Page 1

ProcessLinx OPC

Server to Server

Software

1757-PROCESSLINX

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include intellectual

property liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley

office), describes some important differences between solid-state equipment

and electromechanical devices that should be taken into consideration when

applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

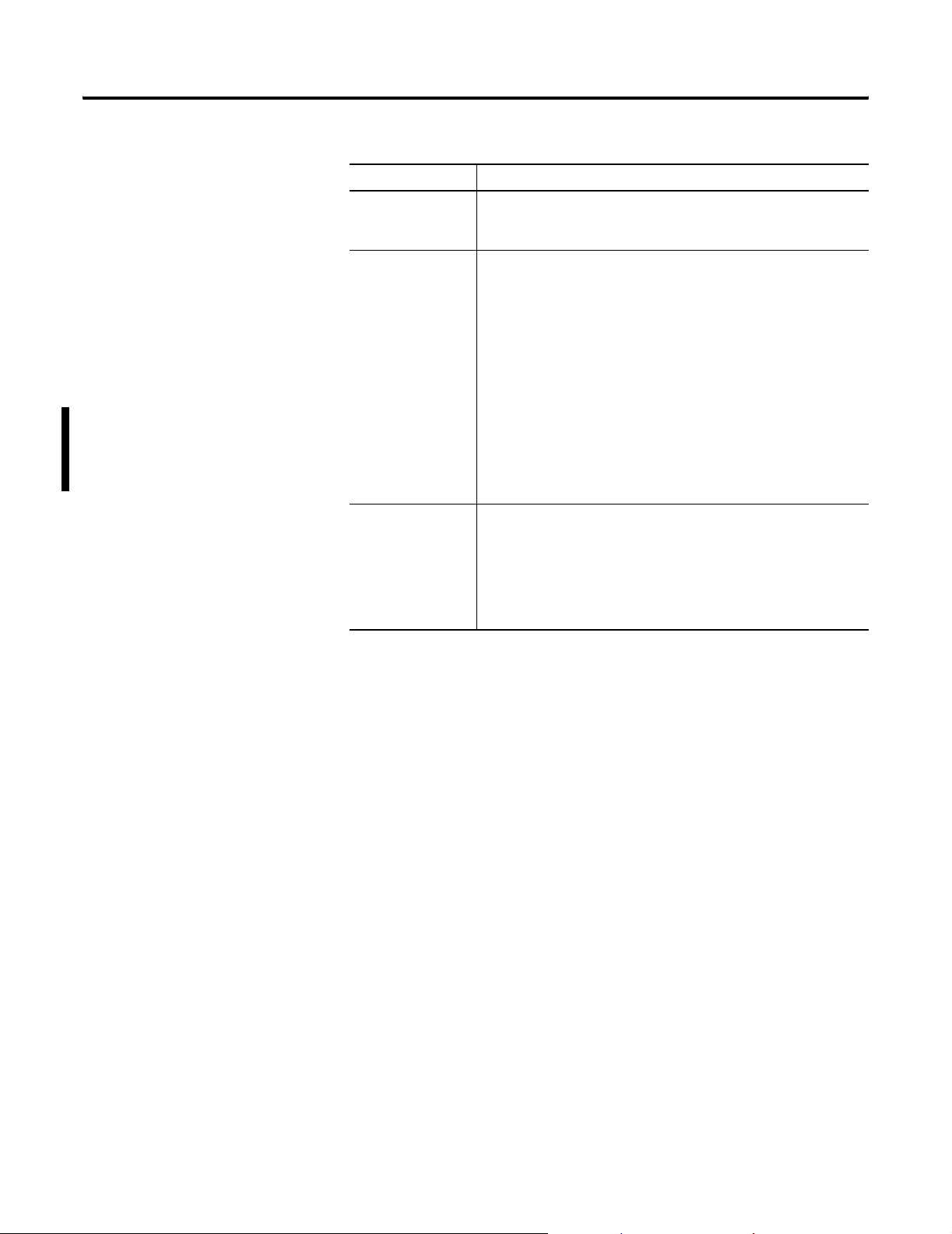

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or circumstances

that can lead to personal injury or death, property damage

or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation, Inc.

Identifies information that is critical for successful

application and understanding of the product.

Page 3

Preface

Introduction

Overview

This document provides an overview of the ProcessLinx application.

ProcessLinx allows two OPC servers to communicate. Normally a server talks

to a client and visa versa. A server cannot talk to another server because the

interfaces are incompatible. ProcessLinx is specilized software that allows two

servers to communicate.

The OPC (OLE for Process Control) Interface within ProcessLinx acts as an

OPC Client to a ProcessLogix OPC Server as well as to another OPC server.

To interface from ProcessLogix to another server, a ProcessLinx TagMap

configuration must be created. This configuration maps the items from one

system to the other. This is accomplished through the exchange of data with

entities known as tags or OPC items. The OPC items can be logically Grouped

together. ProcessLinx supports both local and remote OPC Servers.

This interface supports bi-directional data flow and supervisory control

between ProcessLogix and other control systems. It enables operators to

control digital and analog control loops implemented within ProcessLogix

controllers from external control system operator consoles. Likewise,

ProcessLogix operator stations may also be used for operator control of digital

and analog control loops implemented in other control system processors.

These capabilities depend on the functionality supported by the external OPC

Server being utilized. ProcessLinx is fully compliant with Versions 2.0 and 1.0a

OPC Data Access Servers.

Functional Description

The ProcessLinx interface runs under the Windows NT/Windows 2000

Professional operating system(s). Two modes of operation are associated with

the interface, which are “configure” and “runtime”. In configure mode a user

can change settings and create TagMaps. In runtime mode the interface uses

the currently loaded configuration to communicate with the external OPC

Server(s). ProcessLinx supports the following:

• OPC Server configuration dialog allows user to define the external OPC

Server by browsing and selecting an existing OPC Server.

• Supports redundant ProcessLogix OPC Servers as well as redundant

external OPC servers by recognizing server fail-over mechanisms.

• Simple TagMap definition dialog allows mapping of an external OPC

Server tag to a ProcessLogix OPC Server tag. Tag Map definition will

include attributes such as OPC Item names, description and data source.

Optionally, scaling conversion using translation tables can be defined to

translate values from one system to the other.

• The number of user-defined TagMap definitions is unlimited.

1 Publication 1757-UM002B-EN-P - January 2003

Page 4

P-2

• Tag Map configurations are stored in a serialized compact binary file.

• Supports ability to easily import and export ProcessLinx Tag Map

configurations to/from comma delimited (*.csv) ASCII files, which can

be created and/or edited with Microsoft Excel, Microsoft Access or any

text editor.

• Error and informational messages displayed in the main window in

runtime along with optional user-configurable specification maintaining

this data in daily log files.

• Runtime tag monitoring ability to view and change (read/write) data

values in either OPC Server from main client window.

Publication 1757-UM002B-EN-P - January 2003

Page 5

P-3

Rockwell Automation Technical Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized systems

integrators located throughout the United States alone, plus Rockwell

Automation representatives in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance, first call

your local Rockwell Automation representative, then:

• Network Pre-sales Hotline, 440.646.3638 (3NET)

• Post-sales Technical Support, 440.646.5800

• Web Links

http://www.ab.com — as a registered member, open to

http://www.ab.com/mem/technotes/techmain.html

Your Questions or Comments about This Manual

If you find a problem or have a comment about this manual, please notify us

of it on the enclosed Publication Problem Report (at the back of this manual).

If you have any suggestions about how we can make this manual more useful

to you, please contact us at the following address:

Rockwell Automation, Allen-Bradley Company, Inc.

Control and Information Group

Technical Communication

1 Allen-Bradley Drive

Mayfield Heights, OH 44124-6118

Publication 1757-UM002B-EN-P - January 2003

Page 6

P-4

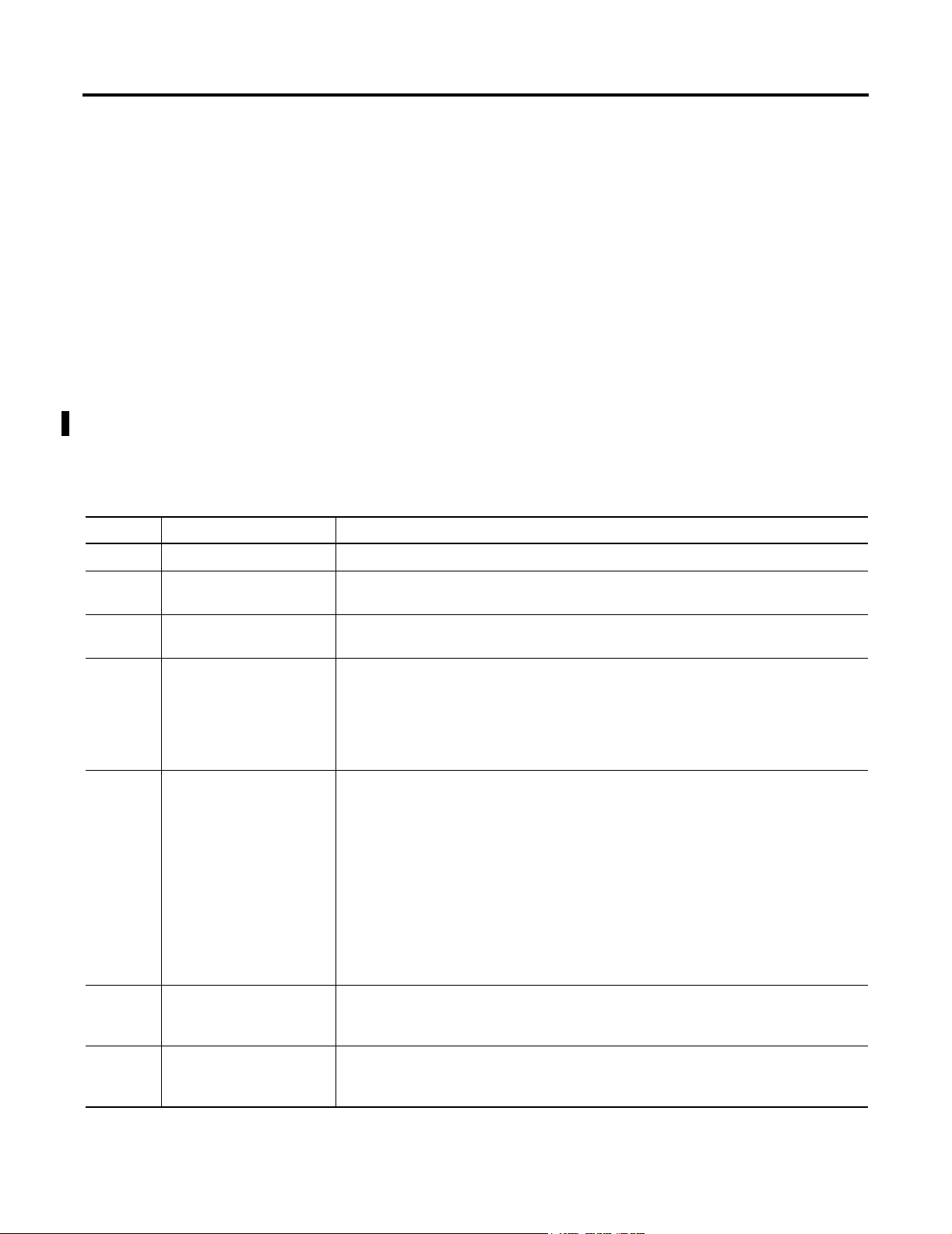

Conventions

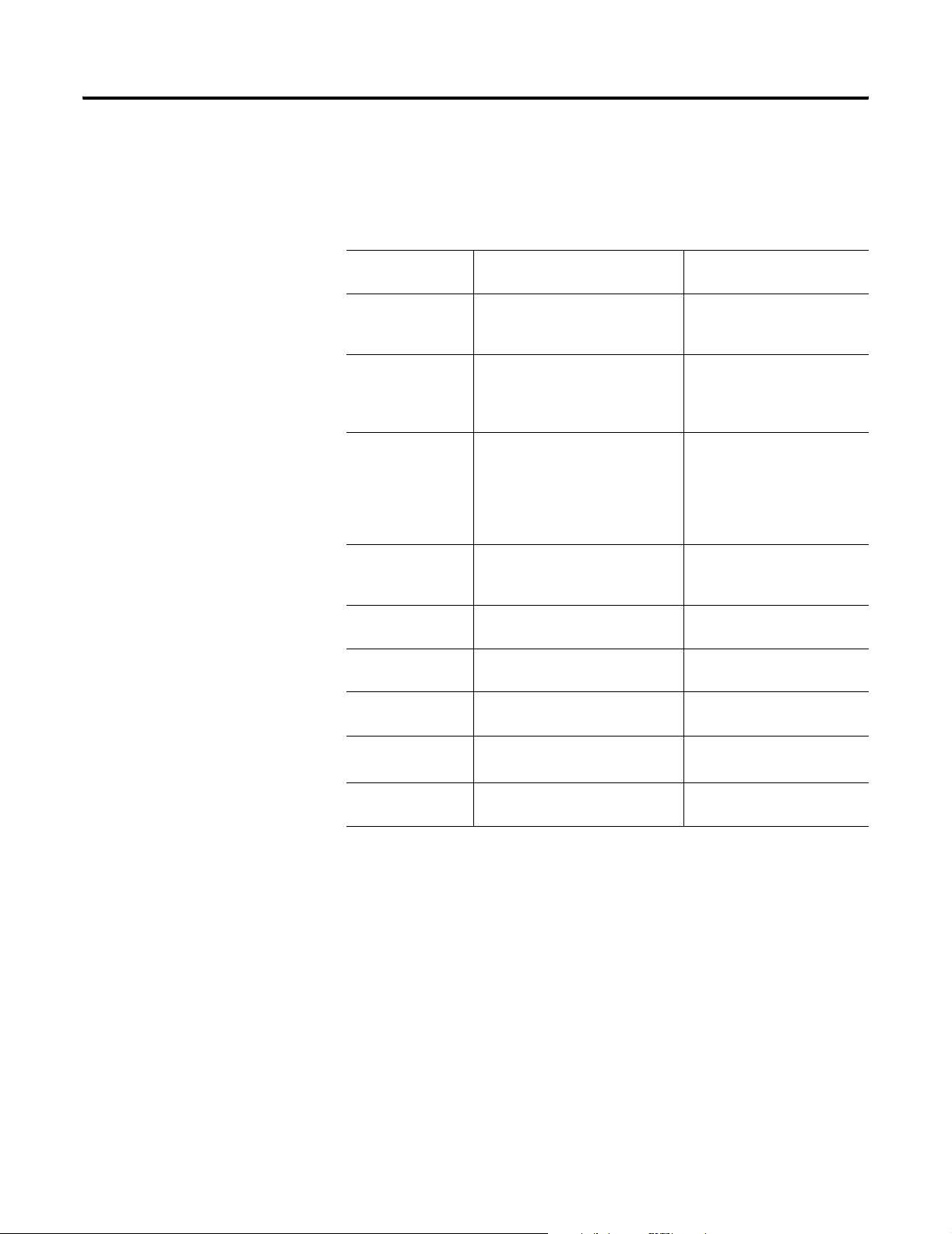

Terms and Type Representations

The following table summarizes the terms and type representation

conventions used in this Guide.

Term/Type

Representation

click, click on, click

[button name]

double-click Click left mouse button twice in

drag Press and hold left mouse button

right-click Click right mouse button once.

Meaning Example

Click left mouse button once.

(Assumes cursor is positioned on

object or selection.)

quick succession. (Assumes cursor

is positioned on object or

selection.)

while dragging cursor to new

screen location and then release

the button. (Assumes cursor is

positioned on object or selection to

be moved.)

(Assumes cursor is positioned on

object or selection.)

Click Apply.

Double-click the Pipe.

Drag the file icon onto the

new folder window.

Right-click, and the pop-up

menu appears.

select click to highlight a menu item or

list choice, or click on a button.

<F1> Keys to be pressed are shown in

angle brackets.

<Ctrl>+<C> Keys to be pressed together are

shown with a plus sign.

File

⇒ New

>D:\setup.exe< Data to be keyed in at prompt or in

Shows menu selection as menu

name followed by menu selection.

an entry field.

Select the OPC Item from the

list box.

Press <F1> to view the online

Help.

Press <Ctrl>+<C> to configure

the Pipe.

Click Edit ⇒ Add New

Group to create a Group.

Key in this path location

>D:\setup.exe<.

Publication 1757-UM002B-EN-P - January 2003

Page 7

Table of Contents

Preface

Chapter1

Setup Procedures

Chapter 2

Getting Started

Chapter 3

ProcessLinx TagMap

Configuration

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Rockwell Automation Technical Support. . . . . . . . . . . . . . . . . . . . . . P-3

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Your Questions or Comments about This Manual . . . . . . . . . . . P-3

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Terms and Type Representations . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Configuring DCS Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Installing OPC Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Defining an Interface Control Strategy. . . . . . . . . . . . . . . . . . . . . 1-2

Creating OPC Server Configurations . . . . . . . . . . . . . . . . . . . . . . 1-2

Configure the OPC Server(s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Installing ProcessLinx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Preparing the Client’s User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Running Updates on the ProcessLinx Client’s Registry. . . . . . . . 1-4

ProcessLinx Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Configure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Runtime Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Configure ProcessLinx Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Creating a ProcessLinx Configuration . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Opening a ProcessLinx Configuration . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Creating a Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Creating a Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Creating a TagMap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Creating a ProcessLinx TagMap Configuration . . . . . . . . . . . . . 3-15

Data Conversion/Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

OPC Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Translation Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Editing a Pipe, Group or TagMap. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Copying/Moving TagMaps between Groups. . . . . . . . . . . . . . . . . . 3-22

Multiple TagMap Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Testing a ProcessLinx Configuration . . . . . . . . . . . . . . . . . . . . . . . . 3-24

i Publication 1757-UM002B-EN-P - January 2003

Page 8

Table of Contents ii

Chapter 4

ProcessLinx Runtime Operation

Chapter 5

Import/Export

Chapter 6

Error Diagnosis and Debugging

Chapter 7

Using DCOM OPC Servers

Monitoring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Reading OPC Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Writing OPC Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Redundant OPC Servers / Fail over . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Server Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Verifying OPC Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Ping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

OPCShutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

CSV File Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Pipe Declarations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Group Declarations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

TagMap Declarations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Translation Table declarations . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Debug Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

OPC Servers on Windows NT/Windows 2000 . . . . . . . . . . . . . . . . . 7-1

OPC Servers on Windows98 / Windows 95 . . . . . . . . . . . . . . . . . . . 7-2

Publication 1757-UM002B-EN-P - January 2003

Page 9

Setup Procedures

Chapter

1

Installation

This chapter contains an overview of the setup procedure and the steps you

need to take to set up a configuration prior to using ProcessLinx.

Configuring DCS Components

IMPORTANT

All DCS Components must be configured first in the setup procedure. This

includes installation and setup of the following:

• ProcessLogix System – The ProcessLogix system must be setup and

installed on the PC used to access the ProcessLogix OPC Server.

• DCS – The other DCS system is assumed to be setup prior to

performing the steps in the section Creating a ProcessLinx TagMap

Configuration on page 3-10.

You are required to configure the DCS components before

installing ProcessLinx. If the DCS components are not

configured correctly, server communications will not

succeed.

Installing OPC Servers

Install the desired OPC servers. If a remote DCOM connection is required,

verify the PC is setup on the network with the TCP/IP protocol installed. The

OPC Servers are specified below:

ProcessLogix OPC Server

All of the software components of the ProcessLogix OPC Server are installed

during the ProcessLogix Server installation.

IMPORTANT

1 Publication 1757-UM002B-EN-P - January 2003

The OPC Server option MUST be included with your

ProcessLogix license.

Page 10

1-2 Setup Procedures

In order for ProcessLinx to connect to the ProcessLogix OPC Server over the

network, the OPC Server Connect option must be installed on the client PC.

Refer to the ProcessLogix Knowledge Builder:

Navigate in Knowledge Builder to

⇒Server and Client Configuration Guide ⇒Using ProcessLogix Data in other Applications

⇒ ProcessLogix OPC Support.

External OPC Server

Consult the External OPC Server documentation for correct installation and

setup on the desired node. This does not have to be the same PC or node

running ProcessLinx. Verify the External OPC Server operation separately.

Defining an Interface Control Strategy

Define the site specific DCS Control Strategy. This step assumes that you have

two working DCS configurations, one in ProcessLogix, and the other in an

external DCS system. This step includes defining exactly which points (control

loops, pumps, motors, etc.) are to be controlled and interfaced and by which

system. This step also tentatively outlines the direction and flow of data

and/or specifies which system is in control of each interfaced point.

It is emphasized that if this step is not performed, data flow direction and

determination of what point is coming from where may get very confusing in

the future. A table laying out all desired interface points, their names within

both systems, and data flow directions should be created and documented for

future reference.

Publication 1757-UM002B-EN-P - January 2003

Creating OPC Server Configurations

Before a ProcessLinx configuration can be realized, an OPC Server database

must be built which defines references to I/O points in the underlying desired

hardware or to control points. With ProcessLogix, this step is not required

since control points defined using Control Builder are immediately available

from the ProcessLogix OPC Server. No OPC Server configuration must be

built for those points in the ProcessLogix OPC Server. This includes points

brought in and defined from other interfaces using the Quick Builder

program.

The External OPC Server configuration (database) must be configured to

define exactly what pieces of hardware or blocks you are interested in. Consult

the External OPC Server documentation for setup.

Page 11

Setup Procedures 1-3

Configure the OPC Server(s)

Installing ProcessLinx

Before ProcessLinx can work properly in runtime, each OPC Server must be

installed and configured correctly. Follow the installation procedure and setup

specified with the documentation for the external OPC Server. A TCP/IP

connection must also exist between the NT ProcessLogix node and any

remote node running an external OPC server for which you wish ProcessLinx

to connect with. Refer to Using DCOM OPC Servers on page 7-1 to setup

and configure remote OPC servers.

Do the following to install the ProcessLinx software:

1. Insert the ProcessLinx CD.

2. Select Start

3. Enter D(CDROM drive letter):setup.exe.

4. Accept the License Agreement.

5. Follow the rest of the dialog boxes to install ProcessLinx in the default

locations.

⇒ Run.

Preparing the Client’s User Accounts

6. To complete the installation, insert the floppy disk with the License

Activation.

7. Follow the instructions for moving the License Activation to the PC.

ProcessLinx installation is complete.

The easiest way to avoid DCOM security problems is to have the same user

account and password on all machines, DCOM security is bypassed. It is

possible however, to allow a remote OPC Client to access the PLX OPC

Server when the correct permissions are specified. This requires user and

group privileges and DCOMCFG settings to be set appropriately. This is not a

trivial undertaking and most people (including network administrators) have

no idea how to do it properly.

Most of the time OPC is set up with user accounts on the Client machine and

Server machine having the same name and password. This is not specific to

ProcessLinx. It is a Microsoft DCOM issue. OPC is written using COM so it

has inherited all the DCOM flaws.

ProcessLinx is not dependent on a specific version of ProcessLogix. It works

the same in R320 as it does in R500. Refer to your Microsoft documentation

on how to add user accounts.

Both the ProcessLogix Client and the Server must have both the MNGR and

Publication 1757-UM002B-EN-P - January 2003

Page 12

1-4 Setup Procedures

ps_user accounts on them. Refer to the sections in Knowledge Builder, About

ProcessLogix-To-OPC Server/Client Communications, Communicating with 3rd Party

Clients, and Creating a MNGR Account for a Third-Party Client.

IMPORTANT

For example, if the ps_user account is not the client, you must add it by doing

the following:

1. Right click on My Computer.

2. Select Manage

3. Right click on the Users folder.

4. Select New User.

5. Add a PS_USER account.

6. On the General Tab, check Password Never Expires.

7. Click the Member Of Tab and be sure Administrators and Users are

visible.

The PS_USER account is now setup on the client.

The following instructions apply only to Windows 2000

and Windows XP. Windows NT is not supported.

⇒ Local Users and Groups ⇒ Users.

Publication 1757-UM002B-EN-P - January 2003

Running Updates on the ProcessLinx Client’s Registry

Because OPC is COM based, the Client needs the GUID (Globally Unique

IDentifier) of the OPC Server. If the Client and Server reside on the same box,

the registry already contains the Server’s GUID so the Client can easily find it.

If the Server resides on a remote computer, the Client’s registry does not

contain the Server’s GUID.

If you have ProcessLinx installed on a third machine you will need to make

sure you have the GUIDs of both OPC servers located in the ProcessLinx

machine. You will need to follow similar steps as noted below. The following

steps put the Server’s GUID into the Client’s registry.

Setting up communication between the OPC Client and OPC Server

Follow these instructions to setup communications between the OPC Client

and the OPC Server:

1. Select Start

⇒ Run.

Page 13

2. Type regsvr32 opcproxy.dll in the Run dialog box.

Setup Procedures 1-5

IMPORTANT

Unless opcproxy.dll is in the Windows\System32 directory

the above command will fail because it can't find the

OPCPROXY.DLL. You need to specify the full path the

the DLL (i.e. regsvr32 “C:\Program Files\Common

Files\OPC Foundation\opcproxy.dll”)

3. On the server machine, go to the

C:\Honeywell\Client\Opcserverconnect, folder and copy the

HSCOPCCONNECT.REG & HSCOPCSERV.REG files to a floppy

diskette.

4. On the ProcessLinx Client machine, create a directory called

C:\Honeywell\Client.

5. Copy the hscopcconnect.reg file and the hscopcServ.reg file from the

floppy, to the C:\Honeywell\Client directory of the ProcessLinx Client.

6. Using Notepad, open then edit the hscopcconnect.reg file.

7. Edit line#19 section. Change the entry

from: @=”d:\\hwiac\\programs\\tps\\hci\\hscopcserv.exe

to: @=”c:\honeywell\client\hscopcserv.exe

8. Go into the C:\Honeywell\Client directory on the Client.

9. Run (double-clicking) each of the .REG files in Step 3,

HSCOPCCONNECT.REG & HSCOPCSERV.REG, one at a time.

All registry changes that tell the Client, the Servers GUID have now

been made to the registry.

Publication 1757-UM002B-EN-P - January 2003

Page 14

1-6 Setup Procedures

Notes:

Publication 1757-UM002B-EN-P - January 2003

Page 15

Chapter

Getting Started

This section provides the required information to setup and configure both

the ProcessLinx software as well as the communications interface to the

ProcessLogix OPC Server and the external OPC Server.

2

ProcessLinx Version

Configure Mode

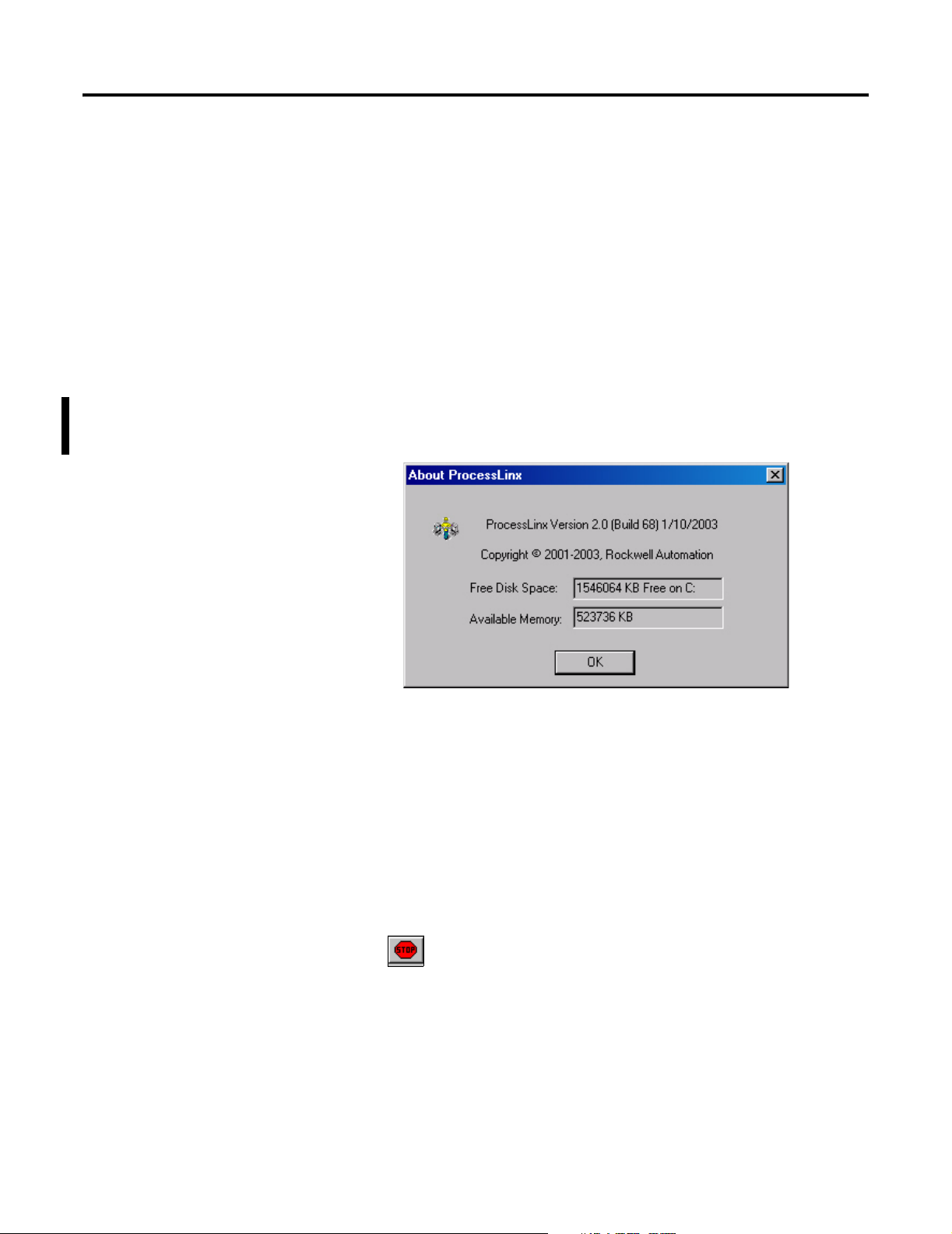

The version of the ProcessLinx can be found by selecting the Help menu in

the main window. The version label below displays Version 2 and Build # is 68,

built on January 10, 2003.

Figure 2.1 ProcessLinx Version Label

In configure mode, you can modify the ProcessLinx Options and Settings

from the main window. ProcessLinx does not communicate with OPC Servers

in configure mode.

To change to configure mode from the menu tab, select Mode

Changing from runtime to configure mode will disestablish all OPC tag items

and Groups and stop all communication with the OPC Servers. You can also

click in runtime or press the keys <Shift+F5> to change back to

configure mode.

1 Publication 1757-UM002B-EN-P - January 2003

⇒ Configure.

Page 16

2-2 Getting Started

Runtime Mode

To change ProcessLinx to runtime select Mode ⇒ Runtime, click

or press <F5>.

While in runtime mode ProcessLinx acts as an OPC Client to both the

ProcessLogix server and the external OPC Server. Initiating runtime mode

establishes all OPC Groups and Items with the specified OPC Server(s). The

opened TagMap configuration (See Figure 2.1) is activated. If an OPC

server(s) connection cannot be established upon startup, an error will be

logged to the Message Log window and the driver will be placed into configure

mode.

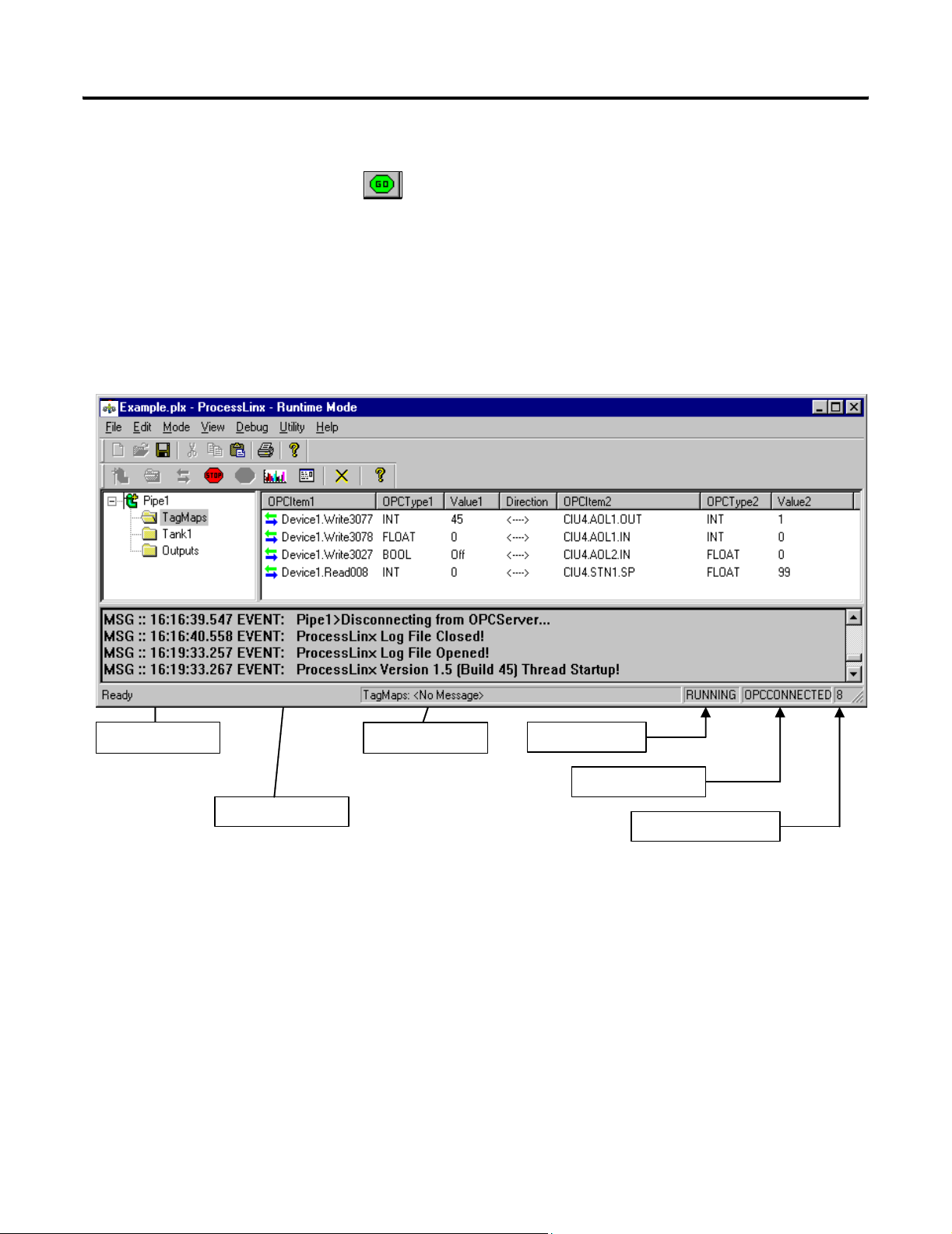

Pipe/Group Pane

Message Log Pane

Publication 1757-UM002B-EN-P - January 2003

Tag View Pane

Runtime Status

OPC Status

Total # of OPC Tags

Figure 2.2 ProcessLinx Example Window

Page 17

Getting Started 2-3

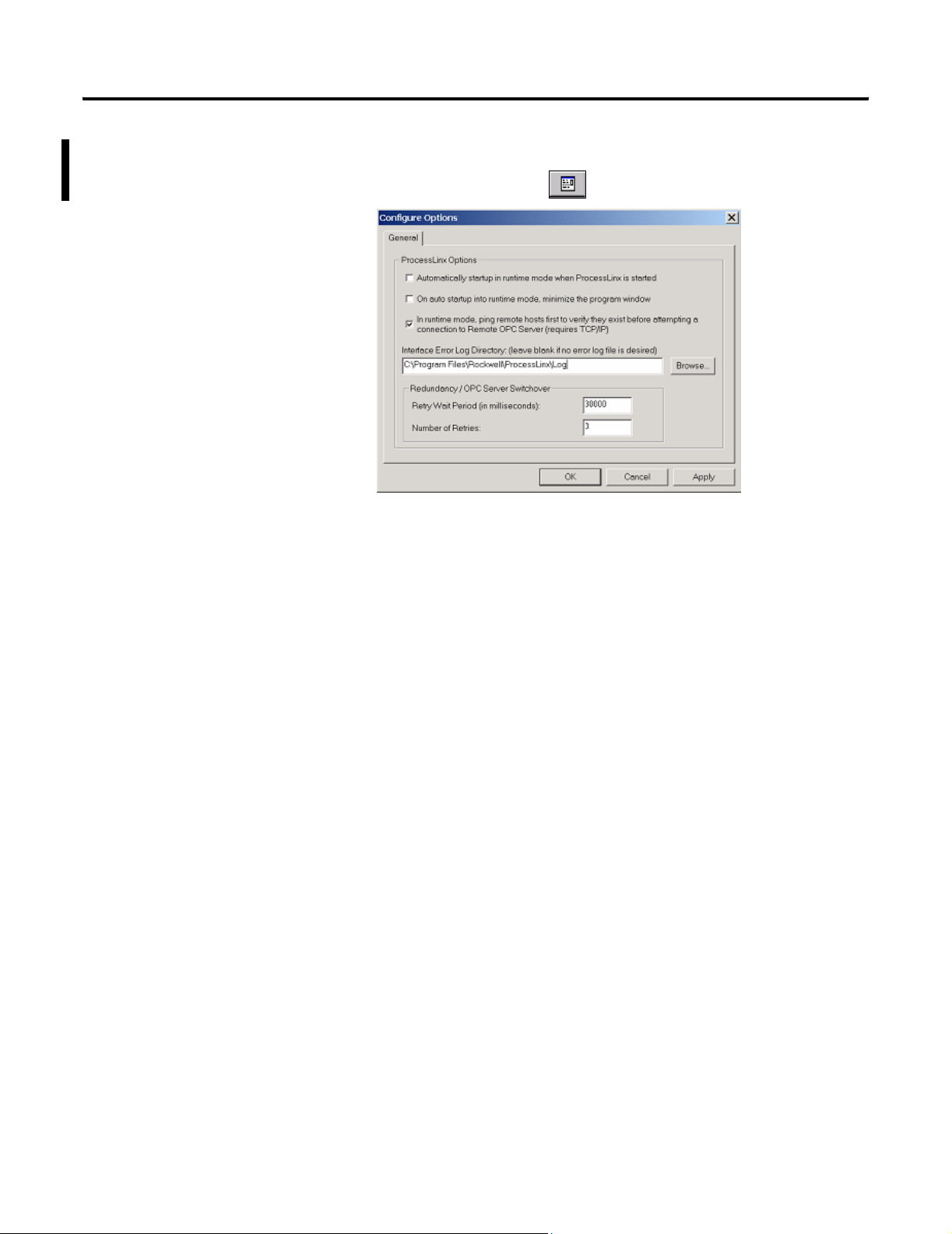

Configure ProcessLinx Options

To configure ProcessLinx Options select from the Utility menu, Utility ⇒

Configure Options or click in the tool bar. You see:

Figure 2.3 Options Dialog Box

Automatically startup in runtime mode when ProcessLinx is started

This option starts ProcessLogix in runtime mode. This change takes

effect the next time you start the program. If unchecked then you must

manually place ProcessLinx in runtime mode. Default is unchecked.

On auto startup into runtime mode, minimize the program window

This option is used to control whether or not the program starts

minimized or not. On startup if the “Automatically startup in runtime

mode…” is checked then the program window will be minimized.

Default is unchecked.

In runtime mode, ping remote hosts first to verify they exist before

attempting a connection to Remote OPC Server (requires TCP/IP)

This option should always be enabled for all remote OPC Server(s)

communicating via TCP/IP. If checked, ProcessLinx pings the remote host

before attempting an OPC connection to it. If this option is not enabled and

Publication 1757-UM002B-EN-P - January 2003

Page 18

2-4 Getting Started

a remote server connection is lost, ProcessLinx may keep trying to connect

with it, you may have to restart ProcessLinx.

ATTENTION

!

For local OPC servers (running on the same PC as ProcessLinx) this option

is not used. The default is checked. If enabled, you can change the settings

and have them recognized while in runtime operation.

Interface Error Log Directory

Use this option to specify the error log destination directory. If a folder

is specified, all error and information messages displayed in the driver’s

log window are logged. ProcessLinx generates a new log file daily. If this

field is left blank, no error or information logging occurs.

Maximum # of Screen Buffer Lines in On-Screen Message Log

Use this option to specify the maximum lines to display in the Message

Log Pane. If the current number of lines is greater or equal to this the

first 50% of these messages are removed. This only concerns on-screen

messages. The messages logged to the log file are not removed.

This restart situation depends on how you

setup DCOM with the COM interface (OPC

Server). Be certain to follow the DCOM steps

in Chapter 7 for best performance when you

configure TCP/IP and DCOM with COM I/F

to OPC Server.

Publication 1757-UM002B-EN-P - January 2003

This option also minimizes memory usage. The buffer can consume up

to 1 MB of memory otherwise.

Clear On-Screen Messages When Limit is Hit

Use this option to specify when the number of lines displayed in the

Message Log Pane hits the limit defined in the option above. The whole

buffer (all on-screen messages) is cleared. If unchecked then only the

first 50% will be removed.

Retry Wait Period (in milliseconds) for Redundancy / OPC Server Switchover

Use this option to specify the retry wait period before attempting to

connect to an OPC Server that has stopped communicating. This is

used in runtime mode during a switchover. Changes to this setting can

be made, and are recognized during runtime operation.

Page 19

Getting Started 2-5

Number of Retries for Redundancy / OPC Server Switchover

This option specifies the number of retries attempts to connect to a

redundant OPC Server. Retries are initiated after communication is lost

with a server. For example, if this is set to three and communication is

lost with the primary server, ProcessLinx will switchover to the

secondary server (if defined). Three connection attempts are made to

the secondary server before switching back to the primary. ProcessLinx

then attempts a connection three times with the primary and so on.

Changes to this setting can be made, and are recognized during runtime

operation.

Publication 1757-UM002B-EN-P - January 2003

Page 20

2-6 Getting Started

Notes:

Publication 1757-UM002B-EN-P - January 2003

Page 21

Chapter

3

ProcessLinx TagMap Configuration

A ProcessLinx TagMap configuration is created to communicate OPC

items (also known as tags) from one OPC server to another. This

configuration maps each data point exchanged between systems using

the OPC protocol.

The ProcessLinx configuration is a hierarchy of user-defined objects.

The top-level object is a Pipe. A Pipe defines which OPC Servers are

used for data exchange. It also defines the primary and secondary PC (if

available) hosts of the external OPC Server(s). The next level down is

called a Group.

Each Pipe contains Groups. Groups contain TagMap definitions. Each

Group object can contain as many TagMaps as needed, collectively

“Grouping” similar tags together. The Group is conceptually similar to

a file folder. All TagMaps in a Group have the same data update rates,

dead band, time bias and data flow direction for all TagMaps. During

runtime, each defined ProcessLinx Group creates and encapsulates an

OPC-standard Group.

A TagMap defines the source and destination OPC Items for each data

point. Each map specifies the actual OPC Item names, OPC Server

Access paths, data flow/data master, and scaling options. In runtime,

the TagMap object contains an OPC-standard Item object for each

server.

1 Publication 1757-UM002B-EN-P - January 2003

Page 22

3-2 ProcessLinx TagMap Configuration

Creating a ProcessLinx Configuration

IMPORTANT

ProcessLinx will not load or open a configuration in

runtime, the interface must be placed into configure mode

first.

To: Select:

Opening a ProcessLinx Configuration

create a ProcessLinx

configuration

save, copy or backup the

configuration

To: Select:

open an existing

ProcessLinx

configuration

edit an object such as a

Pipe, Group or TagMap

File ⇒ New…

An empty Pipe called Pipe1 displays in the tree view of the

main window.

File ⇒ Save (or) Save As… and give it a meaningful name.

The default ProcessLinx TagMap configuration filename is *.plx

file extension.

File ⇒ Open...

The file is loaded into the tree and tag view panes. The

configuration can be edited or placed into runtime mode.

When you have large taglists it takes ProcessLinx longer to

start up and load the lists into memory.

File ⇒ Properties...

In runtime mode you can edit a limited set of properties as well

as save a ProcessLinx configuration.

Creating a Pipe

Publication 1757-UM002B-EN-P - January 2003

To: Sele ct :

create a Pipe Edit ⇒ Add New Pipe... or by pressing <Ctrl+P>

configure the Pipe Edit ⇒ Properties…

Using the Pipe Properties dialog box in Figure 3.1, define the

parameters for the ProcessLogix Server and the External OPC Server.

Redundant ProcessLogix or External OPC Servers are supported if you

provide the remote node information in the respective Secondary Host

Name edit box. If redundancy is not required, leave the Secondary Host

Page 23

ProcessLinx TagMap Configuration 3-3

Name blank or set it to “localHost”.

Included in ProcessLinx 2.0 is an executable that only allows you to

create and/or Import up to 10 Pipes. Configure this setting by

creating/editing a REG_DWORD Registry key value at:

HKLM\SOFTWARE\Rockwell Software\ProcessLinx\Options\MaxPipes

The default is 10 if the Key is not found. If value is set to less than 1 the

default is set to 10 since there should always exist at least 1 Pipe.

Importing more than 10 Pipes and creating more than 10 Pipes has

been tested and in each case a Message Box will prompt you to the

actual limit allowed.

Publication 1757-UM002B-EN-P - January 2003

Page 24

3-4 ProcessLinx TagMap Configuration

Figure 3.1 Pipe Properties Dialog Box

Using the Pipe Properties dialog box

1. Select a meaningful name for the Pipe.

2. If needed, enter comments about the interface in the text description

box.

3. Enter the host name(s) and OPC Server Name(s) for the ProcessLogix

and the External OPC Server for the new Pipe.

a. To browse for an OPC Server click Select…

A “Select OPC Server” dialog box containing all installed OPC

Servers on the local machine will be displayed.

b. Select the desired external OPC Server and click OK.

Publication 1757-UM002B-EN-P - January 2003

Page 25

ProcessLinx TagMap Configuration 3-5

IMPORTANT

If the OPC Server does not show up in the list, then it has

not been properly installed or registered on the machine.

Remote servers do not have to be installed on the local

node in order to connect with them. Their OPC Class

information (GUID, refer to Preparing the Client’s User

Accounts on page 1-3) needs to be registered on the local

machine. Consult the specific OPC Vendor for

documentation on how to register an external OPC Server

to run on a remote node.

If documentation is not provided, obtain a copy of the

executable of the external OPC Server and run it once on

the local machine. Most OPC Servers will register

themselves automatically when they are executed for the

first time.

Enable

The enable checkbox enables or disables the Pipe and all of its children

(Groups and TagMaps) in runtime from communicating with each

other. Be certain to check this if you want the Pipe to run in runtime

mode, otherwise it will be disabled.

This is useful when multiple pipes are configured, and one for each of

several external servers, and at some point, one of the OPC servers or

remote system is brought down (for maintenance, for example) and you

don't want or need that pipe interfacing with the downed OPC Server.

In this case you would simply uncheck the enable checkbox for that

pipe. Otherwise, if left enabled, it may take away processing power from

the interfaces on the other pipes due to time-outs and DCOM

problems.

Status Validation

The Status Validation edit box specifies the interval for checking or

validating the OPC Server. ProcessLinx validates the status of the

primary and secondary external OPC servers at the rate specified by this

dialog. ProcessLinx uses this status to determine if a fail over to the

redundant ProcessLogix Server is required. It is specified in

milliseconds with a default of 5000.

Publication 1757-UM002B-EN-P - January 2003

Page 26

3-6 ProcessLinx TagMap Configuration

Use v1.0 OPC Interfaces

The Use v1.0 OPC Interfaces checkbox indicates that v1.0 OPC

Interfaces are used when reading/writing data with the OPC Server.

This option is for OPC Servers that do not support the v2.0 Interfaces.

By default this option is left unchecked. ProcessLinx will attempt to use

the v2.0 Interfaces if left unchecked, and will automatically revert to the

v1.0 interfaces if the Server does not support v2.0. This option allows

for the explicit selection of the 'old-style' v1.0 interfaces. If this box

becomes checked during runtime, then ProcessLinx found that the

OPC Server did not support v2.0 which may be due to a DCOM

security issue. Refer to Quick Setup on page 6-1 for more information.

Do Polling with Server (not recommended)

The Do Polling With Server checkbox enables polling of the OPC

Server at regular intervals. The Group's Group Rate specifies the polling

interval. Polling the Server implies that ProcessLinx will use the

IOPCSyncIO interface to read all items from cache at the poll interval.

This option is not recommended. If v2.0 Interfaces are working

correctly then there should be no need to read the data synchronously.

This option is provided for OPC Servers that are setup incorrectly

and/or do not support advise subscription mechanisms.

OPC Advise is provided under v1.0 with the IadviseSink Interface and

under v2.0 as the IOPCDataCallback using a ConnectionPoint. If this

box becomes checked during runtime, then ProcessLinx found that the

OPC Server did not support v1.0 Advise which may be due to a DCOM

security issue or other problems with COM. Refer to Quick Setup on

page 6-1 for more information.

Do Polling with the Server: Recommended Number of Tags

Placing an absolute limit on the number of tags is difficult since there

many dependencies, such as Processor speed, memory, OPC Server

type, OPC Server throughput, connection type (serial or Ethernet). 300

tagmaps is approximately the limit.

ProcessLogix throughput is about 280-320 values per second, so any

more tags per second that ProcessLinx has to poll, it becomes

theoretically impossible. Polling is provided as an option as a 'last resort'

effort if callbacks do not work or there is a problem (defect) in the OPC

Server. It is not recommended that the user select this option.

Publication 1757-UM002B-EN-P - January 2003

Page 27

ProcessLinx TagMap Configuration 3-7

Attempt Failover if all OPC Items are Bad Quality

This checkbox will enable or disable failover when all OPC Items are

bad Quality. This option is specifically used with ProcessLogix

redundant Server scheme but can be used with any OPC Server. The

redundant (backup) OPC Server of ProcessLogix will set all OPC Items

to 'Out-of-Service' BAD Quality when the node becomes the backup

and thus this can be used as a trigger for ProcessLinx to failover to the

redundant server. Failover for other reasons (connection time-outs,

server quit) will still automatically occur if the secondary server is

defined.

Successful Failover from one OPC90 Server to Another

A successful failover occurs when the active connected server

[Primary/Secondary] 'fails' and ProcessLinx then connects to the

configured redundant one and after which the redundant one remains

'Connected' and thus is not 'failed'. 'Server Failure' is defined below.

What Triggers a Failover

'Connected to' means that ProcessLinx can establish a link to the

configured server's OPCServer interface, add groups, add items and

have data callbacks setup. In runtime, status of the server is checked at

the periodic rate specified in the Status Validation edit box for the server

in the Pipe dialog box. The GetStatus( ) function on the OPCServer

interface is used to provide an initial decision as to whether processLinx

is connected to the server. The following are conditions that move

ProcessLinx to implement a failover (other than the OPC Server

failing).

• If the GetStatus( ) or Write( ) functions fails 5 times (meaning the

functions return a server level error or Win32 error of

RPC_C_SERVER_UNAVAILABLE) or the server status is returned as

(FAILED, NOCONFIG or SUSPENDED) then the server is marked

as 'failed' and if a redundant server is configured then ProcessLinx will

attempt to connect to that.

• If the 'Attempt failover of all OPC Items are Bad Quality' is checked in

the Pipe dialog box, then all OPC Items of every group for that server

are checked as well at the periodic rate specified in the Status Validation

edit box in the Pipe dialog box.

• If all active tags in any active group in that server are BAD Quality and

the sub-status quality is either CONFIGURATION_ERROR or

OUT_OF_SERVICE then that server is marked as 'Failed'.

Publication 1757-UM002B-EN-P - January 2003

Page 28

3-8 ProcessLinx TagMap Configuration

Creating a Group

• If just one of those active tags is GOOD or QUESTIONABLE quality

then server is not failed on the basis of 'Bad Quality' since data can be

obtained for at least one of the items. This also means that the server

cannot be 'failed' on the basis of Bad Quality if the user set all groups in

that server to Inactive (i.e. No active groups) since there will be no

active tags to check quality with.

To: Sele ct :

create a Group

The Group Properties dialog box in Figure 3.2 displays.

1. Select the Pipe

2. Select

Edit ⇒ Add New Group... from the main

menu or use <CtrlG>.

The “Add Group” function is also available when

you right mouse click on the Pipe, via a pop-up

menu.

Publication 1757-UM002B-EN-P - January 2003

Figure 3.2 Group Properties

The Group Properties dialog box allows specification of the OPC

Group parameters. These parameters affect all TagMaps and OPC

Items contained in the Group. Define a descriptive name for the new

Group. You can also enter a Group description.

Page 29

ProcessLinx TagMap Configuration 3-9

The number of Groups you can add is limited by memory and possible

OPC Server limitations. The OPC Server may set a limit on the number

of groups you can define, if the limit is exceeded then the error

CONNECT_E_ADVISELIMIT is returned and ProcessLinx will

display a message (“the server hit the Advise limit, please limit the # of

groups defined”) that is logged in the log file.

Publication 1757-UM002B-EN-P - January 2003

Page 30

3-10 ProcessLinx TagMap Configuration

Data Flow Direction

IMPORTANT

Data Flow Direction is the only parameter that cannot be

changed in runtime.

The available data flow directions between the ProcessLogix OPC

Server and the External OPC Server for all TagMaps within the Group

are:

Æ Specifies that OPC items are read from the ProcessLogix Server

and written to their map in the External Server.

ÅÆ Specifies that data flows in both directions. The data is read or

written to the ProcessLogix OPC Server and written or read

from External OPC Server.

Å Specifies that OPC items are read from the External OPC

Server and written to their maps in the ProcessLogix OPC

Server.

TIP

The Group parameters, described below, can be changed in

runtime mode. The new settings can be applied

immediately by selecting Apply or OK.

Publication 1757-UM002B-EN-P - January 2003

Page 31

ProcessLinx TagMap Configuration 3-11

Table 3.A Group Parameter Description

Parameter Description

Active Group This checkbox specifies the Group parameter’s active status. Data for

all TagMaps in the Group can only be transmitted if the Group is

active within the OPC Server in runtime. Group communication is

disabled by unchecking this option. This can be modified in runtime to

enable or disable particular Groups.

A disabled (Inactive) Group will neither receive or transmit values for

any items defined within it. All tags within an Inactive Group are still

established in runtime with the Server. You can set a Group inactive in

runtime to disable updates for all the Group’s items.

Update Rate

(mSecs)

Deadband (%) This Group parameter specifies the deadband (in percentage of value)

Time Bias Time bias offsets the time stamp of each OPC item by the specified

This Group parameter specifies the update rate (in milliseconds) for

the OPC Group and is specified to the OPC Server when the OPC

Group is created in runtime mode. The rate tells the OPC server how

often to receive data or check for changes in this Group’s OPC Items.

Most OPC Servers are exception-report based, meaning they will send

data only when it changes. However, some OPC Servers will send

data at this rate even if it does not change. This option can be

changed in runtime mode.

of an OPC Item. Most OPC Servers use this parameter to determine

when to notify a client of a change in value. If the value is noisy, you

may not want the OPC Server sending each value unless it changes by

more than this percentage.

amount. This parameter is required by the OPC standard for creating

OPC Groups within an OPC Server. It is designed to compare time

stamps of the OPC items that may exist in different time zones.

However, most OPC Servers do not utilize this parameter. ProcessLinx

neither uses nor transfers the time stamp date. Time Bias is available

for future implementation. The Default is 0.

Creating a TagMap

TagMap definitions are created within a parent ProcessLinx Group.

These definitions relate OPC Items from an external OPC Server to

OPC Items in the ProcessLogix OPC Server. A tag within the

ProcessLogix Server consists of the Point ID and parameter name (e.g.

TIC101.PIDA.SP). A tag within the External OPC Server consists of its

specific tag or Item ID representation (i.e. DEVICE, BLOCK and

PARAMETER name).

To create a TagMap:

1. Select the desired Group.

Publication 1757-UM002B-EN-P - January 2003

Page 32

3-12 ProcessLinx TagMap Configuration

2. Select Edit ⇒ Add TagMap... from the main menu or right mouse

clicking on the Group and then selecting “Add Single TagMap”. The

TagMap Definition dialog box, (shown below) displays for the TagMap

and can be edited.

Publication 1757-UM002B-EN-P - January 2003

Figure 3.3 Definition Dialog Box

Page 33

ProcessLinx TagMap Configuration 3-13

Attributes are specified as part of defining the TagMap in the above

dialog box. The TagMap parameters are defined below:

Table 3.B TagMap Parameters

Parameter Description

Description You can enter a description for the TagMap entry. This field can

be left blank if desired.

IMPORTANT: Commas are not allowed in the description.

Data Flow / Data Master Data Master defines where the data originates when starting

runtime mode. This selection is only enabled when the Group’s

“Data Flow Direction” attribute is set to both directions (

Valid entries are “ProcessLogix” or “External OPC Server”.

Starting runtime mode for bi-directional Groups produces tag

data from both OPC Servers. The Data Master entry eliminates

any ambiguity by initializing the Group’s data using the

selected OPC Server as the source.

Data Conversion Data Conversion/Scaling provides a method for translating

data. The conversions are stored in Translation Tables. Refer to

to the section Data Conversion / Scaling for details about

creating and modifying translation tables.

ÅÆ).

IMPORTANT

Each of the attributes described in Table 3.C must be

defined for both OPC Servers in the TagMap.

Publication 1757-UM002B-EN-P - January 2003

Page 34

3-14 ProcessLinx TagMap Configuration

Table 3.C TagMap Data Attributes

Attribute Description

Server The Server field displays the defined OPC Server for this half of the

TagMap.

OPC Item Use the OPC Item area to enter the specific tag in the OPC Server.

For OPC v2.0 compliant servers, “Browse” opens the database for

point-and-click OPC Item entry. When the Item is selected, its tag

name is entered in thus field.

Tip: To browse OPC Items from ProcessLogix, export the Control

Builder configuration. Refer to Creating a ProcessLinx TagMap

Configuration on page 3-15.

If you want to only monitor an item from a Server then it is not

necessary to define the OPC Item for the other Server, leave the

OPC Item field blank. In this case, the value of the undefined item

displays as <Invalid Tag> in Monitor mode. OPC items can be

added/edited in runtime.

Access Path Access Path sets the OPC path for the specific OPC Item.

For ProcessLogix OPC Server and most External OPC Servers this

can be left blank. If this parameter is implemented within the

External OPC Server, consult it’s documentation for specifics.

For example, the access path may be COM1 or COM2.

Publication 1757-UM002B-EN-P - January 2003

Page 35

ProcessLinx TagMap Configuration 3-15

Table 3.C TagMap Data Attributes

Attribute Description

Data Type Data Type displays the default OPC tag type for the selected OPC

Item.

This is set to “native” initially. In runtime, the actual OPC Item’s

data type is received from the OPC Server and subsequently

displayed.

Access The OPC Item Access displays in this field.

This attribute is defined in the Parent Group and is read only.

“Read Only” indicates that no value can be written to the OPC

Item.

“Write Only” means the OPC Item is written to and not read.

Exception reported values from the OPC Server are

disregarded if the Item is Write Only.

“Read/Write” indicates the tag is both read from and written to.

In this case, the Data Master entry defines which OPC Server

initializes.

Automatically set

Mode Attribute Tag

(MODEATTR) to

PROGRAM state

This ProcessLogix-Only selection allows proper mode conversion

between an External OPC Server and the ProcessLogix Server.

If the ProcessLogix OPC Item is a control element (such as an OP, SP

or MODE) that is written to from the External OPC Server, this must

be enabled.

In order for an external source to change the value of an OP, SP or

MODE element in ProcessLogix, it needs to set the MODEATTR tag

to PROGRAM state first and then write the value. Otherwise

ProcessLogix will reject the value. By setting this checkbox

ProcessLinx automatically sets the mode to “Program” and writes in

the new value. If the Server is not a ProcessLogix system, the

checkbox does not appear.

Creating a ProcessLinx TagMap Configuration

Once you create the ProcessLogix and the External OPC Server configuration

a ProcessLinx configuration is created.

ProcessLogix Control Points defined within Control Builder can be browsed.

Other points such as Analog, Accumulator and Status Points cannot. To make

the ProcessLogix points browseable, select the desired control blocks from

Control Builder and select File

selected control blocks to UNICODE ASCII files which ProcessLinx parses

and compiles into a browseable list of function blocks for the Tag Maps dialog

box. ProcessLinx uses this compiled list of blocks in conjunction with an OPC

item file. The item file <ProcessLinx.itm> defines all the parameters or OPC

Items for each block type found in the compiled list of function blocks.

⇒ Export. This operation exports the

(This item file should be provided by Rockwell Automation and exists within

the same directory as the ProcessLinx executable.)

Publication 1757-UM002B-EN-P - January 2003

Page 36

3-16 ProcessLinx TagMap Configuration

By default, ProcessLinx attempts to use the item file when browsing

ProcessLogix tags used to map tags. If this file does not exist then each time

the “Add TagMap(s)” function is executed it parses and compiles all exported

function block files and creates the function block list with no connectable

items to map to. If this happens, create a ProcessLinx.itm file manually by

performing the following steps:

1. Run Control Builder and export the desired blocks using the File

Export function from the main menu in ControlBuilder.

2. Stop and exit ProcessLinx.

WARNING

Rockwell Automation holds no responsibility for damages

to property and personnel or loss of time that may occur

when making changes to the Registry.

⇒

!

3. Run the Registry Editor program <Reedited> from the Start

dialog box.

4. Create and set the following keys to specified values under the branch:

<HKEY_LOCAL_MACHINE\SOFTWARE\RockwellSoftware\PrcessLinx\Options>

Table 3.D Registry Key

Registry Key to create Key Type Set the value of this key to:

⇒ Run

Publication 1757-UM002B-EN-P - January 2003

ExportBrowseFileName

ExportBrowseFile

5. Start ProcessLinx and select Add Tag Map(s).

ProcessLinx creates the specified item file to browse available points if

you have defined the HWHsc.OPCServer for the server.

6. Stop and exit ProcessLinx.

7. Delete only the 2 created registry keys above. Do not delete the

<DefaultBrowseFile> registry entry. If these 2 keys are not deleted, the

item file will be created each time the Add Tag Map(s) function is exe-

cuted.

8. Start ProcessLinx again.

9. Execute the Add Tag Map(s) function and the available items appear

STRING C:\Program Files\ProcessLogix\ProcessLinx.itm

or set the path to the location of

ProcessLinx.exe. This setting should match

the <DefaultBrowseFile> string value.

DWORD 1

Page 37

ProcessLinx TagMap Configuration 3-17

under the function blocks. Note: Some of the items are not connectable.

Data Conversion/Scaling

OPC Items

Most analog values exchanged between the ProcessLogix OPC Server

and an External OPC Server are already expressed in engineering units

and therefore, linear scaling of analog values is not required. To

accommodate discrete values not meeting this condition, TagMap

definitions allow scaling.

ProcessLogix OPC Items are accessed from one of four point

types/categories: Status points, Analog points, Accumulator points and

Control Processor points. The ProcessLogix OPC data item addressing

is:

Simple Points

Simple Points are those other than Control Processor points.

• point.parameter [/enum]

Control Processor Points

• point.block.parameter [/enum]

Table 3.E Data Addressing Terminology

Term Description

point point ID

parameter point parameter name listed in “Point Parameter Data

Addressing” section in Knowledge Builder.

Navigate to Knowledge Builder

Configuration Guide

Applications

block control module parameter for Control Processor Points.

/enum – specifies whether the parameter should be treated as an

enumerated type. Defining this after the Item name returns

the string enumerated value for the point (i.e. MAN or AUTO

for a controller mode point).

⇒Using ProcessLogix Data in Other

⇒ProcessLogix OPC Support.

⇒Server and Client

Some OPC Servers do not support string value writes from OPC

Clients, such as ProcessLinx. The “/enum” designation should be used

carefully.

Publication 1757-UM002B-EN-P - January 2003

Page 38

3-18 ProcessLinx TagMap Configuration

Some of the main parameter names along with their data types for each

ProcessLogix point type are given below.

TIP

Refer to the ProcessLogix Server and Client Configuration

Guide documentation in Knowledge Builder for a

complete listing of all supported data types. Refer to

the ProcessLogix Parameter Reference Manual

Knowledge Builder for parameter definitions.

Table 3.F Status Point Parameters

OPC Server parameter name

PV

Mode

OP

PVInError

ModeInError

OutputInError

OPC Type

VT_I4 R/W

VT_I4 R/W

VT_I4 R/W

VT_BOOL Read only

VT_BOOL Read only

VT_BOOL

OPC Access

Read only

in

Publication 1757-UM002B-EN-P - January 2003

Table 3.G Analog Point Parameters

OPC Server parameter

name

PV

Mode

OP

SP

EULO

EUHI

PVInError

OPC Type

VT_I2 R/W

VT_I4 R/W

VT_I2 R/W

VT_I2 R/W

VT_R4 Read only

VT_R4 Read only

VT_BOOL Read only

OPC Access

Page 39

Table 3.G Analog Point Parameters

ProcessLinx TagMap Configuration 3-19

ModeInError

SetPointInError

OutputInError

InLowAlarm

InHighAlarm

PointInAlarm

Table 3.H Accumulator Point Parameters

OPC Server parameter

name

PV

EUHI

VT_BOOL Read only

VT_BOOL Read only

VT_BOOL Read only

VT_BOOL Read only

VT_BOOL Read only

VT_BOOL

OPC Type

VT_I2 R/W

VT_R4 Read only

Read only

OPC Access

RawPVValue

PVInError

VT_I4 R/W

VT_BOOL

Read only

ProcessLogix Control Point parameters are dependant upon the type of

control point or function block being referenced. The following tables

display only the control points used most frequently in interfacing to

other OPC Server blocks.

Table 3.I Table 7.D Control Point Parameters for a PID or PIDA block

OPC Server parameter name

PV

MODE

OP

SP

PVEULO

OPC Type

VT_I4 R/W

VT_I4 R/W

VT_I4 R/W

VT_I4 R/W

VT_R4 Read only

OPC Access

Publication 1757-UM002B-EN-P - January 2003

Page 40

3-20 ProcessLinx TagMap Configuration

Table 3.I Table 7.D Control Point Parameters for a PID or PIDA block

PVEUHI

K

KLIN

K

T1

T2

CVEULO

CVEUHI

OPHILM

OPLOLM

SPHILM

VT_R4 Read only

VT_R4

VT_R4

VT_R4

VT_R4

VT_R4

VT_R4 Read only

VT_R4 Read only

VT_R4

VT_R4

VT_R4

SPLOLM

VT_R4

Table 3.J Control Point Parameters for a Device Control DEVCTL Function Block

OPC Server parameter

OPC Type

OPC Access

name

PV

MODE

OP

MODEATTR

Examples: HS_036.DEVCTLA.PV or pidloop.PIDA.SP.

VT_I2 R/W

VT_I2 R/W

VT_I2 R/W

VT_R4 Read only

Publication 1757-UM002B-EN-P - January 2003

Page 41

ProcessLinx TagMap Configuration 3-21

Translation Table

To enable scaling for a particular TagMap, you must define and select a

translation table. In runtime, the table converts values from one OPC

Server to valid values for the other OPC Server.

This is useful for converting the discrete mode states of a ProcessLogix

DEVCTL function block an External OPC block. You can define as

many translation tables as needed. The correct translation for the

TagMap is selected from the available list. To define a translation table,

open the TagMap Dialog box (for the TagMap) and click “Settings…”.

Figure 3.4 Data Conversion Dialog Box

• To add a new conversion table, click New… and enter a descriptive

name for the table.

• To delete a Translation table select the table and click Delete.

IMPORTANT

If any TagMaps are referencing the table, it cannot be

deleted.

• To copy a translation table, select the translation table and click Copy.

Enter a new descriptive name for the new table.

Publication 1757-UM002B-EN-P - January 2003

Page 42

3-22 ProcessLinx TagMap Configuration

• To add or edit a new translation value map for the selected translation

table, select Add.

Figure 3.5 Translation Value Dialog Box

Enter the given conversion values for either side of this translation.

Repeat the Add... step for all discrete values.

Editing a Pipe, Group or TagMap

TIP

The example in Figure 3.4 shows two ProcessLogix discrete values

mapped to an External OPC Server. In ProcessLogix, the enumerated

values for auto and manual are 1 and 2 respectively, 1 and 0 in the

external system. This map sets the ProcessLogix Auto Mode Value (1)

to the External Value (1). It also sets the ProcessLogix Manual Value (2)

to the External Manual Value (0).

After the Translation table and value maps are setup, click OK and the

TagMap will be set to use this translation table. If o conversion map is

defined, the value is sent as-is to the other OPC Item defined in the

TagMap.

To edit a Pipe, Group or TagMap simply double-click on the object or

select the object and then select Edit ⇒ Properties… from the main

menu or right mouse click on the object and select “Properties…” from

the pop-up menu. Most object properties can be edited in runtime.

ProcessLinx supports changing an OPC Item reference in runtime.

Translations can be added and edited using CSV

files.

Refer to Import/Export on page 5-1 for more

information.

Copying/Moving TagMaps between Groups

Publication 1757-UM002B-EN-P - January 2003

In configure mode, one or more TagMaps can be copied or moved from

one Group to another. Select the TagMaps to copy or move and drag

them to the desired Group. You can select Multiple TagMaps by holding

down the Control or shift keys.

Page 43

ProcessLinx TagMap Configuration 3-23

If you hold down the <Control> key before you drop the object(s), the

objects are copied to the desired Group. Otherwise the TagMaps are

moved to the new Group.

Multiple TagMap Configuration

Multiple tags can be mapped quickly using the “Map Tags” dialog box.

Highlight the desired Group and Select Edit ⇒ Add TagMap(s)...

from the main menu or press <Ctrl T> or right mouse click on the

Group and select Add TagMap(s)….

Figure 3.6 Multiple TagMap Dialog Box

This dialog box displays two tree views. To enable this view and have

Publication 1757-UM002B-EN-P - January 2003

Page 44

3-24 ProcessLinx TagMap Configuration

browse capability the External Server must be registered on the local

PC. Each pane contains a tree view listing of all available OPC items

within the Server.

You select an OPC item on one side and the corresponding item to map

to on the other and click ÅMAPÆ. Alternatively, the user can select an

item from one side and drag it into an OPC Item on the other to create

a tag mapping.

The data flow direction is decided by the direction of the Parent Group.

The tags mapped during the current session are displayed in the

“Selected Mappings” window. Selecting cancel, clears all selected maps

for the current session.

To remove a TagMap from an edit session, select the TagMap you want

to delete in the “Selected Mappings” pane and press Delete. Clicking

OK accepts the new maps (if any) and loads them under the current

Group. TagMaps can be added in runtime mode.

Testing a ProcessLinx Configuration

In ProcessLogix R500 systems, it may be necessary to define groups of

tags within ProcessLogix into Areas. The Areas will display in the OPC

Server address space.

In ProcessLogix R400 systems, the Top Level (root) Node in the

Browse Tree was displayed with an asterisks and all items could then be

defined from this top level name (such as *.FC151.PIDA.SP).

ProcessLogix R500 systems still support the use of the * as a prefix on

an OPC Item but are now displayed under the defined area.

A ProcessLinx configuration can be tested after the above steps are

implemented. It is recommended at the initial onset of testing the

ProcessLinx interface that you set the debug mode to 5, turn on the

Show flags (i.e. Show Errors, Show Events and Show Send), and specify

an error log directory to view any errors. You can use the View ⇒

Monitor function to view the data tag values in real time while testing.

After all TagMaps have been successfully setup and are working

according to the Interface Control Strategy in step 3.3, turn off the

debug flags with the exception of the Show Errors flag.

Publication 1757-UM002B-EN-P - January 2003

Page 45

Chapter

4

ProcessLinx Runtime Operation

Each Pipe created in ProcessLinx provides a conduit to pass information

between OPC Servers. An OPC Server cannot communicate directly to

another OPC Server. Each OPC Server expects responses that are normally

received from an OPC Client. ProcessLinx uses OPC Client responses to

receive data from one OPC Server and transmit it to another OPC Server.

When runtime mode is started, the Groups defined in each ProcessLinx Pipe

are created in the respective OPC Servers. Then, all OPC Items defined by the

Groups’ TagMaps are added. Data is transferred from OPC Server to OPC

Server based on the Group’s settings. The OPC Groups and Items in disabled

Pipes are not connected to in runtime. The Enable checkbox is found in the

Pipe Properties Dialog.

Monitoring Values

In runtime, monitor OPC Items by selecting View ⇒Monitor from the main

menu. Current values appear under the Va lu e1 and Val ue 2 columns in the tag

view pane. If the Server or Group is not connected (or is disabled), the values

are displayed as “Uncertain” or “Bad”. Monitored values are refreshed every

100 milliseconds. Select another Group to view its TagMap values.

IMPORTANT

TIP

Groups that have “write only” data flow may not present

the latest available data from the OPC Server. The

displayed value is the last value written to the OPC Server.

No OPC Server “reads” are executed for these Group

types.

If the tagmap displays with a !, then one or both of the

OPC Items defined within that tagmap are invalid. This

means that the OPC Item does not exist within the Server

or is mis-configured in the ProcessLinx with an incorrect

item name.

Reading OPC Values

1 Publication 1757-UM002B-EN-P - January 2003

ProcessLinx allows any OPC Item to be read during runtime. Select and right

mouse click on the desired TagMap’s OPCItem1 column in Select Read

OPCItem1 or OPCItem2 from the corresponding pop-up menu.

⇒

Page 46

4-2 ProcessLinx Runtime Operation

Writing OPC Values

In runtime, values can be manually written to an OPC Item. Select and right

mouse click on the desired TagMap’s OPCItem1 column. Select Write

OPCItem1 or OPCItem2 from the corresponding pop-up menu.

⇒

Figure 4.1 Writing to an OPC item

Enter the new value in the Current Value field. Click WRITE to force an OPC

write to the specified OPC Item. To verify the value was correctly written, click

READ. WRITE is disabled if the Group data flow property for this Item is set

to “read”.

TIP

The Write Tag dialog box helps debug OPC Item problems. If the OPC Server

for this item has an available sub-status message, it displays in the Message

field.

A ‘?’ displayed for Current Value and/or Current Quality

indicates that the value for the OPC Item is suspect. This

could be the result of an invalid tag reference or a

disconnected OPC Server.

Publication 1757-UM002B-EN-P - January 2003

Page 47

ProcessLinx Runtime Operation 4-3

Redundant OPC Servers / Fail over

ProcessLinx supports redundant OPC Servers using networked hosts. The

Primary and Secondary hosts are configured in the Pipe dialog box. When

runtime mode is started, each Pipe connection is attempted with the defined

primary host. If that connection attempt fails, a new attempt is sent to the

secondary host. If both attempts fail, ProcessLinx control mode is set to

Configure for the user to correct the situation.

After startup, if communication to an OPC Server fails, ProcessLinx

implements a “cold fail-over”. In this case, ProcessLinx disconnects all OPC

links to the “failed” Server and attempts a switch to the redundant Server.

In the first step of the fail-over, ProcessLinx verifies that a redundant Server is

configured. A network ping is sent to the new remote node to verify its

availability. A connection attempt is made to the specified OPC Server on that

node. If the connection attempt succeeds, the switchover is complete. If it

does not succeed, ProcessLinx attempts to re-connect for the “Number of

Retries” specified in the Utility

After the number of retries has been exceeded, ProcessLinx attempts to fail

over to the first Server. This connection attempt / fail over process continues

until a successful connection has been established. Messages for each failed

attempt are logged to the ProcessLinx message pane and error log. Refer

to What Triggers a Failover on page 3-7

⇒ Configure Options menu.

For redundancy to work properly, OPC Items must be configured identically in

the redundant OPC Server pair. If an OPC Item called “Device1.PV1” exists

in the primary OPC Server’s configuration, an OPC Item called

“Device1.PV1” must also exist in the secondary OPC Server’s configuration.

Missing OPC Items will fail and display Invalid OPC Item message. The OPC

Server still indicates running, but one or more OPC Items may not have valid

data.

Publication 1757-UM002B-EN-P - January 2003

Page 48

4-4 ProcessLinx Runtime Operation

Server Status

You can view the runtime status of each Pipe’s OPC Servers. Select Utility ⇒

Server Status…. Or right mouse click on a Pipe or Group and click Server

Status.

Publication 1757-UM002B-EN-P - January 2003

Figure 4.2 Server Status Dialog Box

A switchover to the redundant OPC Server can be forced by clicking Switch

Server. If a redundant Server is not defined, ProcessLinx disconnects from the

primary Server and then reconnects to it. If a redundant Server is defined,

ProcessLinx attempts a connection to it. ProcessLinx attempts the connection

for the “Number of Retries” specified in the Utility

menu. After the number of retries has been exceeded, ProcessLinx then

attempts to fail over to the first Server. This connection attempt / fail over

process continues until a successful connection has been established. Messages

for each failed attempt are logged to the ProcessLinx message pane and error

log.

⇒ Configure Options

Page 49

ProcessLinx Runtime Operation 4-5

Verifying OPC Tags

In runtime, you can verify the status of all active OPC Items. Select Utility ⇒

Veri f y O PC Ta gs from the main menu to check all OPC Items. If an error is

found, a message is displayed in the Message pane. A successful verification

displays these messages:

MSG:: Verifying OPC Tags in Server A...

MSG:: OPC Tags Verified!

MSG:: Verifying OPC Tags in Server B...

MSG:: OPC Tags Verified

When you select the ‘Verify Tags...’ option from the Main Menu in runtime

mode, ProcessLinx verifies each Pipe. For each Pipe both Servers are checked

to see if there is a connection to them, if so then each Active Group of each

client is verified. If not then an error is logged.

Verifying a group means that for each tag in each group ProcessLinx checks

that the tag is active and that is has a connection to its corresponding item in

the Server. If it does not, then a message displays for that item in the Message

pane. A message also displays for each Inactive Group.

Ping

OPCShutdown

The ping function verifies access to a remote node. To ping a remote node,

select Utility

host machine’s name or IP Address and click OK. The node’s status is

displayed in the Message pane. A successful Ping displays the message

“Ping>Host <localhost> is alive!” where localhost is the desired host machine’s

name. A failed Ping message also indicates that the host is unreachable or is

not responding due to a timeout or a network connection problem.

In runtime, ProcessLinx supports the IOPCShutdown interface and the

Shutdown Request functionality from OPC Servers. If supported by the OPC

Server, when the Server needs to shutdown, it can use this interface to send a

shutdown request to ProcessLinx. ProcessLinx will then disconnect all items,

groups and interfaces connected with that Server and will wait the amount of

time specified by the 'Retry Wait Period' before attempting a connection to the

redundant node (if configured).

If redundancy is not defined then ProcessLinx will attempt to connect to the

original Server. The Server must be designed to not start up again (or deny

access) if it is truly 'shutdown'. ProcessLinx will enter an infinite retry loop

where it will continue to try reconnecting with that Server at the 'Retry Wait

Period' until connection is re-established.

⇒ Ping... from the main menu. In the Ping dialog box, enter the

Publication 1757-UM002B-EN-P - January 2003

Page 50

4-6 ProcessLinx Runtime Operation

Notes:

Publication 1757-UM002B-EN-P - January 2003

Page 51

Chapter

5

Import/Export

This chapter provides ProcessLinx TagMap import/export examples. Using

the Import/Export functions, you can edit configurations via text based,

comma-separated-value (CSV) files such as the ProcessLinx configuration

which is stored in a binary file.

To: Sele ct :

export an open

ProcessLinx TagMap

configuration

TIP: Use File

Configuration before attempting a file import operation.

A ProcessLinx configuration can be imported into a new or an existing file.

Open or create a configuration.

To: Sele ct :

import a configuration

ProcessLinx checks the Pipe names in the import file against the Pipe names

in the open configuration. If duplicate Pipe names are found, ProcessLinx

prompts you as show in Figure 5.1.

⇒ Save As… to back up the existing ProcessLinx TagMap

File

⇒ Export CSV…

Enter an export filename and click OK. Edit the

export file using Note Pad, Excel, etc. Be sure to

follow the format and convention described later

in this section.

⇒ Import CSV…

File

Use the dialog box to find and select the desired

CSV file.

Click Open to import the new data. If the import

function fails, an error message is displayed in the

Message pane.

Figure 5.1 Import Confirmation

1 Publication 1757-UM002B-EN-P - January 2003

Page 52

5-2 Import/Export

When you choose Yes, to overwrite the existing Pipe with the import

information, ProcessLinx adds the new Groups, TagMaps, and Translation

Tables to the existing Pipe. The following also occurs:

• All existing Groups and Translation Tables are overwritten with the

settings from the CSV file.

• Existing TagMaps are not overwritten. ProcessLinx adds duplicate

TagMaps.

• Delete TagMaps from the existing configuration before they are

imported again.

If you choose No, to import the data to a new Pipe. ProcessLinx prompts you

for a new Pipe name.

TIP

TagMaps can be dragged from one Group and copied or

dropped into another Group.

Choose Cancel, to abort the import operation.

Publication 1757-UM002B-EN-P - January 2003

Page 53

Import/Export 5-3

CSV File Formats

A CSV file is an ASCII Text file that contains fields delimited by commas. Text

editors, spreadsheet programs, and database packages can create, edit, and save