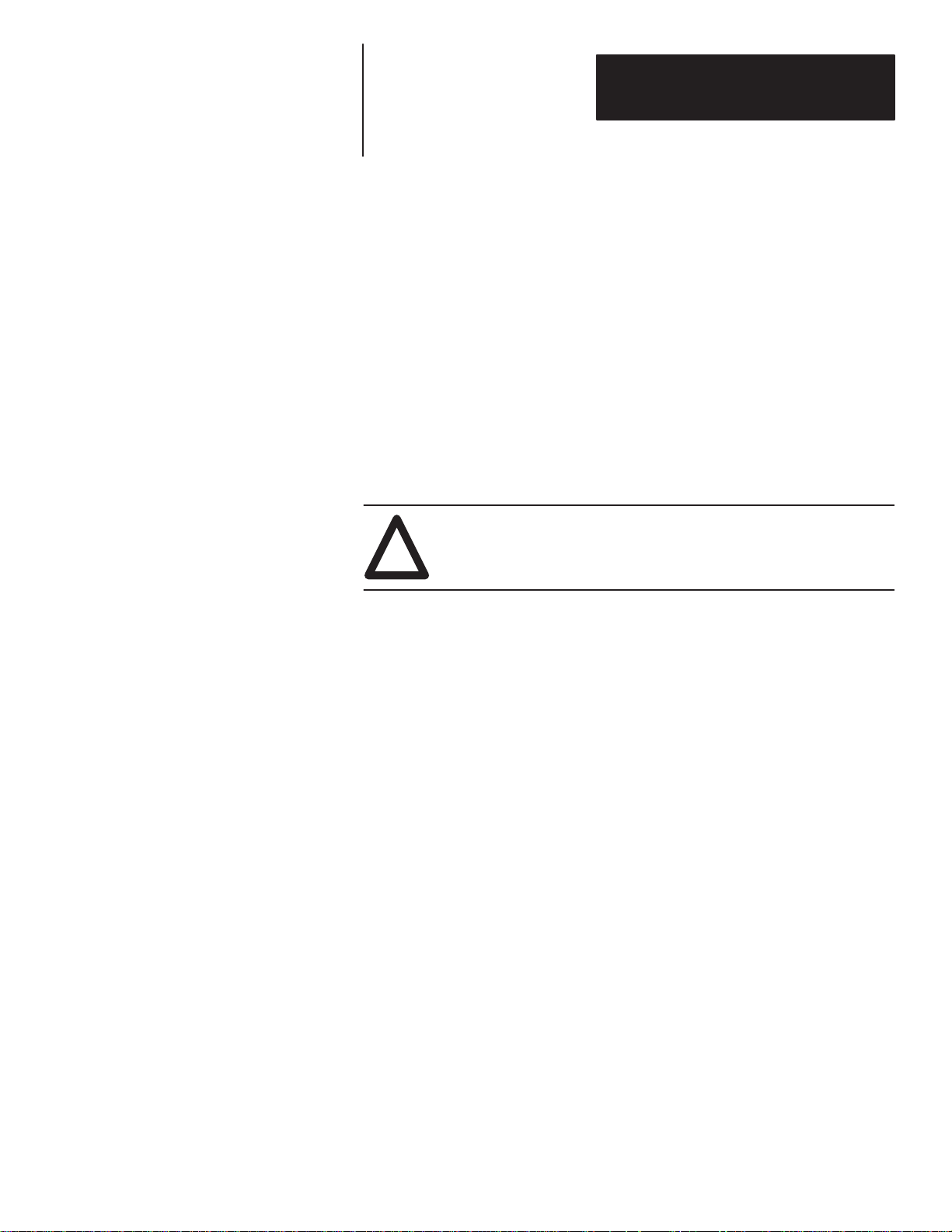

I/O Image Tables for 32 Push Button Modules

Output Image Table

1

/2 Rack (Handshaking and Lamps Enabled, Flash Disabled)

012345671011121314151617

Lamp Control Bits

Lamp Control Bits

Output Image Table

3

/4 Rack (Lamps, Flash and Handshaking Enabled)

012345671011121314151617

Lamp Control Bits

Lamp Control Bits

Flash Control Bits

Flash Control Bits

WORD 0

WORD 1

WORD 2

WORD 3

WORD 0

WORD 1

WORD 2

WORD 3

WORD 4

Input Image Table

1

/2 Rack (Handshaking Enabled)

Switch Status Bits

Switch Status Bits

Input Image Table

3

/4 Rack (Handshaking Enabled)

Switch Status Bits

Switch Status Bits

012345671011121314151617

012345671011121314151617

WORD 5

Output Image Table

Full Rack (Regardless of Configuration)

Input Image Table

Full Rack (Regardless of Configuration)

012345671011121314151617

Lamp Control Bits

Lamp Control Bits

Flash Control Bits

Flash Control Bits

WORD 0

WORD 1

WORD 2

WORD 3

WORD 4

WORD 5

WORD 6

WORD 7

Handshake Bit

Note: In 800T/H Push Button Modules, the cables that connect to the push buttons are marked A00- A17.

This corresponds to input and output bit locations 00-17.

012345671011121314151617

Switch Status Bits

Switch Status Bits

2–11

Page 24

Chapter

Chapter Objectives

A–B

3

Wiring and Installation

This chapter contains the following sections.

Section Page

Electrical Precautions 3–1

Grounding 3–1

Power Requirements 3–2

Connecting Power 3–2

Enclosures 3–3

Space and Clearance Requirements 3–4

Installing the 800A and Sealed Membrane Modules 3–8

Installing the 800EM/EP Modules 3–10

Installing the 800T/H Push Button Modules 3–14

Connecting to a Remote I/O Link 3–16

Connecting to a Scanner Module 3–16

Electrical Precautions

Grounding

Install the Bulletin 2705 Push Button Module using publication NFPA 70E,

Electrical Safety Requirements for Employee Workplaces.

ATTENTION: Do not program any of the devices on the Push

Button Module as emergency stop switches. Emergency stop

!

switches must be hardwired to the master control relay of the

system to turn off all machine power completely.

Additional guidelines to follow include:

• Careful wire routing helps cut down on electrical noise. Route incoming

power to the module by a separate path from the communication cables.

Do not run communications wiring and power wiring in the same

conduit!

• Where wire paths must cross, make their intersection perpendicular.

• Grounding helps to limit the effects of noise due to electromagnetic

interference (EMI). To avoid EMI, use shielded cables.

Grounding is an important safety measure in electrical installations. As

mentioned previously, with solid state systems grounding helps to limit the

effect of noise from EMI (electromagnetic interference).

An authoritative source on grounding requirements is the National Electrical

Code published by the National Fire Protection Association of Boston,

Massachusetts. Refer to an article of the Code that discusses the types and

sizes of wire conductors and safe methods of grounding electrical equipment

and components.

3–1

Page 25

Chapter 3

Wiring and Installation

Power Requirements

Connecting Power

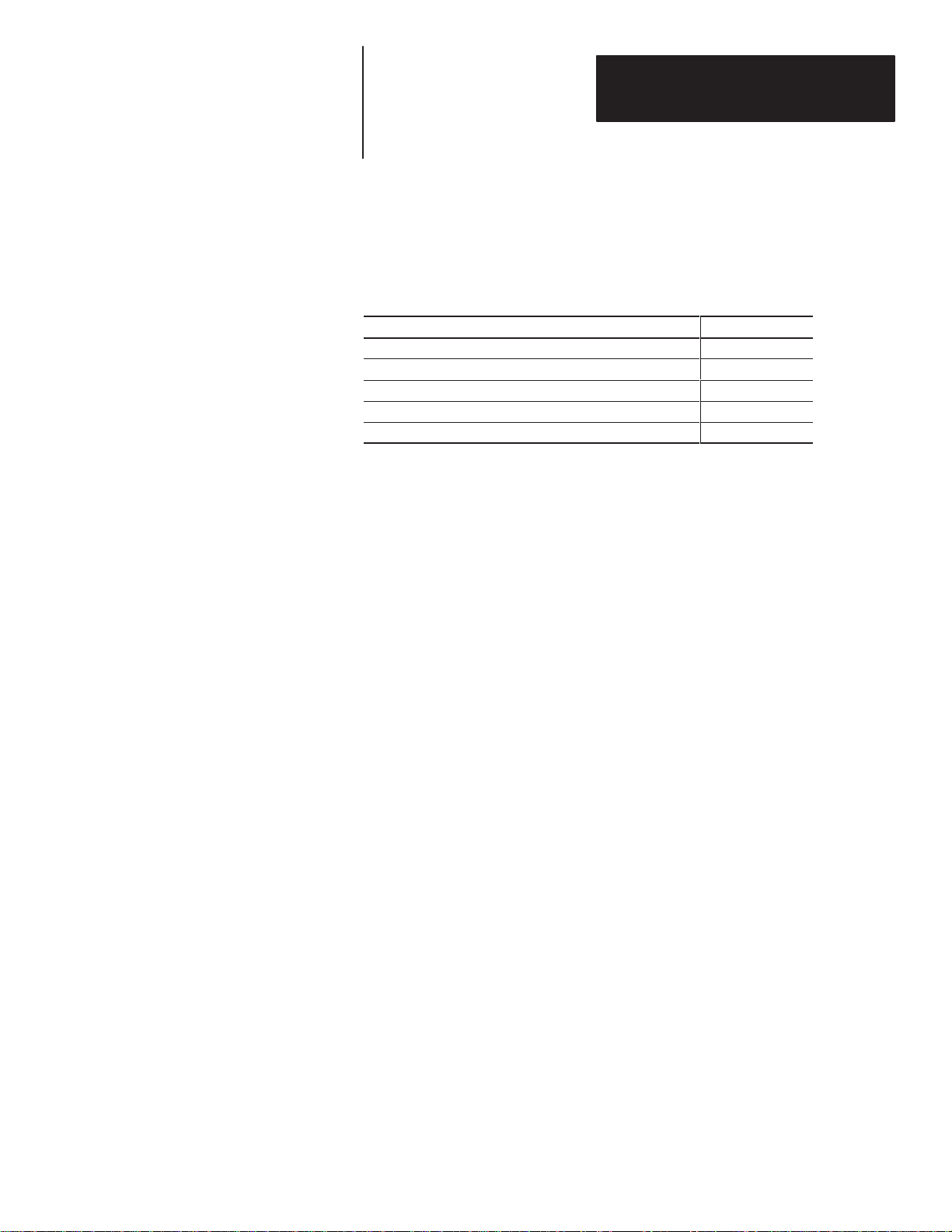

RediPANEL Modules operate with different power sources.

Module Type Power Source

800A

Sealed Membrane

800T/H 120 or 240V AC, 47 - 63 Hz

800EM/EP

90 to 264V AC, 47 - 63 Hz

18 to 30V DC

90 to 264V AC, 47 - 63 Hz

18 to 30V DC

90 to 264V AC, 47 - 63 Hz

18 to 30V DC

The AC power supplies for the 800A and Membrane Modules have an

automatic over voltage shutdown. Automatic shutdown occurs if the output

voltage of the 5V supply rises by 25% or the 12V supply rises by 20%. To

reset the RediPANEL after an automatic shutdown, disconnect AC power as

follows:

For : Disconnect a AC power for:

120V AC Source minimum of 30 seconds

240V AC Source minimum of 60 seconds

Connect power lines to the module as shown below:

Terminal Block Connection

GND Ground Wire

L2/N Neutral Wire

L1 Power Wire

(–) DC 0 Volts

(+) DC +24 Volts

ATTENTION: Do not apply power to the module until all

electrical connections, including communications lines, have

!

been connected.

ATTENTION: The ground terminal (GND) must be connected

to a reliable low impedance earth ground to protect the display

!

against electrical noise. The ground will also help protect

personnel from electrical shock if a voltage is shorted to the

enclosure.

1. Connect ground wire to the GND terminal on the terminal block.

2. Connect the power lines, L1 and L2/N , or (–) and (+DC). Do not apply

power until all connections have been made.

3–2

3. Connect the communications lines as described on page 3-16.

4. Apply power and verify power up operation.

Page 26

Chapter 3

Wiring and Installation

Enclosures

You must use an enclosure to protect the electronics of the Push Button

Module from atmospheric contamination. Standards established by the

National Electrical Manufacturer’s Association (NEMA) define enclosure

types based on the degree of protection an enclosure will provide.

Heat Dissipation

Within the enclosure, the Push Button Module (or Modules) requires room

for convection cooling.

In some applications, other equipment inside (or outside) the enclosure may

produce too much heat. Place blower fans inside the enclosure to circulate

air to reduce hot spots near components. In extreme cases, use air

conditioning to prevent heat build-up.

ATTENTION: Do not use unfiltered outside air. It could

contain contaminants or dirt harmful to the components.

!

3–3

Page 27

Chapter 3

Wiring and Installation

Space and

Clearance Requirements

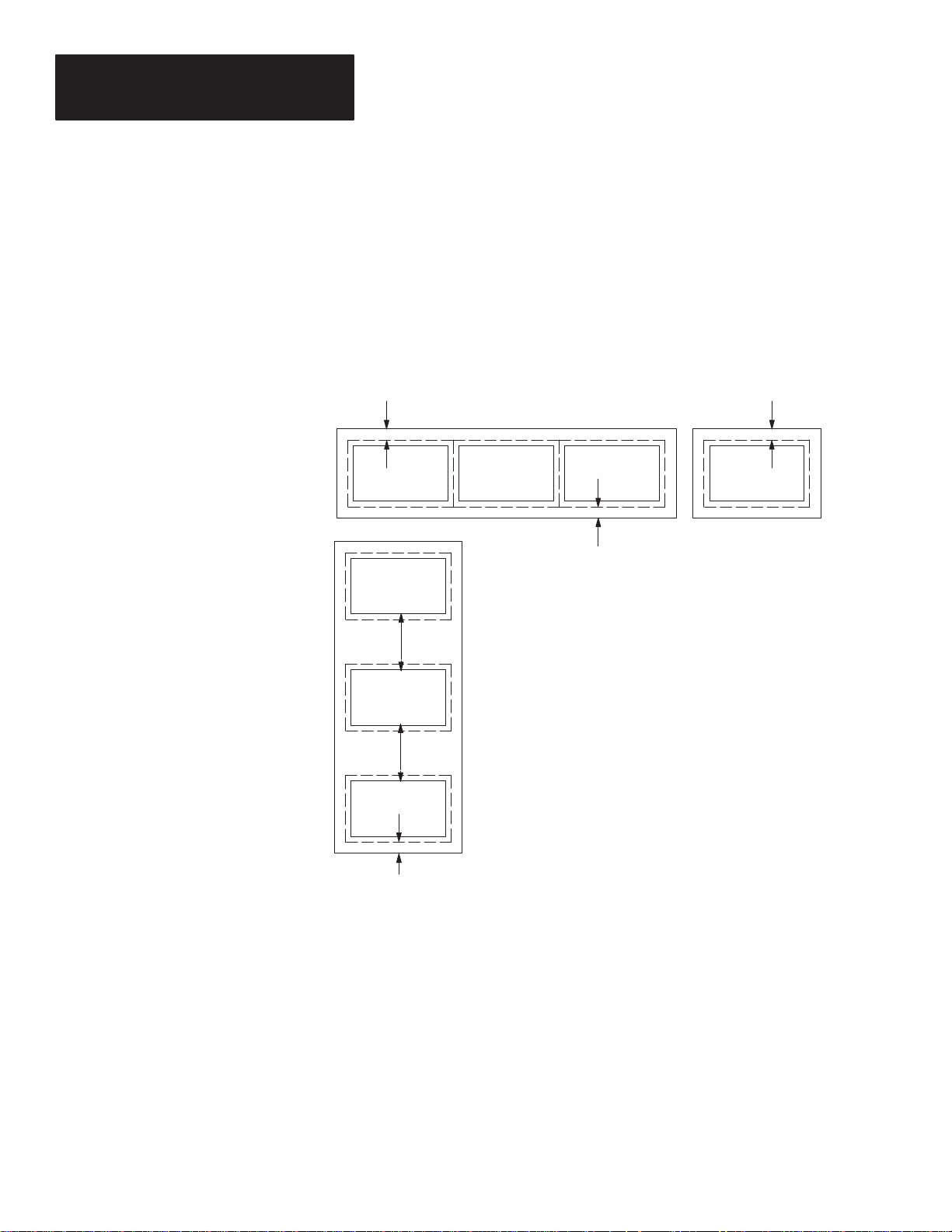

Spacing of 800A Modules

To properly space 800A Push Button Modules, follow these guidelines.

• Vertical stacking of modules: The lower edge of the top cutout must be

at least 6 inches (152mm) from the top edge of the lower cutout. The

enclosure must be at least 8 inches (203mm) deep.

• Horizontal mounting: Mount modules as close together as physically

possible. The enclosure must be at least 8 inches (203mm) deep.

B B

B

A

Recommended minimum spacing:

A = 6 inches (152mm) from lower edge of top cutout to upper

edge of lower cutout

B = 1 inch (25.4mm) from outside edge of mounting flange

Depth of enclosure = 8 inches (203mm) or more.

A

3–4

B

Page 28

Chapter 3

Wiring and Installation

Spacing of 800EM/EP Modules

The 800EM/EP Push Button Modules are available in 3 different

mounting styles:

• Panel Mounting

• Fiberglass Enclosure Mounting

• Steel Enclosure Mounting

Panel Mounting Spacing Requirements

• Vertical stacking of modules: The lower edge of the top cutout must be

at least 6 inches (152mm) from the top edge of the lower cutout. The

enclosure must be at least 8 inches (203mm) deep.

• Horizontal mounting: Mount modules as close together as physically

possible. The enclosure must be at least 8 inches (203mm) deep.

• Mounting Screw Torque: Torque mounting screws to 8 lb-in (.908 N-m)

to ensure good seal between module gasket and panel.

B

B

A

A

Recommended minimum spacing:

A = 6 inches (152mm) from lower edge of top cutout to upper

B

edge of lower cutout

B = 1 inch (25.4mm) from outside edge of mounting flange

Depth of enclosure = 8 inches (203mm) or more.

B

3–5

Page 29

Chapter 3

Wiring and Installation

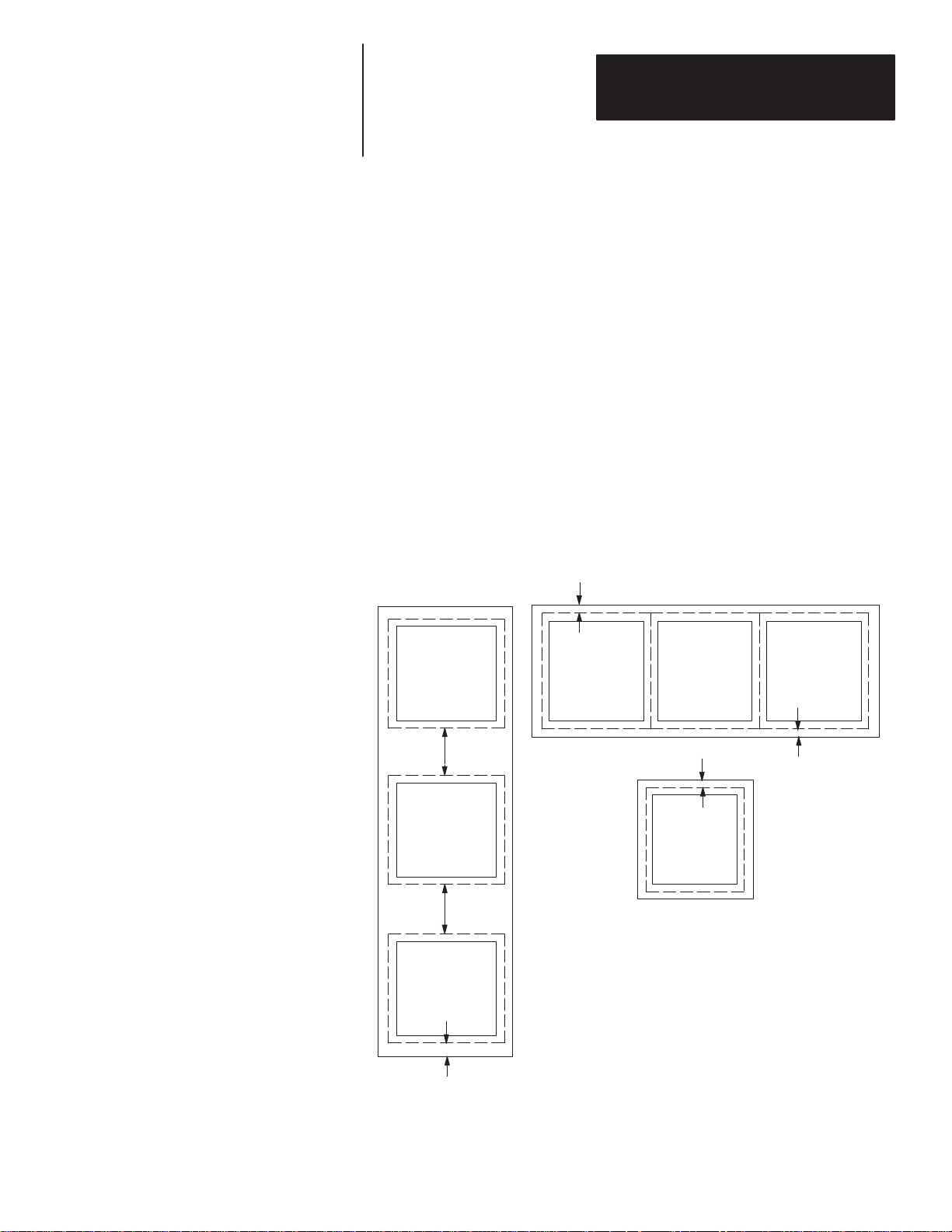

Fiberglass Enclosure Mounting Clearance Requirements

The enclosure mounting style requires a 2 inch (50 mm) clearance on the

latched side for opening and closing the enclosure cover. Adequate clearance

must be provided to allow for a minimum 90_ swing of the cover.

Clearance for Cover Swing

NOTE: If the wiring is run through the

bottom of the enclosure, it must be

secured to the tie wrap holders (provided).

The power wiring and the communications

wiring must be run through separate cutouts.

16 Button Module 13.5 (342.9)

32 Button Module 15.5 (393.7)

Wiring Cutouts (typical)

4.00

(101.6)

Clearance for latches and opening of adjacent door.

Additional clearance may be required depending on

wiring configuration.

4.00

(101.6)

Steel Enclosure Mounting Clearance Requirements

The mounting style requires a 3 inch (76 mm) clearance on the latched side

for opening and closing the enclosure cover. Adequate clearance must be

provided to allow for a minimum 90_ swing of the cover.

Clearance for Cover Swing

NOTE: If the wiring is run through the

bottom of the enclosure, it must be

secured to the tie wrap holders (provided).

The power wiring and the communications

wiring must be run through separate cutouts.

16 Button Module 13.5 (342.9)

32 Button Module 15.5 (393.7)

3–6

Wiring Cutouts (typical)

3.00

(76.2)

Clearance for latches and opening of adjacent door.

Additional clearance may be required depending on

wiring configuration.

Page 30

Chapter 3

Wiring and Installation

Spacing of 800T/H Modules

You can mount 16 and 32 Push Button 800T/H RediPANEL Modules in

either a vertical or horizontal orientation. To mount more than one

RediPANEL Push Button Module in the same enclosure, use a 1 inch (25.4

mm) minimum horizontal/vertical spacing between modules (measured at the

front panel).

16 Push Button 800T/H

Module Front Panel

1 inch (25.4 mm)

minimum clearance

32 Push Button 800T/H

Module Front Panel

3–7

Page 31

Chapter 3

Wiring and Installation

Installing the 800A and

Sealed Membrane Modules

Mounting tabs are built into the Module. After sliding the Module into the

enclosure, the tabs secure the Module until the mounting brackets are in

place. The installation procedure follows.

Mounting Tabs and Brackets

Mounting

Tabs

To install the 800A and Sealed Membrane Modules:

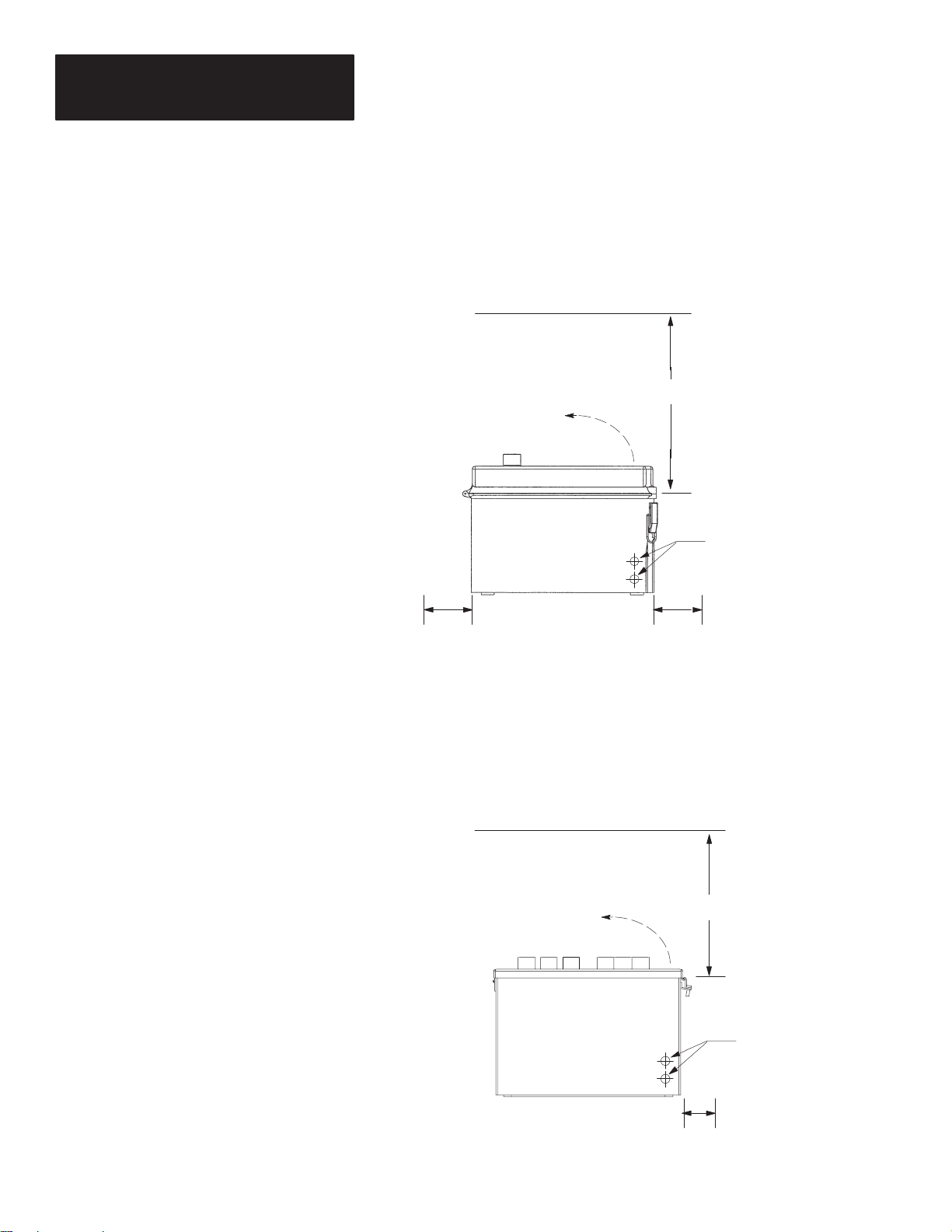

1. Cut an opening in the panel approximately 5.86 inch (148.84mm) H x

8.61 inch (218.69mm) W. See Figure 3.1.

3–8

Figure 3.1

Panel Cutout Dimensions in Inches (mm)

800A and Sealed Modules

9.25

(234.95)

1.06

(26.92)

0.62

(15.75)

➀ These 2 additional 0.312 inch (7.92 mm) diameter holes are required for NEMA Type 4X

push button modules.

7.375

(187.33)

Panel Cutout

5.86 x 8.61

(148.84 x 218.69)

➀

8.61

(218.69)

3.69

(93.73)

0.26

(6.60)

5.86

(148.84)

6.375

(161.93)

3.12 (79.25) Dia.

7.00

(177.8)

4 Places

Page 32

Figure 3.2

Depth Dimensions in Inches (mm)

800A and Sealed Modules

.12 (3.05)

Max Thickness

Chapter 3

Wiring and Installation

.44 (11.18)

Max Height of Buttons

.31

(7.87)

6.88

(174.75) Max.

2. Drill 4 (or 6) 0.312” (7.92mm) diameter holes for the top and bottom

mounting brackets.

3. Slide the Module through the opening. The mounting tabs help seat the

Module against an 1/16” (1.6mm) to 1/8” (3.2mm) thick enclosure.

4. To complete the mechanical installation, apply the mounting brackets and

tighten all the captive knurled thumbscrews. Figure 3.3 shows the

location of these screws. NOTE: Your unit may not have a mounting

bracket and thumbscrews. In that case, tighten the #10-32 nuts that are

provided to complete the installation.

Figure 3.3

Mounting Bracket Thumbscrews

Thumbscrews

Mounting Bracket

3–9

Page 33

Chapter 3

Wiring and Installation

Installing the 800EM/EP

Push Button Modules

The 800EM/EP Push Button Modules are available in 3 different

mounting styles:

• Panel Mounting

• Fiberglass Enclosure Mounting

• Steel Enclosure Mounting

This section shows how to install all 3 versions of the 16 and 32 Push Button

800EM/EP Modules.

800EM/EP Panel Mounting

To install a 16 or 32 Push Button 800EM/EP Faceplate Module:

1. Cut an opening in the panel approximately 12.55 inch (318.8mm) H x

12.75 inch (323.9mm) W. See Figure 3.4.

Figure 3.4

Panel Cutout Dimensions in Inches (mm)

800EM/EP Push Button Modules

14.25

(361.95)

.22 (5.59) Dia.

8 Places

14.25

(361.95)

12.55

(318.8)

12.75

(323.9)

6.64

(168.66)

Panel Cutout

13.28

(337.31)

3–10

6.64

(168.66)

13.28

(337.31)

Page 34

Figure 3.5

Depth Dimensions in Inches (mm)

800EM/EP Push Button Modules

Chapter 3

Wiring and Installation

.83

(21.1)

6.61

(167.9) Max.

2. Drill eight 0.22 in (5.59 mm) diameter holes for the top and bottom

mounting brackes.

3. Slide the module through the opening and against a 1/16 in (1.6 mm) to

1/8 in (3.2 mm) thick enclosure.

4. Fasten the module in place with the enclosed locking nuts. Alternately

.

tighten the nuts to a torque of 8 lb-in (0.908 N

m).

3–11

Page 35

Chapter 3

Wiring and Installation

800EM/EP Fiberglass Enclosure Mounting

To mount a 16 or 32 Push Button 800EM/EP Fiberglass Enclosure

Module:

1. Mark the locations of the four mounting holes. See Figure 3.6

Figure 3.6

Fiberglass Enclosure Mounting Dimensions in Inches (mm)

800EM/EP Push Button Modules

10.00

(254.0)

16 button module

12.00

(304.8)

32 button module

12.96

(329.2)

16 button module

14.96

(380.0)

32 button module

14.55

(369.6)

16 button module

16.55

(420.4)

32 button module

14.94

(379.5)

16 button module

16.94

(430.3)

32 button module

3–12

Fiberglass Enclosure

2. Drill four mounting holes suitable for your mounting hardware. The

mounting flange on the enclosure will acommodate a fastener up to

.50 in (12.7 mm) long x .31 in (7.9 mm) wide.

3. Secure the enclosure with the fastening hardware.

Page 36

Chapter 3

Wiring and Installation

800EM/EP Steel Enclosure Mounting

To mount a 16 or 32 Push Button 800EM/EP Steel Enclosure Module:

1. Mark the locations of the four mounting holes. See Figure 3.7.

Figure 3.7

Steel Enclosure Mounting Dimensions in Inches (mm)

800EM/EP Push Button Modules

14.75

(374.7)

16 button module

16.75

(425.5)

32 button module

15.50

(393.7)

16 button module

17.50

(444.5)

32 button module

10.00

(254.0)

16 button module

12.00

(304.8)

32 button module

12.94

(328.7)

16 button module

14.94

(379.5)

32 button module

Steel Enclosure

2. Drill four mounting holes suitable for your mounting hardware. The

mounting flange on the enclosure will acommodate up to a .25 in

(13 mm) diameter fastener.

3. Secure the enclosure with the fastening hardware.

3–13

Page 37

Chapter 3

Wiring and Installation

Installing the 800T/H

Push Button Modules

.50

(12.7)

.50

(12.7)

.50

(12.7)

6.00

(152.4)

4.00

(101.6)

This section shows how to install 32 and 16 Push Button 800T/H Modules:

To install a 32 Push Button 800T/H Module:

1. Cut an opening in the panel approximately 14 inches (355.60mm) W x 25

inches (635.0mm) H. See Figure 3.8

2. Drill fourteen 0.22 inch diameter holes for the mounting studs.

3. Slide the module through the opening.

4. Fasten the module in place with the enclosed locking nuts.

Figure 3.8

Mounting Dimensions in Inches (mm)

32 Button 800T/H Modules

6.00

(152.4)

4.00

(101.6)

1.50 (38.1)

Max. 800T

.50

(12.7)

.87

(22.1)

0.12

(3.2)

0.25 (6.4)

Gasket

8.49

(215.5)

0.62

(15.9)

Wire Loop

3–14

(152.4)

(152.4)

(152.4)

.50

(12.7)

6.00

6.00

6.00

.50

(12.7)

25.00

(635.0)

PANEL

CUTOUT

15.75

(393.7)

14.00

(355.6)

.22 (5.5) Dia.

(14 Places)

.87

(22.1)

26.75

(679.5)

24.50

(622.3)

#10-32 Mtg. Studs

(14 Places)

8.00

(203.2)

Page 38

1

1.00

(25.4)

.50

(12.7)

3.75

(95.3)

Chapter 3

Wiring and Installation

To install a 16 Push Button 800T/H Module:

1. Cut an opening in the panel approximately 14 inches (355.60mm) W x 15

inches (381.0mm) H. See Figure 3.9

2. Drill ten 0.22 inch diameter holes for the mounting studs.

3. Slide the module through the opening.

4. Fasten the module in place with the enclosed locking nuts.

Figure 3.9

Mounting Dimensions in Inches (mm)

16 Button 800T/H Modules

.50 (38.1)

Max. 800T

0.12

6.50

(165.1)

3.75

(95.3)

(12.7)

.87

(22.1)

.50

(3.2)

0.25 (6.4)

Gasket

8.49

(215.5)

0.62

(15.9)

Wire Loop

(165.1)

(165.1)

1.00

(25.4)

6.50

6.50

.50

(12.7)

15.00

(381.0)

PANEL

CUTOUT

15.75

(393.7)

14.00

(355.6)

.22 (5.5) Dia.

(14 Places)

.87

(22.1)

16.75

(419.1)

#10-32 Mtg. Studs

(14 Places)

8.00

(203.2)

14.50

(368.3)

3–15

Page 39

Chapter 3

Wiring and Installation

Connecting to a

Remote I/O Link

Connecting to

a Scanner Module

The Remote I/O link begins at the scanner module. The scanner modules

and controllers impose physical and logical limitations on the link.

• The push button module is addressed like a remote I/O rack.

• The link can have up to 32 remote I/O devices. Refer to the appropriate

PLC/SLC manual.

• The baud rate limits the maximum cable length (link distance):

Baud Rate Cable Length (Maximum)

57.6 K 3,000 meters (10,000 feet)

115.2K 1,500 meters (5,000 feet)

230.4K 750 meters (2,500 feet)

The connection to the link is through the Serial Data Link cable (Catalog No.

1770-CD). This cable wires into the connector plug of the module.

Connect the Push Button Module to the scanner module with the

Allen-Bradley I/O cable (Catalog No. 1770-CD) or Belden 9463.

A connector plug is provided with each Push Button Module. Wire the

connector to the I/O cable as shown below.

Wiring Connections for Communications Cable

2705 MODULE

CLEAR (LINE 2)

TWIN-AXIAL CABLE

MATING CONNECTOR

SHIELD

BLUE (LINE 1)

A Belden twin-axial cable links the RediPANEL Module to the Remote I/O

communications. It wires the mating connector of the user’s scanner module

to the mating connector of the 2705 module. It is recommended that you

terminate the first and last device on the remote I/O link. Install a 150 ohm,

1/2 watt resistor between lines 1 and 2 at both ends of the link for up to 16

devices and an 82 ohm, 1/2 watt resistor for up to 32 devices on the link.

3–16

Page 40

Chapter

Chapter Objectives

A–B

4

Programming the RediPANEL Modules

This chapter provides information on programming a RediPANEL module

from a PLC or SLC controller. For additional programming information

refer to the user manual for your controller or scanner module.

Section Page

Module Bit Addresses 4–1

Using a PLC-2 with a 1772-SD2 Scanner 4–9

Using a PLC-2 with a Sub I/O Scanner 4–11

Using a PLC-5 4–14

Using a PLC-5 with a Sub I/O Scanner 4–15

Operating Cycles 4–19

Response Time 4–20

Handshake Mode 4–21

Flashing Lamp Example 4–23

SLC-5/02 Programming Example 4–24

Module Bit Addresses

Each push button on the RediPANEL module is assigned a bit address. You

need to know these addresses when writing your PLC program. These bit

addresses are the same for all PLC processors.

This section shows the bit address locations for 8, 16 and 32 button modules.

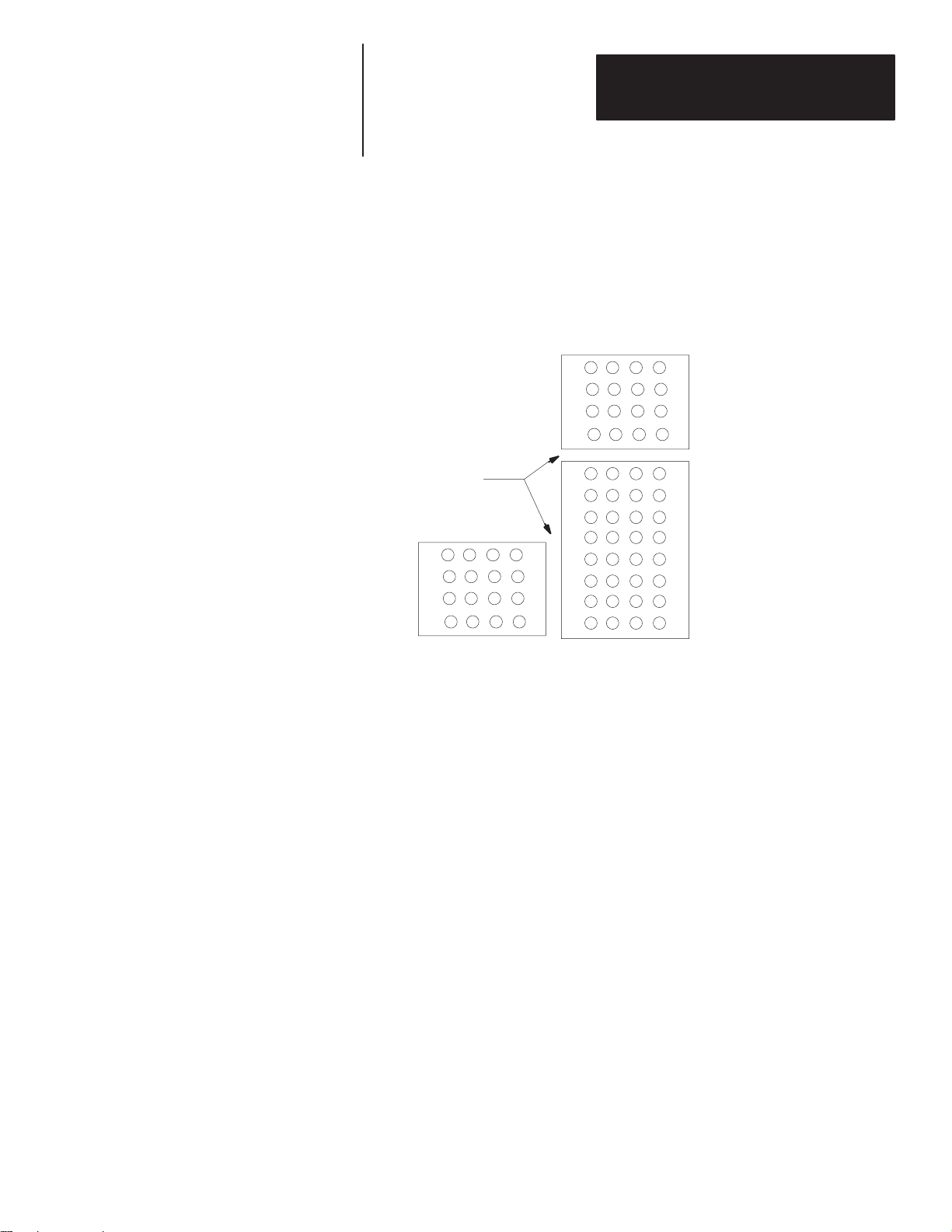

Bit Addresses for 8 Button Modules (Type 800A only)

Octal and Decimal

00 01 02 03

1234

04 05 06 07

5678

The PLC example below shows where these bit addresses appear in your instruction address.

X X X

03 03

Bit Address

Push Button #4

Bit addresses 00 through 07 of the starting

I/O Group Numbers are assigned to lamps

and push buttons 1 through 8.

Starting I/O Group Number

X X X

Bit Address

for Lamp #4

4–1

Page 41

Chapter 4

Programming the RediPANEL Modules

PLC Bit Addresses (Octal) SLC Bit Addresses (Decimal)

Bit Addresses for 16 Button Modules

Bit Addresses for 16 Button

800A and NEMA Type 4X Membrane Modules

1 2 3 4 5 6

00 01 02 03 04 05

7 8 9 10 11 12

06 07 10 11 12 13

13 14

14 15

Front Panel

15 16

16 17

The PLC example below shows where these bit addresses appear in your instruction address.

The SLC example below shows where these bit addresses appear in your instruction address.

Button #

Address Bit #

Starting I/O Group Number

1 2 3 4 5 6

00 01 02 03 04 05

7 8 9 10 11 12

06 07 08 09 10 11

13 14

12 13

Front Panel

X X X

10 10

Bit Address

Push Button #9

Bit Address

for Lamp #9

15 16

14 15

X X X

4–2

Starting I/O Group Number

X X X

08 08

Bit Address

Push Button #9

Bit Address

for Lamp #9

X X X

Page 42

PLC Bit Addresses (Octal)

PB1

1

00

PB5

5

04

PB9

9

10

PB13

13

14

PB2

2

01

PB6

6

05

PB10

10

11

PB14

14

15

PB3

3

02

PB7

7

06

PB11

11

12

PB15

15

16

PB4

4

03

PB8

8

07

PB12

12

13

PB16

16

17

Bit Addresses for 16 Button

800EM/EP Modules

Cable #

Button #

Address Bit #

Front Panel Views

Chapter 4

Programming the RediPANEL Modules

SLC Bit Addresses (Decimal)

PB1

1

00

PB5

5

04

PB9

9

8

PB13

13

12

PB2

2

01

PB6

6

05

PB10

10

9

PB14

14

13

PB3

3

02

PB7

7

06

PB11

11

10

PB15

15

14

PB4

4

03

PB8

8

07

PB12

12

11

PB16

16

15

In 800EM/EP Push Button Modules, the

cables that connect to the push buttons are

marked PB1 – PB16 and diagnostics. This

corresponds to PLC input and output bit

locations 00-17.

The PLC example below shows where these bit addresses appear in your instruction address.

X X X

13 13

The SLC example below shows where these bit addresses appear in your instruction address.

X X X

Starting I/O Group Number

Bit Address

Push Button #12

Starting I/O Group Number

In 800EM/EP Push Button Modules, the

cables that connect to the push buttons are

marked PB1 – PB16 and diagnostics. This

corresponds to SLC input and output bit

locations 00-15.

X X X

Bit Address

for Lamp #12

X X X

11 11

Bit Address

Push Button #12

Bit Address

for Lamp #12

4–3

Page 43

Chapter 4

Programming the RediPANEL Modules

PLC Bit Addresses (Octal)

Bit Addresses for 16 Button

800T/H Modules

SLC Bit Addresses (Decimal)

A00 A01 A02 A03

1234

00 01 02 03

A04 A05 A06 A07

5678

04 05 06 07

A10 A11 A12 A13

9101112

10 11 12 13

A14 A15 A16 A17

13 14 15 16

14 15 16 17

In 800T/H Push Button Modules, the cables

that connect to the push buttons are marked

A00-A17. This corresponds to PLC input

and output bit locations 00-17.

The PLC example below shows where these bit addresses appear in your instruction address.

Cable #

Button #

Address Bit #

Front Panel Views

Starting I/O Group Number

A00 A01 A02 A03

1234

00 01 02 03

A04 A05 A06 A07

5678

04 05 06 07

A10 A11 A12 A13

9101112

08 09 10 11

A14 A15 A16 A17

13 14 15 16

12 13 14 15

In 800T/H Push Button Modules, the cables

that connect to the push buttons are marked

A00-A17. This corresponds to SLC input

and output bit locations 00-15.

X X X

13 13

The SLC example below shows where these bit addresses appear in your instruction address.

Bit Address

Push Button #12

Starting I/O Group Number

Bit Address

for Lamp #12

X X X

11 11

Bit Address

Push Button #12

Bit Address

for Lamp #12

X X X

X X X

4–4

Page 44

PLC Bit Addresses (Octal)

Chapter 4

Programming the RediPANEL Modules

Bit Addresses for 32 Button Modules

Bit Addresses for 32 Button 800A Modules

21 345678

01

00

10

11

9

11

17 18 19

26

25 27 28 29 30 31

11 151413

10

SLC Bit Addresses (Decimal)

21 345678

01

00

10

9

09

12 13 14 15 16

13

12

20 21 22 23 24

12

Front Panel

12 13 14 15 16

11

11

10

Button #

0605040302

07

17

16

151410

0605040302 070100

32

1716

07

0605040302

14

15

131208

Two Module Groups (or words) of bit addresses are needed for the 32 push buttons:

D Bit addresses 00 through 07 and 10 through 17 of the starting I/O group are

D Bit addresses 00 through 07 and 10 through 17 of the next I/O group are

Two Module Groups (or words) of bit addresses are needed for the 32 push buttons:

Bit Address #

assigned to the lamps and push buttons 1 through 16.

assigned to the lamps and push buttons 17 through 32.

Button #

Bit Address #

17 18 19

26

25 27 28 29 30 31

09 131211

08

20 21 22 23 24

0605040302 070100

10

Front Panel

D Bit addresses 00 through 15 of the starting I/O group are assigned to the lamps

and push buttons 1 through 16.

32

1514

See the next section for PLC and SLC addressing examples.

D Bit addresses 00 through through 15 of the next I/O group number are

assigned to the lamps and push buttons 17 through 32.

4–5

Page 45

Chapter 4

Programming the RediPANEL Modules

PLC Bit Addresses (Octal)

*PB1 PB2 PB3 PB4

1 2

00 01 02 03

PB8

PB7

7

07

06

PB14

PB13

14

13

15

14

PB20

PB19

20

19

03

02

PB26

PB25

26

25

11

10

PB32

PB31

32

31

17

16

3 4

PB10

PB9

9

8

10

PB16

PB15

15

16

PB22

PB21

21

04

PB28

PB27

27

12

16

17

28

13

10

11

22

05

PB5

5

04

PB11

11

12

PB17

17

00

PB23

23

06

PB29

29

14

PB6

6

05

PB12

12

13

PB18

18

01

PB24

24

07

PB30

30

15

Bit Addresses for 32 Button

800EM/EP Modules

Cable #

Button #

Address Bit #

Front Panel Views

See next section for

PLC/SLC addressing examples.

SLC Bit Addresses (Decimal)

*PB1 PB2 PB3 PB4

1 2

00 01 02 03

PB8

PB7

7

07

06

PB14

PB13

14

13

13

12

PB20

PB19

20

19

03

02

PB26

PB25

26

25

09

08

PB32

PB31

32

31

15

14

3 4

PB10

PB9

10

9

8

09

08

PB16

PB15

16

15

15

14

PB22

PB21

22

21

05

04

PB28

PB27

28

27

11

10

PB5

5

04

PB11

11

10

PB17

17

00

PB23

23

06

PB29

29

12

PB6

6

05

PB12

12

11

PB18

18

01

PB24

24

07

PB30

30

13

When using a PLC with 800EM/EP Push Button Mod-

*

ules, the cables that connect to the push buttons are

marked PB1 – PB32 and diagnostics. This corresponds

to PLC input and output bit locations 00 – 17.

Two Module Groups (or words) of bit addresses

are needed for the 32 push buttons:

D Bit addresses 00 through 07 and 10 through

17 of the starting I/O group are assigned to

the lamps and push buttons 1 through 16.

D Bit addresses 00 through 07 and 10 through

17 of the next I/O group number are assigned

to the lamps and push buttons 17 through 32.

4–6

*

When using an SLC with 800EM/EP Push Button Modules, the cables that connect to the push buttons are

marked PB1 – PB32 and diagnostics. This corresponds

to SLC input and output bit locations 00 – 15.

Two Module Groups (or words) of bit addresses

are needed for the 32 push buttons:

D Bit addresses 00 through 15 of the starting I/O

group are assigned to the lamps and push

buttons 1 through 16.

D Bit addresses 00 through 15 of the next I/O

group number are assigned to the lamps and

push buttons 17 through 32.

Page 46

PLC Bit Addresses (Octal)

Chapter 4

Programming the RediPANEL Modules

Bit Addresses for 32 Button

800T/H Modules

SLC Bit Addresses (Decimal)

*A00 A01 A02 A03

1 2

00 01 02 03

A04 A05 A06 A07

5

04 05 06 07

A10 A11 A12 A13

9

10 11 12 13

A14 A15 A16 A17

13

14 15 16 17

B00 B01 B02 B03

17

00 01 02 03

B04 B05 B06 B07

21

04 05 06 07

B10 B11 B12 B13

25

10 11 12 13

B14 B15 B16 B17

29

14 15 16 17

10

14

18

22

26

30

6

3 4

7

11 12

15 16

19 20

24

23

27 28

31

32

8

Cable #

Button #

Address Bit #

Front Panel Views

See next section for PLC/SLC addressing examples.

*A00 A01 A02 A03

1 2

00 01 02 03

A04 A05 A06 A07

5

04 05 06 07

A10 A11 A12 A13

10

9

08 09 10 11

A14 A15 A16 A17

13

14

12 13 14 15

B00 B01 B02 B03

17

18

00 01 02 03

B04 B05 B06 B07

22

21

04 05 06 07

B10 B11 B12 B13

26

25

08 09 10 11

B14 B15 B16 B17

29

30

12 13 14 15

6

3 4

7

11 12

15 16

19 20

24

23

27 28

31

32

8

* *

When using a PLC with 800T/H Push Button Modules,

the cables that connect to the push buttons are marked

A00-A17 & B00-B17. This corresponds to the input and

output bit locations as shown. “A” refers to the 1st word;

“B” refers to the 2nd word.

Two Module Groups (or words) of bit addresses

are needed for the 32 push buttons:

D Bit addresses 00 through 07 and 10 through

17 of the starting I/O group are assigned to

the lamps and push buttons 1 through 16.

D Bit addresses 00 through 07 and 10 through

17 of the next I/O group number are assigned

to the lamps and push buttons 17 through 32.

When using an SLC with 800T/H Push Button Modules,

the cables that connect to the push buttons are marked

A00-A17 & B00-B17. This corresponds to the input and

output bit locations as shown. “A” refers to the 1st word;

“B” refers to the 2nd word.

Two Module Groups (or words) of bit addresses

are needed for the 32 push buttons:

D Bit addresses 00 through 15 of the starting I/O

group are assigned to the lamps and push

buttons 1 through 16.

D Bit addresses 00 through 15 of the next I/O

group number are assigned to the lamps and

push buttons 17 through 32.

4–7

Page 47

Chapter 4

Programming the RediPANEL Modules

Addressing Examples for 32 Button Modules

Below are PLC and SLC addressing examples for the 32 button modules.

The PLC example below shows where these bit addresses appear in your instruction address.

Starting I/O Group Number (Word)

X X X

07 07

Bit Address

Push Button #8

Starting I/O Group Number (Word) +1

Bit Address

for Lamp #8

X X X

10 10

The SLC example below shows where these bit address will appear in your instruction address.

Bit Address

Push Button #25

Starting I/O Group Number (Word)

Bit Address

for Lamp #25

X X X

X X X

4–8

X X X

06 06

Bit Address

Push Button #7

Starting I/O Group Number (Word) +1

Bit Address

for Lamp #7

X X X

10 10

Bit Address

Push Button #27

Bit Address

for Lamp #27

X X X

X X X

Page 48

Chapter 4

Programming the RediPANEL Modules

Using a PLC-2 with a 1772-SD2 Scanner

When using a PLC-2/20 or 2/30 with a RediPANEL module, the system must

include a 1772-SD2 Remote I/O Scanner/Distribution Panel (or a 1771-SN

Sub I/O Scanner Module). The 1772-SD2 allows the PLCs to communicate

with as many as 16 remote I/O devices in any configuration totaling 7 logical

racks of I/O or less.

For details on 1771-SD2 wiring connections and switch settings, see

Publication No. 1772-2.18 (The Remote I/O Scanner/Distribution Panel).

Programming Example

Switch Bank #1 on the RediPANEL Module is set to use:

• Rack Address 2 (switch settings 1 - 6)

• Module Group 0 (switch settings 7 and 8)

Figure 4.1 shows typical address instructions and how these instructions are

used in your PLC-2/20 or 2/30 program.

Figure 4.1

PLC-2/20 or 2/30 Programming Example

Press Push

Button #1

00 01 02 03

123 4

04 05 06 07

567 8

10 11 12 13

9101112

14 15 16 17

13 14 15 16

Push Button #1

Illuminate Push

Button #4

Input

00

00 03

Rack #2

Module Group 0

Bits

Push Button #4 Lamp

020120

Module Group 0

Output

020120

03

4–9

Page 49

Chapter 4

Programming the RediPANEL Modules

120

After entering the ladder logic, place the PLC in the RUN or REMOTE RUN

mode to test your logic. Monitor the ON/OFF status of the input and output

bits of the RediPANEL push button module by pressing [SEARCH] 53

followed by the address to monitor. This displays the input or output image

table for that address.

The following figure shows what the I/O image table looks like when you

press push button #1 for the previous example.

00

Input Image Table

1/4 Rack

00000 00001 00000 0 0001

Switch Status Bits

Push Button #1, Illuminate the Lamp in Button #4

Output Image Table

1/4 Rack

Module Group

012345671011121314151617 012345671011121314151617

(Word)

0

1

Lamp Control Bits

Special Considerations

If the MODE SELECT DIP Switch #5 (Fault Table) on the 1772-SD2 is set

to OFF, a remote I/O fault table is generated and remote I/O rack #2 must be

declared used. These fault status bits are generated in the addresses

associated with Module Groups 5 and 6 of remote I/O rack #2. (See

Publication 1772-2.18).

03

4–10

Page 50

Chapter 4

Programming the RediPANEL Modules

Using a PLC-2 with a Sub I/O Scanner

When using a PLC-2 processor with RediPANEL module, the system must

contain a 1771-SN Sub I/O Scanner. Mini PLC-2 processors communicate

with remote I/O using this Sub I/O Scanner. The Sub I/O Scanner is located

in the same chassis as the mini PLC-2 and communicates with the PLC using

block transfers. The 1771-SN Sub I/O Scanner looks like an intelligent I/O

module to the PLC. You can also use Sub I/O Scanner in any chassis of a

PLC-2/20 or 2/30 system.

The 1771-SN requires one PLC scan to receive the output data from the

output image table and another PLC scan to send discrete input data to the

input image table. Anything connected to the Sub I/O Scanner is scanned

asynchronous to the PLC scan. The PLC then scans the Sub I/O Scanner

during the I/O portion of the PLC scan. See the section on Operating Cycles.

Block Transfer Example

Figure 4.2 shows an example of a block transfer between a Sub I/O Scanner

module and a PLC.

Figure 4.2

Block Transfer between Sub I/O Scanner and PLC–2

Read information from the sub-scanner into the PLC.

1

Write information to the sub-scanner from PLC.

2

Buffer the read information from the sub-scanner.

110

3

] [

17

BLOCK X-FER READ

DATA ADDR: 0030

MODULE ADDR: 101

BLOCK LENGTH: 014

FILE: 0200-0215

BLOCK X-FER WRITE

DATA ADDR: 0031

MODULE ADDR: 101

BLOCK LENGTH: 014

FILE: 0300-0315

FILE TO FILE MOVE

DATA ADDR: 0033

POSITION: 001

FILE LENGTH: 014

FILE A: 0200-0215

FILE R: 0400-0415

RAT PER SCAN: 014

010

( EN )