Page 1

Allen-Bradley

Parallel DC

Bus Supply

User

Configurations

(Using Bulletin 2364E NRUs

and Bulletin 2364F RGUs)

Bulletin 2364P

Manual

Page 2

Important User Information Solid-State equipment has operational characteristics differing from

those of electro m echan i ca l equ ip me nt. “Saf ety G u ide lines for the

Application, Installation and Maintenance of Solid-State Controls”

(Publication SGI-1.1) describes some important differences between

solid-state equi pment and hard-wired electromechanic al devices.

Because of this difference, and also because of the wide variety of

uses for solid-state equipment, all persons responsible for applying

this equipment must satisfy th emse lves that e ach inte nded appl ication

of this equipment is acceptable .

In no event will Rockwell Automation be responsible or liable for

indirect or consequential damages resulting from the use of

application of this equipment.

The examples and diagrams in this manual are included solely for

illustrati ve purpose s. Bec ause of th e many var iable s and requi rements

associated with any partic ular installation, the Rockwe ll Automation

cannot assume responsibility or liability for actua l use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect

use of information, circuits, equipment, or software des cribed in this

manual.

Reproduction of the conten ts of this manual, in whole or in part,

without written permission of Rockwell Automation is prohibit ed.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies infor mation about practi ces

or circums tan ce s tha t can lead to p erso n al inj ury or

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequenc es

Datab is a trademark of W . H. Brady Company

NRU, RGU, HIM, Remote I/O, DeviceNet, and ControlNet are trademarks of Rockwell International or its

subsidiaries.

death, property damage or economic loss.

Page 3

Table of Contents

Preface Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Receiving Your Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Chapter 1 Theory of Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

RGU//RGU Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Output of RGU//RGU Configurations . . . . . . . . . . . . . . . . . . . 1-4

NRU//RGU Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Output of NRU//RGU Configurations . . . . . . . . . . . . . . . . . . 1-7

Precharge Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Chapter 2 R1 and S1-Code Parallel Configurations

R1-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

S1-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

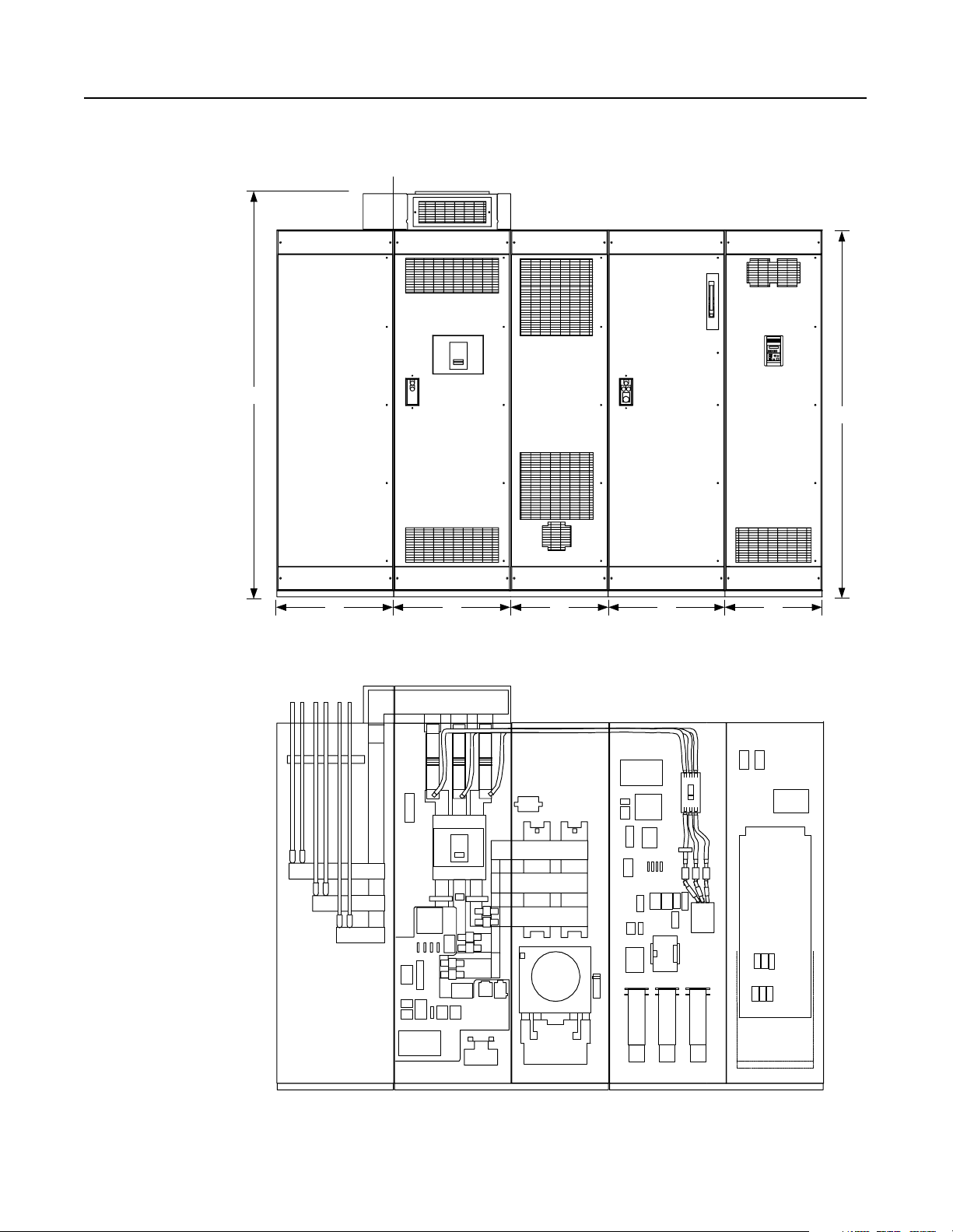

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3 R2 and S2-Code Parallel Configurations

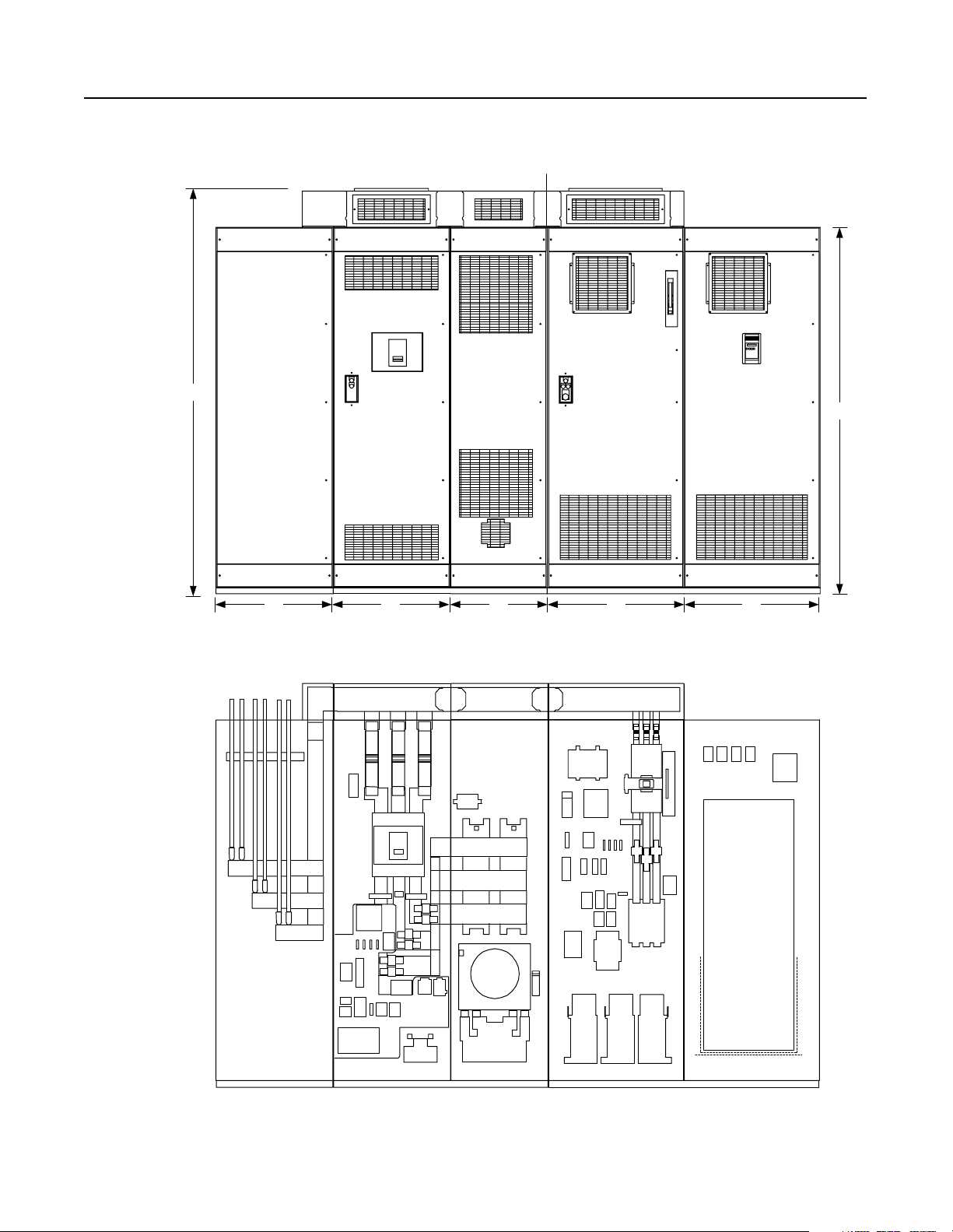

R2-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

S2-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4 R3 and S3-Code Parallel Configurations

R3-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

S3-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Page 4

toc–ii Table of Contents

Chapter 5 R4 and S4-Code Parallel Configurations

R4-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

S4-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Chapter 6 T1 and V1-Code Parallel Configurations

T1-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

V1-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Chapter 7 T2 and V2-Code Parallel Configurations

T2-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

V2-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Chapter 8 T3 and V3-Code Parallel Configurations

T3-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

V3-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Chapter 9 T4 and V4-Code Parallel Configurations

T4-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

V4-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Chapter 10 T5 and V5-Code Parallel Configurations

T5-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

V5-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Chapter 11 T6 and V6-Code Parallel Configurations

T6-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

V6-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Page 5

Chapter 12 W1-Code Parallel Configuration

W1-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

Chapter 13 W2-Code Parallel Configurations

W2-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Chapter 14 W3-Code Parallel Configurations

W2-Code Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

Chapter 15 Installation

Receiving, Handling, and Installing the Parallel Configuration . . 15-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-2

Overhead Bus Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

Ground-Fault Detection Option . . . . . . . . . . . . . . . . . . . . . . . 15-5

Phase-Loss Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

RGU-to-RGU (R2R) Communications . . . . . . . . . . . . . . . . . . . 15-9

Customer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-11

Analog Input/Output (RGU Main Control Board) . . . . . . . . . . 15-11

SCANport (RGU Main Control Board) . . . . . . . . . . . . . . . . . . 15-12

Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-13

Configuring the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-15

Connecting the AC Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Isolation Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

MOV Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Feeder Bay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

Testing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-18

Prepower Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-18

Testing The System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-18

Table of Contents toc–iii

Page 6

toc–iv Table of Contents

Chapter 16 Setting Up the Parallel Configuration

Introduction to the

Human Interface Module (HIM) . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

Basic Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

Starting the RGU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

Programming the RGU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-4

Enabling the RGU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-6

Advanced Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 16-7

Appendix A Specifications

Watts Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Physical Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Appendix B Catalog Numbers and Spare Parts Kits

Understanding Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . B-1

Spare Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Glossary

Index

Page 7

Preface

Preface

Who Should Use This Manual This manual is intende d for those who are re sponsible for instal ling or

operating an Allen-Bradley parallel DC bus supply configuration.

If you do not have a basic understanding of this product, please read

through this m anual. Contact your local Rockwell Automation Drive

Systems represent ative if you have questions about th e conte nt of this

manual or the product.

Purpose of This Manual This manual contains specifications, installation instructions, and

operating instru ctions for the 2364P parallel configuration.

Safety Precautions The following general precautions apply when installing, servicing,

or operating paralle l configurations and drive system li neups:

ATTENTION: Only those familiar with the drive

system, the products used in the system, and the

!

associated machinery should plan or implement the

installation, startup, and future maintenance of the

system. Failure to comply can result in personal injury

and/or equipment damage.

ATTENTION: Verify tha t al l sources of AC and DC

power are deenergized and locked out or tagged out in

accordance with the requirements of ANSI/NFPA 70E,

Part II.

ATTENTION: The system may contain stored ener gy

devices. To avoid the hazard of elec tric al shock, ve rify

that all voltage on capacitors has b een discharge d before

attempting to service, repair, or remove a drive system

or its components. You should only attempt the

procedures in this manual if you are qualified to do so

and are familiar with solid-state control equipment and

the safety procedures in ANSI/NFPA 70E.

Page 8

P-2

ATTENTION: An incorrectly applied or incorrectly

installed drive system can res ult in component damage

!

and/or a reduction in product life. Wiring or application

errors–such as undersizing the motor, incorre ct or

inadequate AC supply, and excessive ambient

temperatures–can result in the malfunction of the drive

equipment.

ATTENTION: This drive system contains parts and

assemblies that are sensitive to ESD (elec trostatic

discharge). Static control precautions a re required

when installing, testing, or repairing this assembly.

Component damage can result if ESD control

procedures are not followed. I f you are not familiar with

static control procedur es, refer to Rockwell Automation

publication 8000-4. 5.2, Guardi ng Against Electr ostatic

Damage, or another adequate handbook on ESD

protection.

Publication 2364P- 5.01 December 1999

Page 9

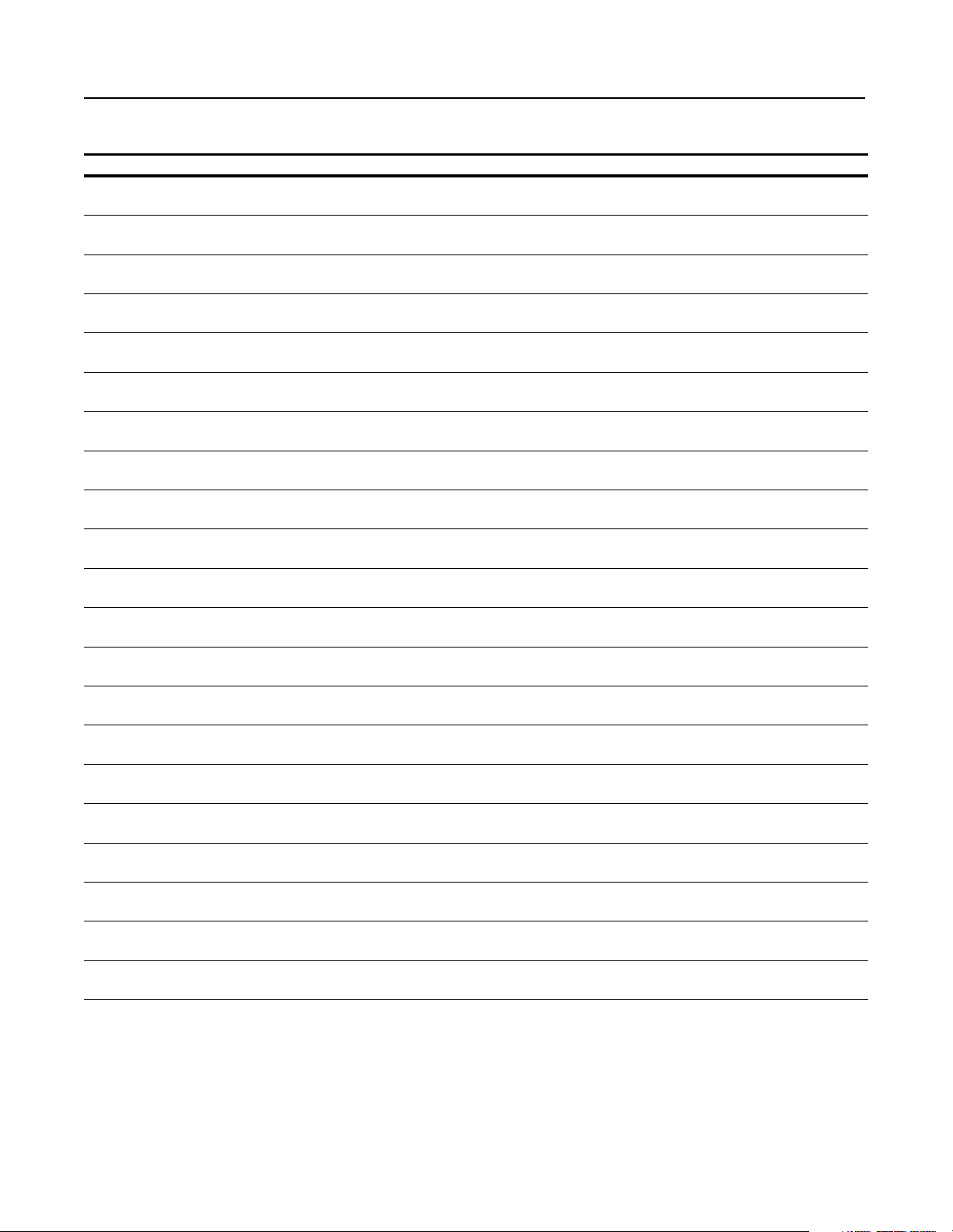

Contents of this Manual

Chapter Title Contents

Preface Safety precautions, reference tables, and support information.

1 Theory of Operation Overview of the parallel configurations. Includes basic theory and operational

information.

2 R1 and S1-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the R1 and

S1-code parallel configurations.

3 R2 and S2-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the R2 and

S2-code parallel configurations.

4 R3 and S3-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the R3 and

S3-code parallel configurations.

5 R4 and S4-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the R4 and

S4-code parallel configurations.

6 T1 and V1-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the T1 and

V1-code parallel configurations.

7 T2 and V2-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the T2 and

V2-code parallel configurations.

8 T3 and V3-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the T3 and

V3-code parallel configurations.

9 T4 and V4-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the T4 and

V4-code parallel configurations.

10 T5 and V5-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the T5 and

V5-code parallel configurations.

11 T6 and V6-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the T6 and

V6-code parallel configurations.

12 W1-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the W1-code

parallel configurations.

13 W2-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the W2-code

parallel configurations.

14 W3-Code Parallel Configurations Schematics, component layout, and overhead bus configuration for the W3-code

parallel configurations.

15 Installation Instructions for installing, wiring, and testing the parallel configuration.

P-3

16 Setting Up the Parallel Configuration Instructions for setting the RGU parameters in the parallel configuration.

A Specifications Operational, environmental, and electrical specifications for the parallel

configuration.

B Catalog Numbers and Spare Parts Kits Information concerning the parallel configuration catalog numbers and spare parts

kits.

C Physical Details Enclosure dimensions and sound levels.

Index

Publication 2364P-5.01 December 1999

Page 10

P-4

Related Documentation The following documents include information that may be helpful

when installing or servic es components in your drive system. To

obtain a copy of any of the Rockwell Automation publ ications,

contact your local Rockwell Autom ation office or distibutor.

For Read This Document Document Number

NRU layout diagrams, schematics, component information, and installation/

setup instructions.

RGU layout diagrams, schematics, component information, installation/setup

instructions, and parameter listings.

Troubleshooting information, testing procedures, and fault descriptions for

the RGU.

Instructions for installing an overhead bus assembly. Overhead Bus Installation Instructions for Bulletin

Information for operating and understanding the Graphic Programming

Terminal (GPT).

Information for installing and configuring the Remote I/O (RIO)

Communications Module.

Information for installing and configuring the DeviceNet Communications

Module.

Information for installing and configuring the Series Communications Module. Bulletin 1203 Series Communications Module–

Information for installing, configuring, programming, and troubleshooting the

1336 FORCE adjustable frequency AC drive.

Information for installing, configuring, programming, and troubleshooting the

1336 PLUS adjustable frequency AC drive.

Instructions for properly handling and moving motor control centers. Receiving, Handling, and Storing Motor Control

Instructions for enclosure and busbar assembly. Bulletin 2300 Family of Drive Systems–Installation

Information for installing, configuring, and programming the SA3000 AC

drive.

Information for installing, configuring, and programming the SA3100 AC

drive.

Instructions for working with FD86N enclosures. FD86N Drive Systems Enclosure Hardware–

Electrical specifications established by the National Fire Protection

Association (NFPA), Boston, MA.

List of documentation available through Allen-Bradley. Allen-Bradley Publication Index SD499

Non-Regenerative DC Bus Supply Unit (NRU)–User

Manual

Regenerative DC Bus Supply Unit (RGU)–User

Manual

Regenerative DC Bus Supply Unit (RGU)–

Troubleshooting Guide

2300 MCCs

Bulletin 1201 Graphic Programming Terminal–

User Manual

Bulletin 1203 Remote I/O Communications

Module–Getting Started Manual

Bulletin 1203 DeviceNet Communications

Module–User Manual

User Manual

1336 FORCE Adjustable Frequency AC Drive–User

Manual

1336 PLUS Adjustable Frequency AC Drive–User

Manual

Centers–Instructions

Manual

SA3000 Binder S-3001

SA3100 Binder S-3053

Installation Manual

National Electrical Code ANSI/NFPA70

2364E-5.01

2364F-5.01

2364F-5.05

2364P-5.10

1201-5.0

1203-5.1

1203-5.3

1203-5.5

1336 FORCE-5.12

1336 PLUS-5.0

2100-5.5

2300-5.1

S-3062

Dictionary of terms that are common to industrial automation. Industrial Automation Glossary AG-7.1

Publication 2364P- 5.01 December 1999

Page 11

P-5

Receiving Your Drive System The Customer is responsibl e for thoroughly inspe cting the equipment

before accepting the shipment from the freight company. Check the

item(s) that you r eceive against your purchase order. If any items are

obviously damaged, do not accept the delivery until the freight agent

has noted the damage on the freight bill. Should you discover any

concealed damage during unpac king, you are responsible for

notifying the freight agent. In such a case, leave the shipping

container intact and request that the freight agent make a visua l

inspection of the equipment.

Rockwell Automation Support Rockwell Automation offers support services worldwide, with Sales/

Support Office s, a uthorized distributors, and authorized Systems

Integrators loc ated throughout the United States, plus Rockwell

Automation representa tives in every major country in the world.

Local Product Support

Please contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to cont act us fo r tech n ical assis ta nce, pleas e rev iew th e

product and troubleshooting information in this manual first.

When you do contact us, please have the catalog numbers of your

products ready when you call so we c an provi de the qui ckest response

for your situation.

Publication 2364P-5.01 December 1999

Page 12

P-6

Publication 2364P-5.01 December 1999

Page 13

Chapter 1

Theory of Operation

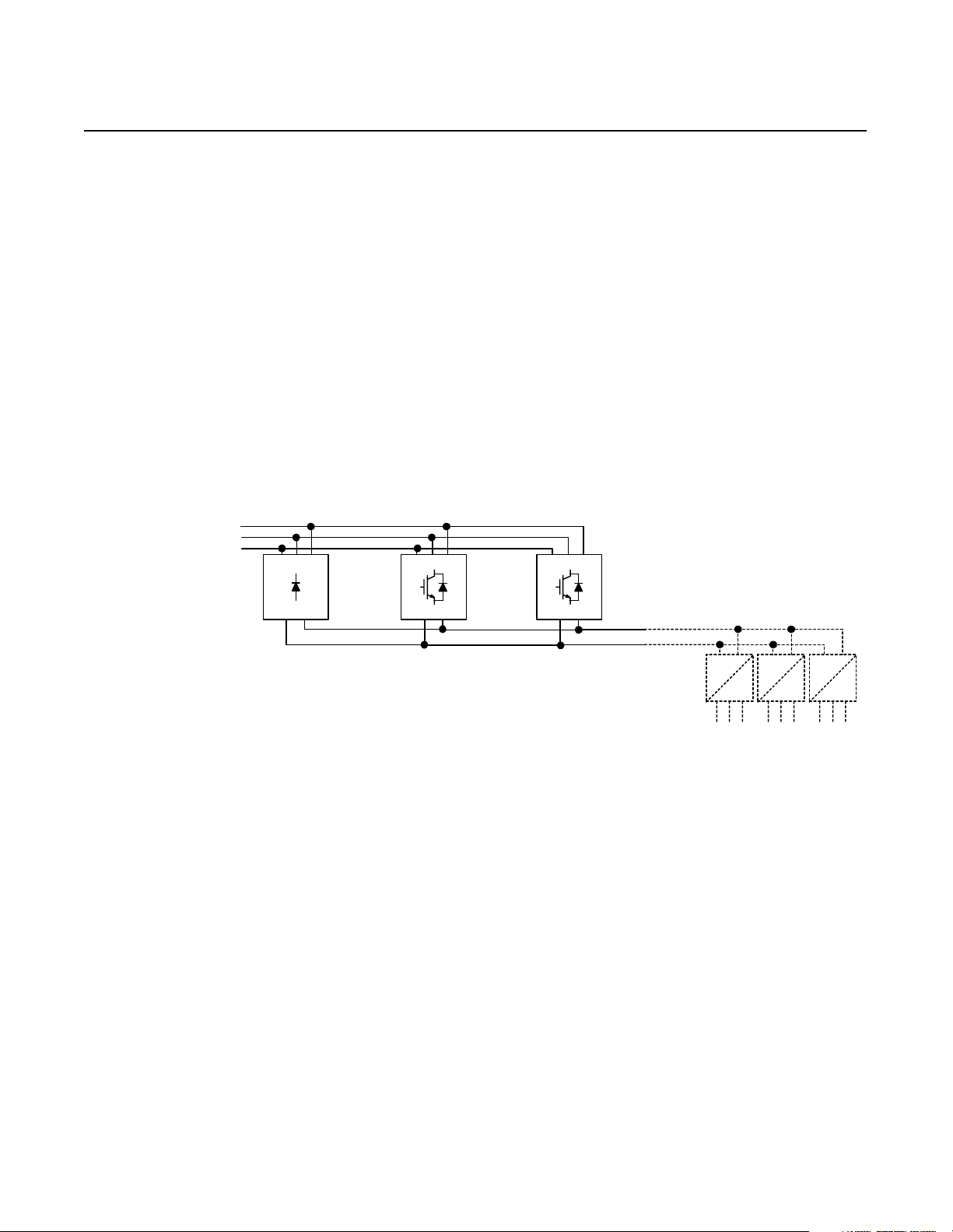

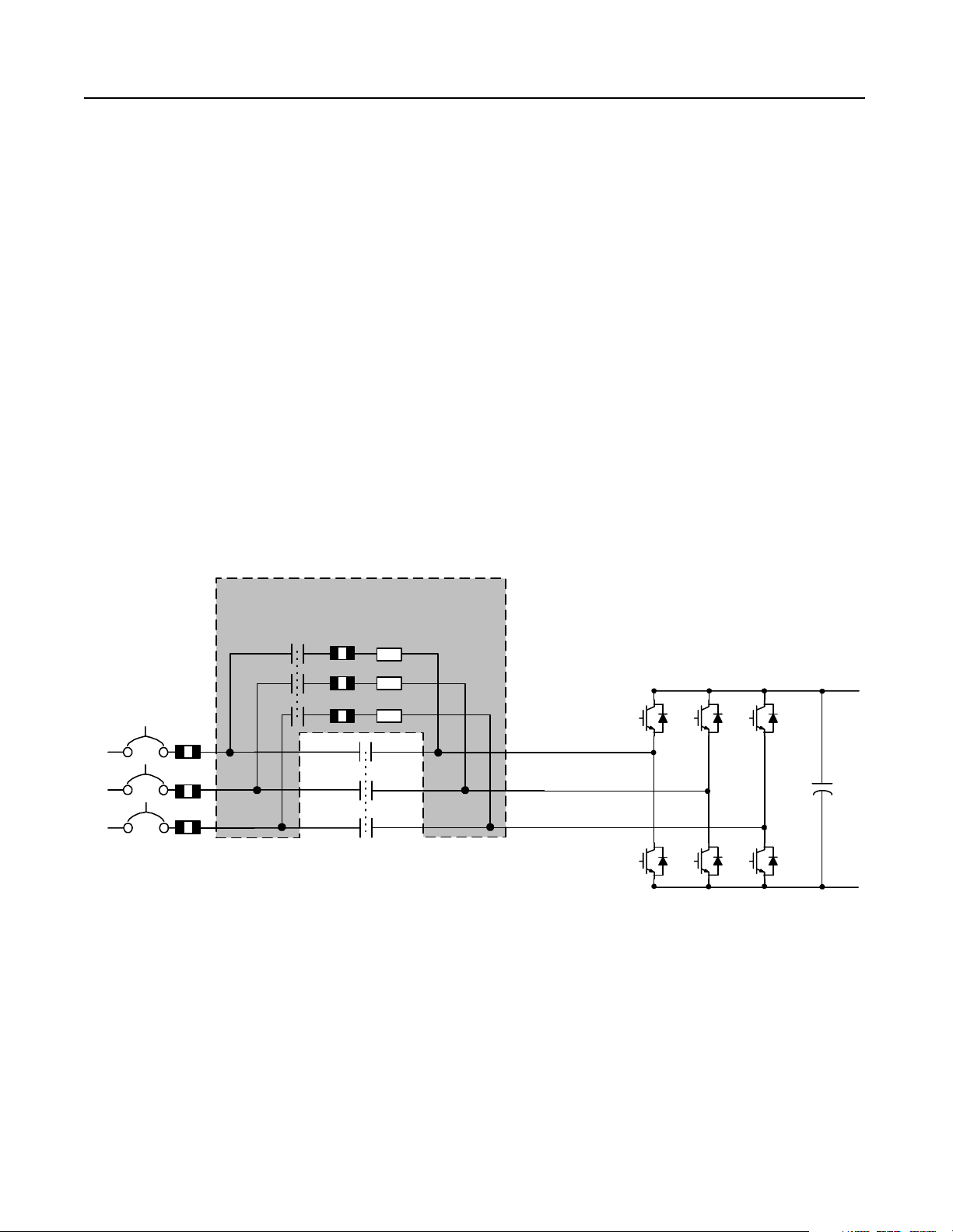

Introduction The parallel configuration, a DC bus supply front-end with

regenerative c apability, is used to supply DC power for AC digital

drive inverter unit s in a common bus drive syste m. Twenty-three

different parallel configurations provide a spectrum of different

supply and regenerative capabilities.

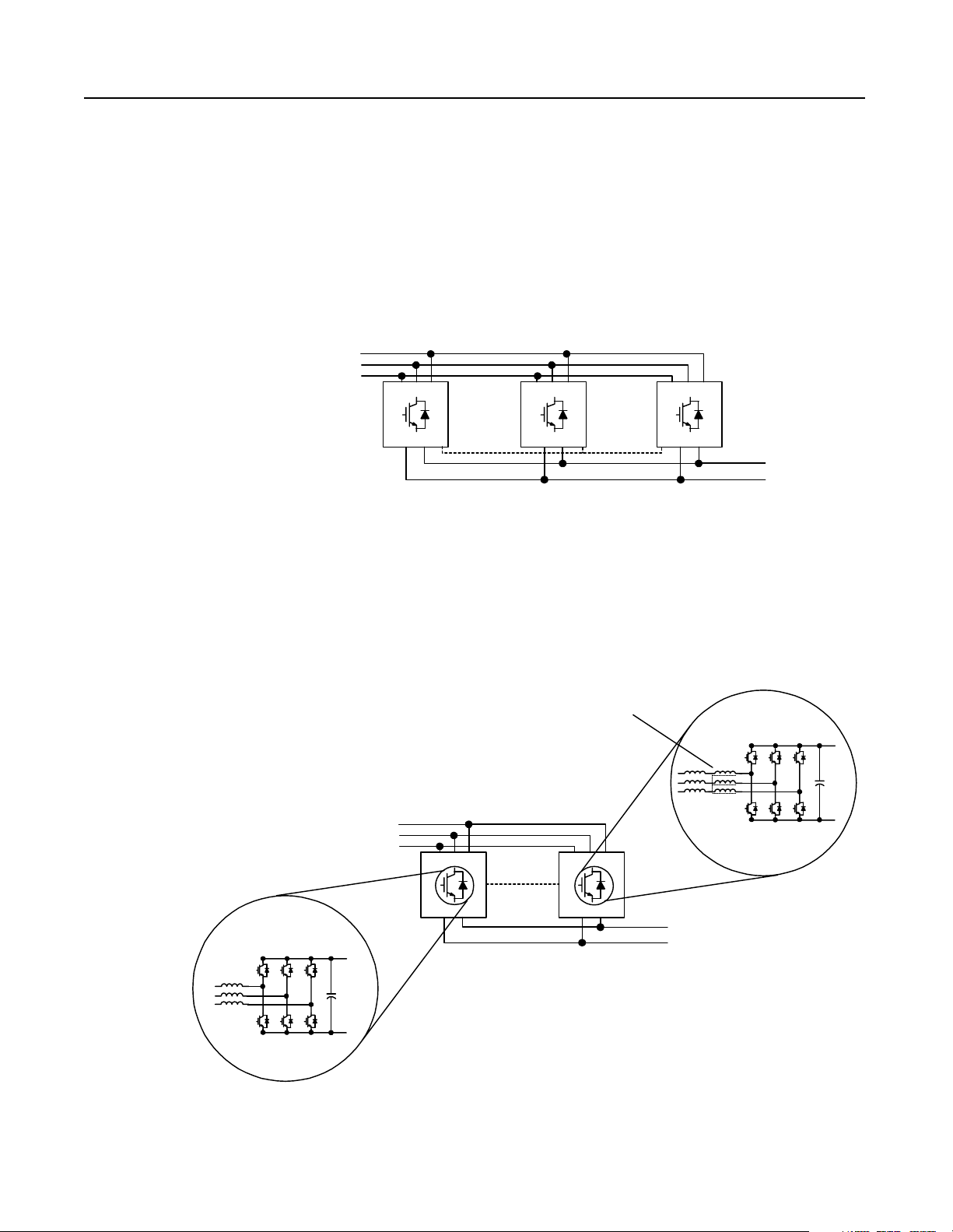

Figure 1.1

Parallel Configuration

3-Phase

AC Line

NRU

RGU RGU

DC Supply for

Drive Lineup

DC

AC

Inverters

DC

AC

DC

AC

Publication 2364P-5.01 December 1999

Page 14

1-2 Theory of Operation

Parallel configur ations use the following front-end units:

• Regenerative DC Bus Supply Unit ( RGU)

• Non-Regenerative DC Bus Supply Unit (NRU)

Each parallel config uration will include one, two, or three

Regenerative DC Bus Supply Units (RGUs). The se units are used to

supply motoring current to the DC bus, and are used to regenerate

current back onto the AC line.

Most of the parallel configur ations will also include a

Non-Regenerative DC Bus Supply Unit (NRU) to supply the

motoring current to the DC bus.

Note: When there is an NRU in the configuration, the NRU

supplies motoring curr ent while the RGUs regenerate most of the

excess capacity (the RGU also cont ributes 10% of its rated

motoring current to the DC bus).

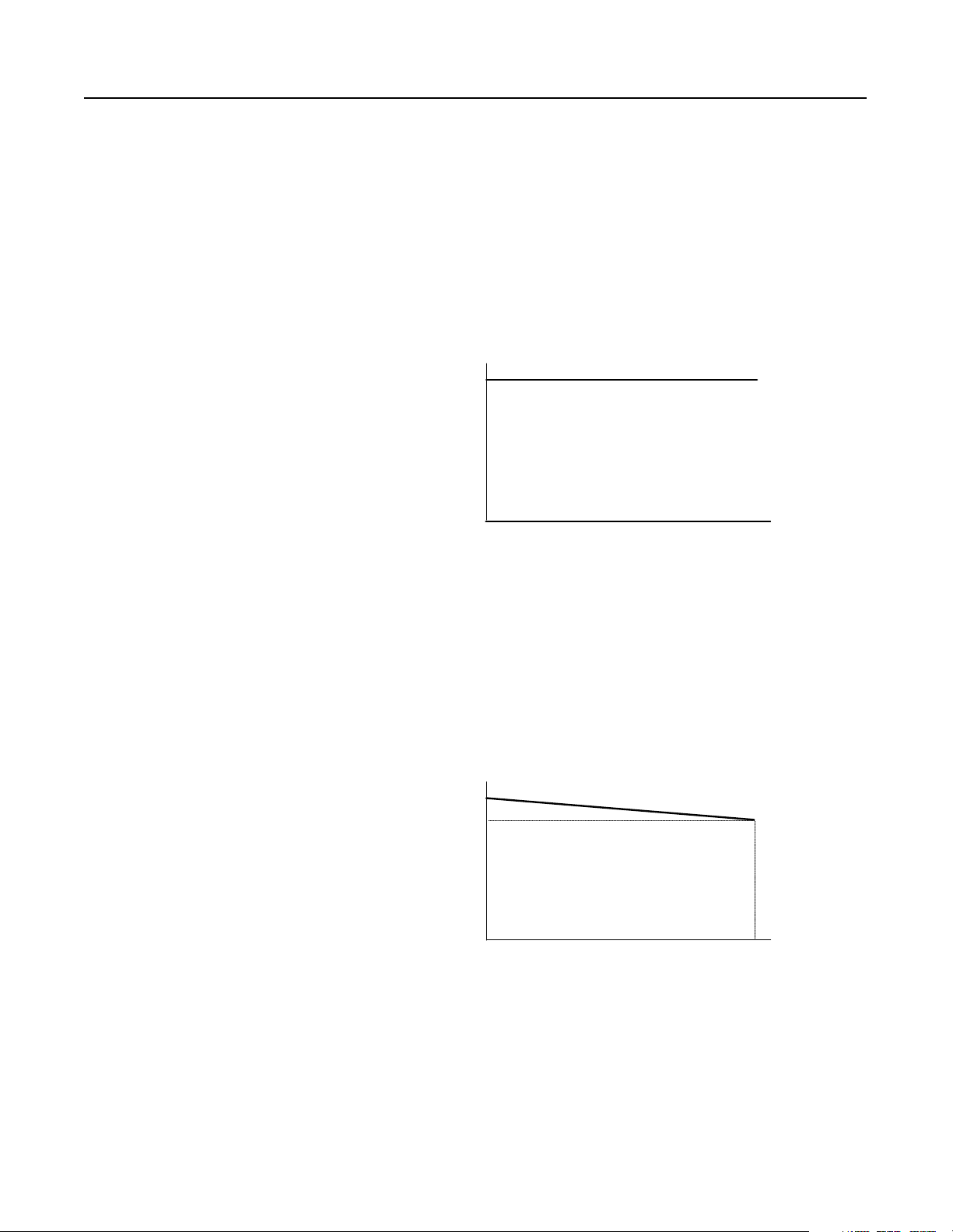

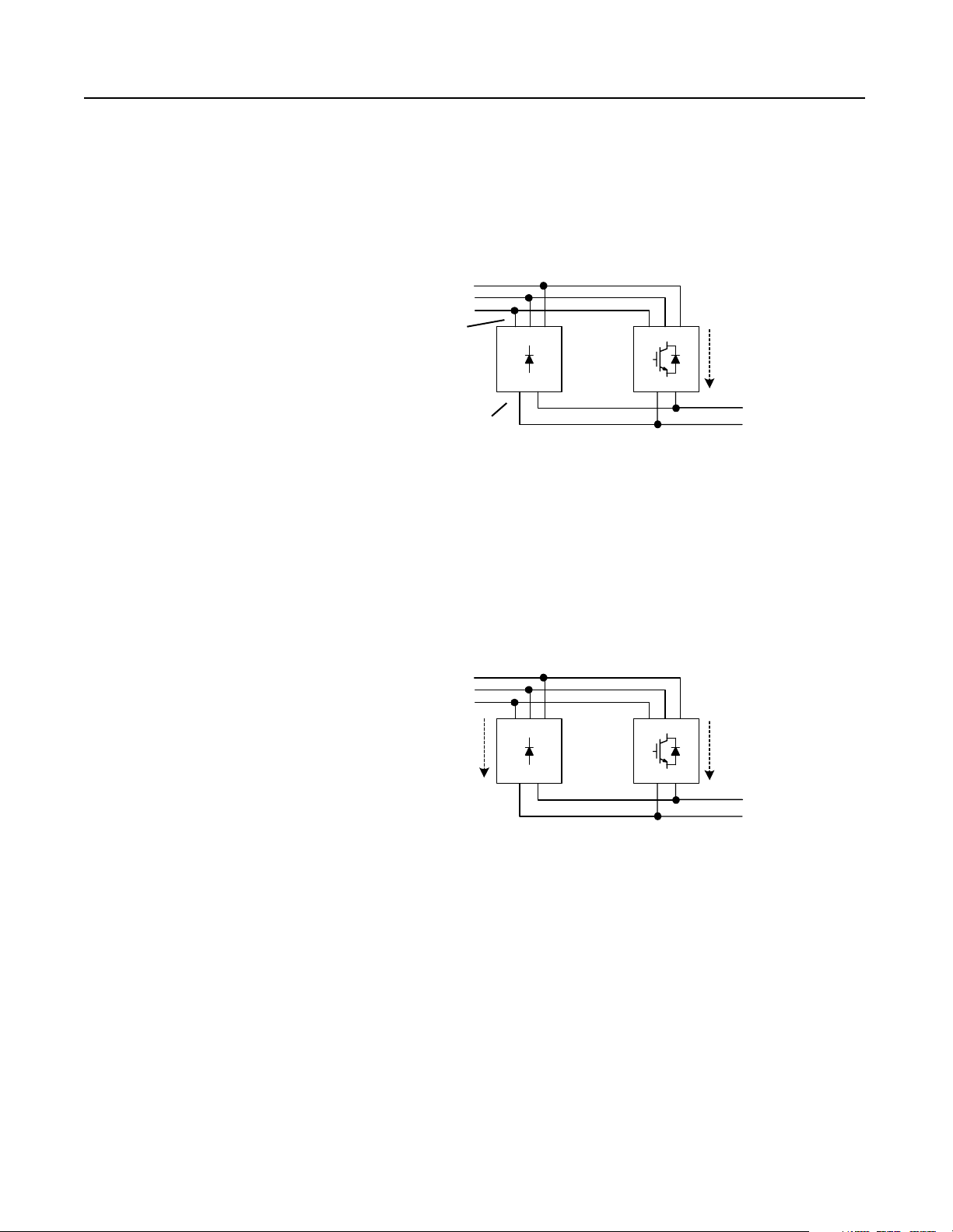

Figure 1.2

NRU and RGU Operation

NRU//RGU Configuration

3-Phase

AC Line

RGU//RGU Configuration

3-Phase

AC Line

Motoring

Current

Motoring

Current

NRU RGU

RGU

Regenerating

Current

10%

Motoring

Current

Motoring

Current

RGU

Regenerating

Current

DC Supply for

Drive Lineup

Regenerating

Current

DC Supply for

Drive Lineup

Publication 2364P-5.01 December 1999

Page 15

Parallel Configuration RGU//RGU Configurations

In an RGU//RGU configuration, each RGU supplies 100% motoring

current and 100% regenerative curr ent. When operating, the master

RGU evaluates the bus voltage and sends cur rent c ommands to the

slave RGUs through an RGU-to-RGU (R2R) communicati on

network. This allows the RGUs to operate together to supply the

appropriate current while maintaining a constant voltage on the DC

bus.

Figure 1.3

RGU//RGU Configuration

3-Phase

AC Line

RGU

RGU-to-RGU

Communications

Each RGU//RGU configuration has one master RGU in parallel with

either one or two slave RGUs. Each slave RGU includes a common

mode choke accommodate for minor switchi ng differences between

the RGUs and to reduce c irculat ing cur rents bet ween the master RGU

and the slave RGUs.

RGU RGU

Theory of Operation 1-3

DC Supply for

Drive Lineup

Master

3-Phase

AC Line

Figure 1.4

RGU//RGU Configuration–Master/Slave

Common Mode Choke

RGU RGU

R2R

Communication

Slave

DC Supply

for Drive

Lineup

Publication 2364P-5.01 December 1999

Page 16

1-4 Theory of Operation

Output of RGU//RGU Configurations

In an RGU//RGU configuration, each RGU (when enabled) switches

its IGBTs to maintain a constant voltage on the DC bus (which is

typically 1.52 times the input voltage).

In this pr ocess, t he maste r R GU evaluat es the bu s vol tage and se nds a

current com ma n d (whi ch is used t o corr ect the bu s voltag e ) to the

slave RGUs. Each RGU switches its IGBTs to regulate the current

(motoring or regenerative) needed to mainta in the bus voltage.

Figure 1.5

RGU//RGU Bus Voltage–Motoring or Regenerating

~1.52 x V AC

DC Bus Voltage

0 V DC

0%

% Load

100%

When the RGUs are not enabled, power is supplied through the freewheeling diodes. The diode bridge produces a voltage of 1.35 tim es

the input voltage with no load, and decre ases to 1.22 times the input

voltage at full load. During this operation, the RGUs do not regulate

the voltage or regenerat e any curr ent.

Figure 1.6

RGU//RGU Bus Voltage–Diode Bridge Operation (RGU Not Enabled)

1.35 x V AC

1.22 x V AC

DC Bus Voltage

0 V DC

0%

% Load

100%

Publication 2364P-5.01 December 1999

Page 17

3-Phase

AC Line

Theory of Operation 1-5

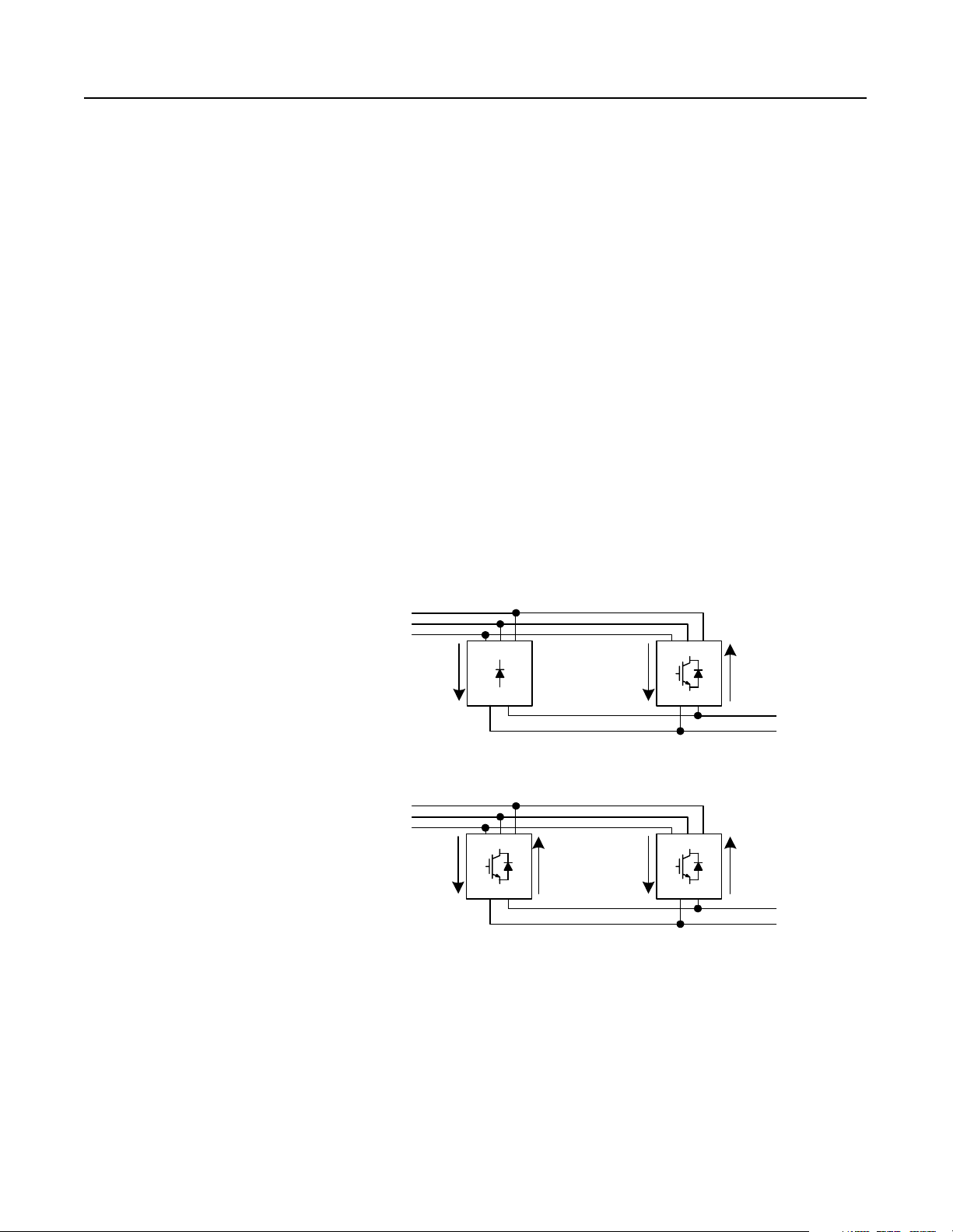

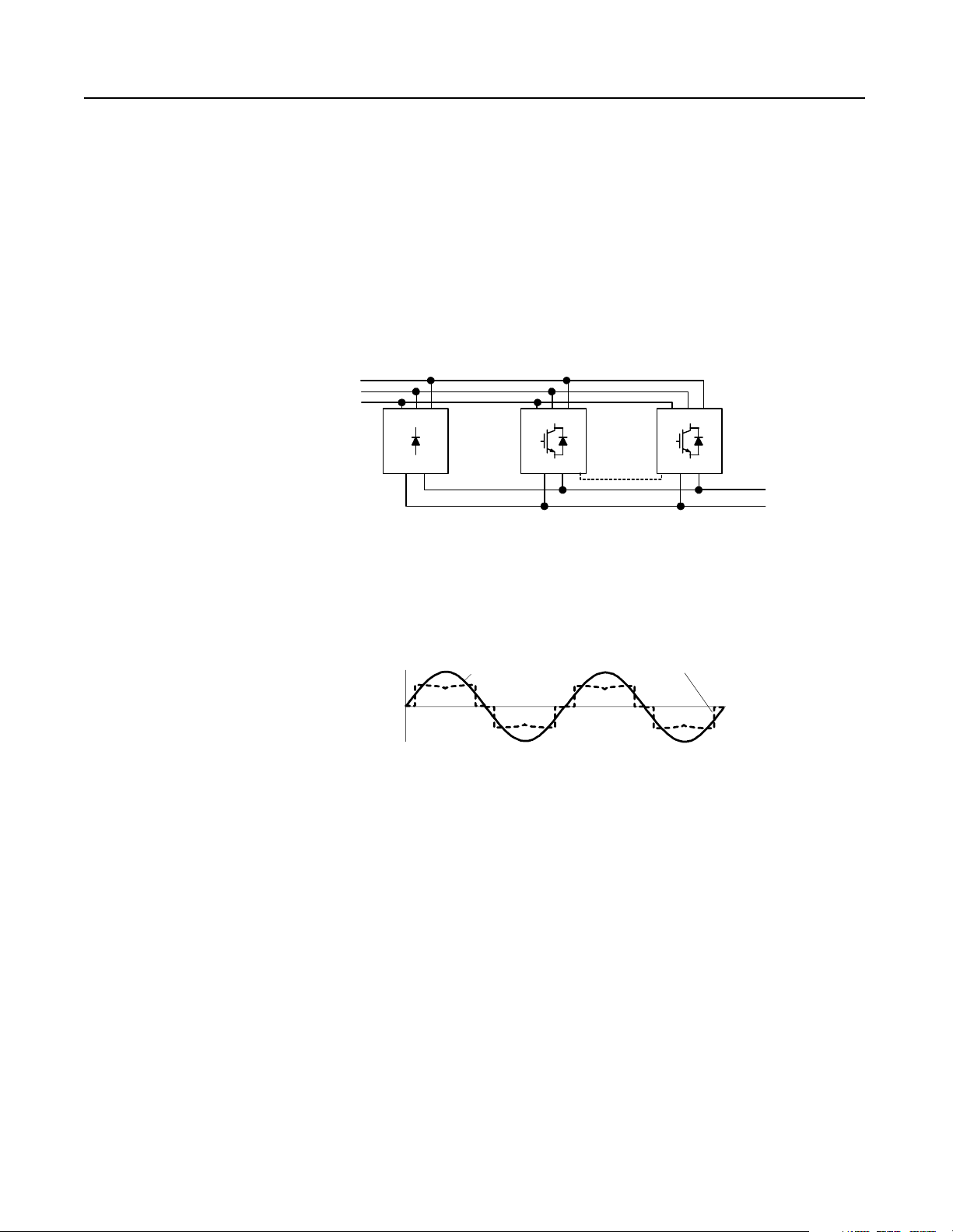

NRU//RGU Configurations

In the NRU//RGU configura tion, the NRU is used to supply m otoring

current to the DC bus, while the RGUs are used to regenerate current

to the AC line.

When motoring, the NRU operates to supply its maximum motoring

current to the DC bus, and the RGUs ope rate to supply 10% of their

maximum motoring current to the DC bus. When regenerating, the

NRU’s diode bridge stops operating, and the RGUs regener ate the

current back onto the AC line.

Figure 1.7

NRU//RGU Configuration

NRU

RGU RGU

RGU-to-RGU

Communications

DC Supply for

Drive Lineup

The NRU supplies motoring c urrent through its diode bridge, and the

RGU supplies motoring and regenerative current through its power

structure.

Figure 1.8

Line Waveform–NRU//RGU Configuration

Line Voltage

Line Current

Publication 2364P-5.01 December 1999

Page 18

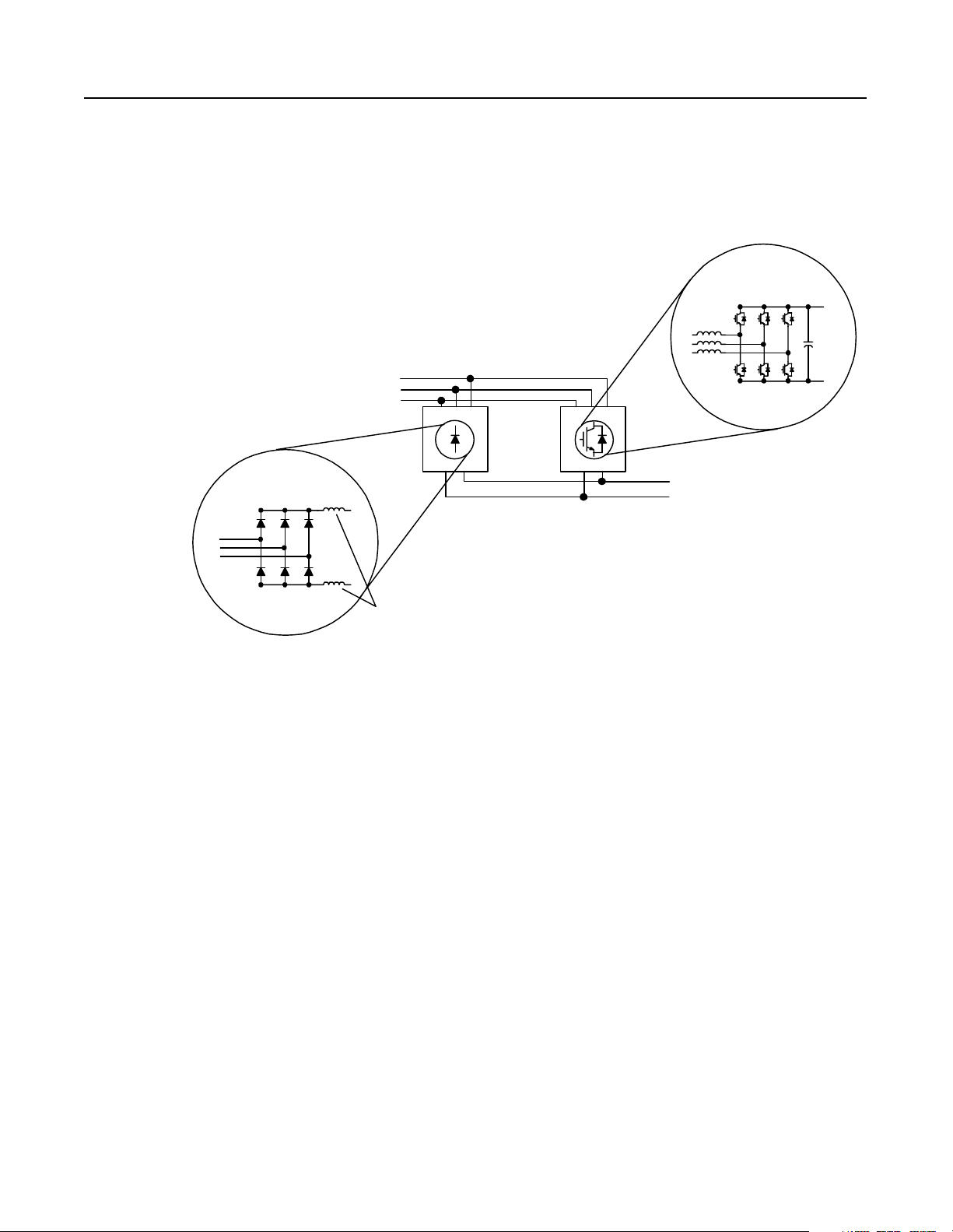

1-6 Theory of Operation

In the NRU//RGU configuration, the NRU has chokes on the DC bus.

These chokes reduce cir culating c urrent between the RGU and NRU.

If a slave RGU is in the configuration, the slave RGU will have a

common mode choke installed on its AC line.

Figure 1.9

NRU//RGU Configuration–Basic Components

Pow er Structure

(w ith IG BTs)

3-Phase

AC Line

NRU RGU

Diode Bridge

DC Supply

for Drive

Lineup

Chokes

The RGU evaluates the bus vo ltage and adjusts it s cu rrent to mai ntain

the nominal bus voltage. If there are two RGUs in the configuration,

the master RGU eva luates the vol tage and sends cur rent commands to

the slave RGU, and both RGUs will switch their IGBTs to regulate

the necessary current on the DC bus.

Publication 2364P-5.01 December 1999

Page 19

Theory of Operation 1-7

Output of NRU//RGU Configurations

The RGUs supply up to 10% of their rated amperes as motoring

current. In this first 10%, the RGUs will regula te the voltage to 1.52

times the line voltage, the voltage on the DC bus will be greater than

the AC line, and the diodes in the NRU will not conduct.

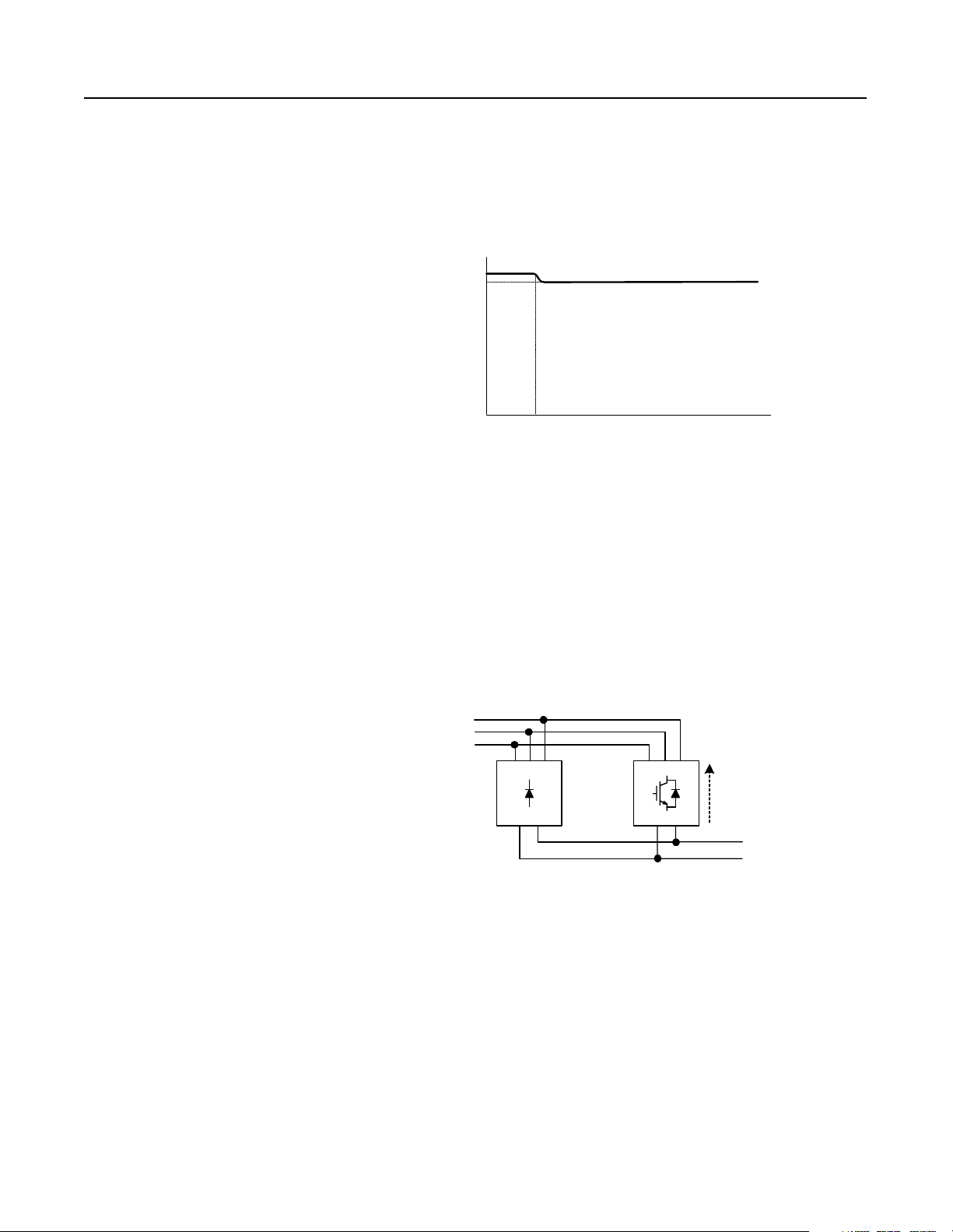

Figure 1.10

RGU Motoring–Load Up To 10% of RGU Rating

3-Phase

AC Line

smaller voltage

No

Current

v

RGUNRU

Current

(Up to 1 0% of the

RGU rating)

greater voltage

V

1.52 x AC Line

Voltage

When the load increases beyond the fir st 10%, the RGU is no longe r

able to regu late the voltage (since the current limit is set to 10%), a nd

the bus voltage drops to a level where the diode s in the NRU can

conduct. The NRU then supplies the motoring current for the

remainder of the load, resulting in a bus voltage of 1.35 times the line

voltage.

Figure 1.11

RGU and NRU Motoring–Load Over 10% of RGU Rating

3-Phase

AC Line

Current

V

RGUNRU

v

Current

(10% of th e

RGU rating)

1.35 x AC Line

Voltage

When the load drops under the 10% capabilit y of the RGUs, the

RGUs will begin to regulate the bus voltage again to 1.52 times the

line voltage, and the diodes in the NRU will stop c onducting.

Publication 2364P-5.01 December 1999

Page 20

1-8 Theory of Operation

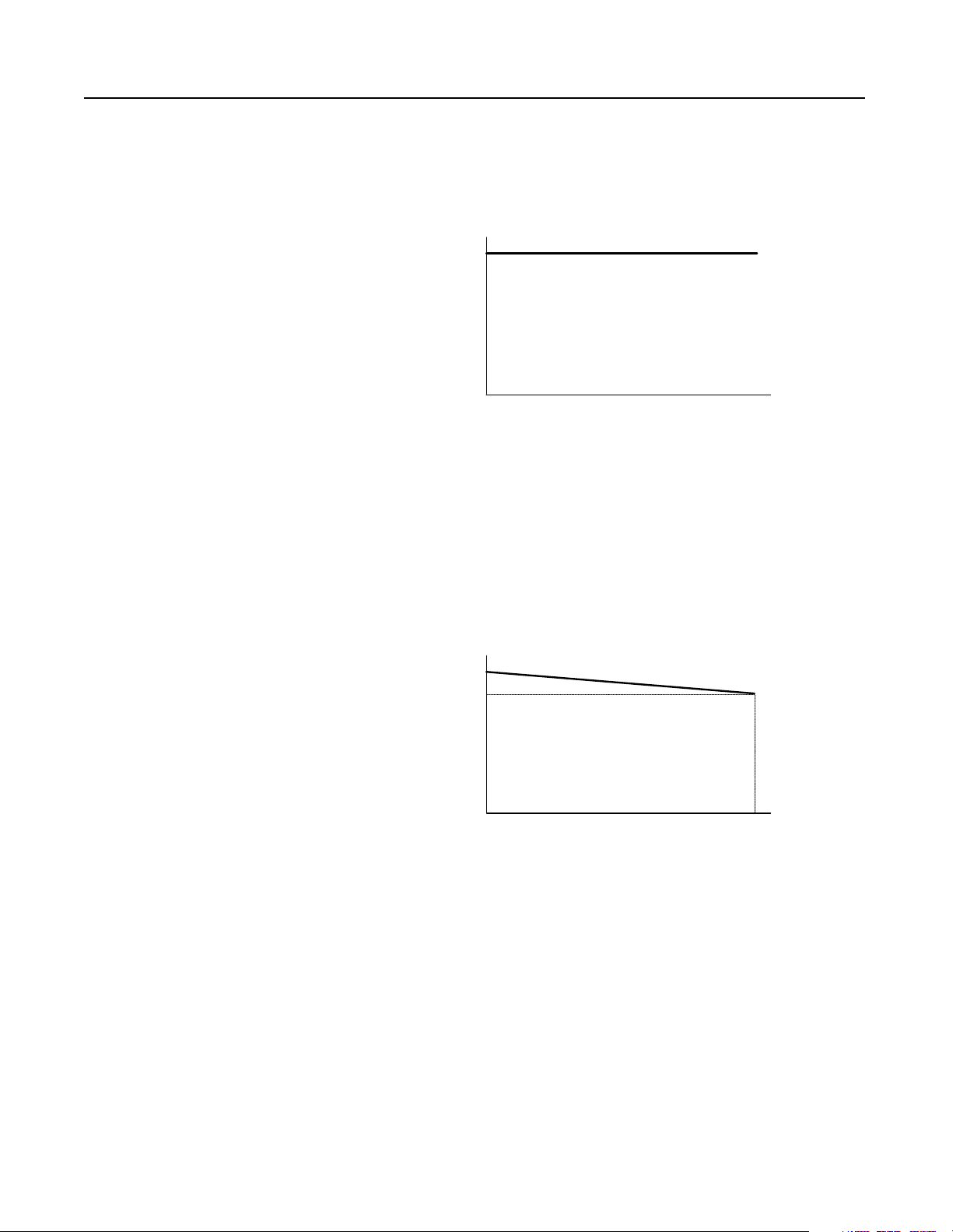

The diagram below shows the NRU//RGU motoring bus voltage. The

RGUs regulate the bus voltage for the first 10% of the rated current

for the RGUs, then the NR Us su ppl y cu rren t fo r the rem ai nd er o f the

load (while the RGU current is limited to 10% of the RGU rating).

Figure 1.12

NRU//RGU Bus Voltage–Motoring

1.52 x V AC

1.35 x V AC

DC Bus Voltage

0 V DC

0%

10%

(of RGU rating)

% Load

100%

(Total NRU rating +

10% of RGU rating)

When the load is under 10% of the maximum motoring current, the

RGUs can regulate (or maintain) the bus voltage. The RGU (master

RGU) will evaluate the voltage on the bus, and will calculate the

current needed to maintai n the bus voltage. If a regenerative current

is needed to m aintain the voltage, the RGUs will begin switching

their IGBTs to regenerate current onto the AC line. The diodes in the

NRU will still not conduct current.

Figure 1.13

RGU Regenerating

3-Phase

AC Line

No

Current

v

RGUNRU

V

Current

(Up to 100% of the

RGU rating)

1.52 x AC Line

Voltage

Publication 2364P-5.01 December 1999

Page 21

Theory of Operation 1-9

The diagram below shows the NRU//RGU regenerative bus volta ge.

The RGUs regenerate up to 100% of their rated curre nt to the AC line

while the NRU diode bridge stops conduct ing.

Figure 1.14

NRU//RGU Bus Voltage–Regenerating

1.52 x V AC

DC Bus Voltage

0 V DC

0%

% Load

100%

When the RGUs are not enabled, only the NRU supplies current to

the DC bus. The bus voltage is 1. 35 times the line voltage at no load,

and decreases to 1.22 times the line voltage at full load. During this

operation, the RGUs do not regulate the voltage or regenerate any

current.

Figure 1.15

NRU//RGU Bus Voltage–RGUs Not Enabled

1.35 x V AC

1.22 x V AC

DC Bus Voltage

0 V DC

0%

% Load

100%

Publication 2364P-5.01 December 1999

Page 22

1-10 Theory of Operation

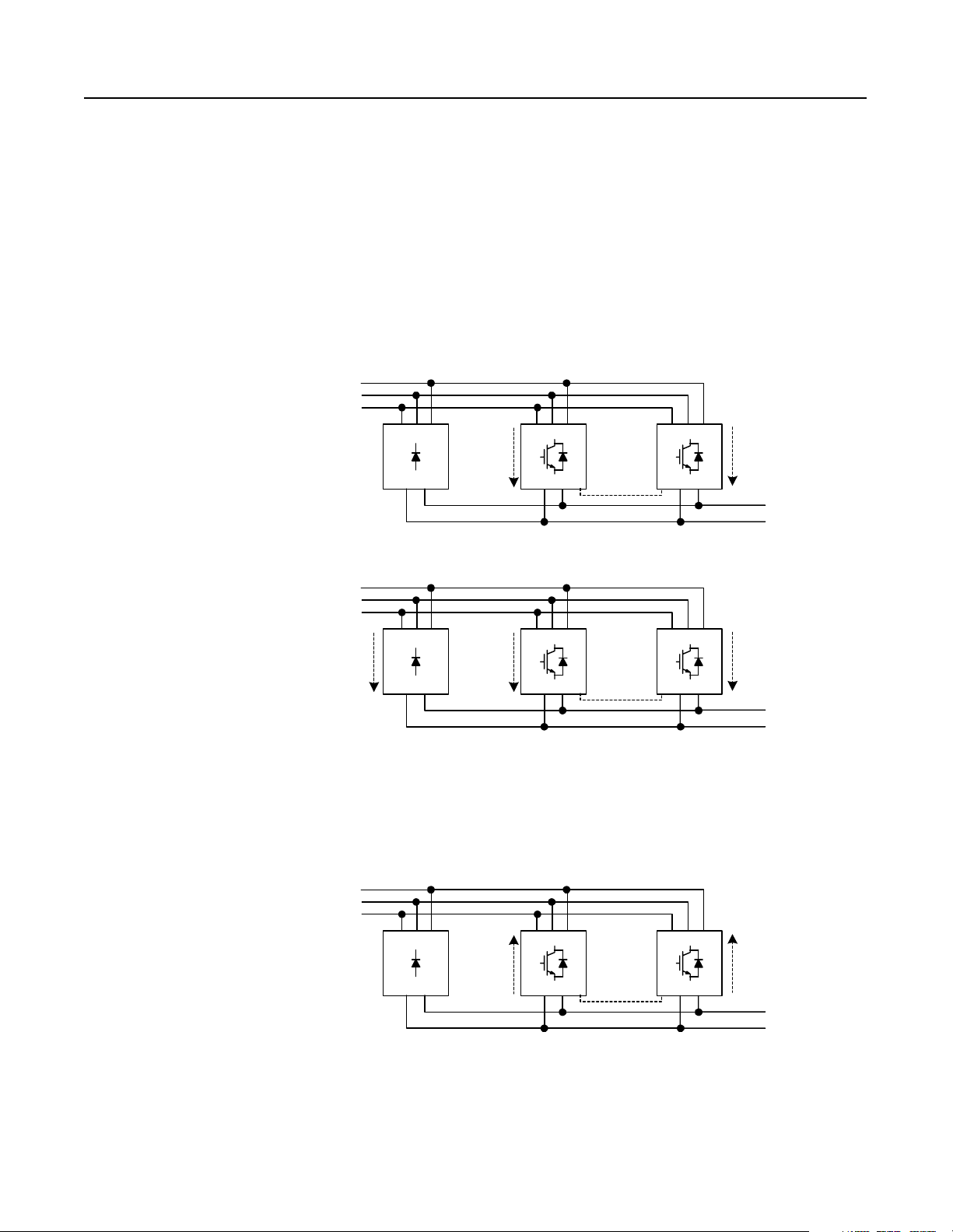

Motoring - Up to 10% of RGU Rated Amperes

3-Phase

AC Line

If there are two RGUs in the configuration, each RGU will supply up

to 10% of its rated motoring current . If the load is in this 10%, the

RGUs will regula te the bus voltage. The master RGU will evaluate

the bus voltage, and will determine the current required to maintai n

the nominal bus voltage (1.52 times the line voltage). The master

RGU will send a current command to the slave RGU, and both R GUs

will begin switching their IGBTs to provide the proper motoring or

regenerative current.

Figure 1.16

NRU With Two RGUs–Motoring

v

No

Current

NRU

V

Current

(Up to 10% of

RGU rated

amperes)

RGU RGU

RGU-to-RGU

Communications

Current

(Up to 10% of

the RGU rated

amperes)

1.52 x AC Line

Voltage

Motoring - Over 10% of RGU Rated Amperes

3-Phase

AC Line

Current

(Up to 100% of

the NRU rated

amperes)

V

NRU

v

Figure 1.17

NRU With Two RGUs–Regenerating

3-Phase

AC Line

No

Current

v

NRU

V

Current

(10% of

RGU rated

amperes )

Current

(Up to 100%

of RGU rated

amperes)

RGU RGU

RGU-to-RGU

Communications

RGU RGU

RGU-to-RGU

Communications

Current

(10% of the

RGU rated

amperes)

1.35 x AC Line

Current

(Up to 100% of

the RGU rated

amperes)

1.52 x AC Line

Voltage

Voltage

Publication 2364P-5.01 December 1999

Page 23

Theory of Operation 1-11

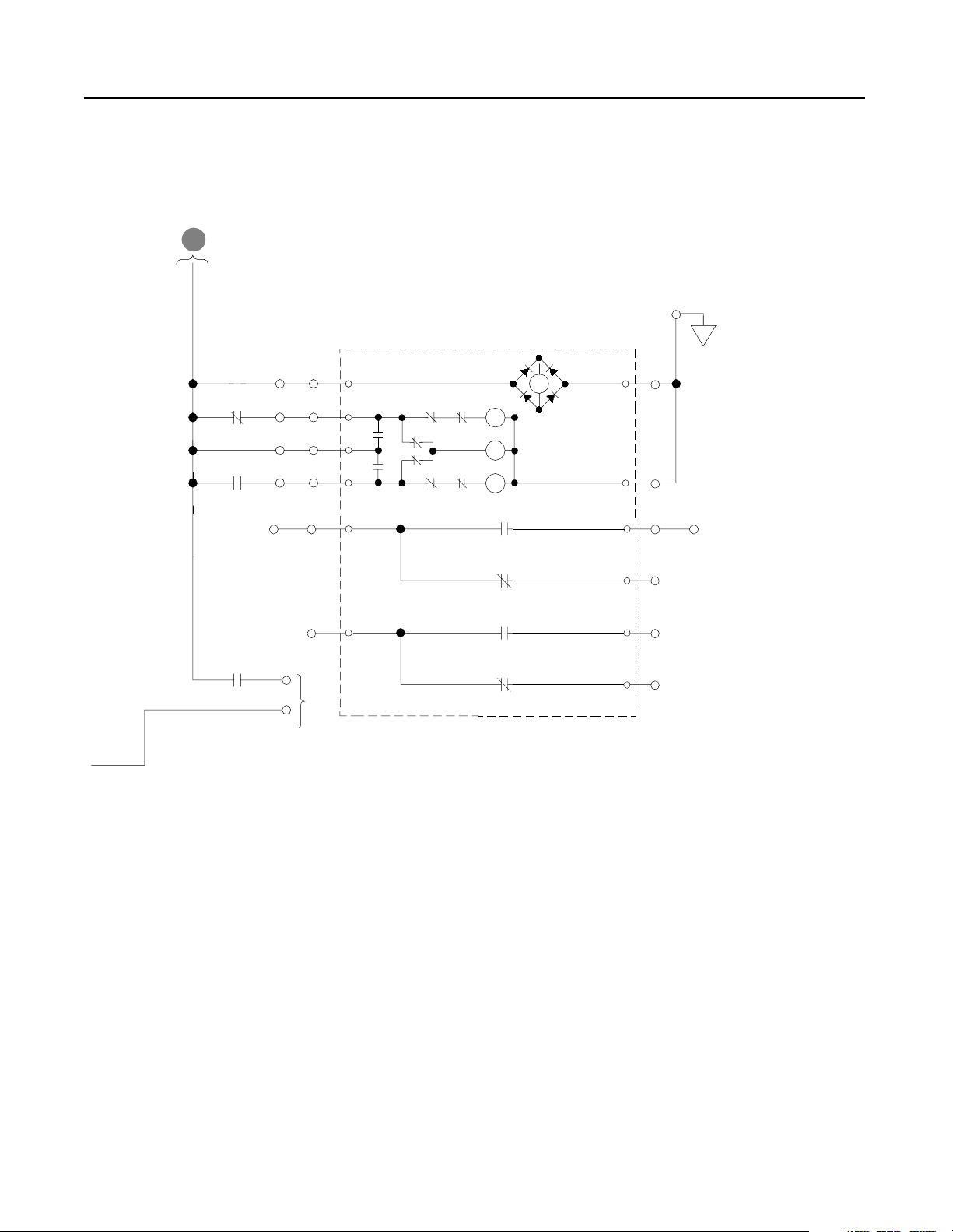

Precharge Operation

When the disconnects are closed and the start switch is turned

on, each RGU in the parallel configuration will begin its

precharge routine. This routine charges the capacitors on the

DC bus (the RGU capacitor bank and inverter capacitors) in a

controlled fashion.

T wo contactors (M1 and M2) are used to perform the precharge

operation in the K, L, a nd M-code RGUs (the N-code RGU precharge

circuit is slightly different).

When the disconnect ( MCP1 or CB1) is closed and the start switch is

turned on, the main contactor (M1) remains open, the precharge

contactor (M2) closes, and c urrent begins to flow through the

precharge circuit (bypassing the main 3-phase circuit). This

precharge circuit (which has a resistive load) charges up the capacitor

bank. As the bank approaches capacity, the main contactor (M1)

closes, the precharge contactor (M2) opens, the NRU circuit breaker

closes, and normal operation begins.

Circuit Breaker or

MCP

(CB1 or MCP1)

Precharge

Contactor

(M2)

Main

Contactor

(M1)

Figure 1.18

Precharge Circuit

Precharge Circuit

R

Note:

The precharge circuitry is slightly

different in the N-code RGU. See the product

schematics for further details.

Publication 2364P-5.01 December 1999

Page 24

1-12 Theory of Operation

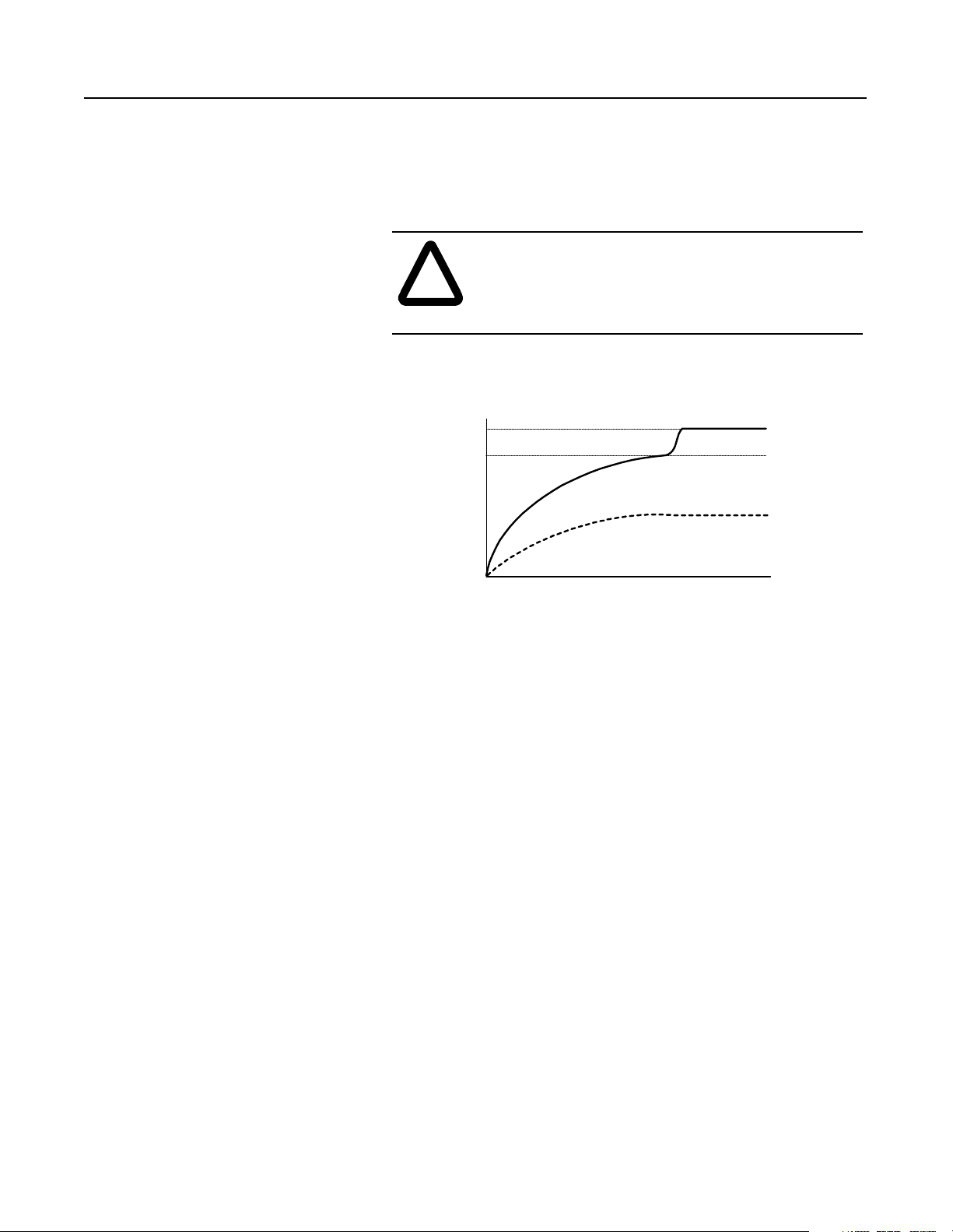

The RGUs will precharge the capa citors on the bus until the bus

voltage rises to be equal to the lin e volt age. Then, the precharge

circuit will open, the main circuit will close, the NRU circuit breake r

will close, and the DC bus voltage will rise to 1.35 times the line

voltage.

ATTENTION: If there is too much capacitance on the

DC bus, the RGUs may not be able to raise the bus

!

voltage to the threshold f or normal operation, resul ting

in damage to equipment.

Figure 1.19

Precharge Voltage

1.35 x V AC

DC Bus Voltage

1 x V AC

0 V DC

0 sec

Precharging

Time

Normal Diode-Bridge

Operation

Unable to Precharge

(Too many inv erters)

t

Publication 2364P-5.01 December 1999

Page 25

Chapter 2

R1 and S1-Code Parallel Configurations

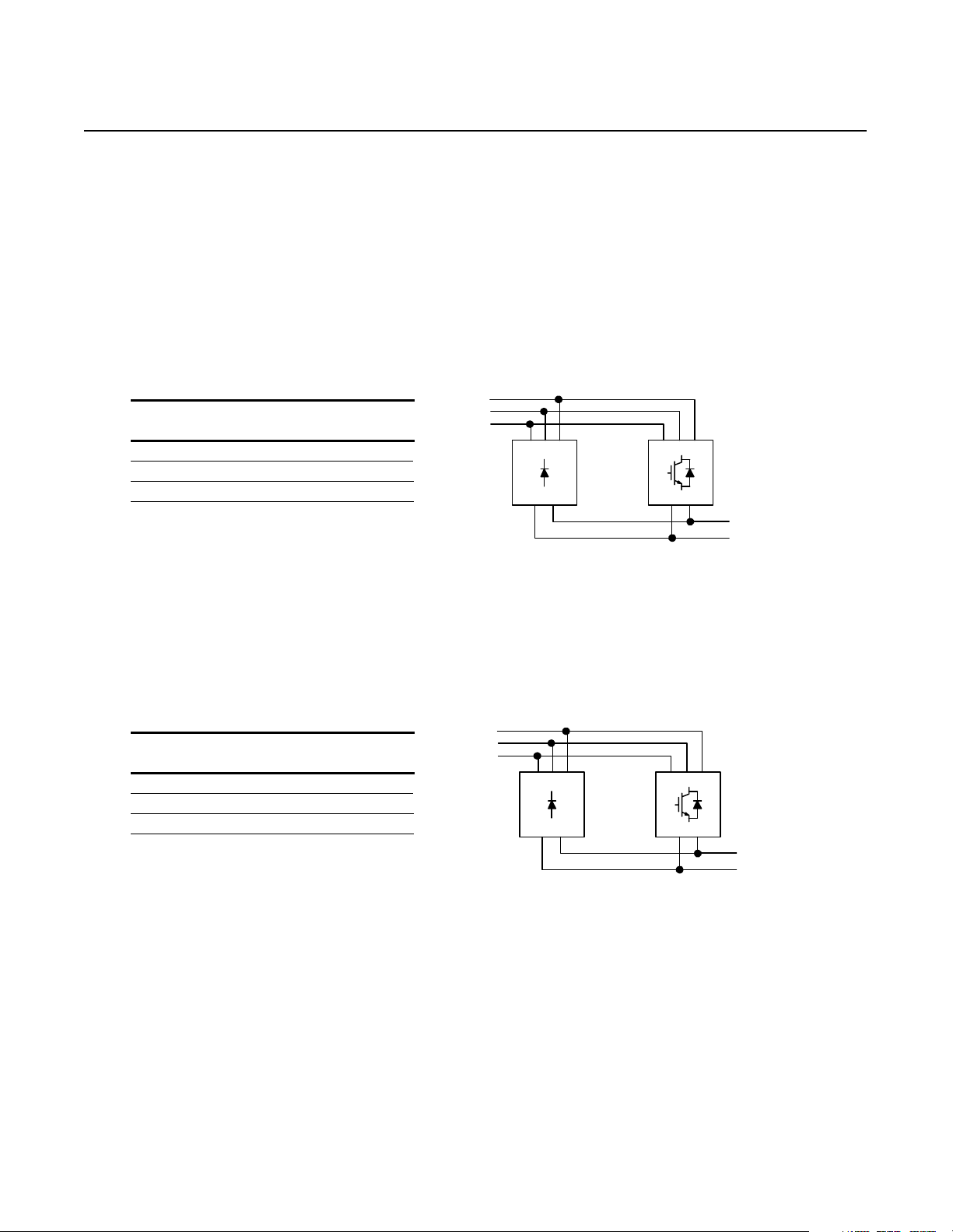

R1-Code Parallel Configuration The R1-code parallel configur ation is a common DC bus front-end

unit consisting of an D-code NRU in parall el with a K-code RGU.

Figure 2.1

R1-Code Parallel Configuration–Information

R1-code Parallel ConfigurationR1-code Ratings

Input Voltage

(V AC)

380 1520

460

575

DC Bus Current

(A DC)

1520

1520

Rated DC Bus

kW

780

944

1180

D-code

NRU

K-code

RGU

S1-Code Parallel Configuration The S1-code parallel configuration is a common DC bus front-end

unit consisting of an E-code NRU in parallel with a K-code RGU.

Figure 2.2

S1-Code Parallel Configuration–Information

S1-code Parallel ConfigurationS1-code Ratings

Input Voltage

(V AC)

380 2020

460

575

DC Bus Current

(A DC)

2020

2020

Rated DC Bus

kW

1036

1254

1568

E-code

NRU

K-code

RGU

Note: Information for the D-code NRU and E-code NRU can be

found in publication 2364E-5.01. Information for the K-code

RGU can be found in publication 2364F-5.01.

Publication 2364P-5.01 December 1999

Page 26

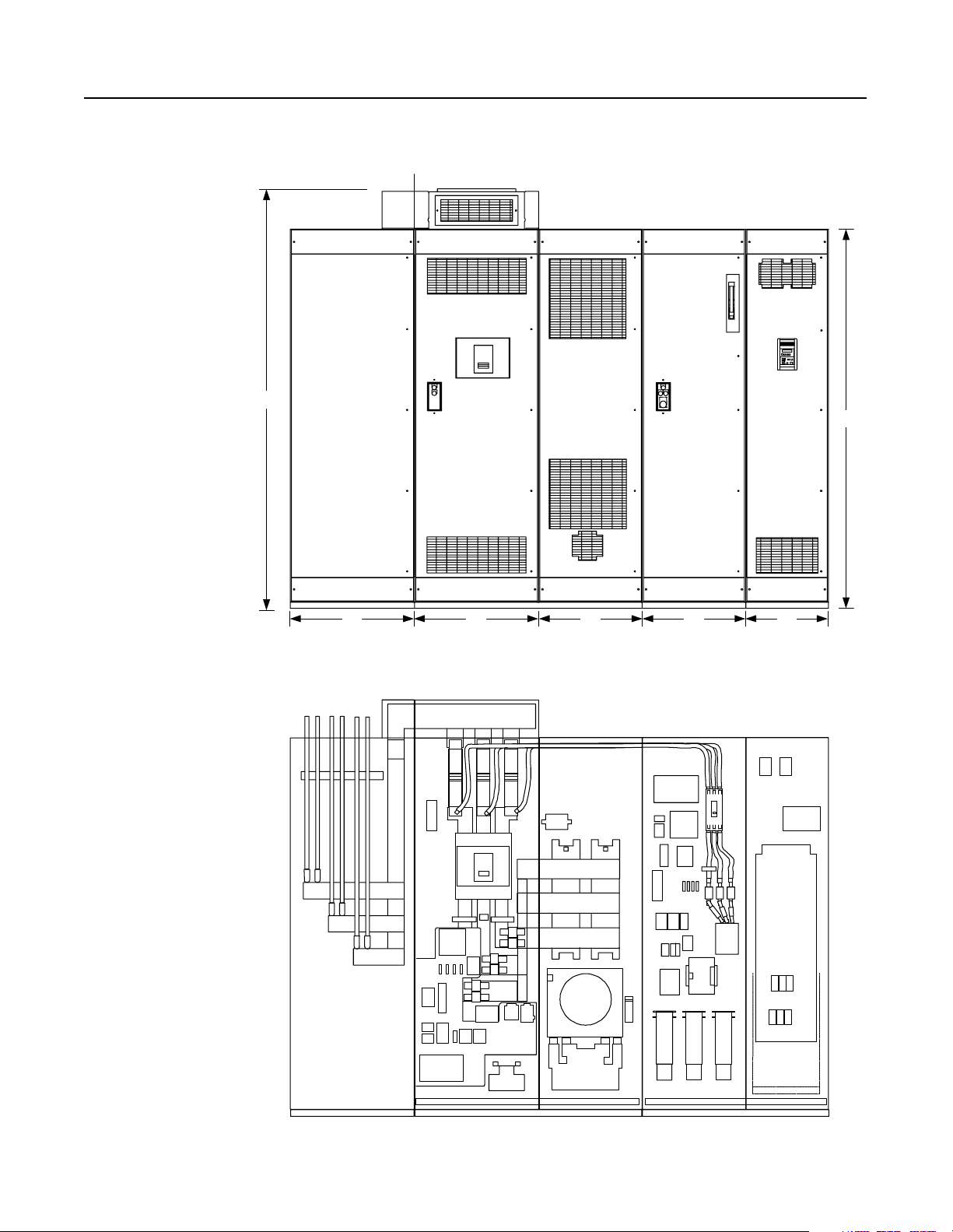

2-2 R1 and S1-Code Parallel Configurations

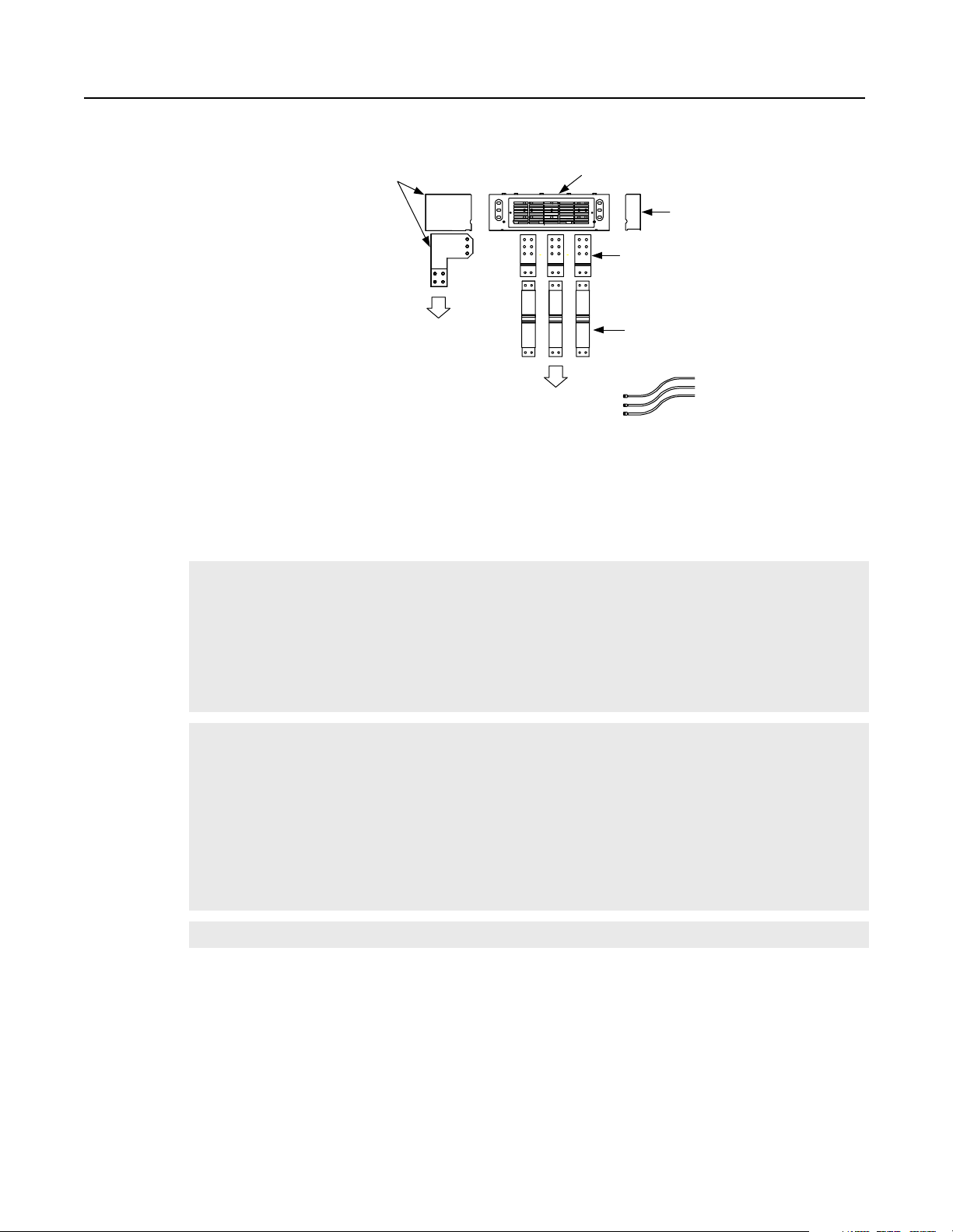

Component Layout Figure 2.3

Enclosure Layout

Front View

Shipping Split

101.25"

91.5"

Cutaway View

30" 30" 25" 25" 20"

Customer Supplied

AC Input Lines

Publication 2364P-5.01 December 1999

Feeder D-code NRU (1500A) K-code RGU

Page 27

Figure 2.4

Overhead Bus Assembly

Feeder

Splice Kit

R1 and S1-Code Parallel Configurations 2-3

30" Overhead

Bus Assembly

End Cap

4" Bus Tabs

To Feeder Buswork

To NRU circuit breaker

Flex Bus

Drop Tabs

New and Revised NRU and RGU Components in the R1 and S1 Configurations

NRU

RGU

CB1 2000A, RD-frame with motor operator, aux contact (2NO/2NC)

EA10

F4, F6

Control power filter, 4kHz

Primary fuse for 5kVA control transformer

Primary fuse for 10kVA control transformer (Opt 6P)

25A, KLDR (for 380V AC input)

30A, KLDR (for 460V AC input)

25A, KLDR (for 575V AC input)

PT1

TB10

CR4

F4, F6

20A, KLDR (for 460V AC input)

17.5A, KLDR (for 575V AC input)

Control power transformer, 5kVA

Control terminal block, 30A, 600V

Precharge Lockout Relay (2NO/2NC)

Primary fuse for 2kVA transformer

Control power transformer, 10kVA (Opt 6P)

10A, KLDR (for 380V AC input)

9A, KLDR (for 460V AC input)

8A, KLDR (for 575V AC input)

F21, F22 DC bus fuses, 250A, 700V, 170M

F25

PT1

TR1

TB4

Fuse, NRU CB1 motor operator, 10A, KLDR

Control power transformer, 2kVA

Timer relay (3NO/1NC)

Control Terminal block, 30A, 600V

35A, KLDR (for 380V AC input)

The RGU AC line is connected to the

bus stubs on the NRU circuit breaker

Overhead bus assembly

Publication 2364P-5.01 December 1999

Page 28

2-4 R1 and S1-Code Parallel Configurations

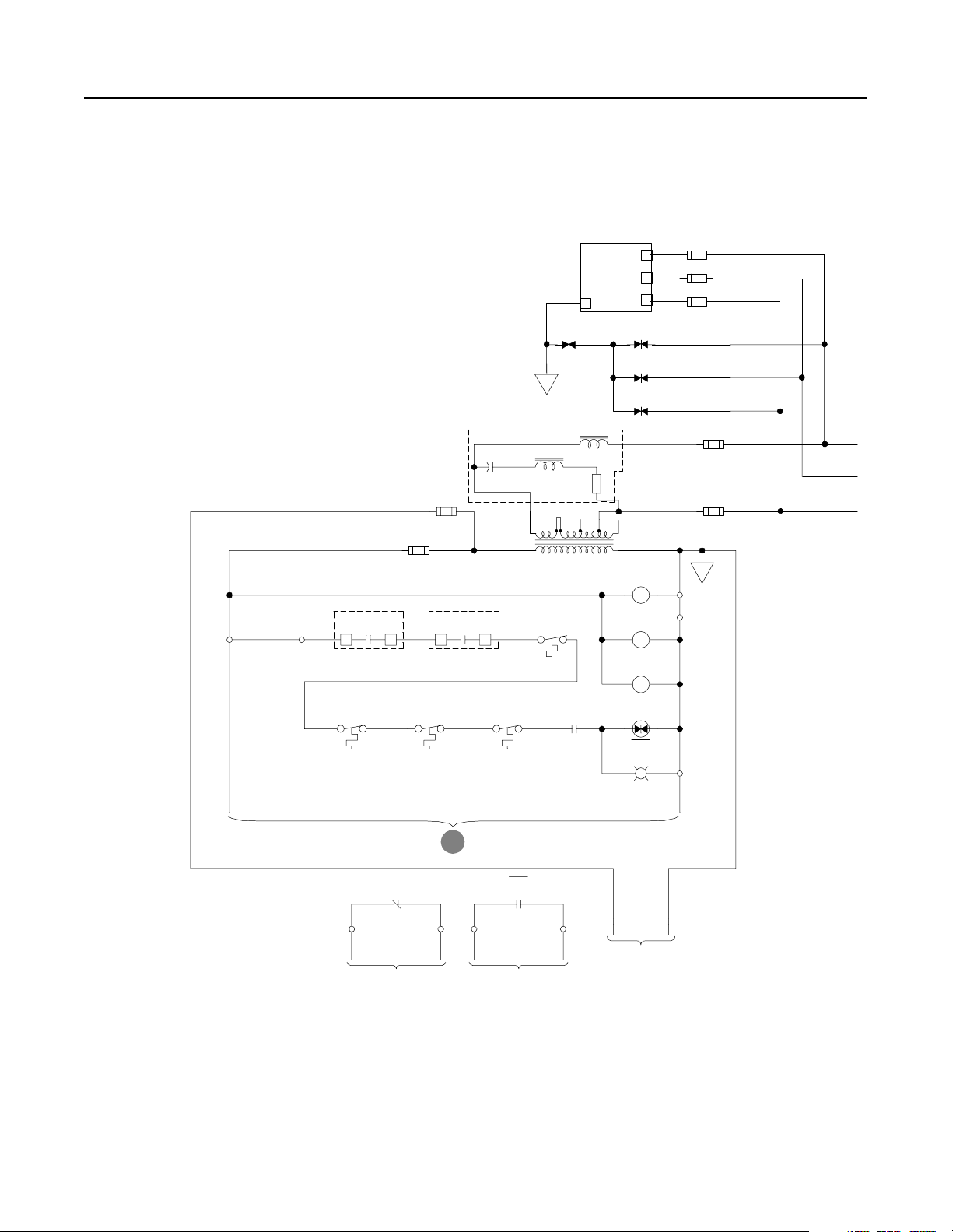

Schematics Figure 2.5

Schematics

NRU

TB1-1

Optional

Remote

Interlock

(JMPR)

TB1-2

Airflow Loss

Bridge Bay

1

EA5-CR

CB Bay

Overtemp

SP4

EA3

Line RC

Suppressor

Com

L1

L2

L3

SP1

F14

F15

F16

SP2

PE

SP3

4KHZ Control Power Filter

EA10

F4

F8

F7

(X1)

460VAC

115VAC

PT1

(X2)

MTR1

Rect. Bridge

MTR2

Choke Comp.

MTR3

CB Bay

CR2

Right

Choke

Overtemp

CH11-TG

CR1

Airflow Loss

3

CB Bay

13

EA6-CR

Heatsink

Overtemp

Left

Heatsink

Overtemp

F6

PE

TB1-9

TB1-10

Publication 2364P-5.01 December 1999

S3

Phase Loss

TB1-3

S1

To Ground Fault Detector

B

and Airflow Sensors

CR1

TB1-4 TB1-5 TB1-6

S2

Fault

CR2

Fault

PL2

A

Not

Faulted

1

L

C

A

V

0

2

1

115VAC

Control Bus To

Inverter Units

N

C

A

V

0

2

1

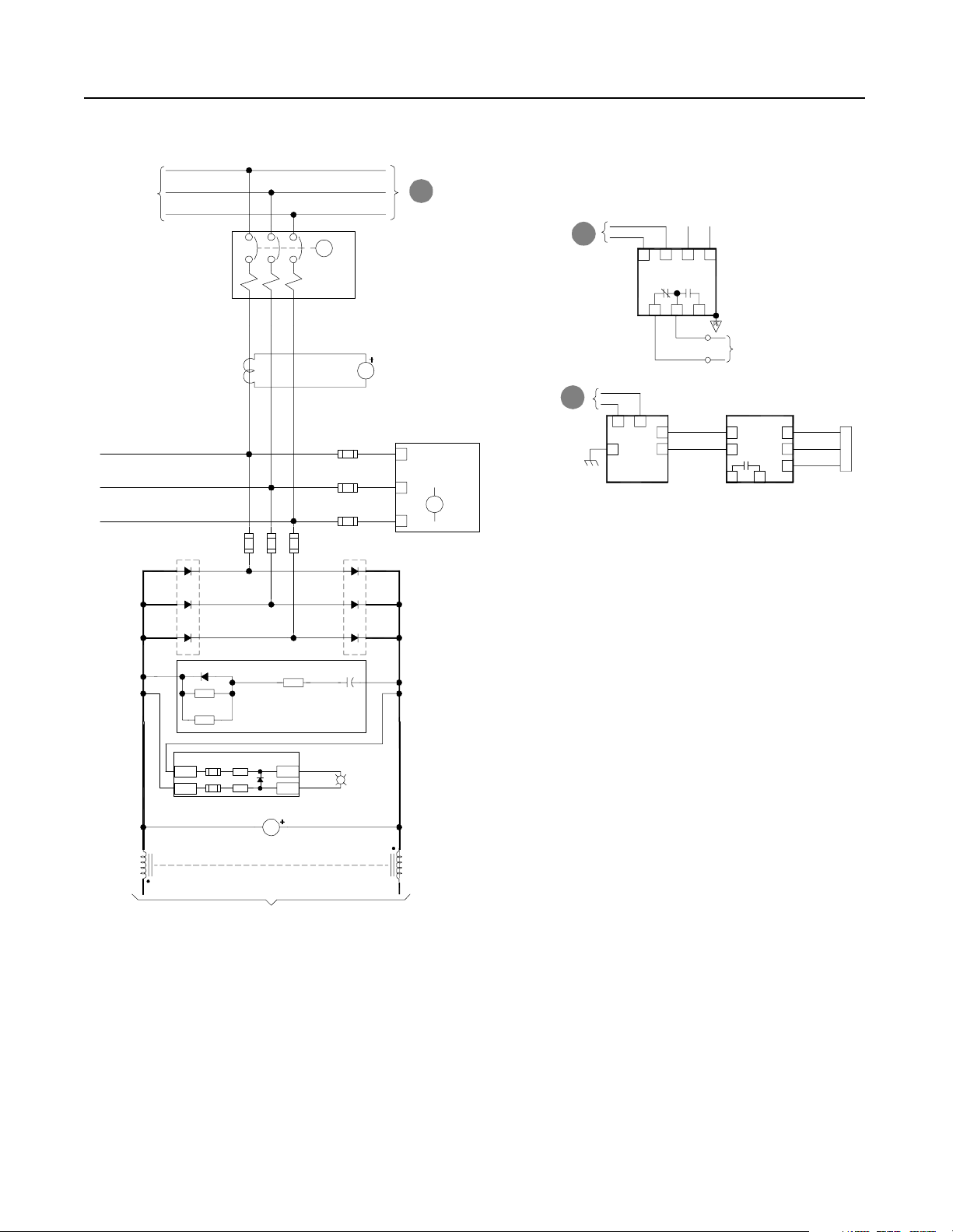

Page 29

R1 and S1-Code Parallel Configurations 2-5

Customer Supplied

3-phase Input

-Bus

Heat

Sink

D1

D3

CT1

F1 F2 F3

M

CB1- NRU

Note:

Control power for this

motorized breaker originates

in the RGU. Do not operate

this breaker manually.

AC Line

Current

AM1

F11

F12

F13

Heat

Sink

D2

D4

A

B

CR

C

+Bus

A

To RGU

AC Input

CR1

Phase

Loss

Relay

B

From NRU

Control Power

B

From NRU

Control Power

7

115VAC

ACN-ACL +

ACG

To Grounding

9

PS1

Resistor

Input

624

TB1-8

TB1-7

1012

Ground Fault

Detector

VM2

J2

3

To Cust omer

Monitoring Device

EA5

J2

In15

Sig 1

In26

+5 2

Com 3

J11

S5

Y

R

B

Flow

Sensor

D5

EA4

Bridge Suppressor

EA2

Bus Indicator PCB

+Bus

-Bus

(X4)

CH11 CH11

(X3)

DC Horizontal Bus To

LED1

LED2

VM1

DC Bus Voltage

Inverter Units

D6HS1 HS2

DC Bus

Energized

R

PL1

(X1)

(X2)

Publication 2364P-5.01 December 1999

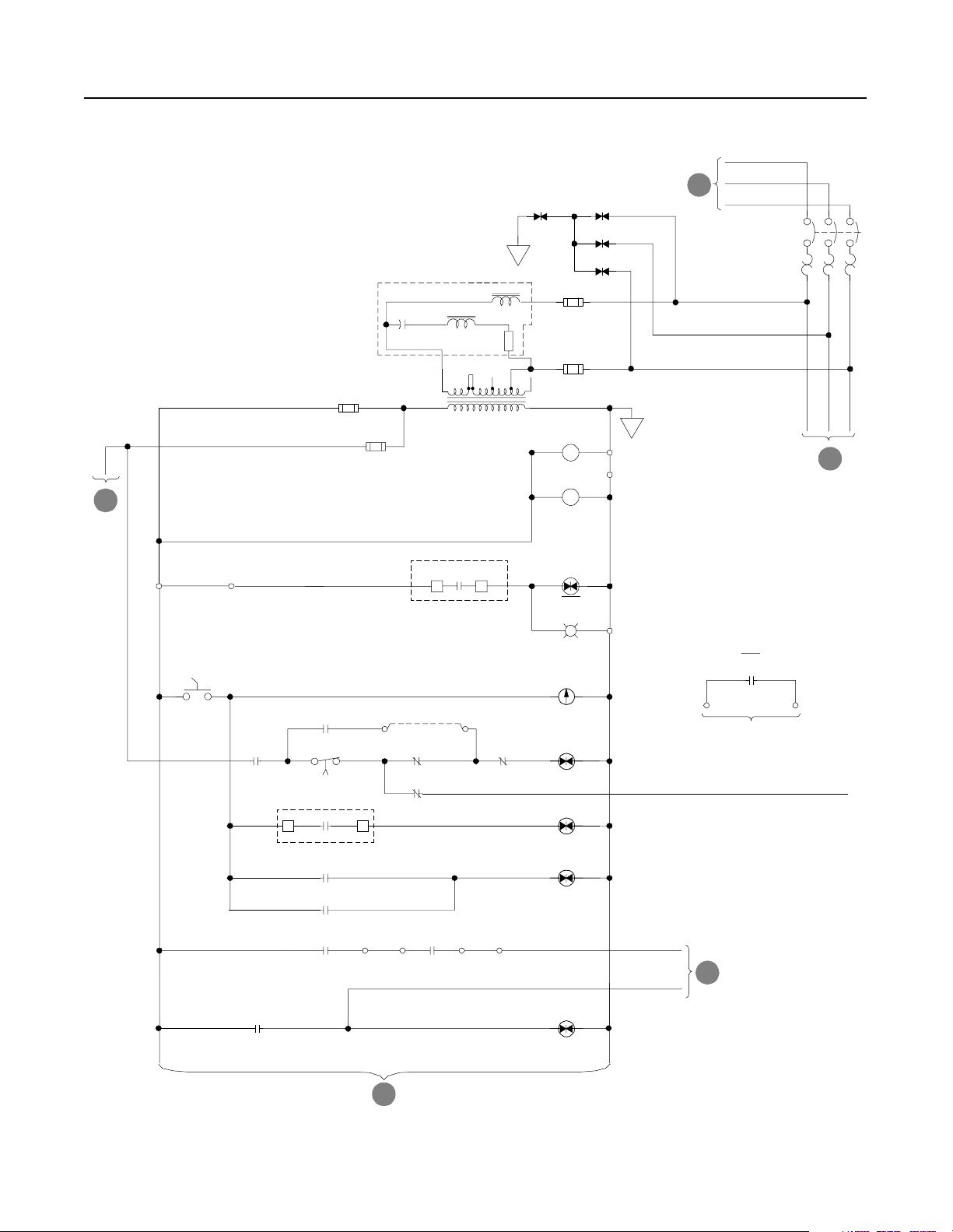

Page 30

2-6 R1 and S1-Code Parallel Configurations

Figure 2.6

Schematics (cont.)

RGU

D

To

CB1-NRU

circuitry

TB1-1

Optional

Remote

Interlock

(JMPR)

RGU/DC Bus

Supply

Off On

S12

TB1-2

TR1

CR4

TR1

From

A

3-phase

AC Input

CB1-RGU

4KHZ Control Power Filter

EA10

SP4

SP1

SP2

PE

SP3

F4

460VAC

F7

(X1)

115VAC

(X2)

F25

RGU Uni t Not

Faulted

14

TB6 TB6

Isolat i on Boa rd

F6

PT1

MTR1

RGU Door Fan

MTR2

RGU Door Fan

CR2

Fault

PL2

A

Not

Faulted

PE

TB1-9

TB1-10

Fault

C

To RGU Input

Fuses

CR2

TB1

TR1

Precharge

11

CR4

12

TB1

CR3

CR4

Timer

M2

Precharge

(20 sec)

TB1-5 TB1-6

Avail able f o r

Customer Use

6

TB6

CR3

Publication 2364P-5.01 December 1999

Bus Control

Isolation Board

CR3

CR4

M1

TB6

TB4-4

9

TB10-7

E

CB1-NRU-A

To RGU

Control

Circuitry

TB10-8

TB4-5

CR3

Pilot

CR4

Precharge

Lockout

M1

Main

External M ain

Enable

F

Isolation Board

To RGU

Page 31

D

Control Power

From RGU

R1 and S1-Code Parallel Configurations 2-7

TB4-8

CB1-NRU

PE

TR1

CR3

TR1

Spring Windup

Wht/Red

TB4-6

TB10-1

Blu

TB4-9

TB10-3

TB4-7 TB10-4

TB4-3

TB10-5

TB10-7

TB4--4 TB4-5

Blk

Red

Blk

LS

X

Y

Y

Y

X

X

LS

M

Y

X

CB1-NRU-A

CB1-NRU-B

Blk

TB10-10

CB1-NRU-A

CB1-NRU-B

TB4-1

Not

Used

TB4-2

Open

Motor

Close

UVR

TB10-2

Wht

TB10-6

Red

TB10-8

Blu

TB10-9

Red

TB10-11

Blu

TB10-12

Publication 2364P-5.01 December 1999

Page 32

2-8 R1 and S1-Code Parallel Configurations

Figure 2.7

Schematics (cont.)

B

From RGU

AC Line

From RGU

Control

Circuitry

AC

Rtn

R10

F2

R11

F3

F4

R12

CT1

F17

F18

F19

Bridge

Fan

Rs

Ss

Ts

0

6

2

2

1

1

-

-

-

1

1

1

J

J

J

CT3

To

PE

Gnd

J7

P1

1

6

-

-

1

1

J

J

M2

CH11

F1

M1

F2

F3

From RGU

E

Control Power

CH1

CH2

CH3

Isolation

Board

TB5

1

Fault

F

Reset

S11

Enable

2

Fault Reset

3

External Main

4

Common

SW1 Settings

115VAC

OffX

24VDCOn

For TB5-1, -2, -3

Burden Resistors

1

TB1

Publication 2364P-5.01 December 1999

To RGU

Control

Circuitry

To RGU

Control

Circuitry

TB6

1

3

4

6

8

9

Aux Control

Fault

Bus

Control

TB2

TB3

3

1

TB2 Resistor

Not Required

3

1

3

J2

Page 33

R1 and S1-Code Parallel Configurations 2-9

d

r

a

o

B

r

e

b

b

u

n

S

To System Network

UP

C1

G

E1

UN

C1

G

E1

J7

Main Bus

DC-DC

Converter

TP3

-t

J6

Bridge Thermal

Sensor (NTC)

J12

Gate Drivers

TP5

-15V+24V +15V

Shd

(+)

Horizontal

DC Bus

(-)

F1

G

G

24V

DC-DC

Aux 24V

J10

WP

C1

E1

Cap

Bank

WN

C1

E1

J10

+15V

-15V

+5V

+12V

-12V

J1

J3

J7

d

r

a

o

B

G

r

e

b

E1

b

u

n

S

VN

C1

G

E1

J8

F1

d

r

a

o

B

r

e

b

b

u

n

S

Gate Driver Board

+24V

VP

C1

Converter

TP8TP4TP6

TP9

+12V+5V -12V

Main Control Bo a rd

J2

RIO Adapter Option

1

1203-GM1

2

3

Y

R

YY

SW1

SW2

J4

Blu

1

SW3

Shd

Clr

2

Off

On

Off

On

Off

On

J1

J8 J9

2

Power

B

T

Supply

Filter

1

Board

B

T

J11

TB7

P13

TB4

TB1

+

-

PE

TE

2

1

1

2

1

2

3

4

5

6

7

8

9

10

+Bus

-Bus

+

-

- Analog In 1

+ Analog In 1

Analog In 1 Common

- Analog In 2

+ Analog In 2

Analog In 2 Common

Analog Out 1

Analog Out 1 Common

Analog Out 2

Analog Out 2 Common

Horizontal DC Bus

To Inve rter Units

EA2

Bus Indicator Board

EA4

Bus Suppressor

LED1

LED2

PL1

R

DC Bus

Energized

RIO Ext SCANport 1 SCANport 2 R2R Comm

Publication 2364P-5.01 December 1999

Page 34

2-10 R1 and S1-Code Parallel Configurations

Publication 2364P-5.01 December 1999

Page 35

Chapter 3

R2 and S2-Code Parallel Configurations

R2-Code Parallel Configuration The R2-code parallel configur ation is a common DC bus front-end

unit consisting of an D-code NRU in parall el with a L-code RGU.

Figure 3.1

R2-Code Parallel Configuration–Information

R2-code Parallel ConfigurationR2-code Ratings

Input Voltage

(V AC)

380 1536

460

575

DC Bus Current

(A DC)

1536

1533

Rated DC Bus

kW

788

954

1190

D-code

NRU

L-code

RGU

S2-Code Parallel Configuration The S2-code parallel configuration is a common DC bus front-end

unit consisting of an E-code NRU in parallel with a L-code RGU.

Figure 3.2

S2-Code Parallel Configuration–Information

S2-code Parallel ConfigurationS2-code Ratings

Input Voltage

(V AC)

380 2036

460

575

DC Bus Current

(A DC)

2036

2033

Rated DC Bus

kW

1045

1265

1578

E-code

NRU

L-code

RGU

Note: Information for the D-code NRU and E-code NRU can be

found in publication 2364E-5.01. Information for the L-code

RGU can be found in publication 2364F-5.01.

Publication 2364P-5.01 December 1999

Page 36

3-2 R2 and S2-Code Parallel Configurations

Component Layout Figure 3.3

Enclosure Layout

Front View

Shipping Split

101.25"

91.5"

30" 30" 25" 30" 25"

Cutaway View

Note: The D-code NRU has only

one AC line fuse per phase.

Customer Supplied

AC Input Lines

Feeder D-code NRU (1500A) or E-code NRU (2000A) L-code RGU

Publication 2364P-5.01 December 1999

Page 37

Figure 3.4

Overhead Bus Assembly

Feeder

Splice Kit

R2 and S2-Code Parallel Configurations 3-3

30" Overhead

Bus Assembly

End Cap

4" Bus Tabs

To Feeder Buswork

To NRU circuit breaker

Flex Bus

Drop Tabs

New and Revised NRU and RGU Components in the R2 and S2 Configurations

NRU CB1 2000A, RD-frame with motor operator, aux contact (2NO/2NC)

RGU

EA10

F4, F6

PT1

TB10

CR4

F4, F6

F21, F22 DC bus fuses, 500A, 700V, 170M

F25

PT1

TR1

TB4

Control power filter, 2kHz

Primary fuse for 5kVA control transformer

25A, KLDR (for 380V AC input)

20A, KLDR (for 460V AC input)

17.5A, KLDR (for 575V AC input)

Control power transformer, 5kVA

Control terminal block, 30A, 600V

Precharge Lockout Relay (2NO/2NC)

Primary fuse for 5kVA transformer

25A, KLDR (for 380V AC input)

20A, KLDR (for 460V AC input)

17.5A, KLDR (for 575V AC input)

Fuse, NRU CB1 motor operator, 10A, KLDR

Control power transformer, 5kVA

Timer relay (3NO/1NC)

Control Terminal block, 30A, 600V

Primary fuse for 10kVA control transformer (Opt 6P)

35A, KLDR (for 380V AC input)

30A, KLDR (for 460V AC input)

25A, KLDR (for 575V AC input)

Control power transformer, 10kVA (Opt 6P)

The RGU AC line is connected to the

bus stubs on the NRU circuit breaker

Overhead bus assembly

Publication 2364P-5.01 December 1999

Page 38

3-4 R2 and S2-Code Parallel Configurations

Schematics Figure 3.5

Schematics

NRU

TB1-1

Optional

Remote

Interlock

(JMPR)

TB1-2

Airflow Loss

Bridge Bay

1

EA5-CR

CB Bay

Overtemp

SP4

EA3

Line RC

Suppressor

Com

L1

L2

L3

SP1

F14

F15

F16

SP2

PE

SP3

2KHZ Control Power Filter

EA10

F4

F8

F7

(X1)

460VAC

115VAC

PT1

(X2)

MTR1

Rect. Bridge

MTR2

Choke Comp.

MTR3

CB Bay

CR2

Right

Choke

Overtemp

CH11-TG

CR1

Airflow Loss

3

CB Bay

13

EA6-CR

Heatsink

Overtemp

Left

Heatsink

Overtemp

F6

PE

TB1-9

TB1-10

Publication 2364P-5.01 December 1999

S3

Phase Loss

TB1-3

S1

To Ground Fault Detector

B

and Airflow Sensors

CR1

TB1-4 TB1-5 TB1-6

S2

Fault

CR2

Fault

PL2

A

Not

Faulted

1

L

C

A

V

0

2

1

115VAC

Control Bus To

Inverter Units

N

C

A

V

0

2

1

Page 39

R2 and S2-Code Parallel Configurations 3-5

Customer Supplied

3-phase Input

-Bus

Heat

Sink

D1

D3

CT1

F1 F2 F3

M

CB1- NRU

Note:

Control power for this

motorized breaker originates

in the RGU. Do not operate

this breaker manually.

AC Line

Current

AM1

F11

F12

F13

Heat

Sink

D2

D4

A

B

CR

C

+Bus

A

To RGU

AC Input

CR1

Phase

Loss

Relay

B

From NRU

Control Power

B

From NRU

Control Power

7

115VAC

ACN-ACL +

ACG

To Grounding

9

PS1

Resistor

Input

624

TB1-8

TB1-7

1012

Ground Fault

Detector

VM2

J2

3

To Cust omer

Monitoring Device

EA5

J2

In15

Sig 1

In26

+5 2

Com 3

J11

S5

Y

R

B

Flow

Sensor

D5

EA4

Bridge Suppressor

EA2

Bus Indicator PCB

+Bus

-Bus

(X4)

CH11 CH11

(X3)

DC Horizontal Bus To

LED1

LED2

VM1

DC Bus Voltage

Inverter Units

D6HS1 HS2

DC Bus

Energized

R

PL1

(X1)

(X2)

Publication 2364P-5.01 December 1999

Page 40

3-6 R2 and S2-Code Parallel Configurations

Figure 3.6

Schematics (cont.)

RGU

D

To

CB1-NRU

circuitry

TB1-1

Optional

Remote

Interlock

(JMPR)

RGU/DC Bus

Supply

Off On

S12

TB1-2

TR1

CR4

TR1

From

A

3-phase

AC Input

CB1-RGU

2KHZ Control Power Filter

EA10

SP4

SP1

SP2

PE

SP3

F4

460VAC

F7

(X1)

115VAC

(X2)

F25

RGU Uni t Not

Faulted

14

TB6 TB6

Isolat i on Boa rd

F6

PT1

MTR1,2

Bay Door Fans

MTR3,4

Bay 1 Door Fans

CR2

Fault

PL2

A

Not

Faulted

PE

TB1-9

TB1-10

Fault

C

To RGU Input

Fuses

CR2

TB1

TR1

Precharge

11

CR4

12

TB1

CR3

CR4

Timer

M2

Precharge

(20 sec)

TB1-5 TB1-6

Avail able f o r

Customer Use

6

TB6

CR3

Publication 2364P-5.01 December 1999

Bus Control

Isolation Board

CR3

CR4

M1

TB6

TB4-4

9

E

CB1-NRU-A

TB10-7 TB10-8

To RGU

Control

Circuitry

TB4-5

CR3

Pilot

CR4

Precharge

Lockout

M1

Main

External M ain

Enable

F

Isolation Board

To RGU

Page 41

D

Control Power

From RGU

R2 and S2-Code Parallel Configurations 3-7

TB4-8

CB1-NRU

PE

TR1

CR3

TR1

Spring Windup

Wht/Red

TB4-6

TB10-1

Blu

TB4-9

TB10-3

TB4-7 TB10-4

TB4-3

TB10-5

TB4-4 TB4-5

TB10-7

Blk

Red

Blk

LS

X

Y

Y

Y

X

X

LS

M

Y

X

CB1-NRU-A

CB1-NRU-B

Blk

TB10-10

CB1-NRU-A

CB1-NRU-B

TB4-1

Not

Used

TB4-2

Open

Motor

Close

UVR

TB10-2

Wht

TB10-6

Red

TB10-8

Blu

TB10-9

Red

TB10-11

Blu

TB10-12

Publication 2364P-5.01 December 1999

Page 42

3-8 R2 and S2-Code Parallel Configurations

Figure 3.7

Schematics (cont.)

B

From RGU

AC Line

From RGU

Control

Circuitry

AC

Rtn

R10

F2

R11

F3

F4

R12

CT1

F17

F18

F19

Bridge

Fan

Rs

Ss

Ts

0

6

2

2

1

1

-

-

-

1

1

1

J

J

J

CT3

To

PE

Gnd

J7

P1

1

6

-

-

1

1

J

J

M2

F1

M1

F2

F3

From RGU

E

Control Power

CH1

CH2

CH3

CH11

Isolation

Board

TB5

1

Fault

F

Reset

S11

Enable

2

Fault Reset

3

External Main

4

Common

SW1 Settings

115VAC

OffX

24VDCOn

For TB5-1, -2, -3

Burden Resistors

1

TB1

Publication 2364P-5.01 December 1999

To RGU

Control

Circuitry

To RGU

Control

Circuitry

TB6

1

3

4

6

8

9

Aux Control

Fault

Bus

Control

TB2

TB3

3

1

TB2 Resisto r

Not Required

3

1

3

J2

Page 43

R2 and S2-Code Parallel Configurations 3-9

e

c

e

a

t

f

a

r

e

G

t

n

I

e

c

e

a

t

f

r

a

e

G

t

n

I

To System Network

C1

G

E1

C1

G

E1

J7

Main Bus

DC-DC

Converter

TP3

-t

J6

Bridge Thermal

Sensor (NTC)

J12

UP

DETAIL

UN

Gate Drivers

TP5

-15V+24V +15V

Shd

(+)

Horizontal

DC Bus

(-)

F1

See U

r

Phase

e

b

b

Detail

u

n

S

VP

See U

Phase

Detail

VN

J8

F1

J2

J4

Blu

1

Shd

Clr

2

TP8TP4TP6

TP9

+12V+5V -12V

RIO Adapter Option

1

2

3

SW1

SW2

SW3

+24V

1203-GM1

R

J1

J8 J9

See U

r

Phase

e

b

b

Detail

u

n

S

WP

See U

Phase

Detail

WN

Gate Driver Board

24V

DC-DC

Converter

Aux 24V

Main Control Bo a rd

Y

YY

Off

On

Off

On

Off

On

J10

r

e

b

b

u

n

S

Cap

Bank

J10

+15V

-15V

+5V

+12V

-12V

J1

J3

J7

2

Power

B

T

Supply

Filter

1

Board

B

T

J11

TB7

P13

TB4

TB1

+

-

PE

TE

2

1

1

2

1

2

3

4

5

6

7

8

9

10

+Bus

-Bus

+

-

- Analog In 1

+ Analog In 1

Analog In 1 Common

- Analog In 2

+ Analog In 2

Analog In 2 Common

Analog Out 1

Analog Out 1 Common

Analog Out 2

Analog Out 2 Common

Horizontal DC Bus

To Inve rter Units

EA2

Bus Indicator Board

EA4

Bus Suppressor

LED1

LED2

PL1

R

DC Bus

Energized

RIO Ext SCANport 1 SCANport 2 R2R Comm

Publication 2364P-5.01 December 1999

Page 44

3-10 R2 and S2-Code Parallel Configurations

Publication 2364P-5.01 December 1999

Page 45

Chapter 4

R3 and S3-Code Parallel Configurations

R3-Code Parallel Configuration The R3-code parallel configur ation is a common DC bus front-end

unit consisting of an D-code NRU in parall el with an M-code RGU.

Figure 4.1

R3-Code Parallel Configuration–Information

R3-code Parallel ConfigurationR3-code Ratings

Input Voltage

(V AC)

380 1575

460

575

DC Bus Current

(A DC)

1575

1569

Rated DC Bus

kW

808

978

1218

D-code

NRU

M-code

RGU

S3-Code Parallel Configuration The S3-code parallel configuration is a common DC bus front-end

unit consisting of an E-code NRU in parallel with an M-code RGU.

Figure 4.2

S3-Code Parallel Configuration–Information

S3-code Parallel ConfigurationS3-code Ratings

Input Voltage

(V AC)

380 2075

460

575

DC Bus Current

(A DC)

2075

2069

Rated DC Bus

kW

1064

1289

1606

E-code

NRU

M-code

RGU

Note: Information for the D-code NRU and E-code NRU can be

found in publication 2364E-5.01. Information for the M-code

RGU can be found in publication 2364F-5.01.

Publication 2364P-5.01 December 1999

Page 46

4-2 R3 and S3-Code Parallel Configurations

Component Layout Figure 4.3

Enclosure Layout

Front View

Shipping Split

101.25"

91.5"

30" 30" 25" 35" 35"

Cutaway View

Note:

The D-code NRU has only

one AC line fuse per phase.

Customer Supplied

AC Input Lines

Feeder D-code NRU (1500A) or E-code NRU (2000A) M-code RGU

Publication 2364P-5.01 December 1999

Page 47

R3 and S3-Code Parallel Configurations 4-3

Figure 4.4

Overhead Bus Assembly

Feeder

Splice Kit

To Feeder Buswork

30" Overhead

Bus Assembly

4" Bus Tabs

Flex Bus

Drop Tabs

To NRU circuit breaker

25" Overhead

Bus Assembly

Joiner-Splice Kits

New and Revised NRU and RGU Components in the R3 and S3 Configurations

NRU CB1 2000A, RD-frame with motor operator, aux contact (2NO/2NC)

EA10

F4, F6

PT1

TB10

Control power filter, 2kHz

Primary fuse for 5kVA control transformer

25A, KLDR (for 380V AC input)

20A, KLDR (for 460V AC input)

17.5A, KLDR (for 575V AC input)

Control power transformer, 5kVA

Control terminal block, 30A, 600V

35" Overhead

Bus Assembly

End

Cap

2" Bus Tabs

Flex Bus

Drop Tabs

To RGU circuit breaker

Primary fuse for 10kVA control transformer (Opt 6P)

35A, KLDR (for 380V AC input)

30A, KLDR (for 460V AC input)

25A, KLDR (for 575V AC input)

Control power transformer, 10kVA (Opt 6P)

RGU

CR4

F4, F6

Precharge Lockout Relay (2NO/2NC)

Primary fuse for 5kVA transformer

25A, KLDR (for 380V AC input)

20A, KLDR (for 460V AC input)

17.5A, KLDR (for 575V AC input)

F21, F22 DC bus fuses, 500A, 700V, 170M

21A, 22A

F25

PT1

TR1

TB4

Fuse, NRU CB1 motor operator, 10A, KLDR

Control power transformer, 5kVA

Timer relay (3NO/1NC)

Control Terminal block, 30A, 600V

Overhead bus assembly

Publication 2364P-5.01 December 1999

Page 48

4-4 R3 and S3-Code Parallel Configurations

Schematics Figure 4.5

Schematics

NRU

TB1-1

Optional

Remote

Interlock

(JMPR)

TB1-2

Airflow Loss

Bridge Bay

1

EA5-CR

CB Bay

Overtemp

SP4

EA3

Line RC

Suppressor

Com

L1

L2

L3

SP1

F14

F15

F16

SP2

PE

SP3

2KHZ Control Power Filter

EA10

F4

F8

F7

(X1)

460VAC

115VAC

PT1

(X2)

MTR1

Rect. Bridge

MTR2

Choke Comp.

MTR3

CB Bay

CR2

Right

Choke

Overtemp

CH11-TG

CR1

Airflow Loss

3

CB Bay

13

EA6-CR

Heatsink

Overtemp

Left

Heatsink

Overtemp

F6

PE

TB1-9

TB1-10

Publication 2364P-5.01 December 1999

S3

Phase Loss

TB1-3

S1

To Ground Fault Detector

B

and Airflow Sensors

CR1

TB1-4 TB1-5 TB1-6

S2

Fault

CR2

Fault

PL2

A

Not

Faulted

1

L

C

A

V

0

2

1

115VAC

Control Bus To

Inverter Units

N

C

A

V

0

2

1

Page 49

R3 and S3-Code Parallel Configurations 4-5

Customer Supplied

3-phase Input

-Bus

Heat

Sink

D1

D3

CT1

F1 F2 F3

M

CB1- NRU

Note:

Control power for this

motorized breaker originates

in the RGU. Do not operate

this breaker manually.

AC Line

Current

AM1

F11

F12

F13

Heat

Sink

D2

D4

A

B

CR

C

+Bus

A

To RGU

AC Input

CR1

Phase

Loss

Relay

B

From NRU

Control Power

B

From NRU

Control Power

7

115VAC

ACN-ACL +

ACG

To Grounding

9

PS1

Resistor

Input

624

TB1-8

TB1-7

1012

Ground Fault

Detector

VM2

J2

3

To Cust omer

Monitoring Device

EA5

J2

In15

Sig 1

In26

+5 2

Com 3

J11

S5

Y

R

B

Flow

Sensor

D5

EA4

Bridge Suppressor

EA2

Bus Indicator PCB

+Bus

-Bus

(X4)

CH11 CH11

(X3)

DC Horizontal Bus To

LED1

LED2

VM1

DC Bus Voltage

Inverter Units

D6HS1 HS2

DC Bus

Energized

R

PL1

(X1)

(X2)

Publication 2364P-5.01 December 1999

Page 50

4-6 R3 and S3-Code Parallel Configurations

Figure 4.6

Schematics (cont.)

RGU

D

To

CB1-NRU

circuitry

TB1-1

Optional

Remote

Interlock

(JMPR)

RGU/DC Bus

Supply

Off On

S12

TB1-2

TR1

F7

Choke

Thermoguards

S1 - 3

CR4

TR1

EA10

F25

11

TB1

CR4

CR4

2KHZ Control Power Filter

460VAC

(X1)

115VAC

RGU Uni t Not

Faulted

14

TB6 TB6

Isolat i on Boa rd

12

TB1

CR3

SP4

PE

PT1

(X2)

Bay 1 Door Fan

Bay 1 Internal Fan

RGU Door Fans

Precharge

Precharge

F4

F6

MTR2

MTR3

MTR1

CR2

Fault

PL2

A

Not

Faulted

TR1

Timer

M2

SP1

SP2

SP3

PE

TB1-9

TB1-10

(20 sec)

From

3-phase

AC Input

A

Fault

CR2

TB1-5 TB1-6

Avail able f o r

Customer Use

CB1-RGU

C

To RGU Input

Fuses

6

TB6

CR3

Publication 2364P-5.01 December 1999

Bus Control

Isolation Board

CR3

CR4

M1

TB6

TB4-4

9

E

CB1-NRU-A

TB10-7 TB10-8

To RGU

Control

Circuitry

TB4-5

CR3

Pilot

CR4

Precharge

Lockout

M1

Main

External Main

Enable

F

Isolation Board

To RGU

Page 51

D

From RGU

Control Power

R3 and S3-Code Parallel Configurations 4-7

TB4-8

CB1-NRU

PE

TR1

CR3

TR1

Spring Windup

Wht/Red

TB4-6

TB10-1

Blu

TB4-9

TB10-3

TB4-7 TB10-4

TB4-3

TB10-5

TB10-7

TB4-4 TB4-5

Blk

Red

Blk

LS

X

Y

Y

Y

X

X

LS

M

Y

X

CB1-NRU-A

CB1-NRU-B

Blk

TB10-10

CB1-NRU-A

CB1-NRU-B

TB4-1

Not

Used

TB4-2

Open

Motor

Close

UVR

TB10-2

Wht

TB10-6

Red

TB10-8

Blu

TB10-9

Red

TB10-11

Blu

TB10-12

Publication 2364P-5.01 December 1999

Page 52

4-8 R3 and S3-Code Parallel Configurations

Figure 4.7

Schematics (cont.)

B

From RGU

AC Line

From RGU

Control

Circuitry

M2

F1

M1

F2

F3

From RGU

E

Control Power

Fault

F

Reset

CH1

CH2

CH3

S11

F2

F3

F4

AC

Rtn

Isolation

Board

TB5

1

Enable

2

Fault Reset

3

External Main

4

Common

R10, R10A

R11, R11A

R12, R12A

CH

F17

F18

F19

Bridge

Fan

CT1

CT2

Rs

Ss

Ts

0

6

2

2

1

1

-

-

-

1

1

1

J

J

J

SW1 Settings

For TB5-1, -2, -3

CT3

CT Power

Supply

CR

To

PE

Gnd

J7

P1

115VAC

OffX

24VDCOn

Burden Resistors

1

TB1

1

6

-

-

1

1

J

J

Publication 2364P-5.01 December 1999

To RGU

Control

Circuitry

To RGU

Control

Circuitry

TB6

1

3

4

6

8

9

Aux Control

Fault

Bus

Control

TB2

TB3

3

1

3

1

3

J2

Page 53

R3 and S3-Code Parallel Configurations 4-9

e

c

e

a

t

f

a

r

e

G

t

n

I

e

c

e

a

t

f

r

a

e

G

t

n

I

To System Networ k

C1

G

E1

C1

G

E1

J7

Main Bus

DC-DC

Converter

TP3

-t

J6

Bridge Thermal

Sensor (NTC)

J12

UP1

DETAIL

UP2

C1

G

E1

UN1

UN2

C1

G

E1

Gate Drivers

TP5

(+)

Horizontal

DC Bus

(-)

+

See U

r

Phase

e

b

b

Detail

u

n

S

VP1

VP2

See U

Phase

Detail

VN1

VN2

J8

F1

-15V+24V +15V

J2

J4

Blu

1

Shd

Shd

Clr

2

TP8TP4TP6

TP9

+12V+5V -12V

RIO Adapter Option

1

2

3

SW1

SW2

SW3

+24V

1203-GM1

R

J1

J8 J9

See U

r

Phase

e

b

b

Detail

u

n

S

WP1

WP2

See U

Phase

Detail

WN1

WN2

Gate Driver Board

24V

DC-DC

Converter

Aux 24V

Main Control Bo a rd

Y

YY

Off

On

Off

On

Off

On

J10

r

e

b

b

u

n

S

Cap

+15V

-15V

+5V

+12V

-12V

Bank

J10

J1

J3

J7

2

Power

B

T

Supply

Filter

1

Board

B

T

J11

TB7

P13

TB4

TB1

-

PE

TE

2

1

1

2

1

2

3

4

5

6

7

8

9

10

+Bus

-Bus

+

-

- Analog In 1

+ Analog In 1

Analog In 1 Common

- Analog In 2

+ Analog In 2

Analog In 2 Common

Analog Out 1

Analog Out 1 Common

Analog Out 2

Analog Out 2 Common

Horizontal DC Bus

To Inve rter Units

EA2

Bus Indicator Board

EA4

Bus Suppressor

LED1

LED2

PL1

R

DC Bus

Energized

RIO Ext SCANport 1 SCANport 2 R2R Comm

Publication 2364P-5.01 December 1999

Page 54

4-10 R3 and S3-Code Parallel Configurations

Publication 2364P-5.01 December 1999

Page 55

Chapter 5

R4 and S4-Code Parallel Configurations

R4-Code Parallel Configuration The R4-code parallel configur ation is a common DC bus front-end

unit consisting of an D-code NRU in parall el with an N-code RGU.

Figure 5.1

R4-Code Parallel Configuration–Information

R4-code Parallel ConfigurationR4-code Ratings

Input Voltage

(V AC)

380 1600

460

575

DC Bus Current

(A DC)

1600

1591

Rated DC Bus

kW

821

994

1235

D-code

NRU

N-code

RGU

S4-Code Parallel Configuration The S4-code parallel configuration is a common DC bus front-end

unit consisting of an E-code NRU in parallel with an N-code RGU.

Figure 5.2

S4-Code Parallel Configuration–Information

S4-code Parallel ConfigurationS4-code Ratings

Input Voltage

(V AC)

380 2100

460

575

DC Bus Current

(A DC)

2100

2091

Rated DC Bus

kW

1077

1304

1623

E-code

NRU

N-code

RGU

Note: Information for the D-code NRU and E-code NRU can be

found in publication 2364E-5.01. Information for the N-code

RGU can be found in publication 2364F-5.01.

Publication 2364P-5.01 December 1999

Page 56

5-2 R4 and S4-Code Parallel Configurations

9

Component Layout Figure 5.3

Enclosure Layout

Front View

101.25"

Shipping Split

Cutaway View

30" 30" 25" 35" 35"

Customer Supplied

AC Input Lines

20"

Feeder D-code NRU (1500A) or E-code NRU (2000A) N-code RGU

Publication 2364P-5.01 December 1999

Page 57

R4 and S4-Code Parallel Configurations 5-3

20" Overhead

Figure 5.4

Overhead Bus Assembly

Feeder

Splice Kit

To Feeder Buswork

30" Overhead

Bus Assembly

4" Bus Tabs

Flex Bus

Drop Tabs

To NRU circuit breaker

25" Overhead

Bus Assembly

Bus Assembly

Joiner-Splice Kits

New and Revised NRU and RGU Components in the R4 and S4 Configurations

NRU CB1 2000A, RD-frame with motor operator, aux contact (2NO/2NC)

EA10

F4, F6

PT1

TB10

Control power filter, 2kHz

Primary fuse for 5kVA control transformer

25A, KLDR (for 380V AC input)

20A, KLDR (for 460V AC input)

17.5A, KLDR (for 575V AC input)

Control power transformer, 5kVA

Control terminal block, 30A, 600V

Primary fuse for 10kVA control transformer (Opt 6P)

35A, KLDR (for 380V AC input)

30A, KLDR (for 460V AC input)

25A, KLDR (for 575V AC input)

Control power transformer, 10kVA (Opt 6P)

35" Overhead

Bus Assembly

End

Cap

2" Bus Tabs

Flex Bus

Drop Tabs

To RGU circuit breaker

RGU