Page 1

SLC

tm

Servo Control

Module

(Catalog No. 1746-HSRV)

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

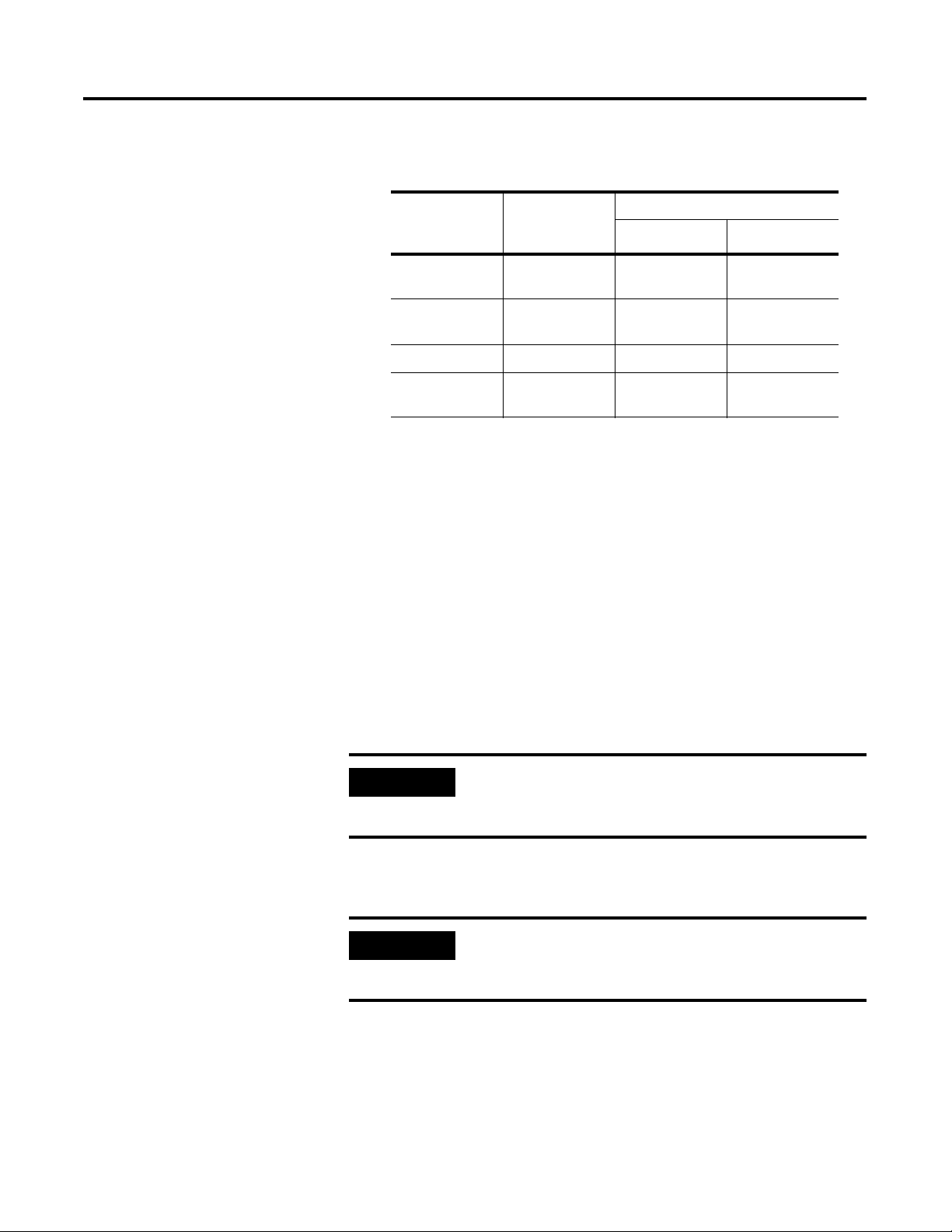

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Page 3

European Communities (EC)

Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical

construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines

For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be

mounted in an enclosure during operation to provide safety

protection.

Page 4

Table of Contents

Using This Manual

Overview of the SLC Servo

Module

Preface

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Contents of this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Conventions Used in this Manual. . . . . . . . . . . . . . . . . . . . P-5

Product Receiving and Storage Responsibility. . . . . . . . . . . P-5

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . P-6

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-6

On the Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-7

Chapter 1

SLC Servo Module Overview . . . . . . . . . . . . . . . . . . . . . . . 1-1

SLC Servo Module Operation. . . . . . . . . . . . . . . . . . . . . . . 1-2

Configuration Mode Operation . . . . . . . . . . . . . . . . . . . 1-3

Command Mode Operation . . . . . . . . . . . . . . . . . . . . . 1-3

SLC Servo Module Specifications and Compatibility . . . . . . 1-4

Selecting Power Supplies,

Chapter 2

Encoders, and Drives

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Selecting a Power Supply for the Backplane. . . . . . . . . . . . 2-1

Calculations for Backplane Current Requirements . . . . . 2-2

Selecting a User-Side Power Supply . . . . . . . . . . . . . . . . . . 2-3

Calculations for User-Side Current Requirements . . . . . . 2-4

Using Fast Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . 2-4

Selecting an Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Selecting a Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Planning Hardware

Chapter 3

Installation

General Wiring Practices . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using Shielded Cables . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

i Publication 1746-6.1.2 - July 2000

Page 5

Table of Contents

ii

Routing Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Classifying Your Conductors . . . . . . . . . . . . . . . . . . . . . . . 3-3

Placing Your SLC Servo Module. . . . . . . . . . . . . . . . . . . . . 3-3

Installing Your SLC Servo

Module

Wiring the SLC Servo

Module

Chapter 4

Unpacking and Inspecting Your SLC Servo Module System. 4-1

Installing the SLC Servo Module. . . . . . . . . . . . . . . . . . . . . 4-2

Grounding the SLC Servo Module . . . . . . . . . . . . . . . . . . . 4-4

Mounting the Termination Panel . . . . . . . . . . . . . . . . . . . . 4-5

Connecting the Termination Panel . . . . . . . . . . . . . . . . . . . 4-7

Chapter 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Complying with European Union Directives. . . . . . . . . . . . 5-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Wiring Fast Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . 5-2

Wiring Hardware Overtravels. . . . . . . . . . . . . . . . . . . . . . . 5-4

Software Overtravel Limits . . . . . . . . . . . . . . . . . . . . . . 5-5

Connecting Home Limit Switch as a Fast Input. . . . . . . . . . 5-5

Wiring Estop Connections . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Wiring the Estop for a One-Axis System . . . . . . . . . . . . 5-7

Wiring for Normal Operation . . . . . . . . . . . . . . . . . . . . . . 5-7

Maintaining Electrical Continuity . . . . . . . . . . . . . . . . . . . 5-7

Verifying Connections and Operation . . . . . . . . . . . . . . . . 5-7

Wiring the Estop for System with Two or More Axes. . . 5-10

Wiring Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Wiring Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Typical Vendor Encoder Wiring . . . . . . . . . . . . . . . . . . 5-15

Encoder Feedback Direction . . . . . . . . . . . . . . . . . . . 5-16

Wiring the SLC Servo to Allen-Bradley Drives. . . . . . . . . . . 5-18

Wiring the SLC Servo Module to 1398 ULTRA 100/200. . 5-27

Wiring the SLC Servo Module – Homing to a Marker . . 5-28

Connecting the Velocity Command . . . . . . . . . . . . . . . . . . 5-32

Testing Your SLC Servo

Module Hardware

Publication 1746-6.1.2 - July 2000

Chapter 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Powering Up Your SLC Servo Module . . . . . . . . . . . . . . . . 6-1

Page 6

Table of Contents

Testing Estop Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

iii

Setting Up Your SLC Servo

Module

Chapter 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Understanding the Theory of Motion Control . . . . . . . . . . . 7-2

Machine Mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Velocity Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Position Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Powering Up the SLC Servo Module. . . . . . . . . . . . . . . . . . 7-3

Configuring the SLC Processor. . . . . . . . . . . . . . . . . . . . . . 7-3

Configuring Your Processor Using AI-500 Software . . . . 7-4

Configuring Your Processor Using APS Software . . . . . . 7-5

Configuring Your Processor Using RSLogix 500 Software 7-7

Automatically Configuring the SLC Servo Module . . . . . 7-7

Manually Configuring the SLC Servo Module. . . . . . . . . 7-8

The SLC Servo Module Interface . . . . . . . . . . . . . . . . . . . . 7-11

Configuring the SLC Servo Module. . . . . . . . . . . . . . . . . . . 7-11

Data Type Conversions . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Before Programming the SLC Servo Module . . . . . . . . . . . . 7-12

Communicating – SLC Processor & SLC Servo Module . . . . 7-13

Entering Encoder Lines and Computing Counts . . . . . . . . . 7-13

Computing Counts Per Position Unit . . . . . . . . . . . . . . 7-14

Computing Maximum Speed Scaler . . . . . . . . . . . . . . . 7-14

Initializing DAC Output Voltage for Drive Symmetry. . . . . . 7-16

Setting Initial Loop Type . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Defining Positive Axis Movement for SLC Servo Module . . . 7-17

Coarse Calibrating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Fine Calibrating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Computing Excess Following Error Limit . . . . . . . . . . . . . . 7-19

Selecting Loop Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Selecting Axis Acceleration Rate. . . . . . . . . . . . . . . . . . . . . 7-21

Determining Velocity and Acceleration Feedforward. . . . . . 7-23

Velocity Feedforward. . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Acceleration Feedforward. . . . . . . . . . . . . . . . . . . . . . . 7-23

Setting Axis and Home Specific Parameters . . . . . . . . . . . . 7-24

Programming Conventions . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Downloading Your Configuration. . . . . . . . . . . . . . . . . 7-24

Configuration Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Configuring the M0 File Data Tables. . . . . . . . . . . . . . . 7-25

Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Feedback Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Servo Loop Parameters. . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Motion Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Publication 1746-6.1.2 - July 2000

Page 7

Table of Contents

iv

Axis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Homing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Homing Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Homing Without a Limit Switch or Marker . . . . . . . . . . 7-32

Homing to a Marker. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Option 1 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Option 2 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Option 3 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Option 4 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Homing to a Limit Switch . . . . . . . . . . . . . . . . . . . . . . 7-37

Homing to a Limit Switch and Marker . . . . . . . . . . . . . 7-38

Programming the SLC

Processor to Run the SLC

Servo Module

Chapter 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Blend Move Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Downloading Your Blend Move Profiles . . . . . . . . . . 8-1

Understanding Configuration Errors . . . . . . . . . . . . . . . . . 8-2

Command and Status Information . . . . . . . . . . . . . . . . . . . 8-4

Module Communication Interface . . . . . . . . . . . . . . . . . . . 8-4

Discrete Bit Commands from the SLC Processor . . . . . . . . . 8-5

Word 0 Discrete Bit Commands . . . . . . . . . . . . . . . . . . . . 8-6

Word 1 Discrete Bit Commands. . . . . . . . . . . . . . . . . . . . 8-8

Discrete Block Commands from the SLC Processor. . . . . . . 8-8

Recovering from Estop. . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Incremental Position Command . . . . . . . . . . . . . . . . . . 8-9

Executing Simultaneous Moves. . . . . . . . . . . . . . . . . . . . 8-10

Simple Move Commands . . . . . . . . . . . . . . . . . . . . . . . 8-11

Using Simple Move Commands . . . . . . . . . . . . . . . . . . . . 8-11

Using the Absolute/Incremental Move Command . . . . . 8-11

Planning an Absolute/Incremental Move. . . . . . . . . . . . . 8-13

Using the Speed Move Command. . . . . . . . . . . . . . . . . 8-15

Planning a Speed Move . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Using the Monitor Move Command . . . . . . . . . . . . . . . 8-17

Planning a Monitor Move . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Using the Run Blend Move Profile Command . . . . . . . . 8-18

Planning the Run Blend Move Profile Command . . . . . . 8-19

Executing a Run Blend Move Profile . . . . . . . . . . . . . . . 8-20

Executing Several Blend Moves . . . . . . . . . . . . . . . . . . . 8-21

Blending Moves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Blending Absolute Moves . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Blending Incremental Moves. . . . . . . . . . . . . . . . . . . . . . 8-24

Blending Speed Moves . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Publication 1746-6.1.2 - July 2000

Page 8

Table of Contents

Plan Synchronized Move . . . . . . . . . . . . . . . . . . . . . . . 8-25

v

Programming System

Variables

Chapter 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Using Position Initialization Commands . . . . . . . . . . . . . . 9-1

Using the Home Axis Command. . . . . . . . . . . . . . . . . . 9-1

Planning a Home Axis Move. . . . . . . . . . . . . . . . . . . . . . 9-2

Using the Set Home Command. . . . . . . . . . . . . . . . . . . 9-3

Typical Set Home Move Data Tables . . . . . . . . . . . . . . . 9-4

Using the Set Retract Position Command. . . . . . . . . . . . 9-4

Typical Set Retract Position Move Data Tables . . . . . . . 9-5

Using the Preset Position Command . . . . . . . . . . . . . . . 9-5

Typical Preset Position Move Data Tables . . . . . . . . . . . 9-6

Using Online Configuration Commands . . . . . . . . . . . . . . 9-6

Using the Set Offset Command. . . . . . . . . . . . . . . . . . . 9-6

Typical Set Offset Move Data Tables . . . . . . . . . . . . . . . 9-7

Using the Set In-Position Band Command. . . . . . . . . . . 9-7

Typical Set In-Position Band Move Data Tables. . . . . . . 9-8

Using the Set Excess FE Limit Command. . . . . . . . . . . . 9-8

Typical Set Excess FE Limit Move Data Tables. . . . . . . 9-9

Using the Set Axis Gain Command . . . . . . . . . . . . . . . . 9-9

Typical Set Axis Gain Move Data Tables . . . . . . . . . . . . 9-9

Using the Set VFF Command . . . . . . . . . . . . . . . . . . . . 9-11

Typical Set VFF Move Data Tables . . . . . . . . . . . . . . . . 9-11

Status Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Word 0 Discrete Bit Status Specifications. . . . . . . . . . . . 9-12

Blend Move Profile Segment Number. . . . . . . . . . . . . . . 9-12

Word 1 Discrete Bit Status Specifications . . . . . . . . . . . 9-13

Word 2 Discrete Bit Status Specs SLC Servo Module . . . 9-14

Word 3 Discrete Bit Status Specifications . . . . . . . . . . . 9-15

SLC Servo Module Processor Status . . . . . . . . . . . . . . . . . . 9-15

Informational Message or Fault Code . . . . . . . . . . . . . . 9-15

Floating-Point Values . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Troubleshooting

Chapter 10

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

HSRV Quick Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Check wiring to diagram . . . . . . . . . . . . . . . . . . . . . . . 10-2

Publication 1746-6.1.2 - July 2000

Page 9

Table of Contents

vi

Do a battery box test. (If unable to control drive) . . . . . 10-2

Software Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Configure the HSRV module. . . . . . . . . . . . . . . . . . . . . 10-2

Downloading Your Configuration. . . . . . . . . . . . . . . . . . 10-2

If CONFIG INV LED is Lit. . . . . . . . . . . . . . . . . . . . . . . 10-3

Configuration Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Jog the Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Using the Speed Move Command . . . . . . . . . . . . . . . . . . 10-5

Troubleshooting LED Indicators. . . . . . . . . . . . . . . . . . . . . 10-6

Error Messages and Diagnosis . . . . . . . . . . . . . . . . . . . . . . 10-7

Informational Messages . . . . . . . . . . . . . . . . . . . . . . . 10-8

Minor Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Major Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Input/Output Quick

Reference

Appendix A

Configuration Output Bit Parameters . . . . . . . . . . . . . . . . . A-1

Word 0 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Word 1 Parameters . . . . . . . . . . . . . . . . . . . . . . . A-4

Word 2 Parameters . . . . . . . . . . . . . . . . . . . . . . . A-5

Multi-Word Parameters . . . . . . . . . . . . . . . . . . . . . A-5

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Output Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Discrete Bit Output Command (Word 0) . . . . . . . . . . . . A-10

Discrete Bit Output Command (Word 1). . . . . . . . . . . . . A-10

Incremental Position Output Cmnd (Words 2 & 3). . . . .A-10

Block Output Command (Word 4). . . . . . . . . . . . . . . . . .A-11

Block Output Command (Word 5). . . . . . . . . . . . . . . . . .A-11

Discrete Bit Input Status Specifications . . . . . . . . . . . . A-11

Word 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

Word 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Word 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Word 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

SLC Servo Module to SLC Processor Discrete Control Status A-13

Blended Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Cable Dimensions and

Wiring Diagram

Publication 1746-6.1.2 - July 2000

Appendix B

1746-HCA Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Page 10

Table of Contents

vii

Programming Examples

Appendix C

SLC Servo Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Ladder Rung Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Rung 0 – Manual Triggering Configuration . . . . . . . . . . C-2

Rung 1 – Download Configuration . . . . . . . . . . . . . . . . C-2

Rung 2 – Timer Delay . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Rung 3 – Checking For Successful Configuration. . . . . . C-5

Rung 4 – Downloading Blend Profiles . . . . . . . . . . . . . C-5

Rung 5 – Setting the Timer Delay . . . . . . . . . . . . . . . . . C-7

Rung 6 – Error Checking For Successful Download . . . . C-8

Rung 7 – Clear Fault Bits Command . . . . . . . . . . . . . . . C-8

Rung 8 – Clear All Faults Bit. . . . . . . . . . . . . . . . . . . . . C-9

Rung 9 – Cancel Move . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Rung 10 – Hold/Unhold. . . . . . . . . . . . . . . . . . . . . . . . C-9

Rung 11 – Program an Estop Request . . . . . . . . . . . . . C-10

Rung 12 – ABSOLUTE Move. . . . . . . . . . . . . . . . . . . . C-10

Rung 13 – INCREMENTAL Move. . . . . . . . . . . . . . . . . C-12

Rung 14 – SPEED Command . . . . . . . . . . . . . . . . . . . C-14

Rung 15 – MONITOR Move . . . . . . . . . . . . . . . . . . . . C-15

Rung 16 – BLEND Move. . . . . . . . . . . . . . . . . . . . . . . C-16

Rung 17 – Clearing Move Bits. . . . . . . . . . . . . . . . . . . C-17

Rung 18 – Copying Status Information . . . . . . . . . . . . C-18

Rung 19 – HOME Axis . . . . . . . . . . . . . . . . . . . . . . . . C-19

Rung 20 – Final Rung. . . . . . . . . . . . . . . . . . . . . . . . . C-21

Wiring Without the

Termination Panel

Appendix D

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Using Fast Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . D-1

Distances to User Devices . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Wiring Your User Devices . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Estop Circuitry Drawings . . . . . . . . . . . . . . . . . . . . . . . D-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Index

Publication 1746-6.1.2 - July 2000

Page 11

Table of Contents

viii

Publication 1746-6.1.2 - July 2000

Page 12

Preface

Read this preface to familiarize yourself with the rest of the manual.

This preface covers the following topics:

• who should use this manual

• purpose of this manual

• safety precautions

• contents of this manual

• related documentation

• conventions used in this manual

• receiving and storage information

• Allen-Bradley support

Who Should Use this

Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting the SLC™ Servo Module (catalog

number 1746-HSRV).

If you do not have a basic understanding of SLC 500™ products,

understand programmable controllers or cannot interpret the ladder

logic instructions required to control your application, contact your

local Allen-Bradley representative for information on available training

courses before using this product.

We recommend that you review one of the following before using the

software:

Publication Publication Number

Getting Results with RSLogix 500

AI Series Installation Guide

This manual is a user guide for the SLC Servo Module (catalog number

1746-HSRV). It gives you an overview of the SLC Servo Module and

describes the procedures you use to install, set up, use, and

troubleshoot the SLC Servo Module.

9399-RL50GR

9399

-AIIG

Safety Precautions

1 Publication 1746-6.1.2 - July 2000

The following general precautions apply to the SLC Servo Control

Module.

Page 13

Preface

P-2

ATTENTION

!

ATTENTION

!

Only those familiar with the SLC Servo Control

Module and associated machinery should plan or

implement the installation, start-up, and subsequent

maintenance of the system. Failure to comply can

result in personal injury and/or equipment damage.

This product contains stored energy devices. To

avoid hazard of electrical shock, verify that all

voltage on the capacitors has been discharged before

attempting to service, repair, or remove this unit. You

should only attempt the procedures in this manual if

you are qualified to do so and familiar with

solid-state control equipment and the safety

procedures in publication NFPA 70E.

The system integrator is responsible for local safety

and electrical codes.

An incorrectly applied or installed controller can

result in component damage or a reduction in

product life. Wiring or application errors, such as

undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures can result

in malfunction of the drive.

Contents of this Manual

Publication 1746-6.1.2 - July 2000

This product contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control

precautions are required when installing, testing,

servicing, or repairing this assembly. Component

damage can result if ESD control procedures are not

followed. If you are not familiar with static control

procedures, refer to Allen-Bradley publication

8000-4.5.2, Guarding Against Electrostatic Damage

or any other applicable ESD Protection Handbook.

This manual provides specific information relevant to the SLC Servo

Module. The following table identifies the chapters, titles, and

contents.

Page 14

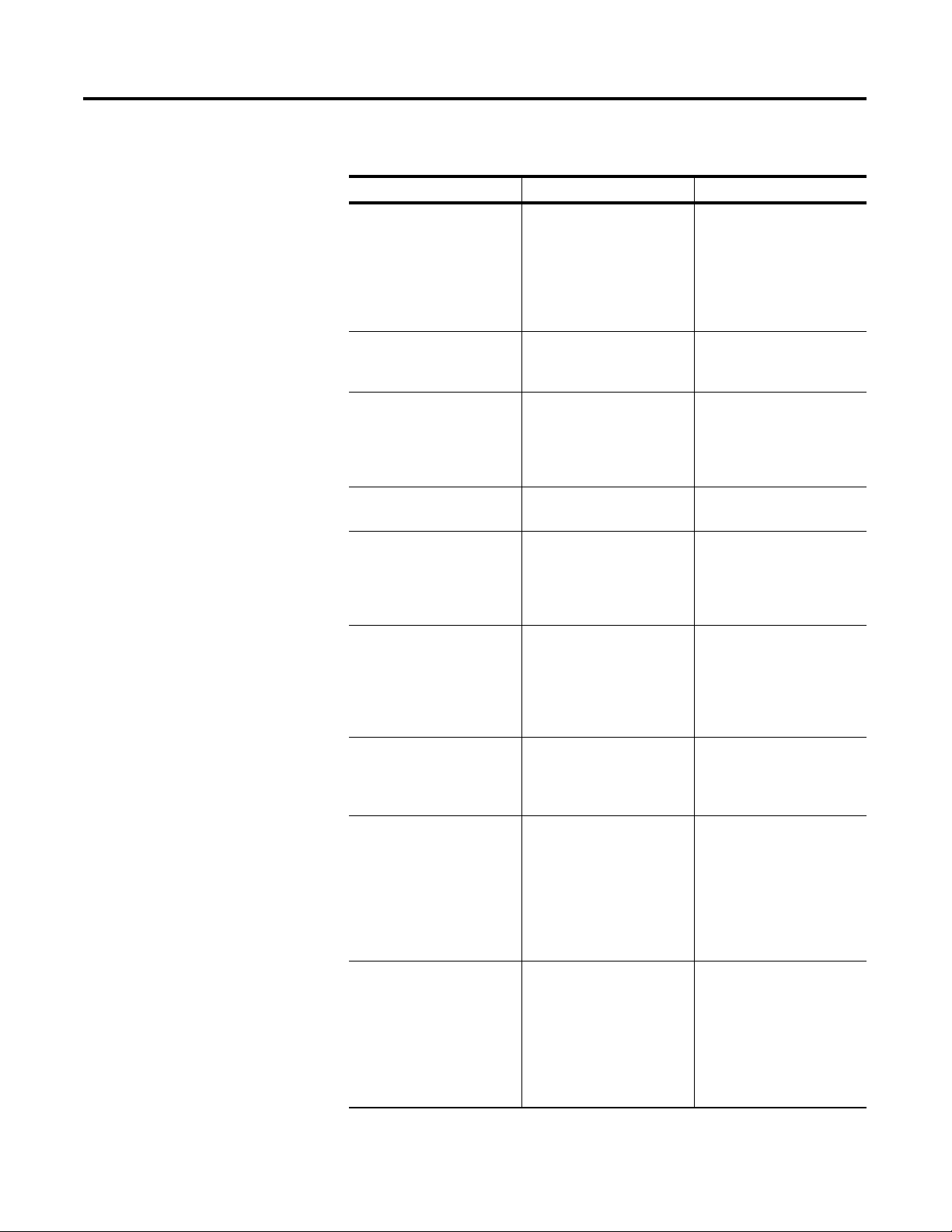

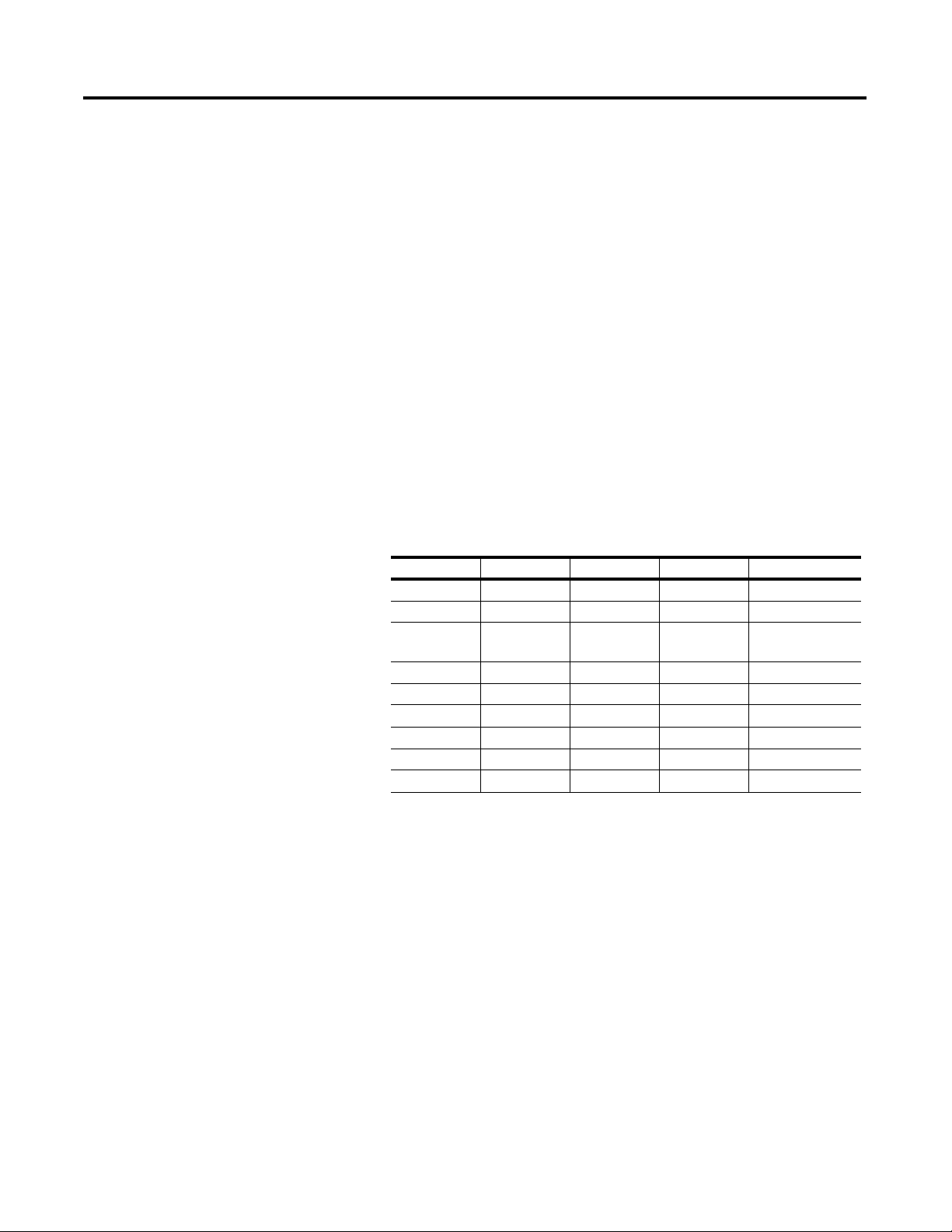

Chapter Title Contents

1 Overview of the SLC Servo

Module

Overview information about

the product, its operation

and hardware features.

Describes interface

selection, the module’s use

of inputs and outputs, and

operating modes.

Preface

P- 3

2 Selecting Power Supplies,

Encoders and Drives

3 Planning Hardware

Installation

4 Installing Your SLC Servo

Module

5 Wiring the SLC Servo

Module

6 Testing Your SLC Servo

Module Hardware

7 Setting Up and Configuring

Your SLC Servo Module

Information about selecting

the hardware to support an

SLC Servo Module.

Interconnection diagrams

for various hardware

interfaces for

communication with the SLC

Servo Module.

Installation information.

Information about wiring

fast inputs, outputs, Estop

connections, power

supplies, encoders and drive

connections.

Information about powering

up the SLC Servo Module,

testing the Estop and the

fast I/O, integrating the axis

and testing the homing

function.

Information about applying

power and configuring the

SLC Servo Module using

command parameters.

8 Programming the SLC

Processor to Run the SLC

Servo Module

9 Programming System

Variables

Information about blend

move profiles, module

communication interface,

command, and status

information. Describes

discrete bit and block

commands from the SLC

Servo Module.

Describes discrete block

commands for programming

position and online system

variables from the SLC

processor. Information to

understand servo module

and processor status

information.

Publication 1746-6.1.2 - July 2000

Page 15

Preface

P-4

Chapter Title Contents

10 Troubleshooting Information about

troubleshooting and error

handling.

Appendix A Input/Output Quick

Reference

Appendix B Cable Specifications Specifications and wiring

Appendix C Application Examples Applications examples for

A quick reference of

parameters, commands,

status specifications, and

move profiles.

diagram for 1746-HCA

cable.

constructing programs using

the SLC processor.

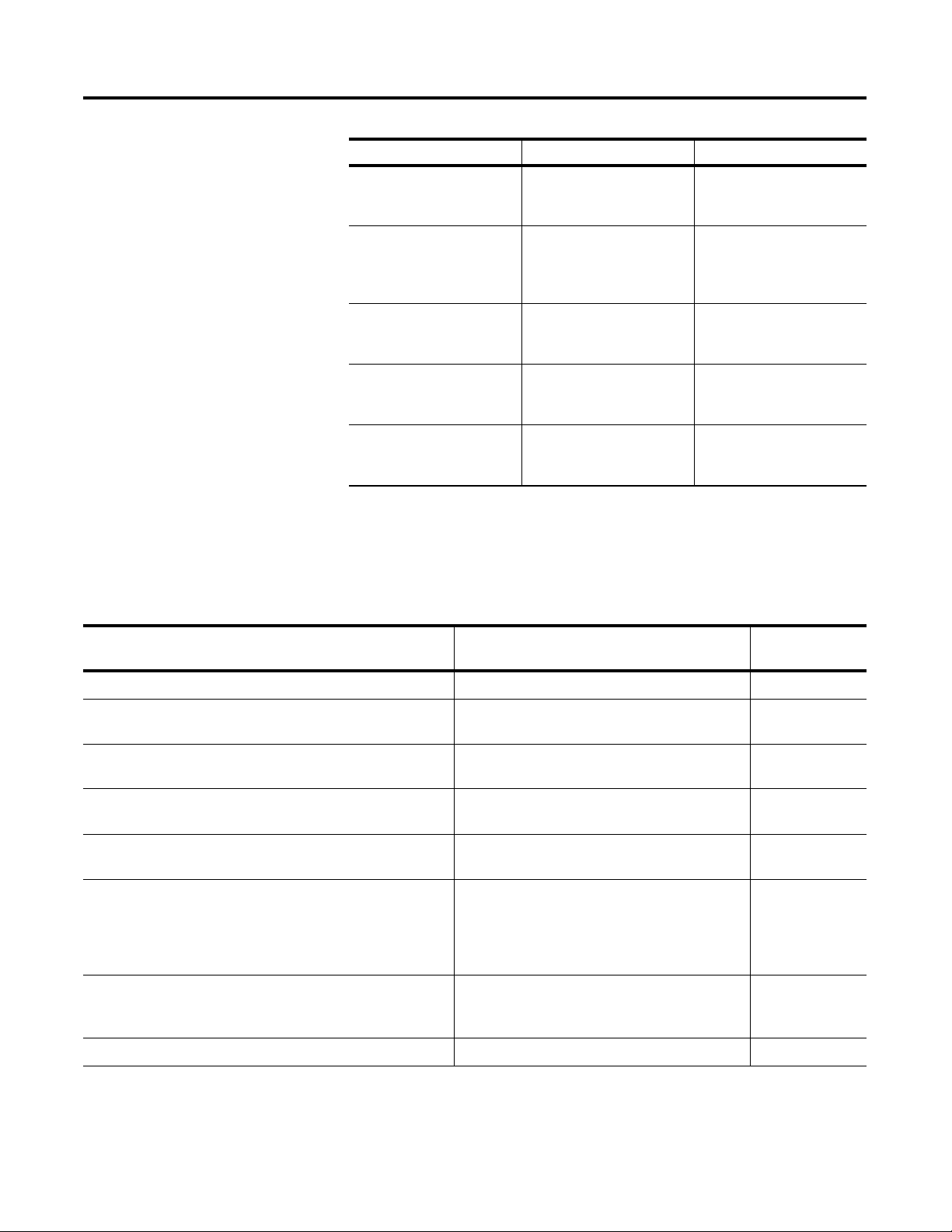

Related Documentation

Appendix D Wiring Without the

Termination Panel

The following documents contain additional information concerning

Information you need to

wire the SLC Servo Module

without a termination panel.

Allen-Bradley SLC Servo and SLC products. To obtain a copy, contact

your local Allen-Bradley office or distributor.

For: Read this Document: Document

Number:

An overview of the SLC 500 family of products SLC 500 Controller System Overview 1747-2.30

A description of how to install and use your Modular SLC 500

programmable controller

A description of how to install and use your Fixed SLC 500

programmable controller

A training and quick reference guide for APS SLC 500 Software Programmer’s Quick Reference

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

SLC 500 Modular Hardware Style Installation &

Operation Manual

SLC 500 Fixed Hardware Style Programmable

Controllers Installation & Operation Manual

Guide

Industrial Automation Wiring and Grounding

Guidelines

1747-6.2

1747-621

ABT-1747-TSG001

1770-4.1

An article on wire sizes and types for grounding electrical

equipment

A complete listing of current Allen-Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multiple languages

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Publication 1746-6.1.2 - July 2000

National Electrical Code Published by the

National Fire

Protection

Association of

Boston, MA

Allen-Bradley Publication Index SD499

Page 16

Preface

P- 5

Conventions Used in this

Manual

The following conventions are used throughout this manual:

• Bulleted lists provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Words that you type or select appear in bold.

• Key names match the names shown and appear in capital

letters.

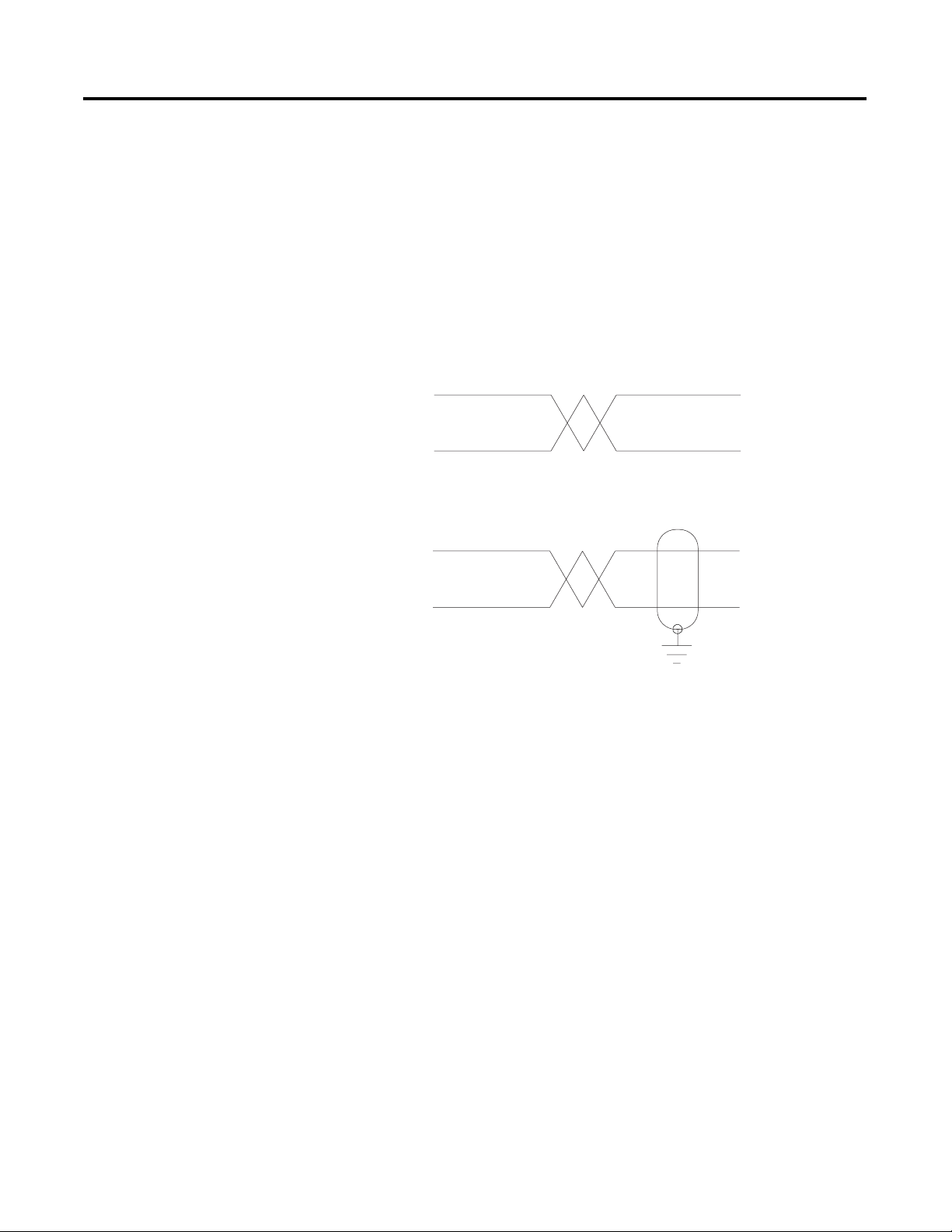

• We use this symbol to represent a twisted pair:

Figure 0.1 Twisted Pair Symbol

Twisted Pair

• We use this symbol to represent a shielded twisted pair:

Figure 0.2 Shielded Twisted Pair Symbol

Shielded Twisted Pair

Product Receiving and

Storage Responsibility

You are responsible for thoroughly inspecting the equipment before

accepting the shipment from the freight company. Check the item(s)

you receive against your purchase order. If any items are obviously

damaged, it is your responsibility to refuse delivery until the freight

agent has noted the damage on the freight bill. Should you discover

any concealed damage during unpacking, you are responsible for

notifying the freight agent. Leave the shipping container intact and

request that the freight agent make a visual inspection of the

equipment.

Publication 1746-6.1.2 - July 2000

Page 17

Preface

P-6

Leave the product in its shipping container prior to installation. If you

are not going to use the equipment for a period of time, store it:

• in a clean, dry location

• within an ambient temperature range of 0° to 65°C (32° to

149°F)

• within a relative humidity range of 5% to 95%, non-condensing

• in an area where it cannot be exposed to a corrosive

atmosphere

• in a non-construction area

Rockwell Automation

Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized

systems integrators located throughout the United States. In addition,

Rockwell Automation representatives are located in every major

country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

please review the information in the Troubleshooting chapter first.

Then call your local Rockwell Automation representative. For the

quickest possible response, we recommend that you have the catalog

number of your products available when you call. The Rockwell

Automation Technical Support number is:

Publication 1746-6.1.2 - July 2000

1-603-443-5419

Page 18

Preface

P- 7

On the Web

For information about Allen-Bradley, visit the following World Wide

Web site:

http://www.ab.com/

Publication 1746-6.1.2 - July 2000

Page 19

Preface

P-8

Publication 1746-6.1.2 - July 2000

Page 20

Chapter

1

Overview of the SLC Servo Module

This chapter explains the basic functions of the SLC Servo Module,

and its hardware requirements. This chapter includes the following

SLC Servo Module topics:

• Overview

• Operation

• Specifications and compatibility

SLC Servo Module

Overview

The SLC Servo Module (catalog number 1746-HSRV) is compatible

with the SLC 500 family and only used with SLC 5/03

5/04

™, or SLC 5/05™

programmed for incremental, absolute or speed moves, depending on

the application.

IMPORTANT

SLC Servo Modules. The SLC Servo Module is

Place the SLC Servo Module as close to the SLC

processor as possible

FRN 5.0, SLC

™

1 Publication 1746-6.1.2 - July 2000

Page 21

1-2

Overview of the SLC Servo Module

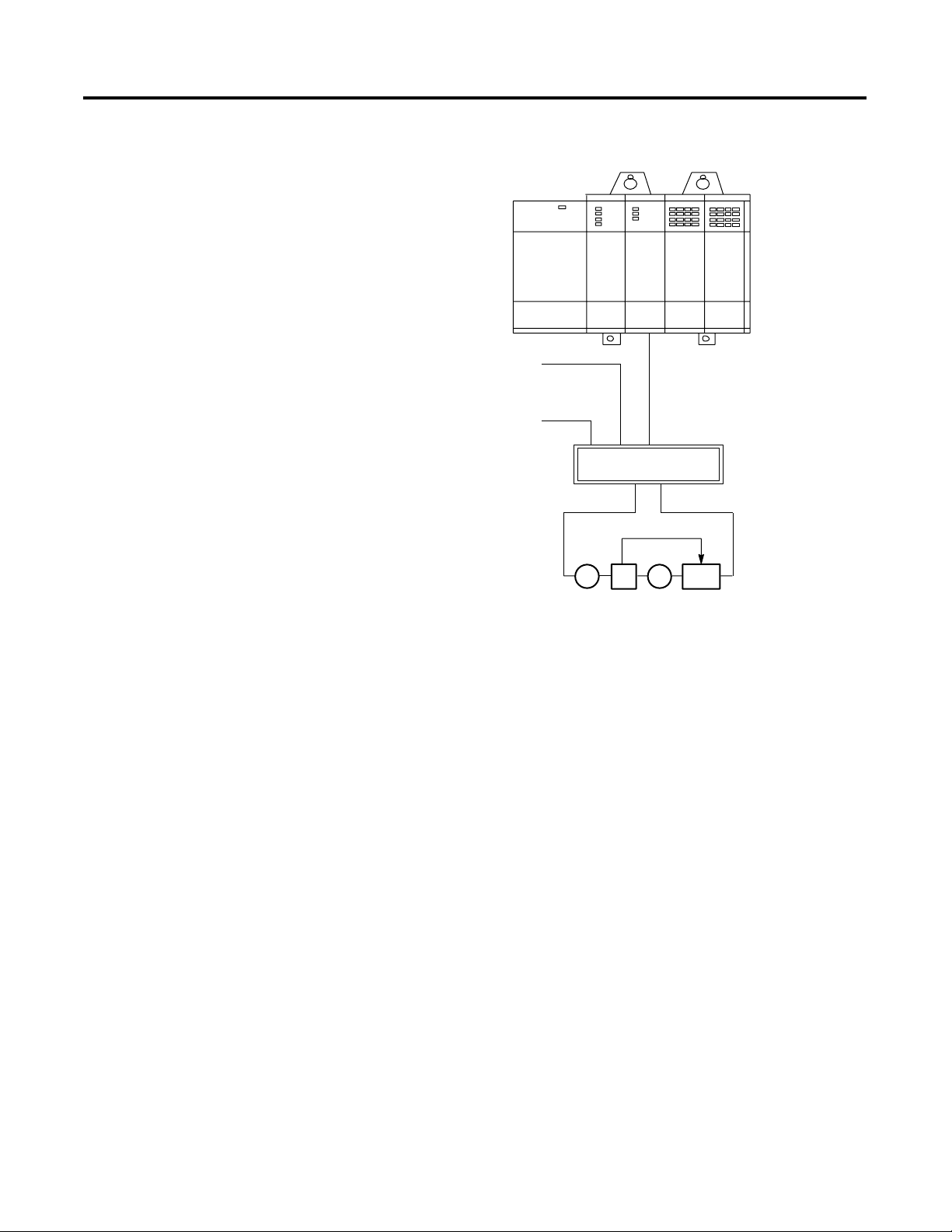

Figure 1.1 Example of an SLC Wiring

SLC Servo Module

Operation

1746IW16

Drive

Amplifier

CR-LPS-0503

+5V & –12V DC

Power Supply

CR-IOPS-241

+24V DC

Power Supply

SLC

5/04

A-B 845

Encoder

1746HSRV

1746-HCA Cable

1746-HT

Termination Panel

Motor

Tach

The SLC Servo Module, compatible with the SLC family, is used with

SLC 5/03 FRN 5.0 (and above) processors using RSLogix 500, AI500 or

APS (version 5.0 or higher) software. Once the SLC processor is

initiated, the execution of the motion block is independent of the scan

time of the processor. Blended motion allows for complicated move

profiles consisting of two to thirty-two segments. The blended move

profiles are stored in the SLC Servo Module’s memory as a series of

absolute moves and can be executed more than once. Other move or

homing operations can be performed between blended move profiles.

Publication 1746-6.1.2 - July 2000

The SLC Servo Module controls absolute position over a range of

32

bits. The SLC Servo Module performs an origin search (also called

homing) and automatically resets the absolute position to the home

position when the SLC processor requests a search function after

detecting one of the following:

• Encoder marker

• Limit switch

• Limit switch and marker

Page 22

Overview of the SLC Servo Module

The SLC Servo Module operates in two modes:

• Configuration

• Command

When operating in the configuration or the command mode, the status

of the module is reported to the SLC processor.

1-3

Configuration Mode Operation

You can enter configuration mode only if the system is in Estop. In the

SLC Servo Module, you configure the SLC Servo Module by using M

files containing data provided by the SLC 5/03 (or versions listed

above) processors. All configuration parameters are internal to the SLC

Servo Module and stored in non-battery backed RAM.

In configuration mode, you select the proper setup configuration to

match the servo drive and motor without setting switches and without

special software. If you do not set up your own configuration, the

configuration is set to the default setting.

Command Mode Operation

Motor operations are performed in command mode. To operate in this

mode, set the mode flag (bit 15 in output word 0) to 0. In the

command mode, the SLC processor issues commands and activates

the following operations or moves:

• Absolute moves

• Incremental moves

• Speed moves

• Monitor moves

• Hold moves

• Unhold moves

• Blend moves

• Emergency stop operations

• Homing operations

• Preset operations

• Clear faults

• Alternate home moves

Publication 1746-6.1.2 - July 2000

Page 23

1-4

Overview of the SLC Servo Module

SLC Servo Module

Specifications and

Compatibility

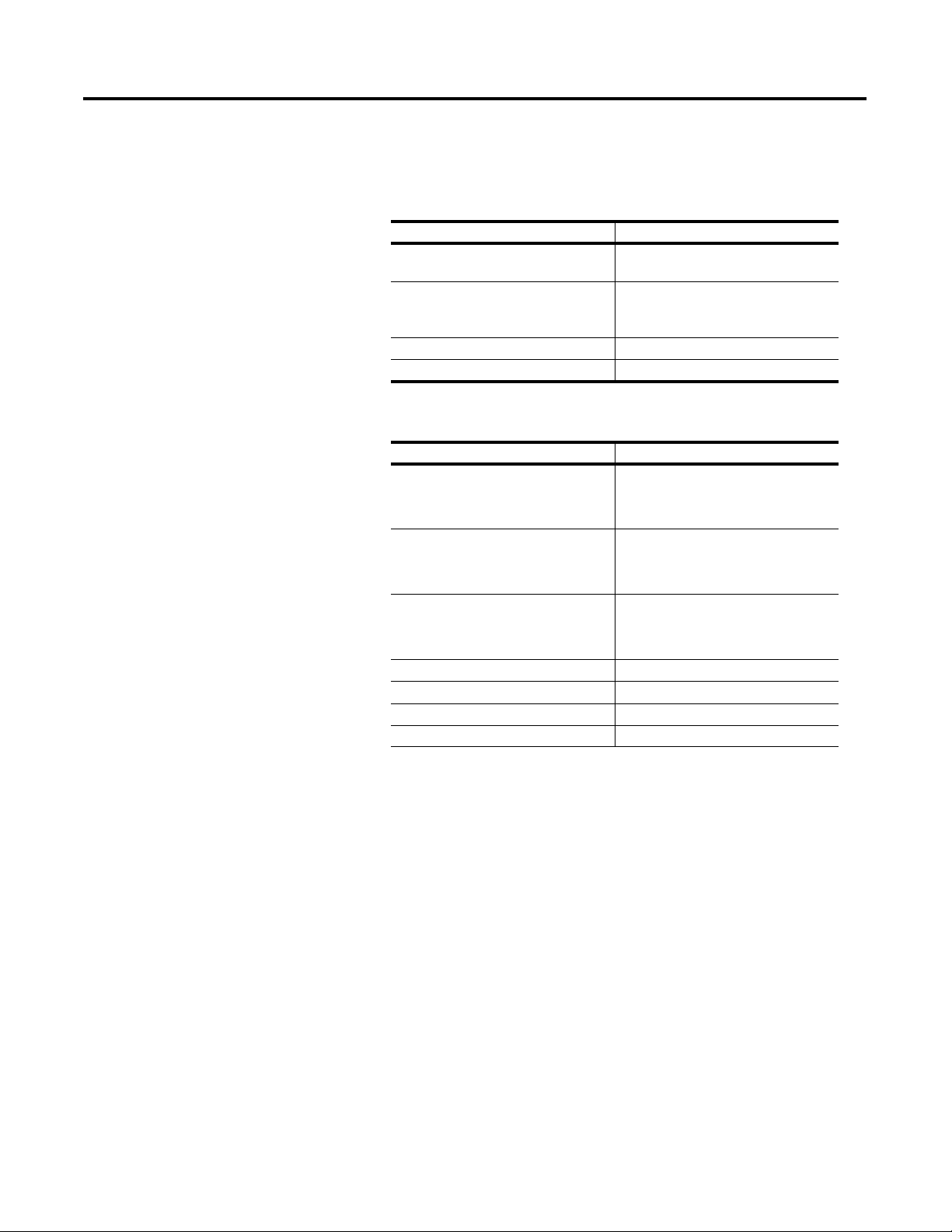

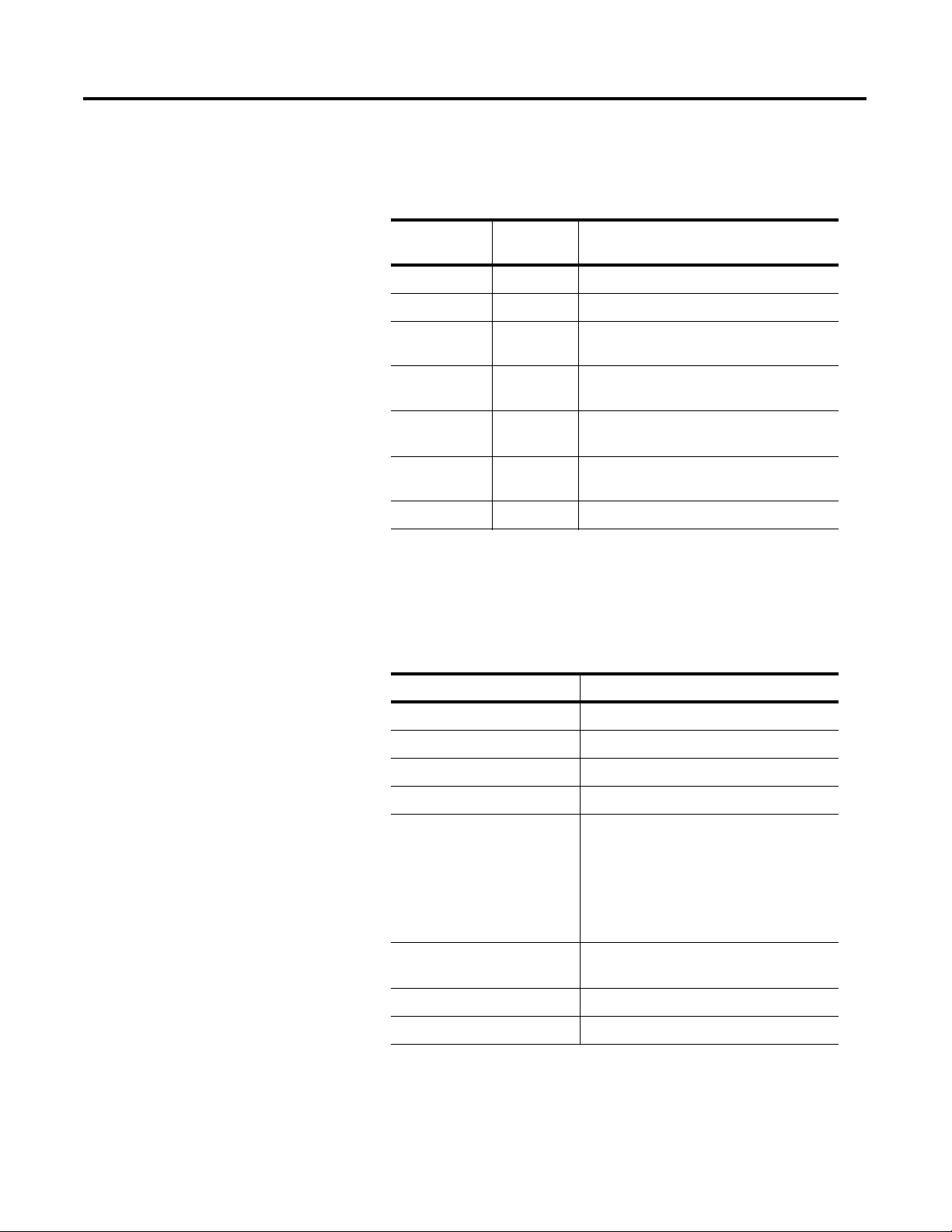

Selected specifications for the SLC Servo Module appear in the table

below.

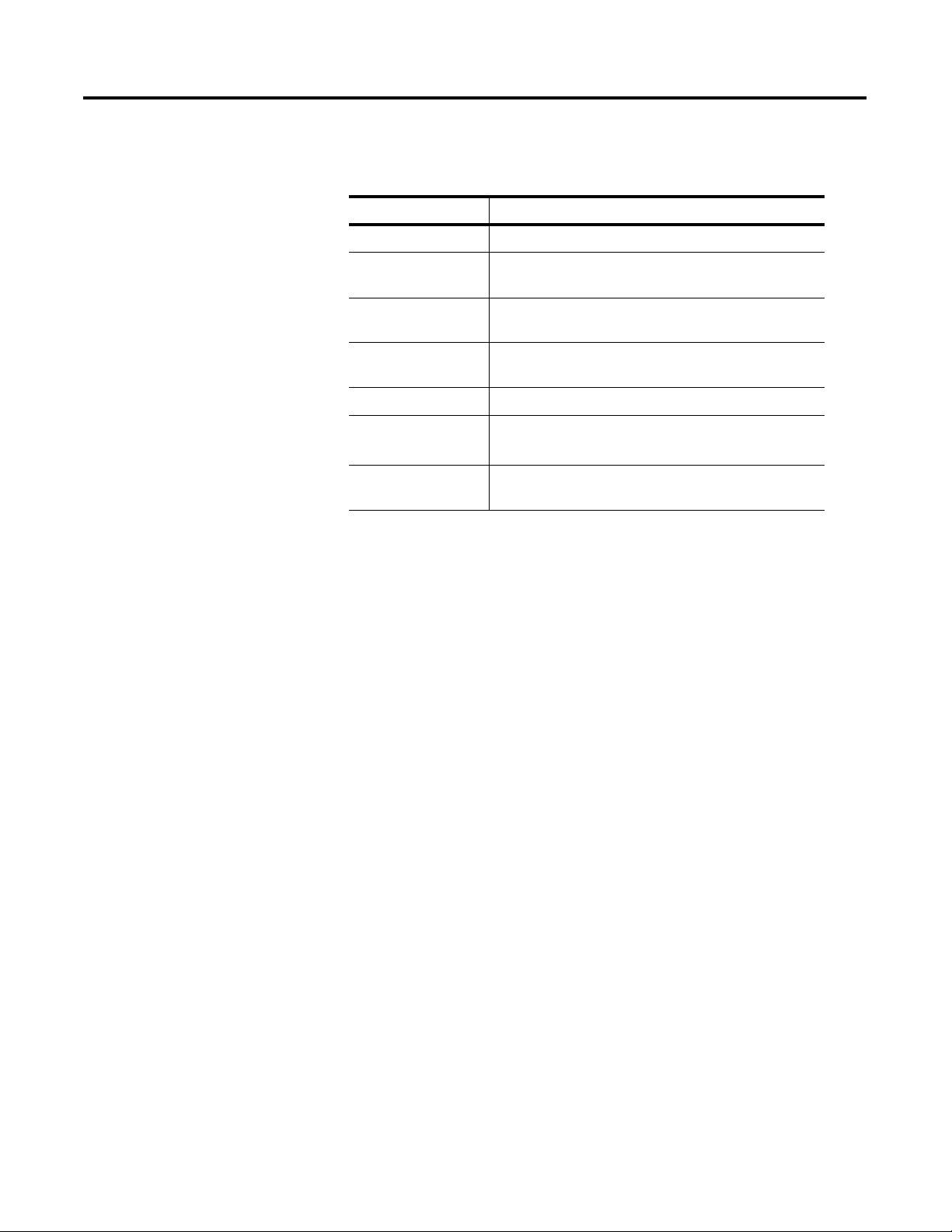

SLC Servo Module Specification

Class 3

Number of Input

Words

Number of Output

Words

Selection for

Configuration

Configuration Mode Uses M files

Recommended I/O

Slot in SLC Rack

Number of HSRVs in

one rack

1

There must not be other modules that generate module interrupts. Also, the STI and FAULT routines execute at a

higher priority than the module interrupt routine that is linked to the SLC Servo Module interrupt.

2

The SLC Servo Module does not function in a remote I/O rack.

12

12

OTHER

(with 10114 as the number specified)

Slot 1 or the lowest numbered I/O slot for SLC

applications using the module interrupt option.

12

with proper power supply

1,2

The SLC Servo Module is compatible with:

• SLC 5/03 FRN 5.0 (and above) processors.

• RSLogix 500, AI500, or APS (version 5.0 or higher) software.

Publication 1746-6.1.2 - July 2000

Page 24

Chapter

Selecting Power Supplies, Encoders, and

Drives

2

Overview

In this chapter we explain how to select the hardware you need to

support an SLC Servo Module system. This chapter includes the

following topics:

• Selecting a power supply for the backplane

• Selecting a user-side power supply

• Using fast inputs and outputs

• Selecting an encoder

• Selecting a drive

The amount of hardware you need depends on how many axes your

application uses. Consult your local Allen-Bradley sales engineer or

distributor to help you select the equipment for your application.

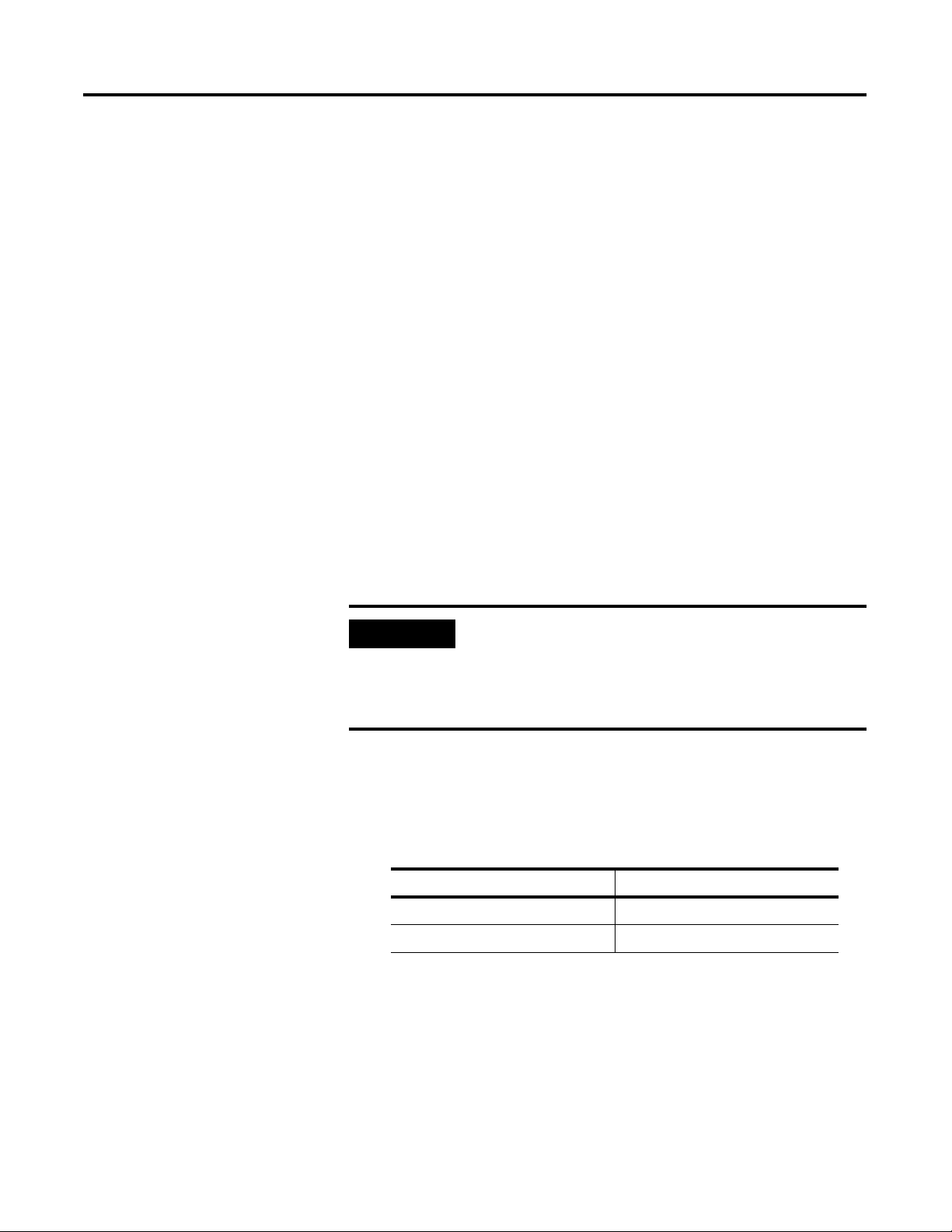

IMPORTANT

The term user-side refers to the control circuitry on

the SLC Servo Module card that is powered by

customer-supplied power sources and isolated from

the control circuitry that is powered by the

backplane of an SLC rack.

Selecting a Power Supply

for the Backplane

1 Publication 1746-6.1.2 - July 2000

Before you select a power supply, calculate the current requirements

for your backplane. Use the table below for SLC Servo Module

backplane current requirements:

Voltage Current Requirement

+5V .300A

+24V .104A

In your calculations, include the current requirements of the I/O

modules in your chassis. Refer to your SLC 500 documentation.

Page 25

2-2

Selecting Power Supplies, Encoders, and Drives

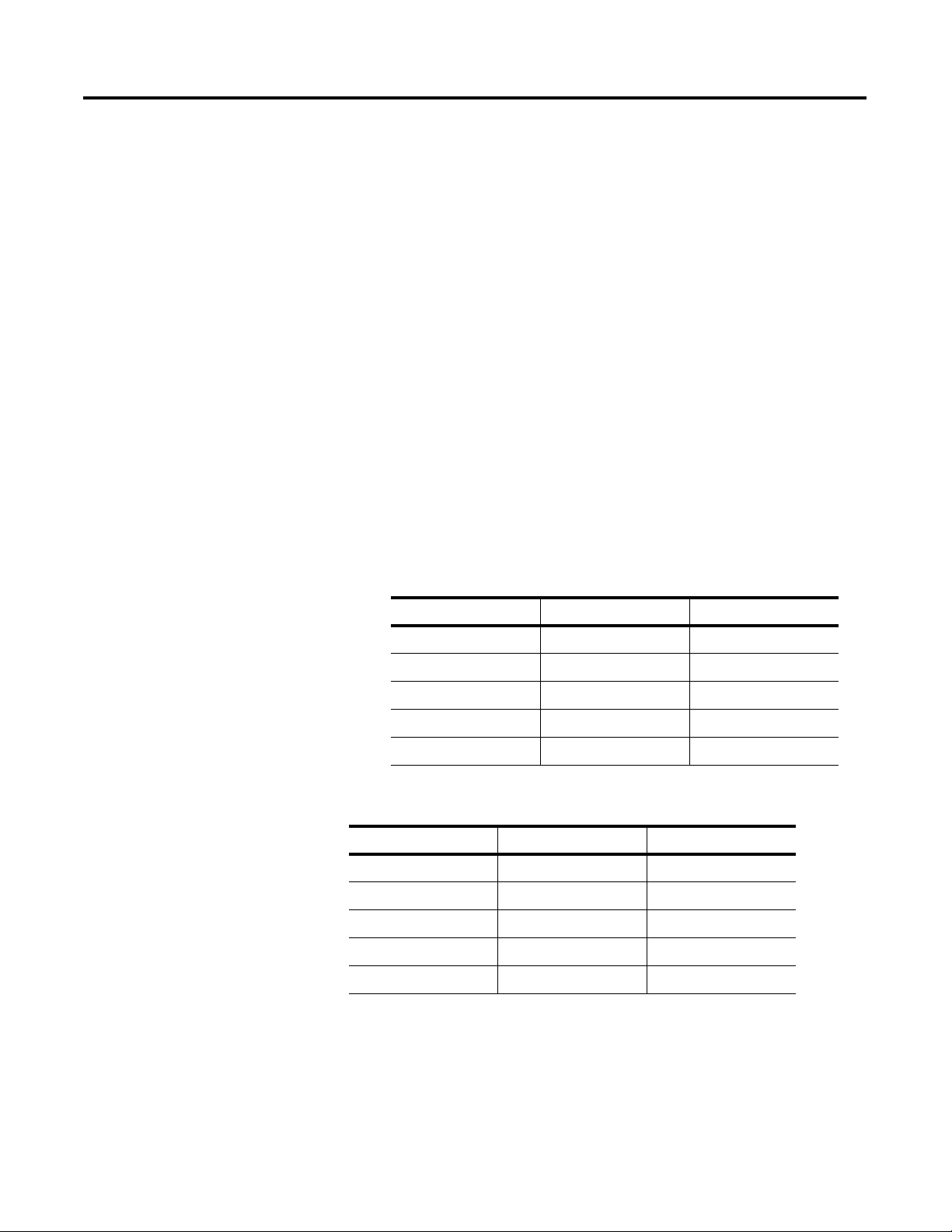

Example of Calculations for Backplane Current Requirements

In this example, the system includes:

• One seven-slot modular rack

• One 1747-L543 CPU module

• One 1746-IB8 DC input module with eight inputs @ +24V

• One 1746-OV8 DC output module with eight outputs @ +24V

• An SLC Servo Module system that contains:

• SLC Servo Modules

• Termination panels

• Allen-Bradley 845H encoders

• Fast inputs

• Fast outputs

Use the table below to find the current requirements of the devices

using backplane power. Those devices that are not included in the

backplane calculations are included in the example’s user-side

calculations.

Device +5V +24V

1746-L543 processor 1A .200A

SLC Servo Module .300A 0

1746-IB8 .040A 0

1746-OV8 .125A 0

Total = 1.465A Total = .200A

If optional processor is used:

Device +5V +24V

1747-L532 processor .500A .175A

SLC Servo Module .300A 0

1746-IB8 .040A 0

1746-OV8 .125A 0

Total = .965A Total = .175A

Publication 1746-6.1.2 - July 2000

Page 26

Selecting Power Supplies, Encoders, and Drives

2-3

Use the table below to find the power supplies Allen-Bradley recommends

for the backplane:

Selecting a User-Side

Power Supply

Power Supply Operating

Voltage

Requirements

1746-P1 85-130V AC or

170-265V AC

1746-P2 85-130V AC or

170-265V AC

1746-P3 19.2-28.8 DC 3.6A .87A

1746-P4 85-132V AC or

170-265V AC

Output Capacity

5V DC 24V DC

2A .46A

5A .96A

10.0A 2.88A

You must provide a power supply that meets your system

requirements. The following devices require user-side power:

• SLC Servo Module

• Encoders

• I/O modules

• Estop circuitry

• Fast inputs and outputs

You must select a power supply that meets the specifications of a NEC

class 2 power supply. The power supply must have +5V, ±15V

capacity, and +24V capacity for fast I/O and Estop circuitry.

IMPORTANT

We recommend that you do not use the +24V

included with the 1746-P1, P2, P3, or P4 to power

your Estop or fast I/O.

Before you select a power supply, calculate the system’s user-side

current requirements.

IMPORTANT

The user-side power must be present for the SLC

processor to communicate with the SLC Servo

Module.

Publication 1746-6.1.2 - July 2000

Page 27

2-4

Selecting Power Supplies, Encoders, and Drives

Example of the Calculations for User-Side Current Requirements

In this example, the system includes:

• One seven-slot modular rack

• One 1747-L541 CPU module

• One 1746-IB8 DC input module with eight inputs @ +24V

• One 1746-OV8 DC output module with eight outputs @ +24V

• An SLC Servo Module system that contains:

• Two SLC Servo Modules

• Two termination panels

• Two Allen-Bradley 845H encoders

• Six fast inputs

• Two fast outputs

Use the table below to find the current requirements of the devices

that draw user-side power.

Using Fast Inputs and

Outputs

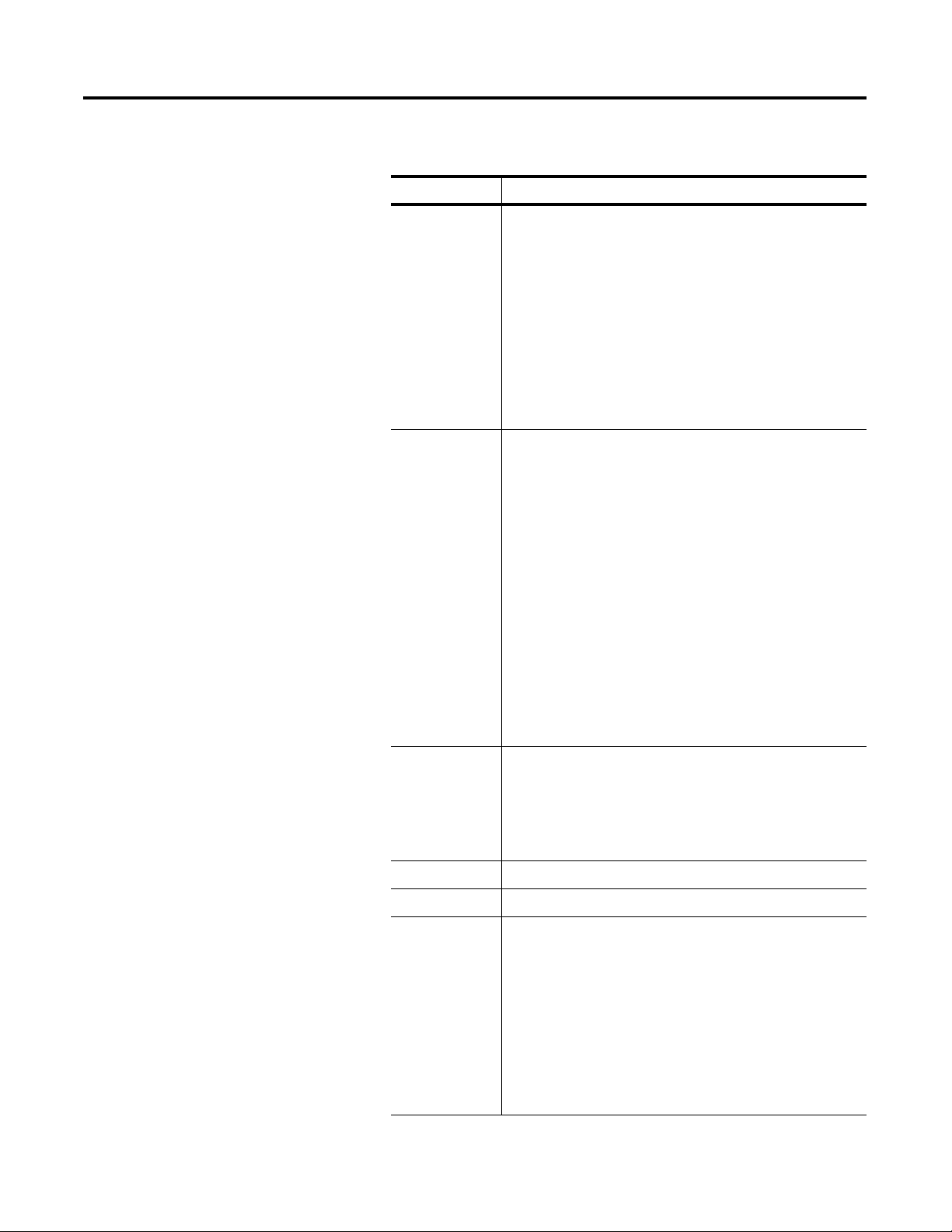

Device +5V +15V –15V +24V

1746-IB8 0 0 0 .064A

1746-OV8 0 0 0 .800A

SLC Servo

Module

Estop circuitry 0 0 0 .100A

6 fast inputs 0 0 0 .015A

2 fast outputs 0 0 0 .100A

845H encoder .200A 0 0 0

845H encoder .200A 0 0 0

.150A .030A .030A 0

Total = .700A Total = .060A Total = .060A Total = 1.079A

The fast I/O (FIN1through FIN3, and FOUT1) are 24V DC compatible

and are used with a user-side +24V power supply. Review potential

Publication 1746-6.1.2 - July 2000

Page 28

Selecting Power Supplies, Encoders, and Drives

2-5

24V DC I/O devices for compatibility with the electrical specifications

as shown in the table below.

Outputs (source drivers)

Specification Rating

oh

V

(high-level, on-state output

voltage)

oh

I

(high-level, on-state output current

for each output)

Turn on time 500 µs

Turn off time 500 µs

Inputs

Specification Rating

VT (input low/high trip threshold) 10.51V (min)

VT (input high/low trip threshold) 6.4V (min)

HYST

V

IN

I

@ 27V 2.5 mA (max)

PD+

T

(input low/high debounce filter) .2 msec (typ)

PD-

T

(input low/high debounce filter) .2 msec (typ)

VIN (absolute max.) +75V (max)

Refer to the specifications for your

user-side power supply

+24V @ .20A (for resistive and

inductive loads); +24V @ .10A (for

capacitive loads)

12.5V (typ)

14.61V (max)

8.3V (typ)

10.3V (max)

1.9V (min)

4.1V (typ)

6.5V (max)

Selecting an Encoder

The SLC Servo Module system supports Allen-Bradley 845H encoders.

Other encoders are compatible if they comply with the specifications

listed in the following table.

Publication 1746-6.1.2 - July 2000

Page 29

2-6

Selecting Power Supplies, Encoders, and Drives

Specification Rating

Maximum

channel

frequency

Maximum axis

speed

Incoming quadrature frequency is limited by the following

relationship:

FQUAD (Hz) = (3334)(90°–EQ)

where:

EQ = quadrature error (degrees, electrical)

For example, for an 845H encoder with 22° quadrature error,

the maximum frequency would be:

FQUAD (Hz) = (3334)(90°-22° quadrature error) = 226,712 Hz

Important:

The maximum quadrature error is a limit, and

system design should include acceptable margins.

The SLC Servo Module decodes the incoming encoder

feedback in quadrature to extract the maximum resolution with

four counts per electrical cycle. The maximum number of

encoder counts per second can be determined by:

Maximum # of counts/second = 4 counts/cycle × F

QUAD

The maximum axis speed as limited by the encoder feedback

would be:

(maximum # of counts/second)(60)

(4E)(N)

where:

E = the number of encoder lines per revolution

N = number of revolutions of the encoder per inch or millimeter

of axis travel. (For a rotary axis, N = number of revolutions of

the encoder per revolution of the axis.) For a linear axis the

units are inches or millimeters per minute. For a rotary axis the

units are revolutions per minute.

Publication 1746-6.1.2 - July 2000

Input signal Encoder feedback must be differential with 5V compatible

output signals, open-collector outputs are not supported (i.e.,

channels A, B, and Z must have source and sink current

capability, 8830 line driver outputs or equivalent). The encoder

input must have a 0.00 to 0.80 for off state and 4.75 to 5.25 for

on state to encoder common reference.

Input sink current 7 mA (max)

Marker channel Gated markers

Cable length Depends on the user-side power supply. Power voltage at the

encoder must be greater than or equal to the power voltage

requirement specified by the manufacturer. The minimum

power requirement for the 845H is 4.75V, and the maximum

limit is 5.25V. To meet the power requirement of the encoder

and still attain maximum cable length, you can:

Raise the voltage of the power supply to meet the

•

encoder requirement, but you cannot exceed the 5.25V

limit of the control.

Increase the gage of the wire from the termination

•

panel to the encoder (12 AWG maximum).

Page 30

Selecting Power Supplies, Encoders, and Drives

2-7

Selecting a Drive

The SLC Servo Module supports Allen-Bradley 1386, 1388, 1389, 1391,

1392, 1394, and 1398 servo drive systems. References that help you

select a suitable drive system appear in the table below.

Allen-Bradley

Drive

1386 1386-2.0 DC Servo Drive Product Data Sheet

1388 1388-2.0 DC PWM Servo Drive Product Data Series B

1389 1389-2.0 AC Servo Amplifier System Product Data

1391 1391-2.0 AC PWM Servo Controller Product Data

1392 1392-2.1 High Performance AC Drive (460V and 230V)

1394 1394-2.0 1394 Digital Multi-Axis Motion Control

1398 1398-2.0 ULTRA Series Product Data

Publication

Number

Title

Sheet

Sheet

Product Data

Systems Product Data

The SLC Servo Module provides a ±10V analog output to one drive

amplifier for a velocity command. This analog voltage is 11 bits plus

an additional sign bit (12 bits total) and interfaces to drive amplifiers

with a 2K through 20K ohm range. Servo drive signal analog out

specifications appear in the table below.

Specification Rating

Resolution 12 bits or 4.88 mV/bit

Output voltage swing ±10V

Load range

Conversion time 100 µs

Output step response (20V

swing)

Differential linearity ±1 LSB Max. (monotonic over the entire

Output offset voltage 500 µV (max)

Gain error drift

Rise time

•

Overshoot

•

Settling time

•

2K through 20K ohms

110 µs typical

5% typical

60µs typical

temperature range)

7 LSB (max)

Publication 1746-6.1.2 - July 2000

Page 31

2-8

Selecting Power Supplies, Encoders, and Drives

Publication 1746-6.1.2 - July 2000

Page 32

Chapter

3

Planning Hardware Installation

This chapter provides guidelines regarding your hardware installation

and includes the following topics:

• Understanding general wiring practices

• Routing wires

• Classifying your conductors

• Placing your SLC Servo Module

Refer to your SLC 500 documentation for more information on these

topics.

General Wiring Practices

General wiring practices include:

• Using shielded cables

• Routing wires

Using Shielded Cables

For many connections, we recommend shielded cable. Using shielded

cables and properly connecting their shields to ground protects

against electromagnetic noise interfering with signals transmitted

through the cables.

ATTENTION

To avoid personal injury or equipment damage

caused by unpredictable axis motion in your system,

use shielded cable as directed in this manual.

!

Within a cable, pairs of wires are twisted together. Using a twisted pair

for a signal and its return path provides further protection against

noise.

Shield wires should be terminated at one end only. The termination

panel is a convenient place to connect all shield wires while providing

the necessary ground connection.

1 Publication 1746-6.1.2 - July 2000

Page 33

3-2

Planning Hardware Installation

Cut the shield wires on the opposite end at the cable jacket and tape it

to prevent contact with ground. We also recommend keeping the

length of leads that extend beyond the shield as short as possible.

In high noise environments, you connect shield wires at both ends of

the cable to improve the noise immunity of the system. If this is done,

terminate one end of the shield to ground through a 0.1 µf capacitor

to avoid ground loops in the system.

Routing Wires

When you plan your wire route, classify wires and cables connecting

your SLC Servo Module system using the information in this table.

The table also tells you how to classify conductors and route cables.

IMPORTANT

Remember to keep low-level signal conductors

separate from high-level power conductors.

Follow the practices outlined in Programmable Controller Wiring and

Grounding Guideline (publication 1770-4.1) to learn how to route

other conductors.

Publication 1746-6.1.2 - July 2000

Page 34

Planning Hardware Installation

3-3

Classifying Your

Conductors

For these wires

and cables:

AC power lines

SLC Servo Module cable

(1746-HCA) and

termination panel wiring

Use the table below for cable routing guidelines and determining wire

and cable functions.

To : Follow these guidelines for routing inside or

outside an enclosure:

Connect high-power AC I/O lines to AC I/O

•

modules that are rated for high power and

high noise immunity.

Connect high-power DC I/O lines to DC I/O

•

modules that are rated for high power or

have input circuits with long time constant

filters for high noise rejection. They typically

connect to devices such as hard-contact

switches, relays, and solenoids.

Connect serial communication cables to

•

programming terminals or data terminals,

and connect them from the scanner to

remote I/O adapter modules or PLC

processors.

Connect low-power AC/DC I/O lines to I/O

•

modules that are rated for low power such

as low-power contact-output modules.

Connect low-power DC I/O lines to DC I/O

•

modules that are rated for low power and

have input circuits with short time constant

filters to detect short pulses. They typically

connect to devices such as proximity

switches, photo-electric sensors, TTL

devices, encoders, motion control devices,

and analog devices.

Route these high-power AC lines with machine

•

power conductors of up to 600V AC (feeding up

to 100 hp devices) if this does not violate local

codes.

Article 300-3 of the National Electrical Code

•

requires that all conductors (AC and/or DC) in

the same raceway are insulated for the highest

voltage applied to any one of the conductors in

the raceway.

Properly shield conductors, where applicable,

•

and route them in separate raceways. If

conductors must cross power feed lines, they

should do so at right angles.

Route these lines at least 1 foot from 110V AC

•

power lines, 2 feet from 240V AC power lines,

and 3 feet from 480V AC power lines.

Route these lines at least 3 feet from any

•

electric motors, transformers, rectifiers,

generators, arc welders, induction furnaces, or

sources of microwave radiation.

If the conductor is in a metal raceway or

•

conduit, that raceway or conduit must be

grounded along its entire length.

Placing Your SLC Servo

Module

When you plan your SLC Servo Module placement:

• Divide modules, as much as possible, into the following types:

AC

•

High-level DC

•

Low-level digital DC (TTL, encoder, pulse output)

•

Analog I/O

•

Intelligent I/O modules (for example, the SLC Servo Module)

•

• Place the SLC Servo Module as close to the SLC processor as

possible.

• Keep your SLC Servo Module as far away as possible from DC

and AC I/O modules. Distance protects the intelligent

(CPU-based) modules from the heat and electrical noise of the

DC and AC I/O modules.

Publication 1746-6.1.2 - July 2000

Page 35

3-4

Planning Hardware Installation

Place the SLC Servo Module on the left side of the chassis along

•

with other in telligent I/O modules and the CPU.

Place DC and AC I/O modules on the right side of the chassis and

•

allow empty slots to remain between them and the SLC Servo

Module.

Publication 1746-6.1.2 - July 2000

Page 36

Chapter

4

Installing Your SLC Servo Module

This chapter provides guidelines for installing your SLC Servo Module

and includes the following topics:

• Unpacking and inspecting the SLC Servo Module system

• Installing the SLC Servo Module

• Grounding the SLC Servo Module

• Mounting the termination panel

• Connecting the termination panel

Unpacking and Inspecting

Your SLC Servo Module

System

ATTENTION

!

Before removing the contents from the shipping

carton, avoid electrostatic discharge that degrades

performances and damages the module by doing the

following:

• Touch a grounded object to eliminate static

charge from your body before handling the

module.

• Wear a wrist strap (for example, catalog number

8000-XESD) that provides a high-resistance path

to ground.

• Keep the module in its static-shield bag when not

in use.

For more information about electrostatic discharge

and how to guard against it, refer to Guarding

Against Electrostatic Damage - Using the ESD Kit

(publication 8000-4.5.2).

1 Publication 1746-6.1.2 - July 2000

Page 37

4-2

Installing Your SLC Servo Module

To verify that you received what you ordered:

1. Check the label on each shipping carton with your order.

2. Check the items received against the bill of lading by matching

the equipment nameplate description with the material ordered.

Installing the SLC Servo

Module

IMPORTANT

Make claims for breakage and damage, whether

concealed or obvious, to the carrier as soon as

possible after receipt of the shipment. Allen-Bradley

gives the buyer reasonable assistance in securing

adjustment for damage claims.

The first component you install is the SLC Servo Module. After

installation, you connect the other components.

Figure 4.1 SLC Servo Module with Door Open

RUN

FDBK/U. PWR

Not used

To Termination Panel

CONFIG INV

Publication 1746-6.1.2 - July 2000

Note: The two switches on back are not used.

The table below provides a legend for the SLC Servo Module LEDs.

When: This LED is on:

Power is applied RUN

The feedback signal or user-side

power is lost

FDBK/U.PWR

Page 38

When: This LED is on:

Installing Your SLC Servo Module

4-3

An invalid configuration is

detected

ATTENTION

To avoid personal injury, equipment damage, or

performance degradation, remove backplane power

from the chassis and disconnect the 1746-HCA cable

before installing or removing a module.

!

ATTENTION

To avoid damage to a module or backplane

connector, do not force modules into the backplane

connector.

!

CONFIG INV

To insert a module into an I/O chassis:

1. Remove backplane power from the I/O chassis.

2. Remove user-side power from the SLC Servo Module.

3. Disconnect the 1746-HCA cable.

4. Align the larger of the two boards of the SLC Servo Module with

the card-edge guide at the bottom of the chassis.

5. Slide the module into the chassis.

6. Press the module firmly to seat it into the backplane connector.

7. Verify that the locking latches on the top and bottom of the

chassis hold the module in place.

IMPORTANT

The term user-side refers to the control circuitry on

the SLC Servo Module card that is powered by

customer-supplied power sources and isolated from

the control circuitry that is powered by the

backplane of an SLC rack.

Publication 1746-6.1.2 - July 2000

Page 39

4-4

Installing Your SLC Servo Module

Grounding the SLC Servo

Module

Control Module

Backplane

B

Side

a

c

k

p

l

a

n

e

Earth ground

through backplane

Isolated

User

Side

Axis

Overall

cable shield

Before you install the rest of the system, you must ground the SLC

Servo Module. All of the shields and signal commons (normally

floating) are tied to earth ground at a single point. Use the EGND

terminal on the termination panel for this purpose.

IMPORTANT

Do not connect shields to earth ground at both ends

to avoid causing circuit loops that are susceptible to

radiated and coupled noise.

Figure 4.2 Typical Grounding and Shielding for the SLC Servo Module System

1746-HCA cable

Twisted

pair (x10)

Shielded

twisted

pair (x3)

Optional

EGND

Termination panel

Axis

External power

+24V

RET

see ATTENTION

User-supplied shielded cable

Drive CMD

Drive

Channel A

Encoder

Channel B

Channel Z

Encoder PWR

User-side power supply

ATTENTION

!

+5V

–15V

RET

To avoid unpredictable operation of your SLC Servo

Module use a separate +24V power supply and tie

the +24V return to the +5V return. (The +5V, +15V,

and -15V returns are tied together on the SLC Servo

Module.)

Publication 1746-6.1.2 - July 2000

Page 40

Installing Your SLC Servo Module

4-5

Mounting the Termination

Panel

Refer to the Figure 4.3 and Figure 4.4 when mounting the 1746HT

termination panel.

To mount the 1746HT termination panel:

1. Snap the termination panel onto the DIN-type rail (1492-DR2).

2. Position an end anchor on either end of the termination panel.

3. Secure the panel by tightening the end anchor screws.

The end anchor prevents the termination panel from sliding in either

direction on the DIN rail.

Figure 4.3 Mounting the Termination Panel

DIN Rail

End Anchor & Screw

DRIVE

DRIVE

DR RET

SHLD

ENCODER

CH A.HI

CH A. LO

AB SHLD

CH B.HI

CH B. LO

ZSHLD

CH Z. HI

CH Z. LO

ENCODER POWER

Termination Panel

Publication 1746-6.1.2 - July 2000

Page 41

4-6

Installing Your SLC Servo Module

Figure 4.4 Termination Panel and its Dimensions

DRIVE

DRIVE

DR RET

SHLD

ENCODER

CH A.HI

CH A. LO

AB SHLD

CH B.HI

CH B. LO

ZSHLD

CH Z. HI

CH Z. LO

ENCODER POWER

+5V

RET

+15V

SHLD

EXT POWER

+5V

RET

+15V

_

+

RET

-15V

+24

+24 R E T

EGND

AXIS

292mm

(11.5 in.)

DRIVE ENABLE

ESTOP

+24

V

RES.PB

RES.PB

RESET

STRING IN

STRING OUT

FAST I/O

FI.1

V

+24

FI.2

+24

FI.3

RET

FO.1

1746HT R EV0 1

TE RMIN A TION P A N EL

70mm

(2.75 in.)

89mm

(3.5 in.)

Publication 1746-6.1.2 - July 2000

Page 42

Installing Your SLC Servo Module

4-7

Connecting the Termination

Panel

After mounting the termination panel, connect it to the SLC Servo

Module with the 1746-HCA cable. To connect the termination panel to

the SLC Servo Module:

1. Set the locking latches above and below the connector so the

latch reads OPEN.

2. Open the door of the SLC Servo Module.

3. Hold the connector as shown in Figure 4.5 (left) and insert it

into the D-sub connector on the SLC Servo Module until the

connector is seated.

4. Insert a small, flat-edge screwdriver next to the locking latch

located between the module door and connector.

5. Slide the locking latch to the right with your screwdriver.

6. Insert the small, flat-edge screwdriver next to the locking latch

located between the module door and connector.

7. Slide the locking latch to the left with your screwdriver.

8. Connect the other end of the cable to the 1746-HT termination

panel, as shown in Figure 4.5 (right).

Publication 1746-6.1.2 - July 2000

Page 43

4-8

Installing Your SLC Servo Module

Figure 4.5 Connecting the 1746-HCA-Cable

Connecting to the

1746-HSRV

1746-HCA

Cable

Connecting to the

1746-HT

EN

OP

1746-HCA

Cable

Publication 1746-6.1.2 - July 2000

Page 44

Wiring the SLC Servo Module

Chapter

5

Overview

Complying with European

Union Directives

After mounting and connecting the termination panel, you wire fast

inputs, outputs, and your Estop string to the termination panel when

you wire the system power supply, encoders, and drives. This chapter

includes the following topics:

• Complying with European Union directives

• Wiring fast inputs and outputs

• Wiring hardware overtravels

• Connecting home limit switch as a fast input

• Wiring Estop connections

• Wiring power supplies

• Wiring encoders

• Wiring Allen-Bradley drive connections

• Connecting the velocity command

If this product is installed within the European Union or EEA regions

and has the CE mark, the following regulations apply.

EMC Directive

If this apparatus is tested to meet Council Directive 89/336

Electromagnetic Compatibility (EMC) in accordance with Article 10

(1), the following standards apply in whole:

• EN 50081-2 EMC-Generic Emission Standard, Part 2-Industrial

Environment

• EN 50082-2 EMC-Generic Immunity Standard, Part 2-Industrial

Environment

The product described in this document is intended for use in an

industrial environment and is not intended for use in a residential,

commercial or light industrial environment.

IMPORTANT

1 Publication 1746-6.1.2 - July 2000

To meet CE requirements, you must use the specified

Allen-Bradley cables and termination panel for the

SLC Servo Module (catalog number 1746-HSRV).

Page 45

5-2

Wiring the SLC Servo Module

Wiring Fast Inputs and

Outputs

On the termination panel, the +24V DC fast inputs and outputs of the

SLC Servo Module are routed from the connector (37-pin D-shell) to

the fast I/O connector (7-pin pluggable) on the termination panel.

The fast I/O consists of:

• Fast inputs FI.1 through FI.3

• Fast output FO.1

• +24V DC and +24V DC return signals

We recommend 18 AWG wire for wiring fast I/O because it allows two

wires for each connection point. The termination panel accepts 12

AWG wire, but this allows only one wire per point.

Figure 5.1 shows a diagram of typical fast I/O connections. For

electrical dampening, a snubber is required to filter out electrical

spikes. The snubber is used for inductive and comparative loads on

the fast output.

Figure 5.2 and Figure 5.3 shows equivalent fast input and output

circuits.

IMPORTANT

The input device must connect between +24V DC

and the appropriate fast input. Fast inputs are +24V

DC referenced. The fast output is ground-referenced.

The output load must connect between the fast

output and ground.

Publication 1746-6.1.2 - July 2000

Page 46

14 AWG

Electrical Cabinet

GND

Figure 5.1 Typical Fast I/O Connections

ESTOP

+24

RES.PB

RES.PB

RESET

STRING IN

STRING OUT

FAST I/O

FI.1

+24V

FI.2

+24V

FI.3

RET

FO.1

GND

Wiring the SLC Servo Module

5-3

Snubbing is required for inductive and

capacitive loads on the fast output.

Capacitive load

Current limiting resistor required. Must

be placed in series with contact load.

RET

FO.1

18173

Publication 1746-6.1.2 - July 2000

Page 47

5-4

Wiring the SLC Servo Module

Figure 5.2 Equivalent Fast Input Circuit

+24V D C

W

15K

47K

W

1746-HCA

11K

W

Control

Module

Termination

Panel

Figure 5.3 Equivalent Fast Output Circuit

1746-HCA

Control

Module

+5V DC

Termination

Panel

K2

Ret

V

+24 DC

FO.1

Wiring Hardware

Overtravels

Publication 1746-6.1.2 - July 2000

Because the system must go into Estop when a hardware overtravel is

tripped, do the following to the hardware overtravel limit switches of

each axis:

• Wire them into the customer Estop string.

• Position them outside the software overtravels (see Figure 5.4).

Page 48

Wiring the SLC Servo Module

Software Overtravel Limits

Software overtravel limits appear in the table below.

Name What it specifies Default Range

5-5

Software overtravels used Whether control checks

software overtravel limits

Yes Yes (used) or

No (not used)

When you are using a check, the SLC Servo Module tests each

program for motion past an overtravel limit before the programmed

motion is executed.

The SLC Servo Module monitors software overtravel limits

continuously during motion. Software overtravels are disabled during

homing and are not active until the axis is homed. Software overtravel

limits are located inside hardware overtravel limits. Hardware

overtravel limits cause Estop when tripped.

Figure 5.4 Software Overtravel Limits

-+

Negative Overtravel Limit

W10-W11

0

Positive Overtravel Limit

W8-W9

Connecting Home Limit

Switch as a Fast Input

Negative Hardware Overtravel Limit

(causes Estop)

IMPORTANT

Check positive and negative software and hardware

overtravel limits only if Overtravels Used (word 0, bit

Positive Hardware Overtravel Limit

(causes Estop)

7) is set.

You can configure the home limit switch to come from the termination

panel, or from the backplane by setting configuration word 1, bit 0.

The 1 represents termination panel Fast Input 3. The 0 represents

Publication 1746-6.1.2 - July 2000

Page 49

5-6

Wiring the SLC Servo Module

backplane input. Though the exact position of home is not important,

it is important that the home position is:

• A repeatable resting place for the axis when it is not used.

• Free of obstruction from another moving axis.

To connect a home limit switch:

1. Place the limit switch near the home position that you want.

2. Adjust the encoder so that the marker is approximately 1/2

revolution from the limit switch closure.

Wiring Estop Connections

IMPORTANT

If you do not adjust the encoder, home can be off by

one encoder revolution.

The SLC Servo Module detects and controls Estop conditions. Each

SLC Servo Module has a separate and independent Estop circuit. Refer

to the documentation that came with your drive for recommendations

on correctly wiring your external Estop string.

A hardware Estop is caused by the following:

• Broken wire in the user power cable.

• Power-fail signal from chassis backplane.

• Watch-dog time-out on SLC Servo Module.

• Software Estop conditions.

• A contact in the external Estop string or a broken/missing wire

opens the string (e.g., when someone pushes the Estop push

button).

Specifications for Estop relay on the SLC Servo Module appear in the

table below.

Publication 1746-6.1.2 - July 2000

Specification Rating

Maximum contact voltage rating 80V DC max

Operate time 500µs average

Contact bounce less than 200µs average

Contact resistance 150 milliohms average

Contact rating 5.0VA @ 0.35A max

Page 50

Wiring the SLC Servo Module

Wiring the Estop for a One-Axis System

To wire the Estop for a one-axis system connect the following:

• Drive enable

• Estop reset pushbuttons (Res P.B., Res P.B., and Reset)

• Customer Estop String (String In and String Out)

5-7

ATTENTION

To avoid personal injury or hardware damage,

develop a fail-safe wiring design for your Estop

string.

!

• An Estop string (Figure 5.5) is connected in series and consists

of:

• Axis hardware overtravels

• Remote Estop

• Motor thermal switch

• Transformer thermal switch

• Drive fault

Wiring for Normal Operation

• Wire the Estop inputs for normal operation.

• Bench test your SLC Servo Modules.

• The Estop Reset pushbutton requires a two-pole single-throw

switch.

Maintaining Electrical Continuity

• Maintain electrical continuity on the termination panel between

the String Out and String In terminals to change from an Estop

state to a run state when pressing the Estop Reset pushbutton.

• While in the run state, loss of continuity between String Out and

String In places the SLC Servo Module in an Estop state.

• All motion is inhibited in the Estop state.

Verifying Connections and Operation

• Verify that the Estop wiring is connected correctly.

• Check the operation of devices wired between String Out and

String In.

Publication 1746-6.1.2 - July 2000

Page 51

5-8

Wiring the SLC Servo Module

Figure 5.5 Ladder Diagram for a One-Axis System

+24V DC

CR1-1

CR1-4

P2-9

Estop

Res. P.B.

P2-8

Reset

To Estop Status

on Control Module

Control Module

P2-7

To Estop Reset Request

on Control Module

P2-6

String Out String In

Customer

Estop

String

+24V D C Ret.

CR1

1N 4001

CR1-2

CR1-3

IMPORTANT

In this equivalent Estop circuit, P2 is a 25-pin D-shell

connector.

CR1-2 and CR1-3 are auxiliary contacts of CR1 used

in the drive interface. Use them for the drive enable

of each drive amplifier. CR1-3 is not always required.

For more information, see the drawings that

accompany your drive.

Specifications for the CR1 (Allen-Bradley P/N 700-HC 14Z24) appear

in the table below.

CR1 Part Number Coil Contact Arrangement

700-HC 14Z24 24V DC, 650 ohms 3A Resistive, 120V AC4 form C

Publication 1746-6.1.2 - July 2000

Page 52

8

6

7

9

Control

Module

Estop

Reset

Request

Control Module

Estop

Contacts

Estop

Status

25-Pin D-Shell Connector

+24V

CR 1-4

CR 1-2

CR 1-3

CR 1

CR 1-1

Res.

P.B.

Res.

P.B.

Termination

Panel

String

Out

String

In

Reset

+24V

To Customer Drive

Enable Circuit

String Pilot

Cr 2-1

Estop

Reset P.B.

(Customer-Supplied)

Refer to Figure 4.1 for

Shield Connections

Cable Length Must

Not Exceed 10 m (32 feet)

Wiring the SLC Servo Module

5-9

ATTENTION

If you do not use the relay shown in Figure 5.8,

verify that your replacement relay has a coil

resistance greater than or equal to 650 ohms.

!

Figure 5.6 Estop Circuitry Diagram for a One-Axis System

Publication 1746-6.1.2 - July 2000

Page 53

5-10

Wiring the SLC Servo Module

Figure 5.7 String Pilot Connection

Drive Fault

Contact Overtravel

Customer

-

EstopString

Thermal

Overload

Remote

E-Stop

CR2

String Pilot

To wire Estop connections, refer to wiring diagrams for the drive you

are using. The wiring of six different Allen-Bradley compatible drives

is shown in the table below.

Figure Wiring Diagram

5.15 1386 DC Servo Drive

5.16 1388 DC PWM Servo Control

5.17, 5.18

1389 AC Servo Amplifier

5.19, 5.20 1391 AC Servo Control Module Amplifier

5.21 1392 AC Servo Amplifier

5.22, 5.22 1394 AC Servo Control Module Amplifier

1

5.24

5.25

1398 ULTRA 100™/200™ Series AC Servo Control

Module Amplifiers

5.26

1

The 1389 servo drive requires a 115V AC power conductor (K1) to supply main power to the

drive amplifier. See the 1389 Servo Amplifier Installation Manual for details

Wiring the Estop for System with Two or More Axes

For a system with two or more axes, you must have a termination

panel and a SLC Servo Module for each axis. See Figure 5.8 and Figure