Page 1

ProcessLogix

R400.0 Installation

and Upgrade Guide

1757-SWKIT4000

Installation Instructions

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Allen-Bradley be responsible or

liable for indirect or consequential damage resulting from the use or

application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware of

safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Page 3

Rockwell Automation Support

Before you contact Rockwell Automation for technical assistance, we

suggest you please review the t roubles hooting inf ormation contained

in this publication first.

If the problem persists, call your local Rockwell Automation

representative or contact Rockwell Automation in one of the

following ways:

Phone United

States/Canada

Outside United

States/Canada

Internet

⇒

1.440.646.5800

You can access the phone number for your

country via the Internet:

1. Go to http://www.ab.com

2. Click on

(http://support.automation.rockwell.com)

3. Under

Information

1. Go to http://www.ab.com

2. Click on

(http://support.automation.rockwell.com)

Product Support

Support Centers

Product Support

, click on

Contact

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the

enclosed How Are We Doing form.

Page 4

Page 5

Table of Contents

Important User Information. . . . . . . . . . . . . . . . . . . . . . . . . . 2

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . 3

Your Questions or Comments on this Manual . . . . . . . . . . 3

Preface

ProcessLogix R400.0 Installation

Introduction

Our Assumptions About Readers . . . . . . . . . . . . . . . . . . . . P-1

Starting Conditions and Assumptions . . . . . . . . . . . . . . P-1

Minimum Hardware Requirements. . . . . . . . . . . . . . . . . . . P-3

Rockwell Automation Technical Support . . . . . . . . . . . . . . P-4

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-4

Your Questions or Comments about This Manual . . . . . P-4

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Terms and Type Representations . . . . . . . . . . . . . . . . . P-5

Contents of Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

ProcessLogix Online User Documentation/Knowledge

Builder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

ProcessLogix R400.0 Installation and Upgrade Guide. . . P-7

Acronyms and Abbreviations. . . . . . . . . . . . . . . . . . . . . . . P-8

Chapter 1

Operating System Support. . . . . . . . . . . . . . . . . . . . . . . . . 1-1

ProcessLogix Component Configuration Table. . . . . . . . 1-1

Operating System Options. . . . . . . . . . . . . . . . . . . . . . . . . 1-1

ProcessLogix Server Supported Installations . . . . . . . . . . . . 1-1

Clean Install. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Upgrade from ProcessLogix R320.0 Server

Currently Running Windows NT 4.0 Workstation. . . 1-2

Re-Deployment Options. . . . . . . . . . . . . . . . . . . . . . . . 1-2

ProcessLogix Client Supported Installations . . . . . . . . . . . . 1-3

Clean Install. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Upgrade: Currently Running Windows NT 4.0 Workstation

with ProcessLogix Client Software . . . . . . . . . . . . . . . . 1-3

i Publication 1757-IN040B-EN-P - March 2002

Page 6

Table of Contents ii

Operating System Installation

Procedures

Chapter 2

Clean System Windows 2000 Server Installation . . . . . . . . . 2-1

Installing Windows 2000 Server on a New System. . . . . 2-1

Starting the Windows 2000 Server Installation . . . . . . . . 2-2

Starting the Installation from the Boot Floppies. . . . . . . 2-4

Starting the Installation from the CD-ROM. . . . . . . . . . . 2-4

Completing the Windows 2000 Server Installation . . . . . 2-5

Clean System Windows 2000 Professional Installation. . . . . 2-10

Starting the Windows 2000 Professional Installation. . . . 2-10

Creating Boot Floppies. . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Starting the Installation from the Boot Floppies. . . . . . . 2-12

Starting the Installation from the CD-ROM. . . . . . . . . . . 2-12

Completing the Windows 2000 Professional Installation. 2-13

Installing Service Pack 2 for Windows 2000 . . . . . . . . 2-17

Checking for Windows 2000 Service Pack 2 . . . . . . . . . 2-17

Installing Windows 2000 Service Pack 2 . . . . . . . . . . . . 2-18

Installing Internet Explorer 5.5 SP1 . . . . . . . . . . . . . . . . . . 2-19

Checking the Internet Explorer Version. . . . . . . . . . . . . 2-19

Upgrading Internet Explorer 5.5 SP1. . . . . . . . . . . . . . . 2-20

Installing Adobe Acrobat Reader 4.05. . . . . . . . . . . . . . . . . 2-22

Additional Operating System Customization Procedures . . . 2-22

Adjusting the Video Settings. . . . . . . . . . . . . . . . . . . . . 2-23

Setting Up Additional Drivers . . . . . . . . . . . . . . . . . . . . 2-24

Third Party Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Other Required System Settings . . . . . . . . . . . . . . . . . . 2-24

Creating an Emergency Repair Disk. . . . . . . . . . . . . . . . . . 2-25

Creating the ProcessLogix User Accounts . . . . . . . . . . . . . . 2-26

Creating the ps_user and erserver accounts. . . . . . . . . . 2-26

Logging on with the ps_user account . . . . . . . . . . . . . . 2-27

Clean System Windows NT 4.0 Workstation Installation . . . 2-28

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Starting the Windows NT Installation . . . . . . . . . . . . . . 2-29

Setting Up Windows NT. . . . . . . . . . . . . . . . . . . . . . . . 2-30

Installing TCP/IP Networking Software . . . . . . . . . . . . . 2-31

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . 2-34

Setting Up the Display Driver. . . . . . . . . . . . . . . . . . . . 2-35

Completing Installation . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Installing Service Pack 6a for Windows NT 4.0 . . . . . . . 2-35

Setting Up Additional Drivers after the

Service Pack Installation . . . . . . . . . . . . . . . . . . . . . 2-37

Configuring System Properties . . . . . . . . . . . . . . . . . . . 2-38

Converting to NTFS after Installing Windows NT. . . . . . 2-39

Creating the ps_user Account. . . . . . . . . . . . . . . . . . . . 2-39

Installing Internet Explorer 5.5 SP 1 . . . . . . . . . . . . . . . 2-39

Checking Required System Settings . . . . . . . . . . . . . . . . . . 2-40

Creating an Emergency Repair Disk. . . . . . . . . . . . . . . . . . 2-41

Publication 1757-IN040B-EN-P - March 2002

Page 7

ProcessLogix Server Installation

Procedures

Table of Contents iii

Chapter 3

Installing ProcessLogix Software on a Clean PC . . . . . . . . . 3-1

Installing Server Software. . . . . . . . . . . . . . . . . . . . . . . 3-2

Installing SQL Server . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing Knowledge Builder . . . . . . . . . . . . . . . . . . . . 3-4

Installing RSLinx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Installing Engineering Tools . . . . . . . . . . . . . . . . . . . . . 3-5

Installing PsAxCtl Document EXE . . . . . . . . . . . . . . . . . 3-6

Installing the ProcessLogix Server. . . . . . . . . . . . . . . . . 3-6

Adding PCIC Hardware Device Drivers . . . . . . . . . . . . . . . 3-10

Moving the RSLinx Activation File . . . . . . . . . . . . . . . . . . . 3-10

About the Activation File . . . . . . . . . . . . . . . . . . . . . . . 3-10

Determining the Current RSLinx Version. . . . . . . . . . . . 3-11

Installing the Activation File . . . . . . . . . . . . . . . . . . . . . 3-12

Configuring RSLinx Drivers for

ControlNet Supervisory Network . . . . . . . . . . . . . . . . 3-13

Updating the 1784-PCIC Firmware . . . . . . . . . . . . . . . . 3-15

Configuring RSLinx Drivers for

Ethernet Supervisory Network . . . . . . . . . . . . . . . . . . 3-18

Completing the ProcessLogix R400.0

Install on a Redundant Server Pair . . . . . . . . . . . . . . . 3-19

Completing the ProcessLogix R400.0

Install on a Non-Redundant Server. . . . . . . . . . . . . . . 3-20

Upgrading Hardware Component Firmware . . . . . . . . . 3-20

Checking Control Builder Operation and Logging On . . 3-20

Backing Up a ProcessLogix Server Hard Drive to Tape . 3-20

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 3-21

ProcessLogix Server Upgrade

Procedures

Chapter 4

Preparing for a ProcessLogix Software Upgrade . . . . . . . . . 4-1

Things to consider before upgrading . . . . . . . . . . . . . . 4-1

Networking the R320.0 and R400.0 Servers . . . . . . . . . . 4-1

Upgrade Procedures for ProcessLogix R320.0 Servers . . . . . 4-3

Backing Up a ProcessLogix R320.0 Server to Tape. . . . . 4-3

Exporting the Engineering Repository Database . . . . . . 4-4

Saving Important Data . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Exporting the ProcessLogix Server Database . . . . . . . . . 4-6

Removing the RSLinx Software Activation File. . . . . . . . 4-7

Restoring the Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Restoring other ProcessLogix Data . . . . . . . . . . . . . . . . 4-8

Restarting SERVERB and synchronizing. . . . . . . . . . . . . 4-8

Synchronizing Server Databases on Redundant Servers . 4-9

Importing the ProcessLogix Server Points Database. . . . 4-10

Importing the Engineering Database. . . . . . . . . . . . . . . 4-11

Upgrading Hardware Component Firmware . . . . . . . . . 4-12

Backing Up a ProcessLogix Server Hard Drive to Tape . 4-13

Publication 1757-IN040B-EN-P - March 2002

Page 8

Table of Contents iv

ProcessLogix Client Installation

and Upgrade Procedures

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Operating System Support. . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Windows 2000 Professional . . . . . . . . . . . . . . . . . . . . . 5-2

Windows NT 4.0 Workstation. . . . . . . . . . . . . . . . . . . . 5-3

Pre-work for systems with ProcessLogix R320.0 . . . . . . . . . 5-5

Saving Important Data . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Removing Selected Components. . . . . . . . . . . . . . . . . . 5-7

Cleaning Up the Registry . . . . . . . . . . . . . . . . . . . . . . . 5-9

Upgrading the Windows NT 4.0 Workstation

Operating System to Windows 2000 Professional . . . . . 5-10

Installing Windows 2000 Service Pack 2 . . . . . . . . . . . . 5-12

Installing Internet Explorer 5.5 SP1. . . . . . . . . . . . . . . . 5-12

Installing ProcessLogix R400.0 Client Software. . . . . . . . 5-12

Updating the Windows NT 4.0 Workstation

Operating System for R400.0 Software 5-12

Checking for Windows NT 4.0 Service Pack 6a . . . . . . . 5-13

Installing Service Pack 6a for Windows NT 4.0 . . . . . . . 5-13

Installing MDAC 2.5 Service Pack 1. . . . . . . . . . . . . . . . 5-14

Recording the NT System Path Value . . . . . . . . . . . . . . 5-15

Installing Windows Installer . . . . . . . . . . . . . . . . . . . . . 5-15

Verifying the NT System Path Value . . . . . . . . . . . . . . . 5-15

Installing Internet Explorer 5.5 SP1. . . . . . . . . . . . . . . . 5-16

Updating the ActiveX Support Files. . . . . . . . . . . . . . . . 5-17

Replacing MFC42.dll . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Installing ProcessLogix R400.0 Client Software. . . . . . . . 5-17

Installing ProcessLogix R400.0 Client Software . . . . . . . . . . 5-18

Installing Knowledge Builder . . . . . . . . . . . . . . . . . . . . 5-19

Installing the ProcessLogix Client Software . . . . . . . . . . 5-20

Verifying ProcessLogix Client Installation . . . . . . . . . . . . . . 5-23

Restoring the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Setting Up a Station With a Non-redundant Server. . . . . 5-24

Setting Up a Station With a Redundant Server Pair. . . . . 5-25

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 5-27

Checking Control Builder Operation and Logging On

(Engineering Workstation Only) . . . . . . . . . . . . . . . 5-28

Generic Comm Layer Settings

(Engineering Workstation Only) . . . . . . . . . . . . . . . 5-28

Publication 1757-IN040B-EN-P - March 2002

Page 9

Additional Redundant Server

Procedures

Table of Contents v

Chapter 6

Adding Redundancy to R400.0

Non-Redundant Server Systems . . . . . . . . . . . . . . . . . 6-1

Changing the Computer Name on a ProcessLogix Server 6-1

Completing the ProcessLogix R400.0

Setup on a Redundant Server Pair . . . . . . . . . . . . . . . 6-1

Changing Hosts File Entries . . . . . . . . . . . . . . . . . . . . . 6-1

Changing TCP/IP address on a Secondary Server

(SERVERB) Node . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Changing the ProcessLogix License. . . . . . . . . . . . . . . . 6-4

Setting up Primary Server (SERVERA) node 6-6

Making Redundant Hardware File Entries . . . . . . . . . . . 6-6

Configuring the Time Service . . . . . . . . . . . . . . . . . . . . 6-8

Setting Up Secondary Server (SERVERB) Node . . . . . . . . . . 6-10

Making Redundant Hardware File Entries . . . . . . . . . . . 6-10

Configuring the Time Service . . . . . . . . . . . . . . . . . . . . 6-10

Confirming Data Link is Available. . . . . . . . . . . . . . . . . 6-10

Configuring Stations in Quick Builder (on SERVERA) . . . . . 6-11

Synchronizing Server Databases on Redundant Server . . 6-13

Confirming Databases are Synchronized . . . . . . . . . . . . 6-13

Setting up the Redundant ERDB . . . . . . . . . . . . . . . . . . 6-15

Setting Up Station on SERVERB . . . . . . . . . . . . . . . . . . . . . 6-16

Setting Up Station on SERVERA . . . . . . . . . . . . . . . . . . . . . 6-18

Restarting Redundant Servers. . . . . . . . . . . . . . . . . . . . . . . 6-21

Synchronizing Other Files . . . . . . . . . . . . . . . . . . . . . . 6-22

Upgrading Hardware Component Firmware . . . . . . . . . . . . 6-22

Checking Control Builder Operation and Logging On . . 6-23

Backing Up a ProcessLogix Server Hard Drive to Tape . 6-23

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 6-23

Firmware Maintenance

Procedures

Chapter 7

1784-PCIC Driver and Firmware Installation . . . . . . . . . . . . 7-1

Install Hardware Device Drivers . . . . . . . . . . . . . . . . . . 7-1

Verify the 1784-PCIC Driver Version . . . . . . . . . . . . . . . 7-2

Updating the 1784-PCIC Firmware . . . . . . . . . . . . . . . . 7-2

Upgrading Hardware Component Firmware . . . . . . . . . . . . 7-4

About Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . 7-4

Firmware Revision Level Reference. . . . . . . . . . . . . . . . 7-5

Important Usage Considerations . . . . . . . . . . . . . . . . . . 7-7

Loading 1757-PLX52, TC-MUX021, or 1757-FIM Boot

and Personality Images. . . . . . . . . . . . . . . . . . . . . . 7-9

Updating Firmware in CNB, ENET, IOM, SRM, PIM

or ControlNet Adapter . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Setting CNB Module NUT Timing . . . . . . . . . . . . . . . . . 7-14

Publication 1757-IN040B-EN-P - March 2002

Page 10

Table of Contents vi

Supplementary Procedures

Chapter 8

Stopping ProcessLogix Applications and Services . . . . . . . . 8-1

Stopping the ProcessLogix Server . . . . . . . . . . . . . . . . . 8-2

Shut Down SQL Server Services . . . . . . . . . . . . . . . . . . 8-2

Stop RSLinx Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Stopping NI-FBUS and Excel . . . . . . . . . . . . . . . . . . . . 8-4

Launching ProcessLogix Knowledge Builder. . . . . . . . . . . . 8-4

SQL Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

SQL Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Cancelling a Software Component Installation . . . . . . . . . . 8-5

Replacing and Repairing Removing ProcessLogix Software

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

SQL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

RSLinx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Manual System Backup/Restore Procedures . . . . . . . . . . . . 8-7

Backing Up a ProcessLogix R400.0 Server to Tape. . . . . 8-7

Restoring a ProcessLogix Server System

From a Backup Tape . . . . . . . . . . . . . . . . . . . . . . . 8-7

Using Network Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

About Network Tools. . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Usage guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Online help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Making First Time Network Tools Settings. . . . . . . . . . . 8-9

Installing and Running VirusScan with ProcessLogix. . . . . . 8-14

About VirusScan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Removing Existing VirusScan NT Program. . . . . . . . . . . 8-14

Installing VirusScan NT and Configuring Directories

for Scan Exclusion . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Changing the Computer Name on a ProcessLogix Server . . 8-16

Saving Important Data . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Shut Down ProcessLogix Server . . . . . . . . . . . . . . . . . . 8-18

Shut Down SQL Server Services . . . . . . . . . . . . . . . . . . 8-18

Removal of Selected Components. . . . . . . . . . . . . . . . . 8-19

Changing the PC Name . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Reinstalling Components . . . . . . . . . . . . . . . . . . . . . . . 8-23

Restoring the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Changing the Computer Name on a ProcessLogix Client. . . 8-27

Changing the Computer Name on a

Windows NT 4.0 Client. . . . . . . . . . . . . . . . . . . . . . 8-27

Changing the Computer Name on a

Windows 2000 Client . . . . . . . . . . . . . . . . . . . . . . . 8-27

Procedure for Configuring a ProcessLogix Client . . . . . . 8-28

Adding 1757-PLX52 Controller Redundancy to R400.0

Non-Redundant 1757-PLX52 Controller Configurations . . . . 8-28

Deleting a Non-Redundant 1757-PLX52 and

Unassigning its Contents . . . . . . . . . . . . . . . . . . . . 8-29

Publication 1757-IN040B-EN-P - March 2002

Page 11

PC Performance for Proc es s Logix

Systems

Table of Contents vii

Installing and connecting Redundant

Chassis Pair (RCP) Hardware . . . . . . . . . . . . . . . . . 8-30

Updating Firmware Revision Levels . . . . . . . . . . . . . . . 8-31

Creating a Redundant 1757-PLX52 . . . . . . . . . . . . . . . . 8-31

Installing Knowledge Builder on a

Non-ProcessLogix System . . . . . . . . . . . . . . . . . . . . . 8-32

Removing Knowledge Builder . . . . . . . . . . . . . . . . . . . 8-32

Installing Service Pack 2 for Windows 2000. . . . . . . . . . 8-33

Installing Internet Explorer 5.5 SP1. . . . . . . . . . . . . . . . 8-33

Installing MDAC2.5 SP1 . . . . . . . . . . . . . . . . . . . . . . . . 8-33

Installing Knowledge Builder . . . . . . . . . . . . . . . . . . . . 8-34

Chapter 9

ProcessLogix Performance Features . . . . . . . . . . . . . . . . . . 9-3

PC Qualification/Installation Services . . . . . . . . . . . . . . 9-3

Redundant Networking . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Server Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Multi-User/Location Control Builder . . . . . . . . . . . . . . . 9-5

Multiple Clients/Stations. . . . . . . . . . . . . . . . . . . . . . . . 9-5

Integrated Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Operating System Tuning . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Service/Kernel Tuning . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Disk Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

File System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

File System Defragmentation . . . . . . . . . . . . . . . . . . . . 9-10

Defragmenting the Disk . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Memory and Swapfile . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Client/Station Memory Settings . . . . . . . . . . . . . . . . . . . 9-13

Servers with 128 MB of Physical RAM or Less.. . . . . . . . 9-13

Servers with 256 MB of Physical RAM or More. . . . . . . . 9-13

Adjusting Swapfile Size on Windows 2000 . . . . . . . . . . 9-14

Network Optimization. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Management of Traffic . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Benefits from other Network Services . . . . . . . . . . . . . . 9-17

System Usage 9-17

Topology Related Settings . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Physical Location of the Systems. . . . . . . . . . . . . . . . . . 9-18

Physical location of the Components . . . . . . . . . . . . . . 9-19

Service Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Network Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Publication 1757-IN040B-EN-P - March 2002

Page 12

Table of Contents viii

New Functions and Features

Chapter 10

Enhanced Foundation Fieldbus Support. . . . . . . . . . . . . . . 10-1

Profibus DP Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

SST-PFBCLX PROFIBUS Interface Module . . . . . . . . . . . 10-2

SST-PFBCLX Module Characteristics . . . . . . . . . . . . . . . 10-2

Functional Exclusions. . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

SST-PFBCLX / PROFIBUS Network Configuration . . . . . 10-4

ProcessLogix Block Architecture. . . . . . . . . . . . . . . . . . 10-4

Limitations and Exclusions . . . . . . . . . . . . . . . . . . . . . . 10-5

Control Builder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Match Dialog Support UCD Tab . . . . . . . . . . . . . . . . . . 10-5

CM Chart Visualization. . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Delta Time Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Naming Convention Change. . . . . . . . . . . . . . . . . . . . . 10-6

CEE Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Four New Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

PUSH Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Engineering Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Displaying Infinity and Handling for Online Changes . 10-11

Block Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Update to Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Refresh Template Capability for FLM. . . . . . . . . . . . . . 10-11

Windows 2000 Platform and Tools. . . . . . . . . . . . . . . . . . 10-11

Series C and D CNBs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Server 10-12

Updated Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

HMIWeb Runtime Browser. . . . . . . . . . . . . . . . . . . . . 10-14

HMIWeb Display Builder . . . . . . . . . . . . . . . . . . . . . . 10-15

Updated Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

Server Scripting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

Updated Display Builder . . . . . . . . . . . . . . . . . . . . . . 10-17

Updated Quick Builder . . . . . . . . . . . . . . . . . . . . . . . 10-17

Updated OPC Support . . . . . . . . . . . . . . . . . . . . . . . . 10-18

Enhanced Area Assignment Support . . . . . . . . . . . . . . 10-18

Updated Alarm Pager Support . . . . . . . . . . . . . . . . . . 10-19

History Archiving Manager. . . . . . . . . . . . . . . . . . . . . 10-19

Updated Universal Modbus Support . . . . . . . . . . . . . . 10-19

Modbus TCP Support. . . . . . . . . . . . . . . . . . . . . . . . . 10-19

User Defined Data Formats . . . . . . . . . . . . . . . . . . . . 10-20

Application Development. . . . . . . . . . . . . . . . . . . . . . 10-20

Diagnostic Improvements. . . . . . . . . . . . . . . . . . . . . . 10-21

Updated Alarming Support. . . . . . . . . . . . . . . . . . . . . 10-21

Windows 2000 Support . . . . . . . . . . . . . . . . . . . . . . . 10-21

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

Publication 1757-IN040B-EN-P - March 2002

Page 13

Performance and Capacity

Specifications

Table of Contents ix

Chapter 11

PC Platform Requirements. . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Summary of R400.0 Enhancements to ProcessLogix System

Capacity & Performance. . . . . . . . . . . . . . . . . . . . . . . . 11-2

Server Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Platform System Configuration Definitions . . . . . . . . . . 11-3

Station/Engineering Client Requirements. . . . . . . . . . . . 11-5

ProcessLogix Server Platform Requirements. . . . . . . . . . 11-6

Application Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

User Interface Capacity and Performance. . . . . . . . . . . . . . 11-9

Control Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Server Redundancy 11-11

Server Notifications 11-11

Communications Capacity and Performance. . . . . . . . . . . 11-12

System Communications Load Philosophy

and Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

System Communications Limits. . . . . . . . . . . . . . . . . . 11-15

Controller Communications . . . . . . . . . . . . . . . . . . . . 11-16

Client/Server Communication Capacity . . . . . . . . . . . . 11-18

Controller Notifications . . . . . . . . . . . . . . . . . . . . . . . . . . 11-18

Controller Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-20

PROFIBUS DP Topology Specifications. . . . . . . . . . . . 11-21

ProcessLogix/PROFIBUS Interface

Topology Specifications . . . . . . . . . . . . . . . . . . . . 11-21

FIM Performance Limits. . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

I/O Module Sample Periods . . . . . . . . . . . . . . . . . . . . 11-25

I/O Network Configuration Rules . . . . . . . . . . . . . . . 11-25

1757-PLX52 Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-26

Major ProcessLogix Software

Components

Chapter 12

Major ProcessLogix FTW Software Revisions . . . . . . . . . 12-1

Major ProcessLogix Server Software Revisions. . . . . . . . 12-2

Embedded Software Components. . . . . . . . . . . . . . . . . 12-3

External, Third Party Qualified Software Components . . 12-5

Miscellaneous SCADA Component Revisions. . . . . . . . . 12-7

Controller, Communication & I/O Firmware . . . . . . . . . 12-7

Publication 1757-IN040B-EN-P - March 2002

Page 14

Table of Contents x

Publication 1757-IN040B-EN-P - March 2002

Page 15

Preface

Our Assumptions About Readers

Before configuring a ProcessLogix R400.0 systrem you MUST:

Be familar with navigating and running applications in a

•

Microsoft Windows NT/2000 environm ent.

Have some experience in loading software applications on a

•

personnal computer (PC).

Be familar with ProcessLogix hardware components.

•

Be familar with ControlNet configuration.

•

Be trained on ProcessLogix R400.0, including Control Buil der

•

and Server components.

If applicable to your system, you must also have appropriate

•

training on other Rockwell Automation products such as

ControlLogix and RSNetworks.

ATTENTION

!

If you have not received ProcessLogix R400.0

training we recommend that you find someone who

does have experience to assist you in loading the

ProcessLogix software and making hardware and

firmware changes in associated ProcessLogix

hardware components.

Contact your local sales offfice for more information

about training schedules and available trained

personnel.

Starting Conditions and Assumptions

You have the following items on hand:

• ProcessLogix R400.0 Software Change Note is incorporated into

this Installation and Upgrade Guide: Chapter 10, New Functions

and Features and Chapter 11, Performance and Capacity

Specifications.

• ProcessLogix R400.0 System Software CD 1 containing process

software such as SQL.

• ProcessLogix R400.0 Syst em Software CD 2 containing

ProcessLogix applications software.

• Proc essLogix R400.0 Knowledge Build er CD containing the latest

version of the online documentation.

1 Publication 1757-IN040B- EN-P - March 2002

Page 16

Preface 2

Windows 2000 Server CD (Microsoft CD, including boot

•

diskettes).

RSLinx OEM Master (Activation) Disk.

•

The Factory CD containing default system drivers for backup

•

purposes only. Please contact Rockwell Automation Technical

Support before using this CD. This CD is only supplied with new

ProcessLogix R400.0 servers.

You must be certain that your PC meets the minimum hardware

requirements for a ProcessLogix Server or ProcessLogix Client.

ProcessLogix Servers require a Windows 2000 Server operating

•

system. See Table 11.C on page 11-6 to review the minimum

platform requirements for the ProcessLogix Serve r.

ProcessLogix Client Stations require either a Windows 2000 or

•

Windows NT 4.0 operating sys tem. See T ab le 11.B on page 11-5

to review the minimum platform requirements for a

ProcessLogix Client.

Publication 1757-IN040B-EN-P - March 2002

Page 17

Preface 3

Minimum Hardware Requirements

ProcessLogix R400.0 Server Software must be installed on a PC that is

specifically qualified. Use of any other PC variations will render the

standard warranty and support agreement null and void.

Refer to Table P.1: Supported Hardware for ProcessLogix R400.0 on

page P-3 to review the hardware requirements for a new R400.0

ProcessLogix Server. See Table 11.B on page 11-5 and Table 11.C on

page 11-6. for minimum hardware requirements for upgrading an

existing system to R400.0.

Only the hardware listed in

Table P.1 below is supported for

ProcessLogix R400.0 Servers. Upgrading from R320.0 requires

new hardware.

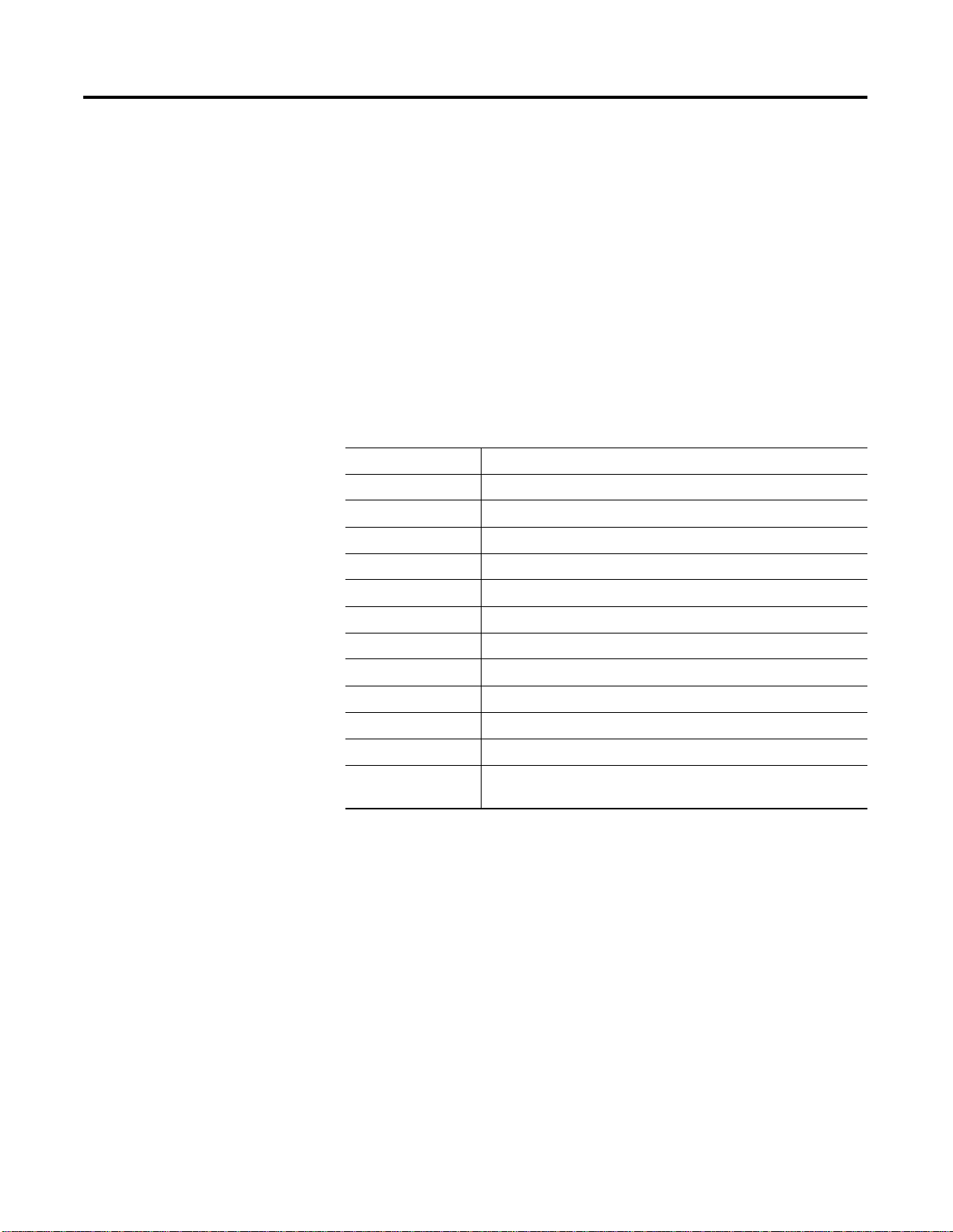

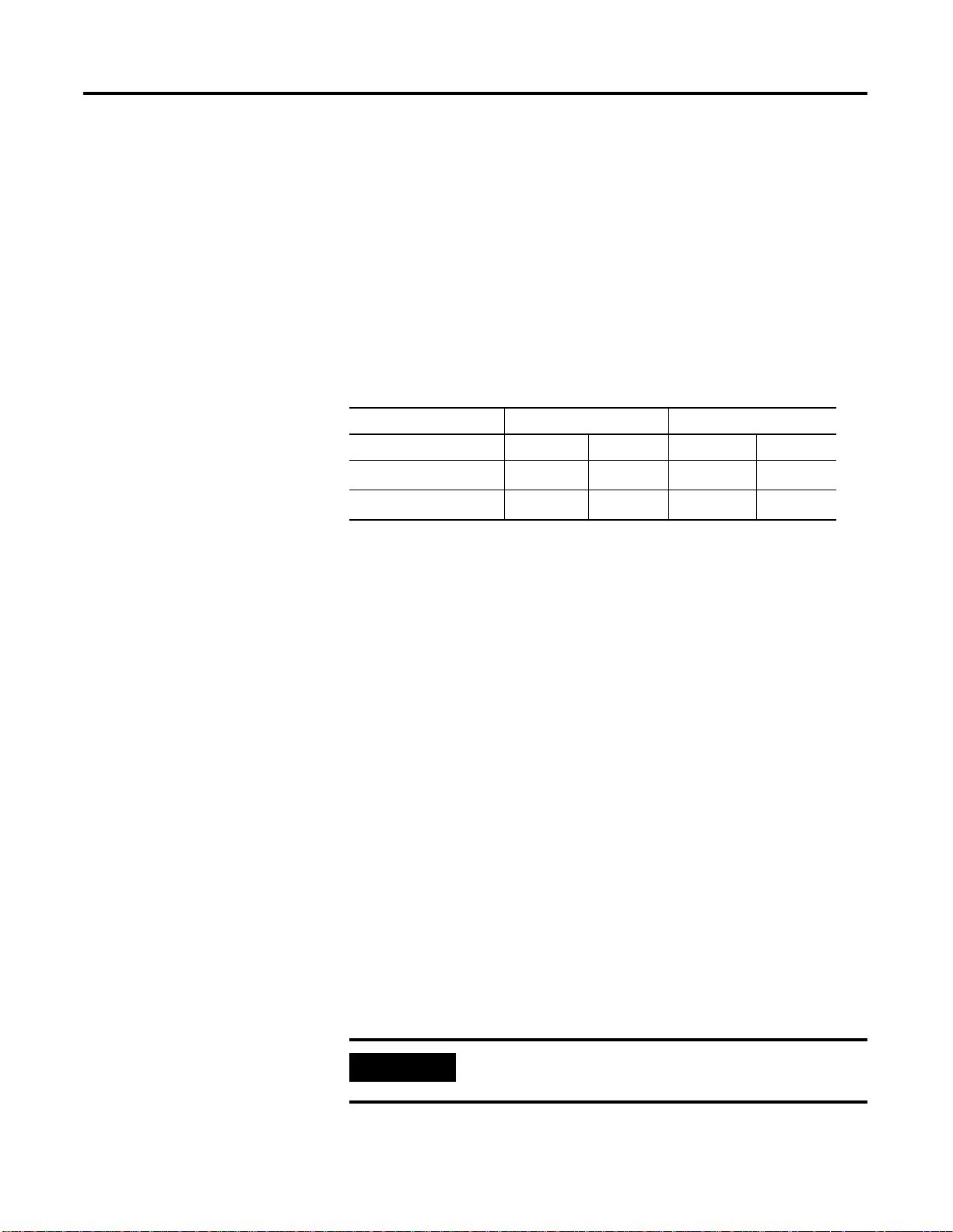

Table P.1: Supported Hardware for ProcessLogix R400.0

Component Description

Base Dell PowerEdge 1400

Processor 1 GHz/133 256K Cache, Pentium III

Mouse Logitec System Mouse

Keyboard Quietkey 104-Key, 6 Pin

System RAM 384MB, DIMM, 133MHz 16x72, 168

CD-ROM 20/48X Black, Compact Disk Drive, IDE

Floppy Drive 1.44MB, F3, NEC P 1400

Hard Drive 18GB 10K, 68P

Tape Drive 20/40G, Tape Backup Unit, Power Vault 100T, DD54

Network Intel Pro 100 Plus, NIC

I/O Expansion 6 PCI

Operating System Microsoft Windows 2000 Server, 5 Client Access Licenses, NTFS,

All hardware component drivers

Publication 1757-IN040B-EN-P - March 2002

Page 18

Preface 4

Rockwell Automation Technical Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized

systems integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Prod uct Support

Contact your loca l Ro ckwell Automation r e pr e s en ta t iv e for:

sales and order support

•

product technical training

•

warranty support

•

support service agreements

•

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

first call your local Rockwell Automation representative, then:

Network Pre-sales Hotline, 440.646.3638 (3NET)

•

Post-sales Technical Support, 440.646.5800

•

Web Links

•

• http://www.ab.com — as a registered member and open to

http://www.ab.com/mem/technotes/techmain.html

http://support. automation.rockwell.com

Your Questions or Comments about This Manual

If you find a problem or have a comment about this manual, please

notify us of it on the enclosed How Are We Doing Form, at the back

of this manual. This form is also available in Knowledge Builder.

If you have any suggestions about how we can make this manual

more useful to you, please contact us at the following address:

Rockwell Automation, Inc.

Automation Control and Information Group

Technical Communication

1 Allen-Bradley Drive

Mayfield Heights, OH 44124-6118

Publication 1757-IN040B-EN-P - March 2002

Page 19

Preface 5

Conventions

Terms and Type Representations

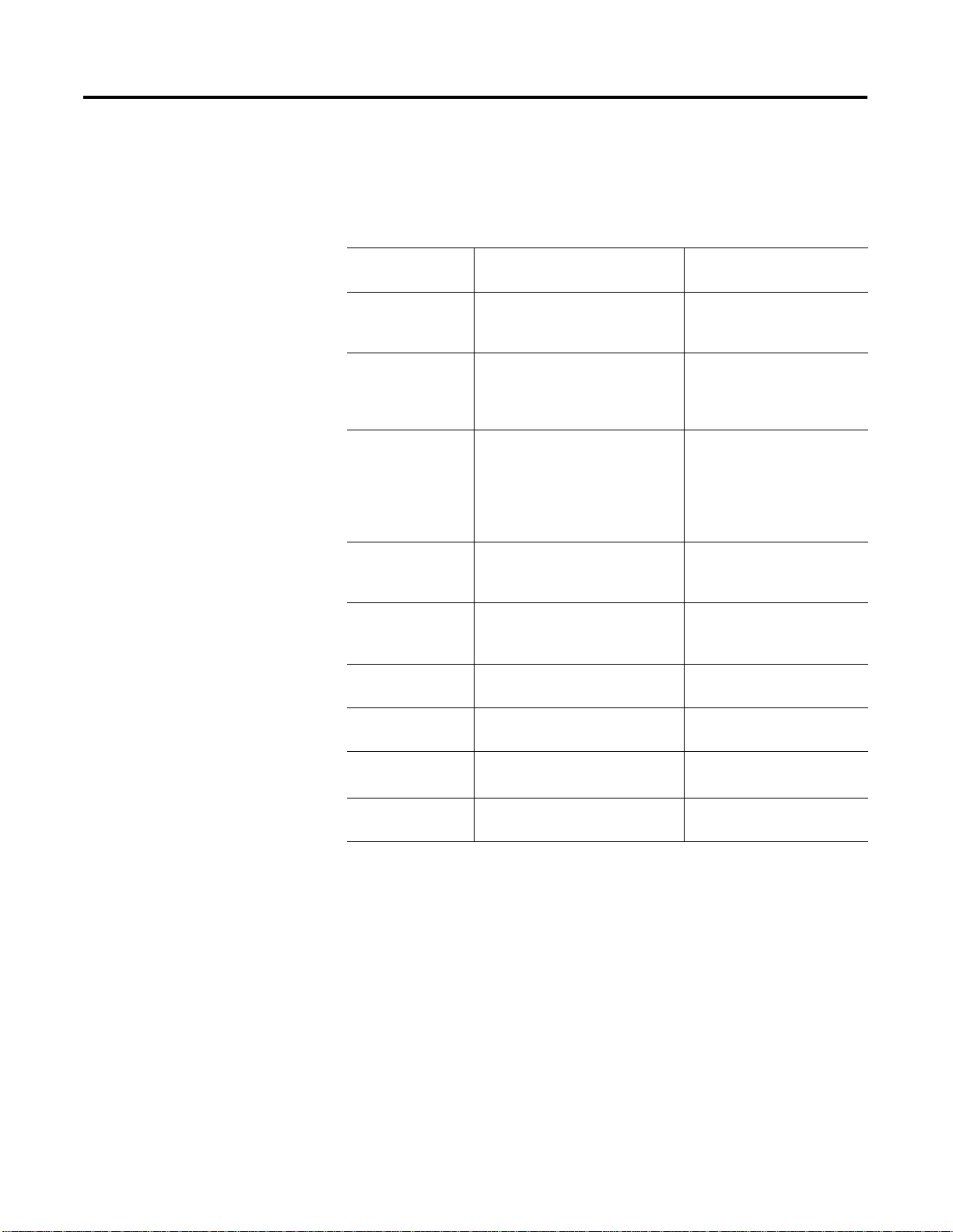

The following table summarizes the terms and type representation

conventions used in this Guide.

Term/Type

Representation

click, click on, click

[button name]

double-click Click left mouse button twice in

drag Press and hold left mouse button

right-click Click right mouse button once.

select click to highlight a menu item or

<F1> Keys to be pressed are shown in

Meaning Example

Click left mouse button once.

(Assumes cursor is positioned on

object or selection.)

quick succession. (Assumes cursor

is positioned on object or

selection.)

while dragging cursor to new

screen location and then release

the button. (Assumes cursor is

positioned on object or selection to

be moved.)

(Assumes cursor is positioned on

object or selection.)

list choice, or click on a button.

angle brackets.

Click Browse.

Double-click the Station icon.

Drag the PID function block

onto the Control Drawing.

Right-click the AND function

block.

Select Configure

Allen-Bradley drivers from the

list box.

Press <F1> to view the online

Help.

<Ctrl>+<C> Keys to be pressed together are

shown with a plus sign.

⇒New

File

>D:\setup.exe< Data to be keyed in at prompt or in

Shows menu selection as menu

name followed by menu selection.

an entry field.

Press <Ctrl>+<C> to close the

window.

Click File⇒New to start new

drawing.

Key in this path location

>D:\setup.exe<.

Publication 1757-IN040B-EN-P - March 2002

Page 20

Preface 6

Contents of Release

The following software and documentation components are included

in the ProcessLogix R400.0 Software/documentation kit

(1757-SWKIT4000).

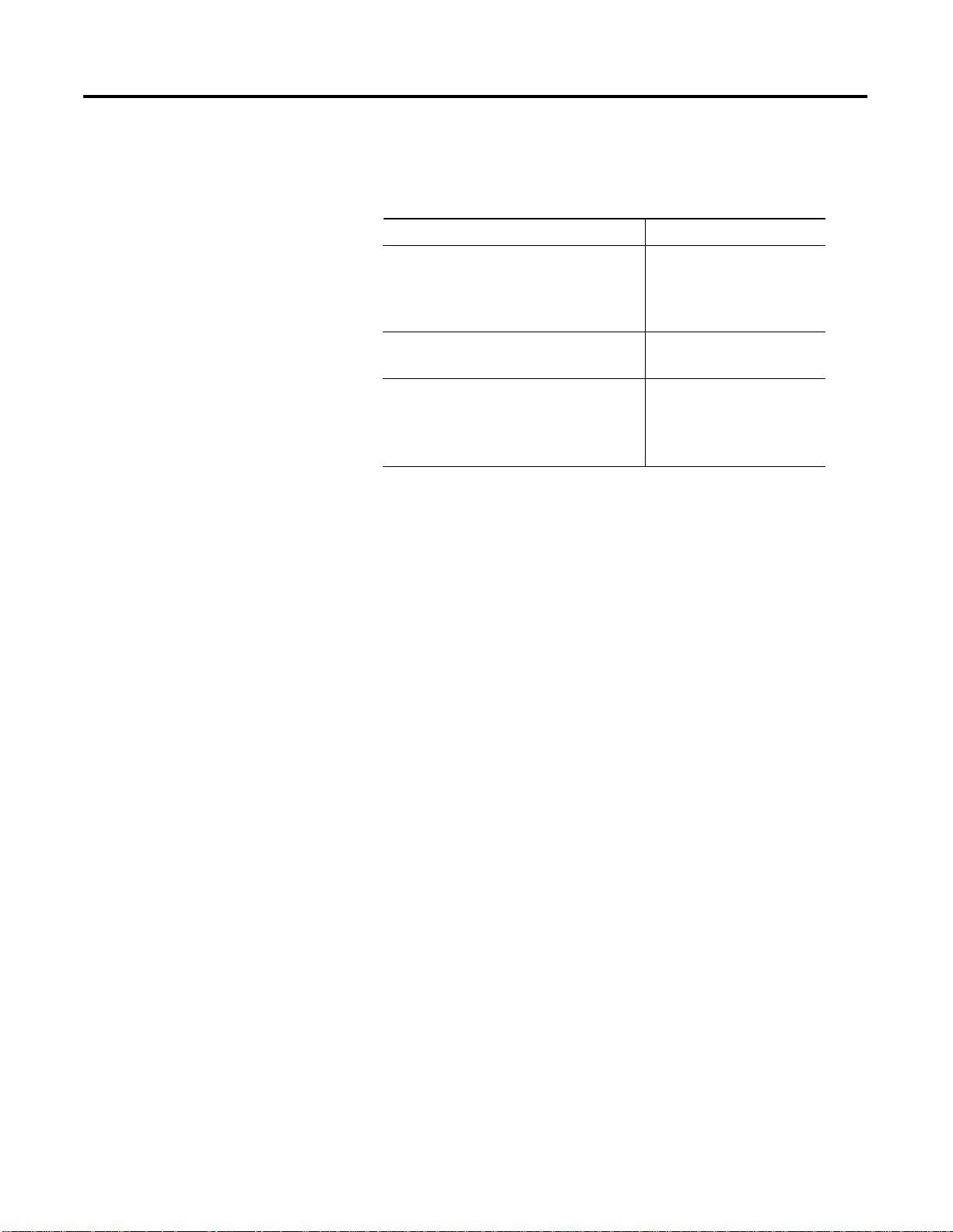

Release Component s Catalog and part numbers

ProcessLogix R400.0 CD 1 and CD 2

ProcessLogix Engineering Tools

ProcessLogix Server Software

RSLinx 2.3

ProcessLogix Knowledge Builder CD 1757-SWKIT4000

ProcessLogix R400.0 Documentation Set

Including:

The ProcessLogix R400.0 Installation

and Upgrade Guide

1757-SWKIT4000

CD 1 957555-50

CD 2 95760375

957555-41

957555-51

1757-IN040B-EN-P

957678-48

ProcessLogix Online User Documentation/Knowledge Builder

ProcessLogix online user documen tati on is included with yo ur

ProcessLogix system in browser format through the Knowledge

Builder. Most of the documents may also b e ordered individually

through Rockwell Automation in print format, visit us at:

www.theautomationbookstore.com

Knowledge Builder provides the user with task-based documentation

within the Server and Client stations and may be accessed while using

any of ProcessLogix’s software programs. Knowledge Builder’s internal

links and search functions allow the user to access process relevant

information and references.

References to Knowledge Builder throughout this document are

illustrated as:

Navigate in Knowledge Builder to Ethernet Implementation

⇒Configuration⇒Setting Up Drivers and IP Addresses for

Guide

more information.

Publication 1757-IN040B-EN-P - March 2002

Page 21

Preface 7

ProcessLogix R400.0 Installation and Upgrade Guide

The ProcessLogix R400.0 Installation and Upgrade Guide is shipped

with a ProcessLogix system and provides:

procedures for upgrading an R320.0 system to R400.0

•

procedures for updating the firmware to R400.0 levels

•

procedures for installing the software on a clean PC

•

procedures for tasks associated with migrating to redundant

•

Server and/or redundant Controller architecture.

The following items used to be included in the SCN Software Change

Notice in previous releases but are now provided in this guide:

descriptions of new features and functions

•

descriptions of performance and capacity specifications

•

listings of major ProcessLogix software components

•

Publication 1757-IN040B-EN-P - March 2002

Page 22

Preface 8

Acronyms and Abbreviations

AI —

AO

— Analog Output

CB

— Control Builder

CCL — Control Component Library

CD

— Compact Disc

CDA

CD-ROM

CEE

— Control Execution Environment

CM

— Control Module

1756-CNB or CNB

CPM

CPU

DI

— Digital Input

Analog Input

— Control Data Access

— Compact Disc Read Only Memory

— ControlNet Bridge module

— Control Processor Module

— Central Processing Unit

LAN

— Local Area Network

LED

— Light Emitting Diode

MAC

— Media Access Control

MB

— Megabytes

NTFS

— Windows NT File System

NUT

— Network Update Time

NTFS

— Windows NT File System

NUT

— Network Update Time

ODBC

— Open Database Communications

OEM

— Original Equipment Manufacturer

PC

— Personal Computer

1784-PCIC or PCIC

1757-PIM

— Pulse Input Module

— PCI ControlNet Interface Module

DNS

— Domain Name System

DO

— Digital Output

DOS

— Disk Operating System

ER

— Engineering Repository

ERDB

— Engineering Repository Database

FB

— Function Block

FSC

— Fail Safe Controller

HTML

— HyperText Markup Language

I/O

— Input/Output

IOM

— Input/Output Module

IRQ

— Interrupt Request

ISA

— Industry-Standard Architecture

PLC

— Programmable Logic Controller

RAM

— Random Access Memory

RCP

— Redundant Chassis Pair

RTU

— Remote Terminal Unit

SCADA

— Supervisory Control and Data Access

SCM

— Sequential Control Module

SCSI

— Small Computer System Interface

1757-SRM or SRM

TC-MUX01

TCP/IP

VGA

WINS

— Serial Interface Module

— Transmission Control Protocol/Internet Protocol

— Video Graphics Array

— Windows Internet Name Service

— System Redundancy Module

Publication 1757-IN040B-EN-P - March 2002

Page 23

Chapter

1

ProcessLogix R400.0 Installation Introduction

Operating System Support

Operating System Options

ProcessLogix Component Configuration Table

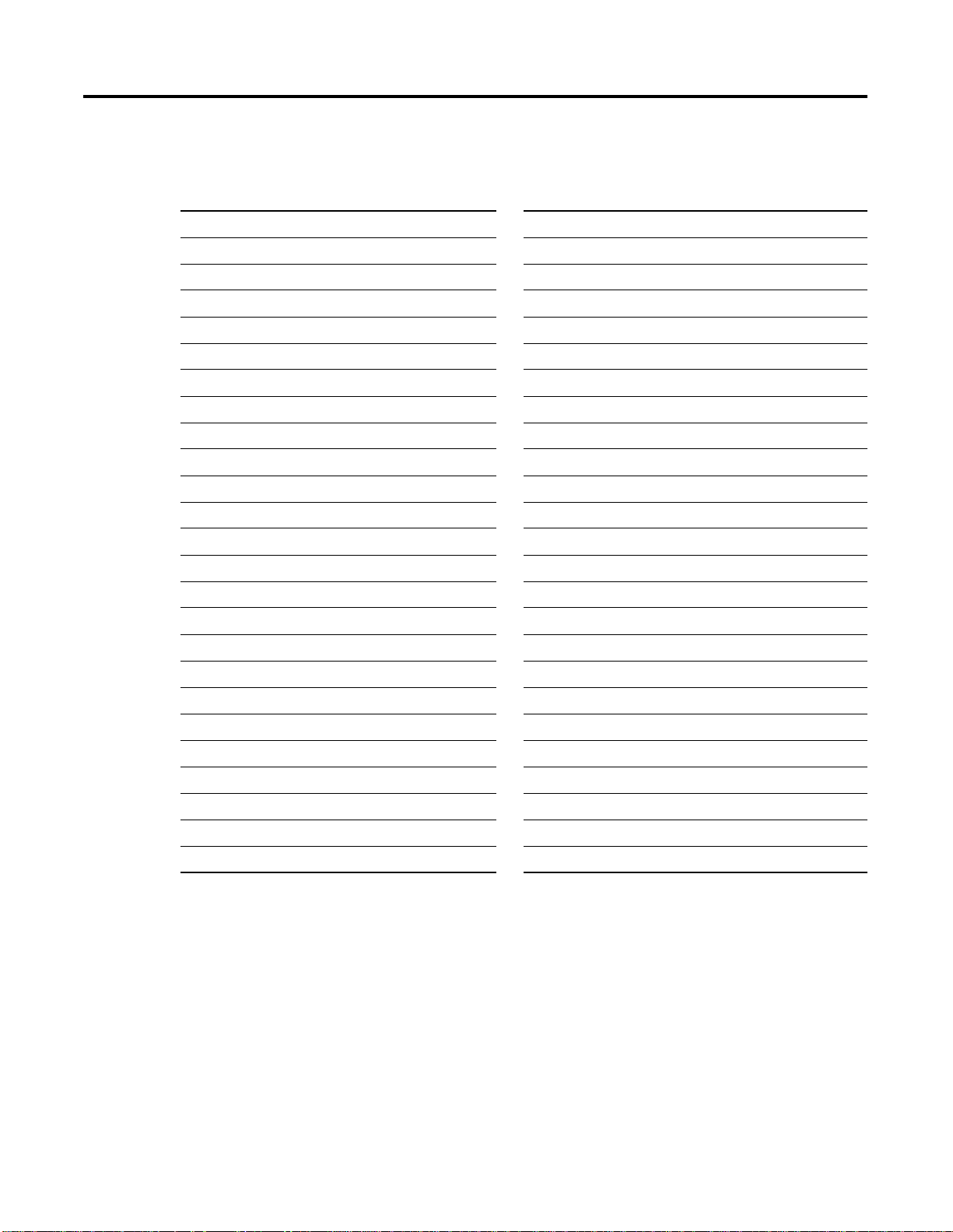

The following table shows the supported operating systems for

ProcessLogix.

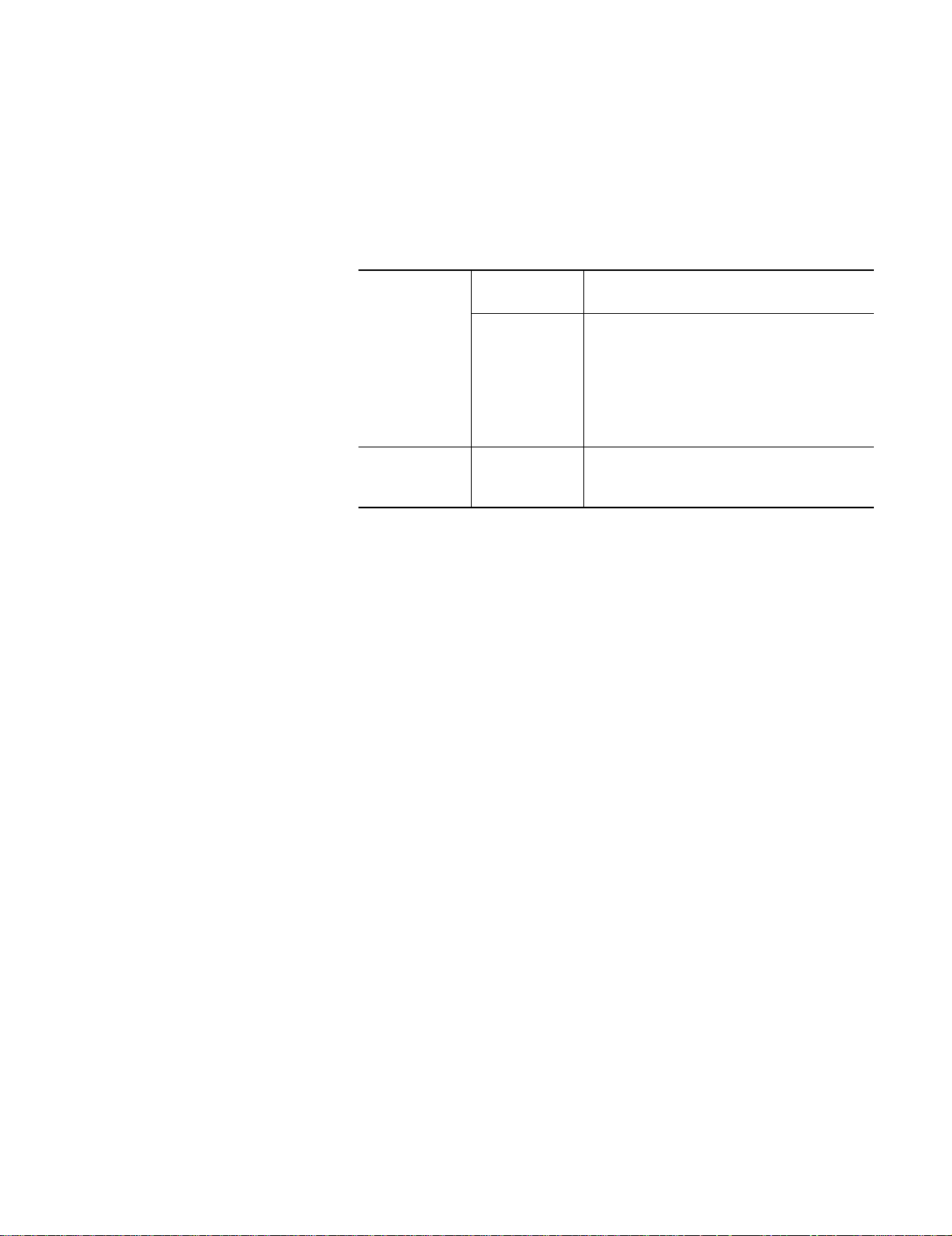

Table 1.A ProcessLogix Component Configuration Ta ble

ProcessLogix NT 4.0 Windows 2000

Workstation Server Professional Server

Server

Client

The hardware platform and all devices contained within it designated

for running the ProcessLogix R400.0 Software should be evaluated for

compatibility with the Window s 2000 operating system.

Systems designated to run Pro cessLogix R400.0 Server software shou ld

be Server Class and certified to run the Windows 2000 Serve r

Operating System.

✔✔✔✔

✔

Systems designated to run Pro cessLogix R400.0 Clien t Software should

be W orkstation/Desktop Class and certified to run the Windows NT4.0

Workstation or Windows 2000 Professional Operating System.

To check to see which certifications your computer and hardware

components have, consult the Microsoft Hardware Compatibility List

http://www.microsoft.com/windows2000/upgrade/compat/default.asp

at:

Review the scenarios below for your curren t operating system

installation and upgrade options.

ProcessLogix Server Supported Installations

IMPORTANT

1 Publication 1757-IN040B-EN-P - March 2002

A PCIC card must already be installed in the

ProcessLogix Server(s).

Page 24

1-2 ProcessLogix R400.0 Installation Introduction

IMPORTANT

If you plan to use Microsoft Excel Data Exchange,

Microsoft Excel 2000 must be installed before

installing ProcessLogix.

Clean Install

The Clean Install is a clean machine installed with ProcessLogix

R400.0 Server software. That is, the installation begins with formatting

the hard disk and installing Windows 2000 Server. Refer to Installing

ProcessLogix Software on a Clean PC on page 3-1.

Upgrade from ProcessLogix R320.0 Server Currently Running Windows NT 4.0 Workstation

ATTENTION

Upgrading to ProcessLogix R400.0 Server requires

that the system be running Windows 2000 Server.

!

IMPORTANT

ProcessLogix R400.0 requires that you replace your current installation

with new hardware and operating software for the Server.

After using the techniques outlined in Saving Important Data on page

4-5 to back up all data or trans fe r th e da ta to anothe r sy s tem , r efe r to

Installing ProcessLogix Software on a Clean PC on page 3-1.

Re-Deployment Options

After using the techniques outlined in Saving Important Data on page

4-5 to back up all data or trans fe r th e da ta to anothe r sy s tem , the

system can be setup to be used as an R400.0 Client. Follow the

instructions in Installing ProcessLogix R400.0 Client Software on page

5-18.

You must upgrade to Rockwell Automation

recommended hardware specifications to be eligible

for Rockwell Automation Technical support.

ProcessLogix R400.0 installations onto R320.0

hardware specifications is not supported.

Publication 1757-IN040B-EN-P - March 2002

Page 25

ProcessLogix R400.0 Insta llation Introduction 1-3

ProcessLogix Client Supported Installations

Clean Install

If you have a new client system, refer to ProcessLogix Client

Installation and Upgrade Procedures on page 5-1.

A clean install is not required for upgrading R320.0 Client software to

R400.0. If performing this option, backup all the data on the system,

then follow the instructions in Saving Important Data on page 5-6.

Upgrade: Currently Running Windows NT 4.0 Workstation with ProcessLogix Clie nt Software

Upgrading the operating system is not required for ProcessLogix

Client software. If your R320.0 system utilized the Windows NT 4.0

Workstation software on a certified system, you have the option of

performing an operating system upgrade to Windows 2000

Professional. Refer to Upgrading the Windows NT 4.0 Workstation

Operating System to Windows 2000 Professional on page 5-10.

After the operating system upgrade, it is required to upgrade the

ProcessLogix Client software to the R400.0 Version.

Publication 1757-IN040B-EN-P - March 2002

Page 26

1-4 ProcessLogix R400.0 Installation Introduction

Publication 1757-IN040B-EN-P - March 2002

Page 27

Chapter

2

Operating System Installation Procedures

Clean System Windows 2000 Server Installation

ATTENTION

!

IMPORTANT

These installation scenarios use a “clean” PC

installation method in which all data on the system

will be removed/erased. This is an irrecoverable

action. All data must be first “backed up” or

transferred to another system before proceeding.

R400.0 ProcessLogix Servers require the Windows

2000 Server operating system.

R400.0 ProcessLogix Client Stations may use

Windows 2000 Professional, Windows 2000 Server,

Windows NT 4.0 Workstation, or Windows NT 4.0

Server operating systems.

If you purchased a new ProcessLogix R400.0 Server

from Rockwell Automation, the operating system has

already been installed. Do not try to reinstall it.

Other Windows 2000 Installation Methods:

Unattended Installation

•

Remote Installation Services

•

Over the Network Installation

•

SysPrep

•

Systems Management Server

•

Consult the Microso f t Docu mentati on s et incl ud ed w ith t he Ope rating

System for these methods.

Installing Windows 2000 Server on a New System

Y o u must install W indows 2000 Server on your s ystem bef ore you can

install or run the ProcessLogix R400.0 software. The current required

Operating System components are Windows 2 000 Server with

Windows 2000 Service Pack 2 applied and Internet Explorer 5.5

Service Pack 1. The Windows 2000 Server software, Service Packs, and

Internet Explorer are licensed products of Microsoft Co rporation.

1 Publication 1757-IN040B-EN-P - March 2002

Page 28

2-2 Operating System Installation Procedures

Copies of the Service Packs and Internet Explorer are included on the

ProcessLogix software CD for your convenience.

The following instructions guide you through the installation of

Windows 2000 Server:

Starting the Windows 2000 Server Installation

•

Creating the Boot Floppies (i f necessary)

•

Perform the installation using one of the following methods:

•

– Starting the installation from the Boot Floppies

– Starting the installation from the CD-ROM

Starting the Windows 2000 Server Installation

This procedure assumes:

All network cards are installed in the PC and they are set to the

•

correct IRQs.

All supporting ProcessLogix system hardware is installed and

•

connected to the PC.

The PC meets specified hardware and software requirements.

•

Navigate in Knowledge Builder to Server and Client Installation

⇒Hardware and Software Requirements for more

Guide

information.

All manufacturers related driver diskettes are available to

•

complete the installation.

If you received your PC from the manufacturer with Windows 2000

Server pre-installed, skip to Installing Service Pack 2 for Windows

2000 on page 2-17.

ATTENTION

Consult the PC Manufacturer for any specialized

instructions/procedures related to the installation of

the Microsoft Windows 2000 Server operating

system.

Publication 1757-IN040B-EN-P - March 2002

!

This procedure lists only the generic installation

procedure. It does not contain any special

instructions for any manufacturer specific driver

installation requirements.

Page 29

Operating System Instal lation Procedures 2-3

Creating Boot Floppies

If your system does not support booting from a CD-ROM, follow these

instructions to create the required Boot Floppies. Otherwise, skip

to Starting the Installation from the CD-ROM on page 2-4.

IMPORTANT

You will need:

4 blank 3.5” 1.44 Mb (High Density) Floppy Disks

•

1.44 MB Floppy Drive

•

CD-ROM Drive

•

DOS or Windows based Operating System with access to

•

CD-ROM and floppy devices.

1. Insert the Windows 2000 Server CD into the CD-ROM drive.

2. Click Start

3. Key in this command in the Open entry field:

>cmd<

and click OK to open the DOS window.

If your installation requires additional Drivers to be

installed for access to the Hard Disk Controller , Disk

Device, or CD-ROM, it may be necessary to start the

installation via the Boot Floppies. (Even if your

system supports booting off of a CD-R OM.).

⇒Run.

4. At the DOS prompt, key in: >D:< and press Enter.

5. Key in this command:

>cd bootdisk<

and press Enter.

6. Key in this command:

>makeboot<

and press Enter.

7. Enter the letter of your floppy disk drive. >A<

Publication 1757-IN040B-EN-P - March 2002

Page 30

2-4 Operating System Installation Procedures

8. Follow the on-screen prompts for inserting, labeling, and

creating the four floppy disks.

IMPORTANT

9. When all the boot floppies have been made, shut down the PC.

Server Boot floppies and Professional Boot floppies

are different.

Starting the Installation from the Boot Floppies

1. With the PCs’ power off, ins ert the dis ke tte tit led W indow s 2000

Setup Boot Disk into the floppy disk drive.

2. Turn on the PC.

3. Insert the Microsoft Windows 2000 Server CD into the CD-ROM

drive.

4. Follow the on-screen prompts to remove and insert the

Windows 2000 Se rver Setup Disk s 2, 3, and 4 when inst ructed to

do so.

5. Continue with Completing the Windows 2000 Server Installation

on page 2-5.

Publication 1757-IN040B-EN-P - March 2002

Starting the Installation from the CD-ROM

1. Turn on the PC.

2. Insert the Microsoft Windows 2000 Server CD into the CD-ROM

drive.

3. When prompted, enter into the computer’s BIOS setup program.

4. Verify that the Boot Priority has the CD-ROM de vice listed first.

(Before the floppy or hard disk devices.)

5. Exit the BIOS and save the setting.

Page 31

Operating System Instal lation Procedures 2-5

6. Press any key to boot from the CD-ROM.

ATTENTION

If your installation requires additional

Manufacturer’s Drivers, press the F6 key during the

boot process and follow the on-screen instructions

for adding the necessary drivers.

!

Completing the Windows 2000 Server Installation

1. Press Enter on Welcome to Setup Screen.

2. If requested, insert the Windows 2000 Server CD into the

CD-ROM drive and press Enter.

ATTENTION

!

If Windows 2000 Setup did not find a suitable

installation device, it will stop and prompt you for

additional Manufacturer’s Drivers. Follow the

on-screen instructions for adding the necessary

drivers.

3. Press F8 to agree to the Windows 2000 Licensing Agreement.

4. If necessary, press ESC(escape) to continue installing a fresh

copy of Windows 2000.

ATTENTION

If existing partitions are found, delete all of them

first before proceeding. Use the on-screen

instructions to perform this task.

!

5. Press Enter to set up Windows 2000 on the Unpartitioned space.

Use the entire hard disk if possible, see note below.

6. Format the part it i on us in g the N TFS fi le sy s te m.

Publication 1757-IN040B-EN-P - March 2002

Page 32

2-6 Operating System Installation Procedures

Setup will format the partition. This takes a few minutes to

complete.

ATTENTION

!

The computer will automatically reboot. Be sure to remove

floppy disk from the floppy disk drive.

7. At the Welcome to Setup window, click Next.

If there is a delay clicking next, setup will continue the

installation automatically.

8. Verify the information on the Regional Settings screen and click

Next.

9. Enter the appropriate Name and Organization name and click

Next.

Certain PCs will limit the size of the partition that

you can create. Windows 2000 supports a boot

partition size up to a 32 Gigabytes on a NTF S

formatted drive.

If your system has a limitation, create the largest

partition you can, and leave the leftover space as

unpartitioned. (You can create and format the

unpartitioned space later.) The minimum partition

size required for this installation is 4 Gigabytes.

10. Enter your Windows 2000 Server Product Key and click Next.

11. Choose your Server’s Licensing Mod e:

Rockwell Automation recommends that you choose the “Per

Seat” licensing option.

ATTENTION

!

12. At the Computer Name and Administrator Password window:

Microsoft requires that you attain the appropriate

number of Client Access Licenses required for your

system. For ProcessLogix Systems, the total number

of clients includes other ProcessLogix Servers

(Redundant Servers), and ProcessLogix Clients.

Publication 1757-IN040B-EN-P - March 2002

Page 33

Enter the Computer Name.

•

Operating System Instal lation Procedures 2-7

ATTENTION

!

The base name cannot contain more than 13

alphanumeric characters and must contain no spaces.

The full computer name cannot contain more than

14 alphanumeric characters. The following naming

conventions are required for given ProcessLogix

system architectures.

For non-redundant Server, be sure the name does

not end in the letter “A” or “B”. The default name is

PLX1.

For redundant Servers, append a letter to the base

name to identify the PC’s function in the system

architecture beginning with the letters A and B for

the primary and secondary Servers, respectively. For

example, use the name PLX1A for the primary Server

(SERVERA) and PLX1B for the secondary Server

(SERVERB). (14 Character total: Up to 13 Base plus

A or B)

For a ProcessLogix Client, be sure the name does not

end in the letter “A” or “B”. The suggested name is

STNxx, where xx is the Station Number (01-20).

Enter the Administrator password.

•

Confirm the password.

•

IMPORTANT

• Click Next.

ATTENTION

!

13. At the Windows 2000 Components window:

• Uncheck the box for the Internet Information Services (IIS)

Be sure to document the Administrator Password. (It

is required later in the procedure.) The Admi nistrator

Account and password gives a user full access to the

system. Care should be taken to who has access to

this information.

In the next section, you have the ability to add

many services and options during the Server

installation. These components are not required for

the base operation of the ProcessLogix R400.0

Software. If any of th ese components are needed

for a custom installation, they can be added later

after the installation.

Publication 1757-IN040B-EN-P - March 2002

Page 34

2-8 Operating System Installation Procedures

Only the Accessories and Utilities, Indexing Service and

•

Script Debugger remain checked.

Click Next

•

14. At the Date and Time Settings window:

If necessary, adjust the Date and Time settings.

•

Set the appropriate Time Zone for your location.

•

Uncheck the Automatically adjust clock for daylight saving

•

changes option.

Click Next.

•

.

ATTENTION

!

15. If setup has not found a suitable Network Device, you will be

prompted for installing one. Follow the instructions for adding a

manufacturer supplied driver or add the Microsoft Loop Back

adapter.

16. Choose the Custom settings option and click Next.

17. At the Networking Components window, select Internet Protocol

(TCP/IP) and click Properties.

18. Choose the IP Address option.

Fill in the appropriate IP address.

•

Failure to uncheck the Automatic adjustment for

Daylight Savings Time will cause Redundant

Systems to loose “Sync” when the time is

automatically adjusted. Choosing not to

automatically adjust the time allows you to decide

when to make the adjustment (at a time that is not

critical to your process).

Publication 1757-IN040B-EN-P - March 2002

ATTENTION

!

In some organizations it is important for these addresses to be

controlled by the IT organization. Consult your company’s

practices and IT organization for the appropriate IP address

information. It will be necessary to use valid IP information to

integrate the ProcessLogix Control system with the Business

Network.

IP Addresses are critical to the communication of

the system. Rockwell Automation suggests, when

possible, to utilize a Private Network for the control

system. (Not connected to any other networks.)

This isolates the control system from interference

from any business communication.

Page 35

Operating System Instal lation Procedures 2-9

The following Private Networking IP Address scheme can be

utilized for the system to operate:

Non-Redundant or Primary Redundant Server:

NIC 1: 192.168.0.1, NIC 2: 192.168.1.1, NIC 3: 192.168.2.1

Backup Redundant Server:

NIC 1: 192.168.0.2, NIC 2: 192.168.1.2, NIC 3: 192.168.2.2

Fill in the appropriate Subnet Mask.

•

All configurations use a Subnet Mask of 255.255.255.0 and a

blank Defaul t Gat e tway.

If necessary, fill in the appropriate Default gateway.

•

Click OK to return to the Networking Components window.

•

19. Click Next.

20. Repeat steps 17 to 19 for additional network cards.

21. At the Workgroup or Computer Domain window:

Choose the No, this computer …. option

•

Enter an appropriate Wo rkGroup Name.

•

Click Next.

•

ATTENTION

All systems which are configured for this Process

Control System should utilize the same Workgroup

Name for easier operations.

!

22. At this point in the installation, setup will finish installing

Windows 2000. This will take some time depending on your

hardware configuration.

23. At the Completing the Setup Wizard window, remove the

Windows 2000 Server CD and click Finish.

24. The PC will reboot.

25. Continue the installation with Installing Service Pack 2 for

Windows 2000 on page 2-17.

Publication 1757-IN040B-EN-P - March 2002

Page 36

2-10 Operating System Installation Procedures

Clean System Windows 2000 Professional Installation

Windows 2000 Professional is the preferred Client op erating system

for ProcessLogix R400.0. The current required Operating System

components are Windows 2000 Professional with Windows 2000

Service Pack 2 applied and Internet Explorer 5.5 Service Pack 1. The

Windows 2000 Professional software, Service Packs, and Internet

Explorer are licensed products of Microsof t Corporation. Copies o f the

Service Packs and Internet Explorer are included on the ProcessLogix

software CD for your convenience.

The following instructions guide you through the installation of

Windows 2000 Professional:

Starting the installation of Windows 2000 Professional

•

Creating the Boot Floppies (i f necessary)

•

Performing the installation using 1 of the following methods:

•

Starting the installation from the Boot Floppies

•

Starting the installation from the CD-ROM

•

Starting the Windows 2000 Professional Installation

This procedure assumes:

All network cards are installed in the PC and they are set to the

•

correct IRQs.

All supporting ProcessLogix system hardware is installed and

•

connected to the PC.

The PC meets specified hardware and software requirements.

•

Navigate in Knowledge Builder to Server and Client Installation

⇒Before Installing ProcessLogix⇒Hardware and Software

Guide

Requirements for more information.

• All manufacturers related driver diskettes are available to

complete the installation.

Publication 1757-IN040B-EN-P - March 2002

Page 37

Operating System Installation Procedures 2-11

If you received your PC from the manufacturer with Windows 2000

Professional pre-installed, skip to Installing Service Pack 2 for

Windows 2000 on page 2-17.

ATTENTION

!

Consult the PC Manufacturer for any specialized

instructions/procedures related to the installation of

the Microsoft Windows 2000 Professional operatin g

system.

This procedure lists only the generic installation

procedure. It does not contain any special

instructions for any manufacturer specific driver

installation requirements.

Creating Boot Floppies

If your system does not support booting from a CD-ROM, follow these

instructions to create the required Boot Floppies. Otherwise, skip

to Starting the Installation from the CD-ROM on page 2-12.

IMPORTANT

If your installation requires additional Drivers to be

installed for access to the Hard Disk Controller , Disk

Device, or CD-ROM, it may be necessary to start the

installation via the Boot Floppies. (Even if you

system supports booting off of a CD-R OM.).

You will need:

4 blank 3.5” 1.44 Mb (High Density) Floppy Disks

•

1.44 MB Floppy Drive

•

• CD-ROM Drive

• DOS or Windows based Operating System with access to

CD-ROM and floppy devices.

1. Insert the Windows 2000 Professional CD into the CD-ROM

drive.

2. Click Start

3. Key in this command in the Open entry field:

>cmd<

and click OK to open the DOS window.

⇒Run.

Publication 1757-IN040B-EN-P - March 2002

Page 38

2-12 Operating System Installation Procedures

4. At the DOS prompt, key in: >D:< and press Enter.

5. Key in this command:

>cd bootdisk<

and press Enter.

6. Key in this command:

>makeboot<

and press Enter.

7. Enter the letter of your floppy disk drive. >A<

8. Follow the on-screen prompts for inserting, labeling, and

creating the four floppy disks.

IMPORTANT

9. When all the boot floppies have been made, shut down the PC.

Server Boot floppies and Professional Boot floppies

are different.

Starting the Installation from the Boot Floppies

1. With the PCs’ power off, ins ert the dis ke tte tit led W indow s 2000

Setup Boot Disk into the floppy disk drive.

2. Turn on the PC.

3. Insert the Microsoft Windows 2000 Professional CD into the

CD-ROM drive.

4. Follow the on-screen prompts to remove and insert the

Windows 2000 Professional Setup Disks 2, 3, and 4 when

instructed to do so.

5. Continue with Completing th e Window s 2 000 Profes sio n al

Installation on page 2-13.

Publication 1757-IN040B-EN-P - March 2002

Starting the Installation from the CD-ROM

1. Turn on the PC.

2. Insert the Microsoft Windows 2000 Professional CD into the

CD-ROM drive.

Page 39

Operating System Installation Procedures 2-13

3. When prompted, enter into the computer’s BIOS setup program.

4. Verify that the Boot Priority has the CD-ROM device listed firs t.

(Before the floppy or hard disk devices.)

5. Exit the BIOS and save the setting.

6. Press any key to boot from the CD-ROM.

ATTENTION

If your installation requires additional

Manufacturer’s Drivers, press the F6 key during the

boot process and follow the on-screen instructions

for adding the necessary drivers.

!

Completing the Windows 2000 Professional Installation

1. Press Enter on Welcome to Setup Screen.

2. If requested, insert the Windows 2000 Professional CD into the

CD-ROM drive and press Enter.

ATTENTION

!

If Windows 2000 Setup did not find a suitable

installation device, it will stop and prompt you for

additional Manufacturer’s Drivers. Follow the

on-screen instructions for adding the necessary

drivers.

3. Press F8 to agree to the Windows 2000 Licensing Agreement.

4. If necessary, press ESC(escape) to continue installing a fresh

copy of Windows 2000.

ATTENTION

If existing partitions are found, delete all of them

first before proceeding. Use the on-screen

instructions to perform this task.

!

5. Press Enter to set up Windows 2000 on the Unpartitioned space.

Publication 1757-IN040B-EN-P - March 2002

Page 40

2-14 Operating System Installation Procedures

Use the entire hard disk if possible, see note below.

6. Format the partit i on using the NTFS file system .

Setup will format the partition. This takes a few minutes to

complete.

ATTENTION

!

7. The computer will automatically reboot. Be sure to remove

floppy disk from the floppy disk drive.

8. At the Welcome to Setup window, click Next.

If there is a delay clicking next, setup will continue the

installation automatically.

9. Verify the information on the Regional Settings screen and click

Next.

10. Enter the appropriate Name and Organization name and click

Next.

Certain PCs will limit the size of the partition that

you can create. Windows 2000 supports a boot

partition size up to a 32 Gigabytes on a NTF S

formatted drive.

If your system has a limitation, create the largest

partition you can, and leave the leftover space as

unpartitioned. (You can create and format the

unpartitioned space later.) The minimum partition

size required for this installation is 4 Gigabytes.

Publication 1757-IN040B-EN-P - March 2002

11. Enter your Windows 2000 Professional Product Key and click

Next.

12. At the Computer Name and Administrator Password window:

• Enter the Computer Name.

ATTENTION

!

• Enter the Administrator password.

The computer name cannot contain more than 14

alphanumeric characters and must contain no spaces.

For a ProcessLogix Client, be sure the name does not

end in the letter “A” or “B”. The suggested name is

STNxx, where xx is the Station Number (01-20).

Page 41

Confirm the password.

•

Operating System Installation Procedures 2-15

IMPORTANT

Click Next.

•

13. At the Date and Time Settings window:

If necessary, adjust the Date and Time settings.

•

Set the appropriate Time Zone for your location.

•

Uncheck the Automatically adjust clock for daylight saving

•

changes option.

Click Next.

•

ATTENTION

!

Be sure to document the Administrator Password. (It

is required later in the procedure.) The Admi nistrator

Account and password gives a user full access to the

system. Care should be taken to who has access to

this information.

Failure to uncheck the Automatic adjustment for

Daylight Savings Time will cause Redundant

Systems to loose “Sync” when the time is

automatically adjusted. Choosing not to

automatically adjust the time allows you to decide

when to make the adjustment (at a time that is not

critical to your process).

14. If setup has not found a suitable Network Device, you will be

prompted for installing one. Follow the instructions for adding a

manufacturer supplied driver or add the Microsoft Loop Back

adapter.

15. Choose the Cust om se tting s option and click Nex t.

16. At the Networking Components wi ndow, select Internet Protoc ol

(TCP/IP) and click Properties.

17. Choose the Use the following IP Address option.

• Fill in the appropriate IP address.

ATTENTION

!

IP Addresses are critical to the communication of

the system. Rockwell Automation suggests, when

possible, to utilize a Private Network for the control

system. (Not connected to any other networks.)

This isolates the control system from interference

from any business communication.

Publication 1757-IN040B-EN-P - March 2002

Page 42

2-16 Operating System Installation Procedures

Navigate in Knowledge Builder to ProcessLogix R400.0

Installation Guide

information.

In some organizations, it is important that these addresses are

controlled by the IT organization. Consult your company’s

practices and IT organization for the appropriate IP address

information. It will be necessary to use valid IP information to

integrate the ProcessLogix Control system with the Business

Network.

The following Private Networking IP Address scheme can be

utilized for the system to operate:

First Client Addressing:

NIC 1: 192.168.0.3, NIC 2: 192.168.1.3

Additional Station Addressing:

NIC 1: 192.168.0.x, NIC 2: 192.168.1.x, where x is the Station

number +2. (for Station Number 2, x=4)

⇒Network Planning Guide for more

Fill in the appropriate Subnet Mask.

•

All configurations use a Subnet Mask of 255.255.255.0 and a

blank Default Gat e tw a y.

If necessary, fill in the appropriate Default gateway.

•

Click OK to return to the Networking Components window.

•

18. Click Next.

19. Repeat steps 15 to 17 for additional network cards.

20. At the Workgroup of Computer Domain window:

• Choose the No, this computer …. option

• Enter an appropriate WorkGroup Name.

• Click Next.

ATTENTION

All systems which are configured for this P rocess

Control System should utilize the same Workgroup

Name for easier operations.

!

Publication 1757-IN040B-EN-P - March 2002

Page 43

Operating System Installation Procedures 2-17

21. At this point in the installation, setup will finish installing

Windows 2000. This will take some time depending on your

hardware configuration.

22. At the Completing the Setup Wizard window, remove the

Windows 2000 Professional CD and click Finish.

23. The PC will reboot.

24. Continue the installation with Installing Service Pack 2 for

Windows 2000 on page 2-17.

Installing Service Pack 2 for Windows 2000

Checking for Windows 20 00 Service Pack 2

Before performing this installation, check the Microsoft Windows 2000

CDs to see if they have Service Pack 2 integrated. (This depends on

when the software was purchased.) If Service Pack 2 has already been

installed, you can skip to Installing Internet Explorer 5.5 SP1 on

page 2-19.

If you are unsure of whether the source CDs included SP2, perform

the following procedure:

1. If necessary, Boot/Turn on the sy s tem.

2. Press Ctrl-Alt-Del to prompt the logon information.

3. Use the Administrator user account and enter the appropriate

password.

TIP

If this is the first time start since the operating system

install, it will be necessary to remove the default

startup Screens

3. Click Start

Professional Systems

1. On the Getting Started with Windows 2000 window, uncheck the

Show this screen at startup checkbox.

2. Click Exit.

Server Systems

1. On the Windows 2000 Configure your Server window , select the I

will configure this Server later option and click Next.

2. Uncheck the Show this screen at startup checkbox and close the

window.

⇒Run.

Publication 1757-IN040B-EN-P - March 2002

Page 44

2-18 Operating System Installation Procedures

4. Key in this command in the Open entry field:

>winver<

and press Enter.

5. In the About Windows window, look to see if the following text

appears: Version 5.0 (Build 2195: Service Pack 2)

If the line appears as shown, you can skip to Installing Internet

Explorer 5.5 SP1 on page 2-19.

If the line does not say Service Pack 2, click OK and continue

with Installing Windows 2000 Service Pack 2 on page 2-18.

Installing Window s 2000 Service Pack 2

1. If necessary, Boot/Turn on the system.

2. Press Ctrl-Alt-Del to prompt the logon i nformation.

3. Use the Administrator user account and enter the appropriate

password.

TIP

If this is the first time start since the operating system

install, it will be necessary to remove the default

startup Screens

Professional Systems

1. On the Getting Started with Windows 2000 window, uncheck the

Show this screen at startup checkbox.

2. Click Exit.

Server Systems

1. On the Windows 2000 Configure your Server window , se lect the I

will configure this Server later option and click Next.

2. Uncheck the Show this screen at startup checkbox and close the

window.

3. Insert the ProcessLogix R400.0 Software CD 2 into the CD-ROM

drive.

Publication 1757-IN040B-EN-P - March 2002

4. Click Start

⇒Run.

5. Key in this path location in the Open entry field or use Browse

to navigate to the w2ksp2.ex e file on the CD.

>D:(or your CD-ROM drive letter)\win2k _ sp\w2 k sp2.exe <

Page 45

Operating System Installation Procedures 2-19