Page 1

Installation Instr uctions

Multi-Channel High-Speed

Counter

1746-HSCE2

Inside

For More Information..................................................................2

Compliance to European Union Direct ives............................. ....3

Hazardous Location Considerations............................................4

Environnements dangere ux................................ .... ......................4

Hardware Features.......................................................................5

LEDs............................................................................................6

Prevent Electrostatic Discharge................................ .... .... ...........6

Setting the Jumpers......................................................................7

Installing the Module................ ... .... ......................... .... .... ...........8

Important Wiring Considerations.................................................9

Removing the Terminal Block...................................................10

Input and Output Connections................ .... .... ......................... ..10

Encoder Wiring..........................................................................10

Electronic Protection......... .... .... ......................... .... ....................14

Specifications............................ ... .... ......................... .... .... .........16

Publication 1746-I N002A-US-P

Page 2

2 Multi-Channel High-Speed Counter

For More Information

As part of our effort to preserve, protect, and improve our environment,

Allen-Bradley is reducing the amount of paper we use. Less paper means more

options for you. In addition to traditional p rinted publications and CD-ROM

versions, we now offer on-line materials with the most up-to-date information

you can get. We recommend that you read the related publications listed below

before starting up your control system.

Related Publications

For Refer to this Document Pub. No.

A more detailed description on how to

install, configur e, and operate your

multi-channel high speed counter.

A detailed description on how to install

and use your modular SLC 500™ system

A reference manual that contains status

file data and instruction set information

for SLC 500 processors.

Multi-channel High Speed

Counter User Manual

SLC 500 Modular Hardware

Style Installation and

Operation Manual

SLC 500™ and

MicroLogix™ 1000

Instruction Set Reference

Manual

1746-6.20

1747-6.2

1747-6.15

How to Get More Informatio n

If you would like a manual, you can:

• download a free electronic version from the internet at

www.theautomationbookstore.com

• purchase a printed manual by:

– contacting your local distributor or Rockwell Auto mation representative

– visiting www.theautomationbookstore.com and placing your order

– calling 1.800.963.9548 (USA/Canada) or

001.330.725.1574 (Outside USA/Canada)

Publication 1746 -IN002A-US-P

Page 3

Multi-Channel High-Speed Counter 3

Compliance to European Union Directives

If this product has the CE mark, it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet the

following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) and the following standard s, in whole or in part,

documented in a technical construction file:

• EN 50081-2

EMC – Generic Emission Standard, Part 2 – Industrial Environment

• EN 50082-2

EMC – Generic Immunity Standard, Part 2 – Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requ ir ements of EN 61131-2 Pr ogrammable Controllers, Pa rt

2 – Equipment Requirements and Tests.

For specific information required by EN61131-2, see the appropriate sections in

this publication, as well as the following Allen-Bradley publications:

• Industrial Automation, Wiring and Grounding Guidelines for Noise Immunity ,

publication 1770-4.1

• Automation Systems Catalog, publication B111

Publication 1746-I N002A-US-P

Page 4

4 Multi-Channel High-Speed Counter

!

WARNING

!

MISE EN

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D, or

non-hazardous locations only. The following ATTENTION statement applies to

use in hazardous locations.

EXPLOSION HAZARD

• Substitution of components may impair suitability for

Class I, Division 2.

• Do not replace components or disconnect equipment unless

power has been switched off, and the area is known to be

non-hazardous.

• Do not connect or disconnect connectors or operate

switches while circuit is live unless the area is known to be

non-hazardous.

• All wiring must comply with N.E.C. article 501-4(b).

Environnements dangereux

Cet équipement est conçu pour être utilisé dans des environnemen ts de Classe 1,

Division 2, Groupes A, B, C, D, ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

DANGER D’EXPLOSION

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe 1,

Division 2.

• Couper le courant ou s’assurer que l’emplacement est

désigné non dangereux avant de remplacer les composants.

• Couper l’alimentation ou s’assurer que l’environnement est

classé non dangereux avant de brancher ou débrancher des

connecteurs ou de faire fonctionner des commutateurs.

Publication 1746 -IN002A-US-P

Page 5

Multi-Channel High-Speed Counter 5

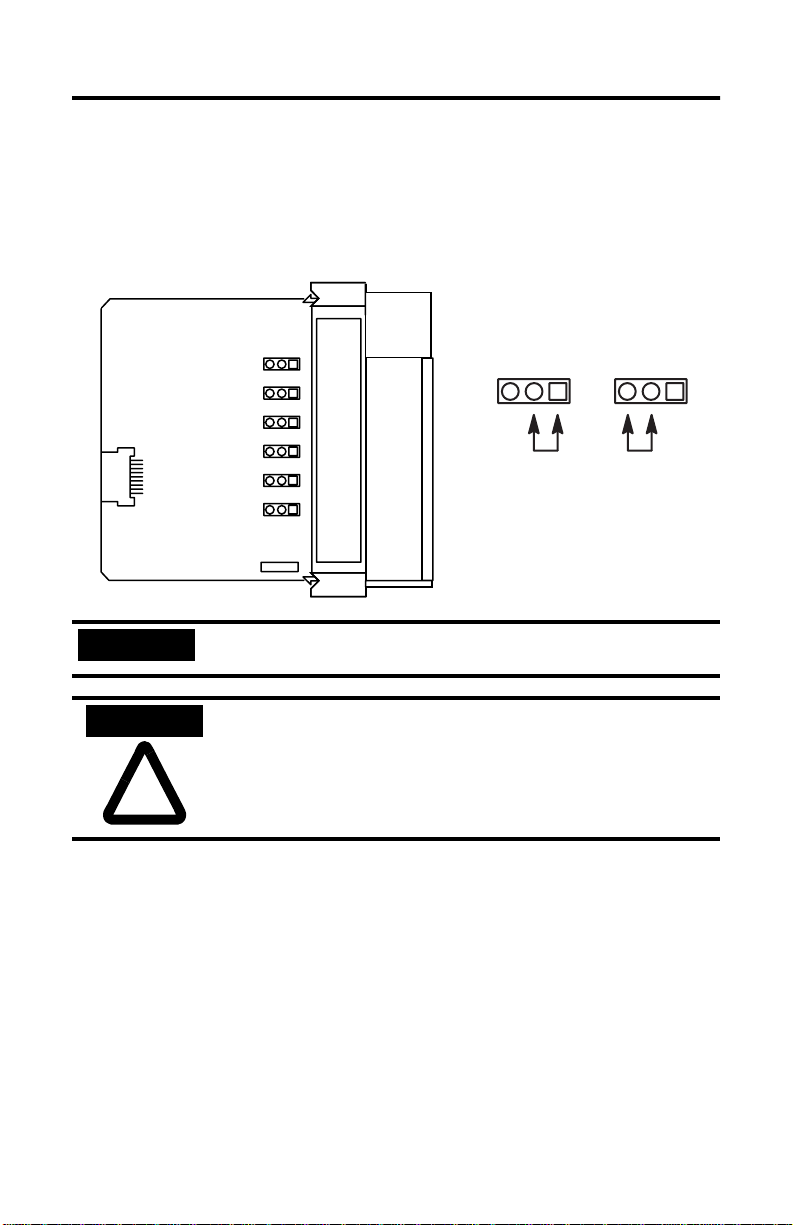

Hardware Features

The module’s hardware features are illustrated below.

COUNTER

Input Status LEDs

Input and Output

Terminals

OUTPUT STATUS

1023

A1 B1 Z1

A2 B2 Z2

INPUT STATUS

HSCE2

Output Status LEDs

Running Status LED

RUN

FLT

Fault Status LED

Publication 1746-I N002A-US-P

Page 6

6 Multi-Channel High-Speed Counter

!

ATTENTION

LEDs

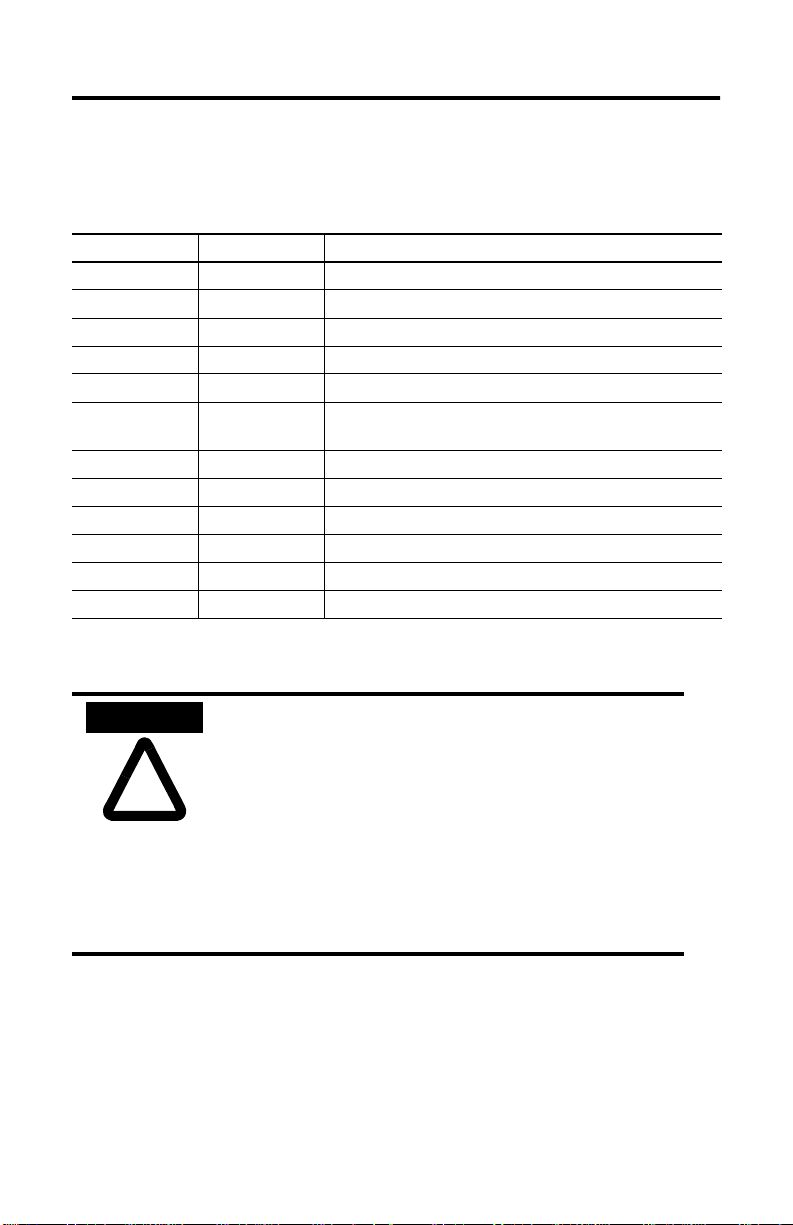

The front panel has a total of twelve indicator LEDs.

LED Color Indicates

0 OUT Green ON/OFF status of real output

1 OUT Green ON/OFF status of real output

2 OUT Green ON/OFF status of real output

3 OUT Green ON/OFF status of real output

RUN Green Running status of the modu le

FLT Red Steady on: Module fault

A1 Yellow ON/OFF status of input A1

A2 Yellow ON/OFF status of input A2

B1 Yellow ON/OFF status of input B1

B2 Yellow ON/OFF status of input B2

Z1 Yellow ON/OFF status of input Z1

Z2 Yellow ON/OFF status of input Z2

Flashing: Output overcurrent

Prevent Electrostatic Discharge

Publication 1746 -IN002A-US-P

Static discharges may cause permanent damage to the

module. Follow these guidelines when you ha ndle the

module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist strap grounding device.

• Handle module by plastic case only. Avoid contact

between module circuits and any surface which can

hold an electrostatic charge.

• If available, use a static-safe work station.

Page 7

Multi-Channel High-Speed Counter 7

IMPORTANT

!

ATTENTION

Setting the Jumpers

Six jumpers are located in a row on the side of the module. Use the jumpers to

select the input voltage for each of the inputs A1, B1, Z1, A2, B2, and Z2. The

settings are shown in the figure below.

Jumper Se ttings

JP1 (A1 )

JP2 (B1)

JP3 (Z1)

JP4 (A2)

JP5 (B2)

JP6 (Z2)

5V dc

4.2-12V dc

24V dc

10-30V dc

(default)

For a 12V dc encoder signal, use the 24V dc jumper setting.

If jumpers are not set to match the encoder type, the module

may be damaged.

The 5V dc settings respond to inputs with a active or high settings between 4.2

and 12 volts. The 24V dc settings respond to inputs with active or high settings

between 10 and 30 volts.

Publication 1746-I N002A-US-P

Page 8

8 Multi-Channel High-Speed Counter

!

ATTENTION

Installing the Module

Disconnect power before attempting to install, remove, o r

wire the module.

1. Make sure your SLC p ower supply has adequate reserve current capaci ty. The

module requires 250 mA at +5V dc.

2. Align the full-sized circuit board with the chassis card guide as shown below.

The first slot of the first chassis is reserved for the processor.

3. Slide the module into the chassis until the top and bottom latches catch. To

remove the module, press the release clips at the top and bo ttom of the mod ule

and slide it out.

4. Cover all unus ed card slots with the C a rd Sl o t Fill er, catalog nu mber 1746-N2.

Publication 1746 -IN002A-US-P

Page 9

Multi-Channel High-Speed Counter 9

Important Wiring Considerations

Use the following guidelines when planning the system wiring for the module:

• Install the SLC 500 system in a NEMA-rated enclosure.

• Disconnect power to the SLC processor and the module before wiring.

• Make sure the system is properly grounded.

• Group this module and low-voltage DC modules away from AC I/O or

high-voltage D C modules.

• Shielded cable is required for high-speed input signals A, B, and Z. Use

individually shielded, twisted pair cable lengths up to 300 m (1000 ft.).

• Shields should be grounded only at one end. Ground the shield wire outside

the module at the chassis mounting screw. Connect the shield at the encoder

end only if the housing is isolated from the motor and ground.

• If you have a junction in the cable, treat the shields as a conductor at all

junctions. Do not ground them to the junction box.

Considerations for Reducing Noise

In high noise environments, the 1746-HSCE2 inputs may accept “false” pulses,

particularly when using low frequency input signals with slowly sloping pulse

edges. To minimize the ef fects of hi gh fr equency no ise on low fr equency s ignals,

the user can do the following:

• Identify and re move noise sources.

• Route 1746-HSCE2 input cabling away from noise sources.

• Install low pass filters on input signals. Filter values are dep endent on the

application and can be determined empirically.

• Use devices which output differential signals, like differential encoders, to

minimize the possibility that a noise source will cause a false input.

Publication 1746-I N002A-US-P

Page 10

10 Multi-Channel High-Speed Counter

!

ATTENTION

Removing the Terminal Block

Remove the terminal block by turning the slotted term inal block release screws

counterclockwise. The screws are attached to the terminal block, so the block

will follow as the screws are turned out.

To avoid cracking the removable terminal block, alternate

removal of the slotted terminal block release screws.

Input and Output Connections

Input and output wiring terminals are shown in the figure below. Each terminal

accepts two #14 A WG wires. T ighten screws only tight enoug h to immobilize the

wire. The torque applied to the screw should not exceed 0.9 Nm (8 in-lb).

Encoder Wiring

Differential encoders provide the best immunity to electrical noise. We

recommend, whenever possible, to use differential encoders.

The wiring diagrams on the following pages are provided to support the

Allen-Bradley encoders you may already own.

OUTPUT COMMON

OUTPUT 1

OUTPUT 3

Release Screw

A1+

B1+

Z1+

A2+

B2+

Z2+

Release Screw

A1-

B1-

Z1-

A2B2Z2-

OUTPUT 0

OUTPUT 2

+Vdc

Publication 1746 -IN002A-US-P

Page 11

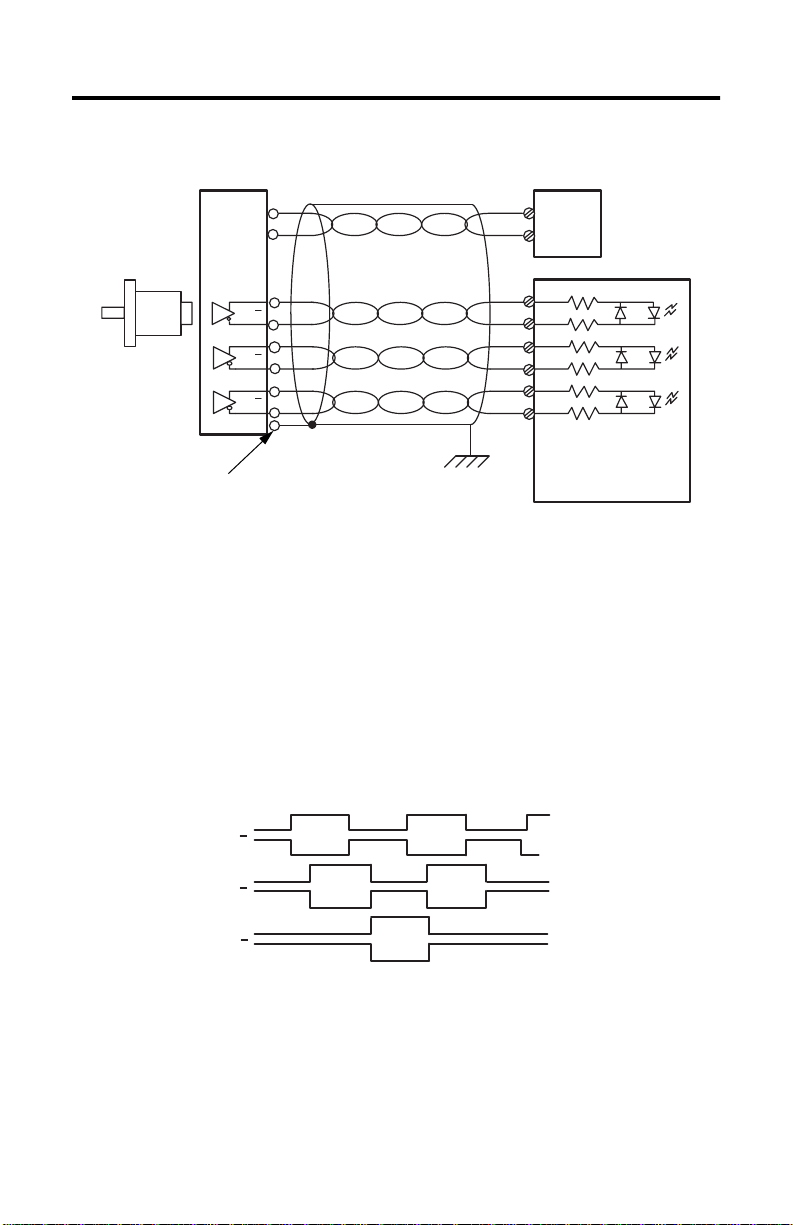

Differential Encoder Wiring

Cable

VS

GND

Multi-Channel High-Speed Counter 11

(1)

+VDC

COM

Power

Suppl

A(+)

A(–)

B(+)

B(–)

Z(+)

Z(–)

Allen-Bradley

845H Series

differential

encoder

A

A

B

B

Z

Z

Shield

shield/housing

Connect only if housing is electronically

isolated from the motor and ground.

Earth

Module Inputs

(1) Refer to your encoder ma nual for proper cable type. The type of c able used should be twisted

pair, individually shielded cabl e wit h a maximum length of 300m (1000 ft .).

Differential Encoder Output Waveforms

The figure below shows the di fferent encoder output waveforms. If your encoder

matches these waveforms, the encoder signals can be directly connected to the

associated screw terminals on the module. For example, the A lead from the

encoder is connected to the module’s A+ screw. If your encoder does not match

these waveforms, some wiring modifications may be necessary. See the user’s

manual for your encoder.

A

A

B

B

Z

Z

Publication 1746-I N002A-US-P

Page 12

12 Multi-Channel High-Speed Counter

R

Single-Ended Encoder Wiring (Open Collector)

(1)

cable

Allen-Bradley

845H Series

VS

GND

(2)

R

A

B

Z

single-ended

encoder

shield

shield/housing

Connect only if housing is electronically

isolated from the motor and ground.

(1) Refer to your encoder ma nual for proper cable type. The type of c able used should be twisted

pair, individually shielded cabl e wit h a maximum length of 300m (1000 ft .).

(2) External resistors are needed if not internal to the encoder. The pull-up resist or (R) value

depends on the power supply value. The table below shows resistor values for typical supply

voltages. To calculate the resistor value, use one of the following formulas:

–()

Vcc Vmin

R

For 5V dc jumper position:

For 24V dc jumper position:

----------------------------------=

Imin

–()

Vcc Vmin

---------------------------------- 1 K

=

Imin

Ω–

where:R = pull-up resistor value

Vcc = power supply voltage

Vmin = 4.2 V dc

Imin = 6.3 mA

Earth

+VDC

COM

A(+)

A(–)

B(+)

B(–)

Z(+)

Z(–)

Power

Supply

Module Inputs

Power Supply Voltage (Vcc)

Pull-up Resistor Value (R)

(1)

5V dc 127 Ω

12V dc 238 Ω

24V dc 2140 Ω

(1) Resistance values may change, depending upon your ap plication.

Single-Ended Encoder Output Waveforms

The figure below shows the single-ended encoder output waveforms. When the

waveform is low , t he encoder outp ut transist or is on. When t he waveform is high,

the encoder output transistor is off.

A

B

Z

Publication 1746 -IN002A-US-P

Page 13

Multi-Channel High-Speed Counter 13

R

Vcc Vmin

–()

Imin

------------------------------------=

Vcc Vmin

–()

Imin

------------------------------------ 1KΩ–

=

Single-Ended Wiring (Discrete Devices)

+VDC

proximity sensor

VS

OUT

COM

VS

OUT

COM

VS

OUT

COM

solid-state

switch

(1)

R

photoelectric sensor

with open collector

sinking output

(1) External resistors are needed if not internal to the sensor. Check your sensor’s documentation.

The pull-up resistor (R) val ue dep en ds on the power supply value. The table below sho ws

resistor values for ty pi cal supply voltages. To calculate the resistor va lue, use one of the

following formulas:

COM

A(+)

A(–)

B(+)

B(–)

Z(+)

Z(–)

Power

Supply

Module Inputs

For 5V dc:

For 24V dc:

where:R = pull-up resistor value

Vcc = power supply voltage

Vmin = 4.2 V dc

Imin = 6.3 mA

Power Supply Voltage (Vcc)

5V dc 127 Ω

12V dc 238 Ω

24V dc 2140 Ω

(1) Resistance values may change, depending upon your ap plication.

Pull-up Resistor Value (R)

Publication 1746-I N002A-US-P

(1)

Page 14

14 Multi-Channel High-Speed Counter

IMPORTANT

IMPORTANT

Electronic Protection

The electronic protection of the 1746-HSCE2 has been designed to provide

protection for the module from short-circuit and overload curr ent conditions. The

protection is base d on a th ermal cut-ou t princi ple. In the event of a short circuit or

overload current condition on an output channel, all channels turn off within

milliseconds after the thermal cut-out temperature has been reached.

The module does not provide protection against reverse

polarity wiring or wiring to AC power sources. Electronic

protection is not intended to replace fuses, circuit breakers, or

other code-required wiring protection devices.

Auto Reset Operation

1746-HSCE2 outputs perform auto-reset under overload

conditions. When an output channel overload occurs as

described above, all channels turn off within milliseconds

after the thermal cut-out temperature has been reached. While

the overcurrent condition is present, the module tries resetting

the outputs at intervals of 500 ms. If the fuse cools below the

thermal cut-out temperature, all outputs will auto-reset and

resume control of their external loads as directed by the

module until the thermal cut-out temperature is again reached.

Publication 1746 -IN002A-US-P

Removing power from an overloaded output channel would

also allow the fuse to cool below the thermal cut-out

temperature, allowing auto-reset to occur when power is

restored. The output channel then operates as directed by the

module until the thermal cut-out temperature is again reached.

To avoid auto-reset of output channels under overload

conditions, monitor the fuse blow n status bit (FB1) in the

module’s status file and latch the output off when an

overcurrent condition occurs. An external mechanical fuse

can also be used to open an output circuit when it is

overloaded.

Page 15

Multi-Channel High-Speed Counter 15

Short-Circuit/Overload Current Diagnostics

If a short-circuit or overload current condition occurs on an output channel:

1. The FLT LED flashes, provided that power is applied to the module. 5V dc via

backplane and load power via an external supply is required.

2. Fuse status bit (FB1) is set (1) when the fuse is tripped. The module tries to

reset the outputs at intervals of 500 ms. During each retry, the fuse status bit is

reset (0). After the overload condition is corrected, the fuse status bit resets (0)

automatically.

When FB1 is set, outputs 0 thro ugh 4 will not function.

3. All output channels will be turned off in the case of a short-circuit or overload

condition.

Recovery fro m Channel Shutdo wn

1. Remove the SLC 500 system power and correct the conditions causing the

short-circuit or overload current condition.

2. Restore the SLC 500 system power. The module automatically resets and

resumes control of the output channel and associated load.

Publication 1746-I N002A-US-P

Page 16

16 Multi-Channel High-Speed Counter

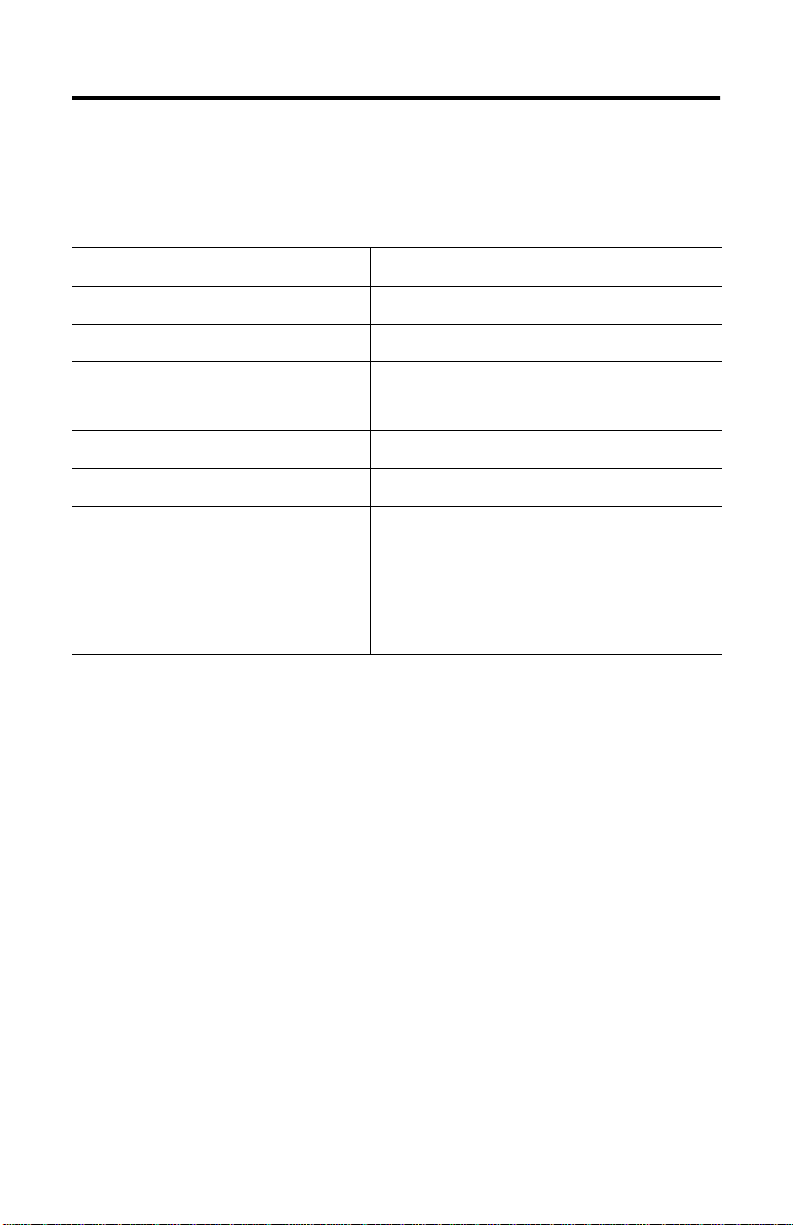

Specifications

General

Operating Temperature 0°C to +60°C (+32°F to +140°F)

Storage Temperature -40°C to +85°C (-40°F to 185°F)

Humidity 5 to 95% without condensation

Backplane Current Consumption

(power supply loading)

Backplane Isolation 1000V dc

Maximum Cable Length 300m (1000 ft.)

Agency Certification UL listed

250 mA at +5V dc

0 mA at +24V dc

C-UL listed

Class I, Division 2, Groups A, B, C, and D

CE certified for all applicable directives

(when product or packaging is marked)

Publication 1746 -IN002A-US-P

Page 17

Multi-Channel High-Speed Counter 17

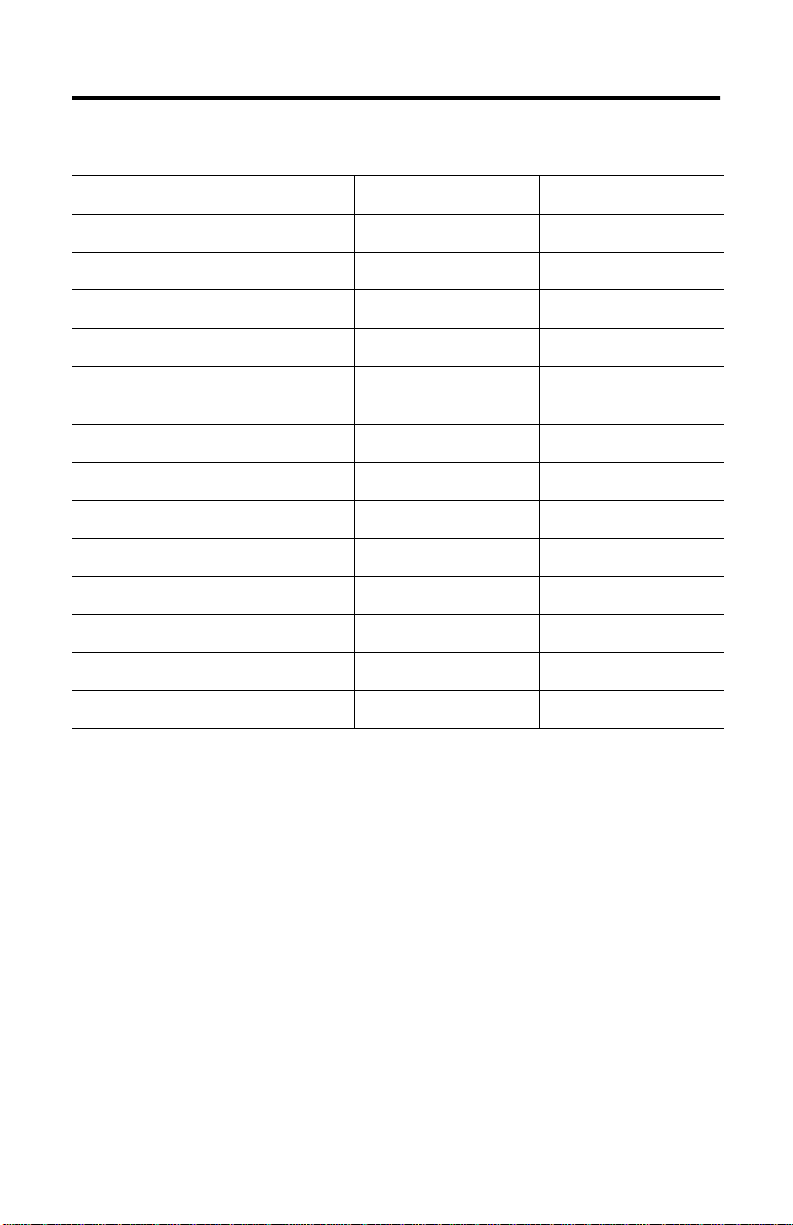

Inputs A, B, and Z

Jumper Setting 5V dc 24V dc

Nominal Input Voltage 5V dc 24V dc

Input Voltage Range 4.2V dc to 12V dc 10V dc to 30V dc

On-State Voltage (min.) 4.2V 10V

Off-St ate Voltage (max.) 0.8V 3V

Maximum Off-state Leakage

Current

Input Current (max.) 8 mA 20 mA

Input Current (min.) 6.3 mA 6.3 mA

Nominal Input Impedance 500 Ω 1500 Ω

Min. Pulse Width 475 ns 475 ns

Min. Phase Separation 200 ns 200 ns

Max. Input Freq uency 1 MHz 1 MHz

Isolation (from backplane) 1000V 1000V

Isolation (from outputs) 500V 500V

100 µA 100 µA

Publication 1746-I N002A-US-P

Page 18

18 Multi-Channel High-Speed Counter

!

ATTENTION

Outputs (sourcing)

Max. On-State Output Current (per

channel)

Max On-State Current (per module) 2.0 A at 40°C

Max. On-State Voltage Drop 0.5V

Max. Off-State Leakage Current 100 µA

Isolation (from backplane) 1000V

Isolation (from inputs) 500V

A transient pulse occurs in transistor outputs when the

external dc supply voltage is applied to the output common

terminals (for example, via the master control relay). This can

occur regardless of the processor having power or not. For

most applications, the energy of this pulse is not sufficient to

energize the load. Refer to the SLC 500 Modular Hardware

Style Installation and Operation Manual, publication

1747-6.2, for more information on transient pulses and

guidelines to reduce inadvertent processor operation.

1.0 A at 40°C

1.0 A at 60°C

1.5 A at 60°C

Publication 1746 -IN002A-US-P

Page 19

Multi-Channel High-Speed Counter 19

Publication 1746-I N002A-US-P

Page 20

Publication 1746-IN002A-US-P - February 2000 PN 40071- 078-01 (A)

Supersedes Publication 1746-5.21 - March 1999 © 2000 Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...