Page 1

NFPA 79 Compliant Bulletin 194RC Cable Operated Disconnect

(Cat 194RC-NJ030P3, -NJ030P4, -NJ030P6, -NJ030P10, -NJ060P3, -NJ060P4, -NJ060P6,

-NJ060P10, -NC030P3, -NC030P4, -NC030P6, -NC030P10, -NN030P3, -NN030P4, -NN030P6,

-NN030P10,-NN060P3, -NN060P4, -NN060P6, -NN060P10, -NJ030M3, -NJ030M4, -NJ030M6,

-NJ030M10, -NJ060M3, -NJ060M4, -NJ060M6, -NJ060M10, -NC030M3, -NC030M4, -NC030M6,

-NC030M10,

-NN030M3,

-NN030M4, -NN030M6, -NN030M10, -NN060M3, -NN060M4,

-NN060M6, -NN060M10, -NJ030S3, -NJ030S4, -NJ030S6, -NJ030S10, -NJ060S3, -NJ060S4,

-NJ060S6, -NJ060S10, -NC030S3, -NC030S4, -NC030S6, -NC030S10, -NN030S3, -NN030S4,

-NN030S6, -NN030S10, -NN060S3, -NN060S4, -NN060S6, -NN060S10)

ATTENTION: To prevent electrical shock, disconnect from power source before installing or servicing. Install in

suitable enclosure. Keep free from contaminants.

Fuse cover must be installed for safe operation.

Check that disconnect switch is in OFF position before assembly.

General Information

The Cable Operated Mechanism provides a means of externally operating the disconnect switch and can be applied

to enclosures of varying heights and depths. The handle can be used with NEMA 1, 3R, 12, 4, 4X enclosure

applications, depending on the accessory components selected. An operating handle, flexible cable, and

mechanism are required for standard application. Different lengths of cables are available for use with the wide

range of depths of various enclosures (3' through 10'). When selecting the length of the Flexible Cable, ensure

Minimum Bending Radius of 6 inches is maintained to operate properly. (See Figure 1-2). The standard method of

shipment includes the mechanism preset at the factory. If minor field adjustments are required see Figure 1-5.

ATTENTION: Before any installation or maintenance is performed, make sure that the disconnect switch is not energized.

Bulletin 194RC Installation

1. Install disconnect switch with four #10-32 screws. (See Figure 1-1).

Attach disconnect mechanism to enclosure back

panel using #10-32 screws through mounting holes

Figure 1-1 Attaching Disconnect to Enclosure Back Panel

Page 2

Bulletin 194RC Installation (Cont'd)

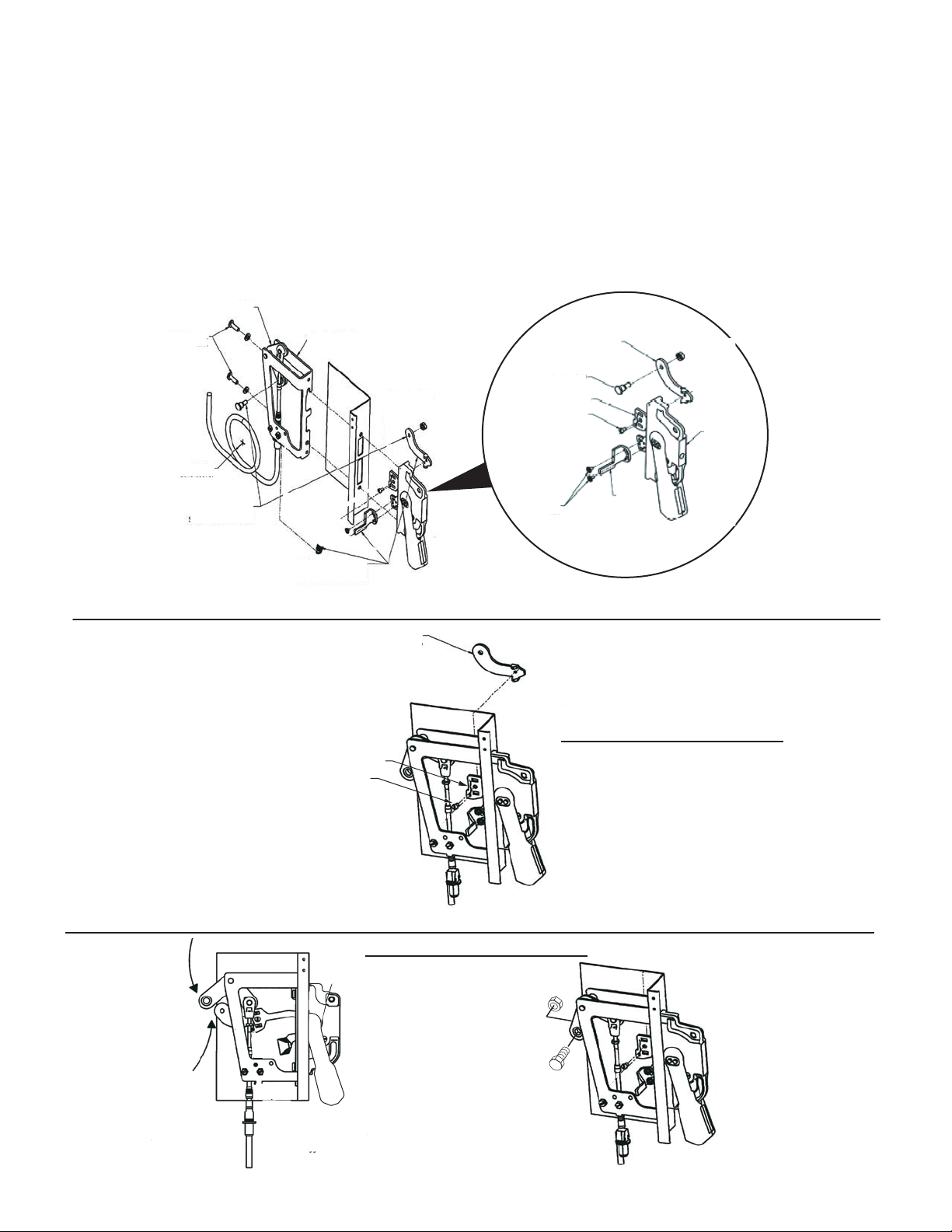

2. Install handle to enclosure by placing the outer handle mechanism with the attached gasket over the enclosure cutout. Insert

the top mounting screw with lockwasher through the enclosure and thread it into the outer handle mechanism for a few turns but

not all the way. (See Figure 1-2).

3. Slide the toggle mechanism assembly over the top handle mounting screw. Insert the bottom handle mounting screw and

lockwasher through the toggle mechanism assembly, through the enclosure and into the handle. Tighten both mounting screws

to specified torque. (See Figure 1-2).

4. Assemble adapter link to actuator link. Tighten to specified torque. (See Figure 1-3).

5. Align adapter link with the bell crank. Attach bell crank to adapter link with shoulder bolt and nut. Tighten to specified torque.

(See Figure 1-4).

6. Mount door hasp to handle using the two screws provided with the handle. (See Figure 1-2).

7. Operate handle mechanism to ensure functionality. To operate either close door or defeat door interlock.

8. If minor adjustments are necessary, refer to adjustment checklist (Page 3).

9. Install appropriate door hardware (supplied). (See Figure 1-7).

Bail

23 - 37 lb-in

Max.

6" Min.

Bend Radius

Connect Adapter Link

to Bell Crank with

Shoulder Bolt and Nut

These items are to be assembled

after handle is mounted to enclosure

Toggle

Mechanism

7 - 11 lb-in

Adapter Link

Shoulder Bolt

18 - 20 lb-in

Actuator Link

18 - 20 lb-in

Max.

Door

Hasp

Figure 1-2 Securing Toggle Mechanism and Handle to Flange

Assemble Adaptor Link

with Screw to Actuator Link

Tighten to 18 - 20 lb-in.

Note: Make sure handle is in OFF position.

Actuator Link

Actuator Link Screw

Handle

Mechanism

Rotate Bell Crank

and Adaptor Link

to line up holes

Figure 1-3 Assembly of Adapter Link to Actuator Link

Note: Make sure handle is in OFF position.

After aligning assemble with

Shoulder Bolt and Nut

Tighten to 18 - 20 lb-in.

(2)

Figure 1-4 Assembly of Adapter Link to Bell Crank Using Shoulder Bolt

(2)

Page 3

ATTENTION: Before any installation or maintenance is performed, make sure that the disconnect switch is not energized.

Adjustment Checklist

Situation:

Handle and Cable Operated Mechanism turns ON, but disconnect switch does not transition to ON.

Adjustment:

Loosen the lifting washer

Check the OFF position of the actuator mechanism, that the lifting nut and sleeve of cable do not come into contact

with the bulkhead connector (Figure 1-5). If they do, move bulkhead connectors accordingly.

Situation:

Handle and Cable Operated Mechanism turns OFF, but disconnect switch does not transition to OFF.

Adjustment:

For the Cable Operated Disconnect Mechanism, loosen the washer

positive action. Tighten both nuts and recheck for ON and OFF positions (Figure 1-5).

Be certain after adjustment to have a minimum of 1 thread past the washer

If any other adjustment problems should arise, contact your local Allen-Bradley representative.

/

nut while tightening the washer / lockwasher / nut, two or three turns should be sufficient (see Figure

NOTICE

/

lock-washer / nut until the Disconnect Switch turns OFF with

NOTICE

/ l

ockwasher / nut assembly (Figure 1-5).

1-5).

Dimensions

Washer / Lockwasher / Nut

Tighten to 40 - 45 lb-in

Lifting Washer / Nut

Slider

Bulkhead Connector

Tighten to 65 - 70 lb-in

Figure 1-5 Cable Operated Disconnect Mechanism

6.891

4.300

ø .210

(3)

5.590

5.990

Page 4

Installation Instructions for Door Interlock

MIN.

2.75

INSIDE

2.25

DATUM

2 CLEARNACE HOLES

IN FLANGE FOR

1/4-20 SCREWS

.56 ±.01

3.44 ±.01

4.690 ±.005

.50 ±.01

"B" = .88

MOUNT HOOK IN UPPER HOLES

"B" = 1.56

MOUNT HOOK IN LOWER HOLES

UPPER HOLE

().25

()4.00

R.250

1.62

MIN.

.62

()B

1.5-2.0

MIN.5.75

()2.10

41053-274-01 (1)

Printed in U.S.A.

Figure 1-6 Flange Drilling Plan for Handle and Interlock Blade Mounting Dimensions

Loading...

Loading...