Page 1

SLC 500 Fast Analog

I/O Module

Catalog Numbers 1746-FIO4I and

1746-FIO4V

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may reach dangerous

temperatures.

Rockwell Automation, Allen-Bradley, TechConnect, RSLogix500, SLC, SLC 500, and SLC 5/02 are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Quick Start

Install and Wire the Modules

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . 7

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

Determine the Module’s Power Requirements . . . . . . . . . . . 11

Determine Compatibility with Other I/O Modules. . . . . . . . . 12

Configure Input Channels . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Select the I/O Rack Slot. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Considerations When Wiring . . . . . . . . . . . . . . . . . . . . . . . . 16

Minimize Electrical Noise Interference . . . . . . . . . . . . . . . . . 18

Wire the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Minimize Ground Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Label the Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Access Files to Configure I/O

Processor and Module

Considerations

Write Ladder Logic

Chapter 3

Click and Drag Configuration . . . . . . . . . . . . . . . . . . . . . . . 23

Read IO Config Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4

Processor Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Module Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 5

Retentive and Non-retentive Programming . . . . . . . . . . . . . . 39

Detect an Out-of-range Input. . . . . . . . . . . . . . . . . . . . . . . . 41

Overview of Scaling Inputs and Outputs . . . . . . . . . . . . . . . 42

Scale an Analog Input and Detect an Out-of-range Condition 44

Scale an Analog Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Scale Offsets When >32,767 or <32,768. . . . . . . . . . . . . . . . 49

Range-check an Analog Input and Scale It for an Output . . . 52

PID Control with Analog I/O Scaling . . . . . . . . . . . . . . . . . . 56

3 Publication 1746-UM009B-EN-P - September 2007

Page 4

4 Table of Contents

Calibrate the Module

Test Module Operation

Maintenance and Safety

Module Specifications

2’s-complement Binary Numbers

Chapter 6

Calibration Tradeoffs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Calibrate an Analog Input Channel . . . . . . . . . . . . . . . . . . . 62

Chapter 7

Test the SLC 500 System . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Test the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 8

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Safety Considerations When Troubleshooting. . . . . . . . . . . . 76

Appendix A

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Appendix B

Use 2’s-complement Binary Numbers. . . . . . . . . . . . . . . . . . 83

Module Input and Output Circuits

Appendix C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Index

Publication 1746-UM009B-EN-P - September 2007

Page 5

Preface

About This Publication

Read this preface to familiarize yourself with the rest of the manual.

This preface covers the following topics:

• Who should use this manual

• The purpose of this manual

• Terms and abbreviations

• Conventions used in this manual

• Allen-Bradley support

This manual is a reference guide for the 1746-NR4 RTD/Resistance

Input Module. The manual:

• gives you an overview of system operation.

• explains the procedures you need to install and wire the module

at the customer site.

• provides ladder programming examples.

• provides an application example of how this input module can

be used to control a process.

Who Should Use This Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use

Allen-Bradley small logic controllers.

You should have a basic understanding of SLC 500 products. You

should understand programmable controllers and be able to interpret

the ladder logic instructions required to control your application. If

you do not, contact your local Allen-Bradley representative for

information on available training courses before using this product.

5 Publication 1746-UM009B-EN-P - September 2007

Page 6

6 Preface

Additional Resources

The following documents contain information that may be helpful to

you as you use Allen-Bradley SLC products.

Resource Description

SLC 500 Systems Selection Guide, publication 1747-SG001

SLC 500 Module Hardware Style User Manual, publication

1747-UM011

Installation & Operation Manual for Fixed Hardware Style

Programmable Controllers, publication 1747-6.21

SLC 500 Instruction Set Reference Manual, publication

1747-RM001

SLC 500 4-Channel Analog I/O Modules User’s Manual, publication

1746-UM005

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

Application Considerations for Solid-State Controls. publication

SGI-1.1

National Electrical Code, published by the National Fire Protection

Association of Boston, MA

An overview of the SLC 500 family of products

A description on how to install and use your modular SLC 500

programmable controller

A description on how to install and use your fixed SLC 500

programmable controller

A reference manual that contains status file data, instruction set,

and troubleshooting information about the software

A resource manual and user’s guide containing information about

the analog modules used in your SLC 500 system.

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

programmable controller products and hard-wired

electromechanical devices

An article on wire sizes and types for grounding electrical

equipment

Conventions

You can view or download publications at

http://literature.rockwellautomation.com

. To order paper copies of

technical documentation, contact your local Rockwell Automation

distributor or sales representative.

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

Publication 1746-UM009B-EN-P - September 2007

Page 7

Chapter

1

Quick Start

This chapter presents an overview of installation and start-up

procedures to help you get the module working quickly.

It refers to full procedures in corresponding chapters of this manual or

in other SLC documentation that may be helpful if you are unfamiliar

with programming techniques or system installation.

We recommend that you use this chapter in either of two ways.

• Use as a fast installation and start-up guide for the experienced

users.

• Use as an overview for using the entire manual for the first-time

user.

Required Tools and Equipment

IMPORTANT

Have the following tools and equipment ready.

• Medium flat-head screwdriver

• Medium Phillips-head screwdriver

• Wire strippers

• Utility knife

• Hot-air blower

• Shrink wrap

• Belden 8761 cable or equivalent

• Analog I/O devices for your application

• I/O modules (1746-FIO4I and/or 1746-FIO4V)

• Programming software

If you have any questions about the abbreviated procedures

presented in this chapter, always read the referenced chapters

and other recommended documentation before trying to apply

the information.

7 Publication 1746-UM009B-EN-P - September 2007

Page 8

8 Quick Start

Procedures

Follow these steps to get your module running in your SLC system.

1. Plan the inclusion of analog I/O modules in your SLC system.

If a new system, specify the type of processor, number of I/O

racks, I/O modules, and power supply. If adding to an existing

system:

• assign modules to slot locations in the I/O rack.

• verify that the power supply for the I/O rack can handle the

increased load.

See SLC 500 Systems Selection Guide, publication 1747-SG001,

for more information.

2. Configure module input channels for current or voltage

operation.

Locate the 2-switch assembly on the module’s circuit board, and

set each channel as follows.

Current (ON)

12

O

N

Switch 1 = Channel 0

Switch 2 = Channel 1

Voltage (OFF)

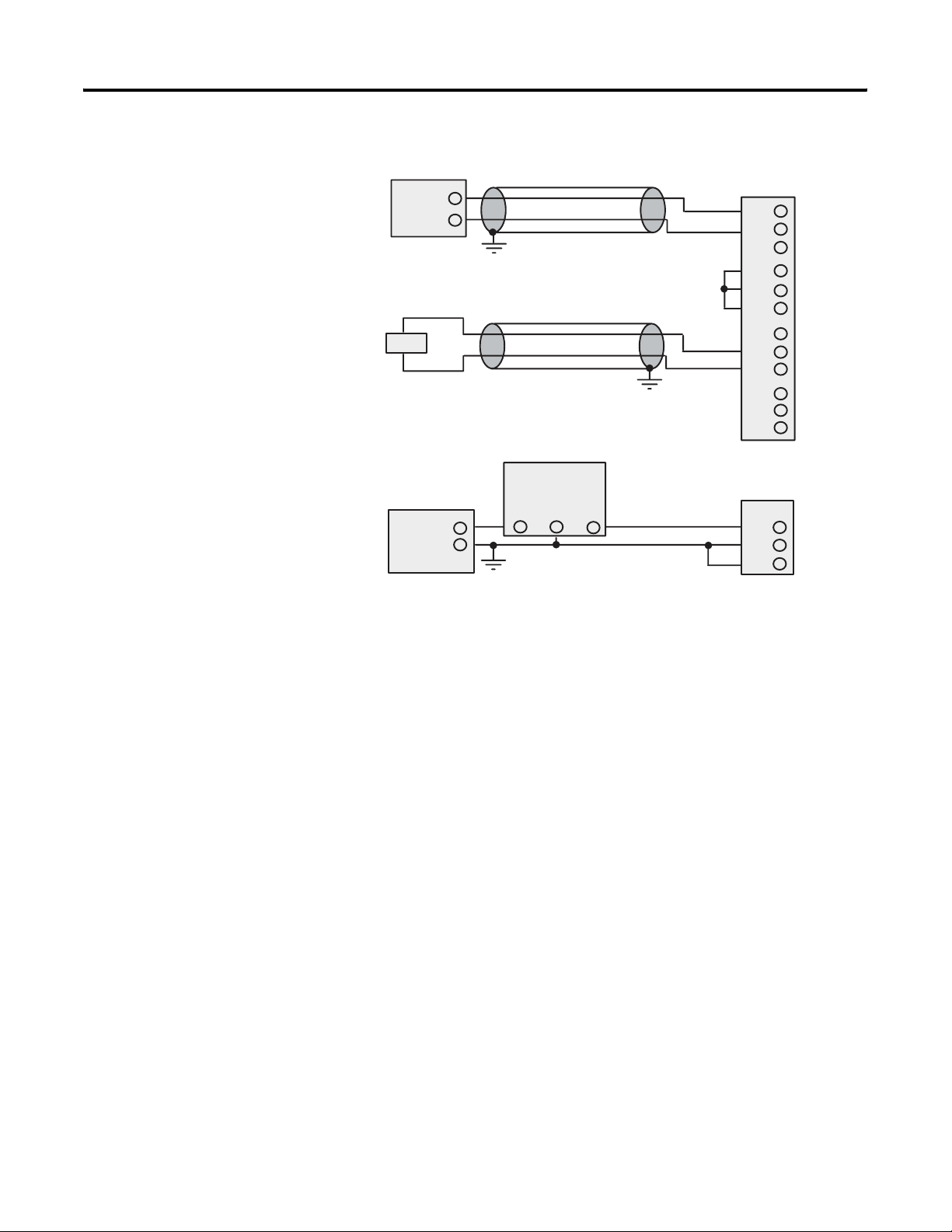

3. Connect I/O devices with cables.

IMPORTANT

• Connect only one end of the cable shield to earth ground.

• Channels are not isolated from each other. All analog commons are

connected together internally.

• The module does not provide loop power for analog inputs.

• Use a power supply that matches the transmitter (sensor)

specifications.

Refer to Install and Wire the Modules on page 11.

Publication 1746-UM009B-EN-P - September 2007

Page 9

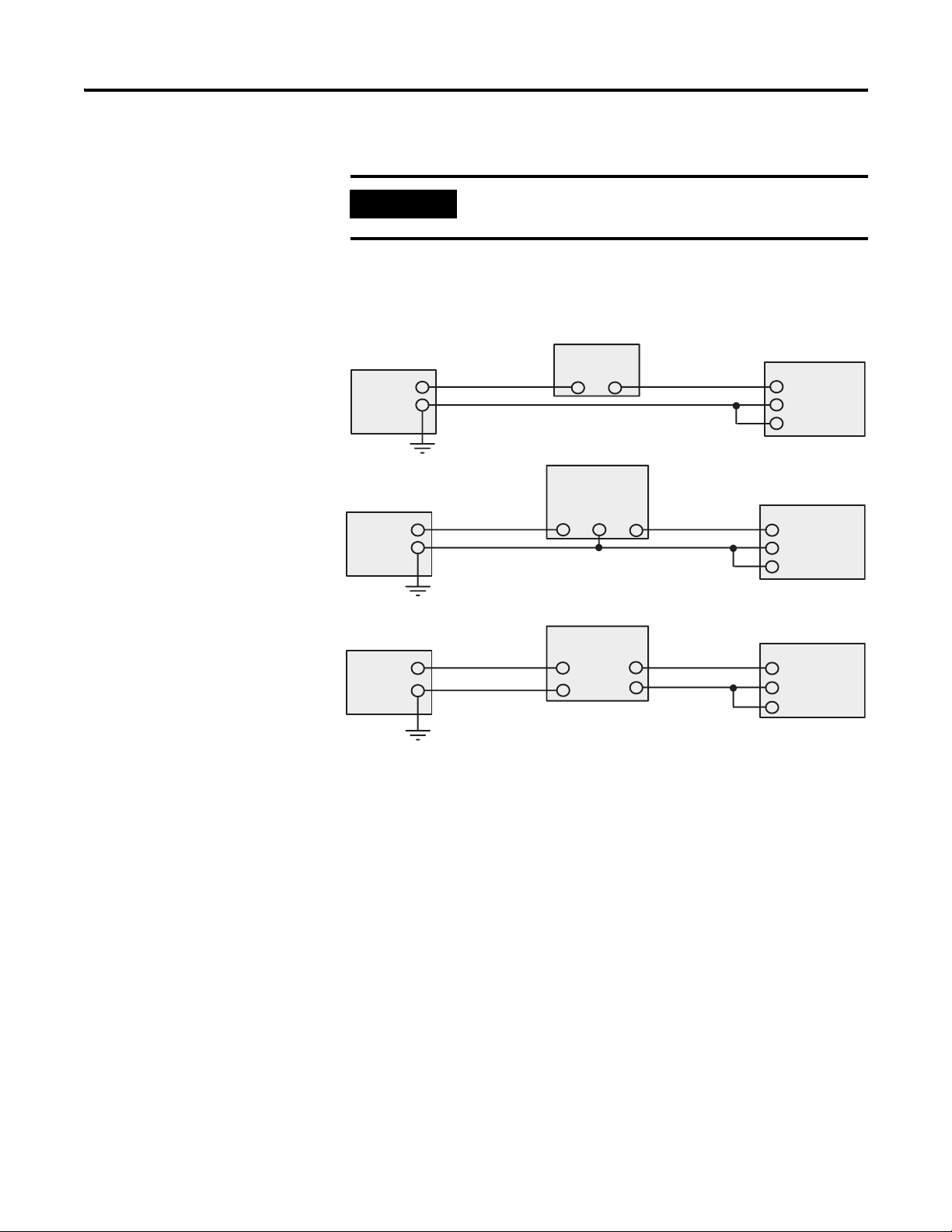

For Differential Inputs

+

Analog

Sensor

–

Earth

Ground

Load

For Single-ended Input

with 3-wire Transmitter

+

Power

–

Supply

Transmitter

GND

Important: Jumper

unused inputs.

Important: Do not

jumper unused outputs.

SignalSupply

Earth

Ground

Quick Start 9

Module

0

1

2

3

4

5

6

7

8

9

10

11

Module

3

4

5

IN 0 +

IN 0 –

ANL COM

IN 1 +

IN 1 –

ANL COM

Not Used

OUT 0

ANL COM

Not Used

OUT 1

ANL COM

IN +

IN –

ANL COM

4. Configure the system I/O and module ID.

With the software, configure the processor, I/O racks, slots, and

I/O modules.

When assigning an I/O module to a slot location, select the

module from the displayed list. If not listed, select OTHER at the

bottom of the list and enter the module’s ID code at the prompt.

ID code for 1746-FIO4I is 3224

ID code for 1746-FIO4V is 3218

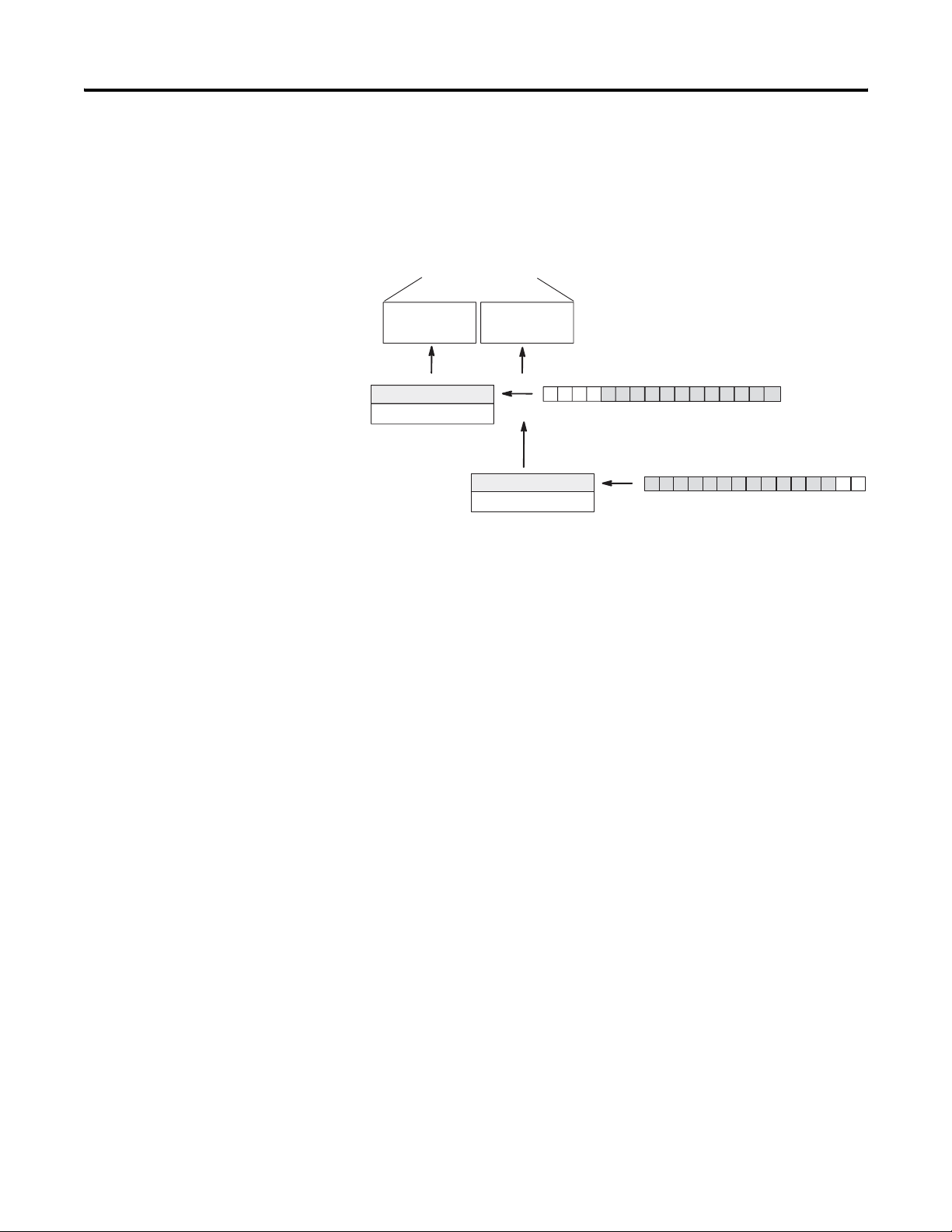

5. Understand A/D & D/A converter resolution on input and

output words.

The module’s I/O channel converters limit bit usage to less than

a full 16-bit word.

The input channel converter resolution is 12 bits, where the

highest four bits are always zero.

The output channel converter resolution is 14 bits, where the

lowest two bits are never used.

Publication 1746-UM009B-EN-P - September 2007

Page 10

10 Quick Start

The lowest two bits have no effect on the output value.

Refer to Processor and Module Considerations on page 29 for

more information.

SLC 500 Processor

Data Files

Input Image

(2 words)

Output Image

(2 words)

Address

I:1.0

I:1.1

lsb

Channel 0 Input Word

Channel 1 Input Word

Address

O:1.0

O:1.1

0000

Bit 15 Bit 11 Bit 0

Channel 0 Output Word

Channel 1 Output Word

(variable input data)msb

variable output data)msb lsb

Bit 15 Bit 2 Bit 0

6. Write ladder logic to process the module’s analog data.

We provide several programming examples that include the

following:

• Clear the output when changing mode or cycling power

• Detect an out-of-range input

• Scale analog outputs

• Scale offsets

• Scale and range-check analog inputs and outputs

• PID control with analog I/O scaling

X

X = not used

X

Publication 1746-UM009B-EN-P - September 2007

Study these examples to understand how to program the

module.

Refer to Write Ladder Logic on page 39.

7. (Optional) Write ladder logic to maintain calibrated inputs.

We show you how to write ladder logic that provides a

calibrated input reference during runtime, and lets you

periodically calibrate module inputs. We suggest that you modify

the logic examples to suit your application and add them to your

application program.

Refer to Calibrate the Module on page 61 for more information.

Page 11

Chapter

2

Install and Wire the Modules

This chapter describes procedures to install fast analog I/O modules in

an SLC 500 system. The procedures include the following tasks.

• determine the module’s power requirements

• determine compatibility with other I/O modules

• configure input channels

• select the I/O rack slot

• install the module

• consider when wiring

– using system wiring guidelines

– grounding the cable

– determining cable length

• minimize electrical noise interference

• wire the module

• minimize ground loops

• label the terminal block

Determine the Module’s Power Requirements

Analog modules require power from the 5V dc and 24V dc backplane

power supplies of the SLC 500 system. This table shows the backplane

power requirements for fast analog I/O modules.

Current Load

Catalog Number Current at 5V dc Current at 24V dc

1746-FIO4I 55 mA 150 mA

1746-FIO4V 55 mA 120 mA

Use this table to compute the module’s portion of total load on the

modular system power supply.

For more information, refer to SLC 500 Systems Selection Guide,

publication 1747-SG001.

11 Publication 1746-UM009B-EN-P - September 2007

Page 12

12 Install and Wire the Modules

Determine Compatibility with Other I/O Modules

Use the I/O Compatibility chart when using the expansion rack of a

fixed controller (1747-L20, 1747-L30, and 1747-L40). The chart

determines compatibility of other I/O modules with fast analog

modules. Compatibility is solely based on current drawn from the

backplane.

For more information, refer to the SLC 500 Fixed Hardware Style

Installation and Operation Manual, publication 1747-6.21.

I/O Compatibility

1746-FIO4I 1746-FIO4V 1746 Module

FIO4I

FIO4V

(1)

•

•• IB8, IB16

•• IB32

•• IG16

•• IM4, IM8, IM16

• IA4, IA8, IA16

•• IN16

•• IO4

• IO8

IO12

•• ITB16, ITV16

•• IV8, IV16, IV32

NIO4I, NIO4V

(2)

∇

•• NR4

•• NT4

•• OA8

•• OB8

•• OG16

∇

• OBP16

NO4I, NO4V

NI4

OA16

OB16, OB32

Publication 1746-UM009B-EN-P - September 2007

•• OV8

• OV16

OV32

Page 13

Install and Wire the Modules 13

I/O Compatibility

1746-FIO4I 1746-FIO4V 1746 Module

• OW4

OW8, OW16

• BASIC

• KE

(1)

The • symbol indicates an allowable combination of 1746 I/O modules.

(2)

The ∇ symbol indicates an auxiliary 24V dc power supply may be needed.

OX8

BASn

DCM

HS

KEn

Configure Input Channels

Your fast analog I/O modules have a two-switch assembly to

configure the input channels for either current or voltage operation.

The switches are on the module’s circuit board. Switch orientation is

shown on the nameplate of the module.

Switch Orientation

ON – Configures channel for current input

OFF – Configures channel for voltage input

Switches labeled 1 and 2 control the input mode of channels 0 and 1

respectively.

Channels 0 and 1 Input Mode

Current (ON)

12

O

N

Voltage (OFF)

Switch 1 = Channel 0

Switch 2 = Channel 1

Publication 1746-UM009B-EN-P - September 2007

Page 14

14 Install and Wire the Modules

Select the I/O Rack Slot

Install the Module

Two factors determine where you should locate the module in the

I/O rack: ambient temperature and electrical noise. Consider the

following conditions when selecting an I/O rack slot for the module.

Position the module:

• in a slot away from ac or high voltage dc modules.

• away from the rack power supply if installed in a modular system.

• in the I/O rack lowest in the enclosure for a cooler ambient.

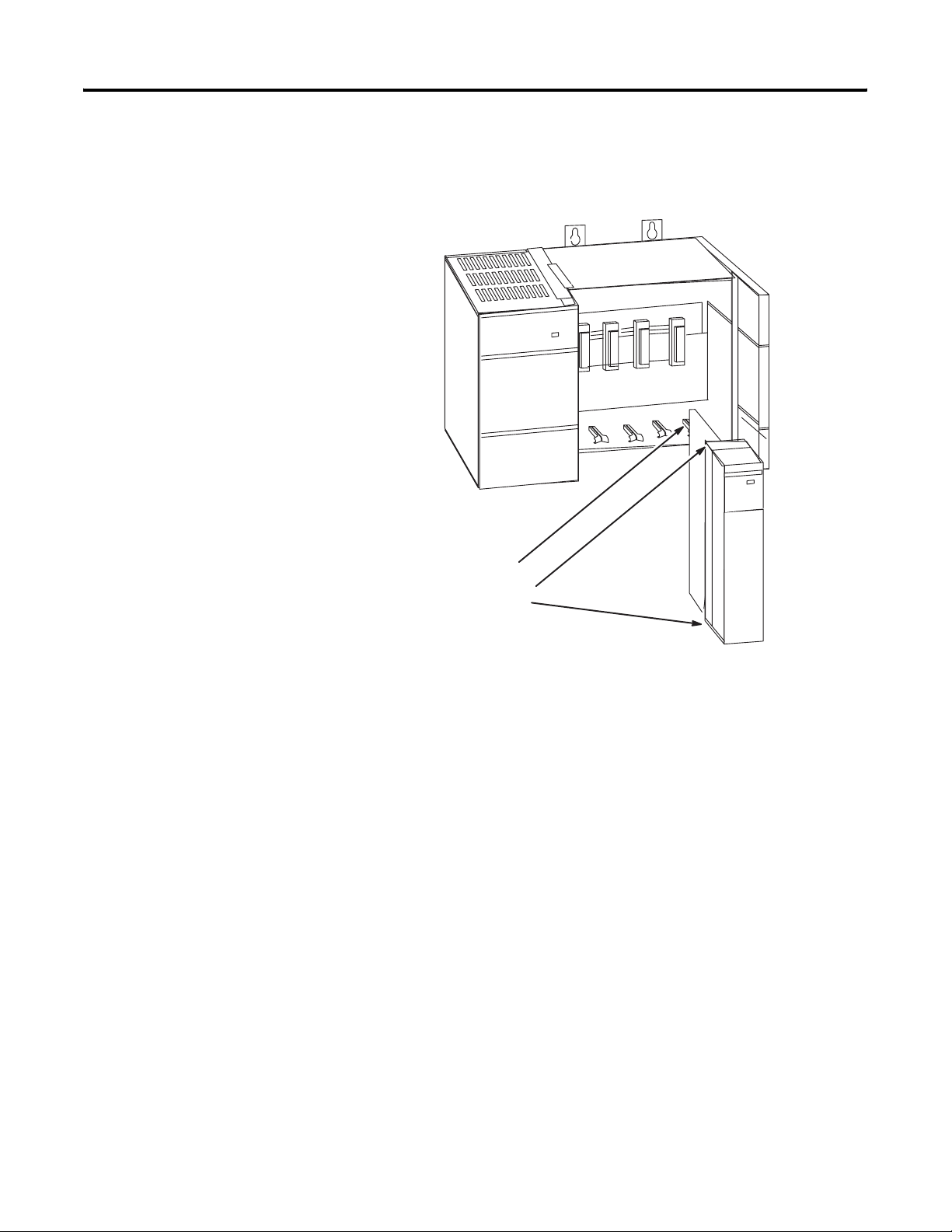

When installing the module in an I/O rack, you do not need to remove

the terminal block from the module. However, if the terminal block is

removed, use the write-on label located on the side of the terminal

block to identify the module location and type. To remove the terminal

block, grasp it on the top and bottom and pull outward and down.

ATTENTION

Never install, remove, or wire modules with power applied to

the I/O rack. Rid yourself of electrostatic charge before

handling the module. Electrostatic discharge can degrade

module performance or destroy analog circuitry.

IMPORTANT

Follow these steps when installing or removing the module.

1. Verify that input configuration switches 1 and 2 are set correctly.

ATTENTION

2. Align the module’s circuit board with the rack’s card guide.

See Installing the Module on page 15.

3. Slide the module in until top and bottom retaining clips are

secured.

Do not tamper with the module’s factory-sealed potentiometer.

It does not require any adjustments.

Take care to avoid connecting a voltage source to a channel

configured for current input. This could result in improper

module operation or damage to the module.

Publication 1746-UM009B-EN-P - September 2007

Page 15

Install and Wire the Modules 15

4. To remove the module, press the retaining clips at the top and

bottom of the module and slide the module out.

Installing the Module

Card Guide

Self-locking tabs secure the

module in the I/O rack.

Publication 1746-UM009B-EN-P - September 2007

Page 16

16 Install and Wire the Modules

Considerations When Wiring

This section provides guidelines on wiring the system, grounding the

cables, determining cable length.

ATTENTION

Before wiring the module, disconnect SLC system power, I/O

rack power, and module power.

System Wiring Guidelines

Use the following guidelines in planning the system wiring to the

module.

• Analog common terminals (ANL COM) are electrically

interconnected inside the module, but not internally connected

to earth.

• Voltages on IN+ and IN– terminals must be within 0…20V with

respect to ANL COM to ensure proper input channel operation.

This is true for current and voltage input channel operation.

• Voltage outputs (OUT 0 and OUT 1) of the 1746-FIO4V module

are referenced to ANL COM. Load resistance (R1) for a voltage

output channel must be equal to or greater than 1 KΩ.

• Current output channels (OUT 0 and OUT 1) of the 1746-FIO4I

module source current that returns to ANL COM. Load resistance

(R1) for a current output channel must be within 0…500 Ω.

• Input connections for single-ended or differential input are the

same.

Publication 1746-UM009B-EN-P - September 2007

Page 17

Install and Wire the Modules 17

Ground the Cable

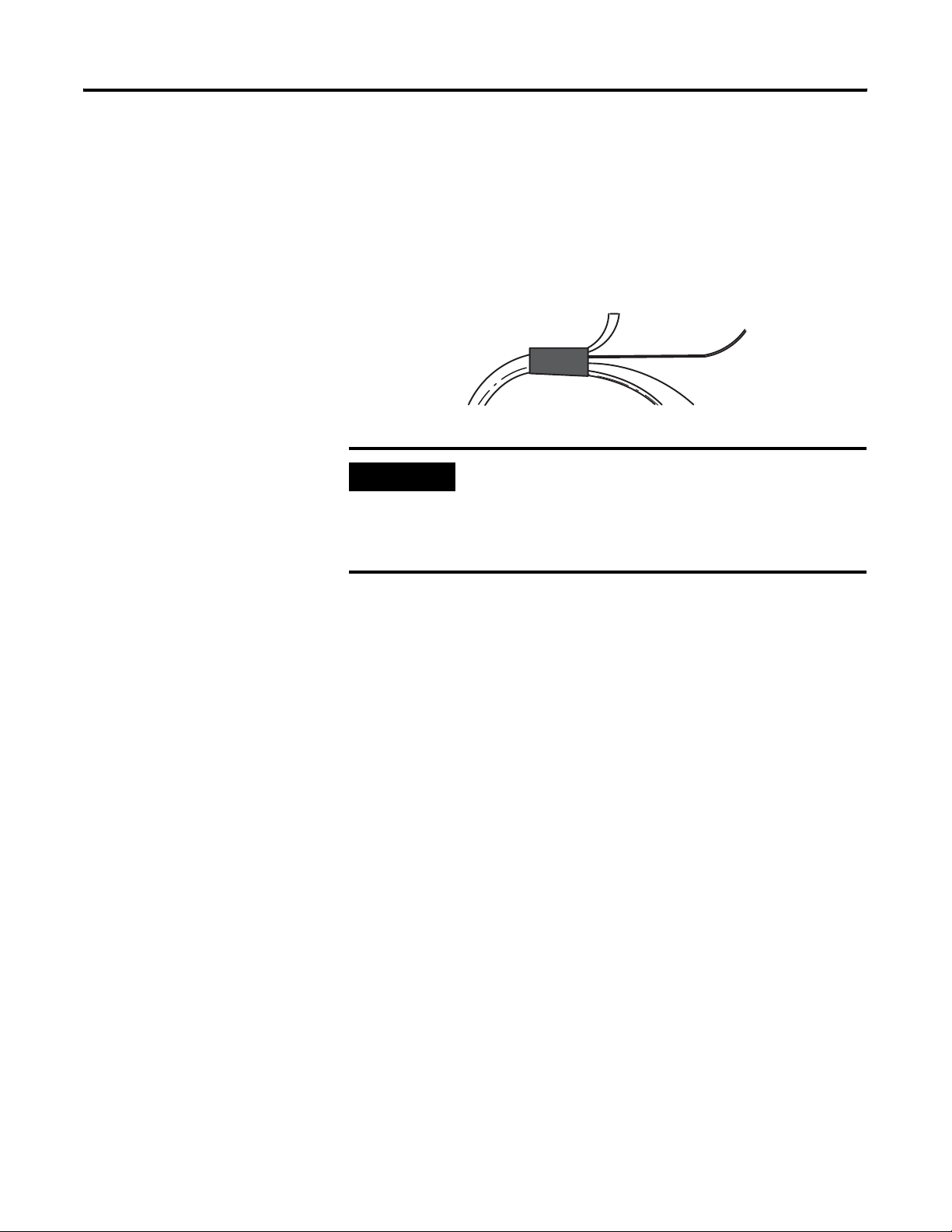

Signal cable such as Belden cable #8761 (or equivalent) has two signal

wires (black and clear), one drain wire, and a foil shield. The drain

wire and foil shield must be grounded at only one end of the cable,

not at both ends.

Typical Signal Cable

Foil Shield

Insulation

Shrink Wrap

Clear Wire

Drain Wire

Black Wire

IMPORTANT

Ground the cable shield at one end having a good earth-ground

connection, such as at an I/O chassis mounting bolt or nearest

ground bus in the I/O enclosure. Make this connection as short

as possible. Do not ground the cable at the module’s terminal

block.

Determine Cable Length

When you determine the length of cable required to connect an I/O

device, remember to include additional length to route the drain wire

and foil shield to earth ground. Route your cable long enough to

avoid areas of high radiated electrical noise, but short enough to avoid

signal attenuation.

Publication 1746-UM009B-EN-P - September 2007

Page 18

18 Install and Wire the Modules

Minimize Electrical Noise Interference

Wire the Module

Because high-speed analog signals are particularly vulnerable to

electrical noise, take precautions when routing your signal cables. To

help reduce the effects of electrical noise on analog signals, we

recommend that you do the following:

• Install the SLC 500 system in a NEMA rated enclosure.

• Make sure that the SLC 500 system is properly grounded.

• Use Belden cable #8761 (or equivalent) for signal wiring.

• Ground the cable properly.

• Route signal cables away from other wiring or in grounded

conduit.

• Group these modules away from ac or high-voltage dc modules.

We recommend re-checking system operation after installing new

machinery or other sources of electrical noise near the system.

For additional information on this subject, refer to Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

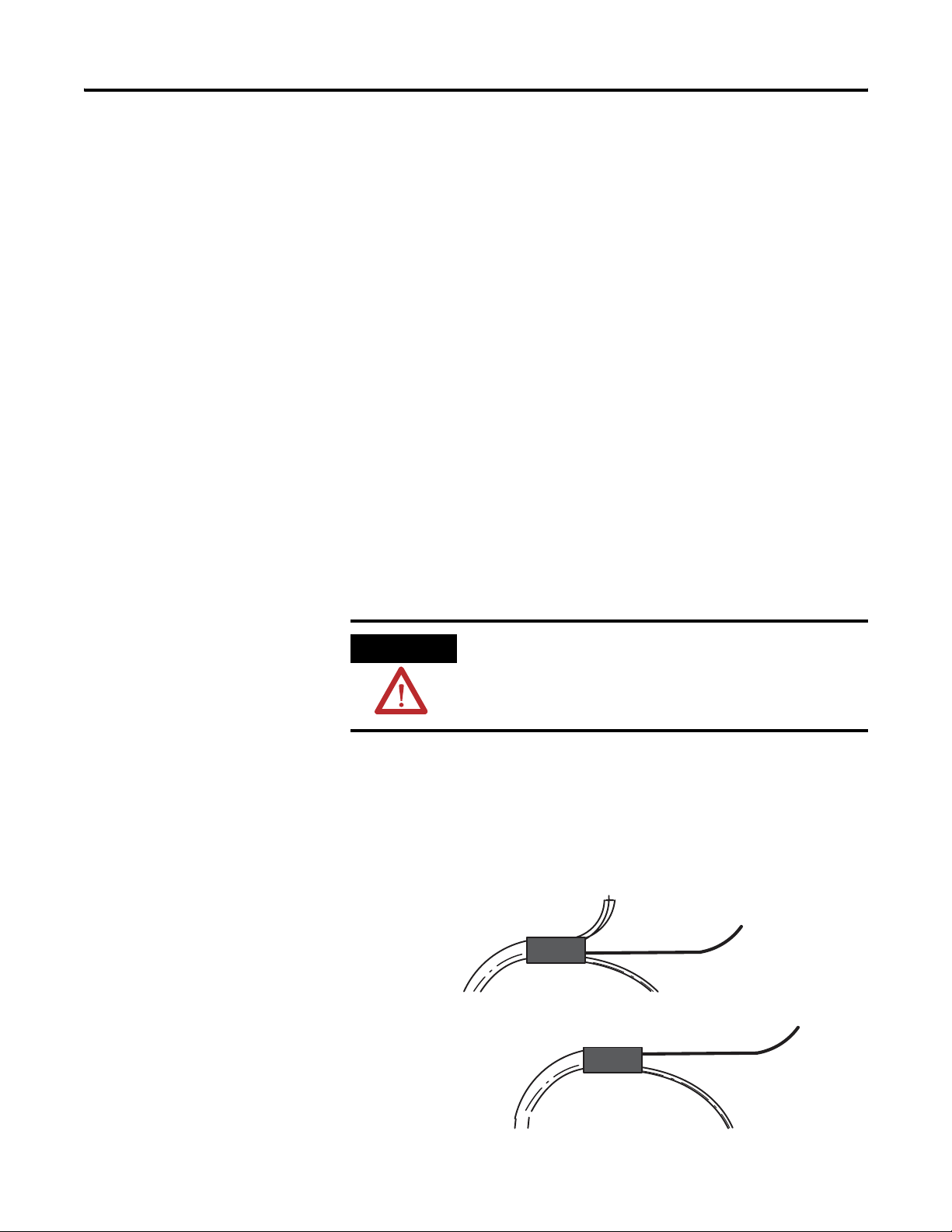

Follow this procedure when wiring your modules.

ATTENTION

Before wiring a module, disconnect power from the SLC 500

system and from any other source to the module.

1. Strip about 7.6 cm (3 in.) of casing to expose the wires at each

end of the cable.

2. Twist the drain wire and foil shield together and bend them

away from the cable at the grounded end of the cable.

Grounded End

Ungrounded End

Casing

Casing

Shrink Wrap

Shrink Wrap

Twisted Foil Shield and Drain Wire

Black Wire

Clear Wire

Black Wire

Clear Wire

Publication 1746-UM009B-EN-P - September 2007

Page 19

Install and Wire the Modules 19

3. Apply shrink wrap where wires leave the casing with the hot-air

blower.

4. Cut off the drain wire and foil shield at the other end of the

cable.

5. Apply shrink wrap to the junction where wires leave the casing.

6. Trim the signal wires to 5 cm (2 in.) lengths. Strip about

4.76 mm (3/16 in.) of insulation away to expose the copper

strands for your connections.

7. Decide where you will connect the cable to earth ground, and

ground it.

Refer to Ground the Cable on page 17.

8. Connect signal wires (black and clear) to the terminal block and

to the input or output device.

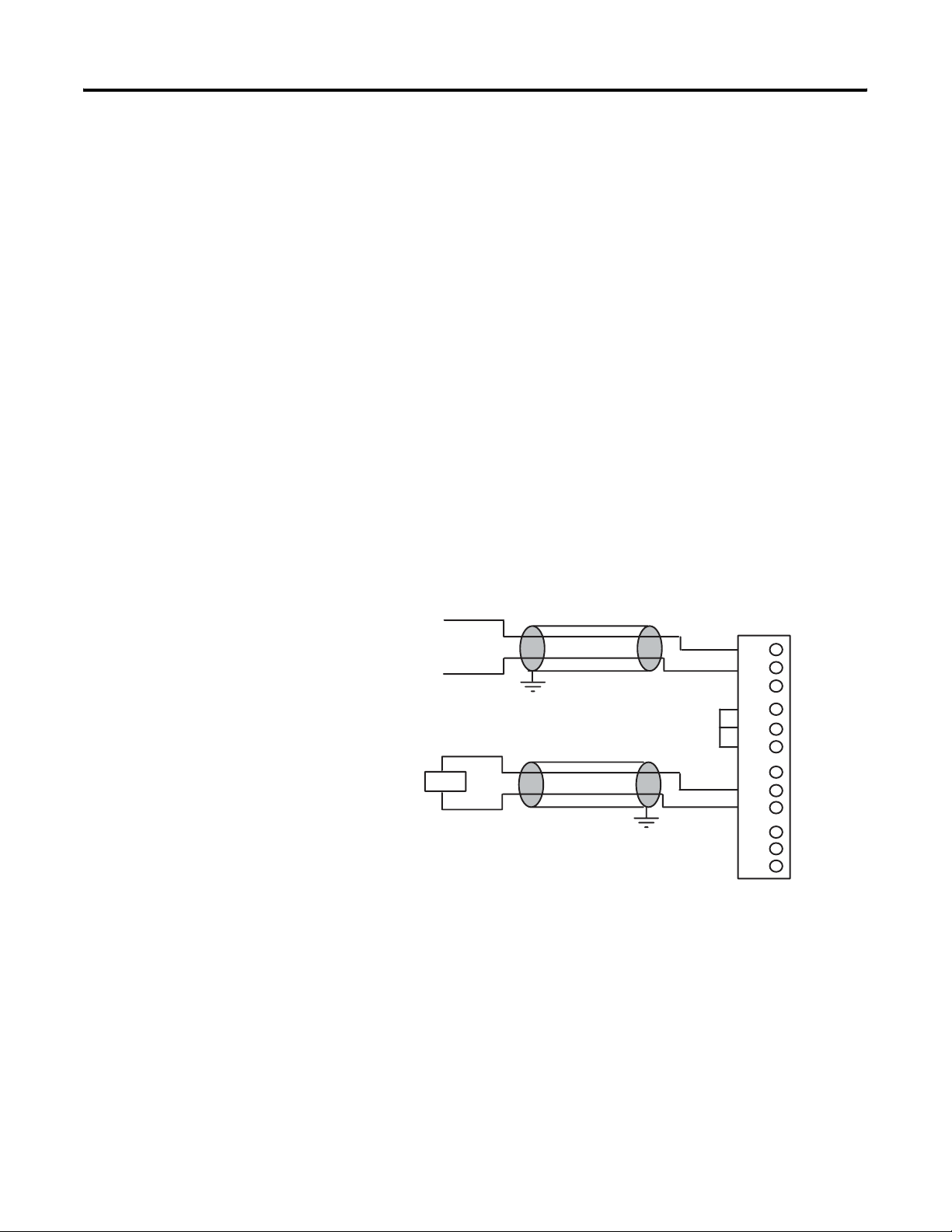

Wiring Diagram for Module, Sensor, and Load (showing differential inputs)

Important: Channels are not isolated from each other.

All analog commons are connected together internally.

+

Analog

Sensor

–

Load

Earth

Ground

Important: Jumper

unused inputs.

Earth

Ground

Important: Do not

jumper unused outputs.

0

IN 0 +

1

IN 0 –

2

ANL COM

3

IN 1 +

4

IN 1 –

5

ANL COM

6

not used

7

OUT 0

8

ANL COM

9

not used

10

OUT 1

11

ANL COM

Publication 1746-UM009B-EN-P - September 2007

Page 20

20 Install and Wire the Modules

IMPORTANT

Single-ended inputs are less immune to noise than are

differential inputs.

Wiring Schematic for Single-ended Current-loop Analog Input Connections

Important: The module does not provide loop power for analog inputs.

Use a power supply that matches the transmitter specifications.

2-wire Transmitter

Transmitter

+

Power

–

Supply

3-wire Transmitter

+

Power

–

Supply

4-wire Transmitter

+

Power

Supply

–

+

Transmitter

GND

Transmitter

+

–

–

SignalSupply

SignalSupply

+

–

Module

IN +

IN –

ANL COM

Module

IN +

IN –

ANL COM

Module

IN +

IN –

ANL COM

Minimize Ground Loops

Publication 1746-UM009B-EN-P - September 2007

9. Repeat steps 1…6 for each channel. For each unused input

channel, jumper together the plus (+), minus (–), and common

(ANL COM) terminals. For each unused output channel, do not

connect terminals.

To keep the ground-loop currents of input circuits to a minimum, we

recommend that you:

• use the same power supply to power both input channels of a

module.

• otherwise, tie together the grounds of separate power supplies.

See Wiring Schematic for Single-ended Current-loop Analog Input

Connections for more information.

Page 21

Install and Wire the Modules 21

Label the Terminal Block

The terminal block has a write-on label. Use it to ensure that you

install the correct terminal block on the corresponding module.

Termin a l B l ock

Note: The black dot on the label

indicates the position of terminal 0.

SLOT ____ RACK ____

MODULE _____

Publication 1746-UM009B-EN-P - September 2007

Page 22

22 Install and Wire the Modules

Publication 1746-UM009B-EN-P - September 2007

Page 23

Chapter

3

Access Files to Configure I/O

There are two ways to configure the SLC Chassis for a 1746-FIO4I/V

module. You can either click and drag items from the list or you can

use the Read IO Config method.

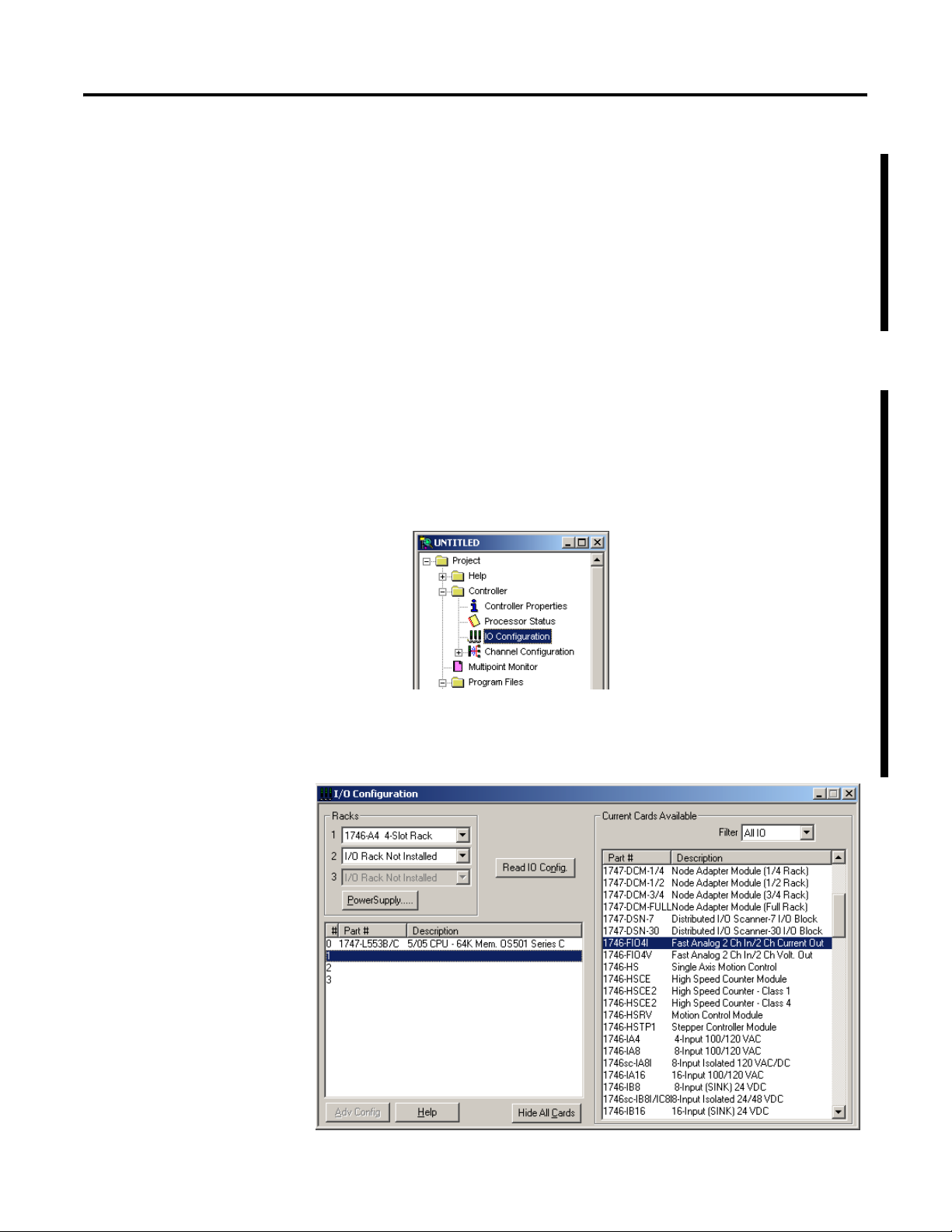

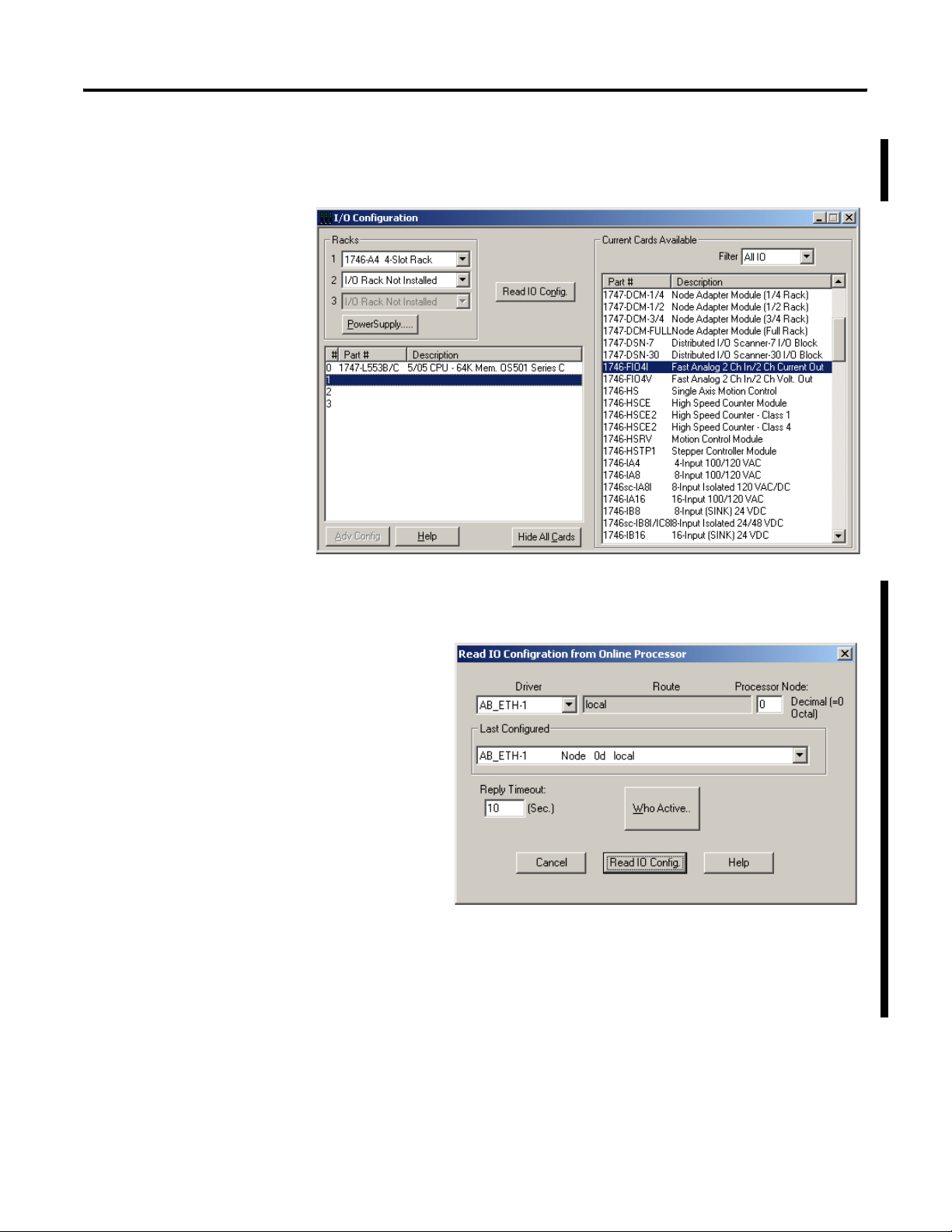

Click and Drag Configuration

Follow these steps to configure the SLC chassis by clicking and

dragging modules.

1. Double-click the menu item to open the IO Configuration menu

in RSLogix500 software.

2. Place the 1746-FIO4I/V module into the correct slot by clicking

and dragging from the list.

23 Publication 1746-UM009B-EN-P - September 2007

Page 24

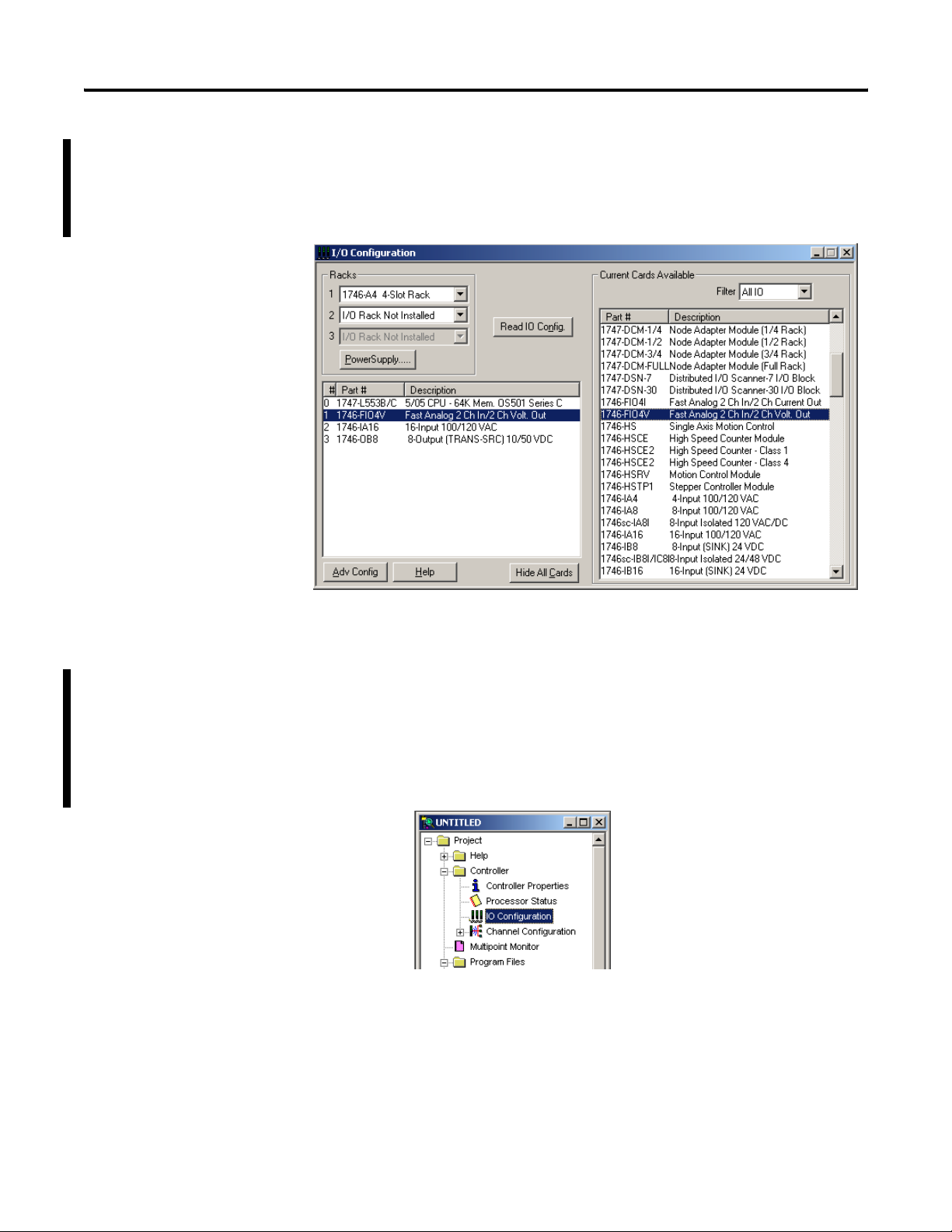

24 Access Files to Configure I/O

The I/O Configuration is now complete. Each slot shows the

corresponding module that is located on the rack. In this

example the 1746-FIO4V is in slot 1.

Read IO Config Method

Follow these steps to configure the SLC chassis by using the Read IO

configuration method.

1. Double-click the menu item to open the IO Configuration menu

in RSLogix500 software.

Publication 1746-UM009B-EN-P - September 2007

Page 25

Access Files to Configure I/O 25

2. Place the 1746-FIO4I/V module into the correct slot by clicking

Read IO Config.

The following screen appears.

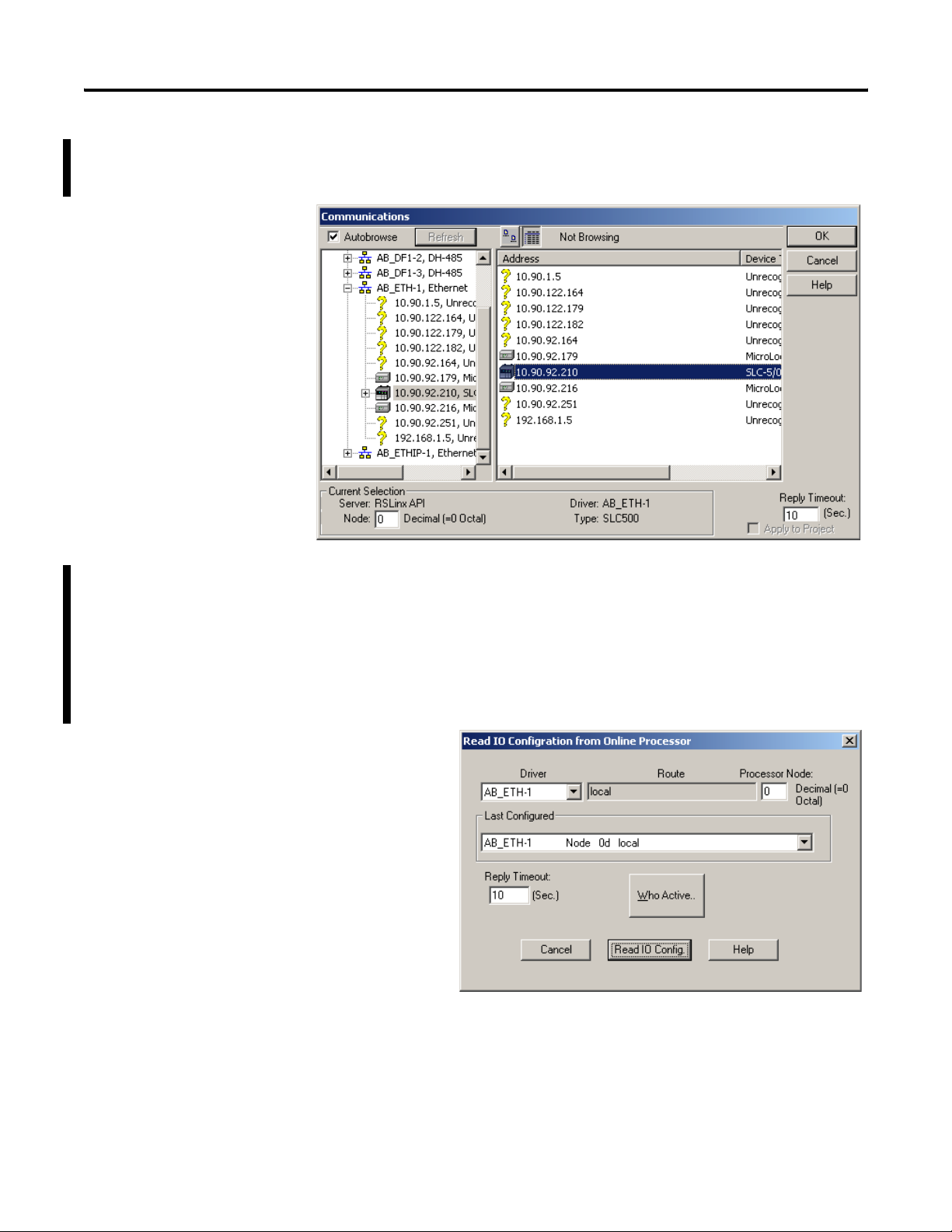

3. Select either the driver and processor node number or use the

Who Active button to browse for the device.

• If you selected the driver and node number, proceed to step 5.

• If you clicked Who Active, the following screen appears.

Publication 1746-UM009B-EN-P - September 2007

Page 26

26 Access Files to Configure I/O

The Who Active screen lets you browse for the SLC device.

4. Locate the SLC Chassis under the appropriate driver and click

OK.

You are brought back to the Read IO Config screen.

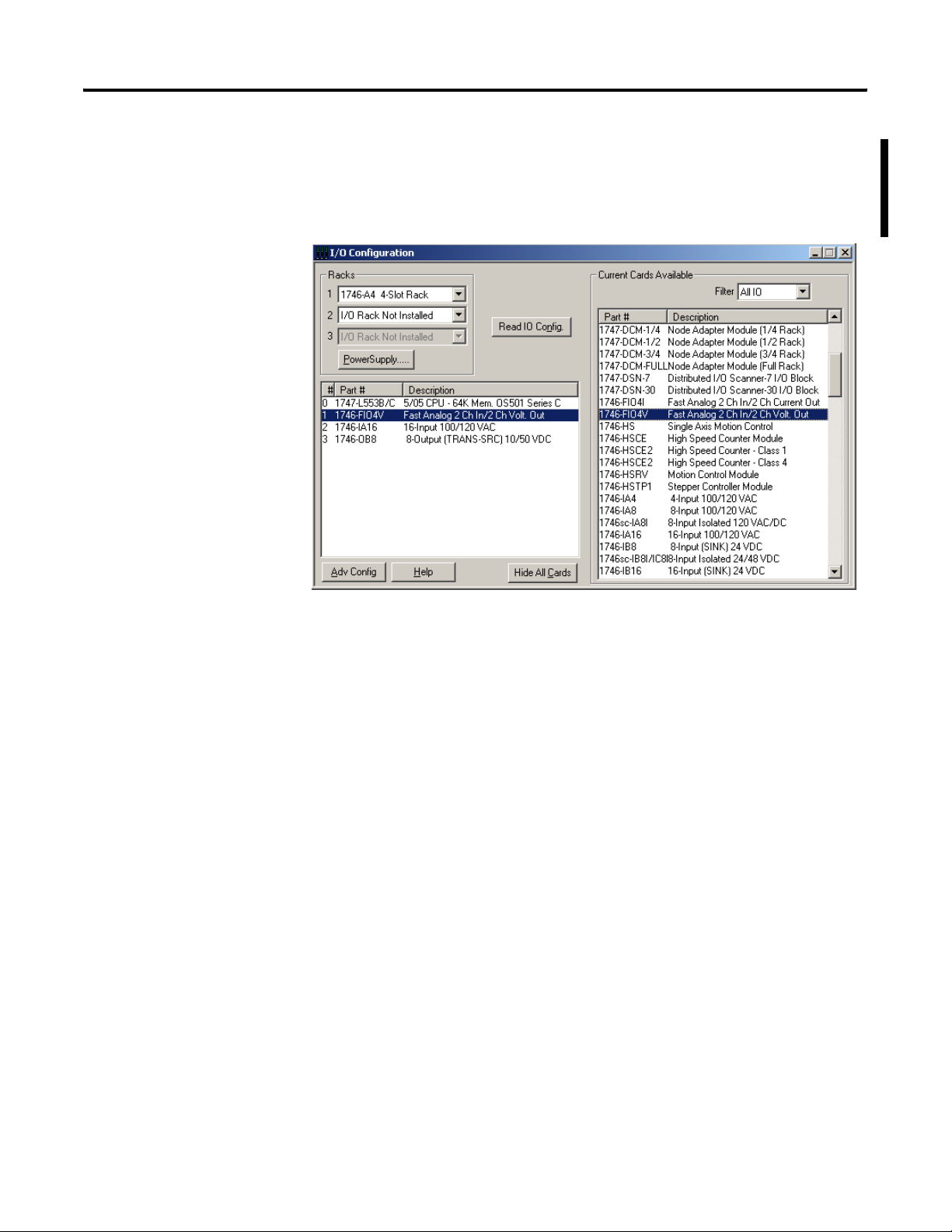

5. Click Read IO Config and the rack is populated automatically.

Publication 1746-UM009B-EN-P - September 2007

Page 27

Access Files to Configure I/O 27

The I/O Configuration is now complete. Each slot shows the

corresponding module on the rack. In this example the

1746-FIO4V is in slot 1.

Publication 1746-UM009B-EN-P - September 2007

Page 28

28 Access Files to Configure I/O

Publication 1746-UM009B-EN-P - September 2007

Page 29

Chapter

Processor and Module Considerations

This chapter describes concepts that you need to understand to

program the fast analog I/O module in an SLC 500 system.

The following are processor considerations.

• Update processor analog I/O data

• Monitor analog I/O data

• Address I/O image words

The following are module considerations.

• Resolve data of the module’s I/O channel converters

• Convert analog input data

• Compute the analog input signal level

• Convert analog output data

• Compute the analog output

• Filter input channel

• Compute time delay for A/D conversion

• Determine response to slot disable

• Determine safe state for outputs

• Enter module ID code

4

29 Publication 1746-UM009B-EN-P - September 2007

Page 30

30 Processor and Module Considerations

~

Processor Considerations

Knowing how the processor works helps you program it more

effectively.

Processor Update of Analog I/O Data

Analog input and output image words are updated by the processor

once every processor scan when the processor scans data and

program files in succession.

Processor scan time depends largely on the size of your program files:

the greater the number of programming instructions, the longer the

time to scan the file. Some instructions take longer to scan than

others.

For information on processor scan time and instruction execution

time, refer to the SLC 500 Instruction Set Reference Manual,

publication 1747-RM001.

If an application requires processor updates of analog data more

frequently than once per scan, use Immediate Input or Immediate

Output instructions. These instructions typically update an analog

channel in 1 ms, but also increase the overall scan time by the same

amount.

Typical update times for SLC processors are:

• 10 ms for a typical 1K program.

• 1 ms per analog channel when using immediate I/O instructions.

Monitor Analog I/O Data

You can monitor analog input and output data in binary or decimal

format. You select the format by its radix. The default radix is binary.

Binary data is presented in 2’s-complement format. Changing the radix

to decimal lets you view analog I/O data as decimal representations of

integer words.

Refer to 2’s-complement Binary Numbers on page 83 for more

information.

Publication 1746-UM009B-EN-P - September 2007

Page 31

Analog Input

Sensors

Input 0

Input 1

Input Module’s

A/D Converter

Bit 15 Bit 0

Input Channel 0

Input Channel 1

Processor and Module Considerations 31

Address I/O Image Words

Each module input channel is addressed as a single word in the

processor’s input image table and each module output channel is

addressed as a single word in the processor’s output image table. The

module uses a total of two input words and two output words.

Processor I/O Image Words Used by the Module

Word Addresses

Analog Output

Devices

Output 0

Output 1

Input

Scan

in I/O Image File

Output Image

O:e.0

O:e.1

Input Image

I:e.0

I:e.1

Bit 15 Bit 0

Output

Scan

e = module’s slot number in I/O rack

Output Channel 0

Output Channel 1

The converted input values from input channels 0 and 1 are addressed

as words 0 and 1 of the slot where the module resides. The output

values for the output channels 0 and 1 are addressed as output words

0 and 1 of the slot where the module resides.

EXAMPLE

You would address the output image word for output O, word 0,

in slot 3 as: O:3.0 where delimiters : and . must be placed as

shown.

module’s I/O rack slot location

Capital Letter

I = Input, or

O = Output

O:e.0-4

I/O image table word

delimiters

Publication 1746-UM009B-EN-P - September 2007

Page 32

32 Processor and Module Considerations

Module Considerations

I:e.0

I:e.1

O:e.0

O:e.1

e = module’s slot number

0000

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0000

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

msb

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

The module’s I/O channel converters affect resolution of I/O data and

bit usage in I/O image words. We show you how to compute I/O

signal levels. Input filtering and input A/D conversion affect input

response time.

Data Resolution of the Module’s I/O Channel Converters

The module’s I/O channel converters limit bit usage to less than a full

16-bit word when converting analog to digital input data and digital to

analog output data. Bit maps show resulting digital data storage in

input and output image words.

Bit Usage for I/O Channel Converters

msb

CH 0 INPUT

CH 1 INPUT

Isb

CH 0 OUTPUT

CH 1 OUTPUT

Isb

Bits not used

Bits not used

Publication 1746-UM009B-EN-P - September 2007

The input channel converter resolution is 12 bits, where the highest

four bits are always zero. The usable range of the channel word is

0…4095.

The output channel converter resolution is 14 bits, where the lowest

two bits are not used. They have no effect on the output value.

IMPORTANT

The module left-justifies the 14-bit data (lsb at bit 2) in the

output channel word. This reduces the output resolution to:

• 2.56348 µA/LSB for current outputs

• 1.22070 mV/SLB for voltage outputs

Page 33

Processor and Module Considerations 33

Convert Analog Input Data

The module converts analog input signals to 12-bit binary values for

storage in the input image table.

The decimal range, number of significant bits, and converter

resolution depend on the input range that you use for the channel.

Input Range Decimal Range

(input image table)

0…10V – 1LSB 0…4095 12

1…5V 409…2047 10

0…20 mA 0…2047 11

4…20 mA 409…2047 10

Significant

Bits

Nominal Resolution

2.4414 mV/LSB0…5V 0…2047 11

9.7656 µA/LSB

Compute the Analog Input Signal Level

Use the following formula to determine what the analog input signal

level (sensor signal) should be for a given decimal value in the input

image table.

Sensor Signal = x Input Image Value

For voltage inputs, a full scale input of 10V dc has a full scale count of

4095 and a full scale input of 5V dc has a full scale count of 2047.

Full Scale Input

Full Scale Count

Sensor Signal = 2.44 mV/count x Input Image Value

For current inputs, a full scale input of 20 mA has a full scale count of

2047.

Sensor Signal = 0.00977 mA/count x Input Image Value

Publication 1746-UM009B-EN-P - September 2007

Page 34

34 Processor and Module Considerations

EXAMPLE

For example, if the input image table value is 409 from a 4…20

mA sensor.

Sensor Signal = x Input Image Value = 0.00977 x 409 = 4 mA

Full Scale Input

Full Scale Count

Convert Analog Output Data

The module converts 16-bit binary values from the output image table

to 14-bit analog output signals and left-justifies the bit code in the

channel word. The output range, decimal representation for the

output range, number of significant bits, and converter resolution are

as shown in the following table.

Analog Output Data

Module Output Range Decimal

Representation

(output image table)

Significant

Bits

Resolution

FIO4I 0…21 mA – 1LSB 0…+32,764 13 bits

2.56348 µA/LSB0…20 mA 0…+31,208 12.92 bits

4…20 mA 6242…31,208 12.6 bits

FIO4V –10…+10V dc –

1LSB

0…10V dc – 1LSB 0…32,764 13 bits

0…5V dc 0…16,384 12 bits

1…5V dc 3277…16,384 11.67 bits

–32,768…+32,764 14 bits

1,22070 mV/LSB

Compute the Analog Output

Use the following formula to compute the output image-table value

(decimal representation) required for a desired analog-output signal

level (to the output device).

Output Image Value = x Desired Signal Level

Full-scale Decimal Representation

Full-scale Output

Publication 1746-UM009B-EN-P - September 2007

Page 35

Processor and Module Considerations 35

~

~

d

EXAMPLE

IMPORTANT

If the module’s output range is 4…20 mA and you want to set

the output to 4 mA, compute the output image value as follows.

Output Image Value =

31,208

20 mA

x 4 mA 6242

The actual resolution for analog current outputs is 2.56348

µA/LSB, where the 14-bit decimal representation is left

justified as follows.

Isbmsb

CHANNEL OUTPUT WORD

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

EXAMPLE

Use the following formula to compute the output image value if

the module’s output range is 1…5V dc and you want to set the

Bits not

output to 1V dc.

16,384

5V dc

x 1V dc 3277

IMPORTANT

Output Image Value =

The actual resolution for analog voltage outputs is 1.22070

mV/LSB, where the 14-bit decimal representation is left

justified as follows.

Isbmsb

Channel Output Word

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bits not use

Publication 1746-UM009B-EN-P - September 2007

Page 36

36 Processor and Module Considerations

Input Channel Filtering

The module’s input filters are designed to attenuate less than 1% of

the input signal in the 0…1000 Hz range.

Percent of Signal Passed

100

99.9

99.8

99.7

99.6

99.5

99.4

99.3

Percent of Signal

99.2

99.1

99

0 100 300 500 1000

The –3dB point is approximately 7000 Hz. The input filter causes a

signal delay of approximately 100 µs. The module’s A/D converter

sees a 95% step change of an input signal in that time.

Input Channel Frequency Response

0

–4

–8

–12

–16

–20

–24

–28

Attenuation in dB

–32

–36

–40

3

10

4

10

Frequency in Hz

10

5

Publication 1746-UM009B-EN-P - September 2007

Page 37

Time Delay for A/D Conversion

The A/D converter uses 7.5 µs for data conversion, 248.5 µs for data

settling, and 256 µs for data transfer to the backplane. New data is

available in 512 µs cycles.

Response Time of A/D Converter

Data

conversion

Start

7.5 µs 248.5 µs 256 µs

The worst-case specification for the SLC processor to read a step

change is 1.1ms between readings. This is true for a step change

occurring just after data conversion (first 7.5 µs of the 512 µs cycle). In

this case, the read cycle cannot begin until the next data conversion.

Data

settling

512 µs

Worst case point for a change of input to occur.

This results in a 1.1ms delay for the processor to read a step change.

Processor and Module Considerations 37

Data transfer to

the backplane

Data ready for

processor read

IMPORTANT

Do not attempt to read data from the module more often than

once every 512 µs. If you do, the module may not be able to

update new data.

Response to Slot Disable

You can disable any I/O rack slot by means of a processor function.

Before disabling a slot containing an analog I/O module, be aware of

the implications.

ATTENTION

Clearly understand the safety implications of disabling an

analog module slot before doing it.

Publication 1746-UM009B-EN-P - September 2007

Page 38

38 Processor and Module Considerations

Input Response to Slot Disable

The module continues to update its inputs for transfer to the

processor, but the processor:

• does not read inputs from the module in a disabled slot.

• retains the last-state input image table values.

• upon re-enabling the slot, reads current inputs in the subsequent

scan.

Output Response to Slot Disable

While the module holds its outputs in their last state, the processor:

• may update its output image table.

• does NOT transfer output image table values to the module.

• upon re-enabling, transfers the current output image in the

subsequent scan.

Safe State for Outputs

Whenever an SLC 500 system is not in RUN mode, the analog

module’s outputs are automatically forced to 0V or 0 mA by the

SLC 500 system. This occurs when the processor is in one of the

following modes:

• Fault

• Program

• Test

ATTENTION

When designing and installing the SLC 500 system, place

devices connected to analog output channels in a safe state

whenever the analog output is zero (± the offset error).

Determine which output conditions must be held ON for a safe

state.

Module ID Code

You must enter the ID code if your programming software does not

include the subject I/O module in its list of modules.

Publication 1746-UM009B-EN-P - September 2007

ID code for FIO4I is 3224

ID code for FIO4V is 3218

Page 39

Write Ladder Logic

This chapter presents these programming examples.

• Retentive and non-retentive programming

• Detect an out-of-range input

• Scale analog inputs and detect an out-of-range condition

• Scale analog outputs

• Scale offsets when > 32,767 or < –32,768

• Scale and range-check analog inputs and outputs

• PID xontrol with analog I/O scaling

Chapter

5

Retentive and Non-retentive Programming

IMPORTANT

The processor’s automatic response for scanning the I/O image table

is described below.

Processor Automatic Response

Conditions Processor Response

• Mode is switched to Program

• Power is turned OFF

• Mode is switched to Run

• Power is turned ON

• Processor detects a minor fault Resets analog outputs to zero, but retains

• Fault condition is corrected Transfers output image data to the module

We present programming examples for instructional purposes

only. Because of the many variables and requirements

associated with any application, Rockwell Automation cannot

assume responsibility or liability for actual use based on these

examples.

Retains the last values in the I/O image

table

Transfers output image data to the module

and input image data from the module

output image values

39 Publication 1746-UM009B-EN-P - September 2007

Page 40

40 Write Ladder Logic

We give you the following examples for programming a different

response.

• Retentive analog output

• Non-retentive analog output

• Clear the output for changing mode or cycling power

Retentive Analog Output

This example loads a program constant into an analog output

channel. Consider a digital I/O module in slot 1, and an analog I/O

module in slot 2. When bit 0 of the digital I/O module is set, the rung

is true, and the full-scale value of 32,764 is moved into the output

image table location corresponding to slot 2, analog output channel 0.

At the end of the scan, the value is transferred to the module and

converted to a corresponding full-scale voltage or current output.

Retentive Example

I:1.0

] [

MOV

MOVE

Source

0

Dest

32764

O:2.0

Non-retentive Analog Output

This example loads a program constant into an analog output channel

and clears it, based on logical conditions. Consider a digital I/O

module in slot 1, and an analog I/O module in slot 2. When bit 0 is set

in word 0 of the digital I/O module, the first rung is true and the

full-scale value of 32,764 is transferred to channel 0. When the bit is

reset to zero, the second rung is true, and the value of zero is

transferred to the channel.

Non-retentive Example

I:1.0

] [

MOV

MOVE

Source

0

Dest

32764

O:2.0

Publication 1746-UM009B-EN-P - September 2007

I:1.0

MOVE

/

[

]

Source

0

Dest

0

O:2.0

Page 41

Write Ladder Logic 41

Clear the Output for Changing Mode or Cycling Power

This example clears analog output channel 0 during the initialization

scan (first processor scan). The first pass bit, S2:1/15, in the Status File

is used to initialize the analog output when you apply power in the

RUN mode or upon setting the processor to the RUN or TEST mode.

This bit goes ON automatically only for the first-pass scan. To clear

another analog output channel, use another rung with a different

MOV destination address. The analog module is in slot 2.

Detect an Out-of-range Input

S2:1/15

] [

MOV

MOVE

Source

Dest

0

O:2.0

Analog modules do not provide an input out-of-range signal to the

processor. However, if this feature is critical to a specific application,

you can program the processor to provide this function.

The following program applies to all SLC 500 processors. It uses

comparison instructions (LES and GRT) to check for analog input

values which exceed low and high limits respectively. Whenever this

happens, the program latches a bit that could serve to trigger an alarm

elsewhere in your ladder program. In this example, the input range is

1…5V dc (decimal range of 409…2047).

MAIN

B3/0

(U)

Turn OFF Alarms

Tur n ON Alar m,

Low Limit Exceeded

LES

LESS THAN

Source A

Source B

B3/1

(U)

B3/0

(L)

I:1.0

409

GRT

GREATER THAN

Source A

Source B

Remainder of Program

I:1.0

2047

END

B3/1

(L)

Tur n ON Alar m,

High Limit Exceeded

Publication 1746-UM009B-EN-P - September 2007

Page 42

42 Write Ladder Logic

We present an alternative program for SLC 5/02 (and later) processors.

It uses a single Limit Test instruction that checks low and high limits.

Whenever the input value exceeds a limit, this program latches a bit

that could trigger an alarm elsewhere in your ladder program. In this

example, the input range is 0…10V dc (decimal range of 0…4095). If

the input range were 4…20 mA, the low and high limits would be

2047 and 408, respectively.

MAIN

LIM

LIMIT TEST (CIRC)

Low Lim

Te st

High Lim

Remainder of Program

END

4095

I:1.0

408

B3/0

(U)

B3/0

(L)

Turn OFF Alarm

Tur n ON Alar m,

Limit Exceeded

Overview of Scaling Inputs and Outputs

In both examples, the analog input value is in word 0 of slot 1 (I:1.0).

Scaling is the application of a ratio on the variable to be scaled, where

the ratio is the scaled range (Δy) to the input range (Δx).

The purpose for scaling values when programming analog I/O

modules is to change data format.

Scaling Inputs and Outputs

When you scale You start with this data

format

Inputs Decimal input range in raw

counts (from the module’s A/D

converter)

Outputs Integer values from the data

table (or from the input image

table)

On a linear graph Δx Δy

And typically change the

format to

Engineering units such as PSI

(stored in the data table)

Decimal output range in raw

counts to match the module’s

output range

Publication 1746-UM009B-EN-P - September 2007

Page 43

Write Ladder Logic 43

Scaled

We illustrate input and output scaling, the source and type of data to

be scaled, and the type and destination of the scaled data.

Data Scaling

Input Scaling Output Scaling

Sensor

Scaled Values

in Engineering

Units for Data

Table (Δy)

Input

Signal

Range

0…5V dc

1…5V dc

0…10V dc

0…20 mA

4…20 mA

Module

A/D

Scaled Values

to Match

Module’s Raw

Counts

Module’s Input in

Module’s Input in

Raw Counts (Δx)

Raw Counts (Δx)

Input Raw

Counts

from A/D

0…2047

409…2047

0…4095

0…2047

409…2047

Input

Image

Table

Data

Tab le

Output

Image

Table

Integer Values (from Data

Table or Input Image)

Input Raw

Counts to

D/A

0…16,384

3277…16,384

0…32,764

-32,768…32,764

0…31,208

6242…31,208

0…32,764

Module

D/A

Output

Signal

Range

0…5V dc

1…5V dc

0…10V dc

-10 …10V

0…20 mA

4…20 mA

0…21 mA

You scale data with ladder logic using arithmetic instructions such as

add, multiply, and double divide; or by using the scaling instruction

available with SLC 5/02 (or later) processors. The scaling computation

is as follows:

Output

Device

value = (input value x slope) + offset

Slope = Δy/Δx = scaled range / input range

= (scaled max. – scaled min.) / (input max. – input min.)

Offset = scaled min. – (input min. x slope)

In this context, the input value and input range are inputs to the

scaling function, not necessarily inputs associated with the sensor

input.

Publication 1746-UM009B-EN-P - September 2007

Page 44

44 Write Ladder Logic

Scale an Analog Input and Detect an Out-of-range Condition

The following example shows input range checking and scaling the

analog input to engineering units for a 1746-FIO4V analog input

module.

We are making the following assumptions:

• The 1746-FIO4V module is located in slot 3 of a modular system.

• A pressure sensor with a 0…10V dc output is wired to input

channel 1.

• The sensor signal voltage is proportional to a range of

100…500 PSI.

• The process pressure must stay between 275…300 PSI.

(If the pressure deviates from this range, your logic sets an alarm

bit.)

• Data is presented in PSI for monitoring and display purposes.

Input Scaling

The scaling operation is displayed in the following graph. It displays

the linear relationship between the input and the resulting scaled

values.

Input Scaling

500 PSI

(scaled max)

Scaled

Value

300 PSI

275 PSI

100 PSI

(scaled min)

0=0Vdc

(input min)

Low

Limit

Process operating range

High

Limit

Input Value

4095 = 10V dc

(input max)

Publication 1746-UM009B-EN-P - September 2007

Page 45

Write Ladder Logic 45

Scaled

I

~

~

)

Calculate the Linear Relationship

Use the following equations to express the linear relationship between

the input value and the resulting scaled value.

value = (input value x slope) + offset

Slope = (scaled max – scaled min) / (input max – input min)

(500 – 100) / (4095 – 0) = 400/4095 = 0.0977

Offset = scaled min – (input min x slope)

(100 – (0 x [400/4095]) = 100

Scaled value = (input value x [0.0977]) + 100

Calculate the Out-of-range Limits

Use the following equation to compute low and high out-of-range

limits.

nput value = (scaled value – offset) / slope

low limit: (275 – 100) / (0.0977) 1750 counts

high limit: (300 – 100) / (0.0977) 2750 counts

Ladder Logic

We present two examples for programming the processor.

The first example uses standard math instructions available in any

SLC 500 processor. This ladder logic prevents a processor fault by

unlatching the mathematical overflow bit S2:5/0 before the end of the

scan.

The second example uses the scaling instruction (SCL) available in

SLC 5/02 (and later) processors. The rate parameter is calculated by

multiplying the slope by 10,000. If the slope exceeds 3.2767, you

cannot use the SCL instruction.

rate = (400/4095) x 10,000 = 977(The slope is 0.0977 so you can use the SCL instruction.

Publication 1746-UM009B-EN-P - September 2007

Page 46

46 Write Ladder Logic

Standard Math Example

Rung 2:0

Check for below range

LESS THAN

Source A

Source B

Rung 2:1

Check for above range

GREATER THAN

Source A

Source B

Rung 2:2

Scale the analog input

Multiply by the

scaled range

Clear fault bit

from overflow

Divide result

by input range

LES

GRT

I:3.1

1750

I:3.1

2750

MUL

MULTIPLY

Source A

Source

Dest

DDV

DOUBLE DIVIDE

Source A

Dest

Below-range

flag

B3/0

(L)

Above-range

flag

B3/1

(L)

I:3.1

400

N7:0

S2:5/0

(U)

4095

N7:0

Add offset

N7:0 contains

process pressure

Rung 2:3

END

ADD

ADD

Source A

Source B

Dest

N7:0

100

N7:0

Example Program Using the Scaling Instruction (SCL)

Rung 2:0

Check for below range

Rung 2:1

Check for above range

Rung 2:2

Scale the analog input

N7:0 contains

process

temperature

Rung 2:3

LES

LESS THAN

Source A

Source B

GRT

GREATER THAN

Source A

Source B

SCL

SCALE

Source

Rate (/10000)

Offset

Dest

I:3.1

1750

I:3.1

2750

I:3.1

977

100

N7:0

END

Below-range

flag

Above-range

flag

B3/0

(L)

B3/1

(L)

Publication 1746-UM009B-EN-P - September 2007

Page 47

Write Ladder Logic 47

Scaled

Scale an Analog Output

This example shows the scaling of analog output values to

engineering units for monitoring or controlling purposes.

We are making these assumptions.

• The FIO4I module is located in slot 2 of an SLC 500 system.

• An actuator of a flow control valve is wired to output channel 0.

• The actuator accepts a 4…20 mA signal for a 0…100% of valve

opening.

• The actuator can not receive a signal out of the 4…20 mA range.

• The percentage of valve opening is manually input to the SLC

processor.

This graph displays the linear relationship.

20mA = 31208

(scaled max.)

Scaled

Value

4mA = 6242

(scaled min.)

0%

(input min.)

Input Value

(from data table)

100%

(input max.)

Calculate the Linear Relationship

Use these equations to compute the scaled output value:

value = (input value x slope) + offset

Slope = (scaled range) / (input range)

= (scaled max – scaled min) / (input max – input min)

= (31208 – 6242) / (100 – 0) = 24966/100

The slope is greater than 3.2767 so you cannot use SCL instruction.

Offset = scaled min – (input min x slope)

= 6242 – [0 x (24966 / 100)] = 6242

Scaled value = [input value x 24966 / 100] + 6242

Publication 1746-UM009B-EN-P - September 2007

Page 48

48 Write Ladder Logic

Ladder Logic

The out-of-range limits are predetermined because any value less than

0% is 6242 and any value greater than 100% is 31,208. The ladder logic

checks for out-of-range limits to verify that not less than 4 mA and not

more than 20 mA is delivered to the analog output channel.

The following ladder logic uses standard math. It unlatches the

mathematical overflow bit S2:5/0 before the end of the scan to

prevent a processor fault.

Example Program for Any SLC Processor

Rung 2:0

Set in-range bit

Rung 2:1

Check for below range

LES

LESS THAN

Source A

Source B

Rung 2:2

Check for above range

GRT

GREATER THAN

Source A

Source B

Rung 2:3

Scale the analog input

B3/0

] [

N7:0

0

N7:0 contains

% valve open

N7:0

100

Multiply by the

scaled range

Clear fault bit

from overflow

Divide result

by input range

MOV

MOVE

Source A

Dest

MOV

MOVE

Source A

Dest

MUL

MULTIPLY

Source A

Source B

Dest

DDV

DOUBLE DIVIDE

Source A

Dest

B3/0

(L)

6242

0:2.0

B3/0

(U)

31208

0:2.0

B3/0

(U)

N7:0

24966

N7:1

S2:5/0

(U)

100

N7:1

Publication 1746-UM009B-EN-P - September 2007

Rung 2:4

Add offset

END

ADD

ADD

Source A

Source B

Dest

N7:1

6242

0:2.0

Page 49

Write Ladder Logic 49

S

~

Scale Offsets When >32,767 or <32,768

Some applications may produce an offset greater than 32,767 or less

than –32,768, the largest value that can be stored in a 16-bit integer or

processed by an SLC processor. If so, you may reduce the magnitude

of the offset by shifting the linear relationship along the input value

axis. When you compute linear relationships, you will see how the

offset is reduced in this manner. The following example applies to a

0.5…9.5V dc output scaled from a narrow input range of 90…100%.

1. First we compute linear relationships and observe that the offset

is beyond –32,768.

9.5 V = 3890

(scaled max)

Scaled

Value

0.5 V = 205

(scaled min)

Input Value

(from data table)

90%

(input min)

100%

(input max)

Use the following equations to compute linear relationships:

caled value = (input value x slope) + offset

Slope = (scaled max – scaled min) / (input max – input min)

(3890 – 205) / (100 – 90) = 3685/10 369 (> 3.2767 so you cannot use SCL)

Offset = scaled min – (input min x slope)

205 – [90 x (368.5)] = 205 – 33165 = –32,960

Scaled value = (input value) x (368.5) – 32,960

Notice the offset is beyond –32,768.

Publication 1746-UM009B-EN-P - September 2007

Page 50

50 Write Ladder Logic

2. Then we shift the linear relationship along the input value axis.

9.5 V = 3890

(scaled max)

Scaled

Value

0.5 V = 205

(scaled min)

90%

(input min)

(input max)

Input Value100%

3. Now we compute the offset for the shifted linear relationship.

Offset = scaled min – (input min x slope)

= 205 – [0 x (368.5)] = 205

The offset is 205, well below 32,767. The slope remains 3685/10

(> 3.2767), so you cannot use the SCL instruction for scaling.

Slope = (scaled range) / (input range) = (3890 – 205) / 10 = 3685/10

Scaled value = (input value x slope) + offset = [input value x 3685 /10] + 205

Publication 1746-UM009B-EN-P - September 2007

Page 51

Write Ladder Logic 51

Ladder Logic

The following ladder logic uses standard math. It unlatches the

mathematical overflow bit S2:5/0 before the end of the scan to

prevent a processor fault. The module is located in slot 2, and the

output device is wired to channel 0.

Scale Offset

Rung 2:0

Set in-range bit

Rung 2:1

Check for below range

LES

LESS THAN

Source A

Source B

Rung 2:2

Check for above range

GRT

GREATER THAN

Source A

Source B

Rung 2:3

Scale the analog input

B3/0

] [

N7:0

0

N7:0

100

Subtract the

input minimum.

Multiply by the

scaled range

Clear fault bit

from overflow

Divide result

by input range

Add offset

MOV

MOVE

Source A

Dest

MOV

MOVE

Source A

Dest

SUB

SUBTRACT

Source A

Source B

Dest

MUL

MULTIPLY

Source A

Source B

Dest

DDV

DOUBLE DIVIDE

Source A

Dest

ADD

ADD

Source A

Source B

Dest

B3/0

(L)

205

0:2.0

B3/0

(U)

3890

0:2.0

B3/0

(U)

N7:0

90

N7:1

N7:1

3685

N7:1

S2:5/0

(U)

10

N7:1

N7:1

205

0:2.0

Publication 1746-UM009B-EN-P - September 2007

Page 52

52 Write Ladder Logic

Scaled

Range-check an Analog Input and Scale It for an Output

This example checks the range of an analog input and scales it for use

as an output. An 1746-FIO4V module is placed in slot 1 of an SLC 500

system. A 4…20 mA signal representing 0…200 PSI from a pressure

sensor is delivered to input channel 0. The input value is checked to

ensure it remains within range. If the ladder logic detects an

out-of-range condition, it sets a flag bit.

The input signal is then scaled and delivered as a 0…1.0V output

signal to a panel pressure meter connected to output channel 0.

The graph displays the linear relationship between the analog input

signal and the 0…1.0 output signal delivered to the panel pressure

meter.

1.0 volt = 3276

(scaled max)

Scaled

Value

0 volt = 0

(scaled min)

409

(input min)

Input Value

(from data table)

2047

(input max)

Calculate the Linear Relationship

Use the following equations to compute the linear relationship

between the input values (from the input image table) and resulting

scaled values for the 0…1V output:

value = (input value x slope) + offset

Slope = (scaled max – scaled min) / (input max – input min)

(3276 – 0) / (2047 – 409) = 3276 / 1638 = 2.0

Since the slope is less than 3.2767, you can use the SCL instruction.

Offset = scaled min – (input min x slope)

0 – (409 x 2) = –818

Scaled value = (input value x 2) – 818

Publication 1746-UM009B-EN-P - September 2007

Page 53

Write Ladder Logic 53

Ladder Logic

We present two examples. The first runs on any SLC 500 processor.

The second uses the scaling instruction available on SLC 5/02 (and

later) processors.

In the first example, the analog input value is checked against the

minimum and maximum input limits. B3:0/0 is the in-range flag bit.

If the input is out of range, the in-range flag bit is reset and the output

is set to its minimum or maximum limit. If the input is in range, the

output value is determined by scaling the input.

Follow these steps to scale an analog input for this example.

1. Multiply the input by the scaled range

Scale range = (scaled max – scaled min) = 3276 – 0 = 3276

2. Divide the 32 bit result by the input range

Input range = (input max – input min) = 2047 – 409 = 1638

3. Add the offset value (in this case negative) = –818

Move the final value to the analog output channel 0.

In this example, the multiply operation generates an overflow bit and

minor error flag whenever the result exceeds 16 bits. Since the divide

operation uses a 32-bit result in the math register, the overflow is no

problem. The minor error flag has to be cleared before the end of the

program scan to avoid a system error.

Refer to the ladder program on the next page.

Publication 1746-UM009B-EN-P - September 2007

Page 54

54 Write Ladder Logic

Example Program for Any SLC Processor

Rung 2:0

Set in-range bit

Rung 2:1

Check for below range

LES

LESS THAN

Source A

Source B

Rung 2:2

Check for above range

GRT

GREATER THAN

Source A

Source B

Rung 2:3

Scale the analog input

B3/0

] [

I:1.0

409

I:1.0

2047

Multiply by the

scaled range

Clear fault bit

from overflow

Divide result

by input range

MOV

MOVE

Source

Dest

B3/0

(U)

MOV

MOVE

Source A

Dest

MUL

MULTIPLY

Source A

Source B

Dest

DDV

DOUBLE DIVIDE

Source A

Dest

B3/0

(L)

0

N7:0

3276

N7:0

B3/0

(U)

I:1.0

3276

N7:0

S2:5/0

(U)

1638

N7:0

Publication 1746-UM009B-EN-P - September 2007

ADD

Add offset

Rung 2:4

Move value to output channel 0

Rung 2:5

END

ADD

Source A

Source B

Dest

MOV

MOVE

Source A

Dest

N7:0

–818

N7:0

N7:0

0:1.0

Using the scaling instruction (SCL) requires less ladder logic. The SCL

instruction uses the same multiply, divide, and add algorithm but it

does so with a single rate instead of using scaled range and input

range values. The rate is determined by this formula.

Page 55

Write Ladder Logic 55

Rate = slope x 10,000

Rate = (scale range / input range) x 10,000

Rate = 3276 / 1638 x 10,000

Rate = 2 x 10,000

Rate = 20,000

If the slope was greater than 3.2767, you could not use the SCL

instruction because the rate would exceed 32,767, a value too large to

handle.

Example Program for SLC 5/02 (or later) Processors

Rung 2:0

Set in-range bit

Rung 2:1

Check for below range

LES

LESS THAN

Source A

Source B

Rung 2:2

Check for above range

GRT

GREATER THAN

Source A

Source B

Rung 2:3

Scale the analog input

B3/0

] [

I:1.0

2047

I:1.0

409

MO

MOVE

Source

Dest

MOV

MOVE

Source A

Dest

SCL

SCALE

Source

Rate (/10,000)

Offset

Dest

B3/0

(L)

0

N7:0

B3/0

(U)

3276

N7:0

B3/0

(U)

I:1.0

20,000

–818

N7:0

Rung 2:4

Move value to output channel 0

Rung 2:5

END

MOV

MOVE

Source A

Dest

Publication 1746-UM009B-EN-P - September 2007

N7:0

0:1.0

Page 56

56 Write Ladder Logic

PID Control with Analog I/O Scaling

With the combination of PID and SCL (scale) instructions or PID and

standard math instructions, you can write and display ladder logic in

engineering units such as PSI or °C.

Follow these steps to display ladder logic in engineering units.

1. Scale the analog input PV by calculating the slope (or rate) of

the analog input range.

For example, an input range such as 1…5V dc has a

corresponding scaled range of 409…2047. You would scale the

409…2047 against 0…16383 for a slope of 10 (SCL rate of

100,000).

IMPORTANT

You cannot use the SCL instruction for scaling inputs if input

rates (slope x 10,000) are too large (exceed 32,767). You must

use standard math instructions instead.

2. Scale the analog output CV by calculating the slope (or rate) of

the analog output range.

For example, an output range such as 4…20 mA has a

corresponding decimal (scaled) range of 6242…31,208. You

would scale the 6242…31,208 against 0…16,383.

Publication 1746-UM009B-EN-P - September 2007

For this output

range

4…20 mA scaled max – scaled min

Compute the slope as follows Compute offset as follows

scaled min – [input min x slope]

input max – input min

31208 – 6242

16383 – 0 16383

= 24966 = 1.5238

= 6242 – [0 x 1.5238]

= 6242

Here are some useful rate and offset parameters for the SCL

instruction when scaling analog output ranges.

SCL Parameter 0…20 mA 4…20 mA 0…5V dc 1…5V dc 0…10V dc

Rate

(slope x 10,000)

Offset 0 6242 0 3277 0

19,049 15,239 10,000 8,000 19,999

Page 57

Write Ladder Logic 57

3. Enter PID parameters in engineering units into the PID

instruction.

For example, if the 4…20 mA analog input range represents

0…300 PSI, enter 0 as the minimum (Smin) and 300 as the

maximum (Smax). You can also enter setpoints and deadband in

engineering units. The data monitor screen for PID displays its

parameters in the same engineering units.

Ladder Logic

We present two examples of PID control logic with analog I/O scaling

for use on an SLC 5/02 (or later) processor.

• Scaled voltage input and output, 0…10V dc

• Scaled current input and output, 4…20 mA

Publication 1746-UM009B-EN-P - September 2007

Page 58

58 Write Ladder Logic

Example Program for SLC 5/02 (or later) Processors (scaled voltage input and

output)

Rung 2:0

Rung 2:1

Rung 2:2

Rung 2:3

IIM

IMMEDIATE IN PUT w MASK

Slot

Mask

Length

MUL

MULTIPLY

Source A

Source B

Dest

PID

PID

Contr ol Block

Proces s Variable

Contr ol Variable

Contr ol Block Length

SCL

SCALE

Source

Rate (/10000)

Offset

Dest

I:1.0

4

N7:0

0

N10:29

0

19999

0

O:1.0

I:1.0

FF FF

1

N10:0

N7:0

N10:29

23

Rung 2:4

Rung 2:5

Publication 1746-UM009B-EN-P - September 2007

+END+

IOM

IMMEDIATE OUT w MAS K

Slot

Mask

Length

O:1.0

FF FF

1

Page 59

Example Program for SLC 5/02 (or later) Processors (scaled current input and

output)

Rung 2:0

Rung 2:1

Scale t he analog input with math instructions.

Multiply by scaled range

Clear overflow fault bit

Divide by input range

Write Ladder Logic 59

IIM

IMMEDIATE IN PUT w MASK

Slot

Mask

Length

MUL

MULTIPLY

Source A

Source B

Dest

DDV

DBL DIVIDE

Source A

Dest

I:1.0

16383

N7:0

S2:5

(U)

1638

N7:0

I:1.0

FF FF

1

0

Add offset

ADD

ADD

Source A

Source B

N7:0

–4091

Publication 1746-UM009B-EN-P - September 2007

Page 60

60 Write Ladder Logic

Brake Monitor Example Program for SLC 5/02 (or later) Processors

Rung 2:2

The nex t 2 rungs ensure that the analog input value to be scaled remains within the limits of 409 and 2047. This

prevent s out-of-range conversion errors in the SCL and PID instructions. The latch bits can be used elsewhere in the

program t o identify the particular out-of-range error which occurred.

Under

Range

LES

LESS THAN

Source A

Source B

N7:0

0

409

B3

(L)

0

MOV

MOVE

Source A

409

Dest

Rung 2:3

GRT

GREATER THAN

Source A

Source B

Rung 2:4

Rung 2:5

The PID c ontrol variable is the input for the scale instruction. The PID instruction guarantees that the CV remains

within the r ange of 16383. The CV is scaled to 6242–31208, the numeric range required for a 4–20 mA output signal.

N7:0

0

2047

Over

Range

B3

(L)

1

MOV

MOVE

Source

Dest

PID

PID

Control Block

Process Variable

Control Variable

Control Block Length

SCL

SCALE

Source

Rate (1/10000)

N7:0

0

2047

N7:0

0

N10:0

N7:0

N10:29

N10:29

0

15239

Rung 2:6

This rung immediately updates the analog output card driven by the PID’s CV.

Rung 2:7

Publication 1746-UM009B-EN-P - September 2007

+END+

Offset

Dest

IOM

IMMEDIATE OUT w MAS K

Slot

Mask

Length

6242

O:1.0

O:1.0

FFFF

Page 61

Chapter

6

Calibrate the Module

This chapter helps you calibrate the module’s analog input channels

to increase the expected accuracy from ± 21 LSB of error to ± 6 LSB.

The combination of calibration program and procedure is designed to

reduce offset and gain errors by:

• scaling the values read during calibration.