Page 1

Installation Instructions

POINT I/O One-piece Terminal Bases

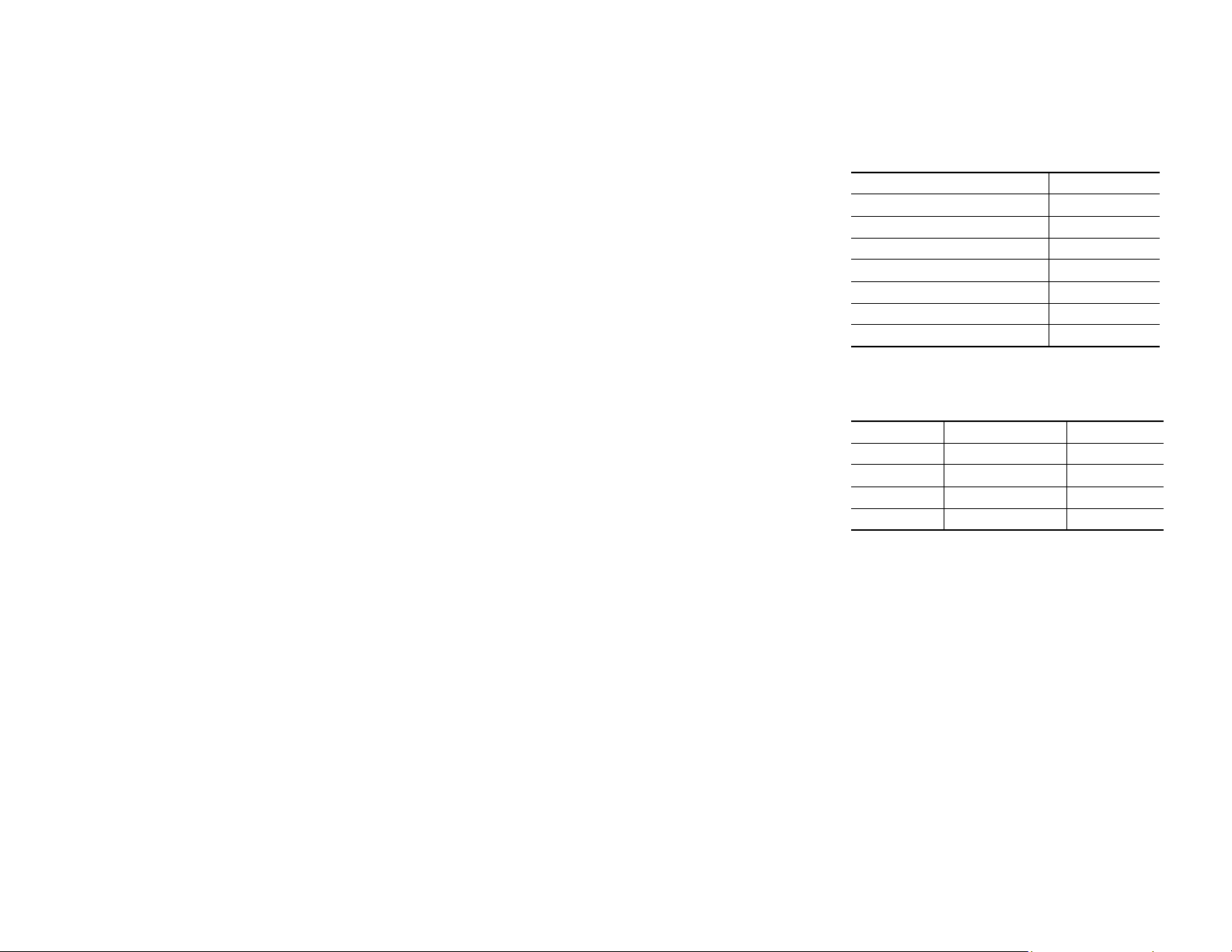

Catalog Numbers 1734-TOP, 1734-TOPS, 1734-TOP3, 1734-TOP3S

Topic Page

About This Publication 1

Important User Information 2

Environment and Enclosure 3

Prevent Electrostatic Discharge 4

Install a Base 5

Remove a Base 6

Specifications 7

About This Publication

Read this publication for information about these terminal bases.

Catalog Number Number of Terminations Termination Type

1734-TOP 8 Screw-clamp

1734-TOPS 8 Spring-clamp

1734-TOP3 12 Screw-clamp

1734-TOP3S 12 Spring-clamp

Publication 1734-IN028B-EN-P - April 2010

Page 2

2 POINT I/O One-piece Terminal Bases

WARNING

IMPORTANT

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (publication SGI-1.1

Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

between solid state equipment and hard-wired electromechanical devices. Because

of this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable. In no

event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.No patent liability is

assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual. Reproduction of the contents of this

manual, in whole or in part, without written permission of Rockwell Automation, Inc.,

is prohibited. Throughout this manual, when necessary, we use notes to make you

aware of safety considerations.

Identifies information about practices or circumstances that can

cause an explosion in a hazardous environment, which may lead

to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application

and understanding of the product.

) describes some important differences

available from your local

Publication 1734-IN028B-EN-P - April 2010

Page 3

POINT I/O One-piece Terminal Bases 3

IMPORTANT

SHOCK HAZARD

BURN HAZARD

ATTENTION

Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or economic

loss. Attentions help you to identify a hazard, avoid a hazard and

recognize the consequences.

Labels may be located on or inside the equipment, for example, a

drive or motor, to alert people that dangerous voltage may be

present.

Labels may be located on or inside the equipment, for example, a

drive or motor, to alert people that surfaces may be dangerous

temperatures.

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

industrial environment, in overvoltage Category II applications (as

defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft)

without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR 11. Without appropriate

precautions, there may be difficulties with electromagnetic

compatibility in residential and other environments due to

conducted and radiated disturbances.

This equipment is supplied as open-type equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable

flame-retardant properties to prevent or minimize the spread of

flame, complying with a flame spread rating of 5VA, V2, V1, V0 (or

equivalent) if non-metallic. The interior of the enclosure must be

accessible only by the use of a tool.

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines,

• NEMA Standard 250 and IEC 60529, as applicable, for

Subsequent sections of this

Rockwell Automation publication

1770-4.1, for additional

installation requirements.

explanations of the degrees of protection provided by

different types of enclosure.

Publication 1734-IN028B-EN-P - April 2010

Page 4

4 POINT I/O One-piece Terminal Bases

ATTENTION

ATTENTION

ATTENTION

Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which

can cause internal damage and affect normal operation.

Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging

when not in use.

POINT I/O is grounded through the DIN rail to chassis ground.

Use zinc plated yellow-chromate steel DIN rail to assure

proper grounding.

The use of other DIN rail materials (for example, aluminum or

plastic) that can corrode, oxidize, or are poor conductors, can

result in improper or intermittent grounding.

Secure DIN rail to mounting surface approximately every

200 mm (7.8 in.) and use end-anchors appropriately.

Do not wire more than 2 conductors on any single terminal.

Publication 1734-IN028B-EN-P - April 2010

Page 5

POINT I/O One-piece Terminal Bases 5

Wiring Block

Mechanical

Keying

(Orange)

44047

1734-TOP and 1734-TOPS

DIN-rail Locking Screw (Orange)

Handle

Interlocking Side Pieces

44050

Wiring Block

DIN-rail Locking Screw (Orange)

Mechanical

Keying

(Orange)

Handle

Interlocking Side Pieces

Install a Base

To install a base on DIN rail, proceed as follows, referring to the figures to identify major parts

of the base.

Publication 1734-IN028B-EN-P - April 2010

Page 6

6 POINT I/O One-piece Terminal Bases

WARNING

DIN-rail locking screw is in

horizontal, locked position.

DIN-rail locking screw is in

vertical, unlocked position.

Refer to your I/O module user manual for keying information and informatin on how to

configure your module.

1. Position the base vertically above the installed units, such as an adapter, power

supply, or existing module.

2. Slide the base down, allowing the interlocking side pieces to engage the adjacent

installed unit.

3. Press firmly to seat the base on the DIN rail until the base snaps into place.

4. Verify that the DIN-rail locking screw is in a horizontal, locked position before

inserting an I/O module.

Remove a Base

Explosion Hazard

Do not disconnect or replace component unless power is

switched off or area is known to be nonhazardous. Do not

pull on the installed wiring to remove a terminal base. A

shock hazard exists if power is applied to the terminal base.

To remove a wiring b ase from t he DIN rai l, you must remove the module installed to the right of

the base, proceeding as follows.

1. Squeeze the module locking mechanism of the module to the right of the base,

pulling up to remove the module.

2. Turn the orange locking screw to a vertical position to unlock the base from the

DIN rail.

3. Slide the base up to release it from its mating units.

Publication 1734-IN028B-EN-P - April 2010

Page 7

POINT I/O One-piece Terminal Bases 7

Specifications

One-piece Terminal Bases -

1734-TOP, 1734-TOPS, 1734-TOP3, 1734-TOP3S

Attribute Value

Dimensions

(HxWxD),

Approx.

Weight,

Approx.

Wire Size

Category

Supply voltage

Supply power

Isolation

Volt age

Enclosure Type

Rating

Field Power

Bus Supply

Volt age

Terminal Base

Screw Torque

Terminal block

torque

(1)

Use this conductor category informat ion for planning conductor routing as described in Industrial

Automation Wiring and Grounding Guidelin es, publication 1770-4.1.

1734-TOP, 1734-TOPS 49 x 12 x 144 mm (1.93 x 0.47 x 5.67 in.)

1734-TOP3, 1734-TOP3S 49 x 12 x 168 mm (1.93 x 0.47 x 6.61 in.)

1734-TOP 63.8 g (2.25 oz), 1734-TOP3 79. 2 g (2.79 oz),

1734-TOPS 55.68 g (1.96 oz), 1734-TOP3 S 66.8 g (2.36 oz)

0.25... 2.5 mm² (22...14 AWG) solid or stranded copper wire rated at 75 °C

(167 °F ), or greater, 1.2 mm (3/64 in.) insulation max

Dependent on I/O module installed in term inal base

300V max terminal voltage

8A max terminal current

Capable of 240V (continuous), Reinforced Insu lation Type, or the lesser of the

installed module.

None (open-style)

28.8V DC, 120/240V AC

(1)

1734-TOP and 1734-TOP3 0.6 Nm (7 lb-in)

0.4Nm (3.5 lb-in) for 1734-TOP and 1734-TOP3 only

Publication 1734-IN028B-EN-P - April 2010

Page 8

8 POINT I/O One-piece Terminal Bases

Environmental Specifications

Attribute Value

Temperature,

operating

Temperature,

nonoperating

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Damp Heat):

Shock, operating IEC 60068-2-27 (Test Ea, Unpackaged Shock): 30 g

Shock, nonoperating IEC 60068-2-27 (Test Ea, Unpackaged Shock): 50 g

Vibration IEC 60068-2-6 (Test Fc, Operating): 5 g @ 10…500 Hz

IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20…60 °C (-4…140 °F)

IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating Cold),

IEC 60068-2-2 (Test Bb, Unpackaged Nonoperating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Nonoperating Thermal Shock):

-40…85 °C (-40…185 °F)

5...95% noncondensing

Certifications

Certification (when the

product is marked)

C-Tick Australian Radiocommunications Act, compliant

c-UR-us UL Recognized Component Industrial Contro l Equipment, certified

CE European Union 2004/108/EC EMC Directive, compliant with:

(1)

See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates,

and other certification details.

Value

(1)

with: AS/NZS CISPR 11; Industrial Emissions

for US and Canada. See UL File E65584.

EN 61326-1; Meas./Control/Lab., Industria l Requirements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clau se 8, Zone A & B)

European Union 2006/95/EC LVD, compliant with:

EN 61131-2; Programmable Controllers (Clau se 11).

Publication 1734-IN028B-EN-P - April 2010

Page 9

POINT I/O One-piece Terminal Bases 9

Notes:

Publication 1734-IN028B-EN-P - April 2010

Page 10

10 POINT I/O One-piece Terminal Bases

Notes:

Publication 1734-IN028B-EN-P - April 2010

Page 11

POINT I/O One-piece Terminal Bases 11

Notes:

Publication 1734-IN028B-EN-P - April 2010

Page 12

Allen-Bradley, POINT I/O, and Rockwell Automation are trademarks of Rockwell

Automation, Inc. Trademarks not belonging to Rockwell Automation are property

of their respective companies.

Publication 1734-IN028B-EN-P - April 2010 PN 75026

Supersedes Publication 1734-IN028A-EN-P - February 2006

Copyright © 2010 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A

Loading...

Loading...