User Manual

PowerFlex Digital DC Drive

PowerFlex DC Drive V1.006…5.006, PowerFlex DC Standalone Regulator V1.006…5.006

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Connected Components Workbench, DriveExplorer, DriveTools SP, PowerFlex, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

This manual contains new and updated information.

Summary of Changes

New and Updated Information

This table contains the changes made to this revision.

Top ic Pa ge

Added a note to Figure 5

terminal sizes apply to which frame D drive ratings.

Added instructions for drive installations in an ungrounded or high-impedance neutral ground or

systems

Updated the Typical Power Wiring Diagrams and the Field Conver ter Connections section to include

the step-down transformer required in the field converter input power supply circuit for 575V and

690V AC input drives.

Updated the Field Converter Connections section to include information on a requirements for a

step down transformer.

Updated the description for Par 469 [Field Mode Sel] option 1 “Field Weaken” to include the

requirement to wire the armature voltage feedback terminals A1 and A2 on the drive to terminals

A1 and A2 on the motor, respectively, when Par 458 [SpdReg FB Bypass] is set to 1 “Enabled.”

Updated the maximum value listed for parameters 7 [Current Limit], 8 [Current Lim Pos], and 9

[Current Lim Neg] from 200% to 250%.

Added a note to Par 458 [SpdReg FB Bypass] requiring, that when set to 1 “Enabled” and Par 469

[Field Mode Sel] is set 1 “Field Weaken,” the armature voltage feedback terminals A1 and A2 on the

drive must be wired to terminals A1 and A2 on the motor, respec tively.

Updated the S-curve parameter descriptions (19, 665, 666, 667, and 668) to better reflect the

function of the ramp time.

Updated the drive armature overcurrent trip specifications. 212

Added the noise level values for each drive frame fan. 215

Updated the Bussmann North American Fuse Block part numbers for frame A and B drives. 219

Added the new S-curve Configuration section. 284

Updated the Ramp Reference Block Diagram to reflect the interaction of the linear and S-curve

ramps.

- Frame D Dimensions - Right Side and Front Views indicating which

Figure 5

35

46 and 56

56

126

127

133

144 and 146

319

Changes to this manual for previous revisions are included in Appendix I History

of Changes on page 351

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 3

.

Summary of Changes

Notes:

4 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Table of Contents

Preface

Installation and Wiring

Drive Storage Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive Nameplate Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drive Frame Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drive Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Standard Drive Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . 15

Standard Drive Catalog Number Explanation, Cont.. . . . . . . . . . . . . . . . 16

Standalone Regulator Catalog Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 1

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating Conditions and Temperatures. . . . . . . . . . . . . . . . . . . . . . . 18

Minimum Mounting Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Approximate Drive Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . 19

Lifting PowerFlex DC Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mounting Frame C and D Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Removing the Drive Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frame A Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frame B and C Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Frame D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Isolation Transformers / Line Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Using Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

AC Input Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DC Output Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dynamic Brake Resistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

General Grounding Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Safety Ground (PE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Encoder/Resolver Ground Connections. . . . . . . . . . . . . . . . . . . . . . . . 34

Tachometer Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Grounding for Installations in an Ungrounded or High-Impedance

Neutral Ground or System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Low Voltage Directive (2006/95/EC). . . . . . . . . . . . . . . . . . . . . . . . . . 40

EMC Directive (2004/108/EC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installation Requirements Related to the Low Voltage Directive. . 41

Installation Requirements Related to EN 61800-3 and the EMC

Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Pollution Degree Ratings According to EN 61800-5-1 . . . . . . . . . . 42

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 5

Table of Contents

Power Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Power Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cable and Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

AC Input Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

DC Output Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Typical Power Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Armature Converter Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Armature Voltage Feedback Connections. . . . . . . . . . . . . . . . . . . . . . . 53

Field Converter Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Field Current Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Set DIP Switch S14 to the Correct Value . . . . . . . . . . . . . . . . . . . . . . . 60

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Thermistors and Thermal Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Control Circuit Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Frame C Heatsink Cooling Fans Power Supply Terminals . . . . . . . 68

Frame D Heatsink Cooling Fan Power Supply Terminals . . . . . . . . 69

Frame C and D Armature Fuse Signal Terminals . . . . . . . . . . . . . . . . 70

DIP Switch and Jumper Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

I/O Signal and Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Digital Encoder Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

DC Analog Tachometer Terminal Block . . . . . . . . . . . . . . . . . . . . . . . 85

Resolver Feedback Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

I/O and Control Wire Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Drive Start Up

Chapter 2

Drive Start Up Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Before Applying Power to the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Verify all Drive Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . 88

Verify the Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Verify the Control and I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Applying Power to the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Apply Voltage to the Control Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . 89

Verify the Control Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Load the Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Configure the Most Commonly Used Parameters . . . . . . . . . . . . . . . 91

Tune the Current Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Verify Motor Rotation and Run Feedback Polarity Checks. . . . . . . 99

Configure the Speed Feedback Parameters . . . . . . . . . . . . . . . . . . . . . 102

Tune the Speed Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Verify Speed Reference Settings and Drive Operation. . . . . . . . . . . 106

6 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Chapter 3

Table of Contents

Programming and Parameters

Troubleshooting

About Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Parameters Table Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

How Parameters are Organized. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

File–Group–Parameter Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Numbered List View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Cross Reference Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Basic Parameter View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Advanced Parameter View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Monitor File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Motor Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Speed Command File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Dynamic Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Applications File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Utility File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Communications File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Input / Output File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Parameter Cross Reference – by Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Parameter Cross Reference – by Number. . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chapter 4

Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Drive Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

HIM Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Manually Clearing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Fault Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Clearing Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Alarm Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Common Drive Symptoms and Corrective Actions . . . . . . . . . . . . . . . . 208

Drive will not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Drive starts but motor does not turn and no armature current . . 209

The motor does not reach commanded speed . . . . . . . . . . . . . . . . . . 209

The motor is turning in the wrong direction . . . . . . . . . . . . . . . . . . 209

The motor reaches maximum speed immediately . . . . . . . . . . . . . . 210

Testpoint Codes and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Supplemental Drive Information

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

IP20 NEMA/UL Type Open Watts Loss . . . . . . . . . . . . . . . . . . . . . . . . . 215

Communication Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Typical Programmable Controller Configurations . . . . . . . . . . . . . 217

Logic Command/Status Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Drive Power Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Frame A and B Fuse Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Frame C and D Fuse Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 7

Table of Contents

HIM Overview

Control Power Circuit Protection Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Switching Power Supply Circuit Board Fuses . . . . . . . . . . . . . . . . . . 233

Frame B Pulse Transformer Circuit Board Fuses . . . . . . . . . . . . . . . 235

Frame C Transient Noise Filter Circuit Board Fuses. . . . . . . . . . . . 236

Frame D Overvoltage Clipping Circuit Board Fuses . . . . . . . . . . . . 237

AC Input Line Reactors and AC Input Contactors. . . . . . . . . . . . . . . . . 238

Isolation Transformers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Dynamic Brake Resistor Kits and DC Output Contactors . . . . . . . . . . 243

DC Contactor Crimp Lug Kit Specifications . . . . . . . . . . . . . . . . . . . . . . 244

Alternate Dynamic Brake Resistor Kits and DC Output Contactors. 245

Alternate EMC Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Terminal Adapter Kits for Frame D Drives . . . . . . . . . . . . . . . . . . . . . . . . 250

Appendix B

External and Internal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

LCD Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

ALT Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Using the S.M.A.R.T. List Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Viewing and Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

LCD HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Removing/Installing the HIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Application Notes

Appendix C

Alpha Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Alpha Test Setup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Analog Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Example 1: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Example 2: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Analog Input Signal Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Current / Speed Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Drive Reference and Feedback Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Armature Voltage Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

DC Analog Tachometer Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Encoder Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Drive Reference and Feedback Scaling Examples . . . . . . . . . . . . . . . 266

Speed Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Droop Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Field Weakening Mode Configuration (v1.006) . . . . . . . . . . . . . . . . . . . 271

Using a DC Contactor Only (Firmware v1.006 Only) . . . . . . . . . . 272

Using a DC Contactor and a Dynamic Brake (Firmware v1.006

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Using an Inverting Fault Device Only (Firmware v1.006

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Using a DC Contactor and an Inverting Fault Device (Firmware

v1.006 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

8 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Table of Contents

Using a DC Contactor, a Dynamic Brake and an Inverting Fault

Device (Firmware v1.006 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

PID Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Configure a Line Speed Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Configure the Feedback Signal in the Follower Drive(s) . . . . . . . . 277

Configure the Tension Set Point Signal in the Follower

Drive(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Reference Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

“Auto” Speed Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

“Manual” Speed Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Changing Speed Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Torque Reference Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Auto/Manual Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Resolver Cable Balance Tuning Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Performing the Cable Balance Tuning Test . . . . . . . . . . . . . . . . . . . . 282

Resolver Type Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

S-curve Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

S-curve Acceleration Ramp Example: . . . . . . . . . . . . . . . . . . . . . . . . . 285

Scale Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Linking Parameters Via the Scale Block Parameters. . . . . . . . . . . . . 287

Speed Regulation Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Adaptive Speed Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Speed Up Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Speed Threshold Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Speed Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Speed Draw Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Speed / Torque Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Zero Torque Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Speed Regulation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Torque Regulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Speed Limited Adjustable Torque (SLAT) Min Mode and

SLAT Max Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Sum Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Start At Powerup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Fine Tuning the Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Manually Adjusting the Current Regulator Tune Settings . . . . . . 302

Fine Tuning the Field Current Regulator. . . . . . . . . . . . . . . . . . . . . .

304

Fine Tuning the Speed Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Fine Tuning the Voltage Regulator in the Field Converter . . . . . . 309

Tuning the Field Current Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Control Block Diagrams

Appendix D

Diagram Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 9

Table of Contents

Appendix E

Installing a Communication Adapter

Optional Analog and Digital I/O

Expansion Circuit Board

Optional 115V AC to 24V DC I/O

Converter Circuit Board

PowerFlex DC Standalone Regulator

Installation

Communication Adapter Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

What The Communication Adapter Kit Includes . . . . . . . . . . . . . . . . . . 337

Tools That You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Installing the Communication Adapter Module in the Drive. . . . . . . . 338

Frame A:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Frames B and C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Frame D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Appendix F

What This Option Board Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

I/O Expansion Board Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Appendix G

What This Option Board Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

I/O Converter Board Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Appendix H

Installation and Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Appendix I

History of Changes

Index

20P-UM001H-EN-P, April 2011. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

20P-UM001G-EN-P, October 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

20P-UM001F-EN-P, June 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

20P-UM001E-EN-P, November 2008 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

10 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Preface

Top ic Pa ge

Drive Storage Conditions Below

Drive Nameplate Data 12

Additional Resources 13

Drive Frame Sizes 12

Convent ions 13

General Precautions 14

Standard Drive Catalog Number Explanation 15

Standalone Regulator Catalog Numbers 16

The purpose of this manual is to provide you with the basic information needed

to install, start-up and troubleshoot the PowerFlex DC drive. This manual is

intended for qualified personnel. You must be able to program and operate DC

drives. In addition, you must have an understanding of the parameter settings and

functions detailed in this manual.

Drive Storage Conditions

If it is necessary to store the drive for any length of time before installation, follow

these storage guidelines in order to ensure satisfactory operation at start up and to

maintain warranty coverage:

• After receipt and inspection, repack the drive in its original shipping

container and store in a clean, dry place.

• Place where the ambient temperatures do not exceed -25° C (-13° F) or

+55°C (131° F)

• Place where the relative air humidity range does not exceed 5…95%.

• At an altitude of less than 3,000 meters (10,000 ft.) above sea level.

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 11

Preface

Note: Certification

Marks Location.

See the data

nameplate label on

your drive for actual

agency certifications.

Drive frame size

Drive serial number

Drive Nameplate Data

Drive Frame Sizes

The PowerFlex DC drive contains a data nameplate label located on the side of

each drive that identifies the specific model number design, applicable AC input

power and DC output power data. All communication with Rockwell

Automation personnel concerning this product should include this information.

Cat No.

20P41AD4P1RA0NNN

UL Type OPEN/IP20

Input: 460VAC 50/60 Hz 3.3A 3 Phase

Output: 500VDC 4.1A REGEN 2.0HP

1 Min Overload Amps

3 Sec Overload Amps

DC Field:

Input: 460VAC 50/60 Hz 10A max. 1 Phase

Output: 360VDC 10A max.

Regulator Power: 115/230VAC 50/60 Hz 1.0/0.5A 1 Phase

MFD. in 2XXX on MMM DD

Made in Italy

6.2

8.2

EXAMPLE ONLY

Series: A

I/O: 24VDC (Standard)

Original Firmware V. 1.001

N223

Frame: A

Serial Number: A23E0042

C

Ind. Cont.

Eq. 31KF

Listed

R

US

Similar PowerFlex DC drive sizes are grouped into frame sizes to simplify spare

parts ordering, dimensioning, etc. The drive frame size can be located just above

the serial number on the data nameplate label. See the Standard Drive Catalog

Number Explanation on page 15

for a list of drive catalog numbers and their

respective frame sizes.

Drive Firmware Version

Specifications

The original firmware version of the drive as shipped from the factory appears on

the data nameplate label just above the certifications. If the firmware version has

been upgraded since the drive was shipped, you can view the current version on

the HIM (if installed). See Diagnostics Menu on page 255

for details.

For drive specification information, see the PowerFlex Digital DC Drive,

Technical Data, 20P-TD001

.

12 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Preface

Additional Resources

Technical Support

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Preventive Maintenance of Industrial Control and Drive

System Equipment, DRIVES-TD001

Safety Guidelines for the Application, Installation and

Maintenance of Solid State Control, SGI-1.1

A Global Reference Guide for Reading Schematic Diagrams,

100-2.10

Guarding Against Electrostatic Damage, 8000-4.5.2 Provides common practices to help guard against ESD.

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://ab.com

Provides a checklist for performing preventive

maintenance.

Provides general guidelines for the application,

installation, and maintenance of solid-state control in the

form of individual devices or packaged assemblies

incorporating solid-state components.

Provides a simple cross-reference of common schematic/

wiring diagram symbols used throughout various parts of

the world.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and other

certification details.

You can view or download publications at: http://

literature.rockwellautomation.com. To order paper copies of technical

documentation, contact your local Allen-Bradley distributor or Rockwell

Automation sales representative.

For Allen-Bradley Drives Technical Support:

Title Online at . . .

Allen-Bradley Drives Technical Support www.ab.com/support/abdrives

Conventions

• To help differentiate parameter names and LCD display text from other

text, the following conventions will be used:

– Parameter Names will appear in [brackets].

For example: [Armature Voltage].

– Display Text will appear in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an

action:

Word Mean ing

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 13

Preface

General Precautions

AT TE NT IO N: This drive contains ESD (Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference A-B publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other applicable ESD protection handbook.

AT TE NT IO N: An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or application errors, such as,

undersizing the motor, incorrect or inadequate AC supply, or excessive

surrounding air temperatures may result in malfunction of the system.

AT TE NT IO N: Only qualified personnel familiar with DC drives and associated

machinery should plan or implement the installation, start-up and subsequent

maintenance of the system. Failure to comply may result in personal injury and/

or equipment damage.

AT TE NT IO N: An incorrectly applied or installed bypass system can result in

component damage or reduction in product life. The most common causes are:

• Wiring AC line to drive output or control terminals.

• Improper bypass or output circuits not approved by Allen-Bradley.

• Output circuits which do not connect directly to the motor.

Contact Allen-Bradley for assistance with application or wiring.

14 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Standard Drive Catalog

Position

1-3 4 5 6 7 8-10 11 12 13 14 15 16

20P 4 1 A D 4P1 R A 0 N N N

abcdef gh i jkl

a

Drive

Code Type

20P PowerFlex DC

b

Motor Operation

Code Type

2 Two Quadrant Operation

4 Four Quadrant Operation

c

Input Type

Code Type

1 6 Pulse

d

Enclosure

Code Enclosure Rating

Conform.

Coat

A IP20, NEMA/UL Type Open

e

Input Voltage

Code Voltage

B 230V AC

D 460V AC

E 600V AC

F 690V AC

f1

f2

Yes

Not available for 230V AC input drives.

Use this code for 400V AC input applications.

f3

f4

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

200

250

300

400

500

600

700

800

900

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

56

75

93

112

149

187

224

298

373

447

552

597

671

4.1

6

10

14

19

27

35

45

52

73

86

100

129

167

207

250

330

412

495

667

830

996

1162

1238

1494

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

C

C

D

D

D

D

D

10

10

10

10

10

10

10

10

10

14

14

14

14

20

20

20

20

20

20

20

40

40

70

70

70

Hp

Armature

Amps

Frame

Field

Amps

Code kW

460V, 60 Hz Input

4P1

6P0

010

014

019

027

035

045

052

073

086

100

129

167

207

250

330

412

495

667

830

996

1K1

1K3

1K4

1.5

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

200

250

300

1.2

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

56

75

93

112

149

186

224

7

9

12

20

29

38

55

73

93

110

146

180

218

265

360

434

521

700

875

1050

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

B

C

C

D

D

10

10

10

10

10

10

10

14

14

14

20

20

20

20

20

20

20

20

40

40

Hp

Armature

Amps

Frame

Field

Amps

Code kW

230V, 60 Hz Input

7P0

9P0

012

020

029

038

055

073

093

110

146

180

218

265

360

434

521

700

875

1K0

50

75

100

200

300

400

500

600

800

900

1000

1250

37

56

75

149

224

298

373

447

597

671

746

932

67.5

101.3

135

270

405

540

675

810

1080

1215

1350

1668

B

B

B

B

B

C

C

D

D

D

D

D

20

20

20

20

20

20

20

40

40

40

40

40

Hp

Armature

Amps

Frame

Field

Amps

Code kW

575V, 60 Hz Input

067

101

135

270

405

540

675

810

1K0

1K2

1K3

1K6

298

373

447

552

597

671

746

820

932

1044

Hp

Armature

Amps

Frame

Field

Amps

Code kW

690V, 60 Hz Input

452

565

678

791

904

1K0

1K1

1K2

1K4

1K5

400

500

600

700

800

900

1000

1100

1250

1400

452

565

678

791

904

1017

1130

1243

1413

1582

C

C

D

D

D

D

D

D

D

D

20

20

40

40

40

40

70

70

70

70

Number Explanation

Preface

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 15

Preface

Position

1-3 4 5 6 7 8-10 11 12 13 14 15 16

20P 4 1 A D 4P1 R A 0 N N N

abcdefgh i jkl

g

Field Supply

Code Type

R Single-Phase Regulated

h

Packaging/Documentation

Code Shipping Carton User Manual

A Yes Yes

i

HIM

Code Operator Interface

0 Blank Cover

Standard - for user installed options, see

Human Interface and Wireless Interface

Modules on page 9.

j

I/O Options

Code Control

N

None (8 - 24V DC Digital Inputs,

4 Digital Outputs, 3 Analog Inputs,

and 2 Analog Outputs are Standard)

k

Communication Options

Code Description

N None

l

Cabinet Options

Code Type

N None

Standard - for user installed options, see

Communication Option Kits on page 10.

All I/O Options are purchased separately and

are user installed. See I/O Options on page 9.

Standard Drive Catalog Number Explanation, Cont.

Standalone Regulator Catalog Numbers

All catalog numbers below are provided with conformally coated circuit boards.

230V / 460V AC Input Regulators 575V / 690V AC Input Regulators Field Amps

Catalog Number Catalog Number

23PMD4 23PMF4 40

23PMD7 23PMF7 70

(1)

23PAMP

(1) Gate Amplifier - used with all voltage classes of the Standalone Regulator. Note: The Standalone Regulator and Gate Amplifier are

currently sold through Rockwell Automation Drive Systems only. Consult the factory for availability.

23PAMP

(1)

(1)

16 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Chapter 1

IMPORTANT

IMPORTANT

Installation and Wiring

Topic Page Topic Page

Mounting Considerations 18 CE Conformity 40

Approximate Drive Dimensions and

Wei ght s

Lifting PowerFlex DC Drives 25 Control Power Protection 43

Removing the Drive Covers 28 Cable and Wiring Recommendations 44

Isolation Transformers / Line Reactors 30 Power Wiring 45

Using Contactors 31 DIP Switch and Jumper Settings 72

General Grounding Requirements 33 I/O Wiring 77

19 Power Circuit Protection 43

This chapter provides information on mounting and wiring the PowerFlex DC

drive.

Most start-up difficulties are the result of incorrect wiring. Every precaution must

be taken to assure that the wiring is done as instructed. All items must be read and

understood before the actual installation begins.

For PowerFlex DC Standalone Regulator (SAR) installations, see Appendix H

for important installation and configuration information. The SAR is identified

by a 23PMDx catalog number contained on the data nameplate on the drive (see

Drive Nameplate Data on page 12

for location).

The PowerFlex DC drive is not designed for use with multiple motor

applications or resistive loads.

The drive to motor horsepower ration must not exceed 2:1.

AT TE NT IO N: The following information is merely a guide for proper installation.

Rockwell Automation cannot assume responsibility for the compliance or the

noncompliance to any code, national, local or otherwise for the proper

installation of this drive or associated equipment. A hazard of personal injury

and/or equipment damage exists if codes are ignored during installation.

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 17

Chapter 1 Installation and Wiring

10 mm

10 mm

50 mm

(0.4 in.)

(0.4 in.) (2.0 in.)

10 mm

(0.4 in.)

150 mm (6.0 in.)

150 mm (6.0 in.)

150 mm (6.0 in.)

STS

POR

T

MOD

NET A

NET B

STS

POR

T

MOD

NET A

NET B

Airflow through the

drive must not be

impeded.

Mounting Considerations

Operating Conditions and Temperatures

PowerFlex DC drives are designed to operate at 0…50 °C (32…122 °F)

surrounding air temperature without derating. The drive must be mounted in a

clean, dry location. Contaminants such as oils, corrosive vapors and abrasive

debris must be kept out of the enclosure. NEMA/UL Type Open, IP20

enclosures are intended for indoor use primarily to provide a degree of protection

against contact with enclosed equipment. These enclosures offer no protection

against airborne contaminants.

Minimum Mounting Clearances

Minimum clearance requirements (indicated in Figure 1) are intended to be from

drive to drive. Other objects can occupy this space; however, reduced airflow may

cause protection circuits to fault the drive. The drive must be mounted in a

vertical orientation as shown below and must not be mounted at an angle greater

than 30 degrees from vertical. In addition, inlet air temperature must not exceed

the product specification.

Figure 1 - Drive Enclosure Minimum Mounting Clearances

18 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Installation and Wiring Chapter 1

A

B

A2

B1

C

STS

PORT

MOD

NET A

NET B

A1

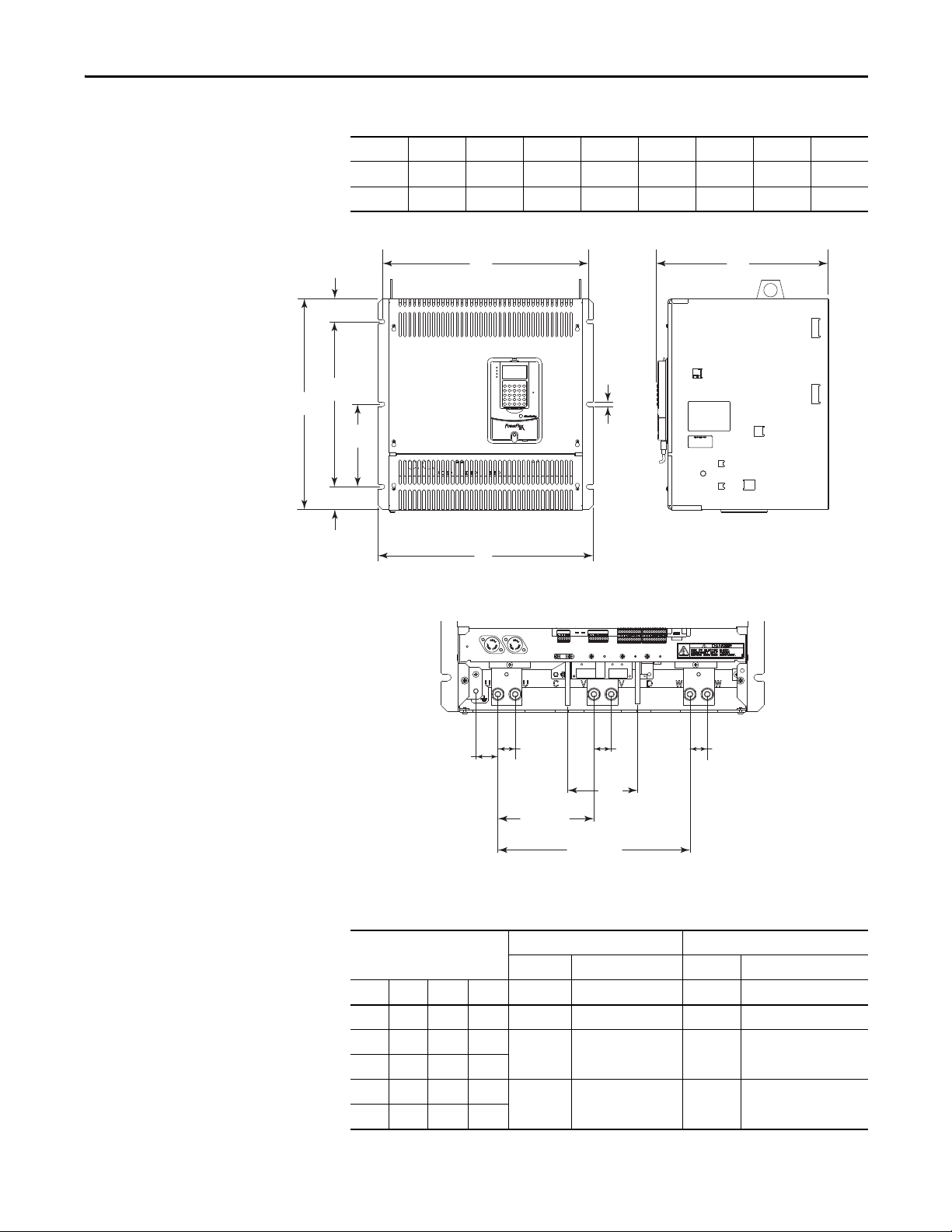

Approximate Drive Dimensions and Weights

The PowerFlex DC drive is available in a NEMA/UL Type Open, IP20 enclosure

only. Follow all mounting dimensions and instructions in order to ensure proper

operation.

ATTENTION: Remove all loose packing materials, including the container(s) of

desiccants (if any), from the drive enclosure before mounting and energizing the

drive.

Figure 2 - Frame A Drive Dimensions

A B C A1A2B1

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

267 (10.5) 359 (14.0) 287 (11.3) 7 (0.3) 250 (9.8) 275 (10.8)

Table 1 - Frame A Weights

Drive Current Rating Code Drive Weight Drive & Packaging Weight

230V 460V kg (lb) kg (lb)‘

7P0 4P1

9P0 6P0

012 010

020 014

–019

029 027

038 035

–052

073 073

093 086

110 100

–129

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 19

8.4 (18.5) 10.5 (23.2)

8.8 (19.4) 11 (24.3)055 045

10.8 (23.8) 13 (28.7)

Chapter 1 Installation and Wiring

A

A1

B1

C

B

A2

STS

PORT

MOD

NET A

NET B

A3

45.2 (1.8)

98.5 (3.9)

53.1 (2.1)

48.5 (1.9)

147.0 (5.8) 53.1 (2.1)

48.5 (1.9)

200.1 (7.9)

248.6 (9.8)

Terminal Details Dimensions in mm (in.)

Figure 3 - Frame B Drive Dimensions

A A1A2A3B B1C

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

311 (12.2) 275 (10.8) 16.5 (0.65) 7 (0.3) 388 (15.3) 375 (14.8) 350 (13.8)

Table 2 - Frame B Weights

Drive w/ND Rating Code Drive Weight Drive & Packaging Weight

230V 460V 575V kg (lb) kg (lb)

146 167 067

25.5 (56.2) 27.5 (60.6)180 207 101

218 – 135

265 250 270 29.5 (65.0) 31.5 (69.5)

360 330 405

434 412 –

32 (70.5) 34 (75)

20 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Installation and Wiring Chapter 1

B1

B2

B3

A

A1 C

B

B4

STS

PORT

MOD

NET A

NET B

B5

310.0 (12.2)

155.0 (6.1)

113.0

(4.5)

28.0

(1.1)

28.0

(1.1)

28.0

(1.1)

35.5 (1.4)

Terminal Details Dimensions in mm (in.)

Figure 4 - Frame C Drive Dimensions

A A1 B B1 B2 B3 B4 B5 C

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

521 (20.5) 499 (19.7) 511 (20.1) 400 (15.7) 200 (7.9) 55 (2.2) 56 (2.2) 10.5 (0.4) 416 (16.4)

Table 3 - Frame C Weights

Drive w/ND Rating Code Weight - Regenerative Drives Weight - Non-regenerative Drives

230V 460V 575V 690V kg (lb) kg (lb) kg (lb) kg (lb)

– 495 – 61 (134.5) 83 (183.0) 57 (125.7) 79 (174.2)

521 667 –

700 – –

– – 540 452

– – 675 565

Drive Drive & Packaging Drive Drive & Packaging

65 (143.3) 87 (191.8) 62 (136.7) 84 (185.2)

72 (158.7) 94 (207.2) 68 (150.0) 90 (198.4)

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 21

Chapter 1 Installation and Wiring

Dimensions of terminals U, V, and W are the same.

Dimensions are shown in mm and (in.)

Lifting flange

Note: 134 mm (5.3 in.) C and D terminals are installed on 460V AC input, 800 and 900 Hp, 575V AC input, 1000 Hp, and 690V AC input,

1100, 1200, 1250, and 1400 Hp drives only. All other frame D ratings have 100 mm (4.0 in.) C and D terminals.

PE C D

PE C D

80.5

(3.2)

Figure 5 - Frame D Dimensions - Right Side and Front Views

544

(21.4)

359

(14.1)

436.5

(17.2)

174

(6.9)

704

(27.7)

25

(1.0)

15

(0.6)

44.5

(1.8)

60

(2.4)

30

(1.2)

42

(1.7)

792

(31.2)

208

(8.2)

144

(5.7)

157.5

(6.2)

252.5

(10.0)

437.5

(17.2)

134

(5.3)

22.6

(0.9)

44.5

(1.8)

134

(5.3)

44.5

(1.8)

10.5

(0.4)

10

(0.4)

44.5

25

(1.8)

15

(1.0)

(0.6)

146

(5.7)60(2.4)

(1.2)

269.5

(10.6)

454.5

(18.0)

1250

(49.2)

32

(1.3)

30

44.5

27.8

(1.1)

(1.8)

100

(4.0)

100

(4.0)

22 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

215.225

(8.5)

103.25

(4.1)

1435 MAX

(56.5)

129

(5.1)

129

(5.1)

227.5

(9.0)

157.5

(6.2)

1230

(48.4)

16

(0.6)

10.5

(0.4)

10

(0.4)

10.5

(0.4)

127

(5.0)

531

(21.0)

541

(21.3)

94

(3.7)

127

(5.0)

127

(5.0)

127

(5.0)

Ø 23

(0.9)

127

(5.0)

127

(5.0)

127

(5.0)

127

(5.0)

94

(3.7)

94

(3.7)

94

(3.7)

Dimensions are shown in mm and (in.)

Mounting holes

Mounting holes

Lifting flange

Installation and Wiring Chapter 1

Figure 6 - Frame D Dimensions - Left Side and Back Views

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 23

Chapter 1 Installation and Wiring

Table 4 - Frame D - 230V AC Input Drive Weights

Drive w/ND

Rating Code

875

1K0

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive & Packaging Drive Drive & Packaging

kg (lb) kg (lb) kg (lb) kg (lb)

203 (447.5) 281 (619.5) 152 (335.1) 230 (507.1)

Table 5 - Frame D - 460V AC Input Drive Weights

Drive w/ND

Rating Code

830

996

1K1

1K4

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive & Packaging Drive Drive & Packaging

kg (lb) kg (lb) kg (lb) kg (lb)

202 (445.3) 280 (617.3) 152 (335.1) 230 (507.1)

215 (474.0) 293 (646.0) 165 (363.8) 243 (535.7)1K3

Table 6 - Frame D - 575V AC Input Drive Weights

Drive w/ND

Rating Code

810

1K0

1K2 215 (474.0) 293 (646.0) 165 (363.8) 243 (535.7)

1K3 222 (489.4) 300 (661.4) 172 (379.2) 250 (551.2)

1K6 241 (531.3) 319 (703.3) 191 (421.1) 269 (593.0)

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive & Packaging Drive Drive & Packaging

kg (lb) kg (lb) kg (lb) kg (lb)

198 (436.5) 276 (608.5) 148 (326.3) 226 (498.2)

Table 7 - Frame D - 690V AC Input Drive Weights

Drive w/ND

Rating Code

678

791

904 200 (440.9) 278 (612.9) 150 (330.7) 228 (502.7)

1K0 202 (445.3) 280 (617.3)

1K1

1K2 165 (363.8) 243 (535.7)

1K4

1K5 191 (421.1) 269 (593.0)

24 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive Drive & Packaging Drive Drive & Packaging

kg (lb) kg (lb) kg (lb ) kg (lb)

198 (436.5) 276 (608.5) 148 (326.3) 226 (498.2)

215 (474.0) 293 (646.0)

241 (531.3) 319 (703.3)

152 (335.1) 230 (507.1)

172 (379.2) 250 (551.2)

Installation and Wiring Chapter 1

IMPORTANT

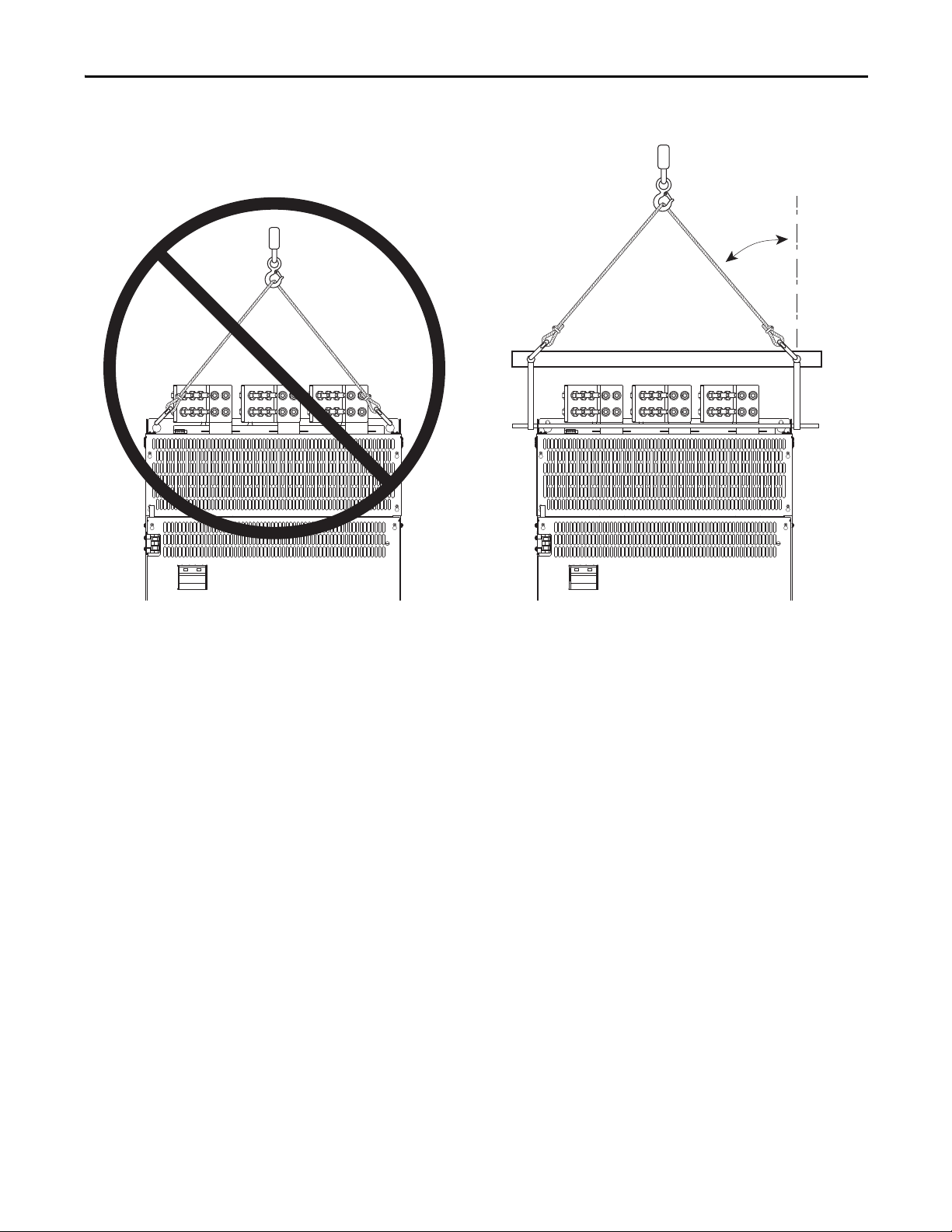

Lifting PowerFlex DC Drives

The dimensions and weights specified above must be taken into consideration

when mounting the device. Use the proper equipment to safely lift and hold the

weight of the drive while mounting.

ATTENTION: To guard against possible personal injury or equipment damage...

• Inspect all lifting hardware for proper attachment before lifting the drive.

• Do Not allow any part of the drive or lifting mechanism to make contact with

electrically charged conductors or components.

• Do Not subject the drive to high rates of acceleration or deceleration while

transporting to the mounting location or when lifting.

• Do Not allow personnel or their limbs directly underneath the drive when it is

being lifted and mounted.

Mounting Frame C and D Drives

All lifting equipment and lifting components (hooks, bolts, lifts, slings, chains,

etc.) must have a minimum

Verify that all mounting screws are properly tightened before and after drive

operation.

lifting capacity of 453.6 kg (1,000 lb).

1. Verify the hole pattern on the panel to which the drive will be mounted.

See Figure 4

2. Install the mounting hardware:

❏ For frame C drives, insert, but do not tighten, a bolt in one of the top

holes in the panel. The bolt must be fully threaded into the panel

before hanging the drive.

❏ For Frame D drives, insert, but do not tighten, the six bolts for the top

mounting flange on the drive into the panel. The bolts must be fully

threaded into the panel before hanging the drive.

3. To limit the pull in forces on the drive, the lifting devices connected to the

hooks must be long enough to make the angle between the chain or cable

and a vertical line extending up from the flange center less than 45° angle as

illustrated in Figure 7

❏ For frame C drives, insert the properly sized and rated lifting hooks

into the holes on the lifting flanges at the top of the drive. See Figure 7

on page 26

❏ For frame D drives, insert the properly sized lifting rod into the holes

on the lifting flanges at the top of the drive. See Figure 8

on page 21 or 22 on page 22.

on page 26 or Figure 8 on page 27.

.

on page 27.

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 25

Chapter 1 Installation and Wiring

Lifting flanges

Must be less

than 45° angle

Figure 7 - Lifting Frame C Drives

26 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Figure 8 - Lifting Frame D Drives

Must be less

than 45° angle

Installation and Wiring Chapter 1

4. Lift the drive into place onto the bolt(s) installed in the panel.

5. Install the remaining bolts into the panel. Tighten M8 bolts to a minimum

torque of 15 N

•m (221.2 lb•in).

N

•m (132.7 lb•in) and M10 bolts to a minimum torque of 25

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 27

Chapter 1 Installation and Wiring

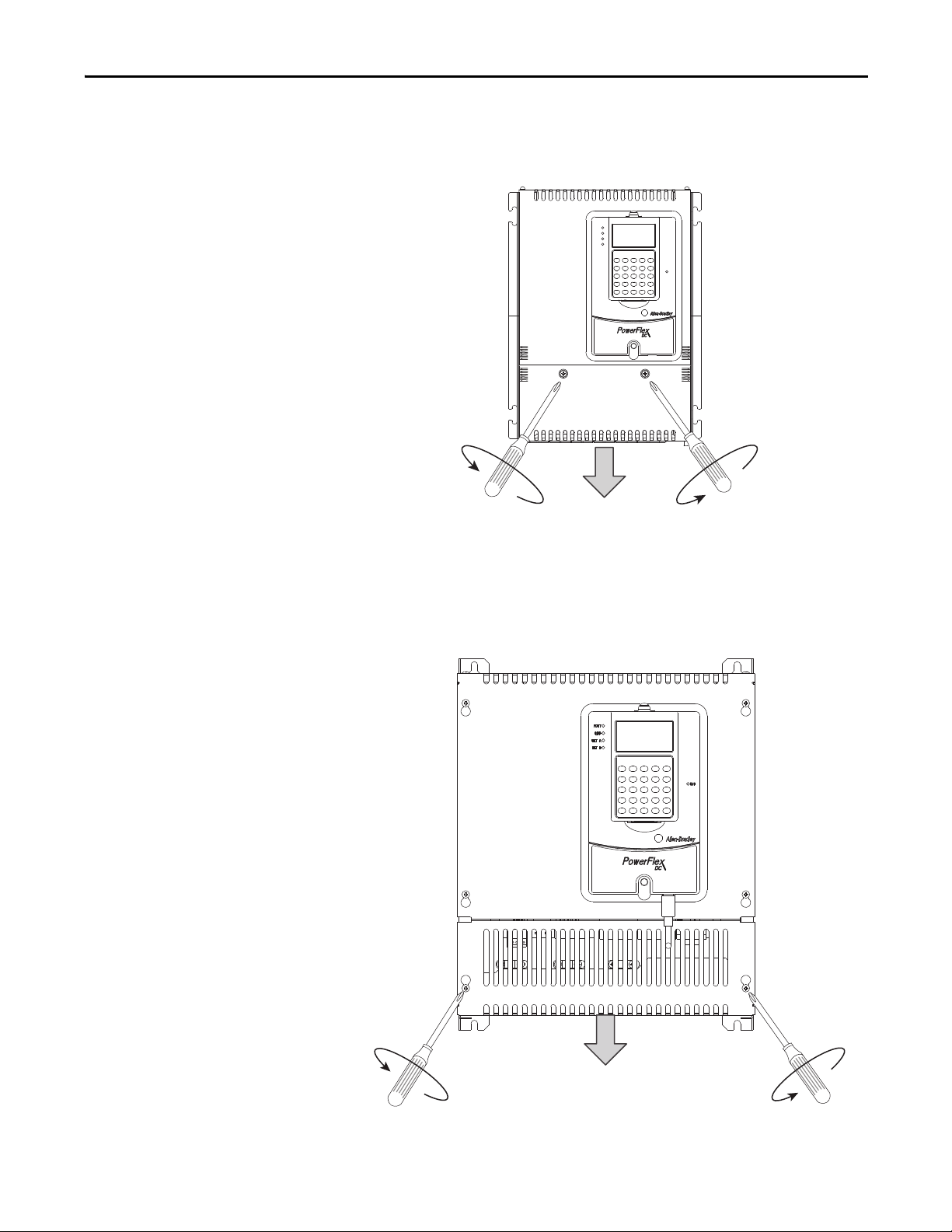

Removing the Drive Covers

The appropriate protective cover(s) must be removed in order to access the drive’s

power and I/O terminals. The upper cover only needs to be removed to install an

optional communication adapter and service the drive. (See Installing a

Communication Adapter on page 337

for information.)

Frame A Drives

You must remove both the lower protective cover and the power terminal cover

on frame A drives to access the power terminals.

Remove the Power Terminal Cover

Remove the two screws as shown below and slide the cover down and off the

chassis.

28 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Installation and Wiring Chapter 1

STS

PORT

MOD

NET A

NET B

Frame B Shown

Remove the Lower Protective Cover

Remove the two screws as shown below and, while gently lifting along the top

edge, slide the cover down and off the chassis.

Frame B and C Drives

Loosen, but do not remove, the two screws that secure the bottom cover. Then,

slide the cover down until the screw heads line up with the key holes and lift the

cover off the chassis.

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013 29

Chapter 1 Installation and Wiring

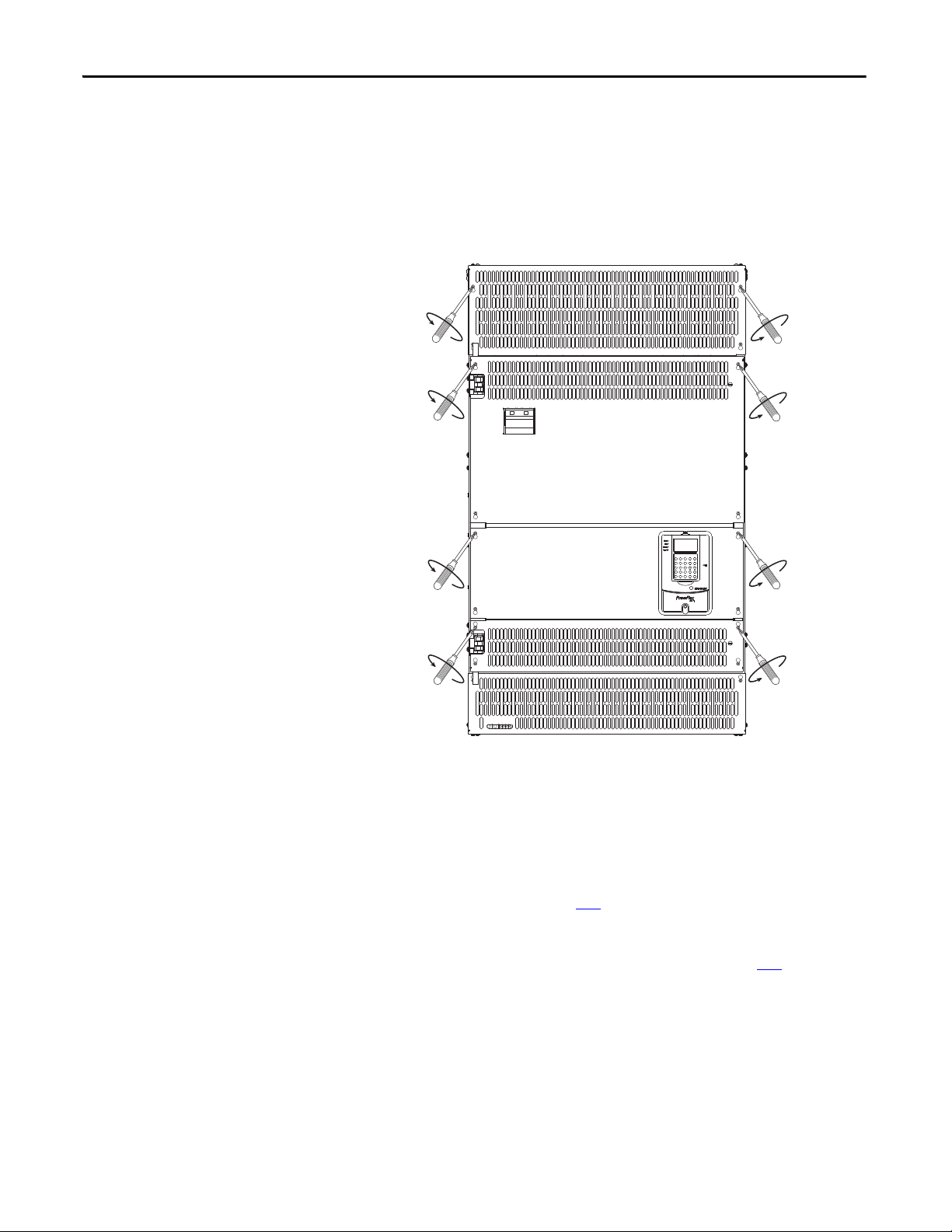

Frame D

For any protective cover, loosen, but do not remove, the Hexalobular head screws

that secure the cover to the drive frame. Then, slide the cover up until the screw

heads line up with the key holes and lift the cover off the chassis. The top and

bottom most covers are also secured by screws at the top and bottom of the drive,

respectively.

Isolation Transformers / Line Reactors

30 Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

When connecting the drive directly to the main distribution system an isolation

transformer and/or 3…5% impedance AC line reactor must be used to guard

against system disturbance. If the isolation transformer provides the required

3…5% impedance, a line reactor is not required.

See Isolation Transformers on page 241

transformers.

See AC Input Line Reactors and AC Input Contactors on page 238

recommended AC line reactors. The type of line reactor used depends upon the

following:

• the current absorbed by the AC input

• the AC input voltage

• the relative short circuit voltage

• the AC input frequency

for a list of recommended isolation

for a list of

Loading...

Loading...