Page 1

ProcessLogix

R320.0 Installation

and Upgrade Guide

1757-SWKIT3200

Installation Instructions

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets al l performance and

safety requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liabilit y (to

include intellectual property liability) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation.

Identifies information that is critical for successful

application and understanding of the product.

Page 3

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to

meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the Allen-Bradley publication

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1.

This equipment is classified as open equipment and must be mounted in

an enclosure during operation to provide safety protection.

Page 4

Page 5

Table of Contents

Important User Information. . . . . . . . . . . . . . . . . . . . . . . . . . ii

European Communities (EC) Directive Compliance . . . . . . . iii

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Preface

Our Assumptions About Readers . . . . . . . . . . . . . . . . . . . . P-1

Starting Conditions and Assumptions . . . . . . . . . . . . . . P-1

Minimum Hardware Requirements. . . . . . . . . . . . . . . . . . . P-2

Rockwell Automation Technical Support . . . . . . . . . . . . . . P-3

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-3

Your Questions or Comments about This Manual . . . . . P-3

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Terms and Type Representations . . . . . . . . . . . . . . . . . P-4

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

ProcessLogix R320.0 Installation and Upgrade Guide. . . P-5

ProcessLogix Online User Documentation/Knowledge

Builder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Contents of Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Acronyms and Abbreviations. . . . . . . . . . . . . . . . . . . . . . . P-7

Chapter 1

Preparing for a ProcessLogix Software Upgrade . . . . . . . . . 1-1

Things to consider before upgrading . . . . . . . . . . . . . . 1-1

Saving Current Controller Data (optional) . . . . . . . . . . . 1-3

Determining Your Hard Drive Free Space Requirements 1-4

Backing Up a ProcessLogix Server to Tape . . . . . . . . . . 1-6

Stopping ProcessLogix Applications and Services . . . . . . . . 1-8

Installing Service Pack 6a for Windows NT 4.0. . . . . . . . . . 1-11

Installing Internet Explorer 5.01. . . . . . . . . . . . . . . . . . . . . 1-12

Upgrading Data Access Components . . . . . . . . . . . . . . . . . 1-13

Uninstalling ProcessLogix Knowledge Builder Software . . . 1-14

Recording the NT System Path Value . . . . . . . . . . . . . . 1-14

Uninstall Knowledge Builder . . . . . . . . . . . . . . . . . . . . 1-14

Verifying the NT System Path Value . . . . . . . . . . . . . . . 1-15

Uninstalling Adobe Acrobat Reader 3.01 . . . . . . . . . . . . 1-15

Installing ProcessLogix Knowledge Builder Software . . . . . 1-16

Removing the 9904/1784-KTCX15 Card

and Installing the 1784-PCIC Card . . . . . . . . . . . . . . . . . 1-18

Upgrading ProcessLogix Software

on a Non-redundant Server Only. . . . . . . . . . . . . . . . . . . 1-19

About Upgrading Software on the Server . . . . . . . . . . . 1-19

Installing Server Software. . . . . . . . . . . . . . . . . . . . . . . 1-20

Installing RSLinx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Installing Engineering Tools . . . . . . . . . . . . . . . . . . . . . 1-22

i Publication 1757-IN032B-EN-P - April 2001

Page 6

Table of Contents ii

Migrating the ERDB. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Installing the ProcessLogix Server . . . . . . . . . . . . . . . . 1-23

Setting Up User Accounts . . . . . . . . . . . . . . . . . . . . . . 1-25

Moving the RSLinx Activation File. . . . . . . . . . . . . . . . . . . 1-26

About the Activation File. . . . . . . . . . . . . . . . . . . . . . . 1-26

Determining the Current RSLinx Version . . . . . . . . . . . 1-26

Installing the Activation File. . . . . . . . . . . . . . . . . . . . . 1-27

Configuring RSLinx Drivers for ControlNet

Supervisory Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Installing the 1784-PCIC Driver . . . . . . . . . . . . . . . . . . 1-29

Updating the 1784-PCIC Card Firmware . . . . . . . . . . . . 1-30

Re-installing the 1784-PCIC Driver . . . . . . . . . . . . . . . . 1-34

Updating the 1784-PCIC Network Address . . . . . . . . . . 1-36

Configuring RSLinx Drivers for Ethernet

Supervisory Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Upgrading Hardware Component Firmware . . . . . . . . . . . 1-39

Making Post ProcessLogix Software Installation

Checks for a Non-redundant Server . . . . . . . . . . . . . . . . 1-39

Things to check after the upgrade . . . . . . . . . . . . . . . . 1-39

Reconfiguring Other RSLinx Clients . . . . . . . . . . . . . . . 1-40

Reloading the 1757-PLX52 Database. . . . . . . . . . . . . . . 1-40

Initiating Redundant Controller Switchover. . . . . . . . . . 1-41

Enabling the ProcessLogix OPC Server. . . . . . . . . . . . . 1-42

Backing up a ProcessLogix Server to Tape . . . . . . . . . . 1-43

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 1-43

Upgrading ProcessLogix Software

on a Redundant Server Pair. . . . . . . . . . . . . . . . . . . . . . 1-45

About Upgrading Software on the Server . . . . . . . . . . . 1-45

Installing Server Software . . . . . . . . . . . . . . . . . . . . . . 1-47

Installing RSLinx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Installing Engineering Tools . . . . . . . . . . . . . . . . . . . . 1-50

Migrating the ERDB (on SERVERB only). . . . . . . . . . . . 1-50

Installing the ProcessLogix Server . . . . . . . . . . . . . . . . 1-51

Setting Up User Accounts . . . . . . . . . . . . . . . . . . . . . . 1-52

Configuring RSLinx Drivers for ControlNet

Supervisory Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-54

Installing the 1784-PCIC Driver . . . . . . . . . . . . . . . . . . 1-54

Updating the 1784-PCIC Card Firmware . . . . . . . . . . . . 1-55

Re-installing the 1784-PCIC Driver . . . . . . . . . . . . . . . . 1-55

Configuring the ControlNet Supervisory Network. . . . . . . . 1-57

Updating the 1784-PCIC Network Address . . . . . . . . . . 1-58

Configuring RSLinx Drivers for Ethernet

Supervisory Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-60

Upgrading Hardware Component Firmware . . . . . . . . . . . 1-61

Making Post ProcessLogix Software Installation

Checks for a Redundant Server Pair. . . . . . . . . . . . . . . . 1-62

Publication 1757-I N0 32B-EN-P - April 2001

Page 7

Table of Contents iii

Things to Check after the Upgrade. . . . . . . . . . . . . . . . 1-62

Creating the Secondary ERDB . . . . . . . . . . . . . . . . . . . 1-62

Synchronizing ERDB on Redundant Servers . . . . . . . . . 1-63

Setting Up Station on SERVERB . . . . . . . . . . . . . . . . . . 1-64

Setting Up Station on SERVERA . . . . . . . . . . . . . . . . . . 1-67

Synchronizing Server Databases on Redundant Servers . 1-71

Synchronizing Other Files . . . . . . . . . . . . . . . . . . . . . . 1-72

Reconfiguring Other RSLinx Clients . . . . . . . . . . . . . . . 1-72

Reloading the 1757-PLX52 Database. . . . . . . . . . . . . . . 1-72

Initiating Redundant Controller Switchover. . . . . . . . . . 1-72

Enabling the ProcessLogix OPC Server . . . . . . . . . . . . . 1-72

Backing up a ProcessLogix Server to Tape . . . . . . . . . . 1-72

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 1-72

Installing ProcessLogix Client Software . . . . . . . . . . . . . . . 1-73

Configuring an Operator Workstation . . . . . . . . . . . . . . . . 1-73

Installing Service Pack 6a for Windows NT 4.0 . . . . . . . 1-74

Installing Internet Explorer 5.01 . . . . . . . . . . . . . . . . . . 1-74

Upgrading Data Access Components . . . . . . . . . . . . . . 1-74

Uninstalling ProcessLogix Knowledge Builder Software. 1-74

Installing ProcessLogix Knowledge Builder Software. . . 1-74

Installing ProcessLogix Operator Workstation Software . 1-74

Configuring an Engineering Workstation . . . . . . . . . . . . . . 1-78

Installing Service Pack 6a for Windows NT 4.0 . . . . . . . 1-78

Installing Internet Explorer 5.01 . . . . . . . . . . . . . . . . . . 1-78

Upgrading Data Access Components . . . . . . . . . . . . . . 1-78

Uninstalling ProcessLogix Knowledge Builder Software. 1-78

Installing ProcessLogix Knowledge Builder Software. . . 1-78

Installing ProcessLogix Engineering

Workstation Software . . . . . . . . . . . . . . . . . . . . . . . . 1-79

Verifying ProcessLogix Client Installation. . . . . . . . . . . . . . 1-83

Things To Consider After The Installation. . . . . . . . . . . 1-83

Setting Up a ProcessLogix Client

With a Non-redundant Server . . . . . . . . . . . . . . . . . . 1-84

Setting Up a ProcessLogix Client

With Redundant Servers . . . . . . . . . . . . . . . . . . . . . . 1-86

Checking Control Builder Operation and Logging On . . 1-89

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 1-89

Publication 1757-IN032B-EN-P - April 2001

Page 8

Table of Contents iv

Chapter 2

Upgrading Hardware Component Firmware . . . . . . . . . . . . 2-1

About firmware upgrades . . . . . . . . . . . . . . . . . . . . . . . 2-1

Firmware revision level reference . . . . . . . . . . . . . . . . . 2-2

Important Usage Considerations . . . . . . . . . . . . . . . . . . 2-4

Updating the 1784-PCIC Card Firmware . . . . . . . . . . . . . 2-5

Loading 1757-PLX52 and TC-MUX021

Boot and Personality Images . . . . . . . . . . . . . . . . . . . 2-10

Updating Firmware in CNB, ENET, IOM, SRM, PIM

or ControlNet Adapter. . . . . . . . . . . . . . . . . . . . . . . . 2-15

Setting CNB Module NUT Timing. . . . . . . . . . . . . . . . . 2-16

Chapter 3

Installing Windows NT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Starting the Windows NT Installation . . . . . . . . . . . . . . . 3-2

Setting Up Windows NT . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Installing TCP/IP Networking Software. . . . . . . . . . . . . . 3-5

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . 3-8

Setting Up the Display Driver . . . . . . . . . . . . . . . . . . . . 3-9

Completing Installation . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Installing Service Pack 6a for Windows NT 4.0. . . . . . . . 3-9

Setting Up Additional Drivers after

the Service Pack Installation . . . . . . . . . . . . . . . . . . . 3-10

Configuring System Properties . . . . . . . . . . . . . . . . . . . 3-11

Converting to NTFS after Installing Windows NT . . . . . 3-12

Creating the plx_user Account. . . . . . . . . . . . . . . . . . . 3-12

Installing Internet Explorer 5.01. . . . . . . . . . . . . . . . . . 3-12

Upgrading Data Access Components . . . . . . . . . . . . . . 3-12

Checking Required System Settings. . . . . . . . . . . . . . . . . . 3-13

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . . . 3-14

Installing ProcessLogix Knowledge Builder Software . . . . . 3-15

Installing the 1784-PCIC Card . . . . . . . . . . . . . . . . . . . . . . 3-15

Installing ProcessLogix Software on a Clean PC . . . . . . . . . 3-16

Installing Server Software . . . . . . . . . . . . . . . . . . . . . . 3-17

Installing RSLinx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Installing Engineering Tools . . . . . . . . . . . . . . . . . . . . 3-19

Installing the ProcessLogix Server . . . . . . . . . . . . . . . . 3-19

Setting up User Accounts. . . . . . . . . . . . . . . . . . . . . . . 3-23

Completing ProcessLogix Install

on a Non-Redundant Server . . . . . . . . . . . . . . . . . . . . 3-23

Configuring RSLinx Drivers for ControlNet

Supervisory Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Installing the 1784-PCIC Driver . . . . . . . . . . . . . . . . . . 3-25

Updating the 1784-PCIC Card Firmware . . . . . . . . . . . 3-26

Re-installing the 1784-PCIC Driver . . . . . . . . . . . . . . . . 3-30

Publication 1757-I N0 32B-EN-P - April 2001

Page 9

Table of Contents v

Configuring the ControlNet Supervisory Network . . . . . 3-31

Updating the 1784-PCIC Network Address . . . . . . . . . . 3-32

Configuring RSLinx Drivers for Ethernet

Supervisory Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Upgrading Hardware Component Firmware. . . . . . . . . . . . 3-34

Making Post ProcessLogix Software Installation

Checks for a Non-redundant Server . . . . . . . . . . . . . . . . 3-34

Checking Control Builder Operation and Logging On . . 3-34

Enabling the ProcessLogix OPC Server . . . . . . . . . . . . . 3-34

Backing Up a ProcessLogix Server Hard Drive to Tape . 3-34

Creating the Emergency Repair Disk . . . . . . . . . . . . . . 3-35

Installing ProcessLogix Client Software on a Clean PC . . . . 3-35

Checking Required System Settings . . . . . . . . . . . . . . . 3-35

Installing ProcessLogix Client software . . . . . . . . . . . . . 3-35

Verifying ProcessLogix Client Installation. . . . . . . . . . . . . . 3-36

Setting Up a ProcessLogix Client

with a Non-redundant Server . . . . . . . . . . . . . . . . . . 3-36

Setting up a ProcessLogix Client

with Redundant Servers . . . . . . . . . . . . . . . . . . . . . . 3-36

Checking Control Builder Operation and Logging On . . 3-36

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 3-36

Chapter 4

Completing ProcessLogix Install on a Redundant Server Pair

and Adding Redundancy to R320.0

Non-Redundant Server Systems . . . . . . . . . . . . . . . . . . . . 4-1

Changing Hosts File Entries . . . . . . . . . . . . . . . . . . . . . . 4-1

Changing TCP/IP address on a Secondary

Server (SERVERB) Node . . . . . . . . . . . . . . . . . . . . . . . 4-4

Changing the Computer Name. . . . . . . . . . . . . . . . . . . . 4-5

Updating the Registry . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Changing the ProcessLogix License . . . . . . . . . . . . . . . . 4-6

Re-installing ProcessLogix Engineering Tools . . . . . . . . . 4-6

Configuring RSLinx Drivers for ControlNet

Supervisory Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Installing the 1784-PCIC Driver . . . . . . . . . . . . . . . . . . . 4-9

Updating the 1784-PCIC Card Firmware . . . . . . . . . . . . 4-10

Configuring the ControlNet Supervisory Network . . . . . 4-10

Updating the 1784-PCIC Network Address . . . . . . . . . . 4-11

Configuring RSLinx Drivers for Ethernet

Supervisory Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Restarting Redundant Servers . . . . . . . . . . . . . . . . . . . . . . 4-13

Setting up Secondary Server (SERVERB) node . . . . . . . . . . 4-13

Setting Up Primary Server (SERVERA) Node. . . . . . . . . . . . 4-19

Upgrading Hardware Component Firmware. . . . . . . . . . . . 4-20

Publication 1757-IN032B-EN-P - April 2001

Page 10

Table of Contents vi

Making Post ProcessLogix Software Installation

Checks for a Redundant Server Pair. . . . . . . . . . . . . . . . 4-20

Synchronizing ERDB on Redundant Servers . . . . . . . . . 4-20

Synchronizing Server Databases on Redundant Servers. 4-20

Synchronizing Other Files . . . . . . . . . . . . . . . . . . . . . . 4-21

Checking Control Builder Operation and Logging On. . 4-21

Enabling the ProcessLogix OPC Server. . . . . . . . . . . . . 4-21

Backing Up a ProcessLogix Server to Tape. . . . . . . . . . 4-21

Creating an Emergency Repair Disk . . . . . . . . . . . . . . . 4-21

Chapter 5

Launching ProcessLogix Knowledge Builder . . . . . . . . . . . . 5-1

Cancelling a Software Component Installation . . . . . . . . . . . 5-1

Removing ProcessLogix Software Components . . . . . . . . . . 5-1

Uninstalling ProcessLogix Knowledge Builder Software . 5-2

Removing the ProcessLogix Server. . . . . . . . . . . . . . . . . 5-2

Removing ProcessLogix Client Software . . . . . . . . . . . . . 5-3

Removing Engineering Tools. . . . . . . . . . . . . . . . . . . . . 5-3

Removing RSLinx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Upgrading an Engineering Database to R320.0. . . . . . . . . . . 5-7

Recovering from Failure of an Automatic

ER Database Migration . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Manual System Backup/Restore Procedures. . . . . . . . . . . . 5-10

Backing Up a ProcessLogix Server to Tape. . . . . . . . . . 5-10

Restoring a ProcessLogix Server System

From a Backup Tape . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Using Network Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

About Network Tools . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Usage guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Online help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Making First Time Network Tools Settings . . . . . . . . . . 5-15

Installing and Running VirusScan with ProcessLogix . . . . . 5-20

About VirusScan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Removing Existing VirusScan NT Program . . . . . . . . . . 5-20

Installing VirusScan NT and Configuring Directories

for Scan Exclusion . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Changing the Computer Name . . . . . . . . . . . . . . . . . . . . . 5-22

Procedure for Configuring a Non-redundant Server . . . 5-22

Procedure for Configuring a ProcessLogix Client . . . . . 5-23

Adding 1757-PLX52 Controller Redundancy to R320.0

Non-Redundant 1757-PLX52 Controller Configurations . . 5-23

Deleting a Non-Redundant 1757-PLX52

and Unassigning its Contents . . . . . . . . . . . . . . . . . . 5-23

Installing and connecting Redundant Chassis

Pair (RCP) hardware . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Checking firmware revision levels . . . . . . . . . . . . . . . . 5-26

Publication 1757-I N0 32B-EN-P - April 2001

Page 11

Table of Contents vii

Creating a Redundant 1757-PLX52 . . . . . . . . . . . . . . . . 5-26

Setting Up User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Creating the plx_user Account . . . . . . . . . . . . . . . . . . . 5-27

Setting up erserver and/or mngr user accounts. . . . . . . 5-28

Setting Up User Accounts to Logon as a Service . . . . . . 5-28

Setting up mngr Account on a ProcessLogix Server

to Logon as a Batch Job . . . . . . . . . . . . . . . . . . . . . . 5-29

Chapter 6

ProcessLogix System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Ethernet Supervisory Network . . . . . . . . . . . . . . . . . . . . 6-1

CCL Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Controller & I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Expanded ControlNet Interoperability . . . . . . . . . . . . . . 6-2

1794 FLEX I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Common SCM’s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

10 1757-PLX52s per Server. . . . . . . . . . . . . . . . . . . . . . . 6-3

1784-PCIC Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Control Builder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Chart Visualization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Printing Enhancements . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Data Base Import/Export. . . . . . . . . . . . . . . . . . . . . . . . 6-5

CB Change Journaling . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Engineering Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Network Diagnostic Manager. . . . . . . . . . . . . . . . . . . . . 6-6

Interrupt Usage Note. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

20 Stations per Server (NT Server) . . . . . . . . . . . . . . . . . 6-8

FSC (Fail Safe Controller) Ethernet . . . . . . . . . . . . . . . . . 6-9

Support for Windows NT v4.0 Service Pack 6a . . . . . . . . 6-9

Support for Internet Explorer v5.01 . . . . . . . . . . . . . . . . 6-9

New Station and Display Builder . . . . . . . . . . . . . . . . . . 6-9

New Quick Builder . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Bristol Babcock OpenBSI Interface. . . . . . . . . . . . . . . . 6-11

Additional Modicon Data Formats . . . . . . . . . . . . . . . . 6-11

Modbus Plus SA85 Adapter Selectable for a Channel. . . 6-12

Support for Siemens S5 TF Driver v5.2 . . . . . . . . . . . . . 6-14

Support for the 1784-PCIC card

on Allen-Bradley SCADA channels . . . . . . . . . . . . . . 6-14

Support for Redundant PLC-5 Controllers on ControlNet 6-15

Improved Industrial Shape Files. . . . . . . . . . . . . . . . . . 6-18

Alarm Pager support for UCP Protocols . . . . . . . . . . . . 6-19

Optional Failover of Redundant Servers On Process

Controller Communications Subsystem Failure. . . . . . 6-19

Station Object Model Extensions . . . . . . . . . . . . . . . . . 6-20

RSLinx 2.2 Service Pack 1 . . . . . . . . . . . . . . . . . . . . . . 6-20

New Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Publication 1757-IN032B-EN-P - April 2001

Page 12

Table of Contents viii

Chapter 7

PC/NT Platform Requirements . . . . . . . . . . . . . . . . . . . . . . 7-1

Server Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Platform System Configuration Definitions . . . . . . . . . . . 7-2

User Interface Capacity and Performance . . . . . . . . . . . . . . 7-9

Control Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Server Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Server Notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Communications Capacity and Performance . . . . . . . . . . . 7-11

Controller Communications . . . . . . . . . . . . . . . . . . . . . 7-11

Client/Server Communication Capacity. . . . . . . . . . . . . 7-12

Controller Notifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Controller Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

I/O Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Input Module Sample Periods . . . . . . . . . . . . . . . . . . . 7-15

Output Module Sample Periods . . . . . . . . . . . . . . . . . . 7-15

I/O Network Configuration Rules . . . . . . . . . . . . . . . . 7-16

1757-PLX52 Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Engineering Tools Resources. . . . . . . . . . . . . . . . . . . . 7-20

Chapter 8

Major ProcessLogix FTW Software Revisions . . . . . . . . . 8-1

Major ProcessLogix Server Software Revisions . . . . . . . . 8-2

Embedded Software Components . . . . . . . . . . . . . . . . . 8-3

External, Third Party Qualified Software Components. . . 8-5

Miscellaneous SCADA Component Revisions . . . . . . . . . 8-7

Controller/Communication/I/O Firmware. . . . . . . . . . . . 8-7

Publication 1757-I N0 32B-EN-P - April 2001

Page 13

Preface

Our Assumptions About Readers

We assume that you are familiar with navigating and running

applications in a Microsoft Windows NT environment. Y ou have some

experience in loading software applications on a personal computer

and are somewhat familiar with ProcessLogix hardware components

as well as the Control Builder application. If you have no software

loading experience and are not familiar with ProcessLogix hardware

components and Control Builder, we recommend that you find

someone who does have experience to assist you in loading the

ProcessLogix software and making hardware and firmware changes in

associated ProcessLogix hardware components.

Starting Conditions and Assumptions

You have the following items on hand:

• ProcessLogix R320.0 Software Ch ange Not e is now incorporated

into the Installation and Upgrade Guide. Refer to Chapters 5, 6,

and 7 in this publication.

• ProcessLogix R320.0 compact disc (CD) containing all

ProcessLogix software components

• ProcessLogix R320.0 Kno wledge Builder CD containing the lat est

version of the online documentation

• Windows NT 4.0 Workstation CD (Microsoft CD, including boot

diskettes)

• RSLinx OEM Master (Activation) Disk

• Your PC meets the minimum hardware requirements for a

ProcessLogix Server or ProcessLogix Client.

1 Publication 1757-IN032B-EN-P - April 2001

Page 14

Preface 2

Minimum Hardware Requirements

ProcessLogix Server Software must be installed on a PC that is

specifically qualified. Use of any other PC variations will render the

standard warranty and support agreement null and void .

IMPORTANT

End users purchasing ProcessLogix 1757-PLXSYS KIT

are not eligible for the standard 90 day technical

support, unless the software is installed by personnel

trained specifically for ProcessLogix installation.

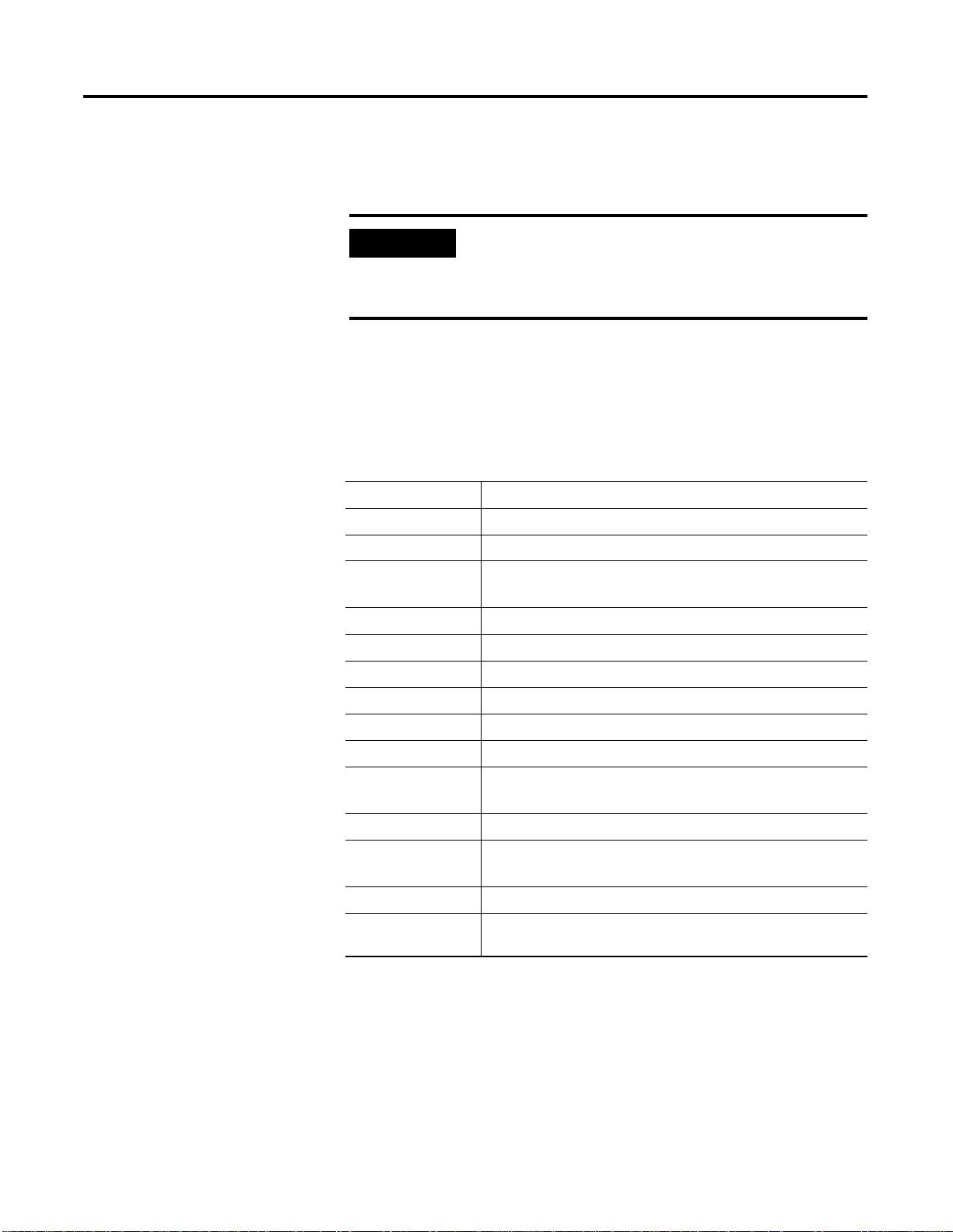

Please refer to the table below to review the hardware requirements

for a new R320.0 ProcessLogix server or client system. ProcessLogix

Clients require a Windows NT operating system to support the

multiple-user configuration nodes architecture that is possible with

R320.0 ProcessLogix systems See Table 7.C on page 7-4 for minimum

hardware requirements for upgrading an existing system to R320.0.

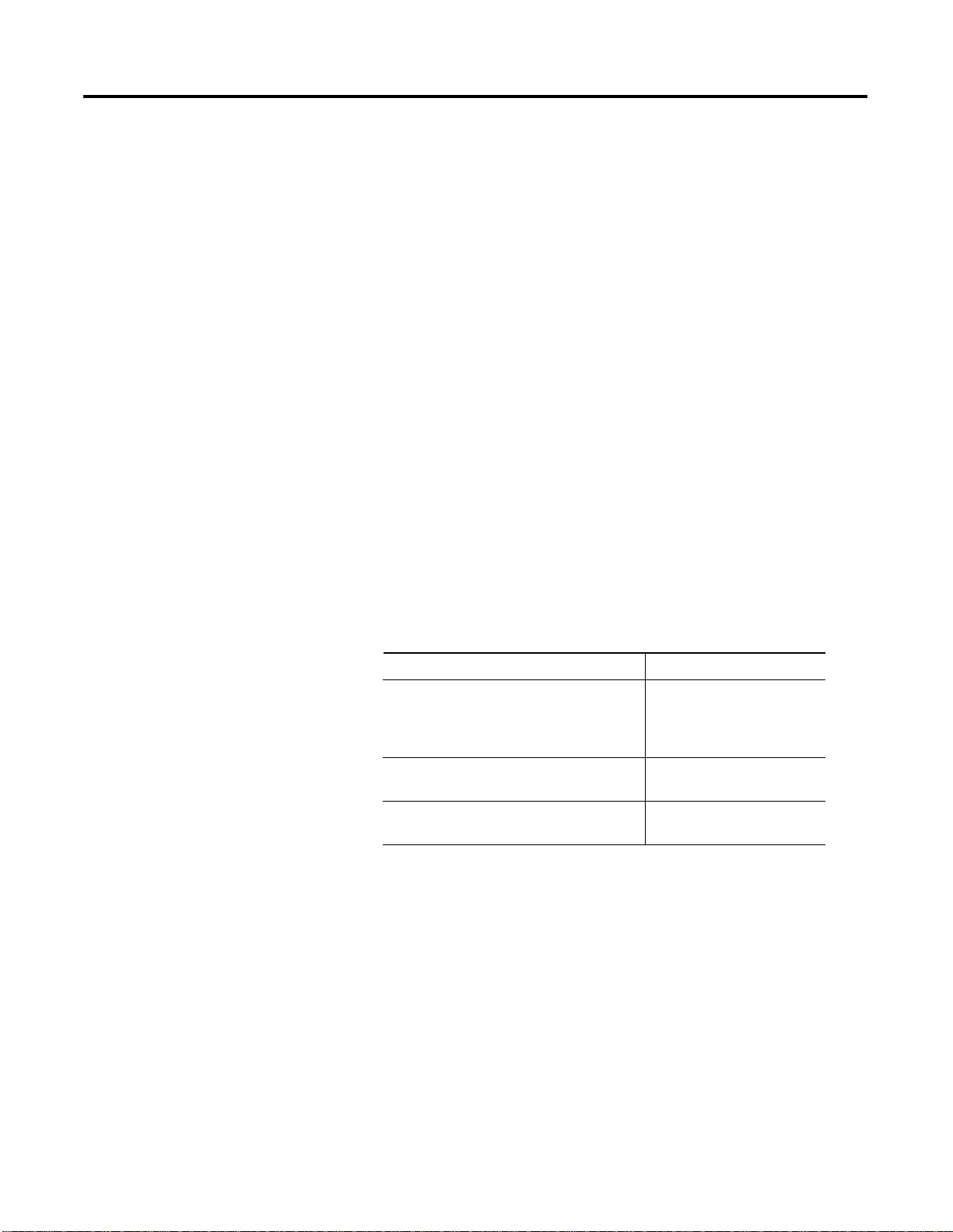

Component Description

Base Dell OptiPlex GX200

Processor 800Mhz,Pentium III, 133Mhz Front Side Bus

Integrated Functions 4X AGP Video w/8MB of Memory

Audio, 512KB Cache 10/100 NIC

Mouse Microsoft Intellimouse

Keyboard Quietkey Spacesaver 104-Key, US

System RAM 256MB, ECC PC700, 1 RIMM

CD-ROM 40X SCSI

Floppy Drive 1.44MB, 3.5"

SCSI Controller Adaptec 29160N Controller

Hard Drive 9.1GB Minimum U2W, 10,000 RPM, SCSI

GX1/M, w/T erm inated Cabl e

Tape Drive 10/20 G, SCSI, TR-5, Tape Backup Unit

Network Integrated 3COM

3C90SC with 1 RJ45 connector

I/O Expansion 5 PCI, 2 ISA/PCI shared slots

Software Microsoft Windows NT4.0 (Service Pack 6a), NTFS

All hardware component drivers

Publication 1757-IN032B-EN-P - April 2001

Page 15

Preface 3

Rockwell Automation Technical Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized

systems integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

first call your local Rockwell Auto mation representative, then:

• Network Pre-sales Hotline, 440.646.3638 (3NET)

• Post-sales Technical Support, 440.646.5800

• Web Links

http://www.ab.com — as a registered member, open to

http://www.ab.com/mem/technotes/techmain.html

Your Questions or Comments about This Manual

If you find a problem or have a comment about this manual, please

notify us of it on the enclosed Publication Problem Report (at the back

of this manual).

If you have any suggestions about how we can make this manual

more useful to you, please contact us at the following address:

Rockwell Automation, Allen-Bradley Company, Inc.

Control and Information Group

Technical Communication

1 Allen-Bradley Drive

Mayfield Heights, OH 44124-6118

Publication 1757-IN032B-EN-P - April 2001

Page 16

Preface 4

Conventions

Term s and Type Representations

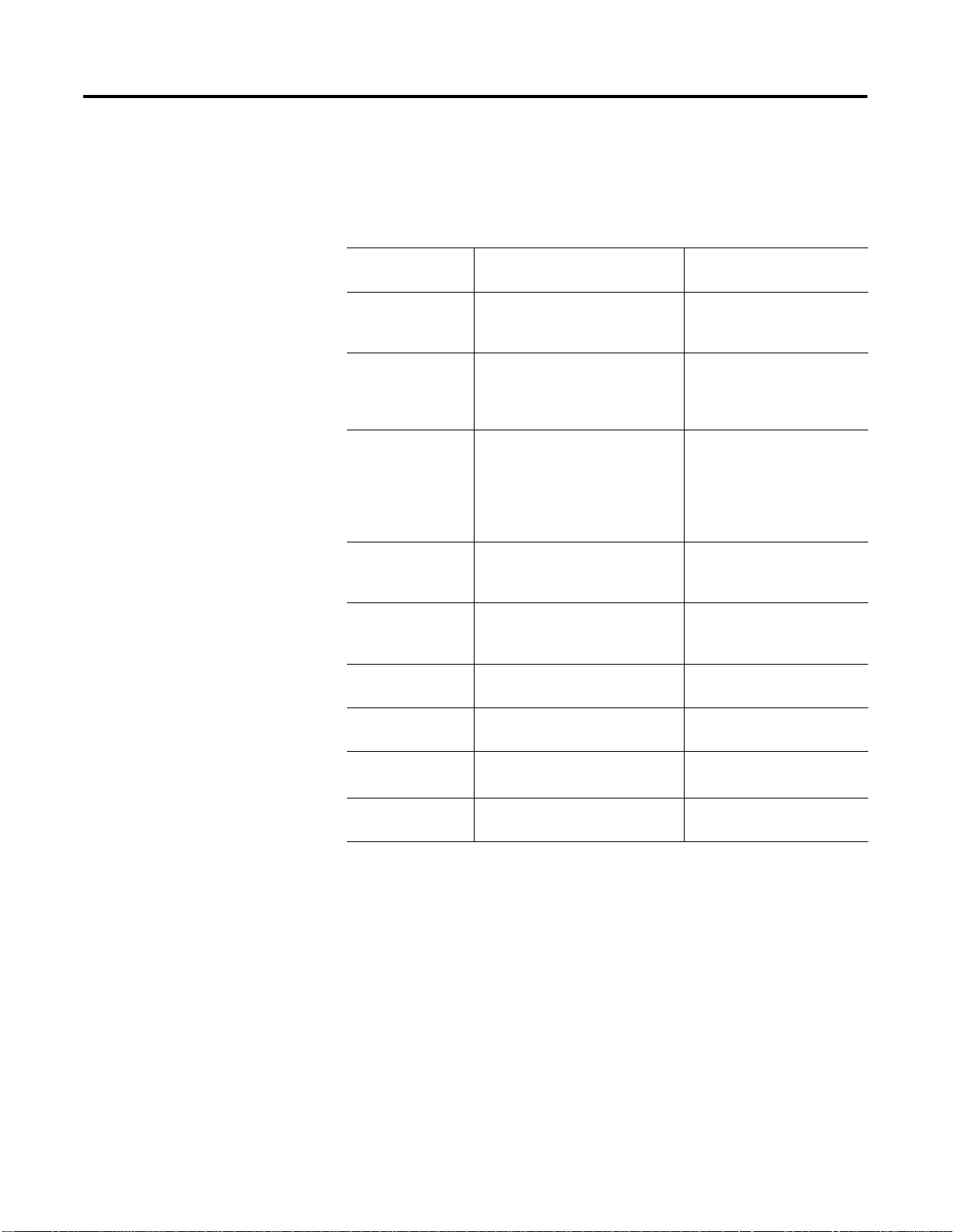

The following table summarizes the terms and type representation

conventions used in this Guide.

Term/Type

Representation

click, click on, click

[button name]

double-click Click left mouse button twice in

drag Press and hold left mouse button

right-click Click right mouse button once.

select click to highlight a menu item or

<F1> Keys to be pressed are shown in

Meaning Example

Click left mouse button once.

(Assumes cursor is positioned on

object or selection.)

quick succession. (Assumes cursor

is positioned on object or

selection.)

while dragging cursor to new

screen location and then release

the button. (Assumes cursor is

positioned on object or selection to

be moved.)

(Assumes cursor is positioned on

object or selection.)

list choice, or click on a button.

angle brackets.

Click Browse.

Double-click the Station icon.

Drag the PID function block

onto the Control Drawing.

Right-click the AND function

block.

Select Configure

Allen-Bradley drivers from the

list box.

Press <F1> to view the online

Help.

<Ctrl>+<C> Keys to be pressed together are

shown with a plus sign.

⇒New

File

>D:\setup.exe< Data to be keyed in at prompt or in

Shows menu selection as menu

name followed by menu selection.

an entry field.

Press <Ctrl>+<C> to close the

window.

Click File⇒New to start new

drawing.

Key in this path location

>D:\setup.exe<.

Publication 1757-IN032B-EN-P - April 2001

Page 17

Preface 5

Related Documents

The following is a list of the printed documents that ship with a

ProcessLogix system. These documents complement the Knowledge

Builder online user documentation and are listed in the suggested reading

order.

ProcessLogix R320.0 Installation and Upgrade Guide

The ProcessLogix R320.0 Installation and Upgrade Guide provides:

• procedures for upgrading a system to R320.0

• procedures for updating the firmware to R320.0 levels

• procedures for installing the software on a clean personal

computer

• procedures for tasks associated with migrating to redundant

Server and/or redundant Controller architecture.

The following items used to be included in the SCN Software Change

Notice in previous releases:

• descriptions of new features and functions

• descriptions of performance and capacity specifications

• listings of major ProcessLogix software components

Publication 1757-IN032B-EN-P - April 2001

Page 18

Preface 6

ProcessLogix Online User Documentation/Knowledge Builder

ProcessLogix online user documen tati on is included with yo ur

ProcessLogix system in browser format through the Knowledge

Builder. The same documents may also be ordered individually

through Rockwell Automation in print format.

Knowledge Builder provides the user with task-based documentation

within the Server and Client stations and may be accessed while using

any of ProcessLogix’s software programs. Knowledge Builder’s internal

links and search functions allow the user to quickly access process

relevant information and references.

References to Knowledge Builder throughout this document are

illustrated as:

Navigate in Knowledge Builder to Ethernet Implementation

⇒Configuration⇒Setting Up Drivers and IP Addresses for more

Guide

information.

Contents of Release

The following software and documentation components are included

in the ProcessLogix R320.0 Software/documentation kit

(1757-SWKIT3200).

Release Component s Catalog and part numbers

ProcessLogix CD

ProcessLogix Engineering Tools

ProcessLogix Server Software

RSLinx 2.2

ProcessLogix Knowledge Builder CD 1757-SWKIT3200

ProcessLogix R320.0 Installation and

Upgrade Guide

1757-SWKIT3200

957445-88

957536-40

1757-IN032B-EN-P

957536-31

Publication 1757-IN032B-EN-P - April 2001

Page 19

Acronyms and Abbreviations

AI —

AO

— Analog Output

CB

— Control Builder

CCL — Control Component Library

CD

— Compact Disc

CDA

CD-ROM

CEE

CM

— Control Module

1756-CNB or CNB

CPM

CPU

DI

— Digital Input

Analog Input

— Control Data Access

— Compact Disc Read Only Memory

— Control Execution Environment

— ControlNet Bridge module

— Control Processor Module

— Central Processing Unit

LAN

— Local Area Network

LED

— Light Emitting Diode

MAC

— Media Access Control

MB

— Megabytes

NTFS

— Windows NT File System

NUT

— Network Update Time

NTFS

— Windows NT File System

NUT

— Network Update Time

ODBC

— Open Database Communications

OEM

— Original Equipment Manufacturer

PC

— Personal Computer

1784-PCIC or PCIC

1757-PIM

— Pulse Input Module

— PCI ControlNet Interface Module

Preface 7

DNS

— Domain Name System

DO

— Digital Output

DOS

— Disk Operating System

ER

— Engineering Repository

ERDB

— Engineering Repository Database

FB

— Function Block

FSC

— Fail Safe Controller

HTML

— HyperText Markup Language

I/O

— Input/Output

IOM

— Input/Output Module

IRQ

— Interrupt Request

ISA

— Industry-Standard Architecture

PLC

— Programmable Logic Controller

RAM

— Random Access Memory

RCP

— Redundant Chassis Pair

RTU

— Remote Terminal Unit

SCADA

— Supervisory Control and Data Access

SCM

— Sequential Control Module

SCSI

— Small Computer System Interface

1757-SRM or SRM

TC-MUX01

TCP/IP

— Transmission Control Protocol/Internet Protocol

VGA

— Video Graphics Array

WINS

— Windows Internet Name Service

— System Redundancy Module

— Serial Interface Module

Publication 1757-IN032B-EN-P - April 2001

Page 20

Preface 8

Publication 1757-IN032B-EN-P - April 2001

Page 21

Preparing for a ProcessLogix Software Upgrade

Chapter

System Software Upgrade Procedures

ATTENTION

This section assumes that you are currently running

ProcessLogix software version R300.1 or 310.0 and

Service Pack 5 for Windows NT 4.0. The tasks

associated with upgrading from an earlier release are

beyond the scope of this docu ment.

!

If you are migrating a system from R300.0 or earlier,

you must upgrade to R300.1 or R310.0 before

proceeding with the R320.0 upgrade.

Refer to the documentation supplied with R300 .1 or

R310.0 ProcessLogix software for instructions on

upgrading from an earlier release to R300.1 or R310.0.

1

• Refer to Installing ProcessLogix Client Software on page 1-73 to

upgrade the Client software on a networked ProcessLogix

Client system.

• Refer to Full PC Software Installation Procedures on page 3-1 to

install ProcessLogix software on a clean PC.

Things to consider before upgrading

ATTENTION

Be certain that your process is off control before you

begin any upgrade procedure. This means the

1757-PLX52 should be in the Idle state.

!

ATTENTION

Before upgrading to this release, be certain that the

ProcessLogix user accounts exist and are set up

correctly. Refer to Setting Up User Accounts on

page 5-27.

!

1 Publication 1757-I N0 32B-EN-P - April 2001

Page 22

1-2 System Software Upgrade Procedures

The following table summarizes some upgrade related functions that you

should consider before upgrading the existing system to R320.0.

Consider this: Because:

New license with

R320.0 ProcessLogix

software

Localization • The localization of an existing system is lost during an

Save Controller Data • This updates the database with current Controller data.

Back Up R300.0 Server

Data

• Your existing R300.1 or 310.0 license will not work with

R320.0.

• Be certain that you have the R320.0 license numbers on

hand before starting the software installation.

upgrade.

• Before starting an upgrade, be certain that you have the

localization toolkit in your language for R320.0.

• Remove the current localization update using the Control

Panel Add/Remove Programs function.

• Select R200 Language Update to change the language for

the Control Builder application back to the default of US

English.

• This is recommended if you plan to make a backup of your

current database.

• Refer to Saving Current Controller Data (optional) on

page 1-3.

• This provides a path for recovering your current system as a

standard precaution.

• Refer to Installing Service Pack 6a for Windows NT 4.0 on

page 1-11.

Have at least 400MB

of Free Disk Space

• This allows sufficient disk space to automatically backup

selected system data during the installation process.

• Refer to Determining Your Hard Drive Free Space

Requirements on page 1-4.

Publication 1757-IN032B-EN-P - April 2001

Page 23

System Software Upgrade Pr ocedures 1-3

Saving Current Controller Data (optional)

IMPORTANT

While not required, we suggest that you use this procedure to update the

ERDB with the most current Controller data before the upgrade. This

procedure assumes that the Control Builder (CB) application is running

and communicating with 1757-P LX52 Controllers in your ProcessLogix

system.

1. If Control Builder isn’t running, start it.

2. Close any open Control Module and/or Sequential Control

Module.

3. For a system with redundant ProcessLogix Servers, be certain that

the databases are synchronized. Refer to Synchronizing ERDB

on Redundant Servers on page 1-63.

4. In Monitoring tab, click the plus s ign in the t ree root path t o the

CPM icon for the controller to display the CEE fo lder icon.

5. Click the CEE folder icon. Click Tools

and then click Continue to upload the existing controller database.

This may take considerable time to complete, depending on the

amount of CM/SCMs (and their number of FBs and/or number of

Steps/Transitions) currently assigned to this CEE.

If you have redundant Servers, you only need to

perform this procedure on the SERVERB node.

⇒Upload with Contents

6. Click the CEE folder icon. Click Tools

Project) and then click Continue to save the existing controller

database.

This may take considerable time to complete, depending on the

amount of CM/SCMs (and their number of FBs and/or number of

Steps/Transitions) currently assigned to this CEE.

7. Repeat Step 4 to Step 6 for each controller (CPM icon) in your

system.

8. In preparation for the software upgrade, inactivate the CMs, SCMs,

and IOMs, and put the CEE in its Idle mode.

9. Close Control Builder.

⇒Update with Contents (to

Publication 1757-IN032B-EN-P - April 2001

Page 24

1-4 System Software Upgrade Procedures

TIP

W e recommend that you make a backup copy of your

erdb_a.mdb database after you save th e curr en t

controller data. The default direct ory location for the

erdb_a.mdb database is:

C:\Honeywell\TPS50\System\ER.

W e recommend that you create a new folder in the C:

directory for this purpose and then rename the database

after it is copied to the folder.

For example, you could name the folder erbackup and

rename the file erdb_a_bu.mdb to readily identify this

as the backup database copy.

Determining Your Hard Drive Free Space Requirements

A base requirement for ProcessLogix software releases is that they fit on

older PCs having 4 GB hard drives. This means that the R320.0 rele ase

needs to fit within a 4 GB partition, regardless of the overall size of the

hard drive. For example, if your PC has an 8 GB hard drive partitioned

into two 4 GB partitions, then all ProcessLogix applications and the

entire operating system (the swap file, Service Pack 6a, etc.) will reside on

the C: partition, while the other partition will be empty.

This means you must provide sufficient space on the C: partition before

you begin an upgrade, or the upgrade will fail at several points due to

insufficient disk space. The software installation routine requires

additional disk space to automatically back up selected system data during

the installation process.

ATTENTION

We recommend that you have free space equal to at

least 1.5 times the size of your C:\Honeywel l directory

and its subdirectories (minimum of 400 MB) before you

begin an upg rade.

!

Use the following steps to compute the minimum free space requirements

for your PC.

1. Open Windows NT Explorer.

2. Right-click the C:\Honeywell folder in the left pane and click

Properties. W ait until the Size number stops updating.

Publication 1757-IN032B-EN-P - April 2001

Page 25

System Software Upgrade Pr ocedures 1-5

3. Take this number and multiply it by 1.5 to find your free space

requirements. If the result is le ss than 400 MB, make the result 400

MB. Click Cance l to clos e th e H one y we l l Properties dialog box .

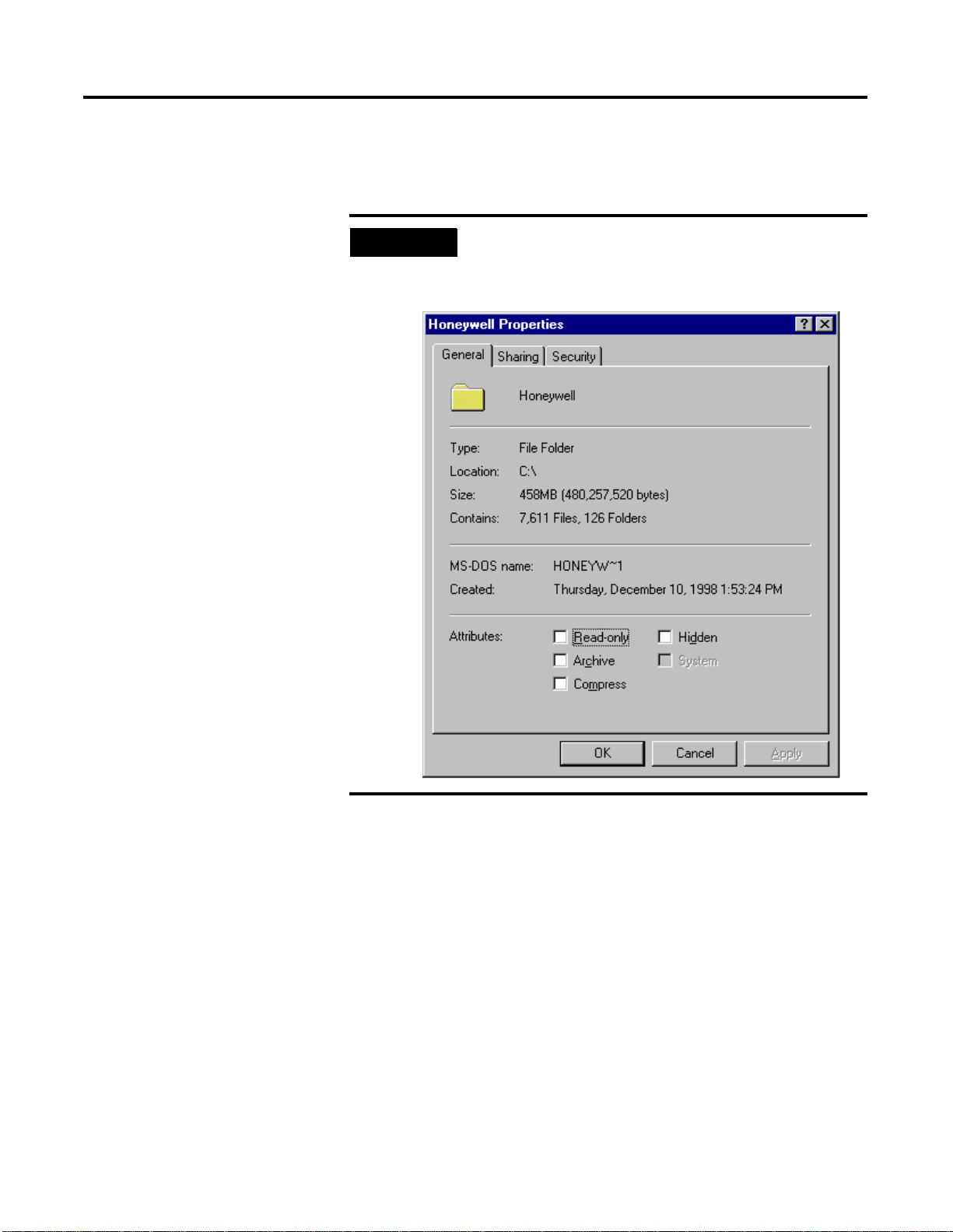

EXAMPLE

In the following example, the C:\Honeywell tree size is

458 MB. Multiplying 458 MB by 1.5 results in 687 MB.

This means you would need at least 687 MB of free disk

space before beginning your upgrade.

4. In Windows NT Explorer, right-click the (C:) drive icon in the left

pane and click properties. Check the free space size listed for the C

drive in the open dialog box. Click Cancel to close the dialog box.

If there is not enough free disk space, refer to the following

paragraph for suggestions on how to increase it.

Publication 1757-IN032B-EN-P - April 2001

Page 26

1-6 System Software Upgrade Procedures

What should you do if you do not meet the recommended

memory requirements:

If you do not me et the minimum free disk space requirement, you

can try one or more of the follow ing actions to increase your free

disk space:

• Compact the ERD B ( Use the Db Adm i n uti lit y :

⇒Programs⇒ProcessLogix Engineering Tools⇒

Start

DBADMIN

• Remove old error logs in directory C:\ErrorHandling,

• Remove old backups you have of the ERDB.

• Remove the Service Pack Uninstall directory C:\WINNT\

$NtServicePackUninstall$.

• Move any of your application files not residing in the

C:\Honeywell tree to the oth er partition, if you have another

partition.

⇒Tools⇒Compact Database.)

Backing Up a P r ocessLogix Server to Tape

Use the following procedure to back up your current ProcessLogix

Server data to tape.

1. If the Server to be backed up is a member of a redundant Server

pair, synchronize the ER and Server databases.

a. Refer to Synchronizing ERDB on Redundant Servers on

page 1-63.

b. Refer to Synchronizing Server Databases on Redundant

Servers on page 1-71.

ATTENTION

!

2. Insert a tape into the PC’s tape drive.

Before continuing, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

Publication 1757-IN032B-EN-P - April 2001

Wait for the tape to mount (stop making noise).

3. Click Start

⇒Run.

Page 27

System Software Upgrade Pr ocedures 1-7

4. Key in this command in the Open entry field:

>cmd<

and click OK to open the DOS window.

5. At the DOS prompt, key in this command:

>fullbkup<

and press >Enter<

This initiates some file copying and then the backup dialog box

appears. No further interaction is needed until the backup

completes. This process may take considerable ti me to complete,

depending on the Server.

TIP

For more information on backup procedures, refer

to the Windows documentation and/or online help

that accompanied your system.

TIP

You may see errors such as: “file xxx skipped”.

These errors are normal and will not affect the

validity of your backup tape.

6. When the backup completes, remove the backup tape from the tape

drive.

7. Exit the DOS window.

Publication 1757-IN032B-EN-P - April 2001

Page 28

1-8 System Software Upgrade Procedures

Stopping ProcessLogix Applications and Services

ATTENTION

Before installing or uninstalling any software

component, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

!

IMPORTANT

Use the following procedure to exit all ProcessLogix applications and

stop all ProcessLogix services.

1. Exit all running ProcessLogix applications, such as Control Builder,

Station, and Network Tools (NTOOLS).

2. Stop the following ProcessLogix services through the Services icon

in Control Panel. When finished, close the Services dialog box.

TIP

• ProcessLogix ER Replicator (redundant SERVERB node only)

• ProcessLogix ER Server

• ProcessLogix System Repository

• ProcessLogix Control Data Access Server

If you have redundant servers, you must complete this

procedure on the SERVERB node first. Then complete

the entire procedure again for the SERVERA node.

Some software services may interact. For example,

stopping the ProcessLogix System Repository

automatically stops the ProcessLogix Control Data

Access Server, if it is running.

Observe the on-screen prompts for details.

Publication 1757-IN032B-EN-P - April 2001

Page 29

System Software Upgrade Pr ocedures 1-9

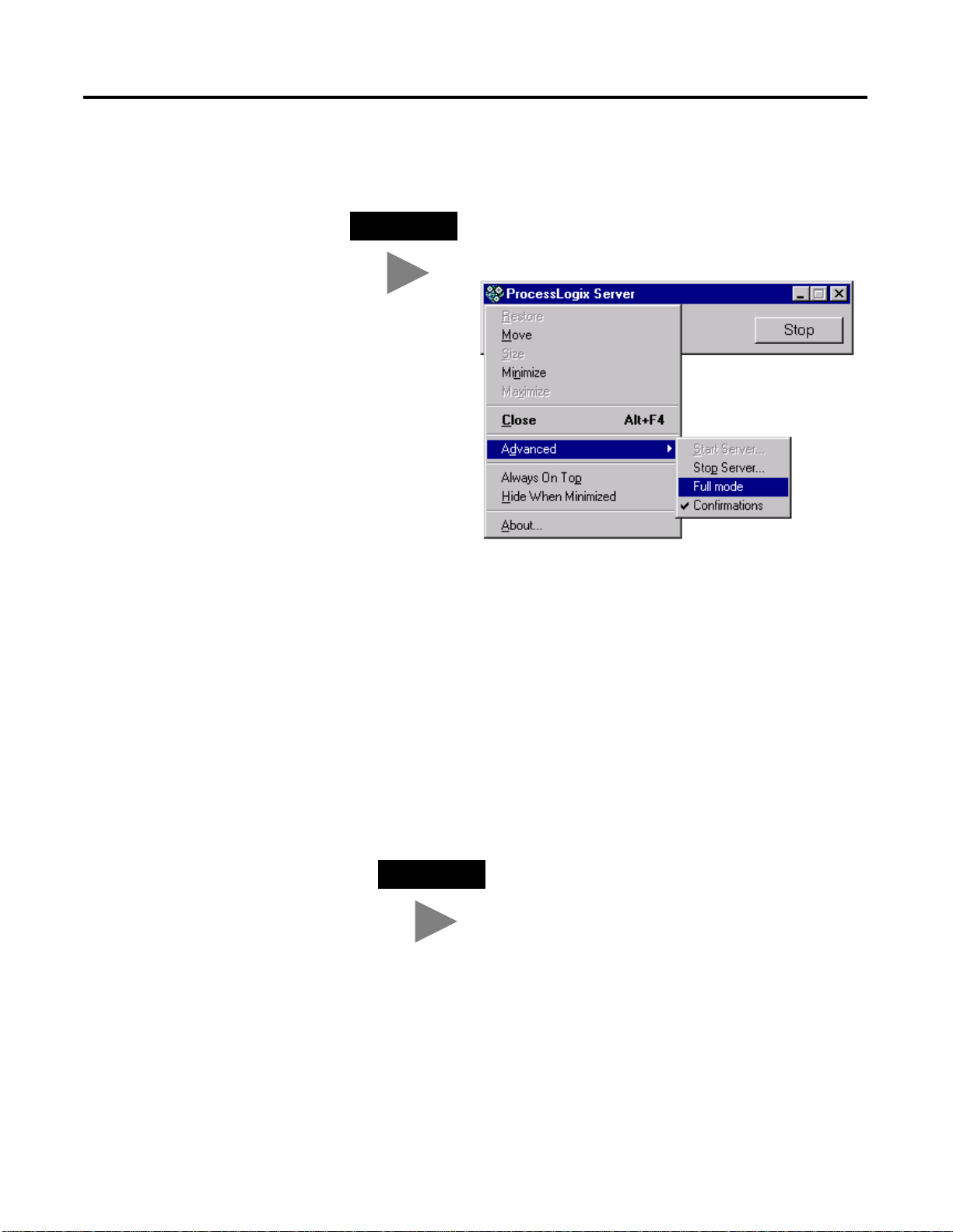

3. Click Start⇒Programs⇒ProcessLogix Server⇒Start-Stop

ProcessLogix Server to call up the ProcessLogix Server dialog box.

TIP

To display the “Full Mode” version of the ProcessLogix

Server dialog box, click the icon on the left of the title

bar and click Advanced

⇒Full Mode.

A checkmark will now appear in front of the Full

Mode selection to show that it is active.

a. With the Full Mode version of the dial og box act ive, cl ick the

Database Unloaded option.

b. Click Yes to confirm the action and wait for the Server to

change its state.

c. Close the ProcessLogix Server dialog box.

4. Click Start

⇒Programs⇒Rockw e ll Software⇒RSLinx⇒RSLinx

Service Control Panel to call up the RSLinx Service Control dialog

box.

a. Click Stop.

TIP

The ProcessLogix Control Data Acces s Server

service must be stopped before you can stop

RSLinx through its control panel.

Publication 1757-IN032B-EN-P - April 2001

Page 30

1-10 System Software Upgrade Procedures

b. Wait for the message RSLinx Service is not running to appear.

Close the dialog box.

5. Skip to Step 9 if NI-FBUS is not running. Otherwise, close the

NI-FBUS configurator.

6. Wait until the FCS shutdown window disappears before

proceeding.

7. Right-click the NI-FBUS 2.3 icon in the taskbar and select Open.

8. Close the NI-FBUS window and click Yes to confirm.

9. Right-click an open space in the taskbar and click Task Manager to

open the Windows NT Task Manager window.

10. Click the Processes tab, scroll through the list box and select any

process with the Image Name of EXCEL.EXE.

11. Click End Process.

12. Close Task Manager.

Stopping the 1784-PCIC(S) devices

After you have installed the 1784-PCIC card and installed the

ProcessLogix R320.0 sof tware, use the foll owing procedure to st op the

PCIC(S) devices.

13. Click Start

14. Double-click the Devices icon.

⇒Settings⇒Control Panel.

Publication 1757-IN032B-EN-P - April 2001

15. Select the A-B Virtual Backplane device driver.

16. Click Stop.

17. Click OK to also stop the A-B 1784-PCIC(S) device driver.

18. Close the Devices dialog box.

Page 31

Installing Service Pack 6a for Windows NT 4.0

System Software Upgrade Procedur es 1-11

IMPORTANT

For your convenience, we have included Service Pack 6a for Windows

NT 4.0 on the ProcessLogix R320.0 software CD. This is also avail able as

a free download from the Microsoft we b site

(www.microsoft.com/downloads/search.asp?)

Use the following procedure to install Service Pack 6a.

Y our system should be running Service Pack 6a. If it is

not running Service Pack 6a, follow this procedure to

install it.

.

ATTENTION

!

1. Insert the ProcessLogix R320.0 software CD into the CD-ROM

drive.

2. Click Start

3. Key in this path location in the Op en entry field or use Bro wse to

navigate to the sp 6i 3 86. e x e fil e on the CD .

>D: (or your CD-ROM drive letter)\nt_sp6a\sp6i386.exe<

4. Click OK to launch the Service Pack 6a setup application.

5. If a third-party system utilities message appears, click OK.

6. At the Setup window, check the boxes:

• Accept the License Agreement

• Backup files necessary to uninstall the Service Pack at a later

time.

Before installing or uninstalling any software

component, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

⇒Run.

7. Click Install to initiate the Service Pack 6a update.

8. If a window appears requesting you to replace a vendor installed

file, click Yes to replace the file with the one provided by the

Service Pack Setup.

9. At the Setup complete window, remove the CD and then click

Restart. The PC automatically restarts.

Publication 1757-IN032B-EN-P - April 2001

Page 32

1-12 System Software Upgrade Procedures

Installing Internet Explorer 5.01

ATTENTION

!

For your convenience, we have included Internet Explor er 5.01 on the

ProcessLogix R320.0 software CD. Use the following procedure to install

Internet Explorer 5.01 on a PC with Windows NT.

If installing on a PC with Windows 95 or 98, complete Steps 1 through

4 and then follow on-screen prompts. If you need help, call Rockwell

Automation Technical Support. Refer to Rockwell Automation

Technical Support in the Preface.

Before installing or uninstalling any software

component, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

1. Insert the ProcessLogix R320.0 software CD into the CD-ROM

drive.

2. Click Start

3. Key in this path location in the Op en entry field or use Bro wse to

navigate to the ie5setup.exe file on the CD.

>D: (or your CD-ROM drive letter)\IEXP_5_0_1\ie5setup.exe<

4. Click OK to launch Internet Explorer setup.

5. Accept the license agreement and click Next.

6. Select the Install Now-Typical option and click Next.

7. When installation completes, click Finish.

The PC automatically restarts.

8. Remo v e th e CD.

⇒Run.

Publication 1757-IN032B-EN-P - April 2001

Page 33

Upgrading Data Access Components

System Software Upgrade Procedur es 1-13

ATTENTION

!

For your convenience, we have included MDAC 2.1 on the

ProcessLogix R320.0 software CD. Use the following procedure to

install MDAC 2.1 on the PC.

1. Insert the ProcessLogix R320.0 software CD into the CD-ROM

drive.

Before installing or uninstalling any software

component, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

2. Click Start

3. Key in this path location in the Open entry field or use Browse

to navigate to the mdac_typ.exe file on the CD.

>D: (or your CD-ROM drive letter)\Mdac21\Mdac_typ.exe<

4. Click OK to launch the MDAC 2.1 setup.

5. Click Yes to accept the license agreement.

6. Click Continue.

7. At the MDAC 2.1 Setup window, click to start the

installation.

8. At the Restart Windows dialog box, remove the CD and click

Restart Windows for the changes to take effect.

If you don’t get a Restart Windows dialog box, click OK, remove

the CD and manually restart the PC for changes to take effect.

⇒Run.

Publication 1757-IN032B-EN-P - April 2001

Page 34

1-14 System Software Upgrade Procedures

Uninstalling ProcessLogix Knowledge Builder Software

If you have a previous version of Knowledge Bu ilder on your PC , you

must first record the system path and uninstall the installed version

before attempting to install the lat est version. Follow the steps below to

record the system path and uninstall the Knowledge Builder software.

Recording the NT System Path Value

If you are running Windows NT, you must record the NT System Path

before uninstalling Knowledge Builder.

1. Click Start

2. Double-click the System icon.

3. Click the Environment tab.

4. Select the Path from the System Variables list.

5. Record the Path Value.

⇒Settings⇒Control Panel.

TIP

Use Notepad to create a file c:\path. txt. Copy the path

value into this file and save.

Uninstall Knowledge Buil der

ATTENTION

!

1. Click Start⇒Settings⇒Contro l Panel.

2. Double-click the Add/Remove Programs icon.

Before installing or uninstalling any software

component, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

Publication 1757-IN032B-EN-P - April 2001

3. Select Knowledge Builder.

4. Click Add/Remove.

Page 35

System Software Upgrade Procedur es 1-15

5. Click Yes to confirm file deletion.

6. When prompted to remove shared files, click Yes to All and click

Yes to continue.

7. When the uninstall completes, click OK.

You can ignore details for any items that were not removed.

8. Close the Add/Remove window.

9. Close the Control Panel.

Verifying the NT System Path Value

1. Click Start⇒Settings⇒Control Panel.

2. Double-click the Syst em icon.

3. Click the Environment tab.

4. Select the Path from the System Variables list.

5. If the Path Value does not match the recorded path value from

before the uninstall, change the path value t o the recorded value.

6. Click Set and then click OK.

7. Close the Control Panel.

Uninstalling Adobe Acrobat Reader 3.01

1. Click Start⇒Programs⇒Adobe Acrobat⇒Uninstall Acrobat

Reader 3.01.

2. Click Yes to confirm file deletion.

3. When the uninstall completes, click OK.

4. Resta rt the PC.

Publication 1757-IN032B-EN-P - April 2001

Page 36

1-16 System Software Upgrade Procedures

Installing ProcessLogix Knowledge Builder Software

Knowledge Builder is the software application used to display

ProcessLogix online documentation. Knowledge Builder (KB) requires

several other software applications and Microsoft components to

function properly. These components include:

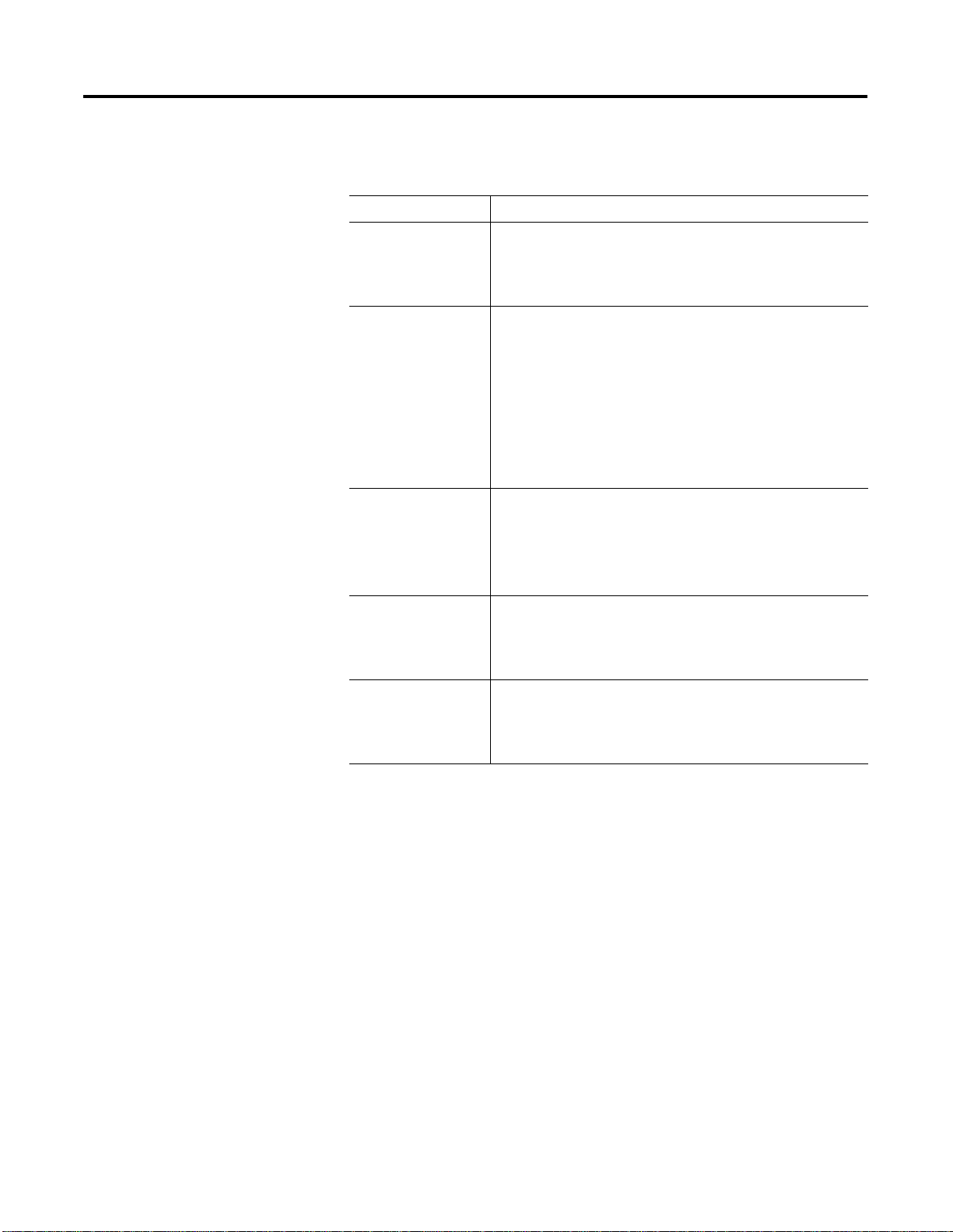

Knowledge Builder requires

this component:

Service Pack 6a for Windows NT • refer to Installing Service Pack 6a

Internet Explorer 5.01 • refer to Installing Internet Explorer

Microsoft MDAC 2.1 • refer to Upgrading Data Access

Adobe Acrobat 4.05 • refer to Uninstalling Adobe

DCOM95 or 98 • automatically installed during the

VB Runtime files • automatically installed during the

You MUST:

for Windows NT 4.0 on page 1-11

5.01 on page 1-12

Components on page 1-13

Acrobat Reader 3.01 on page1-15

• Adobe Acrobat 4.05 will be

installed during the Knowledge

Builder install

Knowledge Builder install

Knowledge Builder install

Since Knowledge Builder is provided on a separate CD, use the following

procedure to install the soft ware and update the online doc umentation

database.

ATTENTION

!

1. Insert the ProcessLogix R320.0 Knowledge Builder CD into the

CD-ROM drive.

2. Click Start

3. Key in this path location in the Op en entry field or use Bro wse to

navigate to the Setup.exe file on the CD.

>D: (or your CD-ROM drive letter)\Knowledge_Builder\Setup.exe<

4. Click OK.

Before installing or uninstalling any software

component, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

⇒Run.

Publication 1757-IN032B-EN-P - April 2001

5. Follow the on-screen prompts to load the software.

Page 37

System Software Upgrade Procedur es 1-17

Accept the defaults for the program and the directory path location

selections. The defaults are:

• Next at the Welcome window

• Yes to accept license agreement

• Full Install and Next

6. At the Acrobat Reader 4.05 Setup window, click Next.

7. Accept the default directory location for Acrobat and click Next.

8. Click OK at the Thank you for choosing Acrobat Reader window.

9. Select No, I will restart my computer later and click OK.

10. Rem ove the CD.

11. Res t a r t th e PC .

Publication 1757-IN032B-EN-P - April 2001

Page 38

1-18 System Software Upgrade Procedures

Removing the 9904/1784-KTCX15 Card and Installing the 1784-PCIC Card

Use the following procedure as a general guide to remove the

9904/1784-KTCX15 drivers for RSLinx from an R300.1 or R310.0

ProcessLogix Server. If you already have a 1784-PCIC card installed, skip

this section.

ATTENTION

!

IMPORTANT

1. Click Start⇒Programs⇒Rockwell Software⇒RSLinx⇒RSLinx

2. Click Communications

Before continuing, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

If you have redundant servers, you must complete this

procedure on the SERVERB node first. Then complete

the entire procedure again for the SERVERA node.

to call up the Rockwell Software RSLinx window.

⇒Configure Drivers to call up the

Configure Drivers dialog box.

3. Select the AB_KTC-1 in the Configure d Drivers list bo x and click

Configure.

4. Record the AB_KTC-1 Network Address.

5. Click Delete.

6. Close RSLinx and power down the PC.

7. Remove ControlNet cables from the KTCX15 card and remove the

KTCX15 card from the PC.

8. Install the 1784-PCIC card and attach the ControlNet cables.

Refer to the installation instructions, Publication

1784-IN003A-EN-P for details.

ATTENTION

!

In order to perform correctly, the 1784-PCIC card

MUST have the PAL part number 99640604. If the

1784-PCIC card does not have this PAL, you must

return your card for the update.

Contact Rockwell Automation Technical Support for

more information. Refer to Rockwell Automation

Technical Support in th e Preface.

Publication 1757-IN032B-EN-P - April 2001

Page 39

Upgrading ProcessLogix Software on a Non-redundant Server Only

System Software Upgrade Procedur es 1-19

IMPORTANT

ATTENTION

If you are upgrading a redundant Server pair, refer

to Upgrading ProcessLogix Software on a Redundant

Server Pair on page 1-45.

Be certain that your process is off control before you

begin any upgrade procedure. This means the

1757-PLX52 should be in the Idle state.

!

About Upgrading Soft wa r e on the Ser ve r

ProcessLogix now automates most of the migration tasks from a previous

version of the system to the current version. The migration

enhancements support error handling and recovery from migration

problems.

While the ProcessLogix R320.0 soft ware CD supports several platforms,

this procedure covers upgrading the ProcessLogix Software from R300.1

or R310.0 to R320.0 on the Server . In this case, the following components

are installed in succession once you start the installation setup.

• RSLinx OEM 2.2

• Engineering Tools

• Server/Client (Display Builder, Station, and Server)

• ProcessLogix Server Upgrade

All files included with the migration wizard will be included as part of the

installation package for the Engineering Tools media included in the

Engineering Tools directory of the ProcessLogix CD. The files that

comprise this utility will be installed into the default location

C:\Honeywell\TPS50\System\ER\Migrate.

Publication 1757-IN032B-EN-P - April 2001

Page 40

1-20 System Software Upgrade Procedures

The following table lists the items that you MUST complete before

attempting to upgrade the ProcessLogix software on a non-redundant

Server pair

Step Item: Refer to page:

1 Preparing for a ProcessLogix Software Upgrade 1-1

2 Stopping ProcessLogix Applications and Services 1-8

3 Installing Service Pack 6a for Windows NT 4.0 1-11

4 Installing Internet Explorer 5.01 1-12

5 Upgrading Data Access Components 1-13

6 Uninstalling ProcessLogix Knowledge Builder

Software

1-14

7 Installing ProcessLogix Knowledge Builder

Software

8 Removing the 9904/1784-KTCX15 Card and

Installing the 1784-PCIC Card

9 Setting Up User Accounts 5-27

ATTENTION

Be certain that your current NT logon is through an

administrator account, such as plx_user, and not an

engr or mngr account.

!

IMPORTANT

Although not recommended, if you do not want to

install a software component, just click Cancel on the

Welcome display to abort the installation.

1-16

1-18

Publication 1757-IN032B-EN-P - April 2001

Installing Server Software

ATTENTION

!

Before installing or uninstalling any software

component, you MUST exit all ProcessLogix

applications and stop all ProcessLogix services.

Refer to Stopping ProcessLogix Applications and

Services on page 1-8.

Page 41

System Software Upgrade Procedur es 1-21

1. If the following pre-upgrade directories exist from a previous Server

migration, delete them:

• C:\Honeywell\ips.preupgrade

• C:\Honeywell\server.preupgrade

2. Insert the ProcessLogix R320.0 software CD into the CD-ROM

drive.

3. Click Start

4. Key in this path location in the Op en entry field or use Bro wse to

navigate to the setup.exe file on the CD.

>D: (or your CD-ROM drive letter)\SETUP.EXE<

5. Click OK to launch the software setup application.

6. Click the ProcessLogix Server option and click Next.

7. At the ProcessLogix R320.0 Welcome window, click Next.

8. Click Yes to accept the license agreement.

IMPORTANT

9. At the Before installing window, click Yes.

⇒Run.

You must have either a 1784-PCIC or Ethernet card

installed in your ProcessLogix Server to install R320.0.

Installing RSLinx

1. At the RSLinx Welcome window, click Next.

2. Click Yes to accept the license agreement.

3. At the Verify System Files window, click Next.

TIP

If a Read only File Detected message appears during

software installation, check the Don’t display again

checkbox and click Yes to acknowledge the message.

Publication 1757-IN032B-EN-P - April 2001

Page 42

1-22 System Software Upgrade Procedures

4. Enter the name, company to whom the RSLinx package is

registered, and the RSLinx OEM serial number (located on the

RSLinx box and/or Master Disk).

5. Click Next.

6. At the Select Components window, be certain that all the

components are checked, including any sublevel listings. Expand

the items to display the sublevels and be certain that all the

components are selected.

7. Click Next.

8. Click the Upgrade the existing version option and click Next.

9. At the Choose Destination Location window, click Next.

TIP

You must not change the directory name or the

ProcessLogix system will not operate properly.

10. At the RSLinx Configuration Security Setting window, click the

Disable option and click Next.

11. At the Setup Complete window, uncheck these checkboxes:

• Activate RSLinx

• View the ReadMe file now

12. Click Finish.

Installing Engineering Tools

1. Engineering Tools is automatically installed. This takes a few

minutes to complete.

Installing PsAxCtl Document EXE

Publication 1757-IN032B-EN-P - April 2001

a. Click OK to acknowledge the change directory warning.

b. At the PsAxCtl Document EXE Set up Welcome window,

click OK.

c. Verify that the destination directory is

C:\Honeywell\TPS50\System\Bin.

Page 43

System Software Upgrade Procedur es 1-23

d. Click the large install button (PC icon).

e. At the Setup complete window, click OK.

Installing CCL Deployment

a. At the Welcome window, click Next.

b. At the CCL Deployment Installation Complete window,

click Finish.

2. At the Engineering Tools Setup Complete window, click Finish.

Migrating the ERDB

1. Wait wh ile the automatic ERDB migrat ion from R300.1 or R310.0

to R320.0 is executed.

The migration activity appears in a DOS window. This may take

some time to complete, depending on the size of your database.

2. When the ERDB Migration is complete, click OK.

If ERDB Migration fails, refer to ref er to Recovering from Failure

of an Automatic ER Database Migration on page 5-8.

Installing the ProcessLogix Server

1. At the Welcome to ProcessLogix Server Setup window, click Next.

2. Click Y es in the Question box t o upgrade the ProcessLogix S erver

to R320.0.

3. Click Y es to replace the detected versions of Display Builder,

Quick Builder, and Station.

Publication 1757-IN032B-EN-P - April 2001

Page 44

1-24 System Software Upgrade Procedures

4. Skip to Step 6 if the Specify Microsoft Excel Directory window

does not appear. Otherwise, click Nex t to accept the default

directory for Microsoft Excel.

ATTENTION

!

5. Click No in response to the question:

Do you want Microsoft Excel Data Exchange to be allowed to

write to a ProcessLogix Server database?

to disable the Microsoft Excel Data Exchange write option.

6. At the Choose point mode acronyms window, click the Default

acronyms option and click Next.

7. Review the software installation details summarized in the

Confirmation window.

• If you need to make changes, click Back to access any previous

entries.

• If the details are okay, click Next to begin the Server setup. This

may take 10 to 15 minutes to complete.

We recommend that you answer No to the question:

Do you want Microsoft Exc el Data Exchange to be

allowed to write to a ProcessLogix Server database?

If you answer Y es, the write option is enabled and it is

possible for anyone with access to the machine to write

to the Server database.

Publication 1757-IN032B-EN-P - April 2001

8. Skip this step if the system does not include Excel Da ta Exchange.

Otherwise, click Enable Macros when requested.

TIP

If a Microsoft Excel dialog box appears, check the Do

not show this dialog again checkbox and click OK.

TIP

If a Read only File Detected message appears during

software installation, check the Don’t display again

checkbox and click Yes to acknowledge the message.

Page 45

System Software Upgrade Procedur es 1-25

9. At the Setup Complete window, click the No, I will restart my

computer later option and click Finish.

IMPORTANT

If the message “Dr. Watson has been installed as default

application debugger,” appears during software

installation, click OK.

10. The ProcessLogix Server Update is automatically installed. At the

ProcessLogix Setup Complete window, click Finish.

11. Rem ove the CD.

IMPORTANT

Do not restart the Server!

Before restarting the PC, you must have all user

accounts configured correctly.

Setting Up User Accounts

1. Configure the plx_user, mngr, and erserver accounts.

Refer to Setting Up User Accounts on page 5-27.

2. Resta rt the PC.

IMPORTANT

TIP

You must restart the PC after all user accounts have

been changed.

If you see any “end task” and “failure to start at least

one service; see Event Viewer” prompts during reboot,

click OK to continue. Logon as plx_user and verify that

all user accounts have been properly configured .

Publication 1757-IN032B-EN-P - April 2001

Page 46

1-26 System Software Upgrade Procedures

Moving the RSLinx Activation File

About the Activation File

Use the following proced ure to move the activation file (evrsi .sys) from

the RSLinx software Master Disk to the hard drive where RSLinx is to be

operated. The PC cannot execute the full OEM version of the RSLinx

application if the activation file is not present on its hard drive.

IMPORTANT

ATTENTION

Complete Step 1 and Step 2 in the following

procedure to determine your current RSLinx version.

If you need to reformat the hard d rive, you must first

move the activation file back to the RSLinx Master

Disk using the same general procedure as follows.

Otherwise, the file wil l be corrupted and you will no t

be able to run RSLinx in the OEM mode.

!

Before you attempt to move the activation file, you

MUST exit all ProcessLogix applications and stop all

ProcessLogix services. Refer to Stopping

ProcessLogix Applications and Services on page 1-8.

Do not manually copy or move the evrsi.sys file.

Moving/coping the evrsi.sys file will disable the OEM

version of RSLinx.

Always use the EVMOVE.EXE program to move the

evrsi.sys file. If the evrsi.sys file is corrupted or

manually moved, resulting in RSLinx changing to Lite

version, you can visit the Rockwell web site

(http://suppport.automation.rockwell.com/resetcodes

/) to recover the RSLinx activation.

Determining the Current RSLinx Version

1. Click Start⇒Programs⇒Rockwell Software⇒RSLinx⇒RSLinx

to open the RSLinx application.

Publication 1757-IN032B-EN-P - April 2001

Page 47

System Software Upgrade Procedur es 1-27

2. Check the application title in the title bar.

• If the title is RSLinx Lite, go to Step 3.

• If the title is RSLinx OEM you already ha ve the O EM versi on

installed and you do not have to install the activation file.

– For ControlNet Supervisory Networks, skip to Configuring

RSLinx Drivers for ControlNet Supervisory Network on

page 1-29.

– For Ethernet Supervisory Networks, skip to Configuring

RSLinx Drivers for Ethernet Supervisory Network on

page 1-38.

3. Close RSLinx.

Installing the Activation File

1. Locate the RSLinx Master Disk and insert it into the floppy drive.

2. Click Start

3. Key in this path location in the Op en entry field or use Bro wse to

navigate to the evm o ve . e xe fil e on the di sk et t e.

>A: (or your floppy drive letter)\EVMOVE.EXE<.

4. Click OK to launch the move executive.

⇒Run.

Publication 1757-IN032B-EN-P - April 2001

Page 48

1-28 System Software Upgrade Procedures

5. Confirm that the floppy drive letter A:, for example, appears in the

From Drive field and the hard drive letter C:, for example, appears