Page 1

User Manual

PowerFlex Digital DC Drive

PowerFlex DC Drive V1.006…6.002, PowerFlex DC Standalone Regulator V1.006…6.002

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Connected Components Workbench, DriveExplorer, DriveTools SP, PowerFlex, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

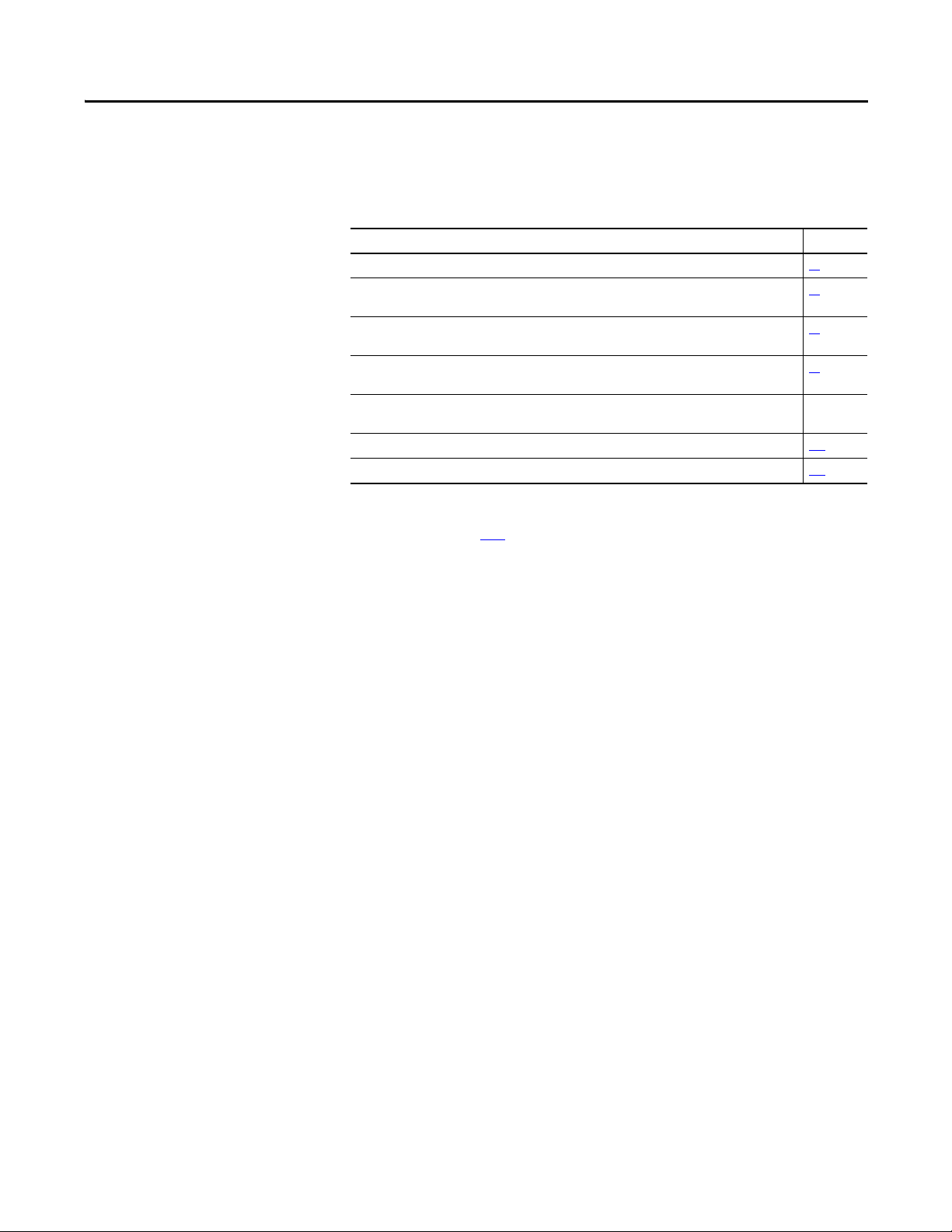

This manual contains new and updated information.

Summary of Changes

New and Updated Information

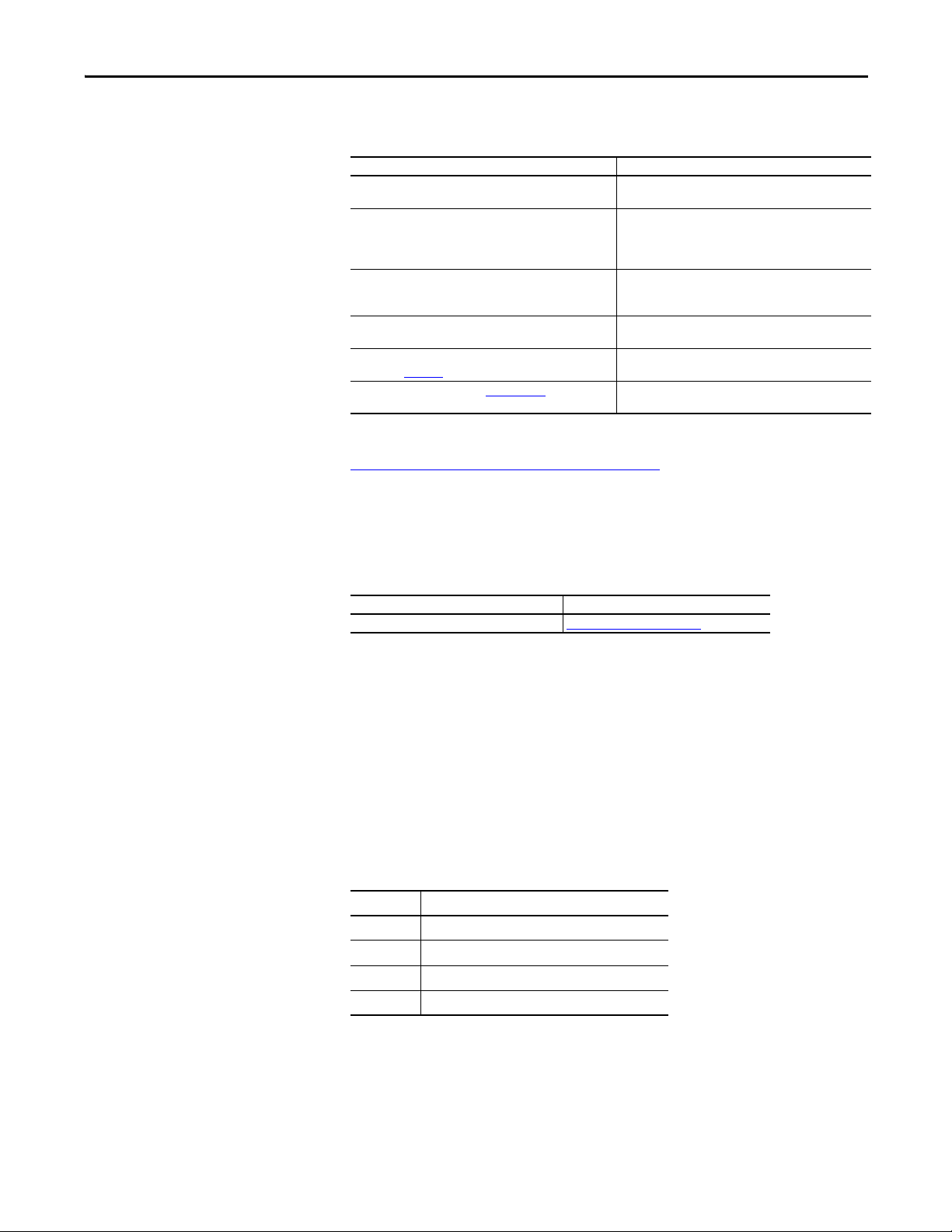

This table contains the changes made to this revision.

Top ic Pa ge

Added the Maximum Surrounding Air Temperature Specifications. 18

Updated the frame B drive dimensions to include a different depth dimension for certain catalog

numbers.

Updated the Typical Power Wiring Diagrams to illustrate connections for bother series A and series B

frame D fans.

Updated the Frame D, Series B Heatsink Cooling Fan Specifications to include information on fan air flow

verification after wiring.

Changed the name of parameter 467 from [Max Fld Curr Pct] to [Max Fld Flux Pct].

Note: The parameter name was only incorrect in this manual.

Added new values to the Testpoint Codes and Functions table. 229

Removed the Certifications and Specifications information. 232

20

45

71

Througho ut

manual

Changes to this manual for previous revisions are included in Appendix I History

of Changes on page 381

.

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 3

Page 4

Summary of Changes

4 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 5

Table of Contents

Preface

Installation and Wiring

Drive Storage Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive Nameplate Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drive Series Letter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drive Frame Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drive Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drive Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Extra Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Standard Drive Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . 15

Standard Drive Catalog Number Explanation, Cont.. . . . . . . . . . . . . . . . 16

Standalone-Alone Regulator Catalog Numbers . . . . . . . . . . . . . . . . . . . . . 16

Chapter 1

Mount the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating Conditions and Temperatures. . . . . . . . . . . . . . . . . . . . . . . 18

Minimum Mounting Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maximum Surrounding Air Temperature Specifications . . . . . . . . . 18

Approximate Drive Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . 19

Lifting PowerFlex DC Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mount Frame C and D Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Remove the Drive Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Frame A Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Frame B and C Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frame D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Isolation Transformers / Line Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

AC Input Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DC Output Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dynamic Brake Resistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General Grounding Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Safety Ground (PE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Encoder/Resolver Ground Connections. . . . . . . . . . . . . . . . . . . . . . . . 33

Tachometer Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Grounding for Installations in an Ungrounded or High-Impedance,

Neutral Ground, or System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation Requirements Related to the Low Voltage Directive. . 40

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 5

Page 6

Table of Contents

Installation Requirements Related to EN 61800-3 and the EMC

Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pollution Degree Ratings According to EN 61800-5-1 . . . . . . . . . . 41

Power Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Control Power Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cable and Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

AC Input Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DC Output Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

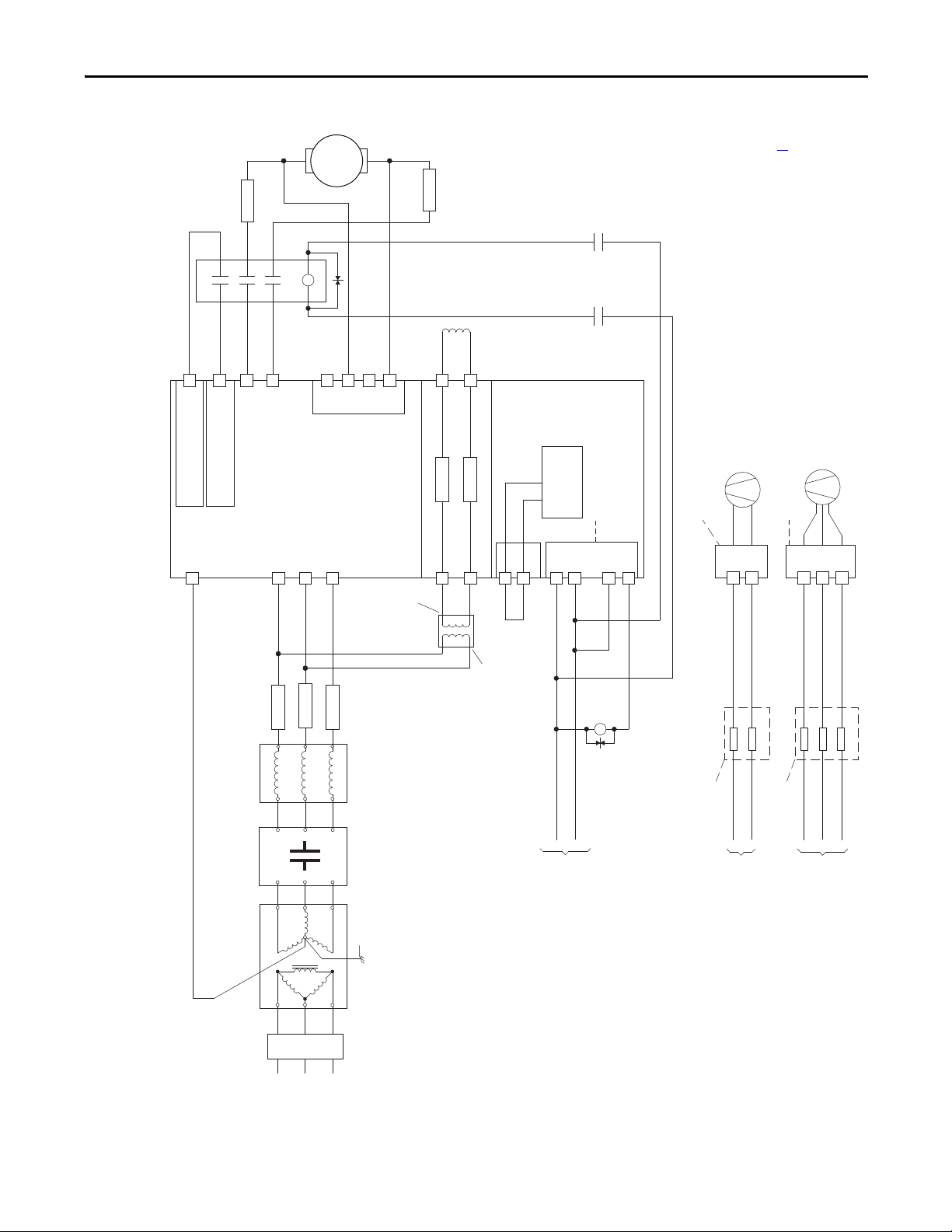

Typical Power Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

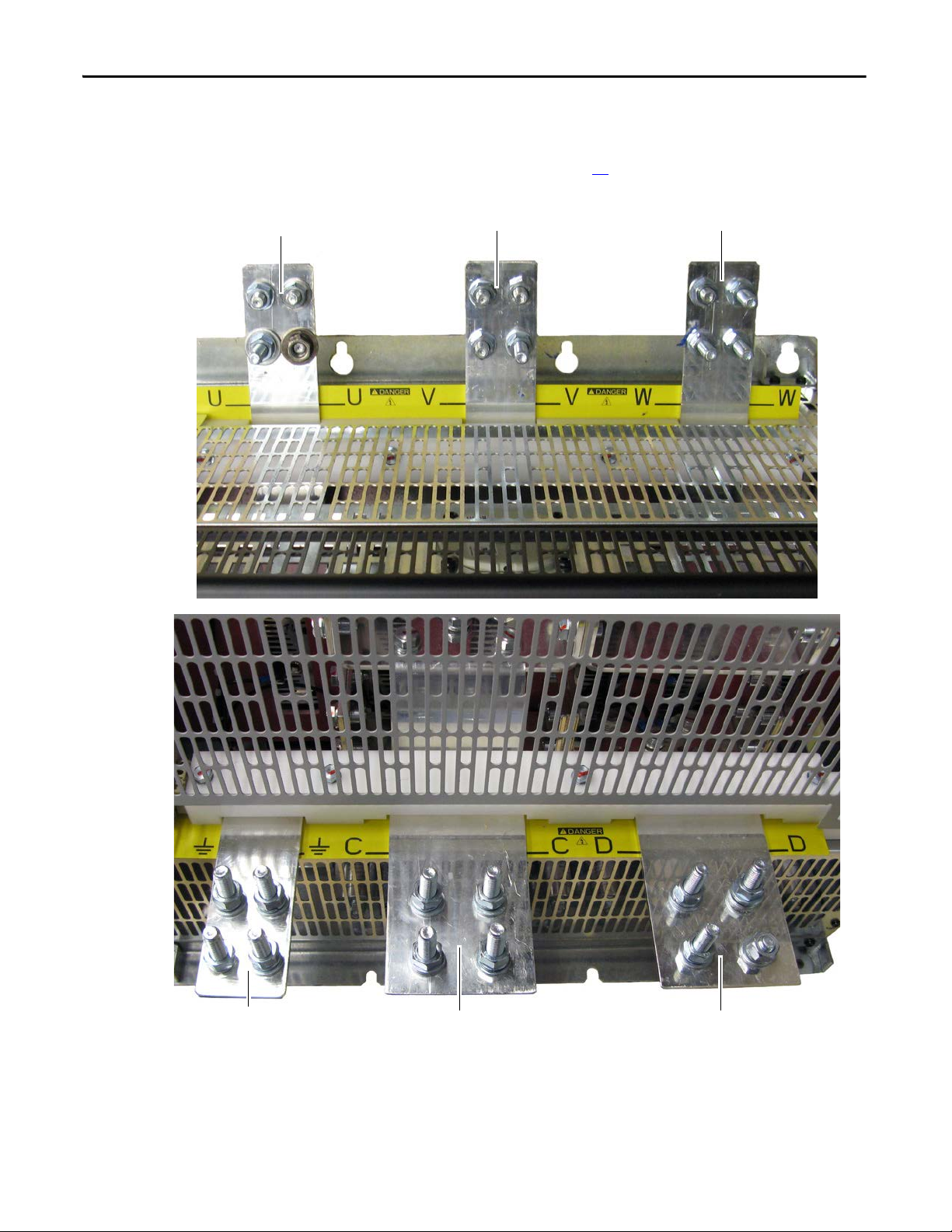

Armature Converter Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Armature Voltage Feedback Connections. . . . . . . . . . . . . . . . . . . . . . . 53

Field Converter Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Field Current Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

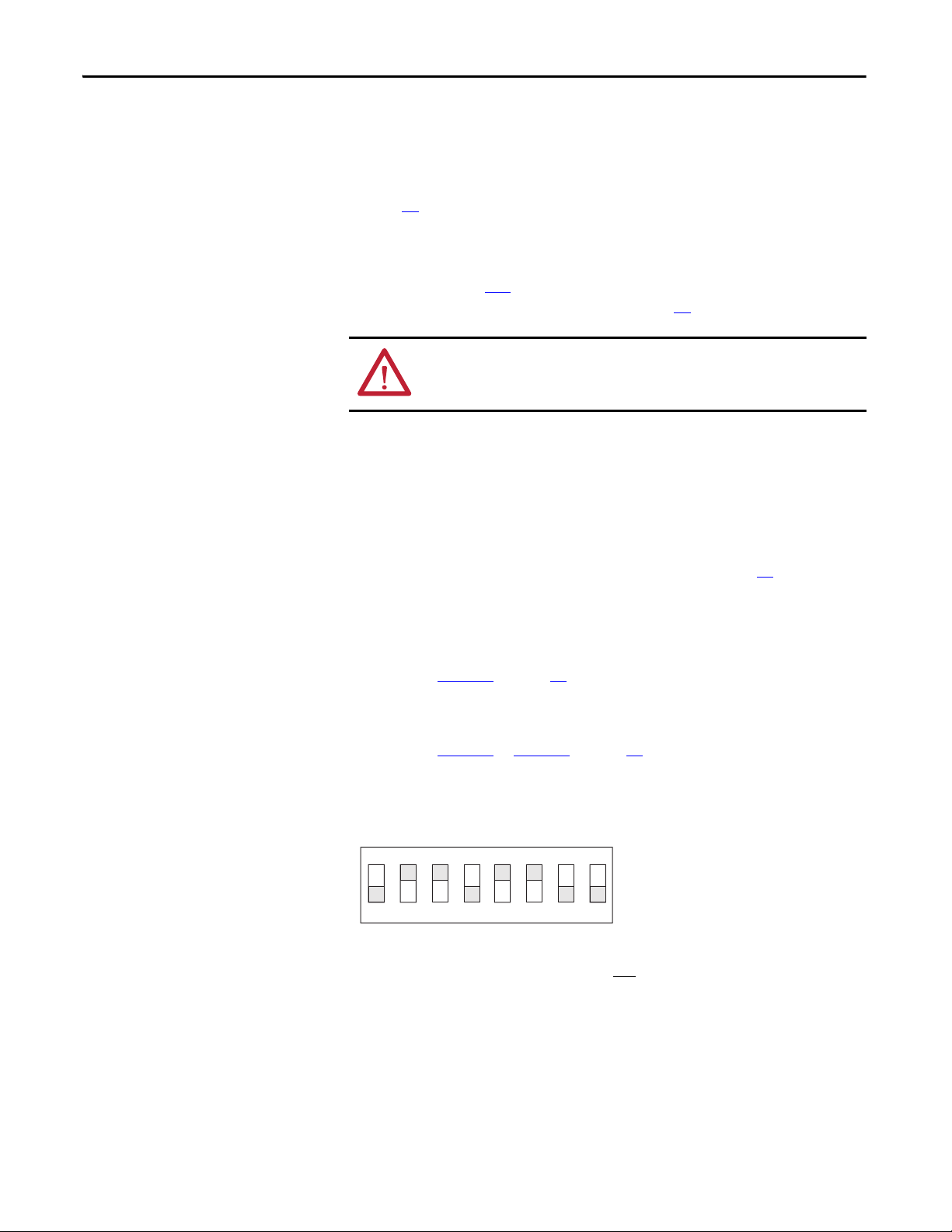

Set DIP Switch S14 to the Correct Value . . . . . . . . . . . . . . . . . . . . . . . 60

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Thermistors and Thermal Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Control Circuit Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Frame C Heatsink Cooling Fan Specifications . . . . . . . . . . . . . . . . . . 69

Frame D, Series B Heatsink Cooling Fan Specifications . . . . . . . . . . 71

Frame C and D Armature Fuse Signal Terminals . . . . . . . . . . . . . . . . 73

DIP Switch and Jumper Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

I/O Signal and Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Digital Encoder Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

DC Analog Tachometer Terminal Block . . . . . . . . . . . . . . . . . . . . . . . 88

Resolver Feedback Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

I/O and Control Wire Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 2

Drive Start Up

6 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Drive Start Up Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Before Applying Power to the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Verify all Drive Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . 92

Verify the Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Verify the Control and I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Applying Power to the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Apply Voltage to the Control Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . 93

Verify the Control Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Load the Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Configure the Most Commonly Used Parameters . . . . . . . . . . . . . . . 95

Tune the Current Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Verify Motor Rotation and Run Feedback Polarity Checks. . . . . . 103

Configure the Speed Feedback Parameters . . . . . . . . . . . . . . . . . . . . . 106

Tune the Speed Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Verify Speed Reference Settings and Drive Operation. . . . . . . . . . . 110

Page 7

Chapter 3

Table of Contents

Programming and Parameters

Troubleshooting

About Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Parameters Table Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

How Parameters are Organized. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

File–Group–Parameter Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Numbered List View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Cross Reference Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Basic Parameter View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Advanced Parameter View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Monitor File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Motor Control File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Speed Command File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Dynamic Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Applications File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Utility File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Communications File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Input / Output File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Parameter Cross Reference – by Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Parameter Cross Reference – by Number. . . . . . . . . . . . . . . . . . . . . . . . . . 209

Chapter 4

Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Drive Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

HIM Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Manually Clearing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Fault Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Clearing Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Alarm Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Common Drive Symptoms and Corrective Actions . . . . . . . . . . . . . . . . 227

Drive will not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Drive starts but motor does not turn and no armature current . . 228

The motor does not reach commanded speed . . . . . . . . . . . . . . . . . . 228

The motor is turning in the wrong direction . . . . . . . . . . . . . . . . . . 228

The motor reaches maximum speed immediately . . . . . . . . . . . . . . 229

Testpoint Codes and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Supplemental Drive Information

Appendix A

Certifications and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

IP20 NEMA / UL Type Open Watts Loss . . . . . . . . . . . . . . . . . . . . . . . . 232

Communication Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Typical Programmable Controller Configurations . . . . . . . . . . . . . 234

Logic Command/Status Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Drive Power Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Frame A and B Fuse Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Frame C and D Fuse Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Control Power Circuit Protection Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 7

Page 8

Table of Contents

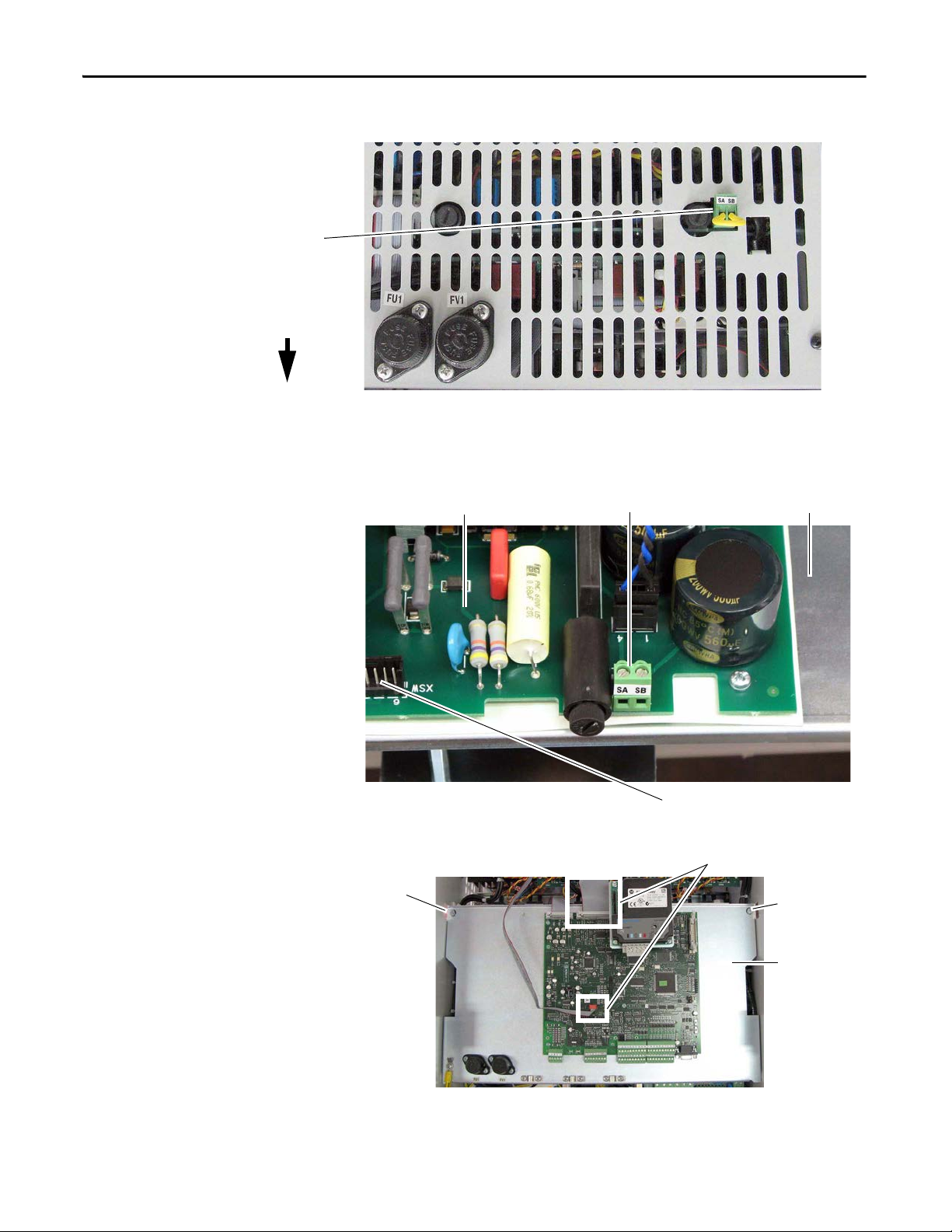

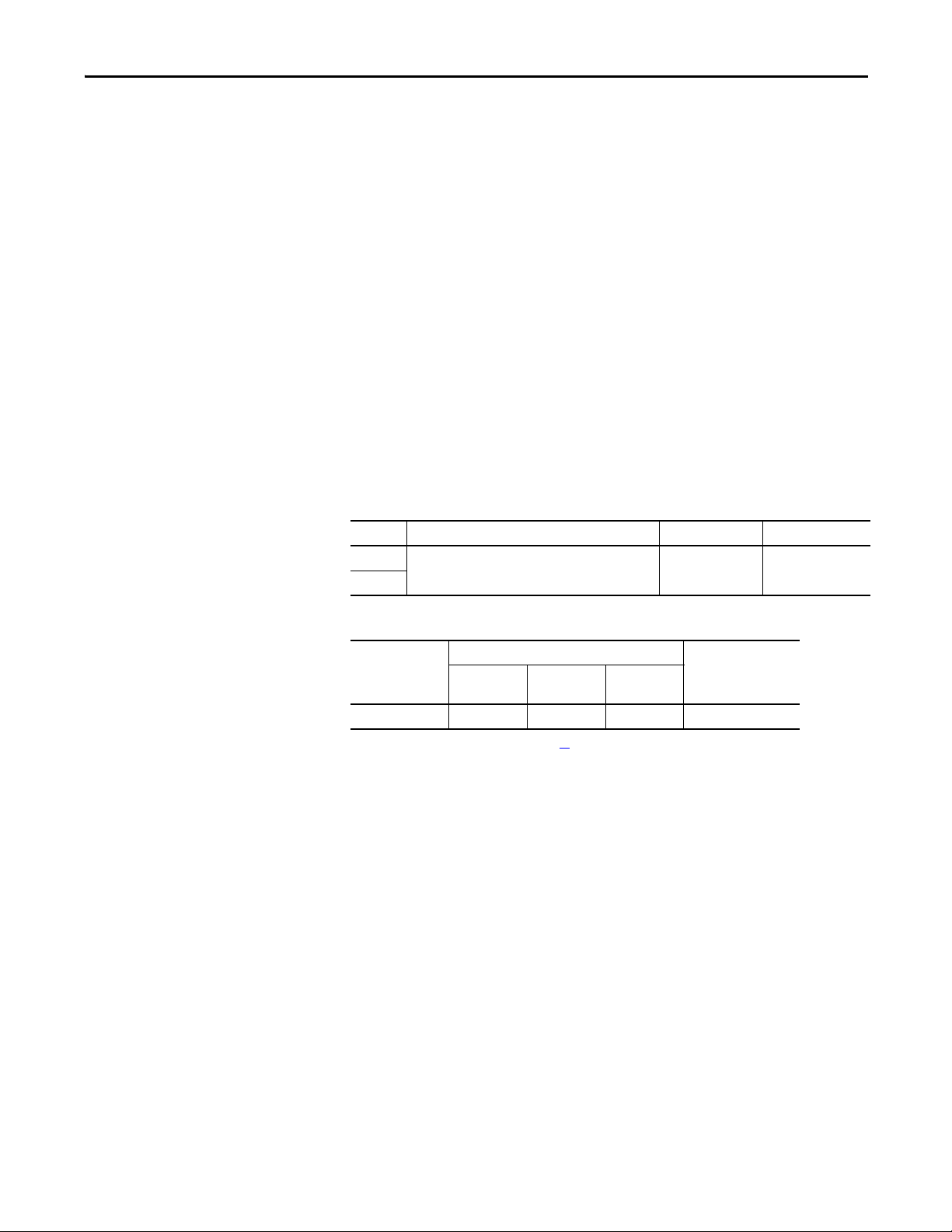

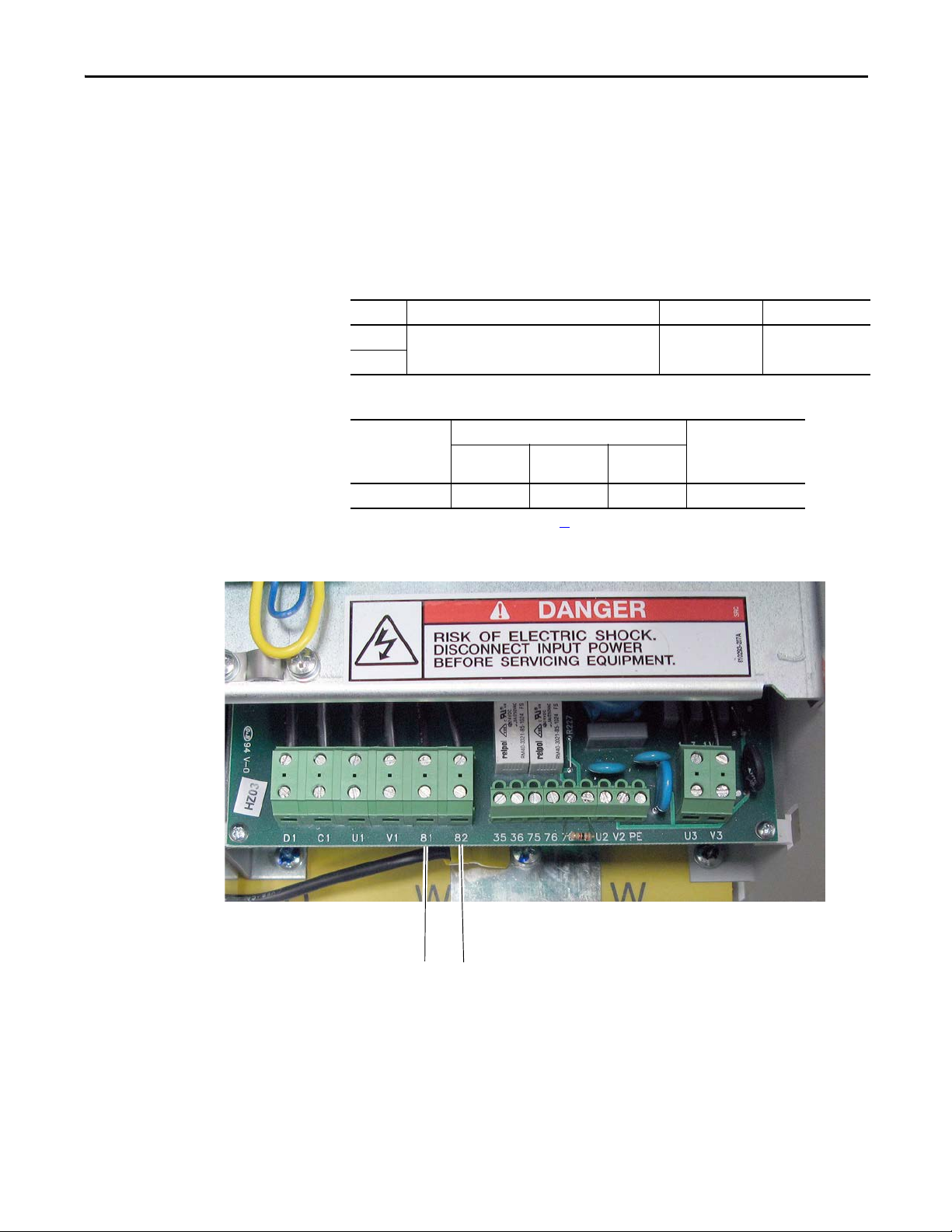

Switching Power Supply Circuit Board Fuses . . . . . . . . . . . . . . . . . . 249

Frame B Pulse Transformer Circuit Board Fuses . . . . . . . . . . . . . . . 251

Frame C Transient Noise Filter Circuit Board Fuses. . . . . . . . . . . . 252

Frame D Overvoltage Clipping Circuit Board Fuses . . . . . . . . . . . . 253

AC Input Line Reactors and AC Input Contactors. . . . . . . . . . . . . . . . . 254

Isolation Transformers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Dynamic Brake Resistor Kits and DC Output Contactors . . . . . . . . . . 258

DC Contactor Crimp Lug Kit Specifications . . . . . . . . . . . . . . . . . . . . . . 259

Alternate Dynamic Brake Resistor Kits and DC Output Contactors. 260

Alternate EMC Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Terminal Adapter Kits for Frame D Drives . . . . . . . . . . . . . . . . . . . . . . . . 264

Appendix B

HIM Overview

Application Notes

External and Internal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

LCD Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

ALT Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Using the S.M.A.R.T. List Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Viewing and Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

LCD HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Removing/Installing the HIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Appendix C

Alpha Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Alpha Test Setup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Analog Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Example 1: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Example 2: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Analog Input Signal Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Current / Speed Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Drive Reference and Feedback Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Armature Voltage Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

DC Analog Tachometer Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Encoder Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Drive Reference and Feedback Scaling Examples . . . . . . . . . . . . . . . 280

Speed Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Droop Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Field Weakening Mode Configuration (v1.006) . . . . . . . . . . . . . . . . . . . 285

Using a DC Contactor Only (Firmware v1.006 Only) . . . . . . . . . . 286

Using a DC Contactor and a Dynamic Brake (Firmware

v1.006 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Using an Inverting Fault Device Only (Firmware v1.006 Only). . 286

Using a DC Contactor and an Inverting Fault Device (Firmware

v1.006 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Using a DC Contactor, a Dynamic Brake and an Inverting Fault

Device (Firmware v1.006 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

8 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 9

Table of Contents

Lifting/Torque Proving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Tuning The Motor For Torque Prove Applications . . . . . . . . . . . . 291

Crane Setup with Encoder/Resolver Feedback . . . . . . . . . . . . . . . . . 291

Crane Setup - Encoderless. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Manually Tuning the Speed Regulator for Firmware Version 6.xxx . . 301

PID Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Configure a Line Speed Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Configure the Feedback Signal in the Follower Drive(s) . . . . . . . . 304

Configure the Tension Set Point Signal in the Follower Drive(s) 306

Reference Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

“Auto” Speed Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

“Manual” Speed Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Changing Speed Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Torque Reference Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Auto/Manual Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Resolver Cable Balance Tuning Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Performing the Cable Balance Tuning Test . . . . . . . . . . . . . . . . . . . . 309

Resolver Type Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Scale Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Linking Parameters Via the Scale Block Parameters. . . . . . . . . . . . . 312

SCR Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Open SCR Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Shorted SCR Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

S-curve Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

S-curve Acceleration Ramp Example: . . . . . . . . . . . . . . . . . . . . . . . . . 316

Speed Regulation Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Adaptive Speed Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Speed Up Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Speed Threshold Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Speed Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Speed Draw Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Speed / Torque Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Zero Torque Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Speed Regulation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Torque Regulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

eed Limited Adjustable Torque (SLAT) Min Mode and SLAT Max

Sp

Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Sum Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Start At Powerup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Fine Tuning the Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Manually Adjusting the Current Regulator Tune Settings . . . . . . 332

Fine Tuning the Field Current Regulator. . . . . . . . . . . . . . . . . . . . . . 334

Fine Tuning the Speed Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Fine Tuning the Voltage Regulator in the Field Converter . . . . . . 339

Tuning the Field Current Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 9

Page 10

Table of Contents

Appendix D

Control Block Diagrams

Installing a Communication Adapter

Optional Analog and Digital I/O

Expansion Circuit Board

Optional 115V AC to 24V DC I/O

Converter Circuit Board

Diagram Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Appendix E

Communication Adapter Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

What The Communication Adapter Kit Includes . . . . . . . . . . . . . . . . . . 367

Tools That You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Installing the Communication Adapter Module in the Drive. . . . . . . . 368

Frame A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Frames B and C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Frame D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Appendix F

What This Option Board Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

I/O Expansion Board Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Appendix G

What This Option Board Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

I/O Converter Board Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

PowerFlex DC Standalone Regulator

Installation

History of Changes

Index

Appendix H

Installation and Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

Appendix I

20P-UM001J-EN-P, February 2014 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

20P-UM001I-EN-P, February 2013 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

20P-UM001H-EN-P, April 2011. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

20P-UM001G-EN-P, October 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

20P-UM001F-EN-P, June 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

10 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 11

Preface

Top ic Pa ge

Drive Storage Conditions 11

Drive Nameplate Data 12

Drive Specifications 12

Extra Resources 13

Technical Support 13

Convent ions 13

General Precautions 14

Standard Drive Catalog Number Explanation 15

Standalone-Alone Regulator Catalog Numbers 16

The purpose of this manual is to provide you with the basic information required

to install, start-up, and troubleshoot the PowerFlex DC drive. This manual is

intended for qualified personnel. You must be able to program and operate DC

drives. In addition, you must have an understanding of the parameter settings and

functions that are detailed in this manual.

Drive Storage Conditions

If it is necessary to store the drive for any length of time before installation, follow

these storage guidelines to provide satisfactory start-up operation and retain

warranty coverage:

• After receipt and inspection, repack the drive in its original shipping

container and store in a clean, dry place.

• Place where the ambient temperatures do not exceed -25°C (-13°F) or

55°C (131°F)

• Place where the range of relative air humidity does not exceed 5…95%.

• At an altitude of less than 3,000 meters (10,000 ft.) above sea level.

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 11

Page 12

Preface

Note: Certification

Marks Location.

See the data

nameplate label on

your drive for actual

agency certifications.

Drive frame size

Drive serial number

Drive series letter

Drive Nameplate Data

The PowerFlex DC drive contains a data nameplate label on the side of each

drive. This nameplate identifies the specific model number, applicable AC input

power, and DC output power data. Include this information when

communicating with Rockwell Automation personnel about this product.

Cat No.

20P41AD4P1RA0NNN

UL Type OPEN/IP20

Input: 460VAC 50/60 Hz 3.3A 3 Phase

Output: 500VDC 4.1A REGEN 2.0HP

1 Min Overload Amps

3 Sec Overload Amps

DC Field:

Input: 460VAC 50/60 Hz 10A max. 1 Phase

Output: 360VDC 10A max.

Regulator Power: 115/230VAC 50/60 Hz 1.0/0.5A 1 Phase

MFD. in 2XXX on MMM DD

Made in Italy

6.2

8.2

EXAMPLE ONLY

Series: A

I/O: 24VDC (Standard)

Original Firmware V. 1.001

N223

Frame: A

Serial Number: A23E0042

C

Ind. Cont.

Eq. 31KF

Listed

R

US

Drive Series Letter

Drive Specifications

Series B drives are identified as such on the data nameplate label. The drive series

letter is on the top, right side of the label.

Drive Frame Sizes

Similar PowerFlex DC drive ratings are grouped into frame sizes to make

ordering spare parts and drive dimensions simpler. The drive frame size is listed

just above the serial number on the data nameplate label. See the Standard Drive

Catalog Number Explanation on page 15

for a list of drive catalog numbers and

their respective frame sizes.

Drive Firmware Version

The original firmware version of the drive as shipped from the factory appears on

the data nameplate label just above the certifications. If the firmware version has

been upgraded since the drive was shipped, you can view the current version on

the HIM (if installed). See Diagnostics Menu on page 269

For drive specification information, see the PowerFlex Digital DC Drive,

Technical Data, 20P-TD001

.

for details.

12 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 13

Preface

Extra Resources

These documents contain more information on related products from Rockwell

Automation.

Resource Description

Preventive Maintenance of Industrial Control and Drive

System Equipment, DRIVES-TD001

Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Control, SGI-1.1

A Global Reference Guide for Reading Schematic Diagrams,

100-2.10

Guarding Against Electrostatic Damage, 8000-4.5.2 Provides common practices that can help guard against

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://ab.com

Provides a checklist for performing preventive

maintenance.

Provides general guidelines for the application,

installation, and maintenance of solid-state control in the

form of individual devices or packaged assemblies that

incorporate solid-state components.

Provides a simple cross-reference of common schematic/

wiring diagram symbols that are used throughout various

parts of the world.

ESD.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and other

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Technical Support

Conventions

For Allen-Bradley Drives Technical Support:

Title Online at. . .

Allen-Bradley Drives Technical Support www.ab.com/support/abdrives

• To help differentiate parameter names and LCD display text from other

text, the following conventions are used:

– Parameter names appear in [brackets].

For example: [Armature Voltage].

– Display text appears in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an

action:

Word Mean ing

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 13

Page 14

Preface

General Precautions

AT TE NT IO N: This drive contains ESD (Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required when you install, test, service,

or repair this assembly. If ESD control procedures are not followed, component

damage can result. If you are not familiar with static control procedures, see

publication 8000-4.5.2, “Guarding Against Electrostatic Damage” or any other

applicable ESD protection handbook.

AT TE NT IO N: An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Installation or application errors, such as,

an undersized motor, incorrect or inadequate AC supply, or excessive surrounding

air temperatures can result in malfunction of the system.

AT TE NT IO N: Allow only qualified personnel, familiar with DC drives and

associated machinery, to plan or implement the installation, start-up and

subsequent maintenance of the system. Failure to comply can result in personal

injury and equipment damage.

AT TE NT IO N: An incorrectly applied or installed bypass system can result in

component damage or reduction in product life. The most common causes are:

• An AC line connection to the drive output or control terminals.

• Improper bypass or output circuits that are not Allen-Bradley approved.

• Output circuits that do not connect directly to the motor.

Contact Allen-Bradley for assistance with your application or installation.

14 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 15

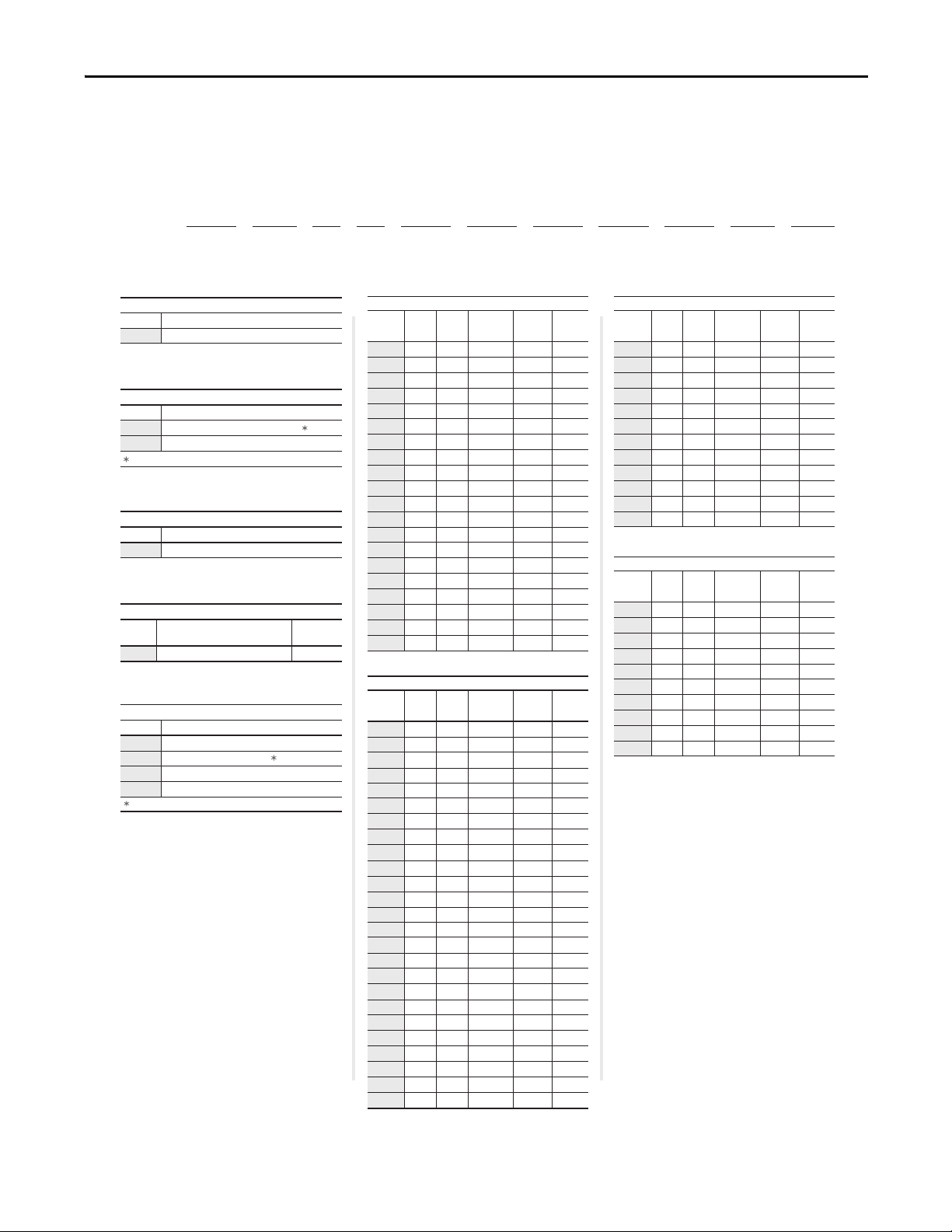

Standard Drive Catalog

Position

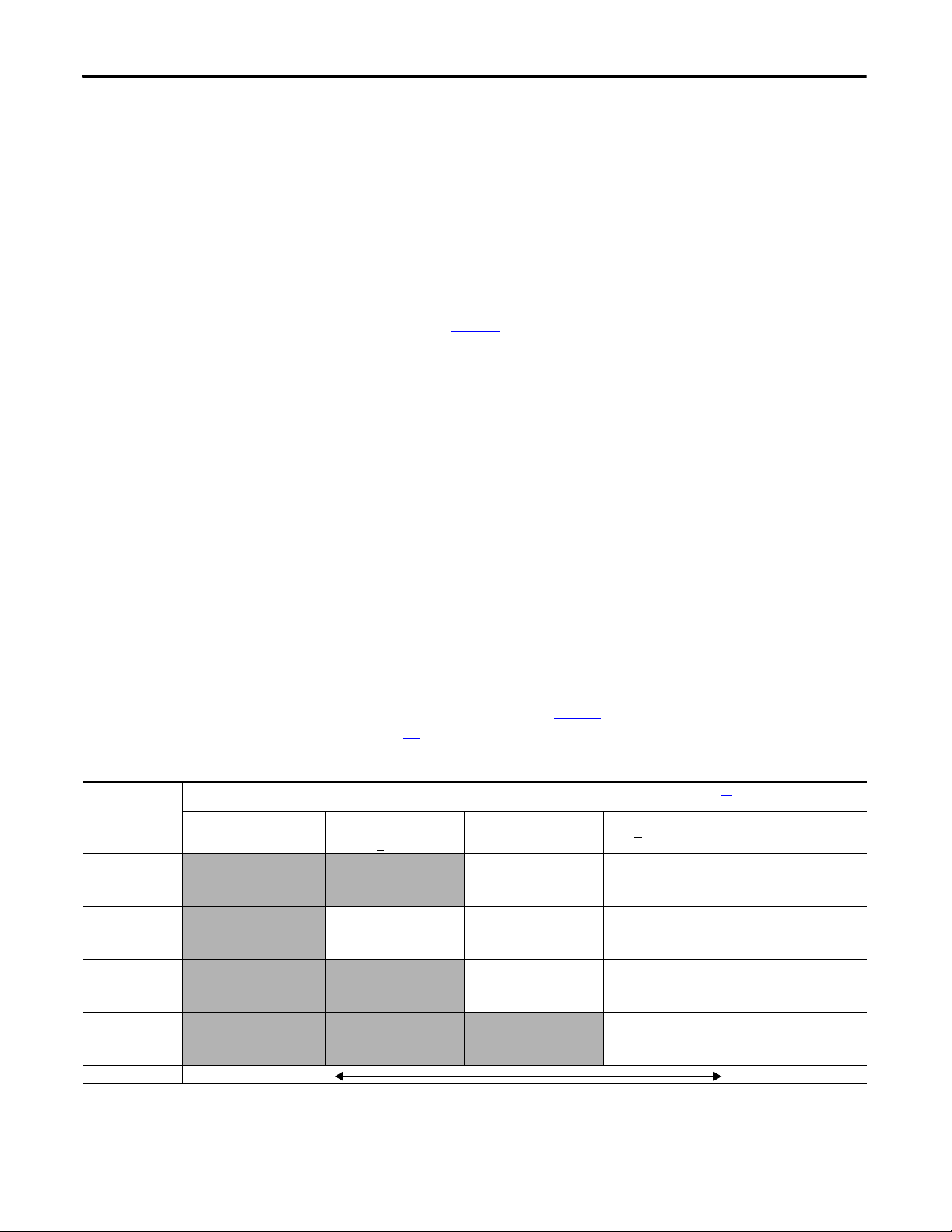

1-3 4 5 6 7 8-10 11 12 13 14 15 16

20P 4 1 A D 4P1 R A 0 N N N

abcdef gh i jkl

a

Drive

Code Type

20P PowerFlex DC

b

Motor Operation

Code Type

2 Two Quadrant Operation

4 Four Quadrant Operation

c

Input Type

Code Type

1 6 Pulse

d

Enclosure

Code Enclosure Rating

Conform.

Coat

A IP20, NEMA/UL Type Open

e

Input Voltage

Code Voltage

B 230V AC

D 460V AC

E 600V AC

F 690V AC

f1

f2

Yes

Not available for 230V AC input drives.

Use this code for 400V AC input applications.

f3

f4

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

200

250

300

400

500

600

700

800

900

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

56

75

93

112

149

187

224

298

373

447

552

597

671

4.1

6

10

14

19

27

35

45

52

73

86

100

129

167

207

250

330

412

495

667

830

996

1162

1238

1494

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

C

C

D

D

D

D

D

10

10

10

10

10

10

10

10

10

14

14

14

14

20

20

20

20

20

20

20

40

40

70

70

70

Hp

Armature

Amps

Frame

Field

Amps

Code kW

460V, 60 Hz Input

4P1

6P0

010

014

019

027

035

045

052

073

086

100

129

167

207

250

330

412

495

667

830

996

1K1

1K3

1K4

1.5

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

200

250

300

1.2

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

56

75

93

112

149

186

224

7

9

12

20

29

38

55

73

93

110

146

180

218

265

360

434

521

700

875

1050

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

B

C

C

D

D

10

10

10

10

10

10

10

14

14

14

20

20

20

20

20

20

20

20

40

40

Hp

Armature

Amps

Frame

Field

Amps

Code kW

230V, 60 Hz Input

7P0

9P0

012

020

029

038

055

073

093

110

146

180

218

265

360

434

521

700

875

1K0

50

75

100

200

300

400

500

600

800

900

1000

1250

37

56

75

149

224

298

373

447

597

671

746

932

67.5

101.3

135

270

405

540

675

810

1080

1215

1350

1668

B

B

B

B

B

C

C

D

D

D

D

D

20

20

20

20

20

20

20

40

40

40

40

40

Hp

Armature

Amps

Frame

Field

Amps

Code kW

575V, 60 Hz Input

067

101

135

270

405

540

675

810

1K0

1K2

1K3

1K6

298

373

447

552

597

671

746

820

932

1044

Hp

Armature

Amps

Frame

Field

Amps

Code kW

690V, 60 Hz Input

452

565

678

791

904

1K0

1K1

1K2

1K4

1K5

400

500

600

700

800

900

1000

1100

1250

1400

452

565

678

791

904

1017

1130

1243

1413

1582

C

C

D

D

D

D

D

D

D

D

20

20

40

40

40

40

70

70

70

70

Number Explanation

Preface

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 15

Page 16

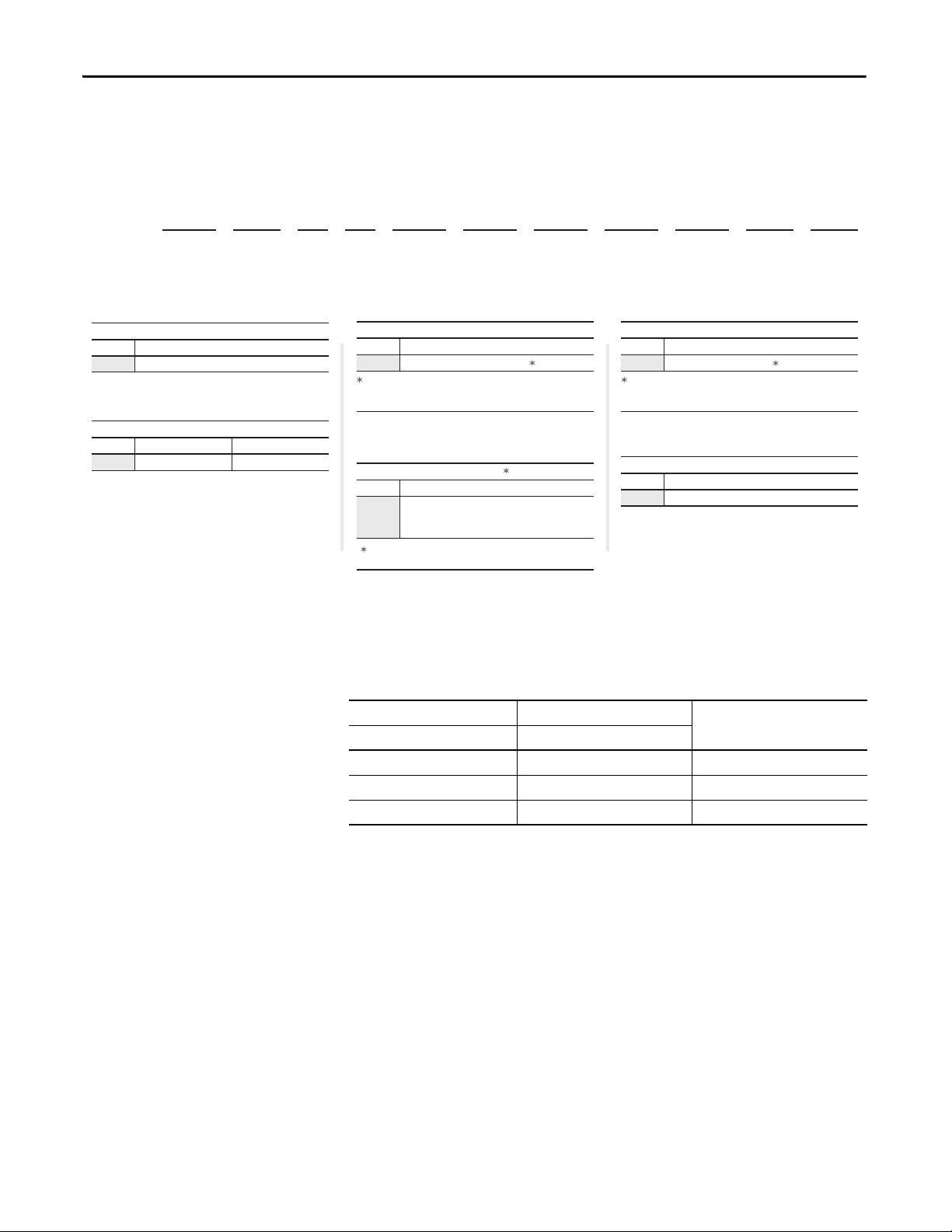

Preface

Position

1-3 4 5 6 7 8-10 11 12 13 14 15 16

20P 4 1 A D 4P1 R A 0 N N N

abcdefghi jkl

g

Field Supply

Code Type

R Single-Phase Regulated

h

Packaging/Documentation

Code Shipping Carton User Manual

A Yes Yes

i

HIM

Code Operator Interface

0 Blank Cover

Standard - for user installed options, see

Human Interface and Wireless Interface

Modules on page 9.

j

I/O Options

Code Control

N

None (8 - 24V DC Digital Inputs,

4 Digital Outputs, 3 Analog Inputs,

and 2 Analog Outputs are Standard)

k

Communication Options

Code Description

N None

l

Cabinet Options

Code Type

N None

Standard - for user installed options, see

Communication Option Kits on page 10.

All I/O Options are purchased separately and

are user installed. See I/O Options on page 9.

Standard Drive Catalog Number Explanation, Cont.

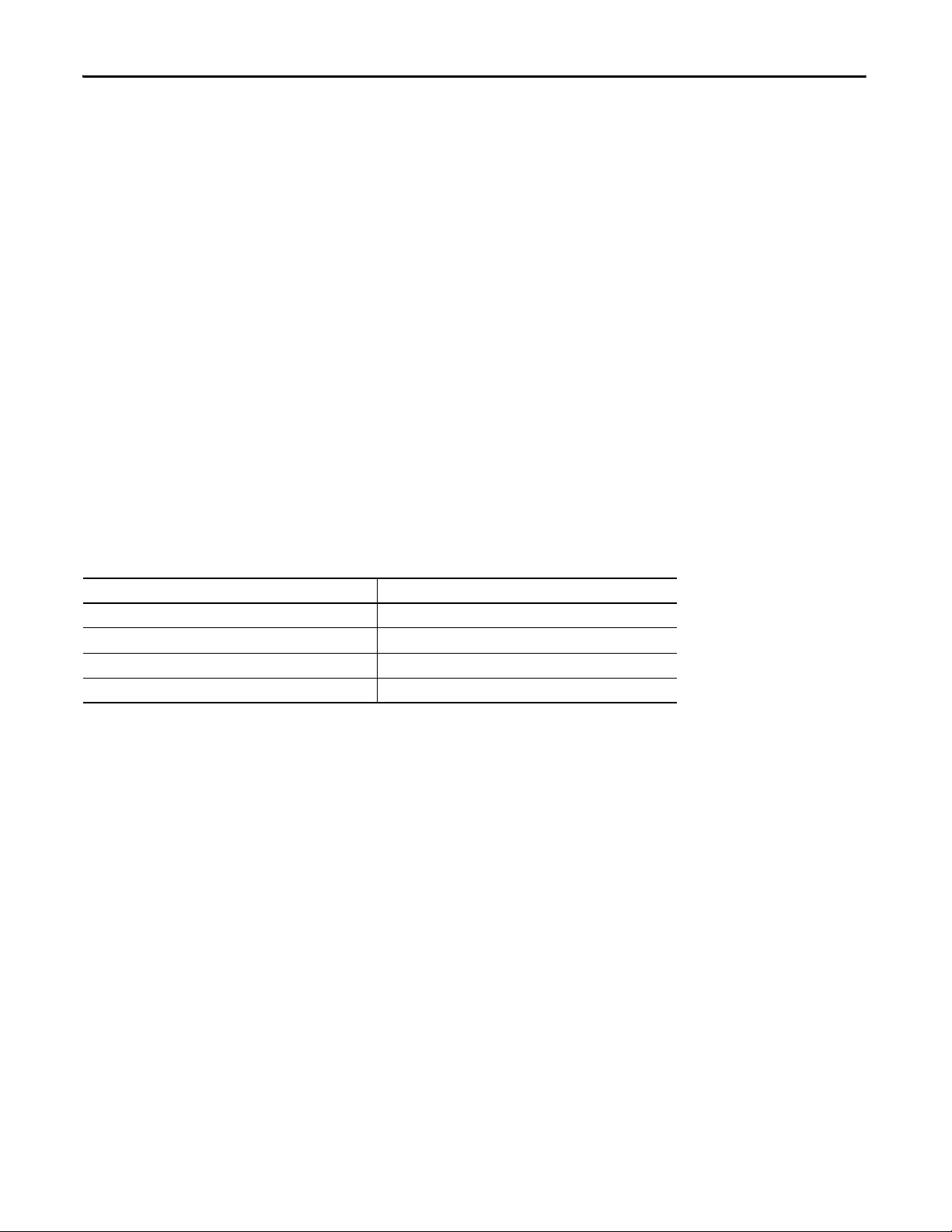

Standalone-Alone Regulator Catalog Numbers

Conformally coated circuit boards are provided with the following catalog

numbers.

230V / 460V AC Input Regulators 575V / 690V AC Input Regulators Field Amps

Cat. No. Cat. No.

23PMD4 23PMF4 40

23PMD7 23PMF7 70

(1)

23PAMP

(1) Gate Amplifier - used with all voltage classes of the Stand-Alone Regulator. Note: The Stand-Alone Re gulator and Gate Amplifier are

currently sold through Rockwell Automation Drive Systems only. Consult the factory for availability.

23PAMP

(1)

(1)

16 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 17

Chapter 1

IMPORTANT

IMPORTANT

Installation and Wiring

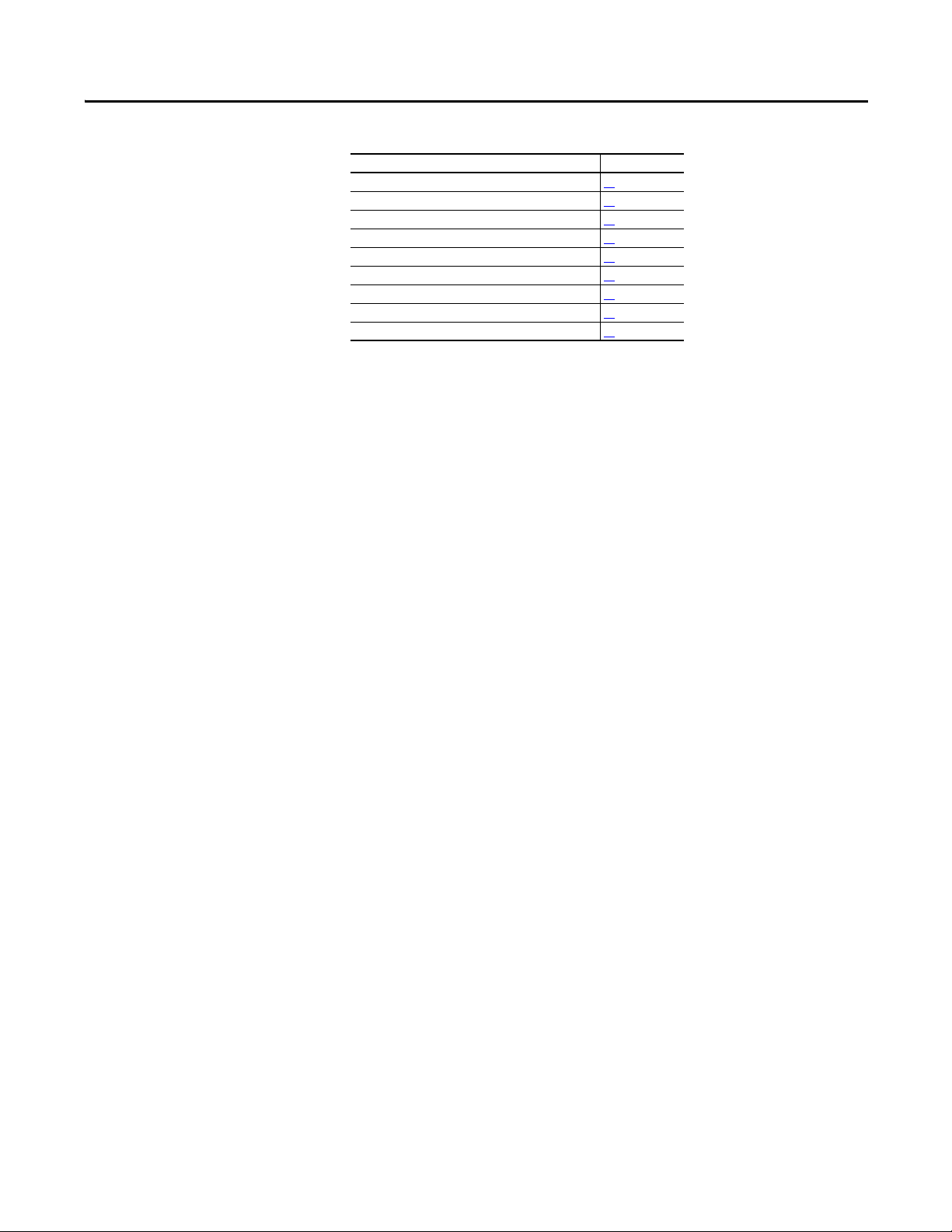

Topic Page Topic Page

Mount the Drive 18 CE Conformity 39

Approximate Drive Dimensions and

Wei ght s

Lifting PowerFlex DC Drives 25 Co ntrol Power Circ uit Protection 42

Remove the Drive Covers 27 Cable and Wiring Recommendations 43

Isolation Transformers / Line Reactors 29 Power Wiring 44

Contac tors 30 DIP Switch and Jumper Settings 75

General Grounding Requirements 32 I/O Wiring 80

19 Power Circuit Protection 42

This chapter provides information on how to mount and wire the PowerFlex DC

drive.

Most start-up difficulties are the result of incorrect wire connections. Take all

precautions to assure that wire connections are done as instructed. All items must

be read and understood before the actual installation begins.

For PowerFlex DC Stand-Alone Regulator (SAR) installations, see Appendix H

for important installation and configuration information. A 23PMDx catalog

number on the data nameplate on the drive identifies a SAR. (see Drive

Nameplate Data on page 12

for location).

The PowerFlex DC drive is not designed for use with multiple motor

applications or resistive loads. Contact your Local Solution Center for multiple

motor applications. See Local Solution Centers, publication

DSDC-BR001

, for more information.

The recommended drive to motor horsepower ratio is 2:1.

AT TE NT IO N: The following information is merely a guide for proper installation.

Rockwell Automation cannot assume responsibility for the compliance or the

noncompliance to any code, national, local or otherwise for the proper

installation of this drive or associated equipment. If codes are ignored during

installation, a hazard of personal injury and equipment damage exists.

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 17

Page 18

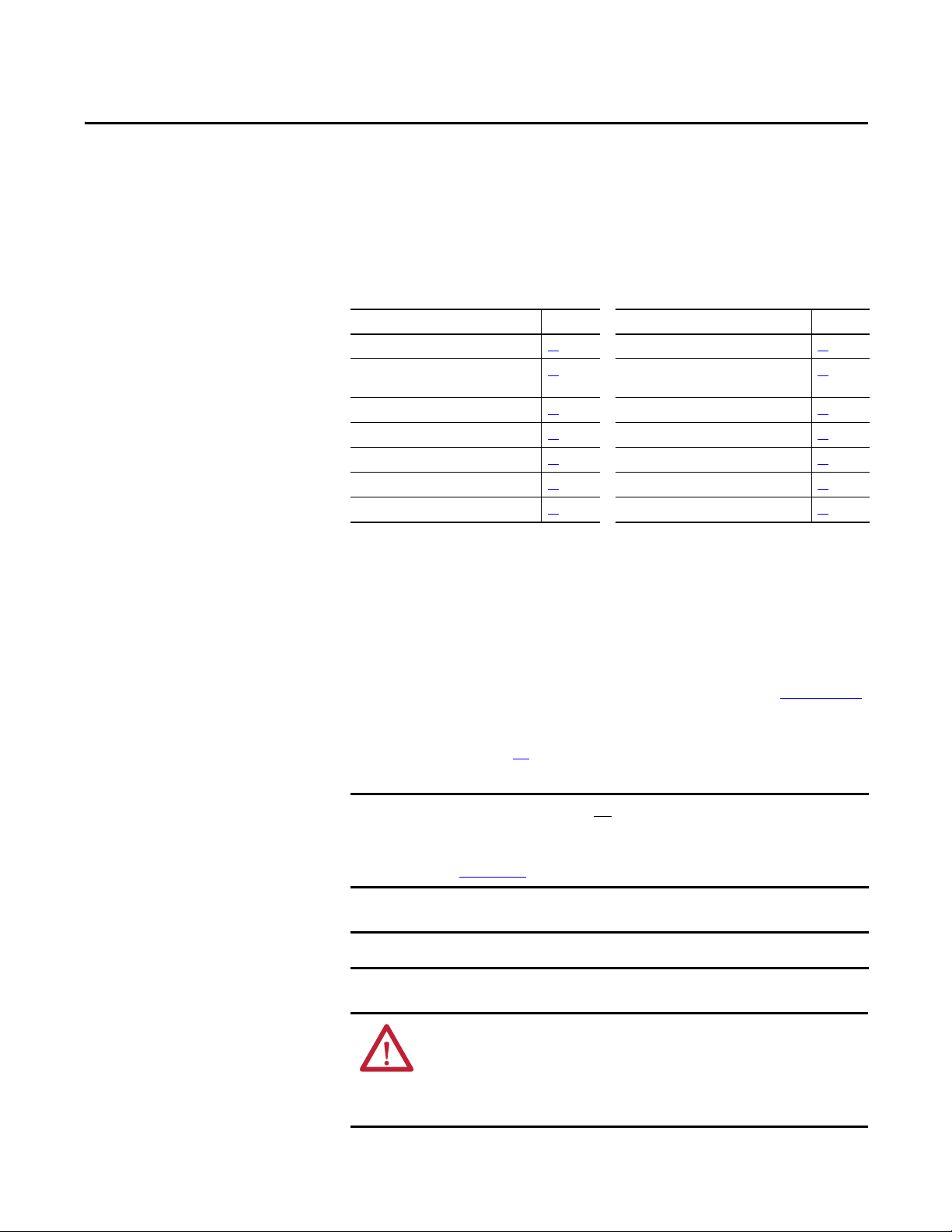

Chapter 1 Installation and Wiring

10 mm

10 mm

50 mm

(0.4 in.)

(0.4 in.) (2.0 in.)

10 mm

(0.4 in.)

150 mm (6.0 in.)

150 mm (6.0 in.)

150 mm (6.0 in.)

STS

PORT

MOD

NET A

NET B

STS

PORT

MOD

NET A

NET B

Airflow through the drive

must not be impeded.

Mount the Drive

Operating Conditions and Temperatures

PowerFlex DC drives are designed to operate at 0…50 °C (32…122 °F)

surrounding air temperature without derating. The drive must be mounted in a

clean, dry location. Contaminants such as oils, corrosive vapors, and abrasive

debris must be kept out of the enclosure. NEMA / UL Type Open, IP20

enclosures are intended for indoor use primarily to provide a degree of protection

against contact with enclosed equipment. These enclosures offer no protection

against airborne contaminants.

Minimum Mounting Clearances

Minimum clearance requirements are intended to be from drive to drive. Other

objects can occupy this space; however, reduced airflow can cause protection

circuits to fault the drive. The drive must be mounted in a vertical orientation as

shown in Figure 1

vertical. Intake air temperature must not exceed the product specification.

Figure 1 - Drive Enclosure Minimum Mounting Clearances

and must not be mounted at an angle greater than 30° from

Maximum Surrounding Air Temperature Specifications

• 0…50 °C (32…122 °F), typical

• De-rate 1.25% for every 1 °C (°F) over 50 °C (122 °F), to 55 °C (131 °F)

• Additional cooling is required for temperatures above 55 °C (131 °F)

18 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 19

Installation and Wiring Chapter 1

A

B

A2

B1

C

STS

PORT

MOD

NET A

NET B

A1

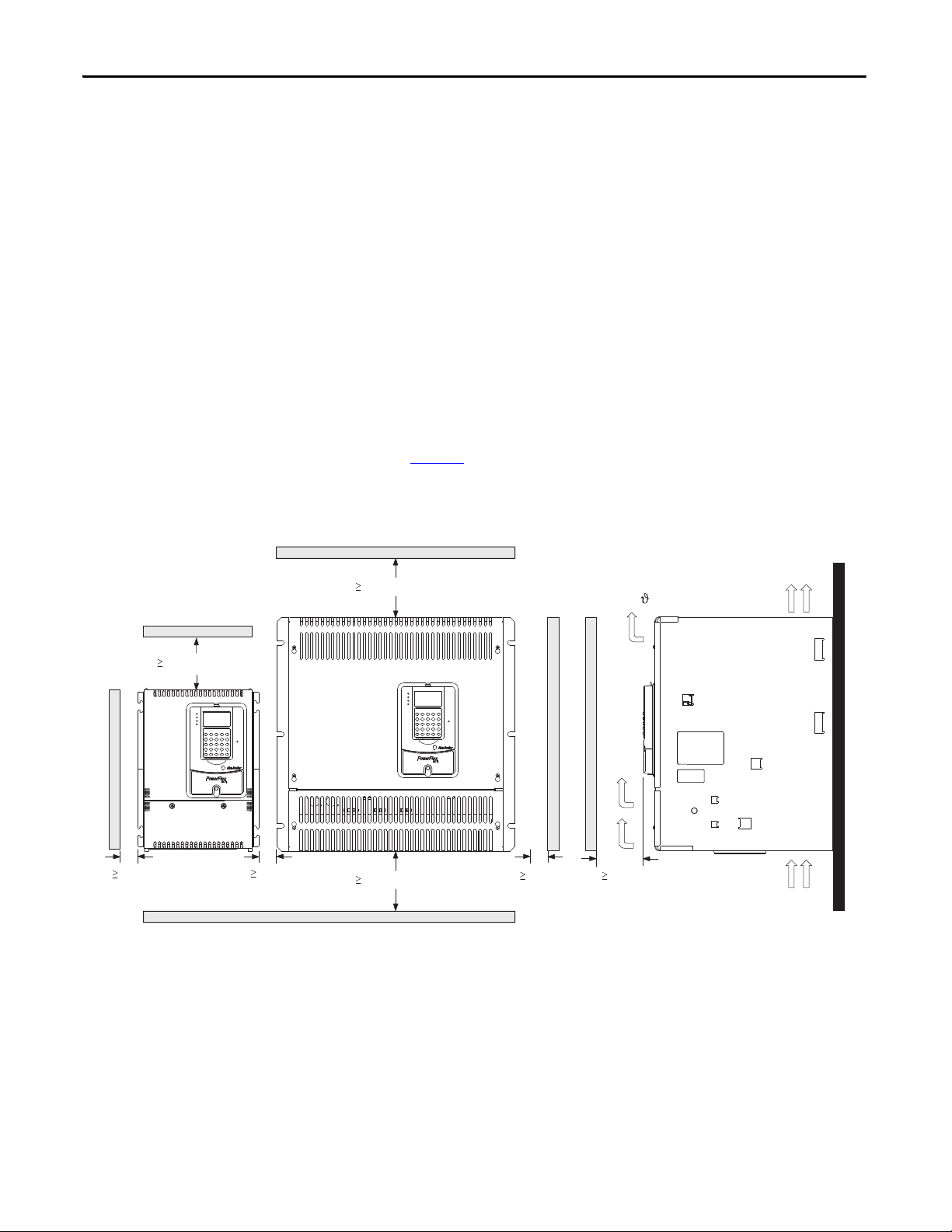

Approximate Drive Dimensions and Weights

The PowerFlex DC drive is available in a NEMA / UL Type Open, IP20

enclosure only. Follow all mounting clearances to provide proper drive operation.

ATTENTION: Remove all loose packing materials, including the containers of

desiccants (if any), from the drive enclosure before you mount and energize the

drive.

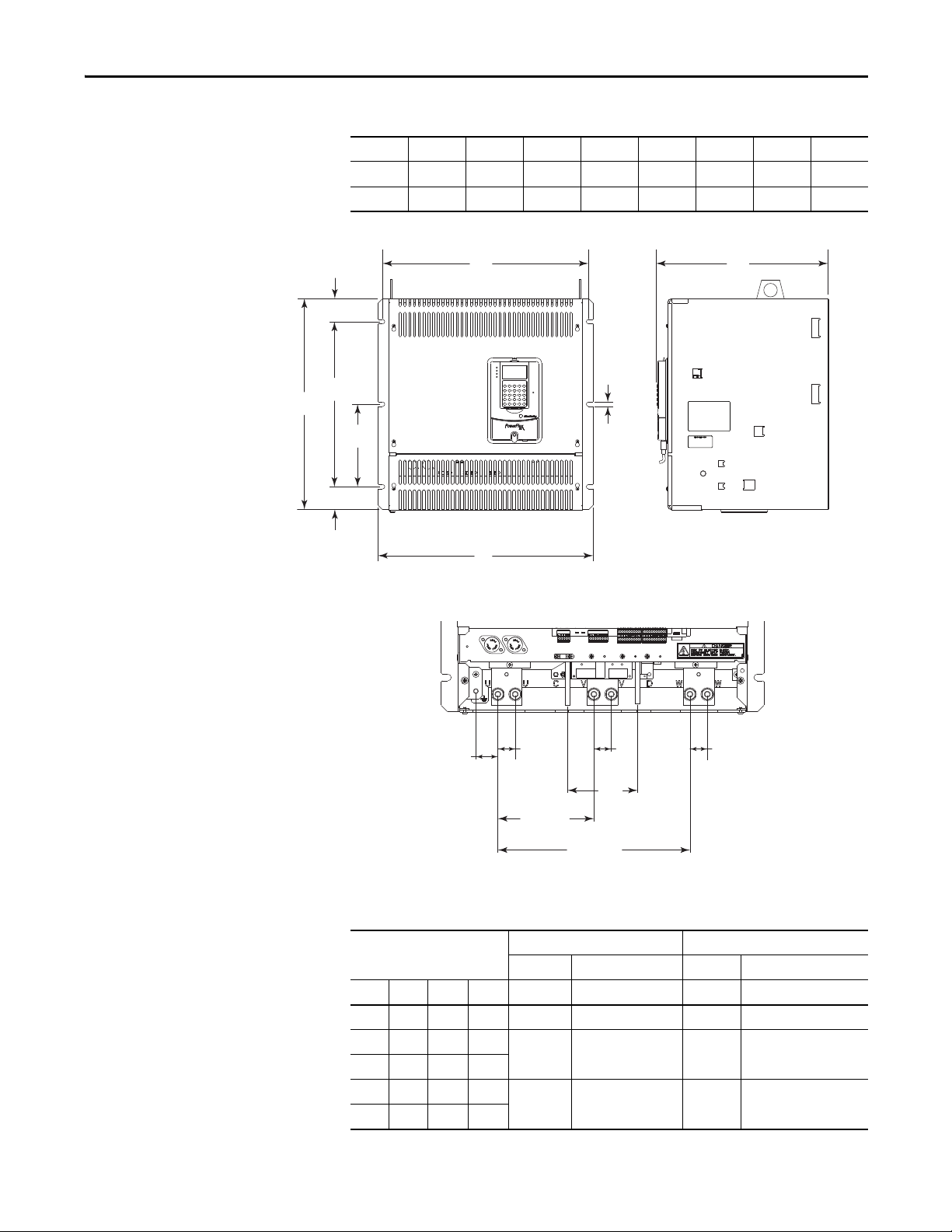

Figure 2 - Frame A Drive Dimensions

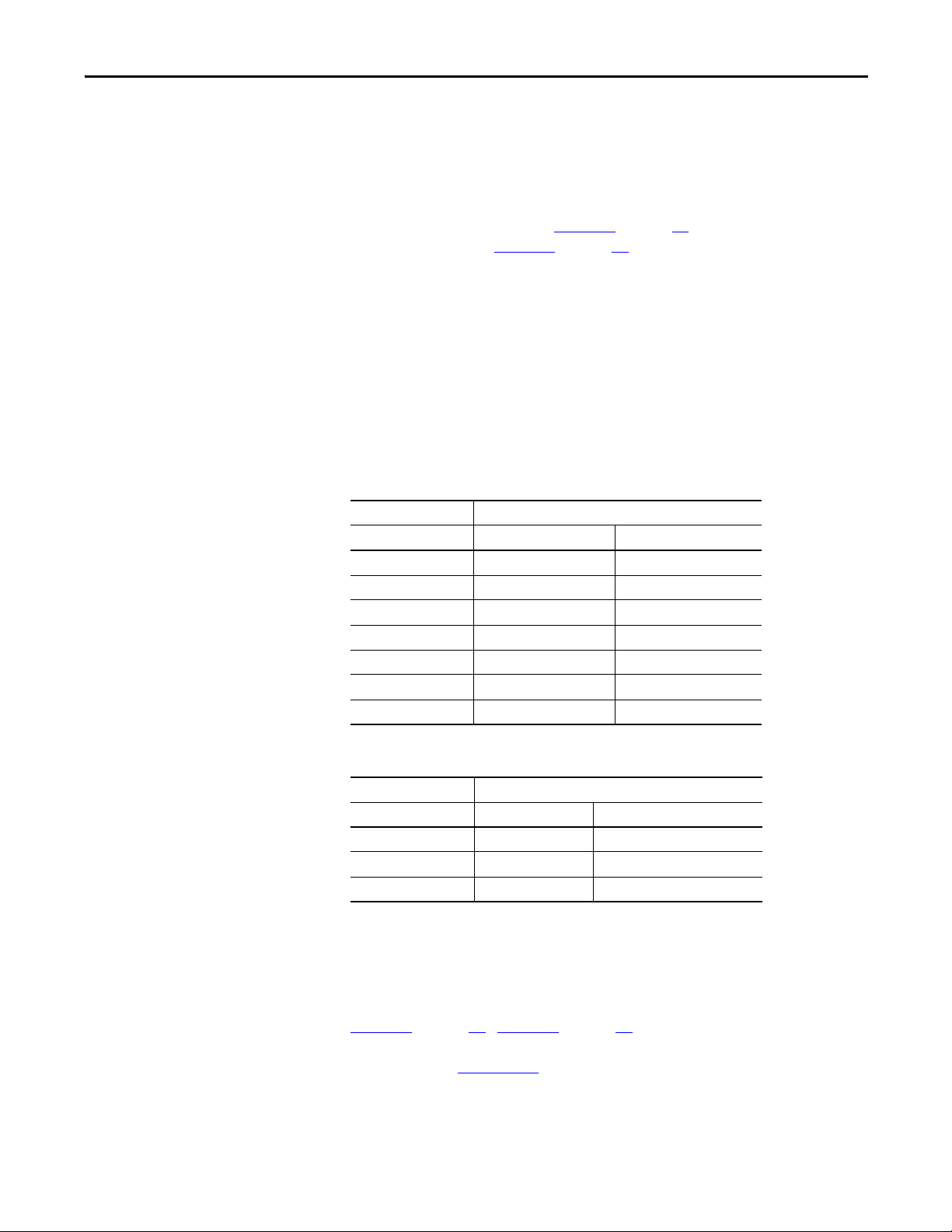

A B C A1A2B1

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

267 (10.5) 359 (14.0) 287 (11.3) 7 (0.3) 250 (9.8) 275 (10.8)

Table 1 - Frame A Weights

Drive Current Rating Code Drive Weight Drive and Packaging

230V 460V kg (lb) kg (lb)‘

7P0 4P1

9P0 6P0

012 010

020 014

–019

029 027

8.4 (18.5) 10.5 (23.2)

038 035

–052

073 073

093 086

8.8 (19.4) 11 (24.3)055 045

10.8 (23.8) 13 (28.7)

110 100

–129

Weig ht

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 19

Page 20

Chapter 1 Installation and Wiring

A

A1

B1

C1

B

A2

STS

PORT

MOD

NET A

NET B

A3

45.2 (1.8)

98.5 (3.9)

53.1 (2.1)

48.5 (1.9)

147.0 (5.8) 53.1 (2.1)

48.5 (1.9)

200.1 (7.9)

248.6 (9.8)

C2

Terminal Details Dimensions in mm (in.)

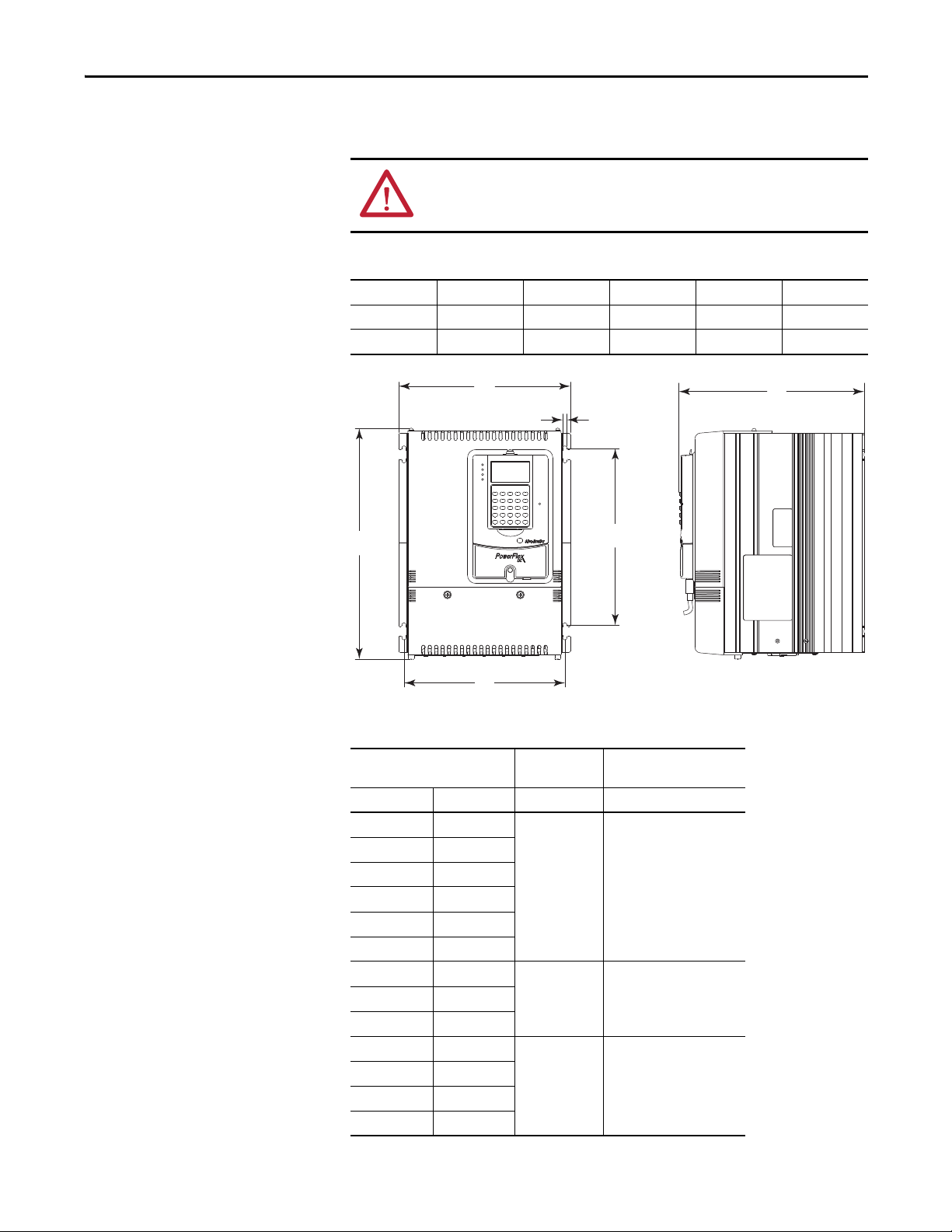

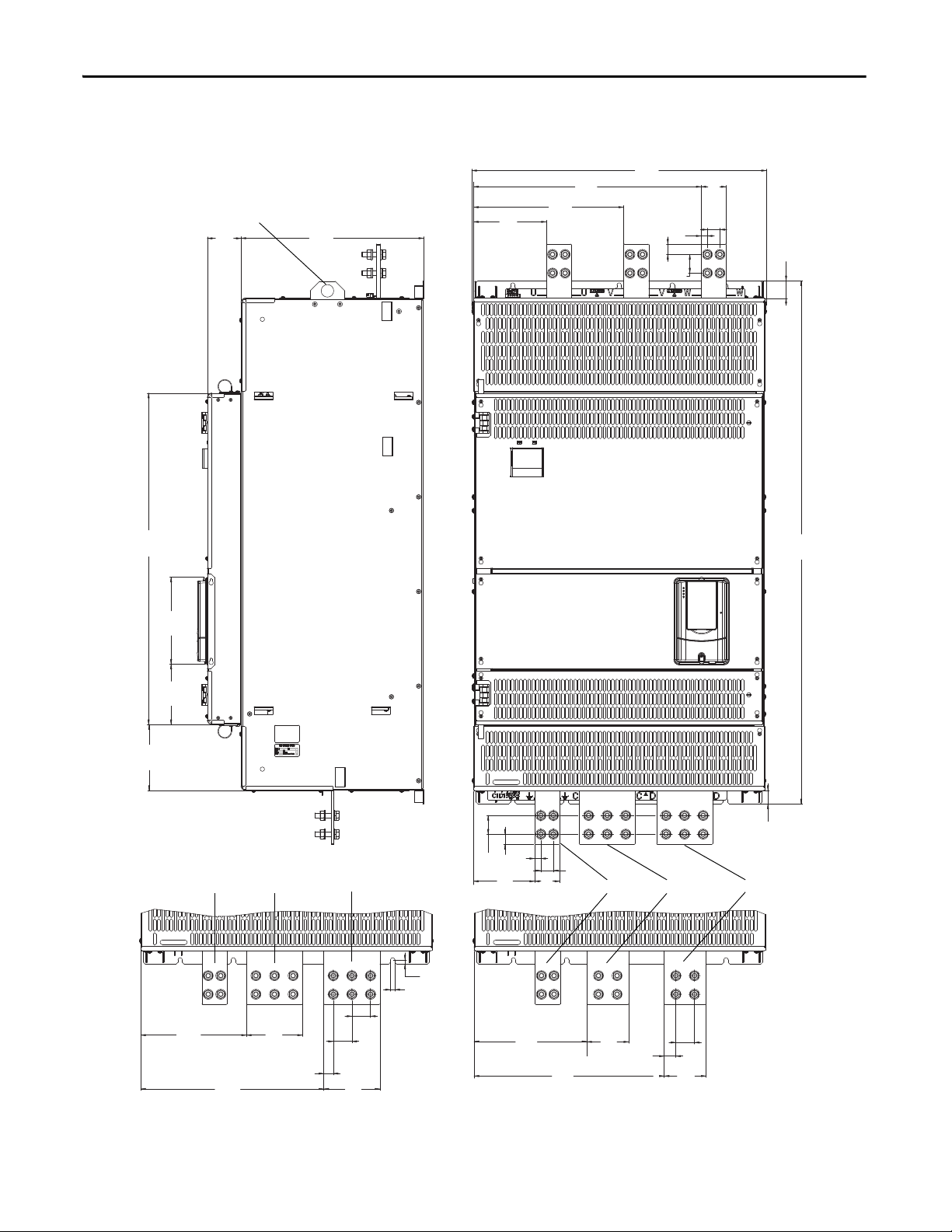

Figure 3 - Frame B Drive Dimensions

A A1A2A3B B1C1C2

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

311 (12.2) 275 (10.8) 16.5 (0.65) 7 (0.3) 388 (15.3) 375 (14.8) 350 (13.8) 380 (15.0)

(1) Only frame B drive catalog numbers 20P21AD330, 20P21AD412, 20P21AE405, 20P41AB36 0, 20P41AB434, 20P41AD330,

20P41AD412, 20P41AE405.

(1)

Table 2 - Frame B Weights

Drive w/ND Rating Code Drive Weight Drive and Packaging Weight

230V 460V 575V kg (lb) kg (lb)

146 167 067

25.5 (56.2) 27.5 (60.6)180 207 101

218 – 135

265 250 270 29.5 (65.0) 31.5 (69.5)

360 330 405

434 412 –

32 (70.5) 34 (75)

20 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 21

Installation and Wiring Chapter 1

B1

B2

B3

A

A1 C

B

B4

STS

PORT

MOD

NET A

NET B

B5

310.0 (12.2)

155.0 (6.1)

113.0

(4.5)

28.0

(1.1)

28.0

(1.1)

28.0

(1.1)

35.5 (1.4)

Terminal Details Dimensions in mm (in.)

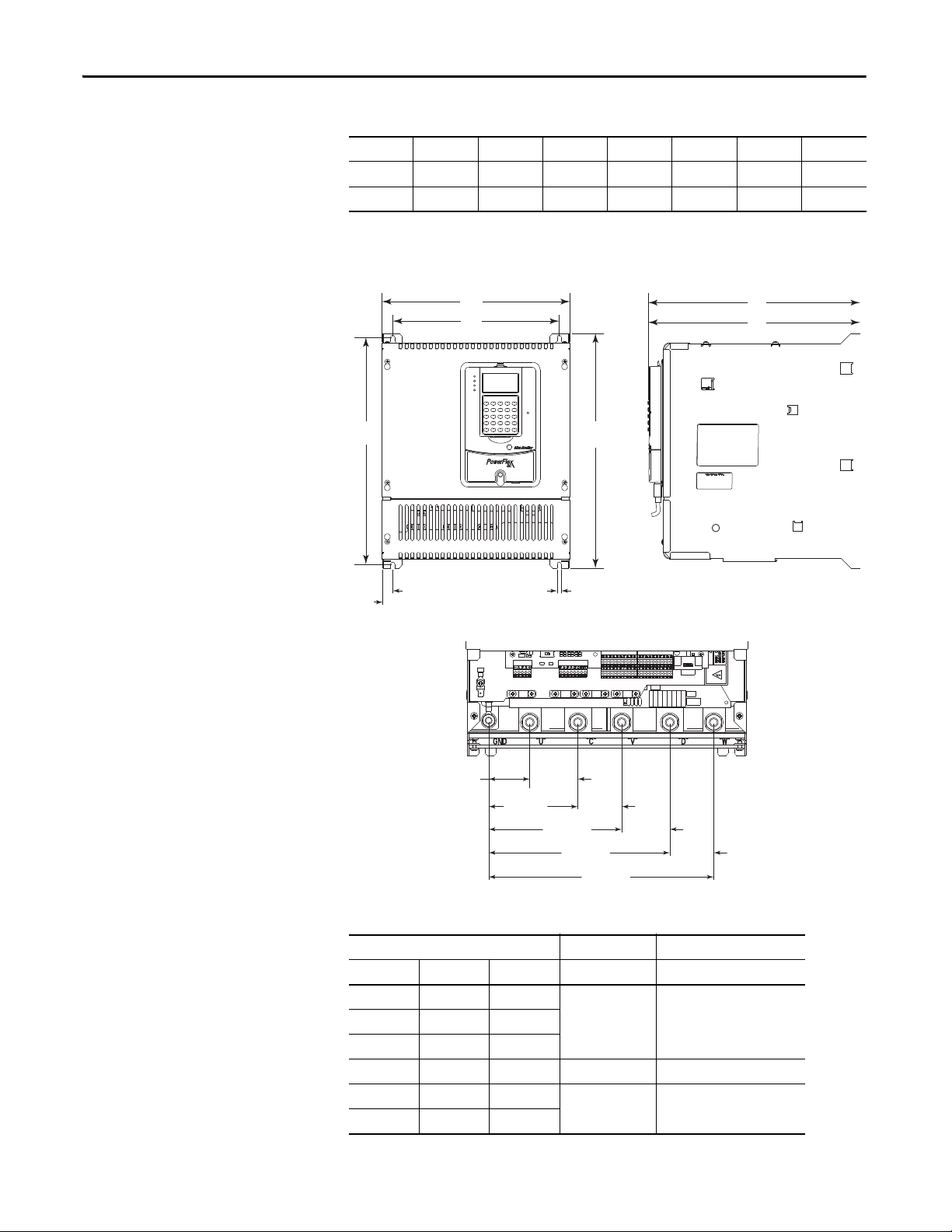

Figure 4 - Frame C Drive Dimensions

A A1 B B1 B2 B3 B4 B5 C

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

521 (20.5) 499 (19.7) 511 (20.1) 400 (15.7) 200 (7.9) 55 (2.2) 56 (2.2) 10.5 (0.4) 416 (16.4)

Table 3 - Frame C Weights

Drive w/ND Rating Code Weight - Regenerative Drives Weight - Non-regenerative Drives

230V 460V 575V 690V kg (lb) kg (lb) kg (lb) kg (lb)

– 495 – 61 (134.5) 83 (183.0) 57 (125.7) 79 (174.2)

521 667 –

700 – –

– – 540 452

– – 675 565

Drive Drive and Packaging Drive Drive and Packaging

65 (143.3) 87 (191.8) 62 (136.7) 84 (185.2)

72 (158.7) 94 (207.2) 68 (150.0) 90 (198.4)

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 21

Page 22

Chapter 1 Installation and Wiring

Dimensions of terminals U, V, and W are the same.

Dimensions are shown in mm and (in.)

Lifting flange

Note: 134 mm (5.3 in.) C and D terminals are installed on 460V AC input, 800 and 900 Hp, 575V AC input, 1000 Hp, and 690V AC input,

1100, 1200, 1250, and 1400 Hp drives only. All other frame D ratings have 100 mm (4.0 in.) C and D terminals.

PE C D

PE C D

80.5

(3.2)

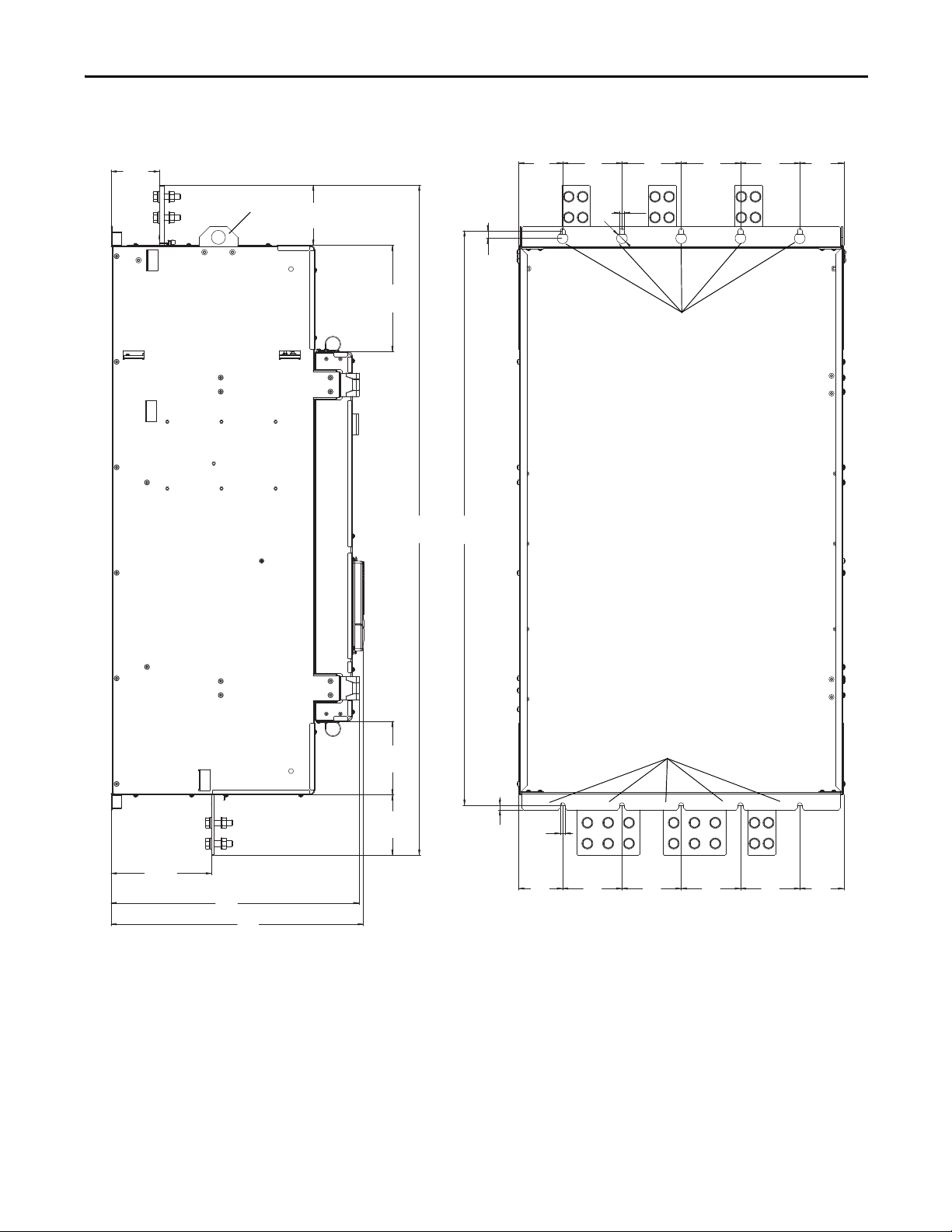

Figure 5 - Frame D Dimensions - Right Side and Front Views

544

(21.4)

359

(14.1)

436.5

(17.2)

174

(6.9)

704

(27.7)

25

(1.0)

15

(0.6)

44.5

(1.8)

60

(2.4)

30

(1.2)

42

(1.7)

792

(31.2)

208

(8.2)

144

(5.7)

157.5

(6.2)

252.5

(10.0)

437.5

(17.2)

134

(5.3)

22.6

(0.9)

44.5

(1.8)

134

(5.3)

44.5

(1.8)

10.5

(0.4)

10

(0.4)

44.5

25

(1.8)

15

(1.0)

(0.6)

146

(5.7)60(2.4)

(1.2)

269.5

(10.6)

454.5

(18.0)

1250

(49.2)

32

(1.3)

30

44.5

27.8

(1.1)

(1.8)

100

(4.0)

100

(4.0)

22 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 23

215.225

(8.5)

103.25

(4.1)

1435 MAX

(56.5)

129

(5.1)

129

(5.1)

227.5

(9.0)

157.5

(6.2)

1230

(48.4)

16

(0.6)

10.5

(0.4)

10

(0.4)

10.5

(0.4)

127

(5.0)

531

(21.0)

541

(21.3)

94

(3.7)

127

(5.0)

127

(5.0)

127

(5.0)

Ø 23

(0.9)

127

(5.0)

127

(5.0)

127

(5.0)

127

(5.0)

94

(3.7)

94

(3.7)

94

(3.7)

Dimensions are shown in mm and (in.)

Mounting holes

Mounting holes

Lifting flange

Installation and Wiring Chapter 1

Figure 6 - Frame D Dimensions - Left Side and Back Views

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 23

Page 24

Chapter 1 Installation and Wiring

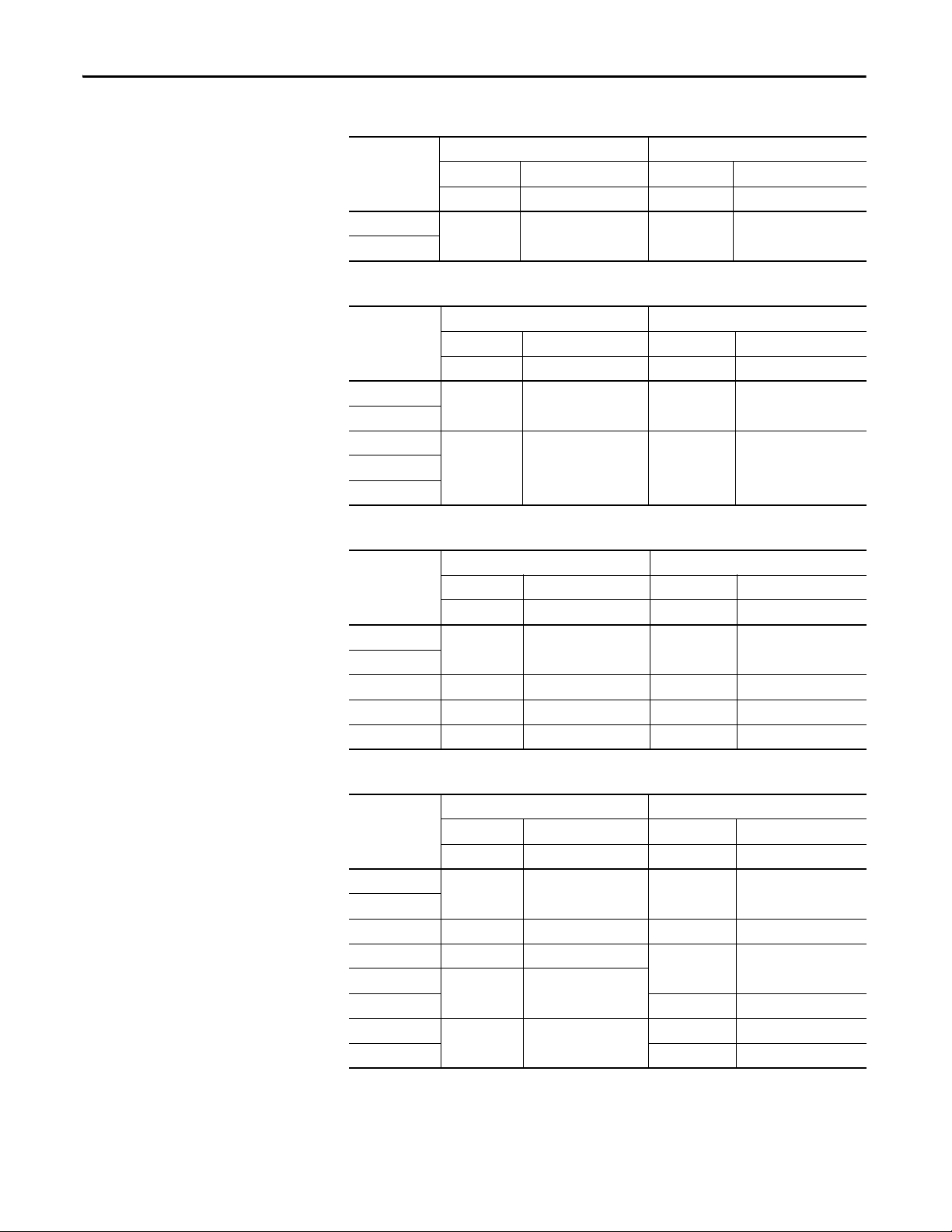

Table 4 - Frame D - 230V AC Input Drive Weights

Drive w/ND

Rating Code

875

1K0

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive and Packaging Drive Drive and Packaging

kg (lb) kg (lb) kg (lb) kg (lb)

203 (447.5) 281 (619.5) 152 (335.1) 230 (507.1)

Table 5 - Frame D - 460V AC Input Drive Weights

Drive w/ND

Rating Code

830

996

1K1

1K4

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive and Packaging Drive Drive and Packaging

kg (lb) kg (lb) kg (lb) kg (lb)

202 (445.3) 280 (617.3) 152 (335.1) 230 (507.1)

215 (474.0) 293 (646.0) 165 (363.8) 243 (535.7)1K3

Table 6 - Frame D - 575V AC Input Drive Weights

Drive w/ND

Rating Code

810

1K0

1K2 215 (474.0) 293 (646.0) 165 (363.8) 243 (535.7)

1K3 222 (489.4) 300 (661.4) 172 (379.2) 250 (551.2)

1K6 241 (531.3) 319 (703.3) 191 (421.1) 269 (593.0)

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive and Packaging Drive Drive and Packaging

kg (lb) kg (lb) kg (lb) kg (lb)

198 (436.5) 276 (608.5) 148 (326.3) 226 (498.2)

Table 7 - Frame D - 690V AC Input Drive Weights

Drive w/ND

Rating Code

678

791

904 200 (440.9) 278 (612.9) 150 (330.7) 228 (502.7)

1K0 202 (445.3) 280 (617.3)

1K1

1K2 165 (363.8) 243 (535.7)

1K4

1K5 191 (421.1) 269 (593.0)

24 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive and Packaging D rive Drive and Packaging

kg (lb) kg (lb) kg (lb) kg (lb)

198 (436.5) 276 (608.5) 148 (326.3) 226 (498.2)

215 (474.0) 293 (646.0)

241 (531.3) 319 (703.3)

152 (335.1) 230 (507.1)

172 (379.2) 250 (551.2)

Page 25

Installation and Wiring Chapter 1

IMPORTANT

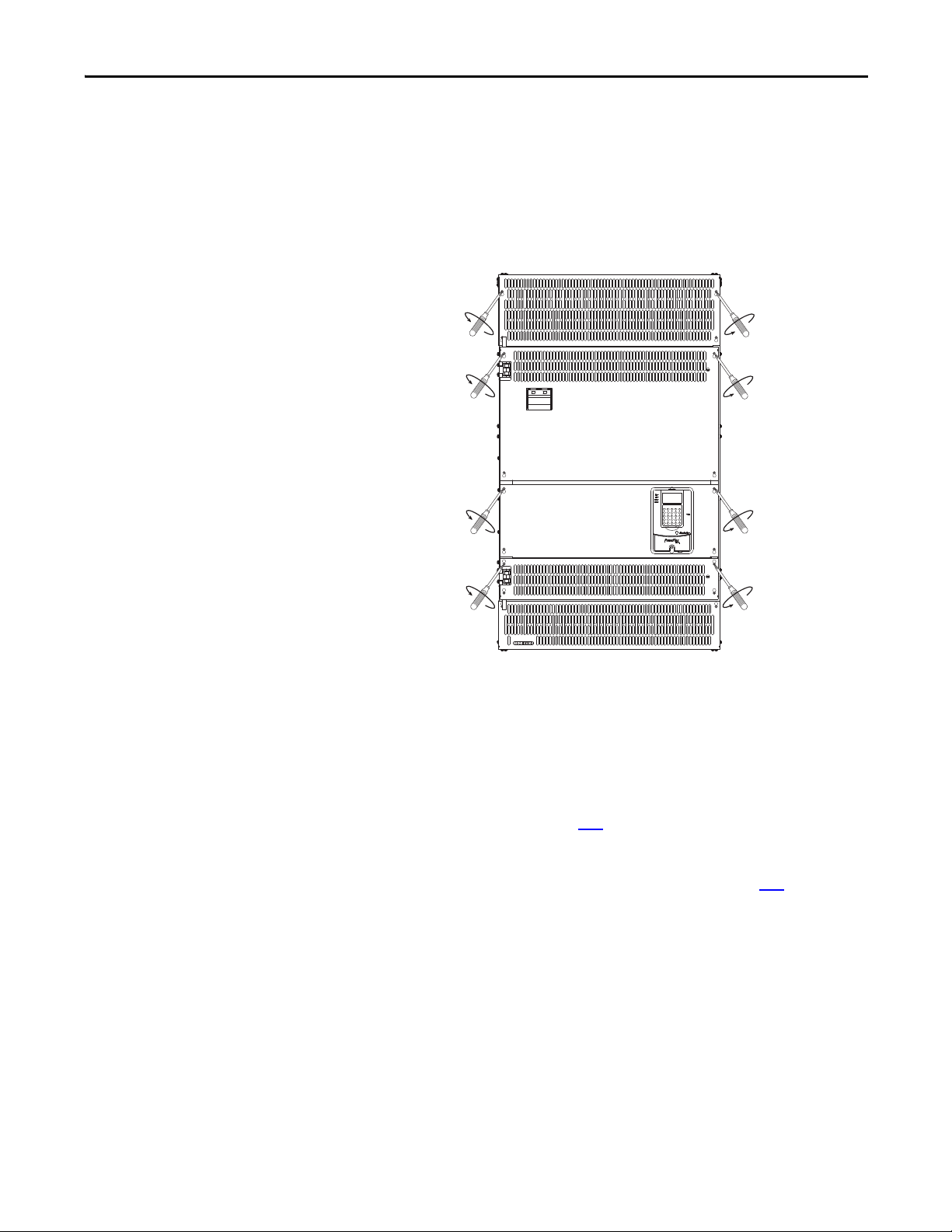

Lifting PowerFlex DC Drives

The dimensions and weights that are specified in Ta b l e 3 on page 21 and

Ta b l e 4

the proper equipment to lift and hold the weight of the drive while mounting.

…Ta b l e 7 on page 24 must be considered when mounting the device. Use

ATTENTION: To guard against possible personal injury or equipment damage...

• Inspect all lifting hardware for proper attachment before lifting the drive.

• Do Not let any part of the drive or lift mechanism to contact electrically charged

conductors or components.

• Do Not subject the drive to high rates of acceleration or deceleration while

transporting to the mounting location or when lifting.

• Do Not let personnel or their limbs be directly underneath the drive when it is

being lifted and mounted.

Mount Frame C and D Drives

All lifting equipment and components (hooks, bolts, lifts, slings, and chains)

must have a minimum

lifting capacity of 453.6 kg (1,000 lb).

Verify that all mounting screws are properly tightened before and after drive

operation.

1. Verify the hole pattern on the panel on which you intend to mount the

drive. See Figure 4

2. Install the mounting hardware:

❏ For frame C drives, insert, but do not tighten, a bolt in one of the top

holes in the panel. The bolt must be fully threaded into the panel

before hanging the drive.

❏ For Frame D drives, insert, but do not tighten, the six bolts for the top

mounting flange on the drive into the panel. The bolts must be fully

threaded into the panel before hanging the drive.

3. To limit the pull in forces on the drive, the lifting devices that are

connected to the hooks must be long enough to make the angle between

the chain or cable and a vertical line that extends up from the flange center

less than 45° angle as illustrated in Figure 7

26

.

❏ For frame C drives, insert the properly sized and rated lifting hooks

into the holes on the lifting flanges at the top of the drive. See Figure 7

on page 26

❏ For frame D drives, insert the properly sized lifting rod into the holes

on the lifting flanges at the top of the drive. See Figure 8

on page 21 or 22 on page 22.

on page 26 or Figure 8 on page

.

on page 26.

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 25

Page 26

Chapter 1 Installation and Wiring

Lifting flanges

Must be less

than 45° angle

Must be less

than 45° angle

Figure 7 - Lift Frame C Drives

Figure 8 - Lift Frame D Drives

4. Lift the drive into place onto the bolts that are installed in the panel.

5. Install the remaining bolts into the panel. Tighten M8 bolts to a minimum

torque of 15 N

N

•m (221.2 lb•in).

26 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

•m (132.7 lb•in) and M10 bolts to a minimum torque of 25

Page 27

Installation and Wiring Chapter 1

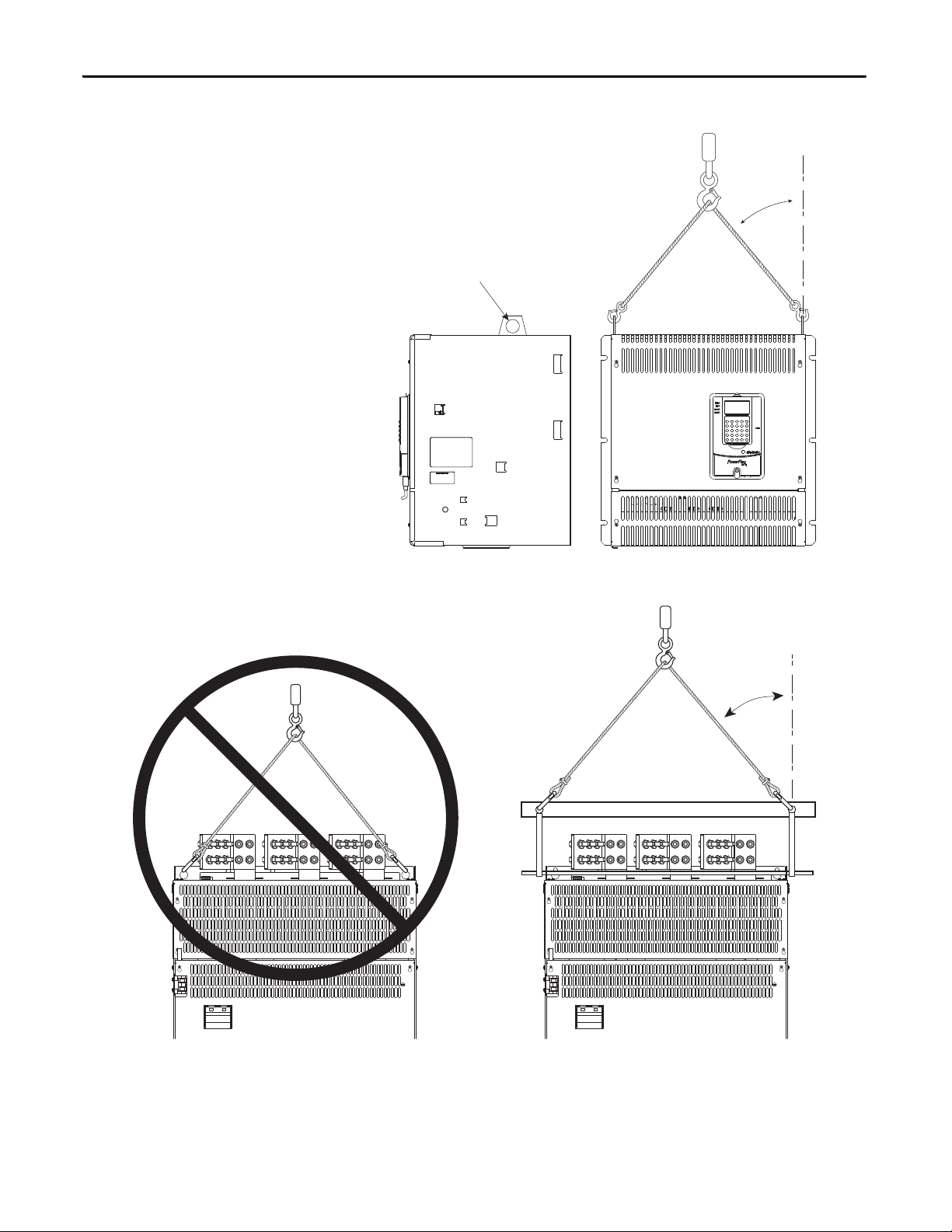

Remove the Drive Covers

Some protective covers must be removed to provide access to the power and I/O

terminals on the drive. Remove the upper cover only to install an optional

communication adapter or service the drive. See Installing a Communication

Adapter on page 367

for information.

Frame A Drives

You must remove both the lower protective cover and the power terminal cover

on frame A drives to access the power terminals.

Remove the Power Terminal Cover

• Remove the two screws as shown here and slide the cover down and off the

chassis.

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 27

Page 28

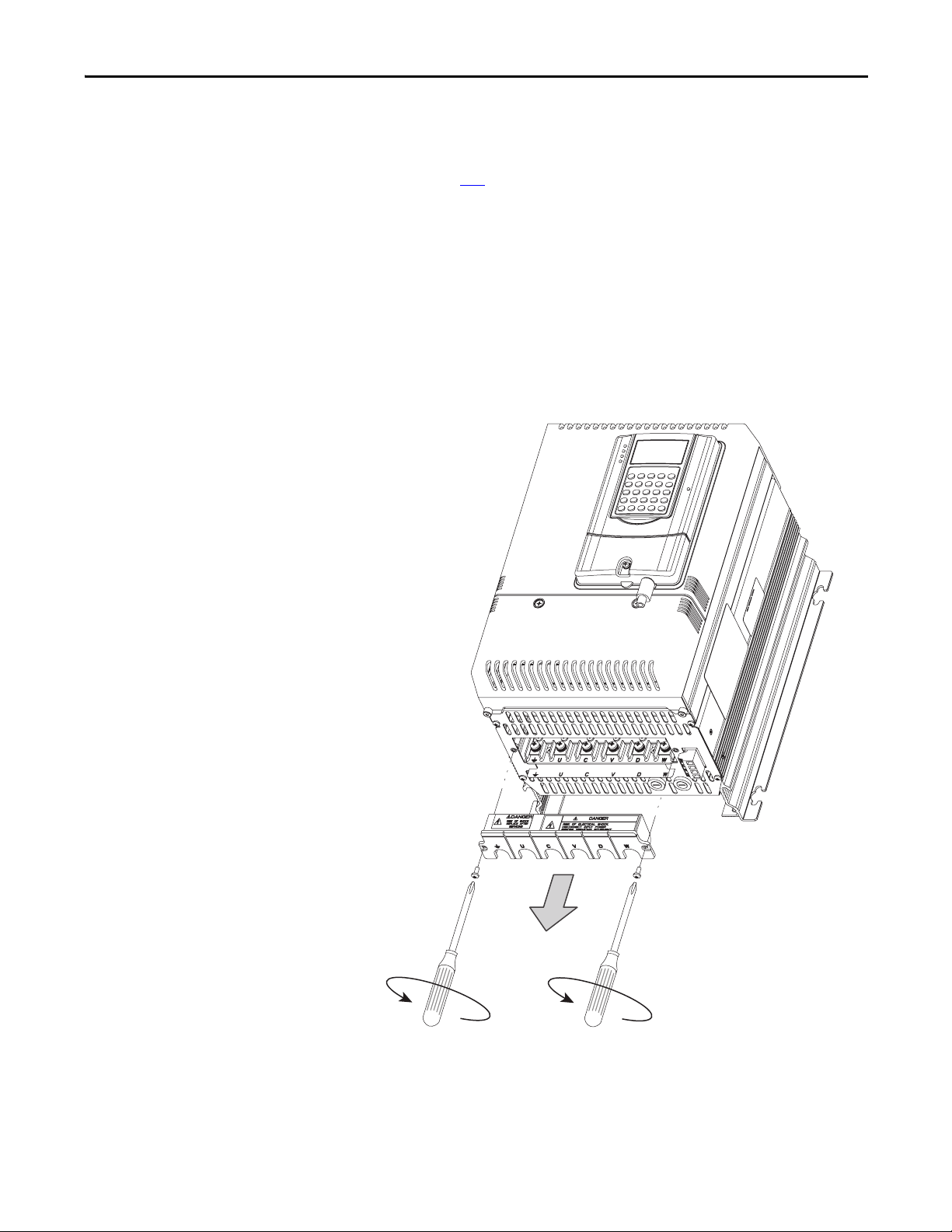

Chapter 1 Installation and Wiring

STS

PORT

MOD

NET A

NET B

Frame B Shown

Remove the Lower Protective Cover

• Remove the two screws as shown here and, while gently lifting along the

top edge, slide the cover down and off the chassis.

Frame B and C Drives

1. Loosen, but do not remove, the two screws that secure the bottom cover.

2. Slide the cover down until the screw heads align with the key holes and lift

the cover off the chassis.

28 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 29

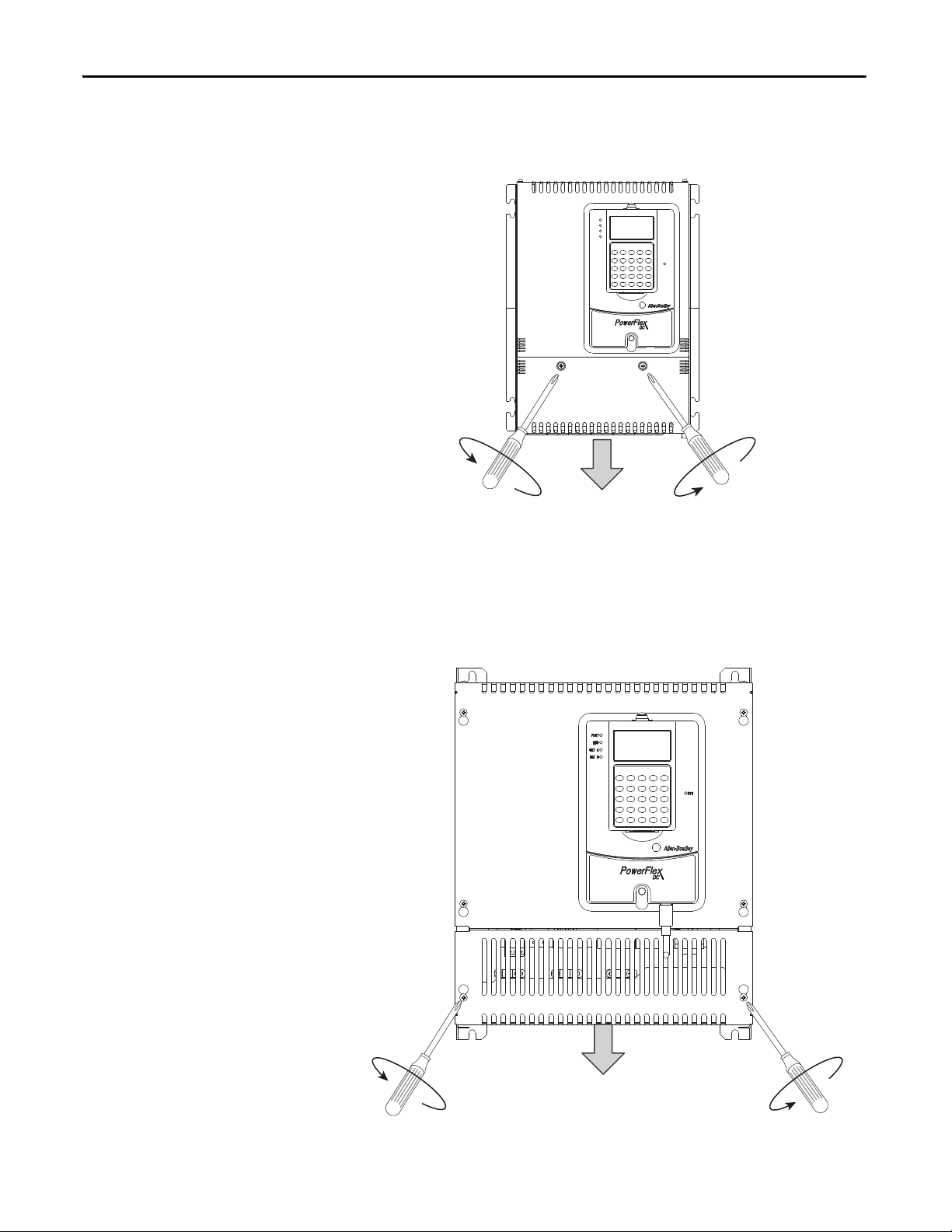

Installation and Wiring Chapter 1

Frame D

1. For any protective cover, loosen, but do not remove, the hexalobular head

screws that secure the cover to the drive frame.

2. Slide the cover up until the screw heads align with the key holes and lift the

cover off the chassis. The top and bottom most covers are also secured with

screws at the top and bottom of the drive, respectively.

Isolation Transformers / Line Reactors

When connecting the drive directly to the main distribution system, an isolation

transformer or 3…5% impedance AC line reactor must be used to guard against

system disturbance. If the isolation transformer provides the required 3…5%

impedance, a line reactor is not required.

See Isolation Transformers on page 256

transformers.

See AC Input Line Reactors and AC Input Contactors on page 254

recommended AC line reactors. The type of line reactor that is used depends

upon the following:

• Current absorbed by the AC input

• AC input voltage

• Relative short circuit voltage

• AC input frequency

for a list of recommended isolation

for a list of

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 29

Page 30

Chapter 1 Installation and Wiring

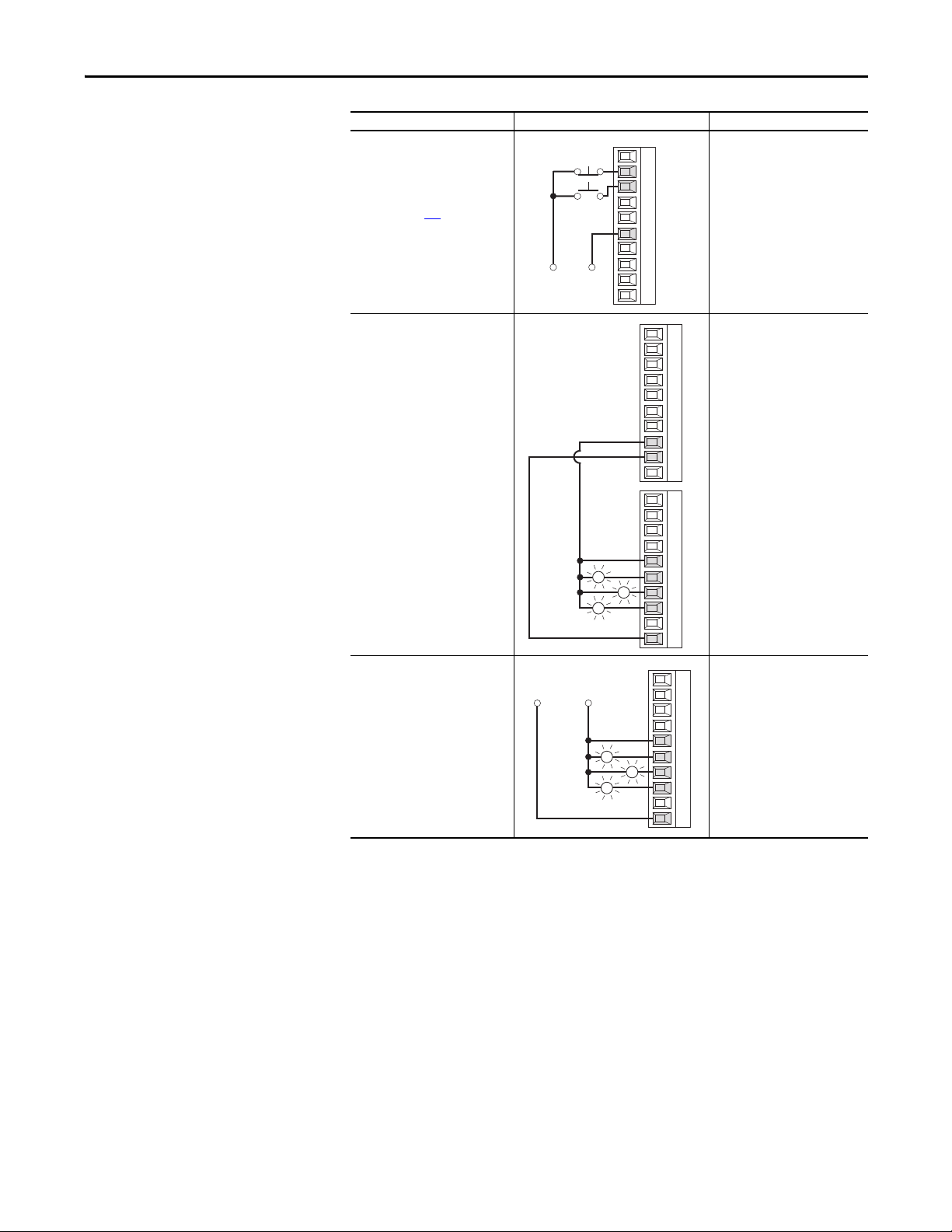

Contactors

When an AC input contactor is used, the IEC AC1 rating of the contactor must

be equal to the rated thermal (RMS) current value at the main input of the drive.

Drive configurations for AC or DC contactors, with or without a dynamic brake

(DB), are as follows (see Typical Power Wiring Diagrams on page 45

for

examples):

• When only an AC contactor is used:

❏ Set parameter 1391

(1)

value)

[ContactorControl] to 1 “AC Cntctr” (default

❏ Set one [Relay Out x Sel] parameter and one [Digital Inx Sel]

parameter to “Contactor” (default value for parameters 1392

Out 1 Sel] and 140

[Digital In8 Sel])

[Relay

• When only a DC contactor is used:

❏ Set parameter 1391

[ContactorControl] to 3 “DC Cntctr”

(1)

❏ Set one [Relay Out x Sel] parameter and one [Digital Inx Sel] to

“Contactor” (default value for parameters 1392

[Digital In8 Sel])

140

[Relay Out 1 Sel] and

• When an AC contactor and dynamic brake contactor are used:

❏ Set parameter 1391

[ContactorControl] to “AC Cntctr+DB”

❏ Set one [Relay Out x Sel] parameter (1392 [Relay Out 1 Sel] or 629

[Relay Out 2 Sel]) to “Contactor” and the other relay output to

“ContactorDB”

❏ Set one [Digital Inx Sel] parameter to “Contactor” (default value for

parameter 140

[Digital In8 Sel])

• When a DC contactor and dynamic brake contactor are used:

❏ Set parameter 1391

[ContactorControl] to “DC Cntctr+DB”

❏ Set one [Relay Out x Sel] parameter (1392 [Relay Out 1 Sel] or 629

[Relay Out 2 Sel]) to “Contactor” and the other relay output to

“ContactorDB”

❏ Set one [Digital Inx Sel] parameter to “Contactor” (default value for

parameter 140

[Digital In8 Sel])

• When a contactor is NOT used:

❏ Set parameter 1391

[ContactorControl] to “None”

(1)

❏ Do NOT set either [Relay Out x Sel] parameter to “Contactor” or

“ContactorDB”

(1)

(1)

❏ Do NOT set any [Digital Inx Sel] parameter to “Contactor”

(1) Par 1391 [ContactorControl] is contained in the “Advanced” parameter configuration group. See How Parameters are Organized on

page 115

for more information.

30 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 31

Installation and Wiring Chapter 1

When operating a drive with firmware version 1.006 in field weakening mode

with a DC contactor or inverting fault device that is installed in the armature

circuit, see Field Weakening Mode Configuration (v1.006) on page 285

.

AC Input Contactors

See AC Input Line Reactors and AC Input Contactors on page 254 for a list of

recommended AC input contactors.

DC Output Contactors

A DC output contactor can be used to connect the output of the armature circuit

to the DC motor. If a DC output contactor is used, an AC input contactor is not

needed.

See Dynamic Brake Resistor Kits and DC Output Contactors on page 258

list of recommended DC output contactors.

for a

Dynamic Brake Resistors

See Dynamic Brake Resistor Kits and DC Output Contactors on page 258 for a

list of recommended dynamic brake resistor kits.

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 31

Page 32

Chapter 1 Installation and Wiring

L1

L2

L3

U

V

W

C

D

PE1/

STS

PORT

MOD

NET A

NET B

Earth

All wires (including motor

ground) must be connected

inside the motor terminal box.

Transformer

Safety

Ground

AC Mai ns Supp ly

AC Line Reactor

General Grounding Requirements

The drive Safety Ground (PE) must be connected to system ground. Ground

impedance must conform to the requirements of national and local industrial

safety regulations and electrical codes. Periodically check the integrity of all

ground connections.

For installations within a cabinet, use a safety ground point or ground bus bar

connected directly to building steel. Ground all circuits, including the AC input

ground conductor, independently and directly to this point/bar.

For installations in distribution systems that have ungrounded or high

impedance, neutral connections or systems, see Grounding for Installations in an

Ungrounded or High-Impedance, Neutral Ground, or System on page 34

.

ATTENTION: To comply with the essential requirements of the CE Low Voltage

Directive 2006/95/EC, PowerFlex DC drives cannot be powered from a cornerearthed (TN with one phase earthed) supply system. When operating PowerFlex

DC drives from an IT or impedance-earthed supply system, only temporary

operation is permitted after an earth fault is detected in the power system.

Figure 9 - Typical Grounding

32 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 33

Installation and Wiring Chapter 1

Safety Ground (PE)

The safety ground for the drive that is required by code. This point must be

connected to adjacent building steel (girder, joist), a floor ground rod, or bus bar

(see Figure 9

industrial safety regulations and electrical codes.

on page 32). Ground points must comply with national and local

Power Feeder

Each power feeder from the substation transformer to the drive must be provided

with properly sized ground cables. Bond the conduit or cable armor to the

substation ground at both ends. Each transformer enclosure or frame must be

bonded to ground at a minimum of two locations.

Encoder/Resolver Ground Connections

If used, the encoder or resolver ground connections must be routed in grounded

steel conduit. The conduit must be grounded at both ends. The encoder/resolver

cable shield must be connected to the shield ground on the drive side. Do not

connect the encoder/resolver cable shield to ground on the motor side.

Tachometer Ground Connections

If used, ground connections must be routed in grounded steel conduit. The

conduit must be grounded at both ends. Ground the cable shield at the drive end

by using only the shield clamps on the grounded metal plate that supports the

control board (see Figure 58

on page 81 for shield clamp location).

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 33

Page 34

Chapter 1 Installation and Wiring

Grounding for Installations

in an Ungrounded or HighImpedance, Neutral Ground,

or System

The PowerFlex DC drive was designed to work in distribution systems where the

isolation transformer Wye neutral is connected to earth ground. PowerFlex DC

drives are not designed to work in distribution systems that have ungrounded or

high-impedance, neutral connections, or systems that have a phase that is

referenced to earth. Symmetrical incoming power is required for correct drive

operation.

The use of a grounded Wye neutral is highly recommended to prevent common

mode rejection problems with the feedback measurement circuits in the drive.

Possible drive damage can occur because of inaccurate feedback measurements of

the incoming AC voltage, armature voltage, or field current.

If the PowerFlex DC drive is installed in a system with an ungrounded Wye

neutral or with an impedance ground connection, see Ta b l e 8

necessary drive modifications that are required for proper installation.

on page 35 for the

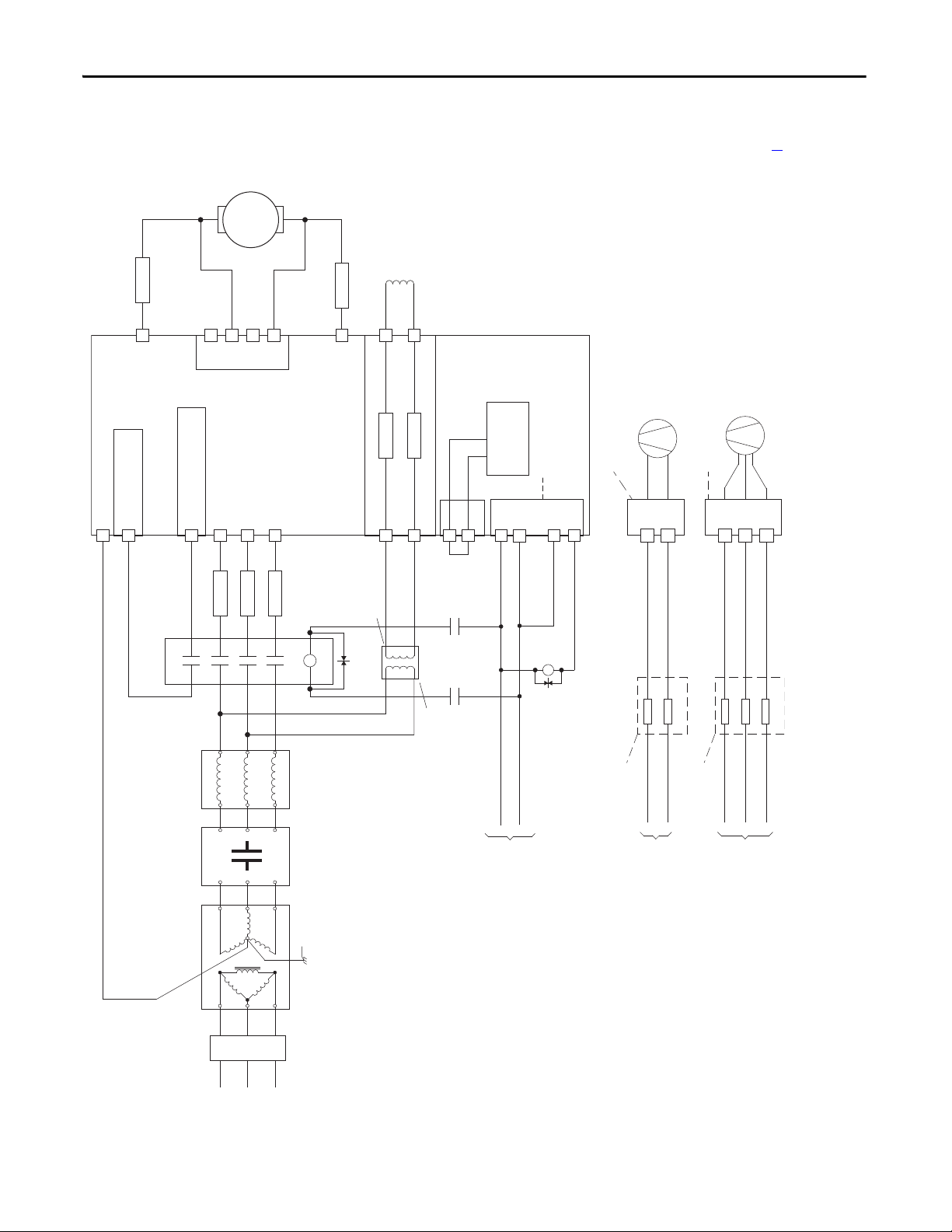

Power Distribution

Figure 10 - Delta/Wye with Grounded Wye Neutral

Rockwell Automation strongly recommends the use of grounded neutral systems

for the following reasons:

• Controlled path for common mode noise current

• Consistent line to ground voltage reference, which minimizes insulation

stress

• Accommodation for system-surge protection schemes

Figure 11 - Ungrounded Secondary

Grounding the transformer secondary is essential to the safety of personnel and

safe operation of the drive. A floating secondary can allow dangerously high

voltages occur between the chassis of the drive and the internal power structure

components.

34 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 35

Installation and Wiring Chapter 1

S9

T01 T04 T02 T05

T03

T06

T1 T4 T2 T5 T3 T6

78 79 35 36 75 76 U2 V2

S4

S3

XY

XR

TR2 TR1

XP

XSW

XSW1

X3

X4

S9

Note: Remove the front covers from the

drive to access the pulse transformer circuit

board. See page 27

for instructions.

Figure 12 - High-impedance Ground

Grounding the Wye secondary neutral through a resistor is an acceptable method

of grounding. In this case, in a short-circuited secondary condition, none of the

output phases to ground will exceed the normal line to line voltage. The resistor

is often used to detect ground current by monitoring the associated voltage drop.

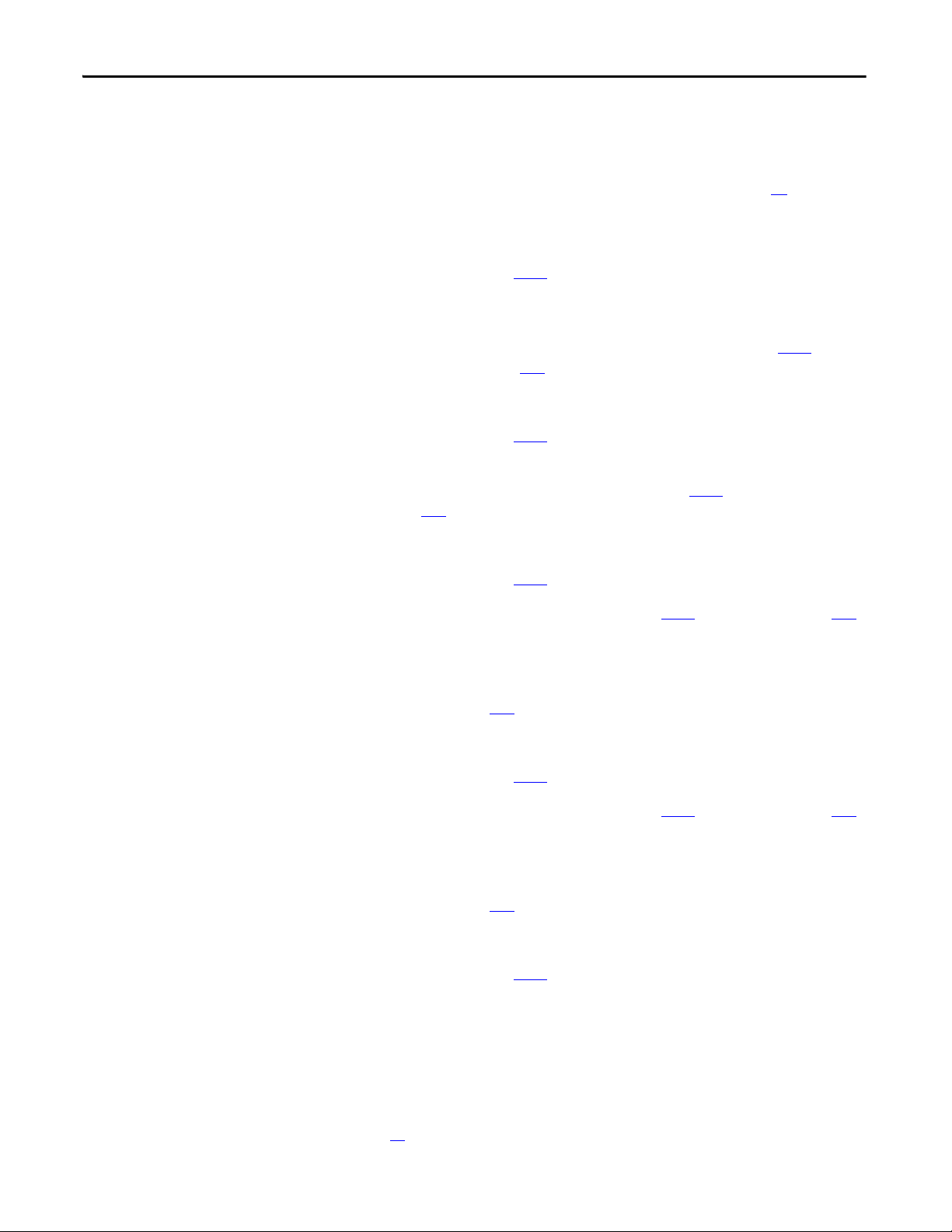

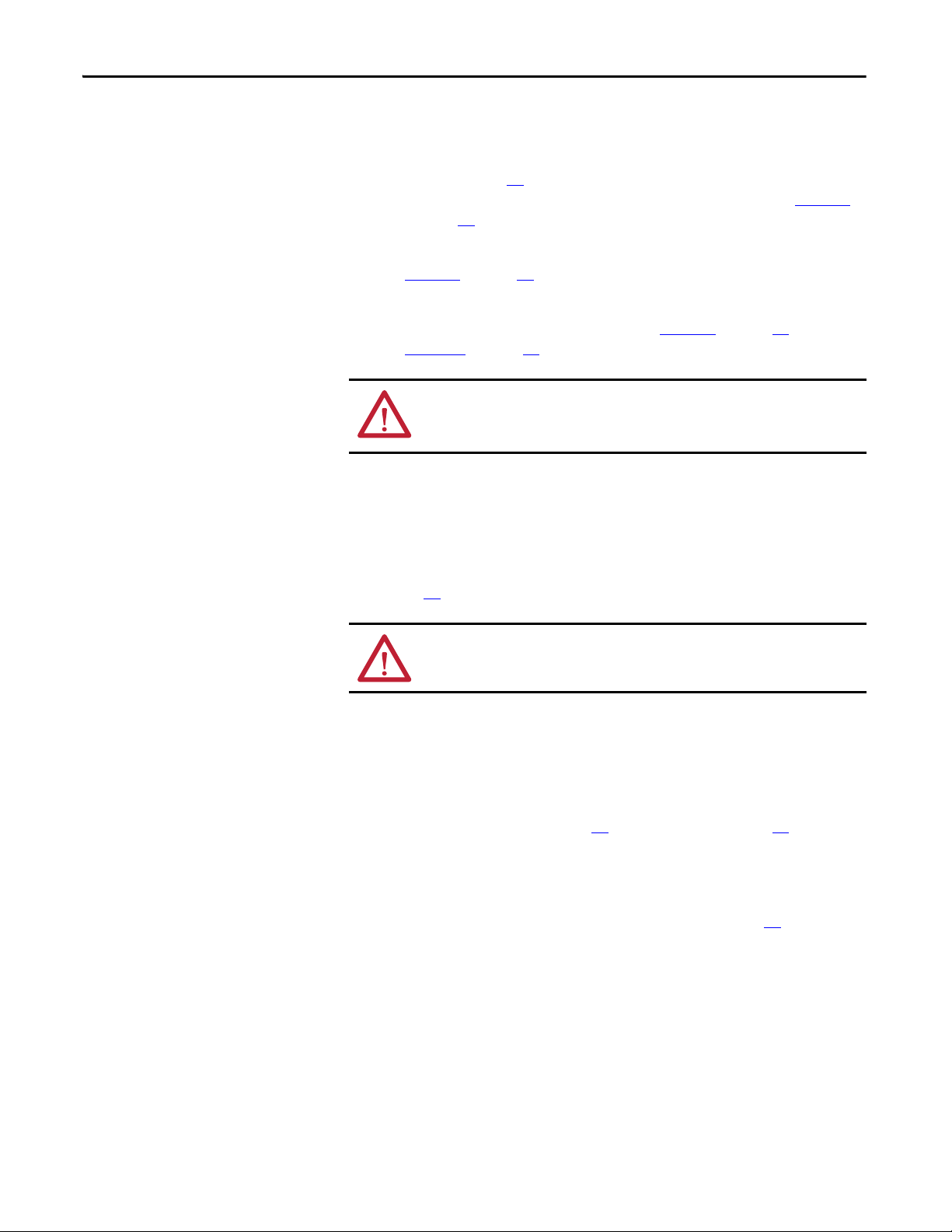

Table 8 - Drive Modifications to Support Ungrounded Wye Neutral or Impedance Grounded

Connections

Frame Circuit Board Jumper/Connection Figure to see for Details

A Pulse transformer (FIR1-xx-xx) Remove jumper S9 Figure 13

B Pulse transformer (FIR2-xx-xx) Remove jumper S9 Figure 1 4 on page 36

C Pulse transformer (FIR3-xx-xx) Remove jumper S9 Figu re 15 on page 36

Transient noise filter (FIL-31),

200V…500V AC drives

Disconnect the filter board yellow/

green (ground) wire from the PE

connection on the drive chassis

Transient noise filter (FIL-57,

Remove jumper S1 Figure 17 on page 37

FIL-69), 575V…690V AC drives

D Pulse transformer (FIR-D-xx-xx) Remove capacitors C121 and C122 Figure 18 on page 38

Overvoltage clipping (CFSF-xxx) Remove jumper S1 Figure 1 9 on page 38

on page 35

Figure 1 6 on page 37

Figure 13 - Frame A Pulse Transformer Circuit Board S9 Jumper Location

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 35

Page 36

Chapter 1 Installation and Wiring

S9

PE

XCD_IO

XTA

78 79 35 36 75 76 U2 V2

T01

T4

T1

T2

T02

T5

T3

T6

T03

T06

T04

T05

TR1

TR2

S9

PE

Note: Remove the front covers from the

drive to access the pulse transformer circuit

board. See page 28

for instructions.

X3

XCD_IO

TO5

TO3

TO6

TO2

KGO2

KGO5

KGO3 KGO6

T5 T3

T6

T2

KG2

KG5

KG3

KG6

XCT

PE

PE1

XCD

S3

S4

XUVW

1

1

XTA

TR3

XR

S9

XCD_IO

PE

PE1

XCD

S9

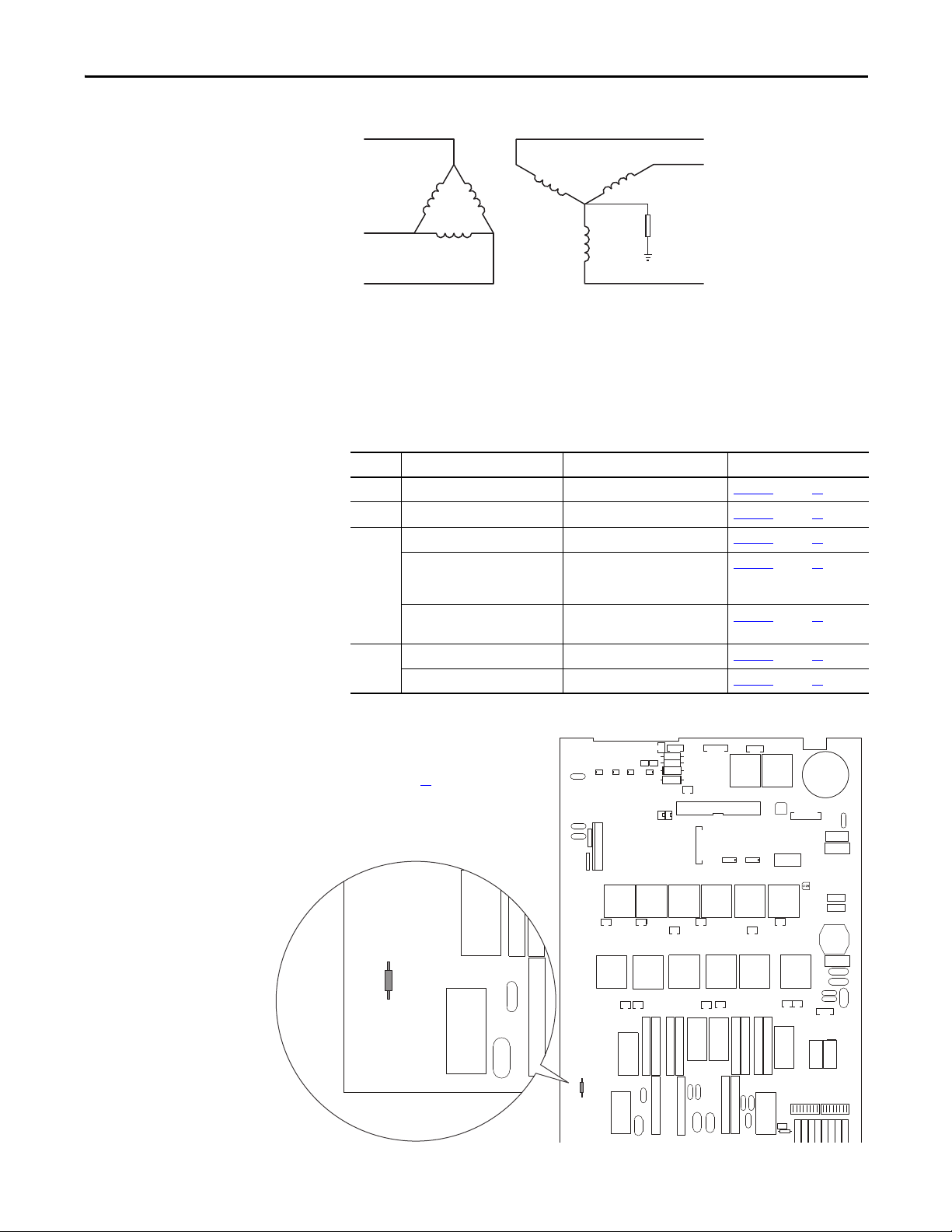

Note: The pulse transformer circuit board is behind the control EMI shield, near the top of the drive. See page 28 for

instructions on removing the front covers from the drive and page 68

for instructions on moving the control EMI shield.

Figure 14 - Frame B Pulse Transformer Circuit Board S9 Jumper Location

Figure 15 - Frame C Pulse Transformer Circuit Board S9 Jumper Location

36 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 37

Installation and Wiring Chapter 1

STS

PORT

MOD

NET A

NET B

U

V

C

Yellow/Green ( ground) wire

Transient noise filter board

Note: Remove the front covers from the drive to access the transient noise filter circuit board. See page 28 for

instructions. The transient noise filter board is between terminals C and D below the control EMI shield.

Note: Remove the front covers from the drive to access the transient noise filter circuit board. See page 28 for

instructions. The transient noise filter board is on the left side of the control EMI shield.

Figure 16 - Frame C Transient Noise Filter Circuit Board (FIL-31), 200V…500V AC Input Drives,

Ground Wire Location

Figure 17 - Frame C Transient Noise Filter Circuit Board (FIL-57, FIL-69), 575V…690V AC Input

Drives, S1 Jumper Location

P4 P3

S1

F1 F2 F3

S1

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014 37

Page 38

Chapter 1 Installation and Wiring

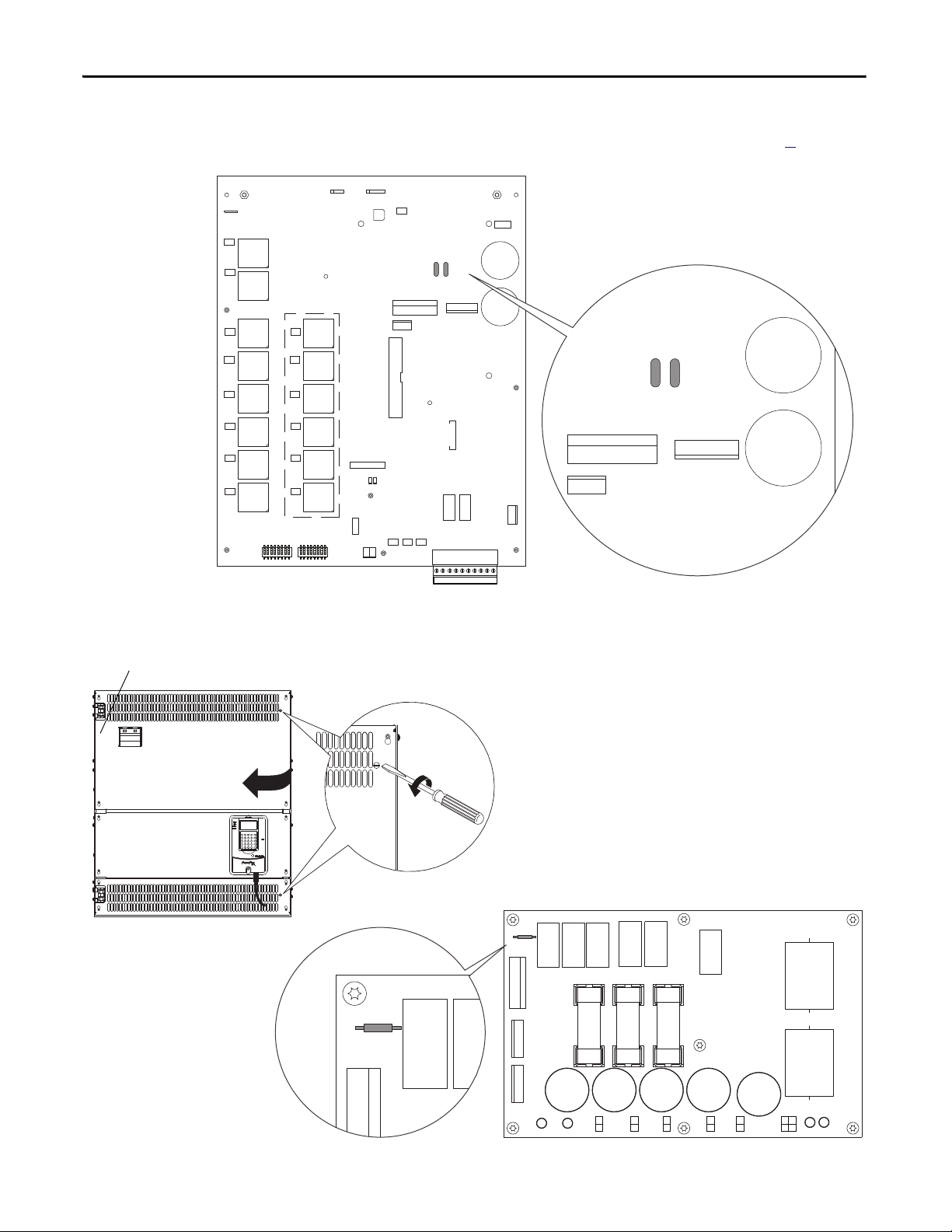

Note: The pulse transformer circuit board is behind the top and bottom control panel covers. See page 29 for

instructions on removing the covers from the drive.

90°

Note: The overvoltage clipping circuit board is behind the control panel on the upper left side of

the drive chassis. See illustration below, left for instructions on opening the control panel.

Overvoltage clipping board

location inside drive

1. Disconnect the DPI cable from the HIM (if present).

2. Insert a flathead screwdriver into the holes in the right side of the protective

covers on the drive and turn the latch 90° counter-clockwise.

3. Open the control panel to the left.

PE

XP1

XP2

KG1

KG4

KG2

KG5

KG3

KG6

Figure 18 - Frame D Pulse Transformer Circuit Board S1 Jumper Location

XSW1

XSW

X3

TR2

C122 C121

TR1

KG01

T1

T4

T2

T5

T3

T6

T01

KG04

T04

KG02

T02

KG05

T05

KG03

T03

KG06

T06

XTA

S3

S4

XCD_IO

XCD

XR

XY

X4 X5 X6

XCT

XUVW

XUV

C122 C121

XCD_IO

XSPF

XUVW

78 79 35 36 75 76 81 82 U2 V2

Figure 19 - Frame D Overvoltage Clipping Circuit Board S1 Jumper Location

S1

XCD

F31 F21 F11

S1

X1UVW1

XUVW

XCD

38 Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Page 39

Installation and Wiring Chapter 1

CE Conformity

Compliance with the Low Voltage Directive and Electromagnetic Compatibility

Directive has been demonstrated by using harmonized European Norm (EN)

standards, references to which have been published in the Official Journal of the

European Communities. PowerFlex DC drives comply with the EN standards

listed here when installed according to this User Manual.

EU Declarations of Conformity are available online at:

www.rockwellautomation.com/products/certification/ce/

Low Voltage Directive

• EN 50178 Electronic equipment for use in power installations.

EMC Directive

• EN 61800-3 Adjustable speed electrical power drive systems Part 3: EMC

product standard including specific test methods.

General Considerations

• For CE compliance, the drive installation must satisfy requirements that are

related to both EN 50178 and EN 61800-3 provided in this document.

• PowerFlex DC drives comply with the EMC requirements of EN 61800-3

when installed according to good EMC practices and the instructions that are

provided in this document. However, many factors can influence the EMC

compliance of an entire machine or installation, and compliance of the drive

itself does not ensure compliance of all applications.

• PowerFlex DC drives are not intended to be used on public low-voltage

networks that supply domestic premises. Without additional mitigation,

radio frequency interference is expected if used on such a network. The

installer is responsible to take measures such as supplementary line filters and

enclosures to prevent interference, in addition to the installation requirements

of this document.

• PowerFlex DC drives generate notching and harmonic current emissions on

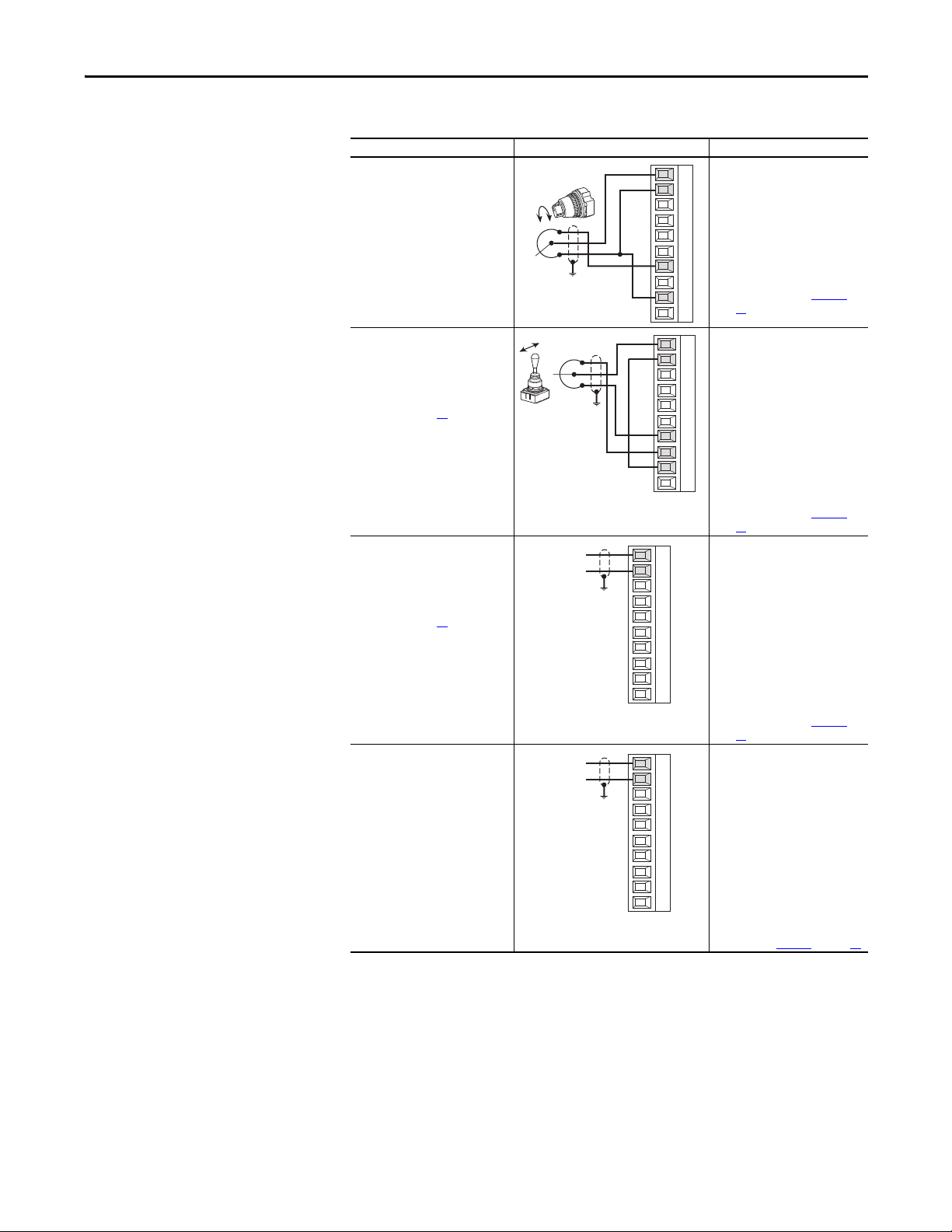

the AC supply system. When operated on a public low-voltage network, it is