Page 1

Installation Instructions

PowerFlex 400 AC Drive Packages for Fan & Pump

Applications

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

This manual contains new and updated information.

Summary of Changes

New and Updated Information

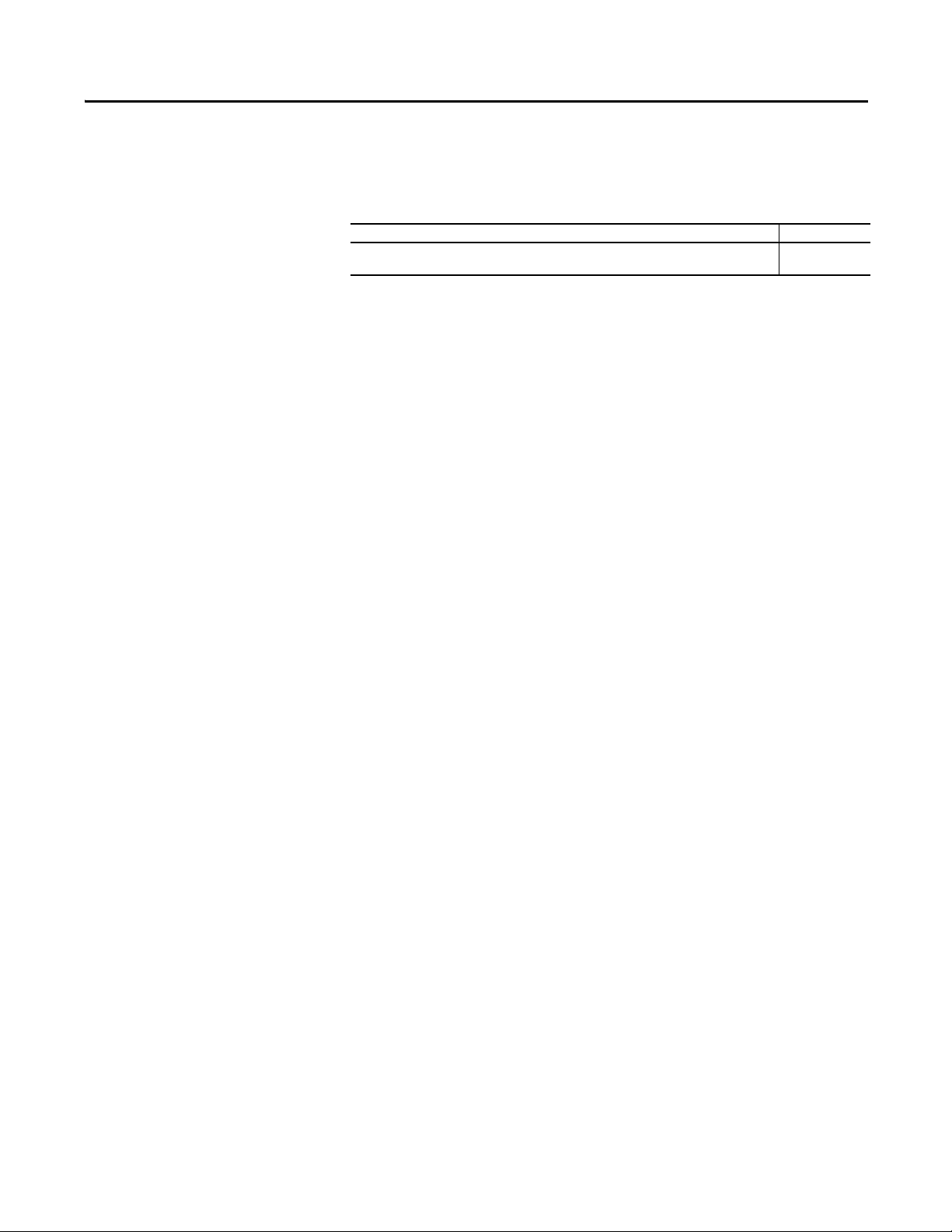

This table contains the changes made to this revision.

Top ic Pag e

Removed all content related to the discontinued 3 Contactor Basic Bypass with Disconnect Package

(Style C)

–

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 5

Table of Contents

Preface

Main Input Disconnect Package

(Style A/M)

Who Should Use this Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What Is Not in this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

Style Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Main Disconnect Switch (DS1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Main Circuit Breakers (CB1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Main Fuses (FU1-FU3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Input Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Output Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Control and Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parameter Defaults (Style A/M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Drawing Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

208V AC Input – Main Input Disconnect Drive Packages

(Style A/M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

460V AC – Main Input Disconnect Drive Packages (Style A/M) 20

Schematic Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Interconnect Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Layout Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Outline Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3 Contactor Full Feature Bypass with

Disconnect Package (Style B/N)

Chapter 2

Style Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Main Disconnect Switch (DS1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Main Circuit Breakers (CB1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Main Fuses (FU1-FU3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Contactors (DIC, DOC, BC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Motor Overload Relay (OL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Control Transformer (T1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Bypass Control Interface (CP1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Input Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Output Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Control and Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Customer Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Freeze/Fire Stat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Autostart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 5

Page 6

Table of Contents

Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Bypass Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Parameter Defaults (Style B/N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Drawing Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

208V AC – 3 Contactor Full Feature Bypass with Disconnect

Package (Style B/N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

460V AC – 3 Contactor Full Feature Bypass with Disconnect

Package (Style B/N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Schematic Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Interconnect Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Layout Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Outline Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Chapter 3

Mechanical Installation

Electrical Installation

Supplemental Information

Mounting Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Maximum Surrounding Air Temperature. . . . . . . . . . . . . . . . . . . . . . 177

Minimum Mounting Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Lifting and Mounting the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Watts Loss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Chapter 4

Power Wire Size Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Power Terminal Block Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Control and Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Installing Input Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Installing Output Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Installing an Optional Transformer or Reactor. . . . . . . . . . . . . . . . . . . . . 187

Installing Fuses for Branch Circuit Protection. . . . . . . . . . . . . . . . . . 188

Installing the Required External/Separate Input Disconnect . . . . 189

Installing Input/Output Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . 189

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Appendix B

Replacement Parts

6 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Common Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Disconnect Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Bypass Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Enclosure Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Page 7

Preface

The purpose of this manual is to provide basic information needed to install,

®

start-up and troubleshoot PowerFlex

Packages for Fan & Pump Applications.

User documentation for the PowerFlex 400 Drive Packages for Fan & Pump

Applications includes these Installation Instructions and the PowerFlex 400 User

Manual, Publication 22C-UM001…. Both manuals are required to properly

install and operate the PowerFlex 400 Adjustable Frequency AC Drive Packages

for Fan & Pump Applications.

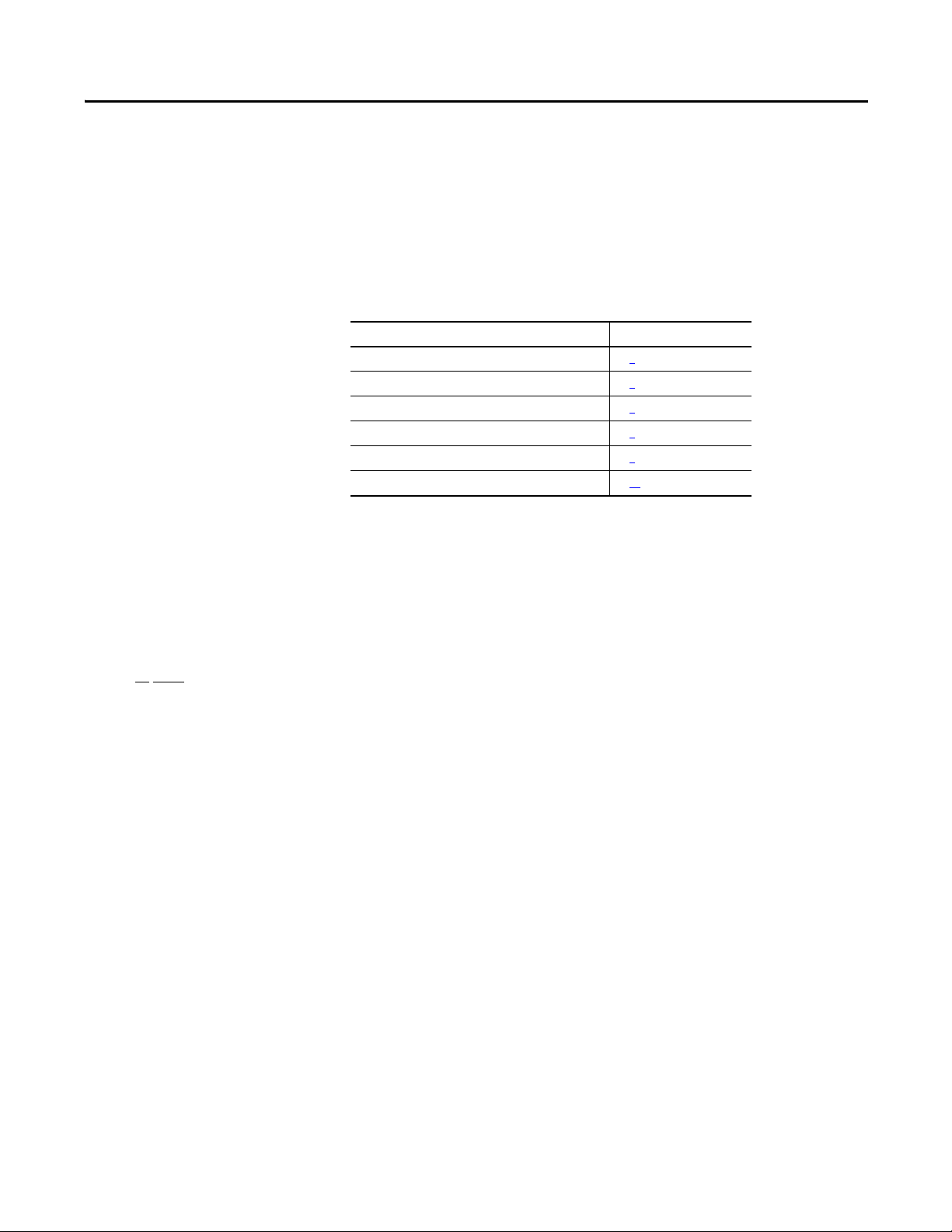

Top ic Pag e

Who Should Use this Manual? 7

What Is Not in this Manual 7

Additional Resources 8

Manual Conventions 8

General Precautions 9

Catalog Number Explanation 10

400 Adjustable Frequency AC Drive

Who Should Use this Manual?

What Is Not in this Manual

This manual is intended for qualified personnel. You must be able to program

and operate Adjustable Frequency AC Drive devices. In addition, you must have

an understanding of the parameter settings and functions.

The PowerFlex 400 Adjustable Frequency AC Drive Packages for Fan & Pump

Applications Installation Instructions is designed to provide only basic

installation and operation information. For this reason, the following topics have

not been included:

• Specifications

• Troubleshooting

• Startup

• Programming and Parameters

Please refer to the PowerFlex 400 User Manual for detailed drive information.

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 7

Page 8

Preface

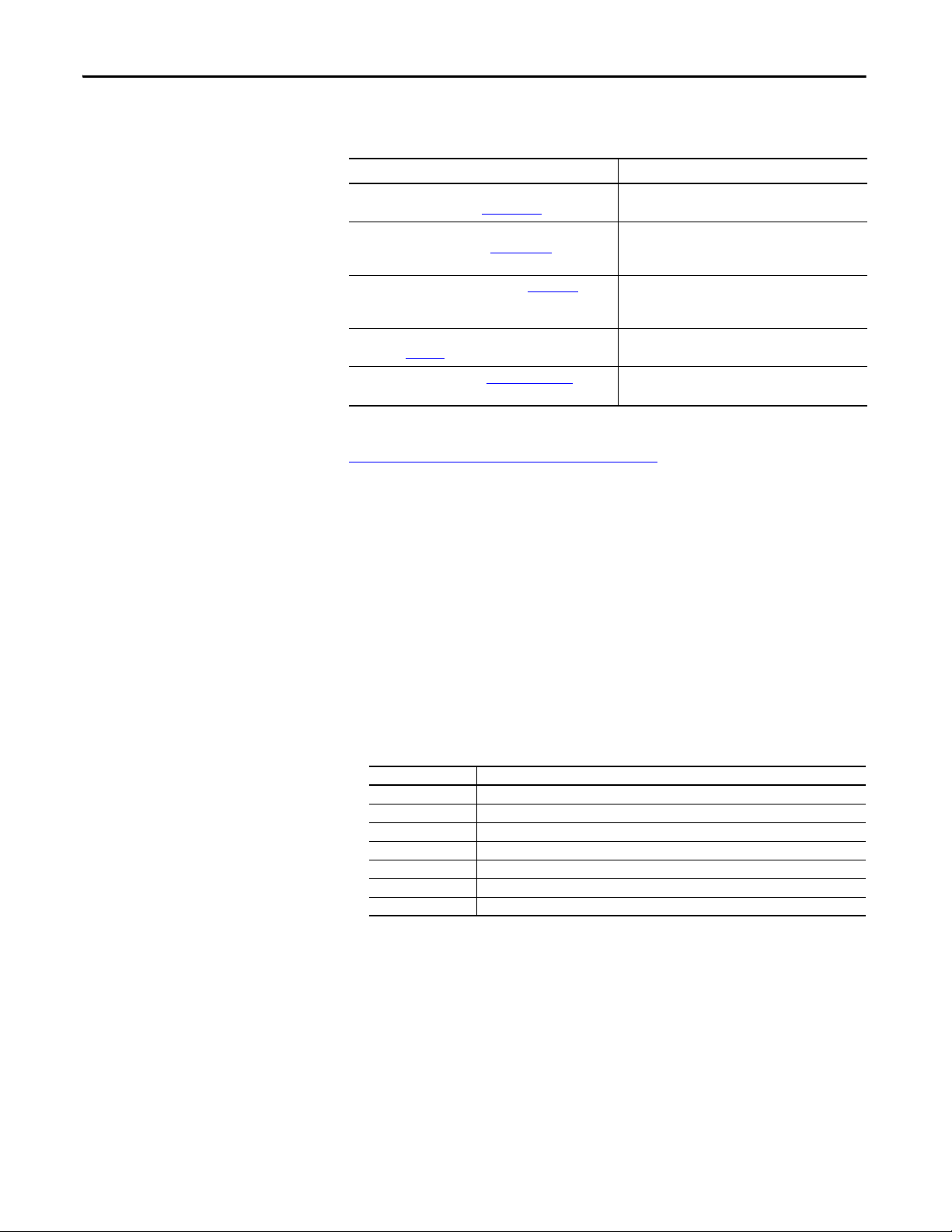

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Wiring and Grounding Guidelines for Pulse Width Modulated

(PWM) AC Drives, publication DRIVES-IN001

Preventive Maintenance of Industrial Control and Drive

System Equipment, publication DRIVES-TD001

PowerFlex 400 User Manual, publication 22C-UM001 Provides the basic information needed to install, start-

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and

Provides the basic information needed to properly wire

and ground Pulse Width Modulated (PWM) AC drives.

Contains a checklist that can be used as a guide to

perform preventive maintenance on variable frequency

AC drives.

up and troubleshoot the PowerFlex 400 Adjustable

Frequenc y AC Drive.

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Manual Conventions

• To help differentiate parameter names and LCD display text from other

text, the following conventions will be used:

• Parameter Names will appear in [brackets].

For example: [DC Bus Voltage].

• Display Text will appear in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an

action:

Word Mean ing

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

8 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 9

General Precautions

Preface

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference A-B publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other applicable ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or application errors, such as,

undersizing the motor, incorrect or inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the system.

ATTENTION: Only qualified personnel familiar with adjustable frequency AC

drives and associated machinery should plan or implement the installation, startup and subsequent maintenance of the system. Failure to comply may result in

personal injury and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged before performing any work on the drive. Measure the

voltage at the drive (Refer to the PowerFlex 400 User Manual for test point

locations). The voltage must be zero.

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 9

Page 10

Preface

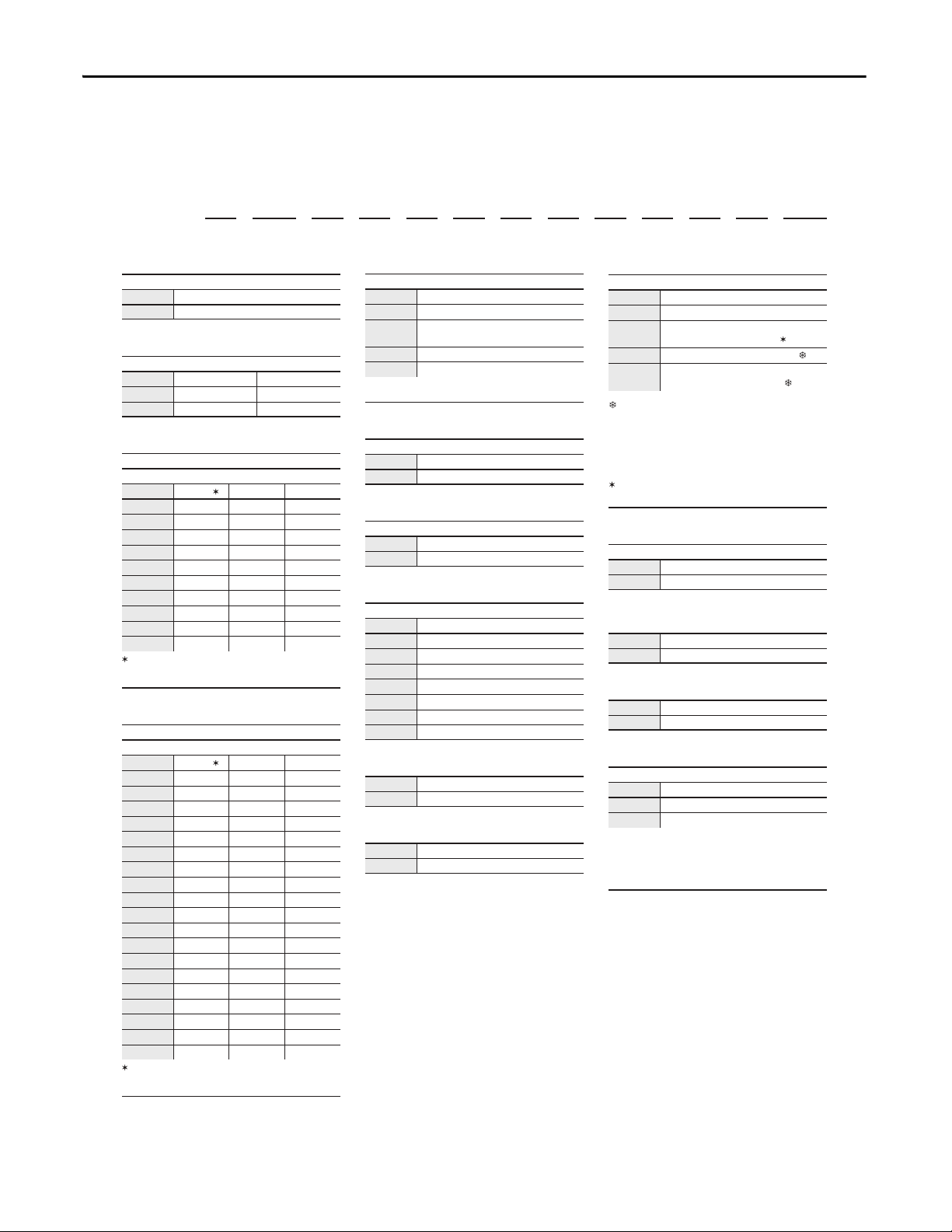

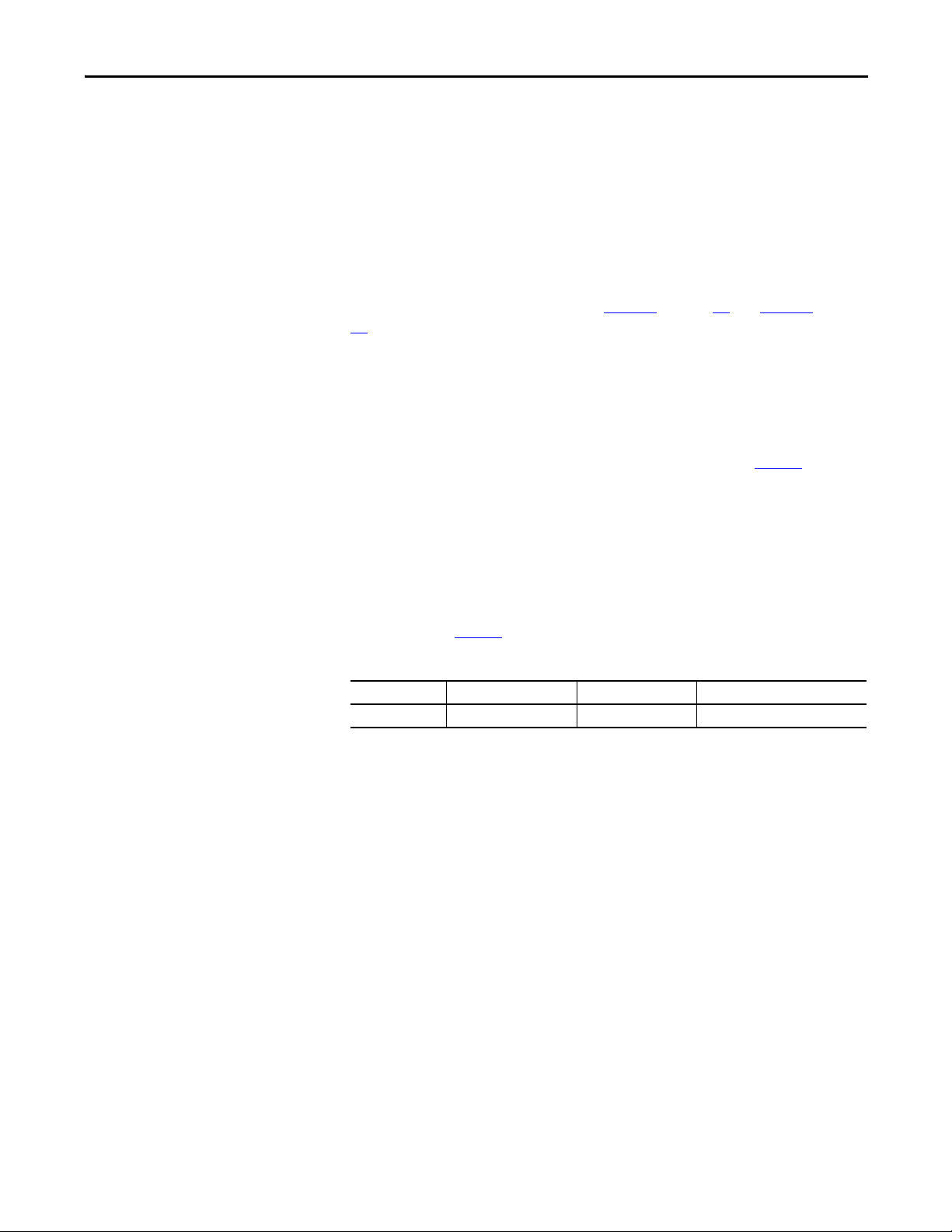

Position

1-345 6-8 9 101112131415161718 19+

23C

– D 038 A 1 0 3 N N B A N N -LR

abcdefghijklmn

a

Drive

Code Type

23C PowerFlex 400

b

Voltage Rating

Code Voltage Ph.

X 208V ac 3

D 480V ac 3

c1

Rating

208V, 60Hz Input

Code Amps kW (Hp) Frame

012 12 2.2 (3.0) C

017 16.8 3.7 (5.0) C

024 24 5.5 (7.5) C

033 30.8 7.5 (10) C

049 46.2 11 (15) D

065 64 15 (20) D

075 75 18.5 (25) D

090 88 22 (30) D

120 114 30 (40) E

145 143 37 (50) E

Congured drive amp ratings may dier from

stand-alone drive ratings. Congured drives

sized per NEC motor amps.

d

Enclosure

Code Enclosure

A NEMA/UL Type 1

H

NEMA/UL Type 12 with Fan and

Filter

X NEMA/UL Type 3R ‡

E NEMA/UL Type 4 ‡

‡ Designed for maximum ambient temperature of

40° C with no direct sunlight exposure.

e

HIM

Code Interface Module

1 Fixed Keypad

f

Emission Class

Code Rating

0 Not Filtered

j

Package

Code Description

A Main Input Disconnect

B

3 Contactor Full Feature Bypass

with Disconnect

M

Main Input Circuit Breaker

N

3 Contactor Full Feature Bypass

with Circuit Breaker

Available with all ratings in NEMA/UL Type 12,

3R, or 4 enclosures (Position d = H, X, or E)

and 160-250 kW (250-350 Hp) ratings in

NEMA/UL Type 1 enclosures (Position d = A).

k

Control

Code Description

A Single Motor

l

Code Rating

N Reserved

c2

Rating

460V, 60Hz Input

Code Amps kW (Hp) Frame

6P0 4.8 2.2 (3.0) C

010 7.6 4.0 (5.0) C

012 11 5.5 (7.5) C

017 14 7.5 (10) C

022 21 11 (15) C

030 27 15 (20) C

038 34 18.5 (25) D

045 40 22 (30) D

060 52 30 (40) D

072 65 37 (50) E

088 77 45 (60) E

105 96 55 (75) E

142 124 75 (100) E

170 156 90 (125) F

208 180 110 (150) F

260 240 132 (200) G

310 302 160 (250) G

370 361 200 (300) H

460 414 250 (350) H

Congured amp ratings may dier from standalone drive ratings. Congured drives sized per

NEC motor amps.

g

Version

Code Version

3 RS485

B BACnet Adapter

C ControlNet Adapter

D DeviceNet Adapter

E EtherNet/IP Adapter

L LonWorks Adapter

P PROFIBUS DP Adapter

h

Code Rating

N Reserved

i

Code Rating

N Reserved

m

Code Rating

N Reserved

n

Options

Code Description

-LR 3% Input Line Reactor §

-E5

Space Heater - Local Power ♣

§ 3% Input Line Reactor not available for all

package styles. Consult product selection

tables for additional detail.

♣ Available with NEMA/UL Type 3R and 4

enclosures only.

‡ Not available with all ratings at 460V. Consult

product selection tables for details.

‡

Not available with all ratings at 460V. Consult

product selection tables for details.

Catalog Number Explanation

The PowerFlex 400 Adjustable Frequency AC Drive Packages for Fan & Pump

Applications catalog numbering scheme is shown below.

10 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 11

Chapter 1

Main Input Disconnect Package (Style A/M)

This chapter describes the features and operation for the Main Input Disconnect

Package (Style A/M).

Top ic Pa ge

Hardware O verview 11

Electrical Installation 13

Parameter Defaults (Style A/M) 16

Drawing Index 17

Schematic Drawings 20

Interconnect Drawings 27

Layout Drawings 32

Outline Drawings 68

Style Explanation

Hardware Overview

• Style A = Fused Disconnect

• Style M = Circuit Breaker

The Main Input Disconnect Package (Style A/M) combines an Adjustable

Frequency AC Drive with a means for disconnecting input power within a single

package. Input power is connected to the PowerFlex drive through a door

interlocked fuse disconnect switch or circuit breaker.

Main Disconnect Switch (DS1)

An Allen-Bradley Bulletin 194R Fused Disconnect Switch with lockable rotary

mounted operator handle is provided. The disconnect switch is designed to meet

disconnect switch requirements for branch circuit protection. The door

mounted handle accepts up to three (3) padlocks.

Main Circuit Breakers (CB1)

An Allen-Bradley Bulletin 140U circuit breaker with lockable rotary mounted

operator handle is provided. The circuit breaker is designed to meet circuit

breaker requirements for branch circuit protection. The door-mounted handle

accepts up to three (3) padlocks.

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 11

Page 12

Chapter 1 Main Input Disconnect Package (Style A/M)

Main Fuses (FU1-FU3)

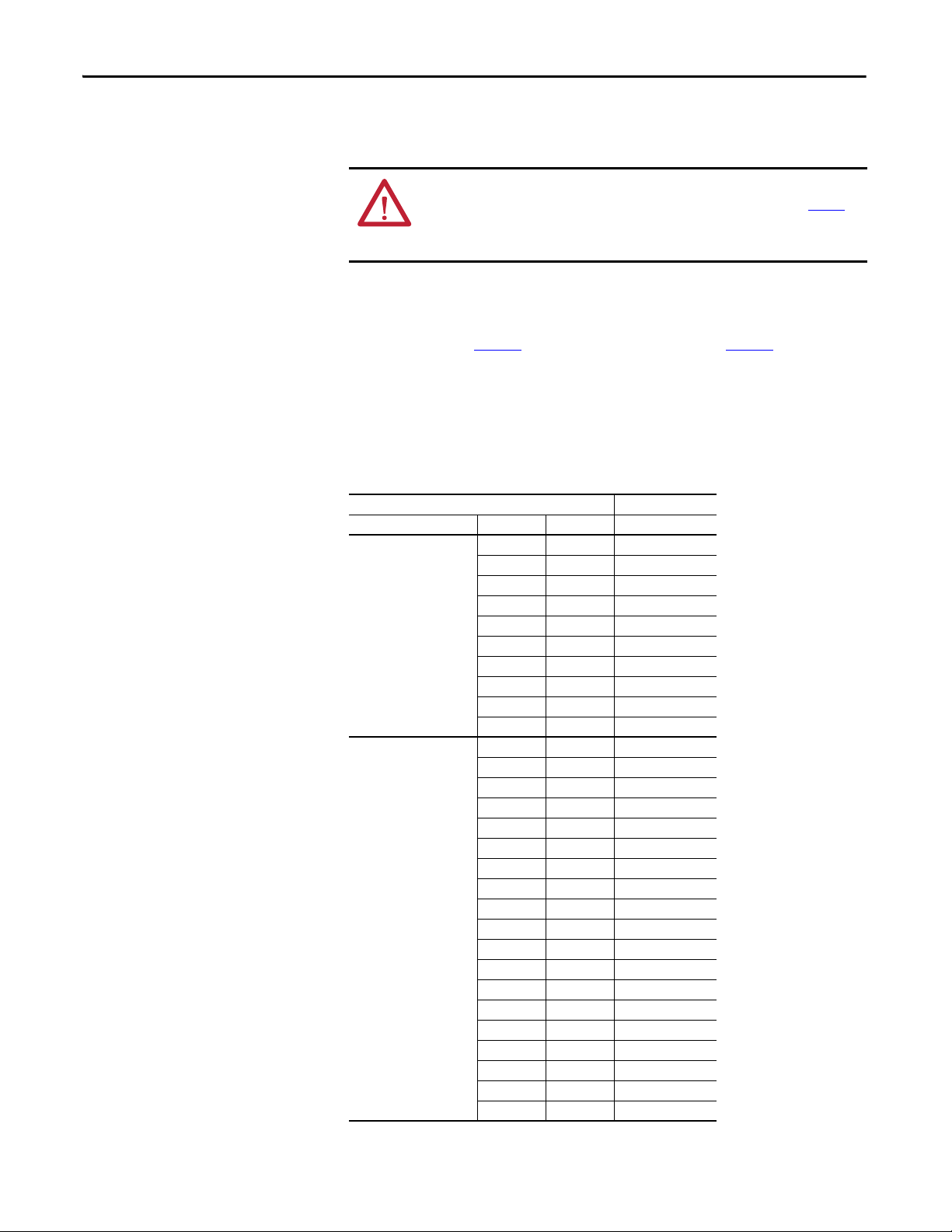

ATT EN TI ON : Most codes require that upstream branch circuit protection be

provided to protect input power wiring. Install the fuses recommended in Tab l e 1

Do not exceed the fuse ratings. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

Input line branch circuit protection fuses must be used to protect the input

power lines. If input fuses are not provided with your drive, recommended fuse

values are shown in Ta b l e 1

for one drive per branch circuit. No other load may be applied to that fused

circuit.

The recommended fuse type for all PowerFlex 400 Drive Packages for Fan &

Pump Applications is UL Class J.

Table 1 - Fuse Recommendations

Drive Rating Fuse Rating

Input Voltage kW Hp Amps

208V AC – 3-Phase 2.2 3.0 20

460V AC – 3-Phase 2.2 3.0 10

. The input fuse ratings listed in Ta b l e 1 are applicable

3.7 5.0 20

5.5 7.5 35

7.5 10 40

11 15 80

15 20 100

18.5 25 125

22 30 150

30 40 200

37 50 250

4.0 5.0 15

5.5 7.5 20

7.5 10 20

11 15 35

15 20 35

18.5 25 60

22 30 70

30 40 80

37 50 100

45 60 150

55 75 175

75 100 200

90 125 250

110 150 350

132 200 400

160 250 500

200 300 600

250 350 700

.

12 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 13

Main Input Disconnect Package (Style A/M) Chapter 1

Electrical Installation

Input Power Wiring

Use 75 °C rated copper conductors only for customer power wiring.

Refer to the PowerFlex 400 User Manual for additional detailed information

about input power wiring recommendations and selection.

ATT EN TI ON : Protect the contents of the options cabinet from metal chips and

other debris while drilling the conduit openings. Failure to observe this

precaution could result in damage to, or destruction of, the equipment.

ATT EN TI ON : Do not route signal and control wiring with power wiring in the

same conduit. This can cause interference with drive operation. Failure to observe

this precaution could result in damage to, or destruction of, the equipment.

To connect AC input power to the drive package:

❏ 1. Select the proper wire size according to NEC and all applicable local codes

and standards. Note that you must punch openings in the Option Cabinet

of the desired conduit size, following NEC and all applicable local codes

and standards. Power terminal block specifications are listed in Ta b l e 2

.

❏ 2. Connect the three-phase AC input power leads (three-wire VAC) to the

appropriate terminals. Connect the AC input power leads to terminals

L1, L2, L3 on the fused disconnect switch.

❏ 3. Tighten the AC input terminal power terminals to the proper torque

according to drive type as shown in Ta b l e 2

Table 2 - AC Input Power Terminal Block Specifications

Volts ACkW Hp Maximum Wire Size

2

208V 2.2…3.7 3.0…5.0 8.4 mm

5.5…7.5 7.5…10 16.0 mm

11…15 15…20 33.6 mm

18.5…30 25…40 250 MCM 10.0 mm

37 50 350 MCM 35.0 mm

460V 2.2…7.5 3.0…10 8.4 mm

11…18.5 15…25 16.0 mm

22…37 30…50 33.6 mm

45…75 60…100 250 MCM 10.0 mm

90…110 125…150 (2) 350 MCM (2) 10.0 mm

132 200 (2) 350 MCM (2) 35.0 mm

160…200 250…300 (2) 350 MCM (2) 70.0 mm

250 350 (2) 400 MCM (2) 70.0 mm

(8 AWG) 2.5 mm2 (14 AWG) 4.0 N•m (35 lb•in)

2

(4 AWG) 2.5 mm2 (14 AWG) 4.0 N•m (35 lb•in)

2

(2 AWG) 2.5 mm2 (14 AWG) 17.5 N•m (155 lb•in)

2

(8 AWG) 2.5 mm2 (14 AWG) 4.0 N•m (35 lb•in)

2

(4 AWG) 2.5 mm2 (14 AWG) 4.0 N•m (35 lb•in)

2

(2 AWG) 2.5 mm2 (14 AWG) 17.5 N•m (155 lb•in)

(1)

Minimum Wire Size Recommended Torque

.

2

(6 AWG) 31.1 N•m (275 lb•in)

2

(1/0 AWG) 31.1 N•m (275 lb•in)

2

(6 AWG) 31.1 N•m (275 lb•in)

2

(6 AWG) 31.1 N•m (275 lb•in)

2

(1/0 AWG) 31.1 N•m (275 lb•in)

2

(3/0 AWG) 31.1 N•m (275 lb•in)

2

(3/0 AWG) 31.1 N•m (275 lb•in)

(1) Maximum/minimum sizes that the terminal block will accept - these are not recommendations. If national or local codes require

sizes outside the range, lugs may be used.

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 13

Page 14

Chapter 1 Main Input Disconnect Package (Style A/M)

❏ 1. Wire the three-phase AC output power motor leads by routing them

Output Power Wiring

Refer to the PowerFlex 400 User Manual for additional detailed information

about output power wiring recommendations and selection.

ATT EN TI ON : Unused wires in conduit must be grounded at both ends to avoid a

possible shock hazard caused by induced voltages. Also, if a drive sharing a

conduit is being serviced or installed, all drives using this conduit should be

disabled to eliminate the possible shock hazard from cross-coupled motor leads.

Failure to observe these precautions could result in bodily injury.

ATT EN TI ON : Do not route signal and control wiring with power wiring in the

same conduit. This can cause interference with drive operation. Failure to observe

this precaution could result in damage to, or destruction of, the equipment.

To connect AC output power wiring from the drive to the motor:

according to the drive option type. Note that you must punch openings in

the option cabinet of the desired conduit size, following NEC and all

applicable local codes and standards. Power terminal block specifications

are listed in Ta b l e 3

.

Do not route more than three sets of motor leads through a single conduit.

This will minimize cross-talk that could reduce the effectiveness of noise

reduction methods. If more than three drive/motor connections per

conduit are required, shielded cable must be used. If possible, each conduit

should contain only one set of motor leads.

❏ 2. Connect the three-phase AC output power motor leads to terminals

U, V, W (T1, T2, T3) on the power terminal block located on the drive.

❏ 3. Tighten the three-phase AC output power terminals to the proper torque

according to drive type as shown in Ta b l e 3

Table 3 - AC Output Power Terminal Block Specifications

Volt s ACkW Hp Maximum Wire Size

2

208V 2.2…7.5 3.0…10 8.4 mm

11…22 15…30 33.6 mm

30…37 40…50 33.6 mm

460V 2.2…15 3.0…20 8.4 mm

18.5…30 25…40 33.6 mm

37…45 50…60 33.6 mm

55…75 75…100 107.2 mm

90…110 125…150 300 MCM 70.0 mm

132…160 200…250 300 MCM 107.2 mm

200…250 300…350 500 MCM 300 MCM 40.0 N•m (354 lb•in)

(8 AWG) 1.3 mm2 (16 AWG) 3.7 N•m (33 lb•in)

2

(2 AWG) 8.4 mm2 (8 AWG) 5.1 N•m (45 lb•in)

2

(2 AWG) 2.5 mm2 (14 AWG) 17.5 N•m (155 lb•in)

2

(8 AWG) 1.3 mm2 (16 AWG) 3.7 N•m (33 lb•in)

2

(2 AWG) 8.4 mm2 (8 AWG) 5.1 N•m (45 lb•in)

2

(2 AWG) 3.5 mm2 (12 AWG) 5.6 N•m (49.5 lb•in)

2

(4/0 AWG) 53.5 mm2 (1/0 AWG) 19.5 N•m (173 lb•in)

(1)

.

Minimum Wire Size Recommended Torque

2

(3/0 AWG) 19.5 N•m (173 lb•in)

2

(4/0 AWG) 29.4 N•m (260 lb•in)

(1) Maximum/minimum sizes that the terminal block will accept - these are not recommendations. If national or local codes require

sizes outside the range, lugs may be used.

14 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 15

Main Input Disconnect Package (Style A/M) Chapter 1

Control and Signal Wiring

Refer to the PowerFlex 400 User Manual for additional detailed information

about control and signal wiring.

The Control I/O Terminal Block (TB1) and Relay Terminal Block (TB2)

located on the drive Main Control Board provide terminals for interfacing

customer supplied control inputs and outputs. All analog and discrete control

wiring will be made at these terminals. Typical customer control and signal wiring

is shown on the Interconnect Drawings Figure 8

28

.

To connect control and signal wiring to the drive package:

❏ 1. Wire the control and signal leads by routing them according to the drive

option type. Note that you must punch openings in the option cabinet of

the desired conduit size, following NEC and all applicable local codes and

standards. I/O terminal block specifications are listed in Ta b l e 4

Control and signal wires should be separated from power wires by at least

0.3 meters (1 foot).

on page 27 and Figure 9 on page

.

❏ 2. Connect the control and signal wiring to the I/O terminals located on the

drive.

❏ 3. Tighten the I/O terminals to the proper torque according to drive type as

shown in Ta b l e 4

Table 4 - I/O Terminal Block Specifications

Voltage Rating Maximum Wire Size

208…460V AC 1.3 mm

(1) Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

.

(1)

Minimum Wire Size Torque

2

(16 AWG) 0.13 mm2 (26 AWG) 0.5…0.8 N•m (4.4…7 lb•in)

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 15

Page 16

Chapter 1 Main Input Disconnect Package (Style A/M)

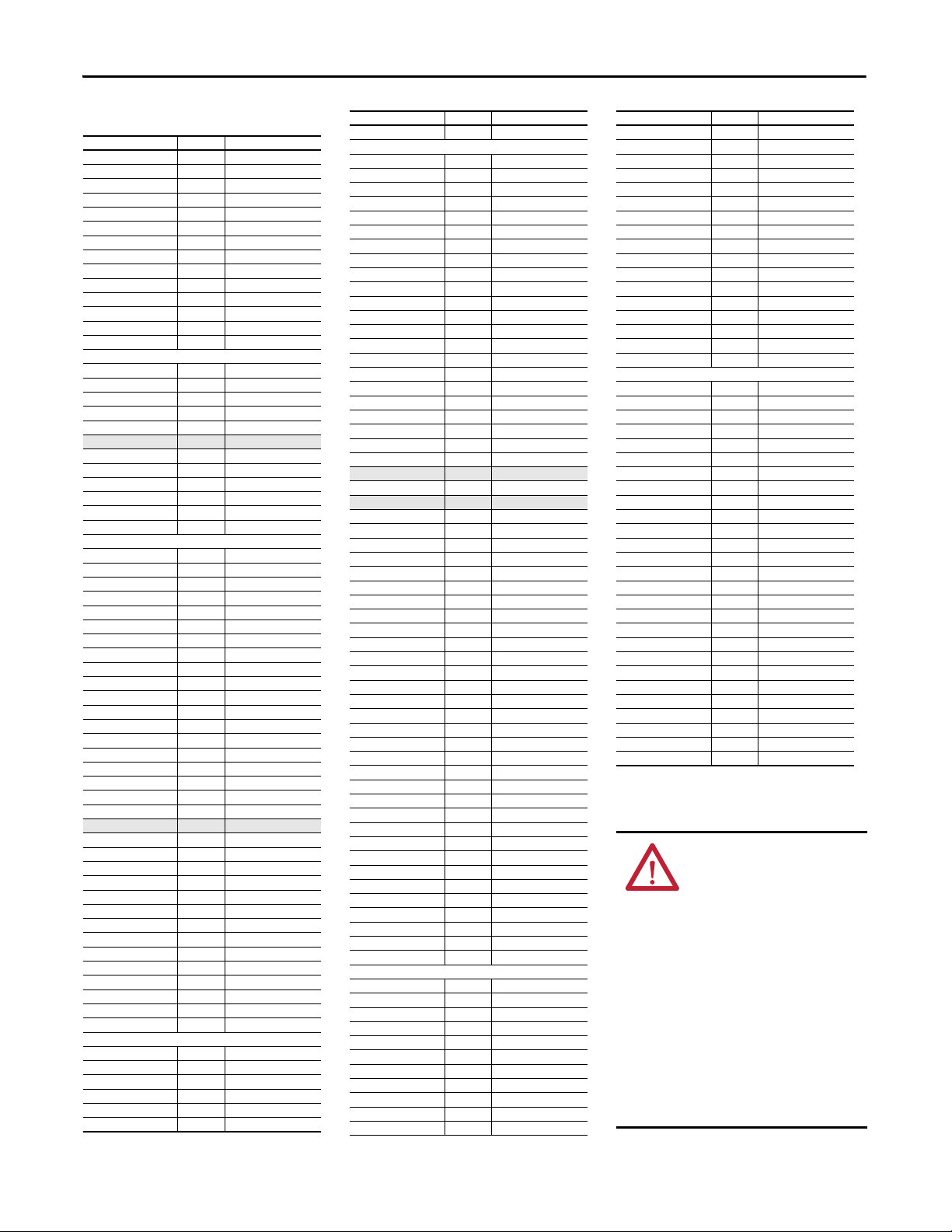

Parameter Defaults (Style A/M)

Parameter Name Number Default

Output Freq b001 Read Only

Commanded Freq b002 Read Only

Output Current b003 Read Only

Output Voltage b004 Read Only

DC Bus Voltage b005 Read Only

Drive Status b006 Read Only

Fault 1 Code b007 Read Only

Process Display b008 Read Only

Output Power b010 Read Only

Elapsed MWh b011 Read Only

Elapsed Run Time b012 Read Only

Torque Current b013 Read Only

Drive Temp b014 Read Only

Elapsed kWh b015 Read Only

Motor NP Volts P031 Drive Rated Volts

Motor NP Hertz P032 60 Hz

Motor OL Current P033 Drive Rated Amps

Minimum Freq P034 0.0 Hz

Maximum Freq P035 60 Hz

Start Source P036 6 “2-W Lvl/Enbl”

Stop Mode P037 1 “Coast, CF”

Speed Reference P038 2 “Analog In1”

Accel Time 1 P039 20.00 Secs

Decel Time 1 P040 20.00 Secs

Reset To Defalts P041 0 “Ready/Idle”

Auto Mode P042 1 “Hnd-Off-Auto”

Digital In1 Sel T051 1 “Purge”

Digital In2 Sel T052 3 “Local”

Digital In3 Sel T053 10 “Clear Fault”

Digital In4 Sel T054 4 “Comm Port”

Relay Out1 Sel T055 0 “Ready/Fault”

Relay Out1 Level T056 0.0

Relay 1 On Time T058 0.0 Secs

Relay 1 Off Time T059 0.0 Secs

Relay Out2 Sel T060 2 “MotorRunning”

Relay Out2 Level T061 0.0

Relay 2 On Time T063 0.0 Secs

Relay 2 Off Time T064 0.0 Secs

Opto Out Sel T065 1 “At Frequency”

Opto Out Level T066 0.0

Opto Out Logic T068 0 “Normally Open”

Analog In 1 Sel T069 2 “0-10V”

Analog In 1 Lo T070 0.0%

Analog In 1 Hi T071 100.0%

Analog In 1 Loss T072 0 “Disabled”

Analog In 2 Sel T073 1 “4-20 mA”

Analog In 2 Lo T074 0.0%

Analog In 2 Hi T075 100.0%

Analog In 2 Loss T076 0 “Disabled”

Sleep-Wake Sel T077 0 “Disabled”

Sleep Level T078 10.0%

Sleep Time T079 0.0 Secs

Wake Level T080 15.0%

Wake Time T081 0.0 Secs

Analog Out1 Sel T082 0 “OutFreq 0-10”

Analog Out1 High T083 100%

Analog Out1 Setpt T084 0.0%

Analog Out2 Sel T085 1 “OutCurr 0-10”

Analog Out2 High T086 100%

Analog Out2 Setpt T087 0.0%

Language C101 1 “English”

Comm Format C102 0 “RTU 8-N-1”

Comm Data Rate C103 3 “9600”

Comm Node Addr C104 100

Comm Loss Action C105 0 “Fault”

Comm Loss Time C106 5.0 Secs

(1)

(1)

Parameter Name Number Default

Comm Write Mode C107 0 “Save”

Purge Frequency A141 5.0 Hz

Internal Freq A142 60.00 Hz

Preset Freq 0 A143 0.0 Hz

Preset Freq 1 A144 5.0 Hz

Preset Freq 2 A145 10.0 Hz

Preset Freq 3 A146 20.0 Hz

Accel Time 2 A147 30.00 Secs

Decel Time 2 A148 30.00 Secs

S Curve % A149 20%

PID Trim Hi A150 60.0 Hz

PID Trim Lo A151 0.0 Hz

PID Ref Sel A152 0 “PID Disabled”

PID Feedback Sel A153 0 “Analog In 1”

PID Prop Gain A154 0.01

PID Integ Time A155 2.0 Secs

PID Diff Rate A156 0.00

PID Setpoint A157 0.0%

PID Deadband A158 0.0%

PID Preload A159 0.0 Hz

Process Factor A160 30.0

Auto Rstrt Tries A163 0

Auto Rstrt Delay A164 1.0 Secs

Start At PowerUp A165 1 “Enabled”

Reverse Disable A166 1 “Rev D isabled”

Flying Star t En A167 1 “Enabled”

PWM Frequency A168 4.0 kHz

PWM Mode A169 1 “2-Phase”

Boost Select A170 4 “45.0, VT”

Start Boost A171 2.5%

Break Voltage A172 25.0%

Break Frequency A173 15.0 Hz

Maximum Voltage A174 Drive Rated Volts

Slip Hertz @ FLA A175 2.0 Hz

DC Brake Time A176 0.0 Secs

DC Brake Level A177 Drive Rated Amps

DC Brk Time@Strt A178 0 (Disabled)

Current Limit 1 A179 Drive Rated Amps

Current Limit 2 A180 Drive Rated Amps

Motor OL Select A181 0 “No Derate”

Drive OL Mode A182 3 “B oth-PWM 1st”

SW Current Trip A183 0.0 (Disabled)

Load Los s Level A184 0 .0 (Disab led)

Load Loss Time A185 0 Secs

Stall Fault Time A186 0 “60 Seconds”

Bus Reg Mode A187 1 “Enabled”

Skip Frequency 1 A188 0 Hz

Skip Freq Band 1 A189 0.0 H z

Skip Frequency 2 A190 0 Hz

Skip Freq Band 2 A191 0.0 H z

Skip Frequency 3 A192 0 Hz

Skip Freq Band 3 A193 0.0 H z

Compensati on A194 1 “Ele ctrical”

Reset Meters A195 0 “Ready/Idle”

Tes tp oin t S el A1 96 4 00

Fault Clear A197 0 “Ready/Idle”

Program Lock A198 0 “Unlocked”

Motor NP Poles A199 4

Relay Out3 Sel R221 0 “Rea dy/Fault”

Relay Out3 Level R222 0.0

Relay Out4 Sel R224 0 “Rea dy/Fault”

Relay Out4 Level R225 0.0

Relay Out5 Sel R227 0 “Rea dy/Fault”

Relay Out5 Level R228 0.0

Relay Out6 Sel R230 0 “Rea dy/Fault”

Relay Out6 Level R231 0.0

Relay Out7 Sel R233 0 “Rea dy/Fault”

Relay Out7 Level R234 0.0

Relay Out8 Sel R236 0 “Rea dy/Fault”

(1)

(1)

Parameter Name Num ber Default

Relay Out8 Level R237 0.0

Aux Motor Mode R239 0 “Disabled”

Aux Motor Qty R240 1 “1 Aux Mtr”

Aux 1 Start Freq R241 50.0 Hz

Aux 1 Stop Freq R242 25.0 Hz

Aux 1 Ref Add R243 0.0%

Aux 2 Start Freq R244 50.0 Hz

Aux 2 Stop Freq R245 25.0 Hz

Aux 2 Ref Add R246 0.0%

Aux 3 Start Freq R247 50.0 Hz

Aux 3 Stop Freq R248 25.0 Hz

Aux 3 Ref Add R249 0.0%

Aux Start Delay R250 5.0 Secs

Aux Stop Delay R251 3.0 Secs

Aux Prog Delay R252 0.50 Secs

Aux AutoSwap Tme R253 0.0 Hr

Aux AutoSwap Lvl R254 50.0%

Control Source d301 Read Only

Contrl In Status d302 Read Only

Comm Status d303 Read Only

PID Setpnt Displ d304 Read Only

Analog In 1 d305 Read Only

Analog In 2 d306 Read Only

Fault 1 Code d307 Read Only

Fault 2 Code d308 Read Only

Fault 3 Code d309 Read Only

Fault 1 Time-hr d310 Read Only

Fault 1 Time-min d311 Read Only

Fault 2 Time-hr d312 Read Only

Fault 2 Time-min d313 Read Only

Fault 3 Time-hr d314 Read Only

Fault 3 Time-min d315 Read Only

Elapsed Time -hr d3 16 Rea d Only

Elapsed Time -min d317 Re ad Only

Output Powr Fctr d318 Read Only

Testpoint Data d319 Read Only

Control SW Ver d320 Read Only

Drive Type d321 Read Only

Output Speed d322 Read Only

Output RPM d323 Read Only

Fault Frequency d324 Read Only

Fault Current d325 Read Only

Fault Bus Volts d326 Read Only

Status @ Fault d327 Read Only

(1) The default values of these parameter s differ from Factory

Defaults. Setting P041 [Reset To Defalts] to 1 “Factory Rset” will

change these parameter settings to the defaults list in the

PowerFlex 400 User Manual.

ATTENTION: Parame ter

A165 [Start At PowerUp] ships

from the factory enabled. This

feature allows a Run

command to automatically

cause the drive to resume

running at commanded speed

after drive input power is

restored. Equipment damage

and/or personal injury may

result if this parameter is used

in an inappropriate

application. Do not use this

function without considering

applicable local, national and

international codes, standards,

regulations or industry

guidelines.

16 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 17

Main Input Disconnect Package (Style A/M) Chapter 1

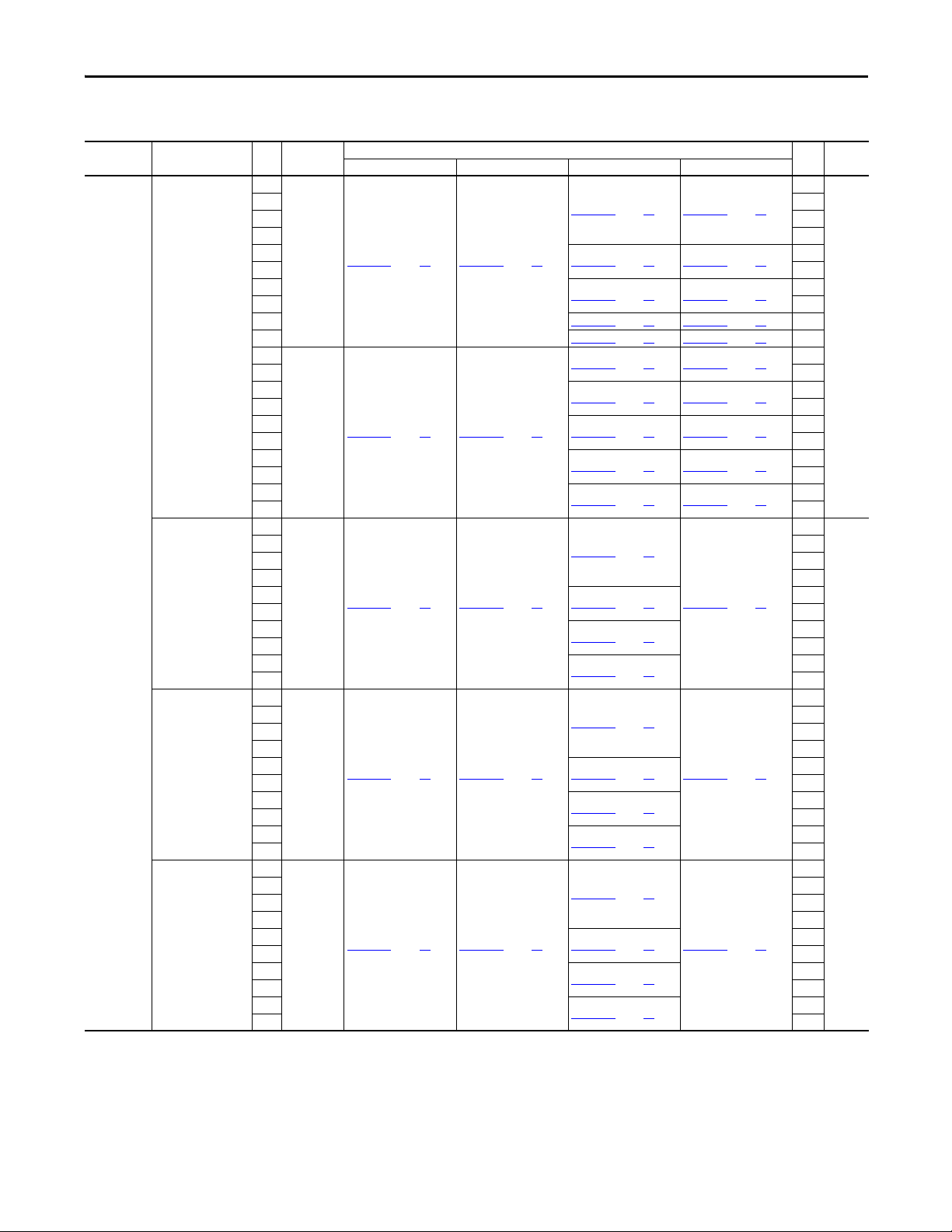

Drawing Index 208V AC Input – Main Input Disconnect Drive Packages (Style A/M)

Input

Voltag e

208V AC

Type Hp Input Line

NEMA/UL Type 1

NEMA/UL Type 12

NEMA/UL Type 4

NEMA/UL Type 3R

Reactor

3

5 5

7.5 7.5

10 10

15

No 98D00697

20 20

25

30 30

40 95D00760 35 95D00693 71 40

50 95D00776

3

5 5

7.5

10 10

15

Yes 98D00756 21 97D00754 28

20 20

25

30 30

40

50 50

3

5 5

7.5 7.5

10 10

15

With or

With out

20 20

25

30 30

40

50 50

3

5 5

7.5 7.5

10 10

15

With or

With out

20 20

25

30 30

40

50 50

3

5 5

7.5 7.5

10 10

15

With or

With out

20 20

25

30 30

40

50 50

Drawing Hp Style

SchematicPage InterconnectPage LayoutPage OutlinePage

3

95D00758 32 95D00689 68

20 97D00696 27

98D01535 24 97D01548 31

25 97D01548 31

98D01537

24 97D01548 31

98D01535

95D00759

33 95D00691 69

34 95D00692 70

95D00775

36 95D00694 72 50

95D00791 40 95D00690 76

41 95D00753 77

95D00792

95D01367

42 95D01359 78

95D01368 43 95D01360 79

44 95D01361 80

95D01369

95D01575 46

47

95D01576

95D02451

48

95D02497 49

95D01563 54

95D01565 55

56

95D02455

95D02495

57

95D01553 61

95D01554 62

95D02453 63

64

95D02493

95D01552 82

95D01551 83

95D01550 84

15

25

3

7.5

15

25

40

3

15

25

40

3

15

25

40

3

15

25

40

A

A & M

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 17

Page 18

Chapter 1 Main Input Disconnect Package (Style A/M)

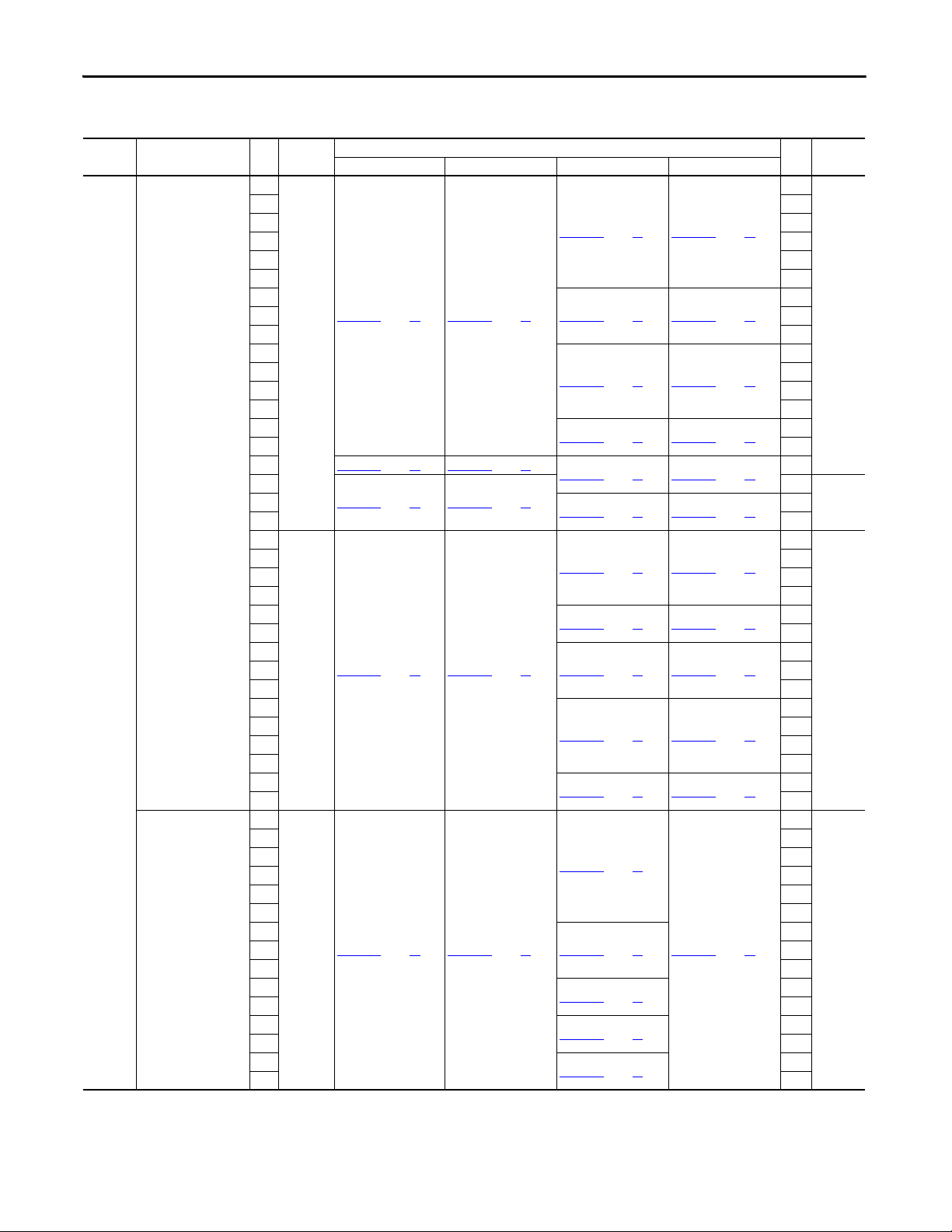

Input

Voltag e

460V AC

Type Hp Input Line

NEMA/UL Type 1

NEMA/UL Type 12

Reactor

3

5 5

7.5 7.5

10 10

15 15

20 20

25

30 30

40 40

50

No

60 60

75 75

100 100

125

150 150

200 98D01888

250

350 350

3

5 5

7.5 7.5

10 10

15

20 20

25

Yes 98D00756

30 30

40 40

50

60 60

75 75

100 100

125

150 150

3

5 5

7.5 7.5

10 10

15 15

20 20

25

With or

30 30

With out

40 40

50

60 60

75

100 100

125

150 150

460V AC – Main Input Disconnect Drive Packages (Style A/M)

Drawing Hp Style

SchematicPage InterconnectPage LayoutPage OutlinePage

3

95D00758 32 95D00689 68

25

98D00697

20 97D00696 27

22 97D01890 29

98D01887

23 97D01889 30

21 97D00754 28

98D01535 24 97D01548 31

95D00759

33 95D00691 69

95D00760

35 95D00693 71

95D01262

37 95D01264 73

95D01862 38 95D01866 74

95D01864 39 95D01868 75

95D00791 40 95D00690 76

95D00792

41 95D00753 77

95D01367

42 95D01359 78

95D01369

44 95D01361 80

95D01370

45 95D01362 81

95D01575 46

95D01576

47

95D02470

50

95D02476 51

95D01579

52

95D01552 82

50

125

200

250

300

3

15

25

50

125

3

25

50

75

125

A

M300

A

A & M

18 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 19

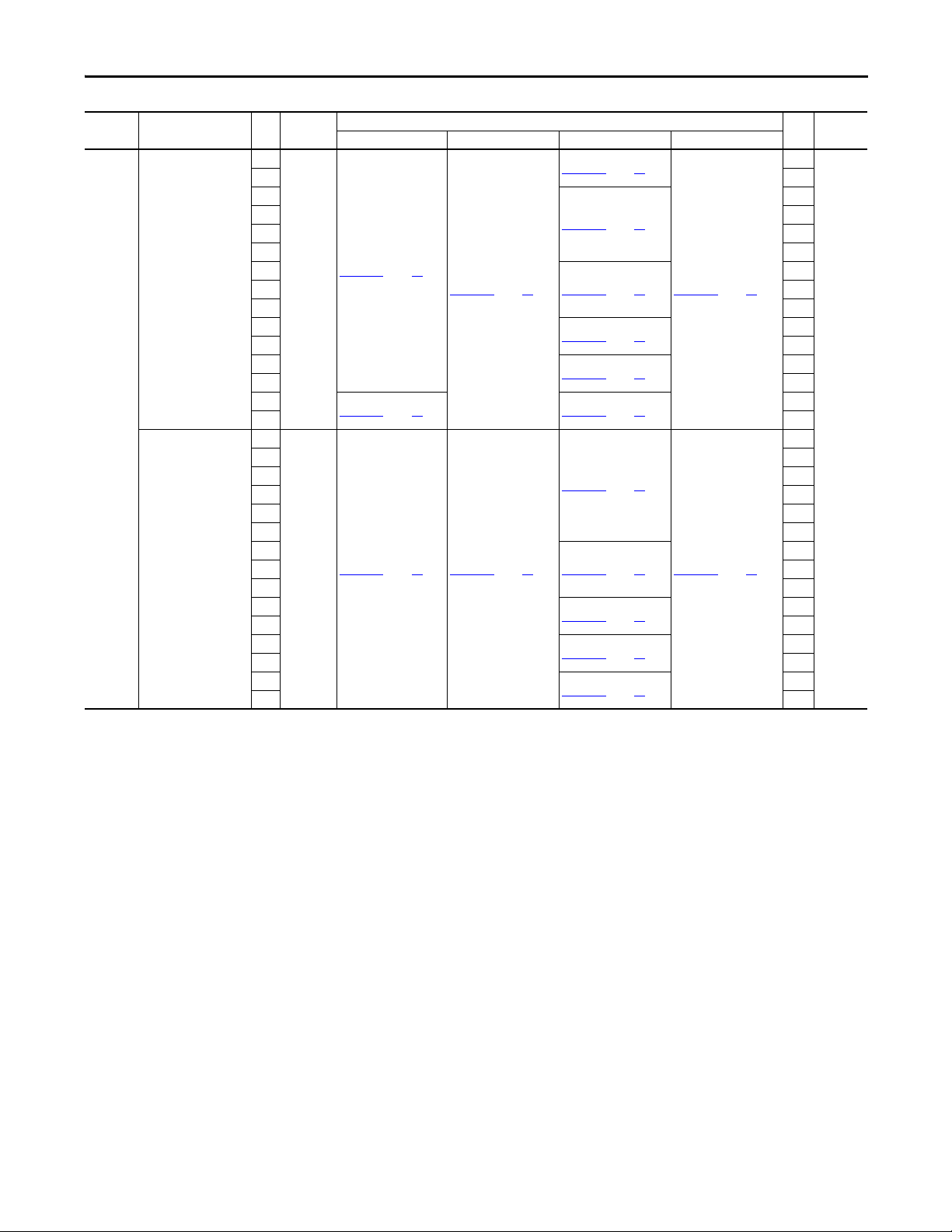

Main Input Disconnect Package (Style A/M) Chapter 1

Input

Voltag e

460V AC

Type Hp Input Line

NEMA/UL Type 4

NEMA/UL Type 3R

Reactor

3

5 5

7.5

10 10

15 15

20 20

25

With or

30 30

With out

40 40

50

60 60

75

100 100

125

150 150

3

5 5

7.5 7.5

10 10

15 15

20 20

25

With or

30 30

With out

40 40

50

60 60

75

100 100

125

150 150

Drawing Hp Style

SchematicPage InterconnectPage LayoutPage OutlinePage

3

7.5

25

50

75

125

3

25

50

75

125

A & M

98D01537 25

97D01548 31

98D01538

26 95D01568 60

98D01535 24 97D01548 31

95D02442 53

95D01563

54

95D01565

55

95D02469

58

95D02475

59

95D01553 61

95D01554

62

95D02468

65

95D02474

66

95D01557

67

95D01551 83

95D01550 84

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 19

Page 20

Chapter 1 Main Input Disconnect Package (Style A/M)

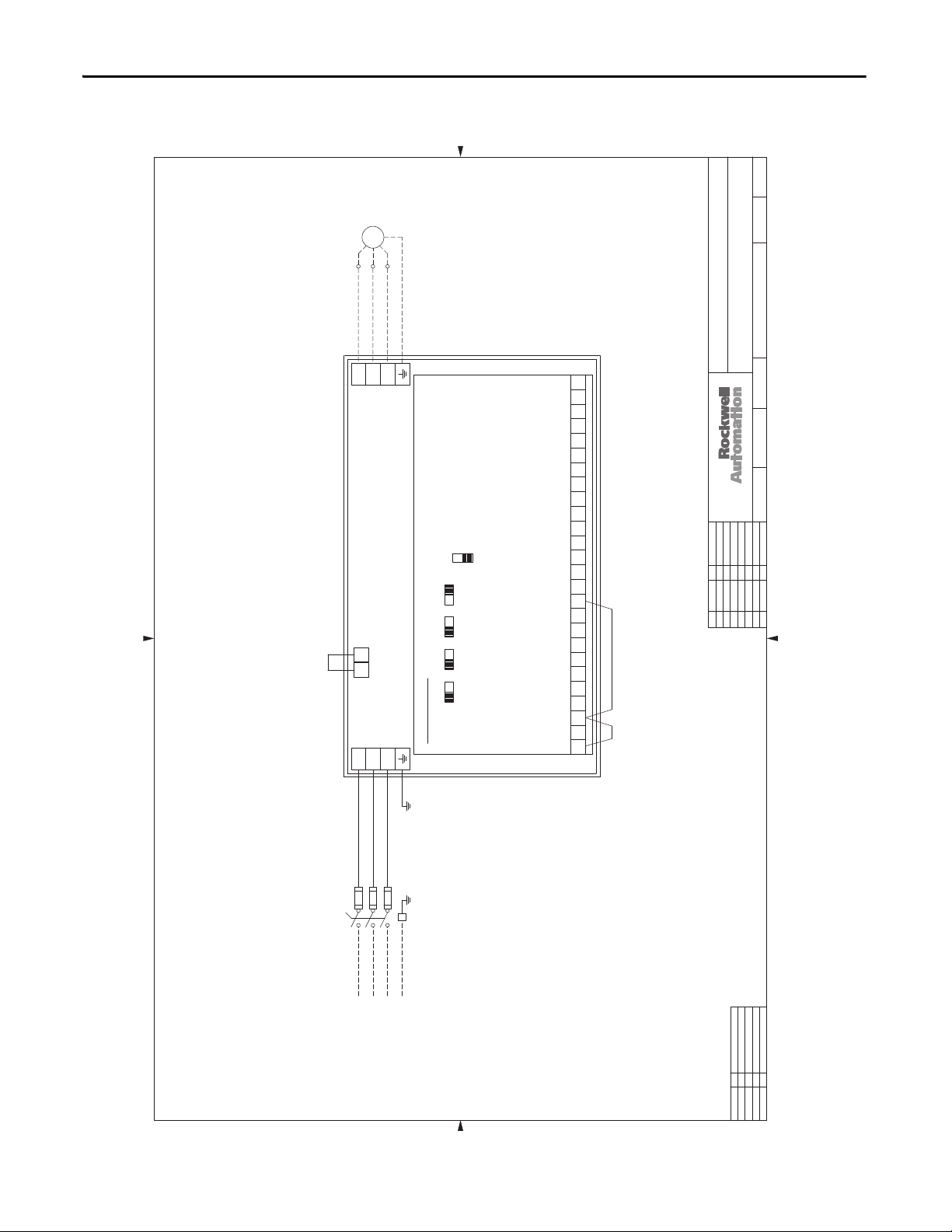

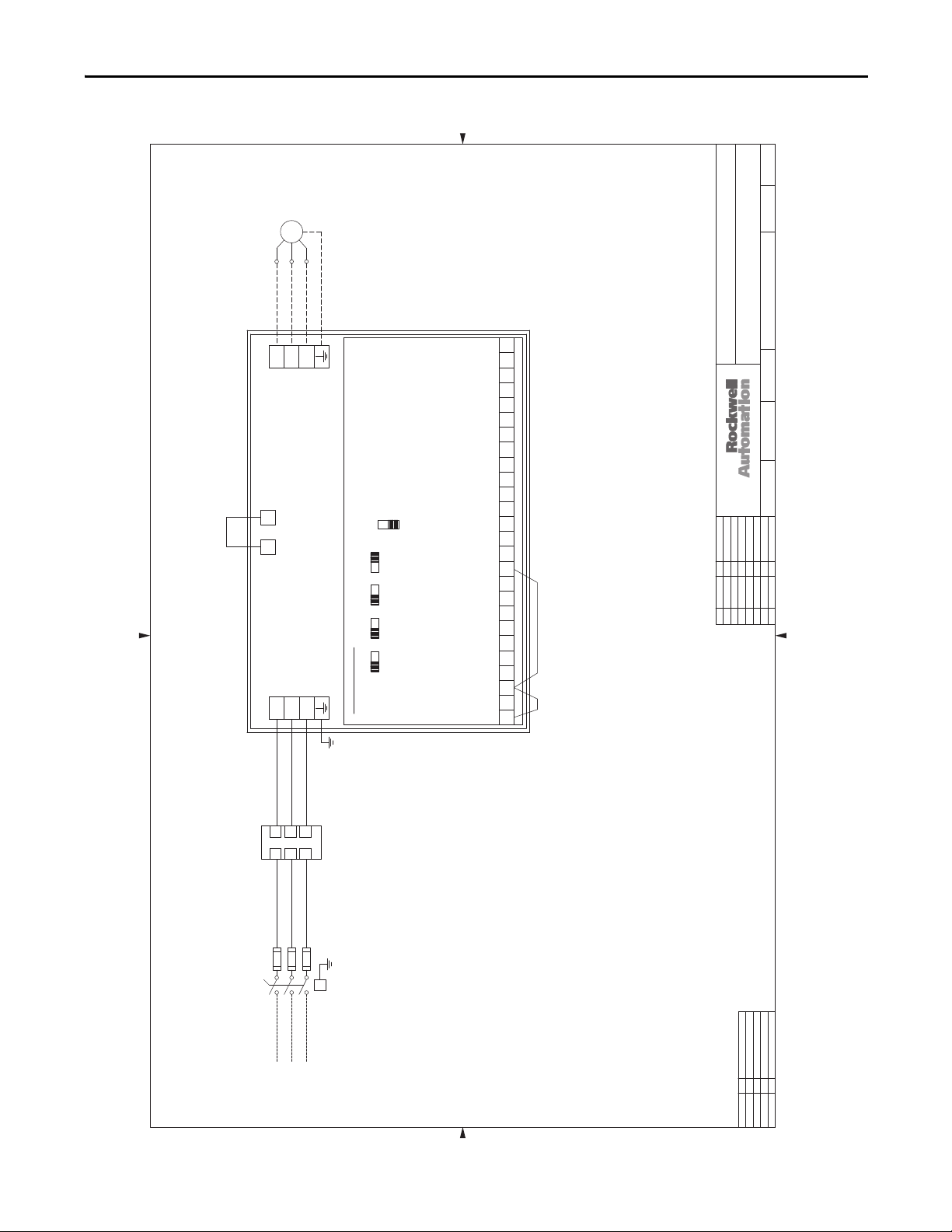

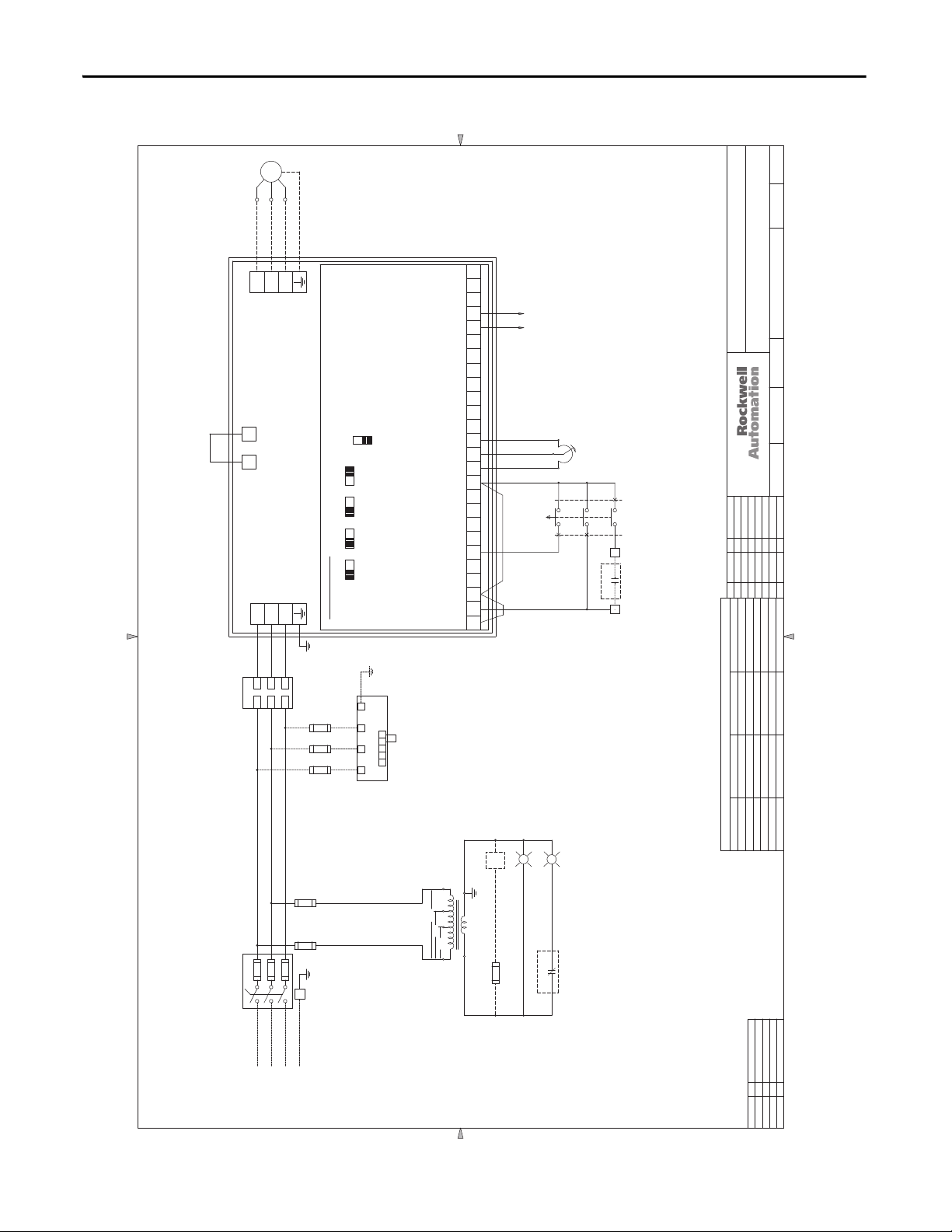

Schematic Drawings

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

Figure 1 - 3.0…50 Hp, 208V AC & 3.0…150 Hp, 460V AC Drives - NEMA/UL Type 1

98D00697

MOTOR

T3T1T2

GND

V/T2

U/T1

POWERFLEX 400

P2P1

R/L1

S/L2

W/T3

T/L3

DM1

CONTROL BOARD

AI2

10V 20MA

10V 20MA

AO2

10V 20MA

AO1 AI1

10V 20MA

SRC

SNK

#2 RELAY N.C.

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

#1 RELAY COMMON

#1 RELAY N.O. (READY/FAULT)

RJ-45 SHIELD

OPTO OUTPUT (AT FREQUENCY)

ANALOG COM #2

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUTPUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

151110 12 13 14 16 17 1918 20 R3R1 R2 R4 R5 R6

ANALOG COM. #1

ANALOG INPUT #1

+ 10VDC

+ 24VDC

OPTO COMMON

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (LOCAL)

DIGITAL INPUT 1 (PURGE)

DIGITAL COMMON

SOFTWARE ENABLE

RUN/FWD

FUNCTION LOSS

JUMPERJUMPER

1 324 75 6 89

11

11/24/04

SH.NEXT

NO.SH.

-

98D00697

NO.DATE DATE

DWG.ENG.

SCHEMATIC DRAWING - PF400, STYLE A

3-50HP @ 208VAC & 3-150HP @ 460VAC

TITLE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

JFH/ACI

4/5/04

CHK. BY

JRF/ACI

4/5/04

DATE

DR. BY

DATEREV. BY ECN/CR. NO.

A 11/24/04 JRF

B 2/3/05 JRF

C 6/7/07 REH

D 8/10/07 REH

E 1/31/11 JLD

L11

L13

L12

FU3

FU2

FU1

01

02030405060708

11

10

09

DS1

SWITCH

MAIN DISC.

12131415161718

L1

L2

f POWER

INCOMING

3

LG

L3

192021

22232425262728

30

29

20 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

31

32333435363738

39

APPROVAL

DESIGN REVIEW

FOR MANUFACTURING

BYDATE

41

40

AS SHIPPED

AS COMMISSIONED

42

Page 21

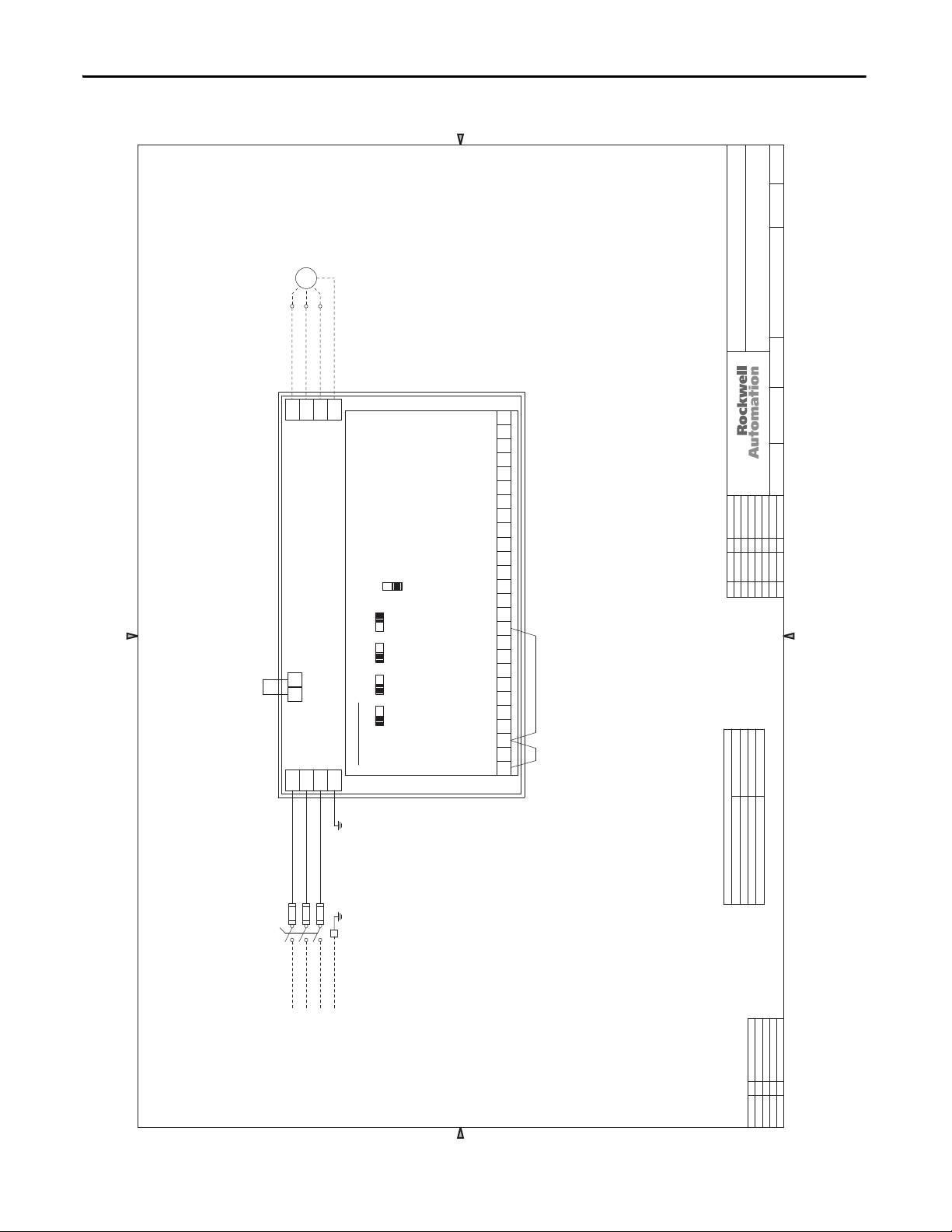

Figure 2 - 3.0…50 Hp, 208V AC & 3.0…150 Hp, 460V AC Drives with Line Reactor - NEMA/UL Type 1

01

02030405060708

09

10

11

12131415161718

192021

30

31

40

41

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

DATEREV. BY ECN/CR. NO.

A 11/24/04 JRF

B 5/18/05 JRF

C 6/7/07 REH

D 1/31/11 JLD

APPROVAL

DESIGN REVIEW

FOR MANUFACTURING

AS SHIPPED

AS COMMISSIONED

BYDATE

SH.NEXT

NO.SH.

-

DWG.ENG.

TITLE

CHK. BY

NO.DATE DATE

DR. BY

DATE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

11

SCHEMATIC DRAWING - PF400, STYLE A, W/LINE REACTOR

3-50HP @ 208VAC & 3-150HP @ 460VAC

98D00756

JRF/ACI

5/17/04

JFH/ACI

5/17/04

11/24/04

CONTROL BOARD

RUN/FWD

FUNCTION LOSS

SOFTWARE ENABLE

1 23

R/L1

T/L3

S/L2

FU3

FU2

FU1

L23

L22

L21

19

OPTO OUTPUT (AT FREQUENCY)

+ 10VDC

+ 24VDC

ANALOG INPUT #1

ANALOG COM. #1

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

ANALOG OUTPUT #2 (OUT CURRENT 0-10V)

ANALOG INPUT #2

ANALOG COM #2

DIGITAL INPUT 1 (PURGE)

DIGITAL COMMON

DIGITAL INPUT 2 (ANALOC 1 IN)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

OPTO COMMON

54 76 981110 151312 14 1716 18

10V 20MA

AI2

10V 20MA10V 20MA

AO1

AO2 AI1

10V 20MA

SNK

SRC

POWERFLEX 400

P1 P2

#1 RELAY N.O. (READY/FAULT)

#1 RELAY COMMON

#1 RELAY N.C.

#2 RELAY N.O. (MOTOR RUNNING)

#2 RELAY COMMON

#2 RELAY N.C.

RJ-45 SHIELD

R3R120 R2 R5R4 R6

MOTOR

T1

T2

T3

L3

G

INCOMING

3

f POWER

L1

L2

C2C1

B1

A1

B2

A2

LR

DS1

MAIN DISC.

SWITCH

OR OPTIONAL

CIRCUIT

BREAKER

LINE

REACTOR

U/T1

W/T3

V/T2

T1

T2

T3

GND

JUMPERJUMPER

T

S

R

98D00756

Main Input Disconnect Package (Style A/M) Chapter 1

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 21

Page 22

Chapter 1 Main Input Disconnect Package (Style A/M)

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

MOTOR

T3T1T2

Figure 3 - 200 Hp, 460V AC Drives - NEMA/UL Type 1

98D01888

GND

434445

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

SCHEMATIC DRAWING (FUSED DISCONNECT)

TITLE

PF400, 200HP/460VAC, NEMA1

46

11

NO.SH.

SH.NEXT

-

98D01888 1

NO.DATE DATE

DWG.ENG.

STYLE A, FRAME G

AWR/ACI

10/5/06

R/L1

S/L2

POWERFLEX 400

P2P1

R/L1

S/L2

L1

L2

PE

T/L3

DM1

AI2

10V 20MA

10V 20MA

AO2

10V 20MA

AO1 AI1

10V 20MA

SRC

SNK

CONTROL BOARD

PE

T/L3

L3

#2 RELAY N.C.

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

#1 RELAY COMMON

#1 RELAY N.O. (READY/FAULT)

RJ-45 SHIELD

OPTO OUTPUT (AT FREQUENCY)

ANALOG COM #2

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUTPUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

151110 12 13 14 16 17 1918 20 R3R1 R2 R4 R5 R6

ANALOG COM. #1

ANALOG INPUT #1

+ 10VDC

+ 24VDC

OPTO COMMON

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (LOCAL)

DIGITAL INPUT 1 (PURGE)

DIGITAL COMMON

SOFTWARE ENABLE

RUN/FWD

FUNCTION LOSS

JUMPERJUMPER

1 324 756 8 9

AWR/AC I

10/6/06

CHK. BY

REH/ACI

10/6/06

DATE

DR. BY

DATEREV. BY ECN/CR. NO.

A 6/7/07 REH

275

260

DISC-L1, L2, L3

GROUND LUG-LG 275

DRIVE HORSEPOWER 200HP

DRIVE-R, S, T & PE

TERMINAL TORQUE VALUES - INCH POUNDS

FU3

FU2

FU1

01

02030405060708

DS1

SWITCH

MAIN DISC.

11

10

09

G

f POWER

INCOMING

3

12131415161718

192021

22232425262728

31

30

29

32333435363738

22 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

APPROVAL

AS SHIPPED

DESIGN REVIEW

AS COMMISSIONED

FOR MANUFACTURING

BYDATE

41

40

434445

39

42

46

Page 23

Main Input Disconnect Package (Style A/M) Chapter 1

Figure 4 - 250…350 Hp, 460V AC Drives - NEMA/UL Type 1

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

98D01887

MOTOR

T3T1T2

GND

434445

SCHEMATIC DRAWING (CIRCUIT BREAKER)

PF400, 250-350HP/460VAC, NEMA1

TITLE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

STYLE A, FRAMES G & H

46

11

NO.SH.

SH.NEXT

-

98D018871

NO.DATE DATE

DWG.ENG.

AWR/ACI

10/5/06

T/L3

R/L1

S/L2

POWERFLEX 400

P2P1

T/L3

R/L1

S/L2

PE

DM1

AI2

10V 20MA

10V 20MA

AO2

10V 20MA

AO1 AI1

10V 20MA

SRC

SNK

CONTROL BOARD

#2 RELAY N.C.

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

#1 RELAY COMMON

#1 RELAY N.O. (READY/FAULT)

RJ-45 SHIELD

OPTO OUTPUT (AT FREQUENCY)

ANALOG COM #2

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUTPUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

151110 12 13 14 16 17 1918 20 R3R1 R2 R4 R5 R6

ANALOG COM. #1

ANALOG INPUT #1

+ 10VDC

+ 24VDC

OPTO COMMON

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (LOCAL)

DIGITAL INPUT 1 (PURGE)

DIGITAL COMMON

SOFTWARE ENABLE

RUN/FWD

FUNCTION LOSS

JUMPERJUMPER

1 324 756 8 9

AWR/ACI

10/6/06

CHK. BY

REH/ACI

10/6/06

DATE

DR. BY

DATEREV. BY ECN/CR. NO.

A 6/7/07 REH

PE

275 275 275

260 354 354

01

02030405060708

CB1

CIRCUIT

BREAKER

11

10

09

L11

L13

L12

TERMINAL TORQUE VALUES - INCH POUNDS

GND

POWER

INCOMING

12131415161718

192021

22232425262728

31

30

29

32333435363738

41

40

39

42

GROUND LUG 275 275 275

CB1-L1, L2, L3

DRIVE HORSEPOWER 250HP 300HP 350HP

APPROVAL

BYDATE

434445

DRIVE-R, S, T & PE

AS SHIPPED

DESIGN REVIEW

FOR MANUFACTURING

46

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 23

AS COMMISSIONED

Page 24

Chapter 1 Main Input Disconnect Package (Style A/M)

01

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

MOTOR

T1

T2

T1

T2

V/T2

U/T1

P1 P2

R/L1

S/L2

Figure 5 - 3.0…50 Hp, 208V AC & 3.0…150 Hp, 460V AC Drives - NEMA/UL Type 12 & 3R

98D01535

T3

T3

GND

#2 RELAY N.C.

PE

W/T3

POWERFLEX 400

PE

T/L3

CONTROL BOARD

AI2

10V 20MA

10V 20MA

10V 20MA10V 20MA

AO1 AO2 AI1

SRC

SNK

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

R3R120 R2 R5R4 R6

#1 RELAY COMMON

#1 RELAY N.O. (READY/FAULT)

RJ-45 SHIELD

OPTO OUTPUT (AT FREQUENCY)

19

ANALOG COM #2

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

ANALOG COM. #1

ANALOG INPUT #1

+ 10VDC

+ 24VDC

OPTO COMMON

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (ANALOG 1 IN)

DIGITAL INPUT 1 (PURGE)

547698 1110 151312 14 1716 18

DIGITAL COMMON

SOFTWARE ENABLE

RUN/FWD

FUNCTION LOSS

123

SEE

3124

LADDER

12 13 14

11

AUTO

SS1

OFF

HAND

6

P1

SPEED

MANUAL

AUTO STA R T

34 35

434445

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

DATEREV. BY ECN/CR. NO.

A 2/17/06 JCL

B 8/3/06 JCL

TITLE

46

11

.SH.

SH.NEXT

NO

-

98D01535

NO.DATE DATE

DWG.ENG.

SCHEMATIC DRAWING - PF400, STYLE A, NEMA 3R, 12

3-50HP @ 208VAC, 3-150HP @ 460VAC

JFH/ACI

11/17/05

JCL/ACI

02/17/06

CHK. BY

11/17/05

DATE

DR. BY

C 11/14/06 REH

D 11/27/06 REH

E 12/15/06 JCL

F 6/7/07 REH

T

S

R

A2

C2C1

B2

LR

01

02030405060708

DS1

09

LINE

OPTIONAL

SWITCH

MAIN DISC.

OR OPTIONAL

10

REACTOR

CIRCUIT

A1

B1

L21

L23

L22

FU3

FU2

FU1

BREAKER

L1

11

G

L3

L2

f POWER

INCOMING

3

12131415161718

OPTIONAL

ONLY

ENCLOSURE

CF2

125, 150HP

HEATER

HTR

23

FU8

ENCLOSURE

FAN

X2

X2

CF1

X2

H4

T

X2

H3H2

460V

FU5

FU4

230V

208V

H1

192021

X1

31

115VAC

22

TH1

THERMOSTAT

21

FU7

22232425262728

LT1

POWER ON

G

31

29

LT2

24R3R2

FAULT

30

DRIVE FAULT

R

31

32333435363738

24 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

PARAMETER SETTING CHANGES

T073 ANALOG IN 2 SEL 2 "0-10V" 1 "4-20MA"

T052 DIGITAL IN2 SET 3 "LOCAL" 14 "ANLG 1 INCTRL"

A165 START AT POWERUP 0 "DISABLED" 1 "ENABLED"

P036 STA R T SOURCE 3 2-W LVL SENS" 6 2-W LVL SENS"

P038 SPEED REF 2 "ANALOG IN 1" 3 "ANALOG IN 2"

P042 AUTO MODE 1 "HND-OFF-AUTO" 0 "NO FUNCTION"

PARAMETER DESCRIPTION DEFAULT CHANGE TO

APPROVAL

AS SHIPPED

DESIGN REVIEW

AS COMMISSIONED

FOR MANUFACTURING

BYDATE

41

40

434445

39

42

46

Page 25

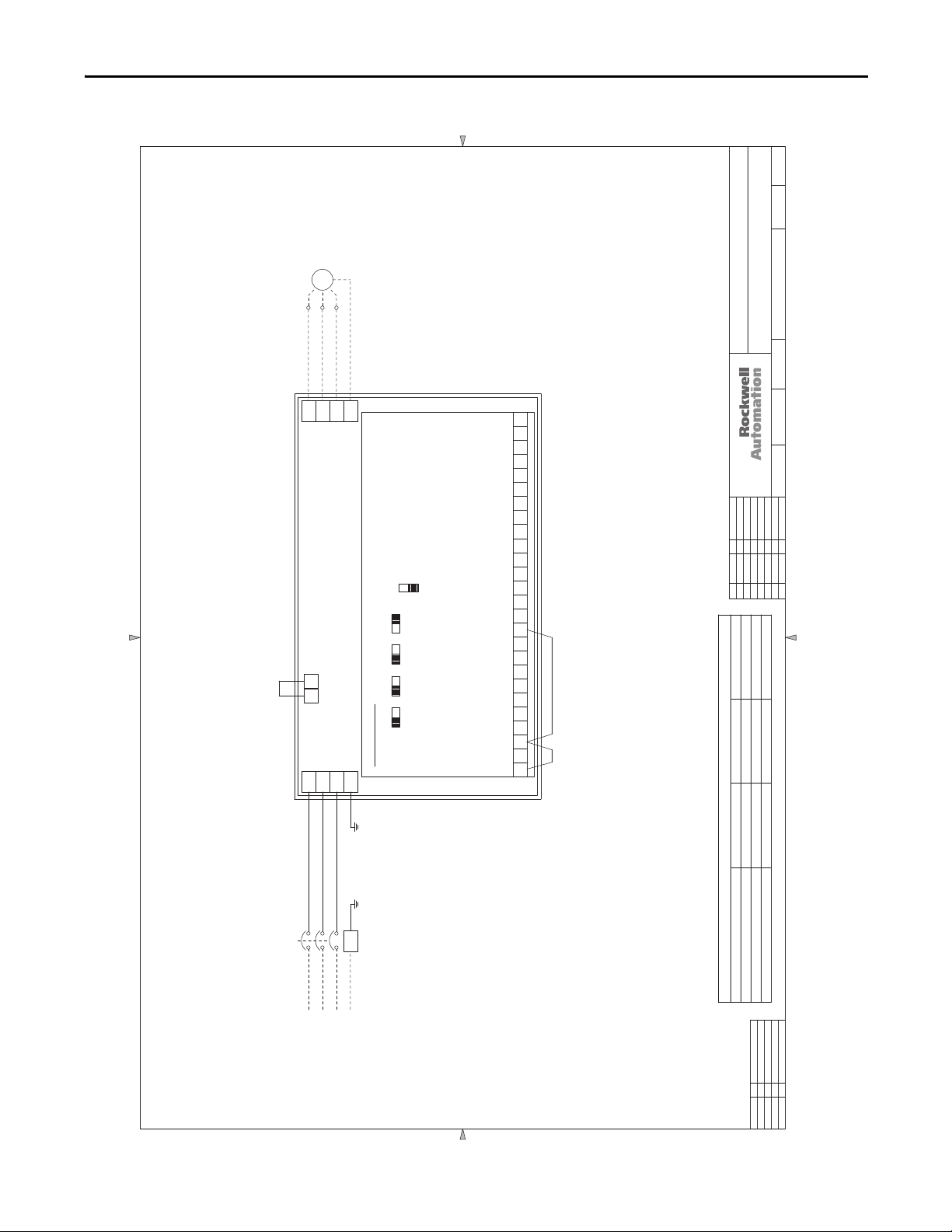

Figure 6 - 3.0…50 Hp, 208V AC & 3.0…100 Hp, 460V AC Drives - NEMA/UL Type 4

MOTOR

T2

T3

T2

T3

V/T2

POWERFLEX 400

S/L2

98D01537

GND

#2 RELAY N.C.

PE

W/T3

SRC

SNK

AI2

10V 20MA

10V 20MA

10V 20MA10V 20MA

AO1 AO2 AI1

CONTROL BOARD

PE

T/L3

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

R3R120 R2 R5R4 R6

#1 RELAY COMMON

#1 RELAY N.O. (READY/FAULT)

RJ-45 SHIELD

OPTO OUTPUT (AT FREQUENCY)

19

ANALOG COM #2

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

ANALOG COM. #1

ANALOG INPUT #1

+ 10VDC

+ 24VDC

OPTO COMMON

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (ANALOG 1 IN)

DIGITAL INPUT 1 (PURGE)

DIGITAL COMMON

SOFTWARE ENABLE

RUN/FWD

FUNCTION LOSS

12 13 14

SS1

547698 1110 151312 14 1716 18

123

01

020304050607080910111213141516171819202122232425262728293031323334

T1

T1

U/T1

P1 P2

R/L1

Main Input Disconnect Package (Style A/M) Chapter 1

5

36373839404142

3124

3

SEE

LADDER

P1

SPEED

MANUAL

11

AUTO

OFF

HAND

6

18 AWG BLU

35

AUTO STA RT

34

434445

TITLE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

DATEREV. BY ECN/CR. NO.

H 6/25/08 AWR

SCHEMATIC DRAWING - PF400, STYLE A, NEMA4

3 -50HP @ 208VAC & 3-100HP @ 460VAC

SH.NEXT

DWG.ENG.

JFH/ACI

JCL/ACI

CHK. BY

REH/ACI

DR. BY

46

11

.SH.

NO

-

98D01537

NO.DATE DATE

11/17/05

02/17/06

2/1/06

DATE

01

02030405060708

DS1

09

LINE

OPTIONAL

SWITCH

MAIN DISC.

OR OPTIONAL

10

REACTOR

CIRCUIT

T

S

R

A2

C2C1

B2

LR

A1

B1

L21

L23

L22

FU3

FU1

FU2

BREAKER

11

G

L1

L3

L2

f POWER

INCOMING

3

12131415161718

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 25

PARAMETER SETTING CHANGES

3-50HP@208VAC

7.5-100HP@460VAC

ENCLOSURE A/C

X2

WHT

X2

H4

T

A/C

X2

FU5

FU4

230V

208V

H1

192021

H3H2

460V

30

115VAC

FU7

RED

X1

FU6

SEE NOTE 1

31

22232425262728

OPTIONAL

ENCLOSURE

HTR

23

GRN

FU8

G

SEE NOTE 1

DRIVE FAULT

POWER ON

HEATER

T073 ANALOG IN 2 SEL 2 "0-10V" 1 "4-20MA"

T052 DIGITAL IN2 SET 3 "LOCAL" 14 "ANLG 1 INCTRL"

A165 START AT POWERUP 0 "DISABLED" 1 "ENABLED"

P036 STA R T SOURCE 3 2-W LVL SENS" 6 2-W LVL SENS"

P038 SPEED REF 2 "ANALOG IN 1" 3 "ANALOG IN 2"

P042 AUTO MODE 1 "HND-OFF-AUTO" 0 "NO FUNCTION"

G

R

LT1

LT2

31

24

R3R2

FAULT

NOTES:

1. NOT USED ON 3-5HP @ 460VAC.

31

30

29

32333435363738

39

PARAMETER DESCRIPTION DEFAULT CHANGE TO

APPROVAL

AS SHIPPED

DESIGN REVIEW

AS COMMISSIONED

FOR MANUFACTURING

BYDATE

41

40

42

434445

46

Page 26

Chapter 1 Main Input Disconnect Package (Style A/M)

01

0203040506070809101112131415161718192021222324252627282930313

MOTOR

T1

T3

T2

T1

T3

T2

GND

Figure 7 - 125…150 Hp, 460V AC Drives - NEMA/UL Type 4

98D01538

2

333435363738394041

42

434445

SH.NEXT

46

11

.SH.

NO

LINE

REACTOR

OPTIONAL

SCHEMATIC DRAWING - PF400, STYLE A, NEMA4

TITLE

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

I 6/25/08 AWR

G 4/19/07 JCL

H12/31/07 JCL

-

98D01538

NO.DATE DATE

DWG.ENG.

125-150HP @ 460VAC

JFH/ACI

11/17/05

JCL/ACI

01/17/06

CHK. BY

JRF/ACI

11/17/05

DATE

DR. BY

#2 RELAY N.C.

V/T2

U/T1

W/T3

SRC

FU11

FU10

FU9

CONTROL BOARD

AI2

10V 20MA

10V 20MA

10V 20MA10V 20MA

AO1 AO2 AI1

L33

L32

L31

SNK

G

L3

43PE21

JP

AC1

L1 L2

X54

X40

P1 P2

POWERFLEX 400

T/L3

R/L1

S/L2

T

S

R

A2

C2C1

B2

LR

A1

B1

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

R3R120 R2 R5R4 R6

#1 RELAY COMMON

#1 RELAY N.O. (READY/FAULT)

RJ-45 SHIELD

OPTO OUTPUT (AT FREQUENCY)

19

ANALOG COM #2

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

ANALOG COM. #1

ANALOG INPUT #1

+ 10VDC

+ 24VDC

OPTO COMMON

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (ANALOC 1 IN)

DIGITAL INPUT 1 (PURGE)

547698 1110 151312 14 1716 18

DIGITAL COMMON

SOFTWARE ENABLE

RUN/FWD

FUNCTION LOSS

123

SEE

LADDER

3124

12 13 14

11

AUTO

SS1

OFF

HAND

6

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

P1

SPEED

MANUAL

35

DATEREV. BY ECN/CR. NO.

AUTO STA R T

34

PARAMETER SETTING CHANGES

L21

L23

01

02030405060708

OR

SWITCH

DS1-MAIN DISCONNECT

FU1

CIRCUIT

BREAKER

CB1-OPTIONAL

L1

09

L22

FU2

L2

f POWER

INCOMING

3

10

FU3

L3

FU5

FU4

LG

11

12131415161718

192021

460V

230V

208V

22232425262728

OPTIONAL

POWER ON

ENCLOSURE

HEATER

X2

HTR

H4

T

X2

H3H2

H1

23

115VAC

X1

FU8

31

DRIVE FAULT

G

R

LT1

LT2

31

R3

FAULT

R2 24

31

30

29

32333435363738

26 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

T073 ANALOG IN 2 SEL 2 "0-10V" 1 "4-20MA"

T052 DIGITAL IN2 SET 3 "LOCAL" 14 "ANLG 1 INCTRL"

A165 START AT POWERUP 0 "DISABLED" 1 "ENABLED"

P036 STA R T SOURCE 3 2-W LVL SENS" 6 2-W LVL SENS"

P038 SPEED REF 2 "ANALOG IN 1" 3 "ANALOG IN 2"

P042 AUTO MODE 1 "HND-OFF-AUTO" 0 "NO FUNCTION"

PARAMETER DESCRIPTION DEFAULT CHANGE TO

APPROVAL

AS SHIPPED

DESIGN REVIEW

AS COMMISSIONED

FOR MANUFACTURING

BYDATE

41

40

39

42

434445

46

Page 27

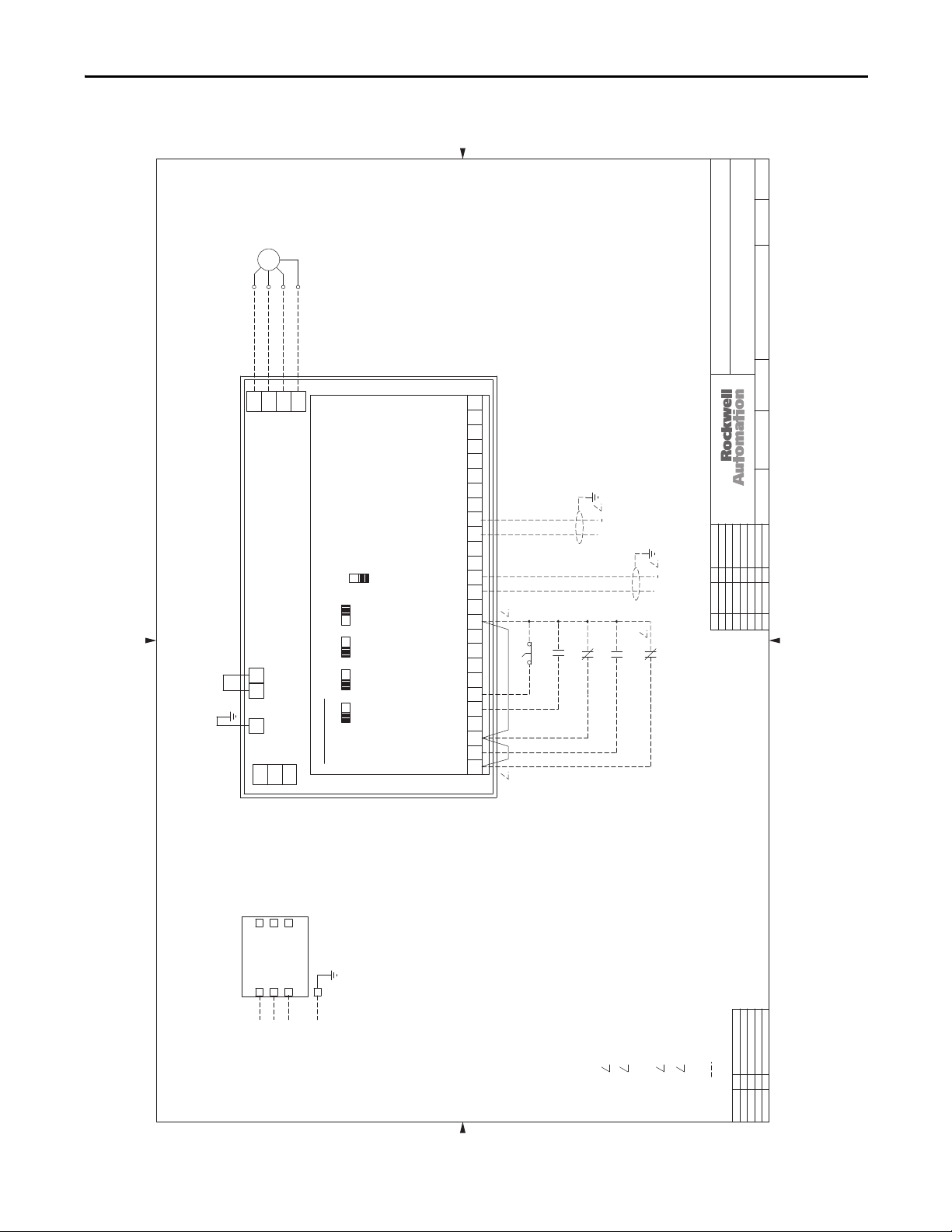

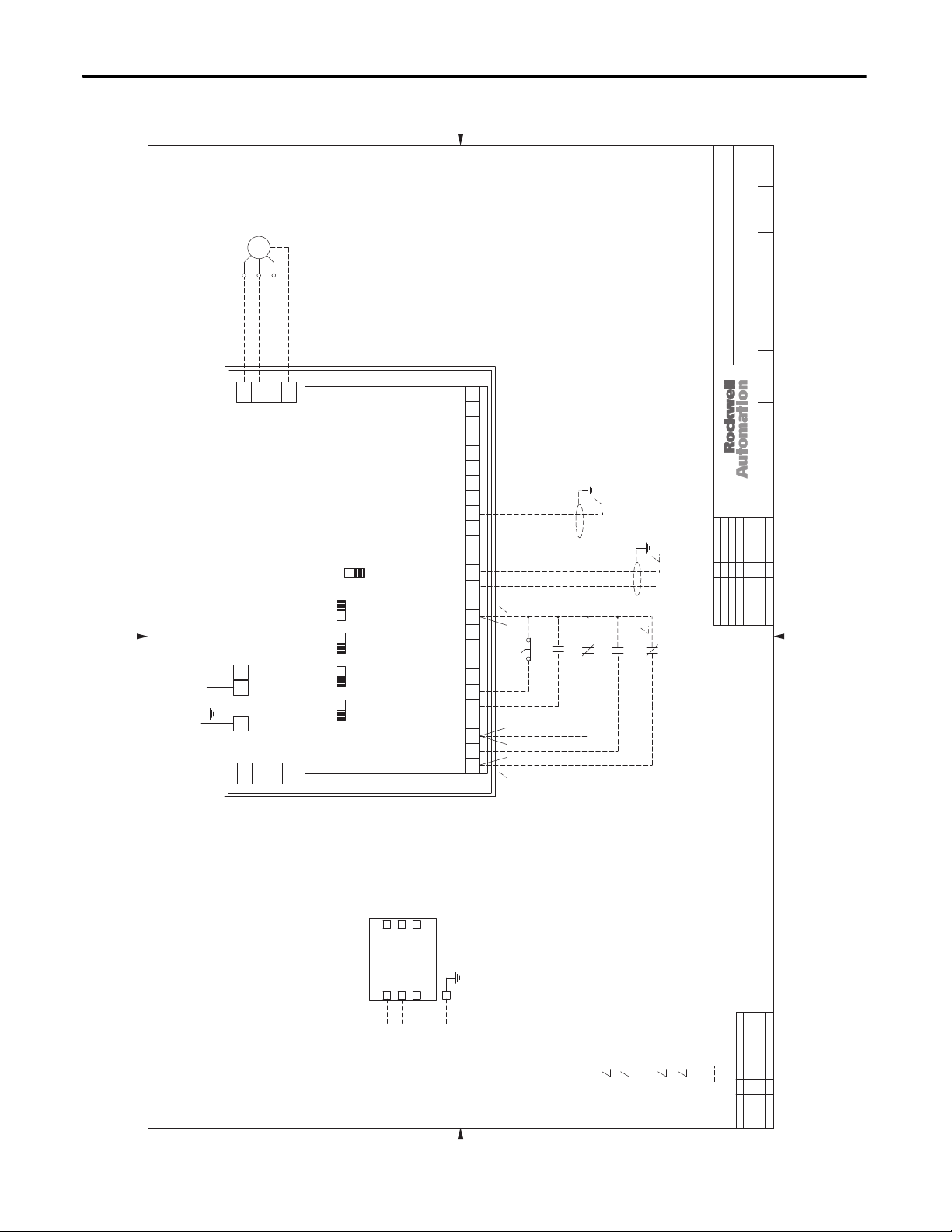

Interconnect Drawings

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

Main Input Disconnect Package (Style A/M) Chapter 1

Figure 8 - 3.0…50 Hp, 208V AC & 3.0…150 Hp, 460V AC Drives - NEMA/UL Type 1

97D00696

SH.NEXT

11

NO.SH.

MOTOR

T1

T2

V/T2

U/T1

POWERFLEX 400

G P2P1

R/L1

S/L2

T3

W/T3

T/L3

G

-

97D00696

NO.DATE DATE

DWG.ENG.

INTER-CONNECT DRAWING - PF400, STYLE A

3-50HP @ 208VAC & 3-150HP @ 460VAC

TITLE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

G

DM1

AI2

10V 20MA10V 20MA

AI1

10V 20MA

AO1 AO2

10V 20MA

SRC

SNK

CONTROL BOARD

#2 RELAY N.C.

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

#1 RELAY COMMON

#1 RELAY N.O. (READY/FAULT)

R1

RJ-45 SHIELD

OPTO OUTPUT (AT FREQUENCY)

ANALOG COM #2

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUTPUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

ANALOG COM. #1

ANALOG INPUT #1

+ 10VDC

+ 24VDC

11 12 1413 15 1716 18 2019 R4R2 R3 R5 R6

OPTO COMMON

10

DIGITAL COMMON

DIGITAL INPUT 4 (COMM PORT)

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (LOCAL)

DIGITAL INPUT 1 (PURGE)

DIGITAL COMMON

SOFTWARE ENABLE

RUN/FWD

FUNCTION LOSS

AUTO

HAND

576 89

324

1

3 4

PURGE

2

INTERLOCKS

+

SPEED REF. INPUT

4-20MA, 250 OHM

AUTO START

INPUT IMPEDANCE

STAT S

FREEZE/FIRE

JFH/ACI

4/5/04

CHK. BY

JRF/ACI

4/5/04

DATE

DR. BY

2

+

SPEED REF. INPUT

1

0 TO +10VDC, 100KOHM

INPUT IMPEDANCE

DATEREV. BY ECN/CR. NO.

A 11/24/04 JRF

B 2/3/05 JRF

C 11/14/06 REH

D 2/2/11 DJK

01

02030405060708

DS1

MAIN

SWITCH

DISCONNECT

L1

INCOMING

G

L3

L2

GROUND

f POWER

3

11

10

09

12131415161718

192021

22232425262728

31

30

29

OPENING OF THE FREEZE/FIRE INTERLOCK

1

WHEN IN "AUTO MODE" SPEED REFERENCE WILL

COME FROM 0-10V SOURCE WIRED TO ANALOG

INPUT #1. IF 4-20mA SOURCE IS TO BE USED,

WIRE TO ANALOG INPUT #2 AND CHANGE PARAMETER

PO38 [SPEED REFERENCE] =3 "ANALOG In2".

IF THE INTERLOCK CONTACT IS USED, THE JUMPER

IF FREEZE/FIRE STAUS INTERLOCK IS USED, THE

WILL REQUIRE MANUAL RESET.

32333435363738

JUMPER WIRE FROM TERMINALS 1 TO 3 MUST BE REMOVED.

2

3

FROM TERMINALS 1 TO 3 MUST BE REMOVED AND

THE JUMPER WIRE FROM TERMINALS 3 TO 11 SHOULD4BE RELOCATED TO CONNECT TERMINALS 1 TO 11.

CONNECTIONS SUPPLIED BY CUSTOMER

39

APPROVAL

DESIGN REVIEW

FOR MANUFACTURING

BYDATE

41

40

AS SHIPPED

AS COMMISSIONED

42

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 27

Page 28

Chapter 1 Main Input Disconnect Package (Style A/M)

01

02030405060708

09

10

11

12131415161718

192021

30

31

40

41

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

DATEREV. BY ECN/CR. NO.

A 11/24/04 JRF

B 4/21/08 TGM

C 6/25/08 AWR

D 2/2/11 DJK

APPROVAL

DESIGN REVIEW

FOR MANUFACTURING

AS SHIPPED

AS COMMISSIONED

BYDATE

SH.NEXT

NO.SH.

-

DWG.ENG.

TITLE

CHK. BY

NO.DATE DATE

DR. BY

DATE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

11

INTER-CONNECT DRAWING - PF400, STYLE A, W/LINE REACTOR

3-50HP @ 208VAC & 3-150HP @ 460VAC

97D00754

JRF/ACI

5/17/04

JFH/ACI

5/17/04

11/24/04

G

L3

INCOMING

3

f POWER

L2

L1

MAIN

DISCONNECT

SWITCH

GROUND

CONNECTIONS SUPPLIED BY CUSTOMER

OPENING OF THE FREEZE/FIRE INTERLOCK

WILL REQUIRE MANUAL RESET.

1

10

OPTO COMMON

AUTO

DIGITAL INPUT 4 (COMM PORT)

DIGITAL COMMON

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (LOCAL)

DIGITAL COMMON

DIGITAL INPUT 1 (PURGE)

SOFTWARE ENABLE

FUNCTION LOSS

STAT S

FREEZE/FIRE

AUTO START

INTERLOCKS

1

RUN/FWD

324

PURGE

HAND

576 89

10V 20MA

AO1 AO2

10V 20MA

CONTROL BOARD

S/L2

T/L3

R/L1

G P2P1

RJ-45 SHIELD

#2 RELAY N.C.

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

#1 RELAY COMMON

OPTO OUTPUT (AT FREQUENCY)

ANALOG COM #2

#1 RELAY N.O. (READY/FAULT)

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUTPUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

ANALOG COM. #1

ANALOG INPUT #1

SPEED REF. INPUT

0 TO +10VDC, 100KOHM

INPUT IMPEDANCE

R1

1

+

SPEED REF. INPUT

4-20MA, 250 OHM

INPUT IMPEDANCE

+

+ 24VDC

+ 10VDC

11 12 1413 15 1716 18 2019 R4R2 R3 R5 R6

10V 20MA10V 20MA

AI1

SNK

AI2

SRC

POWERFLEX 400

W/T3

V/T2

U/T1

MOTOR

T2

T3

T1

2

2

2

WHEN IN "AUTO MODE" SPEED REFERENCE WILL

COME FROM 0-10V SOURCE WIRED TO ANALOG

INPUT #1. IF 4-20mA SOURCE IS TO BE USED,

WIRE TO ANALOG INPUT #2 AND CHANGE PARAMETER

PO38 [SPEED REFERENCE] =3 "ANALOG In2".

DM1

DS1

3 4

IF FREEZE/FIRE STAUS INTERLOCK IS USED, THE

JUMPER WIRE FROM TERMINALS 1 TO 3 MUST BE REMOVED.

3

IF THE INTERLOCK CONTACT IS USED, THE JUMPER

FROM TERMINALS 1 TO 3 MUST BE REMOVED AND

THE JUMPER WIRE FROM TERMINALS 3 TO 11 SHOULD4BE RELOCATED TO CONNECT TERMINALS 1 TO 11.

Figure 9 - 3.0…50 Hp, 208V AC & 3.0…150 Hp, 460V AC Drives with Line Reactor - NEMA/UL Type 1

97D00754

28 Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

Page 29

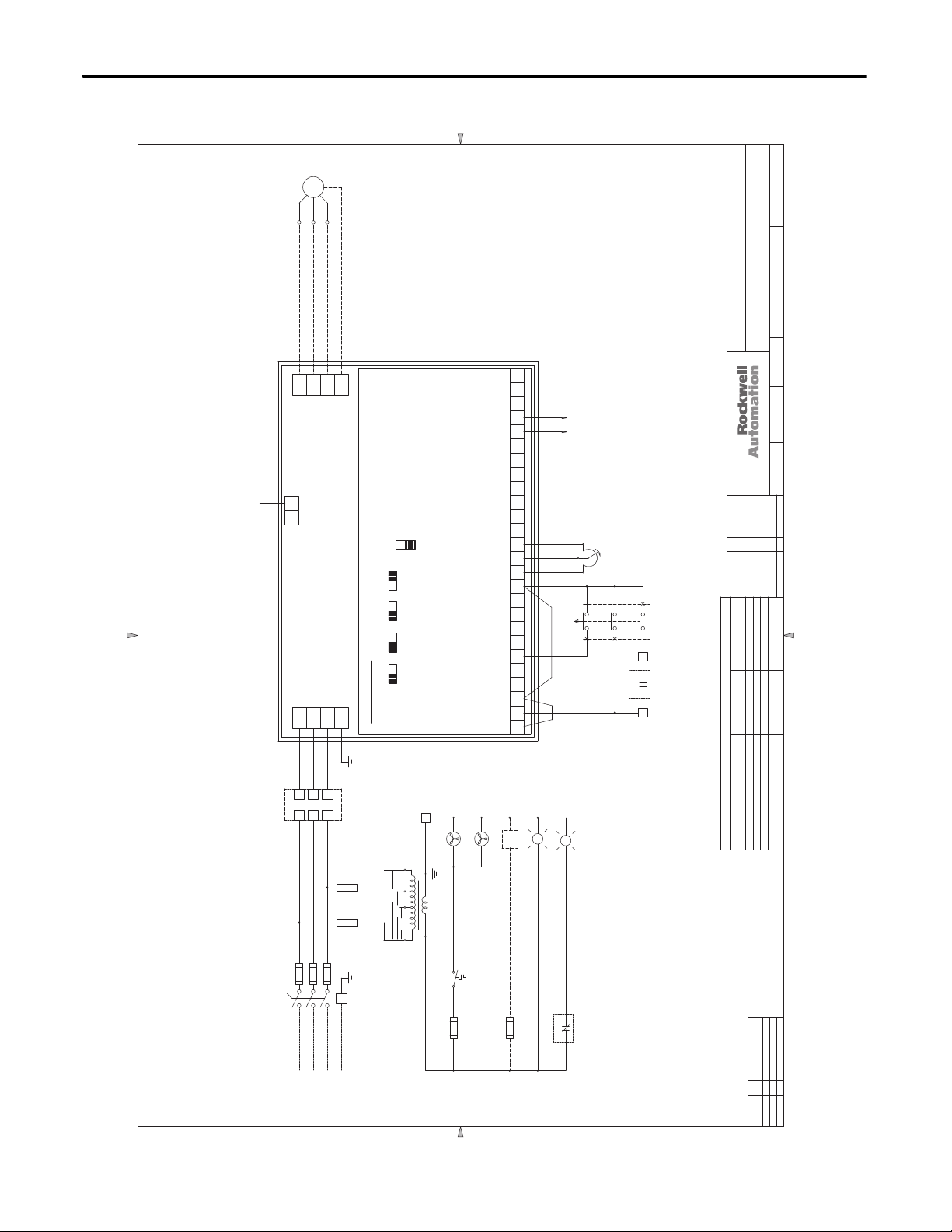

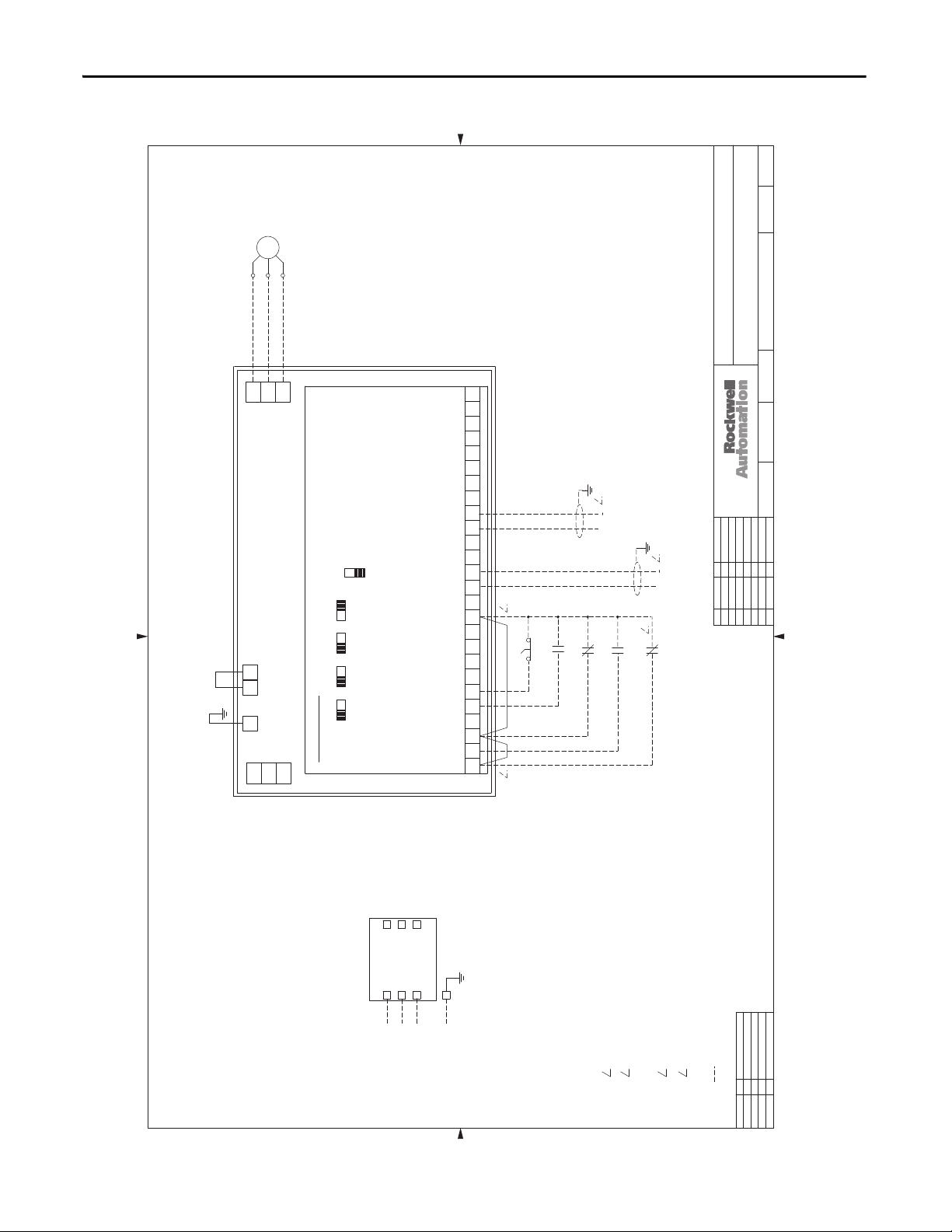

Figure 10 - 200 Hp, 460V AC Drives - NEMA/UL Type 1

01

02030405060708

09

10

11

12131415161718

192021

30

31

40

41

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

DATEREV. BY ECN/CR. NO.

A 4/11/12 JCK

APPROVAL

DESIGN REVIEW

FOR MANUFACTURING

AS SHIPPED

AS COMMISSIONED

BYDATE

SH.NEXT

NO.SH.

-

DWG.ENG.

TITLE

CHK. BY

NO.DATE DATE

DR. BY

DATE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY

PURPOSE EXCEPT AS AUTHORIZED IN WRITING BY ROCKWELL AUTOMATION, INC.

11

INTER-CONNECT DRAWING (DISCONNECT SWITCH)

PF400, 200HP/460VAC, NEMA1

STYLE A, FRAME G, CONTROL

97D01890

REH/ACI

10/9/06

AWR/ACI

10/9/06

AWR/ACI

10/9/06

G

L3

INCOMING

3

f POWER

L2

L1

MAIN

DISCONNECT

SWITCH

GROUND

CONNECTIONS SUPPLIED BY CUSTOMER

OPENING OF THE FREEZE/FIRE INTERLOCK

WILL REQUIRE MANUAL RESET.

1

10

OPTO COMMON

AUTO

DIGITAL INPUT 4 (COMM PORT)

DIGITAL COMMON

DIGITAL INPUT 3 (CLEAR FAULT)

DIGITAL INPUT 2 (LOCAL)

DIGITAL COMMON

DIGITAL INPUT 1 (PURGE)

SOFTWARE ENABLE

FUNCTION LOSS

STAT S

FREEZE/FIRE

AUTO START

INTERLOCKS

1

RUN/FWD

324

PURGE

HAND

576 89

10V 20MA

AO1 AO2

10V 20MA

CONTROL BOARD

S/L2

T/L3

R/L1

G P2P1

RJ-45 SHIELD

#2 RELAY N.C.

#2 RELAY COMMON

#2 RELAY N.O. (MOTOR RUNNING)

#1 RELAY N.C.

#1 RELAY COMMON

OPTO OUTPUT (AT FREQUENCY)

ANALOG COM #2

#1 RELAY N.O. (READY/FAULT)

ANALOG INPUT #2

ANALOG OUTPUT #2 (OUTPUT CURRENT 0-10V)

ANALOG OUTPUT #1 (FREQUENCY 0-10V)

ANALOG COM. #1

ANALOG INPUT #1

SPEED REF. INPUT

0 TO +10VDC, 100KOHM

INPUT IMPEDANCE

R1

1

+

SPEED REF. INPUT

4-20MA, 250 OHM

INPUT IMPEDANCE

+

+ 24VDC

+ 10VDC

11 12 1413 15 1716 18 2019 R4R2 R3 R5 R6

10V 20MA10V 20MA

AI1

SNK

AI2

SRC

POWERFLEX 400

W/T3

V/T2

U/T1

MOTOR

T2

T3

T1

2

2

2

WHEN IN "AUTO MODE" SPEED REFERENCE WILL

COME FROM 0-10V SOURCE WIRED TO ANALOG

INPUT #1. IF 4-20mA SOURCE IS TO BE USED,

WIRE TO ANALOG INPUT #2 AND CHANGE PARAMETER

PO38 [SPEED REFERENCE] =3 "ANALOG In2".

DM1

DS1

3 4

IF FREEZE/FIRE STAUS INTERLOCK IS USED, THE

JUMPER WIRE FROM TERMINALS 1 TO 3 MUST BE REMOVED.

3

IF THE INTERLOCK CONTACT IS USED, THE JUMPER

FROM TERMINALS 1 TO 3 MUST BE REMOVED AND

THE JUMPER WIRE FROM TERMINALS 3 TO 11 SHOULD4BE RELOCATED TO CONNECT TERMINALS 1 TO 11.

PE

97D01890

Main Input Disconnect Package (Style A/M) Chapter 1

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013 29

Page 30

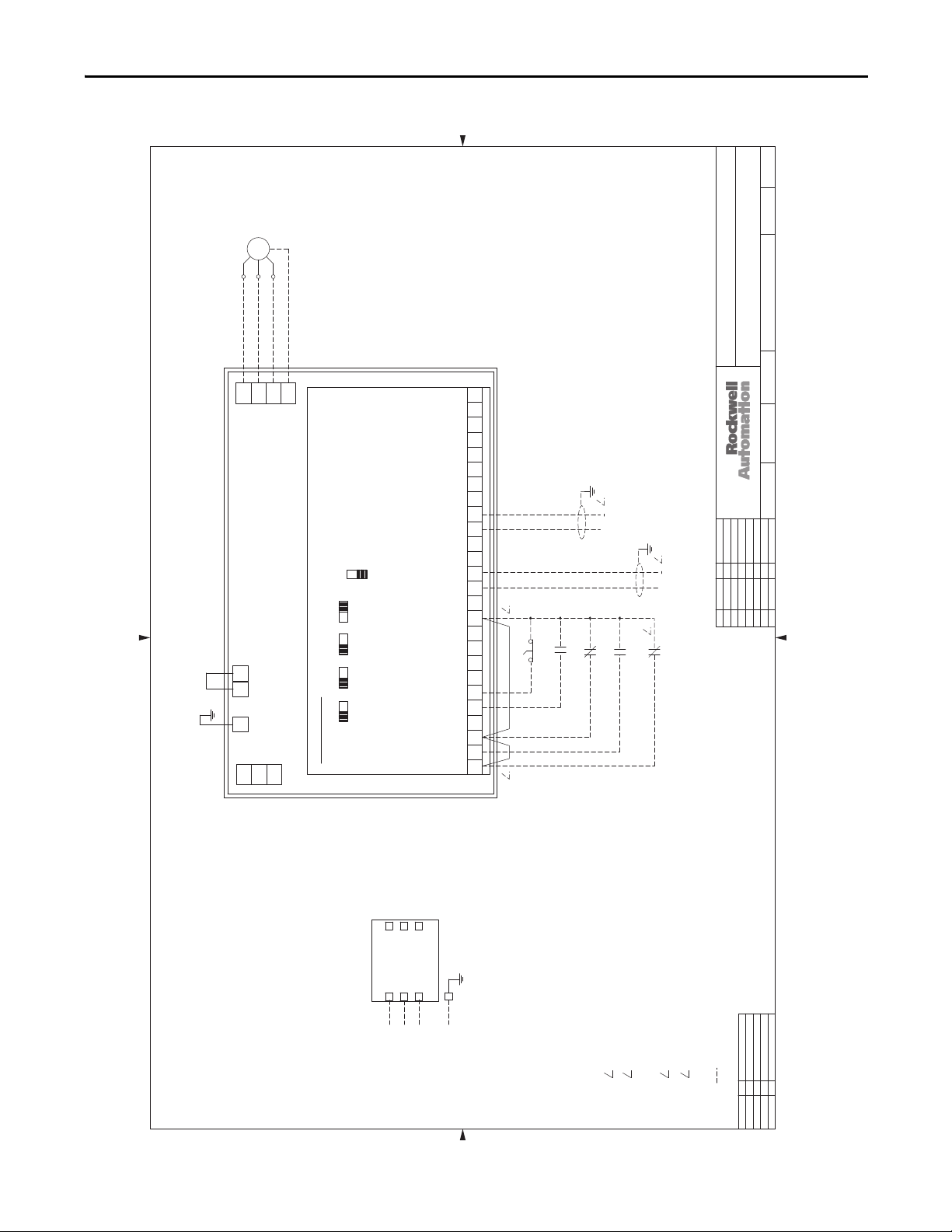

Chapter 1 Main Input Disconnect Package (Style A/M)

01

02030405060708

09

10

11

12131415161718

192021

30

31

40

41

0203040506070809101112131415161718192021222324252627282930313233343536373839404142

01

DATEREV. BY ECN/CR. NO.

A 4/11/12 JCK

APPROVAL

DESIGN REVIEW

FOR MANUFACTURING

AS SHIPPED

AS COMMISSIONED

BYDATE

SH.NEXT

NO.SH.

-

DWG.ENG.

TITLE

CHK. BY

NO.DATE DATE

DR. BY

DATE

THIS DRAWING IS THE PROPERTY OF ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED, USED OR DISCLOSED FOR ANY