Page 1

Barrel Temperature

Control Module

1746-BTM

User Manual

Page 2

ii

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely f or purpo ses of ex ample. Since t here

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

• identify a haza r d

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Publication 1746-UM010B-EN-P - April 2001

Page 3

iii

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1.

This equipment is classified as open equipment and must be mounted

in an enclosure during operation to provide safety protection.

Publication 1746-UM010 B- EN-P - April 2001

Page 4

iv

Publication 1746-UM010B-EN-P - April 2001

Page 5

Summary of Changes

Major changes in this revision include:

• Ladder code addresses have been changed.

• The sample ladder code in Chapter 9 has been enhanced.

• Examples outlining the mathematical relationships involved in

Startup Aggressiveness Factor and Ramp Rates have been

included in Chapter 3.

• Appendixes A and B have been omitted.

• Module specifications can be found in the 1746-BTM Installation

Instructions, Publication 1746-IN014B-EN-P.

1 Publication 1746-UM010 B- EN-P - April 2001

Page 6

2 Summary of Changes

Publication 1746-UM010B-EN-P - April 2001

Page 7

Preface

Using This Manual

This manual shows you how to use the Barrel Temperature Control

Module (cat. no. 1746-BTM) in an A llen- Bradley SLC sys tem fo r barrel

temperature control and other injection molding or extrusion related

temperature control applications. The manual explains how to install,

program, calibrate, and troubleshoot the BTM module.

ATTENTION

Use the 1746-BTM module in a local I/O chassis only

for barrel temperature control of injection molding

applications or extruders. Any other applications are

not supported.

!

Audience

You must be able to program and operate an Allen-Bradley SLC

programmable controller to make efficient use of this module. In

particular, you must know how to configure M0 and M1 files. For

more information, see the appropriate SLC programming manual

before you generate a program for this module.

System Compatibility

System compatibility involves data table use as well as compatibility

with a local I/O chassis and SLC processor.

Data Table

Communication between the module and processor is bi-directional.

The processor transfers output data through the output image table to

the BTM module and transfers input data from the BTM module

through the input image table. The BTM module also requires M files

for configuration and calibration values.

I/O Chassis

You can use this module with 1746-A4, -A7, -A10, -or -A13 chassis,

provided there is an SLC controller in the chassis (local system). You

can place the BTM module in any I/O slot except for the first slot

which is reserved for the processor.

1 Publication 1746-UM010 B- EN-P - April 2001

Page 8

P-2 Preface

SLC Processor

The 1746-BTM module is compatible with any SLC processor that

supports M0/M1 files, such as the SLC 5/05, SLC 5/04, SLC 5/03, and

SLC 5/02 controllers.

Vocabulary

In this manual, we refer to:

• the barrel temperature control module as the “1746-BTM

module,” the “BTM module,” or as “the module”

• the programmable controller as the “SLC processor”, or “the

processor”

• a thermocouple as a “TC”

• a time-proportioned output as “TPO”

• the tuning-assisted processes as “TAP”

• proportional-integral-derivative as “PID”

• cold-junction compensation as “CJC”

Publication 1746-UM010B-EN-P - April 2001

Page 9

Table of Contents

Important User Information. . . . . . . . . . . . . . . . . . . . . . . . . . ii

European Communities (EC) Directive Compliance . . . . . . . iii

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

System Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Chapter 1

Temperature Control Using a BTM Module in an SLC System 1-1

Features of the Temperature Control Module . . . . . . . . . . . 1-2

Module Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Current CV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

TPO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Response to Slot Disabling . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Input response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Output response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2

Avoiding Electrostatic Damage. . . . . . . . . . . . . . . . . . . . . . 2-1

European Communities (EC) Directive Compliance . . . . . . 2-2

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Determining Power Requirements . . . . . . . . . . . . . . . . . . . 2-3

Choosing a Module Slot in a Local I/O Chassis. . . . . . . . . . 2-3

Installation considerations . . . . . . . . . . . . . . . . . . . . . . 2-3

Installing the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Removing the terminal block . . . . . . . . . . . . . . . . . . . . 2-5

Wiring the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Cold Junction Compensation (CJC). . . . . . . . . . . . . . . . 2-6

Wiring considerations. . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Preparing and Wiring the Cables . . . . . . . . . . . . . . . . . 2-8

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Chapter 3

Loop Operation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Word 1, Bits 0 and 1 for Channel 1. . . . . . . . . . . . . . . . 3-1

Type of Loop Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Word 1, Bits 2-5 for Channel 1 . . . . . . . . . . . . . . . . . . . 3-1

Enable Loop Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Word 1, Bit 6 for Channel 1 . . . . . . . . . . . . . . . . . . . . . 3-2

TC Break Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Word 1, Bits 7 and 8 for Channel 1. . . . . . . . . . . . . . . . 3-2

Loop Autotune Gains Level . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Word 1, Bits 10 and 11 for Channel 1 . . . . . . . . . . . . . . 3-2

1 Publication 1746-UM010 B- EN-P - April 2001

Page 10

TOC-2 Table of Contents

Barrel/Non-barrel Control . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Word 1, Bit 12 for Channel 1 . . . . . . . . . . . . . . . . . . . . 3-3

Barrel Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Non–barrel control. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Switching the barrel control . . . . . . . . . . . . . . . . . . . . . 3-3

Inner/Outer Zone Selection. . . . . . . . . . . . . . . . . . . . . . . . 3-4

Word 1, Bit 13 for Channel 1 . . . . . . . . . . . . . . . . . . . . 3-4

High/Low CV Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Words 2 and 3 for Channel 1 . . . . . . . . . . . . . . . . . . . . 3-5

TC Break Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Word 4 or O:e.8 for Channel1 . . . . . . . . . . . . . . . . . . . 3-5

Standby Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Word 5 for Channel 1 . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Heat/Cool Minimum On-times. . . . . . . . . . . . . . . . . . . . . . 3-6

Words 6 and 8 for channel 1 . . . . . . . . . . . . . . . . . . . . 3-6

Heat/Cool TPO Period . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Words 7 and 9 for Channel 1 . . . . . . . . . . . . . . . . . . . . 3-6

PV Rate and Associated Alarm. . . . . . . . . . . . . . . . . . . . . . 3-6

Word 10 and Alarm Bit I:e.4/05 for Channel 1. . . . . . . . 3-6

High/Low Temperature and Deviation Alarms . . . . . . . . . . 3-6

Words 11-14 for Channel 1. . . . . . . . . . . . . . . . . . . . . . 3-6

Alarm Dead Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Word 15 for Channel 1. . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Thermal Integrity Loss Detection . . . . . . . . . . . . . . . . . . . . 3-9

Words 16 and 17 for Channel 1 . . . . . . . . . . . . . . . . . . 3-9

Ramp Rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Words 18 for Channel 1 . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Non-barrel Autotune Disturbance Size . . . . . . . . . . . . . . . . 3-9

Word 20 for Channel 1. . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Implied Decimal Point . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Configuration Block, M1 File, Loops 1-4 N10:0-100. . . . . . . 3-11

Startup Aggressiveness factor. . . . . . . . . . . . . . . . . . . . . . . 3-11

Ramp Rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Publication 1746-UM010B-EN-P - April 2001

Chapter 4

Sequence of Setting PID Gains . . . . . . . . . . . . . . . . . . . . . 4-1

Autotuning the Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Fine-Tuning the Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Using the PID Equation. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Entering Autotune/Gains Values with Implied Decimal Point 4-5

PID Gains/Autotune Block, M0 File for Loops 1–4 . . . . 4-6

Page 11

Table of Contents TOC-3

Chapter 5

Controlling a Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

M1 Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Output Image Table. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Autotune a Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Requirements for Autotune. . . . . . . . . . . . . . . . . . . . . . 5-2

Items to check before autotune . . . . . . . . . . . . . . . . . . 5-4

Autotune barrel control applications. . . . . . . . . . . . . . . 5-4

Example: Autotune non–barrel control applications. . . . 5-7

Troubleshooting Autotune . . . . . . . . . . . . . . . . . . . . . . 5-7

Using the Output Image Table. . . . . . . . . . . . . . . . . . . . . . 5-8

Global Commands to All Loops . . . . . . . . . . . . . . . . . . 5-9

BTM Auto Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Chapter 6

Input Image Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Implied Decimal Point . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Chapter 7

About the Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Calibration Codes and Status . . . . . . . . . . . . . . . . . . . . 7-1

Calibration Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8

Troubleshooting with LED Indicators. . . . . . . . . . . . . . . . . 8-1

Locating Error Code Information . . . . . . . . . . . . . . . . . . . . 8-2

Chapter 9

Obtaining the Sample Program from the Internet . . . . . . . . 9-1

To Access the Internet:. . . . . . . . . . . . . . . . . . . . . . . . . 9-1

RSLogix500 Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

BTM Firmware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Support for 5/03, 5/04, 5/04P, 5/05, and

5/05P Processors Using BTM201.rss . . . . . . . . . . . . . . . . . . 9-1

BTM201.rss Data Table Layout . . . . . . . . . . . . . . . . . . . 9-2

Download and Upload Settings . . . . . . . . . . . . . . . . . . 9-3

BTM201.rss Programming Notes . . . . . . . . . . . . . . . . . . 9-5

Support for 5/02 Processors Using BTM50220.RSS . . . . . . . 9-7

BTM50220.RSS Data table layout. . . . . . . . . . . . . . . . . . 9-7

Download and Upload Settings . . . . . . . . . . . . . . . . . . 9-7

General Notes for Programming the 1746-BTM. . . . . . . . . . 9-9

Publication 1746-UM010 B- EN-P - April 2001

Page 12

TOC-4 Table of Contents

Publication 1746-UM010B-EN-P - April 2001

Page 13

Getting Started

This chapter gives you information on:

• the function of the temperature control module

• features of the temperature control module

• time–proportioned output (TPO)

• module addressing

• response to slot disa bli ng

Chapter

1

Temperature Control Using a BTM Module in an SLC System

ATTENTION

Use the 1746–BTM module only for barrel

temperature control for injection mold ing

applications or extruders in a local I/O chassis. Any

other applications are not supported.

!

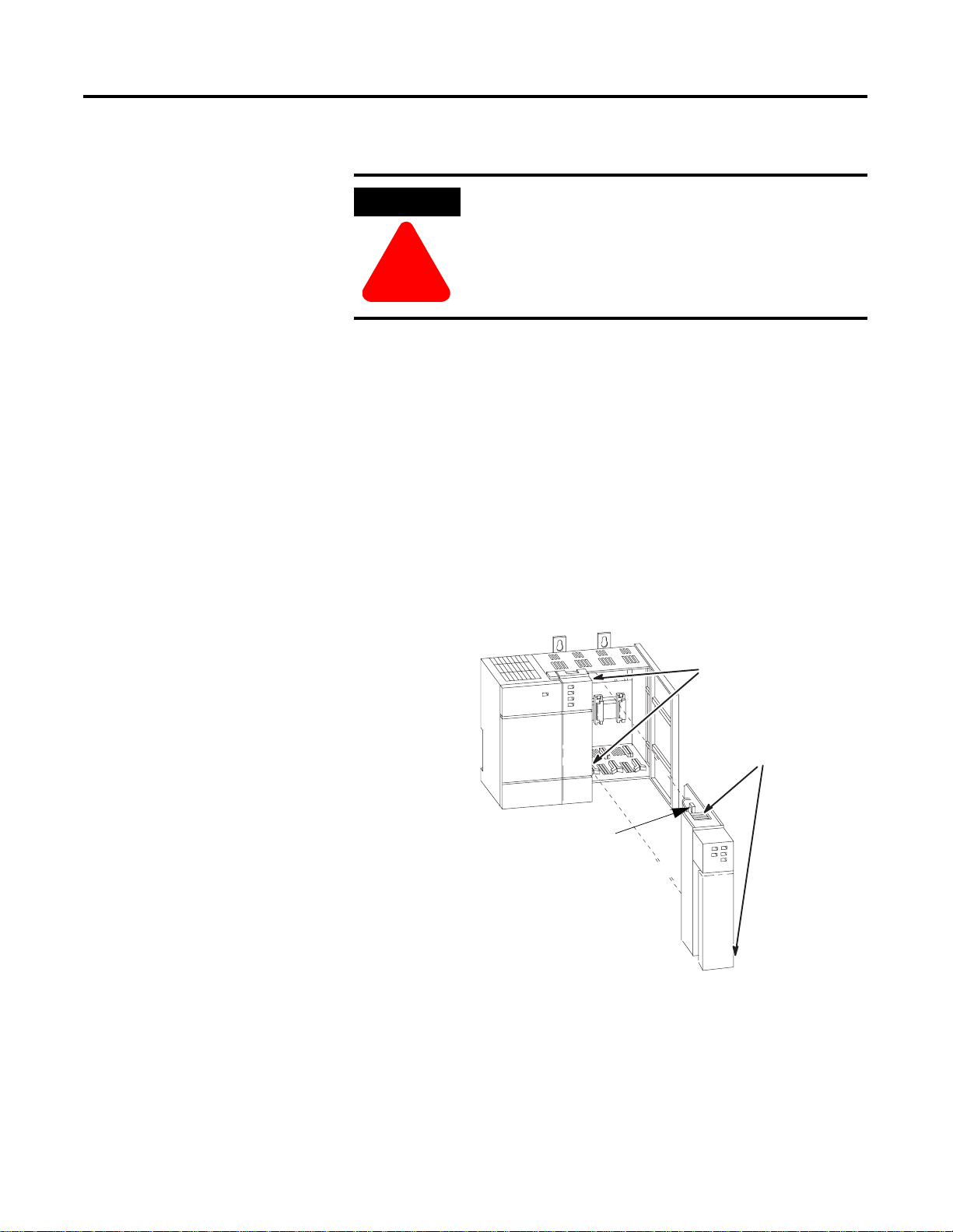

The temperature control module is an intelligent I/O module that can

provide a maximum of 4 PID loops for temperature control. The

module has 4 analog thermocouple (TC) inputs. Each analog input

functions as the process variable (PV) for a PID loop. The PID

algorithm and tuning–assisted–process (TAP) algorithm are performed

on the module for each of the loops. The control–variable (CV)

output of each loop, either analog output or time–proportioned

output (TPO), is sent from the module to the SLC data table. Your

application ladder logic must access the CV value in the data table and

send the analog or TPO data to an output module to close the loop.

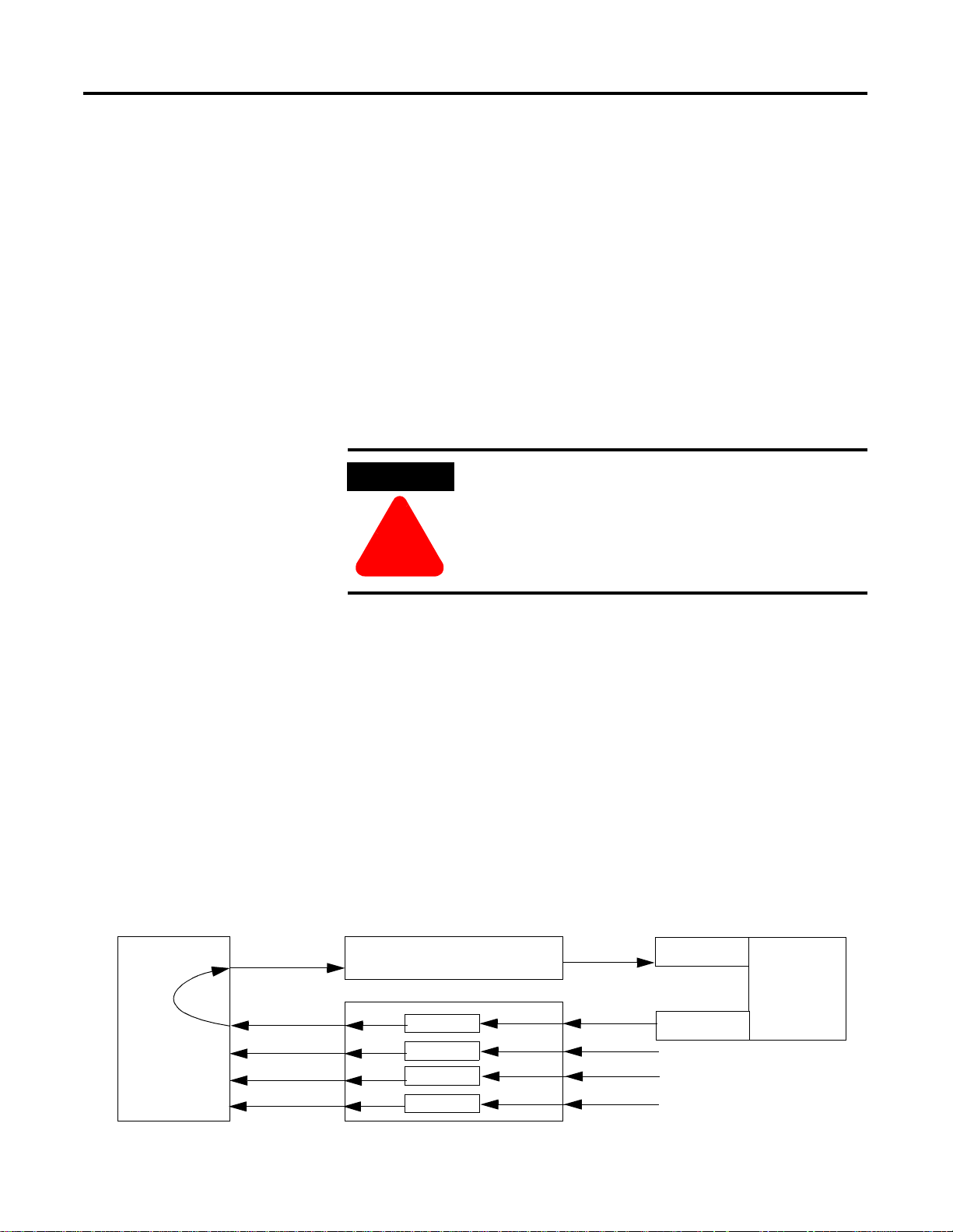

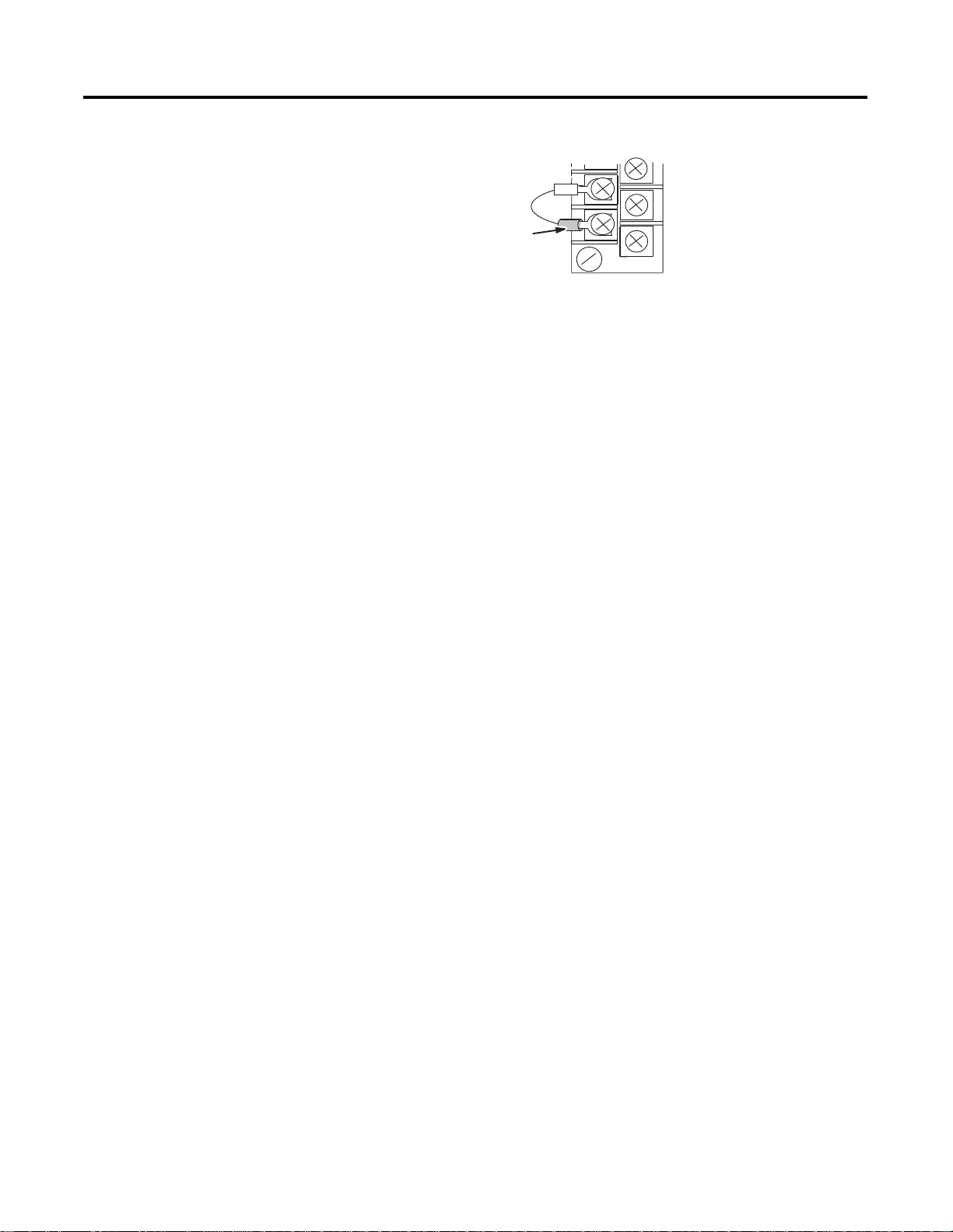

Figure 1.1

A 1746–BTM module with 4 PID logic channels, showing one complete PID loop

SLC data table

CV

1 Publication 1746-UM010 B- EN-P - April 2001

CV

CV

CV

CV

CV

output module

analog or TPO

loop logic

loop logic

loop logic

loop logic

PV

PV

PV

PV

CV

heater

process to be

controlled

TC

Page 14

1-2 Getting Started

Features of the T emperature Control Module

The 1746–BTM module provides:

• 4 independent temperature control loops

• autotune PID loops (one loop or any combination of loops can

be autotuned while other loops are running)

• a unique start–up algorithm to minimize overshoot

• an isolated thermocouple (J and K) input for each PID loop

• 16–bit analog–to–digital converter resolution (0.1° resolution)

• a heat CV signal (for each PID loop) as a numeric % value

• a cool CV signal (for each PID loop) as a numeric % value

• a heat CV signal (for each PID loop) as a TPO bit

• a cool CV signal (for each PID loop) as a TPO bit

• temperature values in C ° or F °

• self–calibration (external reference required)

• user–selectable high and low alarms with dead band for

hysteresis

• input open–circuit detection

Module Outputs

The BTM module sends the control variable (CV) for heating an d/or

cooling each loop to the SLC processor’s input image table as both of:

• numeric value (current CV)

• time–proportioned output (TPO)

Current CV

Y our ladder logic should read the numeric value (current CV), scale it,

and send it to an analog output module to generate the control signal

to an analog temperature control actuator. If using the sample

program look for current CVs in N10:208–211 for loops 1–4. Refer

to Sample Program on page 9-1.

TPO

The module returns the heat TPO (bit 6) and cool TPO (bit 7) in input

image table words 8–11 for loops 1–4. The sample program sends

TPO signals to a digital output module to generate the control signal

to a digital temperature control actuator. Refer to Sample Program on

page 9-1.

Publication 1746-UM010B-EN-P - April 2001

Page 15

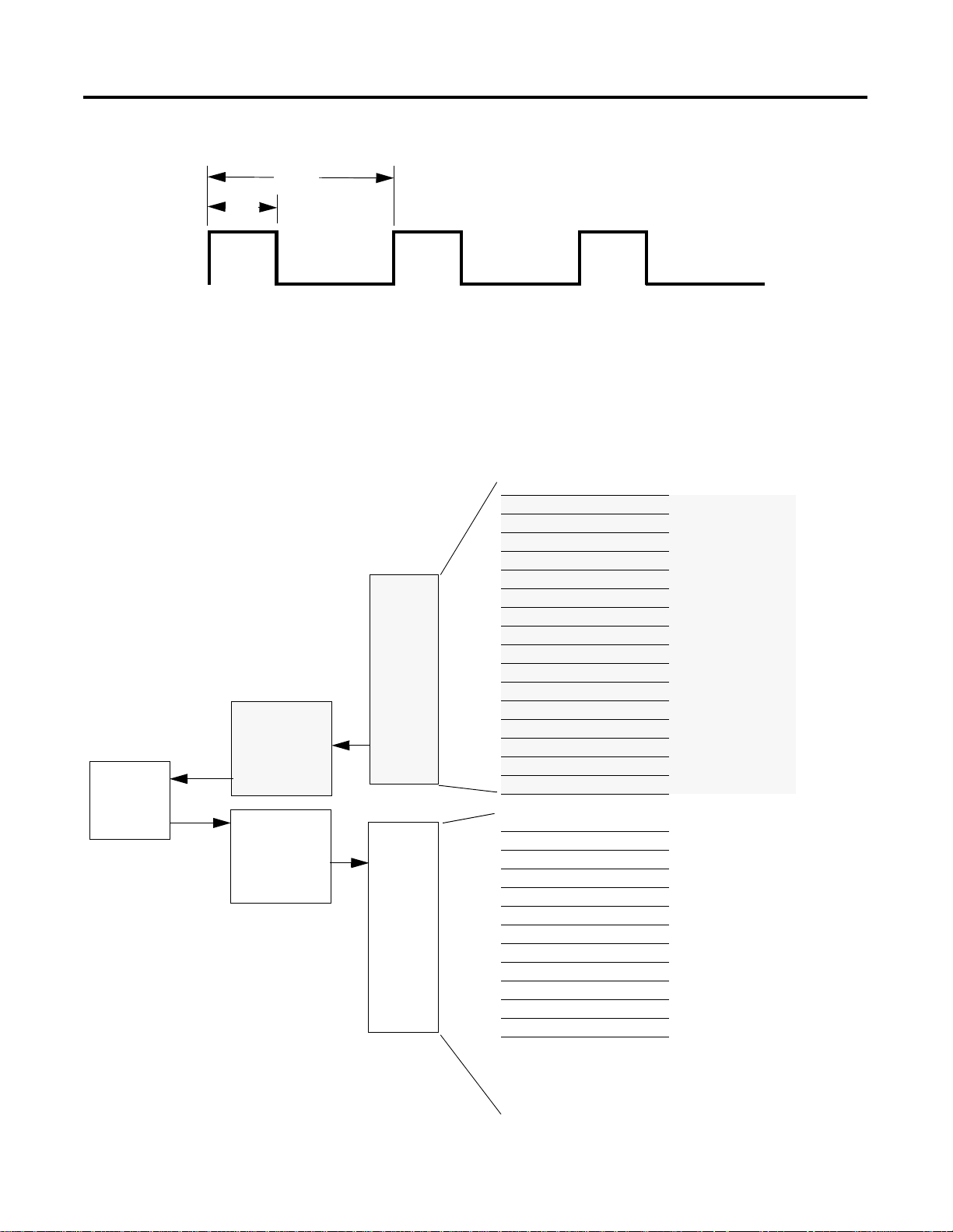

Figure 1.2 TPO timing diagram

Getting Started 1-3

TPO bit

BTM

Module

On

Off

Y

X

SLC 5/0x

I/O Image Table

Output Image

Slot e

See Figure 1.3 on

page 1-4

Input Image

Slot e

See Figure 1.3 on

page 1-4

CV% = (40%)

X = on time (2.0 sec)

Y = TPO period (5.00 sec)

data in parenthesis refers to

sample program values.

The TPO duty cycle (Y) must be considerable shorter in time than

the system dead time. For additional information, Refer to Autotune

a Loop on page 5-2.

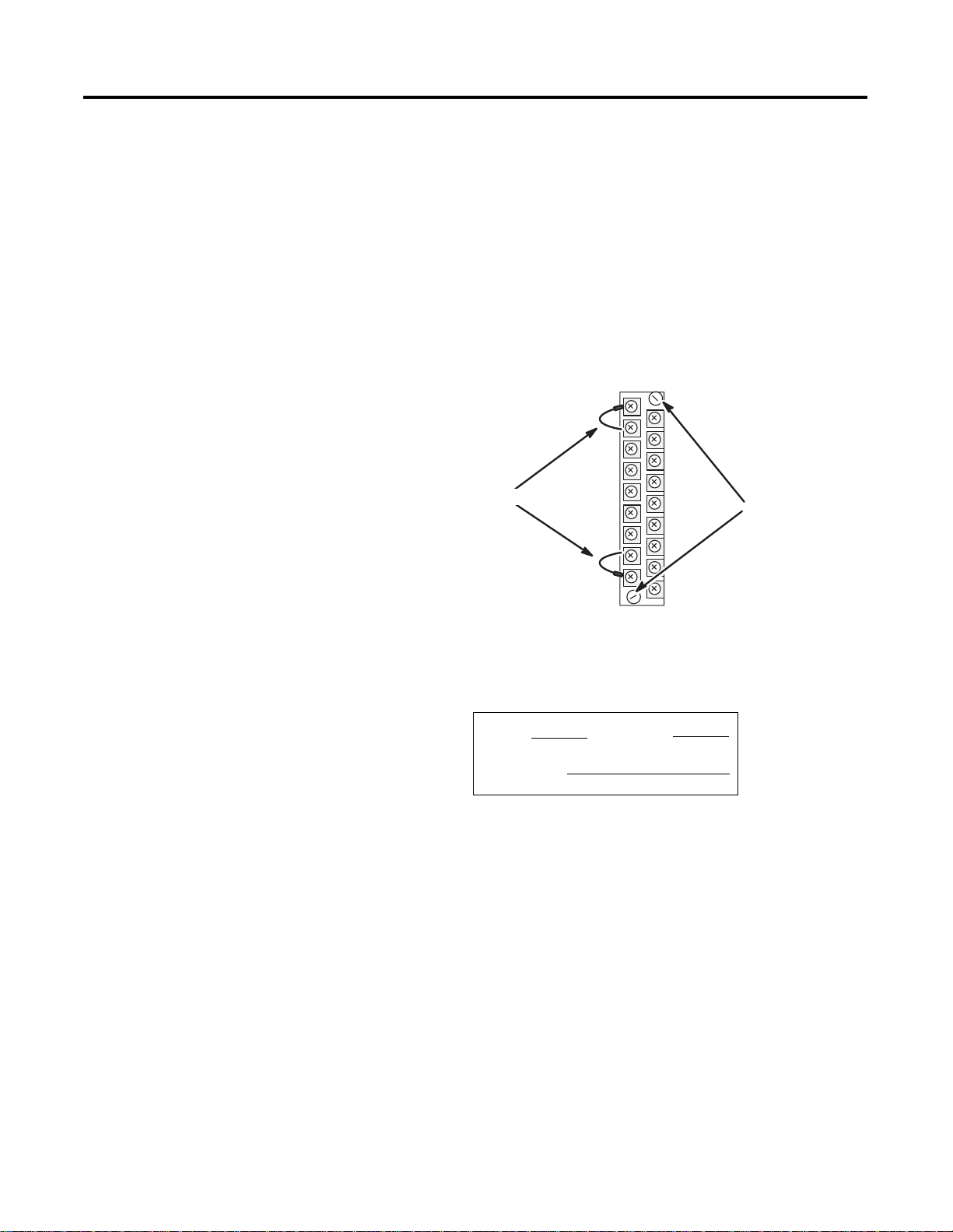

The following memory map shows you how the SLC processor’s

output and input image tables are defined for the module. See Table

9.A: BTM201.r s s N7 Da t a Table on pag e 9-2.

Bit 15 Bit 0 Address

Loop 1 configuration data word 0 O:e.0

Slot e portion of

SLC image table

for BTM module

output

image

16 words

input

image

16 words

Loop 2 configuration data word 1 O:e.1

Loop 3 configuration data word 2 O:e.2

Loop 4 configuration data word 3 O:e.3

Loop 1 run setpoint value word 4 O:e.4

Loop 2 run setpoint value word 5 O:e.5

Loop 3 run setpoint value word 6 O:e.6

Loop 4 run setpoint value word 7 O:e.7

Loop 1 manual output value word 8 O:e.8

Loop 2 manual output value word 9 O:e.9

Loop 3 manual output value word 10 O:e.10

Loop 4 manual output value word 11 O:e.11

miscellaneous control bits word 12 O:e.12

not used word 13 O:e.13

not used word 14 O:e.14

not used word 15 O:e.15

Loop 1 temper ature word 0 I:e.0

Loop 2 temper ature word 1 I:e.1

Loop 3 temper ature word 2 I:e.2

Loop 4 temper ature word 3 I:e.3

Loop 1 configuration status word 4 I:e.4

Loop 2 configuration status word 5 I:e.5

Loop 3 configuration status word 6 I:e.6

Loop 4 configuration status word 7 I:e.7

Loop 1 control status and TPO word 8 I:e.8

Loop 2 control status and TPO word 9 I:e.9

Loop 3 control status and TPO word 10 I:e.10

Loop 4 control status and TPO word 11 I:e.11

If using the sample program,

variables in words 12-15, including

current CVs, are multiplexed and

scanned into N10:200-243

word 12 I:e.12

word 13 I:e.13

word 14 I:e.14

word 15 I:e.15

Publication 1746-UM010 B- EN-P - April 2001

Page 16

1-4 Getting Started

Module Addressing

Input Image Table Address Output Image Table Address

slot slot

file type file type

When you enter the module ID in processor configuration (off-line),

the processor automatically reserves the required number of I/O

image table words. In the figure below, that section of the I/O image

table is designated by “slot e”. Its location in the I/O image table is

determined by the module’s slot location “e” in the I/O chassis. Slot

location “e” is a required addressing unit when referring to the

module in ladder logic. For the sample program’s data table layout,

See Table 9.A: BTM201.rss N7 Data Table on page 9-2. See Figure 1.3

for an explanation of the image table addresses

Figure 1.3 .

word

I : e . 6 O : e . 6

element

delimiter

word

delimiter

element

delimiter

word

word

delimiter

Response to Slot Disabling

By writing to the status file in your modular SLC processor you can

disable any chassis slot. See your SLC programming manual for the

slot disable/enable procedure.

ATTENTION

Always understand the implications of disabling the

module before using the slot disable feature.

!

Input response

When the slot for this module is disabled, the module continues to

update its inputs. However, the SLC processor does not read from a

module whose slot is disabled. Therefore, inputs appearing in the

processor image table remain in their last state, and the module’s

updated inputs are not read. When the processor re–enabl es the

module slot, the current state of module inputs are read by the

controller during the subsequent scan.

Output response

Publication 1746-UM010B-EN-P - April 2001

When the slot for this module is disabled, configuration words in the

SLC processor’s output image table are held in their last state and not

transferred to the module. When the slot is re–enabled, output image

table words are transferred to the module during the subsequent scan.

Page 17

Installing and Wiring

This document gives you information about:

• avoiding electrostatic damage

• compliance with European Union directive

• determining the module’s chassis power requirement

• planning for sufficient enclosure depth

• choosing a module slot in a local I/O chassis

• installing the module

• wiring the module

Chapter

2

Avoiding Electrostatic Damage

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins. Guard against

electrostatic damage by observing the following precautions:

ATTENTION

Electrostatic discharge can degrade performance or

cause permanent damage. Handle the module as

stated below.

!

• Touch a grounded object to rid yourself of charge before

handling.

• Wear an approved wrist strap when handling the module.

• Handle the module from the front, away from the backplane

connector.

• Do not touch backplane connector pins.

1 Publication 1746-UM010 B- EN-P - April 2001

Page 18

2-2 Installing and Wiring

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN 50081-2 EMC — Generic Emissi on Standard, Part 2 —

Industrial Environment

• EN 5001082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1.

This equipment is classified as open equipment and must be mounted

in an enclosure during operation to provide safety protection.

Publication 1746-UM010B-EN-P - April 2001

Page 19

Installing and Wiring 2-3

Determining Power Requirements

Choosing a Module Slot in a Local I/O Chassis

When computing power supply requirements, add the values shown

in Table 2.A to the requirements of all other modules in the SLC

chassis to prevent overloading the chassis power supply.

Table 2.A Power Supply Requirements

5V dc amps 24V dc amps

0.110 0.085

Place your module in any slot of an SLC500 module, or modular

expansion chassis, except for the left–most slot (slot 0), reserved for

the SLC processor or adapter modules.

IMPORTANT

For proper operation, use this module with a local

processor. The module is not designed to operate in

a remote chassis.

Installation conside rations

Most thermocouple–type applications require an industrial enclosure

to reduce the effects of electrical interference. Thermocouple inputs

are highly susceptible to electrical noises due to the small signal

amplitudes (microvolt/C °). Isolate them from other input wiring and

modules that radiate electrical interference.

Group your modules within the I/O chassis to minimize adverse

effects from radiated electrical noise and heat. Consider the following

conditions when selecting a slot location. Position the module away

from modules that:

• connect to sources of electrical noise such as relays and ac

motor drives

• generate significant heat, such as 32–point I/O modules

Publication 1746-UM010 B- EN-P - April 2001

Page 20

2-4 Installing and Wiring

Installing the Module

Follow this procedure:

ATTENTION

Never install, remove, or wire modules with power

applied to the chassis or devices wired to the

module.

!

1. Align the circuit board of the thermocouple module with the

card guides located at the top and bottom of the chassis.

2. Slide the module into the chassis until both top and bottom

retaining clips are secured. Apply firm even pressure on the

module to attach it to its backplane connector. Never force the

module into the slot.

3. Cover unused slots with the card slot filler, catalog number

1746–N2.

4. To remove, press the releases at the top and bottom of the

module, and slide the module out of the chassis slot.

retaining clips

card guides

top and bottom

releases

Publication 1746-UM010B-EN-P - April 2001

Page 21

Installing and Wiring 2-5

Removing th e terminal block

When installing the module, it is not necessary to remove the terminal

block. But if you need to remove it, follow this procedure:

1. Alternately loosen the two retaining screw s to avoid cracking the

terminal block.

2. Grasp the terminal block at the top and bottom and pull

outward and down. When removing or installing the terminal

block be careful not to damage the CJC sensors.

Tip: The R eplacement Part Number

for the Terminal Block with the CJCs

is 1746-RT32.

You cannot purchase a CJC by itself.

CJC sensors

retaining screws

3. Use the write–on label to identify the module and its location.

SLOT

MODULE

RACK

Publication 1746-UM010 B- EN-P - April 2001

Page 22

2-6 Installing and Wiring

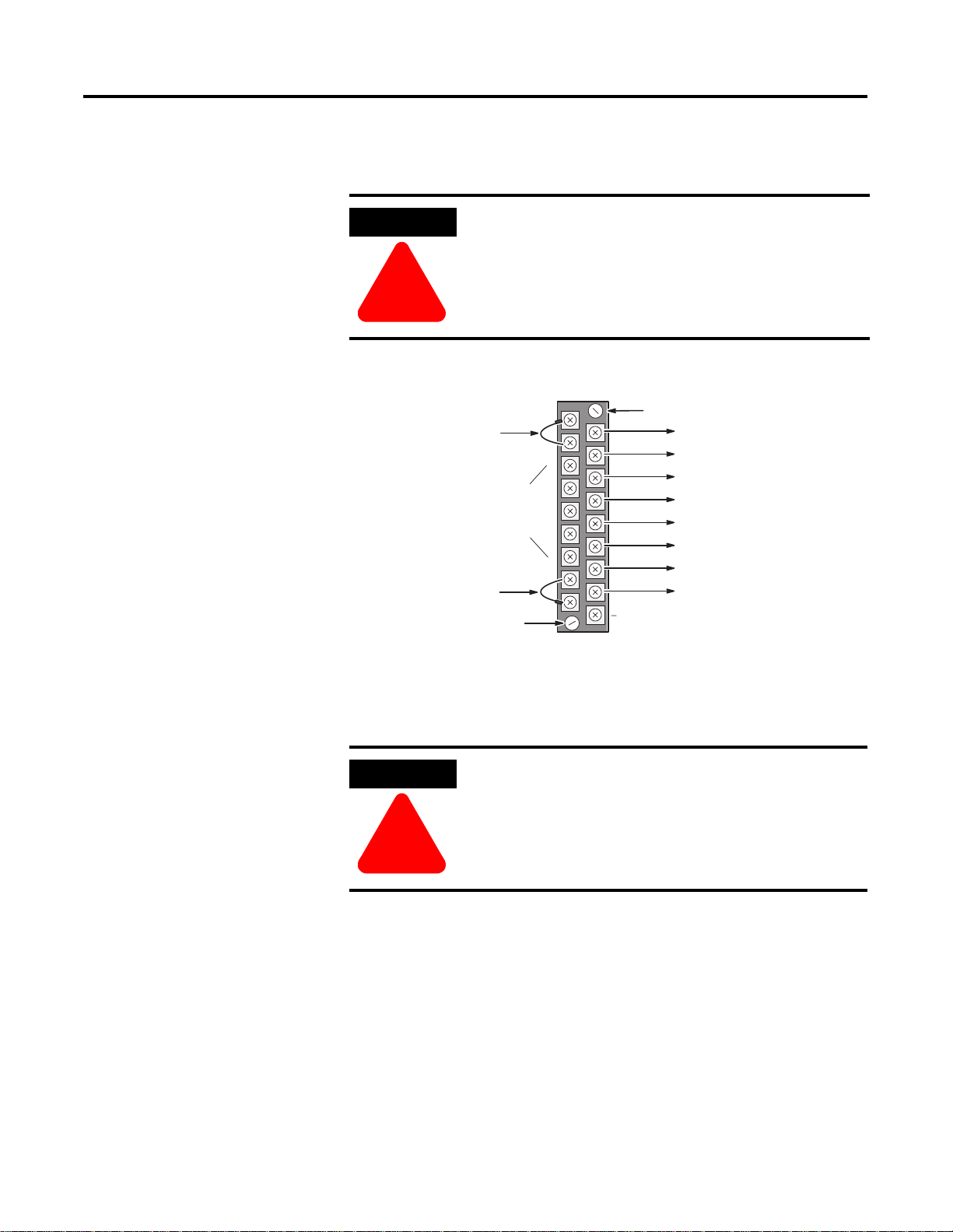

Wiring the Module

The module has an 18–position, removable terminal block. The

terminal block pin–out is shown below.

ATTENTION

Disconnect power to the SLC before attempting to

install, remove, or wire the removable terminal

wiring block.

!

Figure 2.1 Terminal block pin out.

Retaining Screw

Channel 0+

Channel 0Channel 1+

Channel 1-

Channel 2+

Channel 2-

Channel 3+

Channel 3-

spare part catalog number:

n/c

1746-RT32

CJC Assembly

Do NOT use these

connections

CJC Assembly

Retaining Screw

CJC A+

CJC A-

CJC B+

CJC B-

Cold Junction Compensation (CJC)

ATTENTION

!

In case of accidental removal of one or both thermistors, replace them

by connecting them across the CJC terminals located at the top and/or

bottom left side of the terminal block. Always connect the red lug to

the (+) terminal (to CJC A+ or CJC B+).

Do not remove or loosen the cold junction

compensating thermistors located on the terminal

block. Both thermistors are critical to ensure

accurate thermocouple input readings at each

channel. The module will not operate in the

thermocouple mode if a thermistor is removed

Publication 1746-UM010B-EN-P - April 2001

Page 23

Installing and Wiring 2-7

Figure 2.2 Thermistor place me nt on t he bot t om of the terminal block

Always attach red

lug to the CJC+

terminal

Wiring consi derations

Follow the guidelines below when planning your system wiring.

• To limit th e pickup of electrical noise, keep thermocouple and

millivolt signal wires away from power and load lines.

• For high immunity to electrical noise, use Alpha 5121 (shielded,

twisted pair) or equivalent wire for millivolt sensors; or use

shielded, twisted pair thermocouple extension lead wire

specified by the thermocouple manufacturer. Using the incorrect

type of thermocouple extension wire or not following the

correct polarity may cause invalid readings. See IEEE Std. 518,

Section 6.4.2.7 or contact your sensor manufacturer for

additional details.

• When trimming cable leads, minimize the length of unshielded

wires.

• Ground the shield drain wire at only one end of the cable. The

preferred location is at the I/O chassis ground (See Figure 2.4).

• For maximum noise reduction, use 3/8 inch braid wire to

connect cable shields to the nearest I/O chassis mounting bolt.

Then connect the I/O chassis to earth ground (See Figure 2.4).

These connections are a requirement regardless of cable type.

• Tighten terminal scre ws . Ex ce ss i ve ti gh te ni n g c an stri p th e

screw.

• The open–circuit detector generates approximately 20 nano–

amperes into the thermocouple cable. A total lead resistance of

25 ohms (12.5 one–way) will produce 0.5 mV of error.

• Follow system grounding and wiring guidelines found in your

SLC 500 Modular Hardware Installation and Operation Manual,

publication 1747–6.2.

Publication 1746-UM010 B- EN-P - April 2001

Page 24

2-8 Installing and Wiring

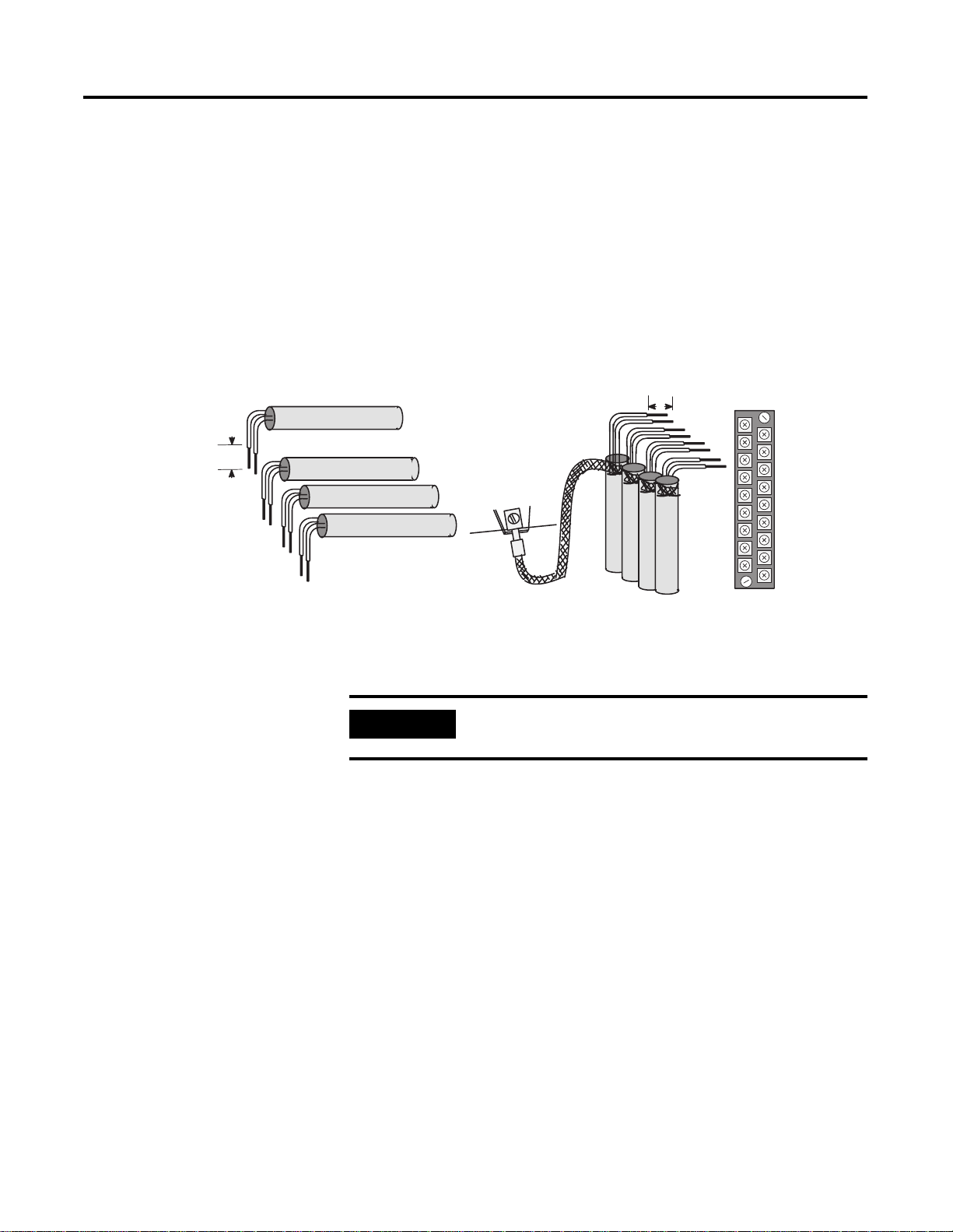

Preparing and Wiring the Cables

To prepare and connect cable leads and drain wires, follow these

steps:

Figure 2.3 Cable lead and drain wire preparation

Remove the foil shield

and drain wire from

sensor-end of the cable

Signal Wires

Extract th e d r ain wire but

remove the foil shield, at

the module-end of the

cable.

Drain Wire

Signal Wires

1. At each end of the cable, s trip s ome casi ng to expo se in divid ual

wires.

2. Trim signal wires to 5–inch lengths beyond the cable casing.

Strip about 3/16 inch (4.76 mm) of insulation to expose the ends

of the wires.

3. At the module–end of the cables:

- extract the drain wire and signal wires

- remove the foil shield

- bundle the input cables with a cable strap

4. Connect drain wires together and solder them to a 3/8” wire

braid, 12” long. Keep drain wires as short as possible.

5. Connect the 3/8” wire braid to the nearest chassis mounting

bolt.

Publication 1746-UM010B-EN-P - April 2001

6. Connect the signal wires of each channel to the terminal block.

Page 25

Installing and Wiring 2-9

7. At the source-end of cables from mV devices (See Figure 2.3

and Figure 2.4):

• remove the drain wire and foil shield

• apply shrink wrap as an option

• connect to mV devices keeping the leads short

Figure 2.4 Cable Preparation to Minimize Electrical Noise Interference

Wires

3/8”

Make

unshielded

wires as

short as

possible.

Limit braid length to 12” or

less. Solder braid to lug on

bottom row of I/O chassis

bolts.

IMPORTANT

Make unshielded wires

as short as possible.

Solder drain wires to

braid at casing.

Connect I/O

chassis bolt to

earth ground

3/8”

Signal

Wires

Cables

Terminal

Block

Chnl 0

Chnl 1

Chnl 2

Chnl 3

n/c

If noise persists, try grounding the opposite end of

the cable. Ground one end only.

Publication 1746-UM010 B- EN-P - April 2001

Page 26

2-10 Installing and Wiring

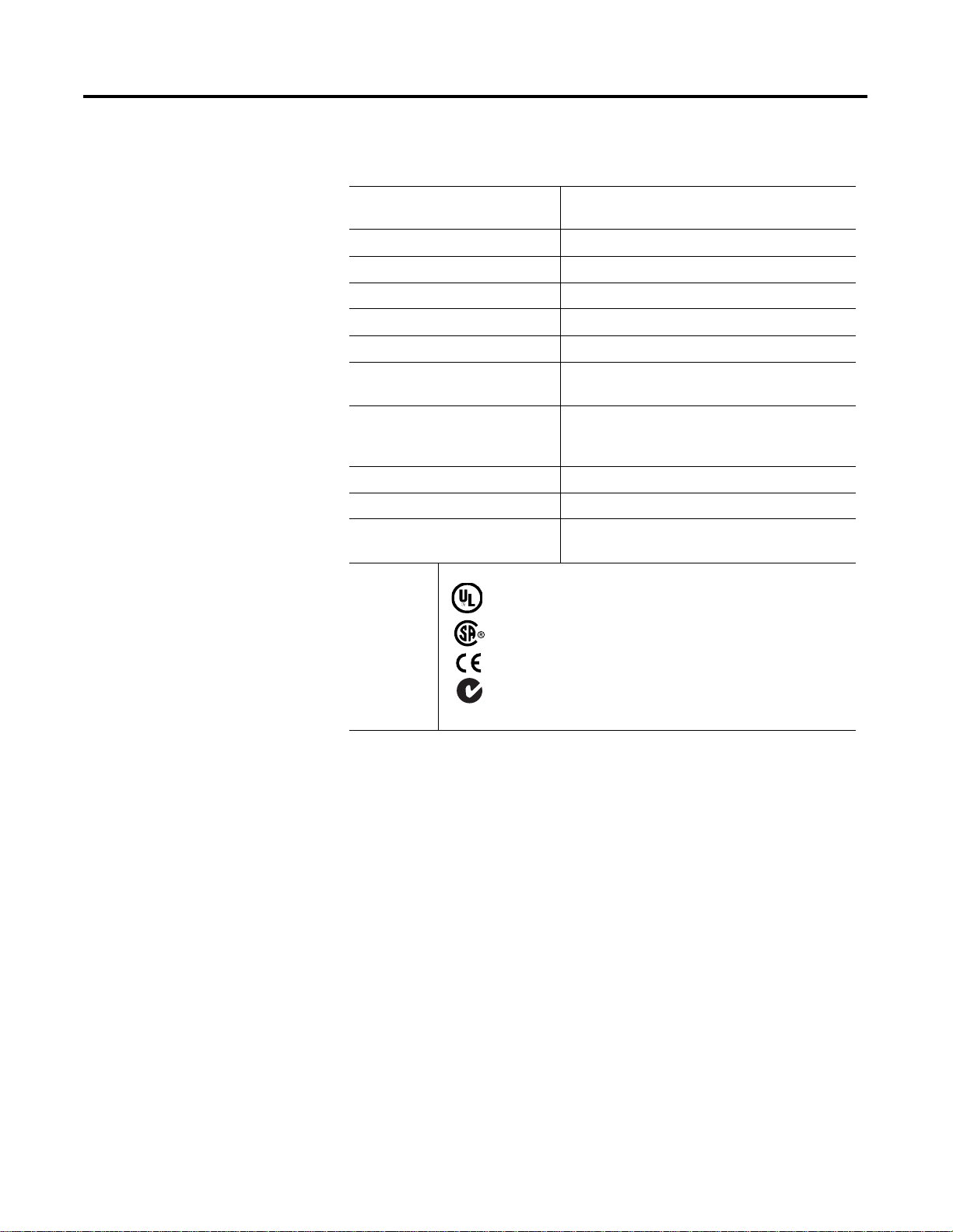

Specifications

Backplane Current

consumption

110 mA at 5V dc

85 mA at 24V dc

Backplane power consumption 0.6W maximum (0.55W @ 5V dc, 2W @ 24V dc)

Number of channels 4 (backplane and channel-to-channel isolated)

I/O chassis location any I/O module slot except 0

A/D conversion method sigma-delta modulation

Input filtering analog filter with low pass digital filter

Normal mode rejection

between [+]input and [-]input

Common mode rejection

between inputs and chassis

greater than 50 dB at 50 Hz

greater than 60 dB at 60 Hz

greater than 120 dB at 50/60 Hz with 1K ohm

imbalance

ground

Channel bandwidth (-3db) 8 Hz

Calibration once every six months

Isolation 1000V transient or 150 VAC continuous

channel-to-channel or channel-to-backplane

Agency

Certifications

When product or

packaging is

marked:

Listed Industrial Control Equipment

Certified Process Control Equipment

Certified for use in Class I, Division 2, Groups A, B, C, D or

nonhazardous locations

Marked for all applicable directives

Marked for all applicable acts

N223

Publication 1746-UM010B-EN-P - April 2001

Page 27

Chapter

3

Configuring the Module

You configure the module by setting words and bits for each loop in

Configuration Block, N10:0–100, which your ladder logic uses to load

the module’s M1 file. We cover bit selections and word descriptions.

Refer to Table 3.B on page 3-13 for selections, units, and defaults.

Loop Operation Mode

Type of Loop Input

Word 1, Bits 0 and 1 for Channel 1

Use these bits to select how you want the loop to perform:

Mode of Loop Operation 01 00

monitor the loop to indicate temperature and alarms 0 0

perform PID loop control with temperature indication and

alarms

disable the loop 1 0

invalid sett ing 1 1

01

Word 1, Bits 2-5 for Channel 1

Use the following bits to sel ect type J or K thermocouple; any other

bit setting is invalid:

TC 05 04 03 02

type J 0 0 0 0

type K 0 0 0 1

1 Publication 1746-UM010 B- EN-P - April 2001

Page 28

3-2 Configuring the Module

Enable Loop Alarms

TC Break Response

Word 1, Bit 6 for Channel 1

Set this bit to enable alarms for the designated loop.

Word 1, Bits 7 and 8 for Channel 1

If the module detects a TC open wire for a loop in automatic mode,

you can select how the module responds in one of the following

ways:

TC Break Response 08 07

disables the loop 0 0

forces CV to TC Break Control value (word 4, below) 0 1

forces CV to manual % output (O:e.8 for loop 1) 1 0

invalid setting 1 1

For additional information, Refer to TC Break Control on page 3-5.

Loop Autotune Gains Level

Word 1, Bits 10 and 11 for Channel 1

You can change and download autotune gains level selection for any

or all zones at any time. When changed, you must redownload the M1

file (configuration) followed by the M0 file (autotune/gains) so the

module can recalculate PID values based on new loop autotune gains.

You do not need to re–autotune.

Autotune Gain Level 11 10

low 0 0

medium 0 1

high 1 0

very high 1 1

Publication 1746-UM010B-EN-P - April 2001

Page 29

Configuring the Module 3-3

Barrel/Non-barrel Control

Word 1, Bit 12 for Channel 1

You select between barrel and non–barrel control.

Select: for these applications: 12

barrel control heat–only or heat/cool 0

non–barrel control heat–only, cool–only, or heat/cool 1

Barrel Control

Select barrel control for multiple–zone applications in which there is

thermal conduction between the zones. Injection molding and

extrusion are good example applications because they use multiple

heater bands (zones) mounted on one thermal conductor (the metal

barrel). The barrel conducts heat between different zones. If you

select barrel control, also select between inner and outer zones (word

1, bit 13 for channel 1). A barrel loop is autotuned as the temperature

rises from a cold start to a temperature setpoint during startup.

Non–barrel con tr ol

Select non–barrel control for applications with independent loops and

no thermal conduction between zones. If you select non–barrel

control, the inner/outer zone selection doesn’t apply.

Switching the barrel control

For some applications, even though the loop s are independent with

no thermal conduction between zones, barrel control might provide

better performance than non–barrel control. If a loop has any of these

characteristics, you might want to use barrel control if the:

• time constant is greater than 10 - 30 seconds

• loop has a problem of overshooting the setpoint

• loop output is saturating (CV is at 100%) for a significant

duration

Publication 1746-UM010 B- EN-P - April 2001

Page 30

3-4 Configuring the Module

)

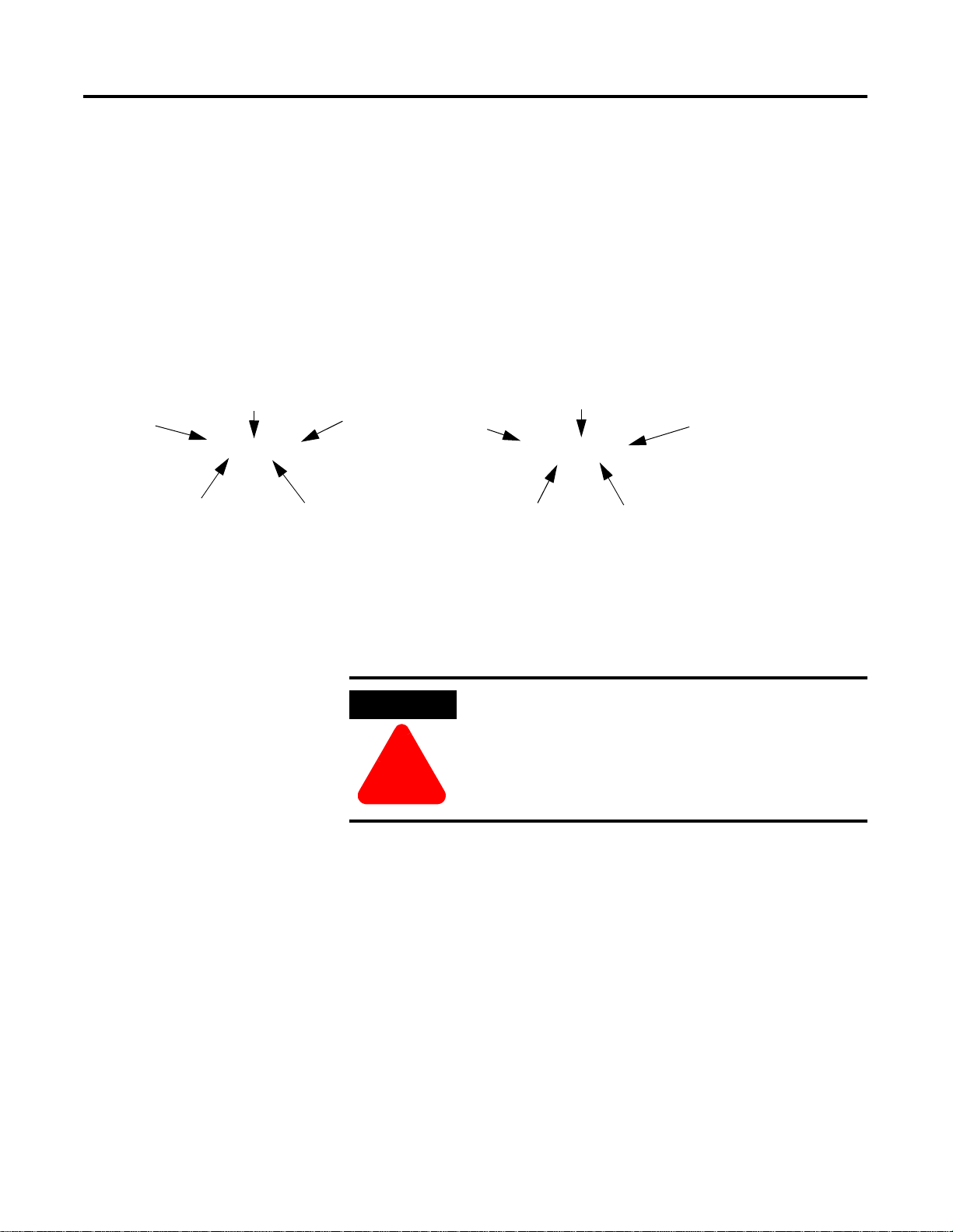

Inner/Outer Zone Selection

ATTENTION

If you switch a loop between non–barrel and barrel

control, you must re–autotune the loop before

operating it. If you don’t re–autotune, the autotune

values will be wrong for the application and the

!

gains will be greatly distorted.

Word 1, Bit 13 for Channel 1

If you make a selection for barrel control, you also must select

whether the loop is an inner zone or outer zone.

Select: for a zone: 13

inner not at either end of the

barrel

outer at either end of the barrel 1

The PID gain calculation algorithm for an inner zone is slightly

different than that for an outer zone to account for an inner zone

being more affected by adjacent zones. The inner zones are treated as

more of an integrating process than the outer zones.

0

Typical plastic injection barrel

with multiple temperature zones

Publication 1746-UM010B-EN-P - April 2001

Outer

Zone

Nozzle

Ts

T = temperature measurement point (thermocouple)

H = heater band (element

Inner

Zone

Zone 1 Zone 2 Zone 3

Hn

Tn

H1 H2 H3

T1 T2 T3

Inner

Zone

Outer

Zone

Ram

(Screw)

Tf

If you change the inner/outer zone selection after autotune, you must

re–autotune.

Page 31

Configuring the Module 3-5

High/Low CV Limits

TC Break Control

Words 2 and 3 for Channel 1

Use CV High and Low Limits to set up the loop mode:

For this loop

mode:

heat, only 0% 100%

cool, only -100% 0

heat/cool -100% +100%

CV

Low:

CV

High:

Word 4 or O:e.8 for Channel1

If a loop input circuit becomes open (open wire) the loop can not

measure temperature. In automatic mode, the lack of temperature

feedback makes it impossible to control the temperature. To guard

against this condition, the BTM module provides TC break detection.

When a break is detected, the module responds in one of these ways:

Standby Setpoint

• disables the loop

• forces CV to this (TC Break Control) value (word 4 for loop 1)

• forces the CV to the manual %–output value (O:e.8 for loop 1)

Once the thermocouple break has been repaired you must d isable the

loop and then re-enable it (through the input image table O:e.0/0

loop 1).

For additional information, Refer to TC Break Response on page 3-2.

Word 5 for Channel 1

When not using the runti me setpoi nt (O:e.4 f or loop 1) , use this value

to hold a lower temperature for faster warm up and/or optimum

standby conditions.

Publication 1746-UM010 B- EN-P - April 2001

Page 32

3-6 Configuring the Module

Heat/Cool Minimum On-times

Heat/Cool TPO Period

PV Rate and Associated

Words 6 and 8 for channel 1

These values determine the minimum cycle time after which loop

TPO bits will turn ON. They are used to allow contactors time to close

or pull in. If the contactor is energized for less than this value, the

contactor will not close, but the attempt will count as a cycle.

For example, suppose you set the TPO period for 10 seconds and the

minimum ON time to 1 second. Then if the module calculates a CV%

of 10% or less, the TPO bit for that zone will not tur n ON .

Words 7 and 9 for Channel 1

When CV loop output is time–proportioned (TPO), use this value to

set the interval between successive turn–ONs. For less than a 100%

output level, the output goes OFF for the balance of the interval.

Word 10 and Alarm Bit I:e.4/05 for Channel 1

Alarm

High/Low Temperature and Deviation Alarms

The PV Rate is a setpoint with an associated alarm that indicate s when

the temperature is rising too rapidly. If the zone’s PV has risen more

than this setpoint in one second (in auto mode), the module sets the

PV rate alarm bit (I:e.4/05, loop 1). The module only reports this

alarm - no action is taken.

Words 11-14 for Channel 1

In the configurat ion block (M1 file) yo u select val ues for the follow ing

temperature–level alarms:

• low temperature alarm (word 11 for channel 1)

• high temperature alarm (word 12 for channel 1)

• low deviation alarm from the set point(word 13 for channel 1)

• high deviation alarm from the set point(word 14 for channel 1)

Publication 1746-UM010B-EN-P - April 2001

Page 33

Configuring the Module 3-7

Set

Point

Temp

0°

High Temperature Alarm Value (absolute)

High Deviation Alarm Value (track setpoint )

Low Deviation Alarm Value (track setpoint)

Low Temperature Alarm Value (absolute)

Time

Publication 1746-UM010 B- EN-P - April 2001

Page 34

3-8 Configuring the Module

Alarm Dead Band

Word 15 for Channel 1

Once the temperature alarm bits are on, they remain on until the

temperature drops below the high alarm by the alarm dead–band

value or rises above the low alarm by this value.

The alarm dead band applies to the CV value at the high and low

temperature alarms and deviation alarm values and provides a

hysteresis effect. Low and high alarms are defined as:

• Low Alarm With Dead Band — When the temperature falls

below the user–defined low alarm value, the low alarm bit is

turned on. When the temperature rises above the level of the

low alarm value but still below the level of the dead–band

value, the low alarm bit remains on. Only when the temperature

rises above the dead–band level will the alarm bit be turned off.

• High Alarm With Dead Band — When the temperature rises

above the user–defined high alarm value, the high alarm bit is

turned on. When the temperature falls below the level of the

high alarm value but still above the level of the dead–band

value, the high alarm bit remains on. Only when the

temperature falls below the dead–band level will the alarm bit

be turned off.

high (CV)

alarm level

low (CV)

alarm level

Deadband

Deadband

Temperature

Time

alarm off

alarm on

Publication 1746-UM010B-EN-P - April 2001

Page 35

Configuring the Module 3-9

Thermal Integrity Loss Detection

Ramp Rates

Words 16 and 17 for Channel 1

The loss of thermal integrity is detected when the loop, in automatic

mode, is not responding to a CV at 100% Detecti ng the loss of thermal

integrity requires an assumption of a minimum rate of change in the

temperature (PV) when the o utput (CV) is at 100%. Exa mples of a loss

of thermal integrity could be the failure of a heating–band contactor to

close, or a sensor not in proper position to measure true temperature.

The values you enter in words 16 and 17 for loop 1 establish a

minimum rate of change (°/min.) in the temperature input (PV) that

you allow when the output (CV) is at 100% in automatic mode. The

temperature change value you enter in word 16 divided by the period

value you enter in word 17 is the thermal integrity rate.

IMPORTANT

Once loss of thermal integrity is detected, you must

clear this condition by disabling the affected loop

and then re–enabling it. To disable this feature, enter

zero in for both setpoints.

Words 18 for Chann el 1

Non-barrel Autotune Disturbance Size

This value ramp s th e se t poi nt in st ep s to the new setpoint.

Word 20 for Channel 1

This is a pure %–output step function for performing a non-barrel

autotune. It is added to the current output (%). It should be applied

under steady–state conditions. The loop operating mode must be

non–barrel.

EXAMPLE

Consider this:

• CV is 10%

• non-barrel Autotune Disturbance Size is 10%

If an autotune is invoked the CV’s output would go

to 20% for the duration of the Autotune.

Publication 1746-UM010 B- EN-P - April 2001

Page 36

3-10 Configuring the Module

Table 3.A Implied Decimal Po i nt Examples

Parameter Given Range

IMPORTANT

Because loop values are stored and reported in

integer files, you must understand the meaning of

implied decimal point (IDP). Otherwise, the

magnitude of your intended value may be in error by

as much as 1000, depending on the position of the

IDP.

Implied Decimal Point

When entering or reading integer values, the range, given in Table

3.A, provides the implied decimal point. It is the number of digits to

the right of the decimal point (for an example (IDP) range of 0.0 thru

3276.7, the implied decimal point is 1).

Status values are similarly read. You must know the range of the value

to read it correctly. For example, if reading a heat integral (0.0000 thru

3.2767), a display of 5000 would have a value of 0.5.

(1)

IDP

Example

Thermal Integrity

Standby Setpoint

TPO Period 0.00 thru 100.00

Cool Proportional 0.000 thru 32.767 3 If you want to store a value of 18, enter 18000.

Heat Integral 0.0000 thru 3.2767 4 If you want to store a value of 0.5, enter 05000.

(1)

IDP indicates the number of digits from the right that locates the implied decimal point.

0 thru 100

0.0 thru 32767.7

sec.

o

o

0

If you want to store a value of 66

1

If you want to store a value of 660.0

2 If you want to store a value of 6 seconds, enter

00600.

o

, enter 00066.

o

, enter 06600.

Publication 1746-UM010B-EN-P - April 2001

Page 37

Configuring the Module 3-11

Configuration Block, M1 File, Loops 1-4 N10:0-100

Startup Aggressiveness factor

Configuration block (M1 file) contains 101 words as listed below. Data

table location for Loops 1-4 are located in N10. For each additional

1746-BTM, add 1 to N10 (N11:0-100).

The startup aggressiveness factor (SAF) modifies the pre-set point

value. The pre-set point value is the temperature at which you switch

from the cold startup algorithms to PID control. The pre-set point

value is calculated from the auto tune data. The value is returned

through the rotator bits. In the example code it would be found in

Nxx:236 thru 239, a value for each channel.

The startup aggressiveness factor increases the pre-set point value by

percentage. For example:

EXAMPLE

Consider:

• setpoint is 400.0°

• preset point for channel 1 (nxx:236) is 75°

• startup aggressiveness factor is 0%

The point at which you would switch from the cold

startup algorithm to PID control would be:

IMPORTANT

SAF

---------- 100

0()

presetpoint×

75.0×

75.0×

325°=–

343.8°=–

setpoint 1

400.00 1

If the startup SAF factor is set to 25%, the poi nt at

which you would switch from the cold startup

algorithms to PID control would be:

400.00 1

The higher the startup aggressiveness factor is, the

closer to setpoint you will go before you switch from

the cold startup algorithms to PID control. If your

pre-set point is too close to the actual setpoint you

can expect overshoot to occur.

If you change the startup aggressiveness factor you

will need to redownload the M1 configuration and

the M0 autotune block for the change to take effect.

–

–

-------- -

–

100

25()

----------

–

100

Publication 1746-UM010 B- EN-P - April 2001

Page 38

3-12 Configuring the Module

Ramp Rates

The ramp rate value modifies the setpoint in steps until it reaches the

new setpoint. This value works in conjunction with the ramp enable

and ramp hold bits in the output image table for each channel.

EXAMPLE

The following outlines the relationship between

ramp rate, TPO:

• ramp rate 10 °/min.

• TPO of 10 sec.

• set point of 300°

• current tempe r at ure of 100°

• your goal is to ramp to the setp oint, but hold at

200° for 10 minutes; then continue to ramp to set

point.

To set the ramp enable bit, do the following:

1. Go to the output image table to set the ramp

enable bit.

2. A snap shot of the current temperature occurs,

which becomes the current setpoint.

3. A calculation is performed to determine the

amount the setpoint needs to be raised every

TPO period, so every TPO period the setpoint

increases 1.67° until the setpoint is reached.

1min

------------ 60

TPO×

10 1.67°=sec× TPO⁄

period

1min

------------ 60

×

ramprate

10°

4. Temperature ramps. Ladder logic determines

when you reach 200°. When 200° is reached,

ladder logic would set the ramp hold bit in the

output image table, and ladder logic would start a

10 minute time.

5. When the 10 minute time runs out, the ladder

logic would reset the ramp hold bit in the output

image table.

6. Ramping of the setpoint would continue until

300° is reached. At that point, ladder logic would

determine 300° was met, and it would reset the

ramp enable bit.

Publication 1746-UM010B-EN-P - April 2001

Page 39

Table 3.B Block Header (word 0 / N10:0) = 8801 (-30719 decimal)

Configuring the Module 3-13

Loops 1-4

Word #

1 2 3 4 bit to Configure Bit Select or Range 15 14 13 12 11 10 9876543210

1265176

0-1 operati on mo de

2-5 input type

6 alarm enable Disable = 0; Enable = 1 X

7-8 TC break configuration

9reserved

10-11 Autotune gains

12 Barrel control Barrel=0;Non-barrel=1 X

13 Zone I nner=0; Outer=1 X

14-15 reserved

2 27 52 77 0-15 High CV limit % -100.00 thru +100.00% default = +100.00%

3 28 53 78 0-15 Low CV limit % -100.00 thru +100.00% default = 0.00%

4 29 54 79 0-15 CV for TC break -100.00 thru +100.00% default = 0.0

5 30 55 80 0-15 Standby setpoint 0.0 thru 3276.7° default = 0.0

6 31 56 81 0-15 Heat on time (min.) 0.00 thru 100.00 sec. default = 0.00

7 32 57 82 0-15 Heat TPO period 0.00 thru 100.00 sec. default = 5.00

8 33 58 83 0-15 Cool on time (min.) 0.00 thru 100.00 sec. default = 0.00

9 34 59 84 0-15 Cool TPO period 0.00 thru 100.00 sec. default = 5.00

10 35 60 85 0-15 PV alarm rate -3276.8 thru 3276.7°/s default = 0.0

11 36 61 86 0-15 Low temp alarm -3276.8 thru 3276.7°/s default = +999.9

12 37 62 87 0-15 High temp alarm -3276.8 thru 3276.7°/s default = +999.9

13 38 63 88 0-15 Low deviation -3276.8 thru 3276.7°/s default = +999.9

14 39 64 89 0-15 High deviati on -3276.8 thru 3276.7°/s default = +999.9

15 40 65 90 0-15 Alarm dead band 0.0 thru 10.0° default = 0.0

16 41 66 91 0-15 T hermal Inte grity Loss 0 thru 100° de fault = 5

17 42 67 92 0-15 Integrity Rate 0 thru 100 minu tes default = 20

18 43 68 93 0-15 r amping 0 thru 100°/min. default = 0

19 44 69 94 reserved

20 45 70 95 0-15 N on-barrel a utotune

21 46 71 96 0-15 Startup

<=25 <=50 <=75 <=99 reserved

disturb size

aggressiveness factor

Monitor, No PID Control

Control loop with PID

Disable loop

Type J

Type K 0001

disable PID loop (CV=0)

Use thermal runaway

CV

Use manual mode CV 10

low gains

medium gains 01

high gains 10

very high gains 11

0.00-100.00% default = 10.00

0 thru 100 default = 0 fo r heat or cool, only; 25 for heat/cool

Set a bit or enter a value

00

01

10

0000

00

01

00

Publication 1746-UM010 B- EN-P - April 2001

Page 40

3-14 Configuring the Module

Publication 1746-UM010B-EN-P - April 2001

Page 41

Chapter

4

Setting Autotune and Gains Values

This chapter shows you how to independently set the gains for each

PID loop of the BTM module. This includes:

• setting PID gains

• autotuning the loops

• fine tuning the loops

• using the PID equation

• configuring the autotuning and gains block

Sequence of Setting PID Gains

Any time you successfully au totu ne the lo op, writ e an aut otun e blo ck

to the module, or write a gains block to the module, a new set of PID

gains is established on the module. The following list summarizes the

process:

• Autotuning causes the module to measure the process dynamics

and calculates PID gains.

• Reading the PID gains block from the module copies the PID

gains generated by autotuning into the SLC files.

• Writing the PID gains block to the module overwrites any PID

gains that had been in the module.

• Autotuning or writing the autotune block to the module causes

the module to calculate PID gains and overwrite any PID gains

that had been in the module.

At initial start–up, you must write the autotune block to the BTM

module or perform autotuning. If you select autotuning, for any loop

that is successfully tuned, the gains are calculated by the module.

Gains you sent to the module for a loop in any gains block previous

to successful autotuning of the loop are superseded by the gains

derived from autotuning. If you then read the gains block, it contains

the gains derived from autotuning.

If autotuning is not successful for any loops (as i ndicated in the status

block) the gains you sent for those loops before autotuning is used by

the module.

1 Publication 1746-UM010 B- EN-P - April 2001

Page 42

4-2 Setting Autotune and Gains Values

Once autotuning is complete, you mus t read th e gain s blo ck from th e

module to store it in SLC processor memory.

You can write the autotune and gains block either of these ways:

• Send autotune block to the module in words 1-24

(NXX:110-134). This causes the module to calculate the PID

gains. In this case, set the block header in word 0 (NXX:110) to

880A hexadecimal.

or

• Send PID gains only in words 25-48 (NXX:145-168). This

overwrites the current PID values in the mod ule. In this case, set

the block header in word 0 (NXX:120) to 880B hexadecimal.

Autotuning the Loops

IMPORTANT

The module’s memory is volatile. Whenever power to the module is

interrupted, you must establish the gains again. If you don’t send an

autotune block, PID block, or both blocks to the module, the module

will not work in automode. Sending the autotune block establishes

the start–up algorithm and the values the module uses to calculate the

PID gains, causing the module to recalculate th e PID gains. H owever,

you can override the autotune gains by sending the gains block after

the autotune block.

IMPORTANT

You select autotuning from the output image table block (Refer

to Using the Output Image Table on page 5-8). For each loo p, you

must turn on the specific bit to enable autotuning for the

corresponding loop. To trigger the start of autotuning, you must also

cause a 0–to–1 transition of word 12, bit 1 of the output image table.

When you download either an autotune or gains

block, the BTM module’s PID algorithm requires

time to adjust, proportional to the thermal mass of

the system. This could cause a slow or unexpected

system response .

You must initially download M0 and M1 files for the

module to operate.

Publication 1746-UM010B-EN-P - April 2001

During autotuning, the module measures system parameters. At the

end of autotuning, the module calculates PID gains based on these

parameters and your selection of low, medium, or high PID gain level

in the configuration block. When autotuning is complete, the PID

gains calculated from autotuning are available in the gains block that

you can read from the module.

Page 43

Configuration Block

Your selection of PID gains level:

• low

• medium

• high

Autotune Block

System parameters

Setting Autotune and Gains Values 4-3

Whenever you write autotune values to the module, it recalculates

PID gains based on measured system parameters stored in the

autotune block and your selection of low, medium, or high PID gain

level stored in the latest conf igu rati on b lock. If yo u chan ged th e level

of PID gains selection in the configuration block in the mean time, the

PID gains calculated would be different from those calculated

originally.

Autotuning

Calculations

Gains Block

PID gains

Fine-Tuning the Loops

After autotuning, you may want to fine–tune the loops by manually

setting the gains. As you fine–tune a loop, first try adjusting the

proportional gain; this will have the greatest impact. Your second

choice for adjustment should be the integral gain. The derivative gain

should be the last choice for fine–tuning a loop.

If the loop over–shoots the set point either at start–up or at a change

of set point, (See Figure 4.1) you may be able to dampen the loop

response by doing one or more of the following (in order of

effectiveness):

1. decrease the proportional gain

2. decrease the integral gain

3. increase the derivative gain

Figure 4.1 Loop Over-shoot

Set Point

Publication 1746-UM010 B- EN-P - April 2001

Page 44

4-4 Setting Autotune and Gains Values

If the loop is slow in reaching the set point either at start–up or at a

change of set point, (See Figure 4.2) you may be able to improve the

loop response by doing one or more of the following (in order of

effectiveness):

1. increase the proportional gain

2. increase the integral gain

3. decrease the derivative gain

Figure 4.2 Loop Slow to Set Point

Set Point

Using the PID Equation

The module provides dependant PID control action. Dependent

control action can be represented by the equation

CV KpEKiEDtK

=

The module is capable of performing PID control by calculating the

solution to an approximation of the PID equation. The approximation

is represented by the equation:

t

Ed

------

+

∫

0

+⋅

z

td

CV KpEKiE ∆tK

=

+

Where:

t

Where:

CV = Control variable

Kp = Proportional gain (no units)

E = Error (SP-PV or PV-SP)

Ki = Integral gain (repeats /seconds)

Kz = Derivative gain (seconds)

t = Time

t

∆E

-------

+⋅

∑

0

z

∆t

Publication 1746-UM010B-EN-P - April 2001

∑

0

E

∆t⋅ E1∆tE2∆tE3∆tetc+⋅+⋅+⋅=

.....

Page 45

Setting Autotune and Gains Values 4-5

Entering Autotune/Gains

The autotune/gains block (M0 file) contains 49 words as listed in

Table 4.A below. For each gain value, you enter a 16–bit integer

Values with Implied

value.

Decimal Point

IMPORTANT

When entering or reading integer values, the range, given in the

associated table, tells you the implied decimal point. It is the number

of digits to the right of the decimal point (for an example range of 0.0

thru 3276.7, the implied decimal point is 1).

Table 4.A Autotune/Gains Values with Implied Decimal Point

Parameter Given Range

Cool Time Constant 0.0 thru 32767.7 sec. 1 If you want to store a value of 660.0, enter 06600.

Heat Gain

0.00 thru 327.67

o

/sec.

Because loop values are stored and reported in

integer files, you must understand the meaning of

IDP. Otherwise, the magnitude of your intended

value may be in error by as much as 1000,

depending on the position of the IDP.

(1)

IDP

Example

2 If you want to store a value of 100.00, enter 10000.

Cool Proportional 0.000 thru 32.767 3 If you want to store a value of 18, enter 18000.

Heat Integral 0.0000 thru 3.2767 4 If you want to store a value of 0.5, enter 05000.

(1)

IDP indicates the number of digits from the right that locates the implied decimal point.

Publication 1746-UM010 B- EN-P - April 2001

Page 46

4-6 Setting Autotune and Gains Values

PID Gains/Autotune Block, M0 File for Loops 1–4

IMPORTANT

Word numbers for loops 1–4 are in left–most

columns. For corresponding NX:xx address, add 110

to word the number.

Table 4.B PID Gains/Autotune

(N10:110-158): Block Header (word 0 / N10:110) = 880B (-30709 decimal)

Loops 1-4 Autotune Values (N10:111-134)

1234To Configure Range

1 7 13 19 Heat gain 0.00 thru 327.67°/sec.

2 8 14 20 Heat time constant 0.0 thru 3276.7 sec.

3 9 15 21 Heat dead time 0.0 thru 3276.7 sec.

4 10 16 22 Cool gain 0.00 thru 327.67°/sec.

5 11 17 23 Cool time constant 0.0 thru 3276.7sec

6 12 18 24 Cool dead time 0.0 thru 3276.7 sec.

Loops 1-4 PID Gains Values (N10:135-158)

1234To Configure Range

25 31 37 43 Heat proportional 0.000 thru 32.767

26 32 38 44 Heat integral 0.0000 thru 3.2767 rpts/

sec.

27 33 39 45 Heat derivative 0.0 thru 3276.7 sec.

28 34 40 46 Cool proportional 0.000 thru 32.767

29 35 41 47 Cool integral 0.0000 thru 3.2767 rpts/

sec.

30 36 42 48 Cool derivative 0.0 thru 3276.7 sec.

Note: Refer to Download and Upload Settings on page 9-3 for

download command bits.

Publication 1746-UM010B-EN-P - April 2001

Page 47

Control and Autotune a Loop

This chapter explains how to:

• control loop operation

• autotune a loop

Chapter

5

Controlling a Loop

At initial start–up, you must write the M1 configuration block to

establish the module’s mode of control. Then, you must update the

output image table any time you want to change the operating mode.

M1 Configuration File

You select the loop control mode in the configuration file:

Words Bit 01 Bit 00 Lets you select

1, 26, 51, 76

for loops 1-4

0 0 monitor the loop

0 1 control the loop with PID

1 0 disable the loop

Output Image Table

If you select “control–the–loop” mode, you control loop operation

with these words and bits in the output image table (abbreviated list):

Words Bit Lets you

0-3

loops 1-4

4-7 n/a enter run temperature setpoints

8-11 n/a enter manual CV% output values

12

global for

all loops

1 Publication 1746-UM010 B- EN-P - April 2001

00 enable or disable the loop

03 enable or disable autotune

01 invoke autotune

02 abort autotune

03 reset error codes

Page 48

5-2 Control and Autotune a Loop

Figure 5.1 Control Mode Selections and Loop Operation

through the M1 configuration bl ock

Control Mode Selectio ns

Disable the Loop

Monitor the Loop

Control the Loop

Autotune a Loop

through the output image table

Loop Operation

Hold CV=0, and no temperature or al ar ms

Hold CV=0, but monitor temperatur e and provide

Disable Loop Control

Enable Loop Control

Manual Mode

Automatic Mode

temperature and alarms in the status block

The manual output value in the configur at ion block

is used as the CV value

The PID algorithm generates the CV value

The BTM module uses the output image table to control loop

operation. See Table 5.C on page 5-8 for the listing of words and

bits. Operating Commands to Loops 1-4

Use the following as a guide:

Requirements for Autotune

• Start autotune from a steady–state temperature. For best results,

do a cold start. If the temperature fluctuates, autotune may not

provide accurate results.

o

• The runtime setpoint for autotune must be at least 50

F (28.7o

C) above current temperature or autotune will not start.

Publication 1746-UM010B-EN-P - April 2001

Page 49

Control and Autotune a Loop 5-3

• Set the TPO period smal ler than the syst em dead time. Autotu ne

algorithm may calculate excessive gains if system dead time is

less than the TPO period. This may cause the PV to overshoot

Figure 5.2 Set TPO Period

output (CV)

changed

Temperature

Output (CV)

system dead time

System dead time should be larger than one

TPO period for autotune to work properly

1 TPO period

t

0

Time

• The autotune algorithm does not take the temperature to

setpoint. When autotune is complete, the zones will return to

the mode (auto or manual) that was selected before autotune.

Figure 5.3 Autotune setpoint zones

Temperature

system dead

time

maximum slope

Time

Return to the control mode

that was selected before

autotune

autotune

complete

Publication 1746-UM010 B- EN-P - April 2001

Page 50

5-4 Control and Autotune a Loop

Items to check before autotune

Each loop must:

• be configured with a valid M1 file and no errors (N10:212-215)

• be set for barrel mode

• be set in manual mode and that run setpoints are selected,

starting from a cold start. If not starting from a cold start, at a

steady state temperature.

• have the TPO period set considerably smaller than the system

dead time.

A good place to start is 5 or 10 seconds.

• not have any existing alarm conditions that could cause

problems (such as a TC break)

Autotune barrel control applications

Autotune enables the mod ule to compute PID values for optimum

temperature control. You must load the program and use the

following procedure to autotune the module.

For barrel control, better results are achieved when you autotune all

loops associated with the barrel at the same time. After autotune,

each zone will return to the mode (auto or manual) that was selected

beforehand.

IMPORTANT

For best results, start from room temperature (cold

start).

Publication 1746-UM010B-EN-P - April 2001

Page 51

Control and Autotune a Loop 5-5

1. Assume using data table N10 in the following example. Set initial

conditions:

Table 5.A Configuration File N10 Data Table Example

N10:1 bits 00 01 set for PID control

N10:26 bits 00 01 set for PID control

N10:51 bits 00 01 set for PID control

N10:76 bits 00 01 set for PID control

remaining bits/words set for your application

Table 5.B Data Table Example:

Output image buffer table words 180–183

bits 00–03 for loops 1–4.

bit 00 1 enables PID control

bit 01 0 puts loop into manual mode

bit 02 1 uses runtime setpoint

bit 03 1 enables autotune

• Set to zero Output image buffer table words 188–191 for

loops 1–4.

• In the sample code, it zeros manual outputs to remove

control signals from loops.

2. Download the M1 Configuration File by setting N7:12/00 = 1.

3. Download the M0 Autotune File by setting N7:12/01 = 1.

4. Verify that the M1 Configuration File downloaded:

a. Check input image buffer words 164–167 bits 03, 04 for loops

1–4 to verify:

• bit 03 = 1 module received a valid M1 file for the loop

•bit 04 = 0 no parameter errors for the loop.

If bit 04 (parameter error) is set for any loop, look for the

error code in N10:212–215.

Refer to Locating Error Code Information on page 8-2.

b. Check input image buffer words 168–171 bits 00–02 for l oops

1–4 to verify that the module:

• bit 00 = 1 enabled PID control

• bit 01 = 0 put loop into manual mode

• bit 02 = 1 used runtime setpoint

Publication 1746-UM010 B- EN-P - April 2001

Page 52

5-6 Control and Autotune a Loop

5. Enter runtime temperature setpoints (at least 50oF (28.7oC)

above current temperature) into output image buffer words 184–

187 for loops 1–4.

IMPORTANT

For implied decimal point, enter 2000 for 200

o

6. Invoke autotune. (Starts autotu ne for loops enabled in step 1.)

Set output image buffer table word 192, bit 1 = 1.

The module needs a 0–1 transition of this bit.

7. Verify autotune is in progress.

Monitor input image buffer word 168, bit 11 for a 0–1 transition.

8. Reset the autotune invoke bit.

Reset output image buffer table word 192, bit 1 = 0.

9. Enable each loop for automatic mode.

This lets each loop control to run setpoint when autotune

completes.

a. Output image buffer words 160–163 bit 01 for loops 1–4 bit

01 = 1 puts loop into automatic mode

10. Verify that autotune is complete and successful.

Input image buffer words 168–171 bits 03 and 04 for loops 1–4

bit 03 = 1 autotune complete

bit 04 = 1 autotune successful

If bit 04 = 0 (not successful) for any loop, look for the error code

in N10:212–215. Refer to Locating Error Code Information on

page 8-2.

Publication 1746-UM010B-EN-P - April 2001

11. Upload the autotune/PID gains block to the processor for

storage. Set word N7:12 = 24. Following a power loss or module

replacement, you can download the autotune/PID gains block

to avoid repeating this procedure.

12. We suggest that you modify our ladder code Refer to Obtaining

the Sample Program from the Internet on page 9-1 to set N7:12 =

3 at power up. This will automatically download M0 autotune

data and M1 configuration data files to the module to start

module operation.

Page 53

Control and Autotune a Loop 5-7

Example: Autotune non–barrel control applications

1. Enter a safe non–barrel autotune disturbance size in the M1 file.

• Disturbance size is the step output that the module uses to

autotune. For example, if disturbance size is 15% and current

CV is:

0% when autotune is invo ked, the CV changes to 15%

10% when autotune is invoked, the CV changes to 25%

• Optimum disturbance lets temperature rise, then level off. If

too large, temperature will not level off and autotune will be

unsuccessful.

2. Make sure all zones have valid M1 fi les and n o parameter e rrors.

3. Start Autotune from a cold start or start from a steady–state

temperature.

• If doing a cold start, invoke autotune after putting loop into

manual mode and setting manual CV output to zero.

• If starting from a steady–state temperature, invoke autotune.

Temperature

4. When autotune completes, upload the autotune and gains block.

5. Return the zone to auto mode.

Temperature for safe autotune disturbance size

Autotune completes when

temperature reaches steady

state

dead time

Time

Tr o ub l es ho otin g Autotune

The module reports successful completion of autotune in status word

N10: 168-171, bits 03, and 04 in the input image buffer table. If

autotune was not successful, look for autotune error codes in

N10:212-215. Refer to Locating Error Code Information on page 8-2.

Publication 1746-UM010 B- EN-P - April 2001

Page 54

5-8 Control and Autotune a Loop

Using the Output Image

The output image table contains 16 words as shown in Table

5.Cbelow. You must enter a 16–bit signed integer value for the run

Table

temperature setpoint and manual output. If you are using the example

code from the manual you will not manipulate the output image table

directly. You will manipulate the output image buffer N10:180-195.

• For a run temperature setpoint, the implied decimal point is 1

place from the right (causing the resolution to be 0.1). For

example, if you want a value of 499.9, enter 04999.

• For the manual output, the implied decimal point is 2 places

from the right (causing the resolution to be 0.01). For example,

if you want a value of 49.99%, enter 04999.