Page 1

User Manual

PowerFlex 525 Embedded EtherNet/IP Adapter

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Roc kwell Automation, Rockwell Sof tware, PowerFlex, Studio 5000 and C onnected Components Workbench are trademarks of Ro ckwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

This manual contains new and updated information.

Summary of Changes

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Parameter Groups N and M added. 24

Configuring a Master-Slave Hierarchy updated. 31

Enabling Datalinks to Write Data updated. 32

Enabling Datalinks to Read Data updated. 32

Changing the Fault Action table updated. 33

Setting the Fault Configuration Parameters table updated. 33

Description of Drive Rating setting of the Module Definition window updated. 43

Tip for Using ADC with RSLogix 5000/Logix Designer updated. 49

Version of RSLogix 5000 for use with drive generic profile updated. 55

Settings for Connection Parameters table updated. 56

Input Image Controller Tag graphic updated. 58

Output Image Controller Tag graphic updated. 58

I/O Image for PowerFlex 525 Drives table updated. 62

Compac tLogix Cont roller for Drive Generic Profile Ladder Logic Program Example

graphic updated.

CompactLogix Example Ladder Logic Program Using a Drive Generic Profile for

Logic Command/Reference diagram updated.

Important table for CompactLogix Examples updated. 71

Example Ladder Logic to Read a Single Parameter diagram updated. 71

Fifth footnote of Scattered Read Message Configuration Screens updated. 76

Tag Tab entry for Scattered Write Multiple Messages Configuration Screens table

updated.

Drive 0 Control Routine diagram updated. 102

Extra table under Instances for Identity Object removed. 126

Description of Device Type entry in Instances Attribute table for Identity Object

updated.

Instance Attribute table for Parameter Object updated. 133

Instances table for DPI Device Object updated. 138

Instances table for DPI Parameter Object updated. 141

Instances table for DPI Fault Object updated. 147

66

68

78

127

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 5

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Summary of Changes

Overview

Getting Started

Setting Up the Adapter

New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preface

Recommended Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Preparing for Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting the Adapter to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Commissioning the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring the Adapter

Configuring the I/O

Using the I/O

Chapter 3

Configuration Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Using the Drive Keypad Interface to Access Parameters . . . . . . . . . . . . . 24

Using the PowerFlex 4-Class HIM to Access Parameters. . . . . . . . . . . . . 25

Using BOOTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the IP Address, Subnet Mask, and Gateway Address. . . . . . . . . . 29

Setting the Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Using Master-Slave Hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Setting a Fault Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Resetting the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Viewing the Adapter Status Using Parameters . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 4

Using RSLinx Classic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CompactLogix Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Limitations in Using MicroLogix 1100/1400 . . . . . . . . . . . . . . . . . . . . . . . 60

Chapter 5

About I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Understanding the I/O Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 5

Page 6

Table of Contents

Using Logic Command/Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Using Reference/Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Using Datalinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Example Ladder Logic Program Information . . . . . . . . . . . . . . . . . . . . . . . 64

CompactLogix Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 6

Using Explicit Messaging

Using Multi-Drive Mode

Troubleshooting

About Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Performing Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

CompactLogix Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Chapter 7

Single-Drive Mode vs. Multi-Drive Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 83

System Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Understanding the I/O Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Configuring the RS-485 Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Using Multi-Drive Add-On Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Multi-Drive Ladder Logic Program for Generic Profile . . . . . . . . . . . . . . 97

CompactLogix Example Using Generic Profile . . . . . . . . . . . . . . . . . . . . . 99

Multi-Drive Mode Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 8

Understanding the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

ENET Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

LINK Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Viewing Adapter Diagnostic Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Viewing and Clearing Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Appendix A

Specifications

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Regulatory Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Appendix B

Adapter Parameters

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Appendix C

EtherNet/IP Objects

6 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Supported Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Register Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

PCCC Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

DPI Device Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Page 7

Logic Command/Status Words:

PowerFlex 525 Drives

Table of Contents

DPI Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

DPI Fault Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

TCP/IP Interface Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Ethernet Link Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Appendix D

Logic Command Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Logic Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Glossary

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 9

Overview

For information on… See page…

Recommended Documentation

Manual Conventions 9

9

Preface

Recommended Documentation

All the recommended documentation listed in this section is available online at

http://www.rockwellautomation.com/literature

.

The following publications provide additional information:

For... See... Publication

EtherNet/IP™ EtherNet/IP Media Planning and Installation Manual

EtherNet/IP Network Infrastructure Guidelines

EtherNet/IP Network Configuration User Manual ENET-UM001

Troubleshoot EtherNet/IP Networks ENET-AT003

EtherNet/IP Design, Commissioning, and

Troubleshooting Quick Reference Drawings

Ethernet Design Considerations Reference Manual ENET-RM002

PowerFlex®520-Series Drives PowerFlex 525 Adjustable Frequency AC Drive User Manual 520-UM001

HIM (Human Interface Module) PowerFlex 4-Class HIM (DSI) Quick Reference 22HIM-QR001

RSLinx® Classic RSLinx Classic Getting Results Guide

RSLogix™ 5000 RSLogix 5000 online help

CompactLogix™ 5370 CompactLogix 5370 Controllers User Manual (1769-L36ERM) 1769-UM021

MicroLogix™ 1100 MicroLogix 1100 Programmable Controllers User Manual 1763-UM001

MicroLogix™ 1400 MicroLogix 1400 Programmable Controllers User Manual 1766-UM001

(1) For ODVA publications, see the ODVA Ethernet/IP library at

http://odva.org/Home/ODVATECHNOLOGIES/EtherNetIP/EtherNetIPLibrary/tabid/76/lng/en-US/Default.aspx

(2) The online help is installed with the software.

(2)

(2)

(1)

(1)

ODVA Pub. 148

ODVA Pub. 35

IASIMP-QR023

LINX-GR001

–

Manual Conventions

This manual provides information about the EtherNet/IP adapter embedded on

the Main Control Board in PowerFlex 525 drives, and using it for network

communication.

The following conventions are used throughout this manual:

• Parameter names are shown in the format axxx [*]. The a represents the

parameter group. The xxx represents the parameter number. The *

represents the parameter name— for example C141 [EN Rate Cfg].

• Menu commands are shown in bold type face and follow the format Menu

> Command. For example, if you read “Select File > Open,” yo u s ho ul d

click the File menu and then click the Open command.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 9

Page 10

Preface Overview

• The Studio 5000™ Engineering and Design Environment combines

engineering and design elements into a common environment. The first

element in the Studio 5000 environment is the Logix Designer

application. The Logix Designer application is the rebranding of

RSLogix 5000 software and will continue to be the product to program

Logix 5000 controllers for discrete, process, batch, motion, safety, and

drive-based solutions. The Studio 5000 environment is the foundation for

the future of Rockwell Automation engineering design tools and

capabilities. It is the one place for design engineers to develop all the

elements of their control system.

• RSLogix 5000 (version 20) was used for the screen captures in this manual.

Different versions of the software may differ in appearance and

procedures.

10 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 11

Chapter 1

Esc

Sel

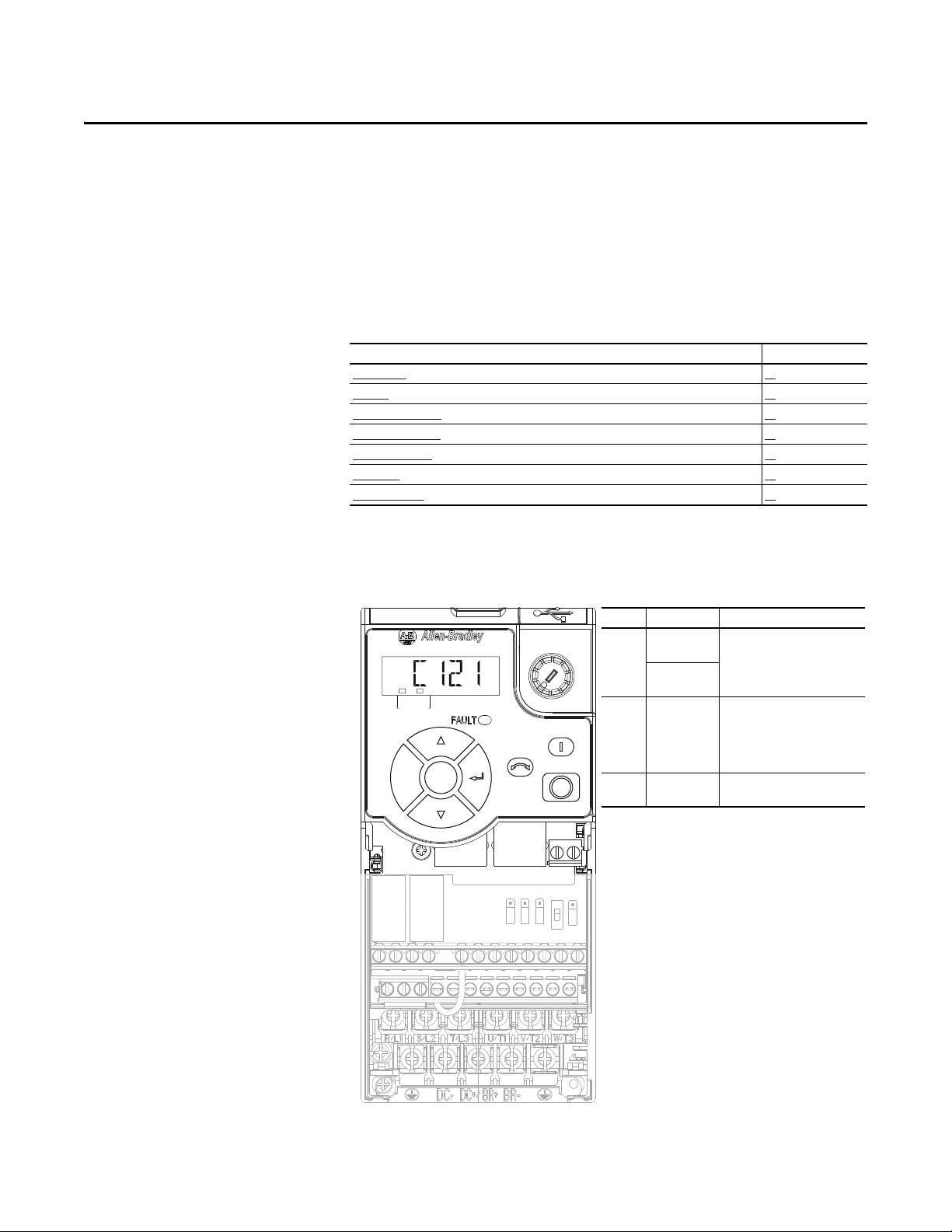

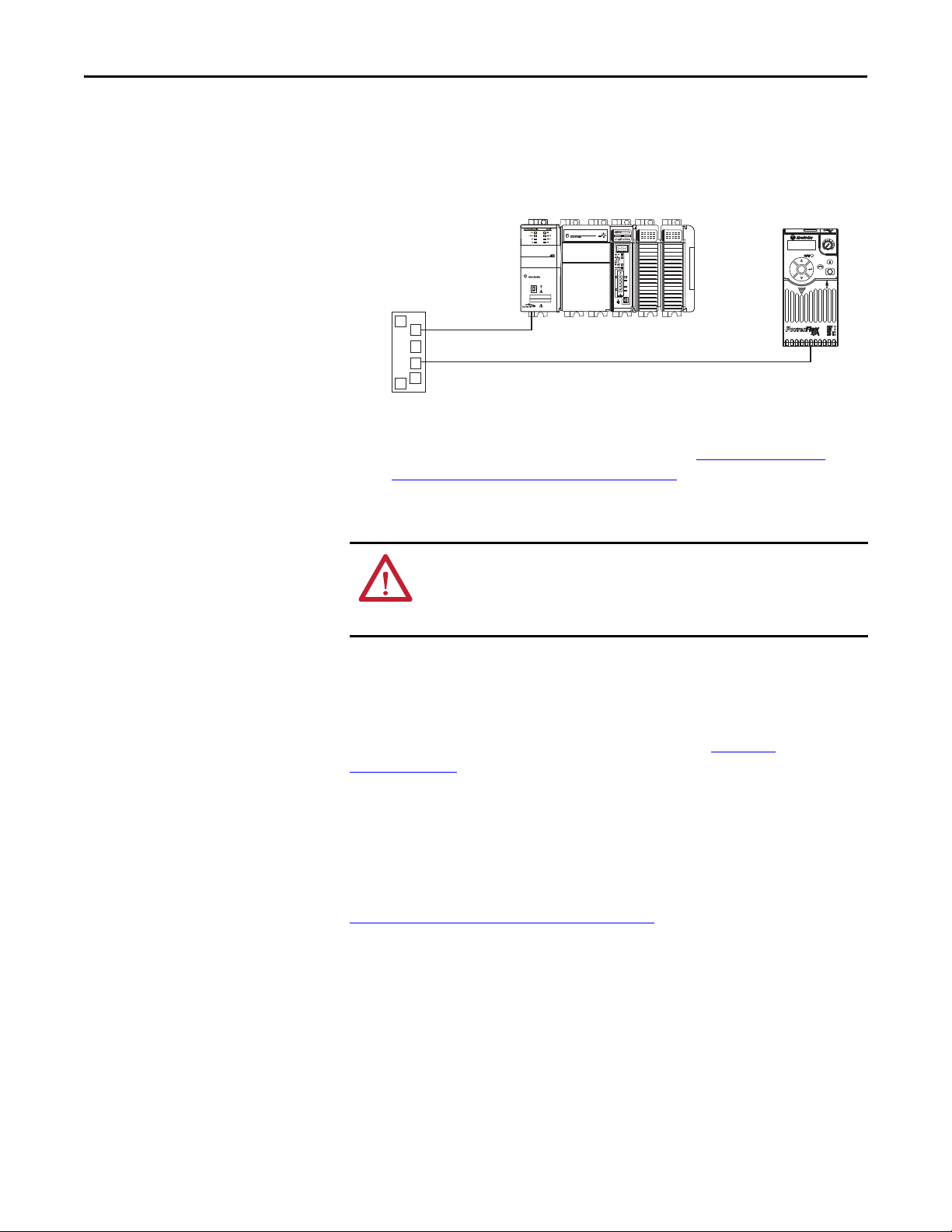

Item Part Description

➊ ENET status

indicator

Two LEDs that indicate the status

of the embedded EtherNet/IP

adapter and network

communications.

LINK status

indicator

➋ Ethernet port An RJ-45 connector for the

Ethernet cable. It is CAT-5

compliant to ensure reliable

data transfer on 100Base-Tx

Ethernet connections.

➌ DSI port An RS485 cable connection for

handheld and remote options.

Shown with control module cover removed

➊

➋➌

Getting Started

The EtherNet/IP adapter, embedded on the Main Control Board in

PowerFlex 525 drives, is used for network communication.

Top ic Pa ge

Components

Feature s 12

Compatible Products 12

Required Equipment 12

Safety Precautions 14

Quick Start 14

Status Indicators 15

11

Components

Components of the Embedded EtherNet/IP Adapter

FWD

ENET LINK

EtherNet/IP

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 11

Page 12

Chapter 1 Getting Started

Features

The features of the embedded EtherNet/IP adapter include:

• Drive parameters to set an IP address – or you can use a BOOTP server to

configure the IP address.

• Compatibility with various configuration tools to configure the embedded

EtherNet/IP adapter and host drive. The tools include the PowerFlex 4/

40-class HIM (Human Interface Module 22-HIM-A3 or 22-HIM-C2S),

and drive-configuration software such as RSLogix 5000 (version 17 or

greater), Logix Designer (version 21 or greater), and Connected

Components Workbench (version 3 or greater).

• Status indicators on the drive’s LCD display that report the status of the

embedded EtherNet/IP adapter and network communications.

• Parameter-configured 16-bit Datalinks in the I/O to meet application

requirements (four Datalinks to write data from the network to the drive,

and four Datalinks to read data to the network from the drive).

• Explicit Messaging support.

• Master-Slave hierarchy that can be configured to transmit data to and from

a controller on the network.

• Multi-drive mode which allows up to five drives to share a single

EtherNet/IP node.

• User-defined fault actions to determine how the embedded EtherNet/IP

adapter and its host PowerFlex 525 drive respond to:

– I/O messaging communication disruptions (Comm Flt Action)

– Controllers in idle mode (Idle Flt Action)

• Automatic Device Configuration (ADC) is an RSLogix 5000 (version 20

or greater), and Logix Designer (version 21 or greater) feature that

supports the automatic download of configuration data upon the Logix

controller establishing an EtherNet/IP network connection to a

PowerFlex 525 drive and its associated peripherals.

Compatible Products

Required Equipment

12 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

At the time of publication, the embedded EtherNet/IP adapter is compatible

with Allen-Bradley PowerFlex 525 drives.

Equipment Shipped with the Drive

Since the EtherNet/IP adapter is embedded on the Main Control Board in the

PowerFlex 525 drive, it is always an integral part of the drive and, therefore, is not

shipped with installation instructions.

Page 13

Getting Started Chapter 1

User-Supplied Equipment

The embedded EtherNet/IP adapter can be configured using the built-in keypad

interface on the drive. In addition, you must supply:

❑ Ethernet cable (see the EtherNet/IP Media Planning and Installation Manual, ODVA publication 148 available on the

ODVA web site at http://odva.org/Home/ODVATECHNOLOGIES/EtherNetIP/EtherNetIPLibrary/tabid/76/Default.aspx

for details)

❑ Ethernet switch (see the Ethernet Design Considerations Reference Manual, Rockwell Automation publication

ENET-RM002

❑ Optional configuration tool, such as:

– PowerFlex 22-HIM-A3/-C2S HIM

– DHCP/BOOTP Utilities

❑ Controller configuration software, such as:

– RSLinx Classic (version 2.50 or later)

– RSLogix 5000 (version 17 or greater) or Logix Designer (version 21 or greater) when using drive-specific Add-On

– Connected Components Workbench (version 3 or greater)

❑ A PC connection to the EtherNet/IP network

for details)

Profile (AOP)

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 13

Page 14

Chapter 1 Getting Started

Safety Precautions

Please read the following safety precautions carefully.

ATT EN TI ON : Risk of injury or equipment damage exists. Only personnel

familiar with drive and power products and the associated machinery should

plan or implement the installation, start up, configuration, and subsequent

maintenance of the drive using this embedded adapter. Failure to comply may

result in injury and/or equipment damage.

ATT EN TI ON : Risk of equipment damage exists. The embedded adapter

contains ESD (Electrostatic Discharge) sensitive parts that can be damaged if

you do not follow ESD control procedures. Static control precautions are

required when handling the adapter. If you are unfamiliar with static control

procedures, see Guarding Against Electrostatic Damage (publication 8000-

4.5.2)

ATT EN TI ON : Risk of injury or equipment damage exists. If the adapter is

transmitting control I/O to the drive, the drive may fault when you reset the

adapter. Determine how your drive will respond before resetting the adapter.

ATT EN TI ON : Risk of injury or equipment damage exists. Drive parameters

C143 [EN Comm Flt Actn] and C144 [EN Idle Flt Actn] let you determine the

action of the embedded EtherNet/IP adapter and drive if I/O communication is

disrupted, the controller is idle, or explicit messaging for drive control is

disrupted. By default, these parameters fault the drive. You may configure these

parameters so that the drive continues to run, however, precautions should be

taken to ensure that the settings of these parameters do not create a risk of

injury or equipment damage. When commissioning the drive, verify that your

system responds correctly to various situations (for example, a disconnected

cable or a controller in idle state).

ATT EN TI ON : Risk of injury or equipment damage exists. When a system is

configured for the first time, there may be unintended or incorrect machine

motion. Disconnect the motor from the machine or process during initial system

testing.

ATT EN TI ON : Risk of injury or equipment damage exists. The examples in this

publication are intended solely for purposes of example. There are many

variables and requirements with any application. Rockwell Automation, Inc.

does not assume responsibility or liability (to include intellectual property

liability) for actual use of the examples shown in this publication.

Quick Start

This section is provided to help experienced users quickly start using the

embedded EtherNet/IP adapter. If you are unsure how to complete a step, refer to

the referenced chapter.

Step Action See...

1 Review the safety precautions for the adapter. Throughout this manual

2 Verify that the PowerFlex drive is properly installed. PowerFlex 525

3 Connect the drive to the EtherNet/IP network.

Verify that the PowerFlex drive is not powered. Then, connect the embedded EtherNet/

IP adapter to the network using an Ethernet cable.

14 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Adjustable Freq uency AC

Drive User Manual

(publication 520-UM001

,

Chapter 2

Setting Up the Adapter

)

Page 15

Getting Started Chapter 1

Esc

Sel

Item Name

➊ ENET indicator

➋ LINK indicator

➊➋

Step Action See...

4 Apply power to the drive.

a. Replace the control module cover.

b. The embedded EtherNet/IP adapter receives power from the drive. Apply power

to the drive. The ENET/LINK status indicators on the drive’s LCD display should

light up and remain steady or flash. If the drive’s Fault LED lights up, there is a

problem. See Chapter 8, Troubleshooting.

c. Configure/verify key drive parameters.

5 Configure the adapter for your application.

Set drive parameters for the following functions as required by your application:

– IP address, subnet mask, and gateway address

– Data rate

– I/O configuration

– Master-Slave hierarchy

– Fault actions

6 Configure the controller to communicate with the adapter.

Use a controller configuration tool such as RSLogix 5000/Logix Designer to configure

the master on the EtherNet/IP network to recognize the embedded EtherNet/IP

adapter and drive.

7 Create a ladder logic program.

Use a controller configuration tool such as RSLogix 5000/Logix Designer to create a

ladder logic program that enables you to:

– Control the embedded EtherNet/IP adapter and drive using I/O.

– Monitor or configure the drive using Explicit messages.

Chapter 2,

Setting Up the Adapter

Chapter 3,

Configuring the Adapter

Chapter 4,

Configuring the I/O

Chapter 5,

Using the I/O

Chapter 6,

Using Explicit Messaging

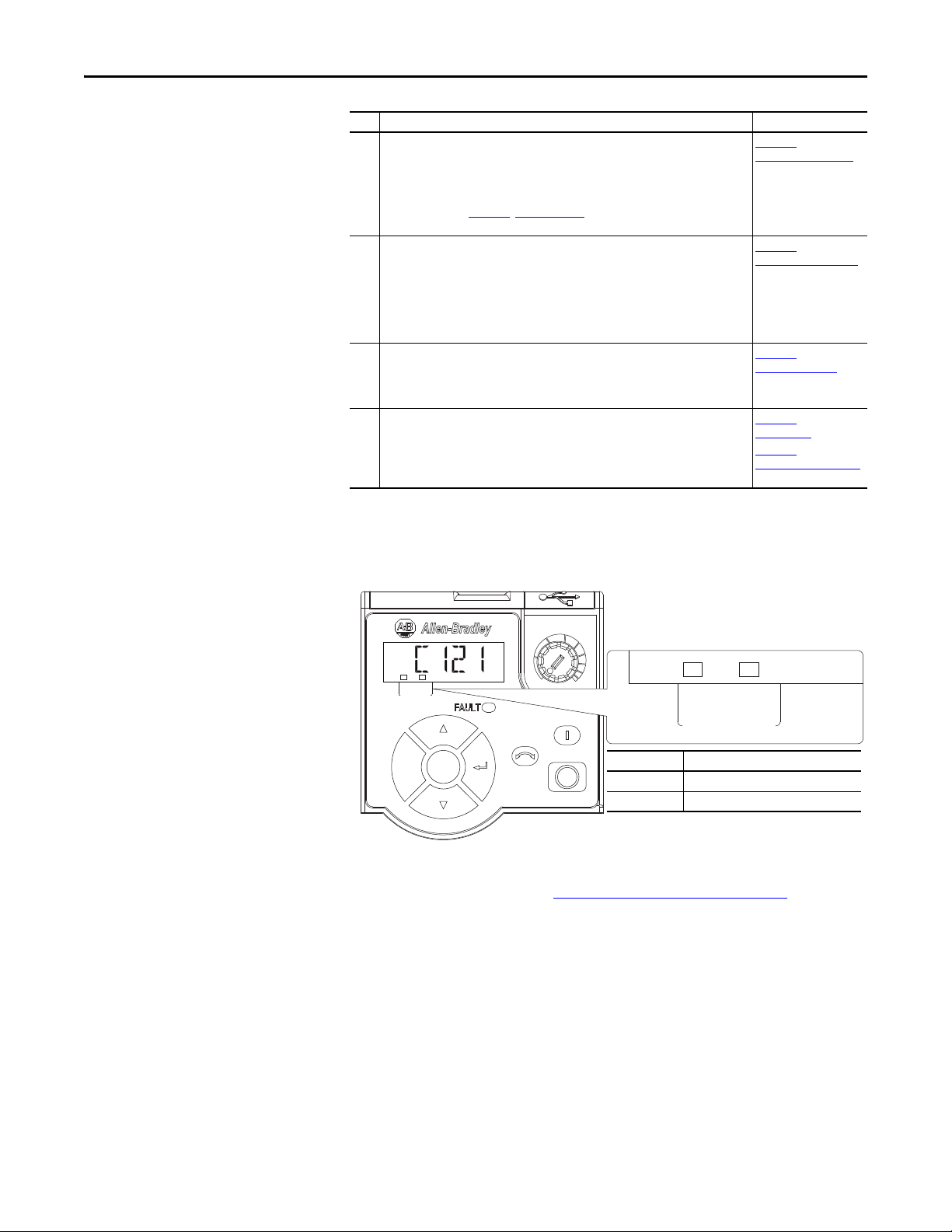

Status Indicators

The embedded EtherNet/IP adapter uses two status indicators to report its

operating status.

FWD

ENET LINK

EtherNet/IP

ENET LINK

EtherNet/IP

After connecting the embedded EtherNet/IP adapter to the network and

applying power to the drive, see Startup Status Indication

on page 19 for possible

start-up status indications and their descriptions.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 15

Page 16

Chapter 1 Getting Started

Notes:

16 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 17

Chapter 2

Setting Up the Adapter

Since the EtherNet/IP adapter is embedded on the Main Control Board in the

PowerFlex 525 drive, the only required step is setting its IP address and

connecting it to the network.

Top ic Pa ge

Preparing for Set-Up 17

Setting the IP Address 18

Connecting the Adapter to the Network 18

Applying Power 19

Commissioning the Adapter 21

Preparing for Set-Up

Before setting up the embedded EtherNet/IP adapter:

• Make sure the Ethernet switch is the correct type. A “managed” switch that

supports IGMP snooping is usually recommended. An “unmanaged”

switch can be used instead if RSLogix 5000 (version 18 or greater) is used

and all devices on the network are configured for “unicast” I/O. For more

details, see the following documents:

– EtherNet/IP Media Planning and Installation Manual

(ODVA publication 148)

– EtherNet/IP Network Infrastructure Guidelines

(ODVA publication 35)

– Ethernet Design Considerations Reference Manual

(Rockwell Automation publication ENET-RM002

• Understand IGMP Snooping/Ethernet Switches

The embedded EtherNet/IP adapter is a multicast device. In most

situations, an IGMP snooping (managed) switch is required. If more than

one or two embedded EtherNet/IP adapters are connected to the switch, a

managed switch is required—otherwise the drive may fault on a Net I/O

Timeout network loss. The embedded EtherNet/IP adapter,

RSLogix 5000 (version 18 or greater), and a ControlLogix or

CompactLogix controller will support unicast. Unicast setup is required

when adding the drive to the I/O. When all embedded EtherNet/IP

adapters are set up as unicast devices, then an IGMP snooping (managed)

switch is not needed.

)

Much of EtherNet/IP implicit (I/O) messaging uses IP multicast to

distribute I/O control data, which is consistent with the CIP producer/

consumer model. Historically, most switches have treated multicast

packets the same as broadcast packets. That is, all multicast packets are retransmitted to all ports.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 17

Page 18

Chapter 2 Setting Up the Adapter

IMPORTANT

IGMP snooping constrains the flooding of multicast traffic by dynamically

configuring switch ports so that multicast traffic is forwarded only to ports

associated with a particular IP multicast group.

Switches that support IGMP snooping (managed switches) “learn” which

ports have devices that are part of a particular multicast group and only

forward the multicast packets to the ports that are part of the multicast

group.

Be careful as to what level of support a switch has of IGMP snooping.

Some layer 2 switches that support IGMP snooping require a router

(which could be a layer 3 switch) to send out IGMP polls to learn what

devices are part of the multicast group. Some layer 2 switches can use

IGMP snooping without a router sending polls. If your control system is a

stand-alone network or is required to continue performing if the router is

out of service, make sure the switch you are using supports IGMP

snooping without a router being present.

• See Appendix A

embedded EtherNet/IP adapter.

• Verify that you have all required equipment. See Required Equipment

page 12.

for the number of CIP connections supported by the

on

Setting the IP Address

Connecting the Adapter to the Network

There are two methods for configuring the embedded EtherNet/IP adapter’s IP

address:

• BOOTP Server – Use BOOTP if you prefer to control the IP addresses of

devices using a BOOTP server. The IP address, subnet mask, and gateway

addresses will then be provided by the BOOTP server. This is enabled by

default.

• Parameters – Use parameters when you want more flexibility in setting up

the IP address, or need to communicate outside the control network using

a gateway. The IP address, subnet mask, and gateway addresses will then

come from the parameters you set.

Regardless of the method used to set the adapter’s IP address, each node on

the network must have a unique IP address. To change an IP address, you must

set the new value and then remove and reapply power to (or reset) the drive.

ATT EN TI ON : Risk of injury or death exists. The PowerFlex drive may contain

high voltages that can cause injur y or death. Remove power from the drive, and

then verify power has been discharged before connecting the embedded

EtherNet/IP adapter to the network.

1. Remove power from the drive.

2. Remove the drive control module cover.

18 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 19

Setting Up the Adapter Chapter 2

1 (Front)1 (Front)1 (Front)

2 (Rear)

00:00:BC:2E:69:F6

Esc

Sel

Ethernet

switch

1769-L36ERM CompactLogix controller

with embedded EtherNet/IP bridge

PowerFlex 525 drive with

embedded EtherNet/IP

adapter (Frame A shown)

3. Use static control precautions.

4. Connect one end of an Ethernet cable to the EtherNet/IP network.

5. Route the other end of the Ethernet cable through the bottom of the

PowerFlex 525 drive, and insert the cable’s plug into the embedded

EtherNet/IP adapter’s mating socket (item 2 in Components of the

Embedded EtherNet/IP Adapter on page 11).

Applying Power

ATT EN TI ON : Risk of equipment damage, injury, or death exists. Unpredictable

operation may occur if you fail to verify that parameter settings are compatible

with your application. Verify that settings are compatible with your application

before applying power to the drive.

Install the control module cover, and apply power to the drive. The embedded

EtherNet/IP adapter receives its power from the drive. When you apply power to

the embedded EtherNet/IP adapter for the first time, the “ENET” status

indicator on the drive LCD display should remain steady after an initialization. If

it does not light up or is flashing, there is a problem. See Chapter 8

Troubleshooting

.

,

Startup Status Indication

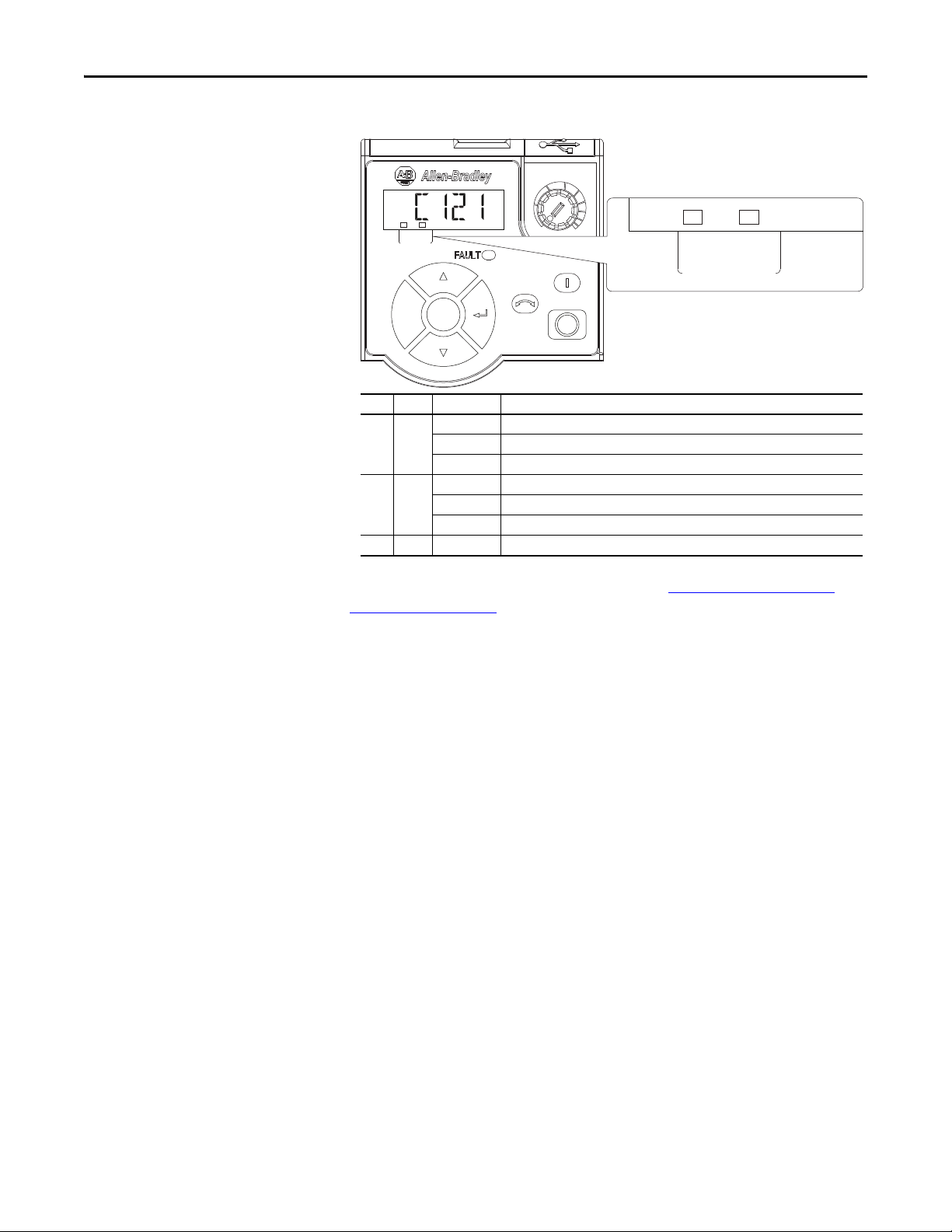

After power has been applied, status indicators for the PowerFlex 525 drive and

embedded EtherNet/IP adapter can be viewed on the drive LCD display. See

Drive and Adapter Status Indicators

status indications.

on page 20 for their location and possible

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 19

Page 20

Chapter 2 Setting Up the Adapter

TIP

Esc

Sel

Item Name State Description

➊ ENET Off Adapter is not connected to the network.

Steady Adapter is connected to the network and drive is controlled through Ethernet.

Flashing Adapter is connected to the network but drive is not controlled through Ethernet.

➋ LINK Off Adapter is not connected to the network

Steady Adapter is connected to the network but not transmitting data.

Flashing Adapter is connected to the network and transmitting data.

➌ FAULT Flashing Red Indicates drive is faulted.

➊➋

➌

Drive and Adapter Status Indicators

FWD

ENET LINK

EtherNet/IP

ENET LINK

EtherNet/IP

20 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

For more details on status indicator operation see Understanding the Status

Indicators on page 111.

Configuring/Verifying Key Drive Parameters

The PowerFlex 525 drive can be separately configured for the control and

Reference functions in various combinations. For example, you could set the

drive to have its control come from a peripheral or terminal block with the

Reference coming from the network. Or you could set the drive to have its

control come from the network with the Reference coming from another

peripheral or terminal block. Or you could set the drive to have both its control

and Reference come from the network.

Configuring the drive parameters can be done using the drive’s keypad, a HIM,

RSLogix 5000/Logix Designer, or Connected Components Workbench. In the

following example, the drive will receive the Logic Command and Reference

from the network.

1. Set the value of drive parameter P046 [Start Source 1]

to 5 “EtherNet/IP”.

2. Set the value of drive parameter P047 [Speed Reference1]

to 15 “EtherNet/IP”.

The PowerFlex 525 drive supports up to three control functions and

three Reference functions.

Page 21

Setting Up the Adapter Chapter 2

IMPORTANT

For more information on how to set different combinations of the control and

Reference functions, see the PowerFlex 525 drive user manual,

publication 520-UM001

.

Commissioning the Adapter

To commission the embedded EtherNet/IP adapter, you must set a unique IP

address. See the Glossary

server or parameters to set the IP address after connecting the adapter to the

network and applying power to the drive.

By default, the adapter is configured to accept an IP address from a BOOTP

server. For details, see Using BOOTP

parameters, see Setting the IP Address, Subnet Mask, and Gateway Address

page 29.

New settings for some parameters (for example, parameters C129 [EN IP

Addr Cfg 1] through C132 [EN IP Addr Cfg 4]) are recognized only when

power is applied to the adapter. After you change parameter settings, cycle

drive power.

for details about IP addresses. Use either a BOOTP

on page 26. To set the IP address using

on

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 21

Page 22

Chapter 2 Setting Up the Adapter

Notes:

22 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 23

Chapter 3

Configuring the Adapter

This chapter provides instructions and information for setting the parameters to

configure the embedded EtherNet/IP adapter.

Top ic Pa ge

Configurat ion Tools

Using the Drive Keypad Interface to Access Parameters 24

Using the PowerFlex 4-Class HIM to Access Parameters 25

Using BOOTP 26

Setting the IP Address, Subnet Mask, and Gateway Address 29

Setting the Data Rate 30

Using Master-Slave Hierarchy 31

Setting a Fault Action 33

Resetting the Ad apter 34

Viewing the Adapter Status Using Parameters 34

23

Configuration Tools

For a list of parameters, see Appendix B

terms in this chapter, see the Glossary

, Adapter Parameters. For definitions of

.

The parameters can be configured using the drive keypad interface (see page 24)

or a PowerFlex 4-class HIM (Human Interface Module, see page 25

).

RSLogix 5000 (version 17 or greater), Logix Designer (version 21 or greater),

and Connected Components Workbench (version 3 or greater) can also be used

to access the parameters.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 23

Page 24

Chapter 3 Configuring the Adapter

HERT

Z

FWD

Esc

FWD

Esc

FWD

or

FWD

Sel

or

FWD

or

FWD

FWD

Sel

or

PROGRAM

FWD

or

PROGRAM

FWD

Sel

PROGRAM

FWD

Esc

or

FWD

FWD

or

Esc

FWD

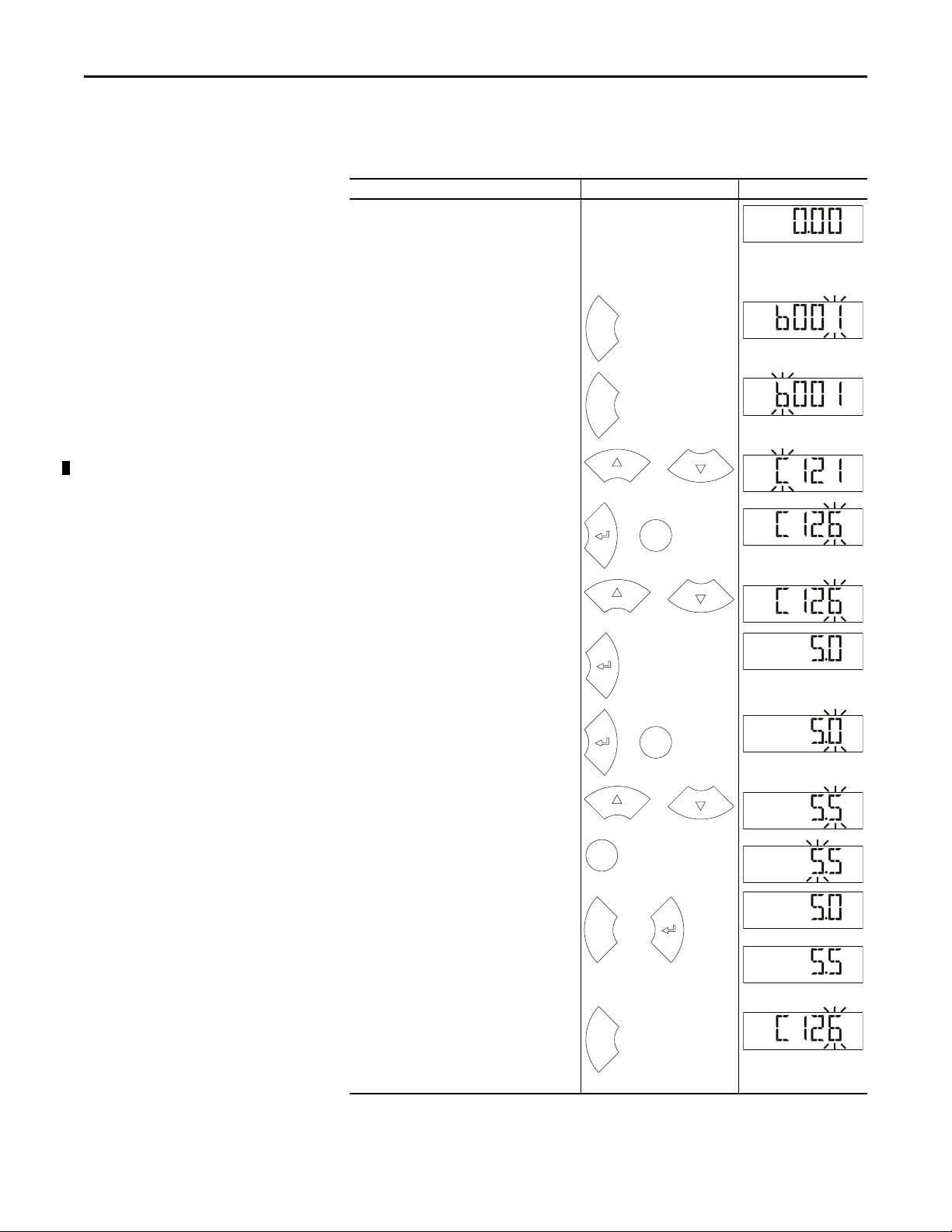

Using the Drive Keypad Interface to Access Parameters

The following is an example of basic integral keypad and display functions. This

example provides basic navigation instructions and illustrates how to program a

parameter.

Step Key(s) Example Display

1. When power is applied, the last user-selected

Basic Display Group parameter number is briefly

displayed with flashing characters. The display

then defaults to that parameter’s current value.

(Example shows the value of b001 [Output

Freq] with the drive stopped.)

2. Press Esc to display the Basic Display Group

parameter number shown on power-up. The

parameter number will flash.

3. Press Esc to enter the parameter group list. The

parameter group letter will flash.

4. Press the Up Ar row or Down Arrow to scroll

through the group list (b, P, t, C, L, d, A, f, N, M,

and Gx).

5. Press Enter or Sel to enter a group. The right

digit of the last viewed parameter in that group

will flash.

6. Press the Up Ar row or Down Arrow to scroll

through the parameter list.

7. Press Enter to view the value of the parameter.

Or

Press Esc to return to the parameter list.

8. Press Enter or Sel to enter Program Mode and

edit the value. The right digit will flash and the

word Program on the LCD display will light up.

9. Press the Up Arrow or Down Arrow to change

the parameter value.

10. If desired, press Sel to move from digit to digit

or bit to bit. The digit or bit that you can change

will flash.

11. Press Esc to cancel a change and exit Program

Mode.

Or

Press Enter to save a change and exit Program

Mode.

The digit will stop flashing and the word

Program on the LCD display will turn off.

12. Press Esc to return to the parameter list.

Continue to press Esc to back out of the

programming menu.

If pressing Esc does not change the display, then

b001 [Output Freq] is displayed. Press Enter or

Sel to enter the group list again.

24 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 25

Configuring the Adapter Chapter 3

Para meters

Groups

Linear List

Changed Params

DIAG

PAR A M DSEL MEM SEL

and

Basic Display

001 Output Freq

002 Commanded Freq

003 Output Current

004 Output Voltage

005 DC Bus Voltage

B PTCSEL

Sel

Communications

121 Comm Write Mode

122 Cmd Stat Select

123 RS485 Data Rate

124 RS485 Node Addr

125 Comm Loss Ac tion

BPTC SEL

and

Communications

121 Comm Write Mode

122 Cmd Stat Select

123 RS485 Data Rate

124 RS485 Node Addr

125 Comm Loss Ac tion

BPTC SEL

RS485 Data Rate

Para meter: # 123

9600

3

VALU E LIMITS SEL

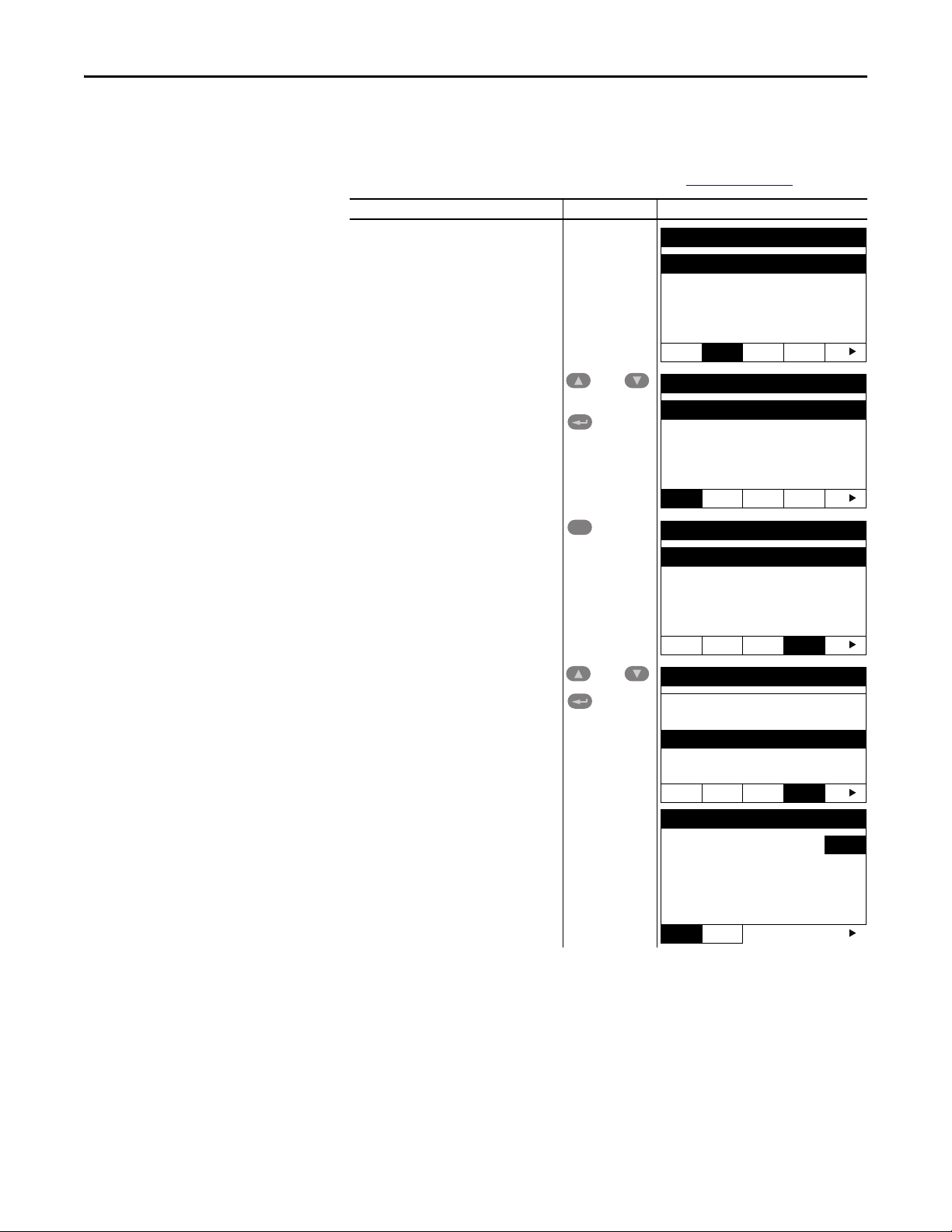

Using the PowerFlex 4-Class HIM to Access Parameters

The PowerFlex 4-class HIM can be used to access parameters in the drive (see

basic steps shown below). It is recommended that you read through the steps for

your HIM before performing the sequence. For additional HIM information,

refer to the HIM Quick Reference card, publication 22HIM-QR001

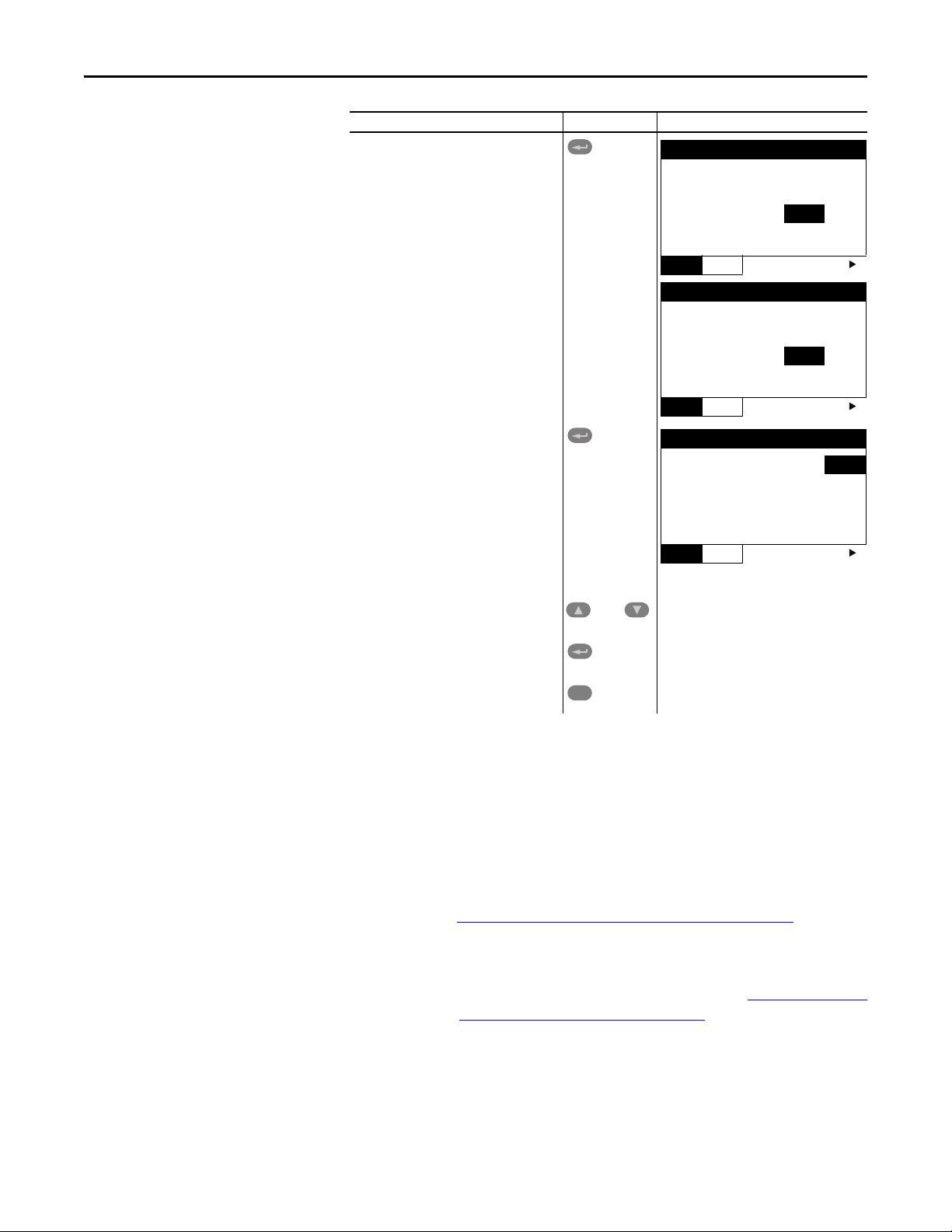

Step Key(s) Example Display

1. Power up the drive. Then connect the HIM

to the DSI port of the drive. The Parameters

tab for the drive will be displayed.

2. Select Groups in the Parameters tab if it is

not already selected using the Up Arrow or

Down Arrow.

Press Enter to selec t Groups.

3. Press Sel repeatedly until the C tab

(Communications parameters) is selected.

.

4. Press the Up Arrow or Down Arrow to scroll

to the Communications parameter you

wish to display or modify, then press Enter.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 25

Page 26

Chapter 3 Configuring the Adapter

RS485 Data Rate

Para meter: # 123

9600

3

VALU E LIMITS SEL

RS485 Data Rate

Para meter: # 123

19,200

4

VALU E LIMITS SEL

RS485 Data Rate

Para meter: # 123

19,200

4

VALU E LIMITS SEL

and

Esc

TIP

Step Key(s) Example Display

5. Press Enter to select the current parameter

value and the numeric keys to enter a new

value.

6 Press Enter to write the new value to the

parameter and the parameter number will

be selected again.

Using BOOTP

7 While the parameter number is selected,

you may:

a. use the arrow keys to select

additional parameters you wish to

modify.

b. press Enter to go to the para meter

number you have input using the

keypad.

c. press Esc to return to the group

parameter list.

By default, the adapter is configured to accept an IP address, subnet mask, and

gateway address from a BOOTP server. You can select from a variety of BOOTP

utilities.

The instructions below use the DHCP/BOOTP Utility (version 2.3 or greater),

a free stand-alone program from Rockwell Automation that incorporates the

functionality of standard DHCP/BOOTP utilities with a graphical interface. It

is available from http://www.ab.com/networks/ethernet/bootp.html

. See the

Readme file and online Help for directions and more information.

If desired, you can disable BOOTP and configure the IP address, subnet mask,

and gateway address using parameters. For details, see Setting the IP Address,

Subnet Mask, and Gateway Address on page 29.

26 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 27

Configuring the Adapter Chapter 3

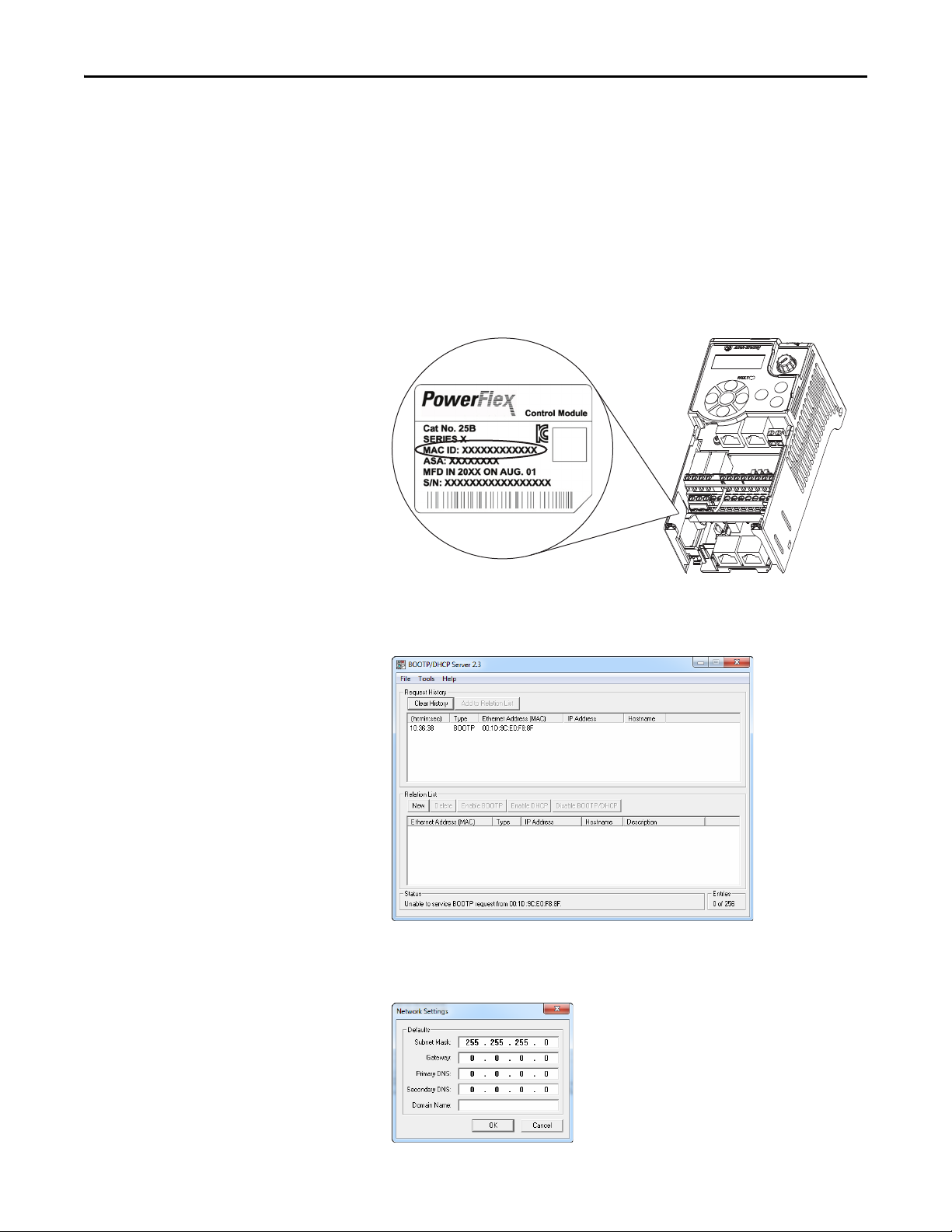

Ethernet Address label example

Configuring the Adapter Using DHCP/BOOTP Utility

1. Verify and note the adapter’s hardware Ethernet Address (MAC), which

will be used in Step 6. There are two ways to do this:

• Use the PowerFlex 525 drive’s keypad or a HIM to access the diagnostic

parameters of the drive. Scroll to parameters F687 [HW Addr 1]

through F692 [HW Addr 6] to view the adapter’s hardware Ethernet

Address (MAC). Finally, convert these decimal values to a hex value.

• Remove the PowerFlex 525 control module front cover and locate the

adapter’s hardware Ethernet Address (MAC) label.

2. On a computer connected to the EtherNet/IP network, start the

BOOTP/DHCP software. The BOOTP/DHCP Server window

appears.

3. To properly configure devices on your EtherNet/IP network, you must

configure settings in the BOOTP/DHCP software to match the network.

Select To o l s > Network Settings to display the Network Settings window.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 27

Page 28

Chapter 3 Configuring the Adapter

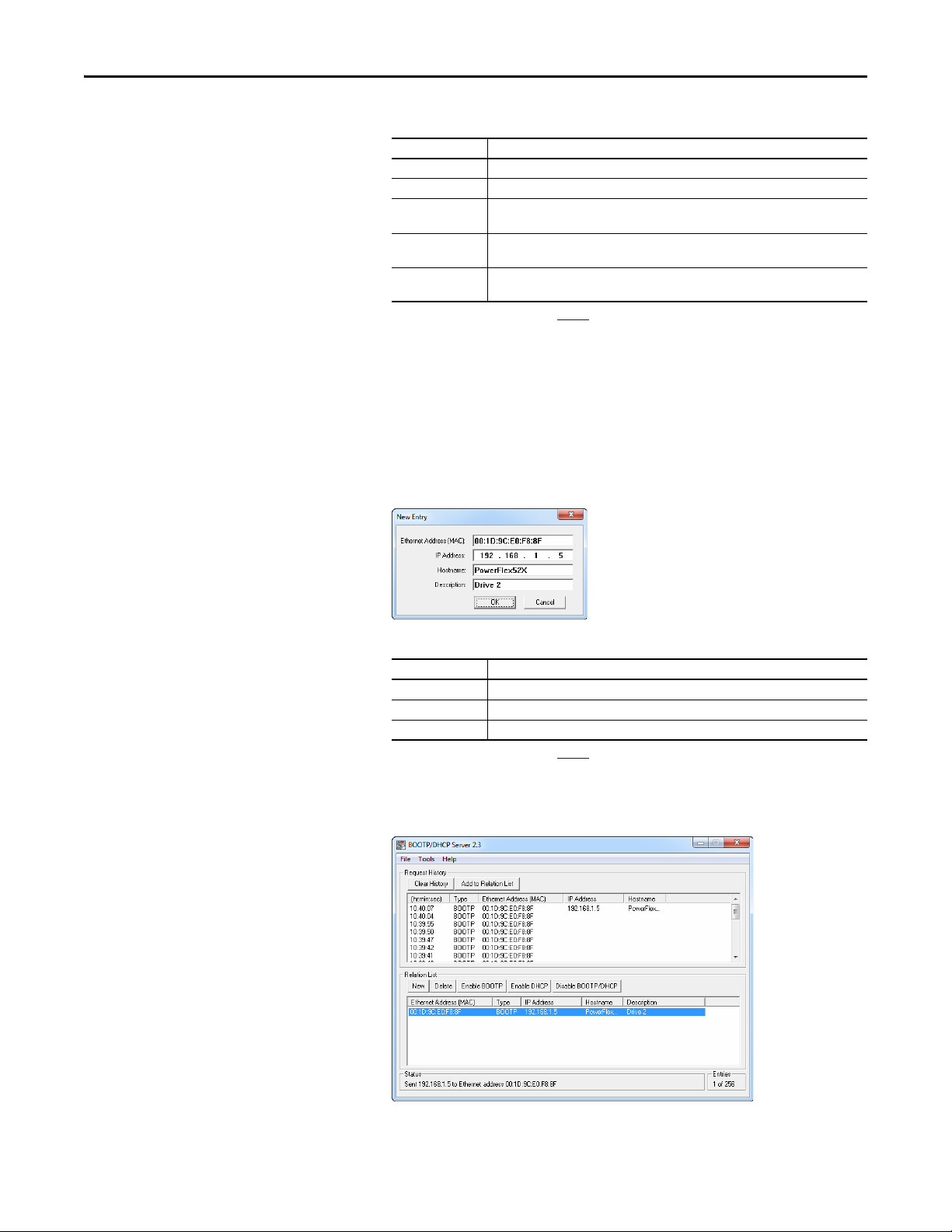

4. Edit the following:

Box Type

Subnet Mask

Gateway

Primary DNS The address of the primary DNS server to be used on the local end of the link for

Secondary DNS Optional – the address of the secondary DNS server to be used on the local end of the

Domain Name The text name corresponding to the numeric IP address that was assigned to the server

(1) For definitions of these terms, see the Glossary.

(1)

(1)

The subnet mask for the adapter’s network.

The IP address of the gateway device on the adapter’s net work.

negotiating with remote devices.

link for negotiating with remote devices when the primary DNS server is unavailable.

that controls the network.

5. Click OK to apply the settings. Devices on the network issuing BOOTP/

DHCP requests appear in the BOOTP/DHCP Request History list.

6. In the BOOTP/DHCP Request History list, either double-click the

adapter’s Ethernet Address (MAC) noted in Step 1, or click New in the

Relation List. The New Entry window appears. In the first case, the

Ethernet Address (MAC) is automatically entered. In the latter case, you

must manually enter it.

7. Edit the following:

Box Type

(1)

IP Address

Host Name Optional

Description Optional

(1) For definitions of these terms, see the Glossary.

A unique IP address for the adapter

8. Click OK to apply the settings. The adapter appears in the Relation List

with the new settings.

28 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 29

Configuring the Adapter Chapter 3

TIP

192.168.1.62

[EN IP Addr Cfg 1]

[EN IP Addr Cfg 2]

[EN IP Addr Cfg 3]

[EN IP Addr Cfg 4]

Default = 0.0.0.0

9. To assign this configuration to the adapter, select the device in the Relation

List and click Disable BOOTP/DHCP. When power is cycled on the

drive, the adapter will use the configuration you assigned it and not issue

new BOOTP/DHCP requests.

To enable BOOTP for an embedded adapter that has had BOOTP

disabled, first select the adapter in the Relation List. Then click Enable

BOOTP and power cycle the drive.

10. To save the Relation List, select File > Save.

Setting the IP Address, Subnet Mask, and Gateway Address

By default, the adapter is configured to accept an IP address, subnet mask, and

gateway address from a BOOTP server. If you want to set these attributes using

parameters instead, you must first disable BOOTP and then set these network

address parameters in the drive.

Disabling the BOOTP Feature

1. Set the value of parameter C128 [EN Addr Sel] to 1“Parameters”.

Options 1“Parameters”

2“BOOTP” (Default)

2. Reset the adapter by power cycling the drive.

After disabling the BOOTP feature, you can then configure the IP

address, subnet mask, and gateway address using parameters.

Setting an IP Address Using Parameters

1. Verify that parameter C128 [EN Addr Sel] is set to 1“Parameters”. This

parameter must be set to “Parameters” to configure the IP address using

parameters.

2. Set the value of parameters C129 [EN IP Addr Cfg 1] through C132

[EN IP Addr Cfg 4] to a unique IP address.

3. Reset the adapter by power cycling the drive.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 29

Page 30

Chapter 3 Configuring the Adapter

Default = 0.0.0.0 255.255.255.0

[EN Subnet Cfg 1]

[EN Subnet Cfg 2]

[EN Subnet Cfg 3]

[EN Subnet Cfg 4]

Default = 0.0.0.0 192.168.1.1

[EN Gateway Cfg 1]

[EN Gateway Cfg 2]

[EN Gateway Cfg 3]

[EN Gateway Cfg 4]

Setting a Subnet Mask Using Parameters

1. Verify that parameter C128 [EN EN Addr Sel] is set to 1“Parameters”.

This parameter must be set to “Parameters” to configure the subnet mask

using parameters.

2. Set the value of parameters C133 [EN Subnet Cfg 1] through C136 [EN

Subnet Cfg 4] to the desired value for the subnet mask.

3. Reset the adapter by power cycling the drive.

Setting a Gateway Address Using Parameters

Setting the Data Rate

1. Verify that parameter C128 [EN EN Addr Sel] is set to 1“Parameters”.

This parameter must be set to “Parameters” to configure the gateway

address using parameters.

2. Set the value of parameters C137 [EN Gateway Cfg 1] through C140

[EN Gateway Cfg 4] to the desired value for the gateway address.

3. Reset the adapter by power cycling the drive.

By default, the adapter automatically detects the data (baud) rate and duplex

setting used on the network. If you need to set a specific data rate and duplex

setting, the value of parameter C141 [EN Rate Cfg] determines the Ethernet

data rate and duplex setting that the adapter will use to communicate. For

definitions of data rate and duplex, see the Glossary

.

1. Set the value of parameter C141 [EN Rate Cfg] to the data rate at which

your network is operating.

Options 0 “Auto detect” (Default)

1 “10Mbps Full”

2 “10Mbps Half”

3 “100Mbps Full”

4 “100Mbps Half”

30 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 31

TIP

Auto detection of data rate and duplex works properly only if the

TIP

device (usually a switch) on the other end of the cable is also set to

automatically detect the data rate/duplex. If one device has the data

rate/duplex hard-coded, the other device must be hard-coded to the

same settings.

2. Reset the adapter by power cycling the drive.

Configuring the Adapter Chapter 3

Using Master-Slave Hierarchy

A hierarchy determines the type of device with which the adapter exchanges data.

In a Master-Slave hierarchy, the adapter exchanges data with a master, such as a

scanner or bridge.

For a Master-Slave hierarchy, the devices exchanging data must be on the same IP

subnet. See “IP Addresses” in the Glossary

for information about IP subnets.

Configuring a Master-Slave Hierarchy

The controller I/O image can have anywhere from zero to eight (four In and four

Out) additional 16-bit parameters called Datalinks. They are configured using

parameters C153 [EN Data In 1] through C156 [EN Data In 4], and C157

[EN Data Out 1] through C160 [EN Data Out 4]. The number of Datalinks

actively used is controlled by the connection size in the controller and the in/out

parameters. See the respective controller example sections in Chapter 4

information on setting the connection size.

When using a ControlLogix or CompactLogix controller and the Generic

Profile, or a MicroLogix 1100/1400 controller, configure the Datalink

parameters now as described in this section.

for more

When using a ControlLogix or CompactLogix controller and an RSLogix 5000

(version 17 or greater) or Logix Designer (version 21 or greater) drive Add-On

Profile, there is no need to configure Datalink parameters at this time. They

will be assigned when configuring the drive Add-On Profile (see Adding the

Drive to the I/O Configuration on page 40).

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 31

Page 32

Chapter 3 Configuring the Adapter

IMPORTANT

IMPORTANT

Enabling Datalinks To Write Data

Always use the Datalink parameters in consecutive numerical order, starting

with the first parameter. For example, use parameters C153, C154, and C155 to

configure three Datalinks to write data. Otherwise, the network I/O connection

will be larger than necessary, which needlessly increases controller response

time and memory usage.

Parameters C153 [EN Data In 1] through C156 [EN Data In 4] control which

parameters in the drive, adapter, or any other connected peripheral receive values

from the network. To configure these parameters, set them to the drive parameter

number you want to write them to.

The following steps are required to enable Datalinks to write data:

1. Set the values of only the required number of contiguous controller-todrive Datalinks needed to write data to the drive and that are to be

included in the network I/O connection.

2. Reset the adapter by power cycling the drive.

After the above steps are complete, the adapter is ready to receive input data and

transfer status data to the master (controller). Next, configure the controller to

recognize and transmit I/O to the adapter. See Chapter 4

, Configuring the I/O.

Enabling Datalinks To Read Data

Always use the Datalink parameters in consecutive numerical order, starting

with the first parameter. For example, use parameters C157, C158, and C159 to

configure three Datalinks to read data. Otherwise, the network I/O connection

will be larger than necessary, which needlessly increases controller response

time and memory usage.

Parameters C157 [EN Data Out 1] through C160 [EN Data Out 4] configure

which parameters in the drive, adapter, or any other connected peripheral send

values to the network. To configure these parameters, set them to the parameter

number you wish to read over the network.

The following steps are required to enable Datalinks to read data:

1. Set the values of only the required number of contiguous drive-tocontroller Datalinks needed to read data from the drive and that are to be

included in the network I/O connection.

2. Reset the adapter by power cycling the drive.

After the above steps are complete, the adapter is ready to send output data to the

master (controller). Next, configure the controller to recognize and transmit I/O

to the adapter. See Chapter 4

32 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

, Configuring the I/O.

Page 33

Configuring the Adapter Chapter 3

Setting a Fault Action

By default, when communications are disrupted (the network cable is

disconnected) and/or the controller is idle (in program mode or faulted), the

drive responds by faulting if it is using I/O from the network. You can configure a

different response to:

• Disrupted I/O communication by using parameter

C143 [EN Comm Flt Actn].

• An idle controller by using parameter C144 [EN Idle Flt Actn].

ATT EN TI ON : Risk of injur y or equipment damage exists. Drive parameters C143

[EN Comm Flt Actn] and C144 [EN Idle Flt Actn] respectively let you determine

the action of the embedded EtherNet/IP adapter and drive if communications

are disrupted or the controller is idle. By default, these parameters fault the

drive. You may configure these parameters so that the drive continues to run,

however, precautions should be taken to ensure that the settings of these

parameters do not create a risk of injury or equipment damage. When

commissioning the drive, verify that your system responds correctly to various

situations (a disconnected network cable or controller in idle state).

Changing the Fault Action

Set the values of parameters C143 [EN Comm Flt Actn] and C144 [EN Idle Flt

Actn] to the desired responses:

Value Action Description

0 Fault The drive is faulted and stopped (Default).

1 Stop The drive is stopped as per P045 [Stop Mode] setting.

2 Zero Data The Reference and Datalink values transmitted to the drive will be set to “0”.

3 Hold Last The Reference and Datalink values transmitted to the drive will be held at their last value.

4 Send Flt Cfg The Logic, Reference, and Datalink values will be transmitted to the drive as configured in

C145 [EN Flt Cfg Logic], C146 [EN Flt Cfg Ref], and C147 [EN Flt Cfg DL 1] through C150 [EN Flt

Cfg DL 4].

Changes to these parameters take effect immediately. A reset is not required. If

communication is disrupted and then re-established, the drive will automatically

receive commands over the network again.

Setting the Fault Configuration Parameters

When setting parameter C143 [EN Comm Flt Actn] and C144 [EN Idle Flt

Actn] to 4 “Send Flt Cfg,” the values in the following parameters are sent to the

drive after a communications fault and/or idle fault for drive control fault occurs.

You must set these parameters to values required by your application. Changes to

these parameters take effect immediately. A reset is not required.

Parameter Description

C145 [EN Flt Cfg Logic] A 16-bit integer value sent to the drive for Logic Command.

C146 [EN Flt Cfg Ref] A 16-bit integer value sent to the drive for Reference.

C147 [EN Flt Cfg DL 1] through

C150 [EN Flt Cfg DL 4]

A 16-bit integer value sent to the drive for a Datalink.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 33

Page 34

Chapter 3 Configuring the Adapter

Resetting the Adapter

Viewing the Adapter Status Using Parameters

Changes to some parameters require that you reset the adapter before the new

settings take effect. You can reset the adapter by cycling power to the drive.

ATT EN TI ON : Risk of injury or equipment damage exists. If the adapter is

transmitting control I/O to the drive, the drive may fault when you reset the

adapter. Determine how your drive will respond before resetting the adapter.

The following diagnostic parameters provide information about the status of the

adapter. You can view these parameters at any time.

Embedded EtherNet/IP Adapter Diagnostic Parameters

Name Description

F681 [Comm Sts - DSI] Displays the status of the RS485 serial (DSI) port to the drive.

F682 [Comm Sts - Opt] Displays the status of the internal communication to the drive.

F683 [Com Sts-Emb Enet] Displays the status of the embedded EtherNet/IP interface to the drive.

F684 [EN Addr Src] Displays the network configuration source currently used by the embedded

F685 [EN Rate Act] Displays the network data rate currently used by the embedded EtherNet/IP

F686 [DSI I/O Act] Displays the drives that are active in Multi-drive mode.

F687 [HW Addr 1] through

F692 [HW Addr 6]

F693 [EN IP Addr Act 1] through

F696 [EN IP Addr Act 4]

F697 [EN Subnet Act 1] through

F700 [EN Subnet Act 4]

F701 [EN Gateway Act 1] through

F704 [EN Gateway Act 4]

F705 [Drive 0 Logic Cmd]

F709 [Drive 1 Logic Cmd]

F713 [Drive 2 Logic Cmd]

F717 [Drive 3 Logic Cmd]

F721 [Drive 4 Logic Cmd]

F706 [Drv 0 Reference]

F710 [Drv 1 Reference]

F714 [Drv 2 Reference]

F718 [Drv 3 Reference]

F722 [Drv 4 Reference]

F707 [Drv 0 Logic Sts]

F711 [Drv 1 Logic Sts]

F715 [Drv 2 Logic Sts]

F719 [Drv 3 Logic Sts]

F723 [Drv 4 Logic Sts]

F708 [Drv 0 Feedback]

F712 [Drv 1 Feedback]

F716 [Drv 2 Feedback]

F720 [Drv 3 Feedback]

F724 [Drv 4 Feedback]

F725 [EN Rx Overruns] A count of the number of receive overrun errors reported by the embedded

F726 [EN Rx Packets] A count of the number of receive packets reported by the embedded EtherNet/IP

F727 [EN Rx Errors] A count of the number of receive errors reported by the embedded EtherNet/IP

EtherNet/IP interface.

interface.

Decimal value of each byte in the adapter’s Ethernet hardware address.

Value of each byte in the adapter’s present IP address. A value of “0” appears if the

adapter does not currently have an IP address.

Value of each byte in the adapter’s present subnet mask. A value of “0” appears if

the adapter does not currently have a subnet mask.

Value of each byte in the adapter’s pres ent gateway address. A value of “0” appears

if the adapter does not currently have a gateway address.

In Multi-drive mode, this is the logic command being transmitted to drive 0.

In Single-drive mode, this is the logic command being used by the drive (whether

HS-DSI, EtherNet/IP, or DSI) at the time. If comms control is NOT being used, and

the drive is in single-drive mode, then this parameter will show 0.

In Multi-drive mode, this is the reference being transmitted to drive 0/1/2/3/4.

In Single-drive mode, this is the reference being used by the drive (whether HS-

DSI, EtherNet/IP, or DSI) at the time. If comms control is NOT being used, and the

drive is in single-drive mode, then this parameter will show 0.

In Multi-drive mode, this is the logic status being received from drive 0/1/2/3/4.

In Single-drive mode, this is the logic status of the drive at the time.

In Multi-drive mode, this is the feedback being received from drive 0/1/2/3/4.

In Single-drive mode, this is the feedback of the drive at the time.

EtherNet/IP interface.

interface.

interface.

34 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 35

Configuring the Adapter Chapter 3

Embedded EtherNet/IP Adapter Diagnostic Parameters

Name Description

F728 [EN Tx Packets] A count of the number of transmitted packets reported by the embedded EtherNet/

F729 [EN Tx Errors] A count of the number of transmit errors reported by the embedded EtherNet/IP

F730 [EN Missed IO Pkt] The number of I/O packets missed.

F731 [DSI Errors] The number of total DSI errors.

IP interface.

interface.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 35

Page 36

Chapter 3 Configuring the Adapter

Notes:

36 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 37

Chapter 4

Configuring the I/O

This chapter provides instructions on how to configure a CompactLogix

controller to communicate with the embedded EtherNet/IP adapter in the

PowerFlex 525 drive.

Top ic Pa ge

Using RSLinx Classic

CompactLogix Example 38

Limitations in Using MicroLogix 1100/1400 60

37

Using RSLinx Classic

RSLinx Classic, in all its variations (Lite, Gateway, OEM, etc.), is used to provide

a communication link between the computer, network, and controller. RSLinx

Classic requires its network-specific driver to be configured before

communications are established with network devices. To configure the RSLinx

driver:

1. Start RSLinx and select Communications > Configure Drivers to display

the Configure Drivers window.

2. From the Available Driver Types pull-down box, choose “EtherNet/IP

Driver” and then click Add New… to display the Add New RSLinx Driver

window.

3. Use the default name or type a name and click OK. The “Configure

driver:” window appears.

4. Depending on your application, select either the browse local or remote

subnet option, and click OK. The Configure Drivers window reappears

with the new driver in the Configured Drivers list.

5. Click Close to close the Configure Drivers window. Keep RSLinx

running.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 37

Page 38

Chapter 4 Configuring the I/O

Esc

Sel

Ethernet

switch

IP Address 192.168.1.3

1769-L36ERM CompactLogix controller

with embedded EtherNet/IP bridge

IP Address 192.168.1.4

PowerFlex 525 drive with embedded

EtherNet/IP adapter (Frame A shown)

Computer with

Ethernet connection

6. Verify that your computer recognizes the drive. Select Communications >

RSWho and, in the menu tree, click the “+” symbol next to the Ethernet

driver.

7. Note that two other RSLinx drivers (Ethernet devices or Remote Devices

through Linx Gateway) may be used. Use one of these drivers if the

“EtherNet/IP Driver” cannot see your drive.

CompactLogix Example

After the adapter is configured, the drive and adapter will be a single node on the

network. This section provides the steps needed to configure a simple EtherNet/

IP network. In our example, we will configure a 1769-L36ERM CompactLogix

controller with embedded EtherNet/IP capability to communicate with a drive

using Logic Command/Status, Reference/Feedback, and eight Datalinks (four to

read and four to write) over the network.

00:00:BC:2E:69:F6

1 (Front)1 (Front)1 (Front)

2 (Rear)

Adding the Controller to the I/O Configuration

38 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

To establish communications between the controller and drive over the network,

you must first add the CompactLogix controller and its embedded EtherNet/IP

bridge to the I/O configuration.

Page 39

Configuring the I/O Chapter 4

1. Start RSLogix 5000/Logix Designer. The application window appears.

Select File > New to display the New Controller window.

Select the appropriate choices for the fields in the window to match your

application. Then click OK. The application window reappears with the

treeview in the left pane.

Note : If you are using a controller without an embedded EtherNet/IP

bridge, you will also need to add the bridge to the I/O configuration. See

the user manual for your controller for details.

2. Configure the IP address/Network Settings on your controller or bridge.

In this example, the Network Settings are set for a private network.

3. Click OK. The controller is now configured for the EtherNet/IP network.

It appears in the I/O Configuration folder. In our example, a

1769-L36ERM controller appears under the I/O Configuration folder

with its assigned name.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 39

Page 40

Chapter 4 Configuring the I/O

There are two ways to add the embedded EtherNet/IP adapter into the I/O

configuration:

• Drive Add-On Profiles (RSLogix 5000 version 17 or greater, Logix

Designer version 21 or greater)

• Generic Profile (RSLogix 5000 or Logix Designer, all versions)

These are described in the following separate sections. If your version of

RSLogix 5000/Logix Designer supports drive Add-On Profiles, we highly

recommend using this method.

Using Drive Add-On Profiles with RSLogix 5000 (version 17 or greater) or Logix Designer (version 21 or greater)

When compared to using the Generic Profile (all versions), the drive Add-On

Profiles provide these advantages:

• Profiles for specific drives that provide descriptive controller tags for basic

control I/O words (Logic Command/Status and Reference/Feedback)

and Datalinks. Additionally, Datalinks automatically take the name of the

drive parameter to which they are assigned. These profiles virtually

eliminate I/O mismatch errors and substantially reduce drive

configuration time.

• New Drive tab eliminates the need for a separate drive software

configuration tool.

• Drive configuration settings are saved as part of the RSLogix 5000/

Logix Designer project file (.ACD) and also downloaded to the controller.

• Unicast connection (RSLogix 5000 version 18 or greater, or Logix

Designer version 21 or greater)

• Drive Add-On Profiles enable I/O to be added online while the controller

is in the Run mode.

• Drive Add-On Profiles can be updated anytime. When a new drive is used

or to benefit from new updates for Add-On Profiles, you will need the

newest Add-On Profile update. Go to www.ab.com/support/abdrives/

webupdate to download the latest RSLogix 5000/Logix Designer drive

Add-On Profile.

Adding the Drive to the I/O Configuration

To transmit data between the controller and the drive, you must add the drive as a

child device to the parent controller. In this example, RSLogix 5000 version 20 is

used with drive Add-On Profile version 1.01.

40 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 41

Configuring the I/O Chapter 4

TIP

1. In the treeview, right-click on the icon and select New

Module… to display the Select Module window. Expand the Drives group

to display all of the available drives with their communication adapters.

If the PowerFlex drive is not shown, go to www.ab.com/support/

abdrives/webupdate and download the latest drive Add-On Profile.

2. In the Select Module Type window, select the drive and its connected

adapter from the list. For this example, we selected “PowerFlex 525EENET.” Then click Create. The drive’s New Module window appears.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 41

Page 42

Chapter 4 Configuring the I/O

3. On the General tab, edit the following data about the drive:

Box Setting

Name A name to identify the drive.

Description Optional – description of the drive.

IP Address The IP address of the adapter.

4. On the New Module window in the Module Definition section, click

Change… to launch the Module Definition window and begin the drive

configuration process.

42 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 43

Configuring the I/O Chapter 4

TIP

5. In the Module Definition window, edit the following information:

You may create a database from a network accessible drive using the

Create Database... button (Recommended).

Box Setting

Drive Rating The voltage and horsepower rating of the drive. If the drive rating is not listed, the drive

Revision The major and minor revision of the firmware (database) in the drive. If the drive’s major

Electronic Keying Compatible Module. The “Compatible Module” setting for Elec tronic Keying ensures the

Input Data Assigns drive or connected peripheral parameters to be READ by the controlle r using

Output Data Assigns drive or connected peripheral parameters to be WRITTEN by the controller using

Mode Select Sets the I/O configuration to either Velocity or Position mode.

database is not installed on your computer. To get the drive rating, use the Create

Database…, or Web Update… button described above.

and minor revision is not available, the drive database is not installed on your computer. To

get the correct database revision, use one of the following buttons at the bottom left of the

Module Definition window:

•Create Database… Creates a database from an online network drive. Clicking this

button displays an RSLinx RSWho window. Browse to the online drive (PowerFlex 525),

select it, and click OK. The database will be uploaded and stored on the computer.

Thereafter, close the Module Definition window and then re-open it to display the new

revisio n.

• Web Update… When a drive is not available online, opens the Allen-Bradley Drives

Web Updates web site to download a specific database file. After downloading the file,

close the Module Definition window and then re-open it to display the new revision.

physical module is consistent with the software configu ration before the controller and

bridge make a connection. Therefore, ensure that you have set the correct revision in this

window. See the online Help for additional information on this and other Electronic Keying

settings. If keying is not required, select “Disable Keying.” Drives do not require keying, and

so “Disable Keying” is recommended.

When using RSLogix 5000 (version 20) or Logix Designer (version 21 or greater) and

Automatic Device Configuration (ADC) with Firmware Supervisor flash support to store

firmware for the drive, always choose “Exact Match.” See the table on page 51

details when using ADC.

Datalinks.

Datalinks.

for full

On the Module Definition window, notice that the automatically-assigned

controller tags Drive Status, Feedback, Logic Command, and Reference

are always used.

When using Datalinks you must still assign parameters C153 [EN Data In

1] through C156 [EN Data In 4] and C157 [EN Data Out 1] through

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 43

Page 44

Chapter 4 Configuring the I/O

IMPORTANT

C160 [EN Data Out 4] to point to the appropriate drive or connected

peripheral parameters. The procedure to configure the Datalinks on the

Module Definition window for the Input Data and Output Data is the

same:

• Click the button to assign a parameter to each input and output

Datalink you require.

Always use the Datalink parameters in consecutive numerical order,

starting with the first parameter. (For example, use parameters C157,

C158, and C159 to configure three Datalinks to write data and/or

parameters C153, C154, C155, and C156 to configure four Datalinks to

read data.) Otherwise, the network I/O connection will be larger than

necessary, which needlessly increases controller response time and

memory usage.

6. Click OK on the Module Definition window to save the drive

configuration and close the window. The drive’s New Module window

reappears.

7. On the New Module window, click the Connection tab.

8. In the “Requested Packet Interval (RPI)” box, set the value to 5.0

milliseconds or greater. This value determines the maximum interval that a

controller should use to move data to and from the adapter. To conserve

bandwidth, use higher values for communicating with low priority devices.

The “Inhibit Module” box, when checked, inhibits the module from

communicating with the RSLogix 5000/Logix Designer project. When

the “Major Fault on …” box is checked, a major controller fault will occur

when the module’s connection fails while the controller is in the Run

Mode. For this example, leave the “Inhibit Module” and “Major Fault On

…” boxes unchecked.

44 Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013

Page 45

Configuring the I/O Chapter 4

9. Click OK on the New Module window.

The new node (“PowerFlex 525-EENET PowerFlex_52X_Drive” in this

example) now appears under the icon in the I/O Configuration

folder. If you double-click on the Input Controller Tag (Controller Input

Ta g s on page 45) and Output Controller Tag (Controller Output Tags on

page 45), you will see that module-defined data types and tags have been

automatically created. Note that all tag names are defined and Datalinks

include the assigned drive parameter name. After you save and download

the configuration, these tags allow you to access the Input and Output data

of the drive using the controller’s ladder logic.

Controller Input Tags

Controller Output Tags

Saving the I/O Configuration to the Controller

After adding the controller and drive to the I/O configuration, you must

download the configuration to the controller. You should also save the

configuration to a file on your computer.

Rockwell Automation Publication 520COM-UM001B-EN-E - March 2013 45

Page 46

Chapter 4 Configuring the I/O

TIP

1. In the RSLogix 5000/Logix Designer window, select Communications >

Download. The Download dialog box appears.

If a message box reports that RSLogix 5000/Logix Designer is unable to

go online, select Communications > Who Active to find your

controller in the Who Active screen. After finding and selecting the