Page 1

SLC 500

Thermocouple/mV

Analog Input

Module

1746-NT8

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Page 3

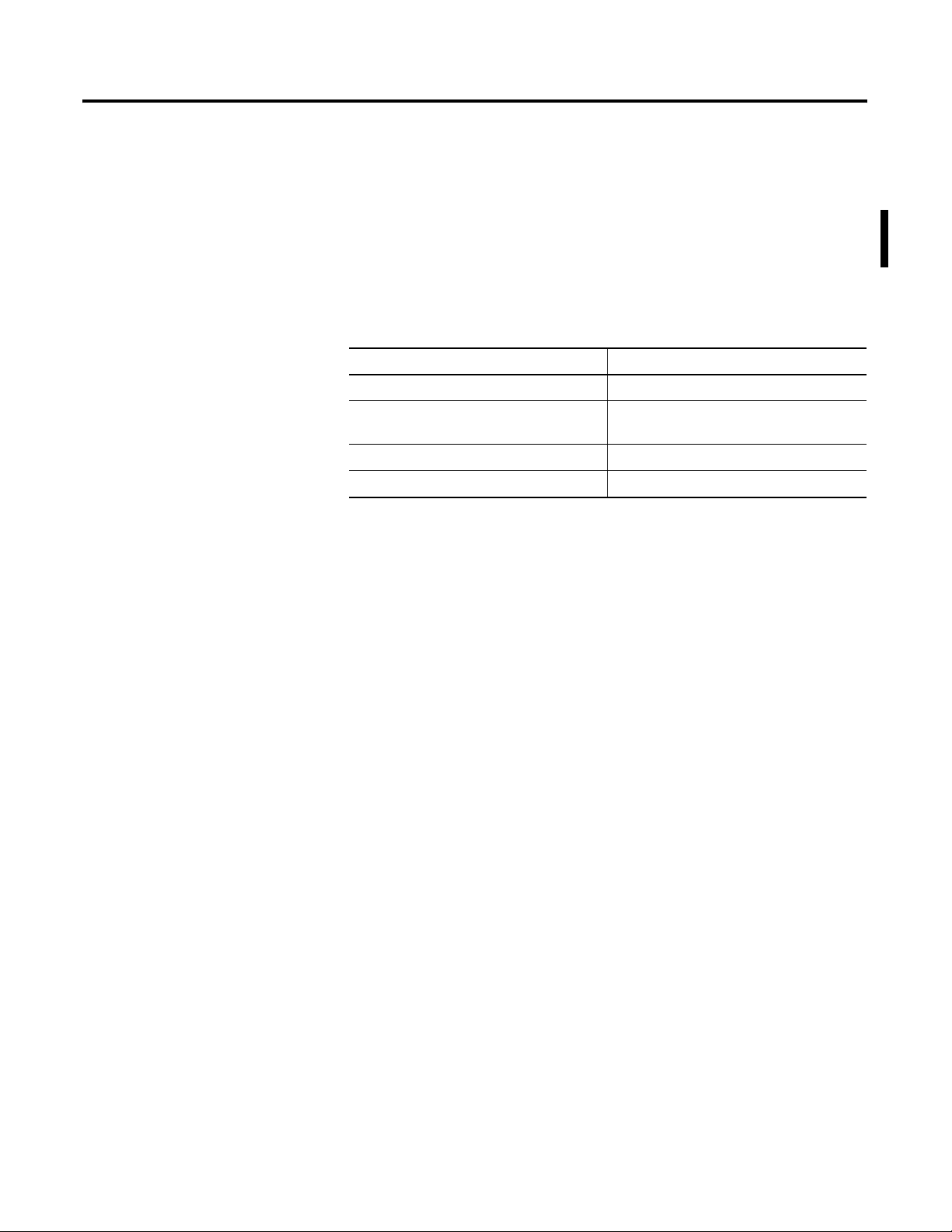

Table of Contents

Preface

Module Overview

Installing And Wiring Your

Module

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . P-1

What This Manual Covers . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Common Techniques Used in this Manual . . . . . . . . . . . . . P-2

Chapter 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Input Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Diagnostic LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Linear Millivolt Device Compatibility. . . . . . . . . . . . . . . 1-7

Chapter 2

Electrostatic Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Considerations for a Modular System . . . . . . . . . . . . . . 2-2

Fixed I/O Chassis - I/O Module Compatibility . . . . . . . . 2-3

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Module Installation and Removal . . . . . . . . . . . . . . . . . . . . 2-5

Terminal Block Removal . . . . . . . . . . . . . . . . . . . . . . . 2-6

Wiring Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Preparing and Wiring the Cables . . . . . . . . . . . . . . . . . 2-9

Cold-Junction Compensation (CJC) . . . . . . . . . . . . . . . . 2-11

Chapter 3

Considerations Before Using Your

Module

i Publication 1746-UM022B-EN-P - January 2005

Module ID Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Output Image - Configuration Words . . . . . . . . . . . . . . 3-2

Input Image - Data Words and Status Words. . . . . . . . . 3-3

Channel Filter Frequency Selection . . . . . . . . . . . . . . . . . . 3-3

Channel Cut-Off Frequencyc . . . . . . . . . . . . . . . . . . . . 3-4

Channel Step Response . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Update Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Update Time Calculation Example . . . . . . . . . . . . . . . . 3-8

Channel Turn-On, Turn-Off, and Reconfiguration Times . . . 3-8

Auto-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Response to Slot Disabling . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Input Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Output Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Page 4

Table of Contents ii

Channel Configuration, Data, and

Status

Chapter 4

Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Channel Configuration Procedure . . . . . . . . . . . . . . . . . . . 4-2

Select Channel Enable (Bit 0) . . . . . . . . . . . . . . . . . . . . 4-5

Select Input Types (Bits 1 through 4) . . . . . . . . . . . . . . 4-5

Select Data Format (Bits 5 and 6) . . . . . . . . . . . . . . . . . 4-5

Using Scaled-for-PID and Proportional Counts . . . . . . . 4-6

Effective Resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Scaling Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Select Open-Circuit State (Bits 7 and 8). . . . . . . . . . . . . 4-9

Select Temperature Units (Bit 9) . . . . . . . . . . . . . . . . . . 4-10

Select Channel Filter Frequency (Bits 10 and 11) . . . . . . 4-10

Unused Bits (Bits 12 through 14) . . . . . . . . . . . . . . . . . 4-11

Select Input Image Type (Bit 15) . . . . . . . . . . . . . . . . . 4-11

Channel Data/Status Word. . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Channel Status Checking . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Channel Status (Bit 0) . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Input Type Status (Bits 1 through 4) . . . . . . . . . . . . . . . 4-14

Data Format Type Status (Bits 5 and 6) . . . . . . . . . . . . . 4-14

Open-Circuit Type Status (Bits 7 and 8) . . . . . . . . . . . . 4-14

Temperature Units Type Status (Bit 9). . . . . . . . . . . . . . 4-14

Channel Filter Frequency (Bits 10 and 11). . . . . . . . . . . 4-15

Open-Circuit E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Under-Range Error (Bit 13). . . . . . . . . . . . . . . . . . . . . . 4-15

Over-Range Error (Bit 14). . . . . . . . . . . . . . . . . . . . . . . 4-15

Channel Error (Bit 15) . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Programming Examples

Troubleshooting Your Module

Publication 1746-UM022B-EN-P - January 2005

Chapter 5

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Automatic Monitoring Thermocouples and CJC Sensors . . . 5-3

Verifying Configuration Changes . . . . . . . . . . . . . . . . . . . . 5-3

Interfacing to the PID Instruction. . . . . . . . . . . . . . . . . . . . 5-7

Monitoring Channel Status Bits . . . . . . . . . . . . . . . . . . . . . 5-8

Monitoring Channel Status Bits Example . . . . . . . . . . . . 5-9

PLC 5 Example with NT8 in Remote I/O Rack . . . . . . . . . . 5-13

SLC 500 Example with NT8 in Remote I/O Rack. . . . . . . . . 5-15

Chapter 6

Module and Channel Diagnostics. . . . . . . . . . . . . . . . . . . . 6-1

Module Diagnostics at Powerup . . . . . . . . . . . . . . . . . . 6-1

Channel Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

LED Troubleshooting Tables. . . . . . . . . . . . . . . . . . . . . 6-3

Channel-status LEDs (Green) . . . . . . . . . . . . . . . . . . . . 6-4

Open-circuit Detection (Bit 12). . . . . . . . . . . . . . . . . . . 6-4

Page 5

Maintaining Your Module And

Safety Considerations

Module Specifications

Table of Contents iii

Out-of-Range Detection (Bit 13 for Under Range, Bit 14 for

Over Range) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Channel Error (Bit 15) . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Module Status LED (Green) . . . . . . . . . . . . . . . . . . . . . 6-5

Interpreting I/O Error Codes . . . . . . . . . . . . . . . . . . . . . . . 6-5

Chapter 7

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Appendix A

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . A-2

Input Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Overall Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Millivolt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Thermocouple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Using Grounded Junction,

Ungrounded Junction, and

Exposed Junction Thermocouples

Configuring the 1746-NT8 Module

with RSLogix 500

Appendix B

Thermocouple Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Grounded Junction . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Ungrounded (Insulated) Junction . . . . . . . . . . . . . . . . . B-2

Exposed Junction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Grounded Junction . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Exposed Junction Thermocouples. . . . . . . . . . . . . . . . . B-4

Appendix C

Glossary

Index

Publication 1746-UM022B-EN-P - January 2005

Page 6

Table of Contents iv

Publication 1746-UM022B-EN-P - January 2005

Page 7

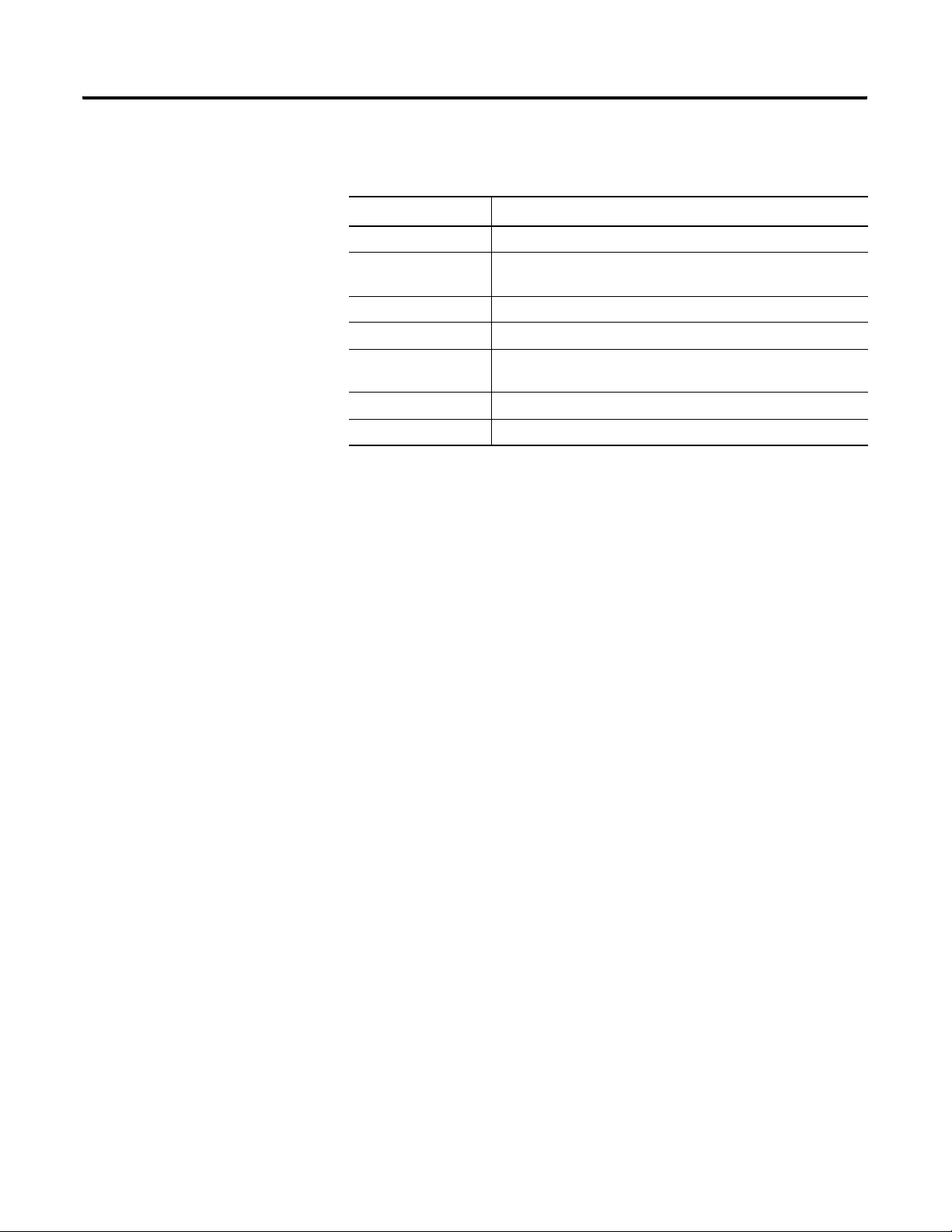

Summary of Changes

The information below summarizes the changes to this manual since

the last printing. Updates to the manual include using RSLogix 500

instead of APS software.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

The table below lists the sections that document new features and

additional or updated information on existing features.

For this information: See

updated data table for initial programming page 5-2

added SLC 500 example with NT8 in

Remote I/O Rack

updated thermocouple graphs page A-8

configuring NT8 with RSLogix 500 page C-1

page 5-15

1 Publication 1746-UM022B-EN-P - January 2005

Page 8

Summary of Changes 2

Publication 1746-UM022B-EN-P - January 2005

Page 9

Preface

Read this preface to familiarize yourself with this user manual. This

preface covers:

• who should use this manual

• what this manual provides

• related documents

• common techniques used in this manual

Who Should Use This Manual

What This Manual Covers

Use this manual if you design, install, program, or maintain a control

system that uses SLC 500 controllers.

You should have a basic understanding of SLC 500 products. You

should also understand electronic process control and the ladder

program instructions required to generate the electronic signals that

control your application. If you do not, contact your local Rockwell

Automation representative for the proper training before using these

products.

This manual covers the 1746-NT8 thermocouple/millivolt analog input

module. It contains the information you need to install, wire, use, and

maintain these modules. It also provides diagnostic and

troubleshooting help should the need arise.

1 Publication 1746-UM022B-EN-P - January 2005

Page 10

Preface 2

Related Documentation

The following table lists several Rockwell Automation documents that

may help you as you use these products.

Publication Number

1746-SG001 SLC 500™ Systems Selection Guide

SGI-1.1 Safety Guidlines for the Application, Installation and

1770-4.1 Industrial Automation Wiringing and Grounding Guidelines

1747-UM011 SLC 500 Modular Modular Hardware Style User Manual

1747-6.21 Installation & Operation Manual for Fixed Hardware Style

1747-RM001 SLC 500 Instruction Set Reference Manual

AG-7.1 Allen-Bradley Industrial Automation Glossary

Title

Maintenance of Solid State Controllers

Programmable Controllers

If you would like to:

• view and download the publication, go to Literature Library at

http://www.rockwellautomation.com/literature

• order printed copies, contact your Allen-Bradley Distributor or

Rockwell Automation Sales Office.

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Text in this font indicates words or phrases you should type.

• Key names appear in bold, capital letters within brackets (for

example, [ENTER]).

Publication 1746-UM022B-EN-P - January 2005

Page 11

Chapter

1

Module Overview

This chapter describes the thermocouple/mV input module and

explains how the SLC 500 processor reads thermocouple or millivolt

analog input data from the module.

Read this chapter to familiarize yourself further with your

thermocouple/mV analog input module. This chapter covers:

• general description and hardware features

• an overview of system and module operation

• block diagram of channel input circuits

General Description

This module mounts into 1746 I/O chassis for use with SLC 500 fixed

and modular systems. The module stores digitally converted

thermocouple/mV analog data in its image table for retrieval by all

fixed and modular SLC 500 processors. The module supports

connections from any combination of up to eight thermocouple/mV

analog sensors.

Input Ranges

The following tables define thermocouple types and associated

temperature ranges and the millivolt analog input signal ranges that

each of the module’s input channels support. To determine the

practical temperature range of your thermocouple, refer to the

specifications in Appendix A.

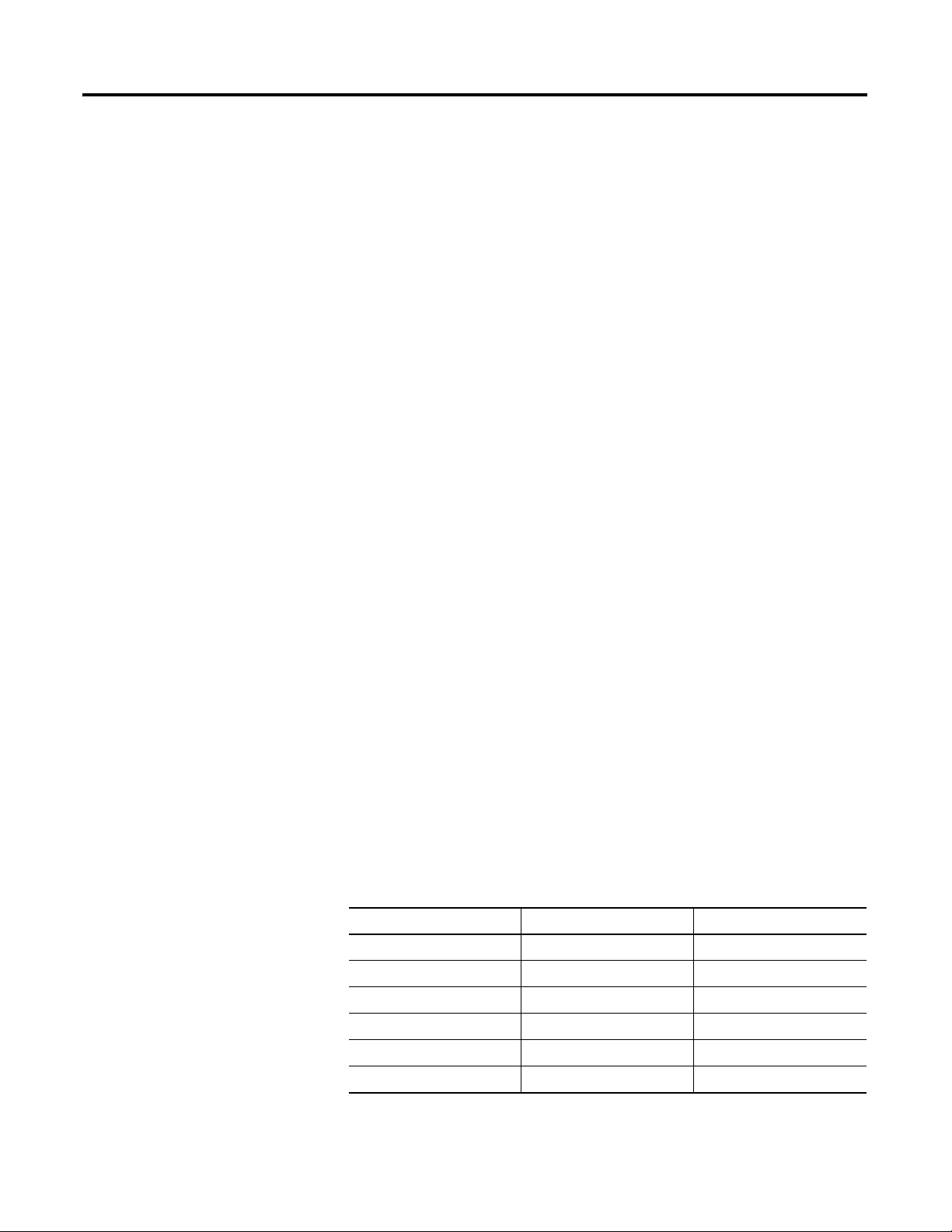

Thermocouple Temperature Ranges

Type °C Temperature Range °F Temperature Range

J -210°C to +760°C -346°F to +1400°F

K -270°C to +1370°C -454°F to +2498°F

T -270°C to +400°C -454°F to +752°F

B +300°C to +1820°C +572°C to +3308°F

E -270°C to +1000°C -454°F to +1832°F

R 0°C to +1768°C +32 F to +3214°F

1 Publication 1746-UM022B-EN-P - January 2005

Page 12

1-2 Module Overview

Type °C Temperature Range °F Temperature Range

S 0°C to +1768°C +32°F to +3214°F

N 0°C to +1300°C +32°F to +2372°F

CJC Sensor -25°C to +105°C -13°F to +221 °F

Millivolt Input Ranges

-50 to +50 mV

-100 to +100 mV

(1)

Each input channel is individually configured for a specific input

device, and provides open-circuit, over-range, and under-range

detection and indication.

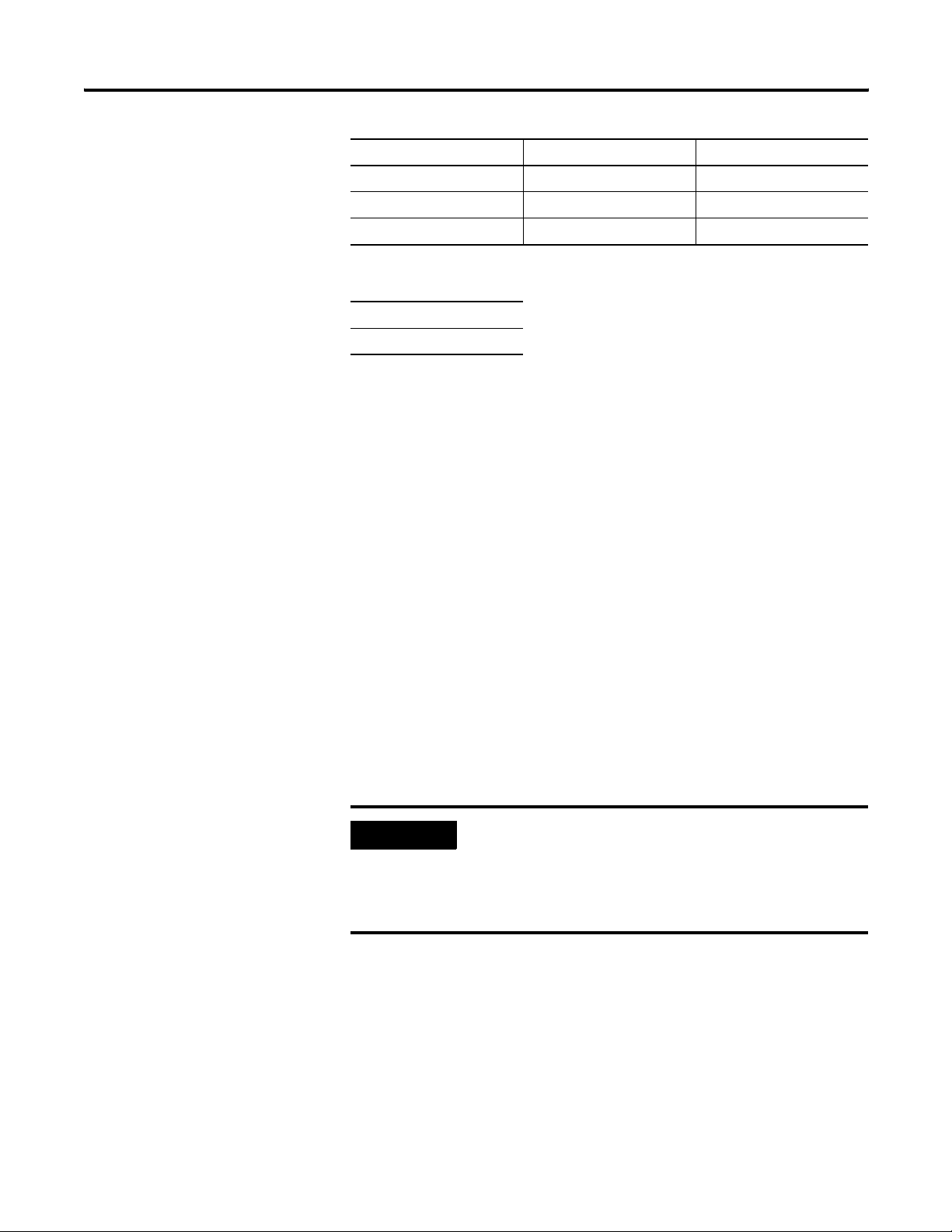

Hardware Features

The module fits into any single slot for I/O modules in either an SLC

500 modular system or an SLC 500 fixed system expansion chassis

(1746-A2), except the zero slot which is reserved for the processor. It

is a Class 1 module using 8 input words and 8 output words.

The module contains a removable terminal block providing

connections for eight thermocouple and/or analog input devices. On

the terminal block are two cold-junction compensation (CJC) sensors

that compensate for the cold junction at ambient temperature. It

should also be noted there are no output channels on the module.

Configure the module with software rather than with jumpers or

switches.

(2)

Publication 1746-UM022B-EN-P - January 2005

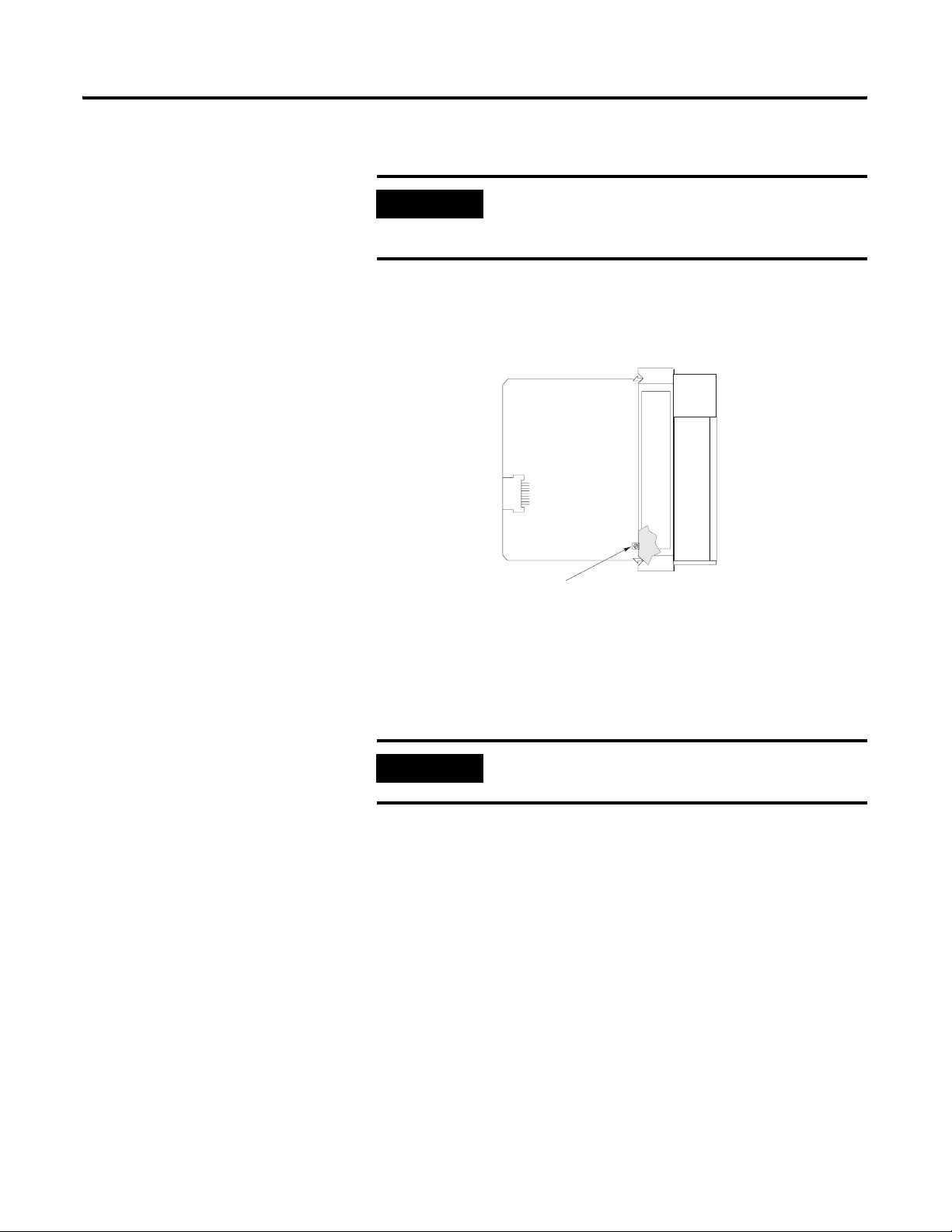

IMPORTANT

There is a jumper (JP1) on the circuit board. The

module is shipped with the jumper in the up

position as illustrated below. Do not change the

position of JP1. The jumper is used for test purposes

only.

(1) Output impedance of input device must be less than 100 ohm to meet accuracy specifications.

(2) Requires use of a Block Transfer when used in a remote rack with a 1747-ASB.

Page 13

Module Overview 1-3

Channel Status

LEDs (green)

Module Status

LEDs (green)

Removable

Terminal Block

CJC Sensors

Cable Tie Slots

INPUT

CHANNEL

014

5

2

123

Door Label

1746-NT8

CJC A+

CJC ACHL 0+

CHL 0SHIELD

CHL 1+

CHL 1CHL 2+

CHL 2SHIELD

CHL 3+

CHL 3CHL 4+

CHL 4SHIELD

CHL 5+

CHL 5CHL 6+

CHL 6SHIELD

CHL 7+

CHL 7CJC B+

CJC B-

Jumper - Do not move

JP1

Self-Locking Tabs

STATUS

MODULE

THERMOCOUPLE/mV

Side Label

CAT

SERIAL NO.

1746 NT4

NT4±xxx x

THERMOCOUPLE/mV INPUT MODULE

SLC 500

SER

FRN

)

CLASS I, GROUPS A, B, C AND D, DIV.2

U

L

FOR HAZ. LOC. A196

LISTED IND. CONT . EQ.

SA

)

OPERA TING

TEMPERA TURE

CODE T3C

THERMOCOUPLE TYPES:

VOLTAGE:

INPUT SIGNAL RANGES

±100mVDC to +100mVDC

±50mVDC to +50mVDC

J, K, T, E, R, S, B, N

MADE IN USAFAC 1M

Hardware Features

Hardware Function

Channel Status LED Indicators Display operating and fault status of

channels 0 to 7

Module Status LED Displays operating and fault status of the

module

Side Label (Nameplate) Provides module information

Removable Terminal Block Provides electrical connection to input

devices

System Overview

Door Label Permits easy terminal identification

Cable Tie Slots Secure and route wiring from module

Self Locking Tabs Secure module in chassis slot

Diagnostic LEDs

The module contains diagnostic LEDs that help you identify the

source of problems that may occur during power-up or during normal

operation. Power-up and channel diagnostics are explained in

Chapter 6, Testing Your Module.

The module communicates with the SLC 500 processor and receives

+5V dc and +24V dc power from the system power supply through

the parallel backplane interface. No external power supply is

required. You may install as many thermocouple modules in the

system as the power supply can support.

Publication 1746-UM022B-EN-P - January 2005

Page 14

1-4 Module Overview

Each module channel can receive input signals from a thermocouple

or a mV analog input device. You configure each channel to accept

either one. When configured for thermocouple input types, the

module converts analog input voltages into cold-junction

compensated and linearized, digital temperature readings. The

module uses National Institute of Standards and Technology (NIST)

ITS-90 for thermocouple linearization.

When configured for millivolt analog inputs, the module converts

analog values directly into digital counts. The module assumes that

the mV input signal is linear.

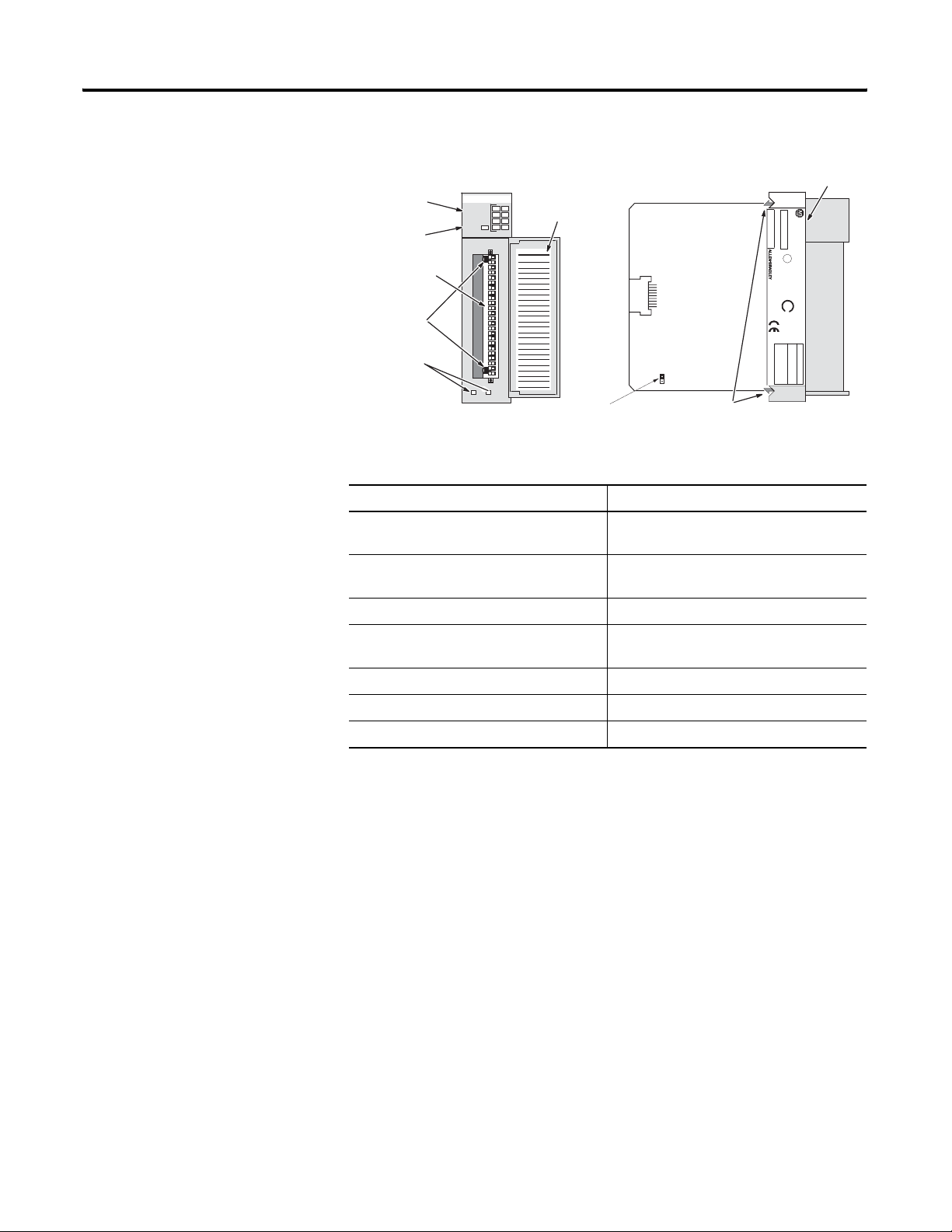

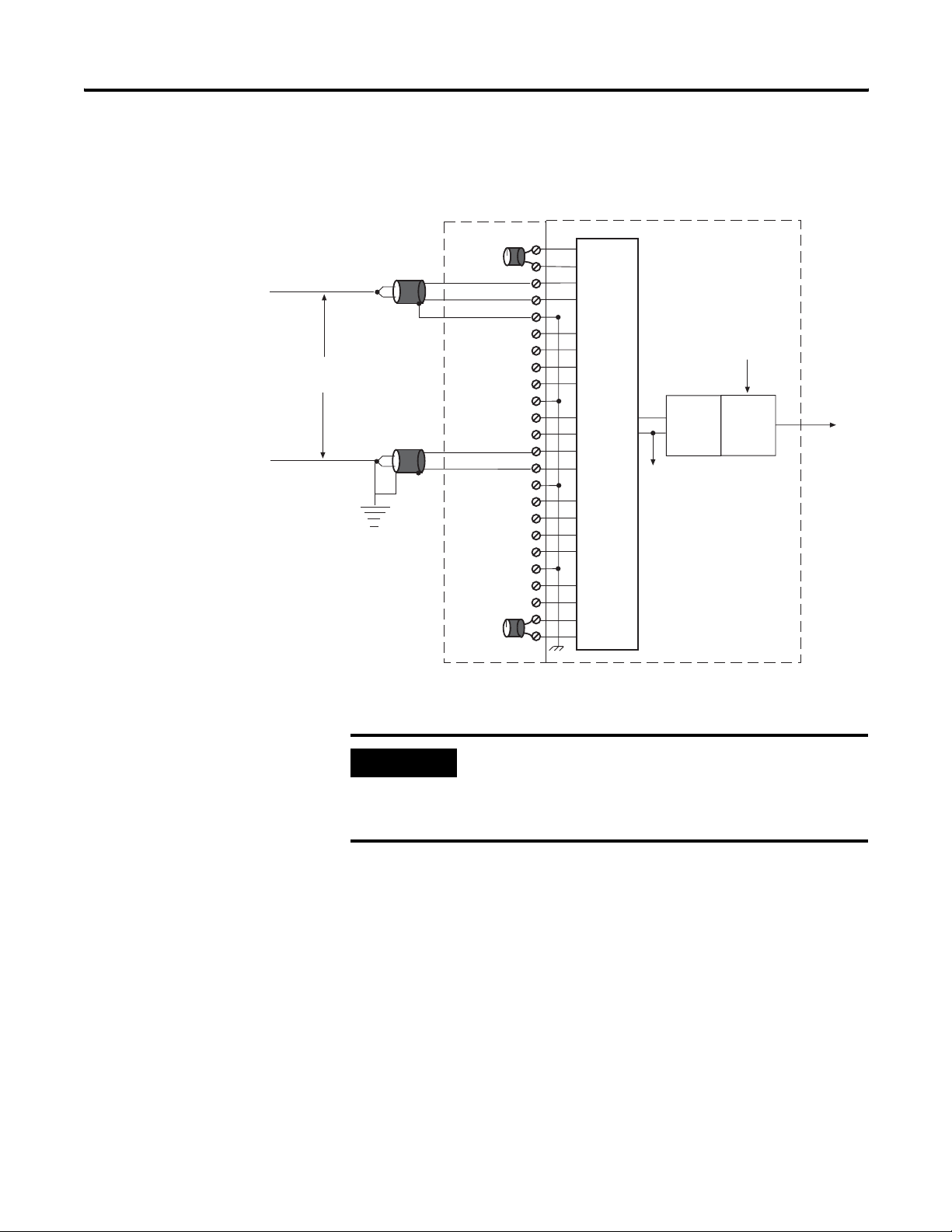

System Operation

At power-up, the module checks its internal circuits, memory, and

basic functions. During this time the module status LED remains off. If

the module finds no faults, it turns on its module status LED.

Channel Data Word

Channel Status Word

Therm ocouple or mV

Analog Signals

Thermocou ple

Input

Module

Channel Co nfiguration Word

SL C 5 00

P rocess or

After completing power-up checks, the module waits for valid channel

configuration data from your SLC ladder logic program (channel status

LEDs are off). After channel configuration data is transferred and

channel enable bits are set, the enabled channel status LEDs turn on.

Then the channel continuously converts the thermocouple or millivolt

input to a value within the range you selected for the channel.

Each time the module reads an input channel, the module tests that

data for a fault, i.e. over-range or under-range condition. If open

circuit detection is enabled, the module tests for an open-circuit

condition. If it detects an open-circuit, over-range, or under-range

condition, the module sets a unique bit in the channel status word

and causes the channel status LED to flash.

The SLC processor reads the converted thermocouple or millivolt data

from the module at the end of the program scan, or when

commanded by the ladder program. After the processor and module

determine that the data transfer was made without error, the data can

be used in your ladder program.

Publication 1746-UM022B-EN-P - January 2005

Page 15

Module Overview 1-5

Module Operation

The module’s input circuitry consists of eight differential analog

inputs, multiplexed into an A/D convertor. The A/D convertor reads

the analog input signals and converts them to a digital value. The

input circuitry also continuously samples the CJC sensors and

compensates for temperature changes at the cold junction (terminal

block).

Module Addressing

The module requires eight words each in the SLC processor’s input

and output image tables. Addresses for the module in slot e are as

follows:

I:e.0-7 thermocouple/mV or status data for channels 0 to 7,

respectively (dependent on bit in configuration word).

O:e.0-7 configuration data for channels 0 to 7, respectively.

See Module Addressing on page 3-2 to see the module’s image table.

Publication 1746-UM022B-EN-P - January 2005

Page 16

1-6 Module Overview

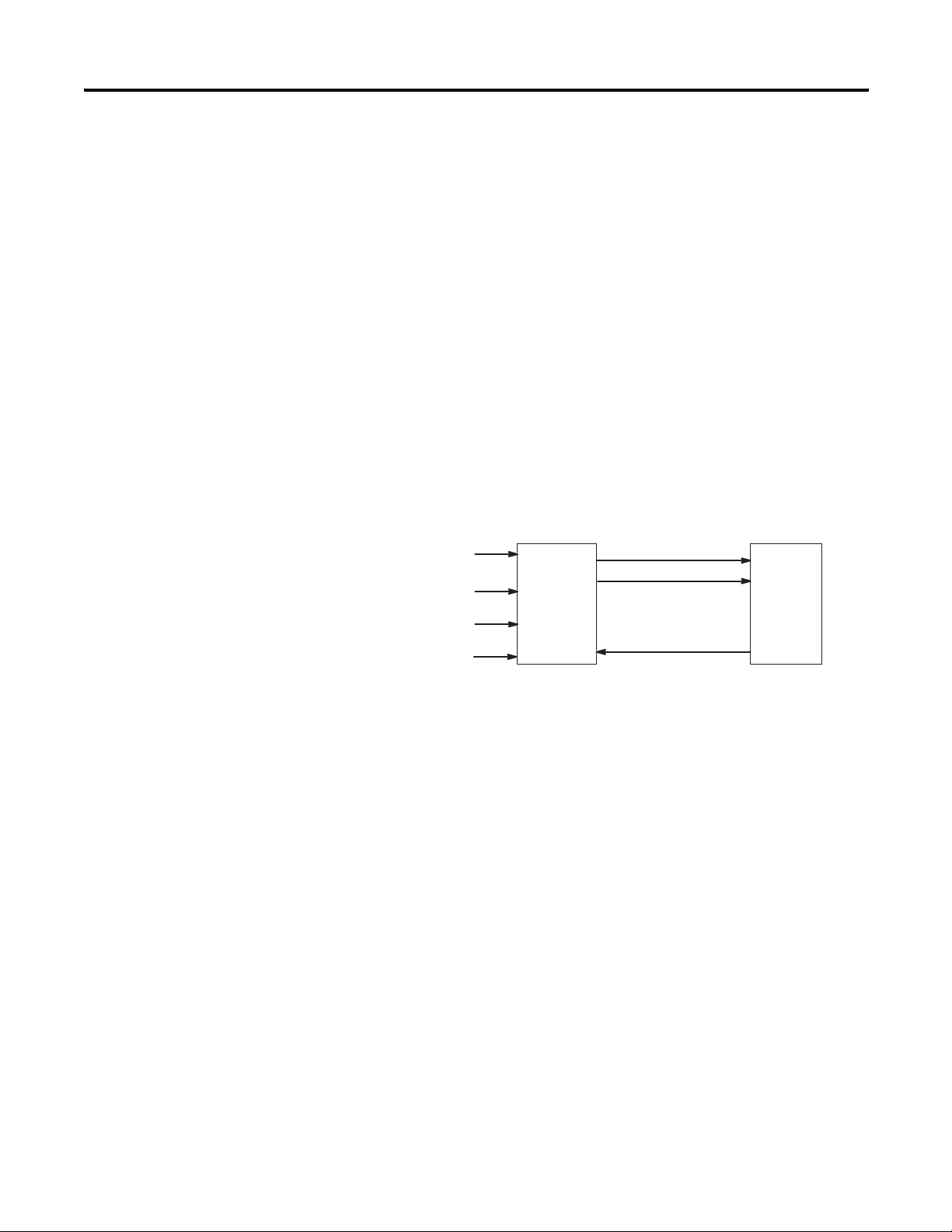

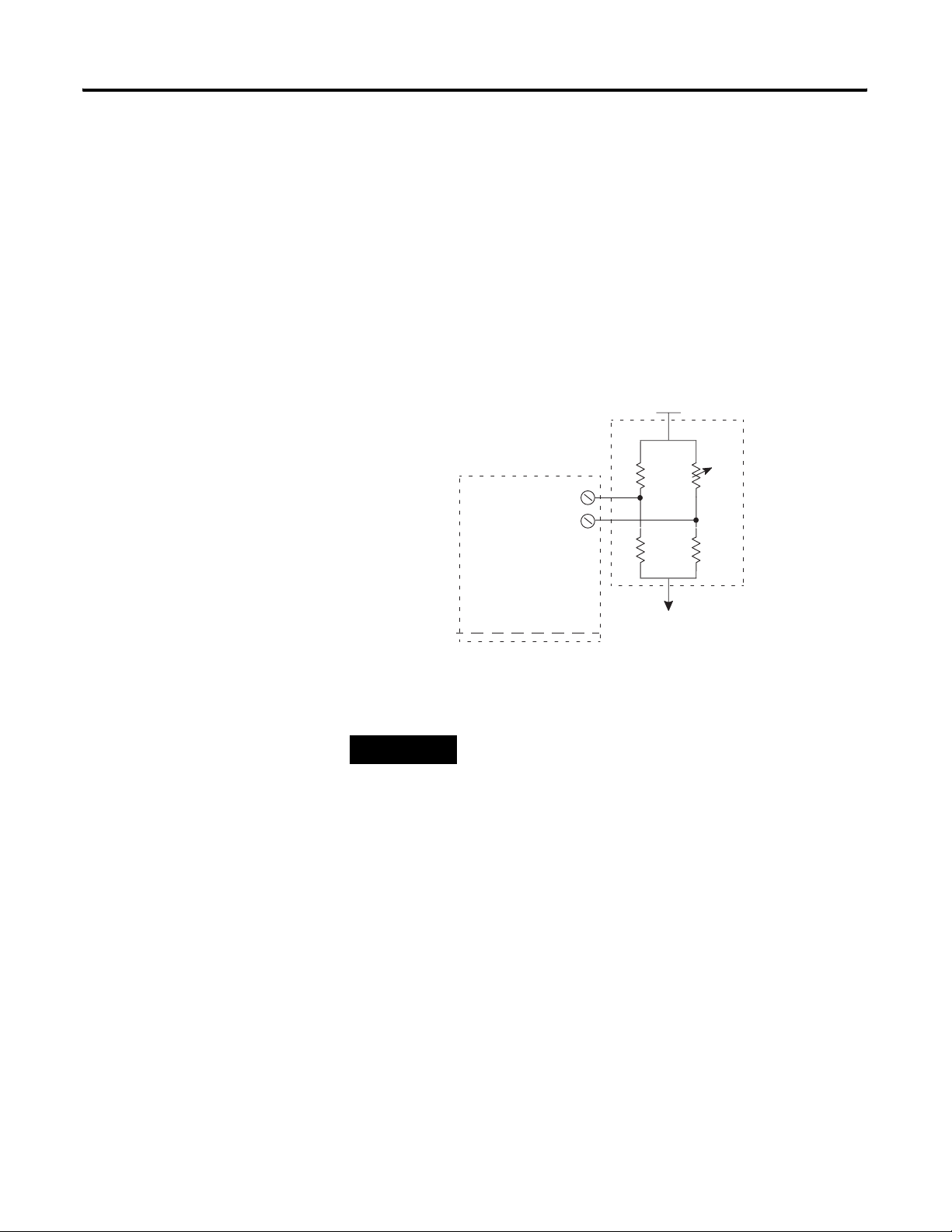

Block Diagram

ungrounded

thermocouple

Wit hin

12.5V

grounded

thermocouple

Terminal Block Module Circuitry

CJCA Sens or

+

-

+

-

Shield

+

-

+

-

Shield

+

-

Shield

multiplexer

Analog

Ground

Analog to

Digital

Converter

User S elected

Filter F requency

+

-

+

-

Shield

+

-

+

CJCB S ensor

-

Digital

Filter

Digital

Va lue

Publication 1746-UM022B-EN-P - January 2005

IMPORTANT

When using multiple thermocouples, the potential

between any two channels cannot exceed the

channel-to-channel differential voltage (12.5 volts).

For more information, see Appendix B.

Page 17

Module Overview 1-7

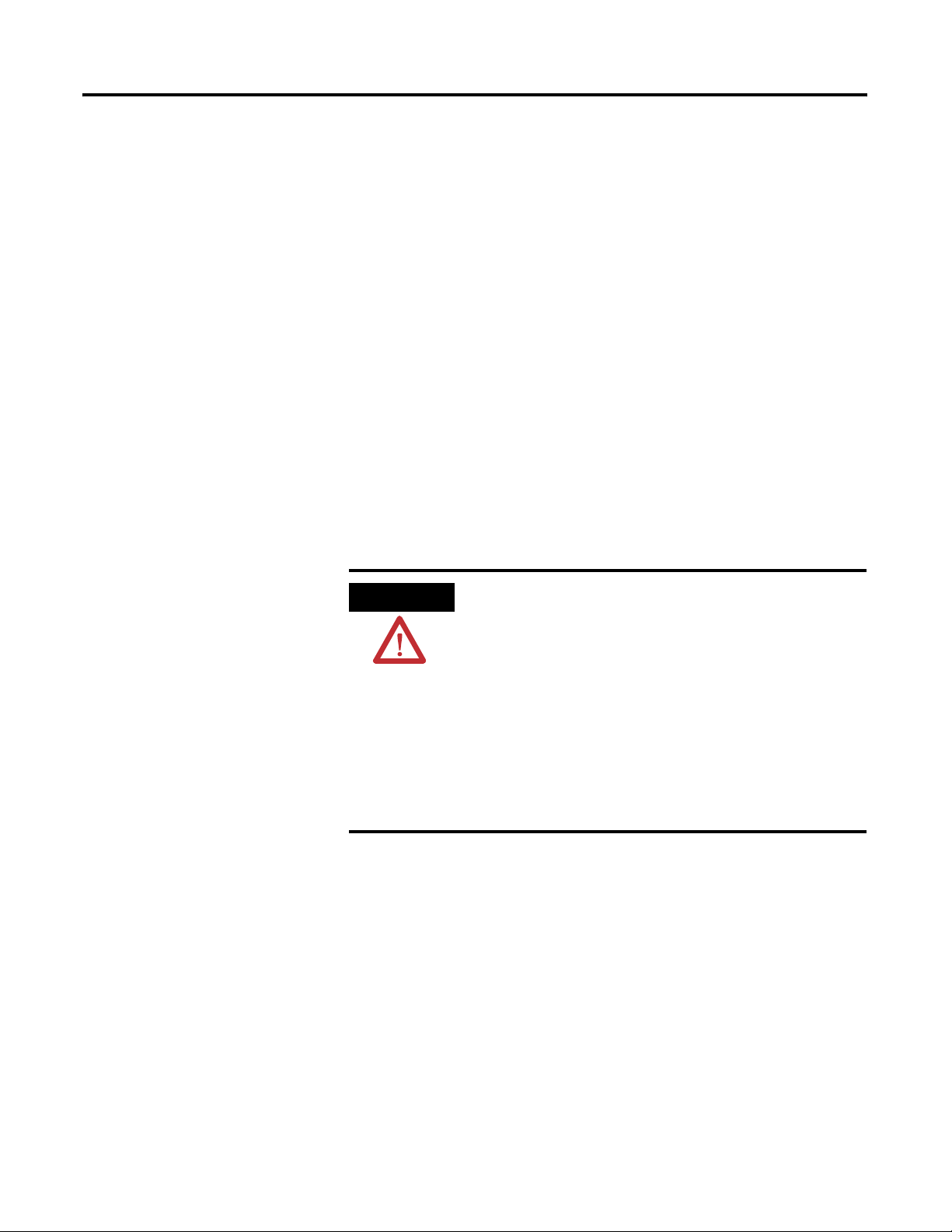

Linear Millivolt Device Compatibility

(1)

A large number of millivolt devices may be used with the 1746-NT8

module. For this reason we do not specify compatibility with any

particular device.

However, millivolt applications often use strain gage bridges. A

resistive voltage divider using fixed resistors is recommended for this

application. The circuit diagram below shows how this connection is

made.

Strain

Gage

Voc

+

variable

fixed

1746-NT8

Channel

Input

Bridge

fixed

+

-

fixed

TIP

The resistors should be selected to ensure that the

differential input voltage is less than or equal to ±100

mV.

(1) Output impedance of input device must be less than 100 ohm to meet accuracy specifications.

Publication 1746-UM022B-EN-P - January 2005

Page 18

1-8 Module Overview

Publication 1746-UM022B-EN-P - January 2005

Page 19

Chapter

Installing And Wiring Your Module

Read this chapter to install and wire your module. This chapter

covers:

• avoiding electrostatic damage

• determining power requirements

• installing the module

• wiring signal cables to the module’s terminal block

2

Electrostatic Damage

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins. Guard against

electrostatic damage by observing the following precautions:

ATTENTION

Electrostatically Sensitive Components

• Before handling the module, touch a grounded

object to rid yourself of electrostatic charge.

• Handle the module from the front, away from the

backplane connector. Do not touch backplane

connector pins.

• Keep the module in its static-shield container

when not in use or during shipment.

Failure to observe these precautions can degrade the

module’s performance or cause permanent damage.

1 Publication 1746-UM022B-EN-P - January 2005

Page 20

2-2 Installing And Wiring Your Module

Power Requirements

The module receives its power through the SLC 500 chassis backplane

from the fixed or modular +5 V dc/+24 V dc chassis power supply.

The maximum current drawn by the module is shown in the table

below.

Maximum Current Drawn by the Module

5Vdc Amps 24Vdc Amps

0.120 0.070

Considerations for a Modular System

Place your module in any slot of an SLC 500 modular, or modular

expansion chassis, except for the left-most slot (slot 0) reserved for

the SLC processor or adapter modules.

When using the module with a modular system, add the values shown

above to the requirements of all other modules in the SLC to prevent

overloading the chassis power supply. Refer to the SLC 500 Modular

Hardware Style User Manual, publication 1747-UM011.

Publication 1746-UM022B-EN-P - January 2005

Page 21

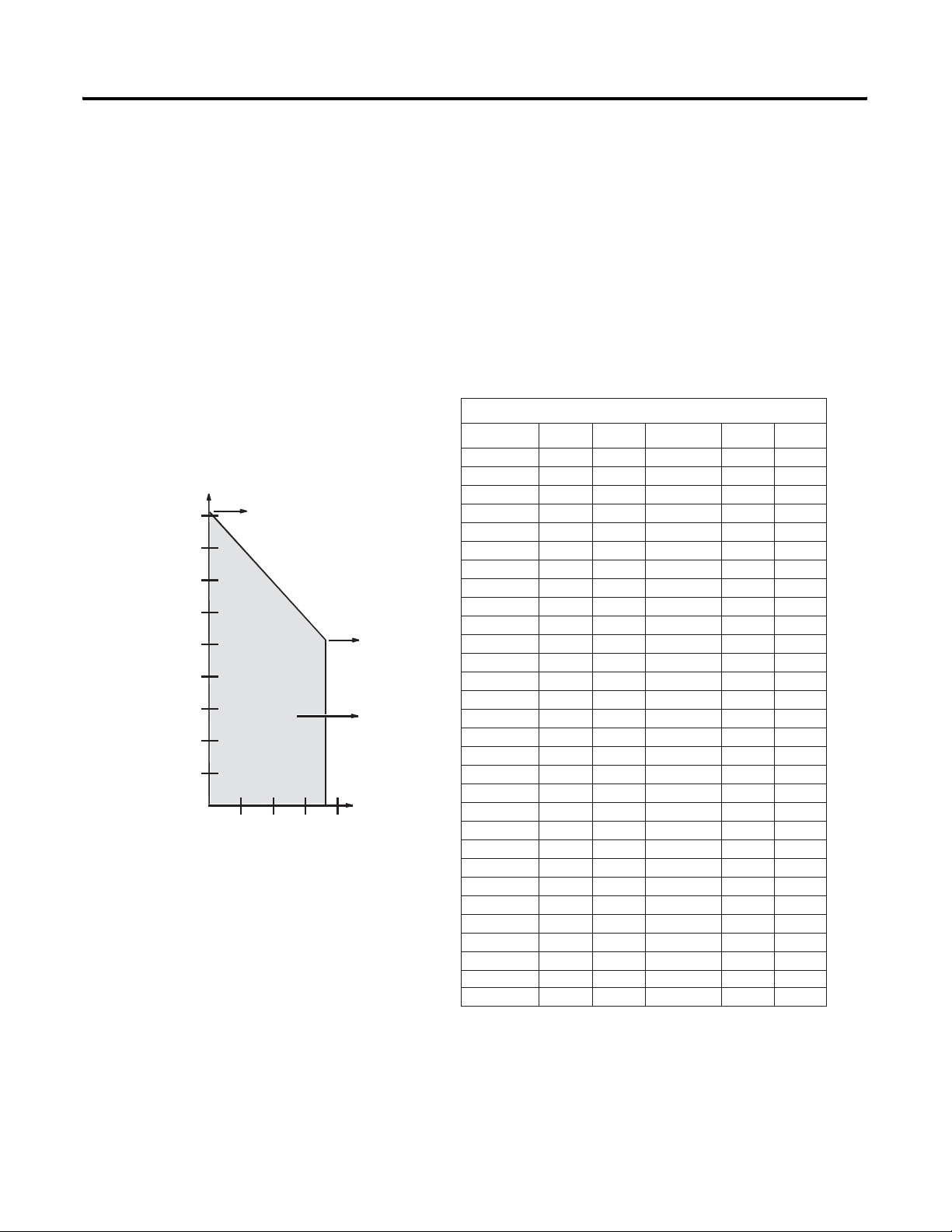

Fixed I/O Chassis - I/O Module Compatibility

The following chart depicts the range of current combinations

supported by the fixed I/O expansion chassis. To use it, find the

backplane current draw and operating voltage for both modules being

used in the chassis. These specifications are found in the table

alongside the chart.

Next, plot each of the currents on the chart below. If the point of

intersection falls within the operating region, the combination is valid.

If not, the combination cannot be used in a 2-slot, fixed I/O chassis.

OW16 and

450

400

350

300

250

Current

(mA)

at 5V dc

200

150

100

50

Example: Plot IN16 and NIO4V

IN16 = 0.085 at 5V dc and 0A at 24V dc

NIO4V = 0.055A at 5V dc and 0.115A at 24V dc

1. Add current draws of both modules at 5V dc to get

0.14 A (140 mA).

2. Plot this point on the chart above (140 mA at 5V dc.

3. Add current draws of both modules at 24V dc to get

0.115 A (115 mA).

4. Plot current draw at 24V dc (115 mA at 24V dc).

5. Note the point of intersection on the chart above

(marked x). This combination falls within the valid

operating region for the fixed I/O chassis.

(0, 455)

Valid Operating

Region

x

50 150 200

100

Current (mA) at 24V

OW16 and IA16

(180, 255)

Plotted from

Example

Shown Below

Installing And Wiring Your Module 2-3

Module Current Draw - Power Supply Loading

I/O Module

BAS .150 .040

BASn .150 .125

DCM .360 .000

FI O4I .055 .150

FI O4V .055 .120

HS .300 .000

HSTP 1 .200 .000

IA4 .035 .000

IA8 .050 .000 NR4 .050 .05 0

IA16 .085 .000

IB8 .050 .000

IB16 .085 .000

IB32 .106 .000

IC16 .085 .000

IG16 .140 .000

IH16 .085 .000

IM4 .035 .000

IM8 .050 .000

IM16 .085 .000

IN16 .085 .000

IO4 .030 .025

IO8 .060 .045

IO12 .090 .070

ITB16 .085 .000

ITV16 .085 .000

IV8 .050 .000

IV16 .085 .000

IV32 .106 .000

KE .150 .040

KEn .125

5V 24V I/O Module 5V 24V

NI4 .025 .085

NI8 .200 .100

NIO4I .055 .145

NIO4V .055 .115

NO4I .055 .195

NO4V .055 .145

120

100 55

120 70

.150

N08I

N08V 120 160*

NR8

NT4 .060 .040

NT8

OA16 .370 .00 0

OA8 .185 .000

OAP 12 .370 .000

OB8 .135 .000

OB16 .280 .000

OB16E .135 .000

OB32 .452 .000

OBP8 .135 .000

OBP16 .250 .000

OG16 .180 .00 0

OV8 .135 .000

OV16 .270 .000

OV32 .452 .000

OVP 16 .250 .000

OW16 .170 .180

OW4 .045 .045

OW8 .085 .090

OX8 .085 .090

250*

* w/jumper set to rack, otherwise 0.0 mA.

Important: The 1747-NO4I and 1746-NO4V analog

output modules may require an external power

supply.

Publication 1746-UM022B-EN-P - January 2005

Page 22

2-4 Installing And Wiring Your Module

When using the BAS or KE module to supply power to a 1747-AIC

Link Coupler, the link coupler draws its power through the module.

The higher current drawn by the AIC at 24V dc is shown in the table

as BASn (BAS networked) and KEn (KE networked). Be sure to use

these current draw values if the application uses the BAS or KE

module in this way.

General Considerations

Most applications require installation in an industrial enclosure to

reduce the effects of electrical interference. Thermocouple inputs are

highly susceptible to electrical noises due to the small amplitudes of

their signal (microvolt/°C).

Group your modules to minimize adverse effects from radiated

electrical noise and heat. Consider the following conditions when

selecting a slot for the thermocouple module. Position the module:

• in a slot away from sources of electrical noise such as recontact

switches, relays, and AC motor drives

• away from modules which generate significant radiated heat,

such as the 32-point I/O modules

In addition, route shielded twisted pair thermocouple or millivolt

input wiring away from any high voltage I/O wiring.

Remember that in a modular system, the processor or communications

adapter always occupies the first slot of the chassis.

Publication 1746-UM022B-EN-P - January 2005

Page 23

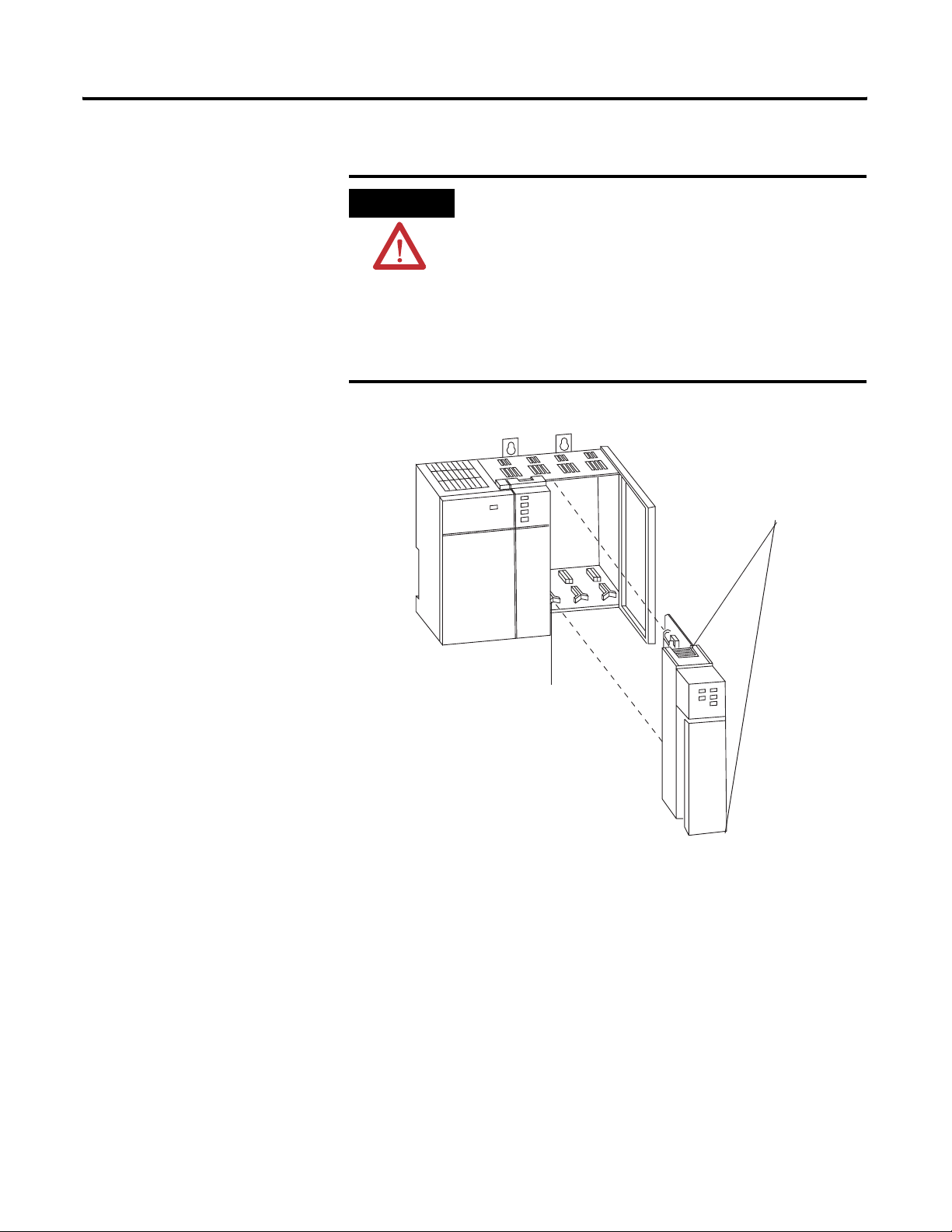

Module Installation and Removal

ATTENTION

Installing And Wiring Your Module 2-5

Possible Equipment Operation

Before installing or removing your module, always

disconnect power from the SLC 500 system and from

any other source to the module (in other words, do

not ’hot swap’ your module), and disconnect any

devices wired to the module.

Failure to observe this precaution can cause

unintended equipment operation and damage.

Top and Bottom

Module Release(s)

Card Guide

To insert your module into the chassis, follow these steps:

1. Before installing the module, connect the ground wire to TB1.

See the figure on page 2-10.

2. Align the circuit board of your module with the card guides at

the top and bottom of the chassis.

3. Slide your module into the chassis until both top and bottom

retaining clips are secure. Apply firm even pressure on your

module to attach it to its backplane connector. Never force your

module into the slot.

Publication 1746-UM022B-EN-P - January 2005

Page 24

2-6 Installing And Wiring Your Module

4. Cover all unused slots with the Card Slot Filler, Allen-Bradley

part number 1746-N2.

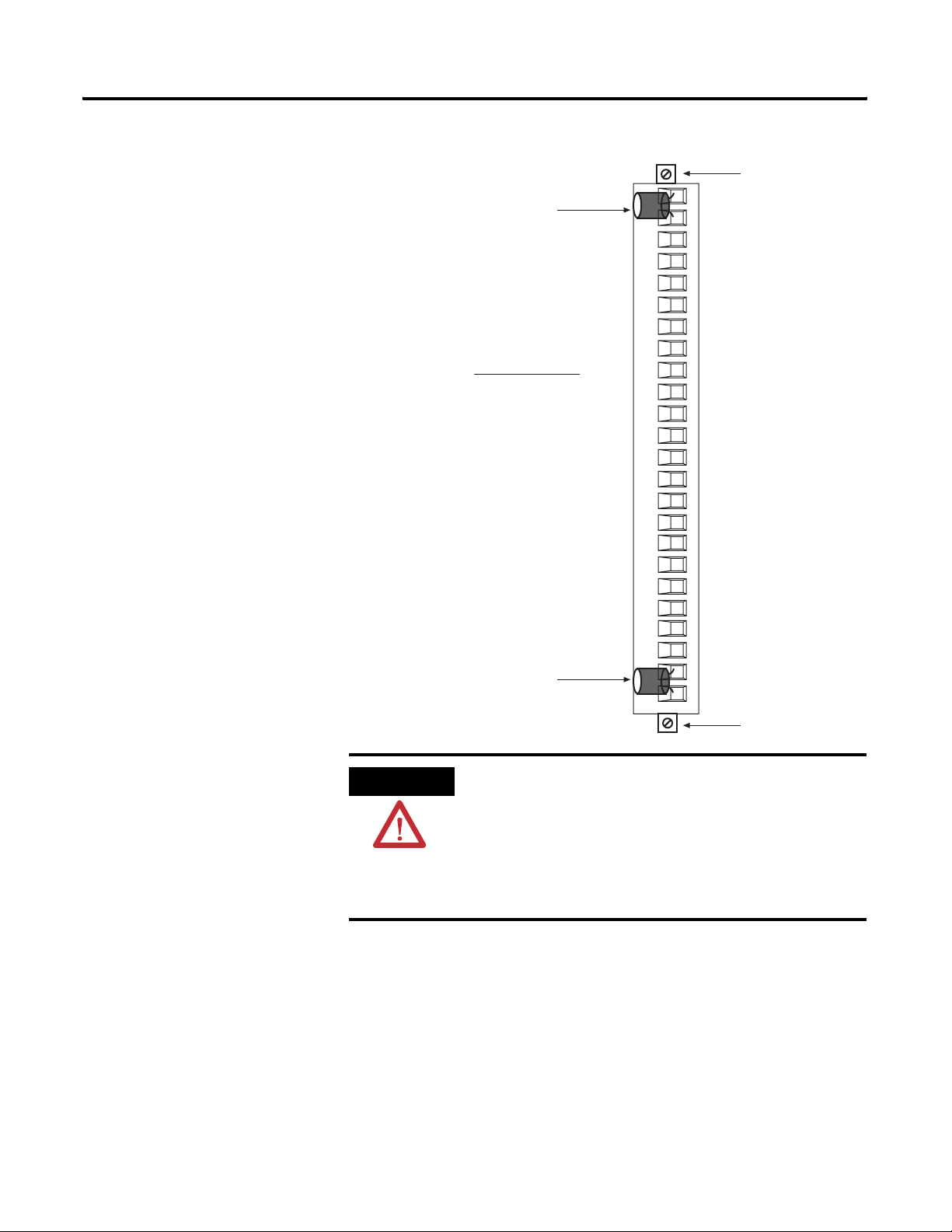

Terminal Block Removal

To remove the terminal block:

1. Loosen the two terminal block release screws. To avoid cracking

the terminal block, alternate between screws as you remove

them.

2. Using a screwdriver or needle-nose pliers, carefully pry the

terminal block loose. When removing or installing the terminal

block be careful not to damage the CJC sensors.

Publication 1746-UM022B-EN-P - January 2005

Page 25

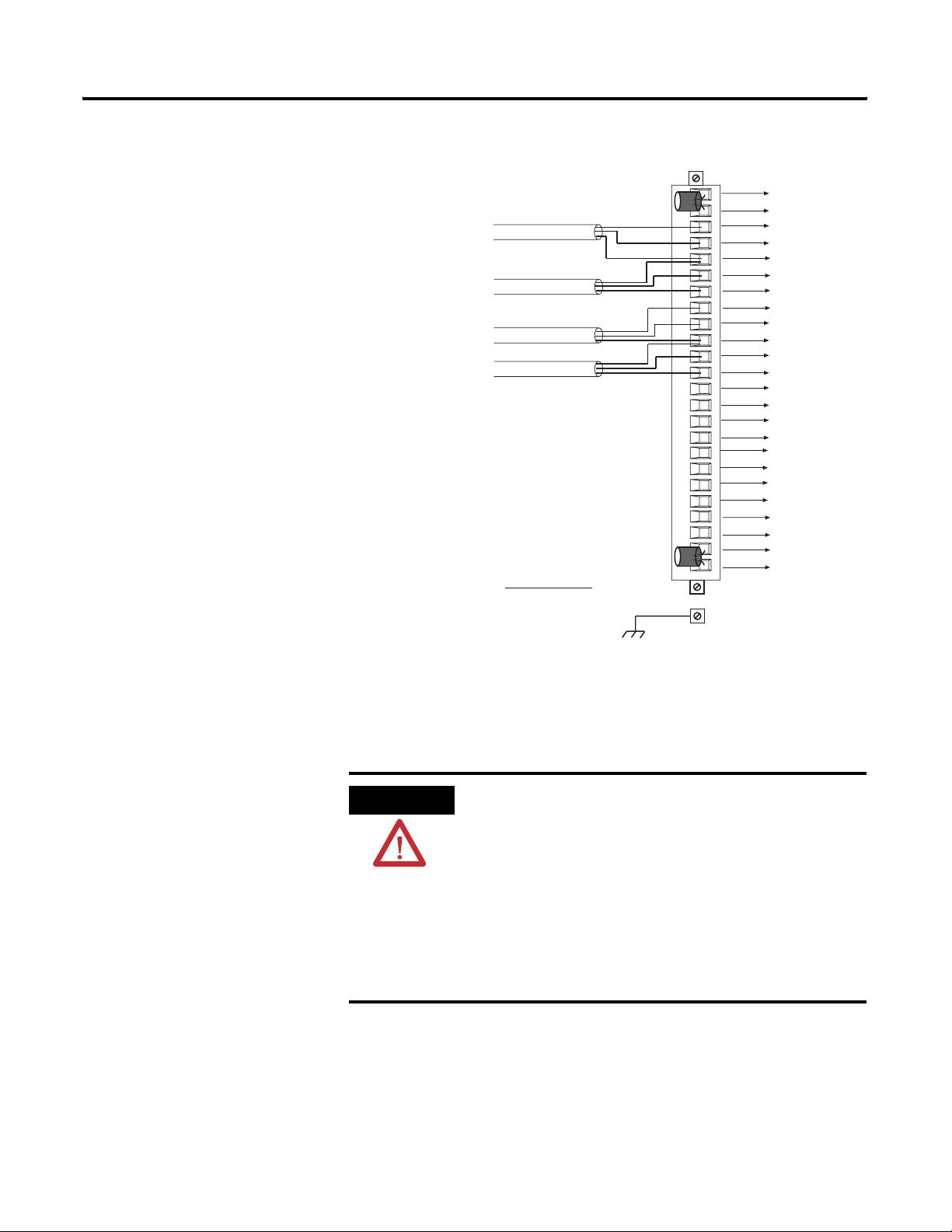

Terminal block diagram with CJC sensors

CJC Sensors

Recomm ended Torque:

wiring screws: 0.25 Nm (2.2 in-lb)

release scre ws: 0.25 Nm (2.2 in-lb)

Installing And Wiring Your Module 2-7

Terminal Block

Release Screws

ATTENTION

CJC Sensors

Terminal Block

Release Screws

Possible Equipment Operation

Before wiring your module, always disconnect

power from the SLC 500 system and from any other

source to the module.

Failure to observe this precaution can cause

unintended equipment operation and damage.

Publication 1746-UM022B-EN-P - January 2005

Page 26

2-8 Installing And Wiring Your Module

Wiring Your Module

Follow these guidelines to wire your input signal cables:

• Power, input, and output (I/O) wiring must be in accordance

with Class 1, Division 2 wiring methods [Article 501-4(b) of the

National Electrical Code, NFPA 70] and in accordance with the

authority having jurisdiction.

• Route thermocouple and millivolt signal wires as far as possible

from sources of electrical noise, such as motors, transformers,

contactors, and ac devices. As a general rule, allow at least 6 in.

(about 15.2 cm) of separation for every 120V ac of power.

• Routing the field wiring in a grounded conduit can reduce

electrical noise further.

• If the field wiring must cross ac or power cables, ensure that

they cross at right angles.

• For high immunity to electrical noise, use Belden™ 8761

(shielded, twisted pair) or equivalent wire for millivolt sensors;

or use shielded, twisted pair thermocouple extension lead wire

specified by the thermocouple manufacturer. Using the incorrect

type of convention thermocouple extension wire or not

following the correct polarity may cause invalid readings.

• Ground the shield drain wire at only one end of the cable. The

preferred location is at the shield connections on the terminal

block. (Refer to IEEE Std. 518, Section 6.4.2.7 or contact your

sensor manufacturer for additional details.)

• Keep all unshielded wires as short as possible.

• Excessive tightening can strip a screw. Tighten screws to 0.25

Nm (2.2 in-lb) or less, based on UL 1059, CSA C22.2 No. 158,

VDE 0110B 2.79 standards.

• Follow system grounding and wiring guidelines found in your

SLC 500 Modular Hardware Style User Manual, publication

1747-UM011 or 1747-SLC 500 Fixed Hardware Style User

Manual, publication 1747-6.21.

Publication 1746-UM022B-EN-P - January 2005

Page 27

Installing And Wiring Your Module 2-9

Preparing and Wiring the Cables

To prepare and connect cable leads and drain wires, follow these

steps:

Cable

Signal Wires

(Remove foil shield and drain wire

from sensor end of the cable.)

Drain Wire

Signal Wires

1. At each end of the cable, strip some casing to expose individual

wires.

2. Trim signal wires to 5-inch lengths beyond the cable casing.

Strip about 3/16 inch (4.76 mm) of insulation to expose the ends

of the wires.

3. At the module end of the cables:

• extract the drain wire and signal wires

• remove the foil shield

• bundle the input cables with a cable strap

4. Connect pairs of drain wires together:

• Channels 0 and 1

• Channels 2 and 3

• Channels 4 and 5

• Channels 6 and 7

Keep drain wires as short as possible.

5. Connect the drain wires to the shield inputs of the terminal

block if appropriate for thermocouple used.

• Channel 0 and 1 drain wires to pin 5

• Channel 2 and 3 drain wires to pin 10

• Channel 4 and 5 drain wires to pin 15

• Channel 6 and 7 drain wires to pin 20

Publication 1746-UM022B-EN-P - January 2005

Page 28

2-10 Installing And Wiring Your Module

6. Connect the signal wires of each channel to the terminal block.

IMPORTANT

Only after verifying that your connections are

correct for each channel, trim the lengths to keep

them short. Avoid cutting leads too short.

7. Connect TB1 chassis ground connector to the nearest chassis

mounting bolt with 14 gauge wire. (Looking at the face of the

module, TB1 is near the lower part of the terminal block on the

primary side of the PCB.)

TB1

Connect ground wire to TB1

before installing module.

8. At the sensor end of cables from thermocouple/mV devices:

• remove the drain wire and foil shield

• apply shrink wrap as an option

• connect to mV devices keeping the leads short.

IMPORTANT

If noise persists, try grounding the opposite end

of the cable. Ground one end only.

Publication 1746-UM022B-EN-P - January 2005

Page 29

Terminal Block Diagram with Input Cable

Thermocouple or mV Ca ble

Recommended Torque :

TB 1 0.3 to 0.5 Nm (2.5 to 4.5 in-lb)

Installing And Wiring Your Module 2-11

CJC A+

CJC AChannel 0+

Channel 0-

Shield for CH0 and CH 1

Channel 1+

Channel 1-

Channel 2+

Channel 2-

Shield for CH2 and CH 3

Channel 3+

Channel 3Channel 4+

Channel 4Shield for CH4 and CH 5

Channel 5+

Channel 5-

Channel 6+

Channel 6-

Shield for CH6 and CH 7

Channel 7+

Channel 7-

CJC B +

CJC B -

TB1

The module also has a ground terminal TB1, which should be

grounded to a chassis mounting bolt with 14-gauge wire.

Cold-Junction Compensation (CJC)

ATTENTION

To obtain accurate readings from each of the channels, the

cold-junction temperature (temperature at the module’s terminal

junction between the thermocouple wire and the input channel) must

be compensated for. Two cold-junction compensating sensors have

been integrated in the removable terminal block. They must remain

installed.

Possible Equipment Operation

Do not remove or loosen the cold-junction

compensating temperature transducers located on

the terminal block. Both CJCs are required to ensure

accurate thermocouple input readings at each

channel. The module will not operate in

thermocouple mode if a CJC is not connected.

Failure to observe this precaution can cause

unintended equipment operation and damage.

Publication 1746-UM022B-EN-P - January 2005

Page 30

2-12 Installing And Wiring Your Module

Publication 1746-UM022B-EN-P - January 2005

Page 31

Chapter

3

Module ID Code

Considerations Before Using

This chapter explains how the module and the SLC processor

communicate through the processor’s I/O image tables. It also

describes the module’s input filter characteristics. Topics discussed

include:

• module ID code

• module addressing

• channel filter frequency selection

• channel turn-on, turn-off, and reconfiguration times

• response to slot disabling

The module ID code is unique number assigned to each 1746 I/O

module. The ID code defines the type of I/O module and the number

of words used in the processor’s I/O image table.

Your Module

The module ID code for the 1746-NT8 module is 3533.

No special I/O configuration is required. The module ID automatically

assigns the correct number of input and output words.

1 Publication 1746-UM022B-EN-P - January 2005

Page 32

3-2 Considerations Before Using Your Module

Module Addressing

SLC 5/0X

Data Files

Slot e

Output Image

Slot e

Input Image

Output

Scan

Input

Scan

The following memory map shows you how the SLC processor’s

output and input tables are defined for the module.

Image Table

Thermocouple

Module

Image Table

Output Image

8 Words

Input Image

8 Words

Bit 15

Channel 0 Configuration Word

Channel 1 Configuration Word

Channel 2 Configuration Word

Bit 15

Channel 3 Configuration Word

Channel 4 Configuration Word

Channel 5 Configuration Word

Channel 6 Configuration Word

Channel 7 Configuration Word

Channel 0 Data or Status Word

Channel 1 Data or Status Word

Channel 2 Data or Status Word

Channel 3 Data or Status Word

Channel 4 Data or Status Word

Channel 5 Data or Status Word

Channel 6 Data or Status Word

Channel 7 Data or Status Word

Bit 0

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Bit 0

Address

O:e.0

O:e.1

O:e.2

O:e.3

O:e.4

O:e.5

O:e.6

O:e.7

I:e.0

I:e.1

I:e.2

I:e.3

I:e.4

I:e.5

I:e.6

I:e.7

Address

Output Image - Configuration Words

Eight words of the SLC processor’s output image table are reserved for

the module. Output image words 0 through 7 are used to configure

the module’s input channels 0 through 7. Each output image word

configures a single channel and can be referred to as a configuration

word. Each word has a unique address based on the slot number

assigned to the module.

Example Address - If you want to configure channel 2 on the

module located in slot 4 in the SLC chassis, your address would be

O:4.2.

Slot

File Type

Elem ent

Delimiter

O:4.2

Word

Word

Delimiter

Publication 1746-UM022B-EN-P - January 2005

Page 33

Considerations Before Using Your Module 3-3

Chapter 4 provides detailed bit information about the data content of

the configuration word.

Input Image - Data Words and Status Words

Eight words of the SLC processor’s input image table are reserved for

the module. Input image words are multiplexed since each channel

has one data word and one status word. The corresponding

configuration word selects whether the channel status or channel data

is in the input image word.

Status bits for a particular channel reflect the configuration settings

that you entered into the configuration (output image) word for that

channel. To receive valid status, the channel must be enabled and the

module must have stored a valid configuration word for that channel.

Each input image word has a unique address based on the slot

number assigned to the module.

Channel Filter Frequency Selection

Example Address - To obtain the status/data word of channel 2

(input word 2) of the module located in slot 4 in the SLC chassis use

address I:4:2.

File Type

Slot

Word

I:4.2

E lement

Delimiter

Word

Delimiter

Chapter 4 provides detailed bit information about the content of the

data word and the status word.

The thermocouple module uses a digital filter that provides

high-frequency noise rejection for the input signals. The digital filter is

programmable, allowing you to select from four filter frequencies for

each channel. The digital filter provides the highest noise rejection at

the selected filter frequency. The graphs to follow show the input

channel frequency response for each filter frequency selection.

Selecting a low value (i.e. 10 Hz) for the channel filter frequency

provides the best noise rejection for a channel, but it also increases

the channel update time. Selecting a high value for the channel filter

frequency provides lower noise rejection, but decreases the channel

update time.

Publication 1746-UM022B-EN-P - January 2005

Page 34

3-4 Considerations Before Using Your Module

The following table shows the available filter frequencies, cut-off

frequency, step response, and a DC effective resolution for each filter

frequency.

Cut-off frequency, Step Response Time, and Effective Resolution (Based on Filter

Frequency)

Filter Frequency Cut-Off Frequency Step Response ADC Effective

Resolution

10 Hz 2.62 Hz 400 ms 20.5

50 Hz 13.1 Hz 80 ms 19.0

60 Hz 15.72 Hz 66.7 ms 19.0

250 Hz 65.5 Hz 16 ms 15.5

The step response is calculated by a 4 x (1/filter frequency) settling

time.

Channel Cut-Off Frequency

The channel filter frequency selection determines a channel’s cut-off

frequency, also called the -3 dB frequency. The cut-off frequency is

defined as the point on the input channel frequency response curve

where frequency components of the input signal are passed with 3 dB

of attenuation. All frequency components at or below the cut-off

frequency are passed by the digital filter with less than 3 dB of

attenuation. All frequency components above the cut-off frequency

are increasingly attenuated, as shown in the graphs on page 3-5.

The cut-off frequency for each input channel is defined by its filter

frequency selection. The table above shows the input channel cut-off

frequency for each filter frequency. Choose a filter frequency so that

your fastest changing signal is below that of the filter’s cut-off

frequency. The cut-off frequency should not be confused with update

time. The cut-off frequency relates how the digital filter attenuates

frequency components of the input signal. The update time defines

the rate at which an input channel is scanned and its channel data

word updated.

Publication 1746-UM022B-EN-P - January 2005

Page 35

Signal Attenuation with 10 Hz Input Filter

Considerations Before Using Your Module 3-5

-3 dB

0

-20

-40

-60

-80

Amplitude (in dB)

-100

-120

-140

-160

-180

-200

2.62 Hz

0

10

20

Signal Attenuation with 50 Hz Input Filter

-3 dB

Amplitude (in dB)

0

-20

-40

-60

-80

-100

-120

-140

-160

-180

-200

0 50 100 150 200 250 300 Hz

30

Signal Frequency

40

50

60 Hz

13.1 Hz

Signal Frequency

Publication 1746-UM022B-EN-P - January 2005

Page 36

3-6 Considerations Before Using Your Module

Signal Attenuation with 60 Hz Input Filter

-3 dB

Amplitude (in dB)

0

-20

-40

-60

-80

-100

-120

-140

-160

-180

-200

0 60 120 180 240 300 360 Hz

15.7 Hz

Signal Attenuation with 250 Hz Input Filter

-3 dB

Amplitude (in dB)

0

-20

-40

-60

-80

-100

-120

-140

-160

-180

-200

0 250 500 750 1000 1250 1500 Hz

Signal Fr equency

Publication 1746-UM022B-EN-P - January 2005

65.5 Hz

Signal Fr equency

Channel Step Response

The channel filter frequency determines the channel’s step response.

The step response is time required for the analog input signal to reach

95% of its expected, final value given a full-scale step change in the

input signal. This means that if an input signal changes faster than the

channel step response, a portion of that signal will be attenuated by

the channel filter. The table on page 3-4 shows the step response for

each filter frequency.

Page 37

Considerations Before Using Your Module 3-7

Update Time

The thermocouple module update time is defined as the time required

for the module to sample and convert the input signals of all enabled

input channels and make the resulting data values available to the SLC

processor. It can be calculated by adding the sum of all enabled

sample times, plus a CJC update time.

Channel 0 Disabled Channel 1 Disabled

Enabled

Sample

Channel 0

Update CJC

Enabled Enabled Enabled

Sample

Channel 1

Calculate

Previous

The following table shows the channel sampling time for each filter

frequency. It also gives the CJC update time.

Channel Sampling Time

Channel Sampling Time for Each Filter Frequency (all values ±1 ms)

CJC Update Time 250 Hz Filter 60 Hz Filter 50 Hz Filter 10 Hz Filter

290 ms 66 ms 125 ms 140 ms 470 ms

Channel 2 Disabled Channel 7 Disabled

Sample

Channel 2

Calculate

Previous

Sample

Channel 7

Calculate

Previous

Sample

CJC

Channel

Calculate

Previous

The times above include a settling time necessary between input

channel readings. The sampling times for filter frequencies listed do

not include a 45 ms open-circuit detection time utilized when the

channel is configured for open-circuit detection. CJC open-circuit

detection does not require the additional 45 ms settling time.

The fastest module update time occurs when only one channel with a

250 Hz filter frequency is enabled.

Module update time = 290 ms + 66 ms = 356 ms

The slowest module update time occurs when eight channels, each

using a 10 Hz filter frequency, are enabled.

Module update time = 290 ms + 470 ms + 470 ms + 470 ms + 470

ms + 470 ms + 470 ms + 470 ms + 470 ms = 4.05 s

Publication 1746-UM022B-EN-P - January 2005

Page 38

3-8 Considerations Before Using Your Module

Update Time Calculation Example

The following example shows how to calculate the module update

time for the given configuration:

Channel 0 configured for 250 Hz filter frequency, enabled

Channel 1 configured for 250 Hz filter frequency, enabled

Channel 2 configured for 50 Hz filter frequency, enabled

Channel 3 through 7 disabled

Using the values from the table on page 3-7, add the sum of all

enabled channel sample times, plus one CJC update time.

Channel 0 sampling time = 66 ms

Channel 1 sampling time = 66 ms

Channel 2 sampling time = 140 ms

CJC update time = 290 ms

Module update time = 562 ms

Channel Turn-On, Turn-Off, and Reconfiguration Times

Auto-calibration

The time required for the module to recognize a new configuration

for a channel is generally one module update time plus 890 µs per

newly configured channel. If the filter frequency selected for the

newly enabled, configured channel is new to the module, then

auto-calibration is performed following configuration recognition.

Turn-off time requires up to one module update time.

Reconfiguration time is the same as turn-on time.

Auto-calibration is performed by the module to correct for drift errors

over temperature. Auto-calibration occurs immediately following

configuration of a previously unselected filter frequency, and

generally every two minutes for all selected filter frequencies of the

system. The time required to perform auto-calibration is defined as

follows:

Auto-calibration Time

250 Hz Filter 60 Hz Filter 50 Hz Filter 10 Hz Filter

325 ms 525 ms 585 ms 1.975 s

Publication 1746-UM022B-EN-P - January 2005

Page 39

Considerations Before Using Your Module 3-9

CJC sensors are acquired at 60 Hz to maximize the trade-off between

resolution and update rate. For example, if some channels are

acquired at 250 Hz and some are acquired at 50 Hz, then the total

auto-calibration time would be:

Frequency Auto-Calibration

250 Hz 325 ms

60 Hz 525 ms

50 Hz 585 ms

1.435 s Total

During auto-calibration, input values are not updated.

Response to Slot Disabling

By writing to the status file in the modular SLC processor, you can

disable any chassis slot. Refer to your SLC programming manual for

the slot disable/enable procedure.

ATTENTION

Possible Equipment Operation

Always understand the implications of disabling a

module before using the slot disable feature.

Failure to observe this precaution can cause

unintended equipment operation.

Input Response

When a thermocouple slot is disabled, the thermocouple module

continues to update its input image table. However, the SLC processor

does not read input from a module that is disabled. Therefore, when

the processor disables the thermocouple module slot, the module

inputs appearing in the processor image table remain in their last

state, and the module’s updated image table is not read. When the

processor re-enables the module slot, the current state of the module

inputs are read by the processor during the subsequent scan.

Output Response

The SLC processor may change the thermocouple module output data

(configuration) as it appears in the processor output image. However,

this data is not transferred to the thermocouple module. The outputs

are held in their last state. When the slot is re-enabled, the data in the

processor image is transferred to the thermocouple module.

Publication 1746-UM022B-EN-P - January 2005

Page 40

3-10 Considerations Before Using Your Module

Publication 1746-UM022B-EN-P - January 2005

Page 41

Chapter

Channel Configuration, Data, and Status

Read this chapter to:

• configure each input channel

• check each input channel’s configuration and status

4

Channel Configuration

Channel configuration words appear in the SLC processor’s output

image table as shown below. Words 0 to 7 correspond to module

channels 0 to 7.

After module installation, configure each channel to establish the way

the channel operates (e.g., thermocouple type, temperature units,

etc.). Configure the channel by setting bits in the configuration word

using your programming device. The SLC configuration words are

shown below.

SLC Output Image (Configuration) Words

bit 0

O:e.0

O:e.1

O:e.2

O:e.3

O:e.4

bit 15

Channel 0 Channel Configuration Word

Channel 1 Channel Configuration Word

Channel 2 Channel Configuration Word

Channel 3 Channel Configuration Word

Channel 4 Channel Configuration Word

O:e.5

O:e.6

O:e.7

Channel 5 Channel Configuration Word

Channel 6 Channel Configuration Word

Channel 7 Channel Configuration Word

e = slot number of the module

1 Publication 1746-UM022B-EN-P - January 2005

Page 42

4-2 Channel Configuration, Data, and Status

The configuration word default settings are all zero. Next, we describe

how you set configuration bits of a channel configuration word to set

up the following channel parameters:

• data format such as engineering units, counts, or scaled-for-PID

• how the channel should respond to a detected open-input

circuit

• filter frequency selection

• temperature units in °C or °F

• whether the channel is enabled or disabled

• whether status or data information is selected for the module’s

input image table

Channel Configuration Procedure

The channel configuration word consists of bit fields, the settings of

which determine how the channel operates. This procedure looks at

each bit field separately and helps configure a channel for operation.

Refer to the chart on page 4-4 and the bit field descriptions that follow

for complete configuration information.

TIP

1. Determine which channels are used in your program and enable

them. Place a one in bit 0 if the channel is to be enabled. Place

a zero in bit 0 if the channel is to be disabled.

2. Determine the input device type (J, K, etc. thermocouple) (or

mV) for a channel and enter its respective four-digit binary code

in bit field 1 through 4 of the channel configuration word.

3. Select a data format for the data word. Your selection determines

how the analog input value from the A/D converter will be

expressed in the data word. Enter your two-digit binary code in

bit field 5 and 6 of the channel configuration word.

When using RSLogix 500 version 6.10 or higher, you

can use the software’s I/O wizard to configure the

NT8 channels. Refer to Appendix C for more

information.

Publication 1746-UM022B-EN-P - January 2005

4. Determine the desired state for the channel data word if an

open-circuit condition is enabled and detected for that channel.

Enter the two-digit binary code in bit field 7 and 8 of the

channel configuration word.

Page 43

Channel Configuration, Data, and Status 4-3

5. If the channel is configured for thermocouple inputs, determine

if the channel data word should read in degrees Fahrenheit or

degrees Celsius and enter a one or a zero in bit 9 of the

configuration word. If the channel is configured for a mV analog

sensor, enter a zero in bit 9.

6. Determine the desired input filter frequency for the channel and

enter the two-digit binary code in bits 10 and 11 of the channel

configuration word. A lower filter frequency increases the

channel update time, but also increases the noise rejection and

channel resolution. A higher filter frequency decreases the

channel update time, but also decreases the noise rejection and

effective resolution.

7. Ensure that bits 12 through 14 contain zeros.

8. Determine whether the channel input image word should

contain data or status. Place a one in bit 15 if channel data is

desired. Place a zero in bit 15 if status is desired.

9. Build the channel configuration word for every channel on each

thermocouple/mV module repeating the procedures given in

steps 1 through 8.

10. Enter this configuration into your ladder program and download

it to the thermocouple module.

Publication 1746-UM022B-EN-P - January 2005

Page 44

4-4 Channel Configuration, Data, and Status

A detailed explanation appears in the following table:

Channel Configuration Word (0:e.0 through 0:e.7) - Bit Definitions

To Select Make these bit settings

1514131211109876543210

Channel

Enable

Input

Ty pe

Data

Format

Open Circuit

Temperature

units

Channel

filter

frequency

Unused

Input Image

Ty pe

(1) For engineering units x 1, values are expressed in 0.1 degrees or 0.01 mV. For engineering units x 10, values are expressed in 1.0 degrees or 0.1 mV.

(2) When millivolt input type is selected, the bit setting for temperature units is ignored.

(3) Ensure unused bits 12 through 14 are always set to zero.

Channel Disable

Channel Enable

Thermocouple J

Thermocouple K 00

Thermocouple T 00

Thermocouple E 00

Thermocouple R 01

Thermocouple S 01

Thermocouple B 01

Thermocouple N 01

-50 to +50 mV 10

-100 to +100 mV 10

Invalid 10

Invalid 10

Invalid 11

Invalid 11

Invalid 11

CJC temperature 11

Engineering Units x 1

Engineering Units x 10

Scaled-for-PID

Proportional counts

Zero on open circuit

Max. on open circuit

Min. on open circuit

Disabled

(2)

°C

(2)

°F

10 Hz input filter

50 Hz input filter

60 HZ input filter

250 Hz input filter

(3)

Unused

Invalid

Status Word

Data Word

(1)

(1)

00

01

10

11

0

1

00

01

10

11

000

111

0

1

00

01

10

11

00

0

1

00

01

10

11

00

01

10

11

00

01

10

11

00

01

10

11

Publication 1746-UM022B-EN-P - January 2005

Page 45

Channel Configuration, Data, and Status 4-5

Select Channel Enable (Bit 0)

Use the channel enable bit to enable a channel. The thermocouple

module only scans enabled channels. To optimize module operation

and minimize throughput times, unused channels should be disabled

by setting the channel enable bit to zero (default value).

When set (1) the channel enable bit is used by the module to read the

configuration word information selected. While the enable bit is set,

modification of the configuration word may lengthen the module

update time for one cycle. If any change is made to the configuration

word, the change is reflected in the status word before new data is

valid (described on page 4-11).

While the channel enable bit is cleared (0), the associated channel

data/status word values are cleared. After the channel enable bit is set

(1), the associated channel data/status word remains cleared until the

thermocouple module sets the channel status bit (bit 0) in the channel

status word.

Select Input Types (Bits 1 through 4)

The input type bit field lets you configure the channel for the type of

input device you have connected to the module. Valid input devices

are types J, K, T, E, R, S, B, and N thermocouple sensors and ±50 mV

and ±100 mV analog input signals. The channel can also be

configured to read the cold-junction temperature calculated for that

specific channel. When the cold-junction compensation (CJC)

temperature is selected, the channel ignores the physical input signal.

Select Data Format (Bits 5 and 6)

The data format bit field lets you define the expressed format for the

channel data word contained in the module input image. The data

types are engineering units, scaled-for-PID, and proportional counts.

The engineering units allow you to select from two resolutions, x1

or x10. For engineering units x1, values are expressed in 0.1 degrees

or 0.01 mV. For engineering units x10, values are expressed in 1.0

degrees or 0.1 mV. (Use the x10 setting to produce temperature

readings in whole degrees Celsius or Fahrenheit.)

The scaled-for-PID value is the same for millivolt, thermocouple, and

CJC input types. The input signal range is proportional to your

selected input type and scaled into a 0 through 16,383 range, which is

standard to the SLC PID algorithm.

Publication 1746-UM022B-EN-P - January 2005

Page 46

4-6 Channel Configuration, Data, and Status

The proportional counts are scaled to fit the defined temperature or

voltage range. The input signal range is proportional to your selected

input and scaled into a -32,768 to 32,767 range.

Using Scaled-for-PID and Proportional Counts

The thermocouple module provides eight options for displaying input

channel data. These are 0.1°F, 0.1°C, 1°F, 1°C, 0.01 mV, 0.1 mV,

Scaled-for-PID, and Proportional Counts. The first six options

represent real Engineering Units displayed by the 1746-NT8 and do

not require explanation. The Scaled-for-PID and Proportional Counts

selections provide the highest NT8 display resolution, but also require

you to manually convert the channel data to real Engineering Units.

The equations below show how to convert from Scaled-for-PID to

Engineering Units, Engineering Units to Scaled-for-PID, Proportional

Counts to Engineering Units, and Engineering Units to Proportional

Counts. To perform the conversions, use the defined temperature or

millivolt range for the channel’s input type. See the Channel Data

Word Format table on page 4-8. The lowest possible value for an

input type is S

, and the highest possible value is S

LOW

HIGH

.

Effective Resolutions

The effective resolution for an input channel depends upon the filter

frequency selected for that channel.

Publication 1746-UM022B-EN-P - January 2005

Page 47

Scaling Examples

Equation: Engineering Units Equivalent = S

Data: Assume type J input type, scaled-for-PID display type, channel data = 3421.

Solution: Engineering Units Equivalent = -210°C + [(760°C-(-210°C)) x (3421/16384)] = -7.46°C.

Equation: Scaled-for-PID Equivalent = 16384 x [(Engineering Units desired -S

Data: Assume type J input type, scaled-for-PID display type, desired channel temp. = 344°C.

Solution: Scaled-for-PID Equivalent = 16384 x [(344°C - (-210°C))/(760°C - (-210°C))] = 9357

Equation: Engineering Units Equivalent = S

Data: Assume type E input type, proportional counts display type, channel data = 21567.

Solution: Engineering Units Equivalent = -454°F + {[1832°F -(-454°F)] x [(21567 + 32768)/65536]} = 1441.3°F

Scaled-for-PID to Engineering Units

+ [(S

LOW

HIGH-SLOW

Want to calculate °C equivalent.

From Channel Data Word Format table, S

LOW

Engineering Units to Scaled-for-PID

Want to calculate Scaled-for-PID equivalent.

From Channel Data Word Format table, S

LOW

Proportional Counts to Engineering Units

+ {(S

LOW

HIGH-SLOW

32768)/ 65536]}

Want to calculate °F equivalent.

From Channel Data Word Format table, S

LOW

Channel Configuration, Data, and Status 4-7

) x (Scaled-for-PID value displayed/16384)]

= -210°C and S

= -210°C and S

HIGH

HIGH

= 760°C.

)/(SHIGH-S

LOW

= 760°C.

) x [(Proportional Counts value displayed +

= -454°F and S

HIGH

=1832°F

LOW

)]

Engineering Units to Proportional Counts

Equation:

Proportional Counts Equivalent = {65536 x[(Engineering Units desired - S

LOW

)/(S

HIGH-SLOW

)]} -32768

Data: Assume type E input type, proportional counts display type, desired channel temp. = 1000°F.

Want to calculate Proportional Counts equivalent.

From Channel Data Word Format table, SLOW = -454°F and SHIGH = 1832°F.

Proportional Counts Equivalent = {65536 x[100°F - (-454°F)/(1832°F - (-454°F)]} - 32768 = 8916.

Solution: Proportional Counts Equivalent = {65536 x[1000°F - (-454°F)/(1832°F - (-454°F)]} - 32768 = 8916.

Publication 1746-UM022B-EN-P - January 2005

Page 48

4-8 Channel Configuration, Data, and Status

1746-NT8 Thermocouple Module - Channel Data Word Format

Data Format

Input Type Engineering Units x10 Engineering Units x1 Scaled for PID Proportional

°Celsius °Fahrenheit °Celsius °Fahrenheit

Counts

J -210 to +760 -346 to +1400 -2100 to +7600 -3460 to +14000 0 to +16383 -32768 to +32767

K -270 to +1370 -454 to +2498 -2700 to +13700 -4540 to +24980 0 to +16383 -32768 to +32767

T -270 to +400 -454 to +752 -2700 to +4000 -4540 to +7520 0 to +16383 -32768 to +32767

E -270 to +1000 -454 to +1832 -2700 to +10000 -4540 to +18320 0 to +16383 -32768 to +32767

R 0 to +1768 +32 to +3214 0 to +17680 +320 to+32140 0 to +16383 -32768 to +32767

S 0 to +1768 +32 to +2372 0 to +17680 +320 to +32140 0 to +16383 -32768 to +32767

B +300 to +1820 +572 to +3308 +3000 to +18200

+5720 to +3276.7

(2)

0 to +16383 -32768 to +32767

N 0 to +1300 +32 to +2372 0 to +13000 +320 to +23720 0 to +16383 -32768 to +32767

±50 mV

±100 mV

(1)

(1)

-500 to +500 -500 to +500 -5000 to +5000 -5000 to +5000 0 to +16383 -32768 to +32767

-1000 to +1000 -1000 to +1000 -10000 to +1000 -10000 to +10000 0 to +16383 -32768 to +32767

CJC Sensor -25 to +105 -13 to +221 -250 to +1050 -130 to +2210 0 to +16383 -32768 to +32767

(1) When millivolts are selected, the temperature setting is ignored. Analog input data is the same for either °C or °F selection.

(2) Type B thermocouple cannot be represented in engineering units x1 (°F) above 3276.7°F. Software treats it as an over range error.

1746-NT8 Thermocouple Module - Channel Data Word Resolution

Data Format

Input

Ty pe

Engineering Units x10 Engineering Units x1 Scaled for PID Proportional Counts

°Celsius °Fahrenheit °Celsius °Fahrenheit °Celsius °Fahrenheit °Celsius °Fahrenheit

J 1°C/step 1°F/step 1°C/step 1°F/step 0.0592°C/step 0.1066°F/step 0.0148°C/step 0.0266°F/step

K 1°C/step 1°F/step 1°C/step 1°F/step 0.1001°C/step 0.1802°F/step 0.0250°C/step 0.0450°F/step

T 1°C/step 1°F/step 1°C/step 1°F/step 0.0409°C/step 0.0736°F/step 0.0102°C/step 0.0184°F/step

E 1°C/step 1°F/step 1°C/step 1°F/step 0.0775°C/step 0.1395°F/step 0.0194°C/step 0.0349°F/step

R 1°C/step 1°F/step 1°C/step 1°F/step 0.1079°C/step 0.1942°F/step 0.0270°C/step 0.0486°F/step

S 1°C/step 1°F/step 1°C/step 1°F/step 0.1079°C/step 0.1942°F/step 0.0270°C/step 0.0486°F/step

B 1°C/step 1°F/step 1°C/step 1°F/step 0.0928°C/step 0.1670°F/step 0.0232°C/step 0.0417°F/step

N 1°C/step 1°F/step 1°C/step 1°F/step 0.0793°C/step 0.1428°F/step 0.0198°C/step 0.0357°F/step

(1)

±50 mV

±100 mV

CJC

0.1mV/step 0.1mV/step 0.1mV/step 0.1mV/step 6.104µV/step 6.104µV/step 1.526µV/step 1.526µV/step

(1)

0.1mV/step 0.1mV/step 0.1mV/step 0.1mV/step 12.21µV/step 12.21µV/step 3.052µV/step 3.052µV/step

1°C/step 1°F/step 1°C/step 1°F/step 0.0079°C/step 0.0143°F/step 0.0020°C/step 0.0036°F/step

Sensor

(1) When millivolts are selected, the temperature setting is ignored. Analog input data is the same for either °C or °F selection.

Publication 1746-UM022B-EN-P - January 2005

Page 49

Channel Configuration, Data, and Status 4-9

IMPORTANT

Data resolution is not equivalent to data accuracy.

Input accuracy of ±50 µV may span multiple steps

for PID and Proportional Counts data types. As an

example, a Type B thermocouple temperature range

of 0 to 1820°C provides a voltage input range of 0 to

13.82mV to the 1746-NT8. This is a very small input

range and, when it is scaled to PID or proportional

counts ranges, a small input change results in many

counts being changed.

Select Open-Circuit State (Bits 7 and 8)

The open-circuit bit field lets you define the state of the channel data

word when an open-circuit condition is detected for that channel. This

feature can be disabled by selecting the disable option.

An open-circuit condition occurs when the thermocouple itself or its

extension wire is physically separated or open. This can happen if the

wire gets cut or disconnected from terminal block.

If either of the two CJC devices is removed from the terminal block,

any input channel configured for either a thermocouple or CJC

temperature input is placed in an open-circuit condition. An input

channel configured for millivolt input is not affected by CJC open

circuit conditions.

The results of the data word in an open-circuit condition depend

upon the selection of bits 7 and 8.

If zero is selected (00), the channel data word is forced to 0 during an

open-circuit condition.

Selecting maximum forces the (01) channel data word value to its

full scale value during an open-circuit condition. The full scale value

is determined by the selected input type and data format.

Selecting minimum forces the (10) channel data word value to its

low scale value during an open-circuit condition. The low scale value

is determined by the selected input type and data format.

Disabling the open-circuit selection (11) may result in unintended

operation on a failure. Generally, with the open-circuit option

disabled, the data word remains unchanged. The open-circuit error bit

and the channel LED flags the condition until the error is resolved.

Publication 1746-UM022B-EN-P - January 2005

Page 50

4-10 Channel Configuration, Data, and Status

For example, if channel one is configured as a thermocouple type

when the CJC breaks in an open-circuit condition, if open-circuit

detection is disabled, the data word remains unchanged. If the circuit

selection is set at minimum, the data word is set to the low scale value

for the range and format.

IMPORTANT

Enabling the open-circuit function adds

approximately 45 ms to the channel update time.

Disabling the open circuit detection removes the

time adder. CJC sensors do not require the additional

time; thus it is recommended that when using a

channel for CJC sensor acquisition, the open-circuit

selection is enabled.

Select Temperature Units (Bit 9)

The temperature units bit lets you select temperature engineering

units for thermocouple and CJC input types. Units are either degrees

Celsius (°C) or degrees Fahrenheit (°F). This bit field is only active for

thermocouple and CJC input types. It is ignored when millivolt inputs

types are selected.

IMPORTANT

If you are using engineering units (x1 mode) and

Fahrenheit temperature units (i.e. 0.1°F), the full

scale temperature for thermocouple type B is not

achievable with 16-bit signed numerical

representation. An over-range error occurs for that

channel if it tries to represent the full scale value.

The maximum representable temperature is 3276.7°F

(instead of 3308°F).

Publication 1746-UM022B-EN-P - January 2005

Select Channel Filter Frequency (Bits 10 and 11)

The channel filter frequency bit field lets you select one of four filters

available for a channel. The filter frequency affects the channel update

time and noise rejection characteristics. A smaller filter frequency

increases the channel update time, but also increases the noise

rejection and channel resolution. A larger filter frequency decreases

the noise rejection, but also decreases the channel update time and

channel resolution.

Page 51

Channel Configuration, Data, and Status 4-11

Guidelines for filter frequency are listed below.

• 250 Hz setting provides minimal noise filtering.

• 60 Hz setting provides 60 Hz AC line noise filtering.

• 50 Hz setting provides 50 Hz AC line noise filtering.

• 10 Hz setting provides both 50 Hz and 60 Hz AC line noise

filtering.

When a CJC input type is selected, filter frequency is ignored. To

maximize the speed versus resolution trade-off, CJC inputs are

sampled at 60 Hz.

Unused Bits (Bits 12 through 14)

Bits 12-14 are not defined. Ensure these bits are always cleared (0).

Channel Data/Status Word

Select Input Image Type (Bit 15)

The input image type bit allows you to select data or status

information in the channel’s input image word. When set (1), the

module places channel data in the corresponding input image word.

When the bit is cleared (0) the module places channel status in the

corresponding input image word.

The actual thermocouple or millivolt input data values or channel

status reside in I:e.0 through I:e.7 of the thermocouple module input

image file. The data values present depend on the input type and data