Page 1

User Manual

MicroLogix 1100 Embedded Web Server

Bulletin 1763 Controllers

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, SLC 5/02, SLC 5/03, PLC-5, MicroLogix, SLC 500, RSLogix 500, RSLinx, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

The information below summarizes the changes to this manual since the last

printing.

To help you find new and updated information in this release of the manual, we

have included change bars as shown next to this paragraph.

The table below lists the sections that document new features and additional or

updated information about existing features. Web view disable function is added.

Top ic

Disable Web View

Browser support is specified as Internet Explorer 6.0 , 7.0, and 8.0.

Internet Explorer 9.0 and above are not supported.

Page

9

1

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 iii

Page 4

Chapter 1

Notes:

iv Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 5

Chapter 1

Table of Contents

MicroLogix 1100 Embedded

Web Server

Use Data Views to Access

Controller Data

Manage User Accounts and

Access Levels

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Browser Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Connect the MicroLogix 1100 controller to the Network . . . . . . . . . . . . . 2

1. Connect the module to the network . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Obtain an IP address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Access the home page of the web server. . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Log into the web server.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Navigate the MicroLogix 1100 Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview of Data Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Change an Access Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Data View Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Change Data Table Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How to Change a Data File Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Disable Web View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

User Accounts and Privilege Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Configure Access Limits for Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Recover with Unknown Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 4

Monitor Diagnostics

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MicroLogix 1100 Controller Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Network Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Index

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 v

Page 6

Table of Contents

Notes:

vi Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 7

Chapter

MicroLogix 1100 Embedded Web Server

1

How to Use This Chapter

Typical Applications

Browser Requirements

Rockwell Automation offers enhanced MicroLogix 1100 controllers for your

EtherNet/IP control systems so you can monitor data remotely via web pages.

This chapter shows how you can use a MicroLogix 1100 controller in your

control system.

Top ic

Typical Applications

Browser Requirements

Connect the MicroLogix 1100 controller to the Network

Navigate the MicroLogix 1100 Controller

The MicroLogix 1100 controller provides access to controller data. This access

opens up different, remote access applications to control systems. Use the

MicroLogix 1100 controller to remotely access controller data using a web

browser. Use a web browser to monitor live controller data.

You can access the MicroLogix 1100 Web Server only with Internet Explorer 6, 7,

or 8. Internet Explorer 9 or above are not supported because of JavaScript

incompatibility.

Page

1

1

2

4

To access data view pages, the browser requires Javascript support.

The supported display size is 640 x 480 or greater. Smaller display sizes work but

might require extensive scrolling to view the information.

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 1

Page 8

Chapter 1 MicroLogix 1100 Embedded Web Server

IMPORTANT

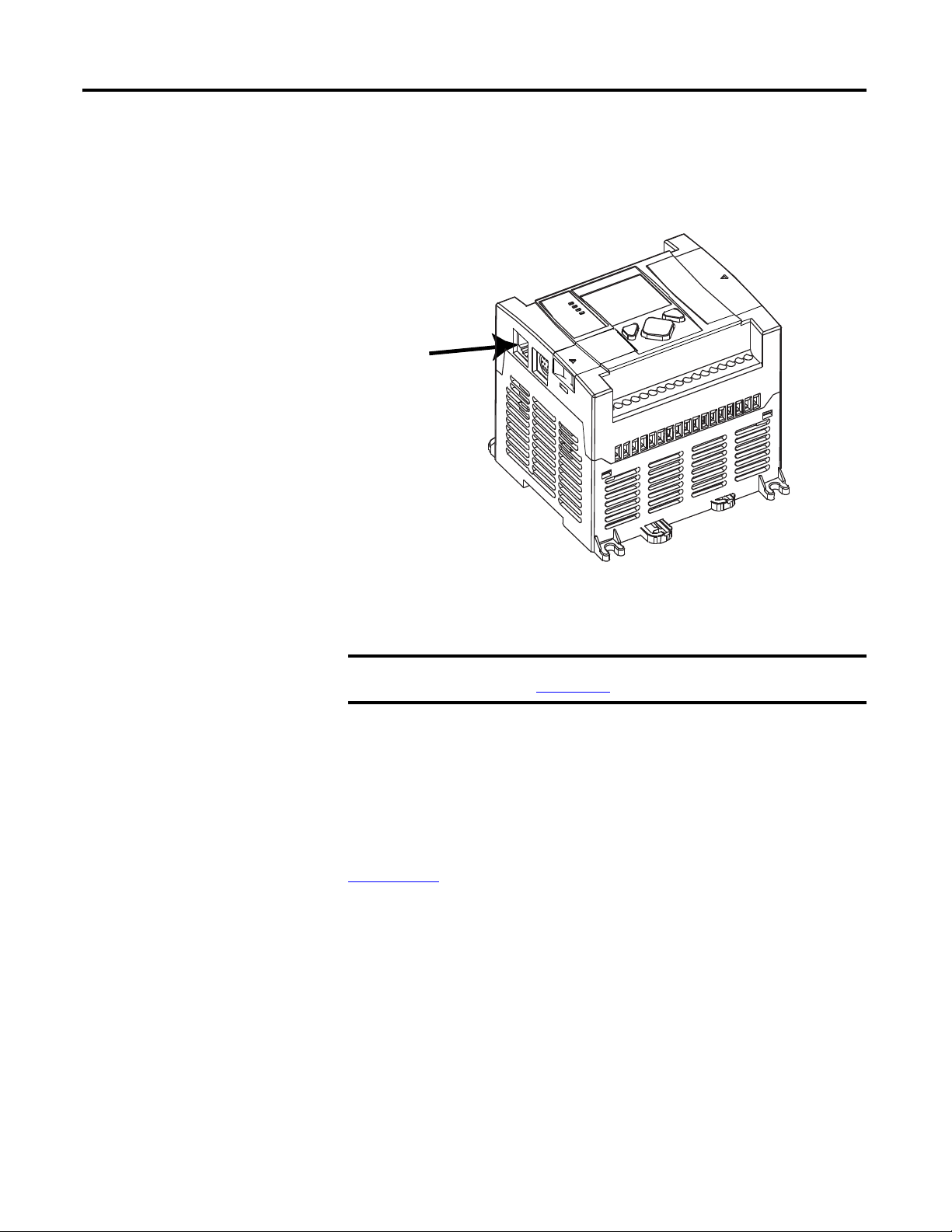

Connect the MicroLogix 1100 controller to the Network

1. Connect the module to the network

Connect the MicroLogix 1100 controller to the Ethernet network. The RJ-45

connector is on the left-hand side of the module.

2. Obtain an IP address.

For more information, see MicroLogix1100 Programmable Controllers

User Manual, 1763-UM001

By default, the MicroLogix 1100 controller is BOOTP enabled. If you connect

the MicroLogix 1100 controller to a network that has a BOOTP server, that

server will assign an IP address to the MicroLogix 1100 controller and the LCD

screen of the MicroLogix 1100 controller will display BOOTP IP address.

If your network does not have a BOOTP server, use one of the methods

described in the MicroLogix 1100 Programmable Controllers User Manual

1763-UM001

to assign an IP address to the MicroLogix 1100 controller.

.

2 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 9

MicroLogix 1100 Embedded Web Server Chapter 1

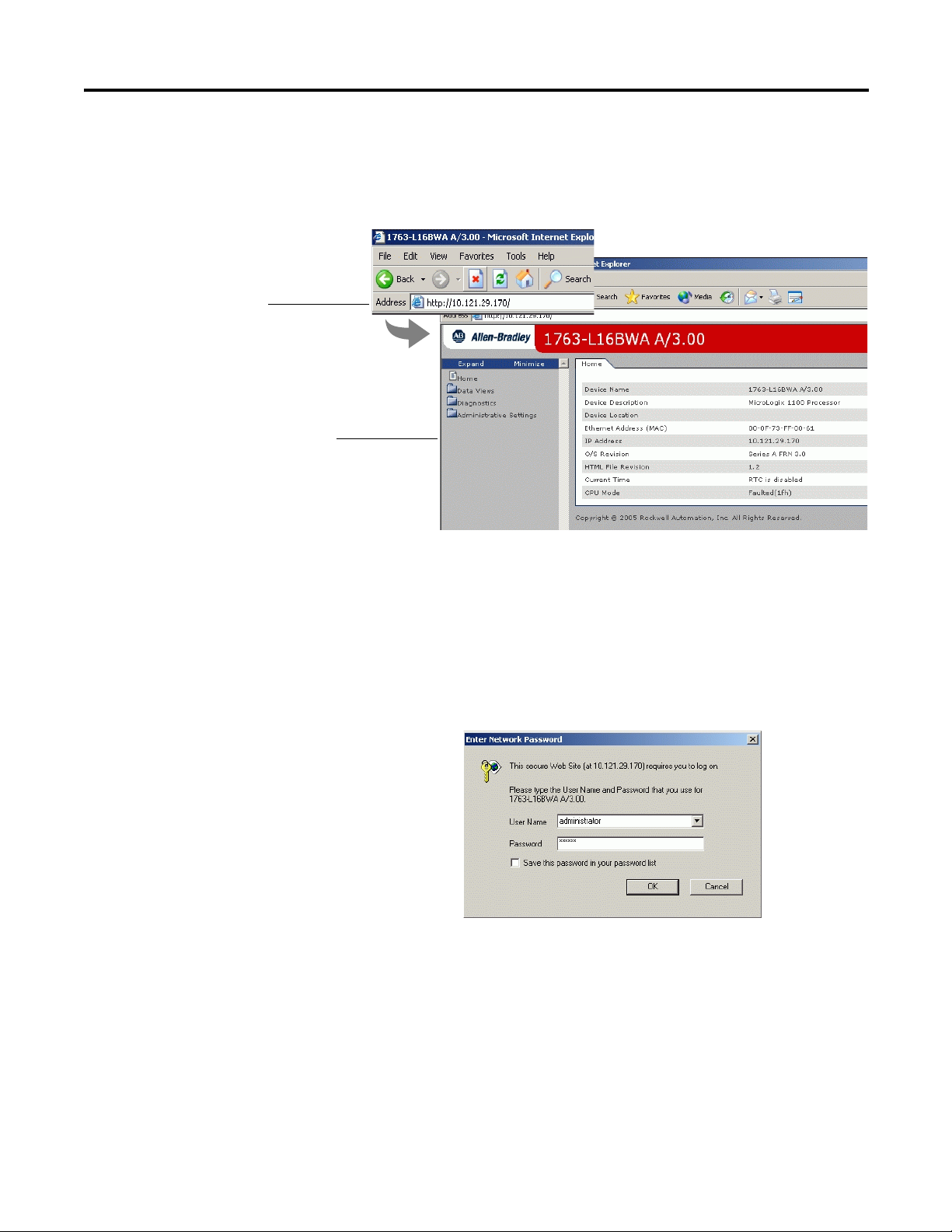

Specify the IP address of the

MicroLogix 1100 controller in the

Address window of your web

browser.

This is the module’s Home page.

Default Access

User Name: administrator or guest

(case sensitive)

Password:

(ml1100 for administrator, guest for guest)

3. Access the home page of the web server.

From your web browser, enter the IP address of the MicroLogix 1100 controller.

The module displays its Home page

4. Log into the web server.

Many of the features of the MicroLogix 1100 controller require you to log in with

appropriate access. If you select a feature, such as Data Views, the MicroLogix

1100 controller prompts you to enter your user name and password. The user

name is either administrator or guest. The password is ml1100 for administrator

and guest for guest.

You can set up as many as 10 user accounts. Each account can have read, write, or

administrator access. For more information, see Chapter 3.

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 3

Page 10

Chapter 1 MicroLogix 1100 Embedded Web Server

Click folders to open and close

additional levels of information.

Click a document to display a

web page showing specific

information.

Tabs across the top match the documents

within a folder, as shown in the left

navigation panel.

Navigate the MicroLogix 1100 Controller

You navigate the web server’s web pages by using the navigation panel on the left

of the screen. There are also tabs across the top you can use to navigate the

sections within folders.

4 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 11

Chapter

2

Use Data Views to Access Controller Data

How to Use This Chapter

Overview of Data Views

The MicroLogix 1100 controllers provide access to the controller data table files.

This chapter shows you how to set up data views of data table files.

Top ic

Overview of Data Views

Change an Access Group

Monitor Data Views and Data Table File

Change Data Table Files

Disable Web View

Data views give you the ability to read from controller through a browser

interface. The MicroLogix 1100 controller provides web pages that let you

configure a set of files (a data view) that can be read.

A data view consists of an HTML file with data file information. The HTML file

is in a readable ASCII format. It contains the File Name, File Type, # of Element,

and Access Group.

Page

5

6

7

7

9

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 5

Page 12

Chapter 2 Use Data Views to Access Controller Data

Change an Access Group

Each data view contains a group of files that you want to monitor. Each

MicroLogix 1100 controller can support multiple data views. One browser

supports one data view, so if you want to look at many data views, you need to run

a corresponding number of browsers.

You change an access group from the Data Views → New Data View page.

1. From the Access Group pull-down menu for the given data table file,

choose the access group type you wish to assign. Choose from:

• Administrator (all access)

• Write (read/write access only)

• Read (read access only)

2. Choose Administrator, Write, or Read from the Access Group pull-down

menu to change a file's access group.

3. Click Apply to change an access group for the data table file you

specified.

6 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 13

Use Data Views to Access Controller Data Chapter 2

Monitor Data Views and Data Table File

Use the Data Views → Data Views page to view existing data table files.

Click the file name to view the data within a data table file.

Data View Page

The Data Views page displays a list of the data table files, their type, and size in

elements for a connected MicroLogix 1100, as shown in the following example.

Change Data Table Files

Each file contains a hyperlink that takes you to the specific Data Views page for

that file. When you click a particular file, the Data Views page appears, displaying

the contents of the data table file you selected.

The available and default display formats depend on the data type of the file.

Click Back to display the previous page. To refresh data, click Update.

The data in the Data File Types such as Binary, Integer, Long, Float, and String

can be changed. The Binary, Integer, and Long types support all the Display

formats. The Binary can be changed by bit, and the octal, decimal, and

hexadecimal can be changed by element. A user account with either Write or

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 7

Page 14

Chapter 2 Use Data Views to Access Controller Data

Administrator access level can change the Data Table Files. When you click N7 in

Data Views, Data Writable appears beside a Data File Type (Integer here) as

shown below.

How to Change a Data File Type

The following steps assume Binary type is used.

1. Change Display As to Binary, then the following screen appears.

2. Double-click the data you want to change, then the background color

becomes pink.

8 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 15

Use Data Views to Access Controller Data Chapter 2

3. Enter a value and either press Enter or click somewhere in the screen, then

a confirmation window appears.

4. Click OK to change the value in the server.

If following screen appears when the value is successfully saved into

the server.

Disable Web View

If the following screen appears, the value is not saved and the value returns

to the original value.

If you want to change the data in Decimal, click pull-down menu to change the

Display As to Decimal and follow the above procedures in sequence. The

procedures are all the same for String too. (This feature is supported only when

the OS FRN is 3 (HTML File Revision is 1.2) or later.

Using RSLogix 500 version 7.20 or higher, you can disable individual data files

from being viewed via any web browser by selecting the data file’s properties page

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 9

Page 16

Chapter 2 Use Data Views to Access Controller Data

and checking the Web View Disable checkbox as shown below. Any data file

property changes must be made offline and downloaded to the processor.

10 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 17

Chapter

IMPORTANT

IMPORTANT

3

Manage User Accounts and Access Levels

How to Use This Chapter

This chapter describes how to configure user access levels to different information

on the module.

Top ic

User Accounts and Privilege Classes

Configure Access Limits for Web Pages

Create User Accounts

Recover with Unknown Password

By assigning user accounts with different access levels, you can manage which

users have access to view network configuration or have access to view and change

data views.

Several pages on the MicroLogix 1100 controller, such as diagnostics pages and

data views pages, have default access protection. Before accessing these pages, you

must authenticate your access by entering a user name and password. The module

displays the log-in box when you access these web pages.

Once authenticated, you do not have to re-enter a user name or

password when accessing subsequent pages. You must close

your browser to log out.

Page

11

12

13

14

The default user name is administrator with password 'ml1100' or guest with

password 'guest'

User Accounts and

Privilege Classes

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 11

The MicroLogix 1100 controller supports multiple user accounts, each with a

user name and password. Each user account is configured for one of these access

levels:

• Administrator (all access)

• Write (read/write access only)

• Read (read access only)

The access level determines which web pages the user can access. You configure

access limits for individual web pages.

.

It is strongly recommended that you change the password for

the default Administrator account.

Page 18

Chapter 3 Manage User Accounts and Access Levels

Configure Access Limits for

Each page in the MicroLogix 1100 controller has one of these protection levels:

Web Pages

The protection levels are hierarchical. Administrator users can access Read

protected pages.

These predefined pages (those web pages that come with the MicroLogix 1100

controller) in the MicroLogix 1100 controller have these default access levels. You

can change the Data View access group, if needed, with administrator privilege.

• Administrator

• Wr i t e

• Read

Web Page Default Protection Level

Home page no protection

Diagnostics pages Read protection

Data Views Read protection

New Data View Administrator protection

User Management page Administrator protection

12 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 19

Manage User Accounts and Access Levels Chapter 3

IMPORTANT

Create User Accounts

You need Administrator access to create and modify user accounts. You can create

as many as 10 individual accounts. You manage accounts from the Administrative

Settings → User Manag ement → Edit Users page.

In this field Do this

User ID Enter the user name for the account.

20 characters maximum

Can contain these characters: A…Z, a…z, 0…9, underscore (_), and

dash (-)

Group Select Administrator, Write, or Read access for the user account

Password Enter the password for the account.

10 characters maximum

Confirm Password Re-enter the same password for the account.

If you use Internet Explorer, the number of characters allowed

for a user ID or password depends on how many characters “fit

in the box.” Larger characters (such as “W”) take more room

and reduce the total number of allowed characters.

A user account with a specific privilege can access the Data corresponding to the

specific access level, that is, a user account with Read access level can not access

the Data belonging to Write or Administrator acess group. The following screen,

which shows only Read Access Group, appears when you log in with the guest

account.

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 13

Page 20

Chapter 3 Manage User Accounts and Access Levels

Recover with Unknown Password

Update the firmware using ControlFlash to initialize both user accounts and the

access level of data view. This feature is supported only when the OS FRN is 3

(HTML File Revision is 1.2) or later.

14 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 21

Monitor Diagnostics

Chapter

4

How to Use This Chapter

MicroLogix 1100 Controller Diagnostics

This chapter describes the diagnostics presented on the user-oriented diagnostic

pages.

Top ic

MicroLogix 1100 Controller Diagnostics

Diagnostic Overview

Network Settings

Network Status

The MicroLogix 1100 controller provides four diagnostic pages of user-oriented

diagnostics. This information is organized into:

For this information Access this web page

Overview of the current configuration of the

MicroLogix 1100 controller

Summary of the network settings configured for

the MicroLogix 1100 controller

Ethernet statistics Diagnostics

Diagnostics → Diagnostic Overview

Diagnostics → Network Settings

→ Ethernet Statistics

Page

15

16

17

18

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 15

Page 22

Chapter 4 Monitor Diagnostics

Diagnostic Overview

The Diagnostics → Diagnostic Overview page presents a summary of the current

configuration and overall status of the MicroLogix 1100 controller. This

summary includes:

• Ethernet configuration.

• Ethernet connection use.

This field Specifies

Ethernet Link

Port Speed whether the Ethernet port is operating @ 10 Mbps or 100 Mbps

Port Duplex whether the Ethernet port is operating @ half duplex or full duplex

Auto negotiate Status whether the port speed and duplex mode were determined via autonegotiation or whether they

Ethernet Connections

Current Ethernet Connections current number of active connections

Incoming Ethernet Connections current number of incoming connections

Outgoing Ethernet Connections current number of outgoing ethernet connections

Ethernet Connection Limit maximum number of Ethernet incoming/outgoing connections

were manually configured

16 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 23

Monitor Diagnostics Chapter 4

Network Settings

The Diagnostics → Network Settings page presents a summary of the current

Ethernet configuration for MicroLogix 1100. This summary includes:

• Ethernet address details.

Any fields not configured remain blank.

This field Specifies

Network Interface

Ethernet Address (MAC) Ethernet (MAC) address of the controller

IP Address IP address for the controller

Subnet Mask subnet mask for the controller

Default Gateway gateway address for the controller

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 17

Page 24

Chapter 4 Monitor Diagnostics

Network Status

The Diagnostics → Network Status page presents a summary of the status of

communication activity on the Ethernet network. This summary includes:

• Ethernet network configuration.

• packets sent and received over the Ethernet network.

• frames sent and received over the Ethernet network.

This field Specifies

Interface Counters

Rx Octets Octets received on the Ethernet interface

Tx Octets Octets sent on the Ethernet interface

Rx Packets Packets received on the Ethernet interface

Tx Packets Packets sent on the Ethernet interface

Command Sent Command sent on the Ethernet interface

Command Received Command received on the Ethernet interface

Replies Sent Replies sent on the Ethernet interface

Replies Received Replies received on the Ethernet interface

Replies Sent with error Outbound packets that contain errors

Replies Received with error Inbound packets that contain errors

Replies Timed Out No reply within a specified time period

Media Counters

Single Collisions Successfully transmitted frames which experienced exactly one collision

Multiple Collisions Successfully transmitted frames which experienced more than one collision

Deferred Transmissions Frames for which first transmission attempt is delayed because the medium is busy

Late Collisions Number of times a collision is detected later than 512 bit-times into the transmission of a packet

Excessive Collisions Frames for which transmission fails due to excessive collisions

MAC Transmit Errors Frames for which transmission fails due to an internal MAC sublayer transmit error

18 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 25

Monitor Diagnostics Chapter 4

This field Specifies

Carrier Sense Errors Times that the carrier sense condition was lost or never asserted when attempting to transmit

MAC Receive Errors Frames for which reception on the Ethernet interface failed due to an internal MAC sublayer

CRC Errors Frames for which CRC error is detected

a frame

receive error

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 19

Page 26

Chapter 4 Monitor Diagnostics

Notes:

20 Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 27

Index

A

access group

creating

access levels

classes

access limits

configuring

accessing

typical application

Administrator access 3-16

authentication 3-15

2-8

3-15

3-16

1-3

B

browser requirements 1-3

C

configuring

access limits

user accounts 3-17

connecting 1-4

creating

access group

3-16

2-8

network settings 4-21

I

installing 1-4

IP address 1-4

M

MicroLogix 1100 Controller Diagnostics 4-19

N

navigating 1-6

P

password 3-15, 3-18

R

Read access 3-16

recovering 3-18

remote access 1-3

requirements, browser 1-3

D

data views

monitoring

overview 2-7

Diagnostic Overview 4-20

diagnostics

diagnostic overview

Ethernet statistics 4-22

2-9

4-20

U

user accounts

3-15

classes

creating 3-17

W

write access 1-5

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014

Page 28

22

Notes:

Publication 1763-UM002D-EN-P - May 2014

Page 29

Rockwell Automation Publication 1763-UM002D-EN-P - May 2014 23

Page 30

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Publication 1763-UM002D-EN-P - May 2014 24

Supersedes Publication 1763-UM002C-EN-P - April 2007 Copyright © 2014 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...