Page 1

User Manual

PowerFlex DC Stand Alone Regulator and Gate

Amplifier

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, PowerFlex, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information.

Topic Page

Removed the reference to the S12 / S12R configuration from the Features list. 12

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 3

Page 4

Summary of Changes

4 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 5

Table of Contents

Preface

Introduction

Stand Alone Regulator

Installation, Wiring and

Configuration

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What This Manual Contains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Drawing Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Stand Alone Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gate Amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2

Prepare for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Terminal/Signal and Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Field Power Module Bridge and Ground Wiring. . . . . . . . . . . . . . . . . . . . 20

AC/DC Voltage and Motor Armature Voltage Feedback Wiring . . . . 21

Power Module Thermal Switch and Current Transformer Wiring . . . 24

SAR Gate Output Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control Circuit Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SAR Motor Field Current Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SAR Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SAR Current Feedback Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SAR Programming and Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Gate Amplifier Installation and

Wiring

Retrofit Guidelines

Power Interface and SCR Firing

Order

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 5

Chapter 3

Prepare for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Operating Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mounting and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Power and Ground Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chassis Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 4

Gate Interface to Non-Rockwell Power Module, Retrofit . . . . . . . . . . . . 59

Gate Interface to Reliance Electric U.S. Power Modules, Retrofit. . . . . 61

Gate Interface to Dierikon Power Modules. . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 5

Parallel Power Modules and Load Share Reactors . . . . . . . . . . . . . . . . . . . 65

Phase Sequence and Armature SCR Firing Order . . . . . . . . . . . . . . . . . . . 65

Page 6

Table of Contents

Appendix A

Specifications

History of Changes

Index

Stand Alone Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Gate Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Gate Coupler Assembly Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Gate Scaling Module Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Appendix B

23P-UM001C-EN-P, September, 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

23P-UM001B-EN-P,

April 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 7

Preface

Purpose of This Manual

What This Manual Contains

Drawing Numbers

This manual provides installation instructions and connection and configuration

information for the PowerFlex® DC Stand Alone Regulator (SAR) and the Gate

Amplifier. It is intended for internal Rockwell Automation use only.

This user manual contains the following sections:

• Description of the SAR and Gate Amplifier products and general

integration information

• Installation, connection and configuration instructions for the SAR

• Installation and connection instructions for the Gate Amplifier

• Guidelines for retrofit installations with DC power modules

• SAR and Gate Amplifier specifications

• Specifications for additional components and cables used with the SAR

and Gate Amplifier products

Throughout this manual, drawings are identified by an eight-digit number, for

example, 99999999. Where a drawing number includes an asterisk (*) in the 8th

digit, the “*” represents the latest version number of the drawing, for example,

999999*.

Additional Resources

These documents contain additional information concerning the PowerFlex DC

Stand Alone Regulator and related Rockwell Automation products.

Resource Description

PowerFlex Digital DC Drive User Manual,

publication 20D-UM001

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, http://ab.com

Provides additional installation, configuration,

and programming information for the Stand

Alone Regulator.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity, certificates,

and other certification details.

You can view or download publications at http://www.rockwellautomation.com/

literature/. To order paper copies of technical documentation, contact your local

Rockwell Automation distributor or sales representative.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 7

Page 8

preface

Notes:

8 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 9

Introduction

Chapter

1

General Precautions

Prior to installation of either the Stand Alone Regulator or Gate Amplifier, read

the following precautions.

ATTENTION: Energized industrial control equipment can be hazardous.

Severe injury or death can result from electrical shock, burn, or unintended

actuation of controlled equipment. Hazardous voltages may exist in the

cabinet even with the circuit breaker in the off position. Recommended

practice is to disconnect and lock out control equipment from power

sources, and discharge stored energy in capacitors, if present. If it is

necessary to work in the vicinity of energized equipment, the Safety

Related Practices of NFPA 70E, “ELECTRICAL SAFETY FOR EMPLOYEE

WORKPLACES” must be followed. DO NOT work alone on energized

equipment!

ATTENTION: The following information is merely a guide for proper

installation. The National Electrical Code and any other governing regional

or local code will overrule this information. Rockwell Automation cannot

assume responsibility for the compliance or the noncompliance to any

code, national, local or otherwise for the proper installation of this drive

regulator or associated equipment. A hazard of personal injury and/or

equipment damage exists if codes are ignored during installation.

ATTENTION: The installation of the Stand Alone Regulator and/or the

Gate Amplifier must be planned such that all cutting, drilling, tapping and

welding can be accomplished with the Gate Amplifier removed from the

enclosure. The Stand Alone Regulator and Gate Amplifier are of the open

type construction and any metal debris must be kept from falling into the

enclosure. Metal debris or other foreign matter may become lodged in the

circuitry resulting in component damage.

ATTENTION: An incorrectly applied or installed Stand Alone Regulator or

Gate Amplifier can result in component damage or a reduction in product

life. Wiring or application errors, such as, incorrect or inadequate supply

voltage or excessive ambient temperatures may result in malfunction of

the system.

ATTENTION: Only qualified personnel familiar with DC drives and

associated machinery should plan or implement the installation, start-up

and subsequent maintenance of the system. Failure to comply may result

in personal injury and/or equipment damage.

ATTENTION: The Stand Alone Regulator and Gate Amplifier contain ESD

(Electrostatic Discharge) sensitive parts and assemblies. Static control

precautions are required when installing, testing, servicing or repairing

this assembly. Component damage may result if ESD control procedures

are not followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 9

Page 10

Chapter 1 Introduction

Product Overview

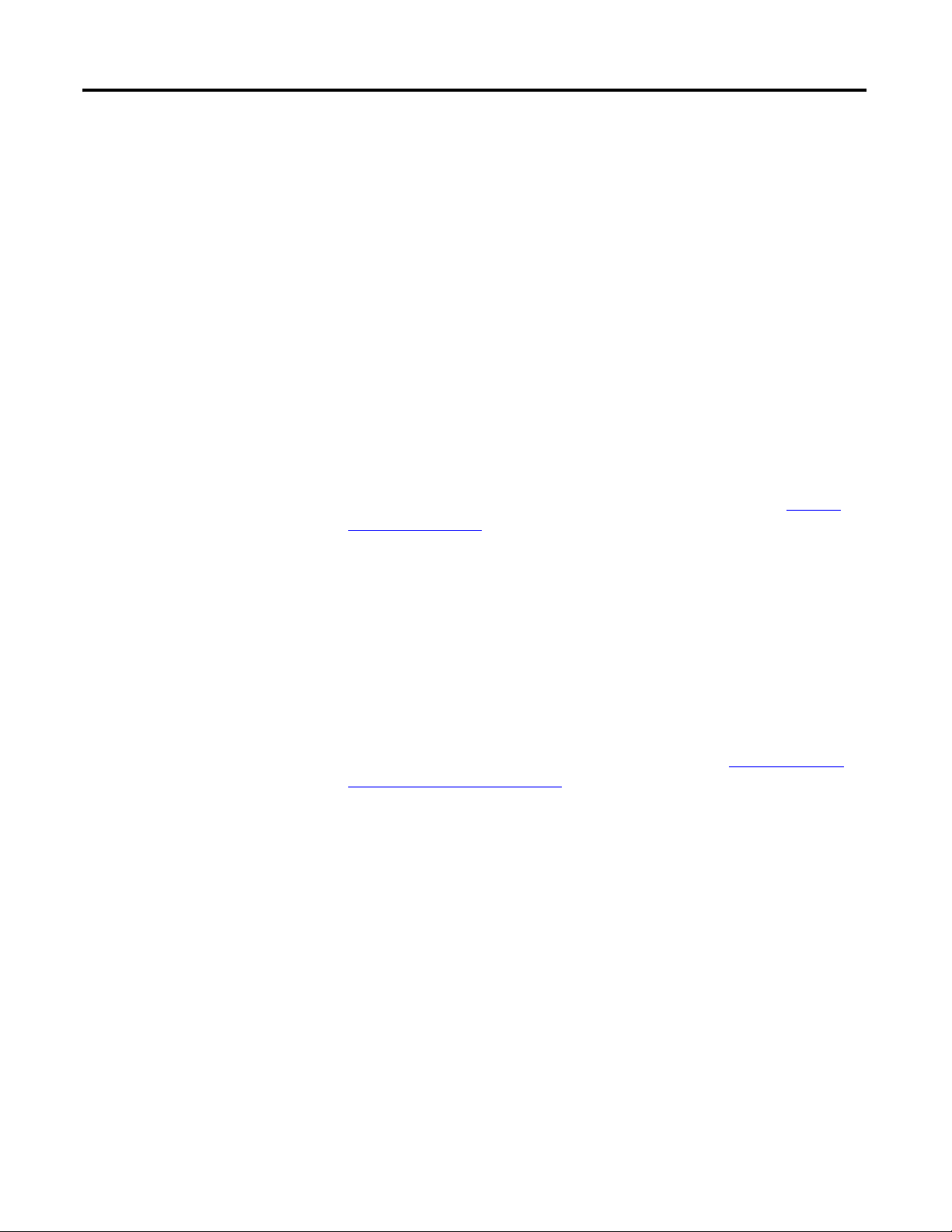

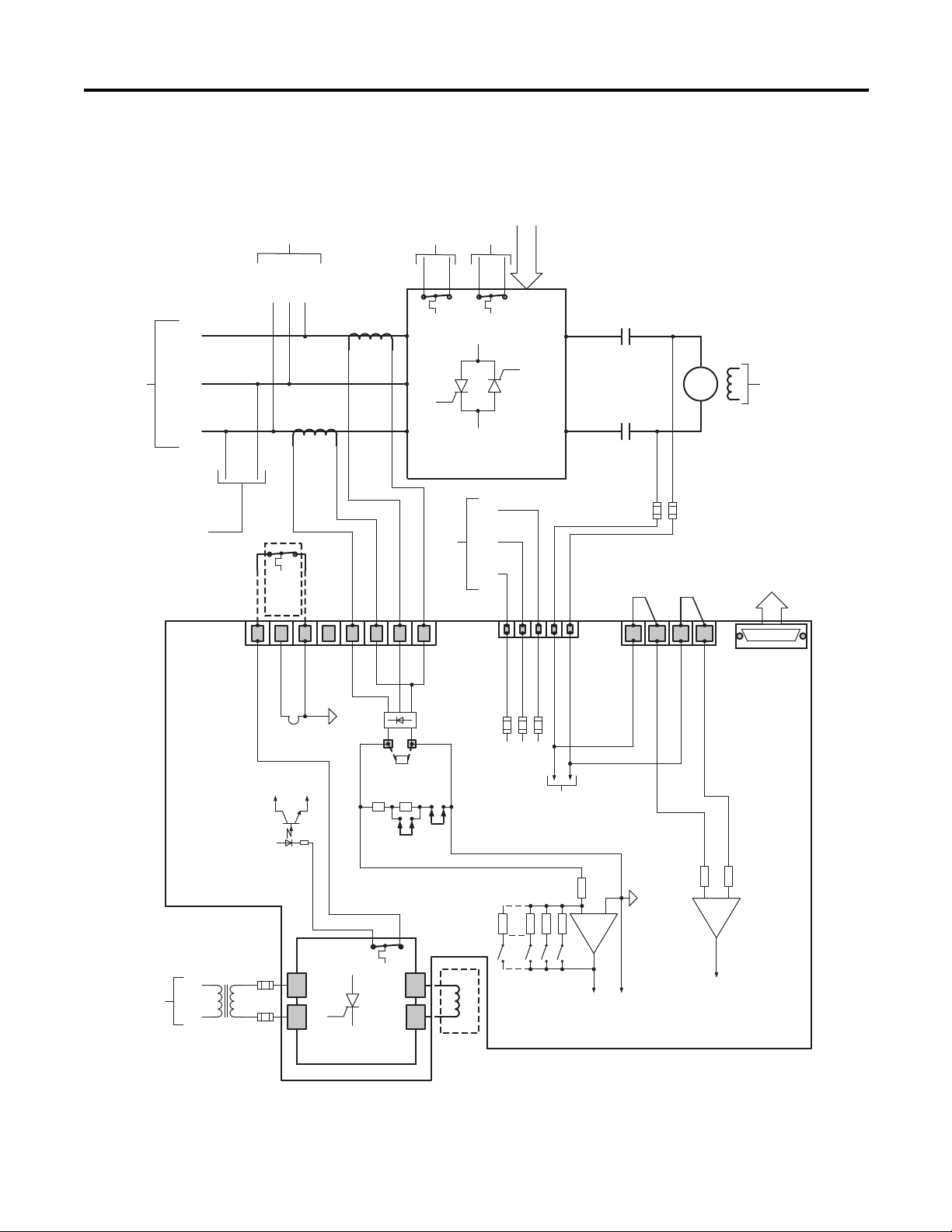

The PowerFlex DC Stand Alone Regulator (SAR) and Gate Amplifier products

provide an integrated solution for controlling external DC power modules.

Stand Alone Regulator (SAR)

The SAR is a DC drive regulator that provides armature regulation, armature

SCR gate signals and a regulated field supply. The SAR field supply consists of a

single phase, two quadrant (non-reversing,) full wave rectified bridge, available as

40 or 70 Amps. The SAR supports an AC line input voltage range of 230VAC to

690VAC and a field input voltage range of 100VAC to 460VAC.

The SAR uses feedback signals from the AC input line to monitor the incoming

voltage level in order to establish the SCR gate firing sequence relative to the AC

line. The SCR gate firing for the field bridge is established from the AC lines that

supply the field, independent of the armature firing circuit. DC feedback signals

are used to monitor the output voltage from the power module. Additionally,

current signals received from current transformers is used by the SAR regulator to

monitor and control current. The SAR catalog numbers are listed in Catalog

Numbers on page 12. The SAR must be used with the Gate Amplifier in order to

interface with a DC power module(s).

Gate Amplifier

The Gate Amplifier is used to amplify the SCR gate signals supplied by a DC

drive regulator. The gate signal source to the Gate Amplifier can be provided by

either the PowerFlex DC SAR, or the SD3000 PLUS. The Gate Amplifier unit

provides a separate input D-Shell connector for each product. The Power

Module Interface (PMI) Rack is also compatible with the Gate Amplifier and

uses the SD3000 PLUS inputs. The Gate Amplifier model number and

corresponding connection cables part numbers are listed in Model and Cable

Model/Part Numbers on page 12.

In addition to amplifying the gate signals, the forward and reverse signals

provided by the Gate Amplifier are “fanned-out” to enable the driving of multiple

power modules. Four S6 bridges forward and four S6 bridges reverse. When the

S6 bridges are connected in an anti-parallel configuration, the topology is an S6R

providing both motoring and regenerative capability.

The external 48V gate power supply capability of the Gate Amplifier provides the

means to supply additional gate current and voltage and also support the firing of

gate coupler boards connected in series (which requires additional voltage).

Connecting gate couplers in series forces the simultaneous firing of the SCRs,

with power connections in series or parallel. An internal “diode OR” circuit

ensures that the gates are powered by whichever gate power supply voltage is the

greater in amplitude, the internal or the external power supply.

10 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 11

Introduction Chapter 1

+

-

PowerFlex DC

Stand Alone Regulator

SD3K

FWD IN

SD3K

REV IN

PFDC

Gate Input

FWD

REV

KPT11

(15 Pin D-Shell)

Field Supply

40 A or 70 A

(2 Quad)

To Motor

Field

Gate Cable

Normally

Open Contacts

to Stop Circuitry

RDY

Ext. P/S

120VAC

Gate Amplifier

48V Ext P/S

(If Required)

To Stop

Circuitry

P/S

MONITOR

RELAY

L1, L2, L3

AC

CT FDBK to PFDC SAR

AC

Input

From Stand-Alone

Regulator

Motor Field

To Encoder or Resolver

Feedback Port

Encoder or Resolver Feedback

Motor

M

+DC and -DC

Power Module

Output

CTs on

L1 and L3

FWD

1

REV

1

GATE COUPLER

ASSEMBLY

GATE COUPLER

ASSEMBLY

C1 D1 D C W V U 1A1 A1 1A2 A2 1 2 3 4 5 6 7 8

KPT31KAKP

Power Module

AC / DC

Feedback

Power Module

Armature Voltage

Feedback

Power Module

Thermostat and

CT Feedback

V1 U1

All Ter minals are located

on the bottom of the unit.

Figure 1 - Typical PowerFlex DC Stand Alone Regulator and Gate Amplifier

Interface to S6R

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 11

Page 12

Chapter 1 Introduction

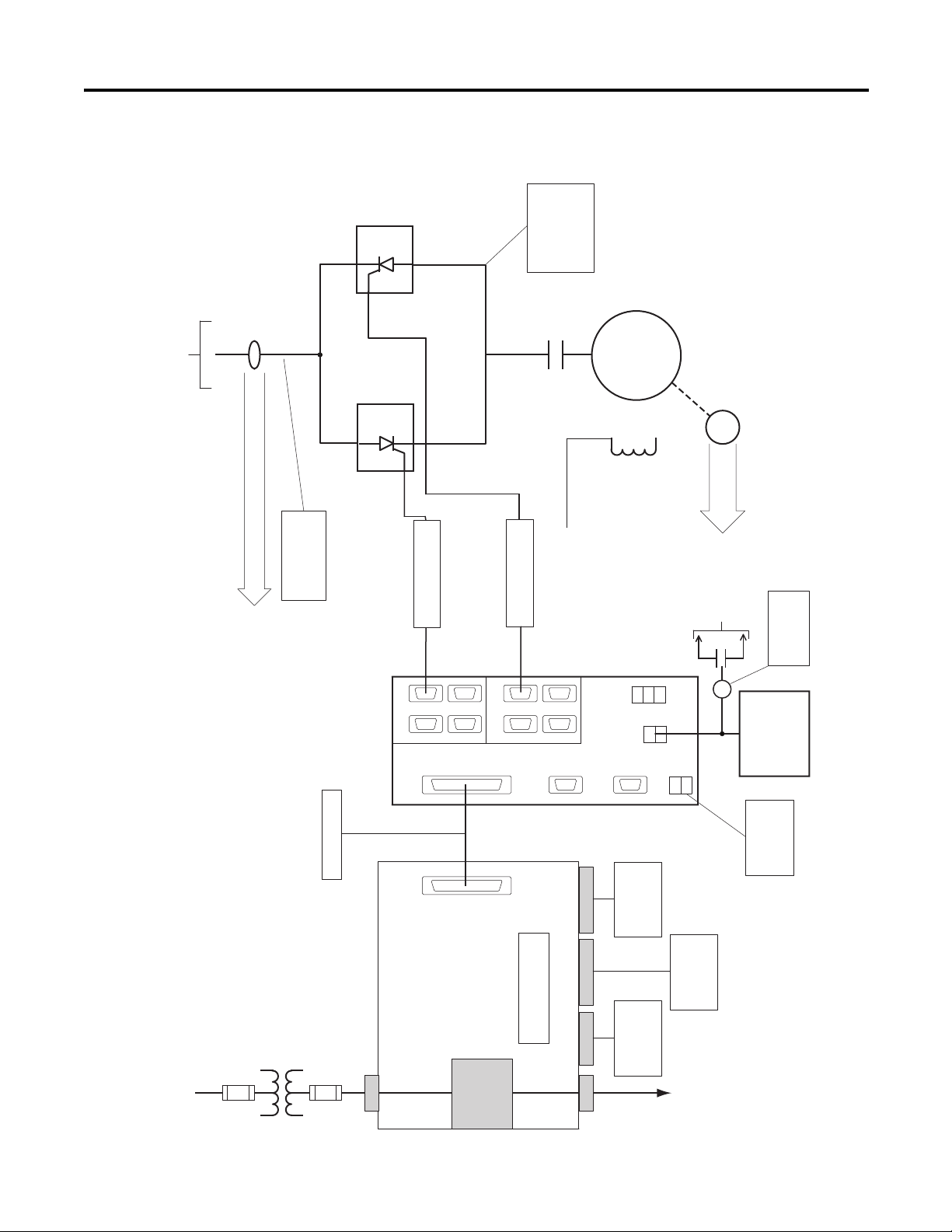

Stand Alone Regulator

Gate Amplifier

Features

• Rockwell Automation Architecture Class networking capable

Available Options

• Resolver Feedback

Catalog Numbers

This table lists the available catalog numbers for the SAR.

230V / 460V AC Input

Catalog Number

23PMD4 23PMF4 40

23PMD7 23PMF7 70

575V / 690V AC Input

Catalog Number:

Field Amps

Note: All models contain conformal coated circuit boards.

Features

• Interfaces to the PowerFlex DC, SD3000 PLUS or PMI regulators

• Flexible configurations S6 and S6R

•Power module interface

• Interlock via “Ready Relay” contacts to main drive control

Available Options

• 48V gate drive capability with an external power supply

Model and Cable Model/Part Numbers

This table lists the cable module numbers and part numbers for the Gate

Amplifier.

Product: Model/Part Number:

Gate Amplifier 23PAMP

PowerFlex DC to Gate Amplifier Cable See Cable Specifications

SD3000 PLUS to Gate Amplifier Forward Cable SD3K-CBLGSCLIFxxx

SD3000 PLUS to Gate Amplifier Reverse Cable SD3K-CBLGSCLIRxxx

PMI Rack to Gate Amplifier Forward Cable 612432-xxxS

PMI Rack to Gate Amplifier Reverse Cable 612433-xxxS

(1) xxx = length in inches.

12 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

on page 78.

(1)

(1)

(1)

(1)

Page 13

Chapter

2

Stand Alone Regulator Installation, Wiring

and Configuration

Prepare for Installation

Mounting Considerations

Prior to installation of the PowerFlex DC Stand Alone Regulator (SAR) read the

General Precautions on page 9

.

Operating Conditions and Temperatures

The SAR is designed to operate at 0°…50° C (32°… 122° F) surrounding air

temperature without derating. The unit must be mounted in a clean, dry location.

Contaminants such as oils, corrosive vapors and abrasive debris must be kept out

of the enclosure. NEMA/UL Type Open, IP20 enclosures are intended for

indoor use primarily to provide a degree of protection against contact with

enclosed equipment. These enclosures offer no protection against airborne

contaminants.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 13

Page 14

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

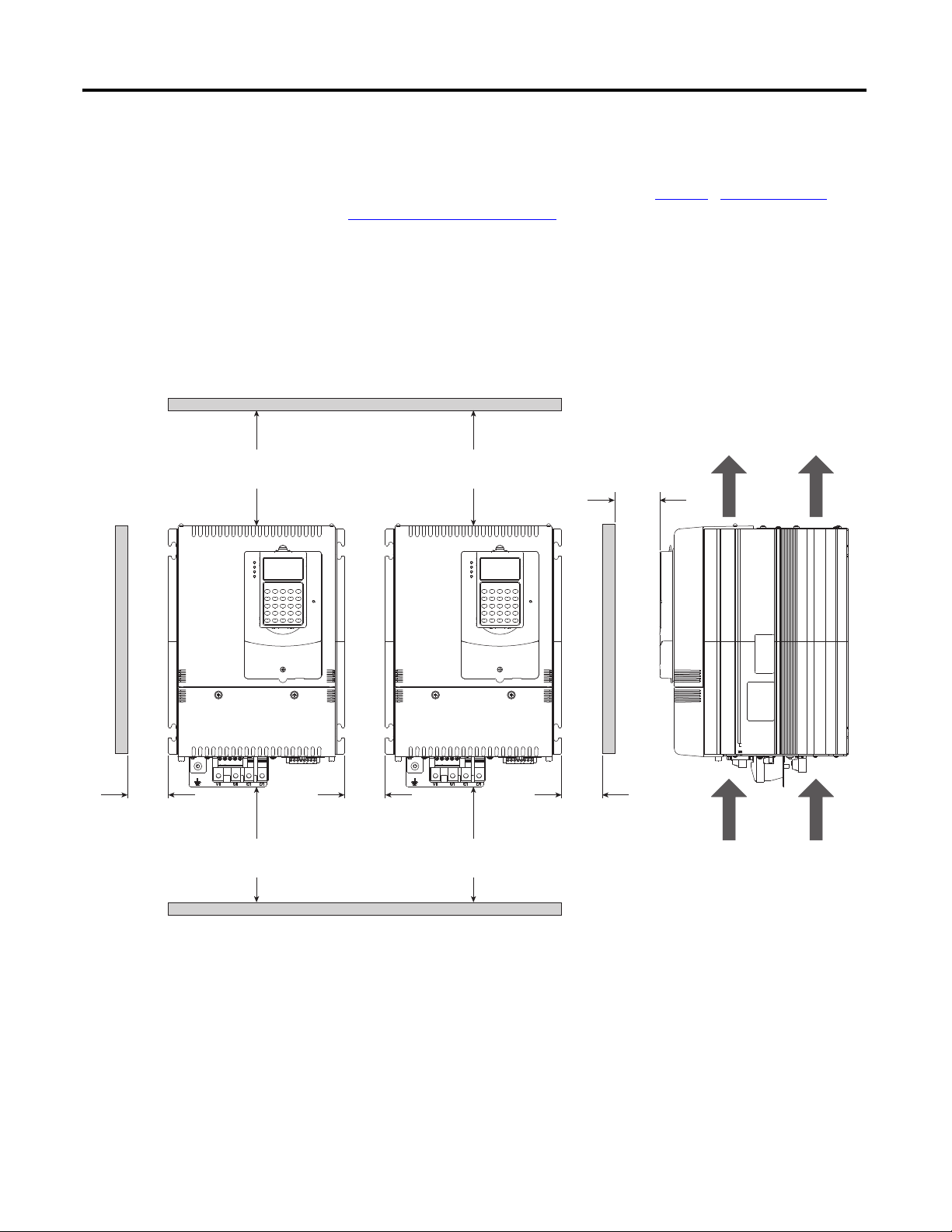

Min. 10 0 mm

(0.4 in.)

Min. 150 mm

(6.0 in.)

Min. 150 mm

(6.0 in.)

Min. 150 mm

(6.0 in.)

Min. 150 mm

(6.0 in.)

Min. 10 0 mm

(0.4 in.)

Min. 50 mm

(2.0 in.)

Min. 10 0 mm

(0.4 in.)

Airflow through the unit

must not be impeded.

Minimum Mounting Clearances

Minimum clearance requirements (indicated in Figure 2 - Drive Enclosure

Minimum Mounting Clearances) are intended to be from enclosure to enclosure.

Other objects can occupy this space; however, reduced airflow may cause

protection circuits to fault the SAR. The SAR must be mounted in a vertical

orientation as shown and must not be mounted at an angle greater than 30

degrees from vertical. In addition, inlet air temperature must not exceed the

product specification.

Figure 2 - Drive Enclosure Minimum Mounting Clearances

14 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 15

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

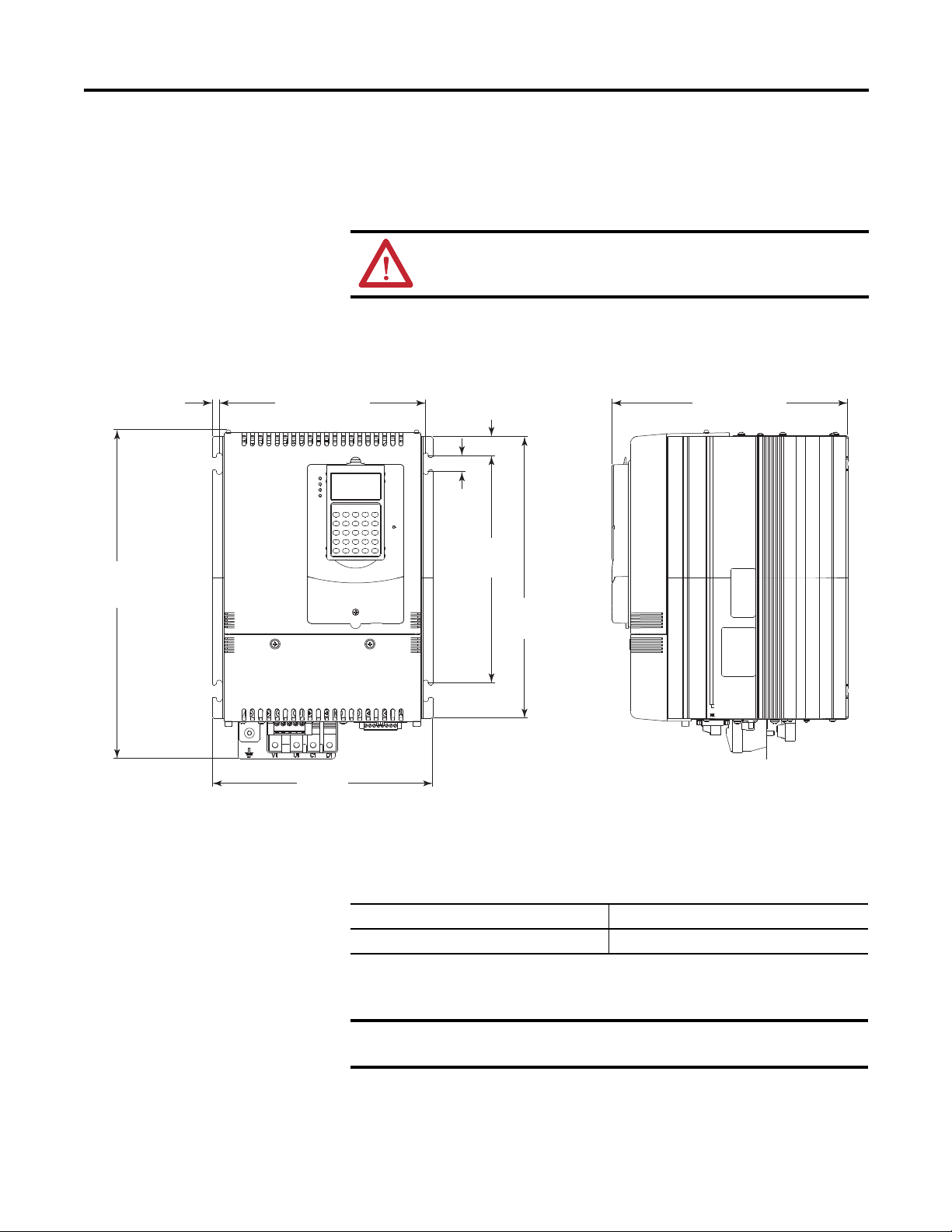

8.4 (0.33) 250.0 (9.84)

19.5

(0.77)

23.3

(0.92)

341.0

(13.43)

275.0

(10.83)

266.8

(10.51)

397.9

(15.67)

285.4 (11.24)

Dimensions are shown in mm (in.)

IMPORTANT

Approximate Dimensions and Weights

The SAR is available in a NEMA/UL Type Open, IP20 enclosure only.

ATTENTION: Remove all loose packaging materials, including any

desiccant packages from the enclosure before mounting and energizing

the SAR.

Table 1 - Stand Alone Regulator Weights

Stand Alone Regulator Stand Alone Regulator and Packaging

12.0 kg (26.5 lb) 14.1 kg (31 lb)

Recommended Mounting Hardware: Metric M6, English 1/4 in.

Provide a minimum of 150 mm (6.0 in.) below the unit for cable

connections.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 15

Page 16

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

CE Conformity

Conformity with the Low Voltage Directive and Electromagnetic Compatibility

Directive has been demonstrated using harmonized European Norm (EN)

standards published in the Official Journal of the European Communities. The

PowerFlex DC Stand Alone Regulator complies with the EN standards listed

when installed according to this User Manual.

CE Declarations of Conformity are available online at:

www.rockwellautomation.com/products/certification/ce/

Low Voltage Directive (2006/95/EC)

• EN 50178 Electronic equipment for use in power installations.

EMC Directive (2004/108/EC)

• EN 61800-3 Adjustable speed electrical power drive systems Part 3: EMC

product standard including specific test methods.

General Considerations

• For CE compliance, the SAR installation must satisfy requirements related

to both EN 50178 and EN 61800-3 provided in this document.

• The SAR complies with the EMC requirements of EN 61800-3 when

installed according to good EMC practices and the instructions provided

in this document. However, many factors can influence the EMC

compliance of an entire machine or installation, and compliance of the

SAR itself does not necessarily ensure compliance of all applications.

• The SAR is not intended to be used on public supply networks which

supply domestic premises. Without additional mitigation, radio frequency

interference is expected if used on such a network. The installer is

responsible to take measures such as supplementary line filters and

enclosures to prevent interference, in addition to the installation

requirements of this document.

Installation Requirements Related to EN 50178 and the Low Voltage Directive

• The SAR is compliant with the CE LV Directive when used at altitudes no

greater than 2000 m (6562 ft).

• The SAR provided in enclosure type IP20 must be installed in a pollution

degree 1 or 2 environment to be compliant with the CE LV Directive.

Characteristics of the different pollution degree ratings are provided in

Tab le 2 on p ag e 17

.

16 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 17

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

Table 2 - Pollution Degree Ratings According to EN 61800-5-1

Pollution Degree Description

1 No pollution or only dry, non-conductive pollution occurs. The pollution has no

2 Normally, only non-conductive pollution occurs. Occasionally, however, a

3 Conductive pollution or dry non-conductive pollution occurs, which becomes

4 The pollution generates persistent conductivity caused, for example by

influence.

temporary conductivity caused by condensation is to be expected, when the

drive is out of operation.

conductive due to condensation, which is to be expected.

conductive dust or rain or snow.

• The SAR must be installed in a suitable enclosure with at least an IP4X

rating at the top of the enclosure.

• The SAR may produce leakage current in the protective earthing

conductor which exceeds 3.5 mA AC and/or 10 mA DC. The minimum

size of the protective earthing (grounding) conductor used in the

application must comply with local safety regulations for equipment with

high protective earthing conductor current.

• The SAR may not be powered from a “corner-earthed” supply system in

order to maintain compliance with the CE LV Directive.

Installation Requirements Related to EN 61800-3 and the EMC Directive

• The SAR must be earthed (grounded) as described in this User Manual.

• Output power wiring to the motor (field excitation) must employ cable

with a braided shield providing 75% or greater coverage, or the cable must

be housed in metal conduit, or equivalent shielding must be provided.

Continuous shielding must be provided from the SAR enclosure to the

motor enclosure. Both ends of the motor cable shield (or conduit) must

terminate with a low-impedance connection to earth.

• At the motor end, the motor field excitation cable shield or conduit must

terminate in a shielded connector which must be properly installed in an

earthed motor wiring box attached to the motor. The motor wiring box

cover must be installed and earthed.

• All control (I/O) and signal wiring to the SAR, including gate firing

control, must use cable with a braided or foil shield providing 75% or

greater coverage, or the cables must be housed in metal conduit, or

equivalent shielding must be provided. Only the SAR end of the cable

shield should be terminated with a low impedance connection to earth.

• Power cabling must be separated from control and signal wiring wherever

possible.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 17

Page 18

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

D, “-”

C, “+”

W, AC_In

AC / DC Feedback

V 1, AC_In

U1, AC_In

C1, DC_Out “+”

Field Bridge, AC Input / DC Ouput

PE (GND)

12345

Power Module Thermal / CT Feedback

Connector

“KP”

Connector

“KPT31”

678

+V _therm, +15V

Therm_Com

IS O_Com

(Not_Used)

CT1 +

CT1 -

CT2 +

CT2 -

Gate Outpu t

Connector

“KPT11”

1A1 A1 1A2

Power Module Armature Feedback

Connector

“KA”

(P M O ut + “C”)A2Motor Arm Fdbk “+”

(PM Out - “D ”)

Motor Arm F dbk “-”

V , A C _I n

U, AC_In

D1, DC_Out “-”

Bottom View

Front of Unit

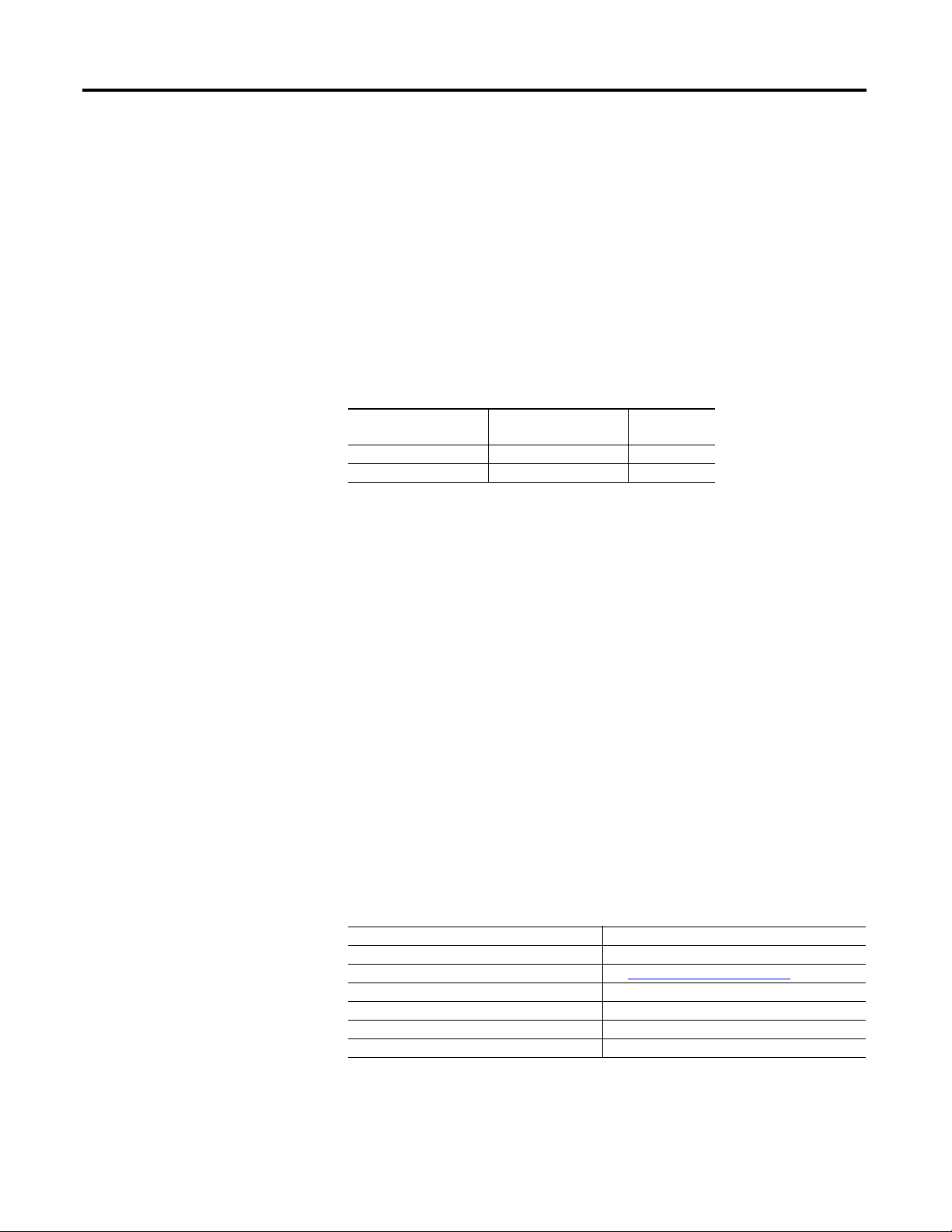

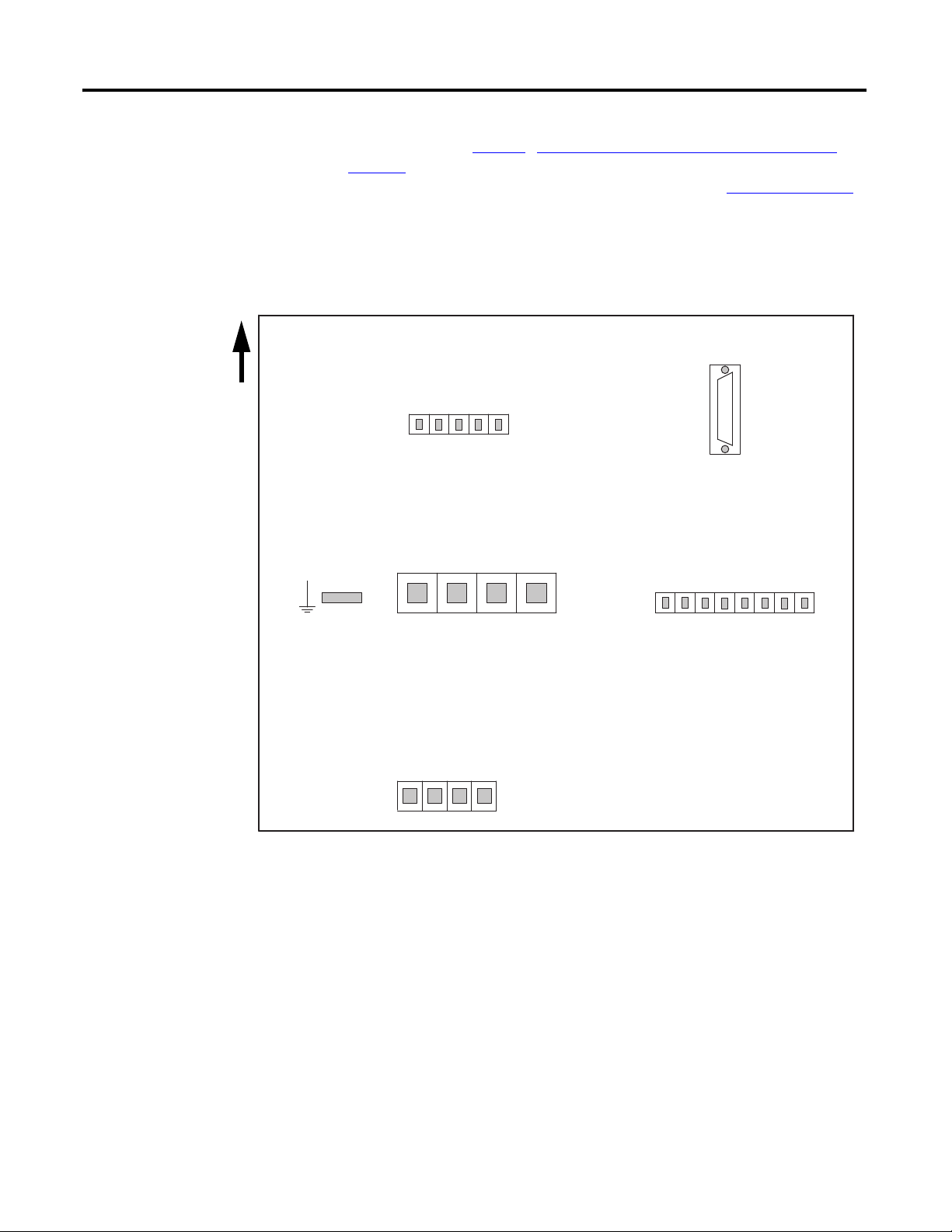

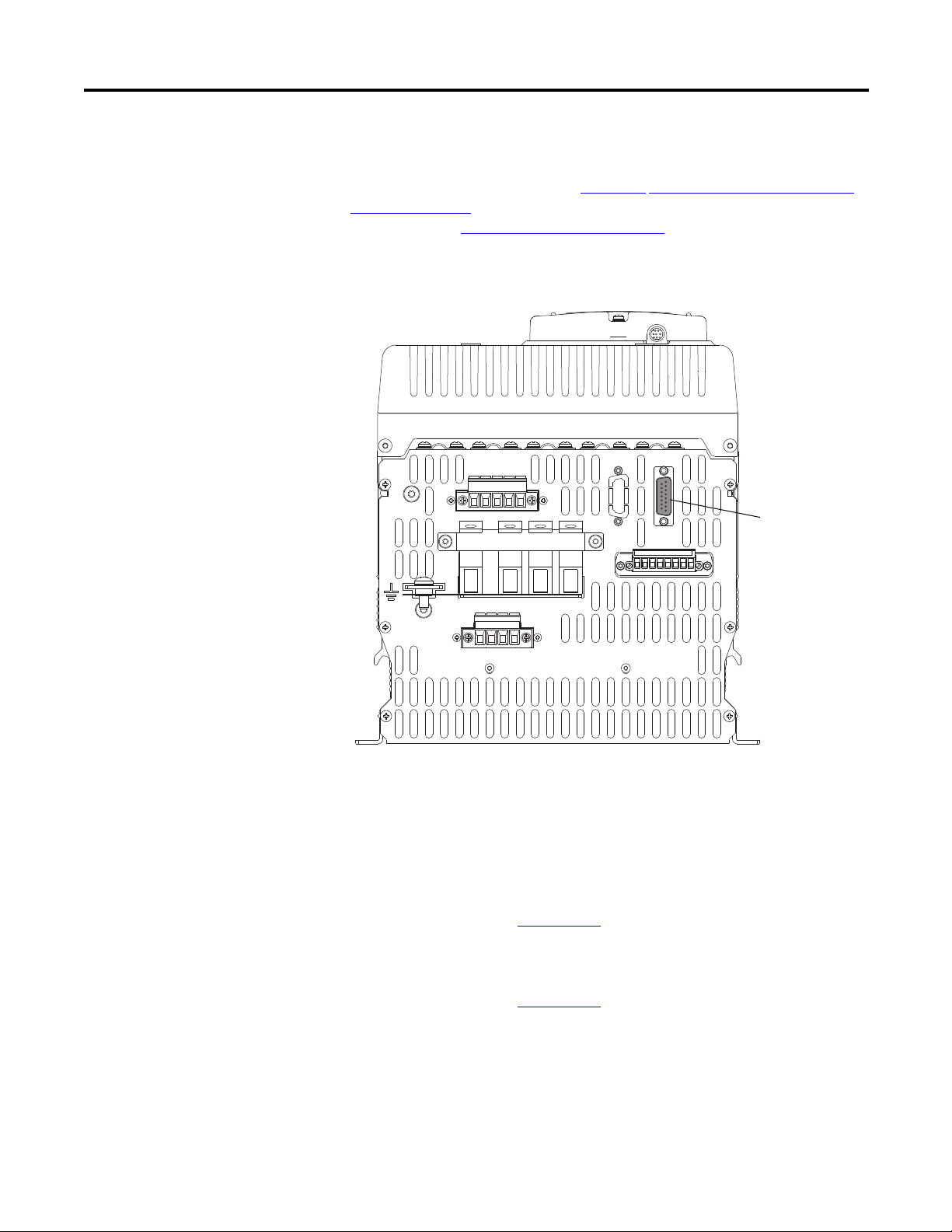

Terminal/Signal and Wiring Diagrams

Use the diagram in Figure 3 - Stand Alone Regulator Terminal/Signal Block

Diagram as a guide for the general location of and connection signals for the main

input/output terminal blocks on the SAR. The diagram in Figure 4 on page 19

represents the recommended wiring for a typical SAR interface to a S6R power

module.

Figure 3 - Stand Alone Regulator Terminal/Signal Block Diagram

18 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 19

Pwr Mod / Arm Fdbk

Conn “KA”

213

4

5

6

7

8

Pwr Mod Thermal / CT Feedback

Conn “KPT31”

U

(L1)

U VW

MM

M

Internal Fuses

From AC Line Above

To SAR

Conn “KP”

Fault

To SAR

Conn “KPT31”

Warning

To Digital I/O

(if available)

Field Regulator (2 Quad)

U V

To Field Power

Module

Transformer

Incoming AC Line

From Incoming AC Line

Transformer

(External to SAR)

Field PM Therm

OT

+15 V ISO

+

-

Motor Field

Motor Field

Supplied by SAR

Field Power Module

(or separately excited)

U1 V1

C1

D1

Ext.

Rb

XCT

J4

J5

Armat ure

Current

Feedback

Gate Input

Gates

Gate Ou tput

Conn “KPT11”

To Gate Amplifier

(refer to gate wiring

diagrams)

Stand Alone Regulator (SAR)

* Note: Armature Voltage

Feedback. Jumpers

must always be in place.

From Gate

Amplifier Output

(refer to gate

wiring diagrams)

Armat ure

Voltage

Feedback

See page 21 for

Fuse Sizes

(External to SAR)

Motor Arm Fdbk “-” A2

(PM Out - “D”) 1A2

Motor Arm Fdbk “+” A1

(PM Out + “C”) 1A1

AC / DC Feedback

Conn “KP”

D, “-”

C, “+”

W, AC_In

V, AC_In

U, AC_In

CT2 -

CT2 +

CT1 -

CT1 +

(Not_Used)

Therm_Com

ISO_Com

+V_Therm, +15V

0V ISO

#S2

(Test

Pt.)

2.5

Ohms

2.5

Ohms

Therm

Fault

On Pwr Mod

V

(L2)

W

(L3)

U, (L1)

V, (L2)

W, (L3)

CT1

CT2

U

(L1)

V

(L2)

W

(L3)

“+”

C

“-”

D

5A, 700V

5A, 700V

*(See

Note)

*(See

Note)

To Voltage

Feedback

Circuits

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

Figure 4 - Typical Stand Alone Regulator Interface to S6R Power Module

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 19

Page 20

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

1A1

(C)

A1 1A2

(D)

A2

1 2 3 4 5 6 7 8

V1 U1 C1 D1

D C W V U

KPT21 KPT11

KPT31

PE

Field Power

Module Bridge

Terminal Block

PE Terminal

Bottom View of SAR

1

2

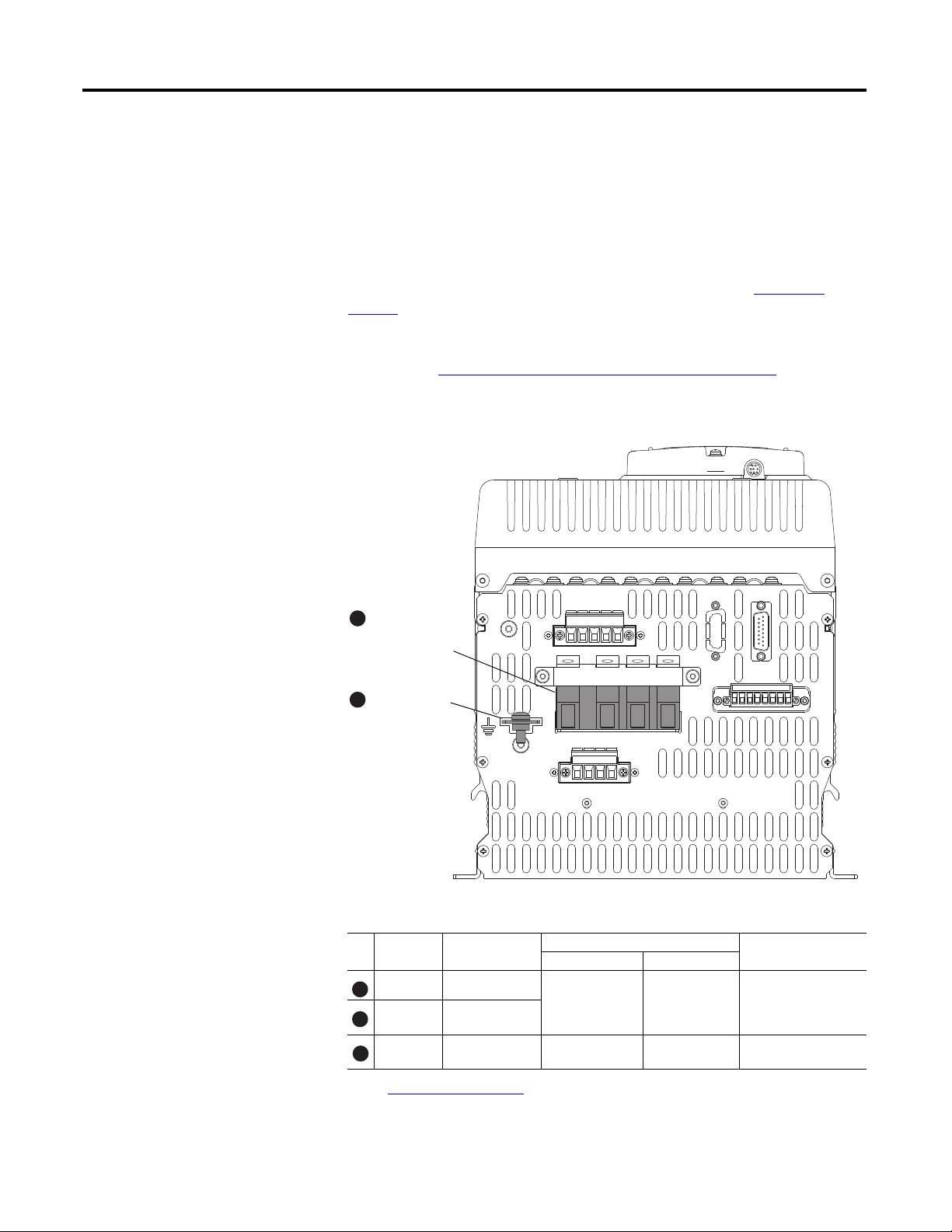

Field Power Module Bridge and Ground Wiring

The SAR contains a two quadrant field power module bridge. The field bridge

input circuit is rated for 100VAC…460VAC, ±10%, 50/60 Hz. The input and

output connections to/from the field bridge are on the bottom of the SAR as

shown.

An external transformer with appropriate primar y fusing is required to supply the

field. External fusing is also required at the input terminals V1 and U1 to protect

the field bridge. The recommended fuse types are shown in the Tab le 4 o n

page 21.

The SAR motor field current must configured with a hardware DIP switch and in

firmware. See SAR Motor Field Current Configuration

on page 26 for more

information.

Figure 5 - Field Power Module Bridge Terminal Block and Ground Connection

20 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Table 3 - Field Power Module Bridge and Ground Terminal Specifications

Wire Size Range

No. Terminal Description

V1, U1 AC Input Power

1

1

PE Safety Ground

2

(1) See Safety Ground (PE) on page 21 for more information.

to Motor Field

(1)

25.0 mm

(2 AWG)

16.0 mm

(6 AWG)

2

2

10.0 mm

(10 AWG)

10.0 mm

(8 AWG)

2

2

Recommended

TorqueMaximum Minimum

4.0…4.5 N•m

(35.4…39.8 lb•in)C1, D1 DC Output Power

6.0…8.0 N•m

(53.1…70.8 lb•in)

Page 21

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

Table 4 - Recommended Field Power Module Bridge Input Fuses

SAR Field

Bridge Rating

40 A FWP-50A22Fa A70QS50-22F 5014006.50

70 A FWP-100A22Fa A70QS100-22F 5014006.100

The recommended fuse holder is a Cooper-Bussman, CH222D or equivalent - to

accommodate 22 mm x 58 mm fuses.

Fuse Type:

Bussmann Ferraz Shawmut Siba

Safety Ground (PE)

The Safety Ground - PE must be connected to system ground. Ground

impedance must conform to the requirements of national and local industrial

safety regulations and/or electrical codes. The integrity of all ground connections

should be periodically checked.

For installations within a cabinet, a single safety ground point or ground bus bar

connected directly to building steel should be used. All circuits should be

grounded independently and directly to this point/bar.

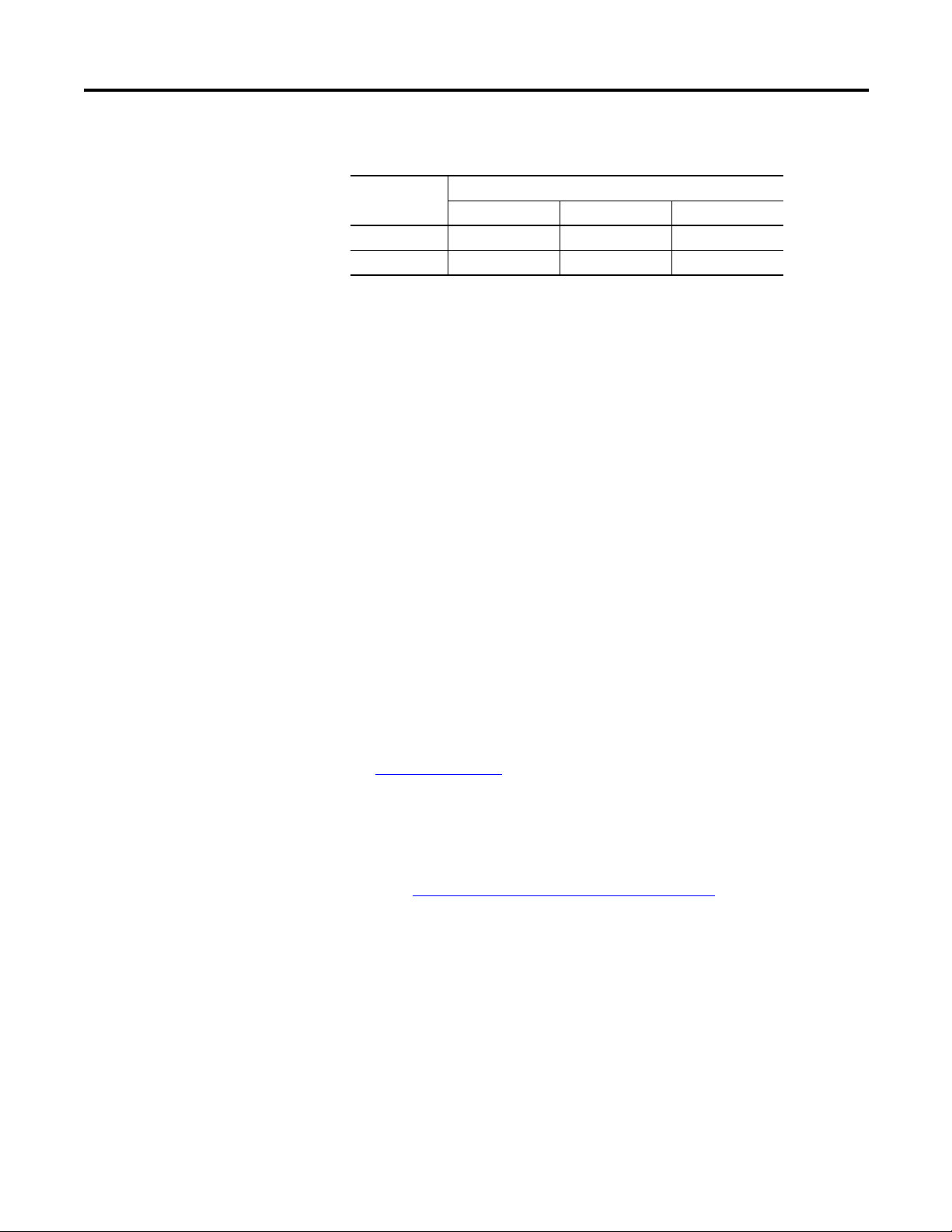

AC/DC Voltage and Motor Armature Voltage Feedback Wiring

The SAR requires AC feedback connections to connector KP (terminals U, V,

and W) from the incoming line to monitor the incoming voltage level and

establish the SCR gate firing sequence relative to the AC line. DC feedback

connections to connector KP (terminals C and D) are required to monitor the

voltage output from the DC power module. The combined information from the

AC and DC feedback inputs is used to determine if the SCRs are firing properly.

See Figure 4 on page 19

S6R.

Fuses are required between the DC output power wiring on the DC power

module to connector KP on the SAR. This will limit the current to the regulator

in the event of an internal fault in the SAR. The recommended fuse types are

shown in DC Feedback Fusing Requirements

for recommended wiring for a typical SAR interface to

on page 22.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 21

Page 22

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

1 2 3 4 5 6 7 8

V1 U1 C1 D1

KPT21 KPT11

KPT31

PE

D C W V U

1A1

(C)

A1 1A2

(D)

A2

AC /DC Voltage

Feedback (KP)

Terminal Block

Bottom View of SAR

Motor Armature

Voltage Feedback

(KA) Terminal

Block

1

2

Figure 6 - AC /DC Voltage Feedback (KP) and Motor Armature Voltage Feedback

(KA) Terminal Blocks

Table 5 - AC / DC Voltage and Motor Armature Voltage Feedback Terminal

Specifications

No. Terminal Description

W, V, U AC Input

1

Feedback

(connector KP)

D, C DC Output

1

Feedback

(connector KP)

2

1A1, A1,

1A2, A2

Motor Armature

Voltage Feedback

(connector KA)

Wire Size Range

2

6.0 mm

(10 AWG)

0.2 mm

(24 AWG)

2

Recommended

TorqueMaximum Minimum

0.7…0.8 N•m

(6.2…7.1 lb•in)

DC Feedback Fusing Requirements

The recommended fuses are:

• Bussmann fuse FWP-5A14F (5 A, 700V, Type FWP, 14 x 51mm), or

equivalent.

Note: The AC voltage feedback inputs on the SAR are fused internally.

22 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 23

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

1A1

(C)

A1 1A2

(D)

A2

Place jumpers between

terminals as shown

Connector KP Wiring

• Connect the motor armature terminal C to terminal C on connector KP

• Connect the motor armature terminal D to terminal D on connector KP

Connector KA Wiring

Connector KA must be wired to provide DC voltage feedback to the field

regulator to control the field current based on the armature voltage. Terminal

1A1 is connected internally to terminal C (on connector KP) and terminal 1A2

is connected internally to terminal D (on connector KP). The default

configuration is shown in Figure 7

• Jumper terminal 1A1 to terminal A1

• Jumper terminal 1A2 to terminal A2

The jumpers will provide the field regulator with the power module/armature

voltage feedback. This is the default wiring scheme for connector KA at the

factory.

and is wired as follows:

Figure 7 - Terminals on Connector KA Jumpered

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 23

Page 24

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

1A1

(C)

A1 1A2

(D)

A2

V1 U1 C1 D1

D C W V U

KPT21 KPT11

KPT31

PE

1 2 3 4 5 6 7 8

Power Module

Thermal Switch and

Current Transformer

(KPT31) Terminal

Block

Bottom View of SAR

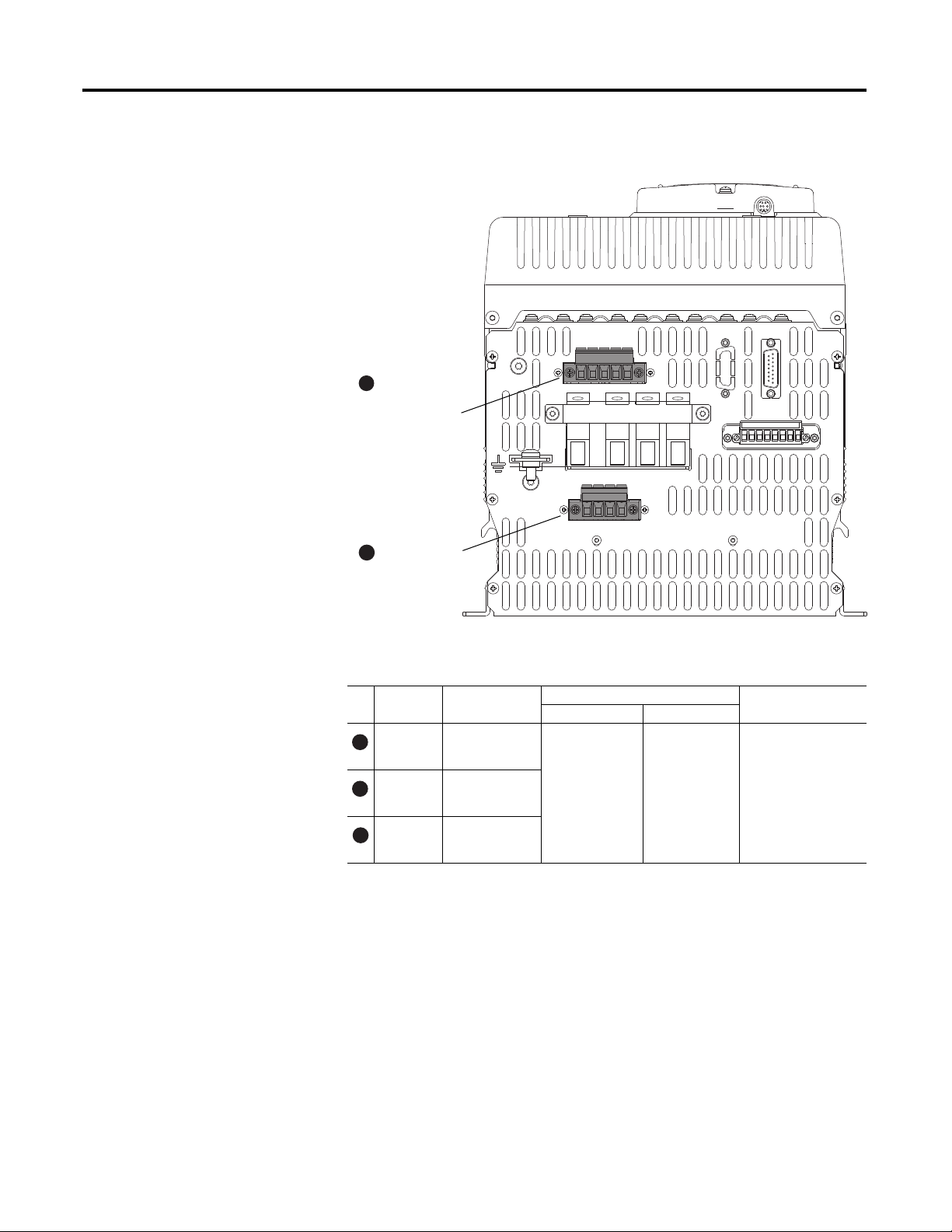

Power Module Thermal Switch and Current Transformer Wiring

Connector KPT31 is used for power module thermal switch monitoring and

current feedback via current transformer connections. Note that the thermal

monitor circuit includes a thermal switch on the field power module within the

SAR.

Figure 8 - Power Module Thermal Switch and Current Transformer Terminal Block

(KPT31)

Table 6 - Power Module Thermal Switch and Current Transformer Terminal

Specifications

Terminal Description

1, 2, 3 Thermal Switch Monitor

5, 6, 7, 8 Current Transformer Feedback

(1) These terminals are jumpered by default. The jumper wires must remain in place if a power module thermal

switch is NOT connected.

Current Transformer Connections

Current transformer 1 (CT1) monitors the U phase, with the “+” output of CT1

connected to terminal 5 of KPT31 and the “-” output of CT1 connected to

terminal 6 of KPT31.

Current transformer 2 (CT2) monitors the W phase, with the “+” output of

(1)

Wire Size Range

2

2.5 mm

(12 AWG)

0.2 mm

(24 AWG)

Recommended

TorqueMaximum Minimum

2

0.5…0.6 N•m

(4.4…5.3 lb•in)

CT2 connected to terminal 7 of KPT31 and the “-” output of CT2 connected to

terminal 8 of KPT31.

The “-” side of the CTs are connected together internally in the SAR.

24 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 25

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

1A1

(C)

A1 1A2

(D)

A2

1 2 3 4 5 6 7 8

V1 U1 C1 D1

D C W V U

KPT21 KPT11

KPT31

PE

SAR Gate Output

Cable (KPT11)

Connector

Bottom View of SAR

SAR Gate Output Cable

Connect the SAR gate output cable (23PAMP-Cx) to connector KPT11 on the

SAR unit. The opposite end connects to the POWERFLEX DC SAR GATE

INPUT on the Gate Amplifier. See Chapter 3

Gate Amplifier Installation and

Wiring on page 41 for more information on Gate Amplifier installation and

connections. See Cable Specifications

on page 78 for information on available

cable lengths for the 23PAMP-Cx cable.

Figure 9 - SAR Gate Output Cable Connection (KPT11)

Control Circuit Power Wiring

The control circuit for the SAR (not identified in the drawings contained in this

manual) must be powered by an external 230V AC or 115V AC, single phase

power supply. This power supply provides power for the SAR cooling fans and a

HIM, communication adapter, I/O, encoder, or DC analog tachometer (if

installed). See “Control Circuit Input Power” in the PowerFlex Digital DC Drive

User Manual, publication 20P-UM001

In addition, the control circuit power input terminals require short circuit

protection. See “Control Power Protection” in the PowerFlex Digital DC Drive

User Manual, publication 20P-UM001

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 25

for details.

for details.

Page 26

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

Relay Output and Thermistor/Thermal Switch Wiring

Two normally open relay outputs and one motor thermistor (PTC) or thermal

switch input are available for use and must be configured with the appropriate

parameters. See “Relay Outputs” and “Thermistors and Thermal Switches” in the

PowerFlex Digital DC Drive User Manual, publication 20P-UM001

I/O, Digital Encoder, and DC Analog Tachometer Wiring

The following standard I/O and feedback options are available with the SAR.

• Eight digital inputs, four digital outputs, three analog inputs, and two

analog outputs are available. Additional digital and analog I/O is available

when using the optional I/O expansion circuit board.

• An input terminal block is available for an incremental, dual channel, two

channel optional (with jumper), differential (recommended) or singleended encoder with an input voltage configurable for +2.5V…5.2V or

+5.4V…15.2V.

for details.

SAR Motor Field Current Configuration

• An input terminal block is available for a DC analog tachometer with a

maximum input voltage of 22.7V, 45.4V, 90.7V, 181.6V, or 302.9V and an

input current of 8 mA full scale.

See “I/O Wiring” in the PowerFlex Digital DC Drive User Manual, publication

20P-UM001

for details.

Resolver Feedback Option Module Wiring

A resolver feedback module is available for purchase separately from the SAR.

The resolver feedback option module includes the PowerFlex DC Drive Resolver

Feedback Option Module Installation Instructions, publication 20P-IN071

the PowerFlex Digital DC Drive User Manual, publication 20P-UM001

resolver configuration details.

The SAR motor field current must be configured with both a hardware DIP

switch (S14) and by setting parameter 374 [Drv Fld Brdg Cur] to the appropriate

value. For each field current rating, in this case 40 and 70 A, there are several

ranges to choose from with regard to the maximum range of the field current.

The lowest range that is greater than the maximum motor field current should be

selected to ensure the best resolution. See “Field Current Configuration” in the

PowerFlex Digital DC Drive User Manual, publication 20P-UM001

instructions.

. See

for

for

26 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 27

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

- A B C +

A+ A- B+ B- Z+ Z- COM +V

A+ A- B+ B- Z+ Z- COM +V

- A B C +

21 22 23 24 25 26 27 28 29 30

1 2 3 4 5 6 7 8 9 10

31 32 33 34 35 36 37 38 39 40

11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

31 32 33 34 35 36 37 38 39 40

DEBUG

S15

S3

S2

S1

S0

RST

ACT

RUN

PWR

1 2 3 4 5 6 7 8

S18

S12

S10

S21

ENC_5 ENC_12

S4

1 2 3 4 5 6 7 8

S14

1 2 3 4 5 6 7 8

S20

S11

S9

ON

XR

XA

XFCD

LA LB

S15

S3

S2

S1

S0

RST

ACT

RUN

PWR

1 2 3 4 5 6 7 8

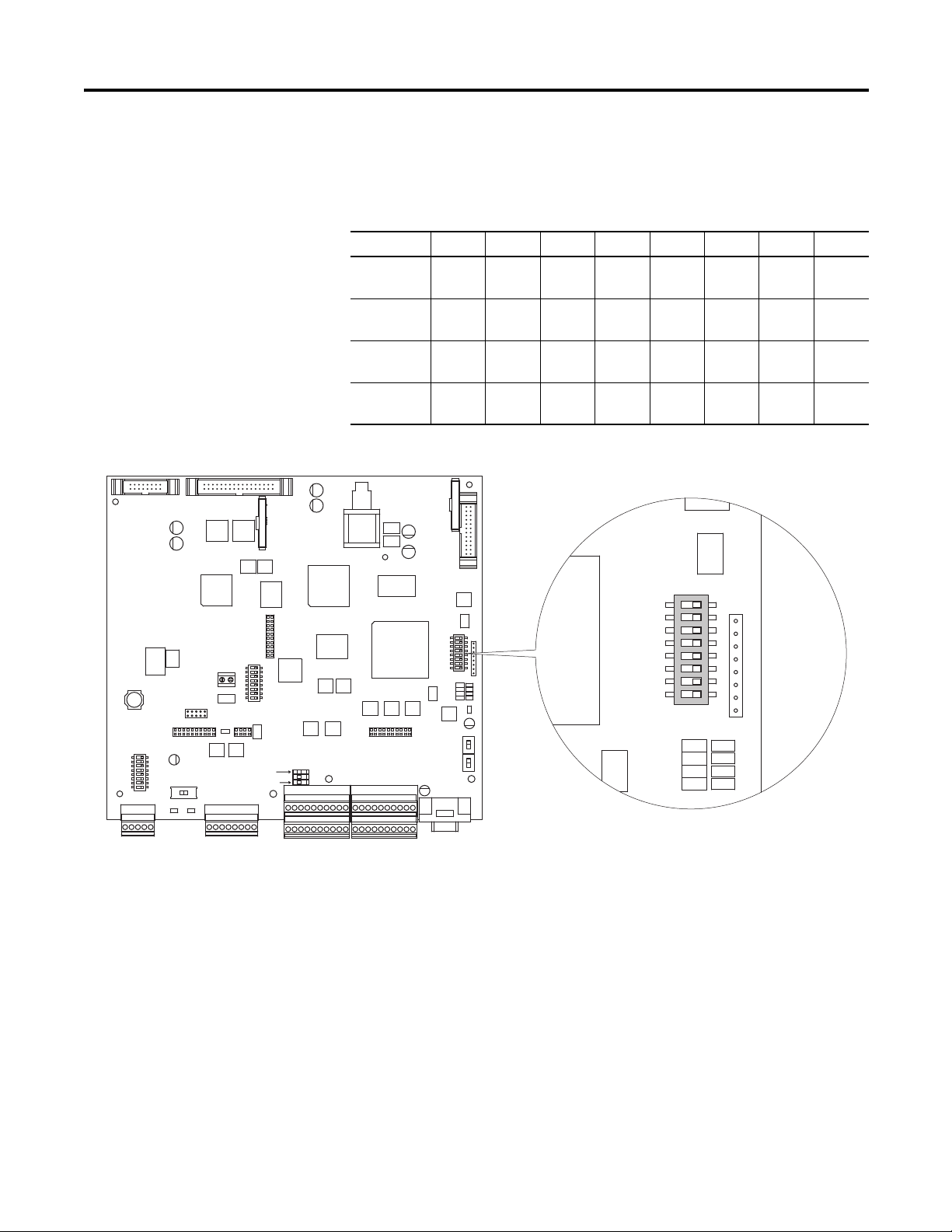

SAR Sizing

DIP switch S15 is configured for the appropriate SAR size at the factory. Do not

change the settings unless you are installing a replacement control board.

Table 7 - SAR DIP Switch S15 Settings

Description S15-1 S15-2 S15-3 S15-4 S15-5 S15-6 S15-7 S15-8

SAR 200V

(230V)

SAR 400V

(460V)

SAR 600V

(575V)

SAR 690V

(690V)

Figure 10 - DIP Switch S15 Location on Control Board

Off Off Off Off Off On Off Off

Off Off Off Off Off On On Off

Off Off Off Off Off On Off On

Off Off Off Off Off On On On

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 27

Page 28

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

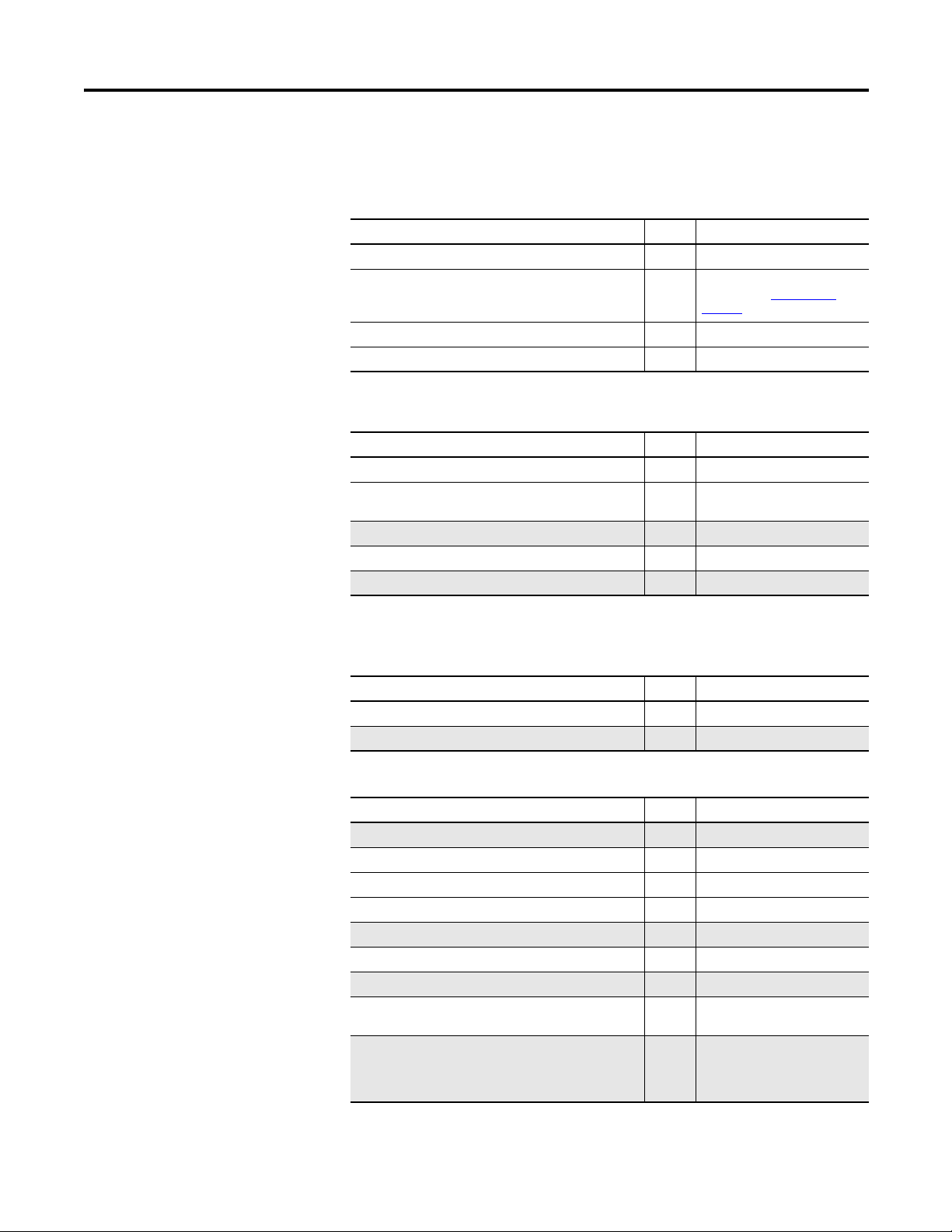

SAR Current Feedback Configuration

Overview

The current feedback to the SAR, provided via current transformers (CTs) that

monitor the U and W phase inputs to the power module, is rectified via a three

phase diode bridge. The output of the diode bridge is connected to a burden

resistor. The voltage across the burden resistor is directly proportional to the

amount of current being drawn by the motor load. This voltage is used by the

regulator to monitor and control the current by comparing its value with the

reference command. There are two on board burden resistor settings to choose

from, depending on the variables of the application. In addition, an optional

external burden resistor may be used for very specific cases. However, consult

with Rockwell Automation Development Engineering prior to using this option

to ensure that the circuit board ratings, as well the power dissipation ratings of the

burden resistor, are properly considered. See Figure 11 on page 37

the burden resistor circuit and Figure 13 on page 39

locations.

Note: The current limit of the on-board burden resistors is 1 Amp. This includes

not exceeding 1 Amp for the internal burden resistors in the event of an

instantaneous over-current (IOC).

For retrofit situations current transformers are often already in place on the L1

(U) and L3 (W) AC incoming line conductors to the power module. However,

the secondary current rating of the current transformers may not be 1 Amp and

not well suited for the current feedback scaling and burden resistors of the SAR.

For high current systems, current transformers with 5 Amp secondary windings

are not unusual. These cases can be handled by using an interposing set of current

transformers (cascading the current transformers) between the existing current

transformers and the SAR. The resulting turns ratio is the product of the existing

current transformer's turns ratio multiplied by the interposing current

transformer's turns ratio.

for burden resistor jumper

for details on

The type of transformer for this application is a wound primary current

transformer. The advantage of this implementation is that existing current

transformers can remain in place, which eliminates the need to disassemble/

reassemble heavy bus bars, and the wiring to the existing and interposing current

transformers is signal level wiring. Care must be taken in the implementation of

the interposing current transformers to ensure that all considerations of sizing the

current transformer configuration are met, such as the following:

• IOC Limits for the existing and interposing current transformers.

• Minimum magnetization currents required.

• Proper resulting turns ratio.

Consult with Engineering for assistance in implementing a current feedback

configuration with interposing (cascade) current transformers.

The voltage across the burden resistor must be normalized for the full load rating

of the power module. The regulator expects a value of 0.612 Volts at the current

feedback input at 100% load of the power module. To ensure that the regulator

receives 0.612 Volts at 100% load of the power module, a scaling operational

28 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

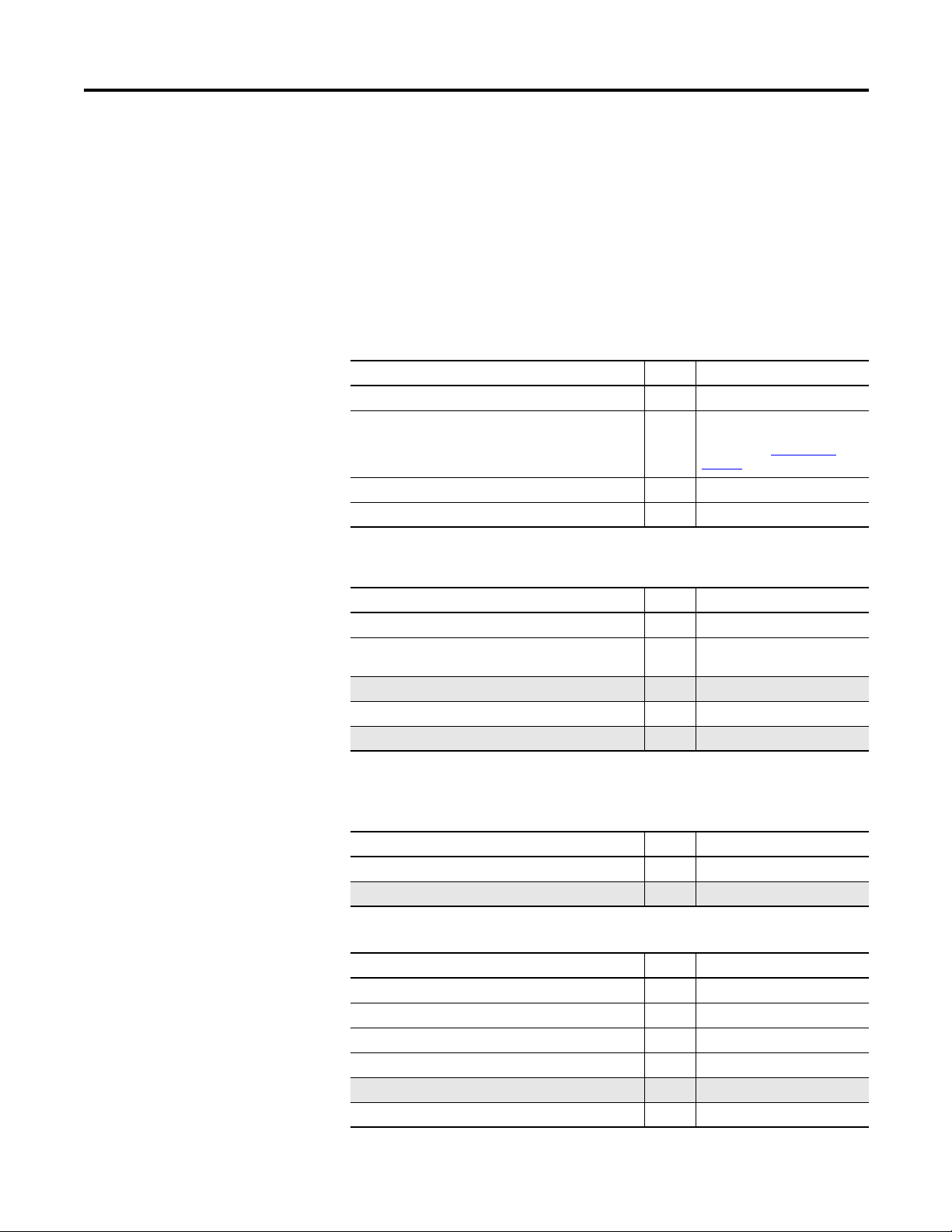

Page 29

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

amplifier (Op-Amp) circuit has been provided. For reference, the name of this

circuit will be called the “Binary Gain Amp,” because the gain of the amplifier is

set via binary DIP switches. See Figure 12 on page 38

Gain Amp circuit and Figure 13 on page 39

for DIP switch locations. When

for a diagram of the Binary

properly configured, the output of the Binary Gain Amp is 0.612 Volts at 100%

load of the power module.

Note that the basis for scaling the current feedback is the power module, not the

motor. This is a different approach than legacy systems where the motor was used

as the basis for all of the current loop feedback scaling. This scaling works well as

long as the power module and the motor are closely matched. However, when

multiple power modules of the same size are used in the same process to run

different size motors, it may be desirable to enter lower values for parameter 465

[Drive Size] and scale the regulator rating from the motor full load amps. This

will reduce the size of the CT required and increase the resolution of the current

feedback signal.

Though the power module is used as the basis for the current feedback

calculation, the motor load must fall within the rating of the power module. If it

does not, the power module may trip on an overload or IOC when the motor is

running within its rating.

For example, if the regulator is configured so that the power module rating and

the motor rating are equal, and the “Heavy Duty” option is chosen for the motor,

the regulator will trip on a power module overload in 10 seconds when the system

is running at 200% current, instead of the 1 minute desired.

In the SAR configuration the power module rating will be entered by the user and

the regulator will use this value to determine overload and IOC trip points.

• Power Module Overload = 150% for 1 minute, or 200% for 10 seconds.

• Motor Overload - Standard Duty = 150% for 1 minute, (selection via

parameter 376 [MtrOvrld Type])

OR

• Motor Overload - Heavy Duty = 200% for 1 minute, (selection via

parameter 376 [MtrOvrld Type])

• Motor Full Load Amps entered in parameter 179 [Nom Mtr Arm Amps]

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 29

Page 30

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

Current Feedback Calculations

Inputs to the CT Calculation:

• The variable “IdN_pm_rtg” used in the calculations is the value of

parameter 465 [Drive Size]

• Rb is the burden resistor which can be either 2.5 Ohms or 5.0 Ohms

• CT_pri is the current transformer primary rating

• CT_sec is the current transformer secondary rating

A range of CT values is initially calculated based on the system constraints of

IOC and the recommended gain range of the Binary Gain Amp. For the

constraint based on IOC, the CT minimum size would be at the IOC trip point

of 250%. The CT sizing based on the Binary Gain Amp is based on the error

encountered when using the DIP switch configuration to select the gain versus

exact resistor values. As the gain is increased, the gain becomes more granular and

the error is greater when compared with the exact gain. A gain value of 1.2 has

been chosen as a guideline to keep the error to 1% or less. Lower values of CT

ratio result in the improvement of “real system” resolution. The comparison

between the exact value of gain and the actual gain is shown at the end of the

calculation. There are trade offs between the value of the burden resistor and the

gain of the amplifier. With a larger value of burden resistor (5.0 Ohms), the

required gain is less and the binary value calculated is greater resulting in a more

accurate signal. However, the feedback level at IOC needs to be considered as

discussed later in this section.

Again, a value of 0.612 Volts represents 100% power module current. The

required gain of the Binary Gain Amp is calculated with this in mind. The value

of 0.612 Volts is divided by the actual voltage across the burden resistor at 100%

power module current. This provides the value of gain required to ensure that

0.612 Volts is fed back to the regulator at 100% power module current.

There is a maximum limit of 2.5 Volts that can be accepted by the regulator

current feedback. Beyond 2.5 Volts the circuitry will saturate. To ensure that this

does not occur, the maximum value of current feedback is calculated at the IOC

level.

The binary switch setting is based on the gain desired. The actual binary switch

setting will be obtained by rounding the calculated value to the nearest integer. To

convert from decimal to the required binary value, a calculator or personal

computer can be used.

30 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 31

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

SAR Current Feedback Calculation Examples

Example 1:

CT, Burden Resistor and Gain Calculation

Input Values Units Description

IdN_pm_rtg: = 2600 Amp Power module rating

Rb:= 5.0 Ohms Jumper J5 in the “On” position

CT_pri: = 10000 Amp

CT_sec: = 1 Amp

Minimum CT Primar y based on IOC trip point of 2.5 x Power Module rating

Value/Calculation Units Description

IOC_mult: = 2.5

CT_pri_min: =

IOC_mult x IdN_pm_rtg x 0.85

CT_pri_min = 5.525 x 10

CT_ratio_min_based_on_ioc: = CT_pri_min / CT_sec

CT_ratio_min_based_on_ioc = 5.525 x 10

3

3

Amp Based on IOC trip point

and jumper J4 in the “Off”

position. See Figure 13 on

page 39 for jumper locations.

0.85 is the ratio of AC to DC

current

Based on IOC trip point

Maximum CT ratio based on Gain Range of Scaling Op-Amp in the Current

Feedback circuit

Value/Calculation Units Description

CT_ratio_max: = 1.2 x (IdN_rtg x Rb) / 0.612

CT_ratio_max = 2.55 x 10

Value/Calculation Units Description

Vf_at_IdN_pm_rtg = 0.612 Volts Fixed Value

CT_ratio: = CT_pri / CT_sec

CT_ratio = 1 x 10

Ib_at_IdN_pm_rtg: = IdN_pm_rtg / CT_ratio

Ib_at_IdN_pm_rtg = 0.26 Amps

Vb_at_IdN_pm_rtg: = (IdN_pm_rtg / CT_ratio) x Rb

Vb_at_IdN_pm_rtg = 1.3 Volts

Gain_Required: = Vf_at_IdN_pm_rtg /

Vb_at_IdN_pm_rtg

Gain_Required = 0.471 Note: Recommended Gain <=

4

4

Based on Gain <= 1.2

1.2 (for best accuracy)

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 31

Page 32

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

Binary Gain Calculation and Checking Gain Error

Binary_Sw_Setting = 108.758

Value to use - 109, Binary = 1101101

MSB LSB

Bit Value B11: = 0 B10: = 0 B9: = 0 B8: = 0 B7: = 0 B6: = 1 B5: = 1 B4: = 0 B3: = 1 B2: = 1 B1: = 0 B0: = 1

DIP Switch

Setting

SW3-1

= Off

SW3-2

= Off

SW3-3

= Off

SW3-4

= Off

SW4-1

= Off

SW4-2

= On

SW4-3

= On

SW4-4

= Off

SW4-5

= On

SW4-6

= On

SW4-7

= Off

SW4-8

= On

R_fdbk: =

For DIP switch SW3 and SW4 layout, refer to Ta b l e 1 4

- Binary Gain Amp DIP

Switch to Bit Layout on page 39.

Resistor values are in K Ohms

1

B11 / 0.50 + B10 / 1 + 9 / 2 + B8 / 4 + B7 / 8 + B6 / 16 + B5 / 32 + B4 / 64 + B3 / 128 + B2 / 256 + B1 / 512 + B0 / 1024

Value/Calculation Units Description

R_fdbk = 9.394

R_input = 20 Fixed input resistor

Gain_Binary_OA: = R_fdbk / R_input

Gain_Binary_OA = 0.47 versus Gain_Required = 0.471 Comparing the “Binary Gain

Per_Cent_Gain_Error: = (Gain_Binary_OA Gain_Required / Gain_Required) x 100

Per_Cent_Gain_Error = -0.222

Amp” to the “Calculated

Required Gain”

32 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 33

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

Example 2:

CT, Burden Resistor and Gain Calculation

Input Values Units Description

IdN_pm_rtg: = 226 Amp Power module rating

Rb:= 2.5 Ohms Jumpers J4 and J5 in the “On”

CT_pri: = 2000 Amp

CT_sec: = 1 Amp

Minimum CT Primar y based on IOC trip point of 2.5 x Power Module rating

Value/Calculation Units Description

IOC_mult: = 2.5

CT_pri_min: =

IOC_mult x IdN_pm_rtg x 0.85

CT_pri_min = 480 Amp Based on IOC trip point

CT_ratio_min_based_on_ioc: = CT_pri_min / CT_sec

CT_ratio_min_based_on_ioc = 480 Based on IOC trip point

position. See Figure 13 on

page 39 for jumper locations.

0.85 is the ratio of AC to DC

current

Maximum CT ratio based on Gain Range of Scaling Op-Amp in the Current

Feedback circuit

Value/Calculation Units Description

CT_ratio_max: = 1.2 x (IdN_rtg x Rb) / 0.612

CT_ratio_max = 1.108 x 10

Value/Calculation Units Description

Vf_at_IdN_pm_rtg = 0.612 Volts Fixed Value

CT_ratio: = CT_pri / CT_sec

CT_ratio = 2 x 10

Ib_at_IdN_pm_rtg: = IdN_pm_rtg / CT_ratio

Ib_at_IdN_pm_rtg = 0.113 Amps

Vb_at_IdN_pm_rtg: = (IdN_pm_rtg / CT_ratio) x Rb

Vb_at_IdN_pm_rtg = 0.283 Volts

Gain_Required: = Vf_at_IdN_pm_rtg /

Vb_at_IdN_pm_rtg

Gain_Required = 2.166 Note: Required Gain = 2.166,

3

3

Based on Gain <= 1.2

which is greater than the

Recommended Gain <= 1.2 (for

best accuracy)

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 33

Page 34

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

Binary Gain Calculation and Checking Gain Error

Binary_Sw_Setting = 23.634

Value to use - 24, Binary = 11000

MSB LSB

Bit Value B11: = 0 B10: = 0 B9: = 0 B8: = 0 B7: = 0 B6: = 0 B5: = 0 B4: = 1 B3: = 1 B2: = 0 B1: = 0 B0: = 0

DIP Switch

Setting

SW3-1

= Off

SW3-2

= Off

SW3-3

= Off

SW3-4

= Off

SW4-1

= Off

SW4-2

= Off

SW4-3

= Off

SW4-4

= On

SW4-5

= On

SW4-6

= Off

SW4-7

= Off

SW4-8

= Off

R_fdbk: =

For DIP switch SW3 and SW4 layout, refer to Ta b l e 1 4

- Binary Gain Amp DIP

Switch to Bit Layout on page 39.

Resistor values are in K Ohms

1

B11 / 0.50 + B10 / 1 + 9 / 2 + B8 / 4 + B7 / 8 + B6 / 16 + B5 / 32 + B4 / 64 + B3 / 128 + B2 / 256 + B1 / 512 + B0 / 1024

Value/Calculation Units Description

R_fdbk = 42.667

R_input = 20 Fixed input resistor

Gain_Binary_OA: = R_fdbk / R_input

Gain_Binary_OA = 2.133 versus Gain_Required = 2.166 Comparing the “Binary Gain

Per_Cent_Gain_Error: = (Gain_Binary_OA Gain_Required / Gain_Required) x 100

Per_Cent_Gain_Error = -1.525 The error exceeds 1%. The

Amp” to the “Calculated

Required Gain”

application will work but it is

not optimal.

34 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 35

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

Example 3:

The only difference between Example 2 and Example 3 is the value of the burden

resistor. In this example the burden resistor is chosen as Rb = 5.0 Ohms.

In this example a standard CT ratio is chosen and the ratio no longer exceeds the

recommended CT ratio based on the gain calculation. This is due to the change

of the burden resistor from 2.5 Ohms to 5.0 Ohms.

CT, Burden Resistor and Gain Calculation

Input Values Units Description

IdN_pm_rtg: = 226 Amp Power module rating

Rb: = 5.0 Ohms Jumper J5 in the “On” position

CT_pri: = 2000 Amp

CT_sec: = 1 Amp

and jumper J4 in the “Off”

position. See Figure 13 on

page 39 for jumper locations.

Minimum CT Primar y based on IOC trip point of 2.5 x Power Module rating

Value/Calculation Units Description

IOC_mult: = 2.5

CT_pri_min: =

IOC_mult x IdN_pm_rtg x 0.85

CT_pri_min = 480 Amp Based on IOC trip point

CT_ratio_min_based_on_ioc: = CT_pri_min / CT_sec

CT_ratio_min_based_on_ioc = 480 Based on IOC trip point

0.85 is the ratio of AC to DC

current

Maximum CT ratio based on Gain Range of Scaling Op-Amp in the Current

Feedback circuit

Value/Calculation Units Description

CT_ratio_max: = 1.2 x (IdN_rtg x Rb) / 0.612

CT_ratio_max = 2.216 x 10

Value/Calculation Units Description

Vf_at_IdN_pm_rtg = 0.612 Volts Fixed Value

CT_ratio: = CT_pri / CT_sec

CT_ratio = 2 x 10

Ib_at_IdN_pm_rtg: = IdN_pm_rtg / CT_ratio

Ib_at_IdN_pm_rtg = 0.113 Amps

Vb_at_IdN_pm_rtg: = (IdN_pm_rtg / CT_ratio) x Rb

3

3

Based on Gain <= 1.2

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 35

Page 36

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

Value/Calculation Units Description

Vb_at_IdN_pm_rtg = 0.565 Volts

Gain_Required: = Vf_at_IdN_pm_rtg /

Vb_at_IdN_pm_rtg

Gain_Required = 1.083 Note: Required Gain = 1.083,

Checking the Maximum Voltage Feedback to Regulator

Value/Calculation Units Description

Binary_Sw_Setting: = 51.2 / Gain_Required

Binary_Sw_Setting = 47.268

Ib_at_IOC: = (IdN_pm_trg x IOC_mult / CT_ratio)

Ib_at_IOC = 0.282 Amps

Vb_at_IOC: = (IdN_pm_rtg x IOC_mult / CT_ratio)

Vb_at_IOC = 1.412 Volts

V_curr_fdbk_to_reg_at_IOC: = Gain_Required x

Vb_at_IOC

V_curr_fdbk_to_reg_at_IOC = 1.53 Volts

which is within the

Recommended Gain <= 1.2 (for

best accuracy)

Maximum allowable value of

V_curr_fdbk_to_reg_at_IOC =

2.5V

Binary Gain Calculation and Checking Gain Error

Binary_Sw_Setting = 47.268

Value to use - 47, Binary = 101111

MSB LSB

Bit Value B11: = 0 B10: = 0 B9: = 0 B8: = 0 B7: = 0 B6: = 0 B5: = 1 B4: = 0 B3: = 1 B2: = 1 B1: = 1 B0: = 1

DIP Switch

Setting

SW3-1

= Off

SW3-2

= Off

SW3-3

= Off

SW3-4

= Off

SW4-1

= Off

SW4-2

= Off

SW4-3

= On

SW4-4

= Off

SW4-5

= On

For DIP switch SW3 and SW4 layout, refer to Ta b l e 1 4

SW4-6

= On

SW4-7

= On

SW4-8

= On

- Binary Gain Amp DIP

Switch to Bit Layout on page 39.

Resistor values are in K Ohms

R_fdbk: =

B11 / 0.50 + B10 / 1 + 9 / 2 + B8 / 4 + B7 / 8 + B6 / 16 + B5 / 32 + B4 / 64 + B3 / 128 + B2 / 256 + B1 / 512 + B0 / 1024

1

36 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 37

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

CT11

CT12-CT22

CT21

XCT

1

2

3

4

J5A J5

J4A

J4

10R

10R

10R

10R

10R

10R

10R

10R

20K

0VI

Off (Park) Position for Jumper J4

Off (Park) Position for Jumper J5

Value/Calculation Units Description

R_fdbk = 21.787

R_input = 20 Fixed input resistor

Gain_Binary_OA: = R_fdbk / R_input

Gain_Binary_OA = 1.089 versus Gain_Required = 1.083 Comparing the “Binary Gain

Amp” to the “Calculated

Required Gain”

Per_Cent_Gain_Error: = (Gain_Binary_OA Gain_Required / Gain_Required) x 100

Per_Cent_Gain_Error = 0.57 The error is now less than 1%.

Figure 11 - Bridge Rectifier and Burden Resistor Circuit Diagram

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 37

Page 38

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

0VI

0VI

0VI

0VI

SW3

SW4

MSB

LSB

500

1K

2K

3K

8K

16K

32K

64K

128K

256K

512K

1024K

0VI

Figure 12 - Binary Gain Amplifier Circuit Diagram

38 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 39

Stand Alone Regulator Installation, Wiring and Configuration Chapter 2

SW3 SW4

J5 J4

0VI RCT

XCT

MSB

LSB

ON

Off

On

Pulse Transformer Board

Burden Resistor

Jumpers

External Burden Resistor

Terminal Block (XCT)

Binary Gain Amp

DIP Switches

IMPORTANT

Figure 13 - Burden Resistor Jumpers (J4 and J5), Binary Gain Amp DIP Switches

(SW3 and SW4), and External Burden Resistor Terminal Block (XCT) Locations

Figure 14 - Binary Gain Amp DIP Switch to Bit Layout

MSB LSB

Bit 11 Bit 10 Bit 9 Bit 8 Bit 7Bit 6Bit 5Bit 4Bit 3 Bit 2Bit 1Bit 0

SW3 SW4

ON

1 2 3 4 1 2 3 4 5 6 7 8

The labels on DIP switches SW3 and SW4 do NOT correspond to the bit

numbers used to set the amplifier gain.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 39

Page 40

Chapter 2 Stand Alone Regulator Installation, Wiring and Configuration

SAR Programming and Startup

SAR programming and startup require a Human Interface Module (HIM) or

DriveExplorer™ or DriveTools SP™ software with a network connection made

using a communication adapter. The SAR is not sold with a HIM or

communication adapter. These products must be purchased separately. See

Appendix B - “HIM Overview” and Appendix E - “Installing a Communication

Adapter”, respectively, in the PowerFlex Digital DC Drive User Manual,

publication 20P-UM001

, for details.

SAR Parameter Configuration

To accommodate incoming line voltages that are greater than 690VAC,

parameter 464 [SAR Volts Scale] is used to scale the actual values of the system

voltages so that they can be displayed on the HIM or in programming software

without having the regulator directly connected to the higher voltage levels. The

upper limit is 1200VAC. However, there are means to accommodate greater

voltages.

The SAR has a maximum rating of 690VAC. The incoming AC line and the

power module output / motor voltage needs to be scaled to ensure that the

voltages the regulator receives are within its’ rating. When the voltage is reduced,

the scaling parameter (464) provides the means to add a multiplier to the voltage

values so that the displayed voltages reflect those at the actual regulator input and

output.

Example:

If the actual voltage that appears at the AC input to the SAR is 400VAC (due to

resistor scaling) and the incoming line is at 1000VAC, then the scaling value is

the ratio of the two voltages:

464 [SAR Volts Scale] = 1000VAC / 400VAC = 2.5

The external scaling of the voltage to the regulator will be done via resistors.

Consult with Development Engineering for component sizing and gate

configuration wiring guidelines, for systems greater than 690VAC incoming line,

or low voltage.

All other parameter settings for the SAR are the same as those documented in

Chapter 3 “Programming and Parameters” in the PowerFlex Digital DC Drive

User Manual, publication 20P-UM001

.

SAR Startup

When installation of the SAR is complete, perform the procedures in Chapter 2

“Drive Start Up” in the PowerFlex Digital DC Drive User Manual, publication

20P-UM001

.

40 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 41

Chapter

Gate Amplifier Installation and Wiring

3

Prepare for Installation

Operating Temperatures

Prior to installation of the Gate Amplifier read the General Precautions on

page 9.

The surrounding air temperature must be within 0 °C to 50 ° C (32 ° F to 122

° F). Humidity must remain between 5% and 95% non-condensing.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 41

Page 42

Chapter 3 Gate Amplifier Installation and Wiring

2.0 in

(50.8 mm)

1.25 in

(31.75 mm)

1.25 in

(31.75 mm)

2.0 in

(50.8 mm)

Mounting and Cooling

The Gate Amplifier is an open type construction and is intended to be installed

on a flat surface in a suitable enclosure. The unit must be mounted in the upright

position (faceplate lettering legible and the mounting back plate vertical) to

ensure effective convection cooling.

Follow these instructions when mounting the Gate Amplifier:

• Mount in a clean, dry location. Contamination from oils, corrosive vapors

and abrasive debris must be kept out of the enclosure.

• Do not mount heat-generating equipment directly underneath the unit.

• Mount the unit in a vertical position only.

• Power dissipation, 50 Watts.

Figure 15 - Minimum Mounting Clearances

42 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Page 43

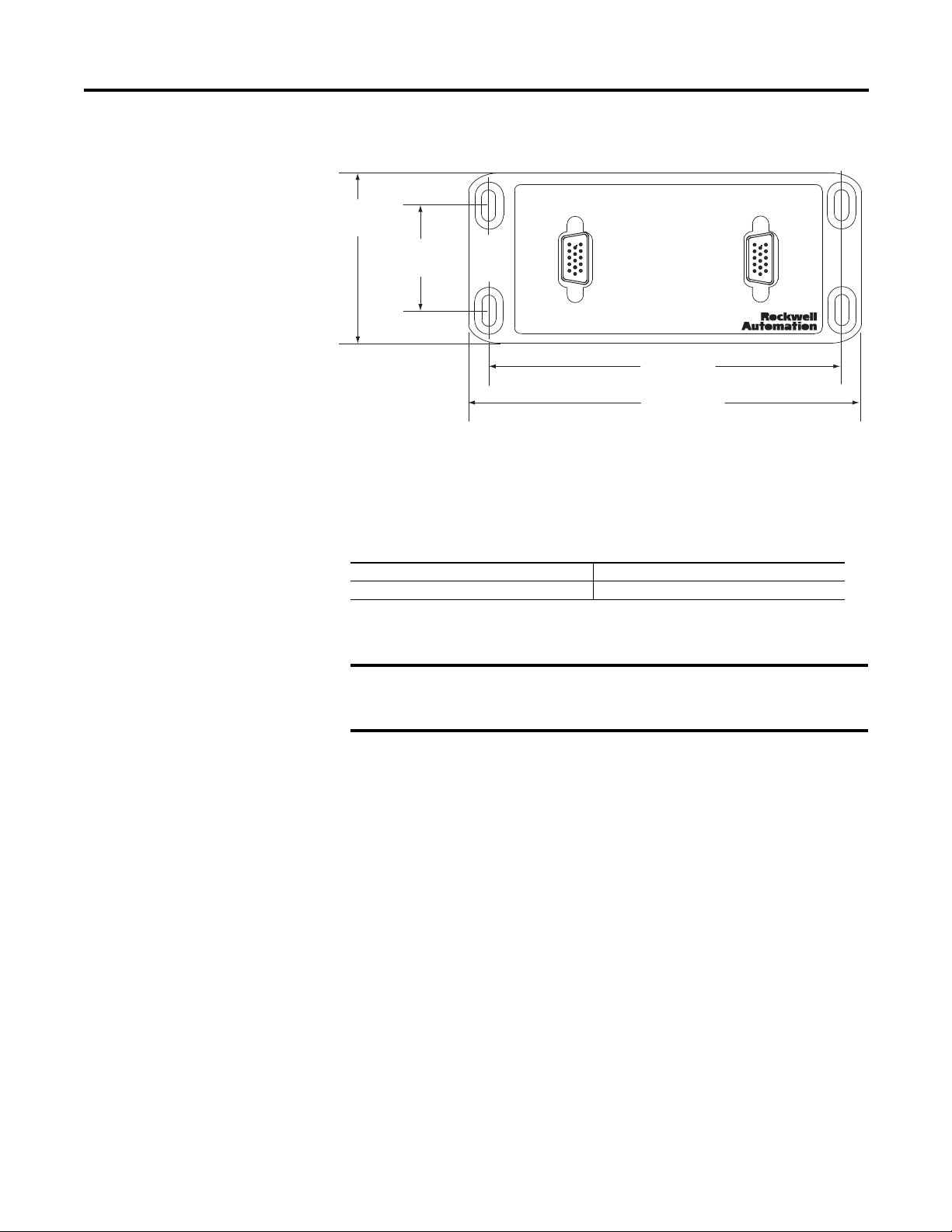

Figure 16 - Approximate Dimensions

4.63

(117.6)

11.63

(295.3)

11.05

(280.7)

0.33

(8.3)

0.86

(21.8)

3.00

(76.2)

10.08

(256.1)

11.66

(296.2)

10.61

(269.4)

Dimensions in inches and (millimeters)

IMPORTANT

Gate Amplifier Installation and Wiring Chapter 3

Table 8 - Gate Amplifier Weights

Gate Amplifier Gate Amplifier & Packaging

5.0 kg (11.0 lb) 5.7 kg (12.5 lb)

Recommended Mounting Hardware: Metric M5, English #10

Provide at least 114 millimeters (4.5 inches) in front of unit for connectors

and cable bend radius.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 43

Page 44

Chapter 3 Gate Amplifier Installation and Wiring

1

2

3

4

1

2

3

4

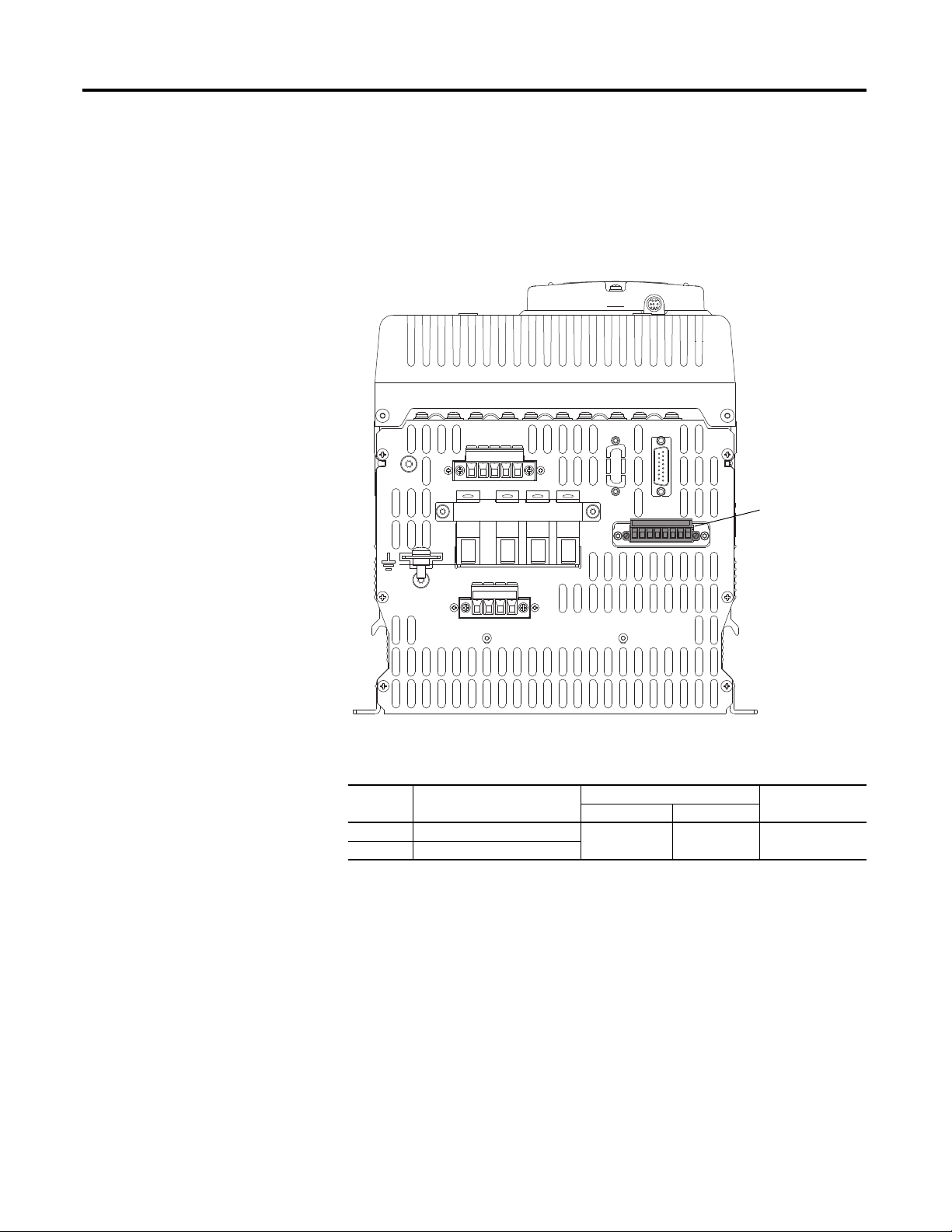

Power and Ground Wiring

Figure 17 - Power and Ground Connections

Table 9 - Terminal Specifications

No. Name Description

Input Power

Terminal Block

L1, L2, Ground

Input power - Line

(L1), Neutral (L2)

and Ground

Ground Stud Chassis Ground Refer to Chassis Grounding

External Gate

Power Supply

External Gate

Power Supply

(provided with Gate Amplifier)

94809302 4.0 mm

on page 45 for more information.

94809301 10 AWG, Twisted Pair,

(if used)

Part Number for Customer Plug

Ready Relay Ready Relay Drive

Run Permissive

(1)

Interlock

(1) Ready relay contacts are normally open rated at 2 Amps, 120VAC.

PN-26501 4.0 mm

44 Rockwell Automation Publication 23P-UM001D-EN-P - July 2012

Wire Size Range Recommended

Maximum Minimum Torque

2

(10 AWG)

2 Twists / in.

2

(10 AWG)

2

2.5 mm

(14 AWG)

18 AWG, Twisted Pair,

2 Twists / in.

2

2.50 mm

(14 AWG)

0.68 N•m

(6.0 lb•in)

0.68 N•m

(6.0 lb•in)

0.55 N•m

(5.0 lb•in)

Page 45

Gate Amplifier Installation and Wiring Chapter 3

Chassis Grounding

A ground stud is provided on the lower right corner of the chassis mounting

flange for making a ground connection. Connect the grounding wire provided to

the ground stud and the metal panel. Make sure that the lug makes a good

connection to the panel.

To provide additional grounding, with regard to noise immunity, the upper and

lower “mounting feet” of the unit have areas that are free of paint to provide a

positive connection between the unit and the enclosure mounting panel.

It is important that the panel that the Gate Amplifier is mounted to is properly

grounded to the power system ground in the customer’s plant. Ideally, the panel

that the Gate Amplifier is mounted on, as well as the associated components

should be at the same potential as the Armature Power Module and the Motor.

Each of the signals that go to/from the Gate Amplifier are bypassed to chassis

ground through small capacitors. These capacitors aid in removing noise from the

signal lines. If the Gate Amplifier or the panel that it mounts to is not properly

grounded, the bypass capacitors can actually inject noise onto the signal lines

resulting in nuisance trips.

For example, if the motor frame and the Gate Amplifier chassis are not grounded

together, the motor frame potential can fluctuate as the drive is run. If the motor

frame fluctuates in potential, the case of the feedback device, resolver or encoder

will also “see” this fluctuation. The capacitive coupling between the case of the

feedback device and the internal wiring and/or electronics can result in a

common mode noise signal being injected into the wiring. This can result in

noise on the feedback lines. Another source of noise in the feedback path are the

voltage fluctuations of the motor shaft, especially in higher hp motors (above 300

Hp). In these cases, an insulated “Thomas” coupling is recommended for

interfacing with the feedback device. The internal part number of an insulated

Thomas coupling is 406041-17, (Power Division Part Number).

For retrofit installations, lack of sufficient bonding/grounding is often the cause

of noise problems. If the regulator components are installed on a sub-panel, a 1/0

fine strand welding cable should be used to connect the panel to the ground bus.

Panels within the cabinet(s) must be bonded together. If the panels within the

cabinet are not bonded together, use 1/0 fine strand welding cable to connect the

panels. Be sure that all paint is scraped off at the connection points; a 2 milliOhms connection or less is ideal. In the absence of a milli-Ohm or micro-Ohm

meter to actually measure the connection resistance, the connections should be

made suitable enough to support the “cranking current required to start a car.”

This means that the connection must be clean and free of paint and other debris.

The supply transformer frame, drive cabinet panels, and motor frame must be

bonded together to provide a “preferred path” for high frequency noise.

Rockwell Automation Publication 23P-UM001D-EN-P - July 2012 45

Page 46

Chapter 3 Gate Amplifier Installation and Wiring

Key Grounding/Bonding Points Outside of the Cabinet

The high frequency grounding/bonding outside of the cabinet should be treated

in a manner similar to a power supply mounted on a ground plane with all of the

components that it supplies, mounted on the same ground plane. In the case of

the drive system, the transformer can be thought of as the power supply for the

downstream components; AC entry bay, drive cabinets, and motors. The high

frequency grounding/bonding of the components is effectively like mounting

them on a virtual ground plane. All components from the power transformer to

the motor needs to viewed as a whole system.

All currents used to run the drives and motors originate at the power transformer.

As the power is being controlled by the drive system to regulate the amount of the

energy supplied to the motor, high frequencies are generated through the

switching action of the drive power components. The capacitive coupling of the

high frequencies to the metal that is within proximity to the conductors creates

ground currents (ic=Cdv/dt). The major components of the system, motor,

conduit, and cabinet will all be “charged” by this capacitive coupling effect. The

ground currents seek a return path back to the source, the drive, and ultimately

the transformer. If a known good path is not provided, more currents will flow

through the machine and other undesirable paths. The power transformer

provides a magnetic isolation barrier that prevents the ground currents from

going into the power grid. In the transformer there is capacitive coupling between

the transformer core and the windings. Attachment of the transformer frame

(which is attached to the core) to the drive cabinet(s) will complete the ground

current path for these components through a known path.

• Motor to cabinet - the connections for the motor ground must be made

directly to the frame of the motor, not the conduit box. The connection

between the motor frame and the conduit box does not provide a good

high frequency conduction path.

• Drive cabinet to bus power entry cabinet.

• Power entry cabinet to power transformer case/frame.

If insufficient grounding/bonding is suspected, then additional wiring must be

added (as shown in the system diagram that follows) to ensure that there is a

proper path for electrical noise.

Welding cable is needed for grounding/bonding where high frequency noise