Page 1

SLC 500

RTD/Resistance

Input Module

1746-NR4

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may be dangerous temperatures.

Rockwell Automation, Allen-Bradley, TechConnect, ControlLogix, RSLogix 500, and RSLinx are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

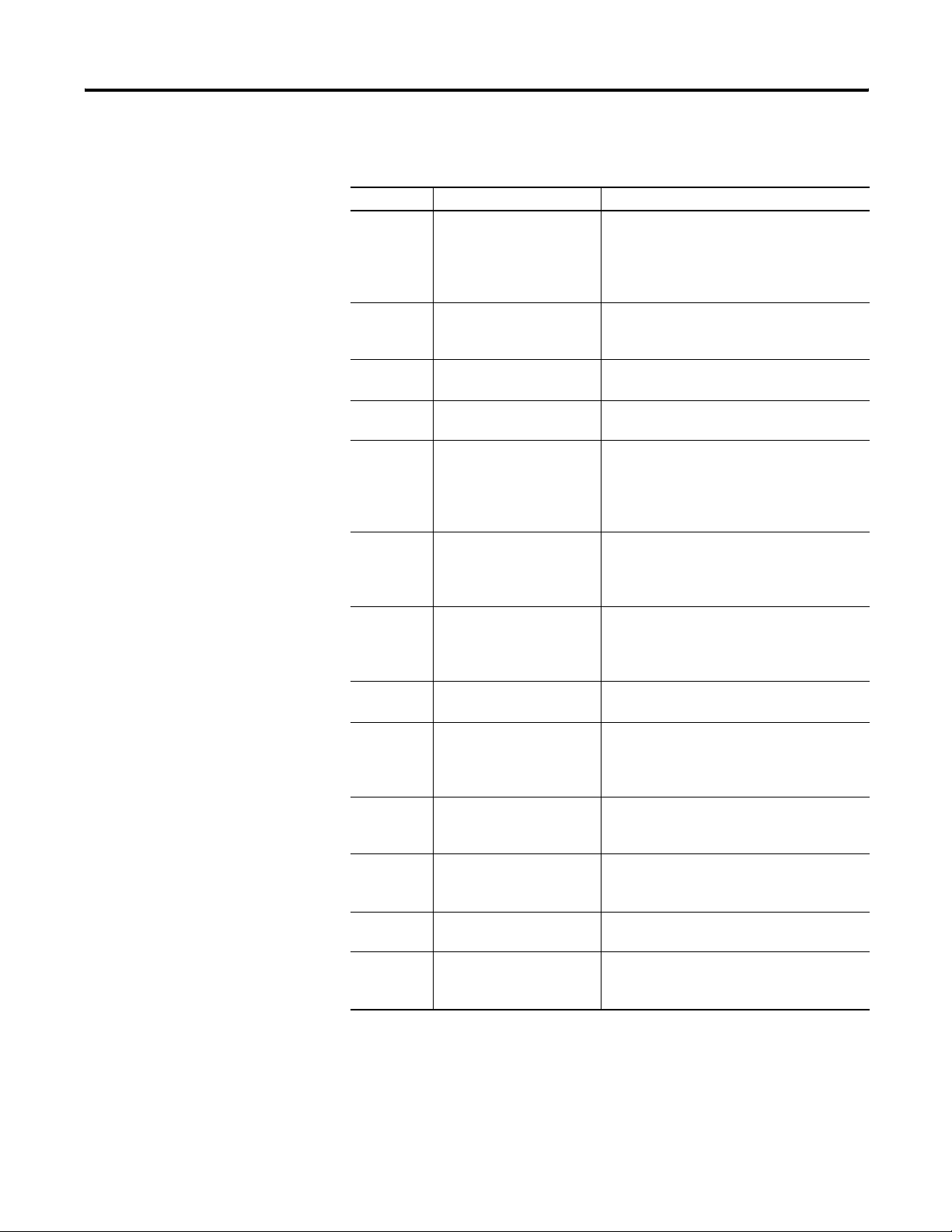

Summary of Changes

New Information

The information below summarizes the changes to this manual since

the last revision.

The table below lists sections that document new features and

additional information about existing features and shows where to

find this new information.

Change Page

Moved terms and abbreviations from

Preface to Glossary.

Updated programming examples to show

RSLogix 500 software.

Updated programming examples. Chapter 6

Updated programming examples. Chapter 8

Added Appendix D, I/O configuration. Appendix D, page 131

Preface

Throughout manual

3 Publication 1746-UM008B-EN-P - December 2006

Page 4

4 Summary of Changes

Notes:

Publication 1746-UM008B-EN-P - December 2006

Page 5

Overview

Quick Start Guide

Install and Wire the Module

Table of Contents

Preface

Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . 7

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Common Techniques Used in This Manual. . . . . . . . . . . . . . . 9

Chapter 1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 2

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . 23

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3

EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Electrostatic Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

NR4 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Module Location in Chassis . . . . . . . . . . . . . . . . . . . . . . . . . 35

Module Installation and Removal . . . . . . . . . . . . . . . . . . . . . 38

Terminal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Preliminary Operating

Considerations

Channel Configuration, Data, and

Status

Chapter 4

Module ID Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Channel Filter Frequency Selection . . . . . . . . . . . . . . . . . . . 54

Scanning Process and Channel Timing . . . . . . . . . . . . . . . . . 58

Channel Turn-on, Turn-off, and Reconfiguration Time . . . . . 61

Response to Slot Disabling . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 5

Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Channel Configuration Procedure . . . . . . . . . . . . . . . . . . . . 64

Channel Data Word. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Channel Status Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5 Publication 1746-UM008B-EN-P - December 2006

Page 6

6 Table of Contents

Ladder Programming Examples

Module Diagnostics and

Troubleshooting

Chapter 6

Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Initial Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Dynamic Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Verify Channel Configuration Changes. . . . . . . . . . . . . . . . . 92

Interface to the PID Instruction . . . . . . . . . . . . . . . . . . . . . . 93

Use the Proportional Counts Data Format with

User-set Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Monitor Channel Status Bits. . . . . . . . . . . . . . . . . . . . . . . . . 96

Invoke Autocalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Module Operation vs. Channel Operation . . . . . . . . . . . . . . 99

Power Turn-on Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 100

Channel Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Contact Rockwell Automation . . . . . . . . . . . . . . . . . . . . . . 106

Application Examples

Specifications

RTD Standards

Configuration Worksheet

for RTD/Resistance Module

I/O Configuration

Chapter 8

Basic Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Supplementary Example . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix A

Module Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Appendix C

Channel Configuration Procedure . . . . . . . . . . . . . . . . . . . 125

Appendix D

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Glossary

Index

Publication 1746-UM008B-EN-P - December 2006

Page 7

Preface

Use This Manual

Who Should Use This Manual

Read this preface to familiarize yourself with the rest of the manual.

This preface covers the following topics:

• Who should use this manual

• Purpose of this manual

• Terms and abbreviations

• Conventions used in this manual

• Allen-Bradley support

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use

Allen-Bradley small logic controllers.

You should have a basic understanding of SLC 500 products. You

should understand programmable controllers and be able to interpret

the ladder logic instructions required to control your application. If

you do not, contact your local Allen-Bradley representative for

information on available training courses before using this product.

Purpose of This Manual

This manual is a reference guide for the 1746-NR4 RTD/Resistance

Input Module. The manual:

• gives you an overview of system operation.

• explains the procedures you need to install and wire the module

at the application site.

• provides ladder programming examples.

• provides an application example of how this input module can

be used to control a process.

7 Publication 1746-UM008B-EN-P - December 2006

Page 8

8 Preface

Contents of this Manual

Chapter Title Contents

Preface Describes the purpose, background, and

scope of this manual. Also specifies the

audience for whom this manual is intended

and defines key terms and abbreviations used

throughout this book.

1 Overview Provides a hardware and system overview.

Explains and illustrates the theory behind the

RTD input module.

2 Quick Start Guide Provides a general procedural roadmap to

help you get started using the RTD module.

3 Install and Wire Provides installation procedures and wiring

guidelines.

4 Preliminary Operating

Considerations

5 Channel Configuration,

Data, and Status

6 Ladder Programming

Examples

7 Module Diagnostics and

Troubleshooting

8 Application Examples Examines both basic and supplementary

Appendix A Specifications Provides physical, electrical, environmental,

Appendix B RTD Standards Provides physical, electrical, environmental,

Appendix C Configuration Worksheet

for RTD/Resistance Module

Appendix D I/O Configuration Contains information on the I/O configuration

Gives you the background information you

need to understand how to address and

configure the module for optimum operation

as well as how to make changes once the

module is in a run state.

Examines the channel configuration word and

the channel status word bit by bit, and

explains how the module uses configuration

data and generates status during operation.

Gives an example of the ladder logic required

to define the channel for operation. Also

includes representative examples for unique

programming requirements such as PID.

Explains how to interpret and correct

problems with your RTD module.

applications and gives examples of the ladder

programming necessary to achieve the

desired result.

and functional specifications for the RTD

module.

and functional specifications for the RTD and

potentiometer.

Provides a worksheet to help you configure

the module for operation.

procedure for RSLogix 500 Version 6.0 and

later software.

Publication 1746-UM008B-EN-P - December 2006

Page 9

Preface 9

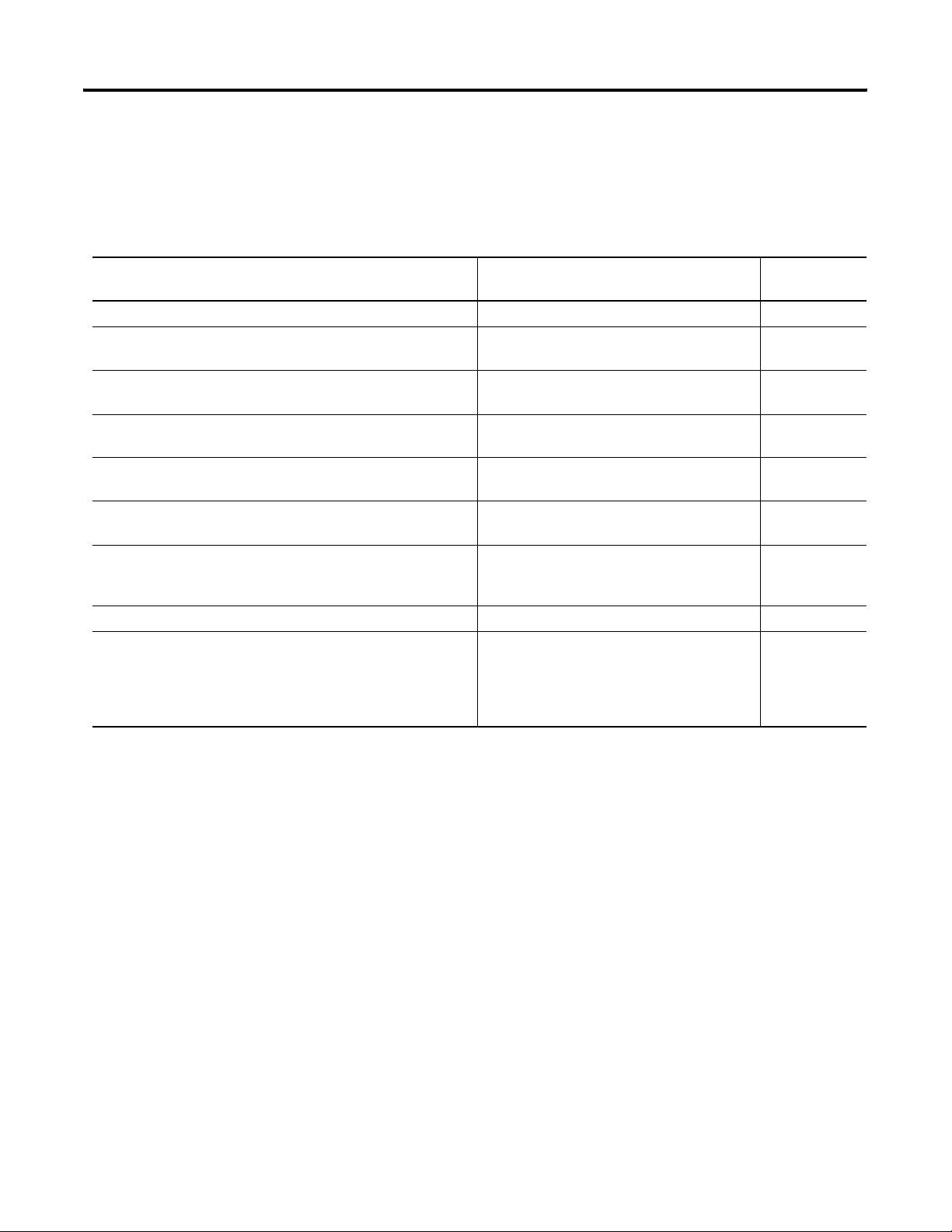

Additional Resources

The following documents contain additional information on Rockwell

Automation products.

For Read This Document Document

Number

An overview of the SLC 500 family of products SLC 500 Systems Selection Guide 1747-SG001

A description on how to install and use your modular SLC 500

programmable controller

A description on how to install and use your fixed SLC 500

programmable controller

A reference manual that contains status file data, instruction set,

and troubleshooting information.

A resource manual and user’s guide containing information about

the analog modules used in your SLC 500 system.

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

programmable controller products and hard-wired

electromechanical devices

A glossary of industrial automation terms and abbreviations Allen–Bradley Industrial Automation Glossary AG-QR071

An article on wire sizes and types for grounding electrical

equipment

SLC 500 Module Hardware Style User Manual 1747-UM011

Installation & Operation Manual for Fixed

Hardware Style Programmable Controllers

SLC 500 Instruction Set Reference Manual 1747-RM001

SLC 500 4-Channel Analog I/O Modules User’s

Manual

Industrial Automation Wiring and Grounding

Guidelines

Application Considerations for Solid-State

Controls

National Electrical Code Published by the

1747-UM009

1746-UM005

1770-IN041

SGI-IN001

National Fire

Protection

Association of

Boston, MA

Common Techniques Used in This Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Text in this font indicates words or phrases you should type.

Publication 1746-UM008B-EN-P - December 2006

Page 10

10 Preface

Notes:

Publication 1746-UM008B-EN-P - December 2006

Page 11

Chapter

1

Overview

This chapter describes the four-channel 1746-NR4 RTD/Resistance

Input Module and explains how the SLC controller gathers RTD

(Resistance Temperature Detector) temperature or resistance-initiated

analog input from the module. Included is:

• a general description of the module’s hardware and software

features.

• an overview of system operation.

For the rest of the manual, the 1746-NR4 RTD/Resistance Input

Module is referred to as simply the RTD module.

Description

The RTD module receives and stores digitally converted analog data

from RTD units or other resistance inputs such as potentiometers into

its image table for retrieval by all fixed and modular SLC 500

processors. An RTD module consists of a temperature-sensing element

connected by two, three, or four wires that provide input to the RTD

module. The module supports connections from any combination of

up to four RTD units of various types (for example: platinum, nickel,

copper, or nickel-iron) or other resistance inputs.

The RTD module supplies a small current to each RTD unit connected

to the module inputs (up to 4 input channels). The module provides

on-board scaling and converts RTD unit input to temperature (°C, °F)

or reports resistance input in ohms.

Each input channel is individually configurable for a specific input

device. Broken sensor detection (open- or short-circuit) is provided

for each input channel. In addition, the module provides indication if

the input signal is out-of-range.

For more detail on module functionality refer to System Overview

page 18.

11 Publication 1746-UM008B-EN-P - December 2006

Page 12

12 Overview

RT D

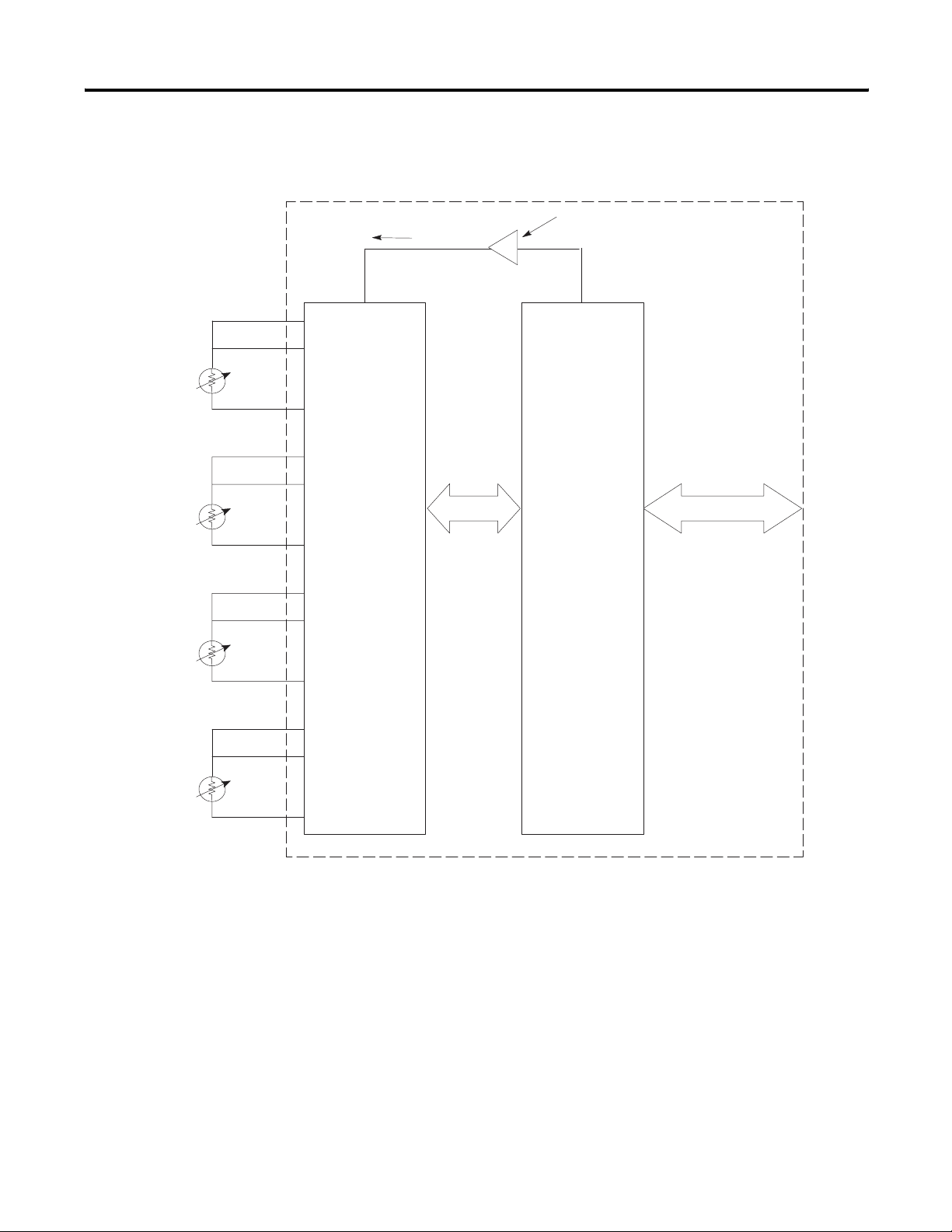

Simplified RTD Module Circuit

I

C= 0.5 or 2 mA

Constant Current Source

RTD Module

RT D

RT D

RT D

Sense

0

Return

Backplane

RT D

Sense

A/D

1

Return

Conversion

Digital Data

µP Circuit

Digital Data

RT D

Sense

2

Return

RT D

Sense

RT D

3

Return

Publication 1746-UM008B-EN-P - December 2006

Page 13

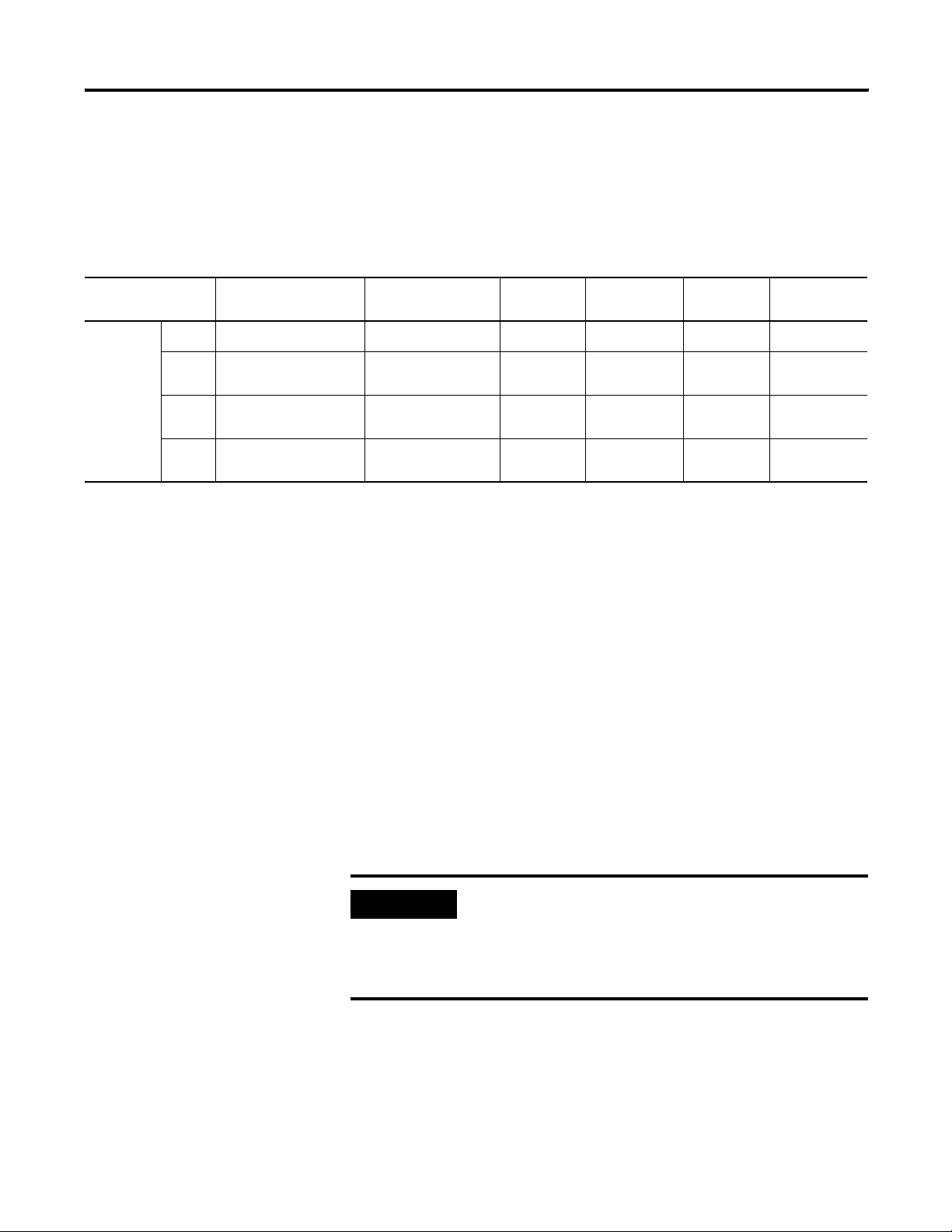

RTD Compatibility

The following table lists the RTD types you can use with the RTD

module and gives each type’s associated temperature range,

resolution, and repeatability specifications.

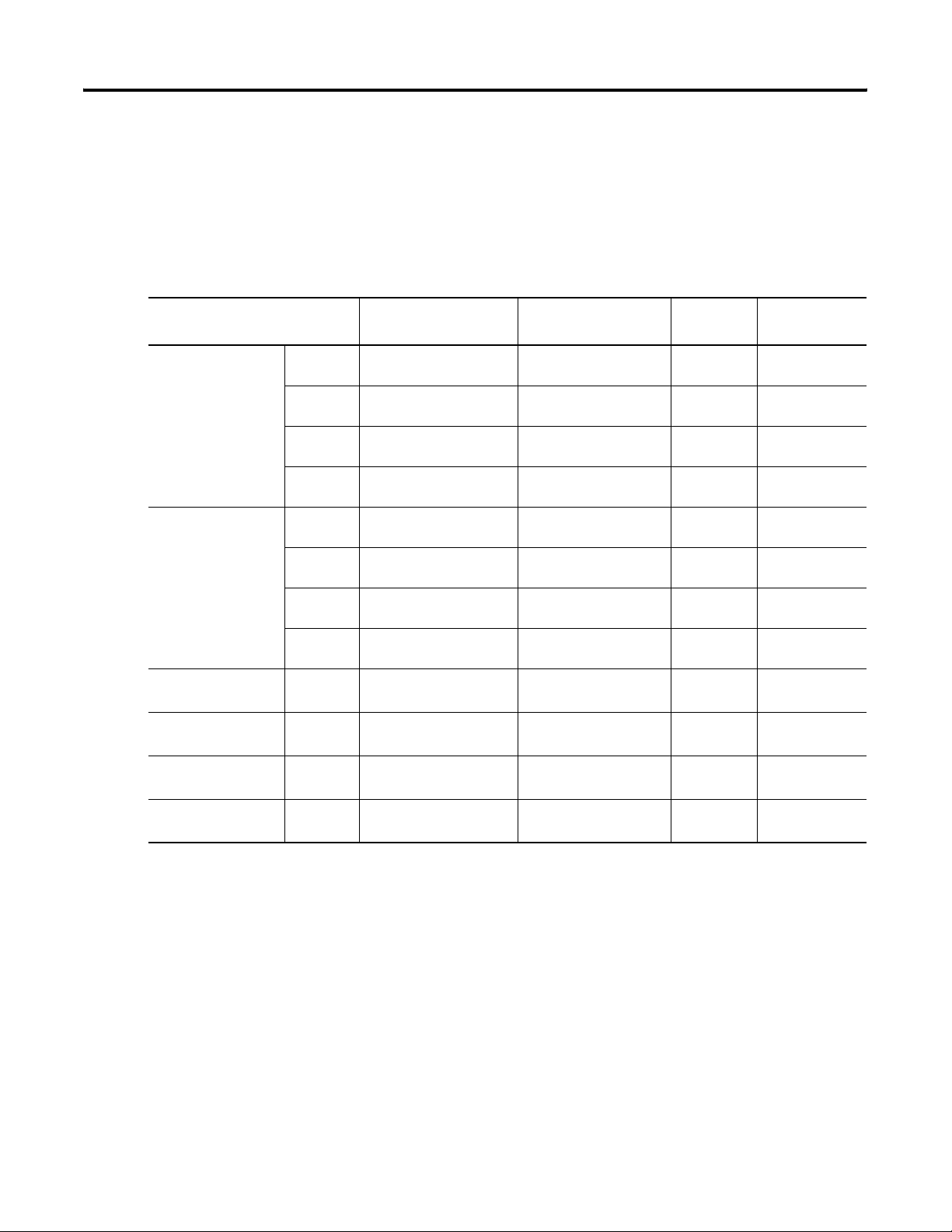

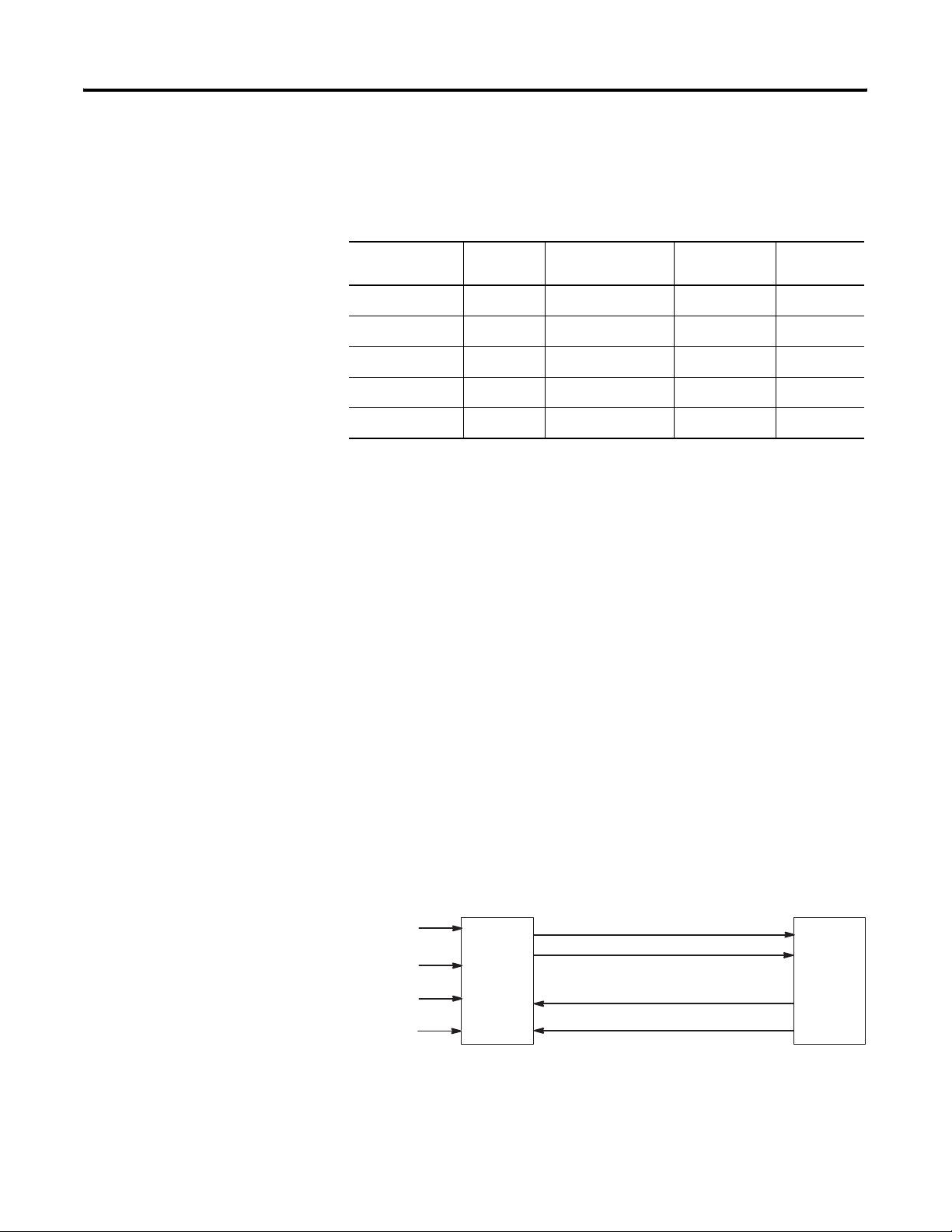

RTD Unit Temperature Ranges, Resolution and Repeatability

Overview 13

RTD Unit Type Temperature Range

(0.5 mA excitation)

100 Ω -200…850 °C

(-328…1562 °F)

200 Ω -200…850 °C

Platinum (385)

(2)

500 Ω -200…850 °C

(-328…1562 °F)

(-328…1562 °F)

1000 Ω -200…850 °C

(-328…1562 °F)

100 Ω -200…630 °C

(-328…1166 °F)

200 Ω -200…630 °C

Platinum (3916)

(2)

500 Ω -200…630 °C

(-328…1166 °F)

(-328…1166 °F)

1000 Ω -200…630 °C

(-328…1166 °F)

Copper (426)

Nickel (618)

Nickel (672)

Nickel Iron (518)

(1)

The temperature range for the 1000 Ω RTD is dependant on the excitation current.

(2)

The digits following the RTD type represent the temperature coefficient of resistance (∝), which is defined as the resistance change per ohm per °C. For

instance, Platinum 385 refers to a platinum RTD with ∝ = 0.00385 Ω/Ω -°C or simply 0.00385 /°C.

(3)

Actual value at 0 °C (32 °F) is 9.042 Ω per SAMA standard RC21-4-1966.

(4)

To maximize the relatively small RTD unit signal, only 2 mA excitation current is allowed.

(5)

Actual value at 0 °C (32 °F) is 100 Ω per DIN standard.

(2)(3)

(2)(5)

(2)

(2)

10 Ω

Not allowed

120 Ω -100…260 °C

(-148 …500 °F)

120 Ω -80 …260 °C

(-112 …500 °F)

604 Ω -100…200 °C

(-148…392 °F)

(4)

Temperature Range

(1)

(2.0 mA excitation)

(-328…1562 °F)

(-328…1562 °F)

(-328…1562 °F)

(-328…464 °F)

(-328…1166 °F)

(-328…1166 °F)

(-328 …1166 °F)

(-328…446 °F)

(-148…500 °F)

(-148…500 °F)

(-112 …500 °F

(-148…392 °F)

-200…850 °C

-200…850 °C

-200…850 °C

-200…240 °C

-200 …630 °C

-200…630 °C

-200…630 °C

-200…630 °C

-100…260 °C

-100…260 °C

-80 …260 °C

-100…200 °C

Resolution Repeatability

(1)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

0.1 °C

(0.2 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.1 °C

(±0.2 °F)

±0.1 °C

(±0.2 °F)

±0.1 °C

(±0.2 °F)

Publication 1746-UM008B-EN-P - December 2006

Page 14

14 Overview

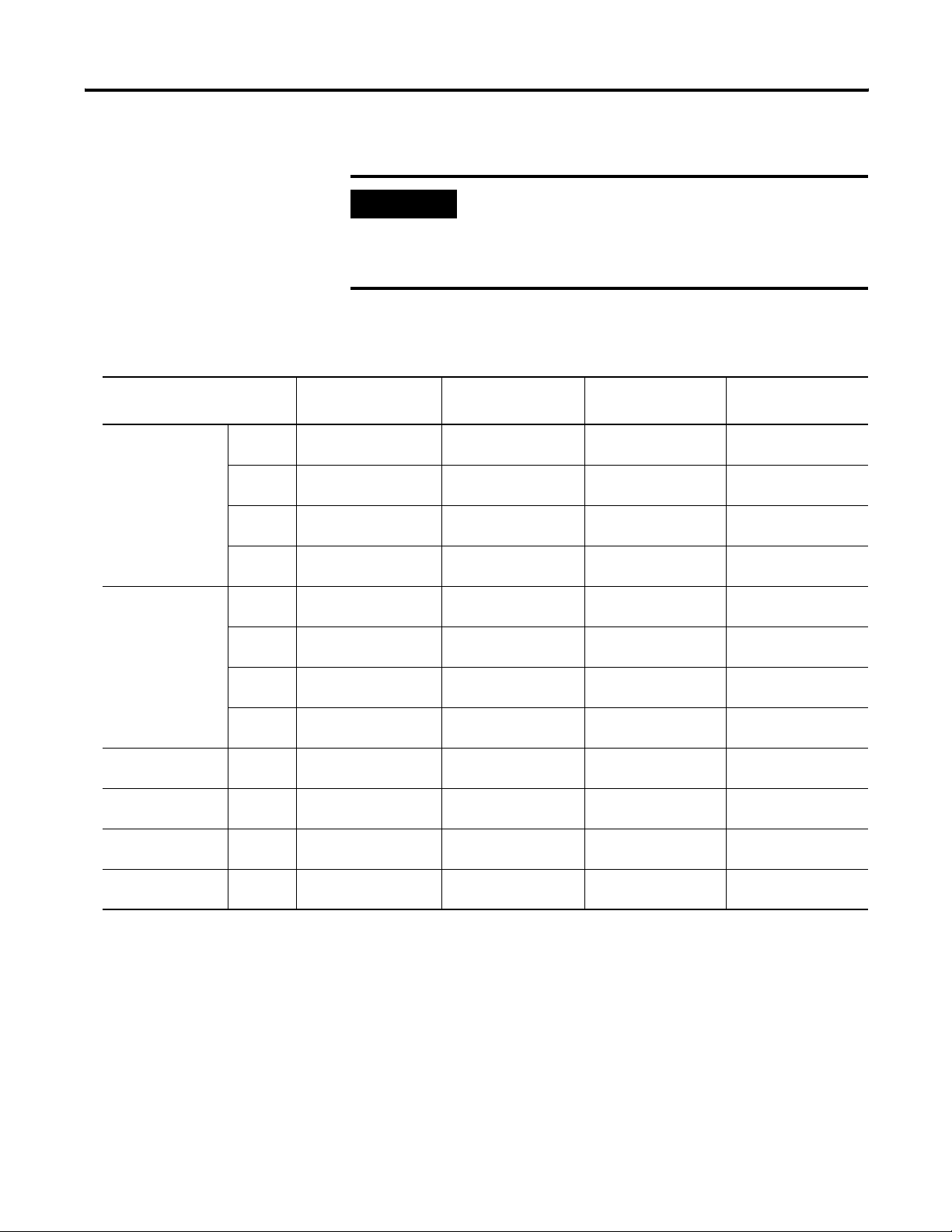

IMPORTANT

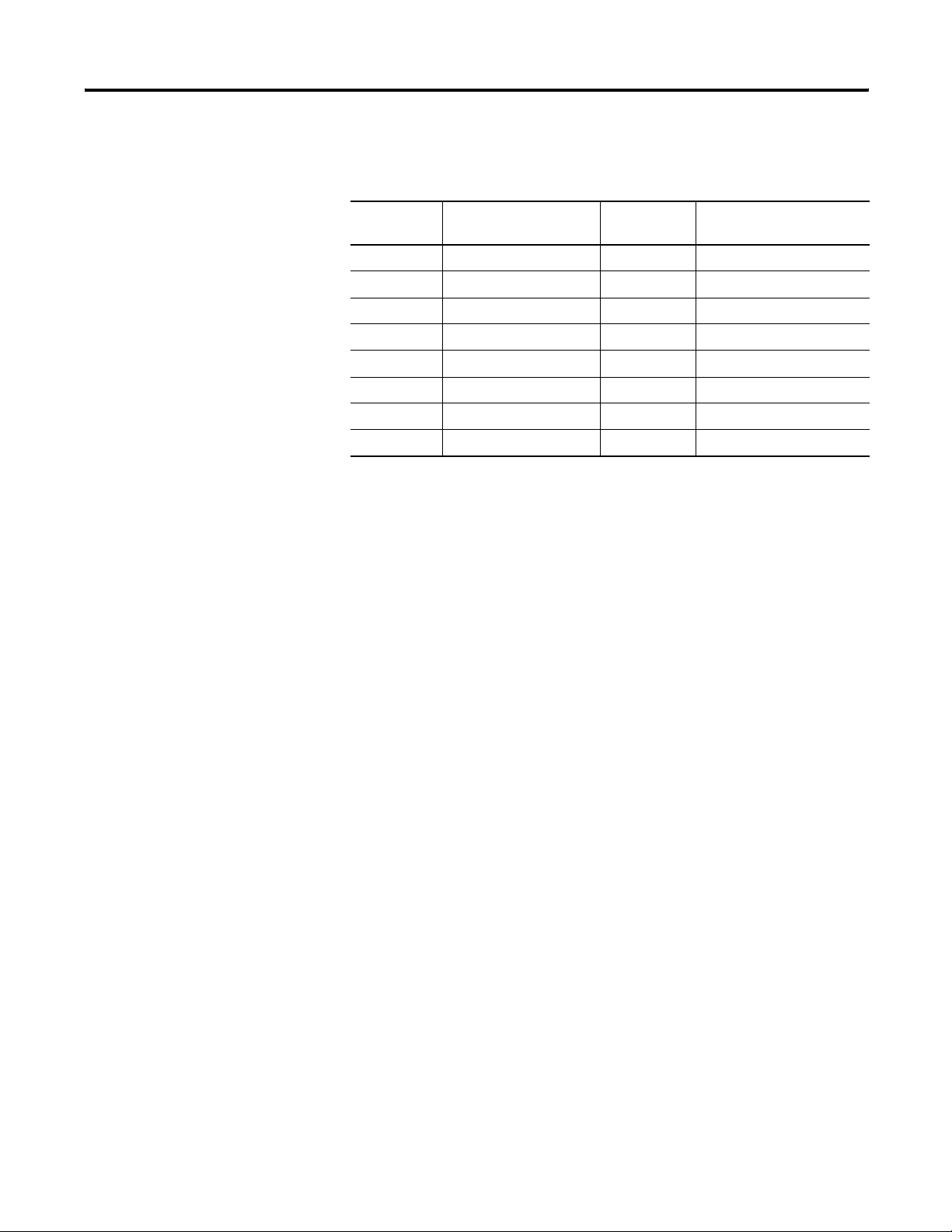

This table shows the accuracy and temperature drift.

Accuracy and Temperature Drift Specifications

RTD Unit Type Accuracy

(0.5 mA excitation)

Platinum (385)

Platinum (3916)

100 Ω ±0.1 °C

200 Ω ±0.1 °C

(3)

500 Ω ±0.6 °C

1000 Ω ±0.6 °C

100 Ω ±1.0 °C

200 Ω ±1.0 °C

(3)

500 Ω ±0.5 °C

(±2.0 °F)

(±2.0 °F)

(±1.1 °F)

(±1.1 °F)

(±2.0 °F)

(±2.0 °F)

(±0.9 °F)

The exact signal range valid for each input type is dependent

upon the excitation current magnitude that you select when

configuring the module.

For details on excitation current, refer to page 119.

Accuracy

(1)

(0.2 mA excitation)

±0.5 °C

(±0.9 °F)

±0.5 °C

(±0.9 °F)

±0.5 °C

(±0.9 °F)

±0.5 °C

(±0.9 °F)

±0.4 °C

(±0.7 °F)

±0.4 °C

(±0.7 °F)

±0.4 °C

(±0.7 °F)

Temperature Drift

(1)

(0.5 mA excitation)

±0.034 °C/°C

(±0.061 °F/°F)

±0.034 °C/°C

(±0.061 °F/°F)

±0.017 °C/°C

(±0.031 °F/°F)

±0.017 °C/°C

(±0.031 °F/°F)

±0.034 °C/°C

(±0.061 °F/°F)

±0.034 °C/°C

(±0.061 °F/°F)

±0.014 °C/°C

(±0.025 °F/°F)

Temperature Drift

(2)

(0.2 mA excitation)

±0.014 °C/°C

(±0.025 °F/°F)

±0.014 °C/°C

(±0.025 °F/°F)

±0.014 °C/°C

(±0.025 °F/°F)

±0.014 °C/°C

(±0.025 °F/°F)

±0.011 °C/°C

(±0.020 °F/°F)

±0.011 °C/°C

(±0.020 °F/°F)

±0.014 °C/°C

(±0.025 °F/°F)

(2)

1000 Ω ±0.5 °C

(±0.9 °F)

Copper (426)

Nickel (618)

Nickel (672)

Nickel Iron (518)

(1)

The accuracy values assume that the module was calibrated within the specified temperature range of 0…60 °C (32…140 °F).

(2)

Temperature drift specifications apply to a module that has not been calibrated.

(3)

The digits following the RTD unit type represent the temperature coefficient of resistance (∝), which is defined as the resistance change per ohm per °C. For instance,

Platinum 385 refers to a platinum RTD with ∝ = 0.00385 Ω/Ω -°C or simply 0.00385 /°C.

(4)

Actual value at 0 °C (32 °F) is 9.042 Ω per SAMA standard RC21-4-1966.

(5)

To maximize the relatively small RTD unit signal, only 2 mA excitation current is allowed.

(6)

Actual value at 0 °C (32 °F) is 100 Ω per DIN standard.

(3)(4)

(3)(6)

(3)

(3)

10 Ω

Not allowed.

120 Ω ±0.2 °C

(±0.4 °F)

120 Ω ±0.2 °C

(±0.4 °F)

604 Ω ±0.3 °C

(±0.5 °F)

(5)

±0.4 °C

(±0.7 °F)

±0.6 °C

(±1.1 °F)

±0.2 °C

(±0.4 °F)

±0.2 °C

(±0.4 °F)

±0.3 °C

(±0.5 °F)

±0.014 °C/°C

(±0.025 °F/°F)

Not allowed.

±0.008 °C/°

(±0.014 °F/°F)

±0.008 °C/°

(±0.014 °F/°F)

±0.010 °C/°

(±0.018 °F/°F)

±0.014 °C/°C

(±0.025 °F/°F)

(5)

±0.017 °C/°C

(±0.031 °F/°F)

±0.008 °C/°C

(±0.014 °F/°F)

±0.008 °C/°C

(±0.014 °F/°F)

±0.010 °C/°C

(±0.018 °F/°F)

Publication 1746-UM008B-EN-P - December 2006

Page 15

Overview 15

When you are using 100 Ω or 200 Ω platinum RTD units with 0.5 mA

excitation current, refer to the following important information about

module accuracy.

IMPORTANT

Module accuracy, using 100 Ω or 200 Ω platinum RTD units with 0.5 mA

excitation current, depends on the following criteria:

• Module accuracy is ±0.6 °C (±33.08 °F) after you apply power to the

module or perform an autocalibration at 25 °C (77 °F) ambient with

module operating temperature at 25 °C (77 °F).

• Module accuracy is ±(0.6 °C + ΔT x 0.034 °C/°C) or

±(33.08 °F + ΔT x 32.06 °F/°F) after you apply power to the module or

perform an autocalibration at 25 °C (77 °F) ambient with the module

operating temperature between 0…60 °C. (32…140 °F).

Where ΔT is the temperature difference between the actual

operating temperature of the module and 25 °C (77 °F) and

0.034 °C/°C (32.06 °F/°F) is the temperature drift shown in the table

above for 100 Ω or 200 Ω platinum RTD units.

Module accuracy is ±1.0 °C (±33.80 °F) after you apply power to the

module or perform an autocalibration at 60 °C (140 °F) ambient with

module operating temperature at 60 °C (140 °F).

Publication 1746-UM008B-EN-P - December 2006

Page 16

16 Overview

Resistance Input Specifications

Resistance Device Compatibility

The following table lists the resistance input types you can use with

the RTD module and gives each type’s associated specifications.

Input Type Resistance Range

(0.5 mA excitation)

150 Δ 0…150 Δ 0…150 Δ

Resistance Range

(2.0 mA excitation)

Accuracy

(2) (3)

(1)

Temperature

Drift

500 Δ 0…500 Δ 0…500 Δ x 0.5 Δ x 0.014 Δ/ ° C

(x 0.025 Δ/ ° F

Resistance

1000 Δ 0…1000 Δ 0…1000 Δ x 1.0 Δ x 0.029 Δ/ °C

(x 0.052 Δ/ ° F

3000 Δ 0…3000 Δ 0…1900 Δ x 1.5 Δ x 0.043 Δ/ °C

(x 0.077 Δ/ ° F

(1)

The accuracy values assume that the module was calibrated within the specified temperature range of 0…60 °C (32 …140 °F).

(2)

The accuracy for 150 Ω is dependant on the excitation current:

x 0.2 Ω at 0.5 mA

x 0.15 Ω at 2.0 mA

(3)

The temperature drift for 150 Ω is dependant on the excitation current:

x 0.006 Ω/°C at 0.5 mA

x 0.004Ω at 2.0 mA

Hardware Overview

Resolution Repeatability

0.01Δ x 0.04 Δ

0.01Δ x 0.2 Δ

0.01Δ x 0.2 Δ

0.01Δ x 0.2 Δ

Publication 1746-UM008B-EN-P - December 2006

The RTD module fits into a single-slot of an SLC 500 chassis.

• Modular system, except the processor slot (0)

• Fixed system expansion chassis (1746-A2)

The module uses eight input words and eight output words.

IMPORTANT

If the RTD module resides in a remote configuration with a

SLC 500 Remote I/O Adapter Module (1747-ASB), use block

transfer for configuration and data retrieval. Block transfer

requires a 1747-SN Remote I/O Scanner (series B) or PLC

processor.

The module contains a removable terminal block (item 3) providing

connection for any mix of four RTD sensors or resistance input

devices. There are no output channels on the module. Module

configuration is done via the user program. There are no DIP

switches.

Page 17

Overview 17

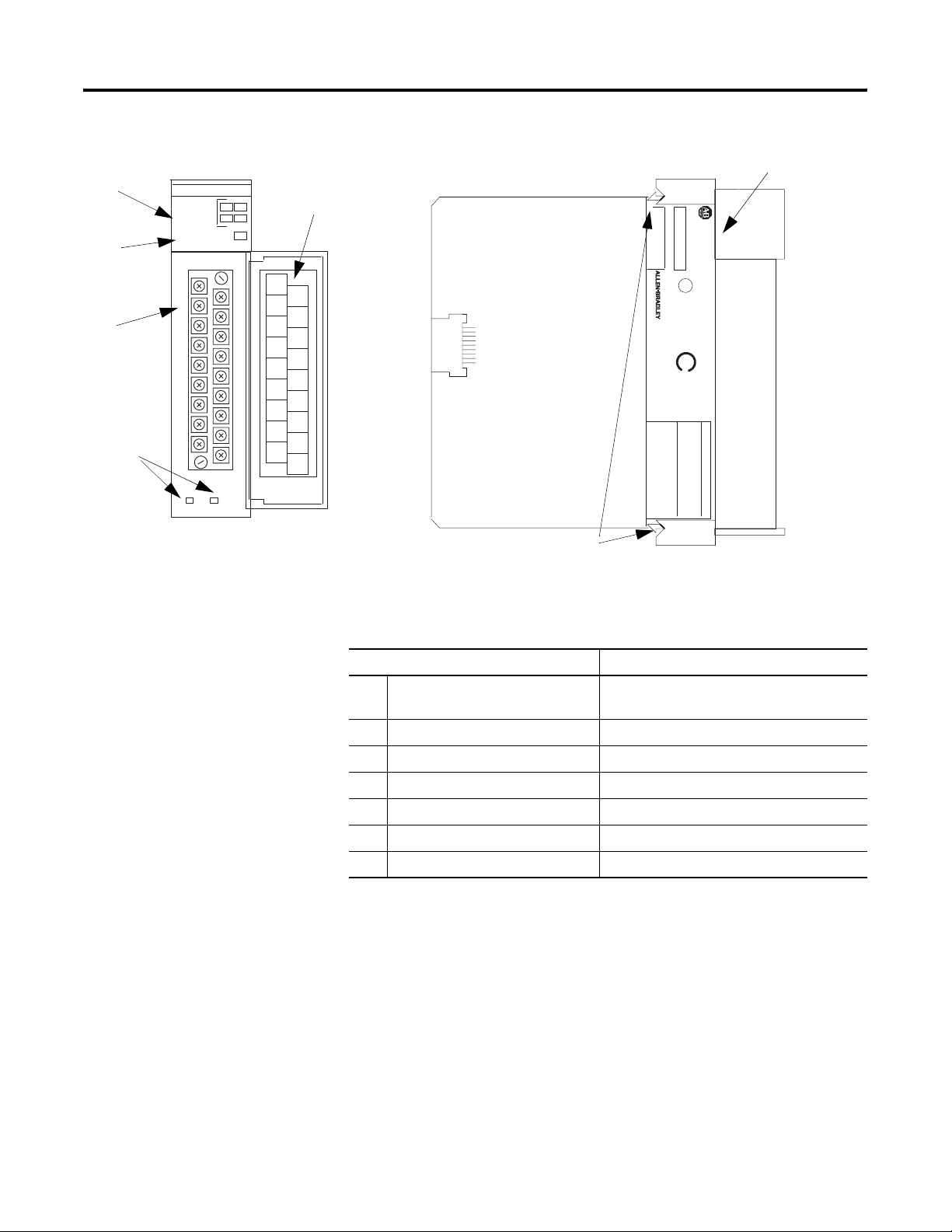

RTD Module Hardware

6

1

2

3

4

CHANNEL

STATUS

MODULE STA

RTD/resistance

INPUT

SHIELD

CHL 0

RTD

CHL 0

SENSE

CHL 0

RETRN

SHIELD

CHL 2

RTD

CHL 2

SENSE

CHL 2

RETRN

SHIELD

SHIELD

CHL 1

RTD

CHL 1

SENSE

CHL 1

RETRN

SHIELD

CHL 3

RTD

CHL 3

SENSE

CHL 3

RETRN

SHIELD

5

012

3

TUS

CAT

SERIAL NO.

1746 NR4

NR4±xxx x

RTD/resistance INPUT MODULE

SLC 500

SER

FRN

)

CLASS I, GROUPS A, B, C AND D, DIV.2

U

L

LISTED IND. CONT . EQ.

FOR HAZ. LOC. A196

SA

)

OPERA TING

TEMPERA TURE

CODE T3C

RESIST ANCE:

RTD TYPES:

INPUT SIGNAL RANGES

150 W , 500 W , 1000 W , 3000 W

PLATINUM, COPPER

NICKEL, NICKEL±IRON

7

Hardware Features

Feature Description

1 Channel Status LED Indicators

(green)

Display operating and fault status of

channels 0, 1, 2, and 3

2 Module Status LED (green) Displays module operating and fault status

3 Removable Terminal Block Provides physical connection to input devices

4 Cable Tie Slots Secure wiring from module

5 Door Label Provides terminal identification

6 Side Label (Nameplate) Provides module information

7 Self-locking Tabs Secure module in chassis slot

General Diagnostic Features

The RTD module contains diagnostic features that can be used to help

you identify the source of problems that may occur while you turn on

the power or during normal channel operation.

The power and channel diagnostics are explained in Chapter 7,

Module Diagnostics and Troubleshooting.

Publication 1746-UM008B-EN-P - December 2006

Page 18

18 Overview

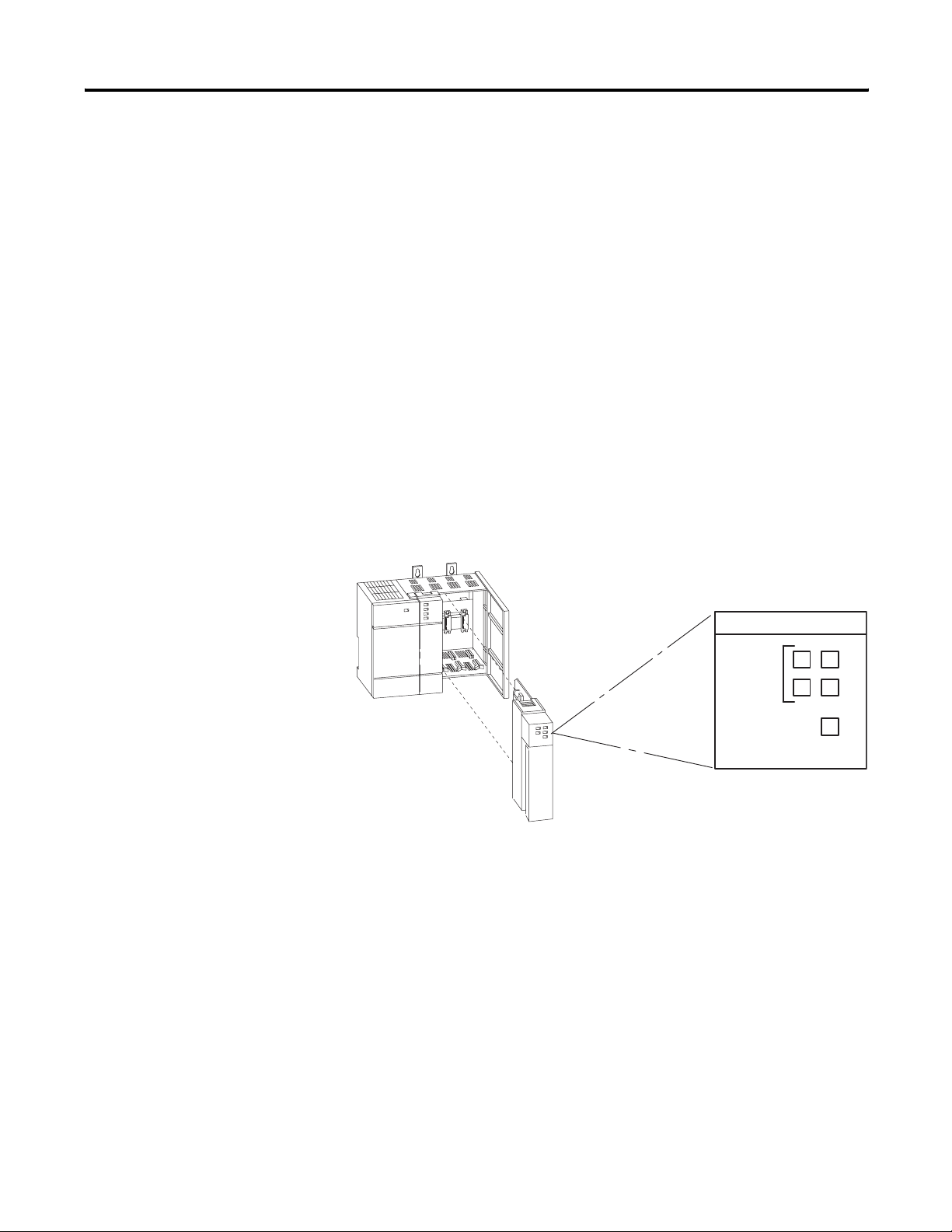

System Overview

The RTD module communicates to the SLC 500 processor through the

parallel backplane interface and receives +5V dc and +24V dc power

from the SLC 500 power supply through the backplane. No external

power supply is required. You may install as many RTD modules in

your system as the power supply can support.

RTD Module Configuration

RTD Modules

SLC Processor

Each individual channel on the RTD module can receive input signals

from two, three or four wire RTD sensors or from resistance input

devices. You configure each channel to accept either input. When

configured for RTD input types, the module converts the RTD

readings into linearized, digital temperature readings in °C or °F.

When configured for resistance inputs, the module provides a linear

resistance value in ohms.

IMPORTANT

The RTD module is designed to accept input from RTD sensors

with up to three wires. When using 4-wire RTD sensors, one of

the two lead compensation wires is not used and the 4-wire

sensor is treated like a 3-wire sensor. Lead wire compensation

is provided via the third wire.

See NR4 Wiring Considerations on page 40 for more

information.

Publication 1746-UM008B-EN-P - December 2006

Page 19

Overview 19

System Operation

The RTD module has three operational states.

• Cycle power

• Module operation

• Error (module error and channel error)

Cycle Power

When you cycle the module’s power, the RTD module checks its

internal circuits, memory, and basic functions via hardware and

software diagnostics. During this time the module status LED indicator

remains off. If no faults are found during the diagnostics, the module

status LED indicator is on.

After the checks are complete, the RTD module waits for valid

channel configuration data from your SLC ladder logic program

(channel status LED indicators off). After configuration data is written

to one or more channel configuration words and their channel enable

bits are set by the user program, the channel status LED indicators go

on and the module continuously converts the RTD or resistance input

to a value within the range you selected for the enabled channels. The

module is now operating in its normal state.

Each time a channel is read by the module, that data value is tested by

the module for a fault condition, for example, open circuit, short

circuit, over range, and under range. If such a condition is detected, a

unique bit is set in the channel status word and the channel status

LED indicator blinks, indicating a channel error condition.

The SLC processor reads the converted RTD or resistance data from

the module at the end of the program scan or when commanded by

the ladder program. The processor and RTD module determine that

the backplane data transfer was made without error and the data is

used in your ladder program.

Module Operation

Each input channel consists of an RTD connection, which provides:

• excitation current.

• a sense connection, which detects lead-wire resistance.

• a return connection, which reads the RTD or resistance value.

Each of these analog inputs are multiplexed to one of two analog

convertors.

Publication 1746-UM008B-EN-P - December 2006

Page 20

20 Overview

The A/D convertors cycle between reading the RTD or resistance

value, the lead wire resistance, and the excitation current. From these

readings, an accurate temperature or resistance is returned to the user

program.

The RTD module is isolated from the chassis backplane and chassis

ground. The isolation is limited to 500V dc. Optocouplers are used to

communicate across the isolation barrier. Channel-to-channel

common-mode isolation is limited to X 1 volt.

LED Indicator Status

The following figure shows the RTD module LED indicator panel

consisting of five LED indicators. The state of the LED indicators (for

example, off, on, or blinking) depends on the operational state of the

module.

See the LED Indicator Status table on page 21.

LED Indicators

INPUT

CHANNEL

STATUS

MODULE STATUS

RTD/resistance

The purpose of the LED indicators is to provide:

• Channel Status - One LED indicator for each of the four input

channels indicates if the channel is enabled, disabled, or is not

operating as configured, due to an error.

• Module Status - If OFF at any time, other than when you cycle

module power, this LED indicator indicates that non-recoverable

module errors (for example, diagnostic or operating errors) have

occurred. The LED indicator is ON if there are no module errors.

0 2

1 3

Publication 1746-UM008B-EN-P - December 2006

Page 21

Overview 21

The status of each LED indicator, during each of the operational states

(for example, powerup, module operation and error), is depicted in

the following table.

LED Indicator Status

LED Indicator Cycle

Power

Ch 0 Status

Ch 1 Status

Ch 2 Status

Ch 3 Status

Mod. Status

(1)

Module is disabled while you cycle module power.

(2)

Channel status LED indicator is ON if the respective channel is enabled and OFF if the channel is disabled.

Off

Off

Off

Off

Off

(1)

(1)

(1)

(1)

(1)

Module Operation

(No Error)

(2)

On/Off

(2)

On/Off

(2)

On/Off

(2)

On/Off

Module Error Channel

Error

Off Blinks

Off Blinks

Off Blinks

Off Blinks

On Off On

Module to Processor Communication

The RTD module communicates with the SLC processor through the

backplane of the chassis. The RTD module transfers data to and

receives data from the processor by means of an image table. The

image table consists of eight input words and eight output words.

Data transmitted from the module to the processor is called the input

image (for example, Channel Data Words and Channel Status Words).

Conversely, data transmitted from the processor to the module is

called the output image (for example, Channel Configuration Words

and Scaling Limit Words).

Details about the input and output images are found in Module

Addressing on page 52 and 53.

Communication Flow

Channel Data Words

RTD/

resistance

Analog

Signals

1746-NR4

Input

Module

Channel Status Words

Scaling Limit Words

Channel Configuration Words

Publication 1746-UM008B-EN-P - December 2006

SLC 500

Processor

Page 22

22 Overview

Image Table

Input Image

Word

0 Channel 0 data 0 Channel 0 configuration

1 Channel 1 data 1 Channel 1 configuration

2 Channel 2 data 2 Channel 2 configuration

3 Channel 3 data 3 Channel 3 configuration

4 Channel 4 data 4 User-set Lower limit scale 0

5 Channel 5 data 5 User-set Upper limit scale 0

6 Channel 6 data 6 User-set Lower limit scale 1

7 Channel 7 data 7 User-set Upper limit scale 1

Function Output

Image Word

Function

The Channel Configuration Words (output image) contain

user-defined configuration information for the specified input channel.

This information is used by the module to configure and operate each

channel. The Channel Status Words (input image) contain status

information about the channel’s current configuration and operational

state. The input data values of the analog input channel are contained

in the Channel Data Word (input image), which is valid only when the

channel is enabled and there are no channel errors (for example,

broken sensor or overrange.)

You set the Scaling Limit Words (output image) to provide a definable

scaling range for the temperature resistance data when using the

proportional counts data type.

Publication 1746-UM008B-EN-P - December 2006

Page 23

Chapter

2

Quick Start Guide

This chapter helps you get started using the RTD module. The

procedures included here assume that you have a basic understanding

of SLC 500 products.

You must:

• understand electronic process control.

• be able to interpret the ladder logic instructions for generating

the electronic signals that control your application.

Because this is a start-up guide, this chapter does not contain detailed

explanations about the procedures listed. It does, however, reference

other chapters in this book where you can get more detailed

information.

Required Tools and Equipment

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommended documentation before

trying to apply the information.

This chapter:

• tells you what equipment you need.

• explains how to install and wire the module.

• shows you how to set up one channel for RTD or resistance

input.

• examines the state of the LED indicators at normal startup.

• examines the channel status word.

Have the following tools and equipment ready.

• Medium blade screwdriver

• Medium cross-head screwdriver

• RTD module (1746-NR4)

• RTD sensor or resistance input

• Appropriate cable (if needed)

• Programming software

23 Publication 1746-UM008B-EN-P - December 2006

Page 24

24 Quick Start Guide

Procedures

Follow these procedures to get your RTD module installed and ready

to use.

Unpack the Module

Unpack the module making sure that the contents include:

• RTD module, catalog number 1746-NR4.

• Installation instructions, publication 1746-IN012.

If the contents are incomplete contact your Allen-Bradley

representative for assistance.

Determine Power Requirements

Review the requirements of your system to see that your chassis

supports placement of the RTD module.

• The fixed, 2-slot chassis supports two RTD modules.

If combining an RTD module with a different module, refer to

the module compatibility table found in chapter 3.

• For modular style systems, calculate the total load on the system

power supply using the procedure described in the SLC 500

Modular Style User Manual, publication 1747-UM011.

For more information refer to chapter 3, Install and Wire and

Appendix A, Specifications.

Publication 1746-UM008B-EN-P - December 2006

Page 25

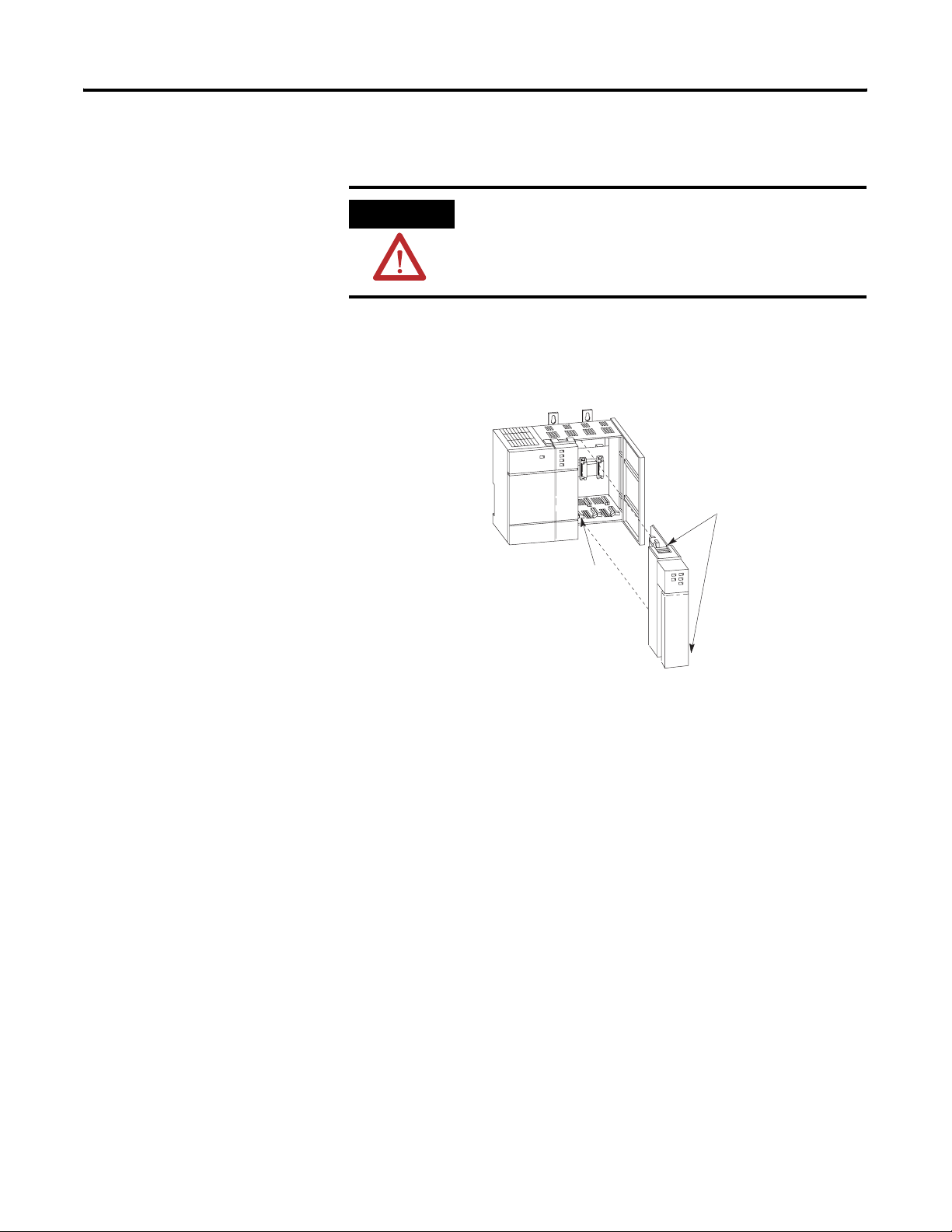

Insert the Module

Quick Start Guide 25

ATTENTION

Never install, remove, or wire modules with power applied to

the chassis or devices wired to the module.

For more information refer to chapter 3, Install and Wire.

Make sure system power is off; then insert the RTD module into your

1746 chassis. In this example procedure, local slot 1 is selected.

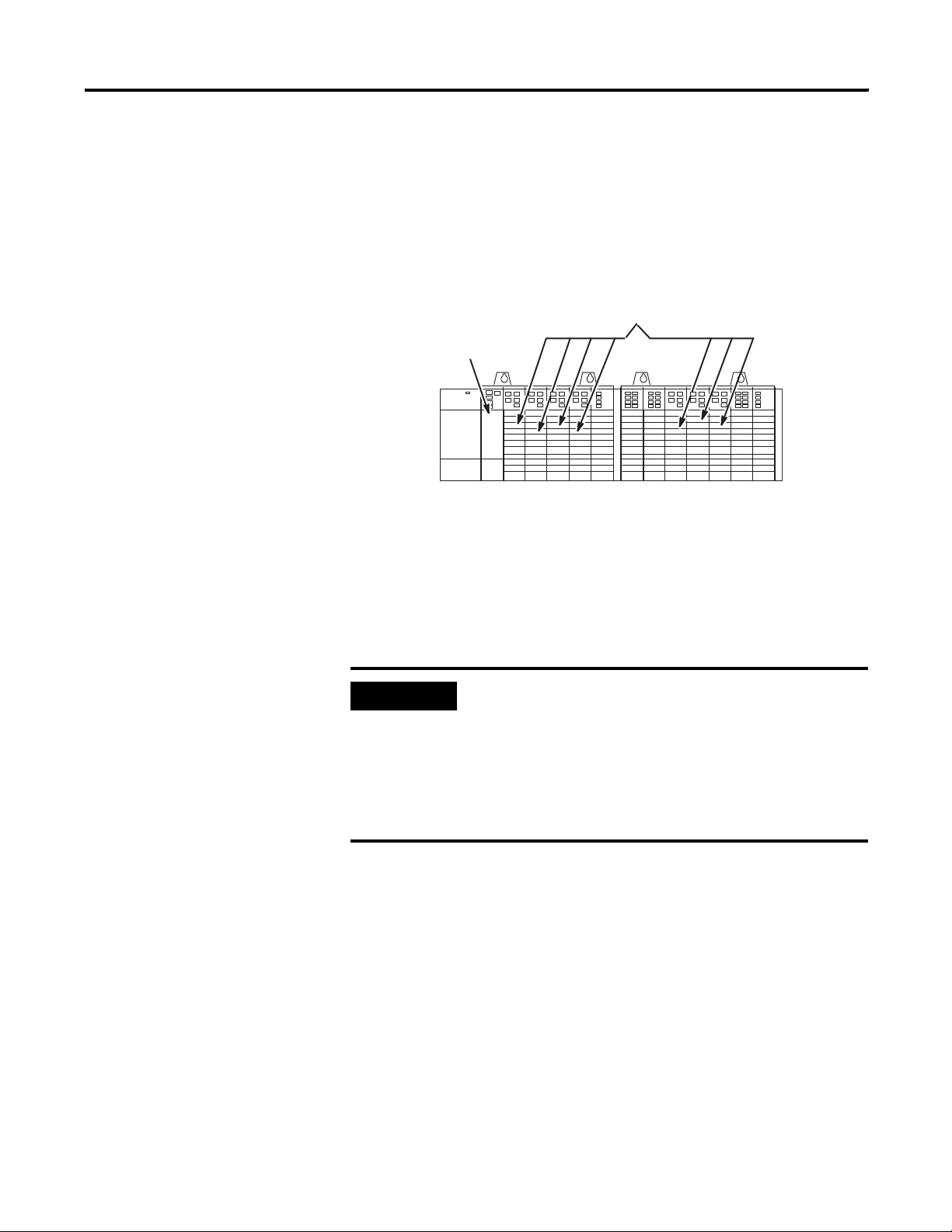

Module Insertion into Chassis

Top and Bottom

Module Release(s)

Card Guide

Wire the Module

Connect RTD module or potentiometer wire leads to channel 0 of the

RTD module.

See RTD Connections to Terminal Block on page 26, Two-wire

Potentiometer Connections to Terminal Block on page 27, or

Three-wire Potentiometer Connections to Terminal Block on page 28.

For more information refer to chapter 3, Install and Wire.

Publication 1746-UM008B-EN-P - December 2006

Page 26

26 Quick Start Guide

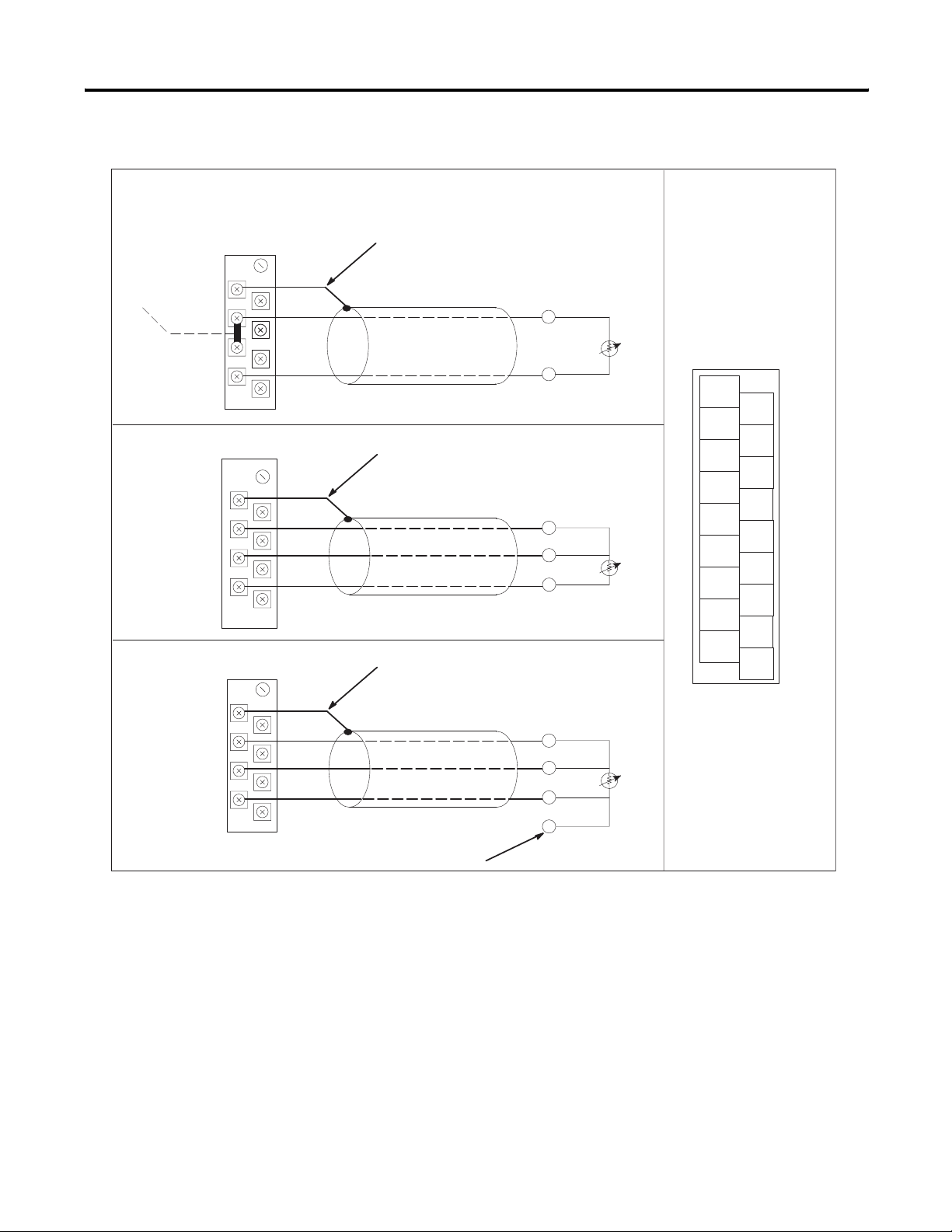

RTD Connections to Terminal Block

For details on wiring an RTD unit to the module, see chapter 3.

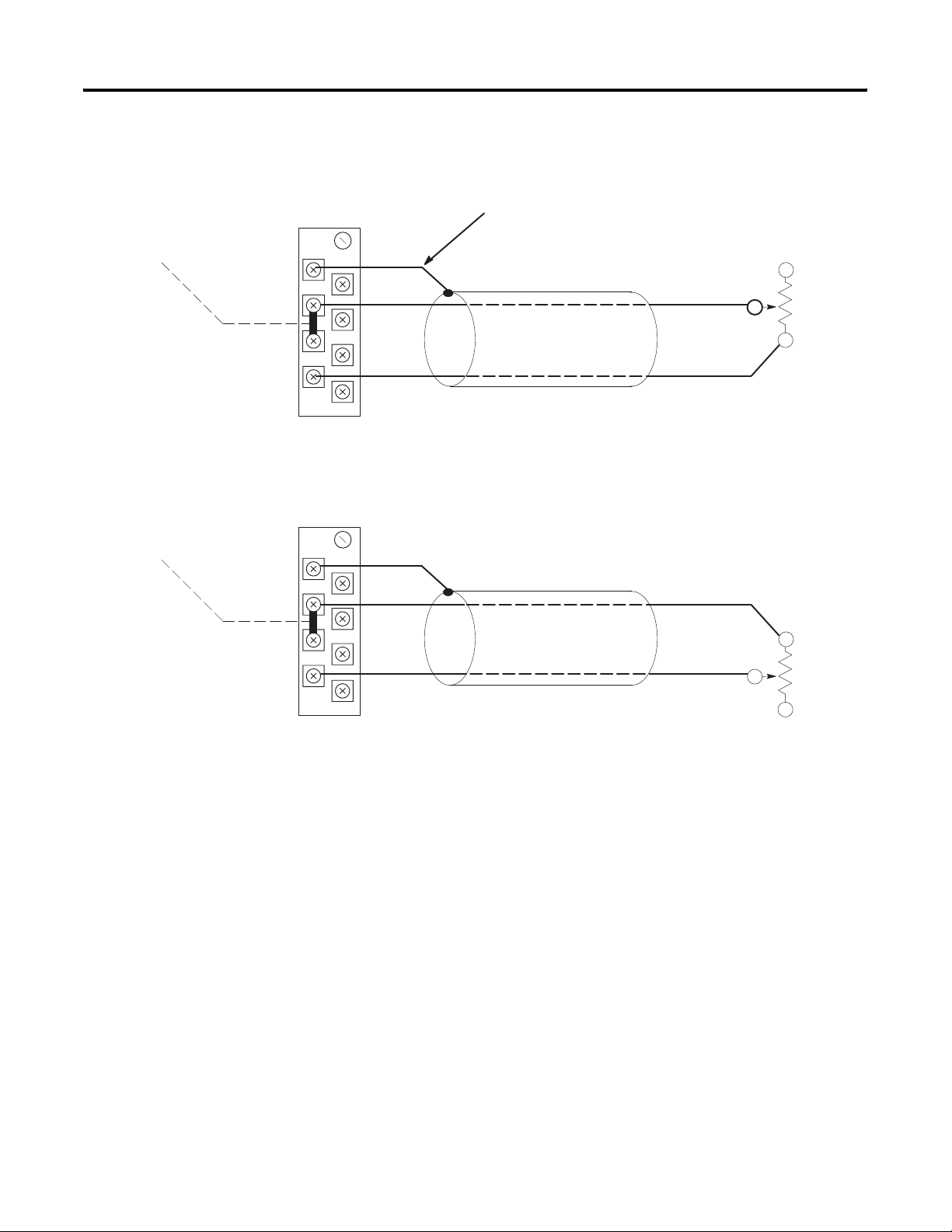

Two Wire RTD Interconnection

Add jumper.

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

Three Wire RTD Interconnection

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

Four Wire RTD Interconnection

Cable Shield

RTD

Return

Belden #9501 Shielded Cable

Cable Shield

RTD

Sense

Return

Belden #83503 or Belden #9533 Shielded Cable

Cable Shield

RTD

Return

RTD

Sense

Return

Terminal Pin-outs

Shield

Shield

Chl 0

RT D

Chl 1

RT D

Chl 0

Sense

Chl 1

Sense

Chl 0

Return

Chl 1

Return

Shield

Shield

Chl 2

RT D

Chl 3

RT D

Chl 2

Sense

Chl 3

Sense

Chl 2

Return

Chl 3

Return

Shield

Shield

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

RTD

Sense

Return

Belden #83503 or Belden #9533 Shielded Cable

Leave one sensor wire open

RTD

Sense

Return

Publication 1746-UM008B-EN-P - December 2006

Page 27

Two-wire Potentiometer Connections to Terminal Block

For details on wiring an RTD unit to the module, see chapter 3.

Cable Shield

Quick Start Guide 27

Add jumper.

Add jumper.

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

RTD

Return

Belden #9501 Shielded Cable

Potentiometer wiper arm can be connected to either the RTD or return terminal

depending on whether the user wants increasing or decreasing resistance.

RTD

Return

Belden #9501 Shielded Cable

Potentiometer

Potentiometer

Publication 1746-UM008B-EN-P - December 2006

Page 28

28 Quick Start Guide

Three-wire Potentiometer Connections to Terminal Block

For details on wiring an RTD to the module, see chapter 3.

Cable Shield Run RTD unit and sense wires from module to

potentiometer terminal and tie them to one point.

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

RTD

Sense

Return

Belden #83503 or Belden #9533 Shielded Cable

Potentiometer wiper arm can be connected to either the RTD or return terminal

depending on whether you want increasing or decreasing resistance.

Cable Shield

RTD

Sense

Return

Belden #83503 or Belden #9533 Shielded Cable

Run RTD and sense wires from module to

potentiometer terminal and tie them to one point.

Potentiometer

Potentiometer

Publication 1746-UM008B-EN-P - December 2006

Configure Your I/O

Configure your system I/O configuration for the particular slot where

the RTD module resides (slot 1 in this example). Select the 1746-NR4

module from the list of modules, or if it is not listed in your software

version, select Other and enter the RTD module ID code (3513) at the

prompt on the I/O configuration display.

For more information refer to chapter 4, Preliminary Operating

Considerations.

Page 29

Quick Start Guide 29

Configure the Module

Determine the operating parameters for channel 0. In this example,

the figure shows the channel 0 configuration word defined with all

defaults (0) except for channel enable (bit 11). The addressing reflects

the location of the module as slot 1.

For details on how to configure the module for your application, refer

to chapter 4 and chapter 5.

A configuration worksheet is included on page 132 to assist you in

channel configuration.

For more information refer to chapter 5, Channel Configuration, Data,

and Status.

Output Image Detail

SLC 500 Controller

Data Files

Input Image

Address

Word 0

O:1.0

Word 1

O:1.1

Word 2

O:1.2

Word 3

O:1.3

Word 4

O:1.4

Word 5

O:1.5

Word 6

O:1.6

Word 7

O:1.7

If proportional counts data format is used, then output words 4…7

can be used to define a user-set scaling range for each channel.

Output Image

(8 words)

Channel 0 Configuration Word

Channel 1 Configuration Word

Channel 2 Configuration Word

Channel 3 Configuration Word

User-set Lower Scale Limit Range 0

User-set Upper Scale Limit Range 0

User-set Lower Scale Limit Range 1

User-set Upper Scale Limit Range 1

Not Defined

Excitation Current Select

Scaling Select *

Filter Frequency Select

Channel Enable

Temperature Units Select

000000000000000

Bit 15 Bit 0

Data Format Select

Broken Input Select

Input T ype Select

0

* Scaling Select bits apply to proportional counts mode.

Limit Scale W ords are only used if scaling select = 01

10 and data format = 11.

Default Settings

• 100 Platinum R TD (385)

• Engineering

Units x 1 (0.1

˚/ step)

• Broken Input (set data word to zero)

• Degrees Celsius ( ˚C)

• 10

Hz Filter Frequency

• Channel Disabled

• 2.0 mA Excitation Current

• Module Defined Scaling

Bit 15

000010000000000

New Setting

Bit 0

0

or

Set this bit (11) to enable channel. Address = O:1.0/11

Publication 1746-UM008B-EN-P - December 2006

Page 30

30 Quick Start Guide

n

Program the Configuration

Follow these steps to complete the programming necessary to

establish the new configuration word setting in the previous step.

1. Create integer file N10 using the memory map function.

Integer file N10 should contain one element for each channel

used. For this example we only need one, N10:0.

2. Enter the configuration parameters for channel 0 into integer

N10:0.

In this example, all the bits of N10:0 are zero except for the

channel enable (N10:0/11).

3. Program an instruction in your ladder logic to copy the contents

of N10:0 to output word O:1.0.

See Output Image Detail on page 28.

For more information refer to chapter 6, Ladder Programming

Examples and chapter 8, Application Examples.

Initial Configuration Word Setting

First Pass Bit

S:1

] [

15

COP

COPY FILE

Source # N10:0

Dest # O:1.0

Length 1

On power±up, the first pass bit

(S:1/15) is set for one scan, enabling

the COPY instruction that transfers a

one to bit 11 of channel configuration

word 0. This enables channel 0,

which directs the RTD module to sca

channel 0 and to present the analog

data to the SLC processor.

Publication 1746-UM008B-EN-P - December 2006

Page 31

Quick Start Guide 31

Write Remaining Ladder Logic

The Channel Data Word contains the information that represents the

temperature value or resistance value of the input channel. Write the

remainder of the ladder logic program that specifies how your

RTD/resistance input data is processed for your application. In this

procedure, the addressing reflects the location of the module as slot 1.

Input Image Detail

SLC 500 Controller

Data Files

Address

I:1.0

I:1.1

I:1.2

I:1.3

•

•

•

I:1.7

Word 0

Word 1

Word 2

Word 3

•

•

•

Word 7

Input Image

(8 words)

Channel 0 Data Word

Channel 1 Data Word

Channel 2 Data Word

Channel 3 Data Word

Channel 0 Status Word

Channel 1 Status Word

Channel 2 Status Word

Channel 3 Status Word

Output Image

Address

I:1.0

000000000000000

(Variable RTD/resistance Input Data)

Bit 15

0

Bit 0

Test Your RTD Program

1. Apply power.

The module status LED indicator and channel 0 status LED

indicator turn on.

2. Download your program to the SLC processor.

3. Make sure the controller is in Run mode.

For more information see chapter 7, Module Diagnostics and

Troubleshooting.

LED Indicator Status

INPUT

CHANNEL

STATUS

MODULE STATUS

RTD/resistance

012

3

Channel LEDs

Module Status LED

Publication 1746-UM008B-EN-P - December 2006

Page 32

32 Quick Start Guide

Program Functional Check (Optional)

Monitor the status of input channel 0 to determine its configuration

setting and operational status. This is useful for troubleshooting when

the blinking channel LED indicator indicates that an error has

occurred.

If the Module Status LED indicator is off, or if the Channel 0 LED

indicator is off or blinking, refer to chapter 7.

For more information see chapter 5, chapter 7, and chapter 8.

Monitoring Status

SLC 500 Controller

Data Files

Input Image

(8 words)

Output Image

Word 1

Word 2

Word 3

Word 7

Channel 0 Data WordWord 0

Channel 1 Data Word

Channel 2 Data Word

Channel 3 Data Word

Channel 0 Status Word

Channel 1 Status Word

Channel 2 Status Word

Channel 3 Status Word

Broken Input Error

Configuration Error

Excitation Current

Out±Of±Range Error

Broken Input

Temperature Units

Data Format

Filter Frequency

Channel Status

000010000000000

Bit 15

Address

Input Type

0

Bit 0

I:1.4

For this example, only bit 11 is set during normal operation.

Publication 1746-UM008B-EN-P - December 2006

Page 33

Chapter

3

Install and Wire the Module

This chapter tells you how to:

• avoid electrostatic damage.

• determine the RTD module’s chassis power requirement.

• choose a location for the RTD module in the SLC chassis.

• install the RTD module.

• wire the RTD module’s terminal block.

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

Electrostatic Damage

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081–2

EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082–2

EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins or other sensitive

areas. Guard against electrostatic damage by observing the

precautions listed next.

ATTENTION

Electrostatic discharge can degrade performance or cause

permanent damage. Handle the module as stated below.

Wear an approved wrist strap grounding device when handling the

module.

33 Publication 1746-UM008B-EN-P - December 2006

Page 34

34 Install and Wire the Module

• Touch a grounded object to rid yourself of electrostatic charge

before handling the module.

• Handle the module from the front, away from the backplane

connector. Do not touch backplane connector pins.

• Keep the module in its static-shield bag when not in use, or

during shipment.

NR4 Power Requirements

The RTD module receives its power through the SLC 500 chassis

backplane from the fixed or modular +5V dc/+24V dc chassis power

supply. The maximum current drawn by the module is shown in the

table below.

5V dc Amps 24V dc Amps

0.050 0.050

When you are using a modular system configuration, add the values

shown in the table above to the requirements of all other modules in

the SLC chassis to prevent overloading the chassis power supply.

When you are using a fixed system controller, refer to the Important

note about module compatibility in a two-slot expansion chassis on

page 35.

Publication 1746-UM008B-EN-P - December 2006

Page 35

Install and Wire the Module 35

Module Location in Chassis

This section contains information on module location in modular and

fixed chassis.

Modular Chassis Considerations

Place your RTD module in any slot of an SLC 500 modular chassis

(except slot 0) or a modular expansion chassis. Slot 0 is reserved for

the modular processor or adapter modules.

Fixed Expansion Chassis Considerations

IMPORTANT

The 2-slot, SLC 500 fixed I/O expansion chassis (1746-A2)

supports only specific combinations of modules. If you are using

the RTD module in a 2-slot expansion chassis with another SLC

I/O or communication module, refer to the Fixed Controller

Compatibility Table to determine whether the combination can

be supported.

When using the Fixed Controller Compatibility Table, be aware that

there are certain conditions that affect the compatibility characteristics

of the BASIC module (BAS) and the DH-485/RS-232C module (KE).

When you use the BAS module or the KE module to supply power to

a 1747-AIC Link Coupler, the link coupler draws its power through the

module. The higher current drawn by the AIC at 24V dc is calculated

and recorded in the table for the modules identified as BASn (BAS

networked) or KEn (KE networked). Make sure to refer to these

modules if your application uses the BAS or KE module in this way.

Publication 1746-UM008B-EN-P - December 2006

Page 36

36 Install and Wire the Module

Fixed Controller Compatibility Table

Modules NR4 5V dc (Amps) 24V dc (Amps)

IA4

(1)

•

0.035 -

IA8 • 0.050 IA16 • 0.085 IM4 • 0.035 IM8 • 0.050 IM16 • 0.085 OA8 • 0.185 OA16 • 0.370 OAP12 • 0.370 IB8 • 0.050 IB16 • 0.085 IV8 • 0.050 IV16 • 0.085 IG16 • 0.140 IH16 • 0.085 OV8 • 0.135 OV16 • 0.270 OB8 • 0.135 OBP8 • 0.135 OG16 • 0.180 OW4 • 0.045 0.045

OW8 • 0.085 0.090

OW16

(2)

0.170 0.180

IO4 • 0.030 0.025

IO8 • 0.060 0.045

IO12 • 0.090 0.070

NI4 • 0.025 0.085

NI8 • 0.200 0.100

NIO4I • 0.055 0.145

NIO4V • 0.055 0.115

FIO4I • 0.055 0.150

FIO4V • 0.055 0.120

DCM • 0.360 HS • 0.300 OB16 • 0.280 OB16E • 0.135 IN16 • 0.085 BASn • 0.150 0.125

BAS • 0.150 0.040

OB32 0.452 OV32 0.452 IV32 • 0.106 IB32 • 0.106 -

Publication 1746-UM008B-EN-P - December 2006

Page 37

Install and Wire the Module 37

Fixed Controller Compatibility Table

Modules NR4 5V dc (Amps) 24V dc (Amps)

OX8 • 0.085 0.090

NO4I

(3)

Δ

0.055 0.195

NO4V • 0.055 0.145

ITB16 • 0.085 ITV16 • 0.085 IC16 • 0.085 KE • 0.150 0.40

KEn • 0.150 0.145

OBP16 • 0.250 OVP16 • 0.250 NT4 • 0.060 0.040

NR4 • 0.050 0.050

HSTP1 • 0.200 -

(1)

A dot indicates a valid combination.

(2)

No symbol indicates an invalid combination.

(3)

A triangle indicates an external power supply is required.

General Considerations

Most applications require installation in an industrial enclosure to

reduce the effects of electrical interference. RTD inputs are susceptible

to electrical noises due to the small amplitudes of their signal.

Group your modules to minimize adverse effects from radiated

electrical noise and heat. Consider the following conditions when

selecting a slot for the RTD module. Position the module in a slot:

• away from power lines, load lines and other sources of electrical

noise such as hard-contact switches, relays, and AC motor

drives.

• away from modules which generate significant radiated heat,

such as the 32-point I/O modules.

Publication 1746-UM008B-EN-P - December 2006

Page 38

38 Install and Wire the Module

Module Installation and Removal

When installing the module in a chassis, it is not necessary to remove

the terminal block from the module. However, if the terminal block is

removed, use the write-on label located on the side of the terminal

block to identify the module location and type.

Write-on Label

SLOT ____ RACK ____

MODULE _______________

•

Remove the Terminal Block

ATTENTION

1. Loosen the two terminal block release screws.

Never install, remove or wire modules with power applied to

the chassis or devices wired to the module. To avoid cracking

the removable terminal block alternate the removal of the

slotted terminal block release screws.

Terminal Block Release Screws

Max. Torque = 0.6 Nm (5.3 in-lbs)

2. Grasp the terminal block at the top and bottom and pull

outward and down.

Publication 1746-UM008B-EN-P - December 2006

Page 39

Install and Wire the Module 39

Install the Module

1. Align the circuit board of the RTD module with the card guides

located at the top and bottom of the chassis.

Top and Bottom

Module Release(s)

Card

Guide

2. Slide the module into the chassis until both top and bottom

retaining clips are secured. Apply firm even pressure on the

module to attach it to its backplane connector. Never force the

module into the slot.

3. Cover all unused slots with the Card Slot Filler, catalog number

1746-N2.

Remove the Module

1. Press the releases at the top and bottom of the module and slide

the module out of the chassis slot.

2. Cover all unused slots with the Card Slot Filler, Catalog Number

1746-N2.

Publication 1746-UM008B-EN-P - December 2006

Page 40

40 Install and Wire the Module

Terminal Wiring

The RTD module contains an 18-position, removable terminal block.

The terminal pin-out is shown in RTD Connections to Terminal Block

on page 42.

ATTENTION

Disconnect power to the SLC before attempting to install,

remove, or wire the removable terminal wiring block.

To avoid cracking the removable terminal block, alternate the

removal of the terminal block release screws.

Terminal Block

Release Screw

Max. Torque =

Shield

Channel 0 RTD

Channel 0 Sense

Channel 0 Return

Shield

Channel 2 RTD

Channel 2 Sense

Channel 2 Return

Shield

Release Screw

Max. Torque =

0.6 Nm (5.3 in-bs)

0.6 Nm (5.3 in-bs)

Shield

Channel 1 RTD

Channel 1 Sense

Channel 1 Return

Shield

Channel 3 RTD

Channel 3 Sense

Channel 3 Return

Shield

Publication 1746-UM008B-EN-P - December 2006

NR4 Wiring Considerations

Follow the guidelines below when planning your system wiring.

Since the operating principle of the RTD module is based on the

measurement of resistance, take special care in selecting your input

cable. For 2–wire or 3–wire configuration, select a cable that has a

consistent impedance throughout its entire length.

Cable Selection

Configuration Recommended Cable

Two-wire Belden #9501 or equivalent

Three-wire less than 30.48 m (100 ft) Belden #9533 or equivalent

Three-wire greater than 30.48 m (100 ft) or

high humidity conditions

Belden #83503 or equivalent

Page 41

Install and Wire the Module 41

For a three-wire configuration, the module can compensate for a

maximum cable length associated with an overall cable impedance of

25 ohms.

IMPORTANT

Details of cable specifications are shown on page 122.

As shown in RTD Connections to Terminal Block on page 42, three

configurations of RTDs can be connected to the RTD module, namely:

• two-wire RTD, which is composed of two RTD lead wires (RTD

and Return).

• three-wire RTD, which is composed of a Sense and two RTD

lead wires (RTD and Return).

• four-wire RTD, which is composed of two Sense and two RTD

lead wires (RTD and Return). The second sense wire of a

four-wire RTD is left open. It does not matter which sense wire

is left open.

IMPORTANT

The RTD module requires three wires to compensate for lead

resistance error. It is recommended that you do not use

two-wire RTDs if long cable runs are required, as it will reduce

the accuracy of the system. However, if a two-wire

configuration is required, reduce the effect of the lead wire

resistance by using a lower gauge wire for the cable (for

example, use 1.291 mm (16 AWG) instead of 0.511 mm

(24 AWG)). Also, use cable that has a lower resistance per foot

of wire. The module’s terminal block accepts two 2.5 mm

2

(14 AWG) gauge wires.

• To limit overall cable impedance, keep input cables as short as

possible. Locate your I/O chassis as near the RTD sensors as

your application will permit.

• Ground the shield drain wire at one end only. The preferred

location is at the RTD module. Refer to IEEE Std. 518, Section

6.4.2.7 or contact your sensor manufacturer for additional

details.

• Each input channel has a shield connection screw terminal that

provides a connection to chassis ground. All shields are

internally connected, so any shield terminal can be used with

channels 0…3.

• Route RTD/resistance input wiring away from any high-voltage

I/O wiring, power lines, and load lines.

Publication 1746-UM008B-EN-P - December 2006

Page 42

42 Install and Wire the Module

Two-wire RTD Interconnection

• Tighten terminal screws using a flat or cross-head screwdriver.

Each screw should be turned tight enough to immobilize the

wire’s end. Excessive tightening can strip the terminal screw.

The torque applied to each screw should not exceed 0.565 Nm

(5 in-lb) for each terminal.

• Follow system grounding and wiring guidelines found in your

SLC 500 Installation and Operation Manual, publication

1747-UM011.

RTD Connections to Terminal Block

Cable Shield

Add Jumper

Shield

Ch 0 RTD

Ch 0 Sense

Ch 0 Return

Three-wire RTD Interconnection

Shield

Ch 0 RTD

Ch 0 Sense

Ch 0 Return

Four-wire RTD Interconnection

RTD

Return

Return

RTD

Sense Sense

Return

Belden #9501 Shielded Cable

Cable Shield

Belden #83503 or Belden #9533 Shielded Cable

Cable Shield

RTD

RTD

Return

RTD

Return

Terminal Pin-outs

Shield

Shield

Chl 0

RT D

Chl 1

RT D

Chl 0

Sense

Chl 1

Sense

Chl 0

Return

Chl 1

Return

Shield

Shield

Chl 2

RT D

Chl 3

RT D

Chl 2

Sense

Chl 3

Sense

Chl 2

Return

Chl 3

Return

Shield

Shield

Shield

Ch 0 RTD

Ch 0 Sense

Ch 0 Return

Publication 1746-UM008B-EN-P - December 2006

RTD

Sense Sense

Return

Belden #83503 or Belden #9533 Shielded Cable

RTD

Return

Leave one sensor wire open

Page 43

Install and Wire the Module 43

When using a three-wire configuration, the module compensates for

resistance error due to lead wire length. For example, in a three-wire

configuration, the module reads the resistance due to the length of

one of the wires and assumes that the resistance of the other wire is

equal. If the resistances of the individual lead wires are much

different, an error may exist. The closer the resistance values are to

each other, the greater the amount of error that is eliminated.

IMPORTANT

To ensure temperature or resistance value accuracy, the

resistance difference of the cable lead wires must be equal to

or less than 0.01 Ω.

There are several ways to insure that the lead values match as closely

as possible.

• Keep lead resistance as small as possible and less than 25 Ω.

• Use quality cable that has a small tolerance impedance rating.

• Use a heavy-gauge lead wire which has less resistance per foot.

Wire the Resistance Devices (Potentiometers) to the NR4 Module

Potentiometer wiring requires the same type of cable as that for the

RTD described in the previous subsection. Potentiometers can be

connected to the RTD module as a two-wire interconnection or a

three-wire interconnection.

See Two-wire Potentiometer Connections to Terminal Block, on

page 44, for 2-wire connection and Three-wire Potentiometer

Connections To Terminal Block, on page 45, for 3-wire connection.

Publication 1746-UM008B-EN-P - December 2006

Page 44

44 Install and Wire the Module

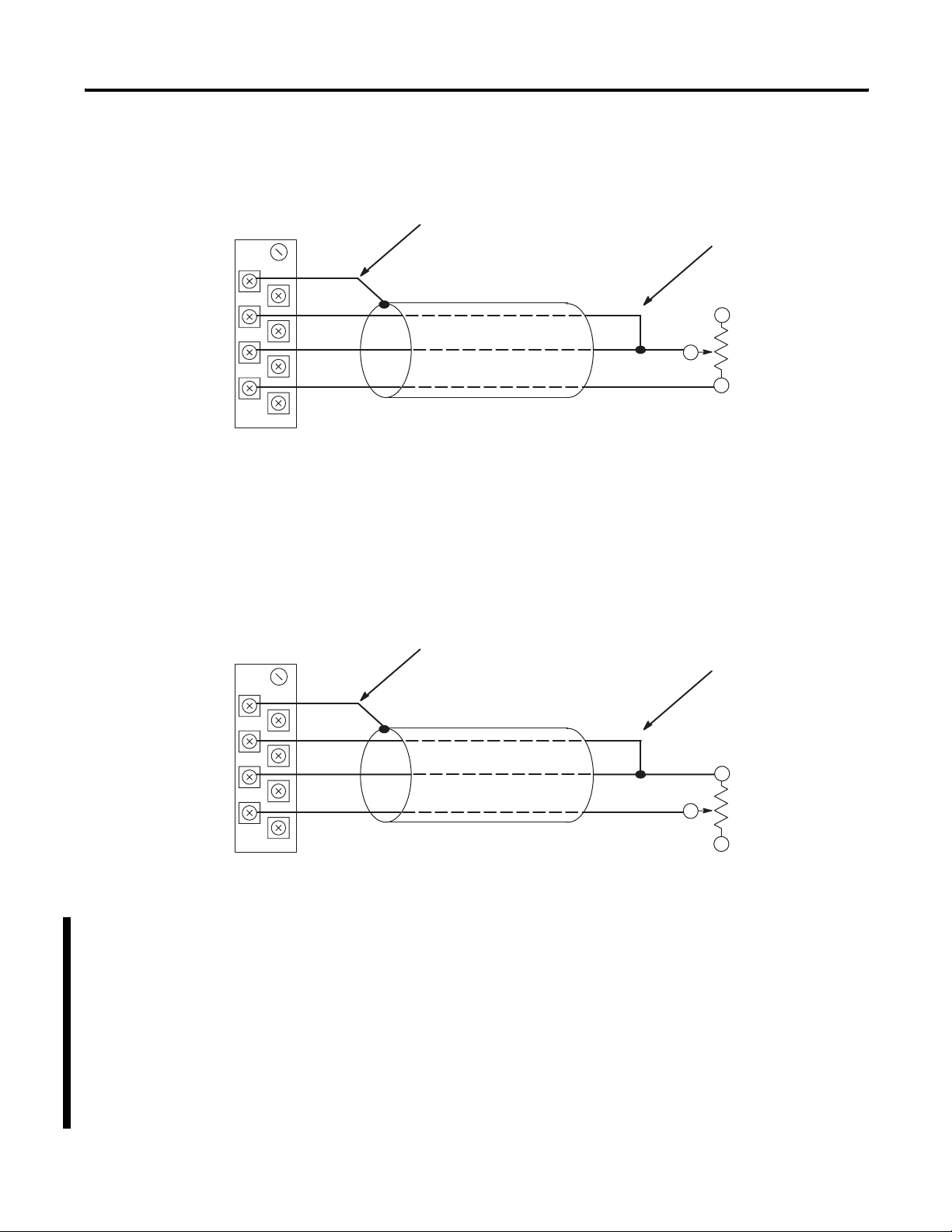

Two-wire Potentiometer Connections to Terminal Block

Cable Shield

Add jumper.

Add jumper.

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

Shield

Chl 0 RTD

Potentiometer

RTD

Return

Belden #9501 Shielded Cable

Potentiometer wiper arm can be connected to either the RTD or return terminal

depending on whether the user wants increasing or decreasing resistance.

RTD

Potentiometer

Chl 0 Sense

Chl 0 Return

Publication 1746-UM008B-EN-P - December 2006

Return

Belden #9501 Shielded Cable

Page 45

Install and Wire the Module 45

Three-wire Potentiometer Connections To Terminal Block

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

RTD

Sense

Return

Cable Shield

Belden #83503 or Belden #9533 Shielded Cable

Potentiometer wiper arm can be connected to either the RTD or return terminal

depending on whether the user wants increasing or decreasing resistance.

Cable Shield

Run RTD and sense wires from module to potentiometer

terminal and tie them to one point.

Potentiometer

Run RTD and sense wires from module to potentiometer

terminal and tie them to one point.

Shield

Chl 0 RTD

Chl 0 Sense

Chl 0 Return

RTD

Potentiometer

Sense

Return

Belden #83503 or Belden #9533 Shielded Cable

Publication 1746-UM008B-EN-P - December 2006

Page 46

46 Install and Wire the Module

Follow these steps to wire your 1746-NR4 module.

1. At each end of the cable, strip some casing to expose the

individual wires.

2. Trim the signal wires to 5.08 cm (2 in.) lengths. Strip about

4.76 mm (3/16 in.) of insulation away to expose the end of the

wire.

3. At one end of the cable twist the drain wire and foil shield

together, bend them away from the cable, and apply shrink

wrap. Then earth ground at the shield terminal.

4. At the other end of the cable, cut the drain wire and foil shield

back to the cable and apply shrink wrap.

5. Connect the signal wires and cable shield to the NR4 terminal

block and the input.

Cable Examples

Signal Wire

Signal Wire

Signal Wire

Signal Wire

Signal Wire

6. Repeat steps 1 through 5 for each channel on the NR4 module.

Two-conductor Shielded Cable

Drain Wire

Drain Wire

Foil Shield

Three-conductor Shielded Cable

Foil Shield

Signal Wire

Signal Wire

Signal Wire

Signal Wire

Signal Wire

Publication 1746-UM008B-EN-P - December 2006

Page 47

Install and Wire the Module 47

Calibration

The accuracy of a system that uses the RTD module is determined by:

• the accuracy of the RTD.

• resistance mismatch of the cable wires that connect the RTD to

the module.

• the accuracy of the RTD module.

For optimal performance at the customer site, the RTD module is

calibrated at the factory prior to shipment. In addition, a

self-calibration feature, called autocalibration, further ensures that the

module performs to specification over the life of the product.

Factory Calibration

The four-pin calibration connector, on the RTD module circuit board,

is used for factory setup only.

Auto-calibration

When a channel becomes enabled, the module configures the channel

and performs an auto-calibration on the channel. The channel is

selected, the excitation current is turned off, and the three input lines

for the channel are connected to analog common. The module’s A/D

converters are configured for the proper gain and filter frequency that

is appropriate for your RTD configuration. Auto-calibration performs

an A/D conversion on the zero voltage (analog common) and the

full-scale voltage (A/D reference voltage) on the following signals:

• Lead wire signal

• RTD/resistance signal

• Excitation current signal

IMPORTANT

These conversions generate offset (zero reference) and full scale (span

reference) coefficients that are saved and used by the module to

perform future A/D conversions on this channel.

Channel calibration time is shown in the Channel Calibration

Time table.

Publication 1746-UM008B-EN-P - December 2006

Page 48

48 Install and Wire the Module

You can command your module to perform an auto-calibration cycle

by disabling a channel, waiting for the channel status bit to change

state (1 to 0) and then re-enabling that channel. Several scan cycles

are required to perform an auto-calibration (refer to page 4-11). It is

important to remember that during auto-calibration the module is not

converting input data.

TIP

To maintain system accuracy it is recommended that

you periodically perform an autocalibration cycle:

• whenever an event occurs that greatly changes

the internal temperature of the control cabinet,

such as opening or closing its door

• at a convenient time when the system is not

making product, such as during a shift change

An auto-calibration programming example is provided in chapter 6.

Single-point Calibration

Single-point calibration is an optional procedure that can be used to

improve the accuracy of the RTD module and cable combination to

greater than +/-0.2

(122

°F) of the calibration temperature). The offset, determined by the

single-point calibration, can be used to compensate for inaccuracies in

the RTD module and cable combination.

°C (32.4 °F) (when the RTD is operating at +/-50 °C

Publication 1746-UM008B-EN-P - December 2006

After single-point calibration is performed, additional calibrations only

need to be performed if the cable is disturbed or degraded. (RTD

replacement should not affect the accuracy of the procedure.)

However, periodic auto-calibrations should be performed. Follow the

steps below to perform a single-point calibration.

1. Cycle power to the SLC 500 chassis.

2. Select a calibration temperature that is near the control point

(+/-10 °C (50

°F)).

3. Determine the exact resistance (+/-0.01 ohm) equivalent to the

calibration temperature by using a published temperature vs.

resistance chart.

4. Replace the RTD with the fixed–precision resistor. (It is

recommended that you use a 2 ppm temperature coefficient

resistor.)

Page 49

Install and Wire the Module 49

5. Use the RTD module to determine the temperature equivalent to

the fixed precision resistor and cable combination.

6. Calculate the offset value by subtracting the calculated

calibration temperature from the measured temperature.

7. Reconnect the RTD to the cable.

8. Use ladder logic to apply (subtract) the offset from the measured

temperature to obtain corrected temperature.

Publication 1746-UM008B-EN-P - December 2006

Page 50

50 Install and Wire the Module

Notes:

Publication 1746-UM008B-EN-P - December 2006

Page 51

Chapter

4

Preliminary Operating Considerations

This chapter explains how the RTD module and the SLC processor

communicate through the module’s input and output image. It lists the

preliminary setup and operation required before the RTD module can

function in a 1746 I/O system. Topics discussed include how to:

• enter the module ID code.

• address your RTD module.

• select the proper input filter for each channel.

• calculate the RTD module update time.

• interpret the RTD module response to slot disabling.

Module ID Code

The module identification code is a unique number encoded for each

1746 I/O module. The code defines for the processor the type of I/O

or specialty module residing in a specific slot in the 1746 chassis.

To manually enter the module ID code, select (other) from the list of

modules on the system I/O configuration display. The module ID

code for the RTD module, 1746-NR4, is 3513.

No special I/O configuration information is required. The module ID

code automatically assigns the correct number of input and output

words.

51 Publication 1746-UM008B-EN-P - December 2006

Page 52

52 Preliminary Operating Considerations

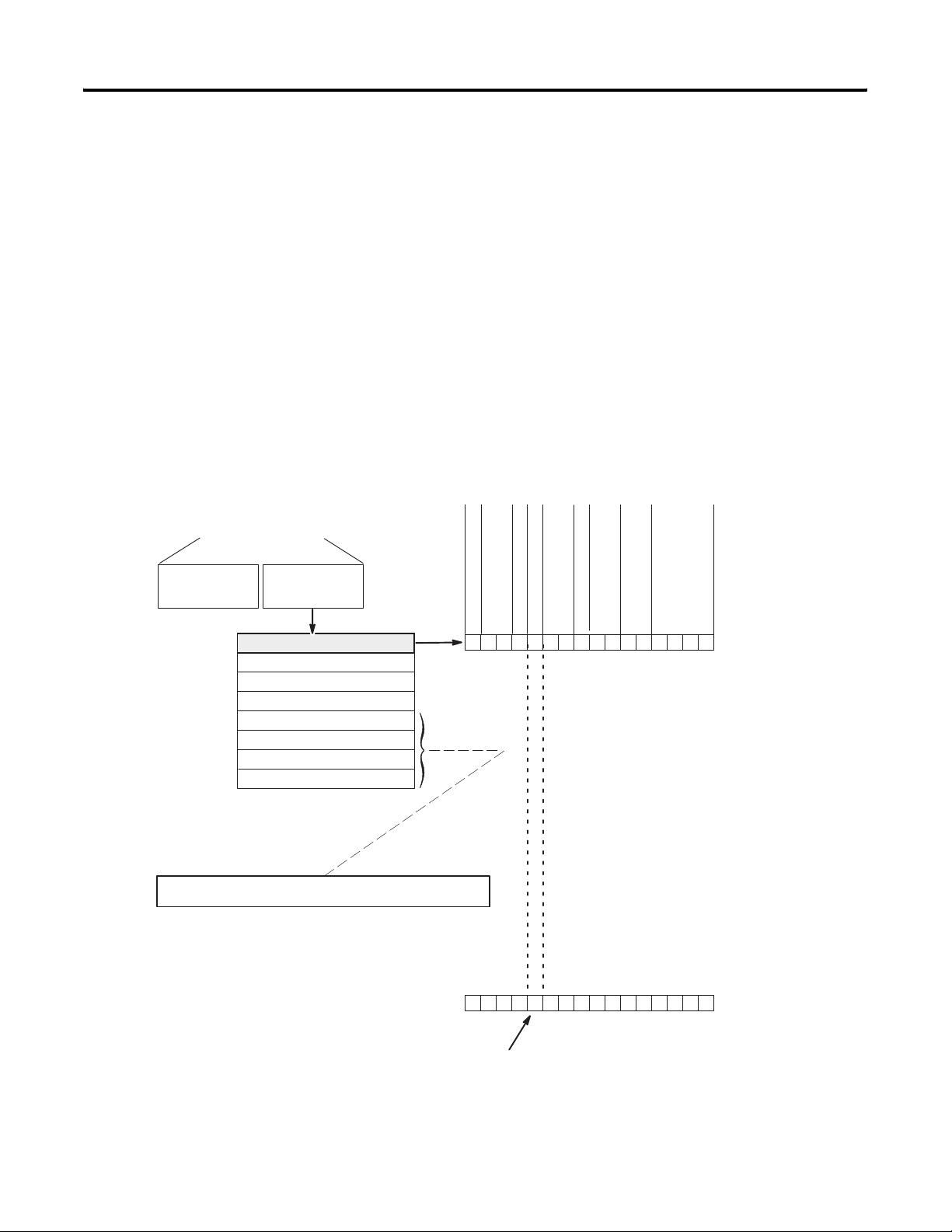

Module Addressing

SLC 5/0X

Data Files

Slot e

Output Image

Slot e

Input Image

The memory map displays how the output and input image tables are

defined for the RTD module.

Output

Scan

Input

Scan

RTD Module

Image Table

Output Image

8 Words

Input Image

8 Words

(Class 1)

Output Image

Input Image

t 15 Bit 0

Bi

Channel 0 Configuration Word

Channel 1 Configuration Word

Channel 2 Configuration Word

Channel 3 Configuration Word

User-set Lower Scale Limit Range 0

User-set Upper Scale Limit Range 0

User-set Lower Scale Limit Range 1

User-set Upper Scale Limit Range 1

Channel 0 Data Word

Channel 1 Data Word

Channel 2 Data Word

Channel 3 Data Word

Channel 0 Status Word

Channel 1 Status Word

Channel 2 Status Word

Channel 3 Status Word

Bit 15 Bit 0

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Address

O:e.0

O:e.1

O:e.2

O:e.3

O:e.4

O:e.5

O:e.6

O:e.7

Address

I:e.0

I:e.1

I:e.2

I:e.3

I:e.4

I:e.5

I:e.6

I:e.7

Output Image - Configuration Words

The 8-word, RTD module output image (defined as the output from

the CPU to the RTD module) contains information that you configure

to define the way a specific channel on the RTD module will work.

These words take the place of configuration DIP switches on the

module. Although the RTD output image is eight words long, only

output words 0…3 are used to define the operation of the module;

output words 4…7 are used for special user-set scaling using the

proportional counts data format. Each output word 0…3 configures a

single channel.

Publication 1746-UM008B-EN-P - December 2006

Page 53

Preliminary Operating Considerations 53

EXAMPLE

If you want to configure channel 2 on the RTD module located

in slot 4 in the SLC chassis, your address would be O:4.2

File Type

Slot

Word

O : 4 . 2

Element

Delimiter

Chapter 5, Channel Configuration, Data, and Status, gives you detailed

bit information about the content of the data word and the status

word.

Word

Delimiter

Input Image - Data Words and Status Words

The 8-word, RTD module input image (defined as the input from the

RTD module to the CPU) represents data words and status words.

Input words 0…3 (data words) hold the input data that represent the

temperature value of the RTD input or ohmic value of the resistance

inputs for channels 0…3. This data word is valid only when the

channel is enabled and there are no channel errors.