Page 1

Pico DeviceNet Communication Interface

1760-DNET

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.rockwellautomation.com/literature) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Page 3

Table of Contents

Preface

Pico DeviceNet Interface

Installation

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Common Techniques Used in this Manual . . . . . . . . . . . . . P-2

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . P-3

Chapter 1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Structure of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Communication Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Hardware and Operating System Requirements . . . . . . . . . 1-2

Use Other Than Intended . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Chapter 2

Connect to the Basic Unit . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Connect the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Connect DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

EMC Compatible Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Potential Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Data Transfer Rates – Automatic Baud Rate Recognition . . . 2-4

Operate the DeviceNet Interface

DeviceNet Functions

Direct Data Exchange with

Pico/GFX (Polled I/O Connection)

Application Examples for Pico

Chapter 3

Initial Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DeviceNet Setting the Slave Address . . . . . . . . . . . . . . . . . 3-1

LED Status Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Cycle Time of the Pico Basic Unit. . . . . . . . . . . . . . . . . . . 3-6

EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Chapter 4

Object Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

DeviceNet Communication Profile . . . . . . . . . . . . . . . . . . . 4-9

Chapter 5

Input data: Mode, S1 – S8 . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Output Data: Mode, R1 – R16 . . . . . . . . . . . . . . . . . . . . . . 5-4

Chapter 6

Read/Write Date and Time . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Read/Write Image Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Read/write function block data . . . . . . . . . . . . . . . . . . . . . 6-20

Analysis – error codes via PicoLink . . . . . . . . . . . . . . . . . . 6-34

Chapter 7

Pico GFX Control Commands

1 Publication 1760-UM003A-EN-P - September 2005

Version history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Read/write date and time . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Read/write image data. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Page 4

Table of Contents 2

Troubleshoot Your Controller

Specifications

Read/write function block data . . . . . . . . . . . . . . . . . . . . . 7-20

Analysis – error codes via PicoLink . . . . . . . . . . . . . . . . . . 7-64

Chapter 8

Chapter A

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Glossary

Index

Publication 1760-UM003A-EN-P - September 2005

Page 5

Preface

Read this preface to familiarize yourself with the rest of the manual. It

provides information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

• Rockwell Automation support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use Pico

controllers.

You should have a basic understanding of electrical circuitry and

familiarity with relay logic. If you do not, obtain the proper training

before using this product.

This manual is a reference guide for Pico controllers and the Pico

DeviceNet Interface. It describes the procedures you use to install,

wire, and troubleshoot the Pico DeviceNet Interface.

Refer to publication 1760-GR001, Pico Controller Getting Results

Manual for a basic overview of Pico and an introduction to Pico

programming.

1 Publication 1760-UM003A-EN-P - September 2005

Page 6

Preface 2

Related Documentation

The following documents contain additional information concerning

Rockwell Automation products. To obtain a copy, contact your local

Rockwell Automation office or distributor.

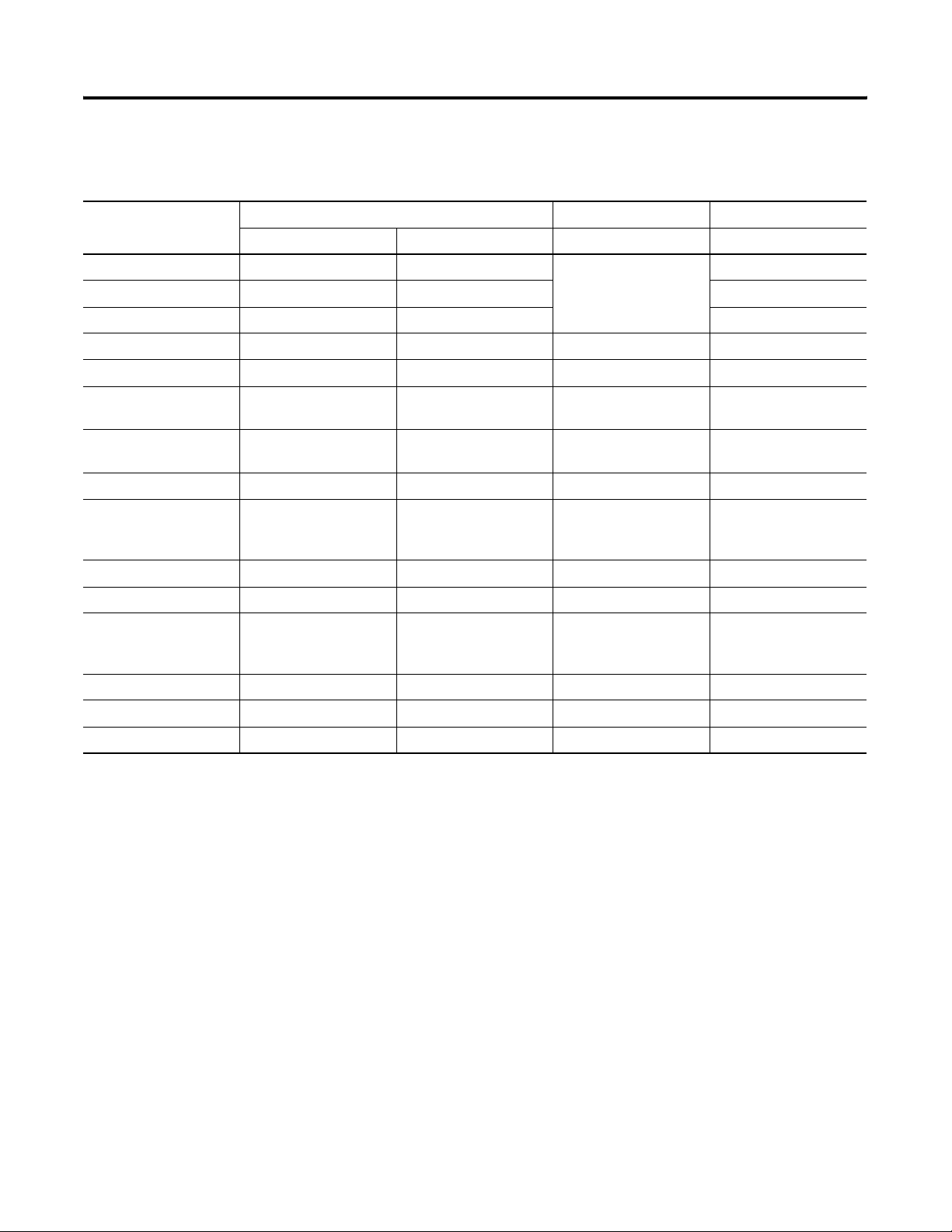

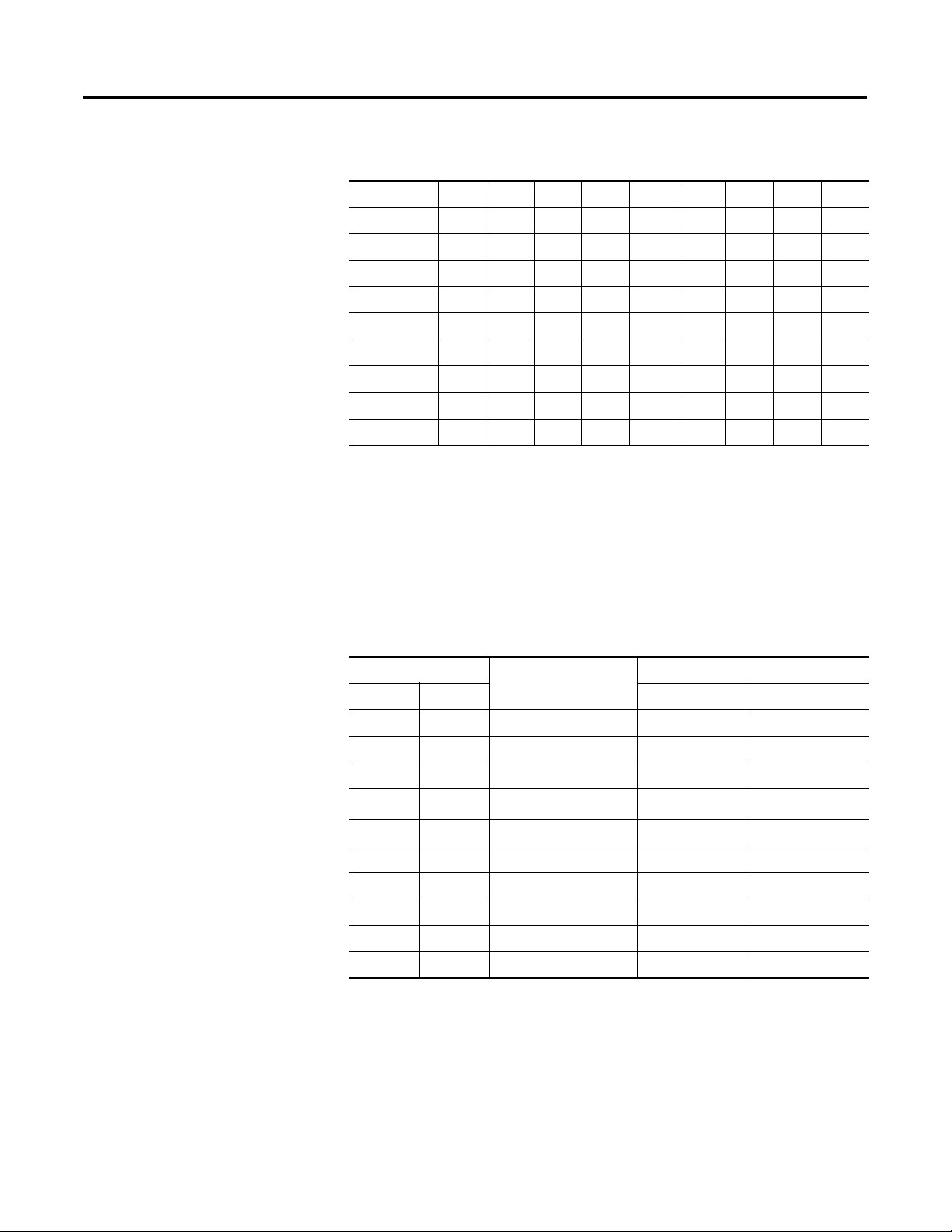

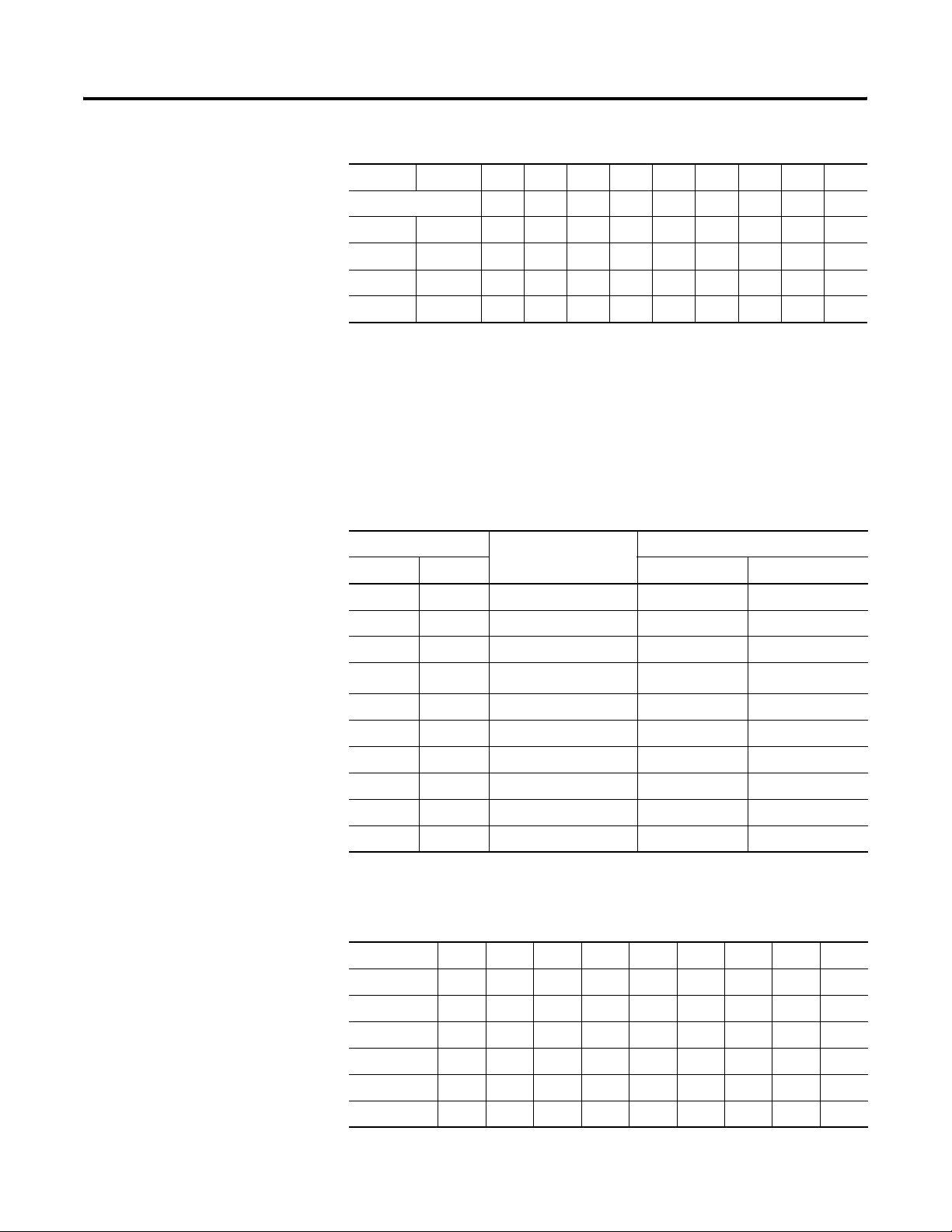

For Read this Document Document Number

A basic overview of Pico and an introduction to Pico programming. Pico Controller Getting Results

Manual

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

programmable controller products and hard-wired electromechanical

devices

An article on wire sizes and types for grounding electrical equipment National Electrical Code - Published by the National Fire

A complete listing of current documentation, including ordering

instructions. Also indicates whether the documents are available on

CD-ROM or in multi-languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

Allen-Bradley Programmable

Controller Grounding and Wiring

Guidelines

Application Considerations for

Solid-State Controls

Protection Association of Boston, MA.

Allen-Bradley Publication Index SD499

Glossary

1760-GR001

1770-4.1

SGI-1.1

AG-7.1

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

Publication 1760-UM003A-EN-P - September 2005

Page 7

Preface 3

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

please review the Troubleshooting section on page 8-1 in this manual

first. Then call your local Rockwell Automation representative.

You can also find a local Rockwell Automation Technical Support

contact at:

• http://support.automation.rockwell.com/contactinformation/

Your Questions or Comments on this Manual

If you find a problem with this manual, or you have any suggestions

for how this manual could be made more useful to you, please

contact us at the address below:

Rockwell Automation

Control and Information Group

Technical Communication, Dept. A602V

P.O. Box 2086

Milwaukee, WI 53201-2086

or visit our internet page at:

http://www.ab.com/pico or http://www.rockwellautomation.com

Publication 1760-UM003A-EN-P - September 2005

Page 8

Preface 4

Publication 1760-UM003A-EN-P - September 2005

Page 9

Chapter

1

Pico DeviceNet Interface

The 1760-DNET communication module has been developed for

automation tasks with the DeviceNet field bus. The 1760-DNET acts as

a ’gateway’ and can only be operated in conjunction with Pico and

Pico GFX-70 controllers.

The system unit consists of the Pico control device and the

1760-DNET DeviceNet gateway and operates exclusively as a slave

station on the DeviceNet fieldbus system.

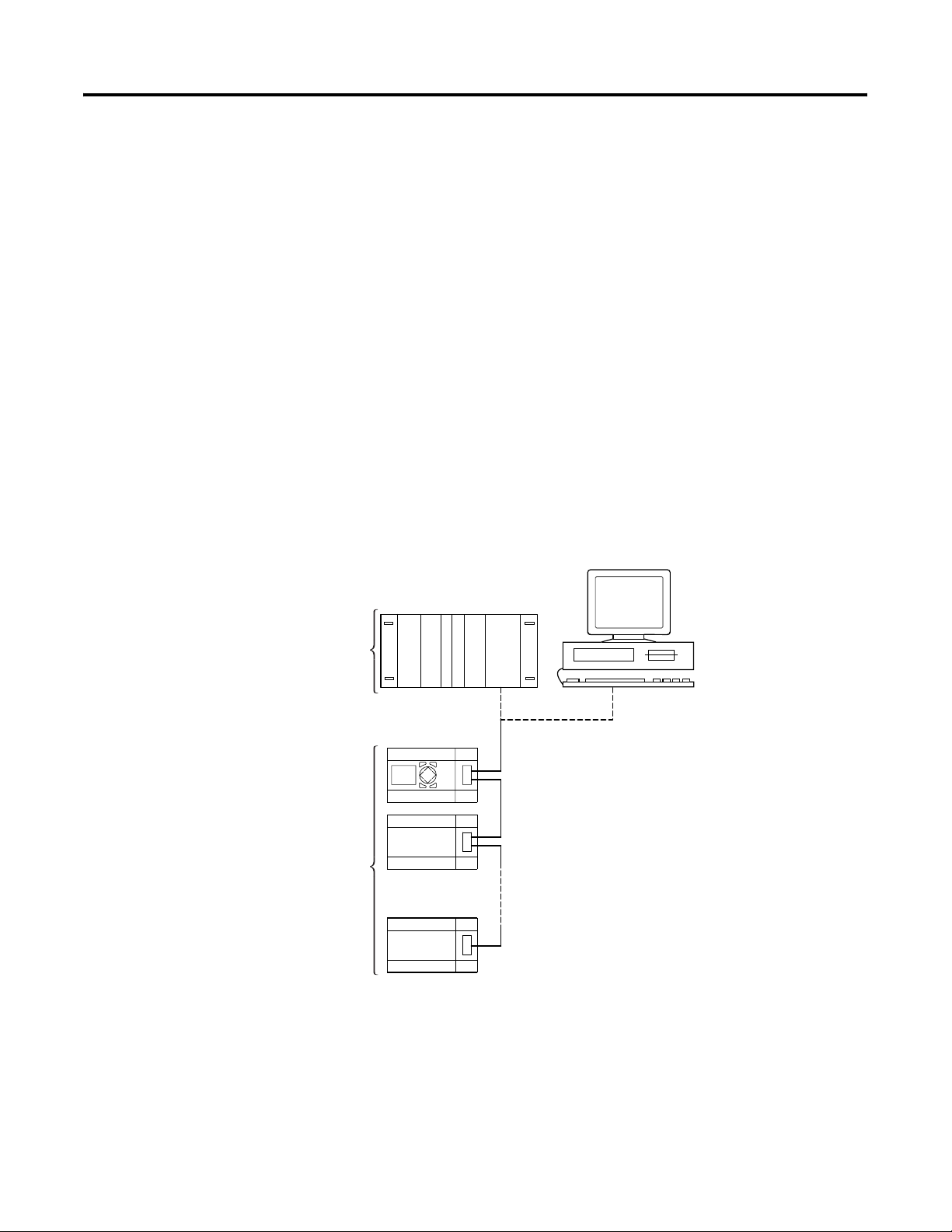

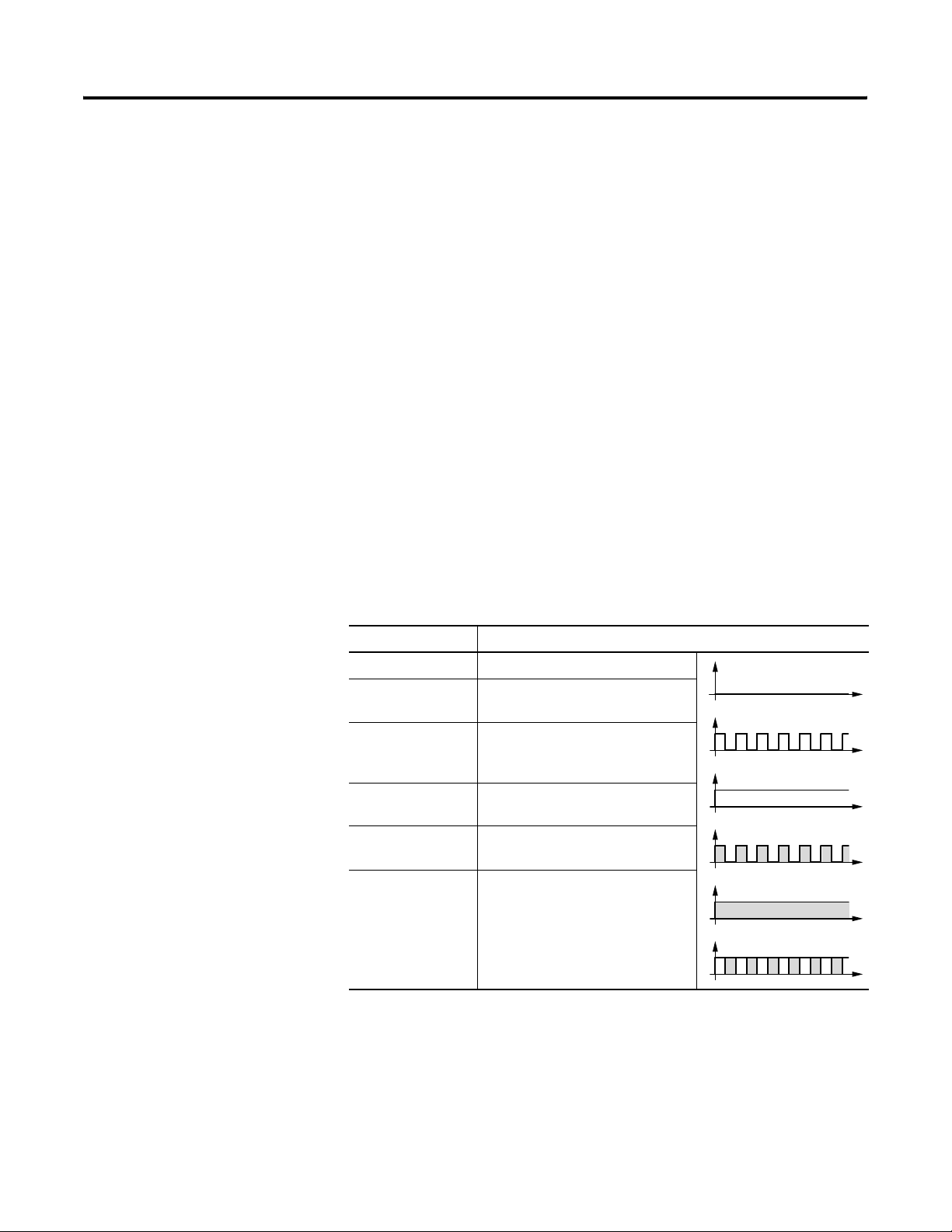

System Overview

The DeviceNet slaves are integrated into a DeviceNet fieldbus system.

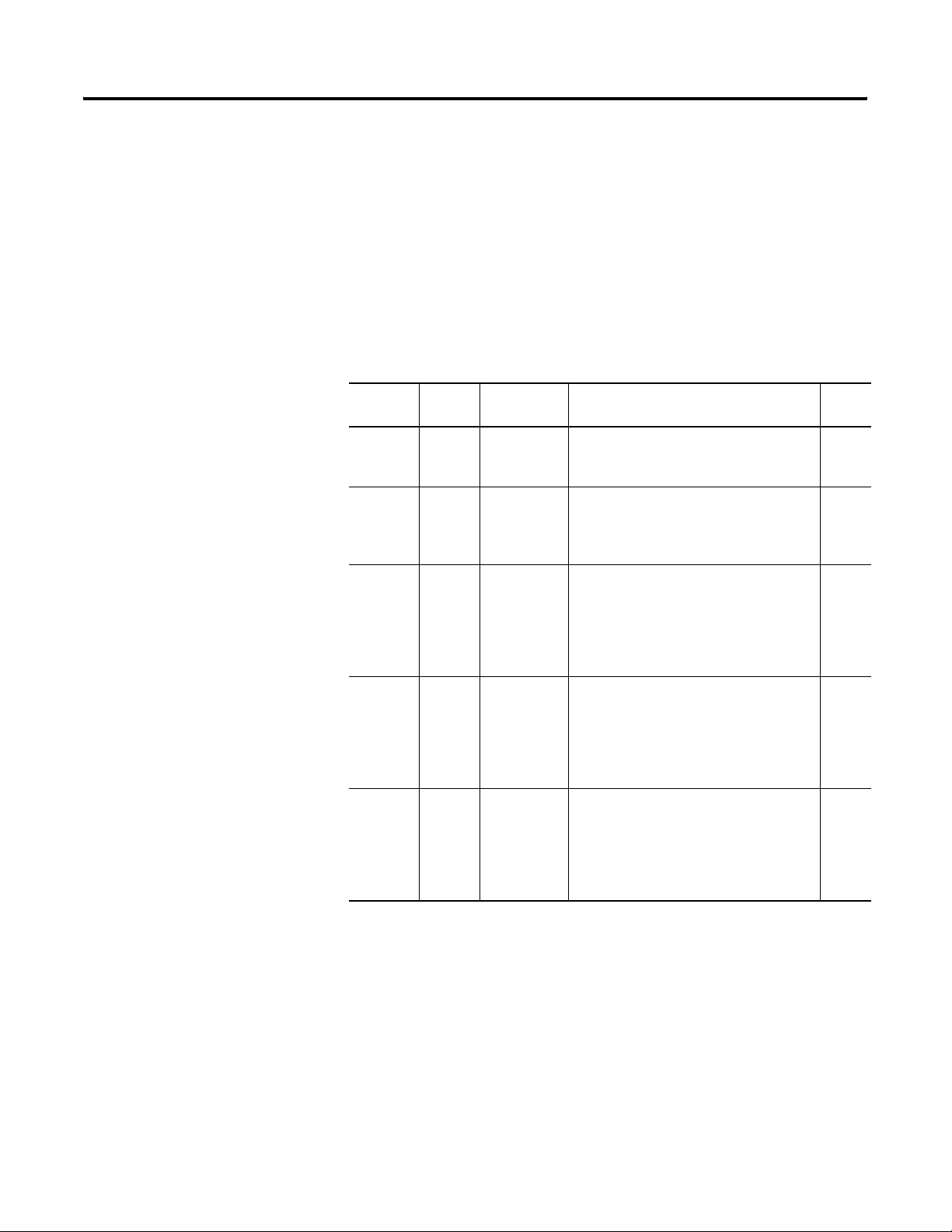

Figure 1.1 Implementation of 1760-DNET in DeviceNet

a

b

a Master area, SLC 500 programmable controller or PC with CAN card

b Slave area, e.g.: Pico or Pico GFX-70 with DeviceNet interface

1 Publication 1760-UM003A-EN-P - September 2005

Page 10

1-2 Pico DeviceNet Interface

Structure of the Unit

Communication Profile

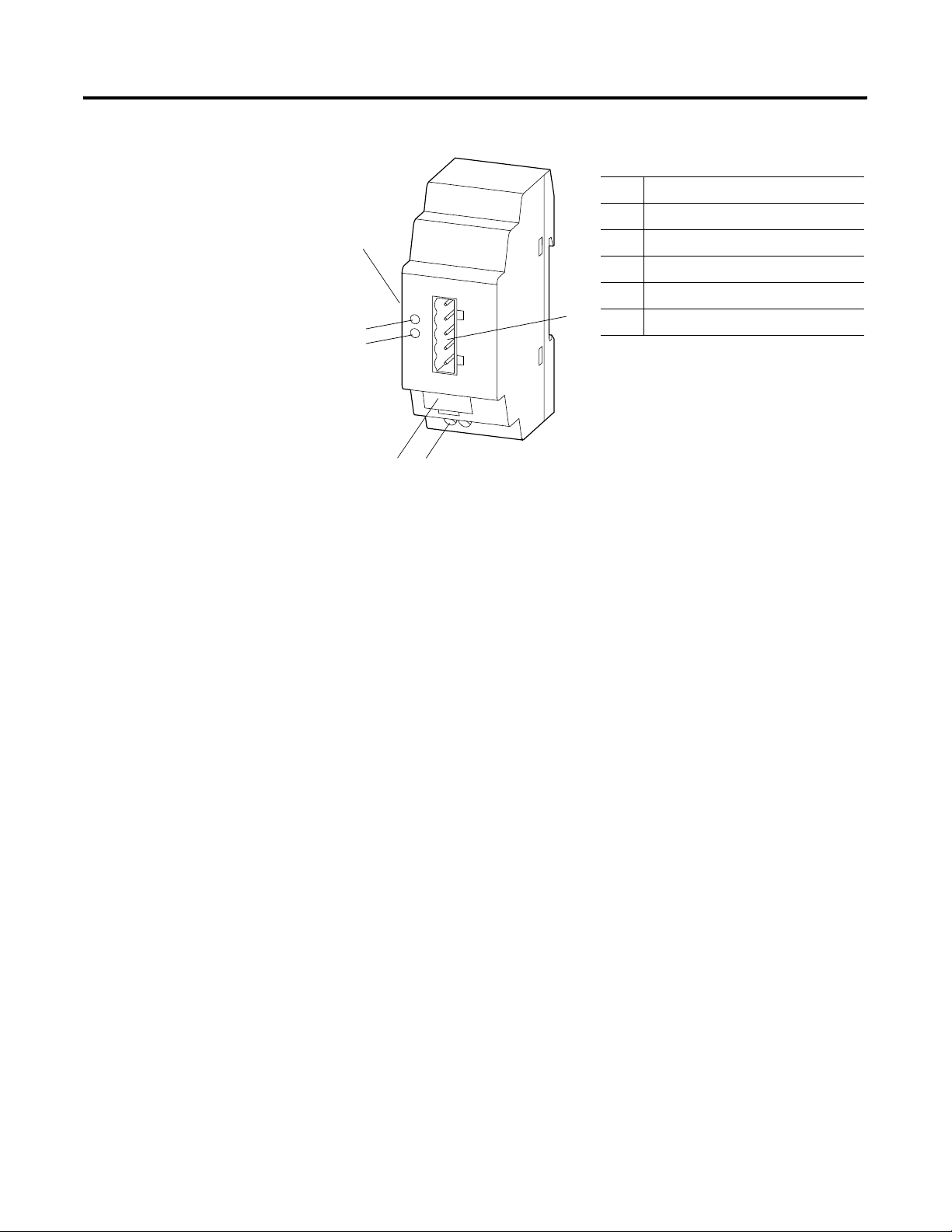

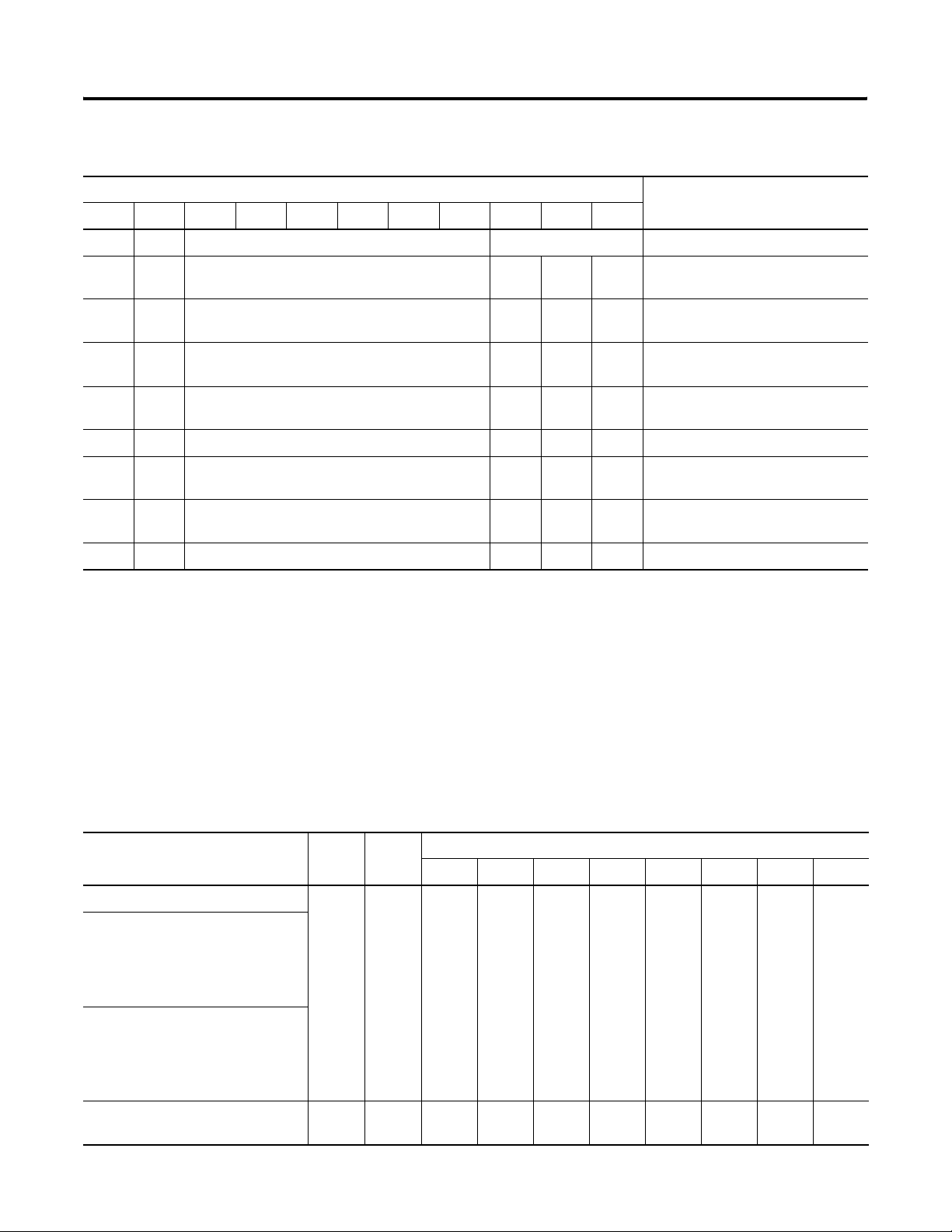

Figure 1.2

1 Pico-Link Socket

2 5-pin DeviceNet Connector

a

f

e

d

MS

NS

c

3 24V dc Power Supply

4 Equipment Rating Plate

5 Network Status LED

b

6 Module Status LED

• Predefined master/slave communication settings

– The I/O polling connection is used for the transfer of 3 bytes

of input data (R1 to R16) and 3 bytes of output data (S1 to S8)

between the base unit with gateway interconnection and the

DeviceNet programmable controller.

– The I/O Change of State/Cyclic connection (acknowledged,

unacknowledged) is used to transfer 2 bytes of diagnostic

data from the control relay to the DeviceNet programmable

controller.

– The explicit connection set-up is used for read/write access

to function relay parameters in the control relay. This type of

connection set-up also supports the configuration, diagnostics

and management services of the control relay.

• DeviceNet Communication adapter profile (device type 12),

which has been expanded by requests

• Group 2 server

• UCMM-capable device

• Dynamic set-up of explicit and I/O connections are possible

• Device Heartbeat Message

• Device Shutdown Message

• Offline communication settings

Hardware and Operating System Requirements

Publication 1760-UM003A-EN-P - September 2005

The 1760-DNET expansion unit operates together with Pico Series B

and Pico GFX-70 controllers.

Page 11

Pico DeviceNet Interface 1-3

Use Other Than Intended

Pico and Pico GFX-70 controllers may not be used to replace

safety-relevant control circuits, e.g.:

• Furnace,

• emergency-stop,

• crane or

• Two-hand safety controls.

Publication 1760-UM003A-EN-P - September 2005

Page 12

1-4 Pico DeviceNet Interface

Publication 1760-UM003A-EN-P - September 2005

Page 13

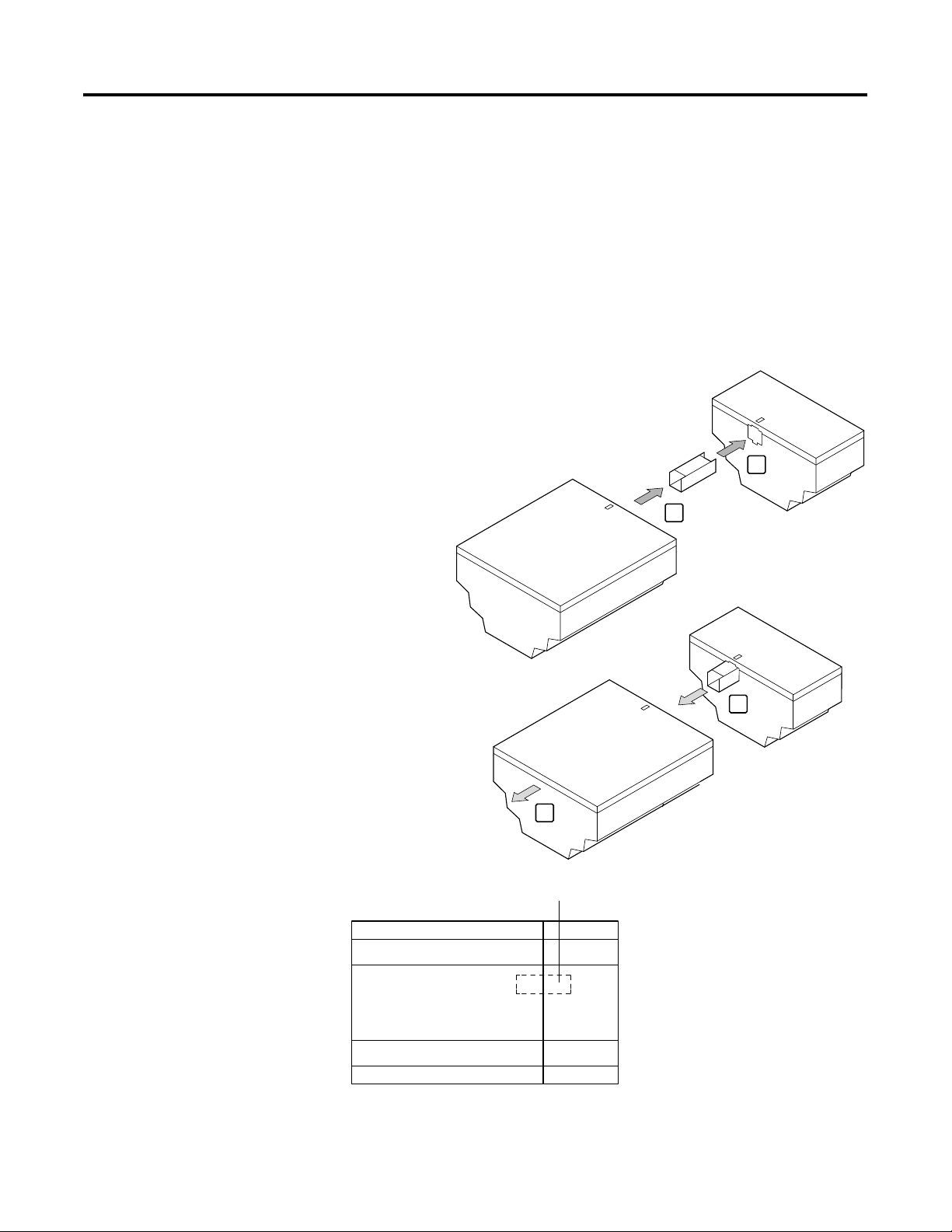

Connect to the Basic Unit

Installation

Mounting is the same as for Pico Expansion I/O modules.

1

2

Chapter

2

Pico

Pico GFX-70

4

3

connector

1760-DNET

1 Publication 1760-UM003A-EN-P - September 2005

Page 14

2-2 Installation

Connect the Power Supply

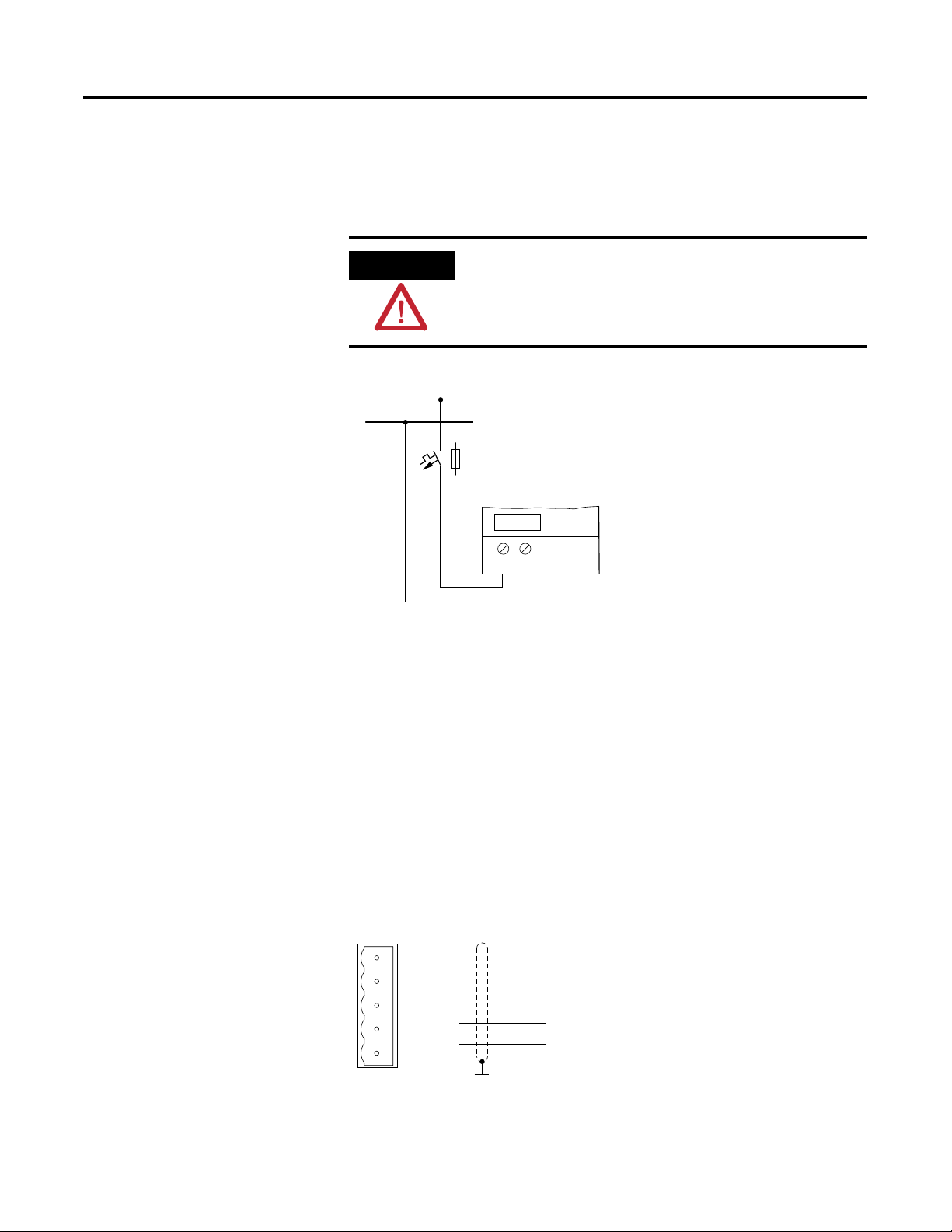

The module operates with a 24V dc supply voltage (see Power Supply

specifications on page A-3).

WARNING

+24 V

0 V

Always ensure safe electrical isolation between the

extra low voltage (SELV) and the 24V power supply.

> 1 A

+24 V 0 V

Connect DeviceNet

A 5-pin DeviceNet plug connects the DeviceNet interface of the

device to the DeviceNet field bus.

Use a special DeviceNet plug and DeviceNet cable for this connection.

Both are specified in the ODVA specification. The type of cable

determines the maximum available cable length and the data transfer

rate.

DeviceNet Pin Assignment

1

1

2

2

3

3

4

4

5

5

V– GND (Black)

CAN_L (Blue)

Shield (Clear)

CAN_H (White)

V+ (24 V) (Red)

Publication 1760-UM003A-EN-P - September 2005

Page 15

Installation 2-3

All pins of the plug must be connected to ensure safe communication

of the

1760-DNET on the fieldbus DeviceNet. This also applies to the

24V bus voltage.

EMC Compatible Wiring

IMPORTANT

The gateway does not participate in communication

on the bus if the bus voltage is not available. The

Network status LED is OFF in this situation.

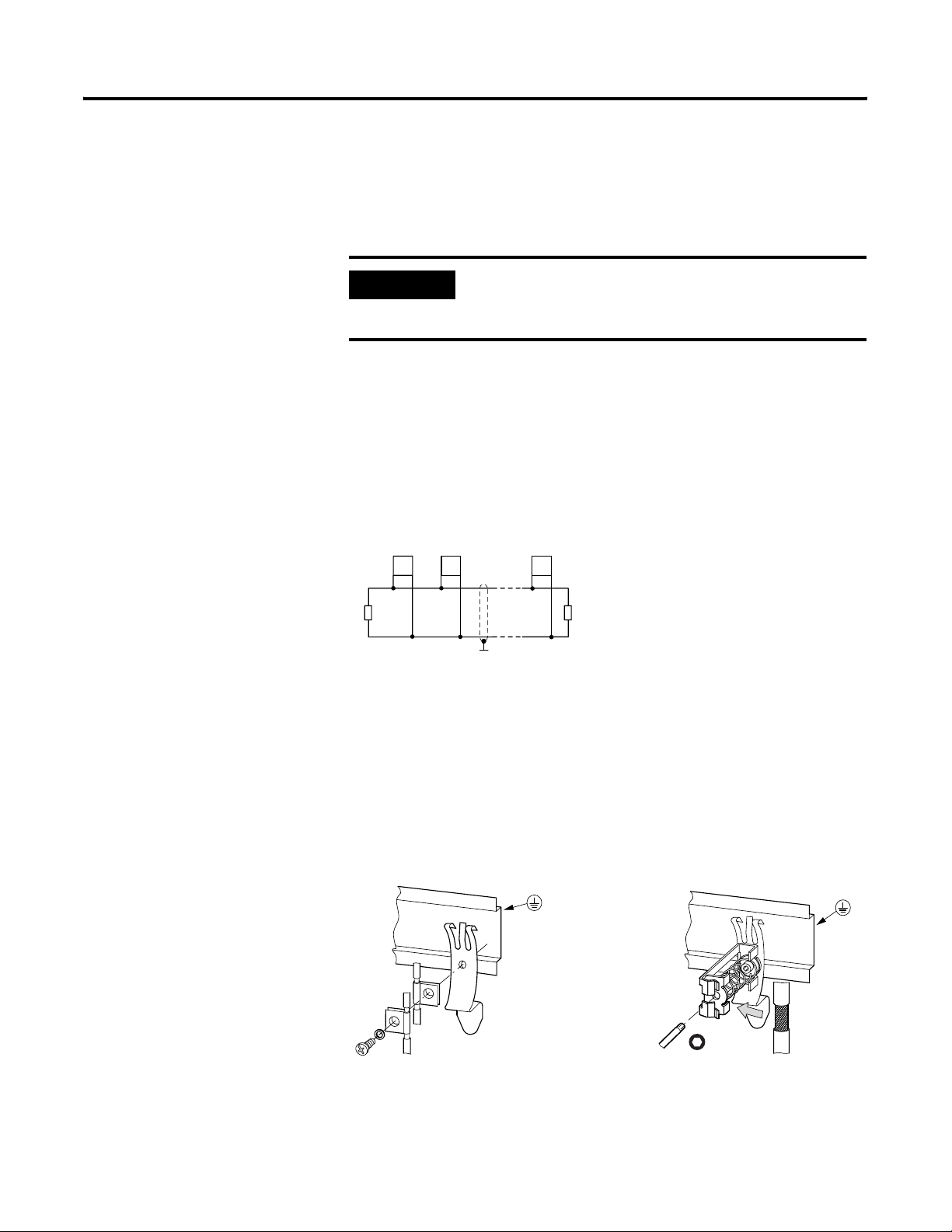

Terminating Resistors

The first and last node of a DeviceNet network must be terminated by

means of a 120 O

interconnected between the CAN_H and CAN_L terminals.

0

R

T

Electromagnetic interference may lead to unwanted effects on the

communications fieldbus, which can be significantly reduced by using

the cable described above, a shielded RJ45 connector and by

terminating the screen.

bus termination resistor. This device is

. . .

1

n

R

T

The two figures below show the correct termination of the shielding.

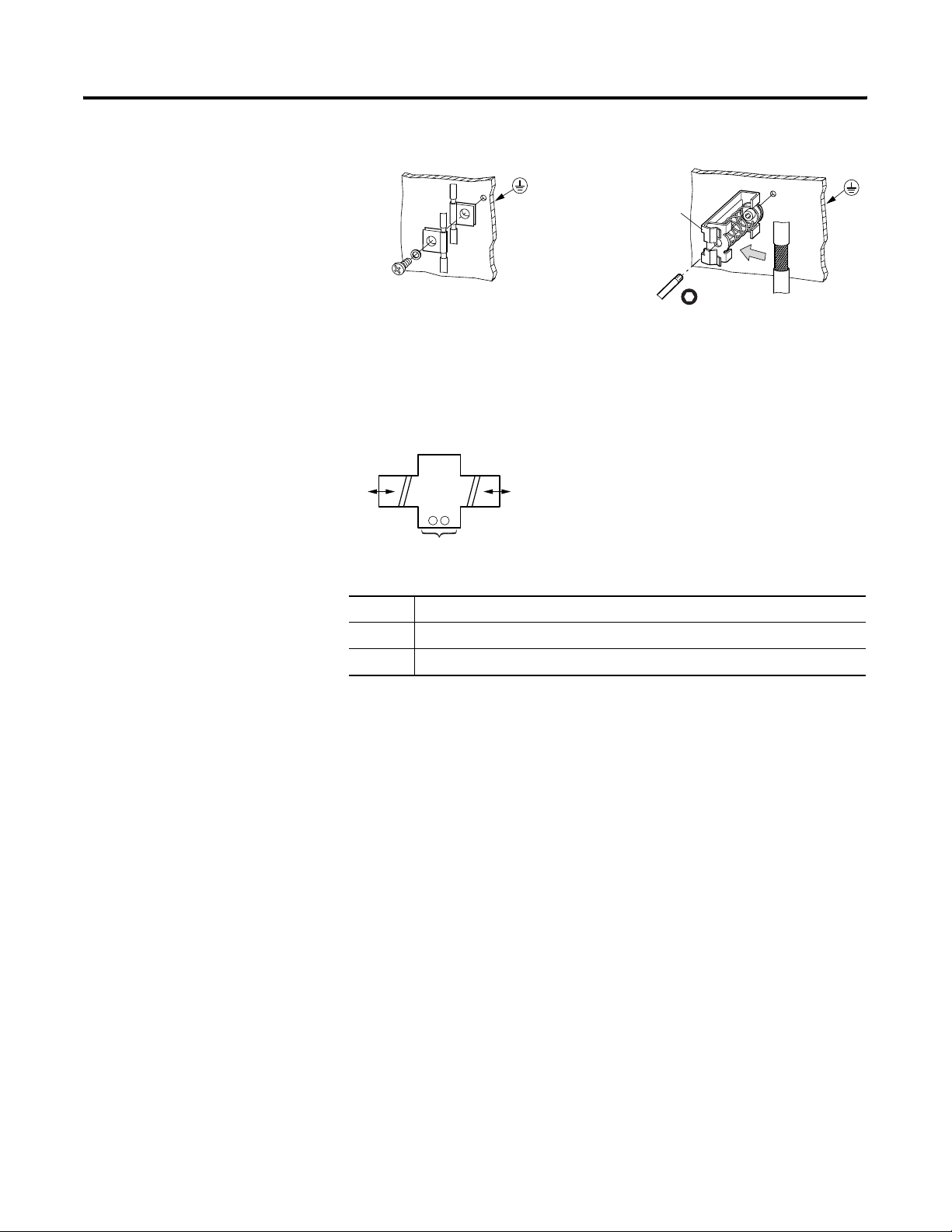

Figure 1.3 Shield Connection to the Mounting Rail

Publication 1760-UM003A-EN-P - September 2005

Page 16

2-4 Installation

Figure 1.4 Shield Connection to the Mounting Plate

Potential Isolation

Data Transfer Rates –

Automatic Baud Rate

Recognition

The following potential isolation specifications apply to 1760-DNET

interfaces:

a

+ –

c

1 Safe electrical isolation between PicoLink and the 240 VAC mains

2 Simple electrical isolation to the DeviceNet communication bus

3 Power supply 24 V DC

After it is switched on, the 1760-DNET module automatically detects

the data transfer rate of the communication network. However, this is

possible only if at least one network node transmits valid message

frames. The device supports the following data transfer rates

according to ODVA:

b

Publication 1760-UM003A-EN-P - September 2005

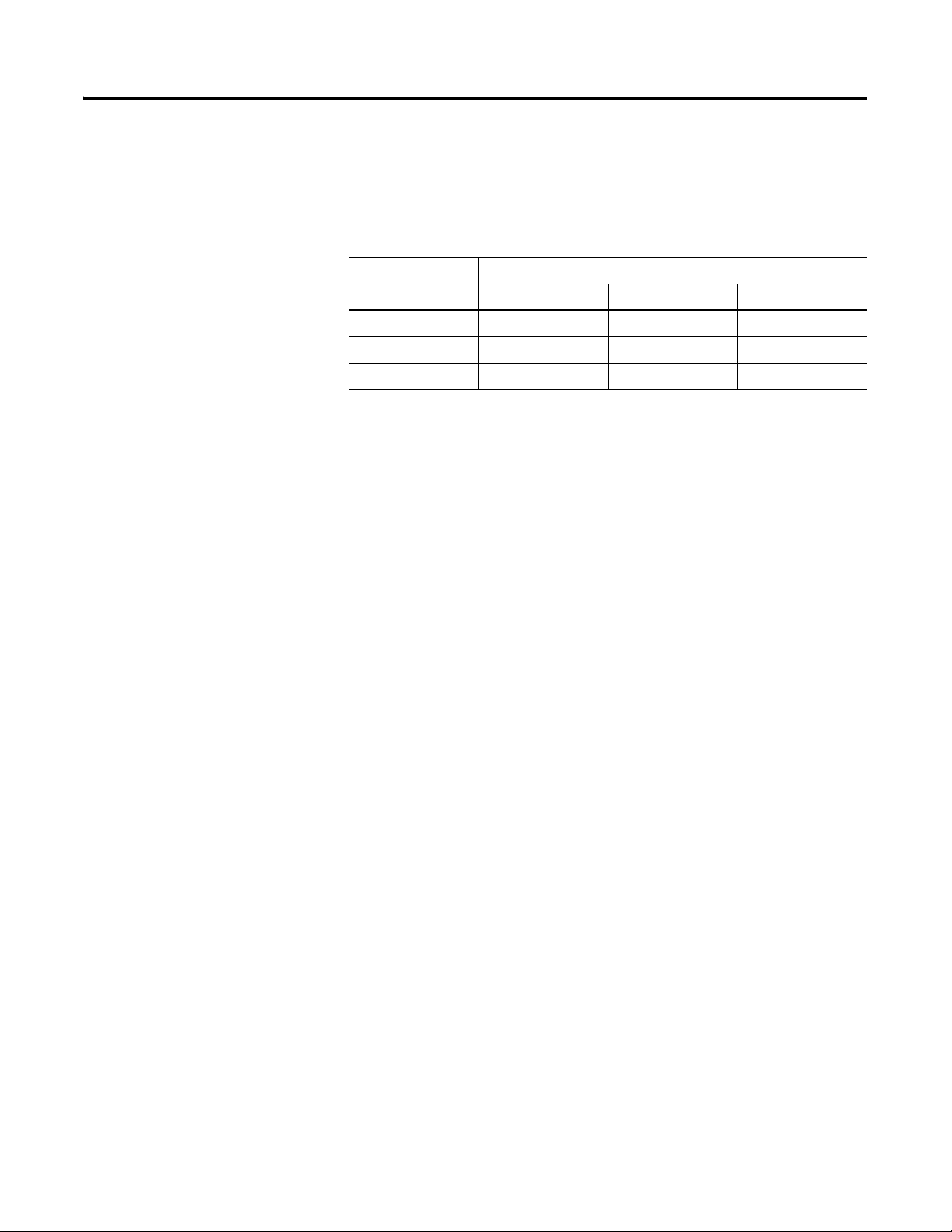

• 125 kbps,

• 250 kbps,

• 500 kbps,

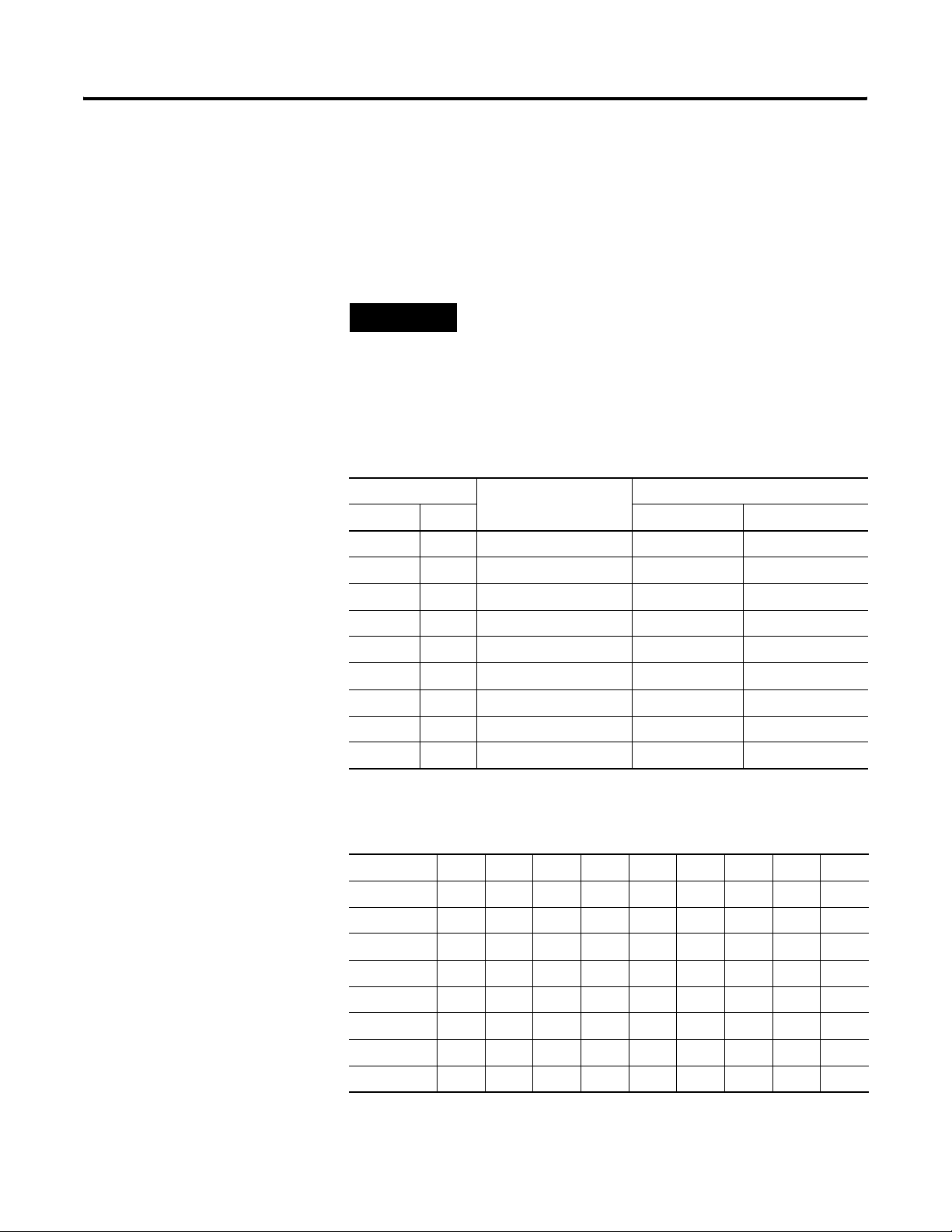

Maximum Distances and Bus Cable Lengths

The max. bus length is not determined by the data transfer rate, but

rather by the cable used. The following cables are permitted:

• Thin Cable,

• Thick Cable

Page 17

• or Flat Cable.

The data cable requirements are specified by the ODVA.

Baud Rate (kbps) Maximum Cable Length (m)

Thick Cable Thin Cable Flat Cable

125 500 100 420

250 250 100 200

500 100 100 100

Installation 2-5

Publication 1760-UM003A-EN-P - September 2005

Page 18

2-6 Installation

Publication 1760-UM003A-EN-P - September 2005

Page 19

Operate the DeviceNet Interface

Chapter

3

Initial Power On

DeviceNet Setting the Slave Address

Before you apply power to the DeviceNet Interface, verify that it is

properly connected to the power supply, to the bus connectors and to

the basic unit. Then, switch on the power supply for the basic unit

and the DeviceNet Interface.

The LEDs of the 1760-DNET flicker.The device automatically detects

the correct baud rate (see Data Transfer Rates – Automatic Baud Rate

Recognition on page 2-4). The GW information (intelligent station

connected) is displayed on the basic unit.

When the device in the network management is switched to the

‘Operational’ status, the state of the GW changes to static even on the

devices with a flashing GW,(see Network Status LED (NS) on

page 3-5).

If the unit has default configuration (node ID = 127), you need to

define the DeviceNet slave address.

Each DeviceNet slave requires a unique address (MAC ID) in the

DeviceNet structure. Within a DeviceNet structure, you can assign a

maximum of 64 addresses (0 to 63). Each MAC ID must be unique

within the entire bus structure.

There are three ways to set the DeviceNet address of an 1760-DNET:

• Using the integrated display and keyboard on the basic unit

• Using Pico-Soft V3.01 or higher on the PC

• Using Pico-Soft Pro on the PC

• Using the configuration software of the installed master

programmable controller (possibly by means of an explicit

message).

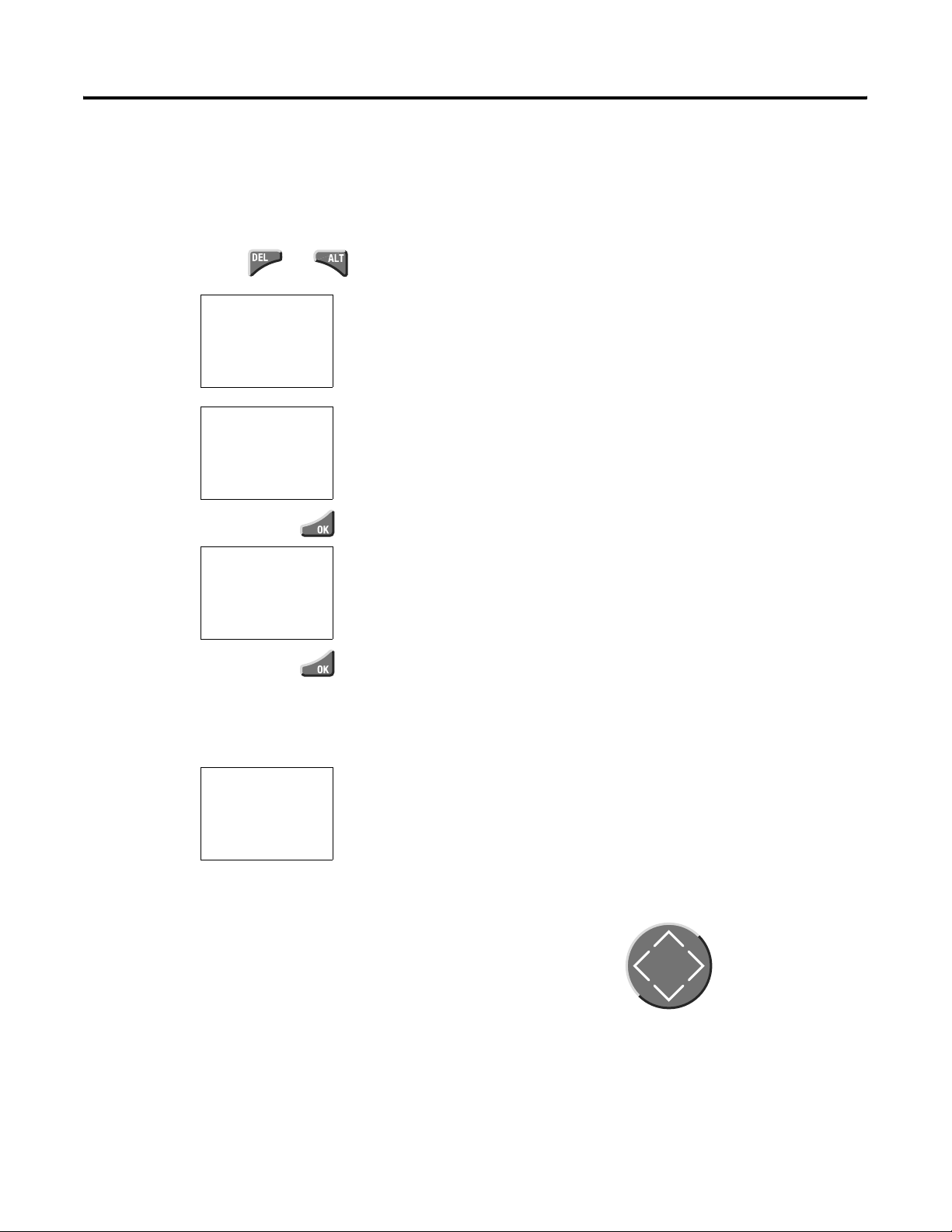

Set the Address on the Controller Unit with Display:

Make sure that:

• The respective basic units and DeviceNet Interface are supplied

with voltage.

1 Publication 1760-UM003A-EN-P - September 2005

Page 20

3-2 Operate the DeviceNet Interface

• The basic unit is accessible (password protection not activated).

• The basic unit has a valid operating system version.

• The basic unit is in STOP mode.

+

PASSWORD...

SYSTEM...

GB D F E I

CONFIGURATOR

PASSWORD...

SYSTEM...

GB D F E I

CONFIGURATOR

NET...

LINK...

1. Press the DEL + ALT keys to change to the special menu.

2. Use the cursor keys

Í or Ú to change to the Configurator.

3. Press OK.

4. Select the LINK.... menu with the Pico-GFX units.

5. Press OK.

DEVICENET

MAC ID 0026

222-01.20- D

Publication 1760-UM003A-EN-P - September 2005

The DEVICENET menu appears.

6. Set the address using the cursor keys:

– Set the current numeric value using the

– You can change the current numeric value using

2 . . . 9 0

1 . . .

o

0 0 01PP000

o

1 0 9 . . .

2 . . .

Í or Ú keys.

ú or í.

1

Page 21

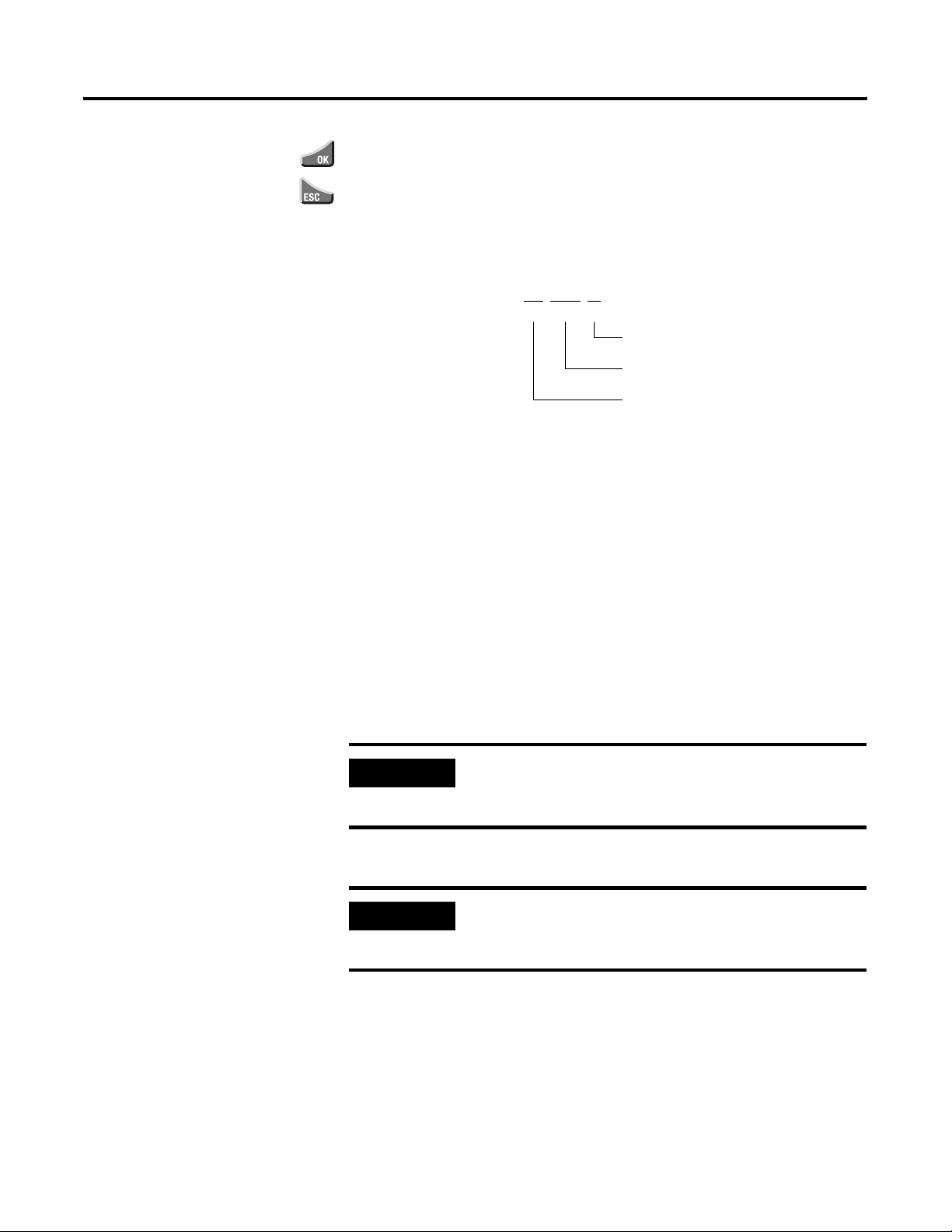

7. Press OK to accept the address.

8. Press ESC to cancel address input.

Information about the 4th display line:

xxx -x x . x x - xx

222 - 02 . 10 - B

Set the Address with Pico-SOFT

With Pico-SOFT, version 3.1

Operate the DeviceNet Interface 3-3

Hardware version, Index: b

Software version, OS version: 2.1

Device identity: 1760-DNET

‹Menu l Online l Configuration of expansion units›

With Pico-SOFT, version 4.01 and later

‹Menu l Communication l Configuration l Expansion units l

1760-DNET›.

IMPORTANT

IMPORTANT

The menu is only available in the communication

view; therefore please activate the ‘Communication’

tab.

After you have modified the MAC ID via the basic

unit, restart the DeviceNet Interface by switching

power off and on.

Set the Address with the DeviceNet Master

The configuration software supplied with your master programmable

controller offers the option of setting or modifying the MAC ID of the

gateway.

Publication 1760-UM003A-EN-P - September 2005

Page 22

3-4 Operate the DeviceNet Interface

For more information, refer to the programmable controller’s

documentation.

You can also use various other software packages to modify the MAC

ID by sending an explicit message. Do so by using the corresponding

service of the DeviceNet object (see DeviceNet Object on page 4-6).

LED Status Displays

The DeviceNet Interface expansion module is equipped with two

indicator LEDs for quick diagnostics. The module monitors itself as

well as the DeviceNet communication bus.

Module Status LED (MS)

The dual-color LED (GREEN/RED) indicates the status of the module.

It monitors whether the device is fully functional and operates without

fault.

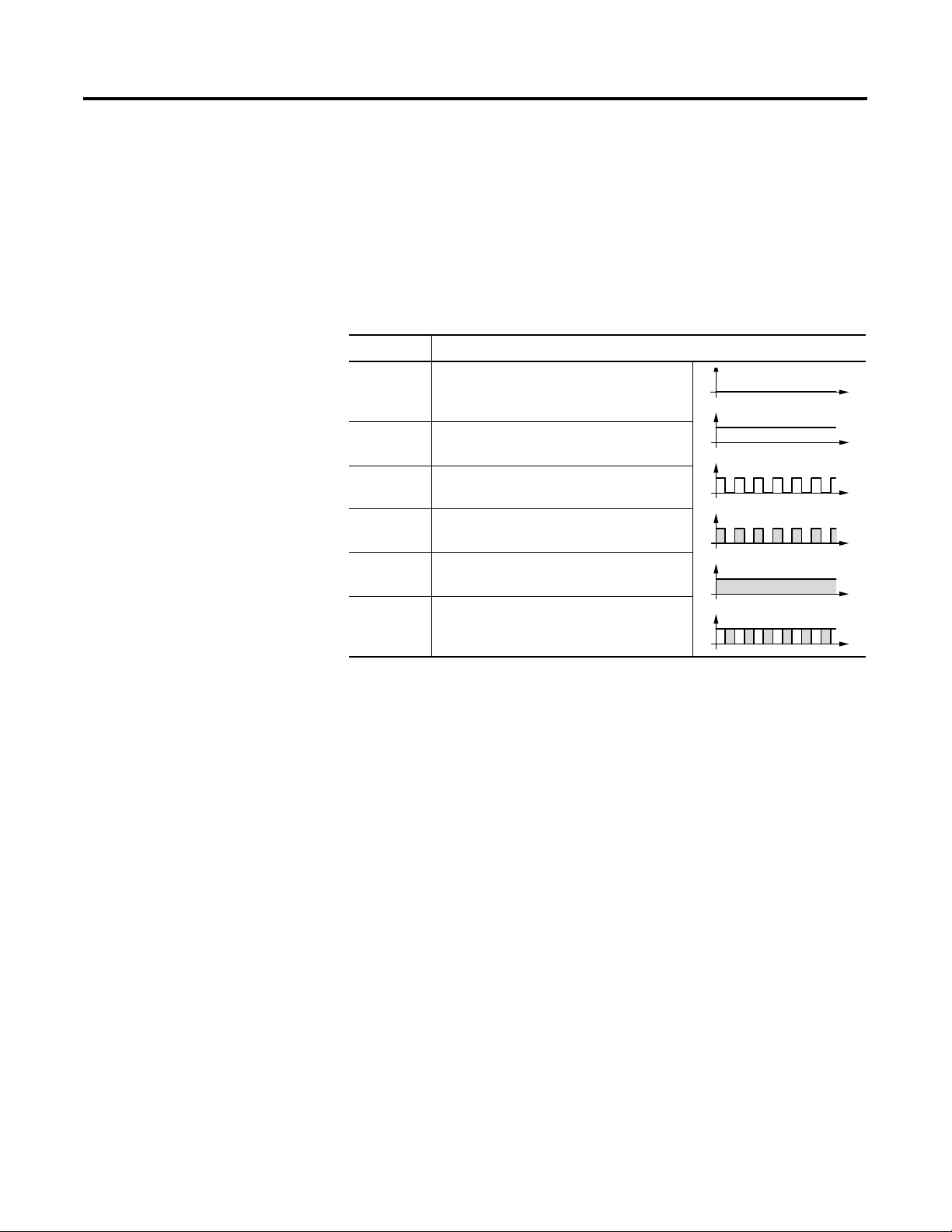

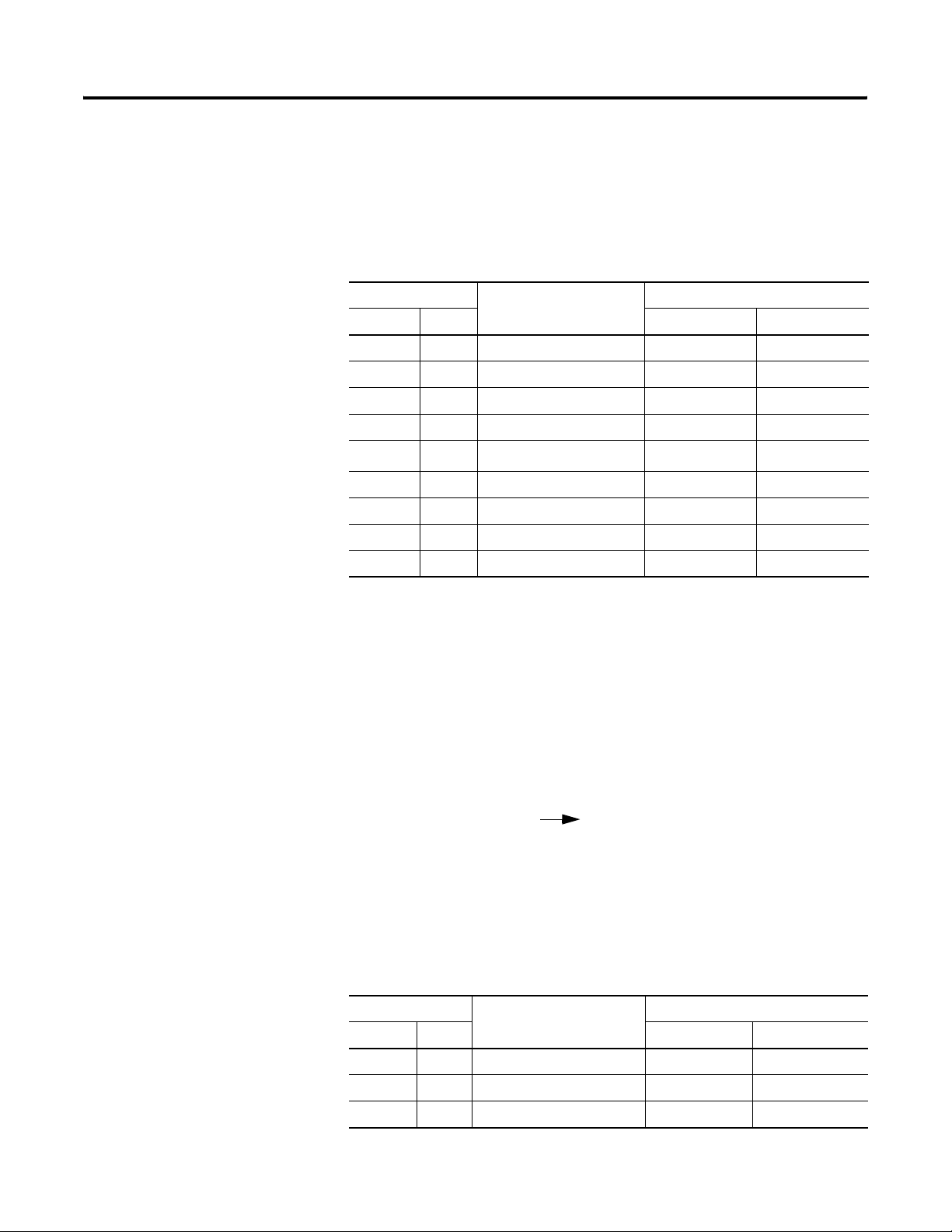

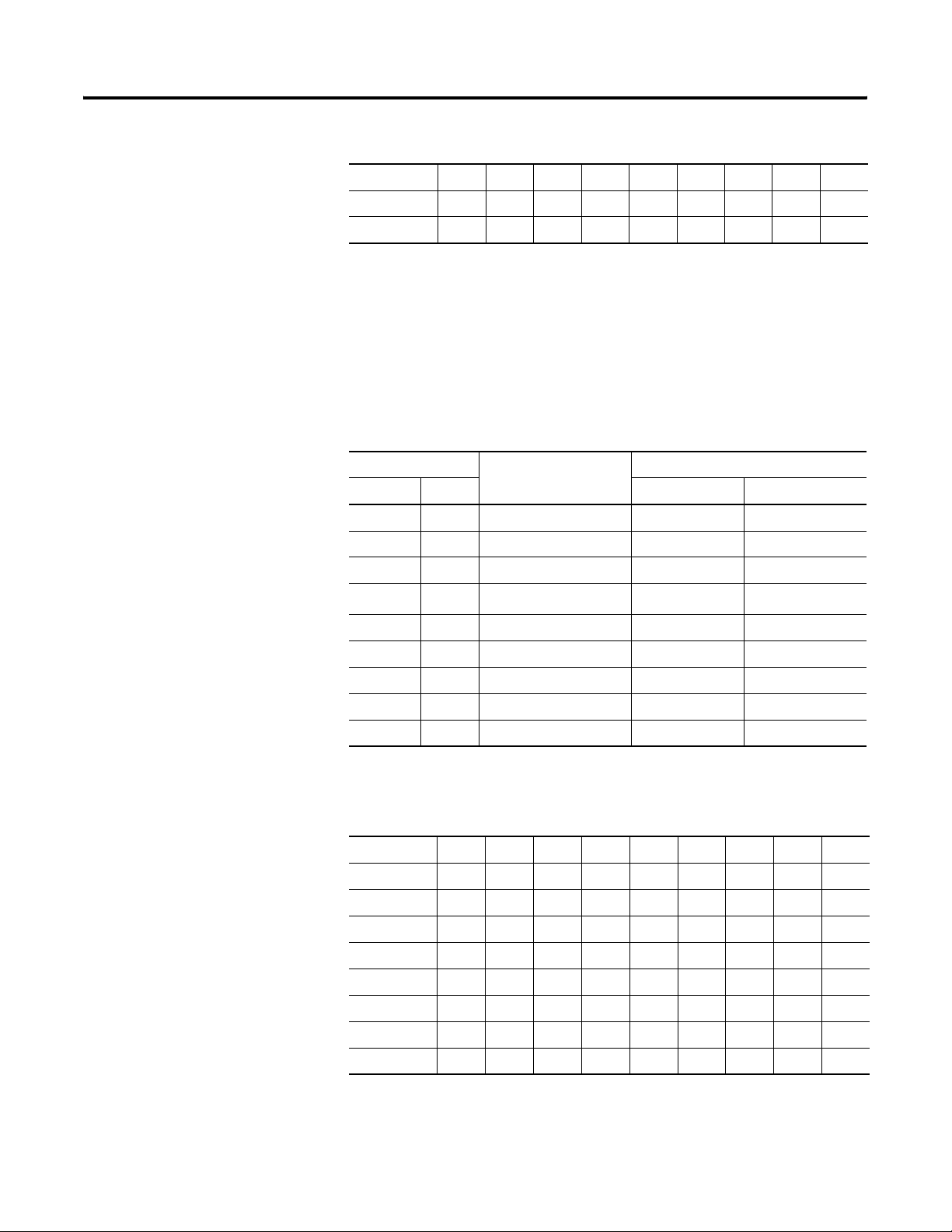

Table 3.1 Module Status LED Description

LED Status Description

Off No power supply at the module.

Green The module is in normal operational

state.

Green flashing The module is in standby mode. The

configuration is faulty or incomplete,

or a configuration does not exist.

t

t

Publication 1760-UM003A-EN-P - September 2005

Red flashing An error has occurred. There is no

need to replace the module.

Red A fatal error has occurred. The

module must be replaced.

Green-Red flashing The module is performing a self-test.

t

t

t

t

Page 23

Operate the DeviceNet Interface 3-5

Network Status LED (NS)

The dual-color LED (GREEN/RED) indicates the status of the

DeviceNet communication bus. This function monitors operability and

correct operation of the module.

Table 3.2 Network Status LED Description

LED Status Description

OFF The module is offline. Either it is performing

a DUP_MAC_ID test or power is missing at

the device or bus.

GREEN

flashing

GREEN The module is online and the connection is

RED

flashing

RED A fatal network error has occurred. The

GREEN-RED

flashing

The module is online. Communication has

not yet been established.

active.

Time-out of at least one I/O connection

(time-out state).

module has shut down communication.

The module has detected a network access

error and is now in communication error

state.

t

t

t

t

t

Cycle Time of the Pico Basic Unit

EDS File

Network traffic between the Pico basic unit and the DeviceNet

Interface via Pico-LINK extends the cycle scan time of the basic unit

In the worst case, this time can be extended by 25 ms.

Please take this factor into account when you calculate the response

times of the basic unit.

You can implement the module into the DeviceNet structure by means

of a standardised EDS file (Electronic Data Sheet).

This EDS file primarily defines the polled I/O connection, the COS I/O

connection and the cyclic I/O connection of the gateway. It does not

contain data or parameters (Pico object) for functions of the controller.

These functions are accessed by means of explicit messages.

You can download updates of the EDS file from:

http://www.ab.com/networks/eds/

Publication 1760-UM003A-EN-P - September 2005

Page 24

3-6 Operate the DeviceNet Interface

Search for the catalog number 1760.

IMPORTANT

The Identity Object entry - Major Revision defines

the current operating system state of the 1760-DNET

communication module. As the device with a newer

operating system version can deviate from the EDS

description in this point, this entry must be modified

accordingly, Identity Object on 4-4.

Publication 1760-UM003A-EN-P - September 2005

Page 25

DeviceNet Functions

Chapter

4

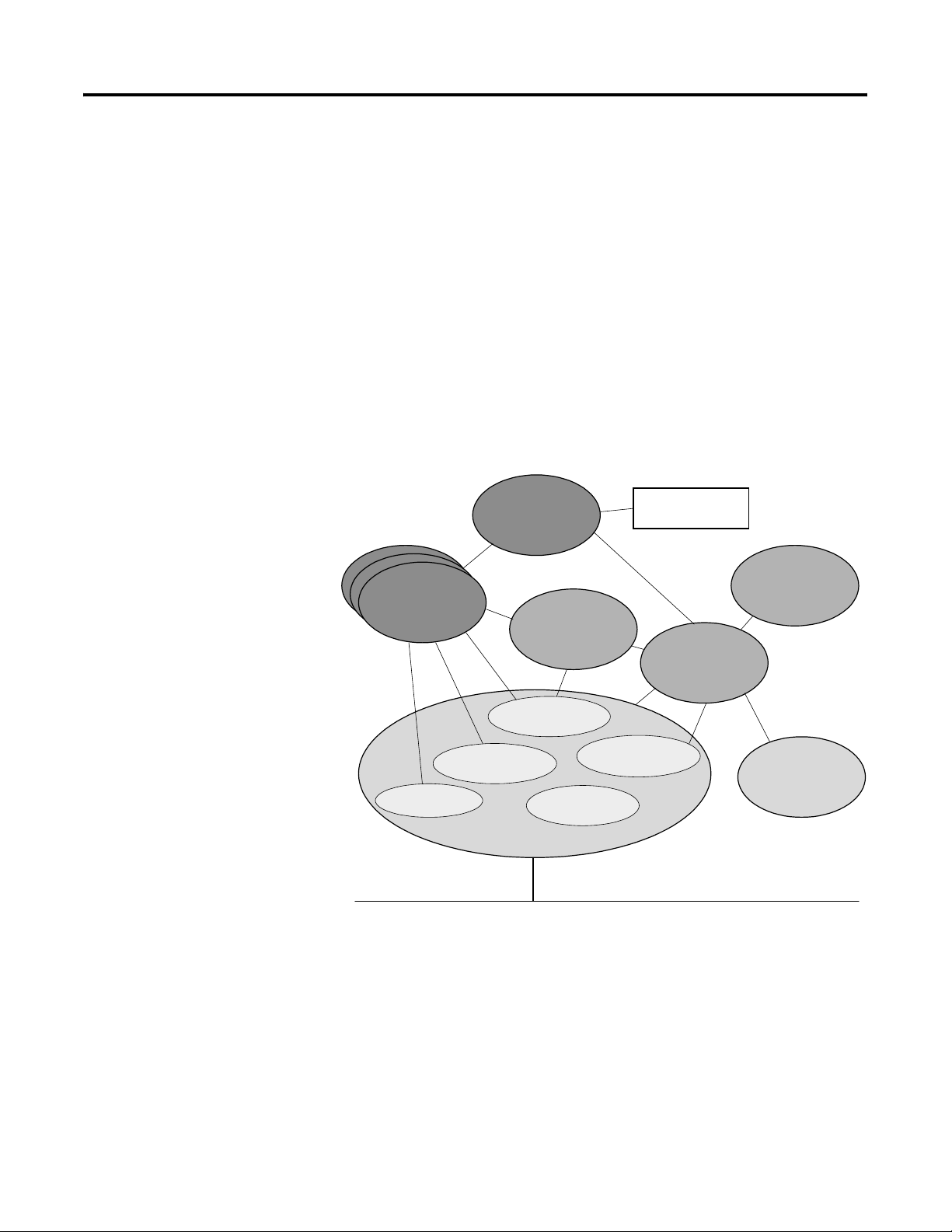

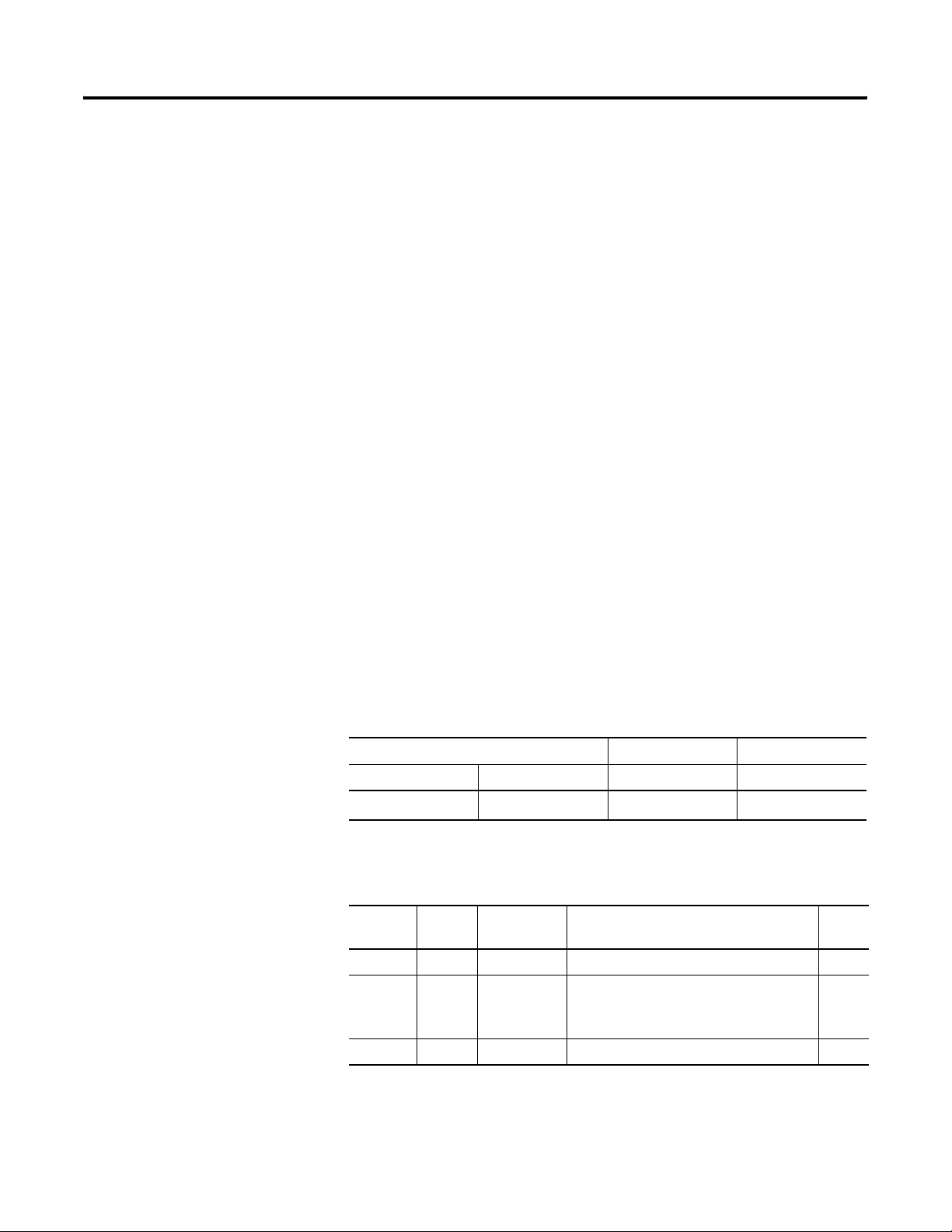

Object Model

The Pico DeviceNet Interface is based on the Communications

Adapter Profile according to the ODVA specifications (Release V2.0).

The DeviceNet object model can be used to describe all 1760-DNET

functions. The object model reflects the principle of communication at

the application layer. This manual deals in the following only with

objects relevant for your application. Primary topic is the

manufacturer-specific class Pico object.

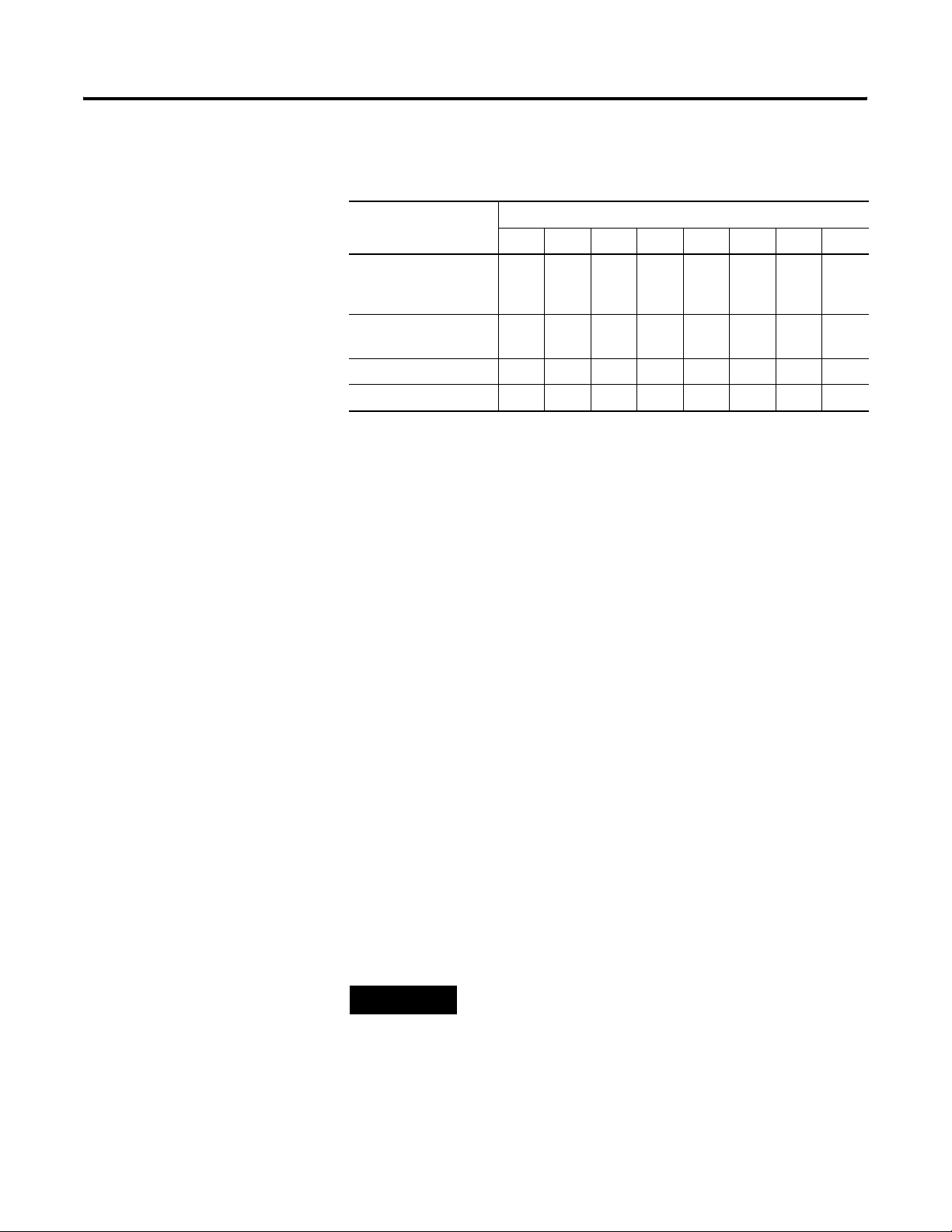

Figure 3.5 DeviceNet Objects

Pico-LINK

Protocol Handler

Identity

Object

Message Router

Object

DeviceNet

Object

Assembly

Object

Object

Polled I/O

Connection

COS/Cyclic I/O

Bit Strobed I/O

Connection

Pico

Object

Acknowledge Handler

Object

Connection

Explicit Message

Connection

Dynamic

Connection

Connection Object

DeviceNet

The DeviceNet objects in the illustration can be compiled again as

‘Management objects’, ‘Connection objects’ and ‘Manufacturer-specific

objects’.

1 Publication 1760-UM003A-EN-P - September 2005

Page 26

4-2 DeviceNet Functions

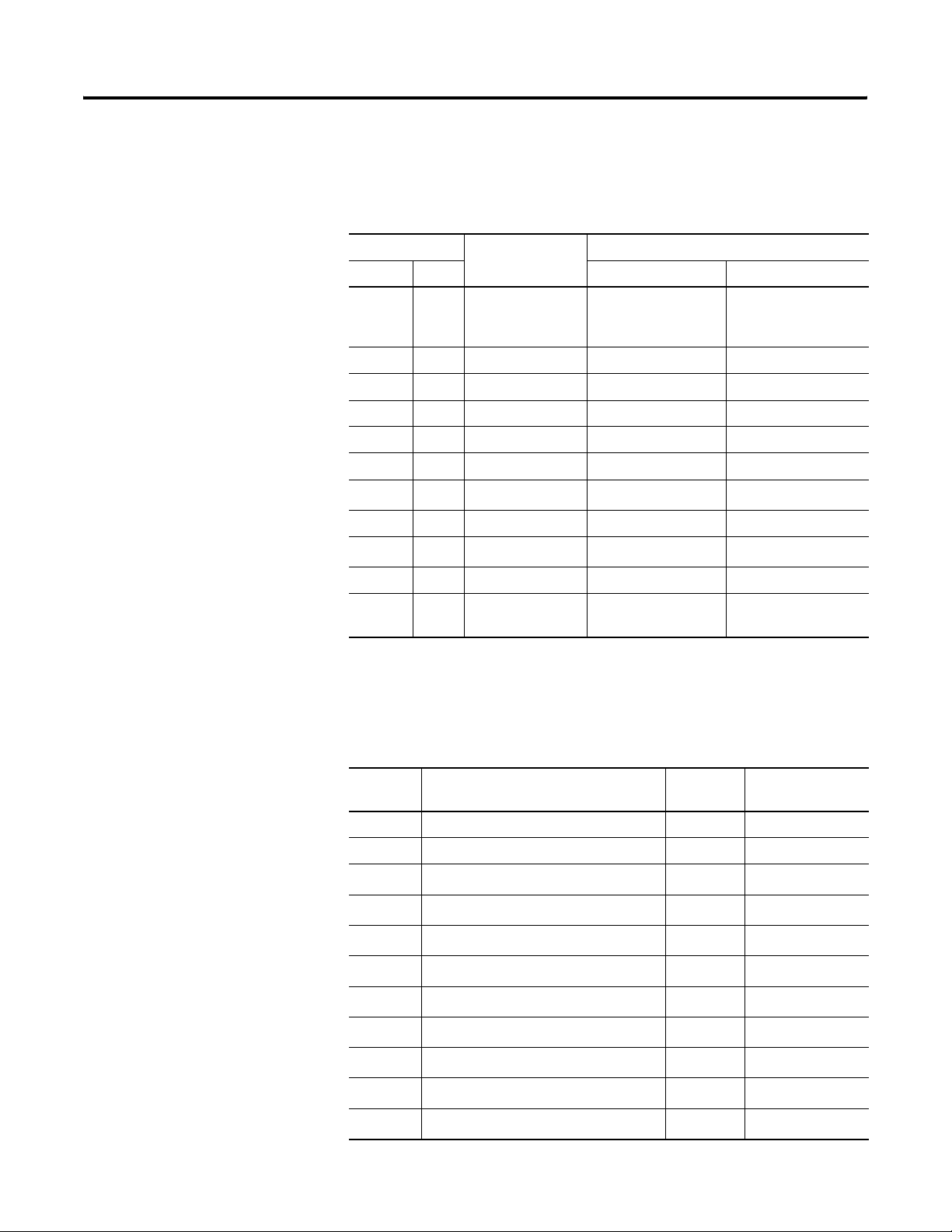

Table 3.3

Objects Object Address Service Address Function

Class ID (Hex) Instance ID (Hex) (Hex) Attribute ID (Hex)

Management Objects

Identity Object 01 01

Message Router 02 01

Connection Objects

DeviceNet Object 03 01

Connection

Object

Manufacturer-Specific

Objects

Pico Object 64 01

Direct Access:

inputs/outputs,

mode

Read 0E

Write 10

Extended access:

time, image data,

function blocks

Pico Series B

Pico GFX-70

Assembly Object 04 64 ... 66

05 01 ... 04,

04 ... 0F

Management Objects

32

Publication 1760-UM003A-EN-P - September 2005

These objects define DeviceNet-specific data and functions and must

be supported by all DeviceNet devices:

• Identity Object

The Identity Object (Class ID 01

) contains all data for unique

hex

identification of a network node, e.g. the Vendor ID, Device

Type and Product Code. It also comprises the actual status of a

device, the serial number and the product name.

Detailed information can be found on page 4-4.

Page 27

• Message Router Object

DeviceNet Functions 4-3

The Message Router Object (Class ID 02

) provides access to

hex

all classes and instances in the device by means of explicit

messages.

Connection Objects

These objects define messages exchanged via DeviceNet:

• DeviceNet Object

All devices must support the DeviceNet object (Class ID: 03

It defines the physical interconnection of a device to the

DeviceNet network, meaning it also contains the device address

(MAC ID) and the currently set transmission speed, for example.

Detailed information page 4-6.

• Connection Object

The Connection Object (Class ID: 05

DeviceNet devices in at least one instance. It defines the access

to data via I/O messages or explicit messages, the path and

length of producer/consumer data, the CAN connection

identifier, the watchdog and the error response.

) is supported by all

hex

hex

).

Publication 1760-UM003A-EN-P - September 2005

Page 28

4-4 DeviceNet Functions

Manufacturer-Specific Objects

These objects define device-specific data and functions (Application

Objects, Parameter Object, Assembly Object).

• Application Objects – Pico Object

Application objects (Class ID: 64

) describe simple

hex

applications for automation engineering. They are either

predefined in the DeviceNet object library or by the user.

Refer to Pico Object on page 4-6.

• Assembly Objects

The Assembly Object (Class ID: 04

) provides the user with

hex

mapping options, that is attribute data of different instances in

different classes can be grouped together to form a single

attribute of an instance in an assembly object.

Identity Object

Object Address Function Access

Class ID Instance ID Attribute ID Service Code

01

hex

01

hex

Table 4.4 Table 4.5

Publication 1760-UM003A-EN-P - September 2005

Table 4.4 Attribute IDs of the Identity Object Instance

Attribute IDAccess Name Description Size

(byte)

1 Read Vendor ID Allen-Bradley Vendor ID = 1 2

2 Read Device type The 1760-DNET belongs to the

communication adapters category. Its

value is 12

3 Read Product code Allen-Bradley product code = 18410 2

dec

.

2

Page 29

DeviceNet Functions 4-5

Table 4.4 Attribute IDs of the Identity Object Instance

Attribute IDAccess Name Description Size

(byte)

4 Read Device

version

Two bytes are returned when reading the

device version.

Hardware

version,

Operating

The low byte defines the hardware

version, the high byte the operating

system version.

1

1

system

version

5 Read Status This attribute describes the global status

2

of the device.

6 Read Serial

number

7 Read Product name The product name 1760-DNET is stored as

The serial number of the device can be

read with this attribute.

4

12

hex value in ASCII format.

9 Read Configuration

consistency

value

10 Read/

Write

Heartbeat

Interval

This attribute returns a counter value that

monitors the number of modifications in

non-volatile memory (E2PROM).

Defines an interval between heartbeat

messages in [s].

2

2

Service Code

The Identity Object Instance and also the following instances support

the services listed in the table below.

Table 4.5 Service Code

Service Code Value Service Name Description

05

hex

Reset Calls the reset function of

the communication module.

0E

hex

Get_Attribute_Single This service can be used to

fetch the value of a selected

attribute from the

communication module.

10

hex

Set_Attribute_Single This service can be used to

set a selected attribute in

the device.

Publication 1760-UM003A-EN-P - September 2005

Page 30

4-6 DeviceNet Functions

DeviceNet Object

Object Address Function Access

Class ID Instance ID Attribute ID Service Code

03

hex

The DeviceNet object instance is used to configure the

communication module and to define the physical environment. The

Service Codes used for the Identity Object also apply in this case.

Table 4.6 DeviceNet Object Instance Attribute IDs

Attribute IDAccess Name Description Size

01

hex

Table 4.6 Table 4.5

(byte)

1 Read/

Write

2 Read/

Write

3 Read/

Write

4 Read/

Write

Pico Object

MAC ID The MAC ID represents the network

address of a network node. It can be read

and set for the module via the DeviceNet

fieldbus by means of this attribute. Range

of values: 0 to 63

Setting the Slave Address on page 3-1)

Baud rate This attribute can be used to read/set the

data transfer rate for communication

functions. Range of values: 0 to 2, 125 to

500 kbps (see Data Transfer Rates –

Automatic Baud Rate Recognition on page

2-4).

BOI (Bus-Off

interrupt)

Bus-Off

counter

This attribute can be used to define the

reaction to a Bus-Off event (CAN-specific).

This values shows how often a Bus-Off

event has occurred. Range of values: 0 to

255.

. (see DeviceNet

dec

1

1

1

1

Publication 1760-UM003A-EN-P - September 2005

Object Address Function Access

Class ID Instance ID Attribute ID Service Code

64

hex

01

hex

Table 4.7 Table 4.8

The Pico object can be used to access Pico/GFX functions via the

DeviceNet communication bus . The table below shows the attributes

Page 31

DeviceNet Functions 4-7

supported by this object. The two bytes of attributes 1 and 2 provide

the diagnostic data of the device. You can use attribute 3 to access the

outputs (S1 to S8) and attribute 4 to access the inputs (R1 of R16) of

the basic unit.

By using a DeviceNet configuration software (e.g. RSNetworx), you

can map these data directly to the corresponding memory areas of a

programmable controller.

Table 4.7

Attribute IDAccess Name Description Size

(byte)

1 Read Pico Status This attribute can be used to read the

status of Pico (RUN or STOP). See

Table 4.9.

2 Read Coupling

Module

Status

This attribute can be used to read the

status of Pico-LINK. See Table 4.9.

1

1

3 Read Inputs –

Send Data

4 Read/W

rite

5 Read/W

rite

Outputs –

Receive Data

Predefined

Outputs

Pico transfers the input data to the

DeviceNet bus. The Pico outputs S1 to S8

must be used for this function. The

structure of these 3 bytes is described in

detail under Input data: Mode, S1 – S8 on

page 5-2, .

The DeviceNet bus transfers the data to

Pico. The Pico inputs R1 to R16 must be

used for this function. The structure of

these 3 bytes is described in detail under

Output Data: Mode, R1 – R16 on page 5-4,

.

This attribute can be used to preset the

output data ("R" data) at the

1760-DNETduring start-up. The structure

of these 3 bytes is described in detail

under Output Data: Mode, R1 – R16 on

page 5-4.

Service Code

The Pico object instance supports the following services.

3

3

3

Publication 1760-UM003A-EN-P - September 2005

Page 32

4-8 DeviceNet Functions

Table 4.8 Service Code

Service Code Value Service Name Description

0E

hex

Get_Attribute_Single This service can be used to

fetch the value of a selected

attribute from the

communication module.

10

hex

Set_Attribute_Single This service can be used to

set a selected attribute in

the device.

32

hex

Extended access

(1)

This service can be used to

address the supplementary

parameters

(1)

of the control

relay:

(1) Additional parameters are “Time”, “Image data” and “Function block”. Addressing of the parameters is Pico

specific and is described in chapters 5 – 7 in detail.

Extended access is implemented via explicit message transfer. This transfer protocol allows the exchange of

control data. Further information about the transfer protocol can be found in section “DeviceNet

Communication profile” on page 9.

Change of State I/O Connection

Table 4.9 Diagnostics Data: 2 Byte

Bytes Meaning Value Meaning

0 Pico status

(attribute ID 1)

1 Coupling module

status (attribute ID

2)

TIP

When communication between the basic unit

Pico/GFX and the expansion unit 1760-DNET goes

down, a corresponding error code will be generated

in the third data byte. Furthermore, the Rx/Tx data of

the gateway will be transferred with the value 00hex.

00

00

04

hex

hex

hex

Static value.

The basic unit is

connected to the

1760-DNET gateway

via Pico-LINK.

The basic unit is

either switched off

or disconnected

from the

1760-DNET gateway

via Pico-LINK.

Publication 1760-UM003A-EN-P - September 2005

Page 33

DeviceNet Functions 4-9

DeviceNet Communication Profile

DeviceNet is based on a connection-oriented communications model,

that is data are exchanged only via the specific connections assigned

to the units.

DeviceNet stations communicate either by means of I/O messages or

explicit messages.

I/O Messages

I/O messages are used for exchanging high-priority process and

application data across the network. Communication between

DeviceNet nodes is based on the client/server model, i.e. a "producer"

application transfers data to one or several "consumer" applications. It

is quite possible in this case that several application objects are

addressed in the same unit.

Prerequisite for communication between the units via I/O messages is

the implementation of an I/O Messaging Connection Object. You can

activate this function in two ways:

• Either by means of a static and in the unit already existing ‘I/O

connection object’ or via the ‘Predefined Master/Slave

Connection Set’, or

• via a dynamically configured ‘I/O connection object’, which you

can configure using an Explicit Messaging Connection Object

that already exist in the unit.

Explicit Messages

Explicit messages are used for exchanging low-priority configuration

data, general management data or diagnostics data between two

specific units across the PtP connection in a client/server system, in

which the server always has to acknowledge client requests.

Same as for I/O messaging, the prerequisite for explicit messaging is

the implementation of a Connection Object, namely the Explicit

Messaging Connection Object. This can be achieved either by

activating an existing static connection object in the unit, or via the

Predefined Master/Slave Connection Set, or dynamically across the

UCMM port (Unconnected Message Manager Port) of a device.

All data of the function relay (Pico basic unit) are processed by means

of explicit messages. The DeviceNet master can thus read/write access

the parameters of the following functions.

Publication 1760-UM003A-EN-P - September 2005

Page 34

4-10 DeviceNet Functions

• Time

• Image data

• Function blocks (counters, timers, analog value comparators,...).

General Method of Operation

The general method of operation with the 1760-DNET should be

presented in the following. The acyclic data transfer is realised with

the aid of explicit messages. The function blocks of the Pico basic unit

can be addressed via the service code = 32

ID is here used to distinguish between different parameters and

functions.

Service Code Object Address

Class ID Instance ID

. The assigned attribute

hex

32

hex

64

hex

01

hex

Digression:

DeviceNet based on the standard CAN protocol and therefore uses an

11 bit message identifier. As a result 211 = 2048 messages (000

7FF

) are distinguishable. Six bits are sufficient for identification of a

hex

hex

-

device as a DeviceNet network is limited to a maximum of 64 stations.

These are referred to as the MAC-ID (device or node address).

Four message groups of differing sizes are available to suit the

utilization model.

In DeviceNet language terms the CAN identifier is referred to as the

Connection ID. This is comprised of the identifier for the message

group (Message ID) and the MAC ID of the device:

• The source and target addresses are possible as the MAC ID; the

definition is dependant on the message group and message ID.

• The significance of the message is defined in the system with the

message ID.

Four message groups are available in the DeviceNet world. The

1760-DNET uses message group 2. This group uses 512 CAN

identifiers (400

hex

- 5FF

). Most of the message IDs defined for this

hex

group are optional and defined for use of the ‘Predefined Master/Slave

Connection Sets’. A message ID is used for network management. The

priority is primarily determined by the device address and then by the

message ID. If the bit position is examined in detail, you will find that

a CAN controller with an 8 bit mask is capable of filtering out its

group 2 messages.

Publication 1760-UM003A-EN-P - September 2005

Page 35

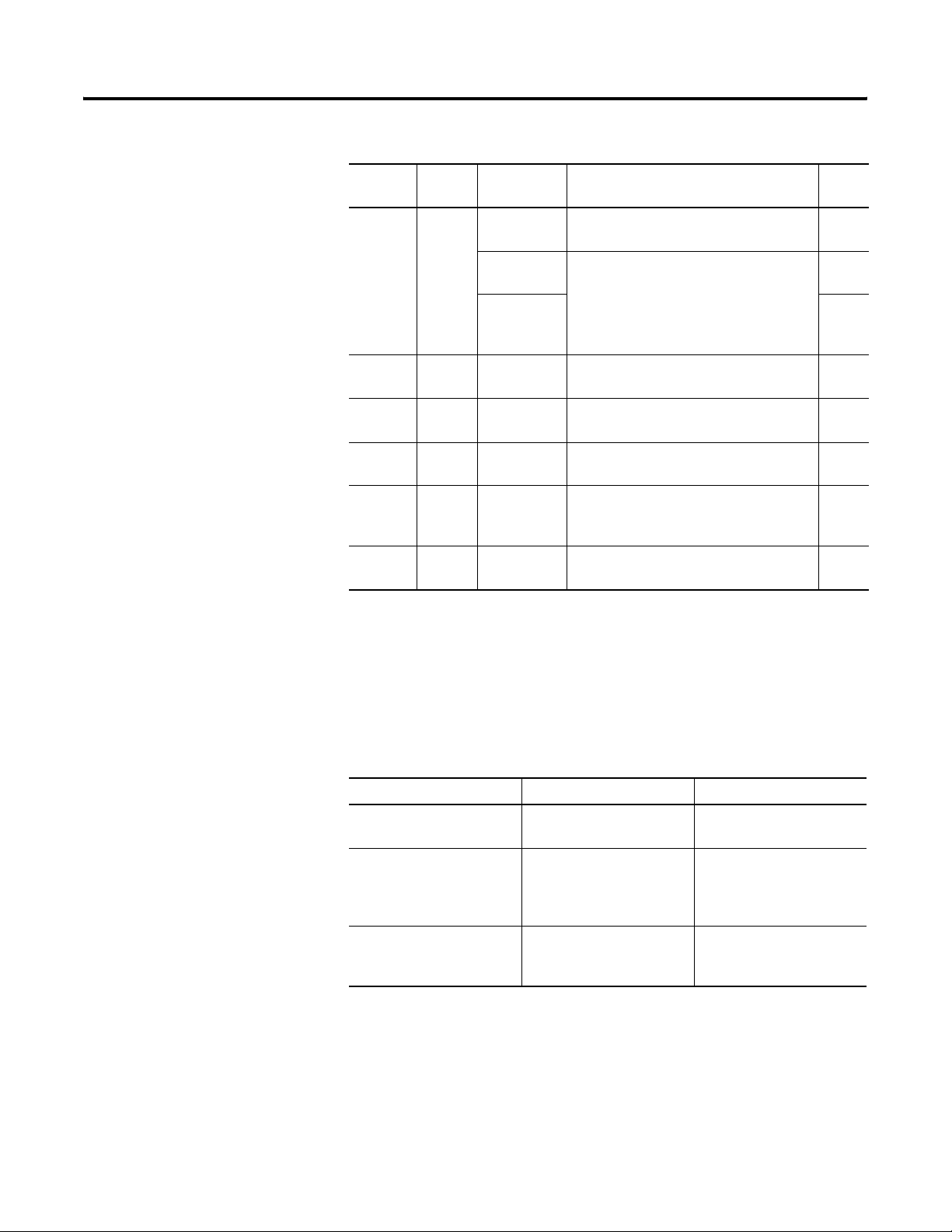

DeviceNet Functions 4-11

Connection ID = CAN Identifier Meaning

109876543210

1 0 MAC ID Message ID Message Group 2

1 0 Source MAC ID 0 0 0 Master’s I/O Bit-Strobe Command

Message

1 0 Source MAC ID 0 0 1 Reserved for Master’s Use - Use is

TBD

1 0 Destination MAC ID 0 1 0 Master’s Change of State or Cyclic

Acknowledge Message

1 0 Source MAC ID 0 1 1 Slave’s Explicit/Unconnected

Response Messages

1 0 Destination MAC ID 1 0 0 Master’s Explicit Request Messages

1 0 Destination MAC ID 1 0 1 Master’s I/O Poll Command/Change

of State/Cyclic Message

1 0 Destination MAC ID 1 1 0 Group 2 Only Unconnected Explicit

Request Messages

1 0 Destination MAC ID 1 1 1 Duplicate MAC ID Check Messages

The data transfer on the DeviceNet communication bus is indicated in

the following table. The data flow indicates the telegram for reading

the date and time in the Pico (see Read/Write Date and Time on page

6-2).

The Pico DeviceNet communication module has MAC ID = 3. It must

be noted with the data stream that access is implemented in

fragmented form. More information can be found in the ODVA

specification.

Description ID

(Hex)

Master sends a request (Hex) with: 41C 8 80 00 32 64 01 93 05 00

DeviceNet Specific:

Byte 2 - Service Code = 32

Byte 3 - CLASS ID = 64

Byte 4 - Instance ID = 01

PicoLINK Specific

Length DeviceNet - Byte (Hex)

01234567

Byte 5 - Attribute ID = 93

Byte 6 - Len = 05

Byte 7 - Index = 0

Confirmation of the slave

(Fragmentation protocol)

41B 3 80 C0 00

Publication 1760-UM003A-EN-P - September 2005

Page 36

4-12 DeviceNet Functions

Description ID

(Hex)

Master sends remaining PicoLINK

41C6 800100000000

Length DeviceNet - Byte (Hex)

01234567

byte

Byte 2 - Data 1 = 00

Byte 3 - Data 2 = 00

Byte 4 - Data 3 = 00

Byte 5 - Data 4 = 00

Acknowledgement of the slave

41B 3 80 C1 00

(Fragmentation protocol)

Slave sends a response to the request 41B 8 80 00 B2 C2 05 00 05 09

Byte 3 – response = C2 (read

successful)

Byte 4 – Len = 05

Byte 5 – Index = 00

Byte 6 – Data 1 = 05

Acknowledgement from master

41C 3 80 C0 00

(Fragmentation Protocol)

Slave sends remaining Pico-LINK

41B5 80810D0504

data:

Data 2 = 0D

Data 3 = 05

Data 4 = 04

Acknowledgement from master

(Fragmentation protocol)

41C 3 80 C1 00

Publication 1760-UM003A-EN-P - September 2005

Page 37

Chapter

5

Direct Data Exchange with Pico/GFX (Polled

I/O Connection)

The DeviceNet master can exchange the following data with the

Pico/GFX via the direct cyclic data exchange:

TIP

• Write operation

– Setting or /resetting of the Pico/GFX inputs (R1 to R16)

– Determination of the RUN/STOP mode.

• Read operation

– Scanning the output states of the Pico/GFX (S1 to S8)

– Scanning the mode of the Pico/GFX.

In order to transfer data between the slave 1760-DNET and a

DeviceNet master control, you must map the respective cyclic data to

the respective slave configuration.

TIP

The terms “input data” and “output data” are used

relative to the point of view of the DeviceNet master.

The interconnection to the DeviceNet controls from

Allen Bradley is implemented using an assignment

table in the RSNetWorx software tool.

1 Publication 1760-UM003A-EN-P - September 2005

Page 38

5-2 Direct Data Exchange with Pico/GFX (Polled I/O Connection)

Figure 4.6 Input and Output Data Relative to the DeviceNet Master

DeviceNet Master

Outputs

Inputs

Input data: Mode, S1 to S8

Write: Output

data

Inputs

R1 – R16

Pico/GFX

Outputs

S1 – S8

Read: Input data

Attribute ID: 3

The cyclic data transfer between DeviceNet master and the Pico

DeviceNet Interface slave is provided by the input data byte 0, 1 and

2.

IMPORTANT

If Index for transferring valid data is not set, you

cannot read the S1 to S8 bits in RSLogix 5000.

Publication 1760-UM003A-EN-P - September 2005

Table 5.10 Byte 0 to 2: Input Data, Mode

Byte Meaning Value

0 Operating mode scan

1 Scan status of the Pico

outputs S1 to S8

2 Not used 00hex

The master reads the following data from bytes 0, 1 and 2:

Page 39

Direct Data Exchange with Pico/GFX (Polled I/O Connection) 5-3

Table 5.11 Byte 0: Operating Mode

Pico

Identification

Without Input

Delay

With Input Delay 0 0 1 0 0 0 0 0/1

Index for

transferring valid

data

Bit

76543210

Stop/Run

00010000/1

00010100

0 = status ’0’ 1 = status ’1’

Explanation:

Value 14

= 00010100

hex

bin

:

Byte 0 must always contain this value if data are to be written to the

Pico/GFX basic unit via the 1760-DNET gateway.

EXAMPLE

Value 21hex = 0010 0001bin:

"Pico" is in RUN mode and operates with input delay

Table 5.12 Byte 1: Status of the Pico/GFX outputs S1 to S8

Pico/GFX Bit

76543210

S1 0/1

S2 0/1

S3 0/1

S4 0/1

S5 0/1

S6 0/1

S7 0/1

S8 0/1

0 = status "0“ 1 = status "1"

Publication 1760-UM003A-EN-P - September 2005

Page 40

5-4 Direct Data Exchange with Pico/GFX (Polled I/O Connection)

EXAMPLE

Byte 2: not used

TIP

Value 19hex = 0001 1001bin:

S5, S4 and S1 are active

If control commands and I/O data are used at the

same time:

• The inputs will retain their previous state until

this control command has been executed.

• The input bytes will be updated again after the

data exchange control command has been

terminated.

If the status value of the coupling module is invalid

(= 04hex), then byte 1 (data byte) is transferred with

the value 00hex to the communication bus.

Output Data:

Mode, R1 – R16

Attribute ID: 4

The cyclic data transfer between DeviceNet master and the Pico

DeviceNet Interface slave is provided by the output data byte 0, 1 and

2.

Table 5.13 Byte 0 to 2: Output Data, Mode

Byte Meaning Value

0 Determine mode

1 Setting/resetting of the

Pico/GFX inputs R9 to R16

2 Setting/resetting of the

Pico/GFX inputs R1 to R8

The master writes the following data to the bytes 0, 1 and 2:

Publication 1760-UM003A-EN-P - September 2005

Page 41

Direct Data Exchange with Pico/GFX (Polled I/O Connection) 5-5

Table 5.14 Byte 0: Operating mode

Pico Operating Mode Bit

76543210

Index for setting the

basic unit to safety

state

Index for transferring

valid data

RUN command 00110100

STOP command 01000100

00000000

00010100

0 = status ’0’ 1 = status ’1’

Explanation:

Value 14

= 00010100

hex

bin

:

Byte 0 must always contain this value if data are to be written to the

Pico/GFX basic unit via the 1760-DNET gateway.

Value 34

= 00110100

hex

bin

:

This value sets the Pico status from STOP to RUN. It is only

interpreted as command and therefore does not permit an additional

transfer of data. The index value 14

Value 44

= 01000100

hex

bin

:

must be used in this situation.

hex

This value sets the "Pico" status from RUN to STOP. It is also used only

as command and is therefore based on the same operating principle

as the RUN command.

Value 00

= 00000000

hex

bin

:

If this value is written to the control byte, the gateway overwrites the

R data with zero. This function is of interest only if a master is to be

set to STOP mode and as resultant measure transfers zero values to all

I/O in order to ensure safety state.

TIP

Even if the I/O of a control relay can be assigned

directly to a specific memory area of the master

programmable controller, it is nonetheless important

to conform with the correct data structure format

(e.g.: input data byte 0 = 14hex).

Publication 1760-UM003A-EN-P - September 2005

Page 42

5-6 Direct Data Exchange with Pico/GFX (Polled I/O Connection)

Table 5.15 Byte 1: Setting/resetting of the Pico/GFX inputs R9 to R16

Pico/GFX Bit

76543210

R9 0/1

R10 0/1

R11 0/1

R12 0/1

R13 0/1

R14 0/1

R15 0/1

R16 0/1

0 = status ’0’ 1 = status ’1’

EXAMPLE

Value 19hex = 0001 1001bin:

Enable R13, R12 and R9.

Table 5.16 Byte 2: Setting/resetting of the Pico/GFX inputs R1 to R8

Pico/GFX

Input

R1 0/1

R2 0/1

R3 0/1

R4 0/1

R5 0/1

R6 0/1

R7 0/1

R8 0/1

Bit

76543210

0 = status ’0’ 1 = status ’1’

Publication 1760-UM003A-EN-P - September 2005

Page 43

Direct Data Exchange with Pico/GFX (Polled I/O Connection) 5-7

EXAMPLE

TIP

Value 2Bhex = 0010 1011bin:

Enables R6, R4, R2 and R1.

If control commands and I/O data are used at the

same time:

• The inputs will retain their previous state until

this control command has been executed.

• The input bytes will be updated after the data

exchange control command has been executed.

Publication 1760-UM003A-EN-P - September 2005

Page 44

5-8 Direct Data Exchange with Pico/GFX (Polled I/O Connection)

Publication 1760-UM003A-EN-P - September 2005

Page 45

Chapter

6

Application Examples for Pico

Control commands can be used to initiate data exchange for special

services:

• Read/Write Date and Time (page 6-2)

• Read/Write Image Data (page 6-4)

• Read/write function block data (page 6-20).

The DeviceNet master in this case returns to the message transfer

protocol of the explicit messages. All parameters are addressed via the

Service Code 32

distinguish between different parameters.

. The assigned attribute ID is here used to

hex

Service Code Object Address

Class ID Instance ID

32

Hex

TIP

IMPORTANT

A data exchange procedure is required in order to ensure the safe

exchange of data via DeviceNet from master to slave and vice versa.

The I/O data retain their previously defined state

while a control command is being executed. The I/O

data will not be updated until data exchange for the

control command has been terminated.

You may use only the values specified for the

instruction code.

Verify data to be transferred in order to avoid

unnecessary errors.

64

Hex

01

Hex

1 Publication 1760-UM003A-EN-P - September 2005

Page 46

6-2 Application Examples for Pico

Read/Write Date and Time

IMPORTANT

The operating mode of the basic unit must

correspond with the status indicated at the LEDs

when the various parameters are being set.

The master transmits a control command to initiate data exchange

between the communication partners. The slave always returns an

answer to this request, which indicates whether data has been

exchanged or not. An error code will be returned if data exchange has

failed. This code is defined in the ODVA specifications. (see

Related

Documentation on page P-2)

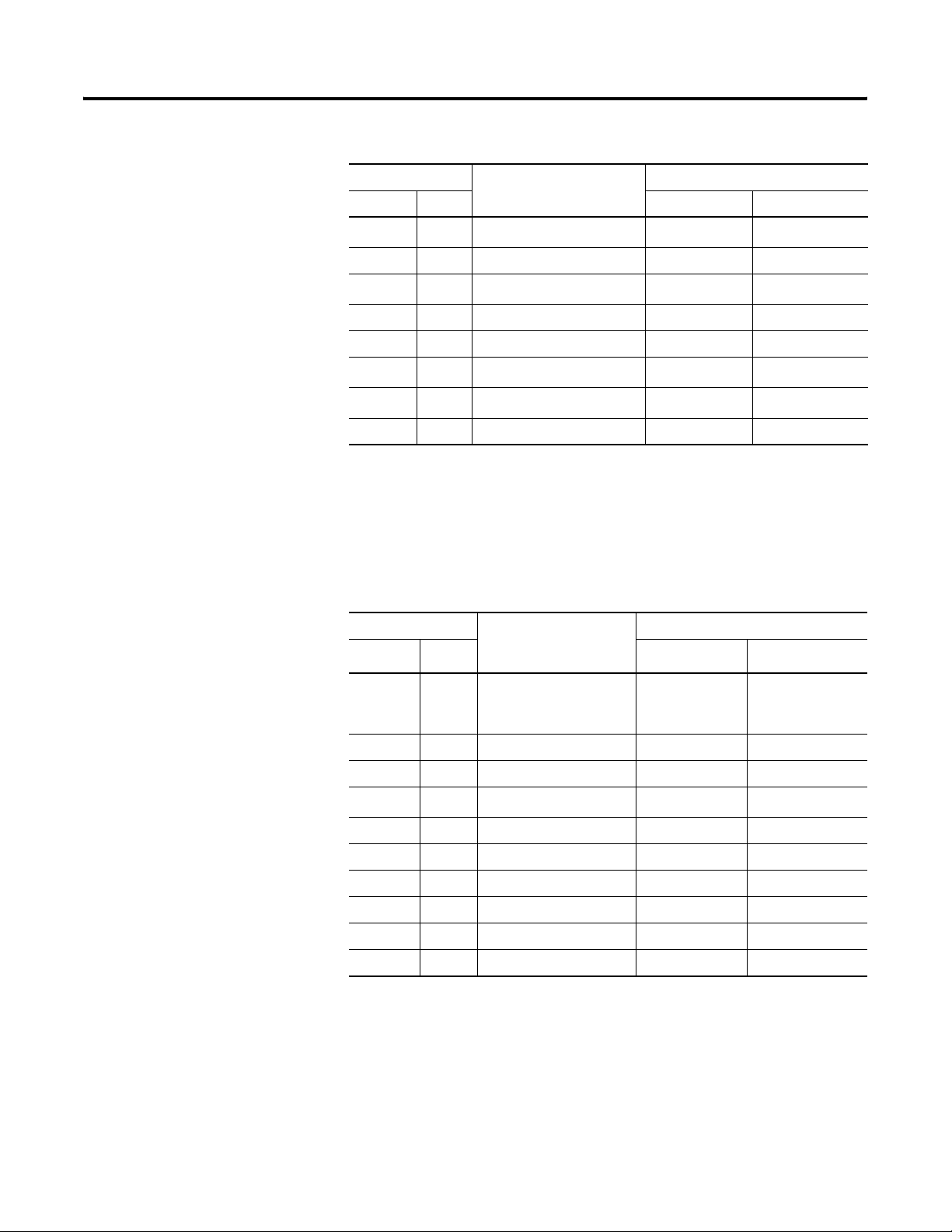

Table 6.1 Telegram Structure

Byte Description Value (Hex), Sent by

Master Slave Master Slave

Attribute ID

Read

Attribute ID

Write

0 Read

Successful

93 -

B3 -

- C2

Write

Successful

Command

Rejected

0 1 Len 05 05

1 2 Index

2 to 6 3 to 7 Data 1 t o5 Depending on

(1) 0 = Time/date , 1 = Summer time, 2 = Winter time

Table 6.2 Index 0 - Date and Time of Real-Time Clock

Byte Content Operand Value (Hex)

Master Slave

2 3 Data 1 Hour 0 to 23 0x00 to 0x17h

3 4 Data 2 Minute 0 to 59 0x00 to 0x3Bh

- C1

- C0

(1)

0 to 2

index

0 to 2

Depending on

index

(1)

Publication 1760-UM003A-EN-P - September 2005

Page 47

Application Examples for Pico 6-3

Table 6.2 Index 0 - Date and Time of Real-Time Clock

Byte Content Operand Value (Hex)

Master Slave

4 5 Data 3 Day Day (1 to 28; 29, 30, 31;

depending on month and year)

5 6 Data 4 Month 1 to 12 0x01 to 0x0Ch

6 7 Data 5 Year 0 to 99 (corresponds to

2000-2099)

Table 6.3 Index 1 - Summer Time

Byte Content Value (Hex)

Master Slave

2 3 Data 1 Area - None 00

Area - Rule 01

Area - Automatic EU 02

0x01 to 0x1Fh

0x00 to 0x63h

Area - Automatic GB 03

Area - Automatic US 04

for ‘Area’ = ‘Rule’

3 4 Data 2 Summer time switching

4 5 Data 3

5 6 Data 4

6 7 Data 5

Table 6.4 Index 2 - Winter Time (only valid if Area = Rule selected)

Byte Content Value (Hex)

Master Slave

2 3 Data 1 Area = Rule 01

3 to 6 4 to 7 Data 2 to 5 Winter Time

rule

switching rule

Switching Rule Bit Array

The following table shows the composition of the corresponding data

bytes.

Publication 1760-UM003A-EN-P - September 2005

Page 48

6-4 Application Examples for Pico

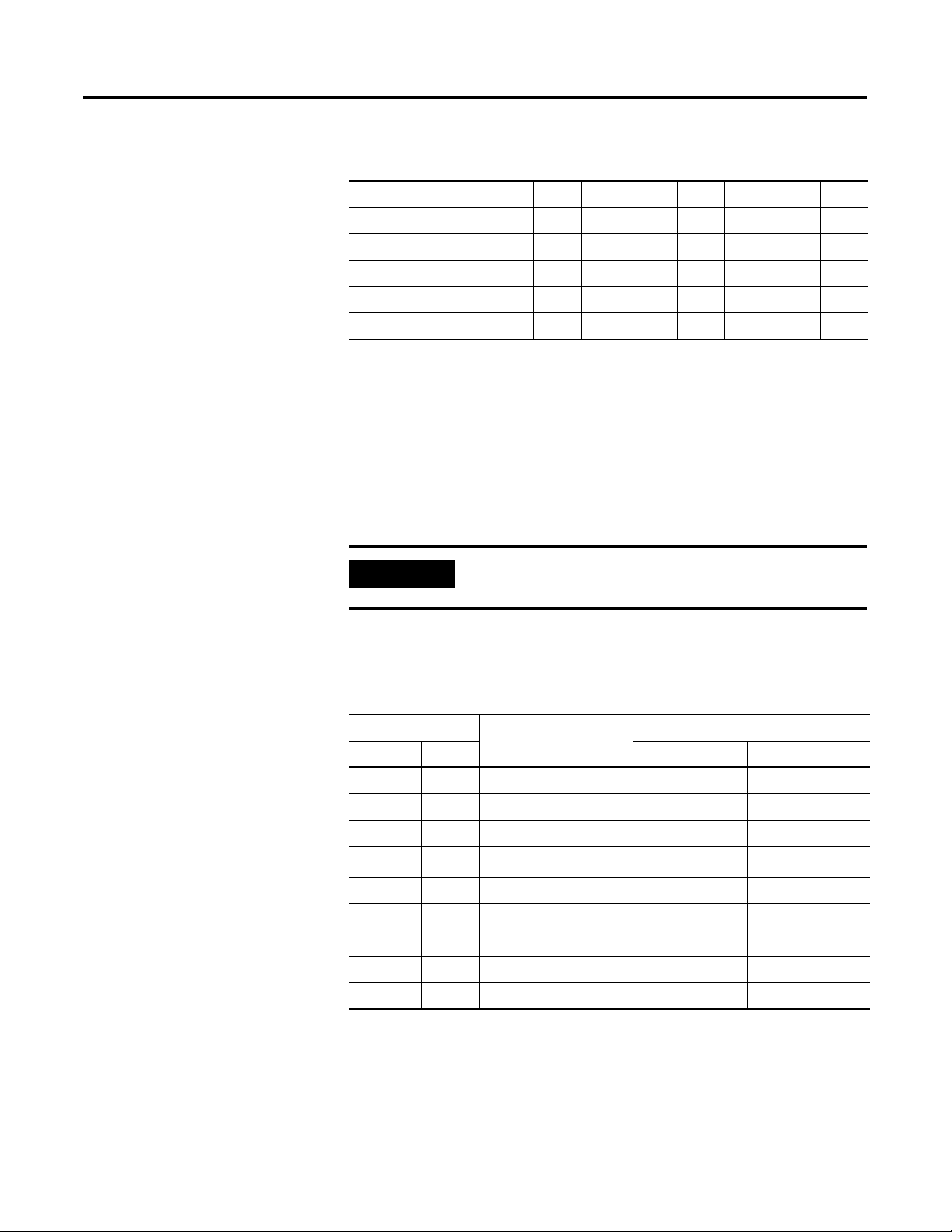

Table 6.5 Switching Rule Bit Array

Data 5 Data 4 Data 3 Data 2

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bit

Difference Time of time change Month Day Rule_2 Day Rule_1

0: 0:30h Minute: 0 to 59 Hour: 0 to 23 0 to 11 0 to 30 0: month 0: Su 0: on

1: 1:00h 1: after 1: Mo 1: on the

2: 1:30h 2: before 2: Tu 2: on the

3: 2:00h 3: We 3: on the

4: 2:30h 4: Thu 4: on the

5: 3:00h 5: Fr 5: on the

6: Sa

first

second

third

fourth

last

Read/Write Image Data

TIP

Refer to the image data provided in the Pico User

Manual, 1760-UM001 or in the PicoSoft help.

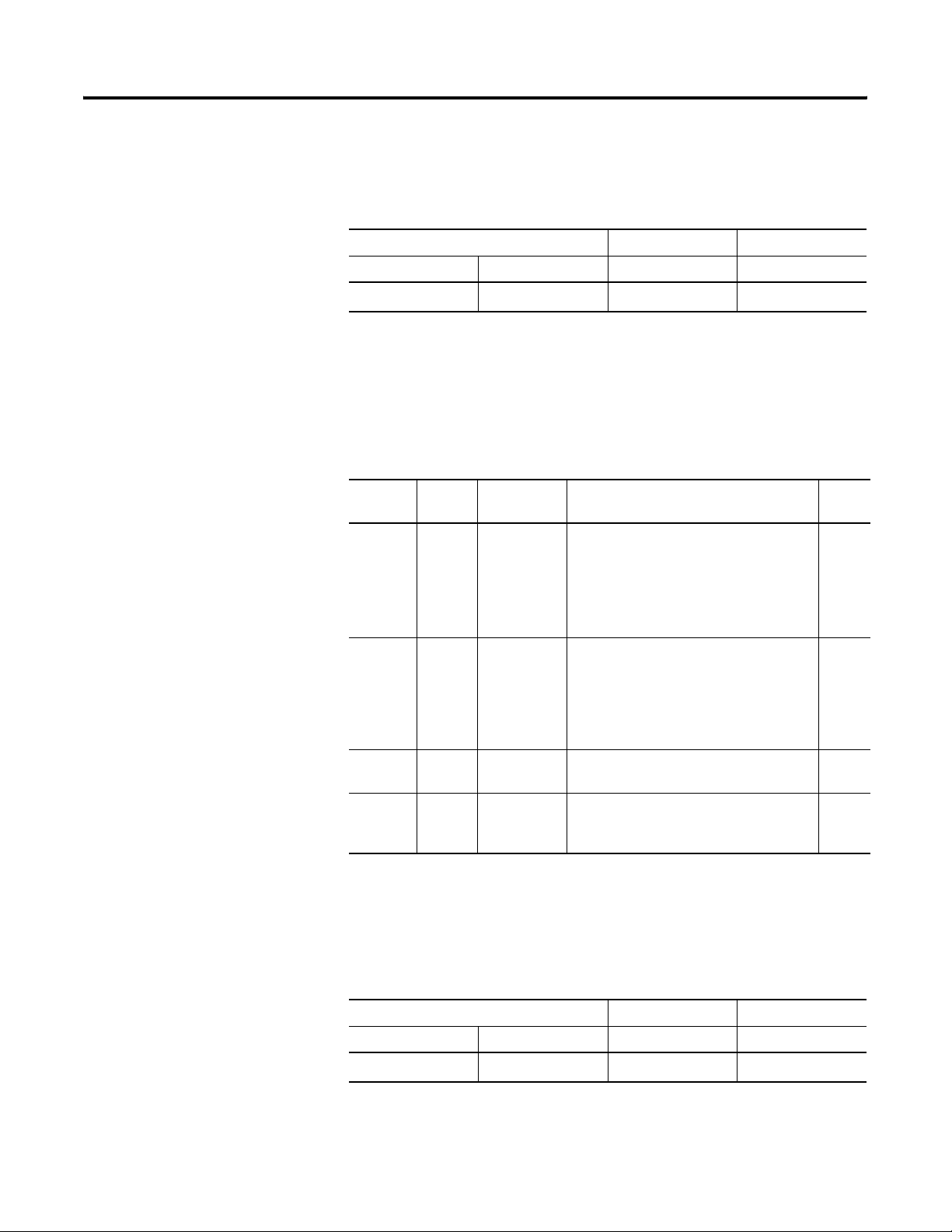

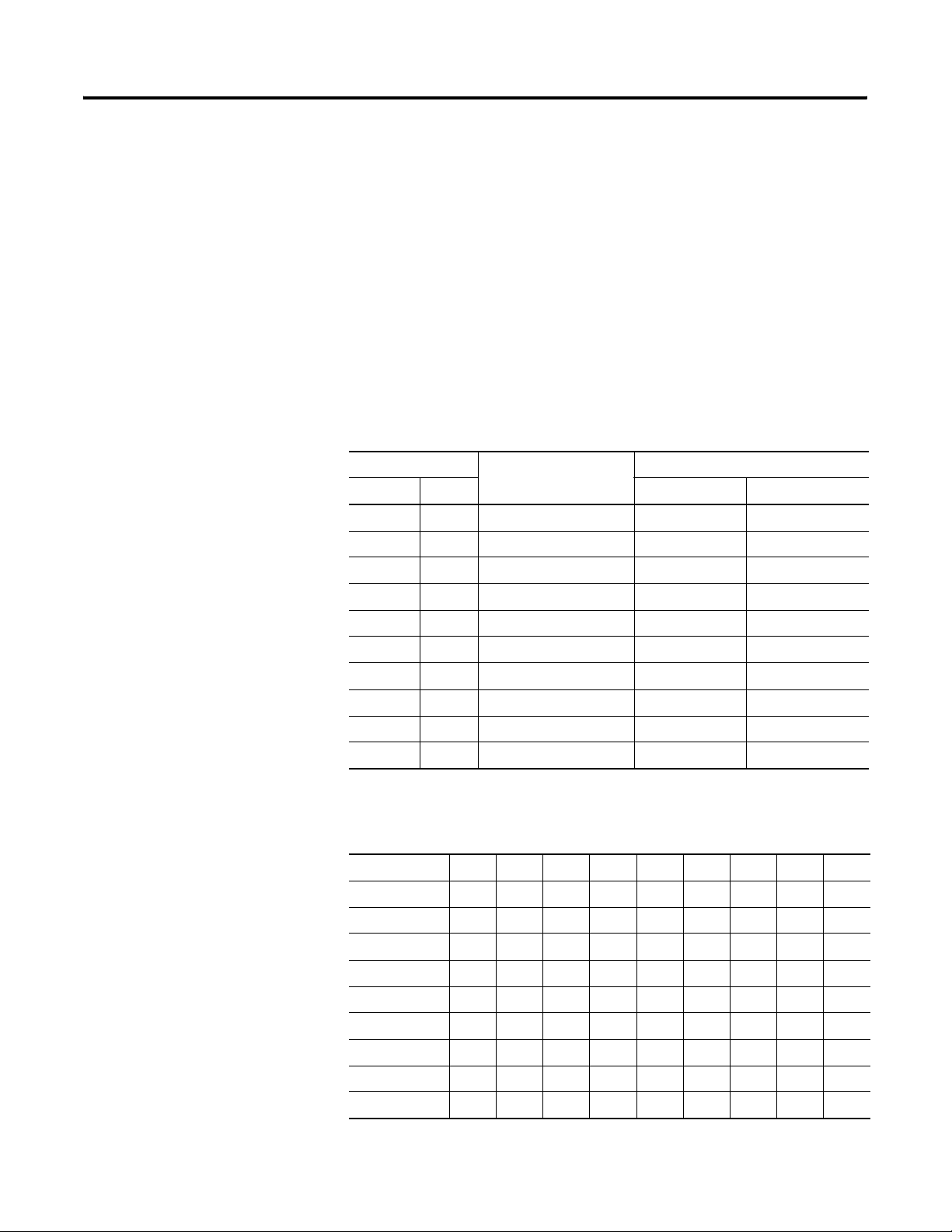

Overview

Table 6.6 Overview

Operands Meaning Read/Write Type

(hex)

A1 – A16 „Analog value comparators/threshold

comparators: A1 – A16“

C1 – C16 „Counters: C1 to C16“ read EE 6-6

D1 – D16 „Text function blocks: D1 – D16“ read 94 6-7

I1 – I16 „Local inputs: I1 – I16“ read 84 6-8

IA1 – IA4 „Local analog inputs: IA1 – IA4“ read 8C 6-9

M1 – M16,

„Write marker: M1 – M16/N1 – N16“ write 86/87 6-10

N1 – N16

read 8B 6-5

Page

Publication 1760-UM003A-EN-P - September 2005

M1 – M16,

„Read marker: M1 – M16/N1 – N16“ read 86/87 6-11

N1 – N16

O1 – O4 „Operating hours counters: O1 – O4“ read EF 6-13

P1 – P4 „Local P buttons: P1 – P4“ read 8A 6-14

Page 49

Table 6.6 Overview

Application Examples for Pico 6-5

Operands Meaning Read/Write Type

(hex)

Q1 – Q8 „Local outputs: Q1 – Q8“ read 85 6-15

R1 – R16/

S1 – S8

T1 – T16 „Timers: T1 – T16“ read ED 6-17

Y1 – Y4 „Year time switch: Y1 – Y8“ read 91 6-18

Z1 – Z3 „Master reset: Z1 – Z3“ read 93 6-19

H1 – H4 7-day time switch: Ö1 – Ö8 read 90 6-19

Analog value comparators/threshold comparators:

„Inputs/outputs of PicoLink: R1 –

R16/S1 – S8“

read 88/89 6-16

Page

A1 – A16

The following commands are used to read the logic state of the

individual analog value comparators A1 to A16.

Table 6.7 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID:

Read

0 Response:

Read successful – C2

Command

rejected

0 1 Len 01 01

1 2 Typ e 8B 8B

2 3 Index 00 00

3 4 Data 1 (Low

Byte)

4 5 Data 2 (Low

Byte)

5 – 6 6 – 7 Data 3 – 4 00 00

(1) See Error Codess page 6-34

88 –

–

00 Table 6.8

00 Table 6.8

C0

(1)

Publication 1760-UM003A-EN-P - September 2005

Page 50

6-6 Application Examples for Pico

Table 6.8 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

Data 1Bit76543210

A1 0/1

A2 0/1

... ...

A8 0/1

Data 2Bit76543210

A9 0/1

A10 0/1

... ...

A16 0/1

Counters: C1 to C16

The following commands are used to read the logic state of the

individual counters C1 to

Table 6.9 Telegram Structure

Byte Meaning Value (hex) sent by

Master Slave Master Slave

0 Response:

0 1 Len 01 01

1 2 Type EE EE

2 3 Index 00 00

3 4 Data 1 (Low

4 5 Data 2 (Low

C16.

Attribute ID:

Read

Byte)

Byte)

Read

Successful

Command

Rejected

88 -

- C2

-

00 Table 6.10

00 Table 6.10

CO

(1)

Publication 1760-UM003A-EN-P - September 2005

5 to 6 6 to 7 Data 3 to 4 00 00

(1) Possible causes page 6-34

Page 51

Application Examples for Pico 6-7

Table 6.10 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

Data 1Bit76543210

C1 0/1

C2 0/1

… …

C8 0/1

Data 2Bit76543210

C9 0/1

C10 0/1

… …

C16 0/1

Text function blocks: D1 – D16

The following commands are used to read the logic state of the

individual text function blocks (D markers).

Table 6.11 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 01 01

1 2 Type 94 94

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.12

4 5 Data 2 (High Byte) 00 Table 6.12

5 – 6 6 – 7 Data 3 – 4 00 00

(1) Possible causes page 6-34.

C0

(1)

Publication 1760-UM003A-EN-P - September 2005

Page 52

6-8 Application Examples for Pico

Table 6.12 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

Data 1 Bit76543210

D1 0/1

D2 0/1

... ...

D8 0/1

Data 2 Bit76543210

D9 0/1

D10 0/1

... ...

D16 0/1

Local inputs: I1 – I16

This command string enables you to read the local inputs of the Pico

basic unit. The relevant input word is stored in Intel format.

Table 6.13 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 02 02

1 2 Type 84 84

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.14

4 5 Data 2 (High Byte) 00 Table 6.14

5 – 6 6 – 7 Data 3 – 4 00 00

(1) Possible causes <bullets>a page 45

C0

(1)

Publication 1760-UM003A-EN-P - September 2005

Page 53

Application Examples for Pico 6-9

Table 6.14 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

Data 1 Bit76543210

I1 0/1

I2 0/1

.. ..

I8 0/1

Data 2 Bit76543210

I9 0/1

I10 0/1

.. ..

I16 0/1

Local analog inputs: IA1 – IA4

The analog inputs on the Pico basic unit (I7, I8, I11, I12) can be read

directly via DeviceNet. The 16-bit value is transferred in Intel format

(Low Byte first).

Table 6.15 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 02 02

1 2 Ty pe 8C 8C

2 3 Index

00 – 03

(2)

3 4 Data 1 (Low Byte) 00 Table 6.16

4 5 Data 2 (High Byte) 00 Table 6.16

5 – 6 6 – 7 Data 3 – 4 00 00

(1)

C0

00 – 03

(2)

(1) Possible causes <bullets>a page 45

(2) 00 = Analog input I7

01 = Analog input I8

02 = Analog input I11

03 = Analog input I12

Publication 1760-UM003A-EN-P - September 2005

Page 54

6-10 Application Examples for Pico

Example:

A voltage signal is present at analog input 1. The required telegrams

for reading the analog value are as follows:

Table 6.16 Example Telegram for Reading the Value at the Analog Input

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response: read successful – C2

0 1 Len 02 02

1 2 Type 8C 8C

2 3 Index

3 4 Data 1 00 4B

4 5 Data 2 00 03

02

(1)

02

(1)

5 6 Data 3 00 00

6 7 Data 4 00 00

(1) 02 = Analog input I11

Byte 4 – Data 1 (Low Byte): 4B

Byte 5 – Data 2 (High Byte): 03

l corresponding 16-bit value: 034B

hex

hex

hex

= 843

The value 843 corresponds to the 10 bit value of the analog converter.

The following conversion is required for the actual analog value:

10V

----------- 1023

10bit×

10V

----------- 1023

843× 8.24V=

Write marker: M1 – M16/N1 – N16

Table 6.17 Telegram Structure

Publication 1760-UM003A-EN-P - September 2005

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Write 8C –

0 Response:

Write successful – C1

Page 55

Application Examples for Pico 6-11

Table 6.17 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Command rejected –

C0

(3)

0 1 Len 01 01

1 2

Typ e

(1)

With M marker 86 86

With N marker 87 87

2 3

3 4

2

Index

Data 1 (Low Byte)

00 – 0F 00 – 0F

(2)

00/01 00/01

4 – 6 5 – 7 Data 2 – 4 00 00

(1) There are 16 M markers and 16 N markers. The markers are addressed by Type and Index: Use Type to select

the M or N marker. Use Index to select the marker number.

(2) The marker is set if a value is written to the data byte that does not equal zero. The marker is reset accordingly

if the value 0 is written to data byte Data 1.

(3) Possible causes page 6-34

Table 6.18 Marker M13 is Set

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Write 8C –

0 Response:

Write successful – C1

Command rejected –

C0

0 1 Len 01 01

1 2 Ty pe

M marker 86 86

2 3 Index 0C 0C

3 4 Data 1 01 00

4 – 6 5 – 7 Data 2 – 4 00 00

(1) Possible causes page 6-49

(1)

Read marker: M1 – M16/N1 – N16

Unlike the write operation, the marker read operation reads the entire

marker area of a particular marker type (M or N) is read.

Publication 1760-UM003A-EN-P - September 2005

Page 56

6-12 Application Examples for Pico

Table 6.19 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

C0

(2)

0 1 Len 01 01

1 2 Ty pe

M marker 86 86

N marker 87 87

2 3

Index

(1)

00 00

3 4 Data 1 (Low Byte) 00 Table 6.20

4 5 Data 2 (Low Byte) 00 Table 6.20

5 – 6 6 – 7 Data 3 – 4 00 00

(1) There are 16 M markers and 16 N markers. The markers are addressed by Type and Index: Use Type to select

the M or N marker. Use Index to select the marker number

(2) Possible causes page 6-34

Table 6.20 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

Data 1 Bit76543210

mN

M1 N1 0/1

M2 N2 0/1

... ... ...

M8 N8 0/1

Data 2 Bit76543210

M9 N9 0/1

M10 N10 0/1

... – ...

M16 N16 0/1

Publication 1760-UM003A-EN-P - September 2005

Page 57

Application Examples for Pico 6-13

Table 6.21 The N Markers are Read

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

C0

0 1 Len 01 01

1 2 Type

N marker 87 87

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 04

4 5 Data 2 (Low Byte) 00 84

5 – 6 6 – 7 Data 3 – 4 00 00

(1)

(1) Possible causes <bullets>a page 49

The markers N3, N11 and N16 are set.

Operating hours counters: O1 – O4

The following commands are used to read the logic state of the

operating hours counters O1 – O4.

Table 6.22 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 01 01

C0

(1)

1 2 Ty pe EF EF

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.23

4 – 6 5 – 7 Data 2 – 4 00 00

(1) Possible causes page 6-34

Publication 1760-UM003A-EN-P - September 2005

Page 58

6-14 Application Examples for Pico

Table 6.23 Byte 3 (master) or byte 4 (slave): Data 1

Data 1 Bit76543210

O1 0/1

O2 0/1

O3 0/1

O4 0/1

... ... ... ... ...

Local P buttons: P1 – P4

The local P buttons are the display cursor buttons of the Pico basic

unit. You can scan the buttons in both RUN and STOP mode.

IMPORTANT

Ensure that the P buttons are also activated via the

System menu (in the basic unit).

Only one byte has to be transferred for the P buttons.

Table 6.24 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 01 01

1 2 Typ e 8A 8A

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.25

4 – 6 5 – 7 Data 2 – 4 00 00

C0

(1)

Publication 1760-UM003A-EN-P - September 2005

(1) Possible causes page 6-348

Page 59

Application Examples for Pico 6-15

Table 6.25 Byte 3 (master) or byte 4 (slave): Data 1

Data 1 Bit76543210

P1 0/1

P2 0/1

P3 0/1

P4 0/1

– 0

– 0

– 0

– 0

Example:

Data 1 = 2

l P3 is active.

hex

Local outputs: Q1 – Q8

The local outputs can be read directly via the DeviceNet fieldbus.

Table 6.26 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 01 01

1 2 Ty pe 85 85

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.27

4 – 6 5 – 7 Data 2 – 4 00 00

(1) Possible causespage 6-34

C0

(1)

Table 6.27 Byte 4: Data 1

Data 1 Bit76543210

Q1 0/1

Publication 1760-UM003A-EN-P - September 2005

Page 60

6-16 Application Examples for Pico

Table 6.27 Byte 4: Data 1

Q2 0/1

.. ..

Q8 0/1

Example:

Data 1 = 52

l Q2, Q5 and Q7 are active.

hex

Inputs/outputs of PicoLink: R1 – R16/S1 – S8

This service allows you to read the local R and S data and the data of

the NET stations (1 – 8) transferred via PicoLink, again from the

relevant Pico image.

Table 6.28 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command

rejected

0 1 Len 01 01

1 2 Typ e

for R data 88 88

for S data 89 89

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.29

4 5 Data 2 (Low Byte) 00 Table 6.29

5 – 6 6 – 7 Data 3 – 4 00 00

(1) Possible causes page 6-34

Table 6.29 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

–

C0

(1)

Publication 1760-UM003A-EN-P - September 2005

Data 1 Bit76543210

RW SW

R1 S1 0/1

R2 S2 0/1

... ... ...

Page 61

Application Examples for Pico 6-17

Table 6.29 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

R8 S8 0/1

Data 2 Bit76543210

R9 – 0/1

R10 – 0/1

... – ...

R16 – 0/1

Timers: T1 – T16

The following commands are used to read the logic state of the

individual timers T1 - T16.

Table 6.30 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

C0

(1)

0 1 Len 01 01

1 2 Type ED ED

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.31

4 5 Data 2 (Low Byte) 00 Table 6.31

5 – 6 6 – 7 Data 3 – 4 00 00

(1) Possible causes page 6-34

Table 6.31 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

Data 1 Bit76543210

T1 0/1

T2 0/1

... ...

T8 0/1

Data 2 Bit76543210

T9 0/1

Publication 1760-UM003A-EN-P - September 2005

Page 62

6-18 Application Examples for Pico

Table 6.31 Byte 3 to 4 (master) or Byte 4 to 5 (slave): Data 1 to 2

T10 0/1

... ...

T16 0/1

Year time switch: Y1 – Y8

The following commands are used to read the logic state of the

individual year time switches.

Table 6.32 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 01 01

1 2 Ty pe 91 91

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.33

4 – 6 5 – 7 Data 2 – 4 00 00

(1) Possible causes page 6-34

Table 6.33 Byte 3 (master) or byte 4 (slave): Data 1

Data 1 Bit76543210

HY1 0/1

HY2 0/1

HY3 0/1

HY4 0/1

HY5 0

C0

(1)

Publication 1760-UM003A-EN-P - September 2005

HY6 0

HY7 0

HY8 0

Example:

Data 1 = 1

l HY2 is active

hex

Page 63

Application Examples for Pico 6-19

Master reset: Z1 – Z3

Table 6.34 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Command rejected –

0 1 Len 01 01

1 2 Typ e 93 93

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.35

4 – 6 5 – 7 Data 2 – 4 00 00

C0

(1)

(1) Possible causes page 6-34

=

Table 6.35 Byte 3 (master) or byte 4 (slave): Data 1

Data 1 Bit76543210

Z1 for Q outputs 0/1

Z2 for M markers 0/1

Z3 for outputs and

markers

... 0 0 0 0 0

0/1

7-day time switch: ö1 – ö8

The following commands are used to read the logic state of the

individual 7-day time switches.

Table 6.36 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID: Read 88 –

0 Response:

Read successful – C2

Publication 1760-UM003A-EN-P - September 2005

Page 64

6-20 Application Examples for Pico

Table 6.36 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Command rejected –

0 1 Len 01 01

1 2 Typ e 90 90

2 3 Index 00 00

3 4 Data 1 (Low Byte) 00 Table 6.37

4 – 6 5 – 7 Data 2 – 4 00 00

(1) Possible causes page 6-34

Table 6.37 Byte 3 (master) or byte 4 (slave): Data 1

Data 1 Bit76543210

HW1 0/1

HW2 0/1

HW3 0/1

C0

(1)

Read/write function block data

HW4 0/1

HW5 0

HW6 0

HW7 0

HW8 0

Example:

Data 1 = 2

IMPORTANT

l ö3 is active.

hex

Refer to the Pico User Manual, 1760-UM001 for

information on function blocks.

General notes

Publication 1760-UM003A-EN-P - September 2005

Always note the following when working with function blocks:

• The relevant data is transferred in Intel format. In other words,

the first byte is the low byte (Byte 5) and the last byte (byte 8)

the high byte.

Page 65

Application Examples for Pico 6-21

• The maximum data length is 4 bytes. All values must be

transferred in hexadecimal format.

Overview

Table 6.38 Overview

Operands Meaning Read/Write Type

(hex)

A1 – A16 „Analog value comparator/threshold

Read/Write 8D 21

comparator: A1 – A16“

C1 – C16 „Counter relays: C1 – C16“ Read/Write 8F 23

O1 – O4 „Operating hours counters: O1 – O4“ Read/Write 92 25

T1 – T16 „Timing relays: T1 – T16“ Read/Write 8E 27

Y1 – Y8 „Year time switch: Y1 – Y8“ Read/Write A2 30

Ö1 – Ö8 7-day time switch: Ö1 – Ö8 Read/Write A1 32

Analog value comparator/threshold comparator: A1 – A16

Table 6.39 Telegram Structure

Byte Meaning Value (hex), sent by

Master Slave Master Slave

Attribute ID

Read 89 –

Page

Write 8D –

0 Response:

Read successful – C2

Write successful – C1

Command rejected –

C0

(2)

0 1 Ty pe 8D 8D

1 2

Instance

(1)

00 – 0F 00 – 0F

2 3 Index Table 6.40 Table 6.40

3 – 6 4 – 7 Data 1 – 4 depending on

index,

Table 6.41

(1) Pico provides 16 analog comparators A1 to A16 for use as required. These can be addressed using the instance

(0 – F).

(2) Possible causes page 6-34

Publication 1760-UM003A-EN-P - September 2005

depending on

index,

Table 6.41

Page 66

6-22 Application Examples for Pico

Table 6.40 Operand overview

Table 6.41 Index 00 – Parameters

Index

Operand Read Write

(hex)

00 Parameters Table 6.41 x

01 Control byte Table 6.42 x

02 Comparison value 1

03 Comparison value 2

04 Gain factor for I1

I1

I2

F1

(1)

x

(1)

x

(1)

x

(2)

c

(2)

c

(2)

c

(I1 = F1 x I1)

05 Gain factor for I2

F2

(1)

x

(2)

c

(I2 = F2 x I2)

06 Offset for value I1 (I1 = OS + actual

OS

(1)

x

(2)

c

value at I1)

07 Switching hysteresis for value I2

(1) A 16-bit value is transferred in data bytes Data 1 – Data 2. It should be remembered that the low byte 1 is in

Data 1 (Byte 5) and the high byte 2 (byte 8) in Data 2.

Example: 5327dec = 14CFhex l Data 1 = 0xCF, Data 2 = 0x14

(2) The value can only be written if it is assigned to a constant in the program.

HY

(1)

x

(2)

c

Meaning Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Appears in the parameter menu

Yes /no 0/1

Compare

FB not used 0 0 0

EQ (=) 0 0 1

GE (f) 0 1 0

LE (F) 0 1 1

GT (>) 1 0 0

LT (<) 1 0 1